Patents

Literature

64results about How to "Control precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

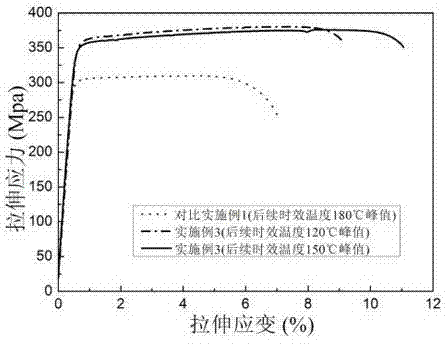

7000 series aluminum alloy material and preparation method thereof

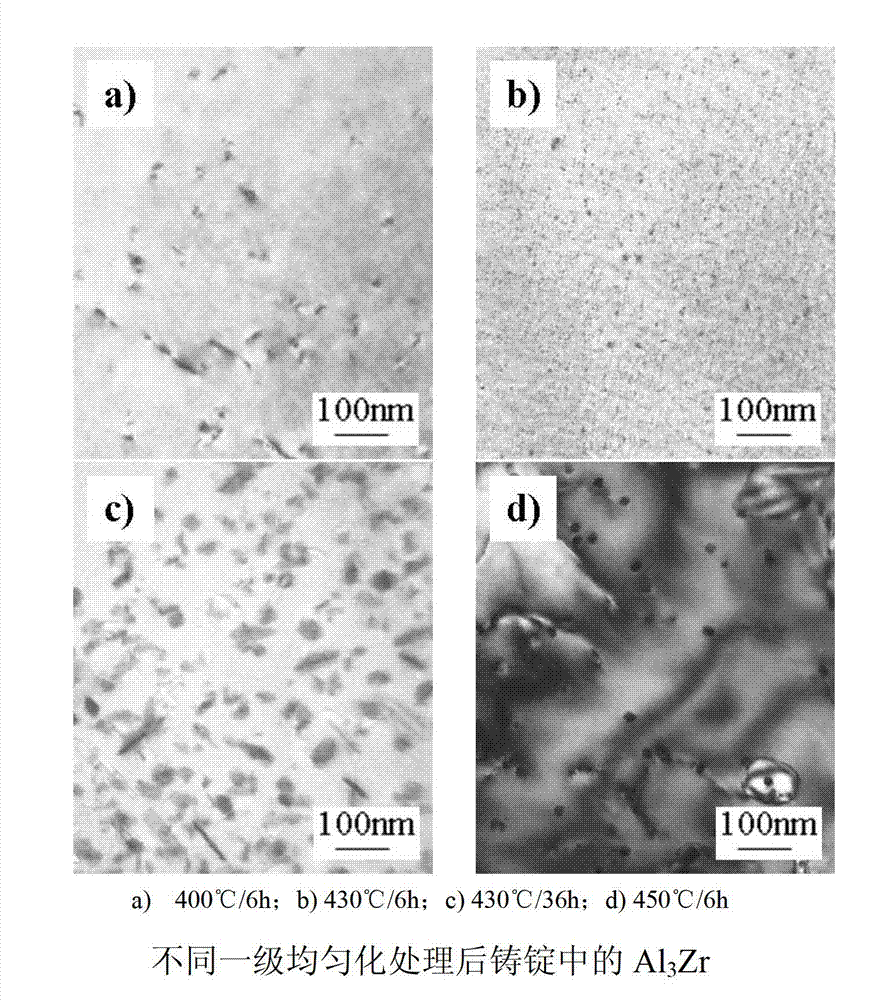

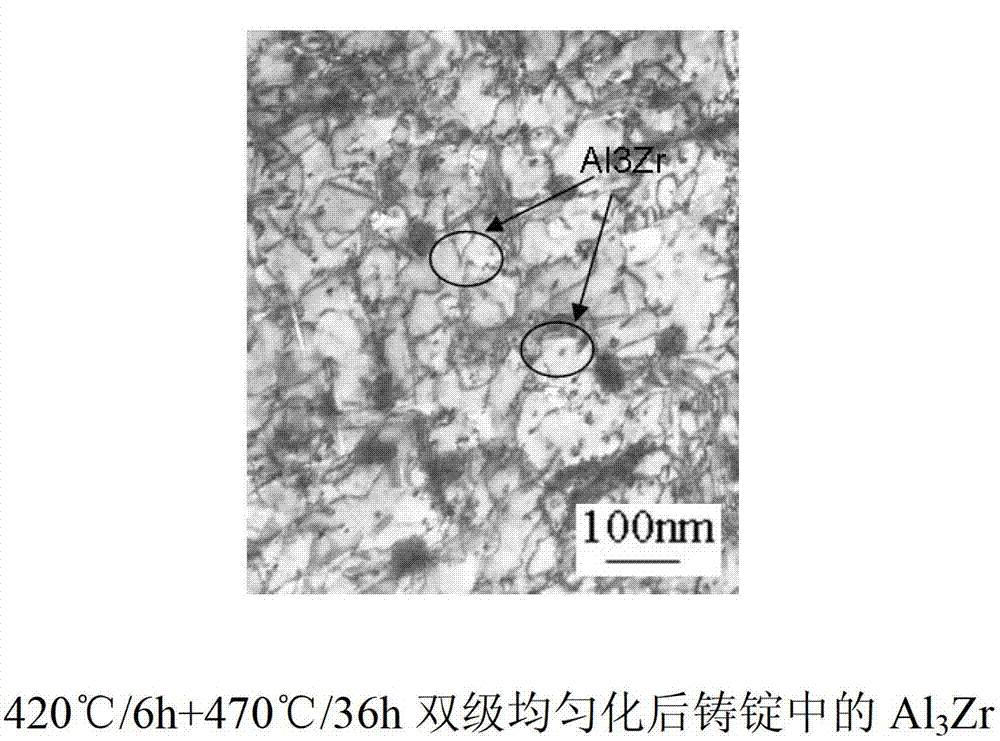

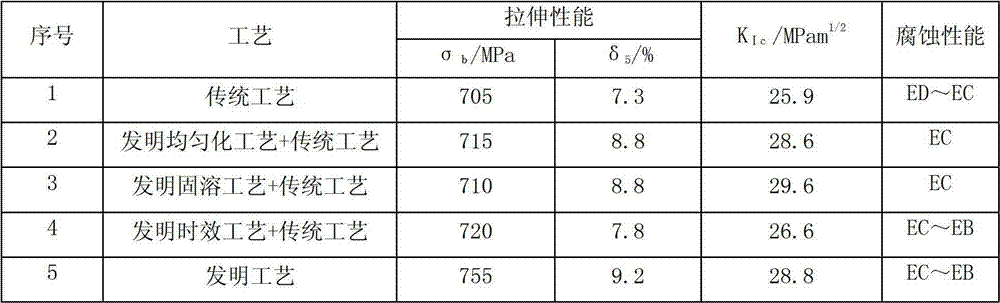

The invention relates to a 7000 series aluminum alloy material and a preparation method thereof. The aluminum alloy material has alloy components of, by weight: 7.6-11.0% of Zn, 1.2-3.0% of Mg, 1.3-2.6% of Cu, 0.04-0.30% of Zr, 0.10-0.60% of Cr, no more than 0.08% of Si, no more than 0.10% of Fe, no more than 0.10% of Ti, no more than 0.15% of total other impurities (wherein the content of single other impurity is no more than 0.05%), and balance of Al. The alloy elements Zr and Cr can be added optionally or simultaneously. The materials are prepared according to the alloy composition; the raw materials are molten; in-furnace refining and standing are carried out; and the material is cast into alloy ingots with required specifications. The alloy ingots are subjected to a preferable graded uniformization process, and is forged or extruded, such that the alloy ingots are molded; the molded materials are subjected to graded solid solution treatment, and are quenched; and artificial forced aging is carried out, such that the material can be processed into parts. The microstructures of the material are uniform, and the property of the material is stable. The ultimate tensile strength of the material can be more than 750MPa. The extensibility of the material is higher than 10%. The T-L direction KIc of the material reaches 28MPam1 / 2.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High-strength high-conductivity copper-chromium-zirconium alloy and preparation method of plate/strip thereof

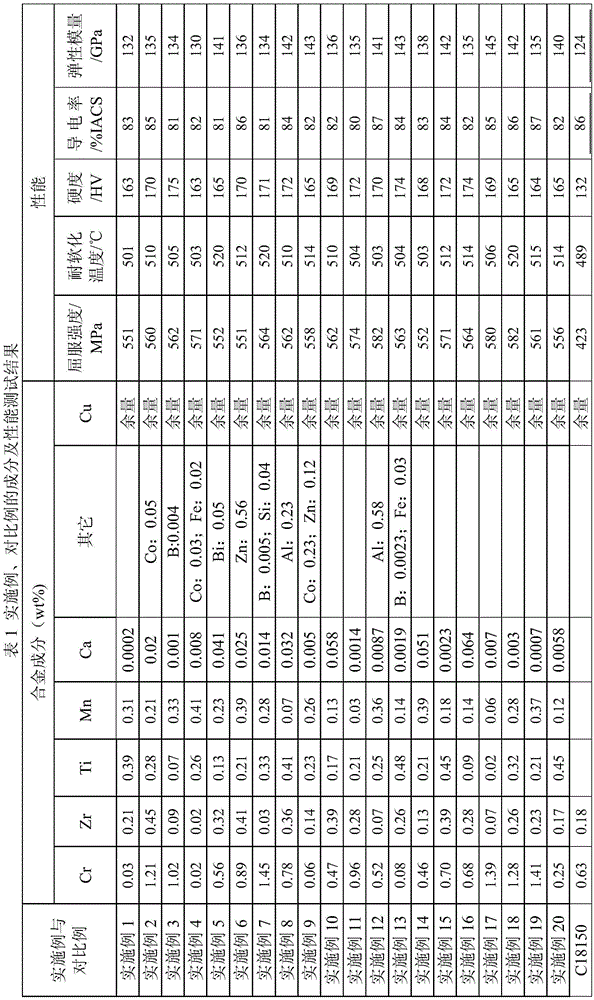

The invention discloses a high-strength high-conductivity copper-chromium-zirconium alloy and a preparation method of a plate / strip thereof. This alloy comprises the chemical composition: 0.01-1.5 wt% of Cr, 0.01-0.5 wt% of Zr, 0.001-0.5 wt% of Ti, 0.01-0.5 wt% of Mn, 0.0001-0.07 wt% of Ca, and the balance of copper and unavoidable impurities; the position and process of the Cu-Cr-Zr alloy are optimized, the provided high-strength high-conductivity copper-chromium-zirconium alloy retains high conductivity (above 80% IACS), elastic modulus up to higher than 130 GPa, softening temperature resistance up to higher than 500 DEG C, yield strength up to higher than 550 MPa and hardness up to 160 HV, the copper-chromium-zirconium plate / strip is imparted high strength, high conductivity and excellent comprehensive performance, this comprehensive performance meets the requirements of products such as a lead frame and a connector upon base material stamping and machining performances, and this plate / strip material is mainly applied to electronic components such as connectors and lead frames.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD

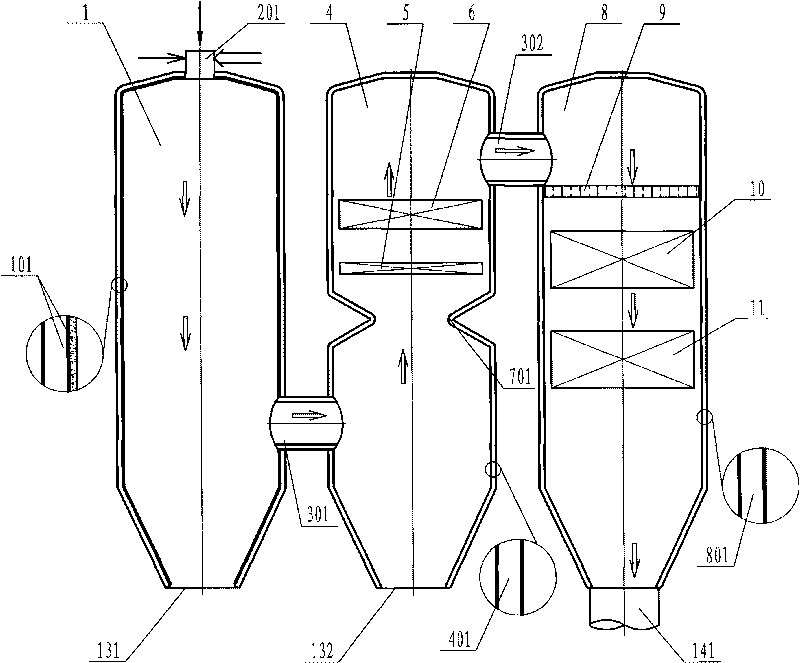

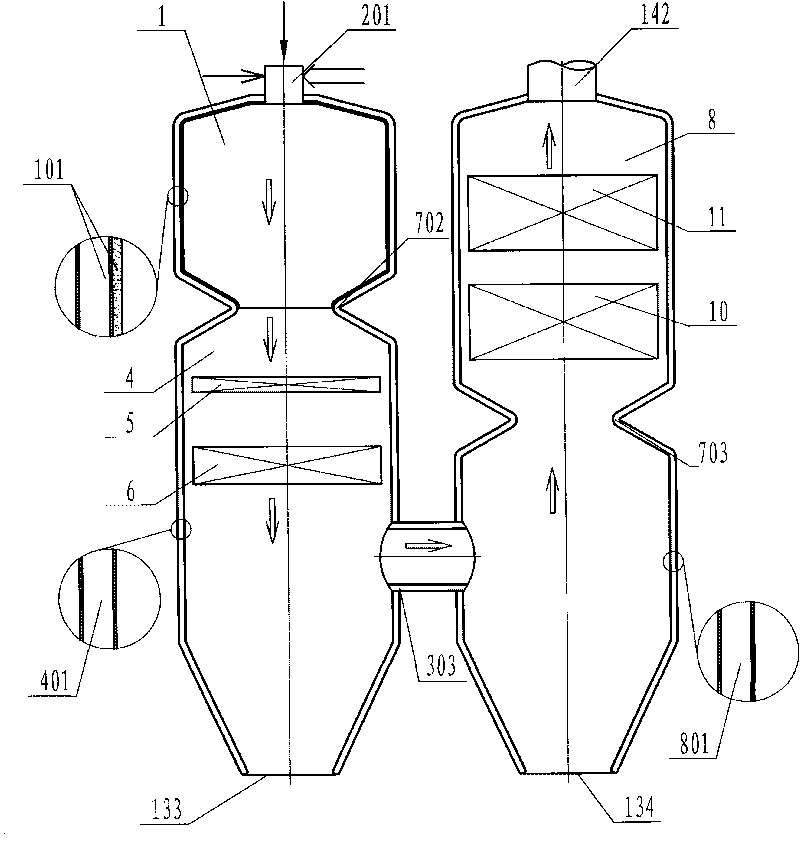

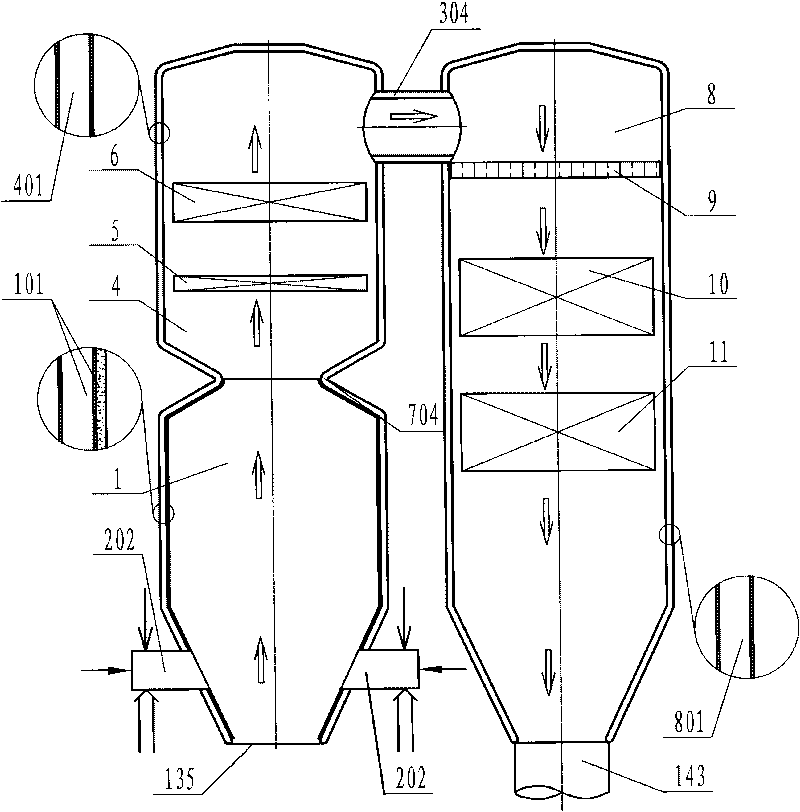

Biomass three-section type entrained flow bed gasification technology with function of waste heat utilization

InactiveCN101709228AAchieve energy efficiencyReduced carbon evolution reactionEnergy inputGasification processes detailsSuperheaterOxygen

The invention discloses a biomass three-section type entrained flow bed gasification technology with the function of waste heat utilization, which relates to the technical field of energy chemical technology. The gasification technology is realized in a way that: carbon powder, pyrolysis gas and oxygen, which are generated after the biomass is pyrolyzed, enter an entrained flow bed to obtain synthetic gas through gasification, and the energy of the gasification waste heat is transferred to water by a heat exchanger of a gasifier, thereby producing superheated steam. The gasifier of the entrained flow bed is divided into a high-temperature entrained flow bed section, a high-temperature heat exchanger section and a low-temperature heat exchanger section, wherein the high-temperature entrained flow bed section adopts a dry ash extraction entrained flow bed gasification technology, and the temperature of the synthetic gas at the outlet is 1280-1320 DEG C; at the high-temperature heat exchanger section, the temperature of the synthetic gas at the inlet is 1280-1320 DEG C, the temperature at the outlet is 580-600 DEG C, a shock chamber and a high-temperature superheater are arranged in the high-temperature heat exchanger section, and the synthetic gas enters the shock chamber at the temperature of 1000-1100 DEG C and leaves at the temperature of 700-800 DEG C; and at the low-temperature heat exchanger section, the temperature of the synthetic gas at the inlet is 580-600 DEG C, the temperature of the synthetic gas at the outlet is 220-230 DEG C, and a low-temperature superheater and a coal economizer are arranged in the low-temperature heat exchanger section. The invention is used for high-efficiency gasification of biomass.

Owner:ZHONGJIEHUAN BEIJING ENERGY TECH

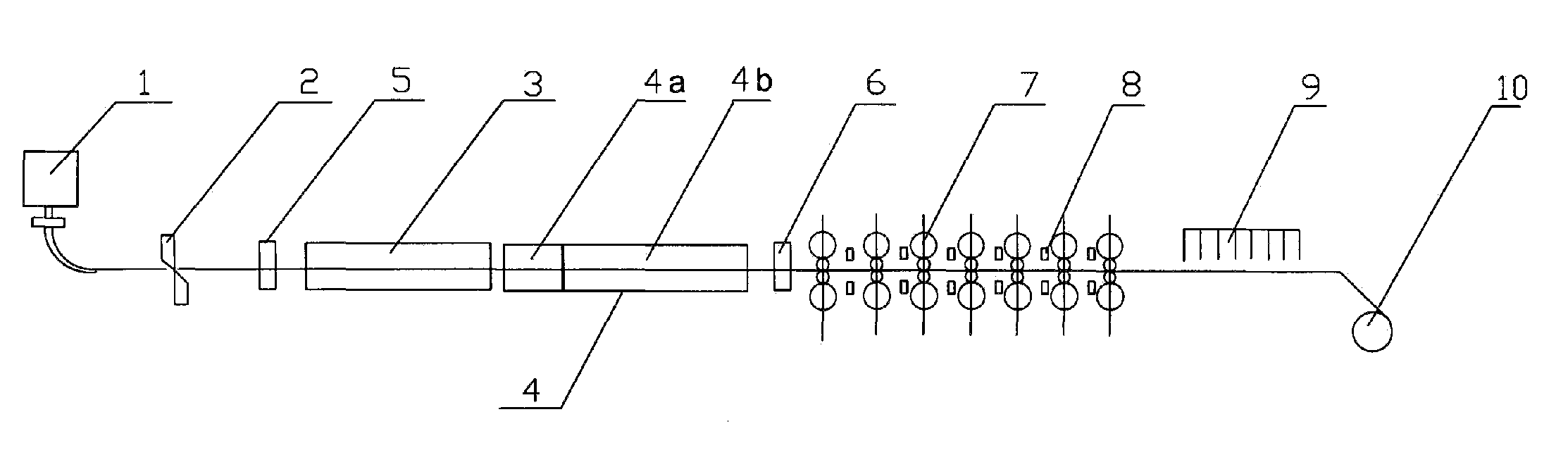

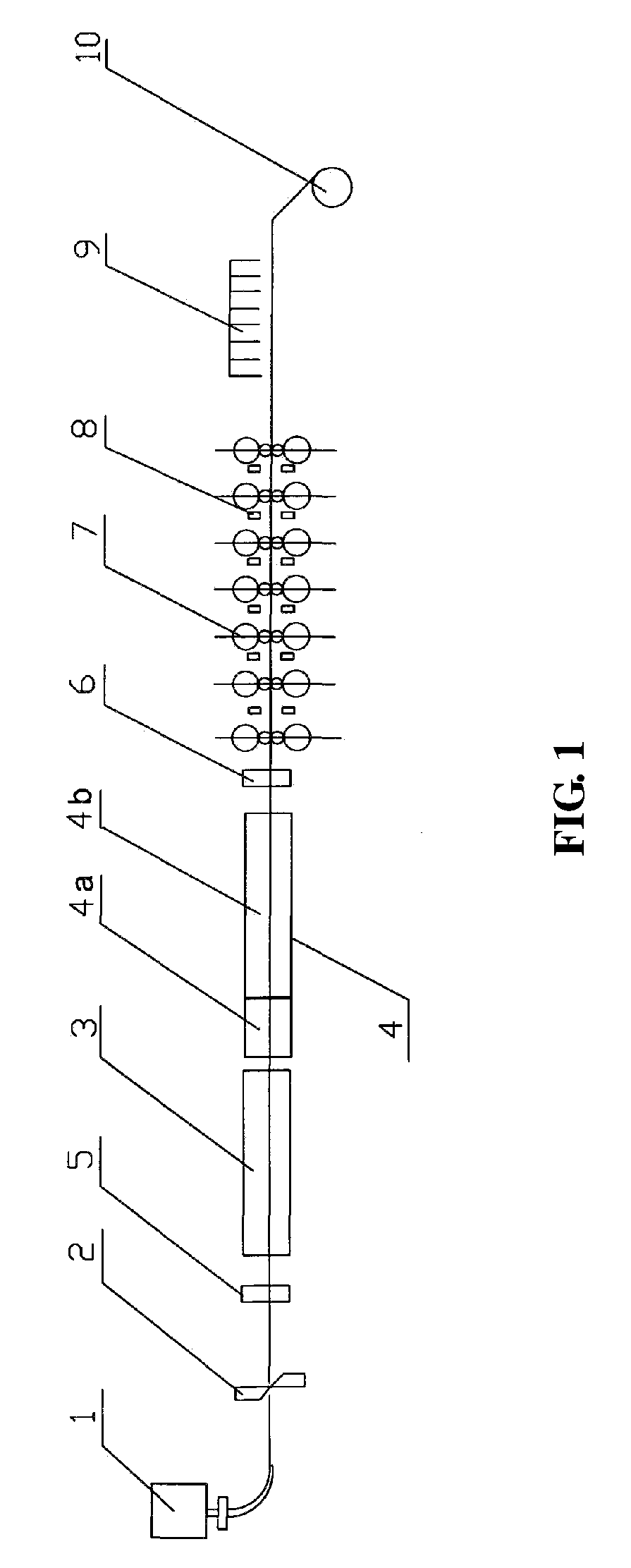

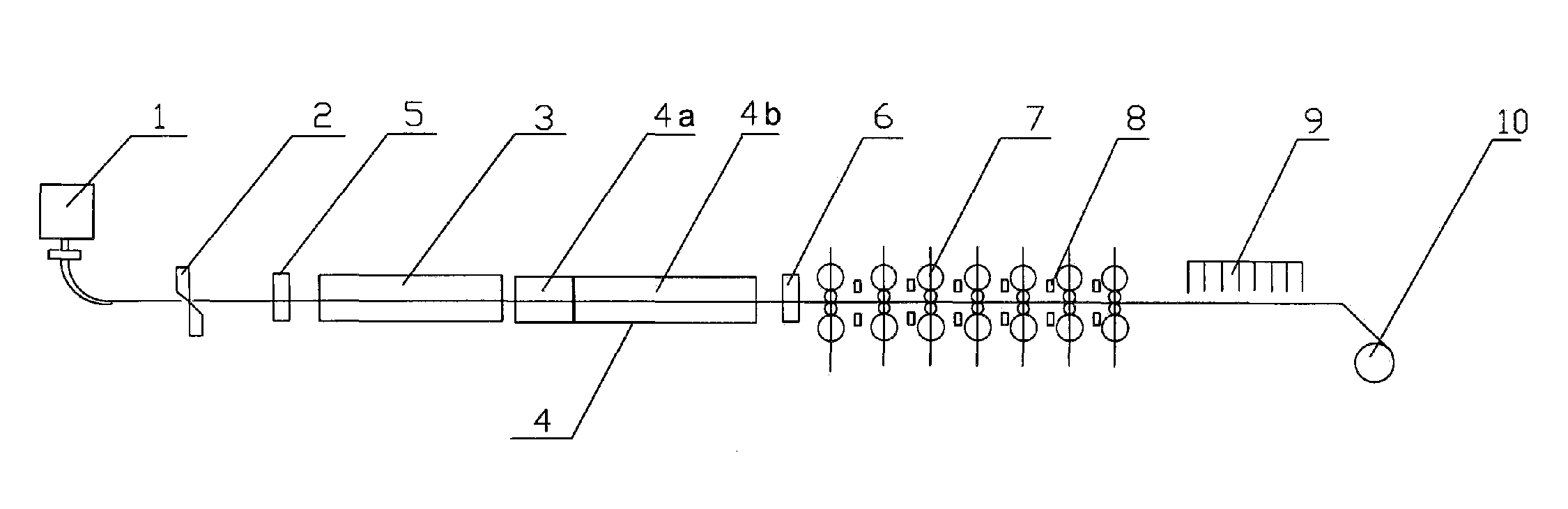

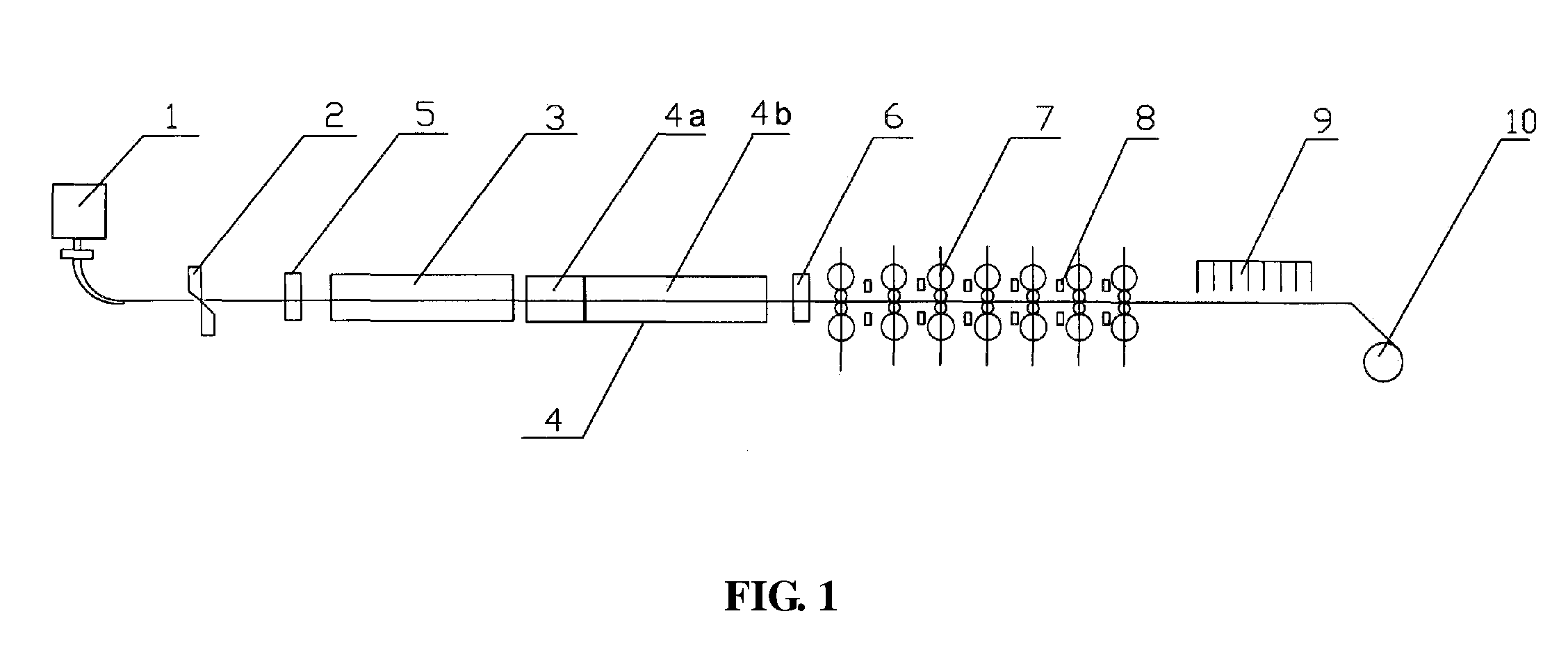

Method and system for producing wide steel strip

ActiveUS7942191B2Low costFlexible processForging/pressing devicesMetal rolling stand detailsMetallurgyNitrogen

A method for producing a wide steel strip using thin slab continuous casting and rolling by the following steps a) casting a molten steel into a thin slab having a thickness of between 50 and 90 mm; b) cutting; c) soaking; d) heating by electromagnetic induction; e) descaling; f) rolling; g) cooling with laminar flow; and h) coiling. The method can effectively control the solution and precipitation of carbon, nitrogen, and sulfide in steel with a low cost. The process is easy and flexible, and steel can be produced in a wide range of categories. Further provided is a system for producing a wide steel strip with thin slab continuous casting and rolling.

Owner:武钢集团有限公司

Method and system for producing wide steel strip

ActiveUS20100218911A1Low costEffectively control solutionForging/pressing devicesMetal rolling stand detailsThin slabNitrogen

A method for producing a wide steel strip using thin slab continuous casting and rolling by the following steps a) casting a molten steel into a thin slab having a thickness of between 50 and 90 mm; b) cutting; c) soaking; d) heating by electromagnetic induction; e) descaling; f) rolling; g) cooling with laminar flow; and h) coiling. The method can effectively control the solution and precipitation of carbon, nitrogen, and sulfide in steel with a low cost. The process is easy and flexible, and steel can be produced in a wide range of categories. Further provided is a system for producing a wide steel strip with thin slab continuous casting and rolling.

Owner:武钢集团有限公司

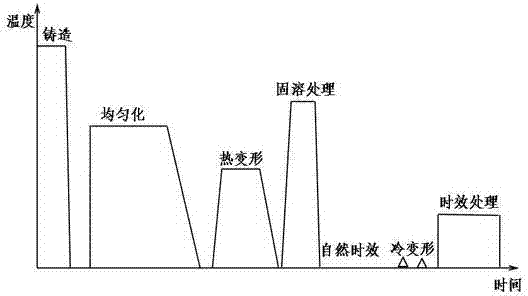

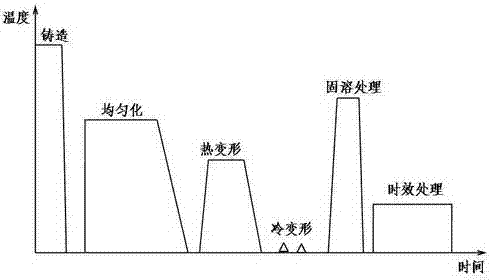

Hot working method for improving strength of wrought aluminium alloy and keeping plasticity of wrought aluminium alloy

The invention belongs to the technical field of metal and alloy fabricating and heat treatment, and provides a hot working method for improving strength of a wrought aluminium alloy and keeping plasticity of the wrought aluminium alloy. The method comprises the steps that the aluminium alloy is cast to form a cast ingot; the cast ingot is subjected to homogenization treatment and heat deformation treatment to form a plate; and the plate is sequentially subjected to solid solution and quenching treatment, natural aging treatment, cold deformation treatment and artificial aging treatment. The method can be used for large-scale production of high-strength aluminium alloys; and compared with the existing hot working method, the manufacturing cost is not increased.

Owner:HUNAN UNIV

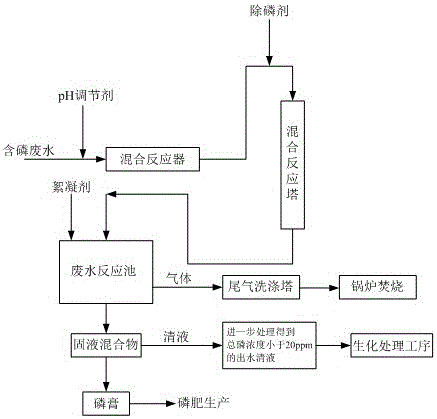

Method for removing phosphorus from high-concentration phosphorus-containing wastewater

InactiveCN106082488AEasy to handleMeet the biochemical treatment conditionsDispersed particle separationMultistage water/sewage treatmentHigh concentrationHydrogen

The invention discloses a method for removing phosphorus from high-concentration phosphorus-containing wastewater. The method includes regulating a pH (potential of hydrogen) value of the high-concentration phosphorus-containing wastewater with the total phosphorus concentration of 5000-25000 ppm, calcifying the high-concentration phosphorus-containing wastewater, removing the phosphorus from the high-concentration phosphorus-containing wastewater to obtain wastewater and then feeding the wastewater into a wastewater reaction tank; adding flocculating agents into the wastewater reaction tank after reaction is completely carried out and forming solid and liquid mixtures; separating solid from liquid in the solid and liquid mixtures to obtain phosphorus paste and clear liquid; treating the clear liquid and then feeding the clear liquid into biochemical treatment working procedures. The method has the advantages that the phosphorus can be continuously removed at steps of pH regulating, calcification and phosphorus removal, treatment by the aid of the wastewater reaction tank and the like, accordingly, the treated high-concentration phosphorus-containing wastewater with the total phosphorus concentration of 5000-25000 ppm can reach wastewater standards under biochemical treatment conditions, filter residues and the phosphorus paste which are obtained in phosphorus removal procedures can be used as raw materials for producing phosphorus fertilizers, technological procedures are simple, the method is low in investment cost and little in environmental pollution, and the like.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

Control method of coating performance surface quality of double-phase steel cold-rolled high-strength automobile board

ActiveCN109136739AIncrease roughnessImprove surface qualityFurnace typesHeat treatment furnacesDouble phaseHigh pressure water

The invention discloses a control method of coating performance surface quality of a double-phase steel cold-rolled high-strength automobile board, which comprises smelting, continuous casting, hot rolling, descaling, acid rolling, continuous annealing and leveling. The descaling process uses a three-stage descaling process, wherein the descaling position comprises descaling after a heating furnace, descaling before rough rolling and descaling before finish rolling, the descaling pressure at each descaling point is greater than or equal to 24MPa, the rough rolling is reciprocating rolling, therolling is carried out for 5 times, and high-pressure water descaling is carried out for every time. By adjusting and optimizing a whole process production process, including controlling the chemicalcomposition of a continuous casting blank, improving the heating and cooling system of the continuous casting, hot rolling, and cold rolling, controlling the hot rolling and descaling processes and cold rolling and acid rolling processes, controlling the roughness of a leveled steel strip, and the like, the surface quality of the double-phase steel cold-rolled automobile board is improved, the element enrichment on the surface of the steel board is inhibited, the quality of a phosphating film is improved, the coating performance of the double-phase steel cold-rolled high-strength automobile board and the anti-corrosion performance of the double-phase steel cold-rolled high-strength automobile board after being coated are improved.

Owner:TANGSHAN IRON & STEEL GROUP +1

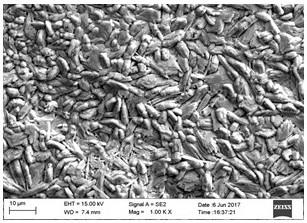

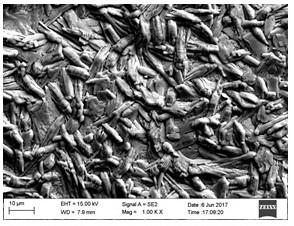

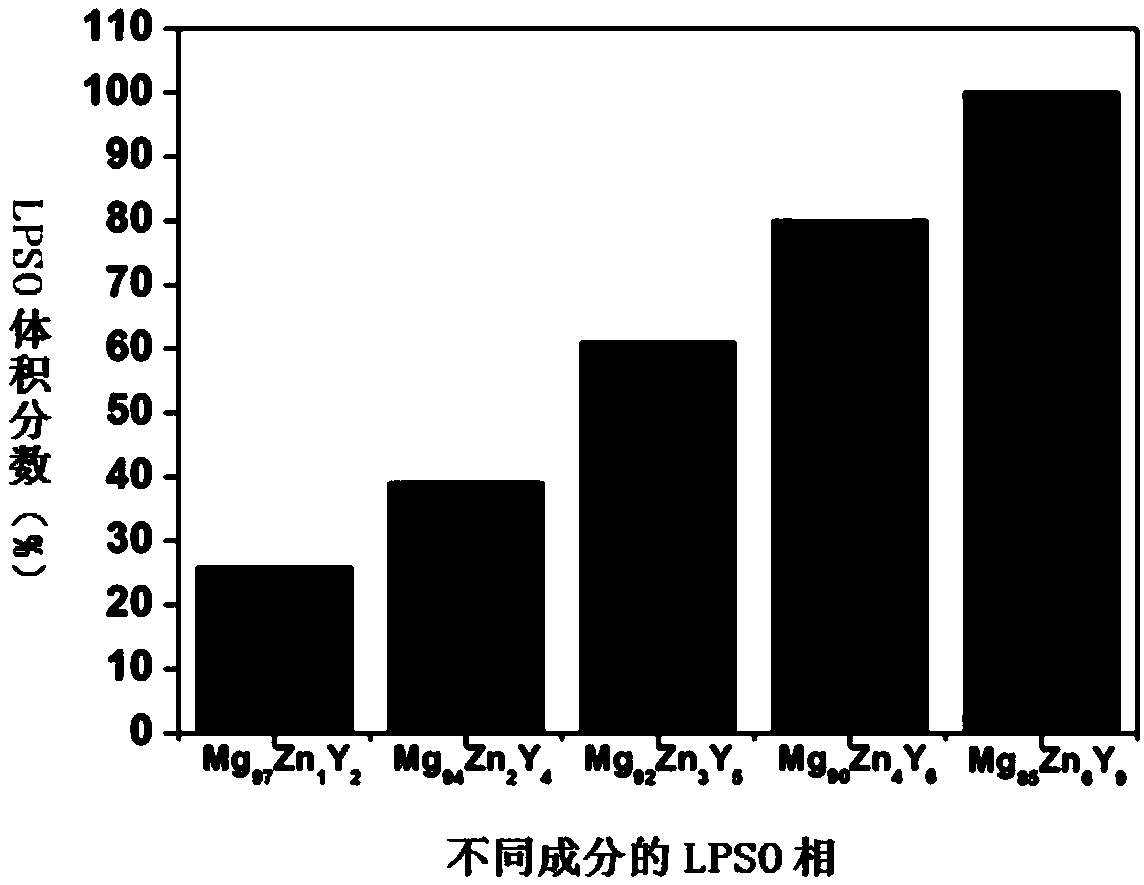

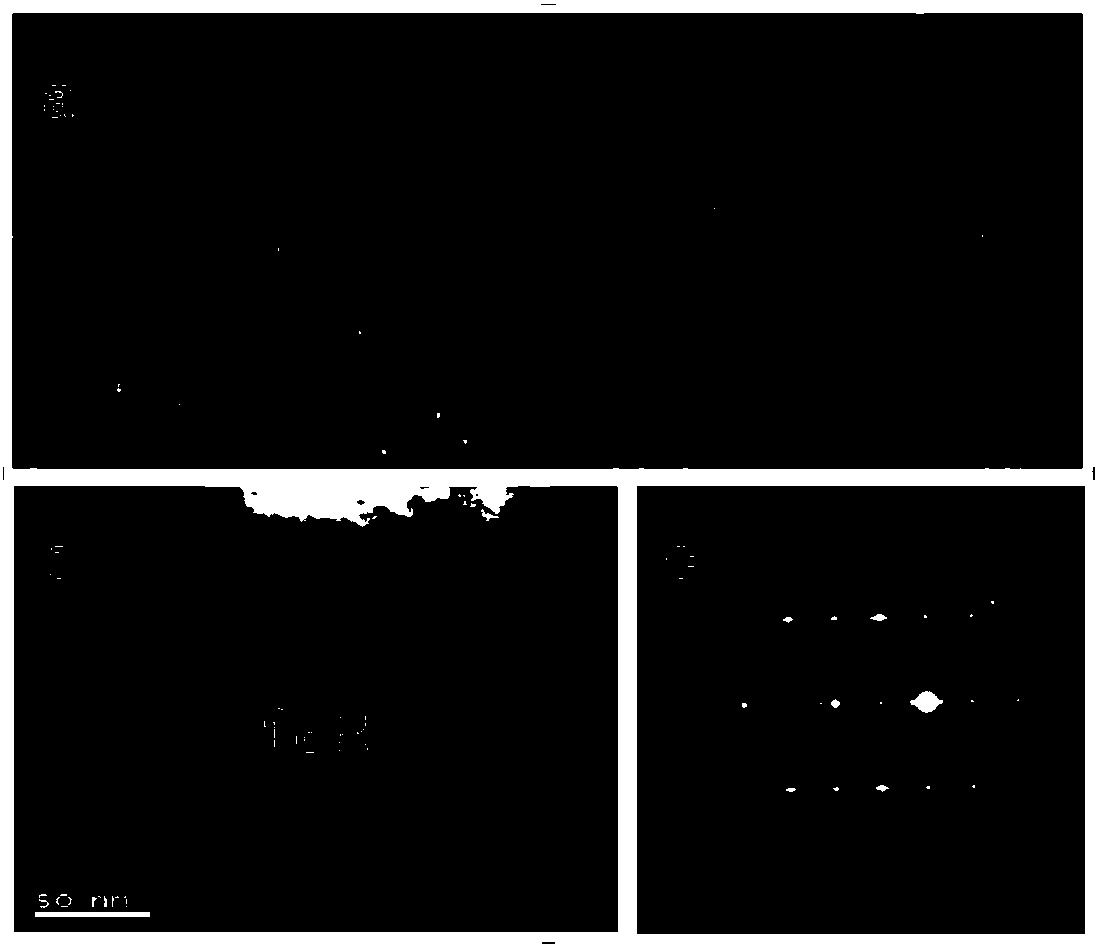

Preparation method of long-periodic-structure particle-reinforced magnesium-base/aluminum-base composite material

The invention relates to a preparation method of a long-periodic-structure particle-reinforced magnesium-base / aluminum-base composite material. The preparation method comprises the steps of adding reinforced particles adopting an Mg-Zn-Y system into magnesium powder, aluminum powder, magnesium alloy powder or aluminum alloy powder, and carrying out hot-pressing and sintering by virtue of an SPS method or a cubic press method, so as to obtain the magnesium-base / aluminum-base composite material. The magnesium-base / aluminum-base composite material does not contain heavy rare earth elements such as Er, obtained reinforced phase particles are converted into nanocrystallines by virtue of high-energy ball milling, are high in hardness and have good bondability with a magnesium matrix / aluminum matrix, and the composite material with excellent performance is prepared.

Owner:HEBEI UNIV OF TECH

Natural fresh-keeping solution for boiled bamboo shoots as well as preparation and use method thereof

ActiveCN103098861AMaintain colorStrong antioxidant effectFruit and vegetables preservationChemistrySodium erythorbate

The invention discloses a natural fresh-keeping solution for boiled bamboo shoots. The fresh-keeping solution comprises the following raw materials: 0.02-0.08 g of sodium isoascorbate, 0.01-0.06 mL of phytic acid, 0.05-0.15 g of ascorbic acid and 2-3 g of glycine which are dissolved in every 100 mL of de-ionized water. The pH value of the prepared fresh-keeping solution is 4-4.4 at room temperature. The raw materials of the prepared fresh-keeping solution are all pure natural animal and plant extracts which are environment-friendly and safe; the preparation method of the fresh-keeping solution is simple and easy to implement; and the fresh-keeping solution has an outstanding fresh-keeping effect on a product.

Owner:JIANGNAN UNIV

Synthesis method of polyvinyl butyral resin

The invention discloses a synthesis method of polyvinyl butyral resin, and belongs to the field of high polymer material preparation. The method comprises the following steps: dissolving polyvinyl alcohol in deionized water, adding an emulsifier, adding n-butyraldehyde to react with an organic acid, then adding an inorganic acid, carrying out a heating reaction, performing neutralizing with an alkaline solution, adjusting the pH value of the reaction solution to 7-9, carrying out solid-liquid separation, treating the solid resin with a stabilizer solution, washing, filtering, and performing drying to obtain the polyvinyl butyral resin. The condensation reaction of polyvinyl alcohol and n-butyraldehyde is catalyzed step by step by adopting organic acid and inorganic acid; the early condensation reaction speed is effectively controlled, resin can be stably separated out from a water phase, the main chain acetal uniformity is improved, inorganic acid is adopted for catalysis in the middleand later periods of the reaction, the condensation reaction speed can be increased, the conversion rate of n-butyraldehyde is increased, and the acetal degree of the resin is improved. The synthesismethod is simple, high in operability and easy for industrial production. The resin can be used in the fields of safety glass, coatings, adhesives and the like.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

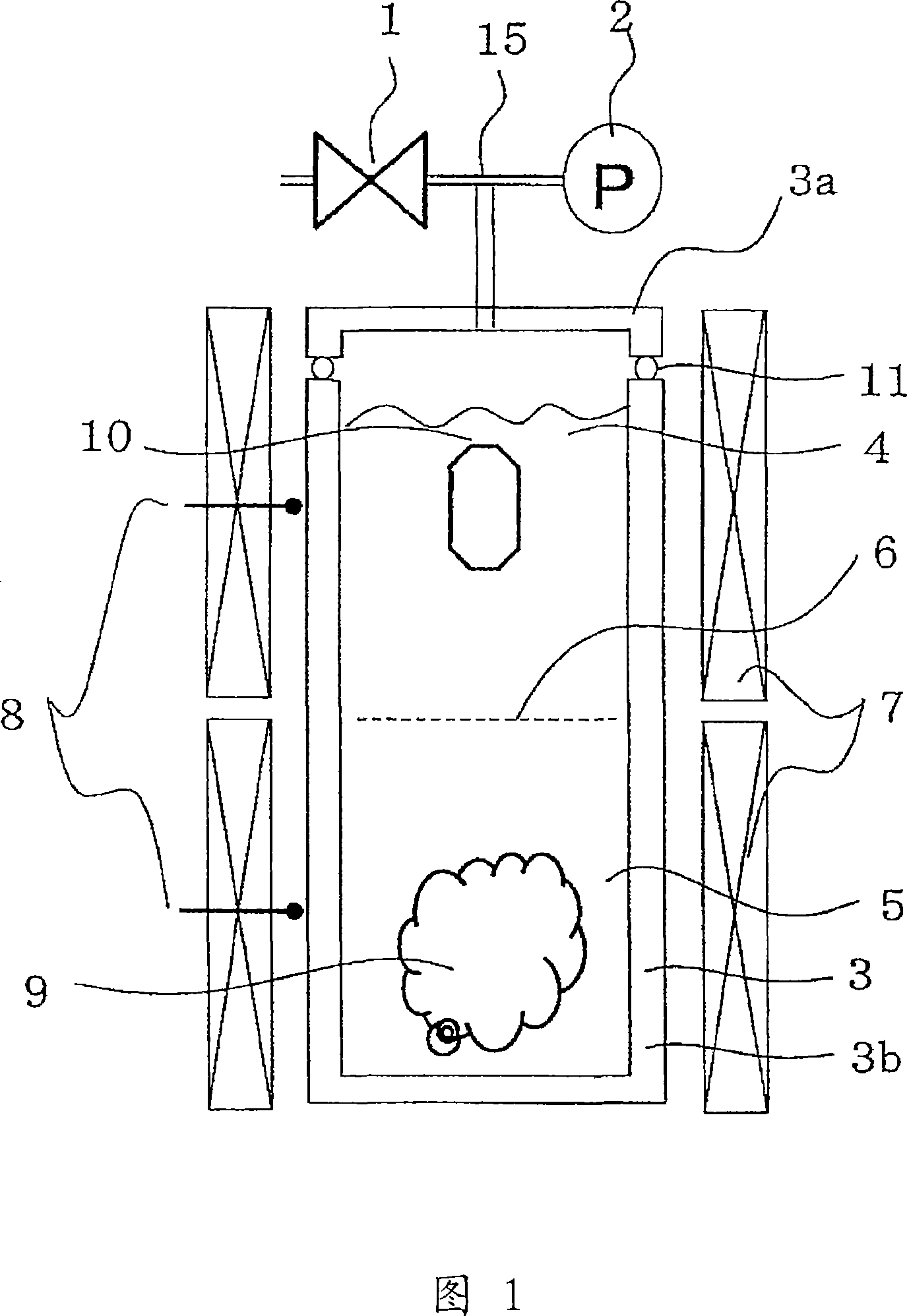

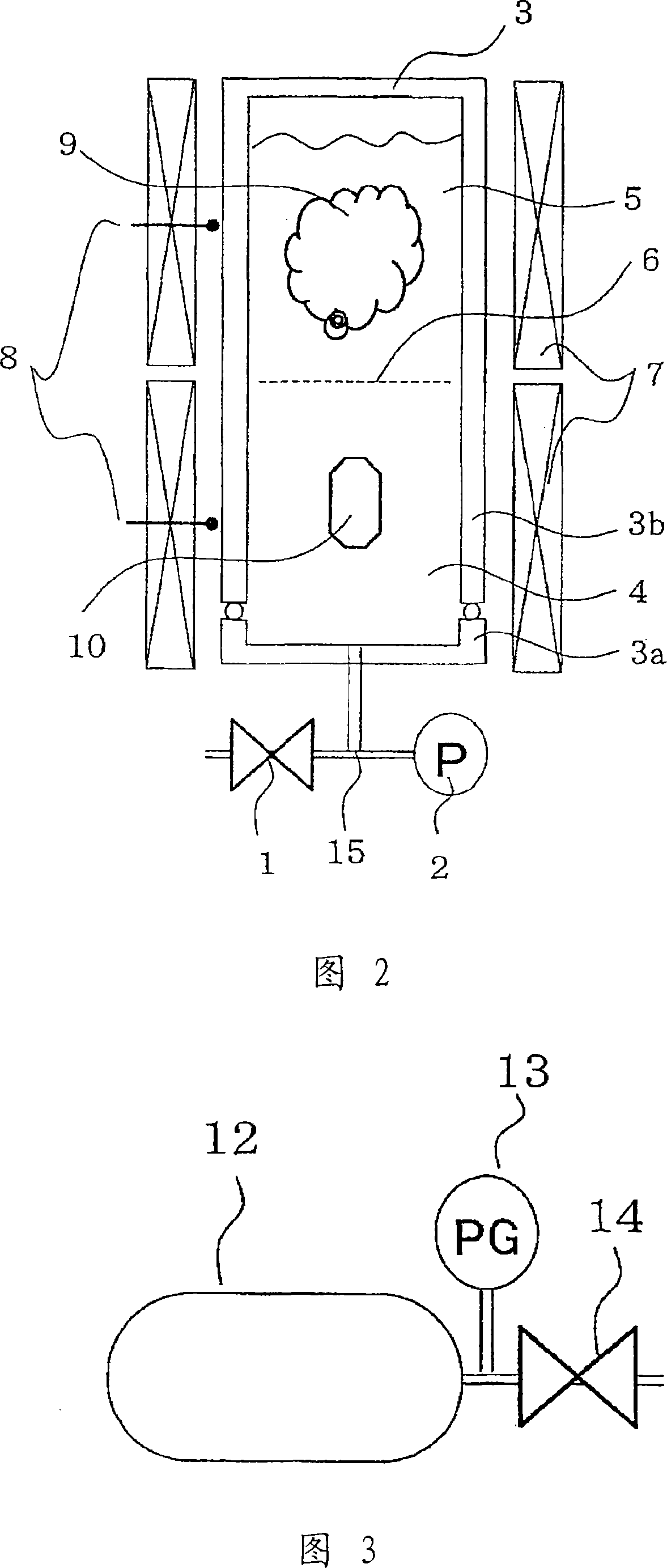

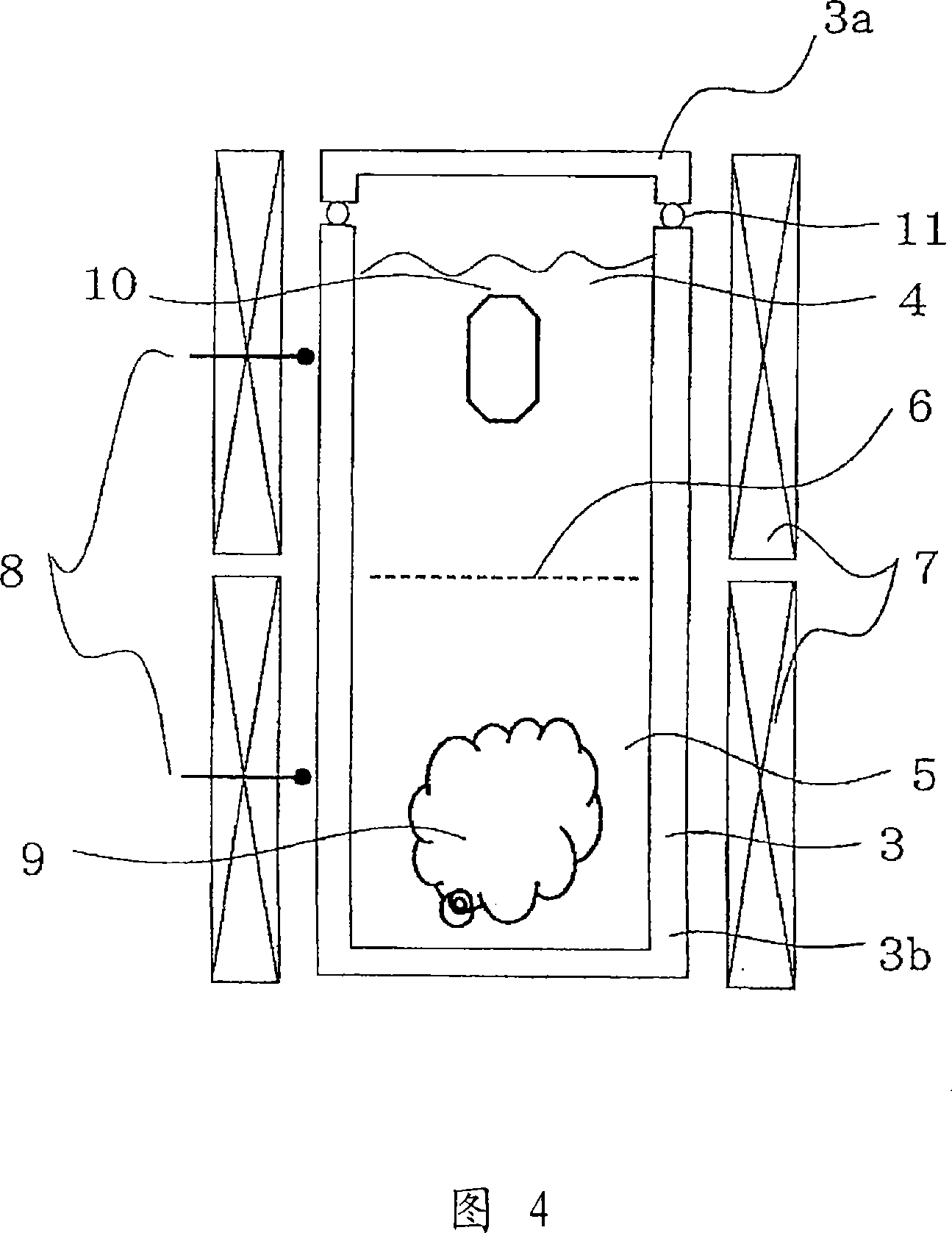

Crystal production method using supercritical solvent, crystal growth apparatus, crystal, and device

InactiveCN101213327AWill not be enlargedWill not complicatePolycrystalline material growthFrom normal temperature solutionsSolventCrystal growth

The purpose of the present invention is to have a predetermined amount of substances different from the critical density of the solvent in the reaction vessel, and carry out crystal growth by solvothermal method, thereby controlling the precipitation position of the crystal, improving the yield of the crystal, and preventing the crystal from being mixed with Impurities, so that the crystals are highly purified. The crystal production method of the present invention is to use a supercritical state and / or a subcritical state solvent and a raw material in a reaction vessel to grow crystals, and it is characterized in that, in the reaction vessel, there is For the substance (X) having a critical density difference of 25% or more, the precipitation position of crystals can be controlled by adjusting the amount of the substance (X).

Owner:MITSUBISHI CHEM CORP +1

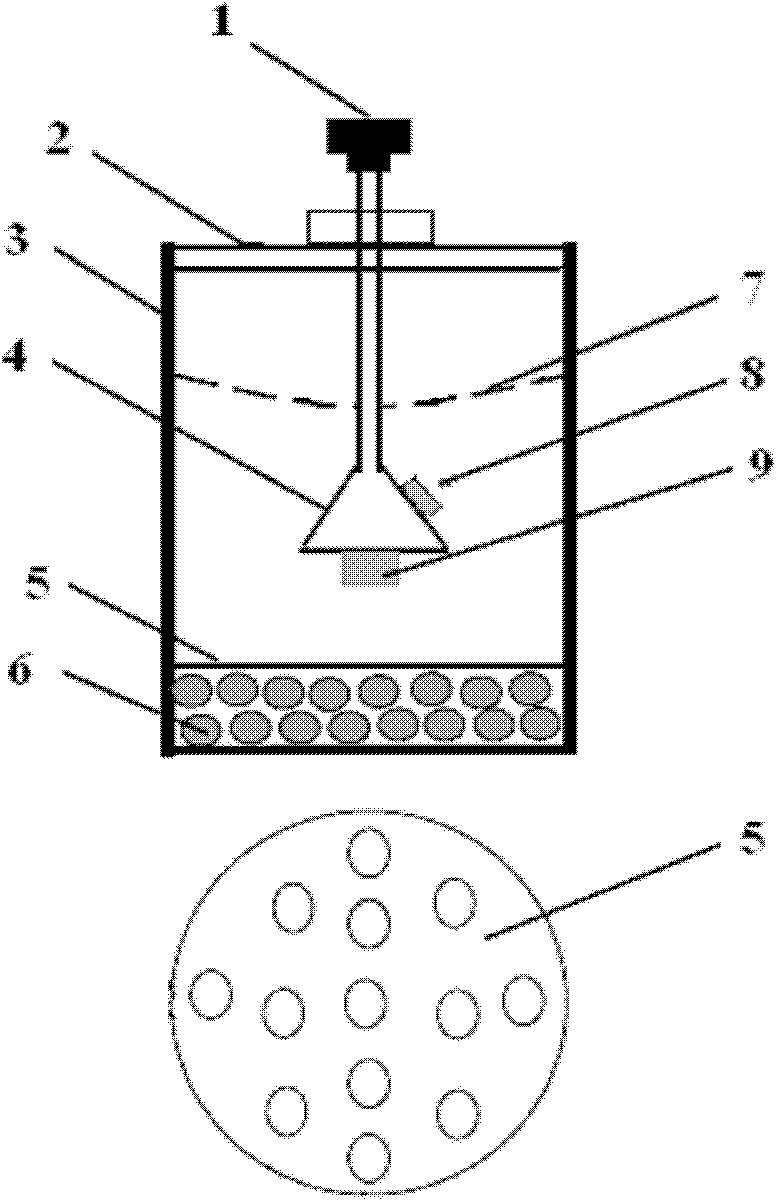

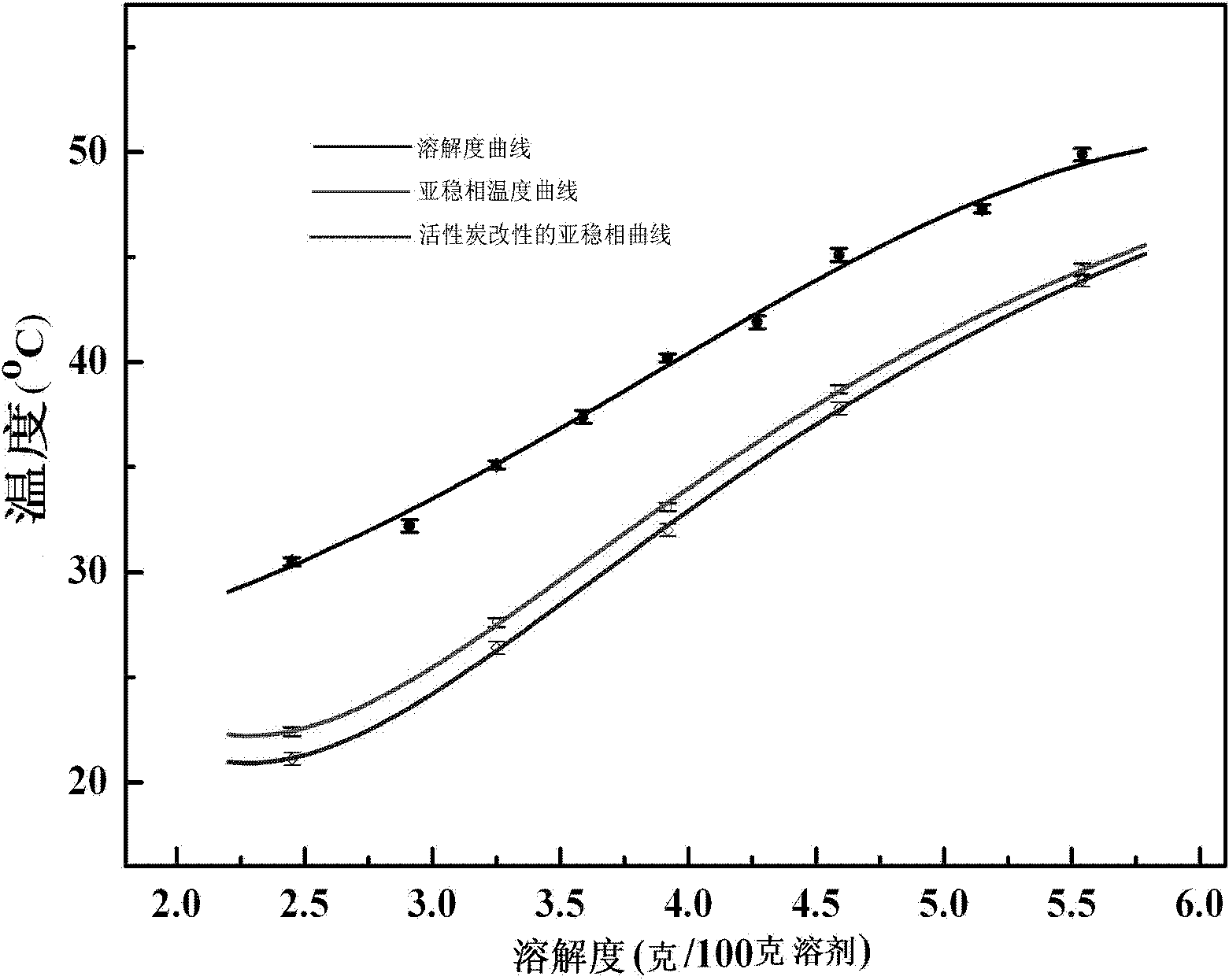

Method for inhibiting mixed crystal from generating in growth process of 4-(4-dimethylaminostyryl) picoline p-toluenesulfonate crystal

ActiveCN102560678AControl precipitationQuality improvementPolycrystalline material growthSingle crystal growth detailsActivated carbonPhysical chemistry

The invention relates to a method for inhibiting mixed crystal from generating in a growth process of 4-(4- dimethylaminostyryl) picoline p-toluenesulfonate (DAST) crystal, belonging to the field of the crystal growth. In the DAST crystal growing process, granular or columnar activated carbon of which the specific surface area is 200-1000m<2> / g is added into a growth solution to serve as adsorbent. The metastable phase interval of the DAST crystal growth solution can be widened by adding the activated carbon to reduce the gathering tendency of crystallite and improve the stability of the growth solution. The method provided by the invention is simple and is convenient to operate, the phenomenon that the mixed crystal is generated in the DAST crystal growth solution can be effectively inhibited or alleviated so as to play the roles on regulating the crystal growth rate and improving the crystal growth habit, defects in the crystal in the growth process can be reduced, and DAST crystal with high optical quality is easy to obtain.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

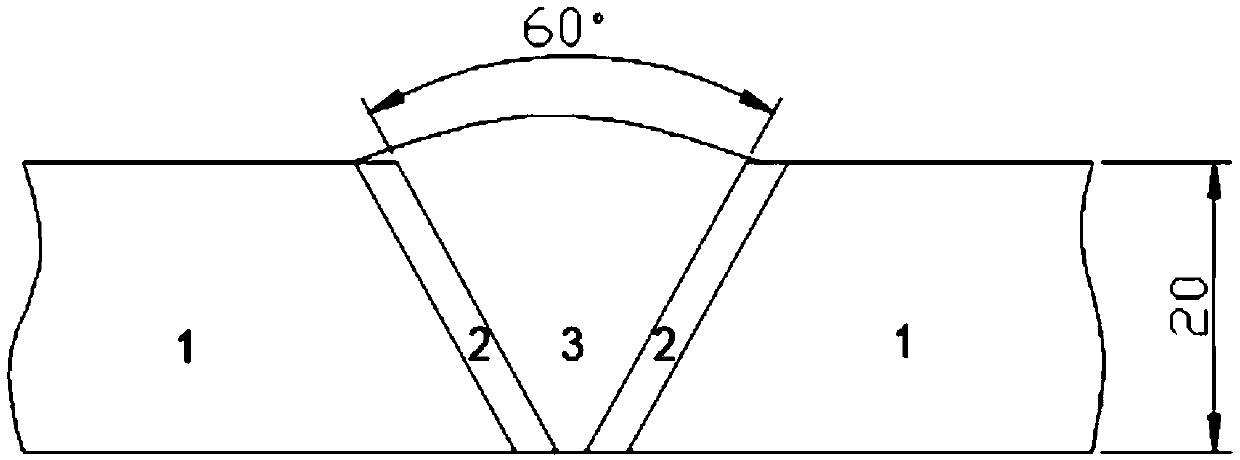

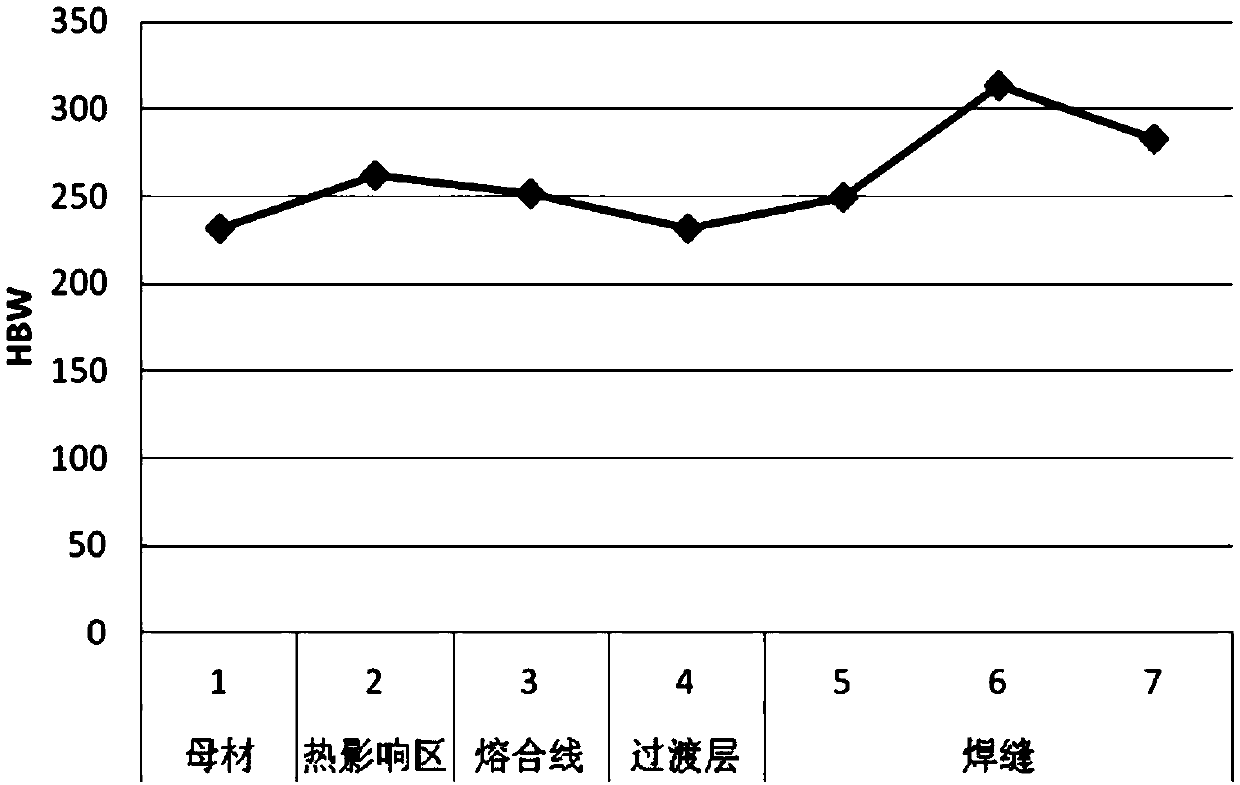

Mn13 high-manganese steel welding technology

InactiveCN110640349AReduce use costGuaranteed performanceArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingManganese

The invention discloses an Mn13 high-manganese steel welding technology, which comprises the following steps that: 1) processing a reasonable welding groove on a butt joint plate material; 2) carryingout transition layer welding, adopting a direct current reverse polarity, immediately carrying out water cooling and hammering after a welding line of which the length is 50-100mm is welded for eachtime, measuring the temperature of a position, which is 10-20mm far away from the groove, of a welded material, cooling to be below 50DEG C, and continuously welding after a surface is cleaned, wherein a welding way is SMAW (Shielded Metal Arc Welding), welding current is 110-130A, electric arc voltage is 35-45V, a welding speed is 150-250mm / min, a cooling way is air cooling, the temperature of alayer channel is less than or equal to 50DEG C, and the thickness of the transition layer is 4-6mm; and 3) welding a filling welding line, adopting argon-rich gas shielded welding for welding, carrying out air cooling to be below 150DEG C after one pass is finished, and carrying out next-pass welding, wherein low-alloy welding wires are adopted as a welding material, welding current is 220-260A, electric arc voltage is 28-31V, a welding speed is 400-450mm / min, a cooling way is air cooling, and the temperature of a layer channel is less than or equal to 150DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

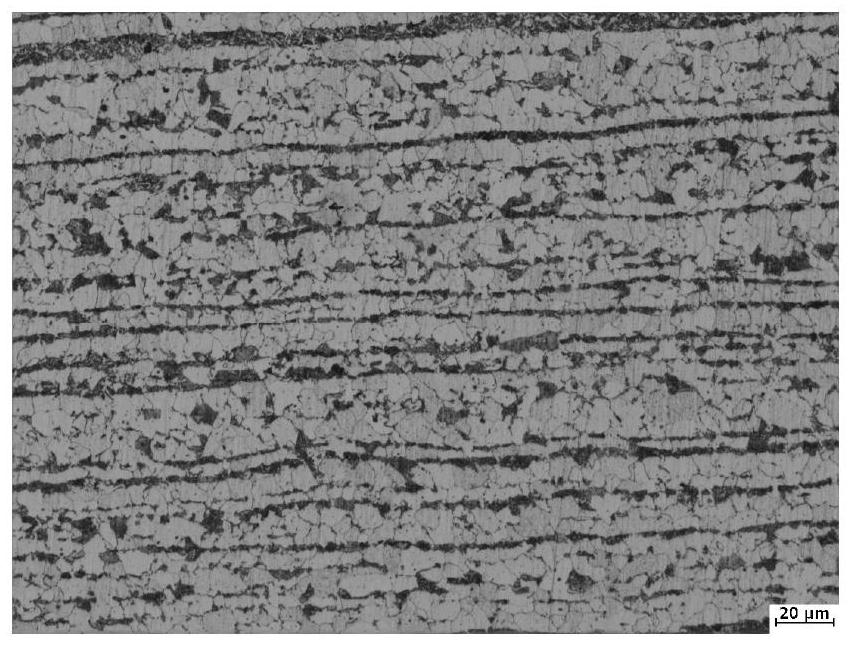

Wear-resistant steel and production method thereof

The invention discloses wear-resistant steel and a production method thereof, and relates to the technical field of steel production, and the wear-resistant steel comprises the following chemical components in percentage by mass: 0.10 to 0.45 percent of C, 0.20 to 0.55 percent of Si, 0.50 to 1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, less than or equal to 0.060 percent of Nb, less than or equal to 0.030 percent of V, 0.008 to 0.025 percent of Ti, 0.20 to 1.00 percent of Cr, less than or equal to 1.80 percent of Ni, less than or equal to 0.50 percent of Mo, 0.025 to 0.055 percent of Al, 0.0010 to 0.0030 percent of B, 0.0010 to 0.0018 percent of Mg, less than or equal to 0.0045 percent of N and the balance of Fe and inevitable impurities. On the premise that the high-strength martensite structure of the wear-resistant steel plate is guaranteed, through quantitative treatment of microalloying elements, the number and the size of carbonitride are reduced, the cooling speed and the austenite temperature of a casting blank are regulated and controlled, a secondary quenching optimization process is adopted, structure grains are refined, structure stress is eliminated, and the wear resistance of the wear-resistant steel plate is improved. The problem of delayed cracks of wear-resistant steel in the cutting and grinding process of casting blanks and steel plates is solved.

Owner:NANJING IRON & STEEL CO LTD

Core-shell structure powder fire extinguishing medium and preparation method and application thereof

ActiveCN110448851AImprove fire extinguishing efficiencyIncrease the areaFire extinguisherSocial benefitsIron salts

The invention discloses a core-shell structure powder fire extinguishing medium and a preparation method and application thereof, and relates to the technical field of fire extinguishing. The core-shell structure powder fire extinguishing medium is prepared from, by weight, 2-10 parts of a shell material and 85-98 parts of a core material, wherein the core material is a potassium salt aqueous solution or an iron salt dispersion liquid. The core-shell structure powder fire extinguishing medium is clean, environmentally friendly, safe and free of toxins, is simple in preparation process, high incooling speed, good in liquidity, low in corrosivity to storage equipment and conveying pipelines, good in stability and wide in application range, can quickly extinguish gas, liquid and solid fires,does not generate harmful gas and environmental pollution in the fire extinguishing process, and has good economic and social benefits.

Owner:中国人民警察大学

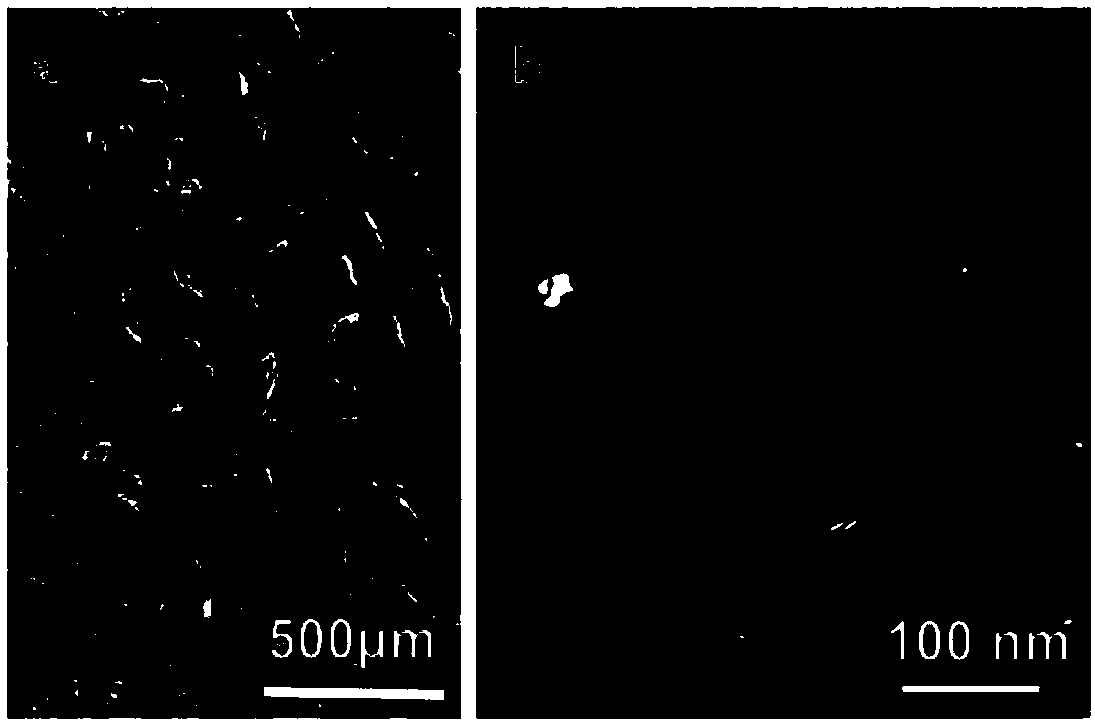

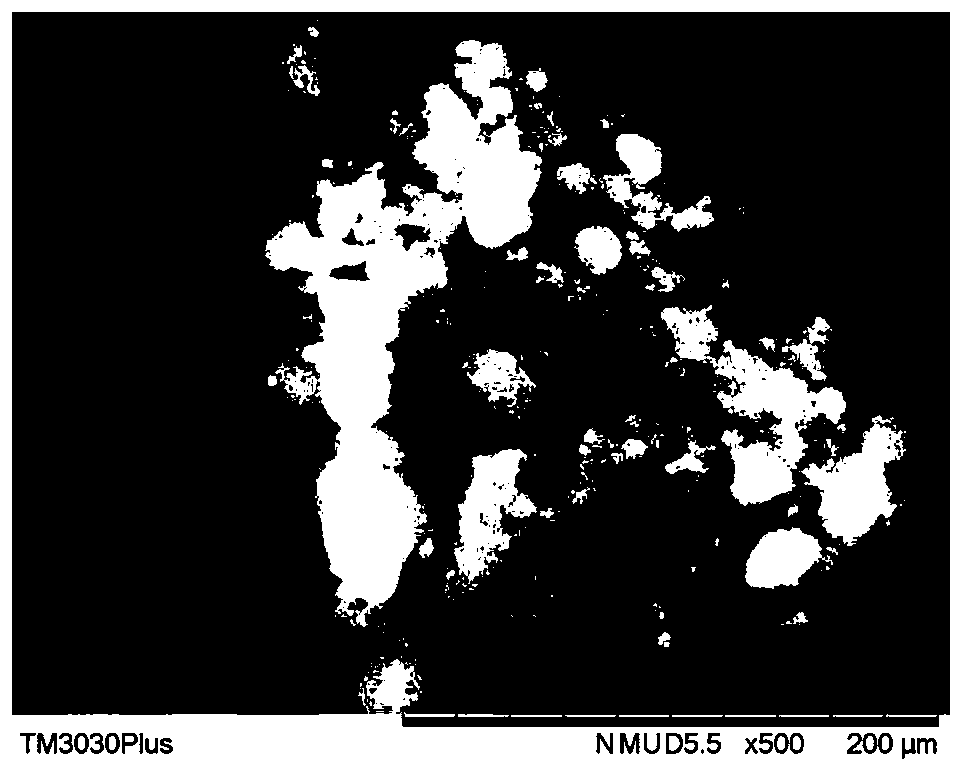

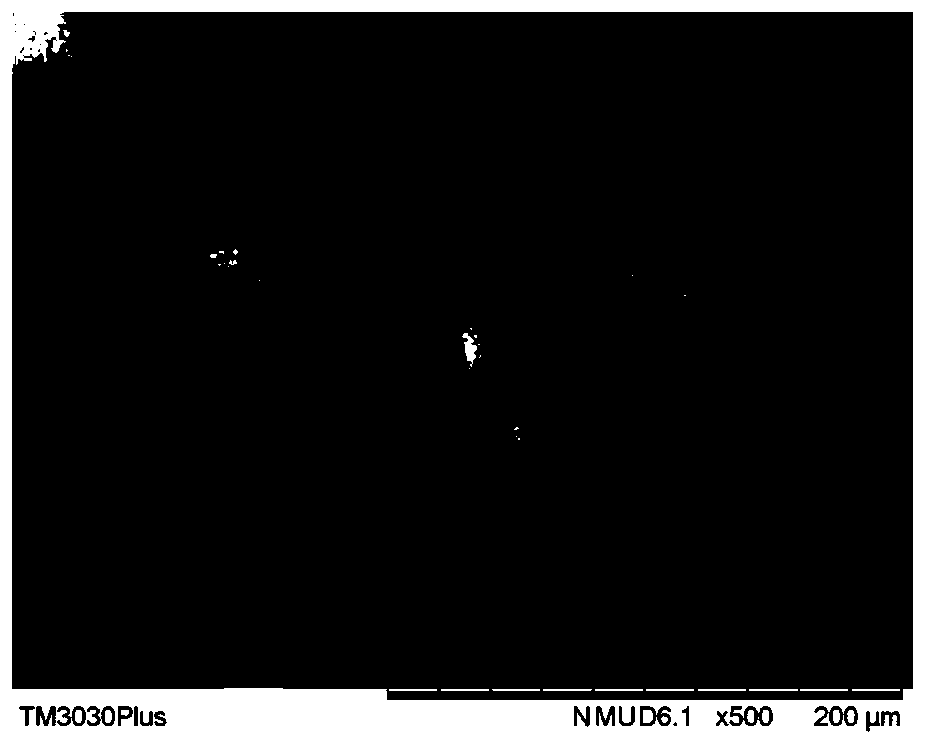

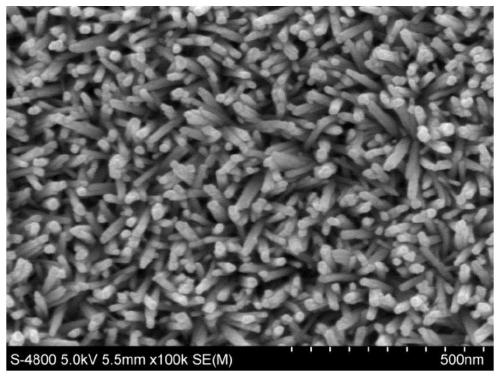

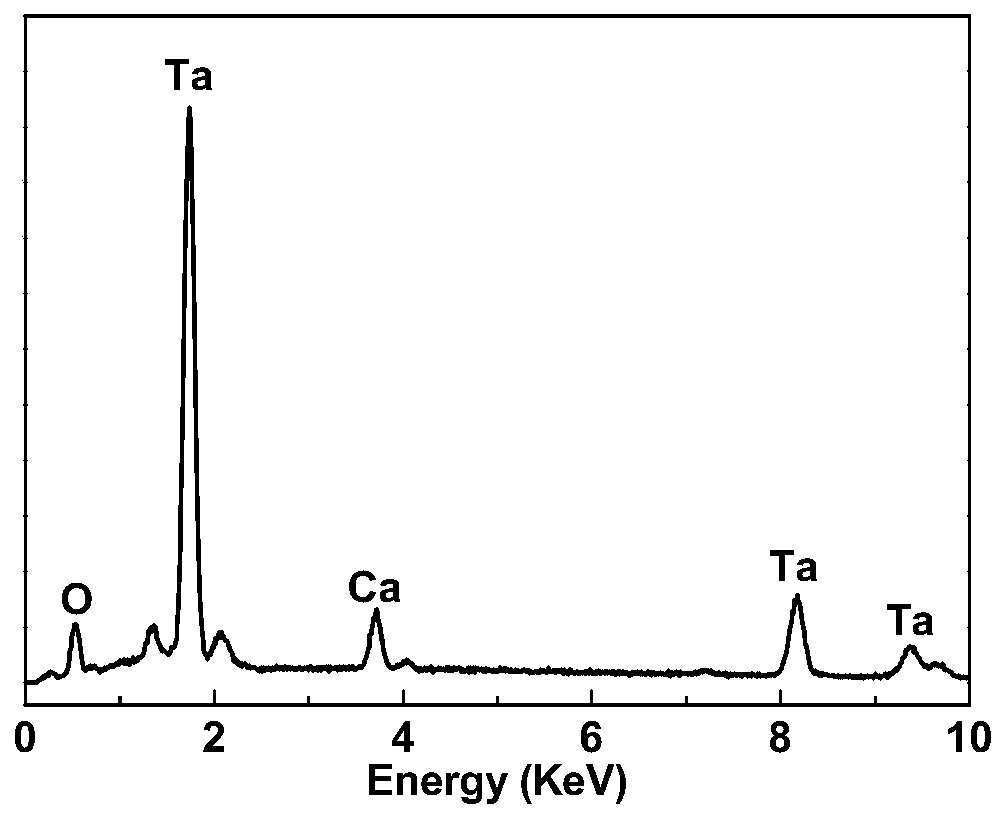

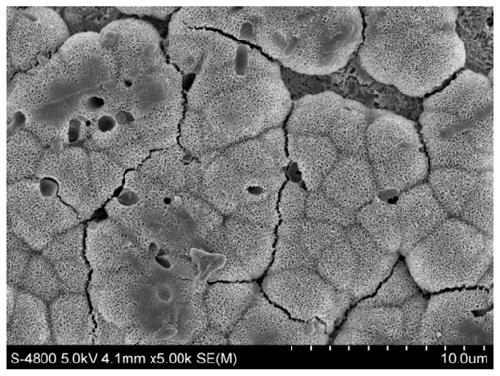

Calcium-mingled tantalum oxide nanometer bar structure biological activity coating and preparation method thereof

InactiveCN109722660ASimple ingredientsEasy to controlMetallic material coating processesProsthesisApatiteDrug biological activity

The invention discloses a calcium-mingled tantalum oxide nanometer bar structure biological activity coating and a preparation method thereof. According to the method, at first, a water solution containing hydrofluoric acid and hydrogen peroxide serves as a water heat solution, different water heat conditions are adopted for carrying out water heat treatment on a tantalum base body, then a tantalum oxide nanometer bar structure coating obtained again is subjected to water heat treatment under the calcium-contained water heat environment condition, the obtained coating microstructure is of a nanometer bar shape, the phase is tantalum pentoxide, and the nanometer bar structure coating is mingled with a calcium element. The high combination strength between the calcium-mingled nanometer bar structure coating and the base body is achieved, the calcium element separated out from the coating is increased gradually along with prolonging of soaking time, bone apatite can be induced and formedrapidly in the liquid-like environment, and the coating has good biological activity.

Owner:SHAANXI UNIV OF SCI & TECH

Coating for lost foam casting of engine cylinder blocks and preparing method thereof

The invention discloses a coating for lost foam casting of engine cylinder blocks and a preparing method thereof, belongs to the technical field of lost foam coating, and aims to provide a lost foam coating with fine coating property, fine breathability and high strength and a preparing method thereof. The technical scheme includes that the coating for lost foam casting of engine cylinder blocks is prepared by the following raw materials: by weight part, 100 parts of quartz sand powder, 5-10 parts of sodium bentonite, 0.1-1 part of cellulose, 5-15 parts of resin, 0.01-0.08 part of tween, 0.02-0.1 part of octanol, 1-5 parts of flour and 60-90 parts of pure water. The coating for lost foam casting of engine cylinder blocks and the preparing method thereof can be applied to various of lost foam casting fields in the prior art widely.

Owner:山西华尔动力机械有限公司

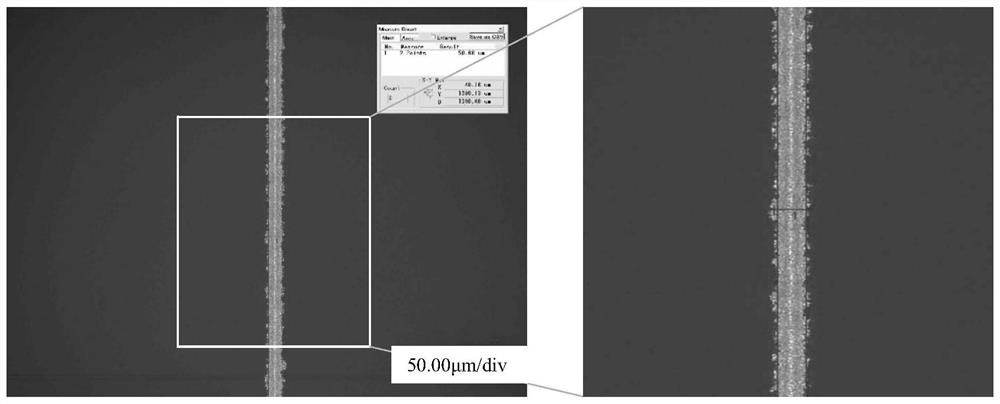

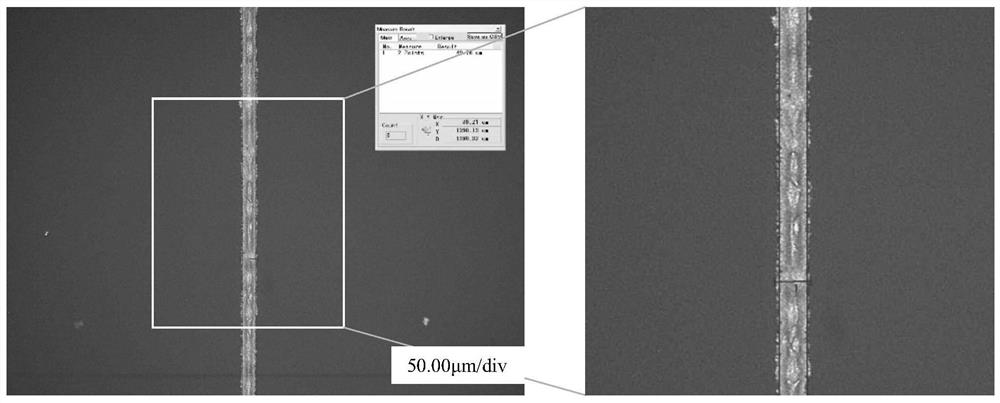

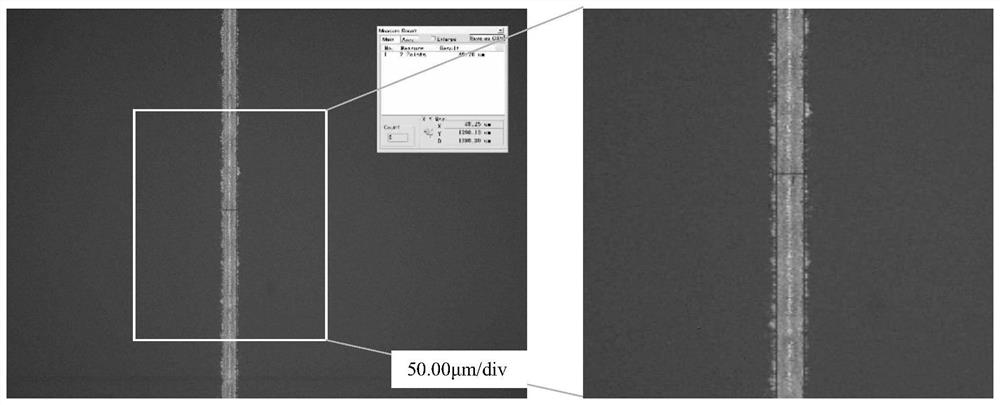

Rolling method of Cu-Cr series alloy plates and strips

ActiveCN111621666ALiquid level is stableConfiguration ratio is easy to controlTemperature control deviceMetal rolling arrangementsSolution treatmentCopper

The invention discloses a rolling method of Cu-Cr series alloy plates and strips. Alloy comprises the chemical components of 0.5-1.5% of Cr, 0.03-1.8% of Zr, <=0.08% of Fe, <=0.1% of Si and the balance of copper and unavoidable impurities. The rolling method comprises the steps of (1) proportioning; (1) upward-drawing continuous casting; (3) hot continuous rolling of a square billet; (4) solutiontreatment; (5) surface milling; (6) rough rolling; (7) aging treatment; (8) surface treatment; (9) finish rolling; (10) take-up; and (11) slitting. The method can lower production cost and improve product quality and the percent of pass of finished products, thereby greatly meeting market demands.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Solar cell grid line slurry, preparation method thereof and solar cell

PendingCN113035408AReduce contact resistanceImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationPolymer resinSolar battery

The invention belongs to the technical field of solar cells, and particularly relates to solar cell grid line slurry which comprises 65%-94% of conductive filler, 0.5%-15% of polymer resin, 0.1%-10% of curing agent, 5.0%-25% of solvent and 0.4%-10% of an auxiliary agent. The auxiliary agent is selected from at least one of a curing accelerator, an alcohol acid diester auxiliary agent and a silicon-containing auxiliary agent. According to the solar cell grid line slurry, the content of conductive filling factors is high, the contact resistance of printed grid lines and the cell is small, the line width is narrow, the height-width ratio is high, and the effective light absorption area of the solar cell is effectively prevented from being reduced, so that the efficiency of the cell is improved.

Owner:SHENZHEN BAROY NEW MATERIAL TECH CO LTD

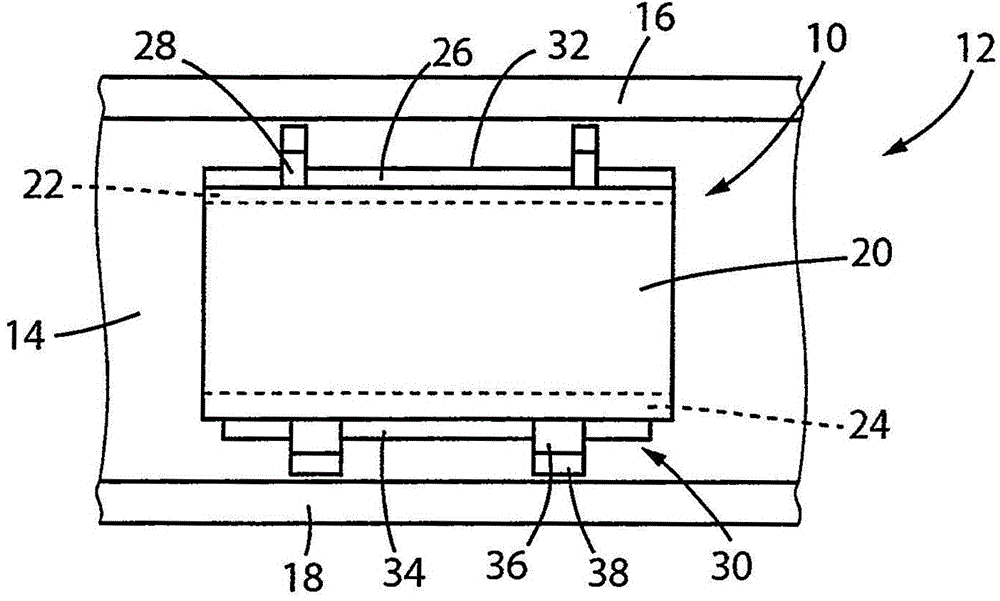

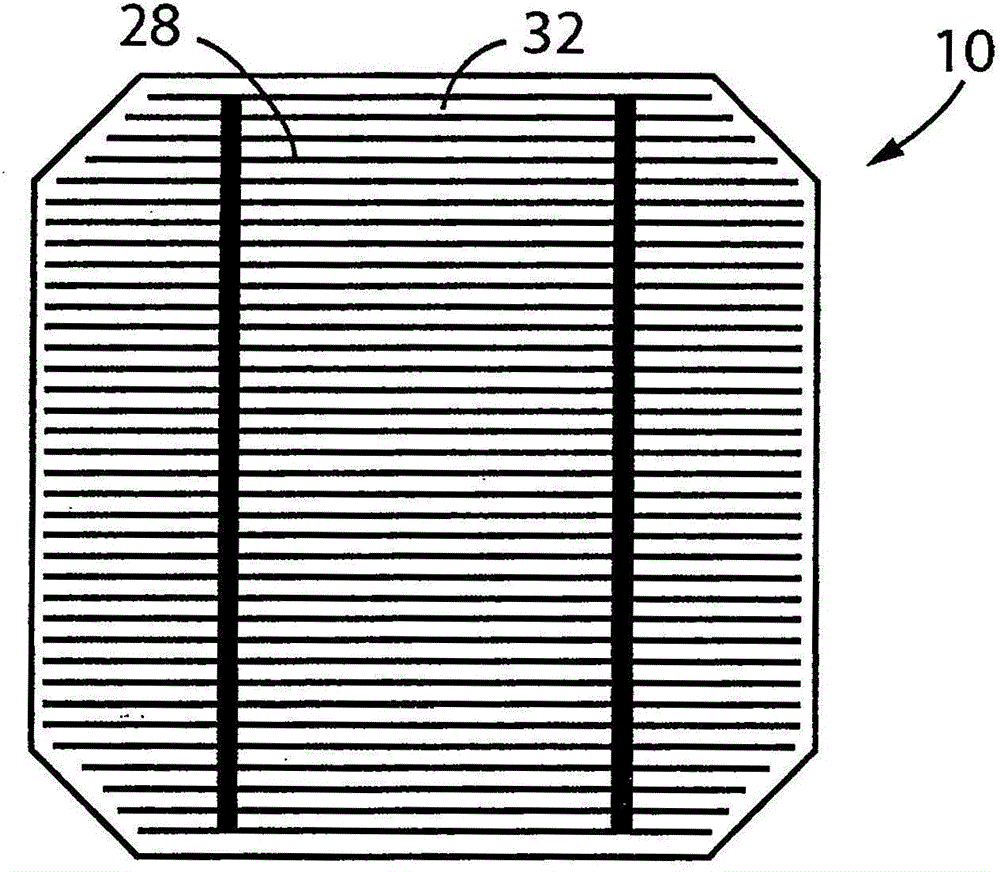

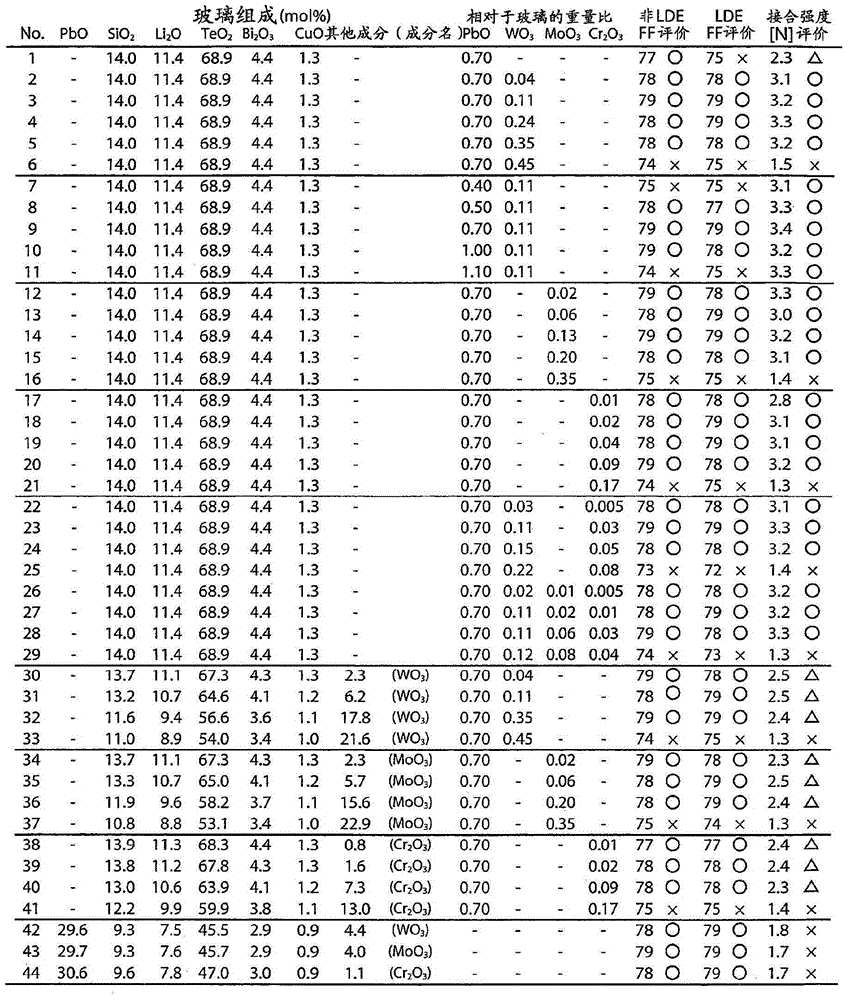

Paste for light receiving surface electrode of solar cell, manufacturing method and solar cell unit

InactiveCN105280731AReduce contact resistanceImprove joint strengthFinal product manufactureNon-conductive material with dispersed conductive materialElectrical batterySolar cell

The invention provides a paste for a light receiving surface electrode of a solar cell, wherein the paste can form an electrode that has high binding strength with a substrate and low contact resistance and furthermore high output can be obtained on condition that an LDE substrate is used, and a manufacturing method of the paste, and a solar cell unit with high output. The conductive paste for forming the light receiving surface electrode comprises leadless tellurite glass with various compositions. Various lead-containing additives and an additive with high-melting-point metal are mixed in the paste. Preferably the lead is carried in appropriate methods of false firing, chemical method, mechanical method, etc. Therefore if the electrode of the light receiving surface is formed through a fire-through manner, an erosion surface which appropriately has recesses and projections can be obtained. Therefore a requirement for a high electric characteristic and high binding strength can be satisfied. Furthermore, because the light receiving surface electrode (28) contains high-melting-point metals and lead, recombination is suppressed. Therefore high output can be obtained even the LDE substrate is equipped.

Owner:NORITAKE CO LTD

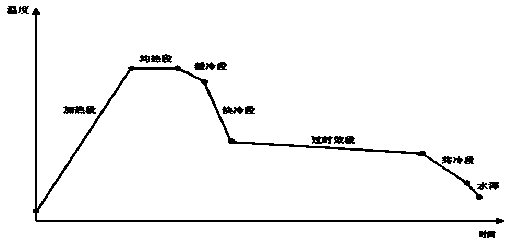

Salt bath heat treatment method for tool and mould steel

InactiveCN108531694AOvercoming the slow coolingHigh thermal conductivityHeat treatment bathsAir coolingMaterials science

The invention relates to a salt bath heat treatment method for tool and mould steel, in particular to a salt bath annealing method for the tool and mould steel. The method has the advantages that thequality and the performance of the annealed structure of materials can be improved. The method comprises the following steps that 1) high-temperature salt bath treatment is carried out, specifically,the tool and mould steel is put in a salt bath with the temperature of 840-920 DEG C for heat preservation so as to enable the temperature of the tool and mould steel to be uniform; 2) isothermal saltbath treatment is carried out, specifically, the tool and mould steel subjected to high-temperature salt bath treatment in the step 1) in put in a salt bath with the temperature of 710-780 DEG C forisothermal treatment; and 3) air cooling is carried out, specifically, air cooling is carried out on the tool and mould steel subjected to isothermal salt bath treatment in the step 2) to reach the room temperature so as to obtain the tool and mould steel with the uniform structure. The tool and mould steel prepared through the method has the advantages of being uniform in structure, uniform in grain size and good in machining performance and using performance.

Owner:SOUTHEAST UNIV +1

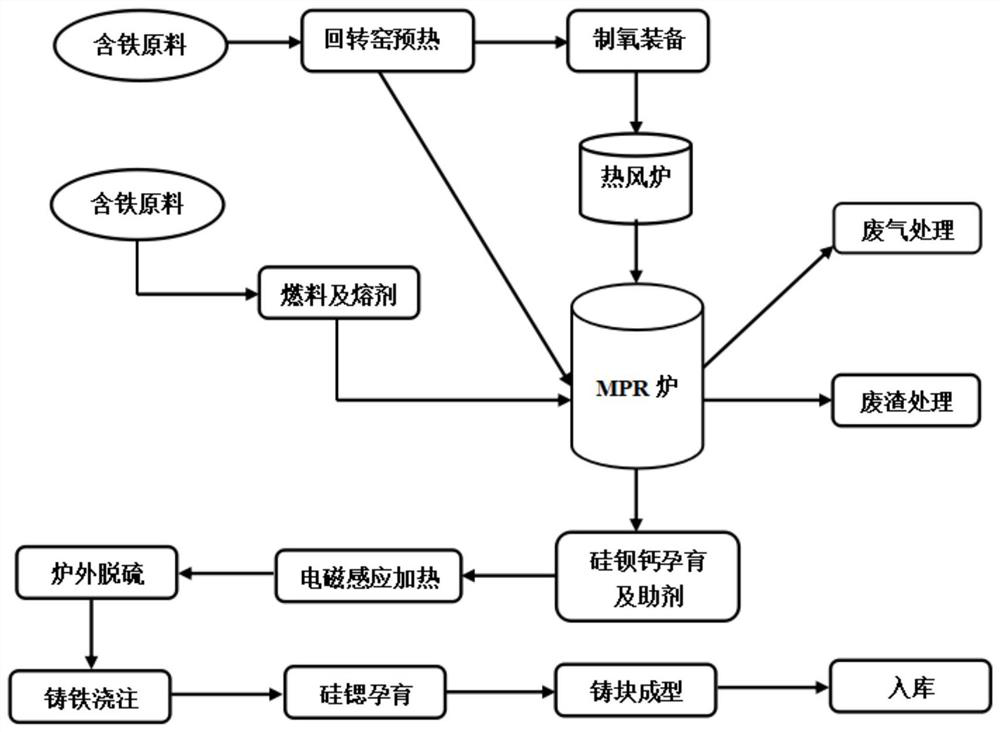

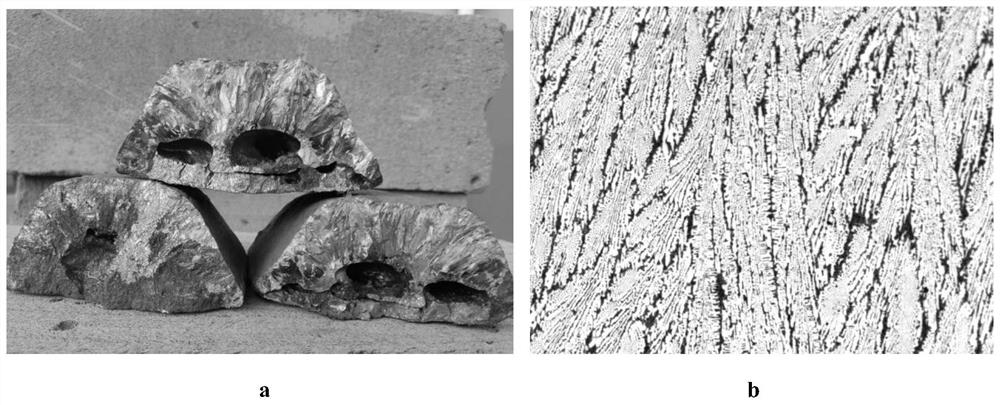

Method for eliminating white structure of high-purity pig iron for hydrogen-based smelting reduction casting and pig iron

ActiveCN113999948AIncrease graphite coreReduce gas contentIncreasing energy efficiencySiliconMaterials science

The invention discloses a method for eliminating a white structure of high-purity pig iron for hydrogen-based smelting reduction casting. The method comprises the characteristics of the high-purity pig iron for casting produced by a hydrogen-based smelting reduction non-blast furnace ironmaking process, and comprises primary inoculation of pig iron liquid, desulfurization, secondary inoculation and external refining degassing (O, N, H) treatment. The high-purity pig iron for casting produced by the hydrogen-based smelting reduction process is low in silicon, phosphorus and titanium, the primary inoculation treatment comprises the step of adding a silicon-barium-calcium inoculant and an auxiliary agent into molten iron, and the secondary inoculation treatment comprises the step of adding a strontium-silicon inoculant into the molten iron to strengthen elements promoted to be graphitized in the molten iron, so that the graphitization capacity of the molten pig iron is enhanced, carbon atoms are separated out, and a white structure generated by carbon and iron compounds formed in the solidification and crystallization process is avoided. By means of the technical scheme, the problem of the high-purity pig iron white structure for casting produced through an existing hydrogen-based smelting reduction process is solved.

Owner:内蒙古赛思普科技有限公司

Asphaltene dispersant, application thereof and method for inhibiting deposition of asphaltene in heavy oil and removing asphaltene deposits in heavy oil

The invention relates to the field of crude oil exploitation, and discloses an asphaltene dispersant, application thereof, and a method for inhibiting deposition of asphaltene in heavy oil and removing asphaltene deposits in the heavy oil. The asphaltene dispersant comprises a biomass phenol compound, oil-soluble resin and a solvent, wherein the biomass phenol compound is cardanol and / or cashew nut shell oil. The asphaltene dispersant provided by the invention can effectively control the deposition of asphaltene in a heavy oil production process, and can effectively remove the existing asphaltene deposits, thereby ensuring the normal production of a heavy oil well.

Owner:CHINA PETROLEUM & CHEM CORP +1

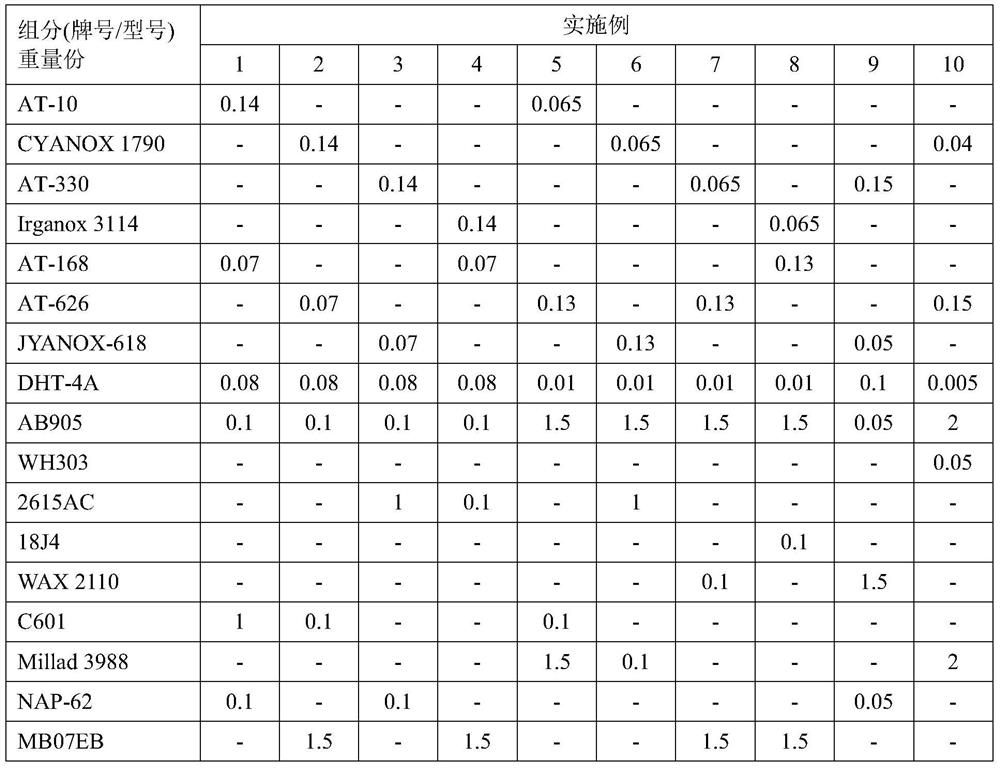

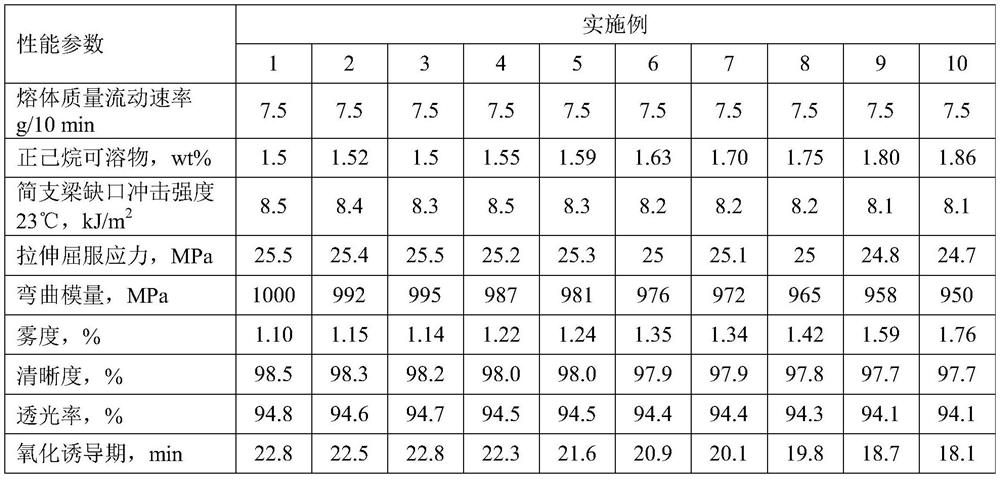

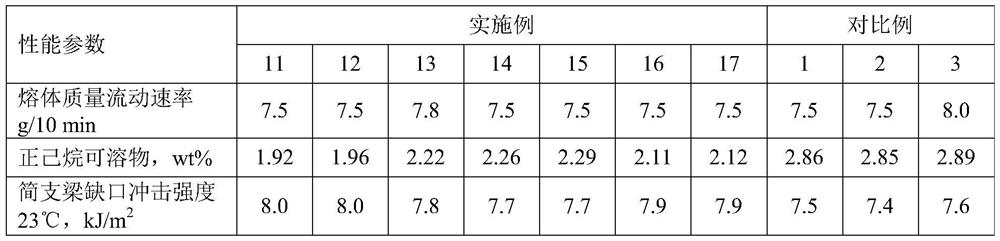

Polypropylene resin composition, special material for aluminum-plated casting polypropylene film, aluminum-plated casting polypropylene film as well as preparation method and application of aluminum-plated casting polypropylene film

The invention relates to the field of polypropylene casting packaging films, and discloses a polypropylene resin composition, a special material for an aluminum-plated casting polypropylene film, the aluminum-plated casting polypropylene film as well as a preparation method and application of the aluminum-plated casting polypropylene film. The polypropylene resin composition comprises an ethylene-propylene random copolymer and a compound auxiliary agent, wherein the compound auxiliary agent comprises a main antioxidant, an auxiliary antioxidant, a halogen absorbent, an anti-sticking agent, a reinforcing agent and a blocking agent. The corona attenuation retention and the aluminizing adhesive force of the aluminizing casting polypropylene film prepared from the composition are obviously improved, and the aluminizing casting polypropylene film is good in transparency and good in mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

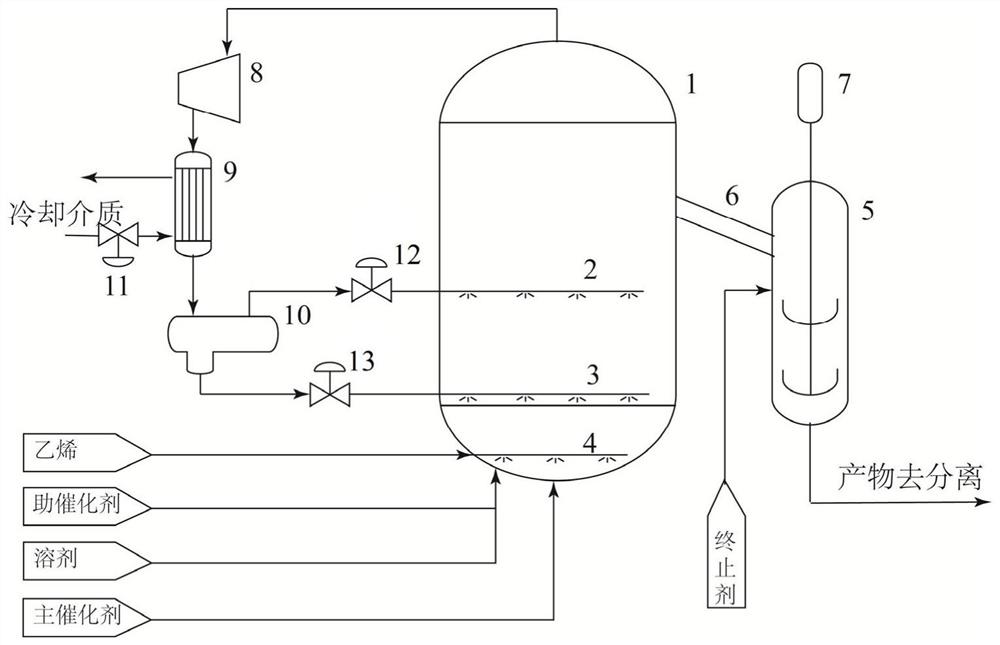

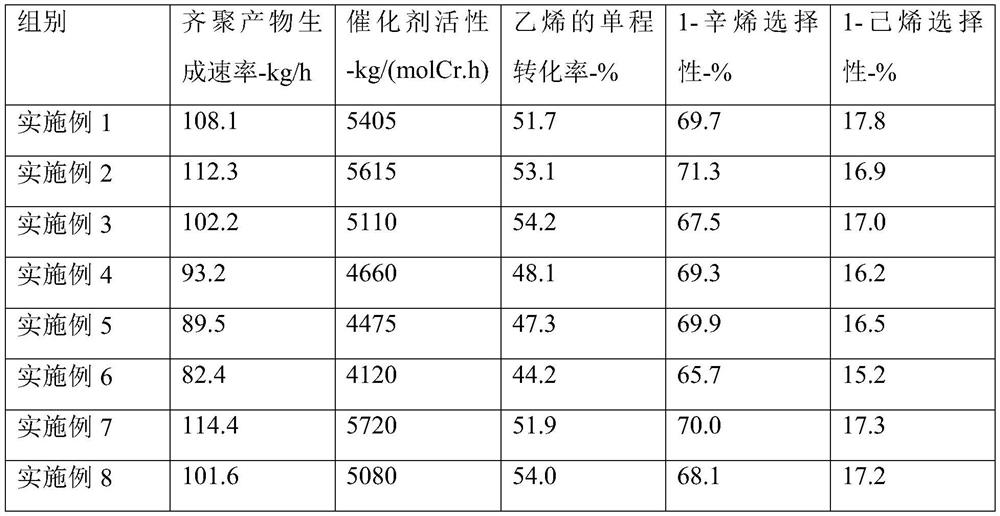

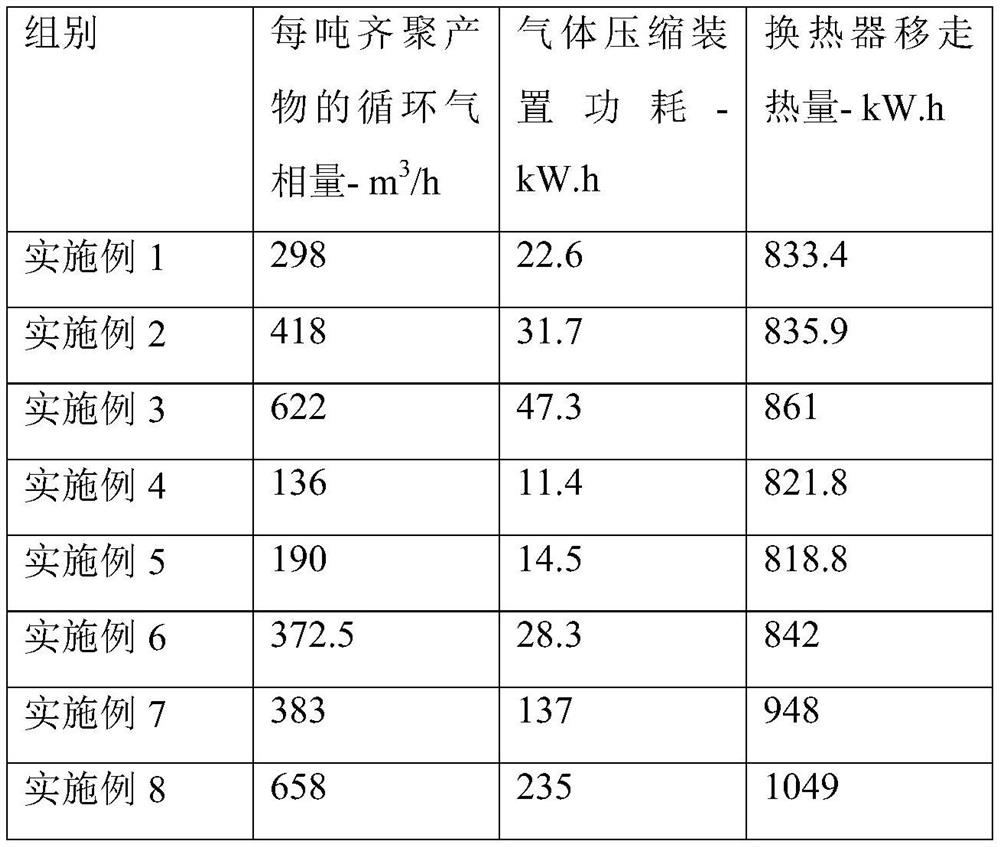

Device and process for producing 1-octylene by ethylene selective oligomerization

PendingCN114210287AAchieve cycleLarge heat transfer temperature differenceCatalystsHydrocarbon preparation catalystsChemical industryOligomer

The invention provides a device and a process for producing 1-octylene by ethylene selective oligomerization, and relates to the field of chemical industry. The device comprises an oligomerization reactor, the circulation pipeline is led out from the top of the oligomerization reactor and returns to the oligomerization reactor, a gas compression device, a heat exchanger and a gas-liquid separator are sequentially arranged on the circulation pipeline, the gas compression device is connected with the top of the oligomerization reactor, and a gas phase outlet and a liquid phase outlet of the gas-liquid separator are respectively communicated with the inside of the oligomerization reactor. A solvent used in the process can comprise a low-boiling-point component and a high-boiling-point component, the low-boiling-point component is selected from C3-C5 hydrocarbons, and the high-boiling-point component is selected from C6-C10 hydrocarbons. According to the device and the process, reaction heat can be effectively and stably removed, precipitation of polyethylene and oligomer generated in the reaction on a heat exchange wall surface is reduced, the cost of a cooling medium is reduced, meanwhile, the reaction temperature is stably controlled, and the reaction efficiency and selectivity are improved.

Owner:浙江智英石化技术有限公司

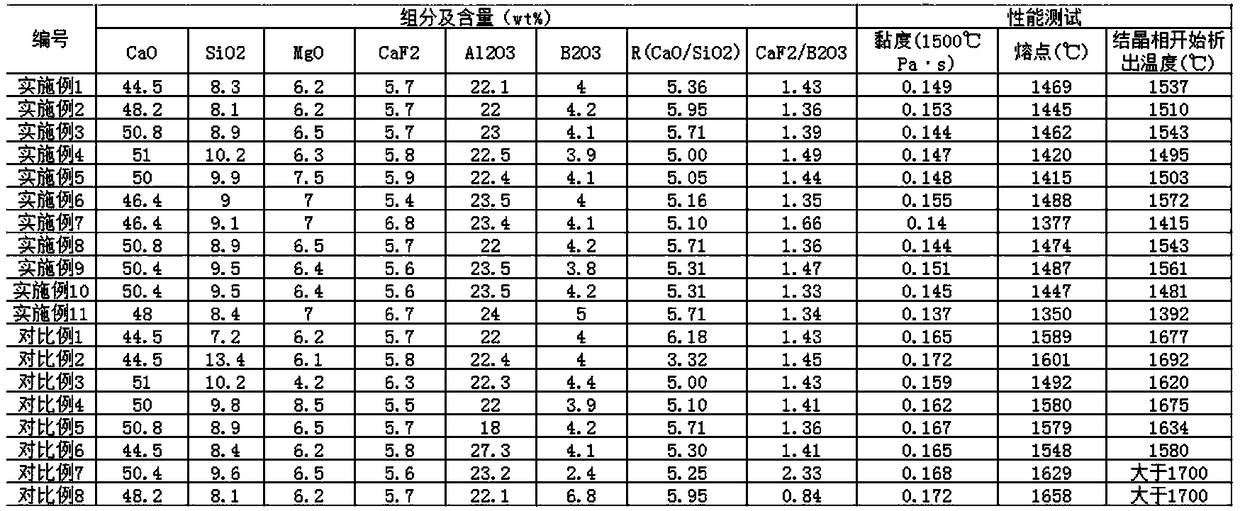

High-performance LF refining slag

The invention provides high-performance LF refining slag. The high-performance LF refining slag comprises following components including 44%-51% of CaO, 8%-12% of SiO2, 6%-8% of MgO, 5%-7% of CaF2, 22%-25% of Al2O3 and 3%-5% of B2O3, and binary basicity R(CaO / SiO2) is 5-6. The obtained LF refining slag has proper viscosity and a proper melting point, separation of a high-melting-point mine phase is well controlled while the phenomenon of refining slag crusting cannot happen in the refining process, and the number of inclusions in steel is effectively reduced.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

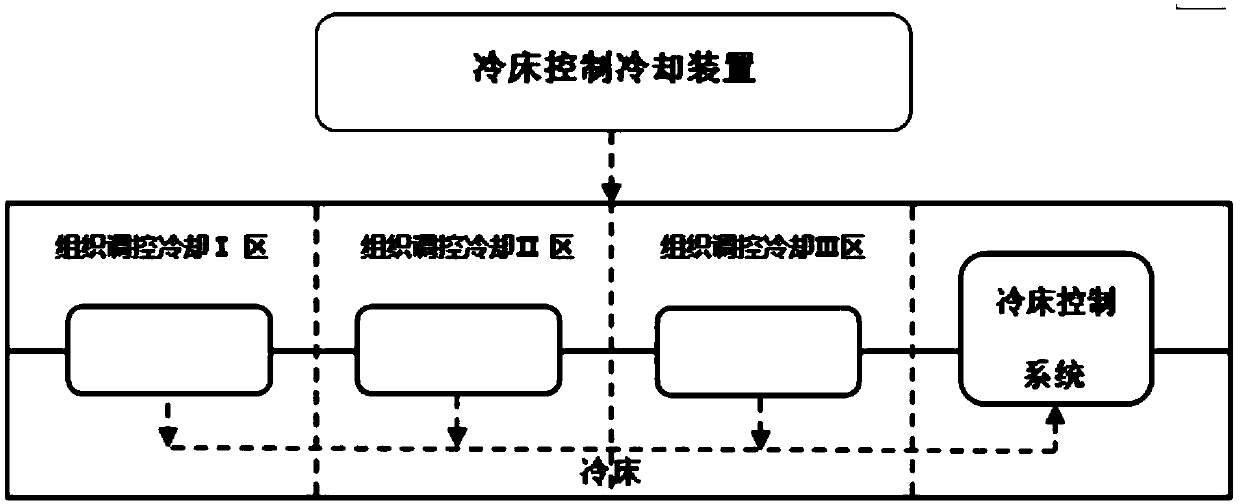

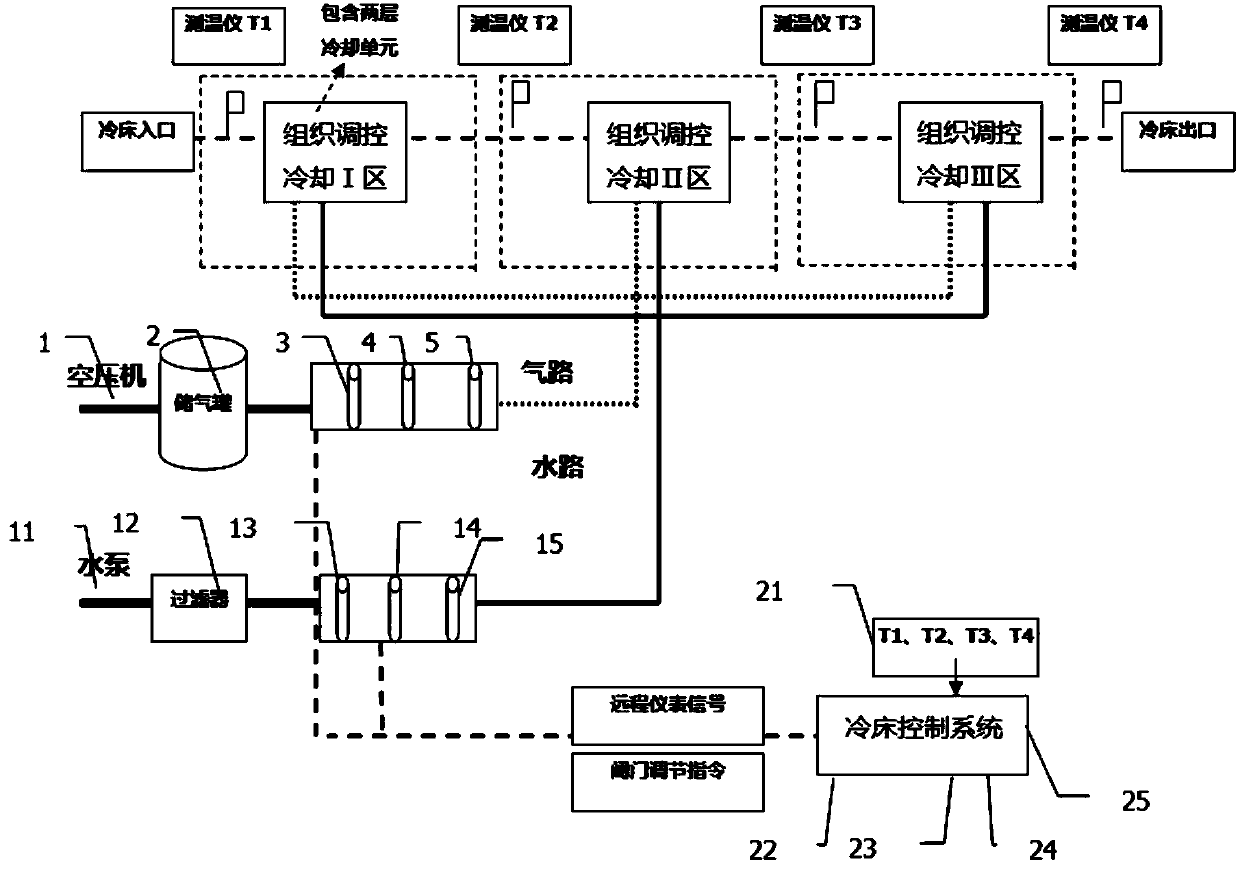

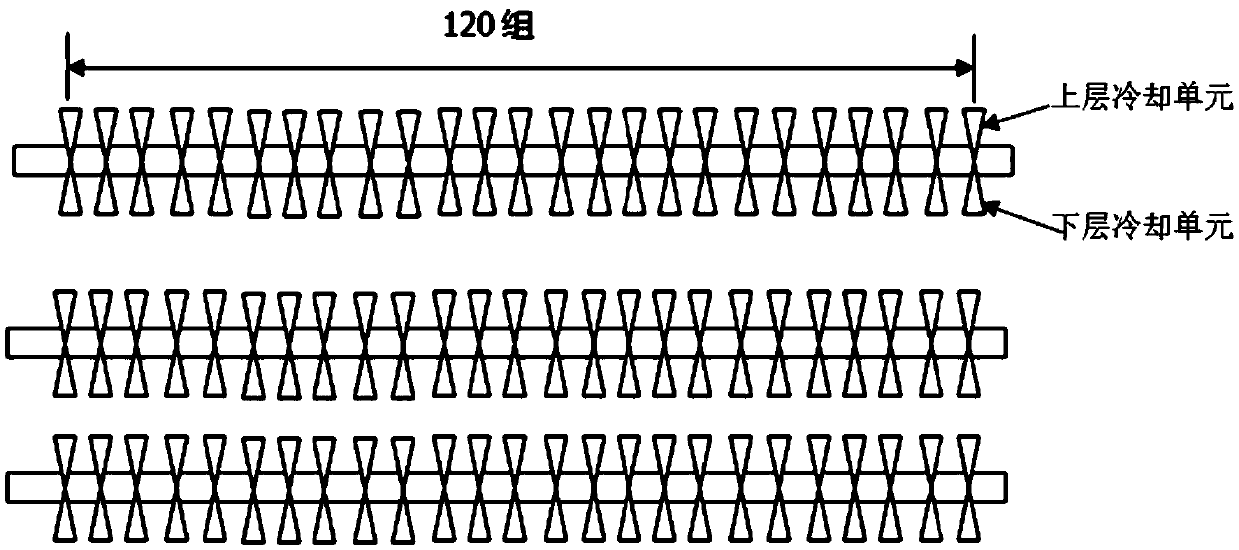

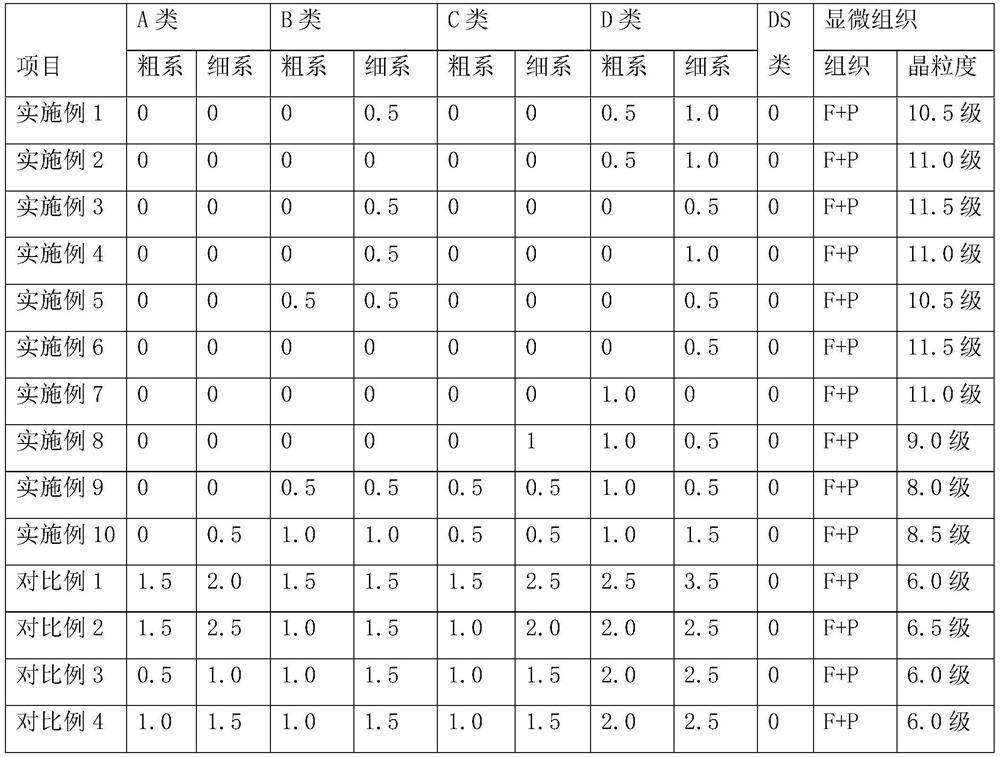

Cooling bed controlled cooling device for hot-rolled micro-alloyed steel bars

PendingCN109675941AControl precipitationControl growthTemperature control deviceCooling bedsAlloy elementRebar

The invention discloses a cooling bed controlled cooling device for hot-rolled micro-alloyed steel bars, and belongs to the technical field of hot-rolled micro-alloyed steel bar equipment. Three cooling sections and a cooling bed control system are included. The three cooling sections are an organization regulation and control cooling area I, an organization regulation and control cooling area IIand an organization regulation and control cooling area III, the length of each section of organization regulation and control cooling area is 100-120 m, and the length of a whole cooling bed is covered. The cooling bed controlled cooling device has the advantages that through segmented arrangement, the cooling path is optimized, a process window is provided for control over precipitation of micro-alloy elements in the cooling process and refining of pearlite sheet interlamellar spacing is provided, and accordingly the refined controlled cooling technology is achieved.

Owner:CENT IRON & STEEL RES INST

Aluminum-containing low-carbon steel and preparation process

InactiveCN113981302AEfficient removalImprove purityManufacturing convertersProcess efficiency improvementSteelmakingAlloy

The invention discloses aluminum-containing low-carbon steel and a preparation process, and belongs to the technical field of steel smelting, the preparation process is as follows: converter primary smelting: (11) after scrap steel is added into molten iron, top-bottom combined blowing is adopted for blowing, a slagging material is added during blowing, the basicity of slag is controlled to be 2.8-3.8, and blowing continues; (12) tapping is performed; refining: (21) after the molten steel enters a CAS furnace, argon blowing, temperature measurement, sampling and analysis are carried out; (22) component adjustment, alloy addition, argon blowing, temperature measurement and sampling are performed according to an analysis result; (23) tapping is performed; and continuous casting: the temperature of a crane ladle is 1595-1605 DEG C, the temperature of a tundish is 1547-1567 DEG C, pouring is performed at a constant pulling speed, and the pulling speed of a casting blank is 0.9-1.25 m / min. According to the preparation process, the purity of the molten steel can be improved, and inclusions in the molten steel are reduced.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

Thermomechanical treatment strengthening process of cu-ni-be alloy

The invention discloses a Cu-Ni-Be alloy thermomechanical treatment strengthening process: heating the Cu-Ni-Be alloy ingot to 960-980°C, keeping it warm for 60-180min; then performing 30-60% hot extrusion forming, The speed of hot extrusion is 0.05~1m / s, and then water cooling. After hot extrusion, the water temperature of the ingot entering the billet is not less than 950°C, and the cooling water temperature of the circulating water is not more than 30°C; finally, the aging treatment is carried out at 470°C×3h, and then air-cooled. The advantages of the present invention are: according to the strengthening basic principle of Cu-Ni-Be alloy products, an integrated treatment process of heating, hot extrusion or hot pressing, water cooling and aging is designed, which promotes the further precipitation of alloy aging precipitation phases, and the precipitation phases The alloy is more fine, uniform and dispersed, and has good comprehensive performance; the invention strengthens the process, simplifies the process steps, saves costs, and at the same time enables the alloy to obtain good comprehensive performance.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com