Patents

Literature

243results about How to "Avoid coarsening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bainitic steels with boron

InactiveUS20100319814A1Improve toughnessImprove solderabilityFurnace typesHeat treatment process controlHigh intensityTitanium

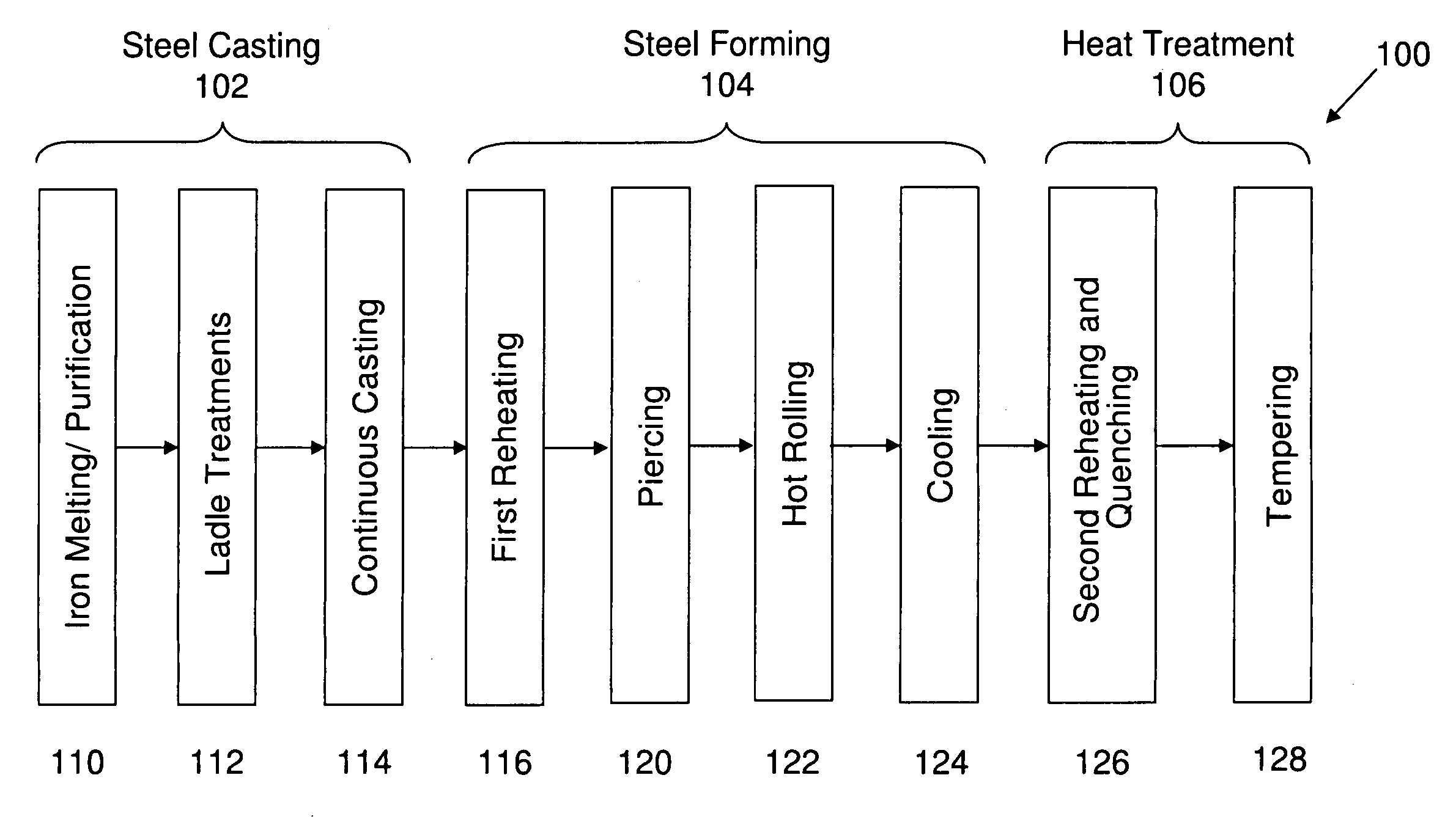

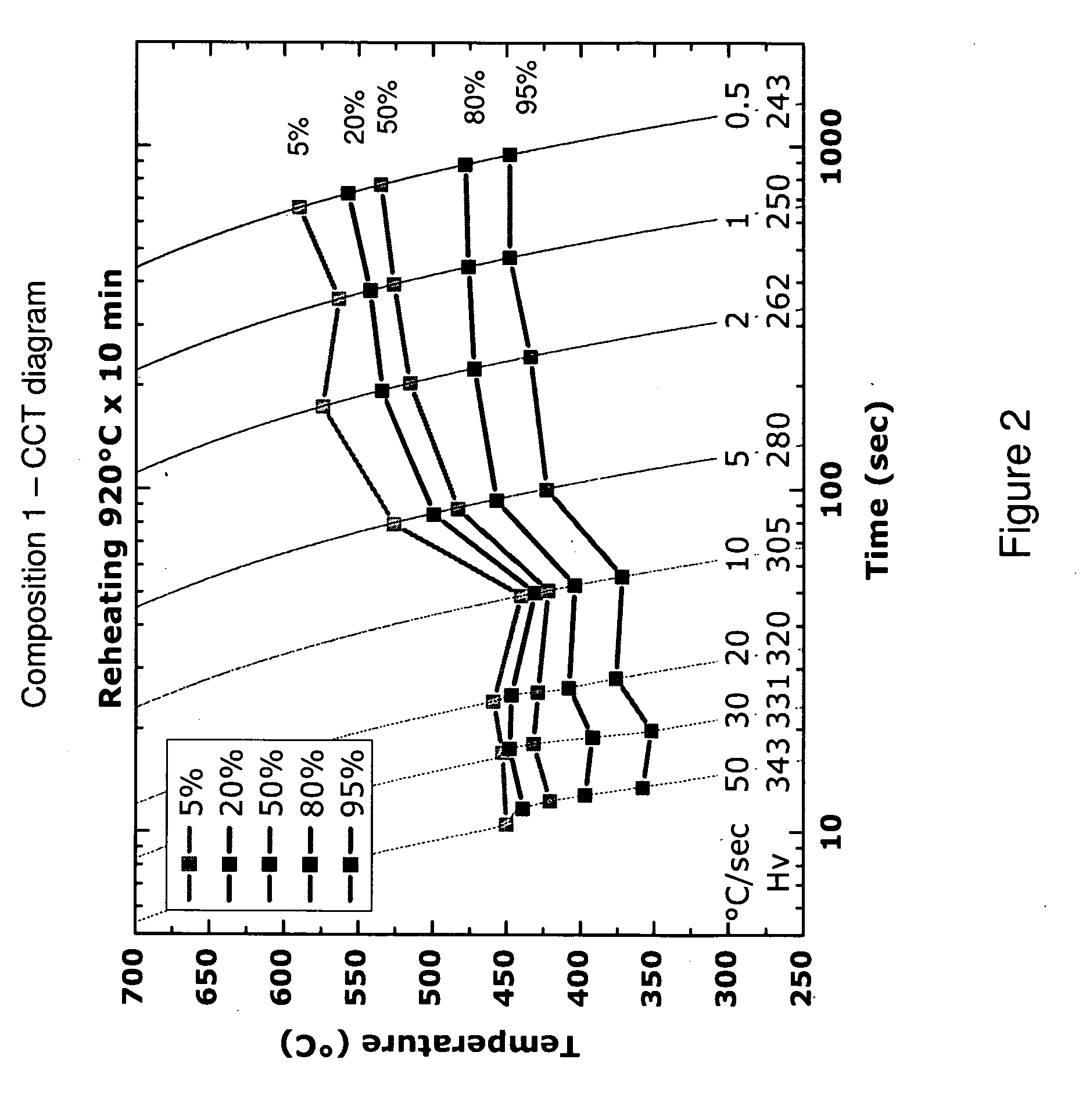

Steel compositions contain micro-alloying additions of boron and titanium, with yield strength of at least 100 ksi (690 MPa), excellent toughness and good weldability. Boron additions are used to increase hardenability. Strong nitride formers, such as titanium, may be added to the steel composition in order to prevent boron nitrides from forming. These compositions may be cooled from hot rolling in air or using accelerated cooling. After air cooling, the composition may be quenched or quenched and tempered. The compositions are suitable for high strength line pipes (for example, X100 in API 5L standard) and other applications.

Owner:TENARIS CONNECTIONS

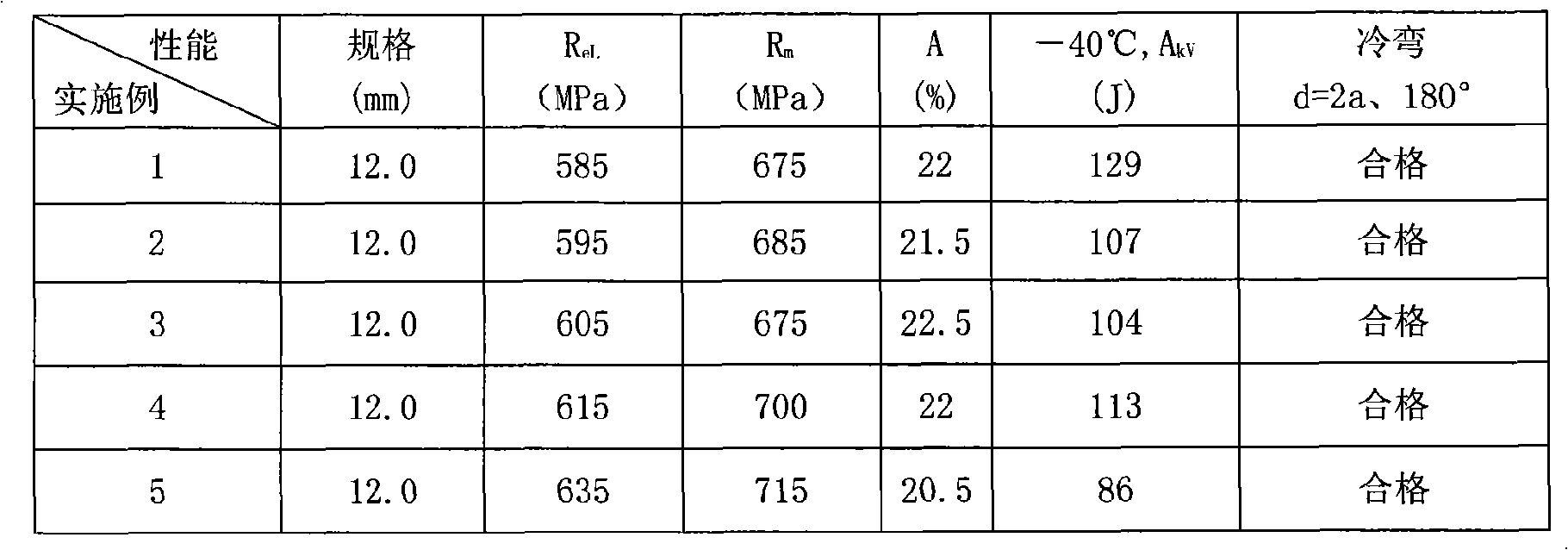

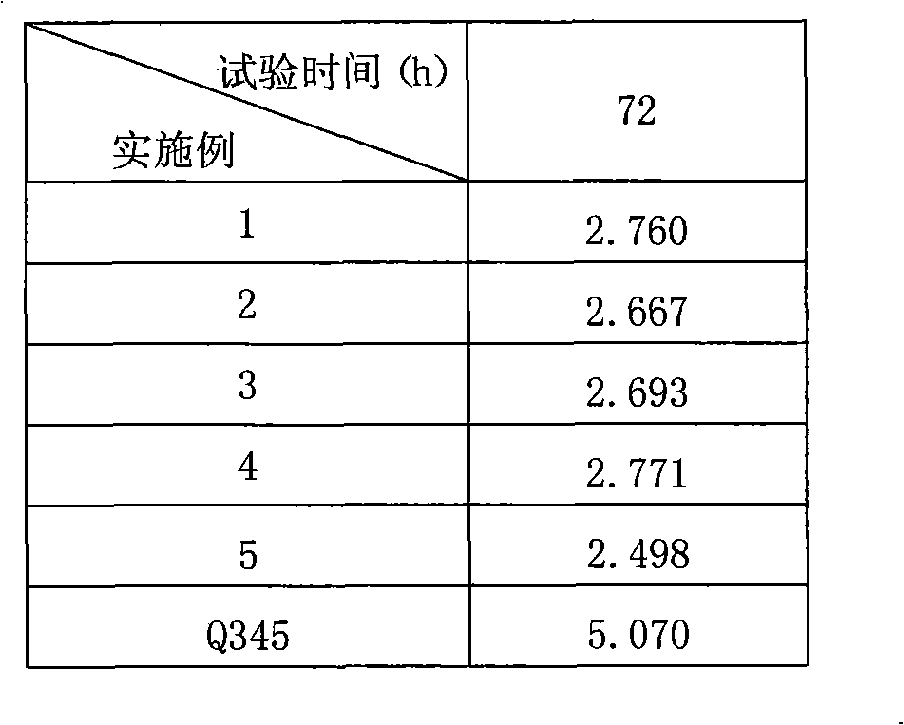

Ultra-low carbon hot rolling weathering steel with yield strength larger than 550MPa

InactiveCN101407892AGood mechanical propertiesSimple chemical compositionMechanical propertyWeathering steel

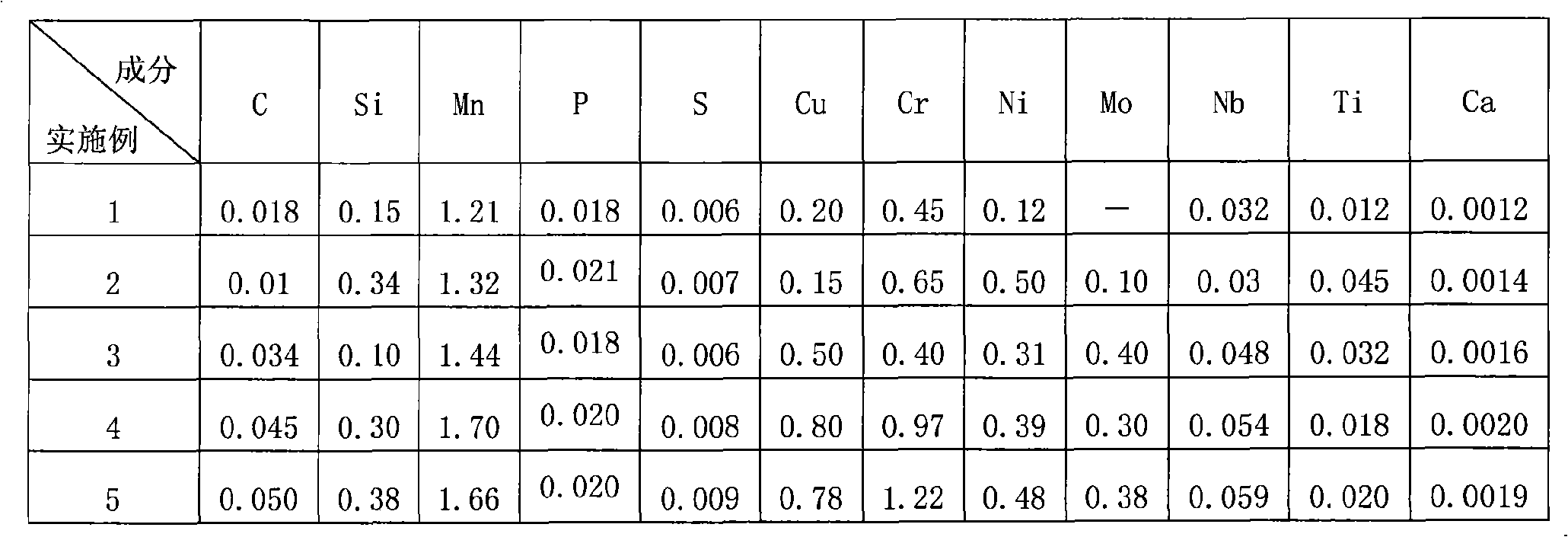

The invention discloses an ultra low carbon hot rolling weathering steel with the yield strength of more than the grade of 550MPa and belongs to the manufacturing field of low alloy steel. The steel consists of the compositions with the following weight percentages: 0.01 to 0.05 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, equal to or less than 0.02 percent of P, equal to or less than 0.010 percent of S, 0.15 to 0.80 percent of Cu, 0.40 to 1.25 percent of Cr, 0.10 to 0.50 percent of Ni, equal to or less than 0.40 percent of Mo, 0.03 to 0.06 percent of Nb, equal to or less than 0.050 percent of Ti, 0.0010 to 0.0020 percent of Ca and the residual quantity of Fe and unavoidable impurities. The steel has good mechanical properties, the yield strength of equal to or more than 550MPa and the tensile strength of equal to or more than 650MPa which are both higher than that of traditional weathering steel. Besides, Ti is included in the compositions of the steel.

Owner:武钢集团有限公司

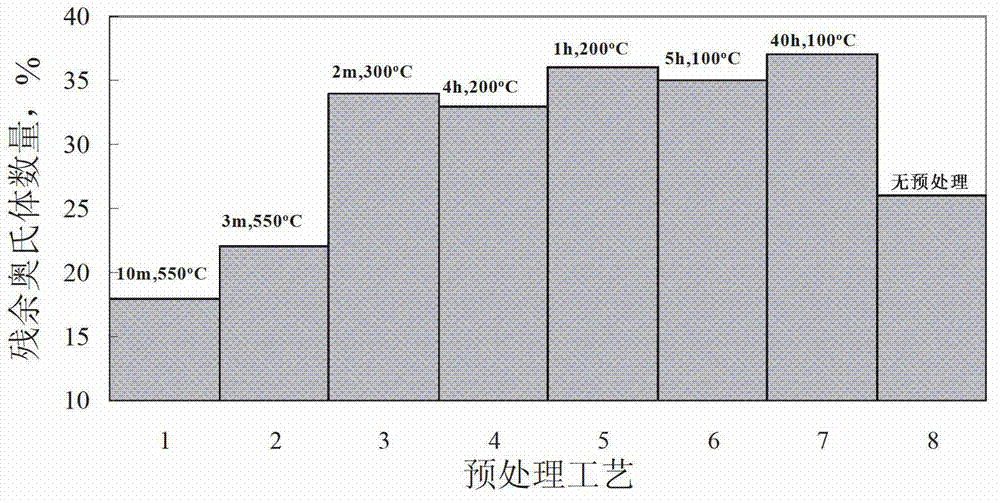

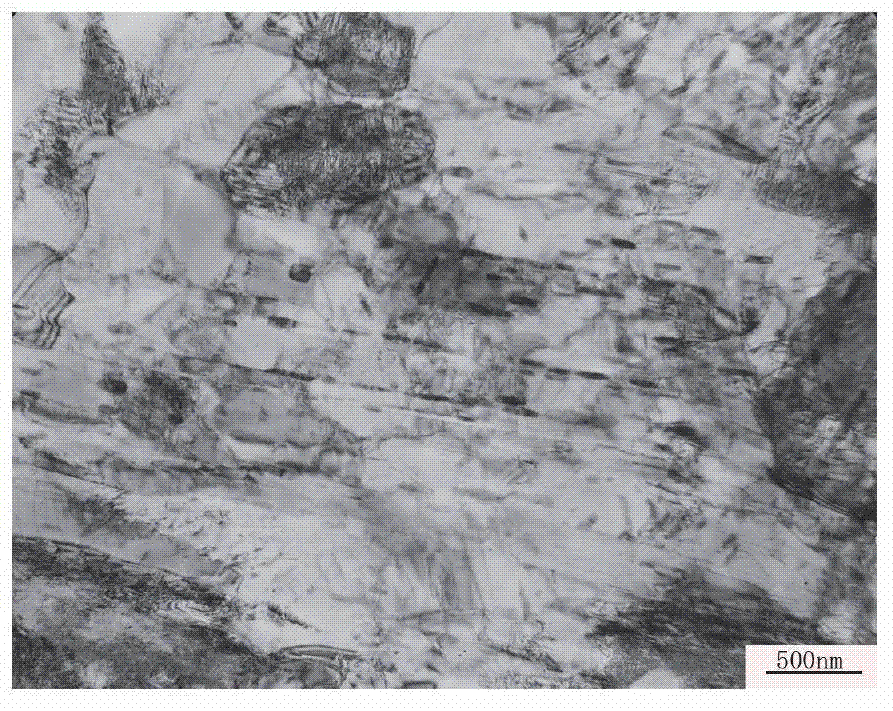

Method for producing high-strength and elongation product automobile steel plate by continuous annealing technology

The invention provides a method for producing a high-strength and elongation product automobile steel plate by a continuous annealing technology, belonging to the technical field of an automobile steel plate. The method comprises the following steps: based on the reasonable chemical component design and the alloy element partition, firstly, obtaining transition carbide with fine dispersion distribution by a cold rolled plate coil importantly, and promoting austenite inverse phase transformation through the solid solution of the fine carbide through two-phase region annealing, to obtain more and stable austenite phases to be remained. According to the method, the strict technological conditions for forming the finely-dispersed carbide and the strict interval for carrying out the technological parameters of the two-phase region annealing are given, so that the method has the advantages that the continuous annealing plate coil which is even in performance and good in surface quality can be obtained due to the short-time annealing of the existing continuous annealing production line of a steel factory, wherein the strength of the steel plate is 0.6-1.2GPa, the percentage elongation of the steel plate is 45-20%, and the product of strength and elongation is 25-40GPa%.

Owner:CENT IRON & STEEL RES INST

WN2 and LiBH4 powder added high-strength aluminum alloy and preparation method thereof

The invention relates to a WN2 and LiBH4 powder added high-strength aluminum alloy and a preparation method thereof. 0.65-1.2% of W powder, 1.3-2.4% of N powder, 0.65-1.2% of Li powder and 0.65-1.2% of B powder are added into a wrought aluminum alloy. In a process of adding aluminum alloy melt together with protective gas in a fluidization form, a specific surface area is much greater than that of a general massive material, rapid dispersion and full contact with the melt can be realized, and the dispersion and homogenization time is obviously shortened. Meanwhile, by adopting the high-strength aluminum alloy provided by the invention, in a casting process, a heterogeneous nucleation core can be effectively increased during alloy solidification, thereby achieving the grain refining effectand enhancing the alloy strength. Moreover, the added elements can promote the formation of interstitial atoms and interstitial phases; the solubility in an alpha (Al) solid solution is large at hightemperature and is very small at room temperature, therefore the alloy has higher heat-treatability; and after heat treatment, the strength and hardness of the alloy are greatly improved.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

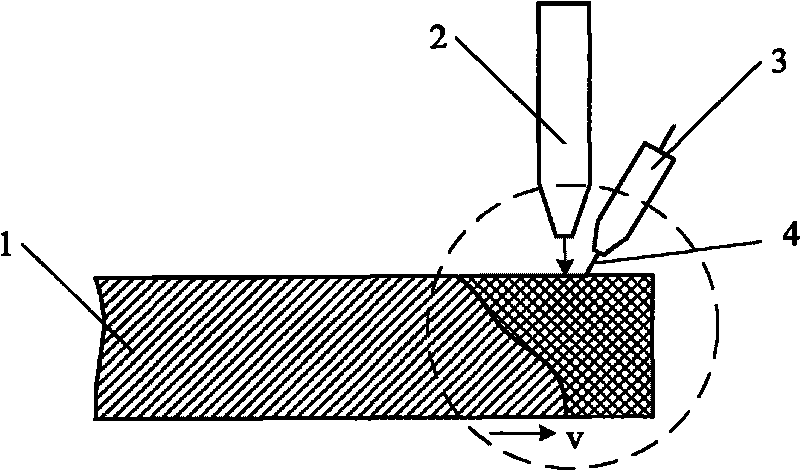

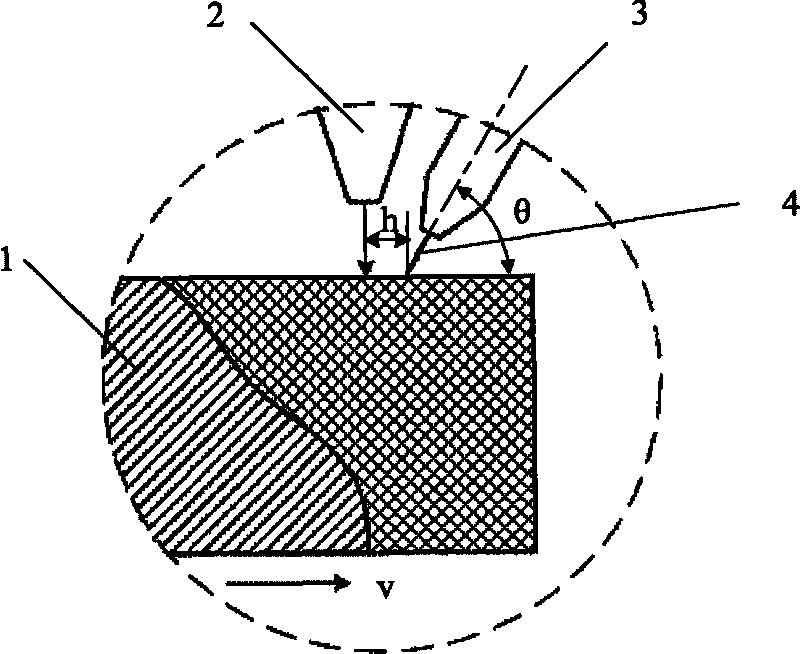

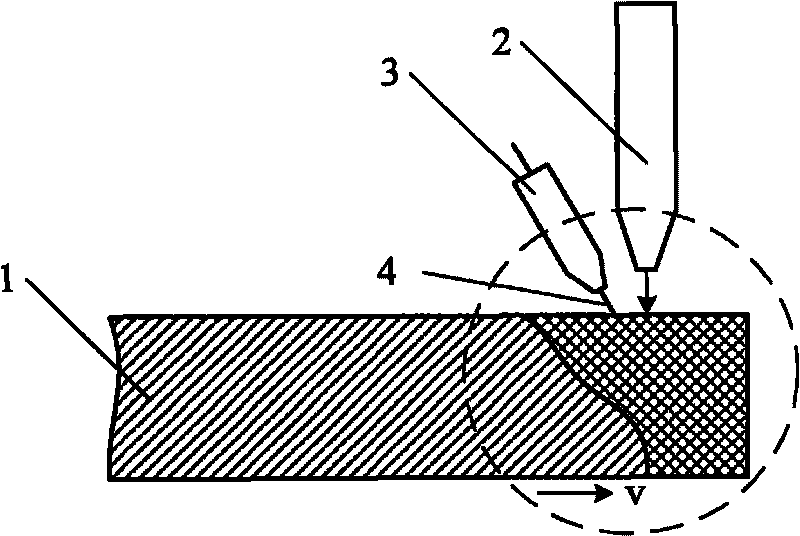

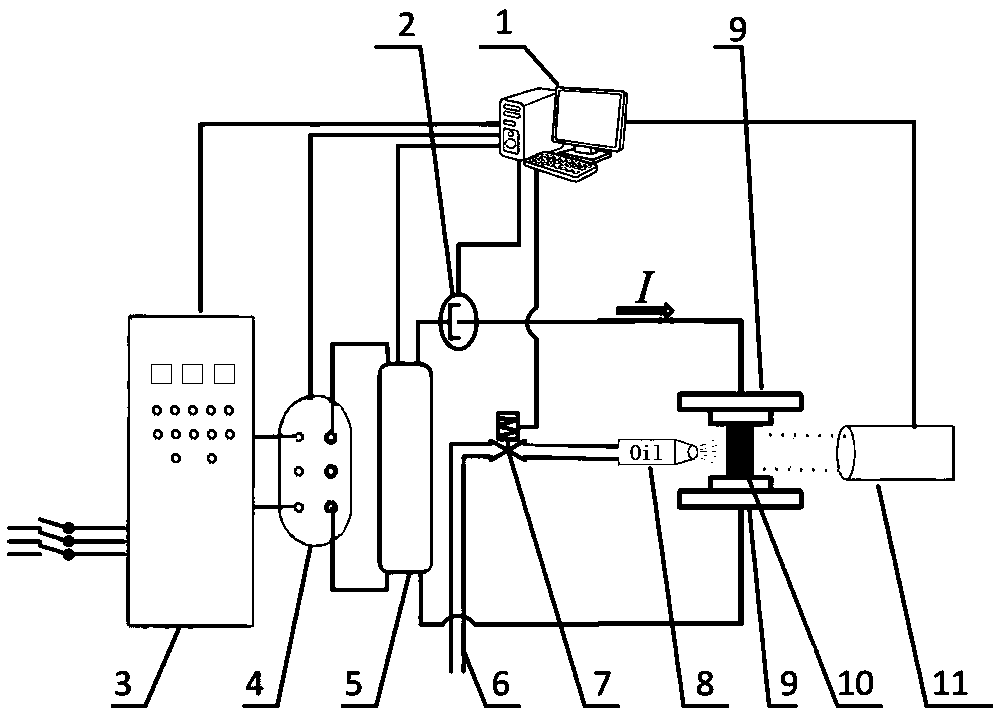

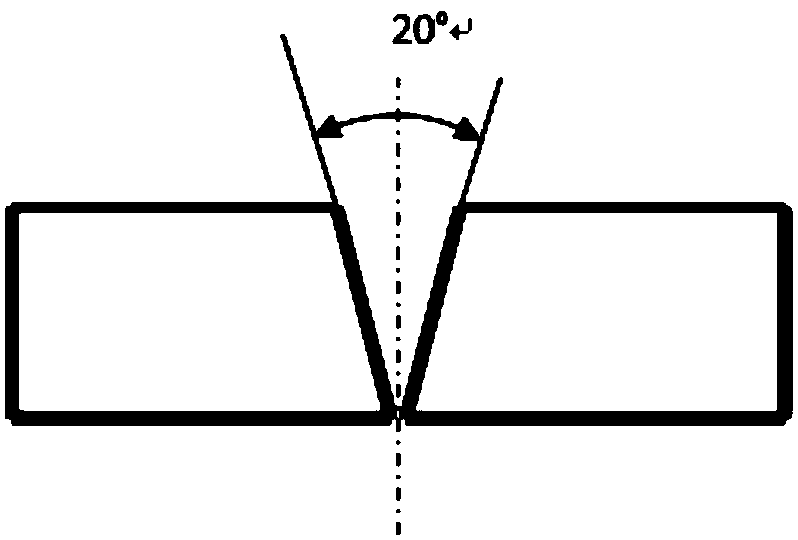

Laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel

InactiveCN101733564AReduced crack susceptibilityAvoid crackingArc welding apparatusLaser beam welding apparatusLaser NozzleSpray nozzle

The invention relates to a laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel, belonging to the technical field of high-strength steel welding. The traditional laser-electric arc composite heat source high-speed welding method of the high-strength or ultrahigh strength steel has overhigh welding linear energy due to low welding speed and large energy input so as to cause the deformation of a welding workpiece; in addition, chevilled silk spacing is overlarge, and stabilization action realized by a laser is reduced because the laser is adopted firstly and the electric arc is adopted subsequently so that a welding process is unstable and easy to generate splashing. The invention adopts laser-electric arc composite heat source welding; the welding workpiece is the high-strength steel or the ultrahigh strength steel; an electric arc welding gun is used for welding firstly and a laser nozzle is used for welding subsequently during welding; the current of electric arc welding is 140-180A, and the voltage of the electric arc welding is 23-25V; an included angle theta between the electric arc welding gun and the surface of the workpiece is 60-65 degrees; the laser power is 3-5kW; the welding speed v is 1-3m / minute; and the chevilled silk spacing h between a laser beam and a welding stick is determined within a range of 1-3mm. The invention realizes the welding of the ultrahigh strength steel without preheating, cold cracks or deformation.

Owner:CHANGCHUN UNIV OF SCI & TECH

Cutting tool for improving coating structure and preparation method thereof

ActiveCN103173761AExcellent oxidation and crater wear resistanceImprove uniformityTurning toolsSuperimposed coating processSingle phaseCast iron

The invention discloses a cutting tool for improving a coating structure. The cutting tool comprises a matrix and a coating covering the matrix. The coating comprises an inner layer B, a transitional layer C and an outer layer D from inside to outside. The inner layer B consists of transitional elements and nonmetal compounds. The transitional layer C comprises a transitional layer C1 and / or a transitional layer C2. The transitional layer C1 and C2 are mainly formed by carbon oxynitride with titanium. The outer layer D has a single phase alpha-Al2O3 structure. The thickness d of the outer layer D is 0.5-4 mu m. The mean grain size S is greater than or equal to 0.2 mu m but less than or equal to 0.5 mu m. The preparation method comprises the following steps of: first, preparing the tool matrix; then, sequentially depositing the inner layer B, the transitional layer C2, the transitional layer C1 and the outer layer D in a same coating period; and then, performing surface treatment to manufacture the cutting tool. The cutting tool provided by the invention is high in hardness and good in wear resistance, and has excellent cutting performance in cutting materials such as steel, stainless steel and cast iron.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Aqueous phosphating composition and process for metal surfaces

InactiveUS6179934B1High-quality coatingLess spaceSolid state diffusion coatingZinc phosphateHydroxylamine

An aqueous zinc phosphate conversion coating that contains 5 to 50 g / L of phosphate ions, 0.2 to 10 g / L of zinc ions, and 0.5 to 4.0 g / L as hydroxylamine of a hydroxylamine source, and also: (1) contains 0.01 to 5.0 g / L polycarboxylic acid or salt thereof and / or starch phosphate; or (2) has a zinc ions / phosphate ions weight ratio below 0.27 and a zinc ions concentration of at least 2.0 g / L forms high quality zinc phosphating coatings on metal surfaces even if the surfaces have not been previously conditioned by contact with a dispersion of colloidal titanium.

Owner:HENKEL CORP

Ni-pt alloy and target comprising the alloy

InactiveUS20070098590A1Easily perform cool rollingGood effectPhotography auxillary processesVacuum evaporation coatingActivated carbon filtrationFiltration

The present invention provides a Ni—Pt alloy superior in workability containing Pt in a content of 0.1 to 20 wt % and having a Vickers hardness of 40 to 90, and a target comprising the Ni—Pt alloy. The present invention also provides a manufacturing method of Ni—Pt alloy superior in workability comprising a step of subjecting a raw material Ni having a purity of 3N level to electrochemical dissolution, a step of neutralizing the electrolytically leached solution with ammonia, a step of removing impurities through filtration with activated carbon, a step of blowing carbon dioxide into the resultant solution to form nickel carbonate and exposing the resultant product to a reducing atmosphere to prepare high purity Ni powder, a step of leaching a raw material Pt having a purity of 3N level with acid, a step of subjecting the leached solution to electrolysis to prepare high purity electrodeposited Pt, and a step of dissolving the resultant high purity Ni powder and high purity electrodeposited Pt. The foregoing method enables the rolling of the Ni—Pt alloy ingot upon reducing the hardness thereof, which results in the stable and efficient manufacture of a rolled target.

Owner:JX NIPPON MINING& METALS CORP

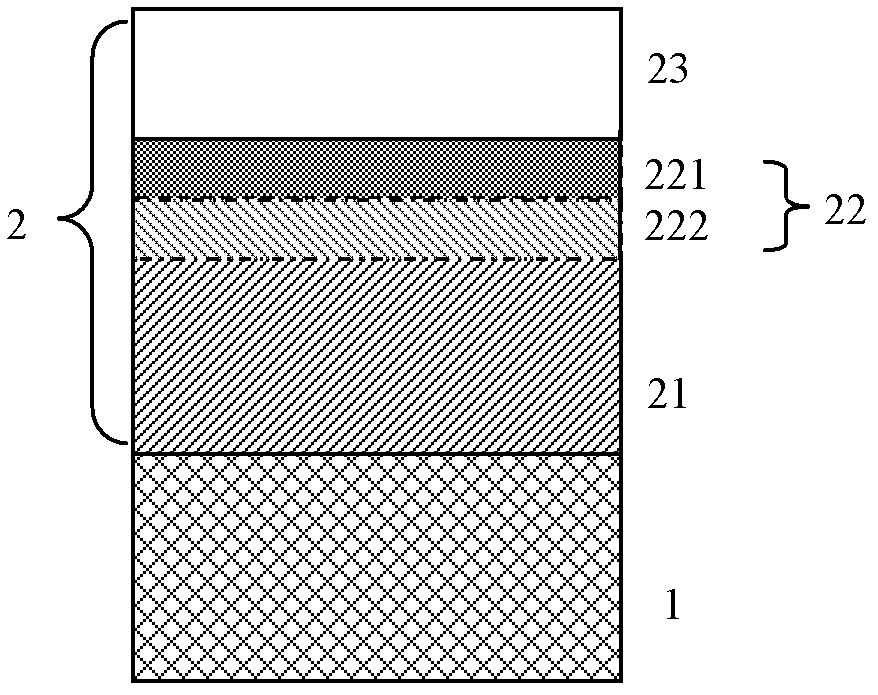

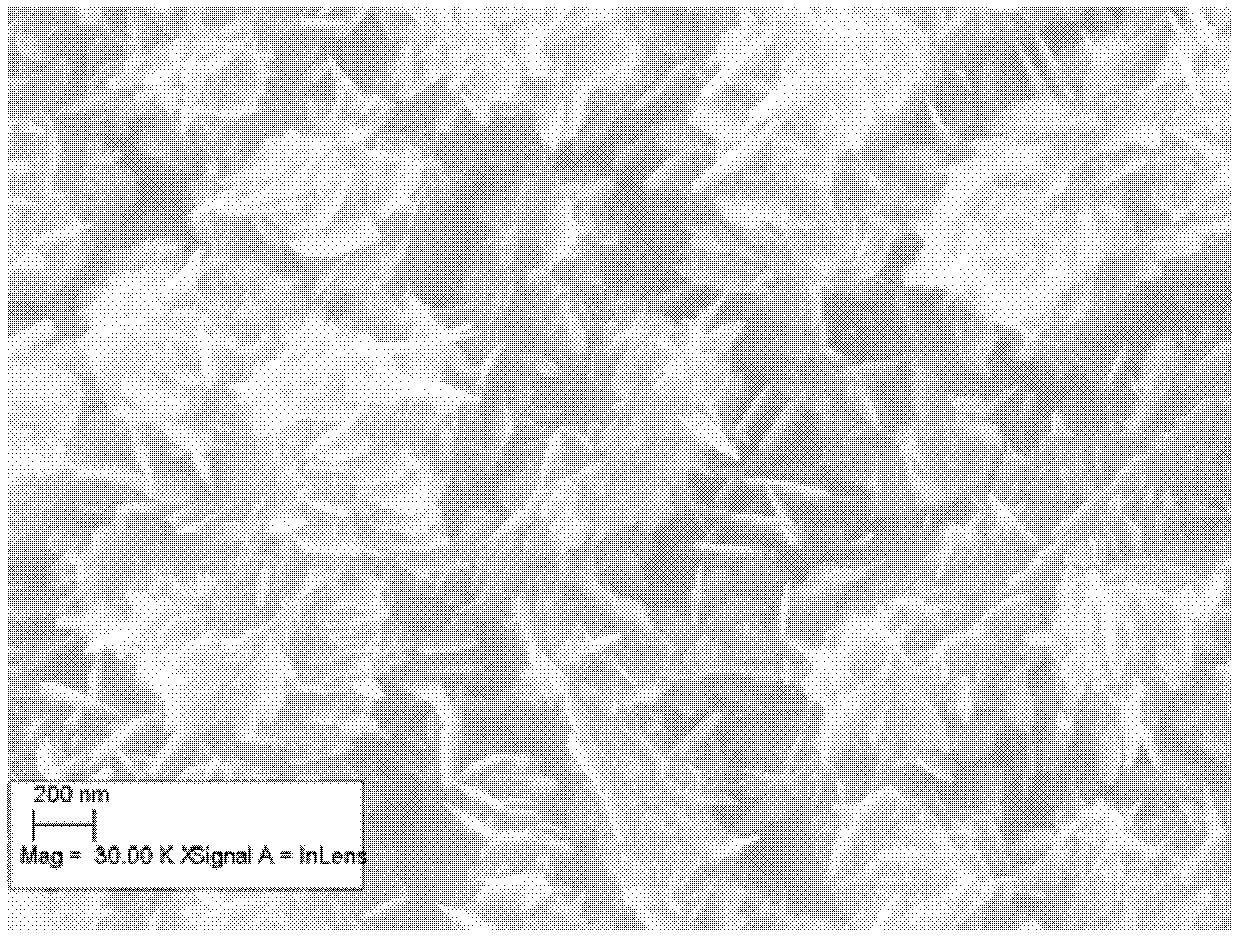

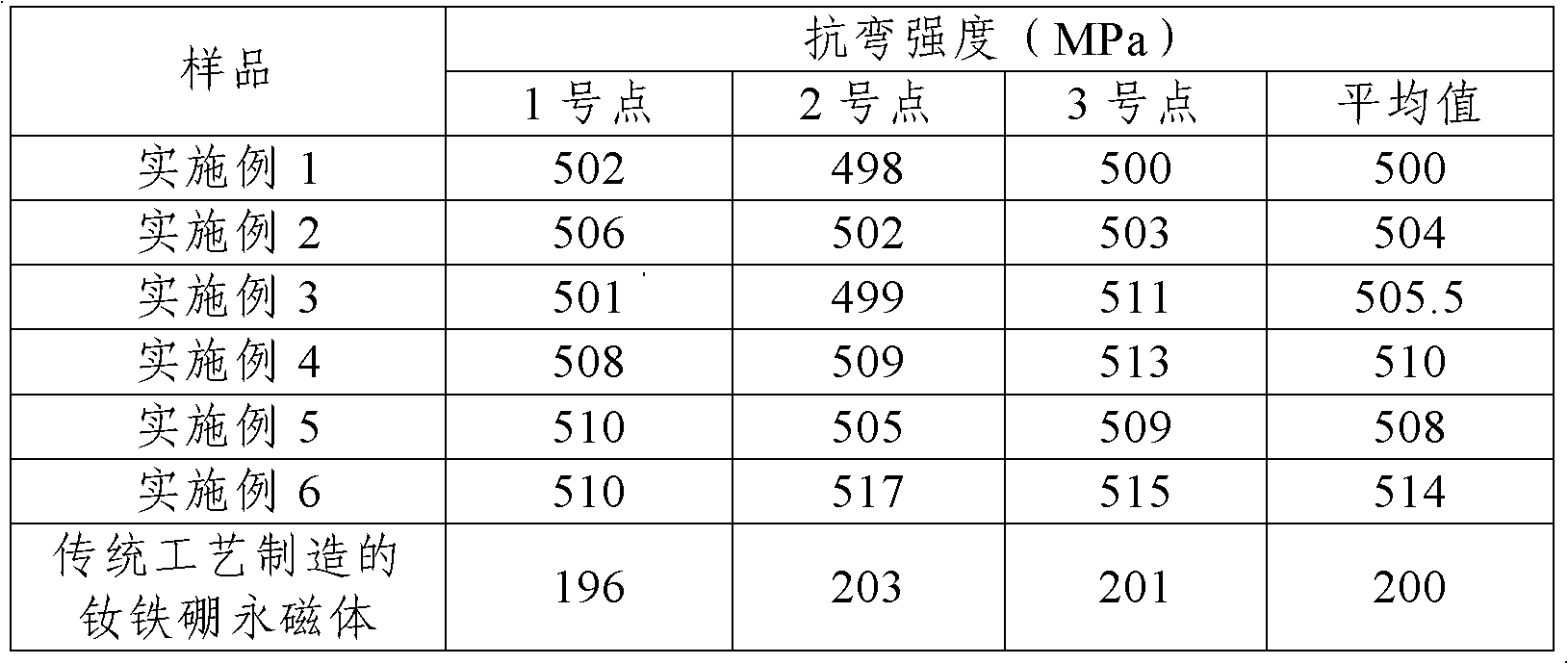

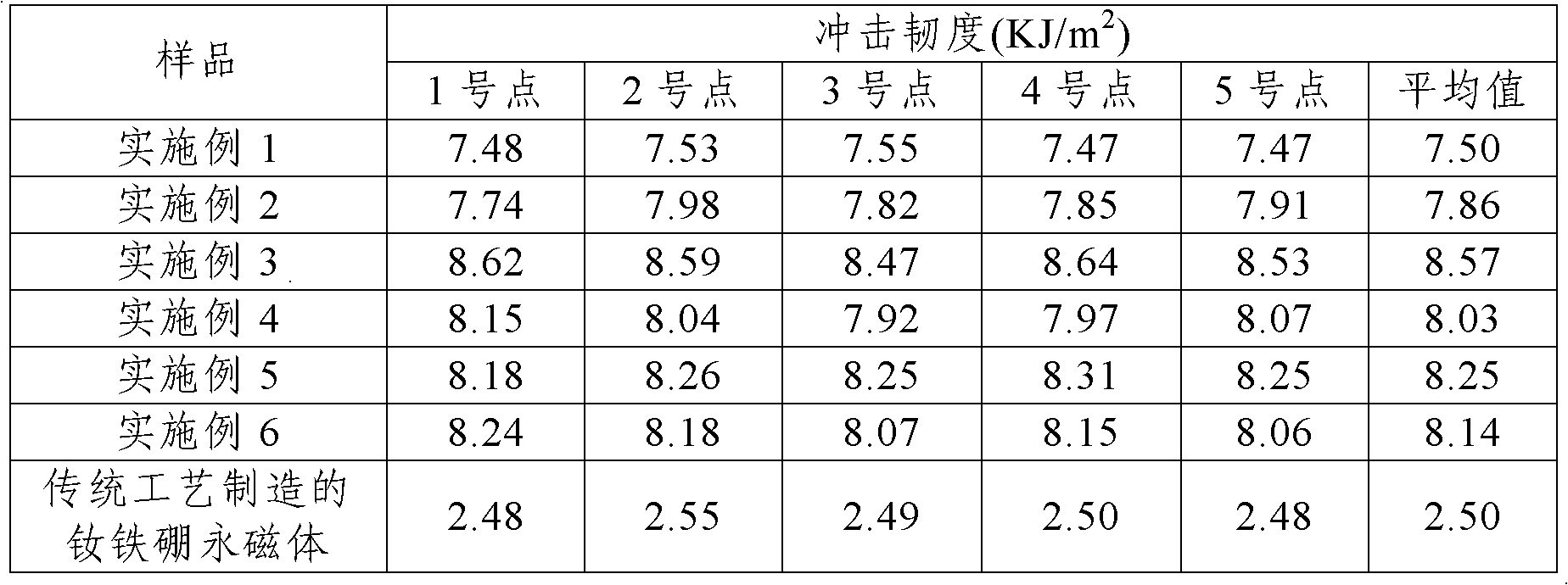

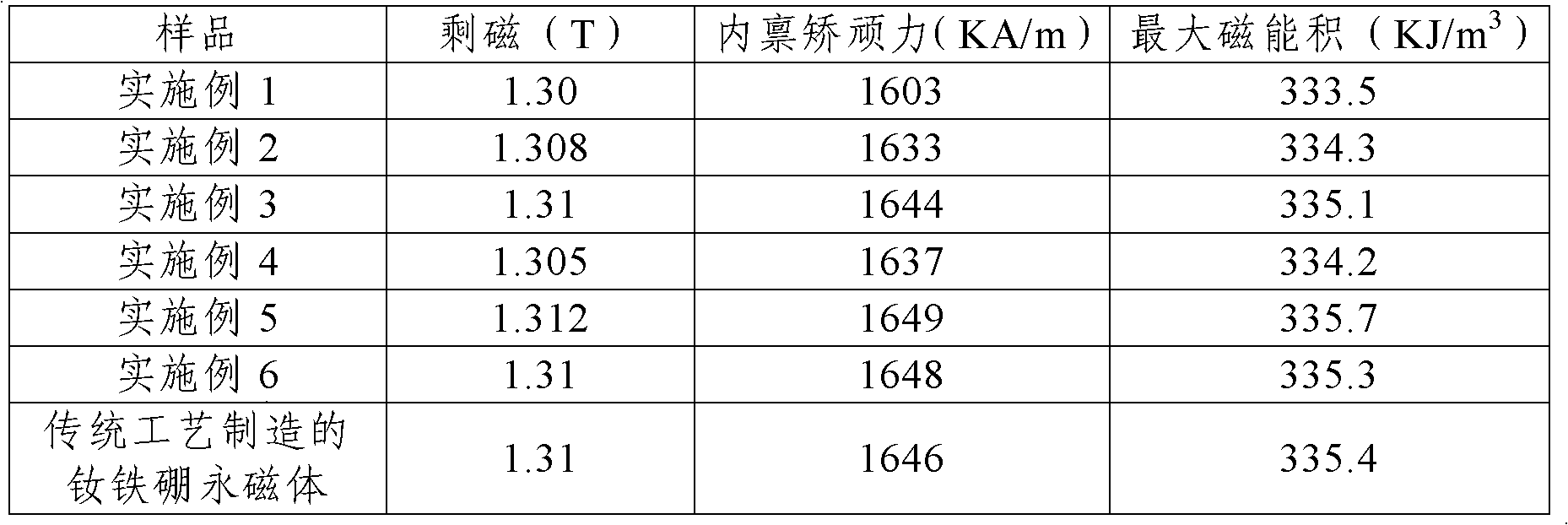

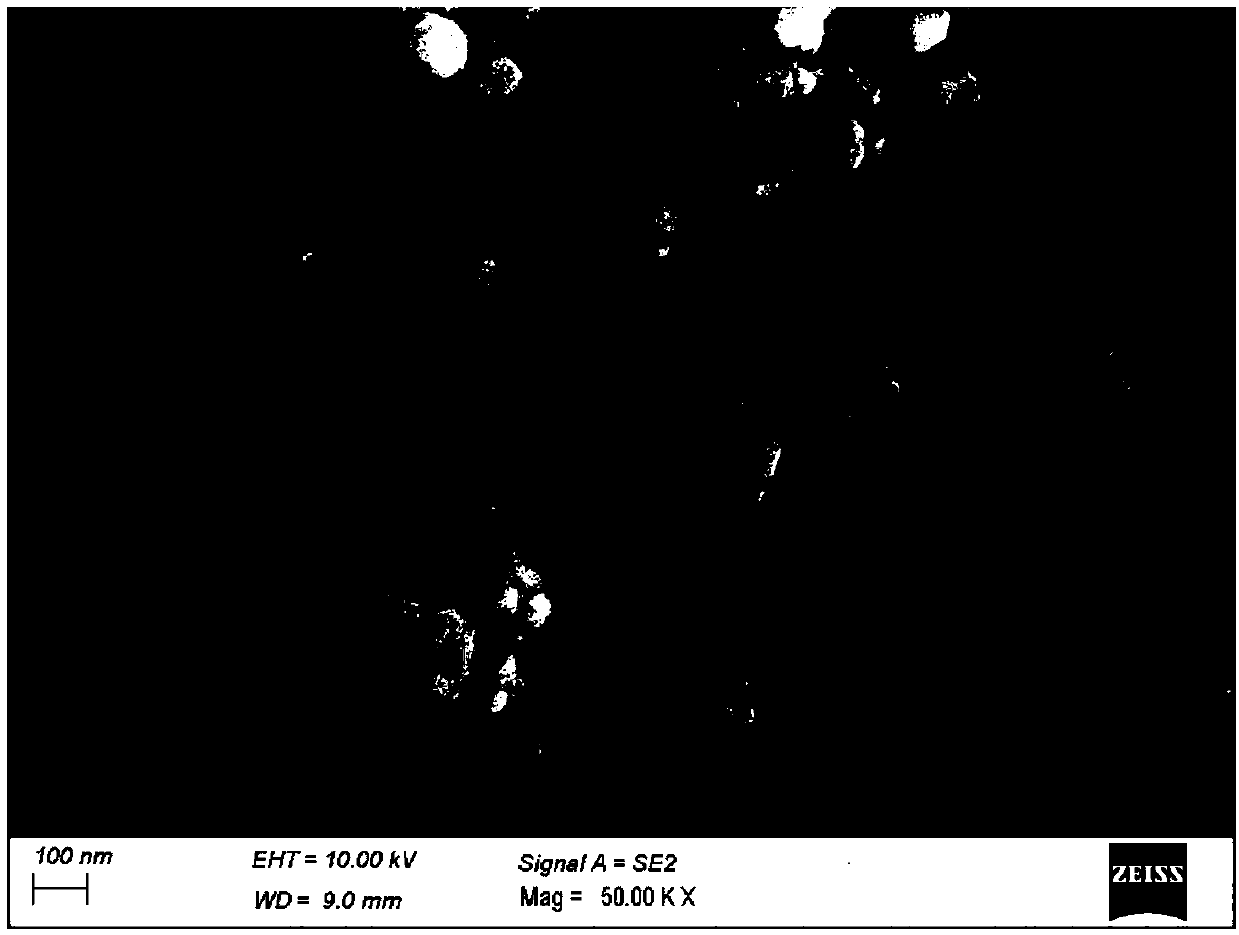

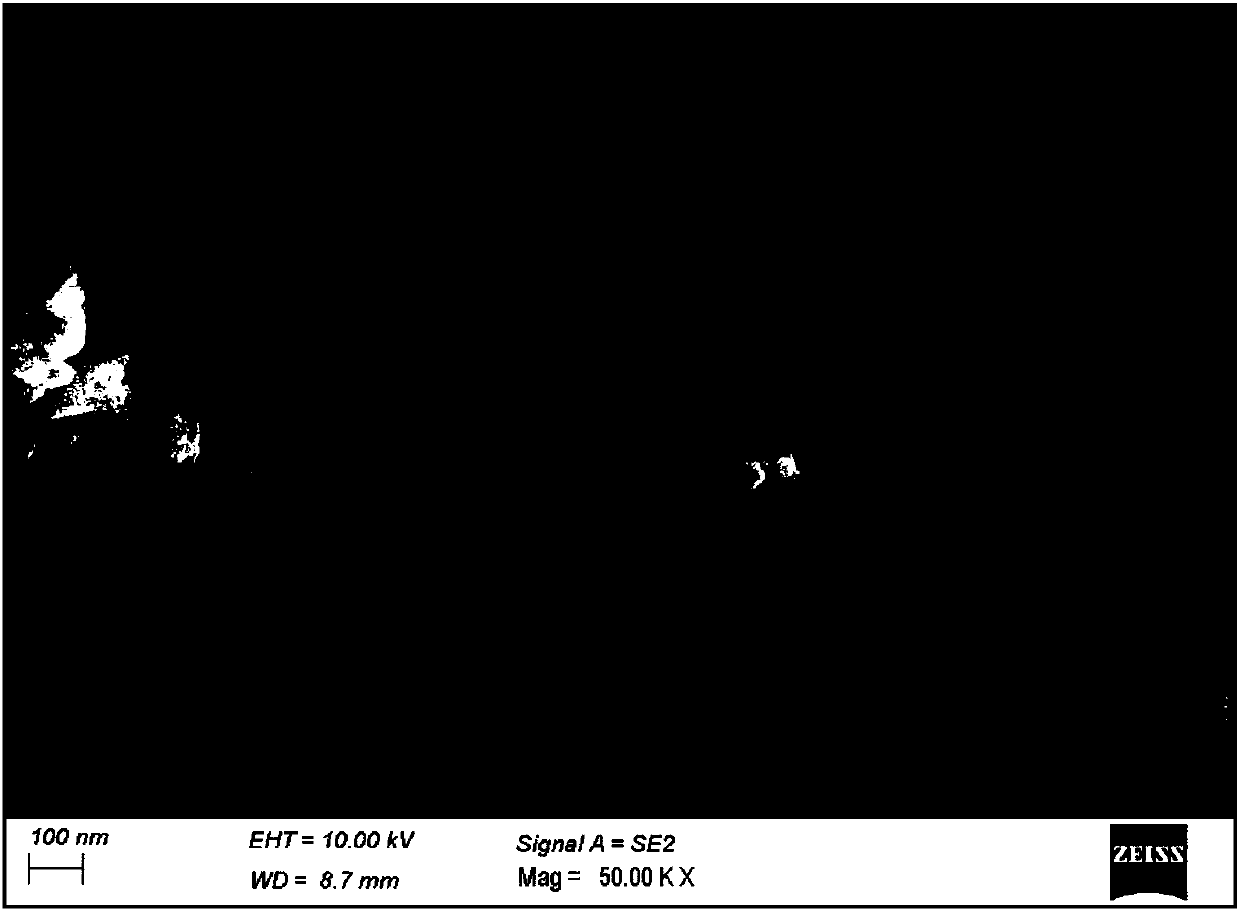

Manufacturing method of high-mechanical-strength sintered neodymium iron boron permanent magnets

ActiveCN102568738AAvoid coarseningHigh strengthPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementCobalt

The invention discloses a manufacturing method of high-mechanical-strength sintered neodymium iron boron permanent magnets, which includes: firstly, utilizing rare-earth elements, iron, titanium, cobalt and boron iron alloy as raw materials and weighing the raw materials; secondly, mixing the weighed raw materials and disposing the same in a vacuum melting induction furnace, and preparing quick-hardened tablets by means of quick hardening process; thirdly, saturating the quick-hardened tablets to absorb hydrogen at the room temperature and dehydrogenating the same to prepare hydrogen decrepitation powder, then preparing magnetic powder by the hydrogen decrepitation powder through jet mill process; fourthly, molding the magnetic powder in an oriented manner, pressing to form magnets, disposing the magnets into a vacuum sintering furnace to be sintered in a vacuum environment, and performing tempering heat treatment to obtain blanks; and fifthly, machining the blanks, cleaning and removing oil, scouring to obtain high-mechanical-strength sintered neodymium iron boron permanent magnets with bending resistance strength not lower than 500MPa and impact toughness not lower than 7.5KJ / m2. By the manufacturing method, processing difficulty of the sintered neodymium iron boron permanent magnets is reduced greatly, application range of the sintered neodymium iron boron permanent magnets is broadened and economic potential thereof is high.

Owner:西安西工大思强科技股份有限公司

Yttria-stabilized zirconia ceramic and preparation method thereof

The invention provides an yttria-stabilized zirconia ceramic and a preparation method thereof. The preparation method disclosed by the invention comprises the following steps: providing nano-ceramic powder containing zirconia, yttria and alumina; pressing the nano-ceramic powder to obtain a ceramic body; and calcining the obtained ceramic body, thereby obtaining the yttria-stabilized zirconia ceramic, wherein the calcination temperature is 1350-1520 DEG C. According to the yttria-stabilized zirconia ceramic and the preparation method thereof disclosed by the invention, the alumina is added inthe preparation process of the yttria-stabilized zirconia ceramic, and because one of the alumina is segregated to a crystal boundary of the ceramic structure, growth of ceramic grains can be hindered, the ceramic sintering temperature is effectively reduced, the effect of refining the ceramic grains is achieved, and the light transmittance and mechanical property of the ceramic are further improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

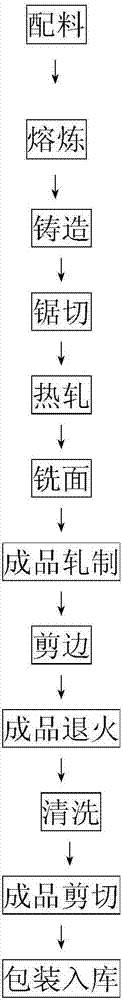

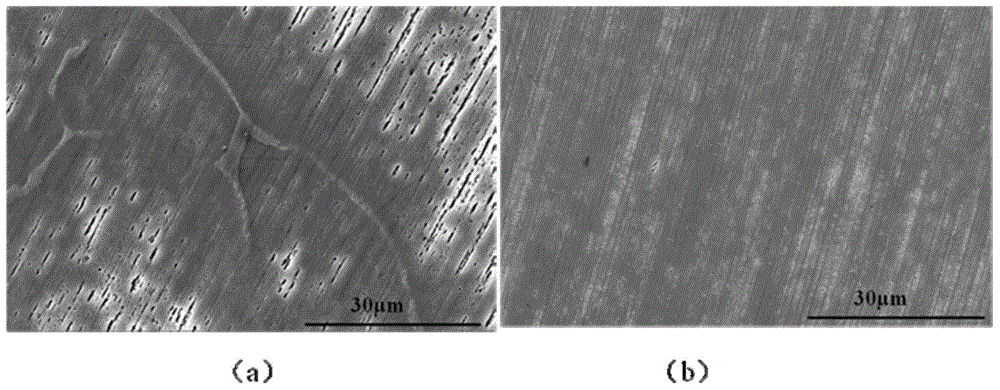

Preparation process of copper strip for framework material

ActiveCN107385270AIncreased strength and softening resistanceAvoid grain coarseningCorrosionScratching

Provided is a preparation process of a copper strip for a framework material. The preparation process comprises the technological steps of proportioning, smelting, casting, saw cutting, hot rolling, face milling, finished product milling, edge shearing, finished product annealing, washing, finished product shearing and packaging and putting into a storage. Compared with a special-shaped framework material manufactured by an original process, the copper strip produced by the preparation process has the remarkable advantages of high strength, good electrical conductivity, good subsequent machining performance and the like, chemical components of the material are stable, the surface is clean, smooth, free of oxidation discoloration, and free of defects like peeling, burrs, bubbles, cracks, layering, inclusion, holes, black points, folding, verdigris, scratching and corrosion, the copper strip can adapt to the more severe use environment, and the service life of a profiled bar is prolonged.

Owner:中铝洛阳铜加工有限公司

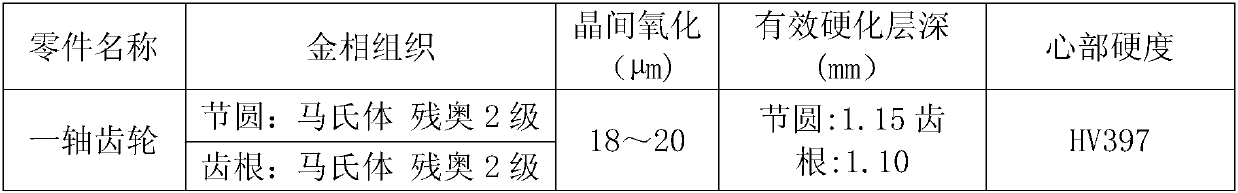

High-hardenability Mn-Cr series carburizing steel

InactiveCN107604253AImprove hardenabilityReduce intergranular oxidationPortable liftingGearing detailsCommercial vehicleHardenability

The invention discloses high-hardenability Mn-Cr series carburizing steel. The high-hardenability Mn-Cr series carburizing steel is composed of the following components of, by mass, 0.18-0.22% of C, less than or equal to 0.20% of Si, 1.20-1.40% of Mn, less than or equal to 0.035% of P, 0.015-0.040% of S, 1.25-1.40% of Cr, less than or equal to 0.10% of Mo, 0.017-0.035% of Al, 0.010-0.020% of N, greater than or equal to 0.10% of Ni, 0.10-0.20% of Cu, less than or equal to 0.0003% of B and the balance Fe and unavoidable impurities. According to the high-hardenability Mn-Cr series carburizing steel, small heat-treatment deformation capability and high reliability are achieved, and the high-hardenability Mn-Cr series carburizing steel is suitable for commercial vehicle heavy load gearboxes anddriving axle gears.

Owner:DONGFENG COMML VEHICLE CO LTD

Visible light catalytic material, and preparation method and application thereof

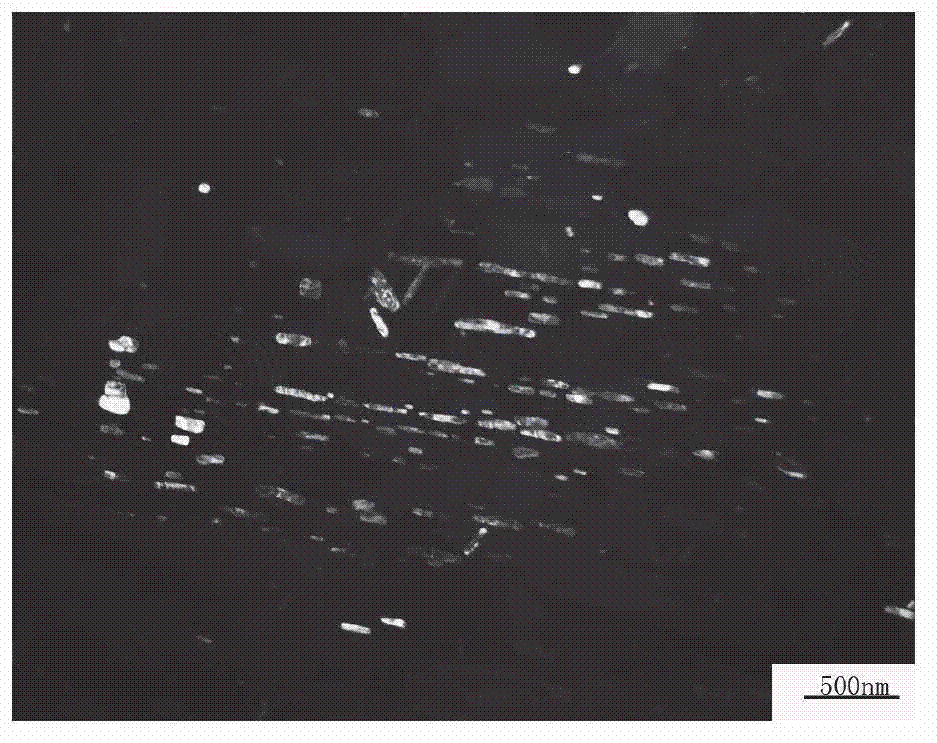

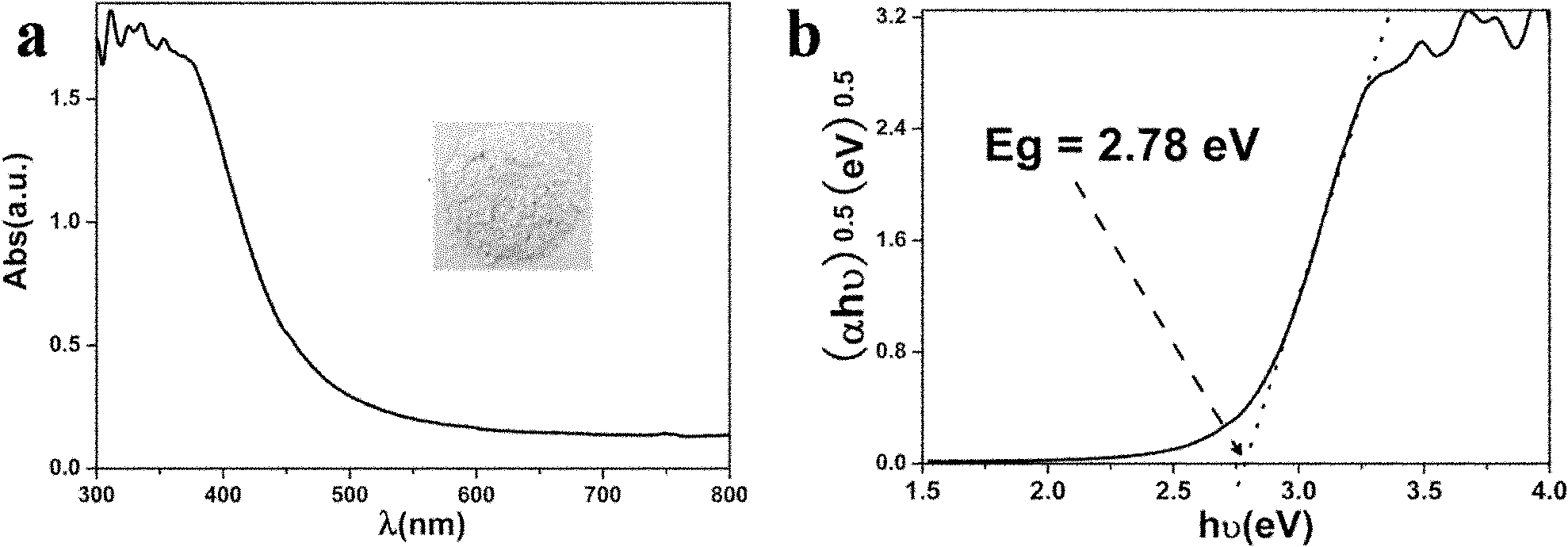

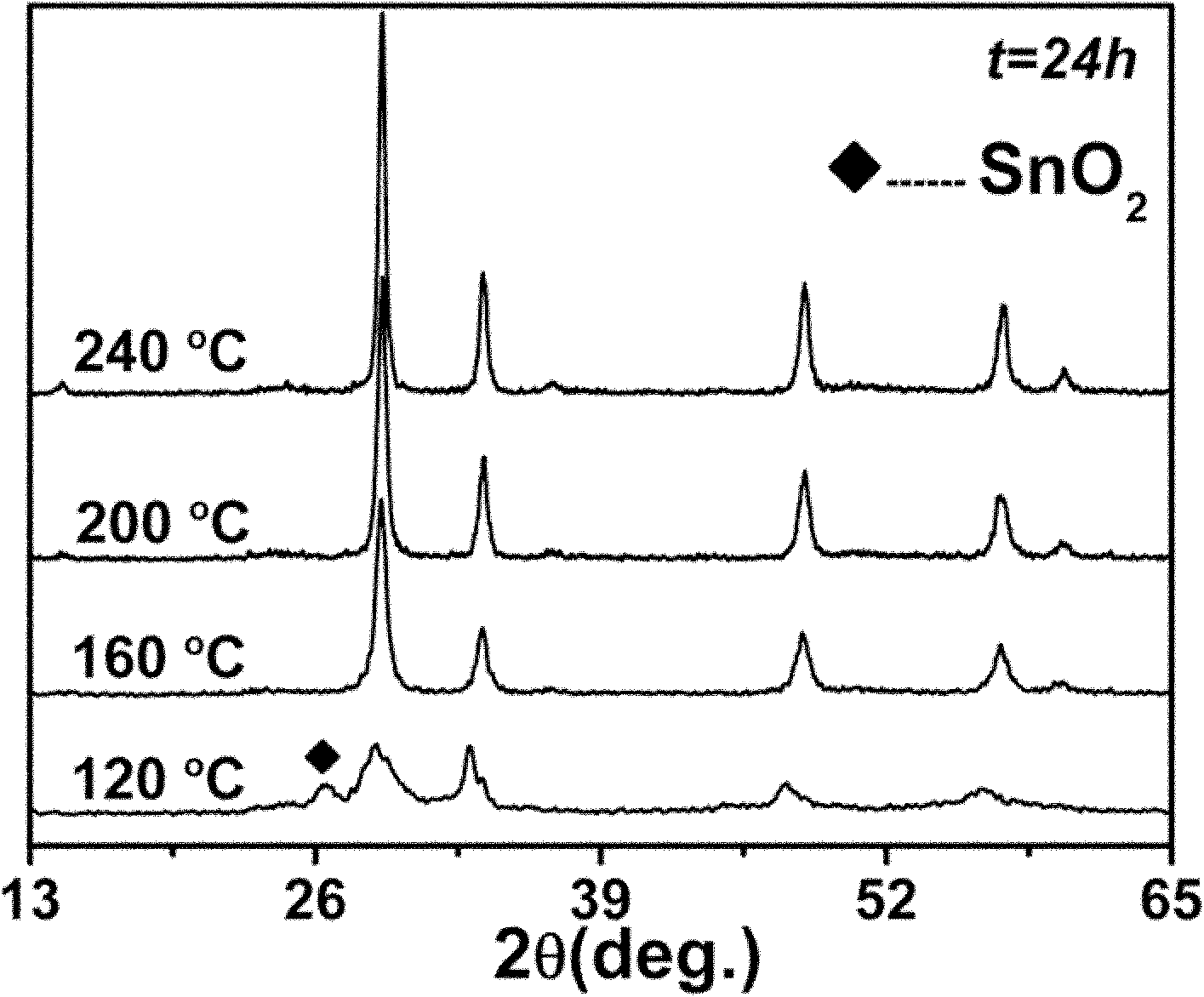

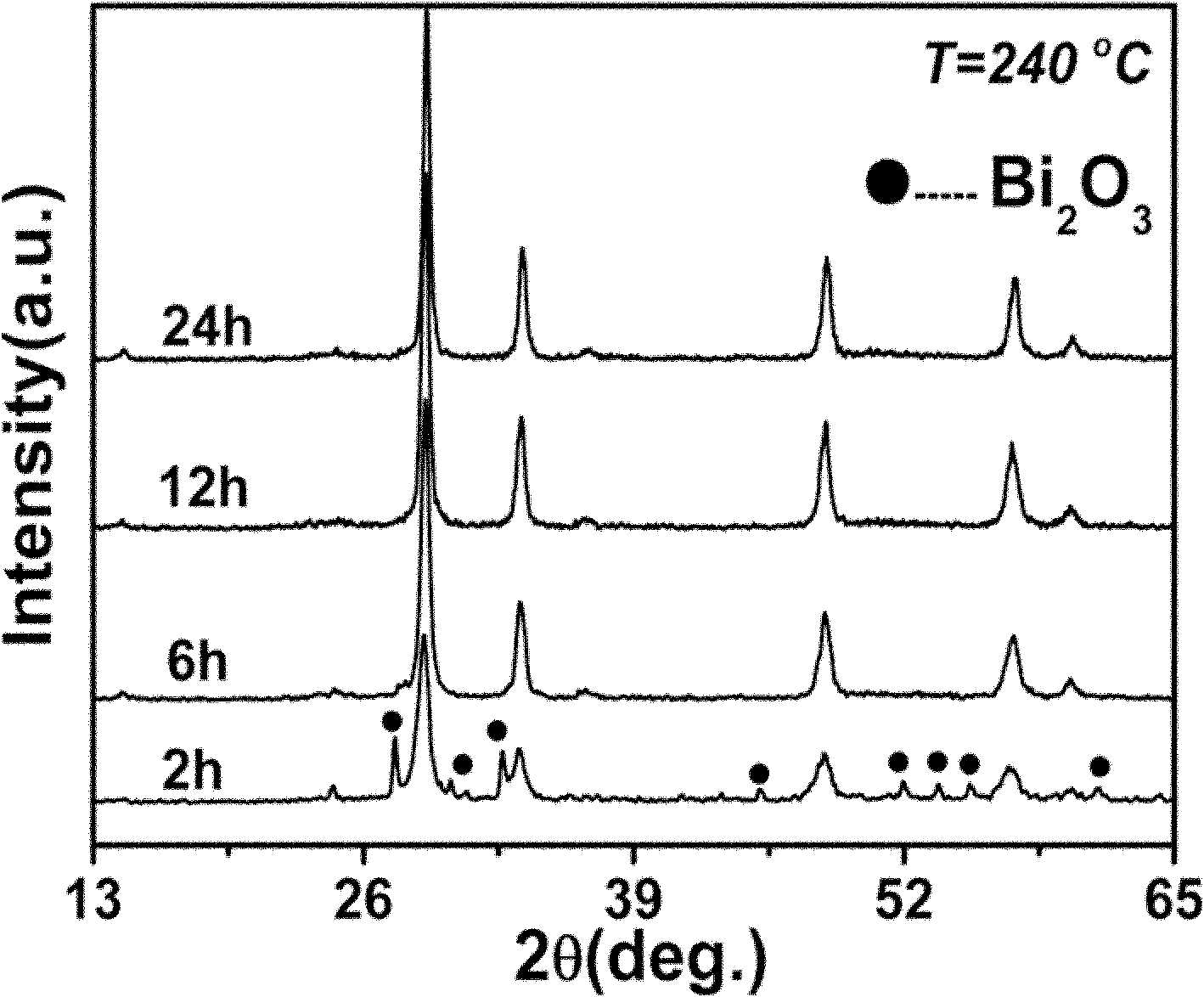

ActiveCN102080262AFast transferEasy to separatePolycrystalline material growthFrom normal temperature solutionsCrystallinityElectronic band structure

The invention discloses a visible light catalytic material used for environmental purification and a preparation method thereof. The visible light catalytic material is an indirect gas semiconductor with a dispersed energy band structure, is a crystalline nano material, comprises the chemical formula of Bi2Sn2O7, has the corresponding optical band gap width of 2.68 to 2.78eV and exhibits high visible light catalytic performance. In the preparation method provided by the invention, Bi2Sn2O7 nanoparticles can be prepared from readily-available raw materials with low cost under moderate conditions only by one-step hydrothermal reaction so as to avoid the coarsening and aggregation of the high-temperature sintered crystal particles; the preparation method is simple to operate; parameters are adjustable in a reaction process, and the crystallinity and material phase compositions of the product are easy to control; in addition, the sample provided by the invention exhibits high stability inphotocatalysis cycle tests of dye degradation and harmful gas purification, and is favorable for industrial application.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Toughening and deformation processing method of magnesium alloy

The invention discloses a toughening and deformation processing method of a magnesium alloy, which performs toughening and deformation processing on a melted and homogenized magnesium alloy billet. The method is combined by any more than two methods of metal plastic deformation processing methods containing forging deformation processing, extruding deformation processing, rolling deformation processing and stamping deformation processing, a latter deformation processing method is carried out on the magnesium alloy directly after the former deformation processing method or after the magnesium alloy is split when the former deformation processing method is finished, heating is not carried out between the two deformation processing methods, the magnesium alloy material after deformation processing is immediately subjected to water spray cooling or blow cooling when the last deformation processing method is finished, and the cooled magnesium alloy material is performed with aging heat treatment. The method in the invention can obviously and evenly refine the interior textures of the magnesium alloy material, improve the mechanical property and uniformity of the magnesium alloy material, avoid texture coarsening of a magnesium alloy deformation workpiece in reheating and heat insulation processes, and save energy.

Owner:GRIMAT ENG INST CO LTD

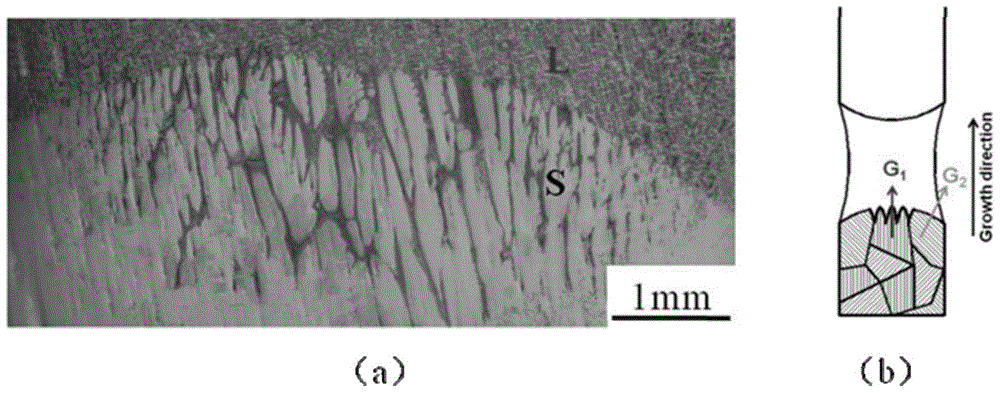

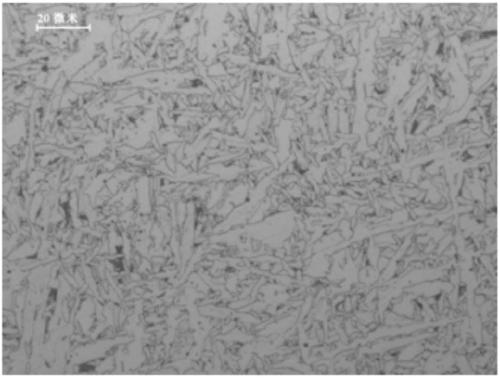

High-temperature high-strength TiAl-Nb monocrystal and preparation method thereof

InactiveCN104878452AImprove high temperature mechanical propertiesSolve pollutionPolycrystalline material growthBy zone-melting liquidsDifferential pressureSingle crystal

The invention discloses a high-temperature high-strength TiAl-Nb monocrystal and a preparation method thereof. Based on the atomic percent, the high-temperature high-strength TiAl-Nb monocrystal comprises the alloy components: Ti-(43-47) Al-(6-10)Nb-(0.1-1)(C, Si), and the balance of Ti. The preparation method comprises the following steps: smelting TiAl-Nb button-shaped master alloy ingot casting by using an electro-magnetic induction suspension method; preparing a cylindrical rod-shaped sample by means of differential pressure suction casting or gravity casting; directionally condensing the cylindrical bar by using an optical float-zone crystal growth system to guarantee that the heating power is between 65% and 70%, the growth velocity is 5-30mm / h, the relative rotation speed is 20-40r / min and the argon flow protection is carried out for 3-5L / min; finally obtaining a TiAl-Nb monocrystal test bar; and performing desegregation heat treatment on the TiAl-Nb monocrystal bar to finally obtain the monocrystal test sample. By adopting the TiAl-Nb monocrystal alloy material prepared by using preparation method disclosed by the invention, the alloy pollution caused by a traditional Bridgman directional condensation method can be effectively avoided, a solid-liquid interface shape during condensation is controlled by regulating the heating power so as to quickly obtain the TiAl-Nb monocrystal, and after the desegregation of the TiAl-Nb monocrystal, the high-strength TiAl-Nb monocrystal alloy of which the yield strength is 637MPa at a temperature of 900 DEG C, the elongation percentage is 8.1% and the ductile-brittle transition temperature is not lower than 900 DEG C can be obtained.

Owner:NANJING UNIV OF SCI & TECH

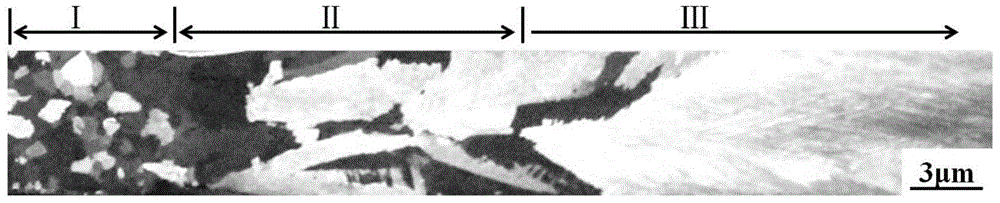

Method for preparing high-solid-solubility ultrafine grain high-speed steel through electric pulses

ActiveCN109825689AHigh hardnessImprove toughnessHeat treatment process controlAustenite grainCarbide

The invention discloses a method for preparing high-solid-solubility ultrafine grain high-speed steel through electric pulses. The method includes the steps that high-speed steel is subjected to conventional austenitizing and then quenched and tempered; then the two ends of the steel are clamped between electrodes of electric pulse equipment, the high-speed steel is discharged in the air environment, the temperature of the material rises to the austenitizing temperature region through pulse currents, austenite grains are ultrafine, and dissolution of carbide is promoted; after electric pulse discharge is completed, quenching is completed through an automatic quenching device; and finally the high-solid-solubility ultrafine grain high-speed steel in a quenched state through electric pulse treatment is tempered three times, and the high-speed steel with excellent comprehensive mechanical performance is obtained. By means of the method, the technical bottleneck that in the traditional heat treatment process, high-speed steel grain refinement and carbide dissolution promotion cannot be taken into account is solved, and the double effects that the high-speed steel austenite grains are ultrafine, and the dissolution quantity of the carbide is increased are achieved. The method is short in technological process, energy saving and high efficiency are achieved, and the hardness and thetoughness of the high-speed steel can be simultaneously improved.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method thereof

ActiveCN1827824AExcellent long-lasting antibacterial effectLow content of alloying elementsTemperature control deviceHeat treatment process controlPre treatmentChromium

Disclosed is a ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method, wherein the stainless steel matrix comprises (by wt%) Cr 12.0-14.0%, Cu 0.70-2.20%, C <=0.08-0.15, the preparing process comprises pre-processing melted iron, passing through composite revolving furnace, vacuum oxygen decarbonization furnace, refined-smelting ladle furnace, continuous plate blank casting, casting blank annealing, tandem rolling, and annealing in a bell-type furnace.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

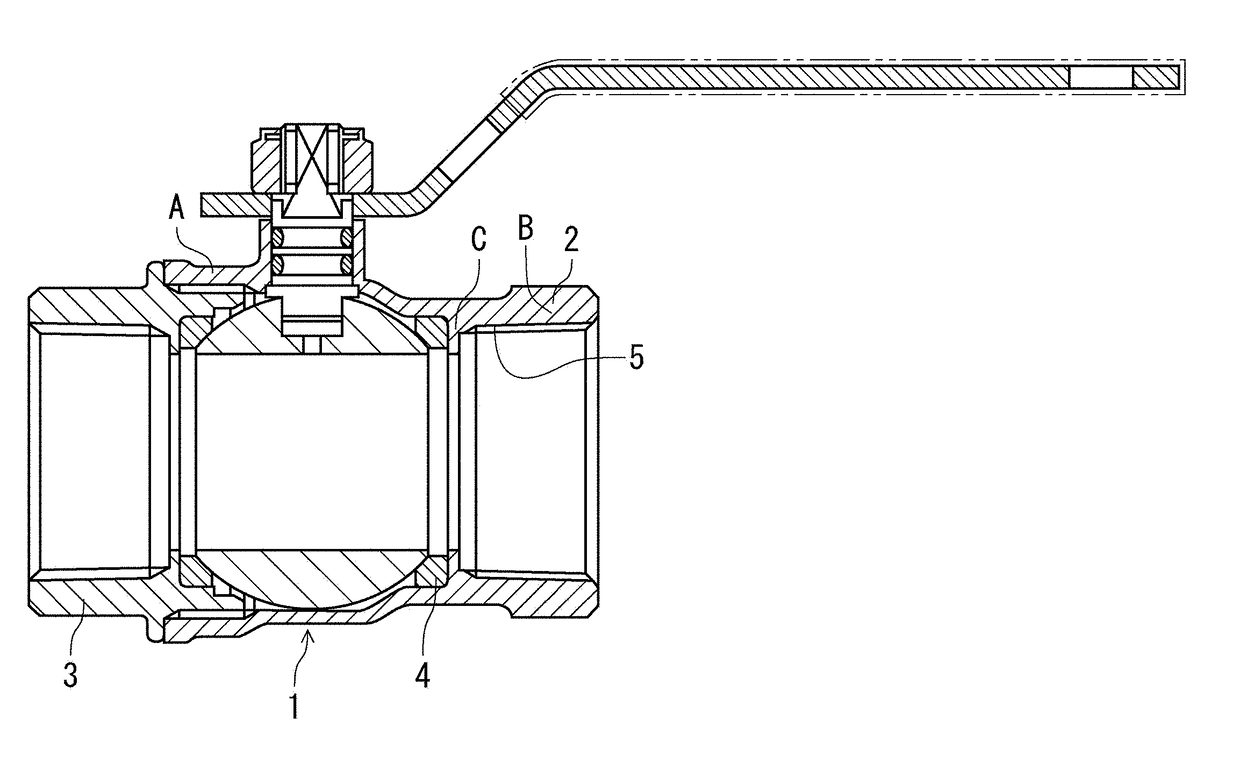

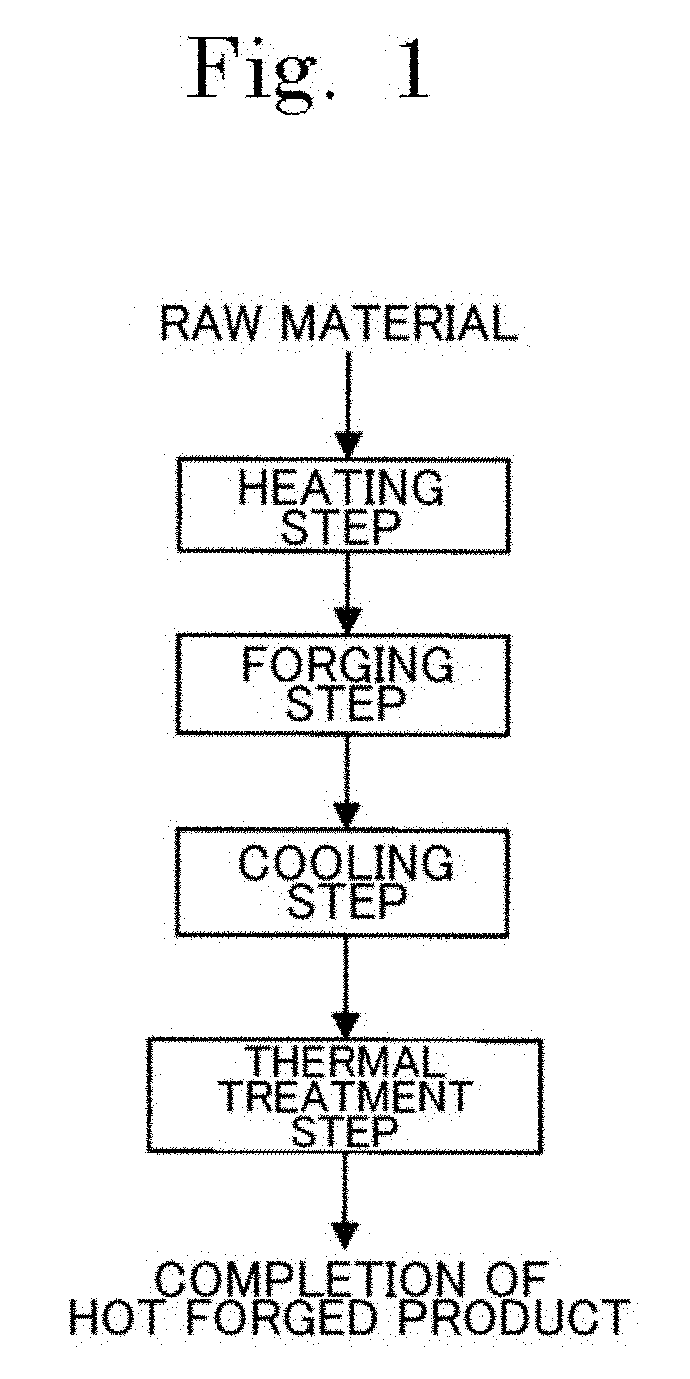

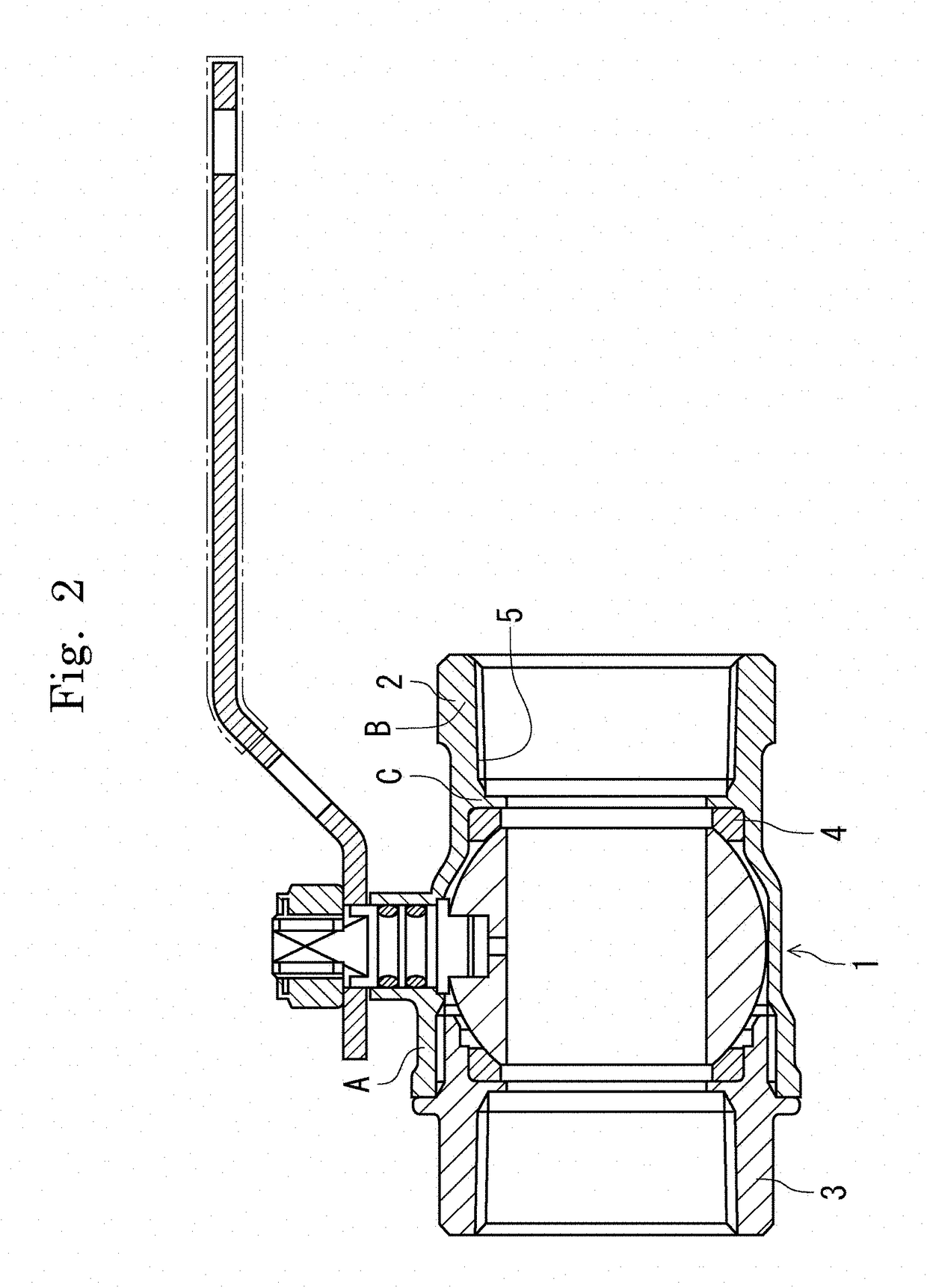

Method of producing hot forged product using brass and hot forged product and wetted product such as valve and water faucet molded using the same

ActiveUS20170211169A1Dezincification resistance can be increasedImproves stress corrosion crackingValve housingsHeat treatedCopper alloy

To contribute to an improvement in a dezincification resistance of a copper alloy, focusing attention on a relation between a dezincification resistance of a copper alloy and the crystal grain size of an α phase, and the specific object is to provide a method of producing a hot forged product using a lead-free brass capable of ensuring corrosion resistances such as a prescribed dezincification resistance and the like even at sites of different thickness and shape, a hot forged product, and a wetted product such as a valve and a water faucet, molded using the same. A method of producing a hot forged product using a brass, comprising heat-treating a raw material to be subjected to forging work using a brass having a composition containing at least 59.2 to 63.0% by mass of Cu, 1.00 to 2.00% by mass of Sn and 0.05 to 0.25% by mass of Pb and containing the residue composed of Zn and inevitable impurities at a heating rate of 5.2° C. / s or more from 350° C. until reaching the forging temperature.

Owner:KITZ CORP

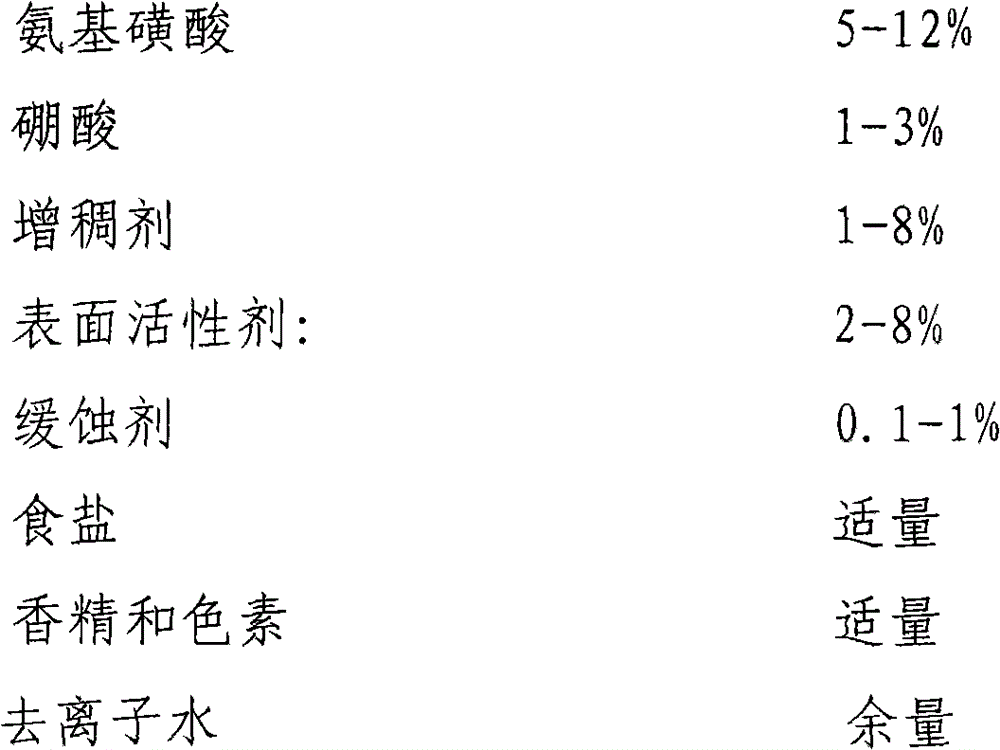

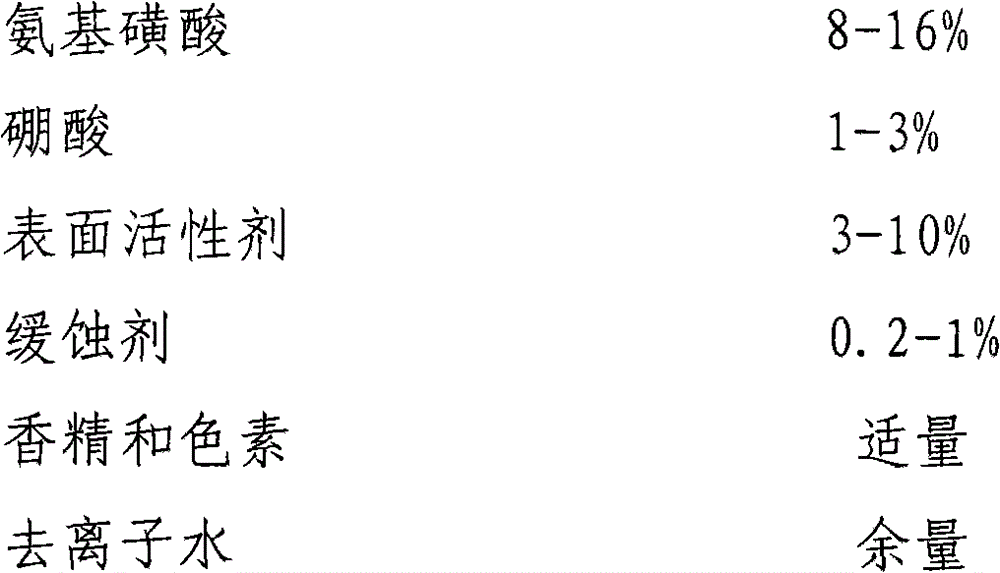

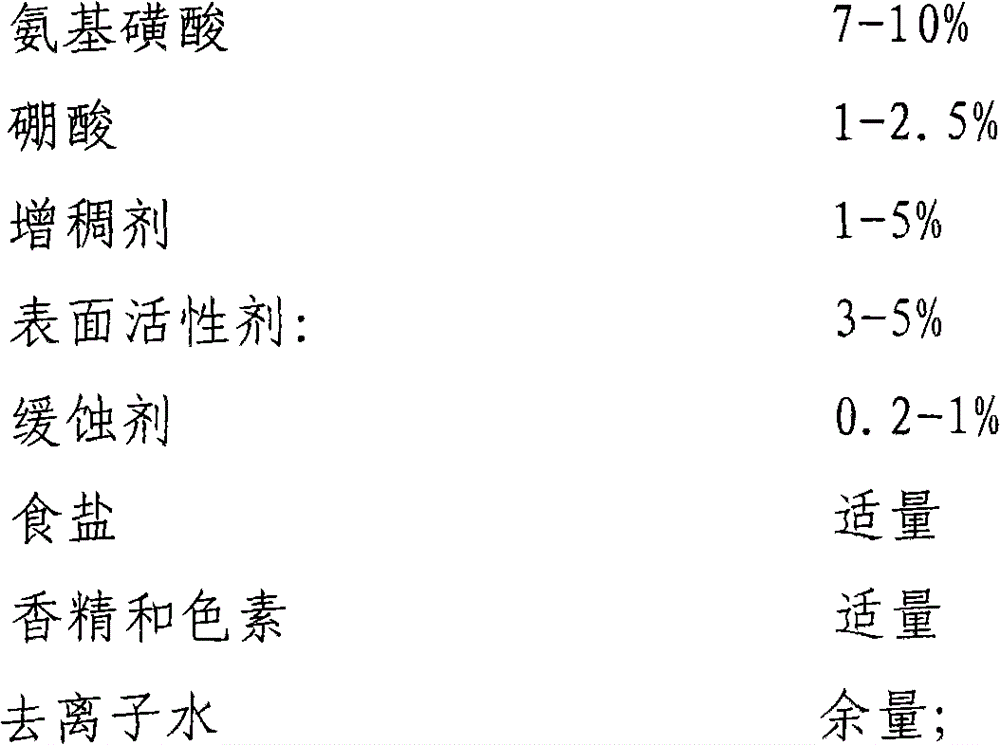

Matched cleaning agent for vacuum drainage pipelines of airplane toilets and preparation method and cleaning process of matched cleaning agent

ActiveCN102746958AHigh viscosityGood wall hangingHollow article cleaningSurface-active non-soap compounds and soap mixture detergentsJet aeroplaneVertical plane

The invention relates to the field of aerospace, in particular to a matched cleaning agent for vacuum drainage pipelines of airplane toilets. The cleaning agent comprises a cleaning agent I and a cleaning agent II which are matched and synergistic for graded cleaning. The cleaning agent I which is an acidic thixotropic cleaning agent and good in wall cling performance is used for cleaning firstly, is capable of effectively removing scale on inclined planes or vertical planes of a pipeline system and can be used for pipe leakage detection; and then the cleaning agent II which is low in viscosity, good in liquidity and high in scaling capability is used for cleaning. The invention further discloses a preparation method of the matched cleaning agent and a cleaning process using the matched cleaning agent. The matched cleaning agent is capable of effectively removing iron rust, water scale, urine scale and other dirt of the vacuum and circulating toilets and plays a protecting role in metal pipelines without corroding the pipelines.

Owner:北京雅迪力特航空新材料股份公司

Large heat input energy welding high-strength EH36 steel plate and making method thereof

The invention relates to a large heat input energy welding high-strength EH36 steel plate which is made of the following components in percentage by weight through smelting: 0.06-0.18% of C, 0.15-0.50% of Si, 1.10-1.60% of Mn, less than or equal to 0.012% of P, less than or equal to 0.003% of S, 0.10-0.40% of Ni, 0.010-0.030% of Nb, less than or equal to 0.010% of Al, 0.010-0.030% of Ti, 0.001-0.010% of Ca and the balance of Fe and inevitable impurities. The maximum thickness of the steel plate is 100mm, the yield strength of the steel plate is greater than or equal to 355MPa, the tension strength of the steel plate is greater than or equal to 510MPa, and the low-temperature impact absorption energy KV2 of the steel plate at minus 40 DEG C is greater than or equal to 150KJ. A production method of the steel plate comprises the following steps: carrying out smelting, LF / RH (Ladle Furnace / Ruhrstahl Heraeus) refining, continuous casting, heating, rolling, and rapid cooling, thereby obtaining a finished product of the steel plate. The steel plate produced by using the method provided by the invention has the characteristics of high purity, high strength, good low-temperature impact resistance, good toughness when the maximum input line energy is 300KJ / CM, and the like, can be widely applied to fields such as shipbuilding, bridges and building structures, and has wide application prospects.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

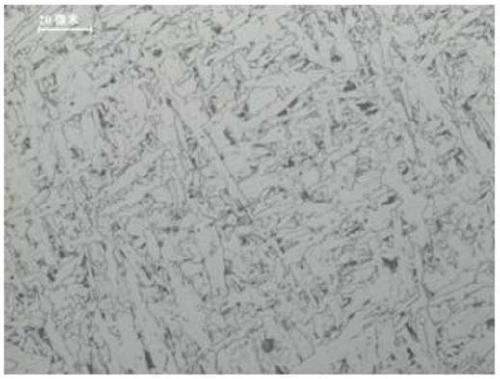

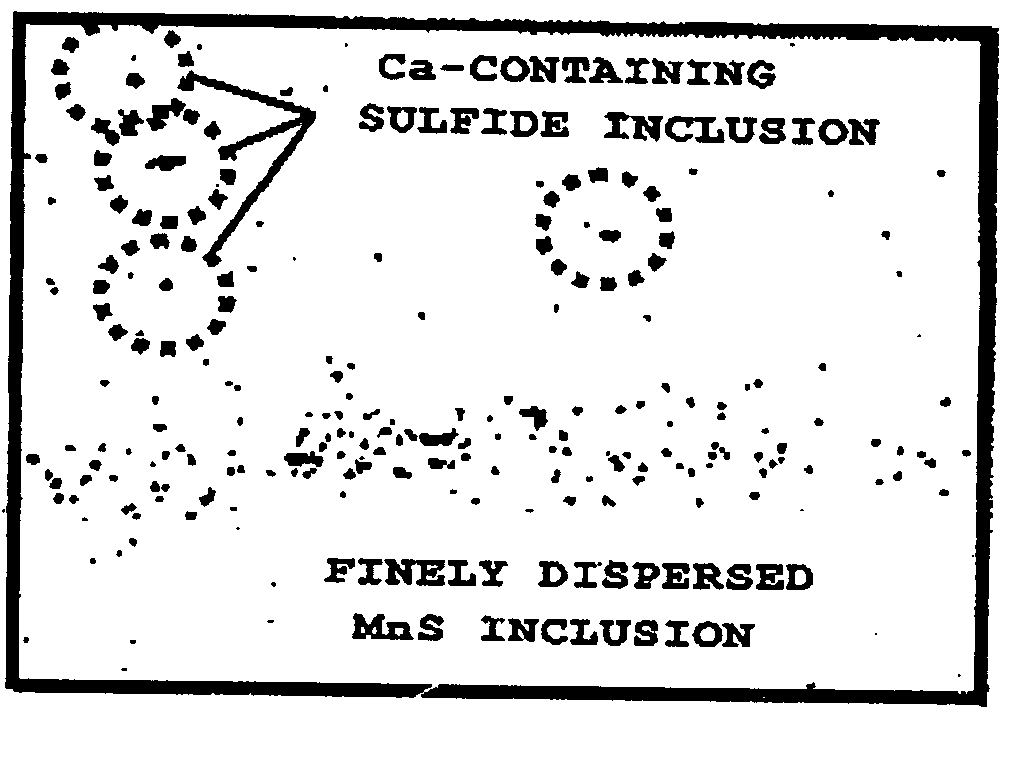

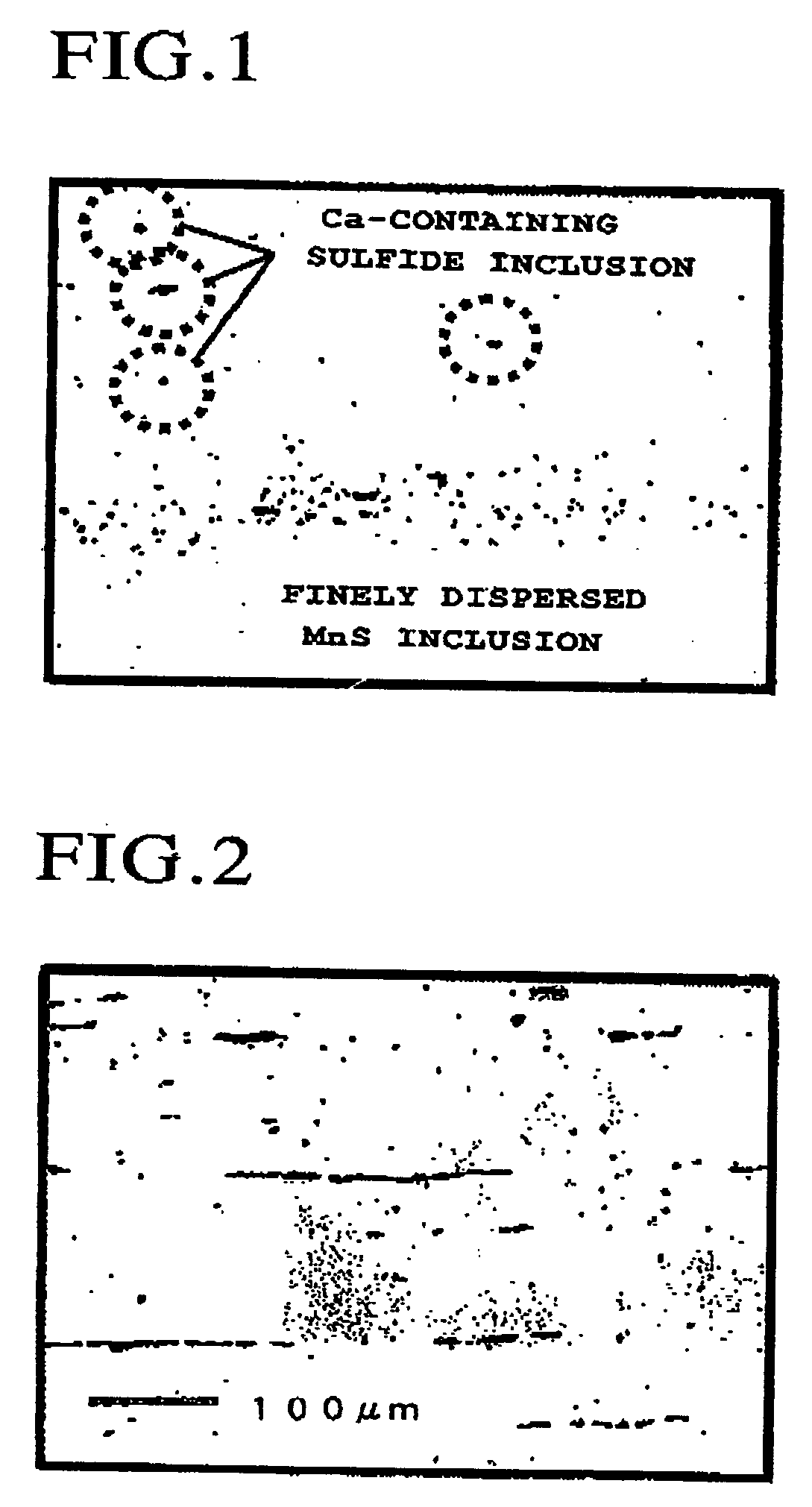

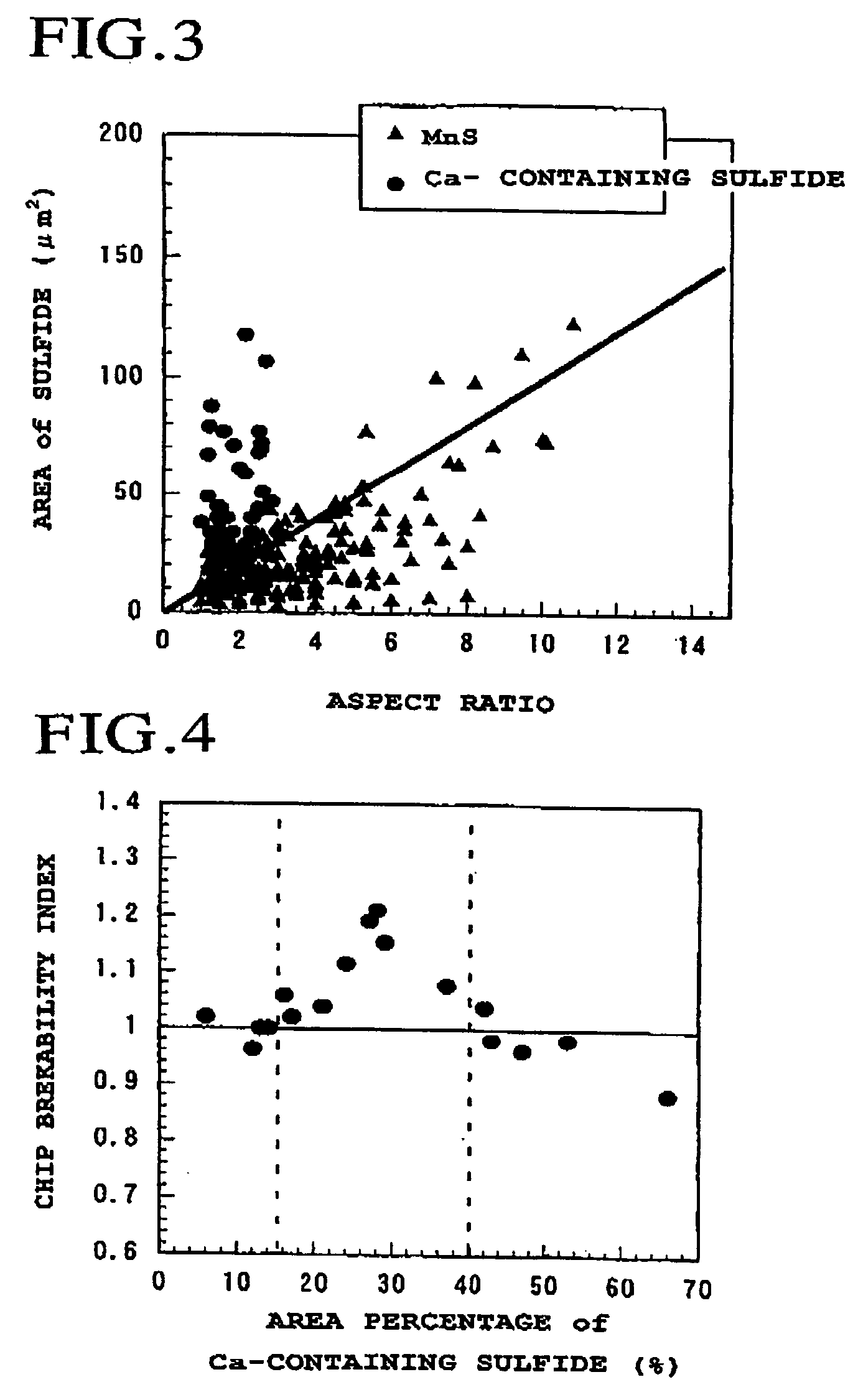

Steel for machine structural use excellent in friability of chips

Disclosed is a free cutting steel for machine structural use having excellent chip-breakability. The steel consists essentially of, by wt. %. C: 0.05-0.8%, Si: 0.01-2.5%, Mn: 0.1-3.5%, S: 0.01-0.2%, Ca or Ca+Mg; 0.0005-0.02%, Ti: 0.002-0.010% and / or Zr: 0.002-0.025%, O: 0.0005-0.010%, and the balance of impurities and Fe. At least five MnS inclusion particles having averaged particles sizes of 1.0 μm or more exists per mm2 per 0.01% of S-content in the steel. The steel satisfies the condition that, in the microscopic fields, (area[μm2] / aspect ratio)≧10, and that the the area percentage of Ca-containing sulfide inclusions containing at least 1.0 wt. % of Ca is in the range of 15-40% of the area of all the sulfide inclusions.

Owner:HONDA MOTOR CO LTD +2

Ni-based alloy improved in oxidation-resistance, high temperature strength and hot workability

A nickel-based alloy is provided for provide parts and members of improved oxidation-resistance and high temperature strength for use in an oxidation atmosphere at high temperatures, such as automobile parts including an electrode for an ignition plug, power plant facility parts including a gas turbine nozzle, inner parts of heat treat furnaces, and fuel cell parts. The alloy improved in oxidation-resistance, high temperature strength and hot workability consists essentially of, in mass percentage, C: 0.003 to 0.1%, Si: 1.0% or less, Mn: 2.0% or less, Cr: 12 to 32%, Fe: 20% or less, Mg: 0.001 to 0.04%, at least one element, of not more than 2.5% in total, selected from the group consisting of Nb, Ta and V, impurity elements of S: 0.01% or less, but the ratio of the Mg-content to the S-content (Mg / S) being 1 or more, and Ti: 0 inclusive to 0.02%, and the rest being Ni and incidental impurities.

Owner:HITACHI METALS LTD

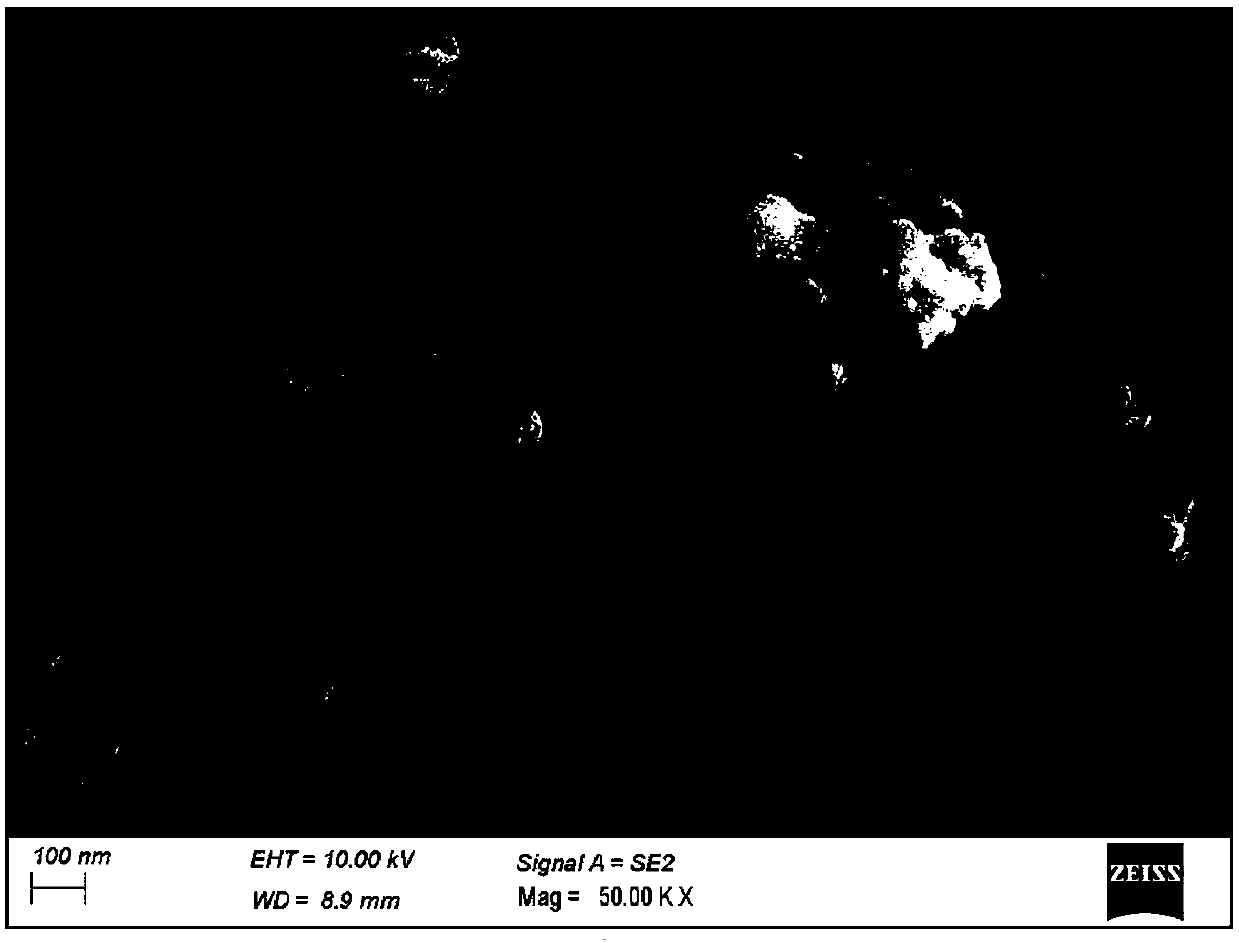

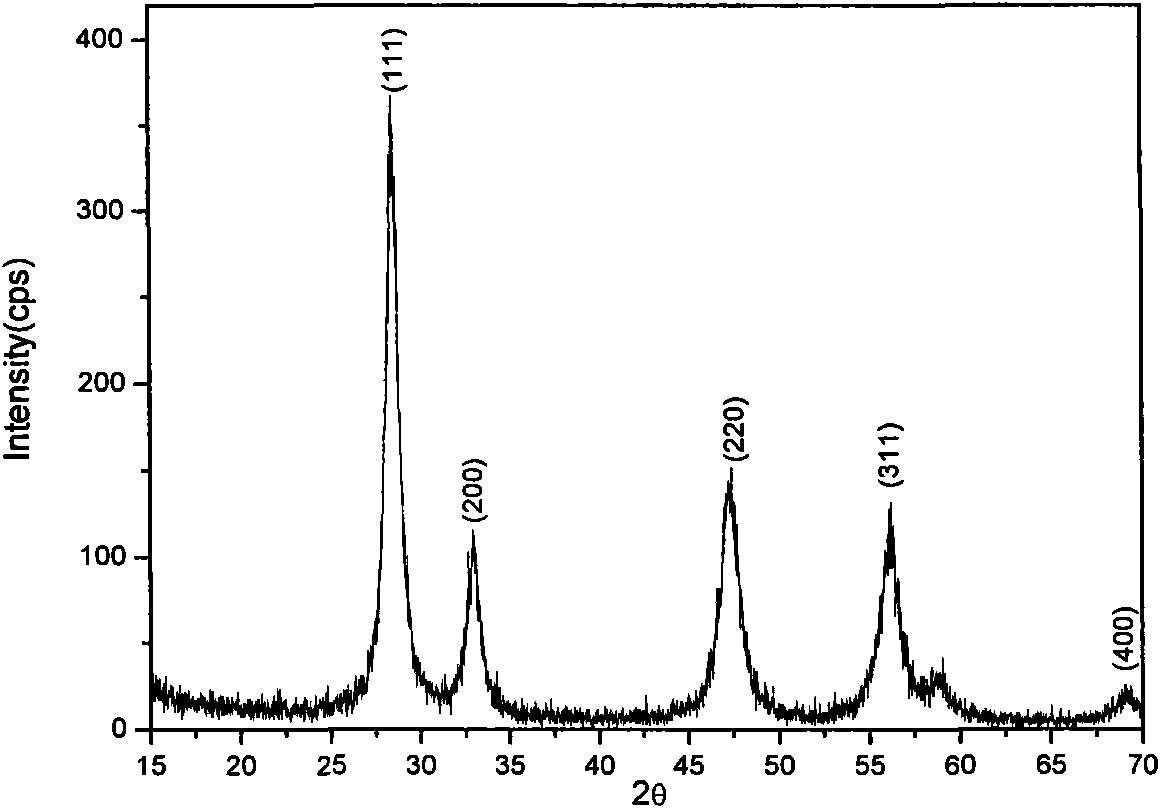

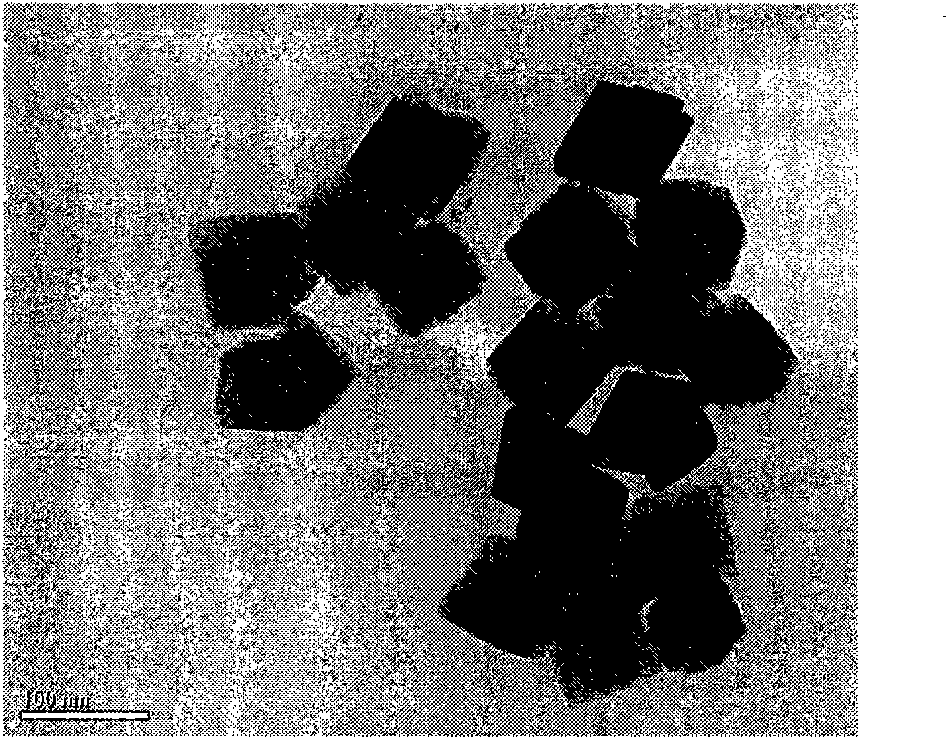

Method for synthesizing monodisperse samarium-doped rare earth cerium oxide nanocrystal

InactiveCN101891236AHigh reactivityUniform particle sizeNanostructure manufactureRare earth metal compoundsCerium nitrateRare earth

The invention relates to a method for synthesizing a monodisperse samarium-doped rare earth cerium oxide nanocrystal, belonging to the functional material preparation technical field. The method comprises the following steps: firstly, preparing an aqueous phase solution by using soluble cerium nitrate and samarium nitrate as raw materials and carbamide as a precipitant; forming an inverse microemulsion by using cetyl-trimethyl ammonium bromide as a surfactant, normal butyl alcohol as a cosurfactant and normal octane as an oil phase and adding the aqueous phase solution; filling the inverse microemulsion into a high-pressure reaction kettle the inner lining of which is made of polytetrafluoroethylene, heating for reaction, removing the normal octane from the reaction product by centrifugal separation, and removing the cetyl-trimethyl ammonium bromide and the normal butyl alcohol by washing to obtain a precursor product; and carrying out light irradiation on the precursor product to obtain the shape-controllable crystallized synthesized monodisperse samarium-doped rare earth cerium oxide nanocrystal which is uniform in particle size.

Owner:南京睿磐内尔环保复合新材料有限公司

Aluminum foil for electric cable and production method

InactiveCN101383200AReduce burning lossReduce segregationNon-insulated conductorsInsulated cablesMagnesiumMaterials science

The invention discloses a cable aluminum foil and a production method thereof. The cable aluminum foil comprises components of the following weight percent: 0.79 to 0.83 percent of Si, 0.22 to 0.26 percent of Fe, at most 0.1 percent of Cu, at most 0.2 percent of Mn, at most 0.05 percent of Mg, at most 0.05 percent of Cr, at most 0.1 percent of Zn, at most 0.08 percent of Ti, at most 0.05 percent of single impurity content, at most 0.15 percent of the total content of impurities and Al as the rest, wherein the content summation of the Fe and the Si in weight percent is less than 1.1 percent. The production method comprises the production technical processes: burdening, melting, component analysis, feeding dilution, powder injection refining, N2 refining, on-line refining outside a furnace, casting, casting plate type detection, blank winding, cold rolling, vertical cutting and splitting, finished product annealing, detection, packing, storage and leaving a factory. The cable aluminum foil has good mechanical property, the tensile strength is from 90 to 105MPa, the extension rate is greater than 25 percent, the production requirement has larger development potential, and the enterprise benefit and the social benefit can be obviously increased.

Owner:河南省银湖铝业有限责任公司

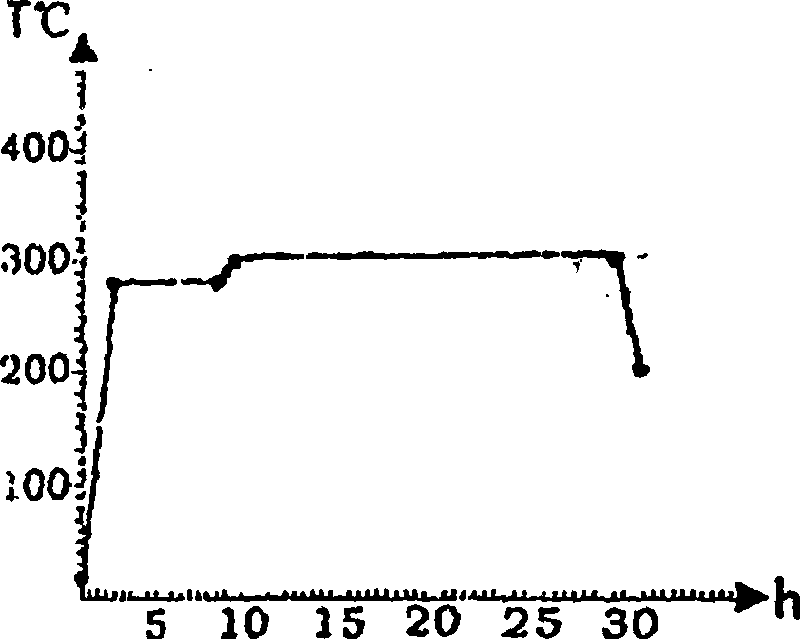

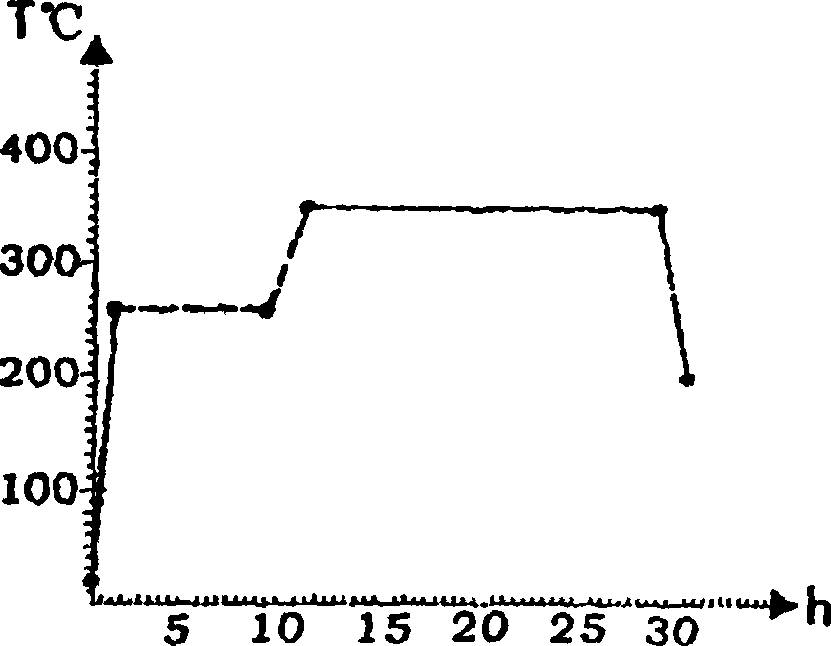

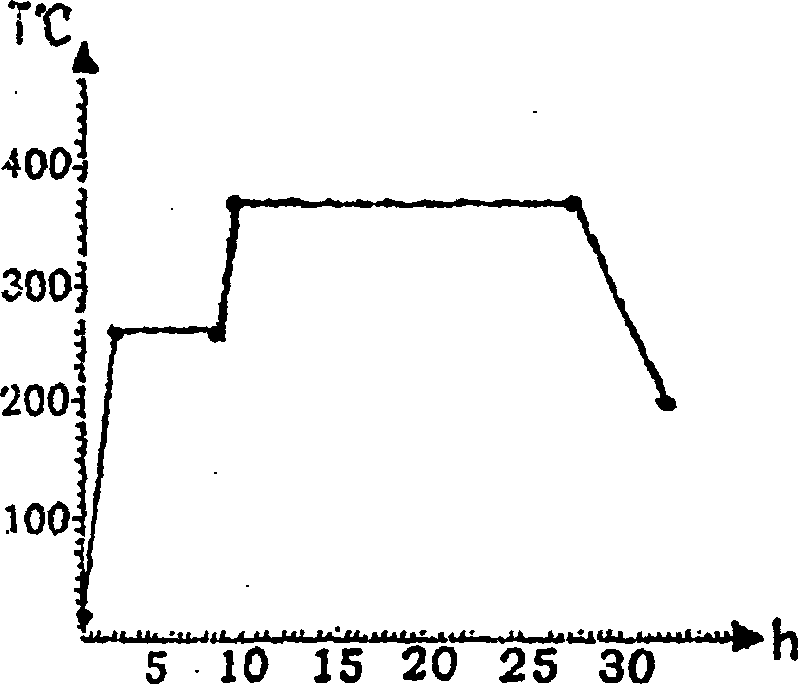

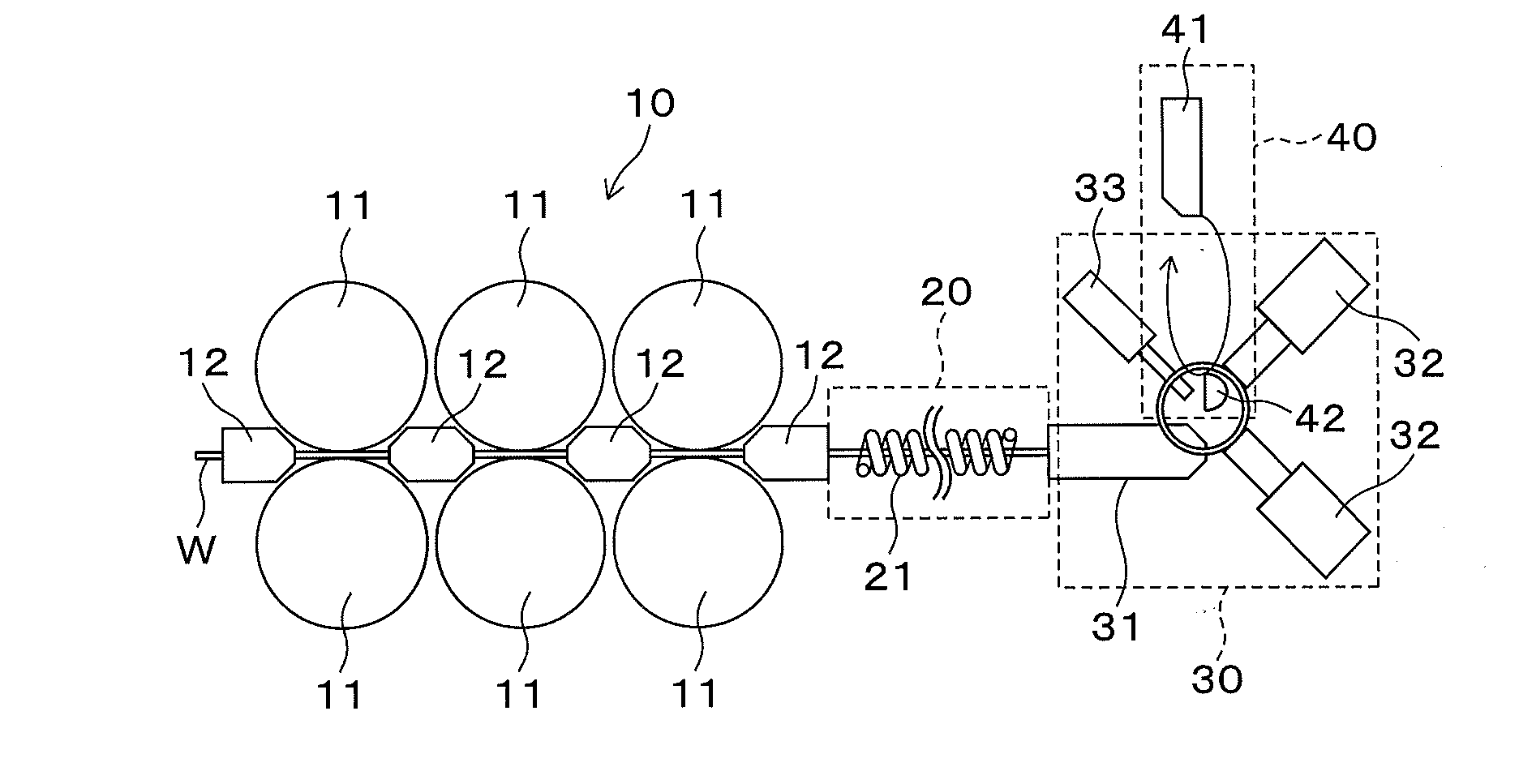

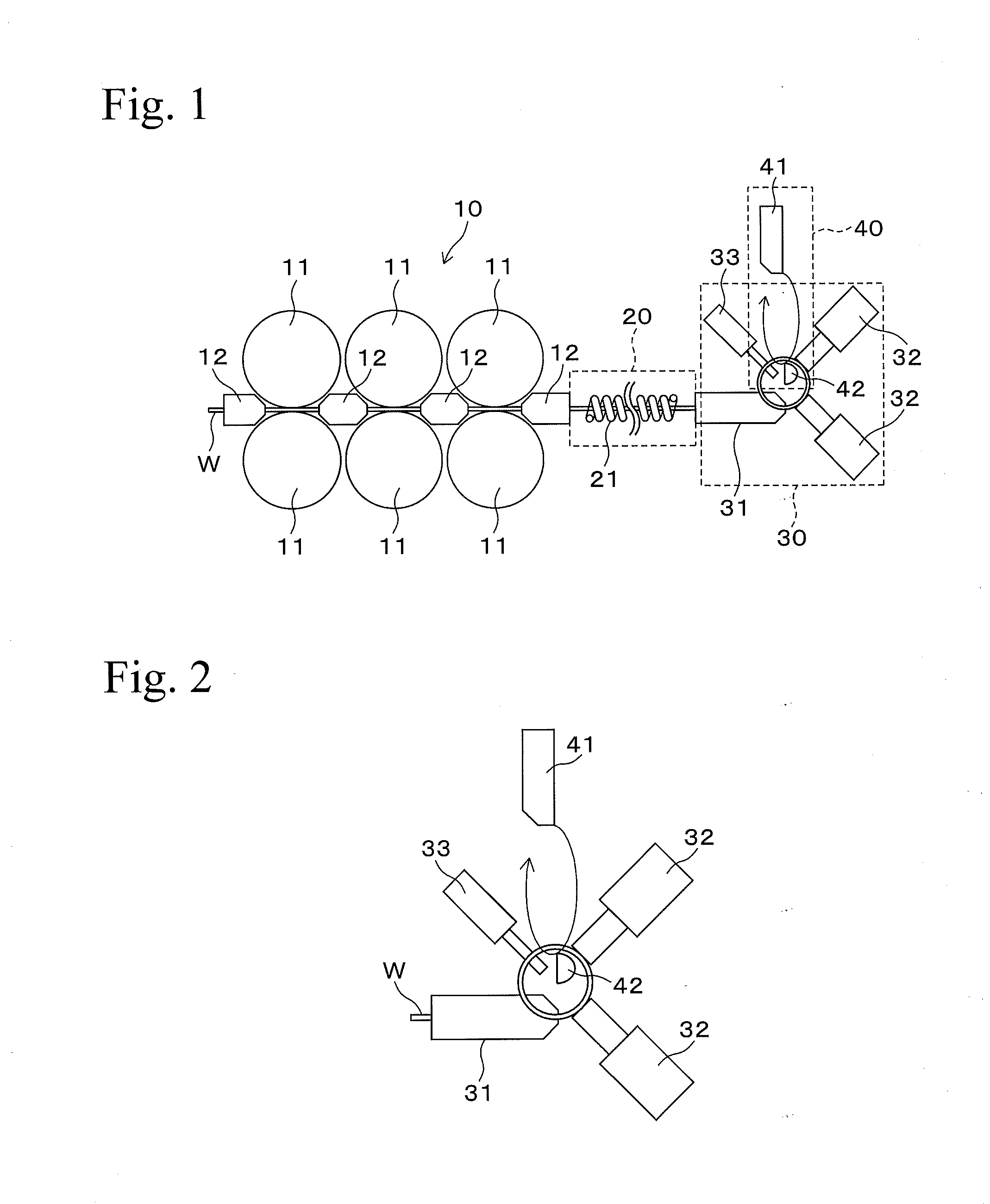

Spring forming device and forming method therefor

InactiveUS20160243607A1Heating evenlyNon-uniformity of heating time of the steel wire by the heating mechanism is preventedWire springsInduction heating apparatusMetallurgy

A spring forming device in which the steel wire can be continuously cut off without stopping the feeding of the steel wire in cutting, and in which the steel wire can be uniformly heated, is provided. The spring forming device has a wire supplying mechanism for supplying a steel wire using a plurality of feeding rollers, a heating mechanism for heating the steel wire, a coiling mechanism for forming in a coil state the heated steel wire, and a cutting mechanism for cutting the steel wire coiled at a given number of turns off the steel wire remained backward. A cutting blade of the cutting mechanism follows tracks having a speed Va that moves to the receiving blade and a speed Vc that moves in an axial direction of the coiled steel wire, in cutting of the steel wire.

Owner:NHK SPRING CO LTD

Preparation method of large-sized magnesium alloy forged disc

ActiveCN103447433AReduce cumbersomeImprove plastic deformation abilityMetal-working apparatusIngotUltimate tensile strength

The invention relates to a preparation method of a large-sized magnesium alloy forged disc and belongs to the technical field of magnesium alloy materialmachining. The preparation method of the large-sized magnesium alloy forged disc comprises the following steps of heating a casting magnesium alloy ingot to 400-430 DEG C and preserving the heat, wherein the casting magnesium alloy ingot after homogenizing thermal treatment is 300-350mm in diameter and 1.5-1.85 in height-diameter ratio; upsetting and drawing out the heated casting magnesium alloy ingot at 400-430 DEG C to obtain a magnesium alloy forged disc; repeating processes of heating, preserving the heat, upsetting and drawing out till the diameter of the magnesium alloy forged disc is larger than or equal to 670mm to obtain the large-sized magnesium alloy forged disc, wherein the temperature when repeating the procedures of preserving the heat and upsetting every time is 10-20 DEG C lower than the temperature when previously repeating the procedures of preserving the heat and upsetting, the forging ratio in each upsetting procedure is 1.5-2, the forging ratio in each drawing-out procedure is 1.02-1.05, and the deformation speeds in the upsetting and drawing-out procedures both are 12-16mm / s. According to the preparation method of the large-sized magnesium alloy forged disc, which is disclosed by the invention, the large-sized magnesium alloy forged disc with the diameter of 670-720mm, the thickness of 80-120mm, the tensile strength of larger than or equal to 300MPa, the yield strength of larger than or equal to 180Mpa and the elongation percentage of larger than or equal to 10% can be manufactured, and the manufactured large-sized magnesium alloy forged disc can completely meet the requirements on the preparation of a large-sized magnesium alloy die forged piece.

Owner:CENT SOUTH UNIV

High-strength aluminum alloy treated by AlH3 and preparation method of high-strength aluminum alloy

The invention discloses a high-strength aluminum alloy treated by AlH3 and a preparation method of the high-strength aluminum alloy. The preparation method comprises the following steps of: heating a hot aluminum ingot or molten aluminum liquid to be completely melted; adding Si, Fe, Cu, Mn, Mg, Zn and Ti to be completely dissolved and melted; refining and keeping the temperature of 700-1000DEG Cto obtain an alloy melt; carrying out deaerating purification on the alloy melt by using nitrogen gas or inert gas or mixed gas formed by the nitrogen gas and the inert gas in any ratio and continuously introducing gas until the reaction is ended; meanwhile, adding AlH3 powder into the alloy melt along with the gas in a fluidizaton mode; stirring the mixture to enable the AlH3 to be uniformly distributed on the alloy melt and sufficiently reacted with the alloy melt; standing and adjusting the temperature to be 680-730DEG C; and discharging the alloy liquid from a furnace for casting production. According to the high-strength aluminum alloy and the preparation method thereof disclosed by the invention, the defects of performances of a traditional aluminum alloy can be overcome; the strongtenacity, the formability and the hardenability of the aluminum alloy are improved; and a high-end substrate for high-efficiency deep processing is provided.

Owner:GUIZHOU ALUMINUM MATERIALS ENG TECHRES CENT

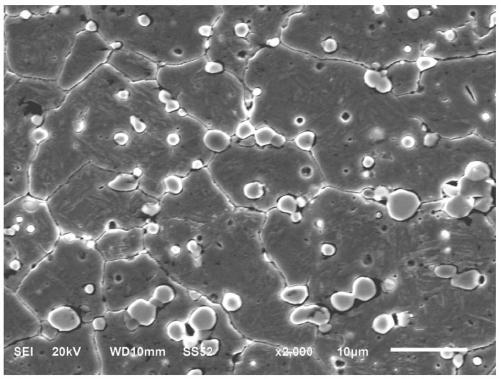

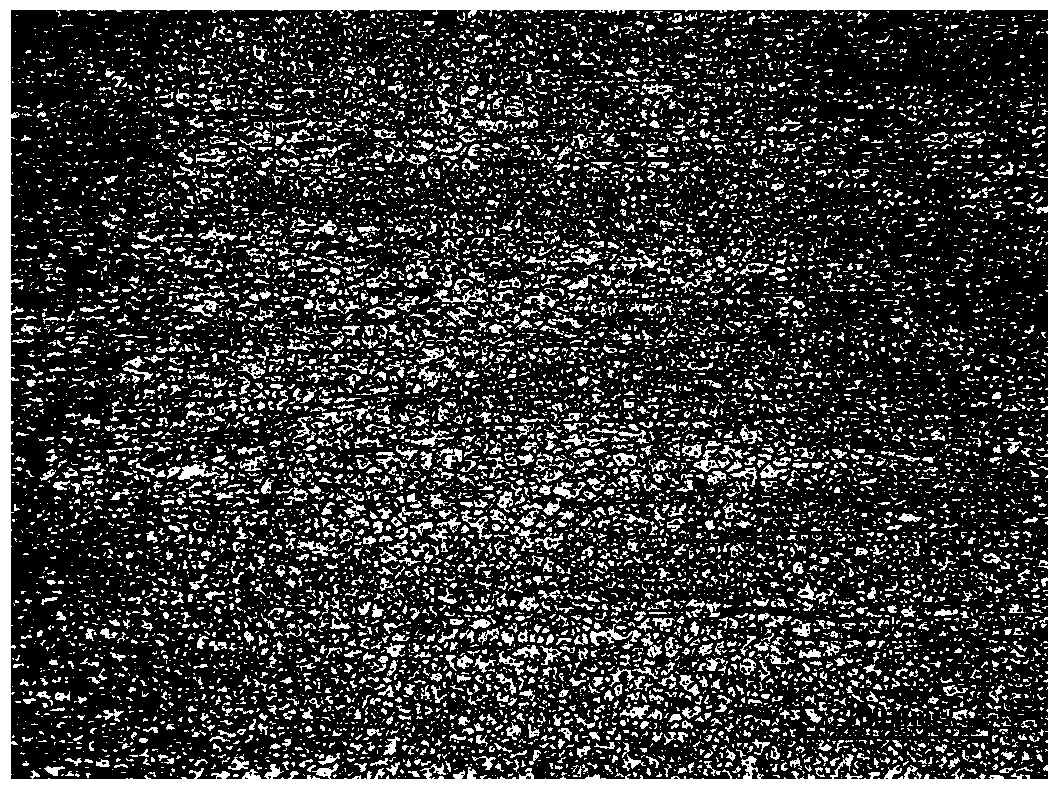

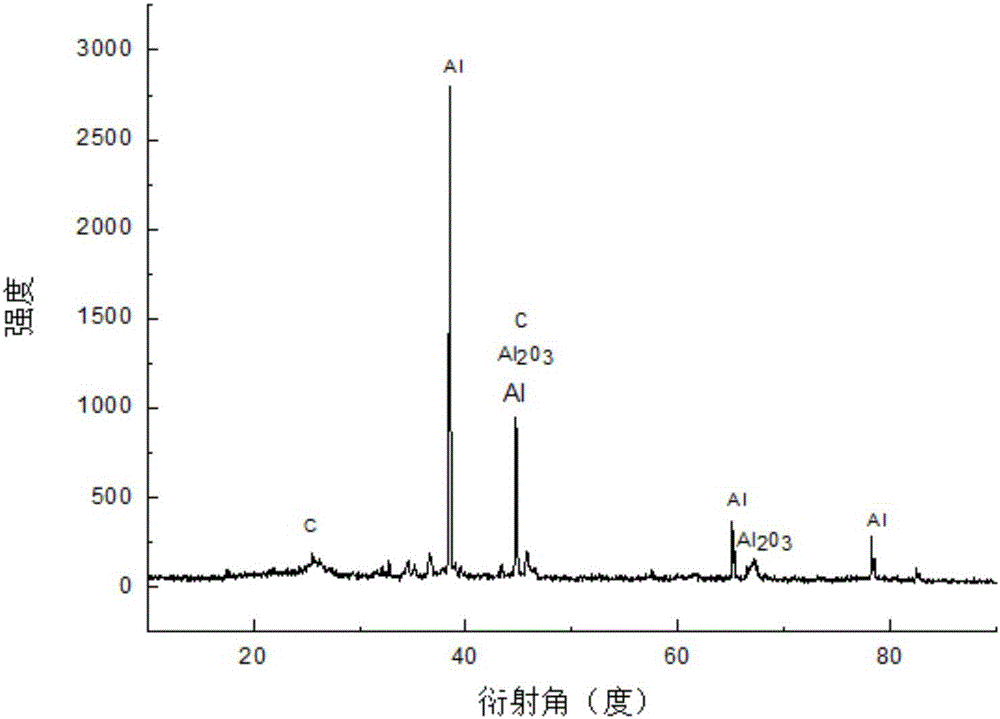

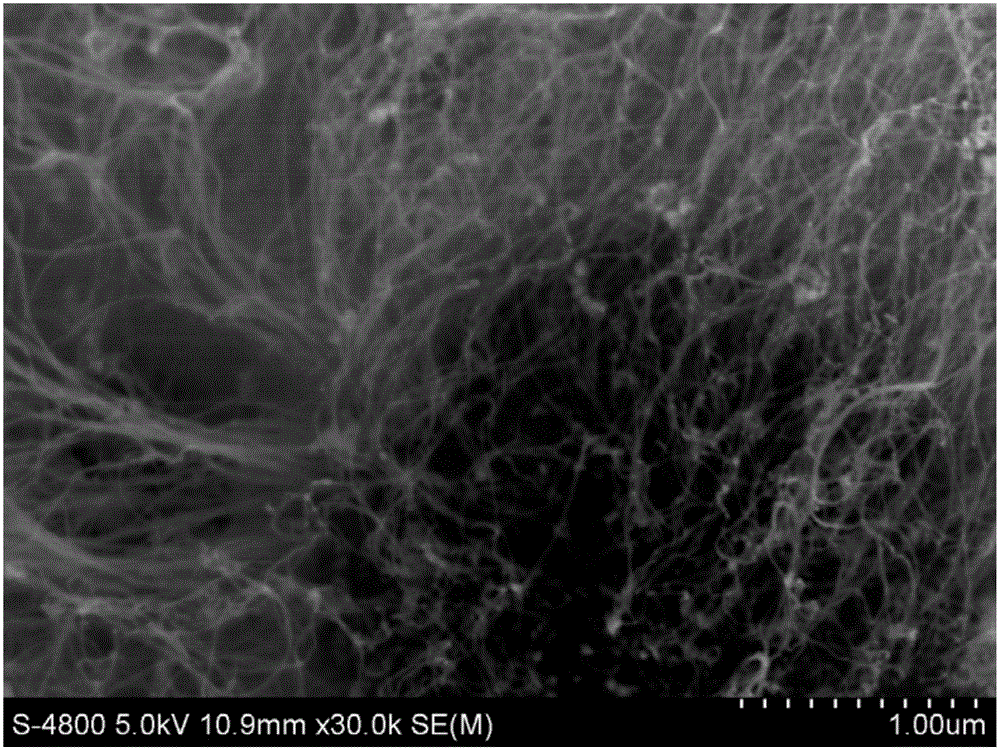

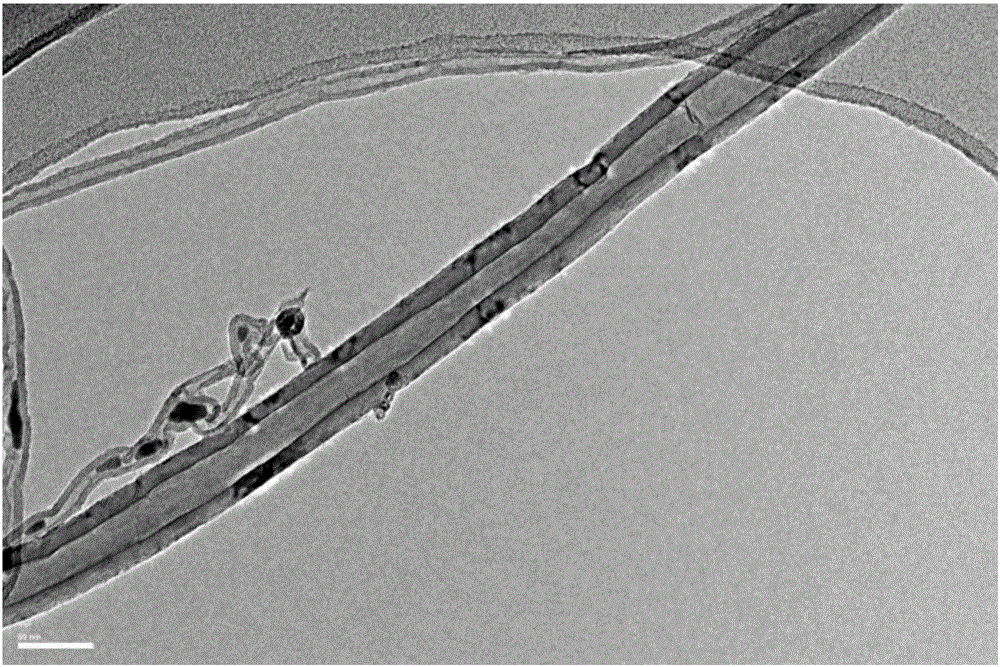

Preparation method for carbon nanotube-alumina mixed reinforced magnesium aluminum alloy composite

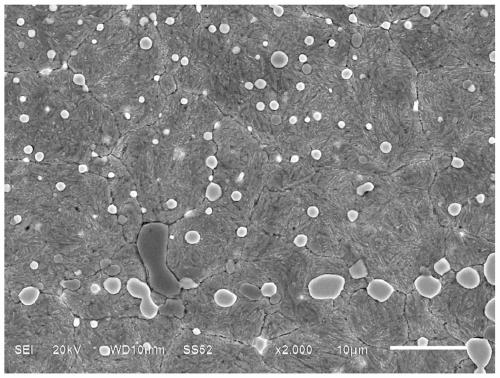

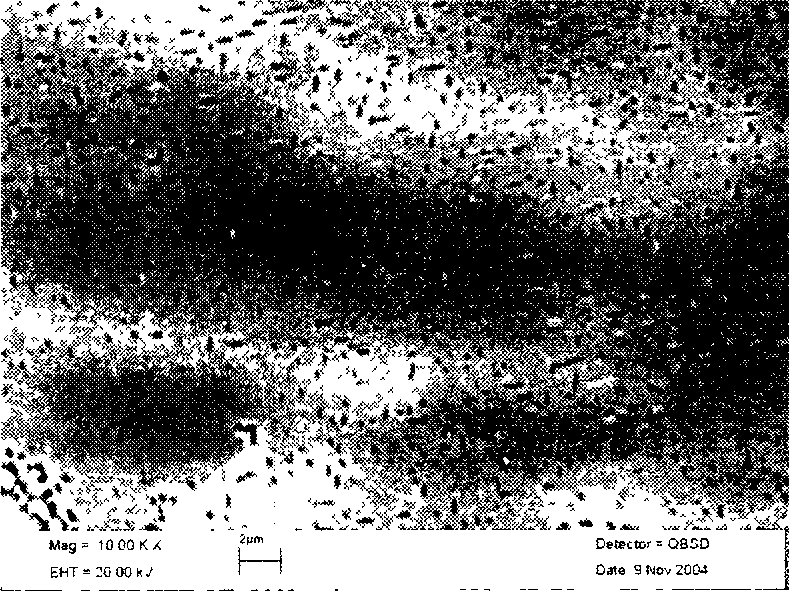

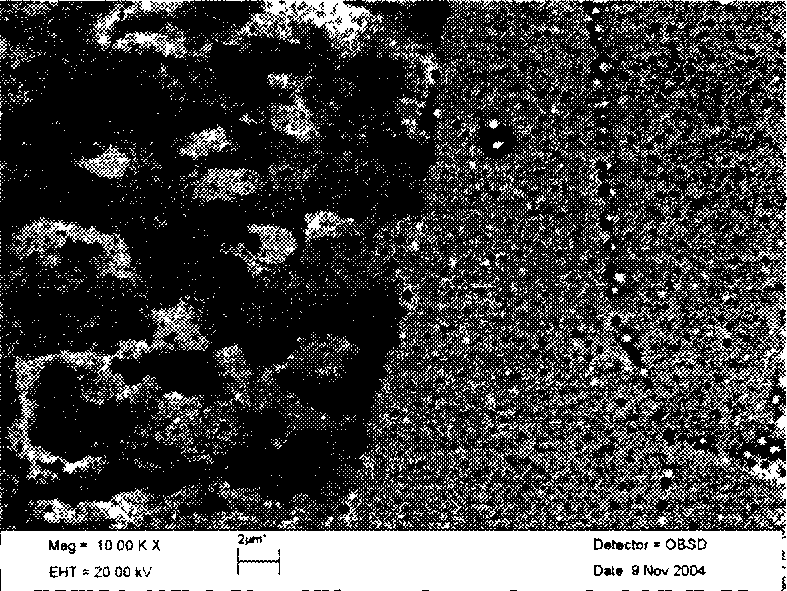

InactiveCN106498225AHighlight substantive featuresImprove mechanical propertiesMaterial nanotechnologyChemical vapor deposition coatingCarbon nanotubeGlobular shaped

Owner:HEBEI UNIV OF TECH

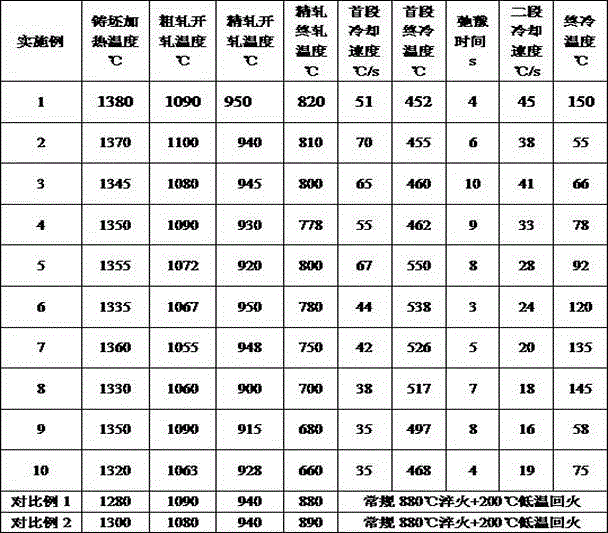

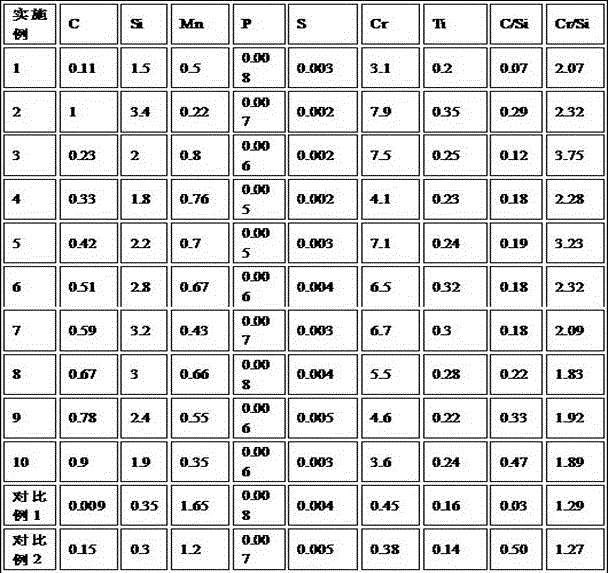

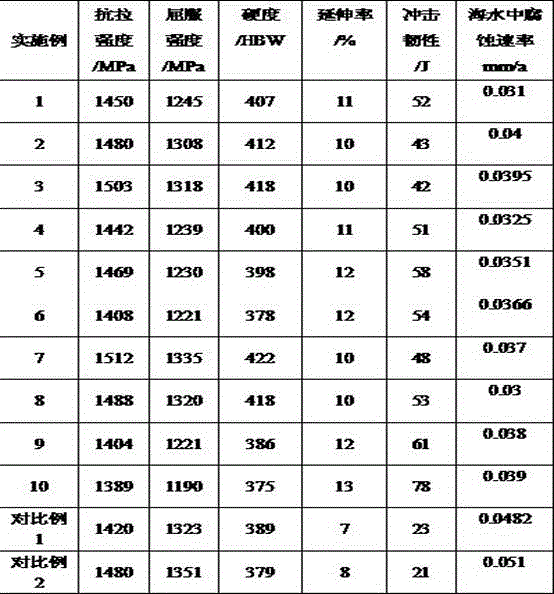

Super wear-resistant steel with hardness not smaller than 400 HBW and production method

Super wear-resistant steel with hardness not smaller than 400 HBW is prepared from, by weight percent, 0.10%-1.00% of C, 1.5%-3.5% of Si, 0.2%-0.8% of Mn, 0.20%-0.35% of Ti and 3.0%-8.0% of Cr. According to the production steps, a casting blank is heated after being formed through conventional smelting and pouring; double-pass high-pressure descaling is conducted till the surface is clean; hot rolling is conducted, and single-piece rolling is adopted; two-segment type cooling is adopted; and pit cooling is conducted till the room temperature. According to the super wear-resistant steel, by obtaining the metallographic structure of tempered martensite and ferrite, the brinell hardness can be larger than 400 HBW; and the corrosion rate does not exceed 0.04 mm / a under seawater soaking.

Owner:武汉钢铁有限公司

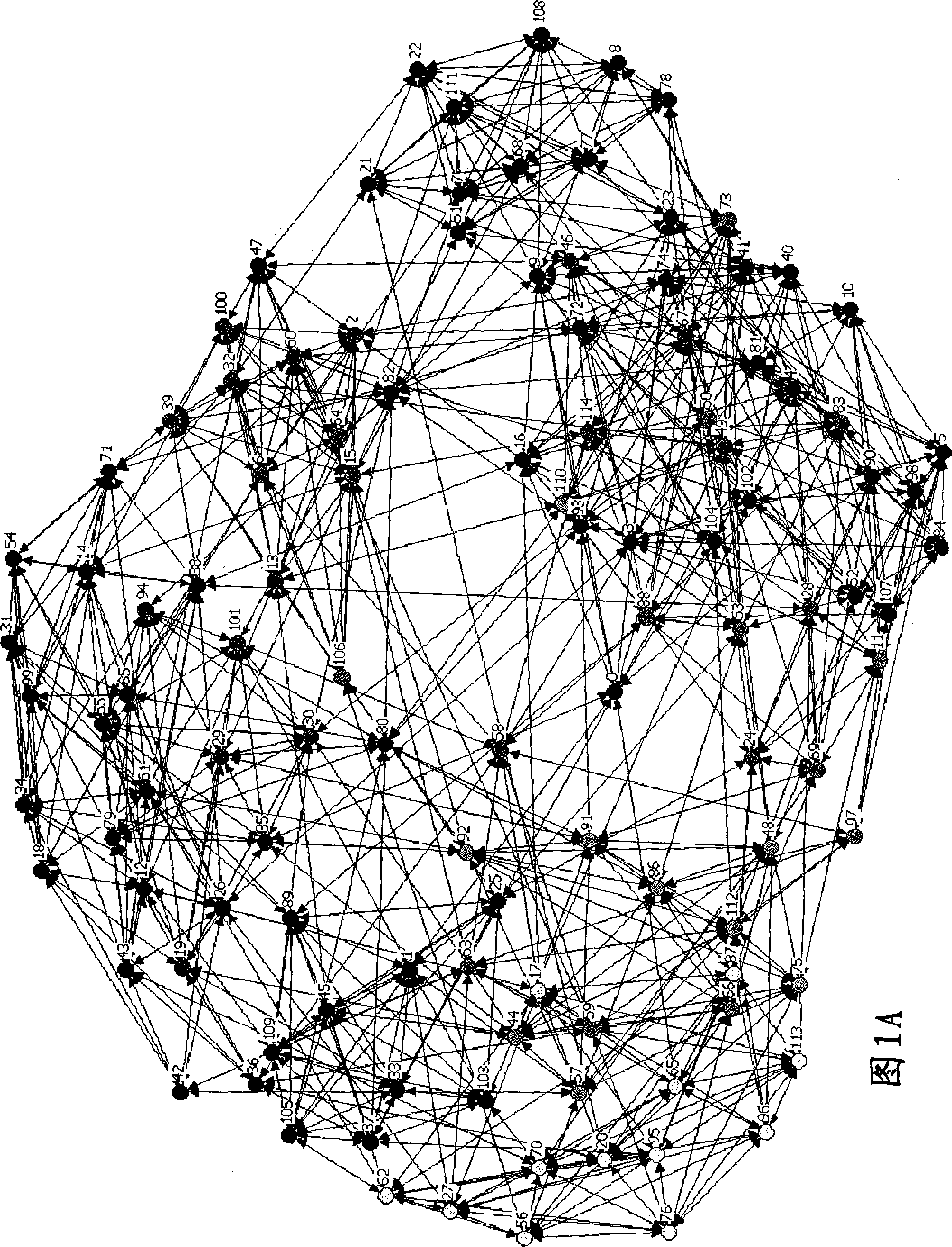

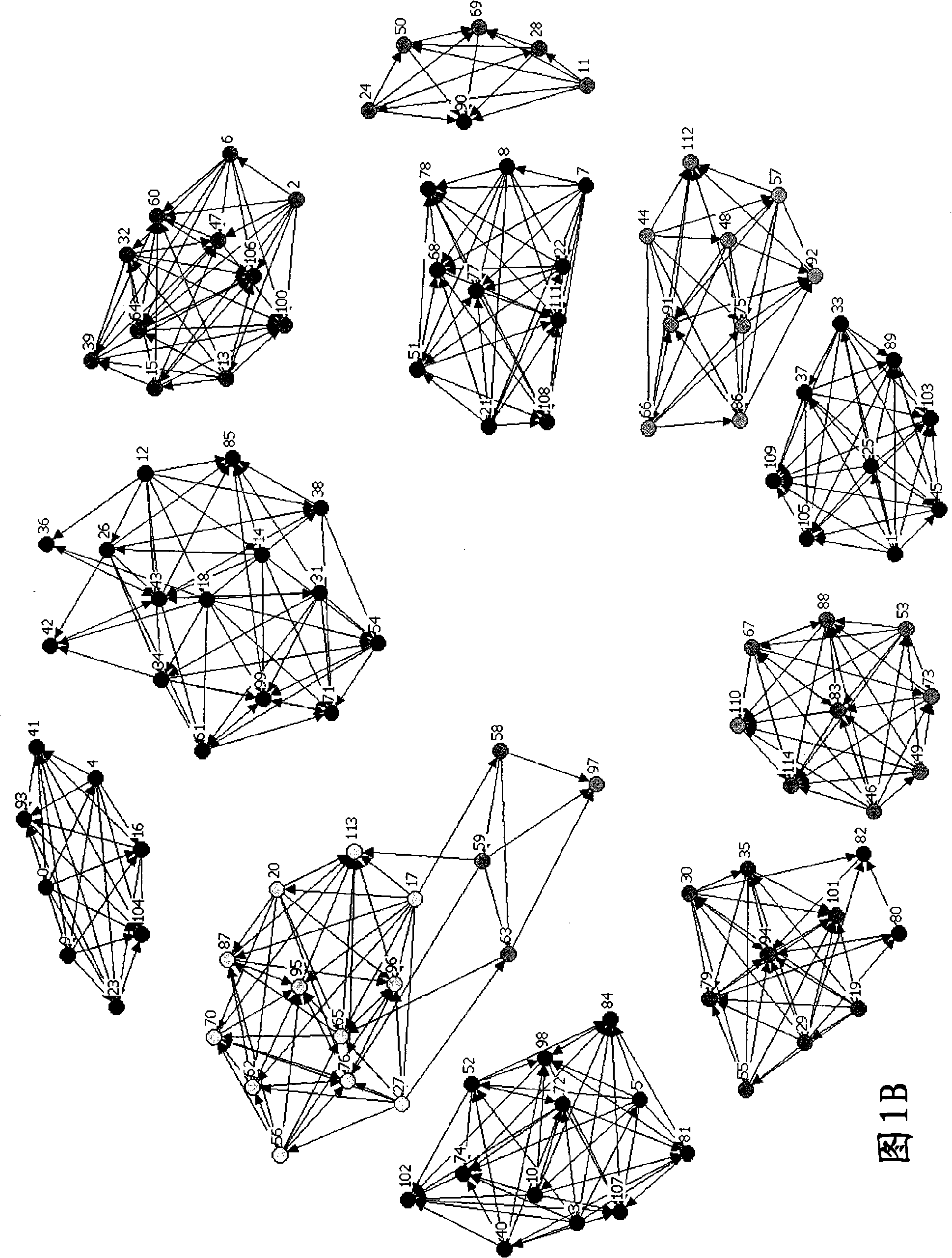

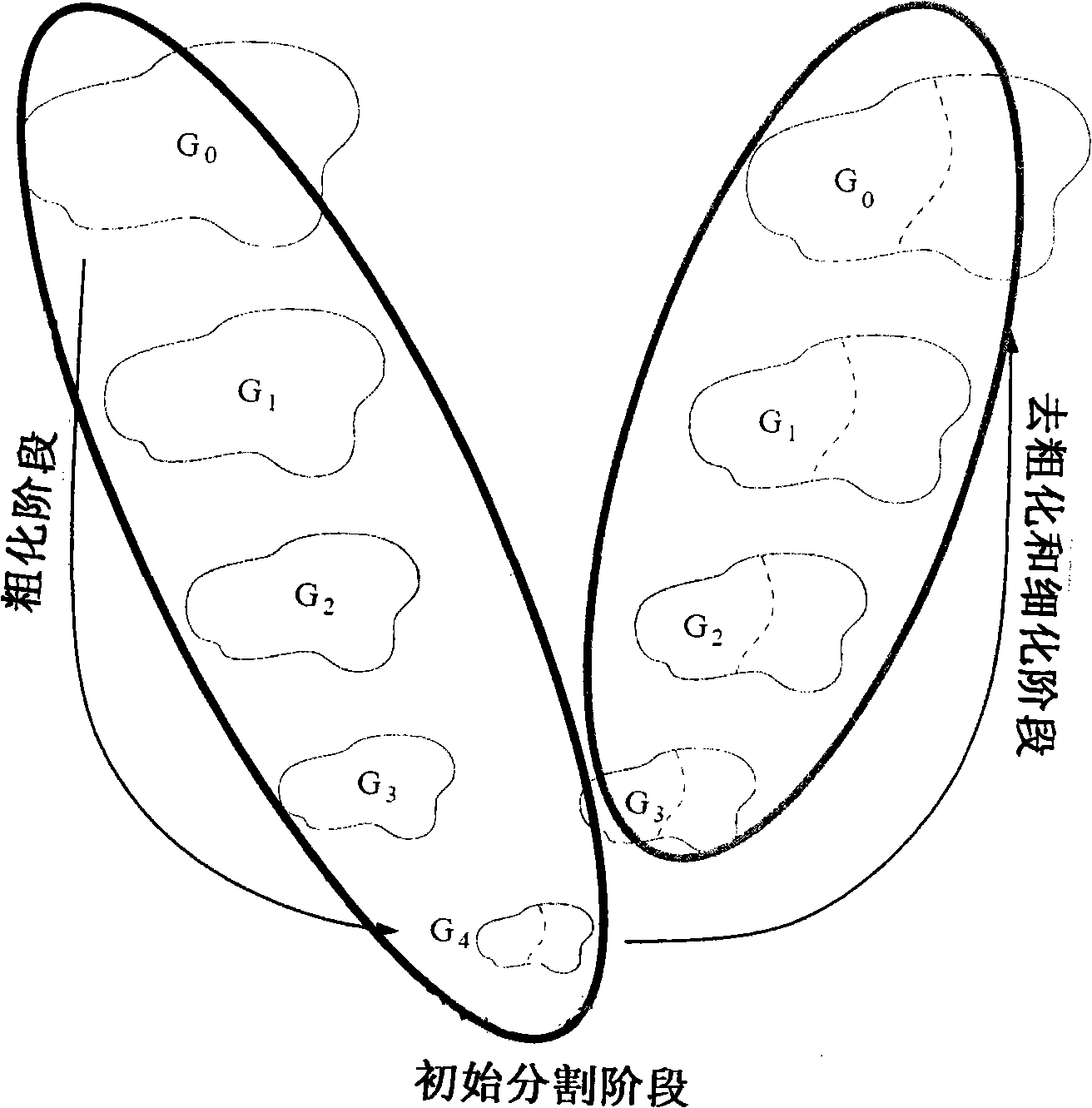

System and method for roughening picture

The invention discloses a system and a method for coarsening a graph. The graph comprises a plurality of vertexes. The method comprises the following steps: (a) calculating merge modularity gain value between a vertex and each adjacent vertex thereof, aiming at the current vertex; (b) calculating similarity value between the current vertex and each adjacent vertex; and (c) determining whether the current vertex is merged into the adjacent vertexes according to the calculated merge modularity gain value and the similarity value; and merging when merging can be conducted. The method can quickly and accurately coarsen the graph.

Owner:INT BUSINESS MASCH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com