Patents

Literature

273results about How to "Control distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

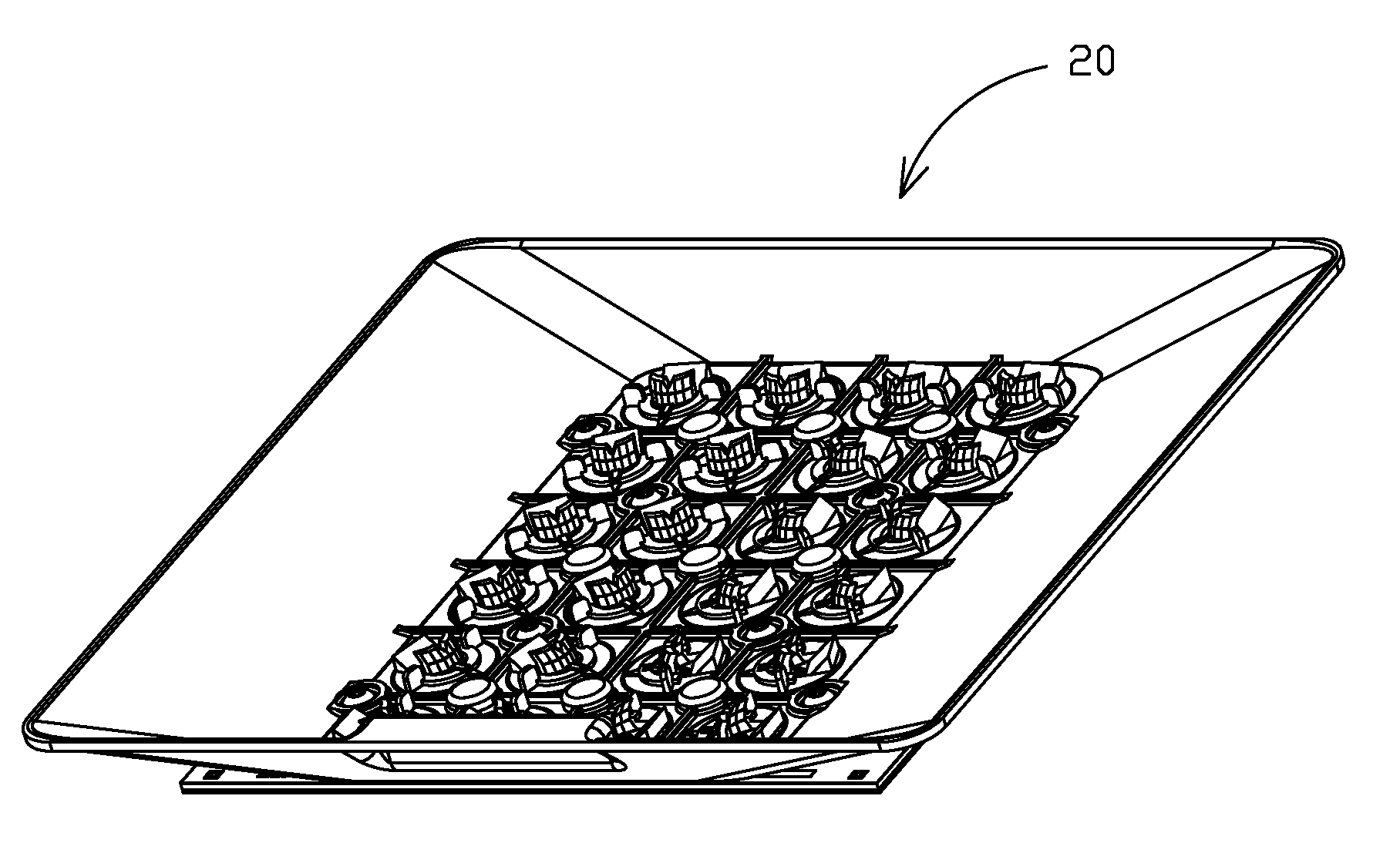

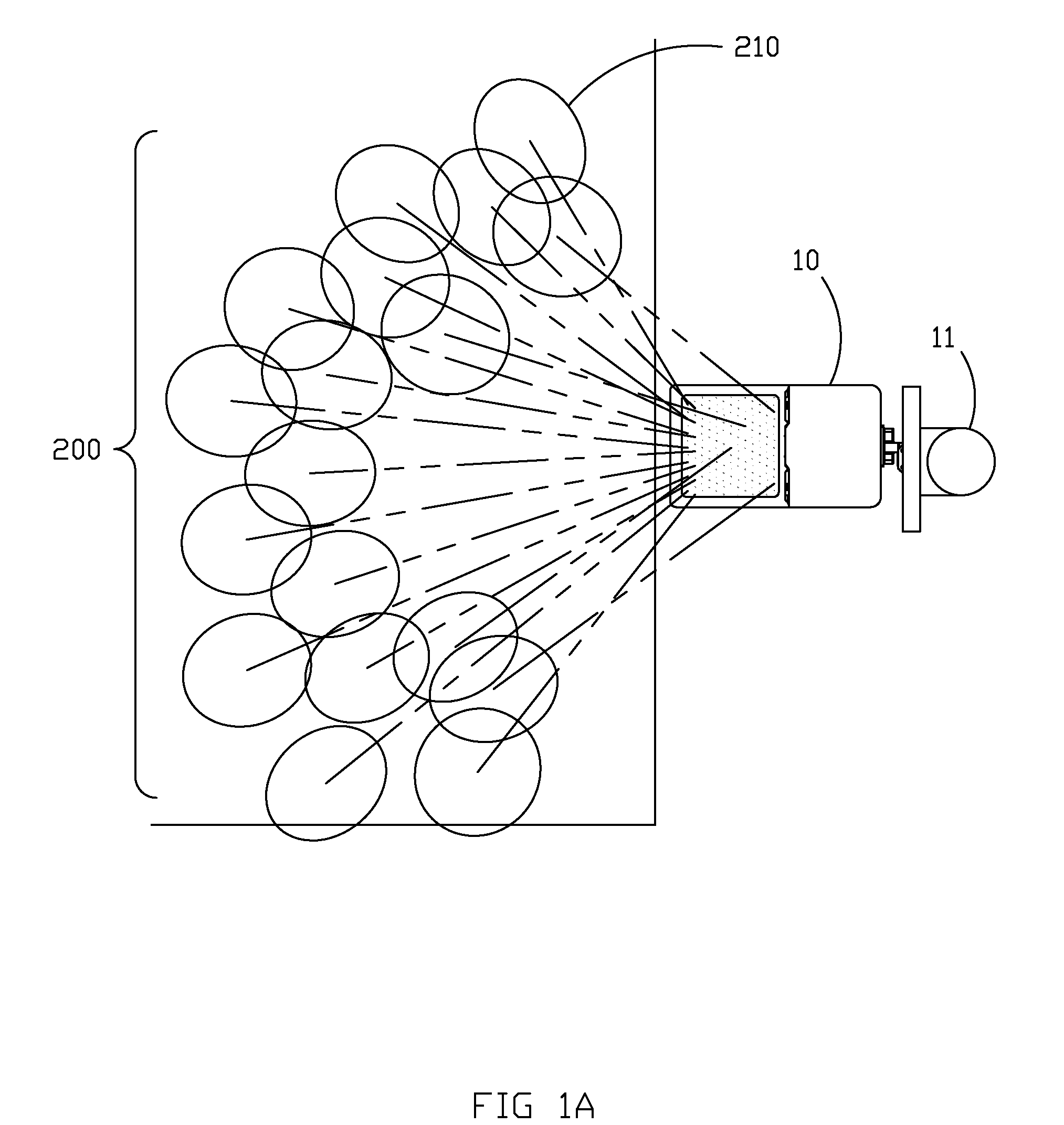

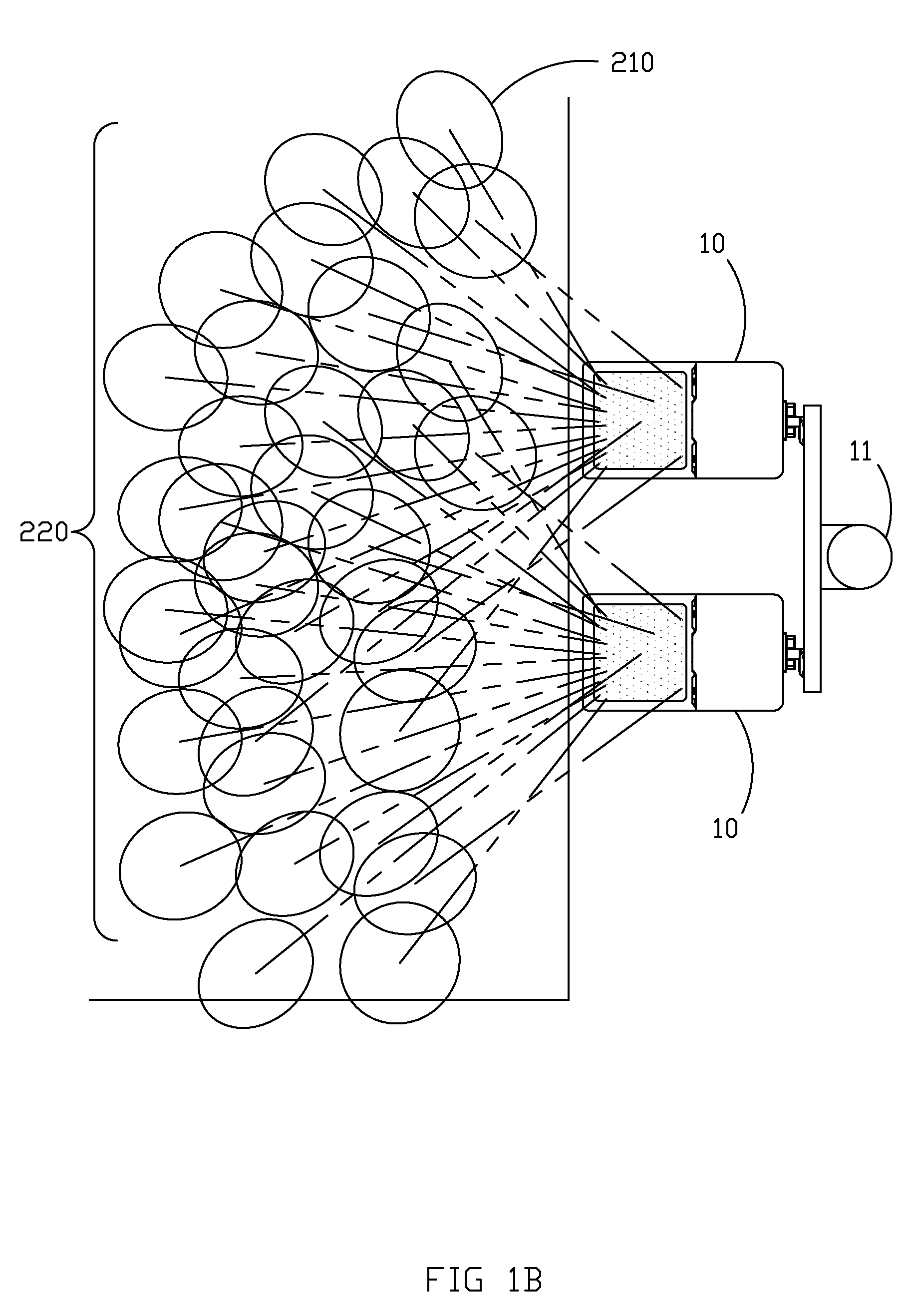

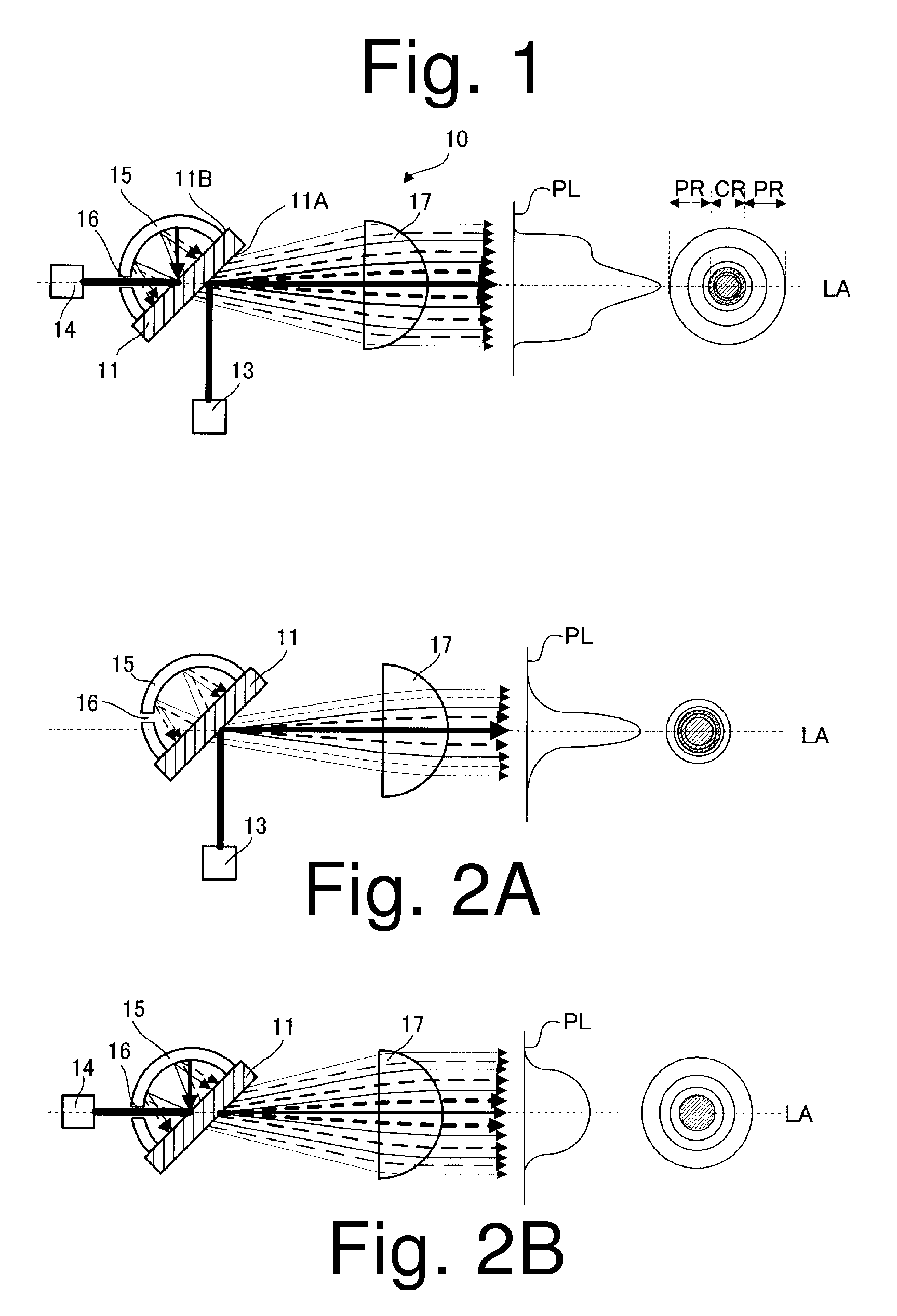

Apparatus, method, and system for highly controlled light distribution using multiple light sources

ActiveUS20100195326A1Easy to controlConvenient lightingPlanar light sourcesMechanical apparatusLight beamEffect light

Disclosed herein are apparatus, method, and system for producing a customizable composite beam from a plurality of solid state light sources. Each light source is associated with individually adjustable fixture components which allow for a variety of lighting needs to be addressed. The composite beam is a collective of the beam projected from each adjustable component / light source combination; each individual beam being of customized shape or standard shape.

Owner:MUSCO

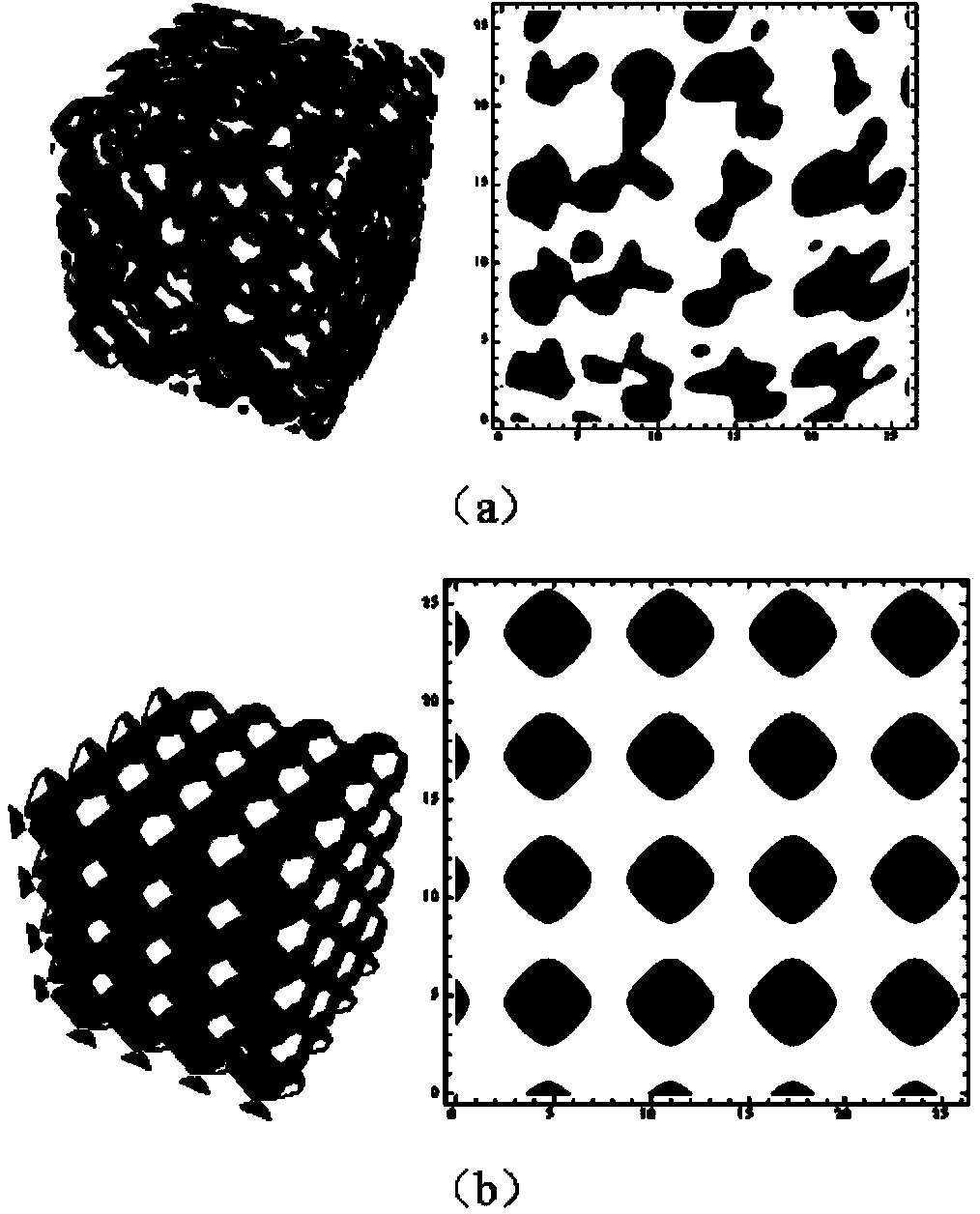

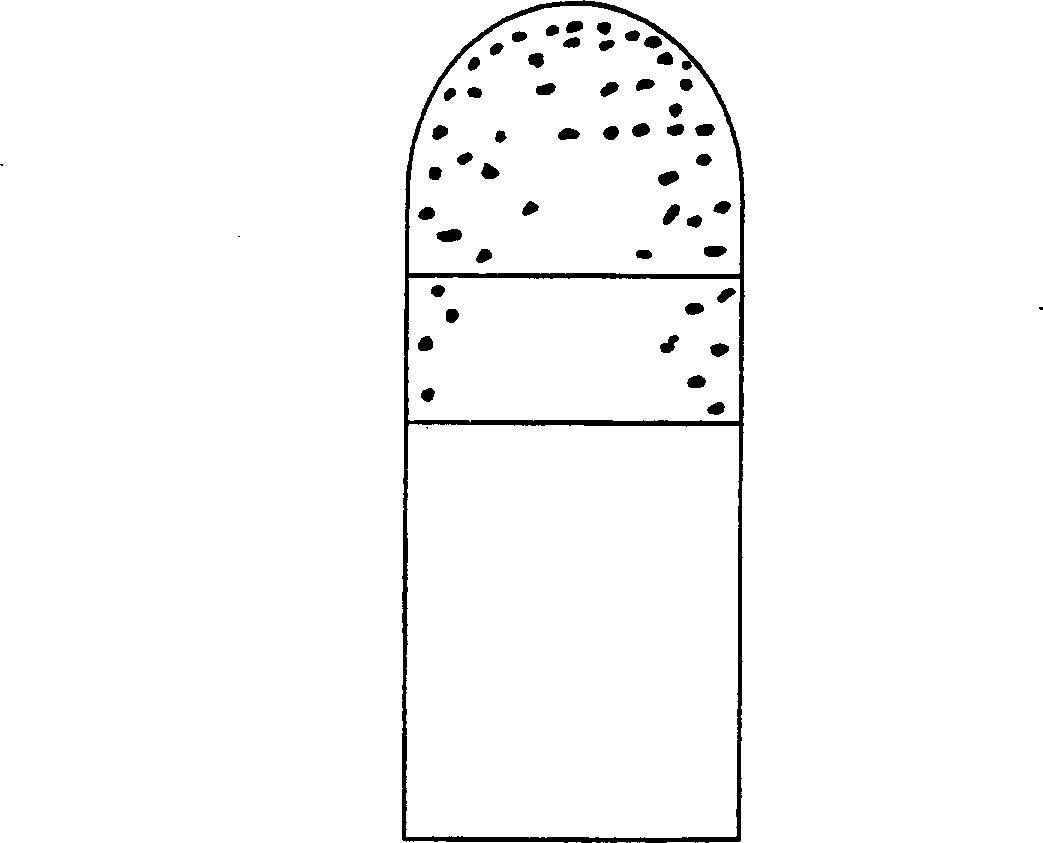

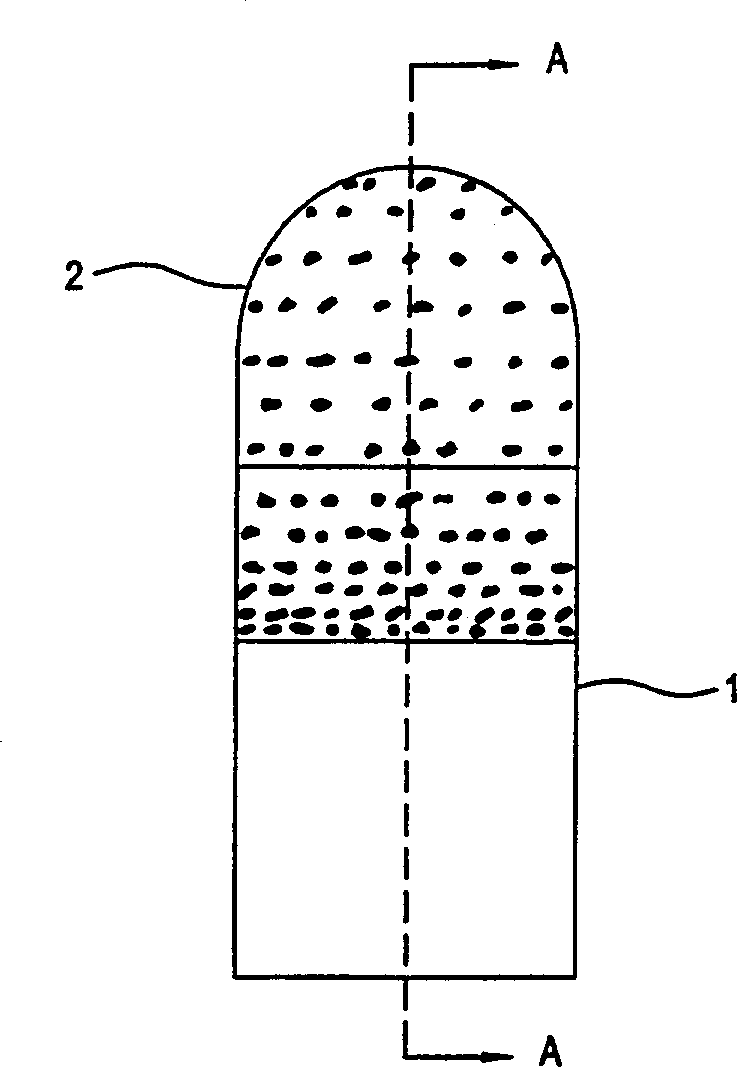

Preparation method of three-dimensional artificial random porous structure tissue engineering scaffold

The invention relates to a preparation method of a three-dimensional artificial random porous structure tissue engineering scaffold, belonging to the technical field of biomaterials. The invention aims to solve the design and manufacturing problems of the bionic structure of tissue engineering scaffold, provides a design method for constructing a random distributed scaffold porous structure with a bionic shape under expected porosity and pore size requirements, and molds by using a 3D additive manufacturing method to produce tissue substitute. The preparation method provided by the invention has the following advantages that the scaffold has a 3D through-hole structure meeting bionic requirements, and ensures nutrient substance transfer and waste metabolism and has certain bionic mechanical properties; the porosity and pore size distribution range of the scaffold can be conveniently controlled, and the random pore structure with expected function gradient is constructed to realize the bionic characteristic of the structure; and the method is suitable for a large range of materials such as metal materials, non-metal materials and medical high molecular materials, and can meets user-personalized tissue repair requirements.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

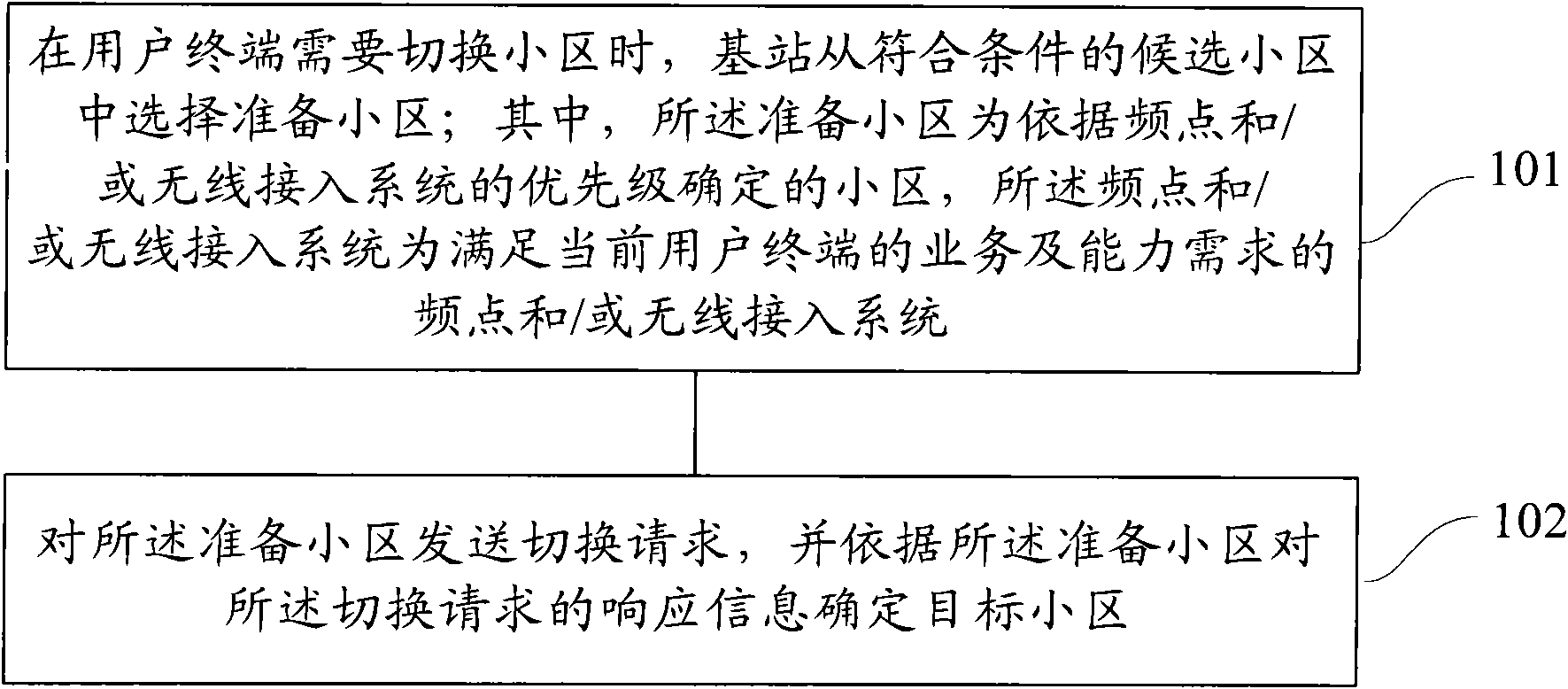

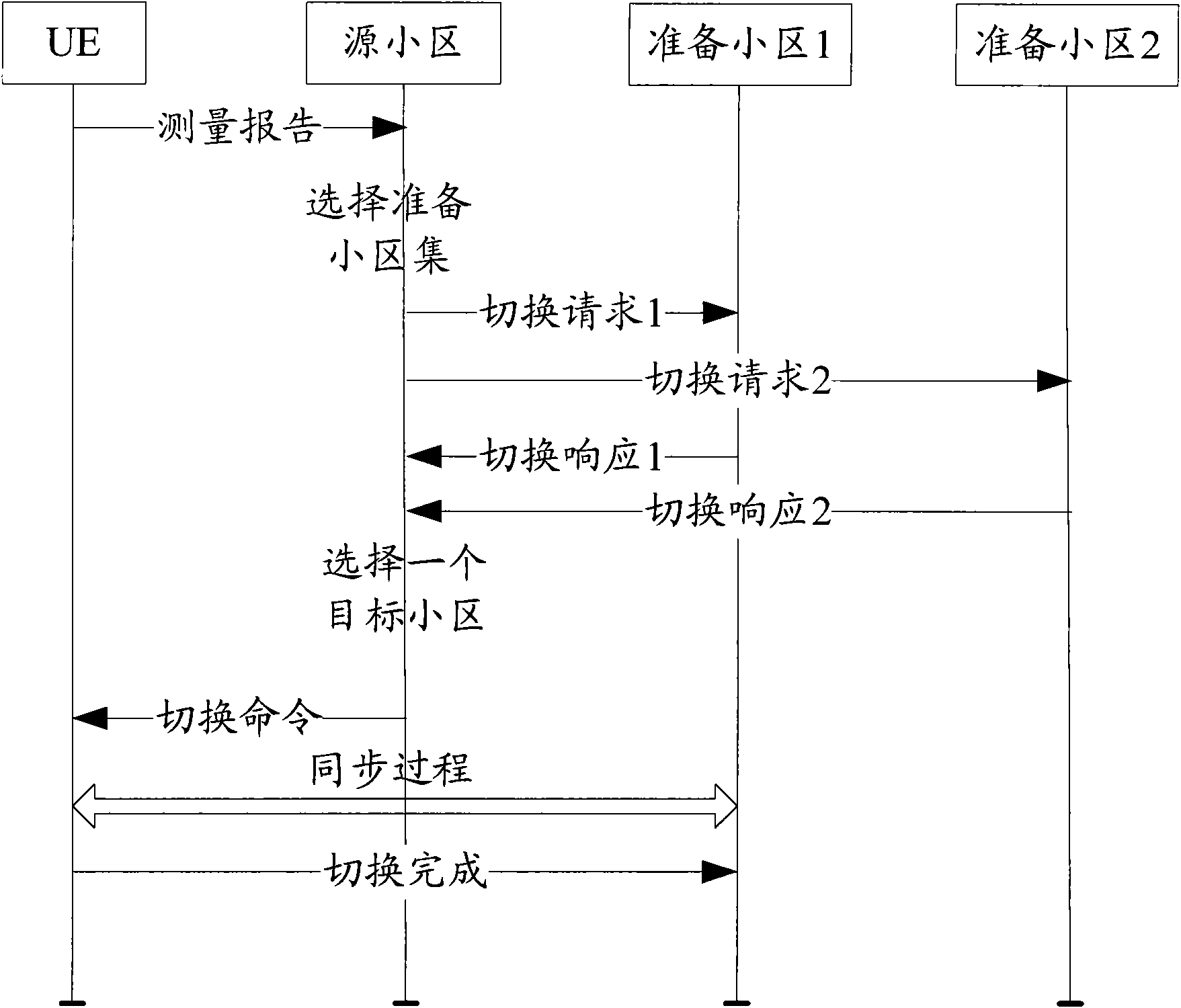

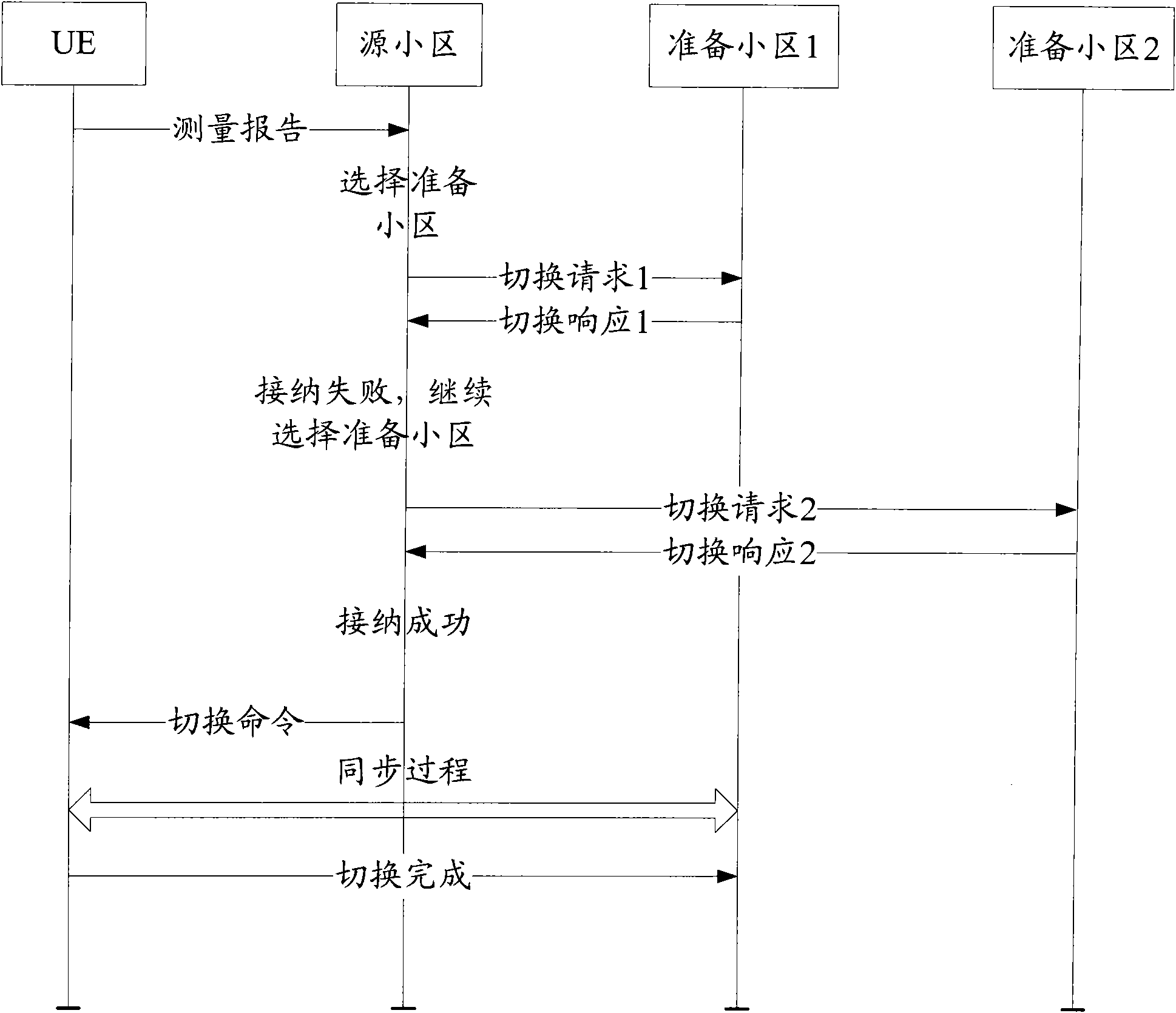

Method, system and base station for selecting target cell

InactiveCN102065495AIncrease capacityBalance cell loadWireless communicationAccess frequencyCurrent user

The invention discloses a method for selecting a target cell. The method comprises the following steps of: when a user terminal needs to switch a cell, selecting a preparation cell from candidate cells satisfying conditions by a base station, wherein the preparation cell is a cell determined according to the priority level of a frequency point and / or wireless access system, and the frequency point and / or wireless access system is the one meeting the service and capacity requirements of the current user terminal; and sending a switching request to the preparation cell, and determining the target cell according to the response information of the preparation cell to the switching request. The method can balance the cell loads of different access frequency point and / or wireless access systems and further improve the capacity of the whole wireless communication network.

Owner:DATANG MOBILE COMM EQUIP CO LTD

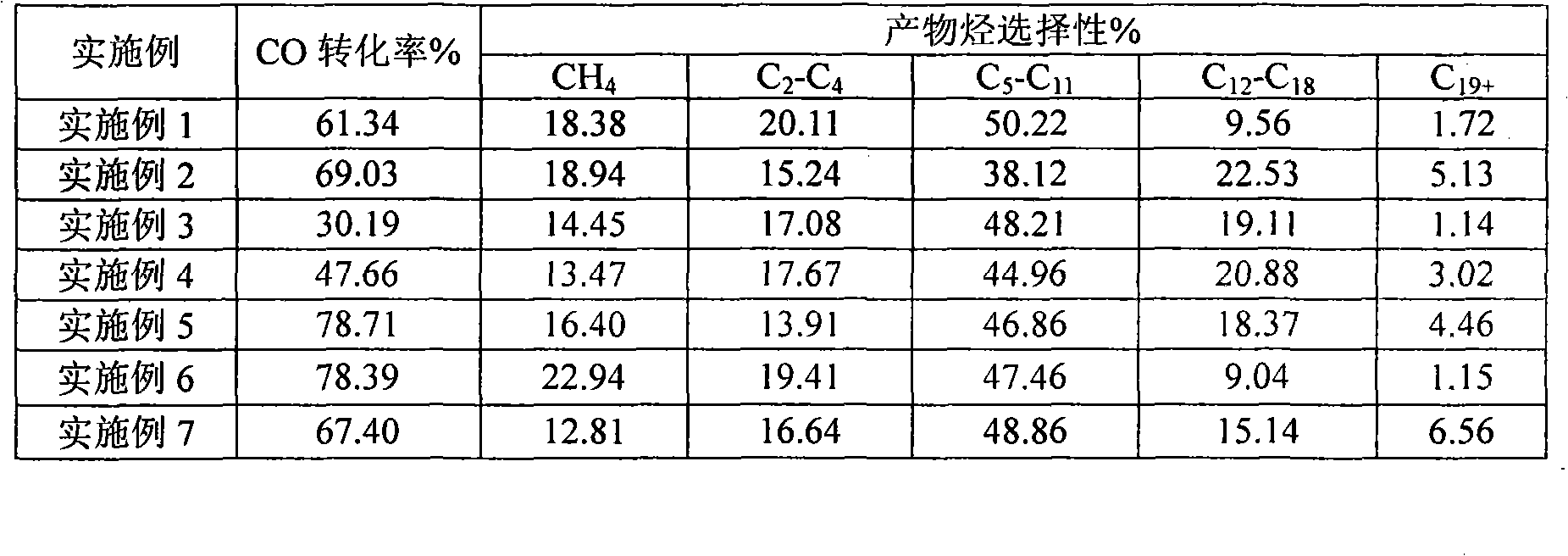

Organic hydrophobic modified cobalt-based fischer-tropsch synthesis catalyst, preparation thereof and application thereof

ActiveCN101811050AThe size is easy to controlControl distributionMolecular sieve catalystsLiquid hydrocarbon mixture productionActive componentSilicon dioxide

The invention provides an organic hydrophobic modified cobalt-based fischer-tropsch synthesis catalyst. The catalyst consists of the following components in percentage by weight: 5.0 to 30.0 percent of cobalt serving as an active component, 50 to 80 percent of carrier, 5 to 20 percent of silicon dioxide and 5 to 40 percent of hydrophobic groups. The catalyst has the advantages of simple preparation process and high selectivity of middle distillate oil.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

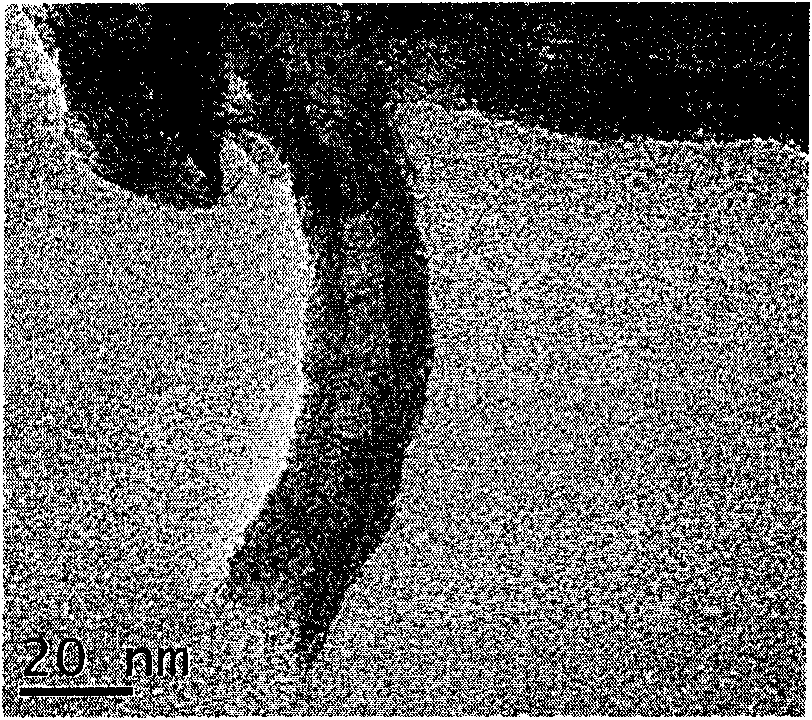

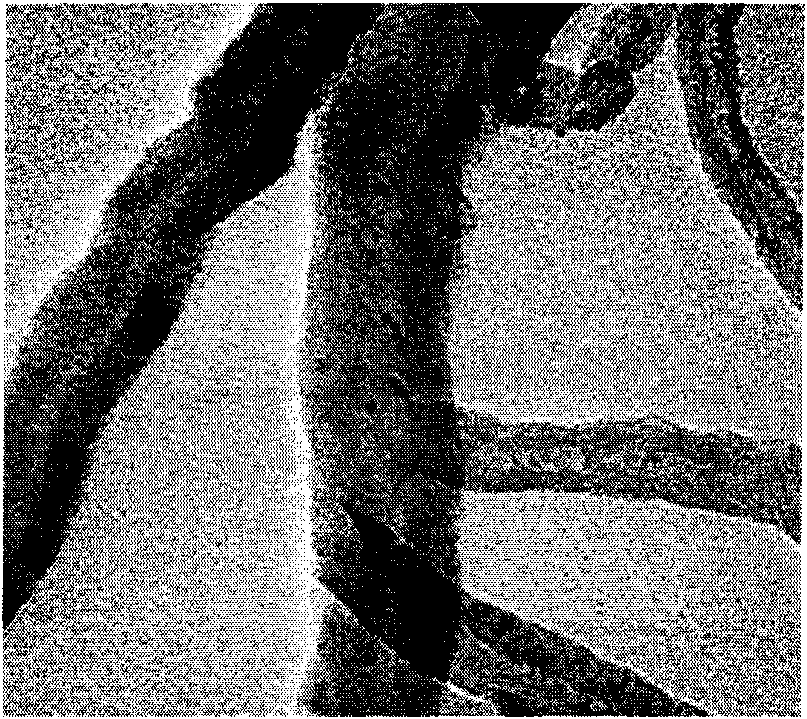

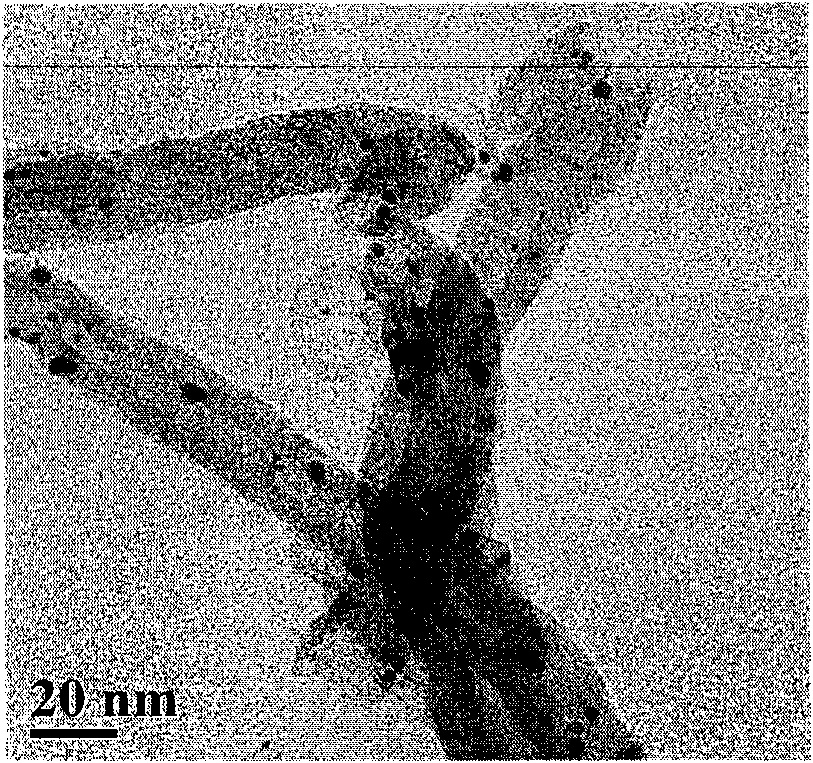

Platinum/carbon nanotube catalyst and preparation method and application thereof

InactiveCN102039121AMild conditionsEasy to manufactureOrganic reductionMaterial nanotechnologyCarbon nanotubeRoom temperature

The invention relates to a platinum / carbon nanotube catalyst suitable for multiphase asymmetric hydrogenation reaction. Platinum is loaded on a carbon nanotube carrier. A preparation method comprises the following steps of: heating a purified carbon nanotube in nitric acid, washing, filtering, washing by using water until the pH value of filtrate is neutral, drying to obtain the carbon nanotube carrier, soaking in aqueous solution of chloroplatinic acid, and performing ultrasonic treatment at room temperature; and stirring and impregnating a mixture of the carbon nanotube and the aqueous solution of chloroplatinic acid, raising the temperature to 110 DEG C from room temperature, drying at the temperature of 110 DEG C, grinding into fine powder, reducing by using aqueous solution of sodiumformate with heating, filtering, washing by using deionized water and drying. The invention also provides the preparation method of the catalyst and application of the catalyst to the multiphase asymmetric hydrogenation reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Producing method of water-base polyurethane

InactiveCN103073692AImprove performanceControl distributionPolyureas/polyurethane adhesivesPolymer scienceSpinning

The invention discloses a producing method of water-base polyurethane, which comprises the steps of preparing a polyurethane prepolymer, preparing polyurethane prepolymer salt and finally obtaining water-base polyurethane. Water-base polyurethane prepared by the method has the characteristics of good strength, moderate crosslinking degree, uniform particle size, good water resistance, high binding power and the like, can be applied to spinning adhesive, and can serve as the spinning adhesive.

Owner:烟台宜彬新材料科技有限公司

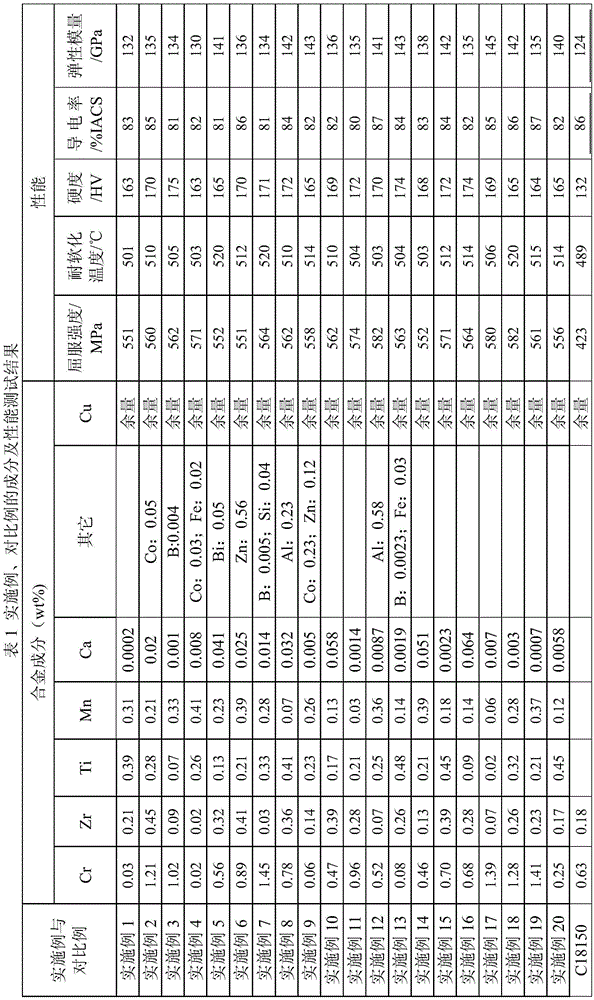

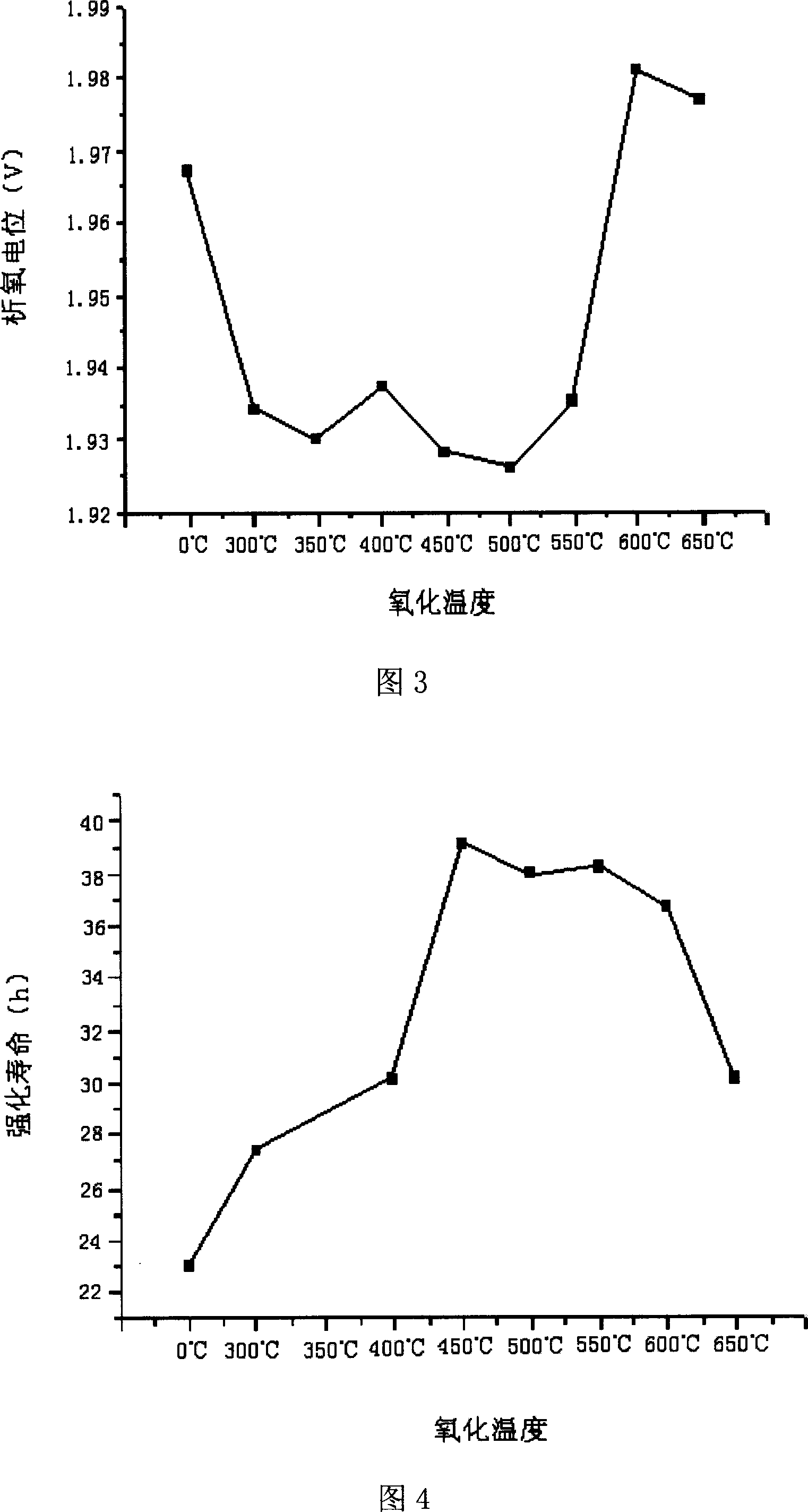

High-strength high-conductivity copper-chromium-zirconium alloy and preparation method of plate/strip thereof

The invention discloses a high-strength high-conductivity copper-chromium-zirconium alloy and a preparation method of a plate / strip thereof. This alloy comprises the chemical composition: 0.01-1.5 wt% of Cr, 0.01-0.5 wt% of Zr, 0.001-0.5 wt% of Ti, 0.01-0.5 wt% of Mn, 0.0001-0.07 wt% of Ca, and the balance of copper and unavoidable impurities; the position and process of the Cu-Cr-Zr alloy are optimized, the provided high-strength high-conductivity copper-chromium-zirconium alloy retains high conductivity (above 80% IACS), elastic modulus up to higher than 130 GPa, softening temperature resistance up to higher than 500 DEG C, yield strength up to higher than 550 MPa and hardness up to 160 HV, the copper-chromium-zirconium plate / strip is imparted high strength, high conductivity and excellent comprehensive performance, this comprehensive performance meets the requirements of products such as a lead frame and a connector upon base material stamping and machining performances, and this plate / strip material is mainly applied to electronic components such as connectors and lead frames.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD

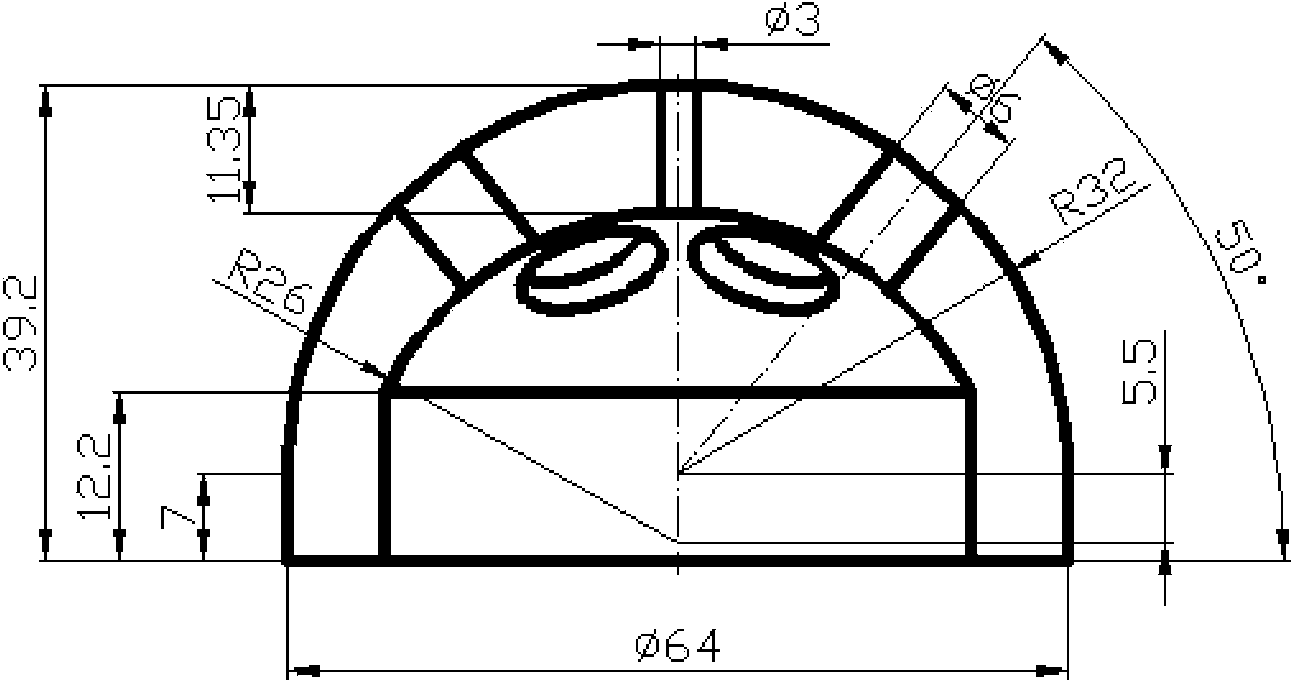

Method of semi-vitreous extrusion molding manufacturing for portiforium type millipore plastics extrusions

InactiveCN101229682ASolve technical problemsSimplify the molding processPlastic materialsMelt extrusion

The invention relates to a method for preparing opening micropore plastic material though slack-melting, extruding and molding. The method includes the processes: after reaching from a feeding device arranged on a double piston extruder to a heating material cylinder, preheating plastic powder with particle size of 40-1500 meshes is extruded by the piston driven by a hydraulic driver and compacted, transported and heated constantly; when the surface temperature of the plastic powder reaches the melt temperature of Tf plus or minus 20 DGE C, the power is extruded from a machine head and a die. Then, extruding matters are cooled and set by a cooling-traction device and the products are finished. By regulating the particle size of the powder, addictive and forming process conditions and so on, the invention can control opening rate, size and distribution of the aperture; the invention has simple process, short production cycle, low forming temperature and pressure as well as short forming time; besides, the invention can greatly reduce the production cost can not be degraded easily when the plastic is processed and can be widely applicable to molding of the opening micropore products of thermoplastic powders, thermosetting power and so on.

Owner:SICHUAN UNIV

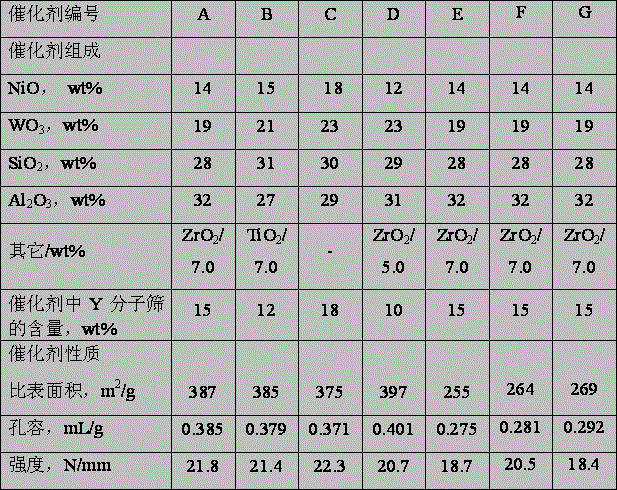

Hydrocracking catalyst preparation method

ActiveCN104588082AEasy to useControl distributionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveHigh activity

The invention discloses a preparation method of a hydrocracking catalyst. According to the method, a nickel and aluminum precipitate is prepared with a straight addition method; a tungsten, silicon and aluminum precipitate is prepared with a parallel flow precipitation method; the two precipitates are mixed, and a suspension liquid of Y type molecular sieve is added, such that the catalyst is prepared. With the method, the distributions of different hydrogenation active metals can be controlled; high-activity phase can be formed among active metals tungsten and nickel; and the interaction between active metals and the carrier can be improved. Therefore, the hydrogenation activity and the cracking activity of the obtained hydrocracking catalyst can cooperate well, and the application performance of the hydrocracking catalyst can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

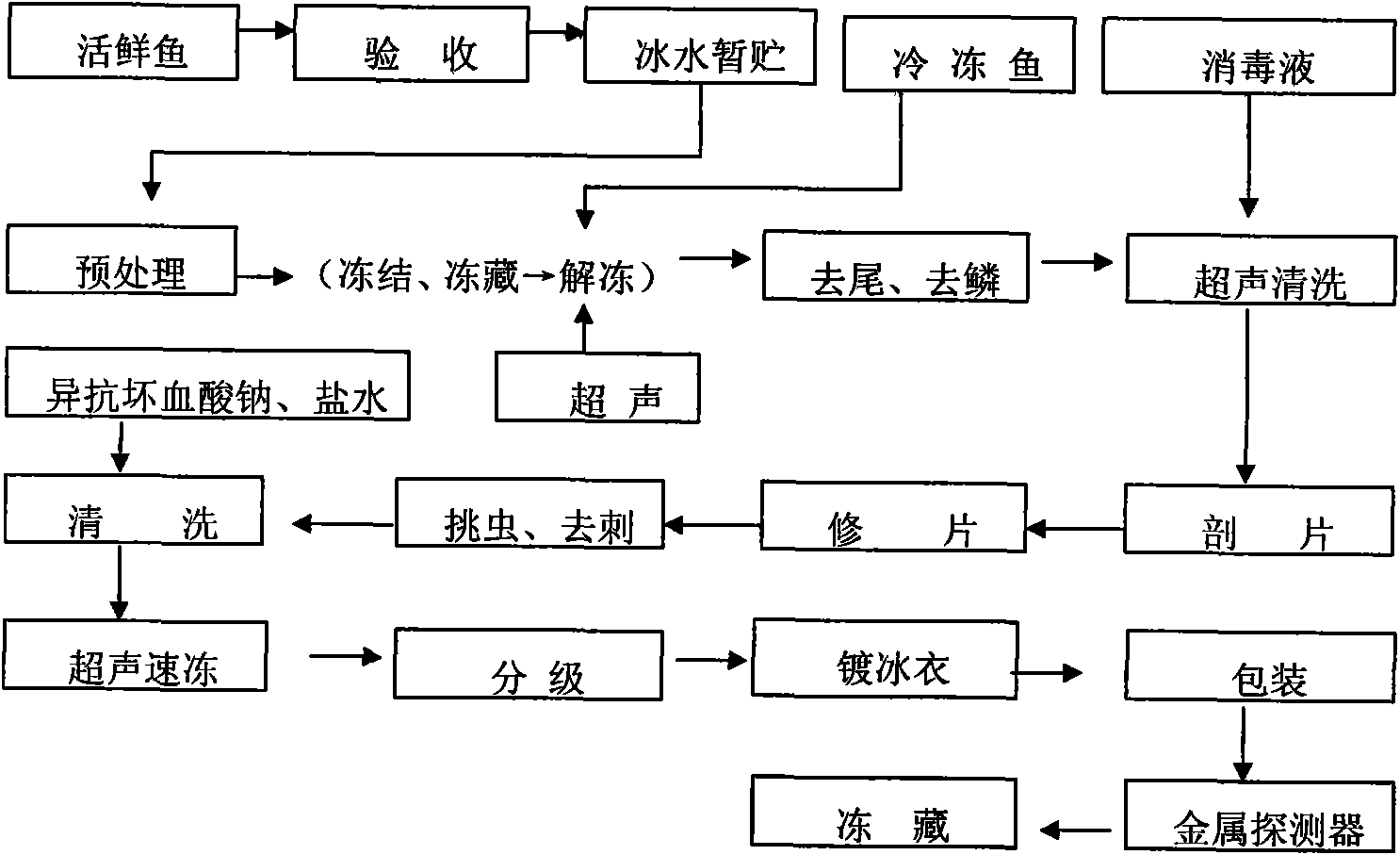

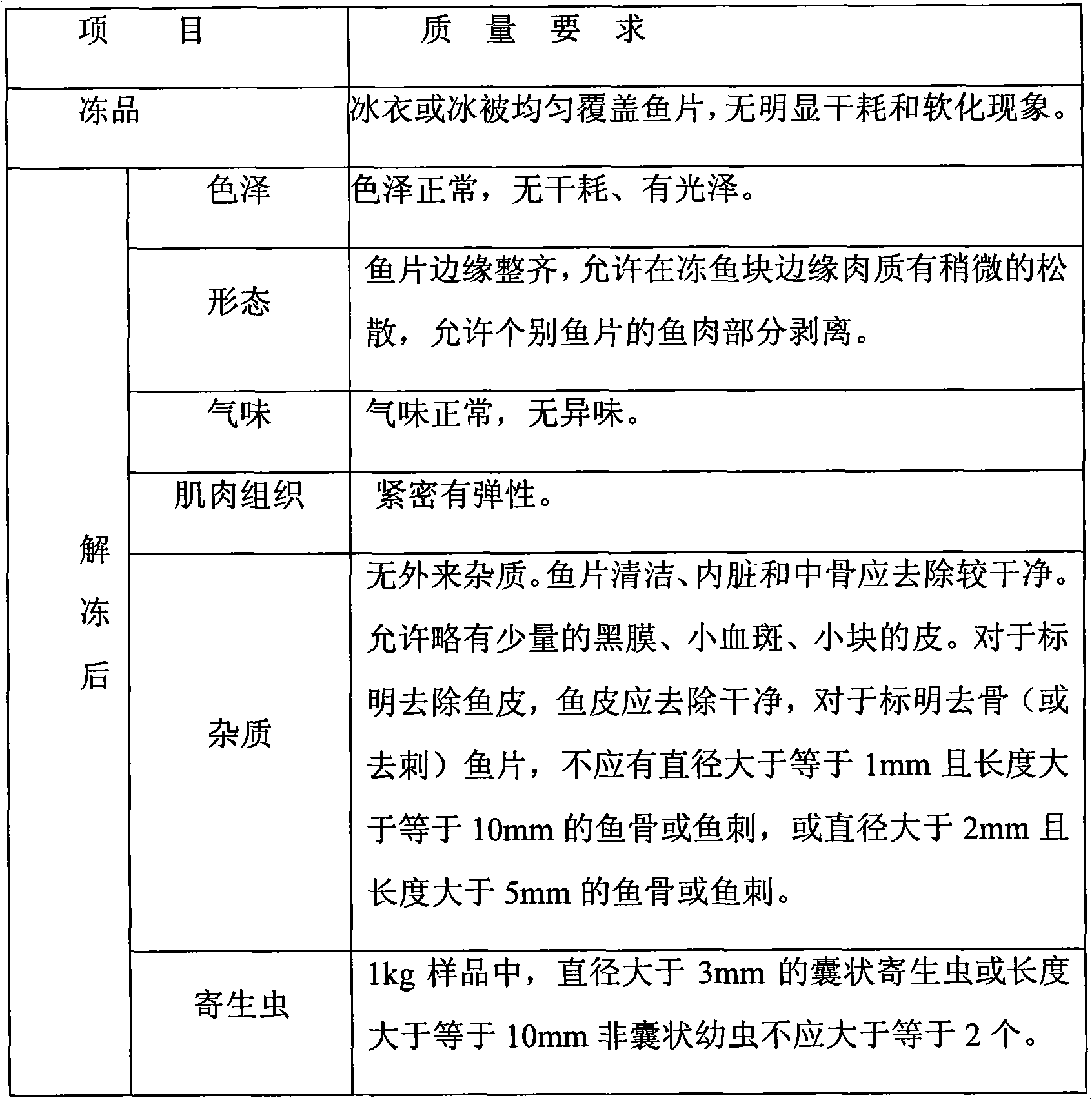

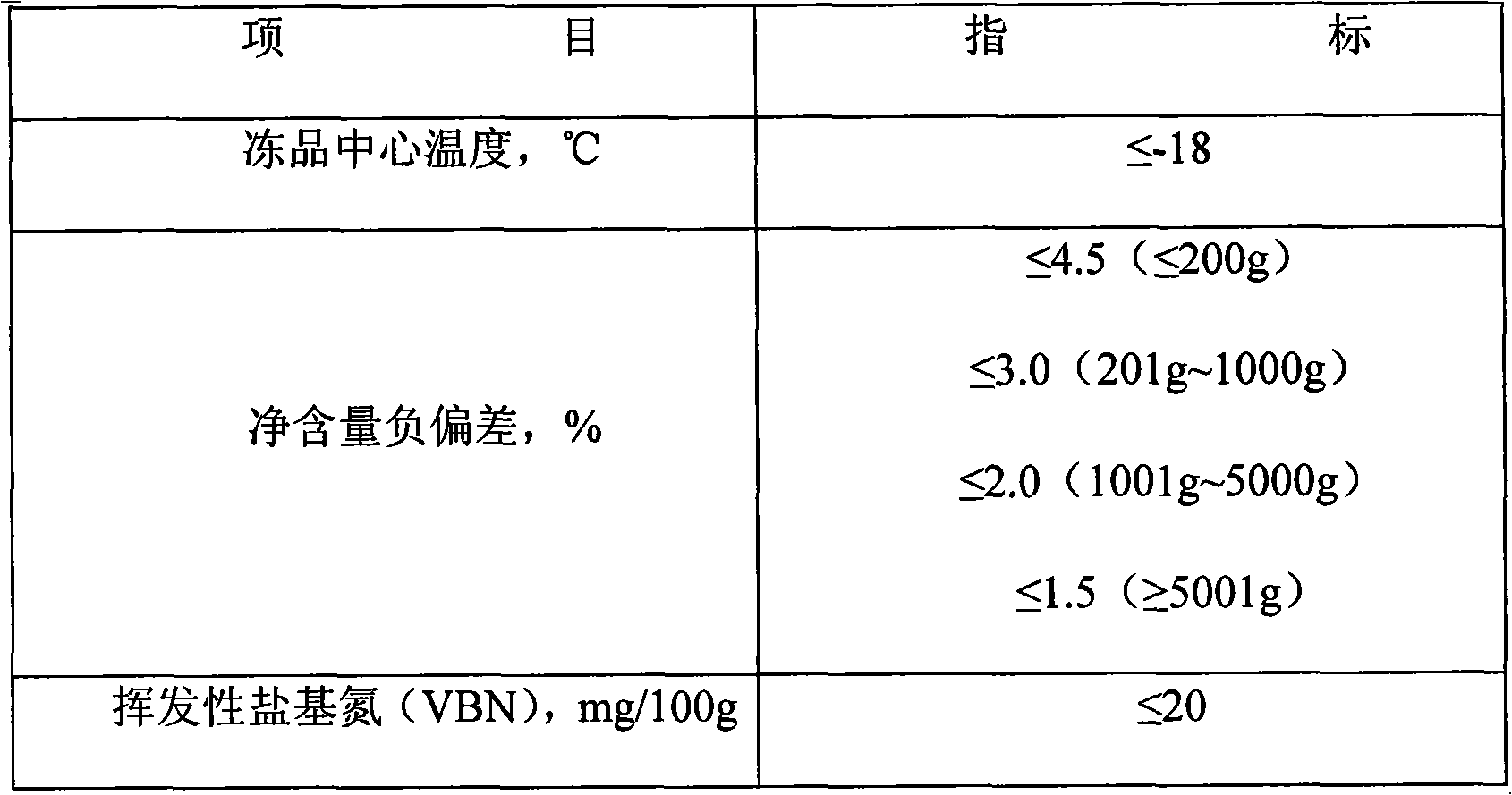

Processing method of sushi sashimi

InactiveCN101919539AExtended shelf lifeAvoid "cooking"Fish washing/descalingMeat/fish preservation by freezing/coolingIce waterAquatic product

The invention provides a processing method of sushi sashimi, which belongs to the field of processing of aquatic products. The processing method comprises the steps of taking a live fresh scaly fish as a raw material, carrying out acceptance, temporary storage in ice water and pretreatment, or taking a frozen scaly fish as the raw material, firstly carrying out ultrasonic thawing, further removing a tail, removing scales, carrying out ultrasonic cleaning, cutting into slices, trimming, picking out insects, removing bones, cleaning, carrying out ultrasonic quick freezing, classifying, glazing, packaging, carrying out metal detection, freezing, and carrying out other process steps for processing the sushi sashimi. The sushi sashimi processed by adopting the method has good quality, and the sensory, the physical and the chemical properties, as well as the safety sanitation quality are in line with requirements; furthermore, the processing method has short thawing time, short freezing time and high processing efficiency, and can be popularized in the processing of the aquatic products.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

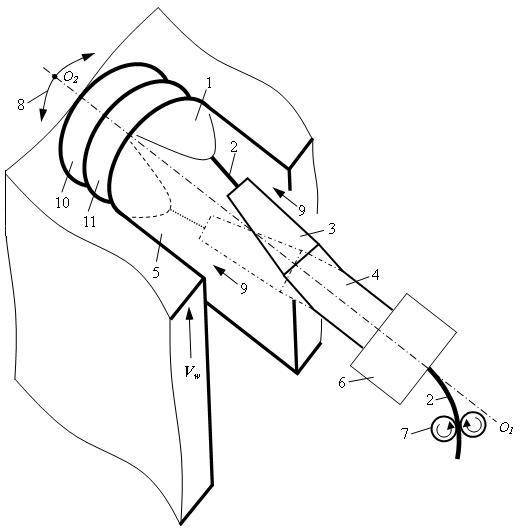

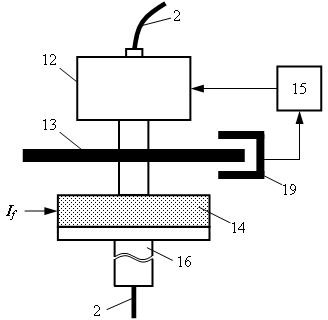

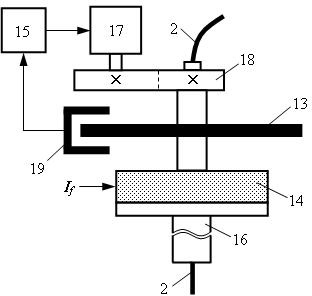

Shaking arc narrow gap melting electrode gas shielded vertical welding method

The invention discloses a rocking-arc narrow-gap vertical gas metal arc welding method comprising the following steps of: assembling metal-piece thick plates into an I-shaped vertical groove to be welded having a gap within a range of 12-15 mm; according to the gap of the groove to be welded and the difference of weld joint passes, firstly selecting a gas protection way, setting an arc rocking frequency, an arc rocking amplitude, arc side wall retention time, an average arc current of pulse welding, an average arc voltage, a welding speed and the dry extension of a welding wire, and selectinga slightly bent conductive rod with an appropriate bending angle; moving a welding torch integrally upwards or downwards in the vertical direction at the welding speed, thereby realizing vertical andautomatic rocking-arc narrow-gap gas metal arc welding in such a manner of single-pass multi-layer welding per layer in a state where a weld joint is freely formed. The method of the invention does not need to form a large welding groove and does not require a forced forming device; besides, the welding device is simple, the welding efficiency is high, the weld joint is formed beautifully, and the performance of the welded joint is good.

Owner:JIANGSU UNIV OF SCI & TECH

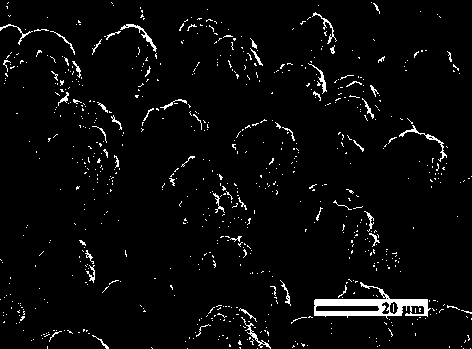

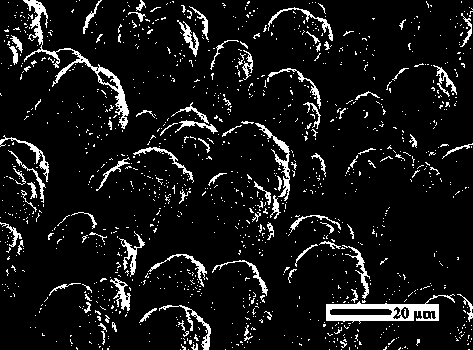

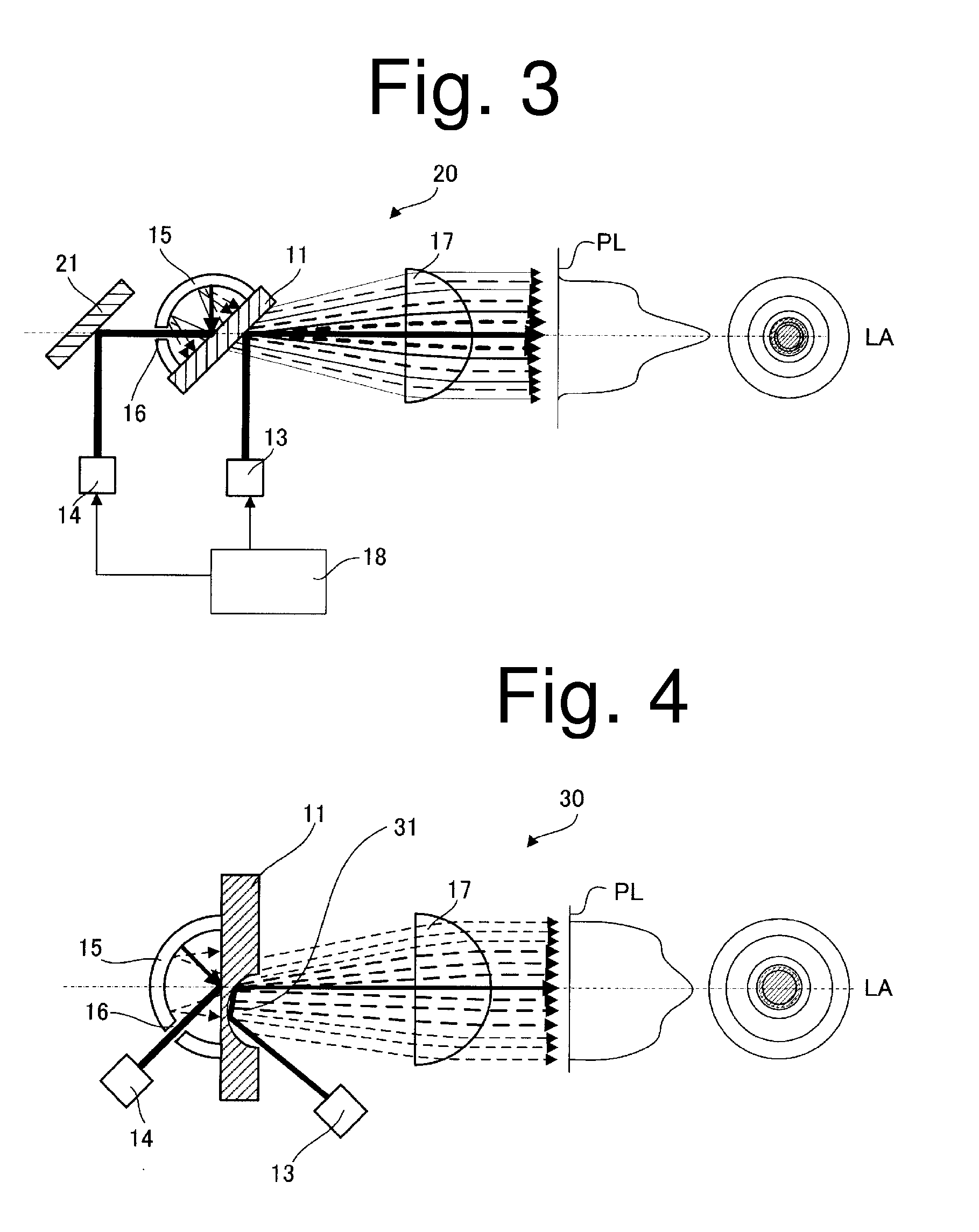

Method for controlling size and distribution of metal surface micro-nanostructure

ActiveCN103433618AThe production process is simpleIncrease productivityLaser beam welding apparatusMicro nanoAngle of incidence

The invention discloses a method for controlling the size and distribution of a metal surface micro-nanostructure. In order to implement the invention, plasma filaments induced by ultrashort pulse laser with the pulse width of 15fs-5ps are utilized to directly irradiate a metal surface, by controlling the ultrashort pulse laser parameters and the scanning speed and scanning spacing to the metal surface of the filaments, control of the plasma filaments on the size and distribution of the metal surface induced micro-nanostructure is realized; by changing the incidence angle of the laser induced plasma filaments, the orientation of the micro-nanostructure is changed; the control on the shape of the micro-nanostructure is realized by changing the polarizing character of the laser. The invention provides a method used for designing parts such as a solar absorber in an optimized manner.

Owner:CHANGCHUN UNIV OF SCI & TECH

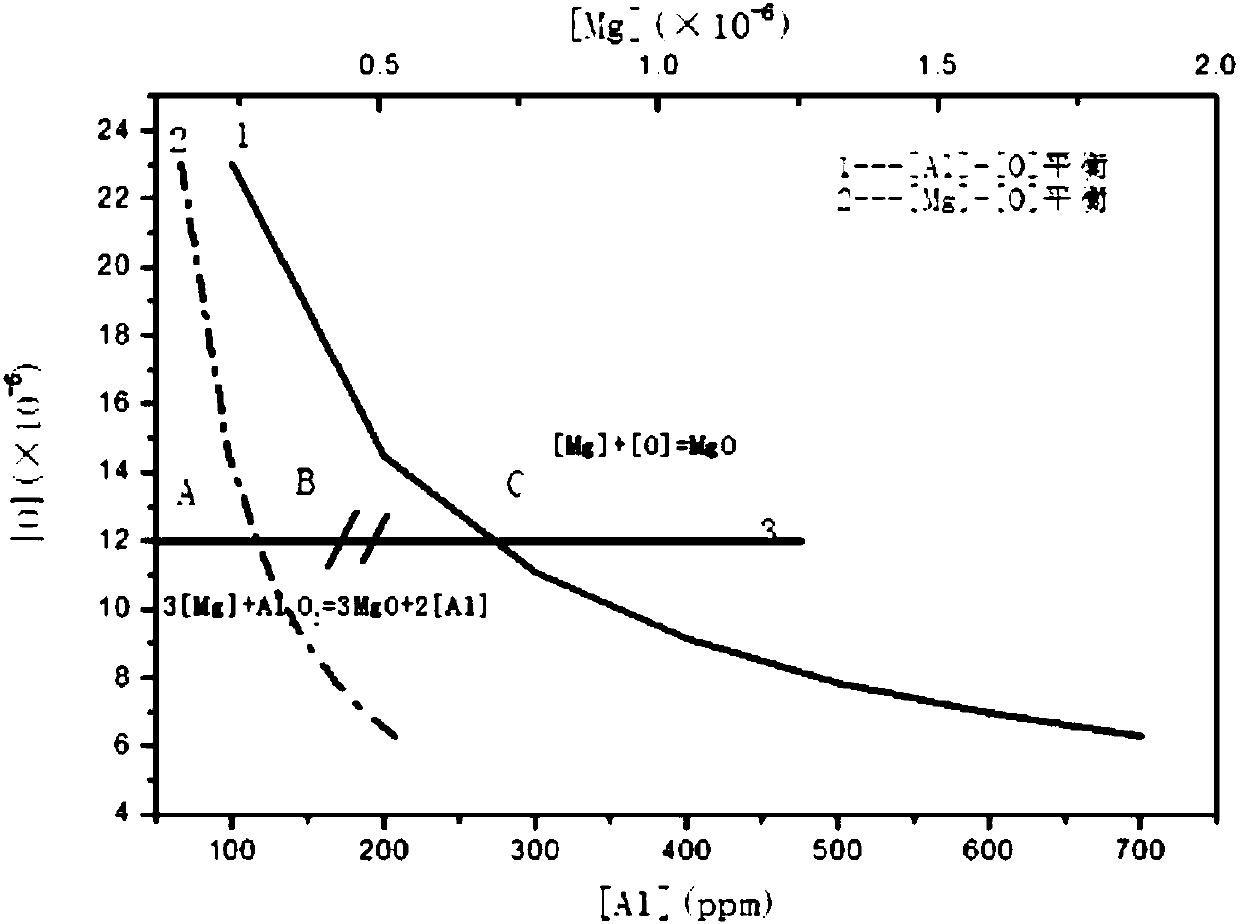

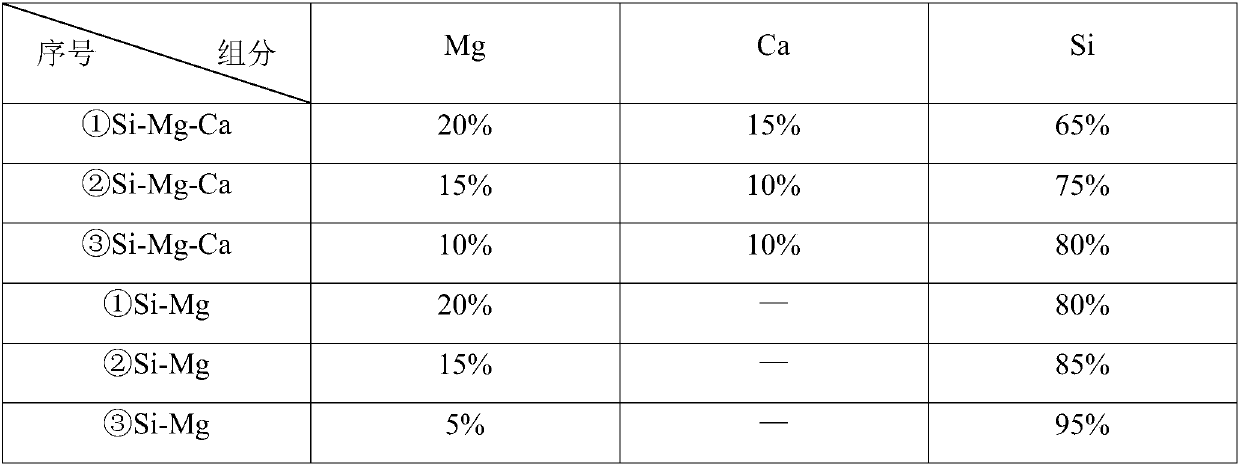

Smelting method for modifying sulfide inclusions in non-quenched and tempered steel or pinion steel

The invention discloses a smelting method for modifying sulfide inclusions in non-quenched and tempered steel or pinion steel. A modification process is mainly realized by the following step: feedinga silicon-magnesium-calcium composite core-spun yarn into refined molten steel, or respectively feeding a silicon-magnesium core-spun yarn and a silicon-calcium core-spun yarn into the refined moltensteel, so that the content of magnesium in the steel is 4-25ppm, and the content of calcium in the steel is 5-25ppm. According to the method, by optimizing the contents of oxygen, sulfur, manganese, calcium, magnesium and aluminum in the steel in a refining process, the sulfide inclusions in the non-quenched and tempered steel and the pinion steel are modified effectively, so that the form, size and distribution of sulfide are controlled, the inclusions in the non-quenched and tempered steel and the pinion steel are transformed into 'internal hard oxide particle and external covered sulfide' composite inclusions, and the quality of special steel is enhanced.

Owner:SHANGHAI UNIV

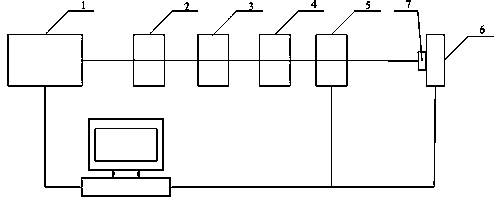

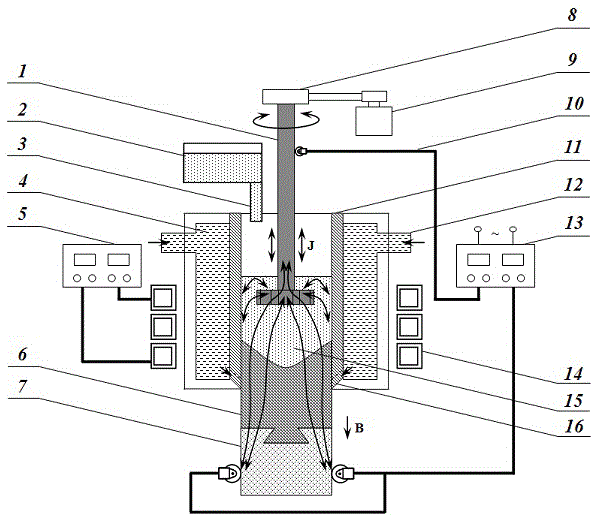

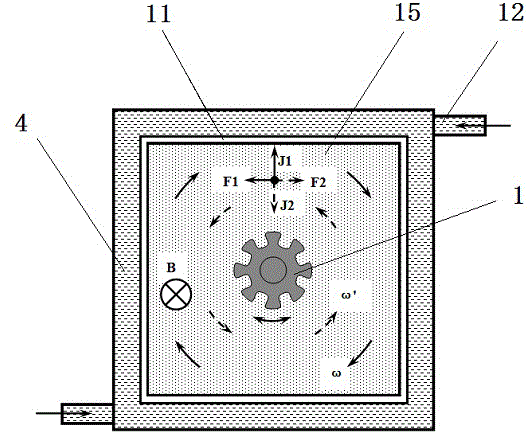

Continuous steel casting process and device with function of electromagnetic excitation compound mechanical stirring

The invention discloses a continuous steel casting process with a function of electromagnetic excitation compound mechanical stirring. According to the process, when alloy melt solidifies, microscopic and macroscopic strong shear flows are generated to break dendritic crystal by the electromagnetic excitation compound mechanical stirring technology, and accordingly, solidification structure refinement, full-equiaxed crystallization and solute segregation reduction are achieved, and alloy properties are improved. The invention further provides a continuous steel casting device mainly comprising a crystallizer, a rotor stirring paddle, a wheel, a program control motor, a magnetic field generator, a coil, and a voltage-regulating frequency-modulating alternating current source. The microscopic flows generated by electromagnetic excitation and macroscopic flows generated by mechanical stirring form complex chaotic flows which form strong shear flows to brake the dendritic crystal, crystal nucleus proliferation is prompted, temperature gradient is reduced, and ultrafine full-equiaxed crystal structure is achieved; meanwhile, segregation of alloy elements is significantly reduced or completely suppressed. The continuous steel casting process and method has the advantages that the energy consumption is significantly lower than that of conventional electromagnetic stirring and energy conservation is significantly effective.

Owner:新兴发展集团有限公司

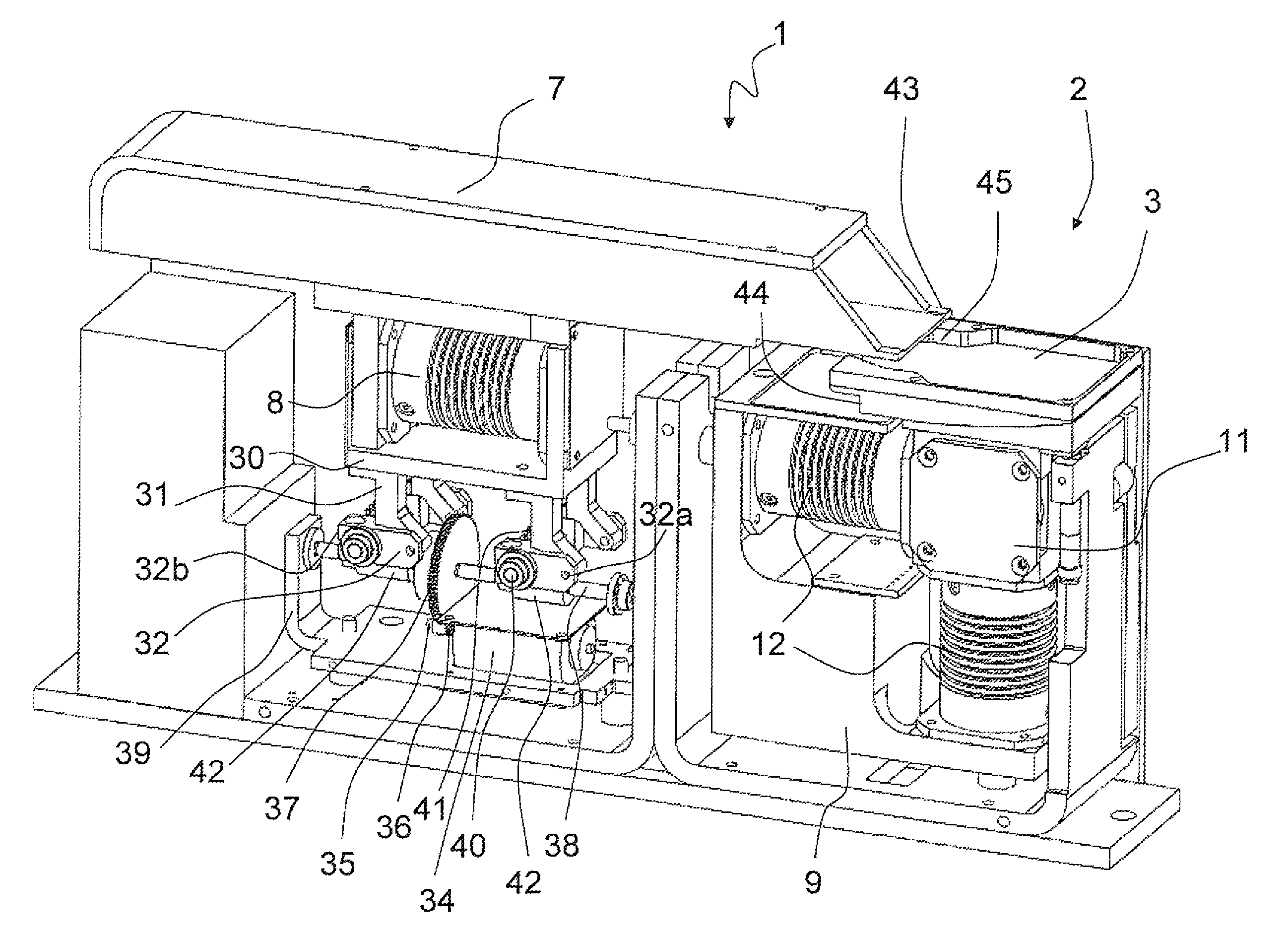

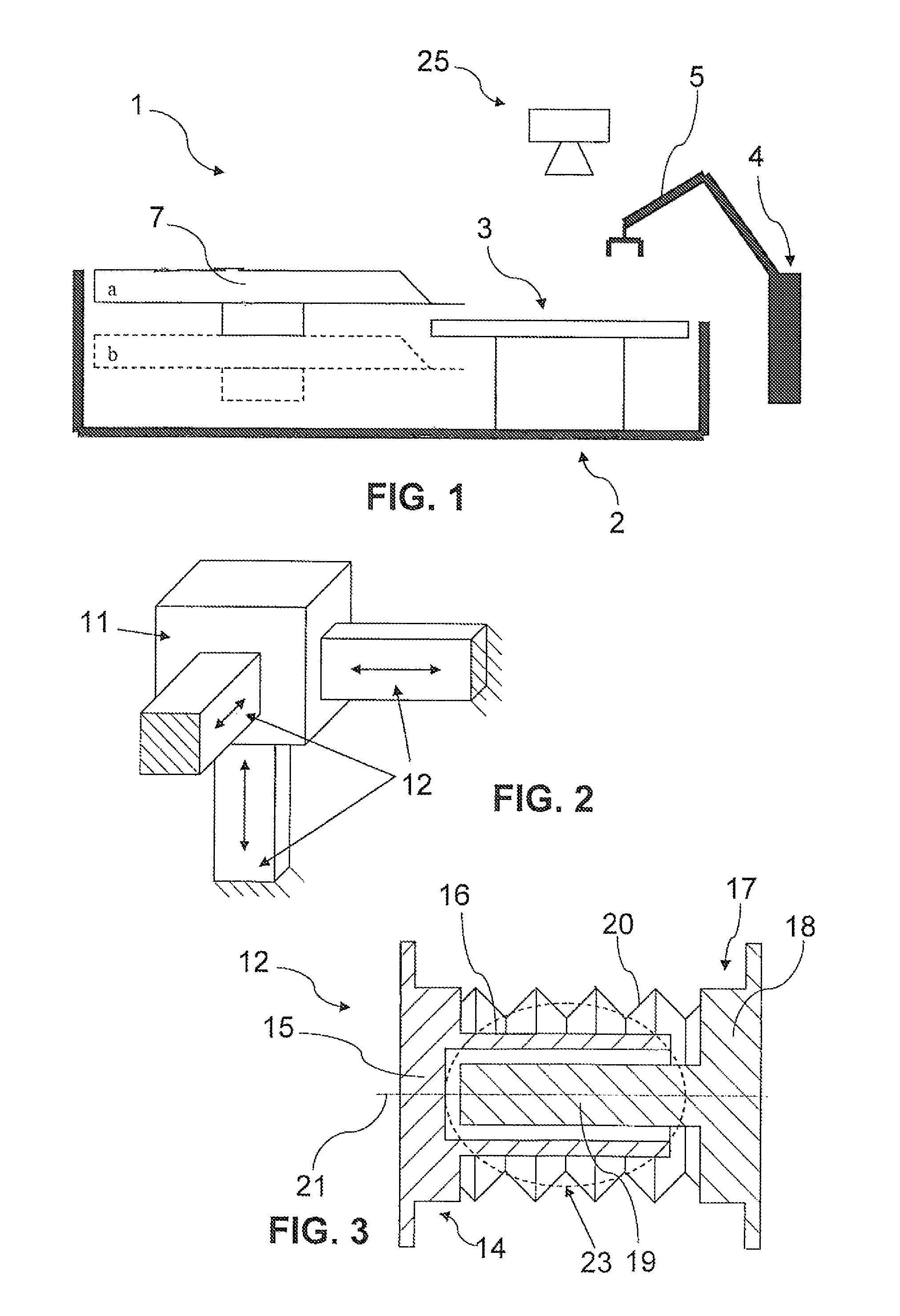

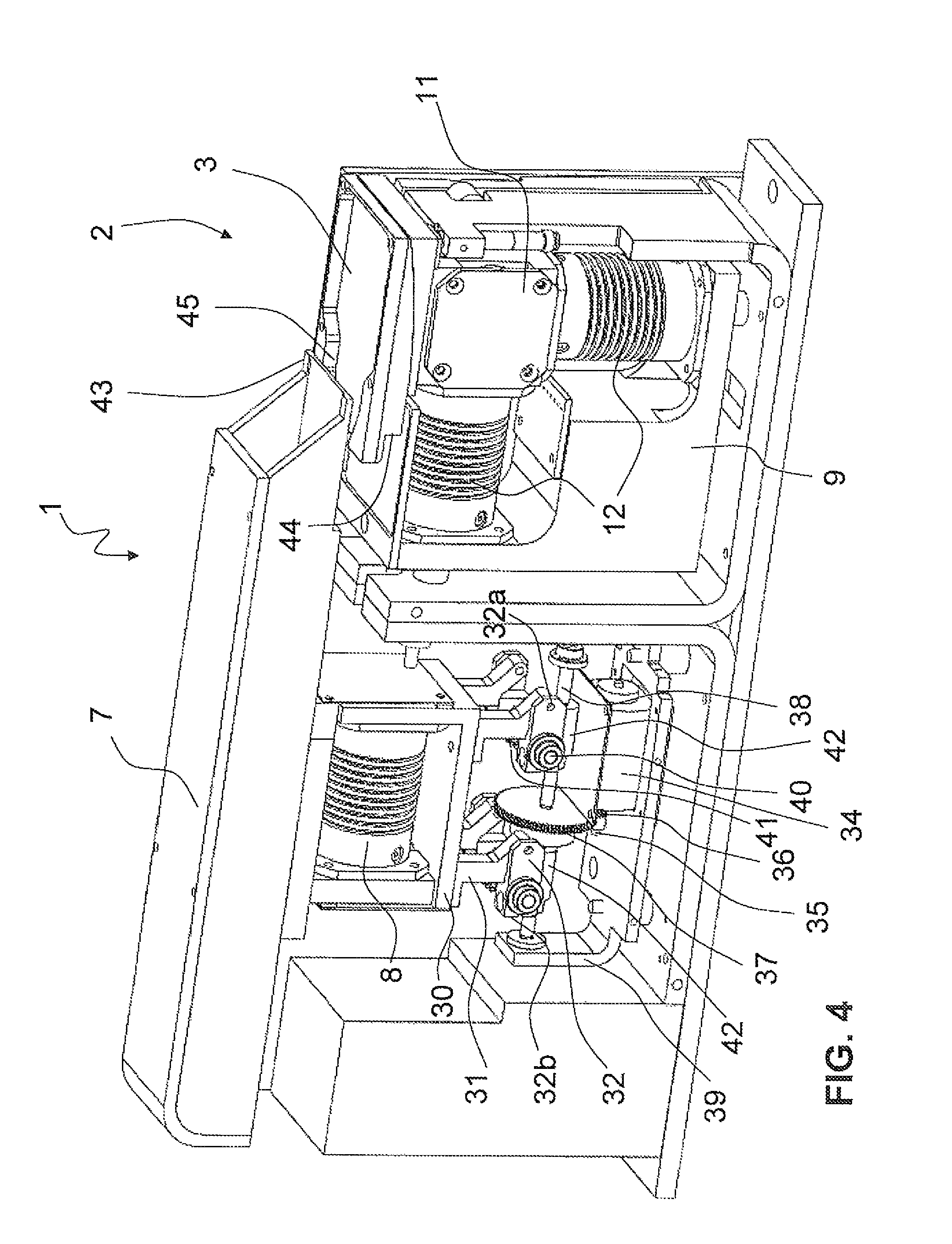

System for supplying components

ActiveUS8550233B2Control distributionIncrease percentageControl devices for conveyorsJigging conveyorsDegrees of freedomActuator

A system (1) for supplying components, particularly for transporting small components includes a vibrating device (2) provided with a plate (3) forming a surface for enabling the components to be grasped by a robot and a vibrating element (12) arranged to be capable of vibrating the plate (3) in one of the three directions in space and to be capable of vibrating the plate (3) in directions corresponding to any combination whatsoever of the three directions x, y and z. For this purpose, the vibrating element includes vibrating actuators (12) respectively including a vibrating element arranged to move with at least five degrees of freedom.

Owner:ASYRIL

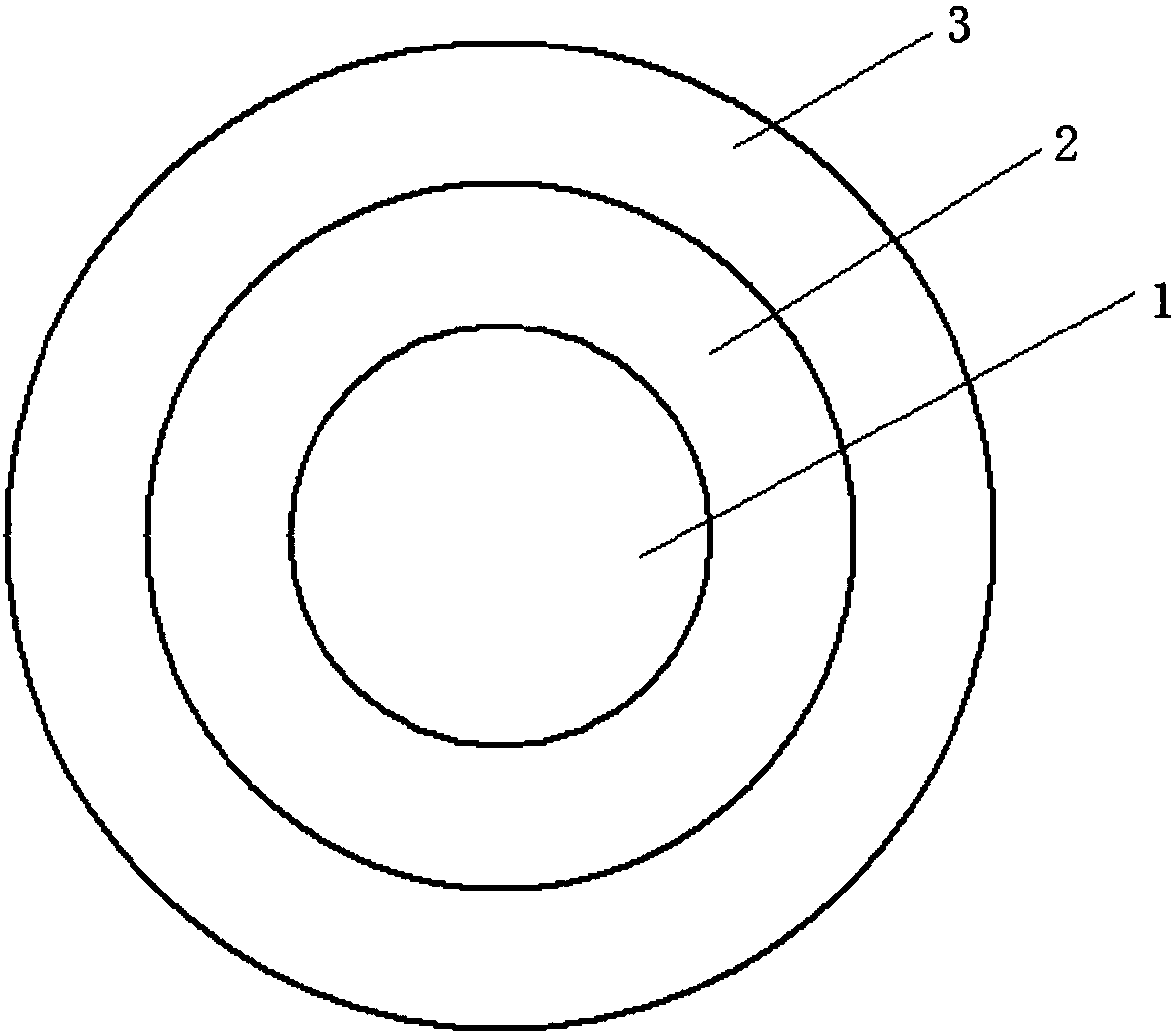

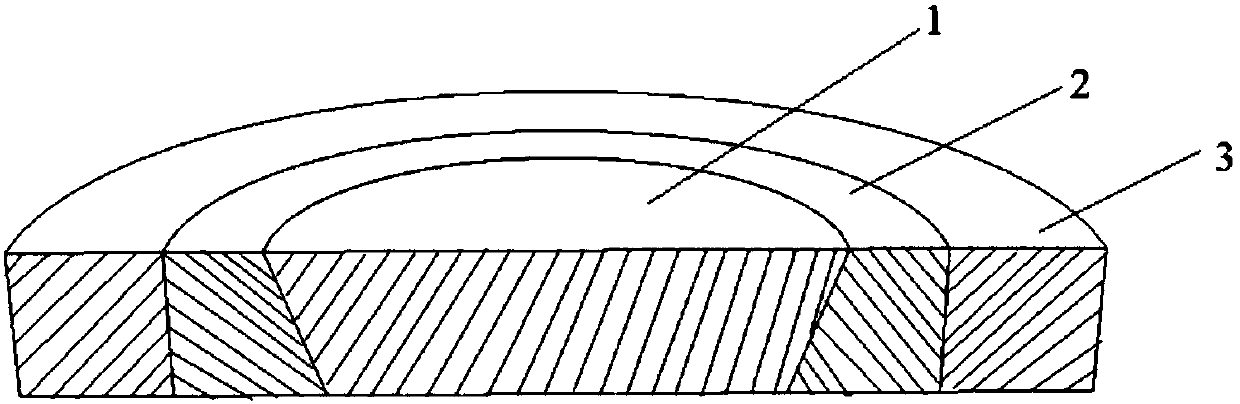

Diffusion connection method for high-temperature TiAl alloy annular piece and Ti2AlNb alloy annular piece

ActiveCN107745178AFirmly connectedControl distributionNon-electric welding apparatusPressure differenceIntermetallic

Disclosed is a diffusion connection method for a high-temperature TiAl alloy annular piece and a Ti2AlNb alloy annular piece. Pressure stress is provided through the expansion pressure difference of aclamp material and to-be-connected materials, and diffusion connection begins in the stepped temperature increasing process. Because the diffusion coefficient of a high-temperature TiAl disc edge islarger than the diffusion coefficient of a Ti2AlNb disc core, certain connecting pressure exists on a connecting interface in the stepped temperature decreasing process, and diffusion connection stillcontinues. In the process that the temperature is decreased to 800 DEG C, the connecting pressure existing in the heat preservation process is reduced gradually, and heat preservation treatment is conducted at the moment so that the excellent performance of a connector can be obtained easily. In the process that the temperature is decreased to the indoor temperature from 800 DEG C, the connectingpressure is increased gradually, heat preservation treatment is conducted at the temperature of 600 DEG C, and thus the excessively-large residual stress of the connector is avoided. Diffusion connection technical parameters are controlled simultaneously through a clamp, reliable connection of the dissimilar intermetallic compound annular pieces is achieved, and research and manufacturing foundations are provided for other complicated alloy annular pieces.

Owner:重庆两航金属材料有限公司

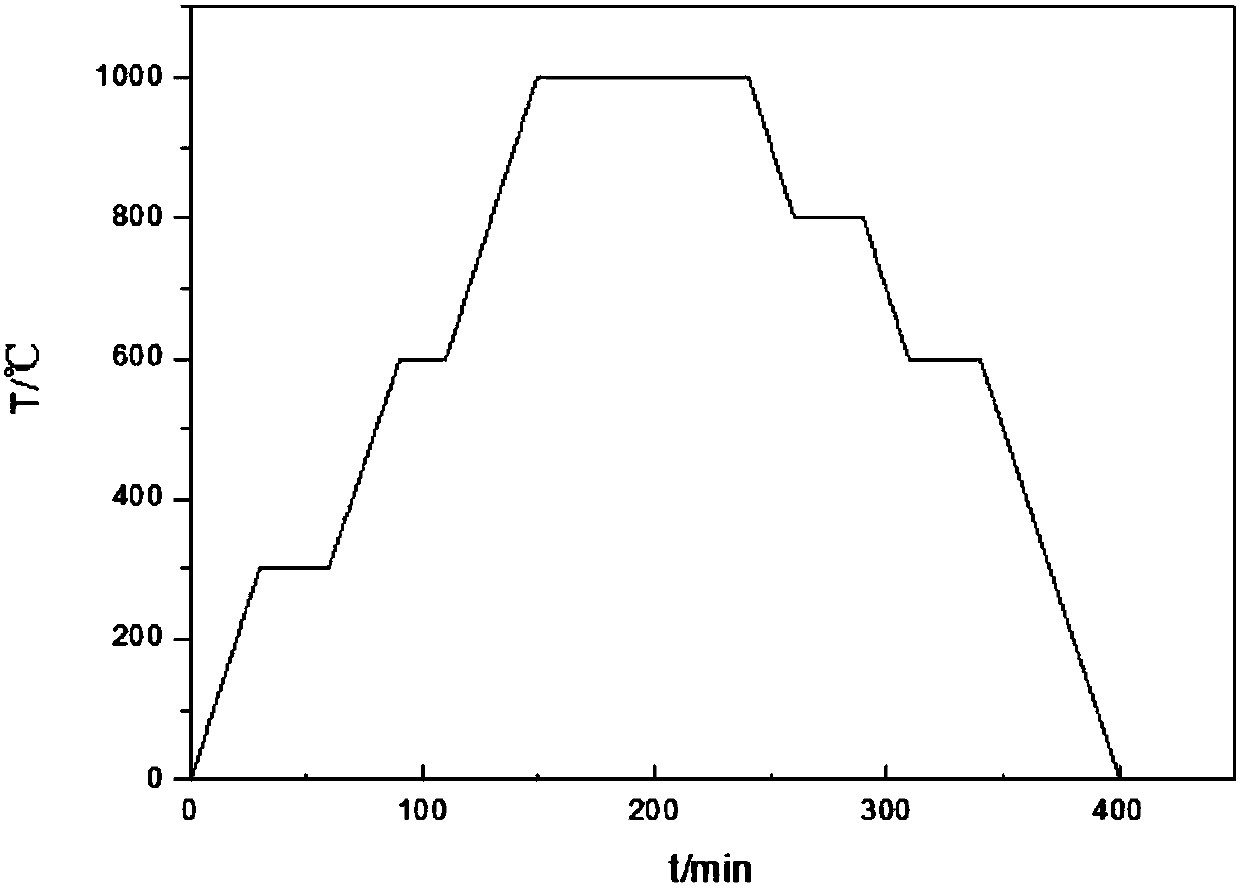

Light-emitting device

ActiveUS20120236536A1Light efficiencyLight excitationVehicle headlampsVehicle lighting systemsLaser lightFluorescent light

A light-emitting device can include a fluorescent plate having a first surface and a second surface opposite to the first surface and configured to emit fluorescent light by laser irradiation. A first laser light source can be disposed such that the first surface of the fluorescent plate is irradiated with first laser light. A second laser light source can be disposed such that the second surface of the fluorescent plate is irradiated with second laser light. A reflector can include a light passing hole through which the second laser light can pass and can include a concave reflecting surface configured to cover an irradiation region with the second laser light at least on the fluorescent plate. A lens can be disposed in a space closer to the first surface of the fluorescent plate.

Owner:STANLEY ELECTRIC CO LTD

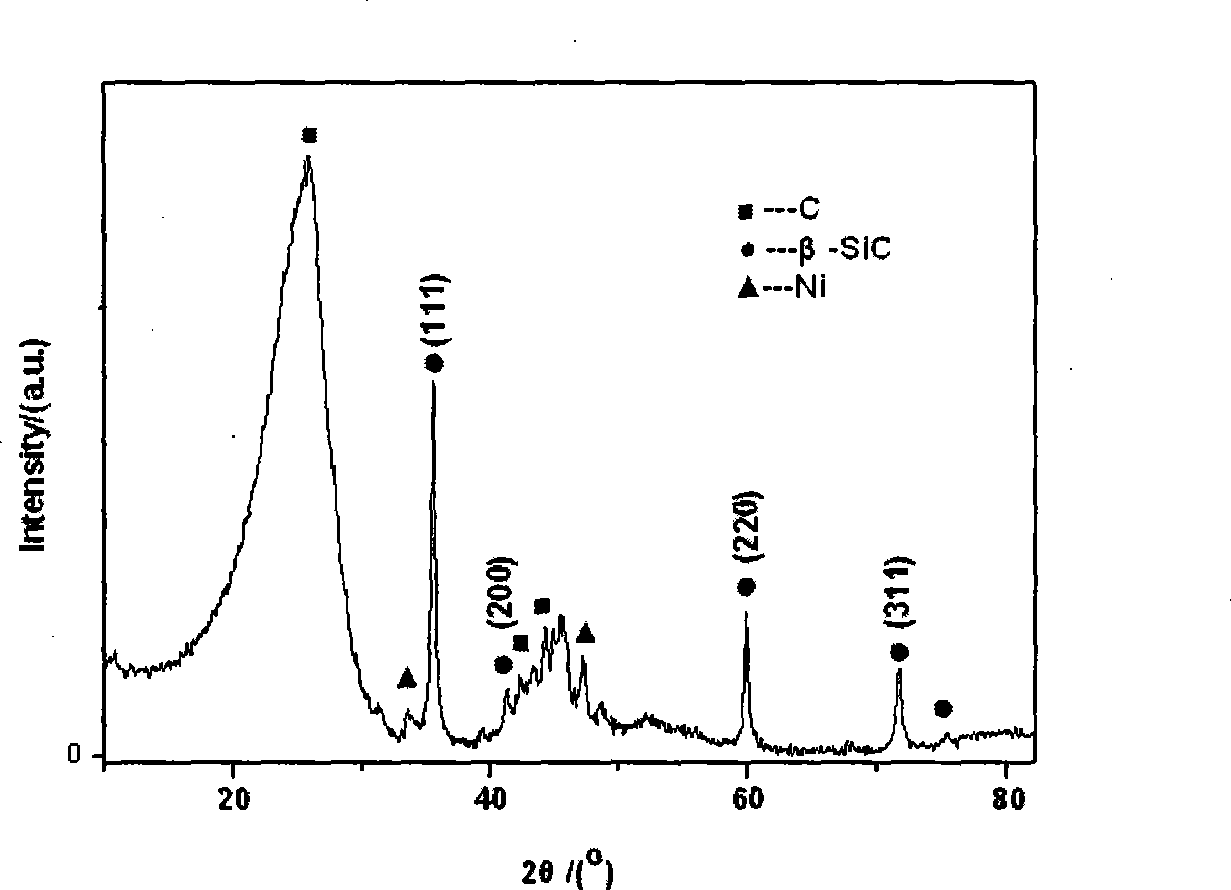

Method for manufacturing silicon carbide nanometer fibre/carbon fibre composite felt body

The invention discloses a method for preparing silicon carbide nano-fiber or carbon fiber composite felt, which comprises following steps: eliminating adhesion of needle integrated carbon felt or not eliminating the adhesion, then, absorbing one of transition group cobalt or nickel on the surface of carbon felt fiber in a mode of fine grained shapes through adopting a method of electroplating or electroless plating, drying, then, depositing silicon carbide in a chemical vapor deposition furnace, controlling the flow capacity of deposition gas source trichloromethylsilanes, carrier gas hydrogen and diluted argon, keeping the furnace pressure to be 20-500Pa when the deposition temperature is 1073-1373K, keeping the depositing time to be 1 to 15 hours, cooling along the furnace, then, taking out of the furnace, and obtaining the composite felt whose carbon felt fiber surface is grown with nanometer silicon carbide fiber. The composite felt which is weaved through adopting the method sufficiently exerts the mechanical and physical properties of each direction in situ growing nano-sic fiber and takes the mechanical and physical properties as an enhanced body of traditional C / C or C / SiC composite materials, the anisotropy of the composite materials is increased, and the using performance is increased.

Owner:CENT SOUTH UNIV +1

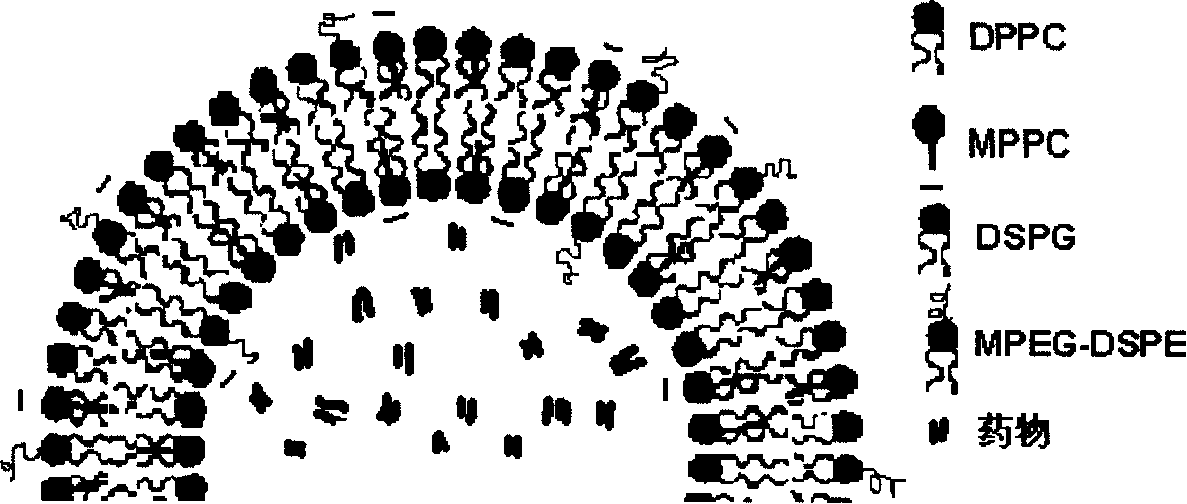

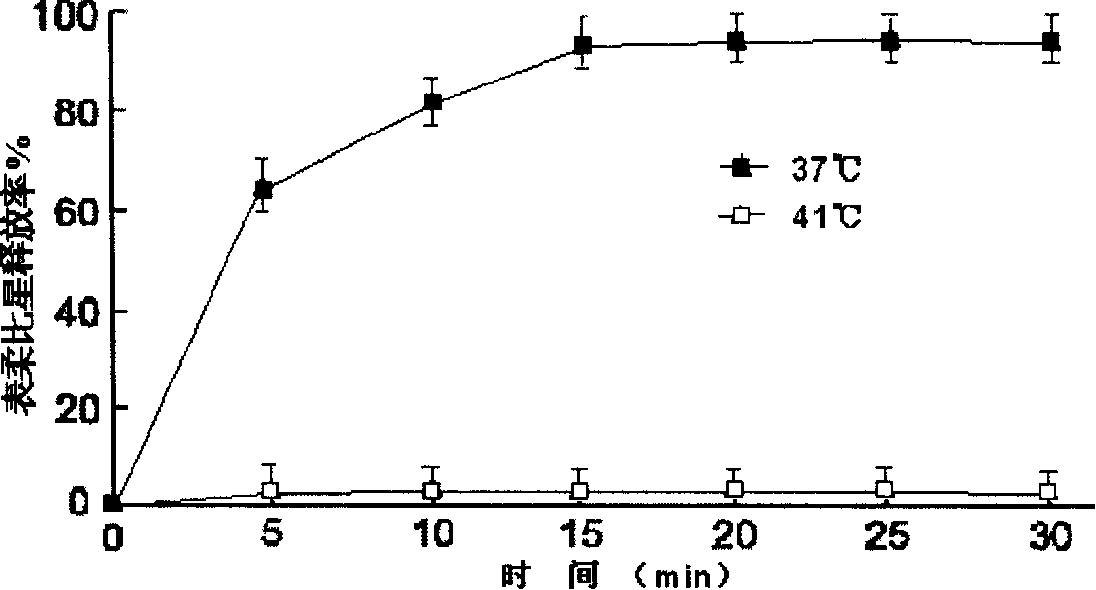

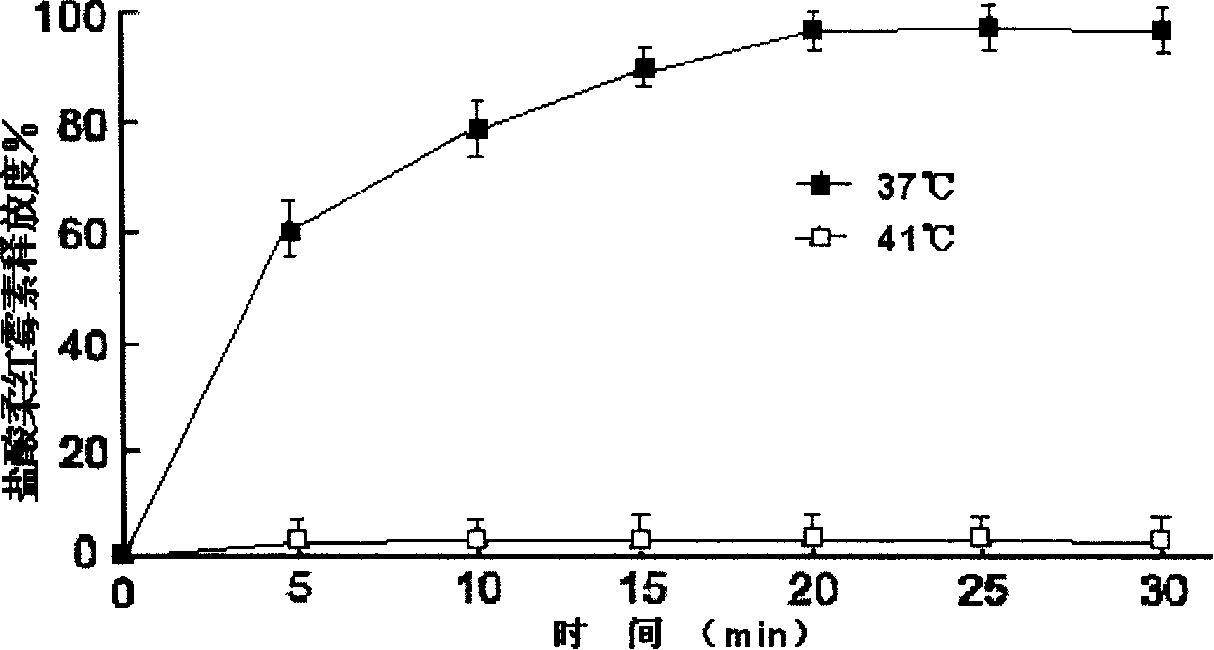

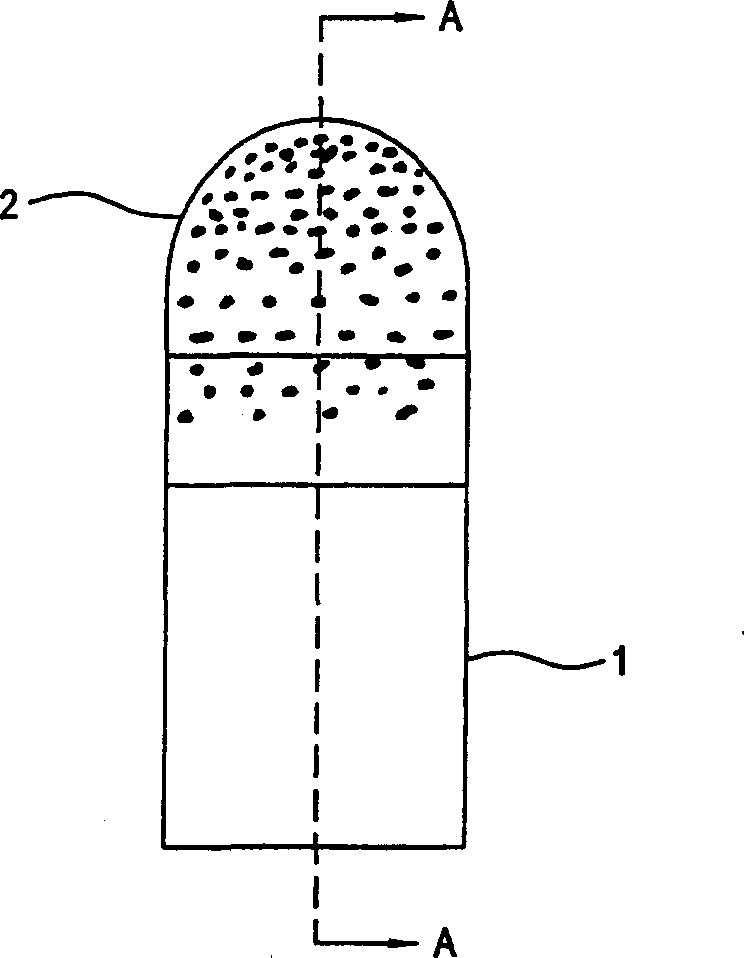

Anthracene nucleus medicinal liposome injection and preparation method

InactiveCN101190188AGood storage stabilityIncreased drug release rateOrganic active ingredientsPowder deliverySide effectFreeze-drying

The invention discloses an anthracycline liposome injection, including the injection and a frozen powder injection and a preparation process of the injection. The frozen liposome consists of the anthracycline or an anthracycline hydrochloride, compound neutral phospholipids, surfactant, negative-charge phospholipids, buffers, PH regulators and freezing protection agent. The preparation process includes the following steps: preparation of a hollow liposome, a homogenized liposome, an anthracycline lopsome and an anthracycline lopsome suspension; adding the freezing protection agent; constant volume; sterilization; sub-package; freezing and drying; storage, etc. The liposome injection can be preserved for 12 months under the room temperature with better stability. And the encapsulation rate can be above 95 percent and a granule diameter is between 30 and 300mm. The side effect is low and the technique is simple, thus being convenient for industrial production.

Owner:北京天衡药物研究院有限公司

Adhesive applicator with polymerization agent and/or bioactive material

A method of applying a bioactive agent and / or a polymerization or cross-linking rate modifier and / or a polymerization initiator to an applicator tip includes dissolving or dispersing the rate modifier, the initiator, and / or the bioactive agent in a low boiling point solvent, applying the resulting solution or dispersion to the applicator tip, and drying the applicator tip. The initiator and / or rate modifier is preferably applied in a methanol solvent and distributed along a concentration gradient on the applicator tip.

Owner:CLOSURE MEDICAL CORP (US)

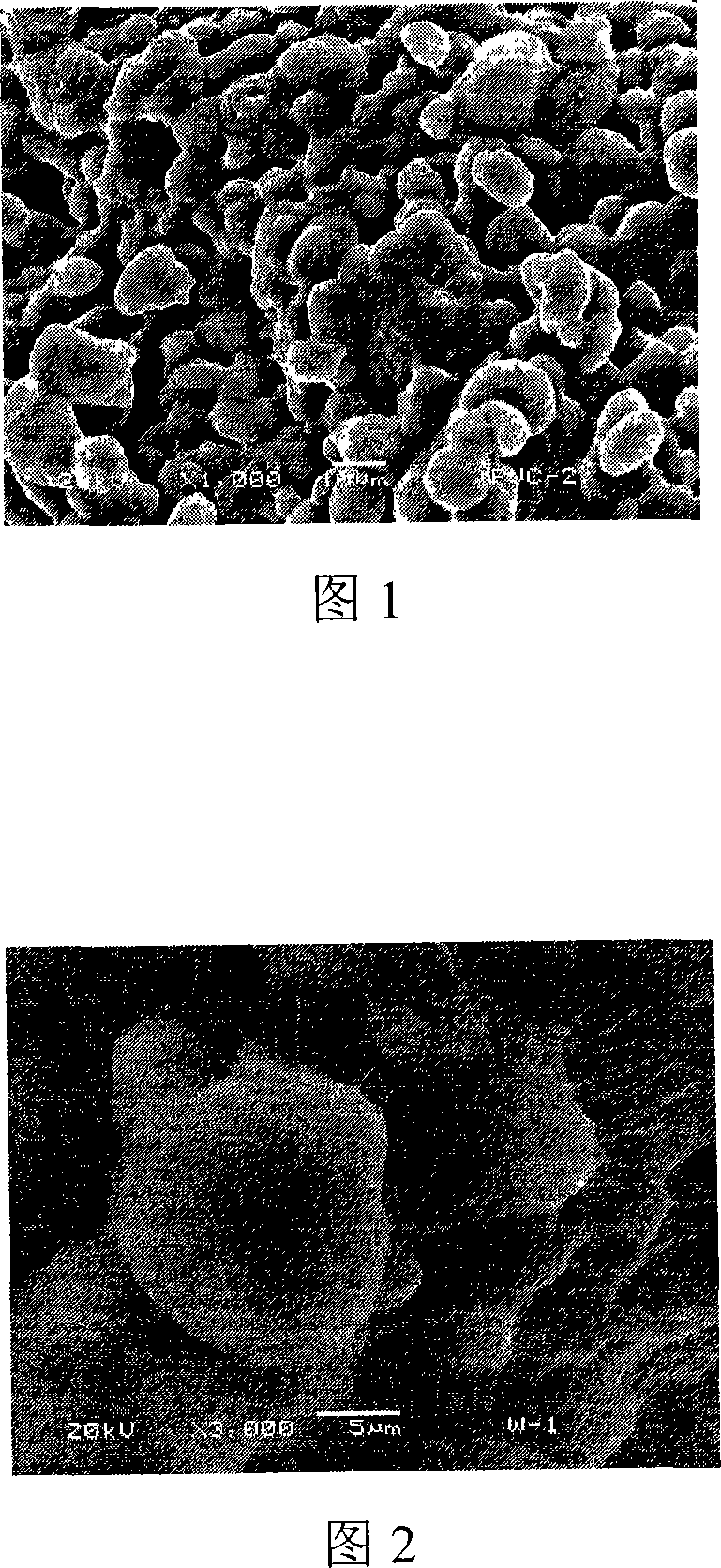

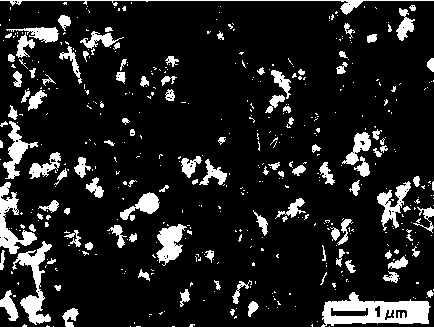

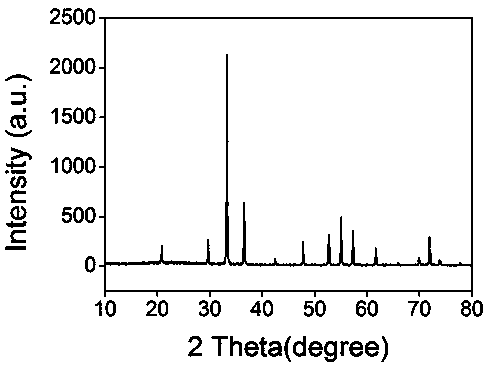

Micronano-structured and graphene based composite visible light catalytic material and preparing method thereof

InactiveCN103480398AImprove cycle stabilityEasy to separatePhysical/chemical process catalystsOrganic dyePhosphate

The invention relates to the technical field of photocatalysis, particularly to a micronano-structured and graphene based composite visible light catalytic material and a preparing method thereof. The method includes the following steps: dissolving oxidized graphene in water, and performing ultrasonic treatment to obtain an oxidized graphene dispersion liquid; ultrasonically dispersing silver nitrate and zinc oxide in deionized water to obtain a mixed solution, stirring and dropwise adding the solution into the oxidized graphene dispersion liquid, so as to obtain a mixed precursor; slowly and dropwise adding a prepared phosphate solution in the mixed precursor of the oxidized graphene, the silver nitrate and the zinc oxide, and continuously stirring, transferring a greyish-green product obtained through reaction into a hydrothermal reaction kettle, performing hydrothermal reaction at a certain temperature, cooling to the room temperature and centrifuging, then washing the product by the deionized water and absolute ethyl alcohol, and obtaining a composite after vacuum drying. According to the invention, the preparing technology is simple, the required raw materials are abundant, the performance of the product is superior, and motivated by visible light, the catalytic material has stronger degradation activity to organic dyestuff rhodamine B.

Owner:JIANGSU UNIV

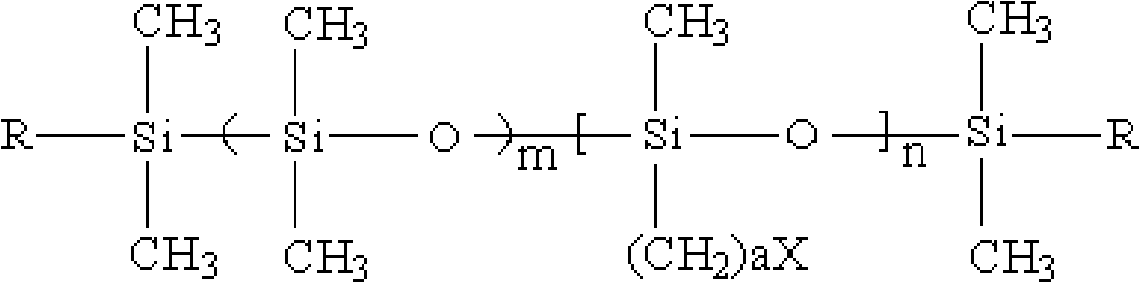

Low-yellowing organic silicon softener, preparation method and application thereof

The invention relates to a low-yellowing organic silicon softener, a preparation method and an application thereof. The schematic constitutional formula of the low-yellowing organic silicon softener provided by the invention is FORMULA, and the invention also discloses a preparation method and an application thereof. The softener provided by the invention has cheap and easily-obtained material and simple synthetic process; the fabric after processed by using the softener provided by the invention has the soft and smooth effects after the treatment of amino silicone oil, and also adds yellowing-proof capacity and fabric durability; moreover, the fabric is not easy to drop when washing.

Owner:东莞市中纺化工有限公司

Preparation method of living cell based complex three-dimensional microchannel porous support

A preparation method of a living cell based complex three-dimensional microchannel porous support. The method comprises steps of: first, preparing two parts of hydrogel collosol with different hydrogel monomer concentrations; then preparing two mixed liquors containing the hydrogel collosol and cell culture solution; putting the two mixed liquors into two sets of different injectors of a cell printer; then printing the mixed liquors on a petri dish surface until formation of a required three-dimensional cell-laden hydrogel support; cultivating the cell-laden hydrogel support in an incubator; then soaking the cell-laden hydrogel support in lauryl sodium sulfate to complete split and kill the cells; flushing with Dulbecco's phosphate-buffered saline and deionized water successively; finally obtaining the three-dimensional porous hydrogel support with complex microchannels. According to the invention, living cells are employed as a porogenic agent; size and density of the holes are controlled through controlling of the cell concentration and culture conditions; distribution of the holes is controlled through controlling of a printing platform; and a complex and controllable microchannel structure is formed in the hydrogel support.

Owner:XI AN JIAOTONG UNIV

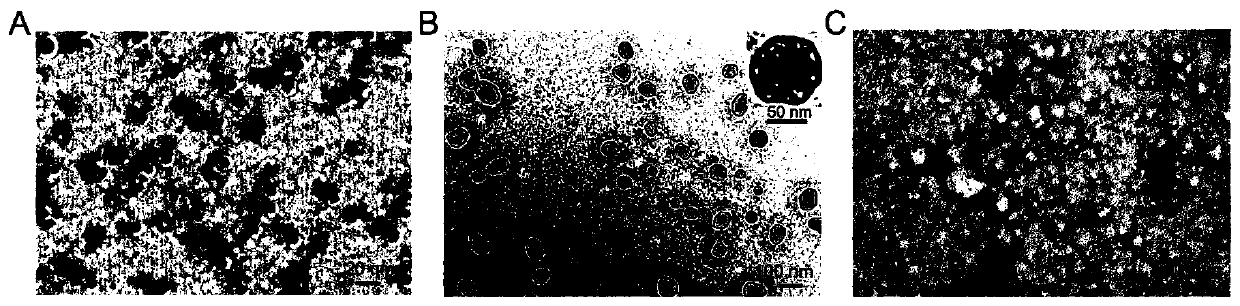

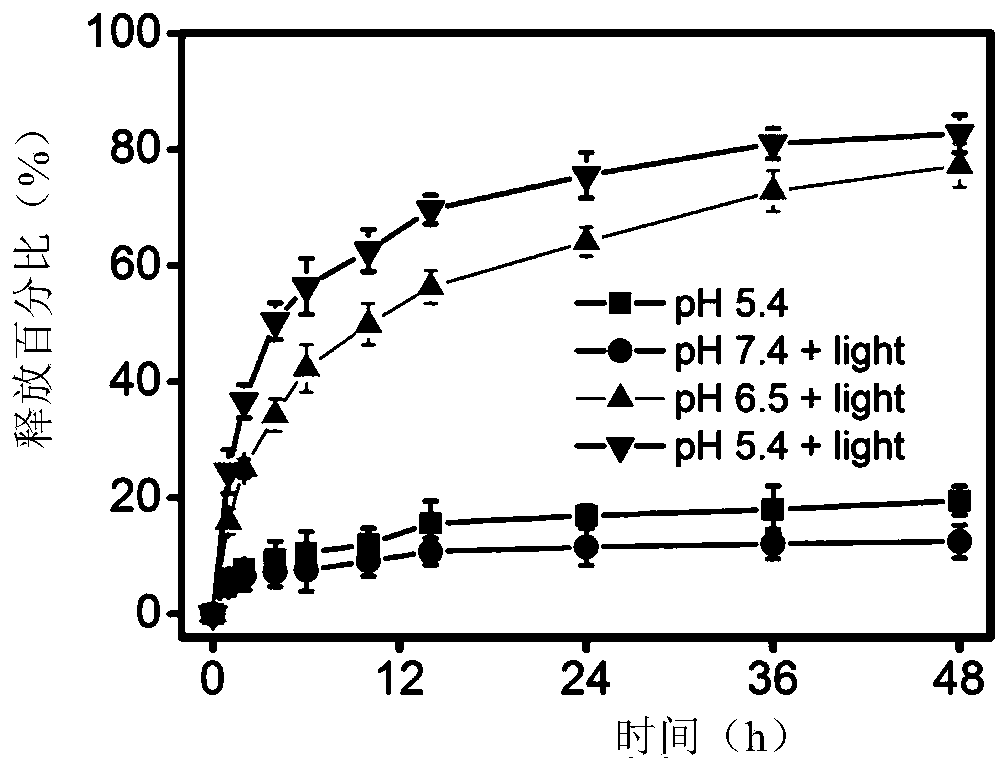

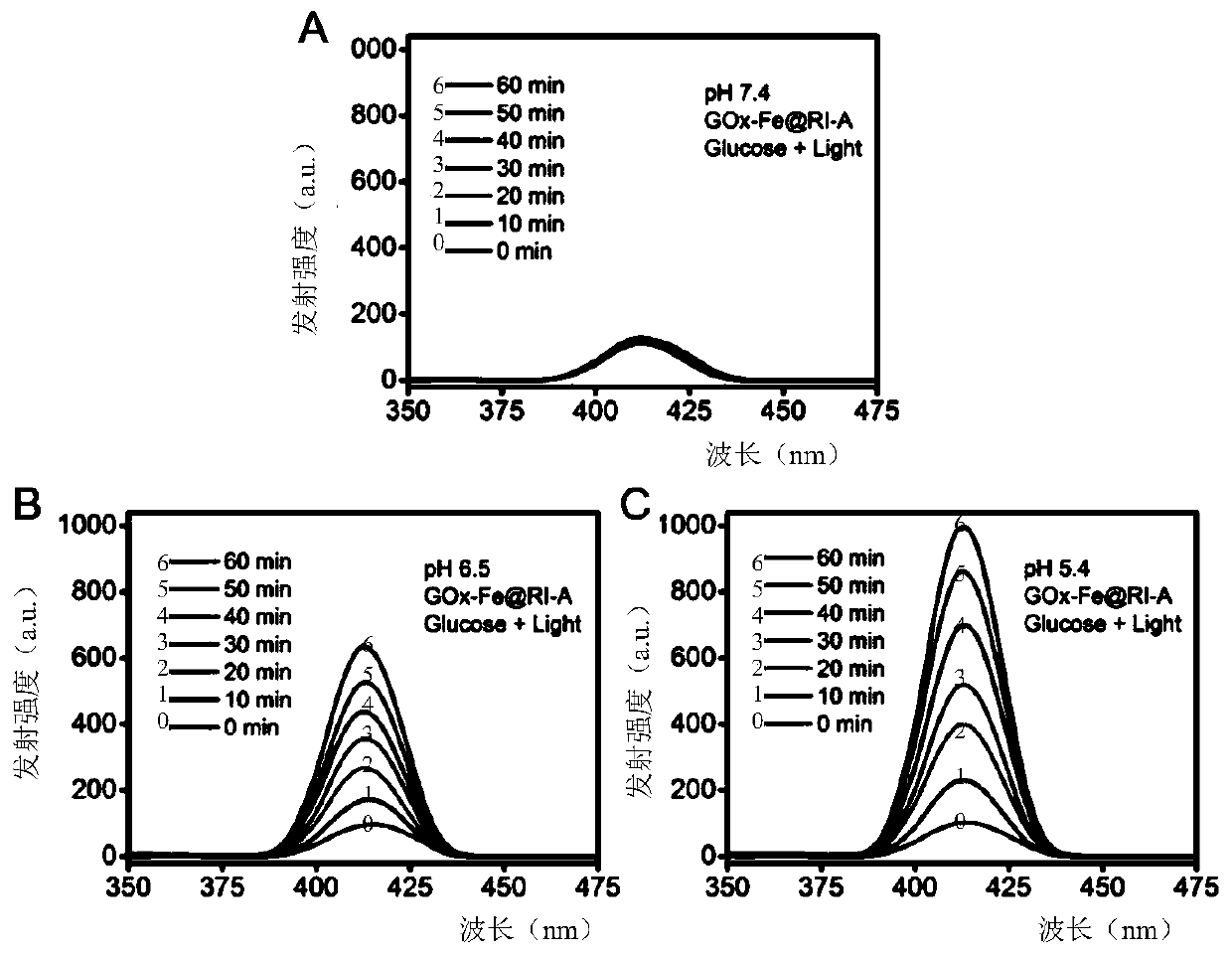

Nano catalyst for tumor treatment, and preparation method and application thereof

ActiveCN110974978AImproving the Efficiency of Cancer TreatmentSmall toxicityHeavy metal active ingredientsDrug photocleavageNano catalystPtru catalyst

The invention provides a nano catalyst for tumor treatment, and a preparation method and application thereof. The nano catalyst provided by the invention comprises an erythrocyte membrane, and a composite nano enzyme and a photosensitizer which are coated in the erythrocyte membrane, wherein the composite nano enzyme comprises glucose oxidase and iron nanoparticles which are coated in an inner cavity of the glucose oxidase. The nano catalyst is preferentially accumulated at a target tumor site through targeted biomimetic delivery, and release of the composite nano enzyme is realized under irradiation of near infrared light. Based on high glucose uptake and a weakly acidic environment at the tumor site, glucose oxidase converts glucose into H2O2, induces iron nano particles to start an in-situ Fenton reaction, generates hydroxyl free radicals after sequential catalysis, induces tumor cells to be subjected to oxidative damage, and further kills the tumor cells. The nano catalyst not onlycan realize high-efficiency loading of the catalyst, but also can effectively prolong in-vivo circulation time, so that accurate and sustained release on a tumor focus part is realized, and a new thought and platform are provided for tumor treatment.

Owner:JINAN UNIVERSITY

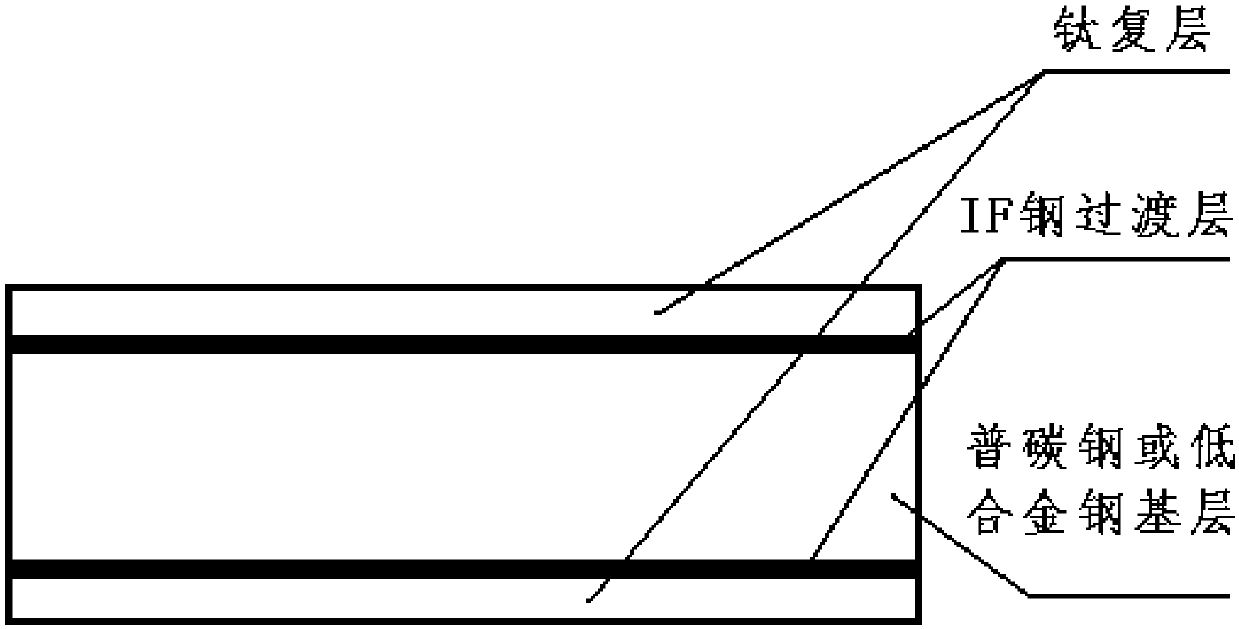

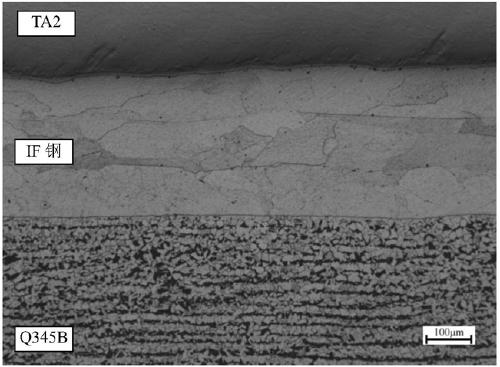

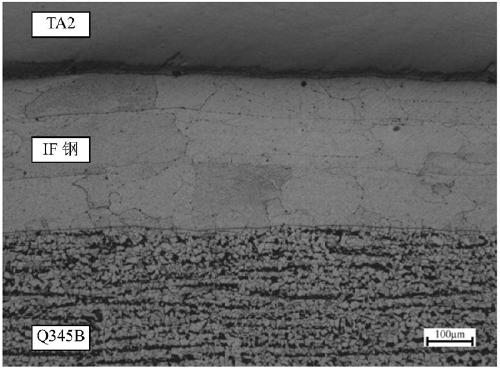

Double-sided titanium steel composite plate taking IF steel as transition layer and high-temperature preparation method thereof

ActiveCN109695000AImprove distributionImprove and enhance bond qualityMetal layered productsComposite plateMechanical property

The invention discloses a double-sided titanium steel composite plate taking IF steel as a transition layer and a high-temperature preparation method thereof. A composite blank for preparing the composite plate comprises a base material, the IF steel and a titanium composite material, wherein the base material is plain carbon steel or low alloy steel with C less than or equal to 0.22%, the titanium composite material is industrial pure titanium TA2, the thickness ratio of the base material to the titanium composite material is 5-10, the length and width of the titanium composite material are smaller than those of the base material, and the margin between the titanium composite material and four sides of the base material is 60-100 mm; and the vacuum welded composite blank is heated to 1040-1060 EDG C for heat preservation, the heat preservation time is 1 min / mm * the total thickness of the composite blank, the initial rolling temperature is 1020-1040 DEG C, the single-pass reduction rate is 15%-25%, the total reduction rate is greater than or equal to 70%, the finish rolling temperature is greater than or equal to 850 DEG C, air cooling is carried out to a room temperature, the thickness of the rolled IF steel transition layer is 280-320 [mu]m, and the double-sided titanium steel composite plate with the thickness of 6-75 mm is obtained after plate splitting, and excellent corrosion resistance and mechanical properties are achieved.

Owner:ANGANG STEEL CO LTD

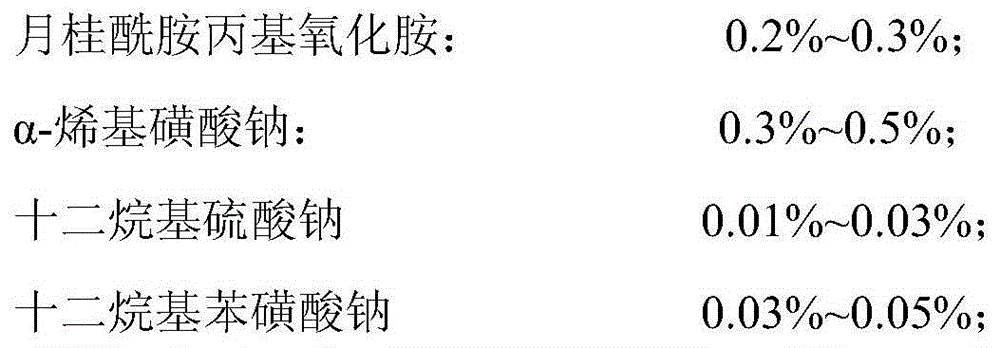

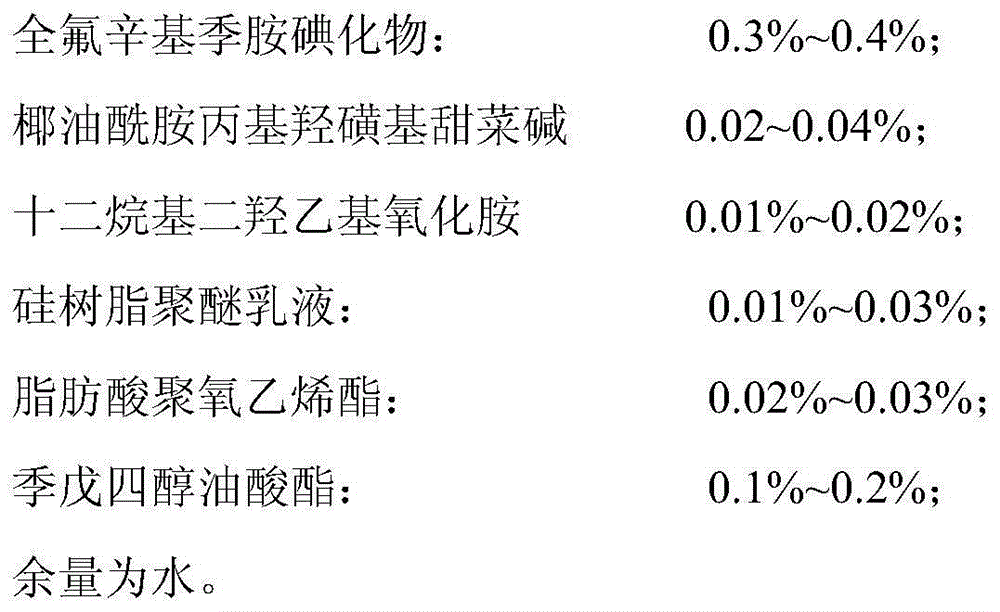

Compound type foam dedusting agent

The invention discloses a compound type foam dedusting agent. The compound foam dedusting agent comprises, by weight, 0.2%-0.3% of alpha olefins, 0.3%-0.5% of alpha-olefin sulfonate, 0.01%-0.03% of lauryl sodium sulfate, 0.03%-0.05% of sodium dodecyl benzene sulfonate, 0.3%-0.4% of trimethyl-1-propanaminium iodide, 0.02%-0.04% of cocoamido propyl hydroxy sulfoBetaine, 0.01%-0.02% of dodecyl dihydroxyethyl amine oxide, 0.01%-0.03% of modified polyethoxylated silicone, 0.02%-0.03% of polyoxyethylene fatty acid, 0.1%-0.2% of pentaerythritol oleate and balance water. Due to the fact that the pentaerythritol oleate was regarded as the corrosion inhibitor and added into the foam dedusting agent, the corrosivity on electromechanical equipment is greatly lowered, and the working environment of the workplace with the high concentration of dust is effectively improved.

Owner:SHANDONG UNIV OF SCI & TECH

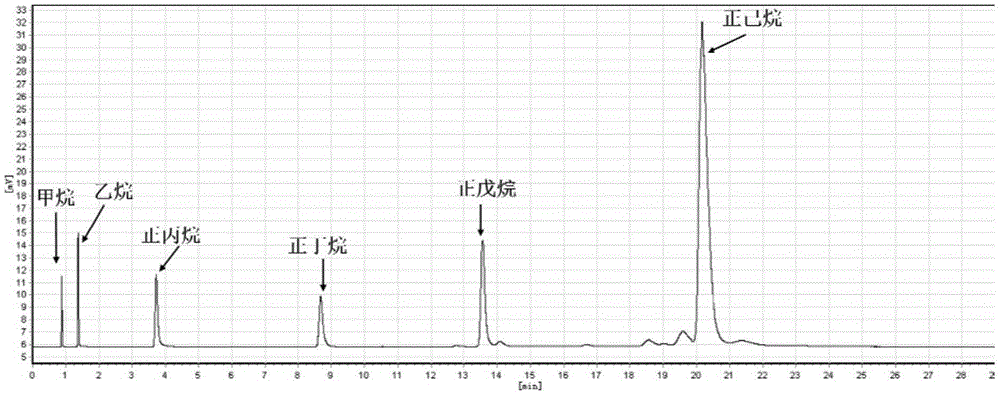

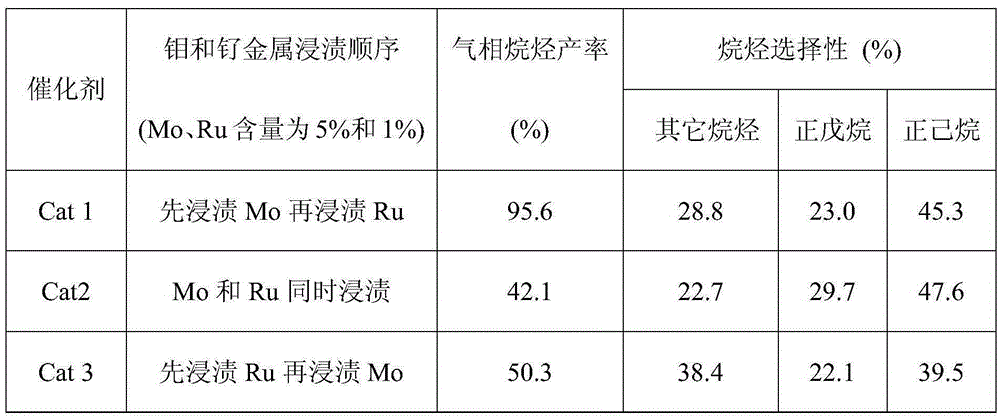

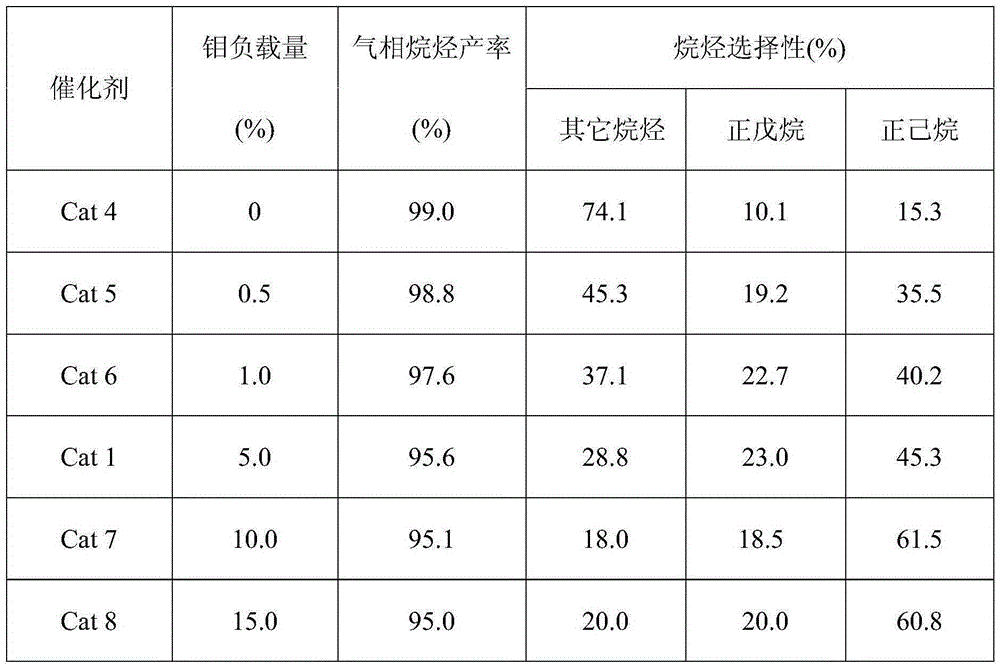

Linear-chain C5/C6 alkane catalyst prepared by sorbitol aqueous phase hydrogenation and preparation method thereof

ActiveCN105289601AHigh selectivityHigh activityHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsAlkaneCarbon–oxygen bond

The invention relates to a preparation method of a linear-chain C5 / C6 alkane catalyst prepared by sorbitol aqueous phase hydrogenation. The method comprises the following steps: (1) selecting activated carbon as a catalyst carrier, and drying at the temperature of 100-200 DEG C; (2) adding the dried activated carbon into an ammonium paramolybdate aqueous solution, and drying to obtain a catalyst carrier precursor containing molybdenum; (3) calcining the catalyst carrier precursor containing molybdenum in a muffle furnace to obtain a catalyst carrier containing molybdenum; (4) adding a ruthenium trichloride solution into the catalyst carrier for soaking, and drying to obtain a catalyst carrier precursor containing ruthenium and molybdenum; (5) calcining the catalyst carrier precursor containing ruthenium and molybdenum to obtain an initial catalyst; and (6) performing hydrogen gas reduction on the initial catalyst at the temperature of 250-400 DEG C for 4-8h to obtain the sorbitol aqueous phase hydrogenation catalyst. According to the method, a step soaking method is adopted to inhibit carbon-carbon bond breakage and selectively break carbon-oxygen bonds, so that the selectivity and the excitation capacity of sorbitol hydrodeoxygenation reaction can be improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

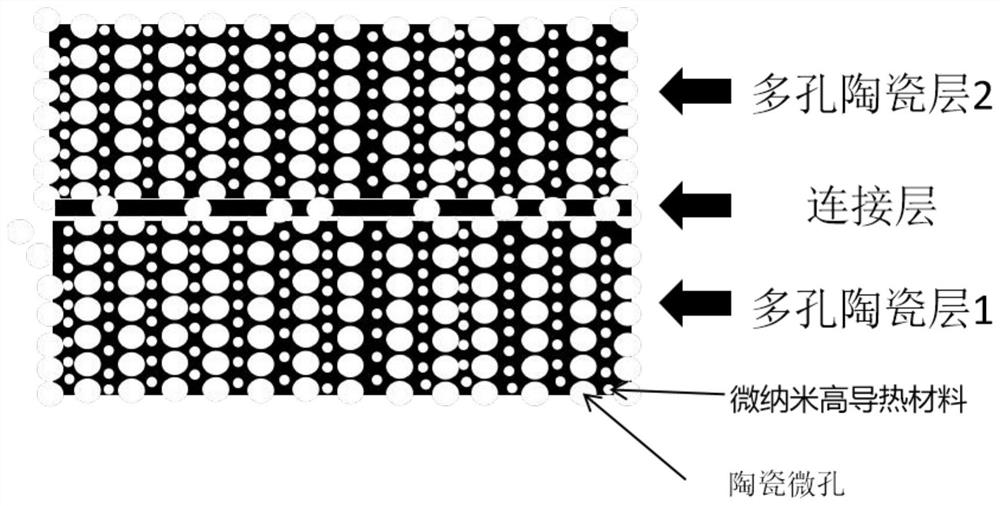

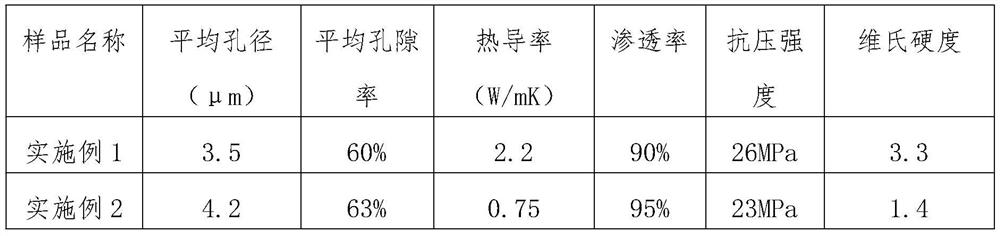

Multi-layer porous ceramic material and preparation method thereof

The invention provides a multi-layer porous ceramic material and a preparation method thereof, and particularly relates to the field of atomizers. The material is composed of multiple layers of porousceramics with different porosities and different thermal conductivities, and all the layers form an integrated composite material through an inorganic connecting layer formed by sintering. The ceramic material is formed by overlapping a plurality of layers of porous ceramics, and an inorganic connecting layer is formed in the sintering process, so that the prepared multi-layer ceramic forms a whole, and the cracking and deformation of the porous ceramic material are avoided. The composite material is ensured to form a unified whole, and the use performance of the material is improved.

Owner:深圳市天士力神通本草技术开发有限公司

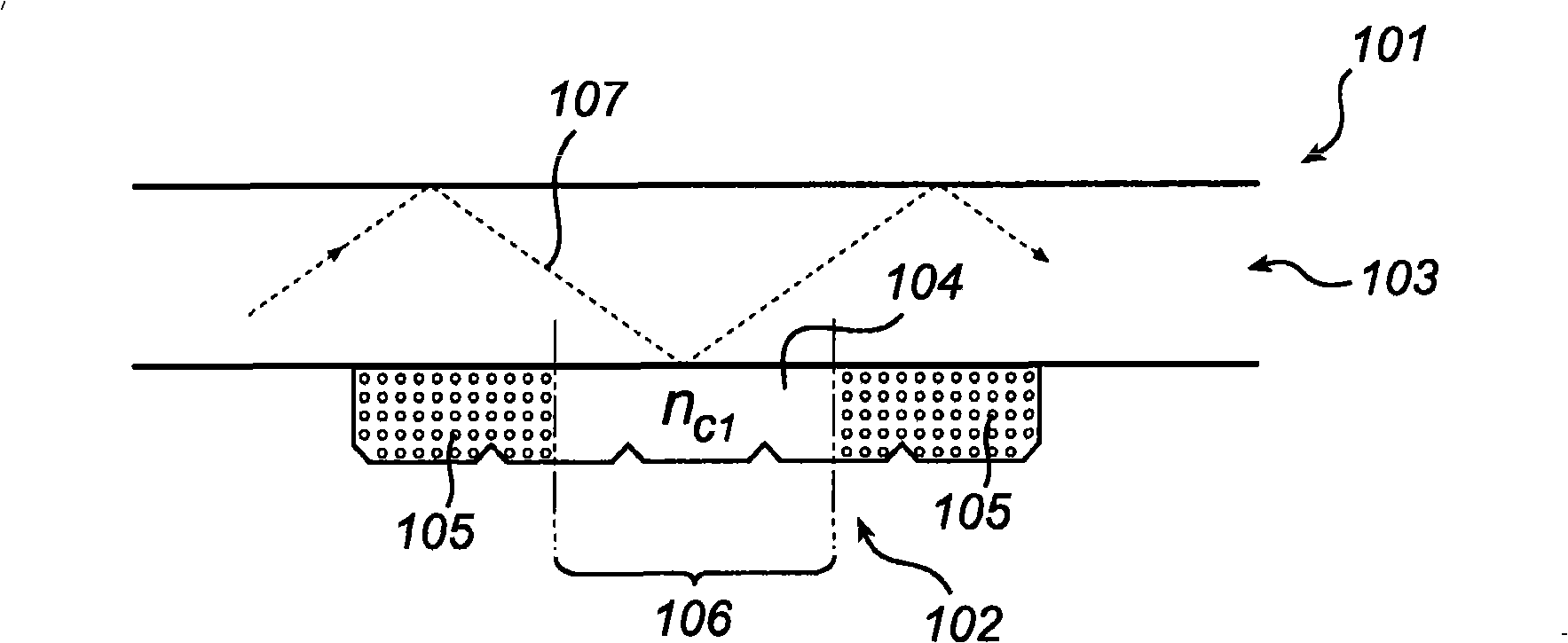

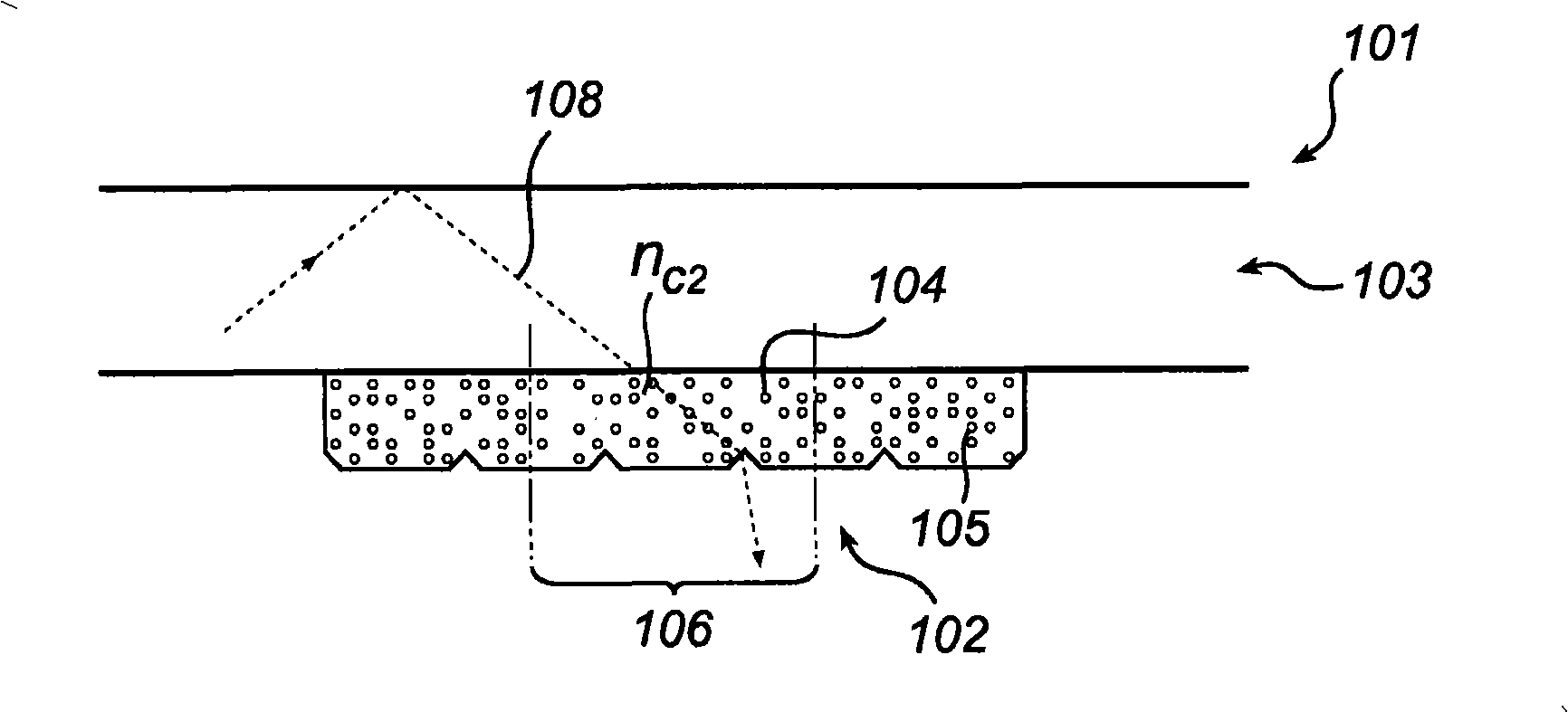

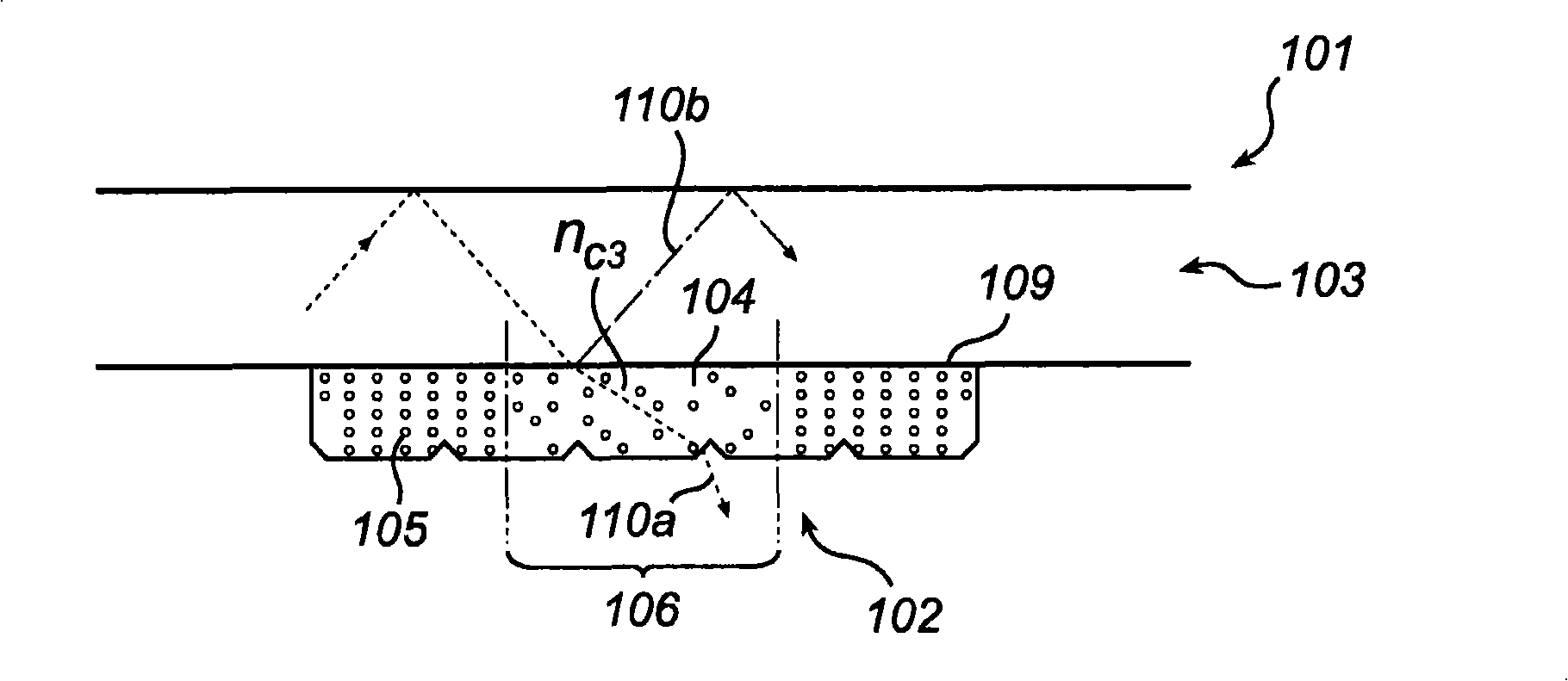

Controllable light guide

A controllable light guide (101; 405) comprises a light guide (103) configured to guide in-coupled light through reflections of the light against a guiding boundary (109) of the light guide (103), and at least one light-modifying member (102; 201-202; 303-304; 414-416) arranged adjacent to the guiding boundary (109) of the light guide (103). The light-modifying member (102; 201-202; 303-304; 414-416) comprises a fluid (104) and a plurality of particles (105) distributed in the fluid. The light-modifying member is controllable between at least a first state having a first particle distribution resulting in at least a portion (106; 209, 210) of the light-modifying member (102; 201-202; 303-304; 414-416) having a first compound refractive index (rid), and a second state having a second particle distribution resulting in the portion (106; 209, 210) of the light-modifying member having a second compound refractive index (nc2). At least the second compound refractive index (nc2) is sufficiently high in relation to the refractive index of the light guide (103) at the guiding boundary (109) so as to allow at least partial outcoupling of light through a corresponding portion of the guiding boundary of the light guide.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com