Patents

Literature

328results about How to "Reduce the possibility of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

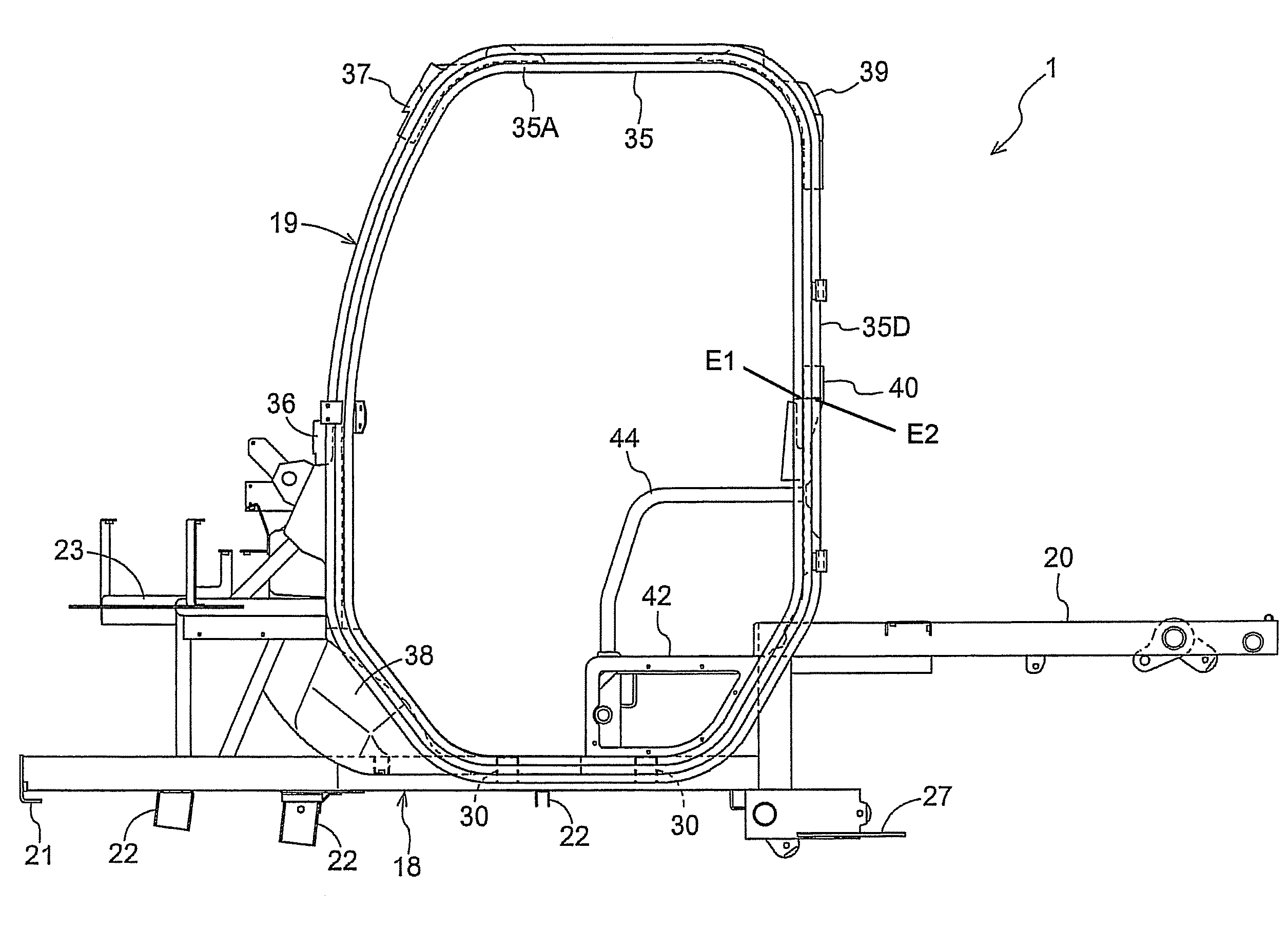

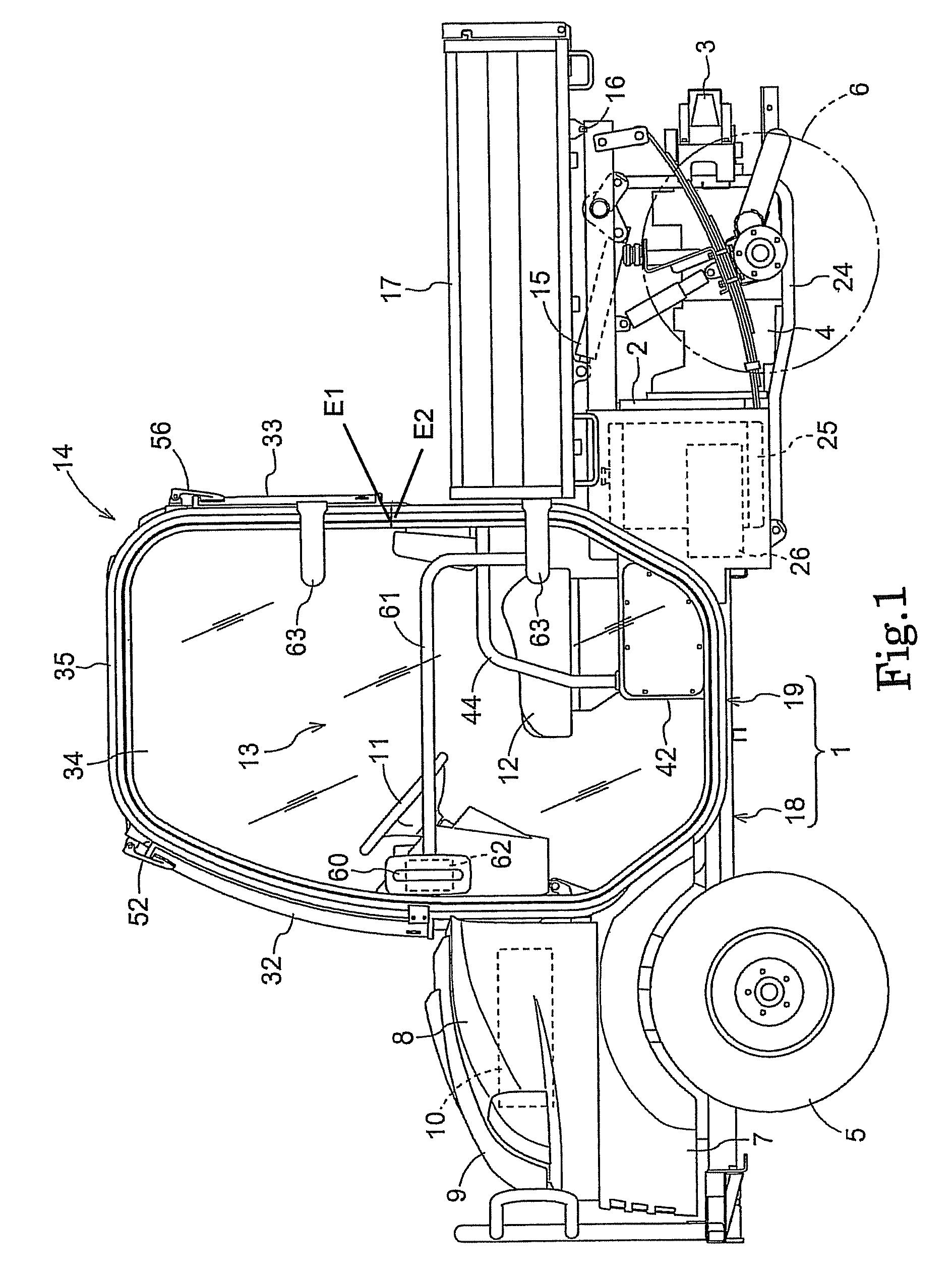

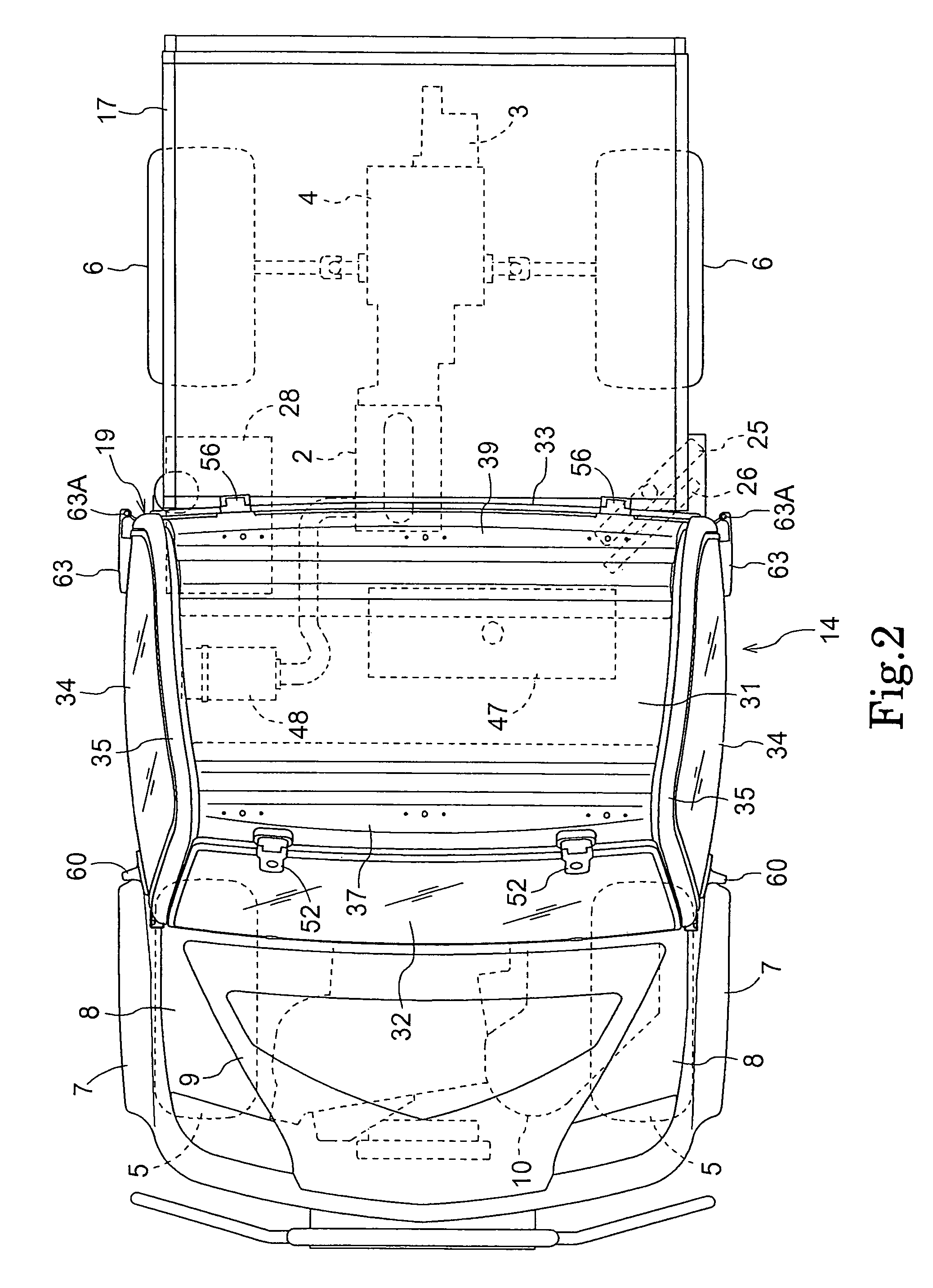

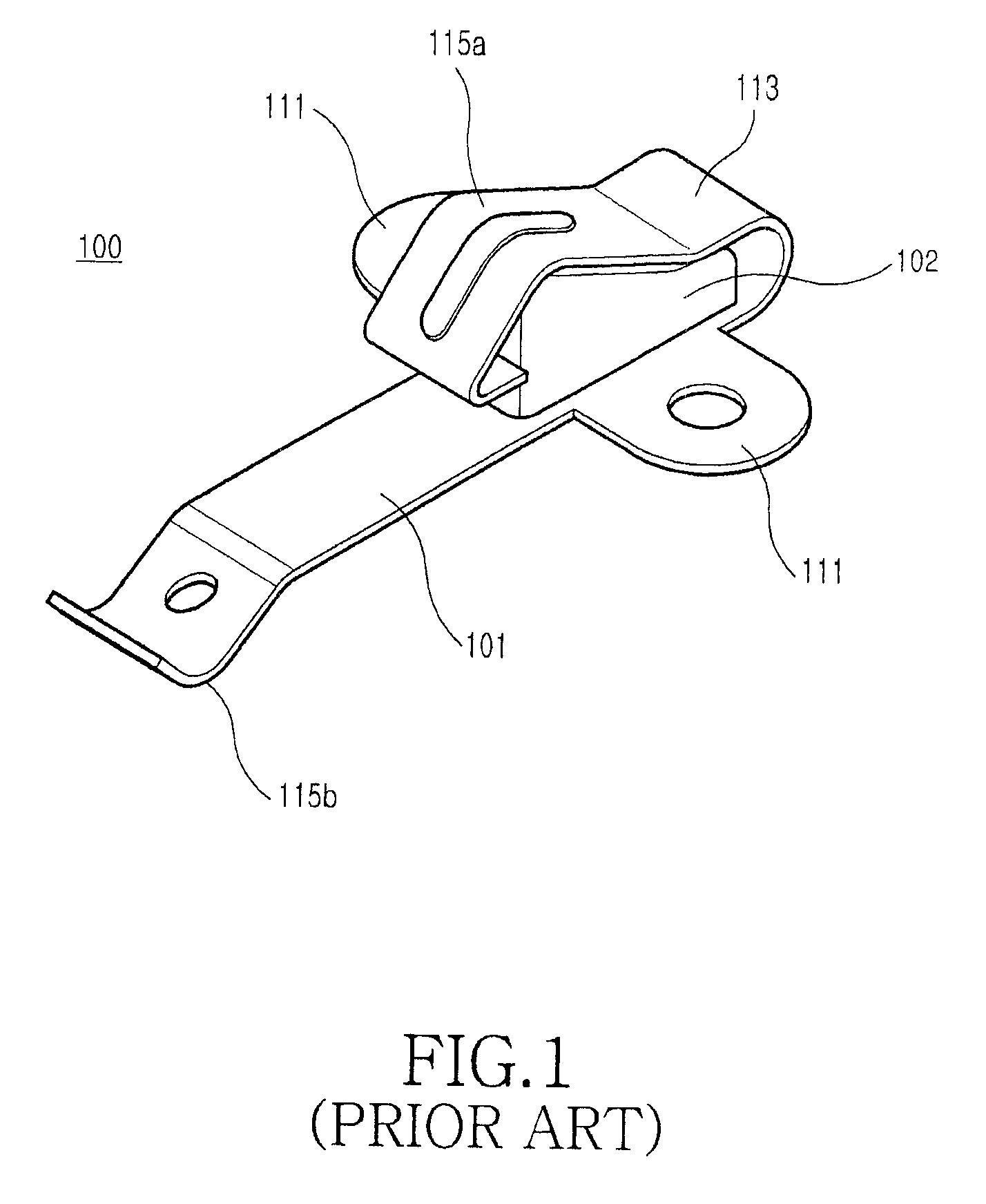

Vehicle frame for work vehicle and method for manufacturing same

ActiveUS7677646B2Reduce the possibility of deformationIncreased complexityVehicle seatsDashboardsVehicle frameEngineering

The vehicle frame for a work vehicle includes a cabin frame that is assembled into a substantially box form. A base frame is welded to the cabin frame. The cabin frame includes left and right side frames, each of which is formed into a loop. The cabin member includes a plurality of cross members for connecting the left and right side frames. Each of the side frames is formed with a single one-piece pipe material having a first end and a second end with the first end connected to the second end such that a tangential direction extending along a region of the first end coincides with a tangential direction extending along a region of the second end. The pipe material has an irregular shape having a recess formed along the entire length between the first end and the second end of the pipe material.

Owner:KUBOTA CORP

Method for preparing absorbing layer of thin film solar cell

InactiveCN101728461AReduce the temperatureReduce softeningFinal product manufactureSemiconductor devicesIndiumNew energy

The invention relates to a method for preparing an absorbing layer of a thin film solar cell, belonging to the technical fields of photoelectric functional material and new energy. The method is characterized in that a Cu-In-Se absorbing layer, a Cu-In-Ga-Se absorbing layer or a Cu-In-Al-Se absorbing layer is prepared by a vacuum magnetron sputtering method; a Cu-In-Se alloy target, a Cu-In-Ga-Se alloy target or a Cu-In-Al-Se alloy target is directly used, and the components of the absorbing layer are controlled by the components of the target; and the film formation quality is controlled by the sputtering technology. The absorbing layer prepared by the magnetron sputtering method can be subsequently treated by annealing in the protection atmosphere, so that the crystallization quality is further improved. The absorbing layer prepared by the method is formed by uniform Cu-In-Se phase, Cu-In-Ga-Se phase or Cu-In-Al-Se phase, so that the component distribution is even, and the components of the absorbing layer are consistent with the components of the target. The method is simple and convenient in technique, easy to control and lower in matrix temperature when in deposition, can select multiple substrates, and ids suitable for industrialized production.

Owner:TSINGHUA UNIV +1

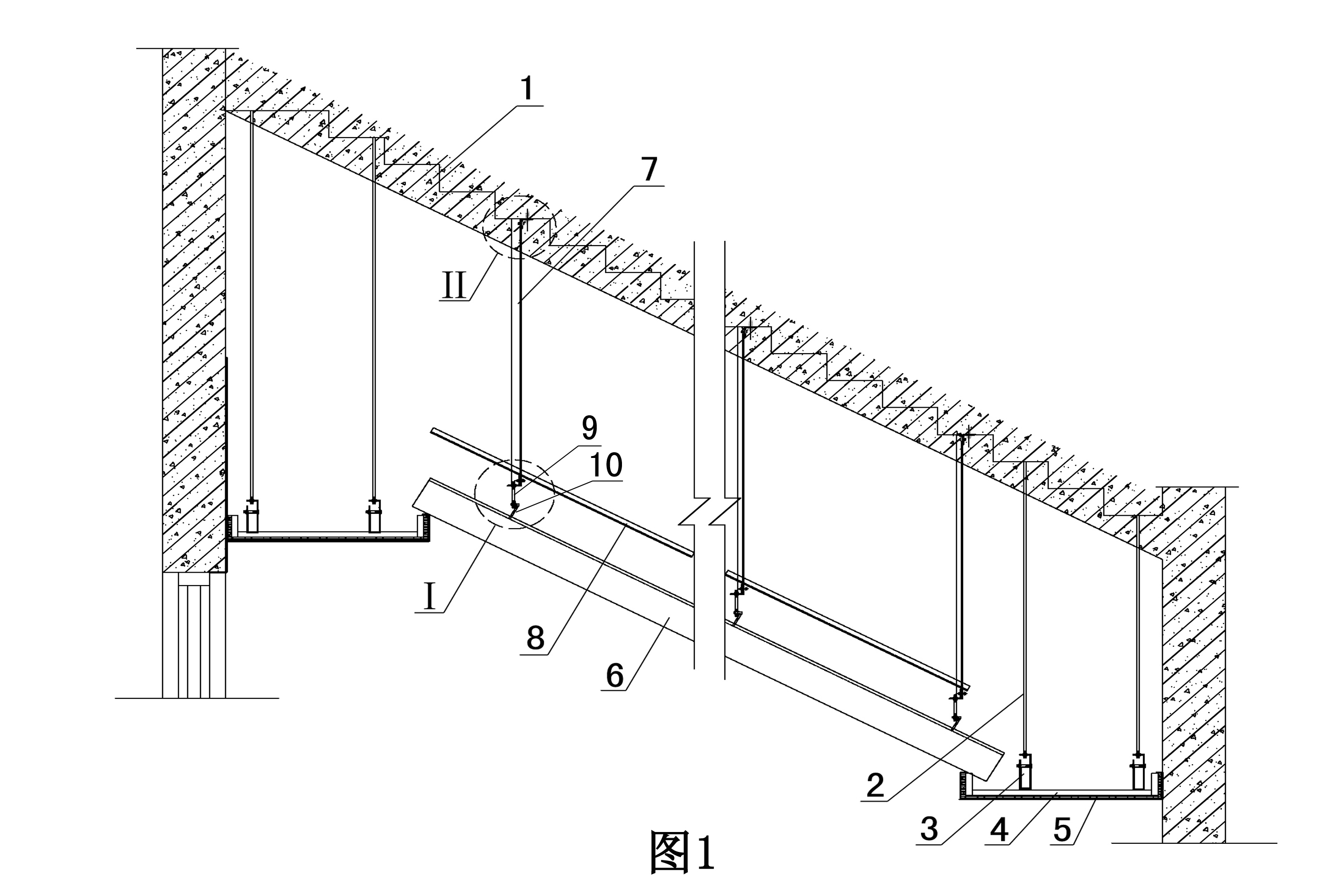

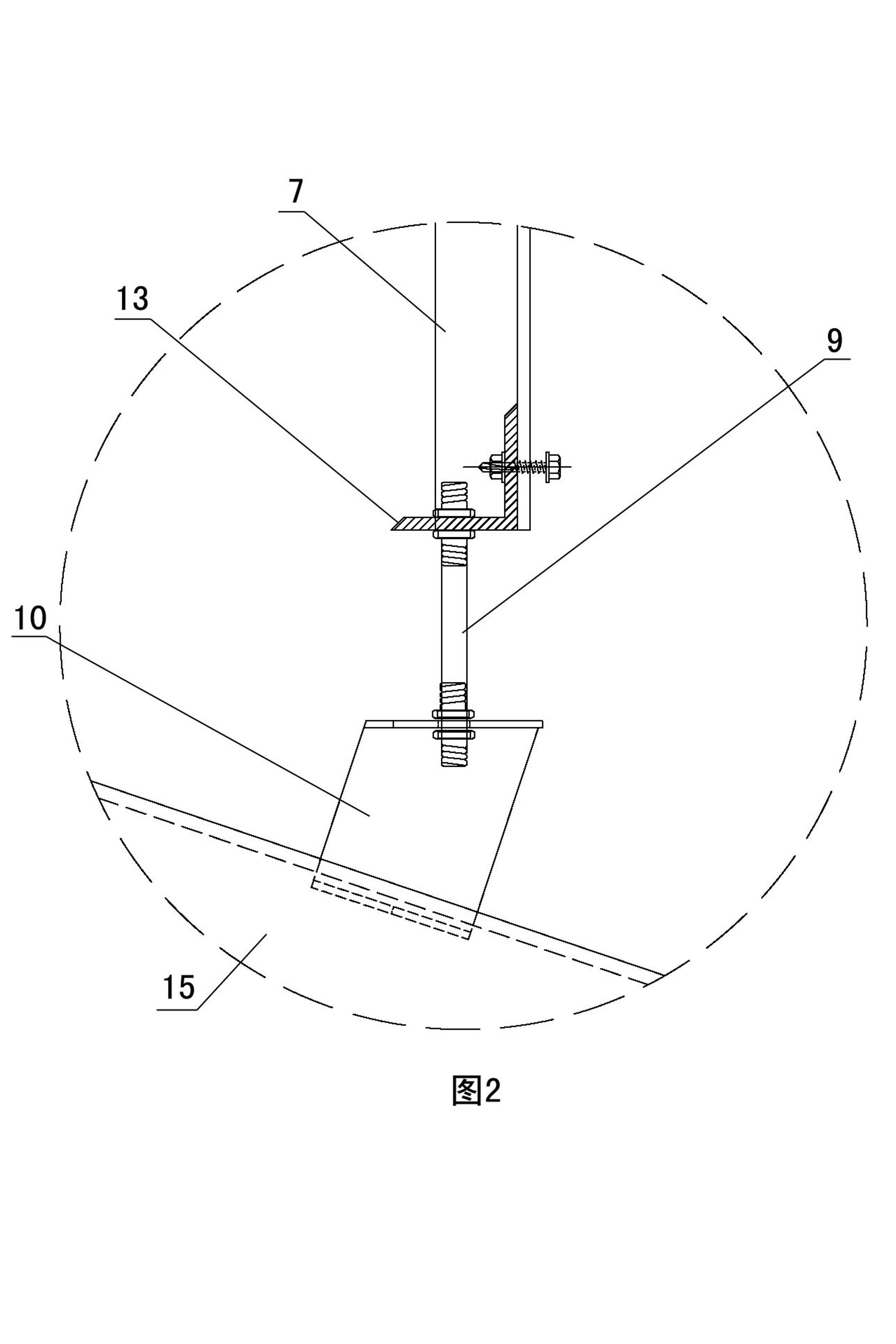

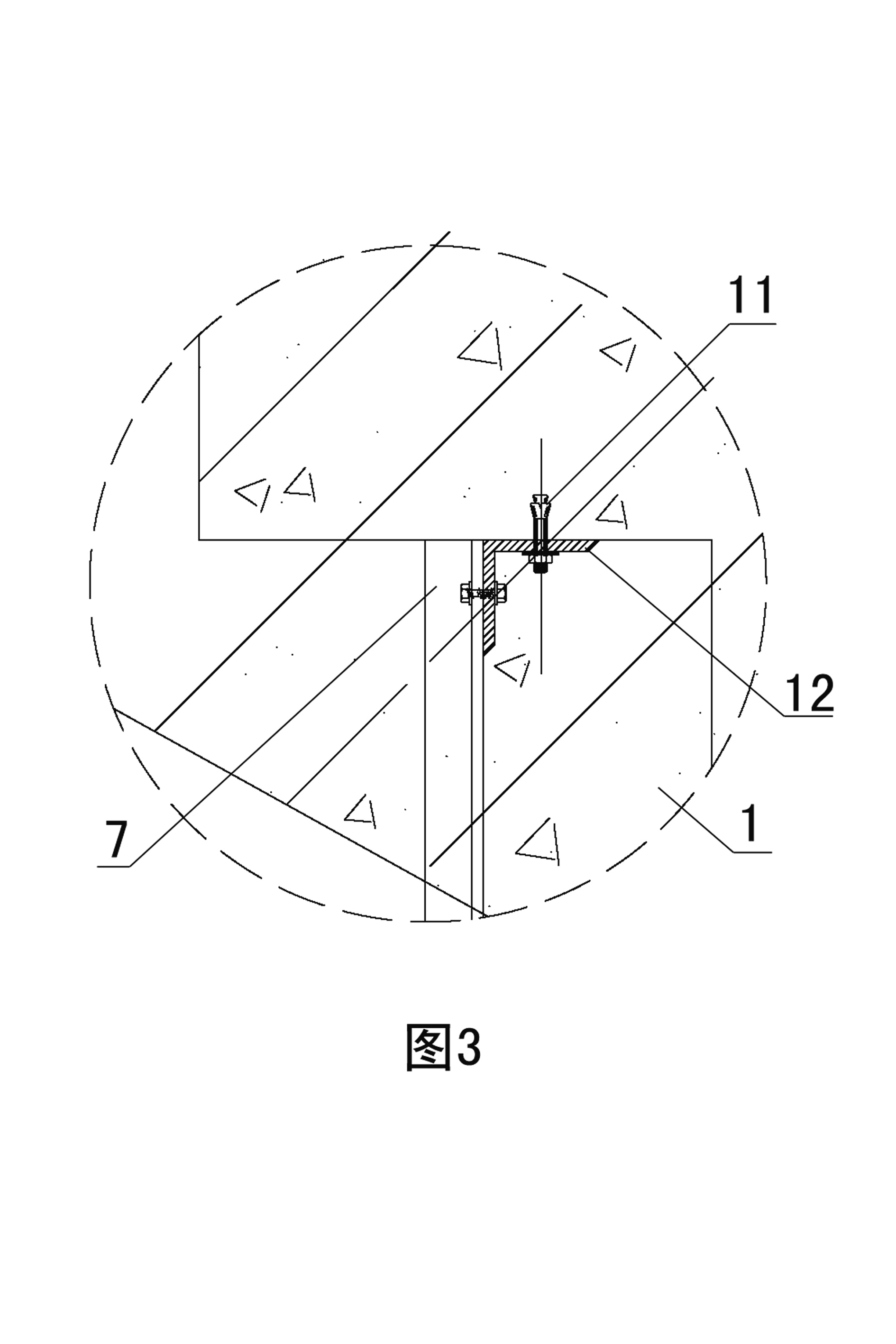

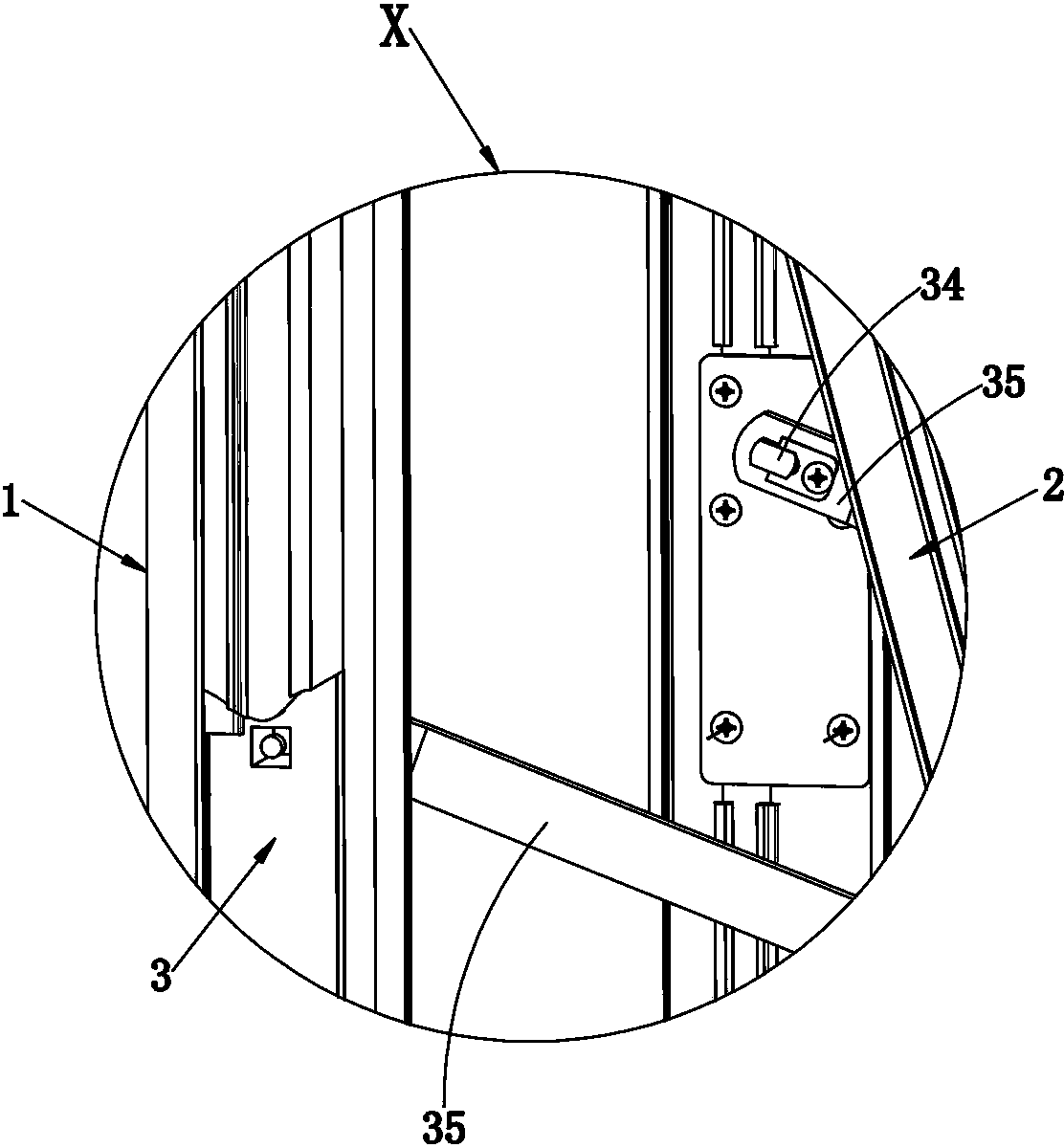

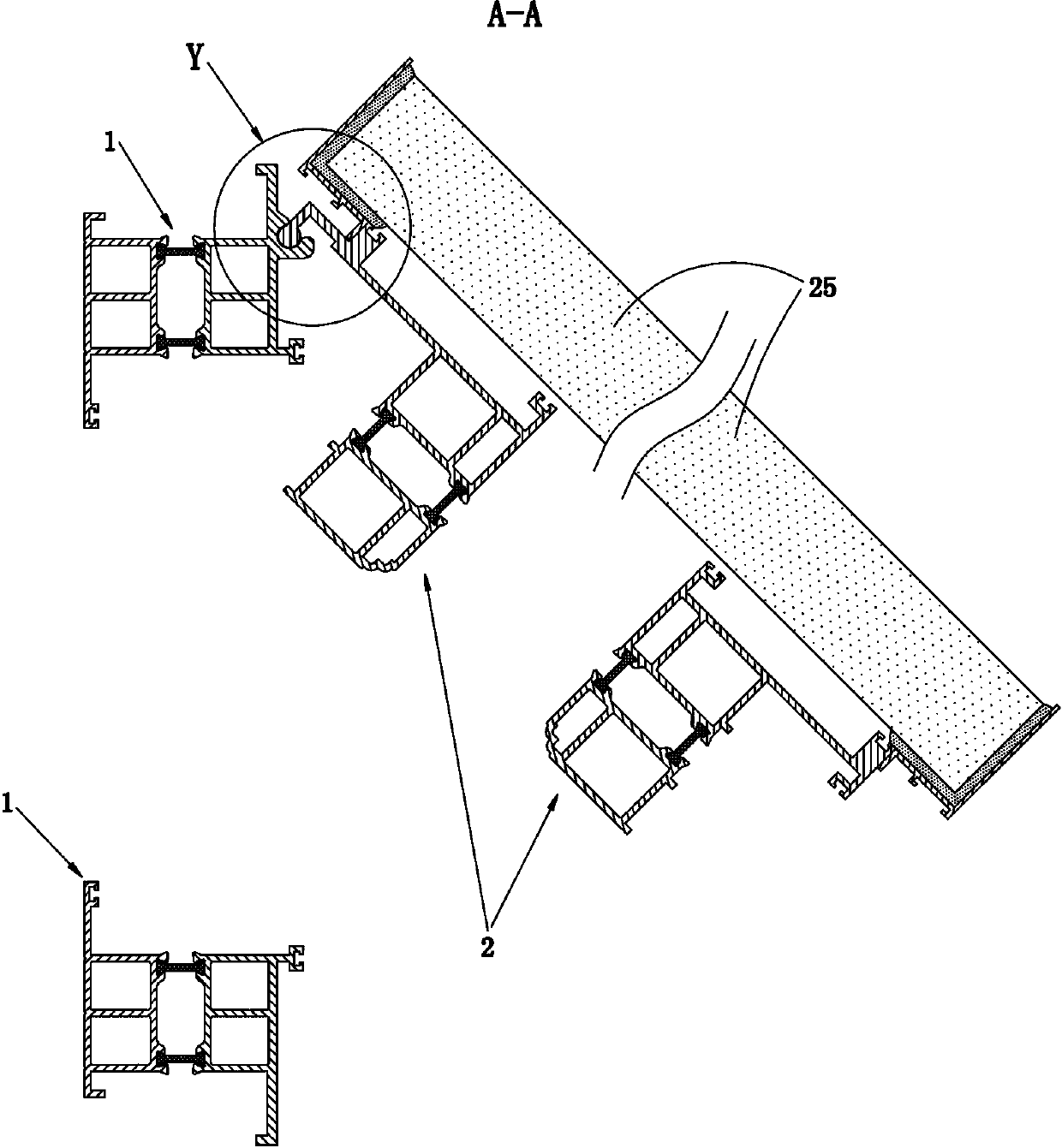

Special aluminum square tube ceiling and construction method thereof

The invention discloses a special aluminum square tube ceiling and a construction method thereof. The special aluminum square tube ceiling comprises a hanging steel bar keel hung under a concrete top plate, a cross-bracing keel and an aluminum square tube ceiling connected at the lower end of the cross-bracing keel, wherein the aluminum square tube ceiling is formed by the spaced distribution of a plurality of aluminum square tubes with U-shaped sections; the hanging steel bar keel is an unequal-length keel; the aluminum square tube ceiling presents the shape of a curved surface; two continuous aluminum square tubes are butt-jointed by a woody connection fitting, the two ends of the woody connection fitting are respectively embedded in U-shaped spaces of the aluminum square tubes, and the two U-shaped edges of the aluminum square tubes are extended to form bent edges which are symmetrical inwards and are covered on the two upper edges of the woody connection fitting. With the advantages of simple structure, labor / time saving, quick construction, low cost, accurate ceiling shape positioning and smooth curve, the invention is applicable to the building ceilings in various curved shapes.

Owner:BEIJING CONSTR ENG GRP CO LTD

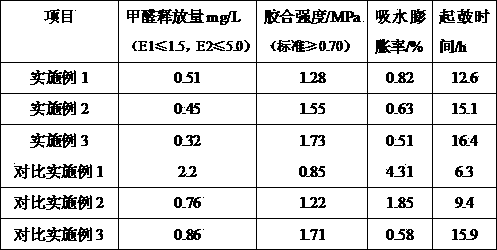

Production method for damp-proof full-eucalyptus laminated wood veneer

ActiveCN103406951AStress reliefReduce water exposurePlywood pressesVeneer pressesWood veneerAdhesive

The invention provides a production method for a damp-proof full-eucalyptus laminated wood veneer. The artificial board is formed by high-temperature pressing and pasting of a base material and melamine impregnated paper, wherein the base material is formed by bonding a plurality of layers of eucalyptus veneers through adhesives. The production method comprises the steps of veneer sorting, gluing, cold pressing, hot pressing, stacking maintenance and pasting of the melamine impregnated paper. The production method is characterized in that three times of cold pressing and hot pressing and two times of thermostatic chamber standing maintenance and cooling maintenance processes are adopted, the cold pressing is performed at the room temperature and under the pressure of 0.8-1.0MPa, the hot pressing is performed under the pressure of 1.5-2.0MPa, the first hot pressing is performed at the temperature of 120-125DEG C, the second hot pressing is performed at the temperature of 115-120DEG C, and the third hot pressing is performed at the temperature of 125-130DEG C; the thermostatic chamber standing maintenance is performed at the temperature of 80-90DEG C for 4-6h; the cooling maintenance is cooled to the room temperature from the temperature of a thermostatic chamber through natural ventilation for 3-4h.

Owner:莫明鑫

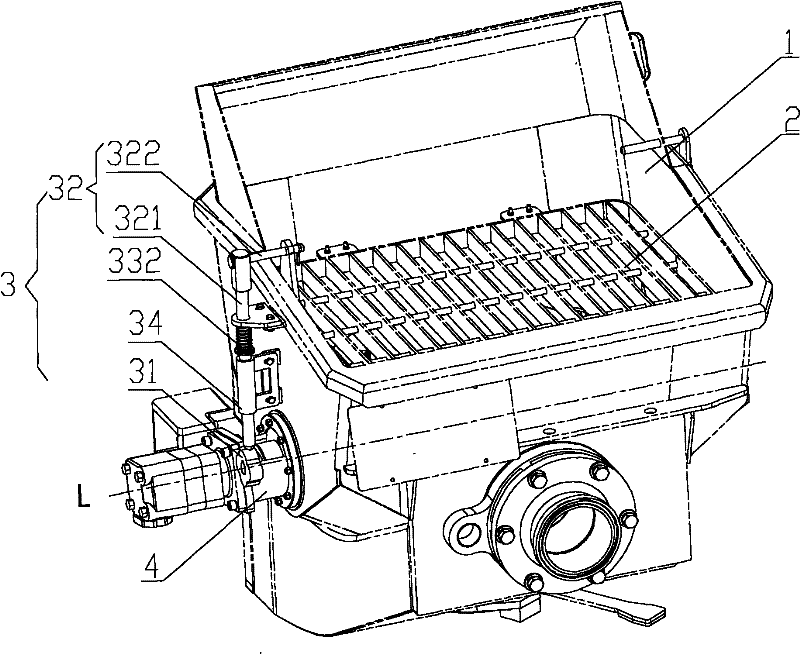

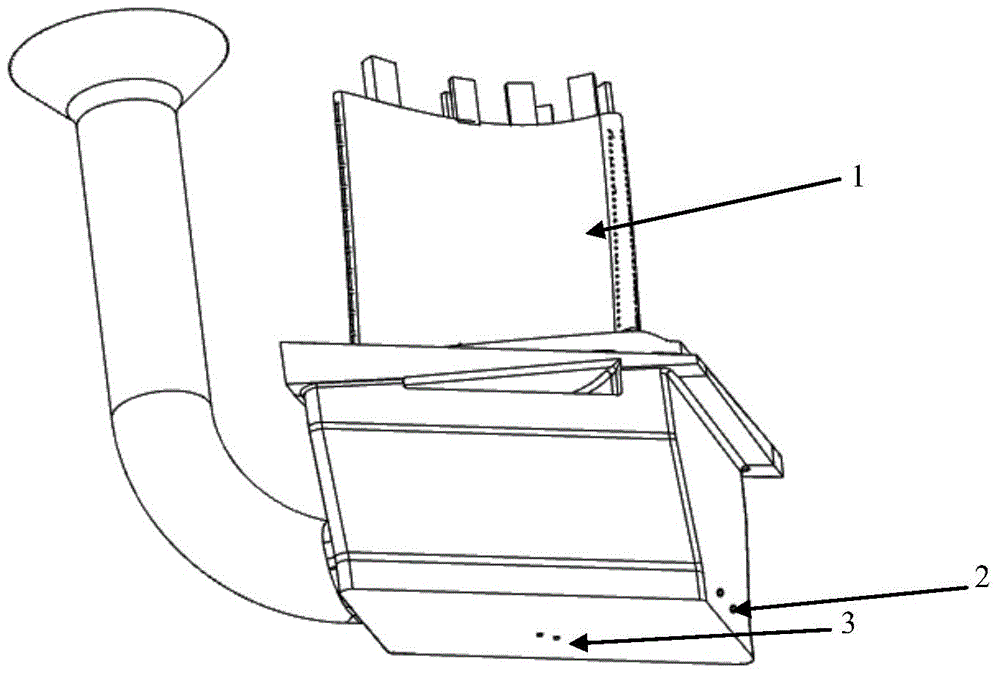

Concrete pump

ActiveCN102192122AEasy accessReduce the amount of accumulationPumpsPositive-displacement liquid enginesDrive wheelReciprocating motion

The invention discloses a concrete pump, which comprises a concrete stirring device, a hopper (1), a fence (2) arranged in the hopper (1), and a vibrating device (3) used for driving the fence (2), wherein the vibrating device (3) comprises a vibrating arm (32) and a driving wheel (31) for driving the vibrating arm (32) to perform reciprocating movement; the driving wheel (31) is a cam and is fixedly connected with a stirring shaft (4) of the concrete stirring device; and the vibrating arm (32) is fixedly connected with the fence (2). The concrete pump solves the problem of easy concrete accumulation on the fence to ensure that concrete can enter the hopper quickly and is pumped smoothly, and the working efficiency and the reliability of the concrete pump are improved.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

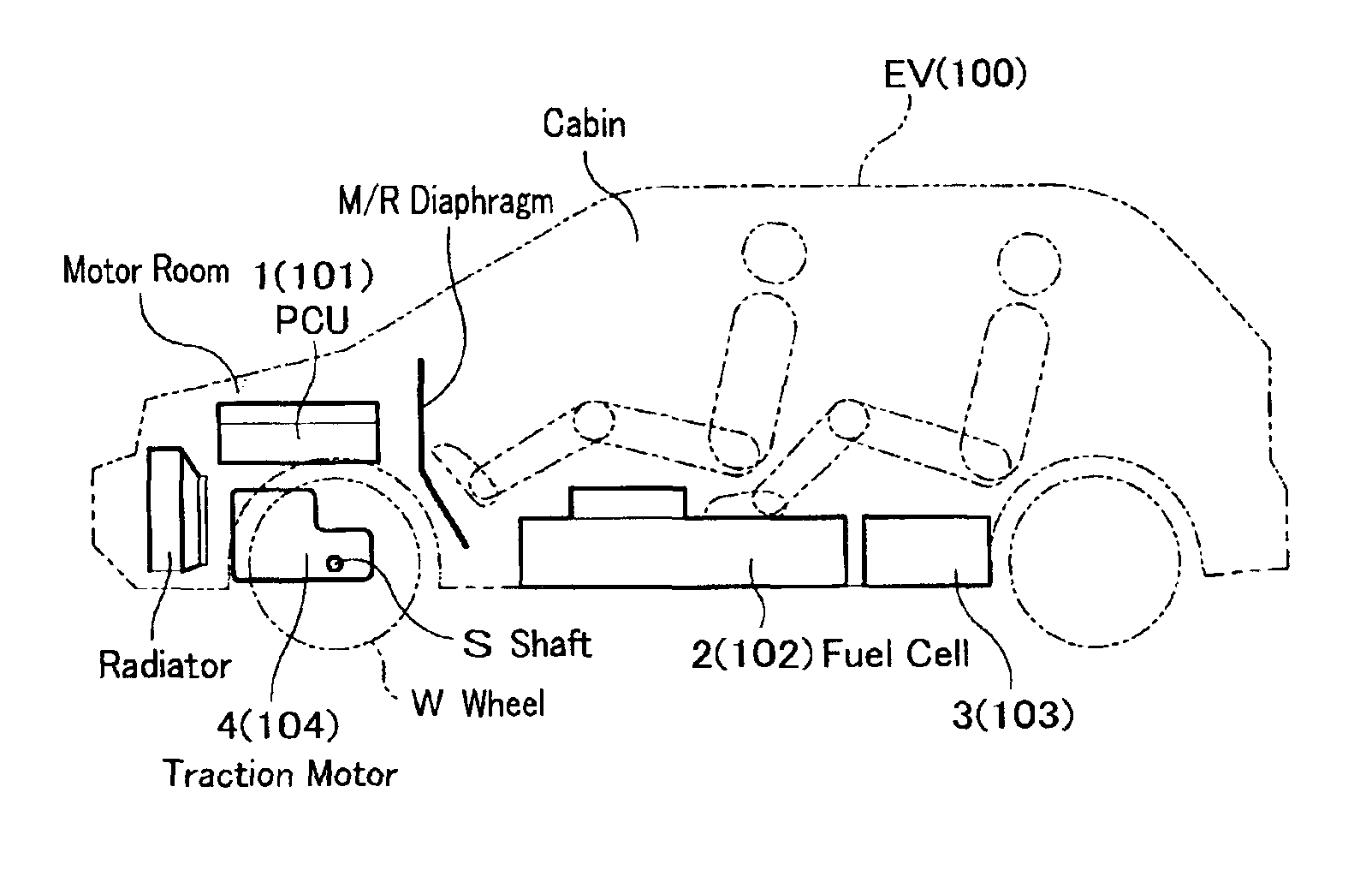

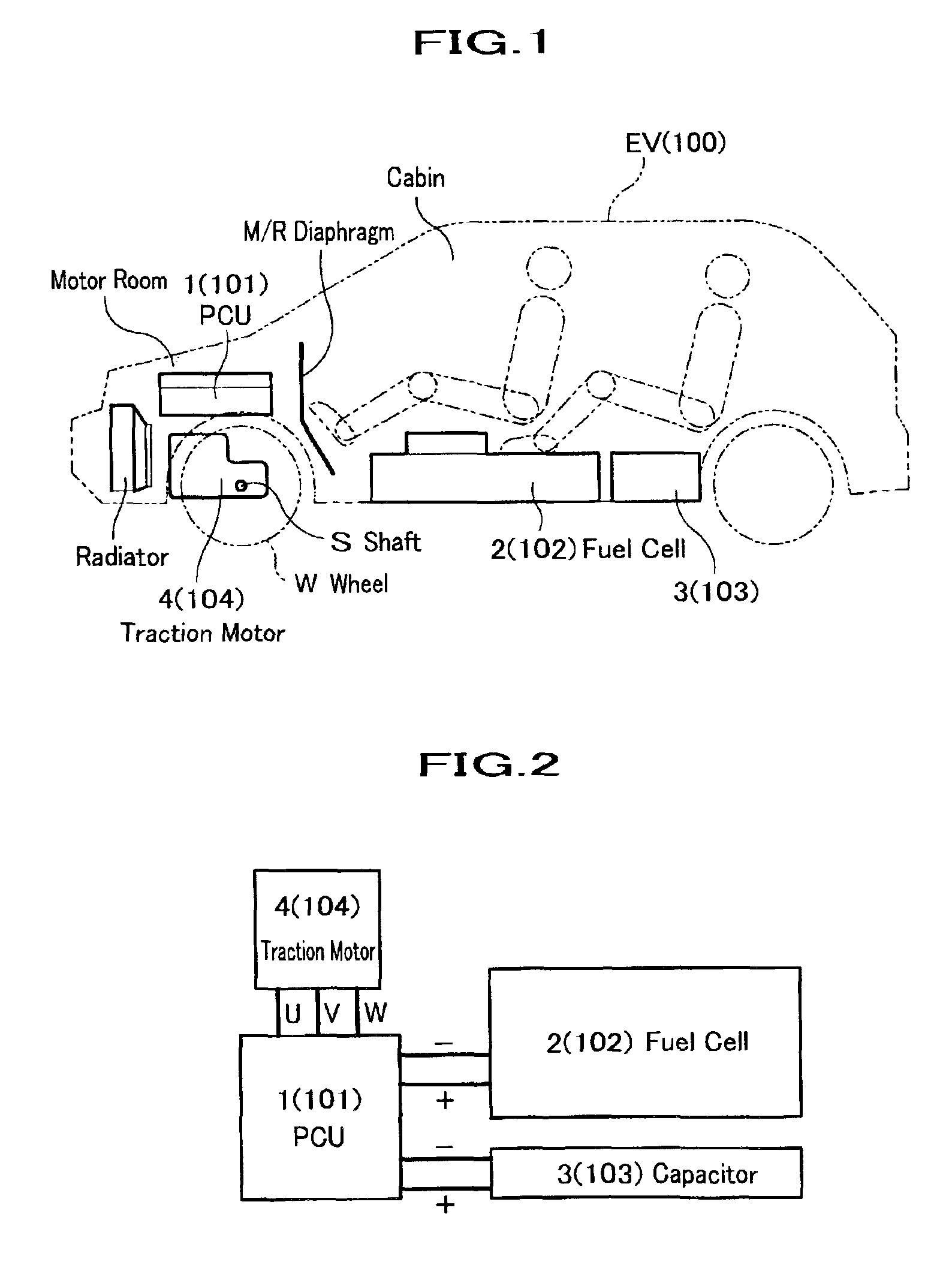

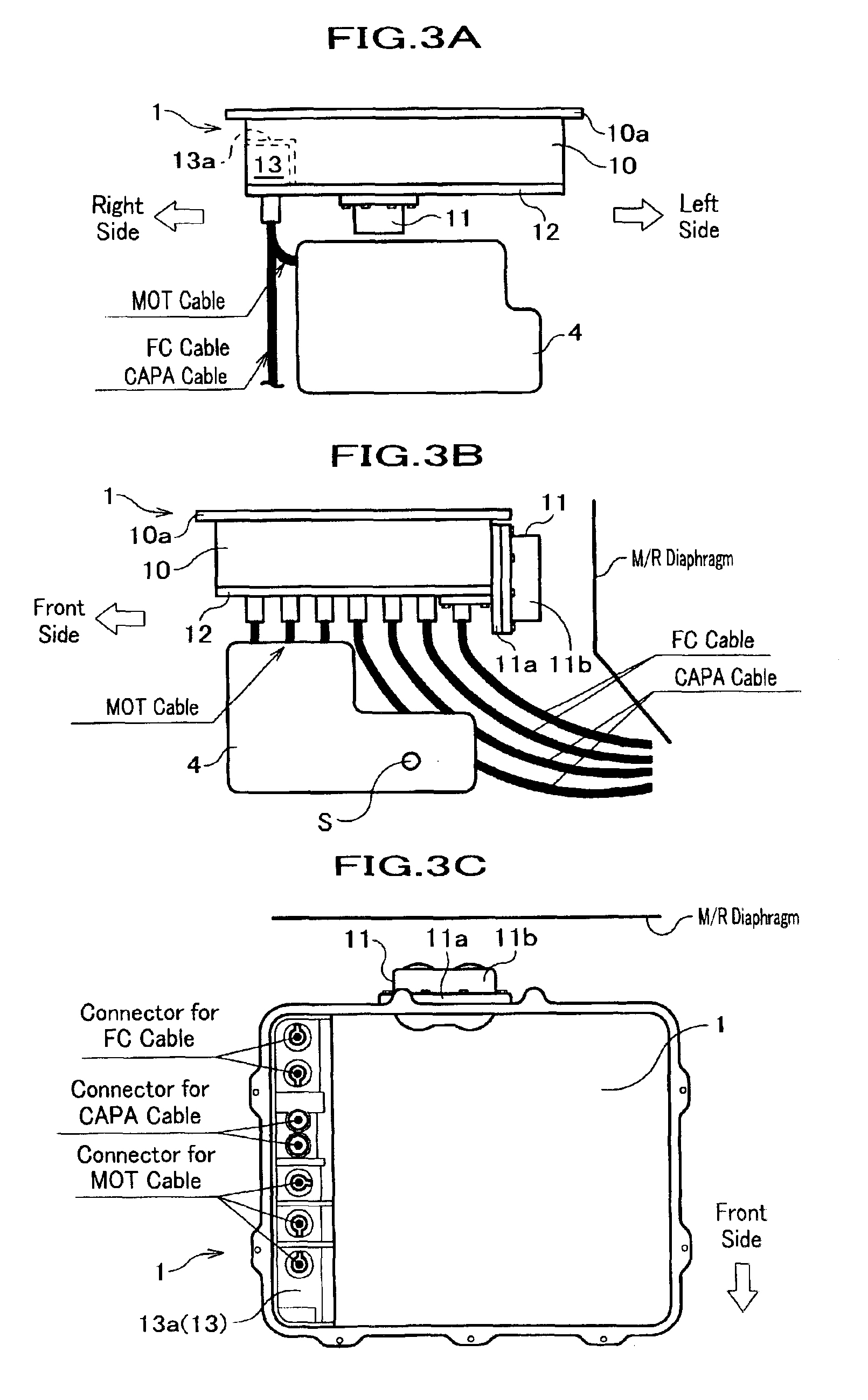

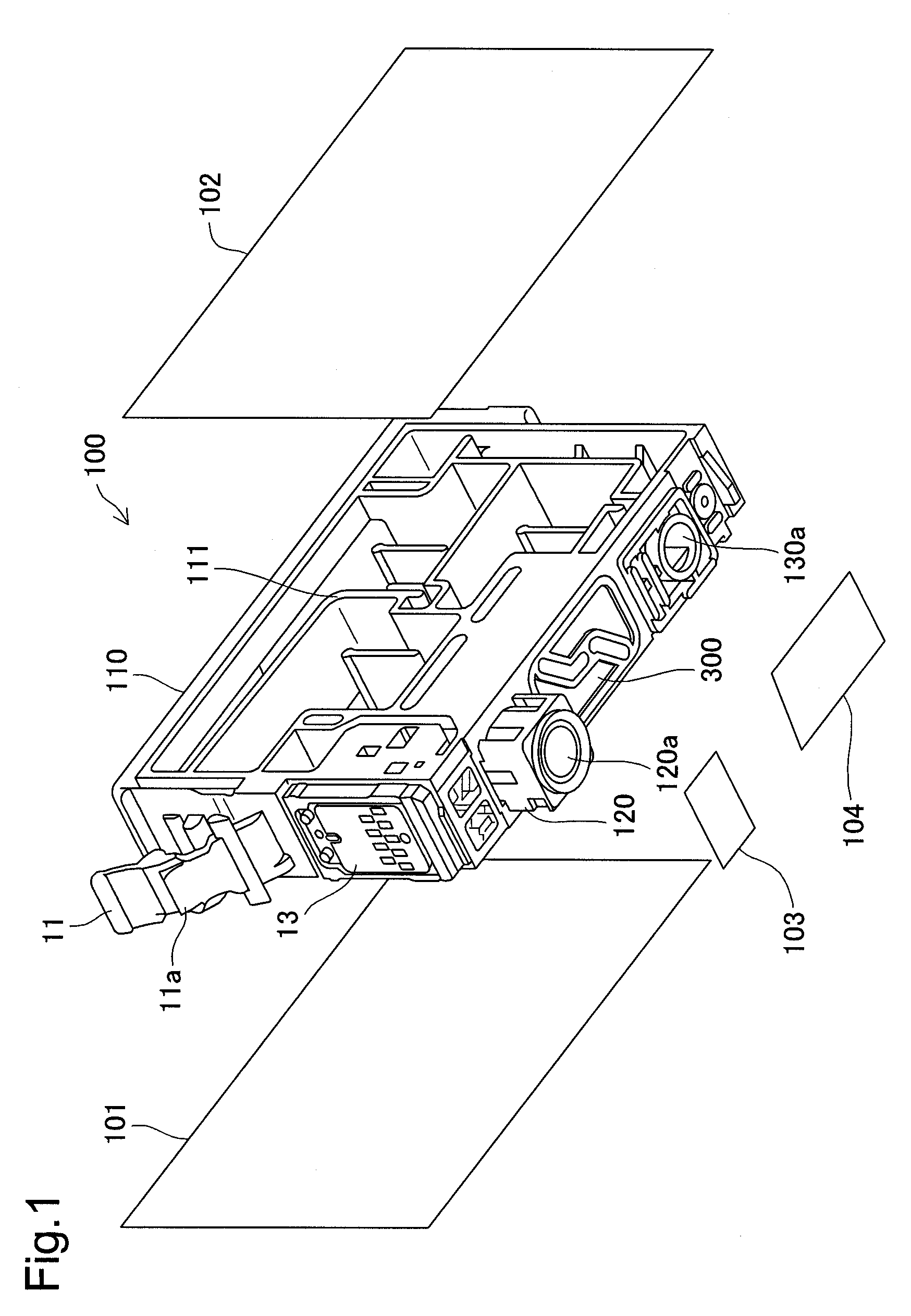

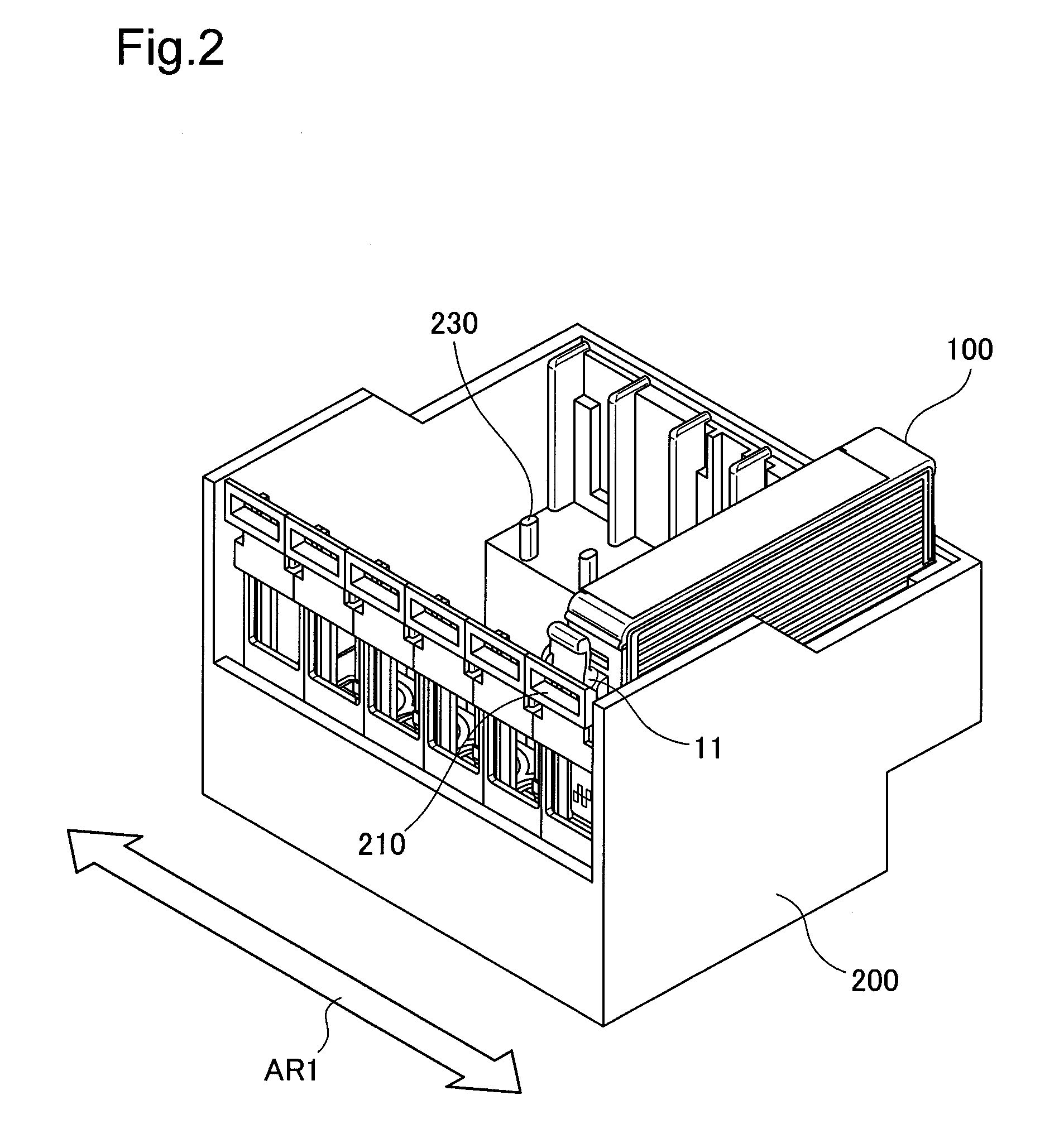

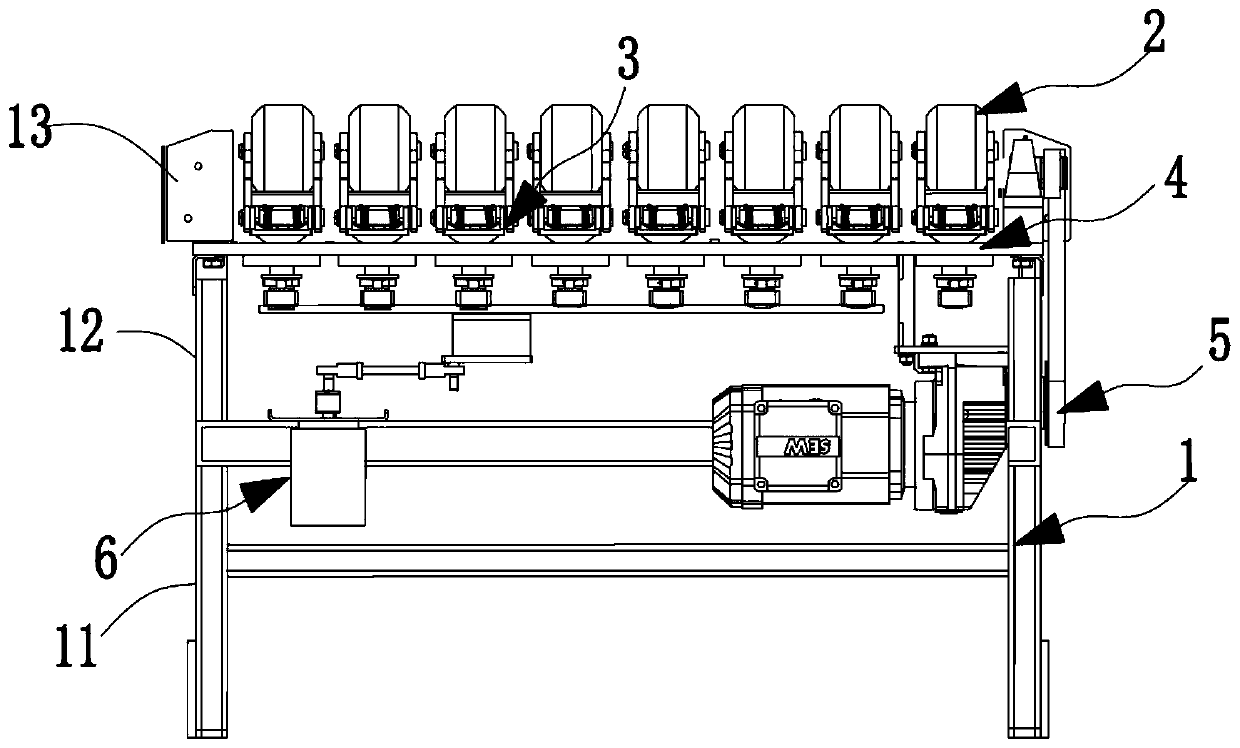

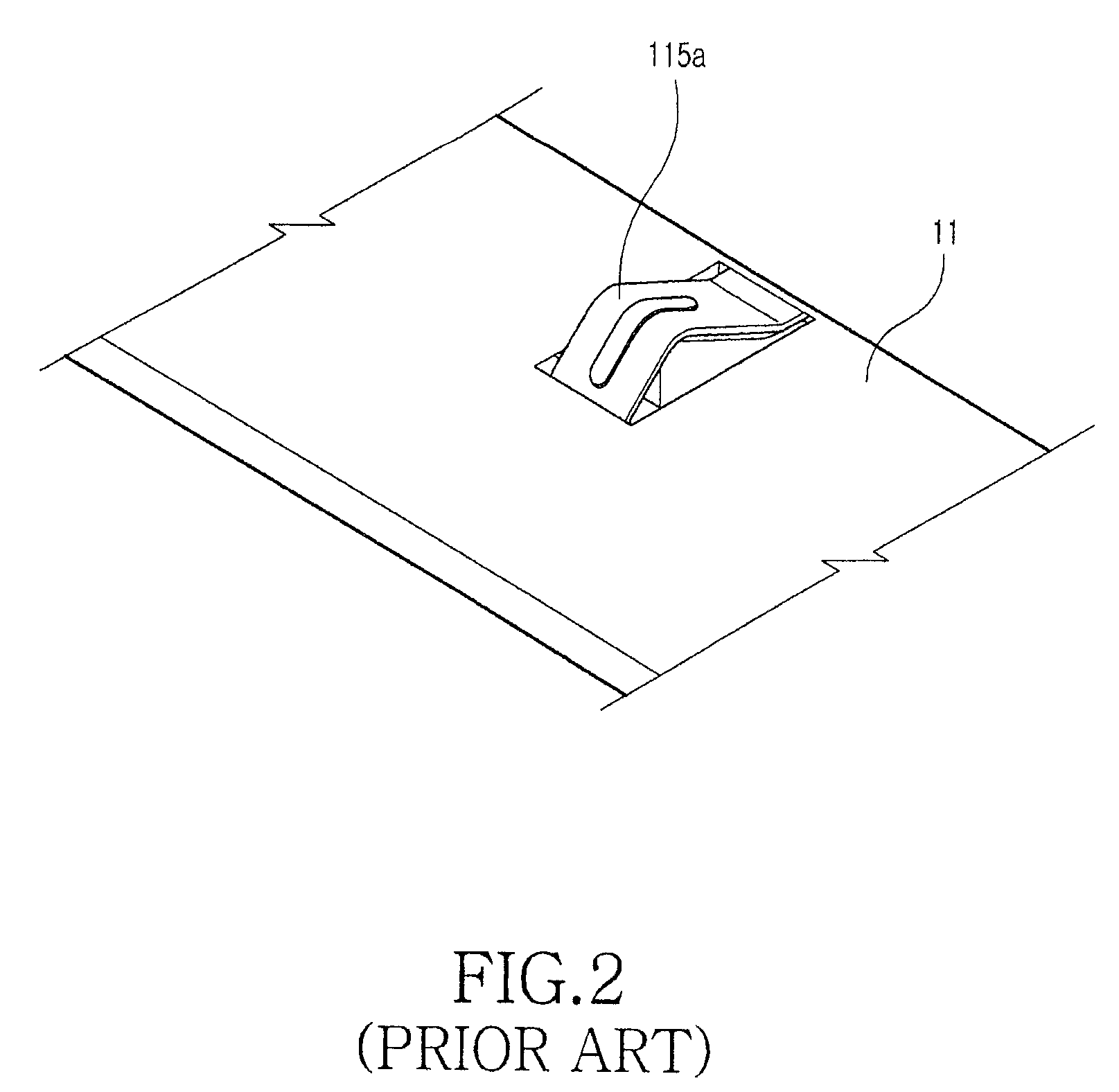

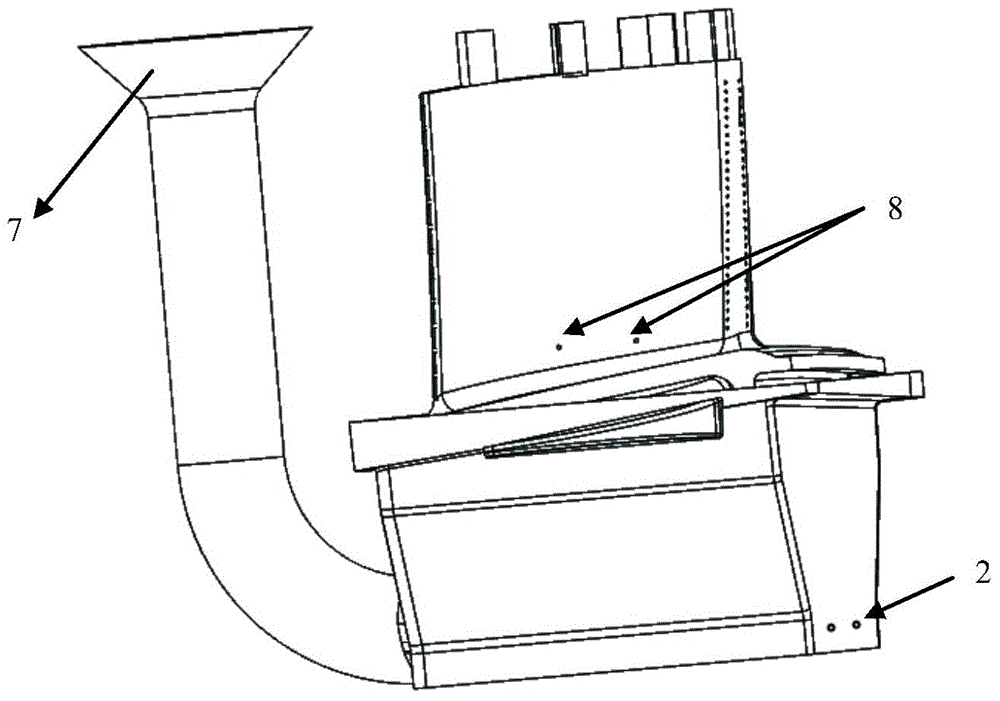

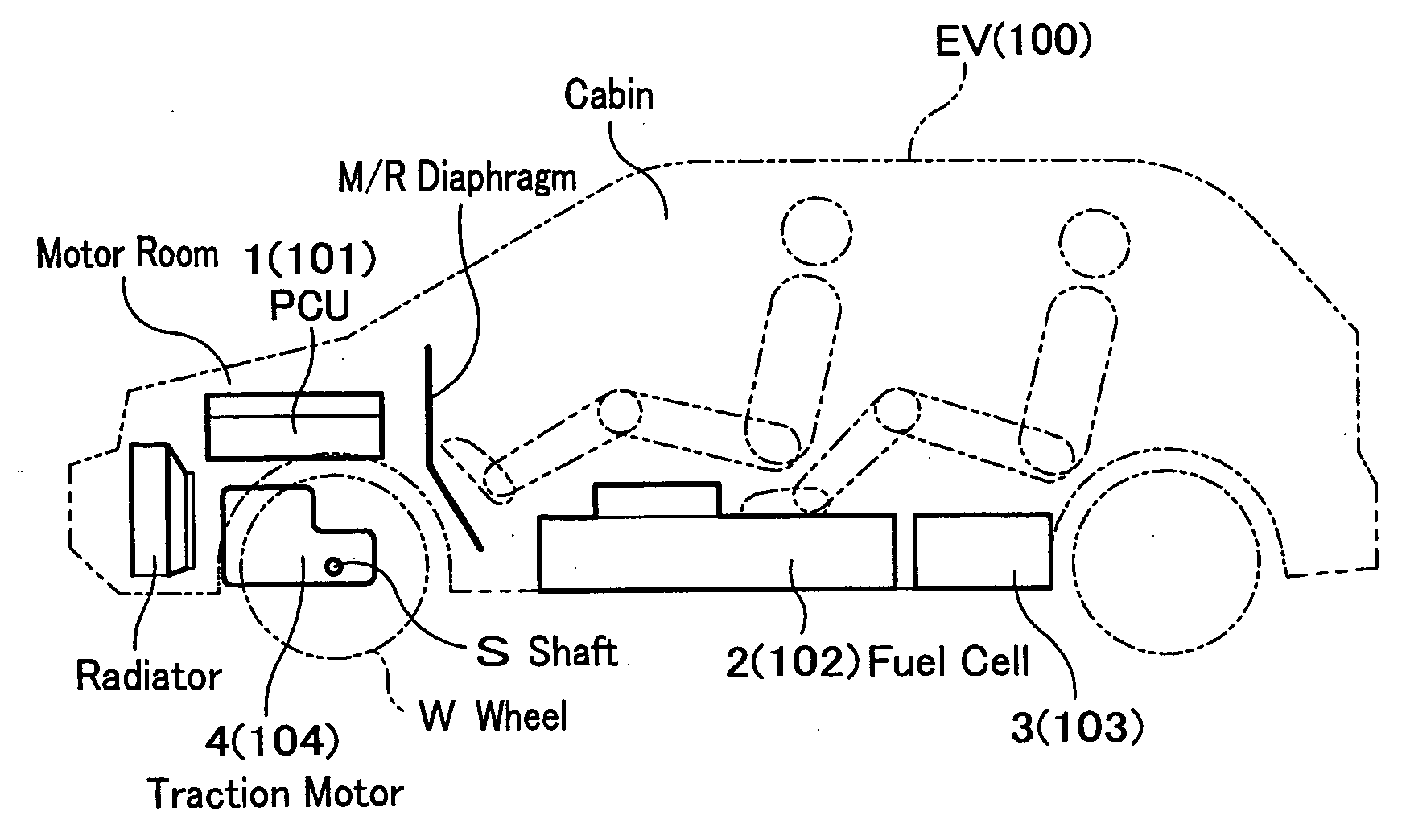

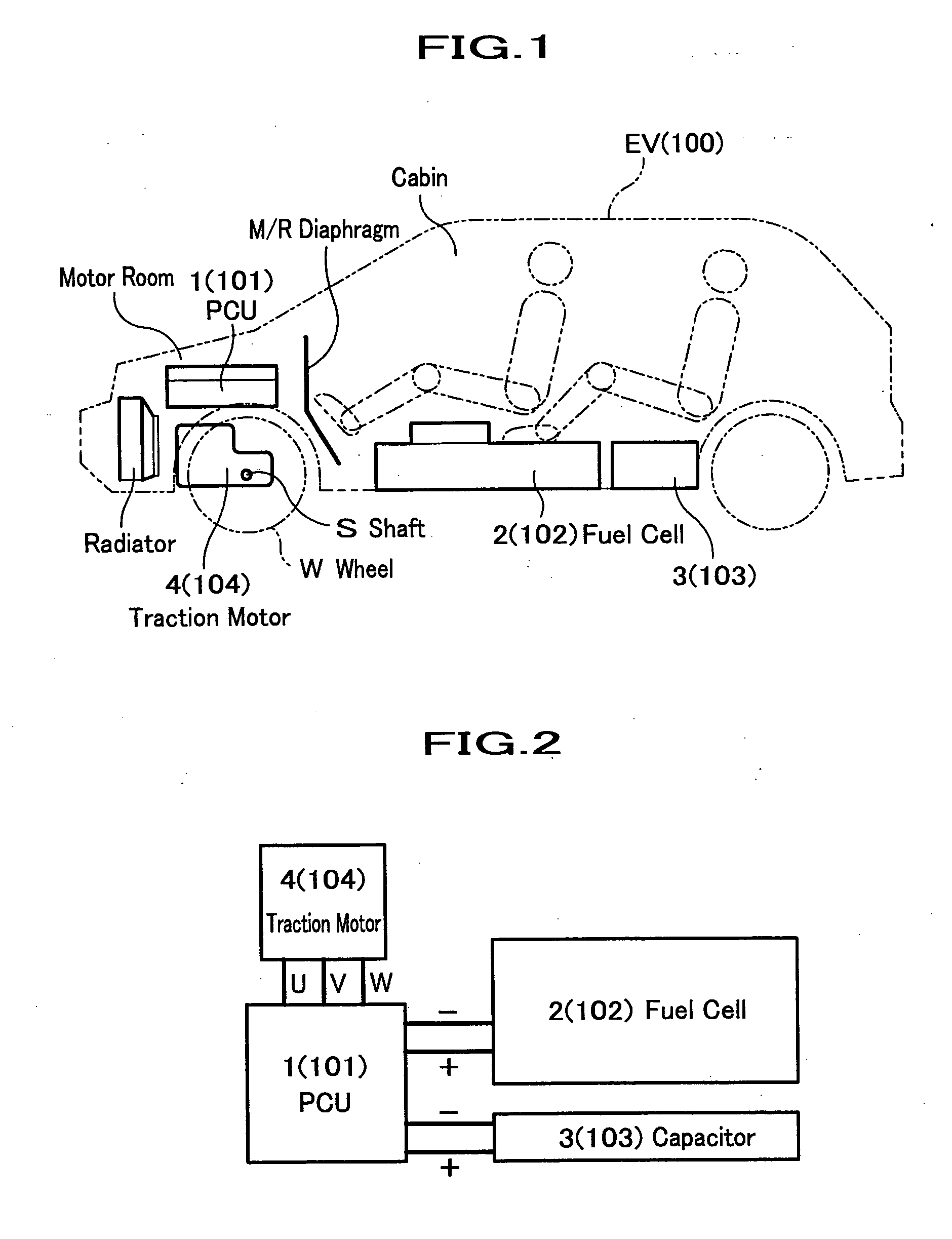

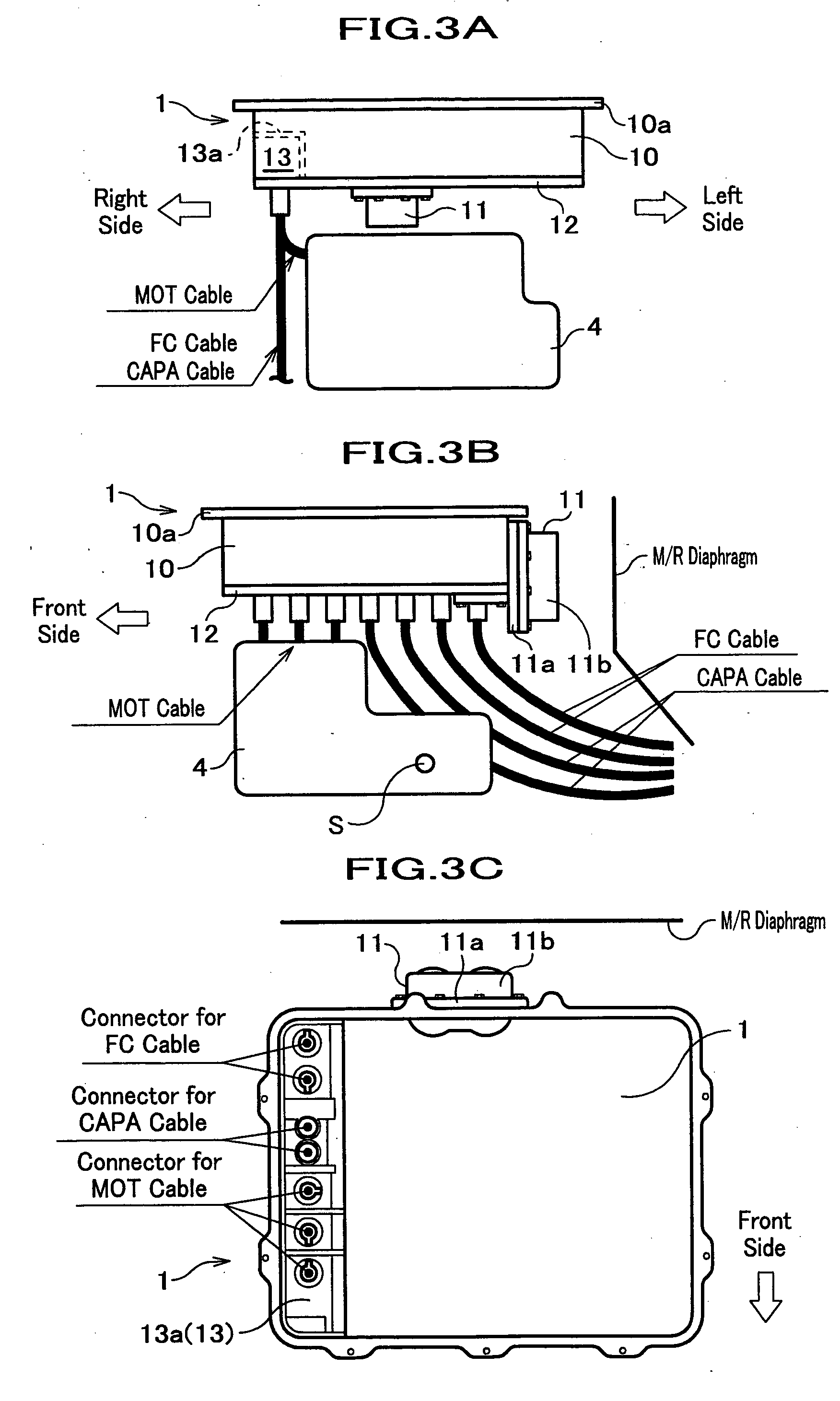

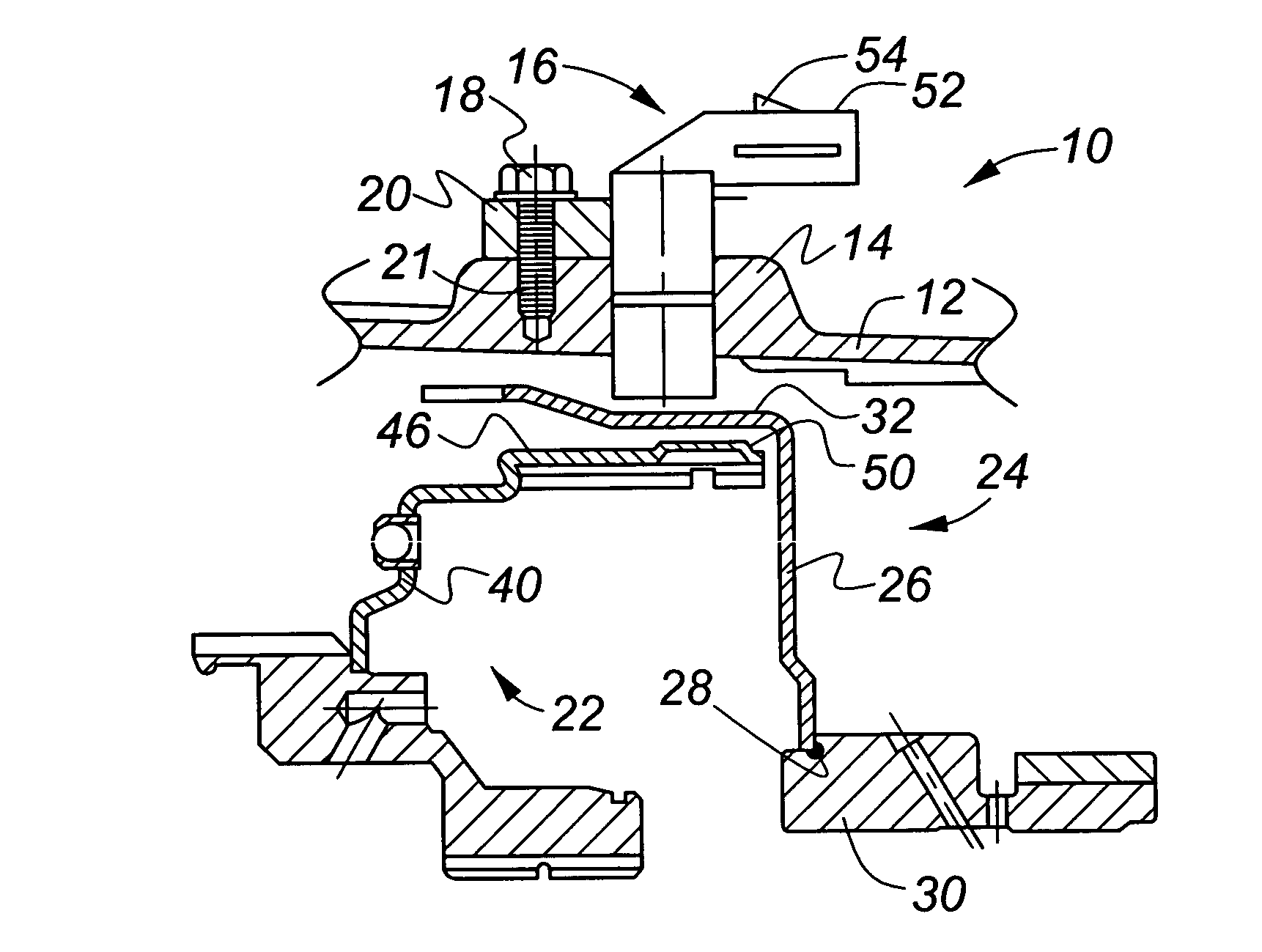

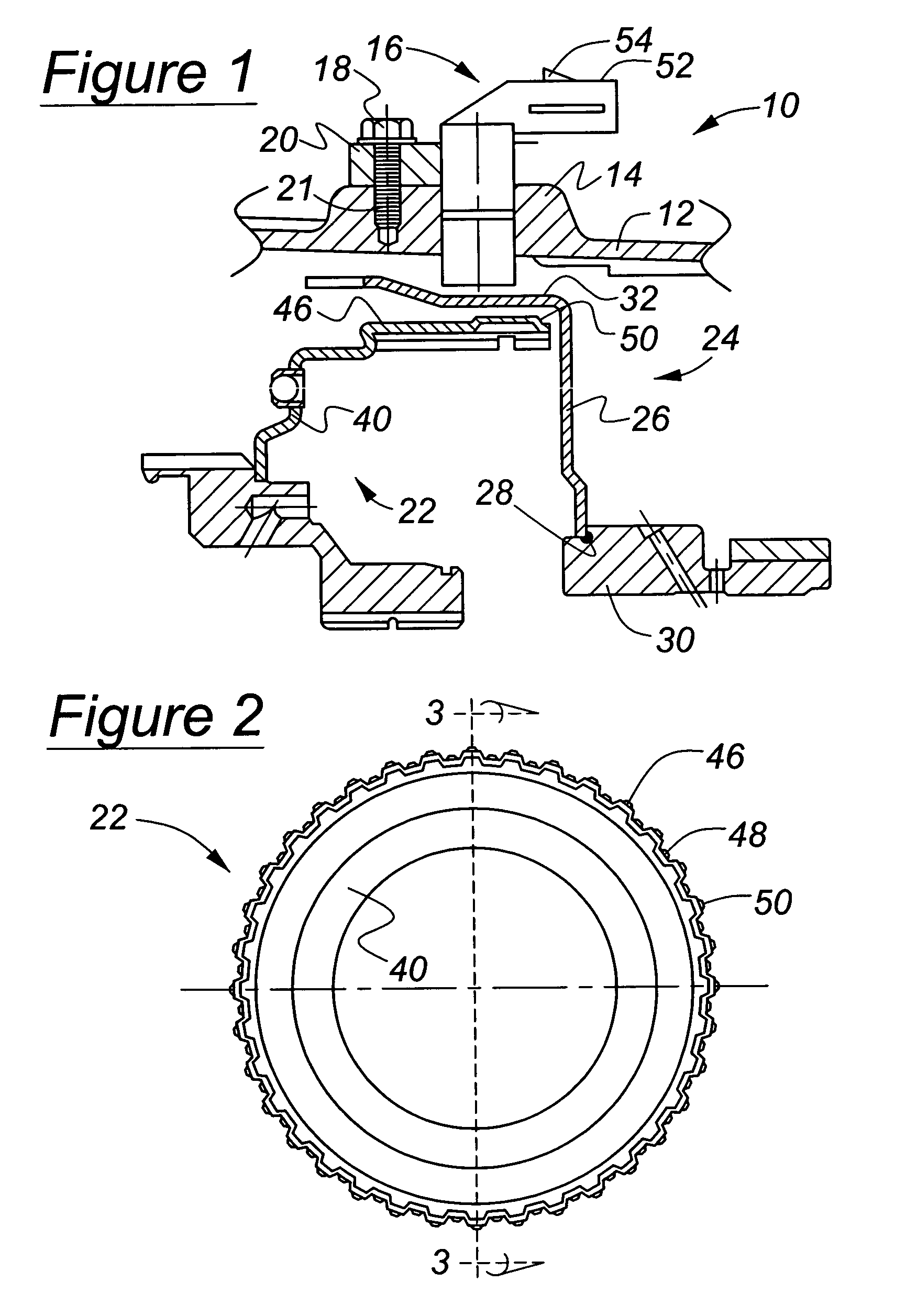

Power control unit for electric vehicle

InactiveUS6907947B2Easy to separateAvoid deformationPropulsion by batteries/cellsVehicular energy storageHead-on collisionEngineering

A power control unit for electric vehicle which can easily detach the high voltage cables even if the motor room is deformed, for example, by head-on collision and / or rear-end collision of the vehicle, which is difficult to be deformed, which can make small, and which can avoid an influence of heat generated by the reactor is disclosed. The power control unit 1 includes a box 10 which accommodates devices for controlling electric power supply of the electric vehicle; a reactor receiver 11a which is provided on a given external surface around the box 10 and supports a reactor R; a heat sink 12 connected to the lower end of the reactor receiver 11a, covering the bottom surface of the box 10, possessing passages including passage wall inside thereof, and performing heat-exchange with the box 10 by allowing coolant water to flow within the passage; and a partition 13a, which is laid on at least one side of the box 10 extending toward the longitudinal direction of the vehicle EV, and is detachably communicated with cables to be connected to the traction motor 4 disposed below the heat sink 12 to supply power.

Owner:HONDA MOTOR CO LTD

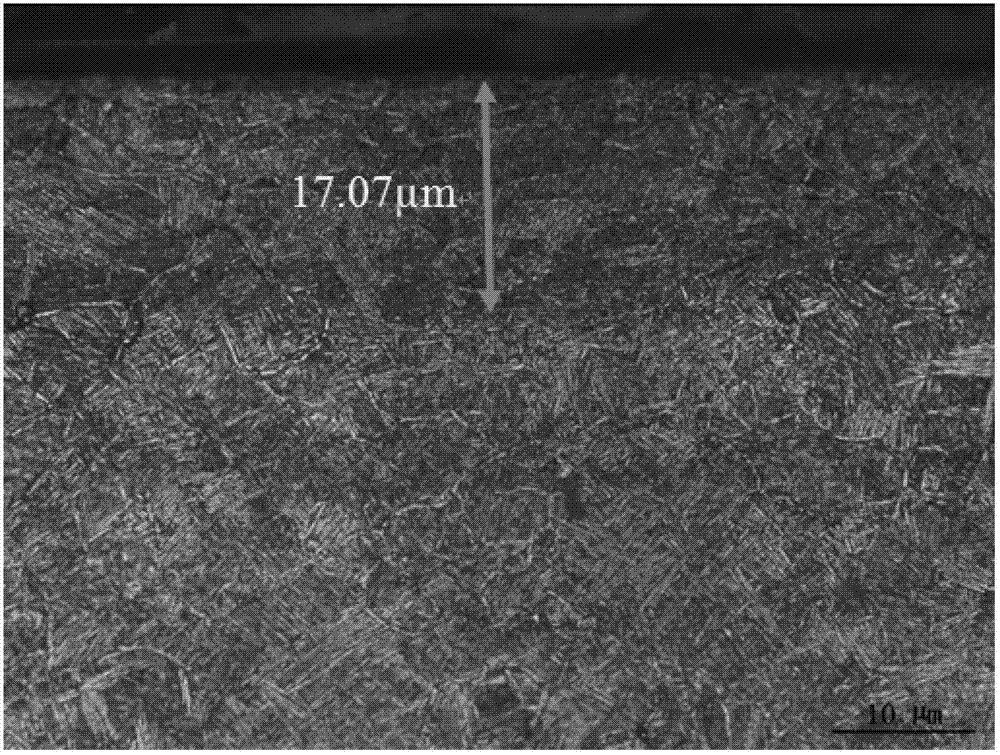

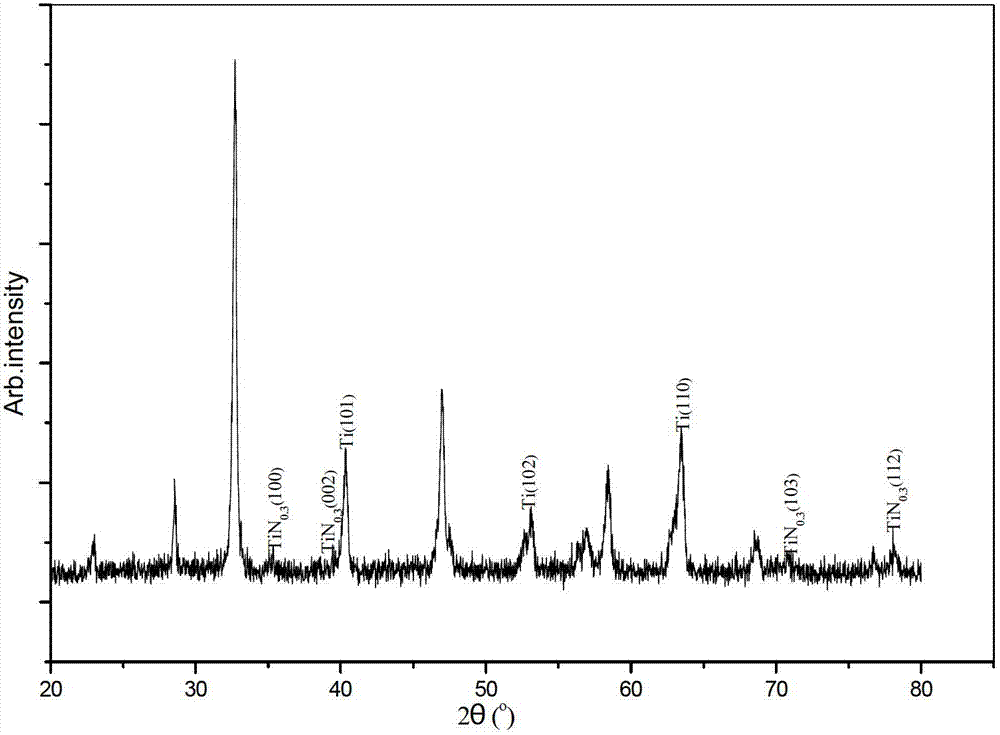

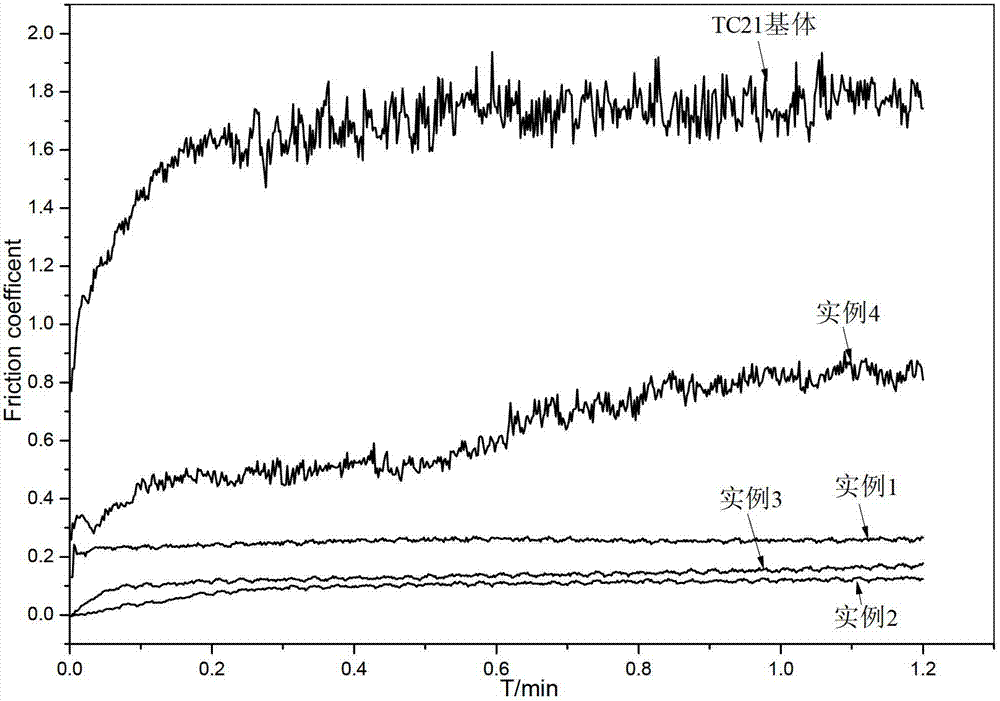

Low-temperature surface nitriding method of titanium alloy

ActiveCN102965613ASimple processImprove controllabilitySolid state diffusion coatingPtru catalystSand blasting

The invention discloses a low-temperature surface nitriding method of a titanium alloy, and belongs to the technical field of metal surface heat treatment and modification. The low-temperature surface nitriding method is characterized by comprising the following steps of: firstly, carrying out sand blasting cleaning on the surface of the titanium alloy, then carrying out chemical mechanical lapping and polishing, then mixing powder crystal sodium cyanate (NaCNO) and granular crystal potassium cyanate (KCNO) and rare earth CeO2 powder in a certain proportion so as to obtain a nitriding reagent, placing the nitriding reagent and the treated titanium alloy in a crucible for compacting and sealing, then drying, and placing the crucible in a high-temperature furnace for heating, wherein NaCNO and KCNO are used as nitriding sources, and rare earth CeO2 is used as a catalyst. According to the low-temperature surface nitriding method, a TiN 0.3-1 nitriding layer is formed on the surface of the titanium alloy TC21, the friction coefficient of the surface of the titanium alloy is remarkably reduced, the surface hardness is increased, and the surface property is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

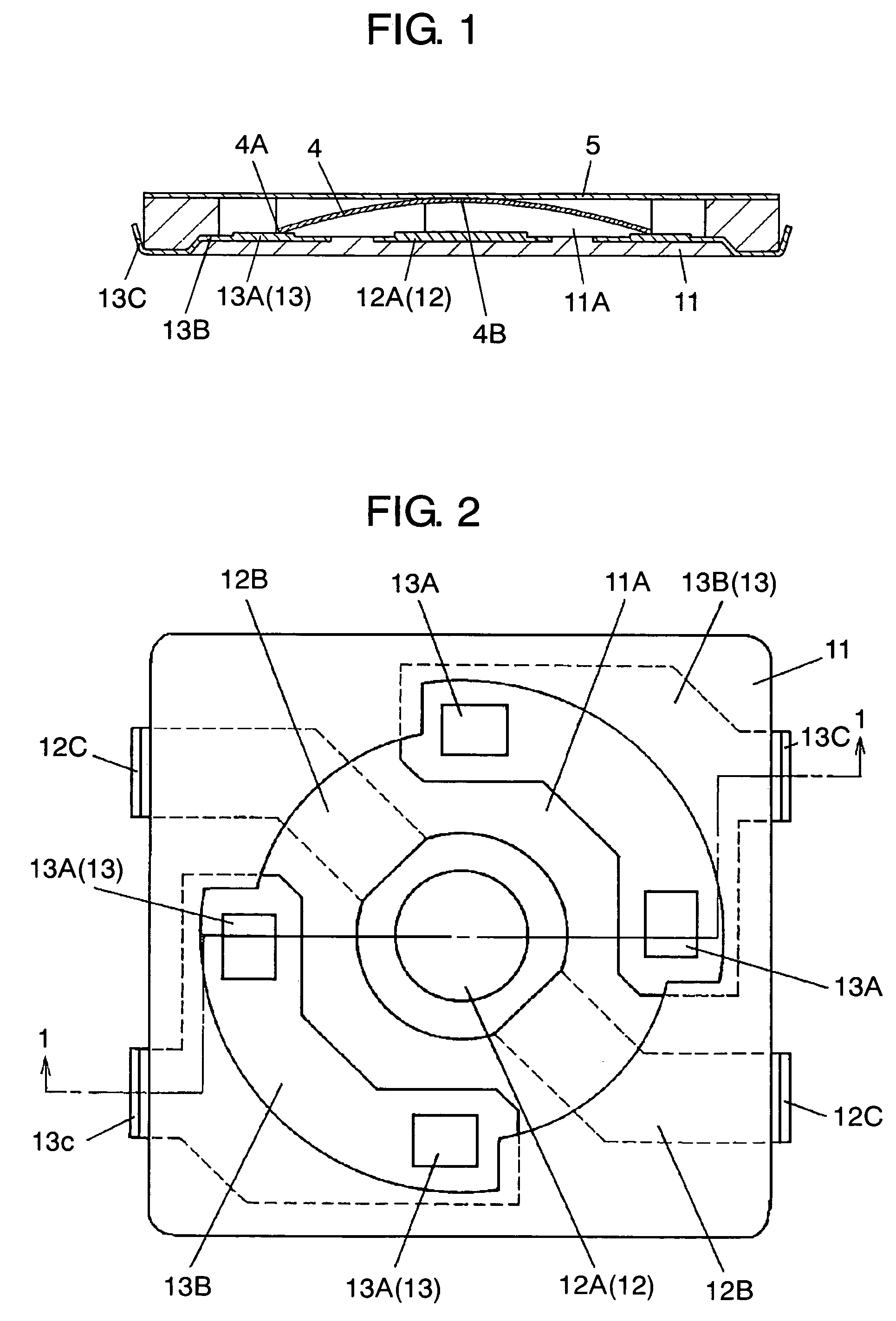

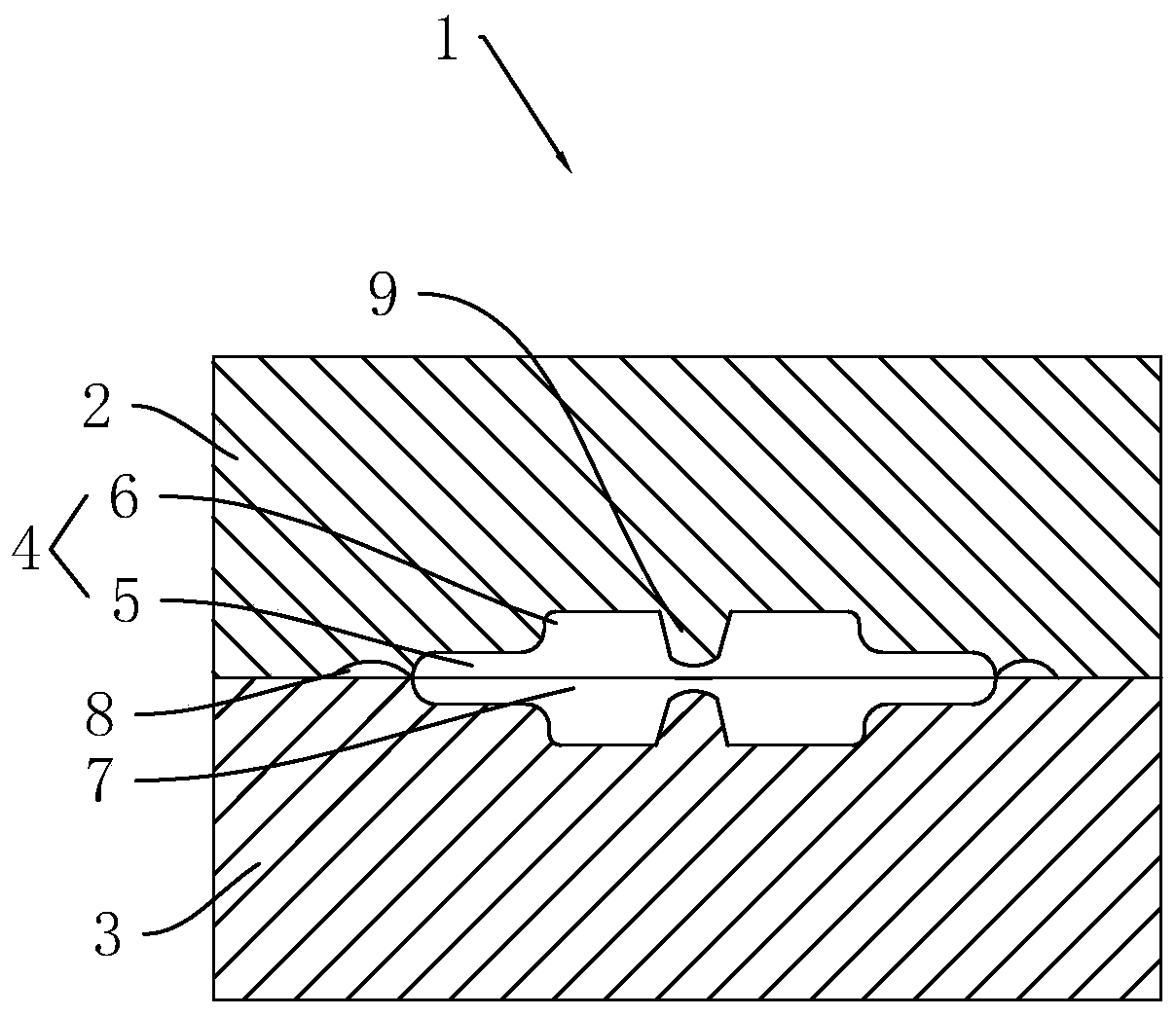

Liquid container and membrane valve

InactiveUS20090244223A1Reduce the possibilityReduce the possibility of deformationDiaphragm valvesEngine diaphragmsElastomerCoil spring

Owner:SEIKO EPSON CORP

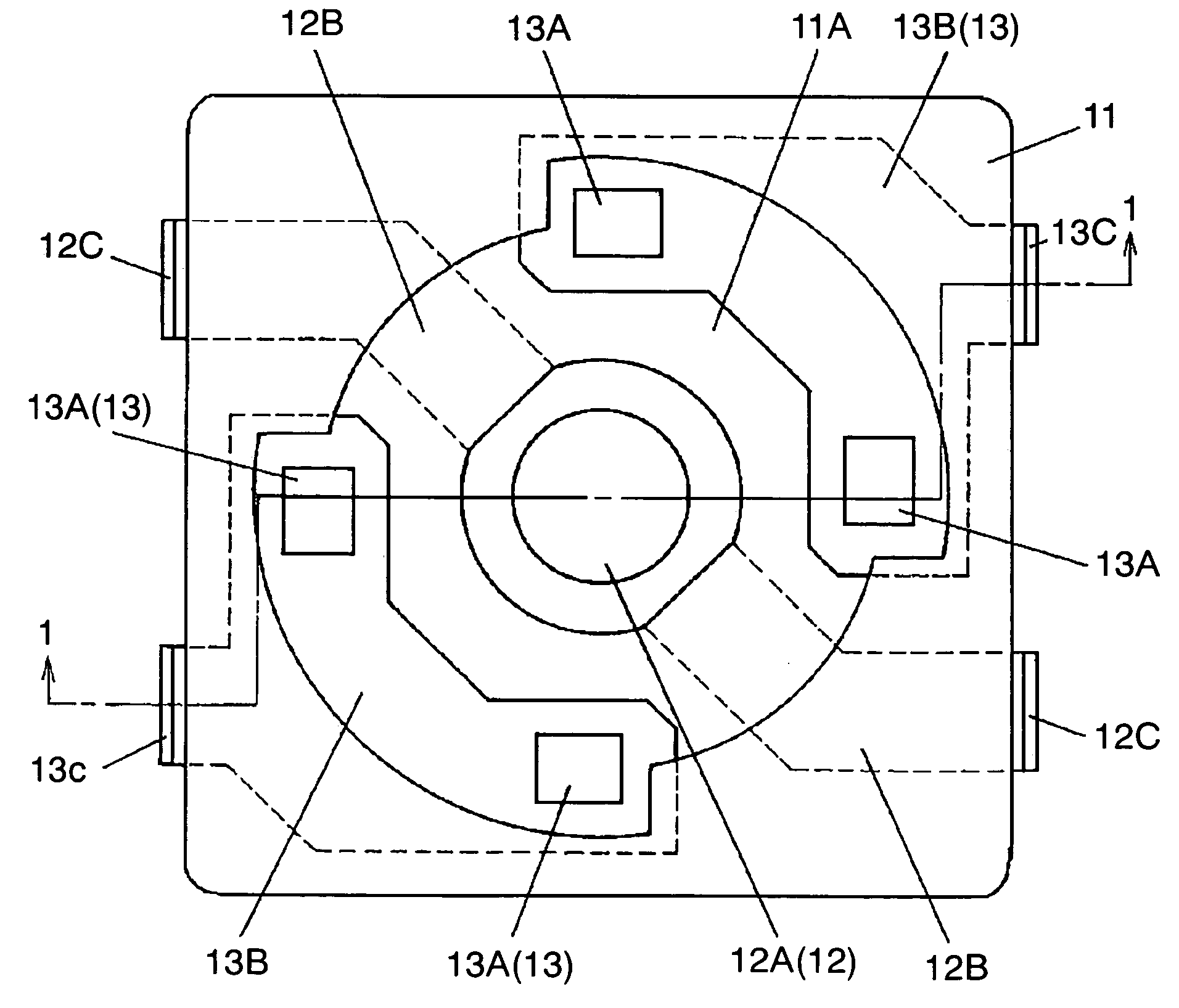

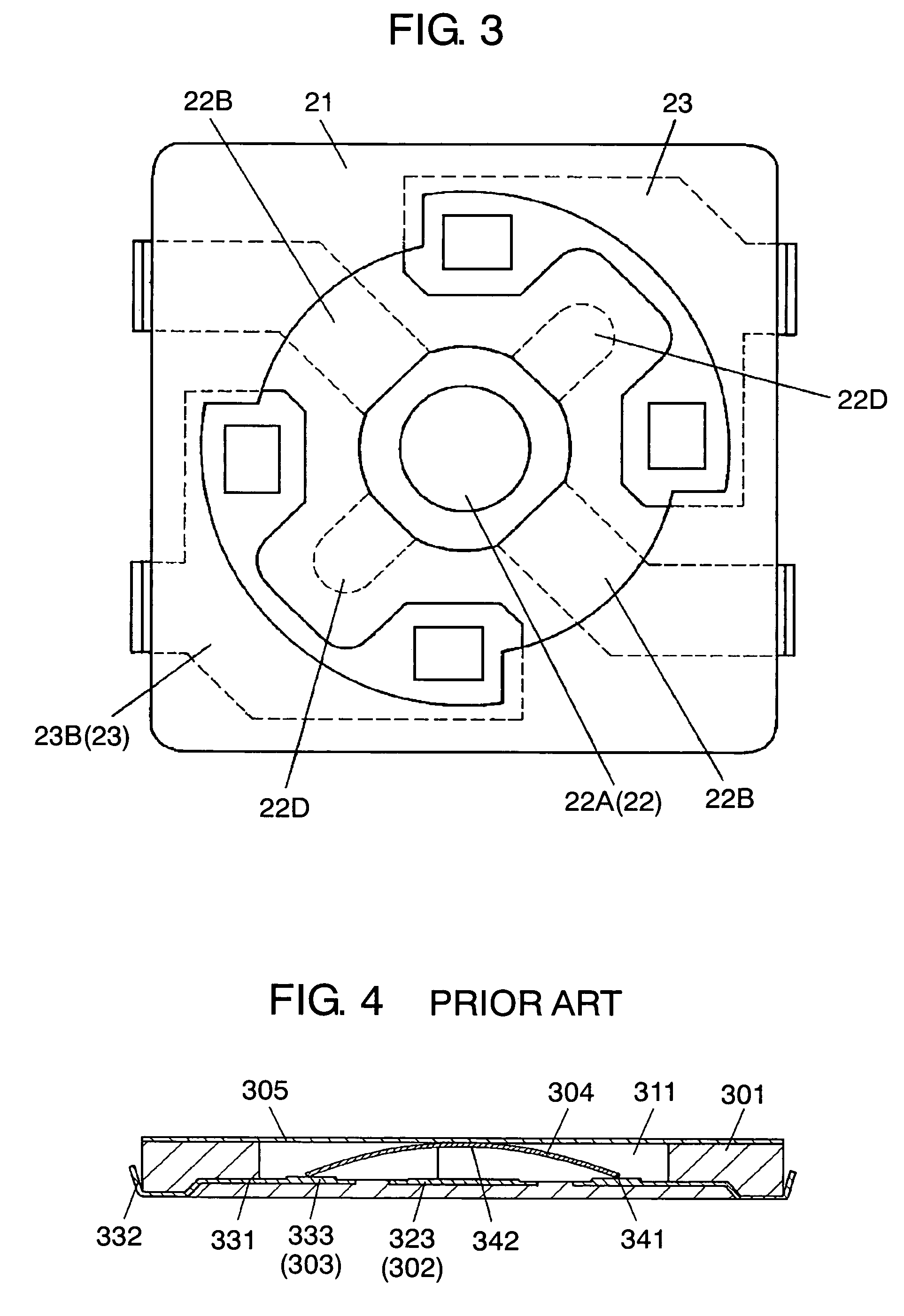

Push-on switch

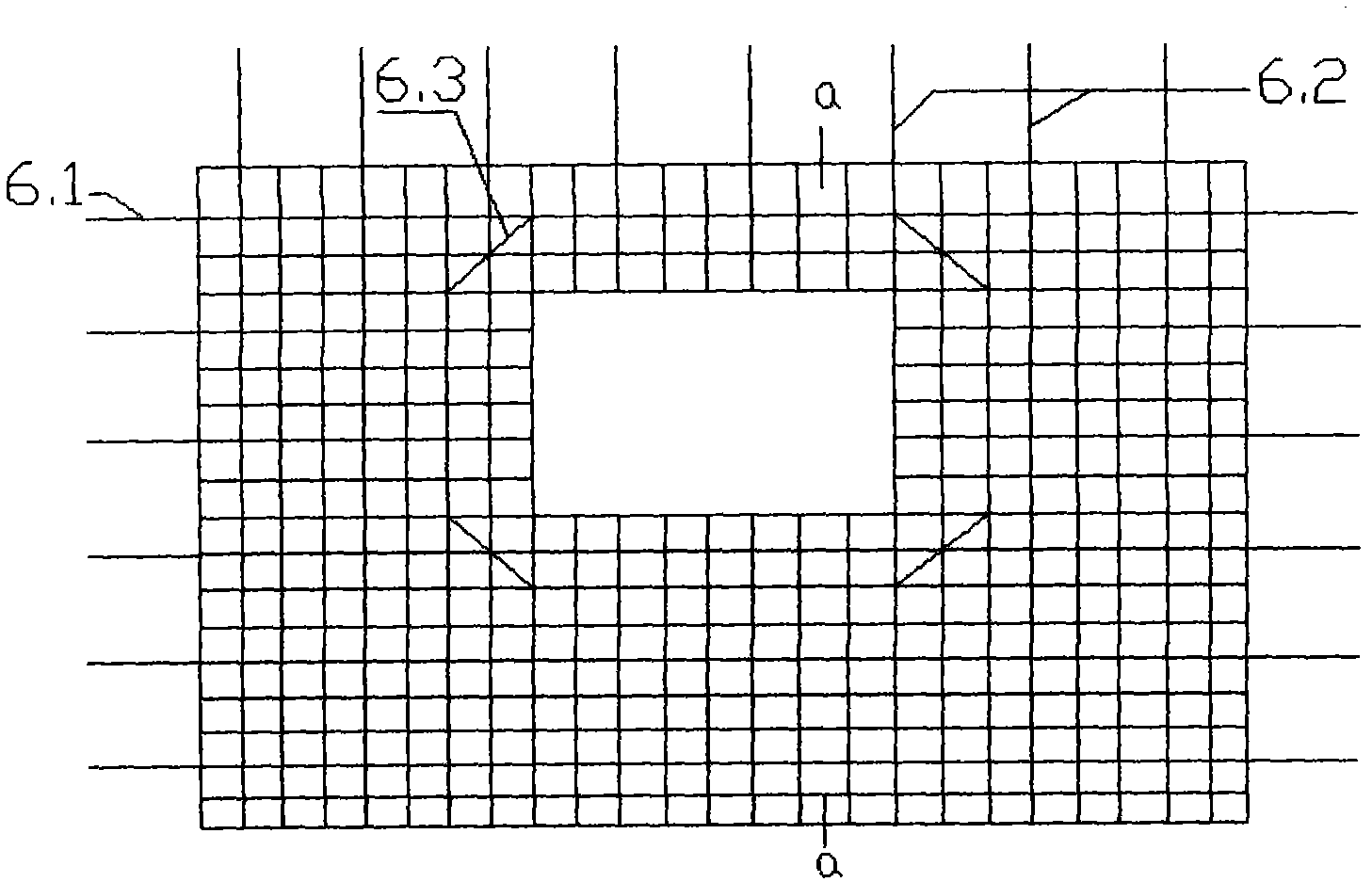

InactiveUS7057128B1Reduce the possibility of deformationImprove performanceContact surface shape/structureSnap-action arrangementsDiagonalEngineering

A first stationary contact (i.e., center stationary contact) has a center contact point exposed at the center on the bottom of a recess in a square-shaped switch base as viewed from the above. The first stationary contact is disposed to the bottom of the recess with its lead paths extended along one of diagonal lines of the square-shaped switch base from the center contact point toward both side edges of the switch base. Second stationary contacts (i.e., outer stationary contacts) are arranged at positions along an outer brim of the recess in a line-symmetrical manner about the one of the diagonal lines in areas opposite each other along the other diagonal line. The first stationary contact and the second stationary contacts are arranged in this manner and secured into embedment by means of insertion molding in the bottom of the recess in the switch base of an insulation resin.

Owner:PANASONIC CORP

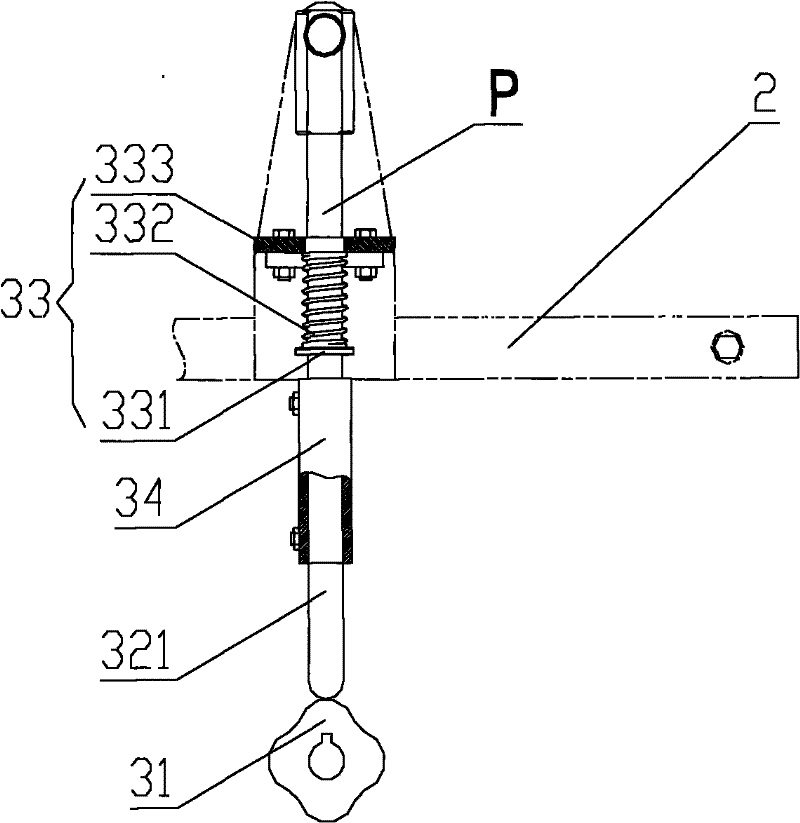

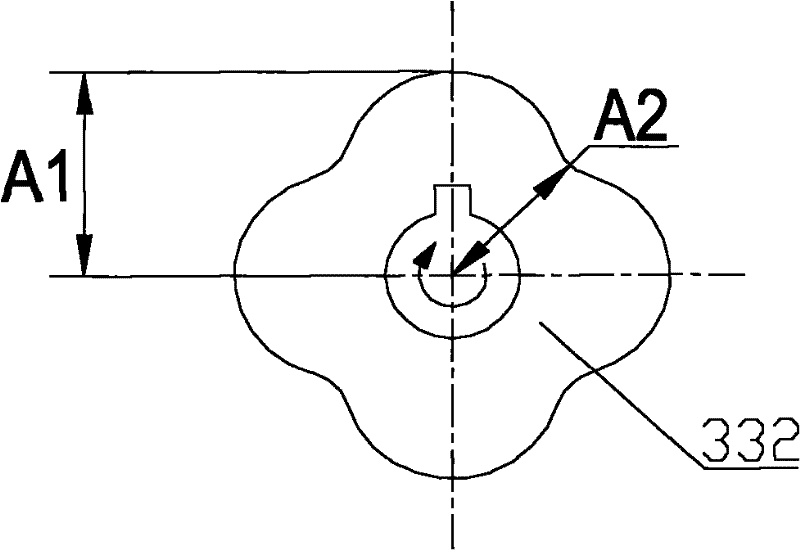

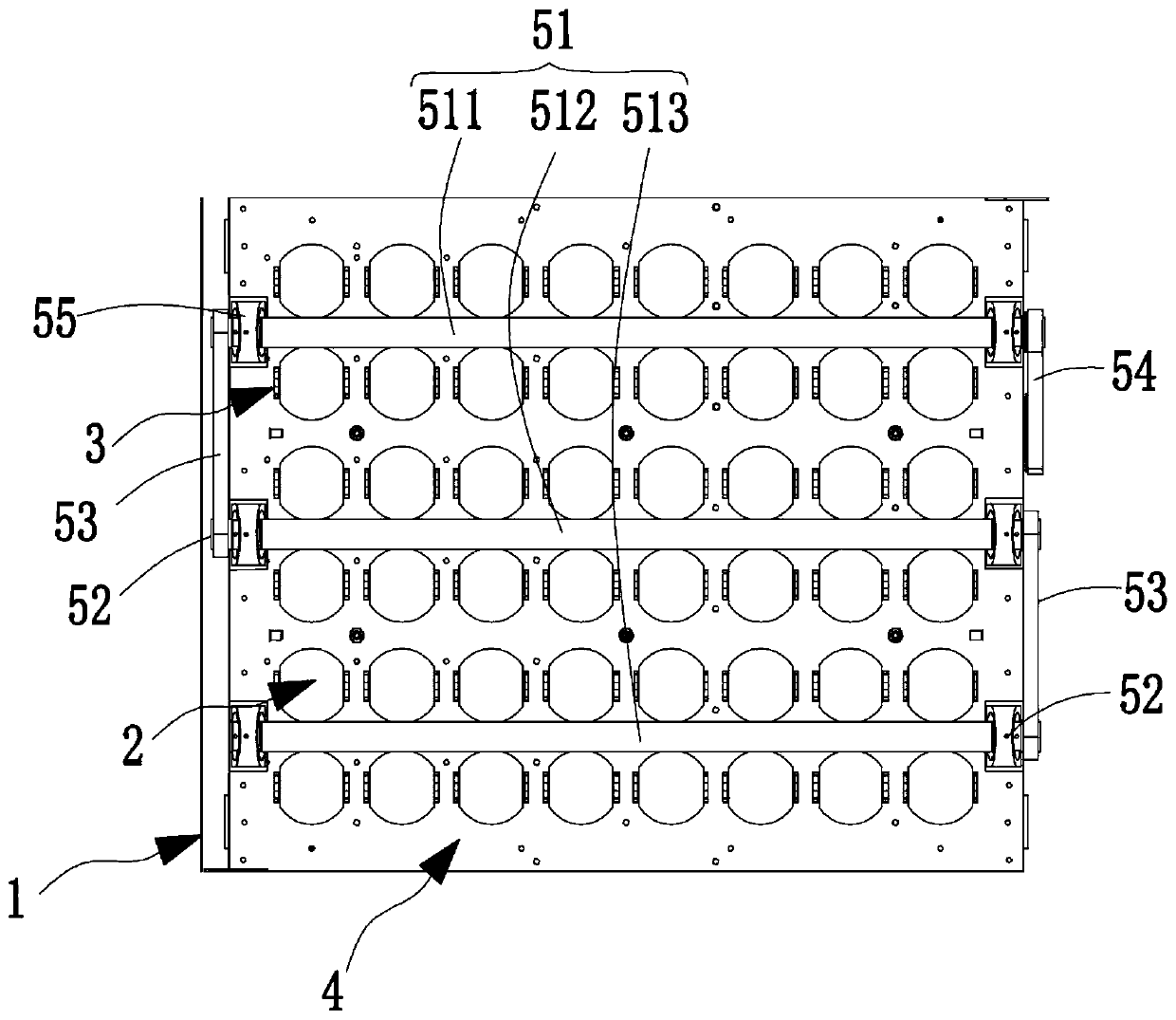

Wheel type conveying line

PendingCN110015540AEasy to assembleGuaranteed reliabilityConveyor partsRoller-waysSelf adaptiveFriction force

The invention discloses a wheel type conveying line which comprises a rack. Multiple rows of eccentric rotating wheels are arranged on the rack in an equal height manner. The axes of all the eccentricrotating wheels are parallel to one another and are parallel to the horizontal plane. Each eccentric rotating wheel is arranged on an installing frame located on the rack in the manner of rotating around the axis of the eccentric rotating wheel. The eccentric rotating wheels on each row are attached to a driving roller, the driving roller makes contact with the lower semicircle of each eccentricrotating wheel, the driving roller is affected by upward elastic force, and thus the eccentric rotating wheels are attached to the driving roller in a self-adapting manner, or the driving roller makescontact with the upper semicircle of each eccentric rotating wheel, the eccentric rotating wheels are affected by the upward elastic force, and the eccentric rotating wheels are attached to the driving roller in a self-adapting manner. The driving roller rotates under the driving of a first power source, and the eccentric rotating wheels are driven to rotate through friction force. According to the wheel type conveying line, the design of the scheme is elaborate, the eccentric rotating wheels or the driving roller are affected by the upward elastic force, thus the eccentric rotating wheels always keep being attached to the driving roller, after abrasion is caused or when the installing position precision is poor, self-adaptive adjusting is achieved, rotating between the eccentric rotatingwheels and the driving roller is effectively ensured, and the conveying stability is improved.

Owner:SUZHOU GP LOGISTICS SYST

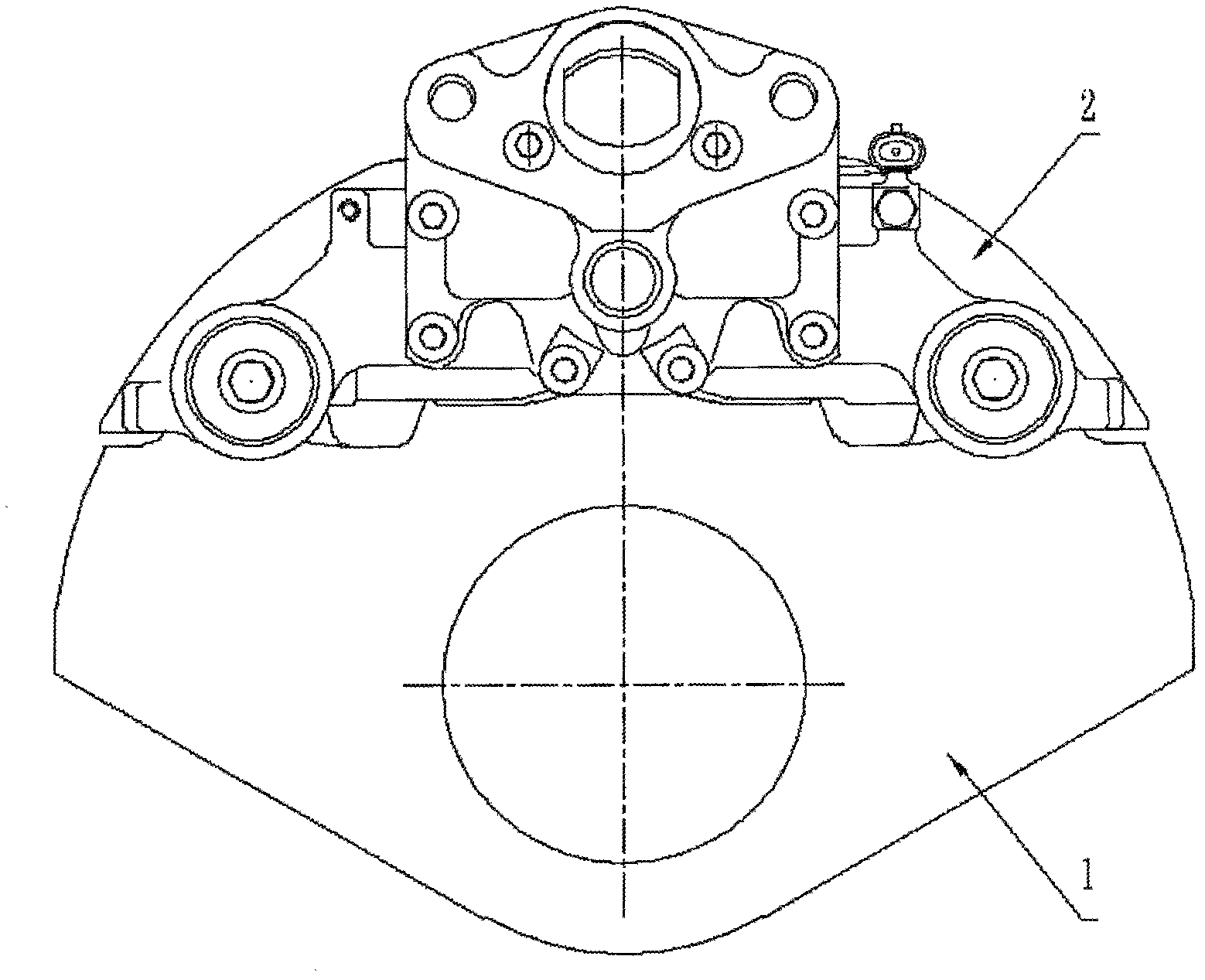

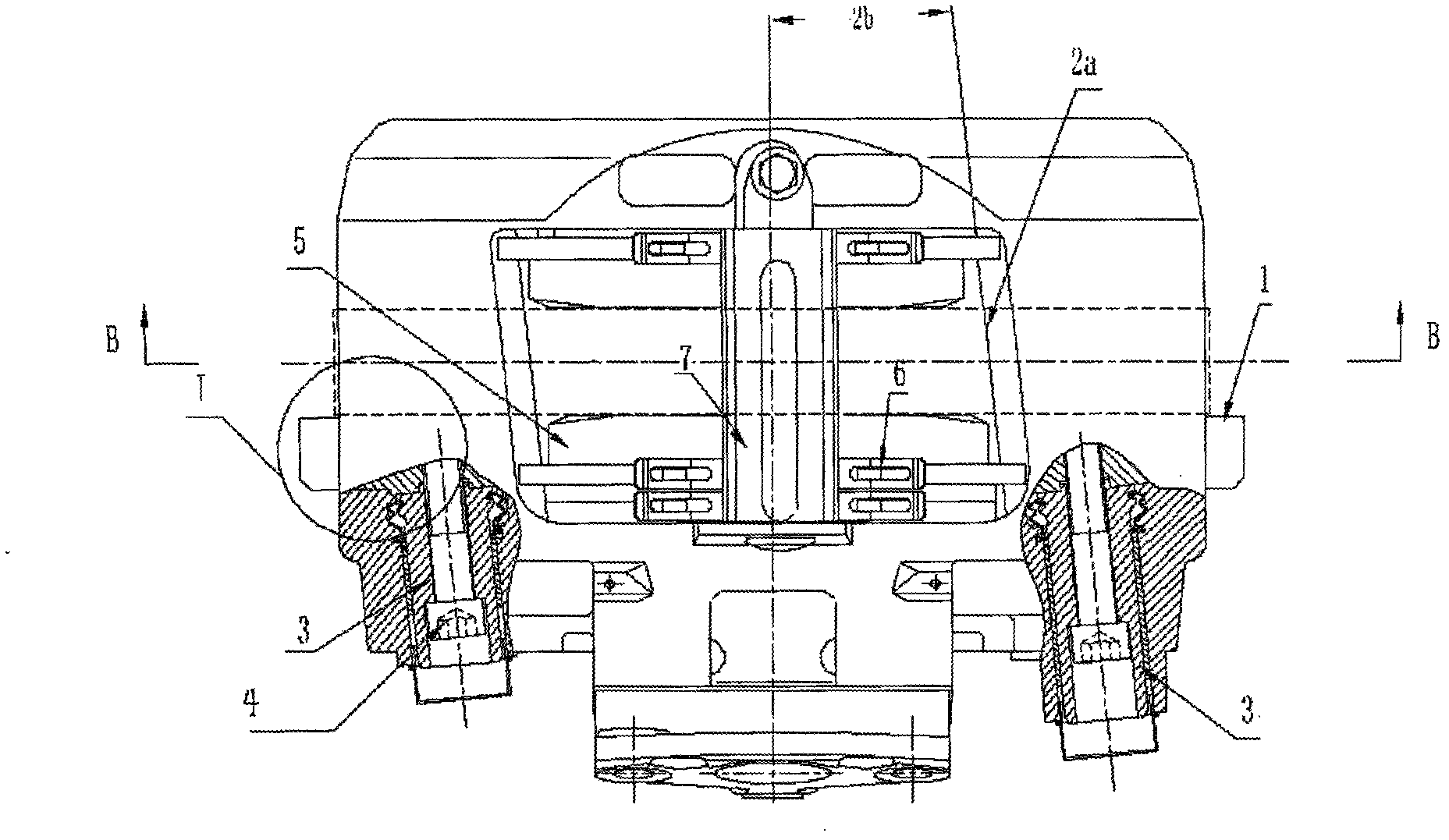

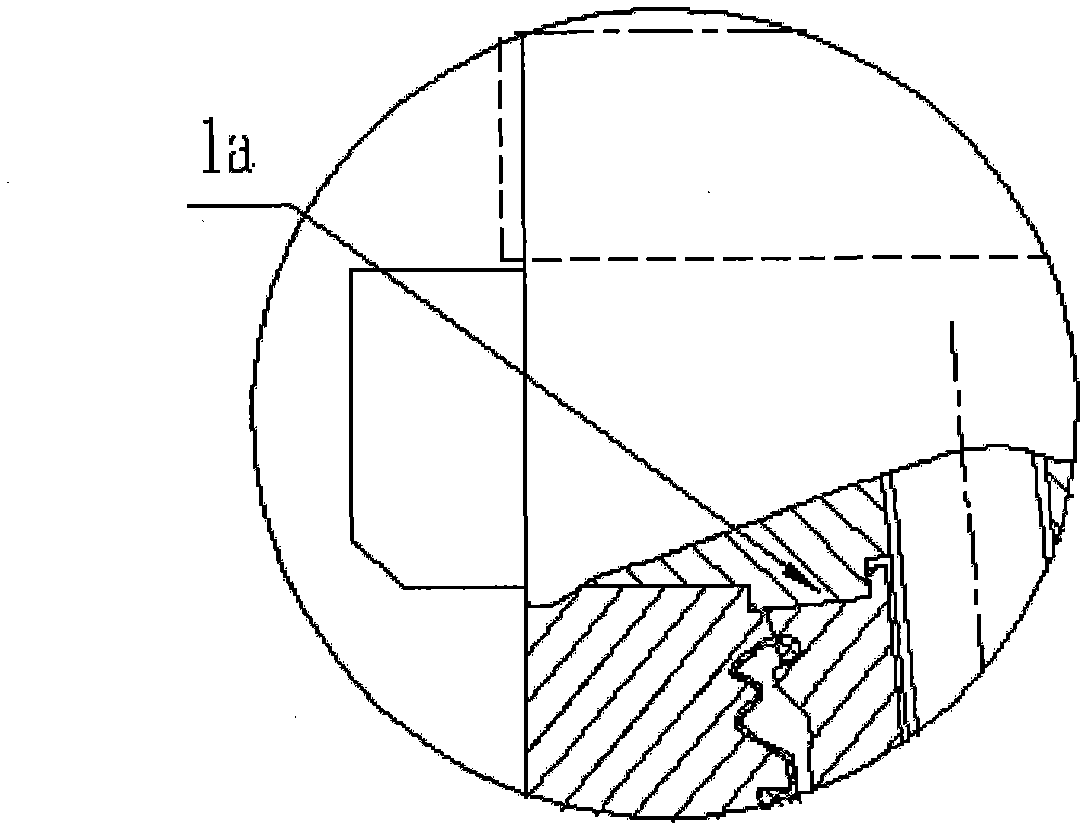

Bracket-free floating air pressure caliper disc brake

ActiveCN102252048ALow costReduce eccentric wearAxially engaging brakesBraking discsCalipersDisc brake

The invention discloses a bracket-free floating air pressure caliper disc brake. The brake comprises a mounting plate (1), a brake caliper assembly (2), two guide pins (3), a screw (4), a friction plate (5), a pressure spring (6) and a pressure plate (7), wherein the mounting plate (1) is provided with a central through hole, the central through hole is centered on a non-steering axle, and the brake caliper assembly (2) is directly fixed on the mounting plate (1) through the guide pins (3). The brake has simple structure, is convenient to assemble and maintain, cancels a bracket, saves the cost and the assembly step, meanwhile, can ensure the braking performance, and eliminates the negative effect of canceling the bracket.

Owner:WUHAN YOUFIN AUTOPARTS

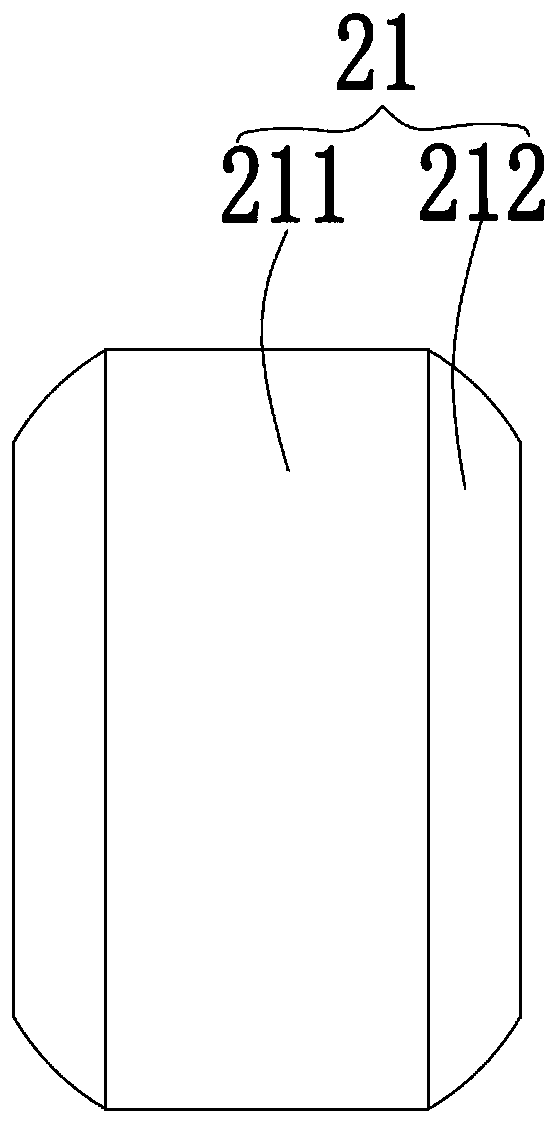

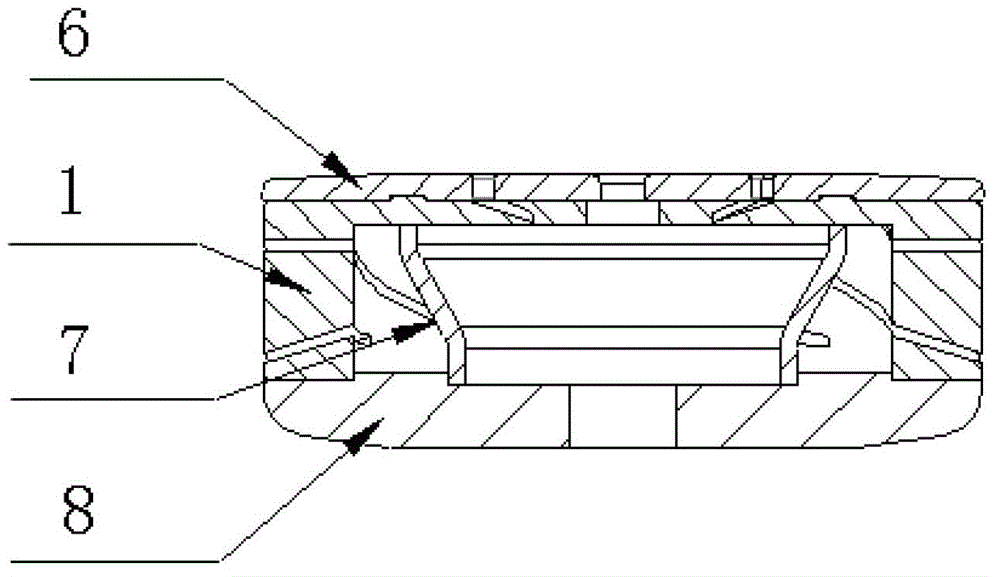

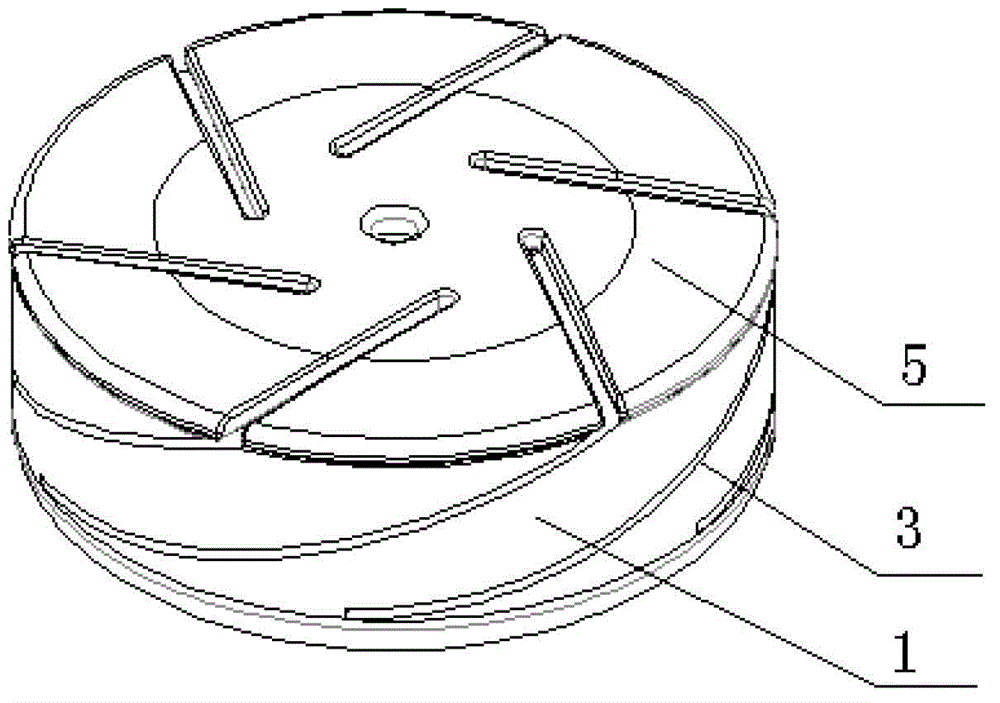

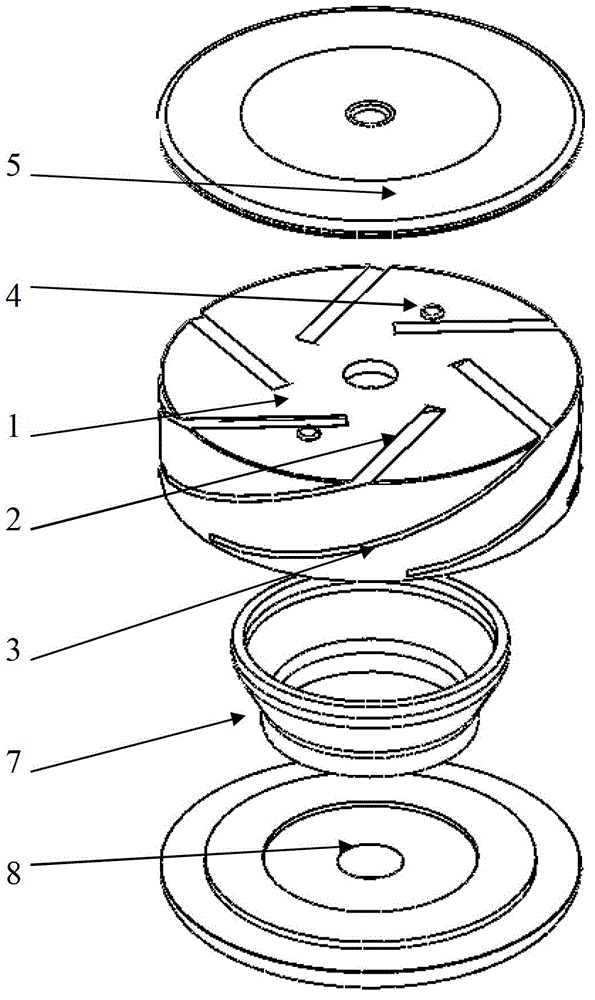

Novel longitudinal magnetic coil structure of vacuum arc extinguishing chamber

InactiveCN102751131APreserve integrityImprove flatnessHigh-tension/heavy-dress switchesAir-break switchesElectrical resistance and conductanceCoil structure

The invention discloses a novel longitudinal magnetic coil structure of a vacuum arc extinguishing chamber. The novel longitudinal magnetic coil structure is characterized by comprising a coil (1), wherein the opening end of the coil (1) is the lower part; the bowl bottom end of the coil (1) is the upper part; two or more than two grooves (2) are arranged above the coil (1); the grooves (2) are connected with inclined grooves (3) on the side wall of the coil (1); the inclined grooves (3) rotate upwards along the circumference of the coil (1); and the surface at the lower part of the coil (1) is an complete ring. According to the novel longitudinal magnetic coil structure, the completeness of the coil is maintained by changing the grooves on the coil; the strength of the coil is enhanced; the transformation is reduced; the influence on the shape transformation caused by the welding is reduced; the influence that a contact resistance is a little large due to the shape transformation is avoided; and moreover, the reliability in positioning is improved by changing the positioning mode of a contact and the coil; and the assembling is simpler, more convenient and faster; and the quality of the vacuum arc extinguishing chamber is improved.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

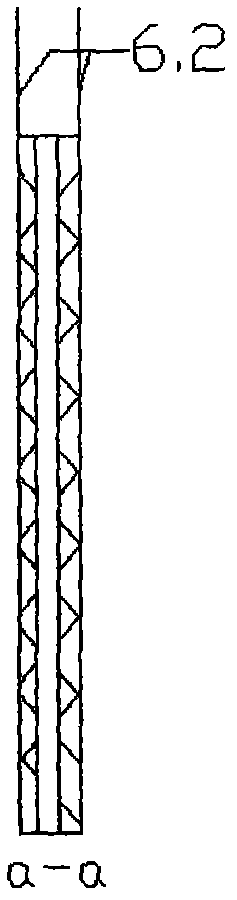

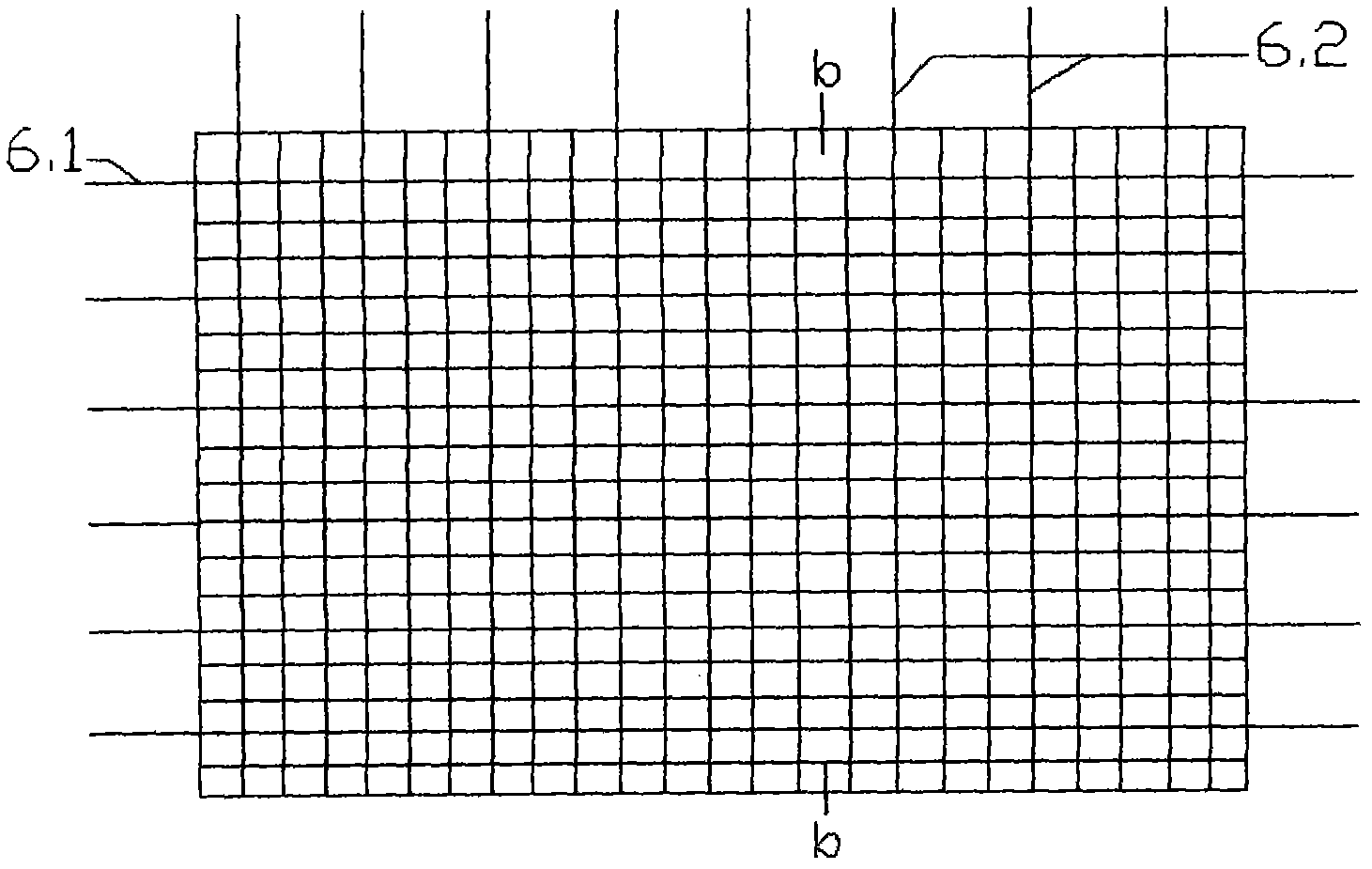

Concrete spray steel mesh sandwich formwork cast-in-place shear wall construction method and shear wall

InactiveCN102182317ARealize integrationImprove integrityWallsBuilding material handlingInsulation layerShear force

The invention relates to a concrete spray steel mesh sandwich formwork cast-in-place shear wall construction method and a shear wall manufactured by using the method. The construction method comprises the following steps: (1) mounting matched inner and outer steel mesh sandwich light plates on the preserved formwork positions; (2) spraying concrete on site on the inner side surface of the inner steel mesh sandwich light plate and the outer side surface of the outer steel mesh sandwich light plate; and (3) and casting concrete in place between the inner and outer steel mesh sandwich light plates. The shear wall is provided with the inner and outer steel mesh sandwich light plates; a middle concrete layer is cast between the inner and outer sandwich light plates; and inner and outer side surface concrete layers are sprayed on the outer side surface of the outer sandwich light plate and the inner side surface of the inner sandwich light plate respectively. By adopting the method in the invention, integration of formwork, insulation and structure is realized, the construction speed is obviously improved, the service life of wall, particularly insulation layer, is obviously prolonged, and the capability of the wall resisting shear force is obviously improved.

Owner:BEIJING HUAMEIKEBO TECH DEV

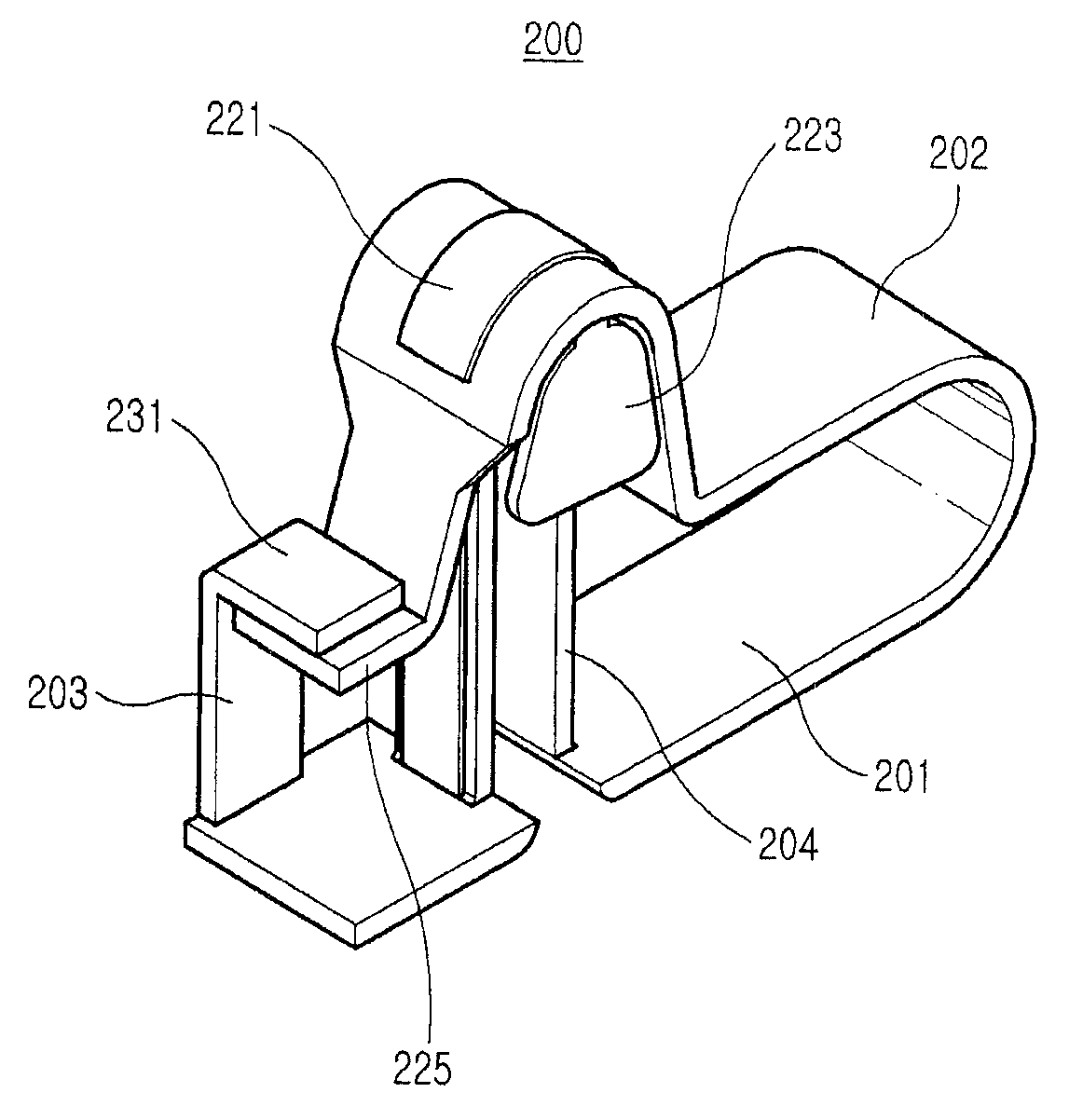

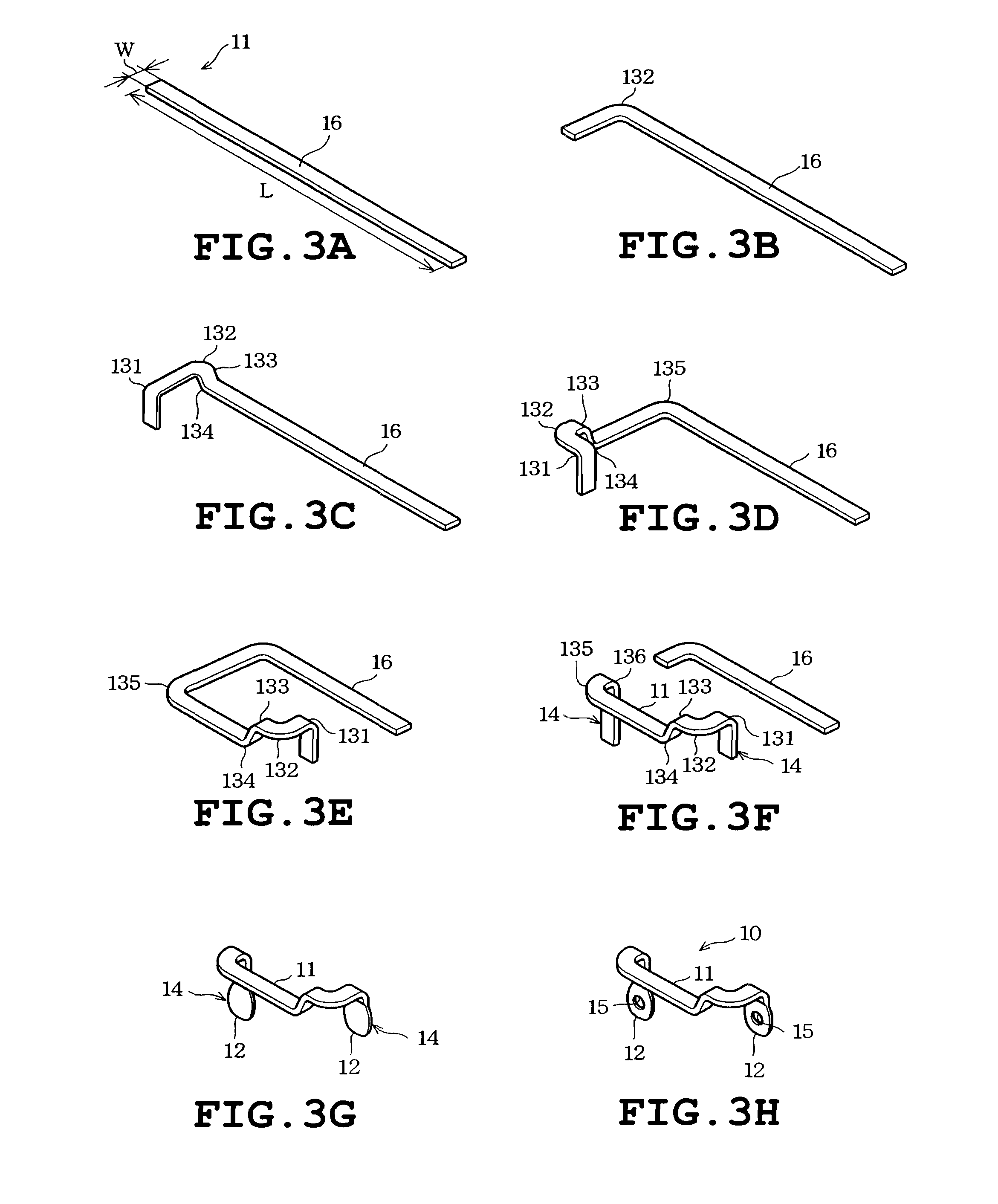

Contact terminal for electronic device

InactiveUS7927158B2Reduce laborLow costCoupling device detailsElectric connection basesSurface mountingEngineering

A contact terminal of an electronic device includes: a fixing member; a contact member extending from the fixing member and a limiting member and extending from the fixing member where one end portion of the limiting member restrains one end portion of the contact member, wherein the contact terminal provides an elastic force upon the contact member in a direction away from the fixing member, and a range where the contact member moves away from the fixing member is limited since the end portion of the limiting member restrains the end portion of the contact member. The disclosed contact terminal can be directly mounted on a circuit board by using a surface mounting device (SMD) process, thereby reducing production costs and interconnection loss.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for improving position accuracy of mold core of integrated type ceramic mold

InactiveCN104526856AHigh positioning accuracyReduce the possibility of deformationCeramic shaping mandrelsCeramic shaping coresFiberLithographic artist

The invention discloses a method for improving the position accuracy of a mold core of an integrated type ceramic mold, and belongs to the field of rapid costing based on stereo-lithography technologies. The method comprises the steps that (1) three-dimensional software is utilized to design a resin mold, and a resin mold prototype with a positioning hole is manufactured by utilizing a stereo-lithography method; (2) a ceramic fiber or a ceramic bar penetrates into the positioning hole according needs; (3) ceramic slurry is poured into the resin mold prototype of turbine blades through a gel casting method to obtain a mold blank; (4) vacuum freeze drying and sintering are carried out on the mold blank to obtain the integrated type ceramic mold of the turbine blades. The position accuracy of the mold core of the integrated type ceramic mold can be effectively improved through the vertically through or non-through mold core, and the method is reasonable in design, is easy and convenient to operate, greatly improves the manufacturing integrity and accuracy of the mold and is suitable for practical production.

Owner:XI AN JIAOTONG UNIV +1

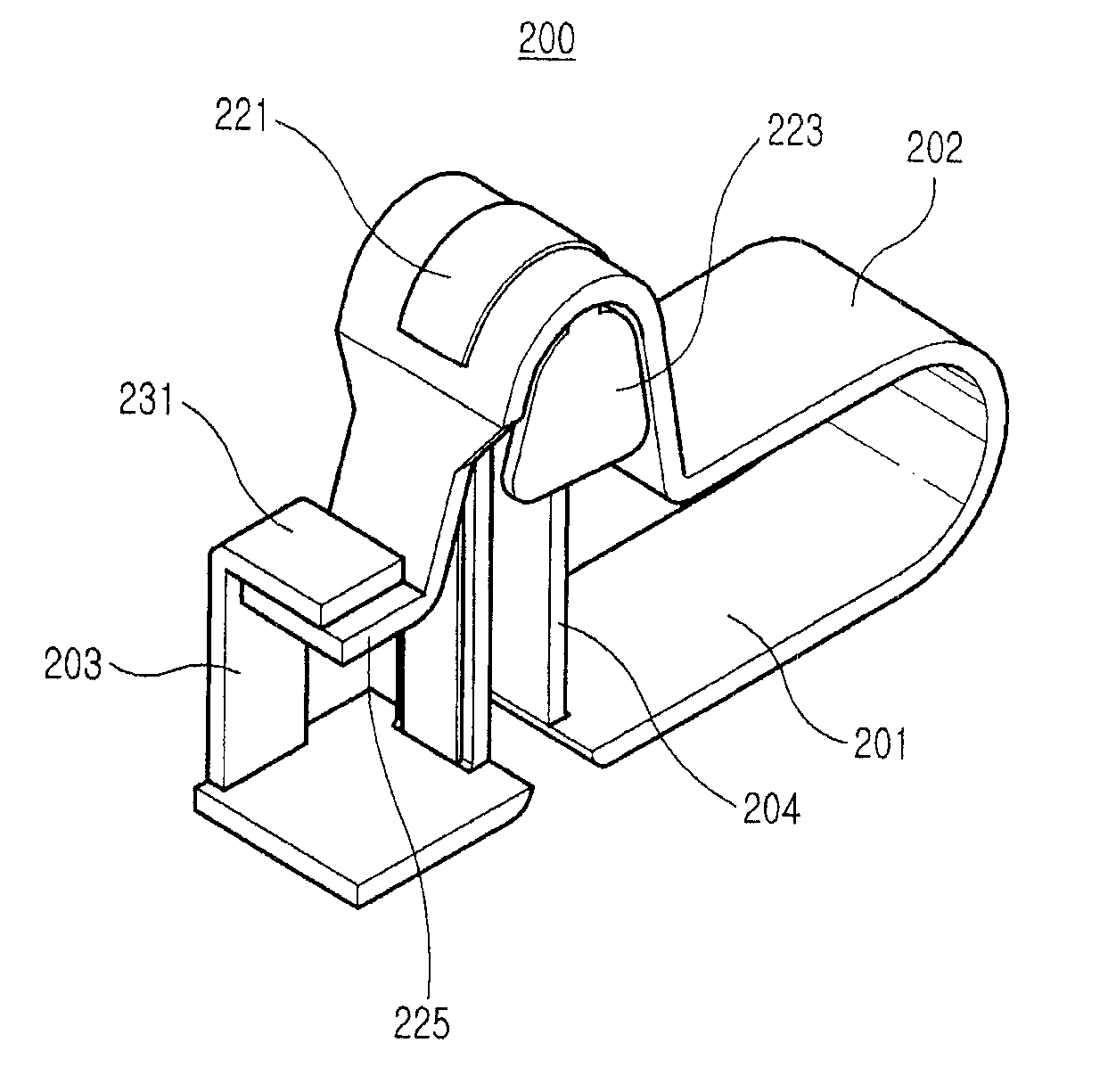

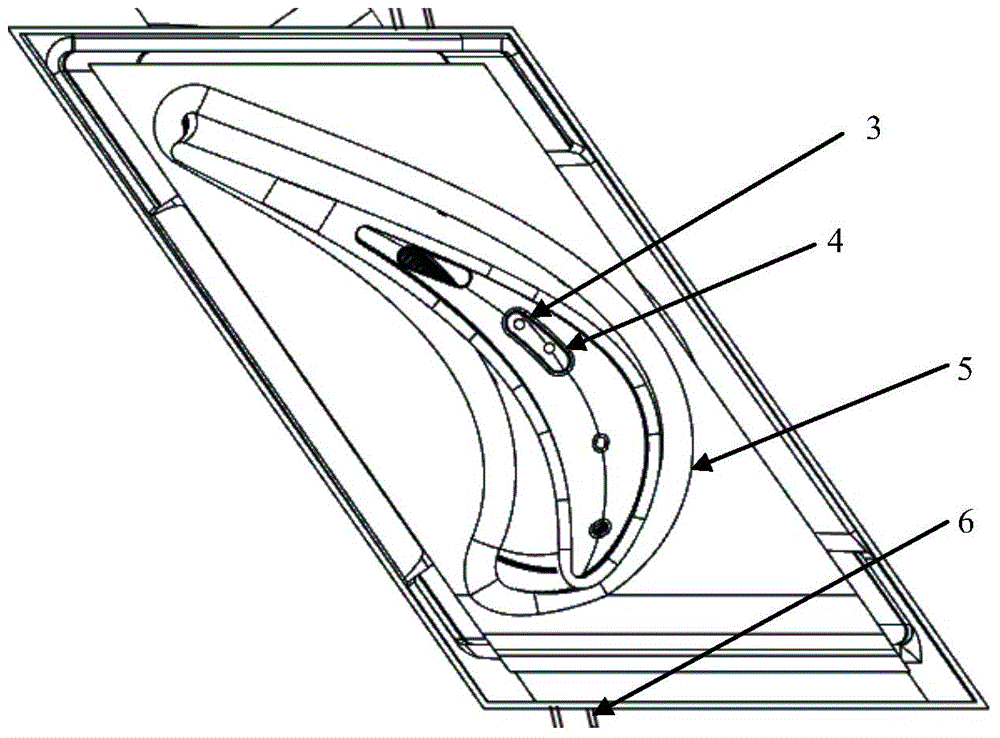

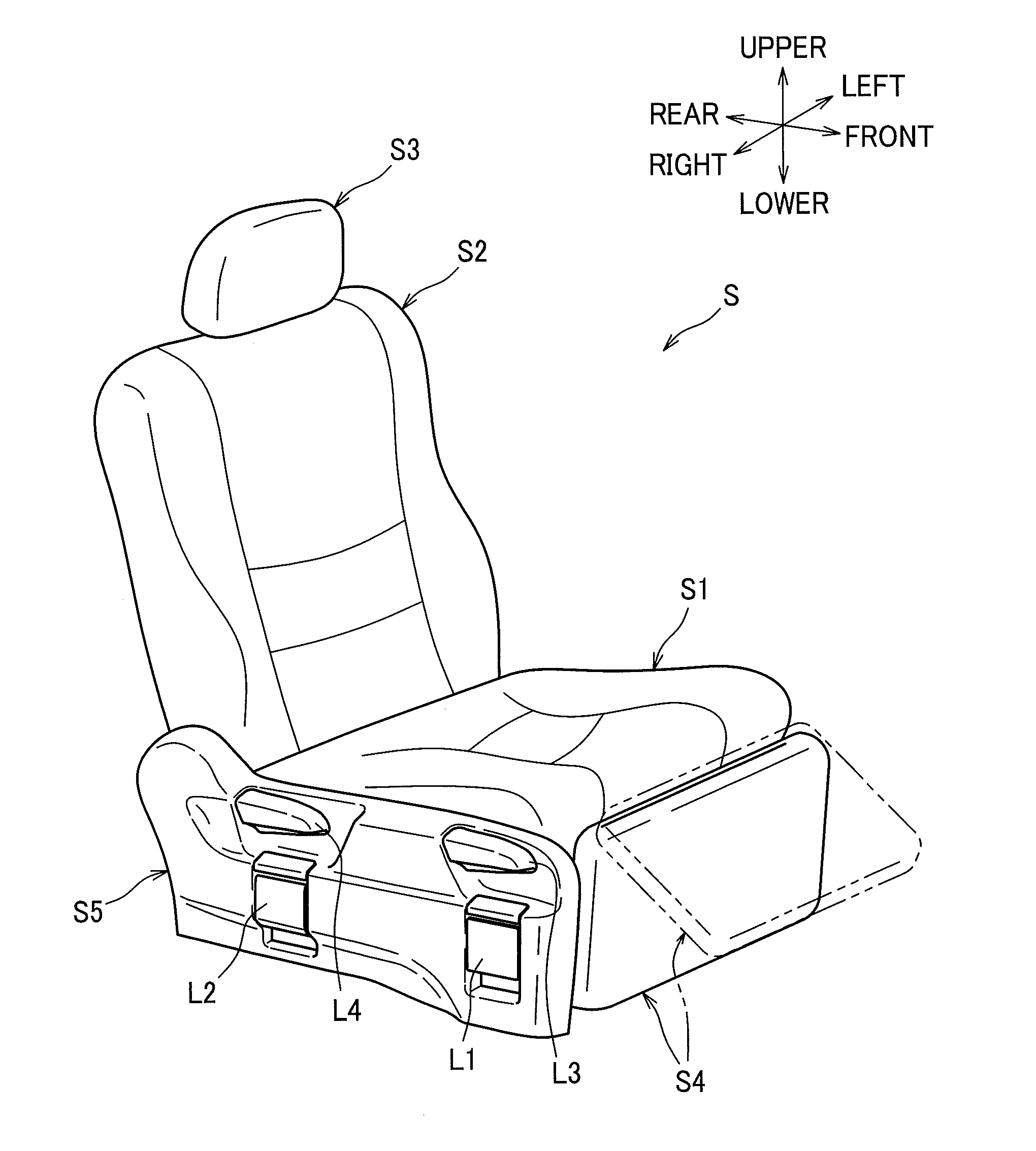

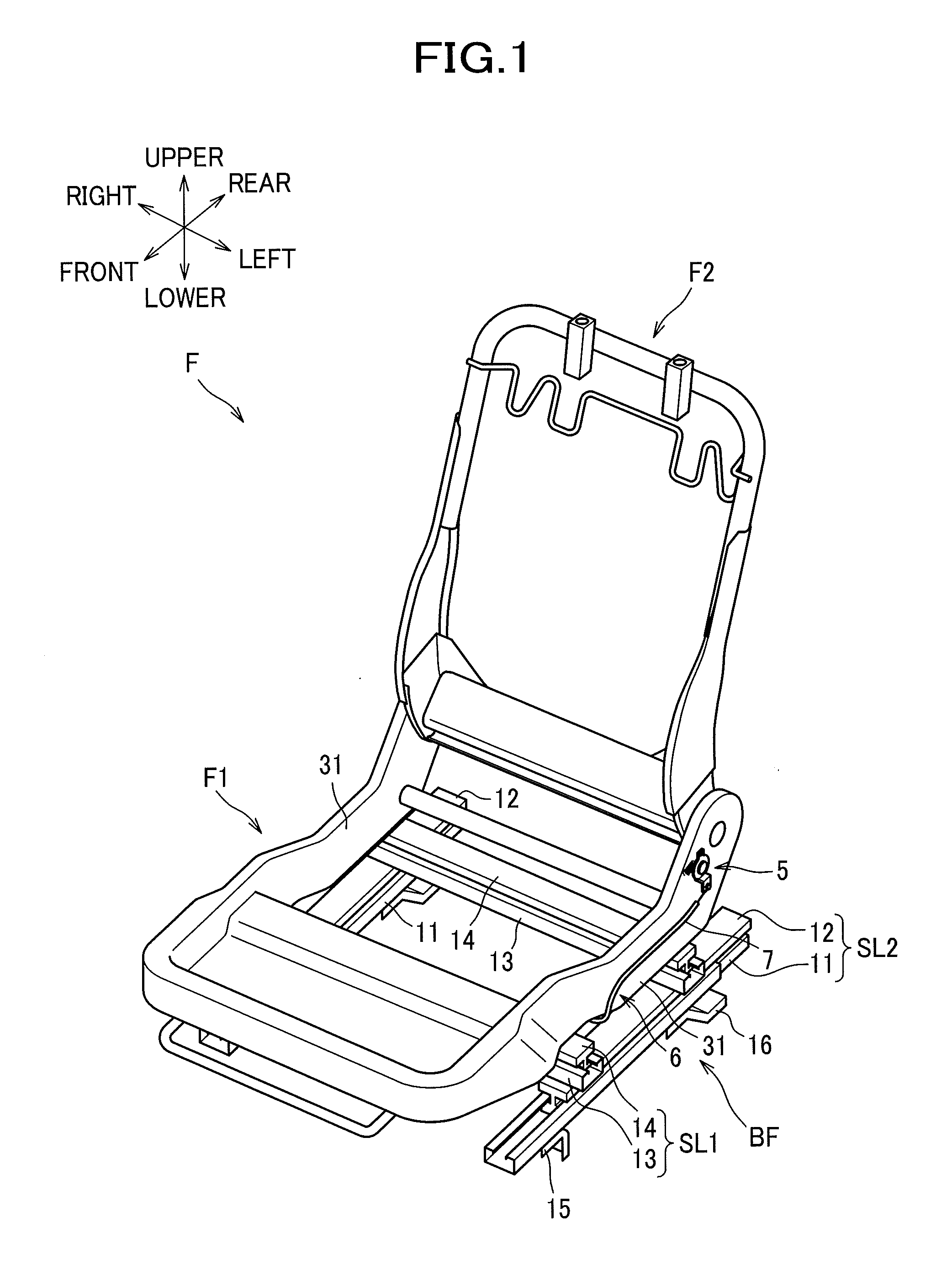

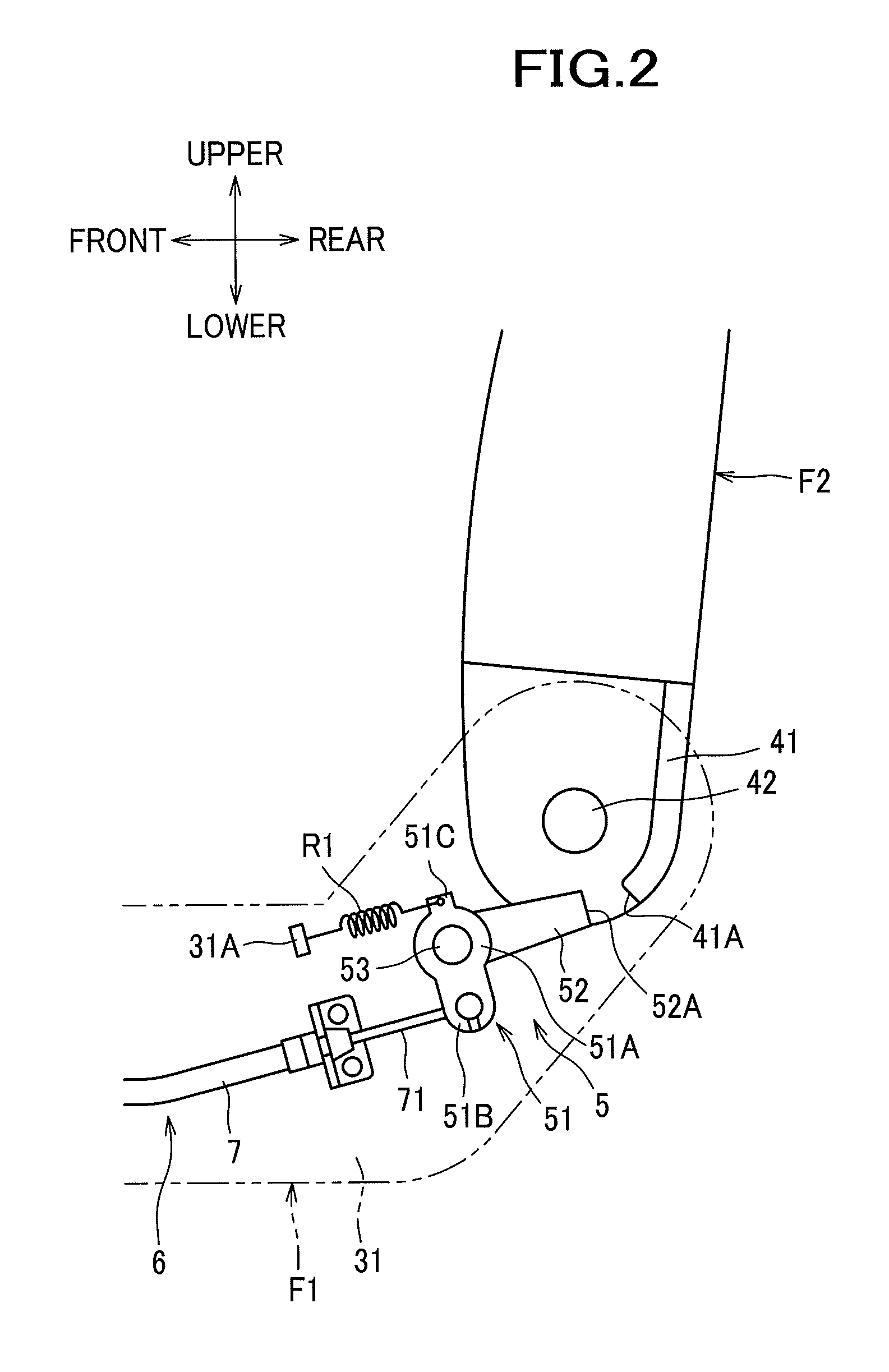

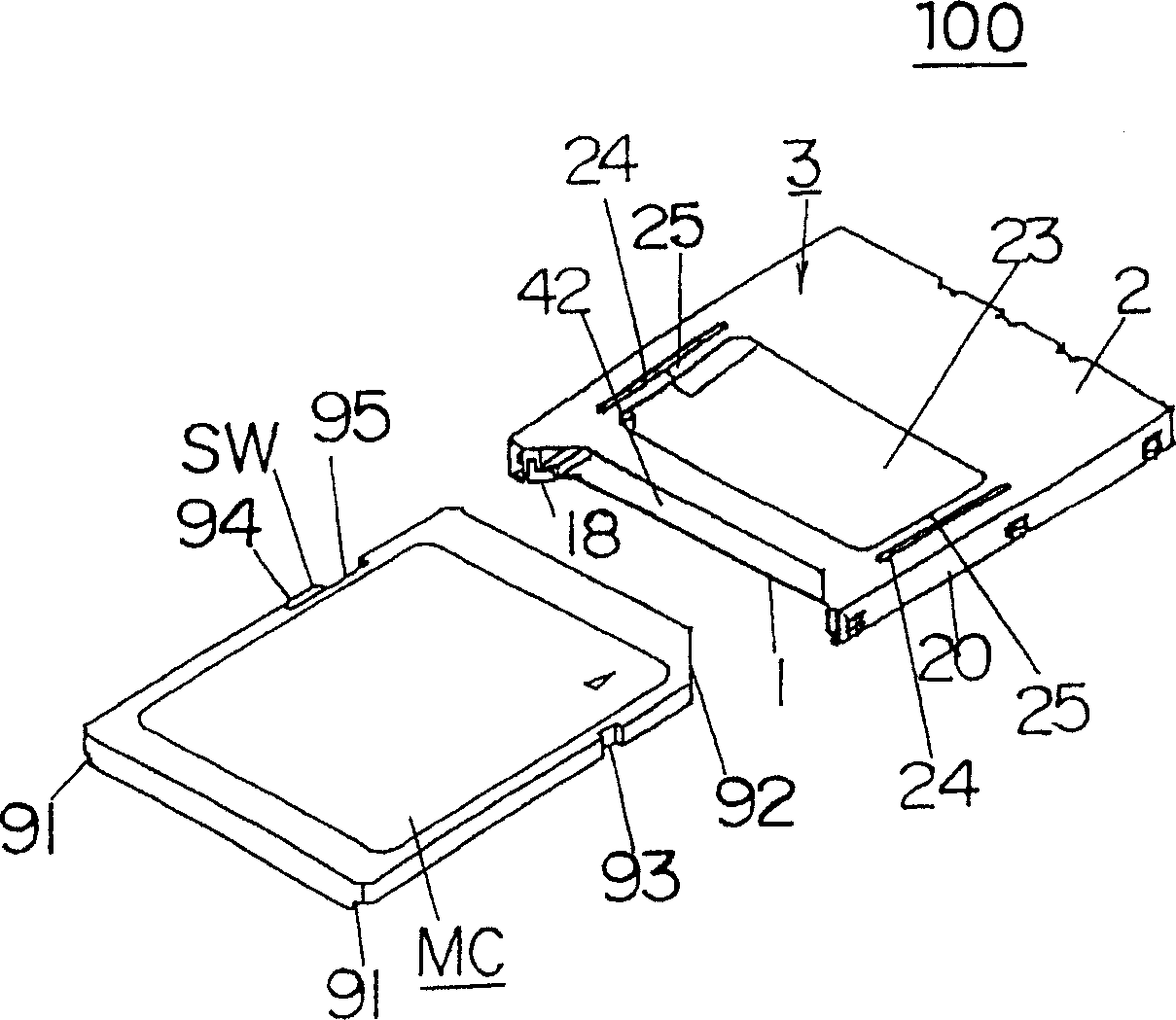

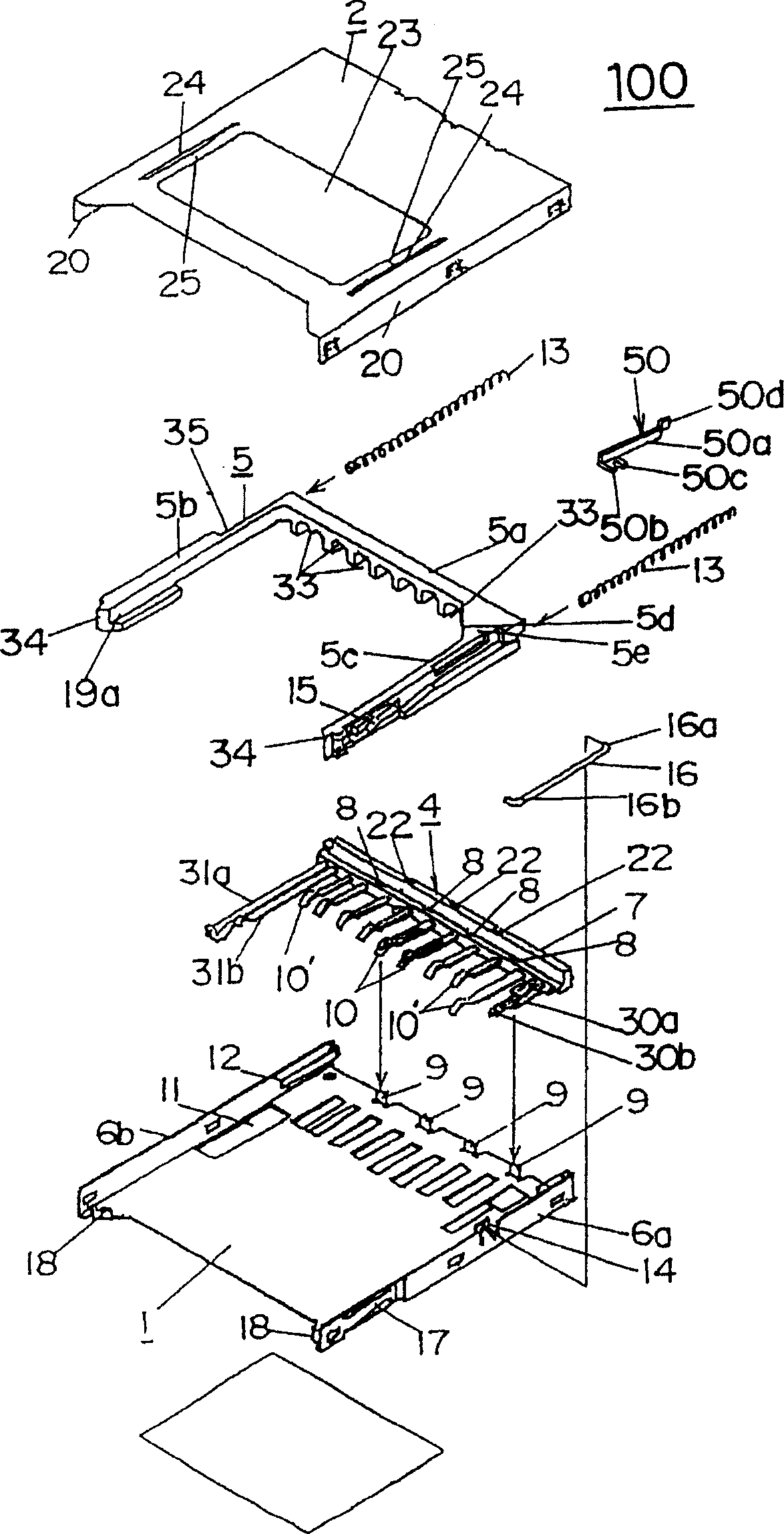

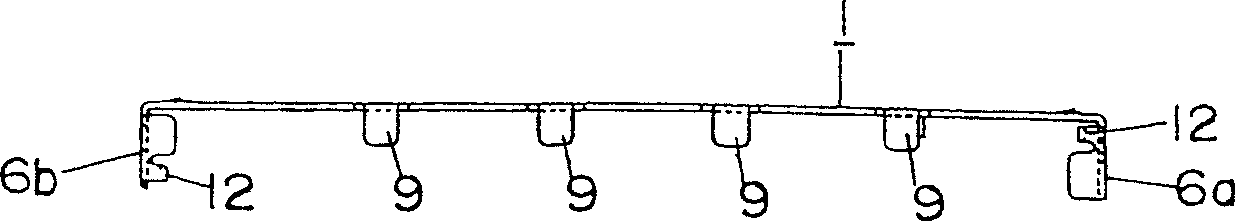

Seat for vehicle

A vehicle seat is provided in which a seat back is constrained from tilting down when a seat cushion is moved to a position in which the seat back cannot be tilted down. The vehicle seat includes a base frame, a seat cushion frame (3) horizontally movable relative to the base frame between a first position and a second position different from the first position, a seat back frame (4) rotatable relative to the seat cushion frame (3), a lock member (5) configured to constrain the seat back frame (4) from tilting rearward, and an unlock mechanism (6) configured to release a lock applied by the lock member (5) when the seat cushion frame (3) is moved from the first position to the second position.

Owner:TS TECH CO LTD

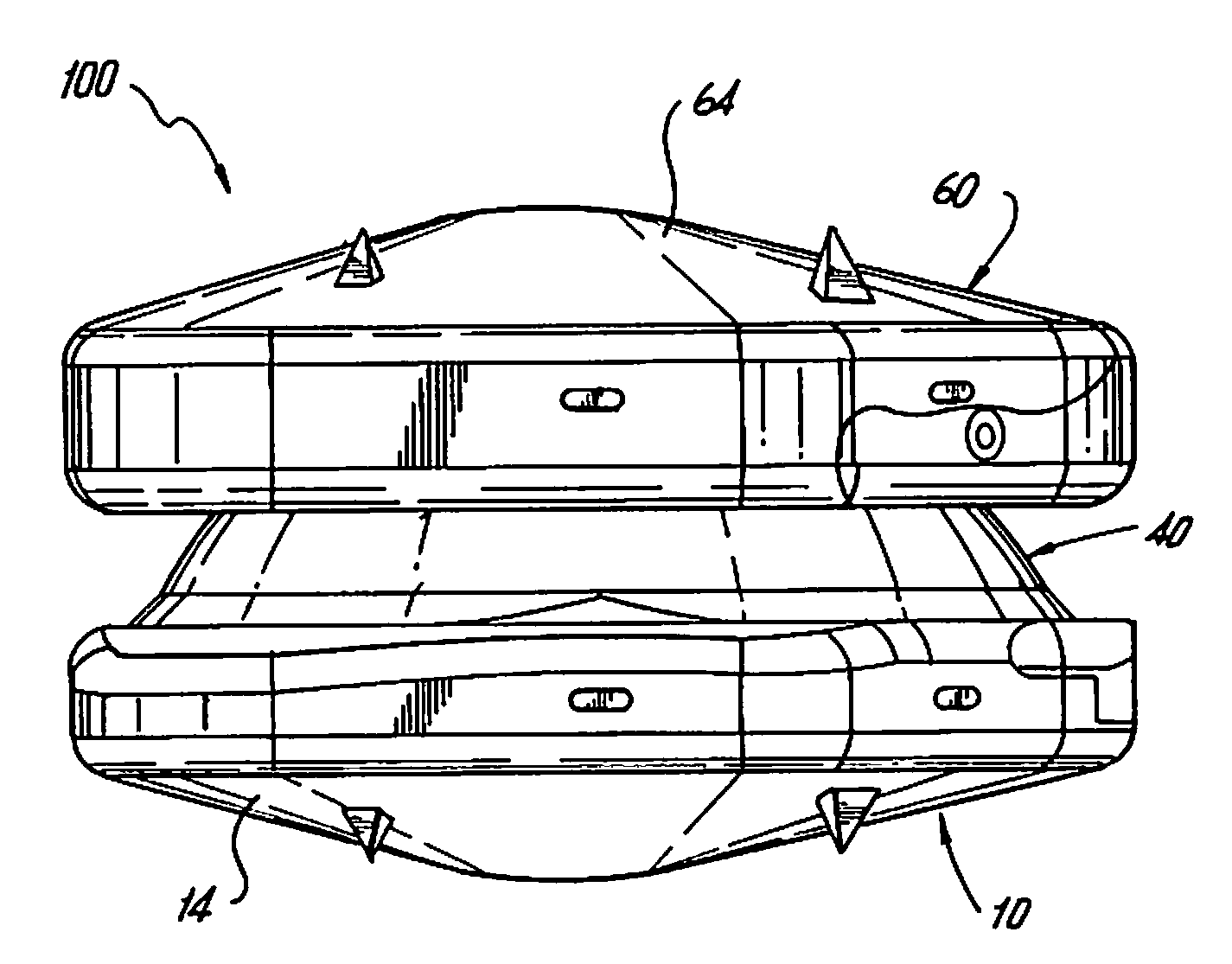

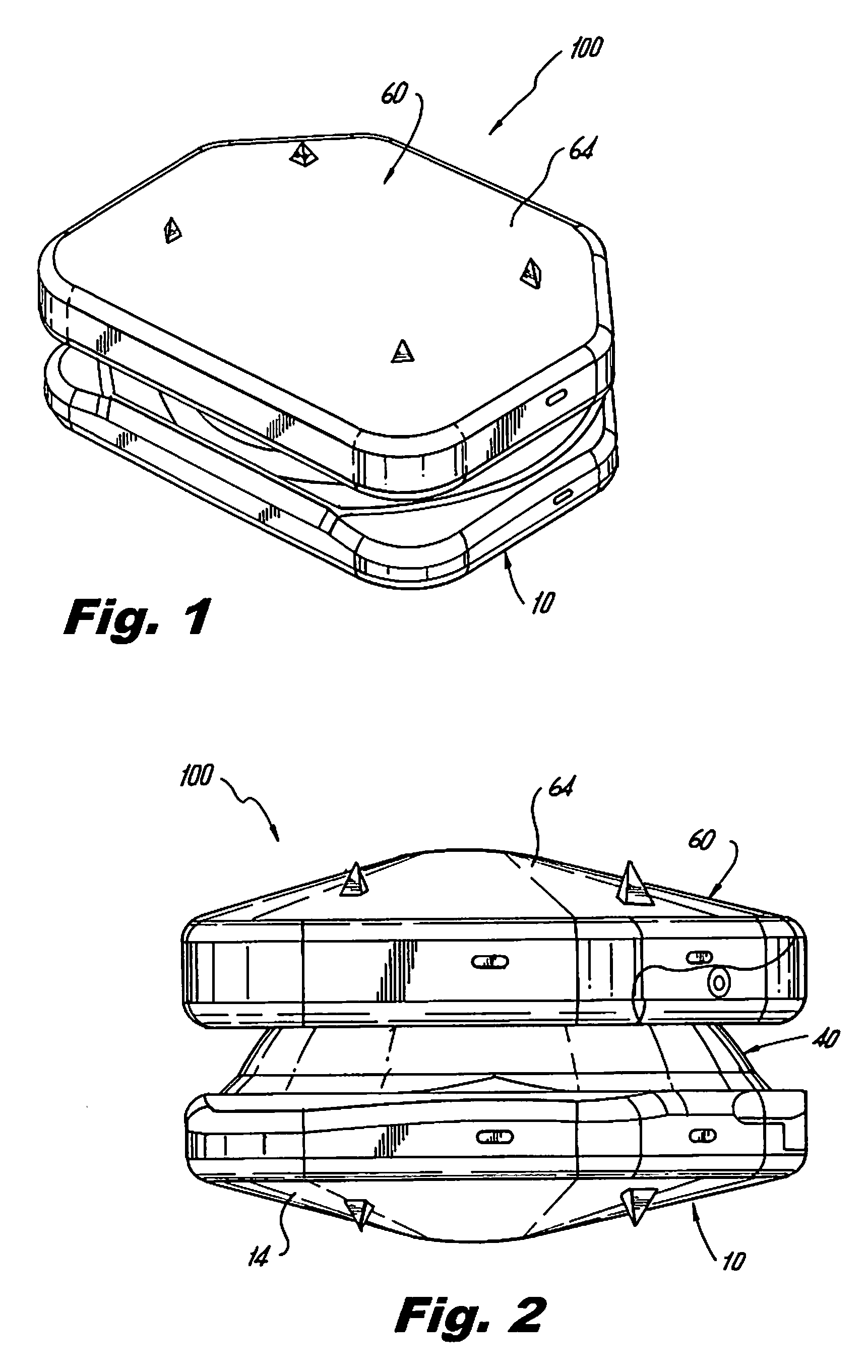

Artificial disc replacement device

InactiveUS20090248161A1Increase distanceReduction in installation forceSpinal implantsArtificial discMechanical engineering

An artificial disk replacement device includes opposing plate members with a pivoting assembly disposed therebetween. The pivoting assembly allows the plate members to pivot relative to each other in a first direction, but inhibit movement of the plate members in a second direction. The plate members may be installed prior to installing the pivoting assembly. An installation tool for use with the artificial disk replacement device is also disclosed.

Owner:K2M

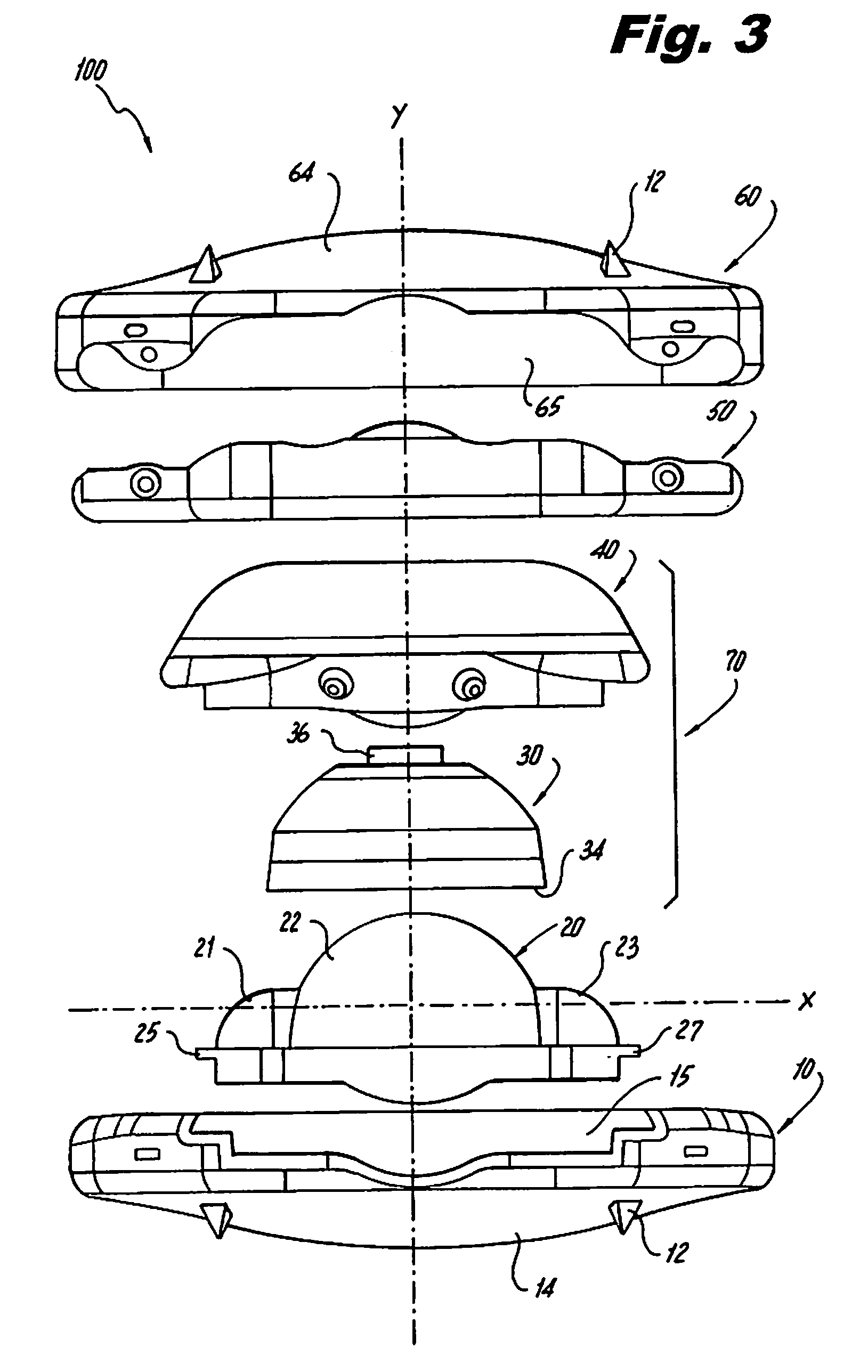

Strength-increasing shield tunneling machine cutter ring machining process

The invention discloses a strength-increasing shield tunneling machine cutter ring machining process, and belongs to the field of shield tunneling machine cutters. According to the technical scheme, the machining process comprises the following steps of S1 electro-slag remelting, S2 cogging, S3 cutting, S4 free forging, S5 die forging, S6 ring grinding, S7 rough inspecting, S8 spheroidizing annealing, S9 secondary inspecting, S10 rough turning, S11 quenching and S12 fine inspecting, wherein in the first step, an electro-slag furnace is utilized for remelting steel ingots into ESR ingots; in the second step, an electro hydraulic hammer is utilized for forging the ESR ingots into raw rod materials; in the fourth step, rod material blanks are subjected to free forging to upsetting; and in thetwelfth step, a cutter ring is cooled, and then the outer diameter, the inner diameter, the inner ring thickness and the outer ring thickness of the cutter ring are inspected. The strength-increasingshield tunneling machine cutter ring machining process has the effect of strengthening the cutter structure.

Owner:JIASHAN XINQIANG STEEL IND CO LTD

Contact terminal for electronic device

InactiveUS20100136855A1Reduce laborLow costCoupling device detailsElectric connection basesSurface mountingEngineering

A contact terminal of an electronic device includes: a fixing member; a contact member extending from the fixing member and a limiting member and extending from the fixing member where one end portion of the limiting member restrains one end portion of the contact member, wherein the contact terminal provides an elastic force upon the contact member in a direction away from the fixing member, and a range where the contact member moves away from the fixing member is limited since the end portion of the limiting member restrains the end portion of the contact member. The disclosed contact terminal can be directly mounted on a circuit board by using a surface mounting device (SMD) process, thereby reducing production costs and interconnection loss.

Owner:SAMSUNG ELECTRONICS CO LTD

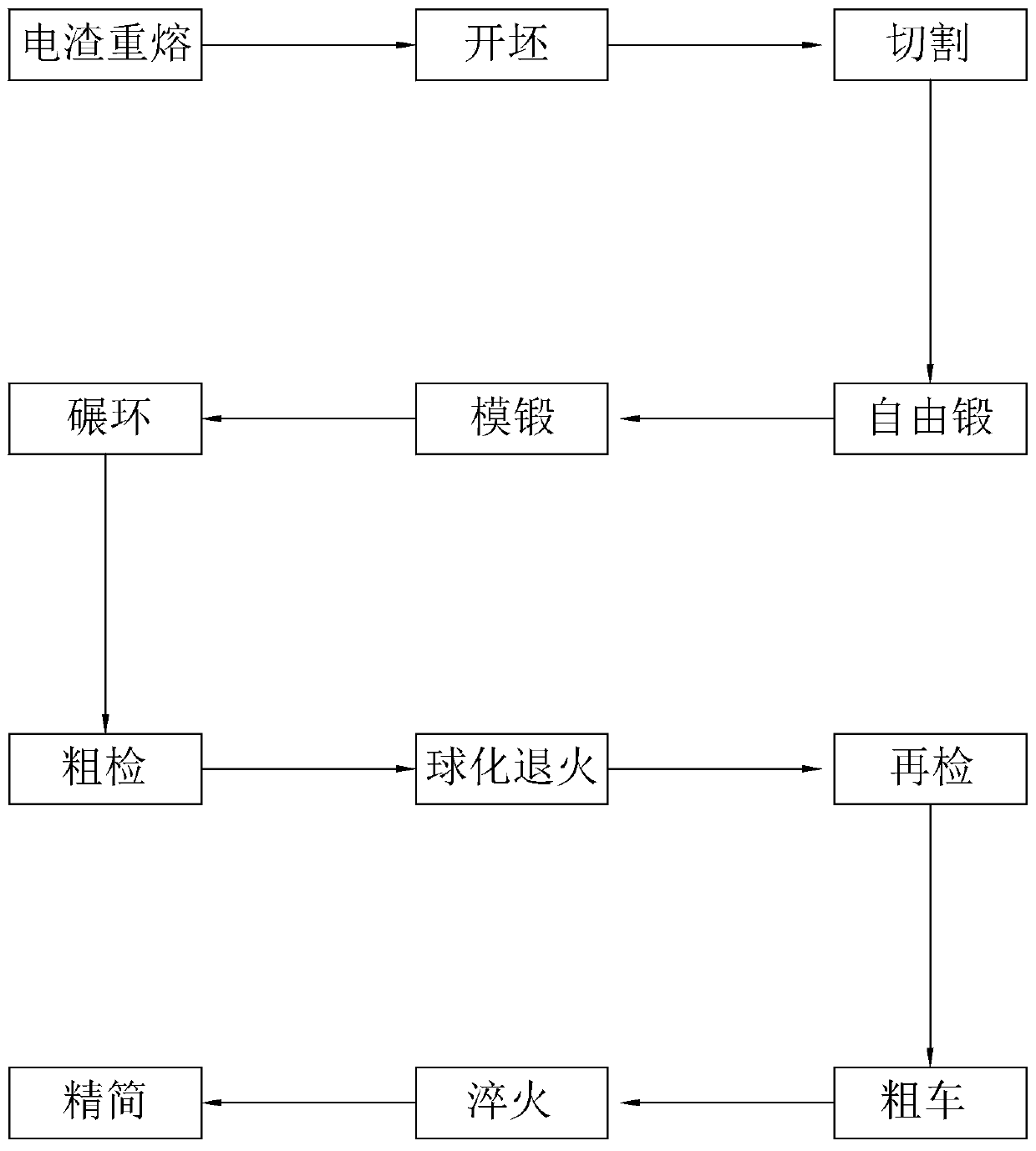

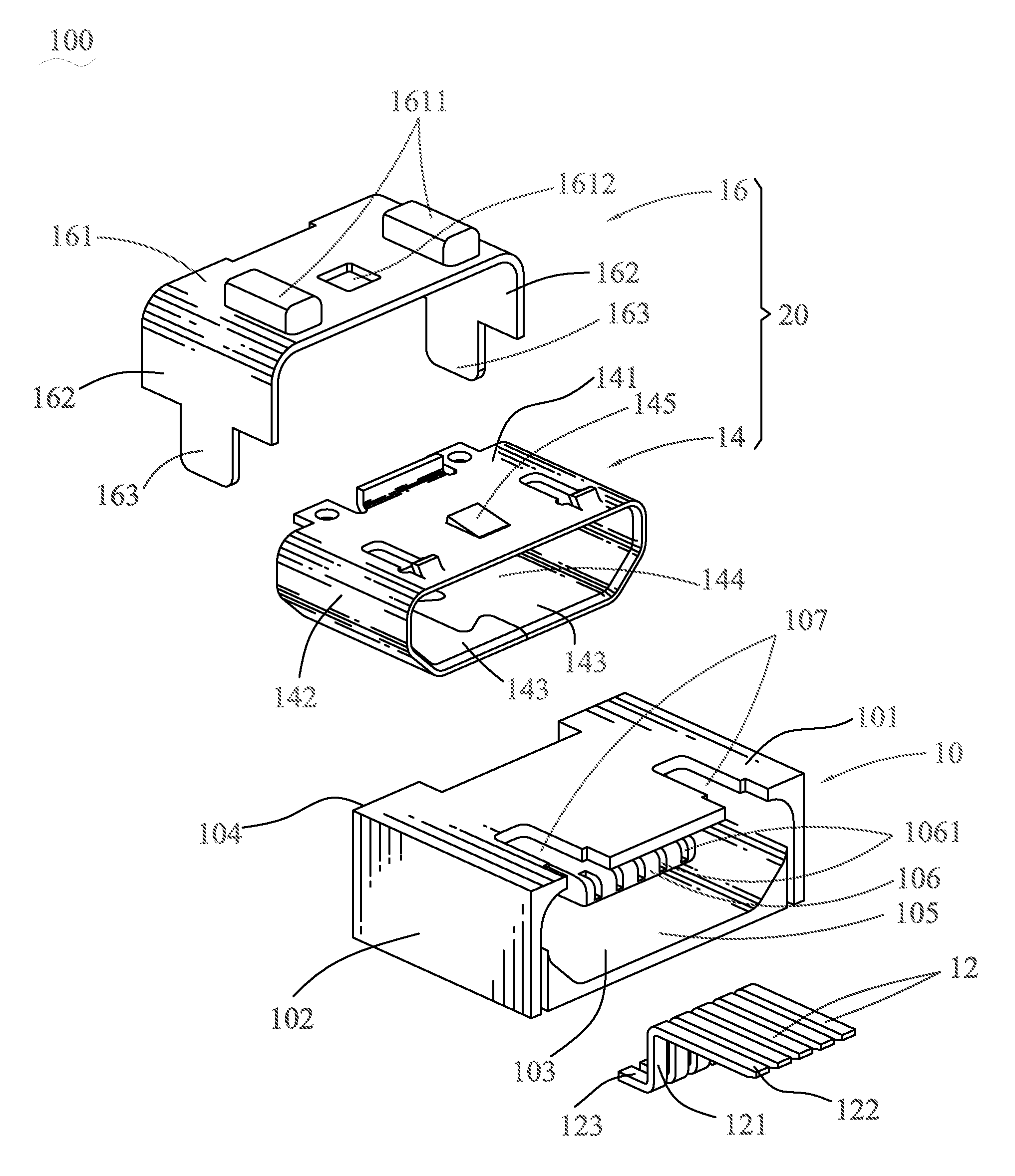

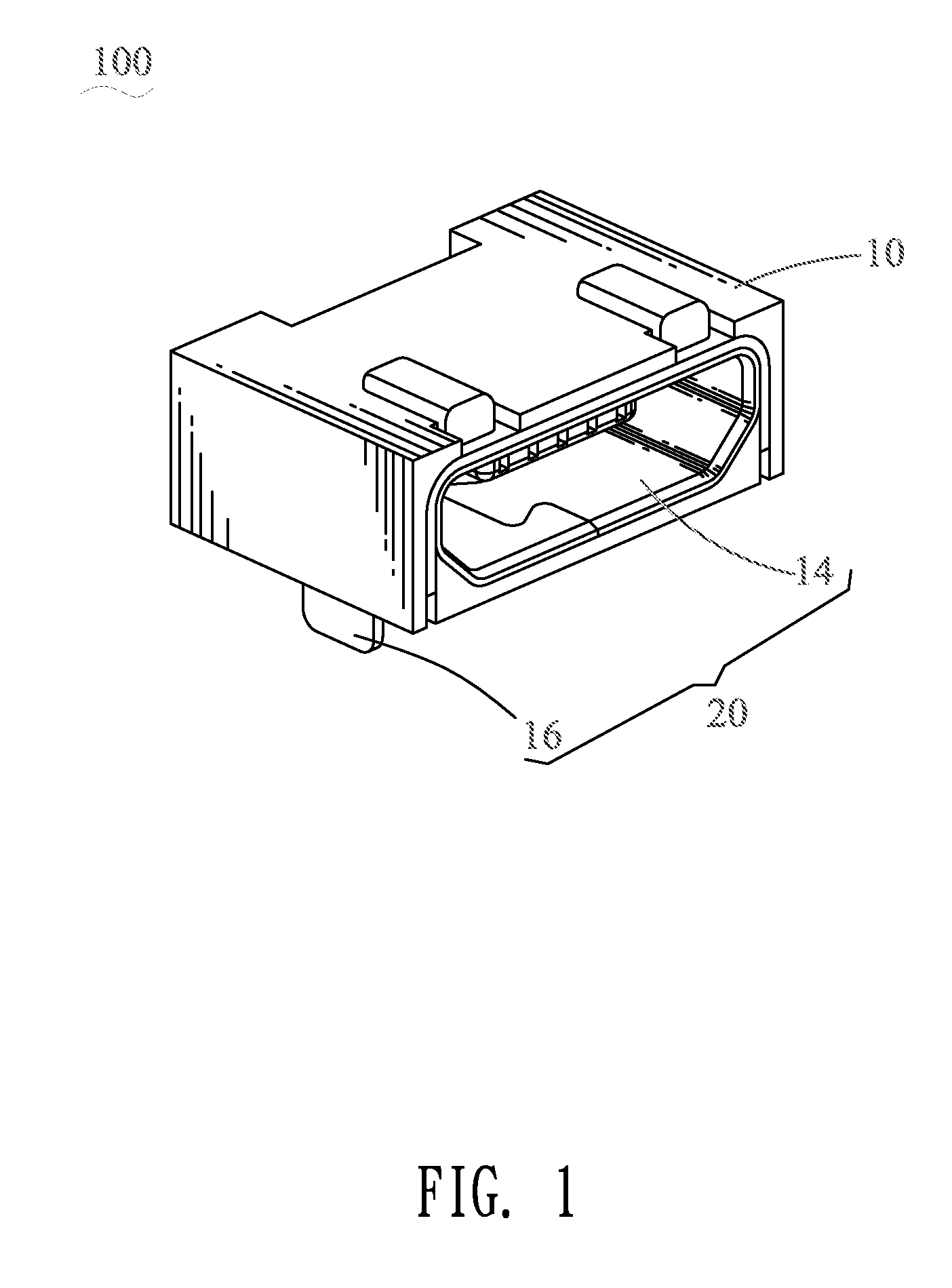

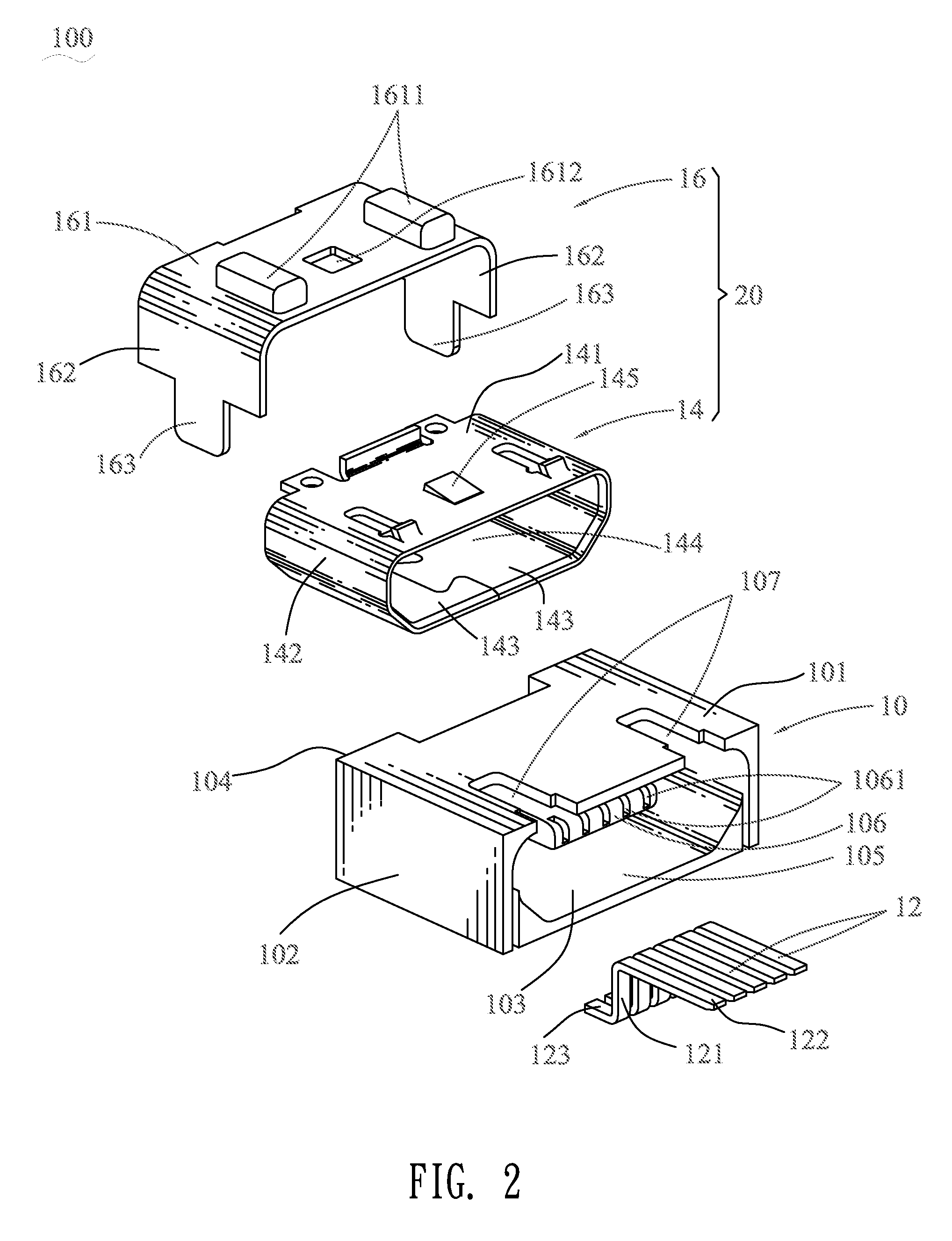

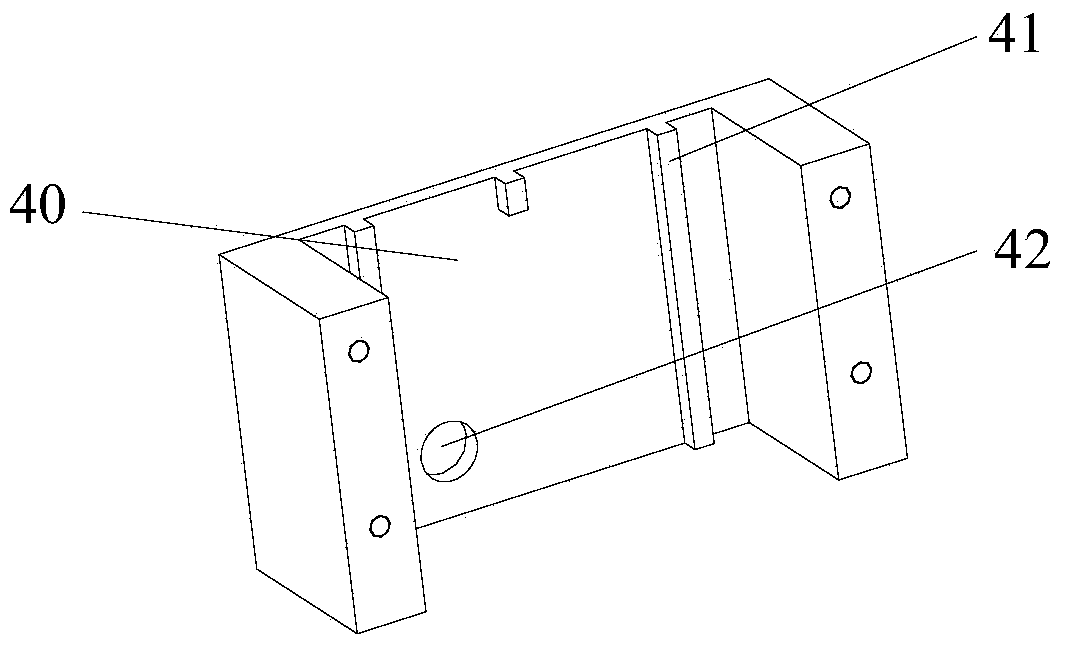

Electrical connector and molding method thereof

InactiveUS8083549B1Improve air tightnessReduce the possibility of deformationElectrically conductive connectionsContact member assembly/disassemblyEngineeringElectrical connector

An electrical connector includes an insulating housing, a plurality of terminals and a shielding shell which are molded integrally. The insulating housing has a top wall, two side walls, a bottom wall and a rear wall which are interconnected to form a box shape with an accommodating chamber formed thereamong. The terminals are molded in the insulating housing with contact portions extended into the accommodating chamber. The shielding shell includes an inner shell and an outer shell fixedly attached on the inner shell. The inner shell includes a top plate, two side plates and a bottom plate which are interconnected together to surround a receiving space thereamong. The shielding shell is molded in a periphery of the accommodating chamber with a portion of the outer shell exposed outside the insulating housing.

Owner:CHENG UEI PRECISION IND CO LTD

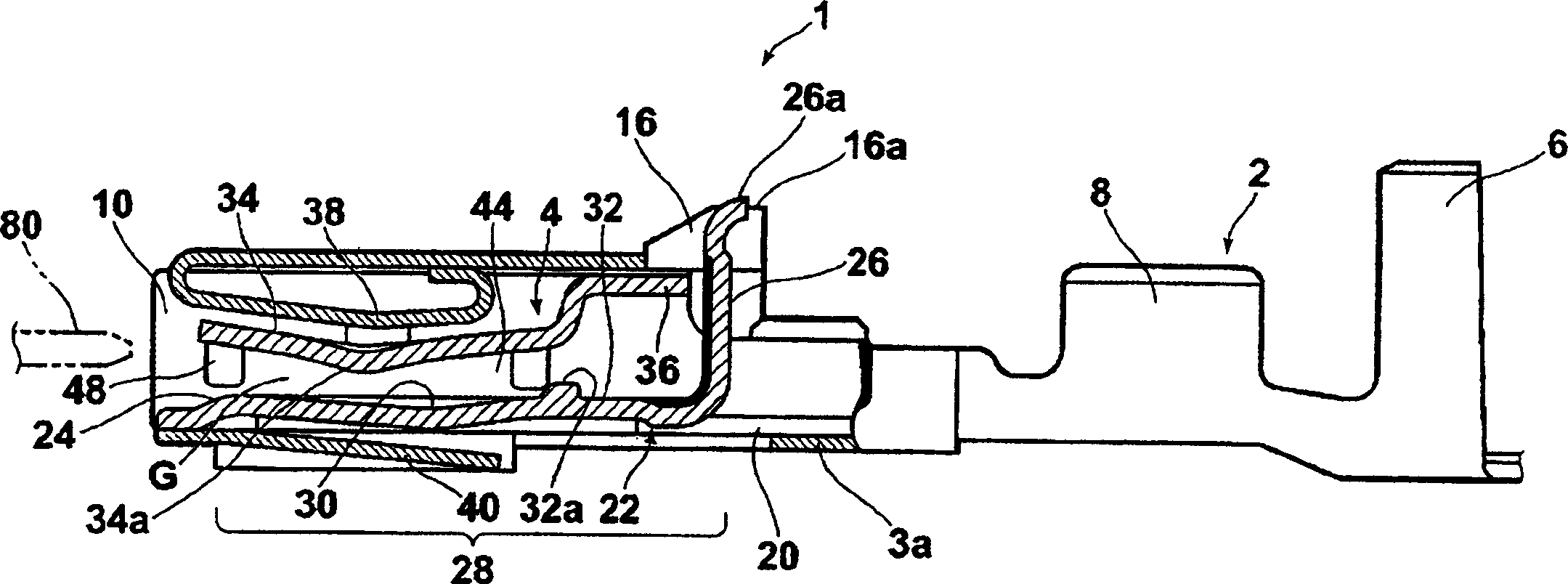

Negative terminal and electric connector using the same negative terminal

InactiveCN1773778AGood operabilityNot easy to reverseContact member manufacturingCoupling contact membersEngineeringElectric wire

The invention provides a female terminal and an electrical connector. The female terminal is not easy to produce micro-sliding wear due to vibration, can obtain strong contact pressure, and has good workability under low insertion force. Also, prevent twisting. A female terminal (1), including two parts, a terminal body (2) and a reinforcing part (3) installed on the terminal body, the terminal body (2) has a plug-in piece that is inserted in the front The elastic contact piece (34) that the terminal (80) contacts, and has the electric wire connecting part (6, 8) that is connected with the electric wire at the back, and the described strengthening part (3) has the spring piece (38), and above-mentioned contact piece ( 34) When deflected due to contact with the above-mentioned blade terminal (80), the spring piece (38) supports the contact piece (34) to strengthen the contact pressure of the above-mentioned contact piece (34).

Owner:TYCO ELECTRONICS JAPAN GK

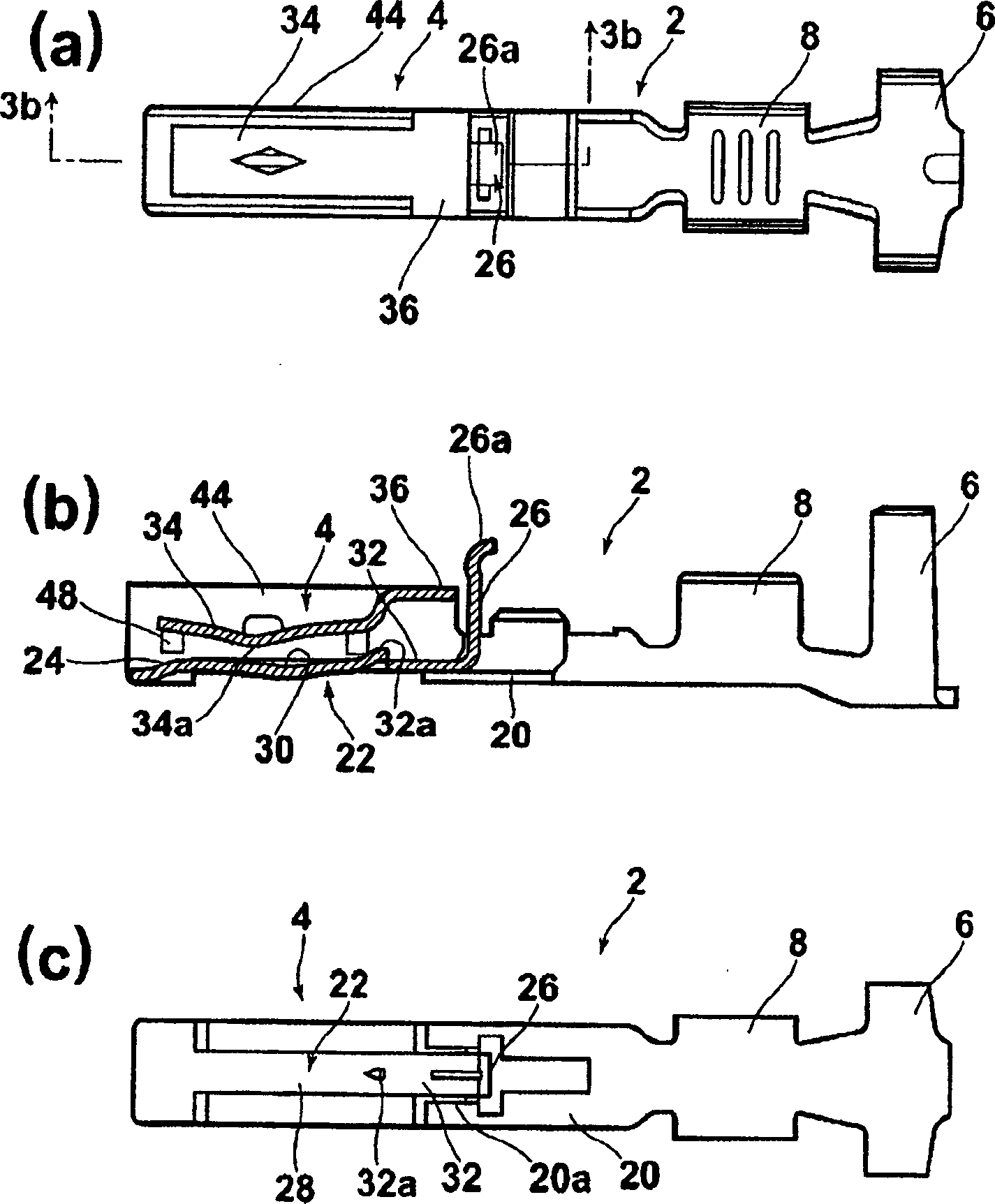

Method and device for carrying out differential temperature incremental forming on aviation light alloy plates

The invention discloses a method and device for carrying out differential temperature incremental forming on aviation light alloy plates. The method comprises the following specific steps: firstly fixing an aviation light alloy plate on a support base which comprises a heat-conducting oil groove, wherein the heat-conducting oil groove comprises a pipeline, a heating device, a temperature control device and an oil liquid level height detection and control system; injecting heat-conducting oil into the heat-conducting oil groove until the heat-conducting oil is in contact with the plate; heating the heat-conducting oil through the heating device and the temperature control device so as to ensure that the temperature of the plate achieves a required temperature and the temperature is uniform; selecting a proper incremental forming process to carrying out differential temperature incremental forming; and in the forming process, measuring the height of the liquid level of the heat-conducting oil in real time through the oil liquid level height detection and control system, and realizing the dynamic adjustment of the height of the liquid level so as to ensure that the unformed part is in contact with the liquid level of the heat-conducting oil all the time to be in the heating state and the formed part is divorced from the liquid level of the heat-conducting oil to undergo online cooling.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

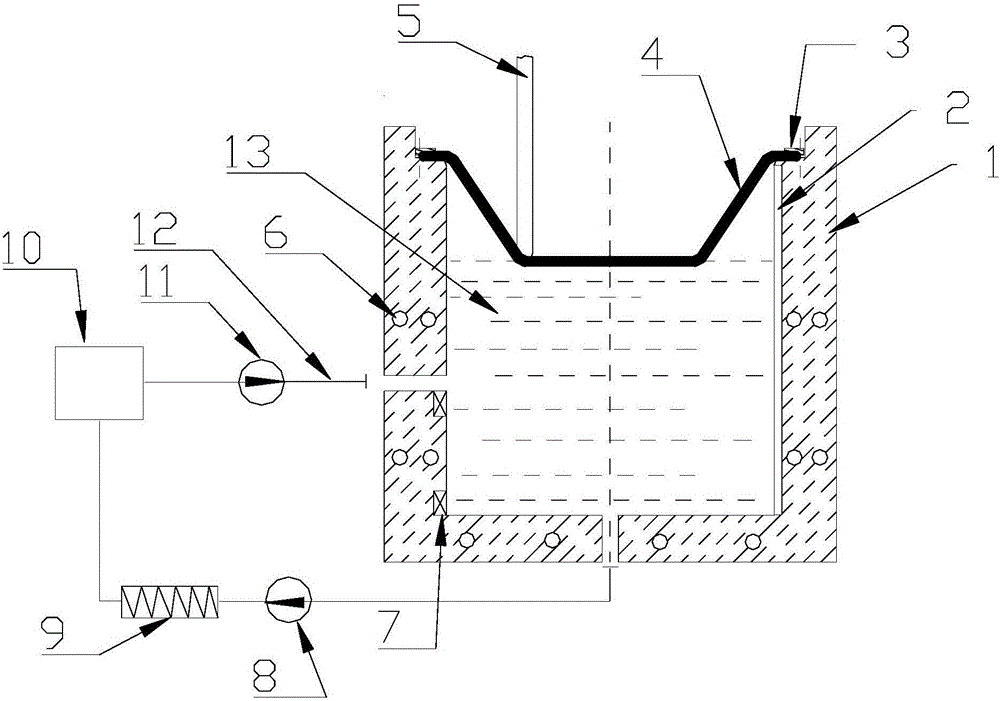

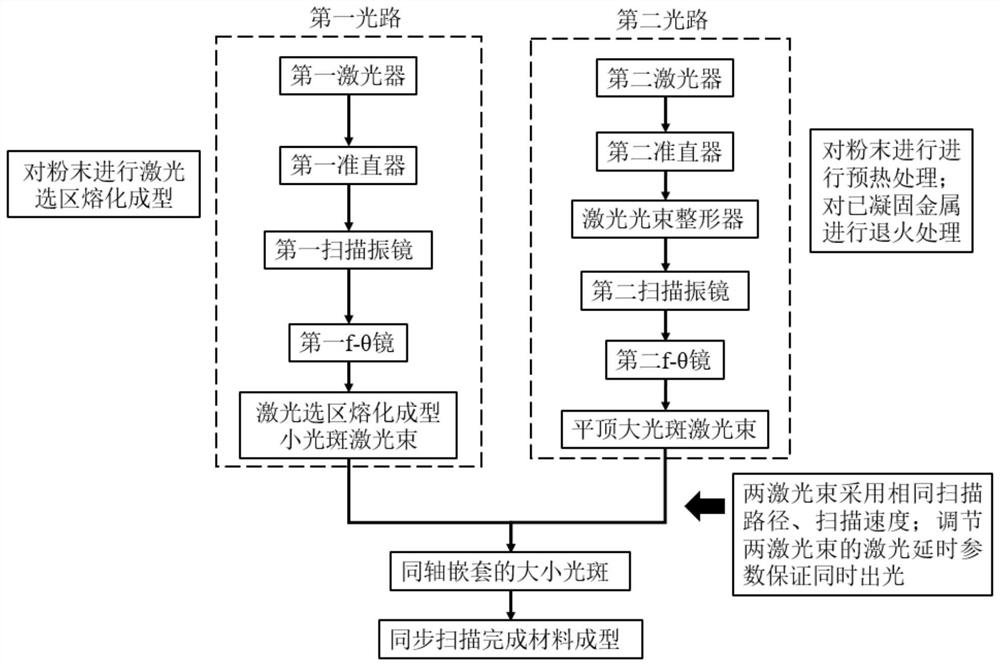

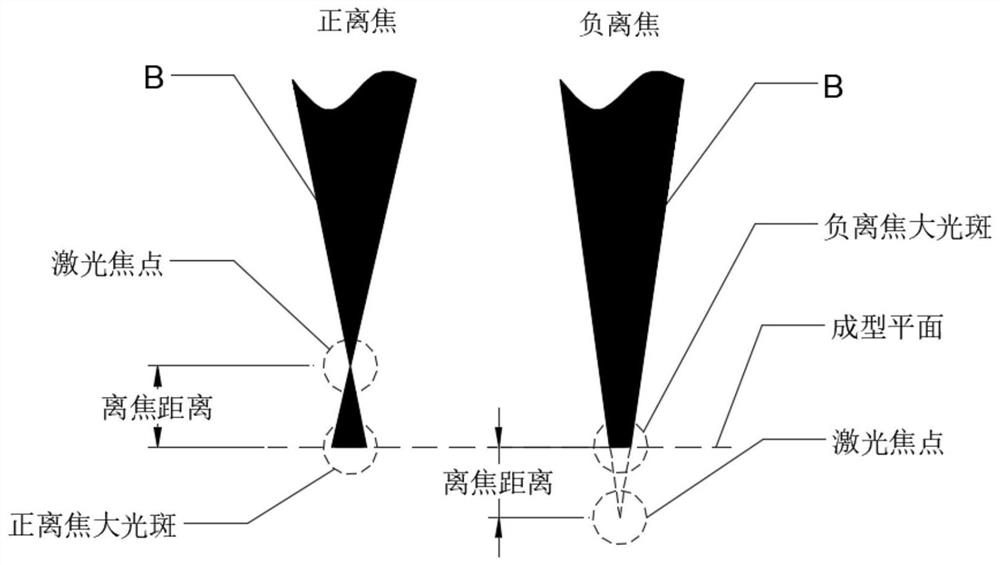

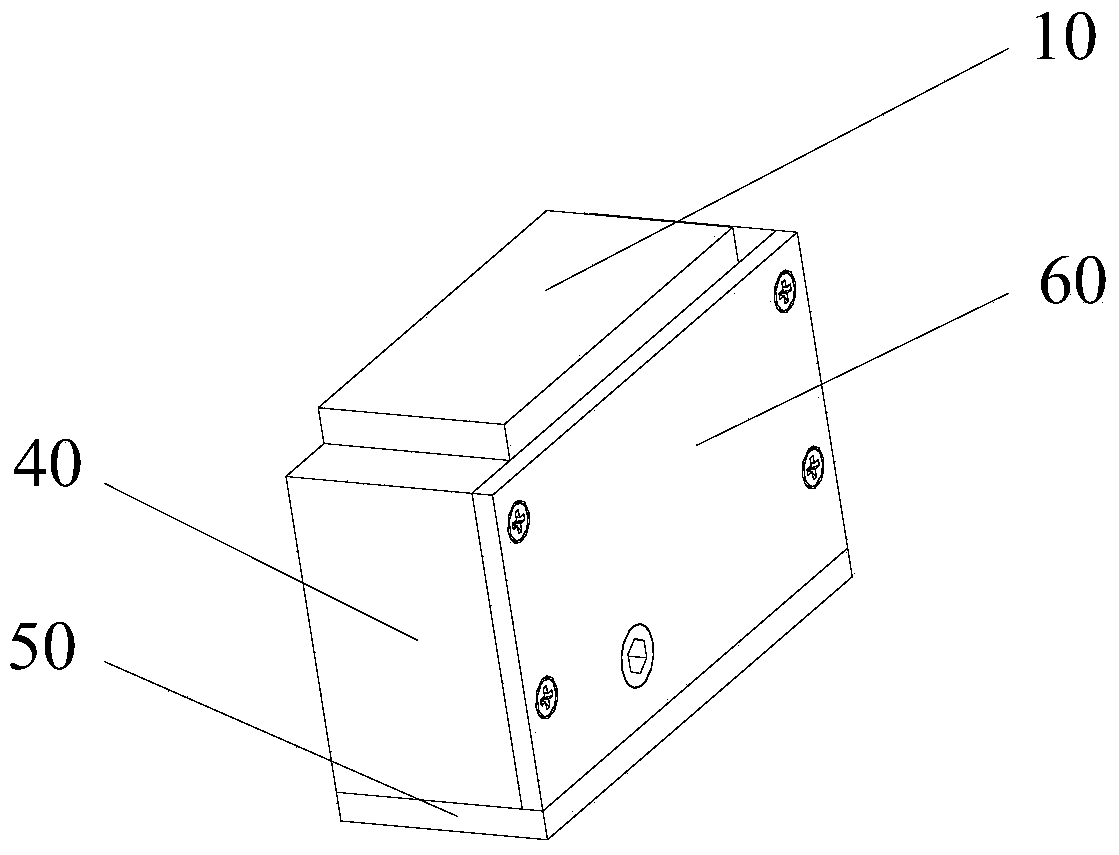

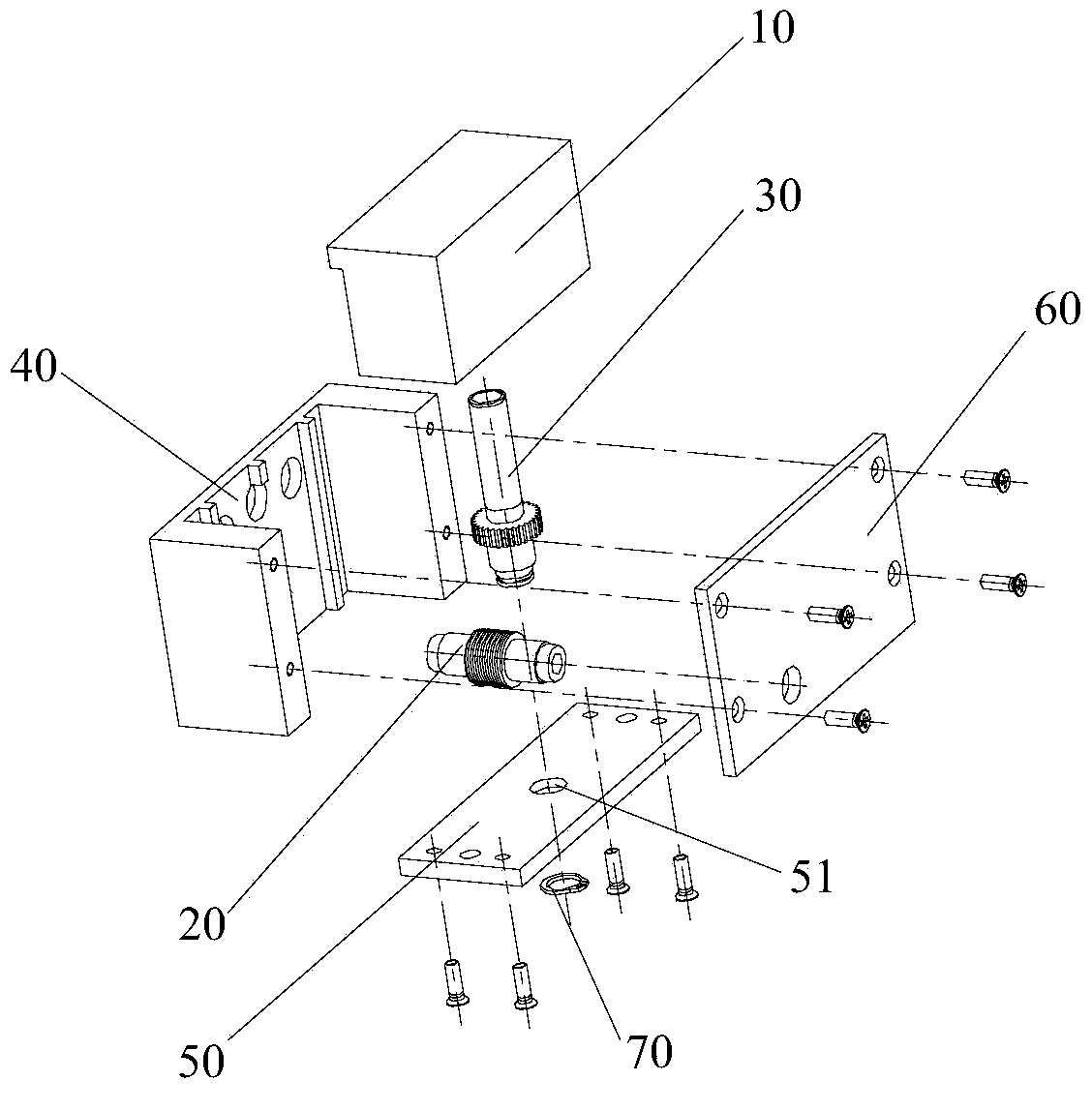

In-situ energy controlled selective laser melting device and method

PendingCN111842892AIncrease input control meansReduce defectsAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing technology

The invention discloses an in-situ energy controlled selective laser melting device and method. According to the in-situ energy controlled selective laser melting device and method, a path of synchronously scanned flat-topped large light spot is additionally arranged, energy below a powder melting point threshold value is provided, the powder preheating / solidification rate is regulated and controlled, formed metal is annealed, the temperature gradient is reduced, and the forming internal stress is reduced, so that behaviors such as deformation and cracking caused by stress are reduced; and meanwhile, due to the fact that energy input lower than the melting point threshold value of a material is provided, material melting can be completed only by providing low energy input for original SLMsmall light spots, and the adverse conditions of molten pool splashing, micro air hole generation and the like are improved. In addition, time and space distribution of laser energy is realized basedon an in-situ energy control mode. Therefore, according to the method, defects generated in the part forming process are effectively reduced, meanwhile, the solidification rate is controlled, the structure evolution is regulated and controlled, and the method plays an important role in stably and efficiently forming high-performance parts and promoting wide application of the additive manufacturing technology.

Owner:SOUTH CHINA UNIV OF TECH

Distance adjusting device and LED display device with same

The invention provides a distance adjusting device and an LED display device with the same. The distance adjusting device comprises a shell, a sliding block (10) and a transmission mechanism, wherein the shell is provided with an inner cavity and an opening face communicated with the inner cavity, the sliding block is arranged at the opening face and is movably arranged in the inner cavity in the direction perpendicular to the opening face, the transmission mechanism is connected with the sliding block (10) in a driving mode to drive the sliding block (10) to move in the direction perpendicular to the opening face. The distance adjusting device achieves the accurate adjustment of the distance between two adjacent installing boards, the gaps between display modules during the splicing process of a display screen are more uniform, and the displaying effect of the display screen is clearer.

Owner:LEYARD

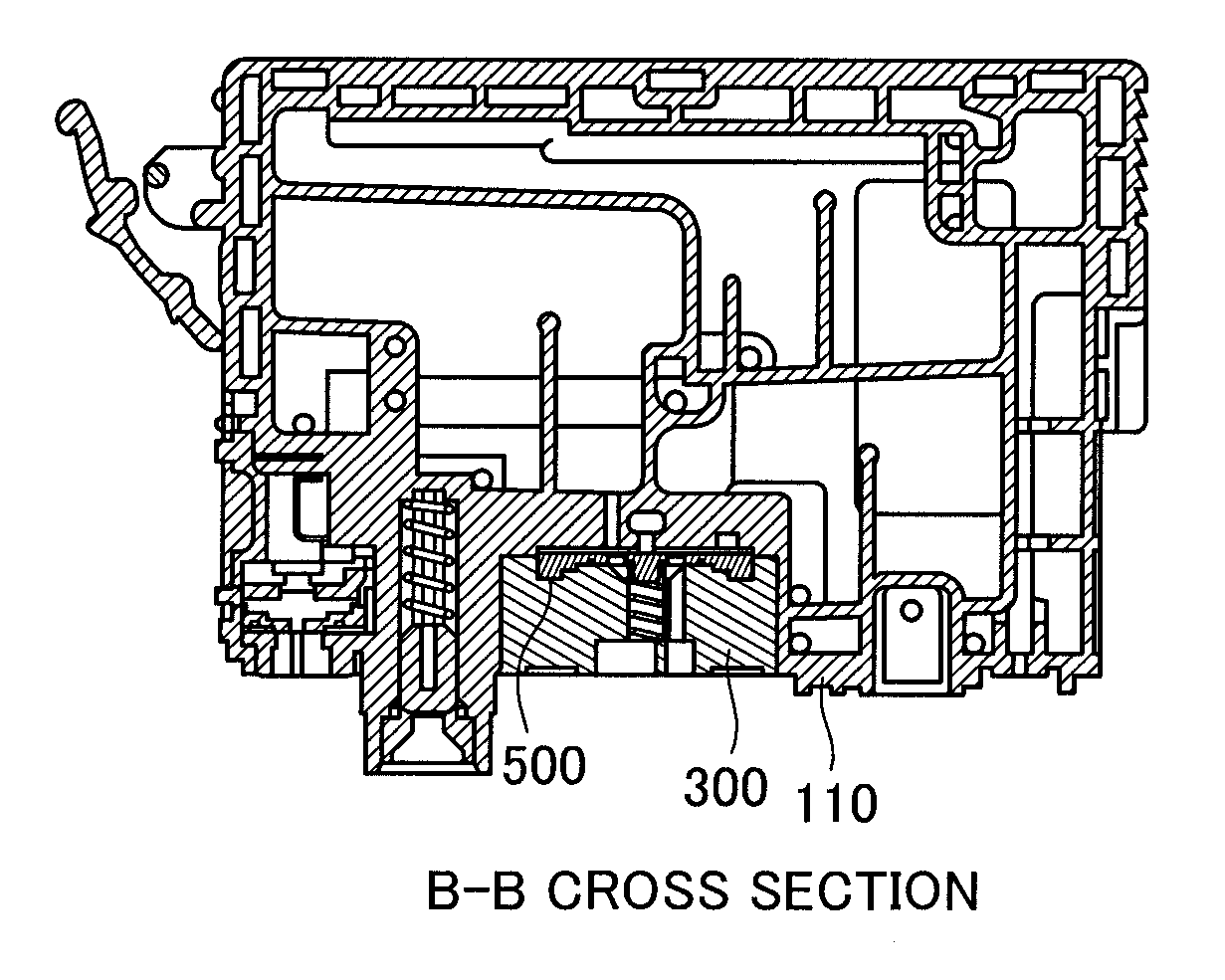

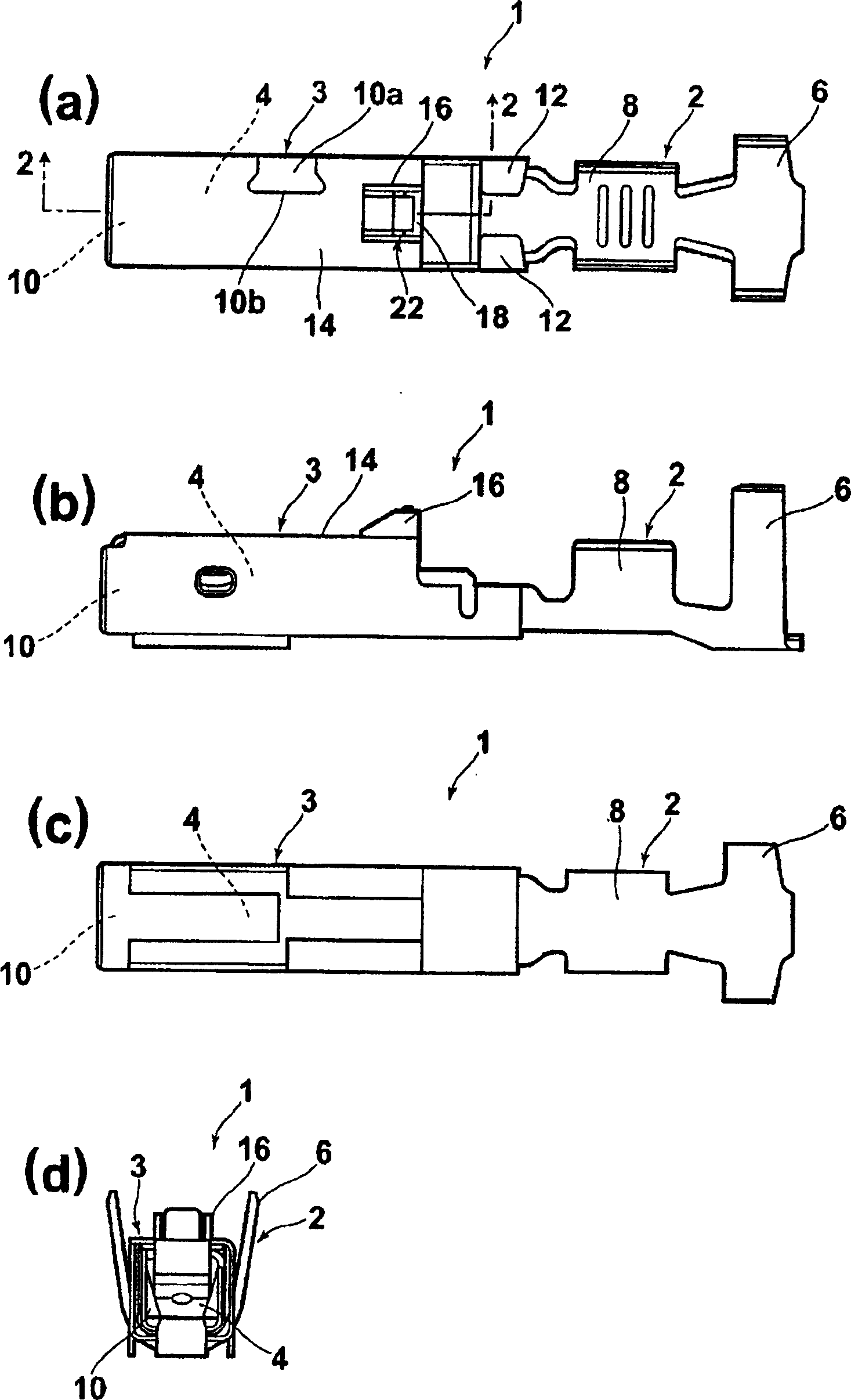

Power control unit for electric vehicle

InactiveUS20050115749A1Easy to separateAvoid deformationPropulsion by batteries/cellsVehicular energy storageHead-on collisionElectric vehicle

A power control unit for electric vehicle which can easily detach the high voltage cables even if the motor room is deformed, for example, by head-on collision and / or rear-end collision of the vehicle, which is difficult to be deformed, which can make small, and which can avoid an influence of heat generated by the reactor is disclosed. The power control unit 1 includes a box 10 which accommodates devices for controlling electric power supply of the electric vehicle; a reactor receiver 11a which is provided on a given external surface around the box 10 and supports a reactor R; a heat sink 12 connected to the lower end of the reactor receiver 11a, covering the bottom surface of the box 10, possessing passages including passage wall inside thereof, and performing heat-exchange with the box 10 by allowing coolant water to flow within the passage; and a partition 13a, which is laid on at least one side of the box 10 extending toward the longitudinal direction of the vehicle EV, and is detachably communicated with cables to be connected to the traction motor 4 disposed below the heat sink 12 to supply power.

Owner:HONDA MOTOR CO LTD

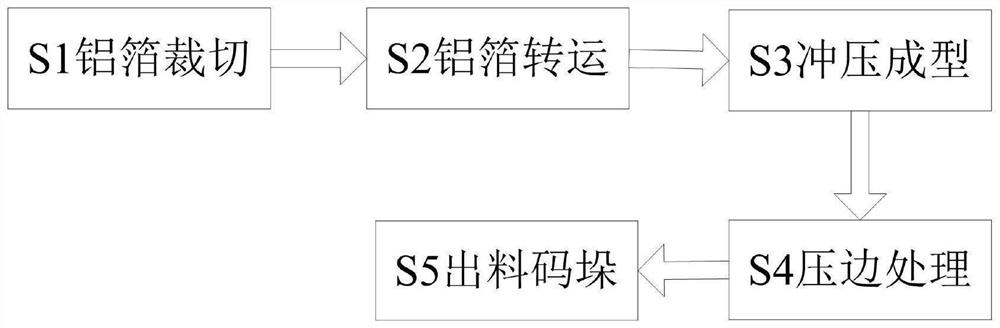

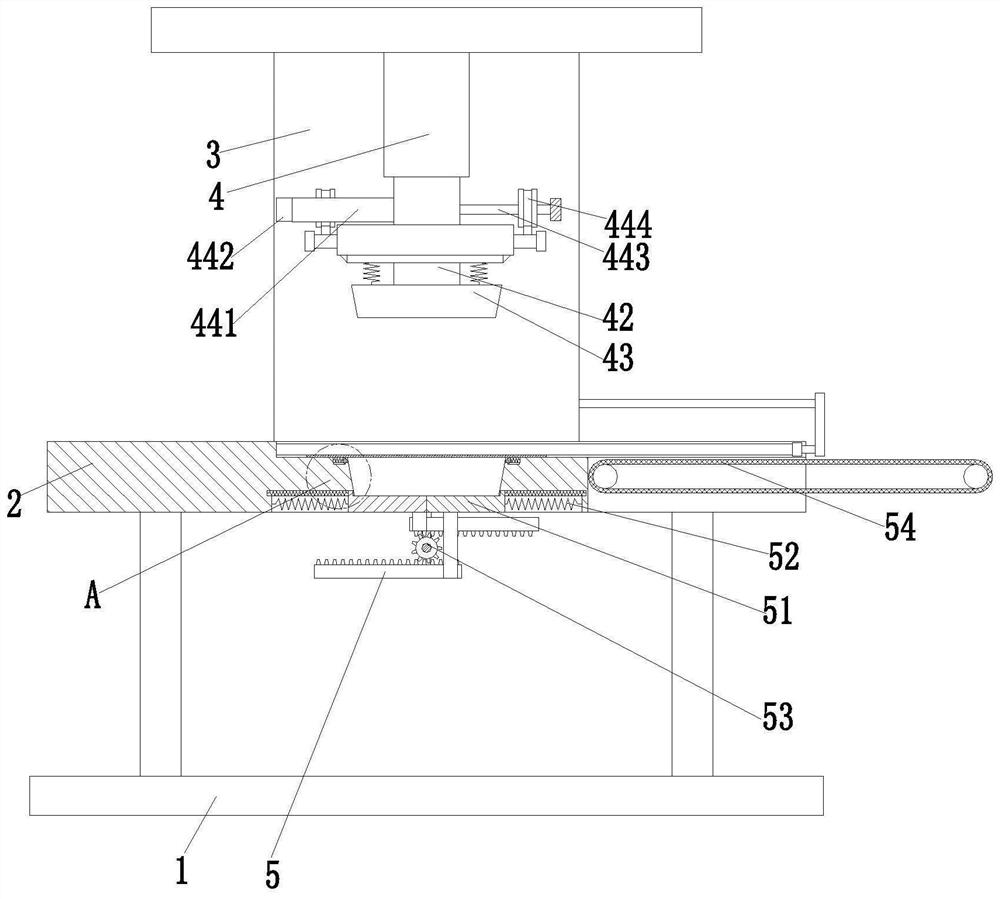

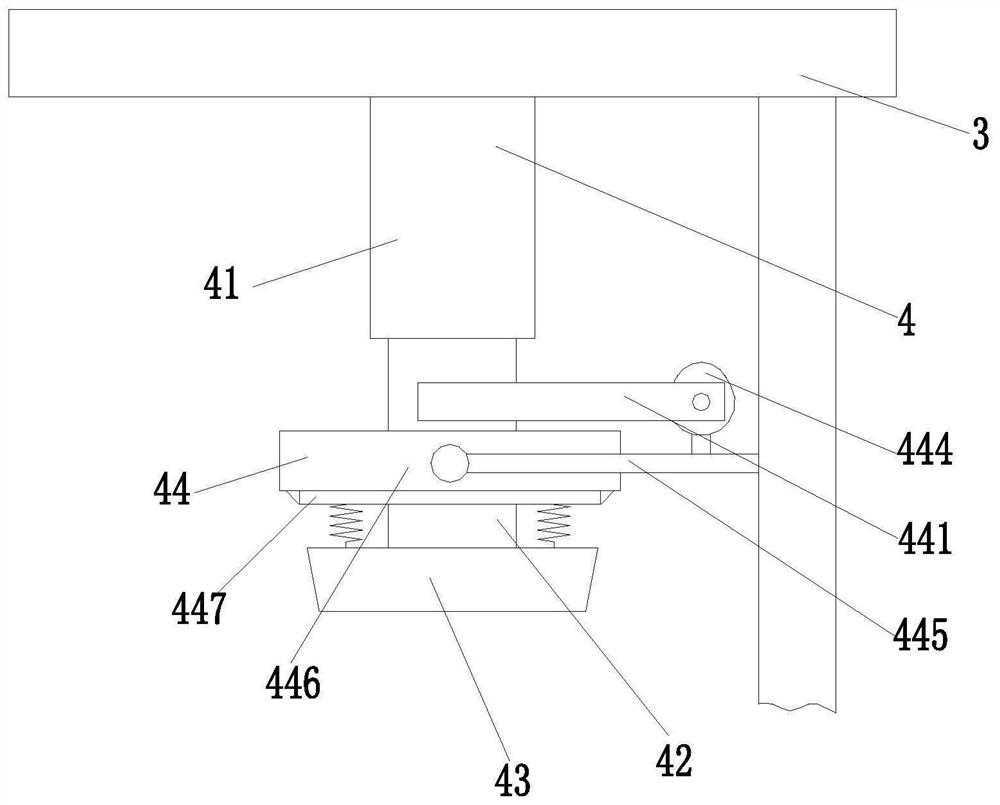

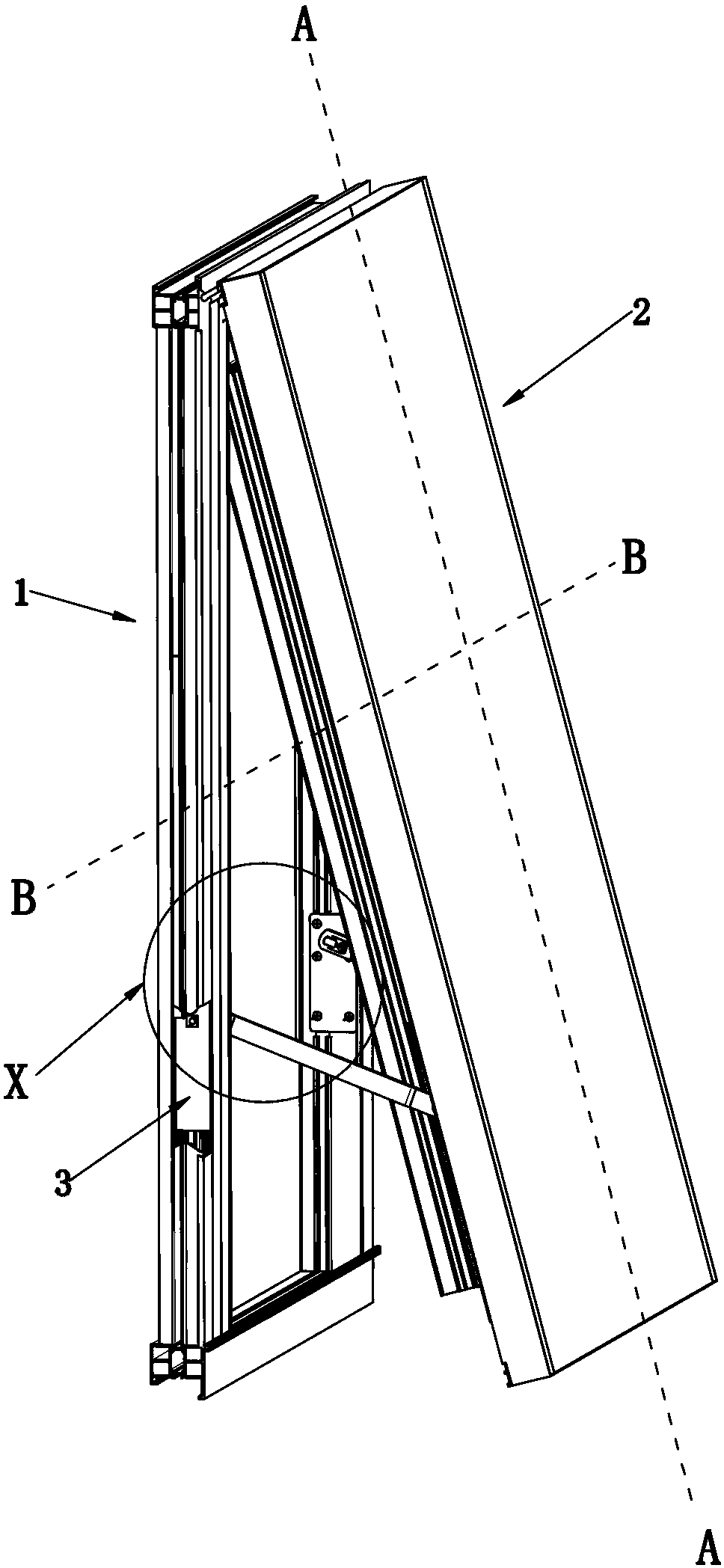

Preparation process of heatable aluminum foil packaging lunch box

ActiveCN112045085AAvoid position shiftWill not deformMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to a preparation process of a heatable aluminum foil packaging lunch box, which uses punch forming equipment. The punch forming equipment comprises a bottom plate, a workbench, amounting frame, a punching device and a material placing device, and the specific process flow for preparing the aluminum foil packaging lunch box by adopting the punch forming equipment is as follows: aluminum foil cutting, aluminum foil transferring, punch forming, edge pressing processing and discharging stacking; a punching device comprises a lifting air cylinder, a mounting block, a punchinghead and an edge pressing mechanism. According to the preparation process of the heatable aluminum foil packaging lunch box provided by the invention, an aluminum foil is punched and formed through the cooperation of the material placing device and the punching device, so that the flaky aluminum foil is made into a lunch box finished product, edge pressing treatment can be conducted on the lunchbox in the punching process at the same time, production equipment for edge pressing of the lunch box does not need to be additionally arranged, and in the aluminum foil moving process, the aluminum foil is guided and positioned in an air blowing mode, position deviation of the aluminum foil is avoided, and meanwhile aluminum foil deformation caused by extrusion is avoided.

Owner:宁波友邦铝箔制品有限公司

Electric wall window or skylight

ActiveCN103422773AImprove waterproof performanceReduce volumeWindow/door framesPower-operated mechanismElectric machineDrive shaft

The invention relates to an electric wall window or a skylight, which comprises a main window frame, a window body and a driving mechanism, wherein one side edge of the window body is rotationally assembled on the main window frame; the window body is used for shielding the main window frame; the driving mechanism is used for driving the window body to rotate; the driving mechanism comprises a shell, and a motor, a speed-reducing gear set and a transmission shaft which are assembled in the shell; the speed-reducing gear set is in transmission connection with a power output rod of the motor; the transmission shaft is in transmission connection with the speed-reducing gear set; the outer end of the transmission shaft is in transmission connection with the window body. The driving mechanism is a component which is used separately, so that the water resistance of the driving mechanism is improved effectively, the motor can be better protected, and the probability of deformation of a power output shaft of the motor by external force is lowered greatly; moreover, another water-proof screen, namely, the main window frame is arranged for a driver, so that the water resistance of the window is further improved, the driving mechanism is hidden, and the safety performance of the window is improved.

Owner:福建闳安智能门窗科技有限公司

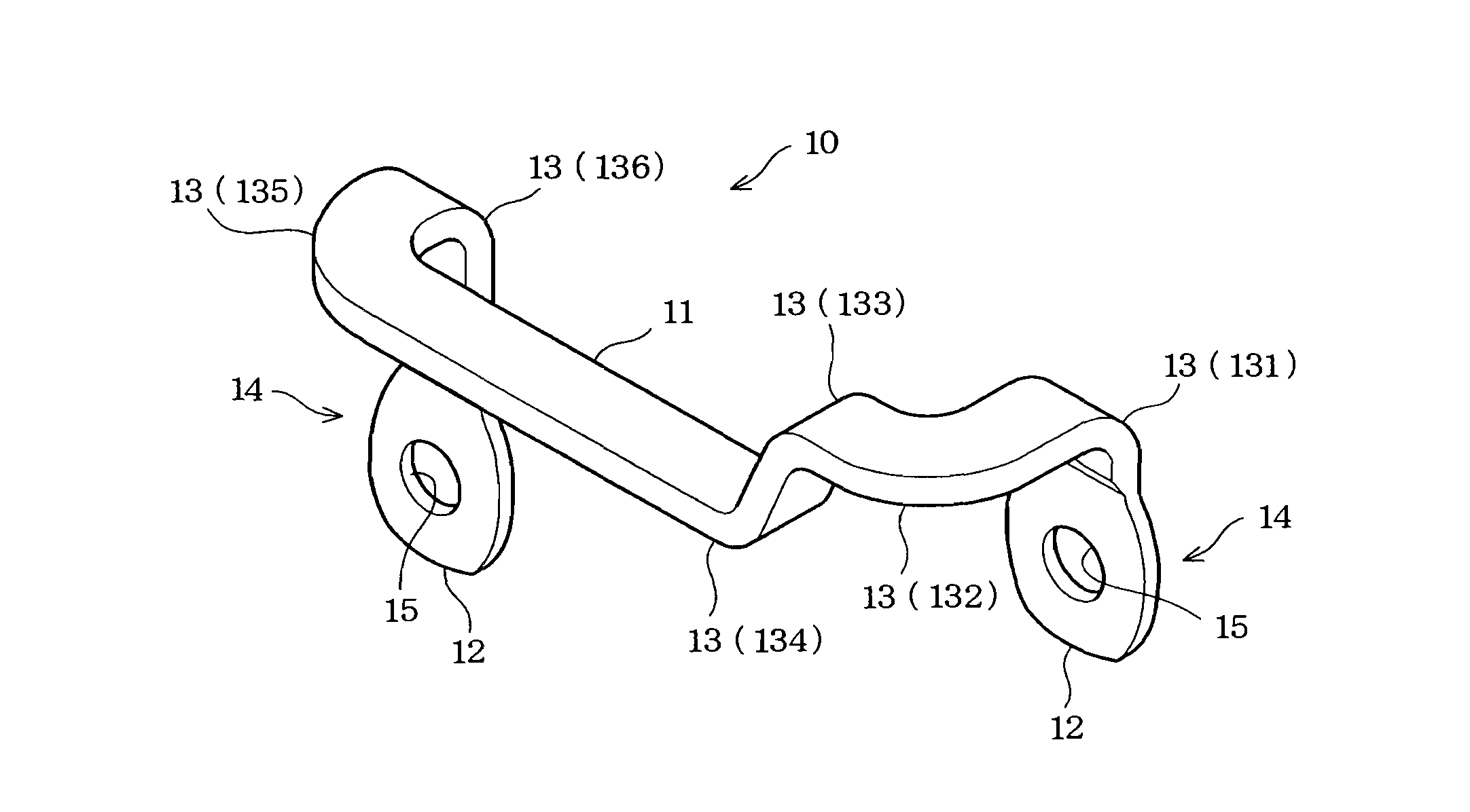

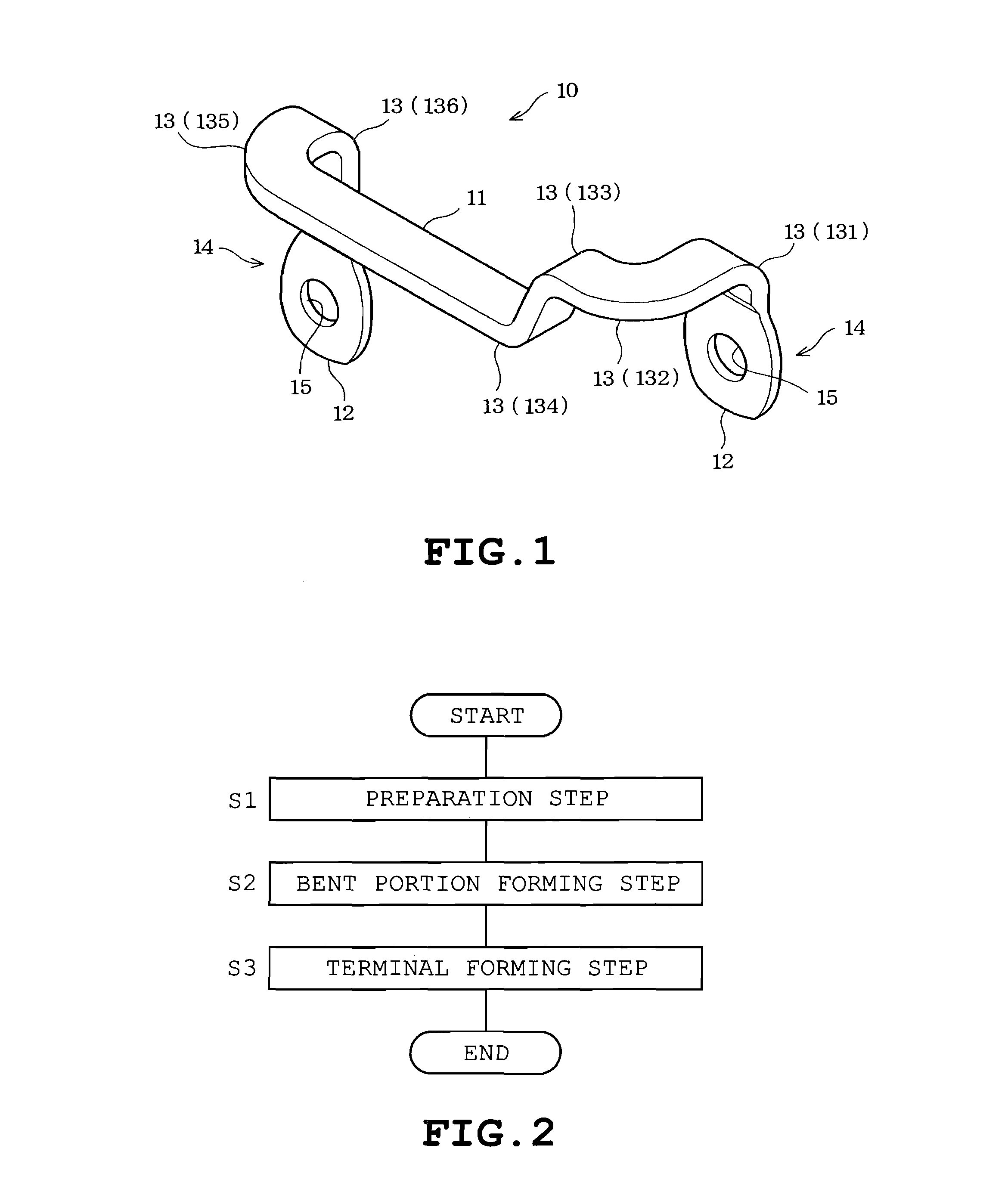

Bus bar and method of manufacturing the bus bar

InactiveUS20130292156A1Avoid misalignmentAvoid less flexibilityCoupling device connectionsBus-bar/wiring layoutsHardnessMechanical engineering

A bus bar includes a body having at least one bent portion and a plate-shaped or bar-like terminal located on at least one end of the body and formed of a material identical with a material of the body integrally with the body in a seamless manner. The terminal has a higher hardness than the bent portion.

Owner:TOGO SEISAKUSYO CORP

Sensing an operating parameter of a target concealed from a sensor by an interposed component

ActiveUS7218098B2Avoid complex processVariable cost and manufacturing costGearing controlUsing electrical meansInstabilityRotation velocity

An assembly that includes a target component mounted for rotation about an axis, a sensor mounted adjacent the inner member and directed toward the inner member to measure the rotational speed of the target component and an outer component interposed between the sensor and the target component. Low magnetic permeability of the outer component is assured by appropriate selection of the material, maintaining the concentration of martensite in the outer component below a reference concentration as indicated by certain reference indices such as the Instability Function, and / or by maintaining the temperature at which a stamping operation is performed on the inner member above a pre-determined temperature.

Owner:FORD GLOBAL TECH LLC

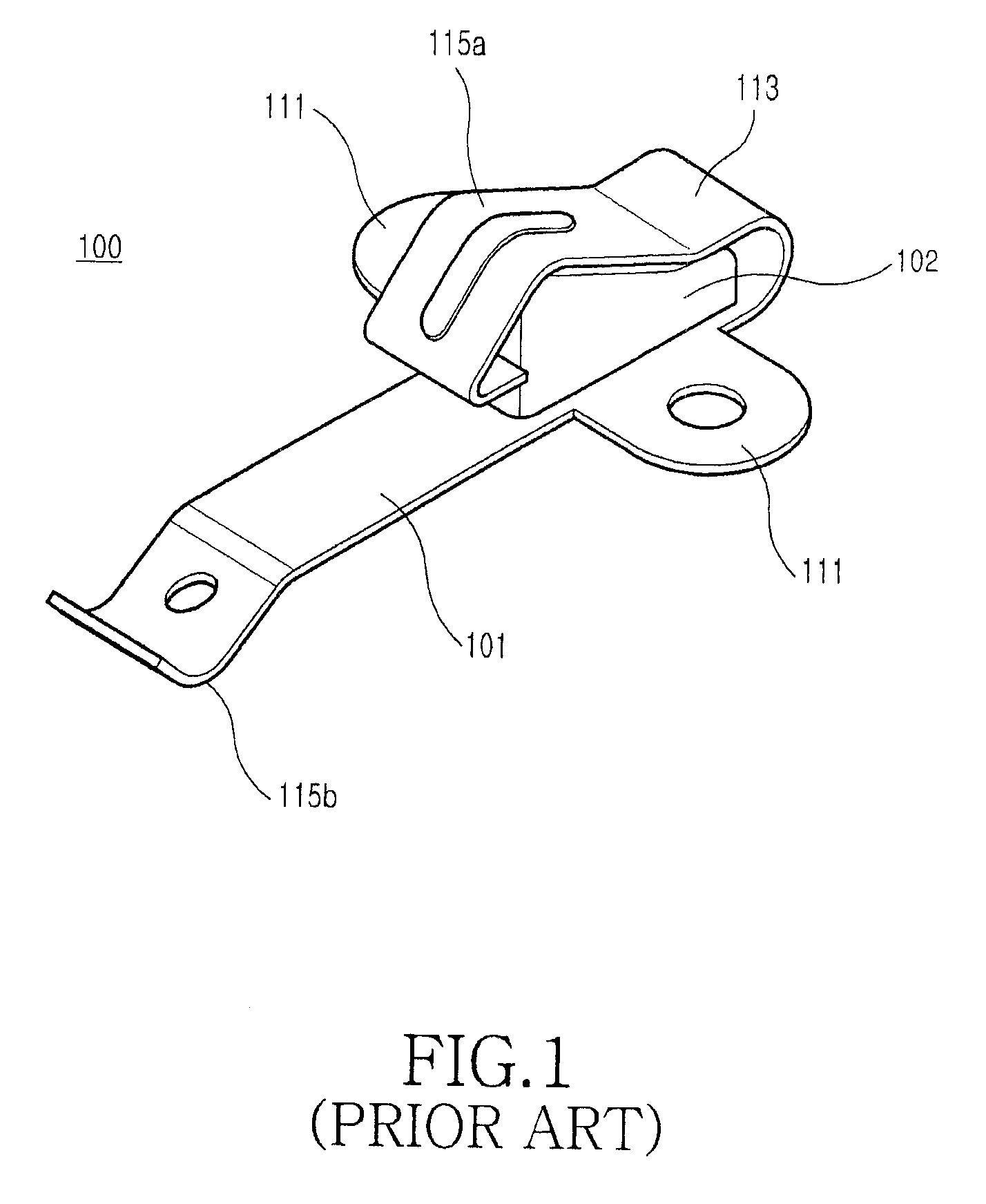

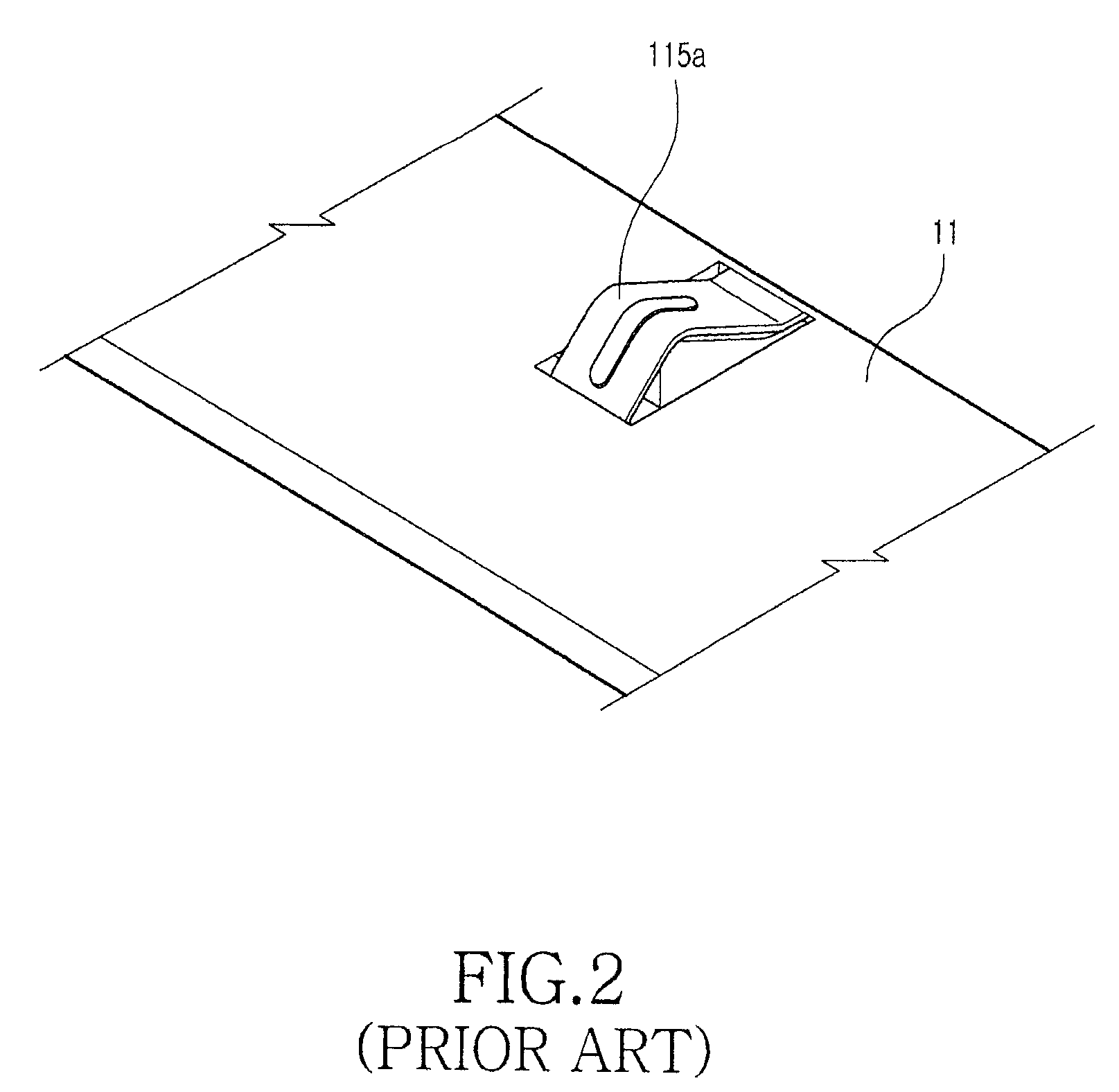

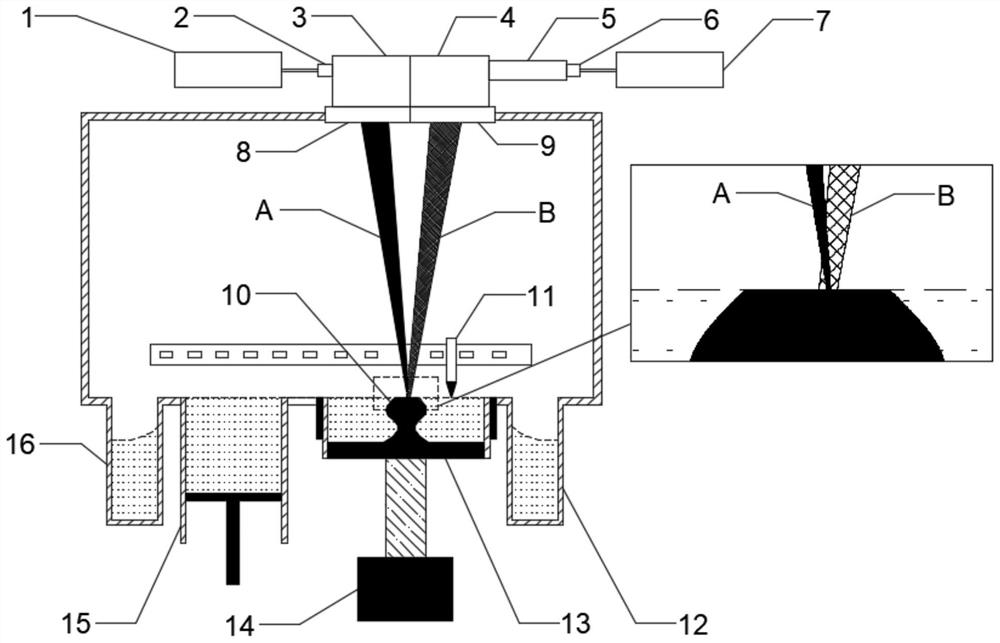

Connector and contact for connector

InactiveCN1685569AIncrease contact pressureHigh mechanical strengthCoupling contact membersCo-operative working arrangementsMechanical engineeringMemory cards

In a connector used for recording and reproducing apparatus of a memory card, it is aimed to prevent an instantaneous make break phenomenon, in which a contact portion of a contact and a terminal of a memory card is instantaneously opened and suppliance of electric power to the memory card is instantaneously stopped when an impact is applied to the connector, and a deformation of the contact due to the impact. Three plate spring portions arranged in parallel with each other and three contact portions respectively provided in the vicinities of front ends of the plate spring portions are formed in the vicinity of a front end of the contact. Two plate spring portions among three plate spring portions, for example, the plate spring portions disposed at both sides are integrally combined at the front end portions of them. A length of another plate spring portion, for example disposed at the center is made shorter than the lengths of the others. Thus, a number of contact portions can be increased without reducing mechanical strength of the front end portion of the contact.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com