Hollow heating floor slab of reinforcing steel bar concrete cast in-site

A reinforced concrete and floor slab technology, which is applied to floors, building components, buildings, etc., can solve problems such as poor load-bearing effect, large floor thickness, and complicated engineering construction, and achieve the goal of improving load-bearing effect, increasing usable space, and simplifying construction technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

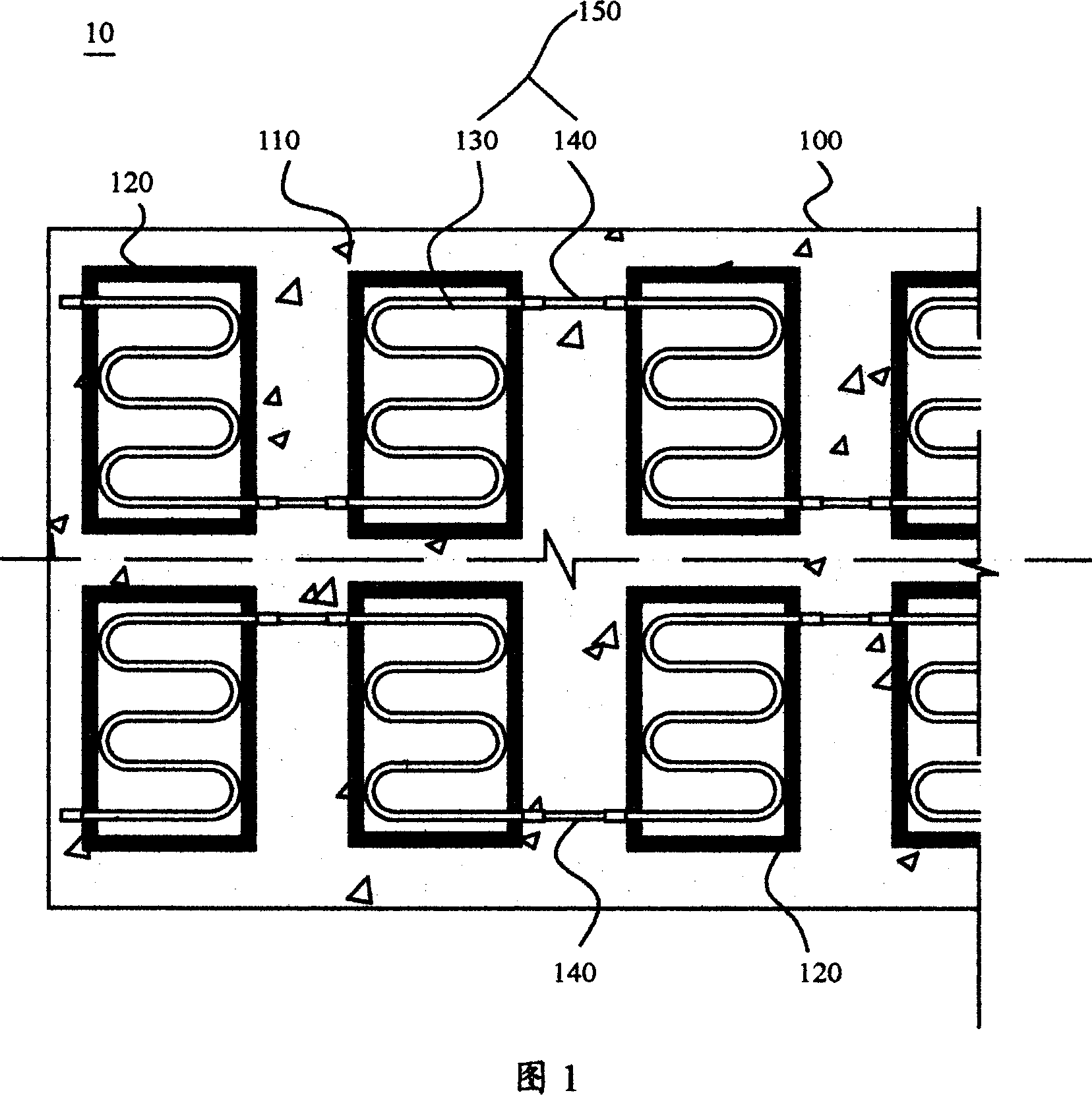

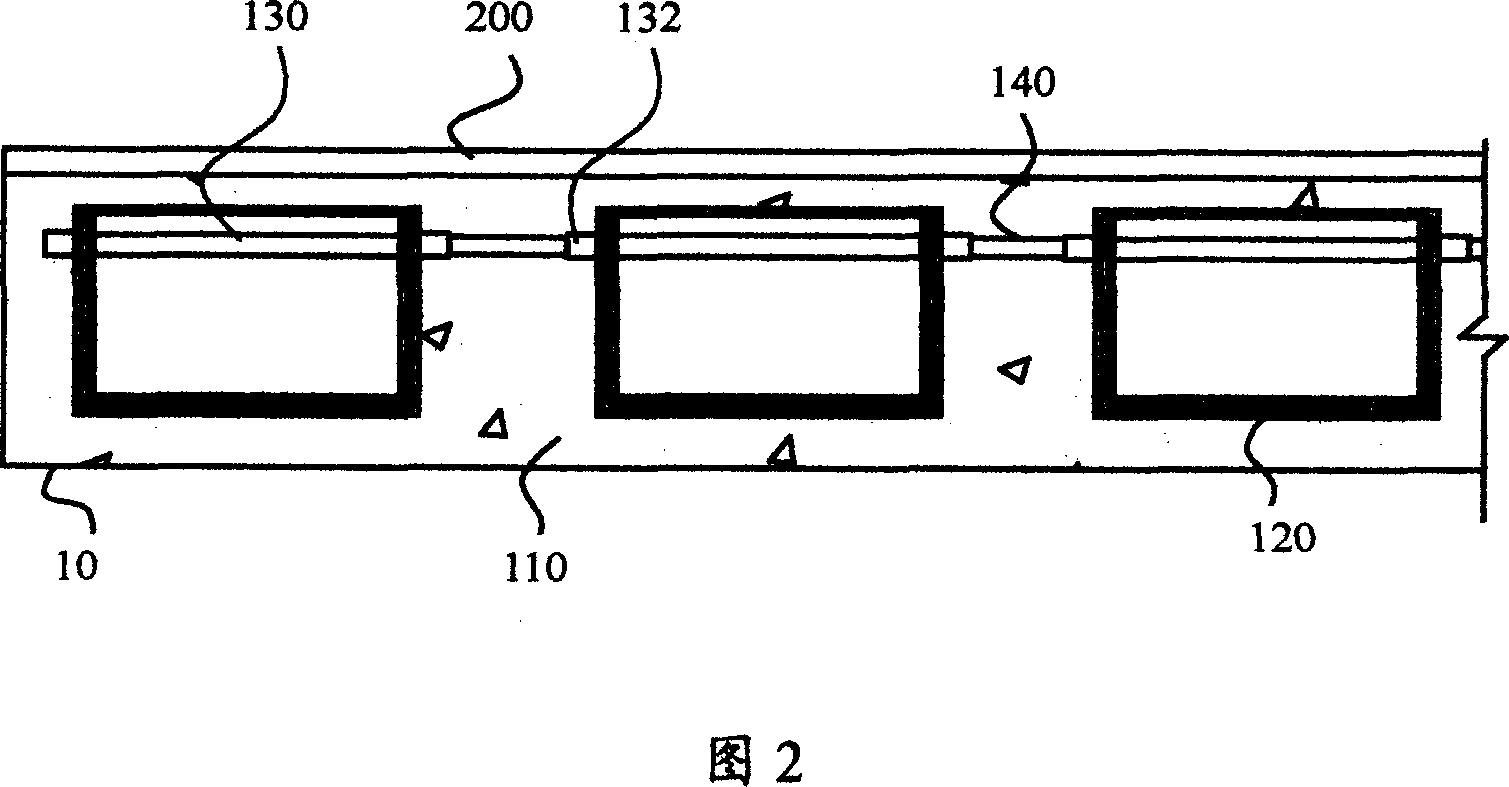

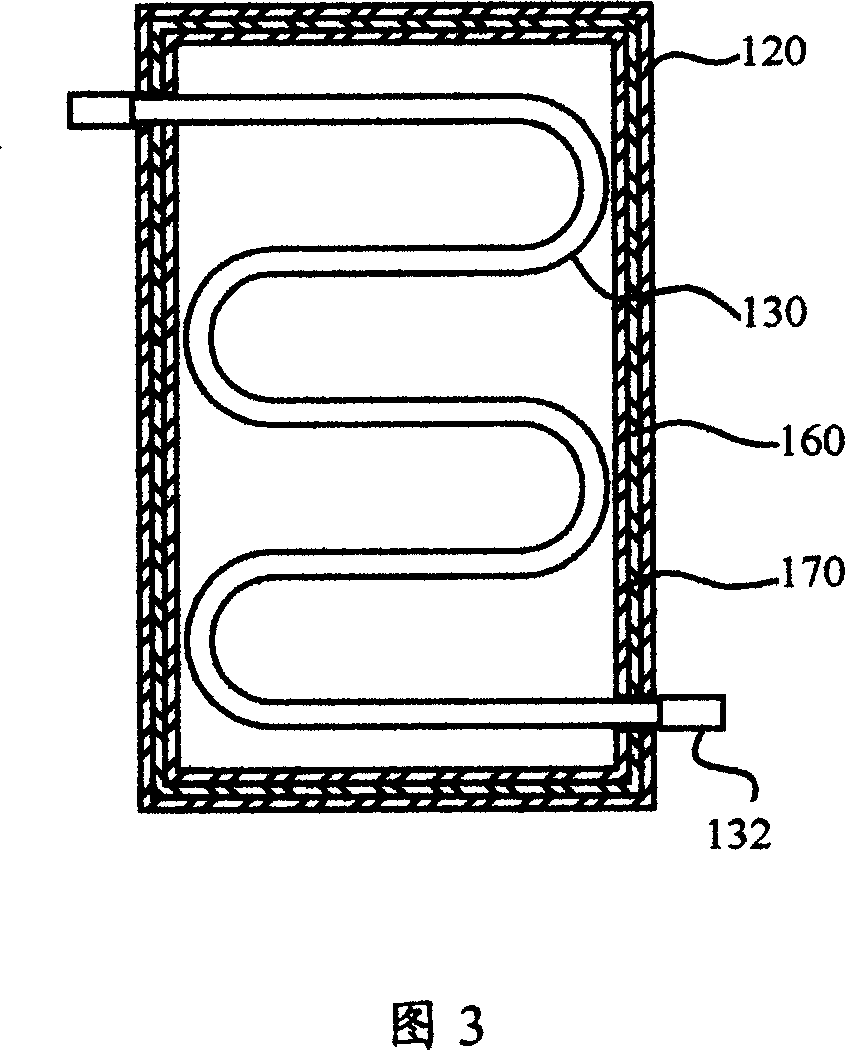

[0016] Referring to Figures 1 and 2, the cast-in-place reinforced concrete hollow heating floor 10 of the present invention includes a floor 100 composed of reinforced concrete 110 and a plurality of cavity members 120 embedded in the reinforced concrete 110. composition. The structure of the slab 100 is the same as that of a general cast-in-place reinforced concrete hollow slab, and the cavity member 120 can be a regular-shaped cavity member such as spherical, tubular, box-shaped, etc., or an irregular-shaped cavity member. . The floor slab 100 is provided with a ground decoration layer 200, and the ground decoration layer 200 can be one of materials such as cement mortar, wooden floor, ceramic tile, marble floor, carpet, plastic floor, etc., and can also be a combination of several materials. . As shown in Fig. 3 and Fig. 4, a heating pipe 130 is arranged inside the cavity member 120, and both ends of the heating pipe 130 are exposed to the cavity member 120, so that the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com