Artificial bone surface function microstructure machining device and machining method

A processing device and microstructure technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of no onlooker processing, artificial bone microstructure processing defects, etc., and achieve the effect of good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

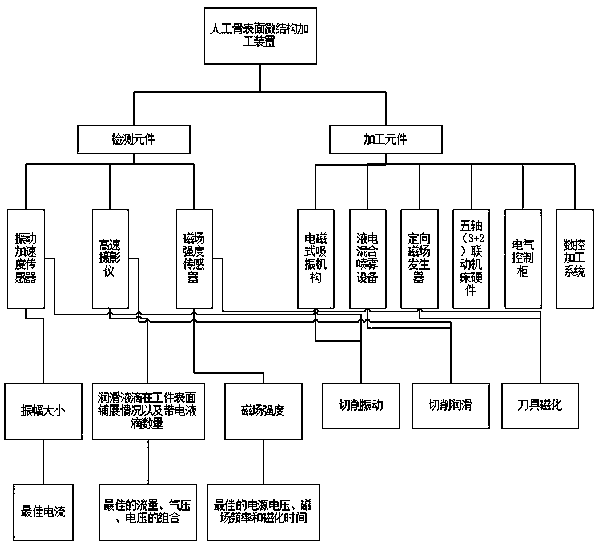

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

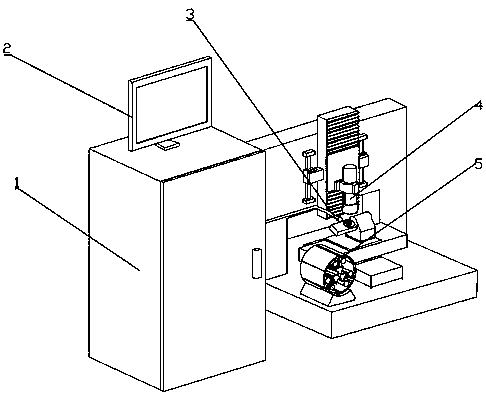

[0042] Example: such as Figure 1 to Figure 5 As shown, the present invention is an artificial bone surface functional microstructure processing device. figure 1 It includes a motor cabinet 1, a computer 2, a liquid-electric hybrid spraying device 3, a directional magnetic field generator 4, and an electromagnetic vibration absorber 5. The nozzle of the hydraulic-electric hybrid spraying device 3 extends into a position about 20 mm away from the workpiece processing surface through a hose. The directional magnetic field generator 4 is clamped on the Z axis by way of interference fit. The electromagnetic vibration absorbing mechanism 5 is connected on the plane of the platform by 4 bolts, adopts double nut anti-loosening method, and tightens anti-loosening through one nut left-handed and one right-handed nut.

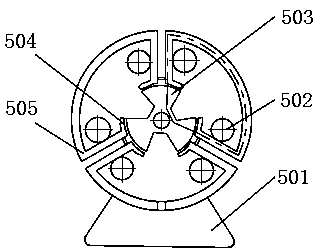

[0043] In this embodiment, the electromagnetic vibration absorbing mechanism includes a base 501 , a coil 502 , a rotor 503 , a stator 504 , and a magnetic conduction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com