High-strength high-corrosion-resistance double-phase heat resistant steel

A high-corrosion-resistant, high-strength technology, applied in the field of heat-resistant stainless steel, can solve the problems of radiation swelling and large thermal expansion coefficient, high-temperature oxidation resistance needs to be improved, and has not yet met the electrical performance requirements, so as to achieve the effect of improving mechanical properties

Active Publication Date: 2015-12-16

ANYANG INST OF TECH

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the one hand, the radiation swelling and thermal expansion coefficient of austenitic heat-resistant steel are relatively large, which has not yet met the performance requirements of the power industry for materials; on the other hand, the high-temperature oxidation resistance of existing duplex stainless steels still needs to be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] The technical solution of the present invention is further illustrated below through specific examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

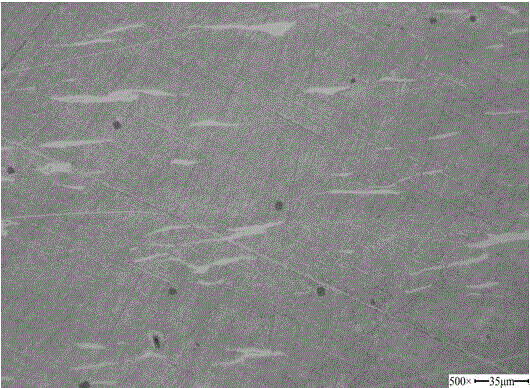

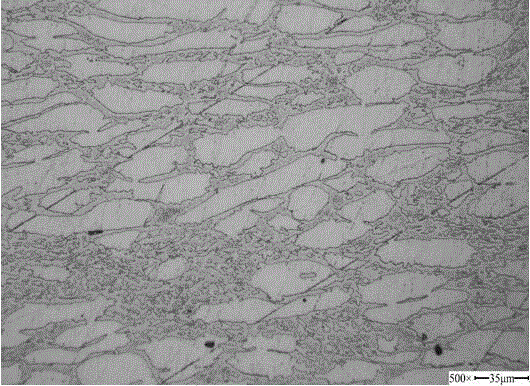

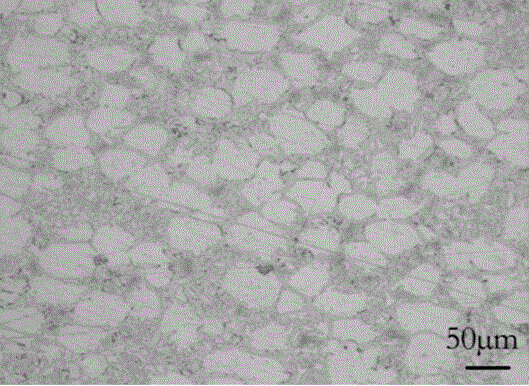

The invention belongs to the field of heat resistant stainless steel and relates to high-strength high-corrosion-resistance double-phase heat resistant steel. The high-strength high-corrosion-resistance double-phase heat resistant steel comprises 0-0.1% of C, 0.1-1.0% of Si, 0-0.5% of Mn, 12-25% of Cr, 15-22% of Ni, 0-4.0% of Mo, 1.0-6.0% of Al, 0.1-1.0% of Nb, 0-0.05% of B, not larger than 0.03% of P, not larger than 0.02% of S and the balance Fe. A preparation method is characterized in that the vacuum degree is strictly controlled to be smaller than or equal to 5 Pa in the smelting process, so that adverse influences of N and Al chemical compounds are avoided; a hammer forging manner is adopted, and the strain rate is controlled to be not smaller than 1s-1in the hot rolling process; and the reduction in a single pass is not smaller than 35%, and the second-phase size is controlled through rapid cooling. The high-strength high-corrosion-resistance double-phase heat resistant steel enables high-temperature corrosion resistance and high strength to be matched, and the comprehensive performance of the high-strength high-corrosion-resistance double-phase heat resistant steel is obviously higher than that of existing double-phase heat resistant steel when the high-strength high-corrosion-resistance double-phase heat resistant steel is used in a high-temperature corrosive environment.

Description

technical field [0001] The invention belongs to the field of heat-resistant stainless steel, is applicable to the technical field of preparation and processing of structural materials for advanced power systems, especially heat-resistant and corrosion-resistant materials for ultra-supercritical power stations and nuclear power systems, and provides a dual-phase stainless steel with excellent comprehensive performance. Heat-resistant stainless steel method. Background technique [0002] With the increasingly severe energy crisis and air pollution, efficient ultra-supercritical (UltraSuper-Critical, USC) power plants and advanced nuclear power systems have become the main development direction of the power industry in the future. However, the harsh environment of high temperature and high pressure puts forward higher requirements on the performance of service materials, such as higher high temperature strength and excellent high temperature oxidation resistance. Therefore, in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/60C22C38/54C22C33/04

Inventor 孙红英何强李占君杨海杰王志刚赵慧丽翟雁孙晓红王美美王可王琳

Owner ANYANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com