Assembling method for jacketed pipe and its pipe lining apparatus

An assembly method and a technology for a pipe-piercing device, which are applied in the directions of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve the problems of inconvenient use, large one-time investment, and complicated construction steps, etc. Efficiency, short time-consuming, guaranteeing the effect of installation quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

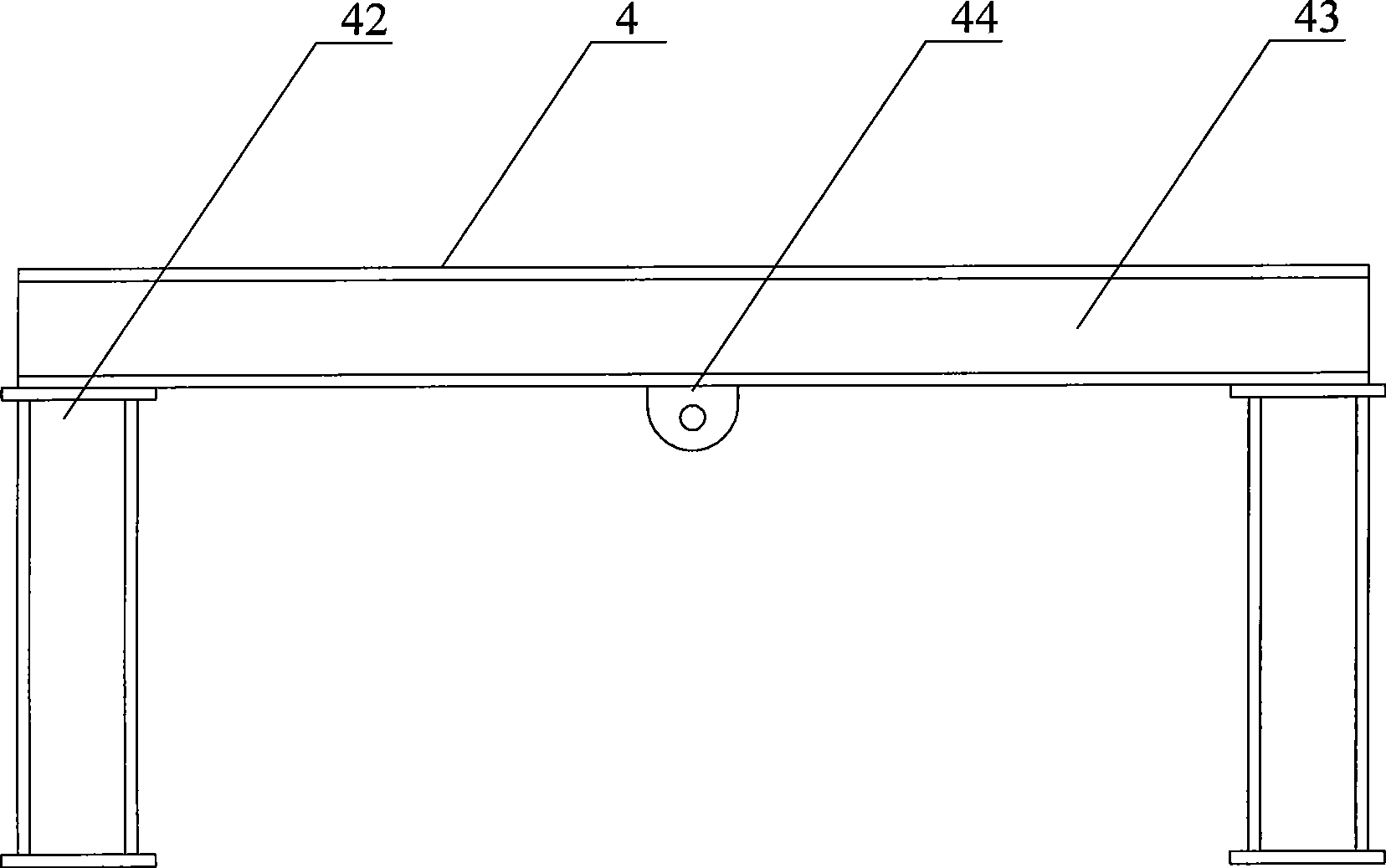

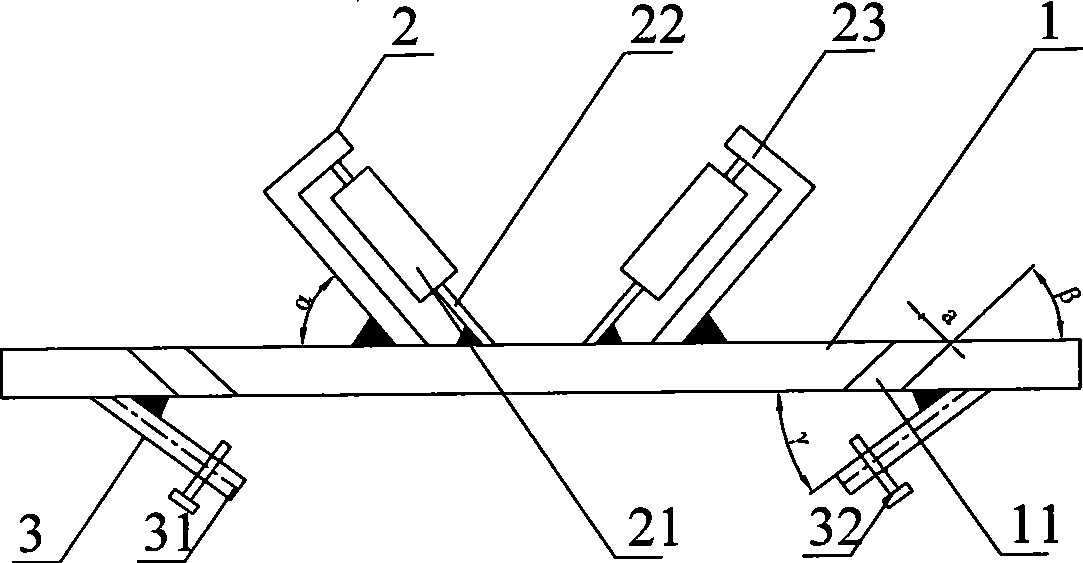

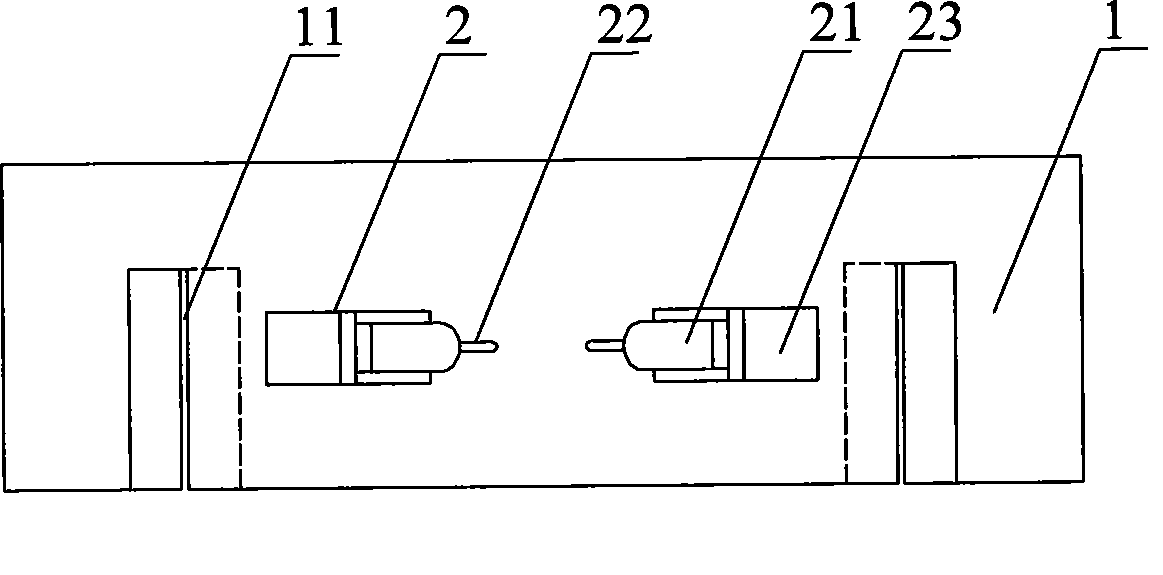

[0029] Such as Figure 1 to Figure 5 As shown, the pipelined high-pressure dissolution project of an alumina project (capacity 400kt / a) uses a three-pipe high-pressure stripper, which is a type of jacketed pipe, that is, a large outer pipe 5 Three small inner pipes 6 (see Figure 4 ), the size of the three inner tubes 6 is the same (it may be different in practice), the size of the outer tube 5 is Φ426×10 (that is, the outer diameter is 426mm, the wall thickness is 10mm, the same below), and the size of the inner tube 6 is Φ133×10. The length of the three casings is 120m. The three sleeves are assembled as follows:

[0030] 1. Treatment of pipe bevel

[0031] The processing of the groove is to use a pipe cutting machine to process the ends of the steel pipes (including the inner pipe and the outer pipe) of the three casings into a single-sided V-shaped groove with an angle of 30°±2.5°, and at the same time cut the surface of the groove Remove the oxide skin and slag, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com