Automatic oil applying and lubricating device for compact shelving underframe chain wheel transmission

A sprocket transmission and oil lubrication technology, applied in the field of compact racks, can solve the problems of high transmission noise, easy mopping, forgetting lubrication, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

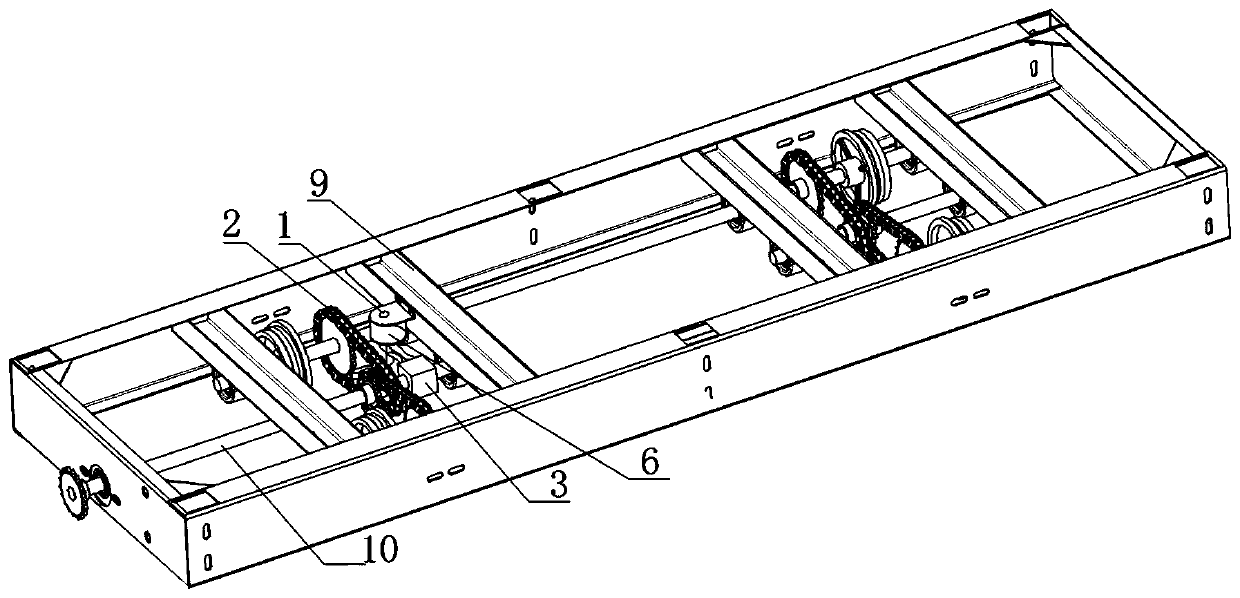

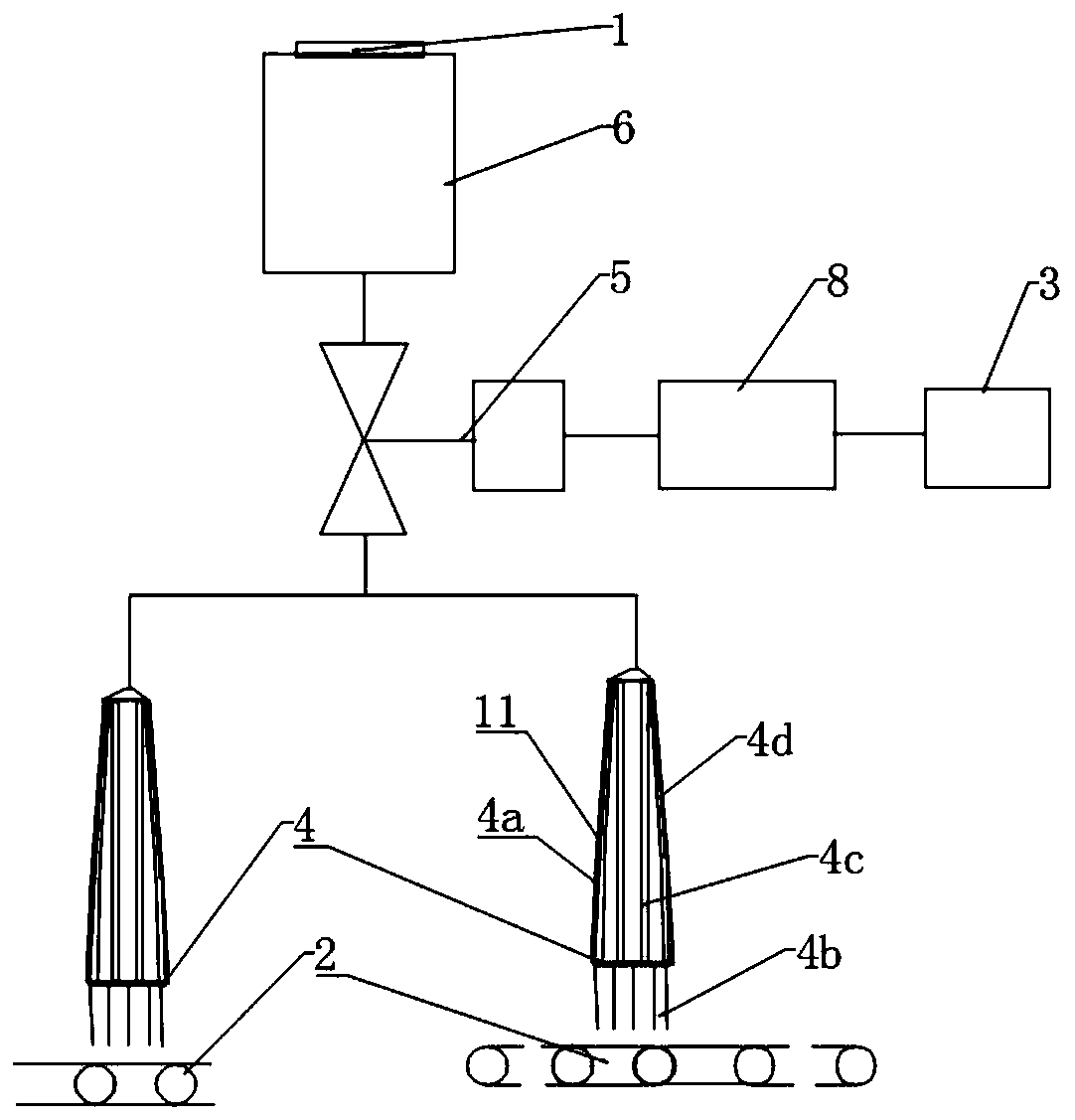

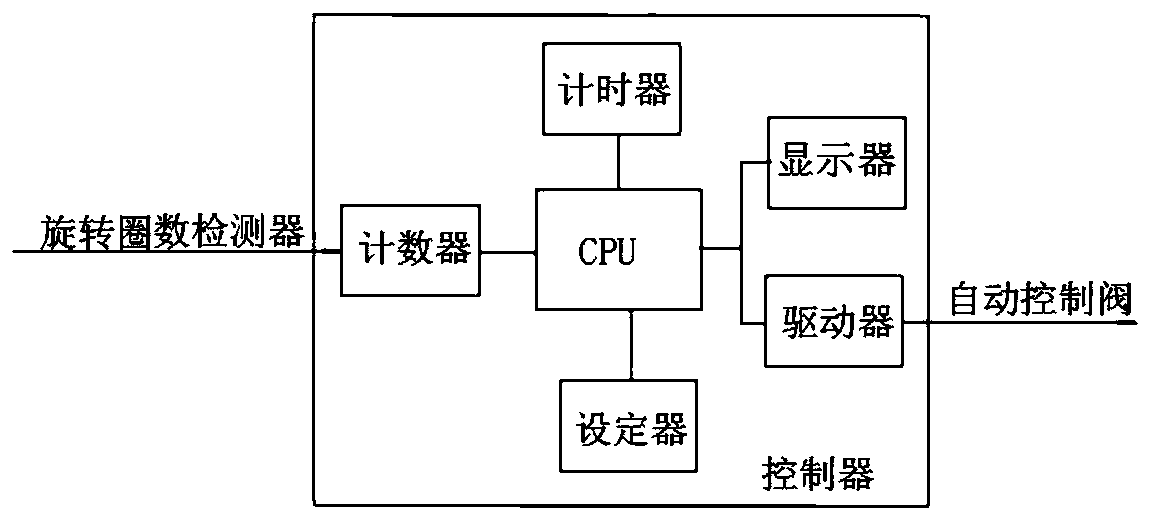

[0010] In order to further understand the technical solution of the present invention, the present invention will be further described through the following examples in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, the automatic oiling and lubricating device for sprocket drive of the underframe of the dense rack in this example includes an oil reservoir 6 arranged on the underframe 9 of the dense rack, a detector for the number of rotations 3, an oiling brush 4, an automatic control stop valve 5, And corresponding controller 8 etc.

[0011] The input port of the automatic control shut-off valve 5 is connected to the lower output port of the oil reservoir, and the output port of the automatic control shut-off valve 5 is connected with a plurality of oiling brushes 4 through a multi-way conversion joint.

[0012] The oiling brush 4 includes an oil supply brush handle 4a, which is connected to the bristles 4b on the bottom wall of the oil supply brush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com