Integrated radiating base plate and making method thereof

A technology for heat-dissipating substrates and metal substrates, which is used in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

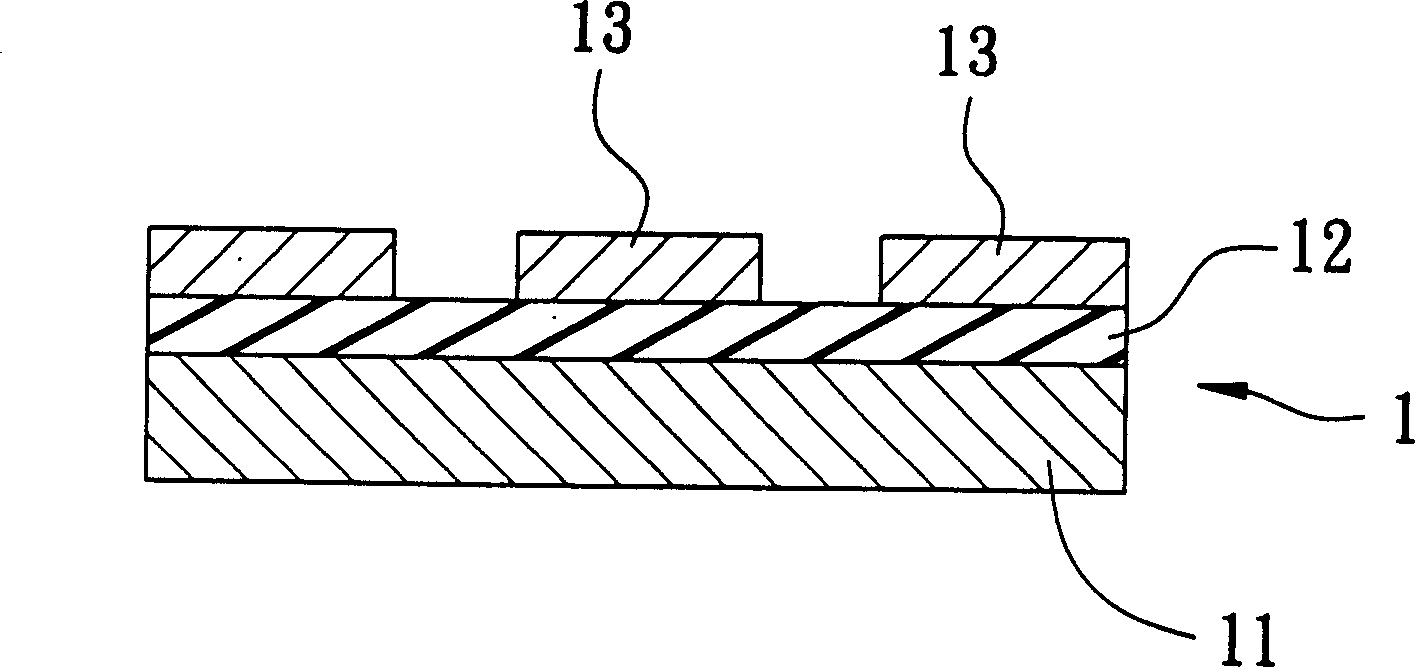

Embodiment 1

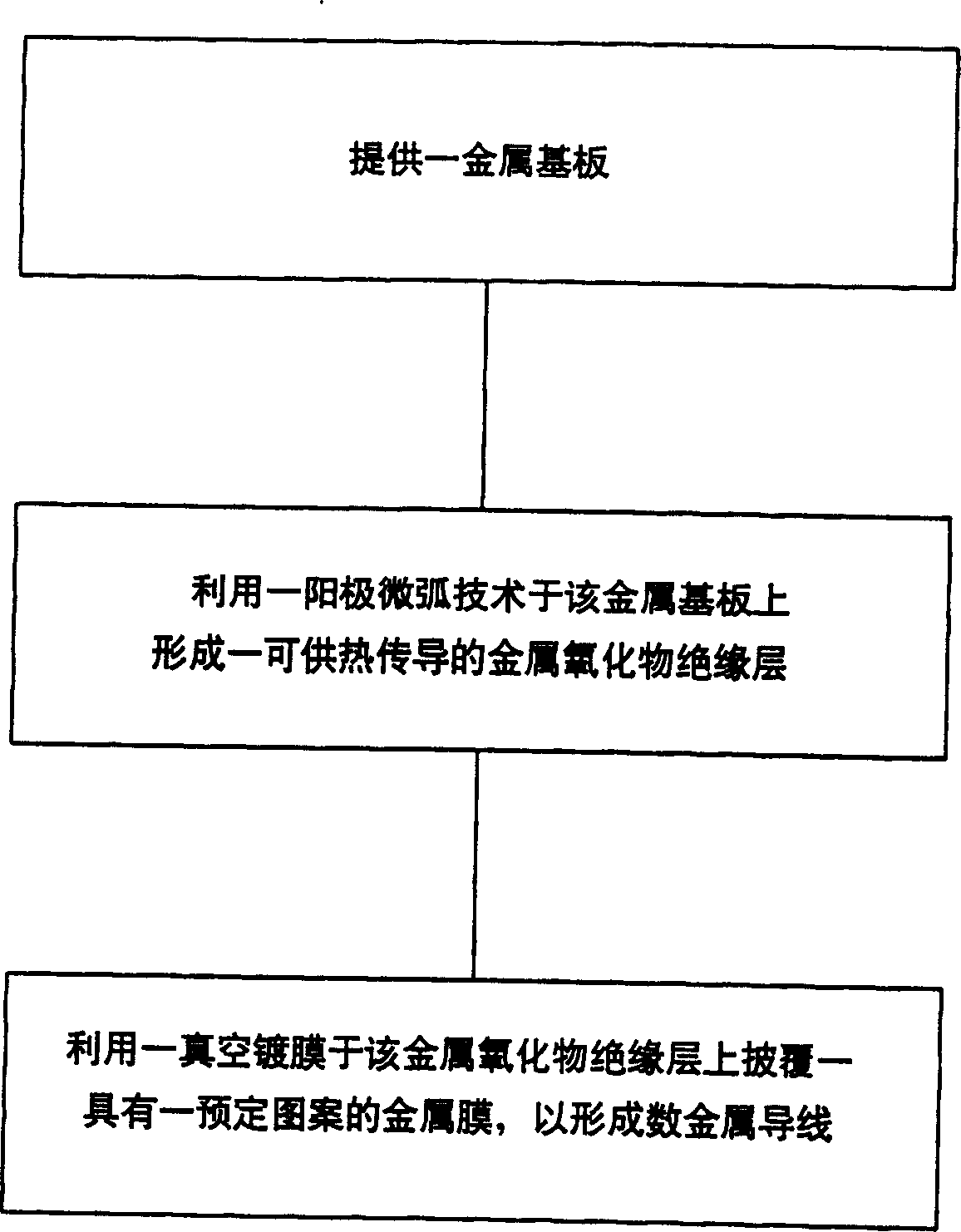

[0064] Place an aluminum substrate in an electrolytic bath of an electrolyte composition composed of an ammonia solution with a concentration of 4.5vol. 2 The current density of the anode micro-arc technique was carried out for 30 minutes, so as to prepare and form an aluminum oxide insulating layer with a thickness of about 15 μm on the aluminum substrate. In the first embodiment, the concentration of the potassium phosphate in the composition is 0.5M, the concentration of the potassium chromate in the composition is 0.1M, and the concentration of the copper acetate in the composition is 0.35M. Relevant descriptions about anode micro-arc technology can be found in patents such as RU2,181,392, CN1,311,354 and DE4,104,847. The previous patents mentioned above are hereby incorporated into this case as a reference.

[0065] Several wires are formed on the alumina insulating layer by a cathodic arc discharge ion plating. First, place the aluminum substrate grown with the alumina...

Embodiment 2

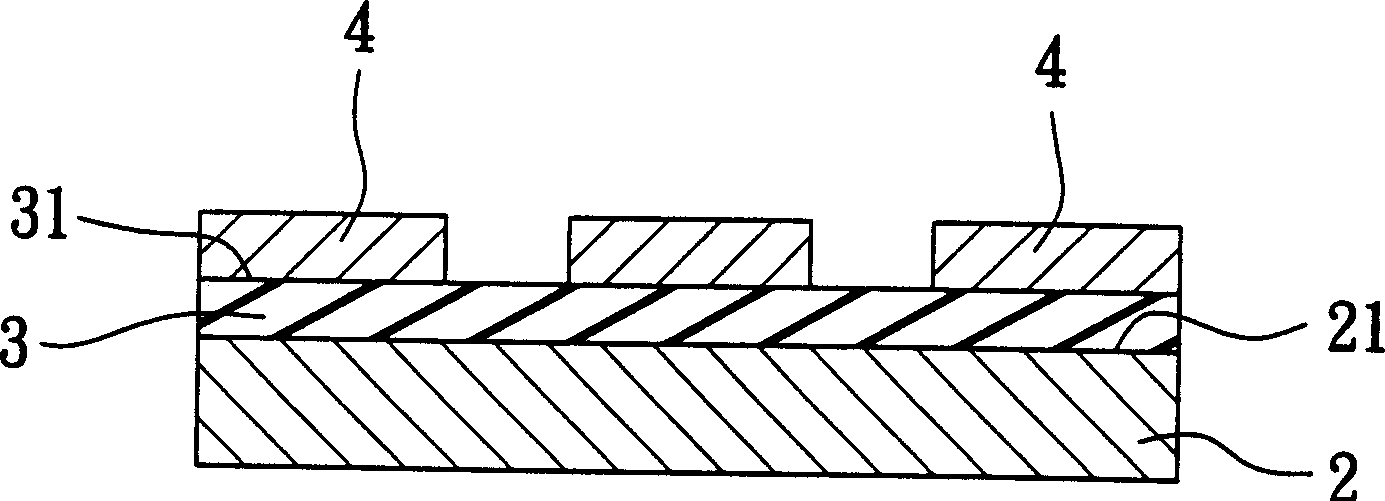

[0070] The second embodiment is substantially the same as the first embodiment, the difference lies in the preparation process of the copper wires. In the second embodiment, the copper wires are formed on the aluminum oxide insulating layer with a photoresist layer with the predetermined pattern by using a photolithographic etching technology, and then using the same process conditions as in the first embodiment. A copper metal film is formed on the aluminum oxide insulating layer with the photoresist layer, and finally the photoresist layer is removed to form the copper wires.

[0071] Therefore, the integrated heat dissipation substrate prepared by the method of the present invention can sort out the following features:

[0072] 1. The thickness of the metal oxide insulator 3 (aluminum oxide insulating layer) is sufficient to provide effective electrical insulation.

[0073] 2. The metal oxide insulator 3 (aluminum oxide insulating layer) has high purity and good compactnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com