Negative terminal and electric connector using the same negative terminal

A female terminal and terminal technology, which is applied in the field of female terminals and electrical connectors using the female terminals, can solve the problems of difficult plugging and unplugging operations, high contact pressure, and micro-slip wear, so as to prevent micro-slip wear and prevent micro-slip Abrasion, not easy to reverse the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

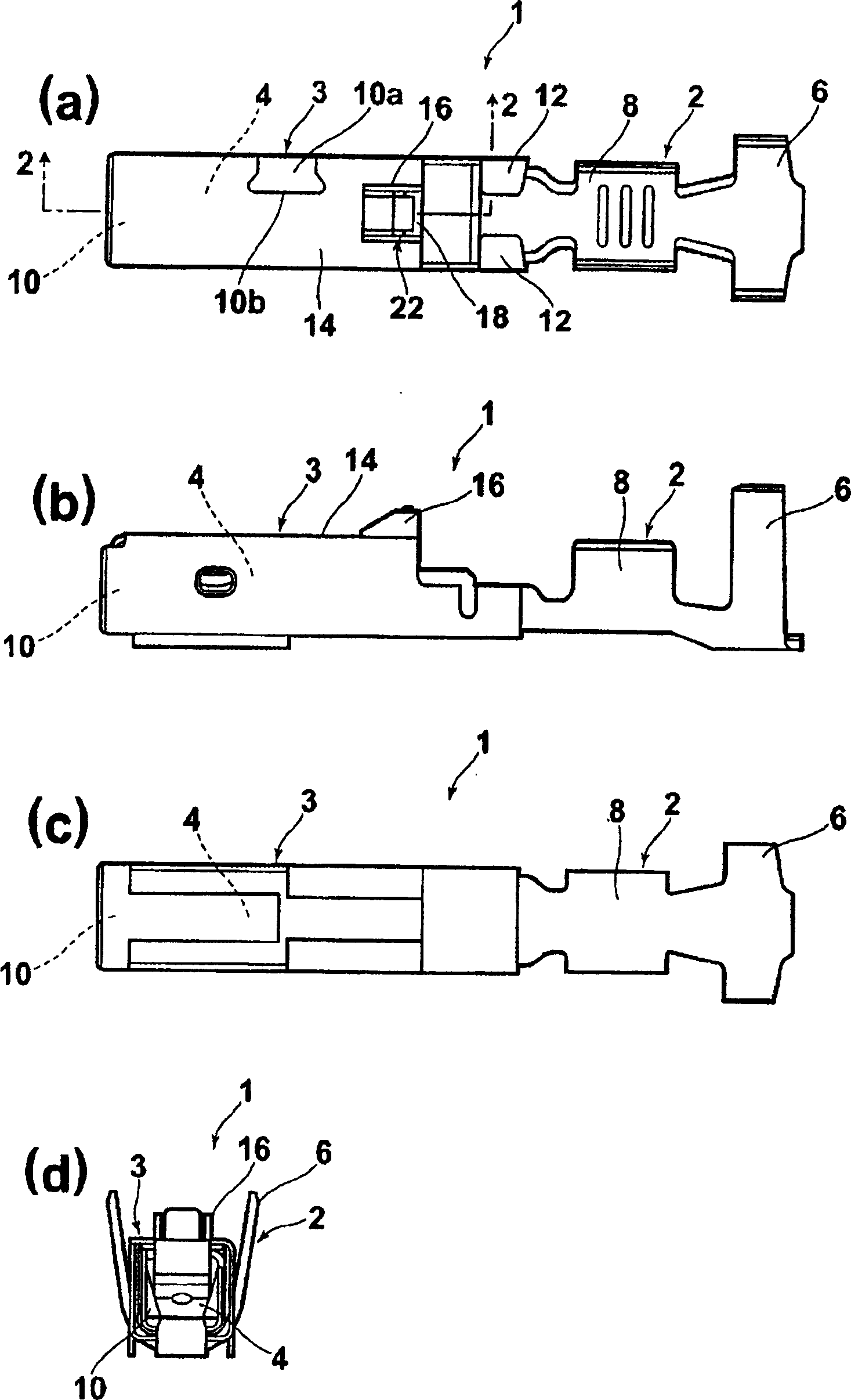

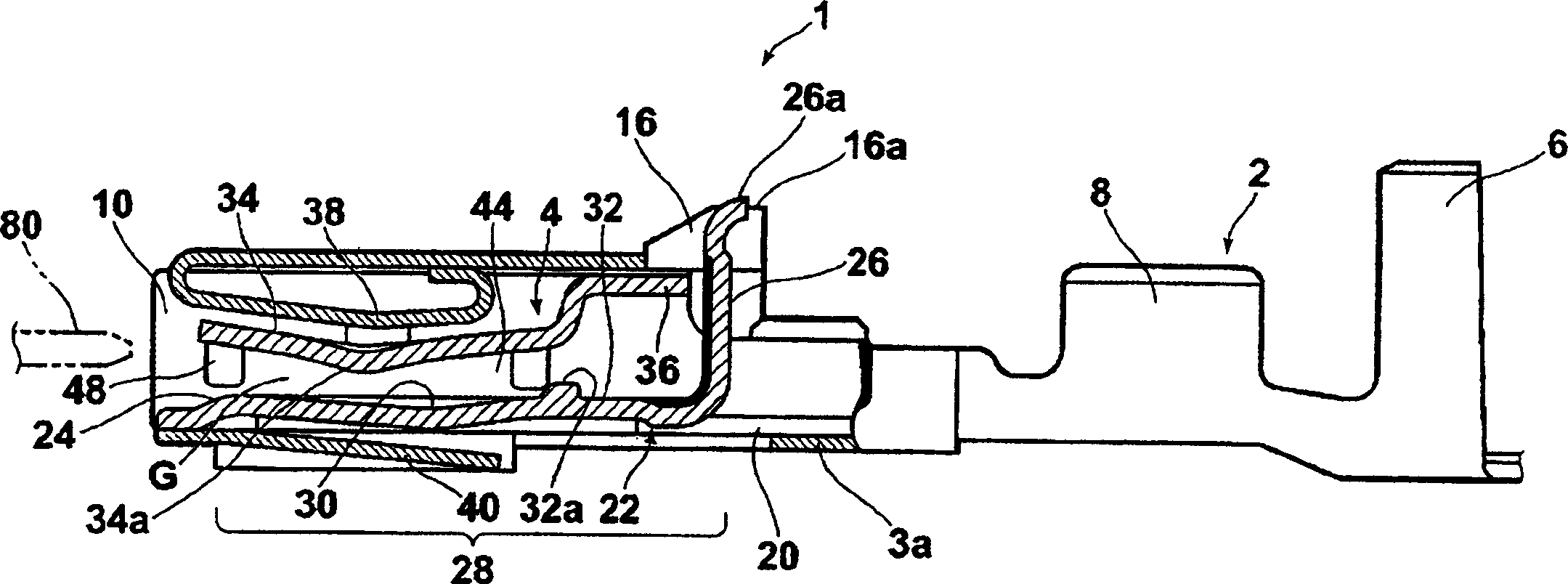

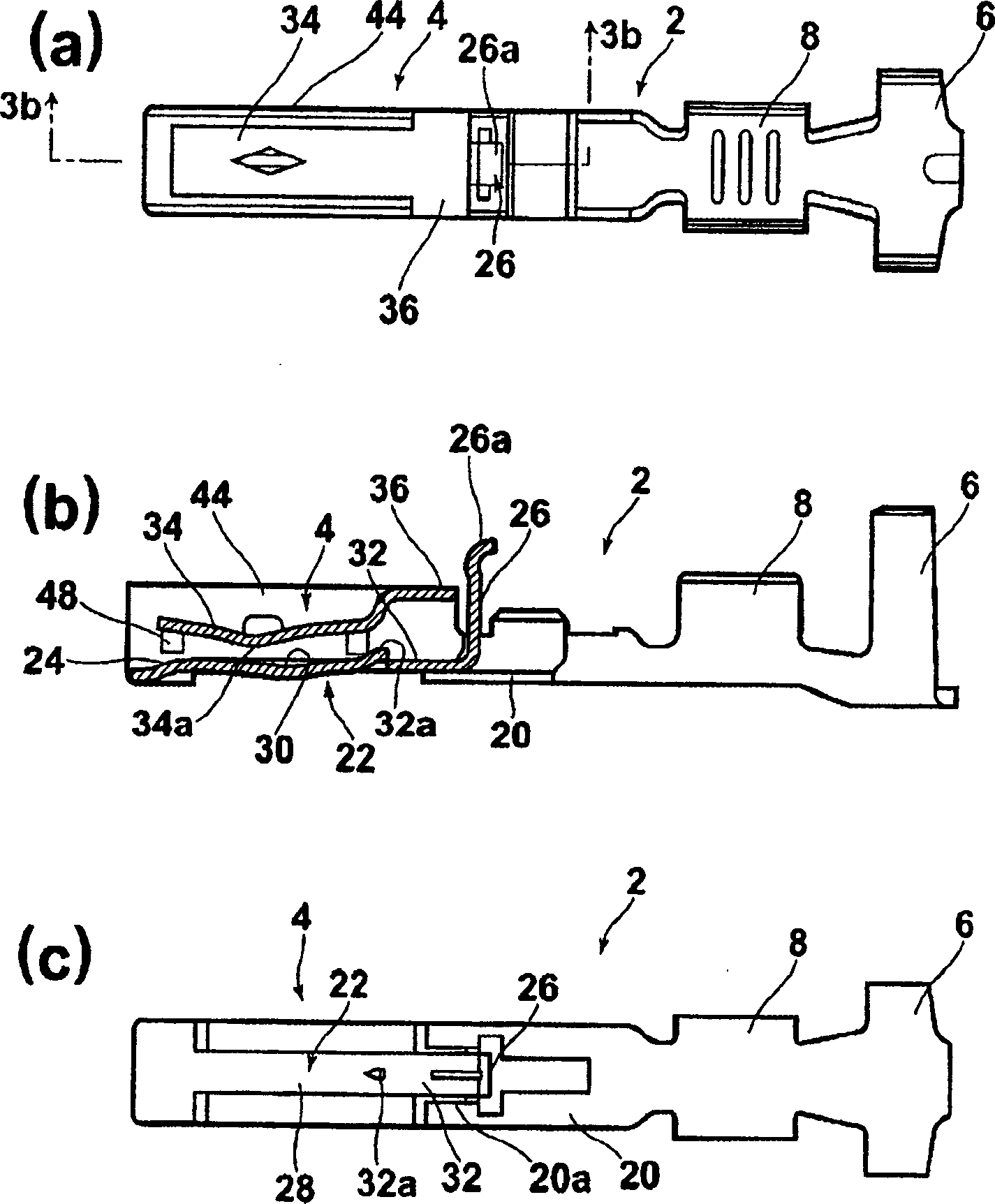

[0025] Hereinafter, preferred embodiments of the female terminal and the electrical connector of the present invention will be described with reference to the drawings. In addition, in the description, the expressions of up, down, left, and right are for the convenience of description, and refer to up, down, left, and right in the drawings. figure 1 represents the female terminal of the present invention, figure 1 (a) represents a top view, figure 1 (b) represents a side view, figure 1 (c) represents a bottom view, figure 1 (d) shows the front view. Such as figure 1 As shown, the female terminal 1 is composed of two parts: a main body (terminal main body) 2 and a reinforcement member 3 which is a cover member attached to the main body 2 . The main body 2 has a matching blade terminal 80 ( figure 2 ) connected contact portion 4 has a sheath 152 ( Figure 9 ) connected tongue-shaped insulating cylinder (barrel) (wire connection portion) 6, and a tongue-shaped condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com