High-strength high-conductivity copper-chromium-zirconium alloy and preparation method of plate/strip thereof

A high-conductivity, copper-chromium-zirconium technology, which is applied in the field of lead frames, high-strength and high-conductivity copper-chromium-zirconium alloys and their strips, and connectors, can solve the problems of unsatisfactory comprehensive properties, achieve good elastic properties, and improve Strength, effect of inhibiting alloy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

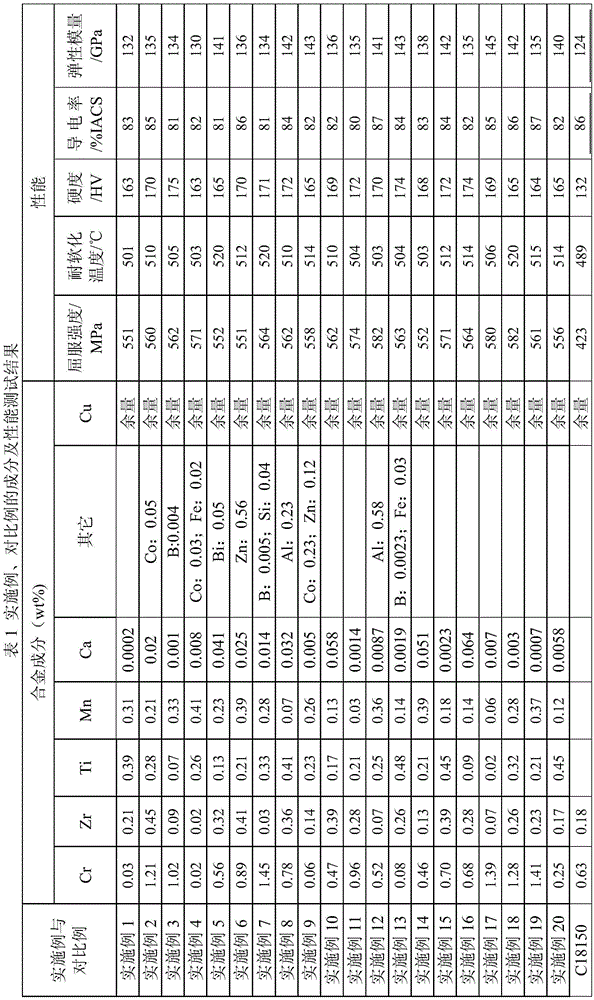

[0032] Below in conjunction with embodiment the present invention is described in further detail.

[0033] 20 example alloys and 1 comparative example alloy (C18150) were selected, all of which were processed into finished strip products with a thickness of 2.0 mm by the preparation method of the present invention. The process flow for preparing the high-strength and high-conductivity copper-chromium-zirconium alloy strip of the present invention is: batching→melting and casting→sawing→homogenizing annealing→hot rolling→primary solution treatment→face milling→primary cold rolling→second solution treatment→ Secondary cold rolling→primary aging treatment→tertiary cold rolling→secondary aging treatment→stretch leveling, which specifically includes the following steps:

[0034] 1) Batching and melting and casting: Prepare raw materials and batching according to the chemical composition of the alloy, and use an electric furnace for melting. The order of adding the alloy is: first a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com