Shield excavation gap synchronous grouting slurry for water-rich powdery soil layer

A technology of synchronous grouting and formation, applied in the field of shield tunnel construction, can solve the problems of insufficient filling strength, short setting time, high strength, etc., and achieve improved compactness and waterproof effect, reasonable component distribution ratio, and high impermeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

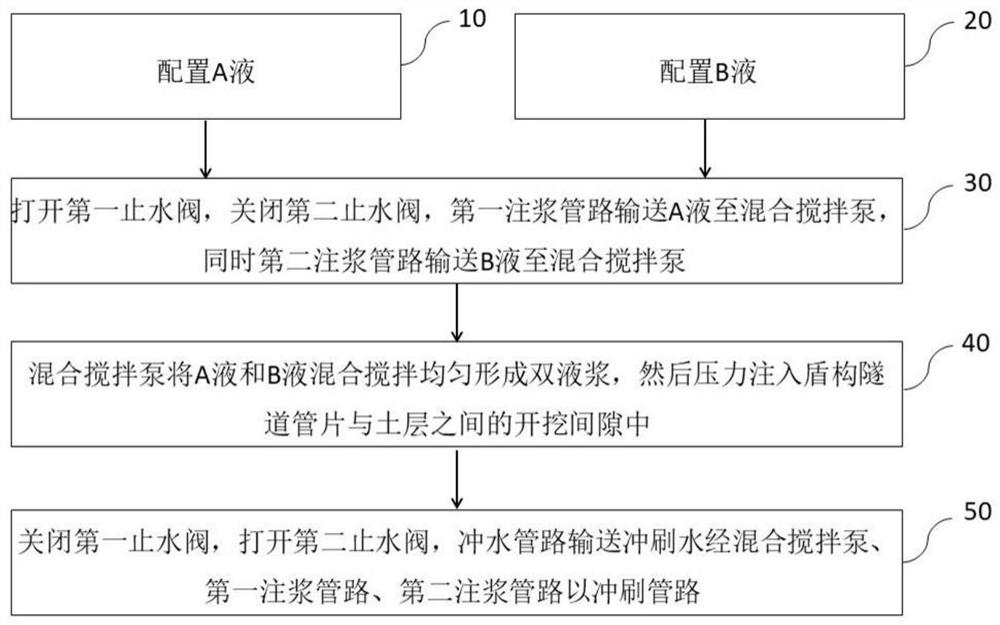

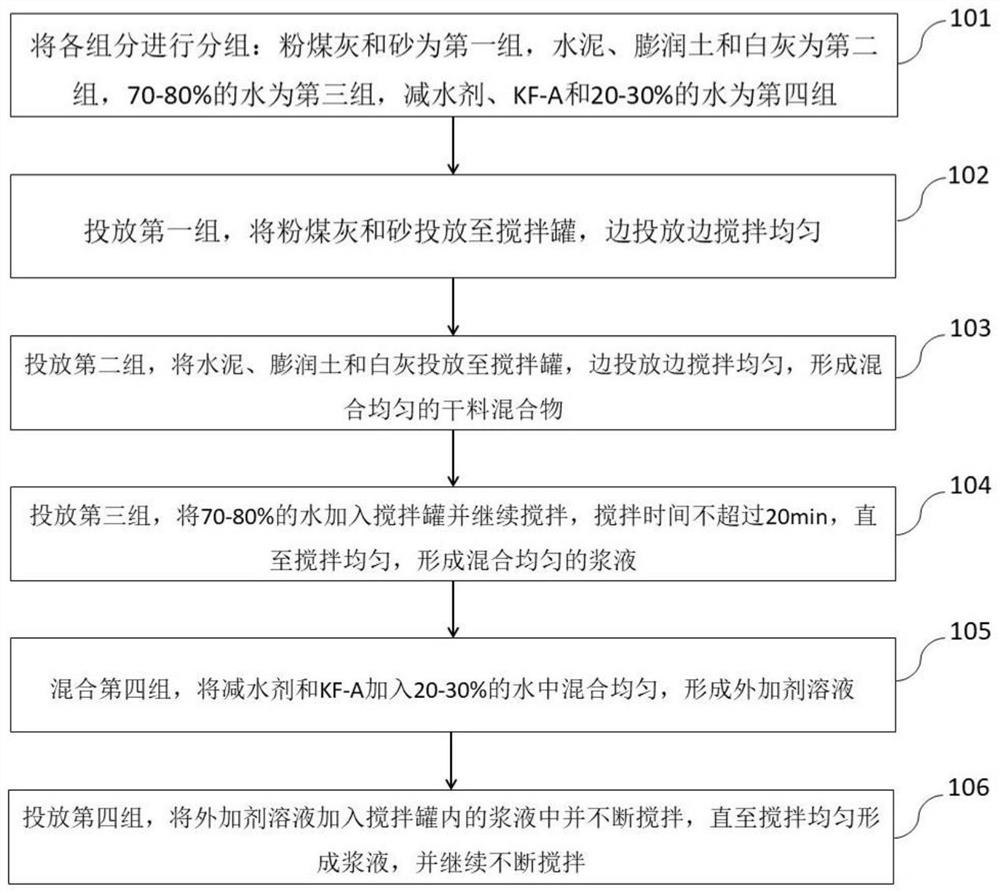

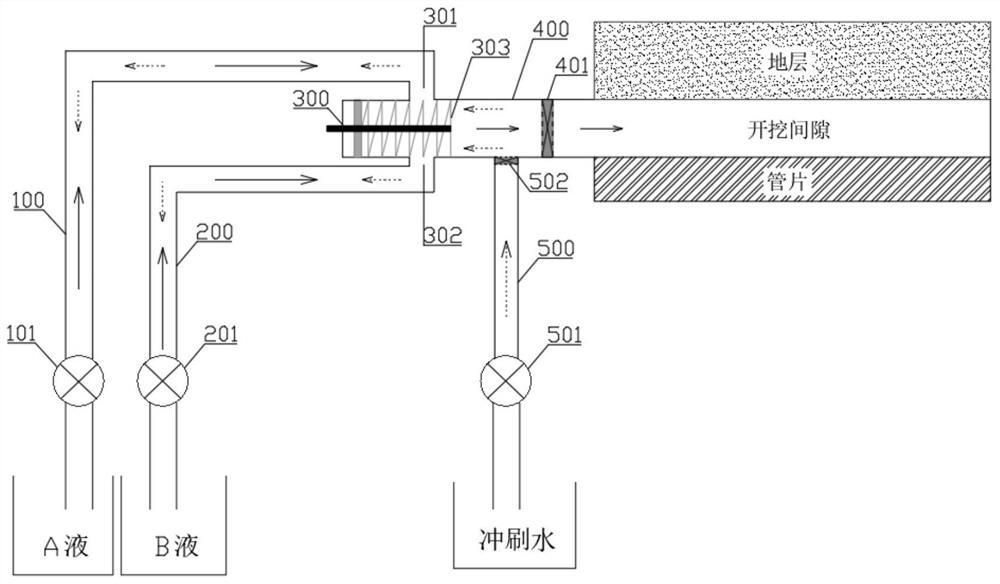

Method used

Image

Examples

example 1

[0072] Example 1: Slurry ratio in the initial and receiving stages of shield tunneling (kg / m3)

[0073] Liquid A—cement: 100; fly ash: 412; bentonite: 48; sand: 620; lime: 20; water: 480; water reducer: 8; KF-A: 10;

[0074] B liquid - water glass solution, meet the volume ratio A liquid: B liquid = 10:1;

[0075] The initial setting time of the double slurry is 20-35s, the slump is not less than 23cm within 4 hours, the slump is not less than 18cm within 10 hours, and the fluidity is not less than 230mm within 8 hours.

example 2

[0076] Example 2: Slurry ratio of shield tunneling in silty clay section (kg / m3)

[0077]Liquid A—cement: 100; fly ash: 503; bentonite: 48; sand: 751; lime: 60; water: 520; water reducing agent: 8; KF-A: 15;

[0078] B liquid - water glass solution, meet the volume ratio A liquid: B liquid = 10:1;

[0079] The initial setting time of the double slurry is 15-25s, the initial slump is between 25±1cm, the slump is not less than 23cm within 4 hours, the slump is not less than 18cm within 10 hours, and the fluidity is not less than 8 hours 230mm.

example 3

[0080] Example 3: Slurry ratio in the silt section of shield tunneling (kg / m3)

[0081] Liquid A—cement: 140; fly ash: 550; bentonite: 65; sandstone: 650; lime: 50; water: 550;

[0082] B liquid - water glass solution, meet the volume ratio A liquid: B liquid = 10:1;

[0083] The initial setting time of the double slurry is 10-25s, the initial slump is between 25±1cm, the slump is not less than 24cm within 4 hours, the slump is not less than 19cm within 10 hours, and the fluidity is not less than 8 hours 230mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com