Bainitic steels with boron

a technology of boron and steel, which is applied in the field of seamless pipes, can solve the problems of poor toughness of steel and overshadow the improvement of property, and achieve the effect of excellent toughness and good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

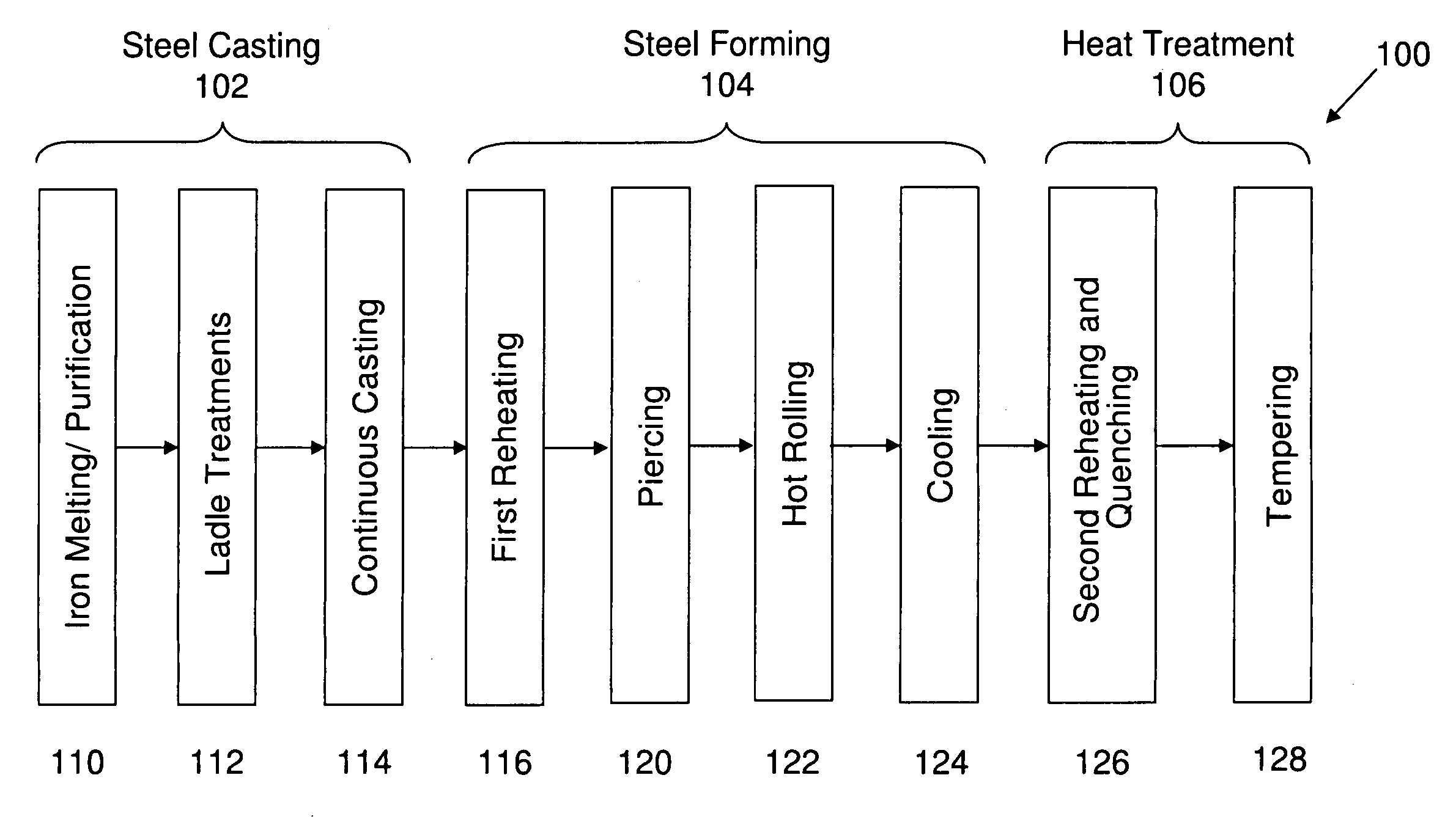

Method used

Image

Examples

example 1

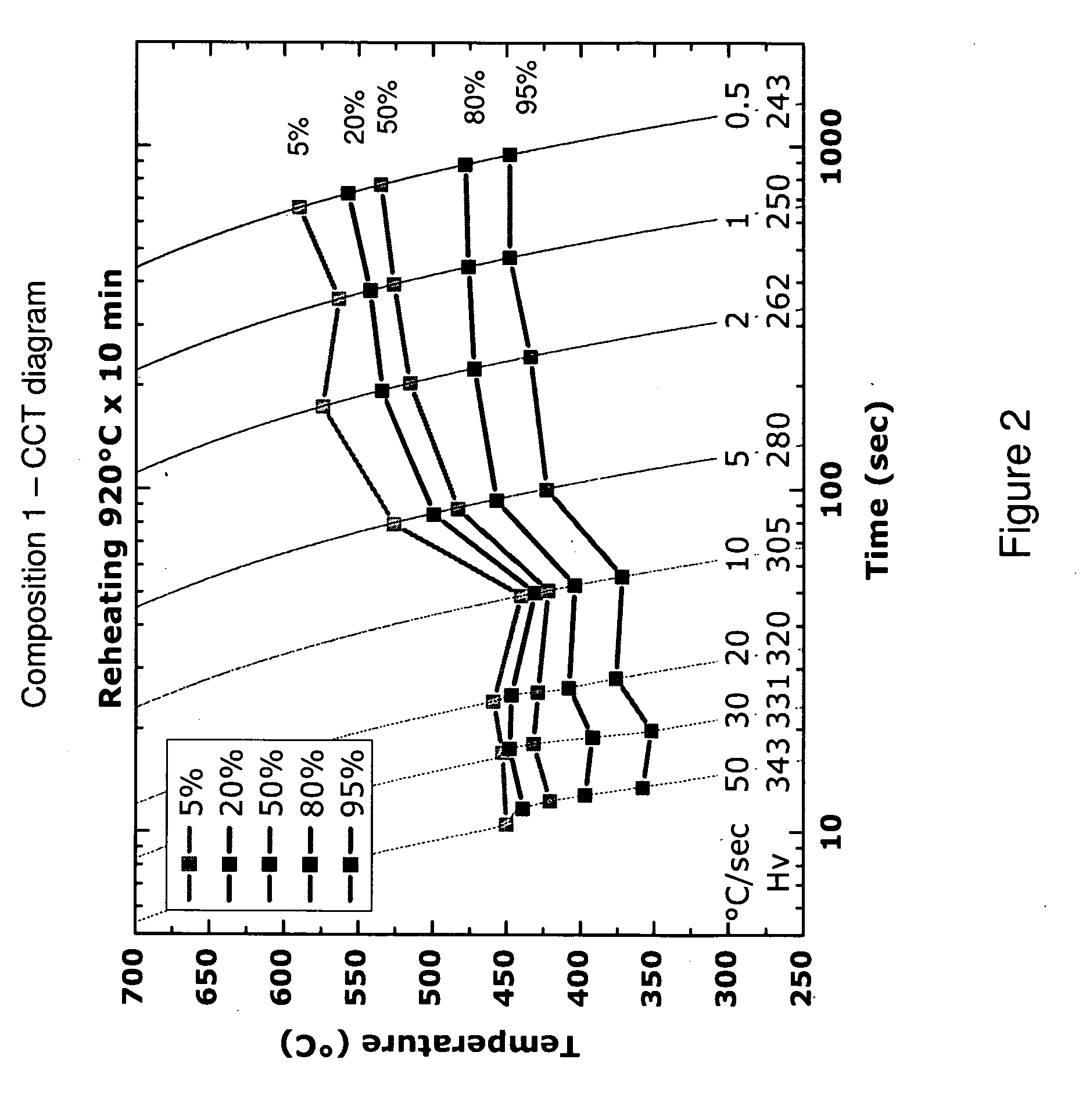

Continuous Cooling Transformation (CCT) Behavior and Microstructural Evaluation of Composition 1 for Cooling Rates Between about 0.5 and 50° C. / s.

[0113]The CCT diagram derived from dilatometric measurements of composition 1 is shown in FIG. 2. Illustrated in FIG. 2 are traces of temperature as a function of cooling rate for transformations of about 5%, 20%, 50%, 80%, and 95%. Due to the reheating condition, about 920° C. over about 10 min, the austenitic grain size prior to transformation was estimated to be about 10-20 μm, based upon the sample cooled at about 50° C. / sec.

[0114]In the CCT diagram of FIG. 2, two transformation regions may be observed, corresponding to cooling rates lower and higher than about 5° C. / sec. For cooling rates less than about 5° / sec, the phase transformation is observed to start at about 550-600° C. The microstructure resulting under these conditions was mainly bainitic, with some retained austenite, as illustrated in the micrographs corresponding to cooli...

example 2

Toughness Evaluation of Composition 1—Accelerated Cooling Condition

[0117]In order to study the impact properties of composition 1 under accelerated cooling conditions, several Charpy tests were conducted using thermal cycles discussed above with respect to the CCT diagram. Samples prepared using cooling rates of about 5° C. / sec, 10° C. / sec, 30° C. / sec, and 45° C. / sec were examined. Charpy tests were performed at temperatures of about 25° C., 0° C., and −20° C. The results of these impact tests are illustrated in Table 3 and FIGS. 4A and 4B, which complementarily plot impact energy (Charpy V-Notch, CVN) as a function of cooling rate and test temperature, respectively.

TABLE 3Impact Energy and Hardness of composition 1 after acceleratedcooling simulations performed at GleebleCoolingImpact EnergyCom-RateHardnessTCVNShearpositionCondition(° C. / sec)(Hv)(° C.)(J)Area (%)1Accelerated 528025284100Cooling 028791−20286891Accelerated1030525335100Cooling027889−20257781Accelerated3033125251100Coo...

example 3

Mechanical Evaluation of Composition 1—As-Quenched

[0119]The tensile and impact properties of composition 1 in the as-quenched condition are illustrated in Tables 4 and 5.

TABLE 4Tensile properties of composition 1 after quenchingYSUTSCompositionCondition(ksi)(ksi)YS / UTSEl (%)1As-1211560.7816Quenched

TABLE 5Impact Energy and Hardness of composition 1 after quenchingCharpy (10 × 10 mm)ShearHardnessCVNAreaCompositionCondition(Hv 1 kg)T (° C.)(J)(%)1As-Quenched363251507908243−204224

[0120]In general, the as-quenched composition exhibited improvements in strength and impact energy over that of as-rolled samples (YS˜69 ksi, UTS˜99 ksi, CVN˜6-8 J at 25° C. to −20° C.). This improvement may be ascribed to a general refinement of the microstructure and the substantial disappearance of large, blocky austenitic regions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com