Forced lubrication device for water tank wire drawing and use method of device

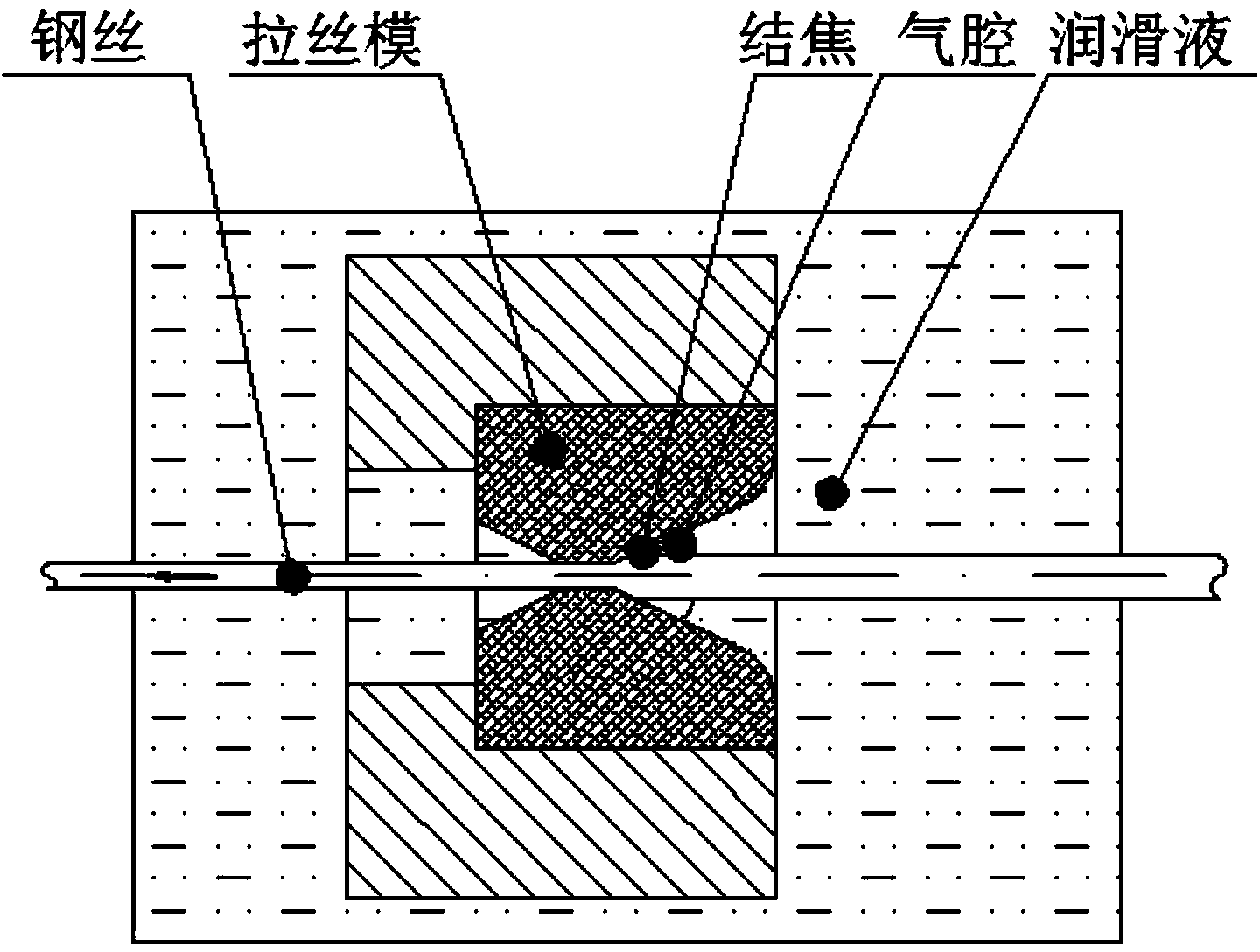

A technology of forced lubrication and water tank drawing, applied in the direction of wire drawing dies, etc., can solve the problems of hindering the lubrication effect, the slag is not easy to discharge, and the influence of the surface quality of the steel wire, so as to achieve the effect of low production cost, good lubrication effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

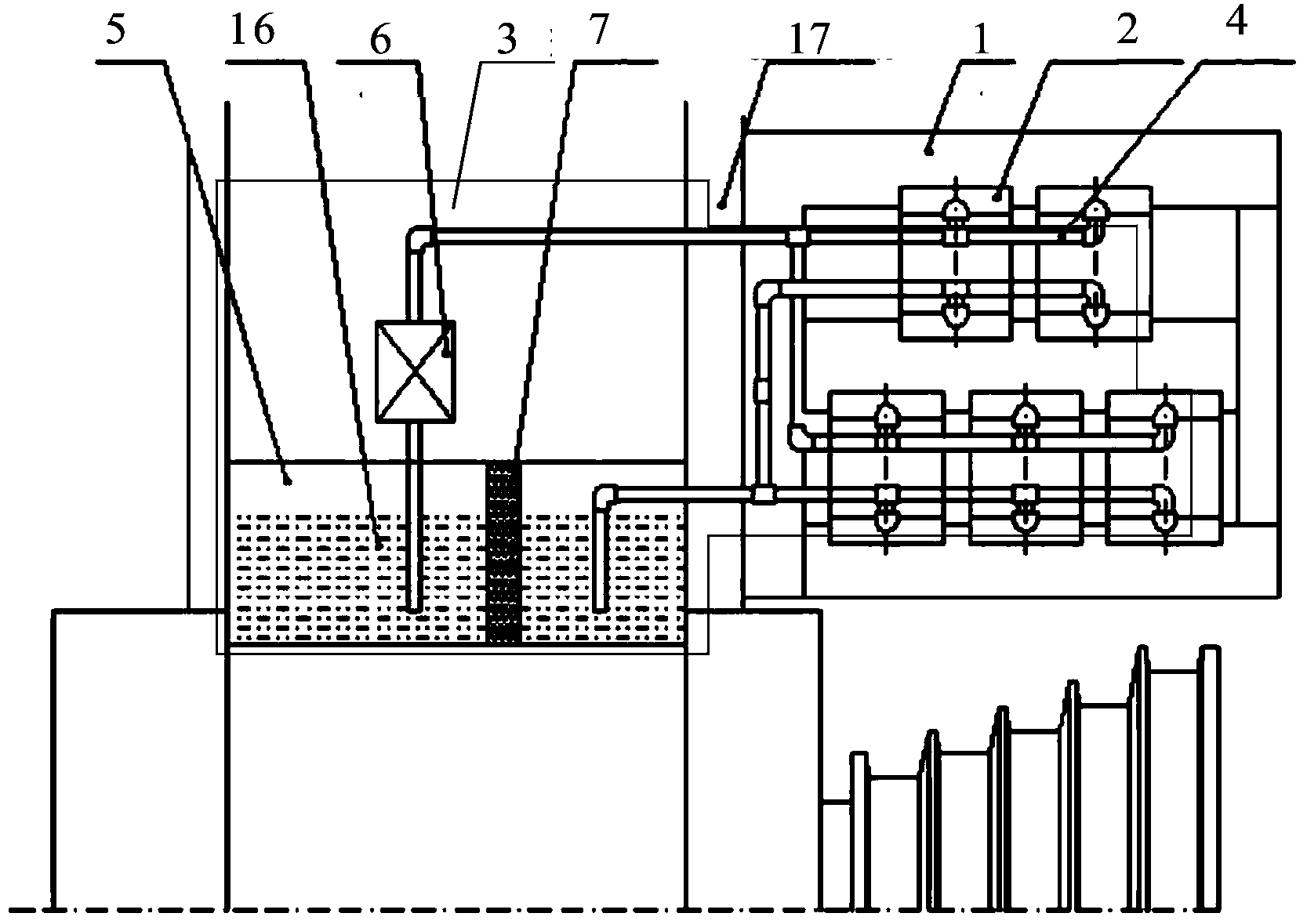

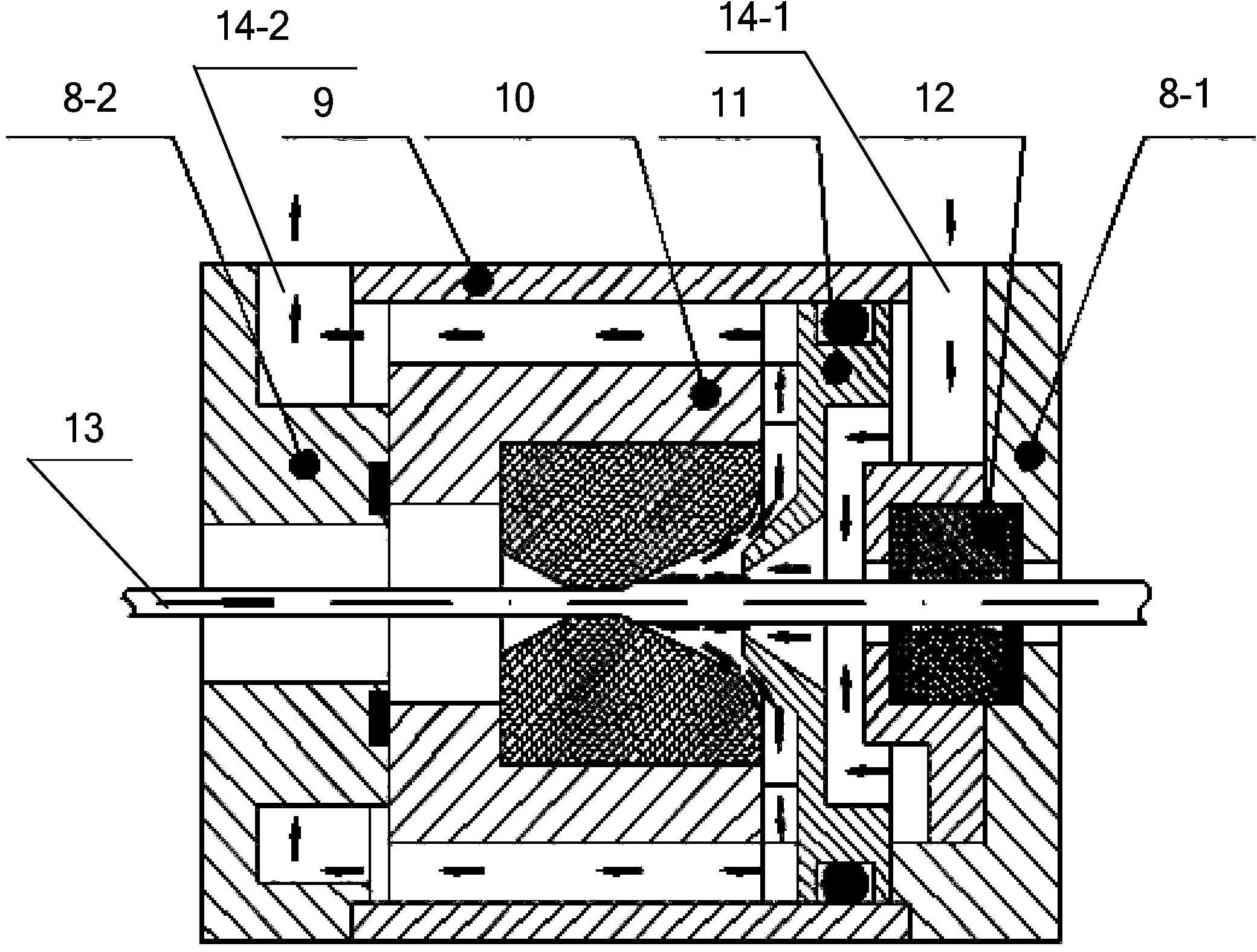

[0036] Such as figure 2 As shown, a forced lubricating device for wire drawing of a water tank includes a formwork 1, a forced lubricating device 2 and a forced circulation device 3. The formwork 1 is provided with multiple drawing passes, and the forced lubricating device 2 is arranged on the side of the formwork 1. On the drawing pass, and the number of drawing passes matches the forced lubrication device 2; the forced circulation device 3 includes a circulation pipeline 4, a circulation pool 5 and a filter device 7; the forced lubrication device 2 passes through the circulation pipeline 4 and the circulation pool 5 phases are connected; lubricating liquid is added in the circulation pool 5, and a filter device 7 is installed at the same time, and the filter device 7 separates the circulation pool 5; it is used to filter impurities in the lubricating liquid flowing out o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com