Processing method of sushi sashimi

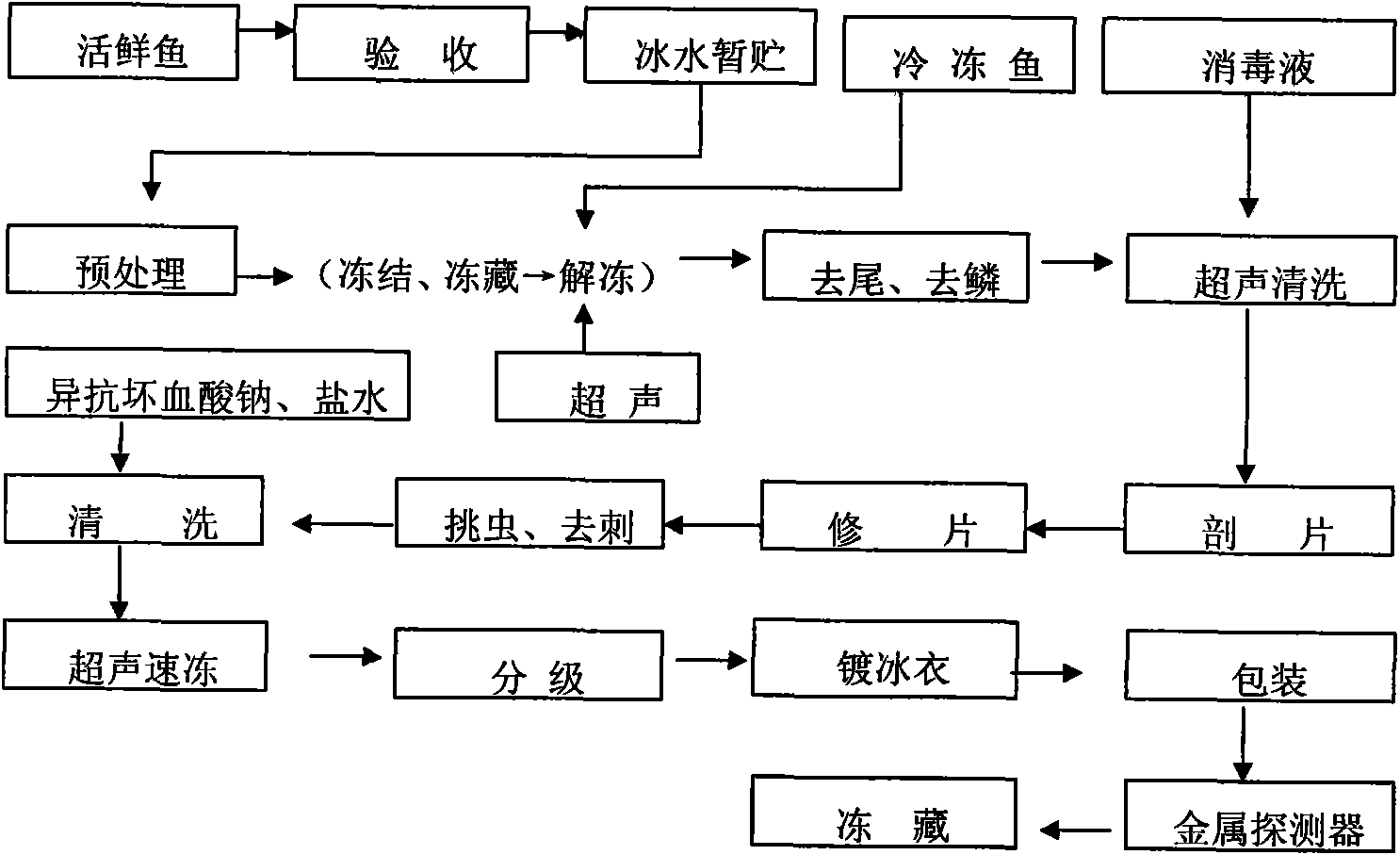

A sushi fish fillet and processing method technology, applied in fish cleaning/descaler, meat/fish preservation through freezing/cooling, food preparation, etc., can solve the problems of fish body soluble substance loss, not suitable for complete thawing, microbial contamination, etc. , to achieve the effect of shortening the freezing time, quick freezing, and promoting crystallization nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0048] Fresh sea bream is used as the raw material, and after temporary storage in ice water, it is killed alive and bled to clean the blood and impurities, remove the head, internal organs, tail and scales. Clean once with purified drinking water with 0.12 mg / L ozone added under the action of ultrasonic waves; then clean with purified water to remove ozone residues. The ultrasonic frequency used is 20 kHz, the electric power is 200 W, and the ultrasonic action time is 2 min. Afterwards, slice, trim, pick insects, remove thorns, wash with ice water first, drain and then wash with 0.3% sodium erythorbate ice water solution, control water, put fish fillets in 45%, -30 ℃ ethanol to freeze The fish fillets are frozen under the action of ultrasonic waves, the ultrasonic frequency is 20kHz, the electric power is 80W, and the ultrasonic freezing time is 13min, then they are graded, ice-coated with 0.3% sodium erythorbate ice solution, packaged, metal detected and frozen for storage. ...

example 2

[0050] Use frozen red sea bream as raw material, thaw in a thawing tank with a flowing ethanol solution under the action of ultrasonic waves, the ethanol concentration is 15%, the temperature of the thawing solution is lower than 15°C, the ultrasonic frequency is 20kHz, the ultrasonic electric power is 500W, and the ultrasonic thawing time is 10min. The fish is half-thawed, the temperature of the fish body is -5°C ~ 0°C, and then the tail, scale and other impurities are removed, and the purified water with 0.15mg / L ozone added under the action of ultrasonic waves can be washed once; Wash with purified water to remove ozone residue. The ultrasonic frequency used is 25Hz, the electric power is 250W, and the ultrasonic action time is 3min. Afterwards, slice, trim, pick insects, remove thorns, wash with ice water first, drain and then wash with 0.3% sodium erythorbate ice water solution, control the water, and freeze the fish fillets in 50% ethanol at -40°C Frozen fish fillets un...

example 3

[0052] Fresh tilapia is used as raw material, after being temporarily stored in ice water, it is killed alive and bled to clean the blood and impurities, remove the head, internal organs, tail and scales. Wash once with directly drinkable purified water added with 0.13 mg / L Tween-80 under the action of ultrasonic waves; then wash with purified water to remove Tween-80 residues. The ultrasonic frequency used is 40 kHz, the electric power is 300 W, and the ultrasonic action time is 4 min. Afterwards, slice, trim, pick insects, remove thorns, wash with ice water first, drain and then wash with 0.3% sodium erythorbate ice water solution, control the water, and freeze the fish fillets in 50% ethanol at -45°C The fish fillets are frozen under the action of ultrasonic waves, the ultrasonic frequency is 80kHz, the electric power is 100W, and the ultrasonic freezing time is 6min, then they are graded, coated with ice-coated 0.3% sodium erythorbate ice solution, packaged, metal detected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com