High-temperature high-strength TiAl-Nb monocrystal and preparation method thereof

A tial-nb, high-strength technology, applied in the field of high-temperature and high-strength TiAl-Nb single crystal and its preparation, can solve the problems of high-temperature mechanical property testing without high-Nb-TiAl single crystal, reducing the mechanical properties of the alloy, affecting the mechanical properties, etc. Universal applicability and promotion value, improving high-temperature mechanical properties, and the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) The atomic percentage of the selected alloy composition is: Ti-45Al-8Nb-0.3C-0.2Si, the balance is Ti, and the initial raw materials are 99.999% high-purity Al, Ti, C and Si and 99.95% high-purity Ti in The water-cooled copper crucible electromagnetic induction suspension melting furnace repeatedly smelts TiAl-Nb button master alloy ingots four times;

[0027] (2) A Φ6mm round rod-shaped alloy was obtained by a differential suction casting method with a pressure difference of 3MPa.

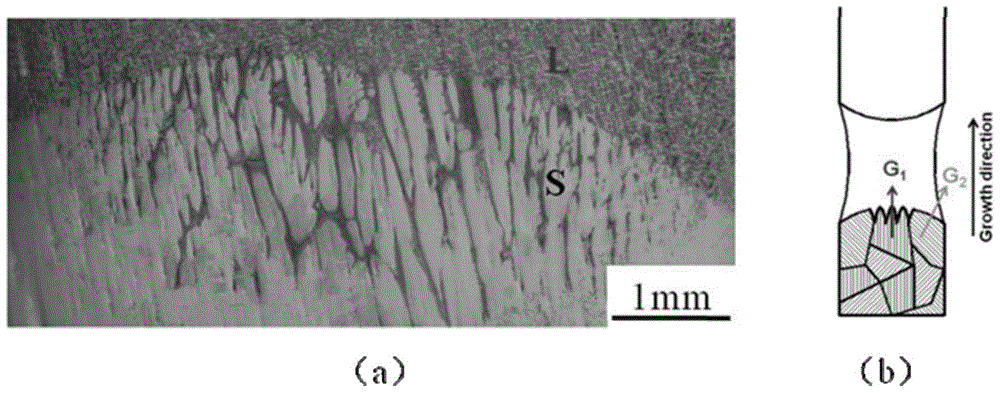

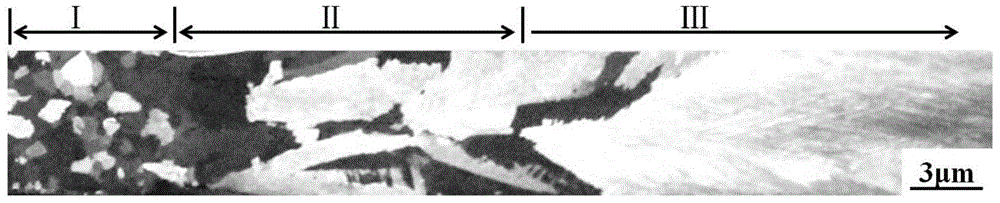

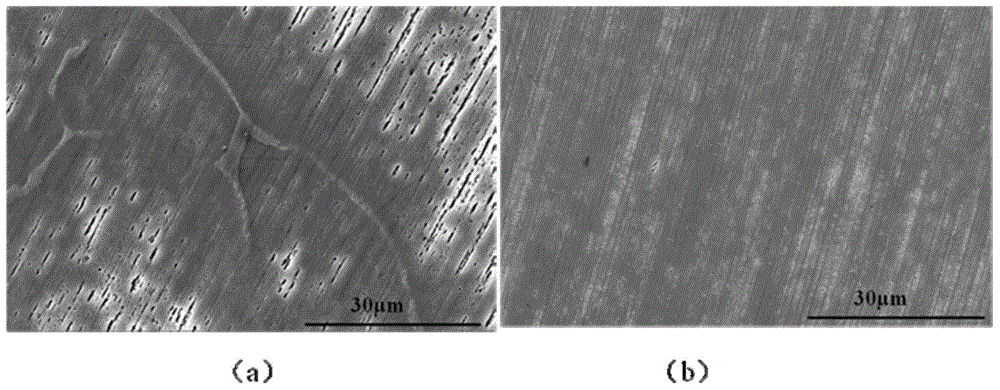

[0028] (3) The optical floating zone method is used for directional solidification, the lower end is a 20mm seed rod, and the upper end is a 150mm feeding rod, and the feeding rod is necked and selected. During directional solidification, first install the feeding rod and the seed rod. The feeding rod and the seed rod must be kept coaxial and perpendicular to the horizontal plane. At the center; the protective gas with a flow rate of 4L / min is introduced, and the seed rod and the feedi...

Embodiment 2

[0032] Adopt the method same as embodiment 1 to prepare Ti-45Al-8Nb-0.4C-0.5Si, the alloy that the balance is Ti, but change and adopt the gravity casting method to obtain the round rod-shaped sample of Φ8mm, because adopt the necking crystal selection process, The alloy with this diameter can also quickly obtain a single crystal sample. After the same desegregation heat treatment, the tensile strength is 618MPa, and the elongation is 9.2%.

Embodiment 3

[0034] Adopt the same preparation method as Example 1, change the alloy composition to be Ti-45Al-8Nb-0.4Si-0.6C, and the balance is Ti (atomic percentage), also adopt the same heat treatment process, because a small amount of C and Si do not greatly The magnitude changes the phase transition temperature point, but brings high temperature strengthening effect, so that the tensile yield strength of the material at 900 ° C is 650 MPa, and the plastic strain is 7.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com