Patents

Literature

412results about How to "Reduce deformation effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic compound based on heteroaryl amine structure and application thereof to OLED (Organic Light Emitting Diode)

ActiveCN109761967AImprove stabilityHigh refractive indexOrganic chemistrySolid-state devicesFlexible organic light-emitting diodeAryl

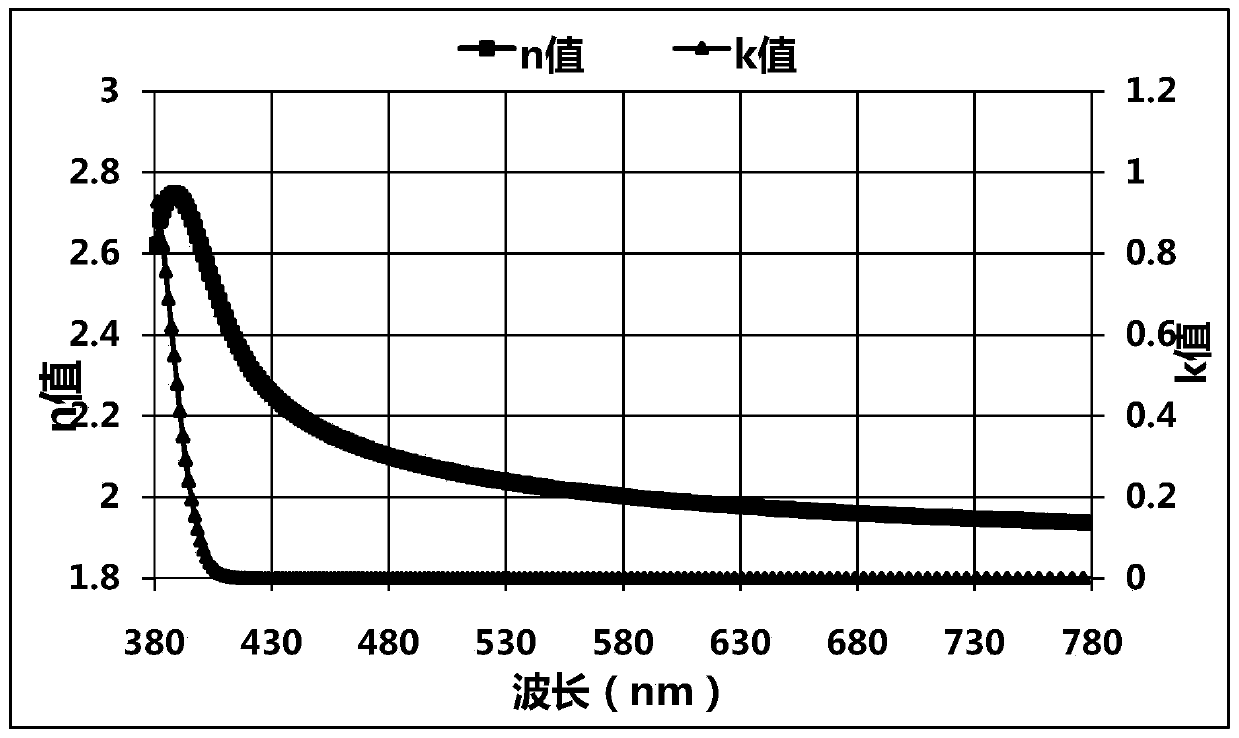

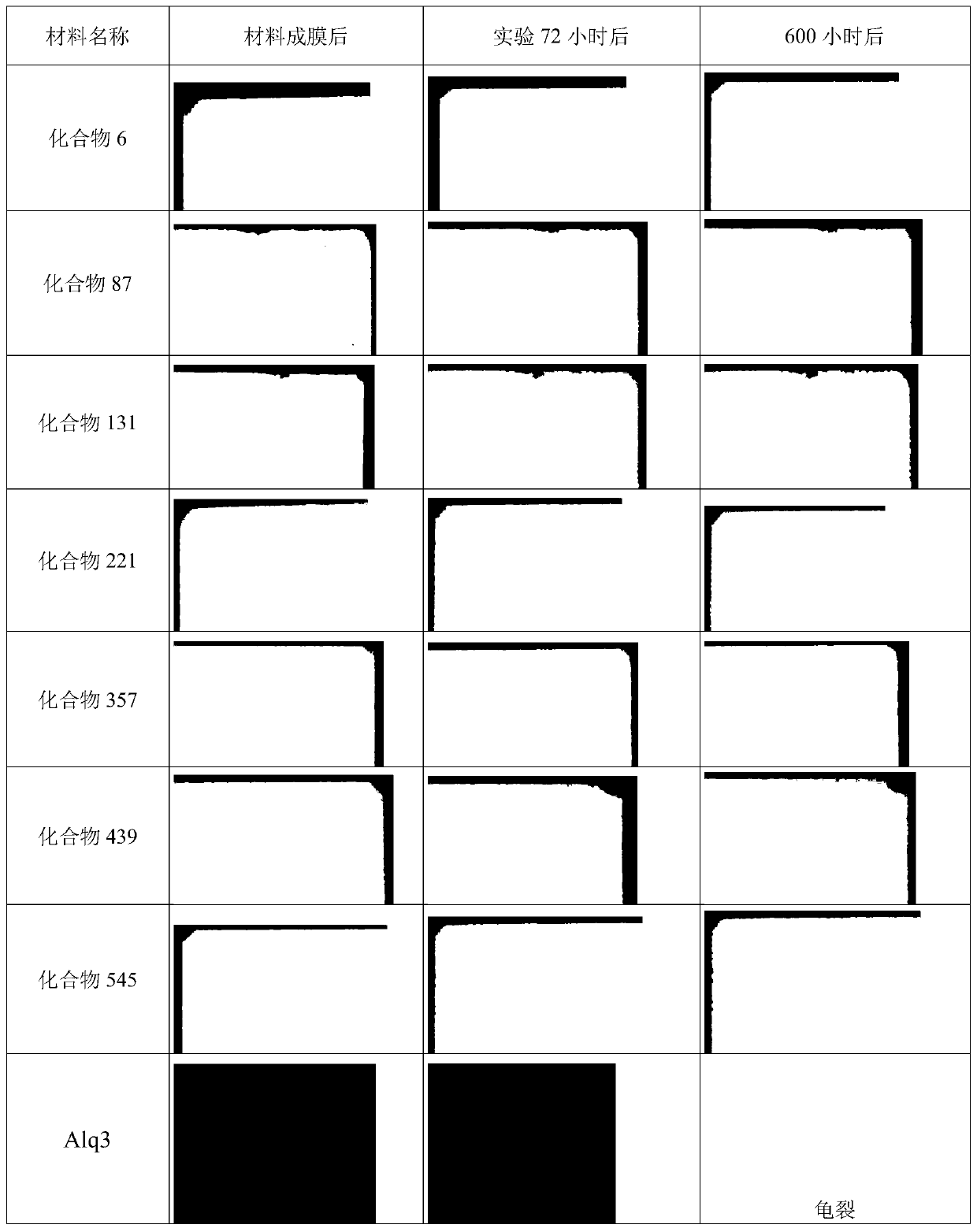

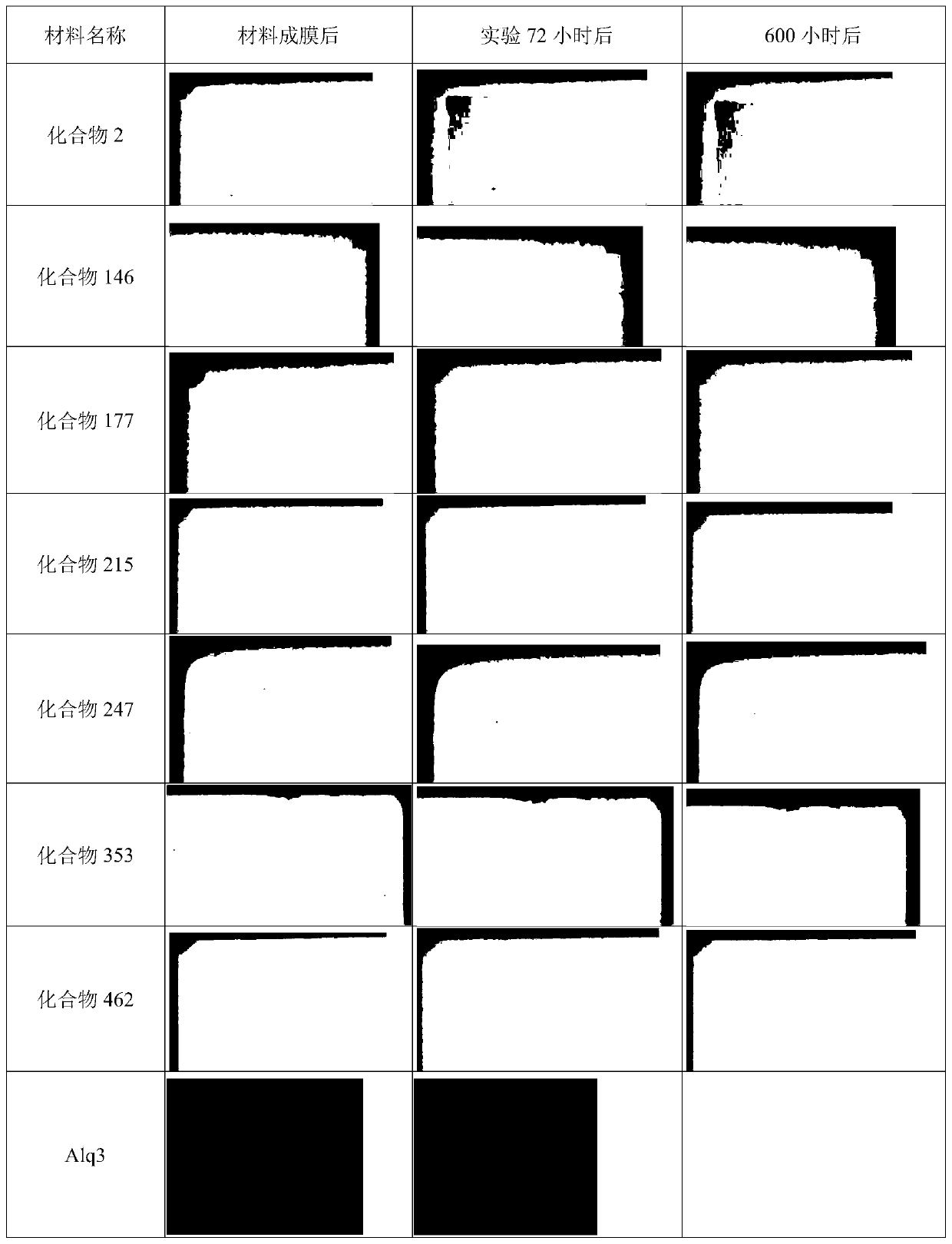

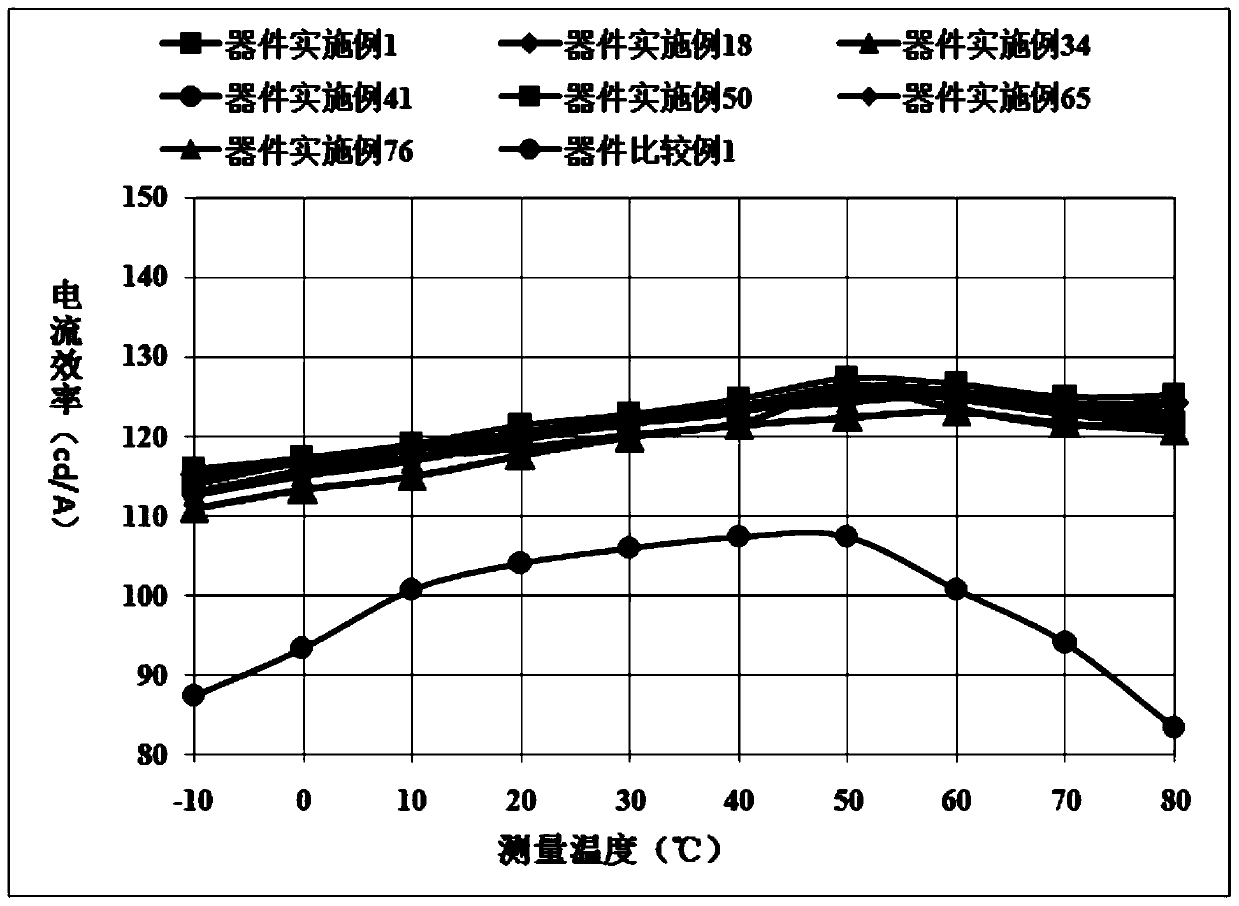

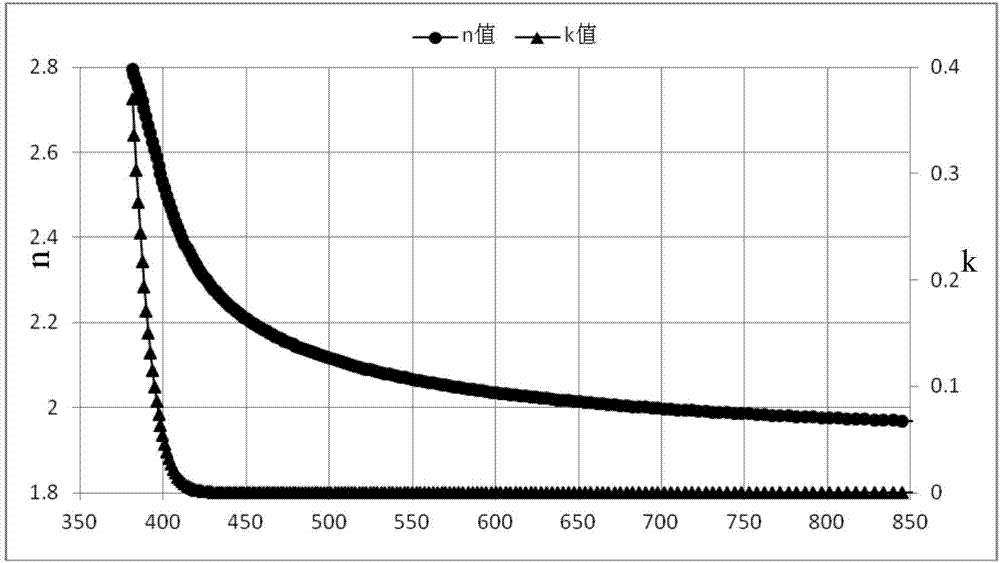

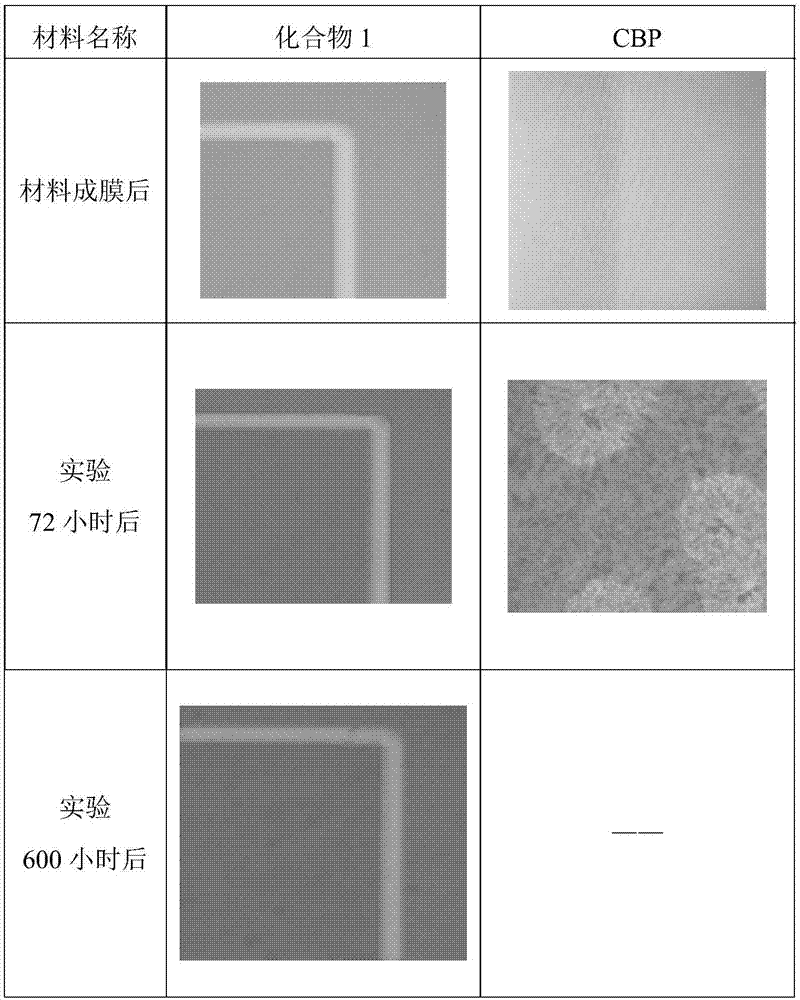

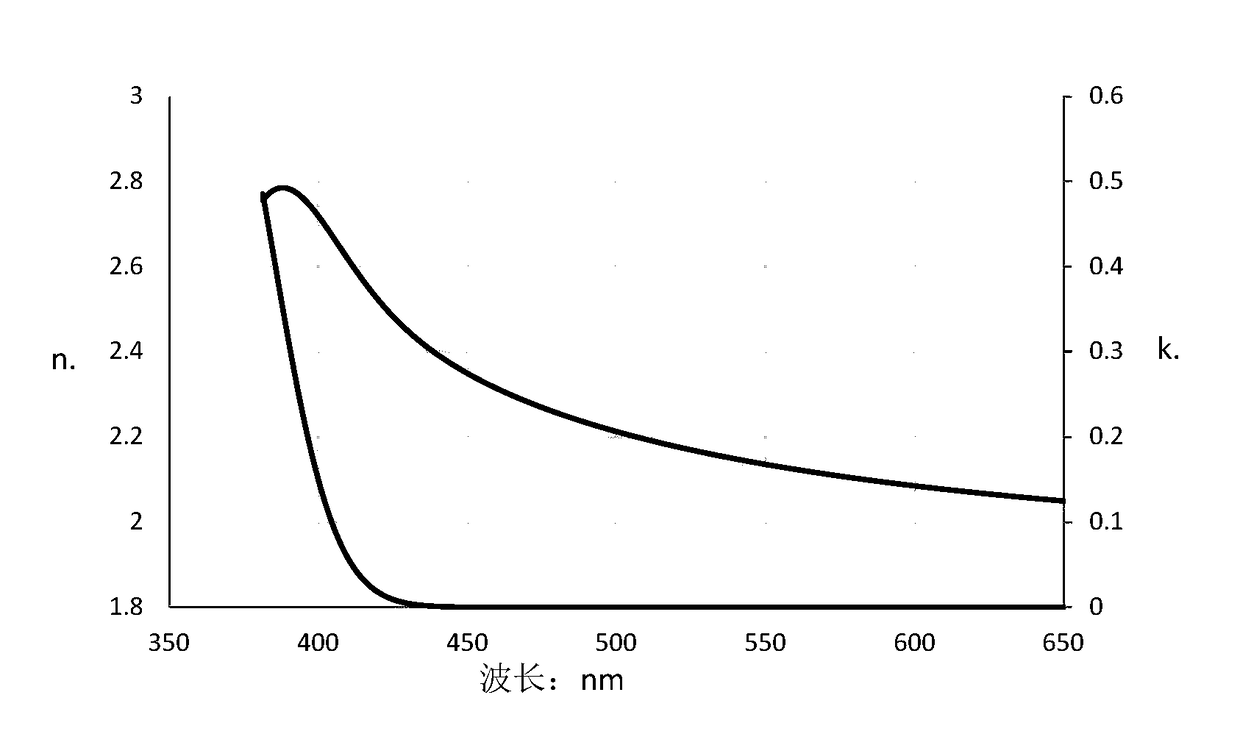

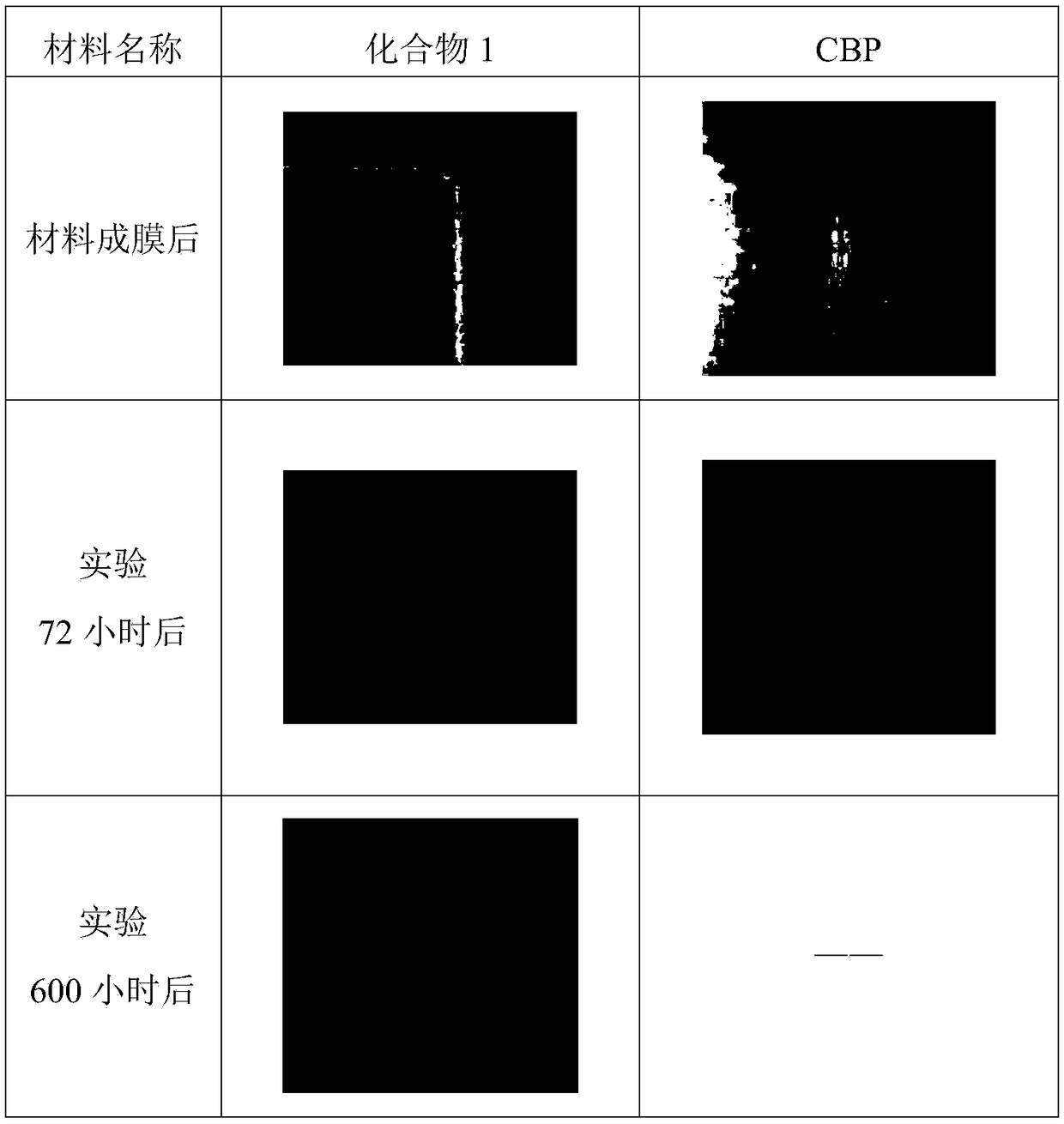

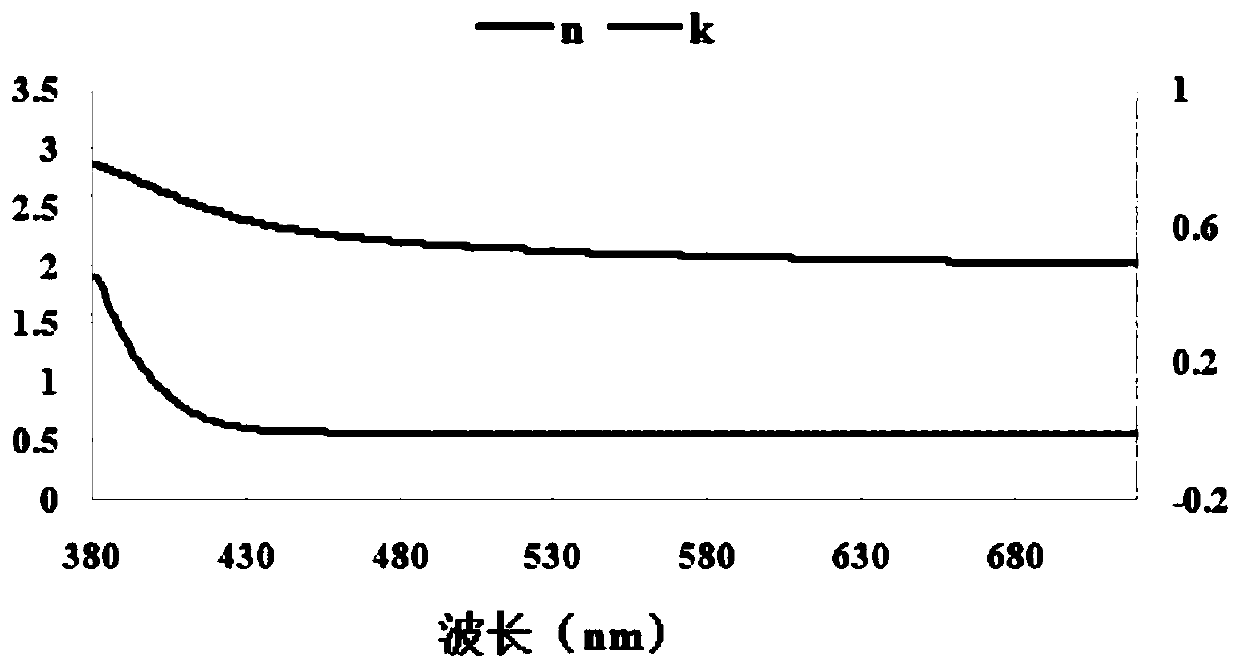

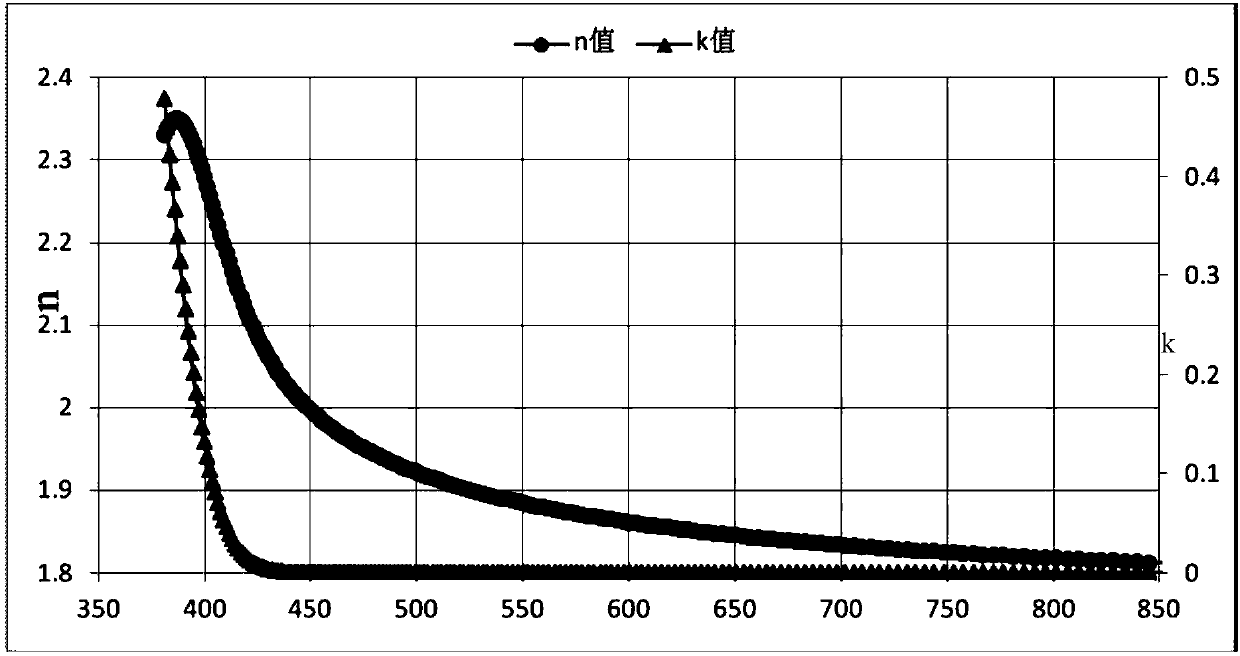

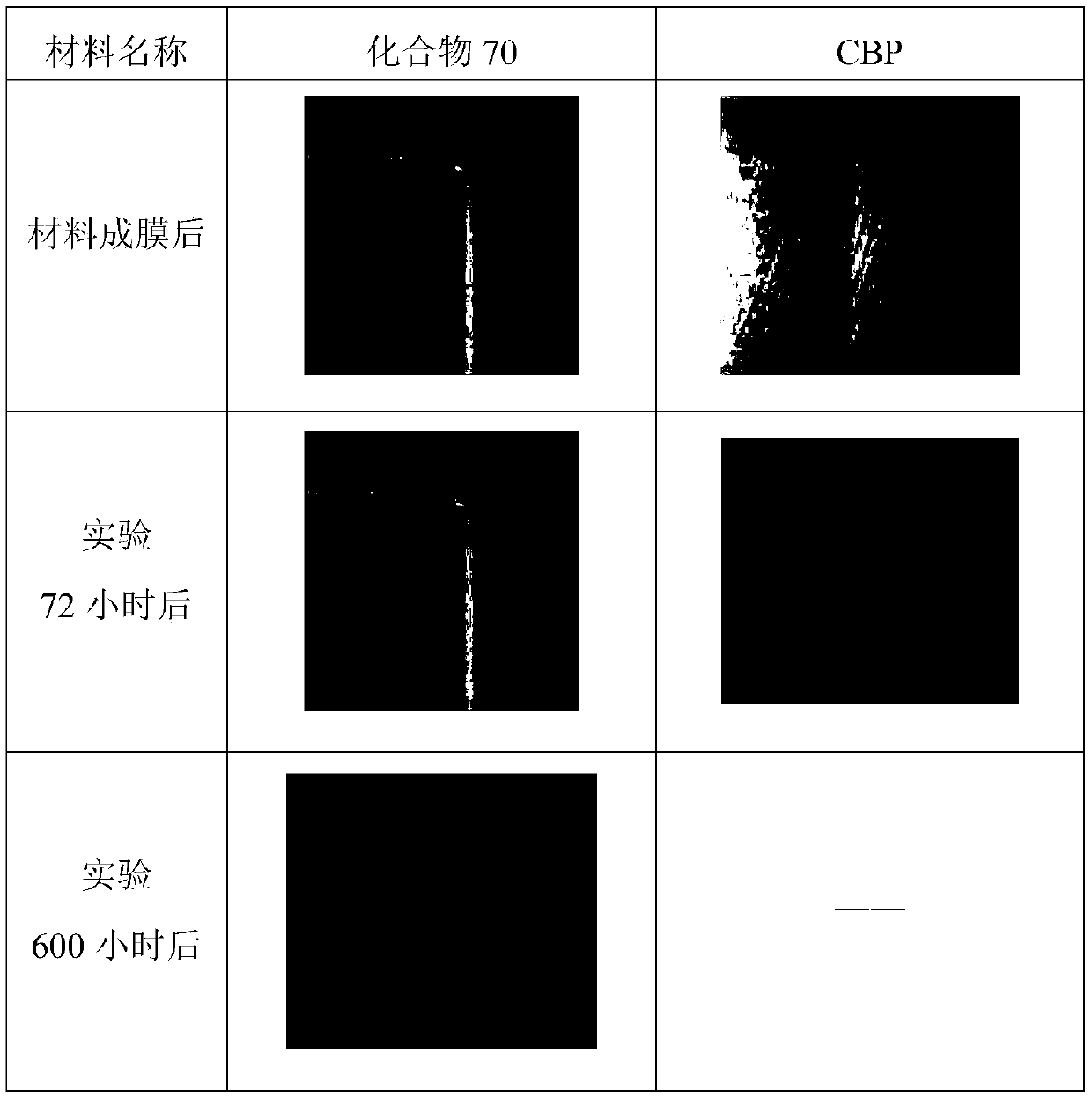

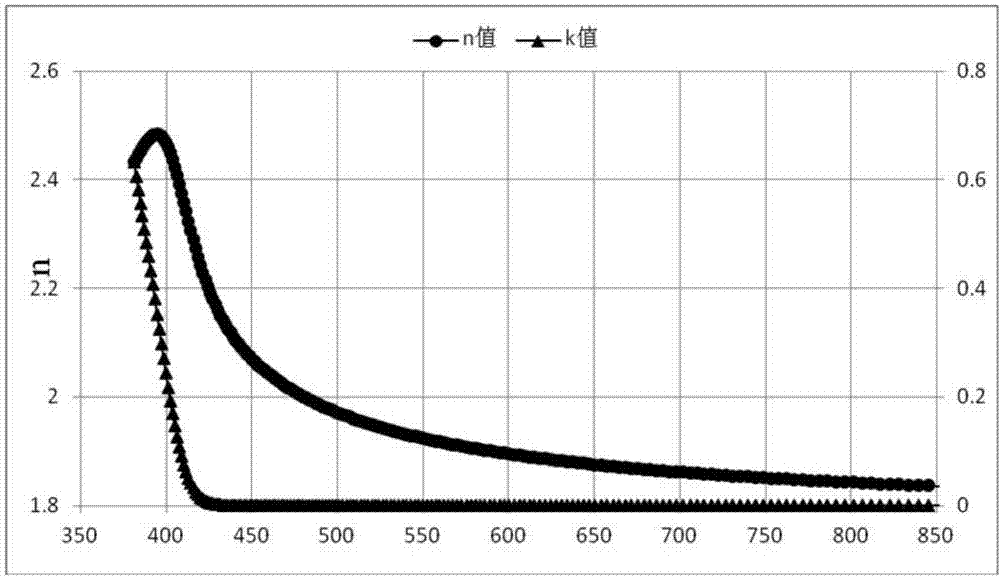

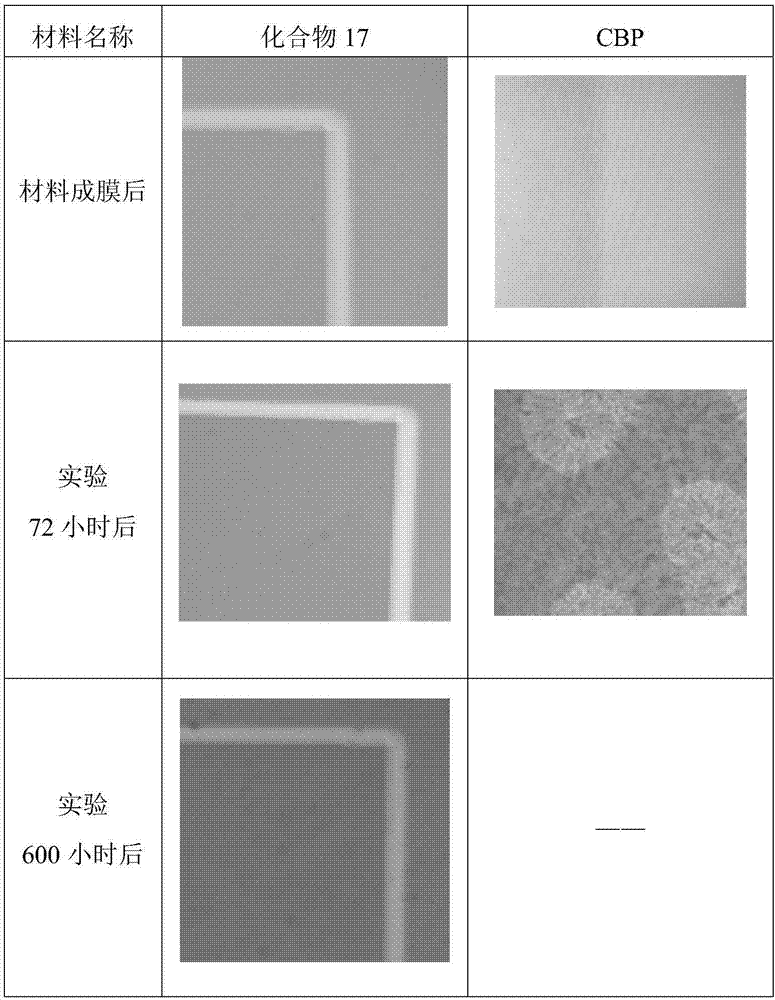

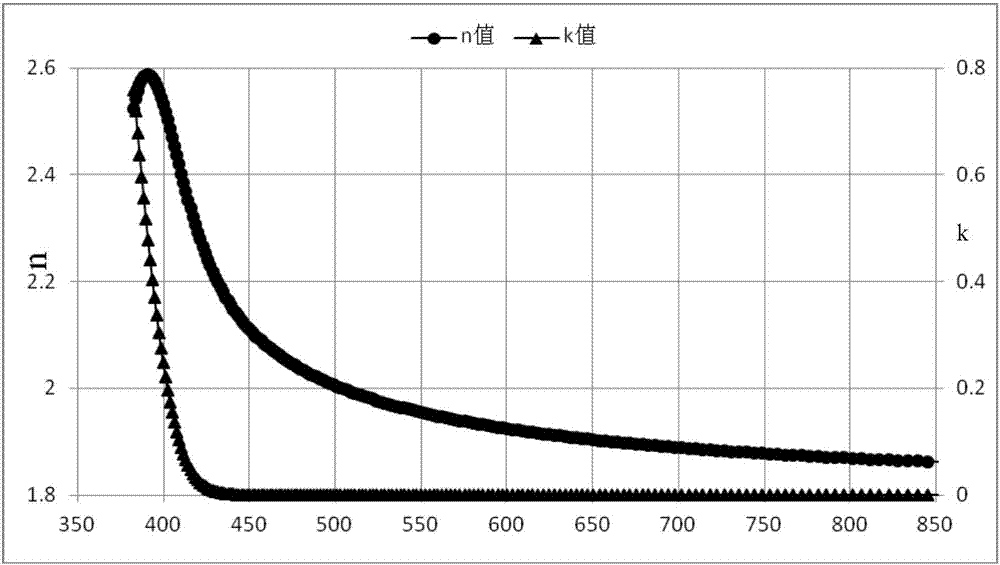

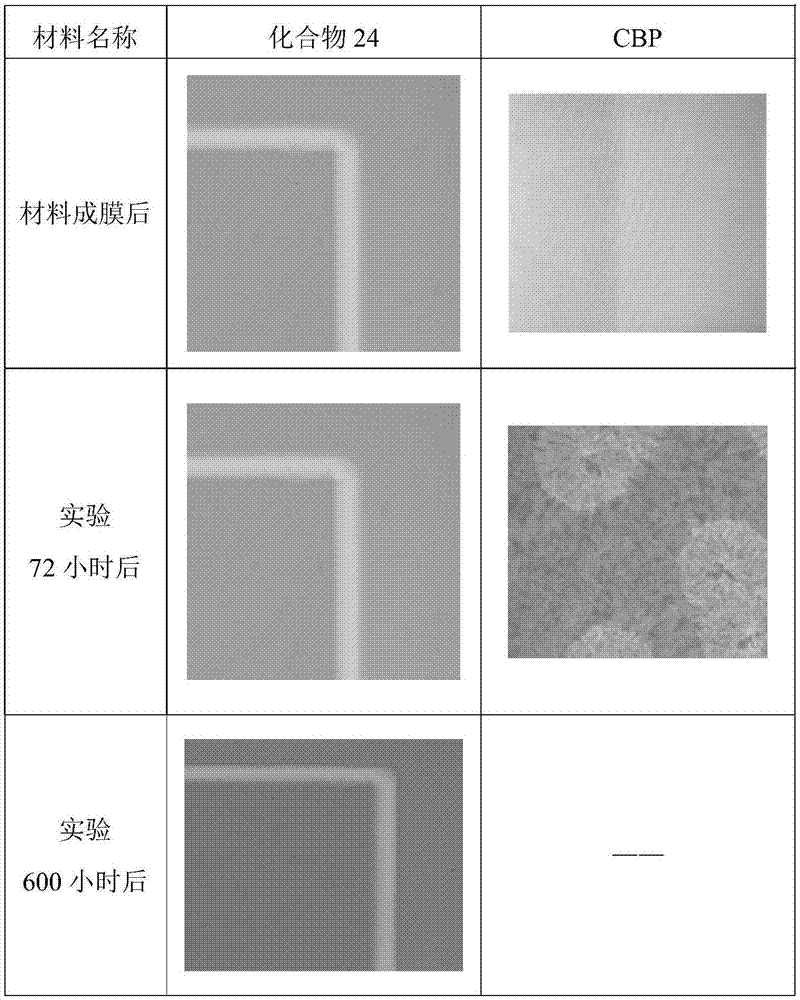

The invention discloses an organic compound based on heteroaryl amine structure and application thereof to an OLED (Organic Light Emitting Diode). The compound structurally contains heteroaryl and benzo-heteroaryl amine structures at the same time, has relatively shallow LUMO energy stage, relatively high glass transition temperature and molecular thermal stability; the absorption in the visible light field is low; the refractive index is high; after the organic compound is applied to the CPL layer of the OLED device, the light extraction efficiency of the OLED device can be effectively improved.

Owner:JIANGSU SUNERA TECH CO LTD

Heteroaryl amine structure based organic compounds and applications thereof

ActiveCN109824659AShallow LUMO levelImprove stabilityOrganic chemistrySolid-state devicesRefractive indexThermal stability

The invention discloses heteroaryl amine structure based organic compounds and applications thereof. The structure of the organic compounds simultaneously comprises different types of heteroaryl groups and amino groups. The organic compounds have a low LUMO energy level, a high glass transition temperature, and high molecular thermal stability, have low absorption and a high refractive index in the visible light range, and can effectively improve the light emission efficiency of an OLED device, after being applied to the CPL layer of the OLED device.

Owner:JIANGSU SUNERA TECH CO LTD

Medium-high-carbon microalloy non-hardened and tempered steel and controlled forging and cooling process

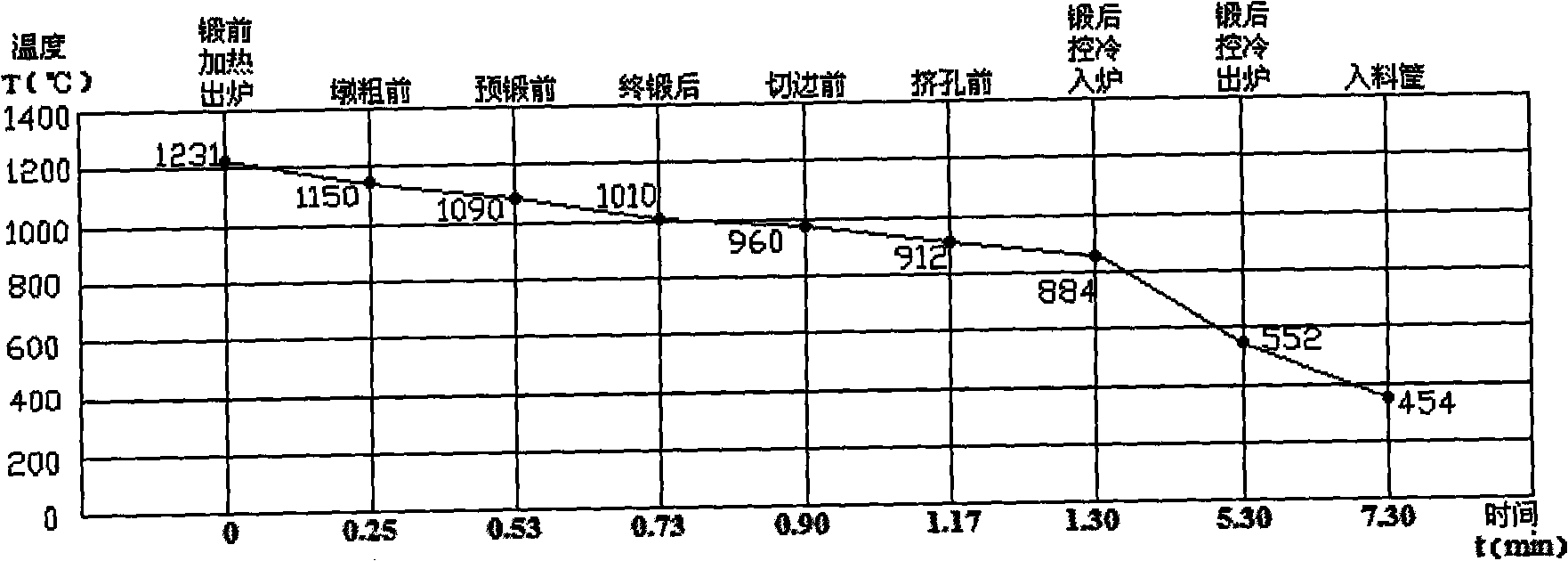

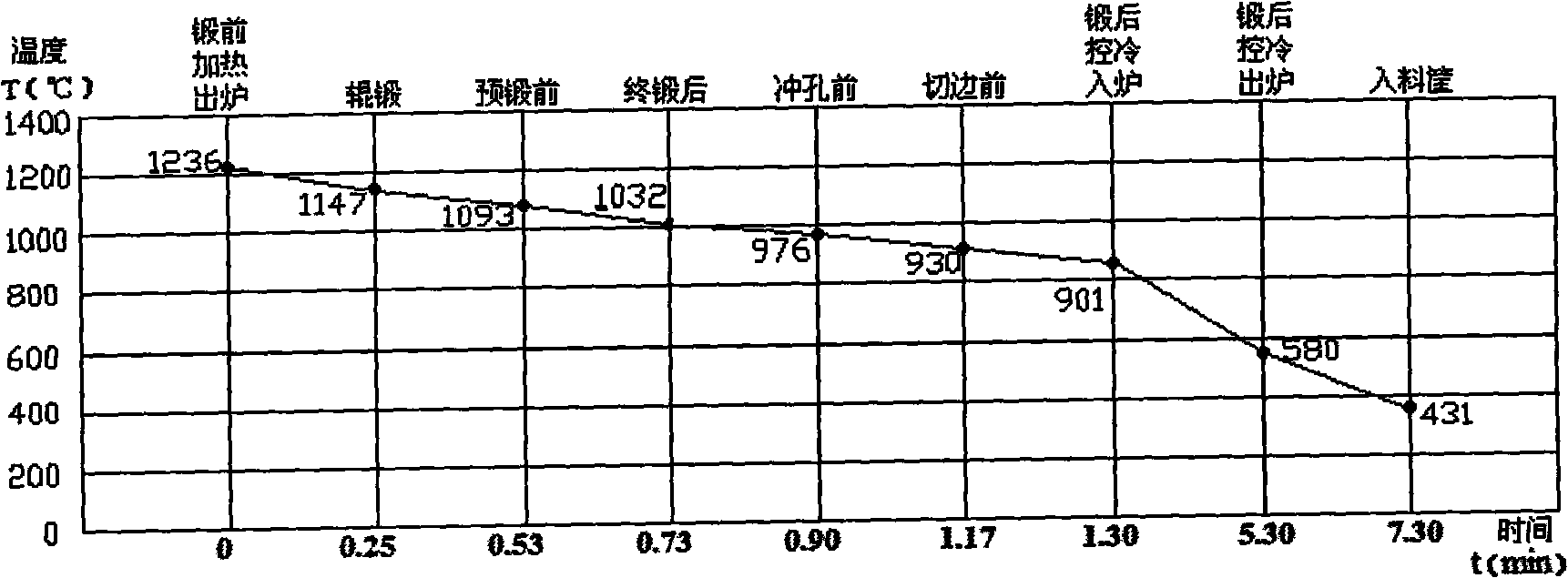

ActiveCN101492787AGood value for moneyIncrease profitFurnace typesHeat treatment furnacesTemperature controlTrace element

The invention discloses composition of medium-and high carbon micro-alloy non quenched and tempered steel. The medium-and high carbon micro-alloy non quenched and tempered steel comprises the following trace elements by the content in total mass: 0.060-0.220% of V, 0.010-0.030% of Ti and 0.020-0.030% of Nb. The invention also discloses a forging-cooling controlled technique method of the micro-alloy non quenched and tempered steel, for example, the method includes the following process: heating before forging, furnace exiting of the heating before forging, widening, preforging, final-forging, trimming cutting, hole extruding, furnace entering of cooling controlling after forging, cooling controlling, furnace exiting of cooling controlling after forging, and charging basket entering. The adoption of the technical proposal aims at producing products satisfying mechanical property by a temperature controlled cooling method without post heat treatment in the casting process.

Owner:WUHU SANLIAN FORGING CO LTD

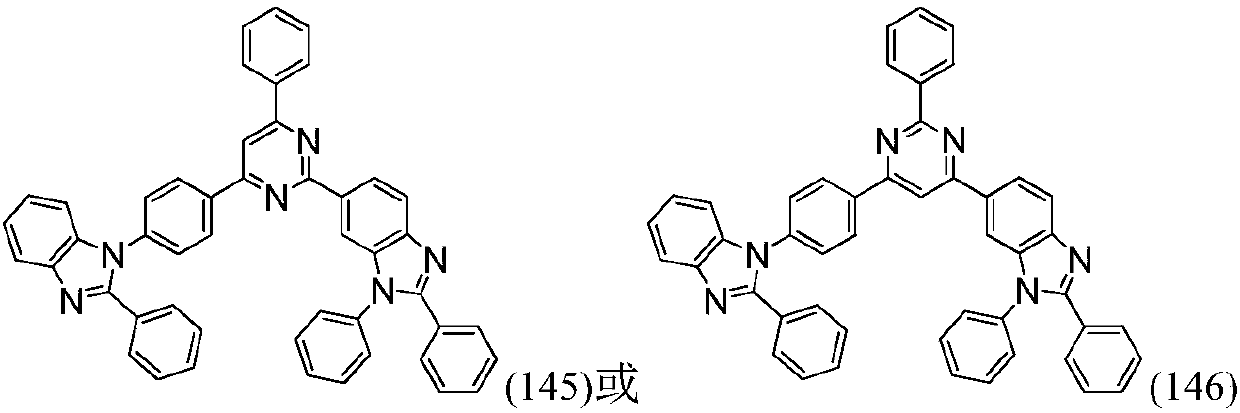

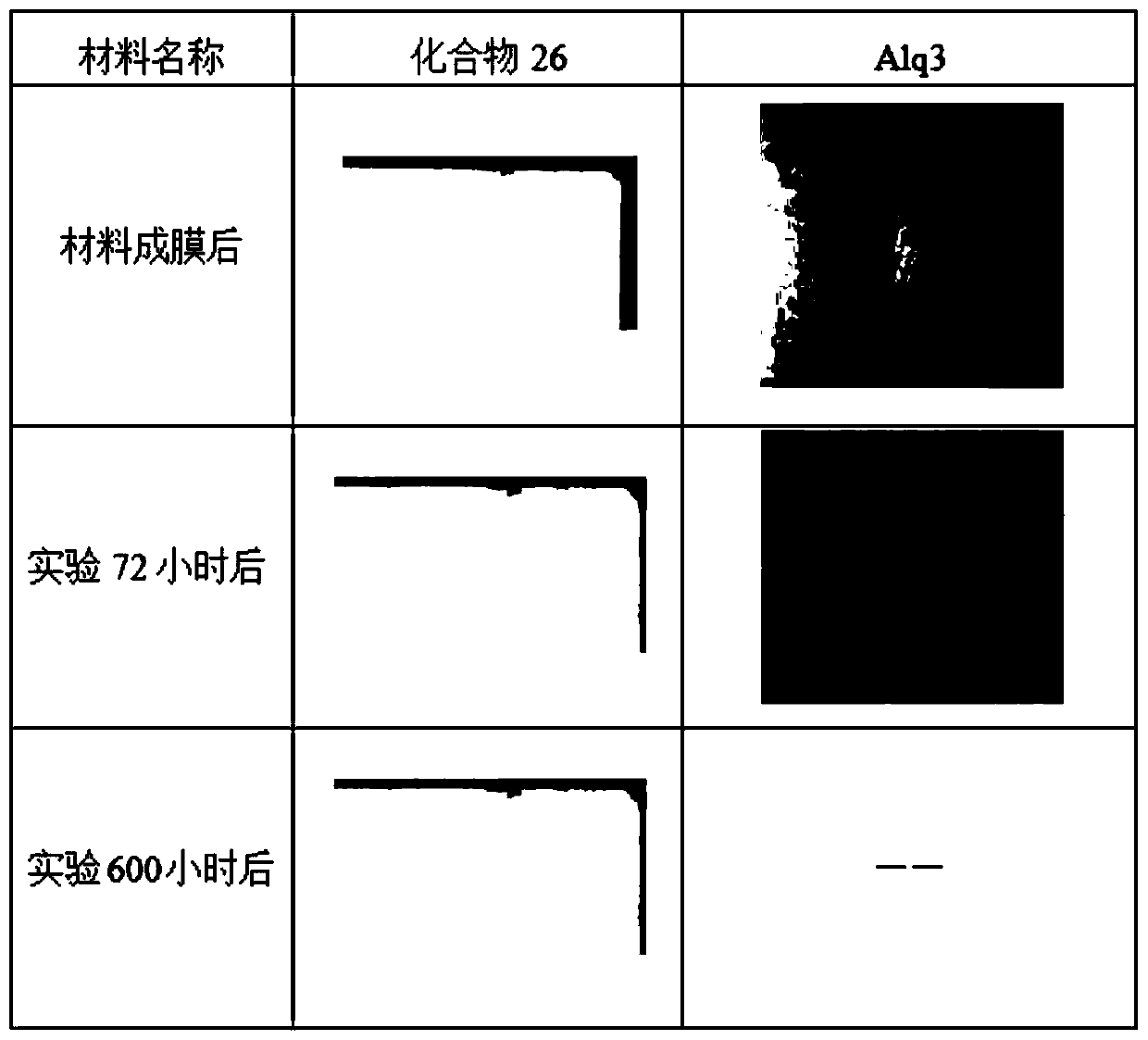

Organic compound based on triazine and benzimidazole and application thereof to organic light-emitting diode (OLED) device

ActiveCN106946853APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesRefractive indexAbsorption rate

The invention relates to an organic compound based on triazine and benzimidazole and application thereof to an organic light-emitting diode (OLED) device. The compound disclosed by the invention has a high vitrification temperature and high molecular thermal stability; the compound has a low absorption rate and a high refraction rate in the field of visible light, and can be applied to a CPL (Circular-Polarizing Filter) layer of the OLED device to effectively increase the light output efficiency of the OLED device; the compound also has a deep HOMO (Highest Occupied Molecular Orbital) energy level and a high electron mobility, can be taken as a hole-blocking / electron transport layer material of the OLED device, and can effectively block holes or prevent energy from being transported from a light-emitting layer to one side of an electron layer, so that the compound efficiency of the holes and electrons on the light-emitting layer is increased, and the light-emitting efficiency and the service life of the OLED device are increased and prolonged.

Owner:JIANGSU SUNERA TECH CO LTD

Organic compound based on triazine and application thereof to organic electroluminescence device

ActiveCN109206420APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesElectronic transmissionRefractive index

The invention relates to an organic compound based on triazine and application thereof to an OLED (Organic Light Emitting Diode) device. The compound has high glass transition temperature and molecular thermal stability; in the visible light field, the absorption is low; the refraction index is high; after the compound is applied to a CPL layer of the OLED device, the light taking-out efficiency of the OLED device can be effectively improved. The compound also has deep HOMO energy level and high electronic mobility and can be used as a hole blocking / electronic transmission layer material of the OLED device; holes or energy can be effectively blocked from being transmitted from the luminescent layer to one side of the electronic layer, so that the compounding efficiency of holes and electrons in the luminous layer is improved; further, the luminous efficiency of the OLED device is improved; the service life of the OLED device is prolonged.

Owner:JIANGSU SUNERA TECH CO LTD

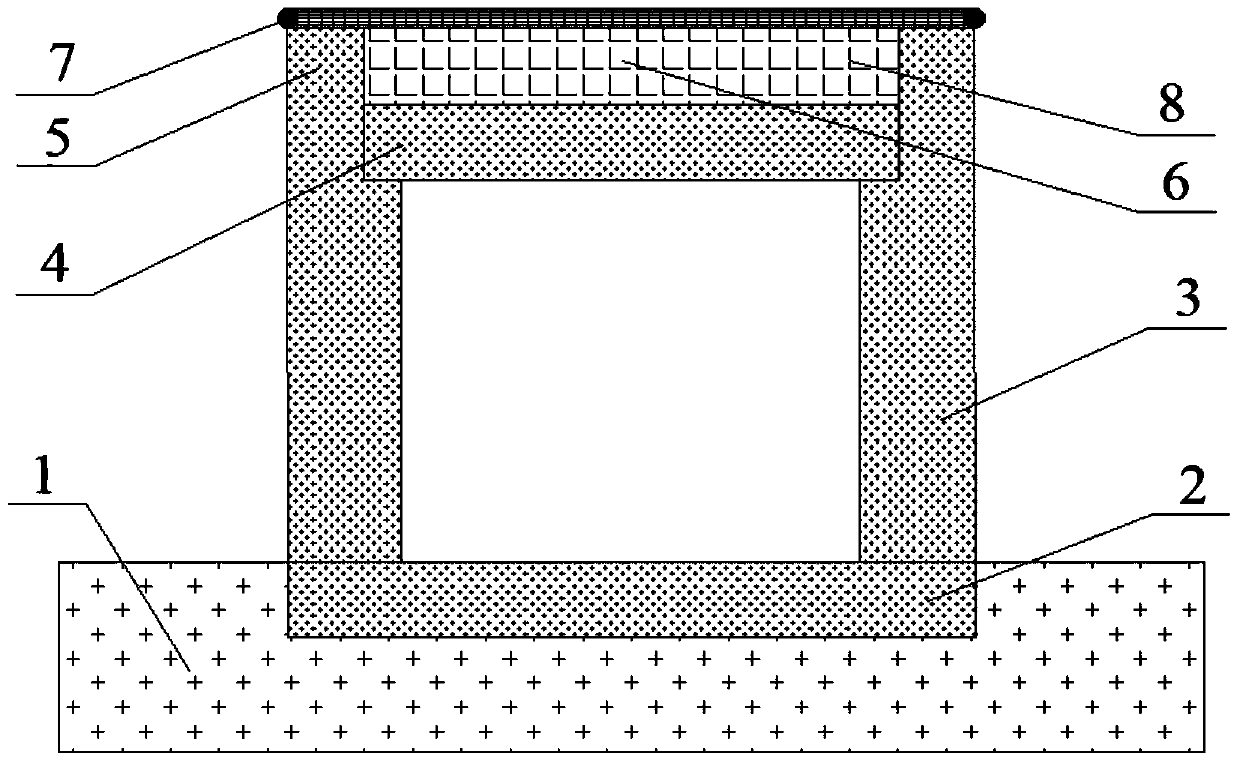

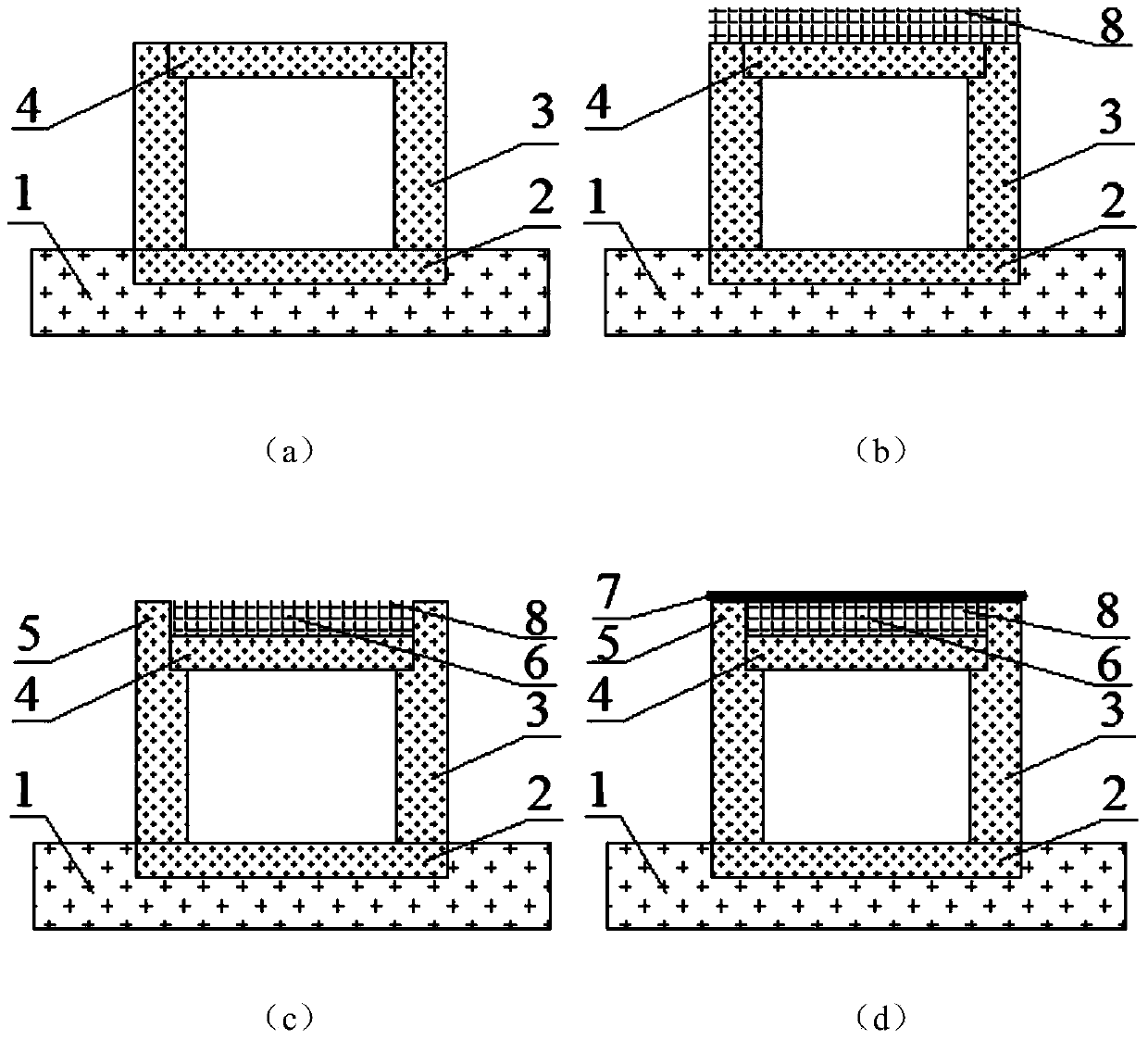

Load-shedding type rigid culvert structure

InactiveCN103952986AReduce the maximum bending momentRelieve pressureGround-workLoad SheddingStress distribution

The invention relates to the technical field of geotechnical engineering and road engineering, and particularly discloses a load-shedding type rigid culvert structure, which comprises a foundation, culvert side walls, a culvert top plate, load-shedding blocks and load-shedding holes, wherein the load-shedding blocks are positioned just above the culvert side walls, and form an integral structure together with the culvert side walls, the load-shedding holes are positioned between the two load-shedding blocks just above a culvert, and the interior of each load-shedding hole is filled with light-weight flexible material. The culvert structure has the advantages that after the structure is adopted, the construction and operation are easy and convenient, and the implementation is easy; the pressure of soil at the top of the culvert is obviously reduced, and the problem of cracking of the culvert is effectively solved; one part of load at the top of the culvert is transferred into the surrounding soil through the soil arch effect at the top of the culvert, the other part of load is transferred to the foundation through the culvert side walls, and then the vertical compressive capability of the culvert side walls is fully realized; the maximum bending moment of the culvert side walls is effectively reduced, and the stress distribution of the culvert is more reasonable; the stress asymmetry of the culvert is effectively reduced, and the separation and cracking of the connecting part of the top of the culvert and the side wall are avoided; the load-shedding effect is obviously improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

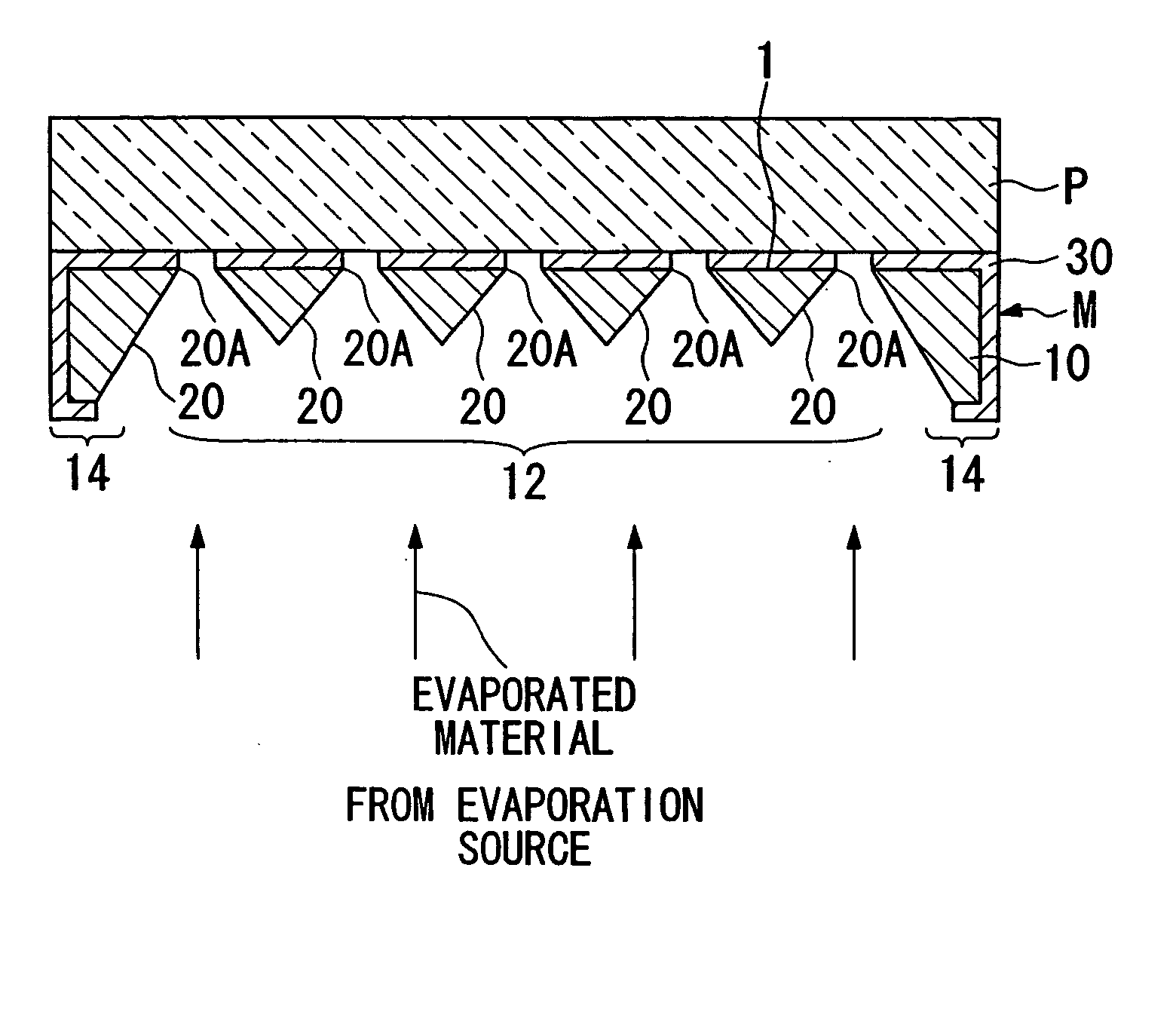

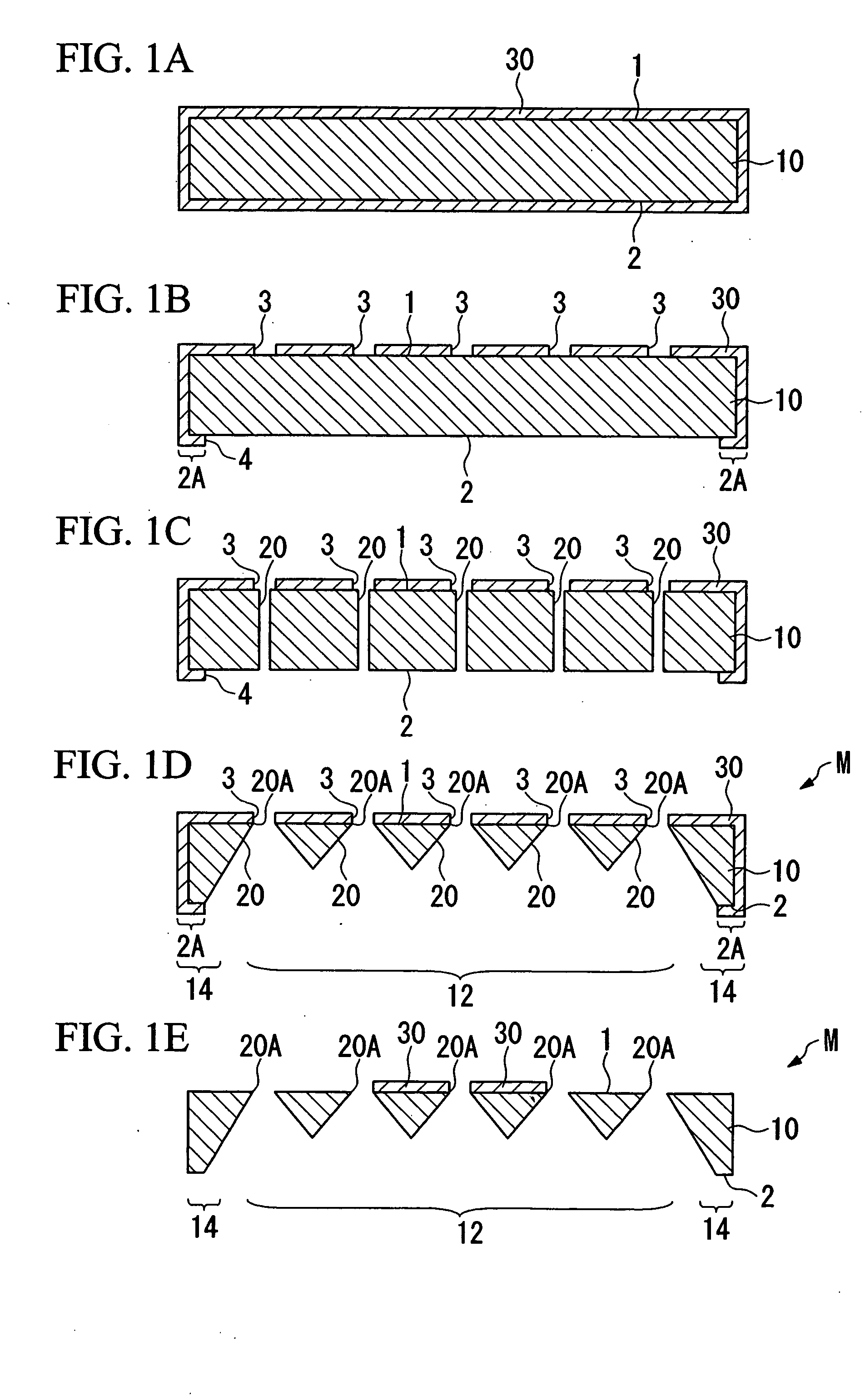

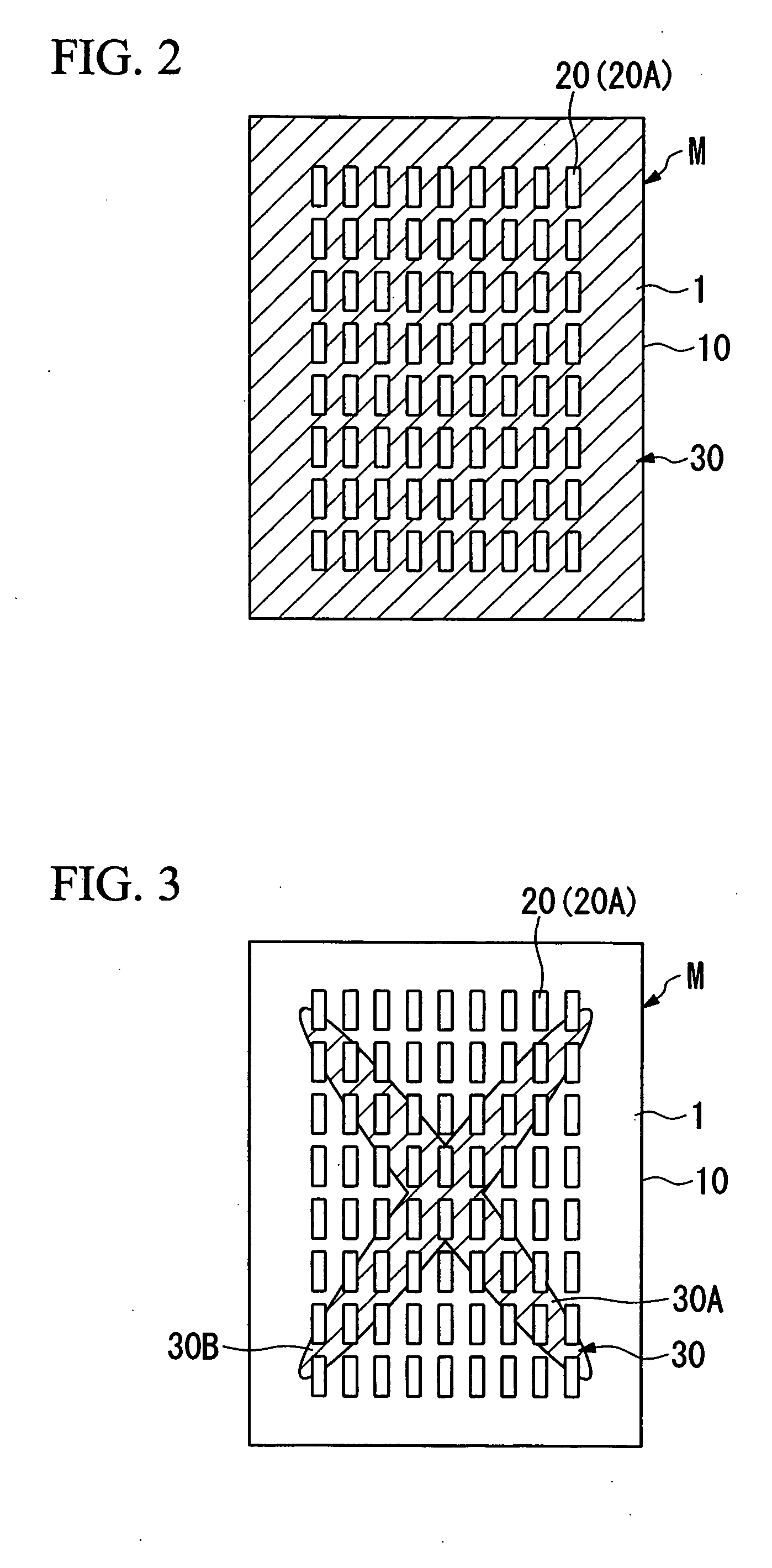

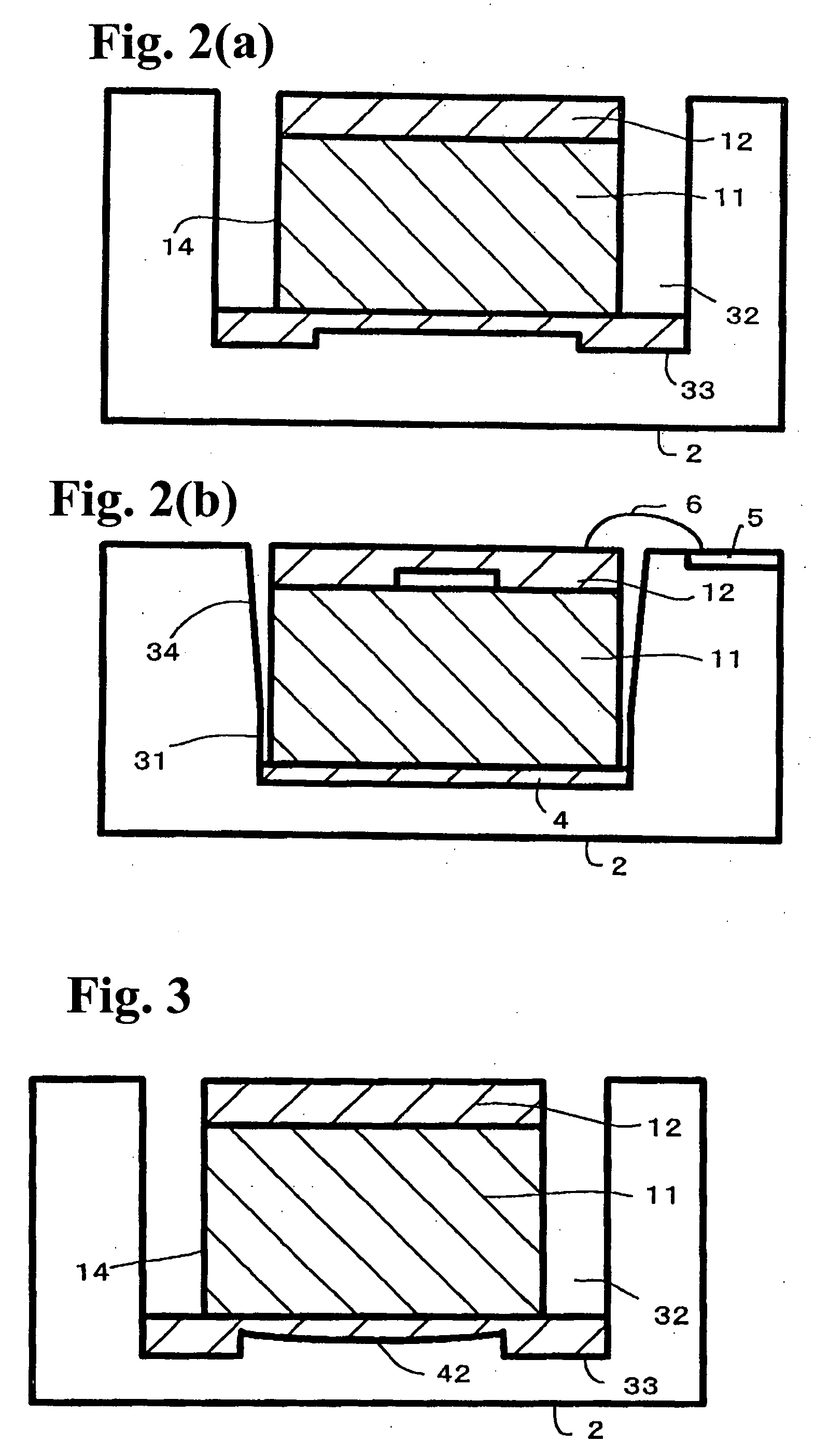

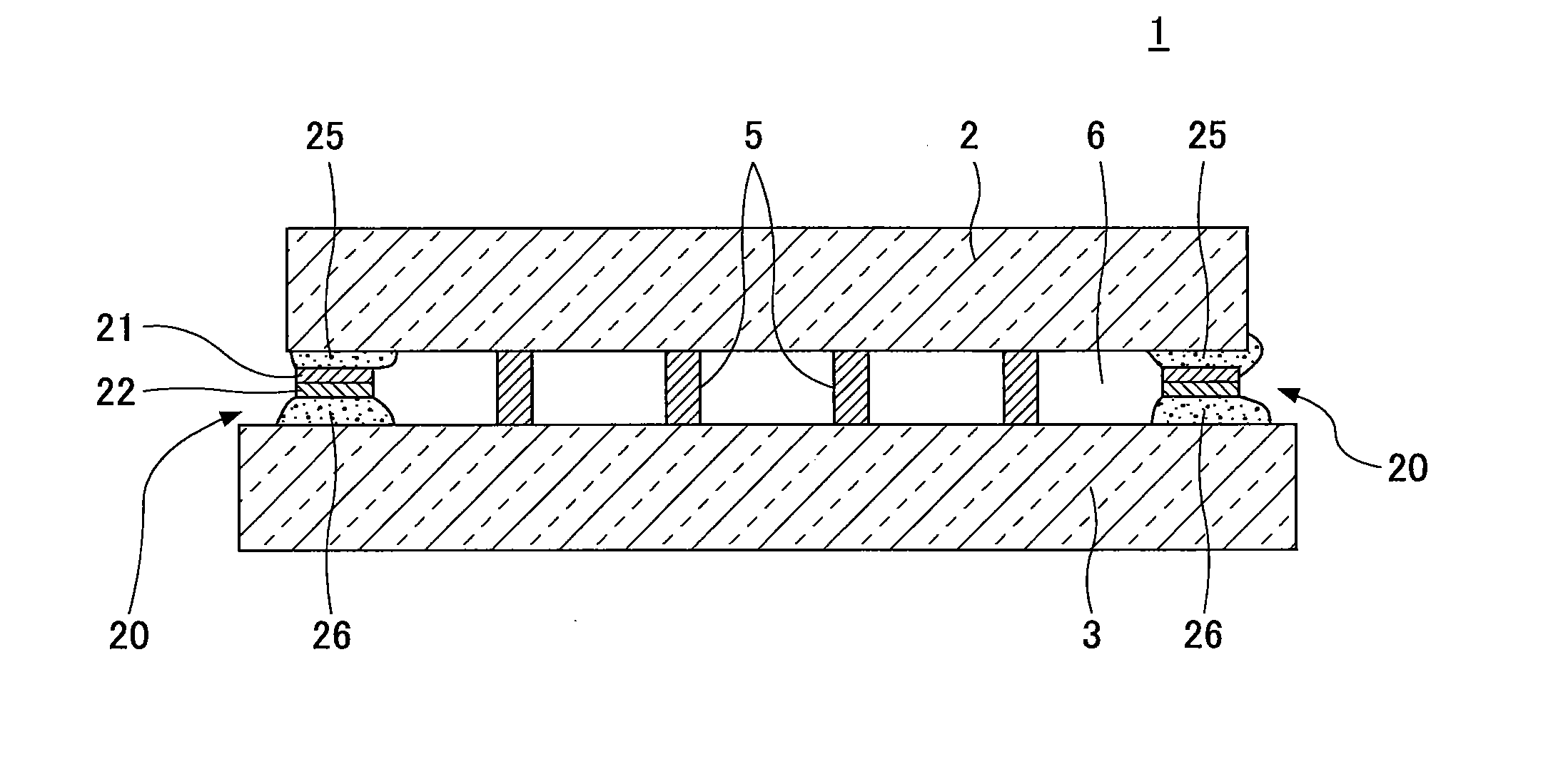

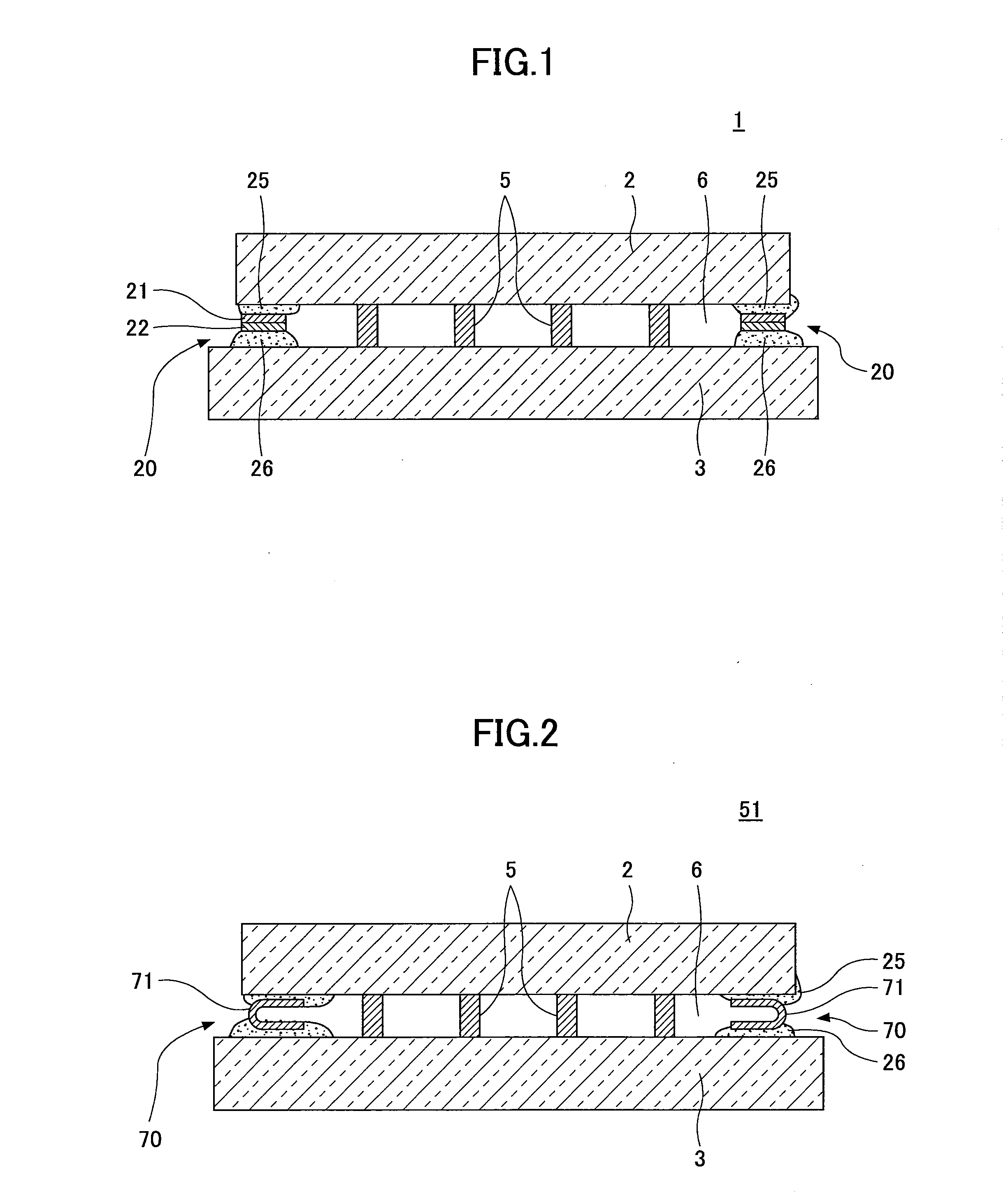

Mask and method for manufacturing the same, method for manufacturing display, method for manufacturing organic electroluminescent display, organic electroluminescent device, and electronic device

InactiveUS20050123676A1Improve the display effectHigh quality displaySemiconductor/solid-state device detailsElectroluminescent light sourcesEngineeringOrganic electroluminescence

A mask includes a substrate which includes a front side and a back side and is provided with through-holes; and a film which adjusts a shape of the substrate provided above at least one of the front side and the back side of the substrate. A method of manufacturing a mask includes the steps of: providing a substrate having a front side and a back side; forming a film which adjusts a shape of the substrate above at least one of the front side and the back side of the substrate; and drilling through-holes in the substrate.

Owner:SEIKO EPSON CORP

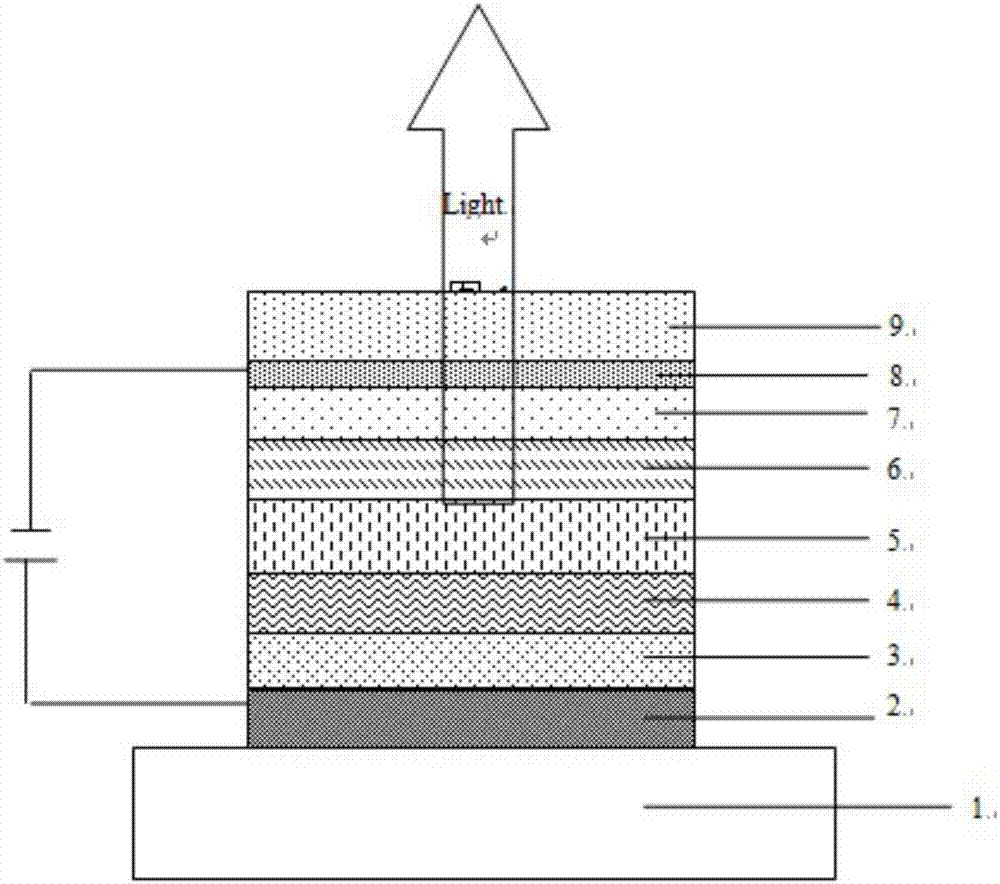

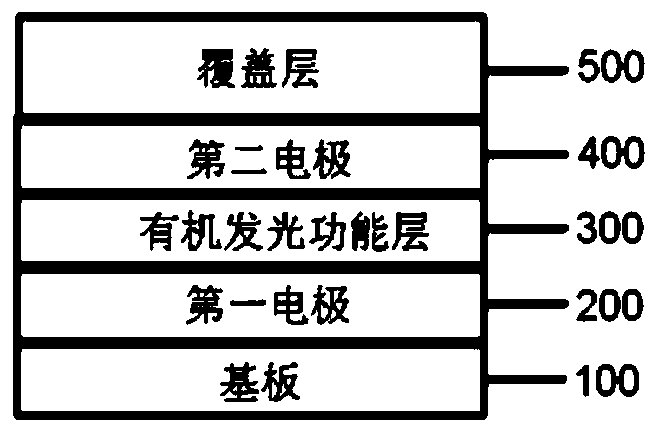

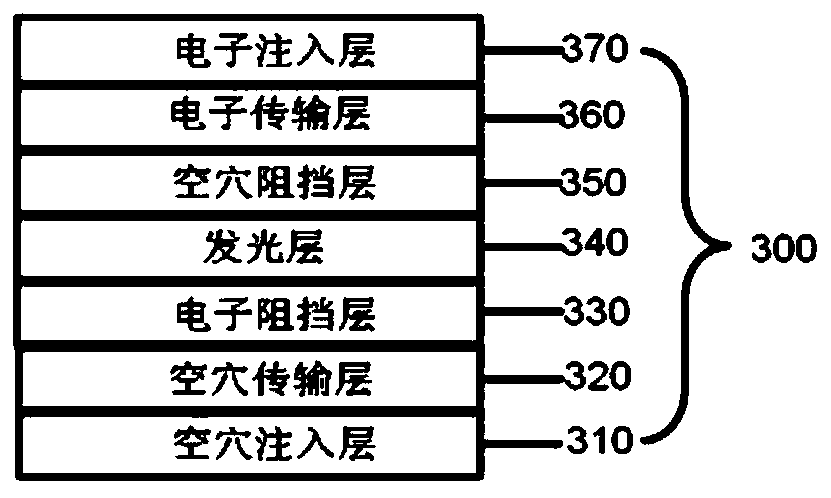

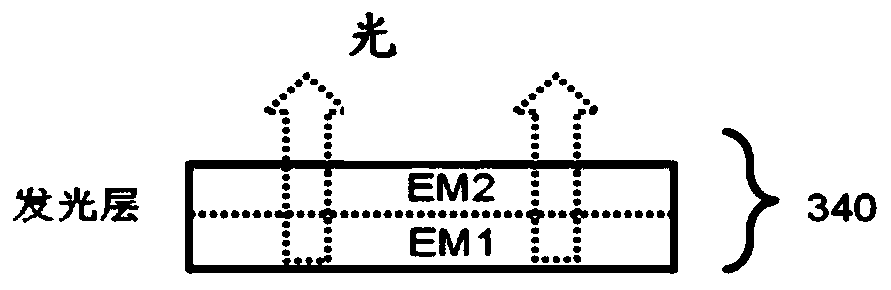

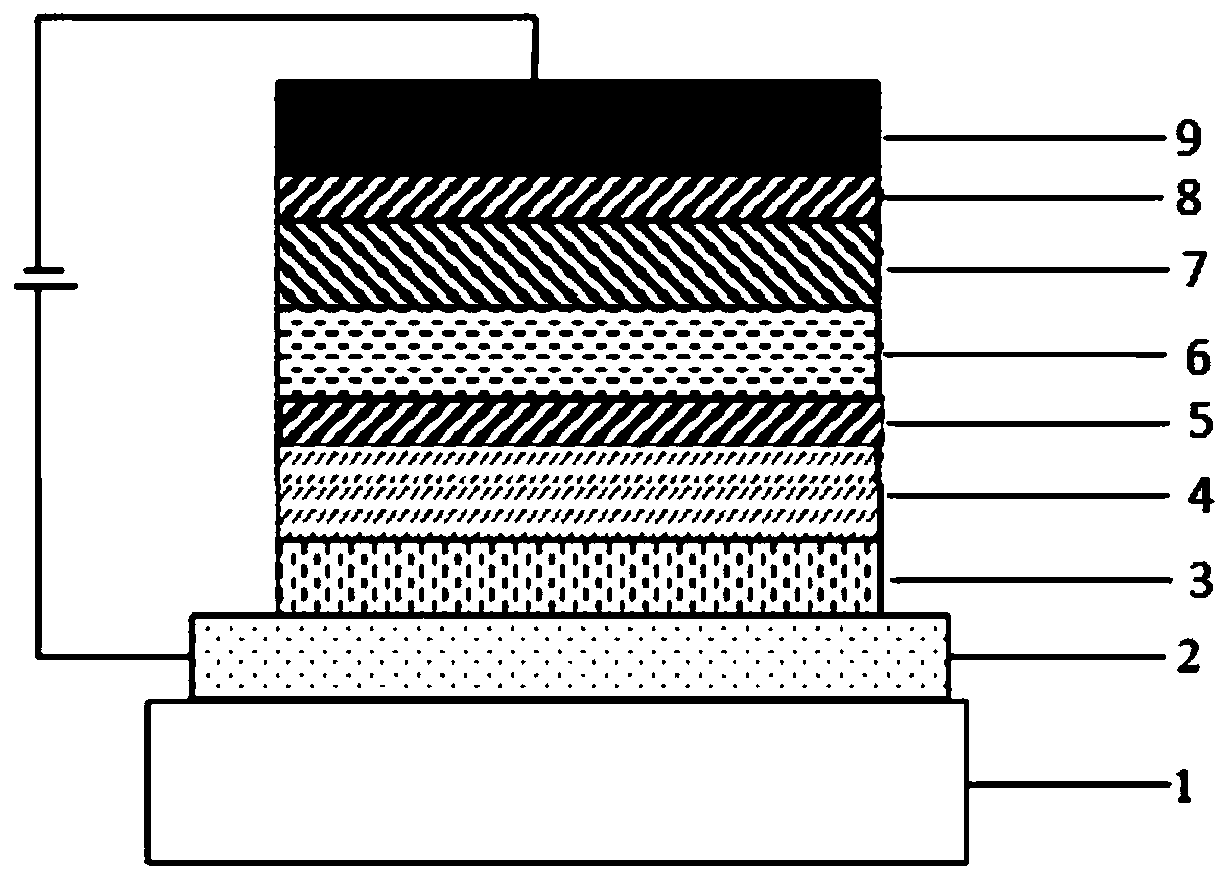

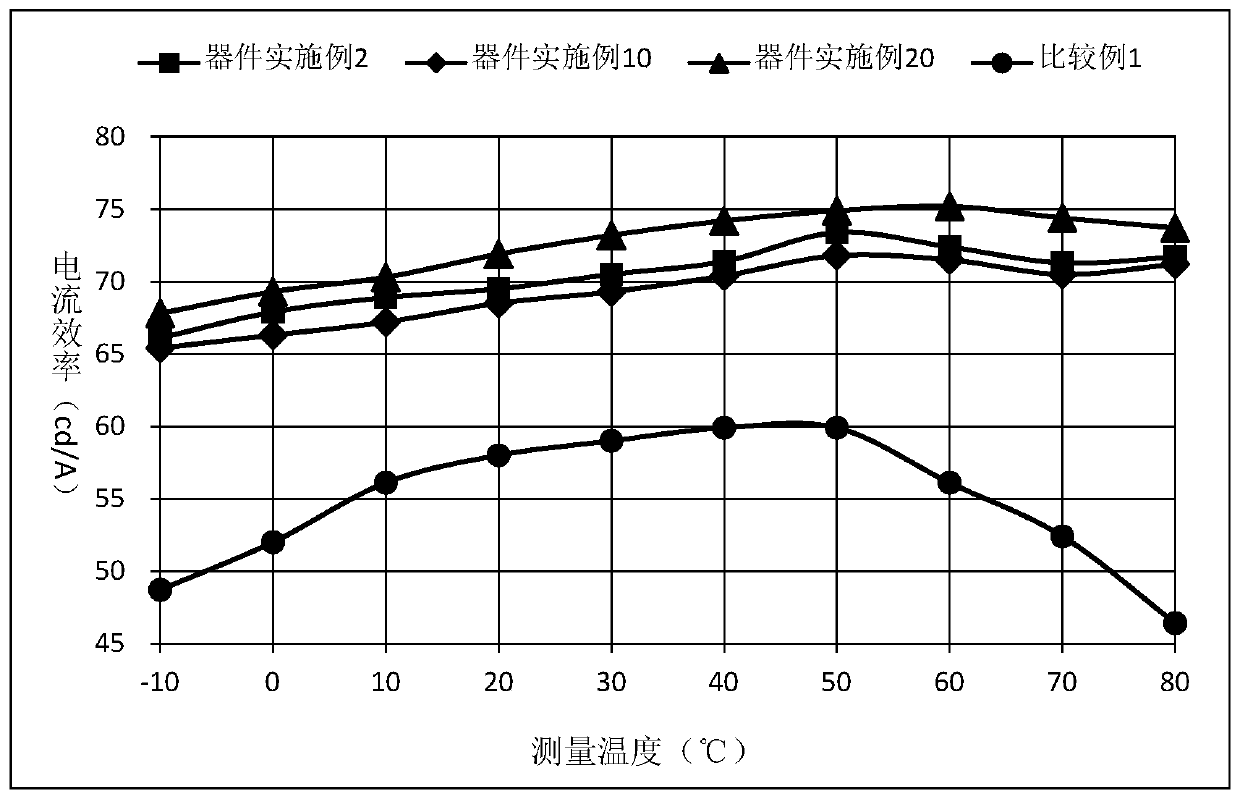

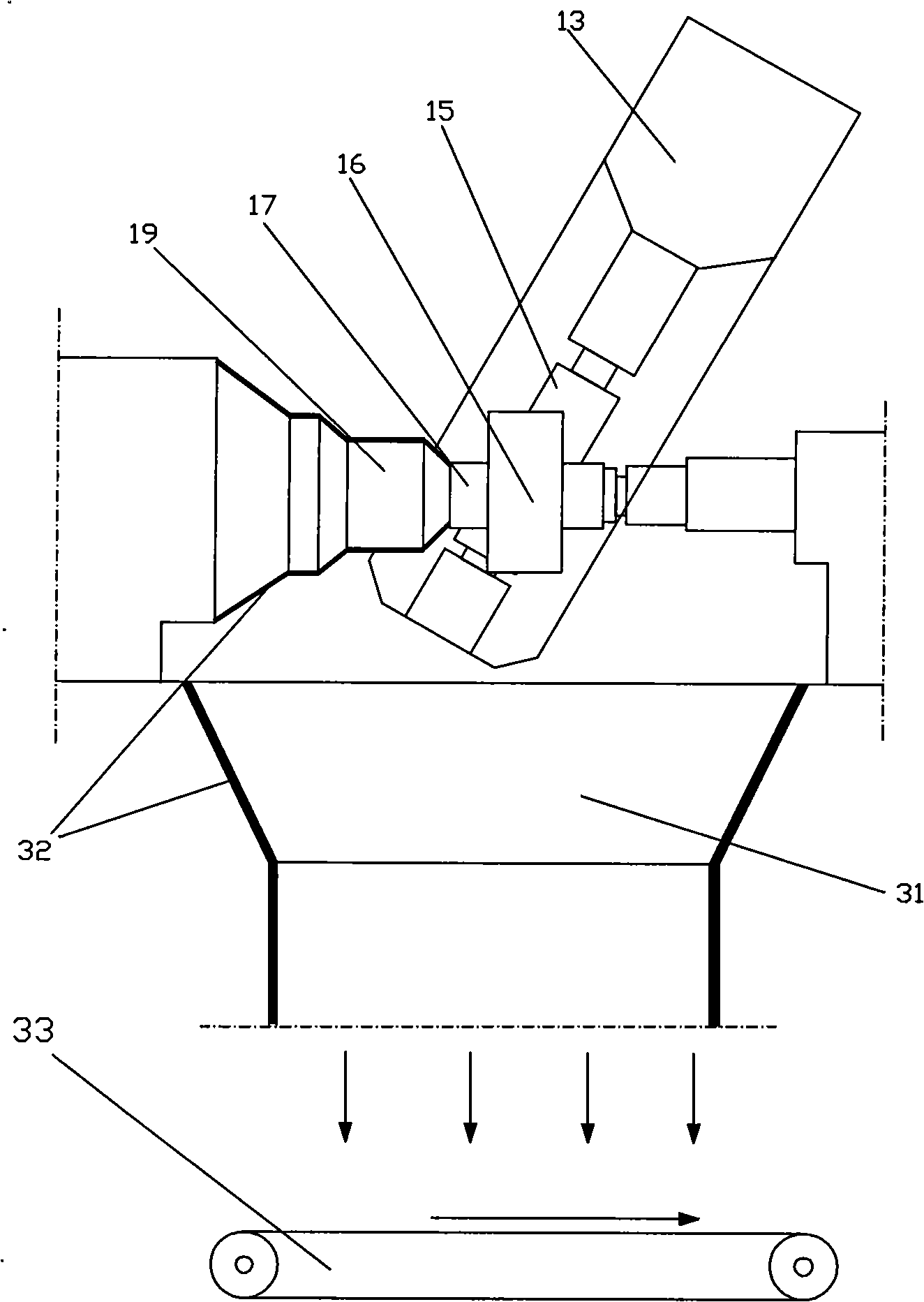

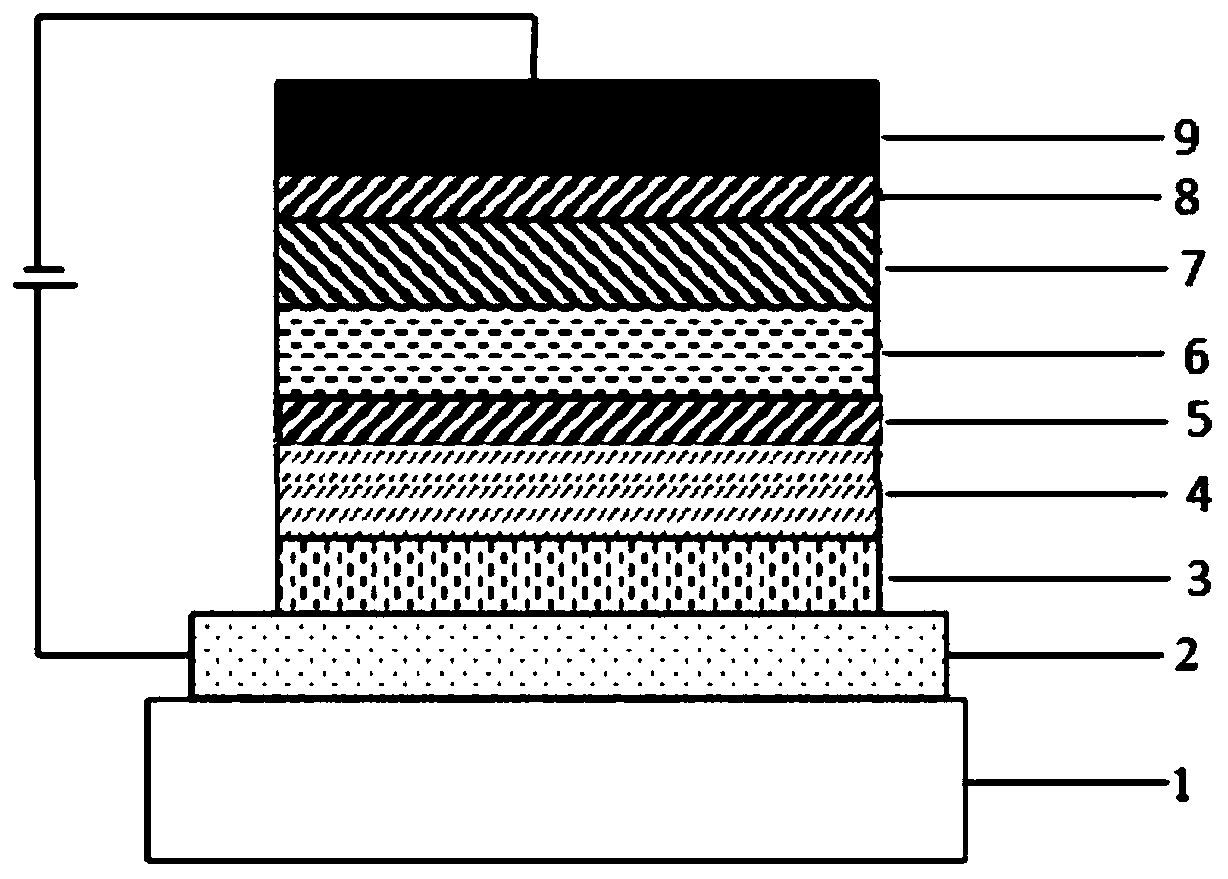

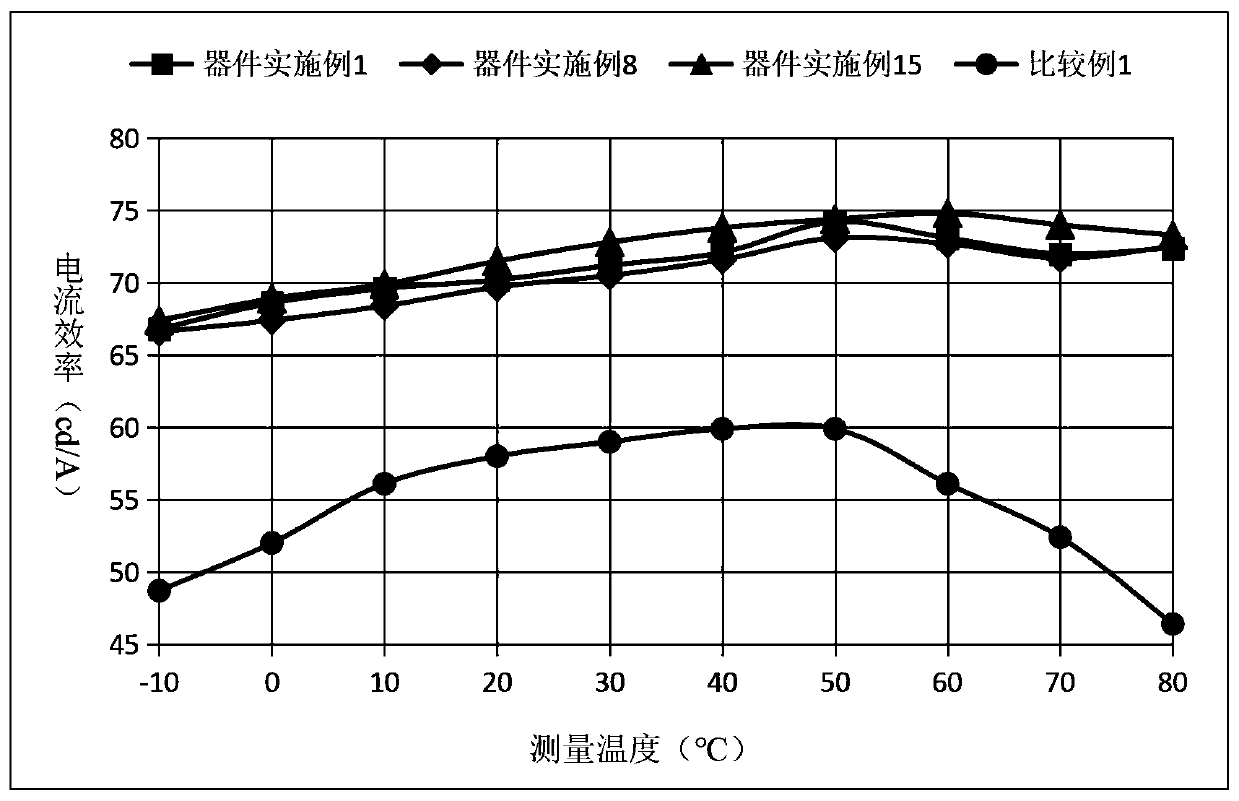

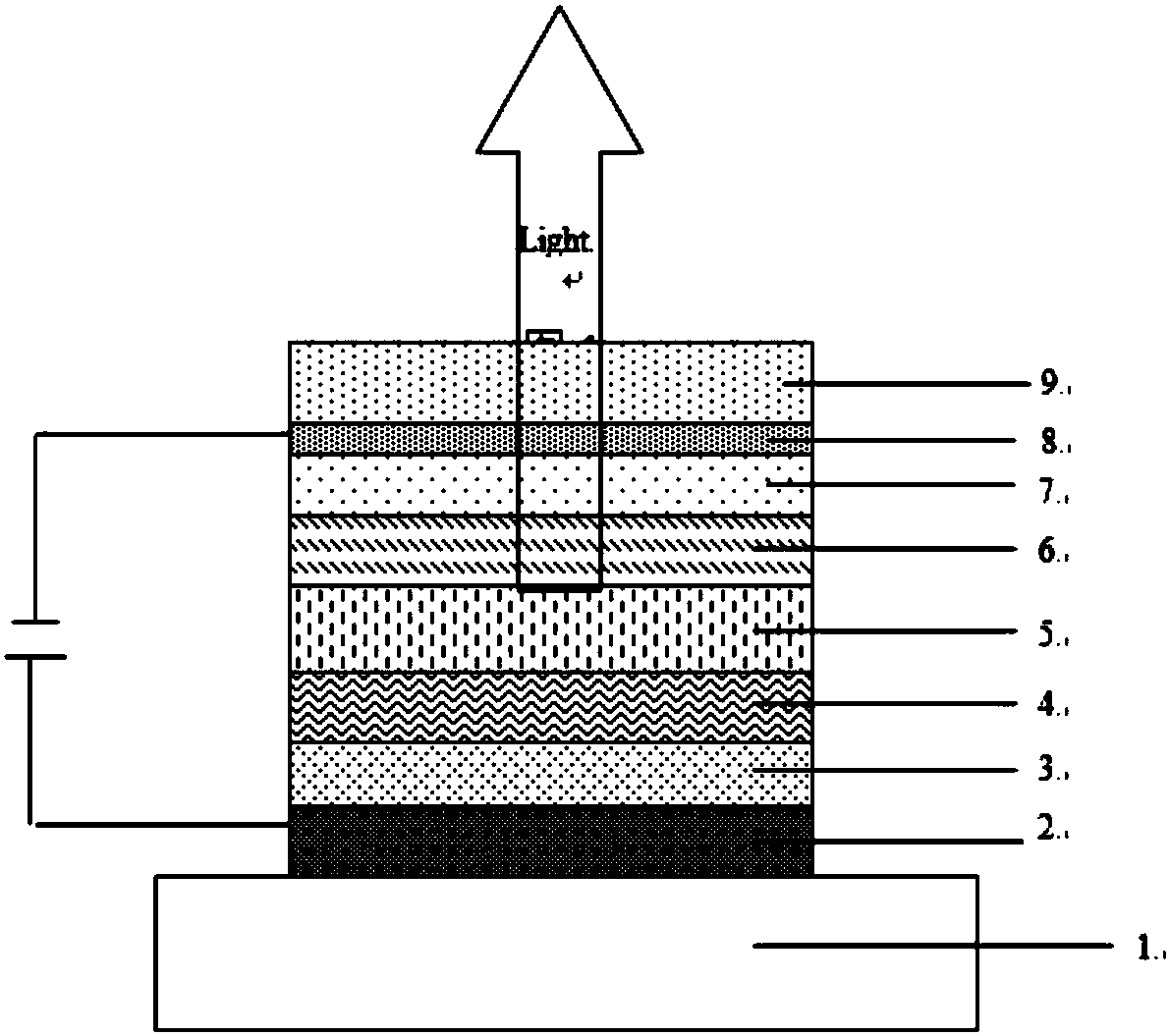

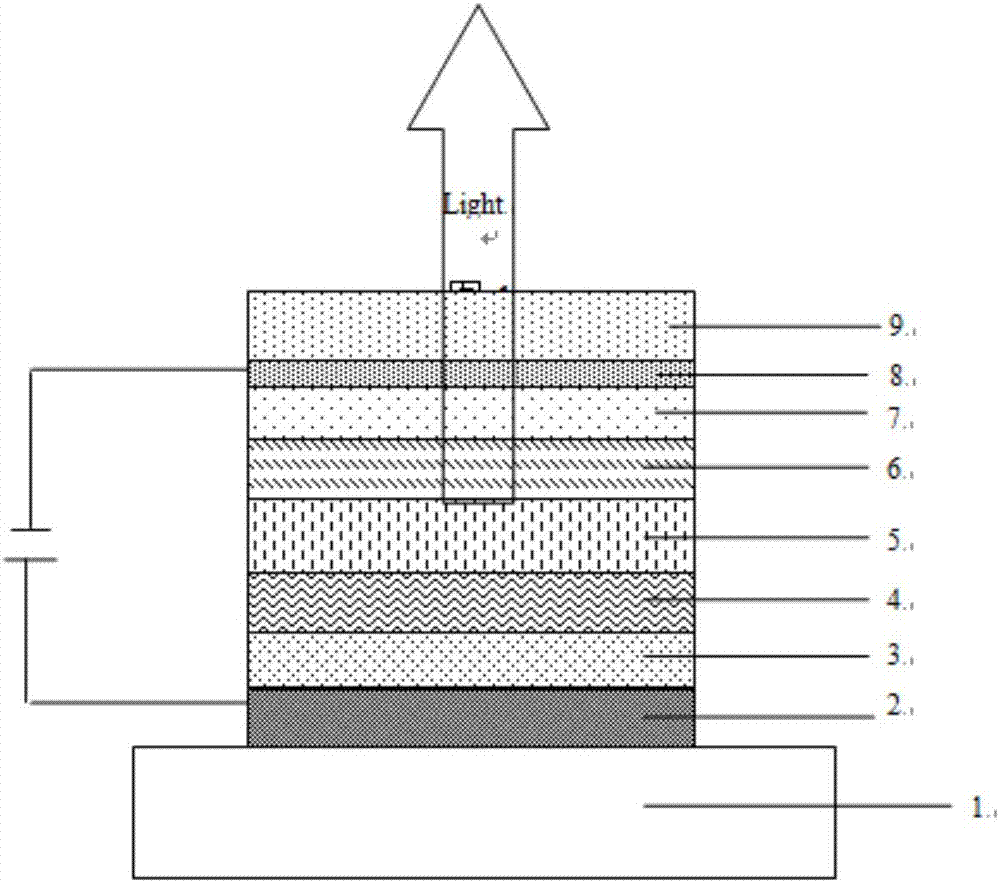

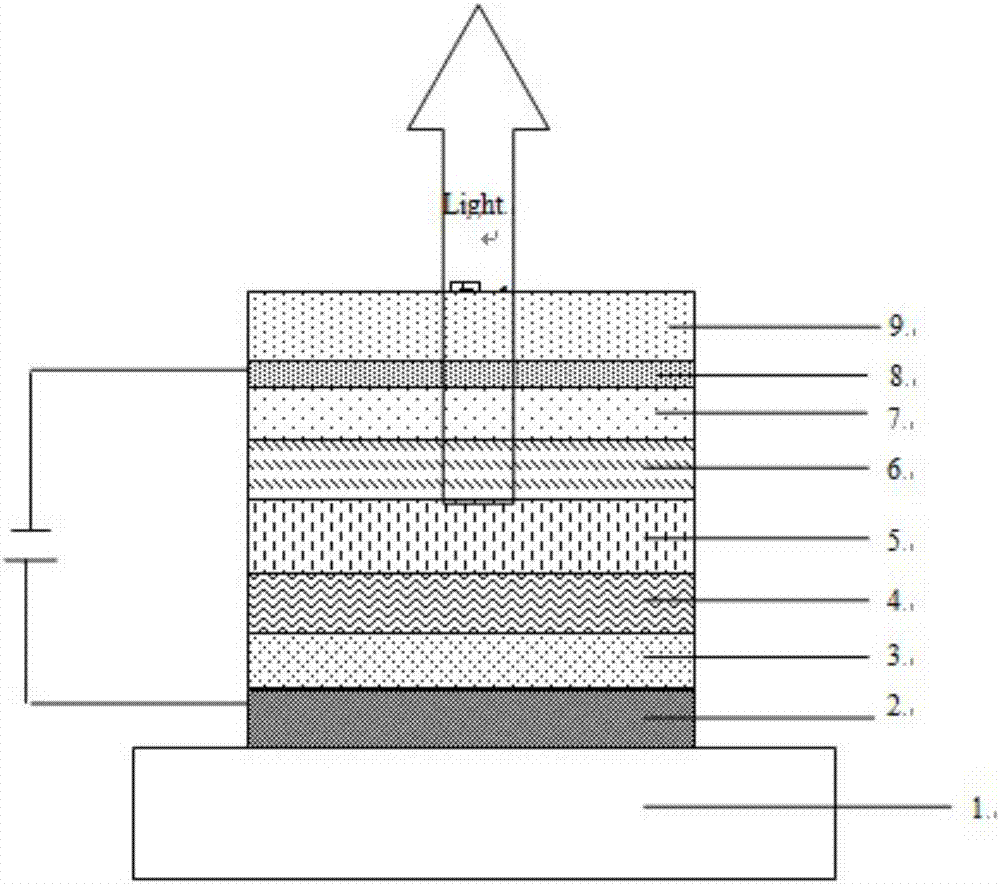

Organic electroluminescent device containing capping layer and application thereof

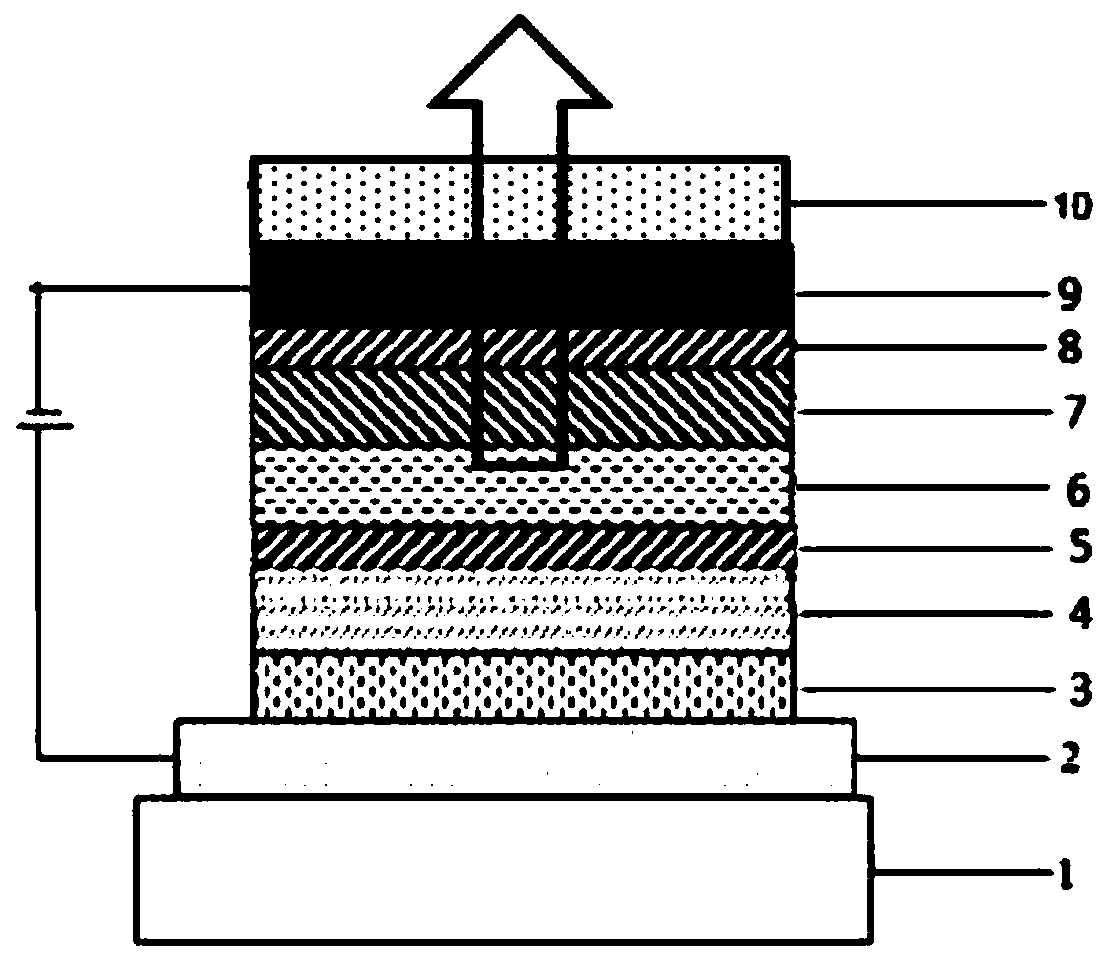

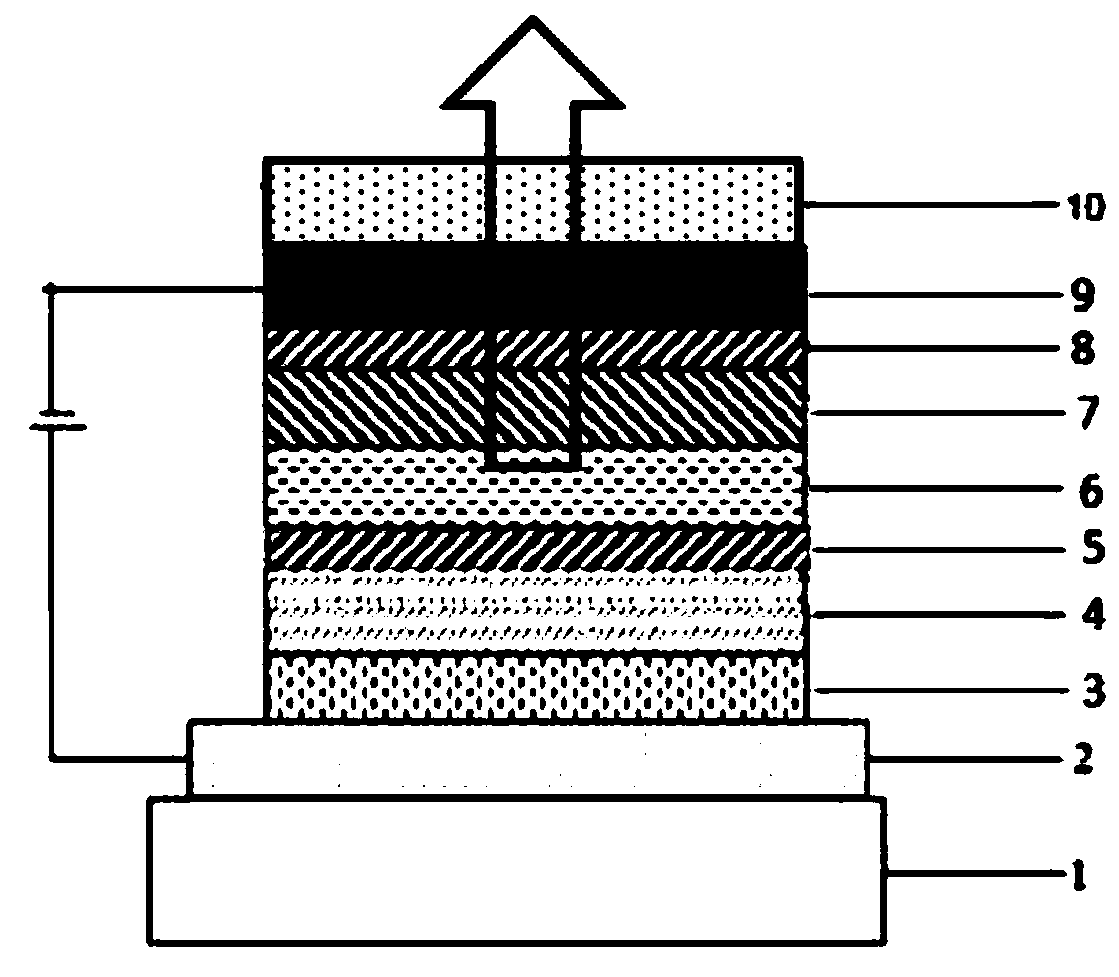

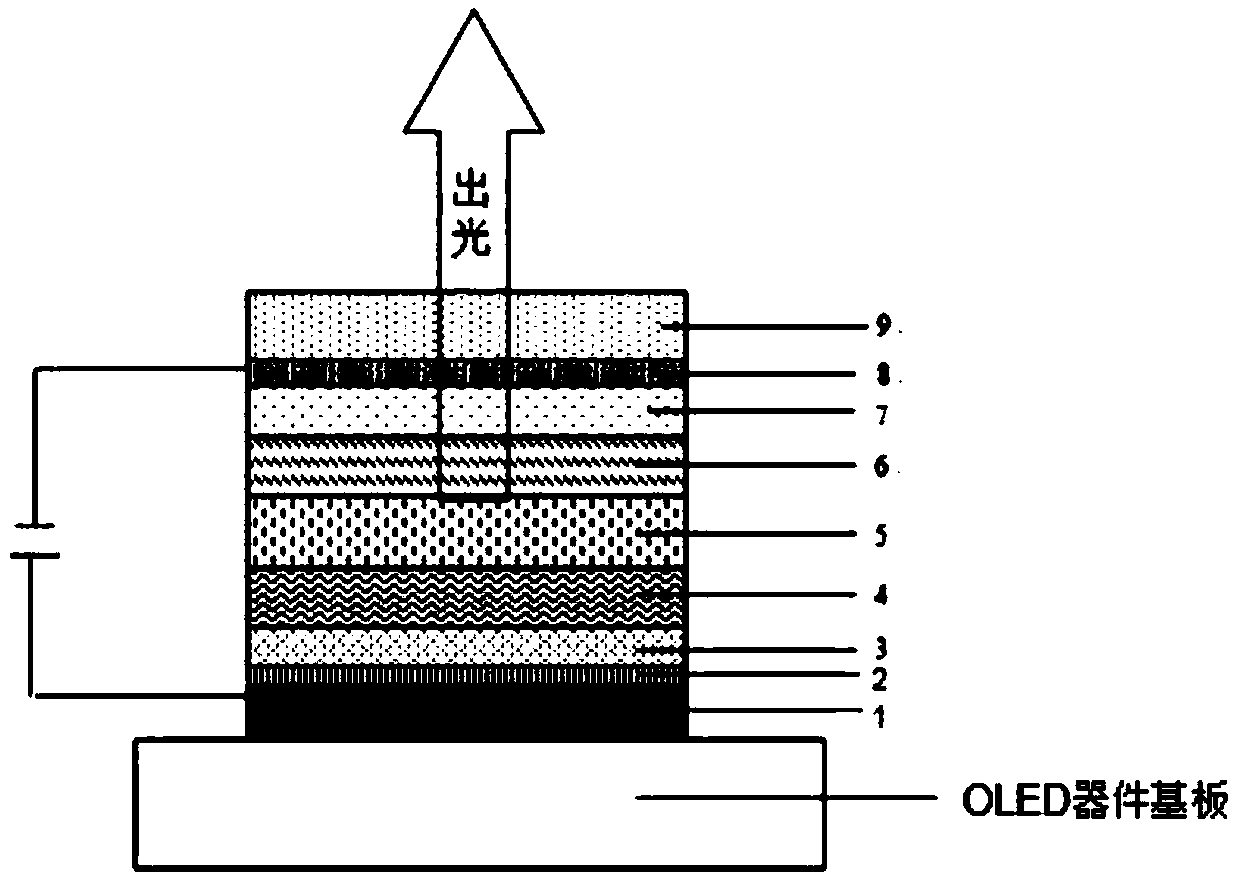

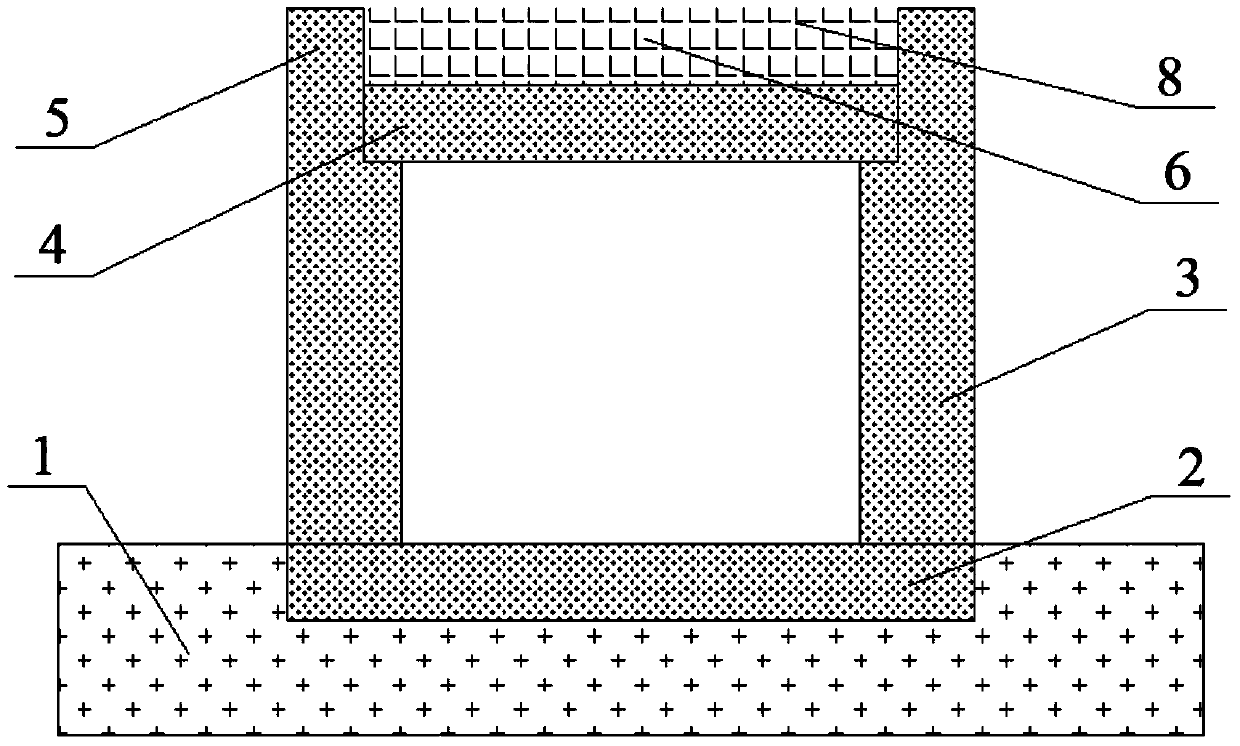

ActiveCN109860425AImprove light extraction efficiencyExcellent viewing angleSolid-state devicesSemiconductor/solid-state device manufacturingSimple Organic CompoundsLight equipment

The invention relates to an organic electroluminescent device containing a capping layer. The organic electroluminescent device containing the capping layer comprises a substrate layer, a first electrode, an organic light emitting functional layer, a second electrode and the capping layer, wherein the first electrode is located on the substrate; the organic light emitting functional layer is located on the first electrode; the second electrode is located on the organic light emitting functional layer; and the capping layer is located on the second electrode, the capping layer comprises an organic compound, the organic compound of the capping layer contains different types of heteroarylamines and has higher glass transition temperature and molecular thermal stability. Low absorption and high refractive index in the visible light field are achieved, and the light extraction efficiency of an OLED device can be effectively improved after the organic electroluminescent device is applied toa CPL layer of an organic light Emission diode (OLED) device. The invention further relates to the application of the organic electroluminescent device containing the capping layer for display or lighting equipment.

Owner:JIANGSU SUNERA TECH CO LTD

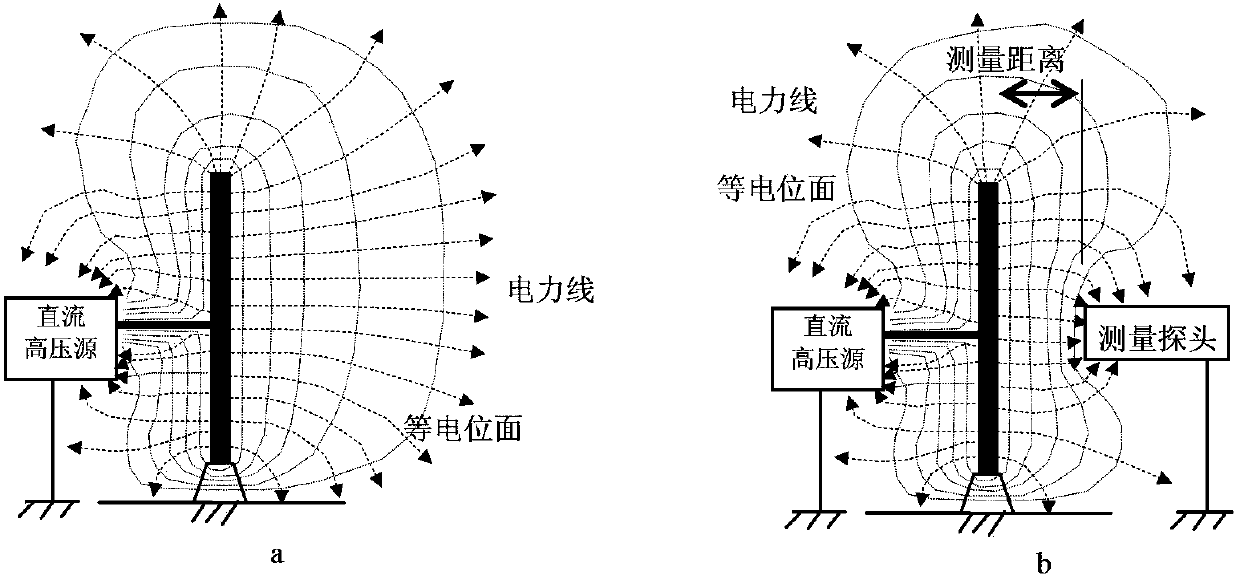

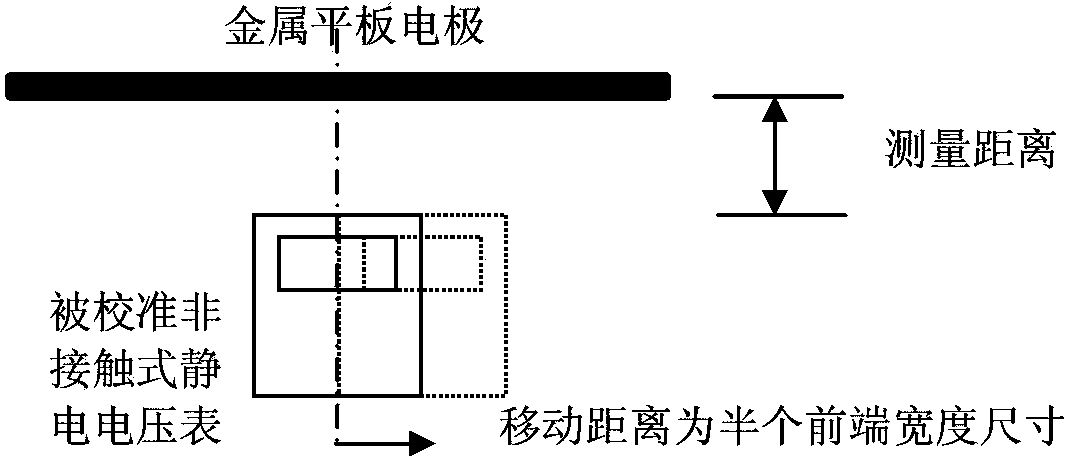

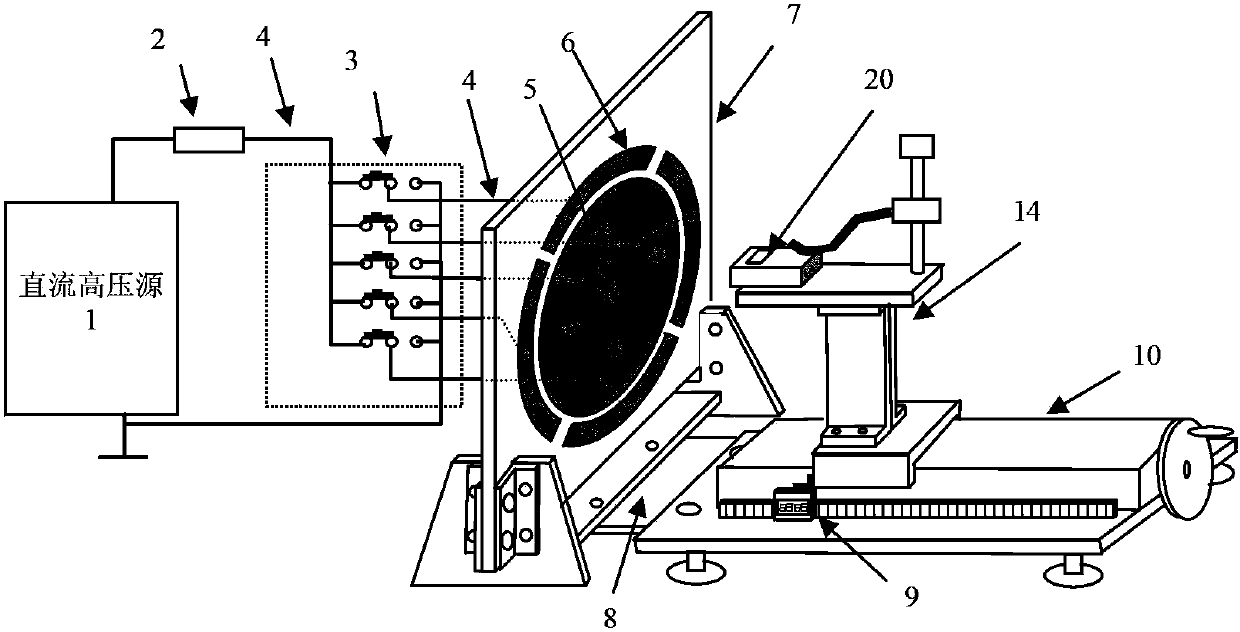

Device and method for calibrating non-contact type electrostatic voltmeter

The invention provides a device and method for calibrating a non-contact type electrostatic voltmeter. The method includes the steps that a direct-current high-voltage power supply and metal plate electrodes are utilized to acquire a standard static filed at local space near the centers of the electrodes, the voltage of the non-contact type electrostatic voltmeter can be traced to the direct-current voltage standard, and an experimental method that the edge effect is increased is adopted to test the edge effect of the metal plate electrodes. The risks that people get an electric shock are reduced through a glass flat plate support which bears the metal plate electrodes and through a protective resistor, and a perpendicular moving mechanism can adjust the test distance of a calibrated meter. A detachable vernier caliper is adopted, and therefore tracing is convenient to conduct.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

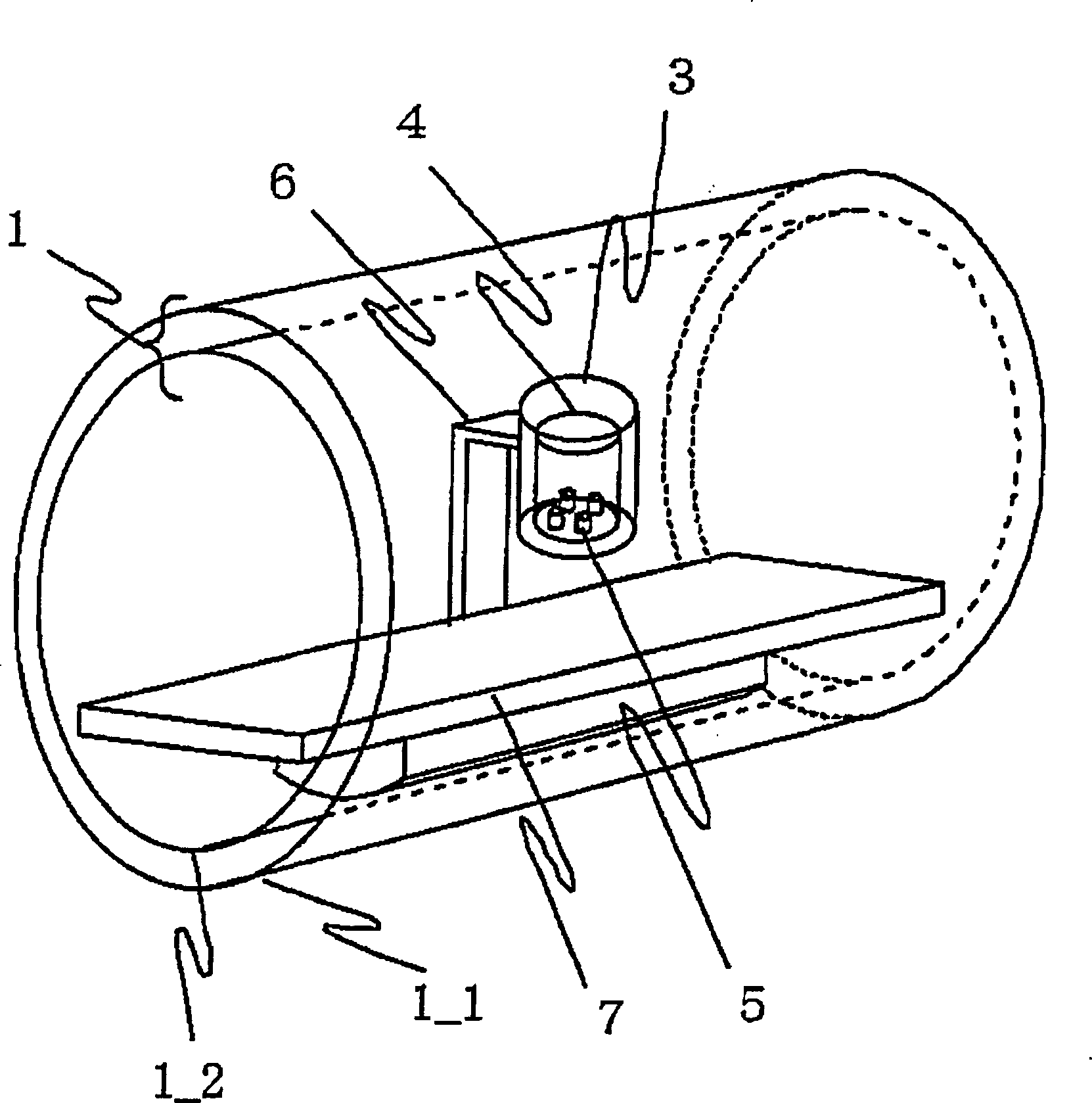

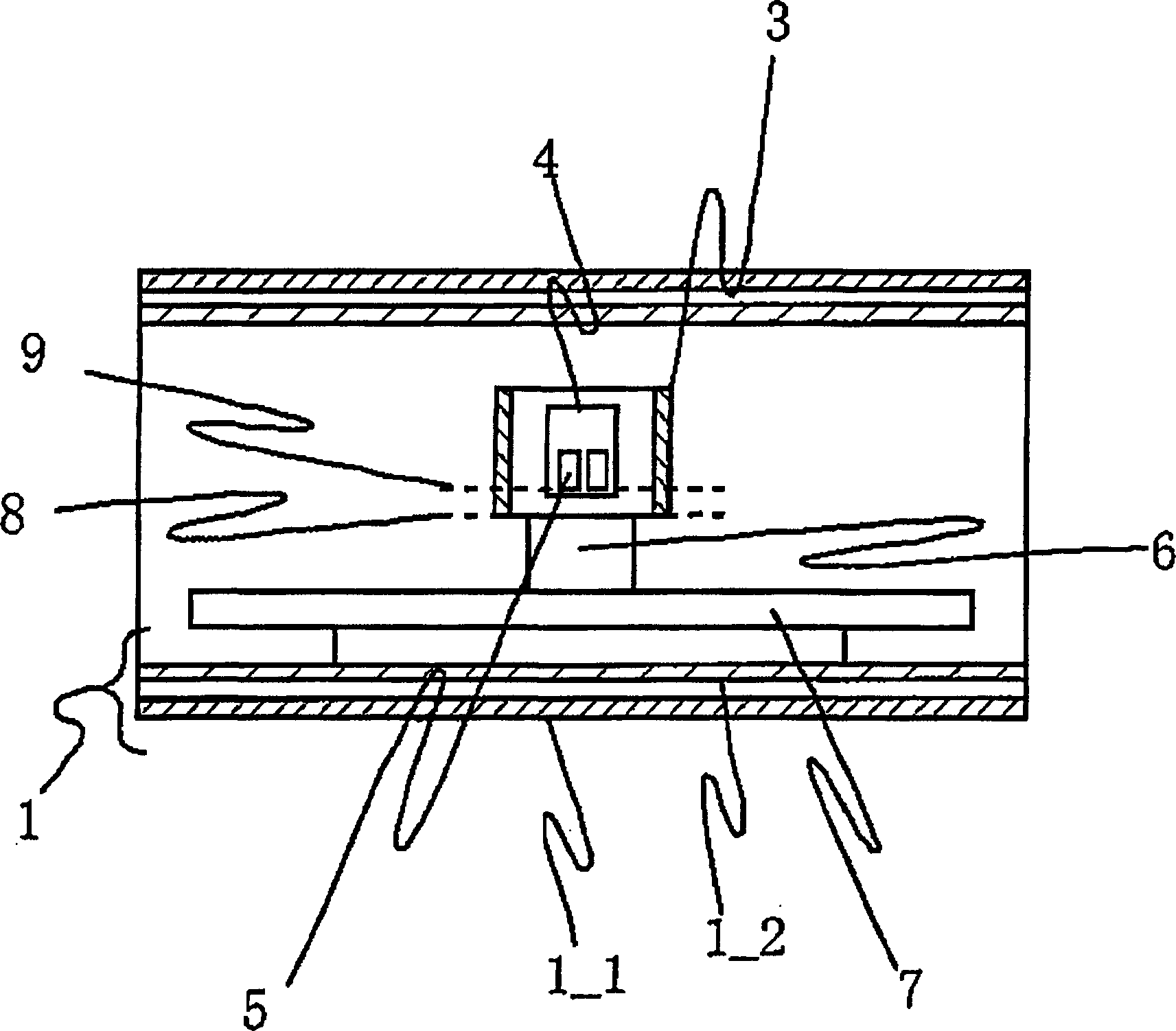

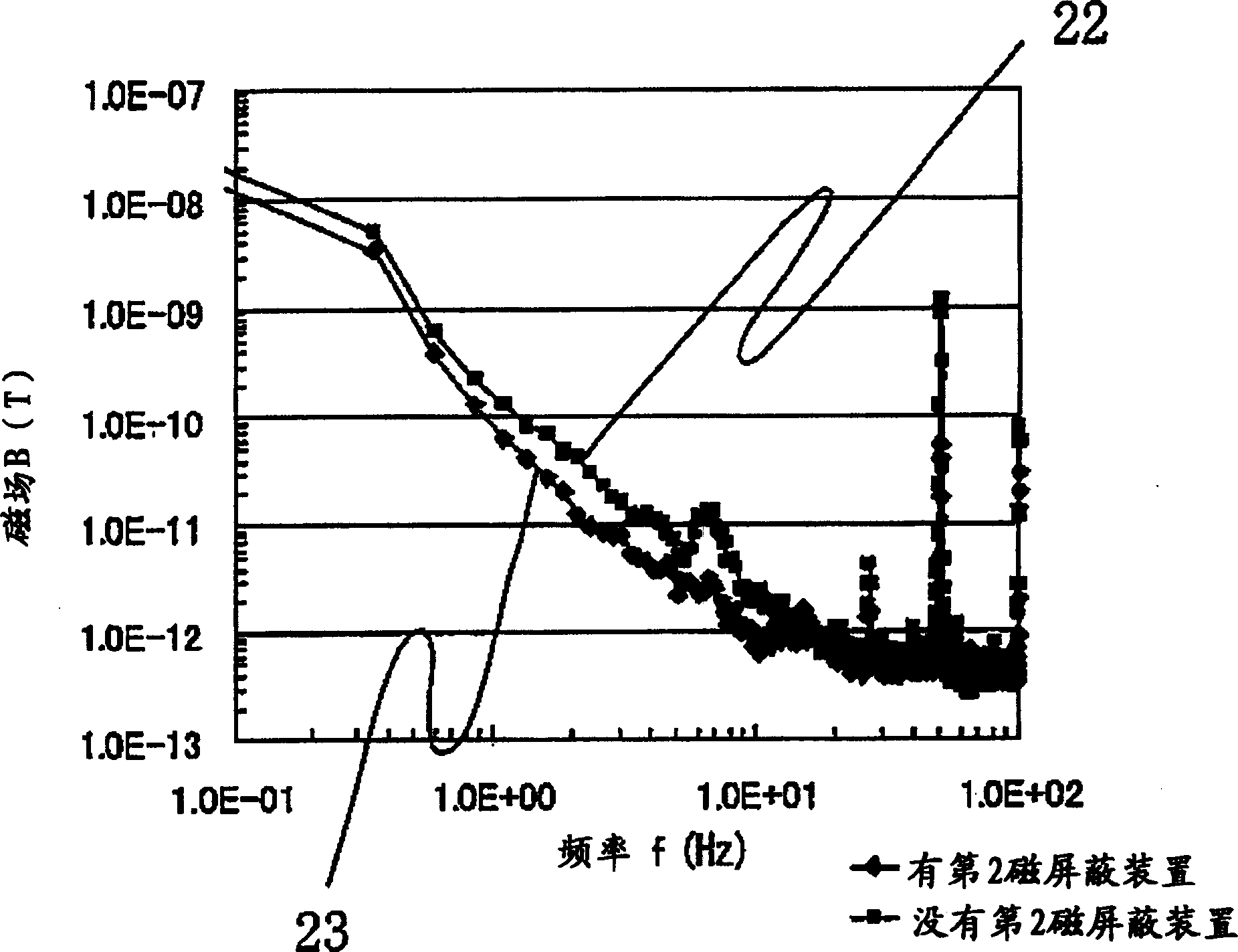

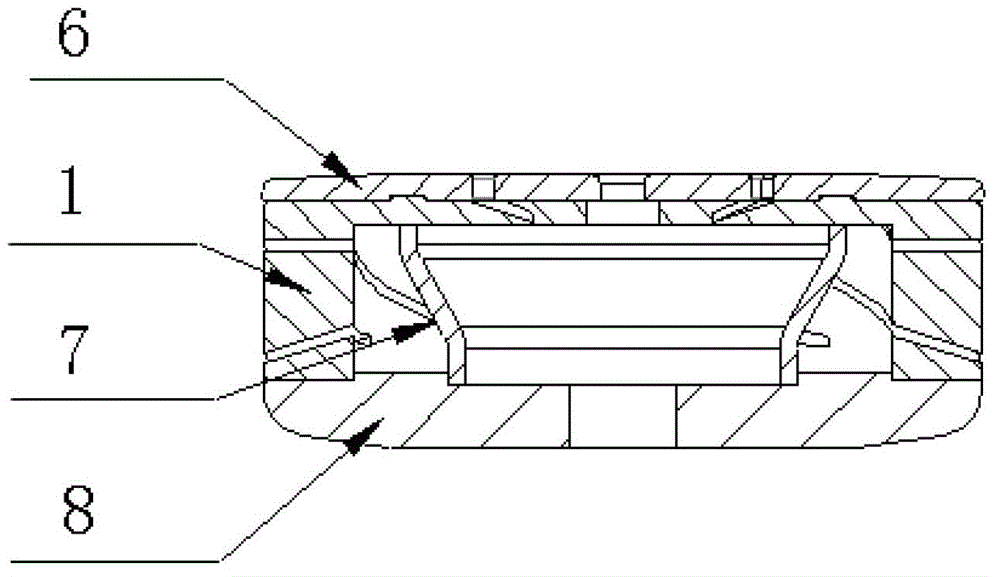

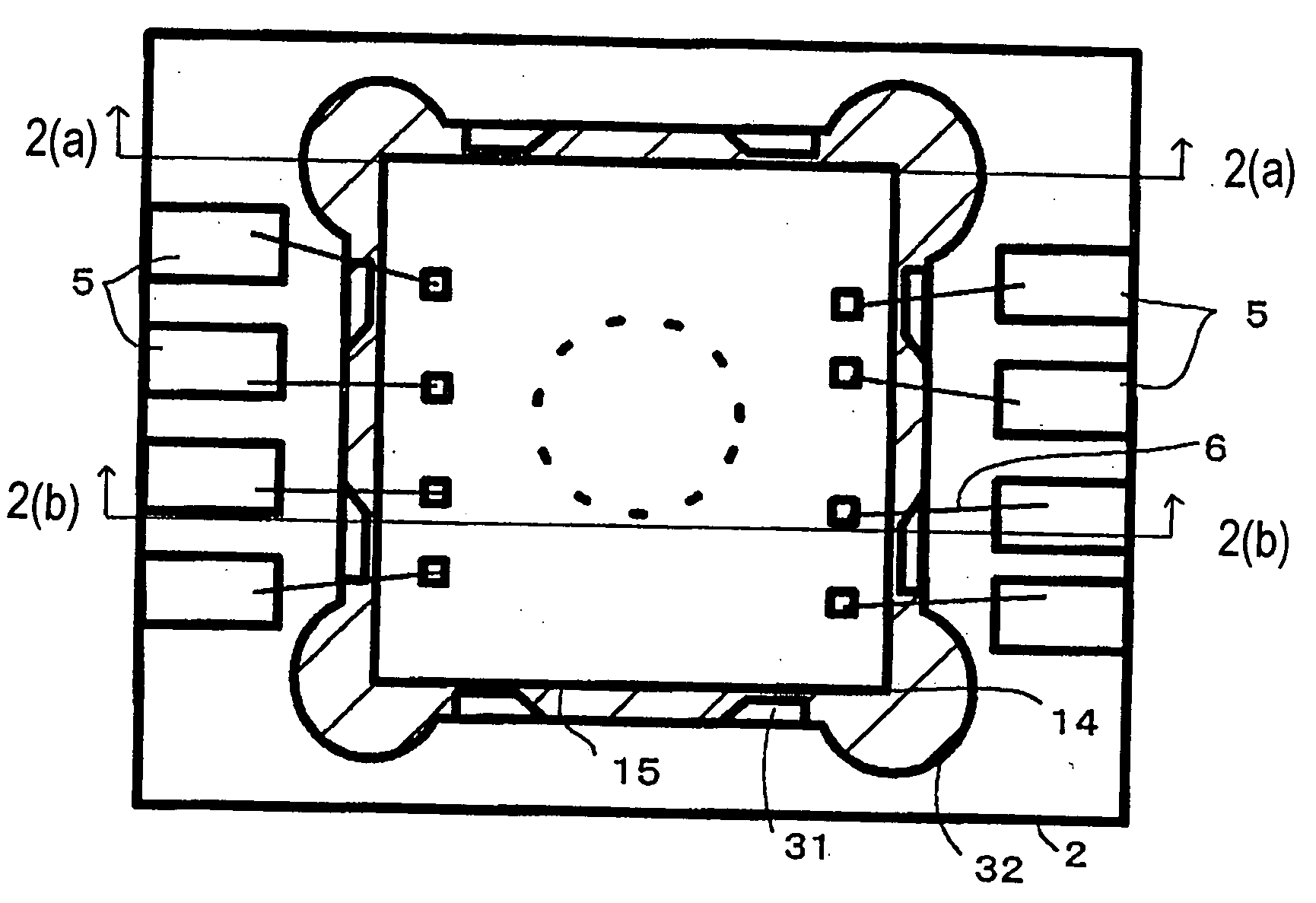

Magnetic signal measurement apparatus

InactiveCN1877354AShorten the lengthReduce deformation effectsMagnetic/electric field screeningMagnetic sensor packagingMagnetic measurementsScreening effect

If the length of cylinder of magnetic screening arrangement is shorter, the magnetic screening effect is reduced. At the two ends of magnetic-measurement, there is the second magnetic screening arrangement, which is in the first magnetic screening arrangement. The second magnetic screening arrangement can shield the magnetic-field component which the first magnetic screening arrangement can't shield.

Owner:HITACHI HIGH-TECH CORP

Method for directly preparing porous metal product by molten salt electrolysis

The invention discloses a method for directly preparing a porous metal product by molten salt electrolysis. The method comprises the following step of: performing molten salt electrolysis for 4 to 30 hours in the presence of argon shielding gas under such conditions that a metal blank is used as cathode, graphite as anode and CaCl2 is used as electrolyte, to obtain a porous metal product with a porosity of 15 to 78%. The temperature of electrolysis is 850 DEG C to 1200 DEG C, the voltage of electrolysis is 2.8 V to 3.8 V, and the metal blank is prepared from metal oxide powders as raw materials by the conventional method in which a pore-forming agent is added prior to pressing and sintering. The porous metal product is prepared by molten salt electrolysis of the metal blank. Since the deoxidation process is an exothermic process, the temperature is increased to produce a sintering effect during cathode reduction, as a result, the strength of the product is increased. Besides, the sintering effect as local sintering effect has a small impact on deformation of the product.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

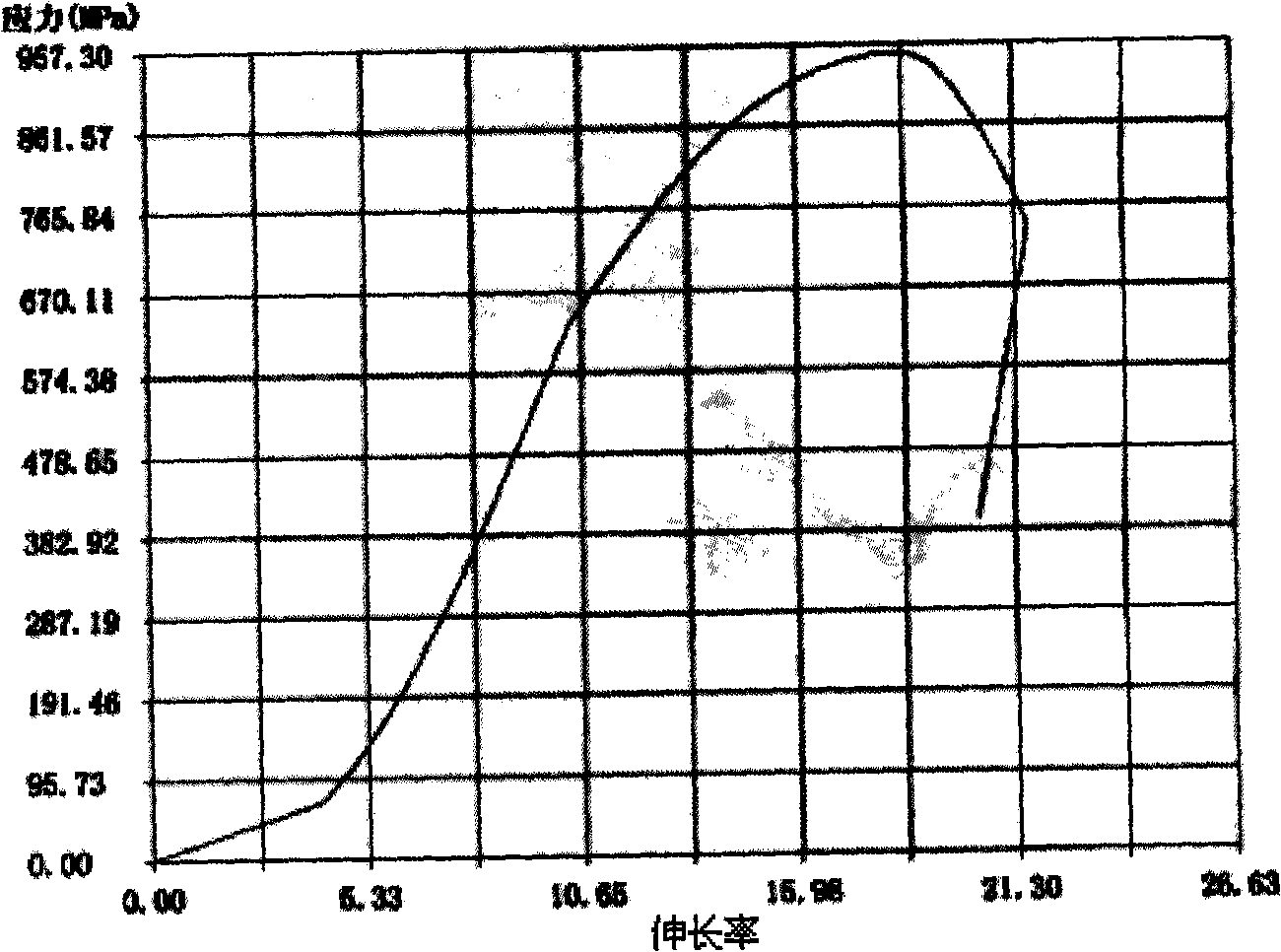

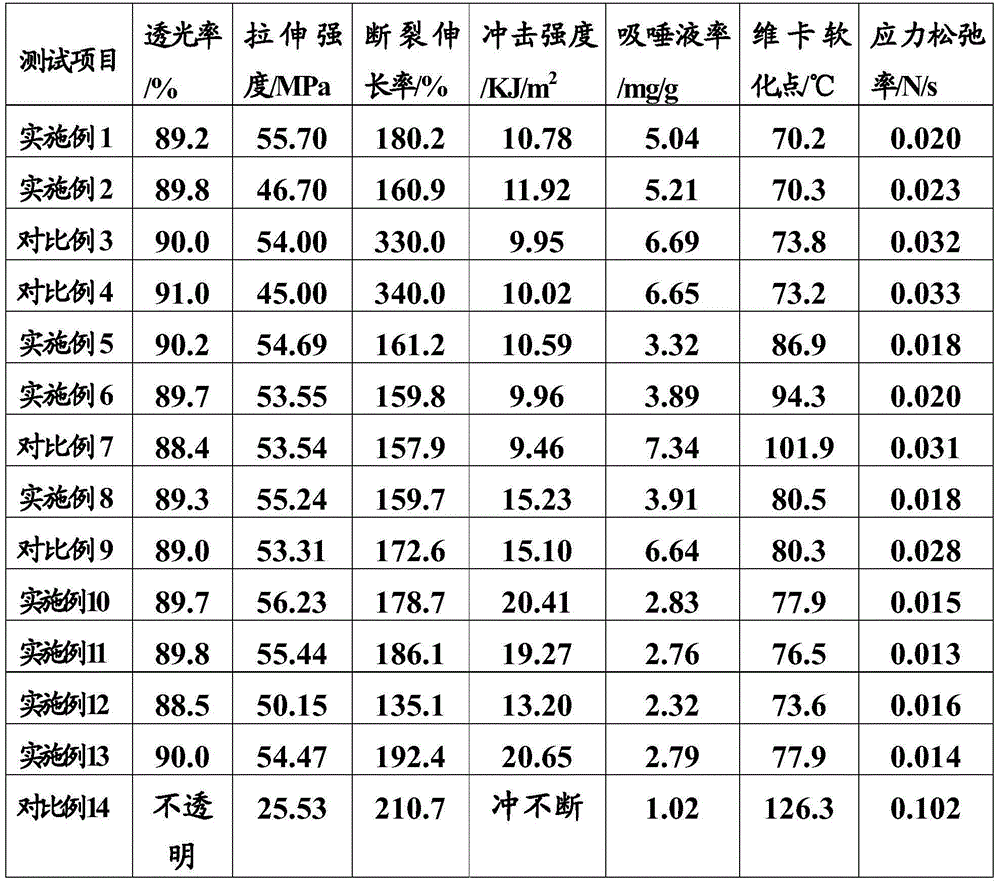

Teeth orthodontic material, preparation and application thereof

InactiveCN105315624AImprove mechanical propertiesReduce saliva intakeOthrodonticsCyclohexanedimethanolPolyethylene glycol

The invention relates to a teeth orthodontic material. On the basis of the total weight of the orthodontic material, the orthodontic material includes, by weight: A) 50-99.7% of polyethylene glycol terephthalate-1,4-cyclohexanedimethanol ester; B) 0-40% of polycarbonate, C) 0-20% of a thermoplastic polyurethane elastomer; and D) 0.3-5% of nano silicon dioxide, the sum of percentage contents of the components is 100 wt%. The teeth orthodontic material has excellent transparent performance, is excellent in mechanical and chemical performances, satisfies sanitary grade, especially is low enough in water absorption rate (or saliva absorption rate) and stress relaxation rate. The invention also relates to preparation of the teeth orthodontic material and an application of the material for preparing a teeth orthodontic device which preferably is dental braces.

Owner:BEIJING UNIV OF CHEM TECH +1

Organic compound based on pyridine and benzimidazole and application thereof in organic light emitting diodes (OLED)

ActiveCN107417668APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesHeat stabilityRefractive index

The invention relates to an organic compound taking pyridine and benzimidazole as a core and application thereof in organic light emitting diode (OLED) devices. The compound disclosed by the invention has higher glass transition temperature and molecular heat stability; the compound has low absorption and high refractive index in the field of visible light; after being applied to CPL layers of the OLED devices, the compound can effectively improve light extraction efficiency of the OLED devices. The compound disclosed by the invention further has a deep HOMO energy level and high electronic mobility, can serve as a cavity blocking / electron transfer layer material of the OLED devices and can effectively prevent cavities or energy from being transmitted to one side of an electronic layer from a luminescent layer; thus, composition efficiency of the cavities and the electrons in the luminescent layer is improved, and further luminous efficiency and service life of the OLED devices are improved.

Owner:JIANGSU SUNERA TECH CO LTD

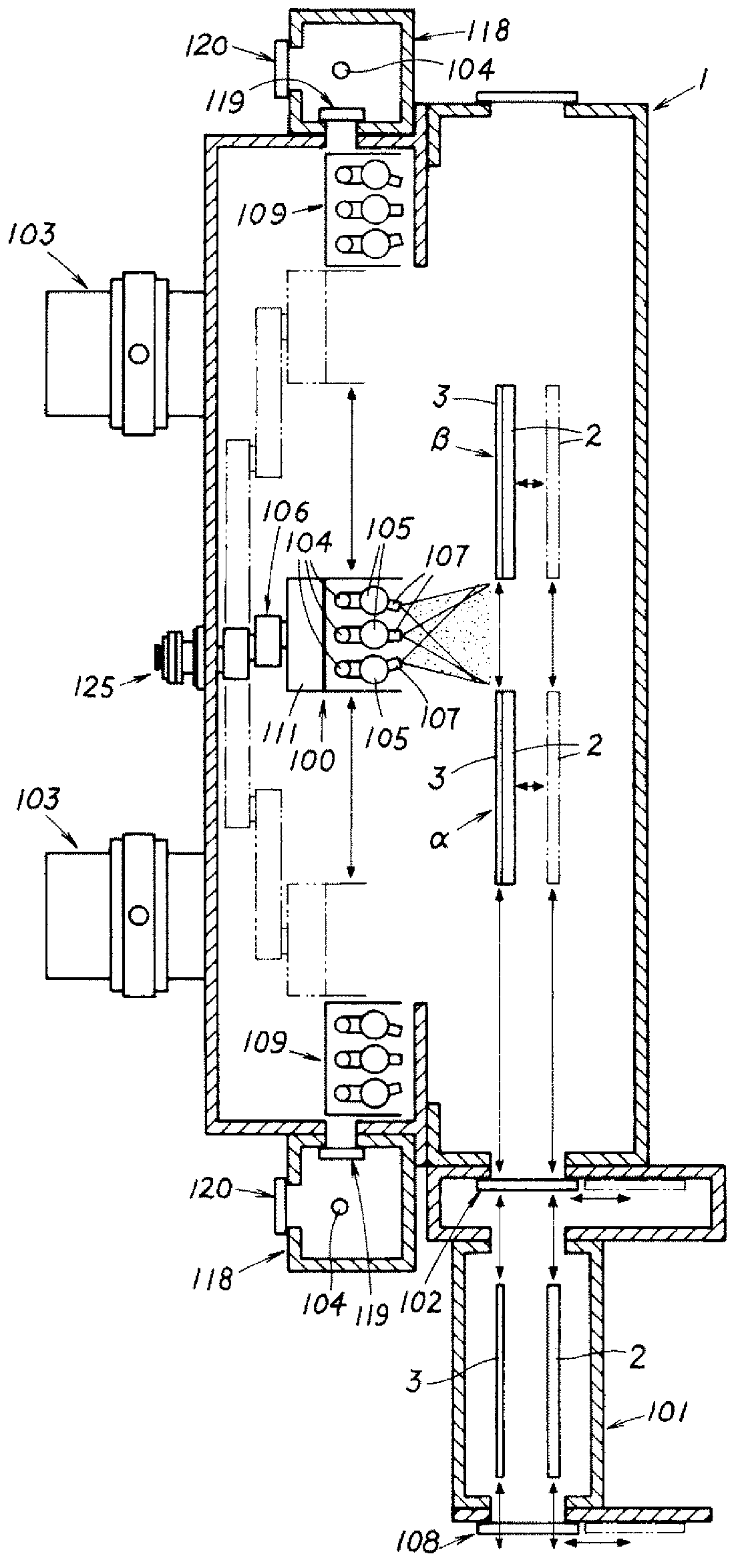

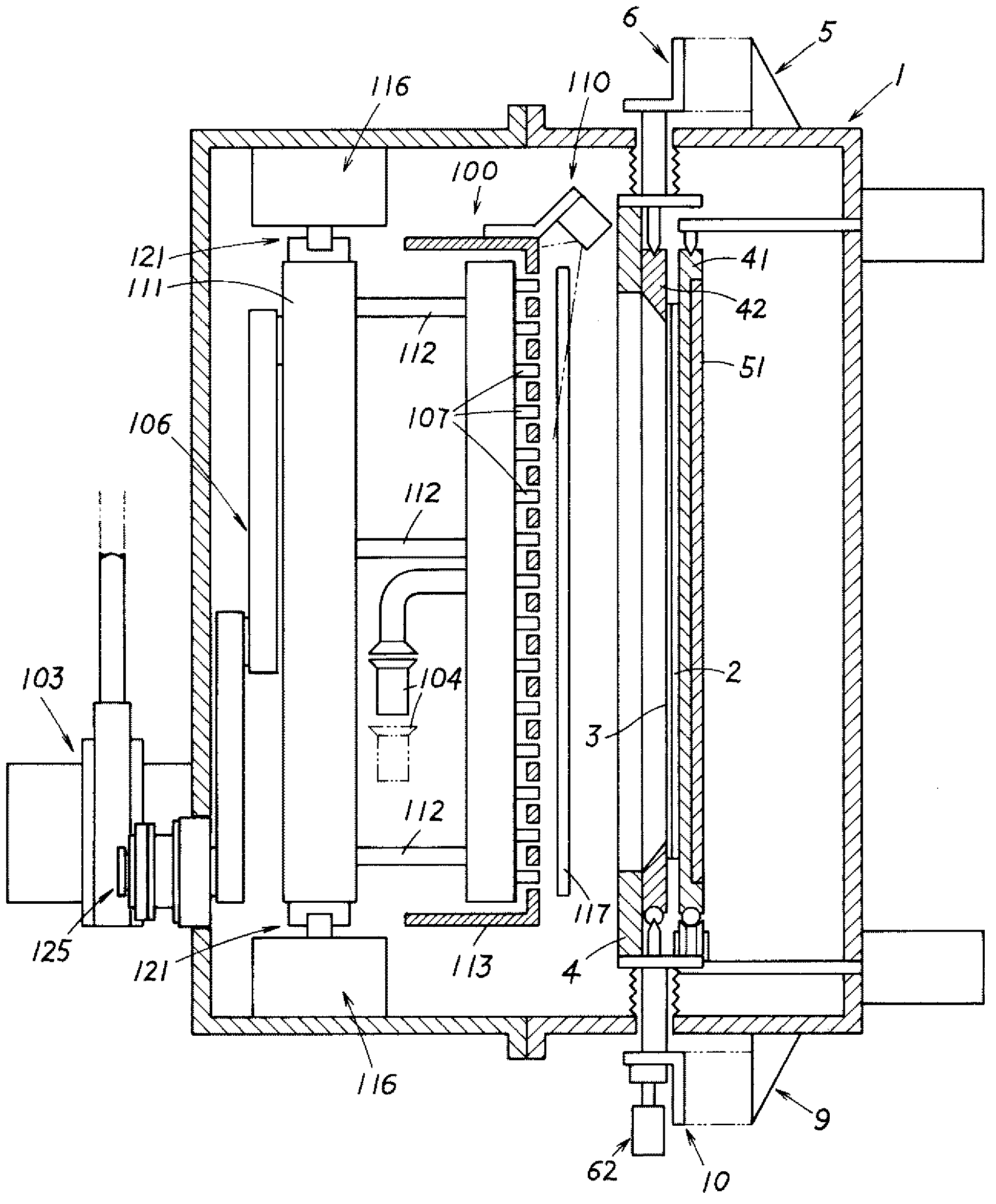

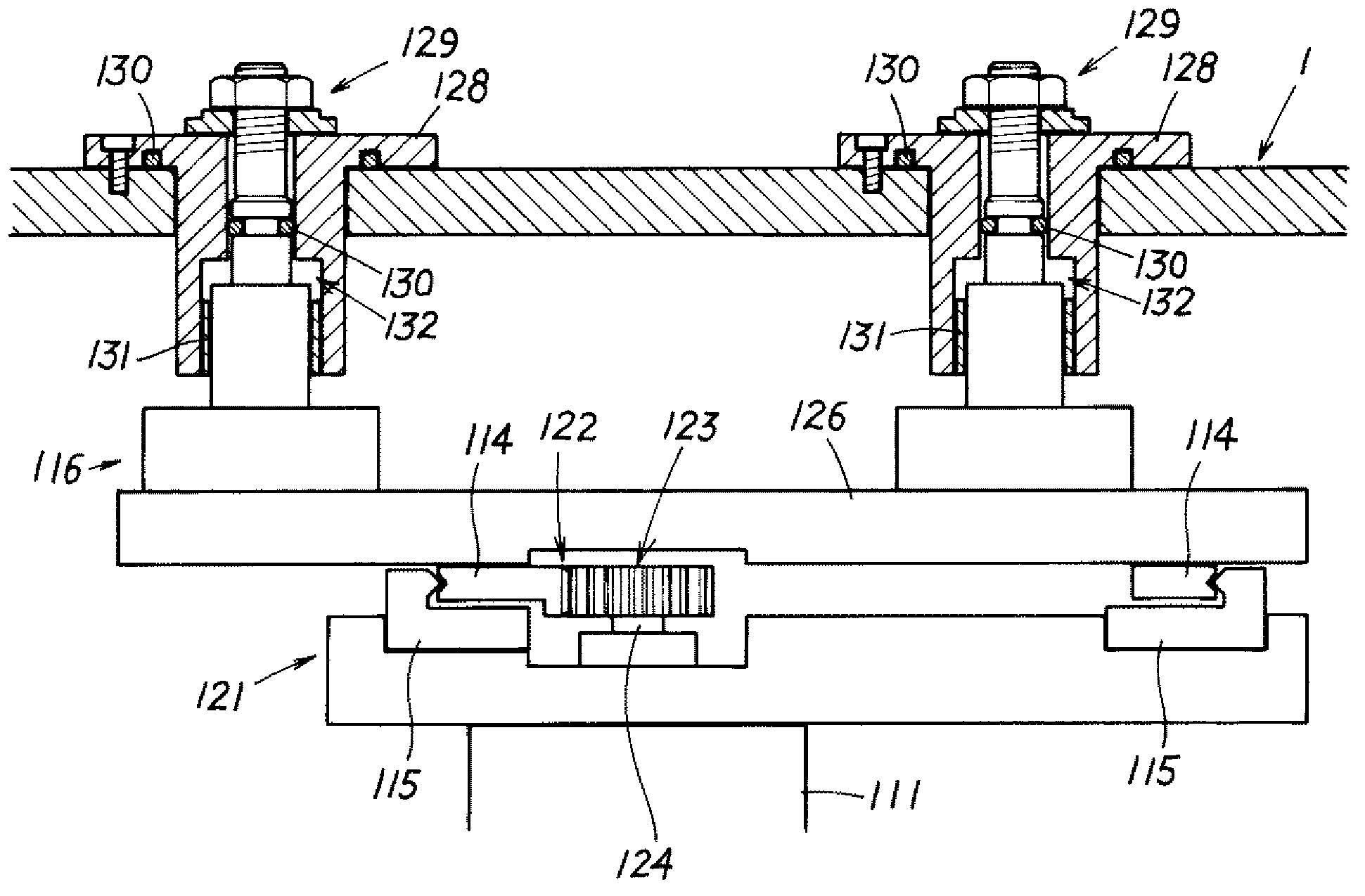

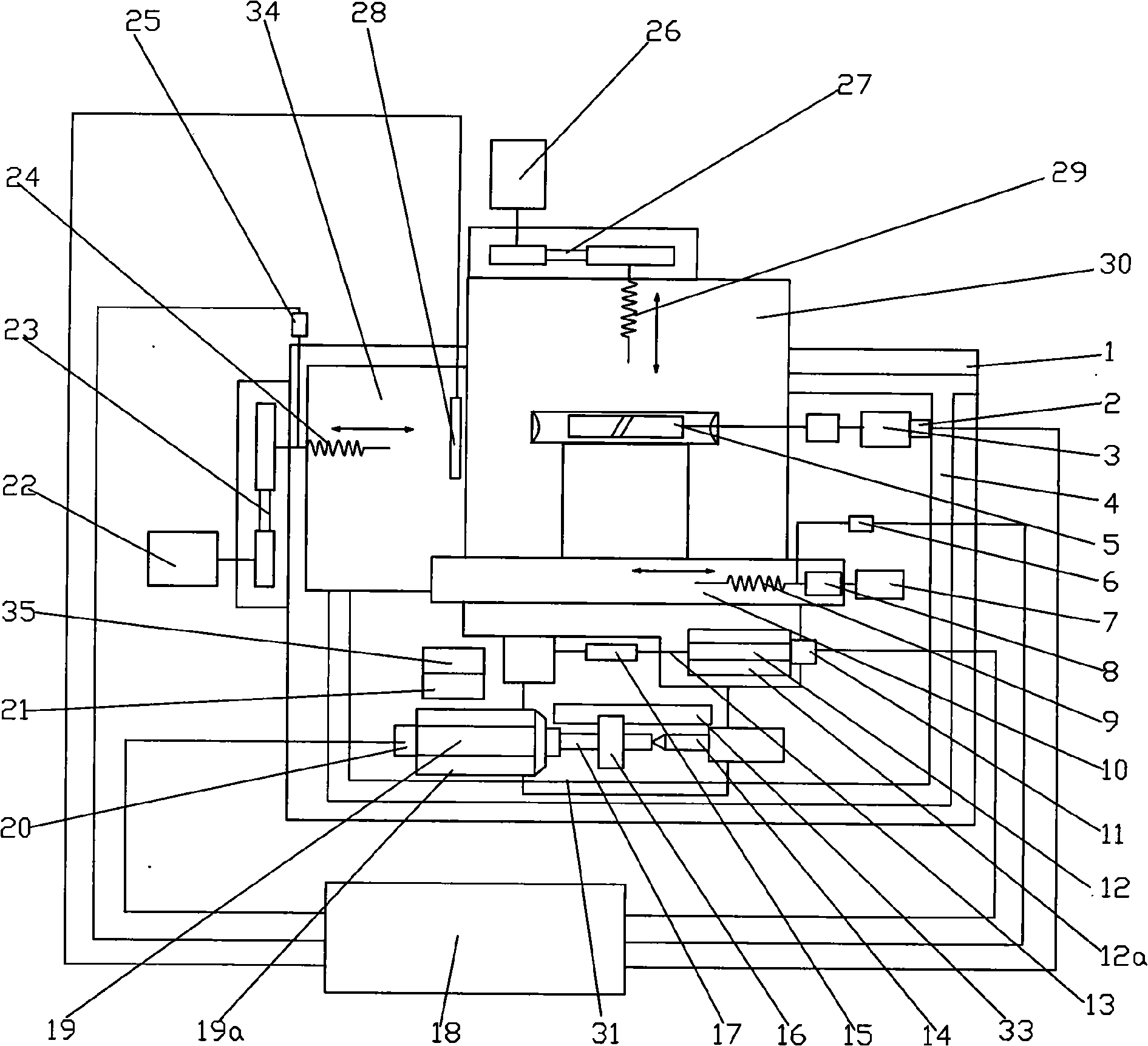

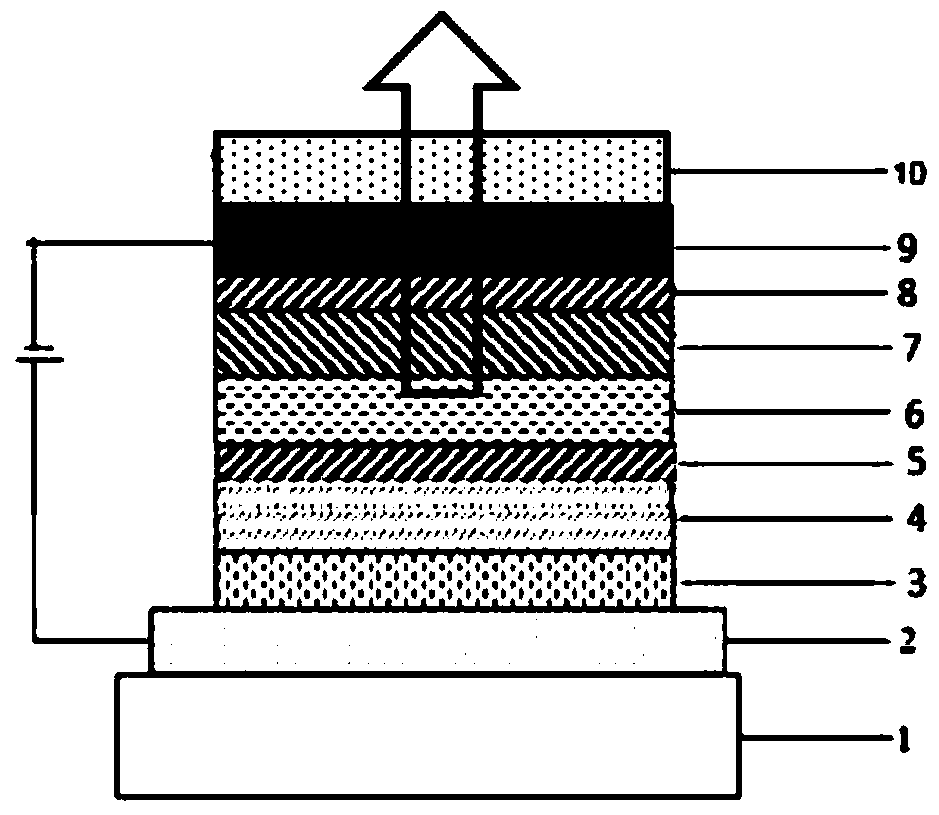

Film-forming apparatus

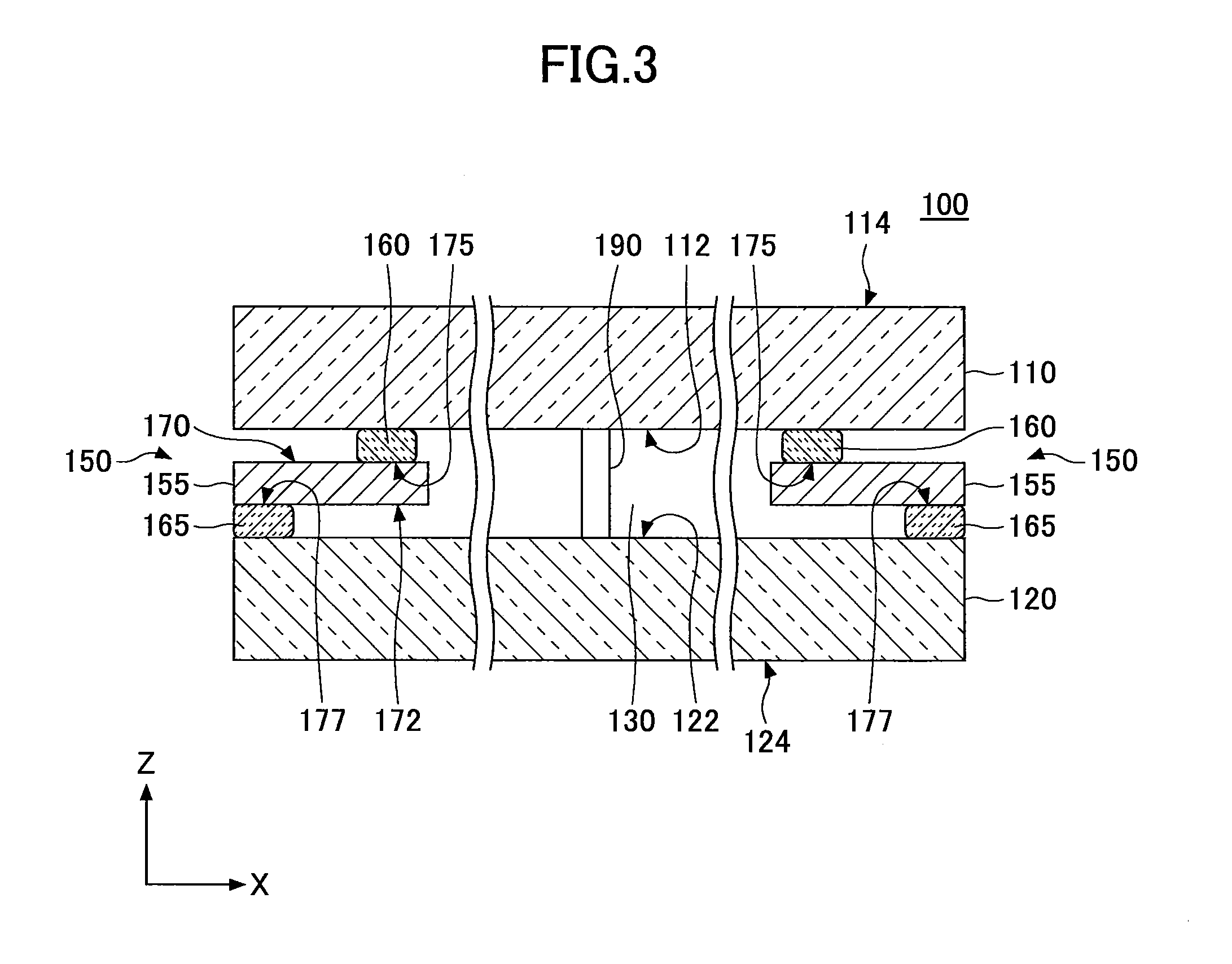

InactiveCN103339281AReduce deformation effectsImprove efficiencyElectroluminescent light sourcesVacuum evaporation coatingEvaporationEngineering

Provided is a film-forming apparatus, which is extremely useful, and which can be applied even to large substrates of the fourth and higher-order generations. The film-forming apparatus is provided with a film-forming chamber (1), in which a film is formed on a substrate (2) by adhering a film-forming material through a mask (3), said substrate being held in an upright state. The film-forming chamber (1) is provided with: an alignment drive mechanism, which aligns the mask (3) and the substrate (2) with each other, such that the mask (3) is at a correct position with respect to the substrate (2); an evaporation source (100), which can move in the transfer direction of the substrate (2) or the mask (3); and a mask transfer mechanism and a substrate transfer mechanism, which respectively transfer the substrate (2) and the mask (3) in the upright state to each of a plurality of film-forming positions facing the evaporation source (100). The film-forming apparatus is configured such that the mask (3) and the substrate (2) are aligned with each other at one film-forming position by means of the alignment drive mechanism, while performing film formation at other film-forming position by means of the evaporation source (100).

Owner:CANON TOKKI CORP

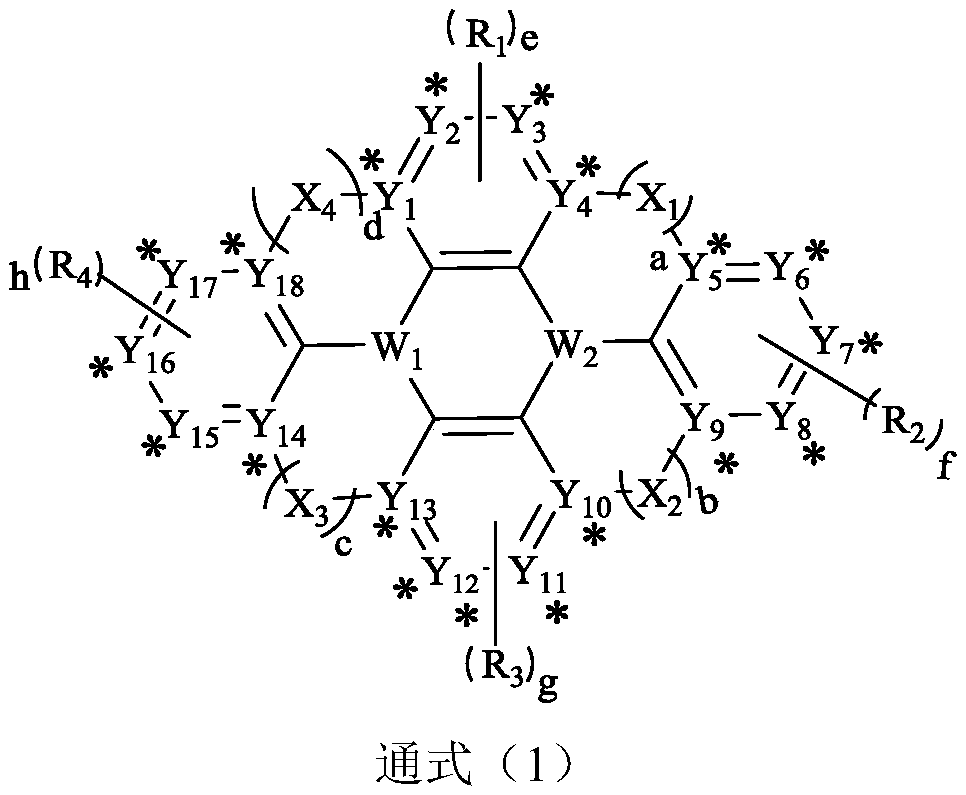

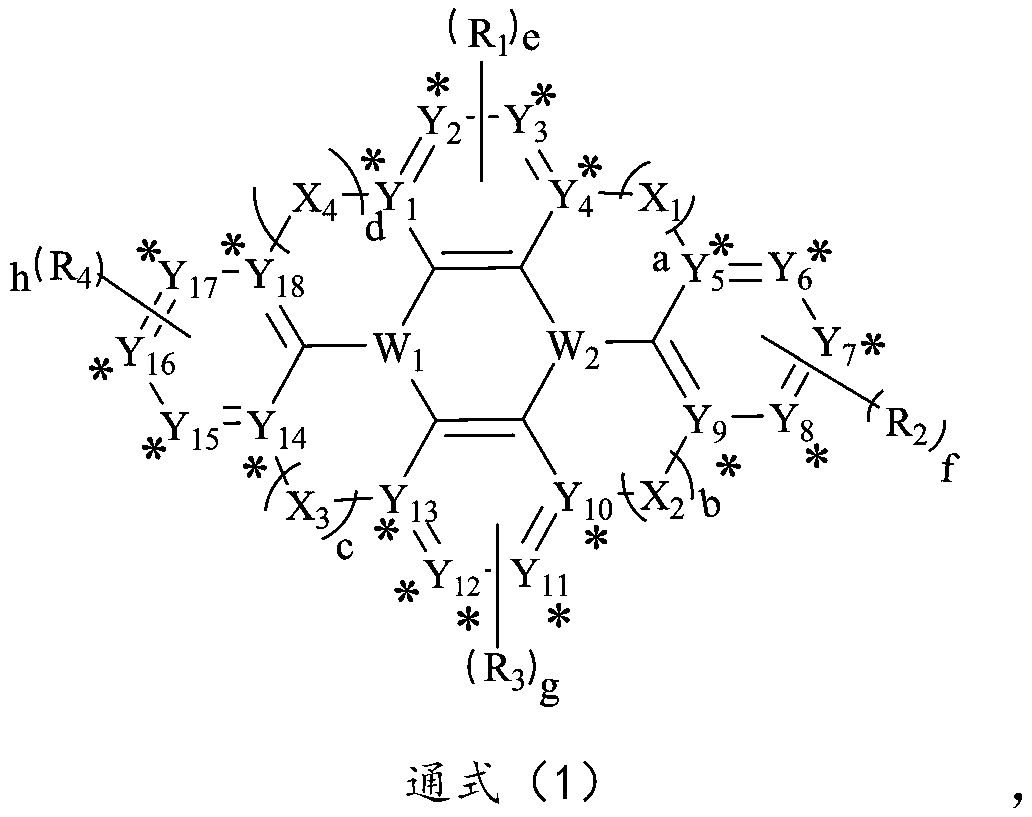

Boron-containing organic compound and application thereof in organic electroluminescent device

InactiveCN111574544ADestroy crystallinityIncrease overlapSilicon organic compoundsSolid-state devicesSimple Organic CompoundsOrganic electroluminescence

The invention relates to a boron-containing organic compound and application of the boron-containing organic compound to an OLED device. The structure of the compound is shown as a general formula (1), the whole molecule of the compound is a large rigid structure, and the introduction of substituent groups reduces the planarity of a material, so the steric hindrance of the material is increased, the material is not easy to rotate, and a three-dimensional space structure is more stable; and therefore, the compound has higher glass transition temperature and molecular thermal stability. In addition, the HOMO and LUMO distribution positions of the compound are separated from each other, so the compound has appropriate HOMO and LUMO energy levels; and therefore, after the compound is applied to the OLED device, the luminous efficiency of the device can be effectively improved, and the service life of the device can be effectively prolonged.

Owner:JIANGSU SUNERA TECH CO LTD

Zero-drive chain digital control gear hobbing machine

InactiveCN101298106AGuaranteed stabilityNo vibrationFeeding apparatusGear-cutting machinesHobbingGear wheel

The invention discloses a numberical control hobbing machine with zero transmission, which comprises a machine body, a main shaft system, a hobbing cutter feeding and angle adjusting system and a control system; the main shaft system comprises a functional part of a hobbing cutter main shaft and a functional part of work-piece main shaft part; the functional part of the hobbing cutter main shaft is an integration of the rotator of the servo motor I and the hobbing cutter main shaft, and the functional part of the work-piece main shaft is an integration of the rotator of the servo motor II and the work-piece main shaft. The numberical control hobbing machine of the invention can remove the manufacturing errors of transmission component of generating motion and the influence on gear process caused by space and assembly error, is able to greatly improve process accuracy and process speed of machine tool. The numberical control hobbing machine of the invention has simple structure, is able to improve overall rigidity of machine tool, solves the wearing problem caused by mechanical transmission chain, improves the retentivity of precision, causes the hobbing speed to be higher than the numberical control hobbing machine with traditional structure, shortens milling time as well as based on which, the hobbing machine is provided with the machine tool conditions required by dry type hobbing through adopting a series of matching technical measures.

Owner:CHONGQING UNIV

Organic compound based on azabenzene and application thereof in OLED

ActiveCN110229145APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesRefractive indexHigh electron

The invention relates to an organic compound based on azabenzene and an application thereof in an OLED device. The compound has relatively high glass transition temperature and molecular thermal stability; the compound has low absorption and high refractive index in the visible light field, and light extraction efficiency of the OLED device can be effectively improved after the compound is appliedin a CPL layer of the OLED device; and the compound also has deep HOMO energy level and high electron mobility, and can be used as a hole blocking / electron transport layer material of the OLED device, transmission of holes or energy from a luminescent layer to the side of an electron layer can be effectively blocked, and thus composite efficiency of holes and electrons in the luminescent layer isimproved, and luminescent efficiency and service life of the OLED device are improved.

Owner:JIANGSU SUNERA TECH CO LTD

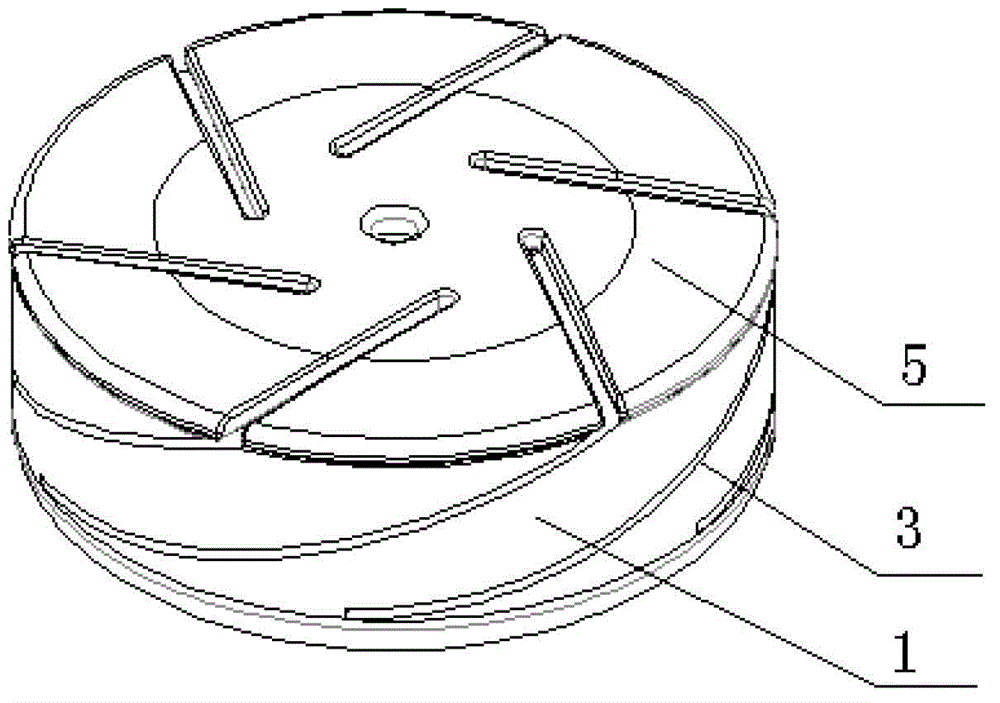

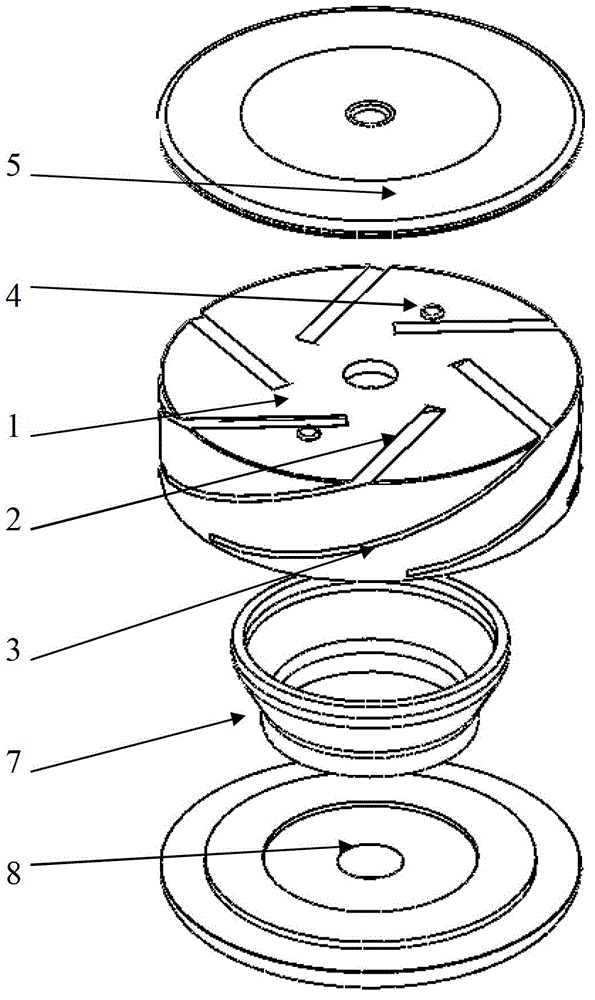

Novel longitudinal magnetic coil structure of vacuum arc extinguishing chamber

InactiveCN102751131APreserve integrityImprove flatnessHigh-tension/heavy-dress switchesAir-break switchesElectrical resistance and conductanceCoil structure

The invention discloses a novel longitudinal magnetic coil structure of a vacuum arc extinguishing chamber. The novel longitudinal magnetic coil structure is characterized by comprising a coil (1), wherein the opening end of the coil (1) is the lower part; the bowl bottom end of the coil (1) is the upper part; two or more than two grooves (2) are arranged above the coil (1); the grooves (2) are connected with inclined grooves (3) on the side wall of the coil (1); the inclined grooves (3) rotate upwards along the circumference of the coil (1); and the surface at the lower part of the coil (1) is an complete ring. According to the novel longitudinal magnetic coil structure, the completeness of the coil is maintained by changing the grooves on the coil; the strength of the coil is enhanced; the transformation is reduced; the influence on the shape transformation caused by the welding is reduced; the influence that a contact resistance is a little large due to the shape transformation is avoided; and moreover, the reliability in positioning is improved by changing the positioning mode of a contact and the coil; and the assembling is simpler, more convenient and faster; and the quality of the vacuum arc extinguishing chamber is improved.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

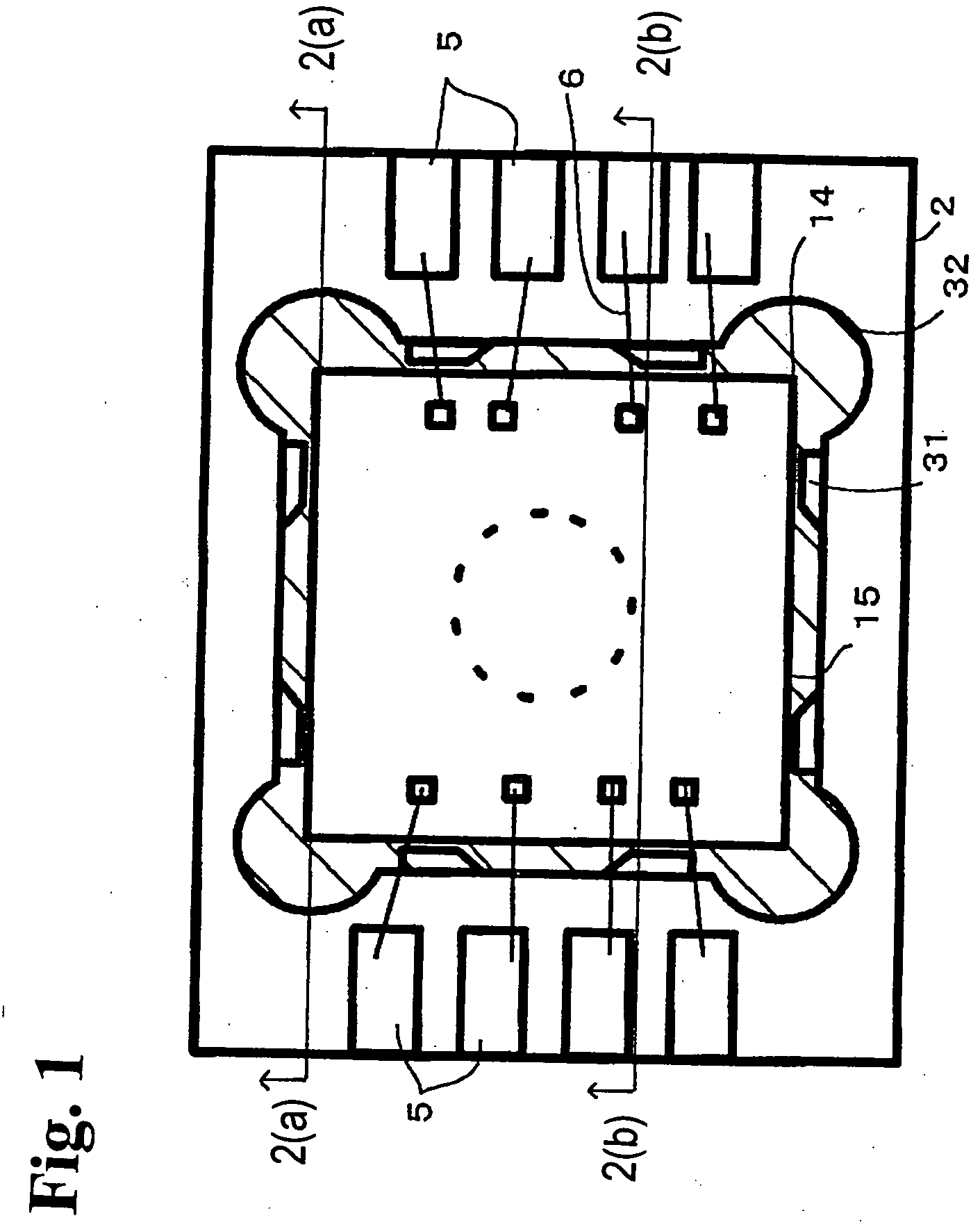

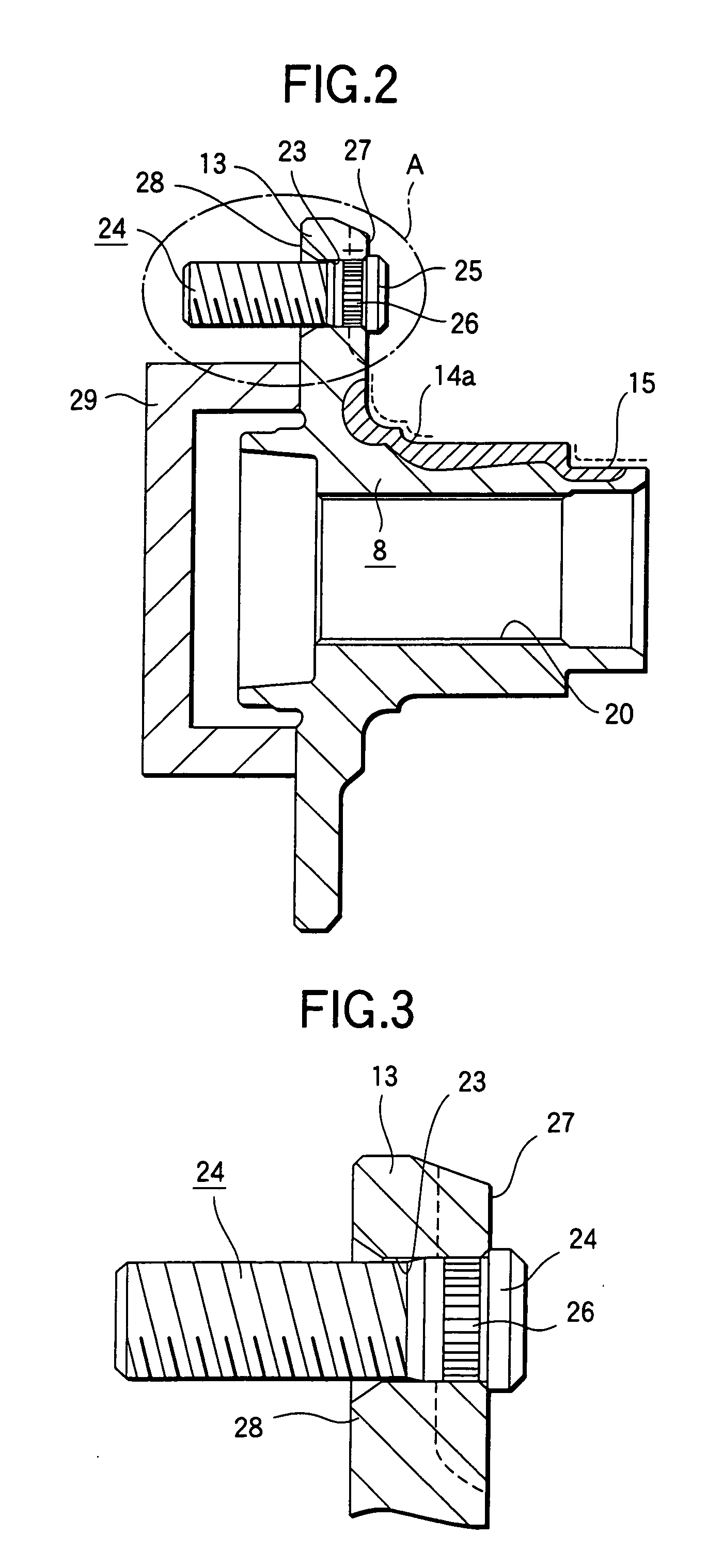

Physical value detecting apparatus and housing for physical value detecting means

ActiveUS20050016289A1Reduce the impactReduce deformation effectsMultiple-port networksGas treatmentEngineeringElectric signal

A physical value detecting apparatus includes a housing having a concave portion; a physical value detecting device housed in the concave portion and having a substantially rectangular shape for converting a physical value into an electric signal and outputting the electric signal; a device for taking out a signal from the physical value detecting device; an adhesive member for adhering the physical value detecting device to the concave portion; and a positioning device provided on an inner wall of the concave portion for positioning the physical value detecting device. The concave portion supports the physical value detecting device at a bottom thereof via the adhesive member without contacting corner parts of the physical value detecting device.

Owner:FUJI ELECTRIC CO LTD

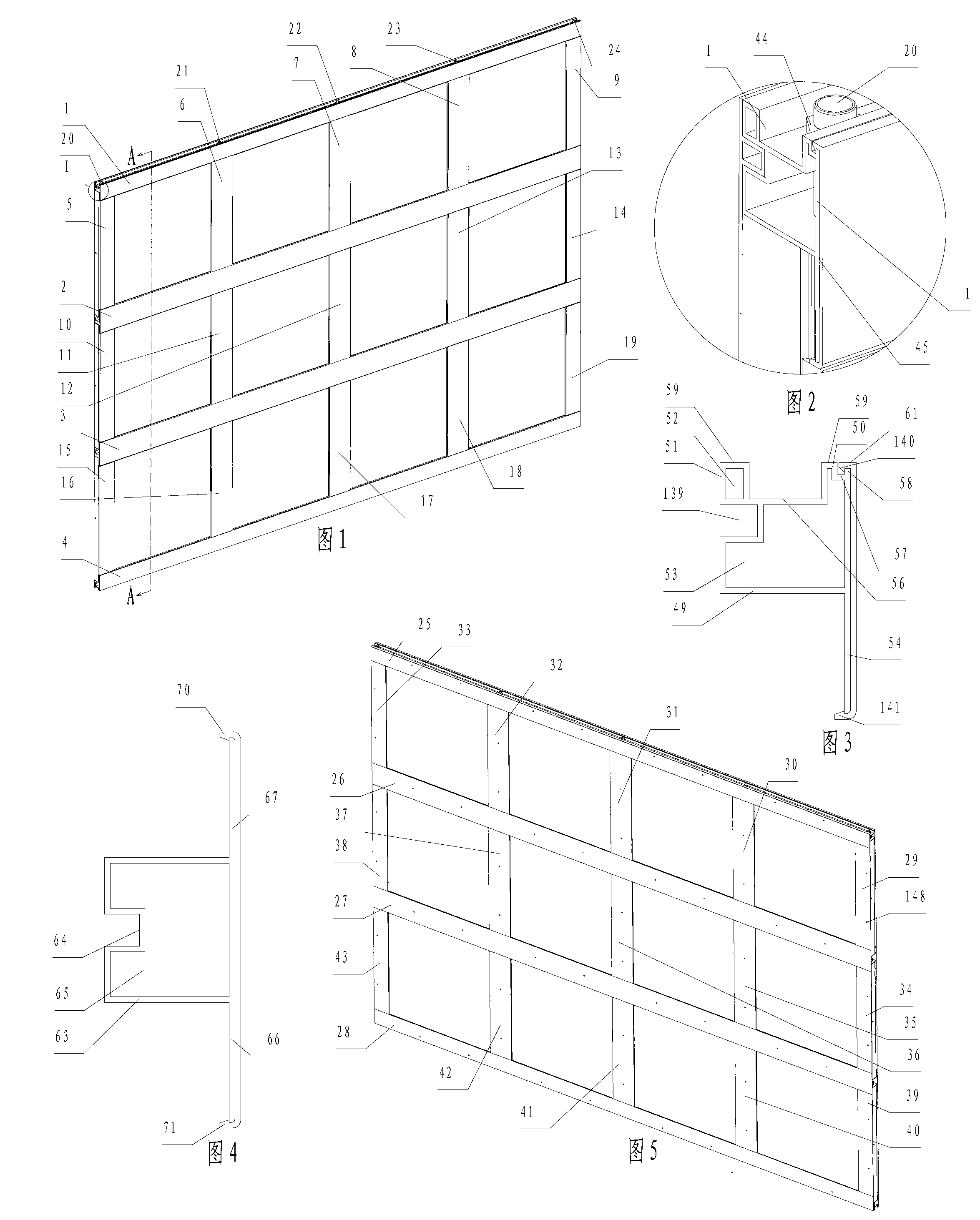

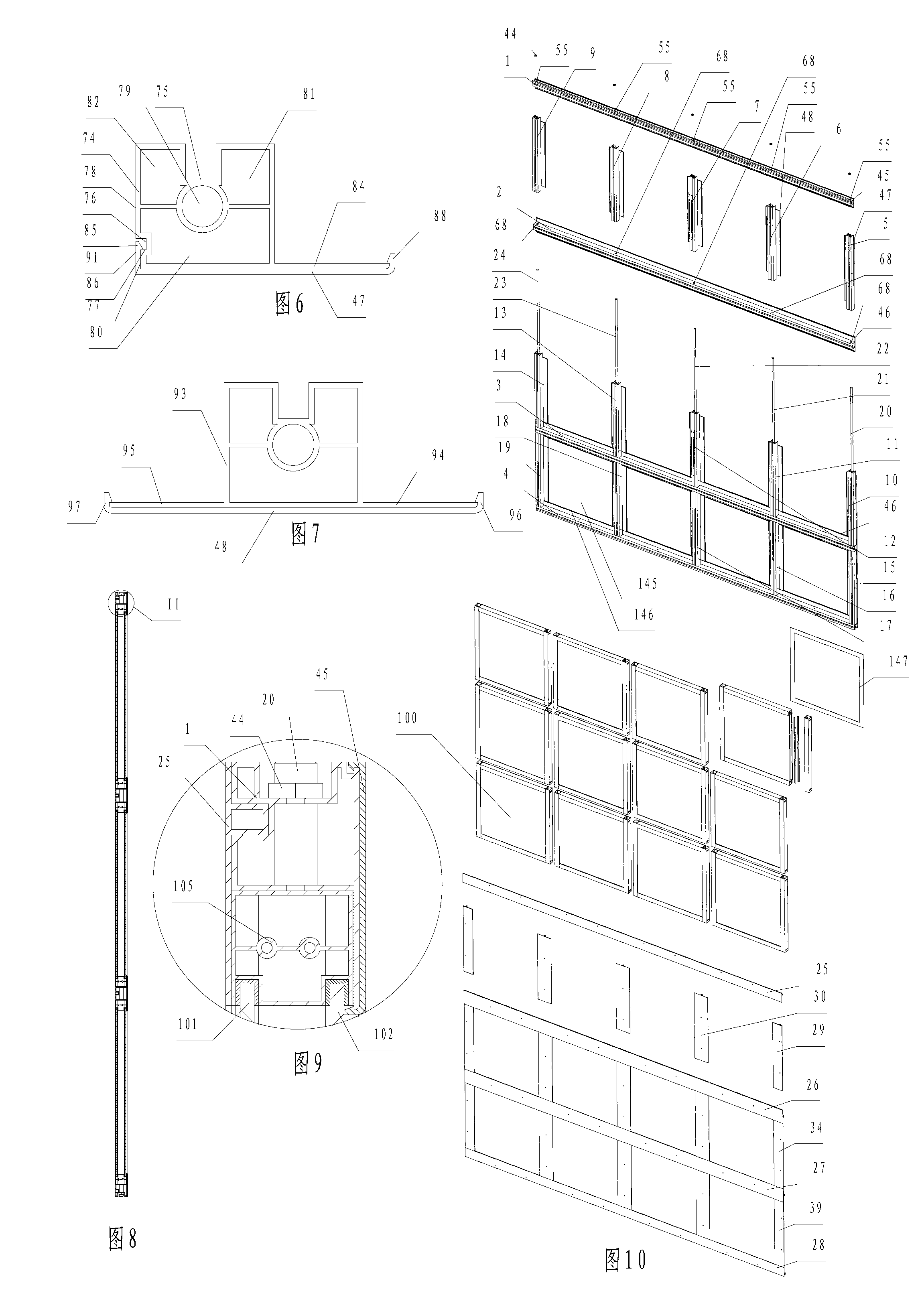

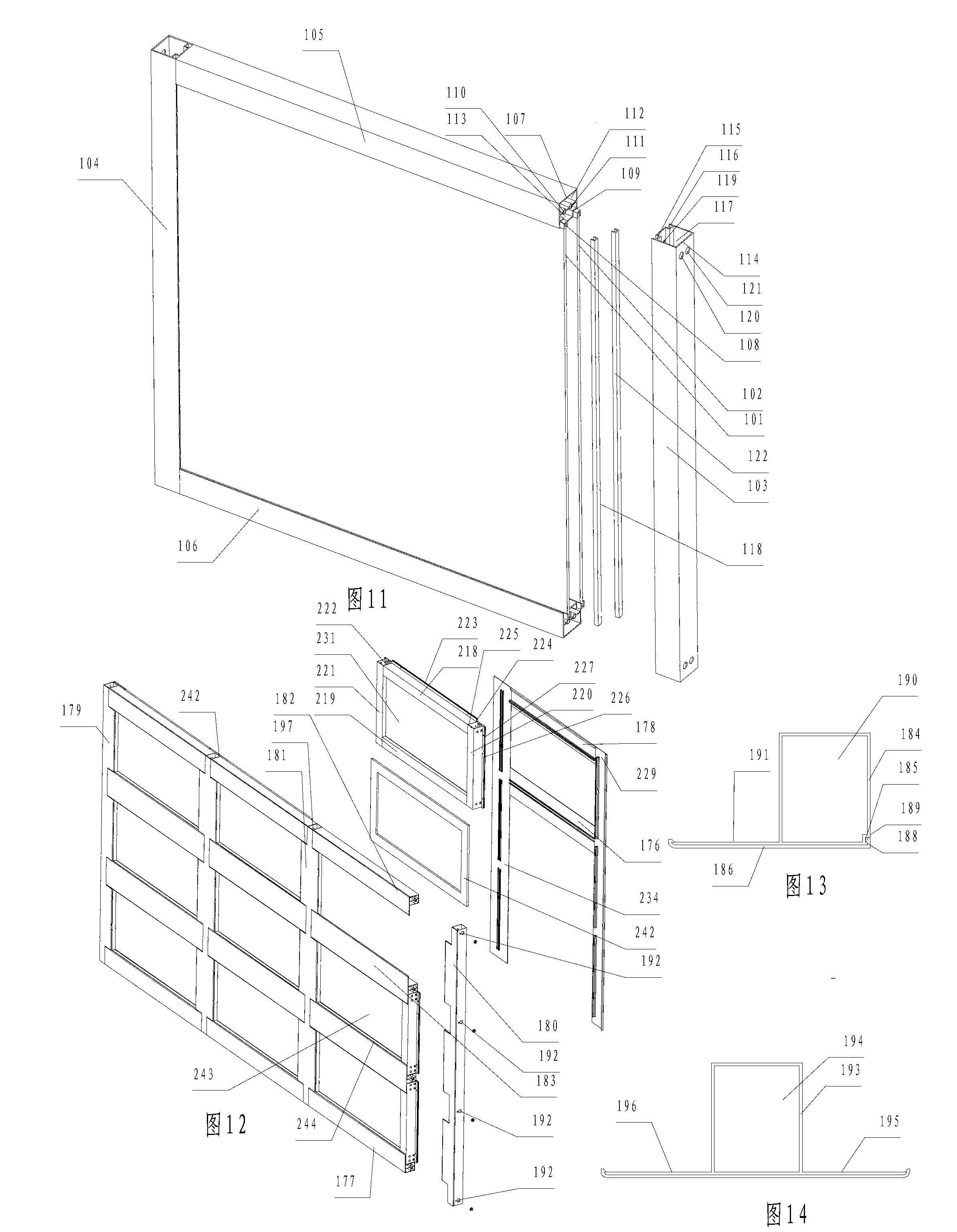

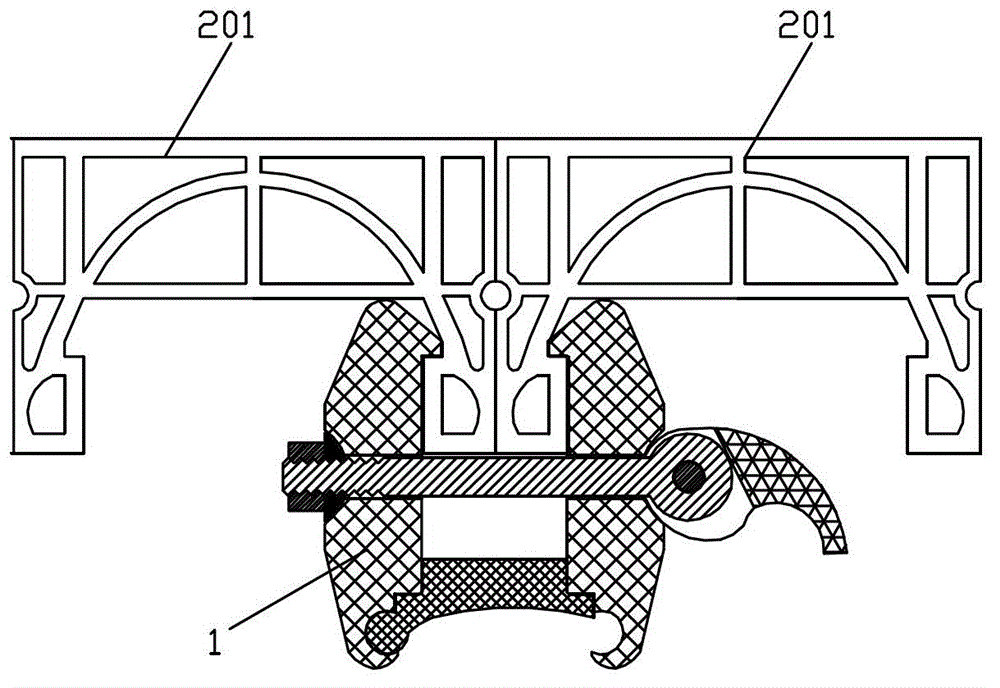

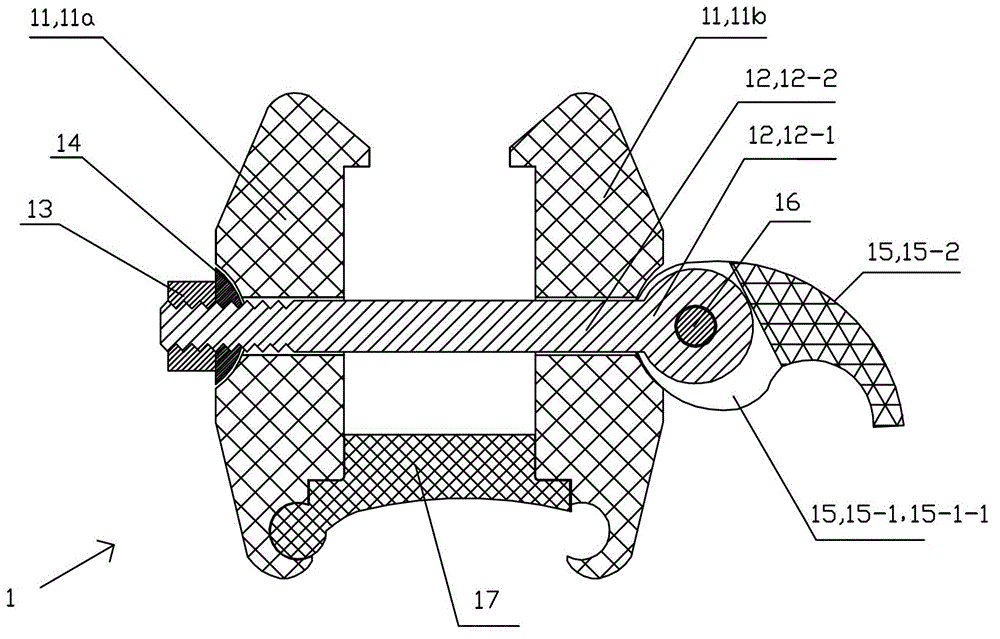

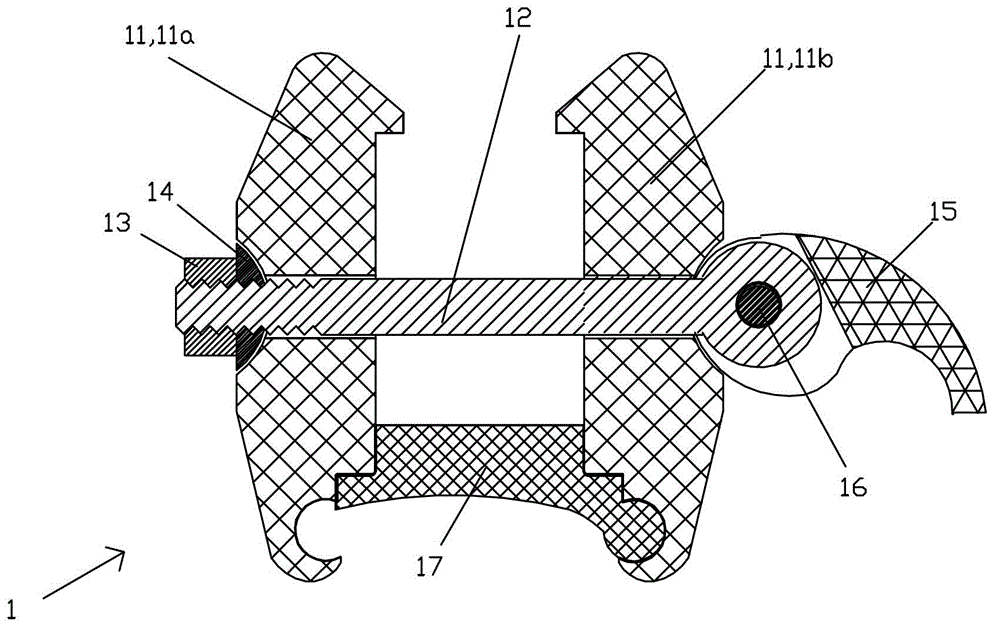

Combined construction structure

ActiveCN103075075AReduce aging speedEasy to replaceShutters/ movable grillesWallsIsolation effectKeel

The invention discloses a combined construction structure which comprises first keels, second keels and an interlayer module; the adjacent two first keels and the adjacent two second keels form a square frame for installing the interlayer module; flanges which are integrated with the corresponding first keels and second keels are arranged on four inner side surfaces opposite to the square frame; elastic buckle-type profile U-shaped first external spacer bars which are laterally buckled onto the first keels, and elastic buckled-type profile U-shaped second external spacer bars which are laterally buckled onto the second keels are also arranged; one of the two buckles of the first external spacer bar of the first keel on the outermost side is buckled on the related flange, and the other is buckled in a first slot; and one of the two buckles on the second external spacer of the second keel on the outermost side is buckled on the related flange, and the other is buckled on a second slot. The combined construction structure has the advantages of good heat isolation and sound isolation effects, convenience and quickness in installation, simple process, good strength and rigidity of main keels, and low cost.

Owner:深圳市华汇设计有限公司

Insulated glazing and method of producing insulated glazing

InactiveUS20150218877A1Reduce deformation effectsEasy to produceTransportation and packagingClimate change adaptationInsulated glazingEngineering

Insulated glazing includes a first glass substrate including a first surface, a second glass substrate including a second surface facing the first surface across a gap, and a sealing member hermetically sealing the gap. The sealing member includes a metal member of a frame shape including third and fourth surfaces, and first and second joining layers. The first joining layer is placed in a frame shape on the first surface of the first glass substrate. The second joining layer is placed in a frame shape on the second surface of the second glass substrate, and is in a position offset from the position of the first joining layer when viewed in a thickness direction of the insulated glazing. The first joining layer is bonded to part of the third surface of the metal member. The second joining layer is bonded to part of the fourth surface of the metal member.

Owner:ASAHI GLASS CO LTD

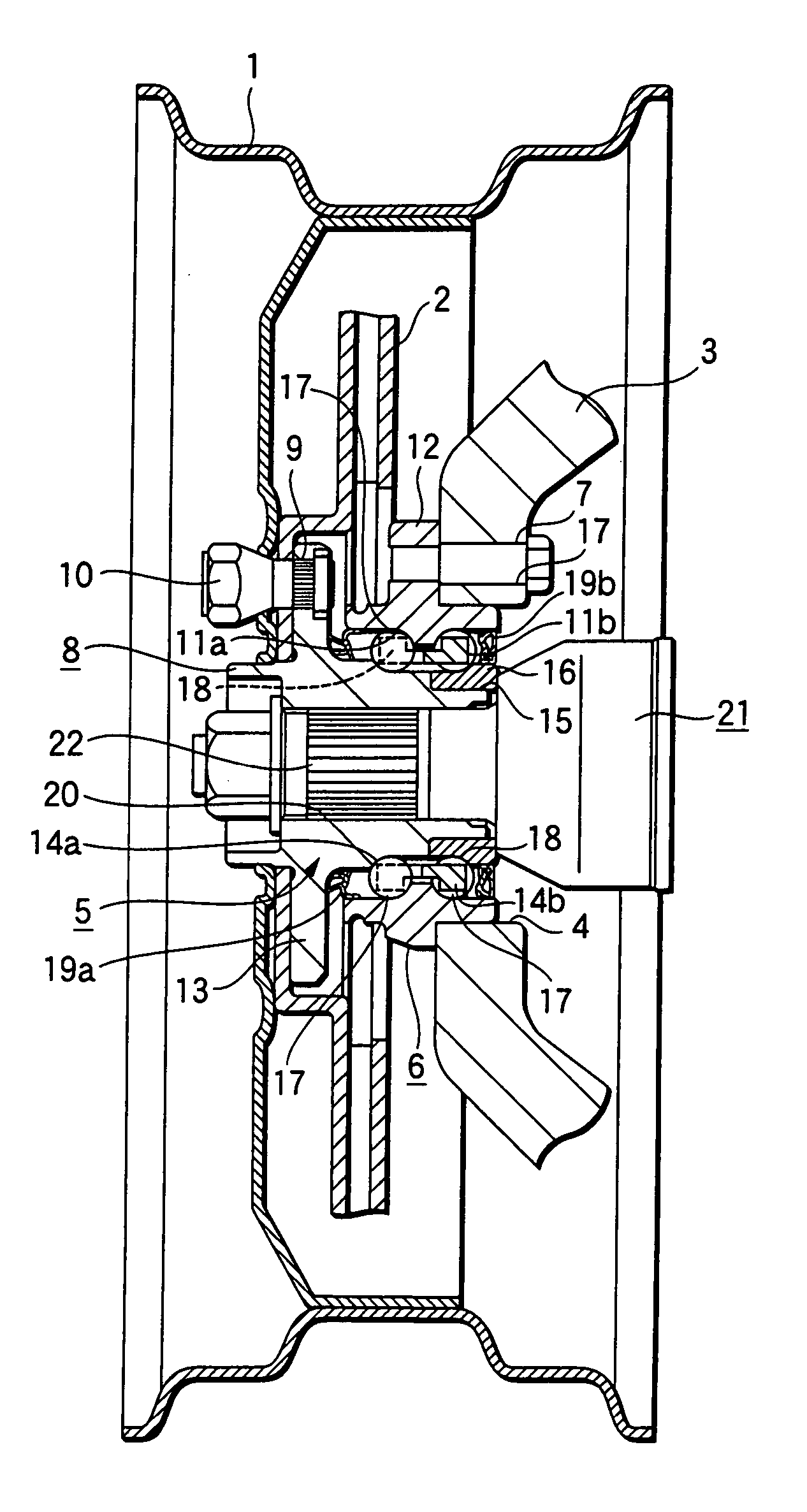

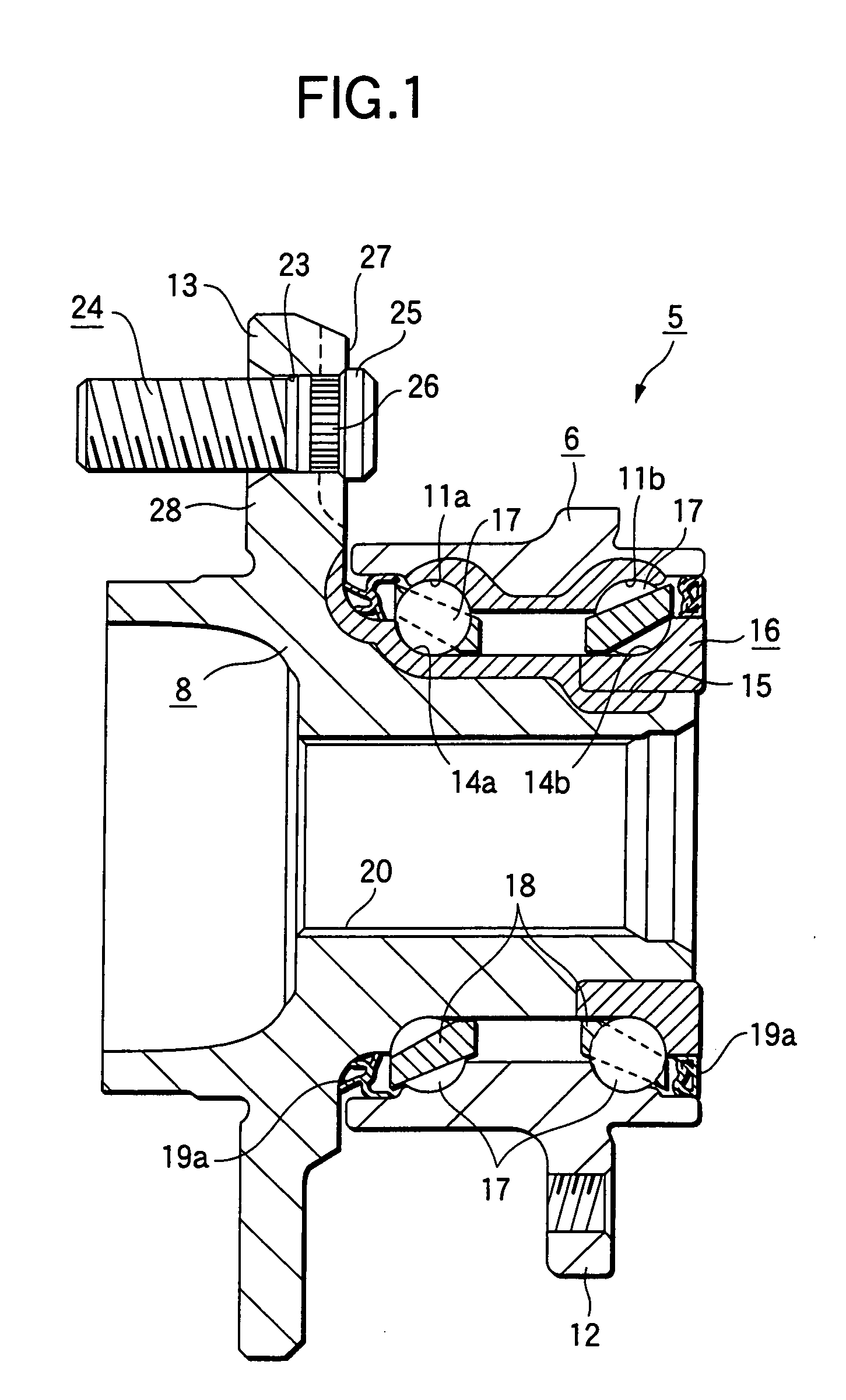

Bearing unit for wheel and method of manufacturing the same

InactiveUS20050115072A1Avoid it happening againReduce deformation effectsRolling contact bearingsHubsFlangeEngineering

At a surface opposite to a mounting surface 28 at a part of the mounting flange 13, a projecting part 27 is provided so as to surround the opening part of the mounting holes 23 for press-fitting each stud thereinto. A finishing process of the mounting surface 28 is carried out after the stud 24 is press-fitted into the mounting hole 23.

Owner:NSK LTD

Boron-containing organic compound and application thereof in organic electroluminescent device

InactiveCN111574543ADestroy crystallinityIncrease overlapSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceOrganic compound

The invention relates to a boron-containing organic compound and application thereof to an organic light-emitting device, belonging to the technical field of semiconductors. The structure of the boron-containing organic compound is shown as a general formula (1). The invention also discloses the application of the boron-containing organic compound in an organic electroluminescent device. Accordingto the boron-containing organic compound, the whole molecule of the compound is of a large rigid structure, the planarity of a material is reduced through introduction of substituent groups, the steric hindrance of the material is increased, the material is not prone to rotation, a three-dimensional space structure is more stable, and therefore, the compound has high glass transition temperatureand molecular thermal stability; in addition, the HOMO and LUMO distribution positions of the compound are separated from each other, so the compound has appropriate HOMO and LUMO energy levels. Therefore, after the compound is applied to the OLED device, the luminous efficiency of the device can be effectively improved, and the service life of the device can be effectively prolonged.

Owner:JIANGSU SUNERA TECH CO LTD

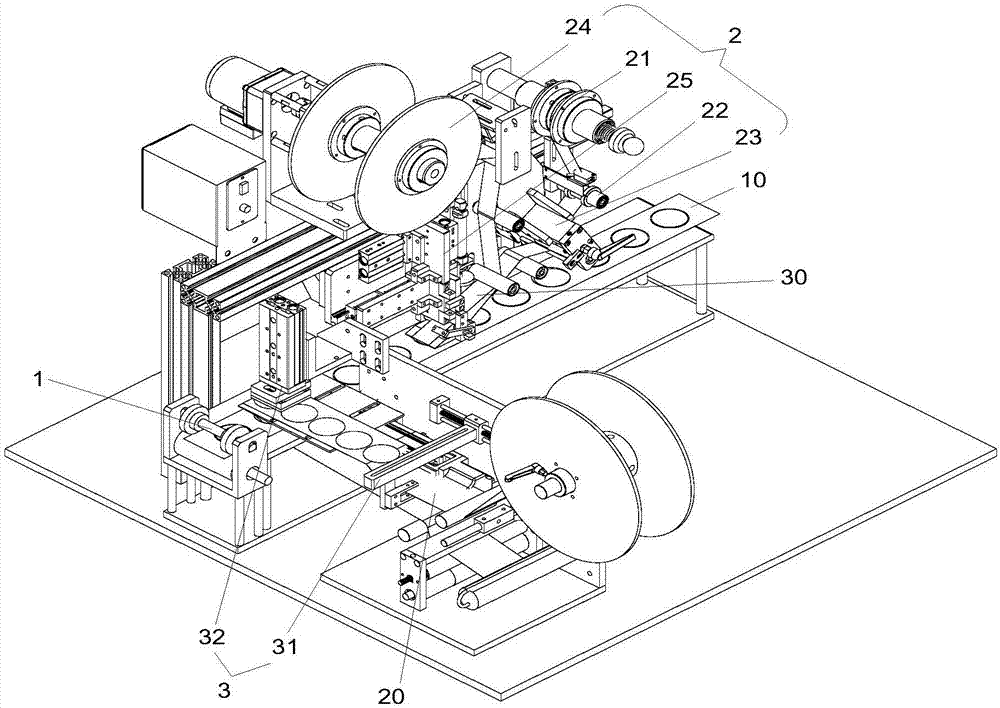

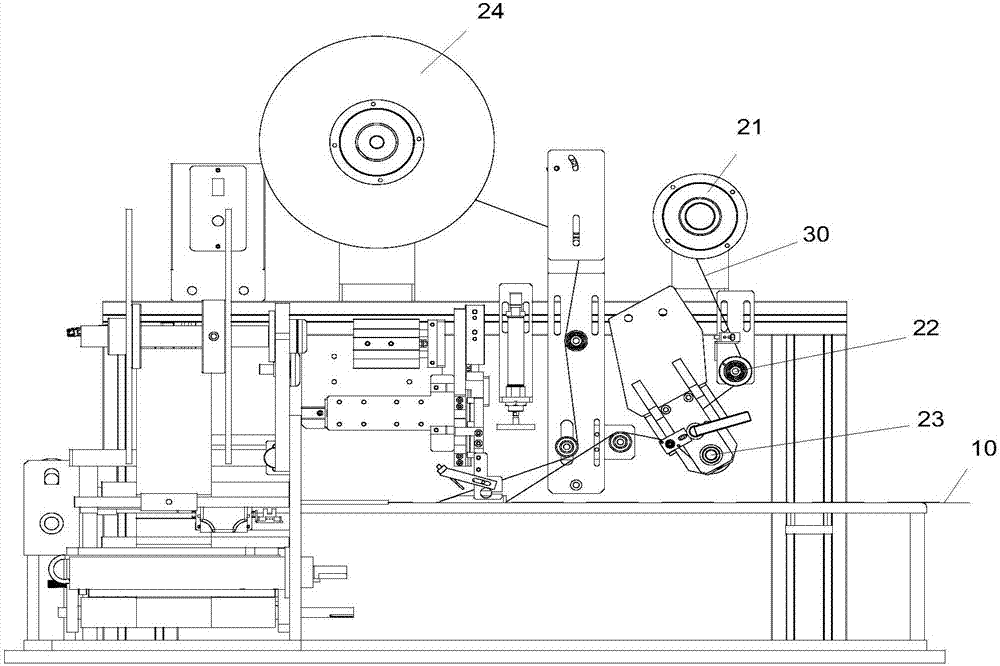

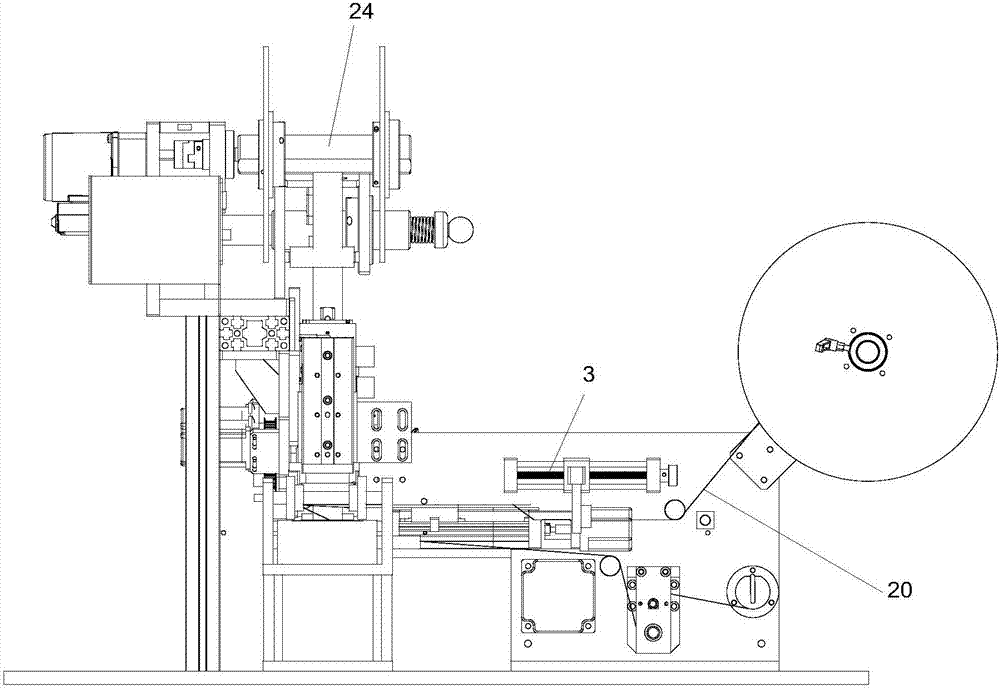

Single defective product removing and supplementing-pasting mechanism and method for die cutting tape

PendingCN107398948AShorten the timeReduce deformation effectsMetal working apparatusProduct inspectionProcess engineering

The invention relates to the technical field of waste discharge of a die cutting tape, in particular to a single defective product removing and supplementing-pasting mechanism and method for the die cutting tape. The mechanism comprises a tape linear conveying device, a film tearing and waste discharging device and a good product supplementing-pasting device; the tape linear conveying device is used for conveying the tape and sending a defective product position to the film tearing and waste discharging device and the good product supplementing-pasting device; the film tearing and waste discharging device is used for discharging waste by adopting an adhesive tape pasting method; and the good product supplementing-pasting device is used for supplementing and pasting a good product at the original defective product position. The single defective product removing and supplementing-pasting mechanism for the die cutting tape is used for automatically removing a defective product of the rolled die cutting tape and then automatically supplementing and pasting a good product on the tape, two tasks of removing the defective product and supplementing and pasting the good product can be completed at a time, the tape does not need to be repeatedly rolled so that the deformation influence on a tape product can be small, and therefore the time for removing the defective product and supplementing and pasting the good product can be greatly shortened, the productivity can be greatly improved, the manpower requirement can be lowered, a plurality of mechanisms can be managed by one person, and the mechanism is an excellent partner of product inspection equipment.

Owner:SHENZHEN HADESHENG PRECISION TECH

Organic compound based on pyridine and quinoxaline and application of organic compound to OLED (organic light emission diode) device

InactiveCN107602538APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesQuinoxalineHeat stability

The invention relates to an organic compound based on pyridine and quinoxaline and an application of the organic compound to an OLED (organic light emission diode) device. The compound has higher glass transition temperature and molecular heat stability, and is low in absorption and high in refractive index in the field of visible light, and light extraction efficiency of the OLED device can be effectively improved after the organic compound is applied to a CPL layer of the OLED device; the compound further has high HOMO energy level and high electron mobility and can be taken as a hole-blocking / electron transfer layer of the OLED device and can effectively prevent holes or energy from being transferred to one side of the electron layer from a luminous layer, so that composite efficiency of the holes and electrons in the luminous layer is improved, the luminous efficiency of the OLED device is improved, and the service life of the OLED device is prolonged.

Owner:VALIANT CO LTD

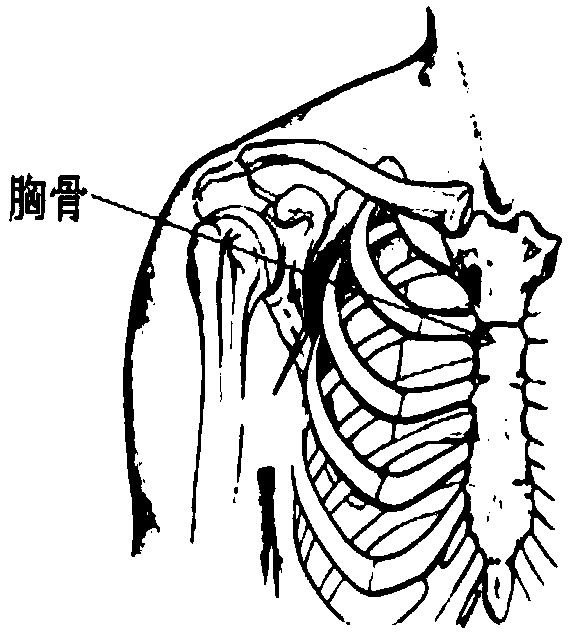

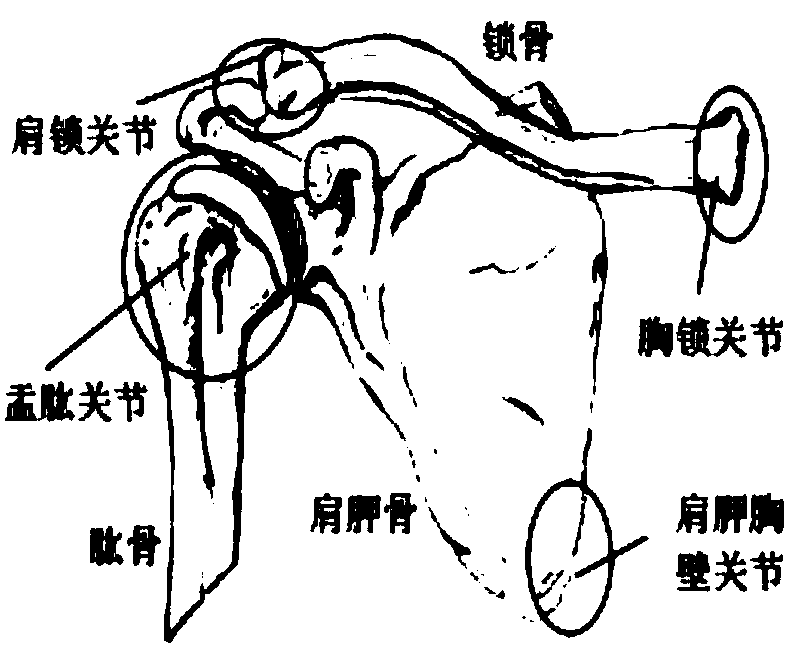

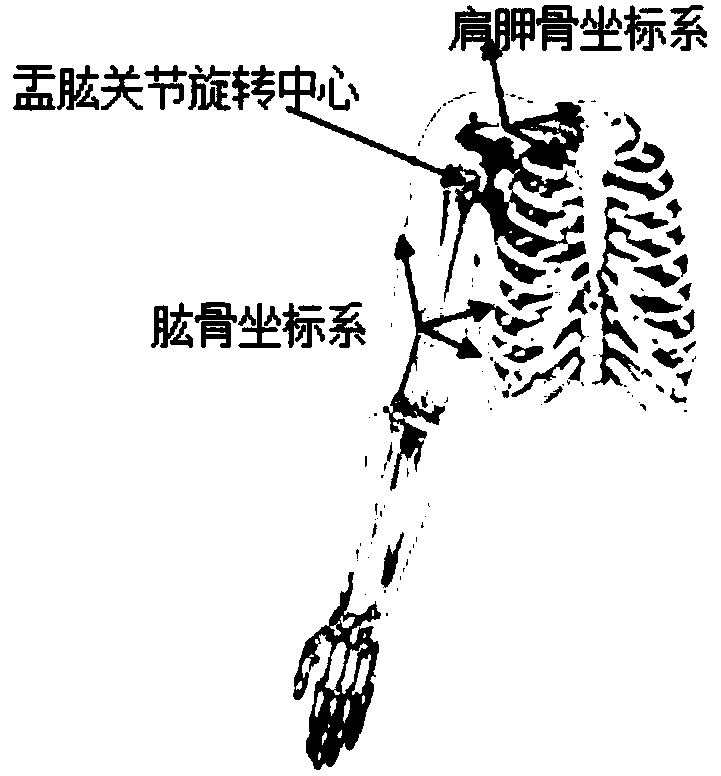

Measuring method of coupling relation of human body upper limb shoulder glenohumeral joint rotation center and upper arm lifting angle

ActiveCN108030496AReduce deformation effectsEasy to measureDiagnostic recording/measuringSensorsMeasurement pointLateral epicondyle

The invention discloses a measuring method of the coupling relation of the human body upper limb shoulder glenohumeral joint rotation center and the upper arm lifting angle. The measuring method comprises the steps of acquiring human body shoulder joint motion data, wherein mark point motion blocks are fixed to the scapula and the humerus, and six mark points are fixed to the 7 th cervical vertebra, the 8 th thoracic vertebra, the jugular notch, the xiphoid, the lateral epicondyle and the medial epicondyle of the human body to obtain motion information of corresponding bones; building a shoulder motion model, wherein the scapula and the humerus are used as a rigid body respectively, and based on rotation geometric knowledge, a kinematic model of which the rotation center is unchanged relative to the adjacent rigid body pose is built; solving the coupling relation of the glenohumeral joint rotation center and the lifting angle, wherein since the joint center is unchanged relative to themark point pose of the adjacent rigid body, regression parameters are obtained, then the instantaneous position of the rotation center is obtained, and thus the coupling relation of the lifting angleand the rotation center is obtained. The measuring points are bond or fixed to the human body through a flange, deformation is reduced, calculation is simple, and measurement is accurate.

Owner:BEIJING UNIV OF TECH

Organic compound taking triazine and benzimidazole as cores and application thereof

InactiveCN106946860AImprove structural stabilityHigh densityOrganic chemistrySolid-state devicesRefractive indexGlass transition

The invention relates to an organic compound taking triazine and benzimidazole as cores and application thereof to an OLED (Organic Light Emitting Diode) device. The compound provided by the invention has relatively high glass transition temperature and molecule thermal stability; the compound has low absorption and high refractive index in the field of visible light; after the compound is applied to a CPL (Circular Polarizing Filter) layer of the OLED device, the light extraction efficiency of the OLED device can be effectively improved; the compound also has a deep HOMO energy level and high electron mobility and can be used as a hole-blocking / electron transferring layer material of the OLED device; and the compound can be used for effectively stopping a hole or energy from being transmitted to one side of an electron layer from a light emitting layer, so that the compounding efficiency of the hole and electrons on the light emitting layer is improved, and furthermore, the luminous efficiency of the OLED device is improved and the service life of the OLED device is prolonged.

Owner:VALIANT CO LTD

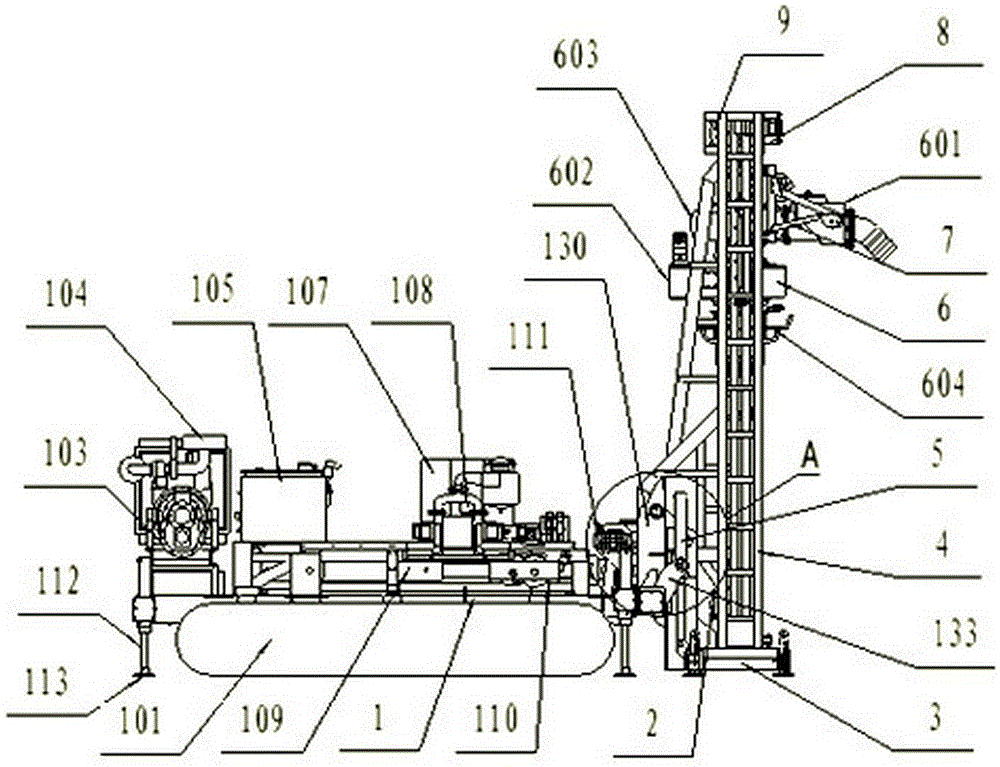

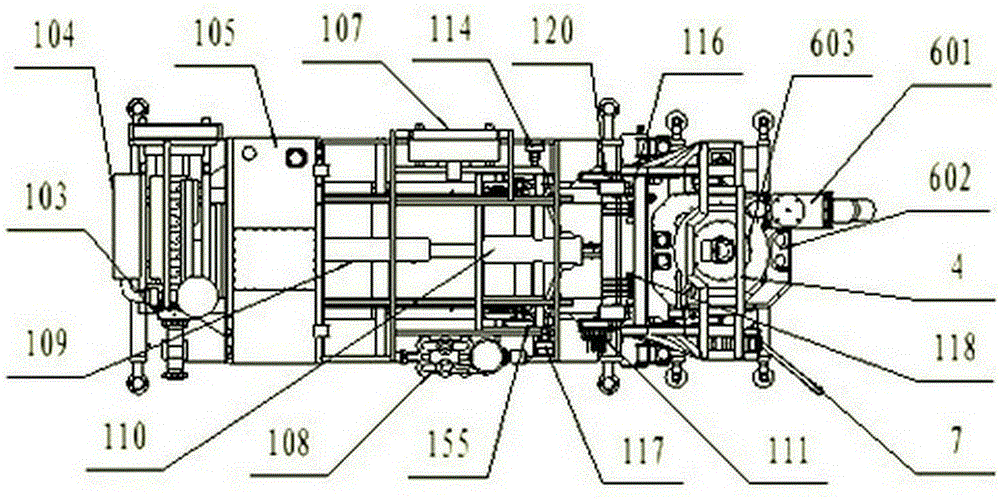

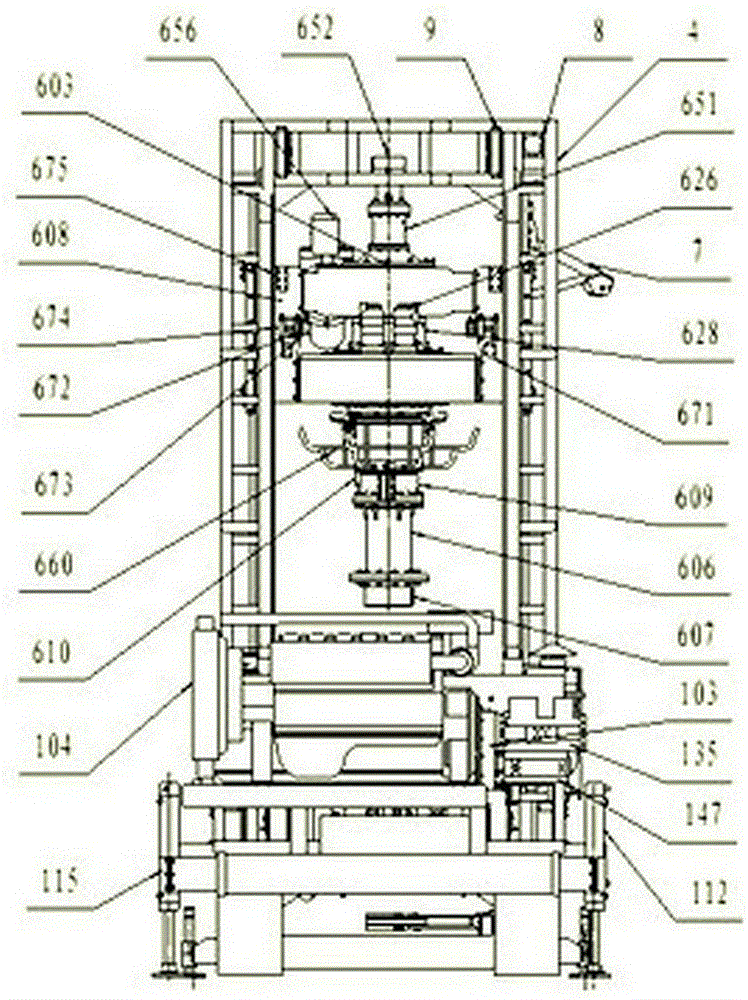

Fully hydraulic reverse circulation drilling machine

InactiveCN105064915AAdapt to the working environmentReduce noiseDrill bitsDrilling rodsGear wheelWinch

The invention provides a fully hydraulic reverse circulation drilling machine, which comprises a walking mechanism, a chassis assembly, a work table frame assembly, a main frame, a main frame turning oil cylinder, a swinging rod assembly, a winch assembly, a drill pipe, a dismounting device, a hydraulic system, a power take-off assembly, an impact drill bit, a rotating wing drill bit, a power assembly and an oil cylinder pulley assembly. A diesel engine or electric power is used for driving; hydraulic motors and oil cylinders are used as executing mechanisms; and the whole process operation of the drilling machine is realized through a hydraulic transmission and control system. The two hydraulic motors and a gear reducer are used for forming a power head to drive a drilling tool to rotate; the hydraulic motors adopt a serial connection or parallel connection mode; and the drill pipe realizes different rotating speeds and can adapt to different-geological-condition and different-hole-diameter operations. The oil cylinders are used for controlling the oil pipe feeding and lifting the drilling tool, so that the power head can vertically move along with the drilling tool and can realize floating, suspension stop and pressurized drilling; the drill pipe can be automatically dismounted and mounted; and the impact drill bit and the rotating wing drill bit are used for realizing the hole drilling of holes with the hole diameter being 2 to 3m and the hole depth exceeding 200m in the pebble bed, the hard rock stratum and the stratum containing large-diameter rock blocks.

Owner:王乐康

Organic compound based on pyridine and benzimidazole and application of organic compound

InactiveCN106967052APrevent free spinsImprove structural stabilityOrganic chemistrySolid-state devicesElectronic transmissionHeat stability

The invention relates to an organic compound taking pyridine and benzimidazole as a core and an application of the organic compound on an OLED (organic light emitting diode) device. The compound has relatively high glass state temperature and molecular heat stability, low absorption and high refractive index in the field of visible light, and can effectively improve light extraction efficiency of the OLED device after the compound is applied to a CPL (circular-polarizing filter) layer of the OLED device. The compound further has an HOMO (highest occupied molecular orbital) energy level and high electron mobility, and can serve as a hole obstruction / electronic transmission layer material of the OLED device and effectively prevent a hole or energy from being transmitted to one side of an electronic layer from a light emitting layer, so that the combination efficiency of the hole and an electron on the light emitting layer is improved; and the light emitting efficiency and a service life of the OLED device are improved and prolonged.

Owner:VALIANT CO LTD

Plastic building templates and buckle connecting pieces

ActiveCN102747834AImprove protectionSave resourcesAuxillary members of forms/shuttering/falseworksForming/stuttering elementsEngineeringSlurry

The invention provides plastic building templates and buckle connecting pieces. Each plastic building template comprises a positive outrigger structure template, a negative outrigger structure template, an internal corner template, an external corner template and a joint angle mould; and the buckle connecting piece mainly comprises clamping plates, an eye bolt, an eccentric spanner, a support plate and the like, wherein the clamping plate is provided with a clamping hook part, clamping main parts and a support part; a clamped part mainly including support legs which are matched with the clamping parts of the clamping plates of the buckle connecting pieces is arranged in each plastic building template; and two lateral connection parts which are spliced with the adjacent plastic building templates are arranged on each plastic building template. When the templates and the buckle connecting pieces are used, the templates are mutually spliced tightly and firmly without leaking slurry, so that the compaction resistant capability of the templates is high, the templates and the buckle connecting pieces are convenient to mount, the detachment is time-saving and labor-saving, and the working hours and the cost are saved.

Owner:CHANGZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com