Rolling line and relative method

A production line and rolling pass technology, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve the problems of harsh working conditions, negative effects of casting process stability, high casting speed, etc., and achieve damage and less sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

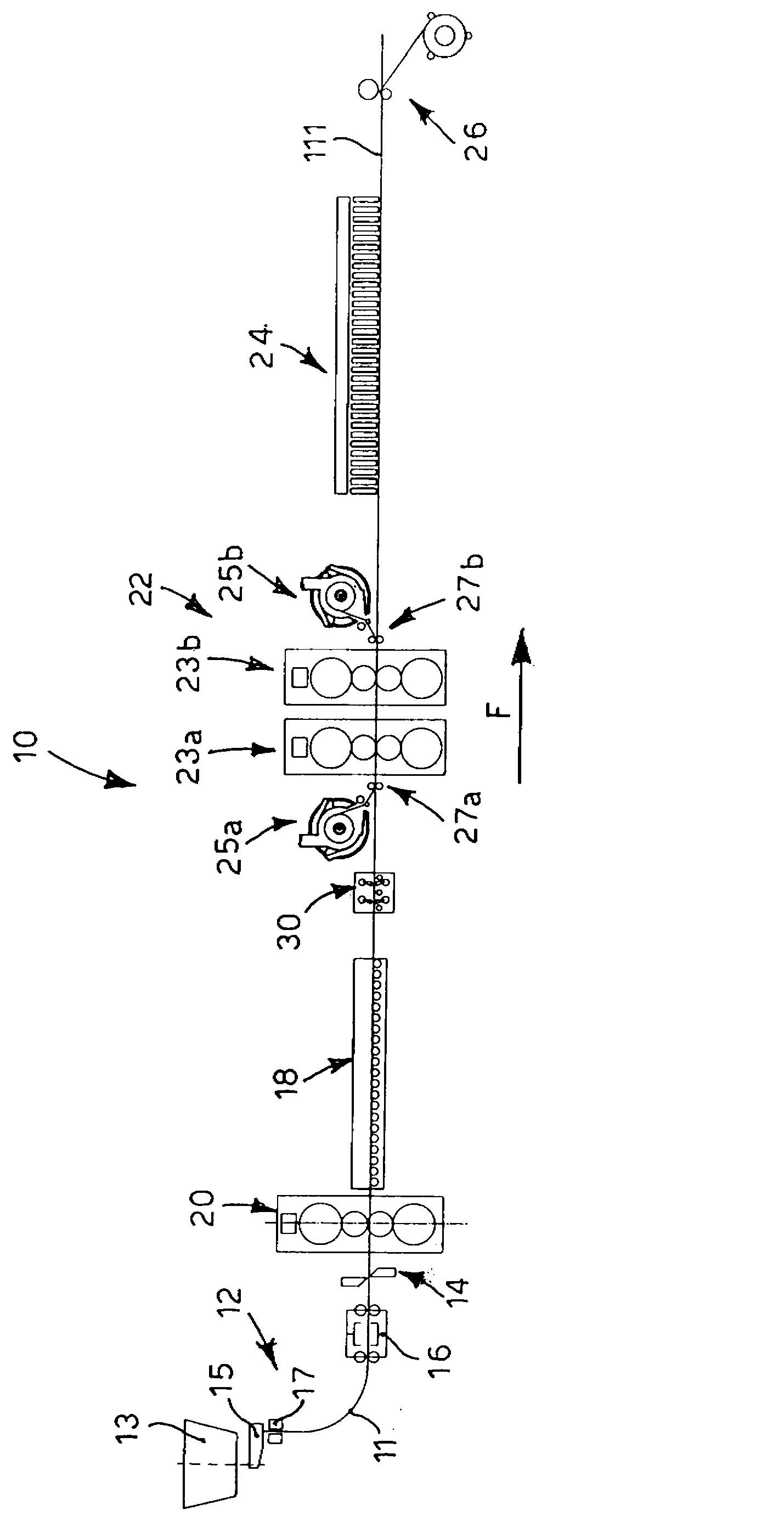

[0061] Referring to the accompanying drawings, Figure 1 shows a thick slab rolling line 50 in the prior art. The rolling line 50 includes one or more walking-feeding heating furnaces 51, a high-pressure water descaler 52, a cropping shear 53, a double-stand Stekel type reversible rolling machine equipped with an edge trimmer 55 Unit 54 , layer shower cooling unit 56 and winding unit 57 . The rolling line 50 processes slabs of standard thickness by means of one or more reversal passes. The rolling line 50 starts from thick slabs with a thickness of 220mm, a width of 800mm-160mm, a maximum length of 11.6m and a maximum slab weight of 30 tons, producing coils of a thickness of 1.6mm-20mm, a width of 800mm-1600mm and a specific gravity of about 20kg / mm.

[0062] Figure 2 shows a prior art rolling line 60 for producing thin slabs. The rolling production line 60 includes a thin slab casting machine 61, a rotary descaler 62, a pendulum shear 63, a tunnel furnace 64, a high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com