Vacuum preloading method for non-water discharge sand cushion

A vacuum preloading method and sand layer technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of poor treatment effect, high construction cost, long construction period, etc., and achieve good vacuum transmission effect, The effect of saving construction materials and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

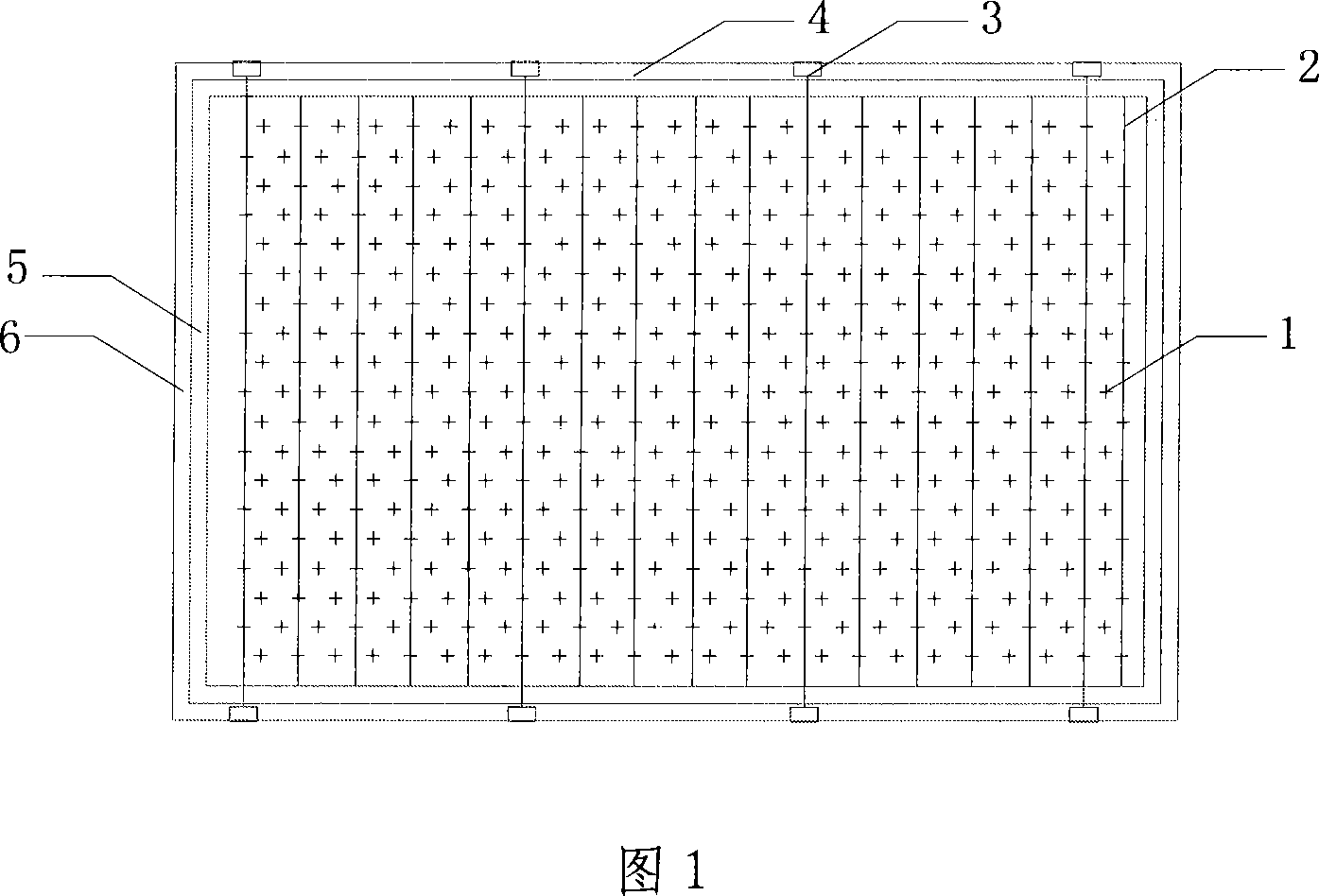

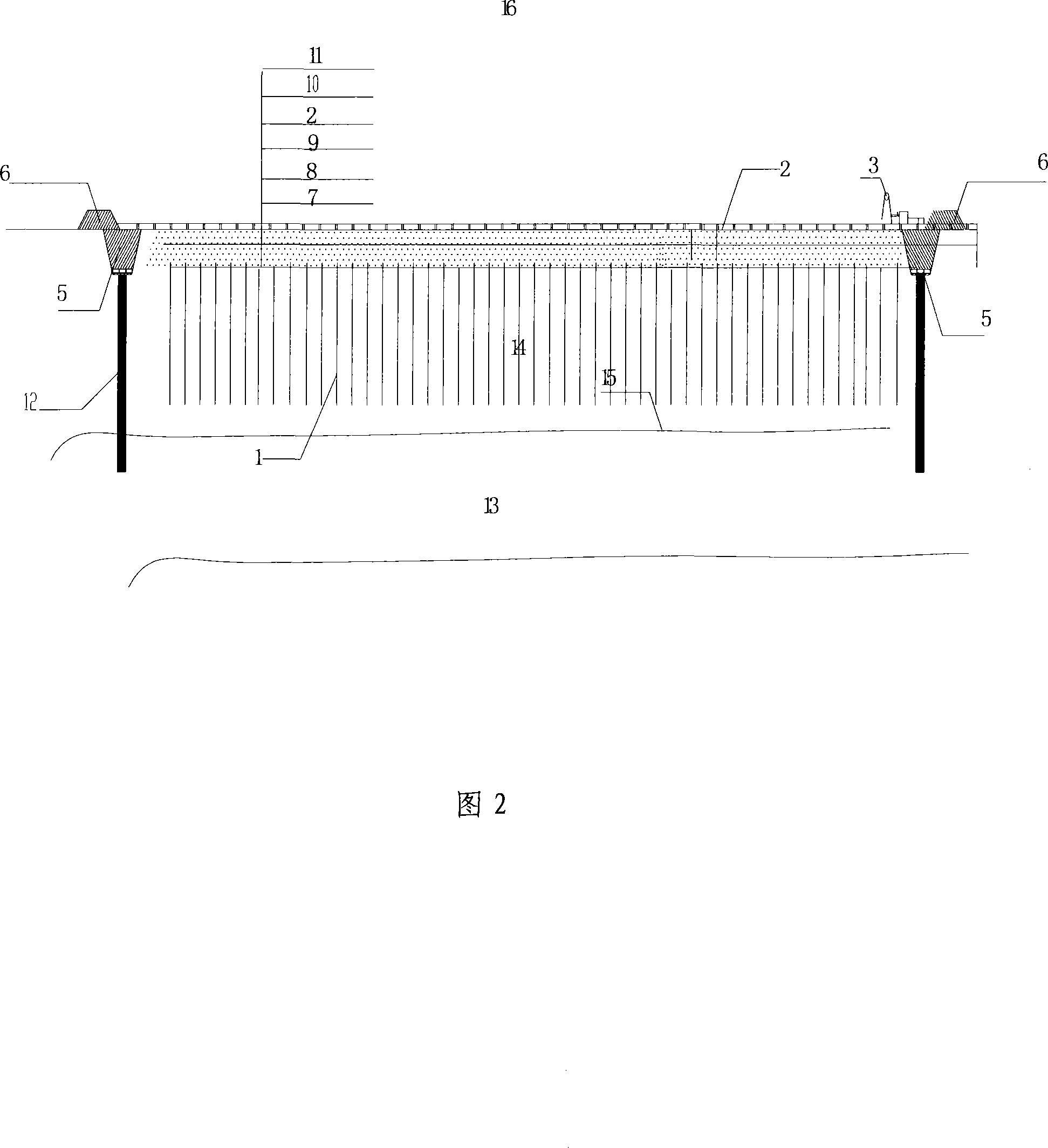

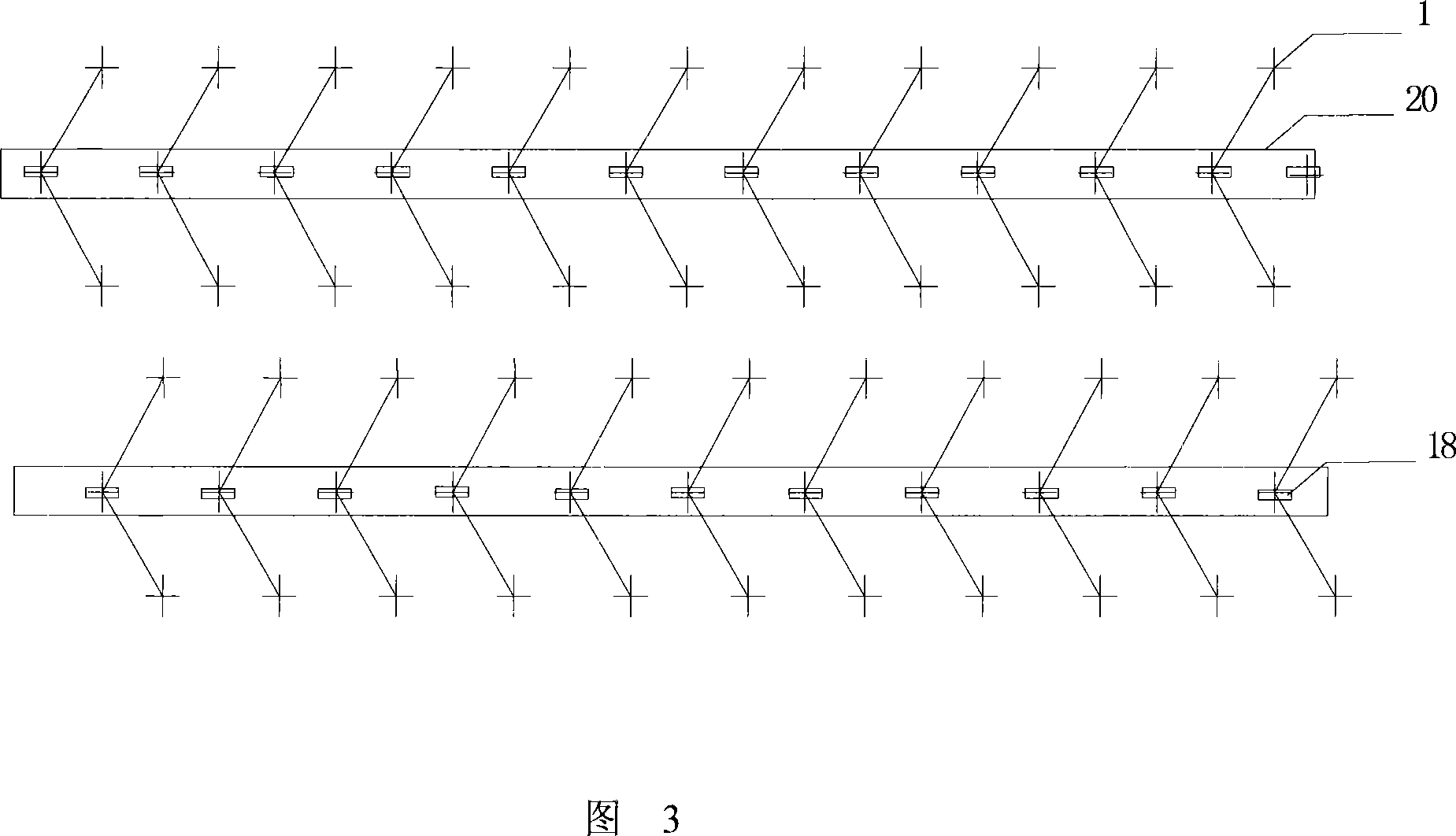

Image

Examples

Embodiment Construction

[0034] Detailed construction steps of the present invention are as follows:

[0035] 1. Clean up the construction site and prepare for construction work.

[0036] 2. Filling soil and fabric: When the bearing capacity of the soft soil layer is not enough to bear the weight of the construction machinery, a geotextile can be laid on the soft soil layer, a layer of geotextile is laid on the filling layer, and then a layer of geogrid is laid The grid is used to facilitate the entry of small-scale plug-in machines. If the bearing capacity is still poor, 50-80cm of local cohesive soil can be filled, and the sealing wall and sealing ditch can be built. Generally, it is more suitable to use glass fiber two-way geogrid soil and woven geotextile.

[0037] 3. Construction of sealing wall and sealing ditch: According to the actual situation of the site, choose to use mixing piles or manual or mechanical mixing method to build.

[0038] 4. Cofferdam construction: build cofferdams around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com