Patents

Literature

152results about How to "Guaranteed welding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

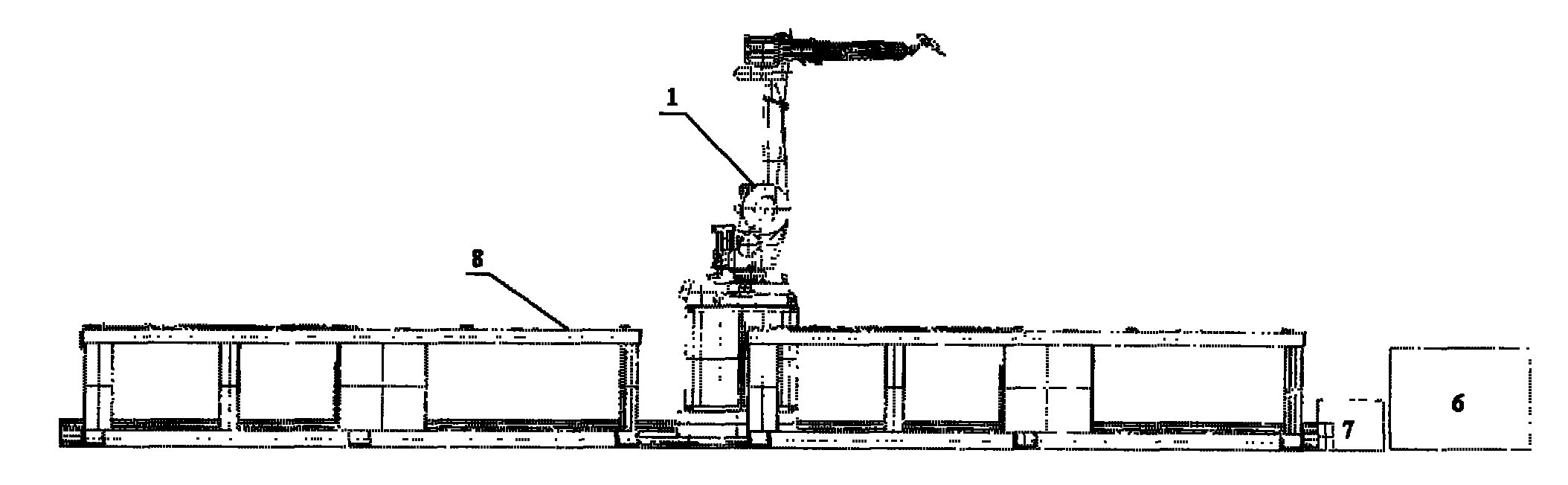

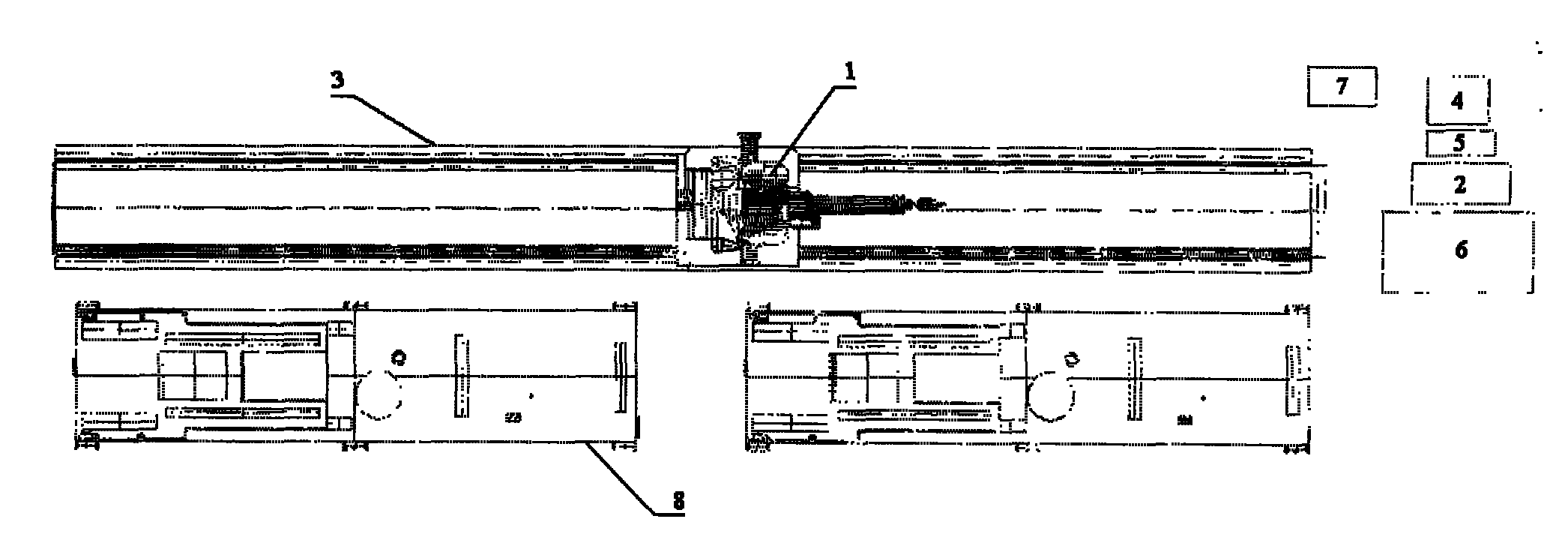

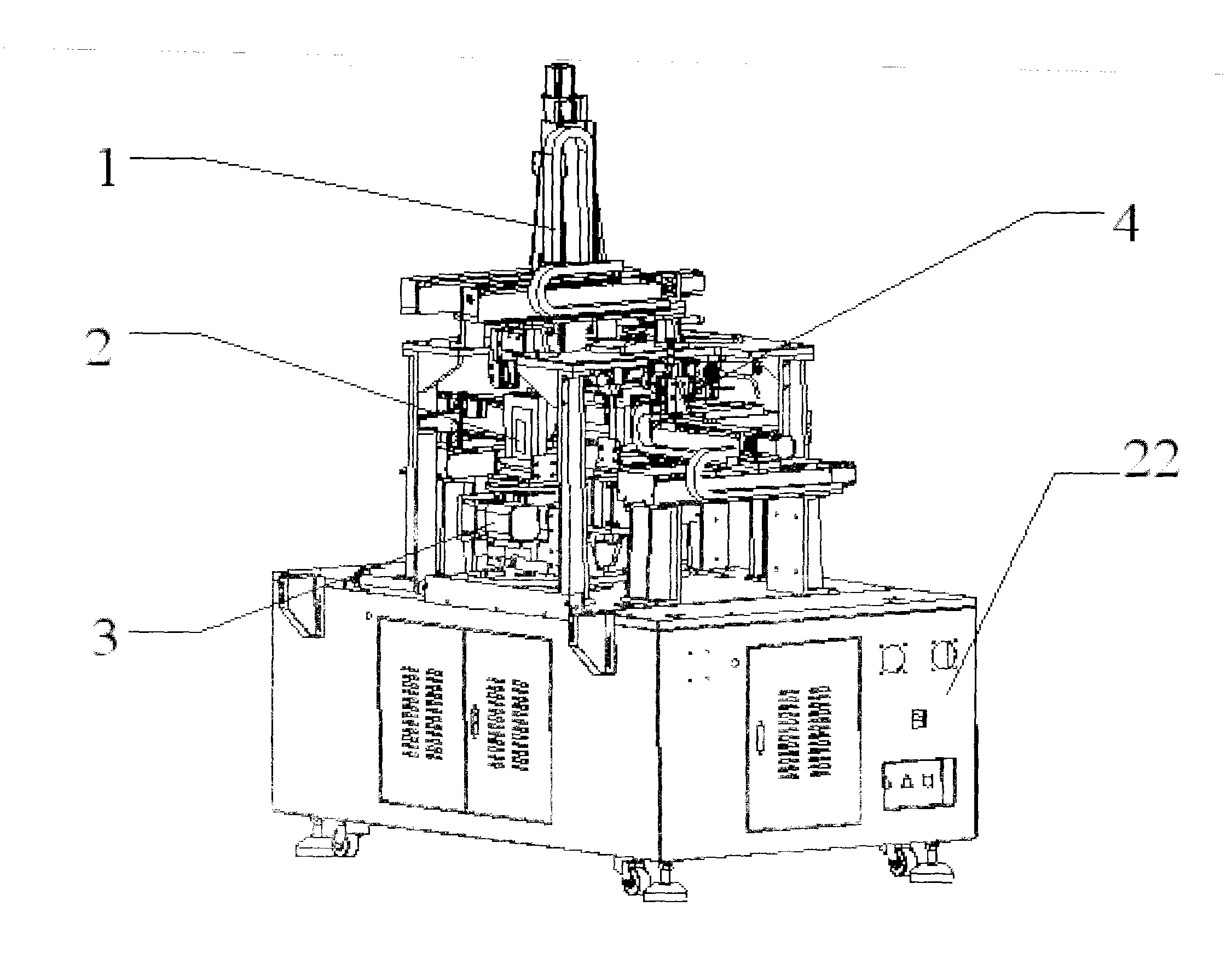

Welding robot workstation system for injection molding machine frame

InactiveCN101780584AGuarantee welding qualityGuaranteed welding efficiencyWelding accessoriesWeld seamRobot control

The invention relates to a welding robot workstation system for an injection molding machine frame, which comprises a welding robot, a welding device, a robot mobile slip way, a welding torch cooling device, an intelligent searching and tracking device and a robot control box, and the welding robot is arranged on the robot mobile slip way; the welding device is respectively connected with the welding robot and the welding torch cooling device; and the robot control box is respectively connected with the welding robot, the robot mobile slip way, the welding device and the intelligent searching and tracking device, to control the movement and the welding of the welding robot. The welding robot workstation system for the injection molding machine frame can automatically carry out MAG welding to a plane on the injection molding frame and other reachable weld seams, thereby ensuring the welding quality and the efficiency of the product.

Owner:NINGBO KAITAI MACHINERY

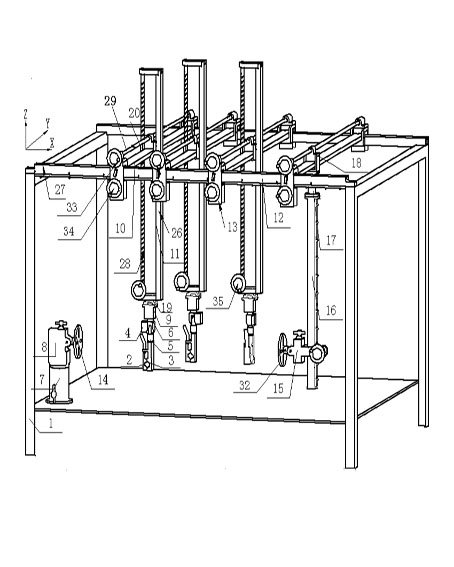

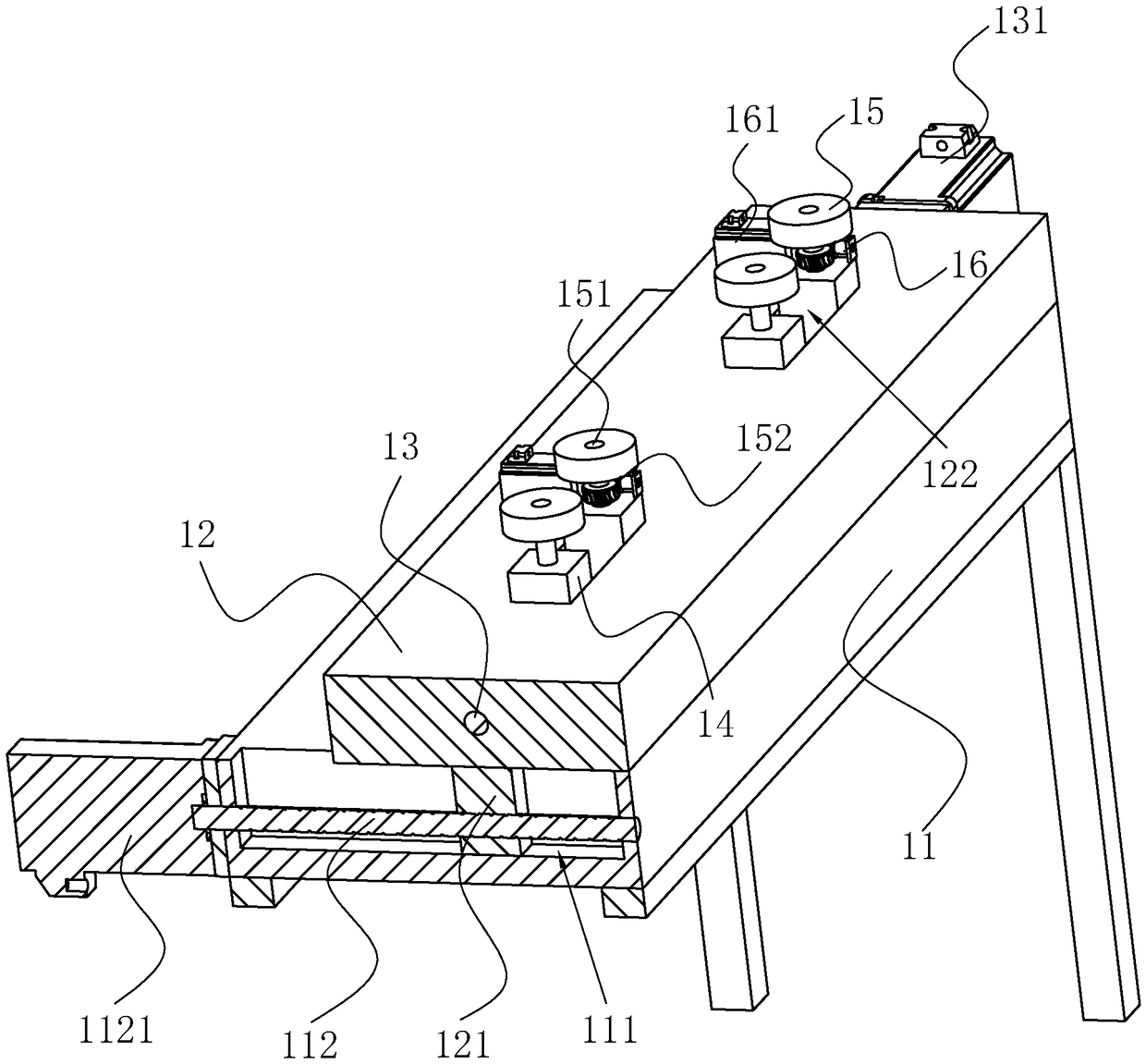

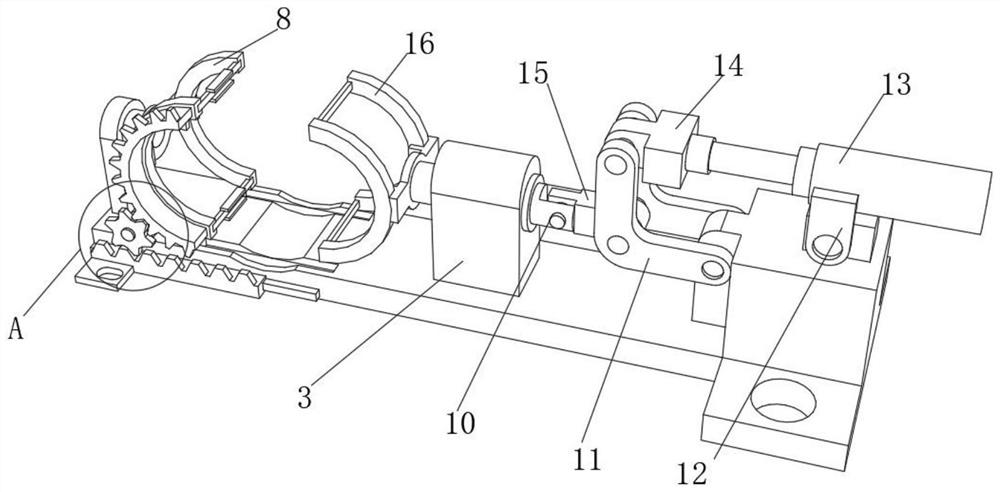

Flexible clamp for pipe fitting welding and adjusting method thereof

InactiveCN102000935AAvoid misalignmentExpand the scope of useWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention discloses a flexible clamp for pipe fitting welding between multi-section pipe fittings and between a pipe fitting and a flange, and an adjusting method thereof. The bottom of a base bracket is provided with a fixed end flange around Z-axis angle adjusting mechanism and a fixed end flange around Y-axis angle adjusting mechanism connected with an equant chute flange plate rotating mechanism; a top Y-direction displacement regulating mechanism, a vertical Z-direction displacement regulating mechanism and a top X-direction displacement regulating mechanism for regulating the pipe fittings and a flange Y-direction displacement regulating mechanism for regulating the flange are arranged on the upper part of the base bracket; and each mechanism is adjusted to make a positioning mechanism rotate around the X, Y and Z directions. The invention can be rapidly and accurately adjusted and positioned so as to clamp the pipe fittings according to diversified space trends of different pipe fittings, and a set of clamp can adapt to welding a series of pipe fitting sections in different specifications.

Owner:JIANGSU UNIV OF SCI & TECH

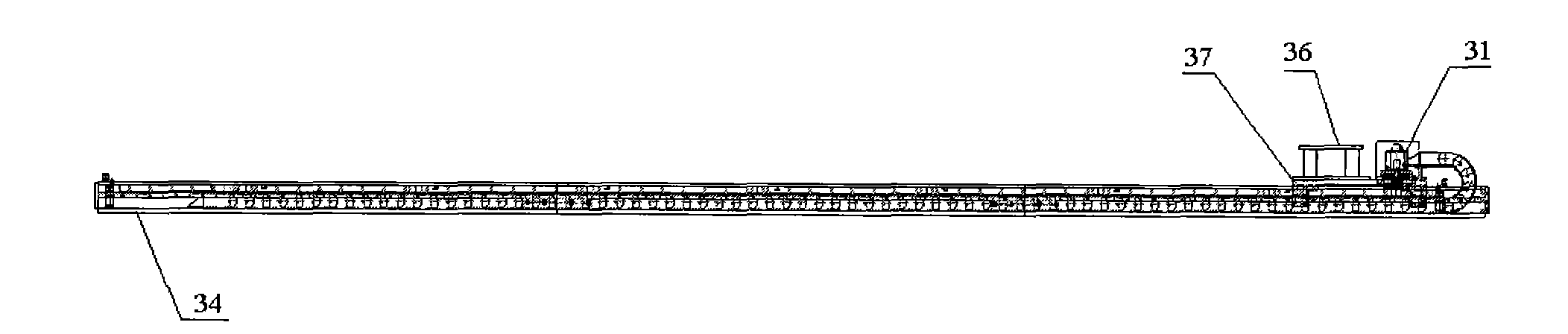

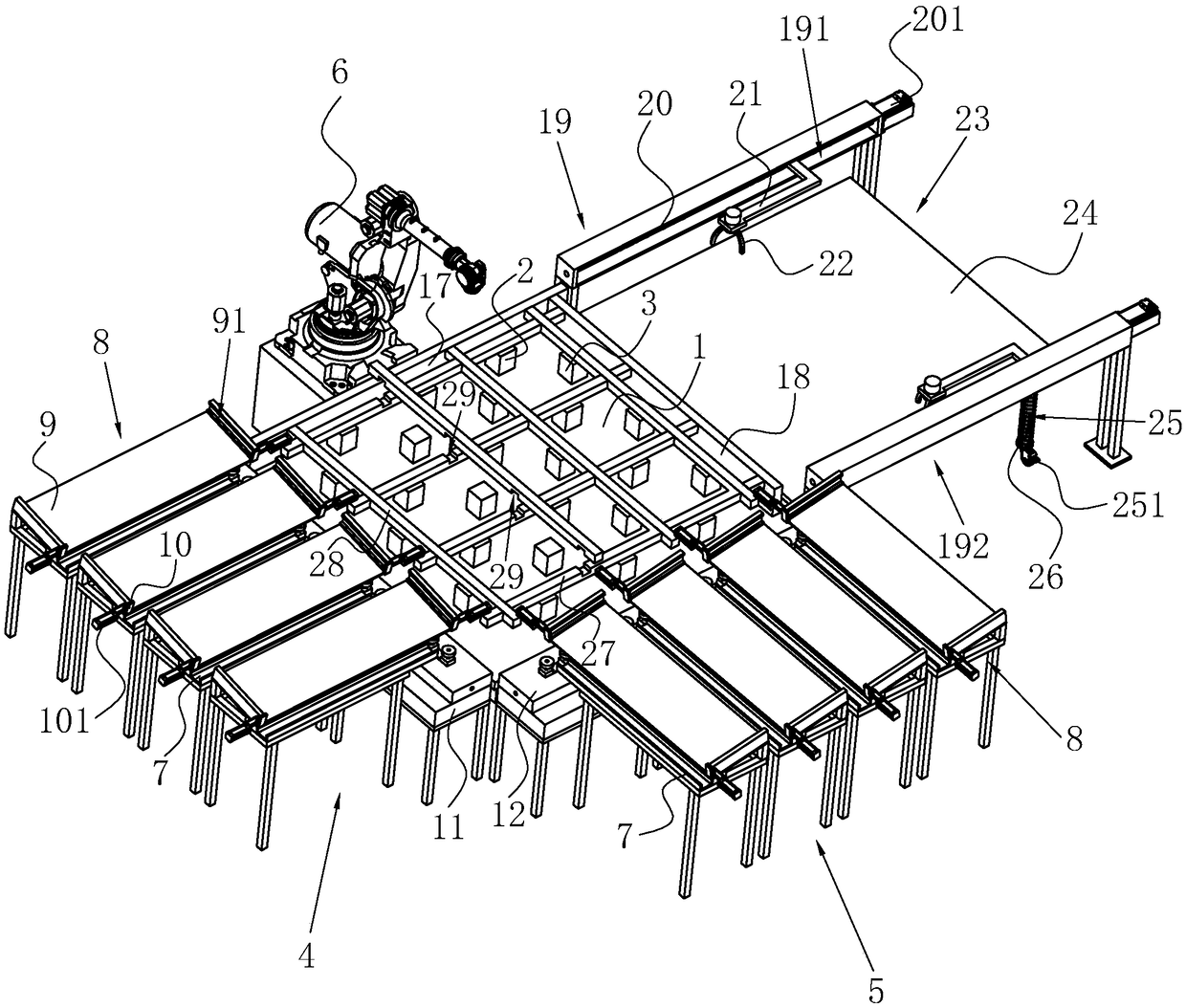

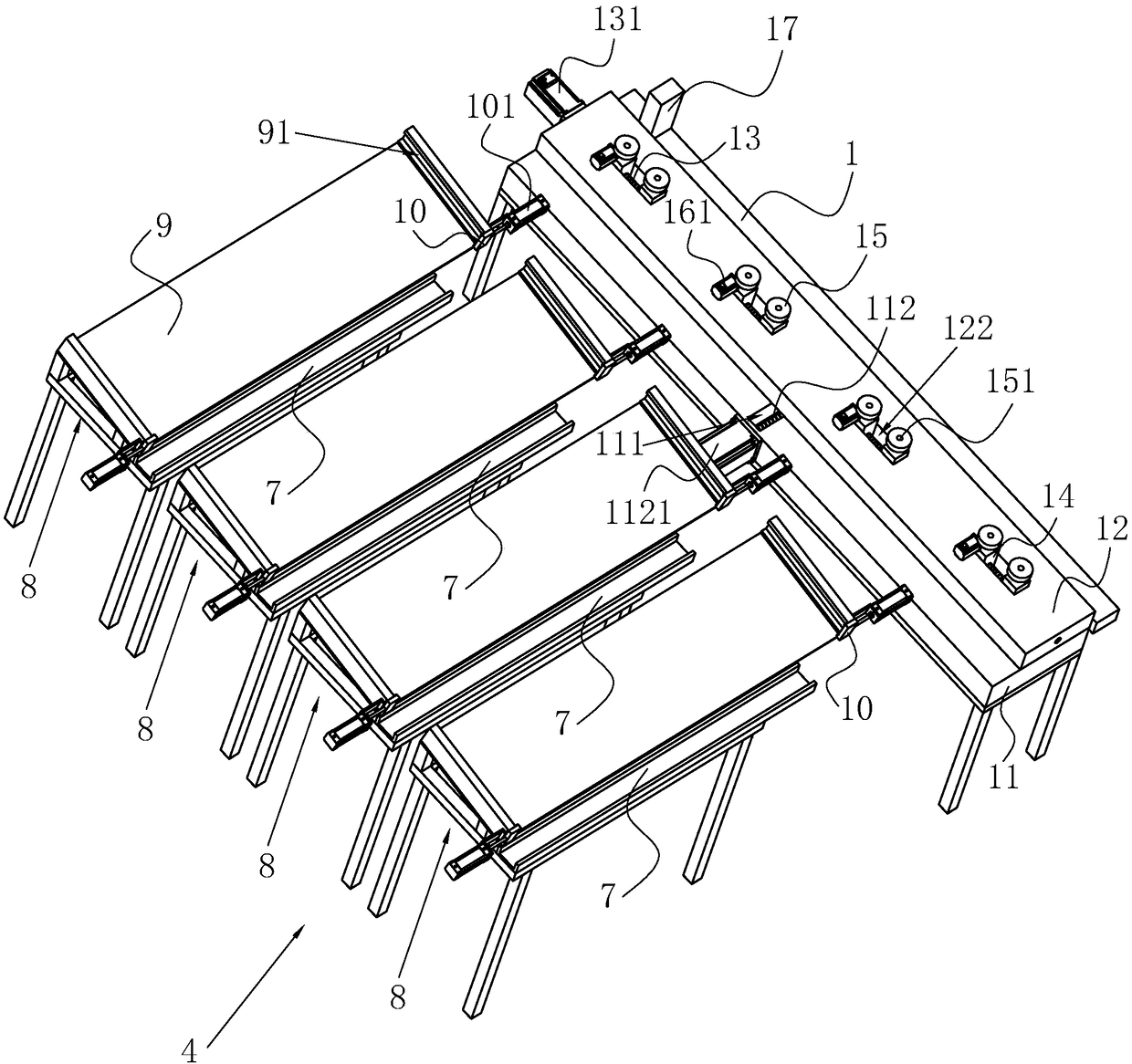

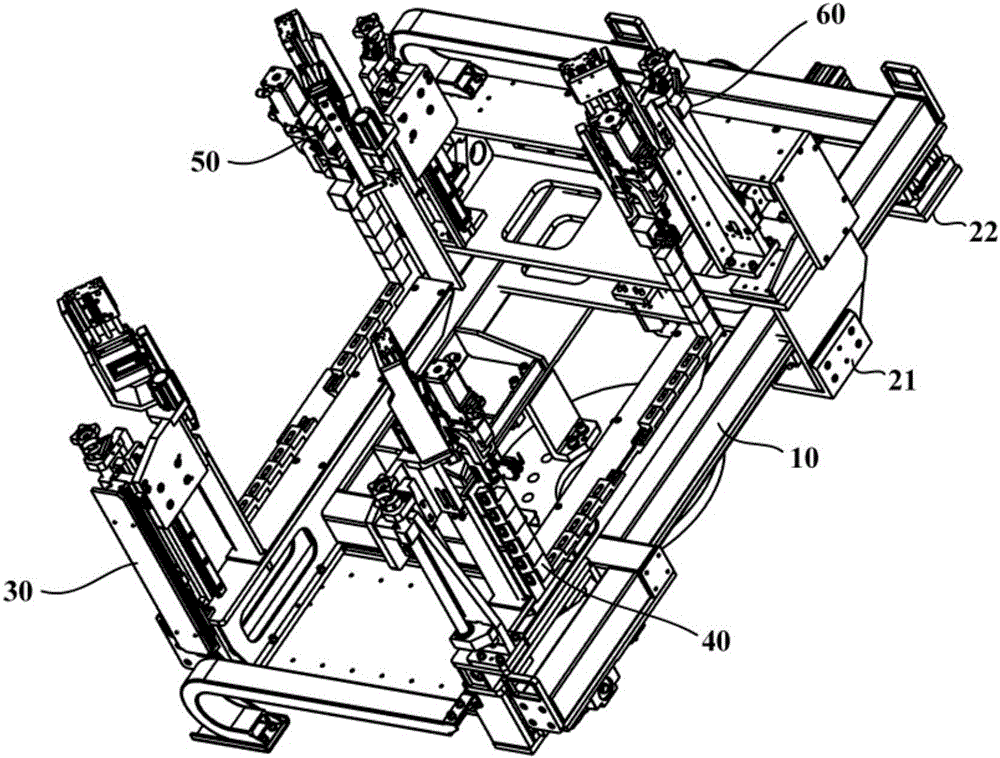

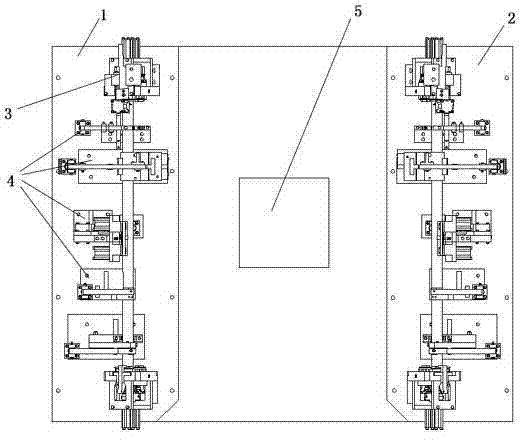

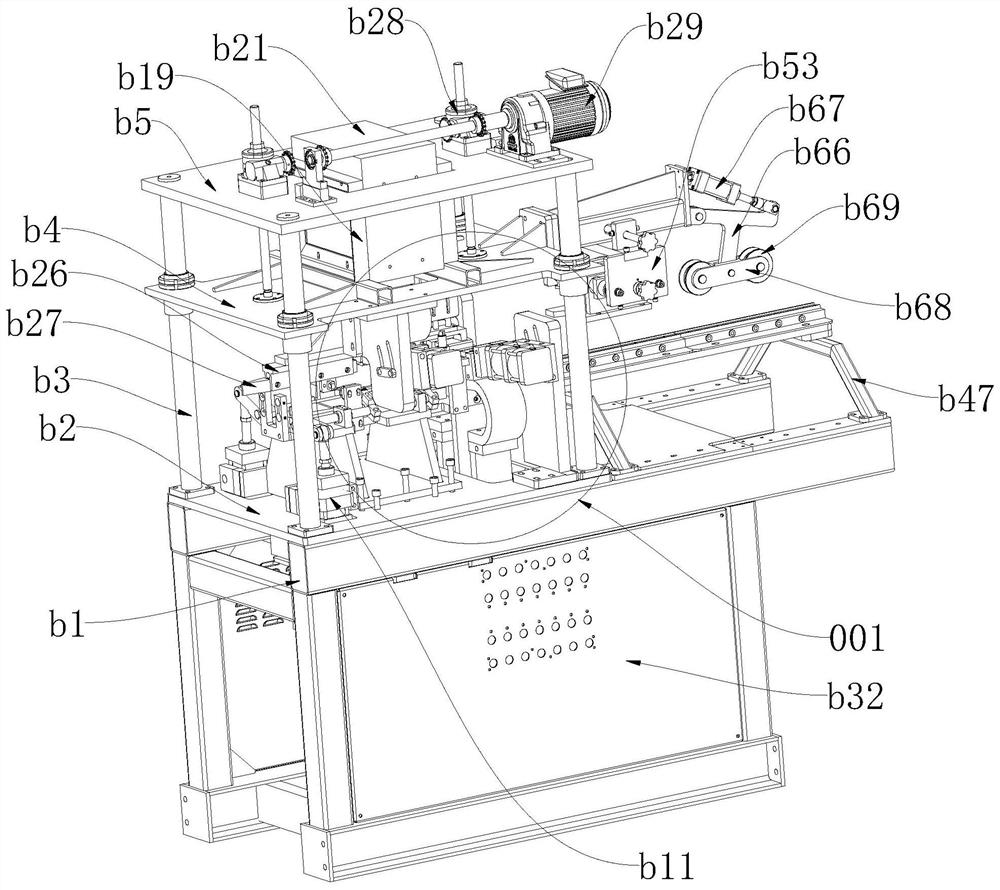

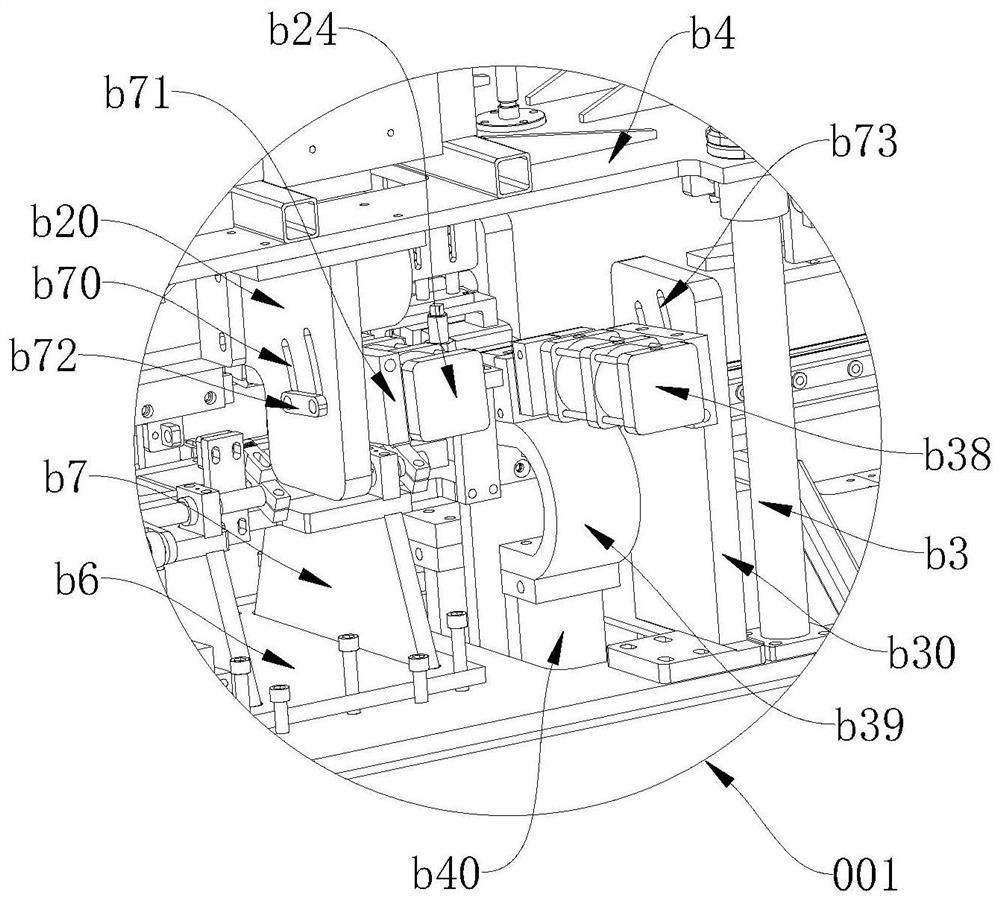

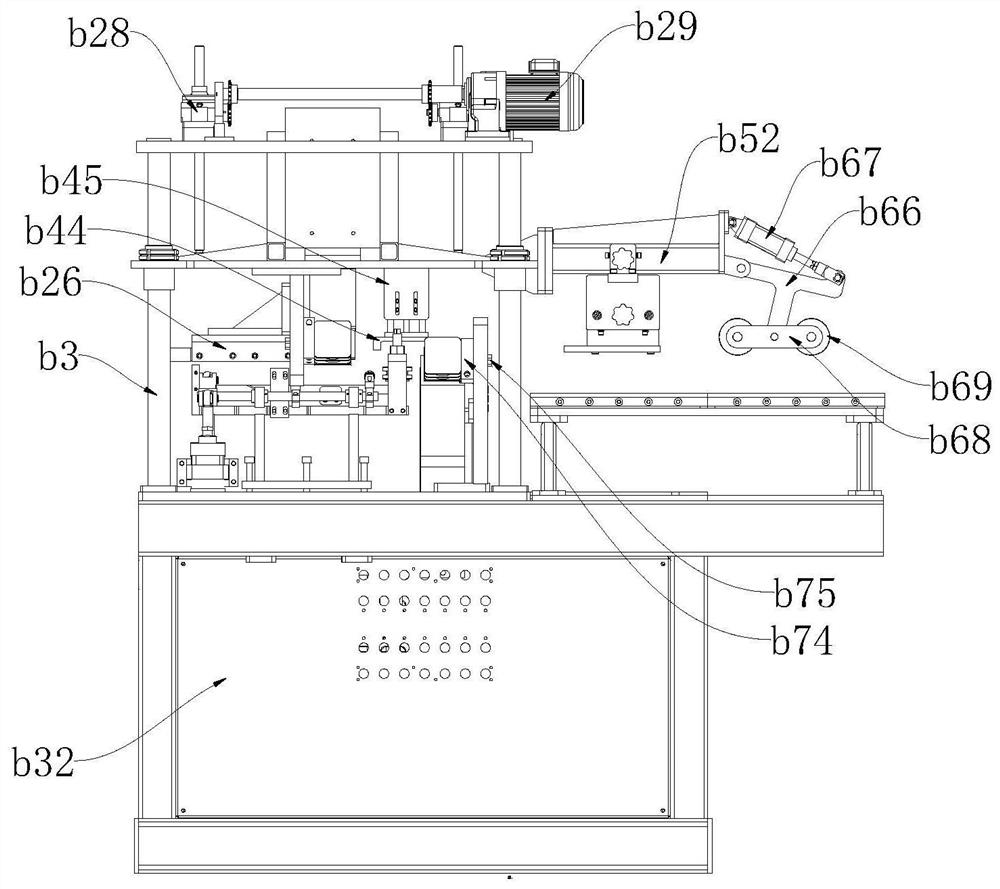

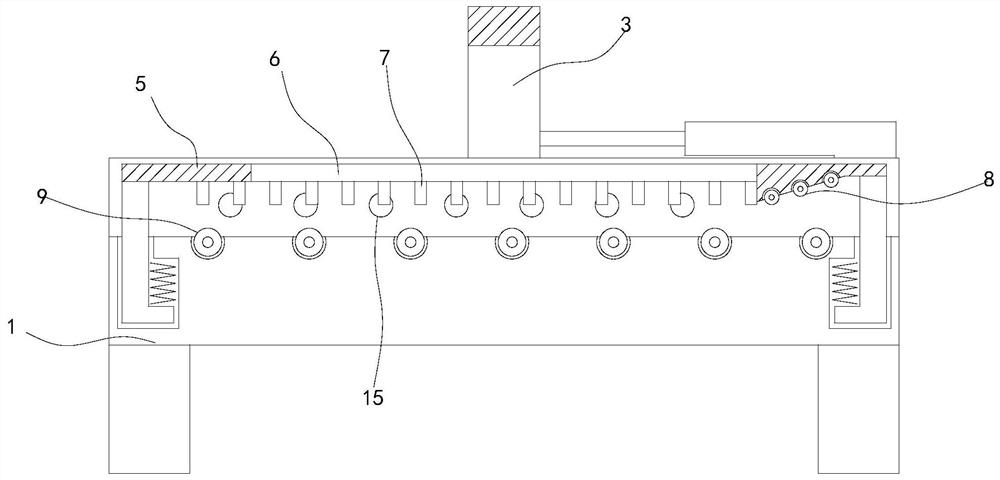

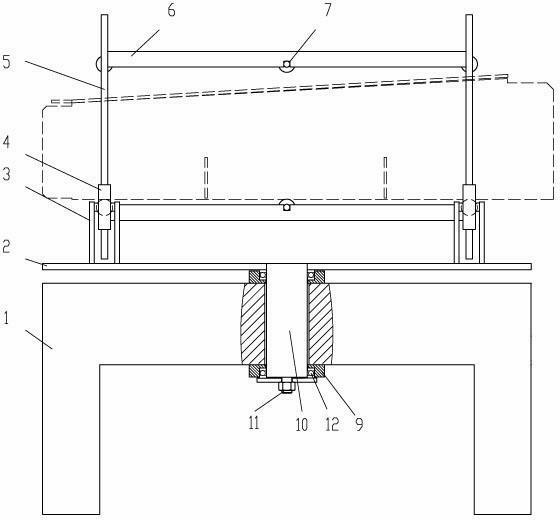

Automatic welding equipment applied to curtain wall framework,

ActiveCN109079370AGuarantee quality and efficiencyGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSlide plateEngineering

The invention relates to automatic welding equipment applied to a curtain wall framework. The automatic welding equipment applied to the curtain wall framework comprises welding tables. A transverse feeding mechanism and a longitudinal feeding mechanism are separately arranged on the adjacent two sides of one group of the welding tables. A positioning mechanism is arranged on the welding tables, and a six-axis welding robot is arranged on the sides, opposite to the transverse feeding mechanism or the longitudinal feeding mechanism, of the welding tables. A discharging mechanism is arranged onthe other sides, adjacent to the six-axis welding robot, of the welding tables. The transverse feeding mechanism comprises transversely arranged guide rails, at least two guide rails are arranged at intervals in the longitudinal direction, and discharging frames are arranged on one sides of the guide rails in the length direction of the guide rails. Longitudinally arranged placing tables are arranged between the guide rails and the welding tables, sliding plates sliding in the length direction of the guide rails are arranged on the placing tables, and a plurality of groups of material conveying mechanisms corresponding to the guide rails one by one are arranged on the sliding plates. Each group of the material conveying mechanisms comprises at least one group of conveying wheels which aresymmetrically arranged, and the guide rails are positioned on the symmetric lines of the conveying wheels. The automatic welding equipment applied to the curtain wall framework effectively ensures thewelding quality and welding efficiency and reduces the labor intensity when working.

Owner:江苏中南建设装饰集团有限公司

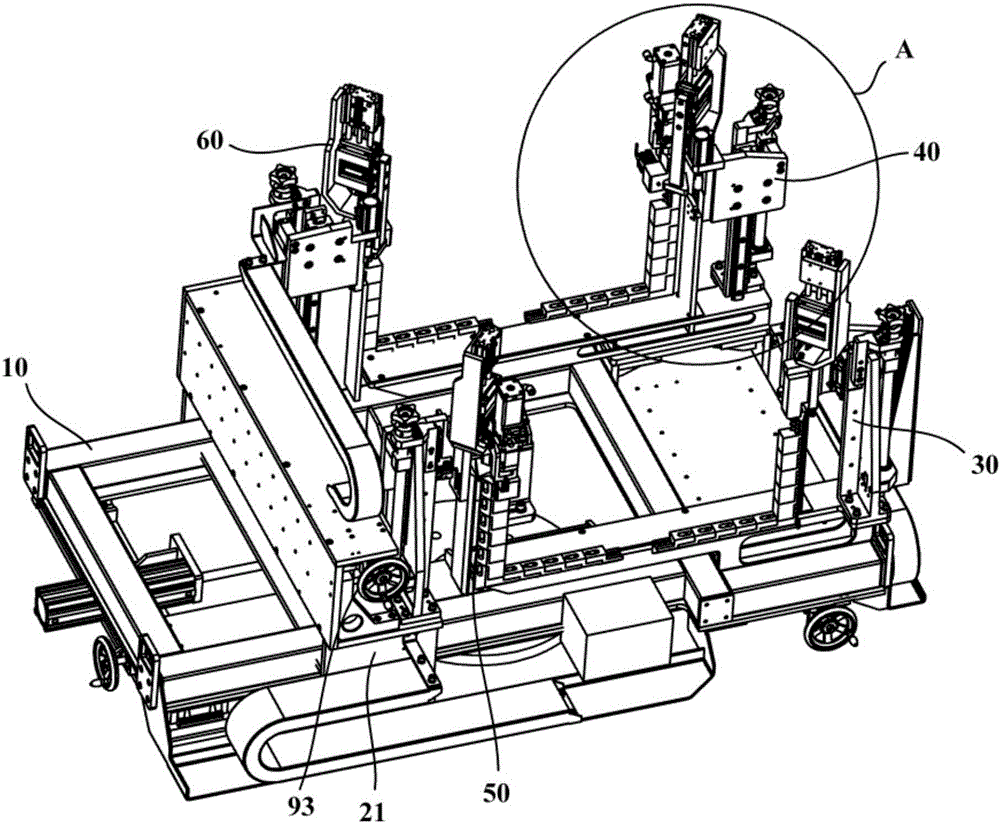

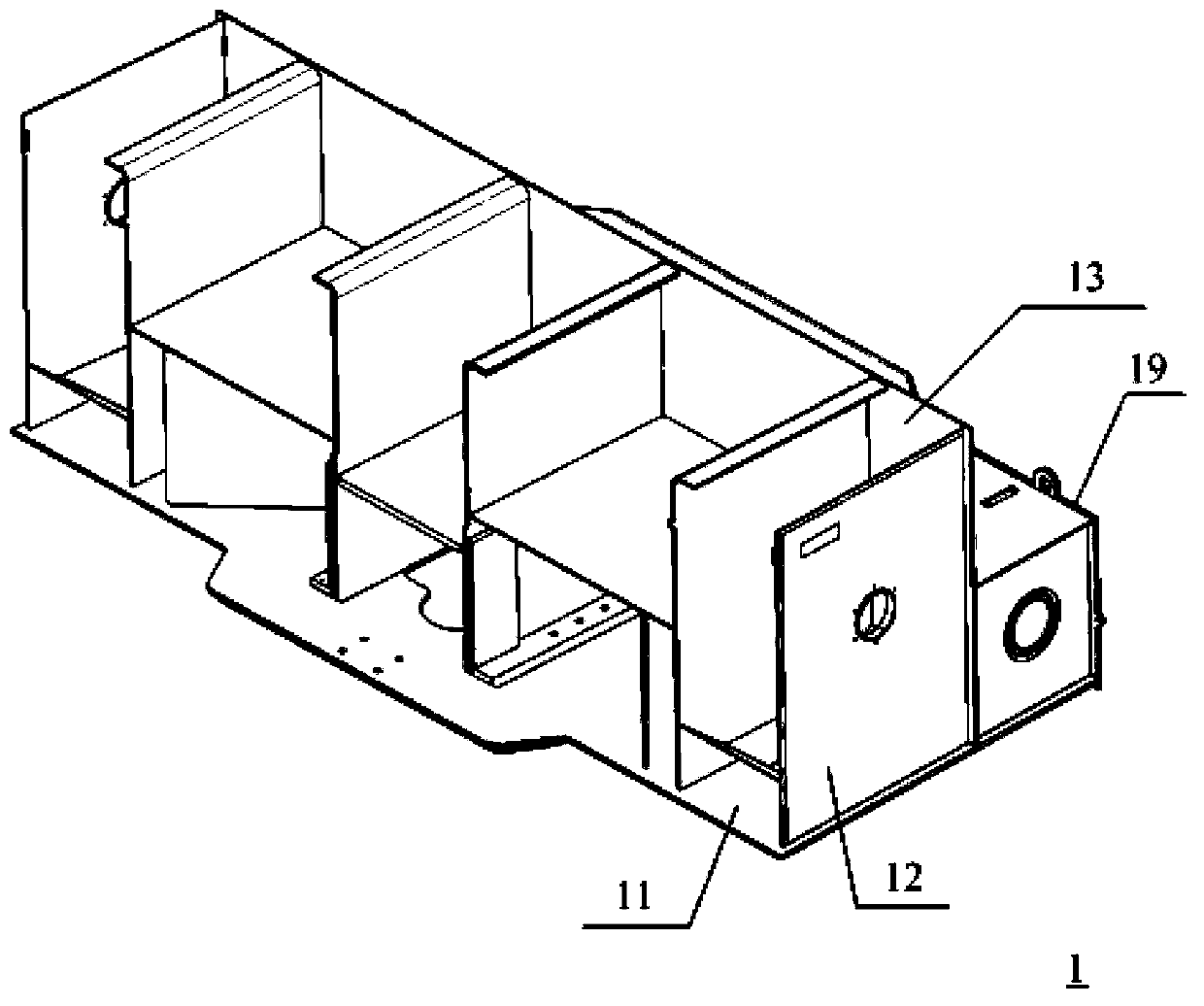

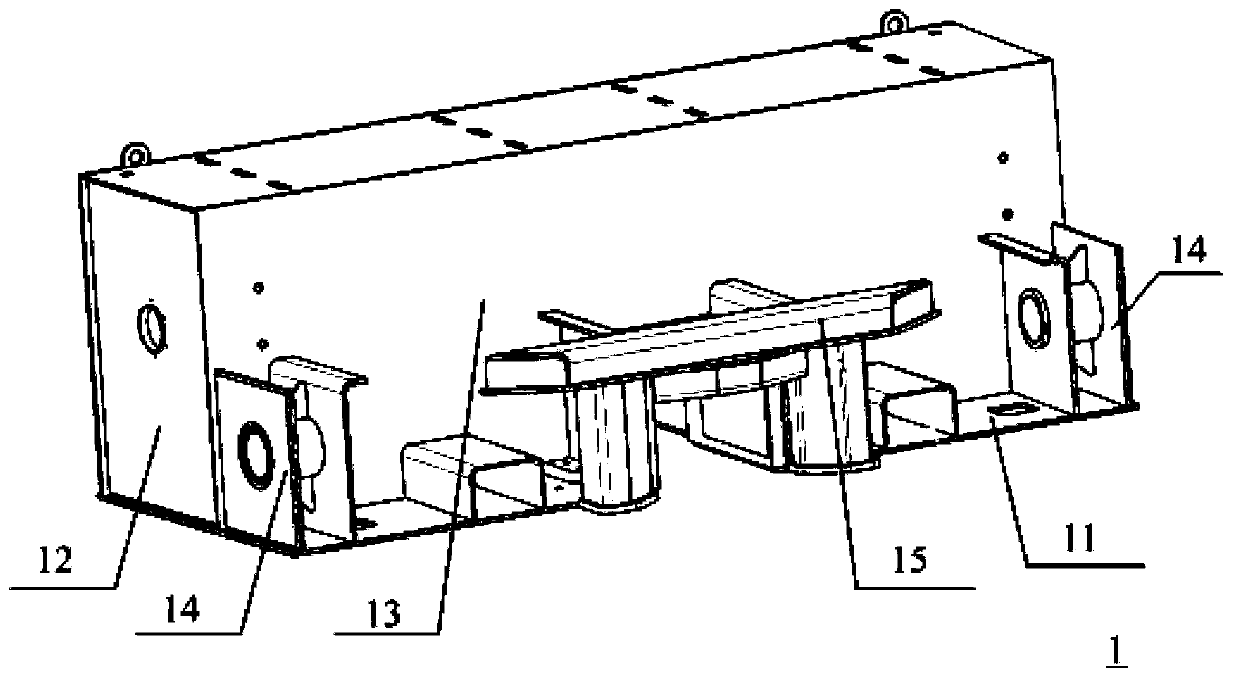

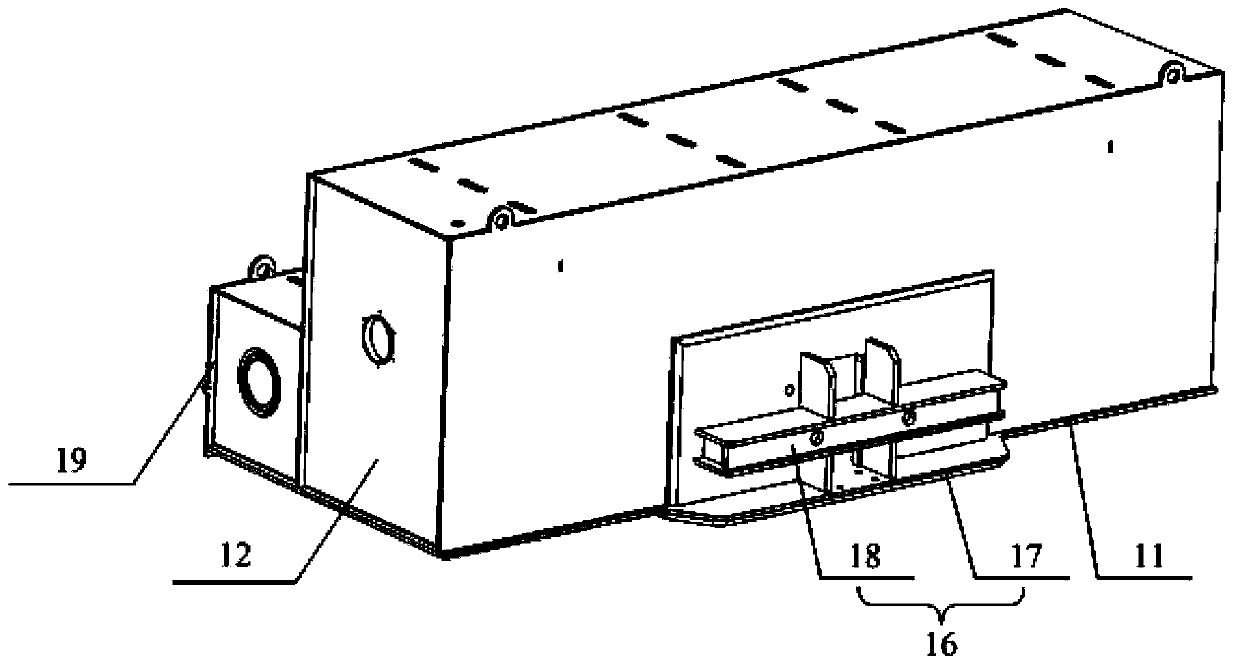

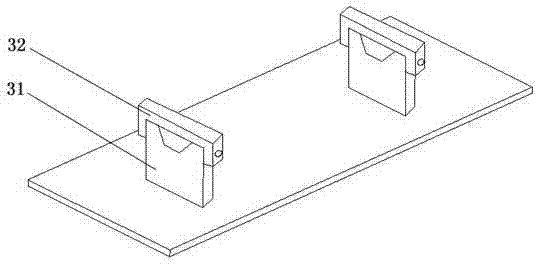

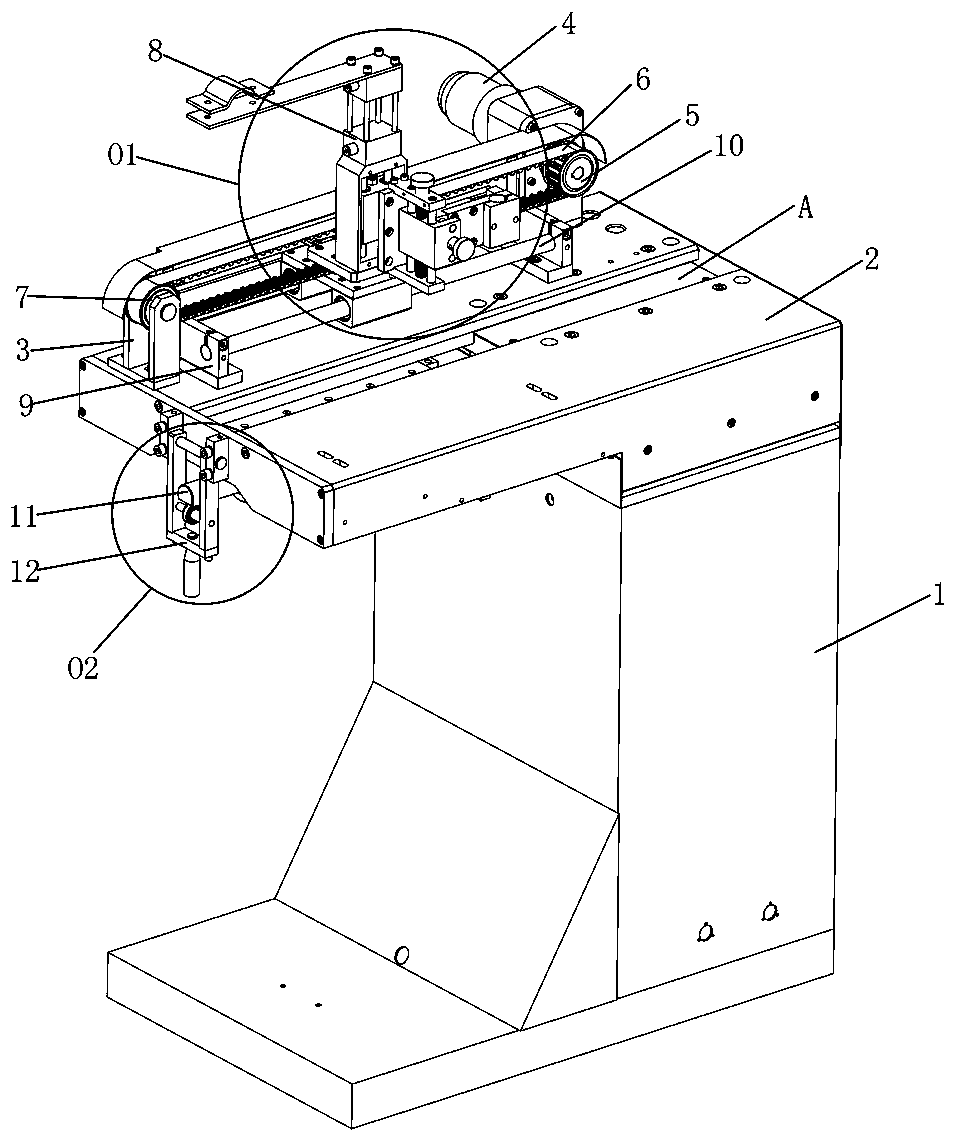

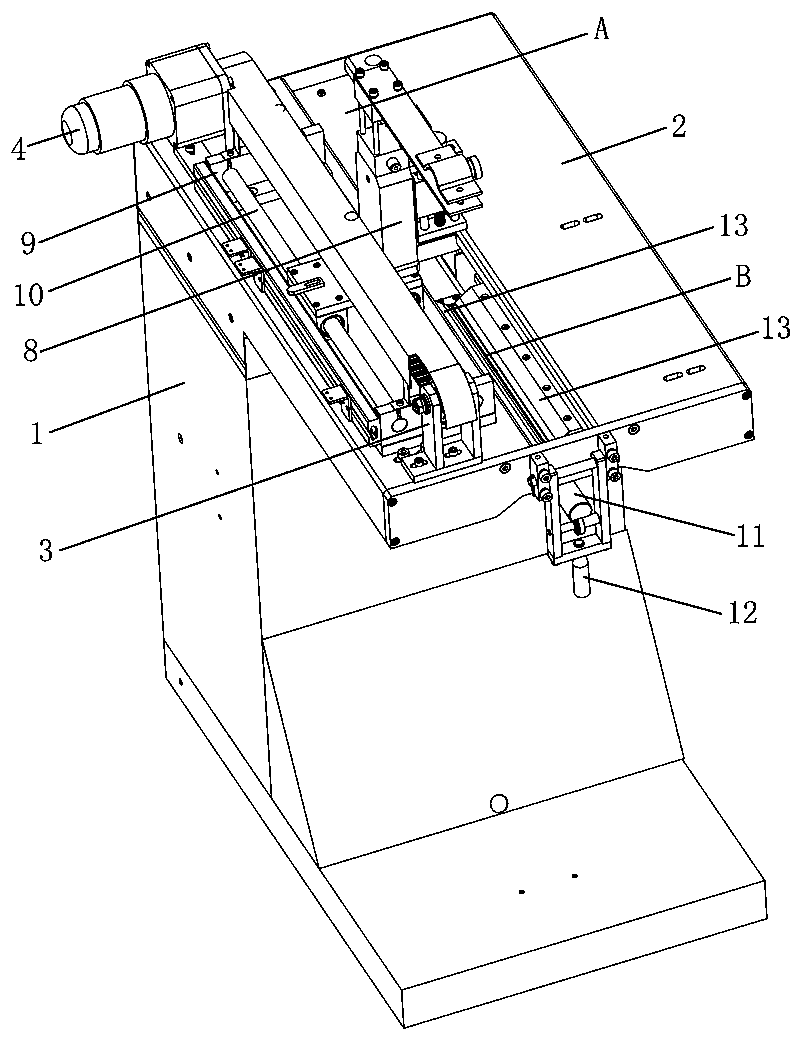

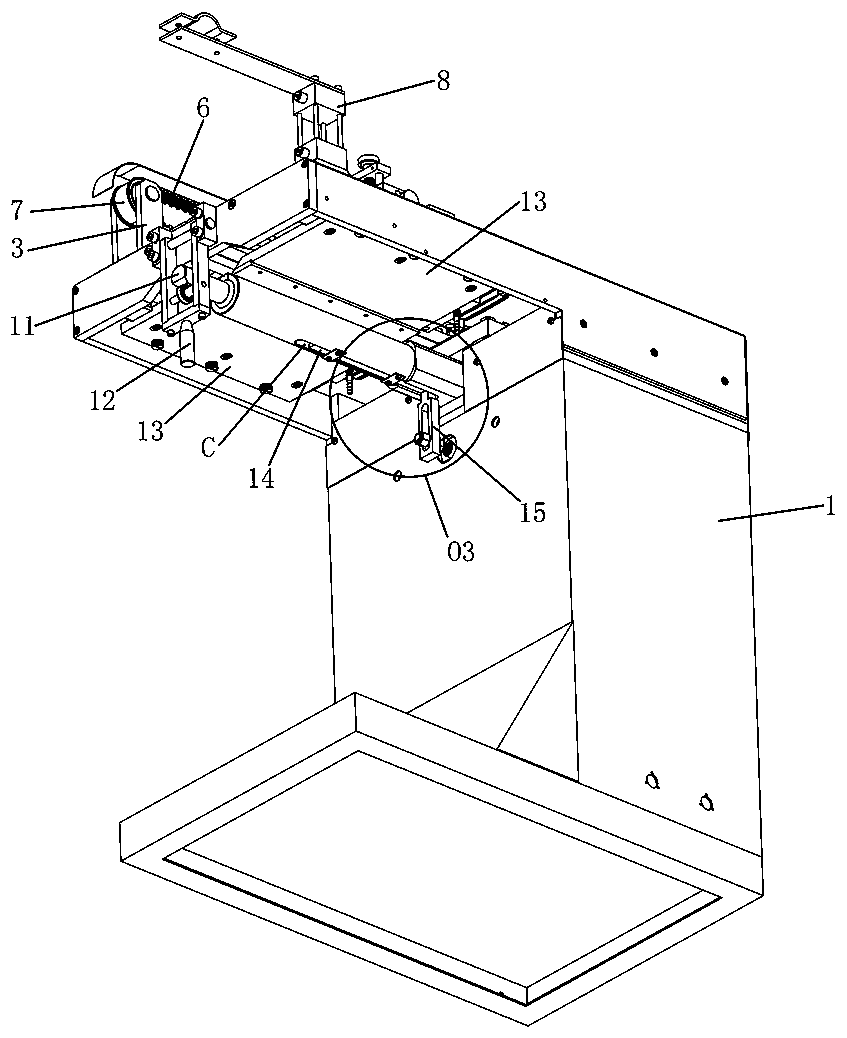

Welding tool for electric cabinets

InactiveCN105773045AQuality improvementGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesCompression deviceSlide plate

The invention provides a welding tool for electric cabinets. The welding tool comprises a tool support, a first sliding plate assembly, a first clamping device, a second clamping device, a third clamping device and a fourth clamping device; the first sliding plate assembly is installed on the tool support in a sliding manner in the transverse direction; the first clamping device is fixed to the tool support and located on one side of the tool support; the second clamping device faces or deviates from the first clamping device and is installed on the tool support in a sliding manner in the longitudinal direction; the third clamping device is fixed to the first sliding plate assembly, and the third clamping device and the first clamping device are located on the same side of the tool support; and the fourth clamping device faces or deviates from the second clamping device and is installed on the first sliding plate assembly in a sliding manner in the longitudinal direction. The first clamping device, the second clamping device, the third clamping device and the fourth clamping device each comprise a compression device and a lifting device, and each lifting device is arranged to driving the corresponding compression device to move in the height direction. The welding tool can be suitable for the electric cabinets in different specifications, the welding efficiency can be guaranteed, and the welding quality can be guaranteed.

Owner:YANTAI WALU ROBOT AUTOMATION CO LTD

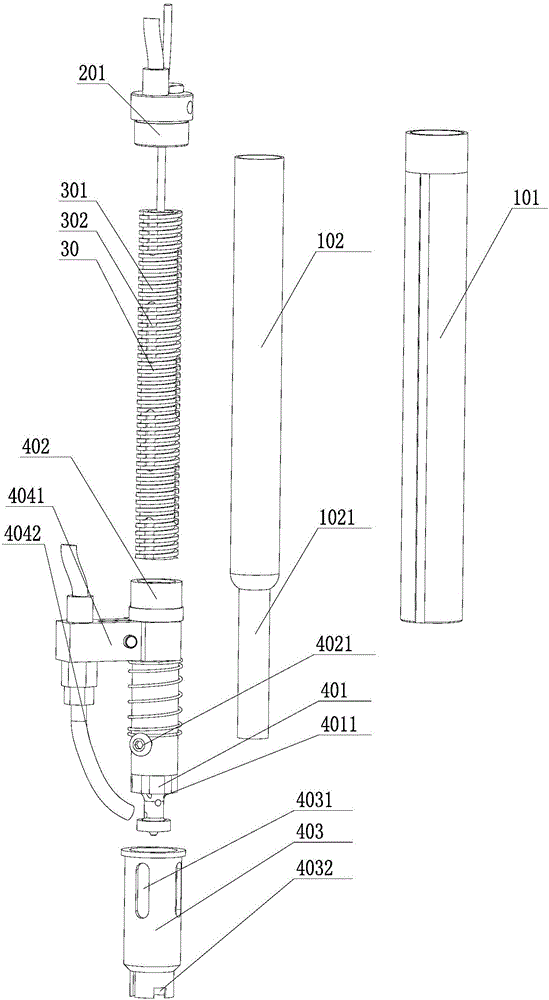

Three-way connector and laser electric-arc composite welding torch

ActiveCN102581530AGood synergyGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a three-way connector and a laser electric-arc composite welding torch, which belong to the technical field of welding tools. The three-way connector comprises a first adjusting part, a second adjusting part and a third adjusting part. The laser electric-arc composite welding torch comprises a first connector, a second connector, the three-way connector, a laser welding gun, an electric-arc welding gun and a servo tracking mechanism. The invention further discloses a laser electric-arc composite welding device on the basis of the laser electric-arc composite welding torch. The three-way connector can move vertically and bilaterally and rotate by a certain angle through the electric-arc welding torch connected with the three-way connector externally; the laser welding gun of the laser electric-arc composite welding torch can move vertically bilaterally and rotate by a certain angle through the three-way connector, so that a gap and an included angle between a laser beam and a welding wire can be adjusted, synergistic effect between the laser and the welding wire can be achieved optimally, and welding efficiency and quality can be guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Full-automatic laser welding machine

ActiveCN102528285AWide range of applicationsBright futureLaser beam welding apparatusEngineeringManipulator

The invention belongs to the technical field of welding machines, and in particular relates to a full-automatic laser welding machine for a square workpiece. The laser welding machine comprises a support table, a clamp turntable arranged on the support table, a loading and unloading manipulator for transferring the workpiece to the clamp turntable and a positioning and welding unit for positioning and welding the workpiece on the clamp turntable, wherein both the loading and unloading manipulator and the positioning and welding unit are arranged on the support table. Compared with the prior art, the laser welding machine has the advantages that: the loading and unloading manipulator can automatically finish loading and unloading of the workpiece; the turntable clamp can ensure that the positioning and welding unit keeps the material in an abundant state all the time, so that the efficiency is improved; the workpiece is jointed with an upper pressing block under the action of a jacking cylinder through a correcting block in the positioning and welding unit and then welded, so that the assembly precision can be ensured, and the high welding quality is ensured; due to double laser heads, the welding efficiency can be ensured, and the high welding quality, the welding efficiency and the welding consistency are improved; and therefore, the laser welding machine has quite broad application range and prospect.

Owner:NINGDE AMPEREX TECH +1

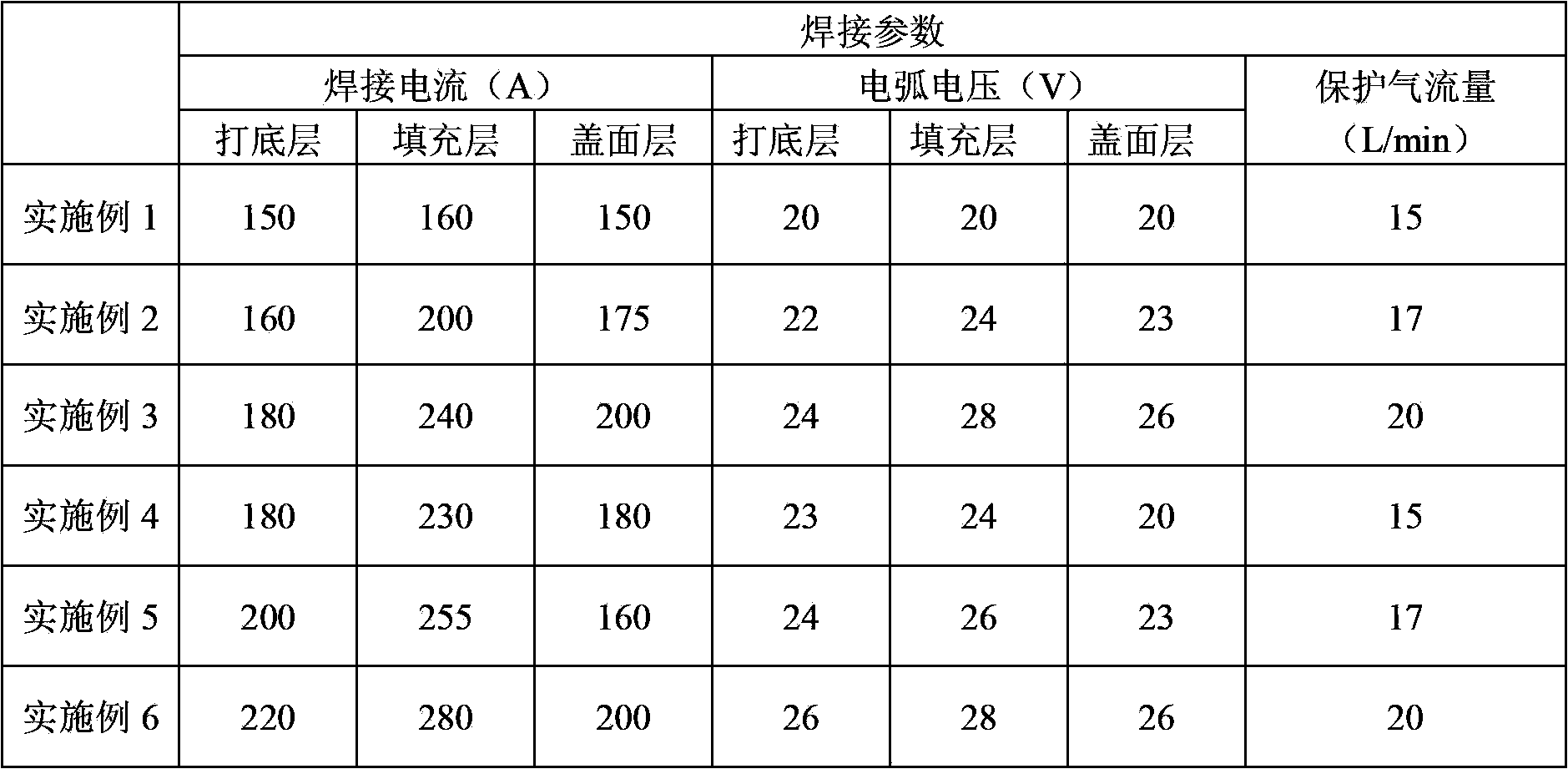

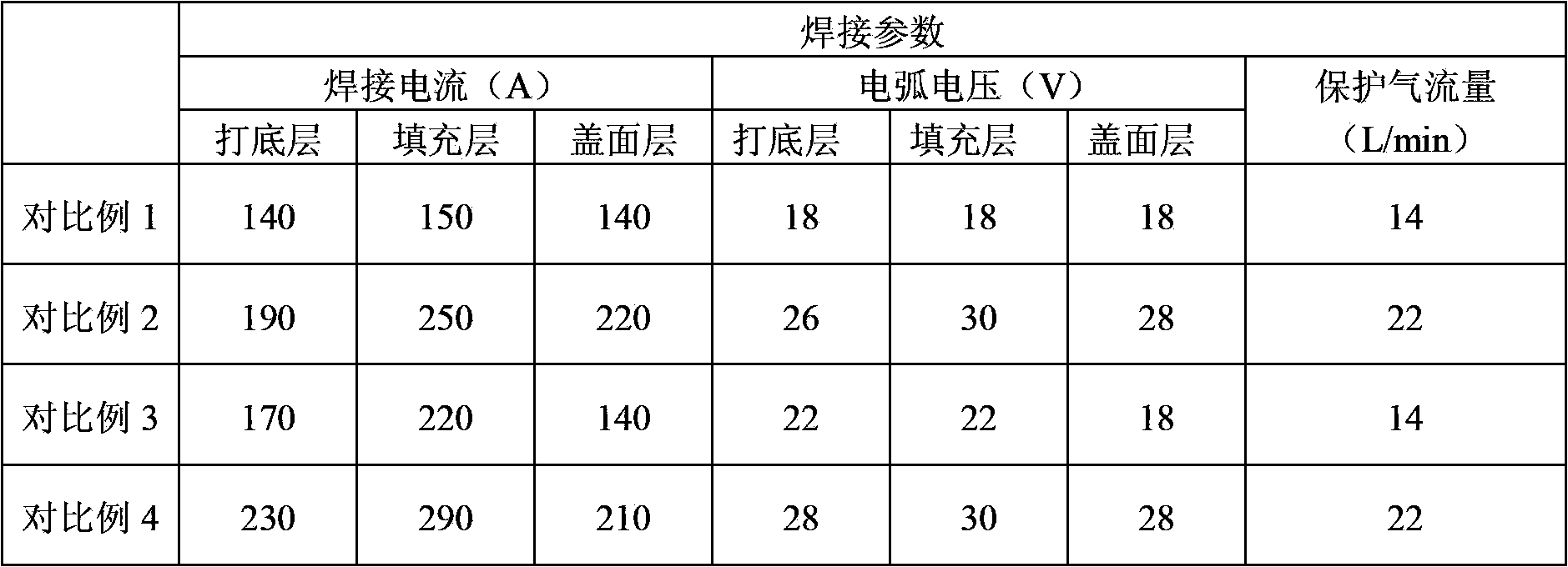

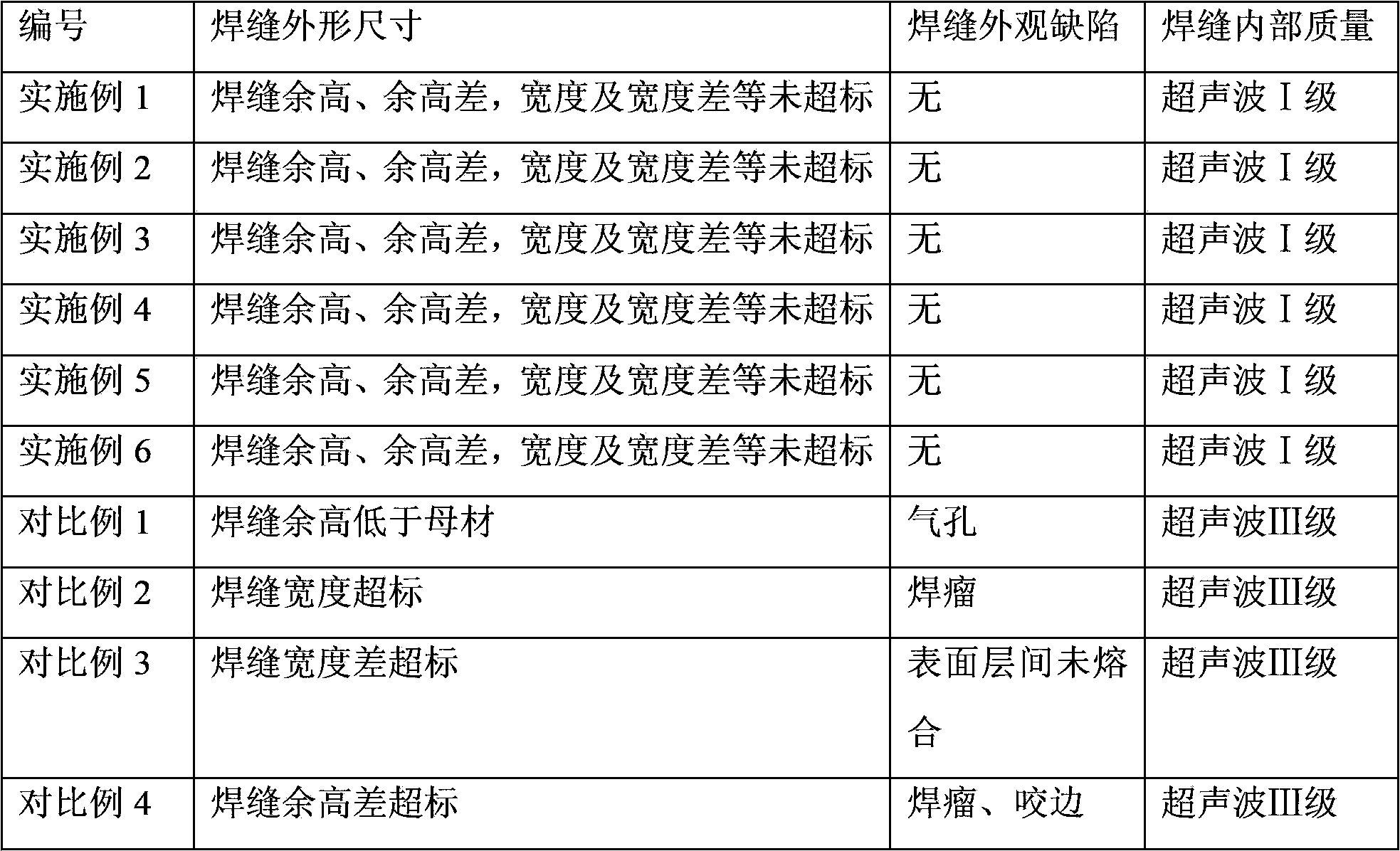

Welding method of CO2 gas shielded welding for solid welding wire with diameter of phi 1.6

InactiveCN103692060AGuaranteed welding efficiencyGuarantee welding qualityArc welding apparatusWelding/cutting media/materialsElectric arcPower flow

The invention relates to a welding method of CO2 gas shielded welding for a solid welding wire with the diameter of phi 1.6. The welding method comprises the step of welding a workpiece by a way of vertical position welding or horizontal position welding, wherein the welding process sequentially comprises the steps of welding a base layer, welding a filler layer and welding a cover surface layer, and the thickness of the welded workpiece is not less than 30mm; when the workpiece is welded in the way of vertical position welding, the welding current is 150-180A, and the arc voltage is 20-24V when the base layer is welded; the welding current is 160-240A, and the arc voltage is 20-28V when the filler layer is welded; the welding current is 150-200A, and the arc voltage is 20-26V when the cover surface layer is welded; when the workpiece is welded in the way of horizontal position welding, the welding current is 180-220A, and the arc voltage is 23-26V when the base layer is welded; the welding current is 230-280A, and the arc voltage is 24-28V when the filler layer is welded; the welding current is 160-200A, and the arc voltage is 20-26V when the cover surface layer is welded.

Owner:PANGANG GRP ENG TECH

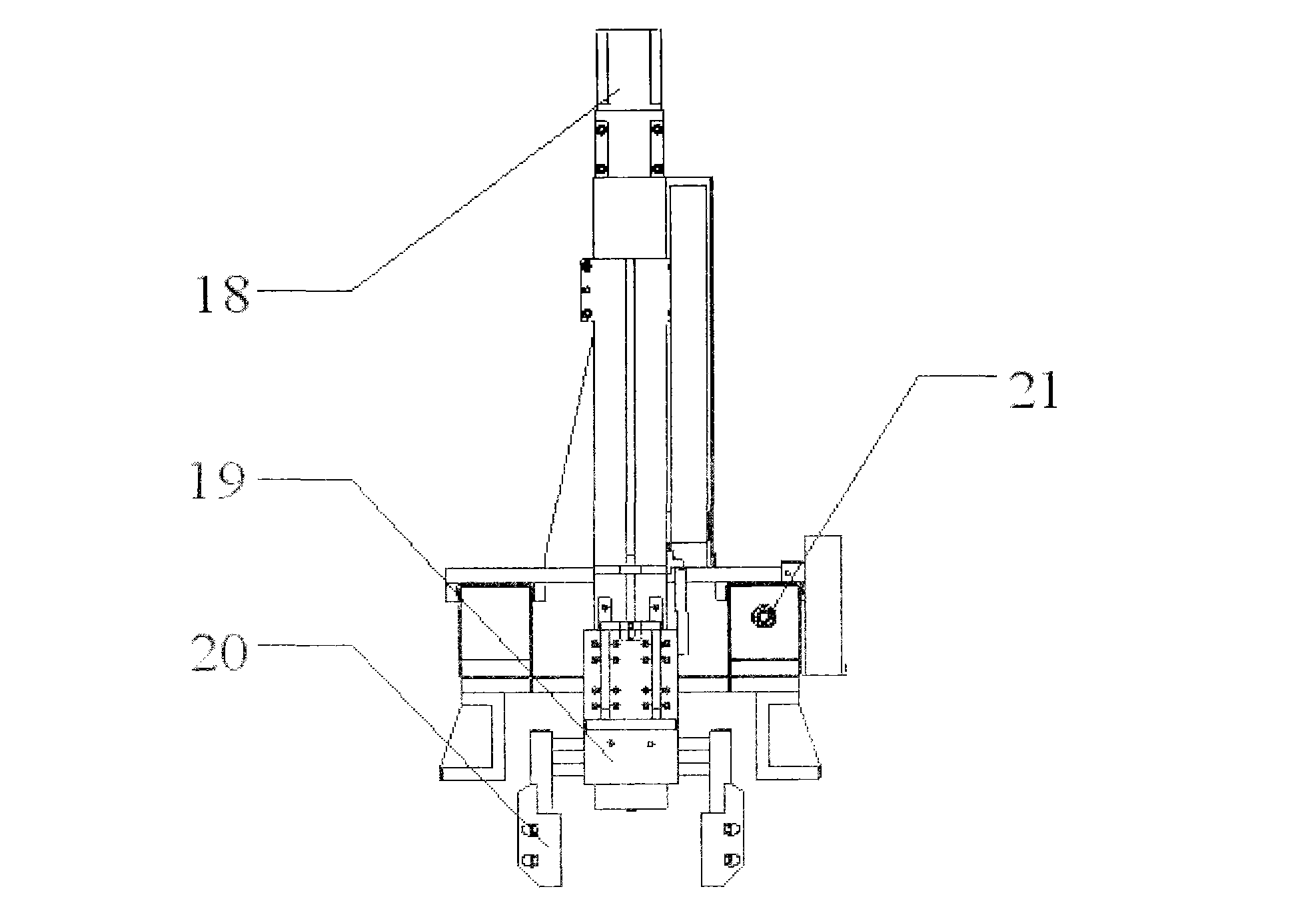

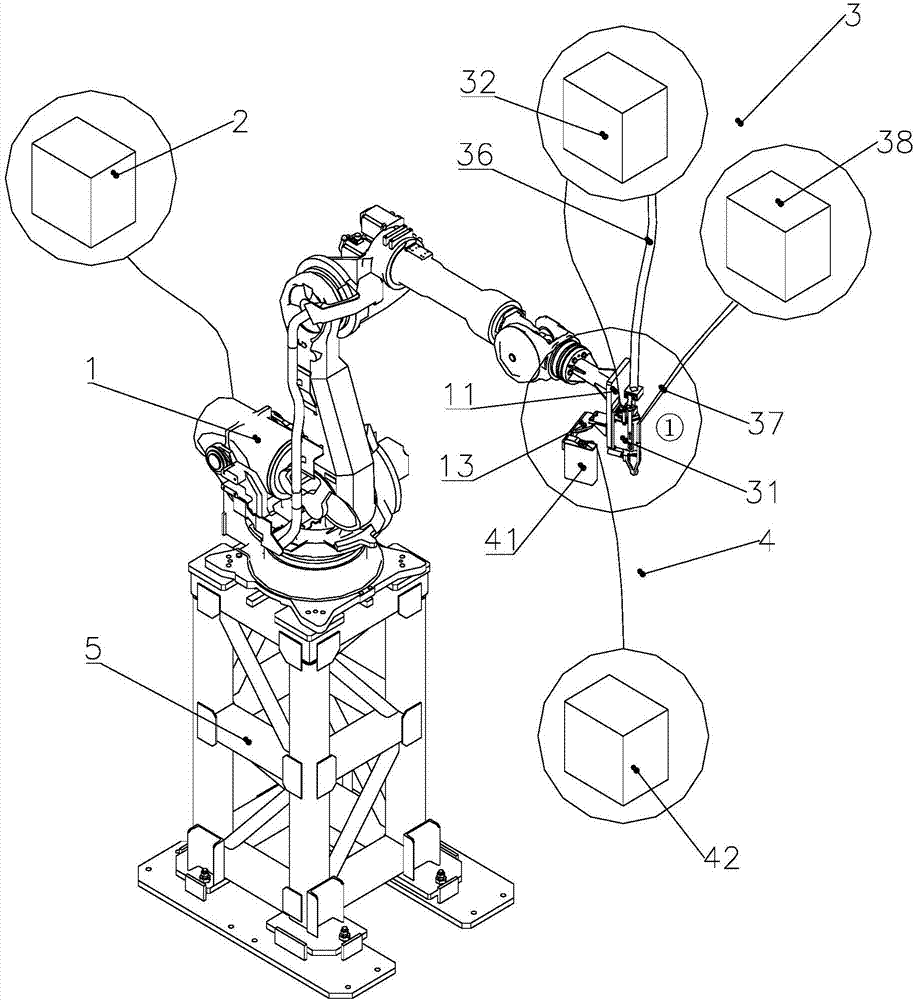

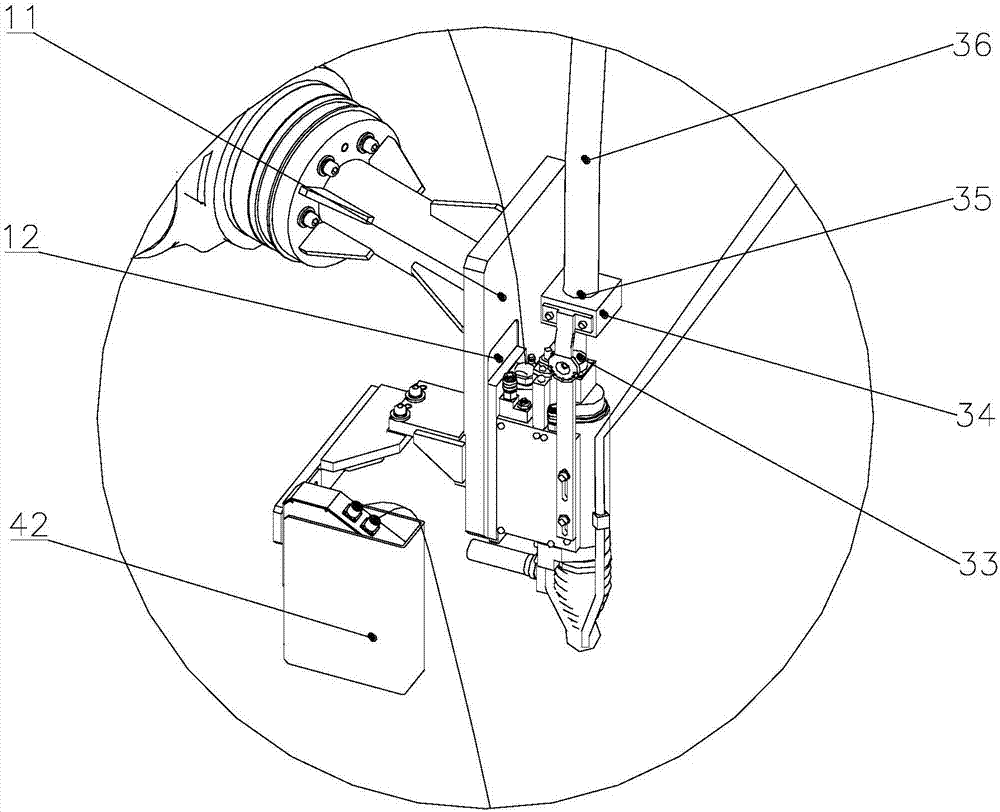

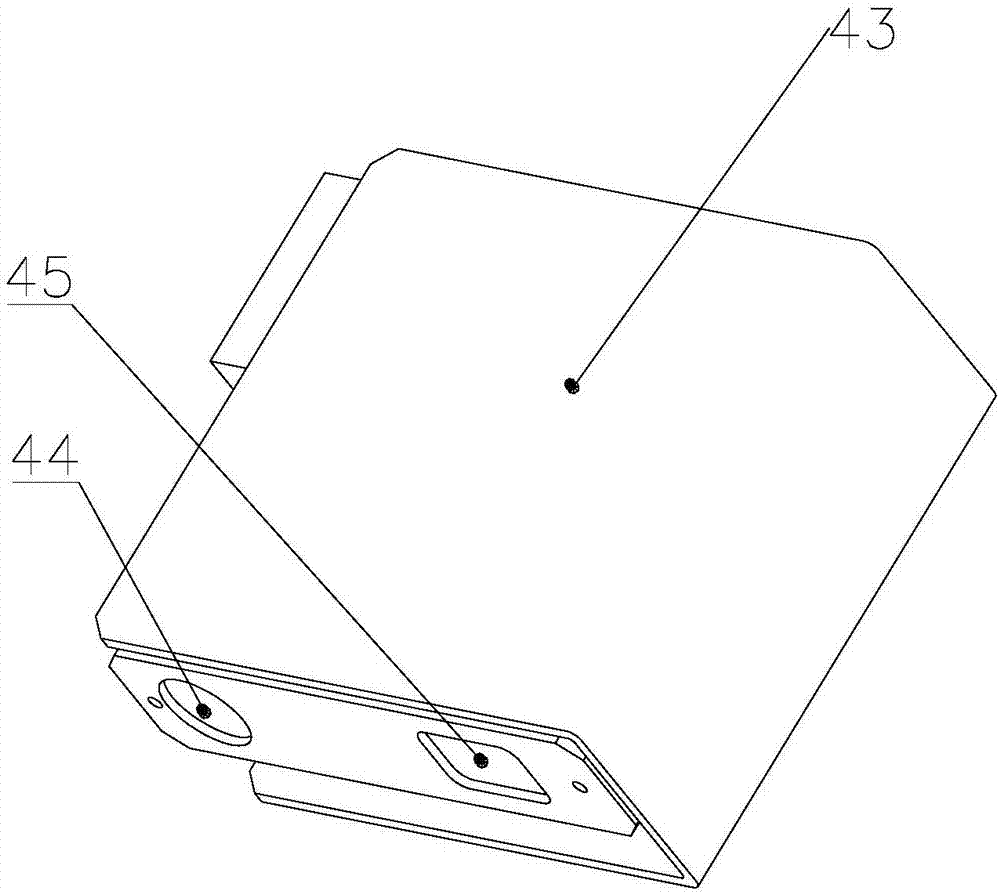

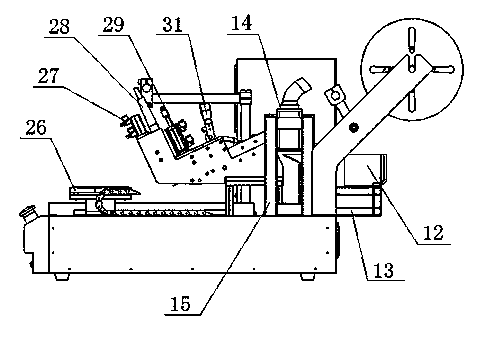

Visual guidance stud welding robot

InactiveCN106994549ARealize automated productionGuaranteed welding efficiencyWelding accessoriesStud weldingRobot control

The invention discloses a visual guidance stud welding robot. The visual guidance stud welding robot comprises a robot and a robot control cabinet of the robot. A visual device and a stud welding gun are arranged at the tail end of the robot. A stud inlet is formed in the tail of the stud welding gun, a supporting block is arranged outside the stud inlet, and a feeding hole is formed in the middle portion of the supporting block. The output end of the stud welding machine is provided with a stud conveying pipe, and the external diameter of the stud conveying pipe and the aperture of the feeding hole are the same. The stud conveying pipe penetrates the feeding hole and is connected to the stud inlet. The stud welding gun is externally provided with a gas supply pipe and a blowing device of the gas supply pipe, and the direction of the gas outlet end of the gas supply pipe and the direction of a gun head of the stud welding gun are the same. The visual guidance stud welding robot with an automatic cleaning fun is used for a visual guidance stud welding system, by means of the visual guidance function, the visual guidance stud welding robot can replace manpower to do complex and diverse stud welding works, and automatic production of stud welding is achieved; and meanwhile, the robot can automatically clear away impurities produced in the welding process through an automatic cleaning device so that the welding efficiency and quality can be guaranteed.

Owner:GUANGZHOU RISONG HOKUTO AUTOMOTIVE EQUIP CO LTD

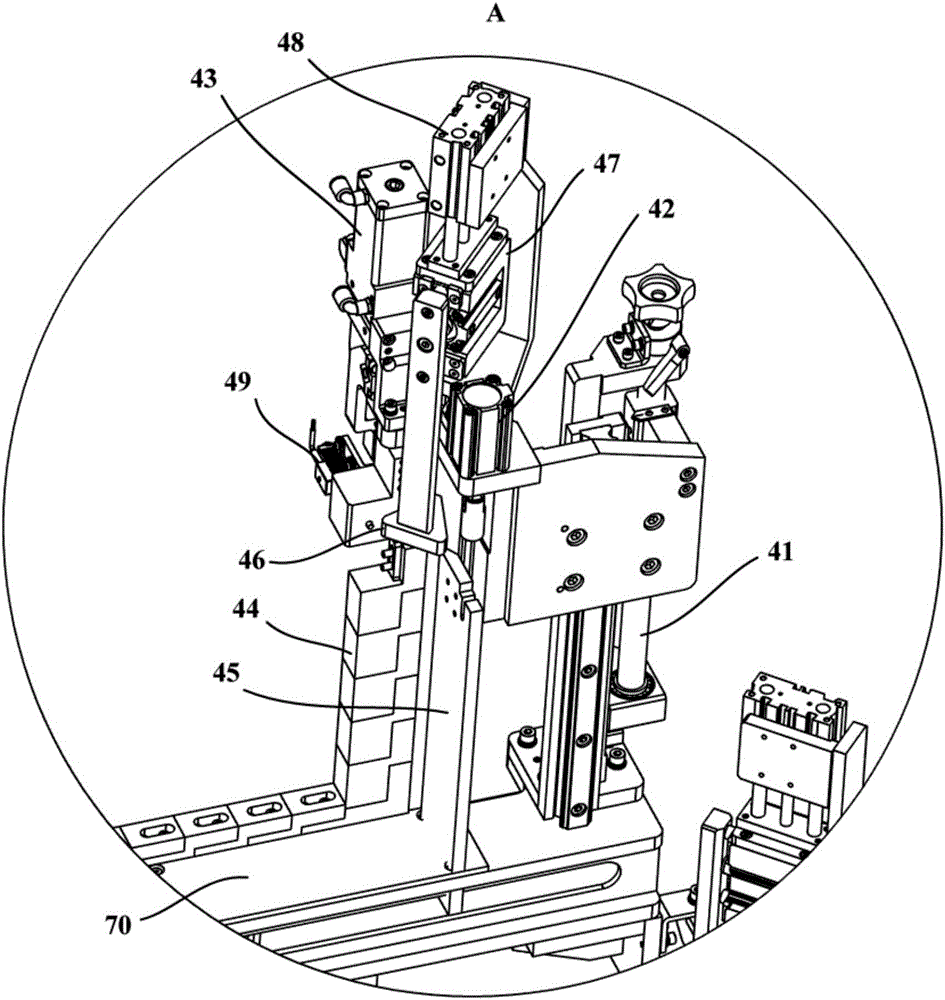

Clamp

ActiveCN103659101AGuaranteed reliabilityMeet welding needsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringChange positions

The invention discloses a clamp. The clamp comprises a supporting component, first abutting components, second abutting components and third abutting components, wherein the supporting component is used for providing supporting, the first abutting components are fixed to the supporting component, and are used for being in cooperation in the vertical direction to clamp an end beam which is processed through spot welding, the second abutting components are fixed to the supporting component, and are used for being in cooperation in the left-and-right direction to clamp the end beam, and the third abutting components are fixed to the supporting component, and are used for being in cooperation in the front-and-rear direction to clamp the end beam. According to the technical scheme, the clamp acts on the positions, without weld joints, of the end beam, and can carry out locating on the end beam in six directions, all the weld joints on the end beam can be exposed, a mechanical arm does not need to continuously change positions to meet the requirement for welding, reliability of locating of the end beam is effectively ensured, the mechanical arm can be smoothly used for carrying out welding operation in the follow-up working procedures, and welding quality and welding efficiency can be ensured.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

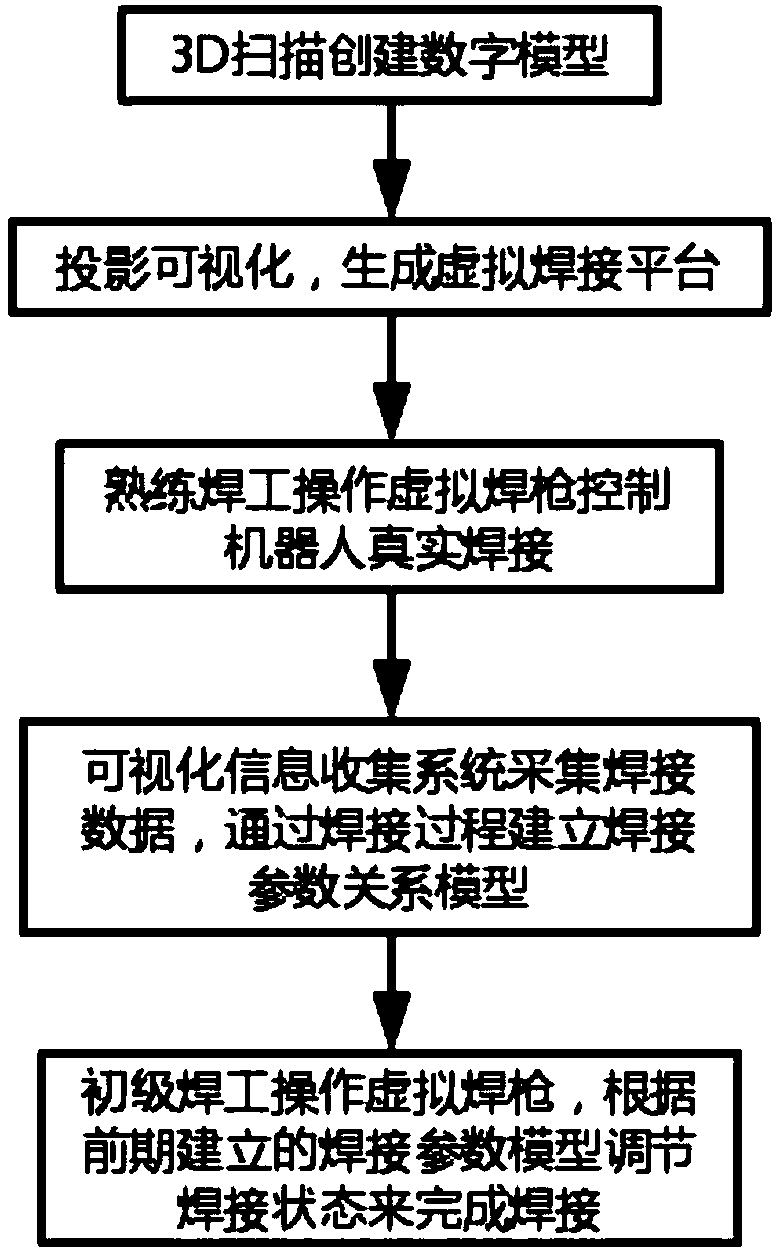

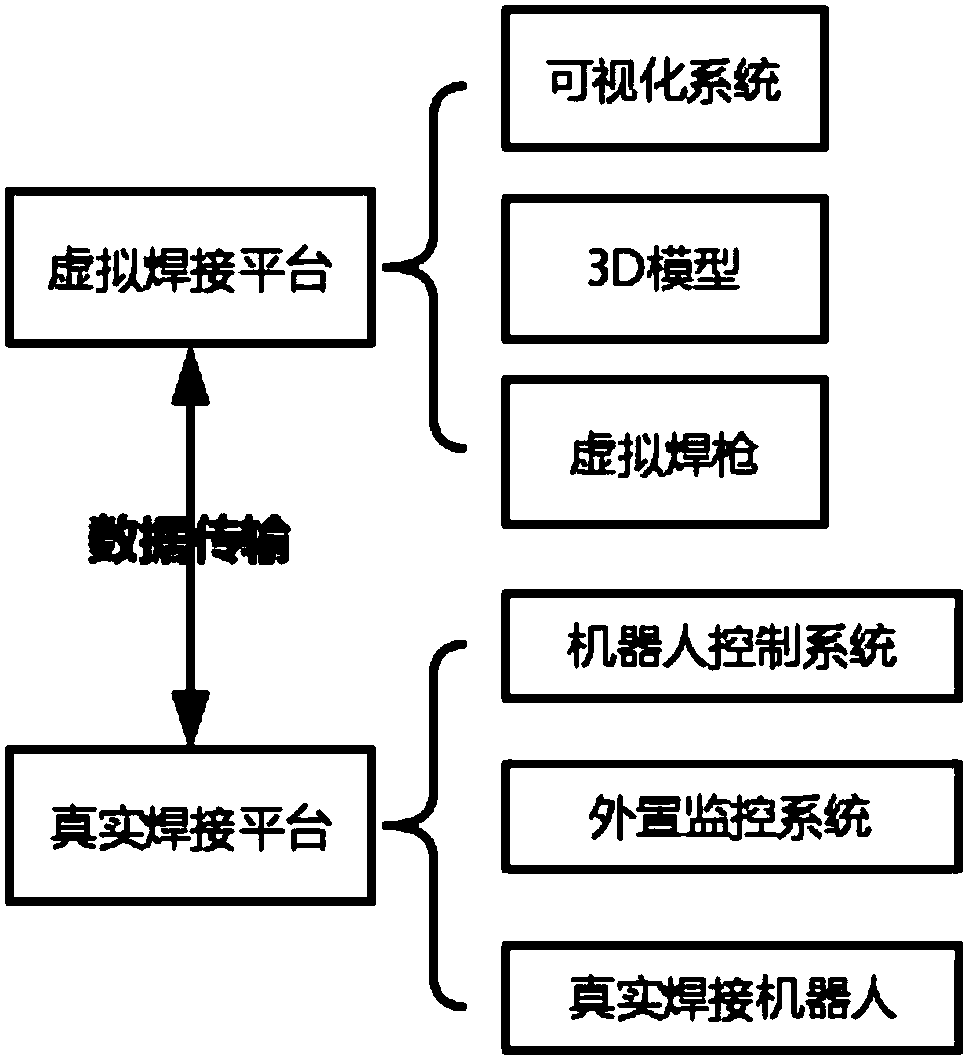

Ocean engineering module structure welding method based on VR technology

ActiveCN109514141AEnsure safetyGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesRelational modelMolten bath

The invention discloses an ocean engineering module structure welding method based on a VR technology. The method comprises the following steps: digital models of real workpieces are built through 3Dscanning, and corresponding 3D solid models are generated; a real welding process is caught by using a camera, and a projector is used for visual displaying on the 3D solid models; skilled welding workers finish the welding process through observing molten bath images and operating a virtual welding gun; a welding robot finishes real welding through welding parameters of the virtual welding gun; an external monitoring system transfers welding information in the robot welding process to a computer; the computer forms speed-current relation models through welding data; and primary welding workers finish welding through operating a virtual welding device according to the speed-current. The method performs virtual-real welding on ocean engineering module structures, so that profile steel and pipelines in the ocean engineering modules are welded more quickly and accurately, and the personal safety and the welding efficiency are guaranteed in the welding process.

Owner:BOMESC OFFSHORE ENG CO LTD

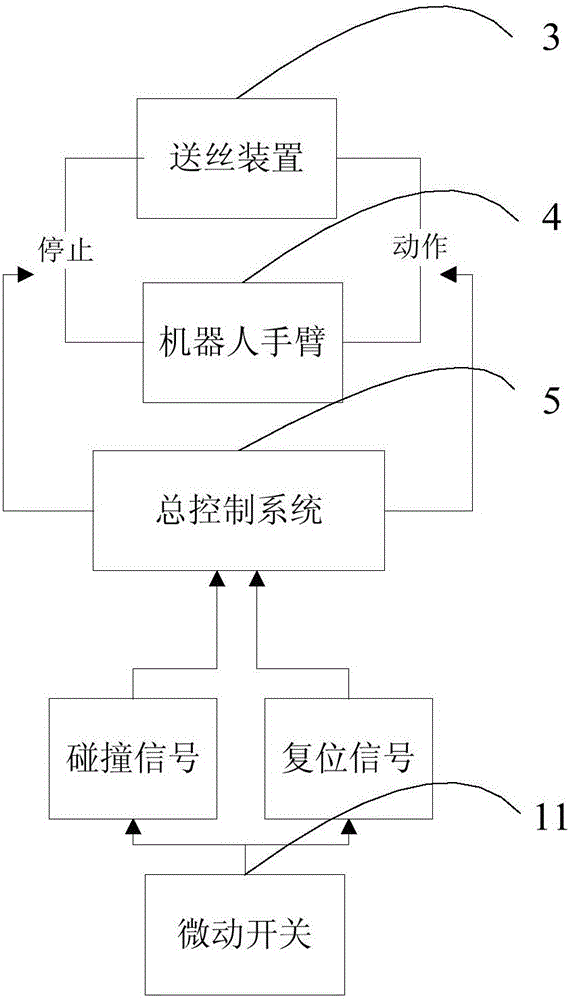

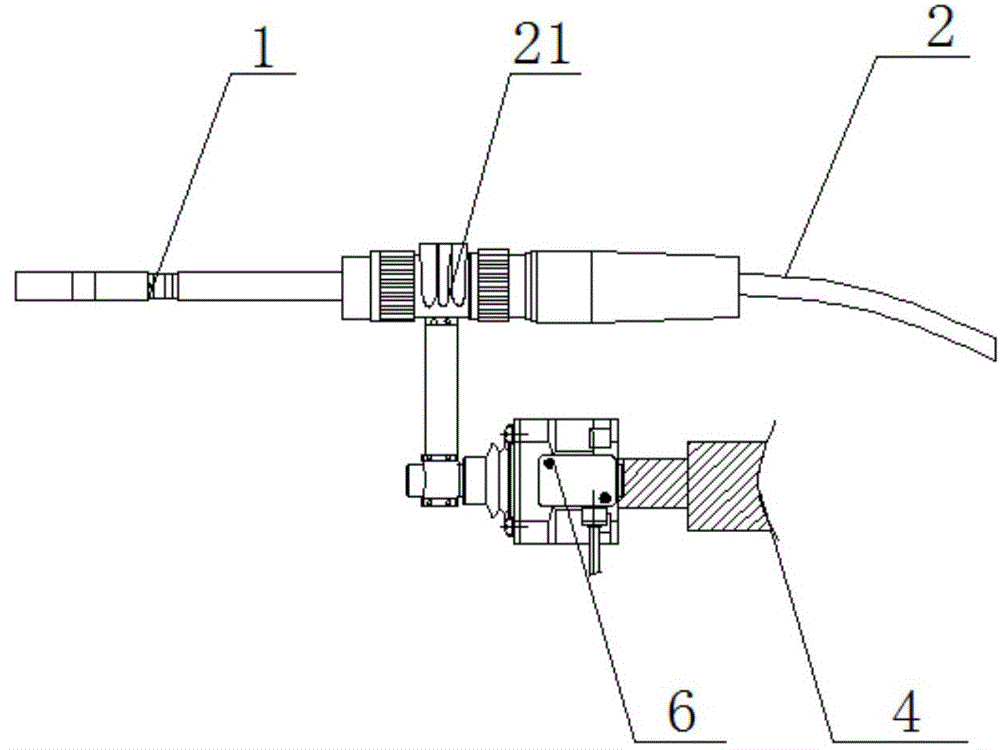

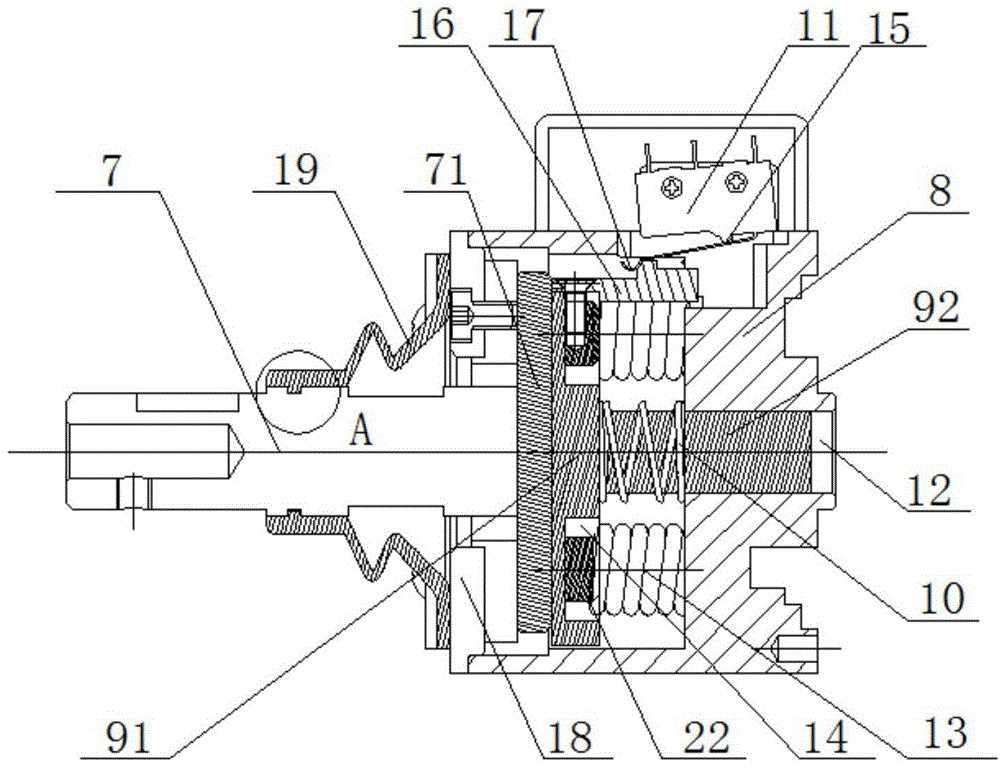

Anti-collision robot welding gun

InactiveCN104959717ATimely and effective adjustment workReal-time detection of collision forceSupport devices with shieldingControl systemRobot welding

The invention provides an anti-collision robot welding gun which comprises a welding gun body, a wire feed device, a robot arm and a master control system. The wire feed device is arranged at the rear end of the welding gun body and connected with the welding gun body through a cable, and the robot arm is used for controlling the action of the welding gun body. The wire feed device and the robot arm are connected with the master control system. An anti-collision sensor is further included, arranged between the welding gun body and the robot arm and used for inducting the collision force of the front end of the welding gun body, the anti-collision sensor is connected with the master control system, and the master control system receives the signal of the anti-collision sensor and controls the robot arm and the wire feed device to move in real time. The anti-collision sensor is added to the robot welding gun, the force in the collision process can be detected, collisions are buffered in time, an alarm is given to the master control system, and the master control system can carry out adjustment effectively in time when collisions happen in the welding process.

Owner:苏州东金机械金属有限公司

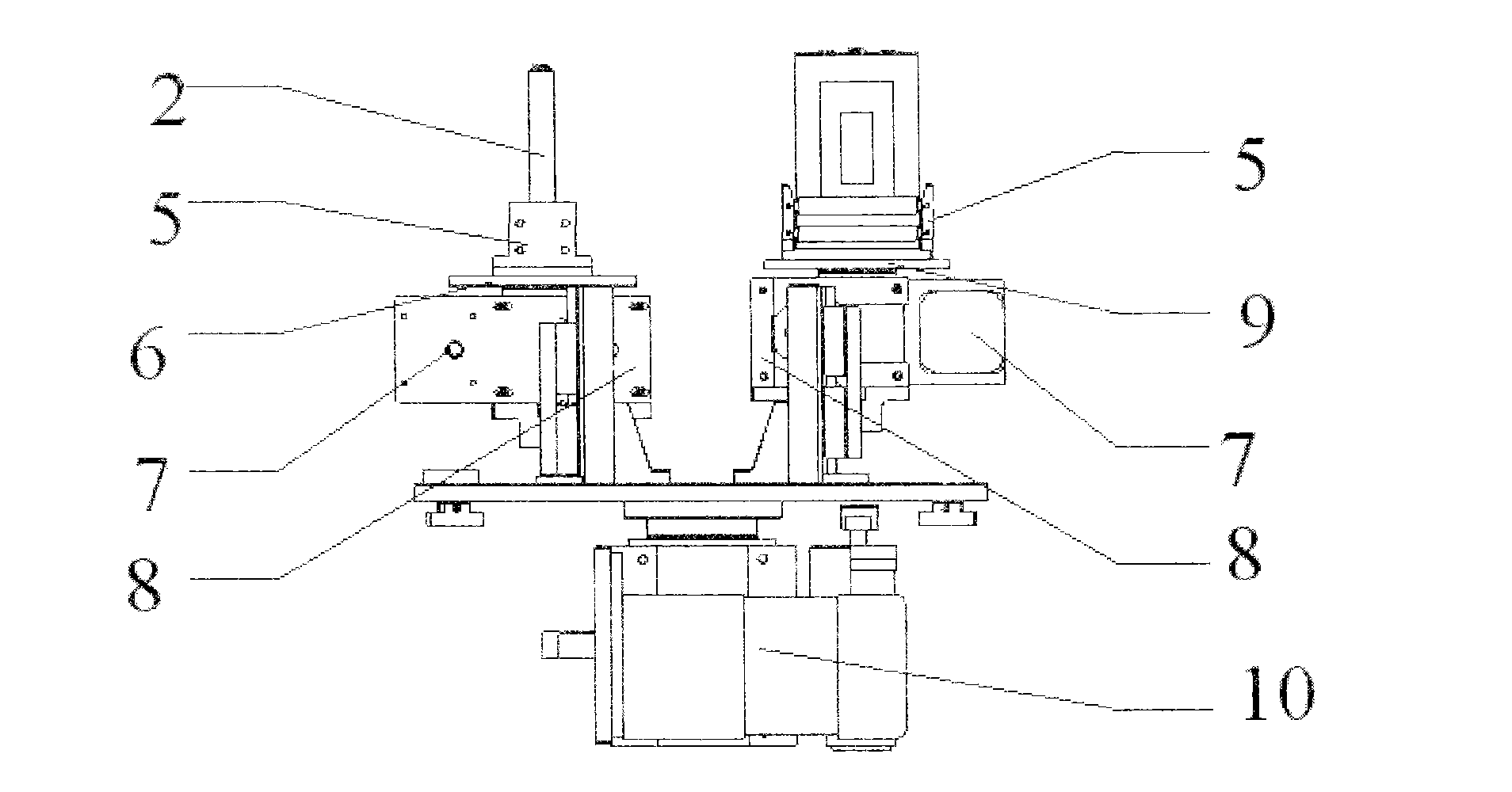

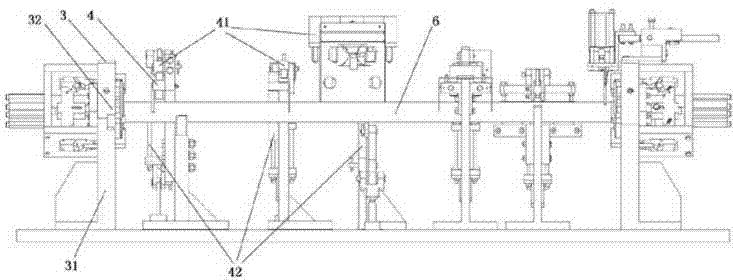

Automatic welding device and method for vehicle console installing support

InactiveCN103934604AGuaranteed welding efficiencyReduce labor costsWelding/cutting auxillary devicesElectrode holder supportersEngineeringWelding

The invention aims to provide an automatic welding device for a vehicle console installing support. The automatic welding device comprises a workbench I, a workbench II, pipe clamping devices, fixtures and a welding robot. The workbench I and the workbench II are arranged oppositely in parallel. The workbench I and the workbench II are respectively provided with the pipe clamping devices and the fixtures. The pipe clamping devices and the fixtures on the workbench I and the pipe clamping devices and the fixtures on the workbench II are in mirror distribution correspondingly. The welding robot is arranged between the workbench I and the workbench II and can rotate 360 degrees. A welding gun arranged on the welding robot can cover welding points of parts corresponding to all the fixtures on the workbench I and the workbench II. The invention further provides an automatic welding method for the vehicle console installing support. The automatic welding device and method have the advantages that welding efficiency is high, welding quality is stable, and production cost is low.

Owner:韦建军 +4

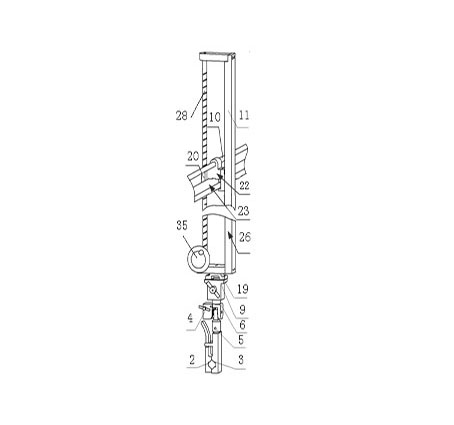

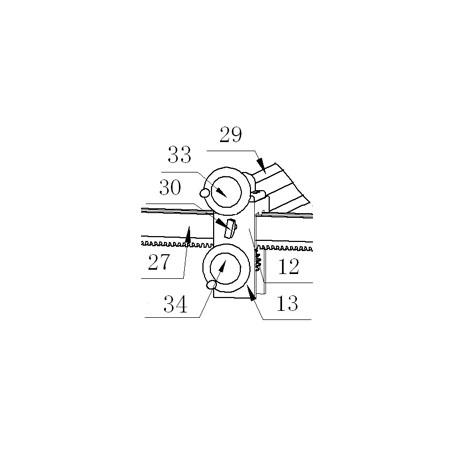

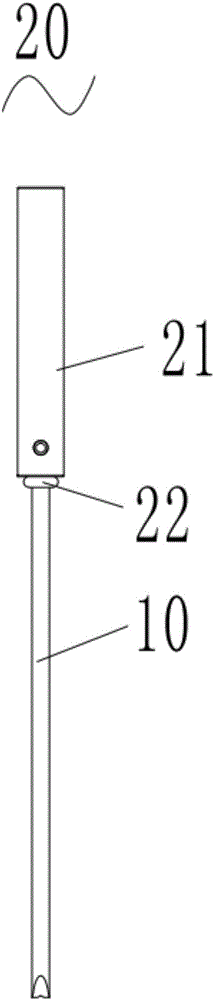

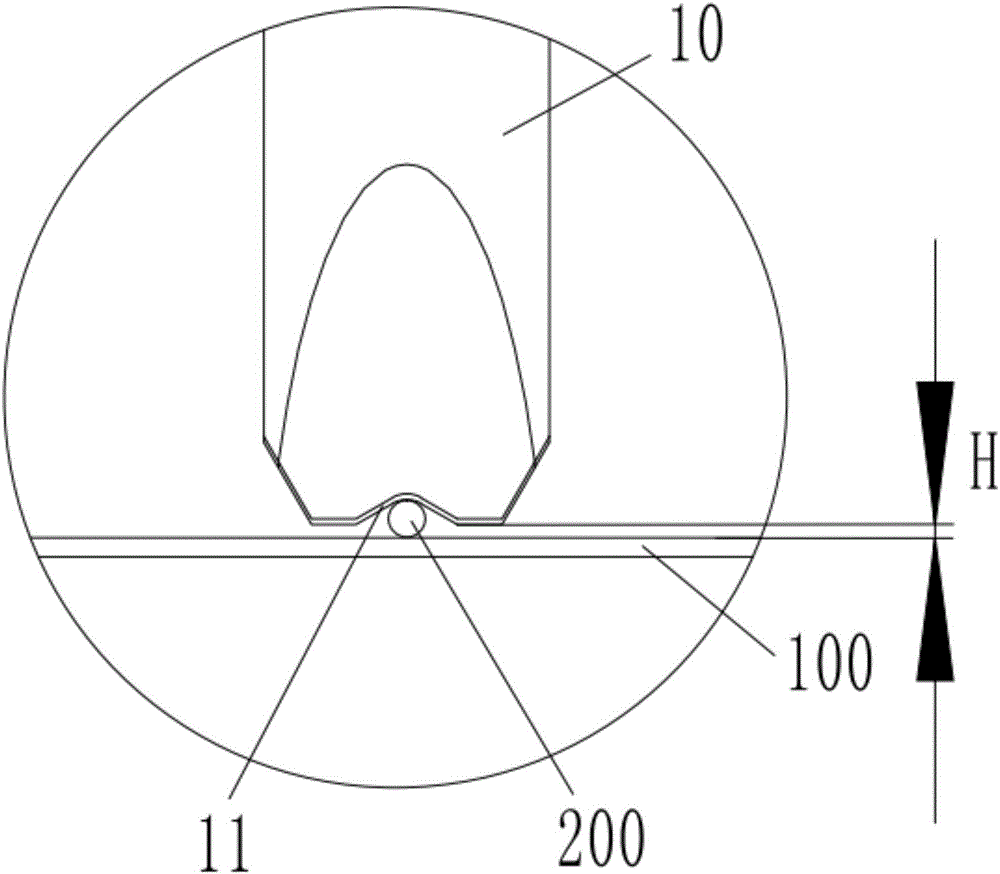

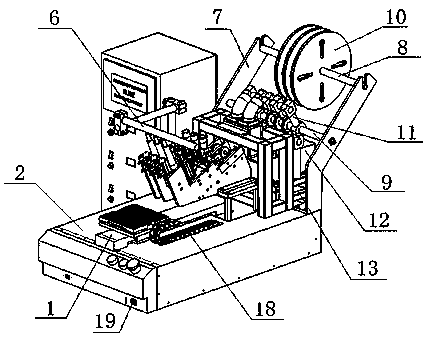

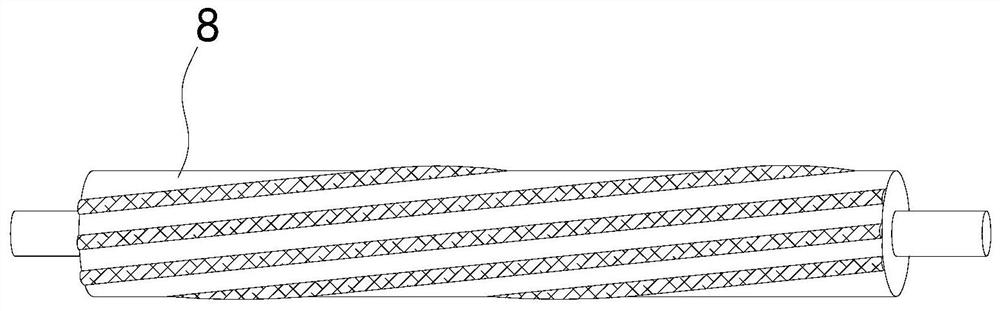

Self-guiding welding strip indenter, self-guiding welding strip righting mechanism, series welding head and series welding machine

InactiveCN106493445AGuarantee welding qualityGuaranteed welding efficiencyMetal working apparatusSoldering auxillary devicesContact forceEngineering

Provided are a self-guiding welding strip indenter and a self-guiding welding strip righting mechanism, and one end of the self-guiding welding strip indenter is made into a groove. When a cell and a circular-arc welding strip are arranged at the welding station of the series welding machine, the self-guiding welding strip righting mechanism is driven by the series welding head to move downward, and the self-guiding welding strip indenter comes into contact with the circular-arc welding strip which is moved toward the center of the groove along the slant wall of the groove. The indenter groove produces contact force to the circular-arc welding strip so that the circular-arc welding strip is righted to the indenter groove, and the indenter groove center is aligned to the main grid line of the cell. Therefore, the circular-arc welding strip is righted to the main grid line of the cell, and the self-guiding welding strip indenter is not in contact with the cell, but only presses the circular-arc welding strip downward and can come into contact with the main grid line of the cell tightly, thereby effectively ensuring the welding quality and efficiency of connection between the circular-arc welding strip and the cell.

Owner:WUXI ZHENGGANG AUTOMATION EQUIP CO LTD

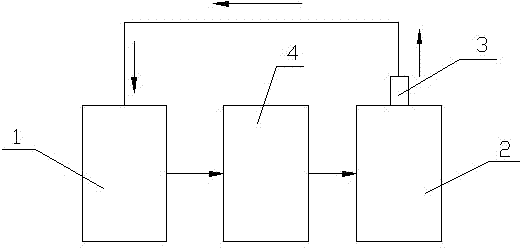

Closed circulation cooling system for welder

InactiveCN102441751AGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCooling channel

A closed circulation cooling system for a welder relates to a cooling system, in particular to a cooling system for a welder, which comprises a welder body with a cooling channel. A cooling device is connected outside the welder body and comprises a cooling liquid tank, a booster pump is arranged outside the cooling liquid tank, a refrigerator is arranged between the welder body and the cooling liquid tank, an outlet end of the cooling liquid tank is connected with the booster pump through a pipeline, an outlet end of the booster pump is connected with an inlet end of the cooling channel on the welder body through a pipeline, an outlet end of the cooling channel on the welder body is connected with an inlet end of the refrigerator through a pipeline, and an outlet end of the refrigerator is connected with an inlet end of the cooling liquid tank through a pipeline. By the aid of the cooling system, the temperature rise of cooling liquid is low, the welder needs no halting in long-term use, welding efficiency is ensured, the temperature of cooling water is low, similarly, the temperature of the cooled welder is also low, and the service life of the welder is longer.

Owner:江苏华光双顺机械制造有限公司

Linear welding device

InactiveCN107717284AHigh positioning accuracyReduce scrap rateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering gun

The invention discloses a linear welding device. The linear welding device comprises a rack, two panels, a transverse drive assembly, a welding gun traveling mechanism, a pushing assembly and fastening assemblies; the rack is arranged on the horizontal plane; the panels are horizontally arranged on the top of the rack; one end of each panel is fixed to the upper portion of the rack, and the otherend of each panel outwards extends to the outer side of the rack; the two panels are arranged in parallel in a spaced mode, and a strip-shaped welding tank is formed between the two panels; workpiecesare arranged on the lower portions of the panels; the transverse drive assembly is arranged on one side of the welding tank; the welding gun traveling mechanism is connected with the output end of the transverse drive assembly; the pushing assembly is arranged on the lower portion of the rack; and the fastening assemblies are arranged on the outer ends of the panels so as to fasten and fix the workpieces from the outer side. The linear welding device has the function of fine adjustment of the mounting position of a welding gun, the operation steps are simplified, the welding efficiency and welding accuracy are improved, and by adoption of a receding groove and the automatic workpiece pushing and fastening structure, the workpieces positioning precision is effectively improved, and the situation that other portions of the workpieces are welded due to errors is avoided.

Owner:吴姣

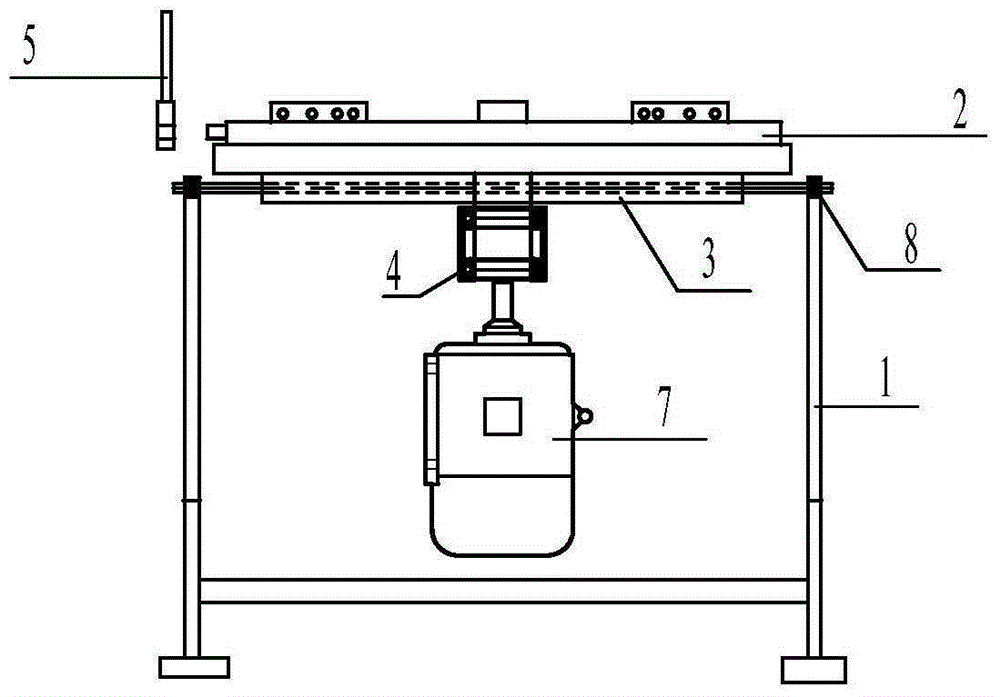

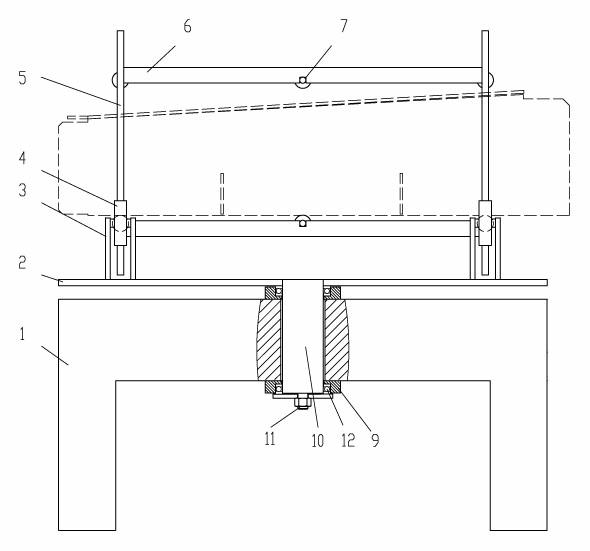

Rotatable welding positioner

InactiveCN105195959AImprove working conditionsGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThree-phase

The invention relates to the field of mechanical welding, in particular to a rotatable welding positioner. The rotatable welding positioner adopts the structure that a supporting rack is arranged on a machine body; a rotatable chuck is mounted at the top end of the supporting rack through a swivel bearing; a positioning pin is arranged at the top end at one side part of the supporting rack; a concave hole is formed in the position, corresponding to the positioning pin, of the rotatable chuck; a three-jaw chuck is arranged on the rotatable chuck coaxially; rotating handles are symmetrically arranged at side parts of the three-jaw chuck; the bottom of the three-jaw chuck is connected with a frequency converter and a three-phase motor through a motor bearing. The rotatable welding positioner has the advantages that the welding efficiency and quality are ensured; the welding efficiency is improved; the labor intensity is reduced; the operation conditions of workers can be improved; mechanized and automatic operation can be realized effectively.

Owner:QINGDAO PETROCHEM M&I ENG

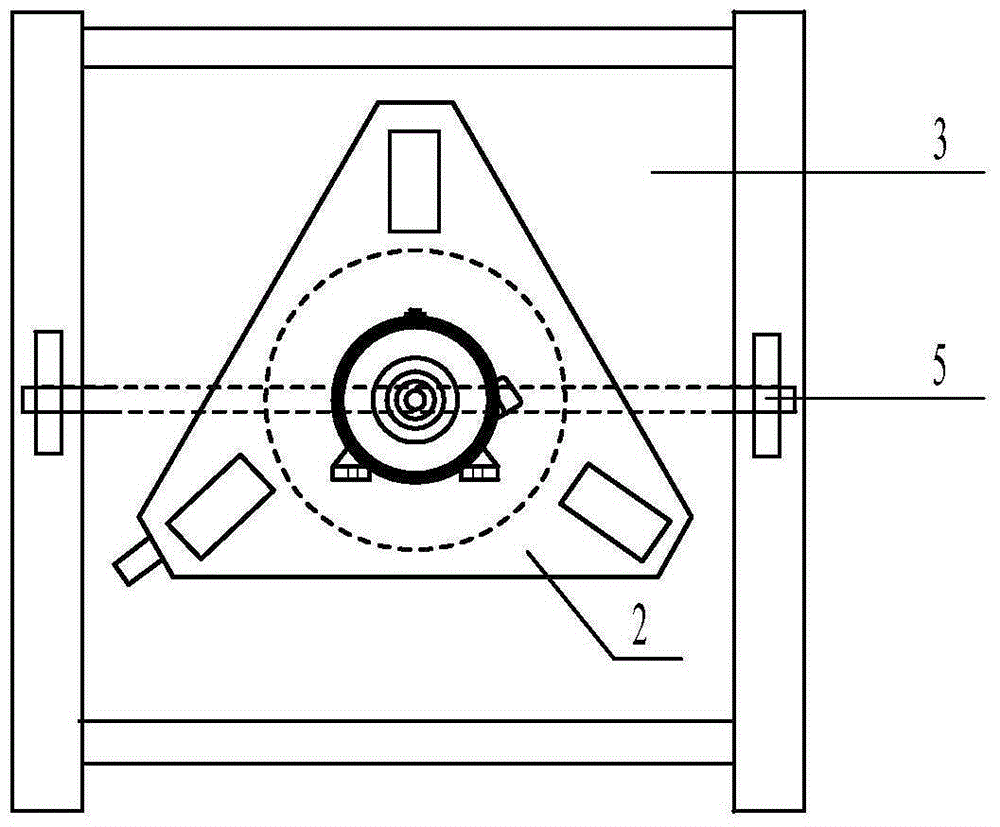

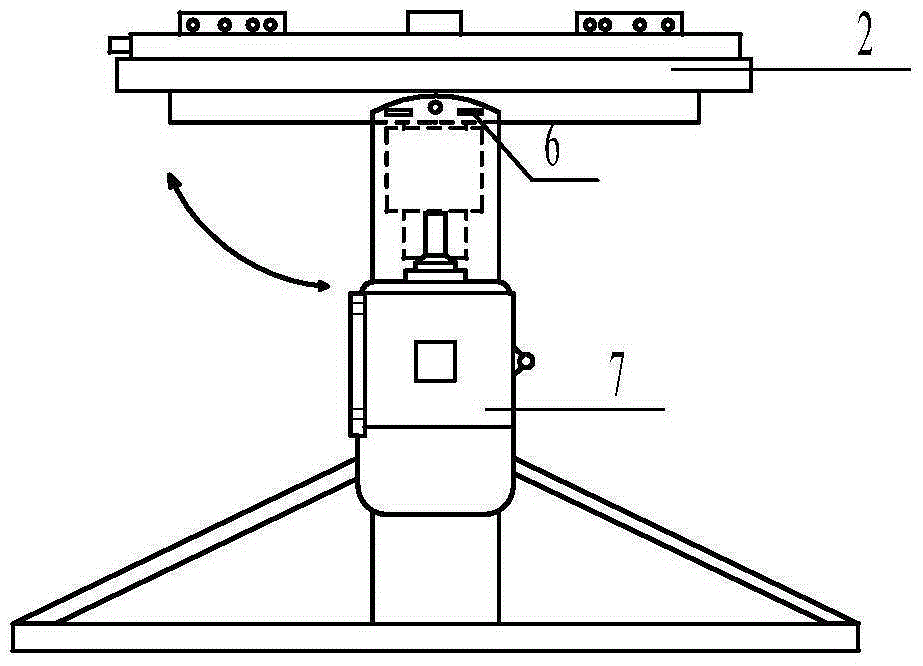

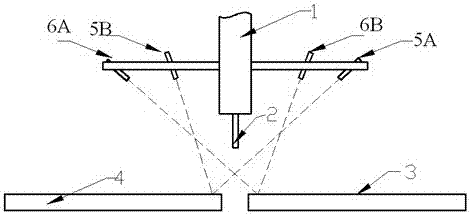

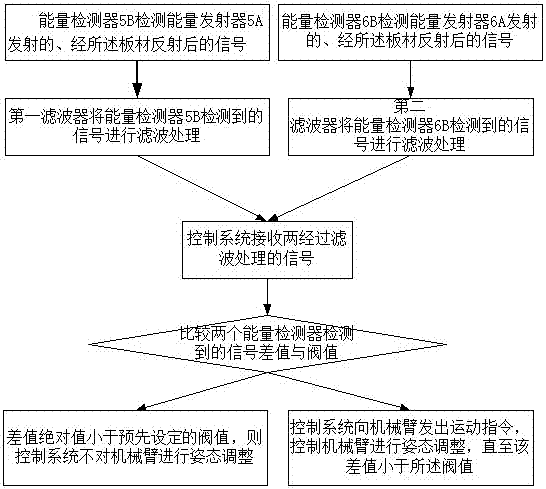

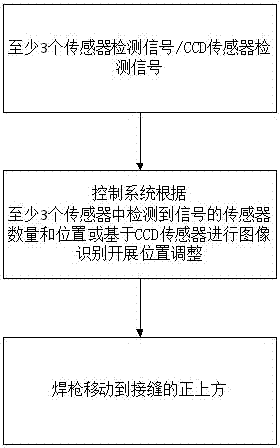

Method for controlling welding path of welding robot

ActiveCN107335899AAvoid interferenceHigh-resolutionProgramme-controlled manipulatorWelding accessoriesControl systemWeld seam

The invention relates to a method for controlling the welding path of a welding robot. A control system detects and adjusts the position and posture of a welding gun in real time, so that the welding gun is always positioned right above a welding seam. Moreover, the control system judges an energy difference value detected by an energy detector according to received information; if the absolute value of the difference value is less than a preset threshold valve, the control system does not adjust the posture of a mechanical arm; if the difference value is greater than or equal to the threshold value, the control system issues a movement command to the mechanical arm and controls the mechanical arm to adjust the posture, until the difference value is less than the threshold value and the welding gun moves to right above the welding seam and is vertical to be plane of a plate.

Owner:JIANGSU MICFIRST AUTOMATION TECH

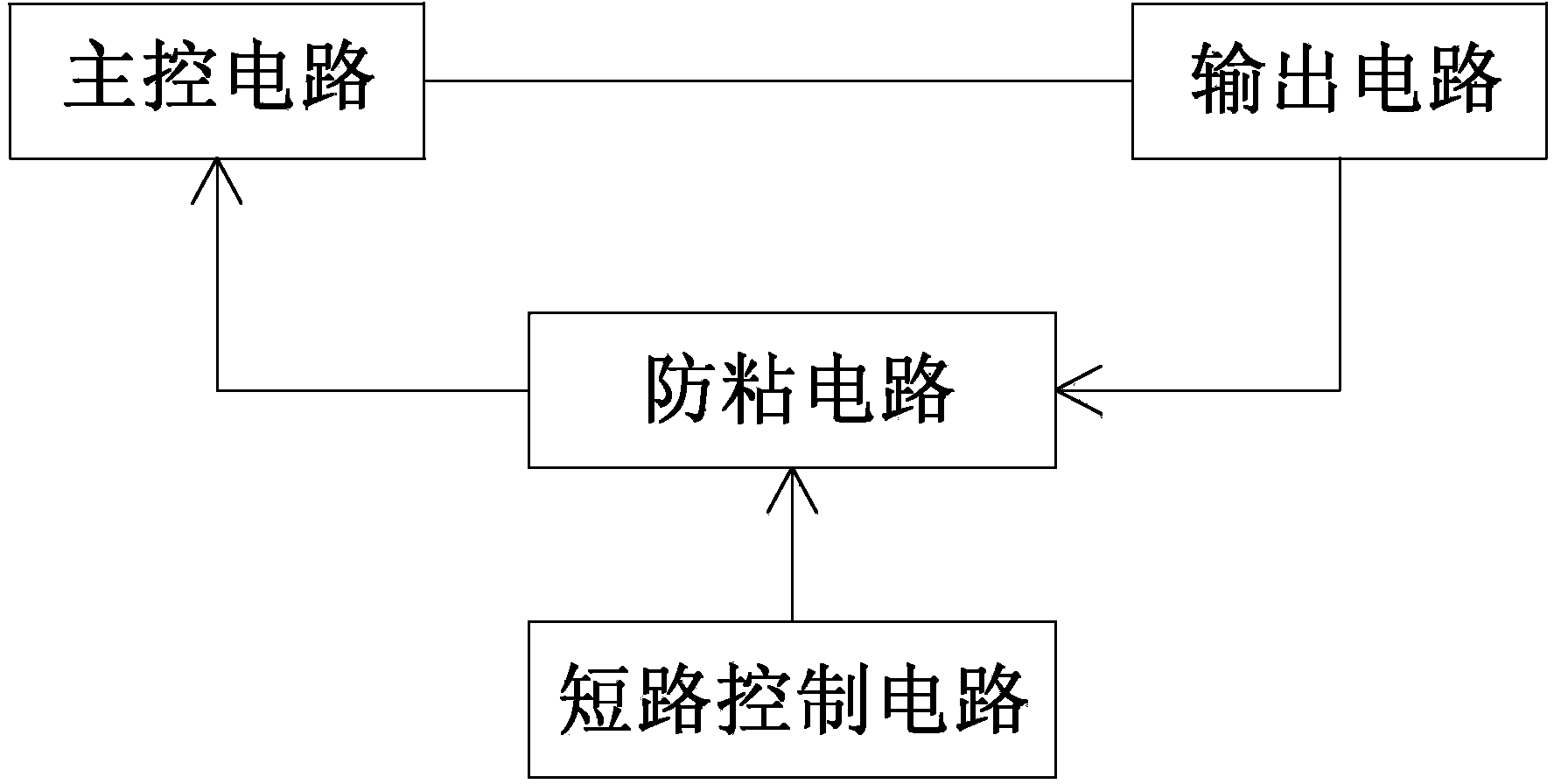

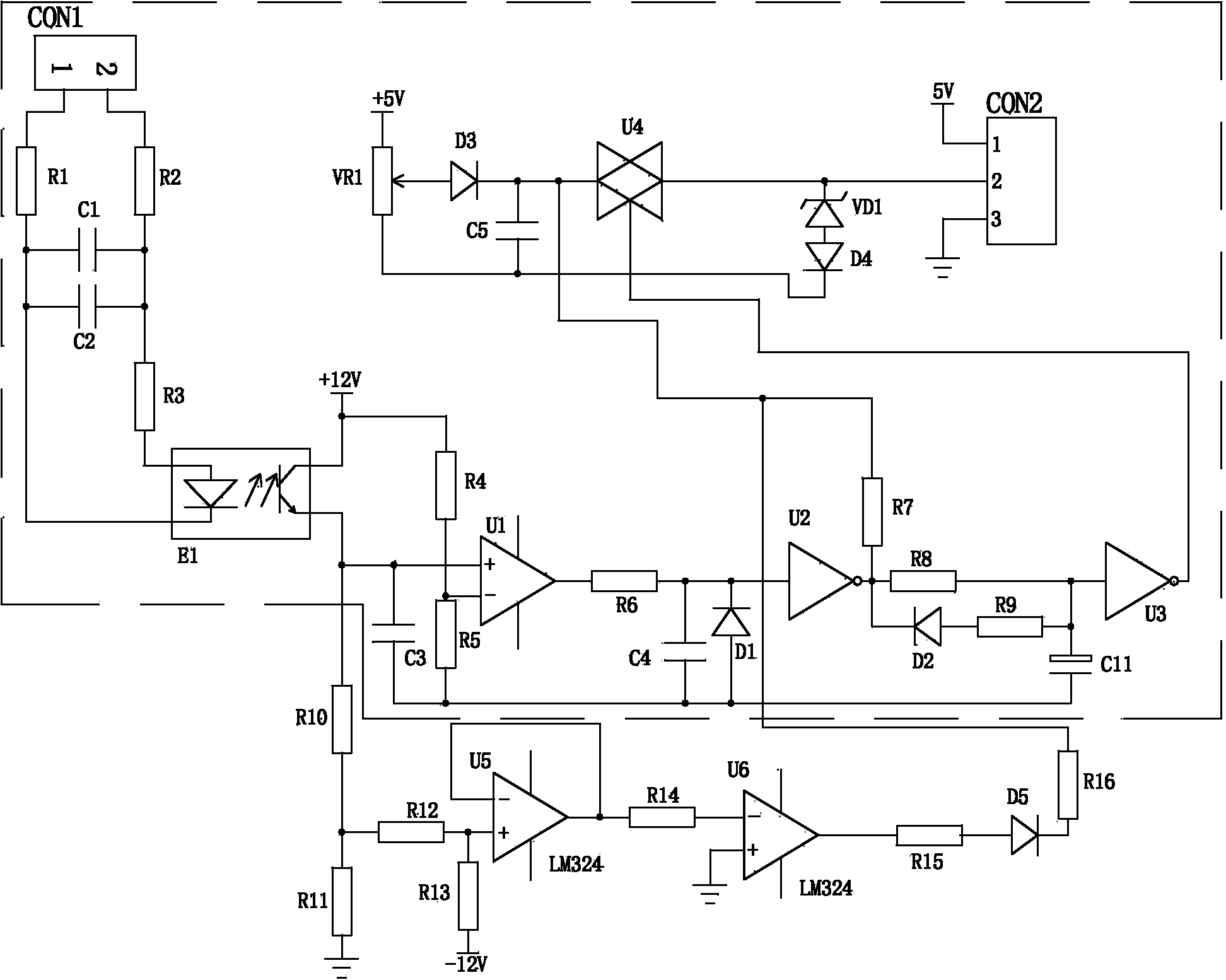

Control circuit of inverter welding machine

ActiveCN104028876AAvoid short circuitProtection against brief short circuitsArc welding apparatusControl circuitComputer engineering

The invention discloses a control circuit of an inverter welding machine. The control circuit comprises a master control circuit and an output circuit, and the master control circuit and the output circuit are connected. The control circuit of the inverter welding machine further comprises an adhesion preventing circuit used for preventing adhesion between a welding rod and a workpiece. The control circuit of the inverter welding machine has the advantage that the welding rod can be avoided from being adhered with the workpiece.

Owner:NINGBO EUROPA WELDING & CUTTING TECH

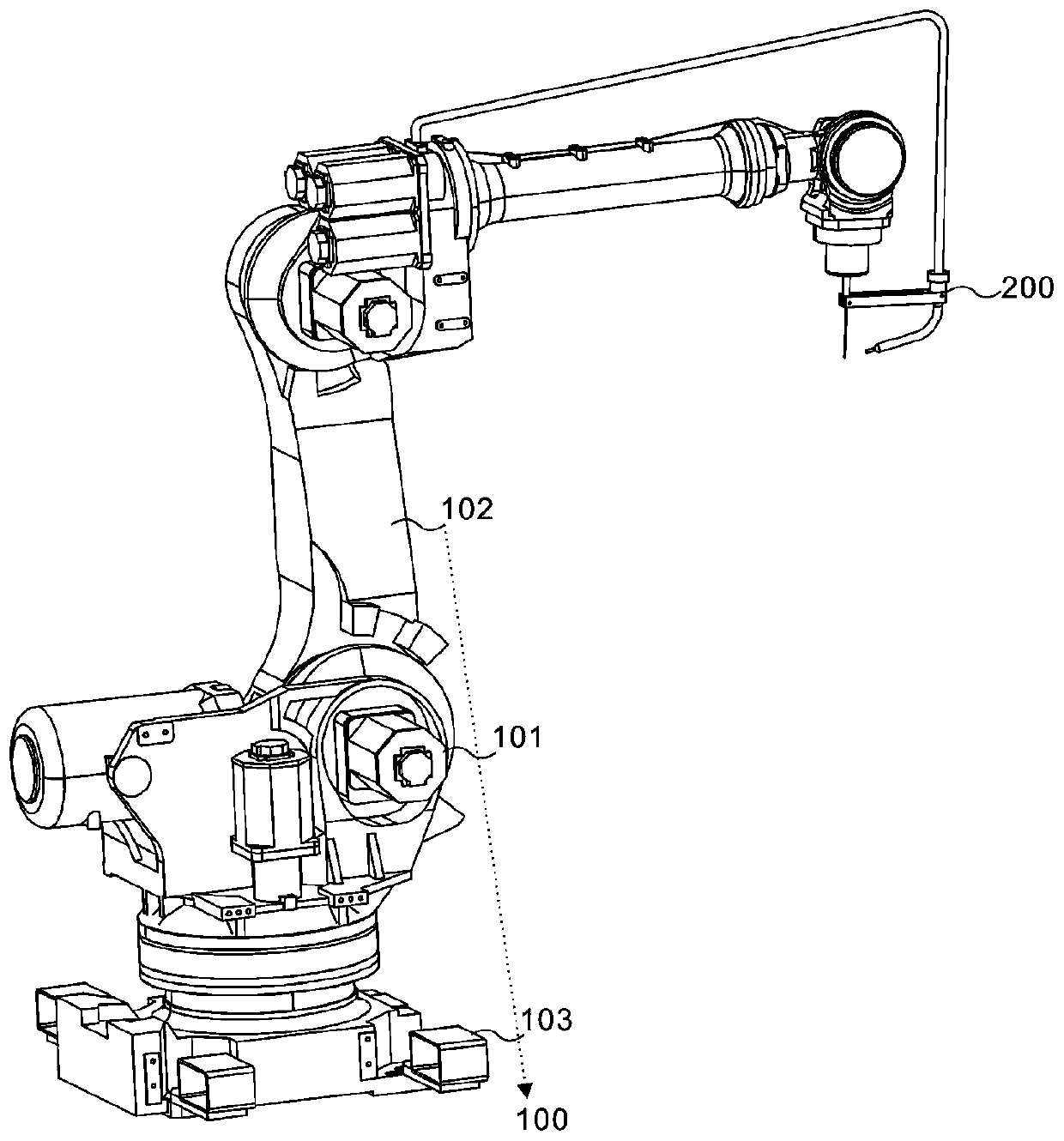

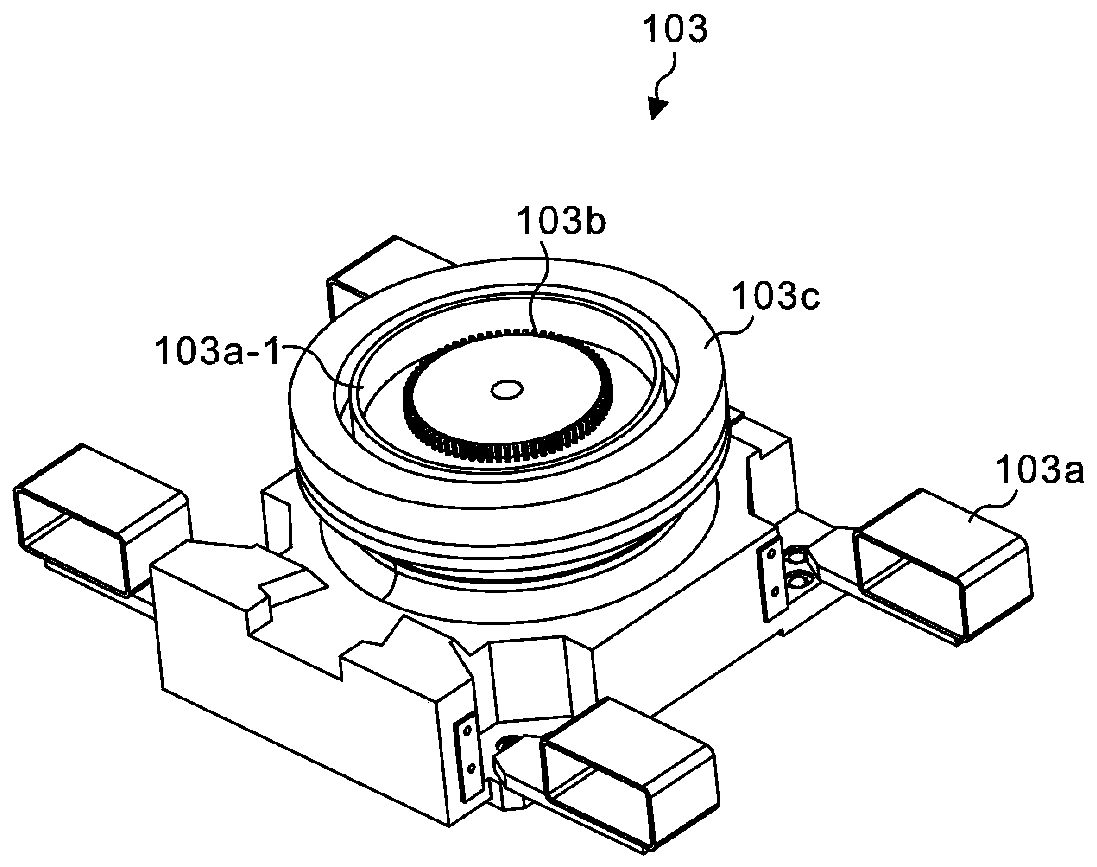

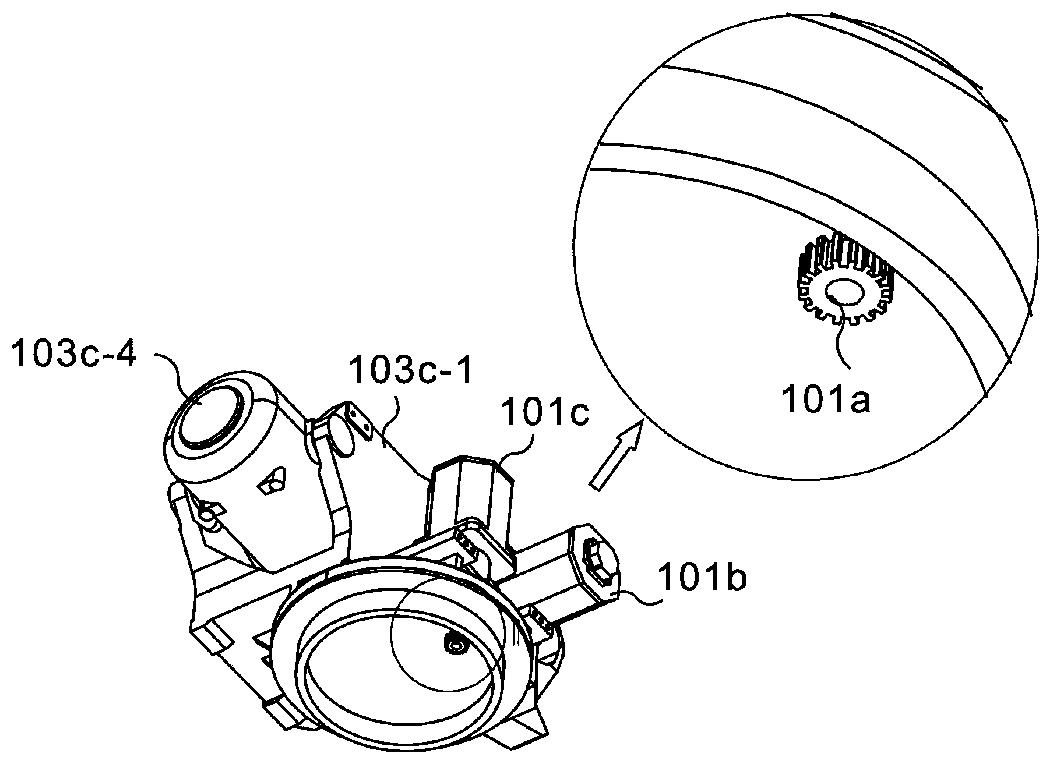

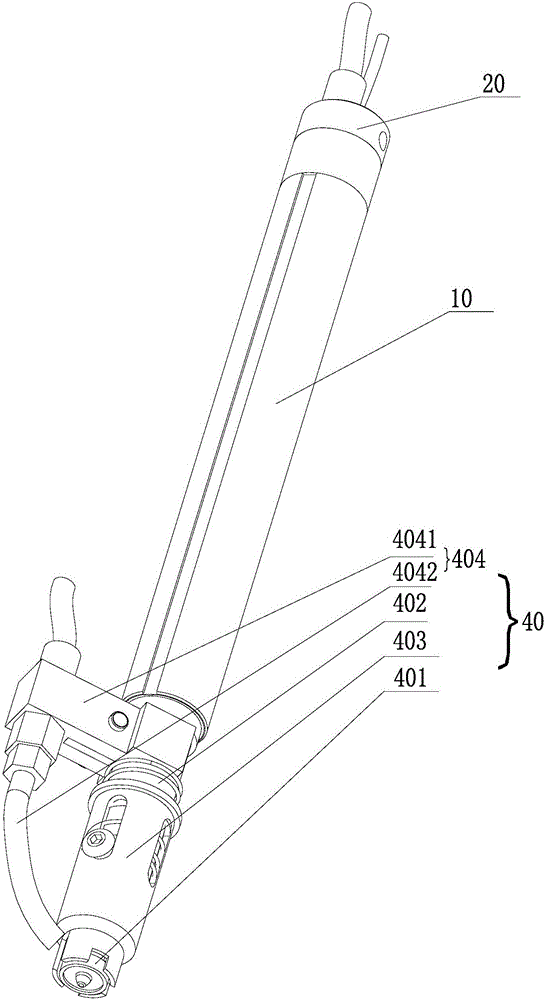

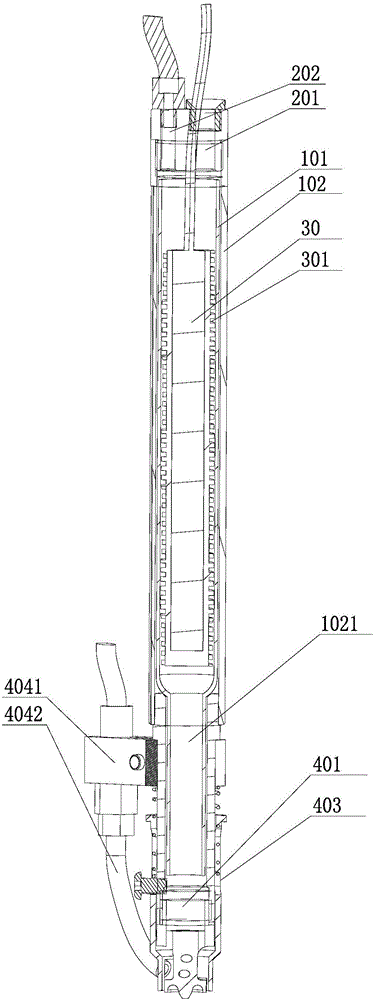

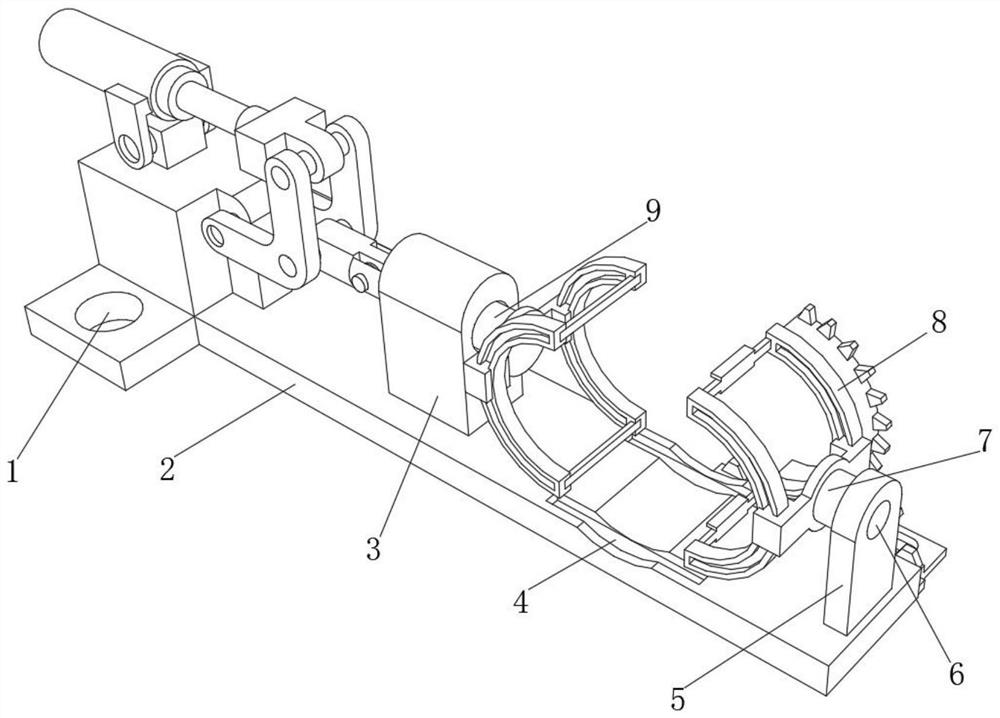

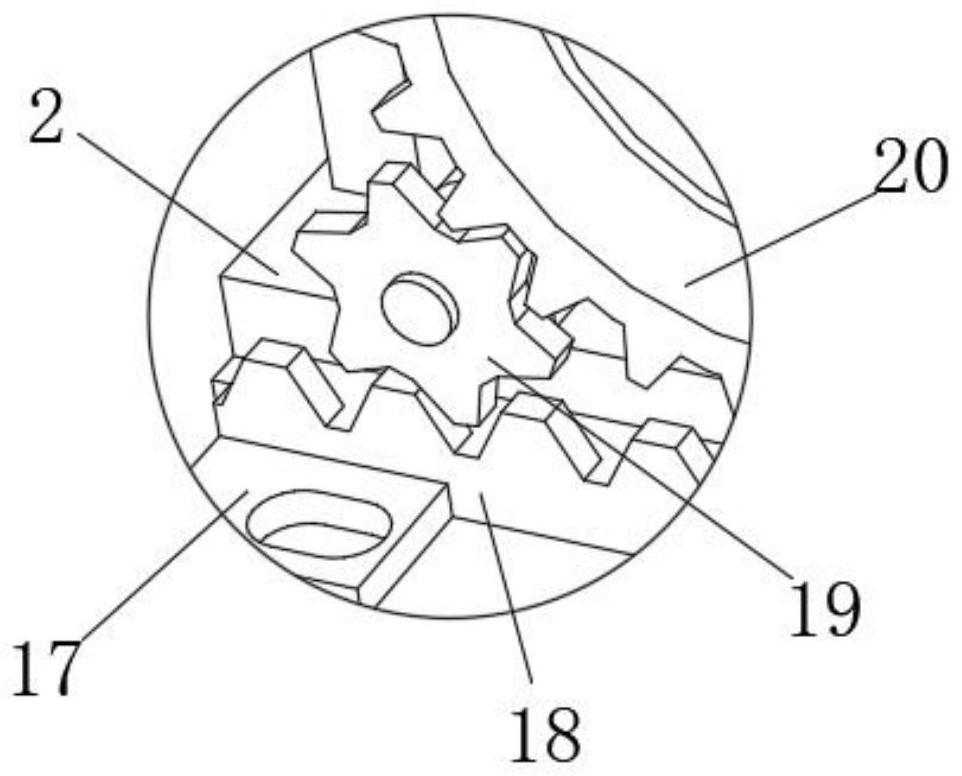

Welding robot

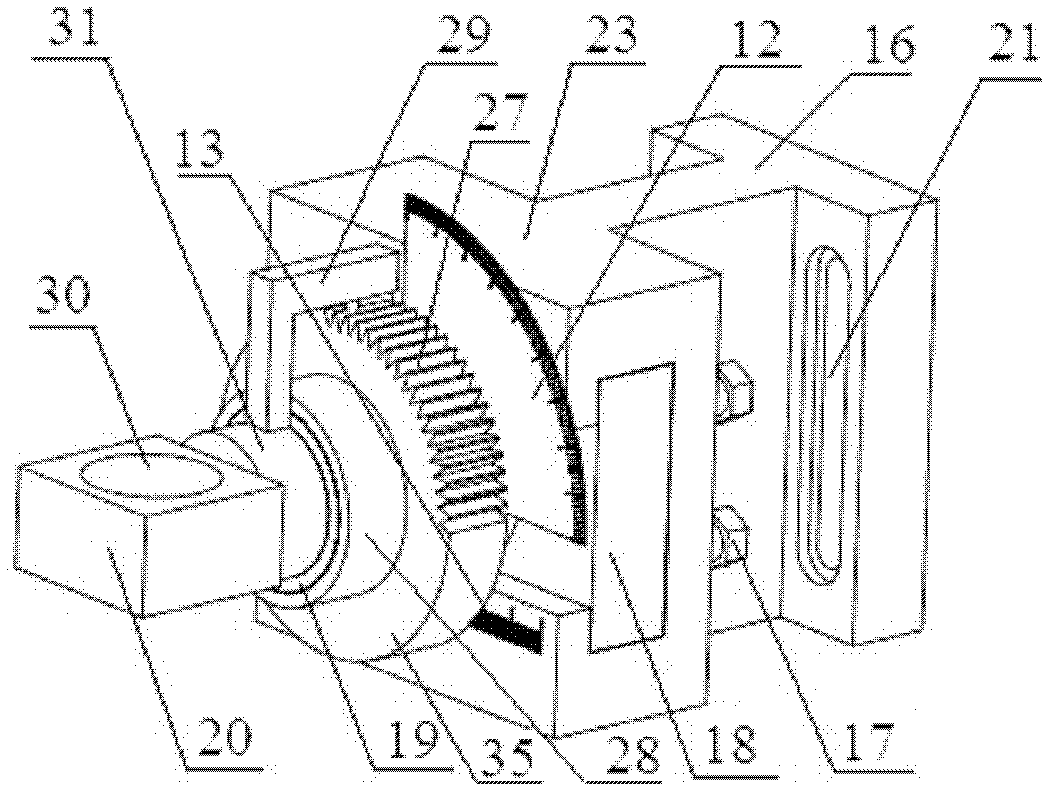

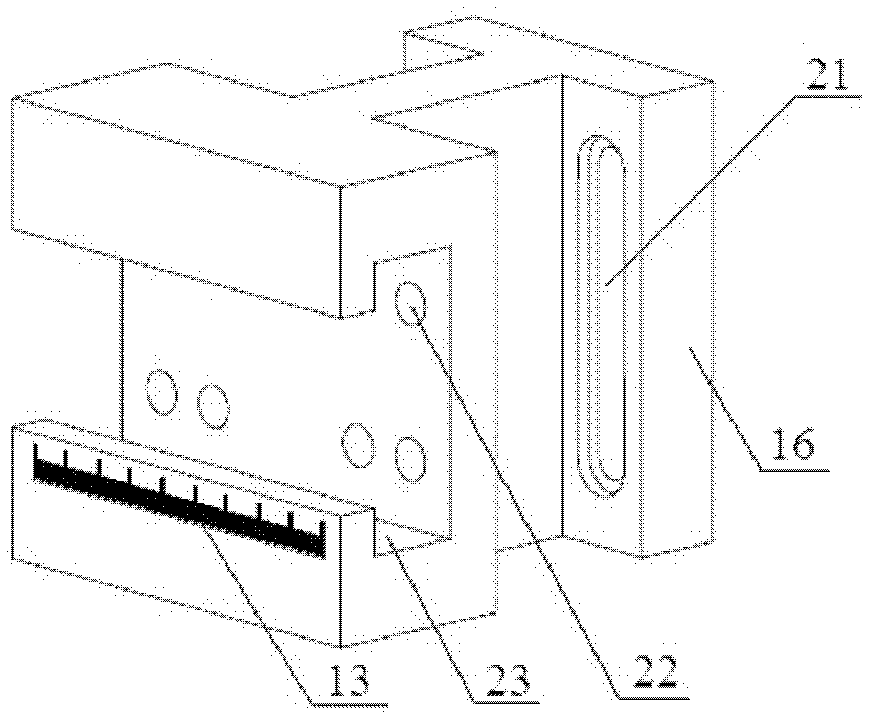

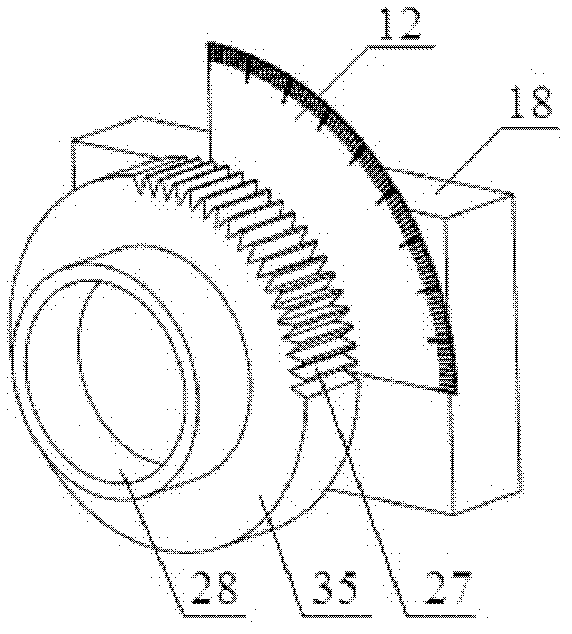

ActiveCN109719436AGuaranteed service lifeGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

The invention discloses a welding robot which comprises a regulating assembly and a welding assembly. The regulating assembly comprises a driving part, a swinging part and a carrying part. The swinging part is arranged on the carrying part, and the driving part is connected to the swinging part and the bearing part, separately; the welding assembly is arranged on the swinging part, the carrying part comprises a base, a fixed gear and a turntable, the fixed gear is arranged in a groove of the base, and the turntable is arranged on the base; and the fixed gear is matched with a rotating gear ofthe driving part. Motors are arranged out of a rocker arm or a base for the convenience of heat dissipation of the motors and operations of maintenance staff, so that the service lives are prolonged and the welding efficiency of the motor is improved. The welding robot is time- and labor-saving, meets the using demands and is convenient to popularize and apply.

Owner:山西华锐钣金制造有限公司

Sealed type hot gas welding unit and plastic welding equipment comprising same

The invention belongs to the technical field of hot gas plastic welding and provides a sealed type hot gas welding unit and plastic welding equipment comprising the same. The sealed type hot gas welding unit comprises a welding pipe part, a gas charging component and a heating tube, wherein the air charging component is connected to the welding pipe part; the heating tube is connected within the welding pipe part, and the two ends of the heating tube are sealed; the welding pipe part comprises a first pipe part and a second pipe part which is connected within the first pipe part; a heat insulating layer is arranged between the first pipe part and the second pipe part; the air charging component communicates with the second pipe part; the heating tube is positioned inside the second pipe part; the outer tube wall of the heating tube clings to the inner wall of the second pipe part; a thread groove is concavely formed in the outer tube wall of the heating tube. By the design, the sealed type hot gas welding unit disclosed by the invention is capable of solving the problems that the existing welding equipment is low in heat utilization rate, the temperature of exhausted gas is not high enough because of short contact time between cold gas and a heating unit, and therefore the welding efficiency is affected.

Owner:深圳市友通塑焊机械有限公司

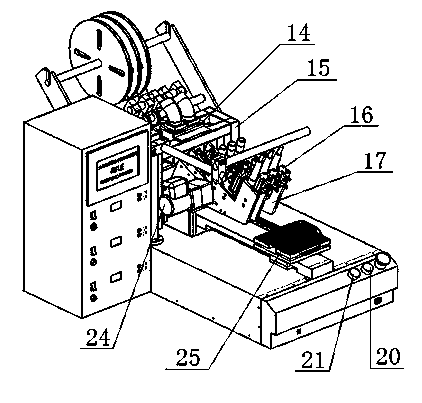

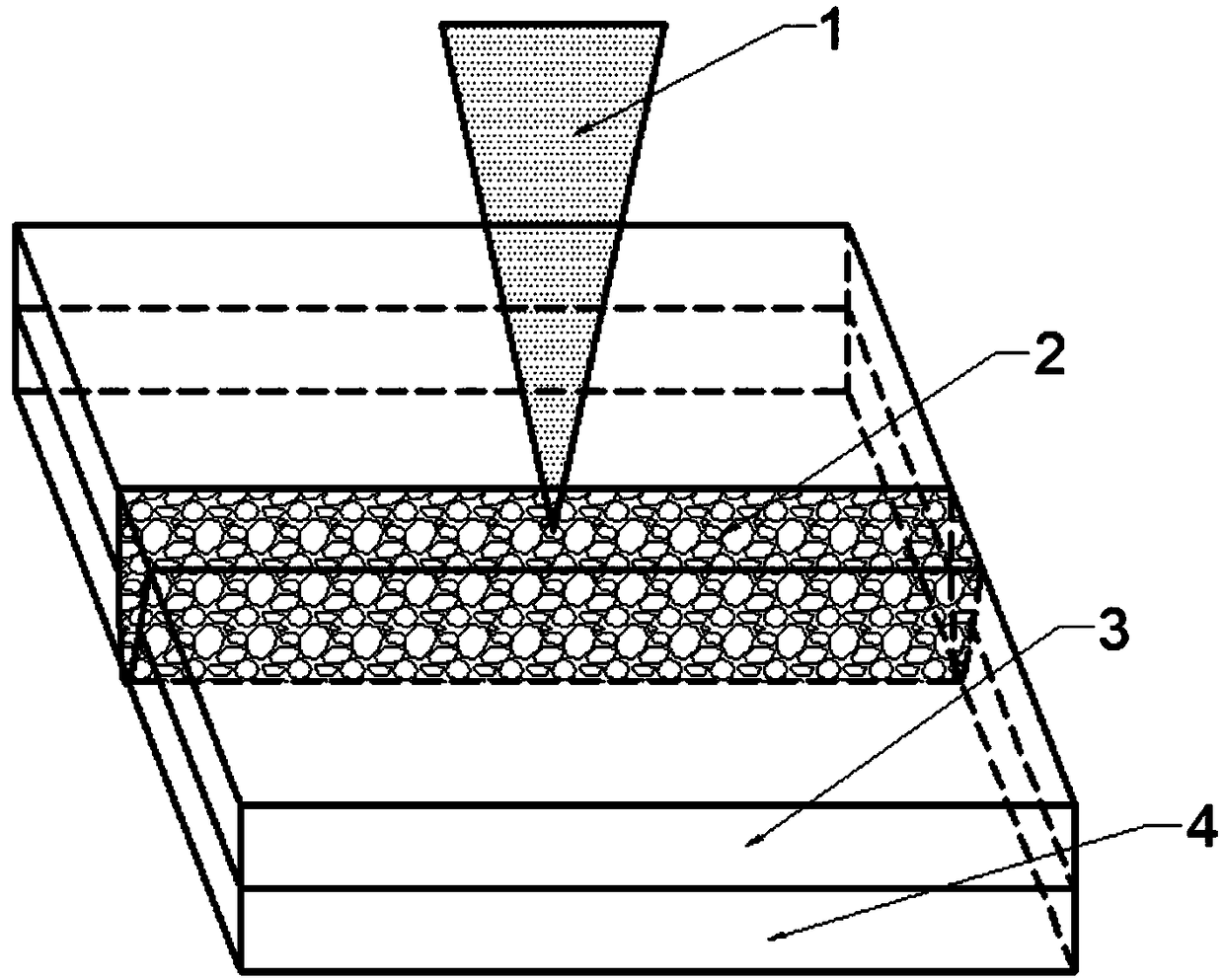

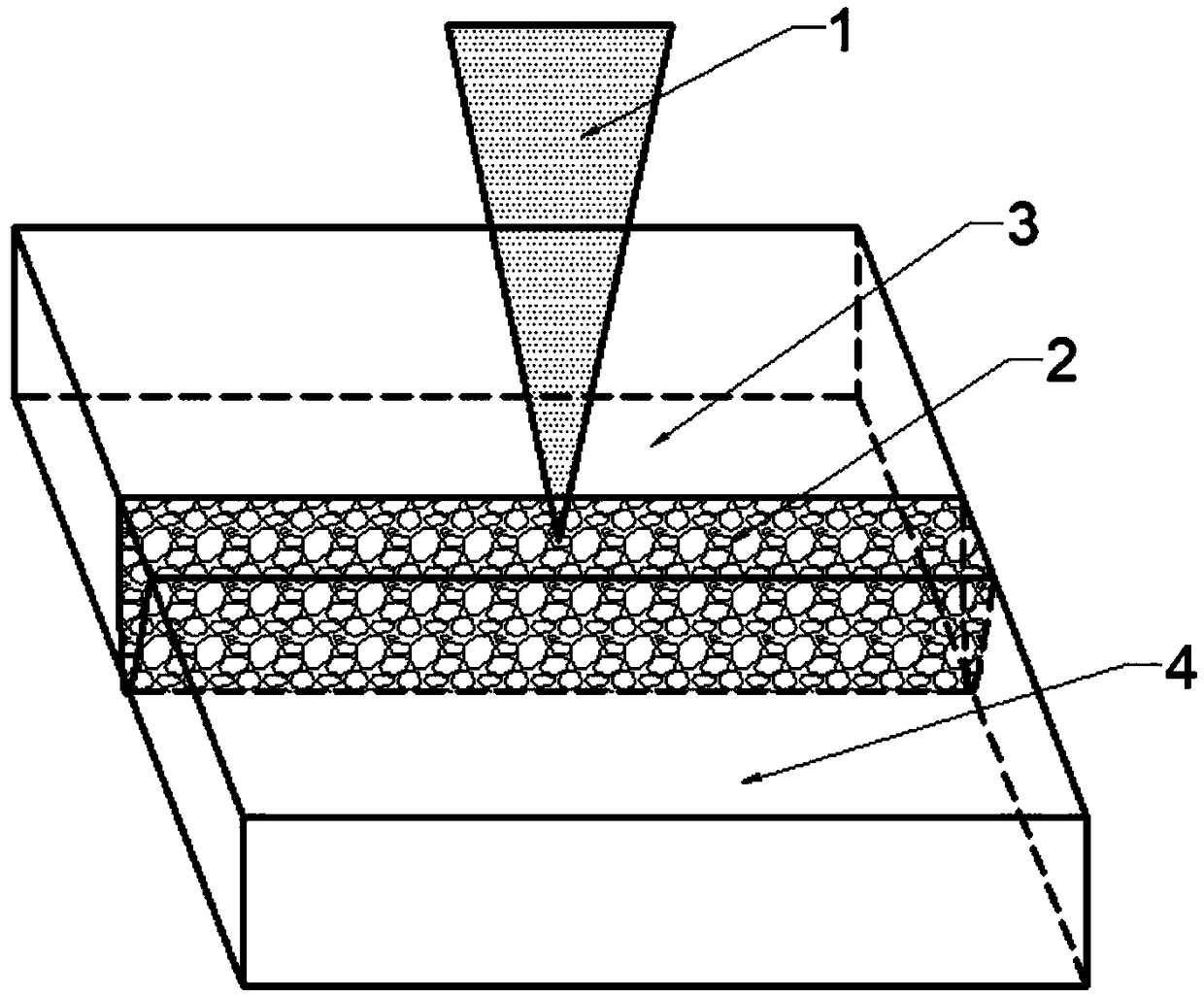

Semi-automatic welding machine for solar panels

InactiveCN103962671ARealize automatic weldingConvenient welding workMetal working apparatusSolder feeding devicesNumerical controlWorking environment

The invention discloses a semi-automatic welding machine for solar panels, and belongs to semi-automatic welding machines for solar panels. The welding machine adopts 1-3 welding guns to be matched with solar panels placed on a workbench moving automatically to complete automatic welding. The welding machine can achieve the automatic welding of a small batch of various welding pieces, adopts numerical control, achieves programmed preheating, performs the numerical control on welded strip length, welding point and welding conditions, ensures the fixed length output and fixed length cutting of the welded strips, improves the working efficiency, guarantees the quality and precision, and avoids low efficiency of manual welding; equipment adopts a preheating system, the preheating system can be pre-heated in advance, and the change of working environment is not needed to be considered; the efficiency and quality of welding in winter are ensured; operations of performing tin-coating treatment on the welded strips, drying and workpiece welding can be synchronously performed in the same equipment; a flux on the surface of the welded strip is heated and dried by adopting infrared heating, so that the welding operation of the welded strip and the battery panels are facilitated.

Owner:大连佳德恒电子工业有限公司

Truss welded steel bar welding mechanism

PendingCN112475699AImprove applicabilityGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention discloses a truss welded steel bar welding mechanism. The truss welded steel bar welding mechanism comprises a support, a truss steel bar feeding end of the support is a front section, and a truss steel bar output end of the support is a rear section; a fixing platform is fixed to the front section of the support, an upper welding supporting assembly used for supporting a truss is installed on the upper surface of the front end of the fixing platform, and web member rib positioning assemblies are symmetrically arranged on two sides of the upper welding supporting assembly; an upper welding mechanism is installed above the adjustable upper welding supporting assembly, and the upper welding mechanism moves vertically through a height adjusting mechanism; a lower welding mechanism used for welding truss lower chord ribs is installed at the rear end of the fixing platform, and an upper chord rib pressing assembly is installed at the front end of the upper portion of the lowerwelding mechanism; and an anti-magnetization guide assembly is installed on the rear section of the support, and an anti-lateral-bending assembly is arranged above the anti-magnetization guide assembly. The truss welded steel bar welding mechanism is high in welding efficiency, capable of saving energy and environmentally friendly.

Owner:CHENGDU GUTE MACHIENRY WORKS

Automatic welding device capable of efficiently replacing filler rods

InactiveCN112975213AReduce the frequency of electrode replacementImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention relates to the field of automatic welding, in particular to an automatic welding device capable of efficiently replacing filler rods. The device comprises a device main body, a moving frame is movably mounted at the upper end of the device main body, a welding rod is movably mounted at the inner side of the moving frame, and a filler rod replacing device is fixedly mounted at the inner side of the moving frame; and fixing blocks are fixedly installed in the filler rod replacing device at equal intervals along the edge, standby filler rods can be placed between the fixing blocks, after the filler rods at the lower end of the welding rod are used up, the filler rod replacing device can be driven by a motor to rotate, so that the filler rod replacing device uses a driving plate arranged in an annular wavy manner and located at the left side of the filler rod replacing device, rotation in a driving groove of a propelling block is achieved, when the driving block abuts against the driving plate in an attached manner through a spring at one side of a connecting rod, the propelling block can move left and right along the track of the driving plate, and therefore the standby filler rods at the outer side of the propelling block are pushed into welding tongs at the lower end of the welding rod along with rotation of the filler rod replacing device, and replacement is completed. Therefore, the frequency of filler rod replacement through device pause is greatly reduced.

Owner:新余山海企业服务有限公司

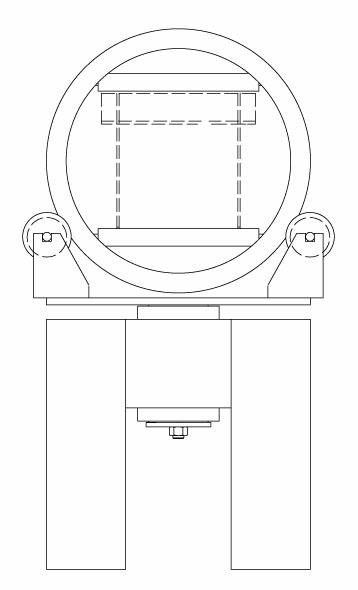

C70E cross beam constitution welding rollover table

InactiveCN102500989AGuarantee welding quality and efficiencySave stamina and energyWelding/cutting auxillary devicesAuxillary welding devicesPhysical strengthEngineering

The invention provides a C70E cross beam constitution welding rollover table, which belongs to the technical field of vehicle manufacturing apparatuses. The rollover table comprises a stand, wherein a vertical shaft which can horizontally rotate relative to the stand is supported by the stand; a rotary tray is fixed on the top of the vertical shaft; a roller which can vertically rotate relative to the rotary tray is supported by the upper surface of the rotary tray; a frame capable of clamping a C70E cross beam constitution is supported on the roller; the frame comprises two frame circular tracks which are arranged at the two ends of the frame and are matched with the roller; the two frame circular tracks are connected by four roller shaft brackets; the four roller shaft brackets are divided into two groups for supporting parallel roller shafts respectively; the device realizes all-directional turnover and positioning of the C70E cross beam through 360-degree rotation of the rotary tray and longitudinal 360-degree turnover; and thus, the welding quality and efficiency can be effectively guaranteed, physical strength and energy are saved, and the tool has a simple structure, stable performance and obvious effect.

Owner:CRRC SHIJIAZHUANG CO LTD

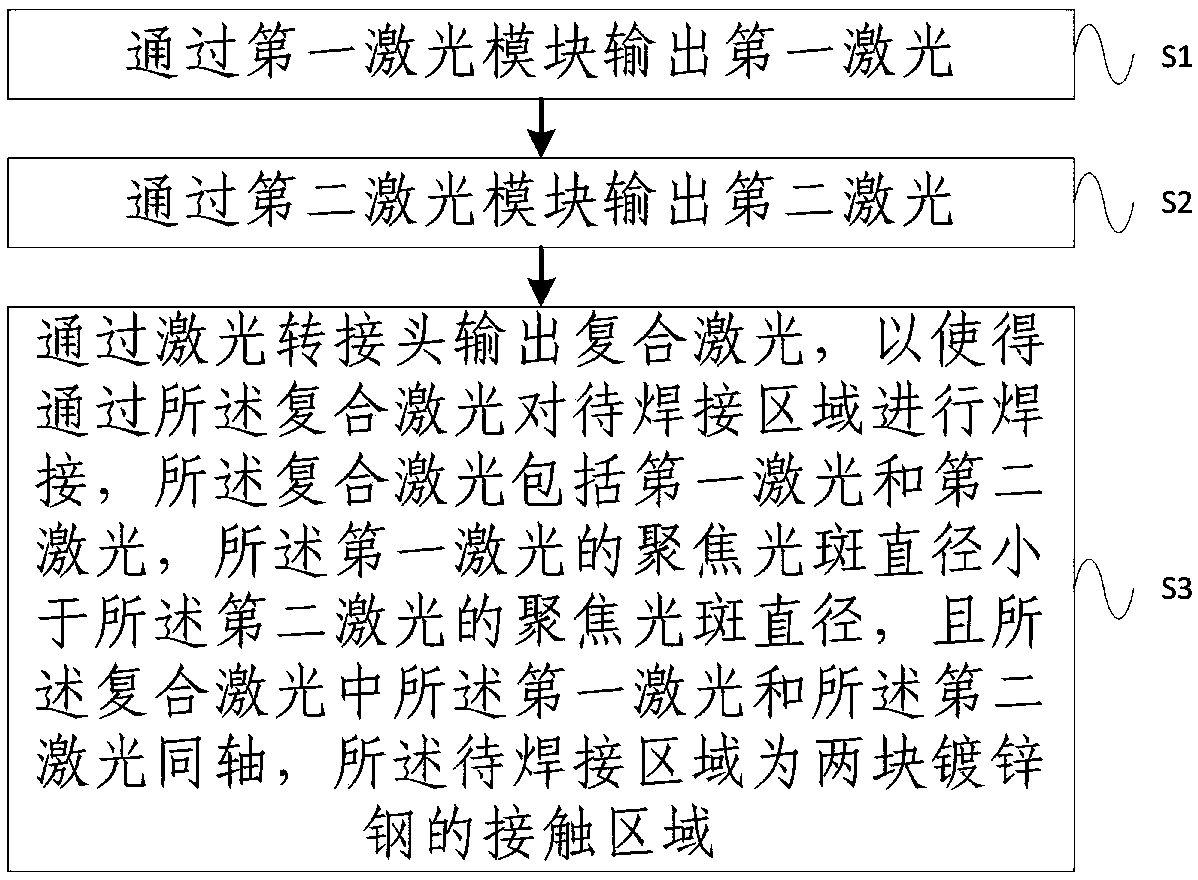

Galvanized steel welding method

InactiveCN109175691AIncrease in sizeReduce cooling rateLaser beam welding apparatusOptoelectronicsWeld seam

The embodiment of the invention provides a galvanized steel welding method. The welding method comprises the steps of conducting collimation on first laser through a first collimating mirror; conducting collimation on second laser through a second collimating mirror; conducting focusing on the collimated first laser and the collimated second laser through a focusing mirror, wherein the focused first laser is coaxial with the collimated second laser. According to the galvanized steel welding method provided by the embodiment of the invention, two laser beams with different focusing spot diameters are adopted, the weld penetration depth and the welding efficiency are ensured through the laser with the small focused spot diameter, and through the laser with the large focused spot diameter, azinc layer of the area to be welded is destroyed, the volume of a molten pool is expanded, and the cooling speed of the molten pool is reduced so that the problem of a great number of pores existing in the welding process can be reduced.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

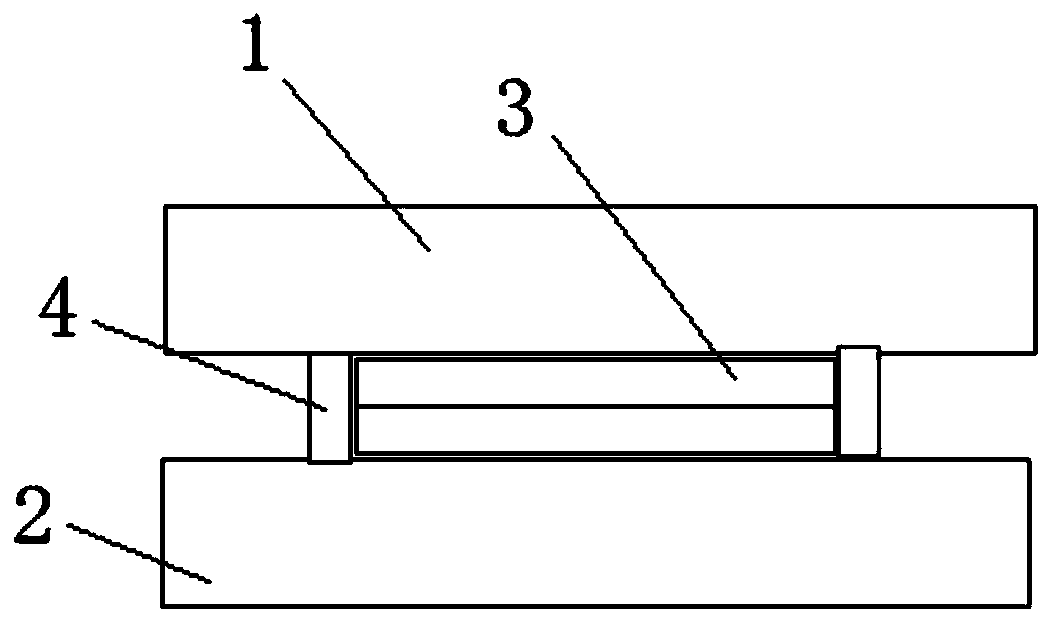

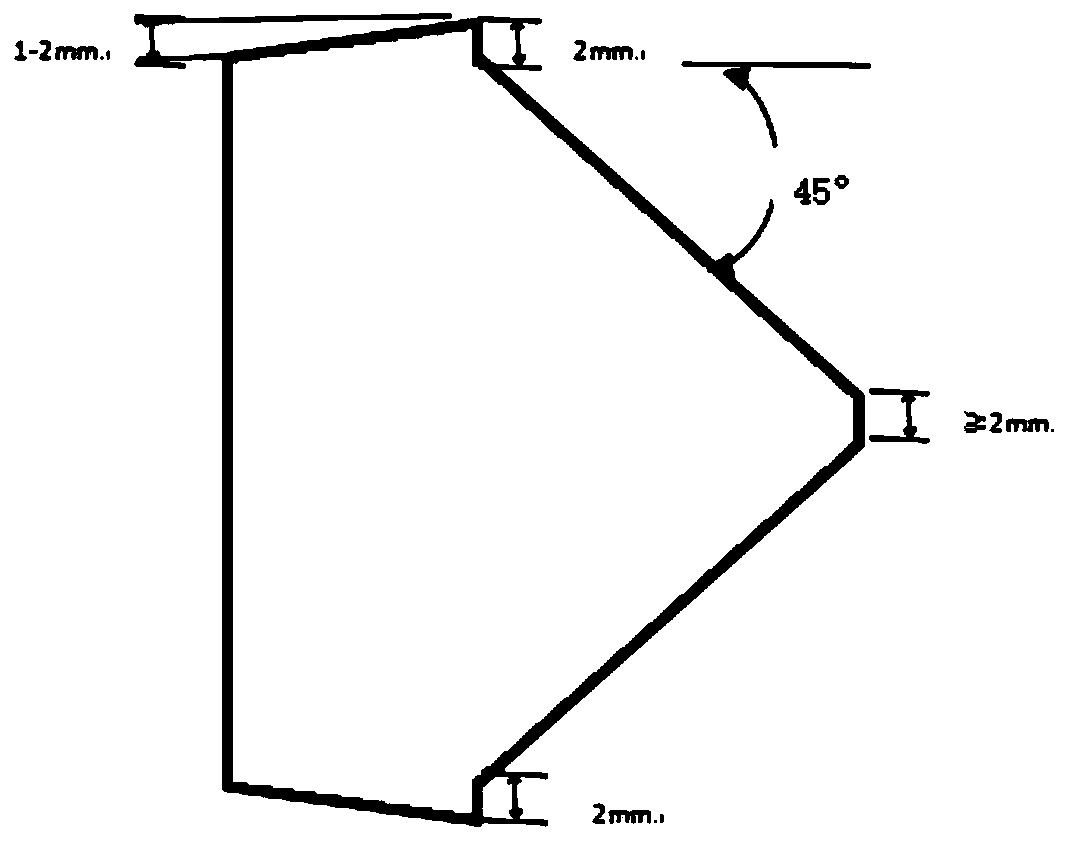

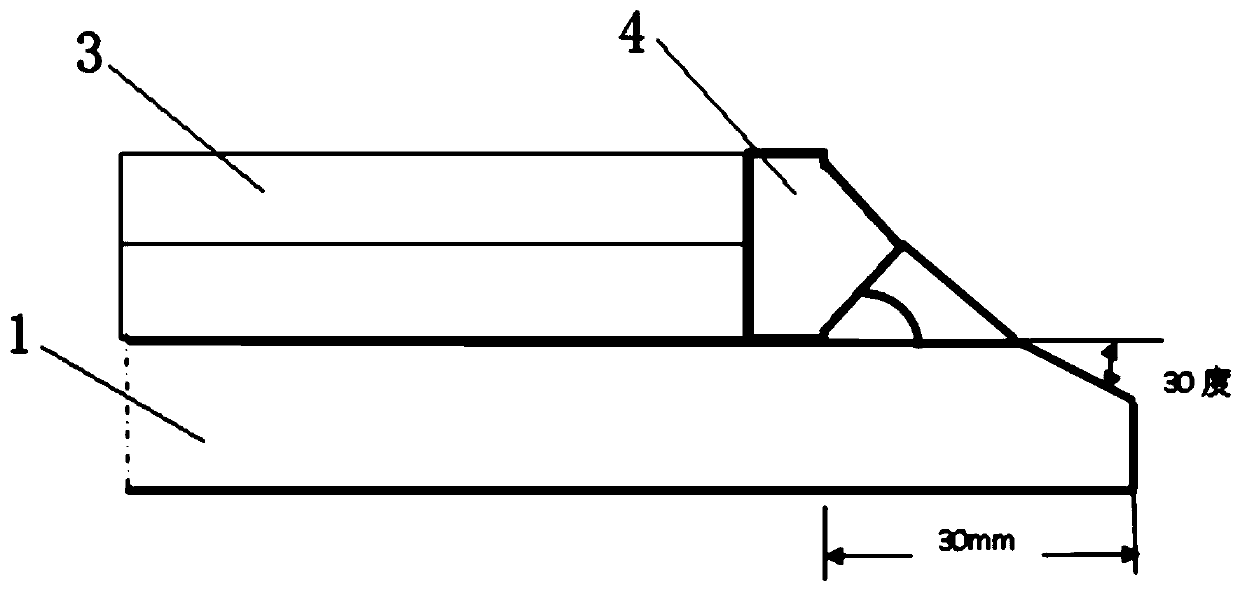

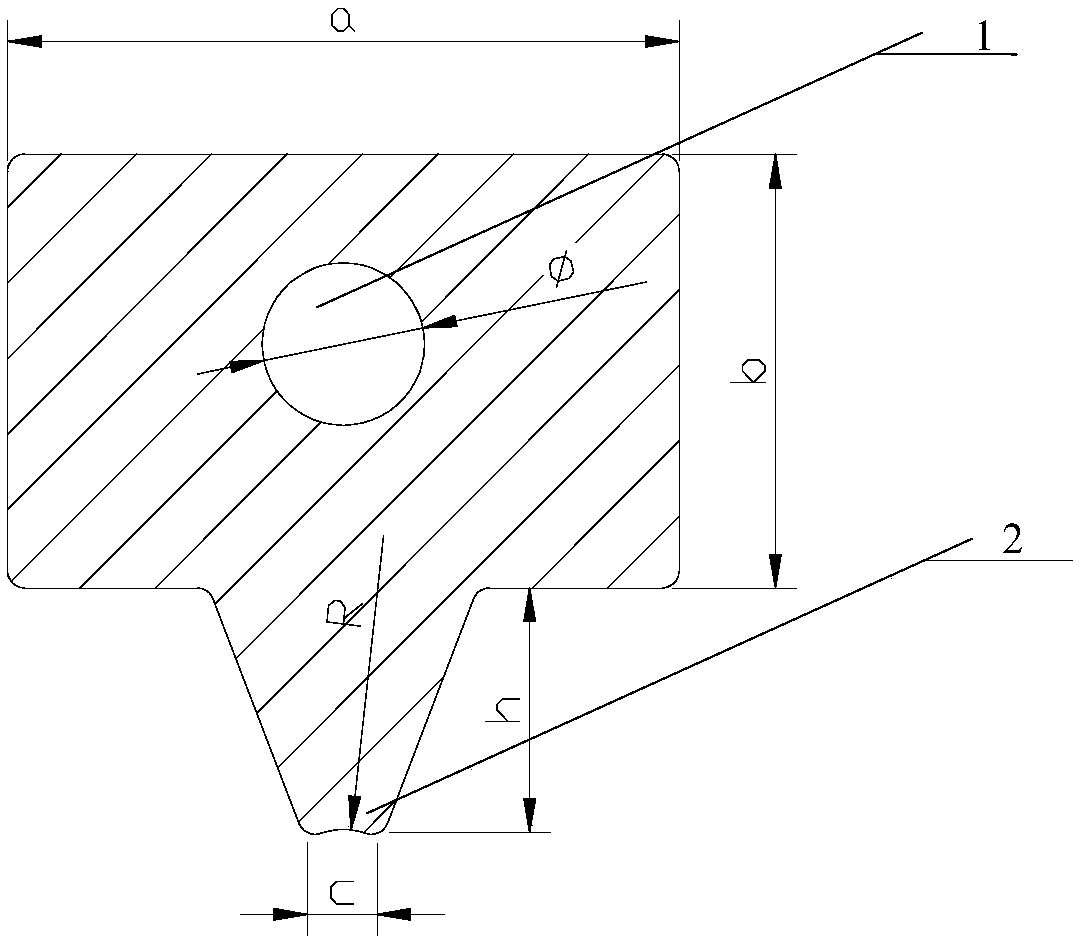

Symmetrical-hot-rolled composite plate blank and seal welding method thereof

ActiveCN111299974ALower manufacturing requirementsReduce manufacturing difficultyLayered productsArc welding apparatusIsosceles trapezoidStructural engineering

The invention relates to a symmetrical-hot-rolled composite plate blank and a seal welding method thereof. An enclosure frame comprises two parts, the first part forms the inner side of the enclosureframe, and the cross section of the first part is an isosceles trapezoid; the second part forms the outer side of the enclosure frame, the cross section of the second part is trapezoidal, and the length of the lower bottom edge of the second part is smaller than the length of the lower bottom edge of the first part; a groove is formed in the side, close to the enclosure frame, of the end of an upper base material; a special groove structure is formed through the innovative enclosure frame structure design, and the seal welding process is innovatively divided into two welding process flows; automatic welding equipment such as an arc welding robot or a special machine is adopted, and laser weld joint tracking and self-adaptive welding equipment is configured; a horizontal position welding mode is adopted, a high-penetration welding process is adopted for a root welding bead, and a high-deposition-rate welding process is adopted for a filling welding bead; and compared with the prior art,high-quality, high-efficiency and low-cost seal welding is realized through unique methods such as enclosure frame structure design, groove structure design, two-step welding process flow, welding process optimization and automatic welding equipment.

Owner:科斯焊接技术(无锡)有限公司

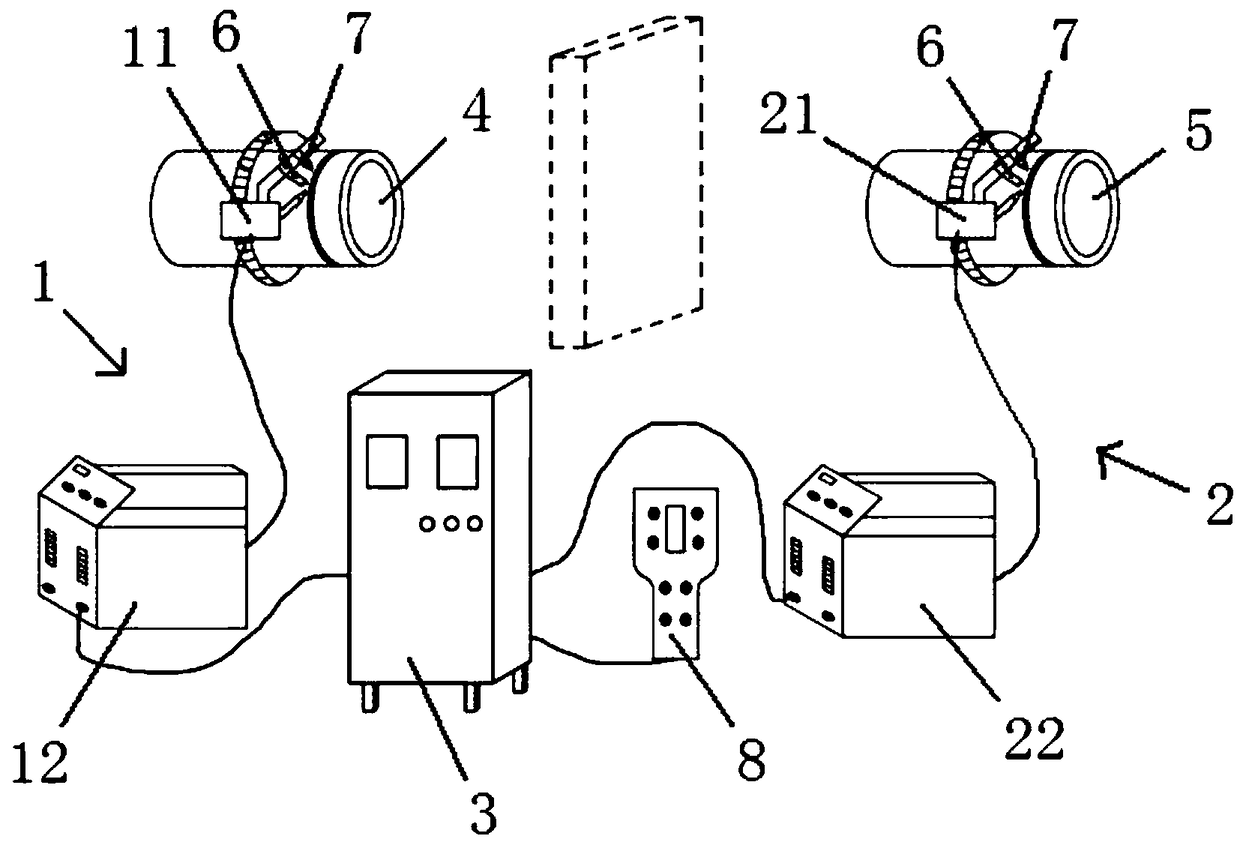

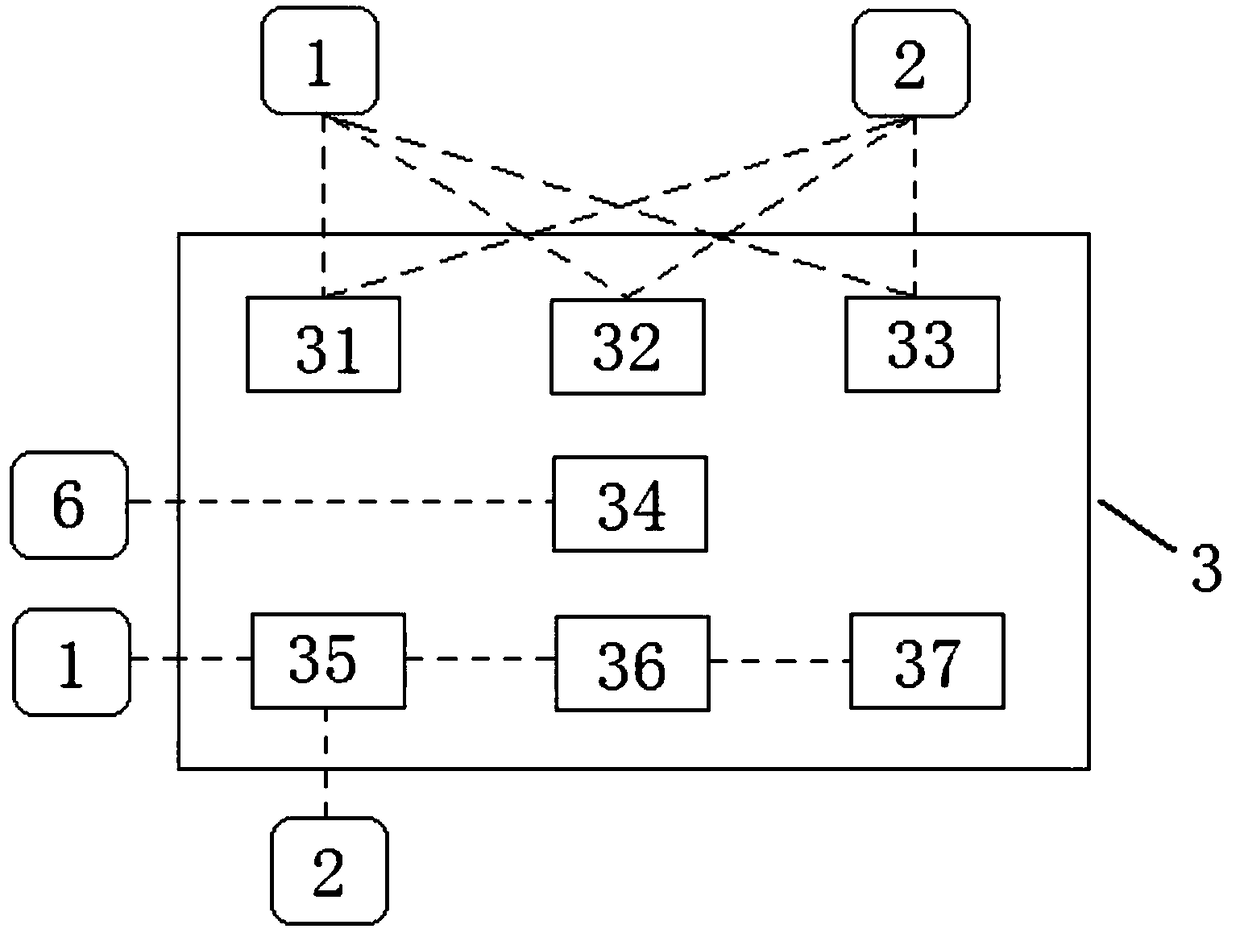

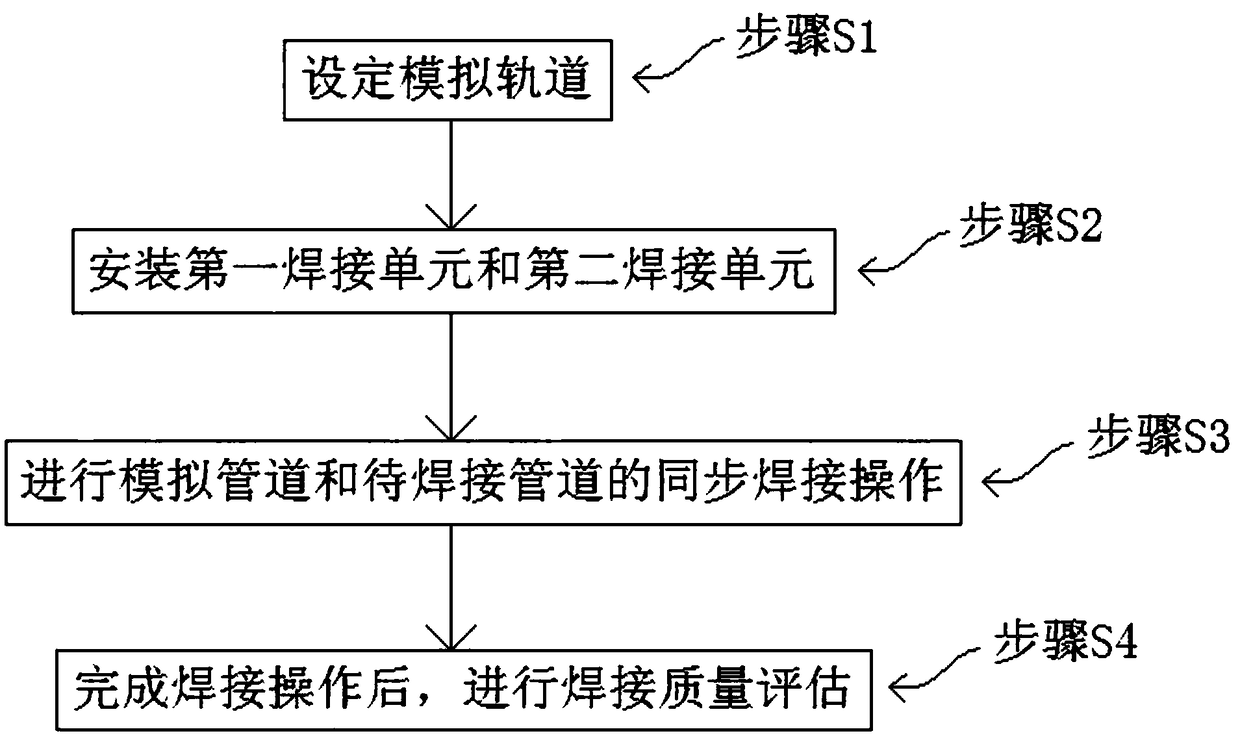

Welding system and method of nuclear engineering pipe under radiation environment

InactiveCN109500490AAvoid welding operationsAchieving health protectionWelding/cutting auxillary devicesAuxillary welding devicesPipe weldingControl unit

The invention belongs to the technical field of nuclear engineering pipeline welding. In order to achieve smooth repairing and welding of the nuclear engineering pipeline under the radiation environment and ensure the efficiency and quality of the welding operation, the invention discloses a welding system and method of the nuclear engineering pipe under the radiation environment. The welding system includes a first welding unit, a second welding unit and a control unit; the first welding unit is connected to the pipeline to be welded, the second welding unit is connected to a simulation pipeline, and the control unit is simultaneously connected to the first welding unit and the second welding unit and controls a first welding machine and a second welding machine to perform synchronous welding operation; and the simulation pipeline is located in a non-radiation area, and the welding condition is the same as the welding condition of the pipeline to be welded. When the welding system isused for repairing and welding the nuclear engineering pipeline under the radiation environment, the standing time of an operator in the radiation environment can be reduced, the protection of the operator can be improved, the welding operation can be completed quickly and smoothly, and the welding efficiency and quality are improved.

Owner:CHINA NUCLEAR IND 23 CONSTR

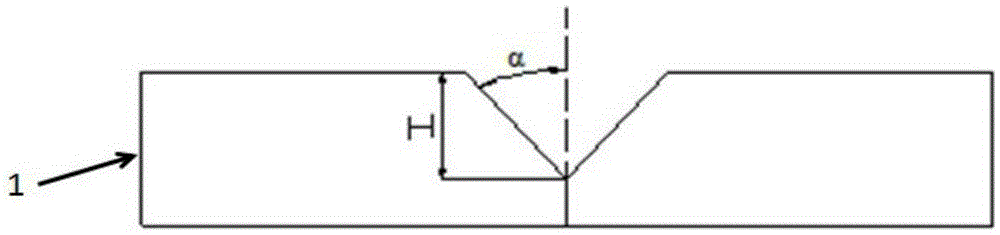

Solid wire gas shielded vertical upward welding method

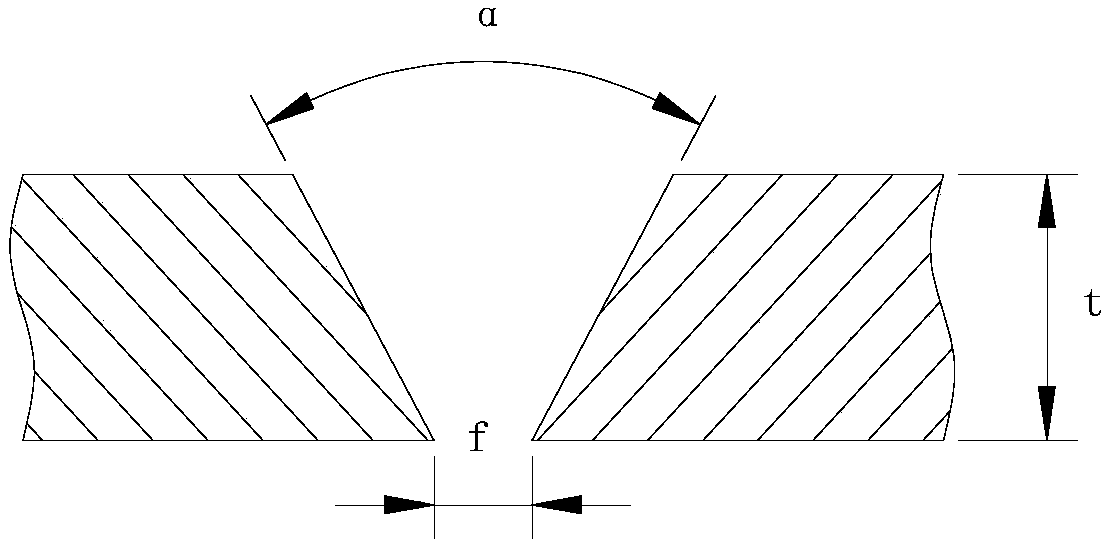

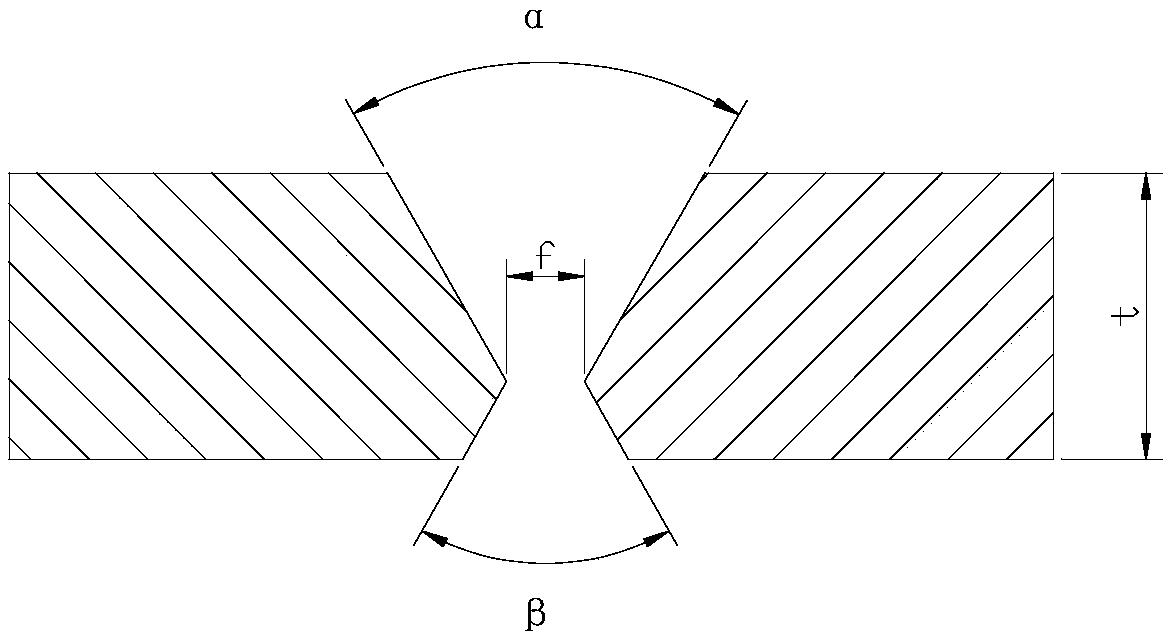

The invention discloses a solid wire gas shielded vertical upward welding method. According to the solid wire gas shielded vertical upward welding method, for automatic welding of a vertical seam of the material having a heat input strict requirement of a storage tank project, the wall thickness range of optional research is larger than or equal to 6 mm, solid wires are adopted, front-side protection is performed through the gas composed of 80% of Ar and 20% of CO2 or 98% of Ar and 2% of O2, and back-side protection is performed through a water cooled copper lining. When the wall thickness is6-12 mm, a V-shaped groove is formed, a gap is reserved, a truncated edge is avoided, the butt joint unfitness is controlled, one-sided welding and double-sided formation are adopted, and the back side is free of back chipping. When the wall thickness is larger than 12 mm, double asymmetrical V-shaped grooves are formed, a gap is reserved, a truncated edge is avoided, the butt joint unfitness is controlled, the water cooled copper lining is added to the back face, and forced formation is performed. Two water cooled copper linings are involved and used for back-sided protection of the V-shapedgroove and the X-shaped groove. The solid wire gas shielded vertical upward welding method solves the problem that in the industry, vertical welded plates of a storage tank device have strict heat input requirement and do not allow electro-gas vertical welding, guarantees the welding quality and welding efficiency and reduces the welding cost.

Owner:NANJING AUTO ELECTRIC

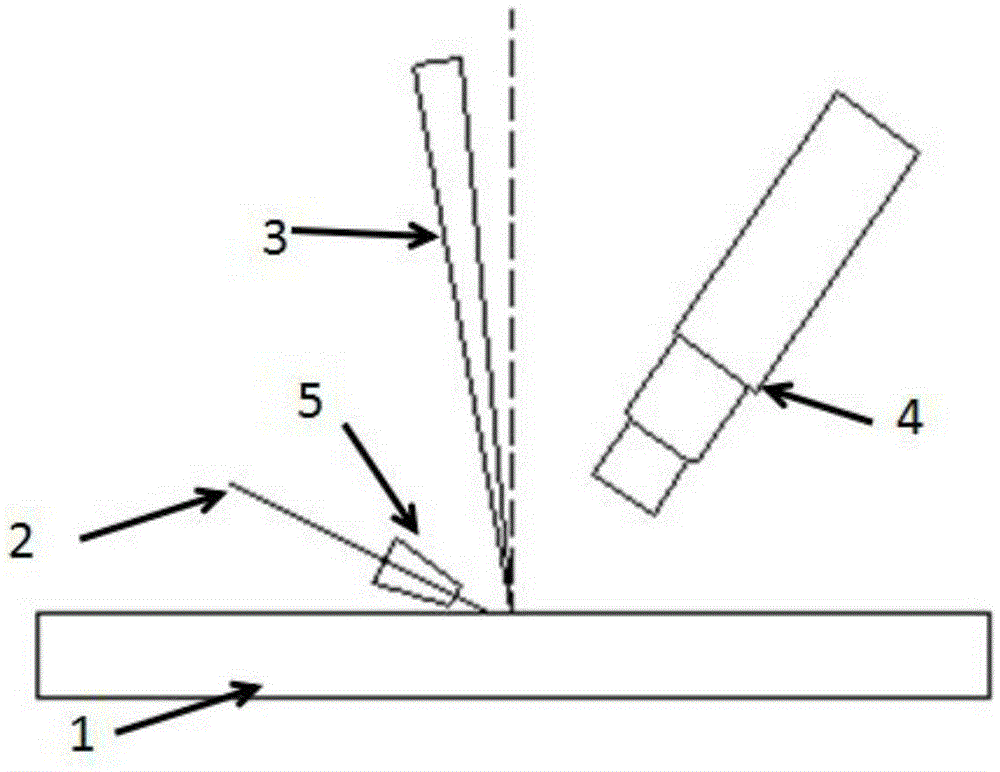

A kind of aluminum alloy laser-tig composite wire filling welding method

ActiveCN104259666BReduce laser powerAvoid Welding DefectsWelding/soldering/cutting articlesLaser beam welding apparatusHeat-affected zoneAlloy composite

The invention discloses an aluminium alloy laser-TIG composite filler rod welding method. The aluminium alloy laser-TIG composite filler rod welding method comprises the following steps: forming V-shaped grooves on a plurality of pieces of aluminium alloy before welding, and butting the pieces of aluminium alloy with the V-shaped grooves in a no-clearance manner, wherein the diameter of a welding stick is 1.0-1.4 mm; simultaneously lifting a laser, a TIG welding gun and a wire feeding mouth during welding, controlling the welding parameters of the first layer and the second layer to be the same, controlling the welding parameters from the third layer to the last layer to be the same, welding the filler rods in the fifth layer, the sixth layer and the seventh layer, and finally realizing welding formation of the aluminium alloy laser-TIG composite filler rods. According to the invention, the laser power and the TIG current are effectively reduced through multiple layers of filer rods, the purpose that a small-HAZ (Heat Affected Zone) welding joint is acquired in the aluminium alloy welding process can be guaranteed to the maximum extent, and welding defects are effectively avoided; through accurate control of the interlayer temperature and the interlayer lifting height, the oxidation layer area coverage of aluminium alloy in the multi-layer welding process can be effectively controlled, and stable welding of multi-layer composite filter rods of aluminium alloy with the thickness of 4-6 mm can be realized.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

Metal pipeline welding device for water conservancy construction and using method thereof

PendingCN114393339AGuaranteed stabilityGuaranteed welding effectWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld seam

The invention discloses a metal pipeline welding device for water conservancy construction and a using method thereof, and relates to the technical field of metal pipeline welding. The problem of the welding angle of a metal pipeline is solved. The device specifically comprises a bottom plate, mounting plates are arranged on the outer walls of the two sides of one end of the bottom plate correspondingly, a supporting plate is arranged on one side of the top of the bottom plate, a hydraulic rod is fixed to the outer wall of one side of the top of the supporting plate through a rotating plate, and a guide block is arranged at the extending end of the hydraulic rod; the top ends of the two L-shaped guide plates are connected with the two sides of the guide block through connecting shafts correspondingly, the middle sections of the two L-shaped guide plates are rotationally connected with connecting plates through guide shafts correspondingly, a support is arranged on the outer wall of the middle of the top of the bottom plate, a sliding hole is formed in one side of the support, and a sliding column is slidably connected into the sliding hole. The welding effect of the welding end of the metal pipeline after clamping and fixing is guaranteed, so that the welding efficiency of a welding joint on a welding seam is improved, and the welding quality is guaranteed.

Owner:沧州昊海水利工程质量检测有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com