Clamp

A fixture and top-tightening technology, applied in the field of machinery, can solve the problems of high risk, difficult to control welding quality, and low efficiency of manual welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Before introducing the technical solution of the embodiment of the present invention, the structure of the end beam will be introduced in detail.

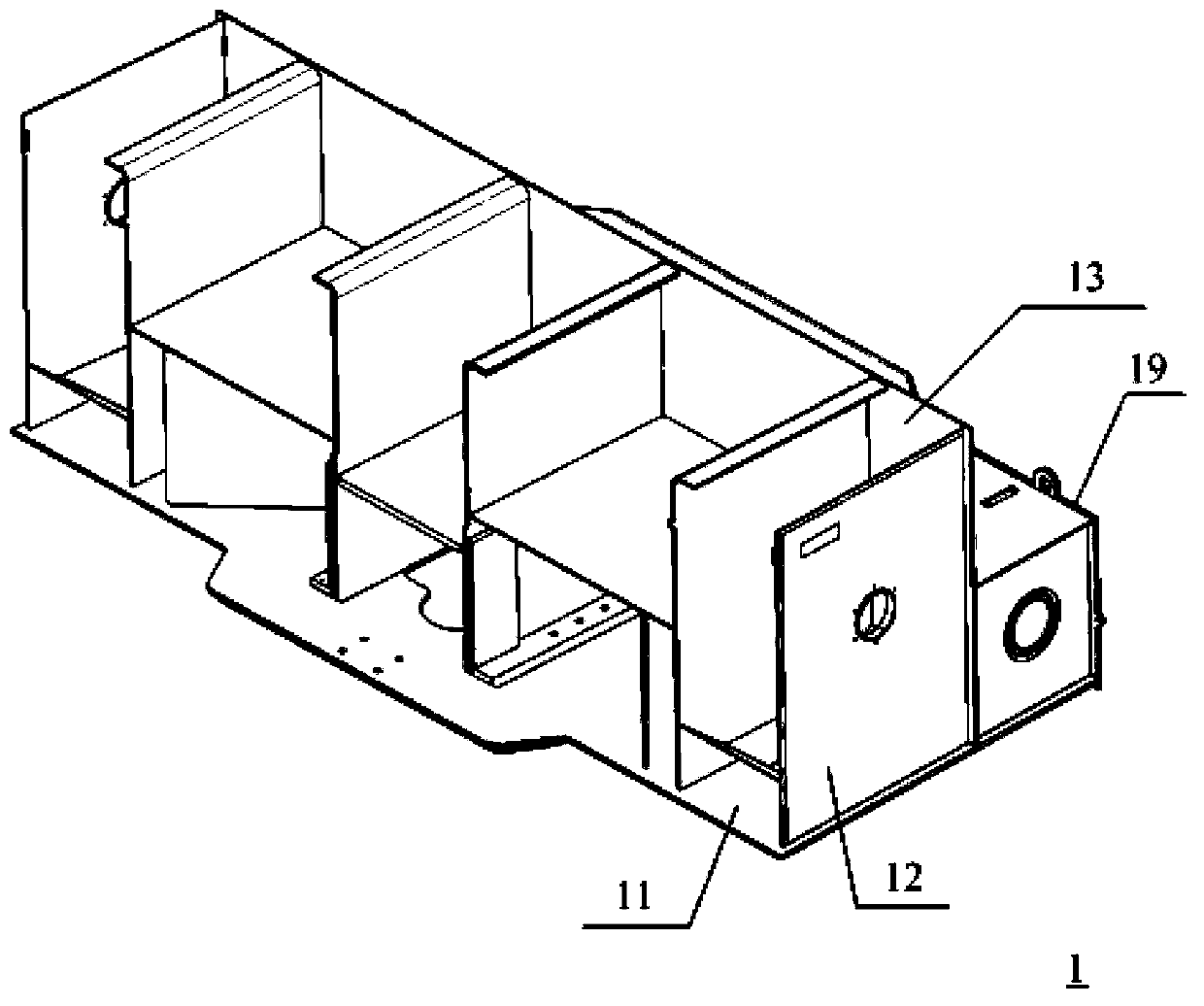

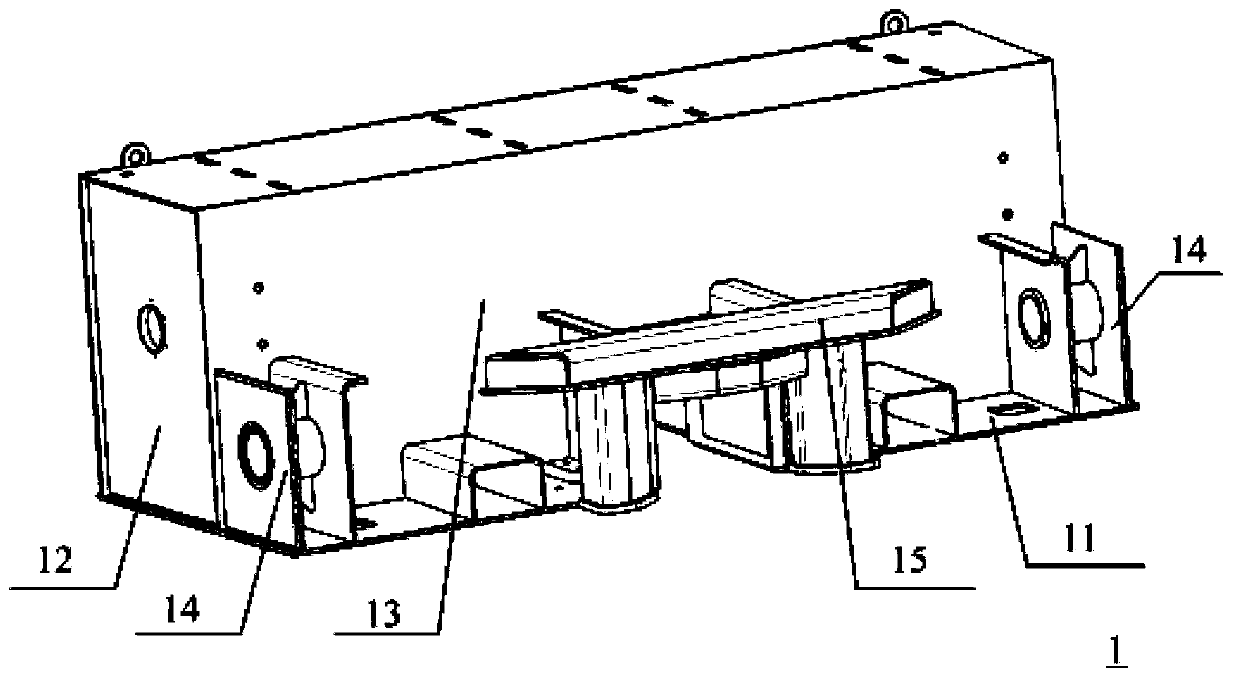

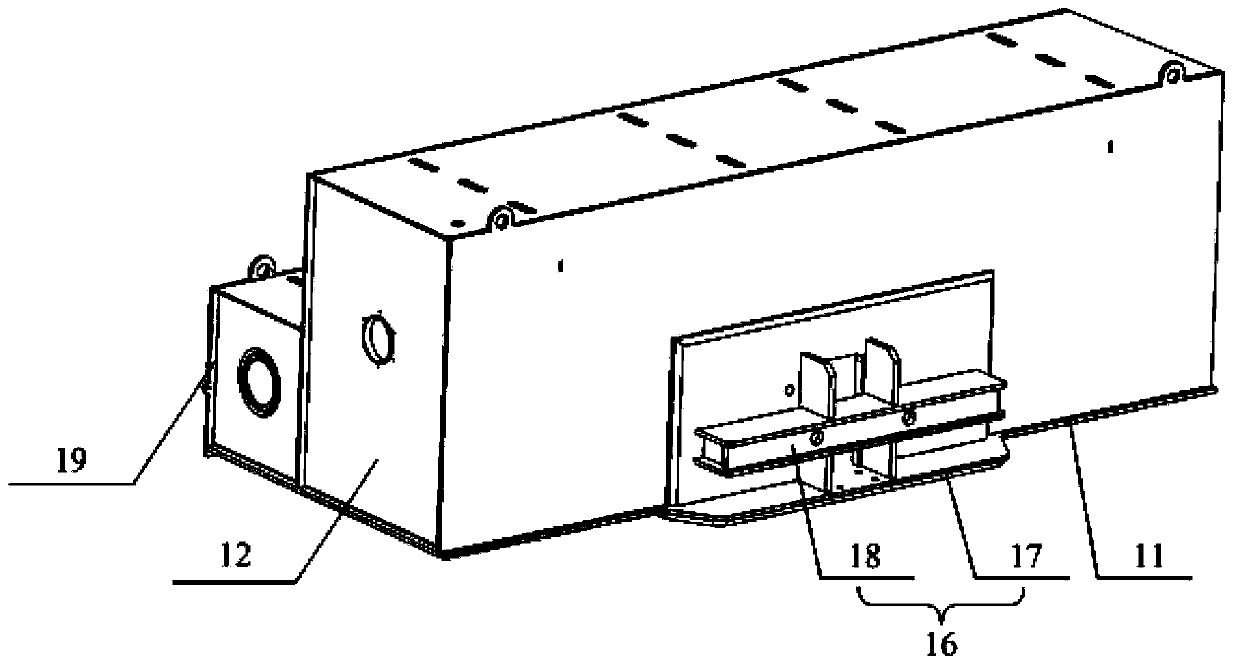

[0028] Figure 1a is the three-dimensional schematic diagram of the end beam, Figure 1b Stereoscopic representation of the end beam Figure II , Figure 1c Stereoscopic representation of the end beam Figure three .

[0029] see Figure 1a-Figure 1c , The end beam 1 includes a base plate 11 , two side plates 12 , a coupler box cluster plate 13 , two suspension seats 14 and a bent plate 15 . The base plate 11 is rectangular, the side plates 12 are fixed on both ends of the base plate 11 , and the coupler box cluster plate 13 is fixed on the base plate 11 and is located between the two side plates 12 . see Figure 1b , The coupler box cluster plate 13 has an inner cavity. Hanger composition 14 is symmetrically fixed on the edge of base plate 11, and leans against on the coupler box cluster plate 13. see Figure 1b , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com