Patents

Literature

69 results about "Rolling velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The velocity of any point in the rolling object is given by , where is the displacement between the particle and the rolling object's contact point (or line) with the surface, and is the angular velocity vector. Thus, despite that rolling is different from rotation around a fixed axis, the instantaneous velocity...

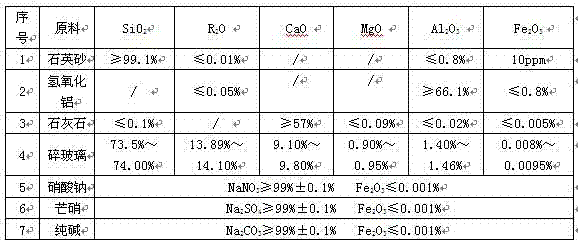

Preparation method of solar ultrawhite ultrathin glass and product thereof

InactiveCN102219376AIron sulfide reductionHigh whitenessGlass furnace apparatusGlass rolling apparatusFragilityIron sulfide

The invention relates to the field of production of ultrawhite rolled glass, in particular to a preparation method of solar ultrawhite ultrathin glass and a product thereof. The preparation method of the solar ultrawhite ultrathin glass comprises the following steps of: selecting and preparing raw materials; conveying the raw materials; melting; forming glass; annealing; detecting; and cutting and packaging. In the preparation method, iron content is controlled by taking different measures in the steps of selecting and conveying the raw materials, so that iron sulfide in the final solar glass is greatly reduced and the whiteness of the glass is improved; in the melting process, bubbles in the melted glass liquid is reduced by exhausting air and debubbling, controlling temperature and adding a glass clarifying agent, so that absorption rate is reduced and light transmittance is improved; and the annealing step of the glass finished product is a key link of the production process and plays an important role in the quality of the ultrathin glass product, so the defects that the ultrathin glass is easy to harden and easy to break during production and has high fragility are overcome by controlling rolling velocity, temperature and annealing rate in the process of glass forming and glass annealing.

Owner:ZHEJIANG JINGXING SOLAR ENERGY TECH

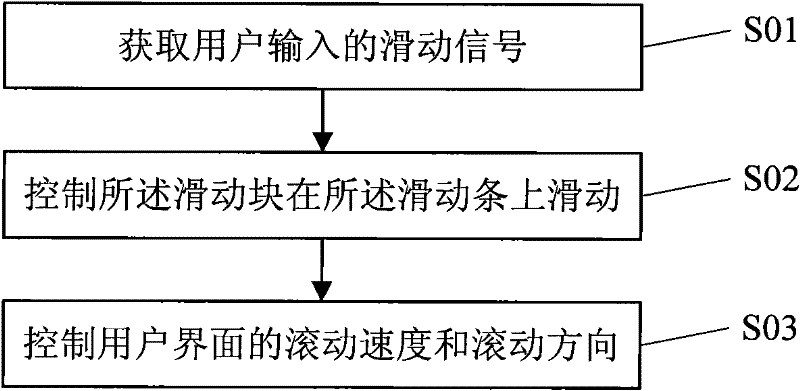

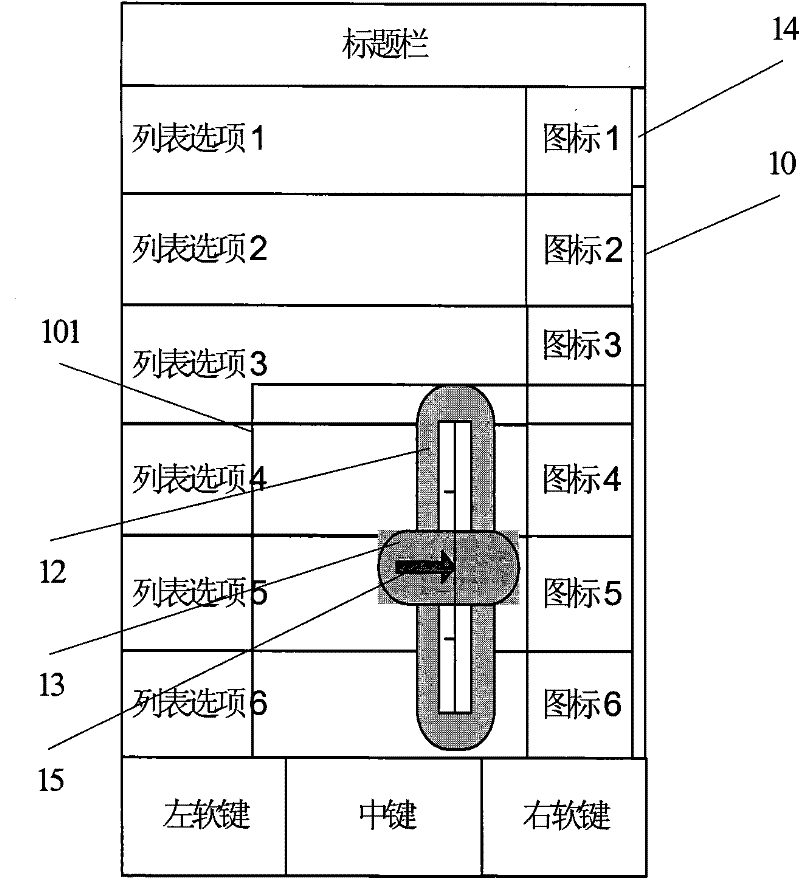

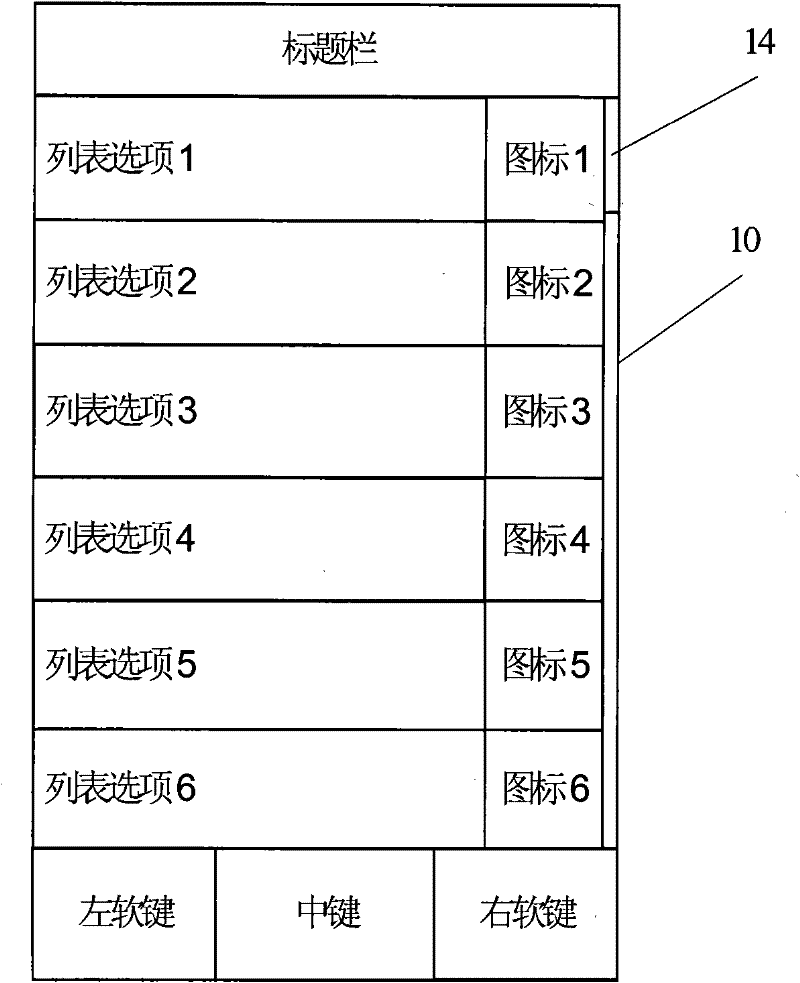

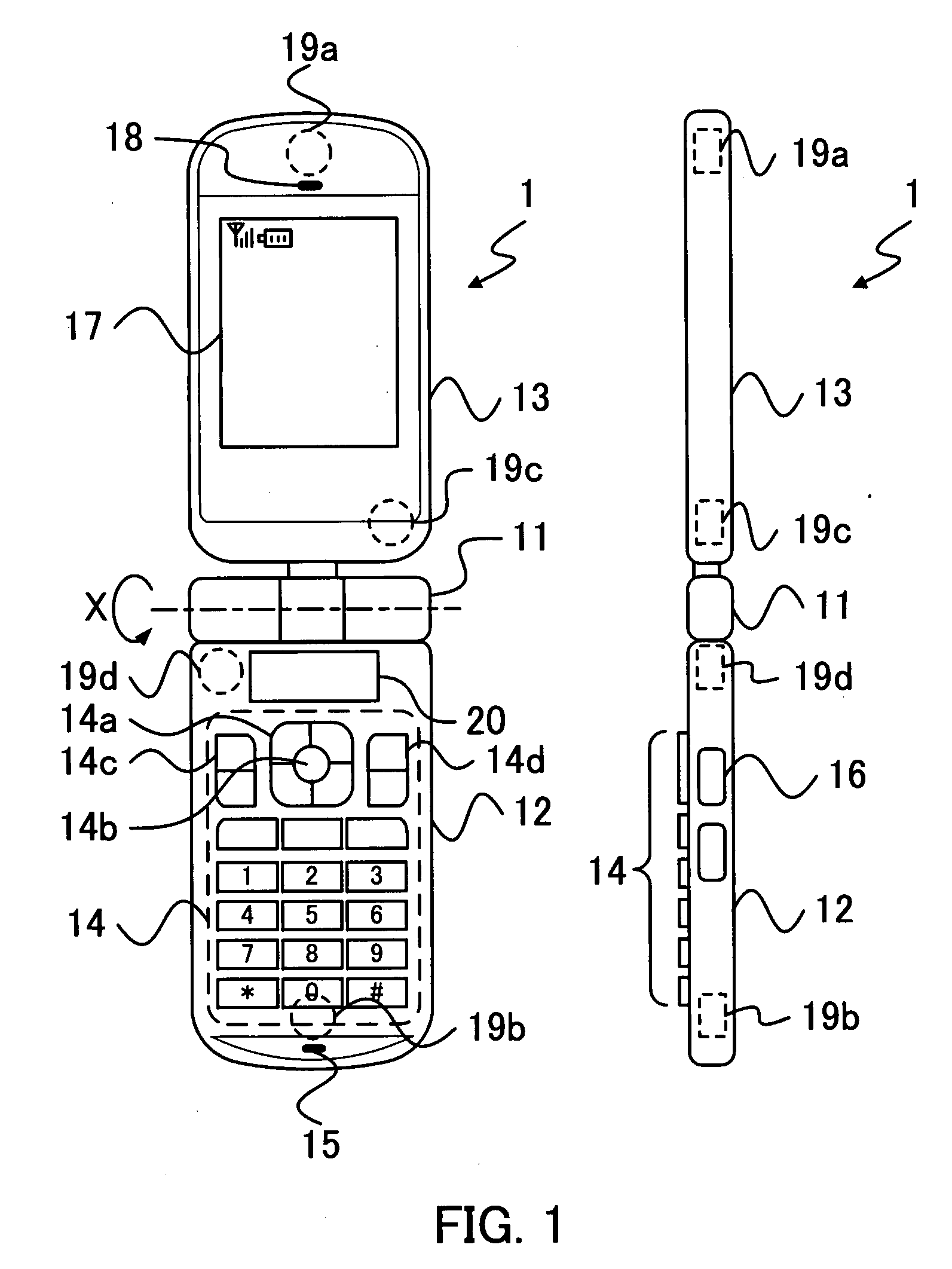

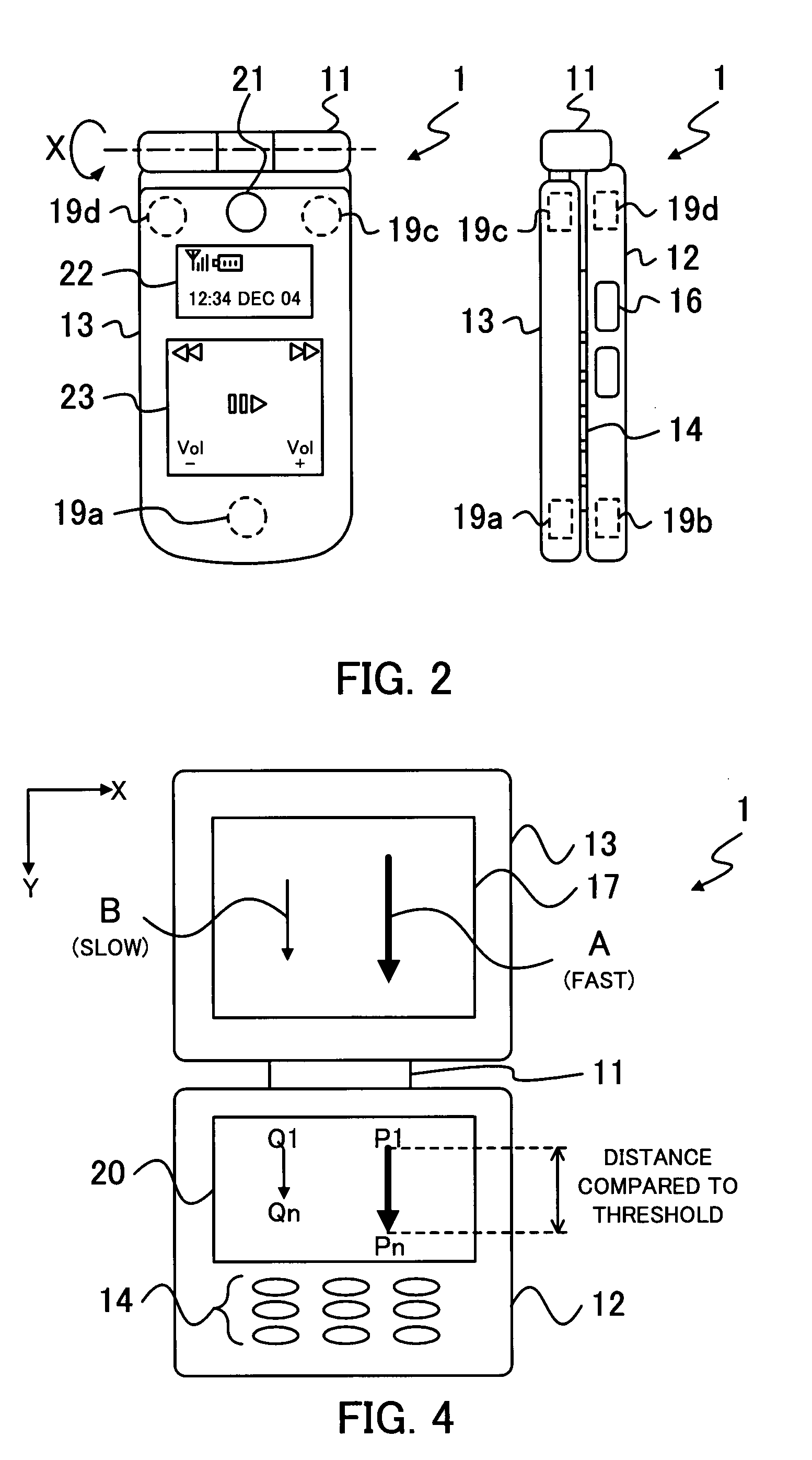

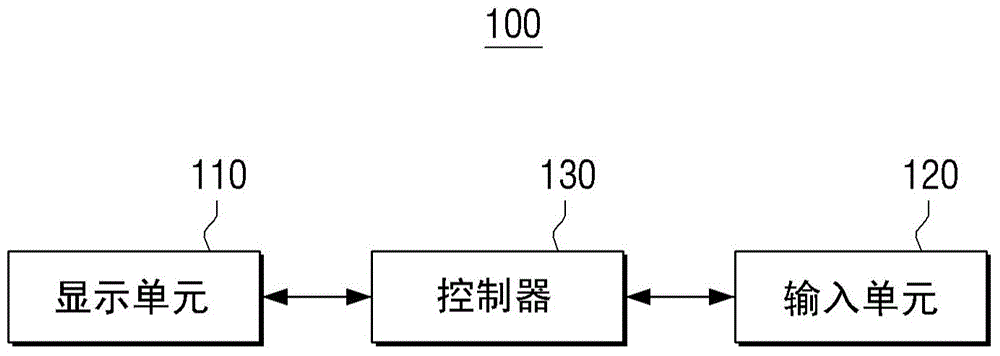

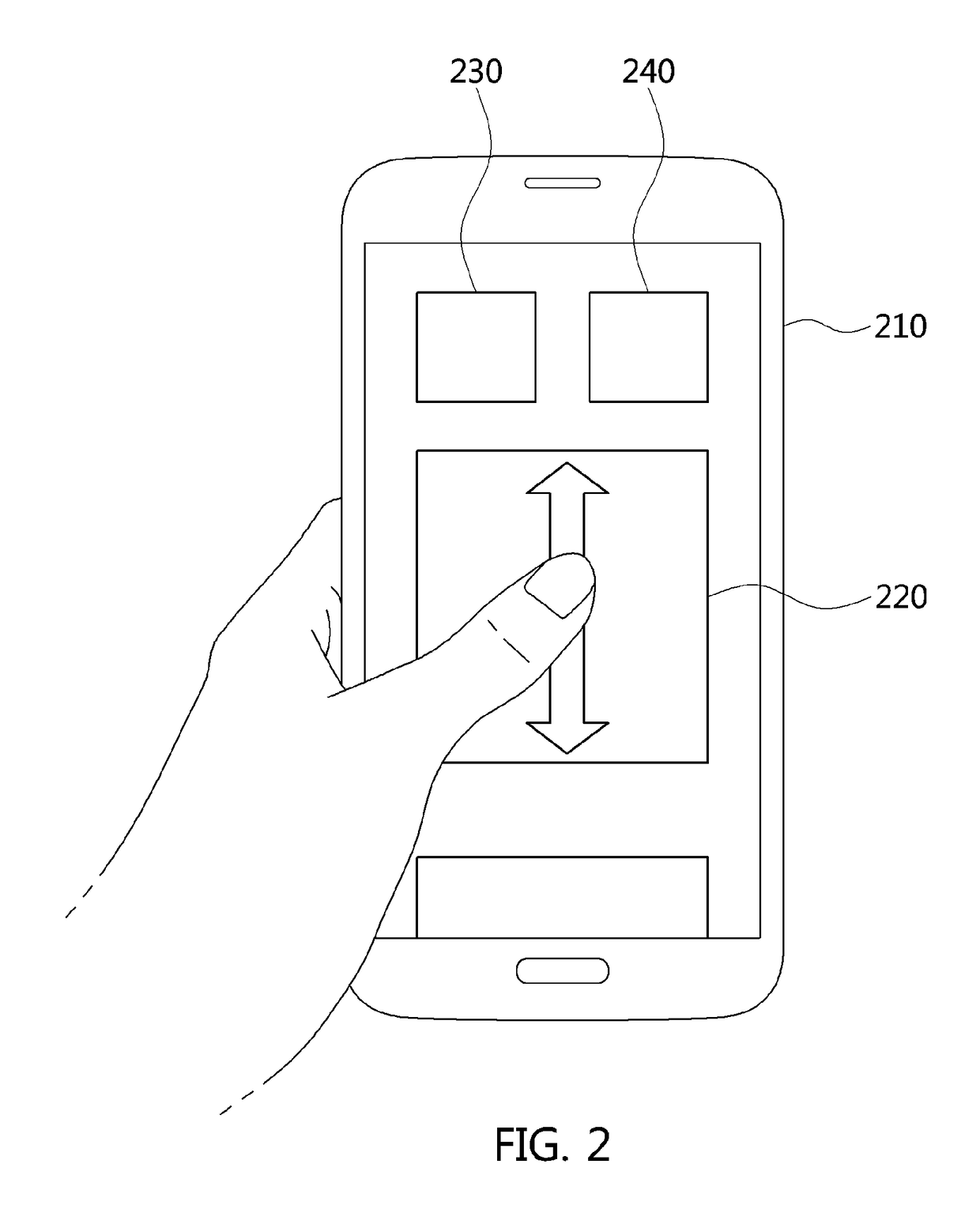

Mobile terminal (MT) and method for realizing scrolling of user interface thereof

ActiveCN102346662AScroll speed visibleEasy to operateSpecific program execution arrangementsInput/output processes for data processingUser inputScrolling

The invention provides a mobile terminal (MT) and a method for realizing scrolling of a user interface thereof. The user interface comprises a control interface, and the control interface comprises a graduated slider and a slide block capable of sliding on the slider. The method comprises the following steps: obtaining a slide signal input by a user; controlling the slide block to slide on the slider according to the slide signal; and according to the direction that the scale of the slider corresponding to the position of the slide block is deviated from the original point of the scale as well as the scale value, obtaining the scrolling direction and scrolling speed of the user interface, and controlling the user interface to scroll according to the scrolling direction and scrolling speed. By adopting the method, the user interface can be quickly scrolled for the MTs with a touch panel and a non-touch panel; and the method is convenient and simple to operate for the user.

Owner:BYD CO LTD

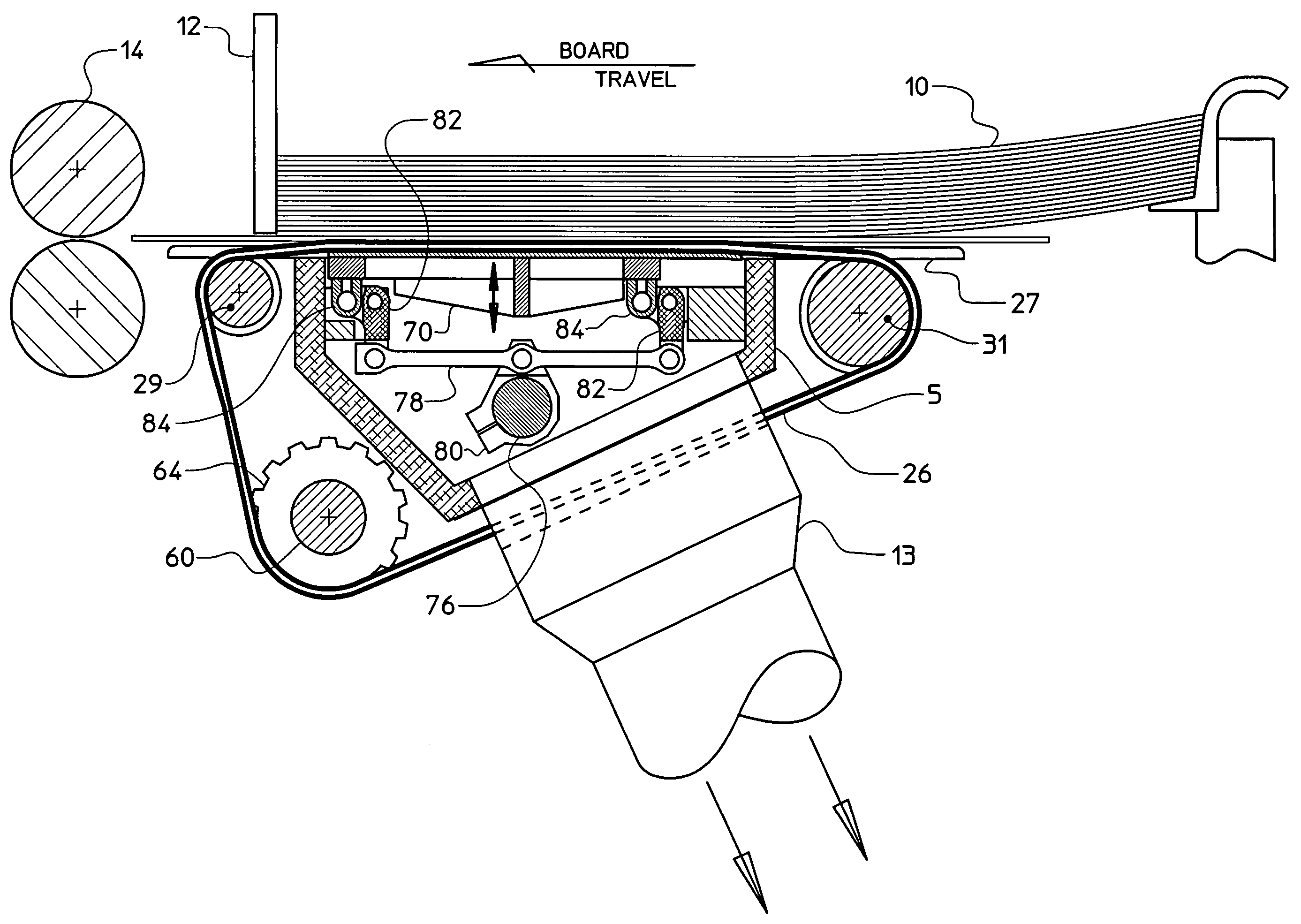

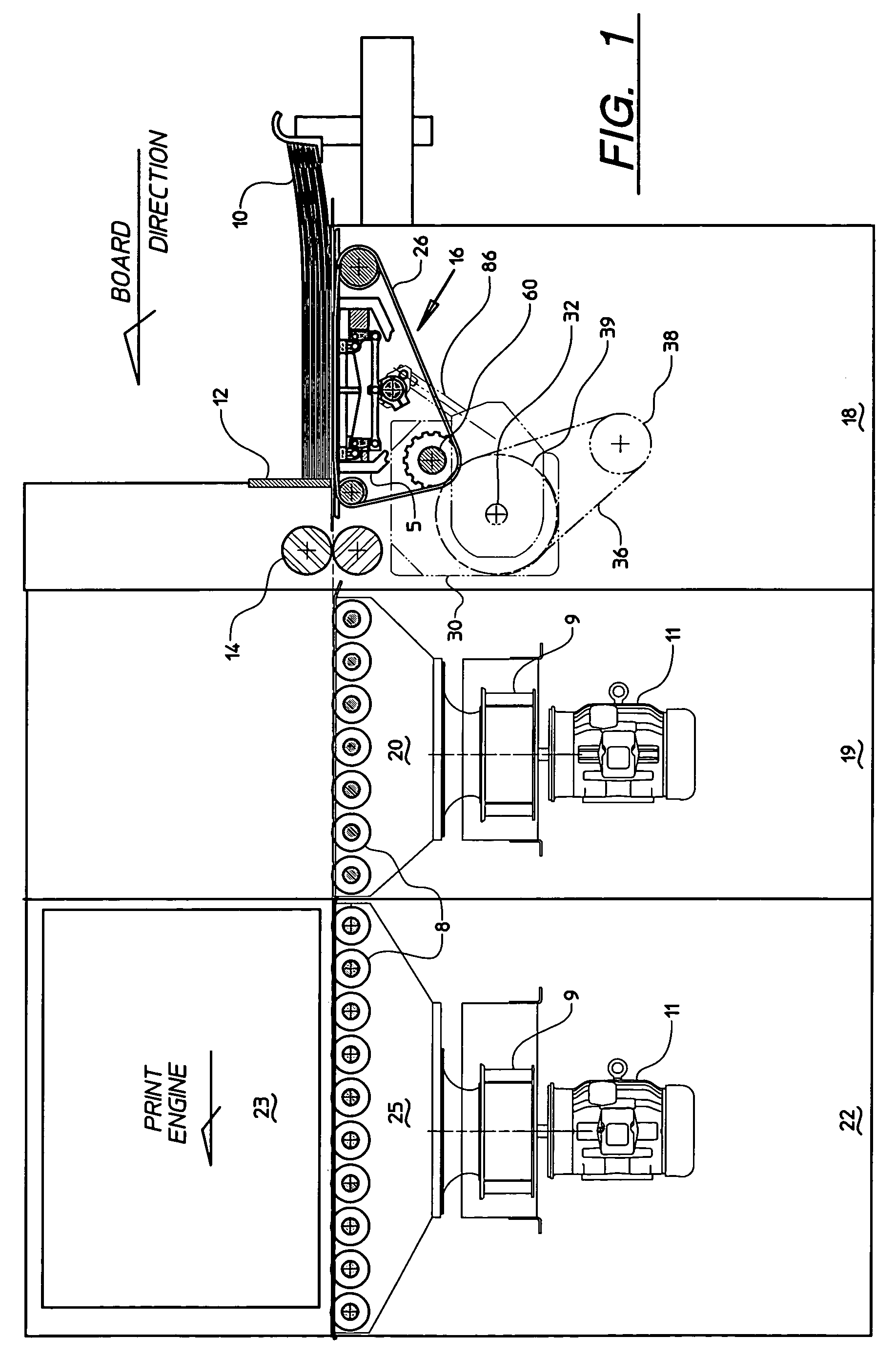

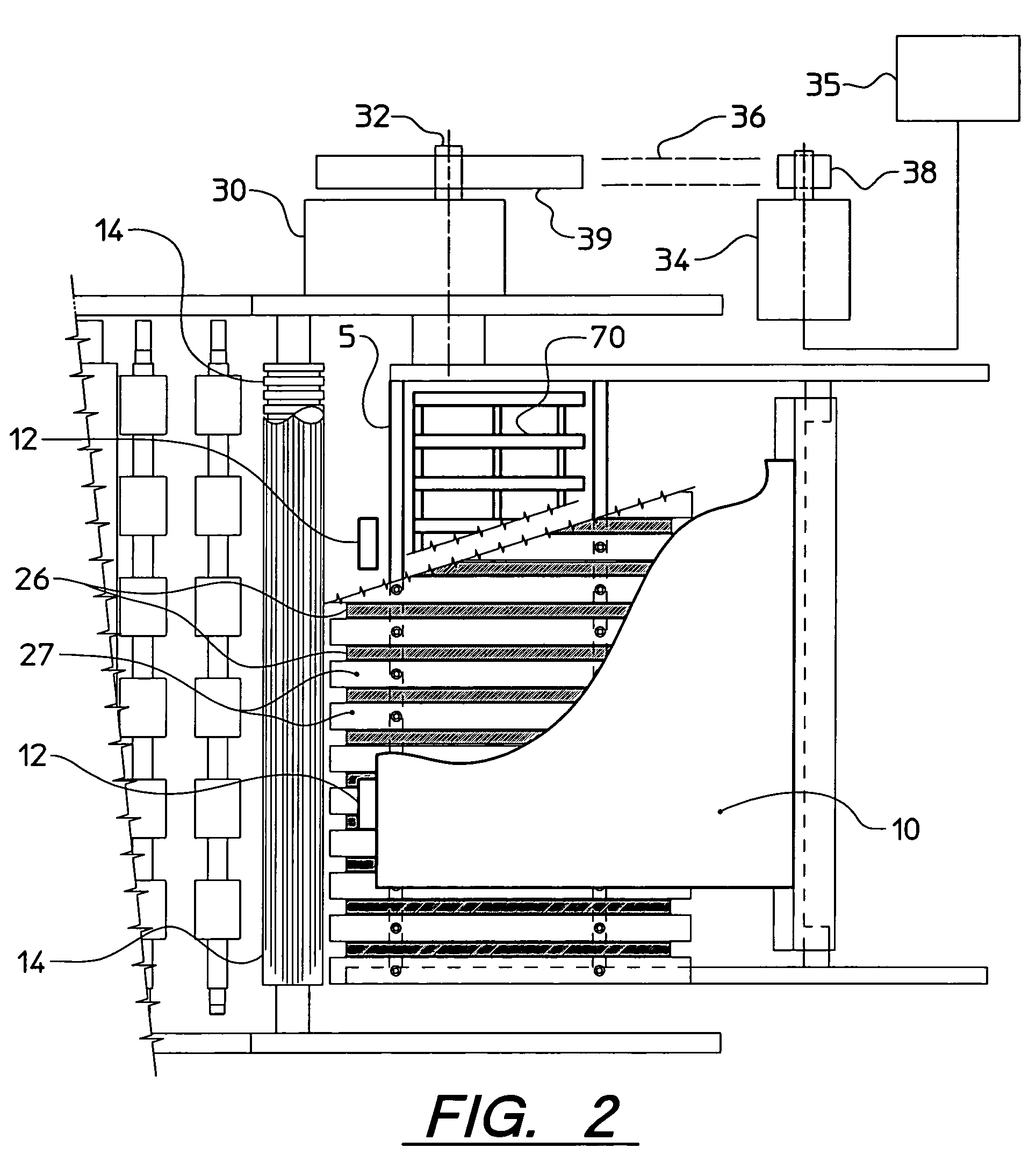

Feeder with adjustable time cycle and method

ActiveUS7635124B2Precise arrangementAccurate timingArticle feedersArticle separationEngineeringRolling velocity

A timed feeder for feeding corrugated boards to nip rolls of a box finishing machine. A feed member is raised to the feed path to engage and drive a board to the nip rolls and then lowered away from the feed path until the next cycle. An indexing drive mechanism, driven by a computer-controlled servo motor, activates the feed member and has a feed phase when it drives the board to the nip rolls, and a dwell phase when the feed member is away from the feed path and the output shaft of the indexing mechanism is at zero velocity. During the feed phase, the output shaft of the indexing mechanism accelerates the feed member and the board beyond the nip roll velocity and then decelerates them to the nip roll velocity at the point where the board enters the nip rolls. During the dwell phase the input shaft which was at constant velocity during the feed phase, is either accelerated and then decelerated or decelerated and then accelerated to shorten or increase the duration of the cycle allowing different size articles to be fed with minimum or zero spacing downstream of the nip rolls.

Owner:SUN AUTOMATION

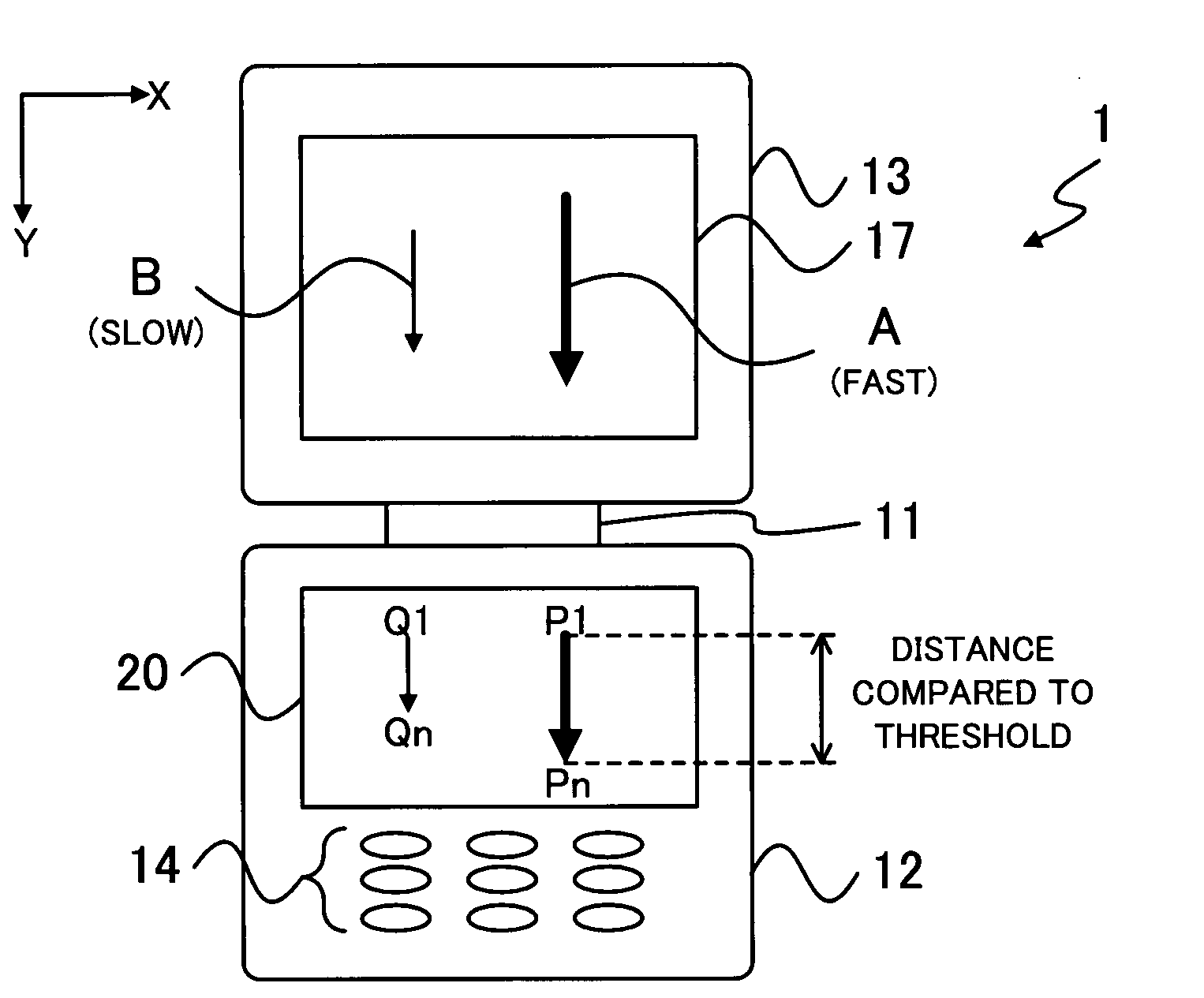

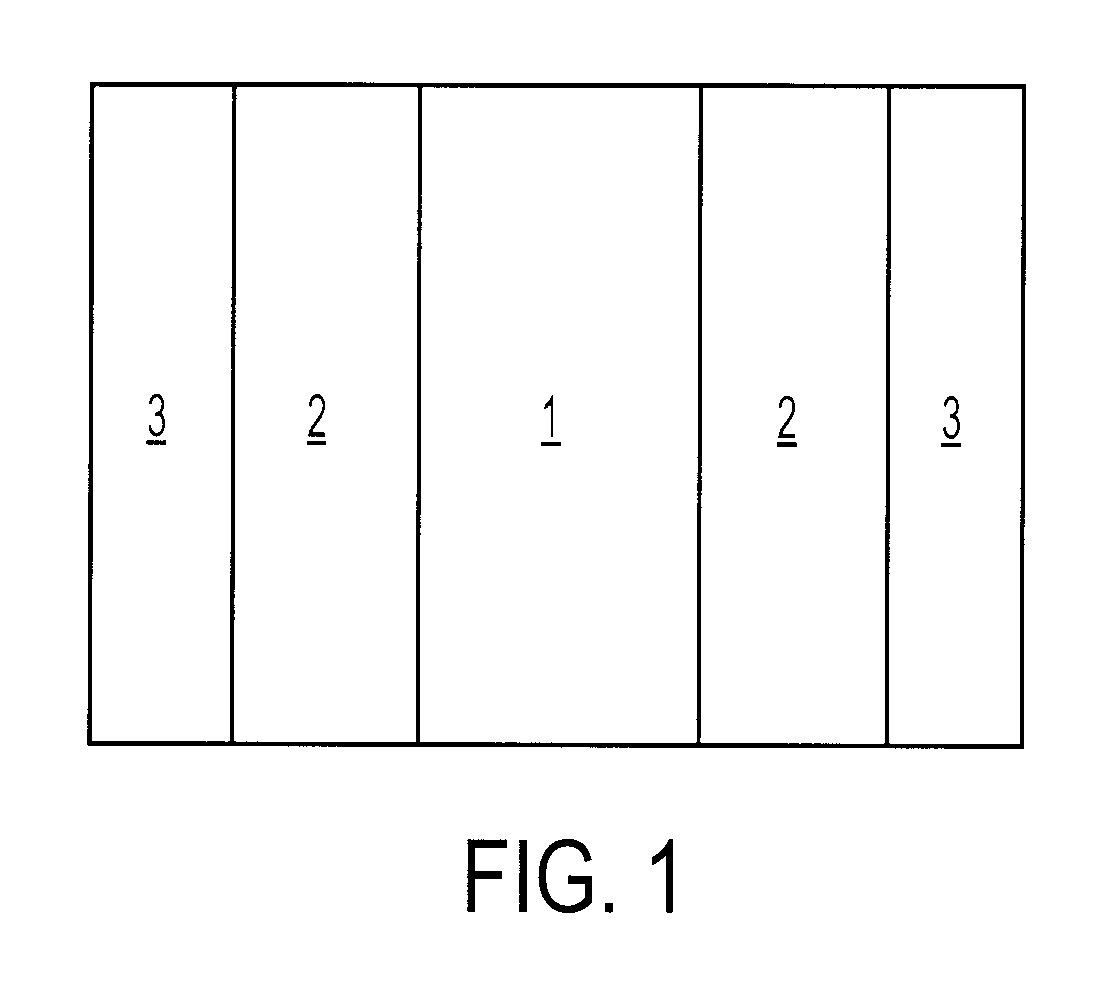

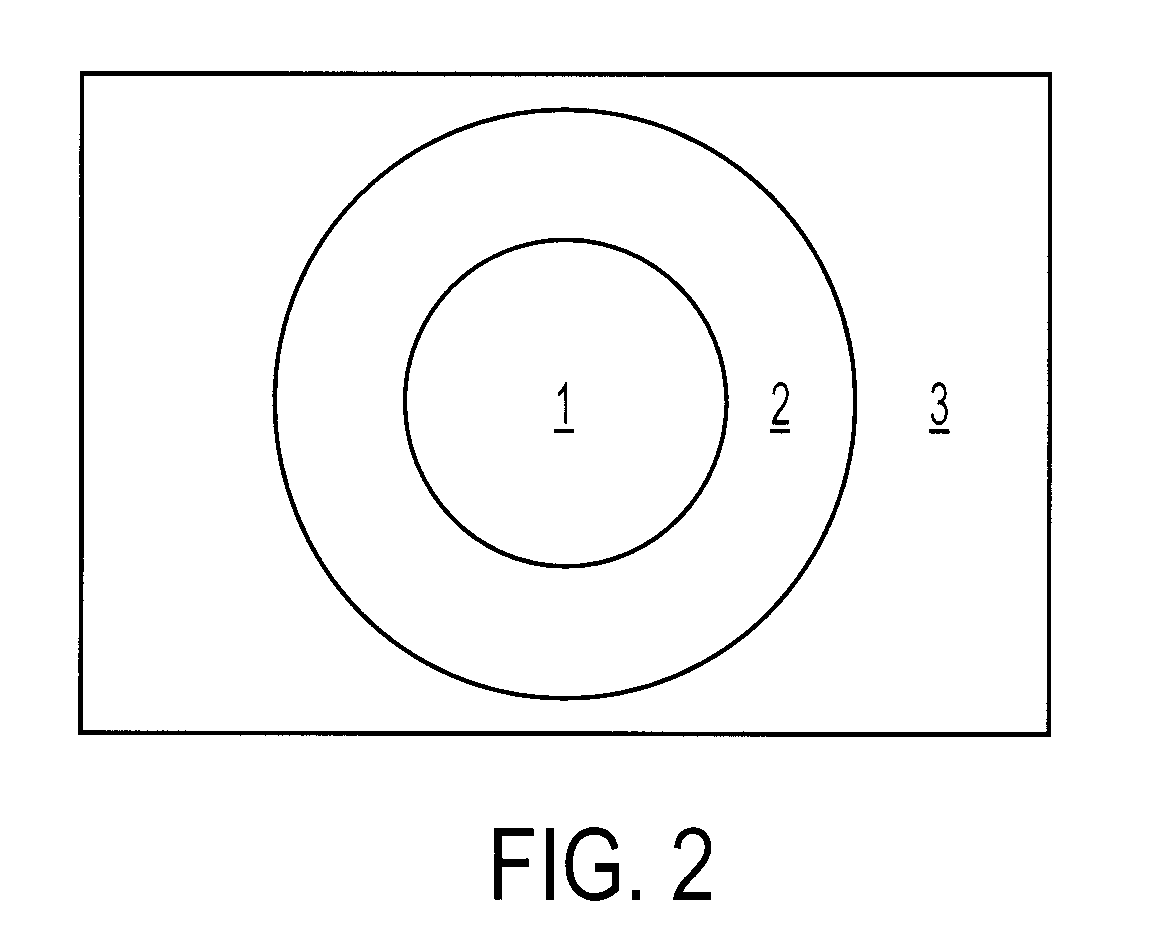

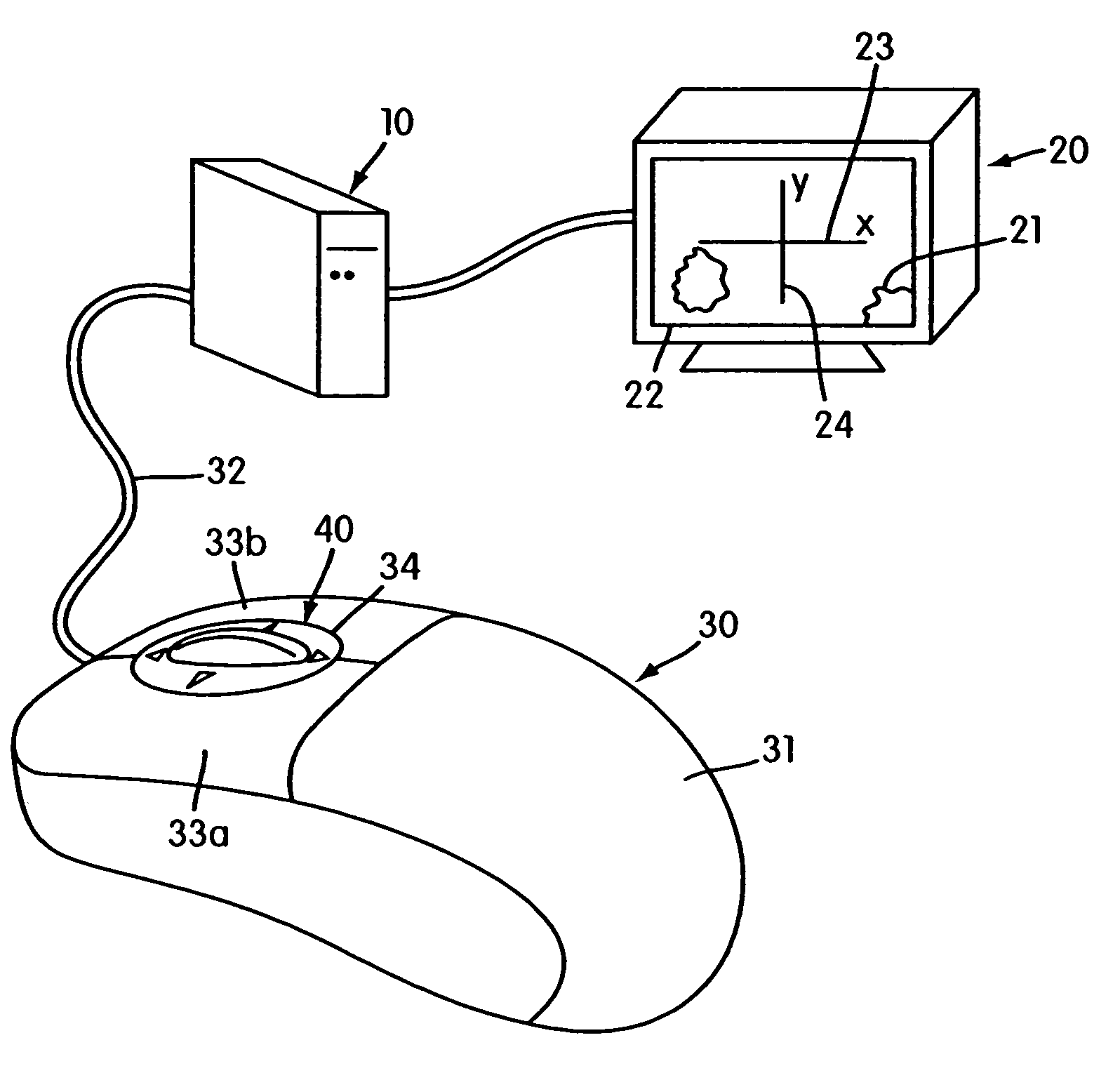

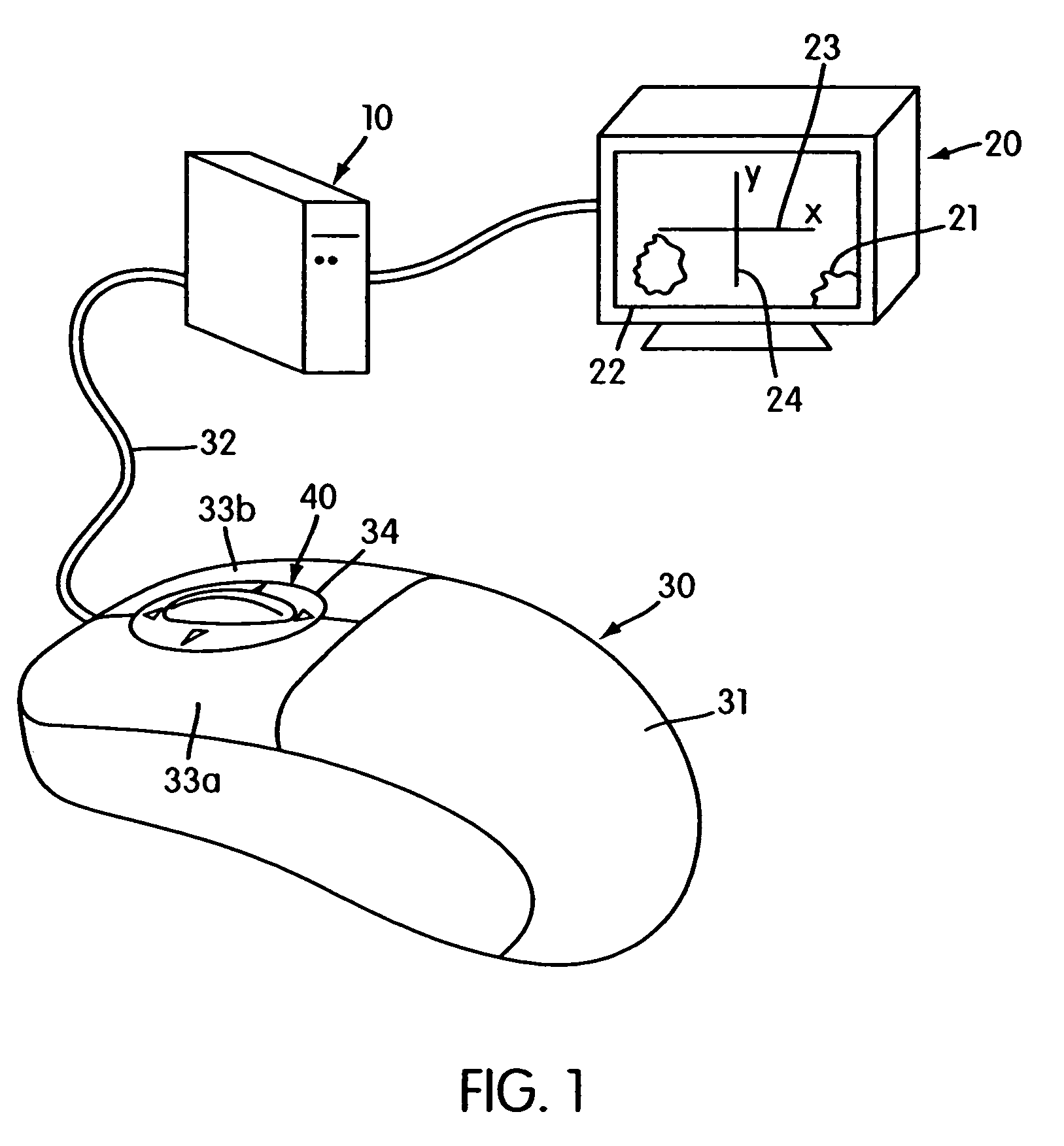

Method and apparatus for selecting scroll condtion of displayed screen

InactiveUS20080046836A1Quick and easy selectionInput/output processes for data processingDisplay deviceData treatment

A data processing apparatus capable of detecting an object being in contact with a portion thereof is provided. The data processing apparatus includes a display, a tactile sensor and a controller. The tactile sensor is configured to detect the object and to locate the object on a sensing surface thereof. The controller is coupled to the display and the tactile sensor, configured to locate an initial location of the object on the sensing surface if the object starts being detected, and configured to locate a final location of the object on the sensing surface if the object ends being detected. The controller is configured to select a scroll direction depending on a direction from the initial location to the final location. The controller is configured to select a scroll speed, and configured to scroll a screen displayed on the display in the scroll direction at the scroll speed.

Owner:KK TOSHIBA

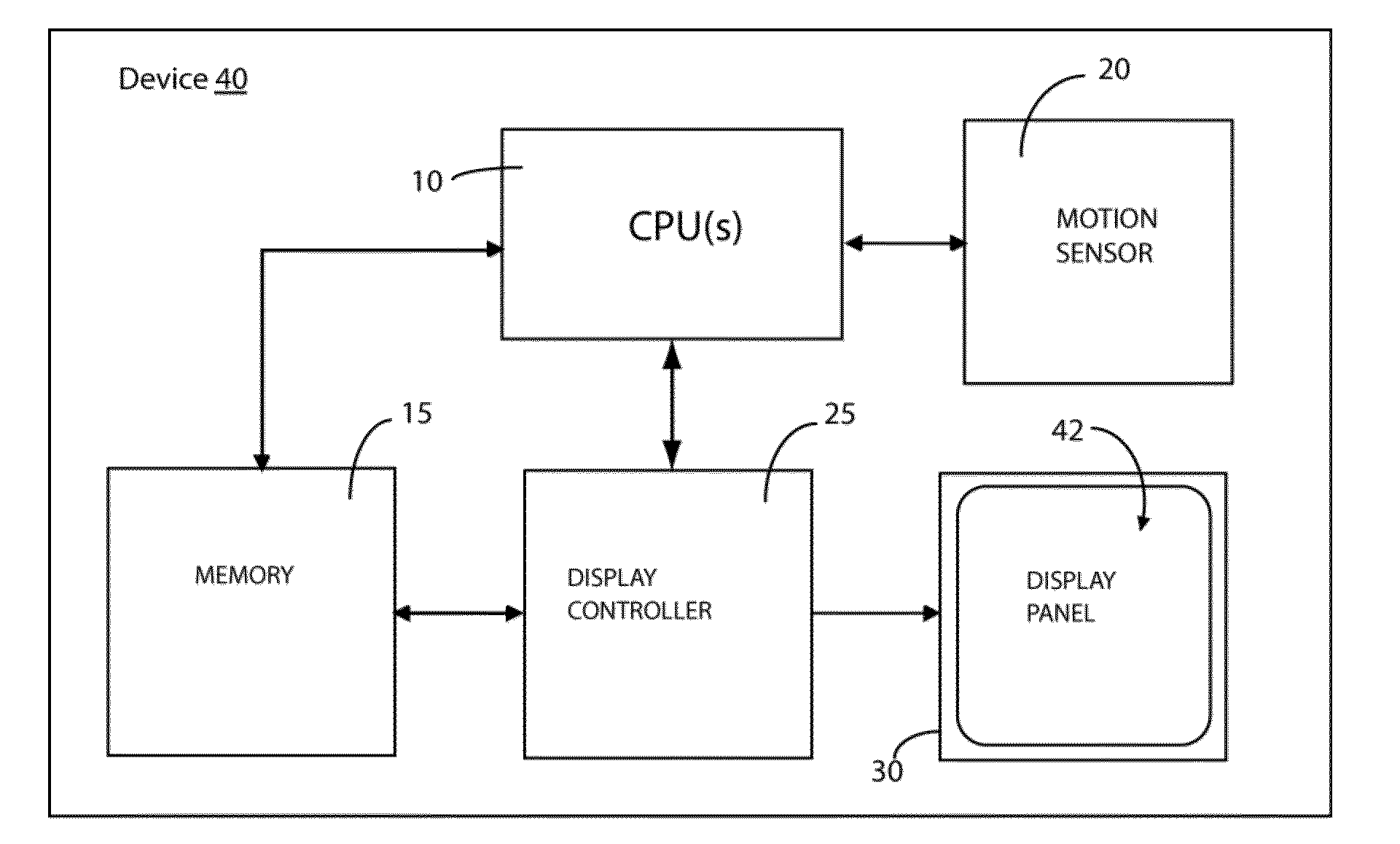

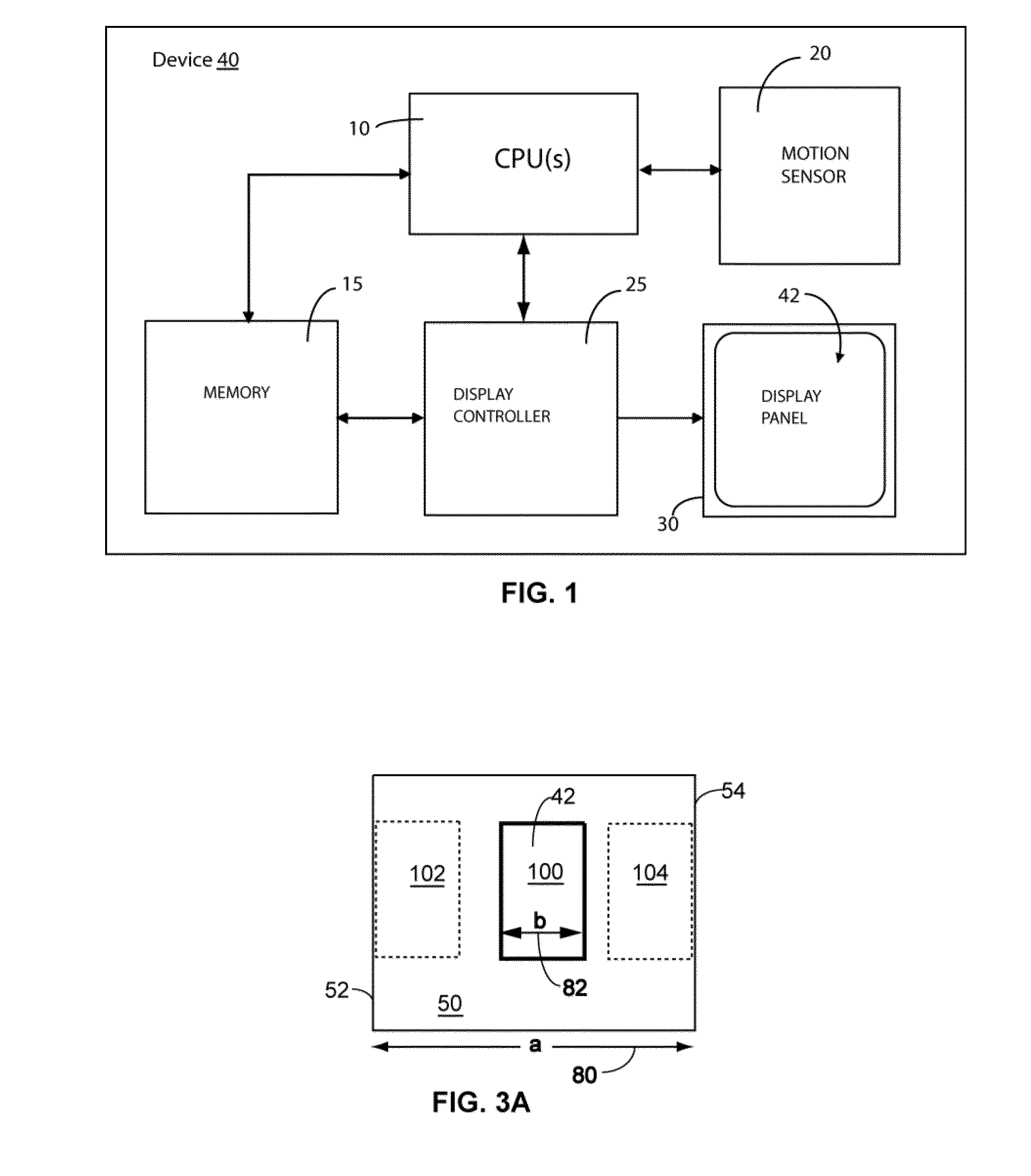

Motion-Based View Scrolling with Proportional and Dynamic Modes

ActiveUS20150029093A1Minimize non-responsive rangeEfficient and convenient methodInput/output for user-computer interactionSurveyDynamic patternScrolling

The present invention provides a system and methods for motion-based scrolling of a relatively large contents view on an electronic device with a relatively small screen display. The user controls the scrolling by changing the device's tilt relative to a baseline tilt. The scrolling control can follow a Proportional Scroll mode, where the relative tilt directly controls the screen position over the contents view, or a Dynamic Scroll mode where the relative tilt controls the scrolling speed. The present invention obtains a criterion for automatically selecting the best scrolling mode when the dimensions of the contents view change. The baseline tilt is updated when the screen reaches an edge of the contents view to eliminate the creation of a non responsive range of tilt changes when the user changes tilt direction.

Owner:INNOVENTIONS INC

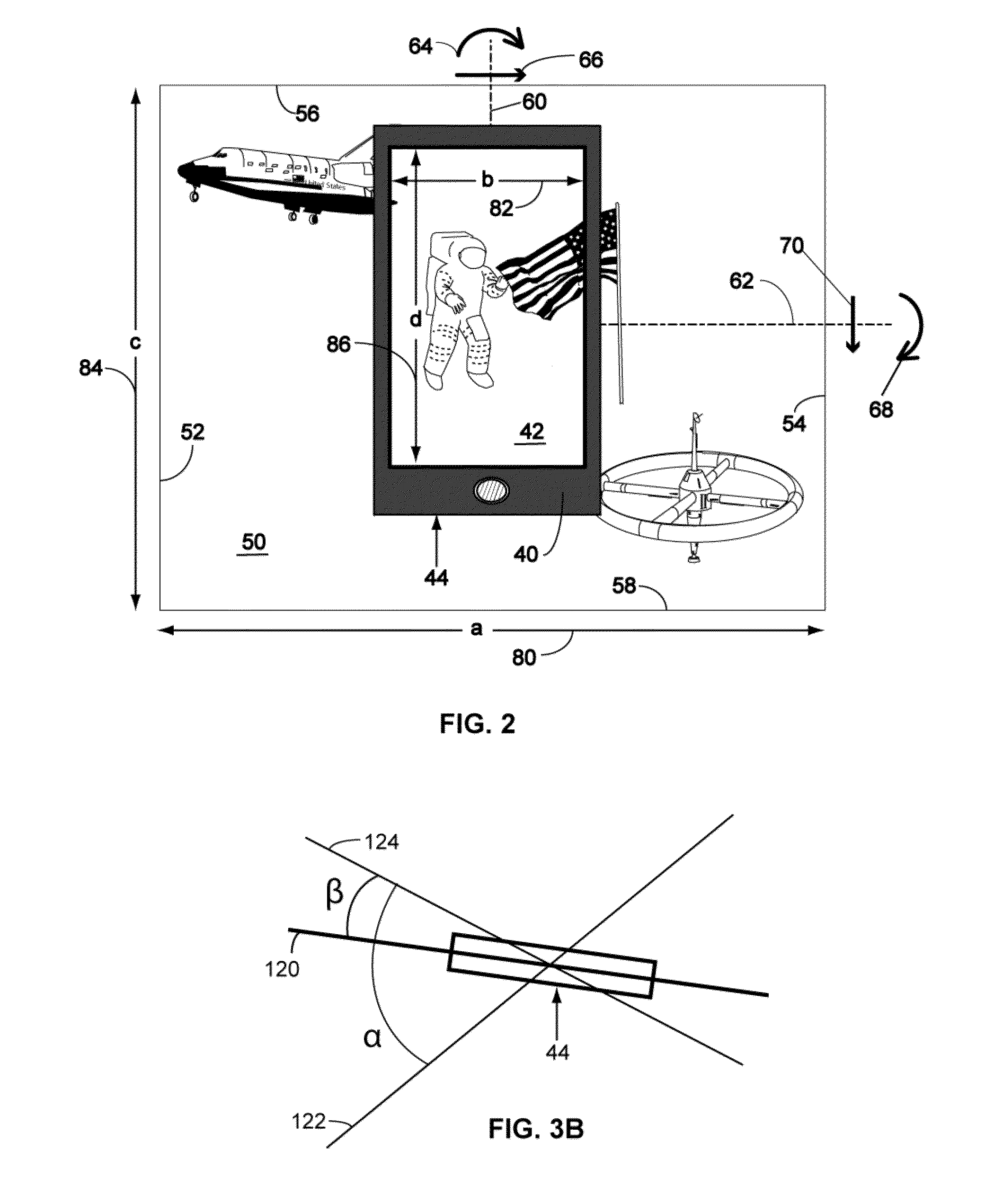

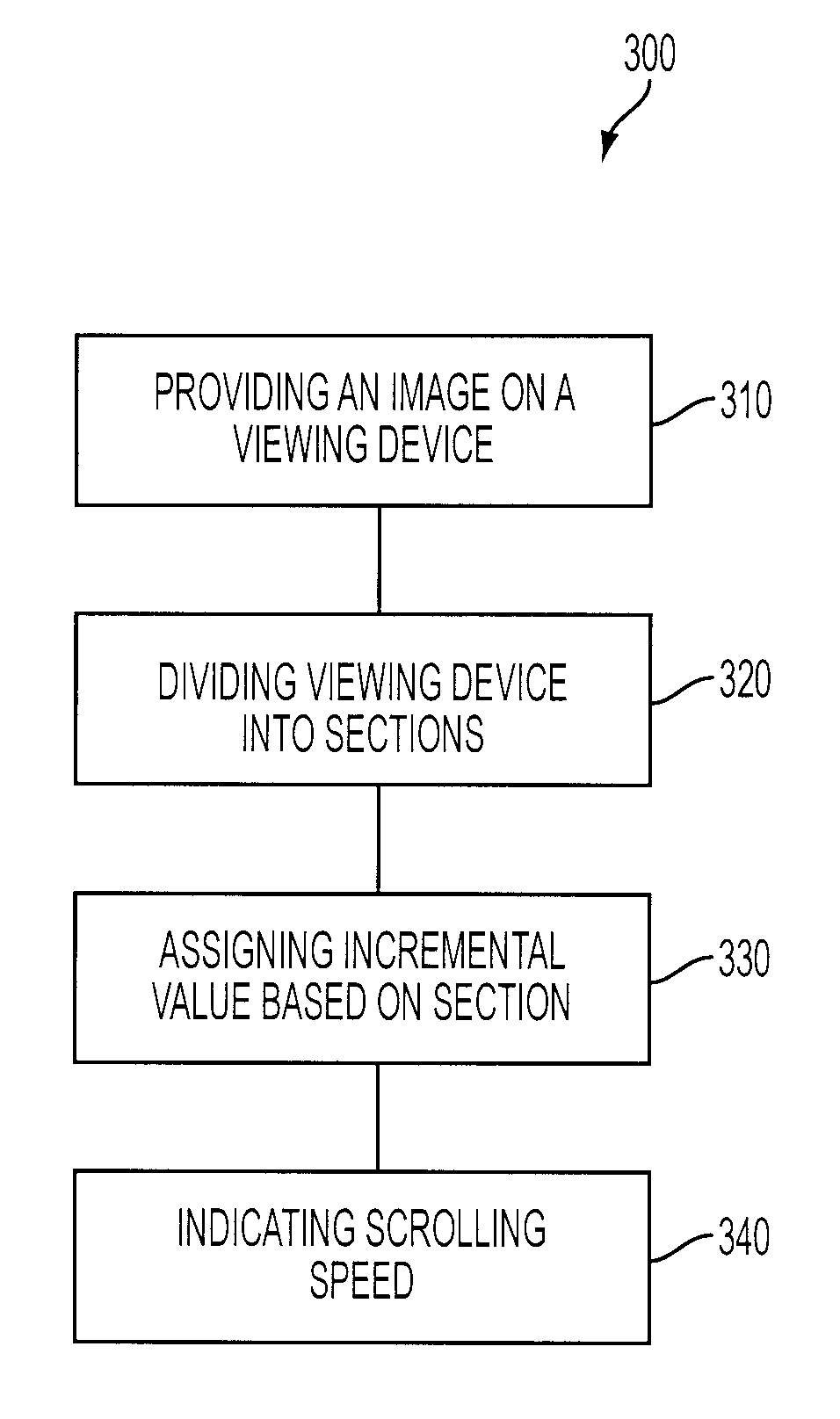

Location Determination For Z-Direction Increments While Viewing Medical Images

InactiveUS20090037840A1Easy to controlEasy to changeMedical imagesMedical image data managementComputer visionScrolling

An apparatus and method for controlling a scrolling speed of an apparatus for selecting an image, having steps of providing the image on a viewing device;dividing the viewing device into a plurality of regions, and assigning an incremental value to each of the plurality of regions, wherein the incremental value is used to calculate the scrolling speed of the apparatus.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

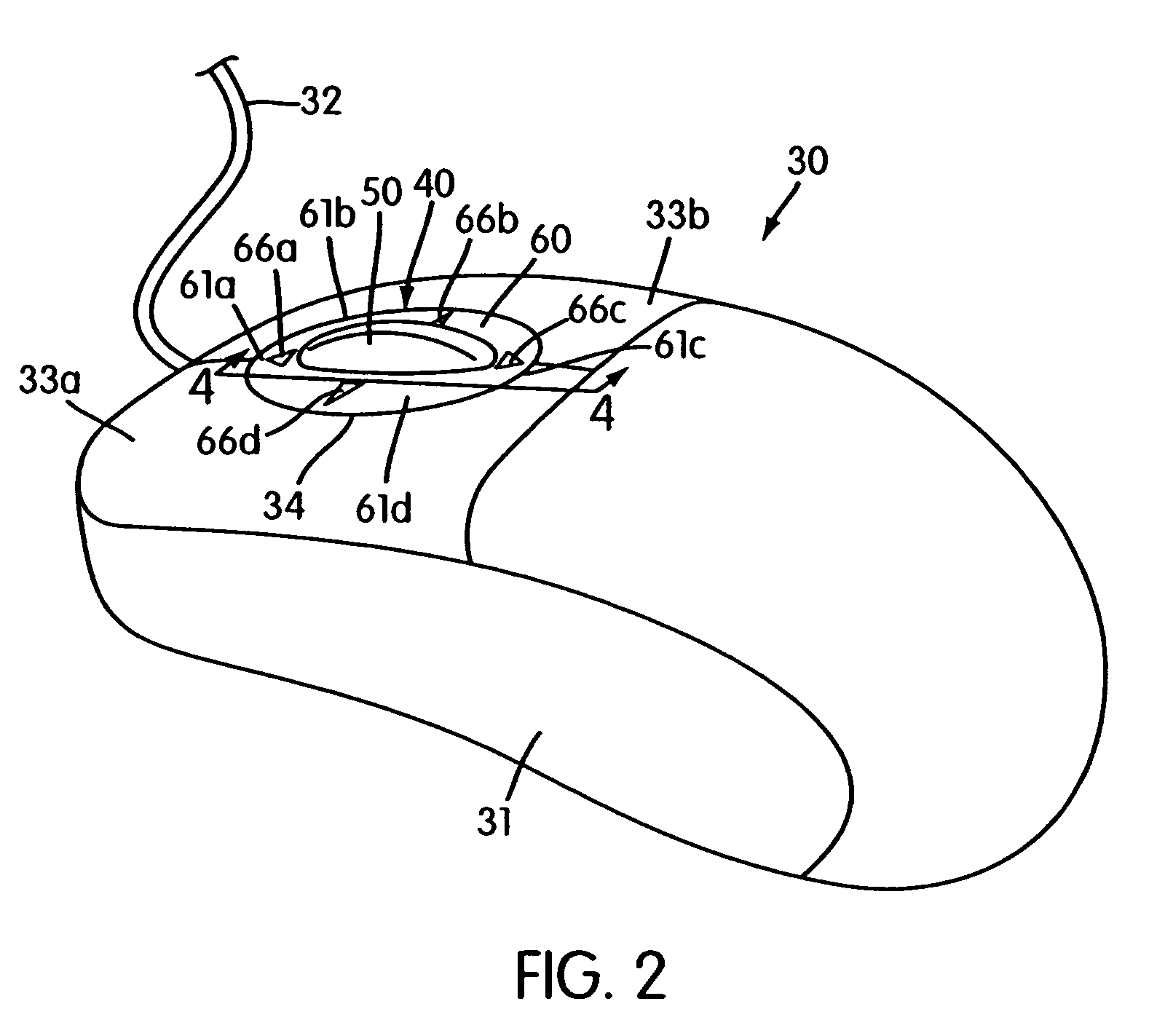

Scrolling apparatus providing multi-directional movement of an image

InactiveUS7193612B2Conveniently scrollSimple finger movementTelevision system detailsCathode-ray tube indicatorsScrollingActuator

The invention is a scrolling apparatus may be incorporated into an input device, such as a pointing device or a keyboard, for example, and operatively connected to a host computer to scroll an image along multiple axes relative to a display screen. The scrolling apparatus includes a rotatable member with the configuration of a wheel or a ball. In addition, the scrolling apparatus includes a depressible actuator located around the rotatable member. Both the rotatable member and the actuator, which scroll the image in different scrolling directions or at different scrolling velocities, for example, may be utilized for scrolling the image.

Owner:MICROSOFT TECH LICENSING LLC

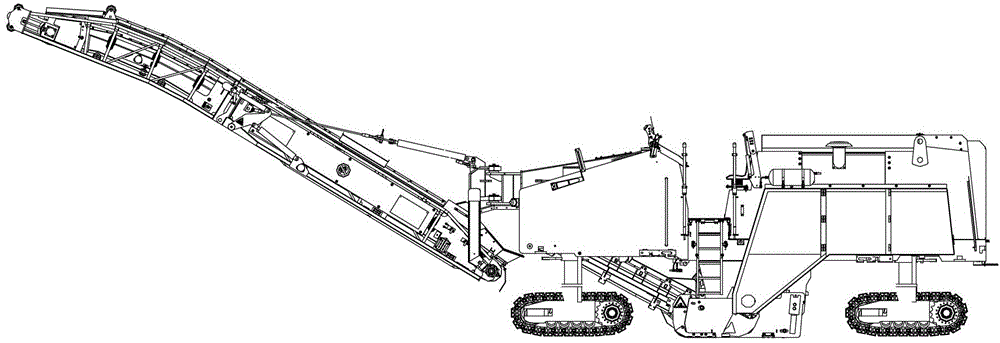

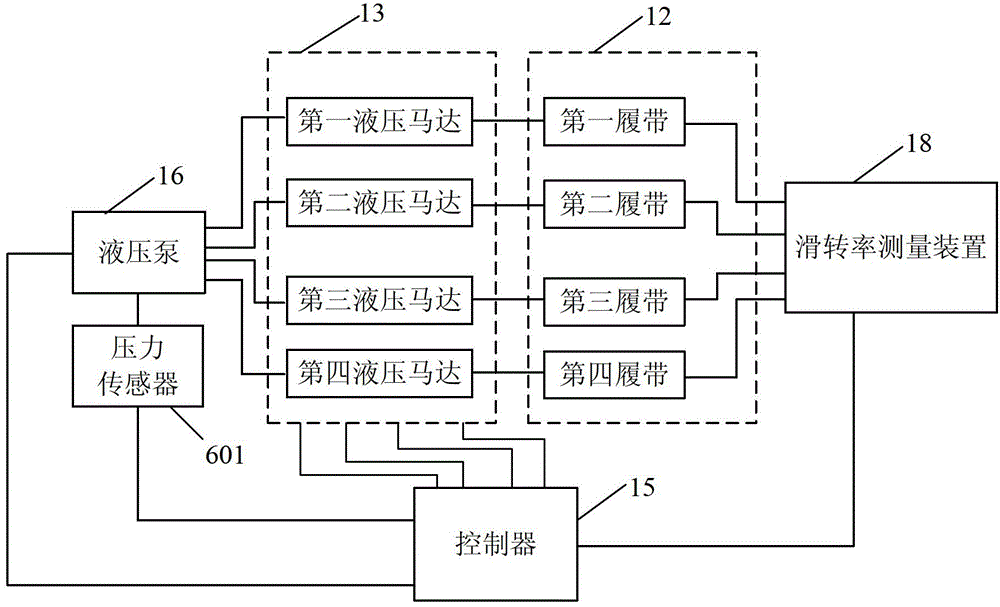

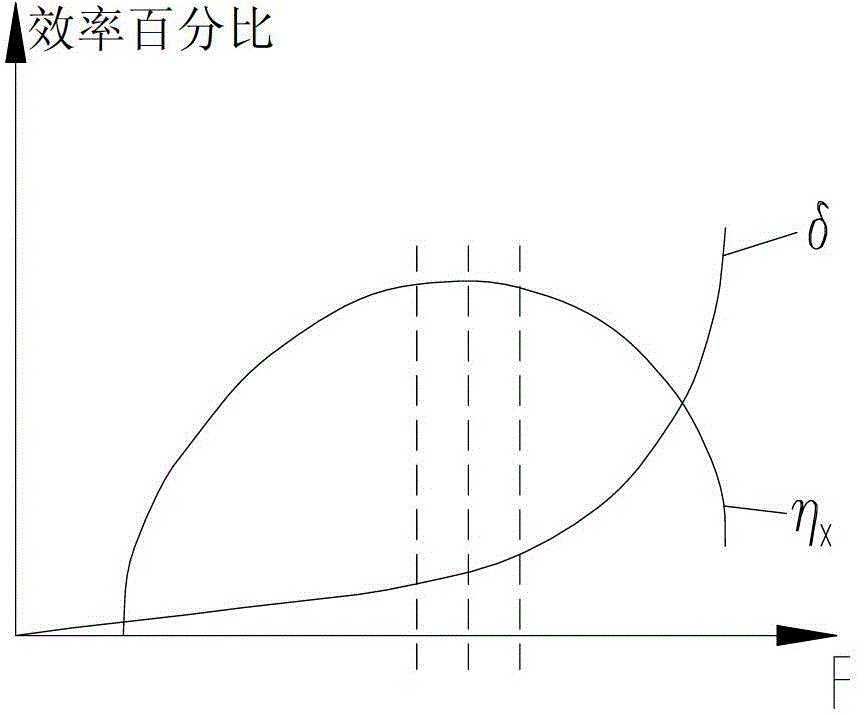

Control method and control system for traveling mechanism of milling planer

ActiveCN103147380AAvoid unnecessary consumption of powerReduce workloadRoads maintainenceControl devicesControl systemHydraulic pump

The invention provides a control method and a control system for a traveling mechanism of a milling planer. The traveling mechanism of the milling planer adopts hydraulic transmission, and oil lines of a plurality of hydraulic motors are connected in parallel to a hydraulic pump and used for respectively driving a corresponding track. The control method for the traveling mechanism of the milling planer comprises the steps of acquiring the working pressure of the hydraulic pump and the slippage rate of each track; judging the minimum value in the slippage rate of each track, and taking the minimum value as a target slippage rate; respectively calculating the working pressure change rate and the target slippage rate change rate according to the working pressure and the target slippage rate; calculating the traveling efficiency change rate according to the working pressure change rate and the target slippage rate change rate; and comparing the traveling efficiency change rate with a preset value, and adjusting the displacement of the hydraulic pump or the displacement of the hydraulic motors according to comparison results. The technical scheme of the invention changes the traveling efficiency of the traveling mechanism by adjusting the rolling speed of the tracks to ensure the traveling efficiency change rate to be stable within a preset range and avoid the unnecessary power consumption of the milling planer.

Owner:ZOOMLION HEAVY IND CO LTD

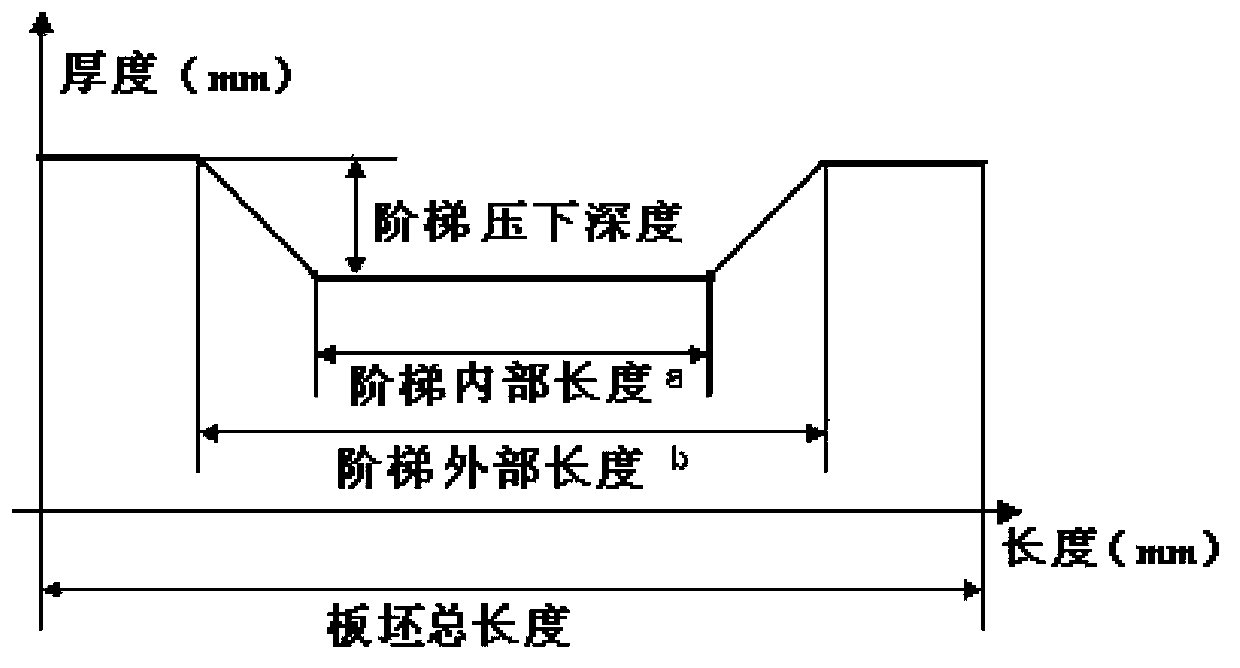

Method for controlling head-to-tail width of high broadening ratio steel plate

ActiveCN103386419AHigh yieldImprove rolling rhythmMetal rolling stand detailsMetallurgyRolling velocity

The invention discloses a method for controlling the head-to-tail width of a high broadening ratio steel plate. The method comprises a forming step, an expanding step and a longitudinal rolling step, wherein in the forming step, the rolling pass is one, the rolling reduction is 15-35mm, the ladder reduction height h is calculated according to a formula that h=2.3*(B / B'); and the rolling velocity V is calculated according to a formula that V=(b-a)*(VHGC / h) / 2. According to the method, by controlling the rolling reduction, the ladder thickness curve and the rolling velocity of the rough rolling forming pass, when the high expansion ratio steel plate is rolled, the high rolling rhythm of a roughing mill is kept, the following features of the ladder thickness curve and the set curve in the forming step can be improved, and the difference between the head-to-tail width and the middle width of the high broadening ratio steel plate is reduced, so that the trimming amount of the edge of the steel plate is reduced and the yield of the steel plate is improved.

Owner:LAIWU IRON & STEEL GRP

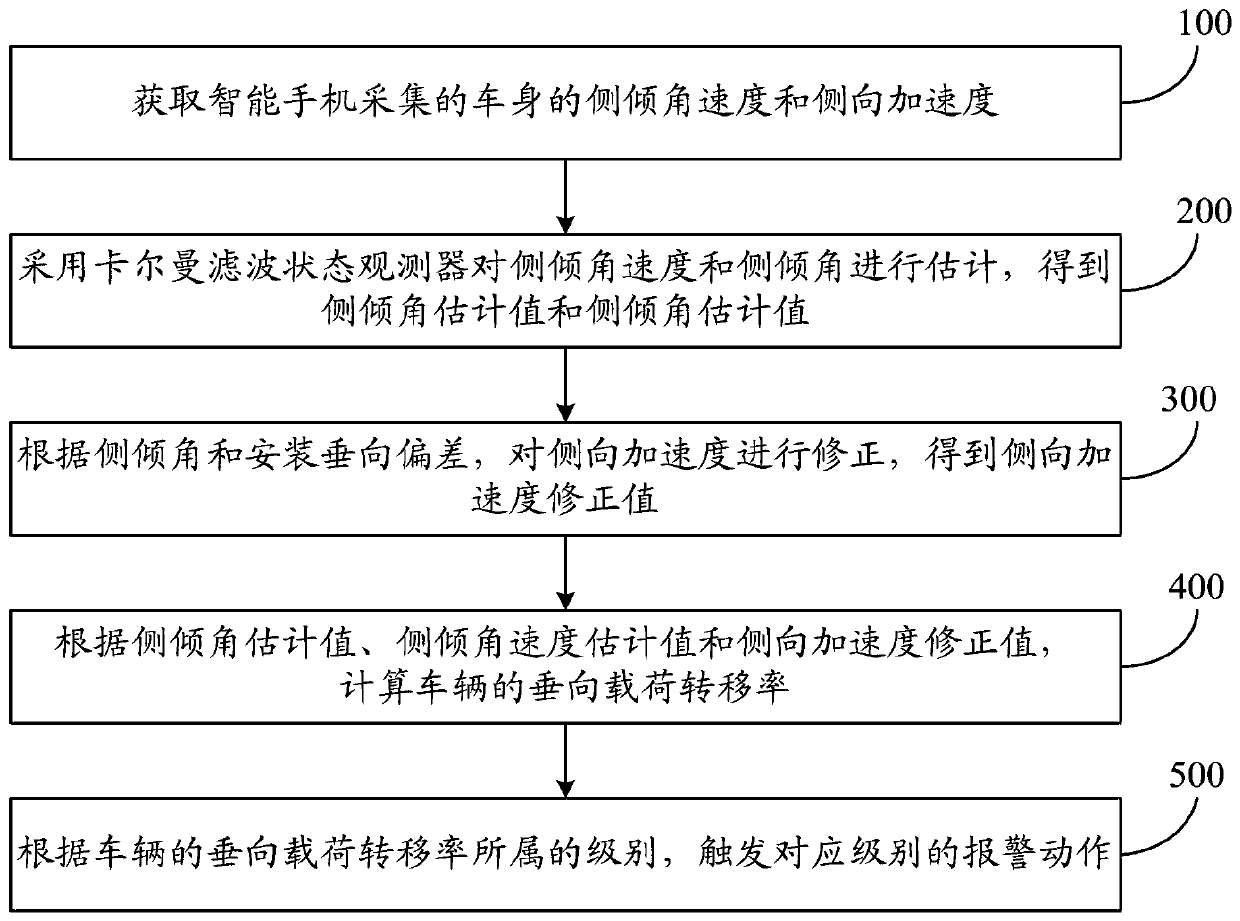

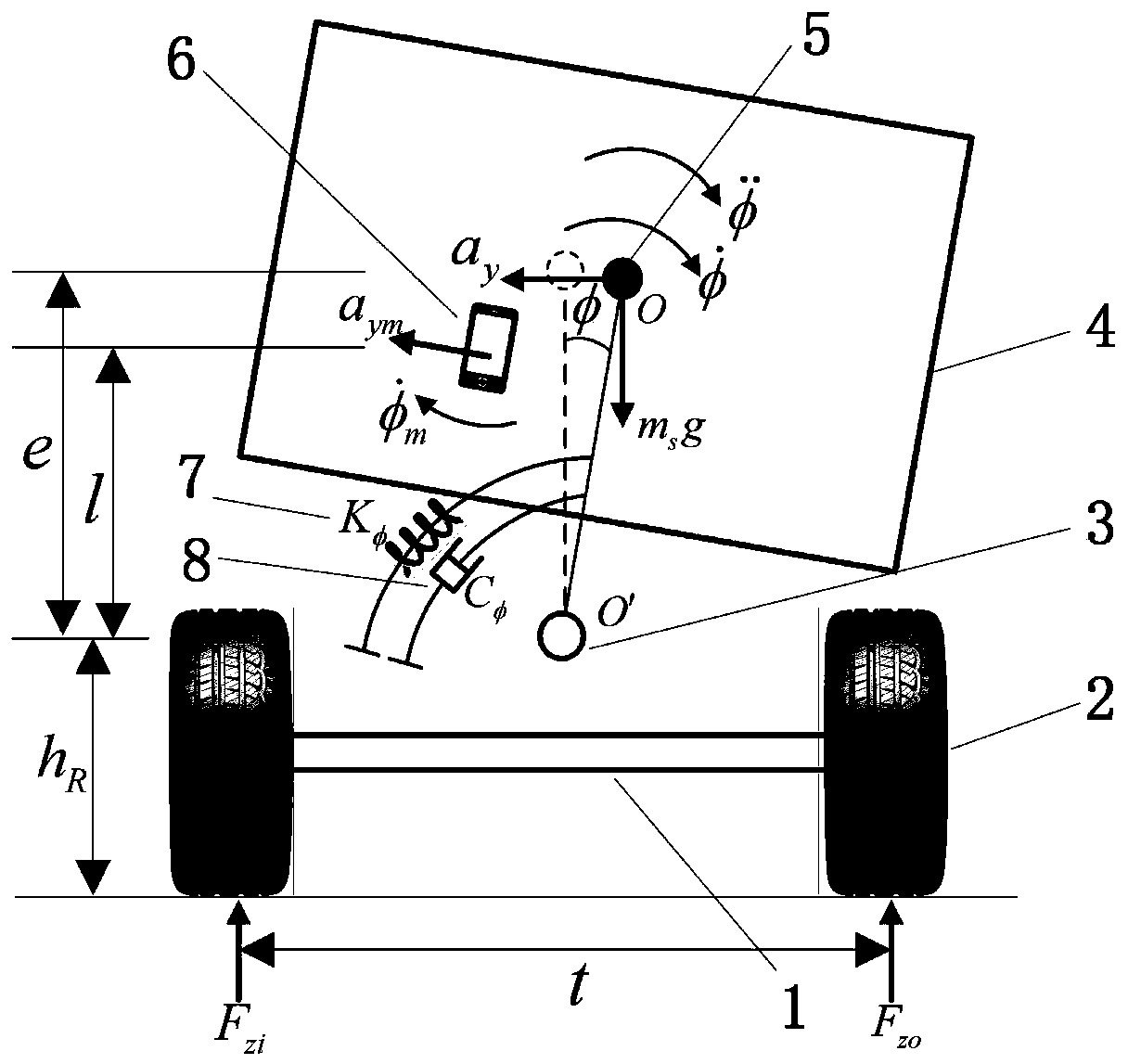

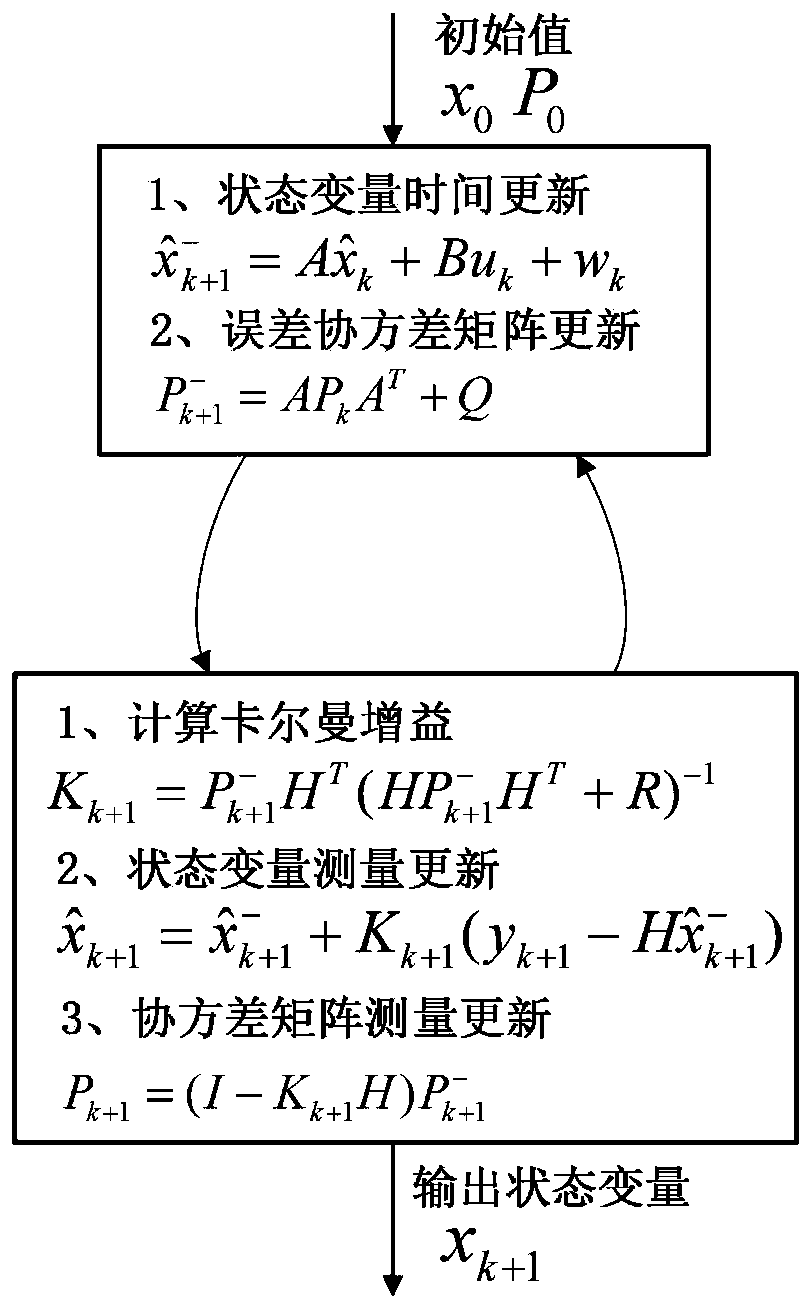

Early warning method and system for vehicle rollover

ActiveCN110239462ALow application costImprove robustnessSubstation equipmentElectric/fluid circuitRolloverState observer

The invention discloses an early warning method and system for vehicle rollover. The early warning method comprises the steps that a roll velocity and a lateral acceleration of a vehicle body collected by a smart phone are obtained; the smart phone is fixed to a center console inside a vehicle; the roll velocity and an angle of roll are estimated by using a Kalman filter state observer, an estimation value of the roll velocity and an estimation value of the angle of roll are obtained; according to the angle of roll and an installation vertical deviation, the lateral acceleration is corrected to obtain a lateral acceleration correction value; according to the estimation value of the angle of roll, the estimation value of the roll velocity and the lateral acceleration correction value, the vertical load transfer rate of the vehicle is calculated; an alarm action of the corresponding level is triggered according to the level to which the vertical load transfer rate of the vehicle belongs; and alarm prompts of different levels correspond to the different levels of vertical load transfer rates, and the different levels of the vertical load transfer rates correspond to different value ranges of the vertical load transfer rates. According to the early warning method and system for the vehicle rollover, the robustness can be improved, meanwhile, the error of the vehicle rollover early warning is reduced, and the accuracy is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

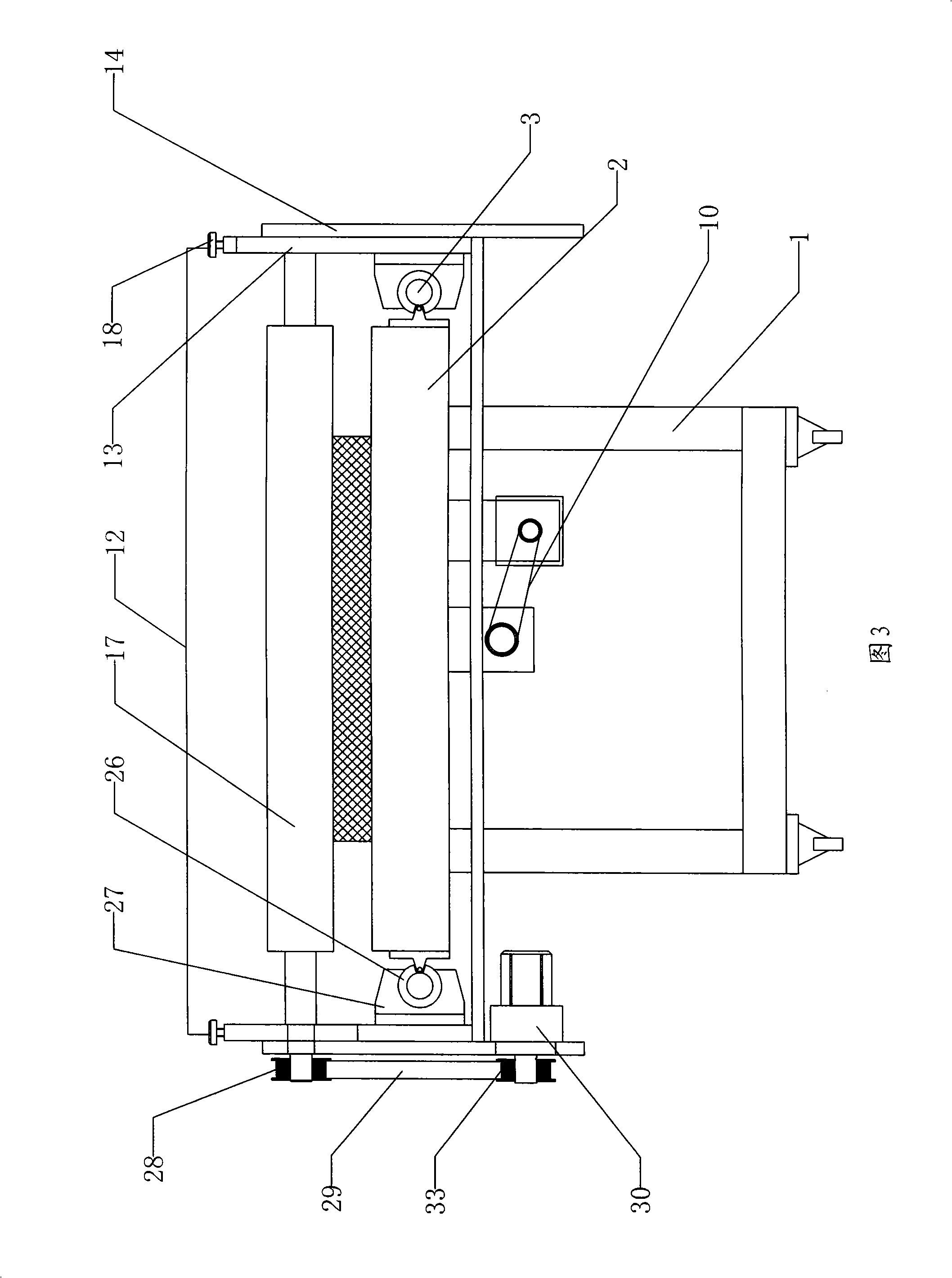

Novel film applicator

InactiveCN101342521AImprove stabilityImprove adhesionLiquid surface applicatorsCoatingsOptical axisEngineering

The invention relates to a novel film coating machine, comprising a machine frame, a work-table, two guide rails, two hanging plates, a lead screw and an electric motor. The work-table is fixed on the machine frame; the guide rails are respectively arranged on both sides of the work-table, and the hanging plates are arranged at both ends of the work-table; the two hanging plates are connected with the two ends of by a bearing; a bearing housing is coated on the bearing, and the right end of the lead screw is connected with a belt wheel; the electric motor is fixed on the lower part of the right hanging plate, the belt wheel on the electric motor is connected with the belt wheel arranged at the right end of the lead screw, and the lead screw is coated in the nut; the film costing device comprises a riser, a slider, a fixing guide rail, an optical axis, a rubber shaft, frame strips, a connect plate, a nut, a linear bearing and an electric motor. The invention has the advantages of that the picture is fixed, the method that the rubber shaft moves horizontally and rolls for film coating in the inverse direction is adopted; the stability of film costing is enhanced and the film coating quality is improved; the gap between the rubber shaft, the movement speed of the rubber shaft and the rolling speed is adjustable; the film coating quality is ensured and the thickness of the film coat is controlled.

Owner:常明旺

Method and apparatus for testing the rolling tack of pressure-sensitive adhesives

InactiveUS20040083819A1Efficient use ofUniform coatingMaterial strength using tensile/compressive forcesUsing mechanical meansEngineeringRepeatability

A method and apparatus for testing tack of Pressure Sensitive Adhesives (PSA) and other sticky materials is disclosed to simplify the measurement of bonding and debonding procedures. A modified rolling tack test is applied using a device attached on to an Instron Universal Testing machine. By predetermining the angle (position) of a cylindrical probe-roller hanging down to the Instron's cross-head and leaning parallel to a rotary drum covered with tacky substance, the pressure of the probe and its rolling velocity (as an expression for dwell time) can be controlled independently. The ease of execution and its high reproducibility enable the use of the new method to study the experimental tack of adhesive materials.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

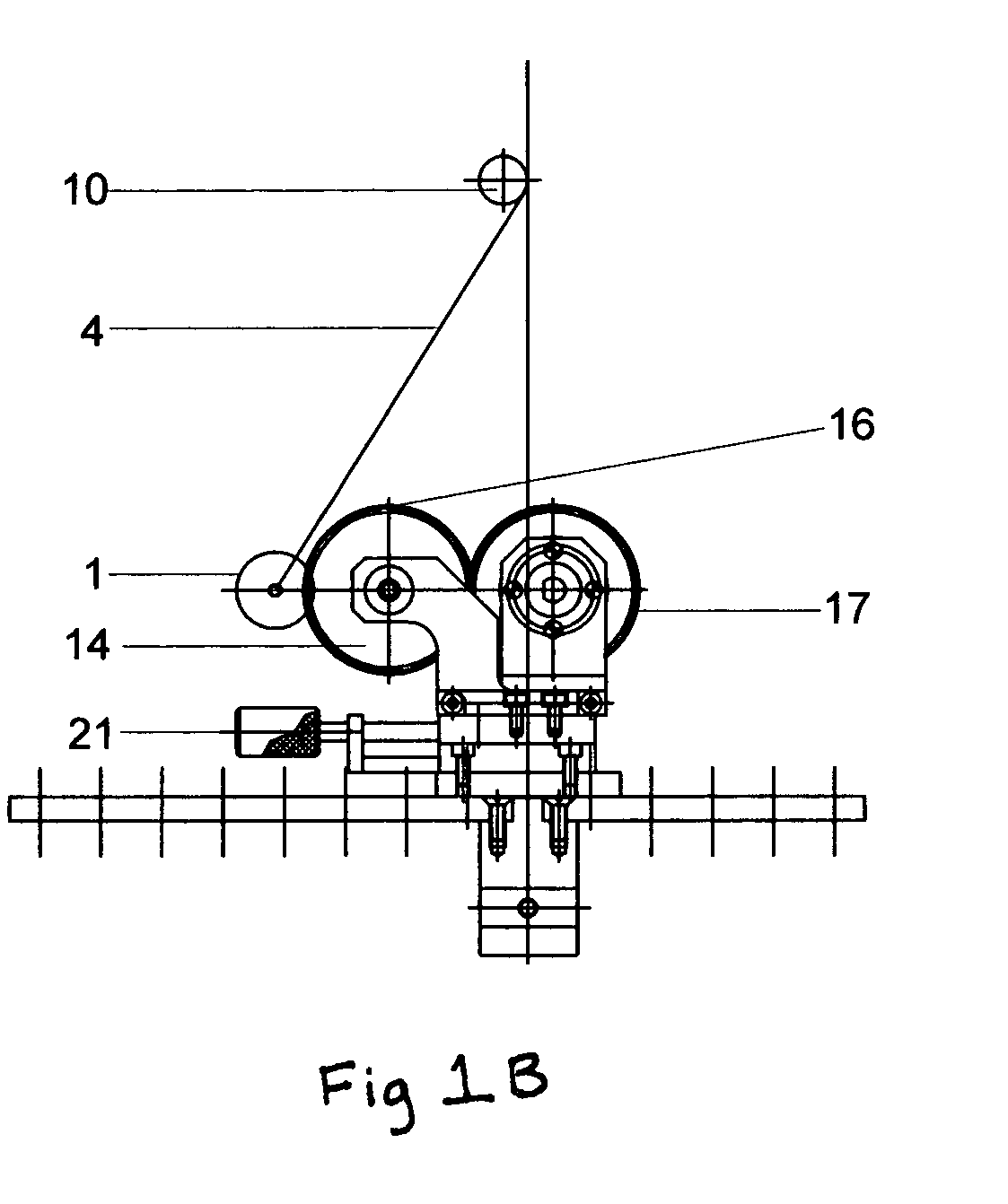

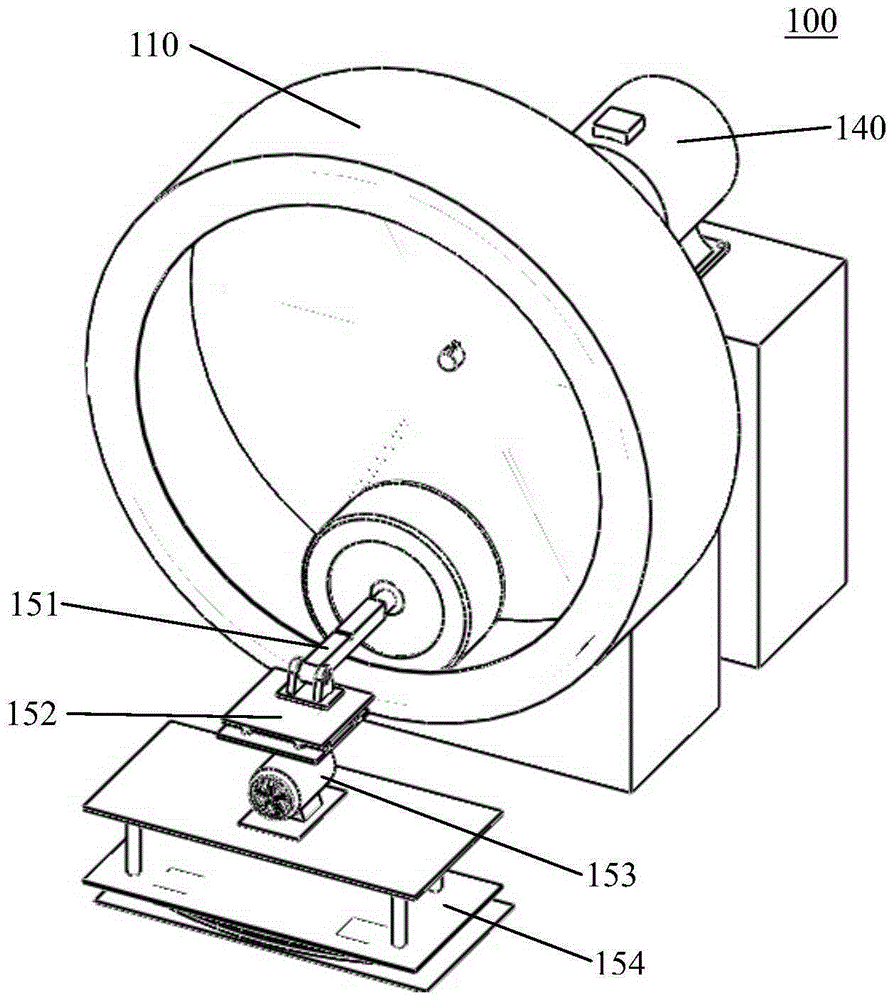

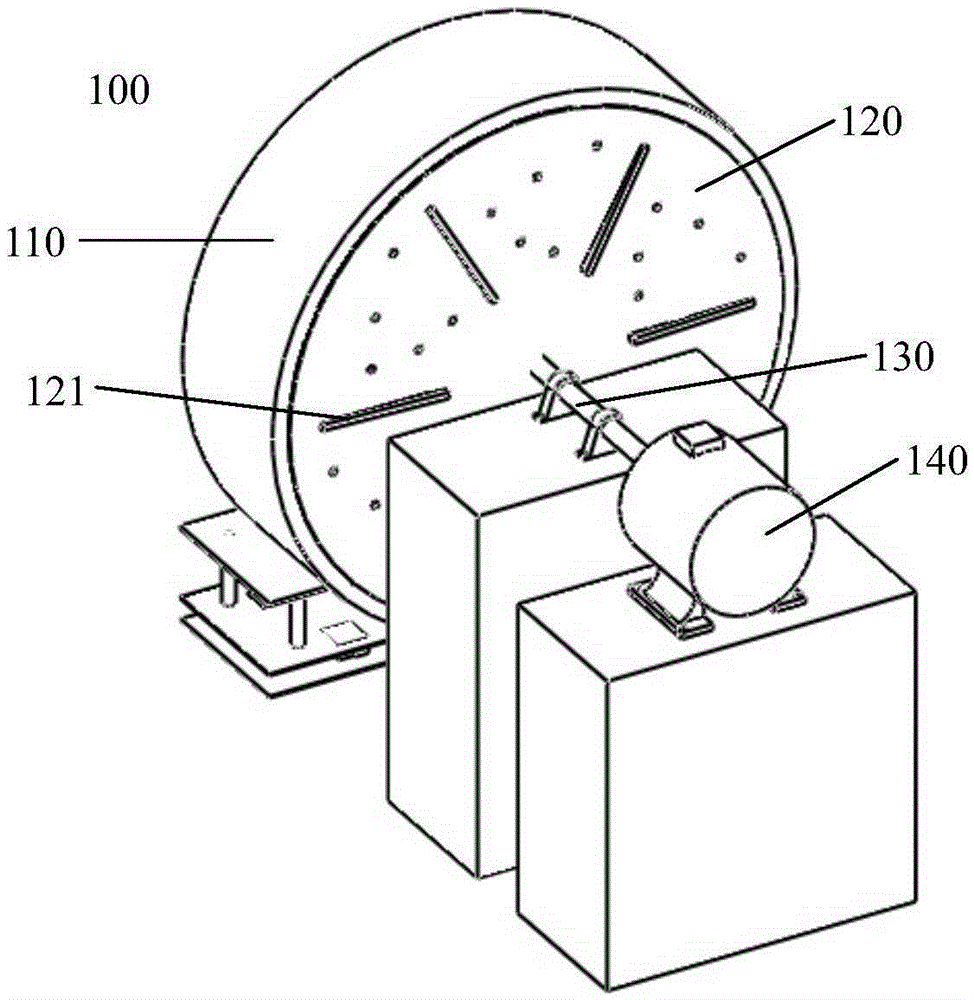

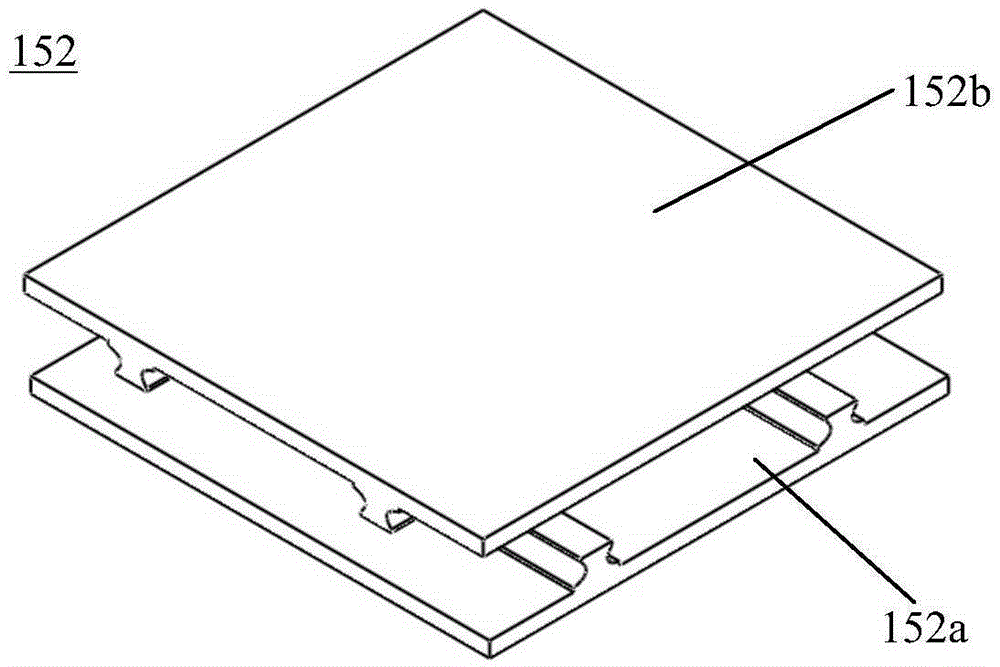

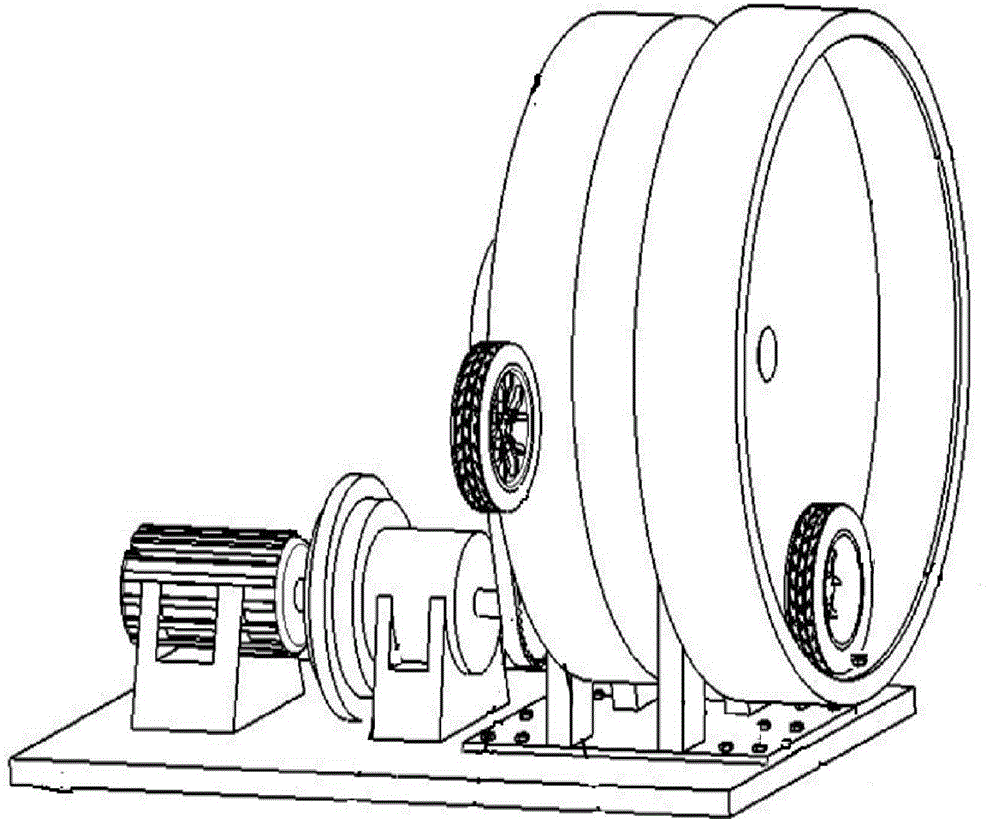

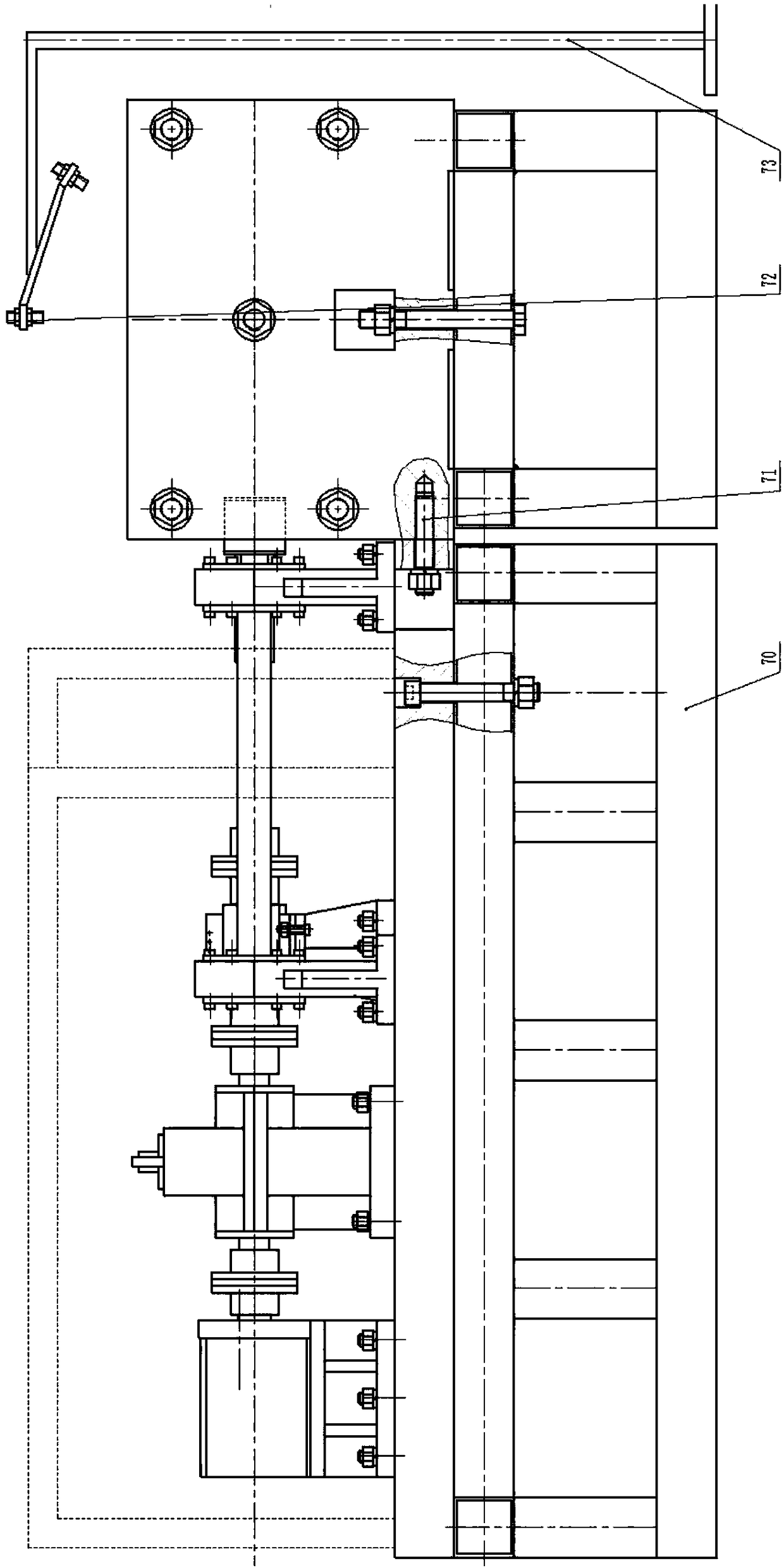

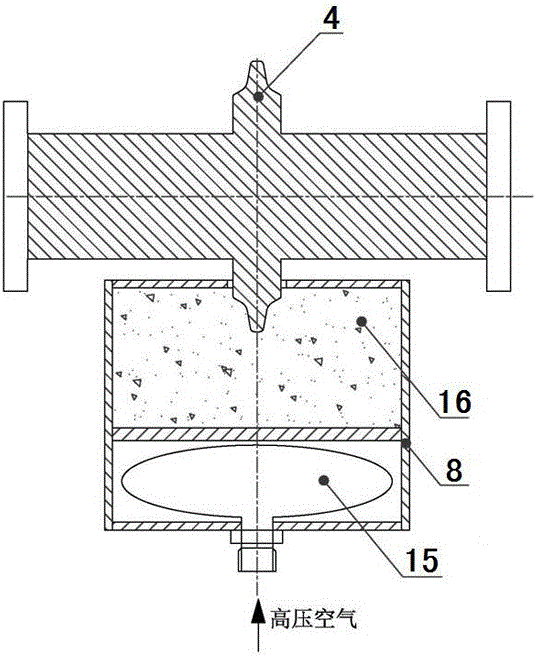

Tire test device

ActiveCN105388027AImprove working conditionEffective researchVehicle tyre testingRoad surfaceRolling velocity

Owner:TSINGHUA UNIV

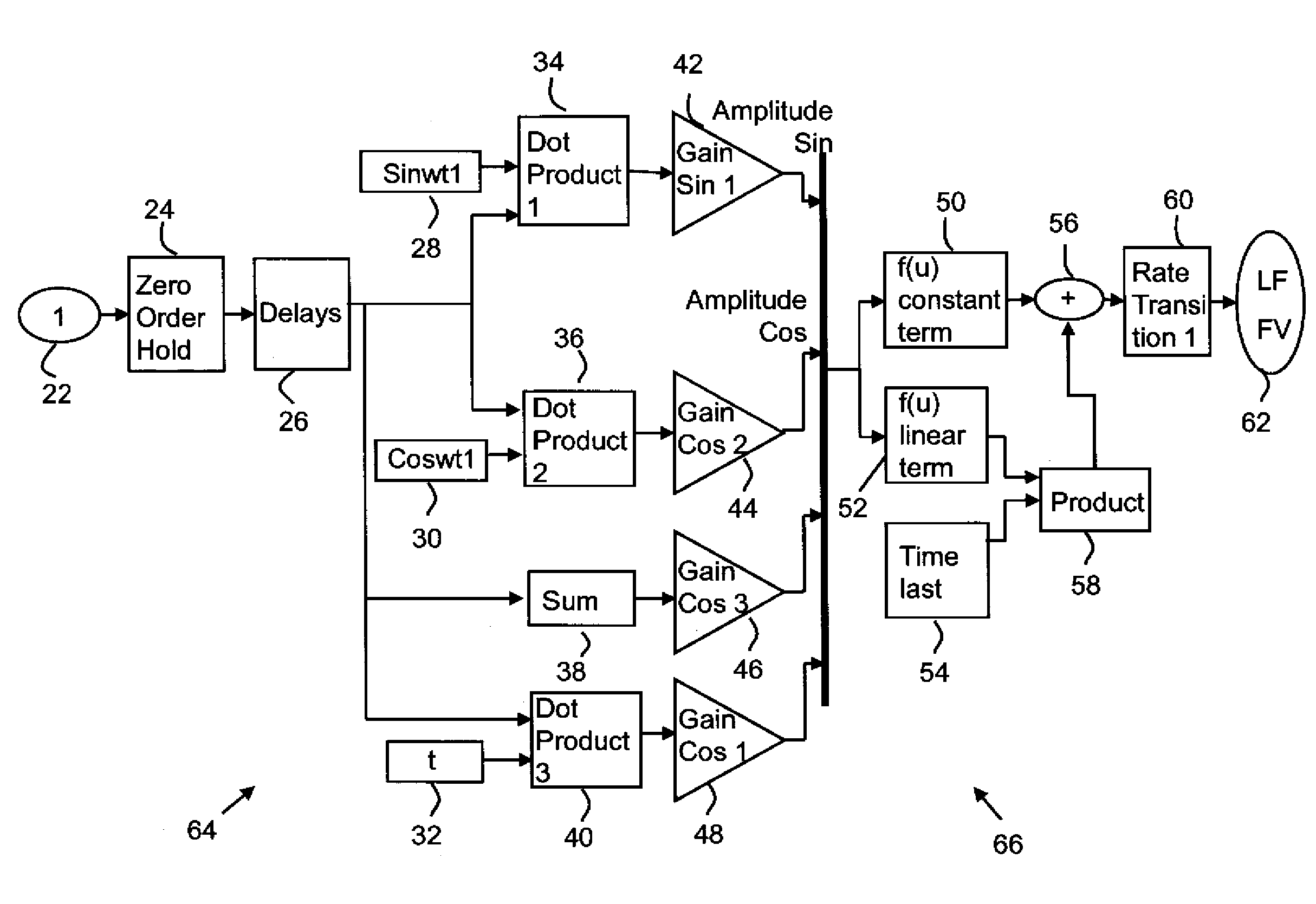

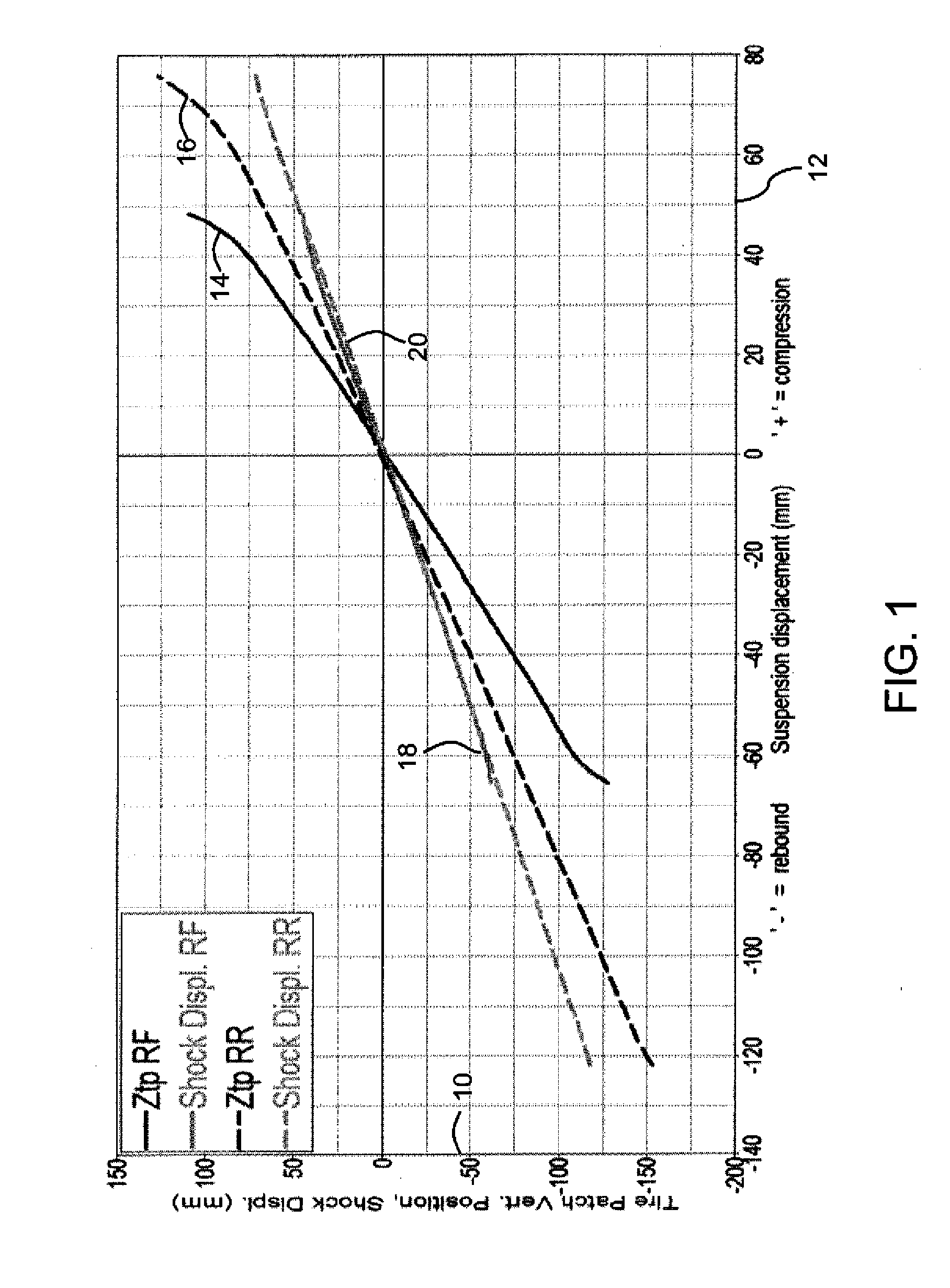

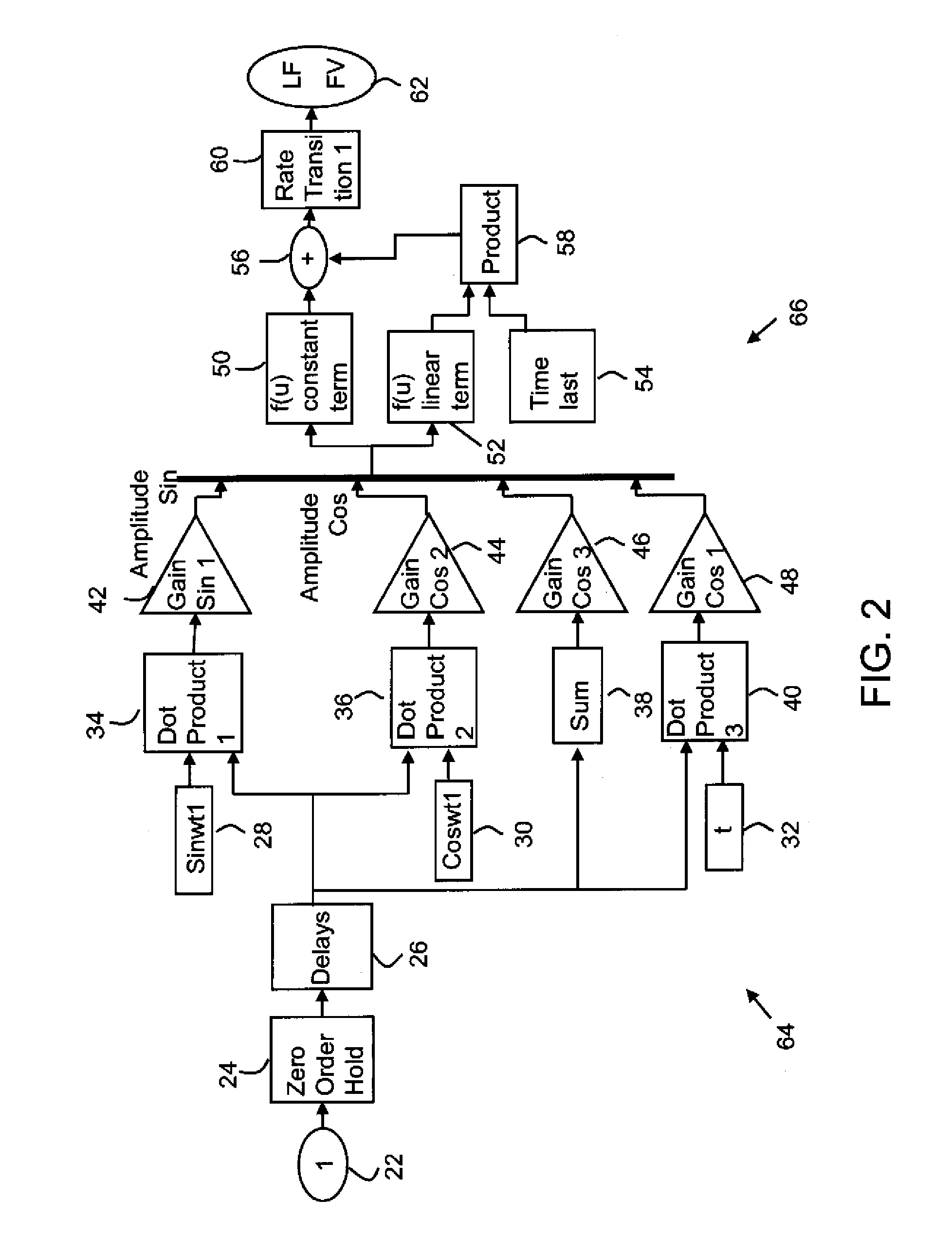

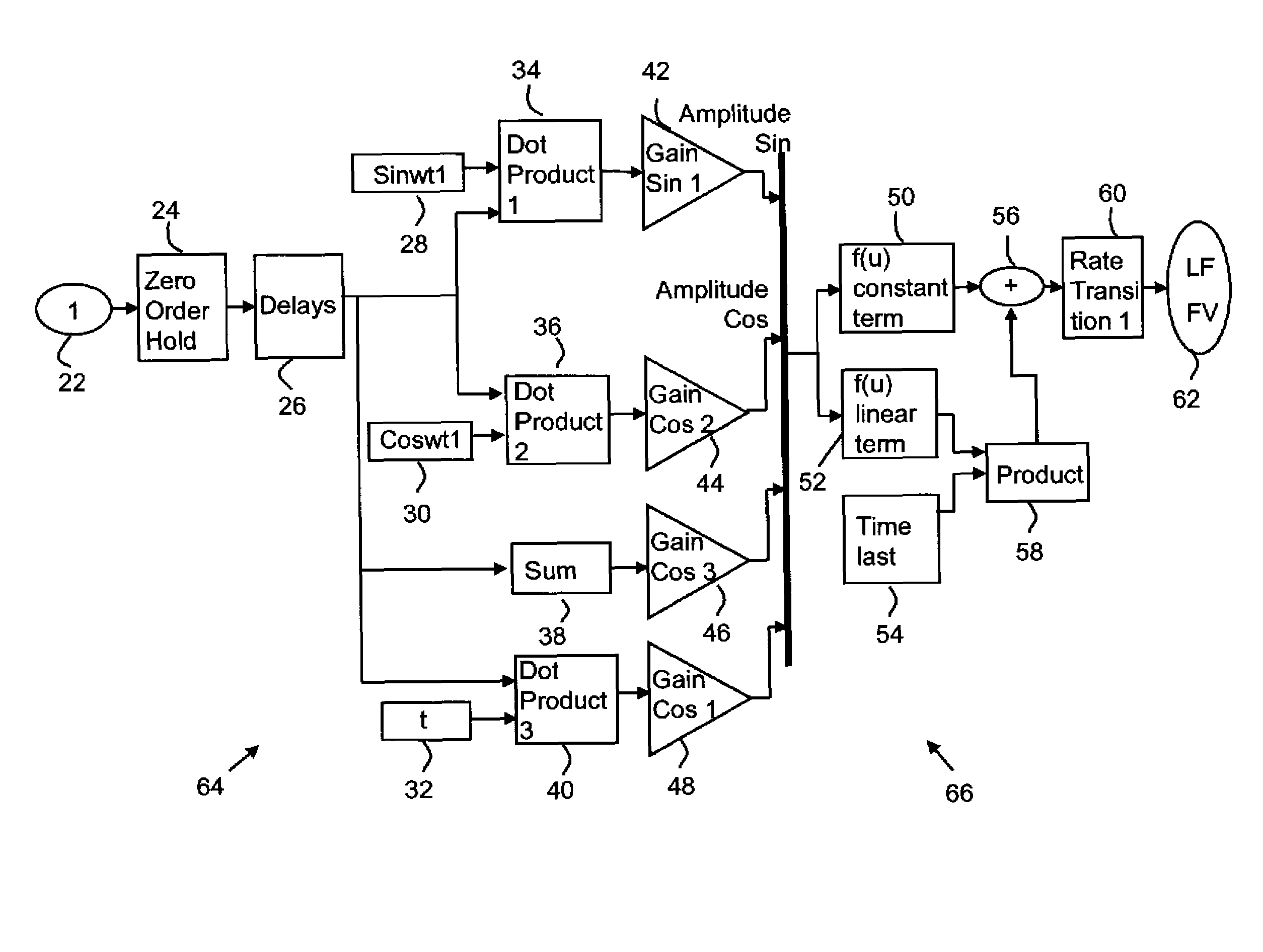

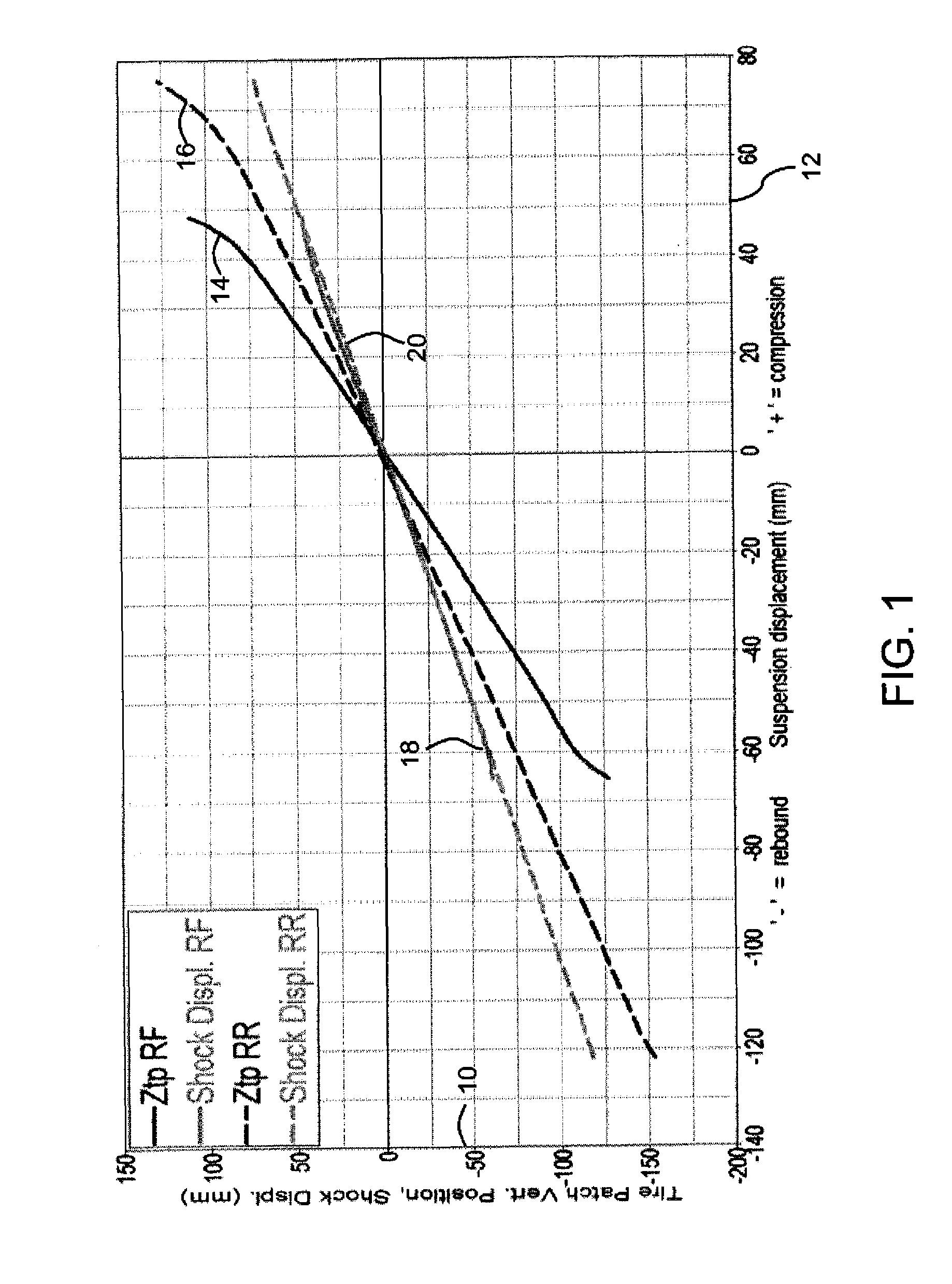

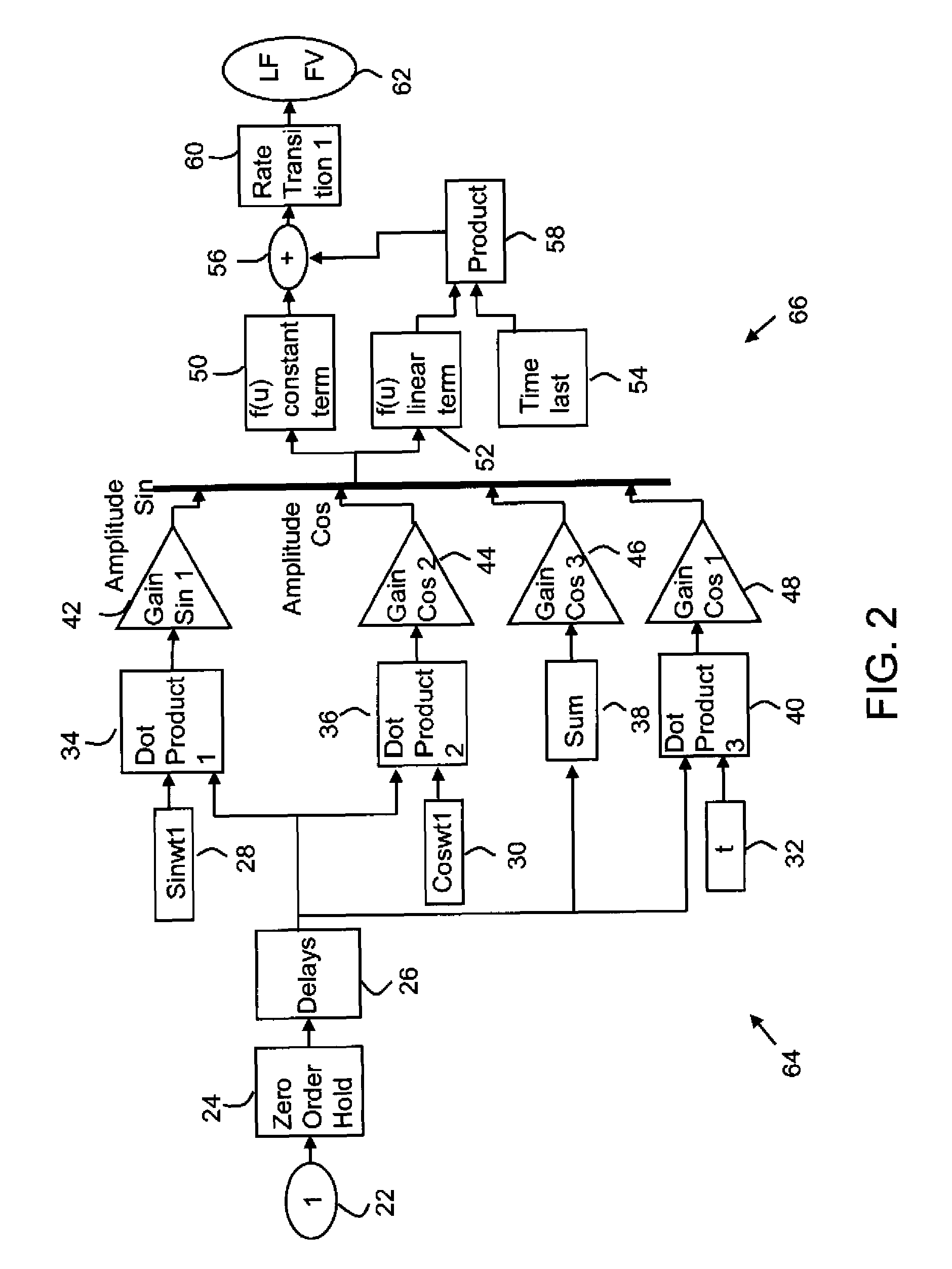

Nonlinear frequency dependent filtering for vehicle ride/stability control

InactiveUS20100082202A1Enabling ride controlEnabling stability controlDigital data processing detailsAnimal undercarriagesNonlinear filterEngineering

A system and method for facilitating ride and stability control of a vehicle. The system includes a plurality of suspension displacement sensors, with each of the plurality of suspension displacement sensors positioned proximate to a suspension element of the vehicle. The system further includes a nonlinear filter for filtering out a wheel hop frequency from the suspension velocity corresponding to at least one of the plurality of suspension displacement sensors to obtain a resultant suspension velocity. The resultant suspension velocity is used by a control unit to determine the pitch velocity, roll velocity and the heave velocity of the vehicle.

Owner:GM GLOBAL TECH OPERATIONS LLC

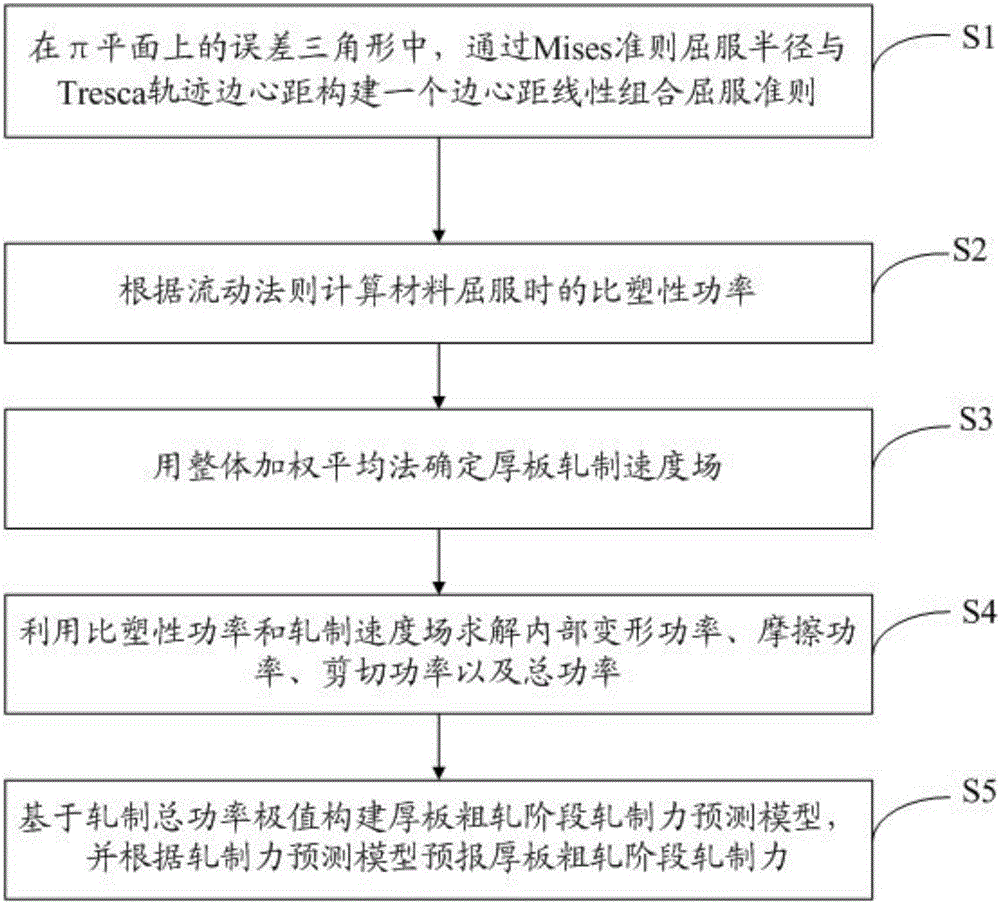

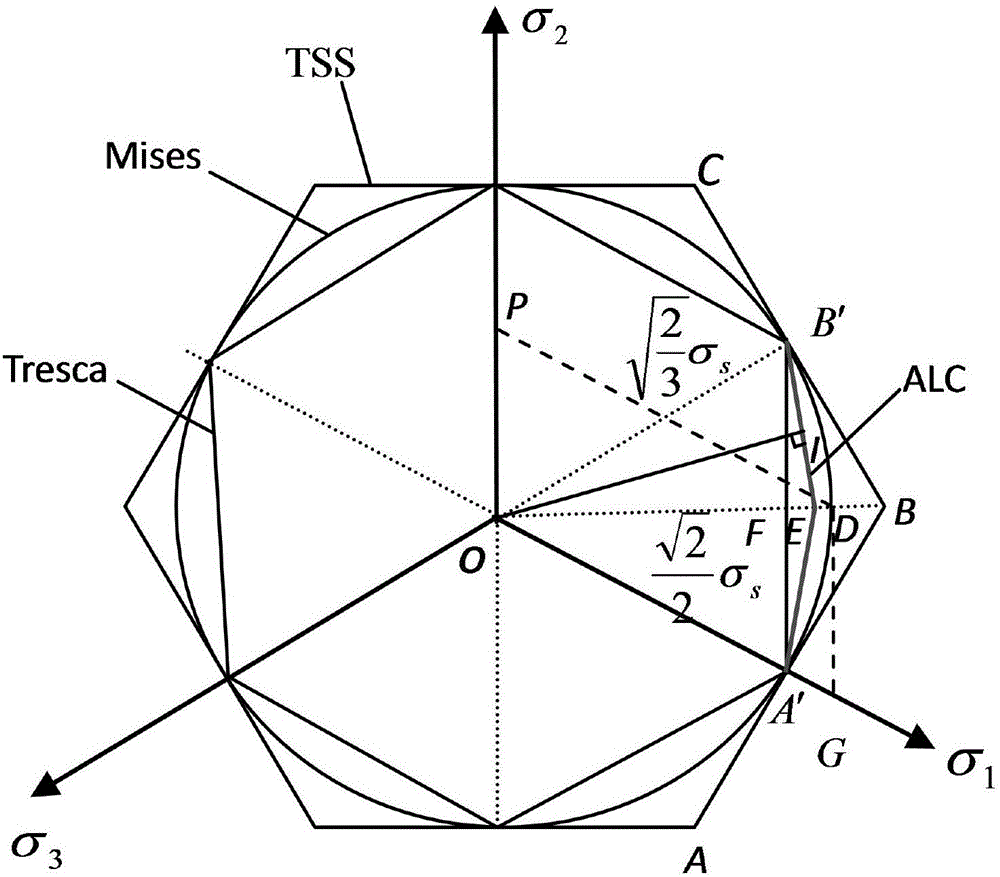

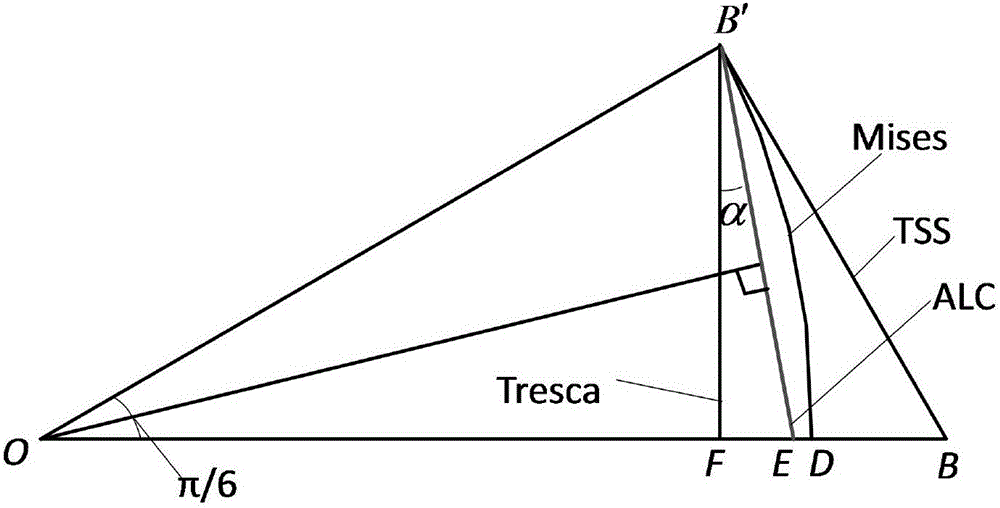

Rolling force prediction method in thick plate rough rolling stage

ActiveCN106623443AStable rollingGeometric CADRoll force/gap control deviceThick plateWeighted average method

The invention discloses a rolling force prediction method in a thick plate rough rolling stage. The method includes the steps that (1), in an error triangle on a Pi plane, an apothem linear combination yield criterion is built through an Mises criterion yield radius and the Tresca trajectory apothem; (2), the specific plastic power in the material yield process is calculated according to a flowing criterion; (3), a thick plate rolling velocity field is determined through an overall weighted average method; (4), internal deformation power, friction power, shearing power and the total power are solved through the specific plastic power and the rolling velocity field; (5), a rolling force prediction model in the thick plate rough rolling stage is built based on the total rolling power extreme value, and the rolling force in the thick plate rough rolling stage is predicated according to the rolling force prediction model. By means of the rolling force prediction method, the rolling force in the thick plate rough rolling stage can be accurately predicated, optimization of intensity check and process parameters of a rolling mill can be guided in a quantitative manner, and it is guaranteed that a thick plate product can be rolled stably.

Owner:SUZHOU UNIV

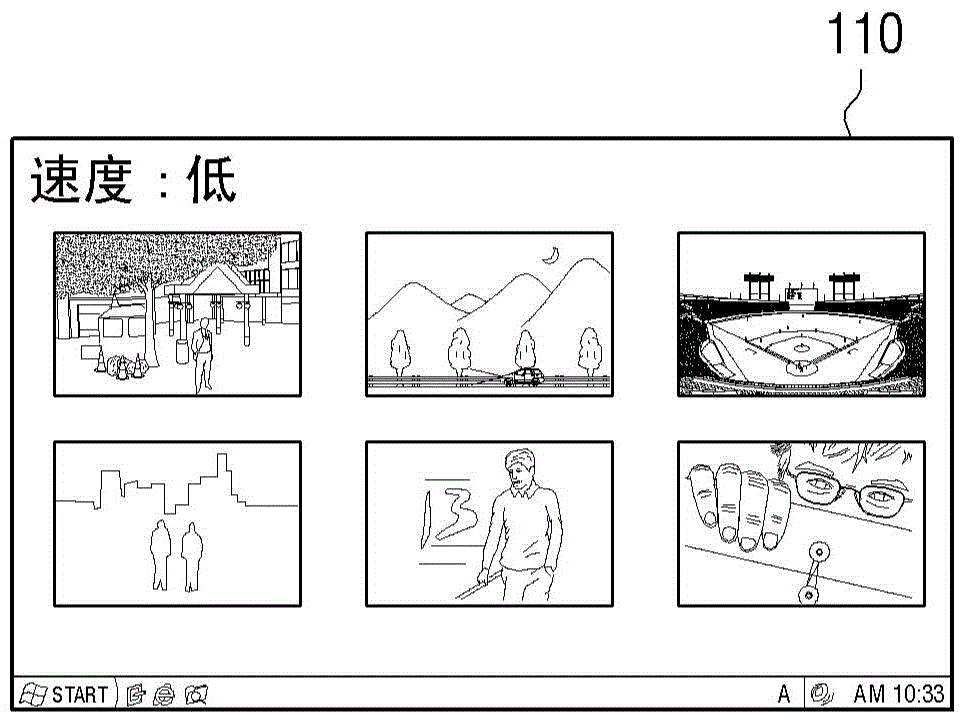

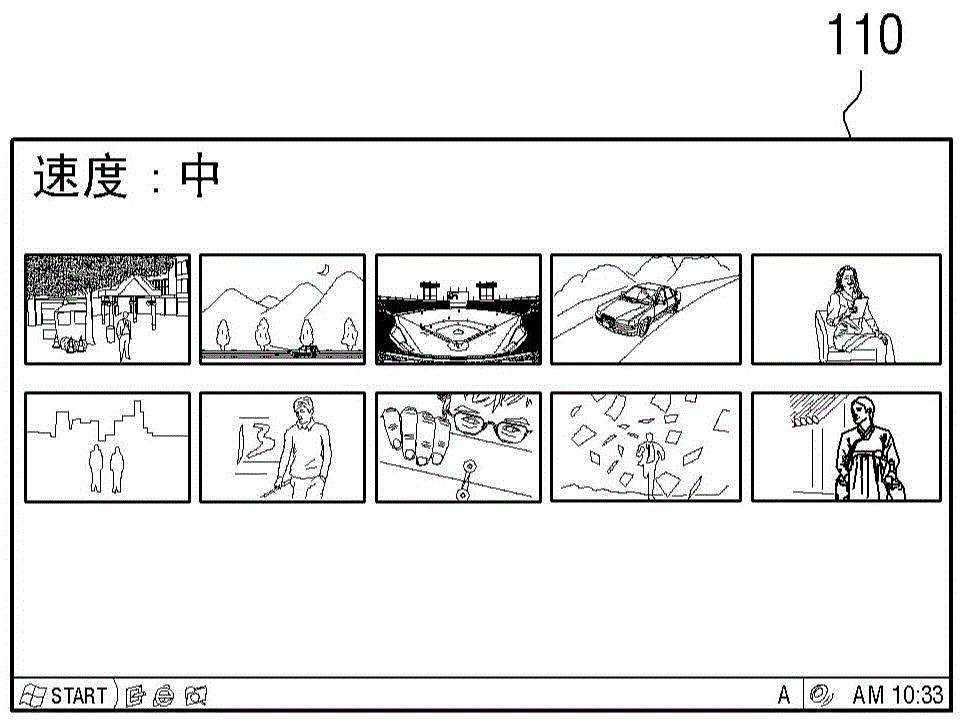

Display method and apparatus for diversely displaying an object according to scroll speed

InactiveCN104077025AIntuitive displayGeometric image transformationDigital output to display deviceUser inputComputer graphics (images)

A display method of a display apparatus is provided. The method includes displaying at least one object in a screen, receiving a user input for performing a scroll for at least one object, and changing the size of the area of the screen in which the at least one object is displayed on the screen according to scroll speed which corresponds to the received user input, and scrolling the at least one object according to the scroll direction.

Owner:SAMSUNG ELECTRONICS CO LTD

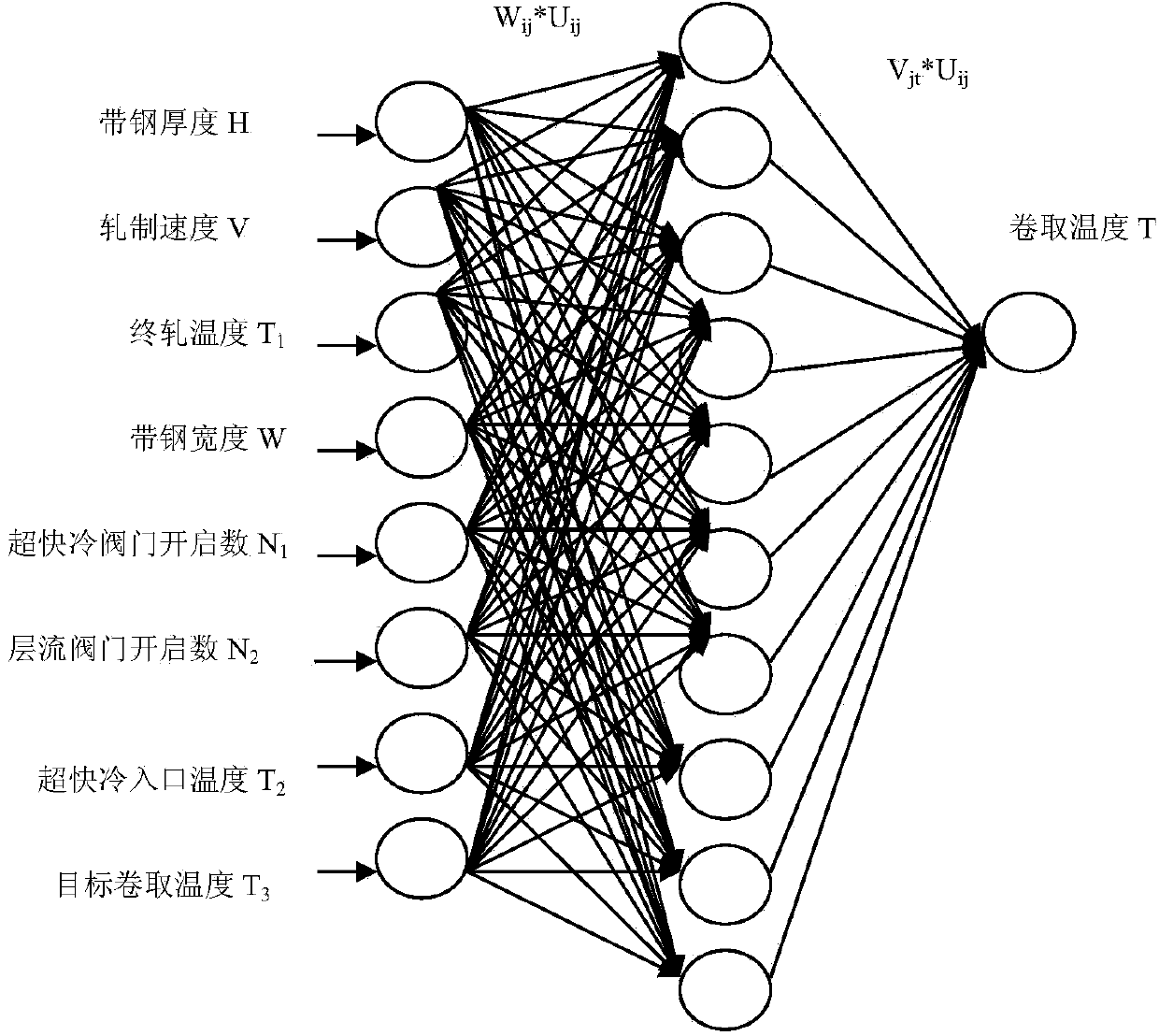

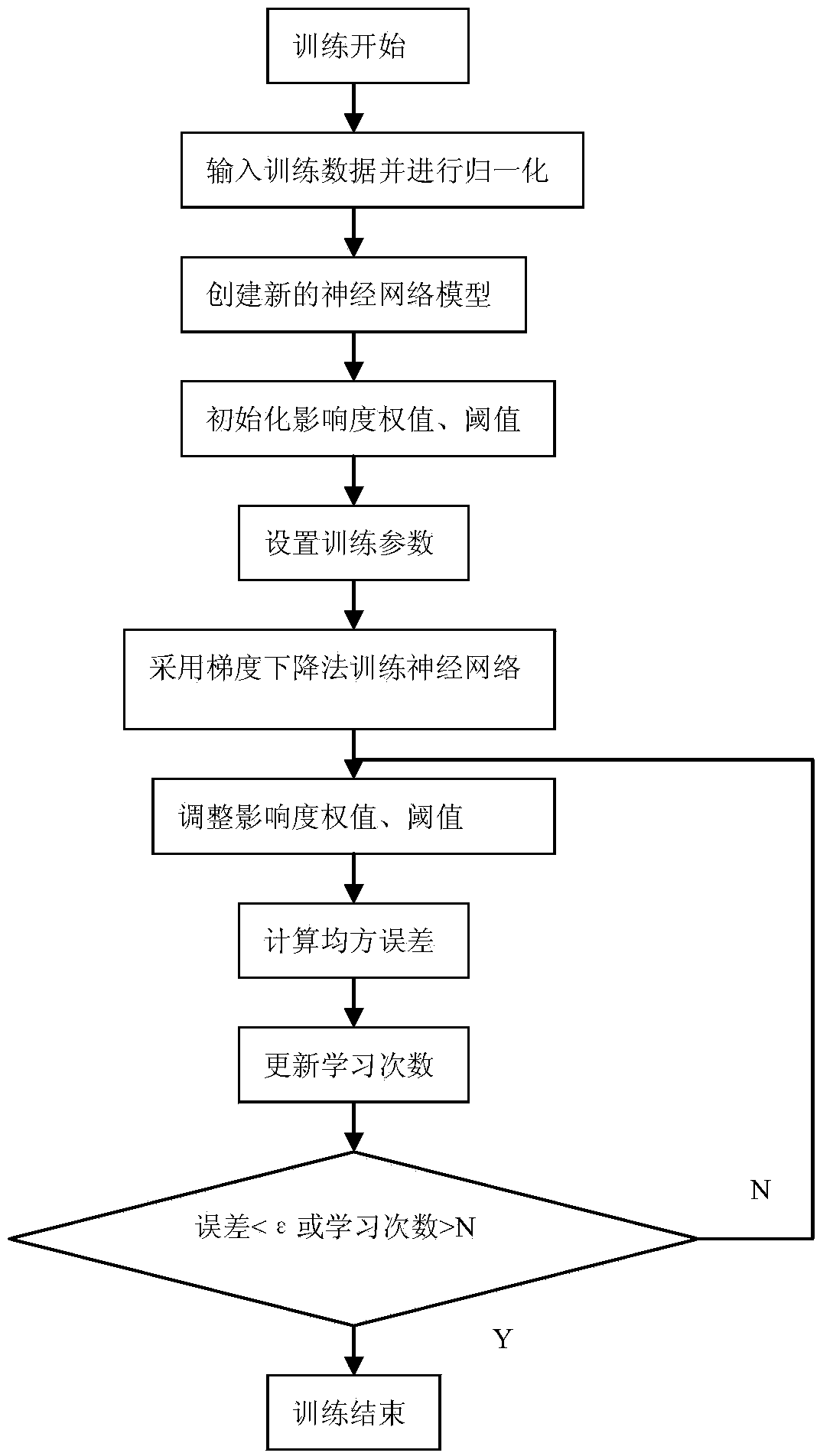

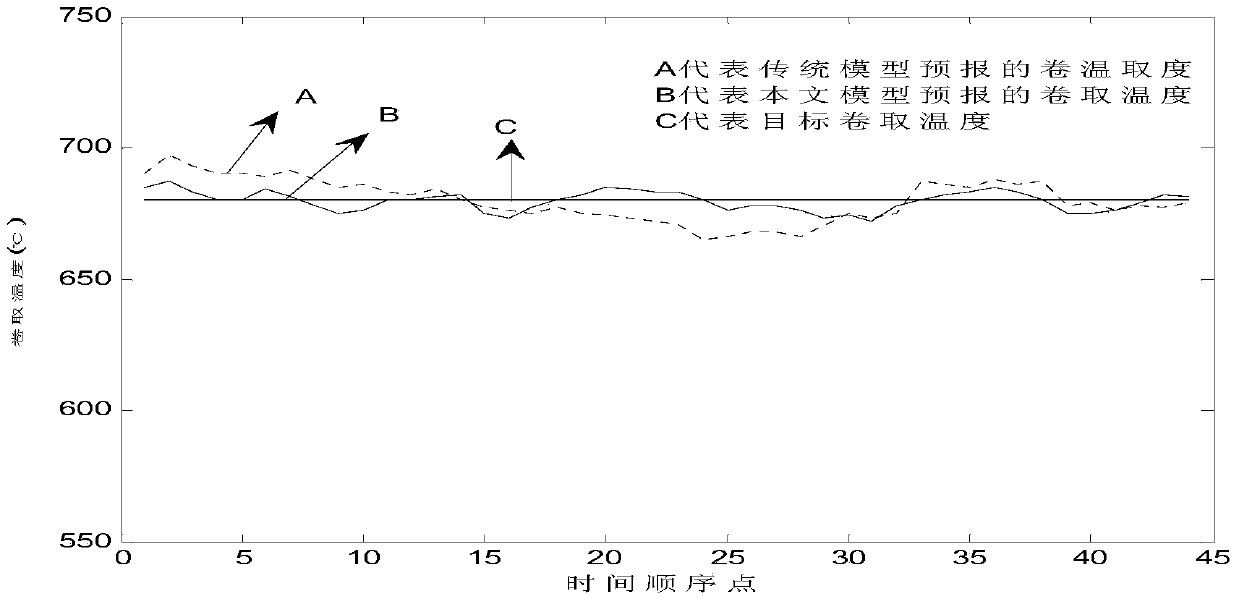

Hot-rolling coiling temperature forecasting method based on relevant neural network

ActiveCN103464475AAccurate coiling temperature controlTemperature control deviceTemperature controlHidden layer

The invention provides a hot-rolling coiling temperature forecasting method based on a relevant neural network. Data of strip steel thickness H, rolling velocity V, finish rolling temperature T1, strip steel width W, super rapid cooling valve opening quantity N1, laminar flow valve opening quantity N2, super rapid cooling inlet temperature T2 and target coiling temperature T3 are collected through a personal digital assistant (PDA) terminal, an input matrix [H, V, T1, W, N1, N2, T2, T3] is built, and an output matrix [T] is built. If [V, T1, W, N1, N2, T2, T3] is supposed to be not changed, Y is defined to be an influence degree of the H. According to influence degrees, corresponding influence degrees are given to the weight of the input end and a hidden layer and to the weight of the hidden layer and an output layer, three layers of ASBP neutral networks are built, the actual coiling temperature is output, ASBP neutral network training is conducted, and coiling temperature forecasting is conducted by using actual testing data. By means of the method, a coiling temperature forecasting error range is reduced from -20 DEG C-20 DEG C to -10 DEG C-10 DEG C, and coiling temperature control is more accurate.

Owner:ANGANG STEEL CO LTD

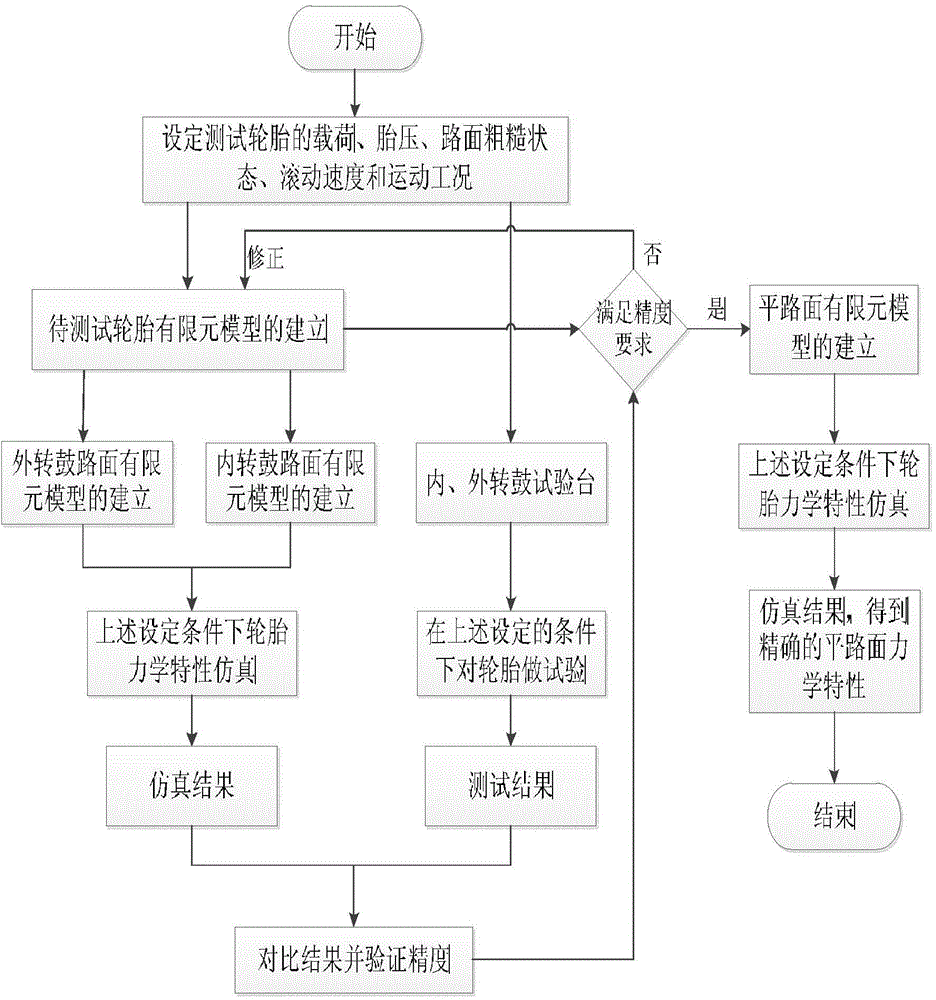

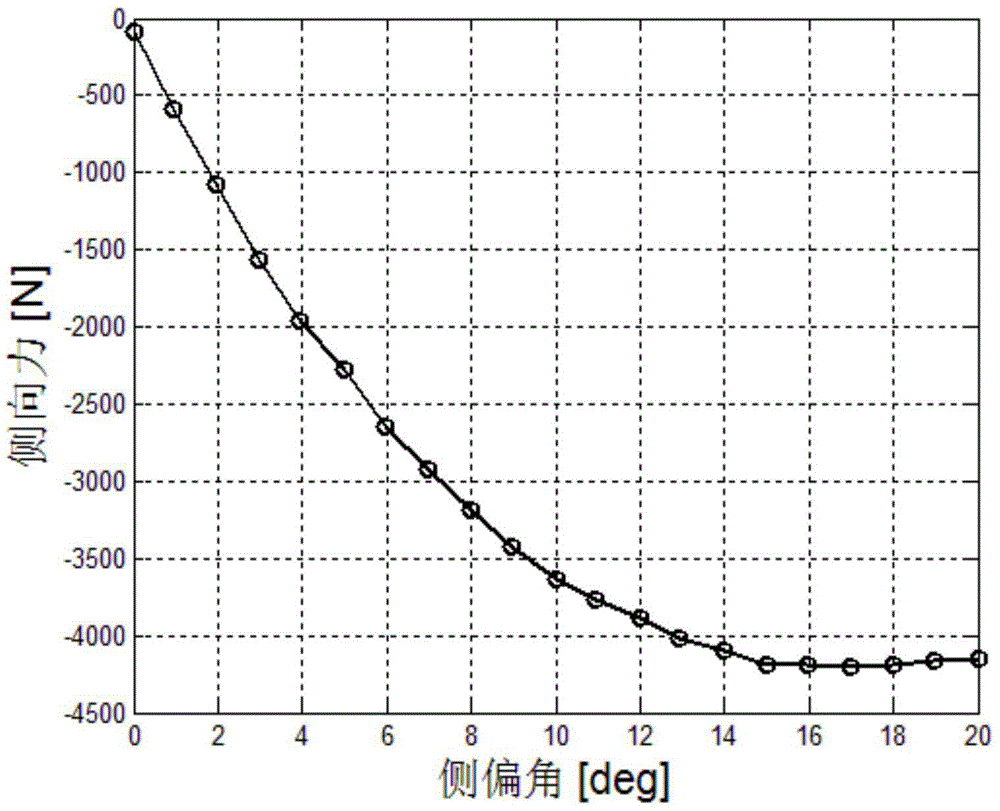

Method of predicating flat-pavement mechanical properties of tyre based on test data of rotary drum test bed

ActiveCN104390794AReliable CorrectionThe mechanical properties of flat pavement are accurately obtainedVehicle tyre testingFinite element techniqueRoad surface

The invention discloses a method for predicating flat-pavement mechanical properties of a tyre based on test data of a rotary drum test bed. The method comprises the following steps of: setting load, tyre pressure, pavement rough state, rolling speed and movement working conditions (lateral deviation, lateral inclination, and the like) of the tested tyre, and implementing the tests and the simulations in the following steps under the conditions; establishing a model for the tested tyre by utilizing ABAQUS software, and respectively stimulating movement of the tyre on inner rotary drum pavement and outer rotary drum pavement; simultaneously correcting the tyre model by using the test data of the inner rotary drum test bed and the outer rotary drum test bed; simulating the tyre movement under the special condition on the flat pavement by using the corrected precise tyre model so as to precisely predicate the flat-pavement mechanical properties of the tyre. The method disclosed by the invention can be used for effectively eliminating influences of the pavement curvature by utilizing the tested data of the rotary drum test bed through a finite element technology to obtain the mechanical properties of the tyre on the flat pavement, has the advantages of simple needed test equipment and high predication precision. Meanwhile, the method is suitable for all tyres including large-load and high-rotation-speed aircraft tyres.

Owner:JILIN UNIV

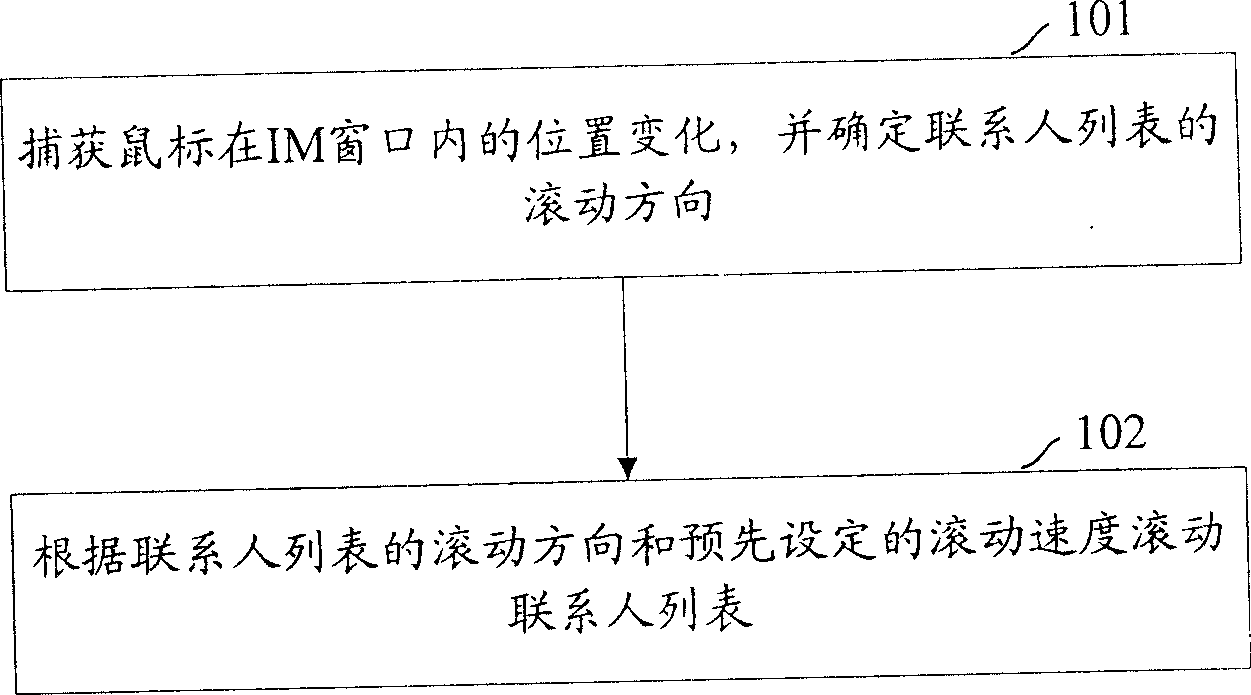

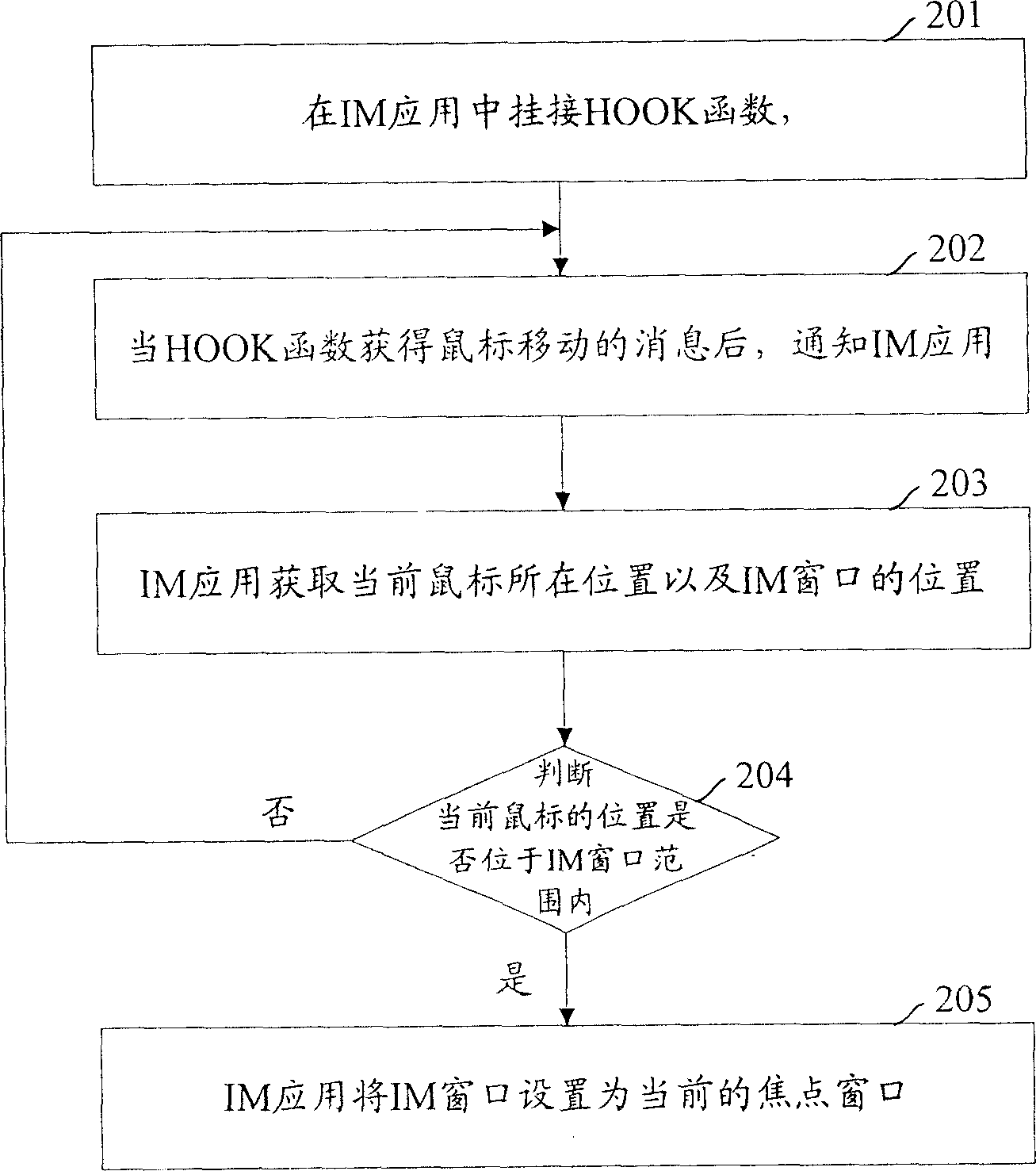

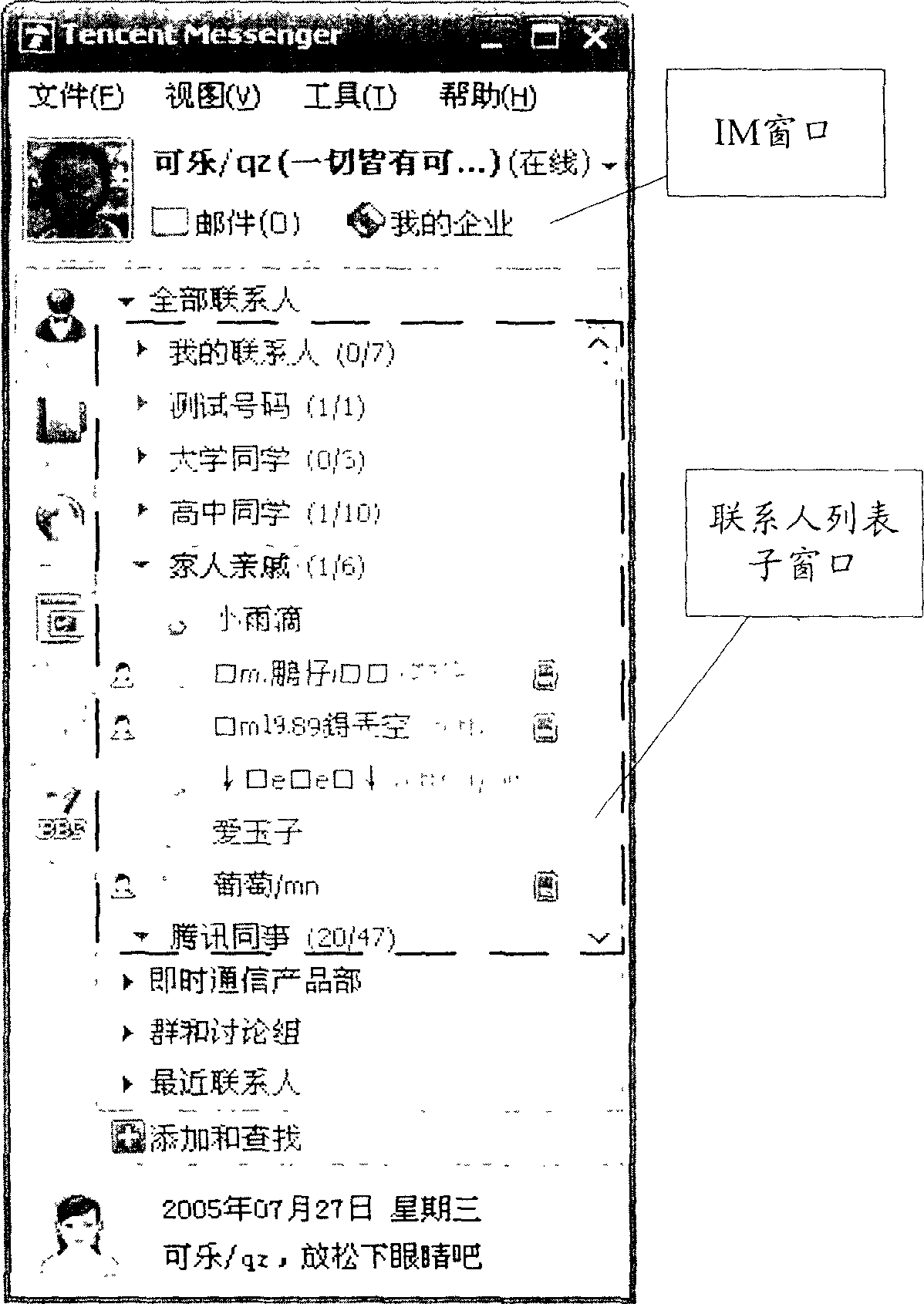

Method for automatic rolling over list of linkman in instant message window

ActiveCN1916825AAvoid cumbersome actionsEasy to operateInput/output processes for data processingComputer scienceRolling velocity

Owner:TENCENT TECH (SHENZHEN) CO LTD

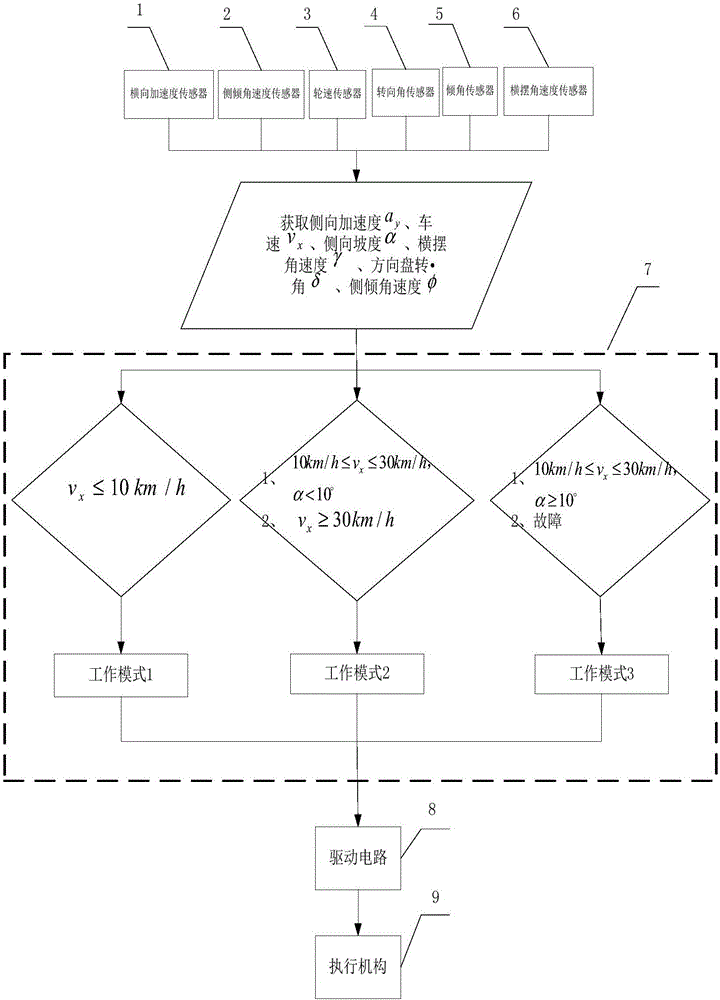

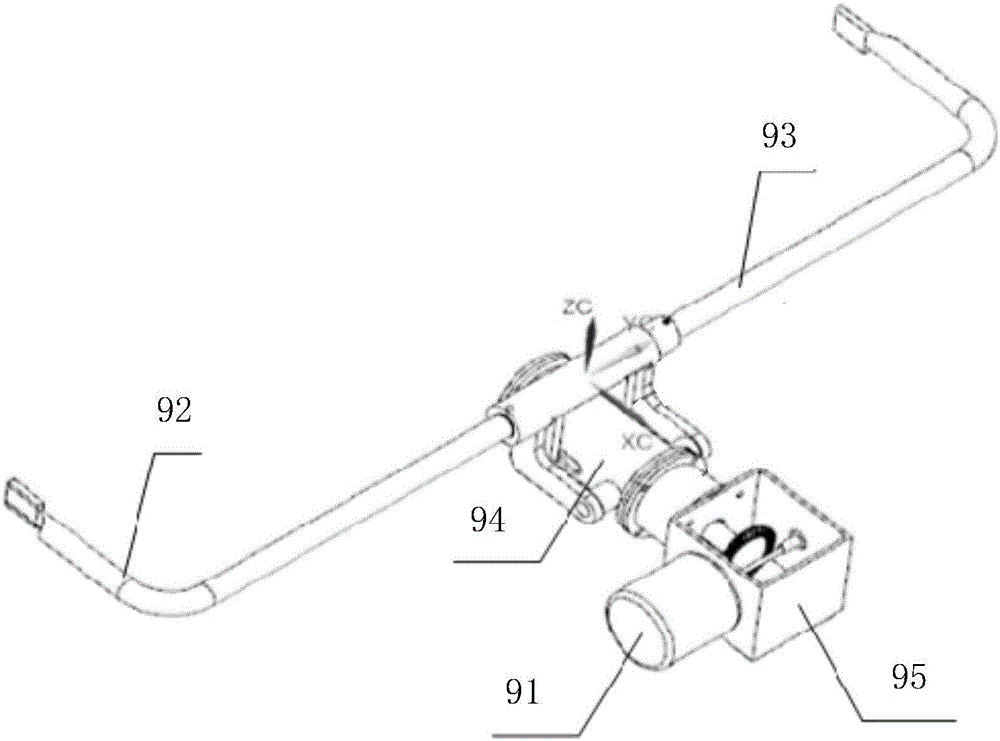

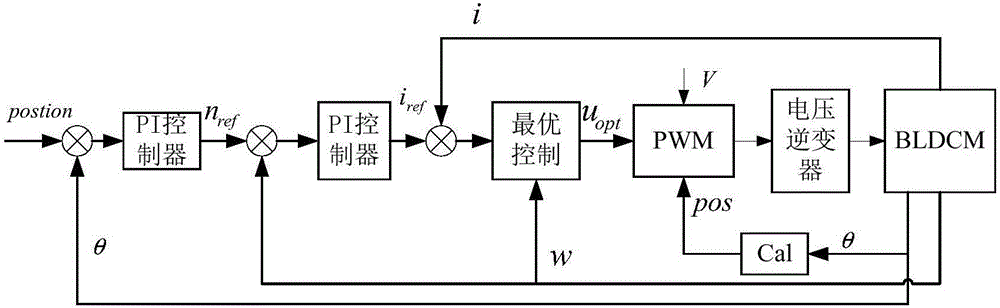

Motor type active stable rod control system

PendingCN106627026ASimple structureEasy to controlInterconnection systemsResilient suspensionsSteering angleWheel speed sensor

The invention discloses a motor type active stable rod control system. The system comprises a transverse acceleration sensor (1), a roll velocity sensor (2), a wheel speed sensor (3), a steering angle sensor (4), a dip angle sensor (5), a yaw velocity sensor (6), an ECU control unit (7), a driving circuit (8) and an executing mechanism (9). The ECU control unit (7) is electrically connected with the executing mechanism (9) through the driving circuit (8), and the transverse acceleration sensor (1), the roll velocity sensor (2), the wheel speed sensor (3), the steering angle sensor (4), the dip angle sensor (5) and the yaw velocity sensor (6) are electrically connected with the ECU control unit (7). The motor type active stable rod control system can select reasonable work modes according to different running conditions of a vehicle, a required rolling moment resistant torque value is adjusted in real time, and rolling of a vehicle body is effectively inhibited.

Owner:NANJING UNIV OF SCI & TECH

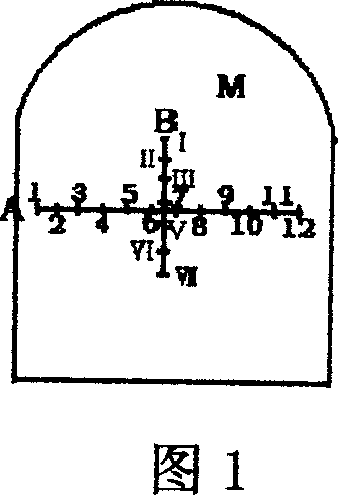

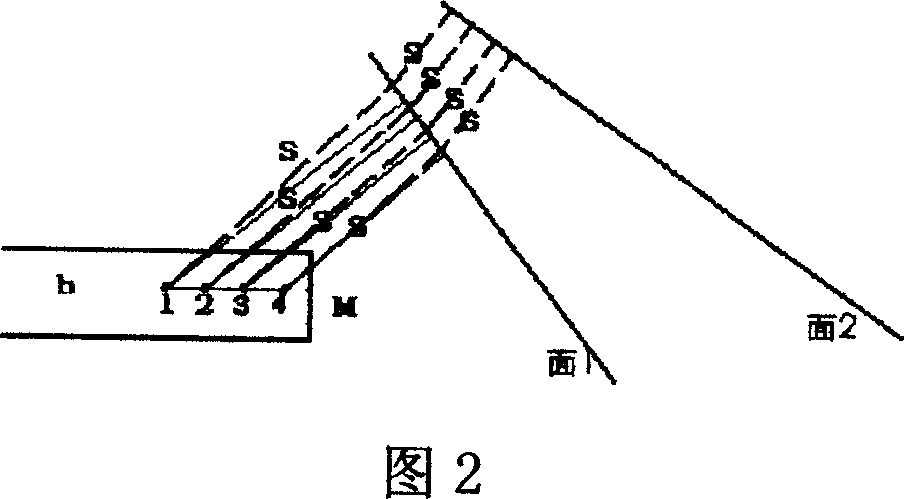

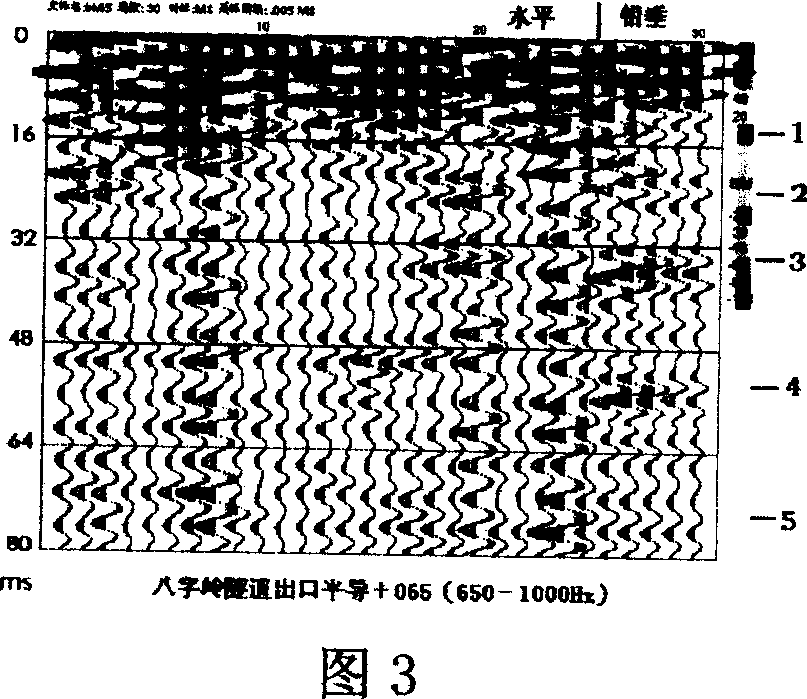

Method for measuring wave speed of rock mass in front of tunnel face in tunnel

The invention discloses the technology to explore palm surface frontage geology and measure frontage rock rolling velocity using reflection in the tunnel and underground engineering. It sets up two intersecting measuring lines in the palm surface, and sets up a measuring point at each certain distance on the line, and each measuring point makes the small shock - distance measuring or the excitation and reception of the small transmitter-receiver distance, and then, by unitary method, the time curves of each measuring point converge to a time profile. With the time profile, when the reflection of each reflector surface corresponding reflecting the axis and each measuring point, it determines each reflector surface, and if the rock rolling velocity known, it calculates the position of each reflector surface according to the reflection time of the measuring points. In the rear sidewall of the palm surface, sets up the measuring lines, and many measuring points on it, to measure the reflection time of each point from the reflector surface. Assuming the rock rolling velocity, according to the measuring point reflection time measured in the palm surface, calculates the invented reflector surface space position, and calculates the reflection time of sidewall measuring points to invented reflector surface under the rolling velocity assumption, and compared with the practical measuring reflection, then to adjust the assumed rolling velocity value, and gradually approaching, to obtain the closest actual rolling velocity value.

Owner:钟世航

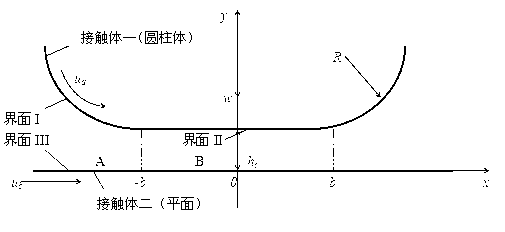

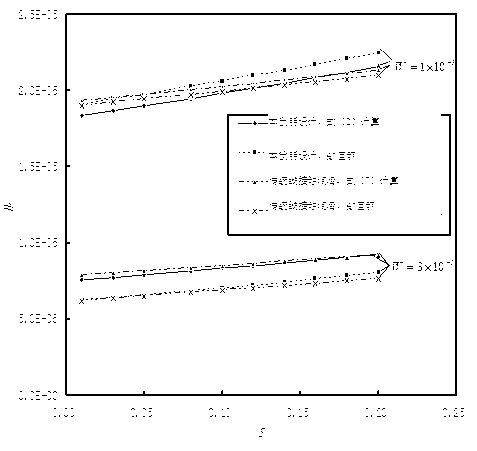

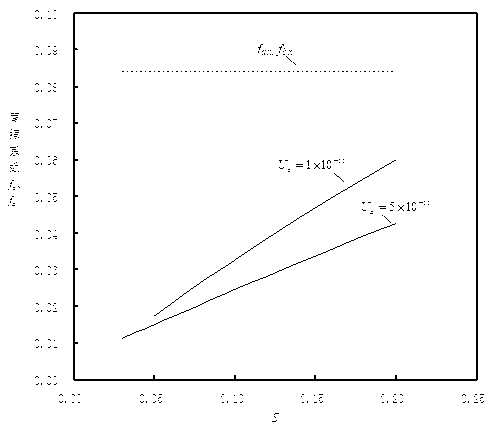

Method for improving line contact hydrodynamic lubrication under small slide-roll ratio

ActiveCN102705372AImprove lubrication qualityImprove carrying capacityBearing componentsContact pressureEngineering

The invention provides a method for improving a line contact hydrodynamic lubrication under a small slide-roll ratio, comprising the following steps of: setting two solids in reverse contact to be a contact body I and a contact body II respectively, controlling the linear speeds of the surfaces of the contact body I and the contact body II which are actually paired, a slide-roll ratio value and a non-dimensional roll speed; coating an oleophylic coating on the surface of the contact body II; and fully filling lubricant oil in a gap between the contact body I and the contact body II, controlling a load (w) applied to the line contact area of the contact body I and the contact body II so that the generated maximum Hertz contact pressure is not greater than 0.5 GPa, thus forming the designed line contact hydrodynamic lubrication. The method can greatly decrease the friction coefficient of the contact area, thereby effectively decreasing the friction coefficients, the friction energy consumptions, and the friction temperature rises of the line contact hydrodynamic lubrications of roller bearings and the like under a small slide-roll ratio, and effectively improving the qualities and the bearing capacities of the hydrodynamic lubrications.

Owner:徐州筑之邦工程机械有限公司

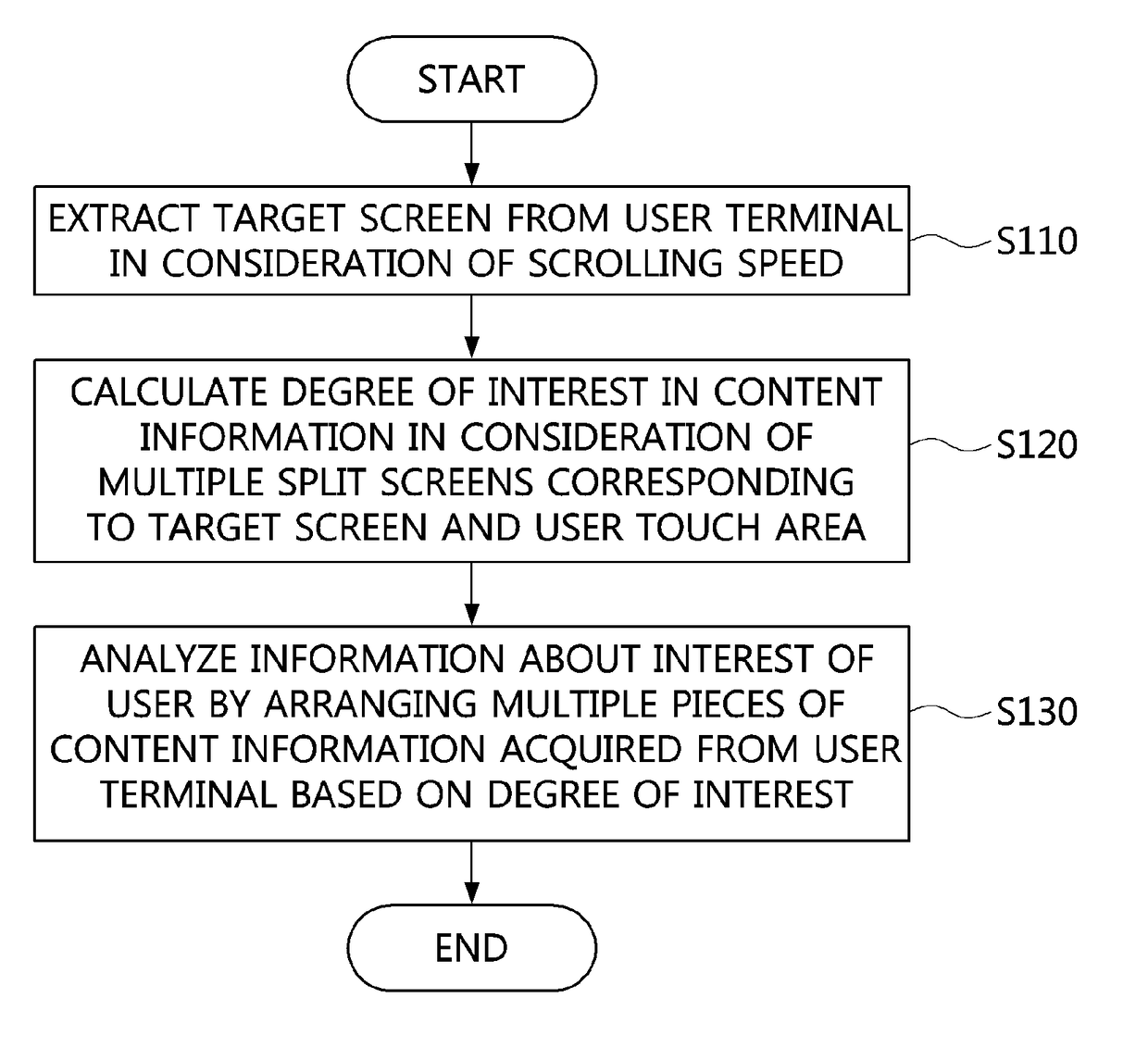

Interest information analysis method using scroll pattern and apparatus using the same

ActiveUS20170364986A1Buying/selling/leasing transactionsSpecial data processing applicationsInformation analysisRolling velocity

Disclosed herein are an interest information analysis method and an apparatus using the same. The method and apparatus are configured to extract a target screen from a user terminal in consideration of scrolling speed, calculate a degree of interest in content information included in the target screen in consideration of multiple split screens corresponding to the target screen and a user touch area, and analyze information about interest of the user by arranging multiple pieces of content information acquired from the user terminal based on the degree of interest. Accordingly, information about interest of the user or a field of interest to the user may be analyzed without referring to a definite intention expressed by the user.

Owner:SK PLANET CO LTD

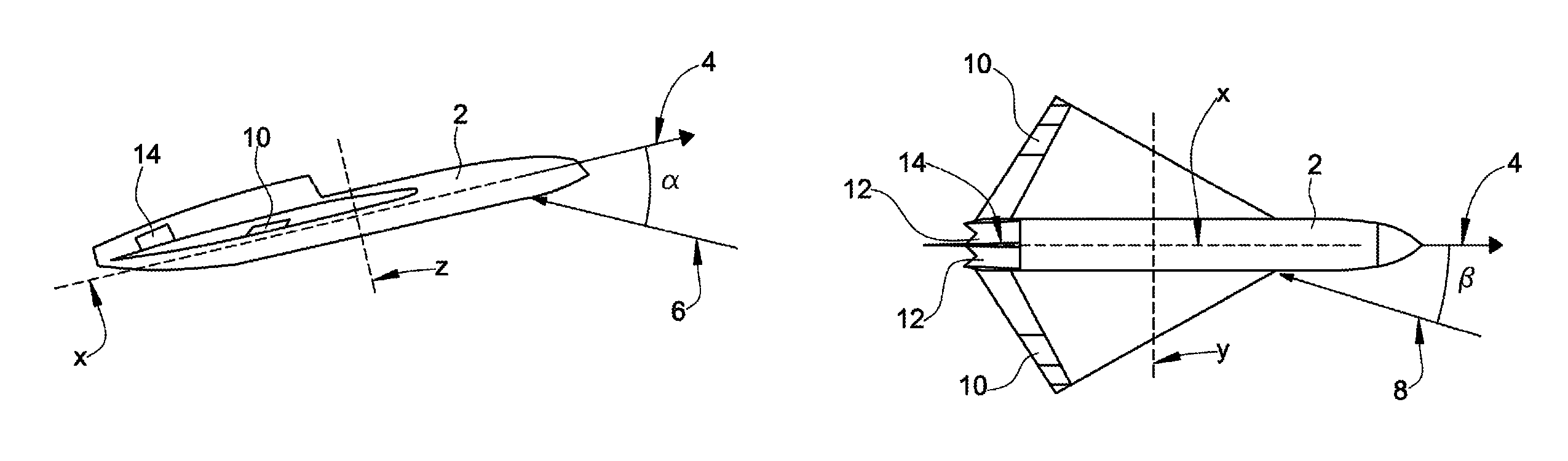

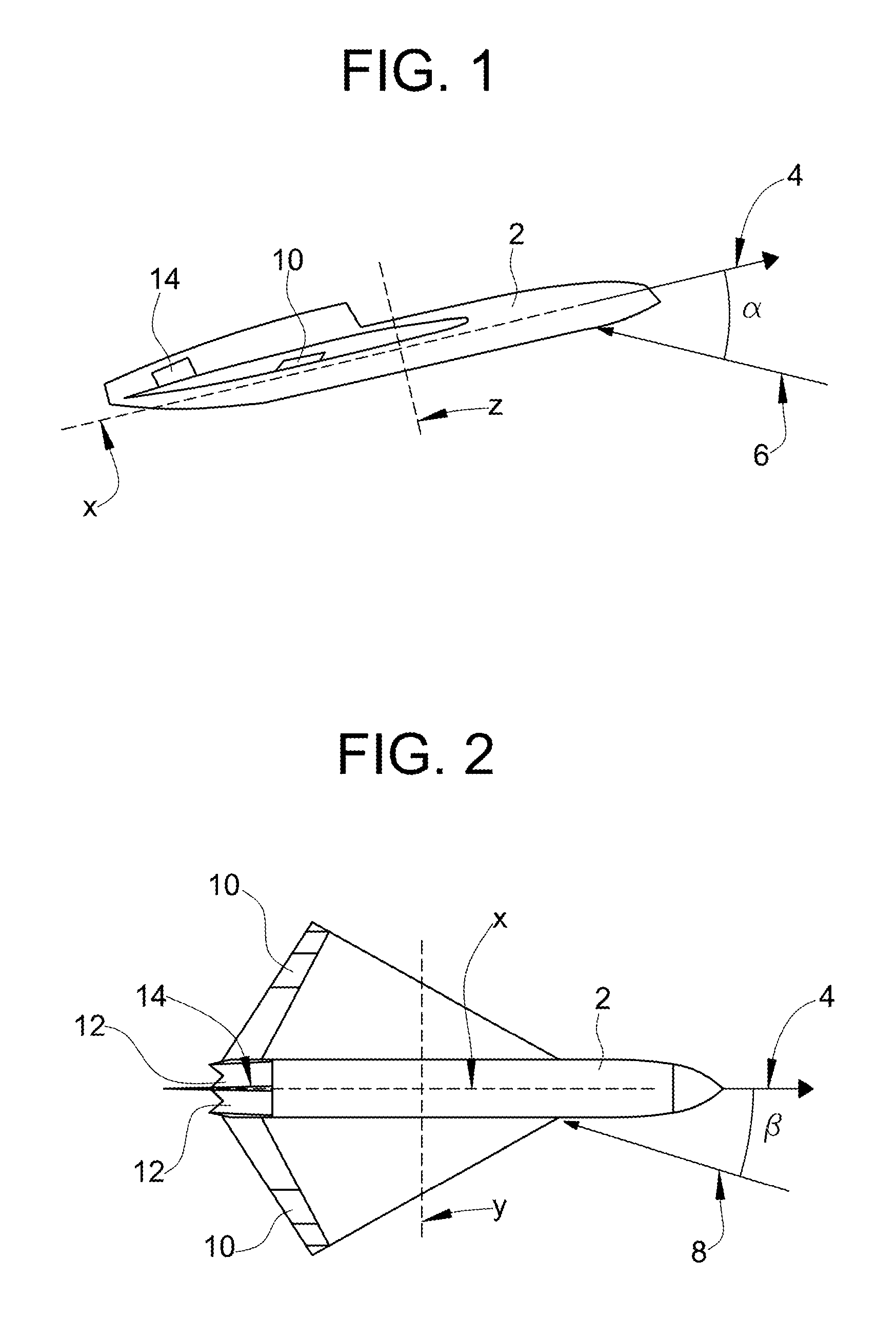

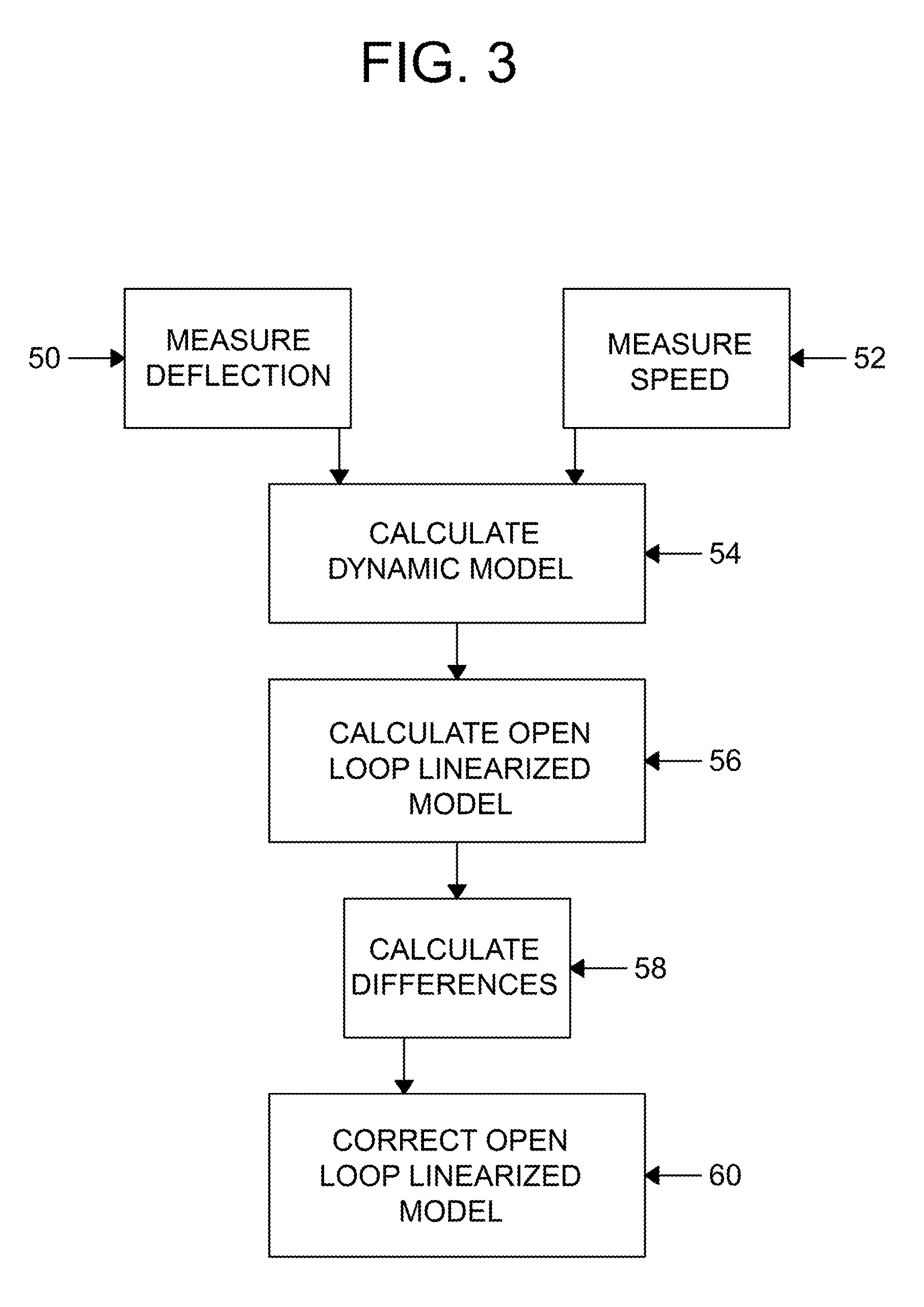

Method of estimating an angle of attack and an angle of sideslip of an aircraft

InactiveUS8340841B2Digital data processing detailsIndication/recording movementState observerAngular degrees

Owner:ALENIA AERONAUTICA SPA

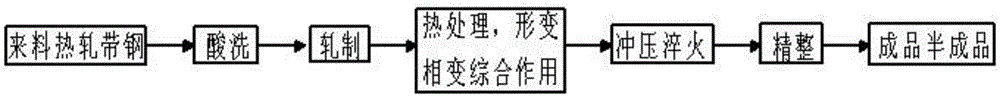

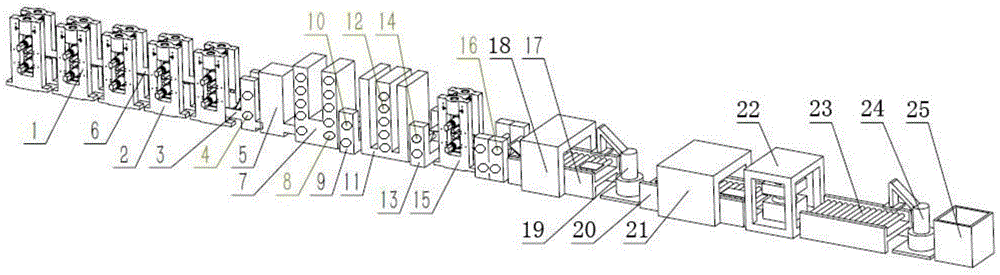

Short-process producing and processing technology and equipment for cold rolling ultrahigh strength steel

ActiveCN105414177AReduce consumptionShort production processForging/pressing devicesMetal rolling arrangementsProcess equipmentQuenching

The invention discloses a short-process producing and processing technology for cold rolling ultrahigh strength steel. The short-process producing and processing technology comprises the following steps: hot rolled strip steel, serving as an incoming material, is treated by procedures before rolling such as acid pickling and the like, cold rolling, heat treatment and deformation and phase transition comprehensive treatment, enters a loop after the heat treatment and the deformation and phase transition comprehensive treatment, is suitable for changes of the rolling velocity and the punch velocity by regulating the loop capacity and can enter a punching and quenching technology after being shorn with fixed length; and after the ultrahigh strength steel is finished, a finished or semi-finished punching part is obtained. Short-process producing and processing equipment for cold rolling the ultrahigh strength steel comprises a cold continuous rolling unit, a degreasing device inlet frame, a degreasing device, a looping tower, an annealing furnace front tension controlling device, an annealing furnace, an annealing furnace back tension controlling device, a collecting box and the like. With the adoption of the short-process producing and processing process and equipment, the energy consumption is reduced, the energy is saved, and the production cost is lowered; and by adding the deformation technology in the heat treatment process of the ultrahigh strength steel, the purpose of synchronous deformation and phase transition of the ultrahigh strength steel is realized, and the using performance of the strip steel is improved.

Owner:YANSHAN UNIV

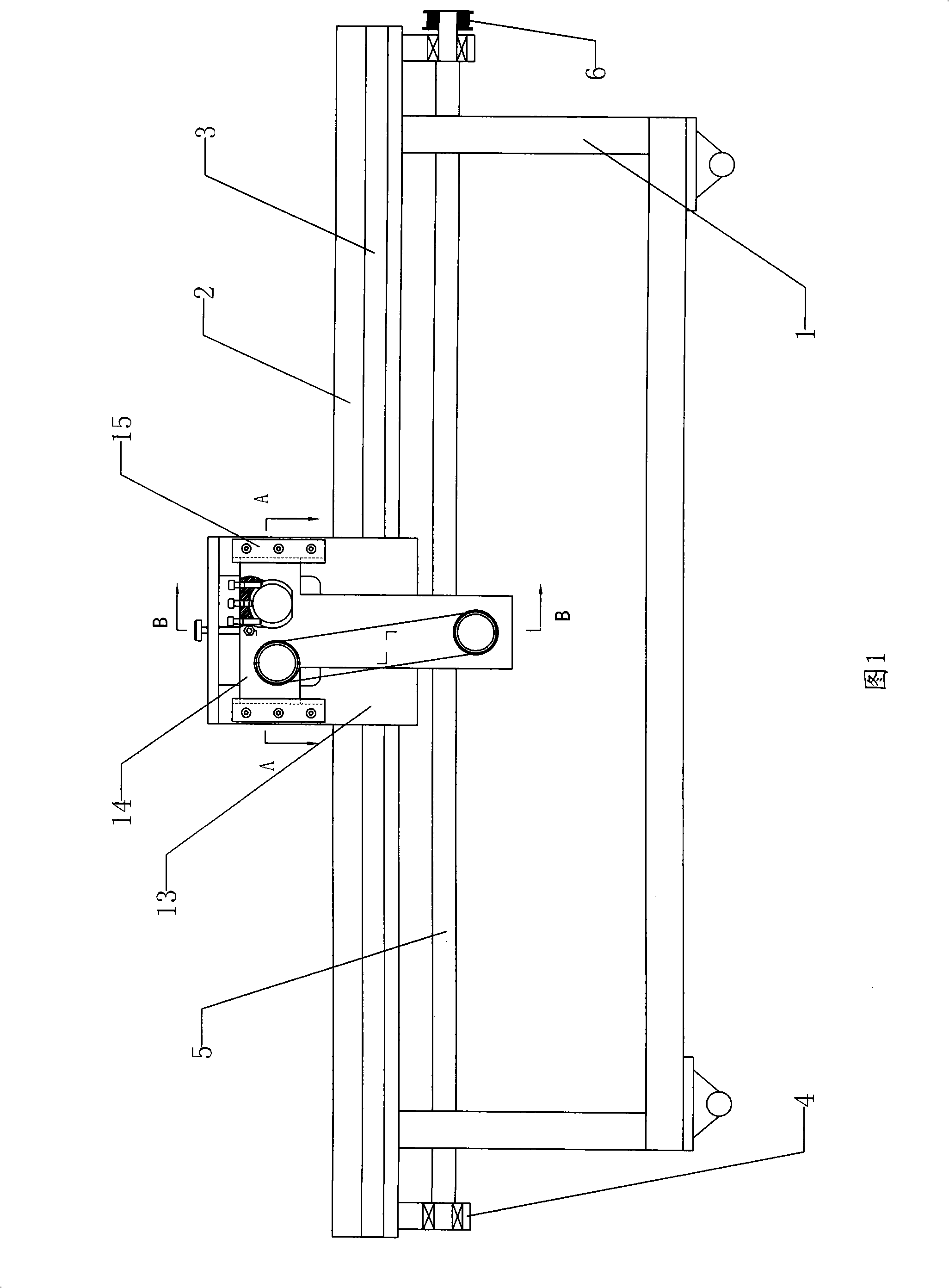

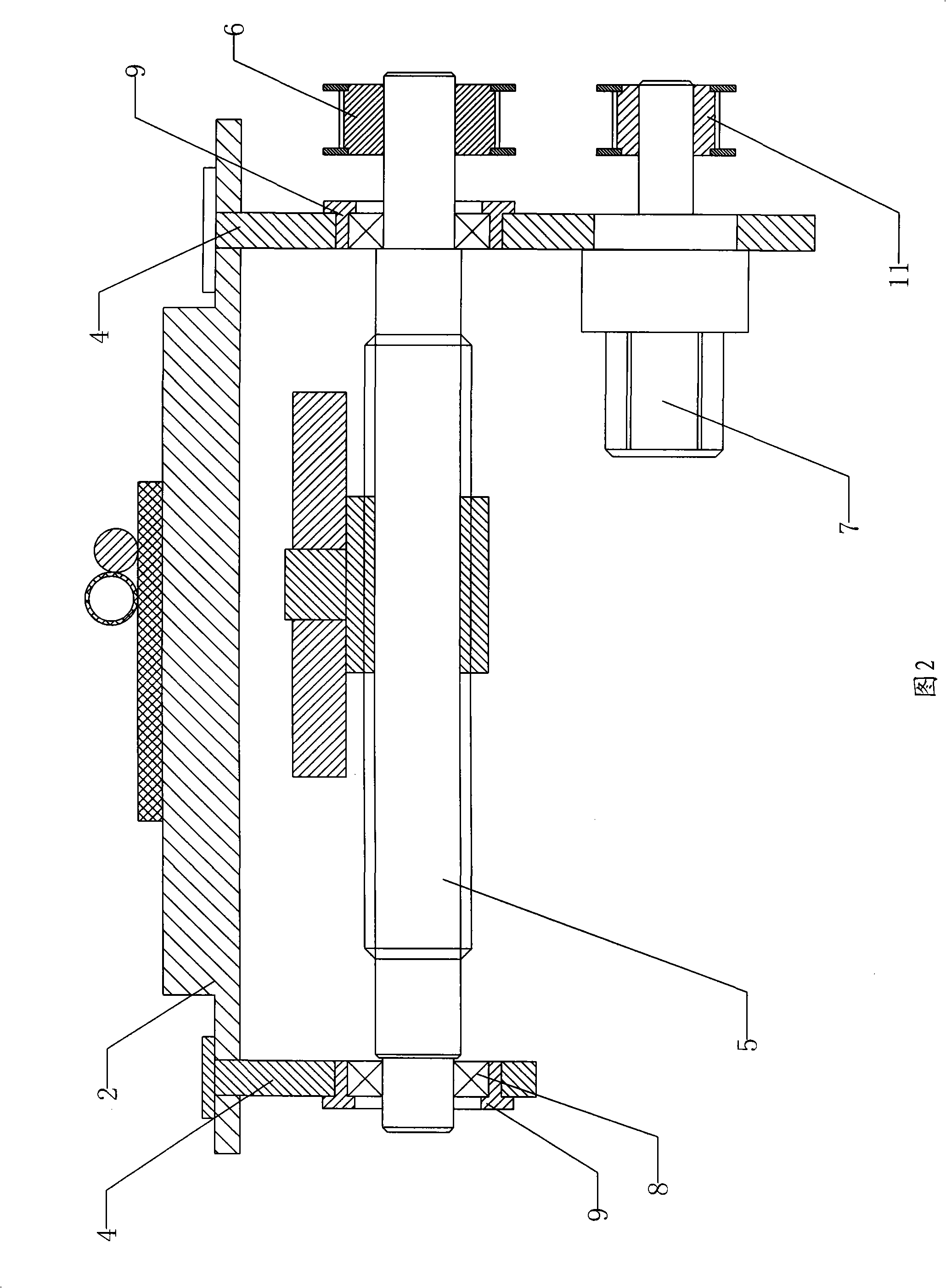

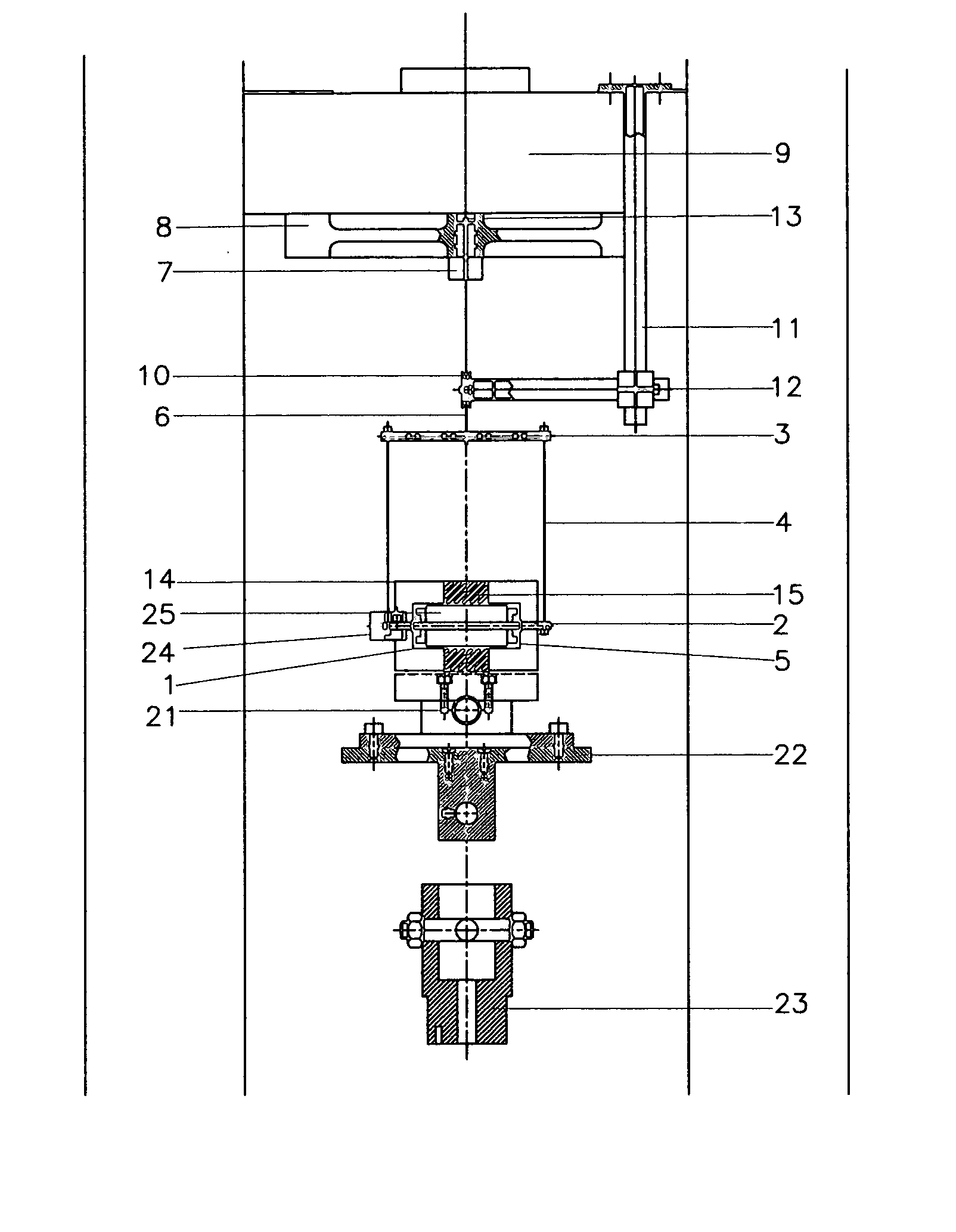

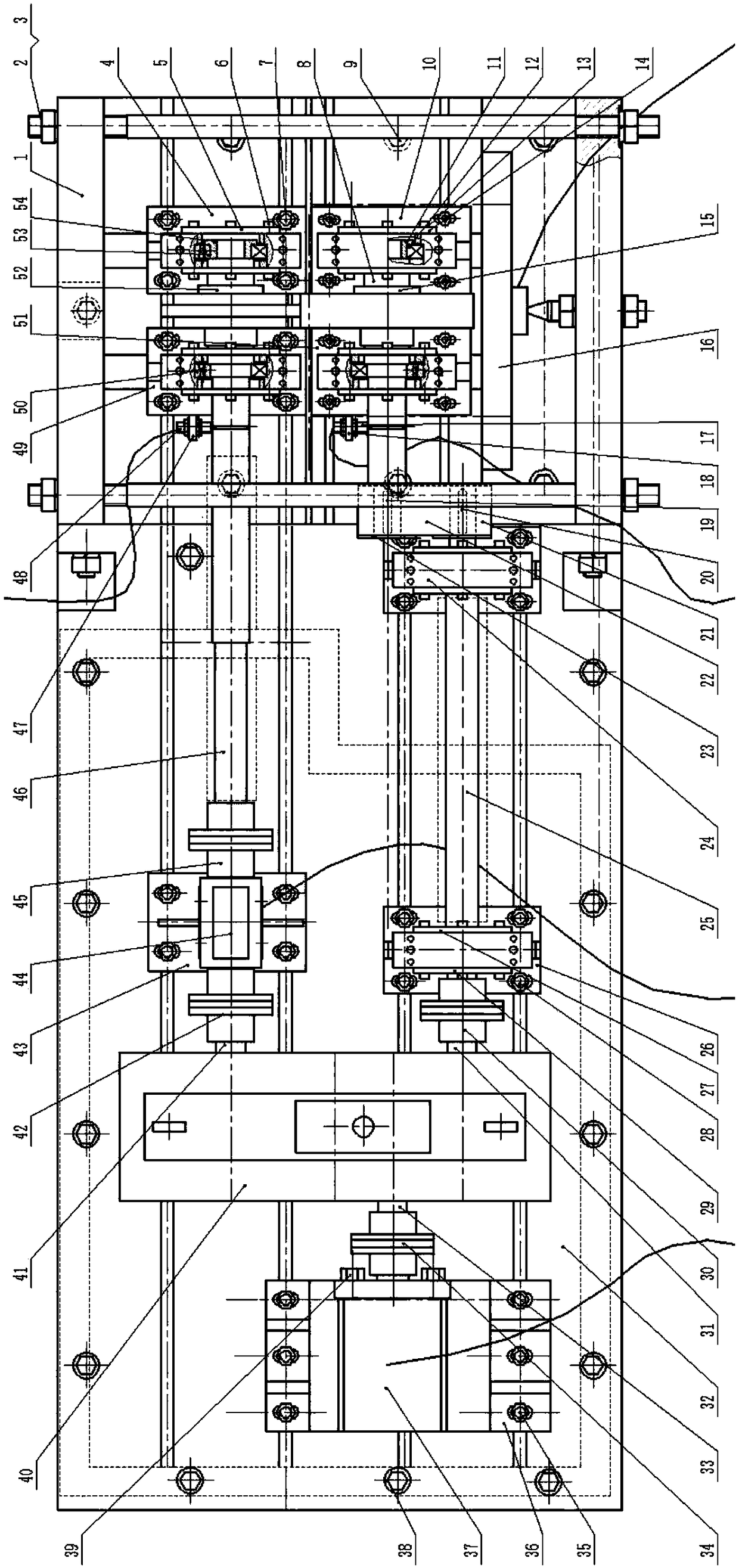

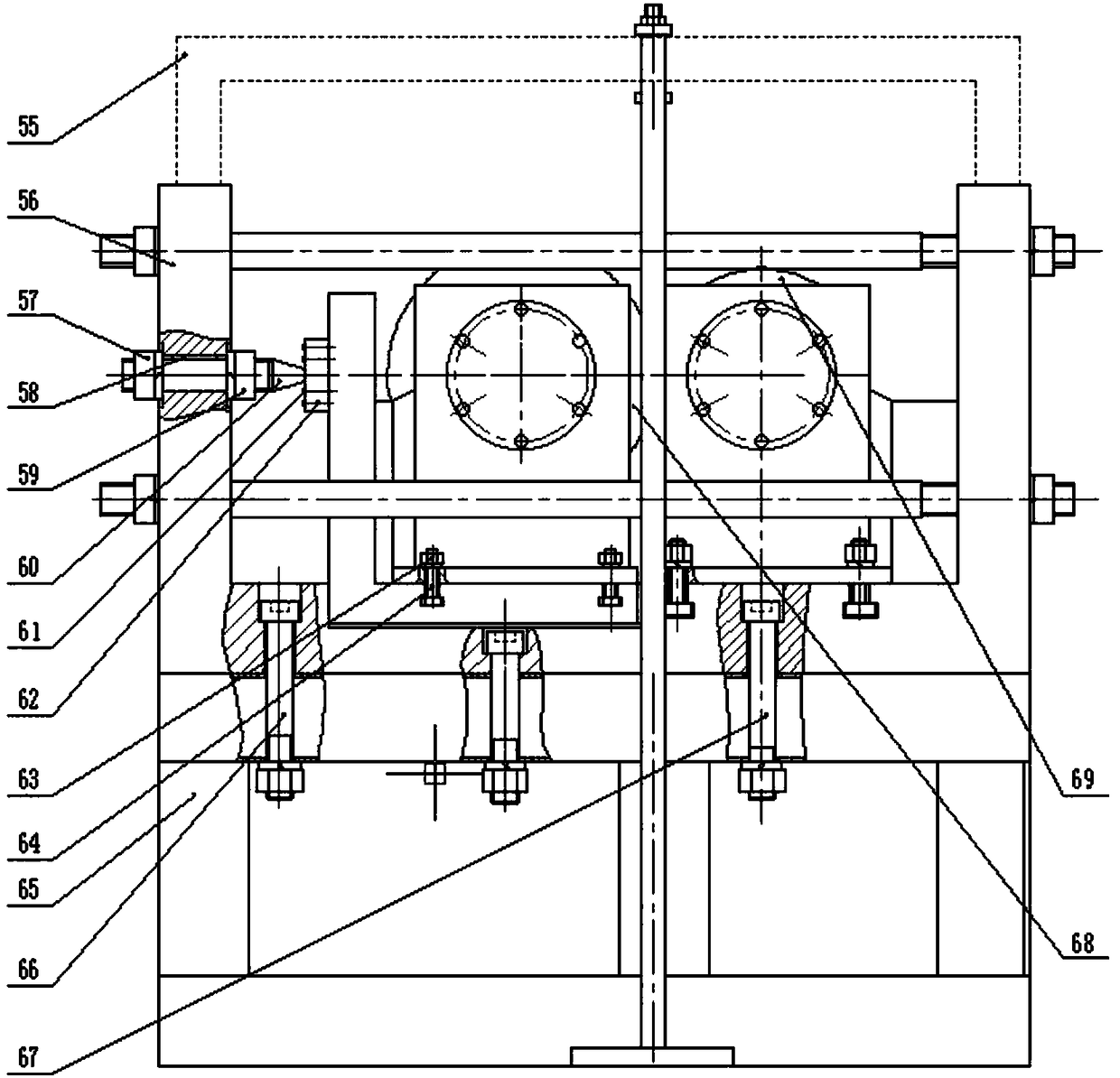

Line contact rolling-slipping friction vibration noise test bed and line contact rolling-slipping friction vibration noise test analysis method

InactiveCN108168689AEasy to replaceReduce volumeSubsonic/sonic/ultrasonic wave measurementUsing mechanical meansFriction torqueElectric machinery

The present invention provides a line contact rolling-slipping friction vibration noise test bed and a line contact rolling-slipping friction vibration noise test analysis method. The method can really simulate friction modes in mechanical parts such as a line contact gear, a vehicle track and the like to dynamic collect a friction moment, a relative sliding speed, a rolling speed and noise signals in real time so as to conveniently achieve research of line contact vibration noise and perform test in variable working conditions; an installation structure capable of conveniently replacing testpieces is provided to conveniently perform mounting and dismounting so as to allow the test bed to achieve research of rolling-slipping friction noise for different loads, different materials and different sizes of the test pieces in different working conditions; and moreover, a servo motor is employed to drive a shunt gear case with single-input and dual-output to form a power enclosing driving mode so as to reduce the volume of the test bed and save the cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Nonlinear frequency dependent filtering for vehicle ride/stability control

A system and method for facilitating ride and stability control of a vehicle. The system includes a plurality of suspension displacement sensors, with each of the plurality of suspension displacement sensors positioned proximate to a suspension element of the vehicle. The system further includes a nonlinear filter for filtering out a wheel hop frequency from the suspension velocity corresponding to at least one of the plurality of suspension displacement sensors to obtain a resultant suspension velocity. The resultant suspension velocity is used by a control unit to determine the pitch velocity, roll velocity and the heave velocity of the vehicle.

Owner:GM GLOBAL TECH OPERATIONS LLC

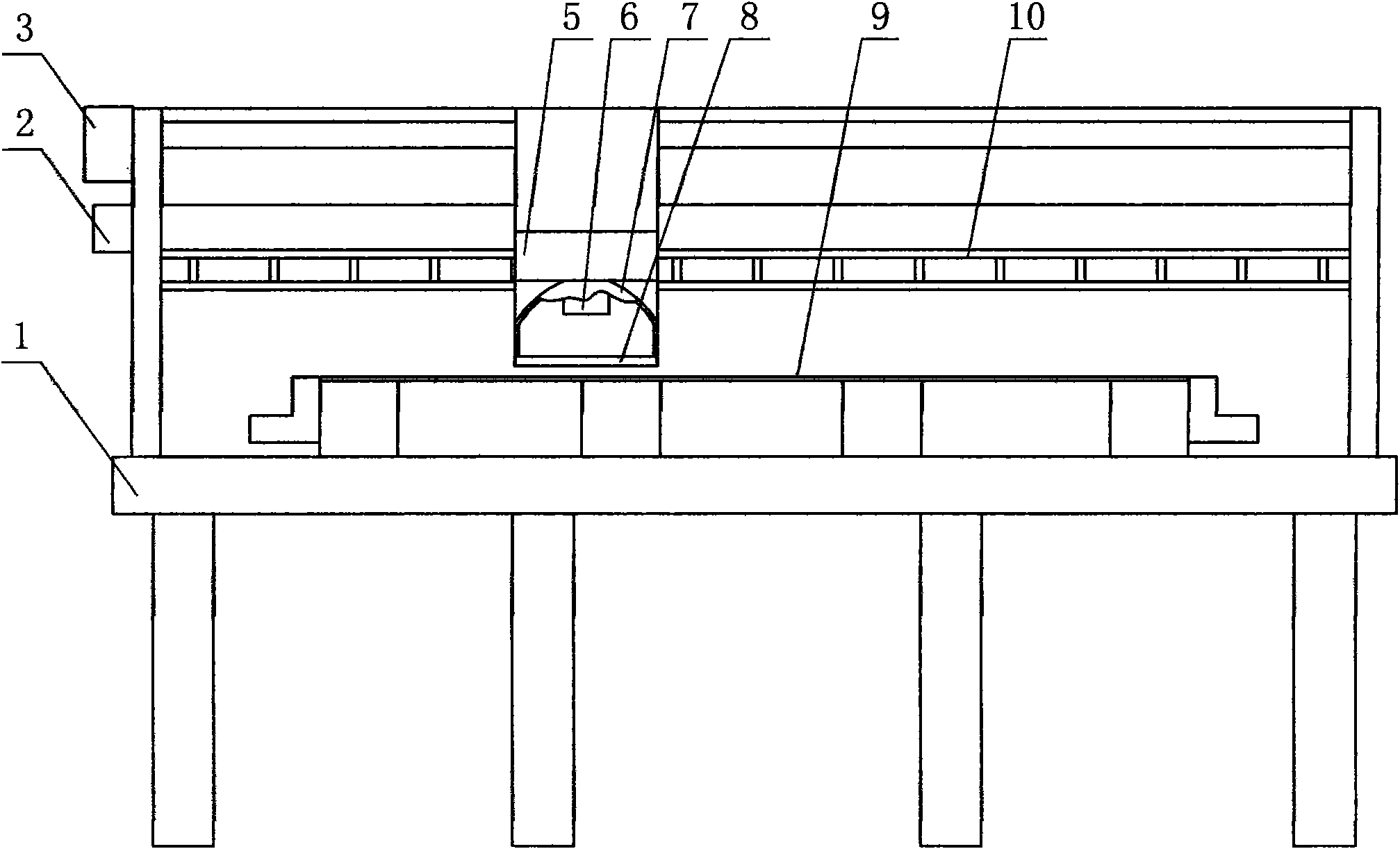

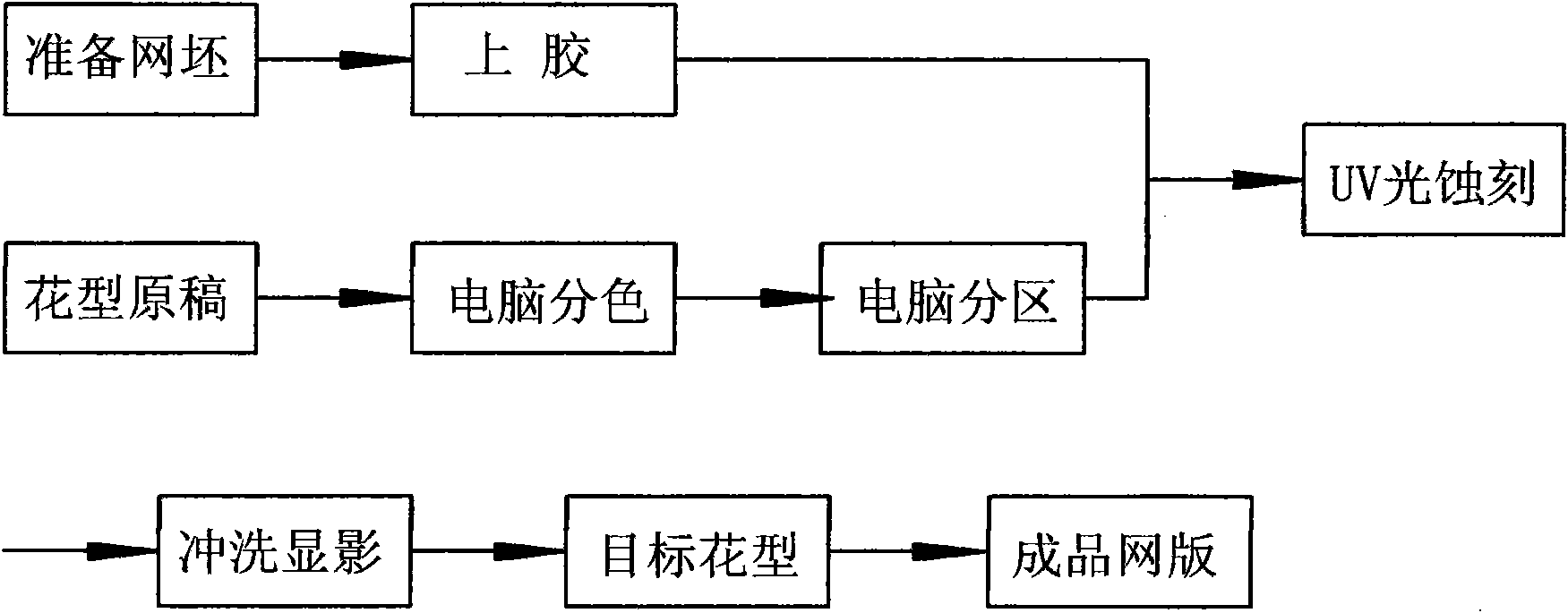

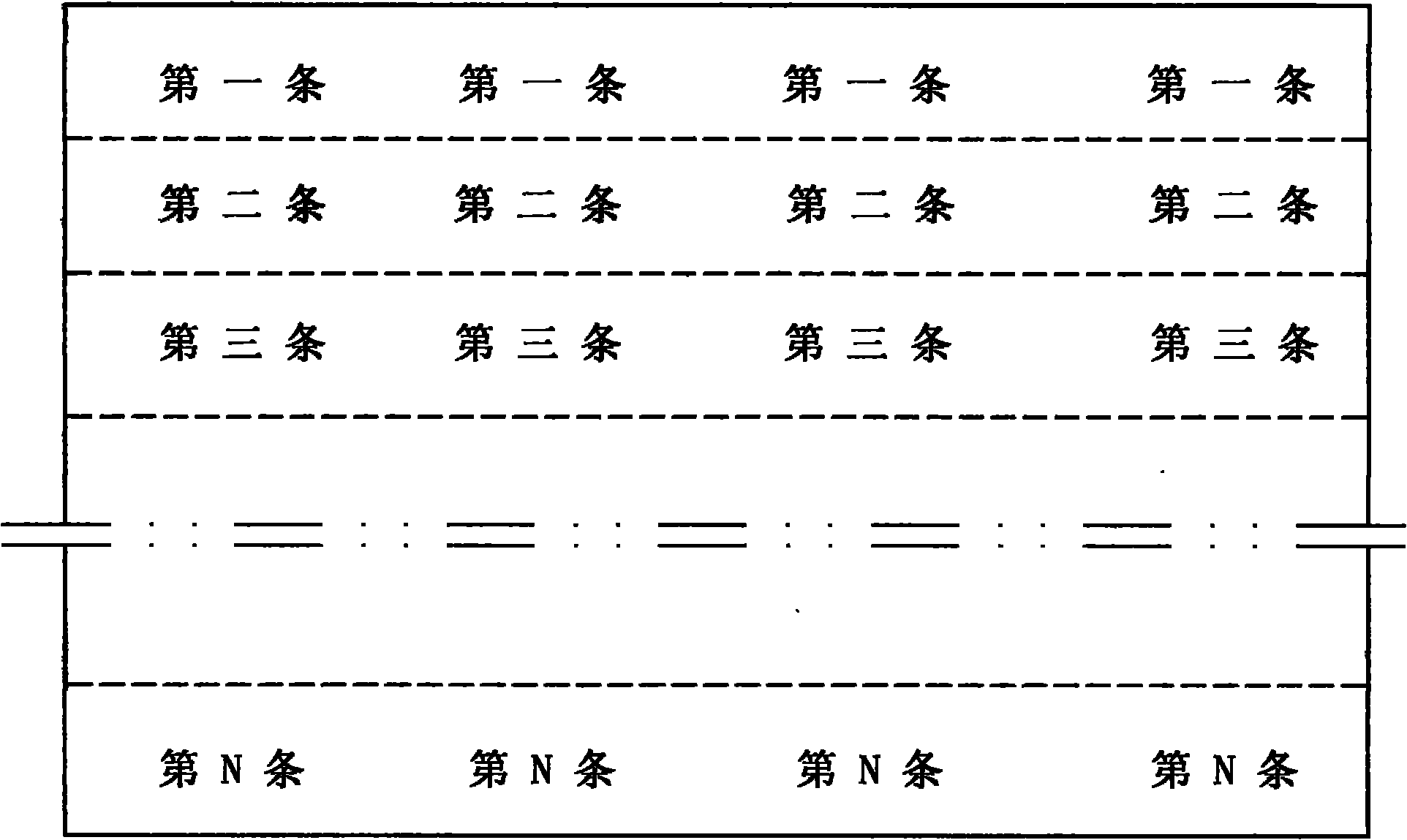

Digital net making machine for plain net and digital net making method for plain net

InactiveCN101859063AAvoid prone to trachoma and other defectsQuality improvementScreening processesLiquid-crystal displayEtching

The invention discloses a digital net making machine for a plain net and a digital net making method for a plain net. The net making machine comprises a walking rack which moves along the Y direction and a UV optical etching head which is arranged on the walking rack and can moves along the X direction, wherein the UV optical etching head comprises a UV optical source and a liquid crystal display; the liquid crystal display is positioned between the UV optical source and a plain net, and is arranged in parallel to the plain net; and the UV optical source and the liquid crystal display are respectively connected with a computer. The digital net making method comprises the following step: carrying out computer color separation; carrying out computer strip-type partition on a monochrome picture performed with color separation and the effective display width of the liquid crystal display; when the velocity of the liquid crystal display moving along the X direction is equal and opposite to the rolling velocity of a scroll bar on the display, utilizing the UV optical source to irradiate the liquid crystal display to carry out UV optical etching; and flushing and developing. Since no photographic film is needed for carrying pictures, the invention has the advantages of greatly saved consumable items, saved manpower, lowered cost, high efficiency, stable quality and lower faulty product ratio.

Owner:郝鹏飞

Titanium alloy No. dfgx-9 rolled tube and preparation method thereof

The invention relates to titanium alloy, specifically to a titanium alloy No. dfgx-9 finished tube and its preparation method. Alloy composition of the titanium alloy No. dfgx-9 finished tube comprises, by weight, the balance Ti, 3-5% of Al, 20-24% of V, Fe being less than or equal to 0.1%, C being less than or equal to 0.1%, N being less than or equal to 0.03%, H being less than or equal to 0.015% and O being less than or equal to 0.12%. The titanium alloy No. dfgx-9 rolled tube has good performance, uniform metallographic structure and good tube surface quality. During warm / cold rolling of a tube billet, online or off-line heating of the tube billet is carried out for rolling, wherein online heating temperature is 400-1200 DEG C; thermal insulation lasts 0-90 min; per-pass deformation is 15-85%; rolling velocity is (20-90) times / min; and a finished product is produced after 1-10 passes of rolling. According to properties of the titanium alloy No. dfgx-9 tube, tensile strength is 680-1300 MPa, ductility is 8-25%, and a metallographic structure is uniform. Two metallographic structures of stress annealing and perfect recrystallization annealing are eliminated.

Owner:忠世高新材料股份有限公司

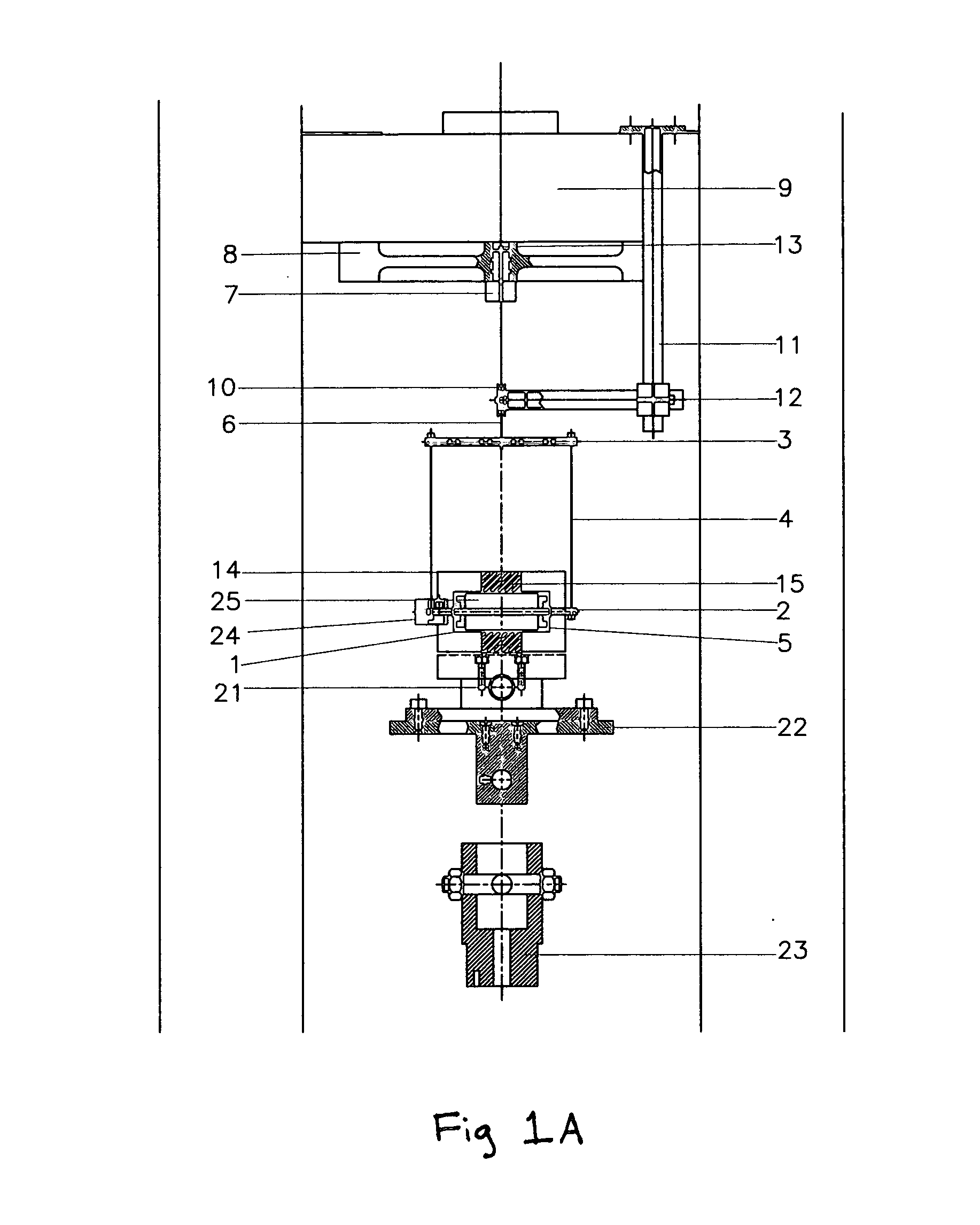

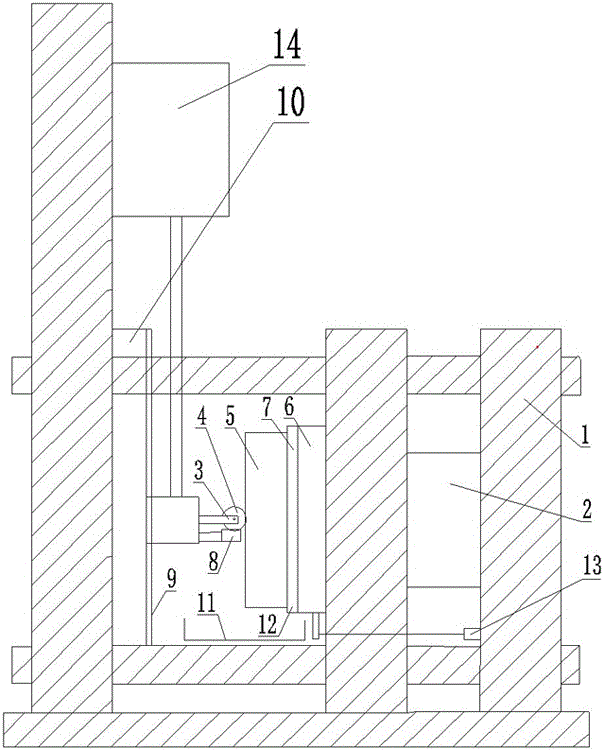

Hob Composite Abrasion Tester

ActiveCN105181503BSimple structureReduce construction costsInvestigating abrasion/wear resistanceAutomatic controlLevel measurement

The invention discloses a hob composite abrasion tester, which comprises a loading frame, a horizontal measurement and control loading measurement and control subsystem, a vertical loading measurement and control subsystem, a mechanism for rock sample and model hob abrasion, and a model hob measurement Mechanism and subsystem integration and realization of automatic control system. The hob compound abrasion tester disclosed by the invention has a simple structure and can perform three experiments including a hob rock breaking abrasion test, a hob cuttings abrasion test and a hob cuttings and rock breaking compound abrasion test. Through the composite abrasion experiment of rock cuttings and rock breaking of hobs, it is possible to explore the impact of different tool thrusts and rolling speeds (reflected to the shield cutterhead as thrust and torque parameters) on tool wear, guide shield tunneling construction, and predict tool replacement positions and quantity, and finally achieve the purpose of reducing the construction cost of shield tunneling and predicting the construction period.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com