Oil pump with inside engaged gear

A gear machine and internal meshing technology, which is applied in the direction of pumps, mechanical equipment, machines/engines, etc., can solve the problems of reducing the working efficiency of the gearbox, abnormal wear of parts, and high friction coefficient of parts, and achieve good low and high speed characteristics, Improved reliability and service life, and high lubrication efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

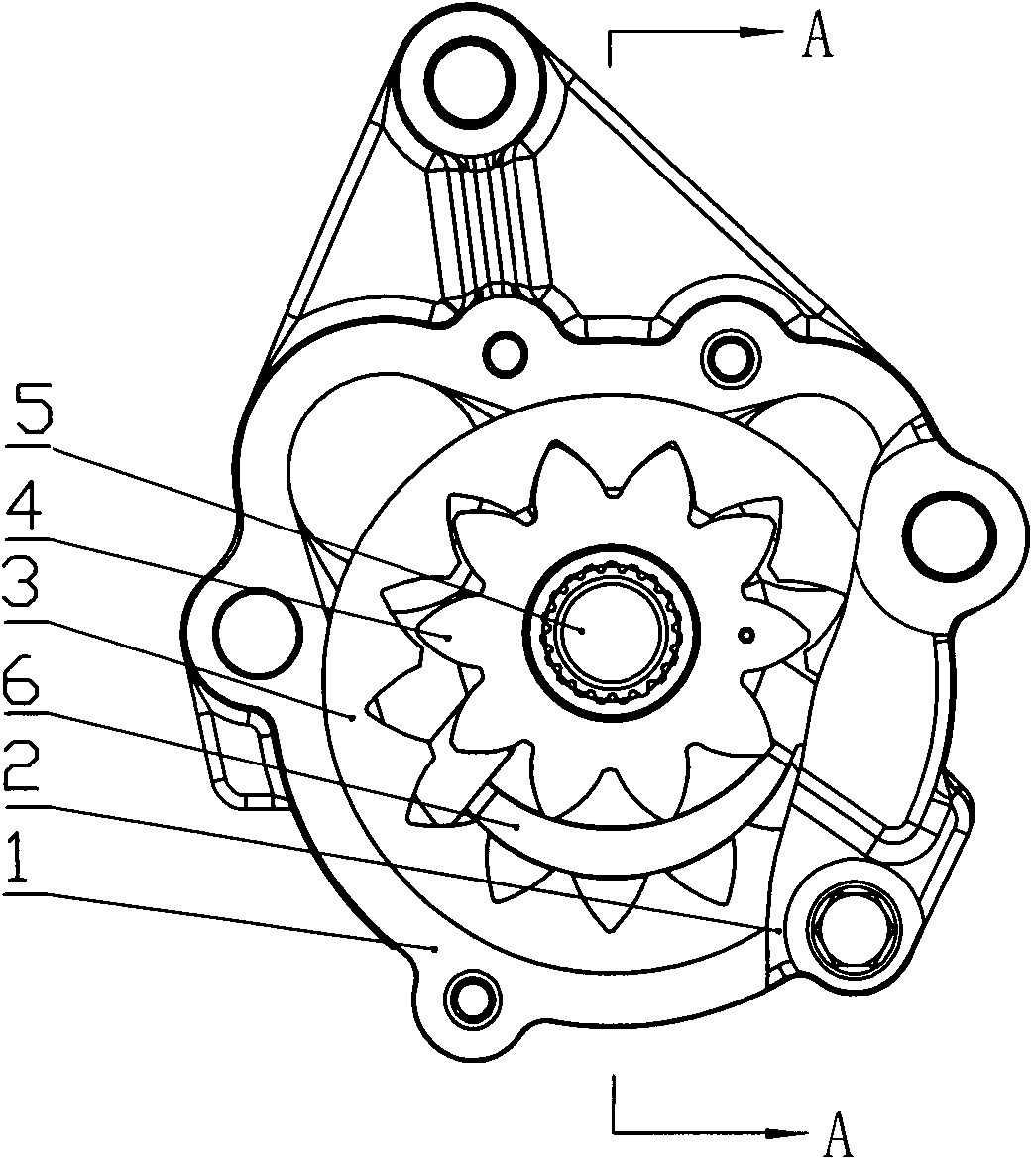

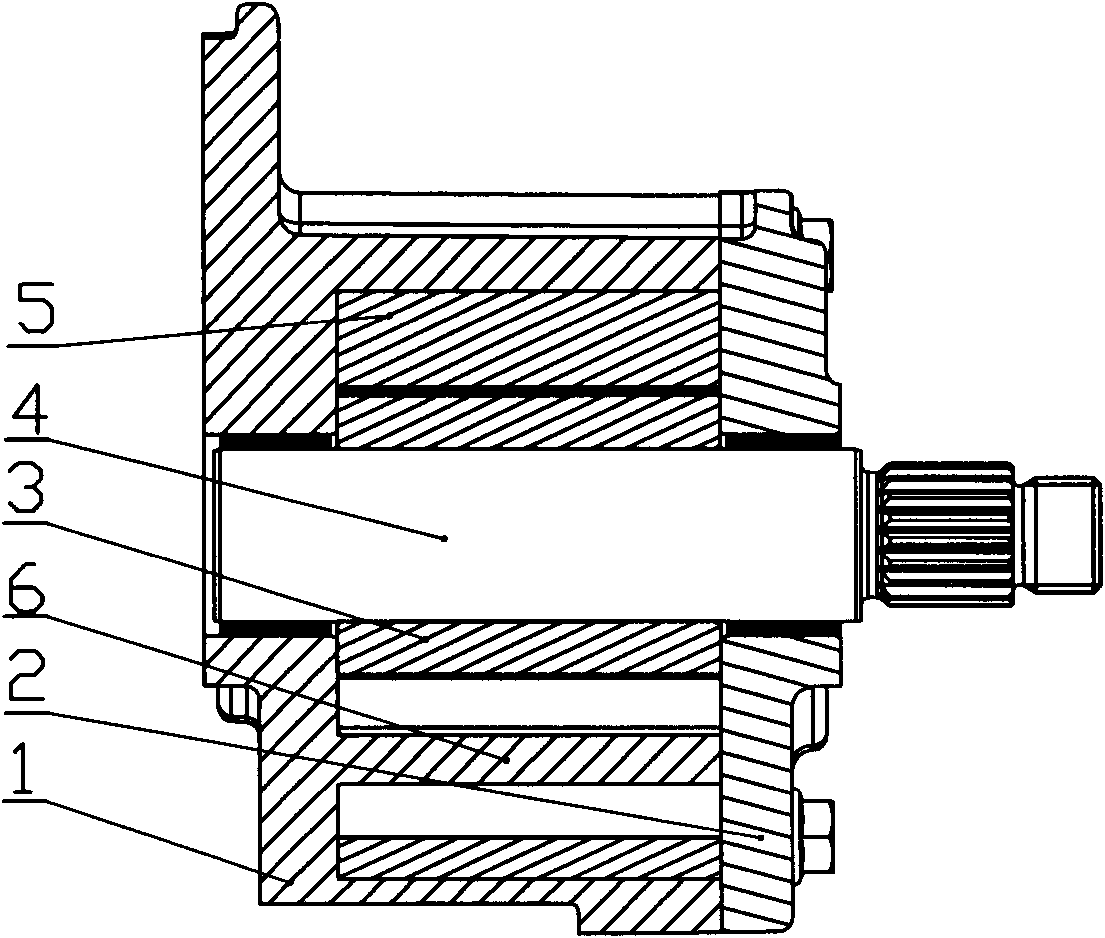

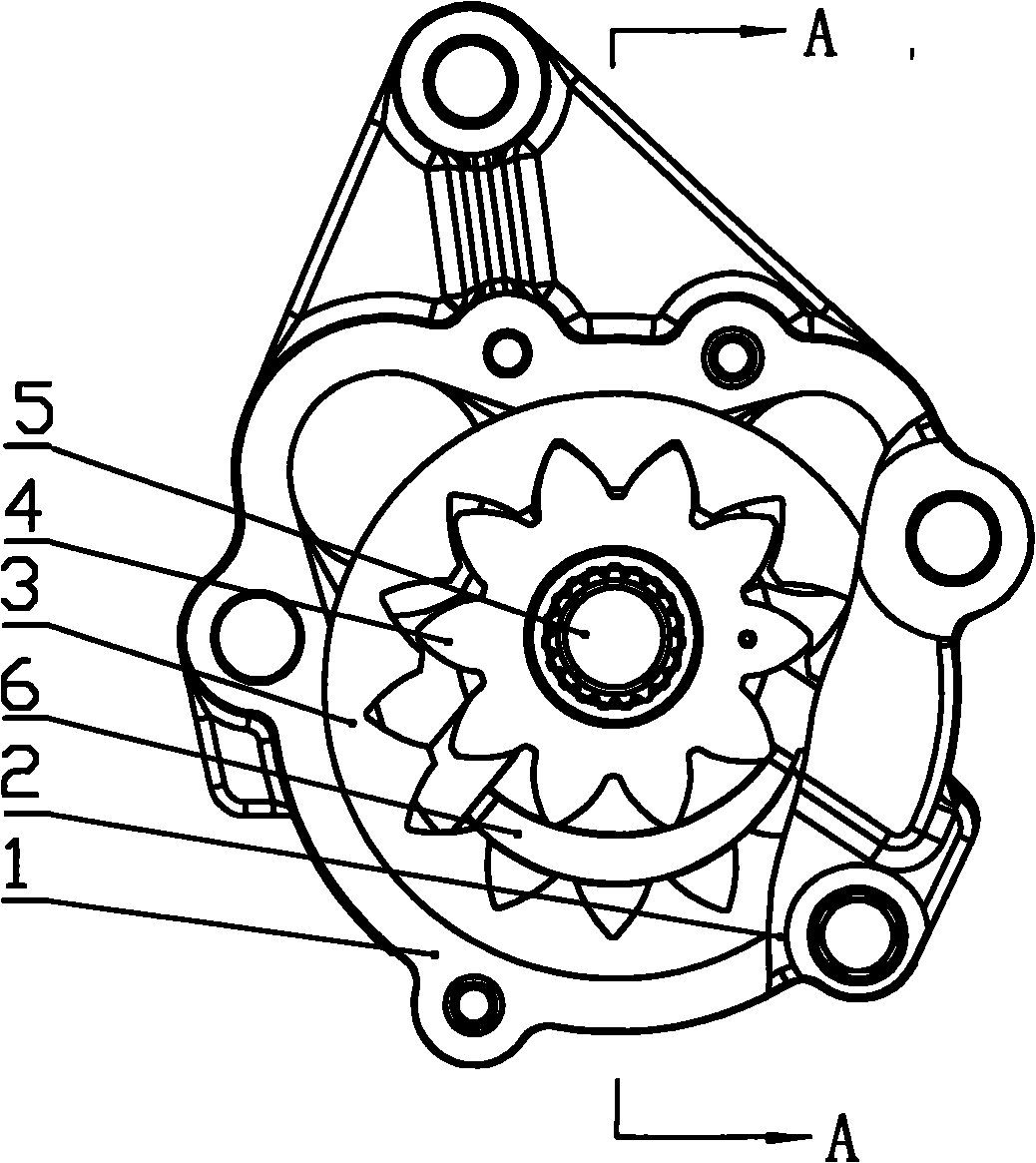

[0012] Such as Figure 1-2 As shown, an internal gear oil pump includes a pump body 1, a pump cover 2, an internal gear 3, an external gear 4, and a transmission shaft 5, and the middle part of the transmission shaft 5 and the external gear 4 are interference-connected and installed with the internal gear 3 as a complete set. In the gear hole and the shaft hole of the pump body 1 and the pump cover 2, there is a crescent-shaped separation plate integrally formed with the pump body 1 in the eccentricity space formed by the outer gear hole and the inner gear hole in the inner cavity of the pump body 1. 6. The isolation plate 6 is not only a channel for the isolation and oil delivery of the lubricating oil in the tooth chambers of the internal gear 3 and the external gear 4, but also an isolation device for blocking the oil outlet chamber and the oil inlet chamber and preventing the return of pressure oil. The isolation plate 6. The inner circular arc line and the top circle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com