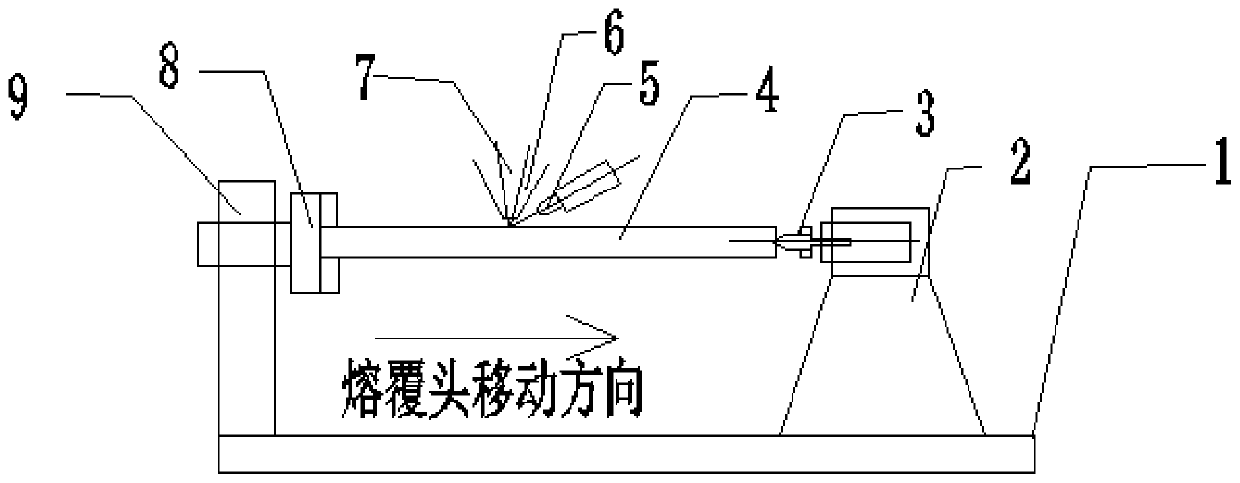

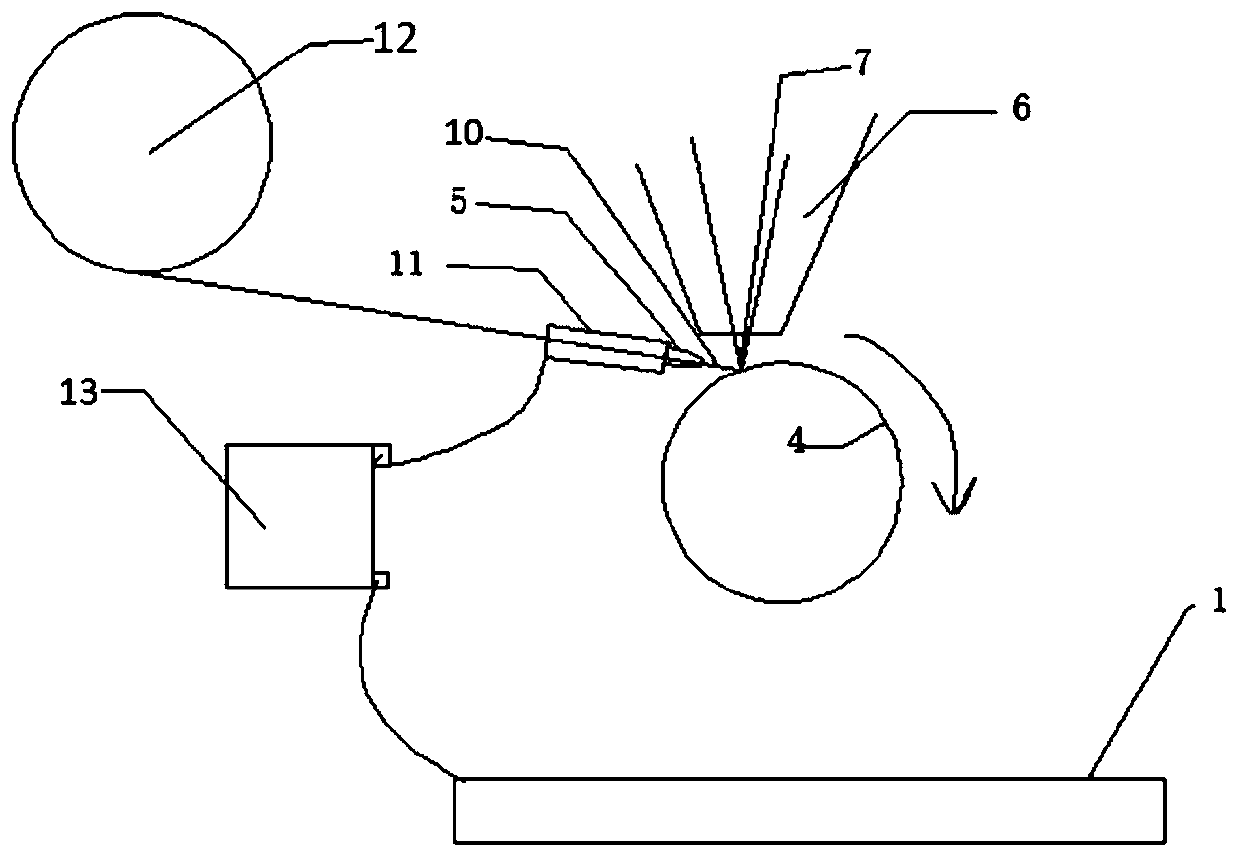

Laser cladding device and method for slender shaft-like workpieces

A technology of laser cladding and slender shafts, which is applied in the coating process of metal materials, coatings, etc., can solve the problems of reducing cladding deformation of slender workpieces, easy deformation of workpieces, and reducing heat input of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1) This embodiment is based on the above-mentioned method of the present invention for the surface metal wire laser cladding of the piston rod of the coal mine hydraulic support cylinder (hereinafter referred to as the piston rod). The standard diameter of the piston rod is φ90mm, and the size before cladding is φ89mm. The total length of the section is 1135mm, the diameter-to-length ratio of the piston rod is 7.8%, and the material is 27SiMn;

[0063] 2) The metal wire laser cladding scheme of the piston rod in this embodiment adopts a 4Kw fiber laser, the laser wavelength is 1064nm, and the spot size is φ3mm;

[0064] 3) The metal wire is stainless steel solid welding wire, material grade: TYG-005s, the cross-section shape of the wire is circular, and the diameter is φ1.2mm; the weight percentage of the main elements of the wire is: C≤0.20, Cr: 17.0-21.0 , Ni: 2.0-4.0, Mo≤1.50, P≤0.04, S≤0.03, Si≤1.50, Mn≤2.0, the rest is Fe;

[0065] 4) The dry elongation of the wel...

Embodiment 2

[0072] 1) This embodiment is based on the above-mentioned method of the present invention to carry out laser cladding on the surface of a corrosion-resistant guide shaft for a certain chemical equipment. The standard size of the workpiece to be clad is φ100mm, and the diameter of the workpiece before cladding is 99mm. The total length of the cladding area is 1500mm, the total length of the workpiece is 1630mm, and the material is 45# steel;

[0073] 2) In this embodiment, the cladding device is a 4Kw fiber laser, the laser wavelength is 1064nm, and the spot size is φ3mm;

[0074] 3) The metal wire is 316L stainless steel welding wire, the diameter of the welding wire is φ1.2mm; the weight percentage of each element in the wire material is: C≤0.04, Cr: 17.0-20.0, Ni: 11.0-14.0, Mo: 2.0-3.0, P ≤0.04, S≤0.03, Si≤1.00, Mn: 0.5-2.5;

[0075] 4) The length of the wire protruding from the wire guide nozzle is 15mm;

[0076] 5) Set the parameters of the wire cladding process as foll...

Embodiment 3

[0082] 1) This embodiment is based on the above-mentioned method of the present invention for the surface laser cladding of the coal mine hydraulic support cylinder piston rod (hereinafter referred to as the piston rod). The diameter of the piston rod is φ85mm, the size before cladding is φ84mm, and the total length of the cladding area is 735mm , the diameter-to-length ratio of the workpiece is 11.4%, and the material is 27SiMn;

[0083] 2) The metal wire laser cladding scheme of the piston rod in this embodiment adopts a 4Kw fiber laser, the laser wavelength is 1064nm, and the spot size is φ3mm;

[0084] 3) The metal wire is stainless steel solid welding wire, material grade: TYG-005s, the cross-section shape of the wire is circular, and the diameter is φ1.2mm; the weight percentage of the main elements of the wire is: C≤0.20, Cr: 17.0-21.0 , Ni: 2.0-4.0, Mo≤1.50, P≤0.04, S≤0.03, Si≤1.50, Mn≤2.0, the rest is Fe;

[0085] 4) The length of the wire protruding from the wire gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com