Method for improving line contact hydrodynamic lubrication under small slide-roll ratio

A fluid lubrication, contact body technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of increased friction coefficient, increased wear, reduced lubrication friction coefficient, lubricating oil film heating and temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

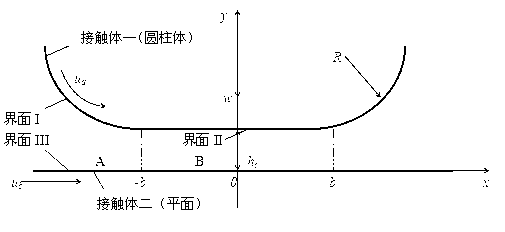

Method used

Image

Examples

Embodiment

[0066] Example: Both contact body 1 and contact body 2 are made of steel, and the lubricating oil is 50# mechanical oil, , , , when Time:

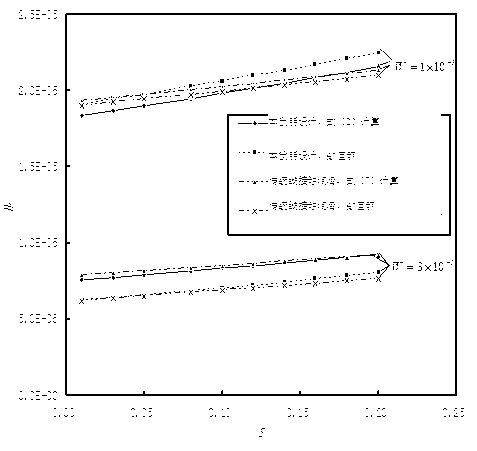

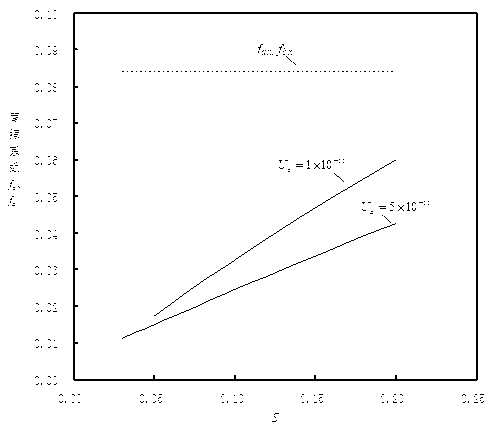

[0067] when , , When coating the entire surface of the contact body with a mica powder coating modified by a silane coupling agent, , The central film thickness of the line contact fluid lubrication of the present invention is , The friction coefficient of the two contacting surfaces is = = . Such as figure 2 As shown, the thickness of the line contact fluid lubrication center film of the present invention is smaller than that of the traditional line contact fluid lubrication center film thickness. Such as image 3 As shown, the friction coefficient of the line contact fluid lubricated contact surface of the present invention is lower than the friction coefficient of the traditional line contact fluid lubricated contact surface.

[0068] when , , When coating the entire surface of the contact body with a mica powder coating mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com