Novel longitudinal magnetic coil structure of vacuum arc extinguishing chamber

A vacuum interrupter and coil technology, which is applied to high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve the problems of affecting welding quality, affecting breaking effect, and large contact resistance, so as to avoid excessive contact resistance, The effect of improving the first pass rate and improving the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

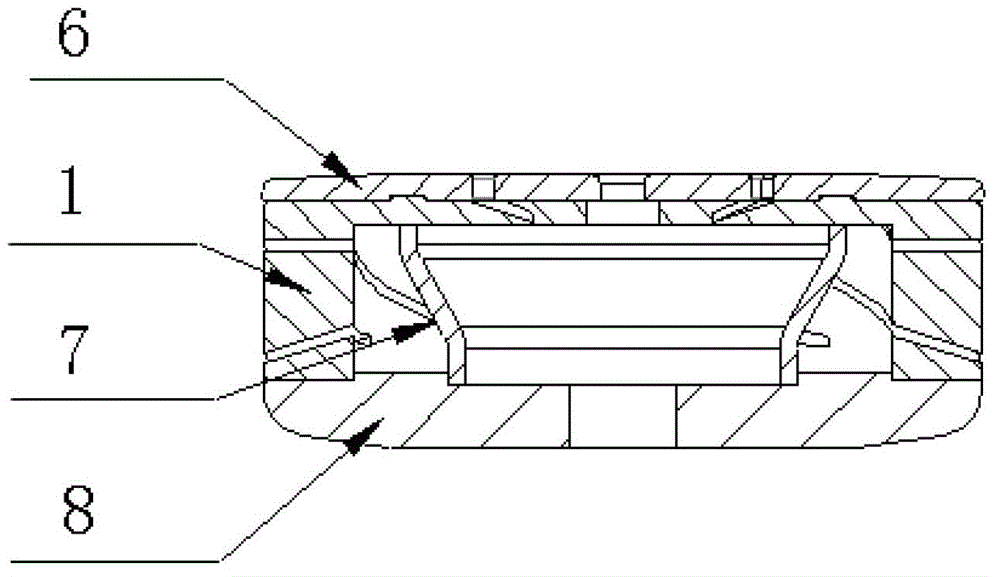

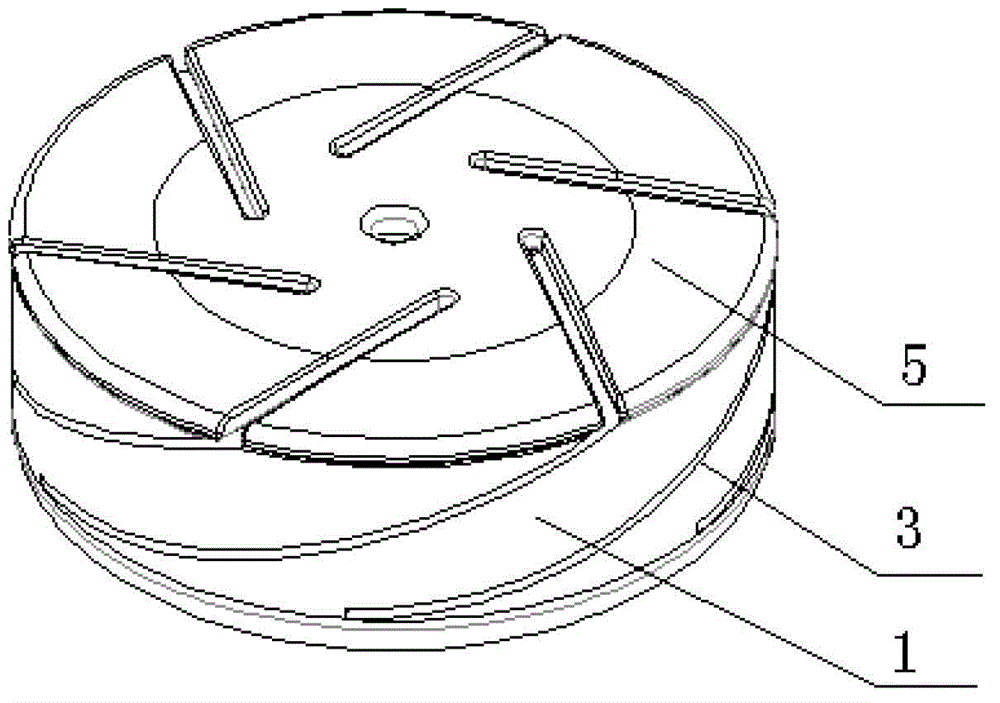

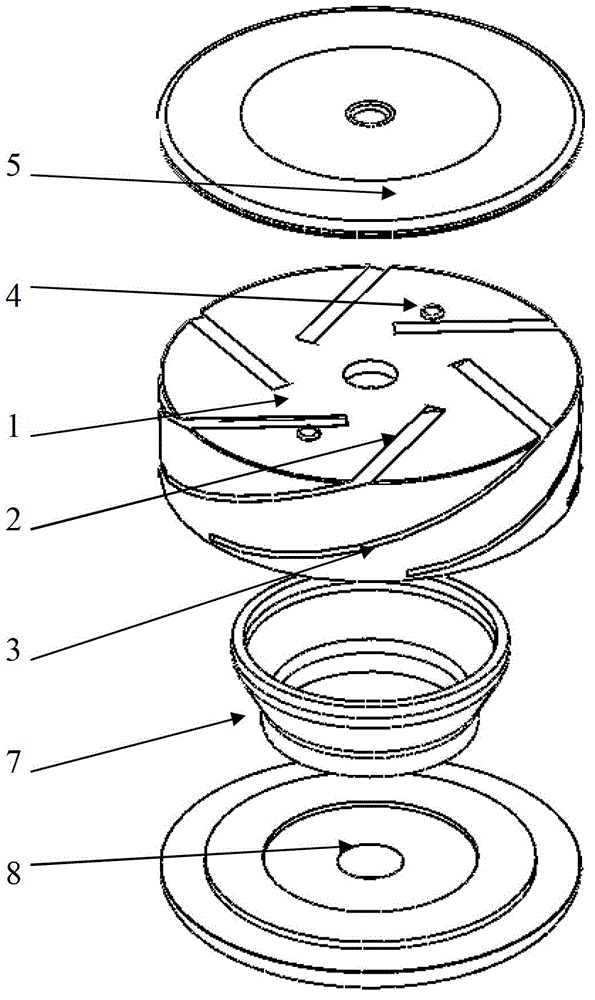

[0016] detailed description : A novel longitudinal magnetic coil structure for a vacuum interrupter, such as figure 1 with 2 As shown, the longitudinal magnetic coil structure is composed of a coil 1 , a contact 5 , a rib 7 and a cup holder 8 . The contact 5 and the coil 1 are connected by brazing, and the contact 5 can be a slotted structure or a non-slotted structure, such as figure 2 with image 3 shown. The coil 1 and the cup holder 8 are connected by brazing, and the reinforcing rib 7 is installed between the coil 1 and the cup holder 8 to increase the strength; the coil 1 is a bowl-shaped structure, and the bottom of the bowl of the coil 1 has two or more Groove 2, groove 2 is at an oblique angle to the axis of coil 1, groove 2 is connected to chute 3, and the chute 3 is non-penetrating below the coil during processing, and the distance between the bottom of chute 3 and the open end surface of coil 1 0.5-3mm. During assembly, the top of the coil 1 can be directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com