Lubricant for wall reduction and drawing of titanium alloy pipe and using method thereof

A titanium alloy and lubricant technology, applied in the lubricant field, can solve the problems of slow lubricant replenishment and poor surface wettability, and achieve the effects of simple formula, moderate fluidity and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

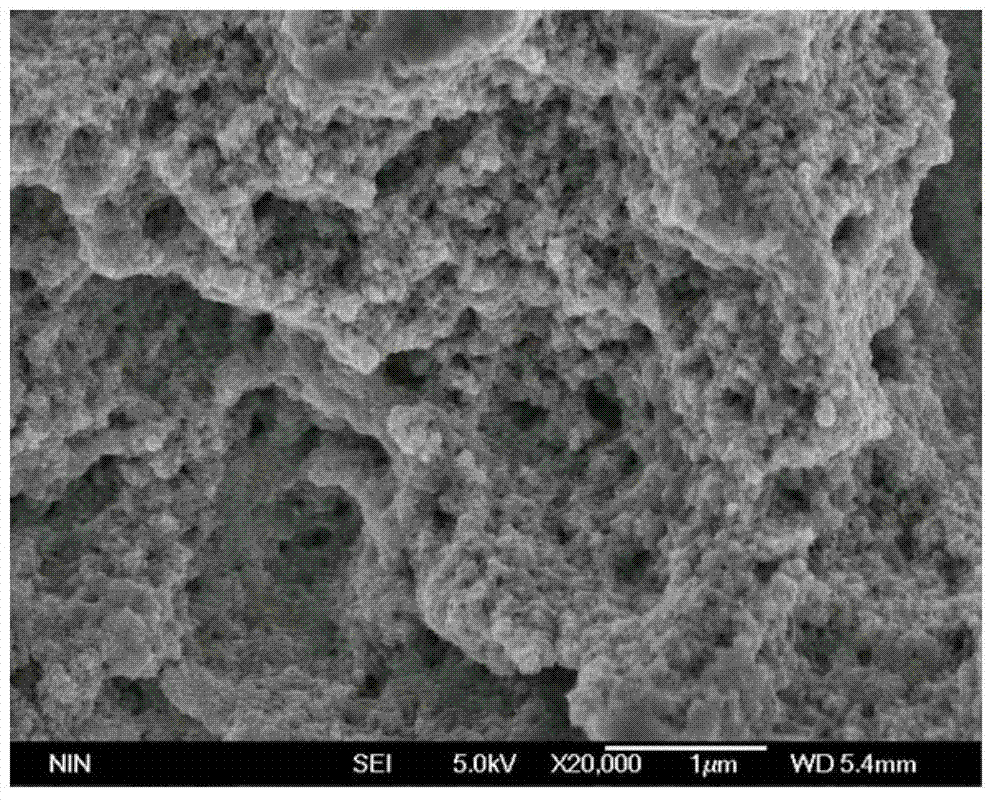

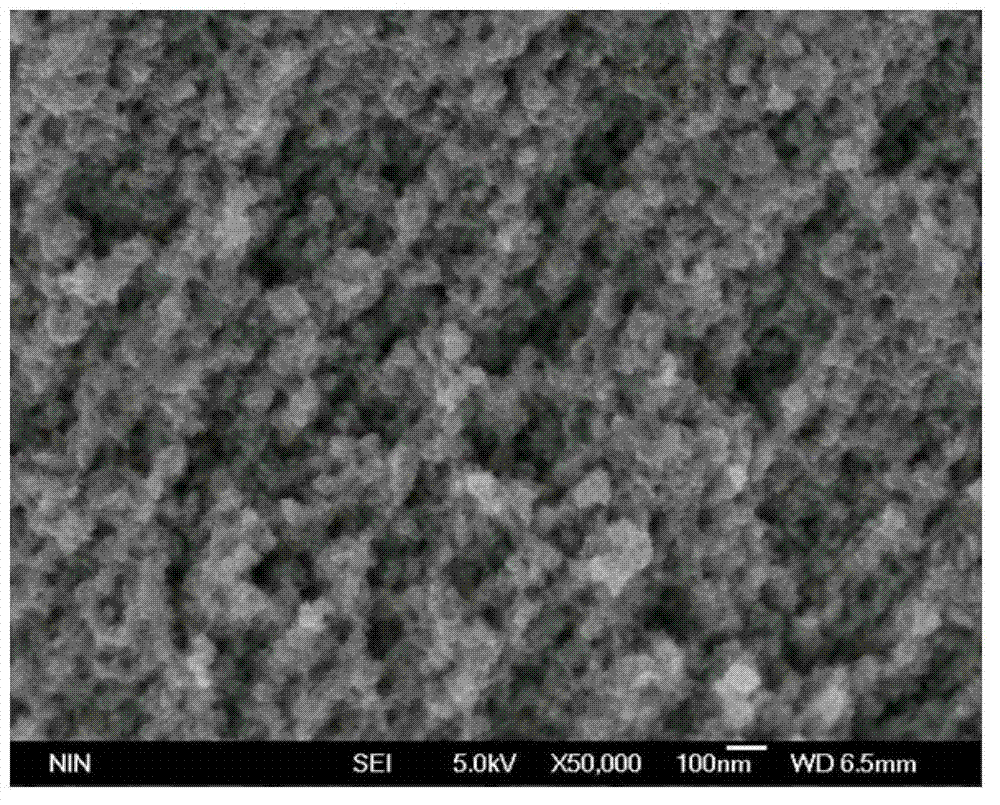

Image

Examples

Embodiment 1

[0021] In this embodiment, the lubricant for drawing titanium alloy pipes for wall reduction is composed of the following components by weight percentage: 96% chlorinated paraffin, 4% BN; 96% by weight of chlorinated paraffin 52 and 4% by weight of BN Mix and stir evenly to obtain the lubricant for wall reduction and drawing of titanium alloy pipes in this embodiment. The chlorinated paraffin is chlorinated paraffin 52, and the BN is hexagonal boron nitride powder with an average particle size of 0.6 μm; the viscosity of the lubricant for wall reduction and drawing described in this embodiment is 200 mPa·s.

[0022] The use method of the lubricant for drawing the titanium alloy pipe material for wall reduction in this embodiment is as follows: clean the titanium alloy pipe material, heat treat the titanium alloy pipe material after drying, and then apply the lubricant to the inner and outer surfaces of the titanium alloy pipe material after heat treatment. Apply a layer of lub...

Embodiment 2

[0025] In this embodiment, the lubricant for drawing titanium alloy pipes for wall reduction is composed of the following components by weight percentage: 90% chlorinated paraffin, 10% BN; 90% by weight of chlorinated paraffin 52 and 10% by weight of BN Mix and stir evenly to obtain the lubricant for wall reduction and drawing of titanium alloy pipes in this embodiment. The chlorinated paraffin is chlorinated paraffin 52, and the BN is hexagonal boron nitride powder with an average particle size of 0.6 μm; the viscosity of the lubricant for wall reduction and drawing described in this embodiment is 265 mPa·s.

[0026] The use method of the lubricant for drawing the titanium alloy pipe material for wall reduction in this embodiment is as follows: clean the titanium alloy pipe material, heat treat the titanium alloy pipe material after drying, and then apply the lubricant to the inner and outer surfaces of the titanium alloy pipe material after heat treatment. Apply a layer of l...

Embodiment 3

[0029] In this embodiment, the lubricant for drawing titanium alloy pipes for wall reduction is composed of the following components by weight percentage: chlorinated paraffin 85%, BN 15%; the weight percentage is 90% chlorinated paraffin 52 and the mass fraction is 10% BN Mix and stir evenly to obtain the lubricant for wall reduction and drawing of titanium alloy pipes in this embodiment. The chlorinated paraffin is chlorinated paraffin 52, and the BN is hexagonal boron nitride powder with an average particle size of 0.6 μm; the viscosity of the lubricant for wall reduction and drawing described in this embodiment is 300 mPa·s.

[0030] The use method of the lubricant for drawing the titanium alloy pipe material for wall reduction in this embodiment is as follows: clean the titanium alloy pipe material, heat treat the titanium alloy pipe material after drying, and then apply the lubricant to the inner and outer surfaces of the titanium alloy pipe material after heat treatment....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com