Automatic drilling and tapping device and method

A tapping device and automatic technology, applied to other manufacturing equipment/tools, large fixed members, metal processing machinery parts, etc., can solve the problems of limited travel of processing equipment, low processing accuracy, low efficiency, etc., to improve processing accuracy and processing efficiency, improve surface quality, and good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

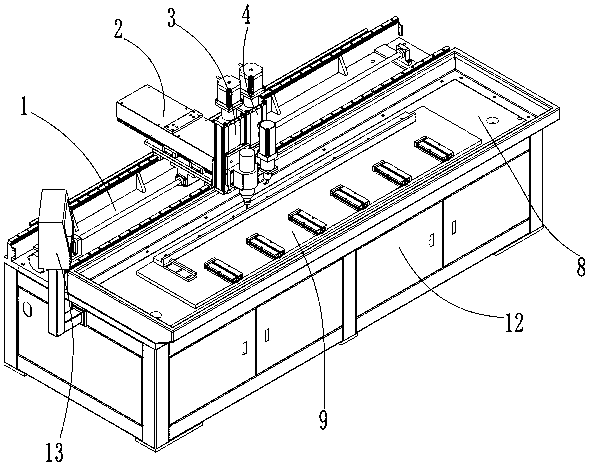

[0047] Such as Figure 1 to Figure 9 As shown, the automatic drilling and tapping device of this embodiment is used for processing the connection holes on the module grooves made of aluminum profiles. Since the module grooves are provided with a plurality of continuous connection holes, drilling and tapping are required. Tapping processing, so the traditional processing method has the disadvantages of low processing efficiency and poor processing accuracy.

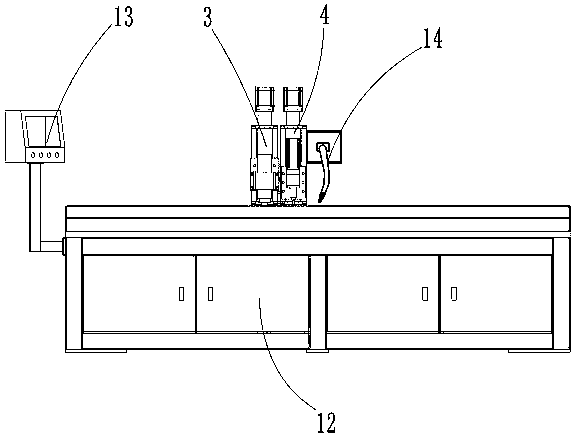

[0048] The automatic drilling and tapping device of this embodiment includes a work area installation platform 8 and a five-axis linkage mechanism for installing processing equipment. The operation area installation platform 8 is provided with a positioning installation part 9 for locating the product to be processed. The five-axis linkage mechanism includes a lateral movement module 1 and a longitudinal movement module 2 that are mutually matched and connected. The modules are respectively the first vertical module 3 and...

Embodiment 2

[0052] Such as Figure 1 to Figure 9 As shown, according to the automatic drilling and tapping device described in Embodiment 1, a two-way sliding seat 10 is provided between the lateral movement module 1 and the longitudinal movement module 2, and the two-way sliding seat 10 includes a horizontal movement module. The horizontal guide part that cooperates with group 1, and the longitudinal guide part that cooperates with the vertical movement module 2. The connection and coordination of the lateral movement module and the vertical movement module are completed by the two-way sliding seat, and the two-way sliding seat is respectively equipped with a transverse guide part and a longitudinal guide part, which respectively adapt to the movement requirements of the horizontal movement module and the longitudinal movement module, and realizes the replacement. to move.

[0053] Further, the transverse guide part includes a slide plate 1002, two rows of transverse guide blocks 1001 a...

Embodiment 3

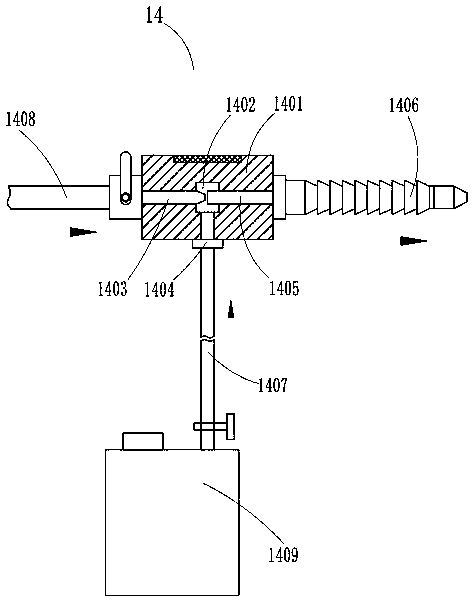

[0060] Such as Figure 1 to Figure 9 As shown, according to the automatic drilling and tapping device described in embodiment 1 or 2, the automatic drilling and tapping device of this embodiment is also equipped with a cooling mechanism 14, and the cooling mechanism 14 includes a cooling system with a mixing chamber 1402 The coolant mixture 1401, the coolant mixture 1401 is respectively provided with an air inlet hole 1403 and an oil inlet hole communicating with the mixing chamber 1402, and is also provided with a coolant outlet hole 1405 communicating with the mixing chamber 1402, in the coolant mixture 1401 A spray pipe 1406 communicated with a coolant outlet hole 1405 is arranged on the outside.

[0061] Such as image 3 As shown, an oil storage tank 1409 and an oil inlet pipe 1407 are arranged outside the oil inlet hole, and an oil inlet joint 1404 is arranged, and an air inlet pipe 1408 is arranged outside the air inlet hole 1403 .

[0062] The oil inlet hole in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com