A kind of aluminum alloy laser-tig composite wire filling welding method

A welding method and technology of aluminum alloy, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of unstable welding process, large TIG current, large laser power and TIG current, etc., to avoid Welding Defects, Guaranteed Efficiency, Reduced Effect of Heat Affected Zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

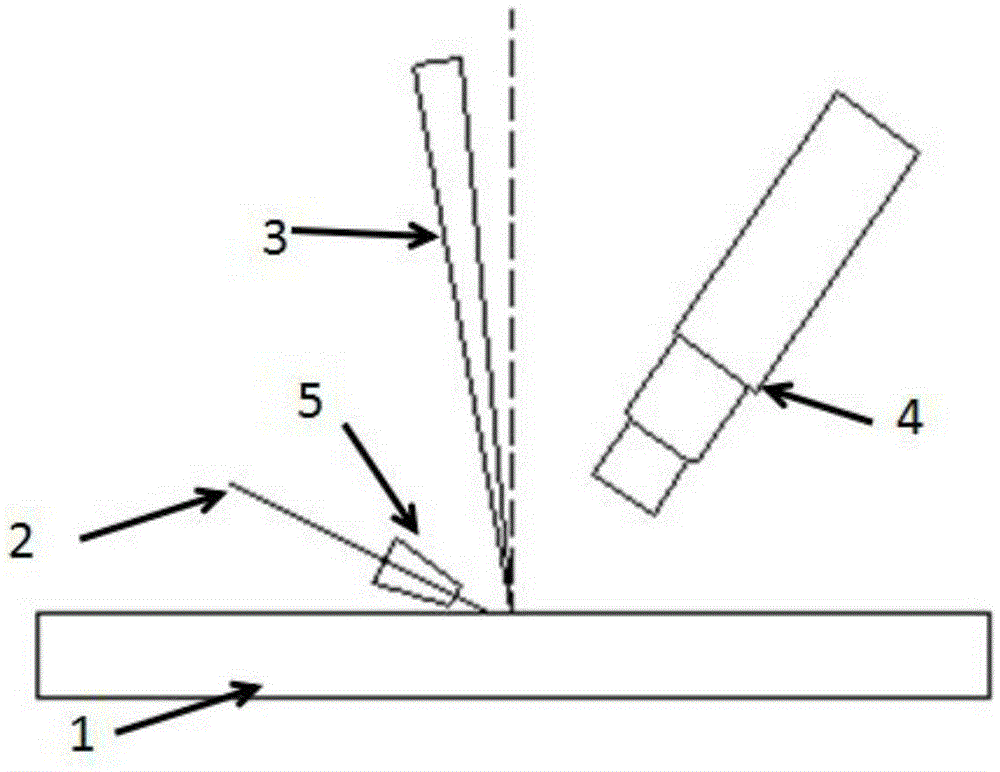

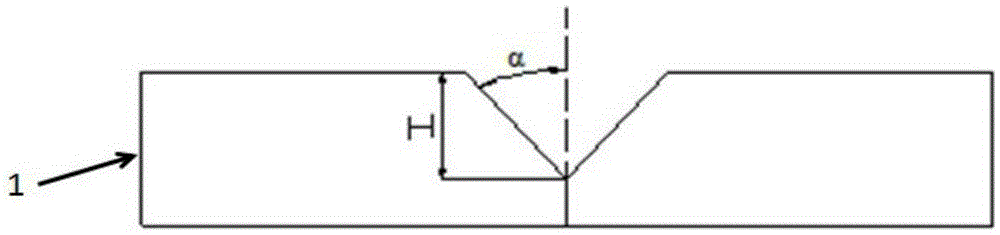

[0022] Example 1: Taking 5mm thick 6061 aluminum alloy 1 as an example, before welding, 5mm thick 6061 aluminum alloy 1 is V-shaped grooved, the depth H of the V-shaped groove is 3mm, and the unilateral angle α is 45°; The 5mm thick 6061 aluminum alloy of the type groove is butt-jointed without gaps, and the welding wire 2 with a diameter of 1.2mm is selected; the relative positions of the laser 3, TIG welding torch 4 and wire feeding nozzle 5 are adjusted to realize simultaneous lifting of the laser 3, TIG welding torch 4 and wire feeding nozzle 5.

[0023] The welding process parameters of the first layer of wire-filled welding are 450W laser power, TIG current 150A, interlayer temperature 310°, and interlayer lifting height 0.5mm; the second layer and the first layer welding process parameters are the same, laser power 450W, TIG current 150A, The interlayer temperature is 310°, and the interlayer lifting height is 0.5mm; the laser power of the third layer is 380W, the TIG cu...

Embodiment 2

[0024] Example 2: Taking the 4mm thick 6061 aluminum alloy 1 as an example, a 4mm thick 6061 aluminum alloy 1 is made into a V-shaped groove before welding, the depth H of the V-shaped groove is 2.5mm, and the unilateral angle α is 42°; 4mm thick 6061 aluminum alloy with V-shaped groove butt joint without gaps, choose welding wire 2 with a diameter of 1.0mm; adjust the relative positions of laser 3, TIG welding torch 4 and wire feeding nozzle 5, and realize simultaneous lifting of laser 3, TIG welding torch 4 and wire feeding nozzle 5 .

[0025] The welding process parameters of the first layer of wire filler welding are 400W laser power, TIG current 160A, interlayer temperature 300°, interlayer lifting height 0.48mm; the second layer and the first layer welding process parameters are the same; the third layer laser power is 350W, TIG The current is 140A, the interlayer temperature is 270°, and the interlayer lifting height is 0.35mm; the welding process parameters of the 4th,...

Embodiment 3

[0026] Example 3: Taking the 6mm thick 6061 aluminum alloy 1 as an example, a 6mm thick 6061 aluminum alloy 1 is opened with a V-shaped groove before welding, the depth H of the V-shaped groove is 3.5mm, and the unilateral angle α is 43°; 6mm thick 6061 aluminum alloy with V-shaped groove butt joint without gaps, choose welding wire 2 with a diameter of 1.4mm; adjust the relative positions of laser 3, TIG welding torch 4 and wire feeding nozzle 5, and realize simultaneous lifting of laser 3, TIG welding torch 4 and wire feeding nozzle 5 .

[0027] Welding process parameters of the first layer of wire-fill welding: laser power 430W, TIG current 155A, interlayer temperature 330°, interlayer lifting height 0.53mm; third layer laser power 380W, TIG current 145A, interlayer temperature 290°, interlayer lifting height The height is 0.45mm; the welding process parameters of the 4th, 5th and 6th layers are the same as those of the 3rd layer; by adding 6 layers of welding wire 2, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com