Sleeve assembly

A sleeve and assembly technology, applied in bearing components, engine components, sliding contact bearings, etc., can solve the problems of wear of the sleeve body and the mandrel, shortened service life, etc., to achieve good lubrication effect, reduce wear, and enhance lubrication effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

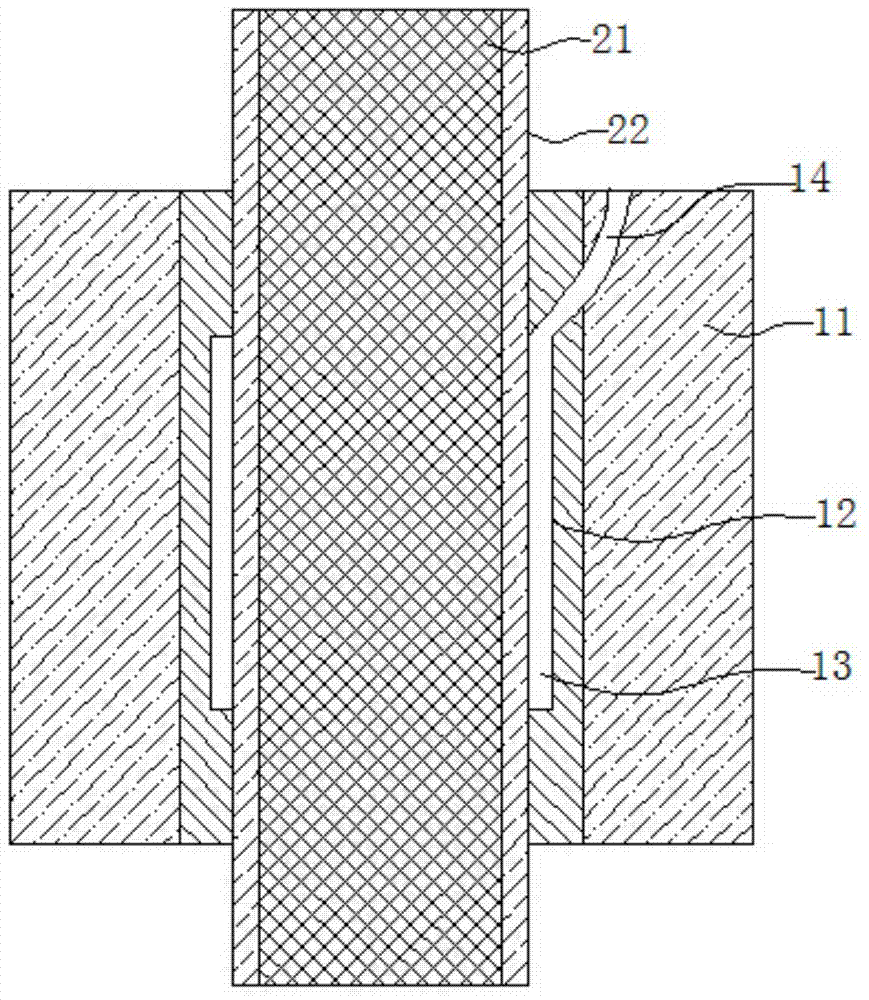

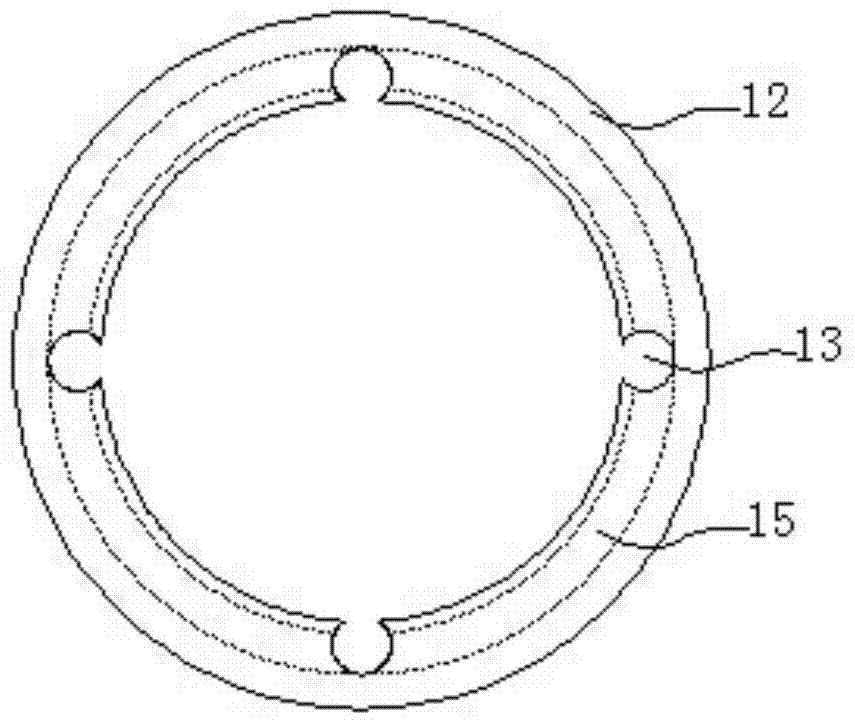

[0020] see Figure 1~2 , the sleeve assembly of the present embodiment includes a sleeve body 11 and a mandrel 21, the middle part of the sleeve body 11 is provided with a through hole for the mandrel 21 to pass through, the inner wall of the through hole is provided with an annular graphite layer 12, and the annular graphite The layer 12 is provided with grooves 13 along the axial direction, the number of grooves 13 is 4-6, and the annular graphite layer 12 is provided with an annular passage 15 passing through the grooves 13 along the radial direction.

[0021] Graphite has the advantages of high strength, wear-resistant lubrication, good thermal shock resistance, and easy precision machining. It is an ideal inorganic non-metallic material. The sleeve assembly of the present invention, on the one hand, the annular graphite layer 12 has good wear-resistant lubricat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com