Patents

Literature

88results about How to "Good lubrication effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

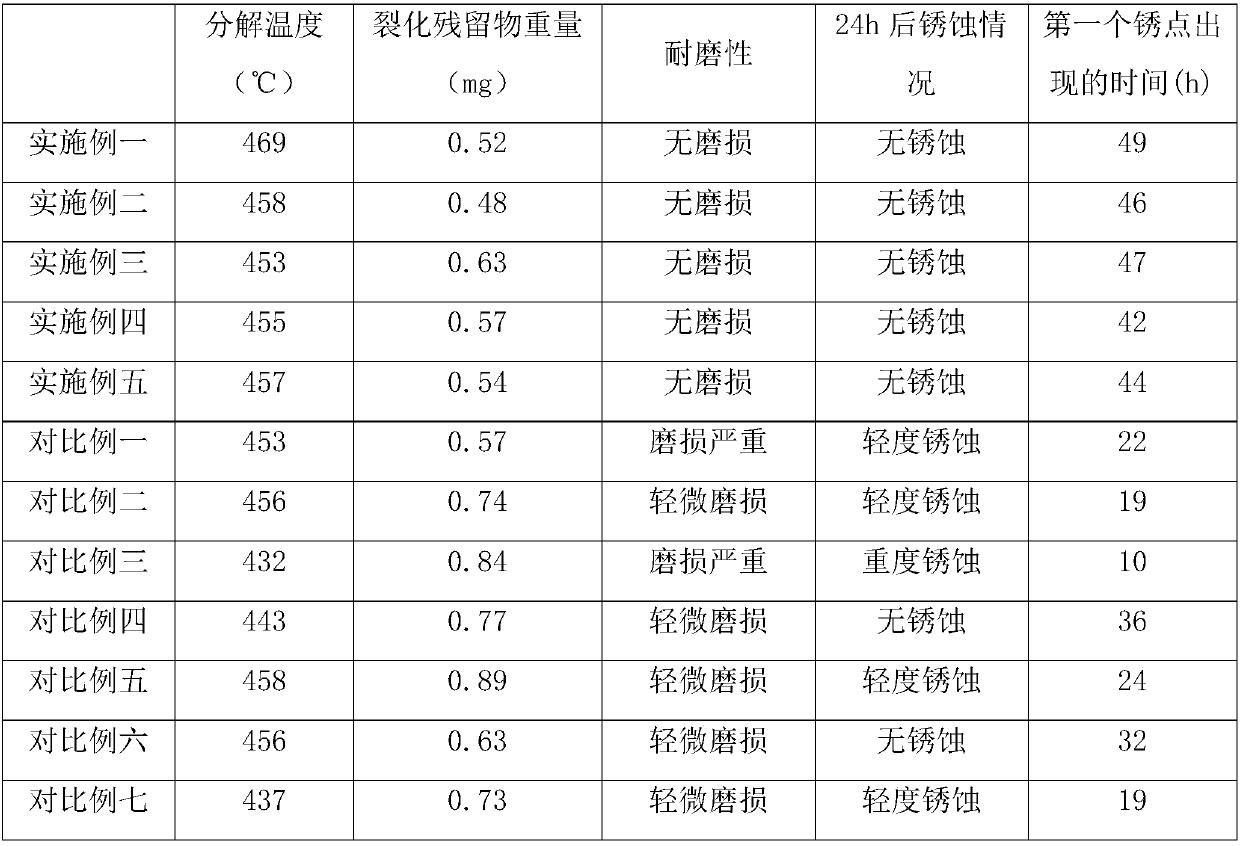

Conversion type organic binding dry film lubricant and preparation thereof

InactiveCN101302459AGood lubrication effectExtended service lifeAdditivesBase-materialsLubricationChemistry

The invention provides convertible organic bonding dry film lubricant and a method for preparing the same, belonging to the lubrication technical field. The lubricant consists of macromolecular resins, solid lubricant, metallic conversion agent, talcum powder and dispersant. The method for preparing the convertible organic bonding dry film lubricant is as follows: firstly, the macromolecular resins are dissolved into a part of the dispersant to obtain macromolecular resin dispersion liquid; secondly, the solid lubricant, the talcum powder and the metallic conversion agent are dispersed into the other part of the dispersant and fully grinded to obtain the other dispersion liquid; thirdly, after the macromolecular resins are fully dissolved, the two parts of dispersion liquid are mixed and stirred at a high temperature, and the convertible organic bonding dry film lubricant is prepared. The lubricant provided by the invention can form a lubricating solid dry film on rustless or rusty metallic surface through synchronous implementation of conversion of metals and trace metal oxides and spray coating of the lubricant, and has the advantages of good bonding force with the metals, rust protection, lubrication, long service life, quick drying, convenient use and low cost; and the paint film can endure the high temperature of 200 DEG C and is particularly suitable for repair and maintenance of parts and components.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

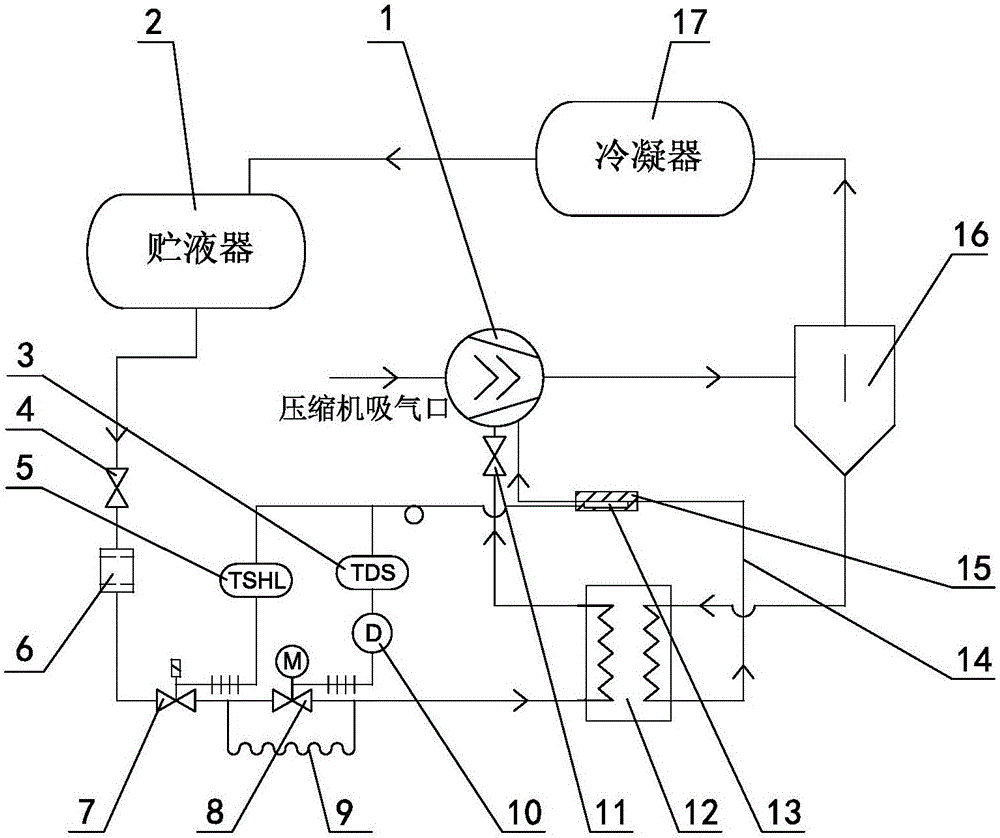

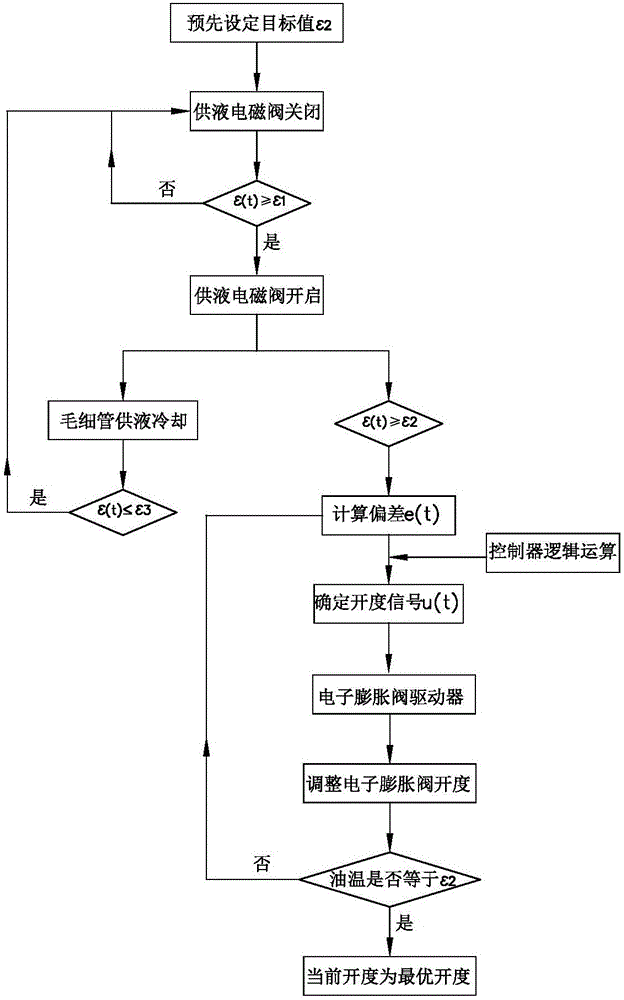

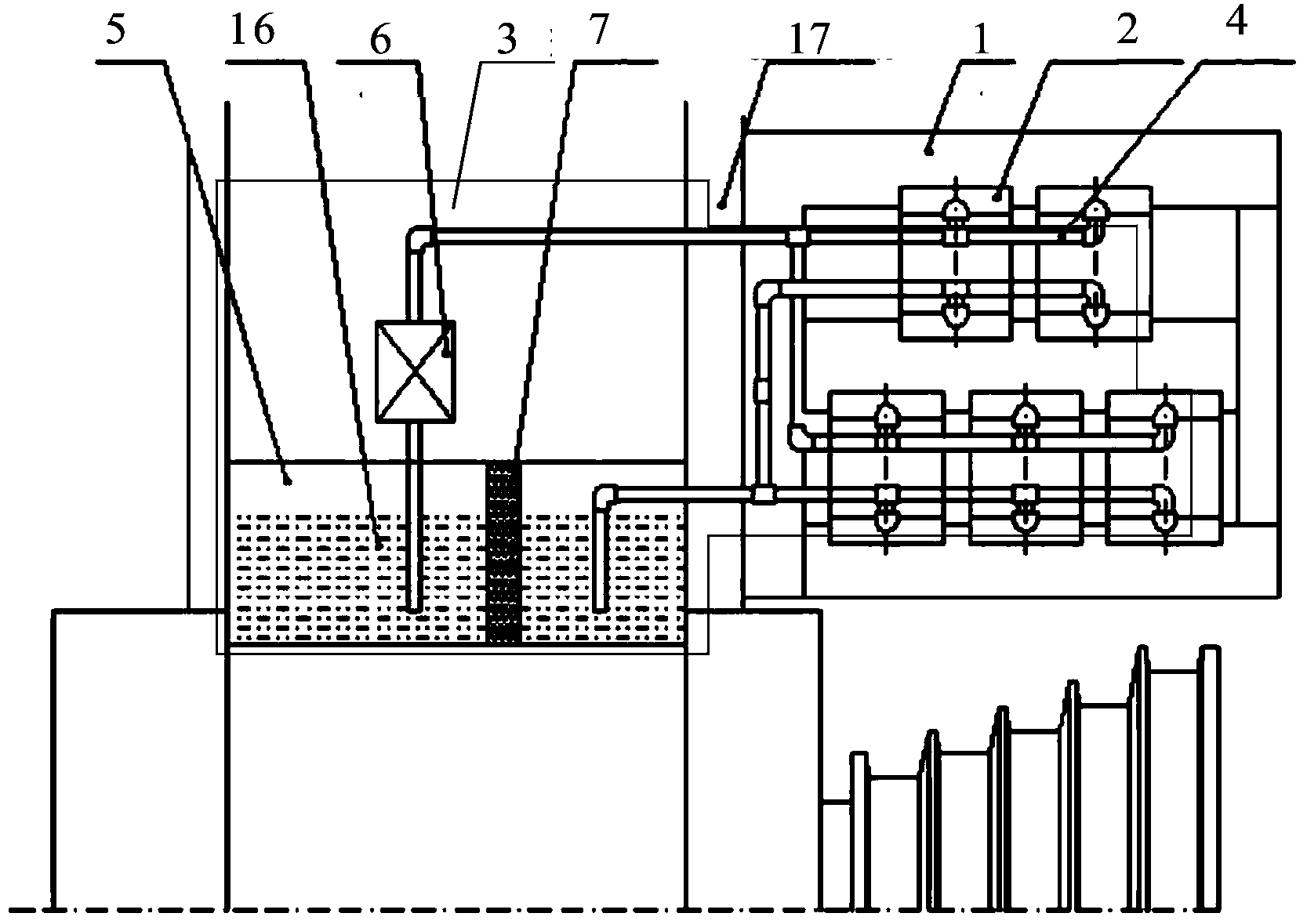

Compressor lubricating oil cooling system and control method thereof

ActiveCN105115197AGood lubrication effectLow failure rateEfficient regulation technologiesFluid circulation arrangementElectricityOil supply

The invention discloses a compressor lubricating oil cooling system. The compressor lubricating oil cooling system is characterized by comprising a compressor, an oil separator, a condenser, a liquid reservoir, a liquid reservoir outlet stop valve, a drying filter, a solenoid valve, an electronic expansion valve and a plate type heat exchanger which are sequentially communicated through a pipeline, wherein a lubricating oil outlet of the plate type heat exchanger is communicated with the compressor through an oil supply tube; a temperature sensor for measuring a lubricating oil reflux temperature is arranged on the oil supply tube; the temperature sensor is electrically connected with the electronic expansion valve through a series controller and an electronic expansion valve driver; and the temperature sensor is electrically connected with the solenoid valve through a series temperature switch. The invention further discloses a control method for the compressor lubricating oil cooling system. According to the compressor lubricating oil cooling system and the control method thereof, the oil return temperature of the lubricating oil can be kept stable; the fault rate of the compressor is reduced; and the service life of the plate type heat exchanger is prolonged.

Owner:PANASONIC APPLIANCES REFRIGERATION SYST DALIAN CO LTD

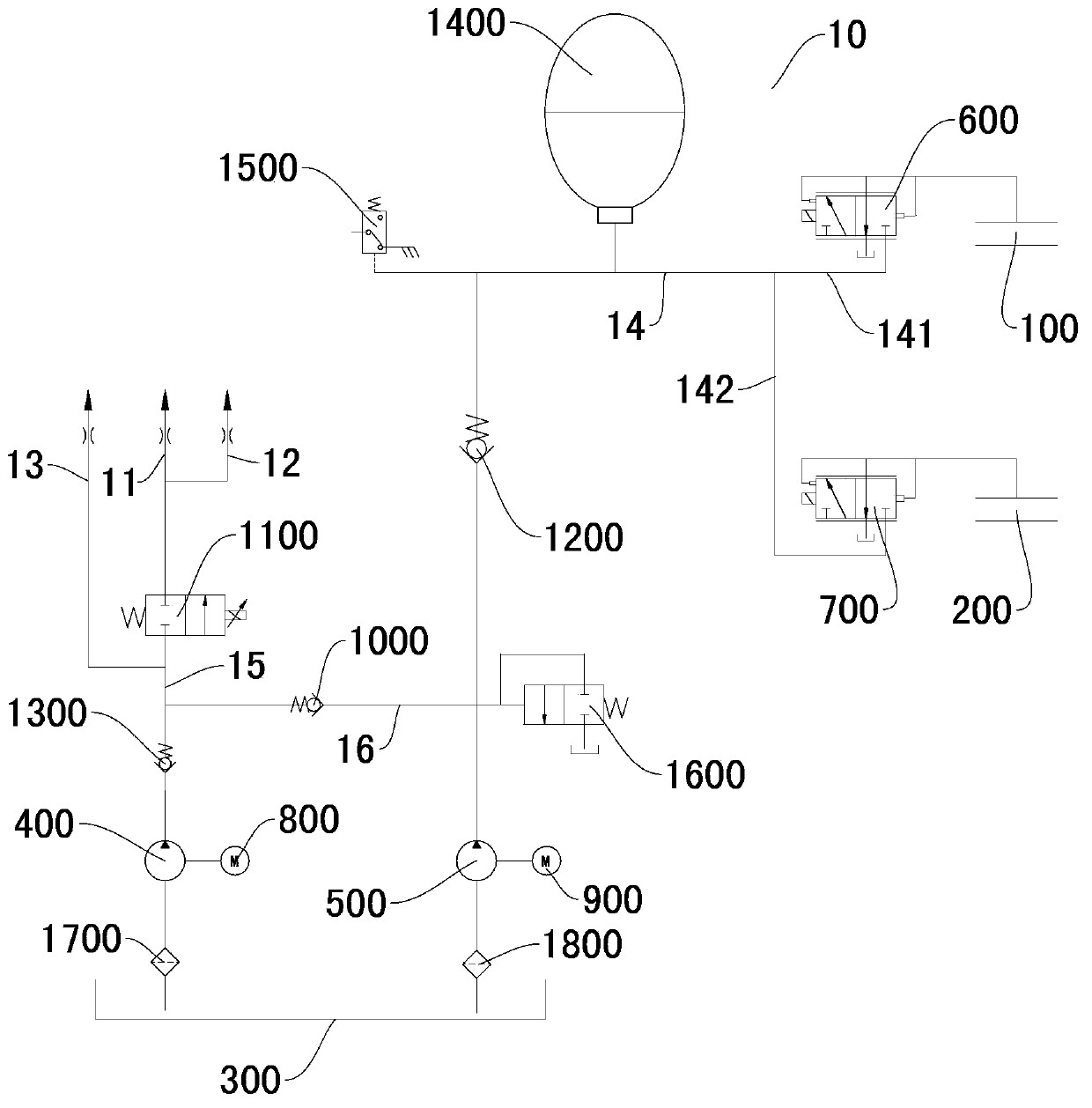

Dual clutch transmission and vehicle with same

InactiveCN103363030AGood lubrication effectReduce processing difficultyToothed gearingsGearing controlClutchVariator

The invention discloses a dual clutch transmission and a vehicle with the dual clutch transmission. The dual clutch transmission comprises a first clutch, a second clutch, an oil pan, a gear set, a first oil pump, a second oil pump, a first control valve and a second control valve, wherein the first oil pump is provided with an inlet and an outlet; the inlet of the first oil pump is connected with the oil pan; the outlet of the first oil pump is respectively connected with a lubricating oil channel of the first clutch, a lubricating oil channel of the second clutch, and a lubricating oil channel of the gear set; the second oil pump is provided with an inlet and an outlet; the inlet of the second oil pump is connected with the oil pan; the first control valve is connected between the first clutch and the outlet of the second oil pump so as to control switching on and switching off of the first clutch; and the second control valve is connected between the second clutch and the outlet of the second oil pump so as to control switching on and switching off of the second clutch. The dual clutch transmission provided by the embodiment of the invention is good in lubricating effect, simple in structure and low in manufacturing cost.

Owner:GREAT WALL MOTOR CO LTD

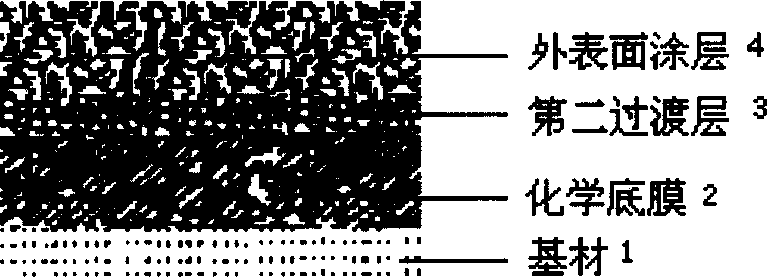

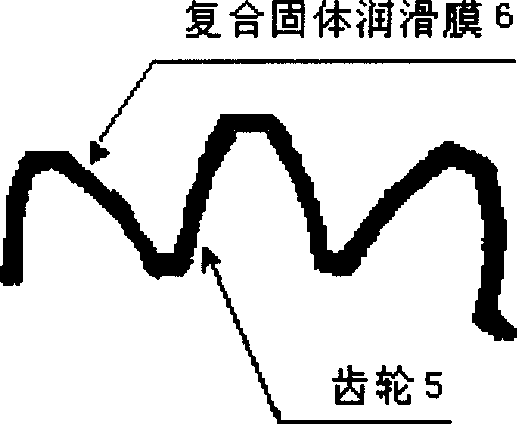

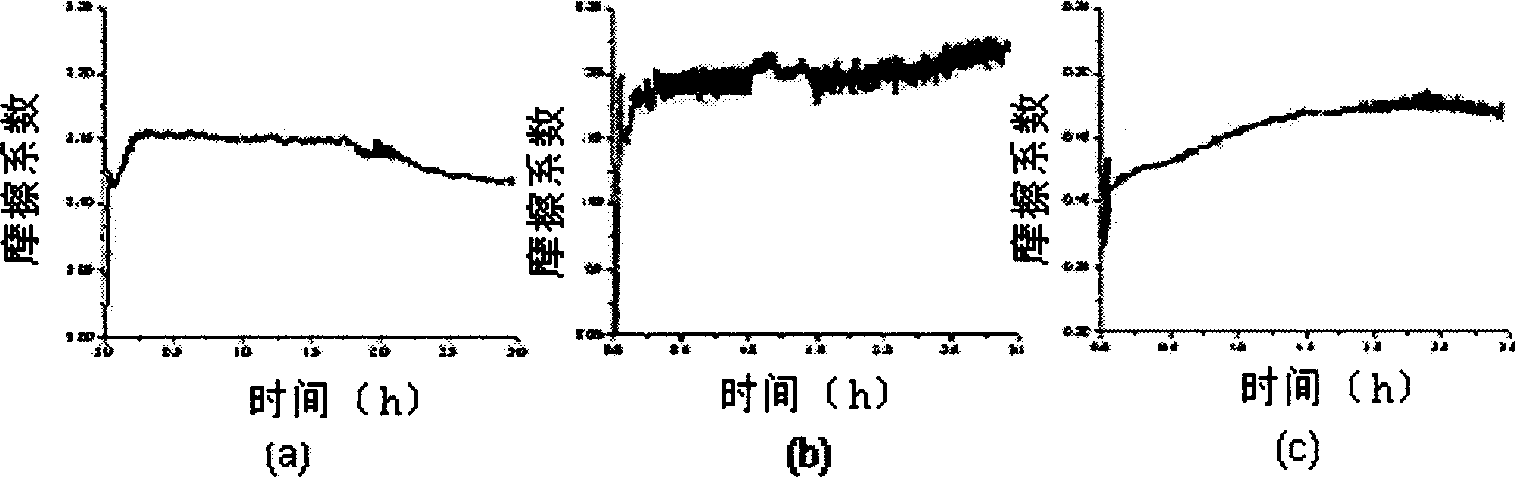

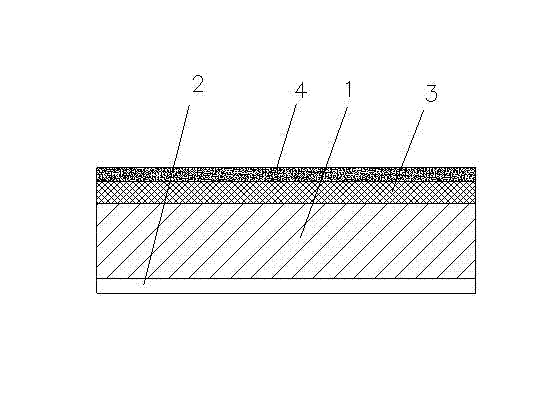

Powder coating type composite solid lubricant film preparation method and gear wheel with solid lubricant film

InactiveCN1727455AGood lubrication effectExtended service lifePowdery paintsBase-materialsMetallic substratePowder coating

A powder paint type lubricating solid membrane is prepared through cleaning the surface of metallic basic body, preparing priming member by chemical reaction, coating solid lubricant to form a transition layer, and spraying high-molecular powder layer. A gear with said lubricating solid membrane is also disclosed.

Owner:SHANGHAI UNIV

Human body lubricant and preparation method thereof

The invention relates to a human body lubricant which mainly comprises a wetting agent, a nutrient, a thickening agent, a disinfectant and deionized water. The invention also relates to a method for preparing the human body lubricant, and the method comprises the following steps: mixing the components in sequence; uniformly stirring; and filling. The human body lubricant has proper stickiness, is not easily dried, can be cleaned easily and has the advantages of broad-spectrum antibacterial property, bactericidal effect, no toxicity or irritation, non sensitization and safety in use.

Owner:QINGDAO MINGYAOTANG MEDICAL TECH DEV

Continuous-casting crystallizer casting powder for high-aluminum steel

The invention belongs to the technical field of steelmaking and particularly relates to continuous-casting crystallizer casting powder for high-aluminum steel. The continuous-casting crystallizer casting powder for the high-aluminum steel comprises the chemical ingredients of, in percentage by mass, 31-39% of CaO, 20-28% of SiO2, 3-7% of MgO, 2-4.5% of Li2O, 5-10% of Al2O3, 5-10% of Na2O, 2-5% ofF, 3-10% of MnO, 4-8% of C and the balance impurities. By means of the casting powder, the defect that aluminum oxide in high-aluminum molten steel enters and deteriorates slag is overcome, and the qualified rate of an obtained casting blank is high.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

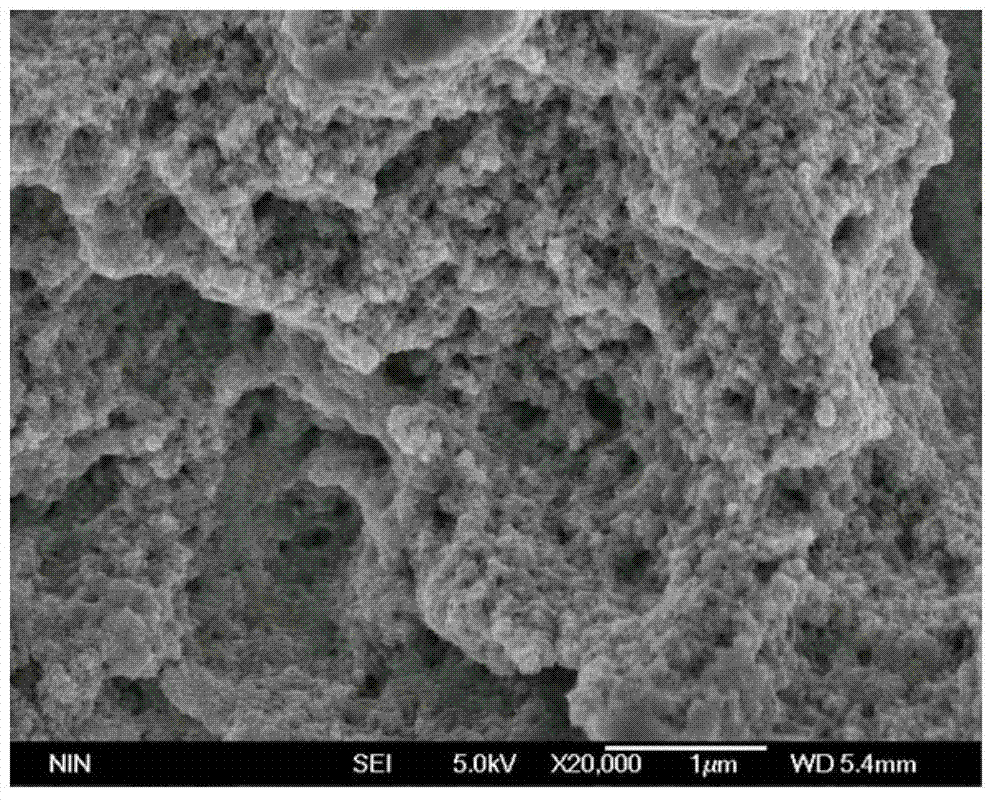

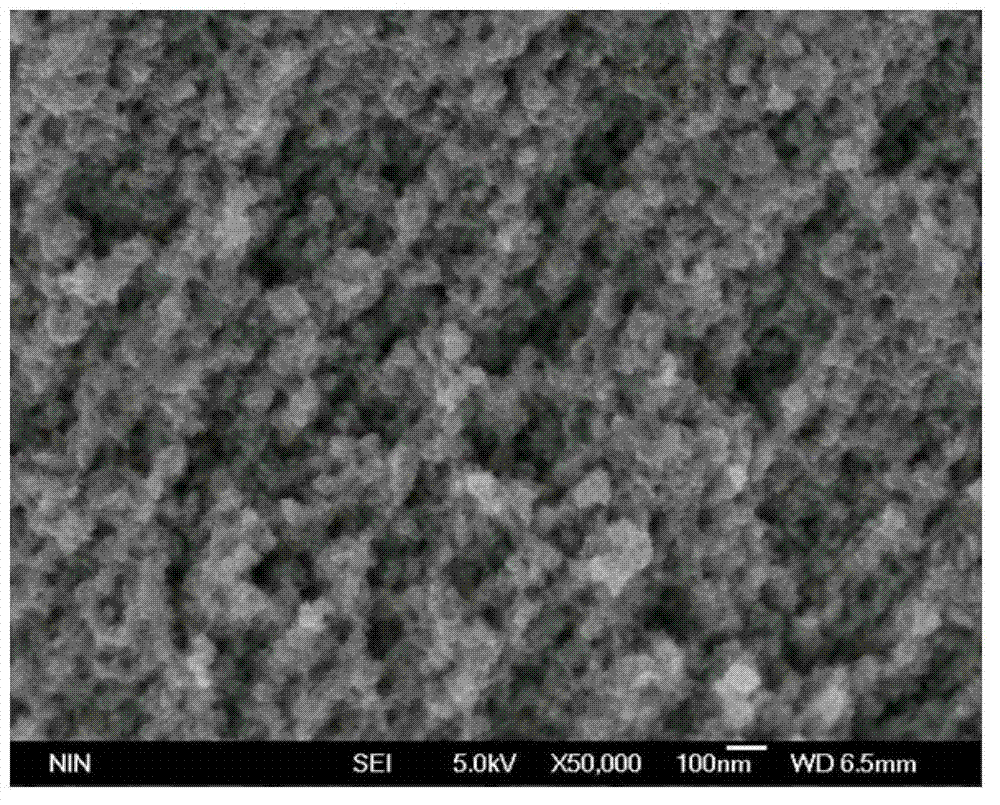

Niobium alloy target material and preparation method thereof

ActiveCN103866245AGood lubrication effectGood surface qualityVacuum evaporation coatingSputtering coatingLubricationNiobium alloy

The invention provides a preparation method of a niobium alloy target material. The preparation method comprises the steps: firstly, carrying out hot extrusion of a niobium alloy tube blank, then carrying out inner hole processing of the niobium alloy tube blank after hot extrusion, and thus obtaining the niobium alloy target material. In the preparation process of the niobium alloy target material, firstly, the surface of the niobium alloy tube blank is coated with a glass powder; because the surface of the niobium alloy tube blank is spray-coated with the glass powder, the niobium alloy tube blank is allowed to have relatively good lubrication effect in the hot extrusion process, and thus the surface quality of the niobium alloy tube blank is relatively good; the subsequent hot extrusion processing and heat treatment are conducive to refinement and homogenization of crystal grains of the niobium alloy tube blank; and finally, the niobium alloy tube blank after hot extrusion is subjected to mechanical processing, and an inner hole of the niobium alloy tube blank is bored and milled by selected special tools, so that chip breaking can be allowed to be continuously discharged from the inner hole, the problem that chip breaking is accumulated in the inner hole to affect processing of the inner hole surface is avoided, and thus the niobium alloy target material with uniform and fine internal crystal grains and relatively low surface roughness value is obtained. The invention also provides the niobium alloy target material.

Owner:NINGXIA ORIENT TANTALUM IND

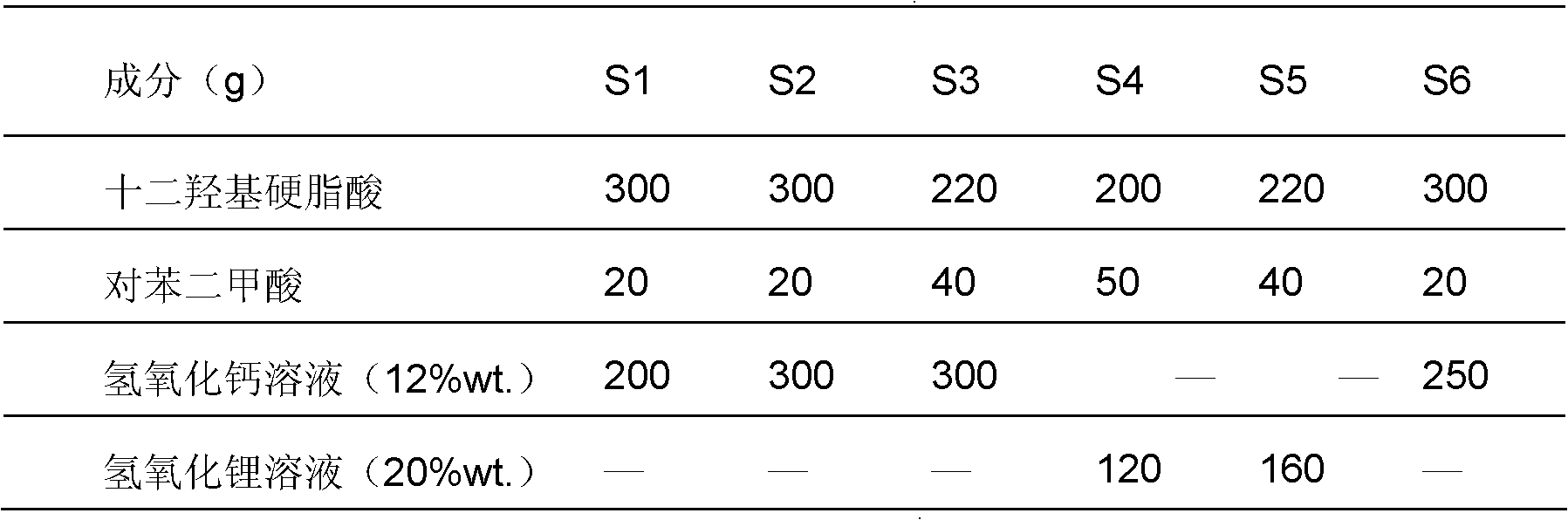

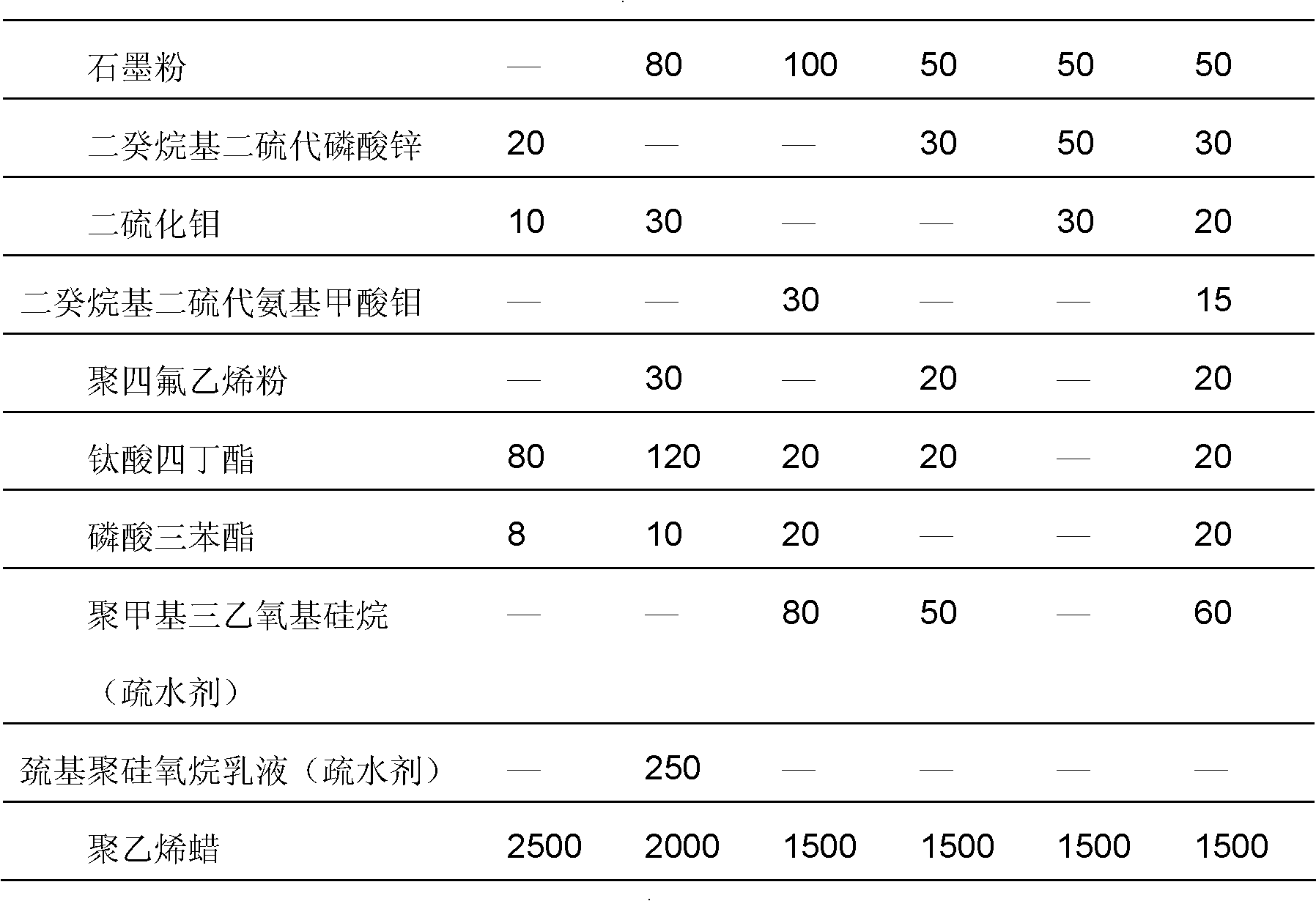

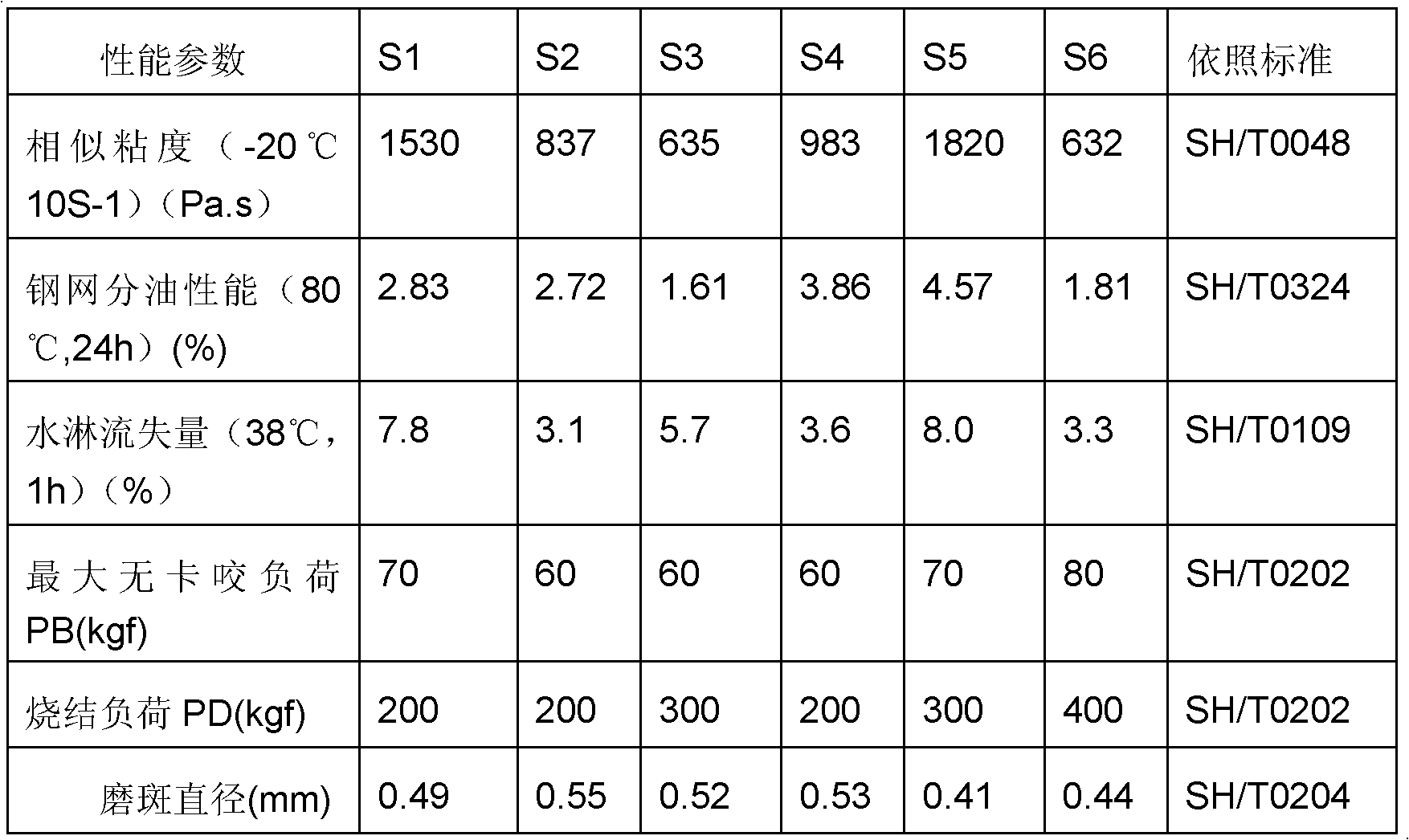

Grease for low speed and heavy duty

InactiveCN101974362AGood low temperature resistanceGood lubrication effectLubricant compositionZincLow speed

The invention relates to grease for low speed and heavy duty. The grease contains 8-20% of thickening agents, 1-4% of graphite powder, 0.3-6% of other extreme pressure additives, 0.3-6% of organic ester and the balance base oil by weight, wherein other extreme pressure additives are one or more of zinc dialkyldithiophosphate, molybdenium disulfide, molybdenum dialkyldithiocarbamate and other organic molybdenum salt containing alkyl; and the organic ester is tetrabutyl titanate, phosphate ester or combination of tetrabutyl titanate and phosphate ester.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Lubricant used for swing and rolling forming and use method thereof

The invention relates to a lubricant used for swing and rolling forming of tantalum and tantalum alloy parts and a use method thereof. The lubricant contains the components: (1) any two of molybdenum disulfide, graphite and boron nitride, (2) any one or two of borax, ceresin wax, silica and sodium sulfate and (3) water. The lubricating treatment process comprises the following steps of surface cleaning, preheating, spraying and drying. The lubricant and the use method thereof can meet the demand of carrying out severe deformation swing and rolling forming on tantalum and tantalum alloy blanks, thereby effectively reducing the friction between blanks and moulds; products have high surface quality, and the service lives of the moulds are long.

Owner:GRIMAT ENG INST CO LTD

Wearable hot roll

InactiveCN102847713AGood lubrication effectImprove mechanical and chemical propertiesRollsMetal rolling arrangementsNanometreCeramic coating

The invention discloses a wearable hot roll which comprises a hot roll body, wherein a water cooling layer is arranged on the internal wall of the body; and a tungsten carbide hard alloy layer coated with a nanometer ceramic coating outside is coated on the external wall of the body. According to the wearable hot roll, the tungsten carbide hard alloy layer is coated on the surface of the body, and the nanometer ceramic coating is coated outside the tungsten carbide hard alloy layer, so the wearable hot roll has the effect of heat insulating, has no falling and no burning, is waterproof and moisture-proof, and is good in effect of lubricating; the mechanical performance and the chemical performance of the hot roll are greatly improved; and meanwhile, good effect of cooling can be achieved via the water cooling layer, therefore, the longer service life can be ensured.

Owner:虞伯林

Lightning arrester device and regulating method for detecting automatic balance of direct current supply of transformer substations

The invention discloses a lightning arrester device and a regulating method for detecting the automatic balance of direct current supply of transformer substations. The lightning arrester device comprises a hollow barrel. The hollow barrel is arranged at the upper end of an insulating telescopic rod and is perpendicular to the insulating telescopic rod, an annular magnet is arranged on a side of the barrel, the size of the annular magnet is matched with the diameter of a hole of the barrel, a motor is arranged in the barrel via a slide mechanism, a turntable sleeves an end of a rotary shaft of the motor, a conductive brush is arranged on the outer side of the turntable, a turntable tightness compression regulating mechanism is arranged in the barrel, and an elastic conductive sheet which is connected with the rotary shaft of the motor is arranged in the barrel. The lightning arrester device and the regulating method have the advantages that wires can be shifted onto metal components of a lightning arrester only by a single person in a time-saving and labor-saving manner and are in excellent contact with the metal components, the person does not need to climb to clean corrosion substances of the metal components, accordingly, the labor intensity is extremely low, more importantly, an integral wiring procedure can be completed by the single person in one minute, and the wiring efficiency is extremely high.

Owner:国网河南省电力公司桐柏县供电公司

Engine cam shaft cover with oil sump

The present invention proposes one kind of cam shaft cover with oil sump for engine. The cam shaft cover has screw holes for screw fixing onto the cylinder cover of the engine, curved surface in the middle part for fitting the cam shaft, and one prolonged end with oil sump communicated to the main oil path in the cylinder cover. The cam shaft cover makes the lubricant oil flowing through the curved surface between two screw holes well contact with the cam shaft, so as to increase the lubricating area and raise the lubricating effect. The present invention has the advantages of simple structure and good lubricating effect.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Medium carbon steel chamfering copper plate continuous casting mold covering slag and preparation method thereof

The invention relates to medium carbon steel chamfering copper plate continuous casting mold covering slag and a preparation method thereof. The casting slag comprises, by weight, 40-45% of CaO, 19-25% of SiO2, 3-7% of MgO, 1-2.5% of Li2O, 2-5% of Al2O3, 7-10% of Na2O, 5-7% of F and 4-8% of C. The covering slag is obtained through the steps of proportioning, melting, water quenching, drying, smashing, preparation and spray granulation, the medium carbon steel chamfering copper plate continuous casting mold covering slag is rational and adequate in proportioning of chemical components, good in heat-transfer capability, high in heat transfer uniformity and good in lubricating effect, and quality defects such as corner crack, narrow-edge bulging and transverse corner cracks of casting blanks of medium carbon steel are avoided effectively.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Lubricating oil for piston

InactiveCN104830451AGood lubrication effectImprove wear resistanceLubricant compositionSodium dodecylbenzenesulfonateSuccinchlorimide

The utility model provides a lubricating oil for a piston, which comprises the following raw materials in part by weight: 3-5 parts of monoethanolamine, 2.5-3.5 parts of sodium methylene bis-naphthalene sulfonate, 2-3 parts of acrylic acid-2-ethyl ester, 3-5 parts of zinc sulfate, 5-9 parts of sodium dodecylbenzene sulfonate, 8-14 parts of ultra-high alkali synthesis calcium sulfonate, 3-5 parts of trilinolein, 4-7 parts of calcium sulfurized alkyl phenate, 2-5 parts of modified polysiloxane, 1-4 parts of stannous sulfate, 2-5 parts of zinc dialkyl dithiophosphate, 2-5 parts of phenyl-naphthyl amine, 2.3-4.5 parts of boride polyisobutylene succinimide, and 26-36 parts of low-viscosity poly-alpha-alkene. The lubricating oil is applied to pistons and has the advantages of good lubricating effect, high wear resistance and good high pressure resistance.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

Pump body assembly and compressor

PendingCN108930651AReduce leakage problemsGood lubrication effectRotary piston pumpsRotary piston liquid enginesSlide platePetroleum engineering

The invention provides a pump body assembly and a compressor. The pump body assembly comprises a main shaft, the main shaft is provided with slide plate slots, the tail end of every slide plate slot is a backpressure oil chamber, the backpressure oil chambers are at least a part of an oil channel, the oil outlets of the backpressure oil chambers are located at the tops of the backpressure oil chambers, and the inlets of the backpressure oil chambers are lower than the oil outlets of the backpressure oil chambers, so a lubricating medium enters the backpressure oil chambers through the oil inlets of the backpressure oil chambers, fills up the backpressure the oil chambers, and flows out from the tops of the backpressure oil chambers. The problem of insufficient backpressure of slide platesin the prior art is solved in the invention.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Automobile drive axle wheel-side planet axle with oil duct

InactiveCN102135129AReasonable structureGood lubrication effectShaftsEngine lubricationCar drivingPlanet

The invention discloses an automobile drive axle wheel-side planet axle with an oil duct, belonging to automobile driving devices. The automobile drive axle wheel-side planet axle with the oil duct is characterized in that a left end section and a right end section of a long-cylindrical shaft body are stepped cylindrical sections so that the shaft body is sequentially provided with a left stepped cylindrical section, a shaft body section and a right stepped cylindrical section from left to right, and the diameters of the left stepped cylindrical section and the right stepped cylindrical section are smaller than the diameter of the shaft body section; junctures of the left, the right stepped cylindrical sections and the shaft body section are respectively provided with a grinding wheel undercut; in addition, the shaft body is provided with an axial central through hole, the middle part of the shaft body section is provided with a radial through hole communicated with the axial central through hole, and the axial central through hole and the radial through hole form a lubricating oil duct; therefore, lubricating oil can circulate, and the lubricating oil in a wheel-side shell can flow into a needle roller along the lubricating oil duct in the planet axle; and the lubricating effect is good.

Owner:安徽福马车桥有限公司 +1

Lubricant for wall reduction and drawing of titanium alloy pipe and using method thereof

The invention discloses a lubricant for wall reduction and drawing of a titanium alloy pipe and a using method thereof. The lubricant is made by uniformly mixing and stirring the following raw materials in percentage by weight: 85-96% of chlorinated paraffin and 4-15% of BN (Boron Nitride). The using method of the lubricant comprises the following steps of: cleaning the titanium alloy pipe, carrying out heat treatment on the titanium alloy pipe after baking, respectively smearing a layer of the lubricant on the inner and the outer surfaces of the titanium alloy pipe after the heat treatment, rolling one end of the titanium alloy pipe, putting a moving core head in the titanium alloy pipe and carrying out the wall reduction and the drawing to obtain the titanium alloy pipe. The lubricant disclosed by the invention has the characteristics of capability of continuous self-lubrication, good lubricant adhering effect, simplicity in composition proportioning, easiness in cleaning and removing, environmental protection, no pollution and the like. By adopting the lubricant disclosed by the invention, the titanium alloy pipe drawing production efficiency can be effectively increased.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Automobile clutch diaphragm special-purpose water-based milling liquid and production method

InactiveCN101255378AGood lubrication effectGuaranteed surface qualityLubricant compositionClutchTriethanolamine

The invention discloses a water-based grinding fluid specialized for automobile clutch diaphragm which can reduce grinding temperature and force to maximum extent, improve process efficiency of grinding, ensure grinding precision and surface quality, prolong life of grinding wheel, reduce cost, satisfy requirements of environmental protection and production method thereof. Raw materials of water-based grinding liquor and weight percentages are phytic acid 1.8-2.2%, sodium benzoate 5-7%, alkylol amine 7-9%, sodium carbonate 3.5-4.5%, hyposulfite of soda 0.8-1.2%, polyethyleneglycol 11-13%, oleate triethanolamine 2.5-3.5%, sodium dodecylbenzene sulfonate 1.8-2.2%, foam killer 1.8-2.2%, 2-methyl-3(2H)-isothiazolone 0.4-0.6%, de-ionized water 58-61%. The production method is synthesis with stirring under condition of normal temperature - medium temperature - normal temperature.

Owner:DALIAN SANDAAOKE CHEM

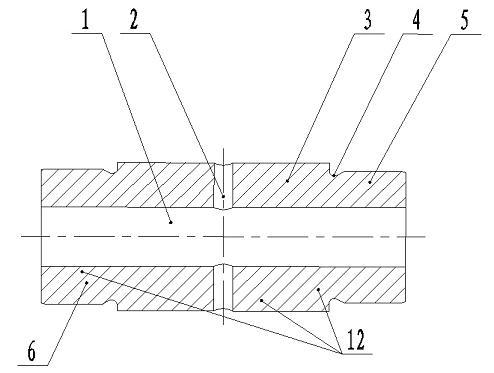

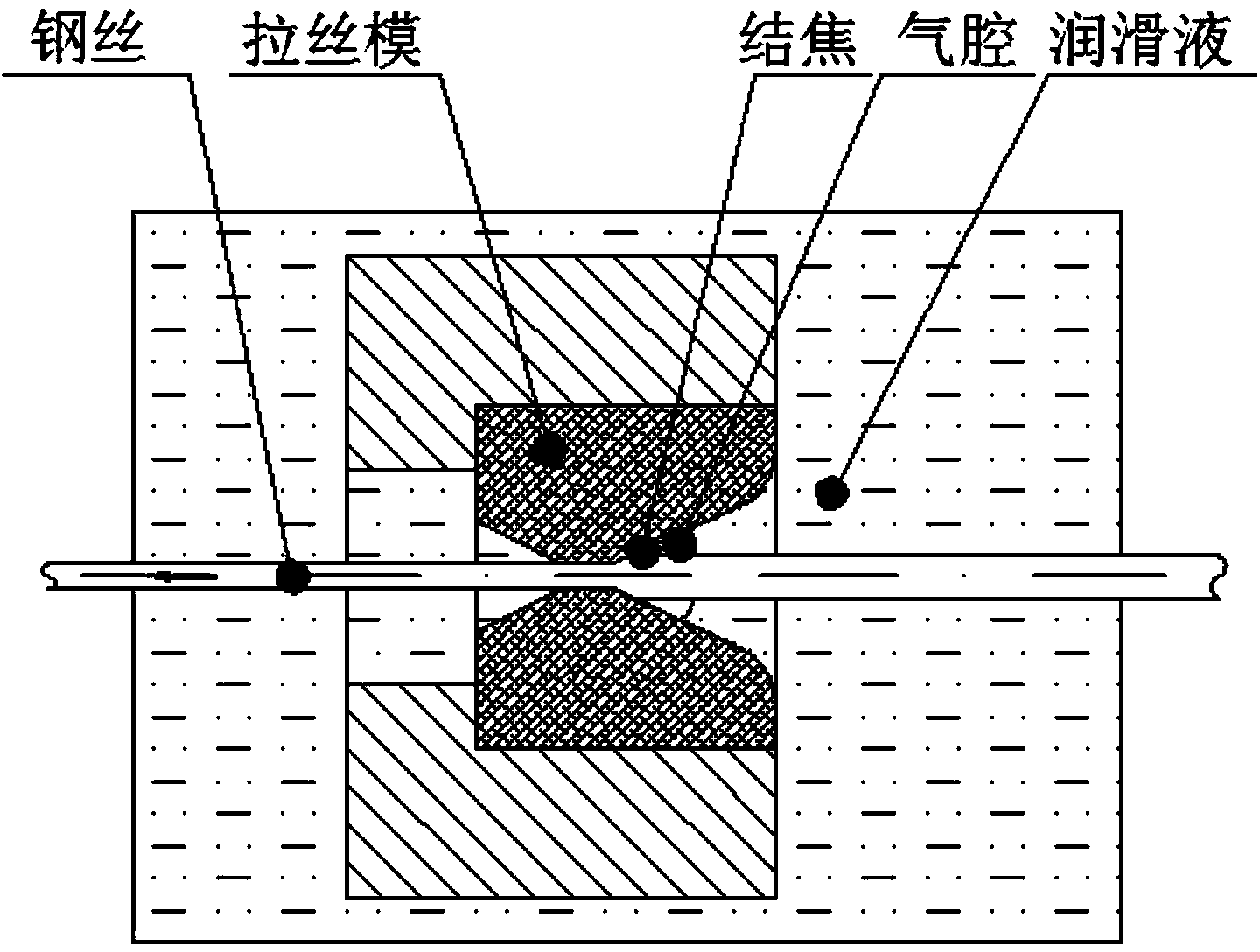

Forced lubrication device for water tank wire drawing and use method of device

The invention provides a forced lubrication device for water tank wire drawing and a use method of the device. The forced lubrication device comprises a mold frame, forced lubrication device bodies and a forced circulation device, wherein a plurality of drawing passes are arranged in the mold frame; the forced lubrication device bodies are arranged on the drawing passes of the mold frame and are matched with the drawing passes in number; the forced circulation device comprises a circulation pipeline, a circulation pond and a filtering device; the forced lubrication device bodies are connected with the circulation pond through the circulation pipeline; lubrication liquid is added into the circulation pond; the filtering device is arranged in the circulation pond and is used for spacing the circulation pond and filtering impurities in the lubrication liquid flowing out of a liquid outlet pipeline. The forced lubrication device has good cooling and lubricating effects, has the characteristics of low manufacturing cost, high efficiency and the like, and has huge potential market economy and society benefits.

Owner:马克菲尔(长沙)新型支档科技开发有限公司

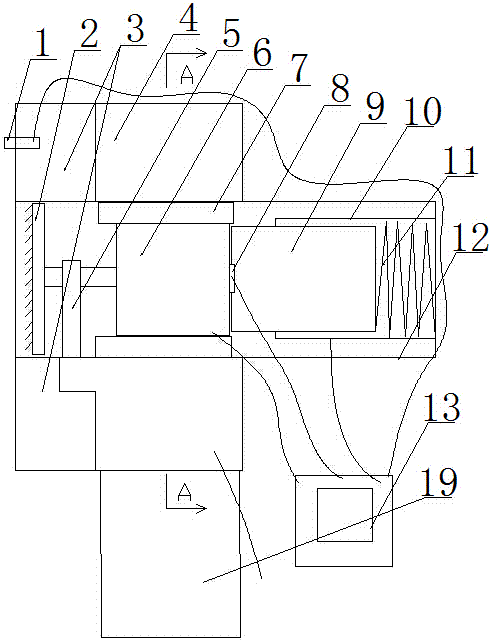

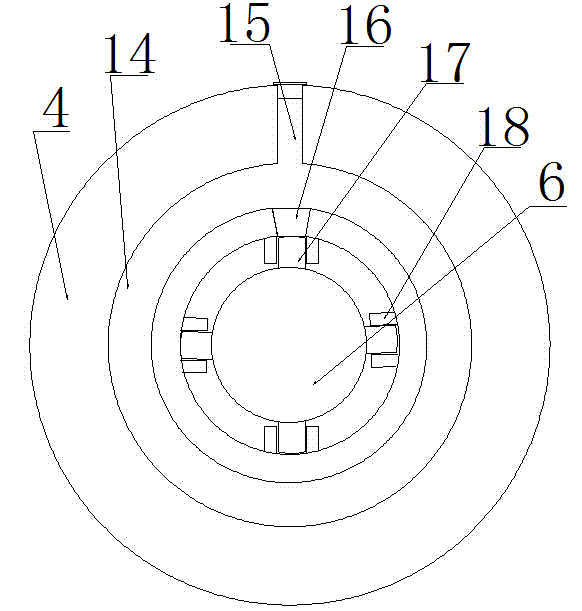

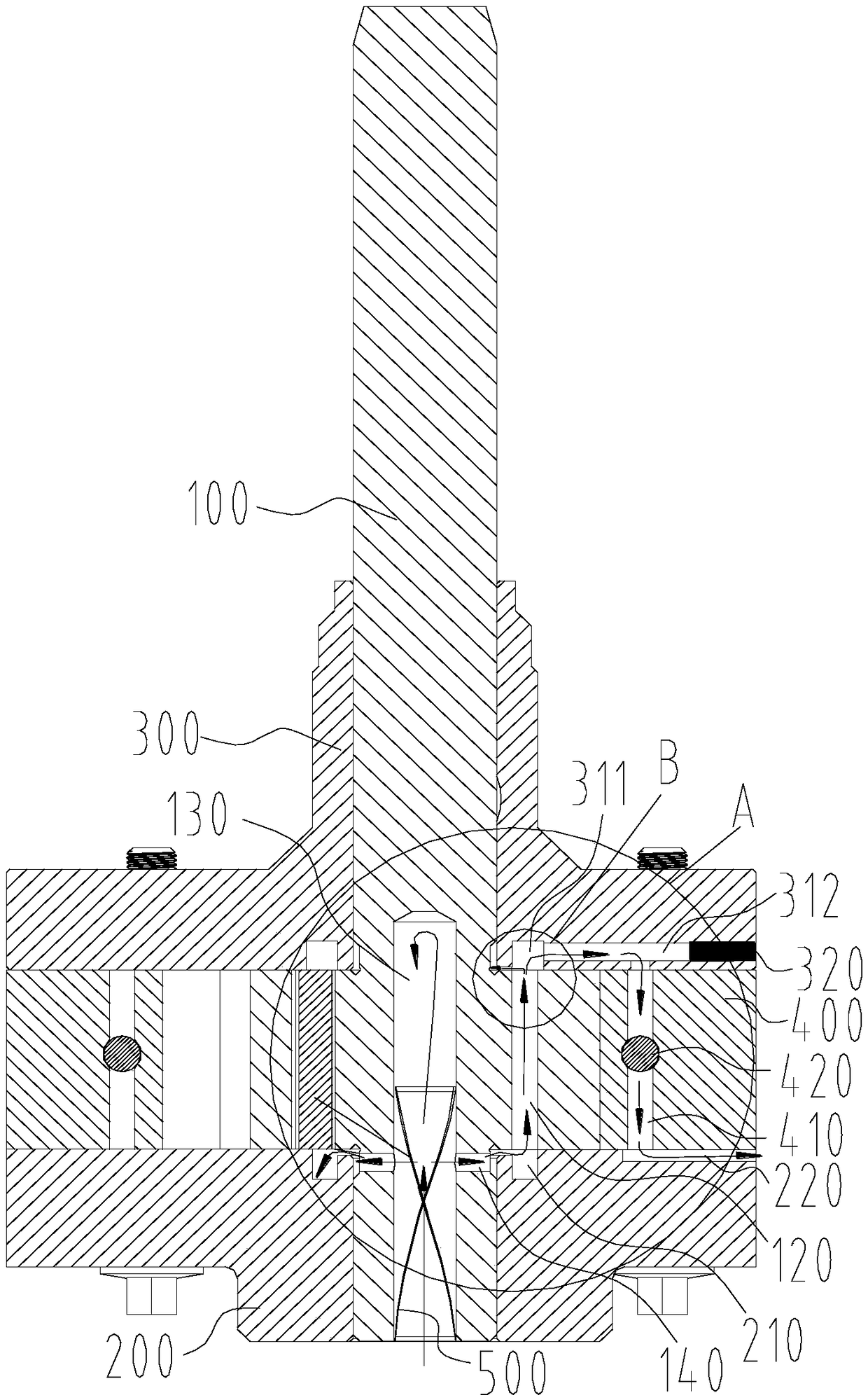

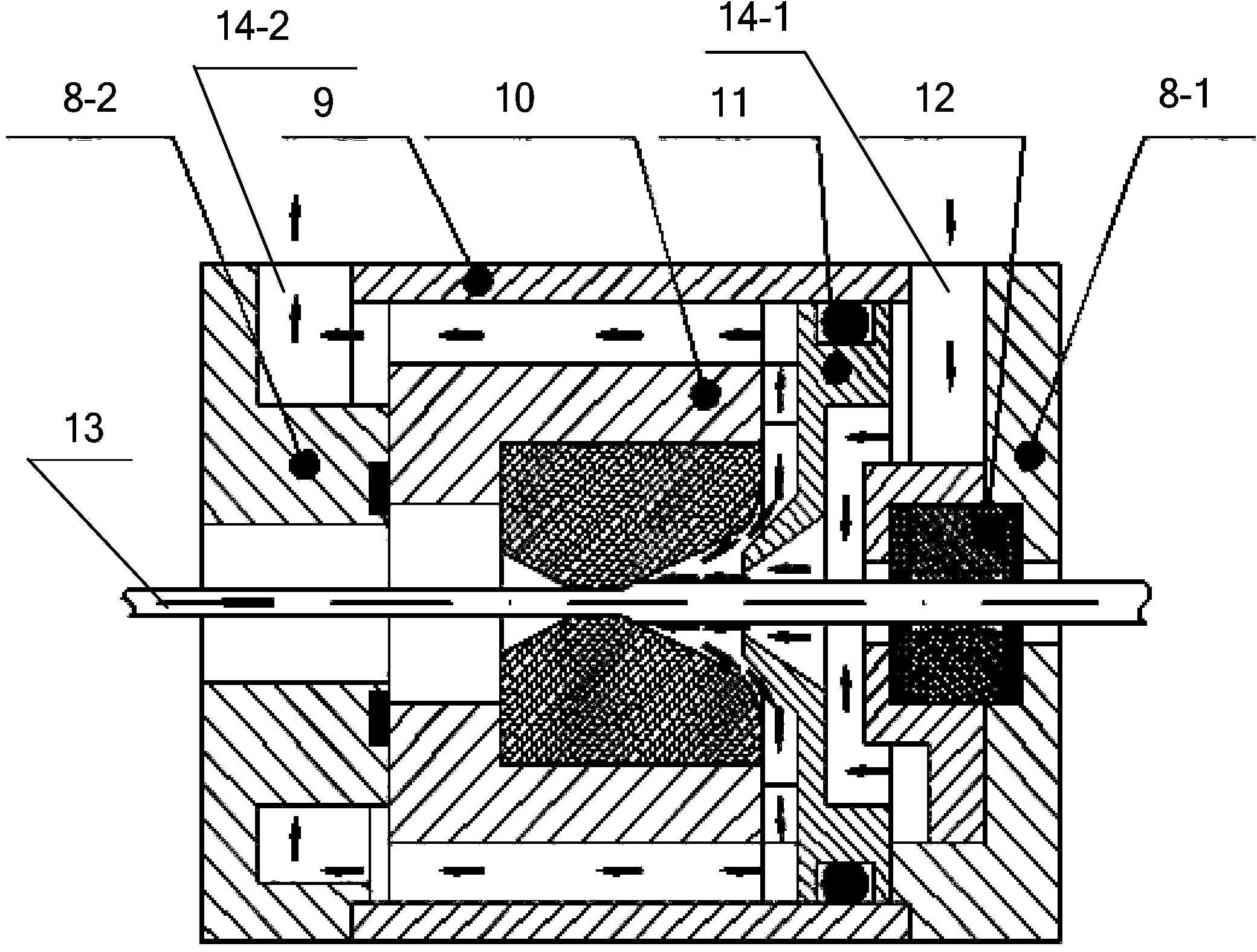

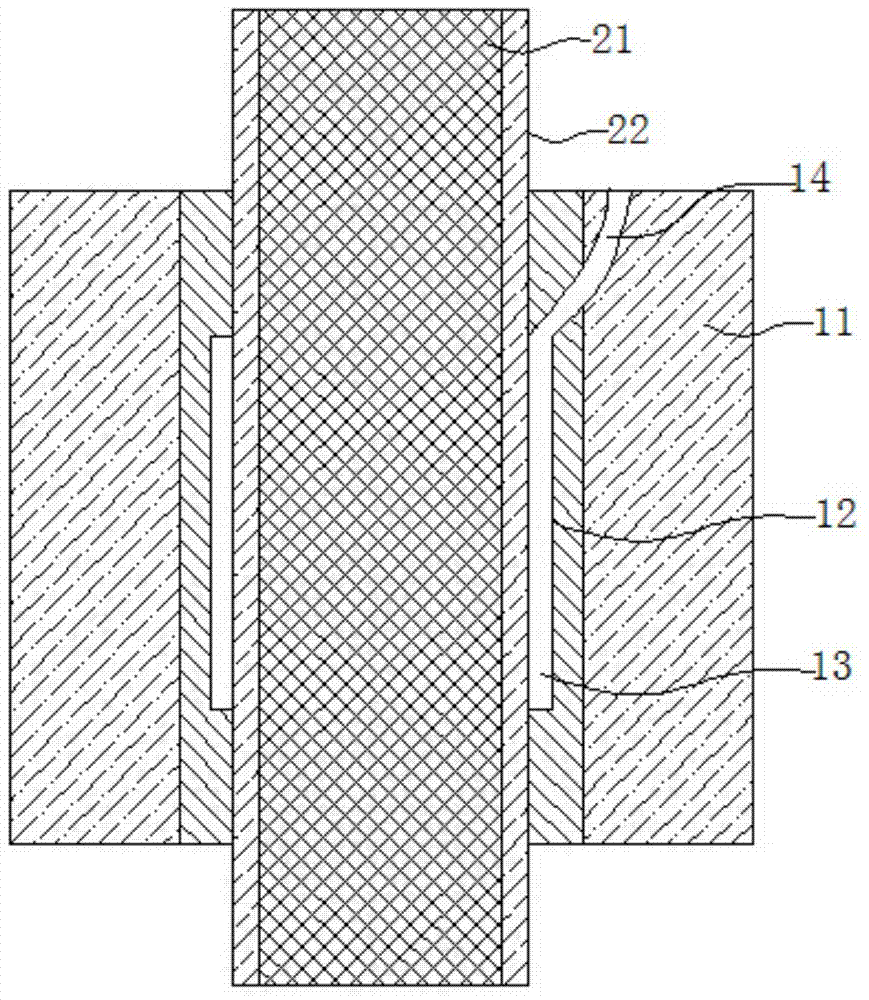

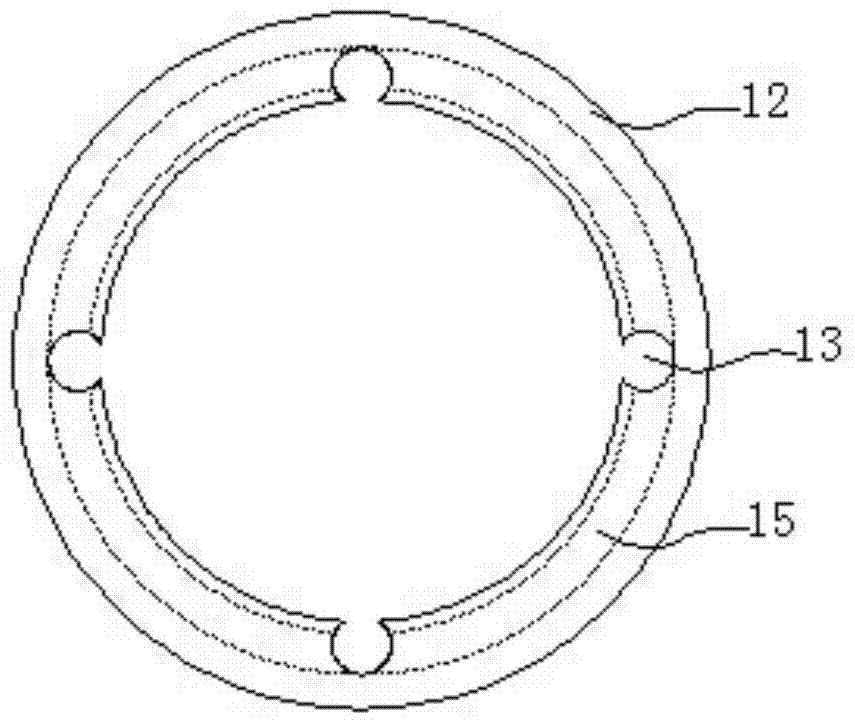

Rotary supporting lubrication structure of rotary type compressor

ActiveCN102966547AGood lubrication effectImprove the lubrication effectRotary/oscillating piston pump componentsLiquid fuel engine componentsLubricationCrankshaft

The invention provides a rotary supporting lubrication structure of a rotary type compressor, which comprises a crankshaft, an oil duct extended along the axial direction of the crankshaft is provided in the crankshaft, the crankshaft comprises a first shaft t segment, a second shaft segment and an eccentric shaft segment; a first bearing and a second bearing are respectively arranged on an upper end face and a lower end face of a cylinder of the rotary type compressor, the first bearing and the second bearing are respectively support the first shaft segment and the second shaft segment, the eccentric shaft segment is positioned in the cylinder, an annular oil chamber is arranged between a first annular contact part and a second annular contact part; a first end of the first shaft segment is contacted to the annular oil chamber arranged in the first bearing, the contact part of the first bearing and the crankshaft is divided into a first contact part and a second contact part, so that lubricating oil can lubricate the first contact part and the second contact part through the annular oil chamber, and the good lubrication effect can be reached.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

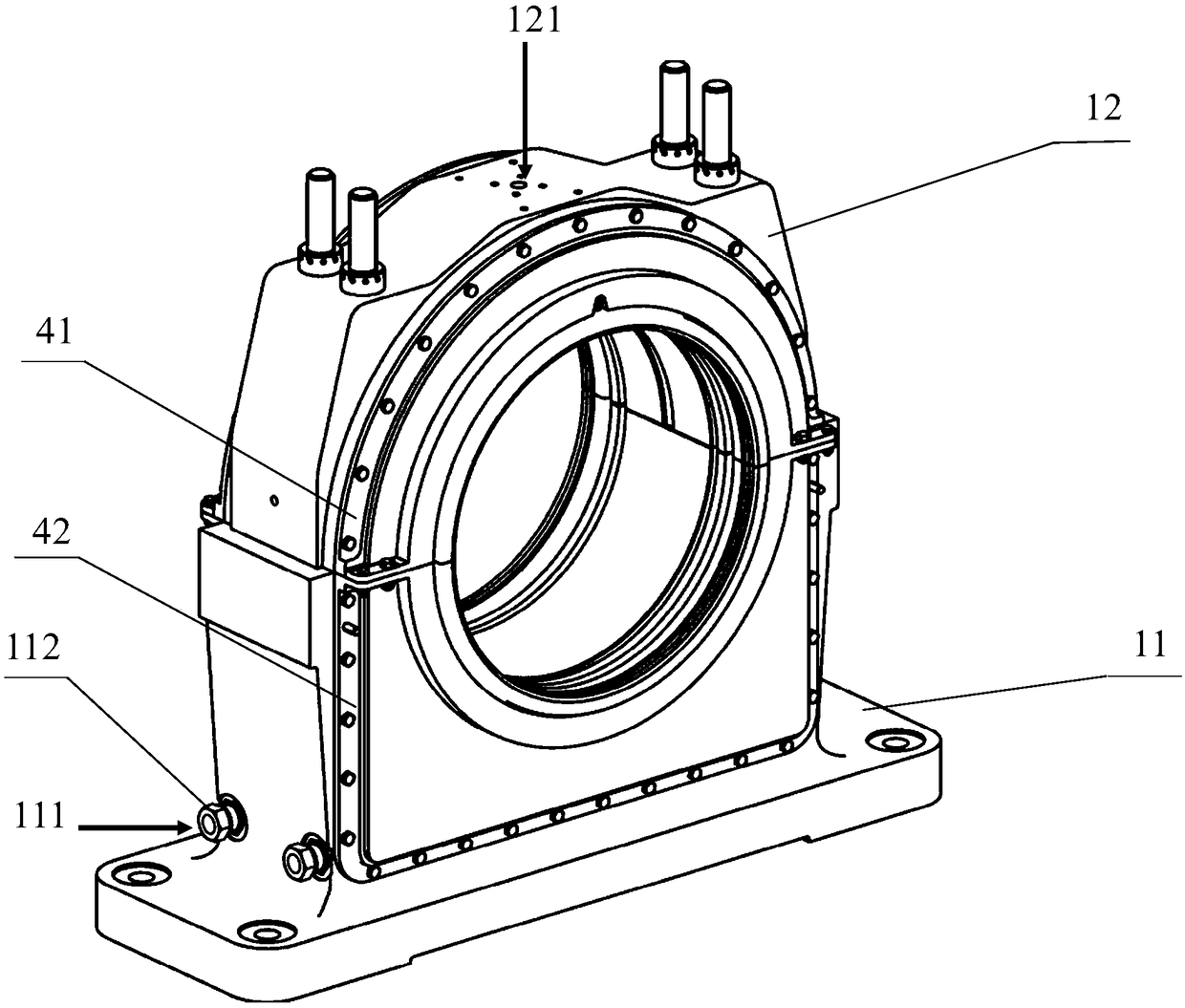

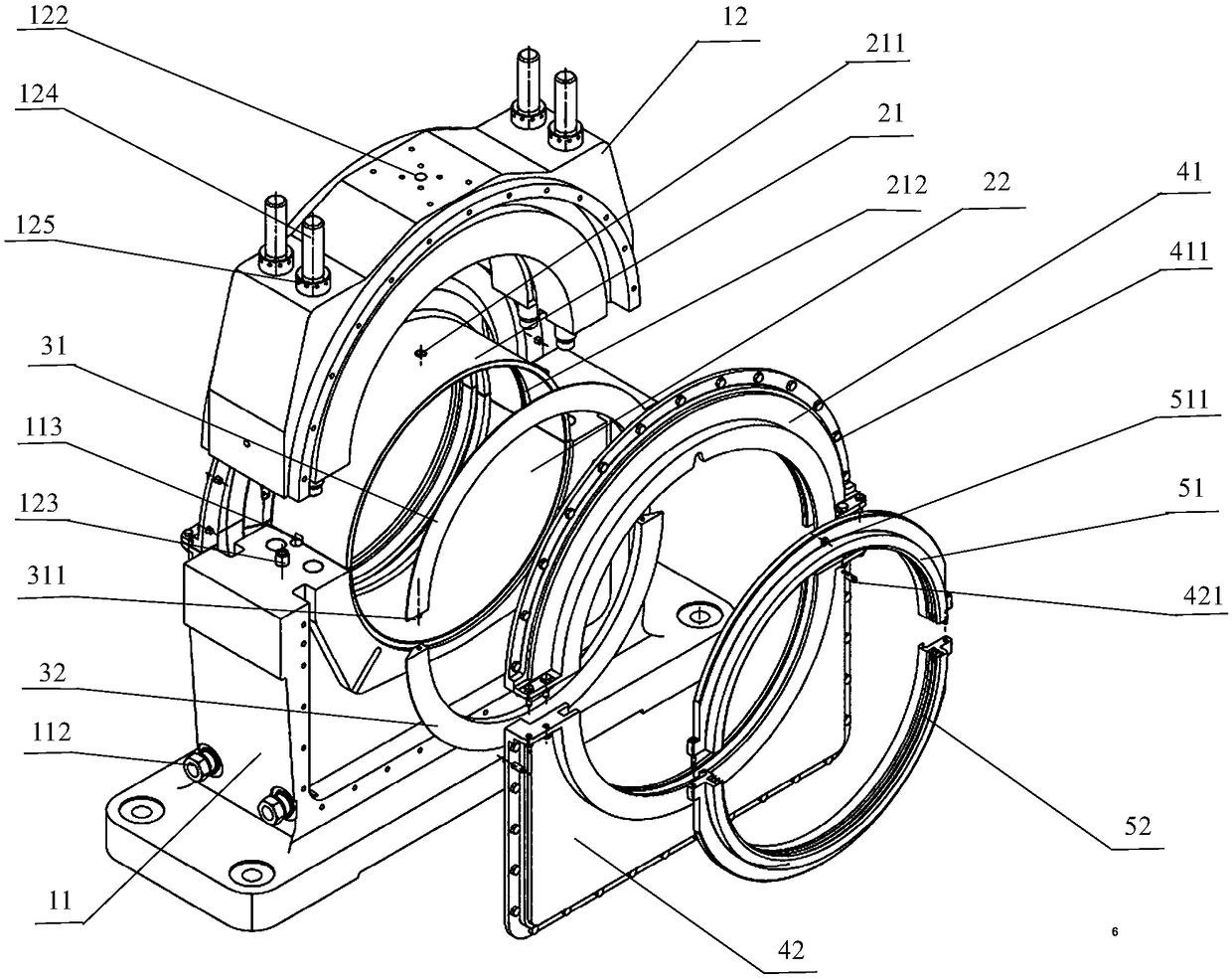

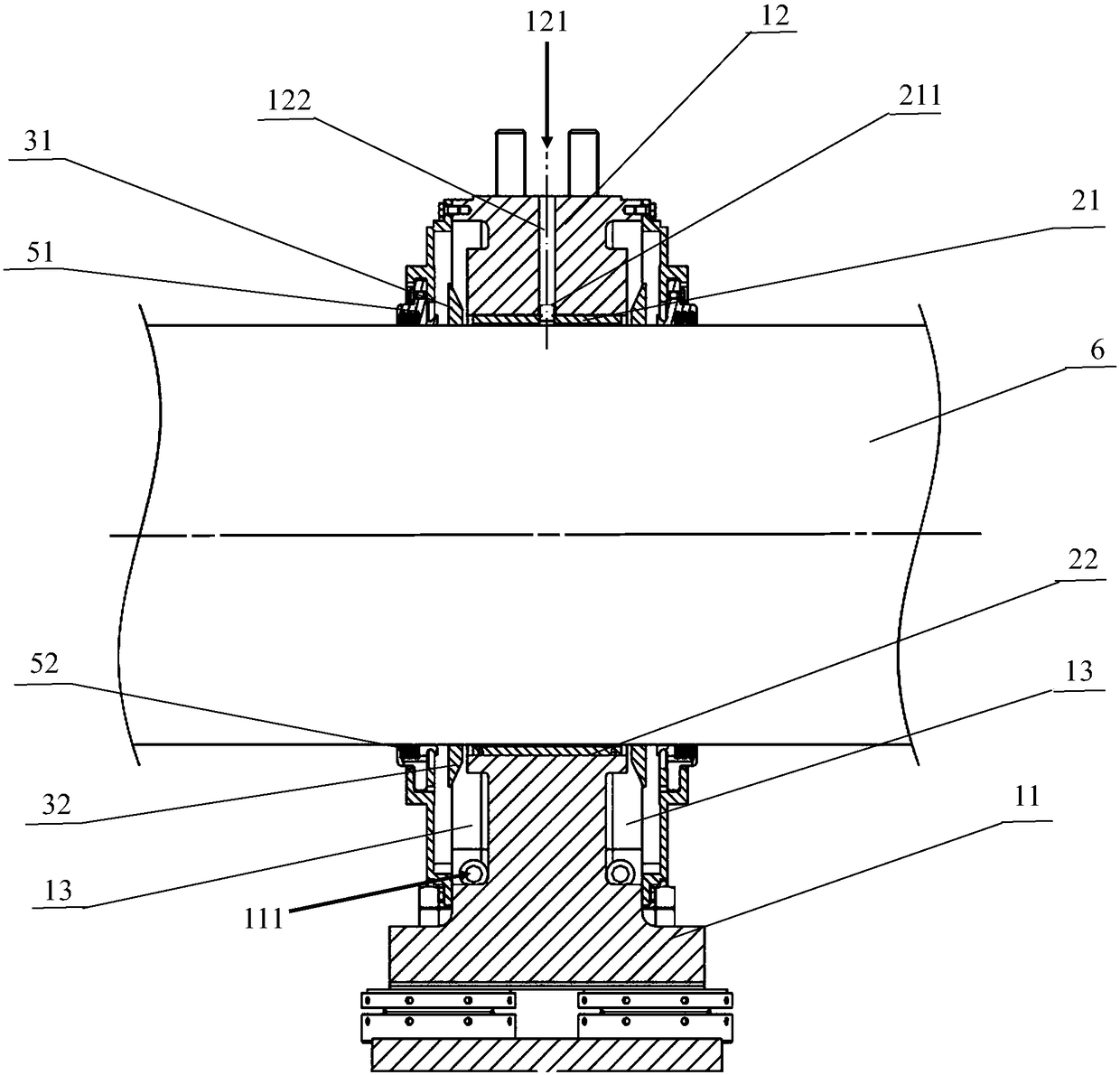

Bearing supporting device

InactiveCN109340268AGood lubrication effectImprove carrying capacityBearing unit rigid supportOil coolingPetroleum engineering

The invention relates to the technical field of bearings, and discloses a bearing supporting device. The bearing supporting device comprises a bearing body, an upper bearing bush, a lower bearing bush, housing structures and oil throwing devices, wherein the upper bearing bush and the lower bearing bush are connected. The bearing body is provided with a first penetration hole, the upper bearing bush and the lower bearing bush are arranged in the first penetration hole, a rotation shaft can penetrate through the part between the upper bearing bush and the lower bearing bush, and the bearing body and the upper bearing bush are provided with communication oil inlet holes. The housing structures are arranged on the two sides of the bearing body and matched with the bearing body to form oil cavities, and each oil cavity communicates with an oil outlet hole formed in the bearing body. The oil throwing devices are arranged on the two sides of the upper bearing bush and located in the oil cavities and are connected with the rotation shaft. According to the disclosed bearing supporting device, it is guaranteed that in the rotation shaft running process, fresh lubricating oil with certain pressure constantly lubricates the rotation shaft, the lubricating effect is good, and the rotation shaft bearing capability is improved; and in addition, lubricating oil cooling through cooling water is not needed any more, and the integral structure of the machine is simpler.

Owner:CSSC POWER INST CO LTD

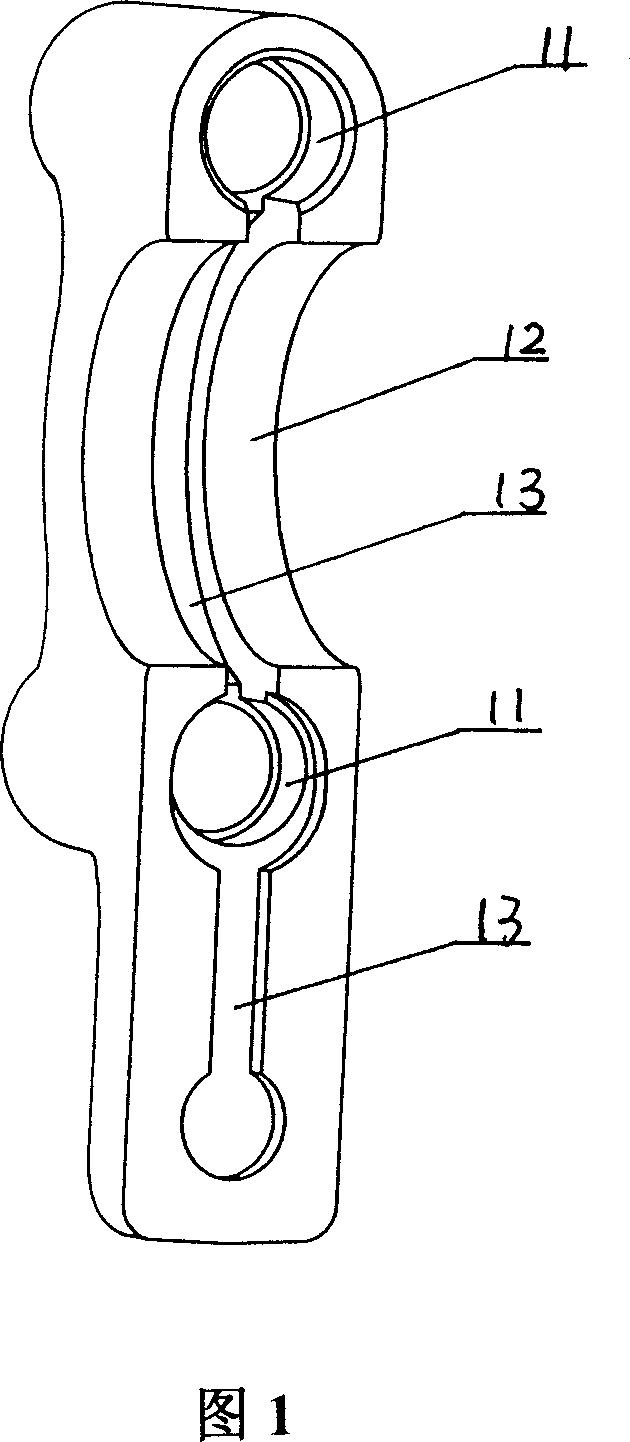

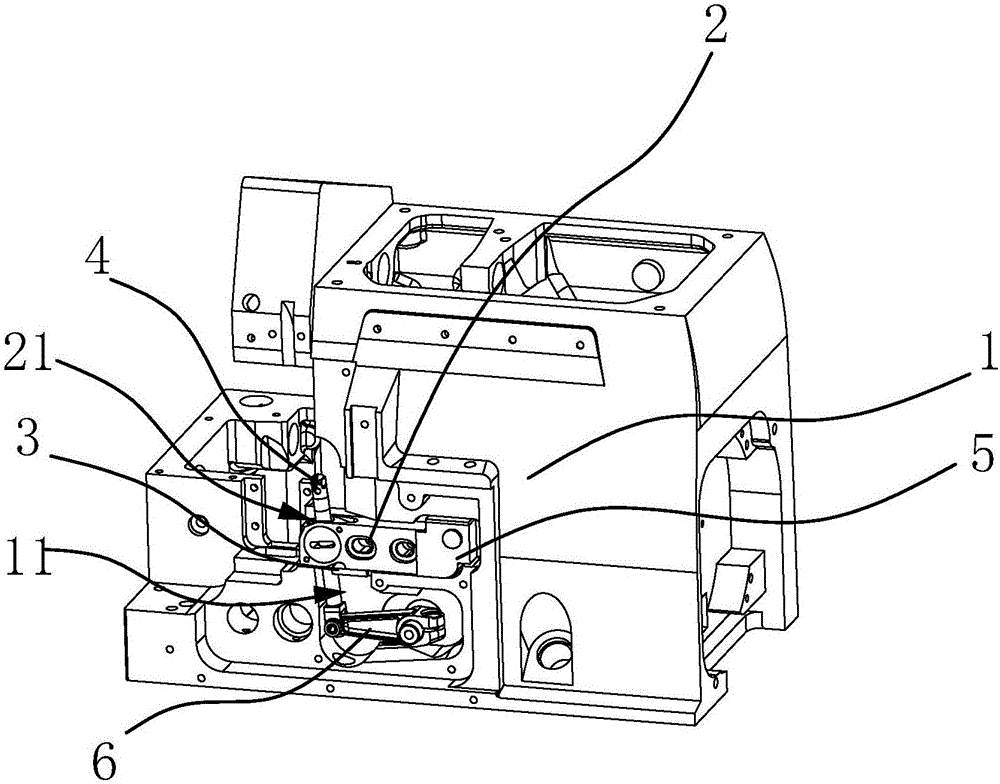

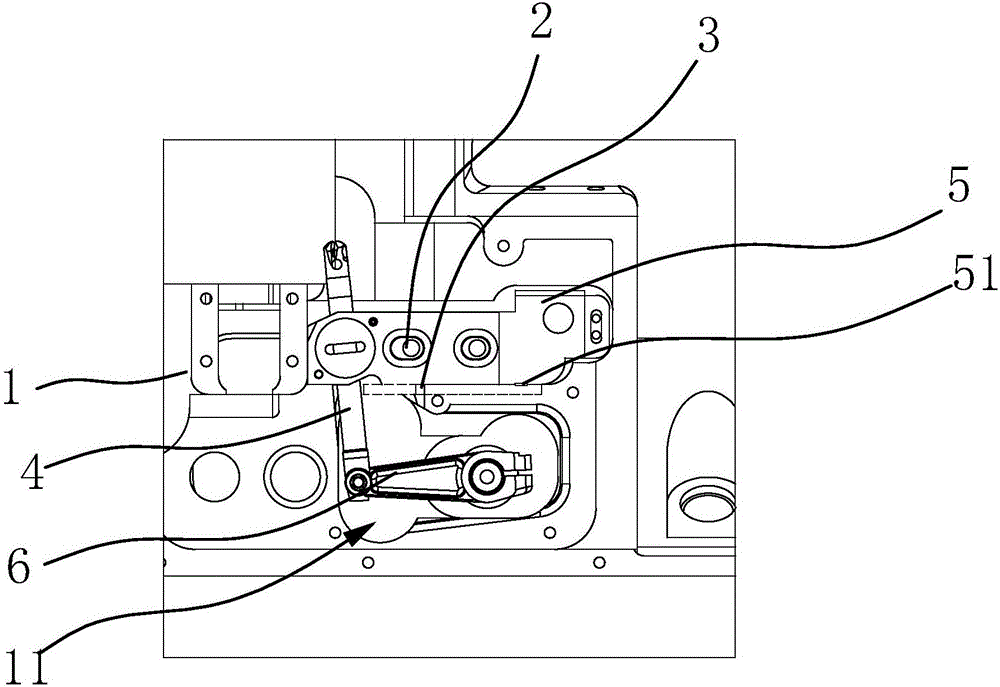

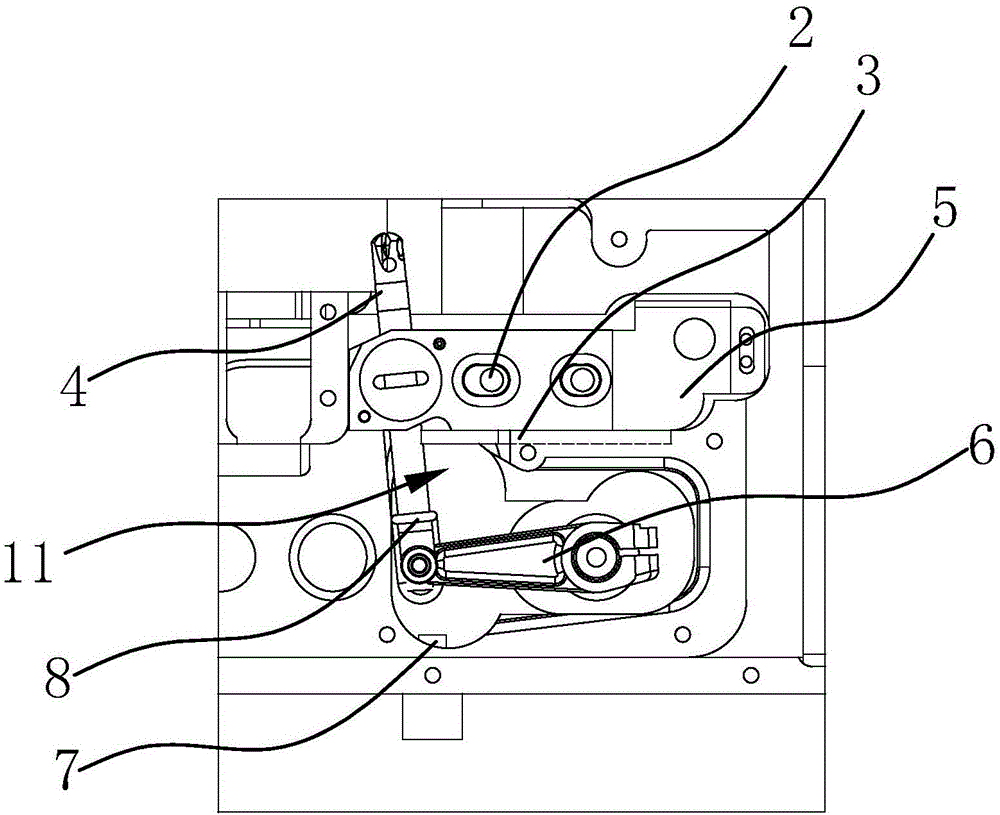

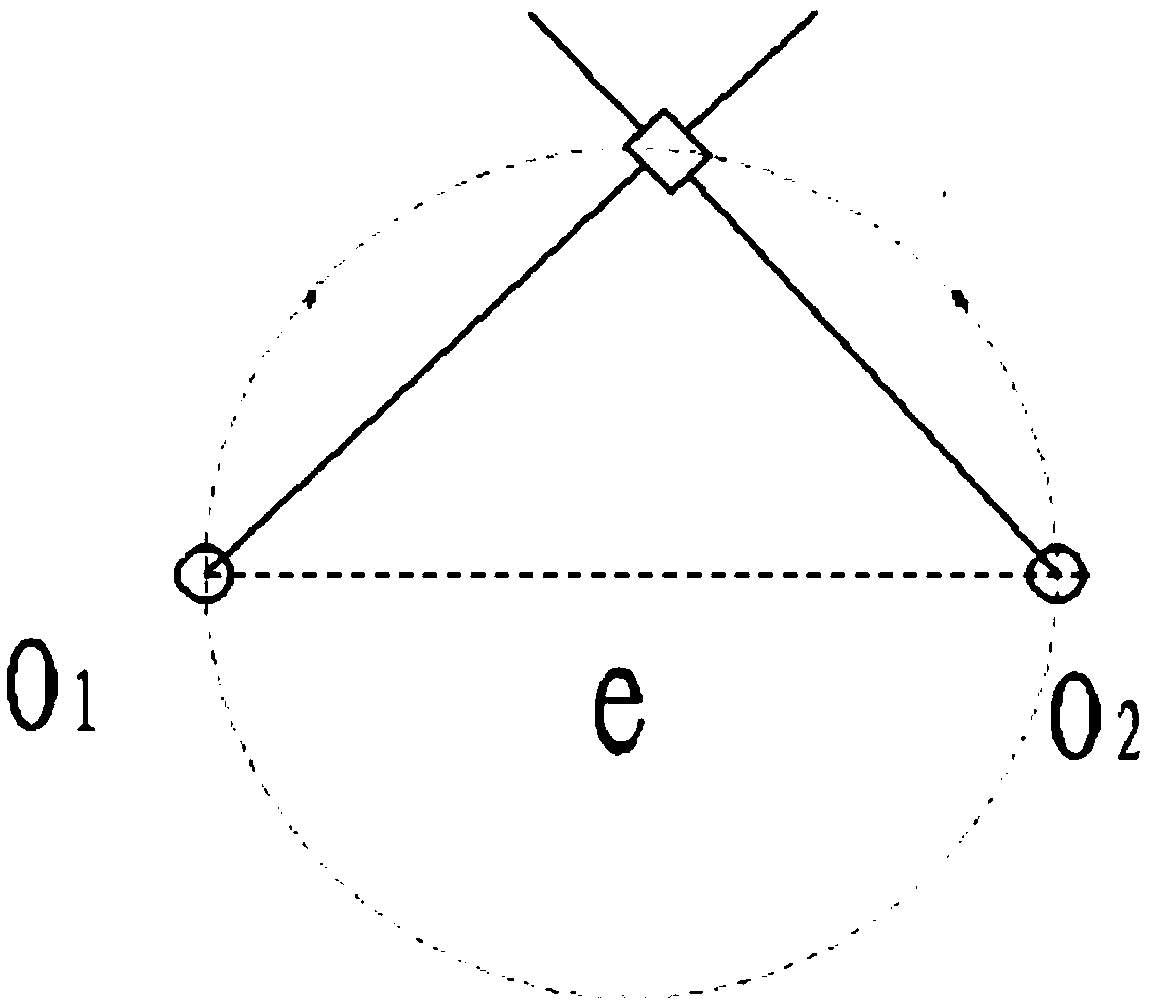

Sewing machine and lubricating structure of curved needle slide bar on sewing machine

InactiveCN106757856AGuaranteed lubrication abilityGood lubrication effectLubrication/cooling devicesLubricationYarn

The invention provides a sewing machine and a lubricating structure of a curved needle slide bar on the sewing machine and belongs to the technical field of sewing equipment. The sewing machine solves the technical problems that lubricating oil on the curved needle slide bar on an existing sewing machine is unlikely to leak and the lubricating effect for a long time is not excellent. The sewing machine comprises a housing, a slide bar and a slide block, wherein a perforated through hole is formed in the slide block, and the slide bar is slidably inserted into the through hole. The lubricating structure comprises an oil storage tank arranged on the housing and an oil immersing piece immersed in oil grease; oil grease is filled with the oil storage tank, and an oil outlet is formed in the bottom of the oil storage tank; and one end of the oil immersing piece is located at the oil outlet of the oil storage tank, and the other end of the oil immersing piece faces the outer peripheral surface of the slide bar. According to the sewing machine provided by the invention, lubrication by liquid lubricating oil is changed to lubrication by grease, so that an oil leakage phenomenon in the slide bar part can be reduced and sewing yarns and sewing materials are prevented from being polluted. Meanwhile, by arranging the oil storage tank, the oil immersing piece can be continuously supplemented with grease, so that the long-term lubricating ability and good lubricating effect of the oil immersing piece are guaranteed.

Owner:JACK SEWING MASCH CO LTD

Partially-fluorinated-alkyl compound, lubricant comprising the compound, and recording medium using the lubricant

InactiveUS6989356B2Good lubricityGood lubrication effectOrganic chemistryProtective coatings for layersChemistryLubricity

To provide a lubricant for recording medium, which is advantageous not only in that it maintains excellent lubricity under various conditions for use and excellent lubricating effect over a long time, but also in that it can impart excellent transport properties and excellent abrasion resistance as well as excellent durability. For example, when C18H37—CH(CH2COOC10H6OH)COORf (wherein Rf represents a saturated or unsaturated partially-fluorinated-alkyl group) is used as a lubricant for magnetic recording medium, there can be obtained a magnetic recording medium having excellent transport properties and excellent abrasion resistance as well as excellent durability.

Owner:SONY CORP

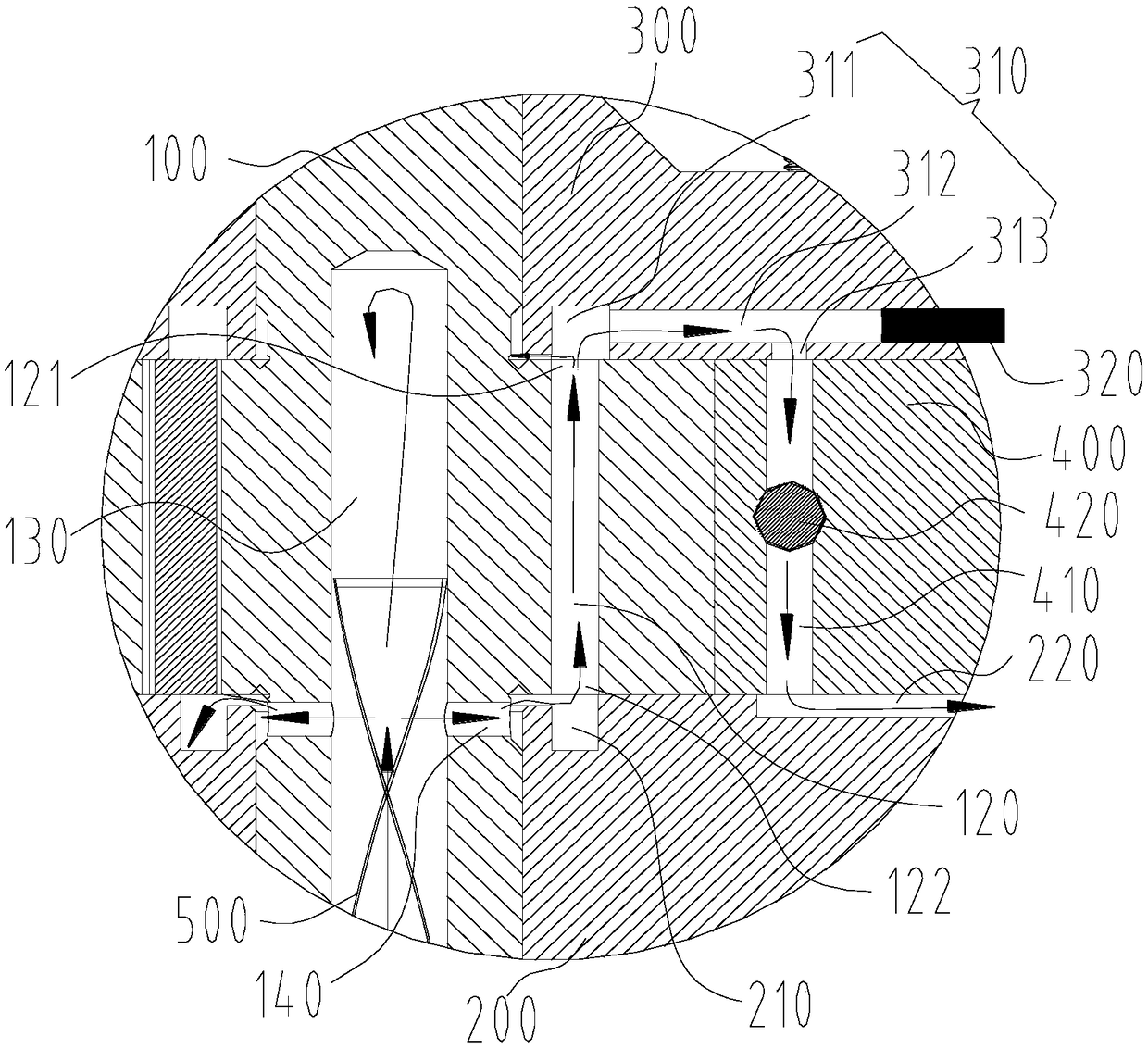

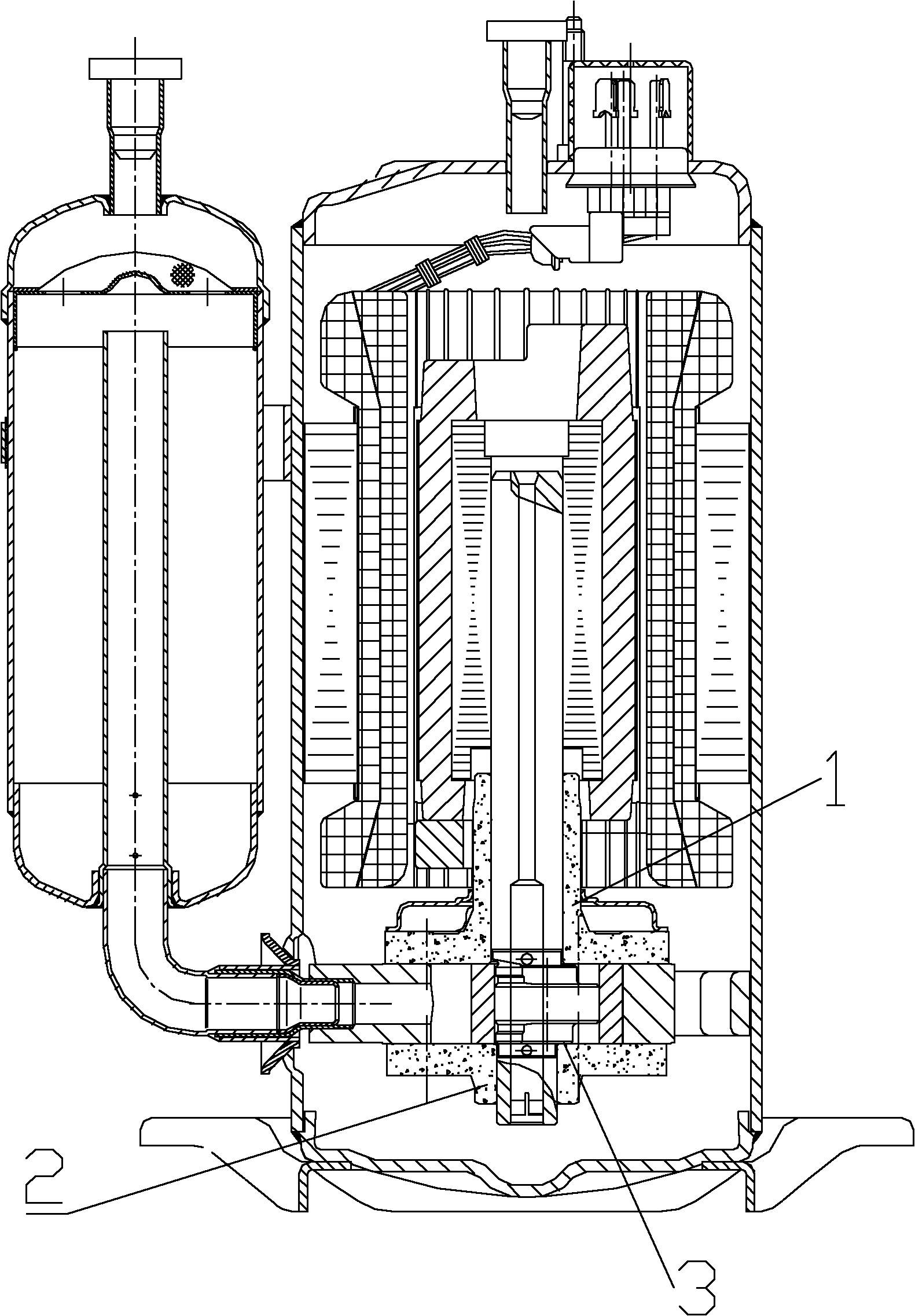

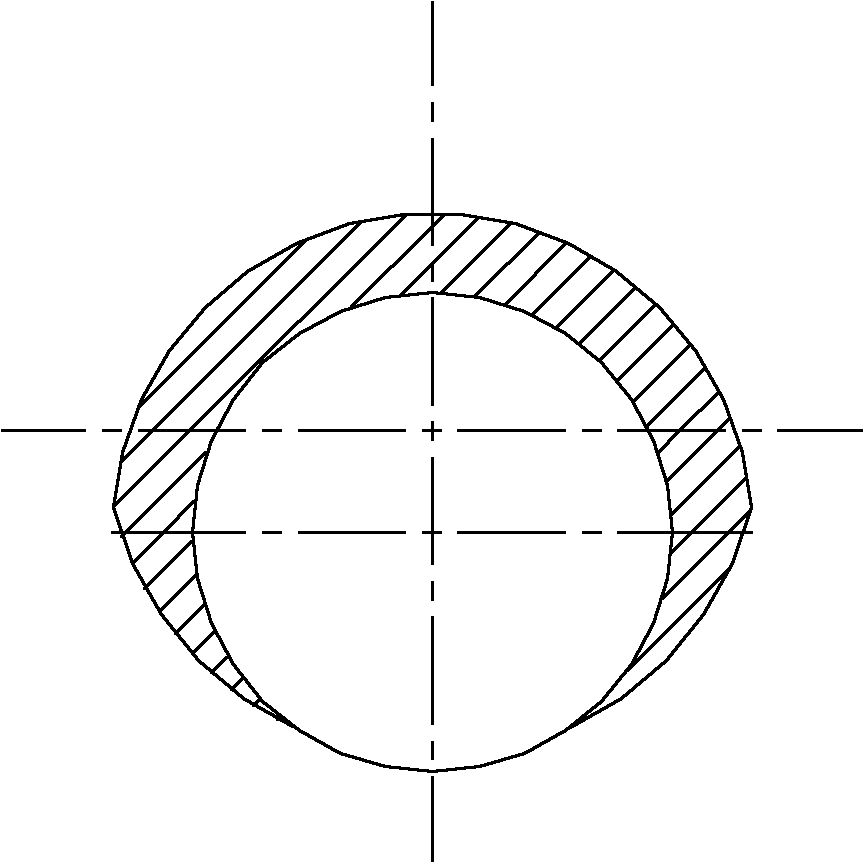

Pump body structure of rotary cylinder piston compressor and rotary cylinder piston compressor

PendingCN109595159AGuaranteed continuityGood lubrication effectRotary piston pumpsRotary piston liquid enginesPistonEngineering

The invention provides a pump body structure of a rotary cylinder piston compressor and the rotary cylinder piston compressor. The pump body structure of the rotary cylinder piston compressor comprises an air cylinder, at least one outer circle matching structure and an oil guide groove, wherein the air cylinder comprises a cylinder body and a convex shaft which extends out outwards from at leastone end of the cylinder body, a rotating shaft mounting hole and at least one oil guide hole are formed in the convex shaft, and the oil guide hole penetrates through the side wall of the convex shaftand communicates with the rotating shaft mounting hole; the at least one outer circle matching structure is arranged at the at least one end of the air cylinder and is provided with a matching hole suitable for allowing the convex shaft to be installed therein, the hole diameter of the matching hole is smaller than the outer diameter of the air cylinder, and the air cylinder rotates relative to the outer circle matching structure; and the oil guide groove is arranged on the hole wall of the matching hole, and extends from the end, facing the cylinder body, of the hole wall of the matching hole to the end, away from the cylinder body, of the hole wall of the matching hole, or, the oil guide groove is arranged on the outer peripheral surface of the convex shaft, and extends from the end, connected with the cylinder body, of the convex shaft to the end, away from the cylinder body, of the convex shaft. According to the pump body structure of the rotary cylinder piston compressor and therotary cylinder piston compressor, lubricating can be performed between the outer peripheral surface of the convex shaft and the hole wall of the matching hole, so that the abrasion between the air cylinder and the outer circle matching structure is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Ultrahigh-temperature-resistant lubricating oil and synthesis method thereof

InactiveCN108048176AGood lubrication effectGood lubrication durabilityLubricant compositionGrapheneBase oil

The invention discloses ultrahigh-temperature-resistant lubricating oil and a synthesis method thereof, and belongs to the field of lubricating oil. The lubricating oil is prepared from, by weight, 120-150 parts of base oil, 2-20 parts of inorganic thickener, 0.1-15 parts of modified graphene and 0.1-10 parts of additive. The lubricating oil has the advantages that phenylmethylsilicone fluid is adopted as the base oil of an ultrahigh-temperature-resistant lubricating agent; through the addition of modified graphene and in coordination with the effect of the inorganic thickener, the viscosity and abrasion resistance of the lubricating oil are adjusted, so that the lubricating oil still remains in a paste shape at 450 DEG C, shows an excellent lubricating effect and has good lubricating durability.

Owner:董小琳

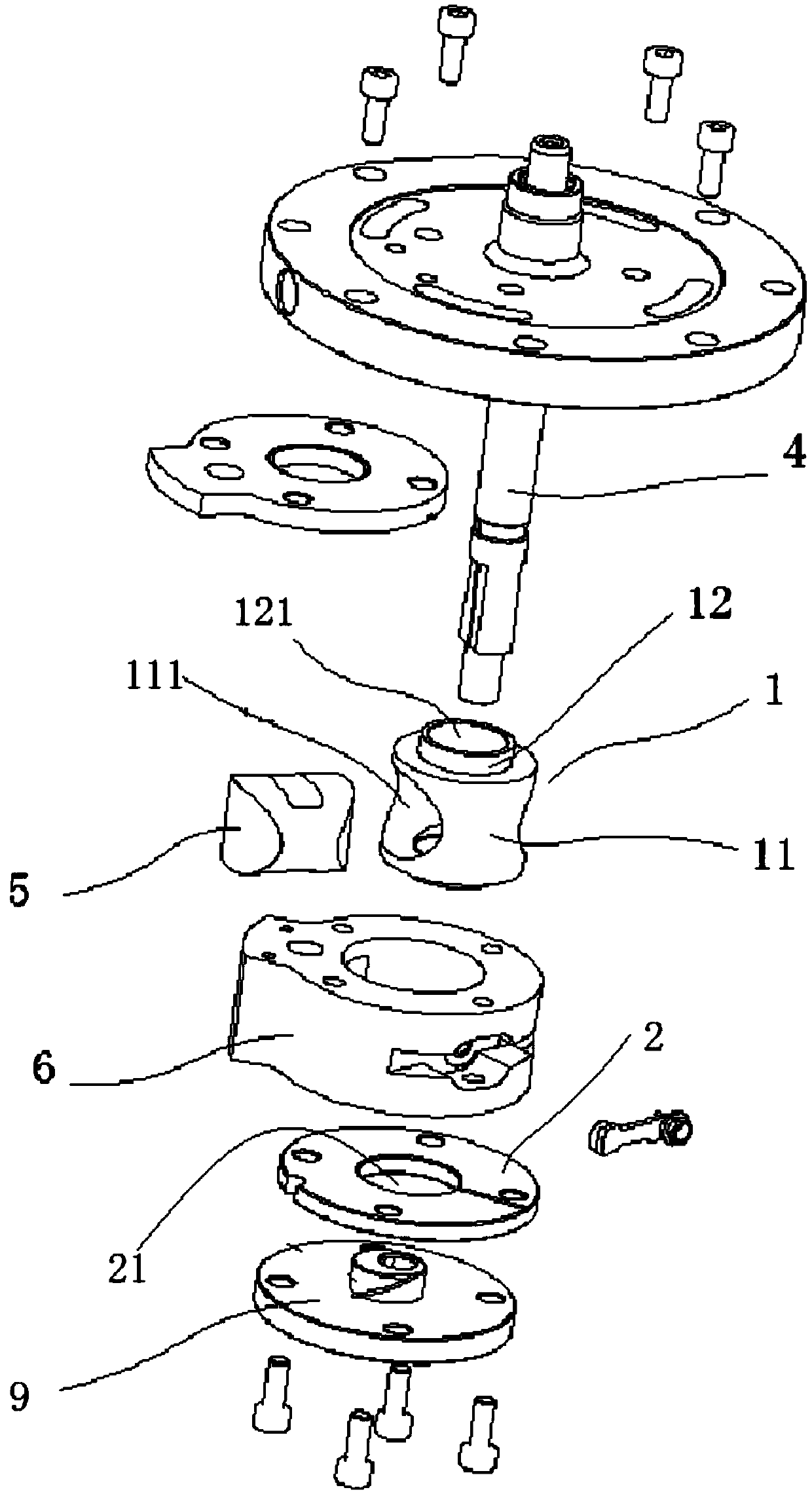

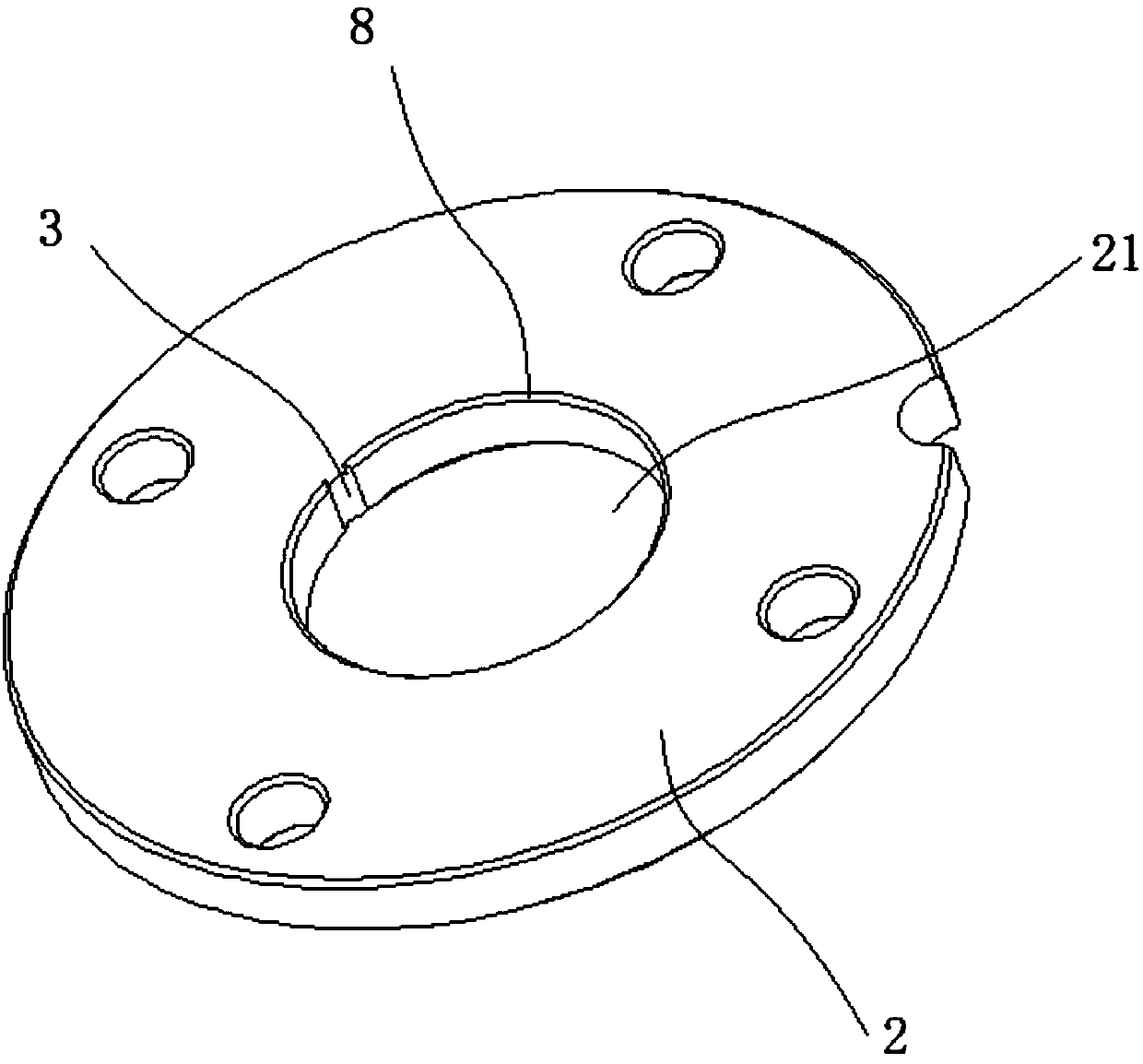

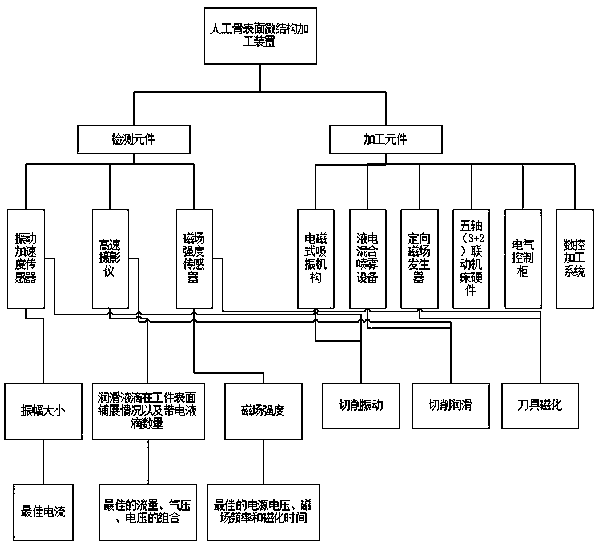

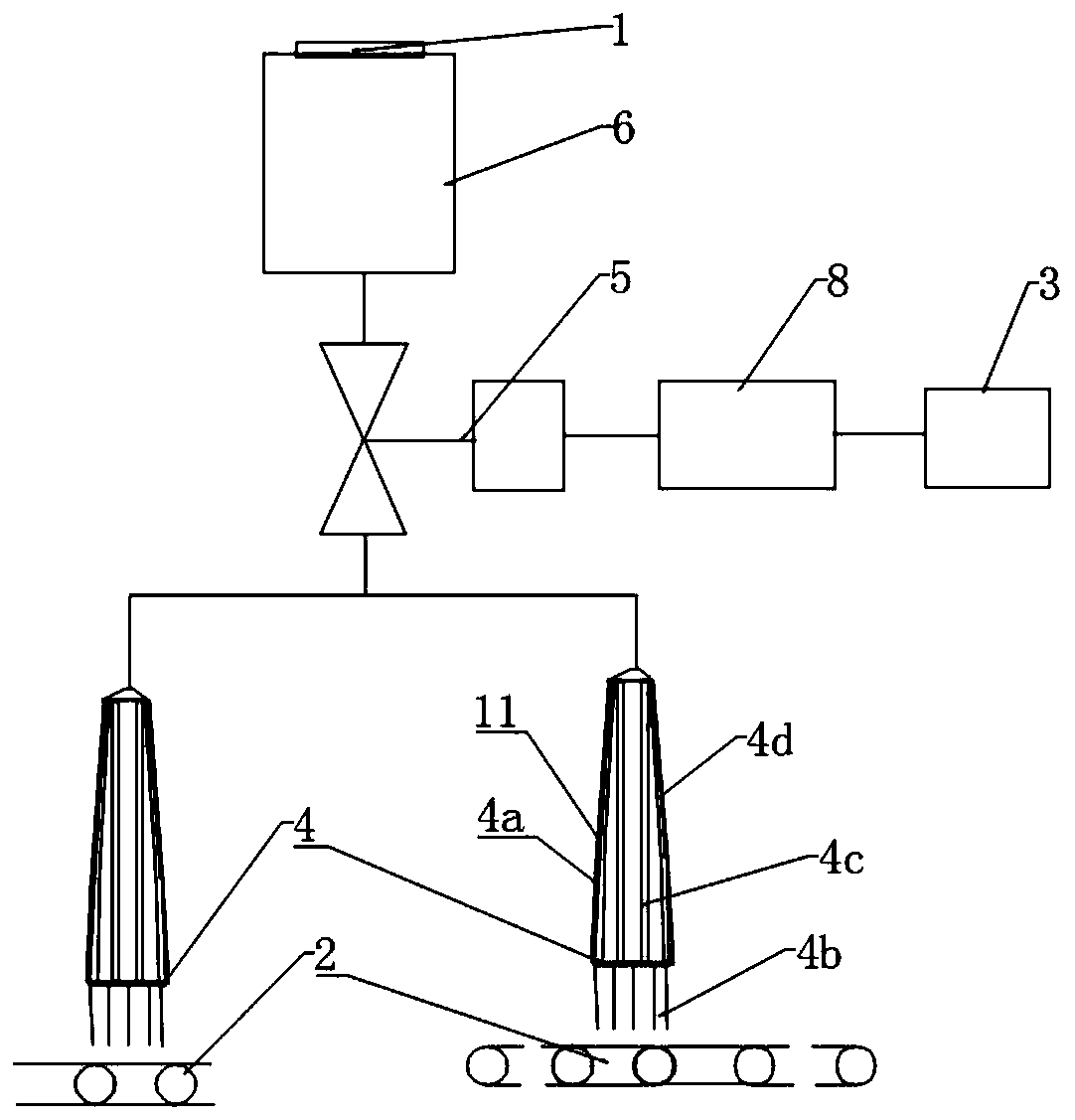

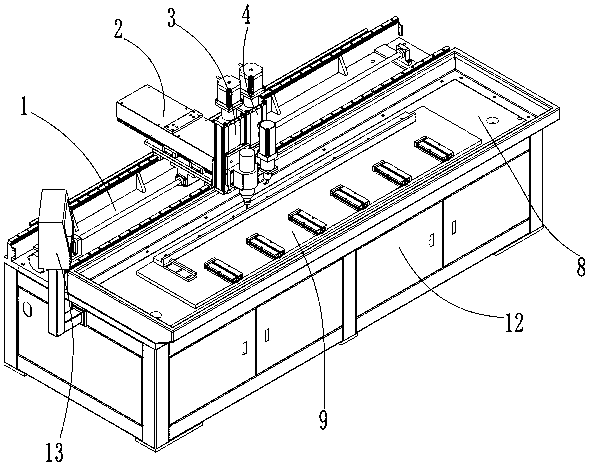

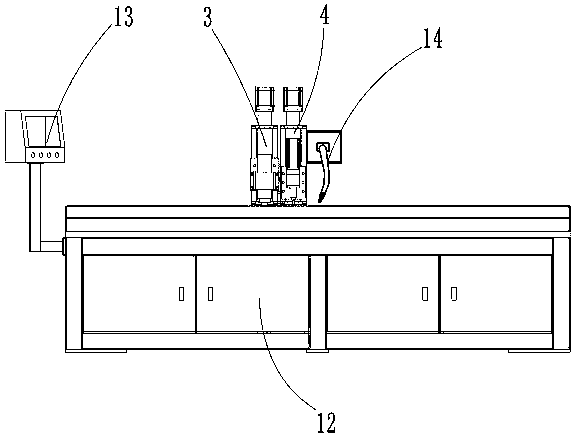

Artificial bone surface function microstructure machining device and machining method

ActiveCN110757092AGood lubrication effectHigh precisionMetal working apparatusMaintainance and safety accessoriesPhysicsSystem development

The invention relates to the technical field of device platforms, in particular to an artificial bone surface function microstructure machining device and method. Hardware of the device comprises double-rotating-table five-axle linkage machine tool hardware, an electromagnetic vibration absorbing structure, hydroelectric mixed spraying equipment, an oriented magnetic field generator, an electric control cabinet and a real-time detecting device; and software develops an artificial bone function module based on a linuxcnc software development platform, and comprises a set of numerical control systems of human-computer interface development, main control system development and motion control system development. The device is applied to the artificial bone surface machining after completion ofdebugging. During artificial bone surface microstructure machining, aiming at the defects on three aspects of related platform vibration, machining lubrication and cutter performance generated in high-speed machining, the electromagnetic vibration absorbing structure, the hydroelectric mixed spraying equipment and the oriented magnetic field generator are used for artificial bone machining experiment research to verify that the device and the machining method can truly improve the artificial bone machining surface quality.

Owner:JIANGSU UNIV OF SCI & TECH

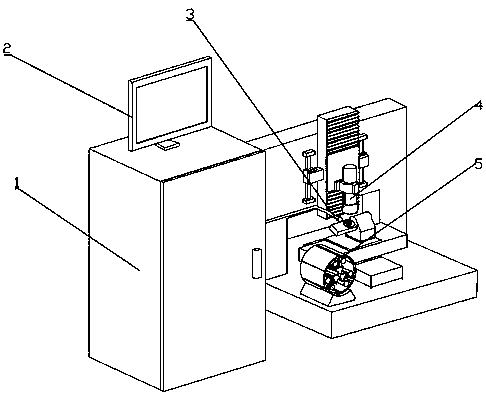

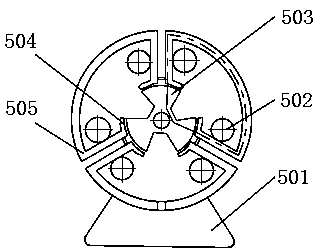

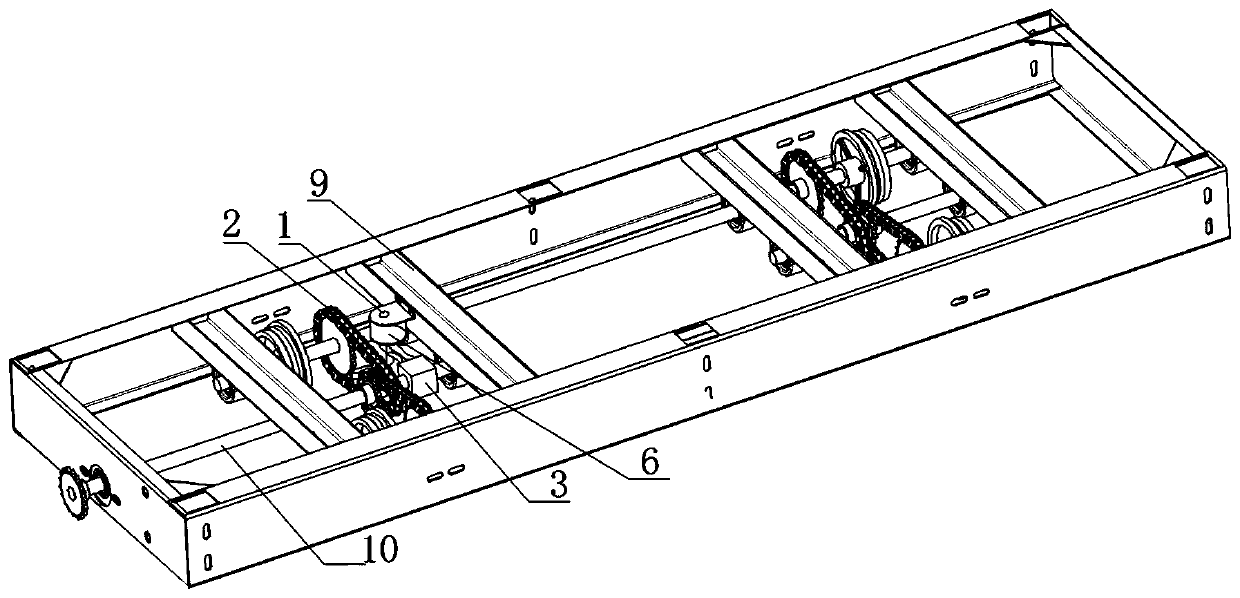

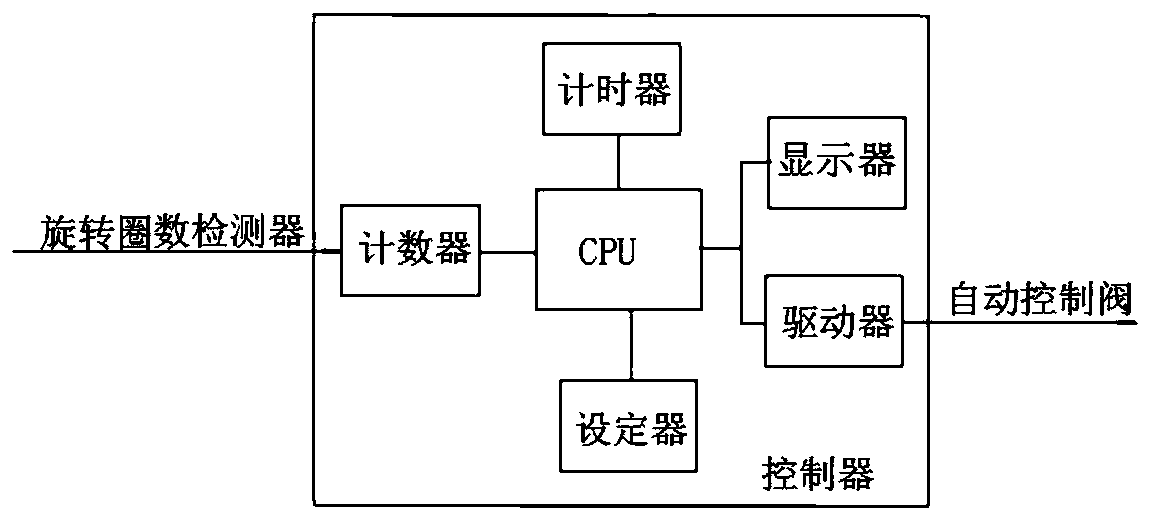

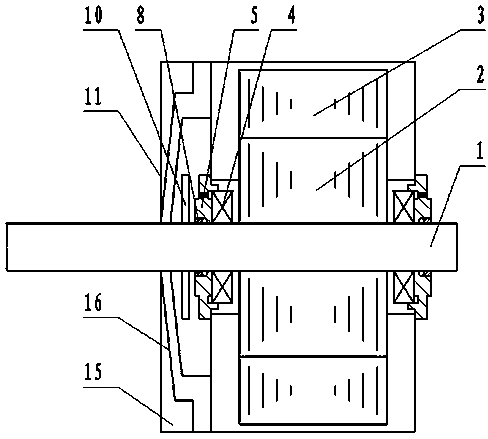

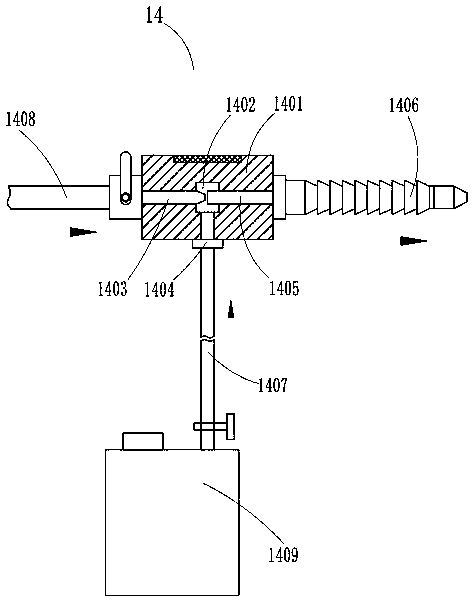

Automatic oil applying and lubricating device for compact shelving underframe chain wheel transmission

PendingCN111140649AVery simple structureGood lubrication effectBook cabinetsGearing detailsAutomatic controlLubrication

The invention discloses an automatic oil applying and lubricating device for compact shelving underframe chain wheel transmission. The device comprises a lubricating oil applying device, the lubricating oil applying device is an automatic oil applying device, the automatic oil applying device comprises a rotation circle number detector connected to a corresponding transmission wheel shaft, an automatic control valve connected to an output port of an oil reservoir, a controller and an oil applicator, wherein the oil applicator is connected to an output port of a valve and corresponds to the corresponding transmission chain and / or chain wheel, and the controller is connected to the rotation circle number detector and the automatic control valve. The automatic oil applying and lubricating device for the compact shelving underframe chain wheel transmission is simple, scientific and reasonable in structural composition and capable of achieving automatic lubrication.

Owner:江西金虎保险设备集团有限公司

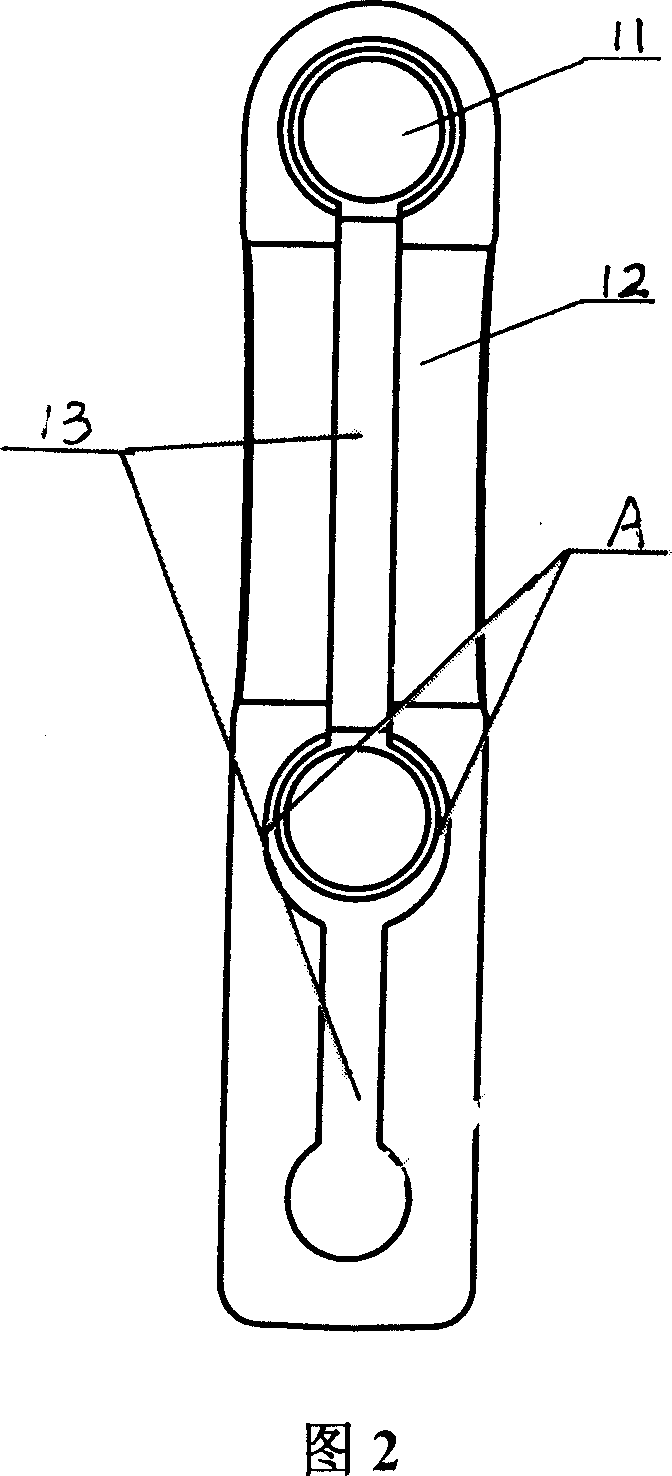

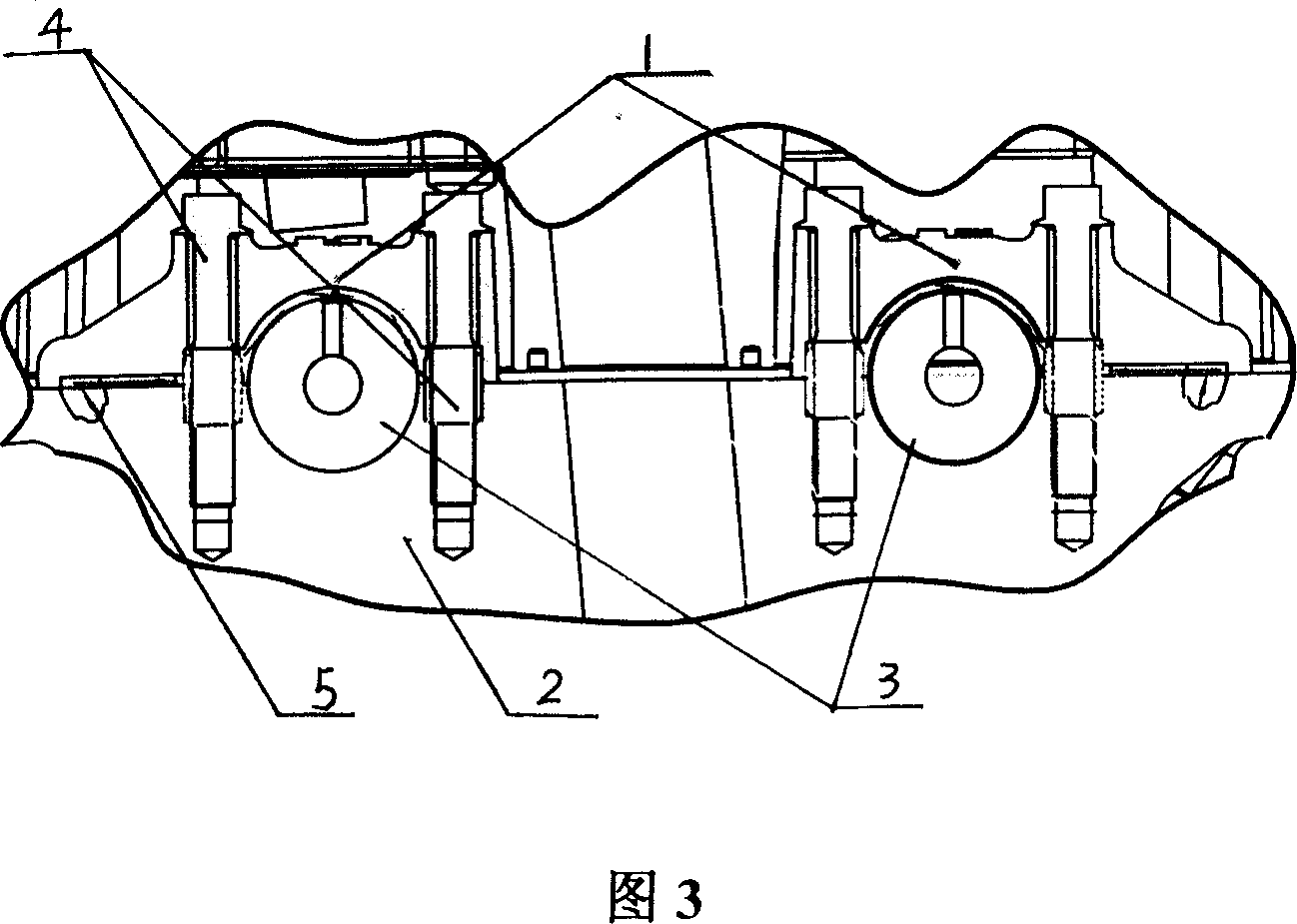

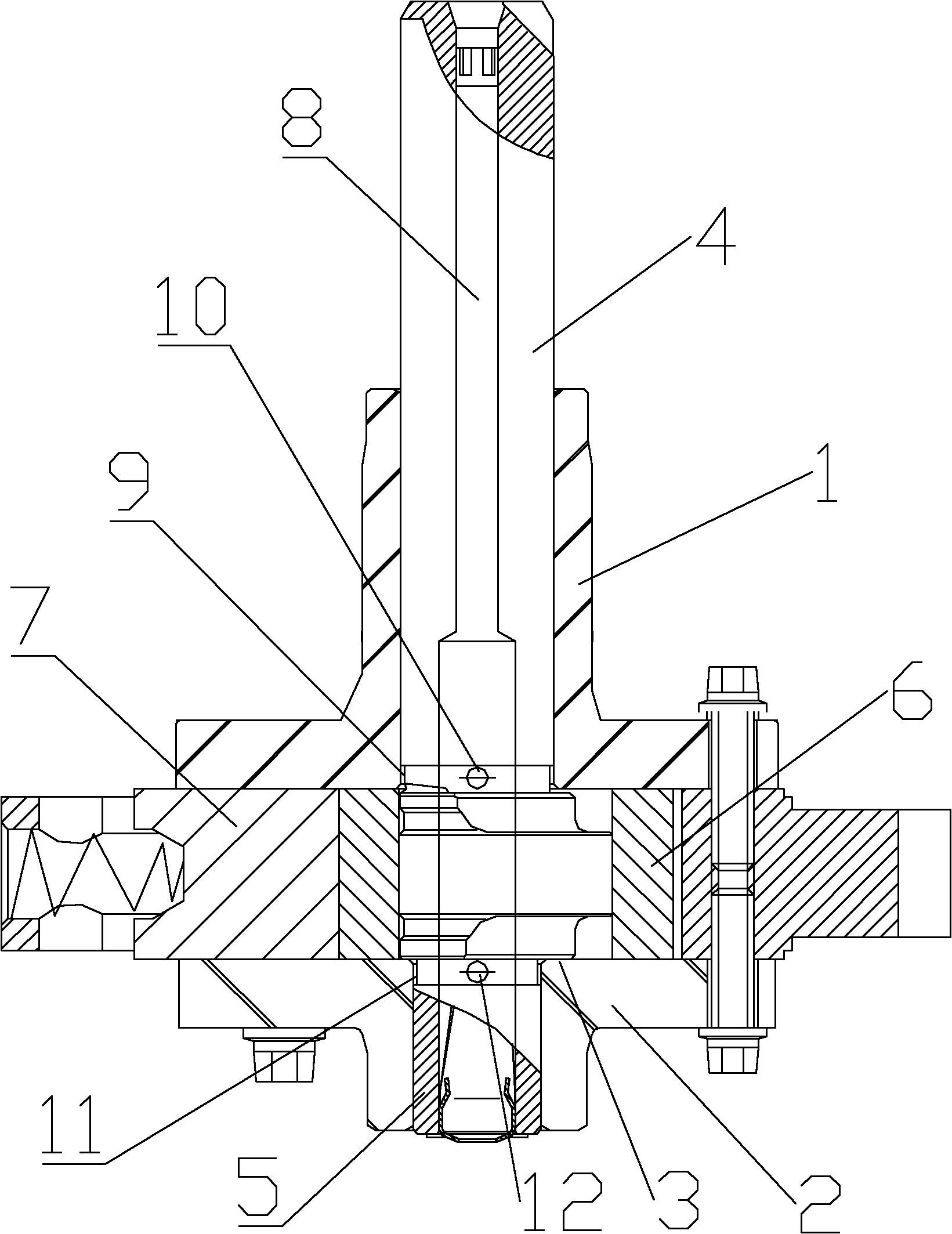

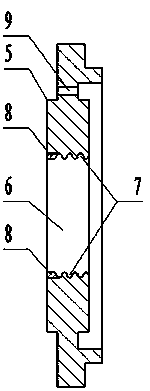

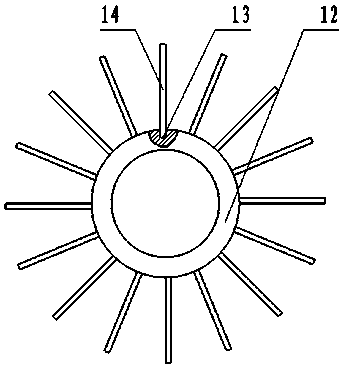

Durable washing machine motor

InactiveCN104269957AGood oil storage functionGood lubrication effectCooling/ventillation arrangementSupports/enclosures/casingsPhysicsElectric machinery

The invention discloses a durable washing machine motor which comprises a rotating shaft (1), rotors (2) and stators (3). The positions, on the two sides of the rotors (2), of the rotating shaft are symmetrically provided with bearings (4) and bearing end covers (5) in a sleeved mode. Shaft holes (6) are formed in the bearing end covers (5), the hole walls of the shaft holes (6) are provided with wave-shaped oil storage grooves (7), one sides of the oil storage grooves are provided with rubber sealing rings (8), and oil conveying holes (9) are formed above the oil storage grooves (7). The left sides of the bearing end covers (5) on the left sides of the rotors (2) are sequentially provided with heat dissipation devices (10) and outer end covers (11). The heat dissipation devices (10) comprise shaft sleeves (12), the outer peripheries of the shaft sleeves (12) are provided with a plurality of evenly-distributed mounting grooves (13), and heat dissipation pieces (14) are arranged on the mounting grooves (13). In this way, the durable washing machine motor has the advantages that the bearing end covers are not prone to abrasion, and the heat dissipation effect is good; besides the motor is prevented from being damped, and durability is enhanced greatly.

Owner:HUZHOU NANYANG ELECTRIC MOTOR

Sleeve assembly

InactiveCN104500572AGood wear resistance lubrication and strength propertiesGood lubrication effectBearing componentsSliding contact bearingsLubricationWear resistant

The invention discloses a sleeve assembly, which comprises a sleeve body and a core shaft; a through hole through which the core shaft can pass is formed in the middle of the sleeve body; an annular graphite layer is arranged on the inner wall of the through hole; and a groove is formed in the annular graphite layer along the axial direction. According to the sleeve assembly disclosed by the invention, one one hand, the annular graphite layer has the good wear-resistant, lubrication and strength properties and has the good lubrication effect, on the other hand, a lubricating agent / oil is added into the sleeve body and can be stored in the groove for a long time; when the sleeve body and the core shaft are used in a matched manner, the lubrication effect is further enhanced, so that the mutual abrasion is greatly reduced, and the service life is prolonged.

Owner:昆山旭祥钣金工业有限公司

Automatic drilling and tapping device and method

InactiveCN108526897AGood lubrication effectImprove surface qualityOther manufacturing equipments/toolsLarge fixed membersEngineeringMachining

The invention discloses automatic machining equipment and provides an automatic drilling and tapping device. The automatic drilling and tapping device comprises an operating area mounting platform anda five-axis linkage mechanism used for mounting machining equipment. The operating area mounting platform is provided with a locating mounting part for locating a product to be machined. The five-axis linkage mechanism comprises a transverse moving module and a longitudinal moving module which are connected in a matched mode. The transverse moving module is fixed to the operating area mounting platform. The longitudinal moving module is provided with two vertical modules including the first vertical module and the second vertical module. A steering mechanism is arranged on one vertical module. The automatic drilling and tapping device conducts locating on the product to be machined through the log mounting part, drives the machining equipment to do high-precision motion in an operating area through the five-axis linkage mechanism, provides a long travel and greatly improves the machining precision and machining efficiency.

Owner:CHENGDU FUYU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com