Patents

Literature

277results about How to "Save construction materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

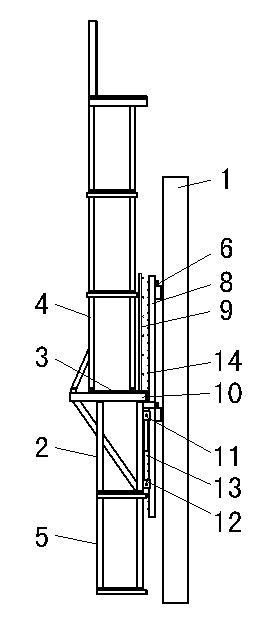

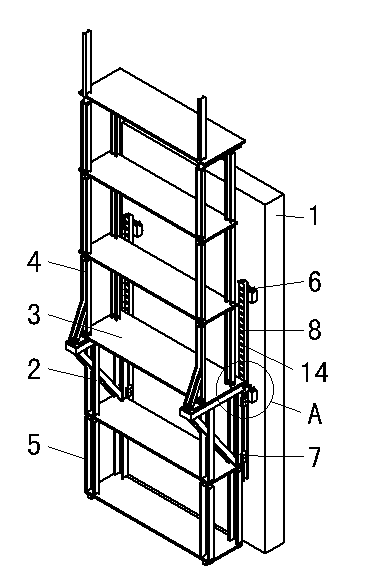

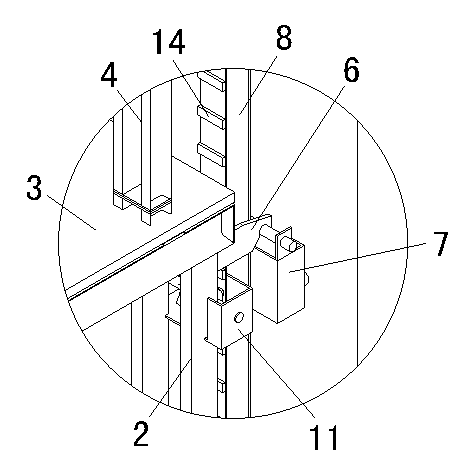

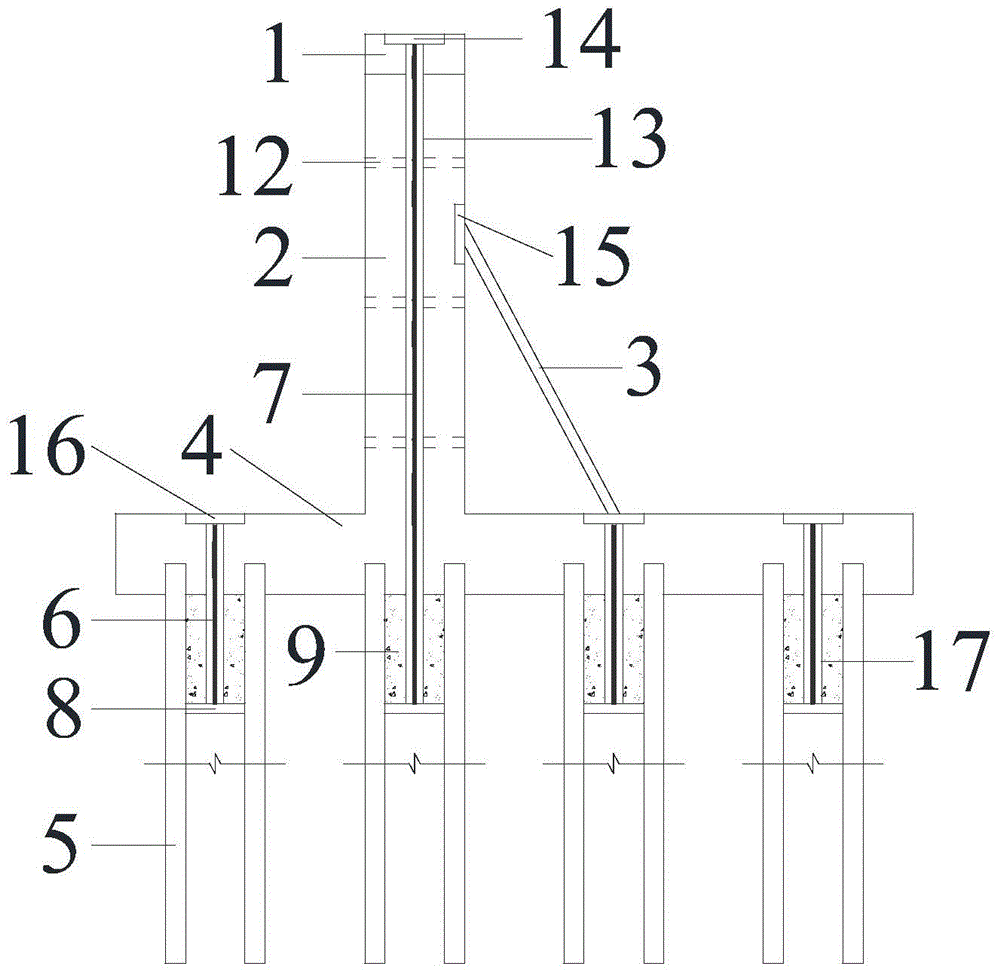

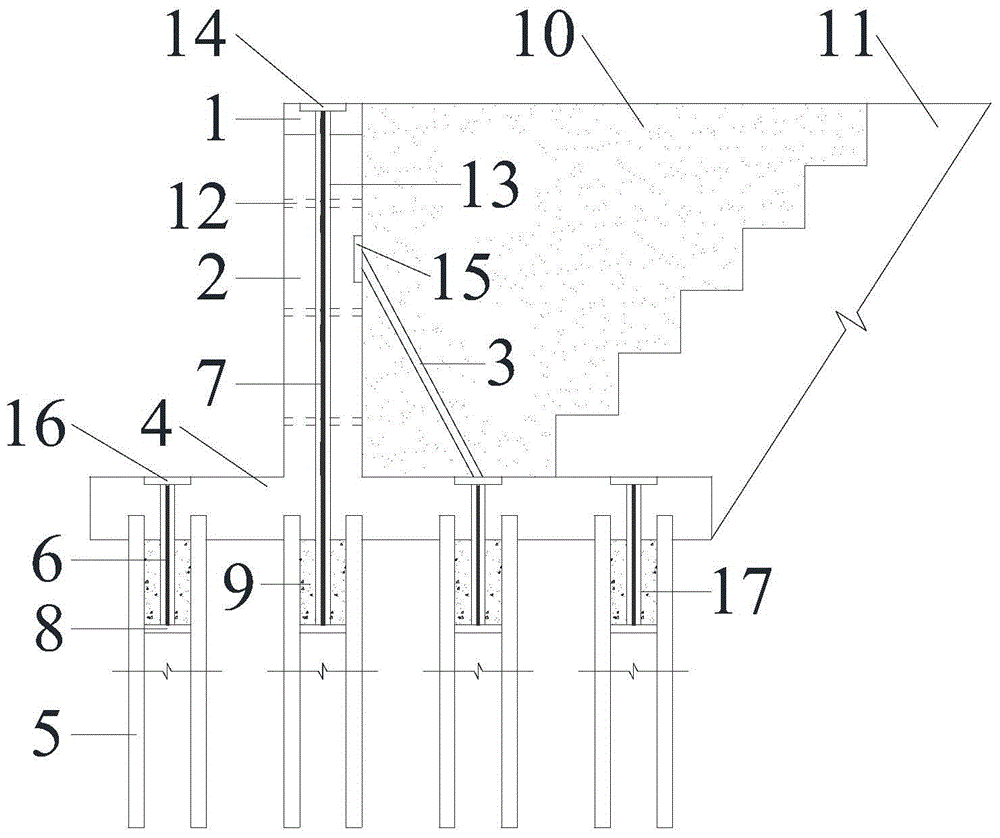

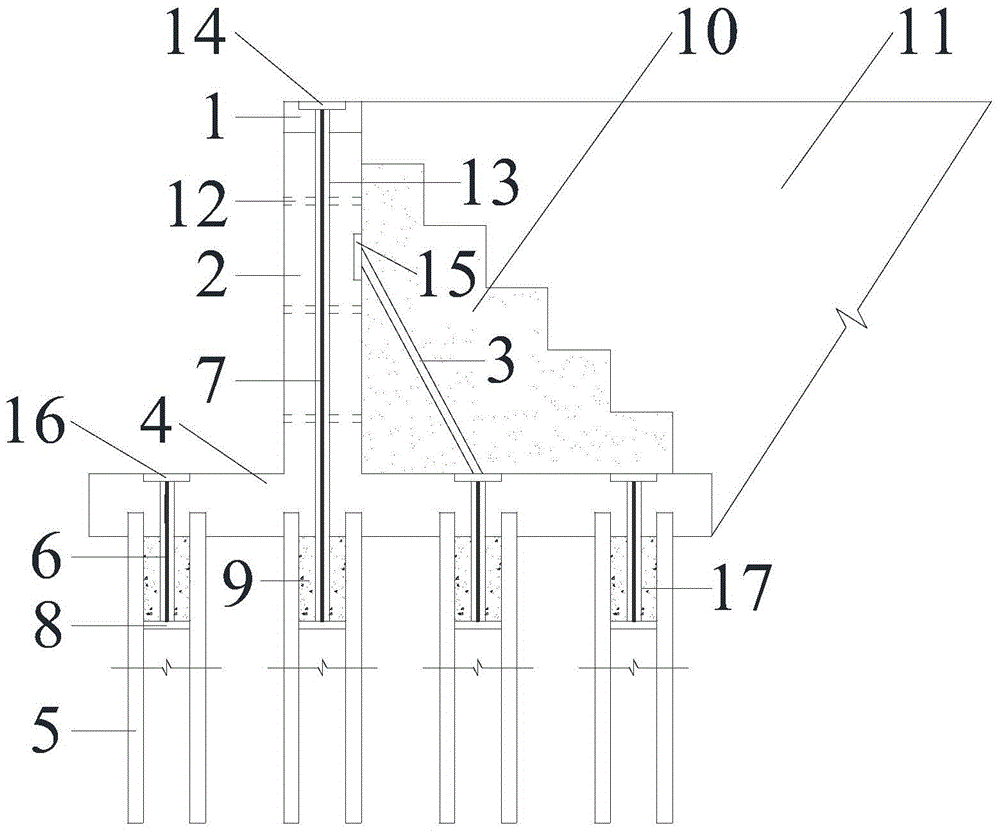

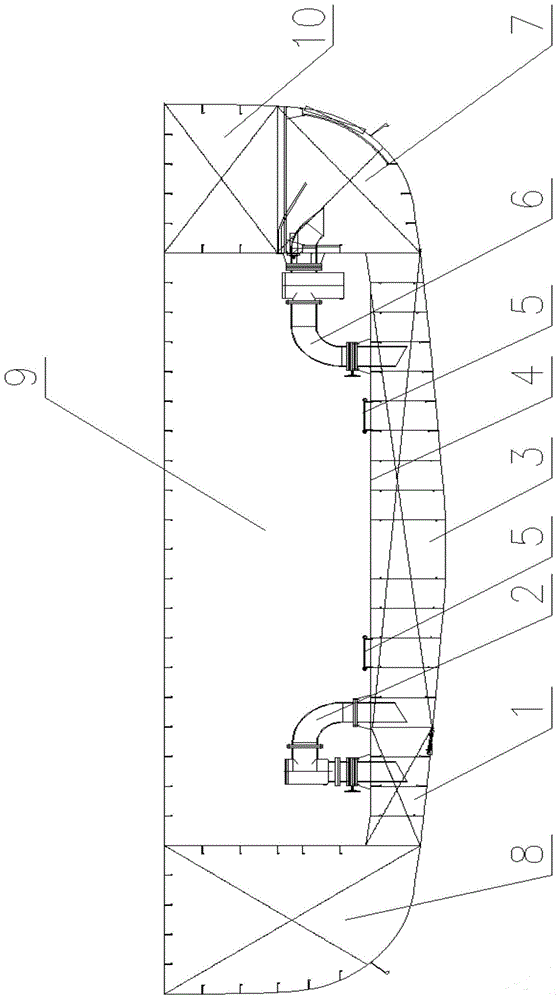

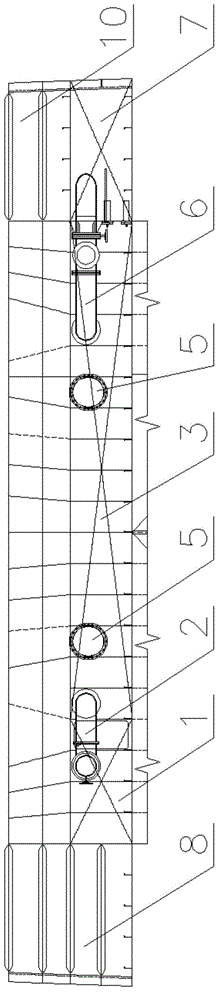

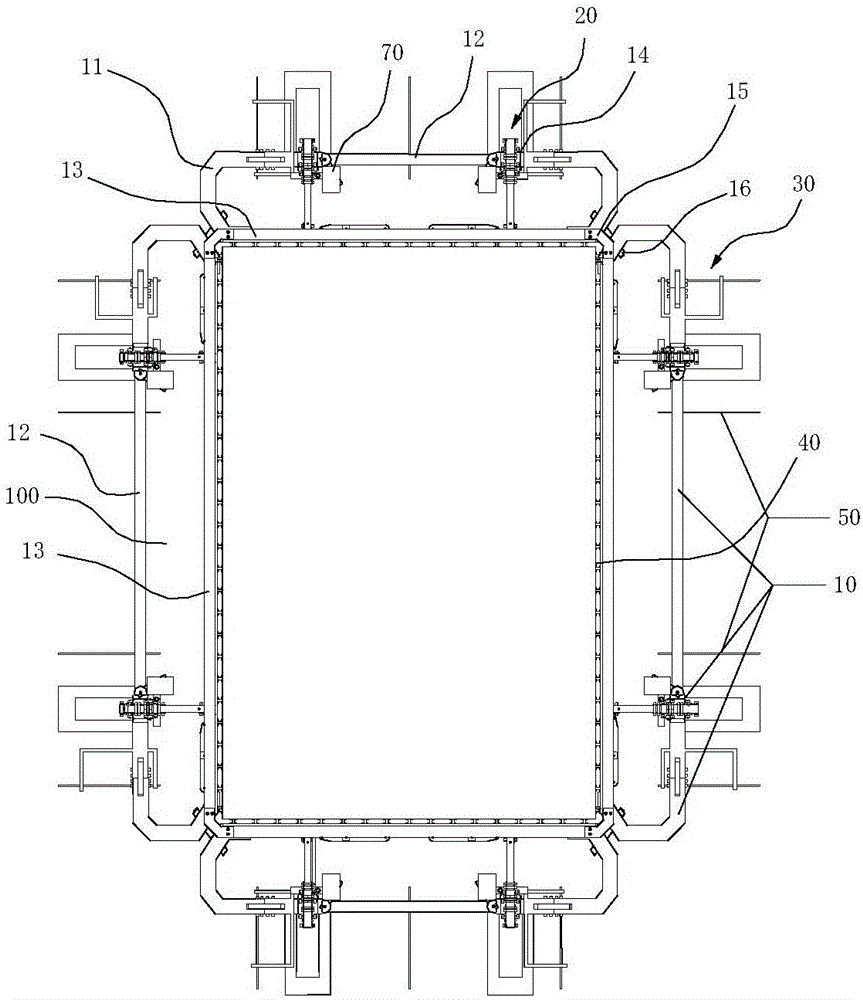

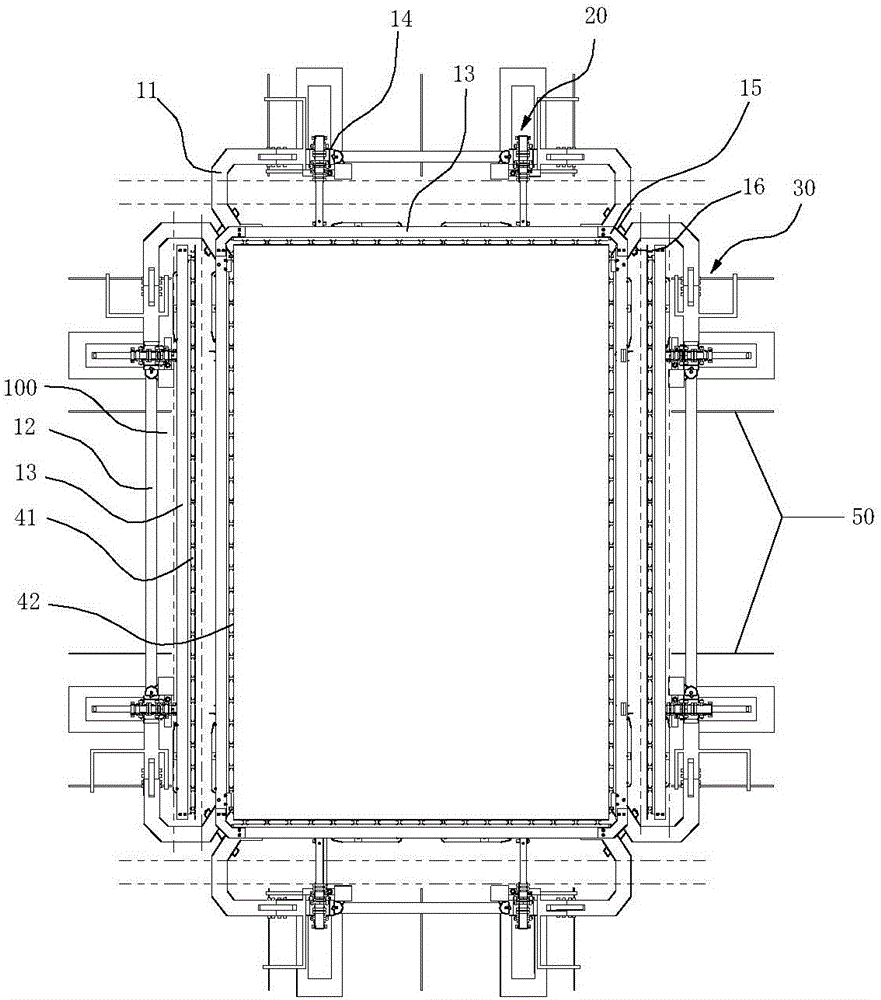

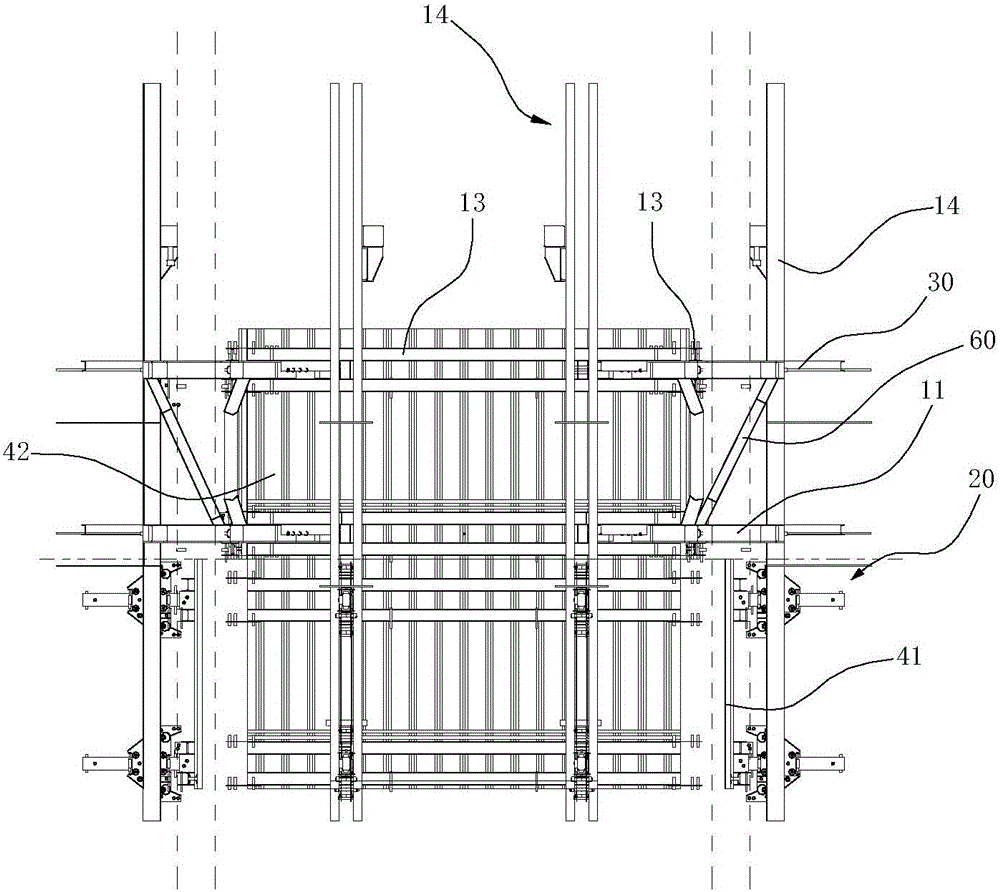

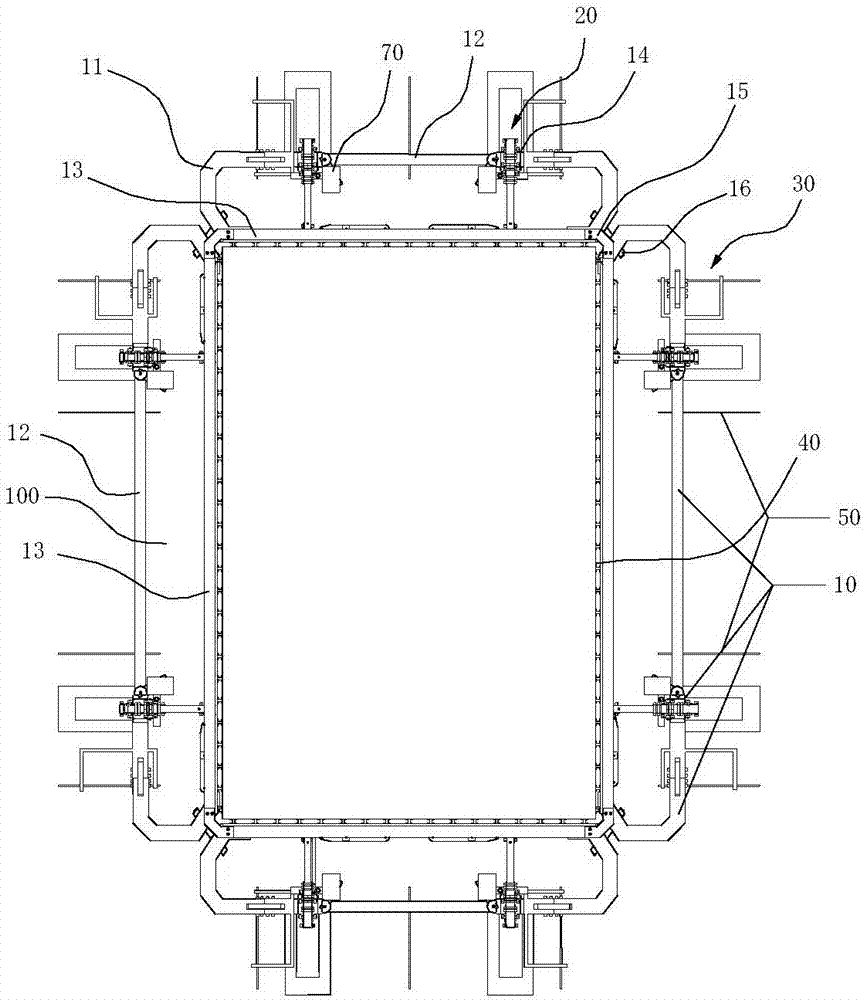

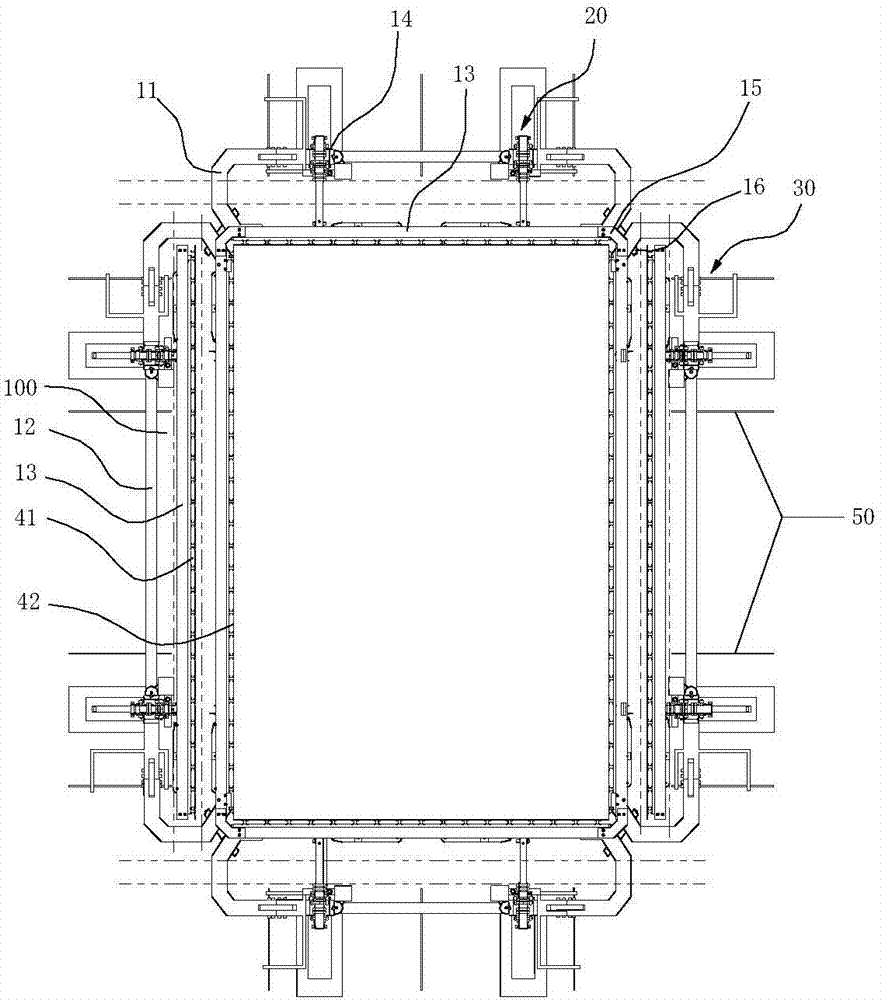

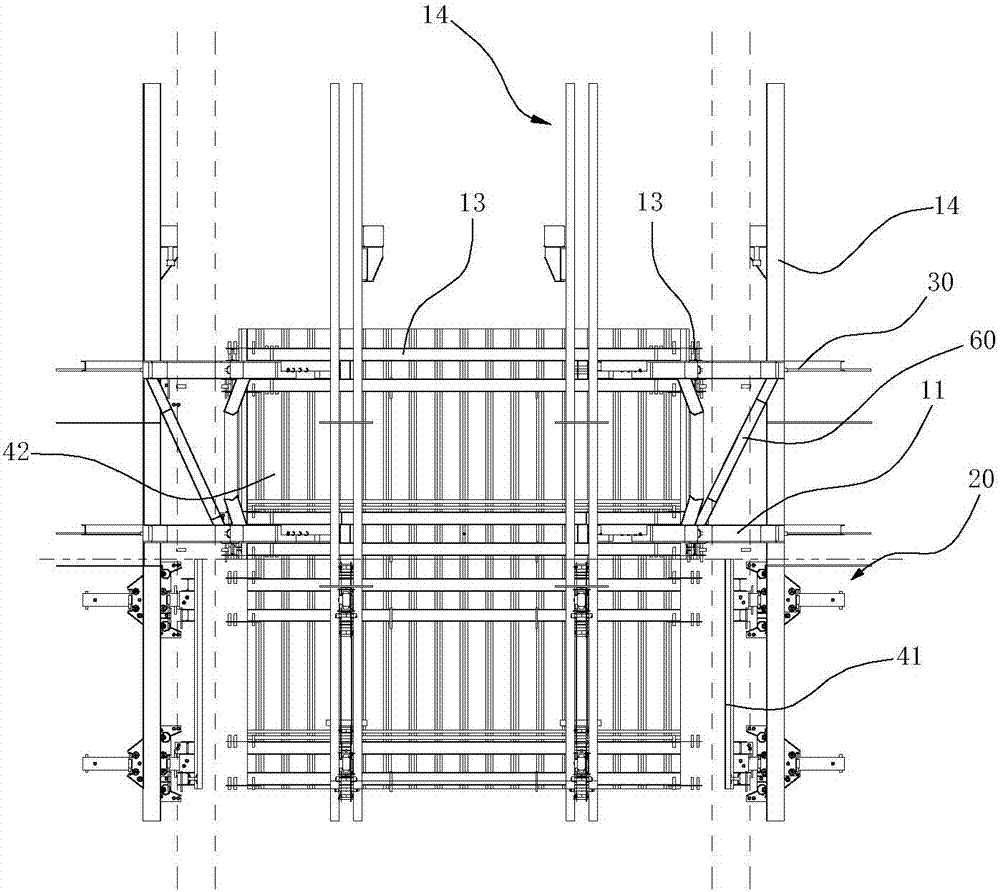

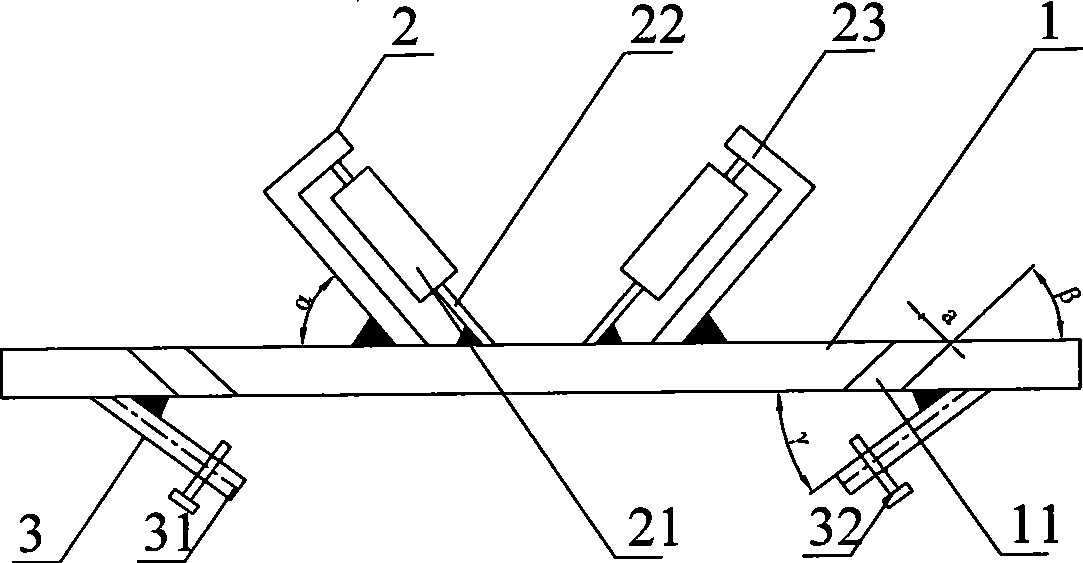

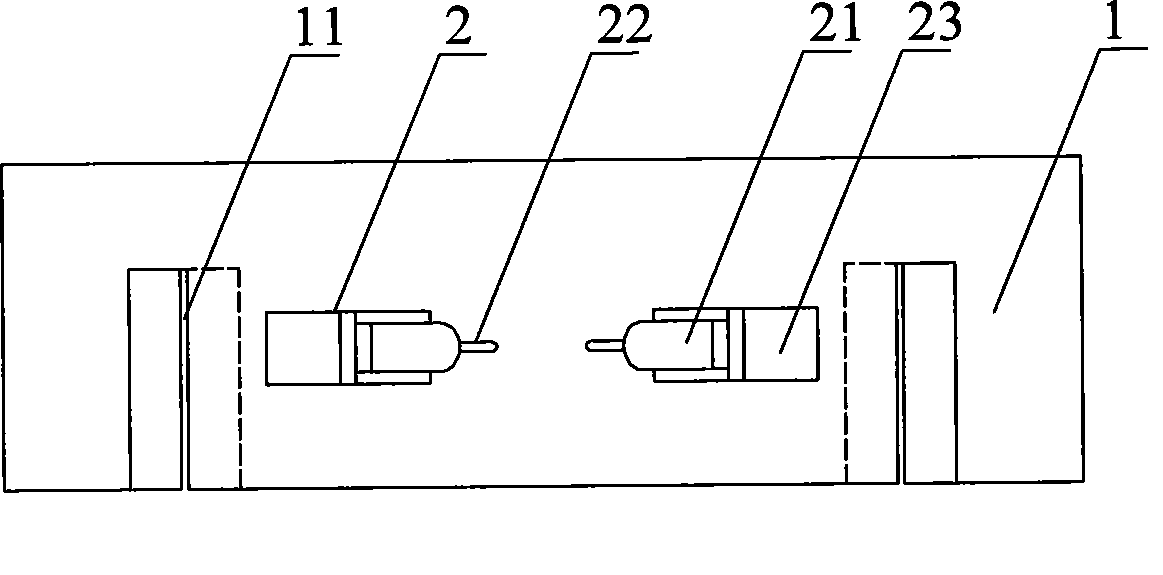

Method for constructing core tube wall through self-climbing formwork and adopted self-climbing formwork

InactiveCN104131703AGood climbing stabilitySmooth connectionForms/shuttering/falseworksBuilding material handlingTube (structure)Architectural engineering

The invention discloses a method for constructing a core tube wall through a self-climbing formwork and the adopted self-climbing formwork. The method comprises the steps that the core tube wall is constructed from bottom to top layer by layer; when a first-layer wall body is constructed, a first pre-buried component is pre-buried, and pouring of the first-layer wall body is completed; after construction of the first-layer wall body is completed, a second-layer wall body is constructed, and a second pre-buried component is pre-buried in the second-layer wall body; each pre-buried component is provided with a wall attachment device, after pouring of the second-layer wall body is completed, a guide rail is arranged between the first wall attachment device and the second wall attachment device, a self-climbing device on the formwork is connected with the guide rail, alternate mutual climbing of the formwork and the guide rail is achieved through the self-climbing device, a form board is arranged on the formwork, and the construction of the core tube wall is completed layer by layer through the form board. The method is suitable for core tube construction of a super high-rise building of a frame core tube structure of 200 m to 400 m, a wide platform is provided for operating personnel for construction, safety is guaranteed well, construction efficiency is greatly improved, and construction cost is lowered.

Owner:CHINA CONSTR FOURTH ENG DIV

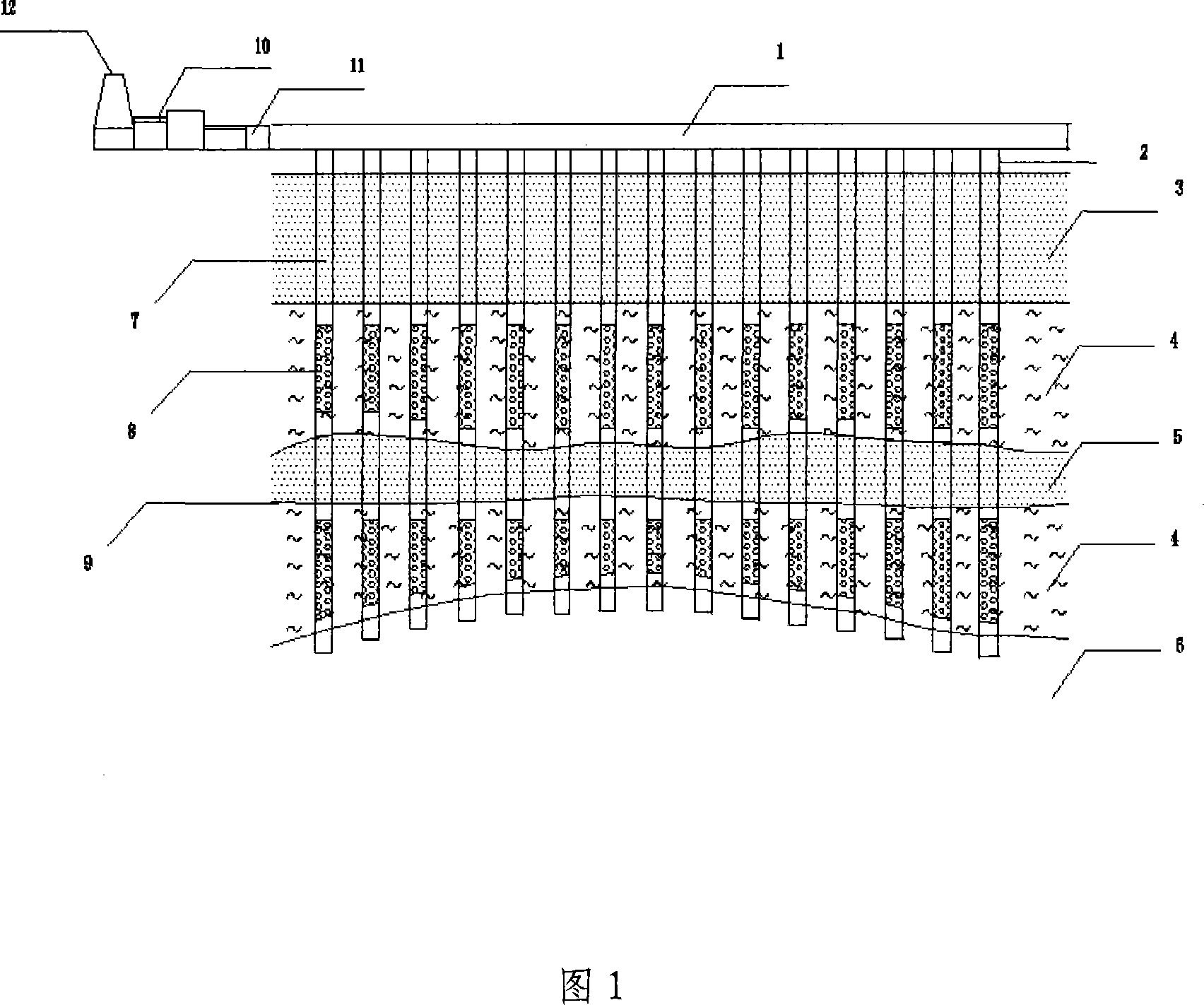

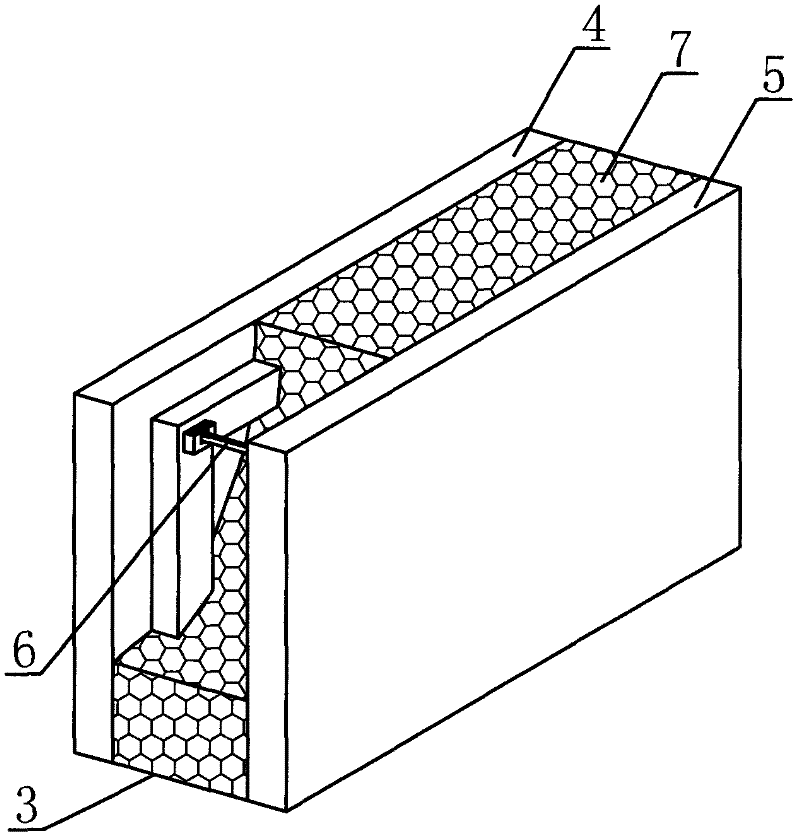

Packingless fast vacuum prepressing dynamic consolidation method

InactiveCN101130952AShort construction periodSmall vacuum lossSoil preservationEngineeringSoil horizon

The present invention relates to large area foundation treatment, and is especially process of treating large area soft foundation. The process includes the following steps: 1. arranging filter openings according to the stratum state; 2. inserting PVC filter pipes with filter pores in the calculated size into stratum, connecting the upper ends of the filter pipes beyond the soil layer to the main pipe and connecting the main pipe directly to the vacuumizing equipment; 3. vacuumizing based on the design requirement; and 4. withdrawing filter pipes after the soft soil layer consolidates and ramming to reach even high foundation strength. The process of the present invention has short construction period, less vacuum degree loss, saving in construction material and high foundation reinforcing effect.

Owner:汤连生 +1

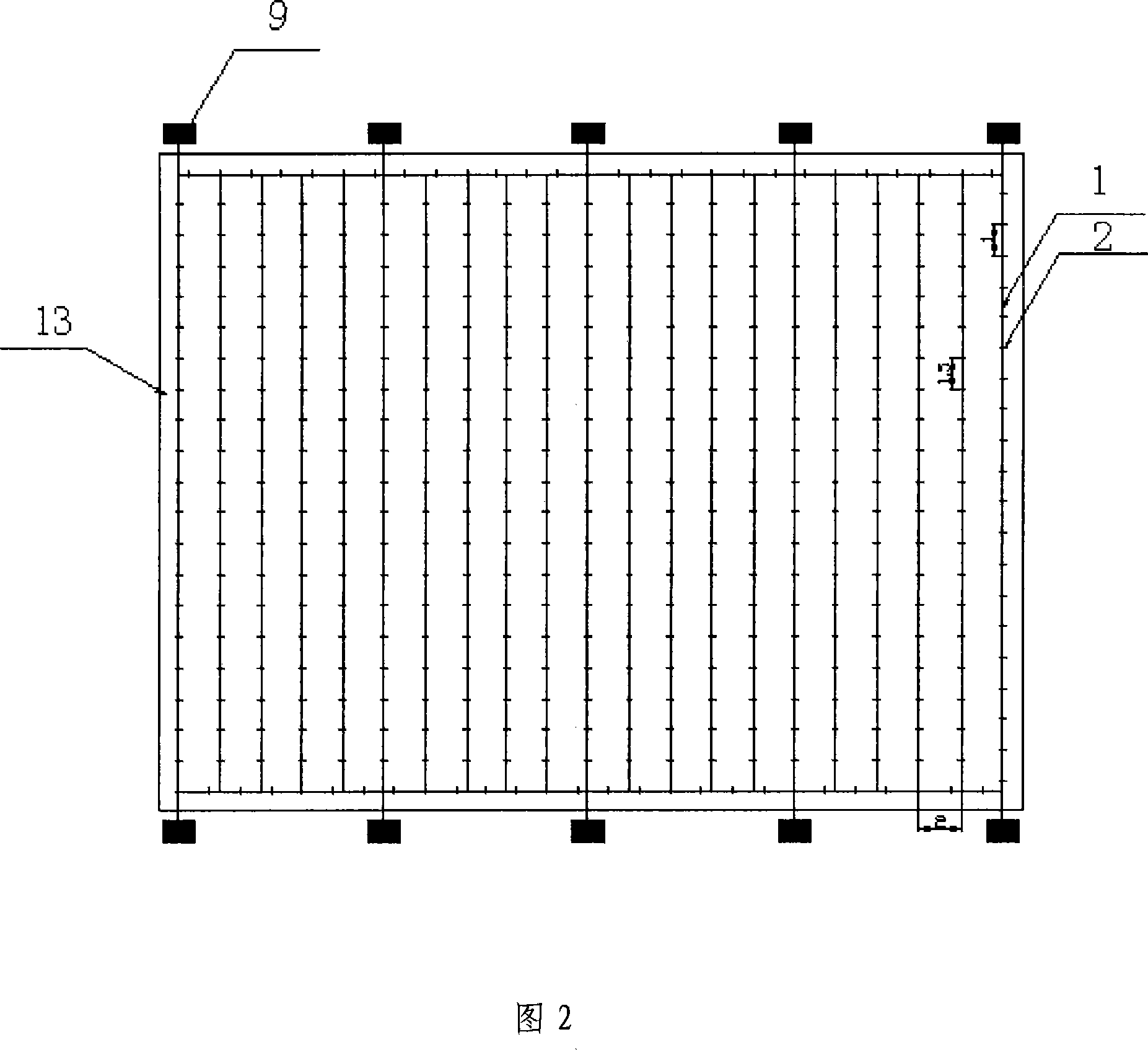

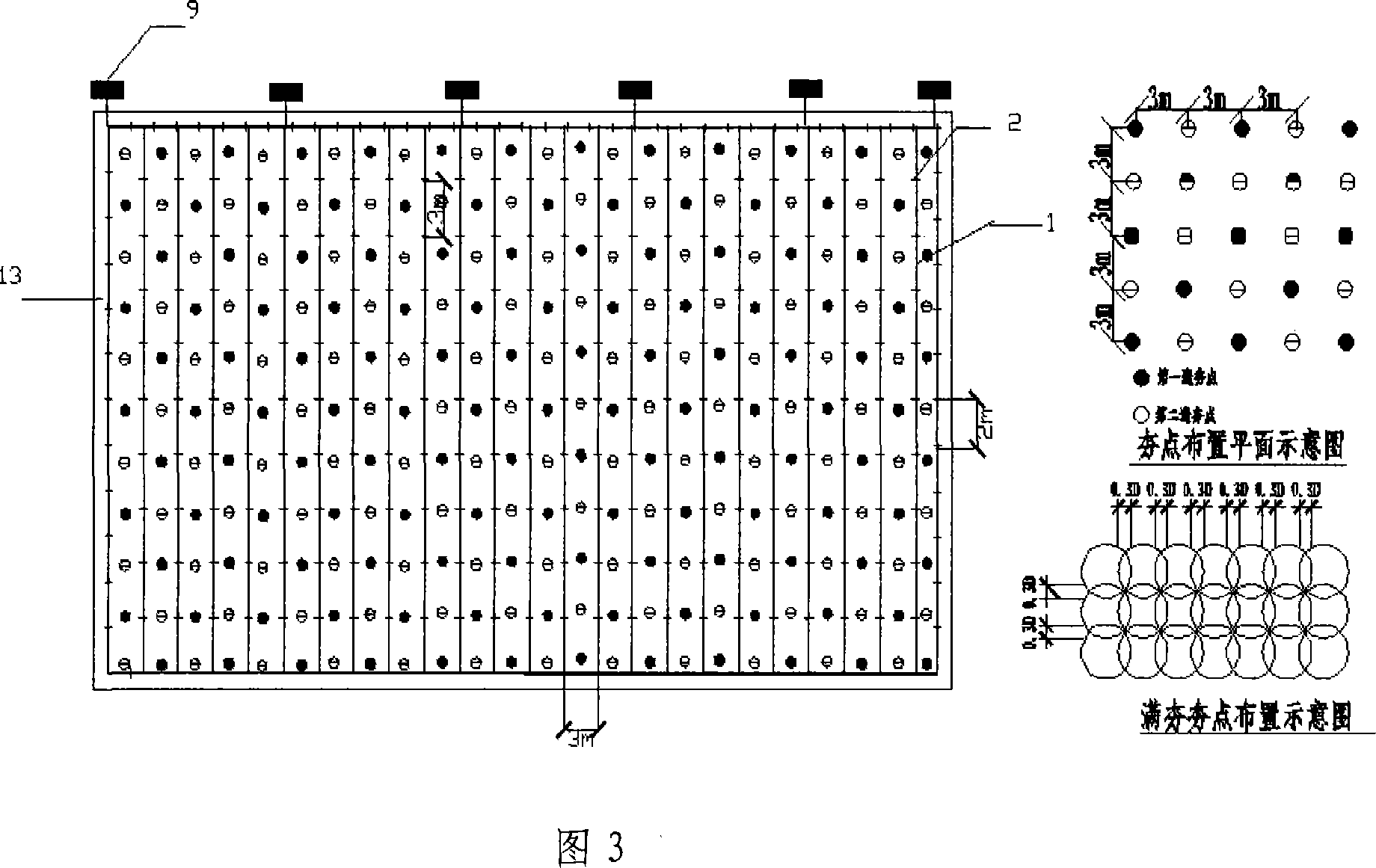

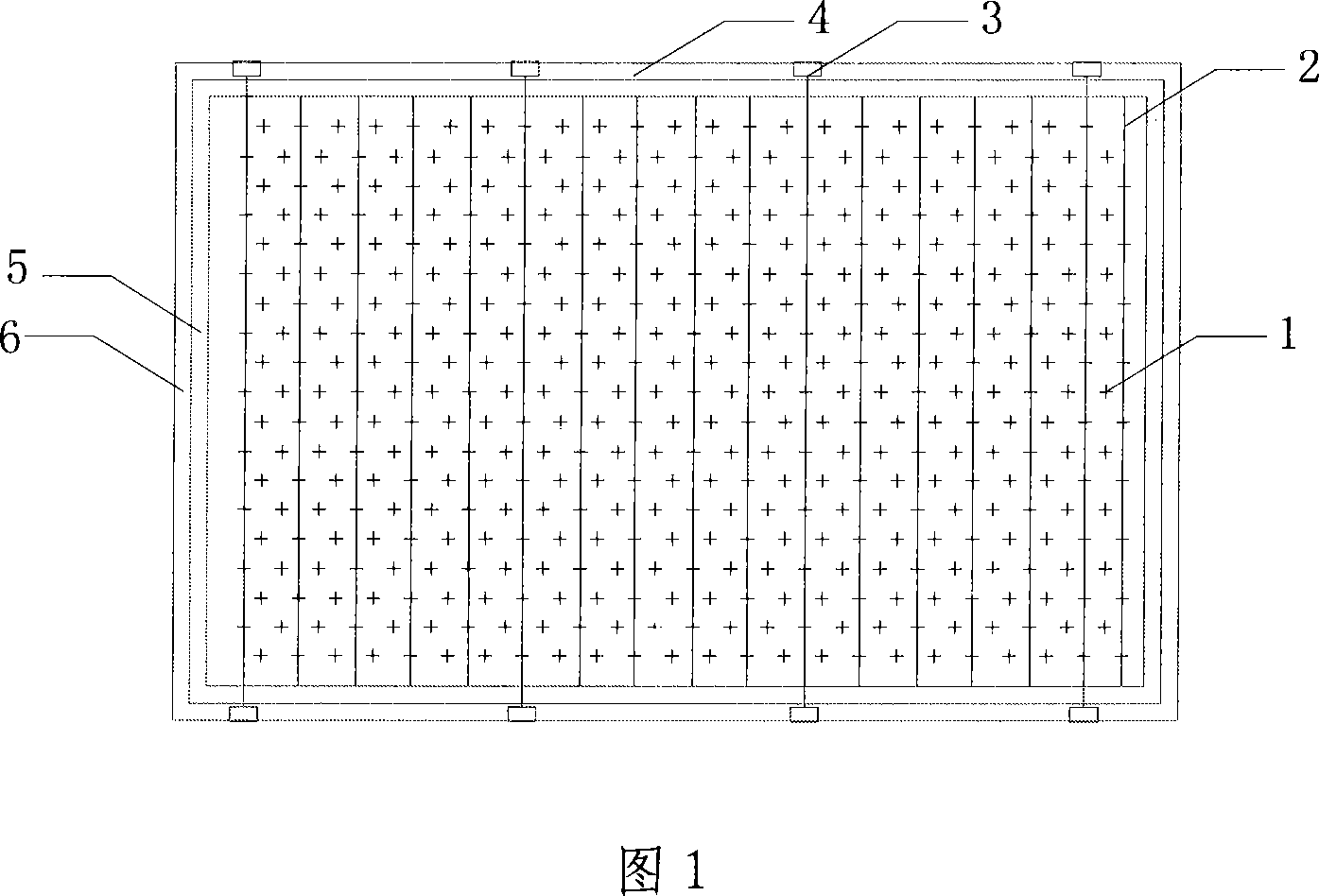

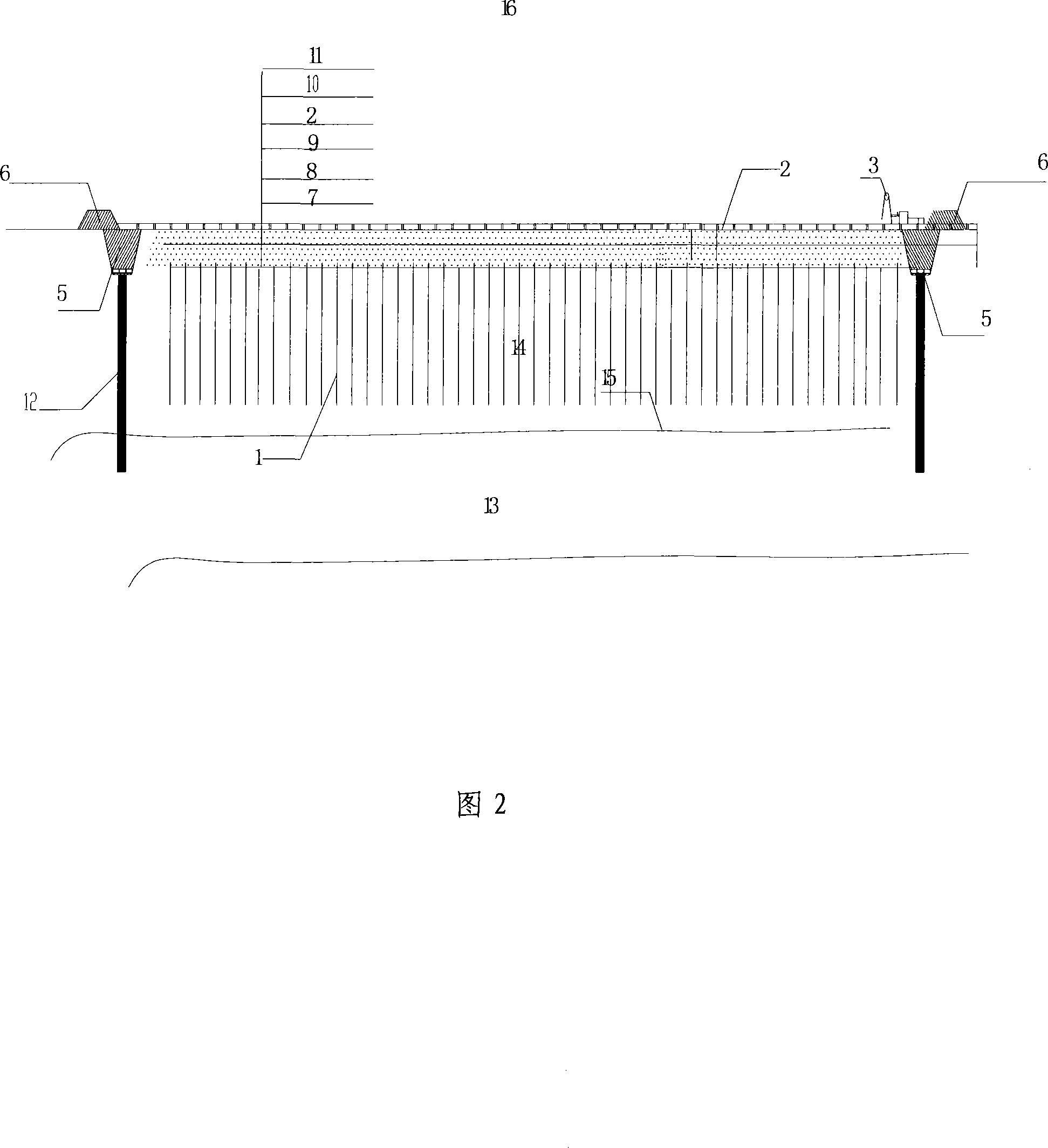

Vacuum preloading method for non-water discharge sand cushion

InactiveCN101220598AShorten the construction periodGood vacuum transfer effectSoil preservationVacuum pumpingWater discharge

The invention relates to a treatment method of large-area soft ground, in particular to a non-discharge sand cushion layer vacuum preloading method. The invention comprises the following steps: 1) installing drainage plates in a style of quincuncial piles in a treatment site; 2) replacing the horizontal discharging system of medium coarse sand cushion layer used in previous vacuum preloading construction with one of the two paving methods; 3) connecting the main pipe of the horizontal discharging system to a vacuum device, and carrying out vacuum pumping construction. The non-discharge sand cushion layer vacuum preloading method of the invention is suitable for reinforcement of large-area soft ground, more particularly have rather good effect on the reinforcement of dredger fill and recently deposited super soft soil; besides, the invention saves the investment of paving sand cushion layer, has good effect of vacuity transmitting; wherein, the horizontal discharging system with a paving way of combination of a steel spring tube, a tube plate connector and the drainage plates can realize large-scale finished product, normalized construction, short paving time, can be recycled and reused, and has the unique advantages of short construction period and being economical.

Owner:GUANGZHOU SHENGZHOU FOUND ENG

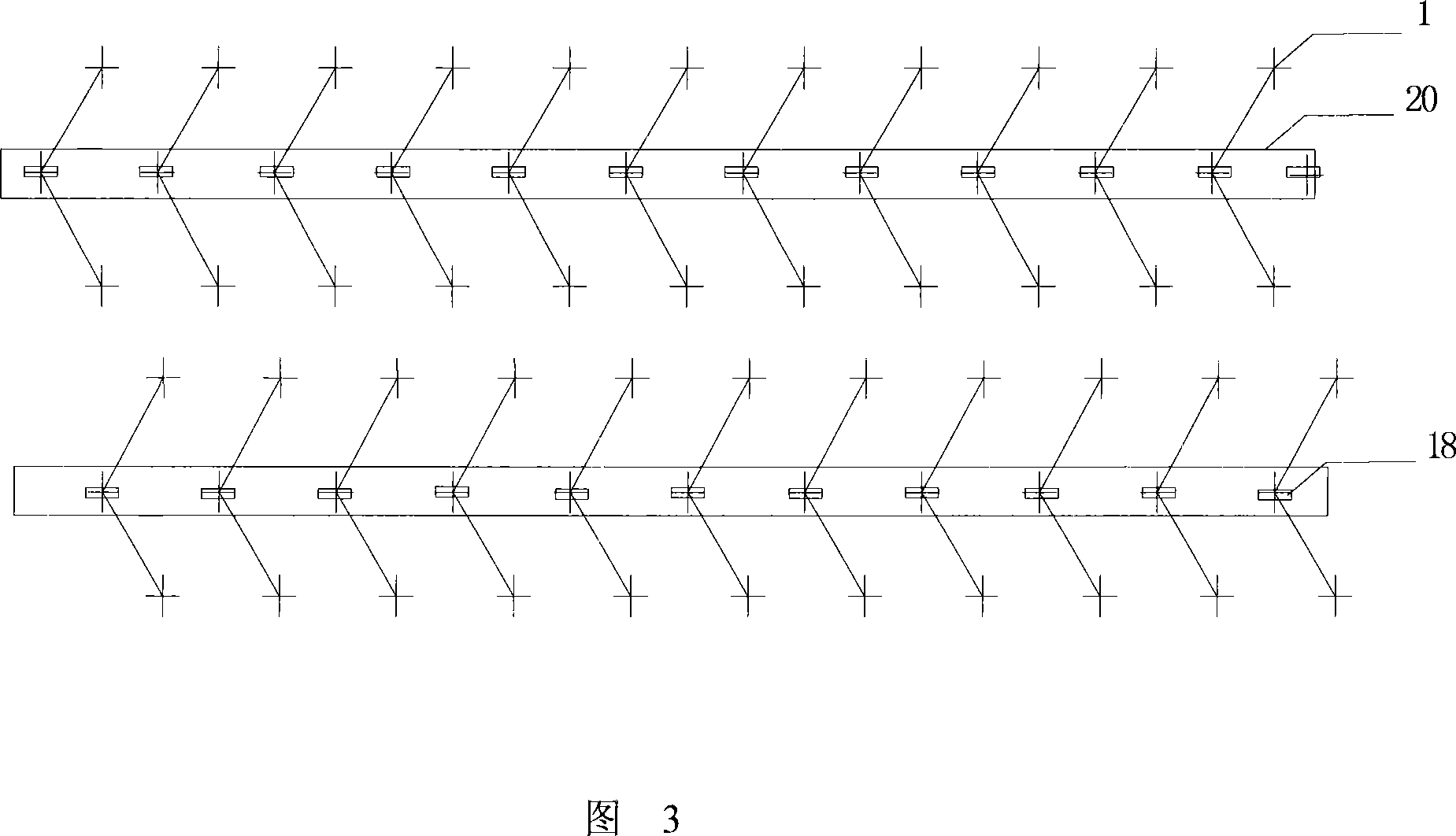

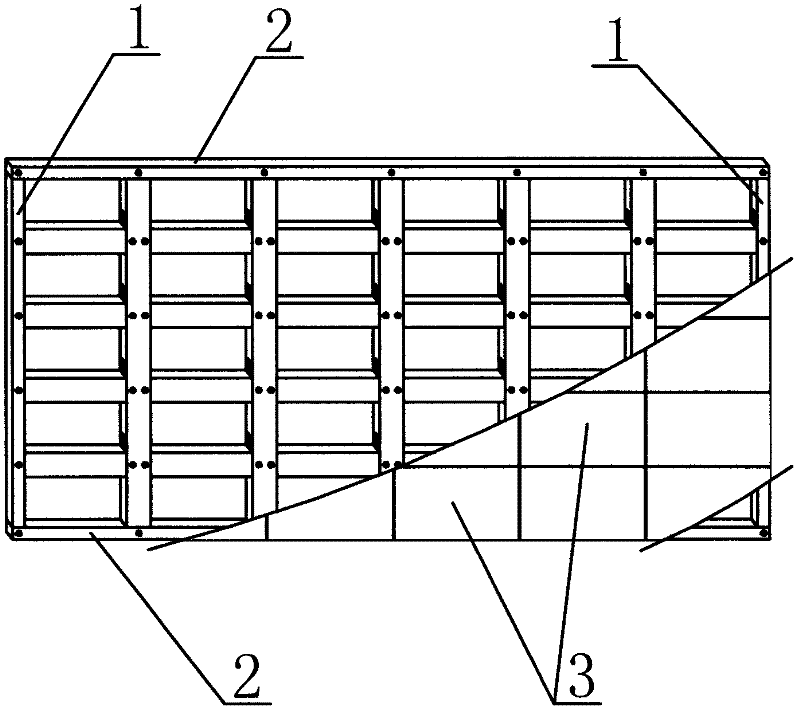

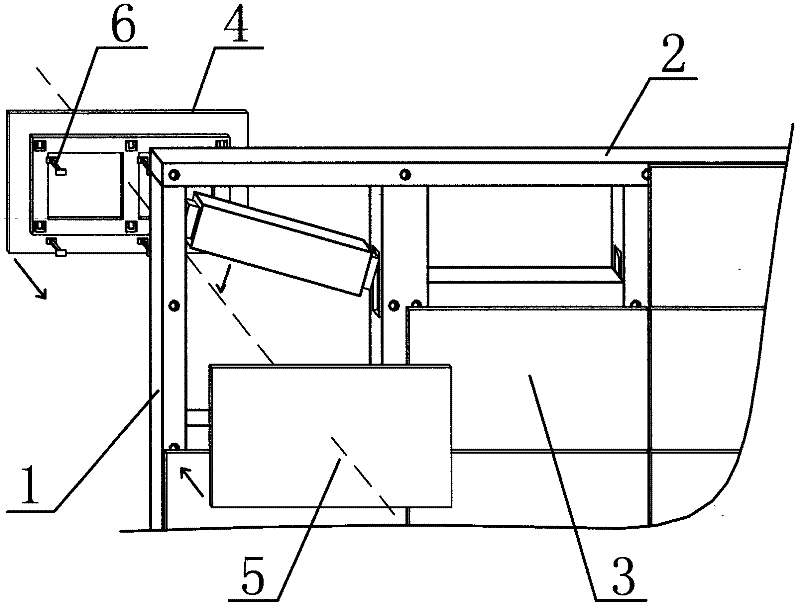

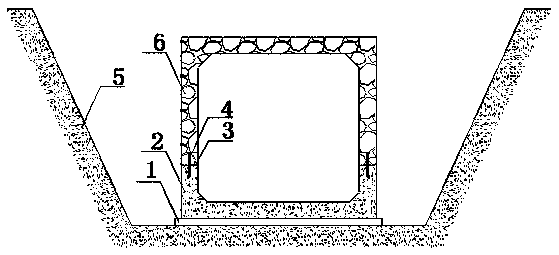

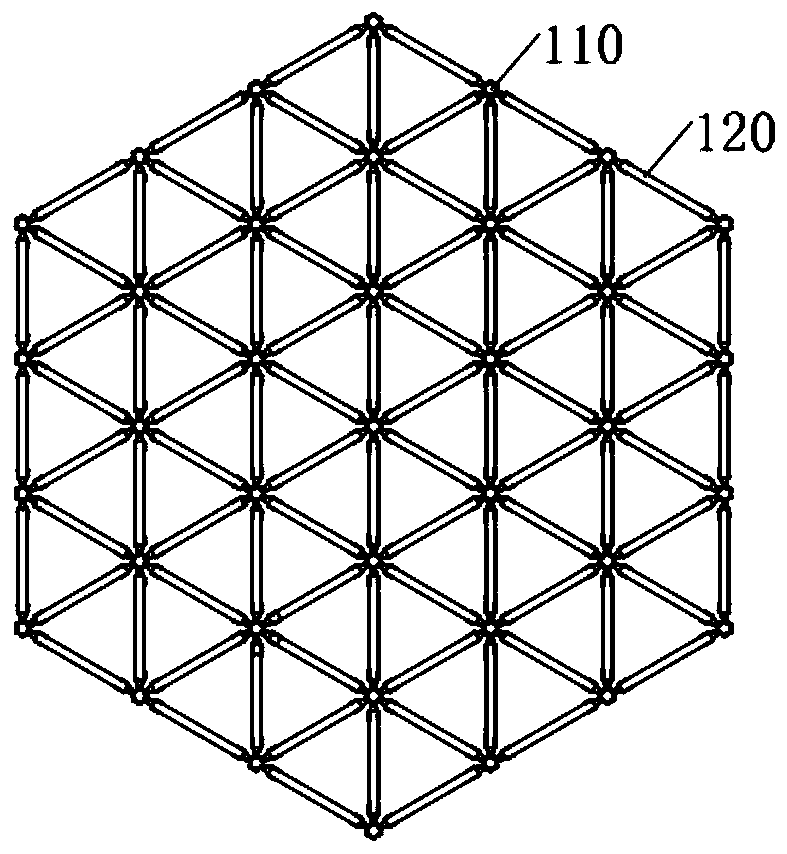

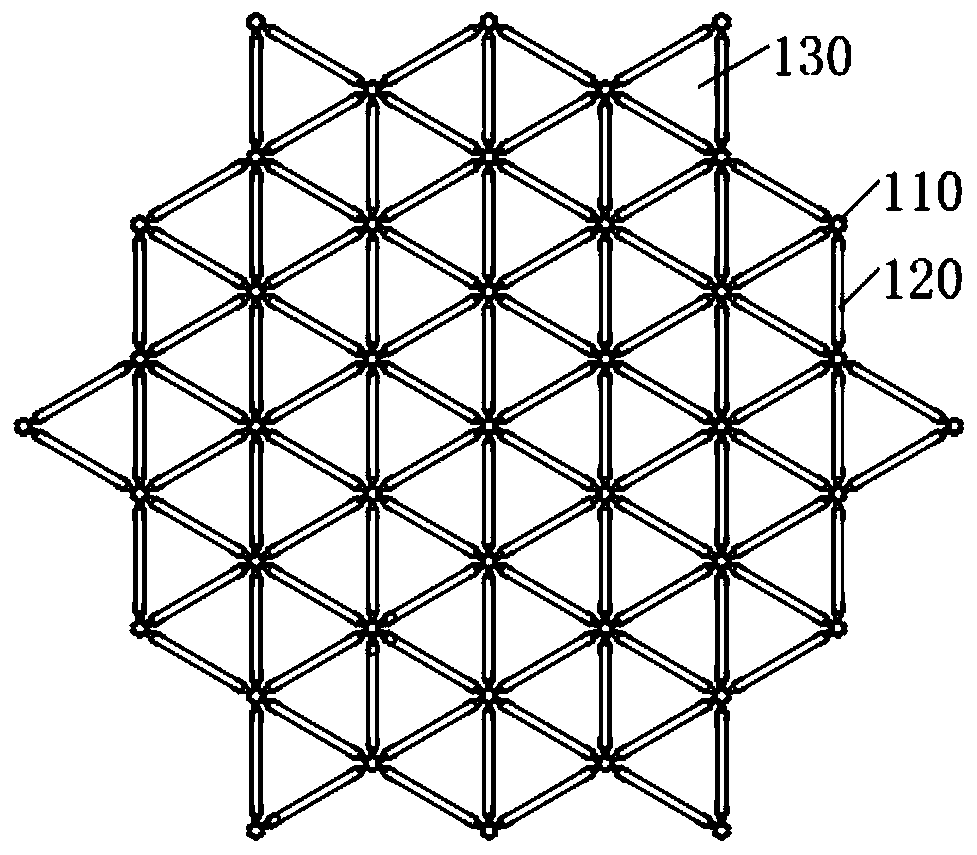

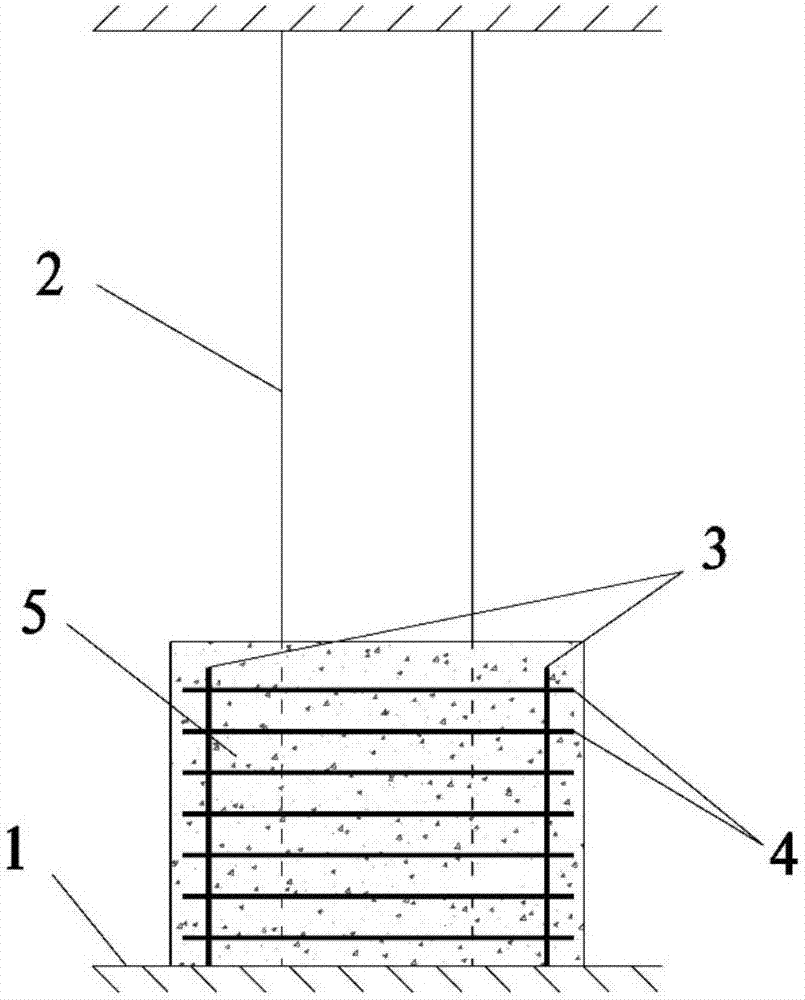

Bidirectional intensively ribbed mold clamp wall body

ActiveCN102383506AIncreased load-bearing capacityImprove shear resistanceConstruction materialWallsWeather resistanceInsulation layer

A bidirectional intensively ribbed mold clamp wall body comprises rib columns (1), rib beams (2) and mold clamp building blocks (3) and is characterized in that at least one mold clamp block (3) is embedded in a space defined by at least one rib column and at least two rib beams (2) or at least two rib columns (1) and at least one rib beam (2). The mold clamp building blocks (3) are formed by assembling outer face plates (4) and inner face plates (5) through connecting pieces (6). The bidirectional intensively ribbed mold clamp wall body can effectively enhance bearing performce, anti-shearing performance, anti-bending performance, anti-folding performance and quake-proof performance of a wall body. Bidirectional intensively ribbed grid structure type division enables the integrity and air tightness of the wall body to be enhanced. A heat preservation layer and a heat insulation layer are flexibly arranged, thereby cutting off a heat bridge channel to the largest extent and having good weather resistance. Advanced bin-division type fire-proof concept not only meets the requirements of the nation for buildings, but also reduces loss caused by fire hazard to the largest extent. Assembly type construction can achieve water-free and dust-free operation, thereby being fast, hygiene and environment-friendly, saving materials and lowering manufacture cost.

Owner:HUBEI SYNTHETIC SPACE TECH CO LTD

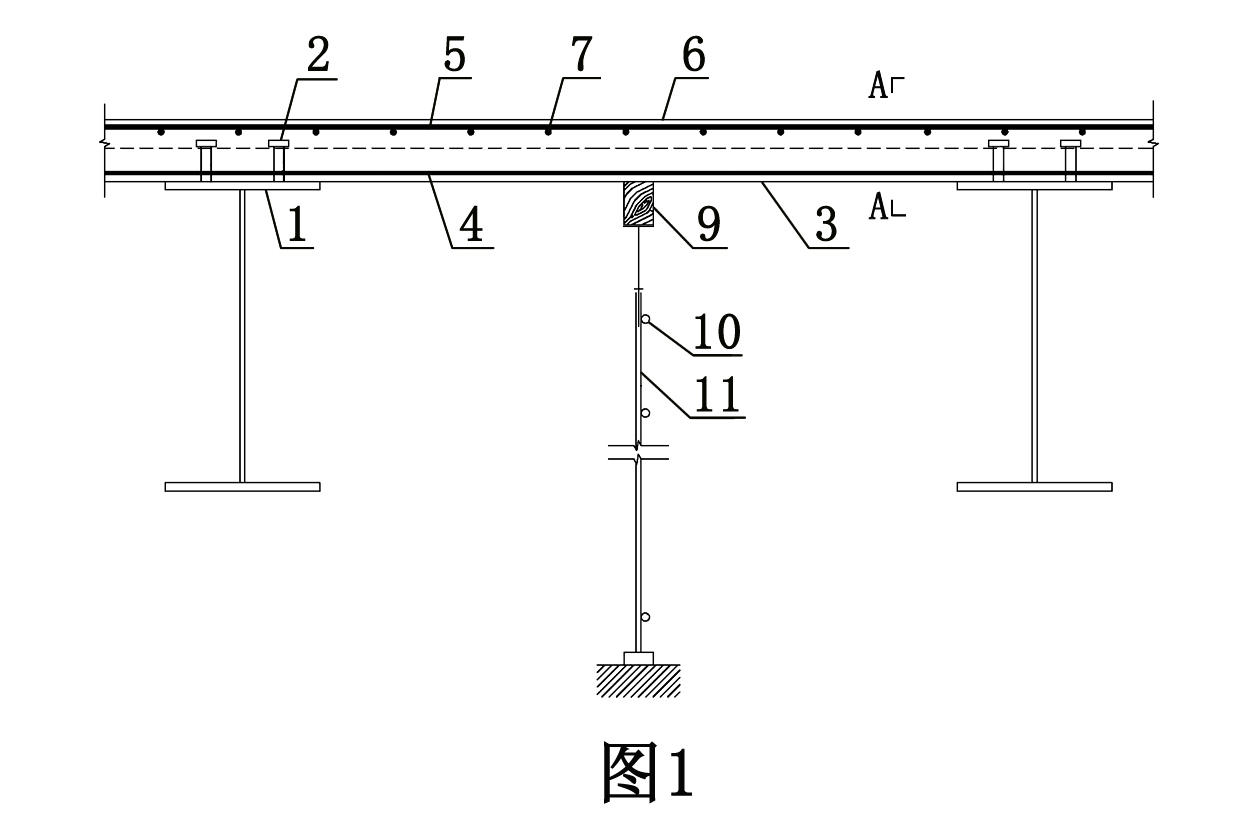

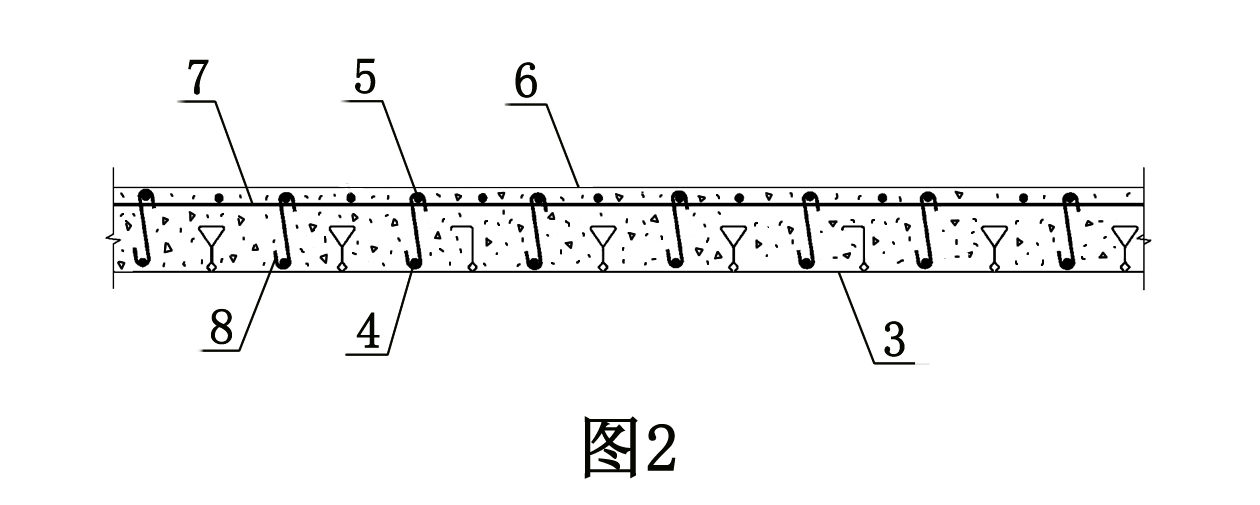

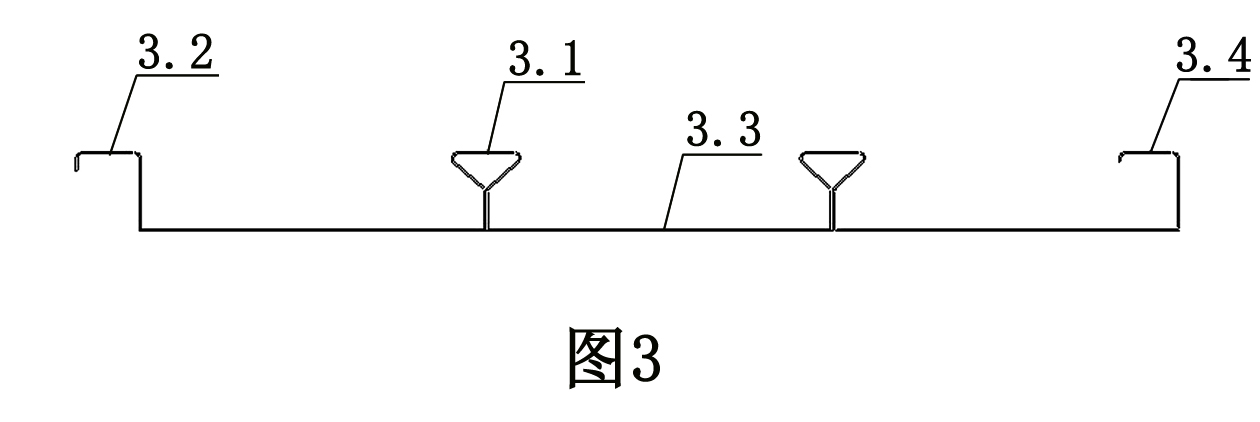

Closed-section profiled steel sheet-concrete combined floor and construction method thereof

InactiveCN101839033AImprove fire resistanceLose weightFloorsBuilding material handlingSheet steelFloor slab

The invention relates to a closed-section profiled steel sheet-concrete combined floor and a construction method thereof. The combined floor comprises a closed-section profiled steel sheet and concrete cast on the closed-section profiled steel sheet which is laid on steel beams of a steel structure main body, the bottom of the closed-section profiled steel sheet is fixedly connected with the steel beams, a top support is erected under the closed-section profiled steel sheet between steel beams, a lower iron forced bar is arranged in each wave trough of the closed-section profiled steel sheet, and an upper iron forced bar is correspondingly arranged above each lower iron forced bar, connected with the lower iron forced bar by a tensile bar and erected on an upper iron distribution bar into a groined shape. In the invention, the closed-section profiled steel sheet is also utilized as a floor bottom die to save construction material. By using the construction method, the construction period can be shortened, the cost can be decreased, the structural bearing force requirement is met, and the construction quality is ensured so that the invention is particularly suitable for public construction structures with high fireproof requirement.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

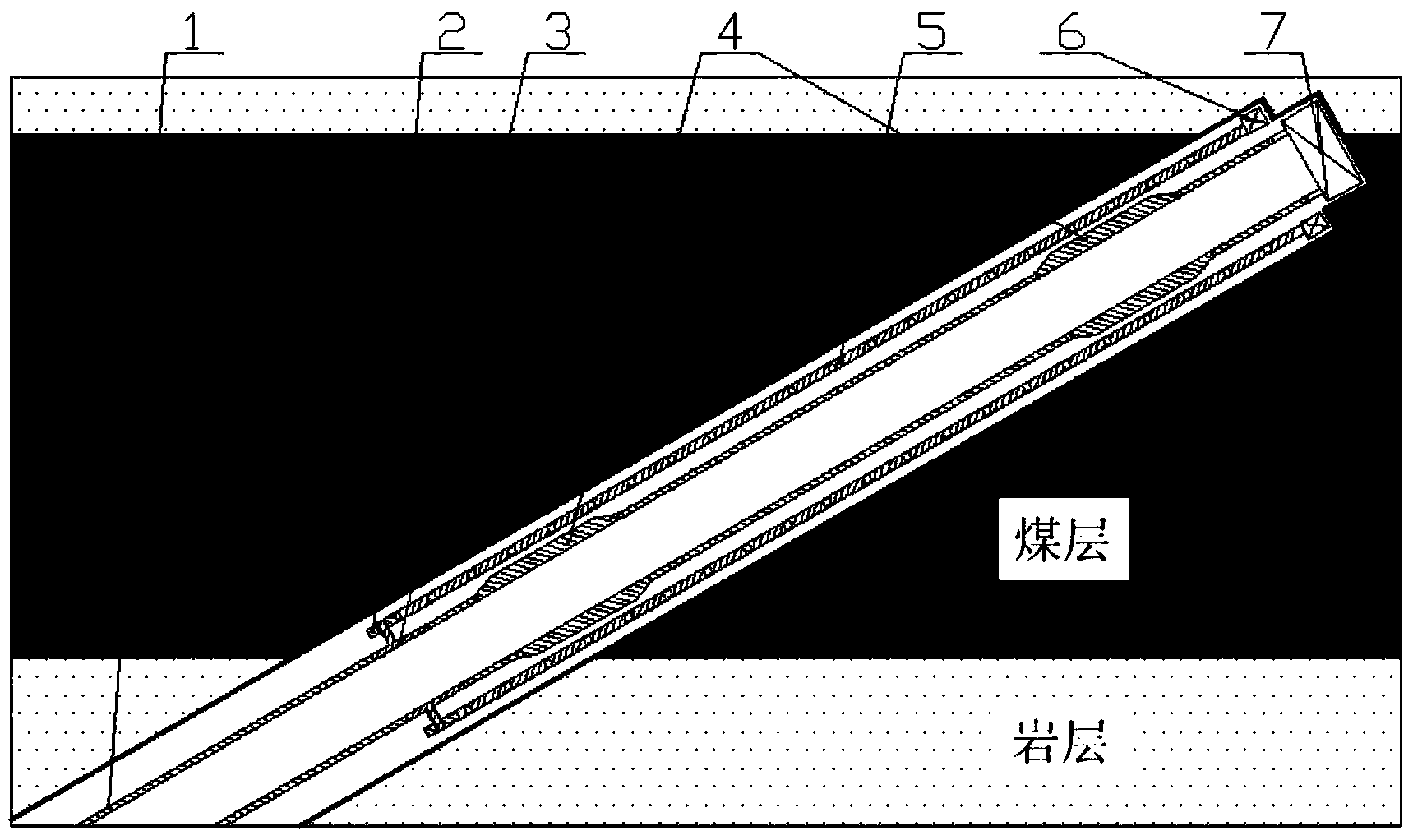

Sieve tube drilling process for outburst coal seam section in underground coal mine

InactiveCN103643893AImprove securityImprove efficiencyDrilling rodsFluid removalTorque transmissionCoal

A sieve tube drilling process for an outburst coal seam section in an underground coal mine comprises the following steps: preparation: calculating the length of the outburst coal seam section; drilling: drilling to the hole drilling depth by a drilling machine, mounting an orifice pipe, sealing holes and fixing the orifice pipe; synchronous drilling: adopting a sieve tube drilling rig combination to drill to the designed hole depth, wherein each sieve tube drilling rig comprises an active drill rod and a sieve opening sleeve surrounding the outer side of the active drill rod, and a torque transmission device is arranged between the rear end of the sieve opening sleeve and the active drill rod; withdrawing the drill rod: rotating the active drill rod in the reverse direction by 1-2 turns to enable a torque transmission male connector to be separated from a torque transmission female connector, withdrawing the active drill rod, and leaving the sieve opening sleeve in the outburst coal seam section. After the drilling is performed to the designed hole depth, the active drill rod is rotated in the reverse direction and withdrawn, the drilling process and the sieve tube lowering process are combined, the safety and the efficiency are improved, the cost is reduced, and the problems in the prior art are solved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

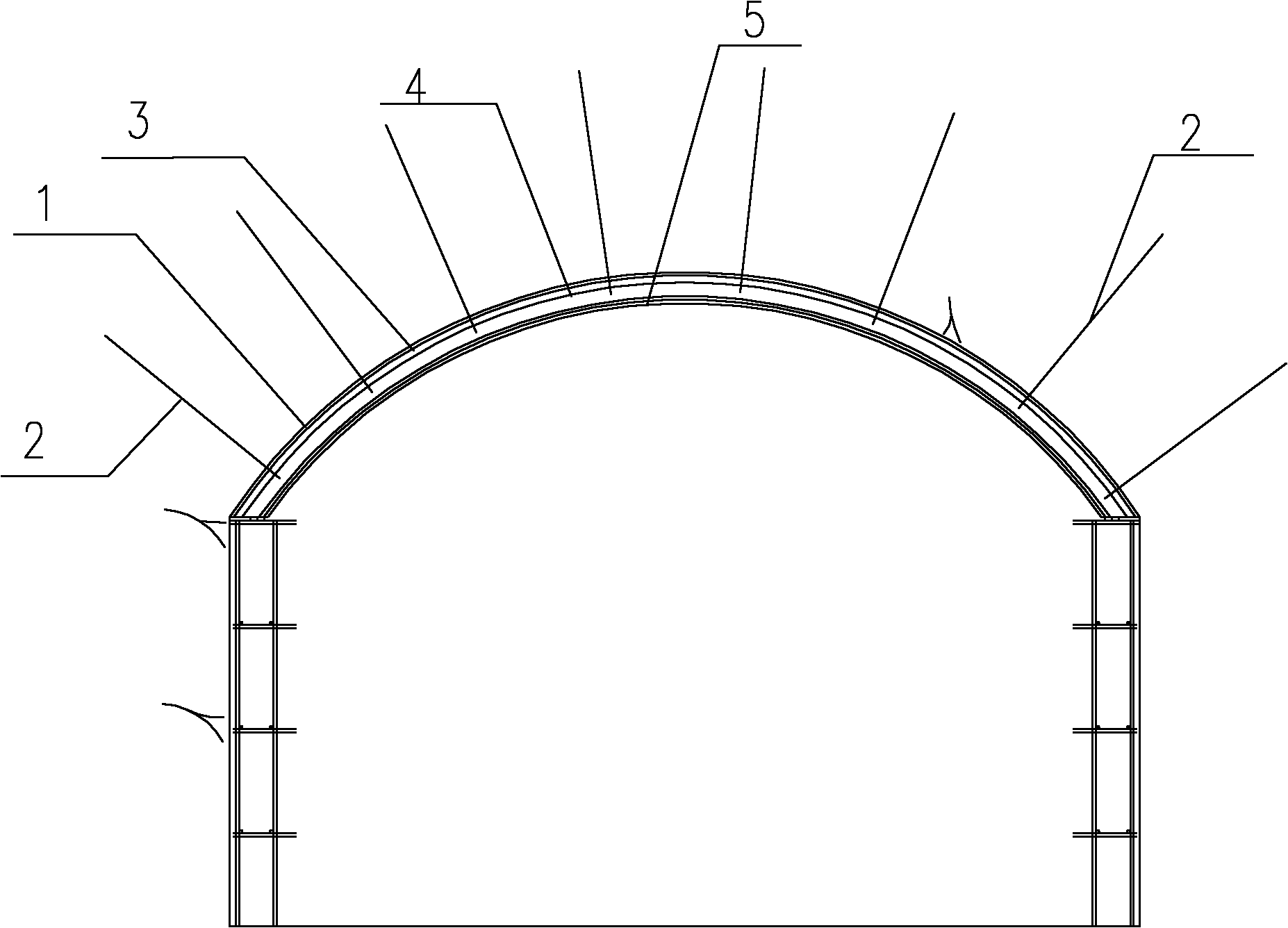

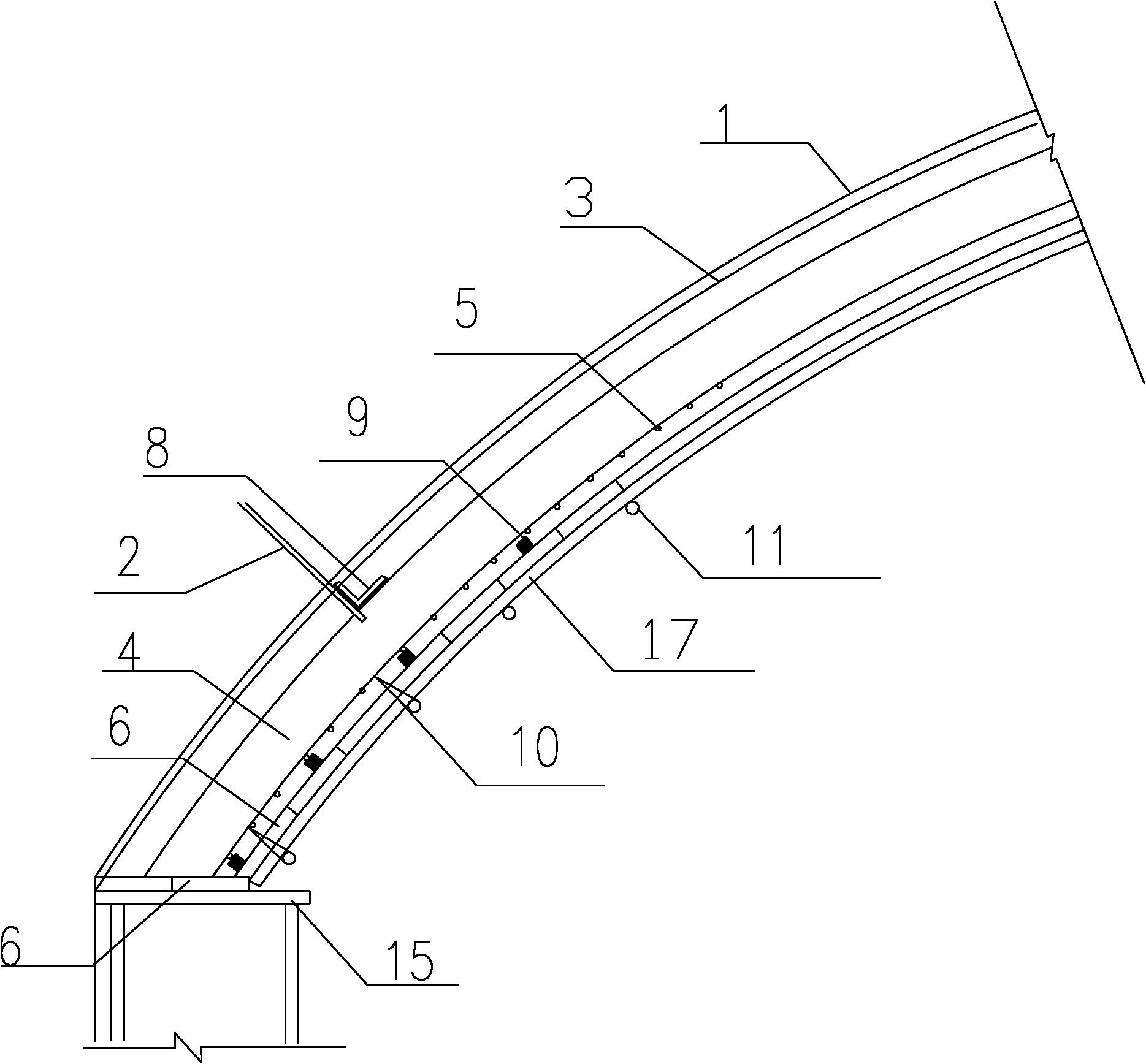

Cavern arch mould spraying concrete construction structure and process

ActiveCN101936170AEffectively closedShort construction periodUnderground chambersBuilding reinforcementsFalseworkUnderground cavern

The invention discloses a cavern arch mould spraying concrete construction structure and a cavern arch mould spraying concrete construction process. The structure comprises an anchor rod, a steel structure, concrete and a template, wherein the anchor rod is fixed in a bed rock; the steel structure is fixed through the anchor rod; the detachable template is suspended and fixed and forms a cavern arch pouring space with the bed rock together; and the concrete is sprayed into the pouring space through the template. The construction process comprises the following steps of: rock bed surface treatment, anchor rod construction, inner steel fabric installation, I iron installation, outer steel fabric installation, template installation, concrete spraying and the like. The construction needs no concrete delivery pump, does not need to build a full bearing scaffold and needs only a few constructors and spraying equipment. Therefore, construction materials are greatly saved; the construction period is short; arch lining concrete can be substituted by the mould spraying concrete of an underground cavern permanent structure; and the arch mould spraying concrete is more convenient to operate and the quality is assured.

Owner:SINOHYDRO BUREAU 7 CO LTD

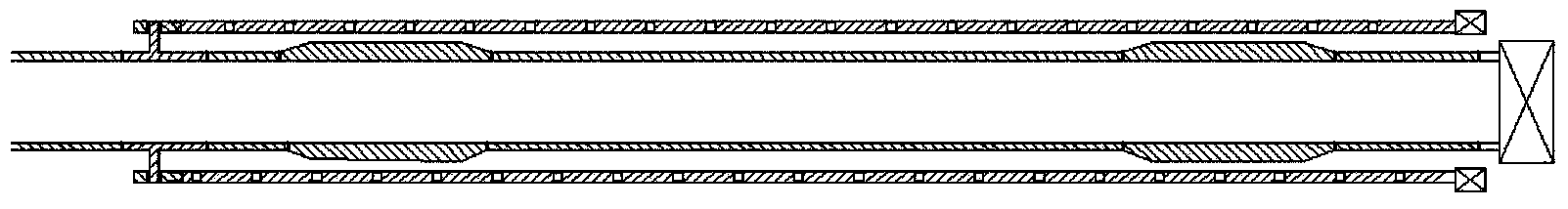

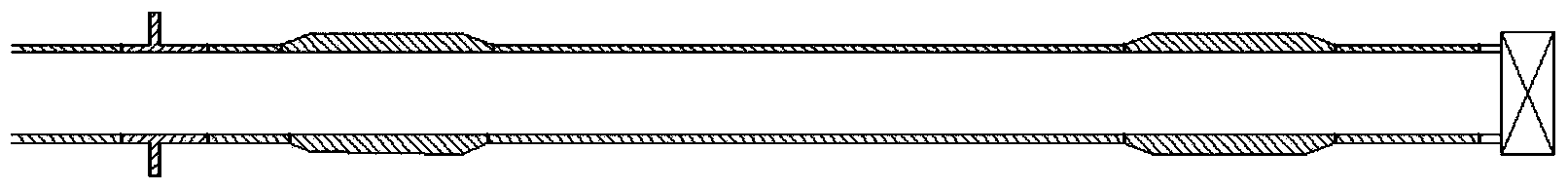

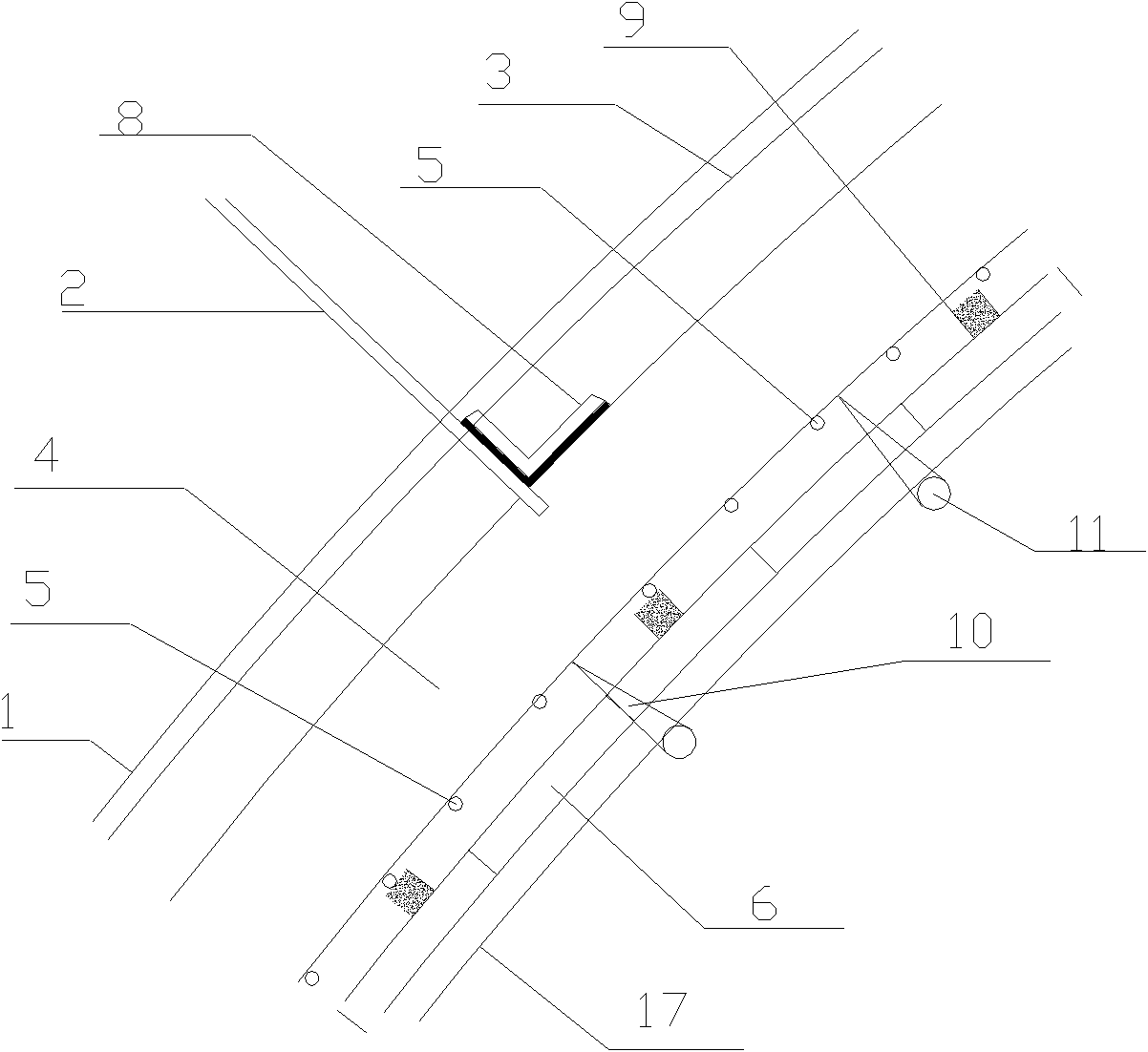

Continuous construction method for aluminum alloy template for comprehensive pipe rack

ActiveCN108914965AFast constructionShorten the construction periodArtificial islandsUnderwater structuresMaterials scienceAluminium alloy

The invention relates to underground comprehensive pipe rack construction, in particular to a continuous construction method for an aluminum alloy template for a comprehensive pipe rack. The continuous construction method comprises the following steps that A, first-time pouring construction of a first-section comprehensive pipe rack body is conducted; B, second-time pouring construction of the first-section comprehensive pipe rack body and first-time pouring construction of a second-section comprehensive pipe rack body are conducted at the same time; C, form removal of the first-section comprehensive pipe rack body is conducted; D, second-time pouring construction of the second-section comprehensive pipe rack body is conducted; and F, first-time pouring construction of a third-section comprehensive pipe rack body is conducted. According to the continuous construction method, the continuous cyclic work is achieved, rapid turnover construction is achieved, the construction speed is increased, the construction period is shortened, construction materials are saved, and the construction environment is safer and more environment-friendly. Meanwhile, a concrete structure formed through the continuous construction method is flat and smooth in surface quality, the requirements of facing and bare concrete are met, secondary plastering is not needed, and the construction cost is saved.

Owner:22MCC GRP PRECISION FORGING

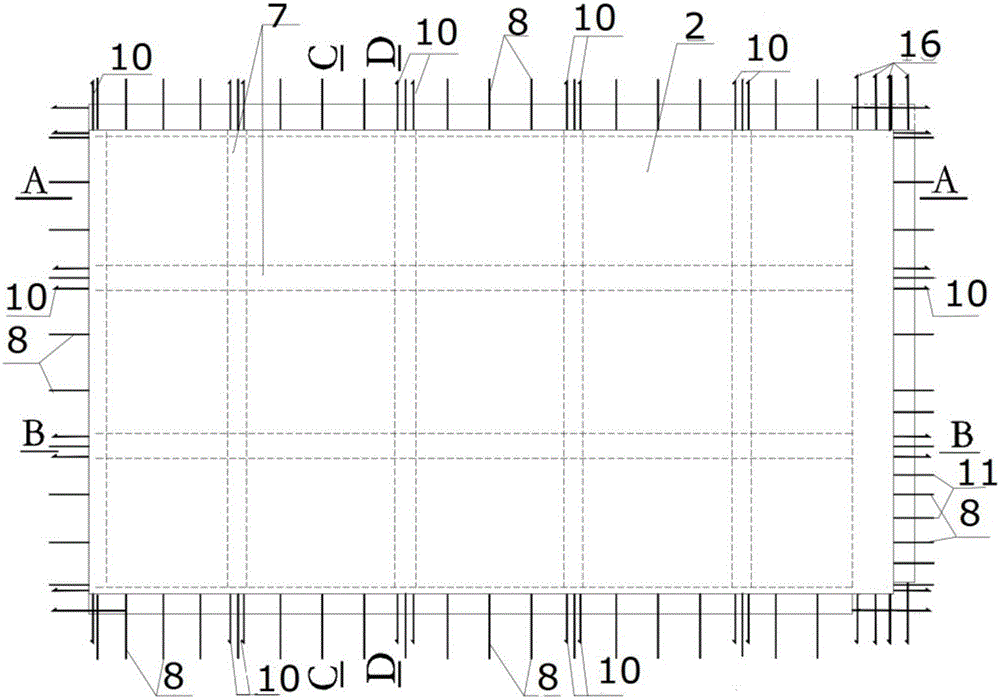

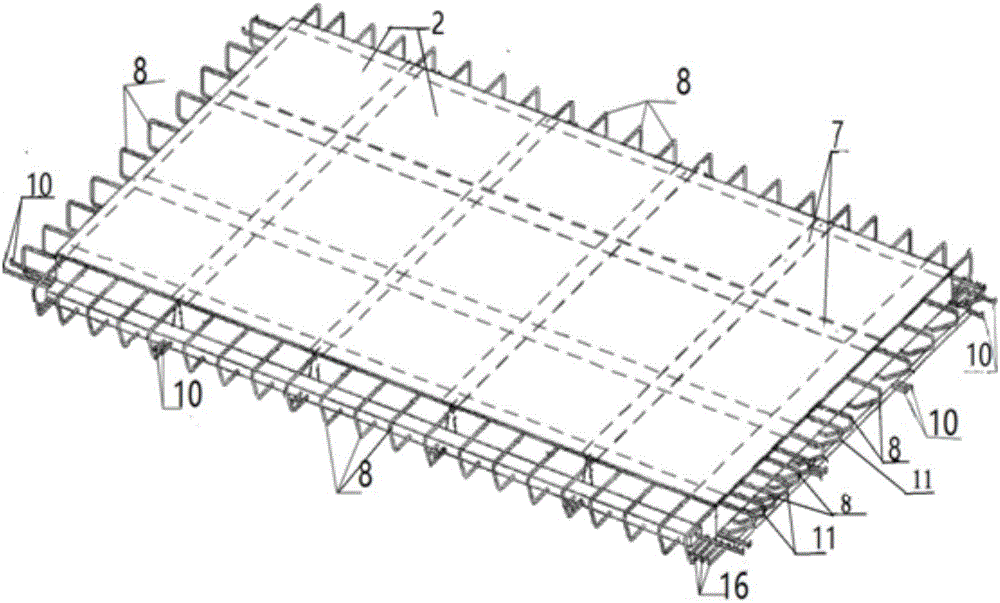

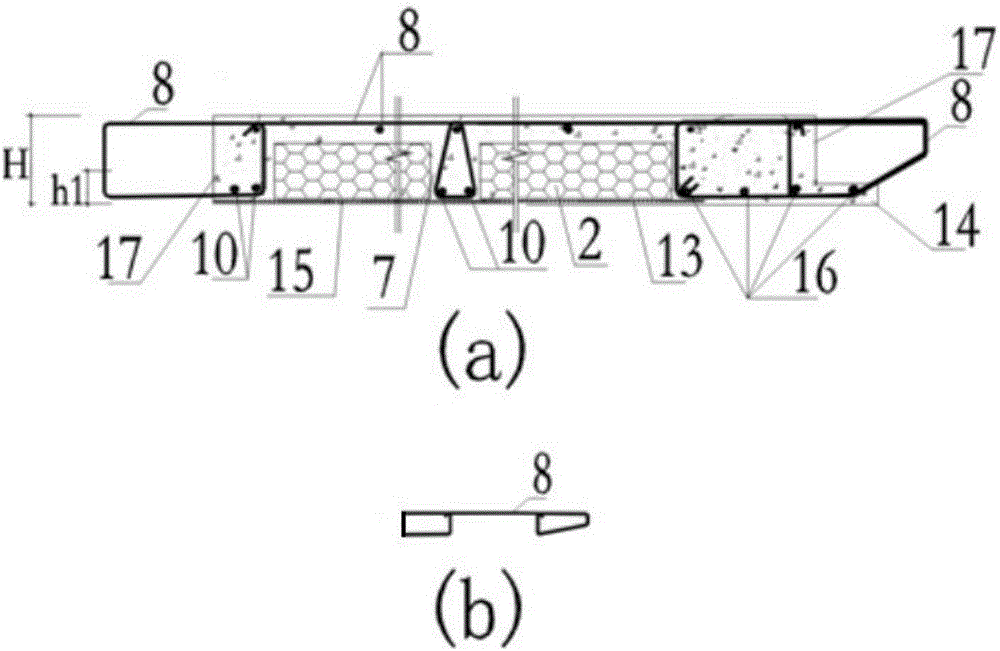

Connecting node of assembled whole thick prefabricated slab unit and slab unit thereof

The invention discloses a connecting node of an assembled whole thick prefabricated slab. Connecting steel bars are reserved on the connecting surface of a prefabricated slab unit in the mode, the exposed parts of the connecting steel bars are ' '-shaped, and the exposed parts and the connecting surface form a closed polygon. In the connecting mode for the prefabricated slab unit and a beam or a wall, the connecting steel bars of the prefabricated slab unit are inserted with steel bars configured for the beam or the wall together at the connecting positions in a penetrating mode. Viewing from the cross section of the whole connecting node, the connecting steel bars and the steel bars configured for the beam or the wall form a single closed stirrup or a composite stirrup, and longitudinal bolt steel bars penetrate into the inner corner position of the single closed stirrup or the composite stirrup. The connecting node of the whole thick prefabricated slab unit can achieve the equivalent performance as a prefabricated slab connecting nodes and a cast-in-place concrete structure while achieving higher prefabrication rate and assembly rate. The invention further provides the whole thick prefabricated slab unit for achieving the connecting mode.

Owner:刘祥锦

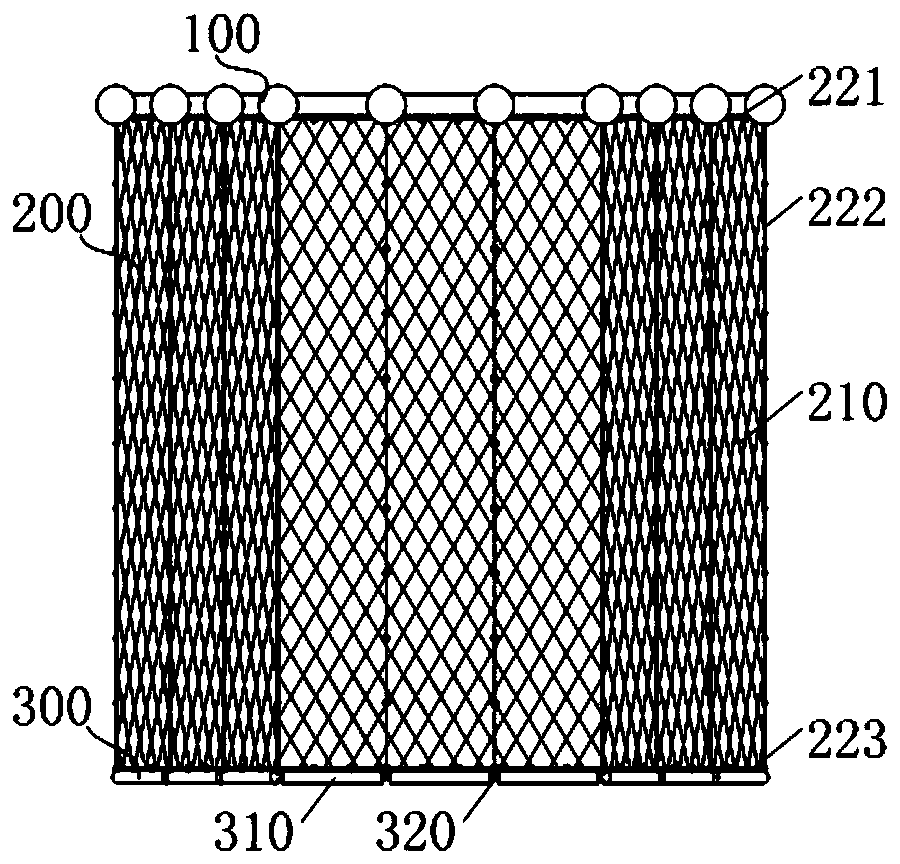

Breeding net cage

PendingCN109874716APlay a stabilizing roleImprove adaptabilityClimate change adaptationPisciculture and aquariaMaricultureSea waves

The invention provides a breeding net cage, and relates to the technical field of mariculture. The breeding net cage comprises a flexible floating frame device, a net device and drooping weight devices; the flexible floating frame device can float on the sea surface, and multiple sets of anchoring devices are connected with the surrounding portion of the flexible floating frame device; the top ofthe net device is connected with the flexible floating frame device, the net device is strutted under the sea surface to form a space used for breeding marine organisms, and multiple sets of droopingweight devices are connected to the bottom of the net device. The problems that an existing net cage is complex in structure and high in cost and can be easily damaged by sea wave impacting are effectively solved.

Owner:肖志东 +1

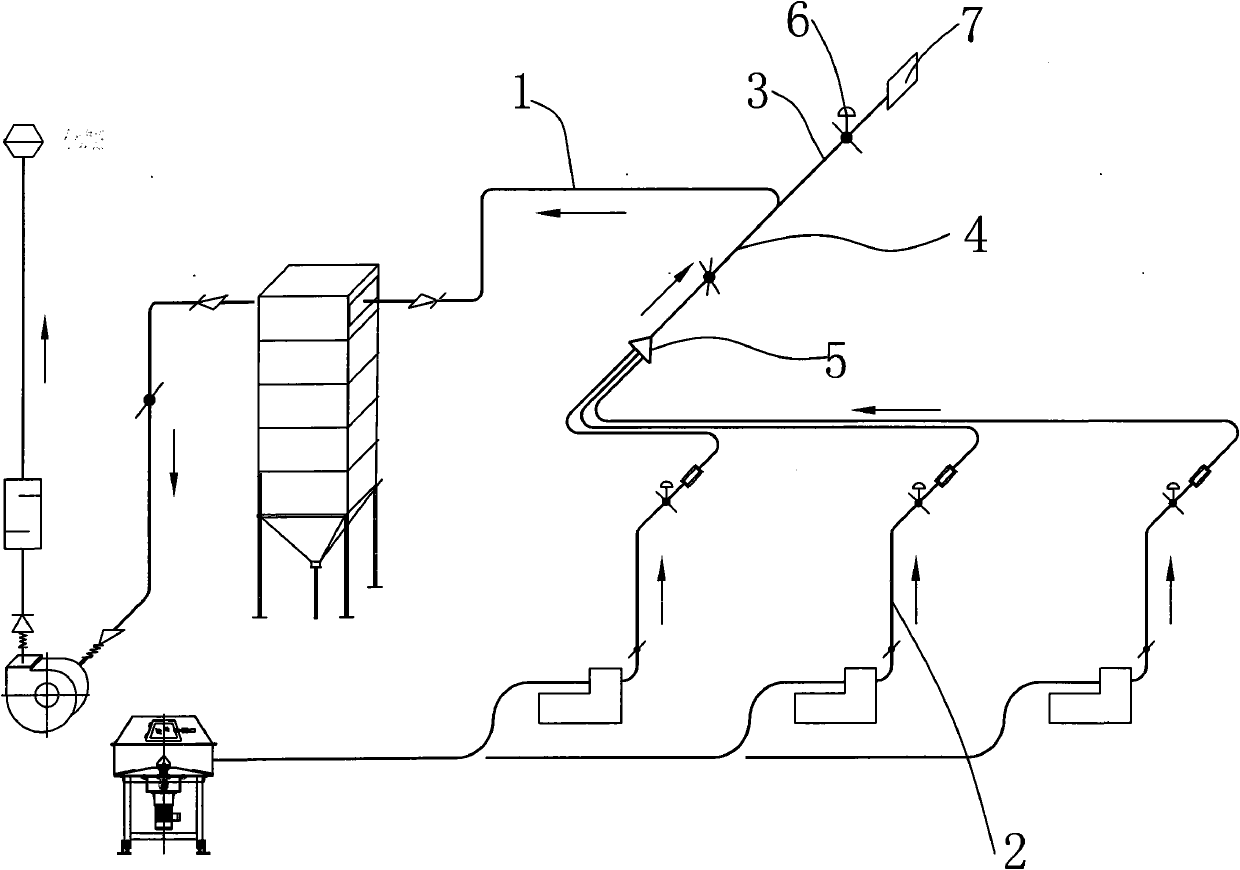

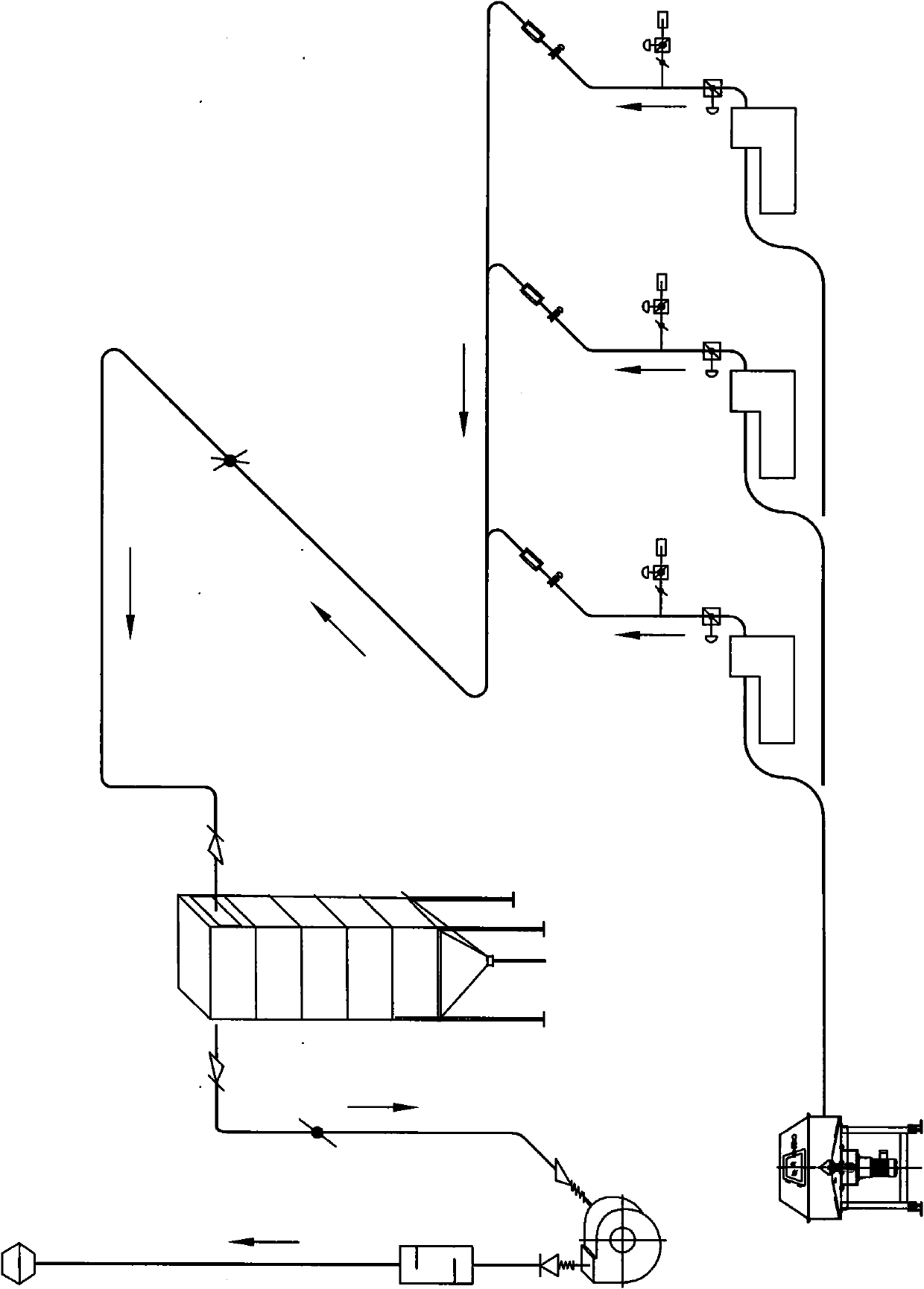

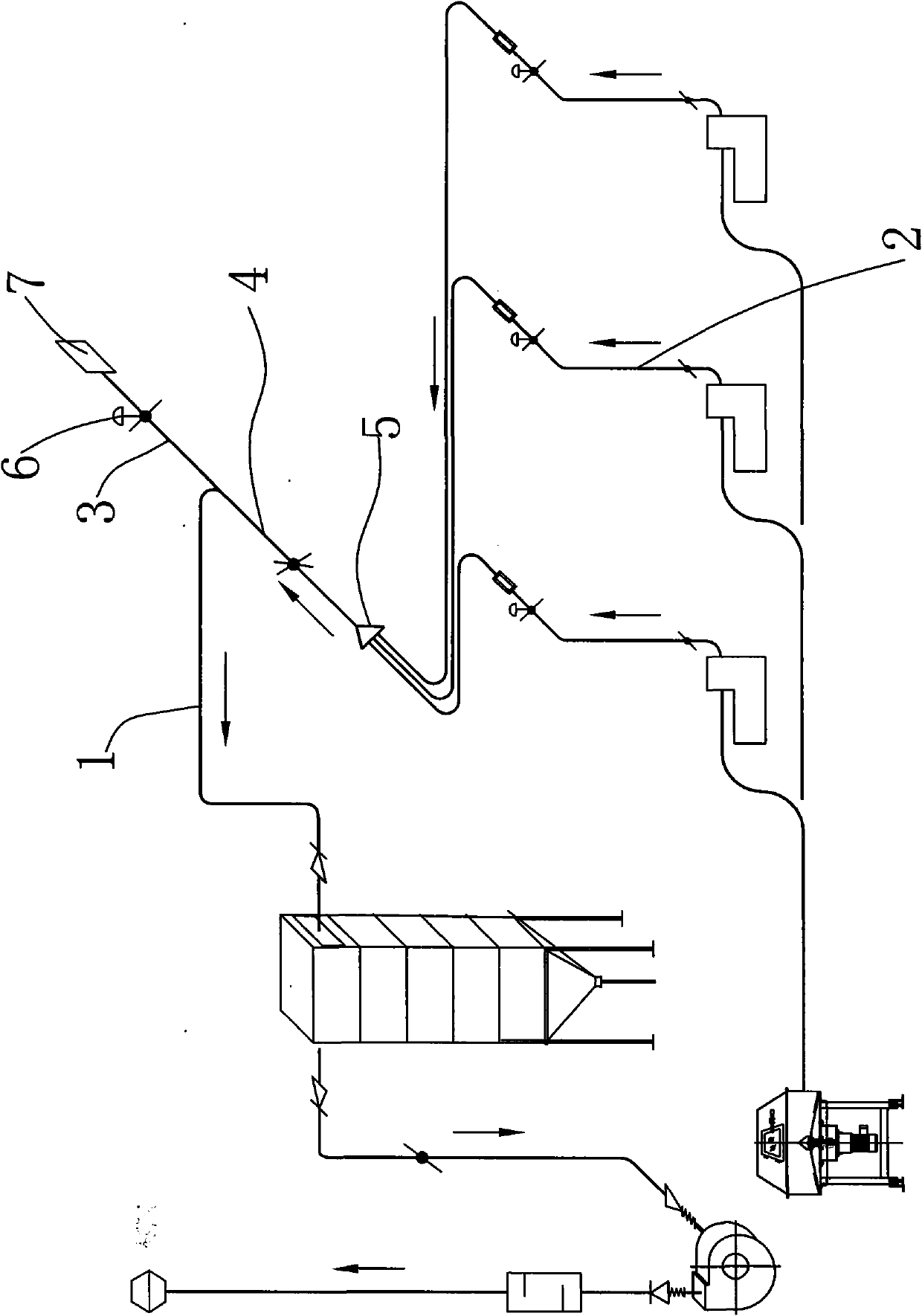

Wind power dedusting system for rolling process of cigarettes factory

InactiveCN101904559AStable designUnified designCigarette manufactureCleaning using gasesControl valvesWind power

The invention discloses a wind power dedusting system for a rolling process of a cigarettes factory. The wind power dedusting system comprises a deduster connecting pipe, a plurality of branch wind pipes and a plurality of pieces of rolling and packing equipment, wherein each piece of rolling and packing equipment is connected with a branch wind pipe; the wind power dedusting system also comprises a wind compensating pipe with a wind compensating silencer and a main wind pipe; the deduster connecting pipe and the wind compensating pipe are respectively communicated with the main wind pipe; the main wind pipe is respectively communicated with each branch wind pipe through a pipe collector; and the wind compensating pipe is provided with a control valve which is used for automatically switching on to compensate wind when a certain branch wind pipe is stopped. The wind power dedusting system can concentrate wind power for supply, and ensure stable wind quantity, wind pressure and wind speed; the pipeline design is more standardized and unified; and the effective operability and the yield of the rolling and packing equipment are improved, the production cost is reduced and the service environment of workers is improved.

Owner:长沙赛普尔自动化工程设备有限公司

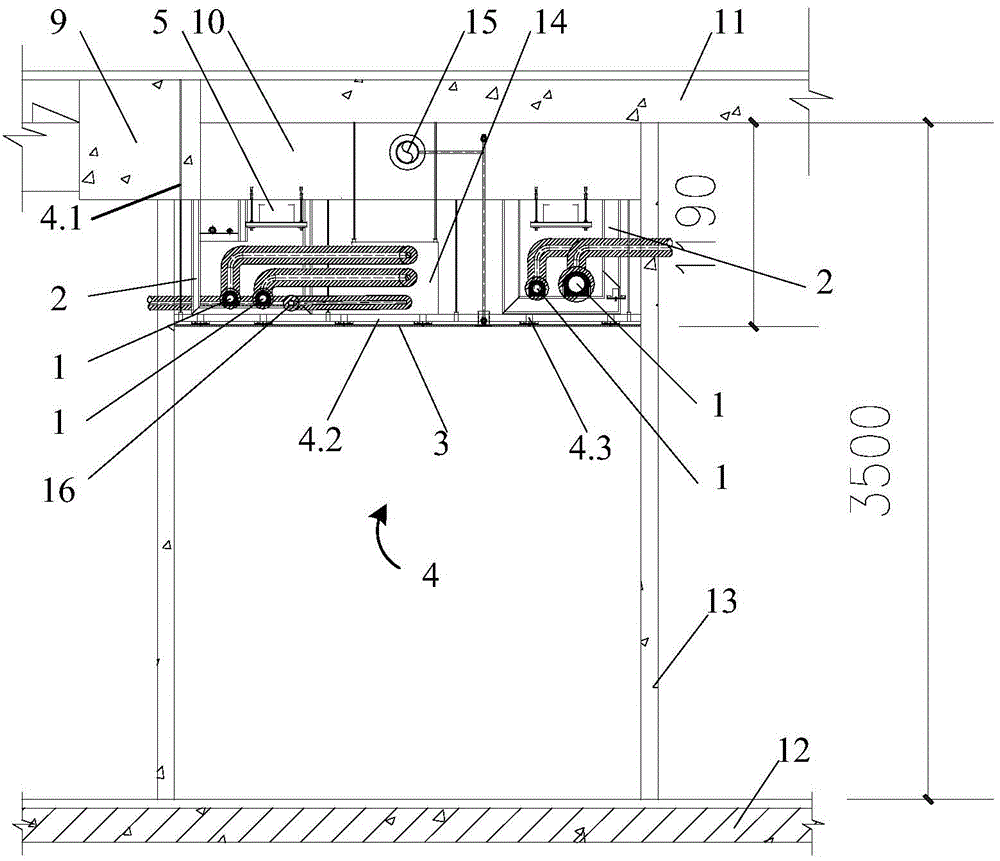

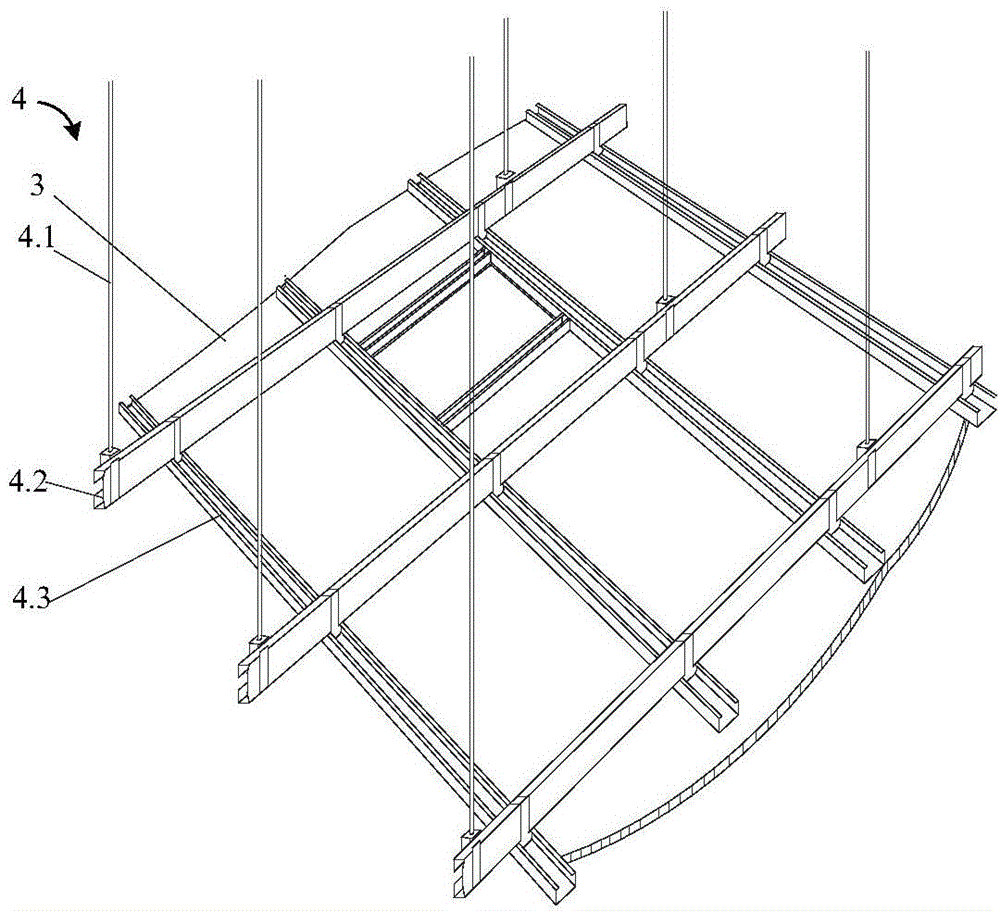

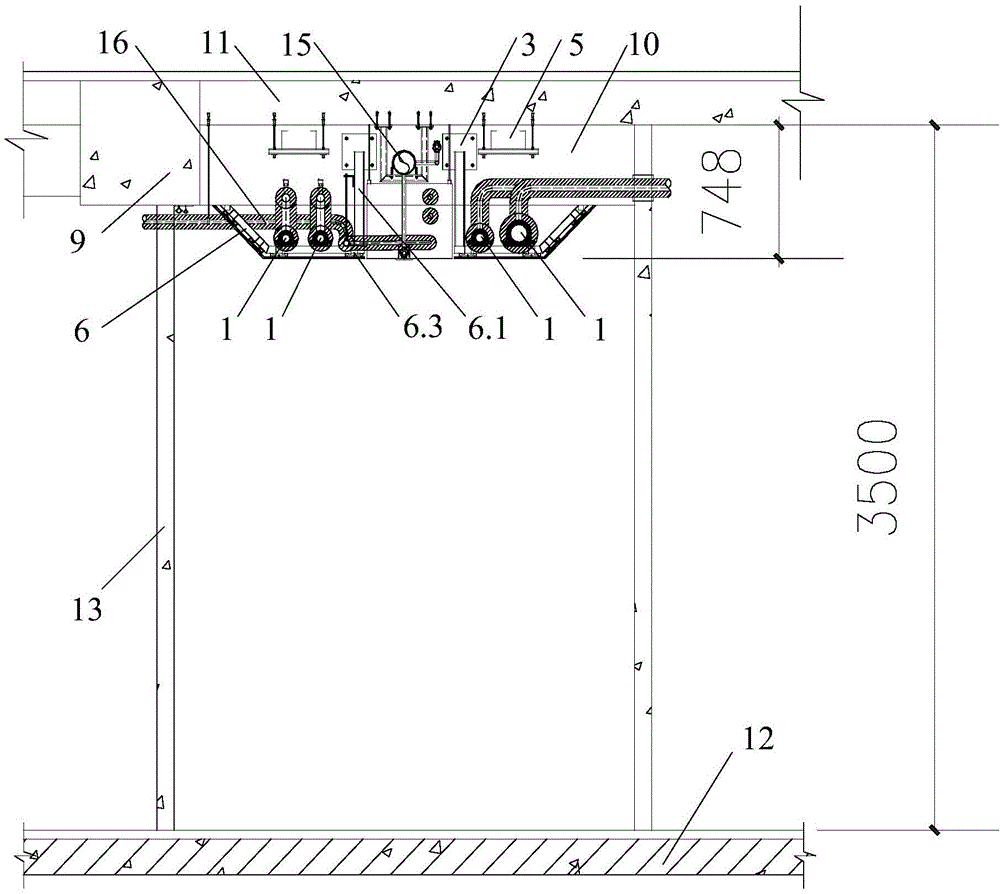

Structure and method for increasing height of corridor ceiling

ActiveCN104405071AIncrease heightSave construction materialsPipe supportsCeilingsKeelDropped ceiling

The invention provides a structure and a method for increasing the height of a corridor ceiling. The structure comprises a pipeline ceiling combined supporting hanger, a strong current wire groove and an air-conditioner cold water supply and water returning pipe which are arranged along the longitudinal direction of a main beam, wherein the pipeline ceiling combined supporting hanger is hung to a secondary beam or a floor top plate; the air-conditioner cold water supply-return pipe is directly arranged on the pipeline ceiling combined supporting hanger; the strong current wire groove is hung below the floor top plate. Due to the fact that except the part, which passes the secondary beam and is provided with a lower concave part used for crossing the secondary beam, of the strong current wire groove, the other parts of the strong current wire groove are arranged in the space between the bottom surface of the secondary beam and the bottom surface of the floor top plate, the ceiling elevation of a corridor is obviously improved. Due to the fact that a pipeline supporting hanger and a ceiling supporting hanger are combined into the pipeline ceiling combined supporting hanger, and the pipeline ceiling combined supporting hanger simultaneously plays the role of supporting the air-conditioner cold water supply-return pipe, a keel and a ceiling, so that a main keel in the original ceiling supporting hanger is eliminated, and the ceiling is further lifted.

Owner:SHANGHAI INSTALLATION ENG GRP

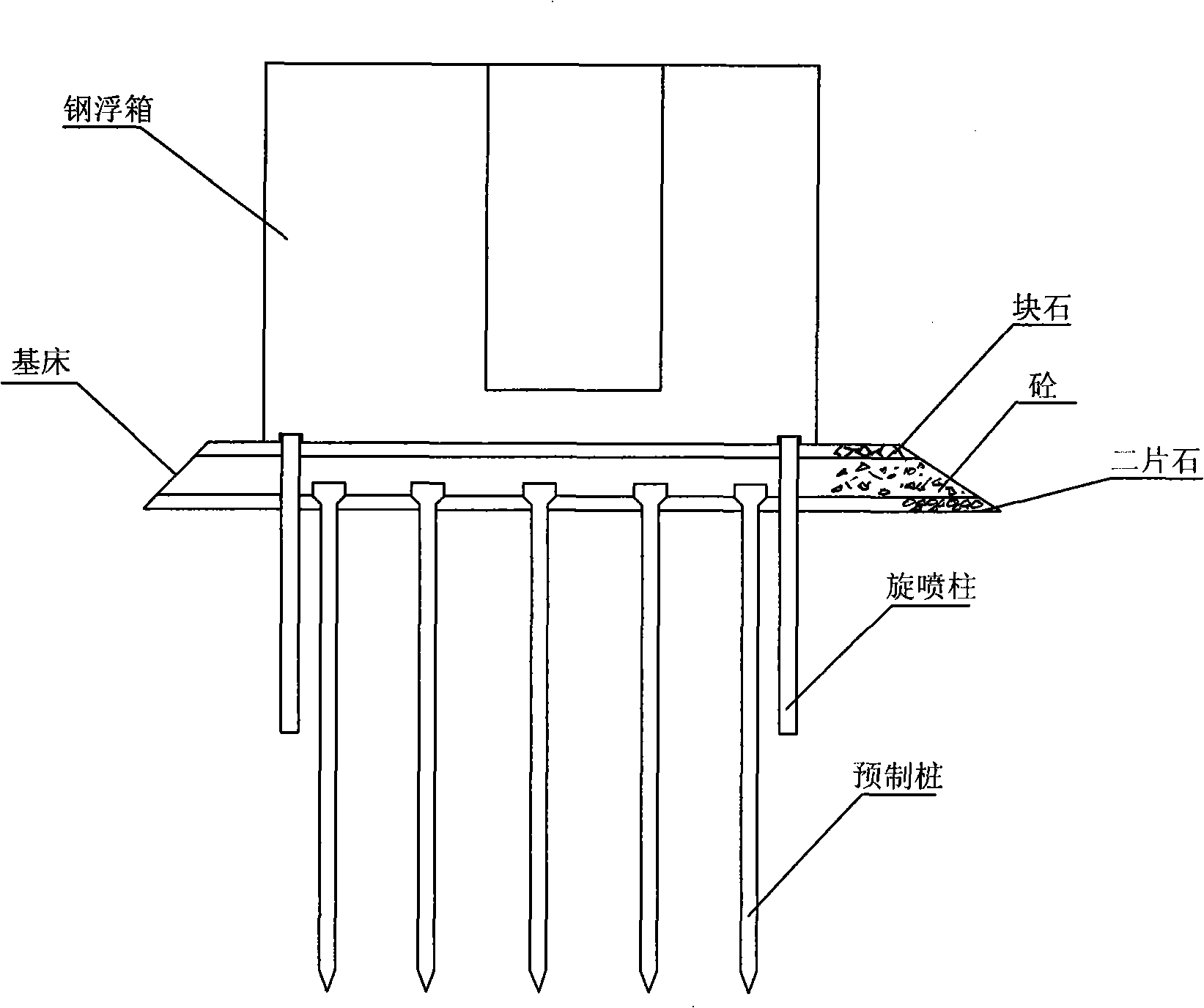

Soft soil foundation large scale steel float lock head construction method

InactiveCN101260664AAdaptableSave construction materialsDry-docksClimate change adaptationCushionWater depth

The invention discloses a soft soil base large-scale steel floating box lock head construction method, which is characterized in that the specific construction steps comprise that: a foundation trench is excavated and silt is removed; a precast pile is beaten; a foundation bed is ripraped and a concrete cushion coat is poured and tamped; a steel floating box is precast and submerged; a waterproof purdah is jet grouted. Compared with the prior art, the invention has the characteristics of strong applicability, mass construction material saving, low construction cost and reliable construction quality; a lock head steel floating box can be also used as construction cofferdam; the soft soil base large-scale steel floating box lock head construction method is in particular suitable for building the lock head in an area with a soft soil base and deep water and can achieve good waterproof effect no matter how depth the foundation bed is.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

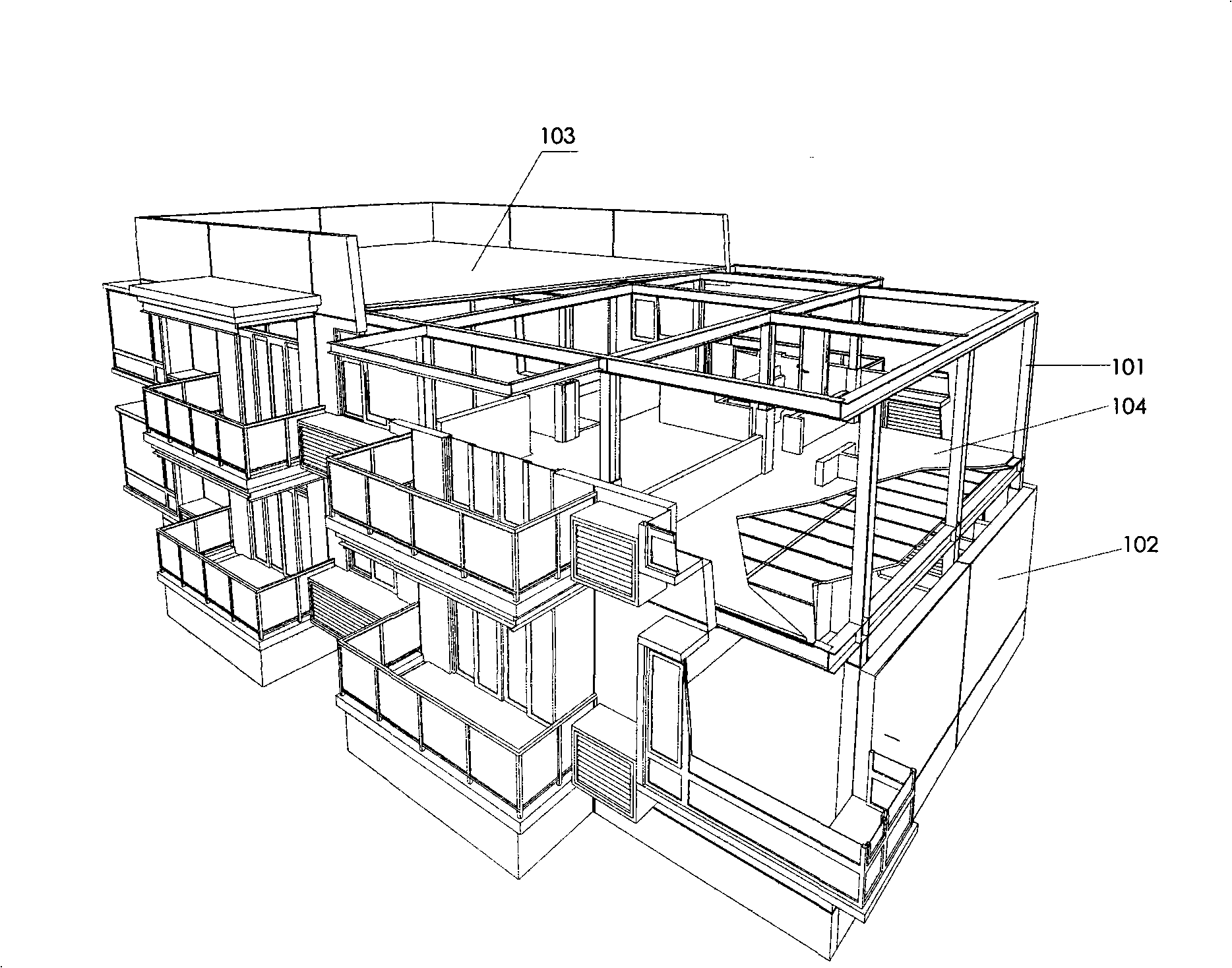

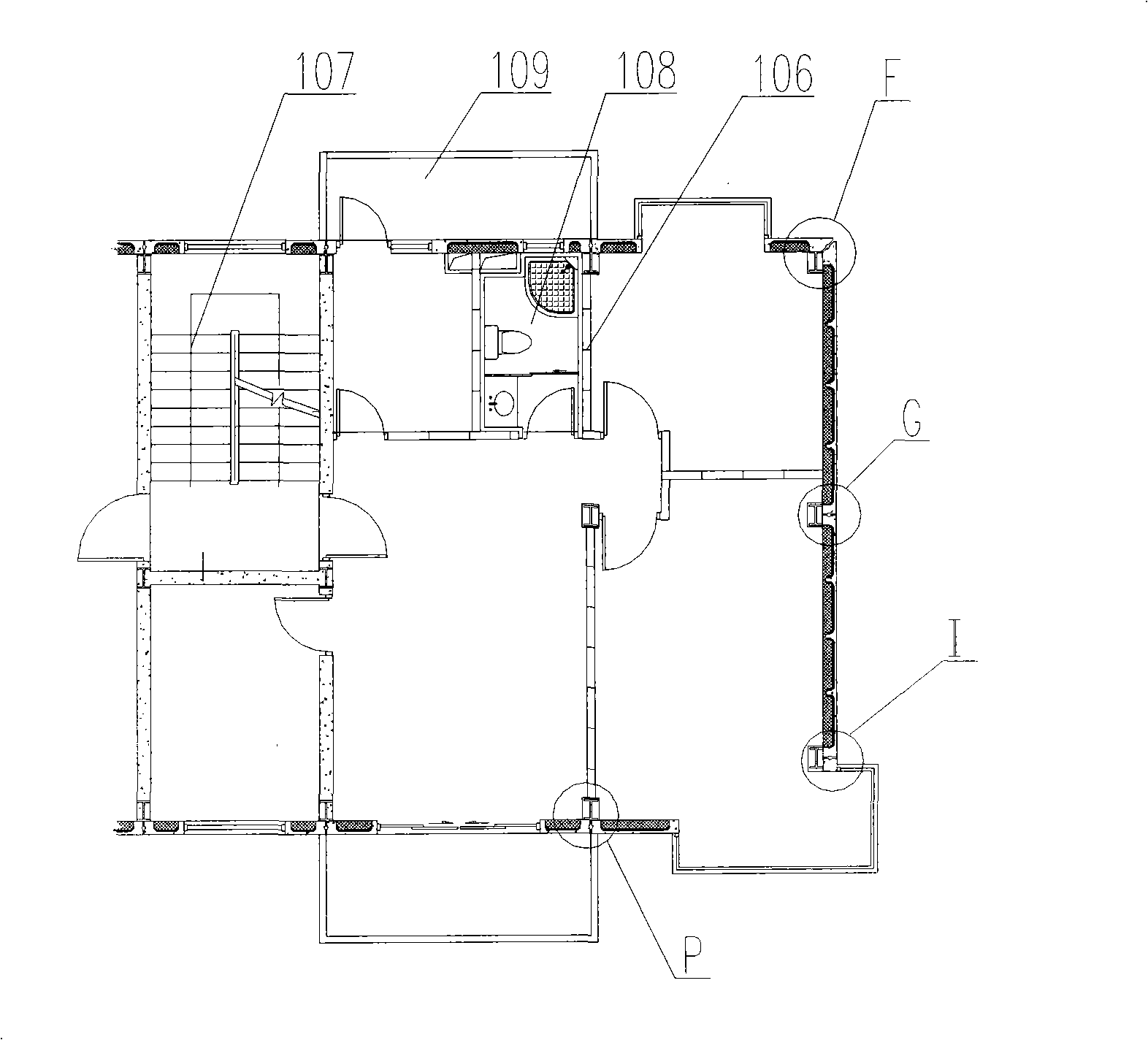

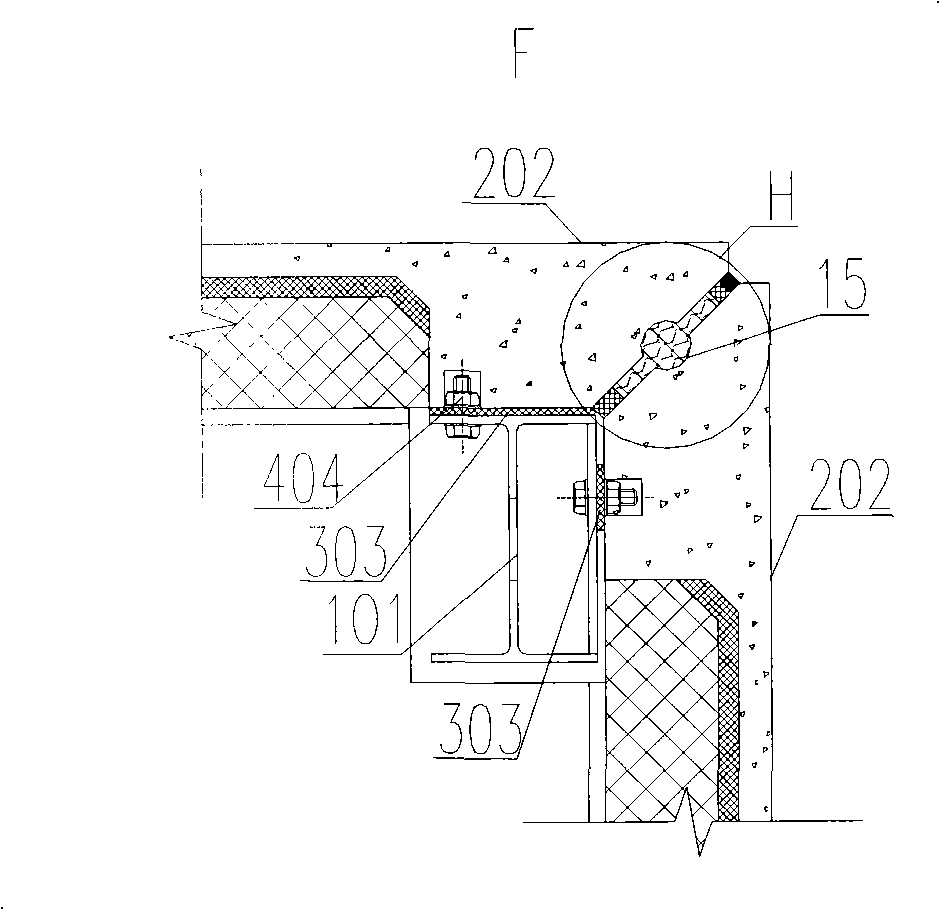

Industrialization energy-saving building house

ActiveCN101353929AAchieve aestheticsReduce consumptionFloorsDwelling buildingArchitectural engineeringShock resistance

The invention discloses an industrialized energy-saving building which comprises a load-carrying frame, an enclosing exterior wall, a floor cover slab and a roof cover plate; the enclosing exterior wall is formed by the assembly of entirely prefabricated composite exterior wall boards and fixed on the load-carrying frame of a main body by a shock-resistance and energy-dissipation connecting part. The building is an industrialized energy-saving building which lessens construction energy consumption, water consumption and work area, saves construction material, reduces construction noise and the influence of dust on the environment and the ecology, shortens the construction period, has function of shock resistance and energy dissipation and is capable of saving energy, material, water, land and protecting environment.

Owner:黄涛 +1

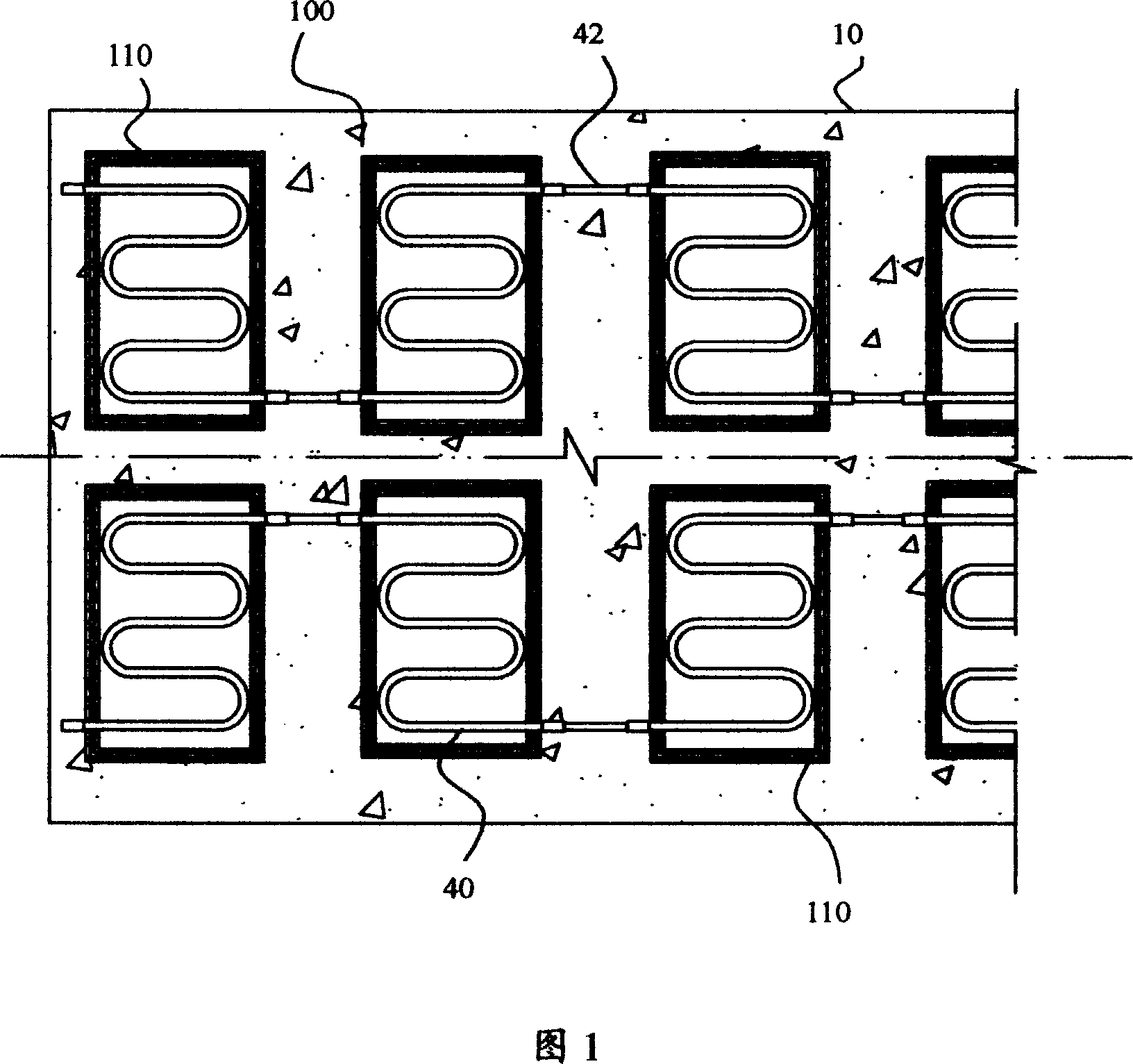

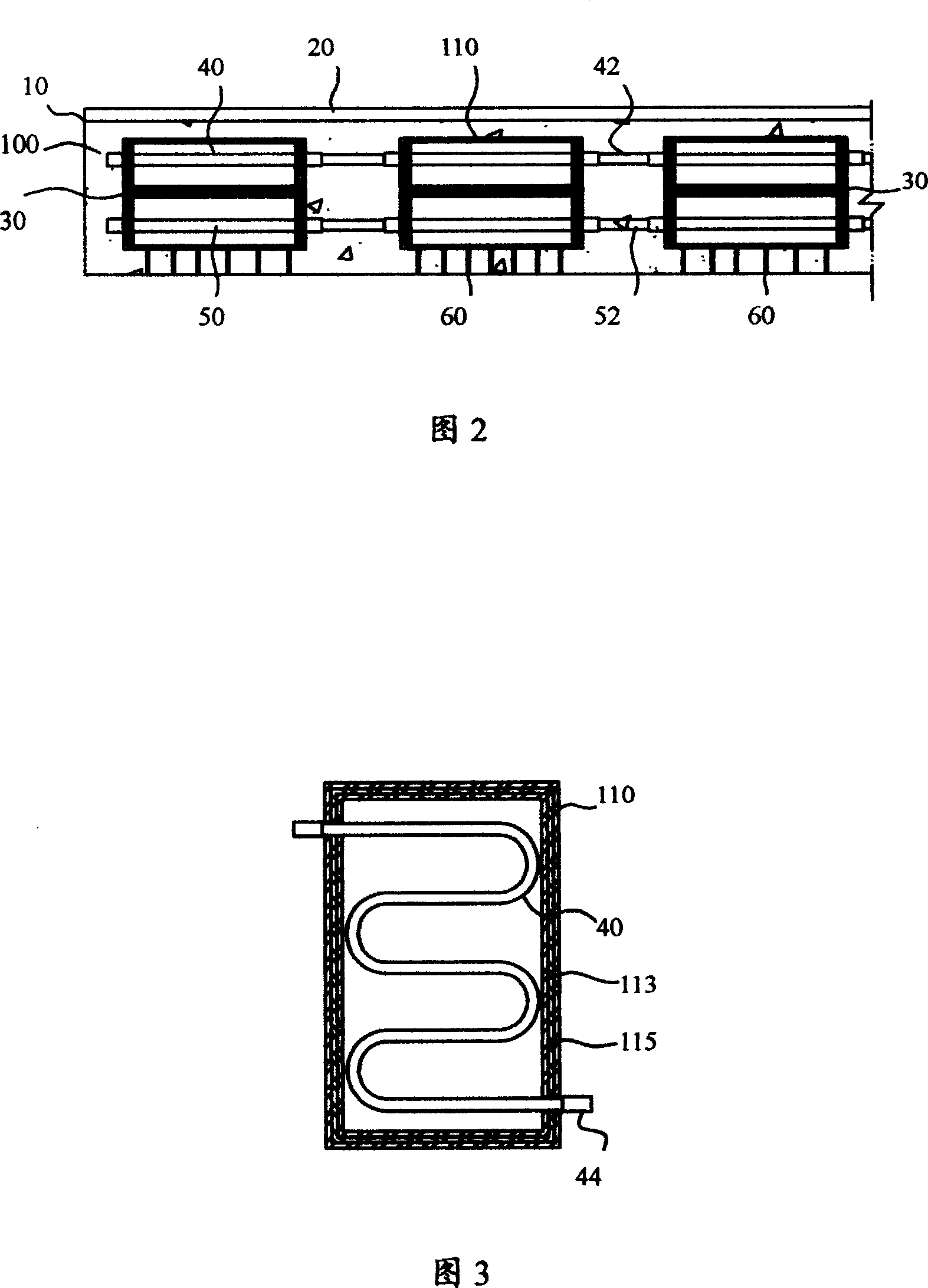

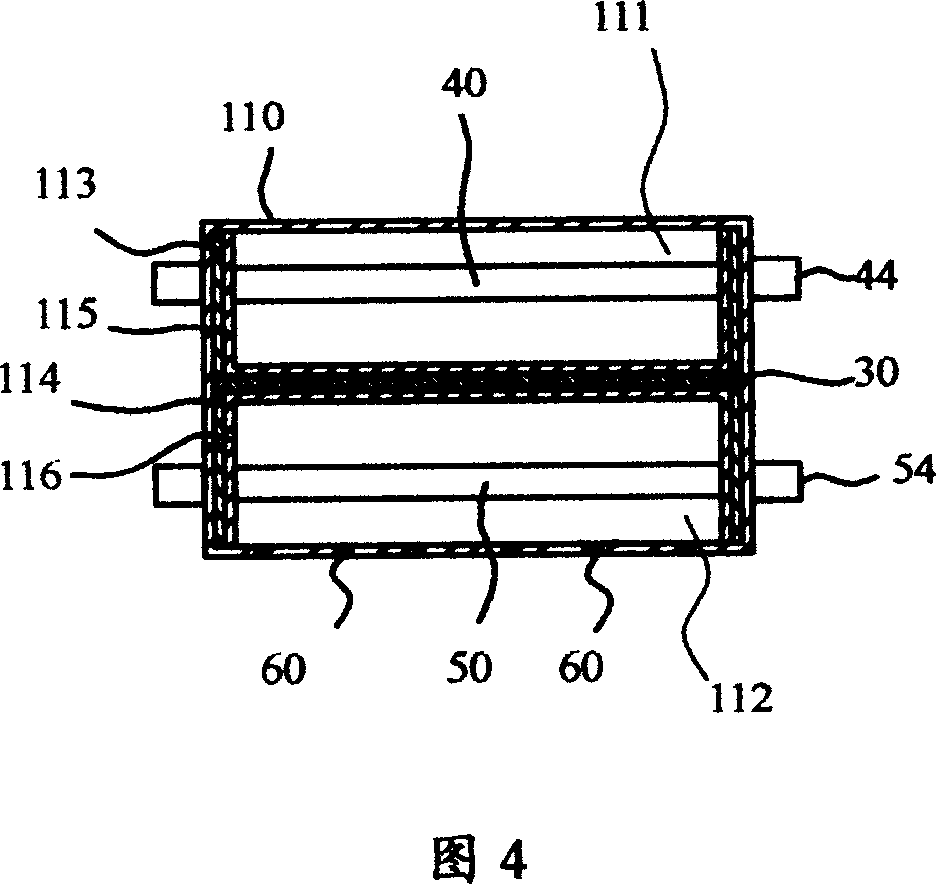

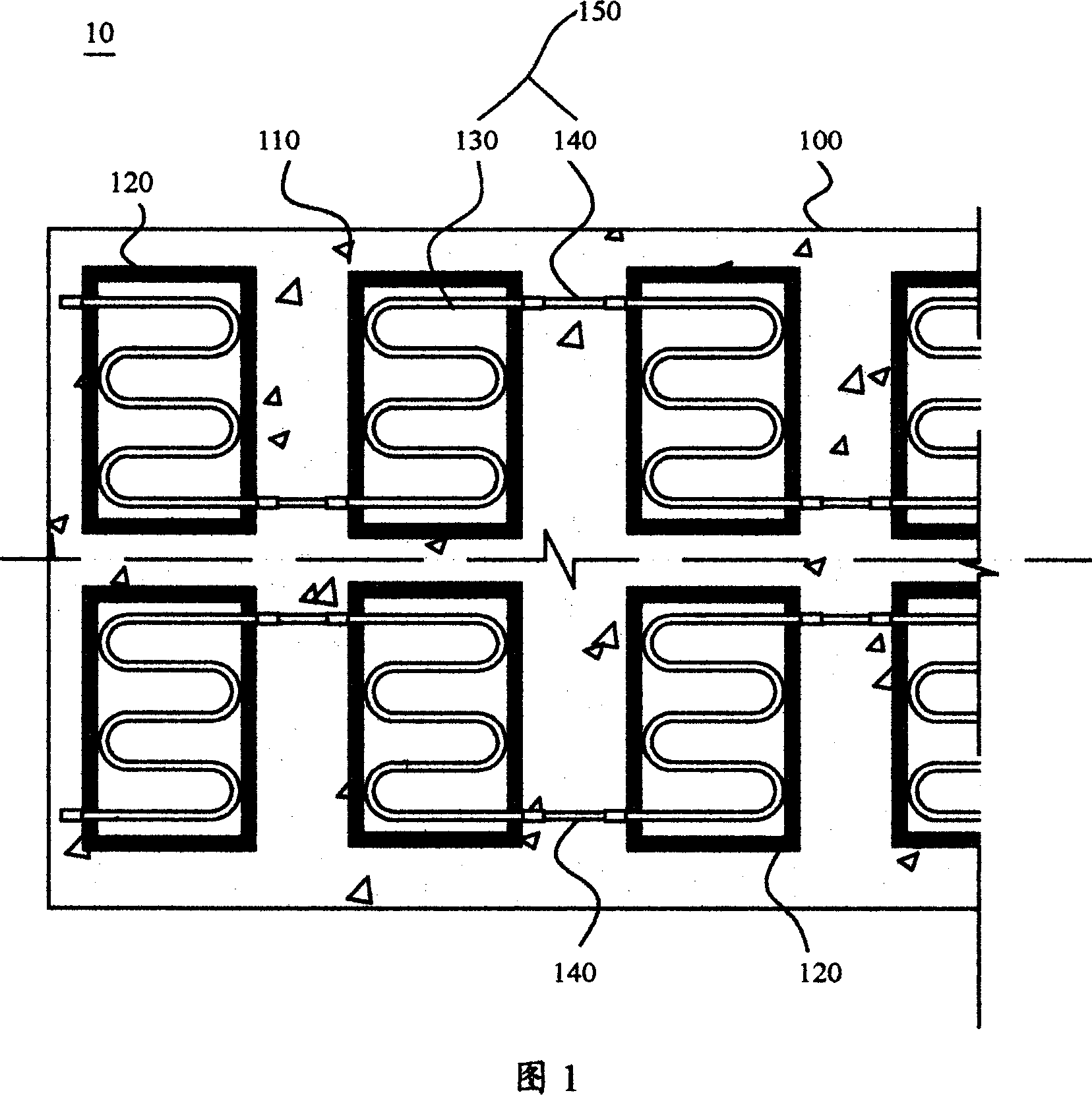

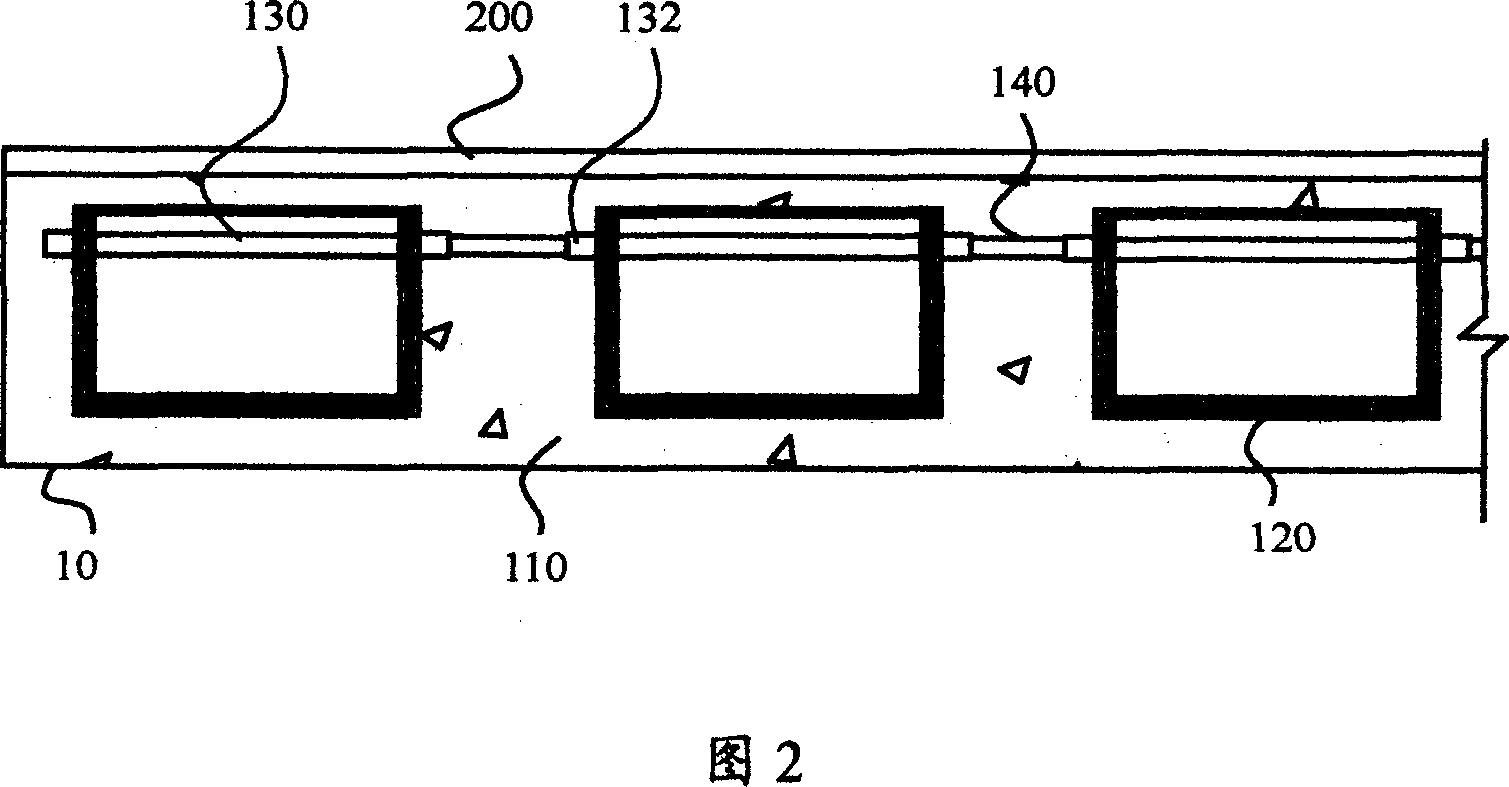

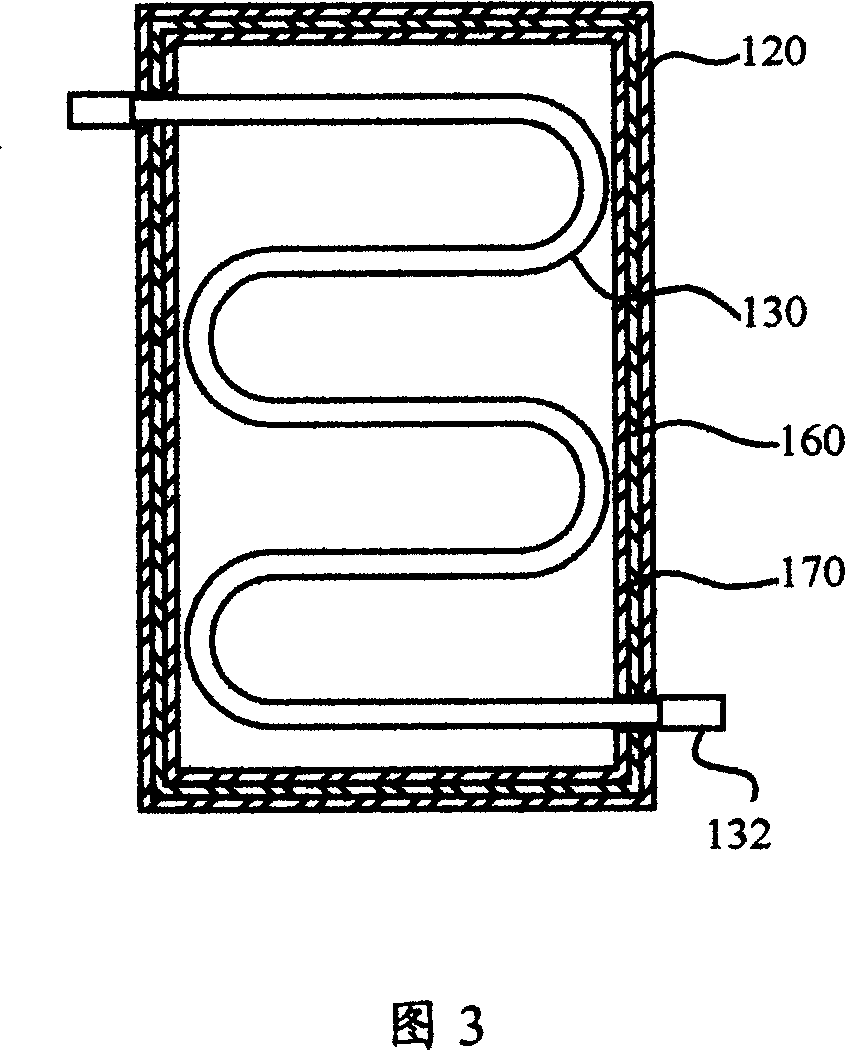

Hollow building floor with air-conditioning function for cast-in-situs reinforcing bar

InactiveCN1982614AIncrease usable spaceIn line with physiological characteristicsEnergy efficient heating/coolingFloorsFloor slabReinforced concrete

The invention discloses an cast-in-place reinforced concrete hollow heating and cooling floor, comprising floors which is made of reinforced concrete beams, ribs, plates and the cavity components in it, in the centre of cavity components is an insulation board separating the cavity into upper and lower cavity, the upper cavity is installed with heating pipe, both ends of the heating pipe are exposed to the stated cavity components, a number of heating pipe are connected through the first connecting pipe forming heating pipe group, the lower cavity is installed with cooling pipes , both ends of the cooling pipe are exposed to the stated cavity components, a number of cooling pipe are connected through the first connecting pipe forming cooling pipe group. The heating pipe group and the heat media supply system are connected, the heat media flows through the heating pipe to heat environmental space on the floor, the cooling pipe group and the cold media supply system are connected, the cold media flows through the cooling pipe group to supply cool to the environmental space on the floor. The invention is simple in structure, with good heating or cooling effect and low cost, and there may be helpful in expanding the applicable space.

Owner:傅礼铭

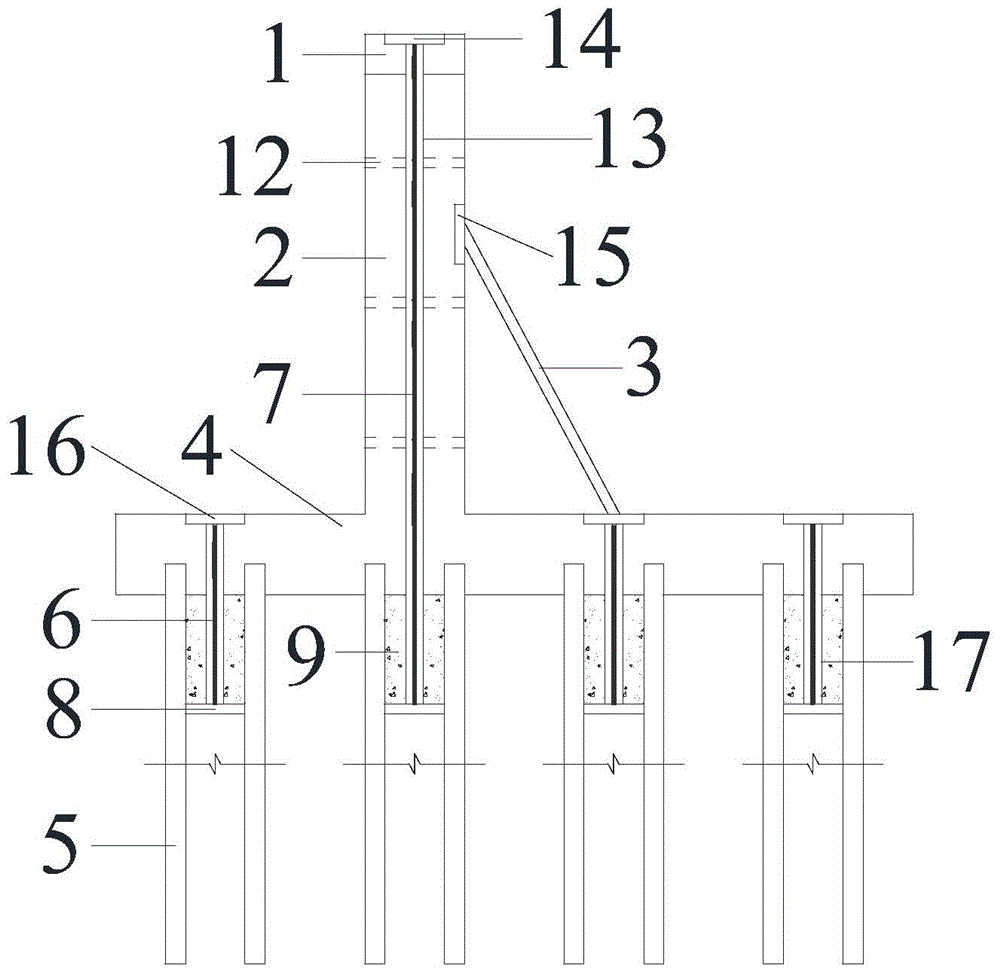

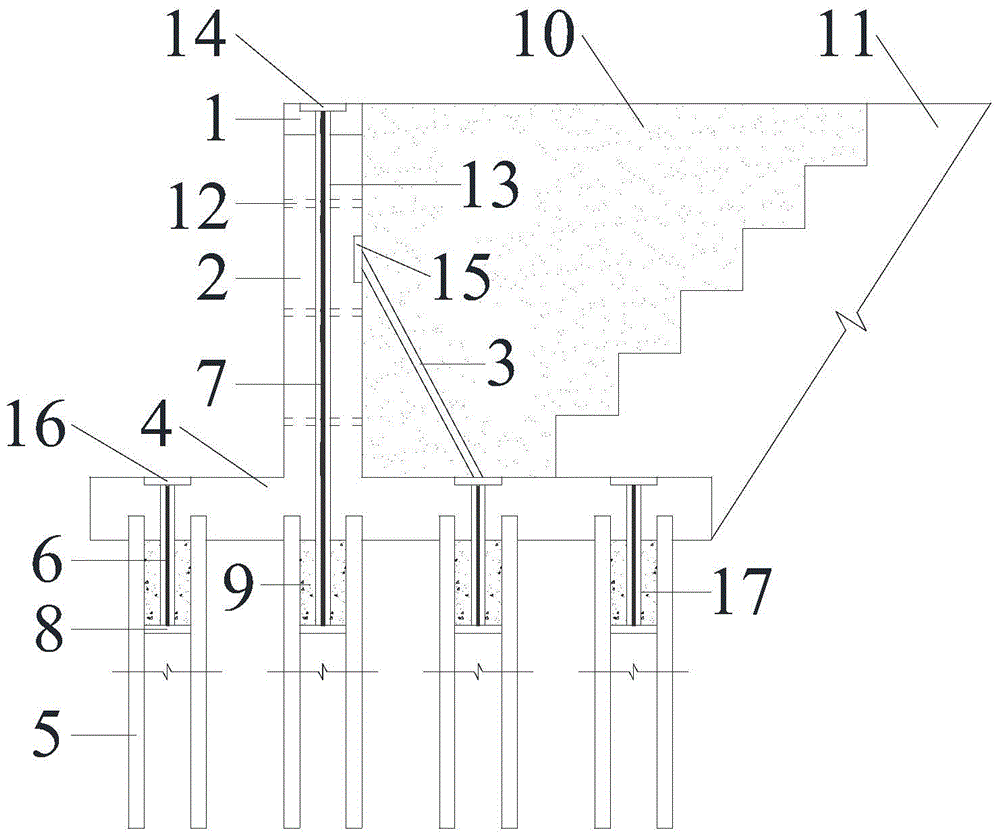

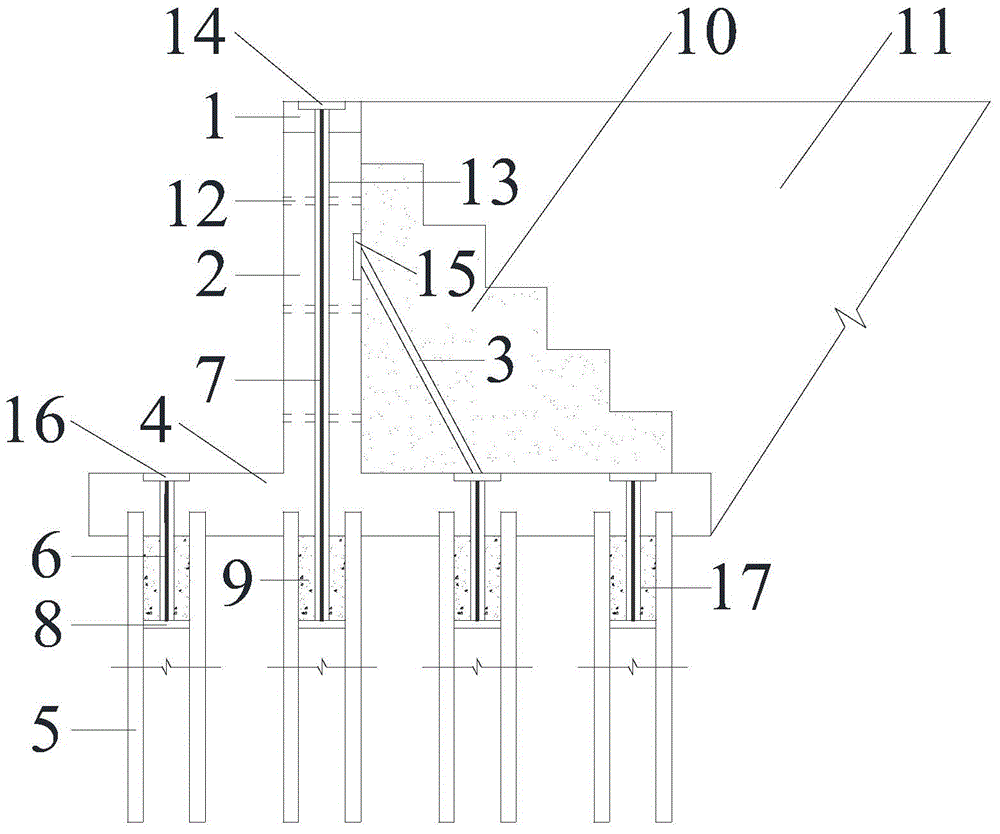

Construction method of pile foundation anchor rope prestress high retaining wall

ActiveCN104389320AImprove integrityEnsure the uniformity of settlementArtificial islandsUnderwater structuresRebarReinforced concrete

The invention relates to a construction method of a pile foundation anchor rope prestress high retaining wall. A coping section is arranged on the upper part of a cantilever board, the bottom of the cantilever board is provided with a bottom board; a tubular pile is embedded into the bottom board; a bracing piece is arranged behind the cantilever board and is fixedly arranged on the upper part of the bottom board; the bracing piece is connected with the cantilever board and the bottom board through a fixed end; an anchor rope penetrates through the cantilever board, the bottom board and the inner side of the tubular pile through the fixed end; the coping section and the bottom board are of a reinforced concrete structure; the top of the coping section is provided with a fixing end; the upper part of the bottom board is provided with a fixing end; an anchor rope preformed hole is pre-arranged for connecting a prestress anchor rope to form the pile foundation anchor rope prestress high retaining wall. The technology has favorable technical economic benefit.

Owner:ANHUI ROAD & BRIDGE GRP

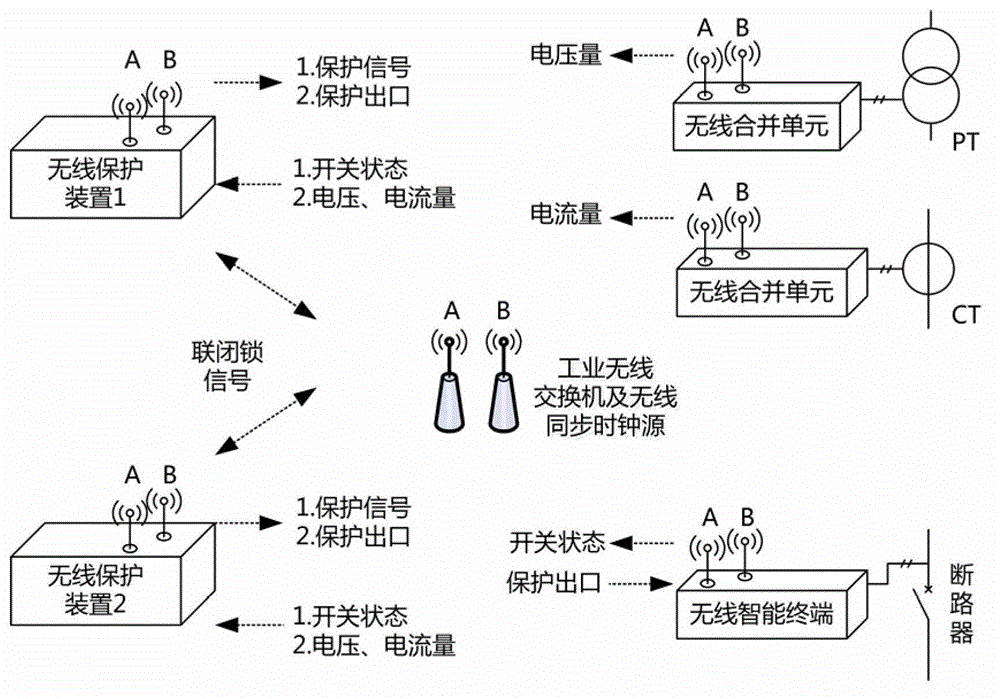

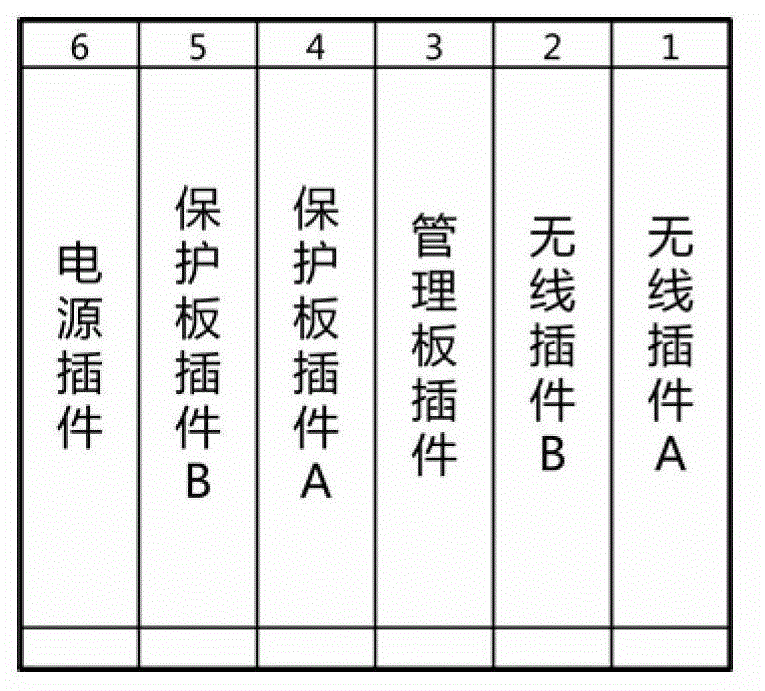

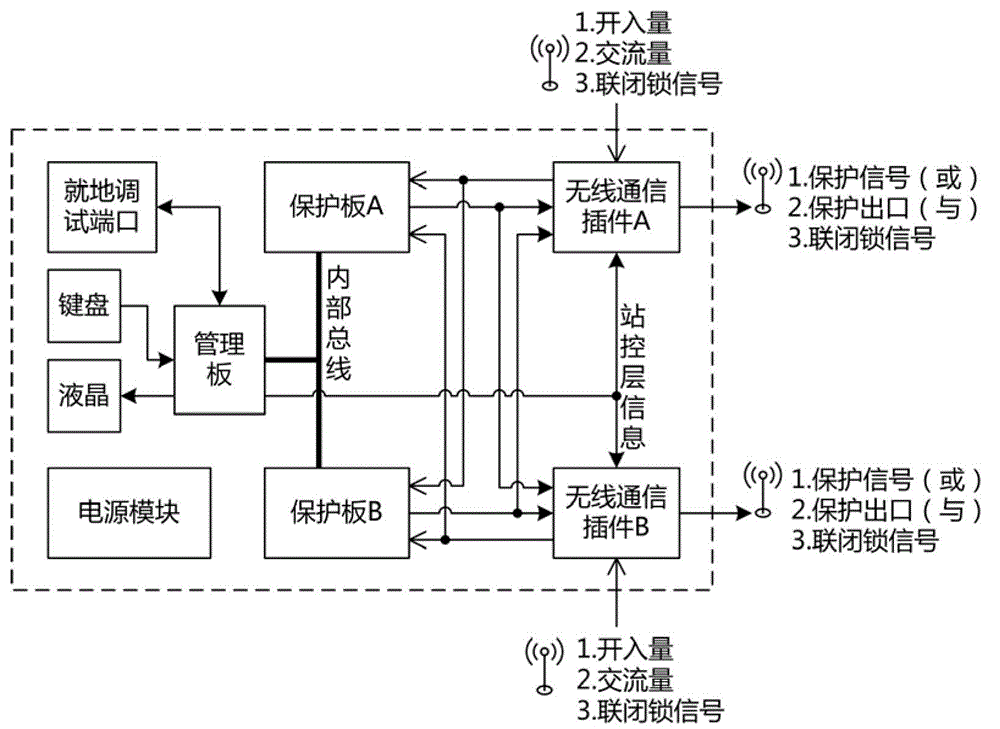

Power system relay protection system based on wireless transmission

InactiveCN102946089ASave construction materialsPrevent misoperationEmergency protective circuit arrangementsSustainable buildingsWireless transmissionElectric power system

The invention provides a power system relay protection system based on wireless transmission. The power system relay protection system based on the wireless transmission comprises the following components: (1) an industrial wireless switch; (2) a wireless synchronization clock device; (3) a wireless merging unit device; (4) a wireless intelligent terminal device; and (5) a wireless protection device, wherein the wireless relay protection device comprises a wireless plugin, a management board plugin, a protection plugin, a power plugin and the like. The power system relay protection system based on the wireless transmission, provided by the invention, can effectively reduce building materials such as optical cables, copper cables and the like which are used during secondary wiring in a substation, shortens the construction period, saves the construction investment, reduces a secondary return circuit, prevents locking and misoperation of protection caused by the secondary return circuit problem improves the reliability of the protection system, is convenient to install and debug, and can reduce the workload of maintenance personnel.

Owner:CHINA ELECTRIC POWER RES INST +1

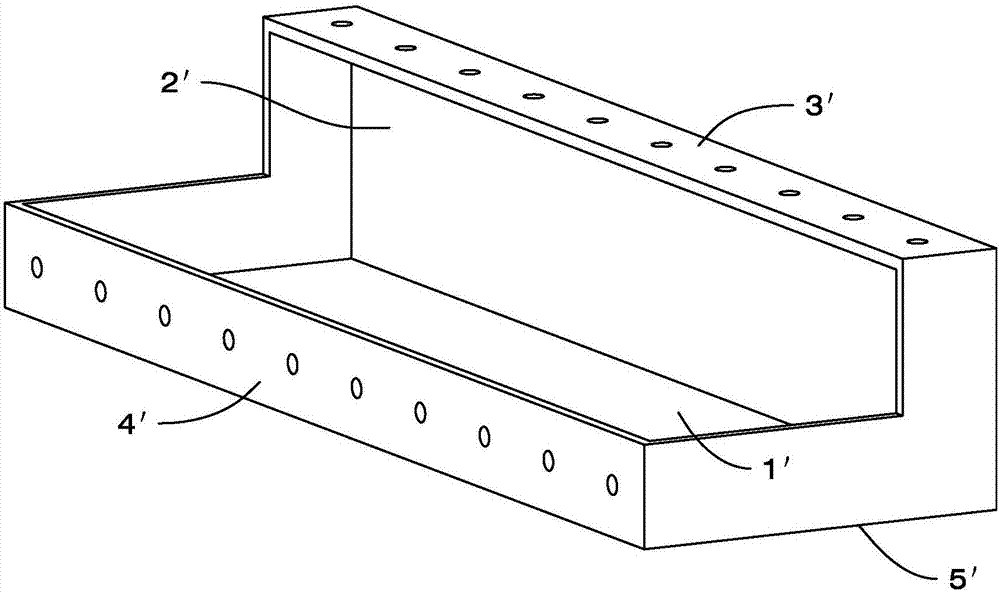

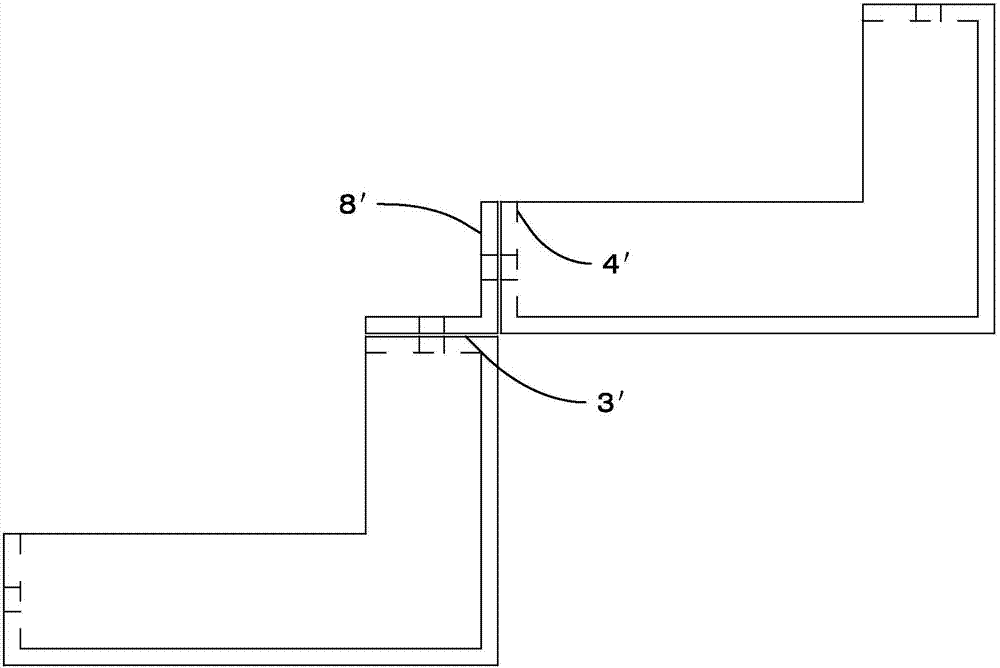

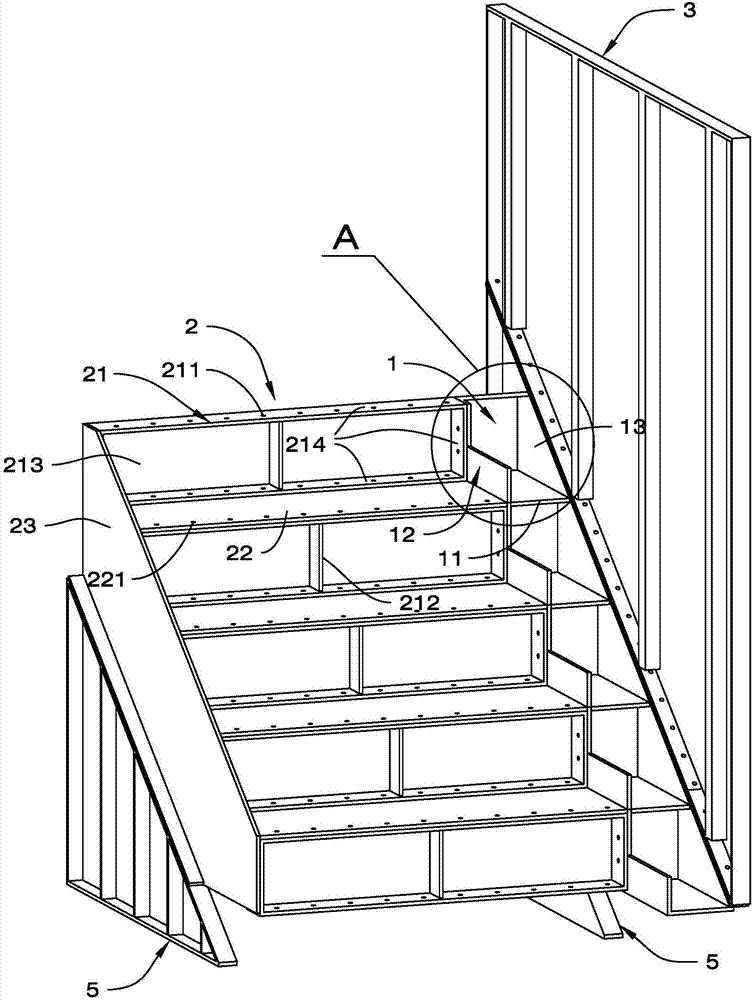

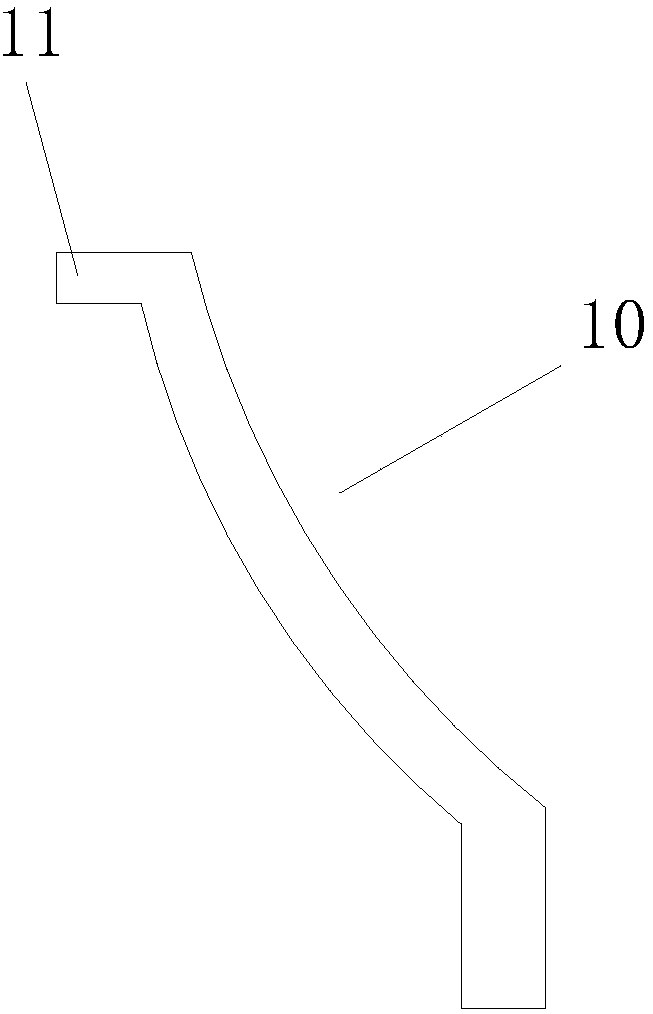

Stair connecting piece, manufacturing method, aluminum formwork system utilizing stair connecting pieces and stair construction method

PendingCN107165286ASimple structureStable structureForms/shuttering/falseworksBuilding material handlingMechanical engineeringManufacturing engineering

The invention provides a stair connecting piece, a manufacturing method, an aluminum formwork system utilizing the stair connecting pieces and a stair construction method. The stair connecting piece comprises a stepped main body, wherein side plates perpendicular to a step surface are arranged on two sides of each step of the main body, pin holes A are formed in the side plates, connecting plates perpendicular to the side plates are fixedly arranged on the corresponding side plates, and pin holes are formed in the connecting plates. The aluminum formwork system comprises stair aluminum formworks and wall aluminum formworks, each stair aluminum formwork is connected with the corresponding wall aluminum formwork through the corresponding stair connecting piece. During stair construction, the wall aluminum formworks are arranged firstly, then the stair connecting pieces are arranged and connected with the wall aluminum formworks, then the stair aluminum formworks are built and connected with the stair connecting pieces, concrete is poured, and the equipment is disassembled after the concrete is set. The stair connecting piece which is simple in structure, low in cost and simple and convenient to operate, facilitates splicing of the stair aluminum formworks and the wall aluminum formworks and provides great convenience for construction, the manufacturing method of the stair connecting piece, the aluminum formwork system utilizing the connecting pieces and the stair construction method utilizing the system are provided.

Owner:SHANDONG XINHUOXIN MATERIAL TECH CO LTD

Construction Method of Prestressed High Retaining Wall with Anchor Cable of Pile Foundation

ActiveCN104389320BImprove integrityEnsure the uniformity of settlementArtificial islandsUnderwater structuresReinforced concretePre stress

Owner:ANHUI ROAD & BRIDGE GRP

Main seawater pipe system applied auxiliary vessel of oceanographic engineering

The invention provides a main seawater pipe system applied an auxiliary vessel of oceanographic engineering. The system comprises a bottom seawater box, a main seawater pipe, a bilge seawater box, an U-shaped pipeline, an L-shaped pipeline, a cabinet inner bottom and a manhole cover, wherein the bottom seawater box and the main seawater pipe are distributed below the cabin inner bottom; the bilge seawater box is arranged on the vertical side surface adjacent to the cabin inner bottom; the bottom seawater box is communicated with the main seawater pipe through the U-shaped pipeline; the bilge seawater box is communicated with the main seawater pipe through the L-shaped pipeline; the manhole cover is arranged on the level of the cabin inner bottom. The system can be widely applied to various auxiliary vessels of oceanographic engineering, has obvious advantages on space saving, material saving, mounting design, overhaul and maintaining, and is practical and worthy of popularization and application.

Owner:欧赛德船舶设计(上海)有限公司

Hollow heating floor slab of reinforcing steel bar concrete cast in-site

The present invention relates to a cast-in-situ reinforced concrete hollow heating floor. It includes floor, said floor is formed from reinforced concrete and several hollow cavity members contained in the reinforced concrete, on said floor a ground surface decoration layer is set, in said hollow cavity member a heating pipe is set, two ends of said heating pipe are exposed from said hollow cavity member, several heating pipes are successively connected by means of connecting pipe to form heating pipe group. Said heating pipe group is connected with heat source supply system.

Owner:HUBEI SYNTHETIC SPACE TECH CO LTD

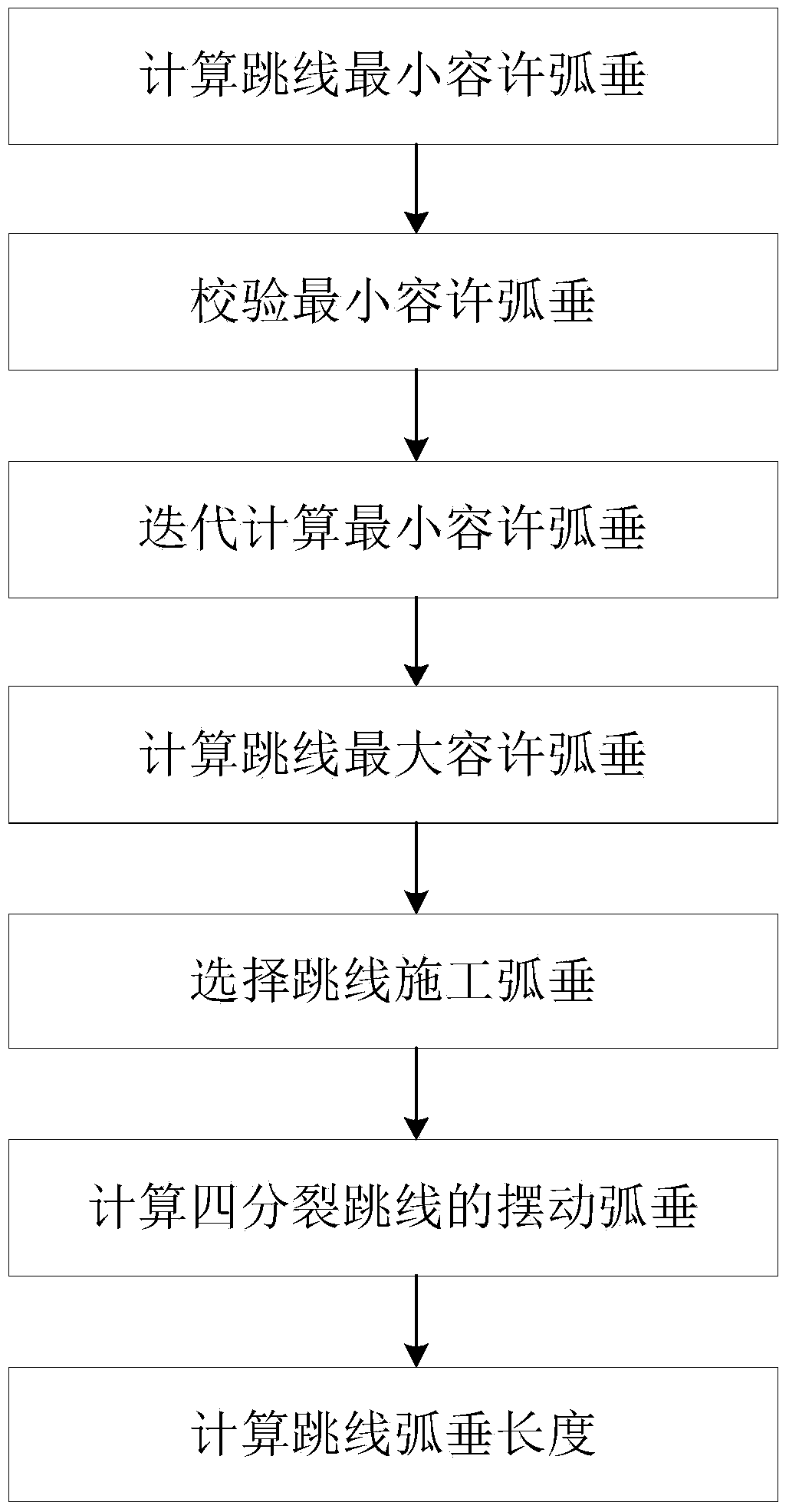

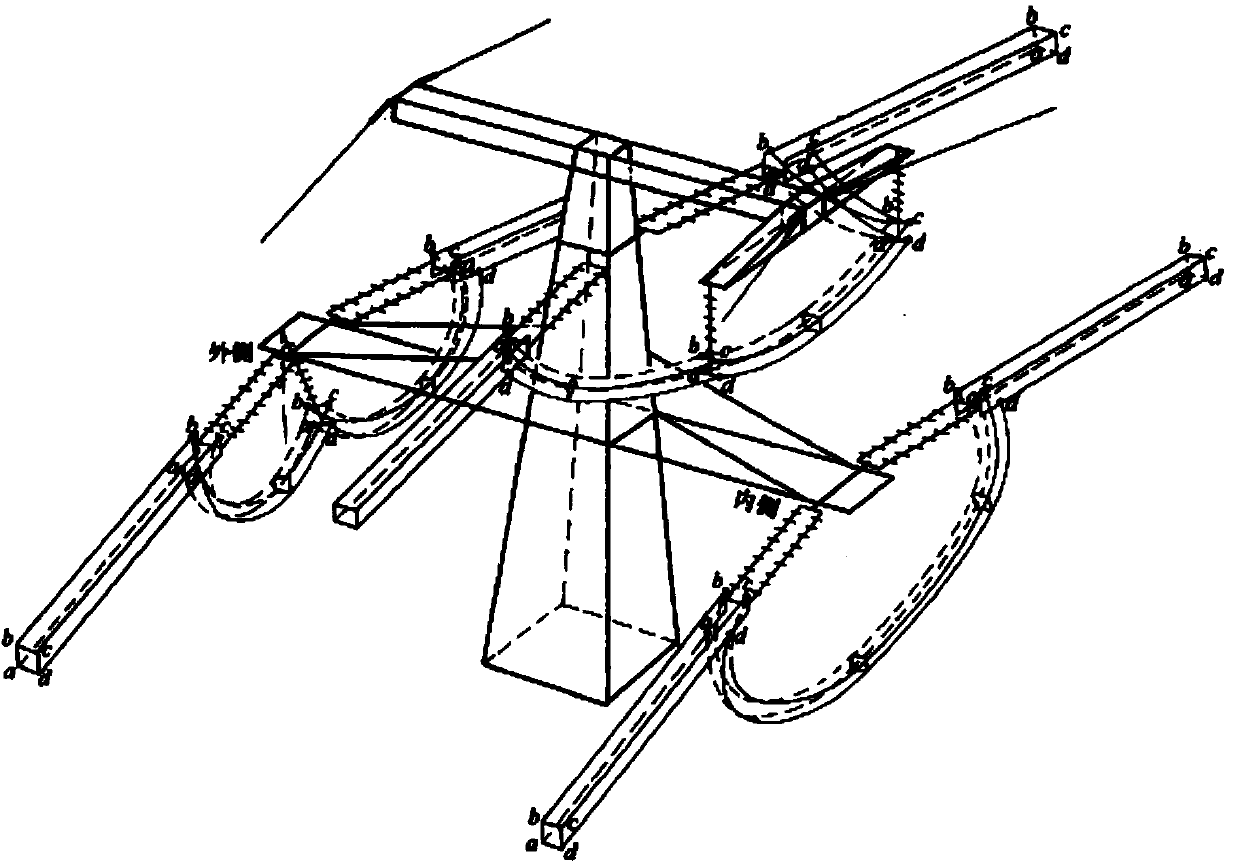

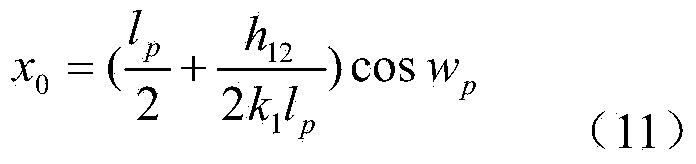

GIS (geographic information system) based three-dimensional jumper sag determination method

InactiveCN104201631ALow costImprove work efficiencyAdjusting/maintaining mechanical tensionGeographic information systemQuality by Design

The invention relates to a GIS (geographic information system)-based three-dimensional jumper sag determination method. The method includes (1) calculating the minimum tolerance sag f<pm> of the jumper; (2) examining the minimum tolerance sag f<pm>; (3) calculating the minimum tolerance sag f<pm> in an interactive manner; (4) calculating the maximum tolerance sag f<pm> of the jumper; (5) selecting a jumper construction sag f<p0>; (6) calculating a swing sag of a quad-bundle jumper; (7) calculating the sag length of the jumper. By the use of the method, operation efficiency and safety on a tower are improved so as to shorten the construction period, save labor and enhance mounting quality; construction cost is lowered during the construction, safety and efficiency are improved, use requirement of line project is met, and design quality is increased; wire number is available before construction, thus wire waste is avoided during the construction, construction cost is reduced, construction materials are saved, and construction benefits of the project department are increased.

Owner:STATE GRID CORP OF CHINA +1

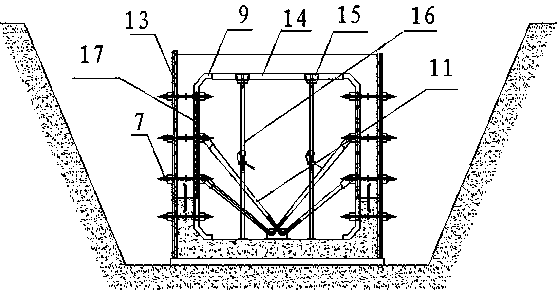

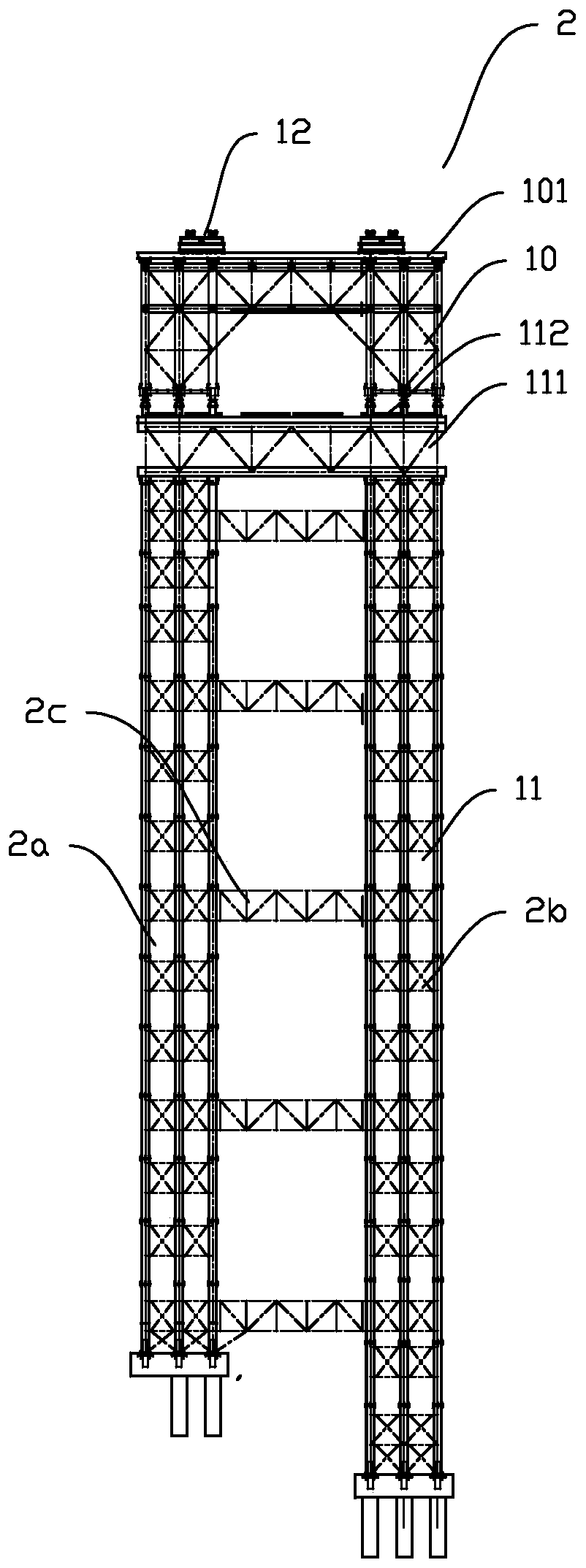

High bridge pier self-lifting outer frame over-form construction technology

ActiveCN105839543ARealize cycle upliftAvoid it happening againBridge structural detailsBridge erection/assemblySupporting systemUpper floor

The invention discloses a high bridge pier self-lifting outer frame over-form construction technology which is simple in construction, high in construction safety and high in construction efficiency. The over-form construction technology comprises the following steps that firstly, formworks are installed, and upper layer concrete and lower layer concrete are poured; secondly, outer support systems and telescopic devices are installed; thirdly, the lower layer formworks are detached, lifted and installed; fourthly, the outer support systems are lifted; fifthly, the telescopic devices freely side downwards to an upper layer formwork system to be connected with formworks of the upper layer formwork system. The over-form construction technology is easy to operate, quality is controlled more easily, the speed is higher, cost is lower, and safety is higher.

Owner:CHINA 19TH METALLURGICAL CORP

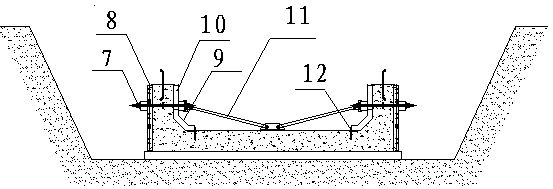

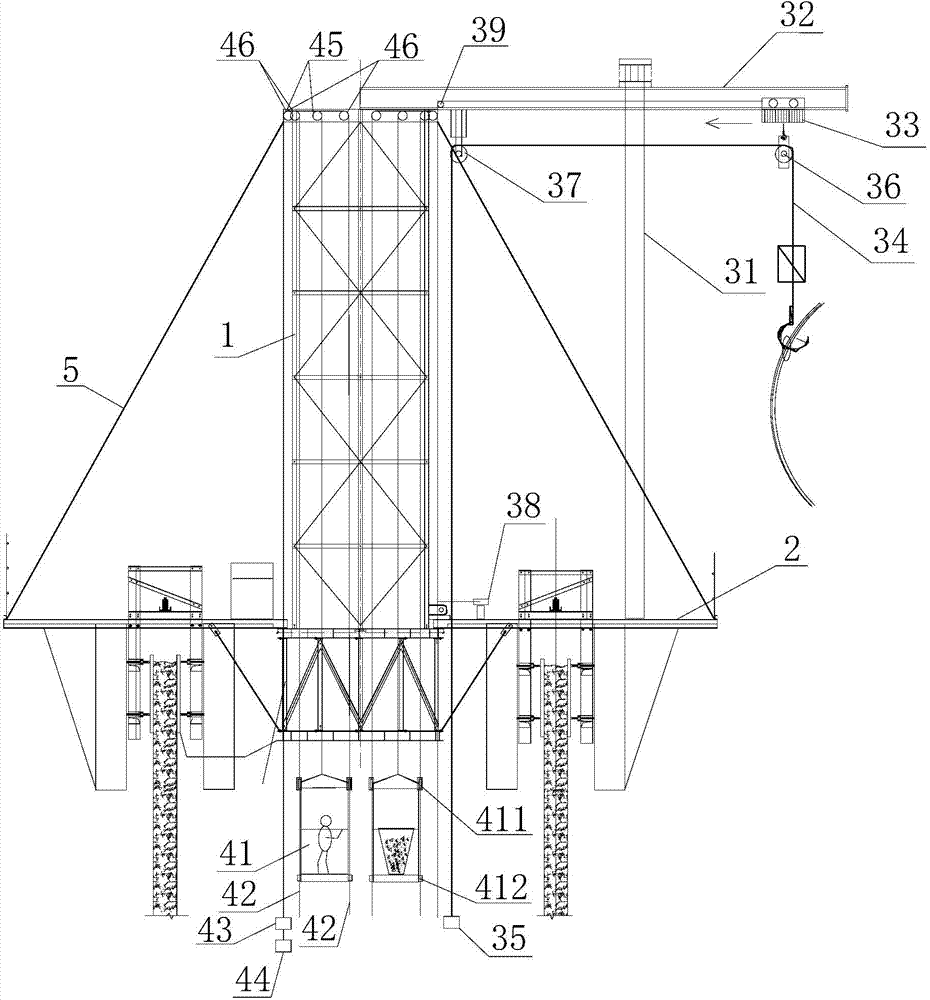

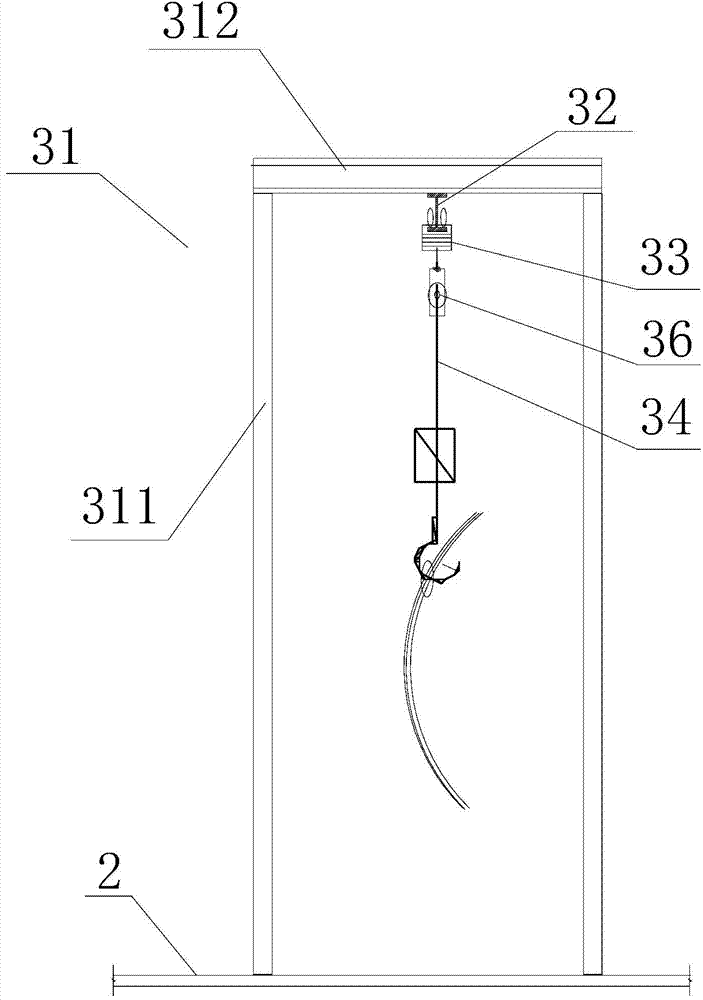

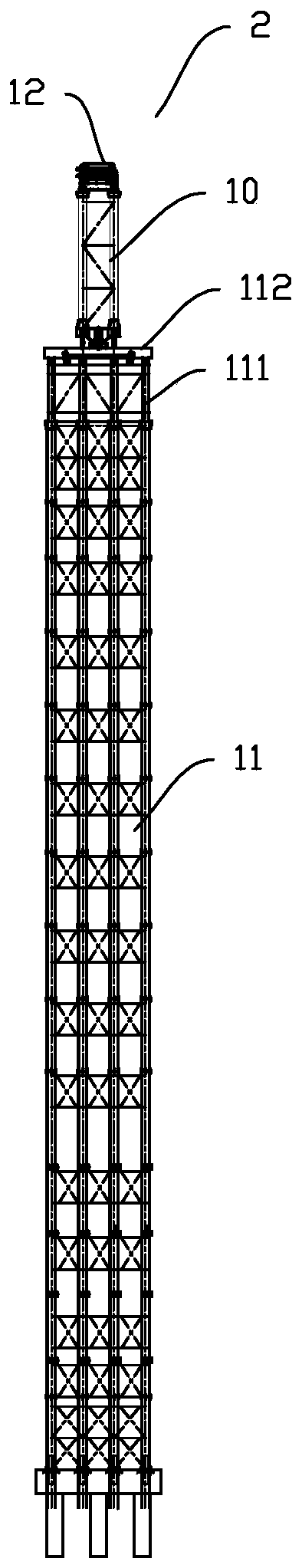

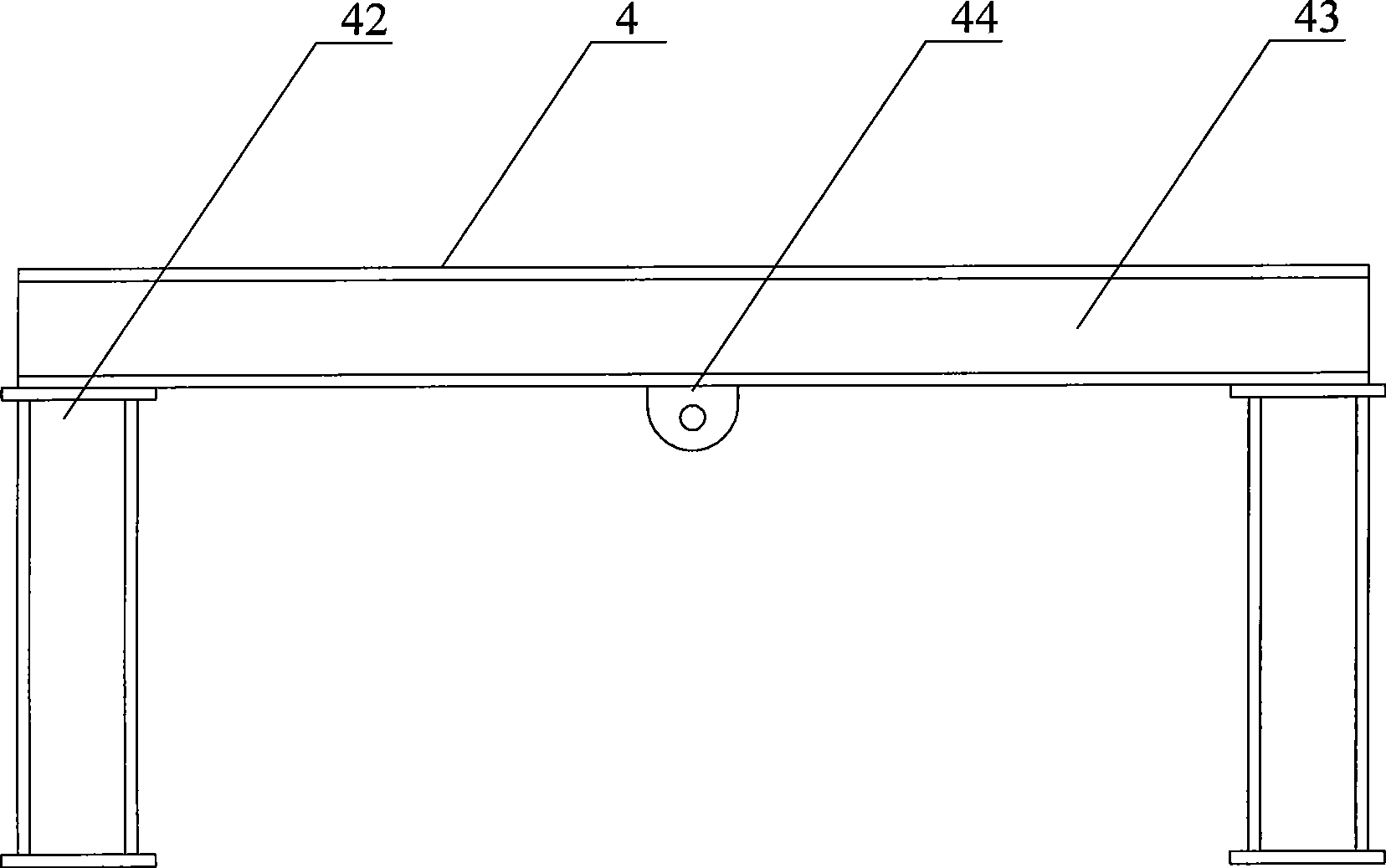

Large water tower cylinder hydraulic slip-form vertical-transportation system and method

InactiveCN104727545AImprove efficiencyEnsure personal safetyForms/shuttering/falseworksTowersTransit systemEngineering

The invention discloses a large water tower cylinder hydraulic slip-form vertical-transportation system and method which are high in working efficiency and high in safety performance. The large water tower cylinder hydraulic slip-form vertical-transportation system comprises a well following derrick and a working platform, wherein the well following derrick is fixed to the working platform. The large water tower cylinder hydraulic slip-form vertical-transportation system further comprises an extra-cylinder lifting device, wherein the extra-cylinder lifting device comprises a supporting frame, a rigid slideway, an electric hoist, a load-bearing rope and a driving device A, the supporting frame is fixed to the working platform, one end of the projection of the rigid slideway is located outside a working platform region, the other end of the projection of the rigid slideway is located in the working platform region, the electric hoist is fixed to the rigid slideway and can slide along the rigid slideway, the lower end of the electric hoist is connected with a pulley A, and the load-bearing rope winds across the pulley A to be connected with the driving device A. According to the large water tower cylinder hydraulic slip-form vertical-transportation method, the safety of the device is checked, and a flexible slideway is tensioned by means of a slideway tensioning device. The large water tower cylinder hydraulic slip-form vertical-transportation system and method have the advantages that it is guaranteed that a weight is lifted safely and efficiently, materials are saved, and cost is reduced.

Owner:CHINA 19TH METALLURGICAL CORP

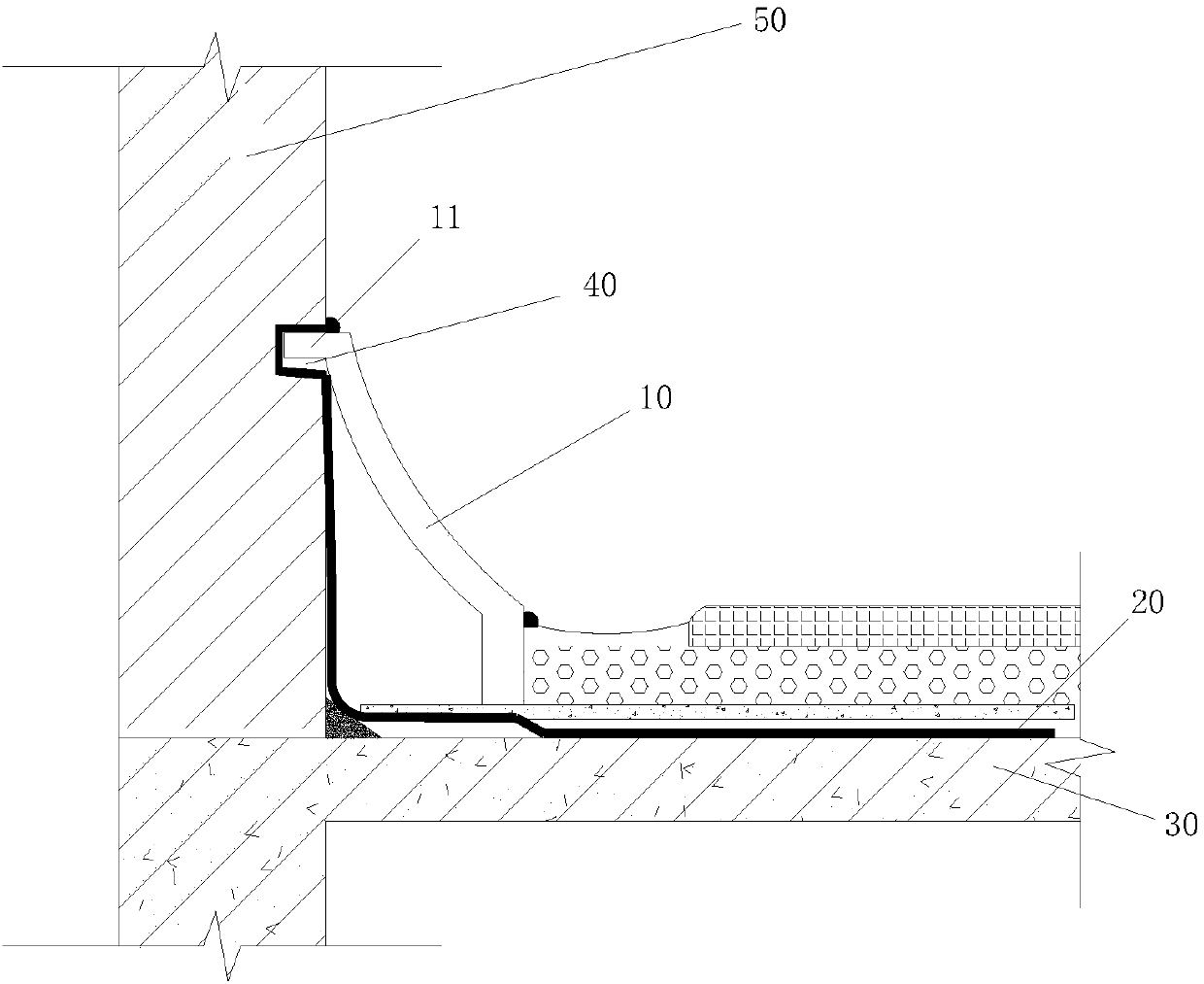

Constructing method for flashing structure of parapet wall

ActiveCN107558671AFast pre-productionConstruction quality is easy to controlRoof drainageRoof covering insulationsWater leakageSurface layer

The invention provides a constructing method for a flashing structure of a parapet wall. The constructing method comprises the construction steps of prefabricating flashing members, installing the flashing members, filling and compacting between the adjacent flashing members, coating a waterproof coating material and the like. The constructing method adopts a mode of prefabricating the flashing members, rapid pre-production of the flashing members is realized, the construction efficiency is improved, construction quality of the flashing members is convenient to control, and processing workshopconcentrated machining forming is achieved; construction pollution can be effectively reduced, construction materials are saved, and construction waste is reduced; phenomena of cracking and hollowingon the surfaces of the prefabricated flashing members cannot happen, and common technical problems are overcome; by using air permeability between the prefabricated members and a waterproof layer, the effect of heat resistance of the prefabricated members is good, deformation of the waterproof layer caused by water temperature changes is reduced, falling-off and water leakage of the waterproof layer can be effectively prevented, and the waterproof service life is prolonged; and the prefabricated flashing structure has a better appearance effect, the flashing height, width and radian are consistent, a later waterproof coating surface layer cannot fall off, and the long-term aesthetic effect can be achieved.

Owner:坤发建筑有限公司

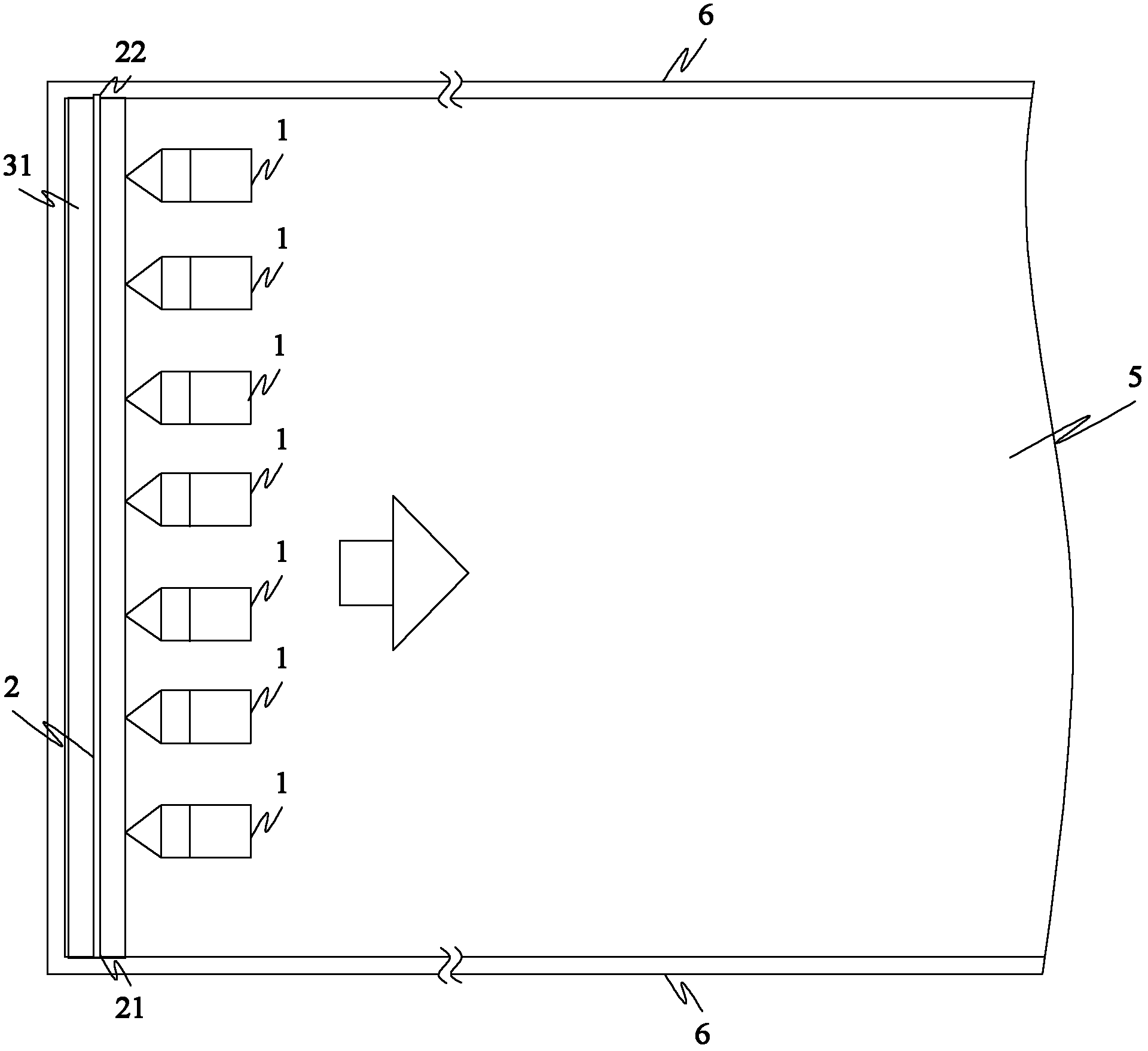

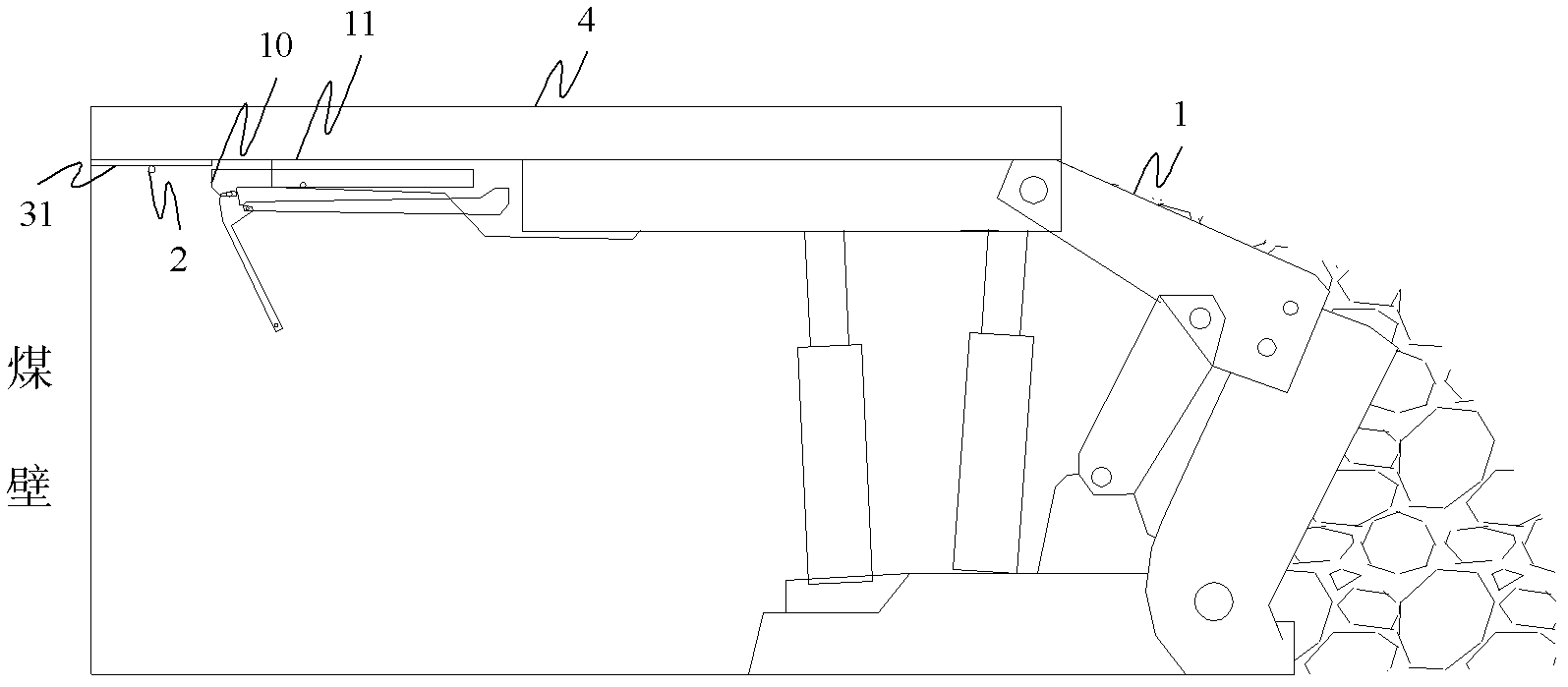

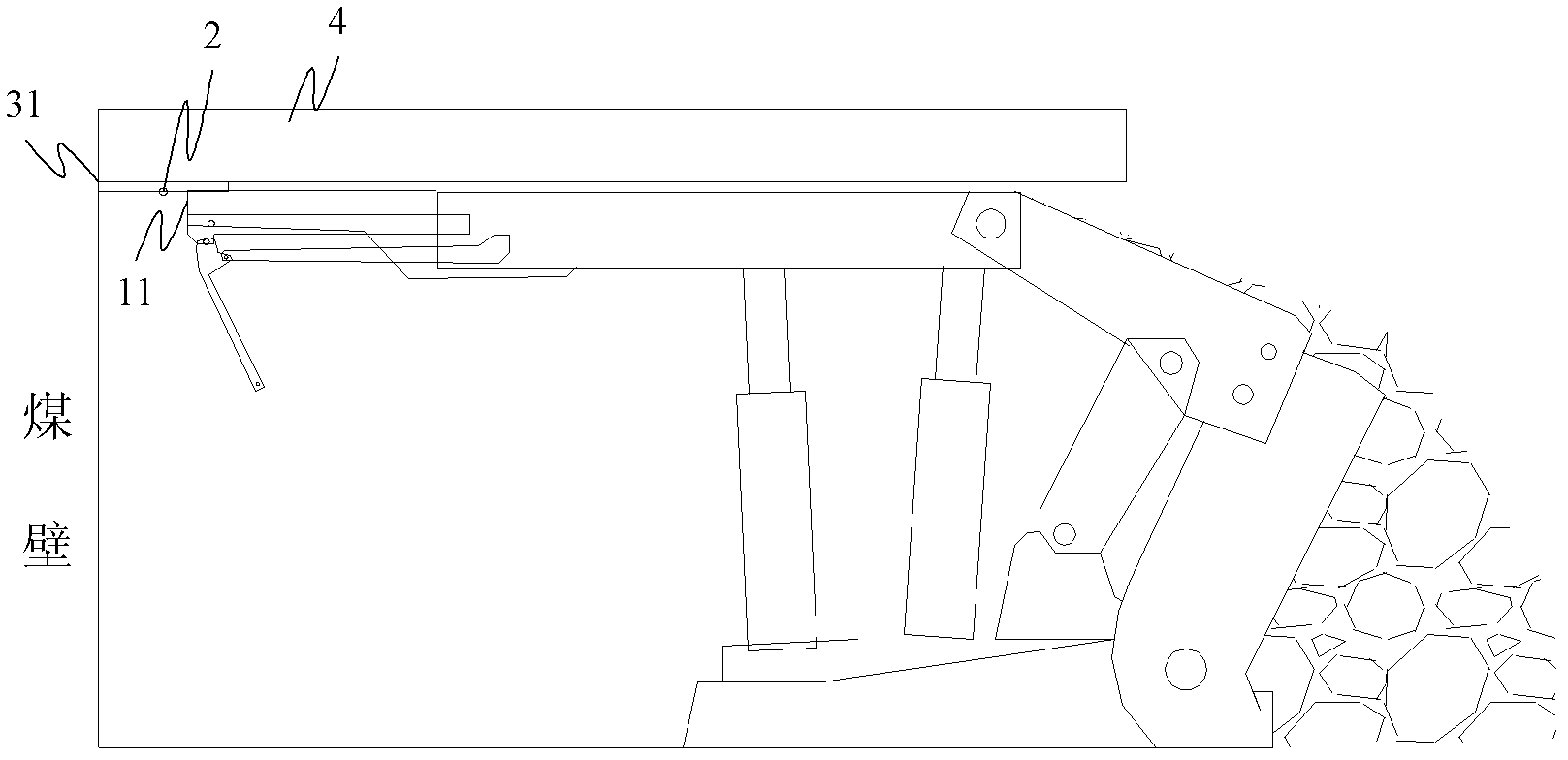

Laying method of metal mesh false roof

ActiveCN103133021AReduce labor intensitySimple construction processProtective coversEngineeringMetal

The invention provides a laying method of a metal mesh false roof. The laying method of the metal mesh false roof is used for fully-mechanized coal mining. The laying method of the metal mesh false roof comprises the following steps: fixing the other end of a steel wire rope on the other side roadway of the top wall of a fully mechanized working face and arranging a metal mesh on the top wall of the fully mechanized working face along the width direction of the fully mechanized working face, enabling hydraulic support top beams to abut against the lower side of the metal mesh in sequence, arranging and fixing the steel wire rope on the lower side of the metal mesh in a supporting mode, moving hydraulic supports and enabling space for laying a mesh in next link to be reserved between the hydraulic support top beams and the metal mesh, and repeating the procedures, laying metal meshes on all the working face top walls and connecting the edge of two adjacent metal mesh. The laying method of the metal mesh false roof achieves quick laying of the metal mesh false roof and solves the technical problems that due to the fact that half round wood or a steel pipe and the like must be used to be arranged on the metal mesh in a pressing mode, before laying the metal mesh, the top beams are lowered to form reserved working space, safety cannot be ensured, steps are trivial, working efficiency is low and the like in the prior art.

Owner:HUAINAN MINING IND GRP

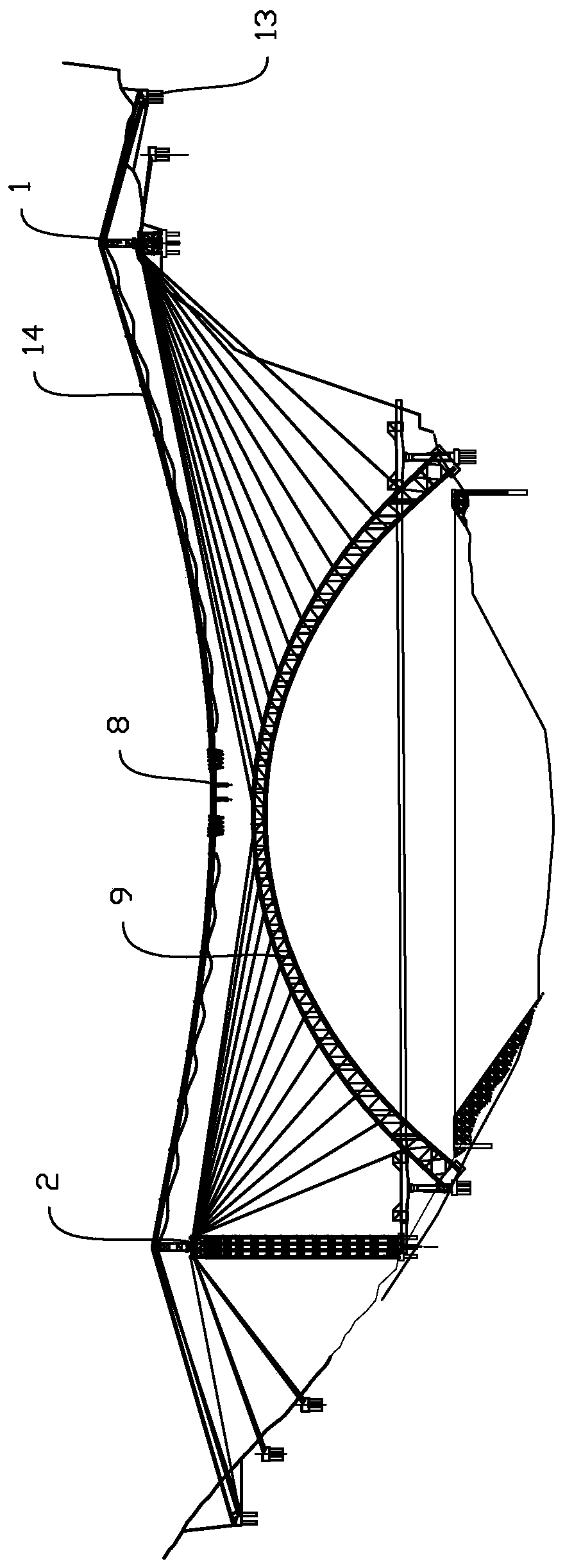

Construction method of asymmetric cable crane

ActiveCN109750600ASave construction materialsGuaranteed force balanceSuspension bridgeBridge structural detailsTerrainHeight difference

The invention discloses a construction method of an asymmetric cable crane. The engineering terrain situation is integrated, the characteristic of craggedness of large-mileage side mountain is utilized, thus a large-mileage side tower frame is arranged on a mountain slope with the precipitous mountain valley, the terrain height difference is reasonably utilized, thus a construction material of thelarge-mileage side tower frame is saved, stable force-bearing of two sides is ensured, the construction difficulty is also lowered, the distance between the large-mileage side tower frame and the center of a bridge is greater than the distance between a small-mileage side tower frame and the center of the bridge, through formed unequal edge span design, force-bearing balance of the large-mileageside tower frame and the small-mileage side tower frame under the unequal elevation situation is ensured, the structural stability is improved, and the construction method is used for the technical field of bridge construction.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +3

Self-elevating outer frame turning device for bridge high pier

ActiveCN105839542BRealize cycle upliftAvoid it happening againBridge structural detailsBridge erection/assemblySupporting systemSupport system

Owner:CHINA 19TH METALLURGICAL CORP

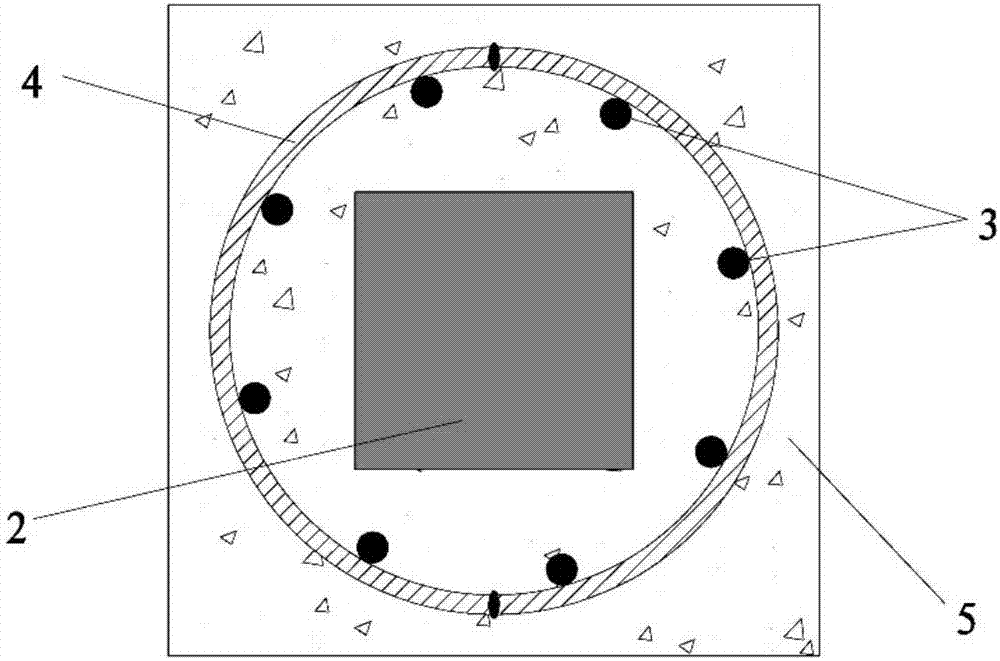

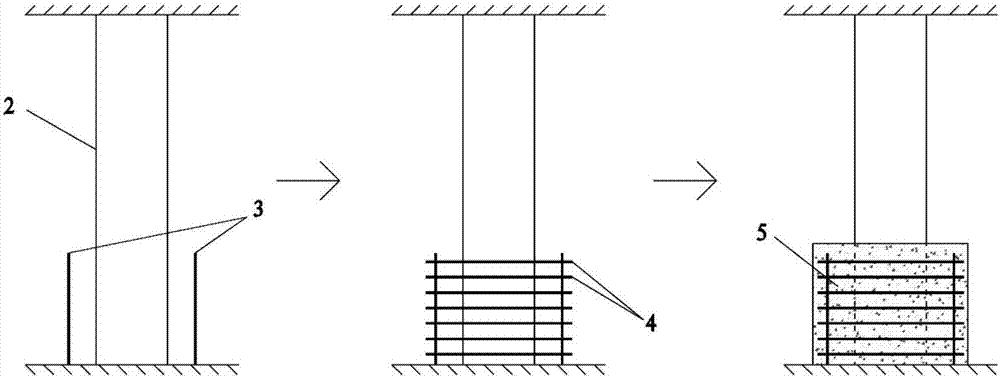

Reinforced concrete column welding ring rib reinforced structure and construction method thereof

PendingCN106968453AReduce construction workloadSave construction materialsStrutsBuilding repairsRebarEarthquake resistant

The invention discloses a reinforced concrete column welding ring rib reinforced structure. A reinforced cage is arranged on the side face of the bottom of a to-be-reinforced reinforced concrete column, the height of the reinforced cage is equal to the length of a column bottom plastic hinge area of the to-be-reinforced reinforced concrete column, the reinforced cage comprises more than one vertical longitudinal ribs and more than one welding ring ribs, the vertical longitudinal ribs are located inside the welding ring ribs, the welding ring ribs are fixedly connected with the vertical longitudinal ribs, and a concrete layer covering the reinforced cage is poured on the side face of the bottom of the to-be-reinforced reinforced concrete column. The invention also discloses a construction method of the reinforced concrete column welding ring rib reinforced structure. The reinforced concrete column welding ring rib reinforced structure is used for realizing small construction workload and simple construction process, aiming to the phenomenon that the column end of the reinforced concrete column is damaged in the earthquake, the weak column bottom is reinforced, and part of the reinforced concrete column is reinforced to achieve anti-seismic reinforcement of the whole column.

Owner:SOUTH CHINA UNIV OF TECH

Assembling method for jacketed pipe and its pipe lining apparatus

InactiveCN101463923AGuarantee welding qualityGuaranteed installation qualityPipe laying and repairEngineeringStructural engineering

The invention discloses an assembly method of jacketed pipes and a pipe inserting device. The method comprises the following steps: firstly, welding inner pipes of the jacketed pipes in pairs, and sheathing outer pipes of the jacketed pipes after heat treatment, weld seam detection and a hydraulic test; lifting the welded inner pipes while sheathing the outer pipes, and then lifting the outer pipes to ends of the inner pipes; mounting the pipe inserting device respectively on a front end and a rear end of the outer pipe; translating and sheathing the outer pipes outside the inner pipes one by one; and finally welding various outer pipes, and finishing assembly. The assembly method has the advantages of saving construction materials, having low equipment investment and simple construction steps, being capable of effectively protecting jacketed pipe materials and the like; and the pipe inserting device has the advantages of simple structure, convenient installation and use, less construction materials, lower equipment investment, simplified construction steps and the like.

Owner:五矿二十三冶建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com