Patents

Literature

94results about "Forging/pressing devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

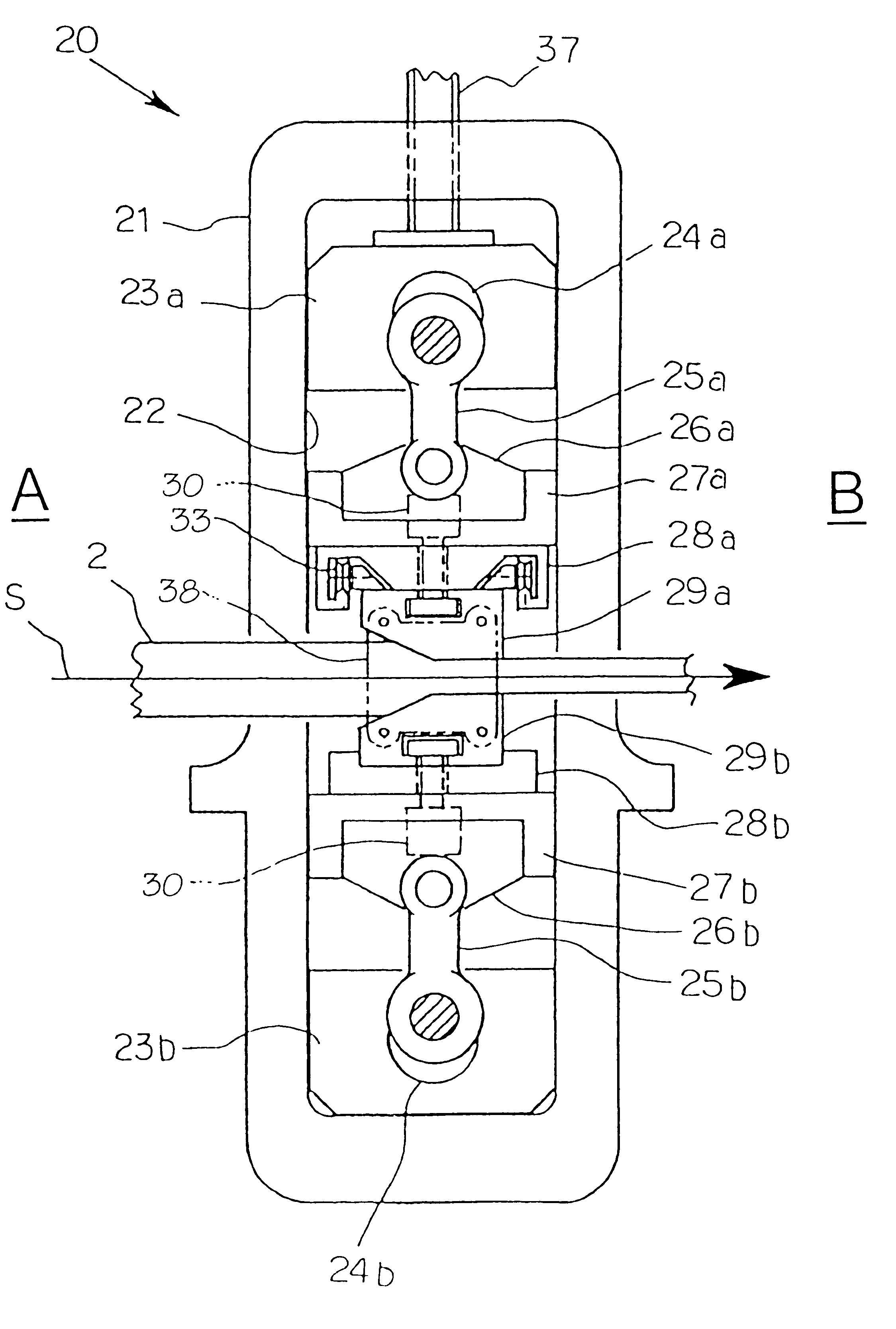

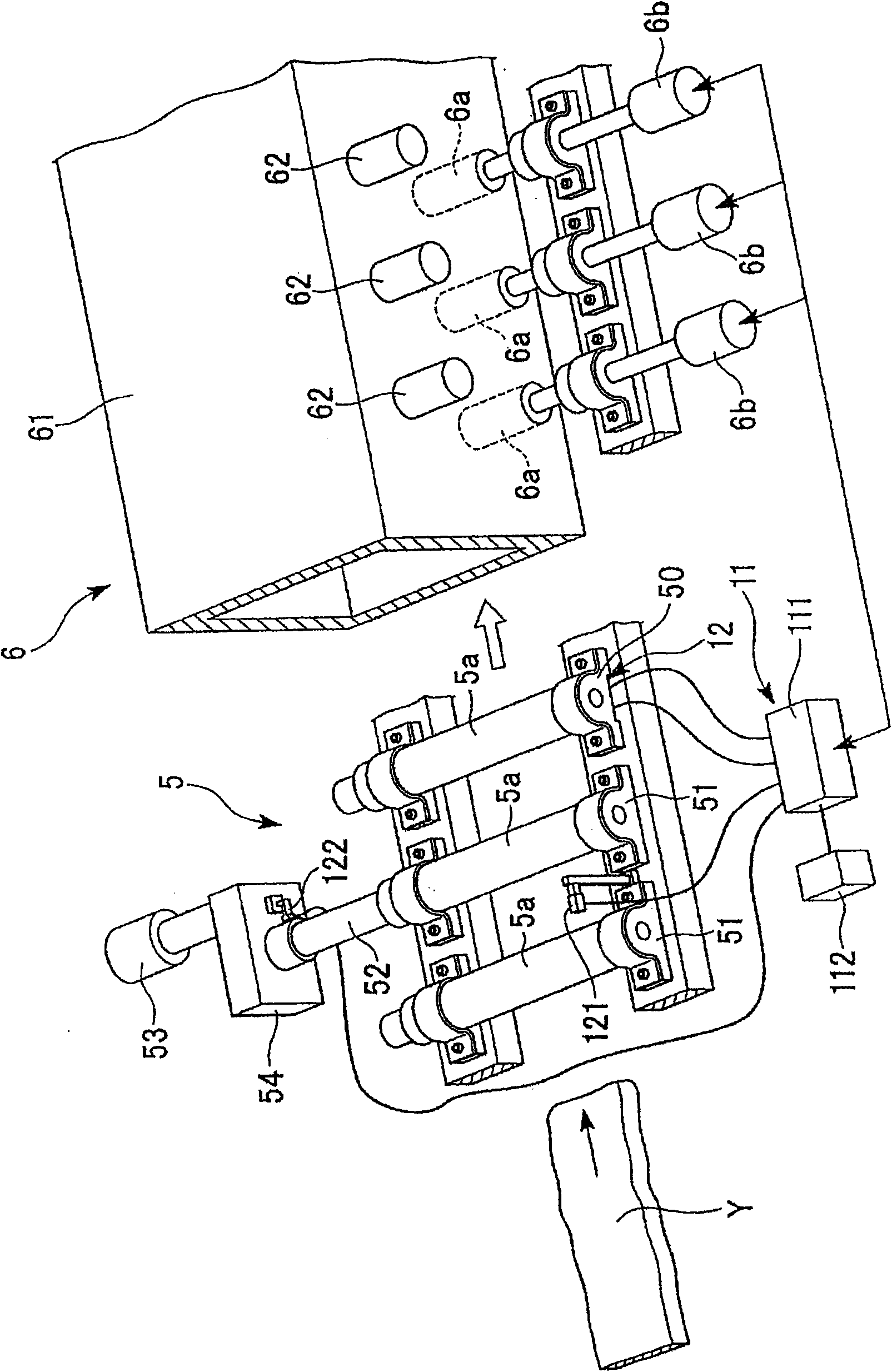

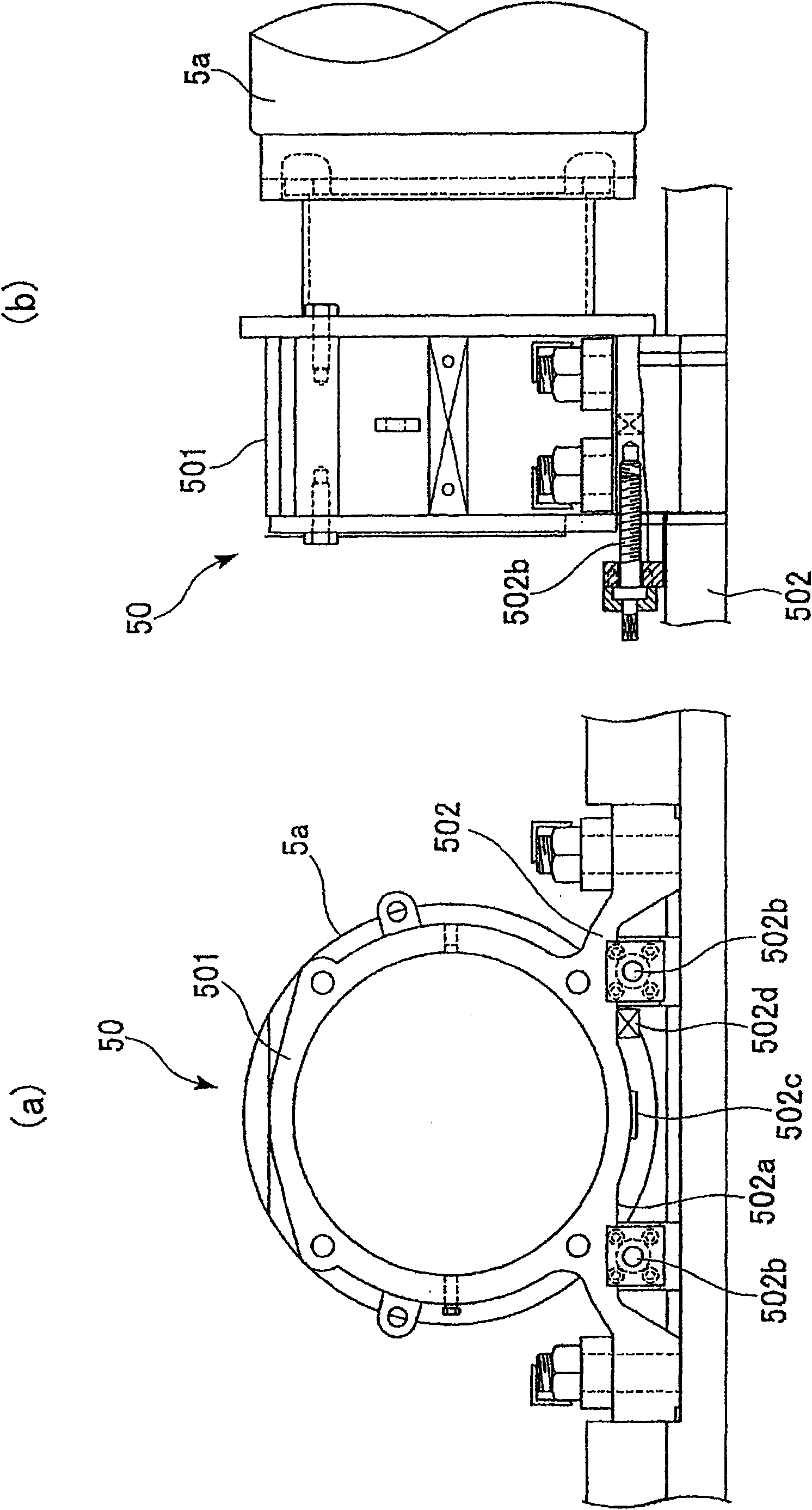

Apparatus and method for changing dies

The die changing apparatus for a plate reduction press machine, comprises an upper die support holder 28a and a lower die support holder 28b that are arranged vertically on opposite sides of a transfer line, and support holder guide rails 31 installed on the upper die support holder and extending substantially horizontally in the lateral direction of the transfer line, and an upper die 29a and a lower die 29b are mounted on the upper and lower die support holders, respectively using the rollers onto the dies, fixing devices 30 that fix the upper and lower dies on the upper and lower die support holders, respectively, die fastening members 38 which are placed on each side of the upper and lower dies, opposite each other in such a manner that they can be fastened to both dies, and a die changing mechanism that can move one of the die fastening members in a direction perpendicular to the transfer line.

Owner:JFE STEEL CORP +2

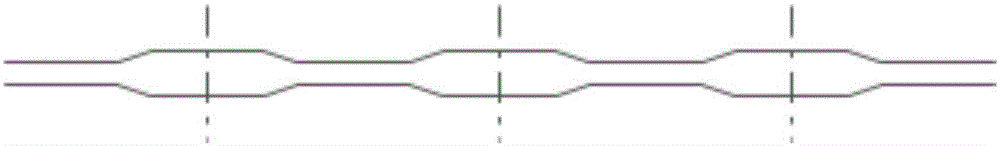

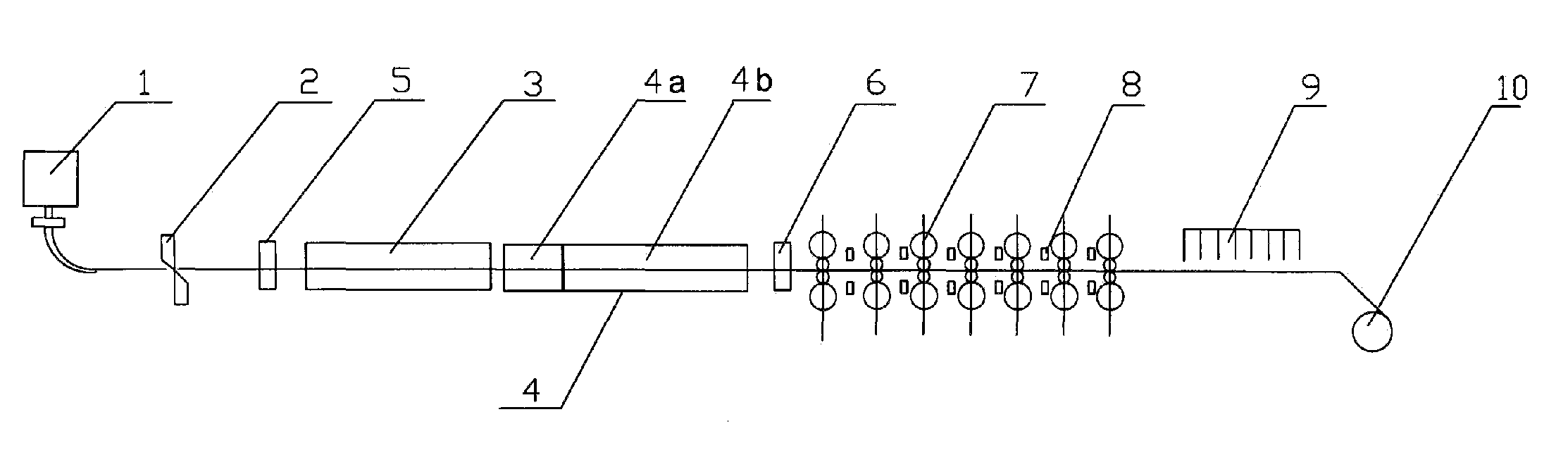

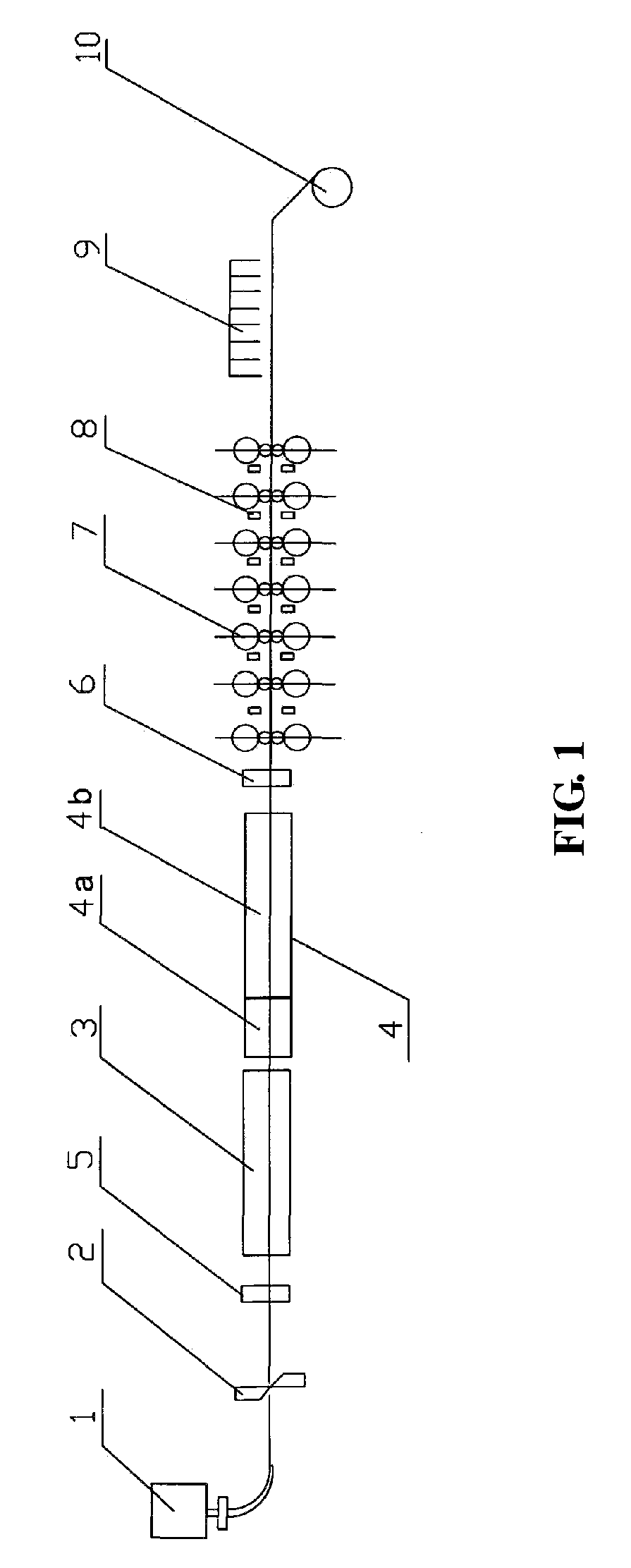

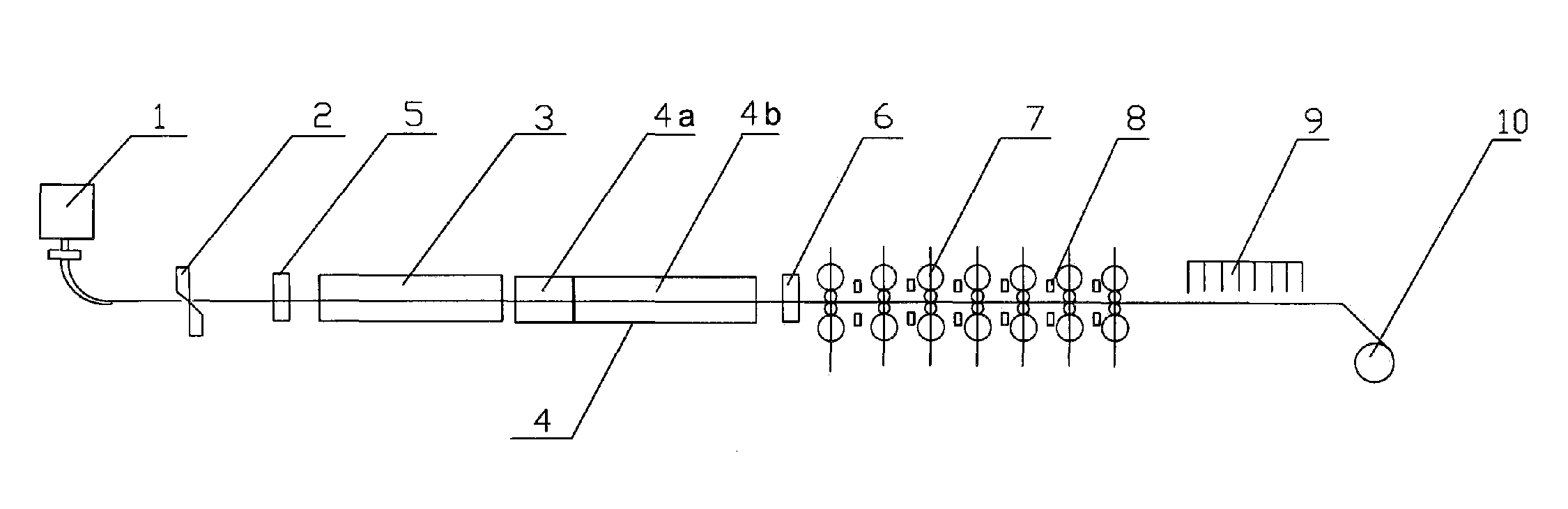

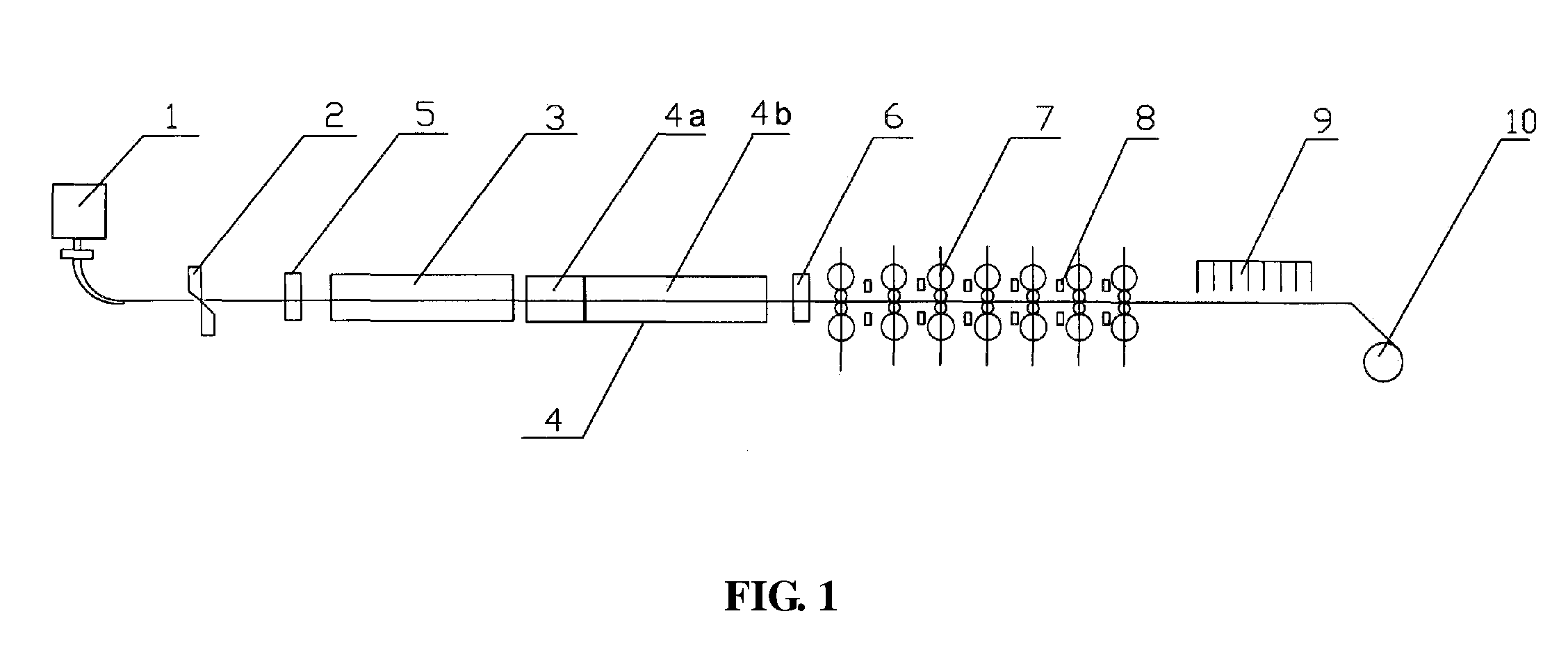

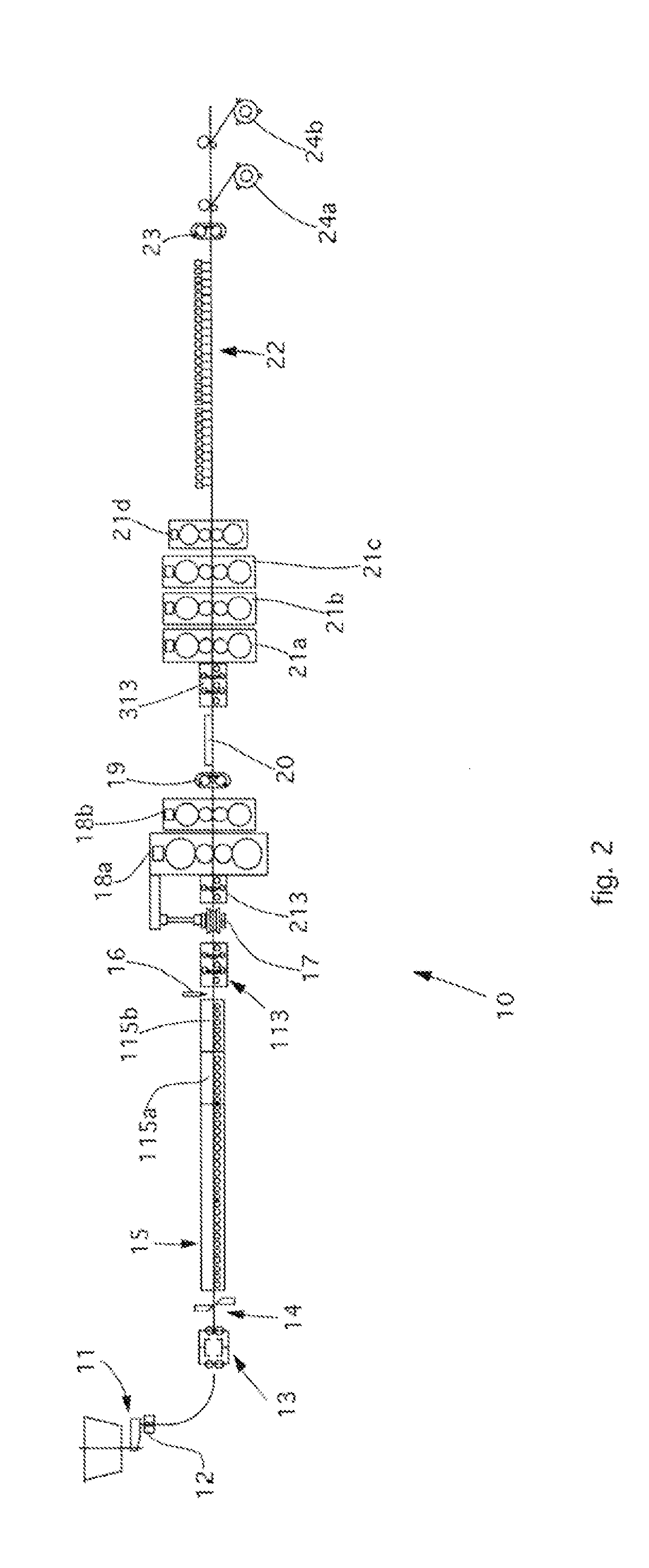

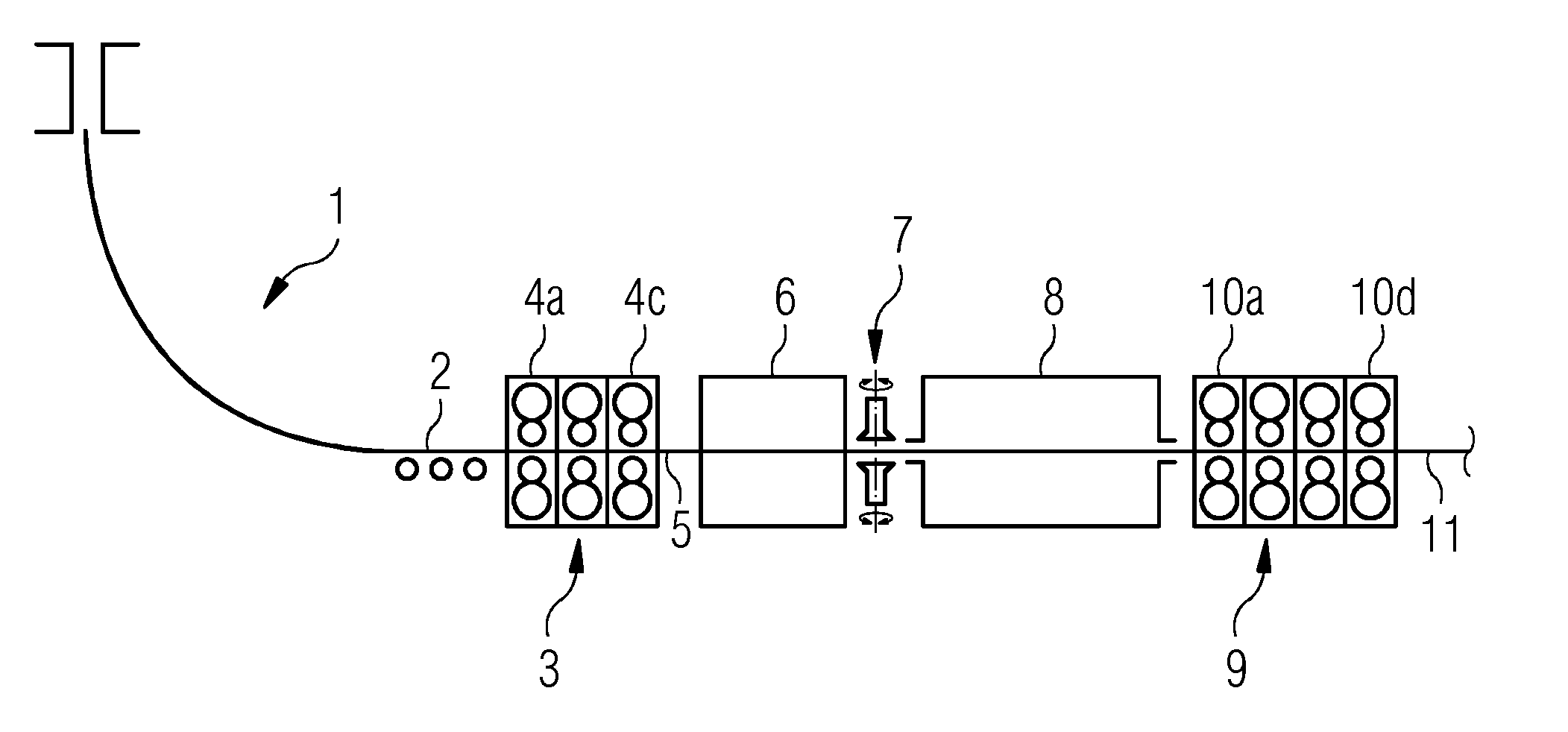

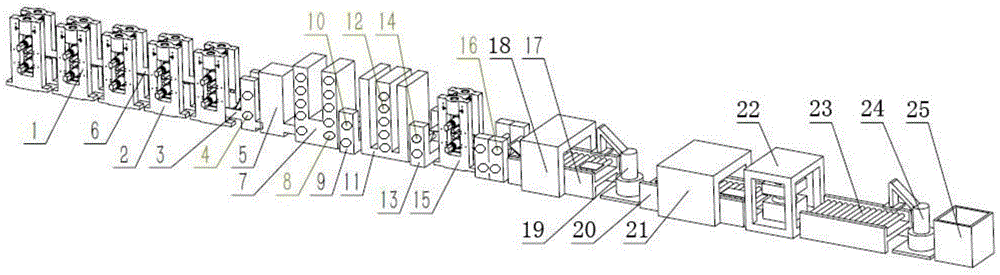

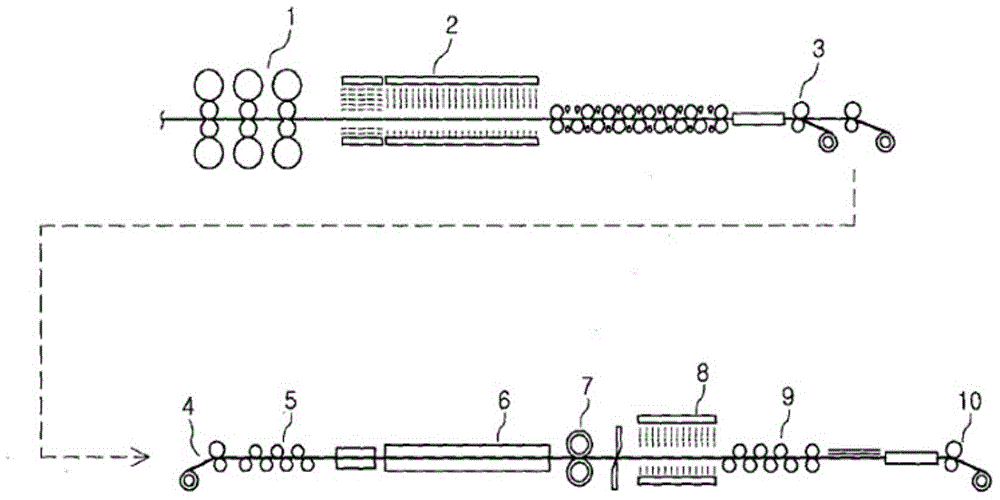

Continuous production method and line for variable-thickness profile

ActiveCN106623421ARealize continuous productionThickening rollingForging/pressing devicesMeasuring devicesVariable thicknessMaterials science

The invention discloses a continuous production method and line for a variable-thickness profile. Hot-rolled and pickled or cold-rolled equal-thickness strip steel is used as a raw material, all processes from rolling to surface coating to forming and cutting and the like of the strip steel are completed on line, production processes such as uncoiling, welding, variable-thickness rolling, degreasing, on-line heat treatment, online coating, flattening, roll-in forming, cutting and stacking are integrated, and the continuous production method is used for the fully-continuous automatic production of the variable-thickness profile. By using the continuous production method disclosed by the invention, the continuous production and coating of the variable-thickness profile can be realized, the defects of high production cost, high labor intensity, continuous production incapability and surface coating incapability of the existing variable-thickness profile are overcome, the production efficiency of the variable-thickness profile is greatly increased, and the favorable economic benefit is obtained. By using the continuous production method, a single or partially continuous production process in the prior art can be replaced, the production process of the variable-thickness profile can be simplified, and the continuous production of the variable-thickness profile can be realized.

Owner:上海宝钢型钢有限公司 +1

Method and system for producing wide steel strip

ActiveUS7942191B2Low costFlexible processForging/pressing devicesMetal rolling stand detailsMetallurgyNitrogen

A method for producing a wide steel strip using thin slab continuous casting and rolling by the following steps a) casting a molten steel into a thin slab having a thickness of between 50 and 90 mm; b) cutting; c) soaking; d) heating by electromagnetic induction; e) descaling; f) rolling; g) cooling with laminar flow; and h) coiling. The method can effectively control the solution and precipitation of carbon, nitrogen, and sulfide in steel with a low cost. The process is easy and flexible, and steel can be produced in a wide range of categories. Further provided is a system for producing a wide steel strip with thin slab continuous casting and rolling.

Owner:武钢集团有限公司

Method and system for producing wide steel strip

ActiveUS20100218911A1Low costEffectively control solutionForging/pressing devicesMetal rolling stand detailsThin slabNitrogen

A method for producing a wide steel strip using thin slab continuous casting and rolling by the following steps a) casting a molten steel into a thin slab having a thickness of between 50 and 90 mm; b) cutting; c) soaking; d) heating by electromagnetic induction; e) descaling; f) rolling; g) cooling with laminar flow; and h) coiling. The method can effectively control the solution and precipitation of carbon, nitrogen, and sulfide in steel with a low cost. The process is easy and flexible, and steel can be produced in a wide range of categories. Further provided is a system for producing a wide steel strip with thin slab continuous casting and rolling.

Owner:武钢集团有限公司

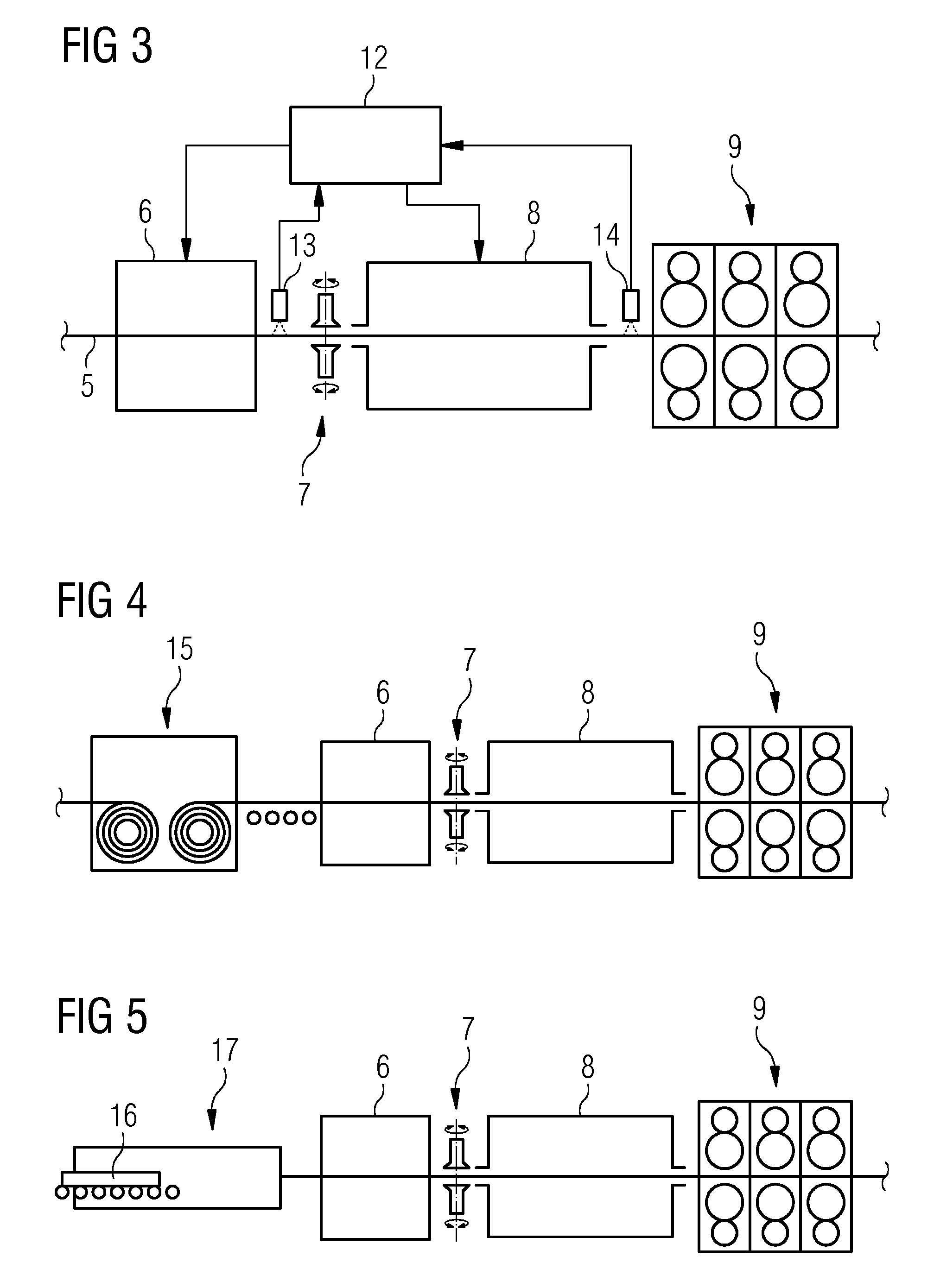

Method and plant for the production of flat rolled products

ActiveUS20110272116A1Reduce decreaseWithout losing productionForging/pressing devicesMetal rolling stand detailsProduction lineStrip mill

A rolling method in a rolling line, to obtain strip with a thickness varying from 0.7 mm to 20 mm, for steel which can be cast in the form of thin slabs with a thickness from 30 mm to 140 mm, the line includes a continuous casting device; a tunnel furnace for maintenance / equalization and possible heating; a rolling train having a roughing train and a finishing train; a rapid heating unit, with elements able to be selectively activated, interposed between the roughing train and the finishing train. For each lay-out of the rolling line, the position of the rapid heating unit which defines the number of stands which form the roughing train, disposed upstream of the unit, and the number of stands which form the finishing train, disposed downstream of the unit, is calculated as a function of the product of the thickness and speed of the thin slab.

Owner:DANIELI & C OFF MEC SPA

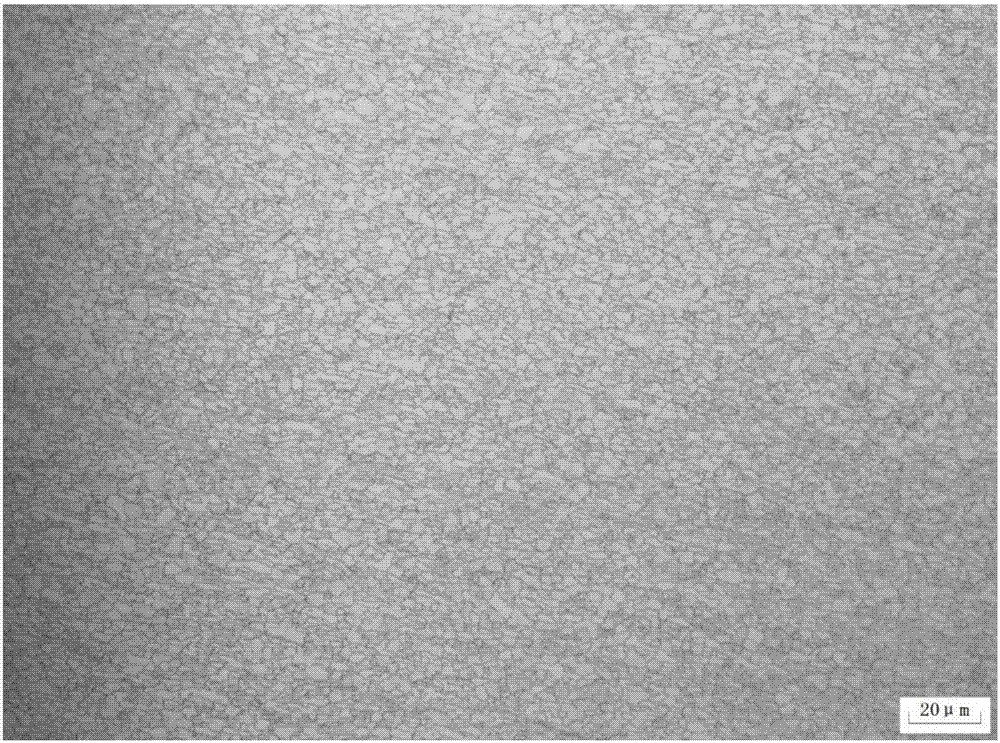

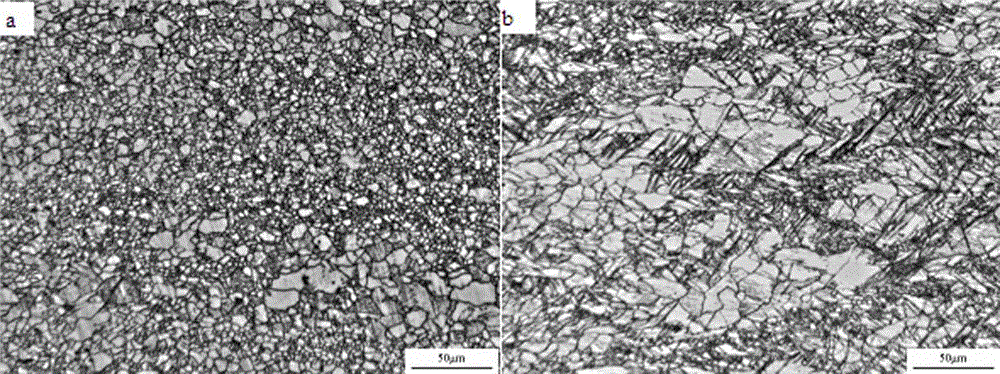

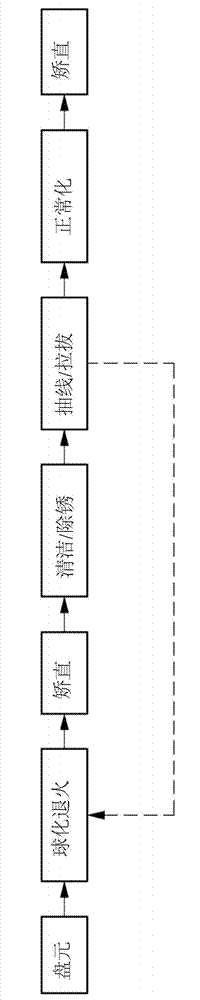

Processing method of SP700 titanium alloy sheet for superplastic forming

ActiveCN106955893AImprove consistencyImprove stabilityForging/pressing devicesMetal rolling arrangementsBeta phaseWater cooling

The invention belongs to the technical field of processing of titanium alloy materials, and relates to a processing method of an SP700 titanium alloy sheet for superplastic forming. The processing method comprises step I, carrying out heating number casting around a beta phase transformation point, and carrying out water cooling to obtain an intermediate billet; step II, carrying out first hot rolling, so as to obtain a first hot rolled plate blank; step III, carrying out second hot rolling, so as to obtain a second hot rolled plate blank; step IV, carrying out intermediate annealing treatment; step V, carrying out cold rolling, so as to obtain a hot rolled plate blank; and step VI, carrying out annealing treatment on a finished product, so as to obtain the SP700 titanium alloy sheet of which the thickness is 0.5 mm to 1.2 mm. According to the processing method, operation is simple, the technology is stable and controllable, and the prepared SP700 titanium alloy sheet is uniform in structure, fine in grains and good in performance consistency, and meets the relative technological requirement of superplastic forming.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

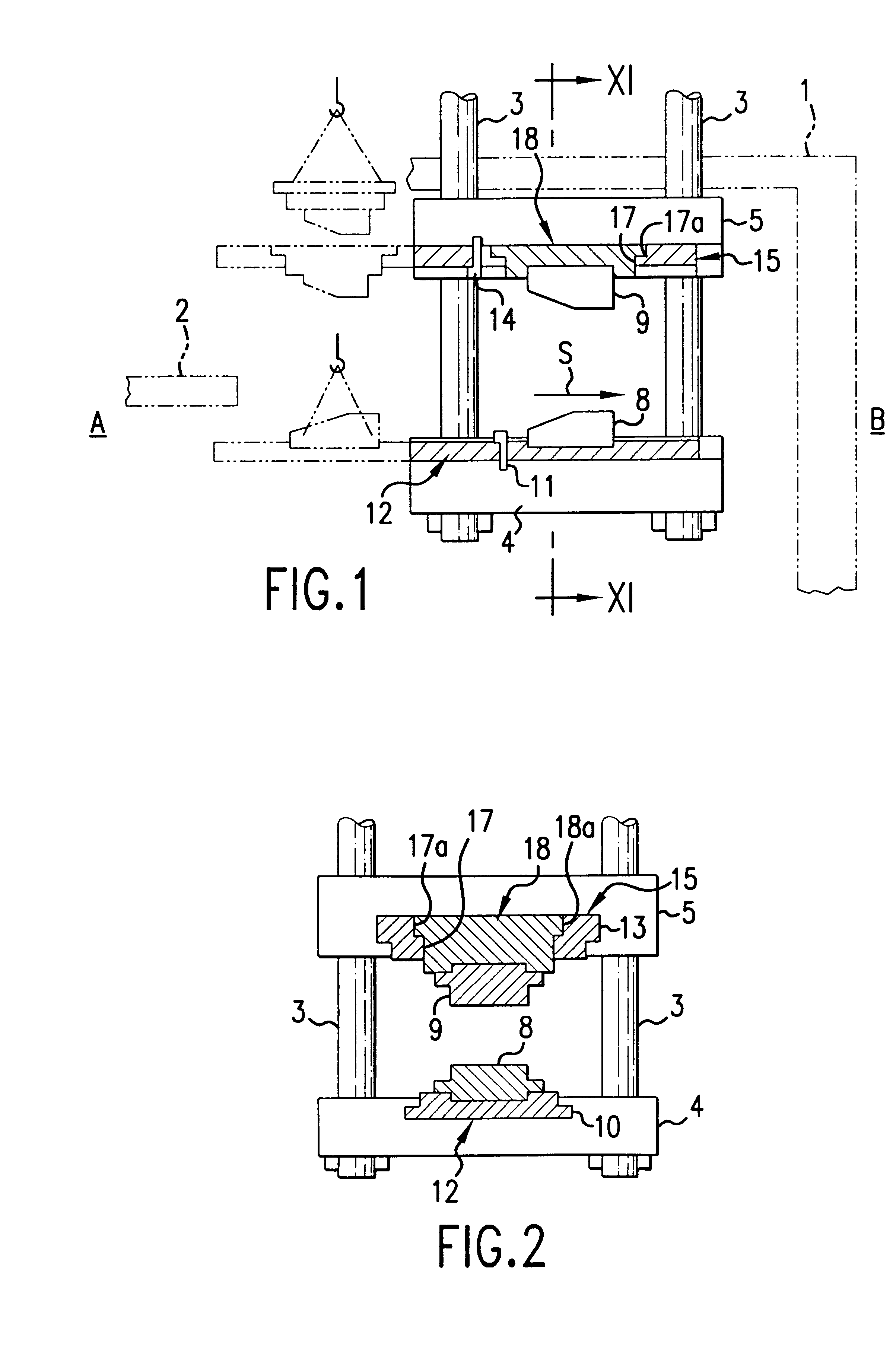

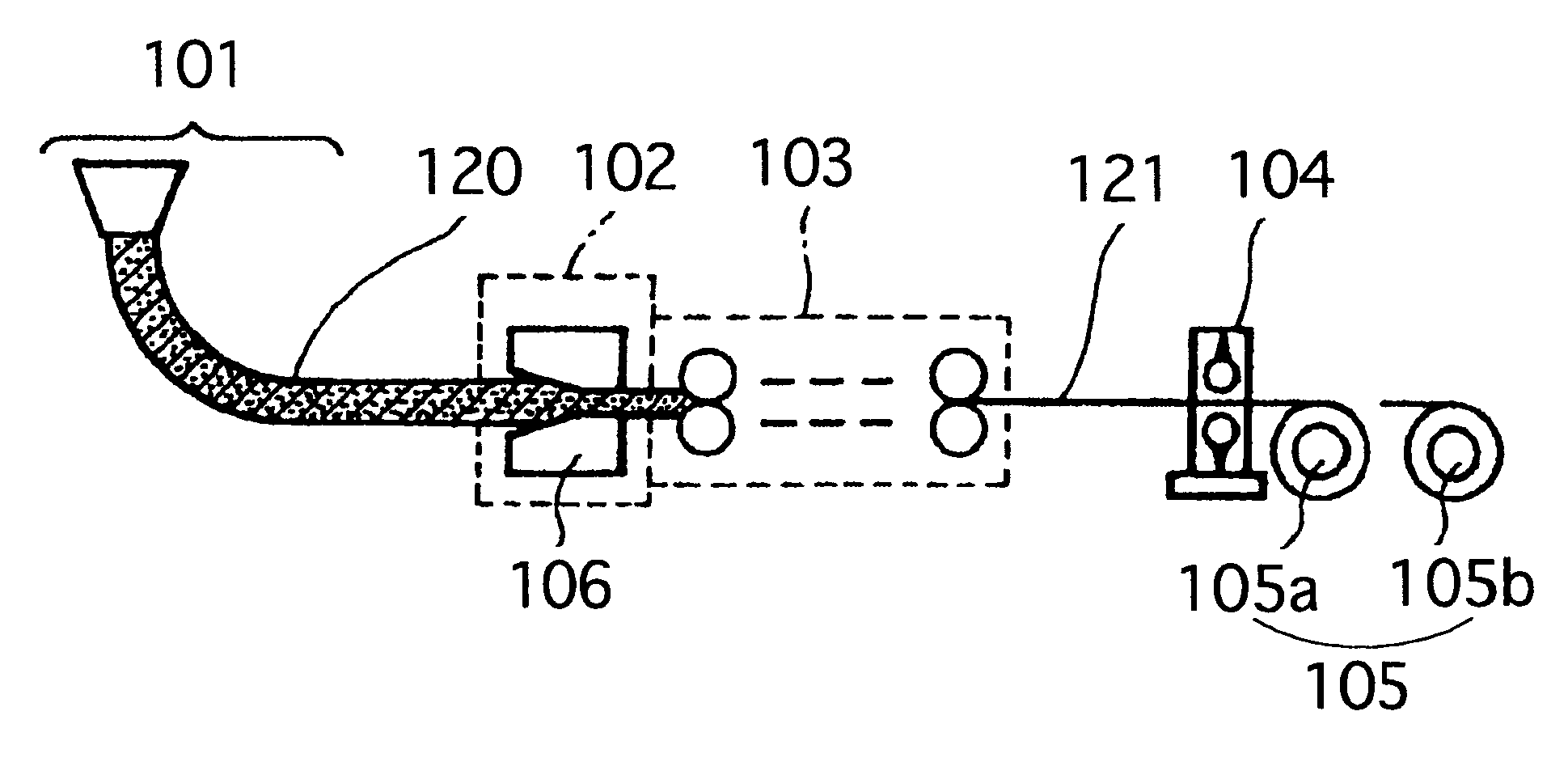

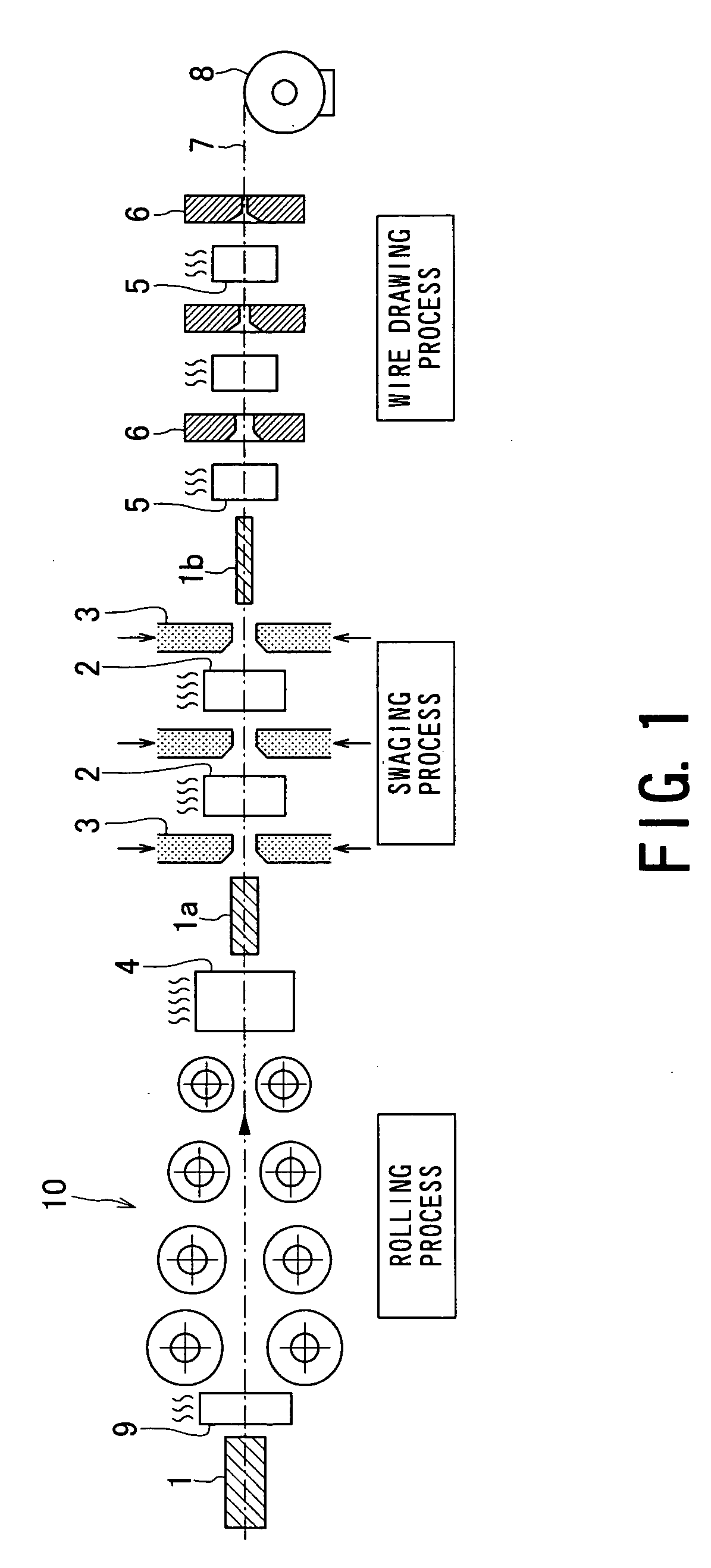

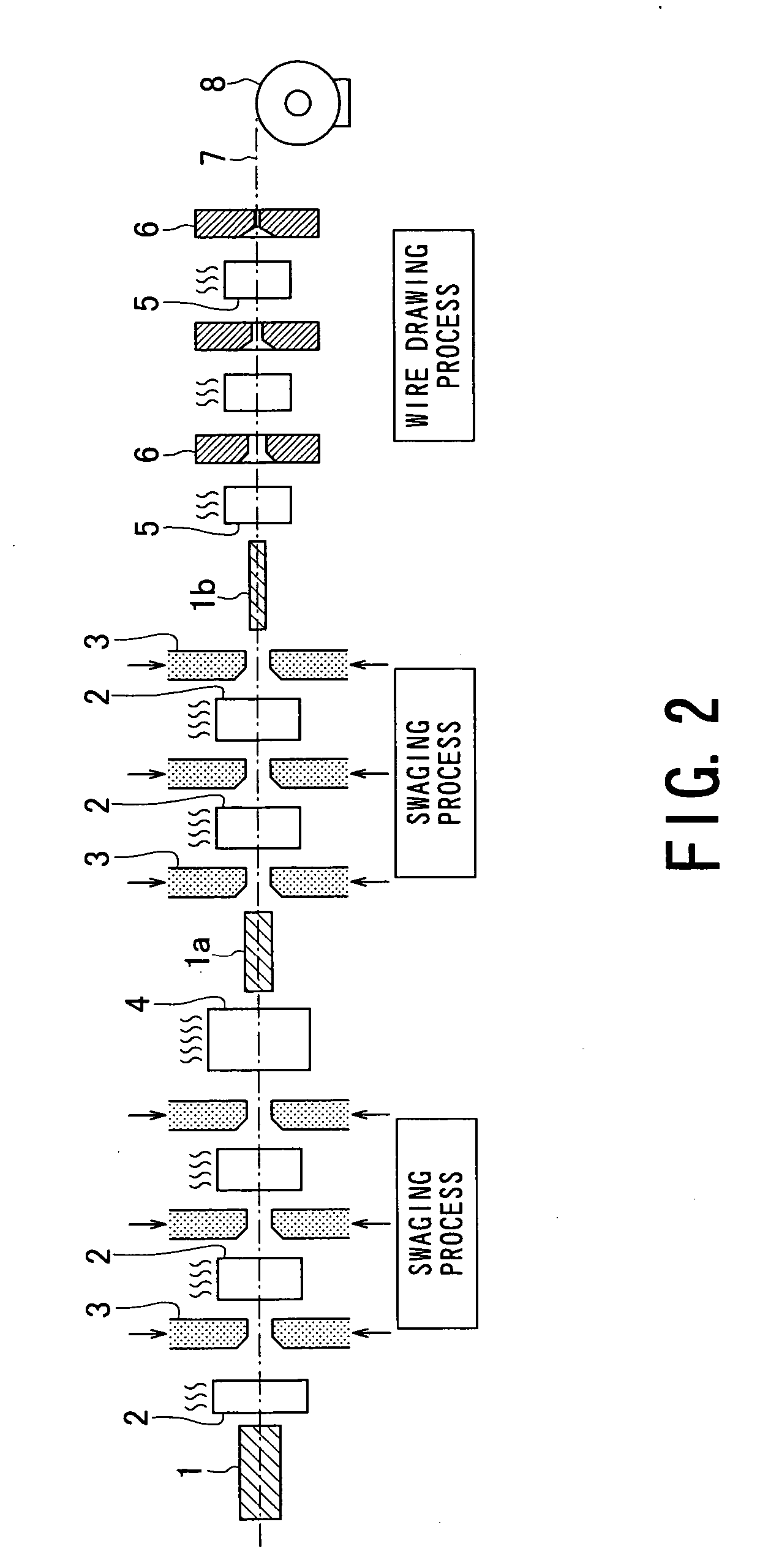

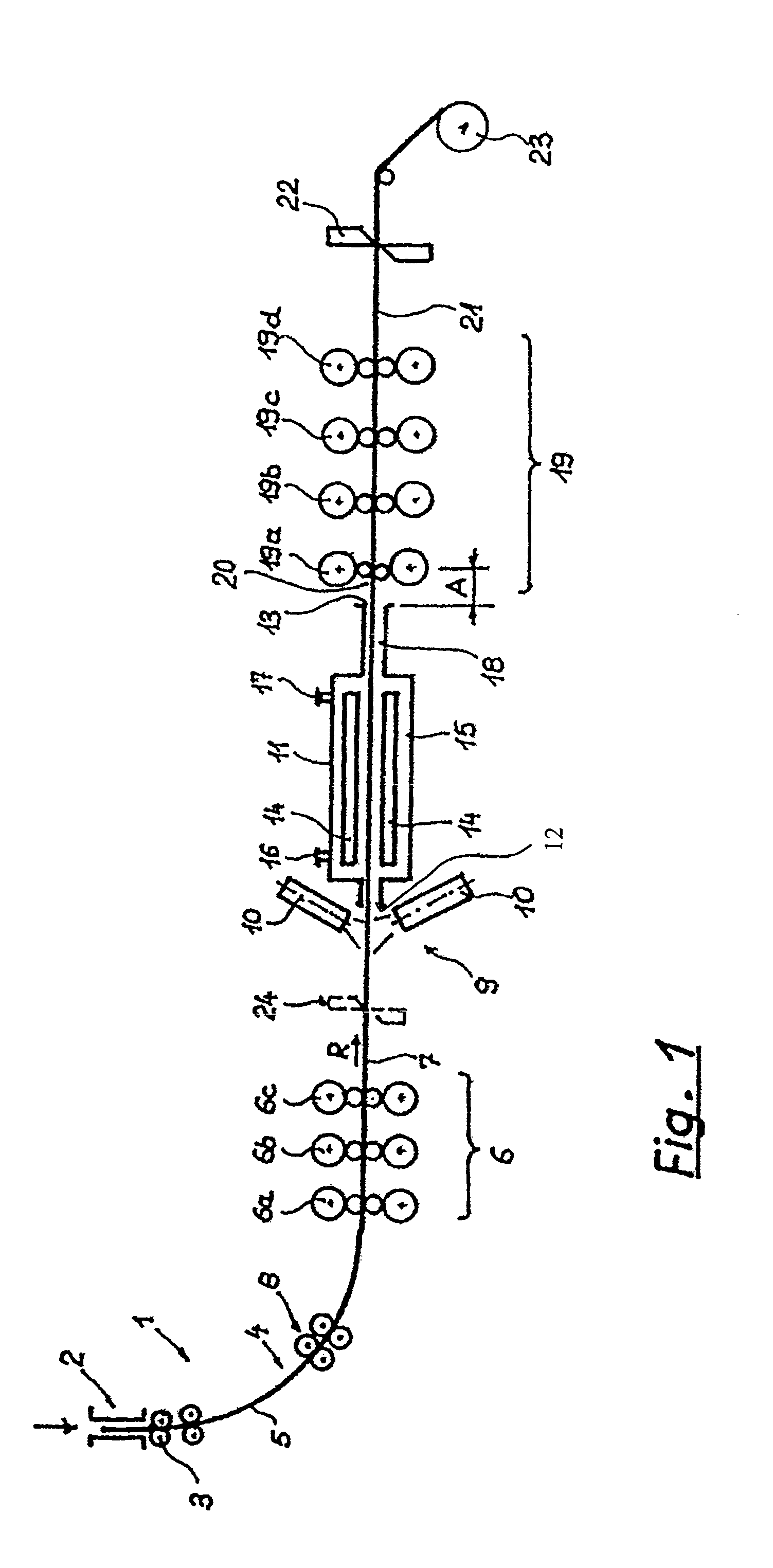

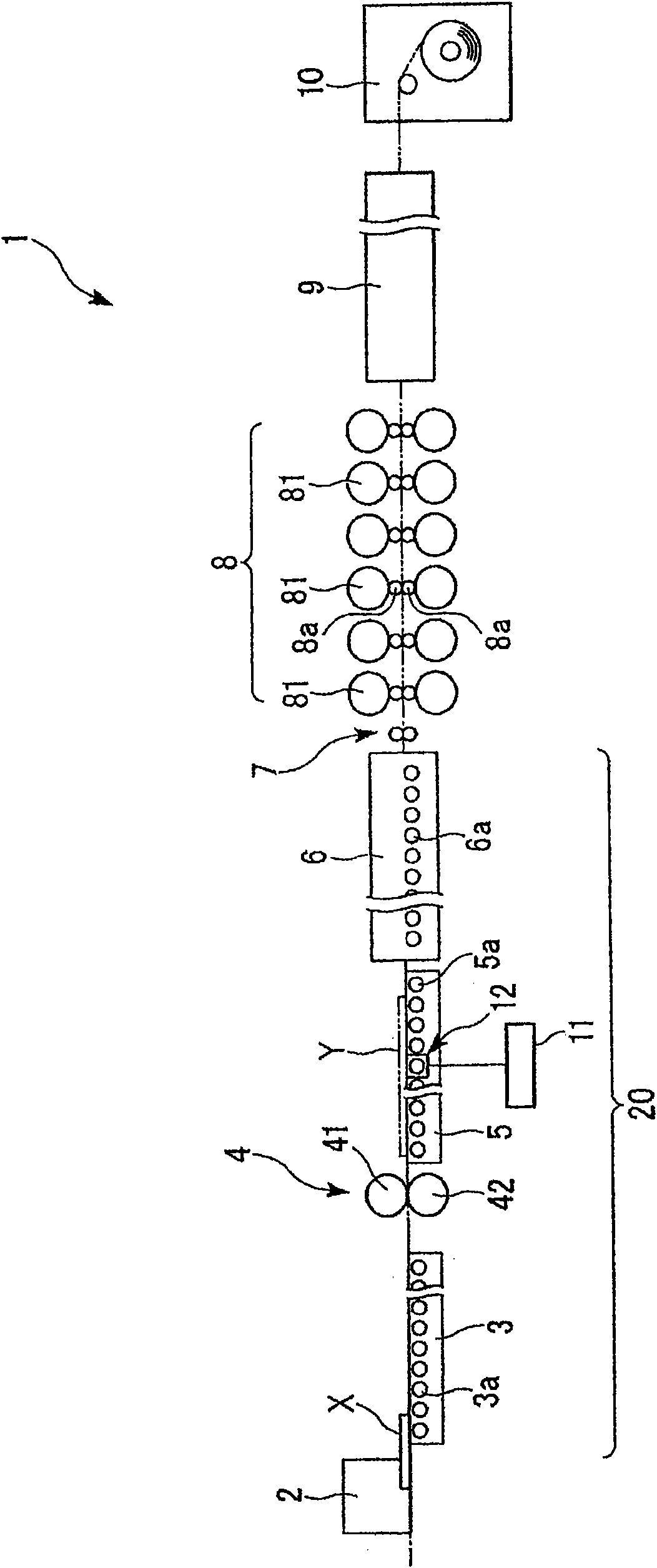

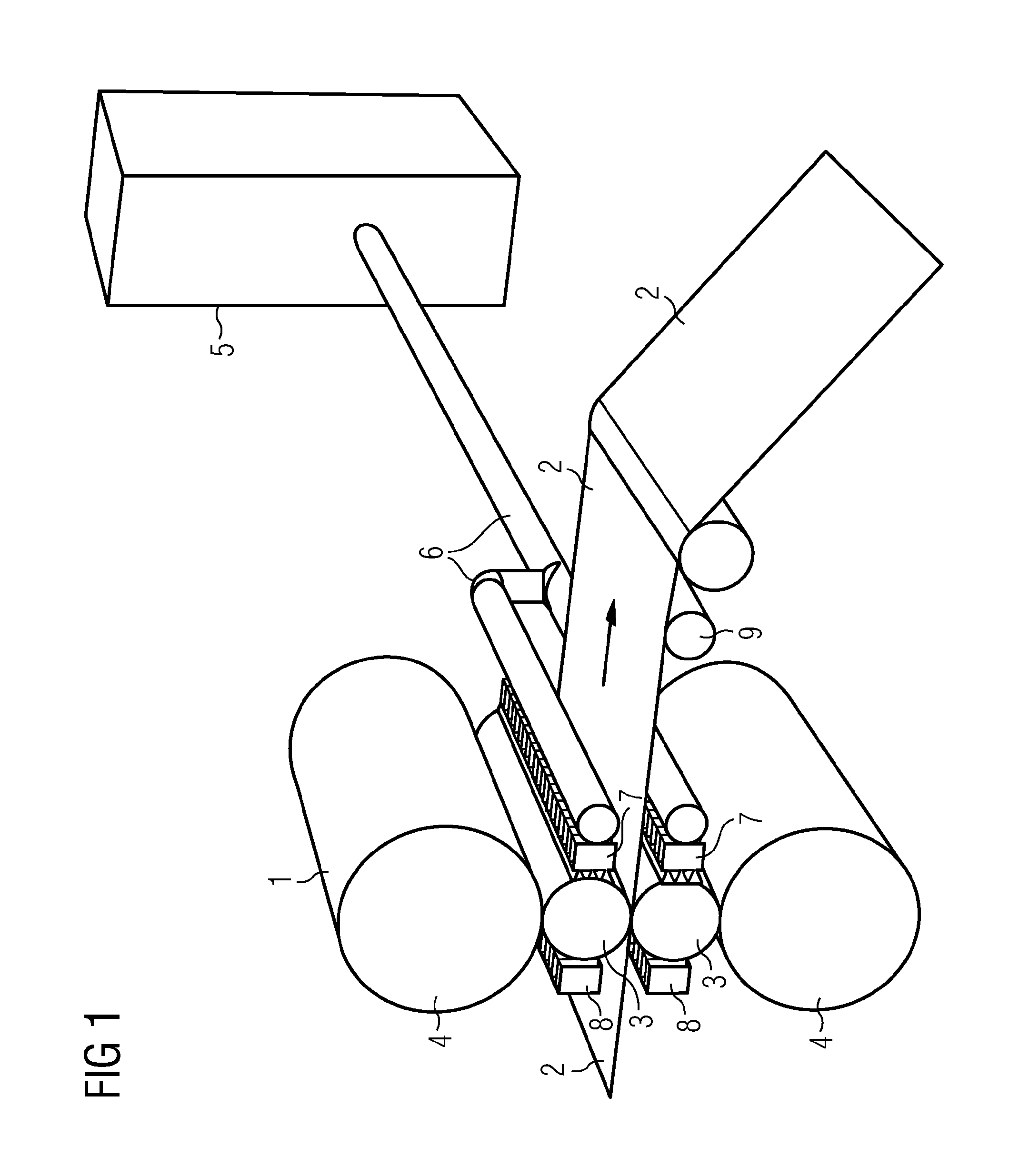

Apparatus and methods for manufacturing hot rolled steel sheets

InactiveUS6463652B1DesignedReduce vibrationForging/pressing devicesMetal rolling stand detailsProduction rateSheet steel

A high-quality hot rolled steel sheet is manufactured with a high production efficiency and a low cost, from a long, hot slab, using a combination of continuous casting facilities and a plate reduction press machine.

Owner:IHI CORP +2

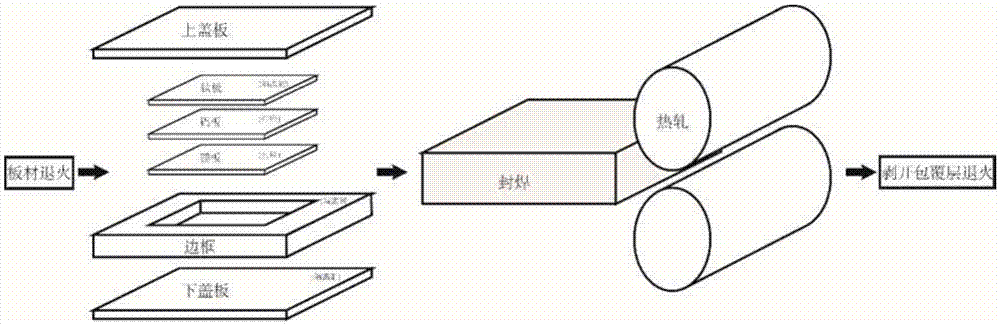

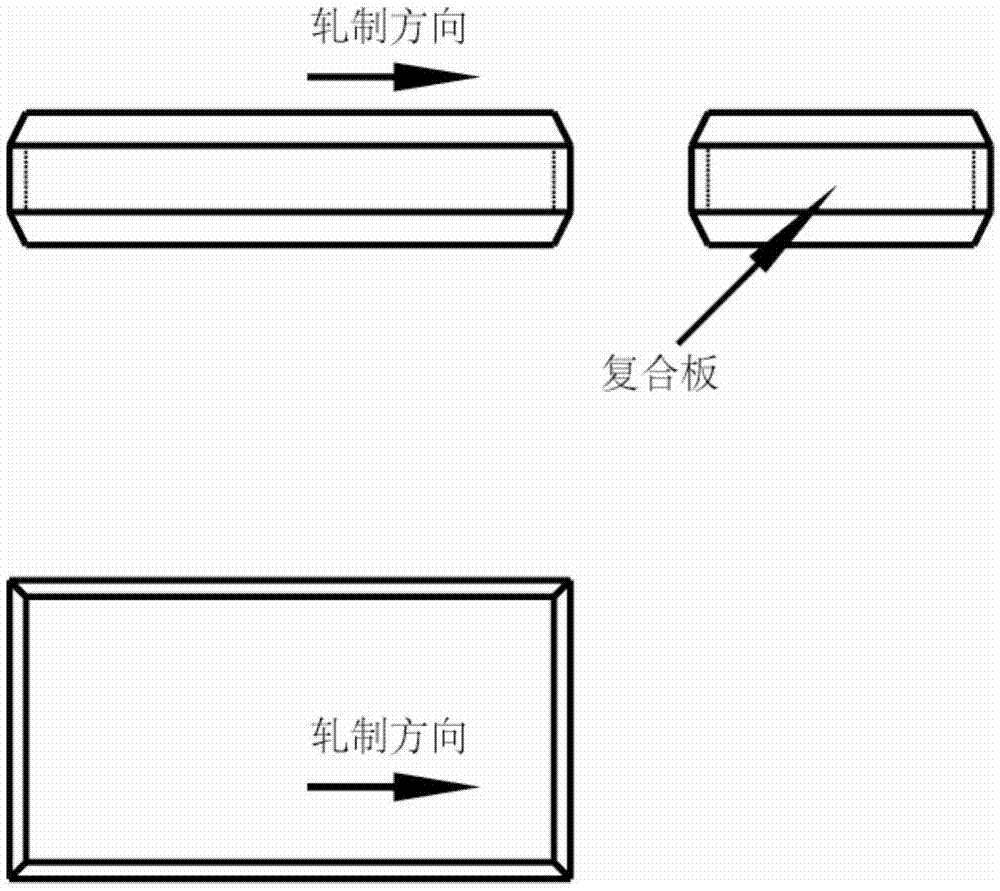

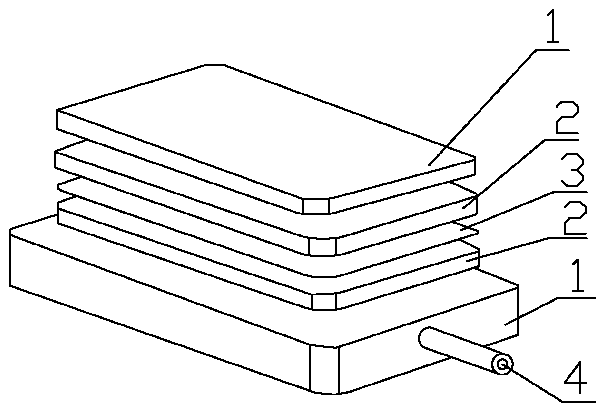

Magnesium/aluminum/titanium composite board cladding-rolling method

InactiveCN105436203AEffectively Constrains Deformation BehaviorEasy to transformForging/pressing devicesMetal rolling arrangementsTitaniumShape optimization

The invention discloses a magnesium / aluminum / titanium composite board cladding-rolling method. According to the method, a cladding layer is used for the composite board during rolling, and through shape optimization of upper and lower cover plates of the cladding layer and design of rolling process parameters, the cladding layer and the cladded composite board can achieve coordinated deformation during rolling, so that the deformation behavior of the cladded composite board can be effectively restrained, the composite interface of the composite board is straight, and the bonding strength of the composite board is improved; the cladding layer can effectively reduce invasion of impurities and harmful gas to the composite interface, so that the bonding strength of the composite board can be further improved; and meanwhile, the use of the cladding layer can slow down loss of heat, so that metal is easy to deform during rolling.

Owner:CHONGQING UNIV

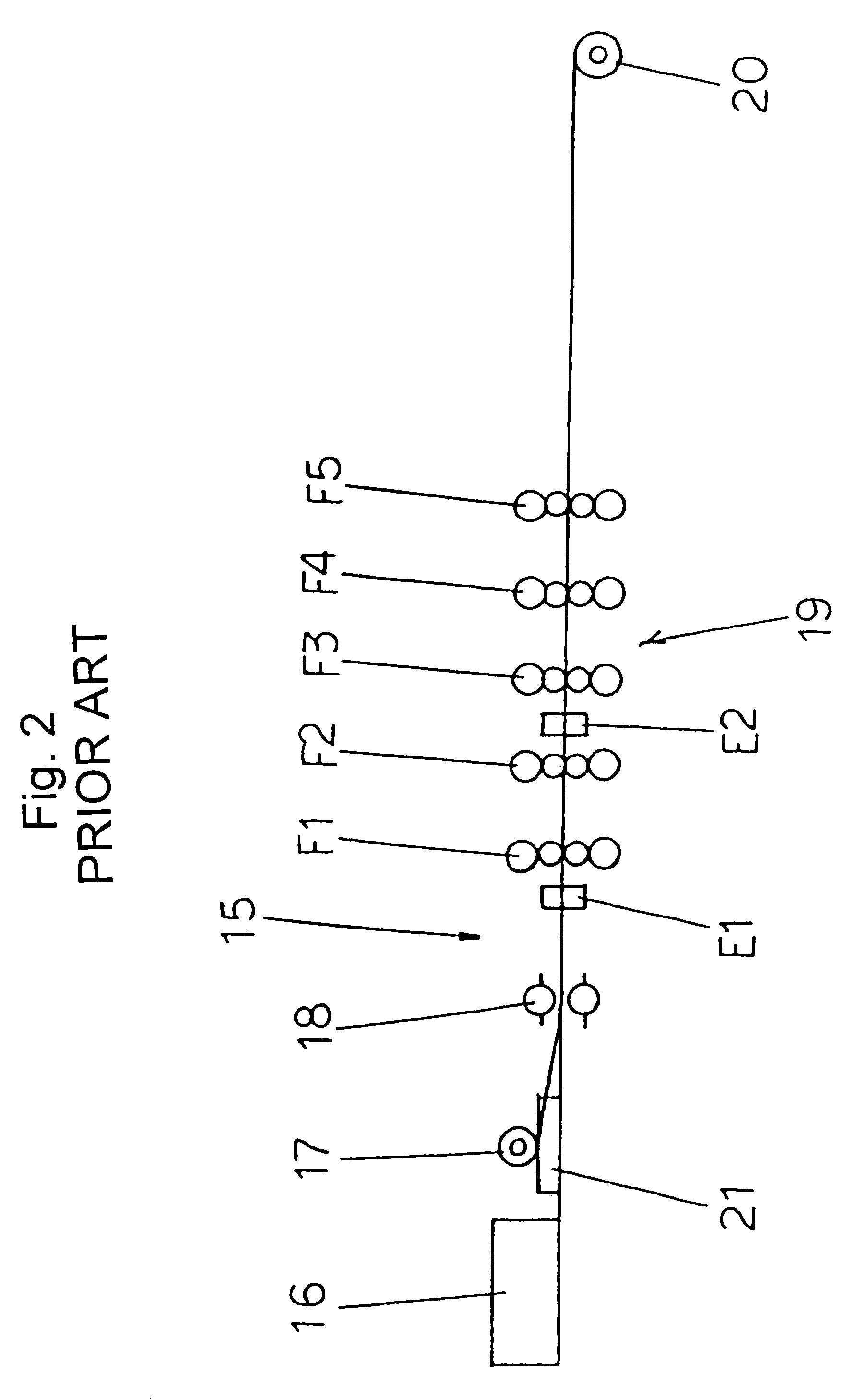

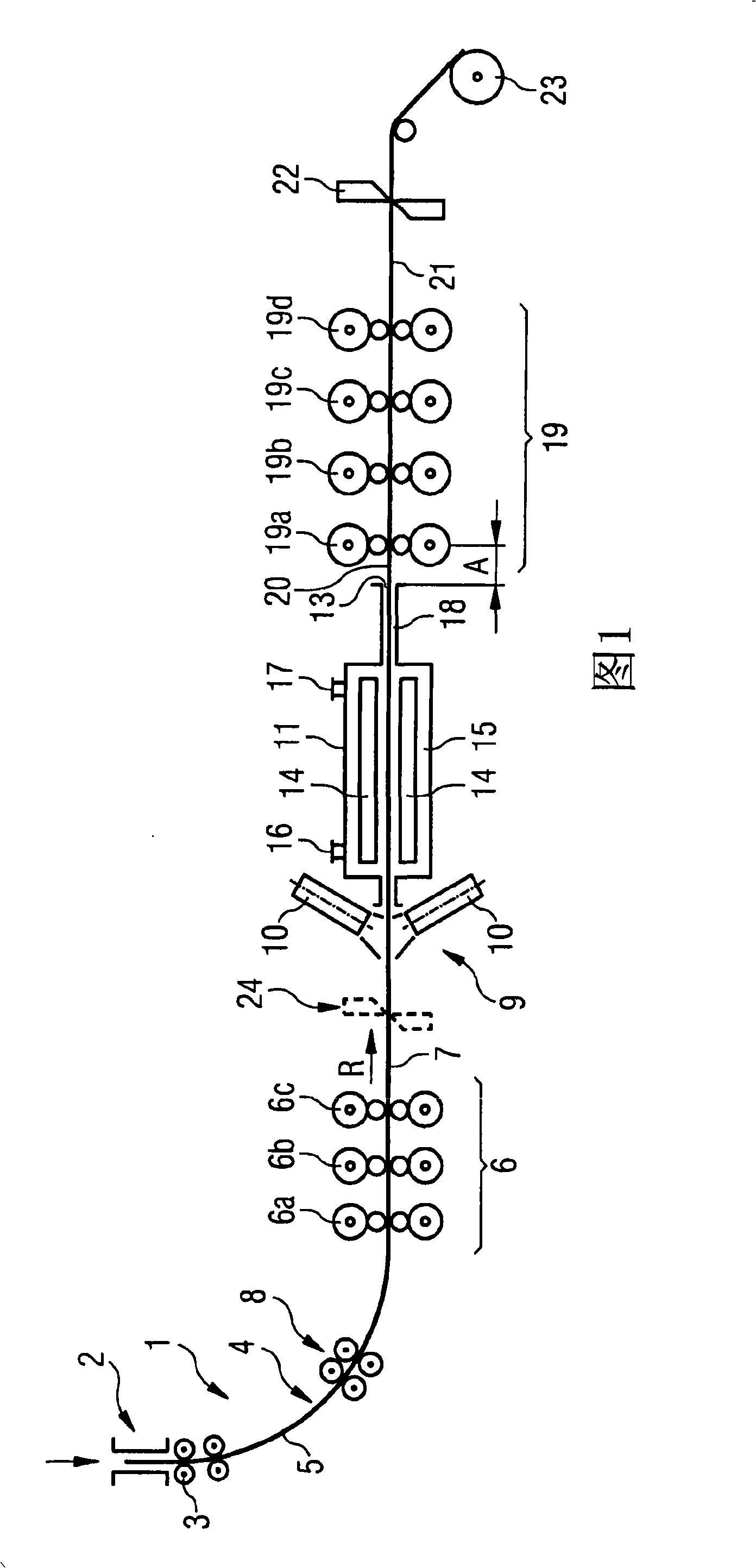

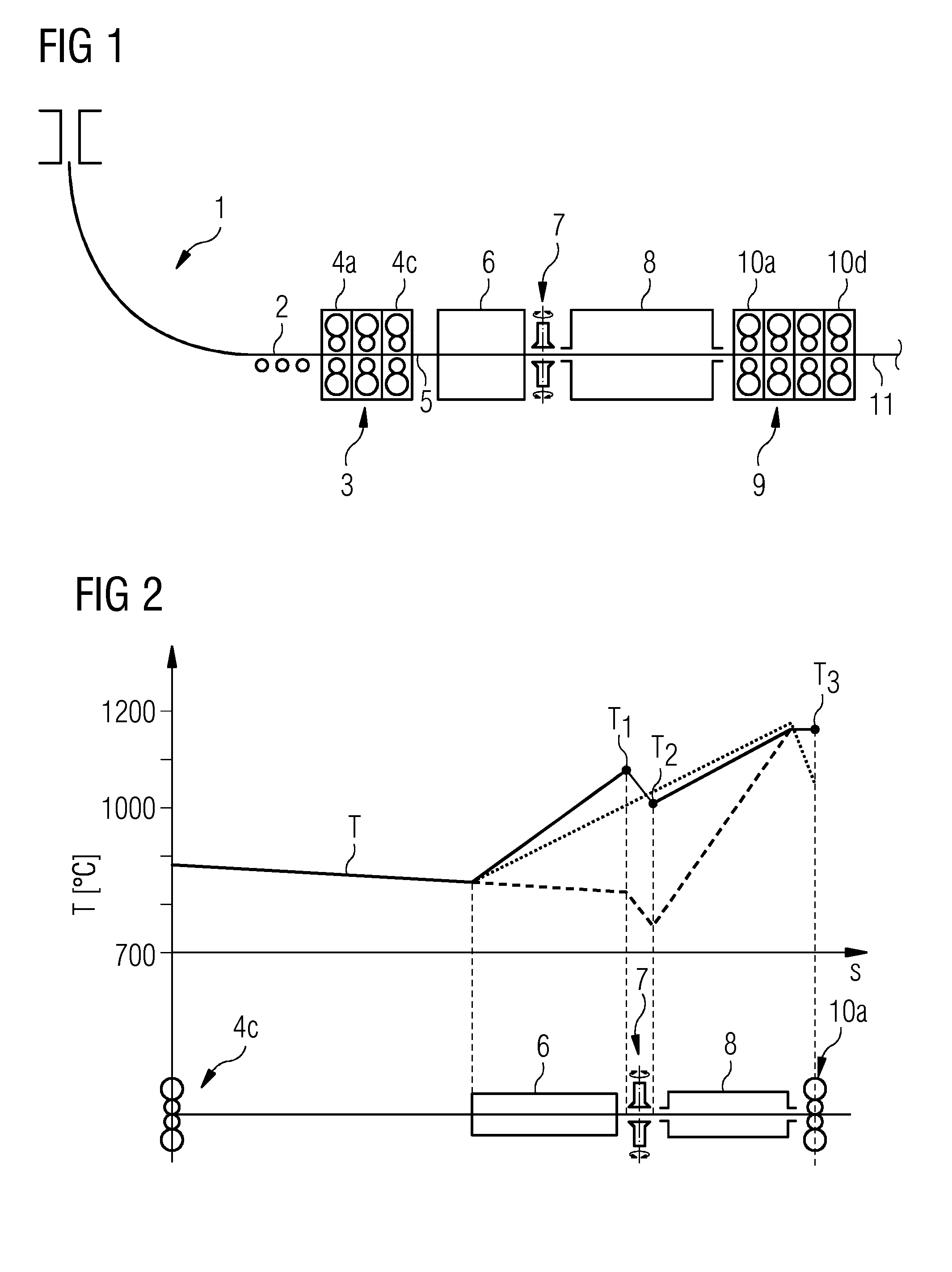

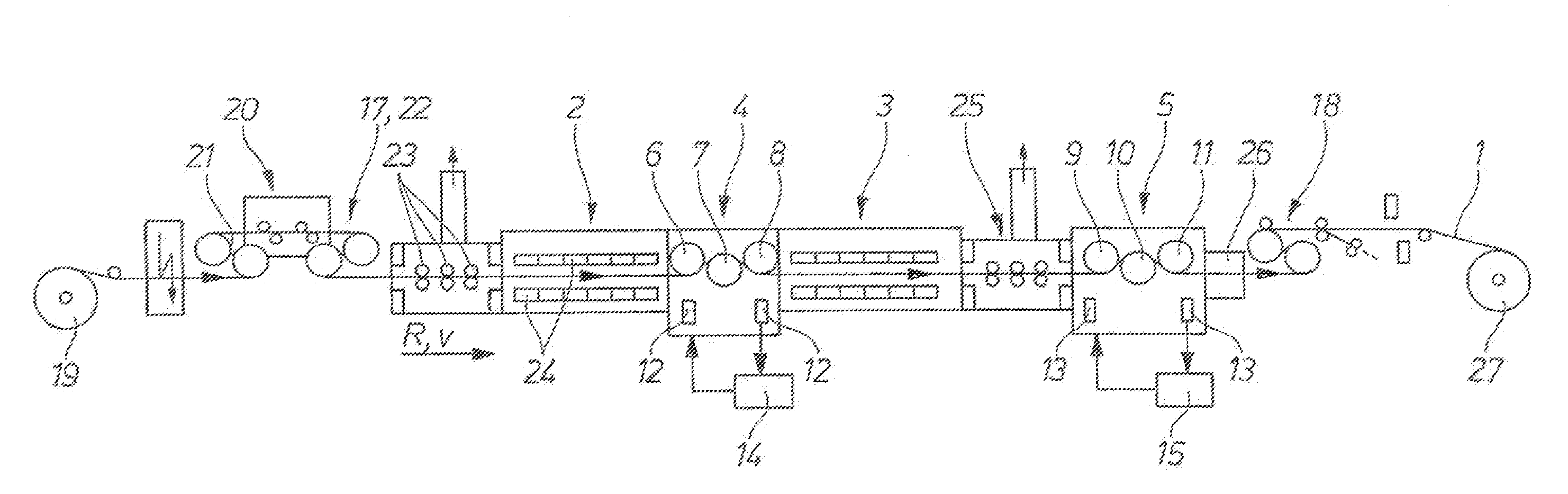

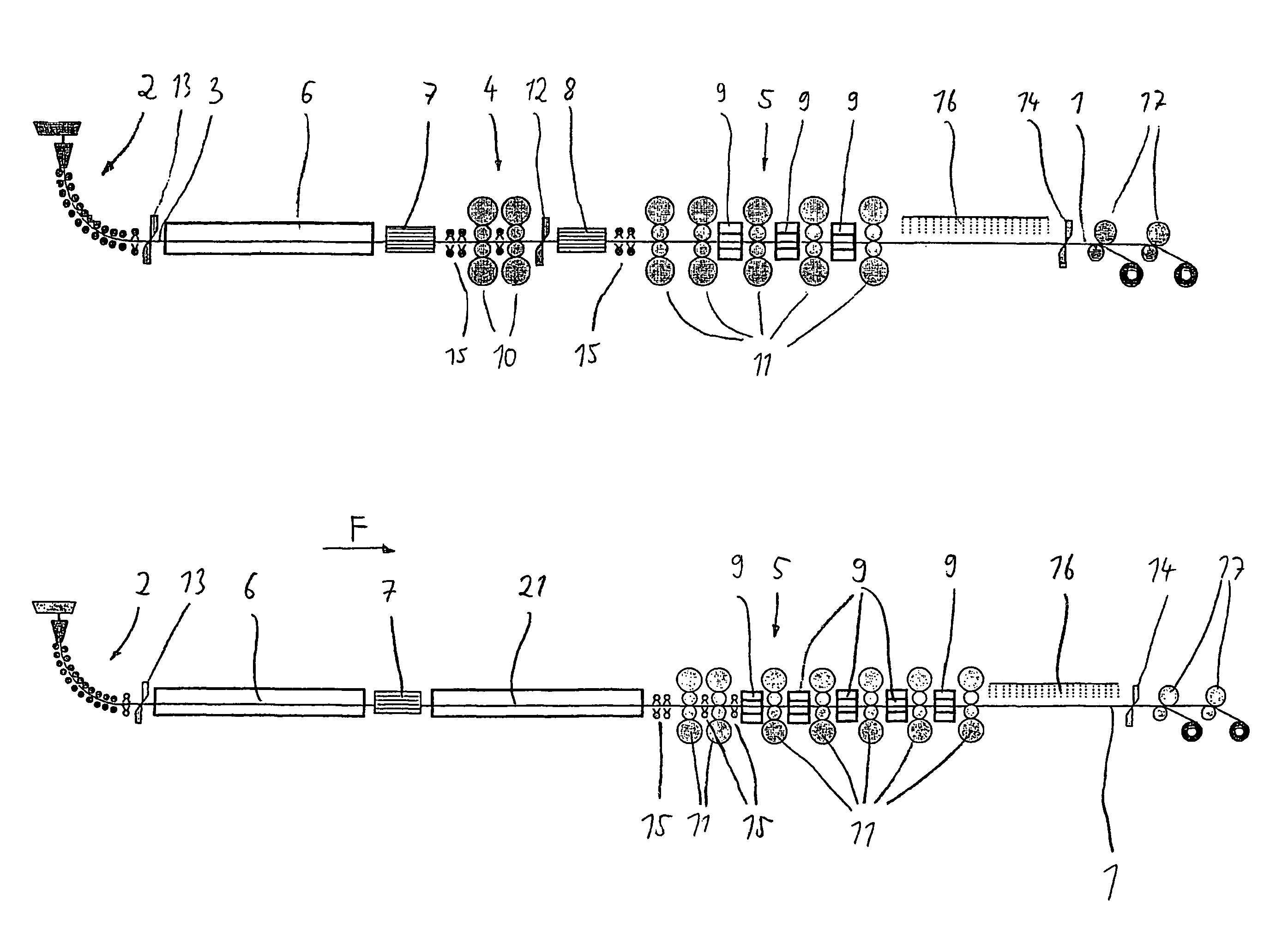

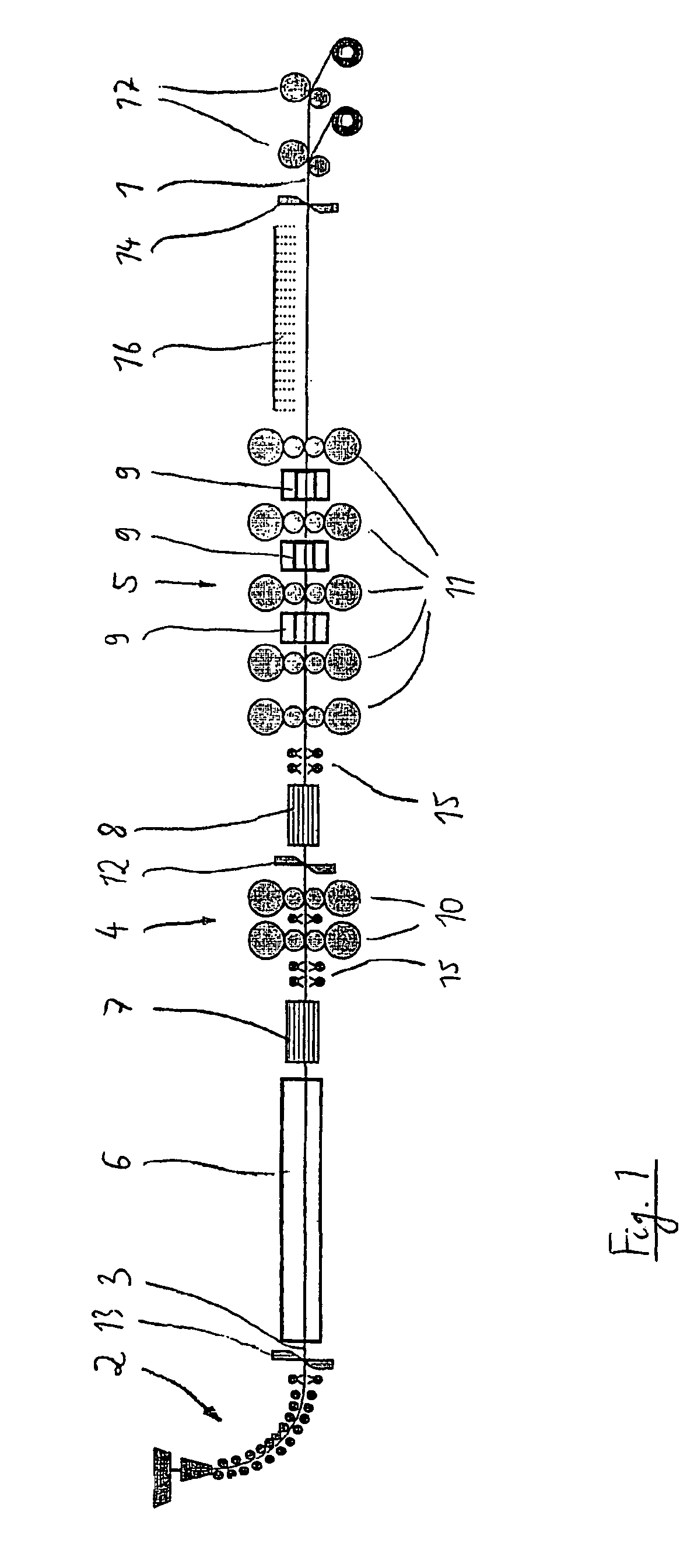

Method for producing a hot-rolled steel strip and combined casting and rolling installation for carrying out the method

InactiveCN101304819ALow running costReduce energy costsForging/pressing devicesMetal rolling stand detailsShielding gasRoll forming

A method for producing a hot-rolled steel strip from a steel melt in a continuous production process, with the strip running through uninterruptedly, comprises the following method steps: continuous casting of a steel strand (5) in a continuous casting mould (2) of a continuous casting installation (1), roll forming of the cast steel strand in a first group of roll stands (6) to form a pre-rolled hot strip (7), further roll forming of the pre-rolled hot strip in a second group of roll stands (19) to form a hot-rolled steel strip (21), setting the pre-rolled hot strip to rolling temperature between the first group of roll stands and the second group of roll stands in a temperature setting device (14), and winding up the hot-rolled steel strip into coils or dividing up the hot-rolled steel strip into panels. In order to increase flexibility in the production of different grades of steel and keep investment costs and operating costs low, it is proposed that the pre-rolled hot strip is descaled immediately before entering the temperature setting device, the pre-rolled hot strip is kept in a protective gas atmosphere in the temperature setting device and the pre-rolled hot strip is roll-formed in the second group of roll stands immediately after running through the temperature setting device. Furthermore, a combined casting and rolling installation for carrying out the method is proposed.

Owner:西门子VAI金属技术有限责任公司

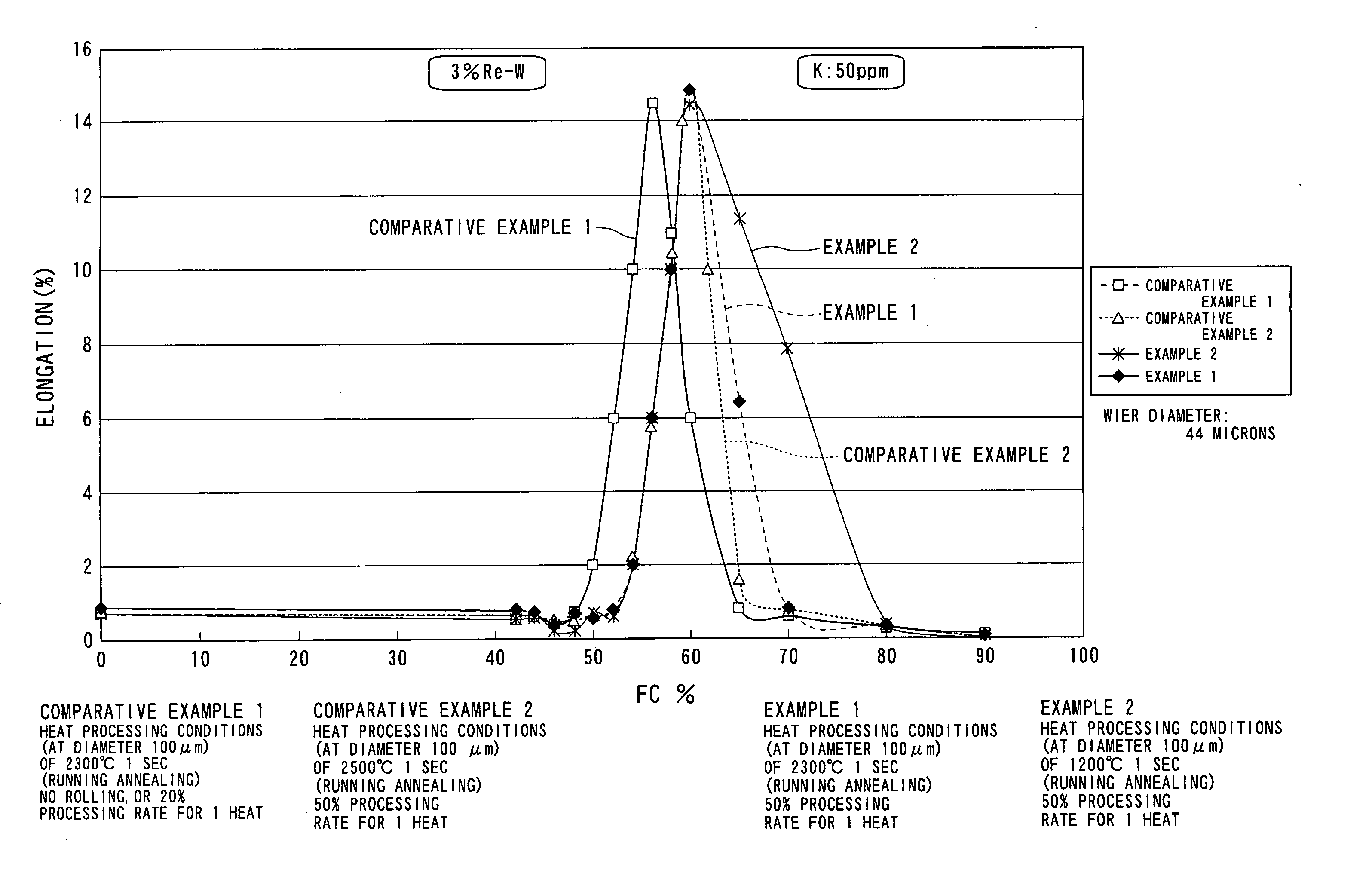

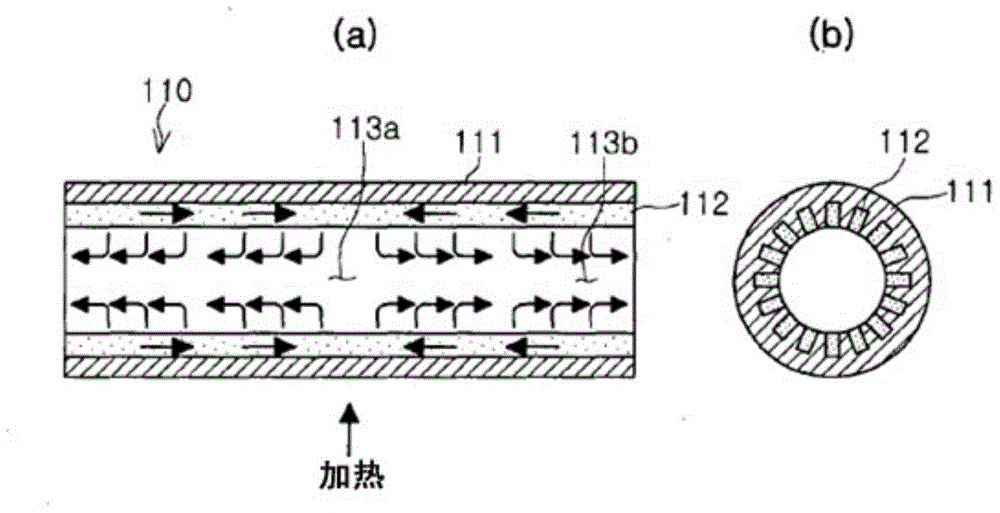

Tunsten wire, cathode heater, and filament for vibration service lamp

InactiveUS20040244879A1Efficient preparationHigh elongationForging/pressing devicesElectric discharge tubesRheniumHorizontal axis

A tungsten wire containing 1 to 10% by mass of rhenium has a point which indicates a 2% elongation within a quadrangle formed by joining points with straight lines, where the values of x and y are point (20, 75), point (20, 87), point (90, 75), and point (90, 58), in this order, wherein the wire diameter of the aforementioned tungsten wire is represented by x mum, and the elongation of the tungsten wire is 2% after electrically heating with an electrical current which is a ratio of y % to the fusion current (FC) at the wire diameter x mum, and wherein a semi-logarithmic system of coordinates is expressed by a horizontal axis using a logarithmic scale of the aforementioned wire diameter x and a vertical axis using a normal scale of ratio y to the fusion current. According to the above-described configuration, a tungsten wire having a great elongation even under conditions of high temperature can be provided, and the tungsten wire can exhibit an excellent durability when used as component material for constituting cathode heaters and so forth, and the tungsten wire can be manufactured efficiently.

Owner:KK TOSHIBA

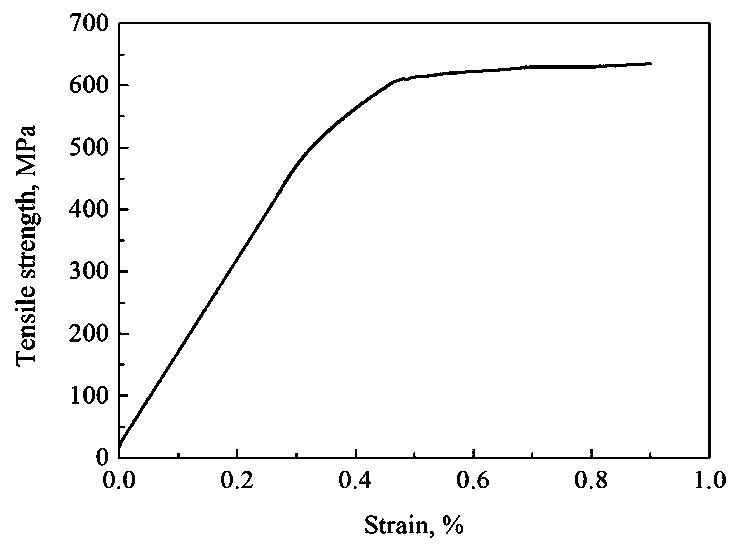

Pulse current assisting titanium-TiAl composite plate non-sheath rolling method

ActiveCN110711774AImprove organizational formImprovement ingredientsForging/pressing devicesMetal rolling arrangementsBond interfaceTitanium

The invention relates to the field of preparing of alloy materials, in particular to a pulse current assisting titanium-TiAl composite plate non-sheath rolling method. The pulse current assisting titanium-TiAl composite plate non-sheath rolling method aims at solving the problems that a plate prepared through an existing foil metallurgy method for titanium-TiAl composite plates is small in size, not uniform in thickness, large in component deviation and low in strength and plasticity, and the problems that a sheath hot rolling method is high in cost, complex in technology and high in rolling temperature, and the quality and performance of composite plates need to be further improved are solved. The pulse current assisting titanium-TiAl composite plate non-sheath rolling method includes thespecific steps that firstly, a titanium alloy plate is prepared; secondly, a TiAl alloy plate is prepared; thirdly, non-sheath assembling is conducted; fourthly, pulse current auxiliary hot rolling is conducted; and fifthly, separating and subsequent treatment are conducted, and a titanium-TiAl composite plate can be obtained. The composite plate obtained in the pulse current assisting titanium-TiAl composite plate non-sheath rolling method is good in surface quality, free of oxide layer disengagement, free of edge portion and end portion cracking, uniform and small in plate organization, good in bonding interface and good in mechanical performance.

Owner:TAIYUAN UNIV OF TECH

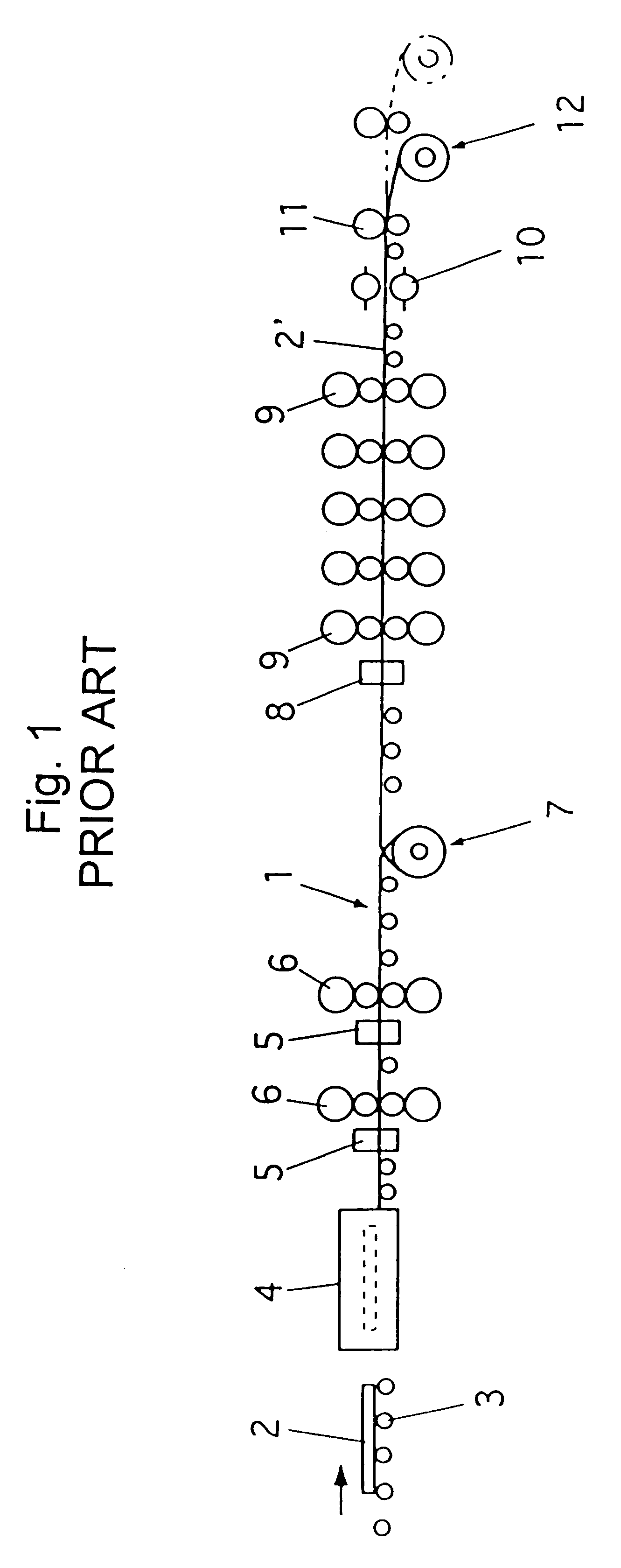

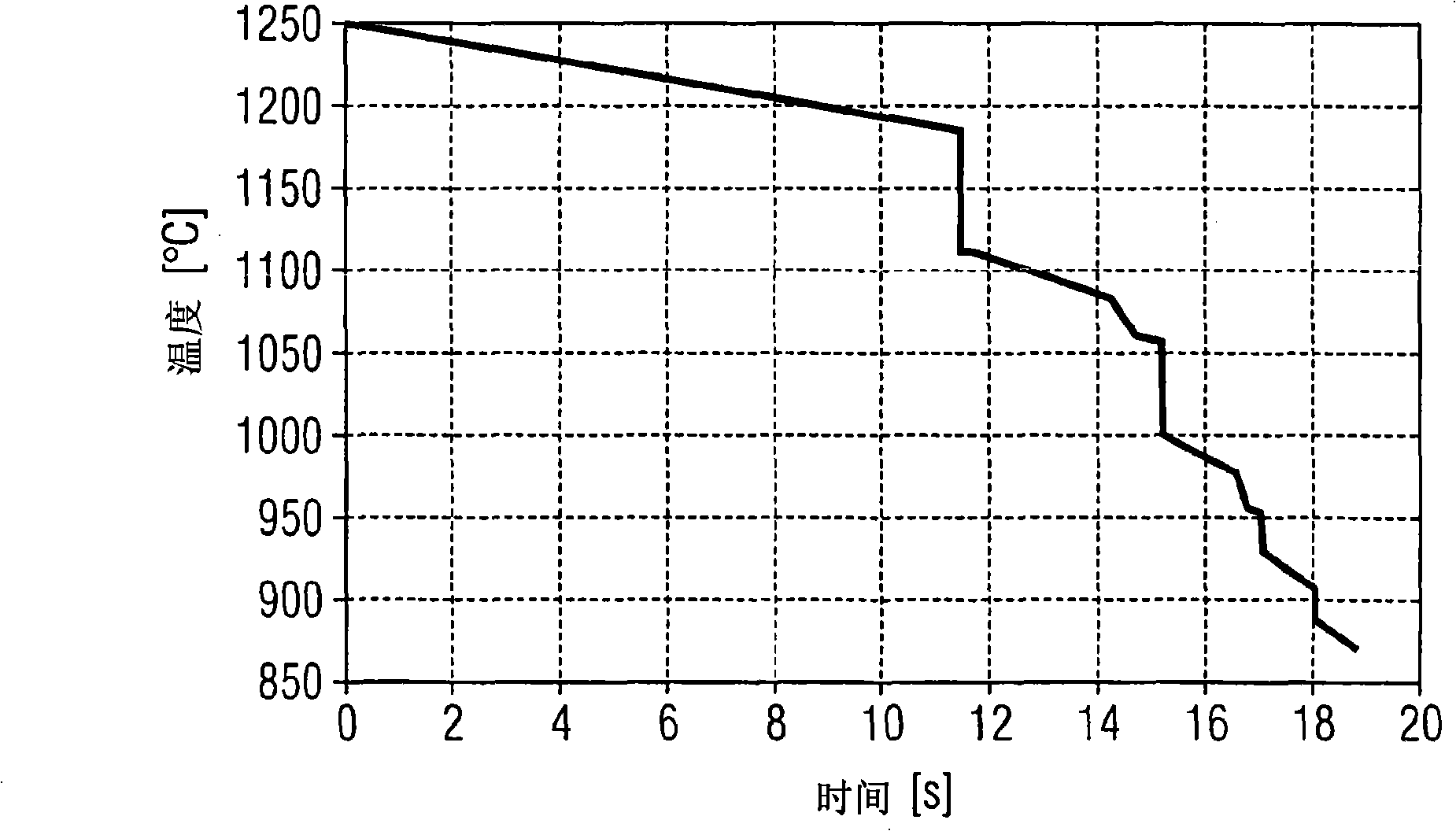

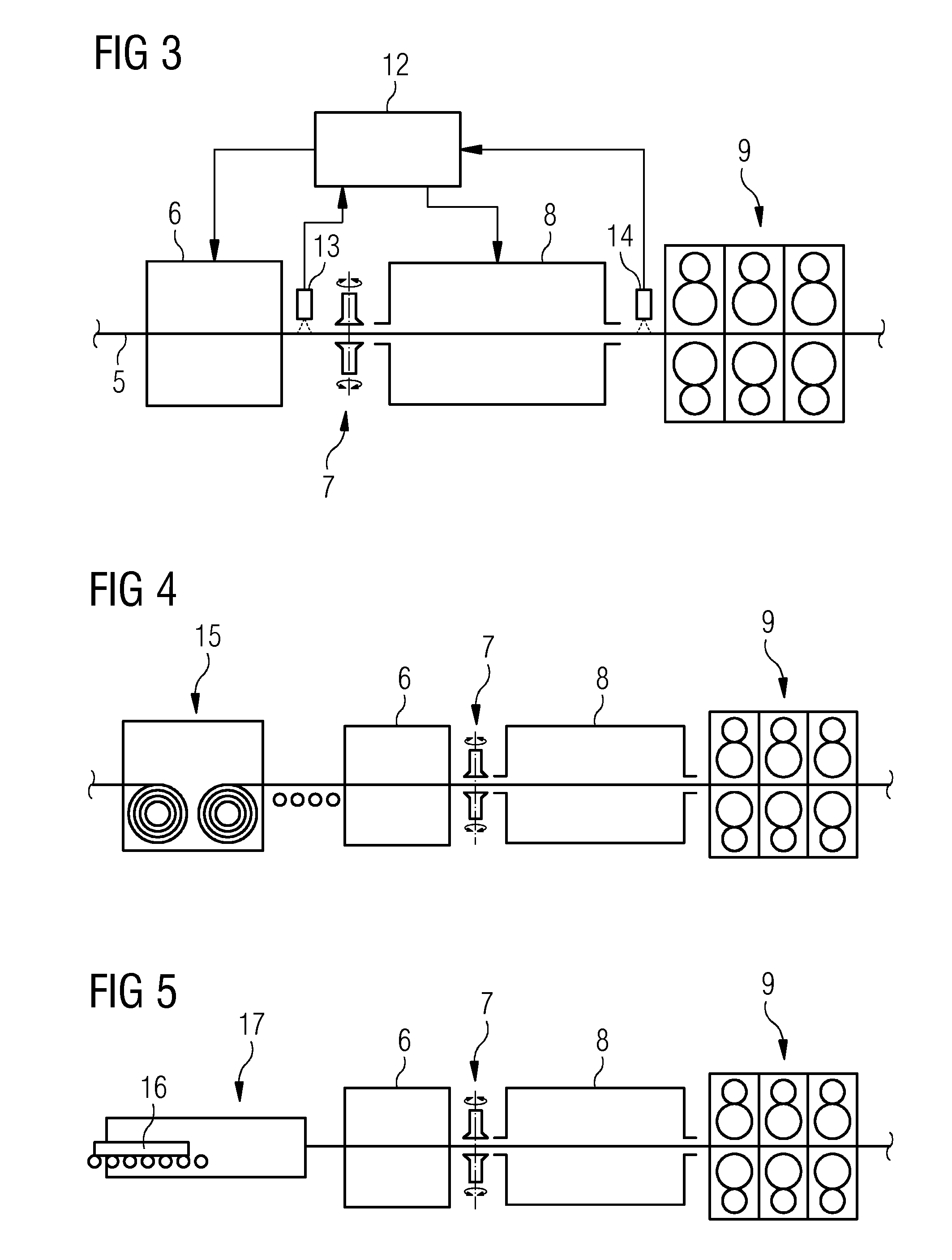

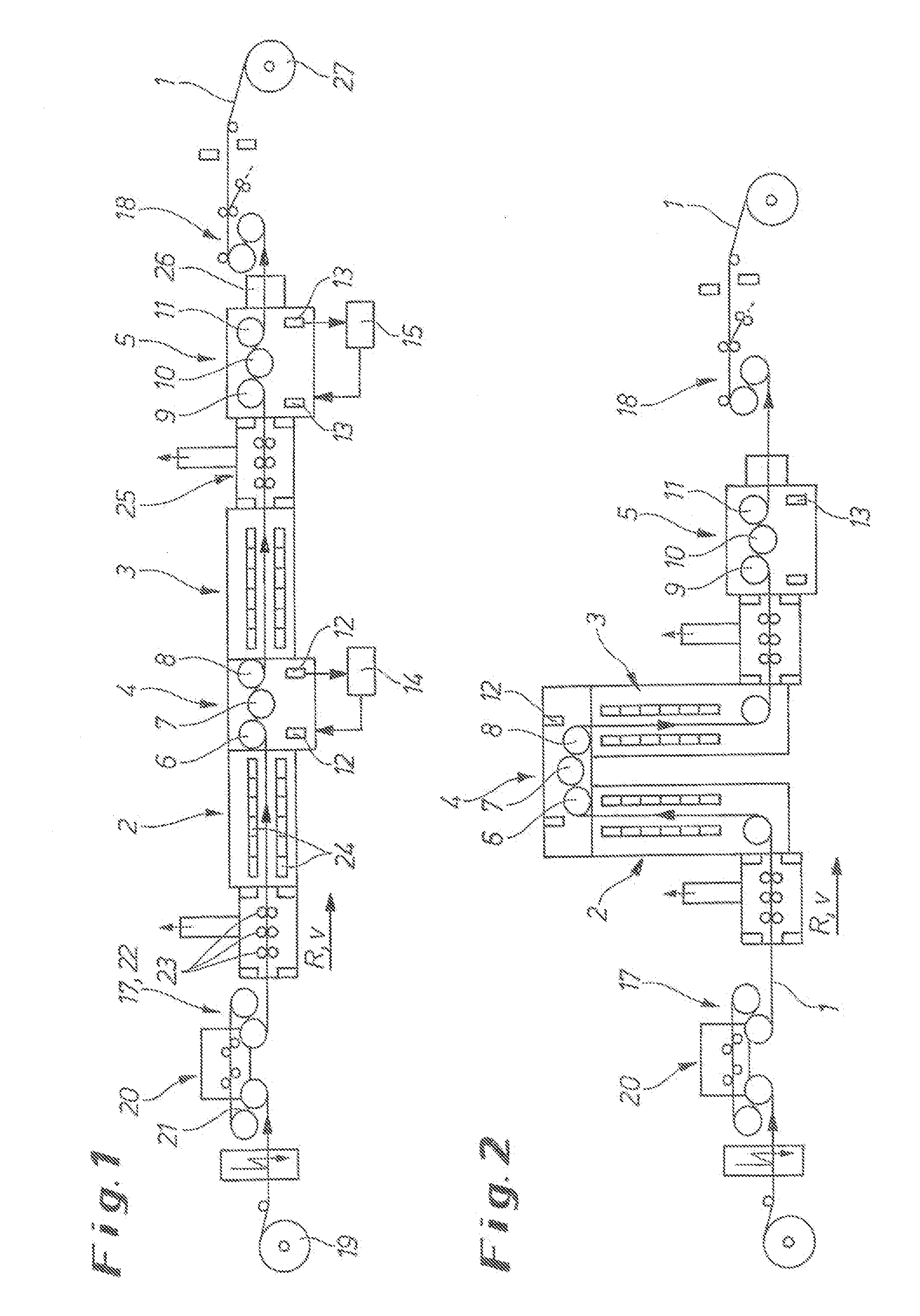

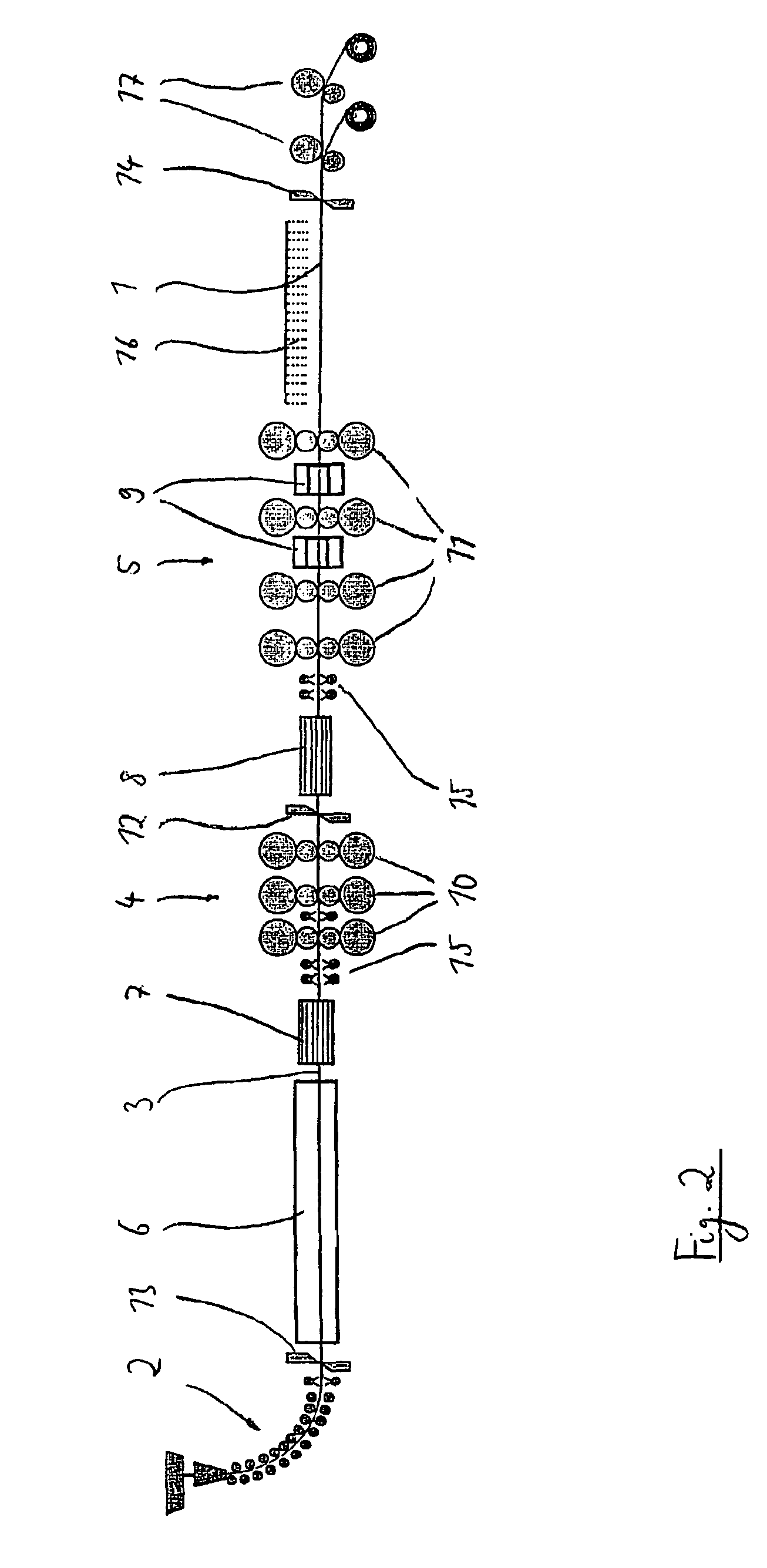

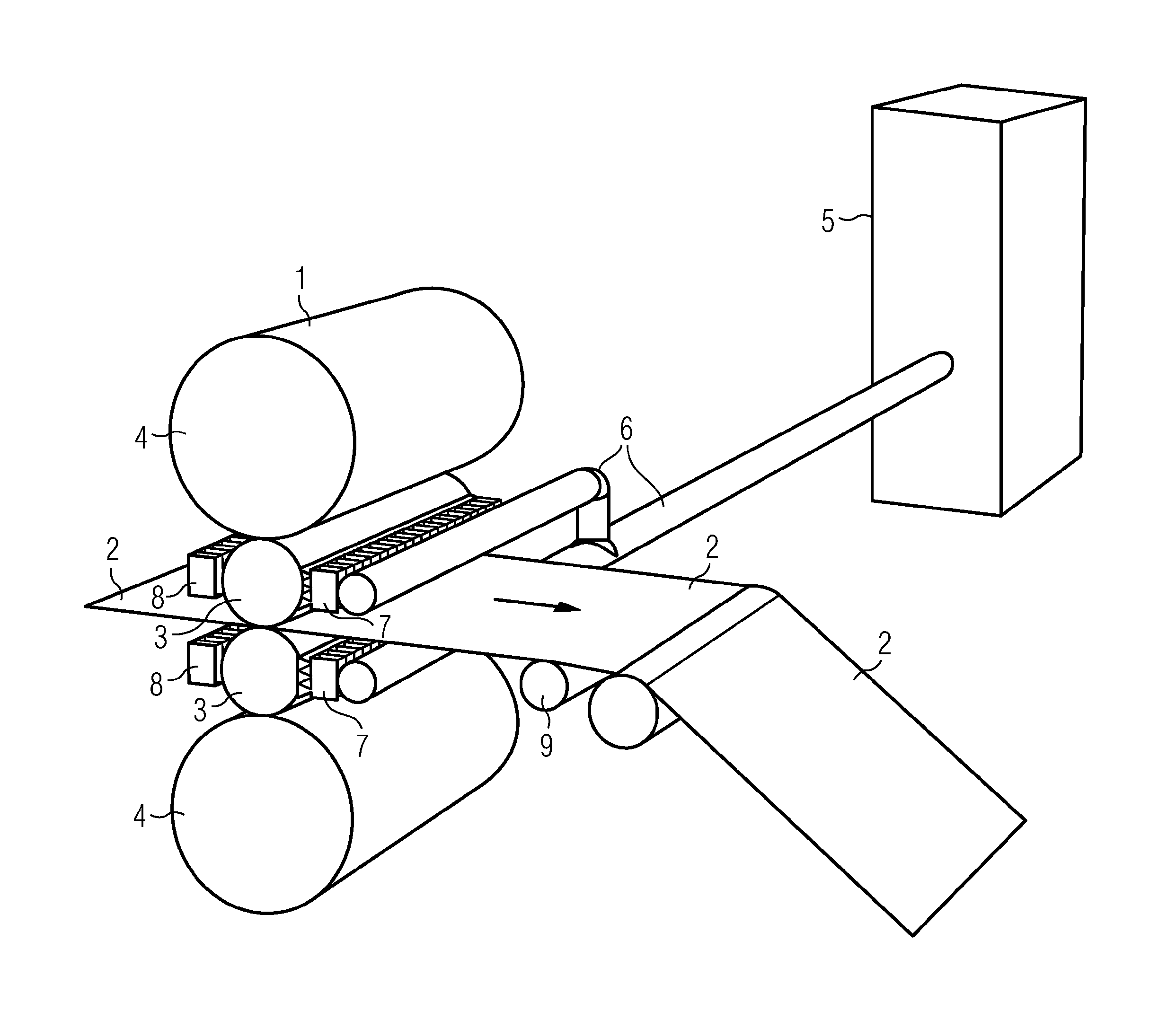

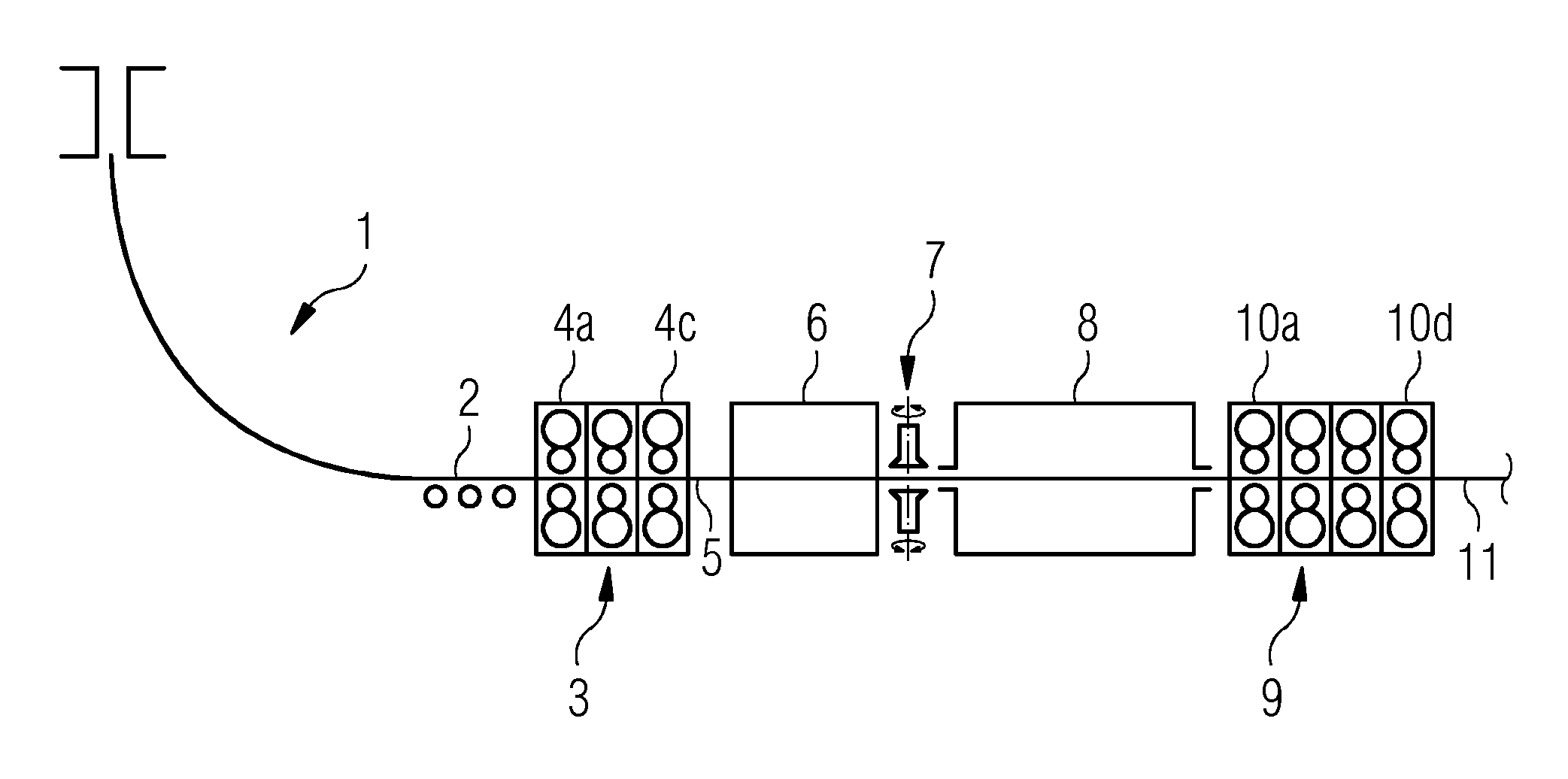

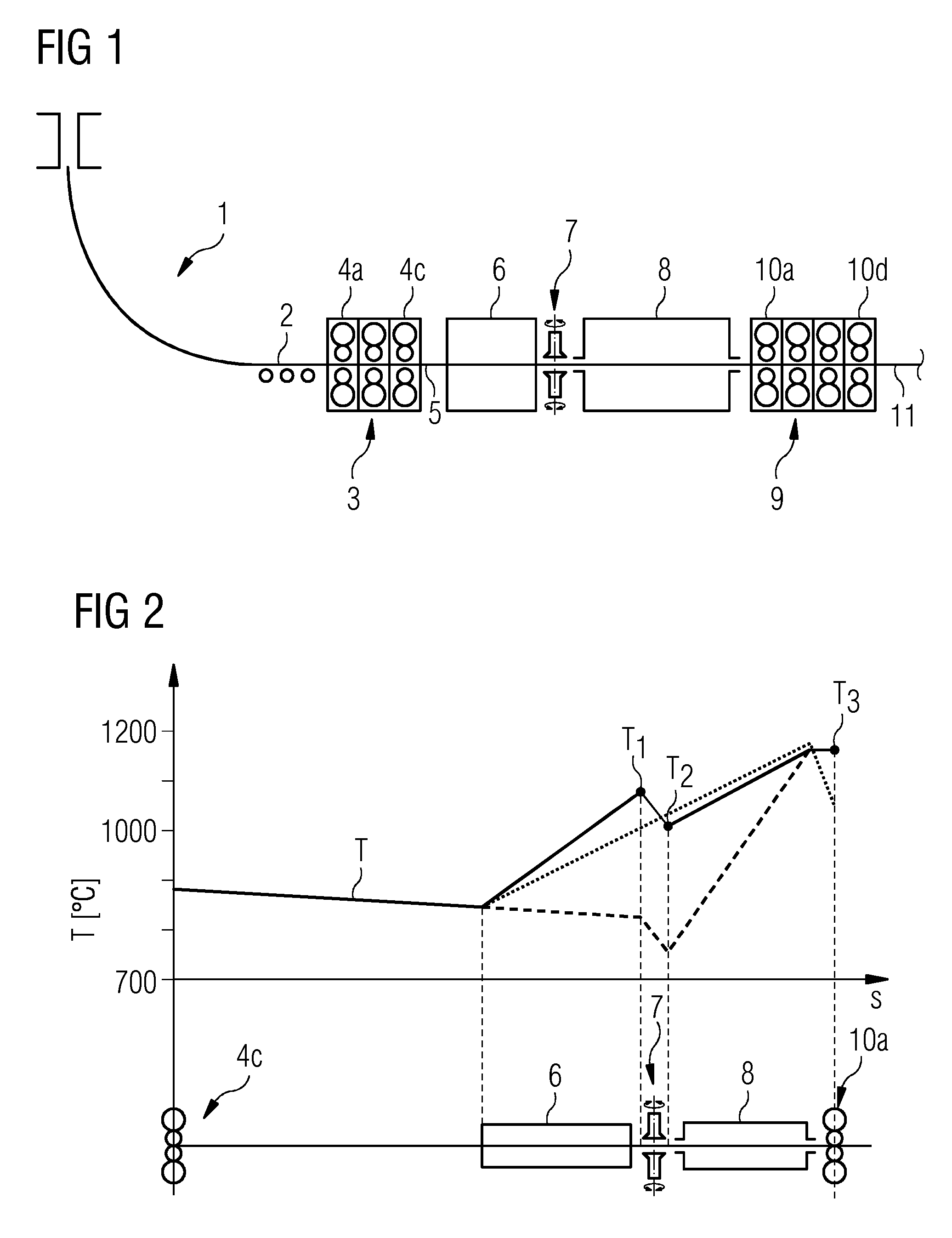

Method and apparatus for preparing steel stock before hot rolling

InactiveUS20140096578A1Reliable heatingReduce thicknessForging/pressing devicesMeasuring devicesShielding gasInduction furnace

A process and an apparatus for preparing steel stock before hot rolling. The steps of preheating the stock (5, 16, 22) in a first induction furnace (6) so that the preheated stock enters a subsequent descaling apparatus (7) with a surface temperature of T1≧1000° C.; descaling the preheated stock by a plurality of water jets in a descaling apparatus (7); direct subsequent heating of the descaled stock in a second induction furnace (8), where the descaled stock enters the second induction furnace (8) at a temperature T2 which is ≧Tcurie of the stock and heating in the second induction furnace 8 is either in a largely inert or largely reducing protective gas atmosphere; passing the heated stock in a rolling mill (9), where the heated stock enters the rolling mill (9) at a temperature 1220° C.≧T3 1050° C.

Owner:PRIMETALS TECH AUSTRIA GMBH

Method for the production of hot-rolled steel strip and combined casting and rolling plant for carrying out the method

InactiveUS8479550B2Increasing introductionLow costForging/pressing devicesMetal rolling stand detailsShielding gasCasting mold

A method for the production of a hot-rolled steel strip from a steel melt in a continuous manufacturing process: continuously casting a steel strand in a continuous casting mold of a continuous casting plant, roll-forming the case steel strand in a first group of roll stands into a pre-rolled hot strip, roll-forming the pre-rolled hot strip in a second group of roll stands into a hot-rolled steel strip, setting the hot strip to a rolling temperature between the first and second groups, and winding or dividing the hot-rolled steel strip; further: descaling the hot strip before temperature setting, holding the hot strip in a protective gas atmosphere during temperature setting. A combined casting and rolling plant for the method is disclosed.

Owner:PRIMETALS TECH AUSTRIA GMBH

Method and device for descaling a metal strip

InactiveUS20110195200A1Negative effect on the microstructure of the metal stripQuality improvementHot-dipping/immersion processesForging/pressing devicesMetal stripsAutomatic control

A method and a device for descaling a metal strip, in which the metal strip is guided in a direction of conveyance through at least one plasma descaling unit in which it is subjected to a plasma descaling. The metal strip is subjected to an automatically controlled cooling process in a cooling unit following the plasma descaling in the one or more plasma descaling units in such a way that it has a well-defined temperature downstream of the cooling unit.

Owner:SMS DEMAG AG

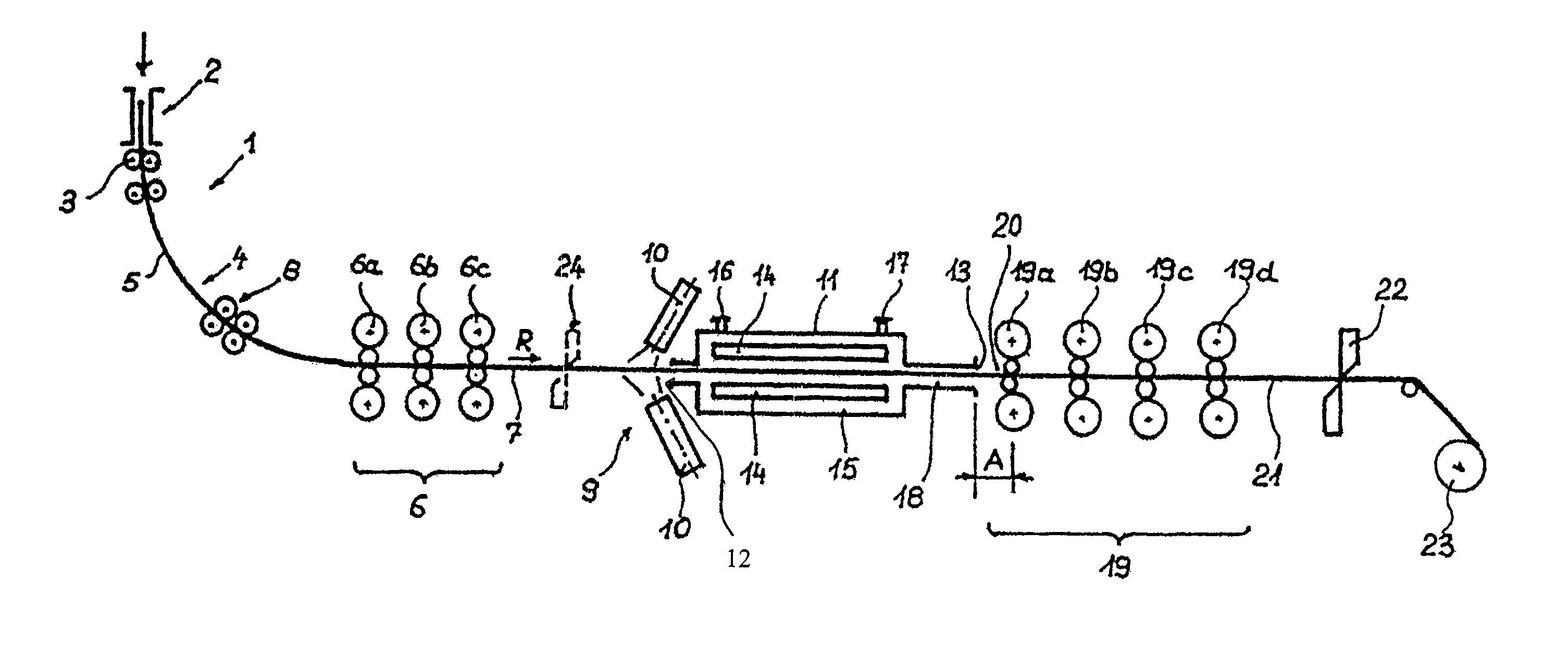

Method and device for producing a metal strip by continuous casting and rolling

ActiveUS8365806B2Reduce or avoid damageLow failure rateForging/pressing devicesMetal rolling stand detailsMetal stripsOperation mode

A method and a device for producing a metal strip by continuous casting and rolling, in which a thin slab is initially cast into a casting machine, and is subsequently rolled in at least one rolling train using primary heat from the casting cycle. The cast thin slab is passed between the casting machine and the at least one rolling train and at least one holding oven as well as at least one induction oven. The holding oven and the induction oven are activated or deactivated according to a selected mode of operation, that is, a first mode of operation for the continuous production of the metal strip and a second mode of operation for the discontinuous production of the metal strip.

Owner:SMS DEMAG AG

Carrying apparatus and hot-rolling apparatus, and carrying method and hot-rolling method

InactiveCN101939119AIncrease delivery speedReduce conveying speedForging/pressing devicesCharge manipulationThermodynamicsProcess engineering

Disclosed is a carrying apparatus, which comprises a plurality of carrying rollers supported in parallel at a predetermined spacing, so that a workpiece is carried from a rolling machine to the inside of a heat keeping-applying furnace by the carrying rollers. The carrying apparatus is characterized by further comprising a shock-predicting data collection unit for acquiring such data upstream of the heat keeping-applying furnace as to predict the magnitude of shocks to be applied by the workpiece to that one of the carrying rollers, which is disposed in the heat keeping-applying furnace, and a control unit for predicting the magnitude of the shocks from that data acquired by the shock-predicting data collection unit, thereby to adjust the carrying speed of carrying the workpiece in the heat keeping-applying furnace in accordance with the magnitude of the shocks.

Owner:IHI CORP

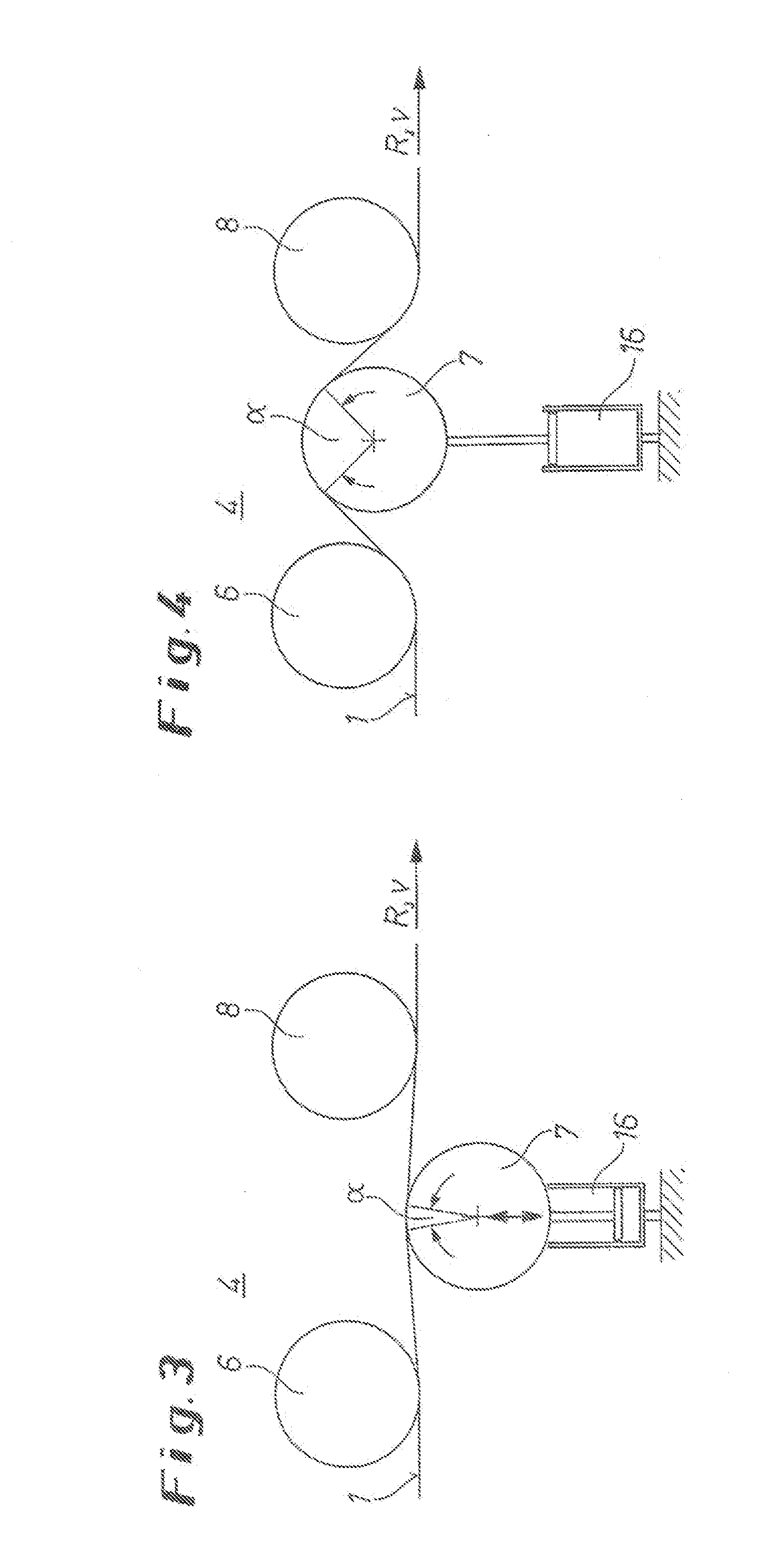

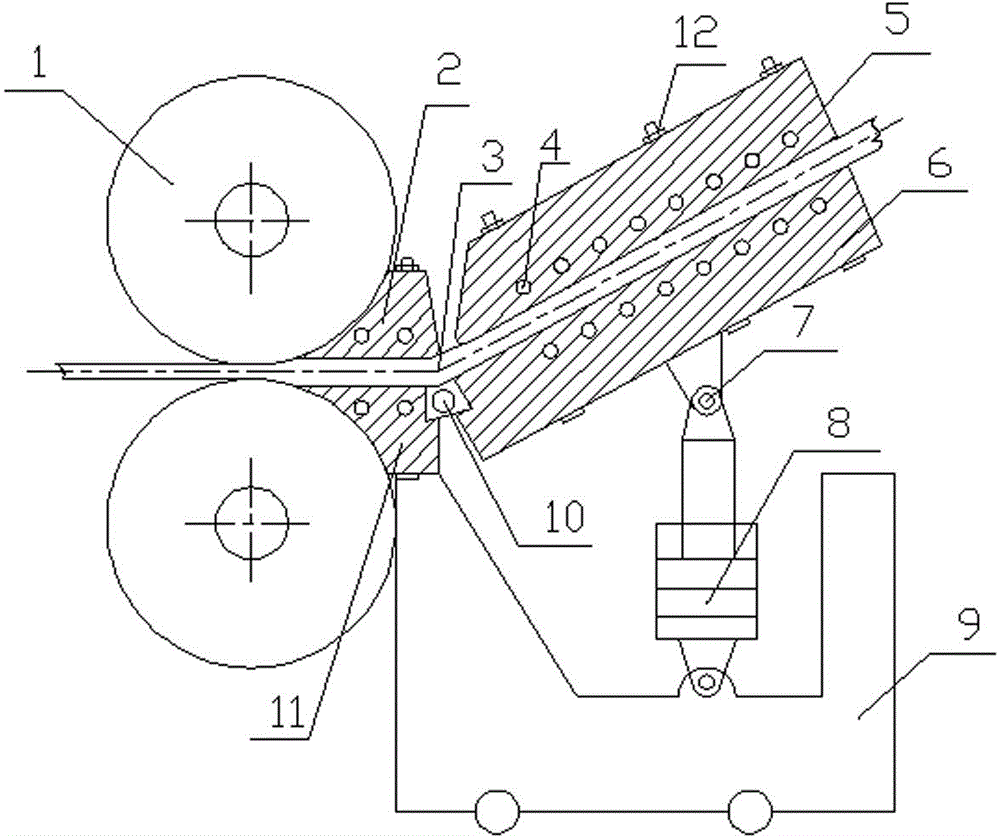

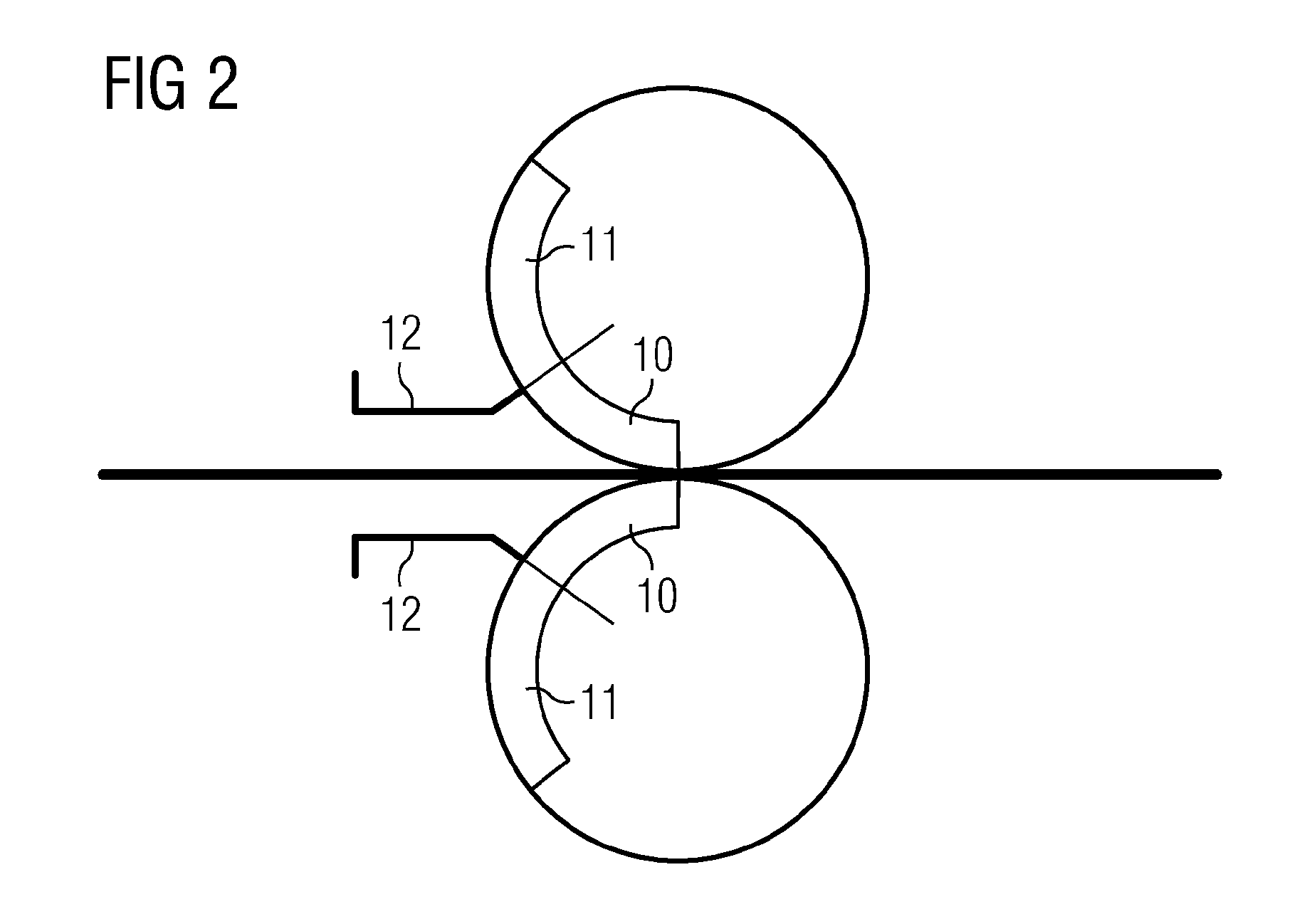

Strong-shear rolling forming method and device for metal plate

ActiveCN104646416AGrain refinementImprove microstructureForging/pressing devicesMetal rolling arrangementsRoll formingShearing deformation

The invention discloses a strong-shear rolling forming method and a strong-shear rolling forming device for a metal plate. Power is provided by friction force between the plate and rollers during rolling deformation, and the plate is subjected to the strong-shear deformation of dies, and then enters a part between the rollers for plate rolling deformation. The device comprises a double-roller rolling mill, a movable die upper template, a movable die lower template, a stand, a fixed die lower template and a fixed die upper template, wherein the fixed die lower template is fixedly arranged on the stand; the movable die lower template is hinged to the fixed die lower template, and is arranged on the stand through an oil cylinder; the fixed die upper template and the movable die upper template are arranged on the fixed die lower template and the movable die lower template through bolts respectively; the double-roller rolling mill is arranged at an outlet of a metal plate passage. The method and the device are flexible in die equal channel angular adjustment and low in cost; the rolling deformation and the shear deformation of the metal plate such as a magnesium plate and an aluminum plate can be effectively combined, crystal grains of the plate can be refined, the texture evolution of the plate can be controlled, and the mechanical performance and the forming performance of the plate can be improved.

Owner:HUNAN UNIV OF SCI & TECH

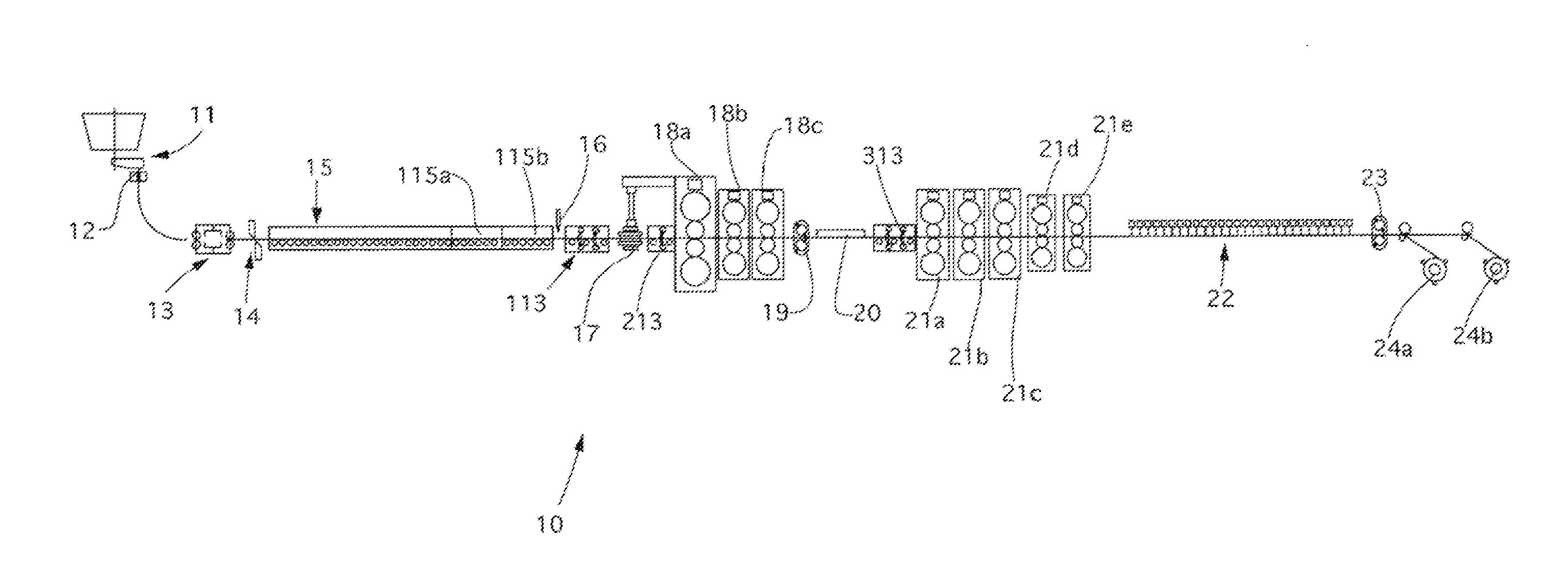

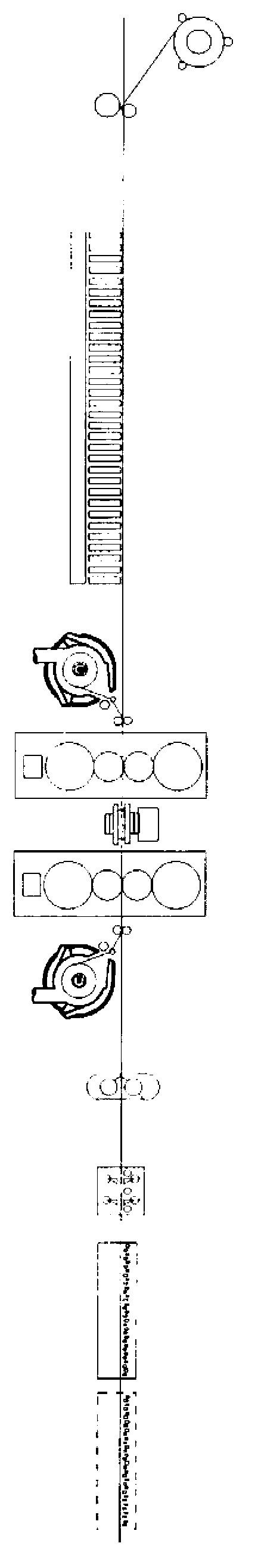

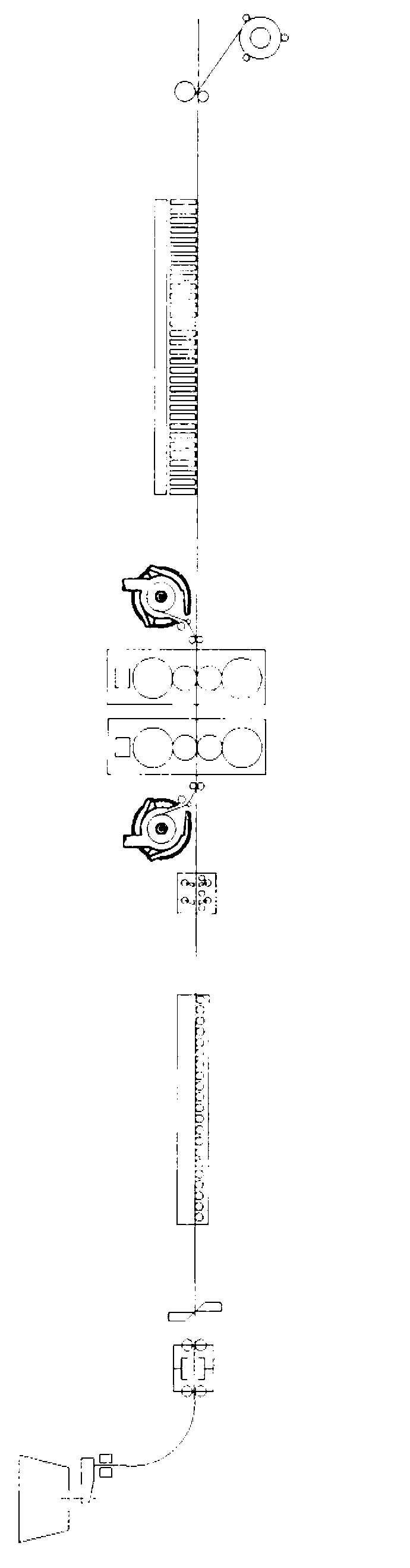

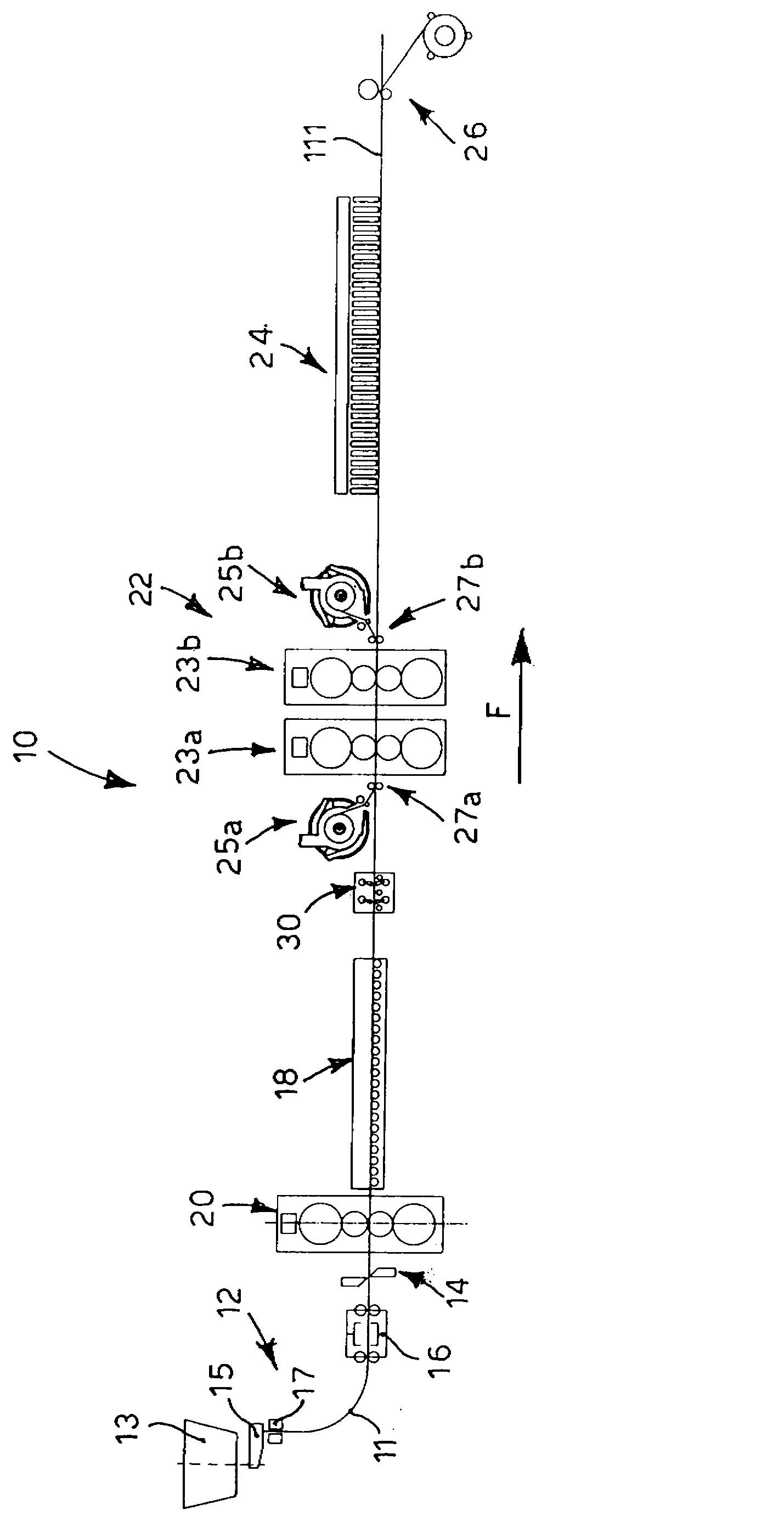

Rolling line and relative method

ActiveCN103180062ASave energyImprove productivityForging/pressing devicesMetal rolling stand detailsThin slabEngineering

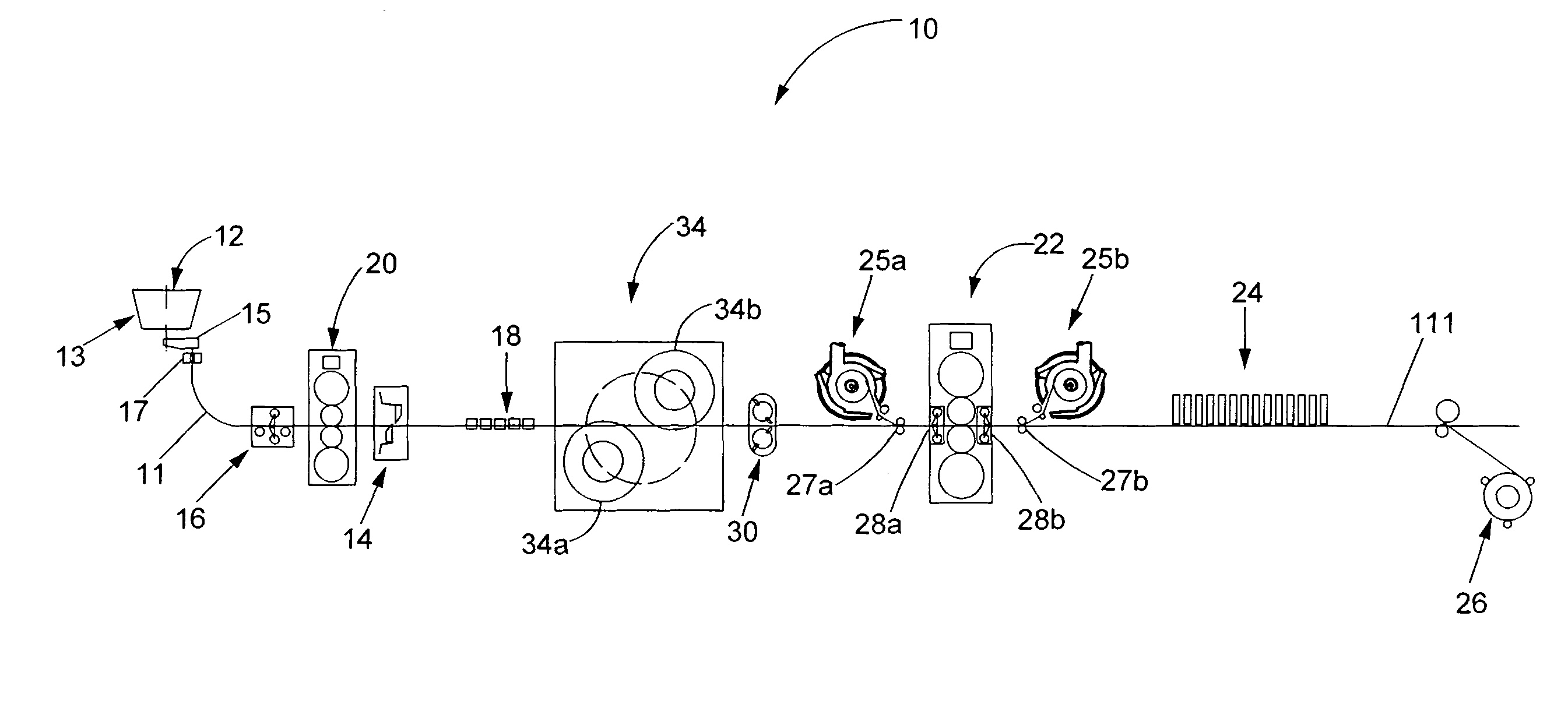

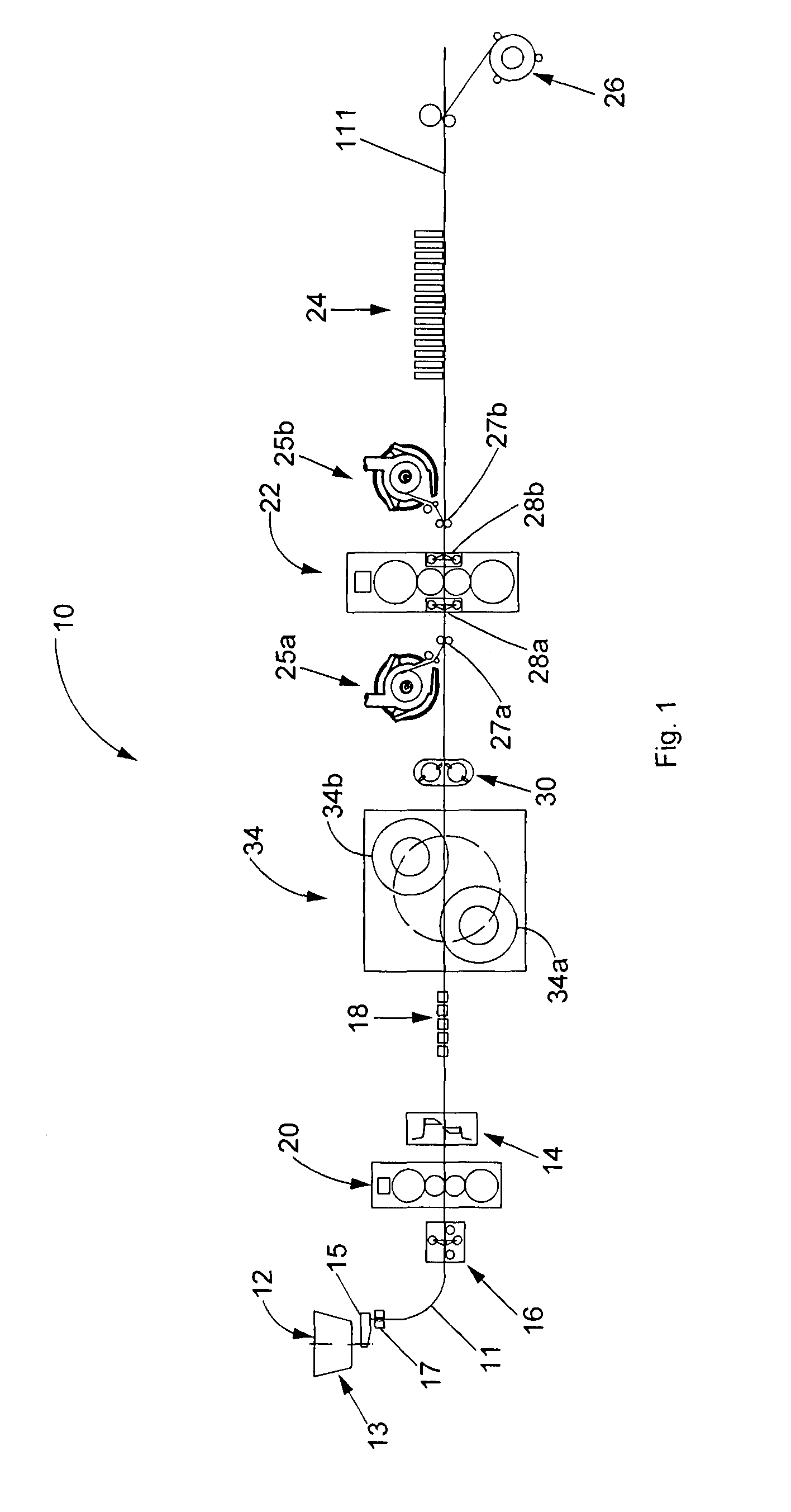

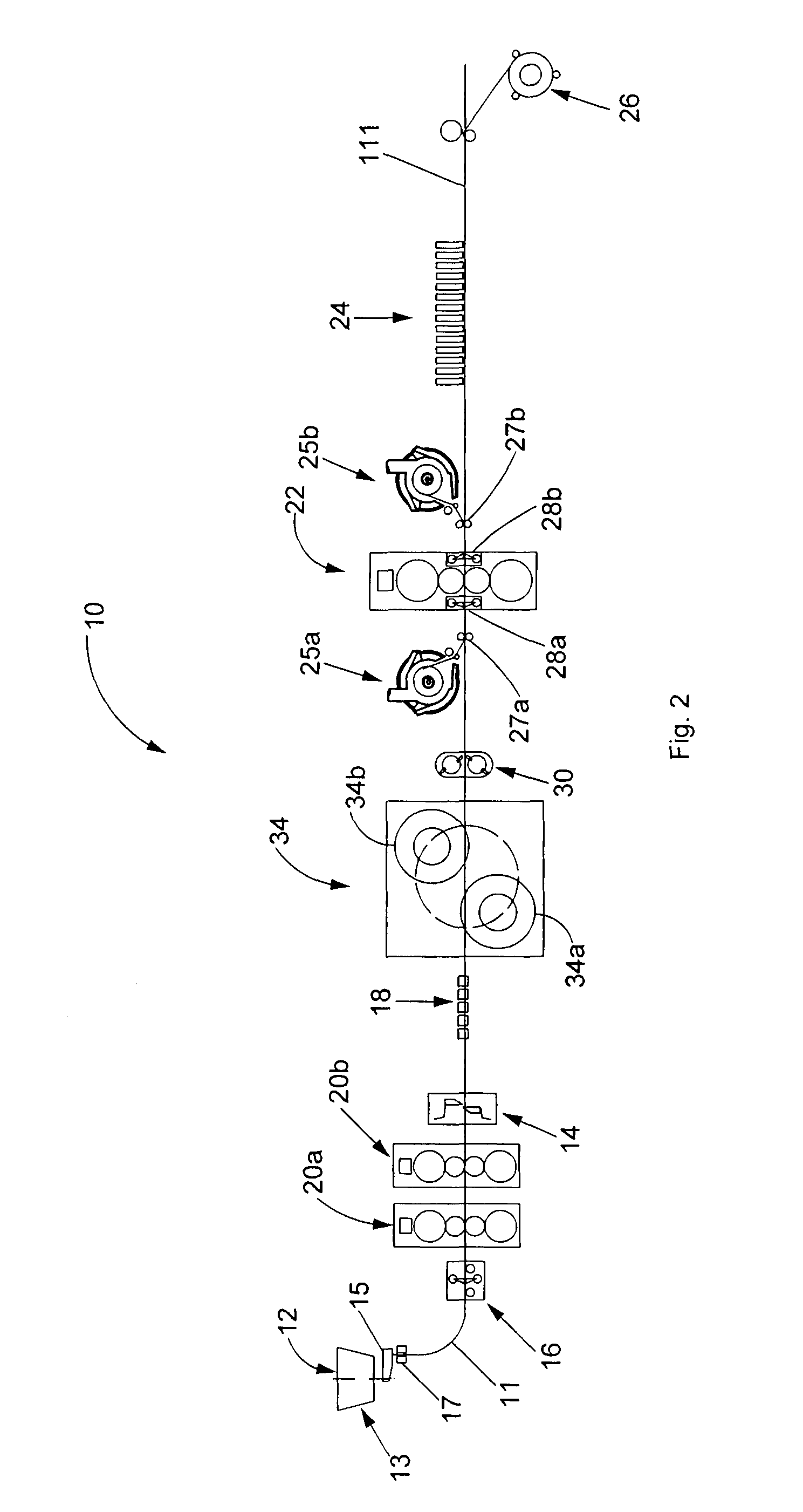

A rolling line (10) for the production of flat products (1 1 1) comprises a casting machine (12) suitable to continuously cast a thin slab (1 1), a temperature maintenance and homogenization unit (18), a rolling unit (22) comprising at least a double rolling stand (23a, 23b) of the Steckel reversing type downstream of the temperature maintenance and homogenization unit (18), at least a forming stand or roughing stand (20), directly connected immediately to the exit of the casting machine (12) and upstream of the temperature maintenance and homogenization unit (18), and suitable to reduce the thickness of the slab (1 1) just solidified.; The forming stand or roughing stand (20) is configured to perform an adaptive reduction of the thickness of the cast slab (1 1) smaller than or equal to about 65% at least as a function of the thickness, width and type of material of the finished flat product. The rolling unit (22) is configured to perform a reduction of the reduction of the thin slab (1 1) coming from the temperature maintenance and homogenization unit (18) to a thickness comprised between about 1.2 mm and about 20 mm by means of at most three double rolling passes through the double rolling stand (23a, 23b).

Owner:DANIELI & C OFF MEC SPA

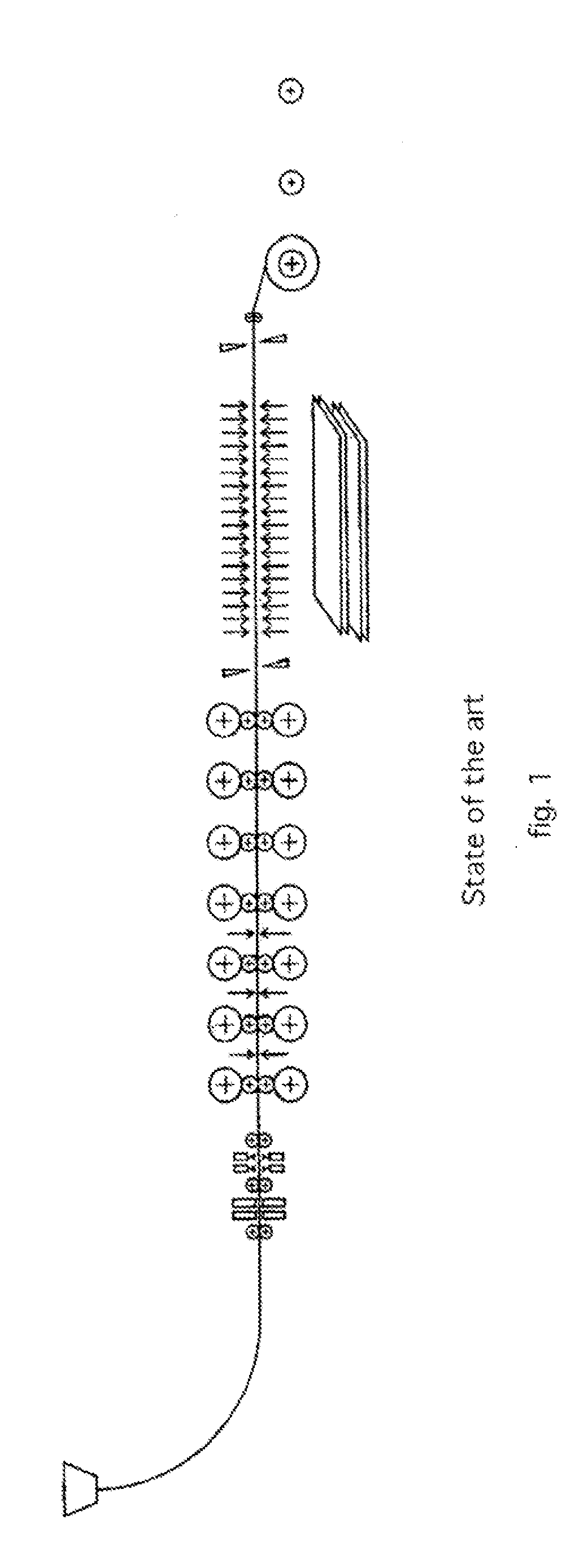

Rolling method for strip and corresponding rolling line

InactiveUS20140034264A1Quality improvementDecrease productivityForging/pressing devicesMetal rolling stand detailsProduction rateStrip steel

Rolling method for the production of flat products with low productivity, which comprises a continuous casting step at a speed comprised between 3.5 m / min and 6 m / min of a thin slab with a thickness comprised between 25 and 50 mm. It also comprises a roughing step to reduce the thickness in at least one roughing stand to a value comprised between 6 mm and 40 mm, and suitable for winding, a rapid heating step by means of induction in order to at least restore the temperature lost in the segment downstream of casting and in the roughing step, a winding / unwinding step in a winding / unwinding device with two mandrels. The method also comprises a rolling step in a rolling unit that consists of a single reversing stand of the Steckel type to roll the product unwound by the winding / unwinding device, which comprises at most five rolling passes, or four inversions, in order to obtain a final product with a thickness comprised between about 1.4 mm and 10 mm, preferably between about 1.4 mm and 8 mm, a cooling step and a step of winding the final product.

Owner:DANIELI & C OFF MEC SPA

Rolling mill temperature control

ActiveUS20110308288A1Prevent intrusionEqually distributedForging/pressing devicesTemperature control deviceTemperature controlStrip mill

For controlling the flatness of the strip during the rolling of aluminium strip or foil, the system consists of a full width bank of cryogenic roll cooling devices acting on the roll(s) and a full width bank of roll heating devices also acting the roll(s). Both or either of the cooling and heating banks are divided into individually controllable zones. A process automation system controls the action of the cooling and heating banks via feedback from a strip shape meter and / or a predictive process model, in order, by thermal growth / contraction, to create the best roll profile for rolling flat strip.

Owner:PRIMETALS TECH

Method and apparatus for preparing steel stock before hot rolling

InactiveUS9108234B2Reduce thicknessEasy to set upForging/pressing devicesMeasuring devicesInduction furnaceAtmosphere

Owner:PRIMETALS TECH AUSTRIA GMBH

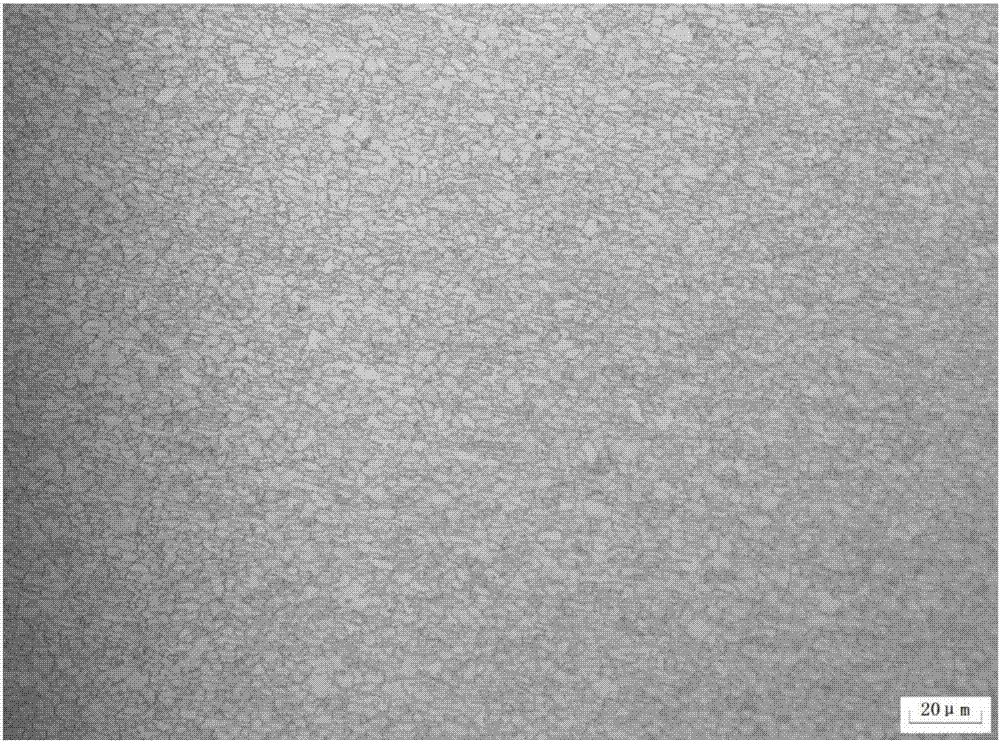

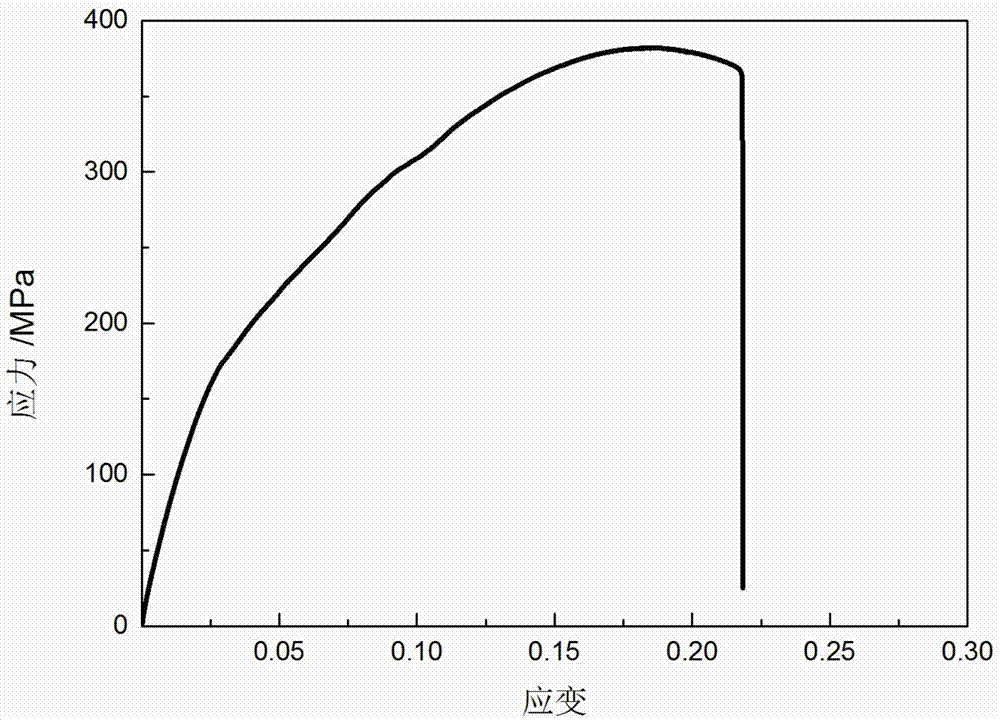

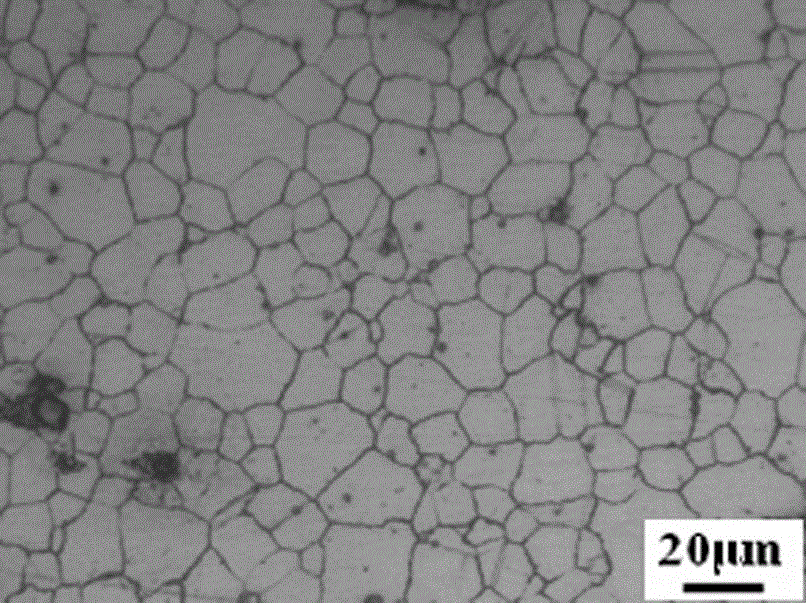

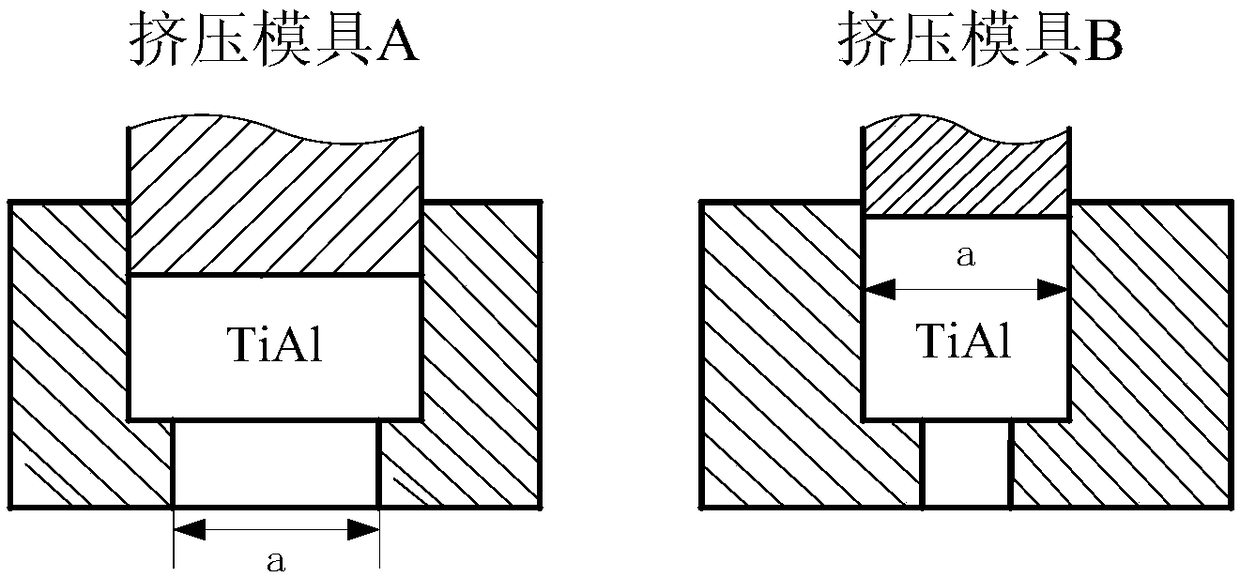

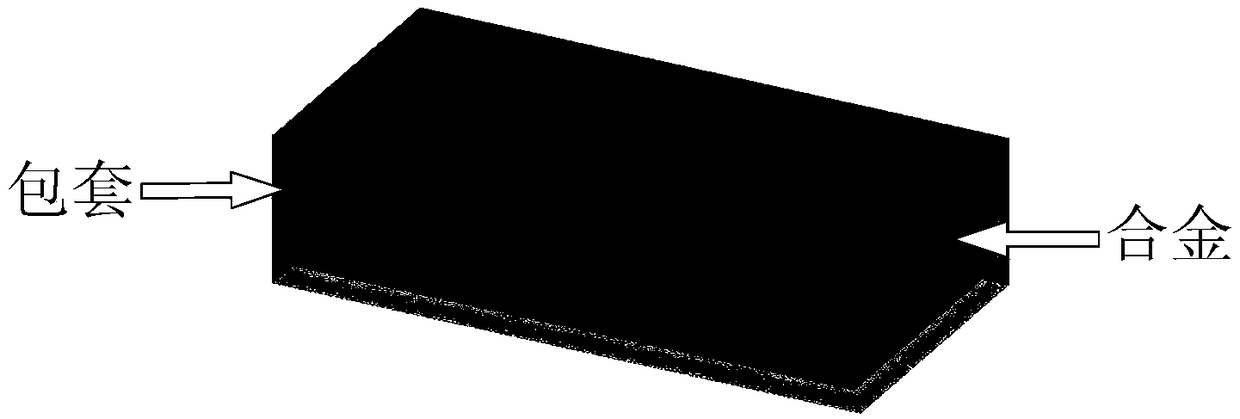

One-step large-deformation rolling method of beta solidification TiAl alloy plate

ActiveCN108787750AAvoid bulkyAvoid small amount of deformation in a single passForging/pressing devicesFurnace typesBeta phaseRoom temperature

The invention provides a one-step large-deformation rolling method of a beta solidification TiAl alloy plate. The method comprises the following steps that 1, raw materials are weighed; 2, a TiAl alloy casted ingot is manufactured by utilizing a vacuum induction melting technology, and heat treatment is carried out; 3, two-step hot extrusion deformation is carried out on the alloy; and 4, one-steplarge-deformation packing rolling is carried out on the alloy, and a pack is removed so as to obtain the TiAl alloy plate which is uniform and fine in structure. According to the one-step large-deformation rolling method of the beta solidification TiAl alloy plate, the beta solidification TiAl alloy with excellent high-temperature deformation capability is adopted, the beta phase content is controlled to be 15%-25%, and the excellent high-temperature deformation capability of the TiAl alloy is ensured; meanwhile, the alloy structure of a blank is refined violently through the two-step extrusion so as to remarkably improve the structure uniformity of the alloy, and therefore, one-step large-deformation rolling of the blank can be guaranteed, finally, the TiAl alloy plate with the uniform and fine structure and good room temperature plasticity is obtained, and the problems that in the prior art, a TiAl alloy rolled blank is coarse in structure, plate forming is difficult, and the platestructure uniformity is poor are solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

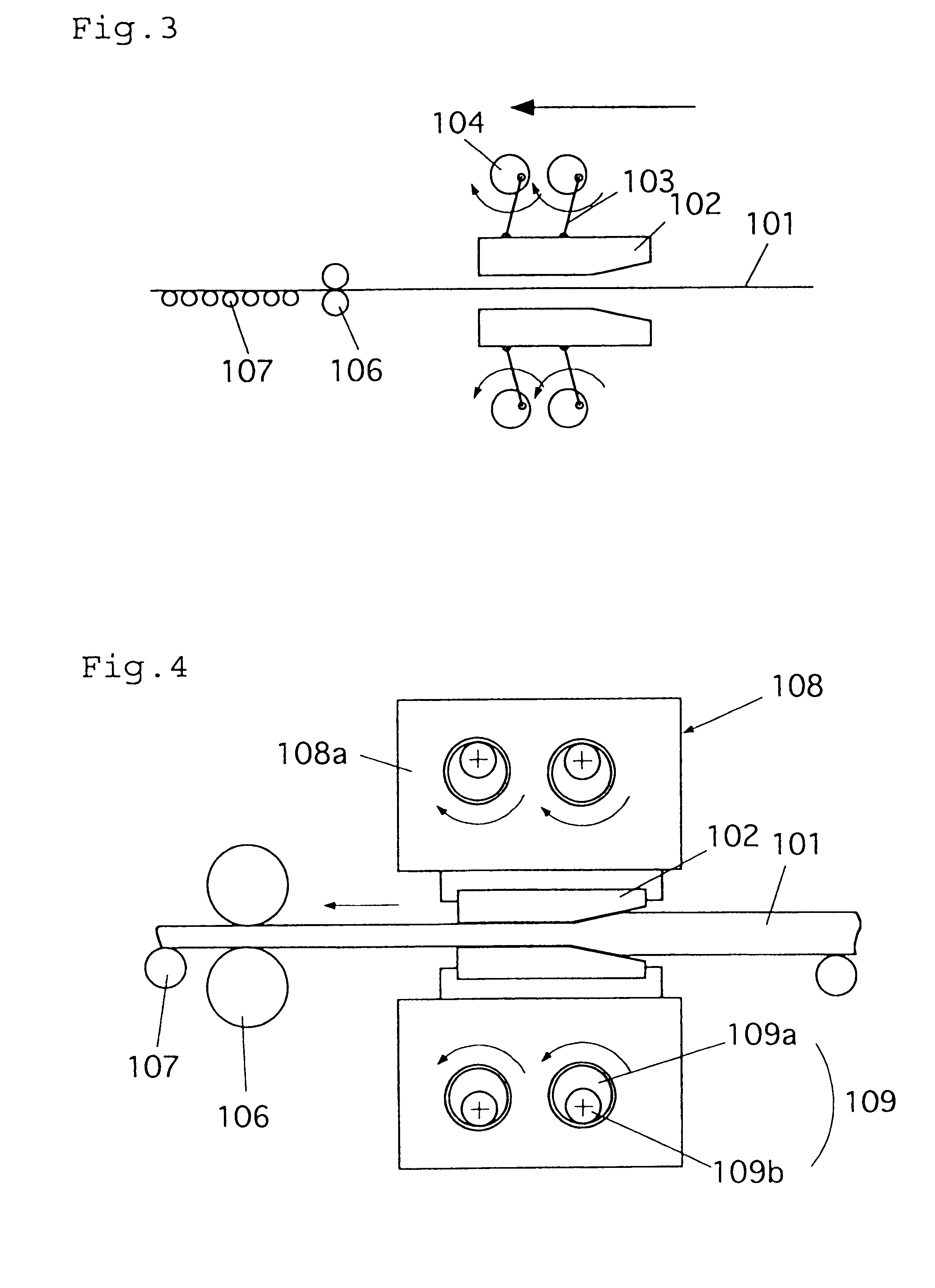

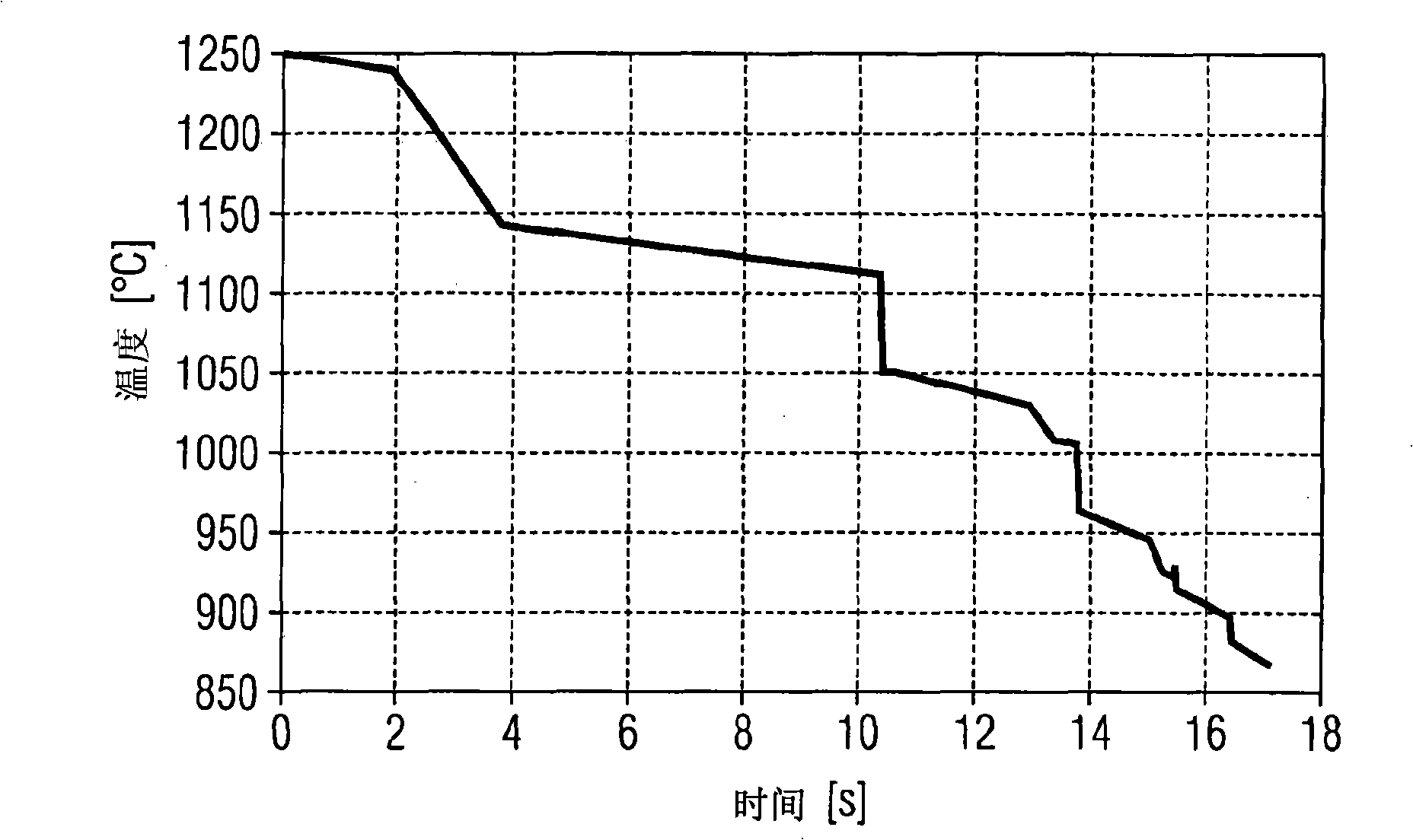

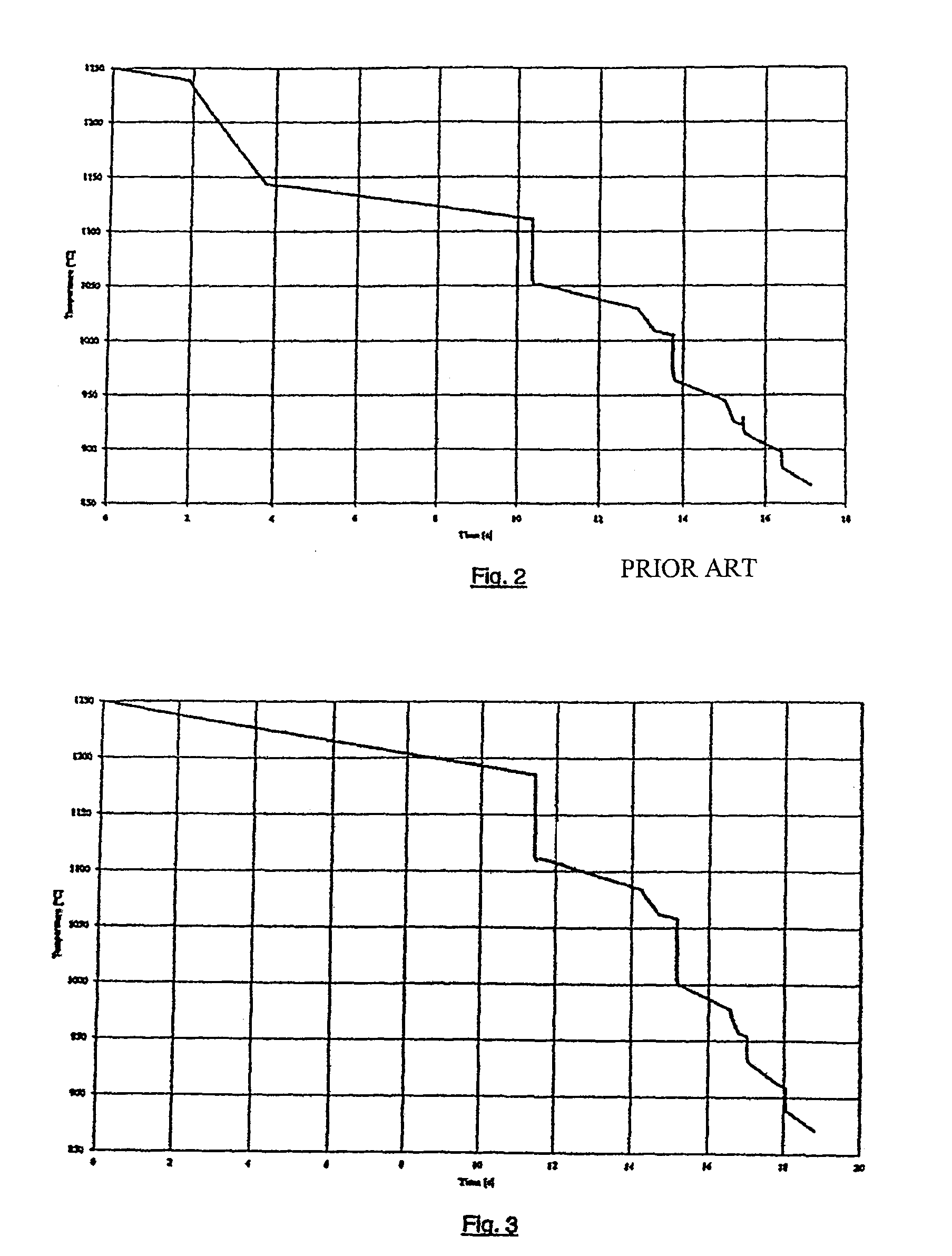

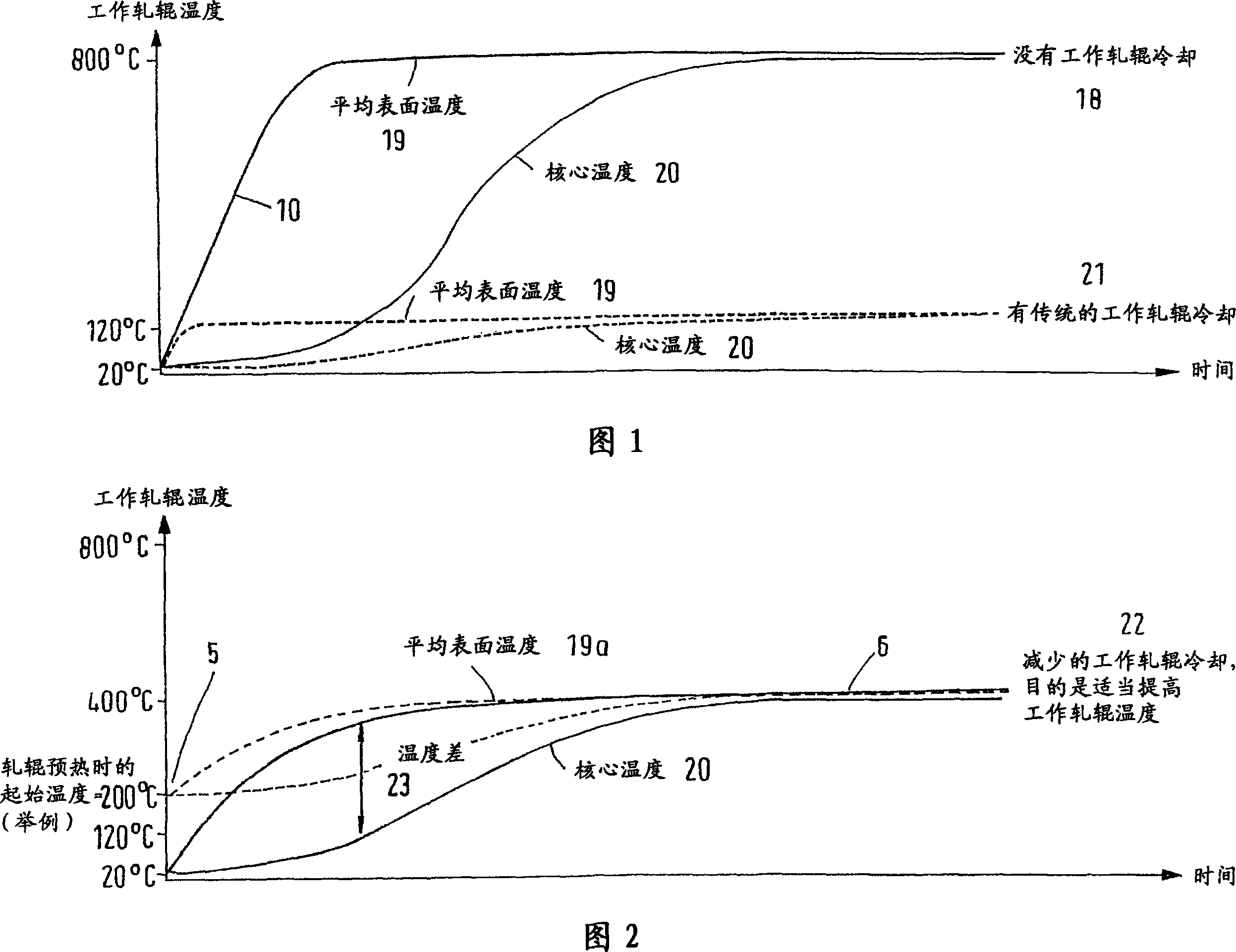

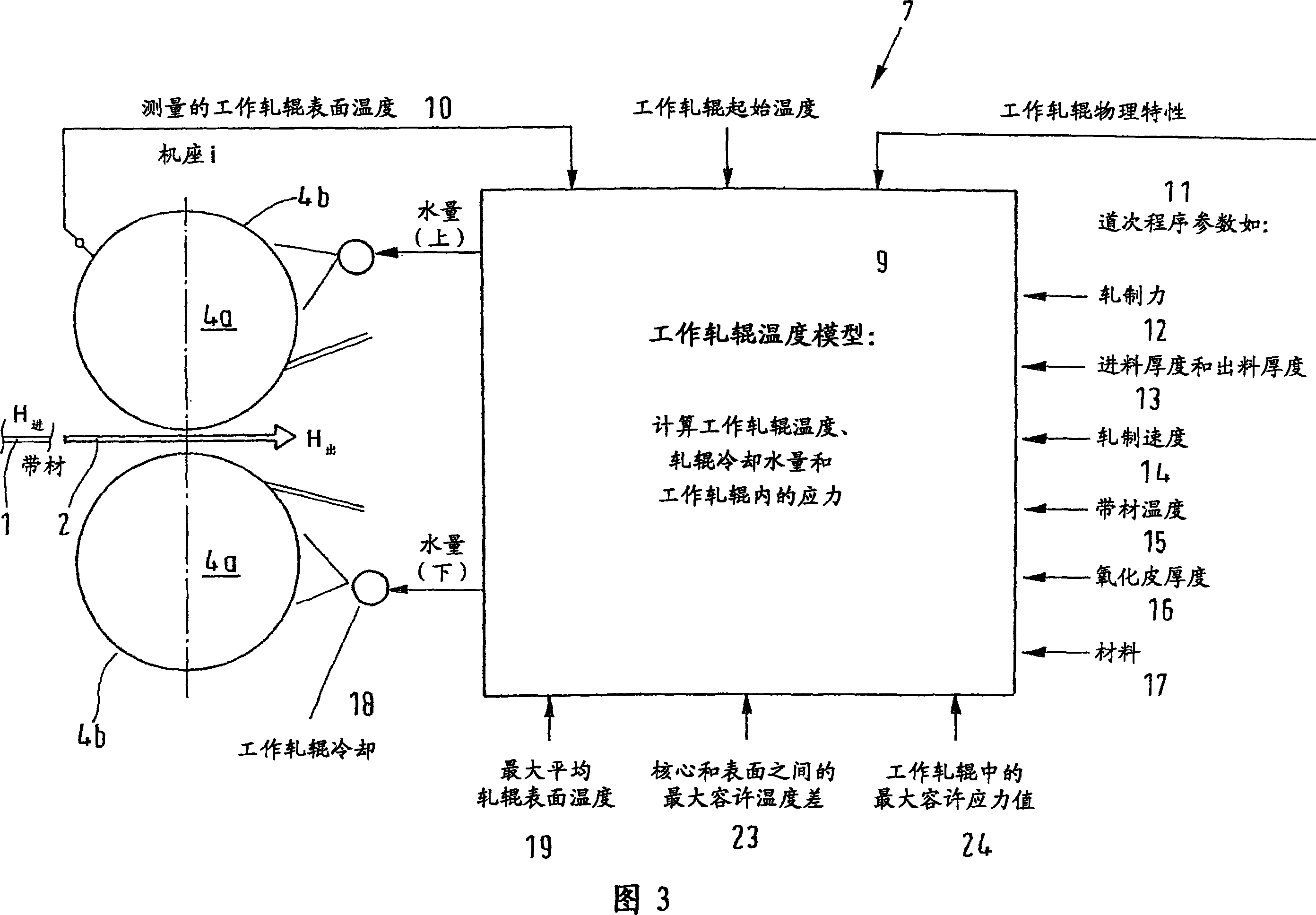

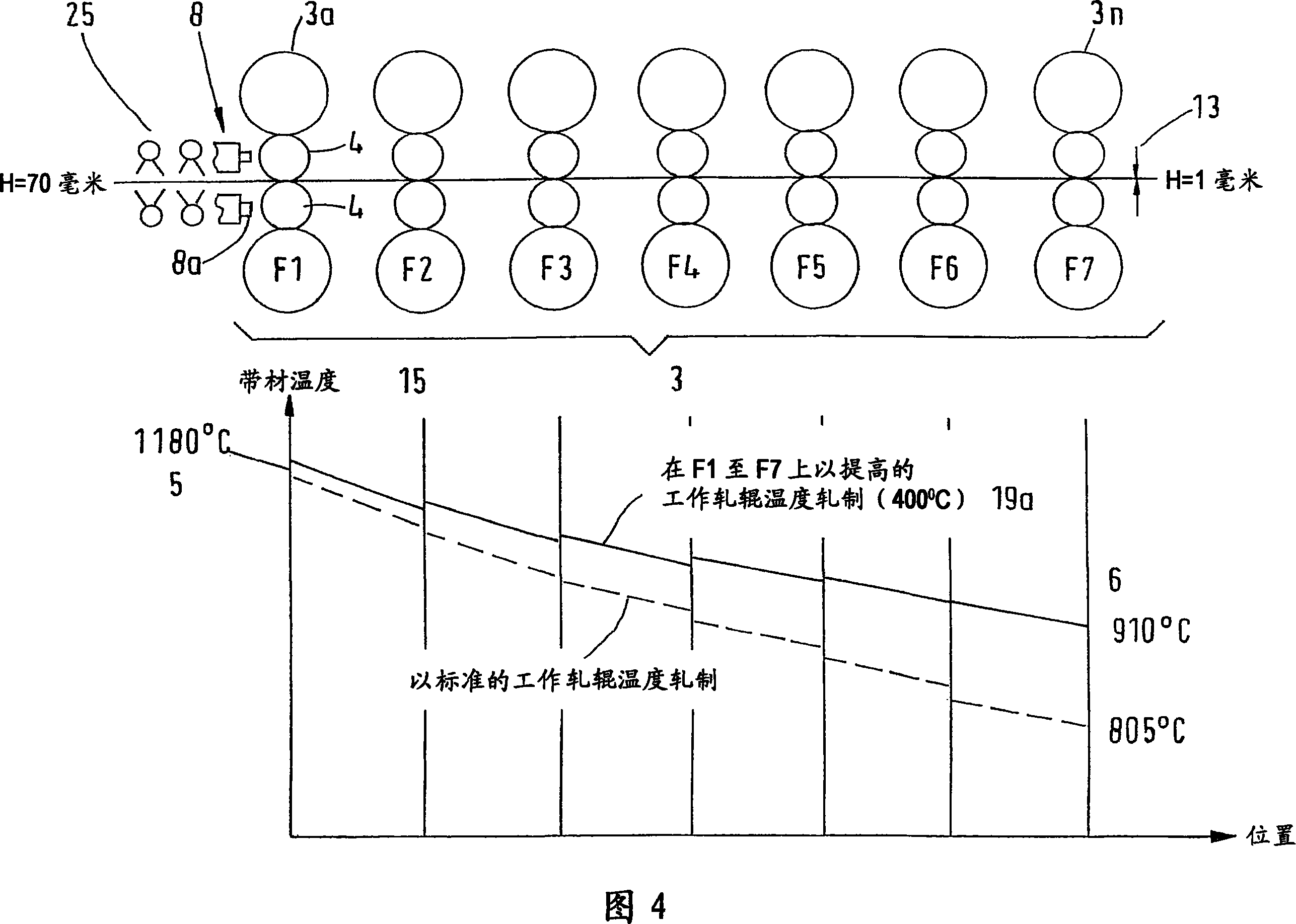

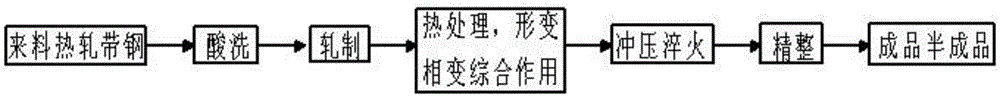

Method for continuous casting and rolling with an increased casting rate and subsequent hot-rolling of relatively thin metal strands, especially steel strands, and continuous casting and rolling devic

The invention relates to a method for continuous casting and rolling with a high casting rate and subsequent hot-rolling of relatively thin metal strands, especially steel strands (1), the target temperatures (6) of the hot strip (2) being pre-defined. Said method enables temperature losses on the hot strip (2) to be reduced by increasing the temperatures of the work rolls (4) with a pre-determined rate of increase starting from a low initial temperature (5), and by adjusting the temperature (15) of the strip to a target roll temperature (6) of the hot strip (2) and / or by regulating or controlling the intensity of the roll cooling (18).

Owner:SMS DEMAG AG

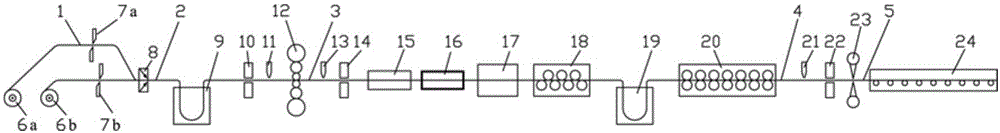

Short-process producing and processing technology and equipment for cold rolling ultrahigh strength steel

ActiveCN105414177AReduce consumptionShort production processForging/pressing devicesMetal rolling arrangementsProcess equipmentQuenching

The invention discloses a short-process producing and processing technology for cold rolling ultrahigh strength steel. The short-process producing and processing technology comprises the following steps: hot rolled strip steel, serving as an incoming material, is treated by procedures before rolling such as acid pickling and the like, cold rolling, heat treatment and deformation and phase transition comprehensive treatment, enters a loop after the heat treatment and the deformation and phase transition comprehensive treatment, is suitable for changes of the rolling velocity and the punch velocity by regulating the loop capacity and can enter a punching and quenching technology after being shorn with fixed length; and after the ultrahigh strength steel is finished, a finished or semi-finished punching part is obtained. Short-process producing and processing equipment for cold rolling the ultrahigh strength steel comprises a cold continuous rolling unit, a degreasing device inlet frame, a degreasing device, a looping tower, an annealing furnace front tension controlling device, an annealing furnace, an annealing furnace back tension controlling device, a collecting box and the like. With the adoption of the short-process producing and processing process and equipment, the energy consumption is reduced, the energy is saved, and the production cost is lowered; and by adding the deformation technology in the heat treatment process of the ultrahigh strength steel, the purpose of synchronous deformation and phase transition of the ultrahigh strength steel is realized, and the using performance of the strip steel is improved.

Owner:YANSHAN UNIV

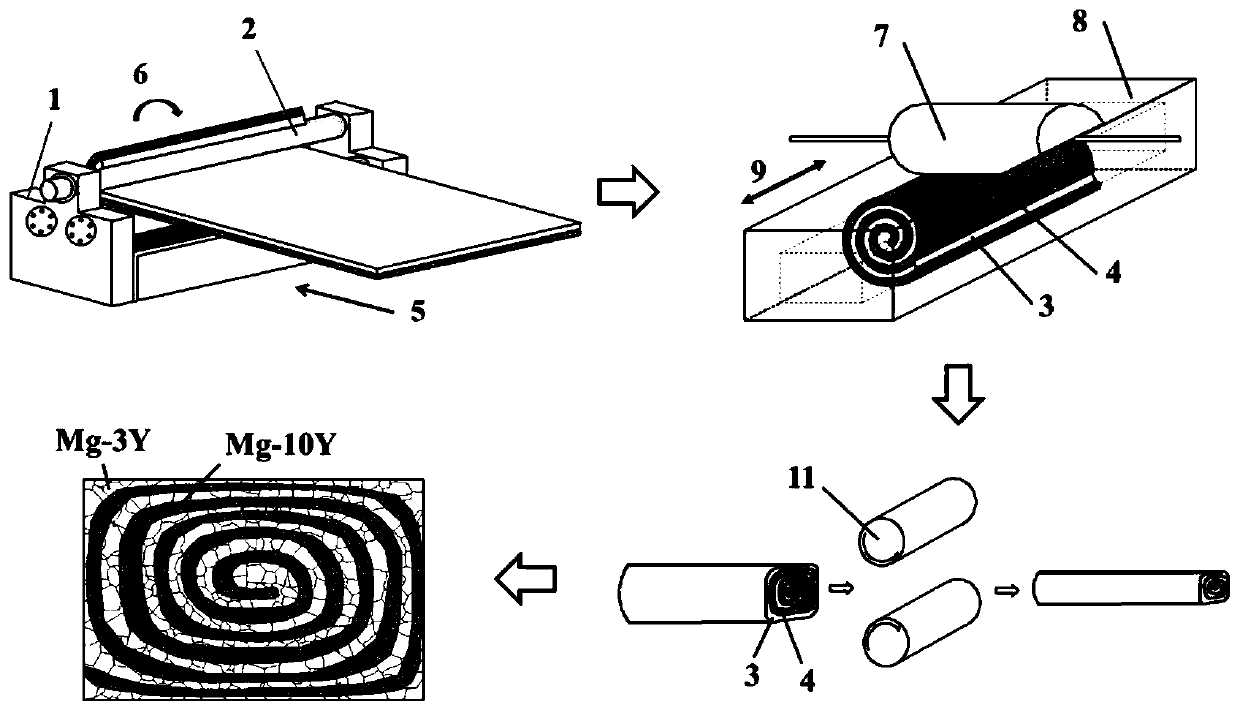

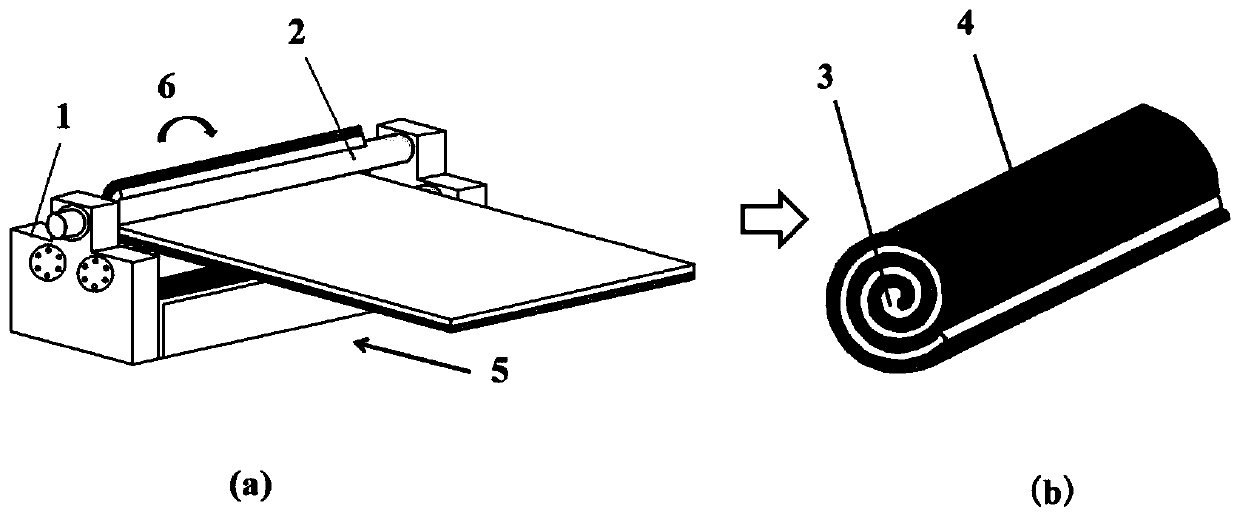

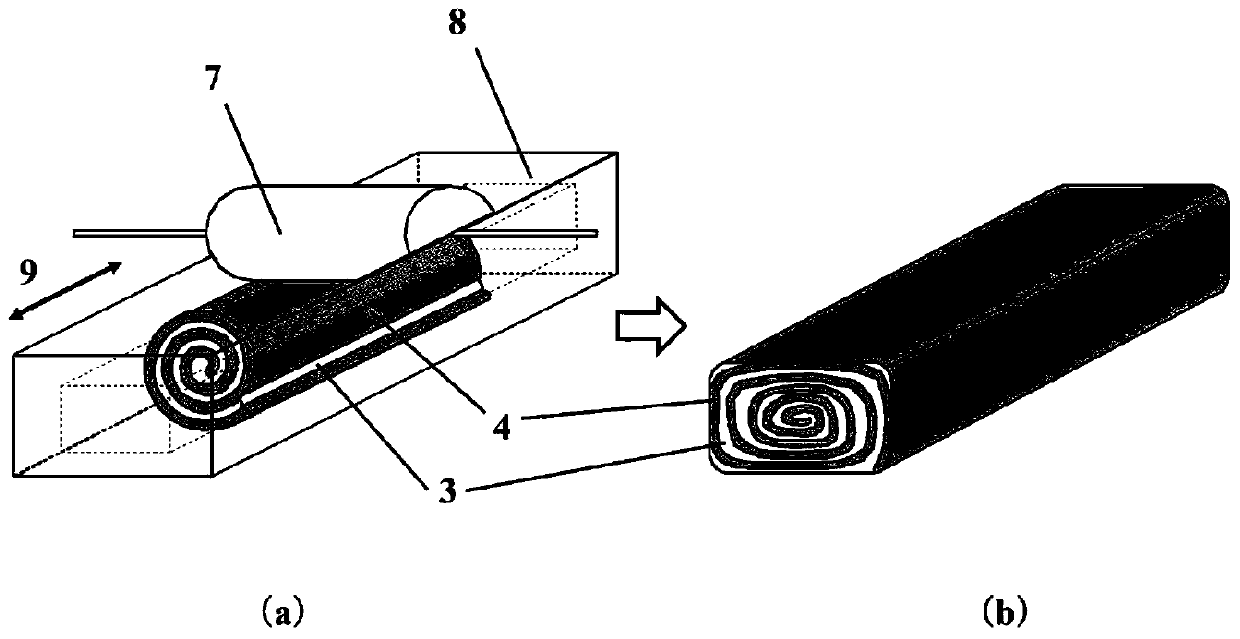

Method and system for preparing multi-scale precipitated nano heterogeneous magnesium alloy plates

ActiveCN111408623ALarge structureIncrease flexibilityForging/pressing devicesFurnace typesThick plateUltimate tensile strength

The invention belongs to the field of material preparation, and particularly relates to a method for preparing multi-scale precipitated nano heterogeneous magnesium alloy plates. The method comprisesthe following steps of rolling, wherein a plurality of magnesium alloy plates with two or more aging precipitation behaviors are alternately stacked and then rolled into bars; rolling, wherein the bars are rolled to prepare a multi-layer heterogeneous magnesium alloy thick plate blank; hot rolling, wherein the layer thickness is reduced through hot rolling, the interface bonding degree is improved, and the multi-layer heterogeneous magnesium alloy plates are prepared; and multi-scale precipitation, wherein multi-scale precipitation in the heterogeneous magnesium alloy plates is regulated and controlled through solid solution and aging treatment, and the multi-scale precipitation reinforced nano heterogeneous magnesium alloy plates are obtained. The heterogeneous magnesium alloy plates areprepared through a double-alloy or multi-alloy rolling and hot rolling method, and has great microstructure design directivity and flexibility. The prepared alloy has toughness and strength of a softphase and a hard phase, and the high-strength and high-toughness double-system or multi-system precipitation reinforced magnesium alloy with excellent comprehensive performance is obtained.

Owner:NANJING UNIV OF SCI & TECH

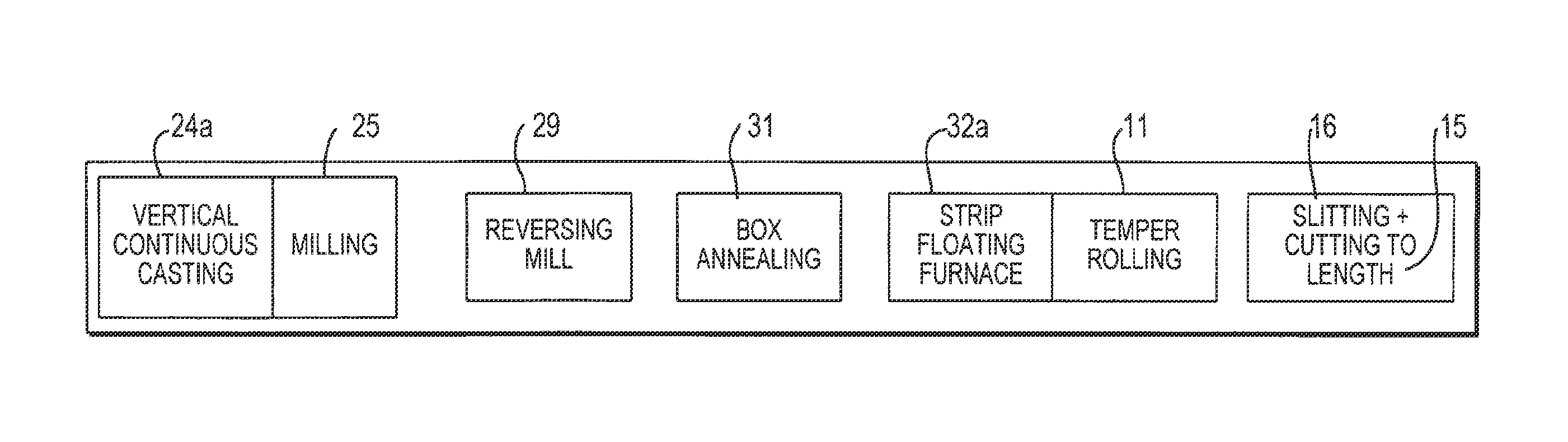

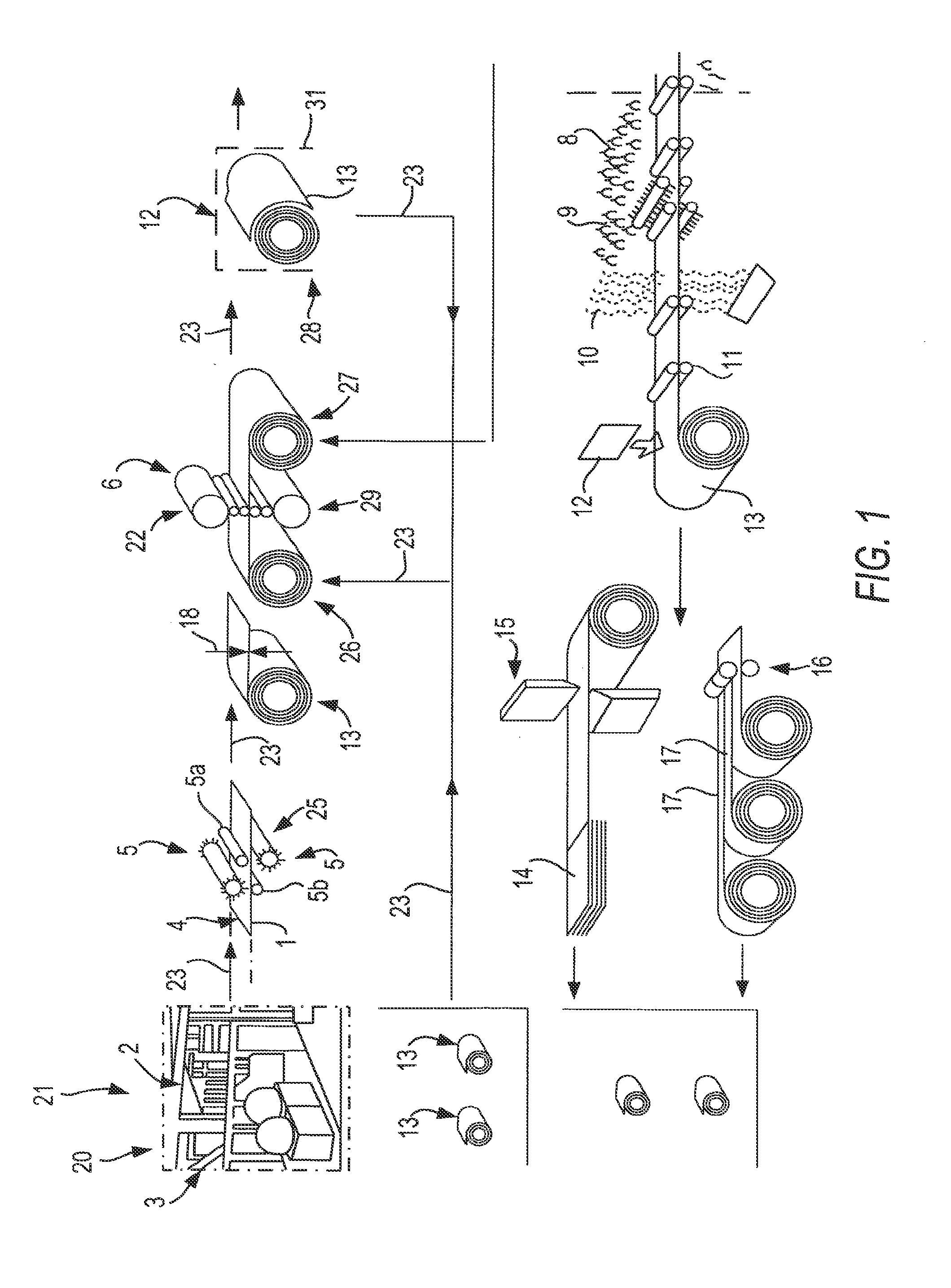

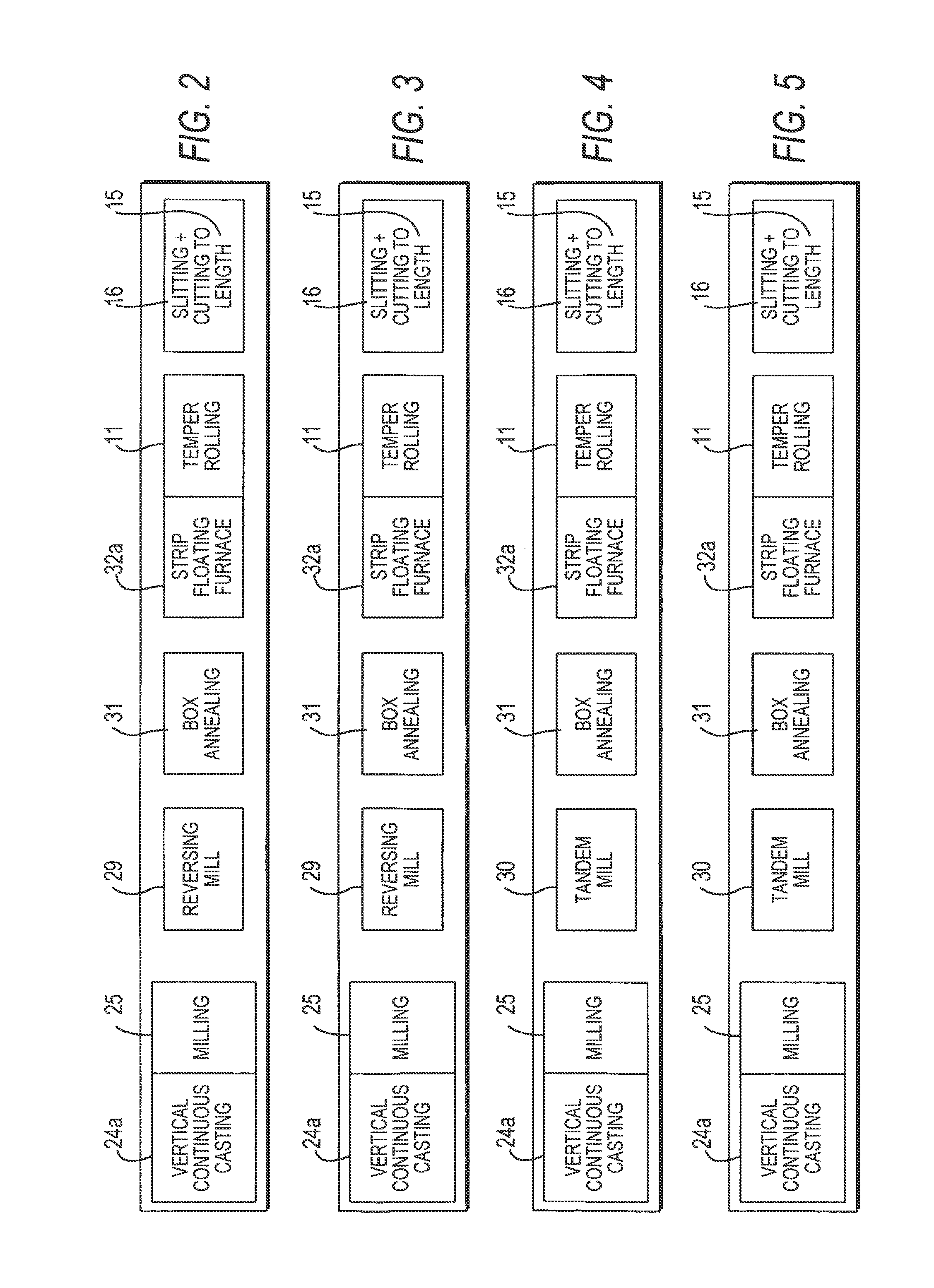

Method and production line for manufacturing metal strips made of copper or copper alloys

InactiveUS20110214834A1Increase capacityReduce operating costsForging/pressing devicesMetal rolling stand detailsProduction lineStrip steel

A production line for manufacturing metal strips made of copper or copper alloys by means of casting and rolling. In order to lower the investment cost and operating expenses therefore, the melt is cast into a copper strip in a vertical and / or horizontal continuous strip casting process, and the hot copper strip is cleaned by milling the top and bottom face thereof, is subjected to a cold rolling process, and is prepared for shipping, or is subjected to an inspection and then prepared for shipping after being annealed, pickled, washed, dried, and optionally temper rolled.

Owner:SMS DEMAG AG

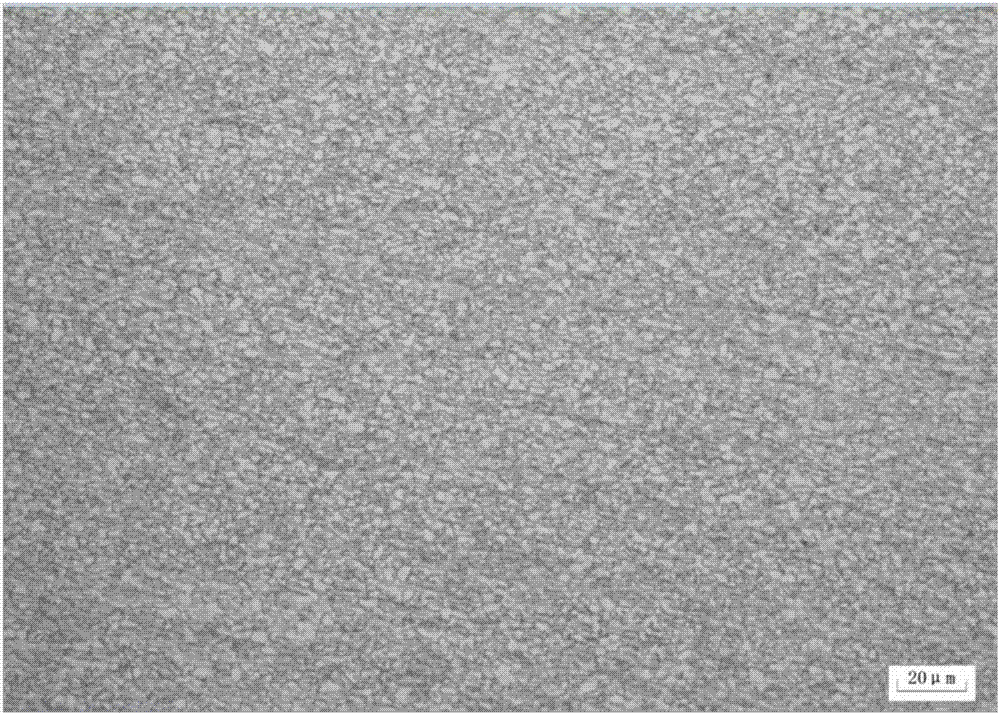

Preparation method of fine-grain TA15 titanium alloy foil

ActiveCN113578959AControl microstructureControl mechanical propertiesForging/pressing devicesFurnace typesTitanium alloyMaterials science

The invention discloses a preparation method of fine-grain TA15 titanium alloy foil. The preparation method specifically comprises the following steps of (1) heating a TA15 titanium alloy cast ingot at 1000-1100 DEG C, and then carrying out cogging forging to obtain a plate blank; (2) carrying out heat preservation at 900-960 DEG C, and then carrying out rolling; (3) carrying out heat treatment at 30-50 DEG C above a beta phase transformation point, and then carrying out water quenching cooling; (4) carrying out heating at 900-940 DEG C, and then carrying out rolling; (5) carrying out assembly welding on the obtained blank to obtain a cladding ply-rolling pack; (6) carrying out heating at 900-940 DEG C, and then carrying out rolling for the fourth time; (7) opening the ply-rolling pack, and then carrying out assembly welding on the blank to obtain a cladding ply-rolling pack; (8) carrying out heating at 920-940 DEG C, and then carrying out rolling in a direction perpendicular to the previous rolling direction; (9) carrying out annealing, creep correction, alkali pickling and sanding on the blank to obtain a plate with the thickness of 0.6 mm; (10) shearing the plate, and then carrying out cold rolling multiple times to obtain rolled foil with the thickness ranging from 0.1 mm to 0.2 mm; and (11) carrying out vacuum annealing heat treatment to obtain the finished foil with the thickness ranging from 0.1 mm to 0.2 mm.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

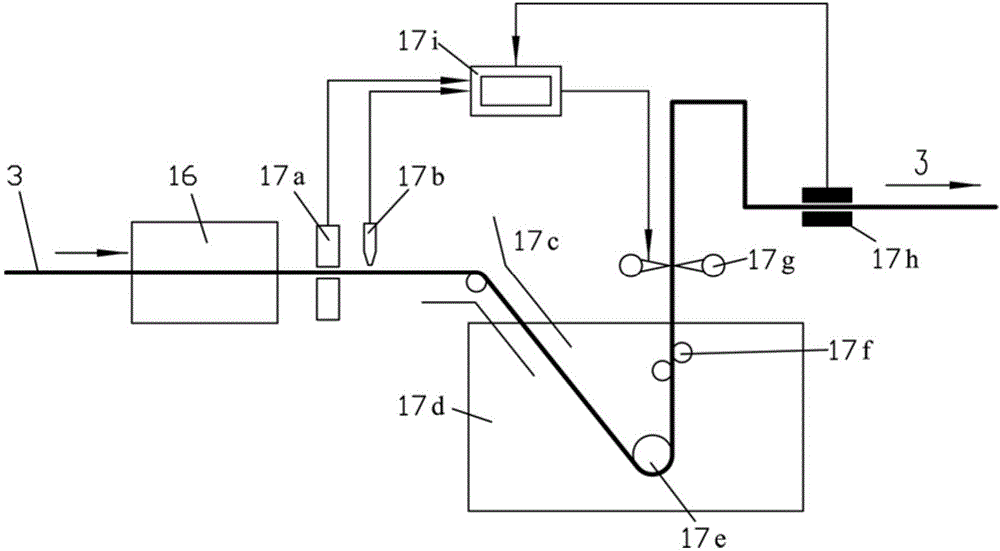

Continuous near-net-type rolling equipment of linear Slide rail material

InactiveCN104741375AWon't cause cracksShorten production timeForging/pressing devicesRollsManufacturing cost reductionPower control system

The present invention discloses a continuous rolling apparatus near-net type linear slide material, including a wire feeding mechanism, a tension control mechanism, at least one group for rolling extension mechanism, an electromagnetic induction heating system and a four-roll type near Net type rolling mechanism. The wire feed mechanism is used to transport a timber embryos; the tension control mechanism is used to control a germ material to maintain proper speed of transport and transport tension; the mechanism for rolling extension that contains the electromagnetic induction heating system and the four-roll style near-net-type rolling mechanism, in which the electromagnetic induction heating system comprises a temperature feedback control device and the frequency with a power control system, the temperature feedback control means for detecting germ material surface temperature and the frequency and power control systems heating embryo timber and timber control embryos maintained at a temperature suitable for rolling; the four-roll type rolling near-net mechanism is used for the embryo rolling plastic processing material, and includes four planetary arrangement of rolls, which are for simultaneously rolling section of the embryo surrounding material delay. Rolling apparatus of the present invention may be continuous mass production, and dramatically reduce the manufacturing time and reduce manufacturing costs.

Owner:CHIH CHANG ENTERPRISE

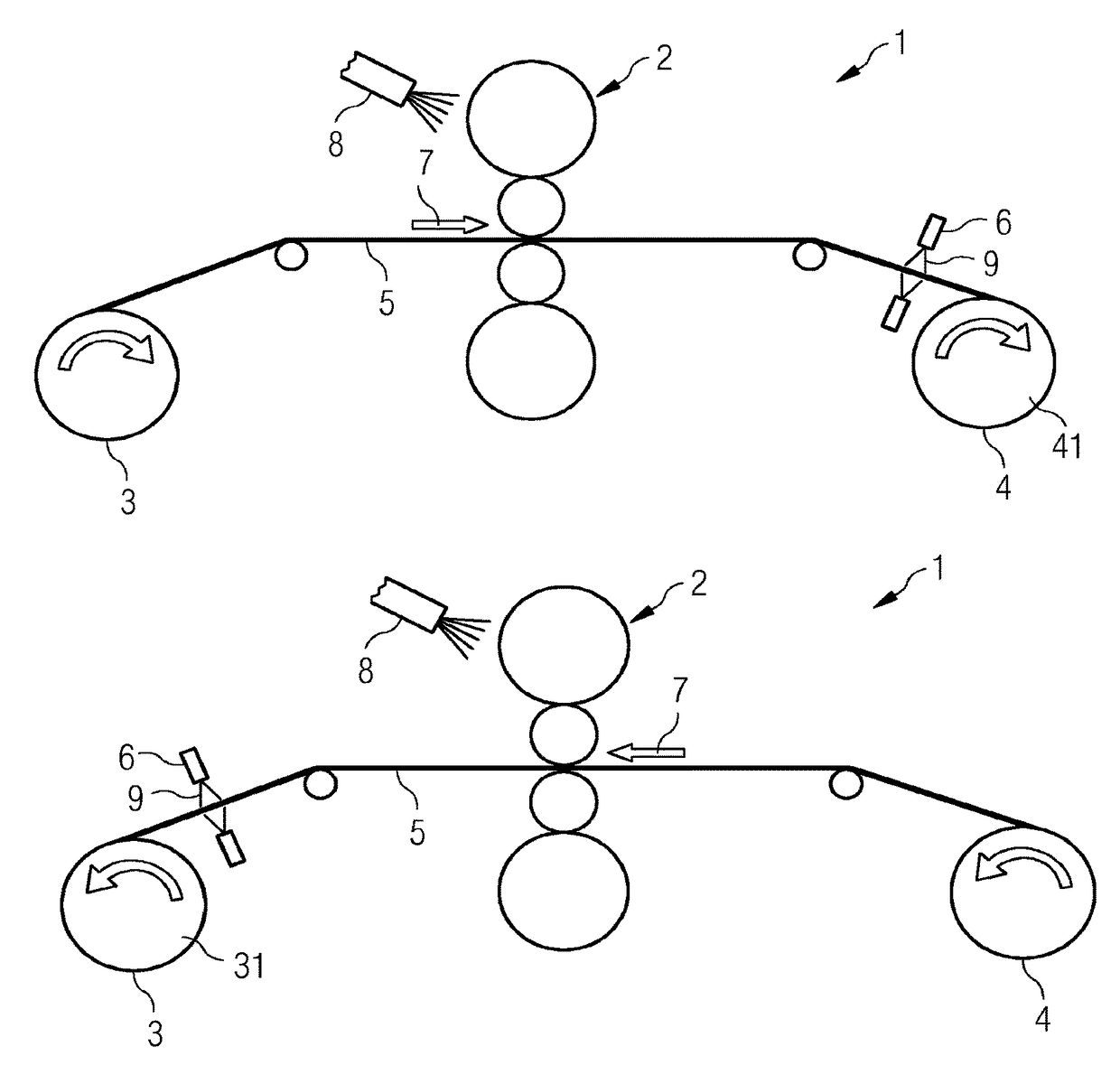

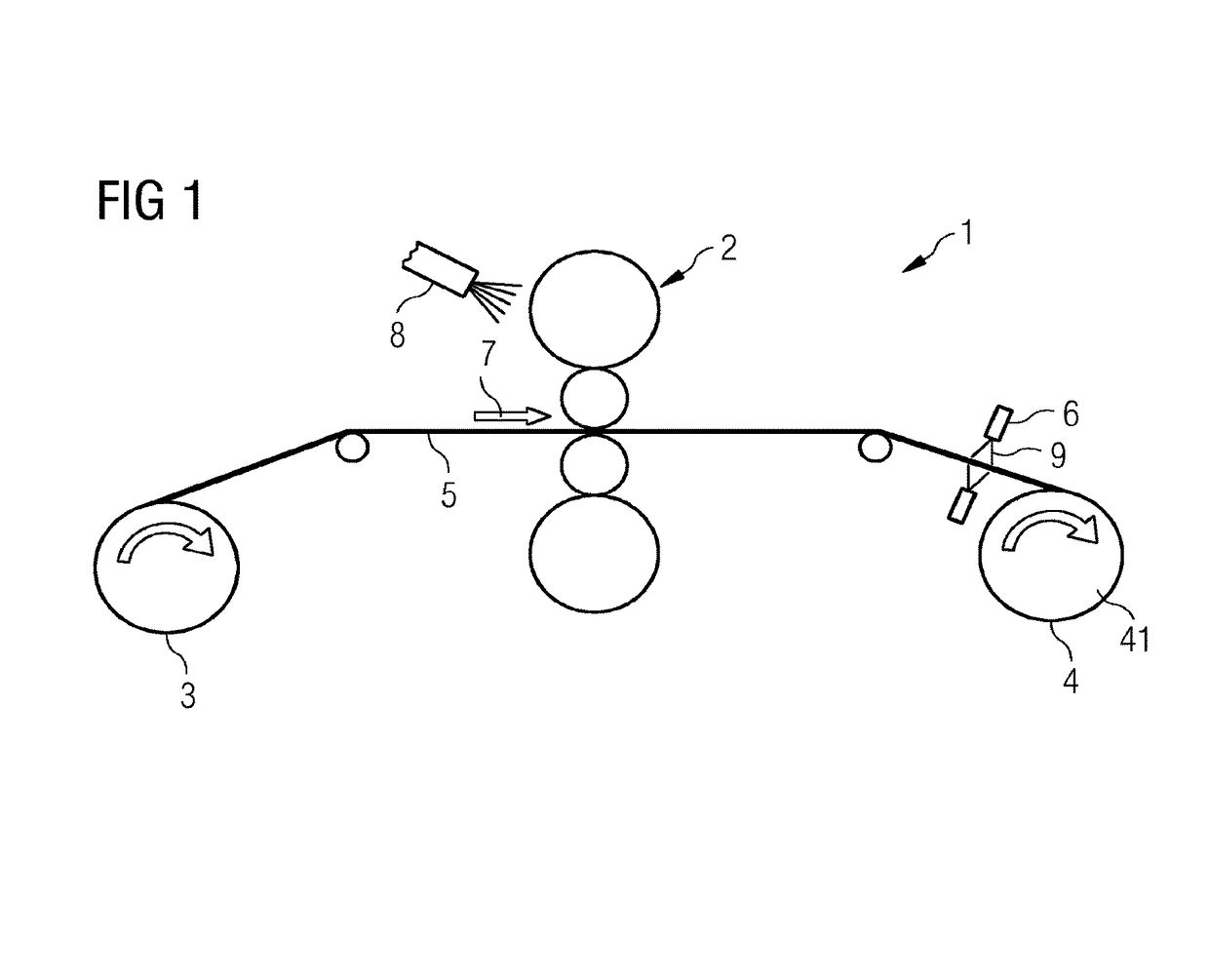

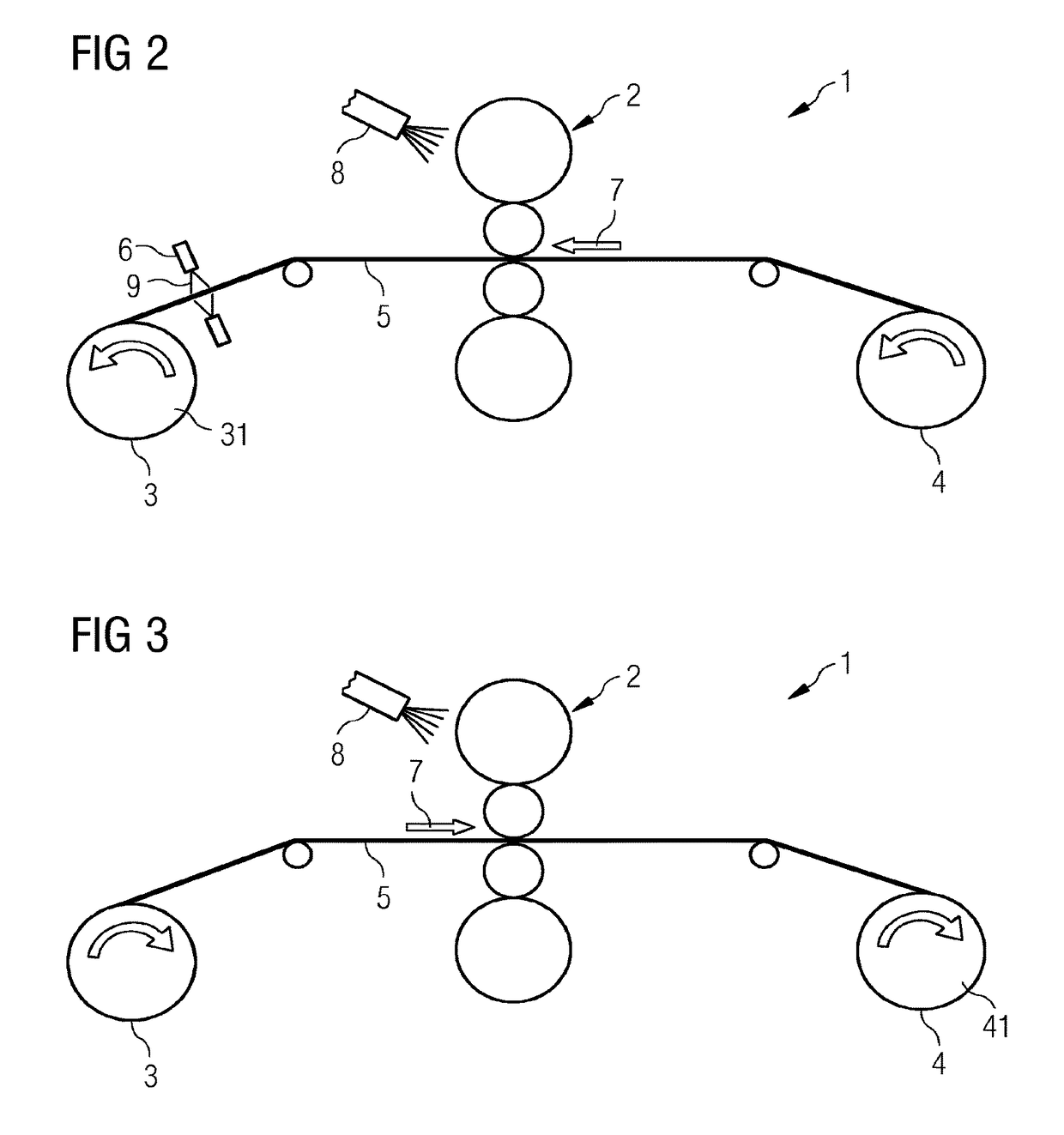

Reversing rolling mill and operating method for a reversing rolling mill

ActiveUS9815101B2Reduce fuel consumptionMaintaining good roll gap lubricationForging/pressing devicesWork cooling devicesStrip millEngineering

Operating method for a reversing rolling mill having at least one reversing rolling stand (2) for rolling a rolled metal stock (5), wherein the stock (5) passes the at least one reversing rolling stand (2) in a sequence of alternating direction passes (7) and after each pass, the stock is wound up by a reversing reel (3, 4), wherein only rolling oil, without water as a carrier medium, is applied to the stock (5) by rolling-oil applicator (6), between the at least one reversing rolling stand (2) and the winding-up reel (31, 41).

Owner:PRIMETALS TECH AUSTRIA GMBH

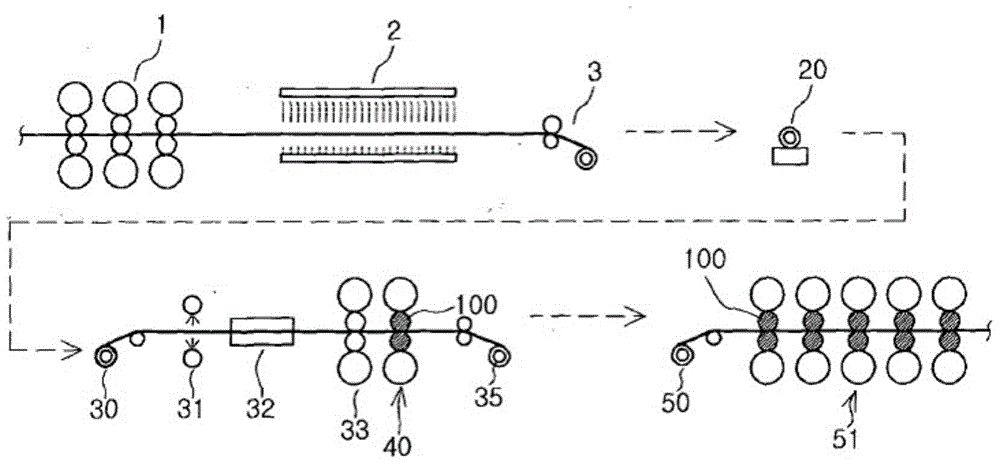

Shape-correcting and rolling method and shape-correcting device for high-strength steel

ActiveCN104870115AAchieve shape correctionImprove shape correction abilityForging/pressing devicesWork treatment devicesHigh intensityConductor Coil

The present invention provides a shape-correcting and rolling method for high-strength steel, whereby it is possible to effectively achieve shape correction of high-strength steel, and provides a shape-correcting and rolling method for high-strength steel, the method comprising: a hot-rolling skin-pass-mill direct-coupling forwarding step in which a hot-rolled coil is sent to a pay-off reel, or a step in which the coil is forwarded after having been passed through a cooling step; an unwinding step in which the coil is spooled out from the pay-off reel; a shape-correcting step in which a heat-pipe roll is used to correct the shape of the unwound strip; and a re-winding step in which the strip is re-wound into a coil.

Owner:浦项股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com