Patents

Literature

55results about How to "Not easy to reverse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

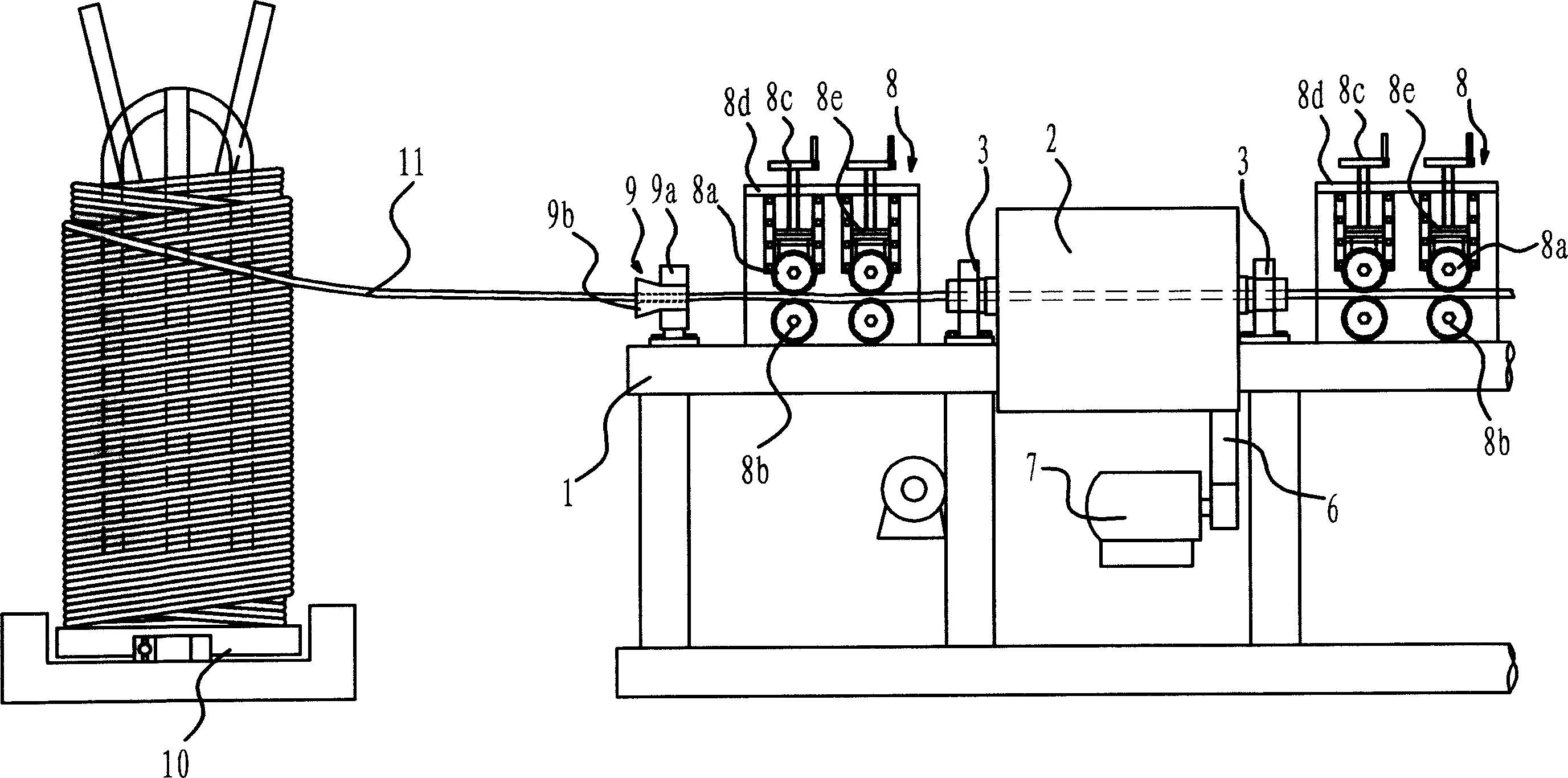

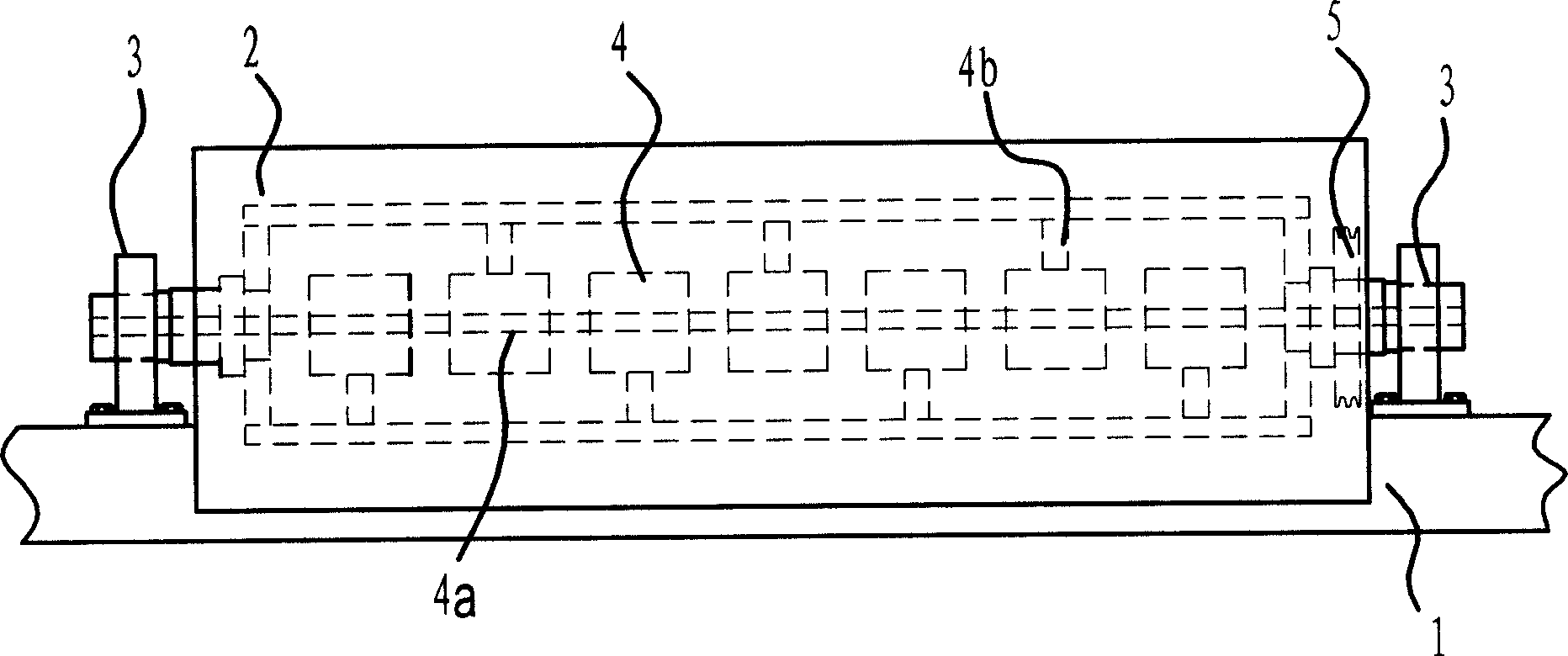

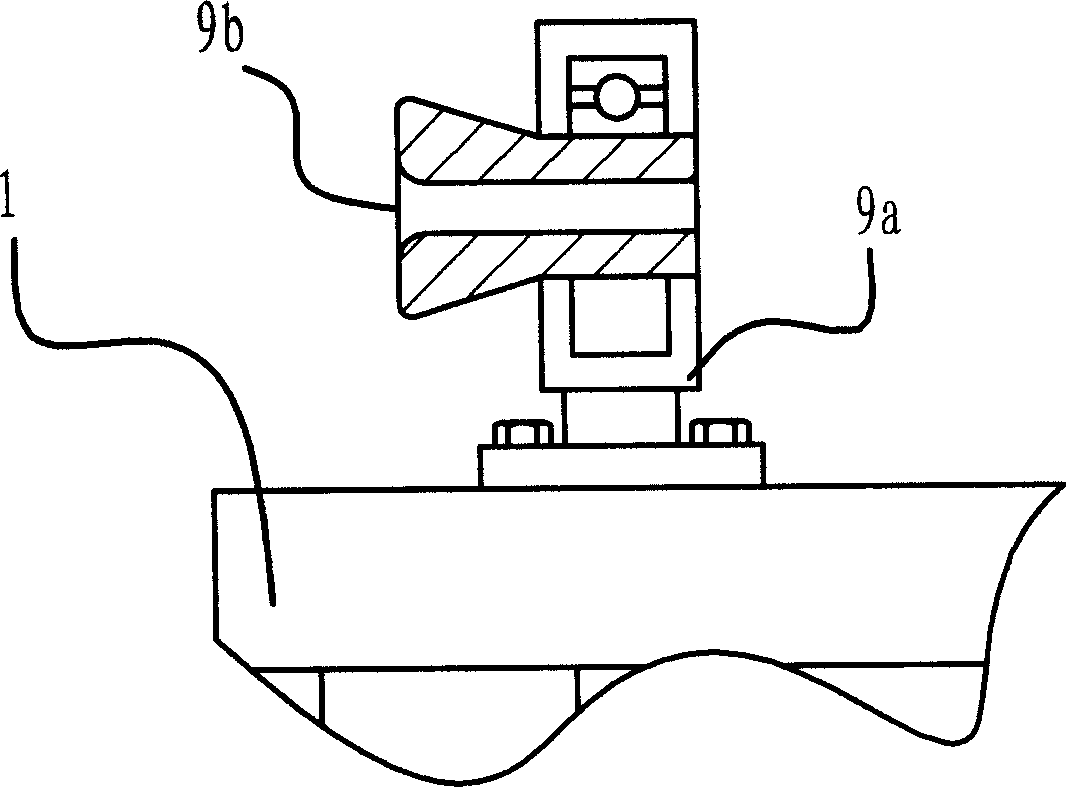

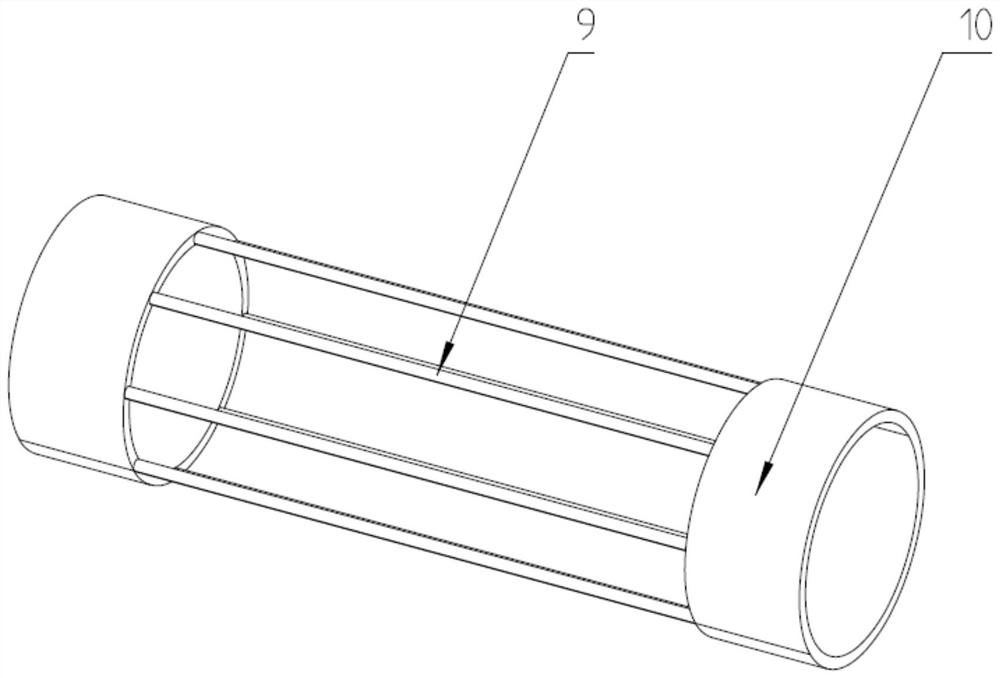

Wire rod straightener for wire hook formation machine

A wire straightening machine for the wire hook forming machine has a rotary drum supported by two bearings, and several straightening blocks which are serially and coaxially arranged in said rotary drum and have a hole for each block. All the holes are coaxial and the wire passes through the rotary holes for straightening it.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

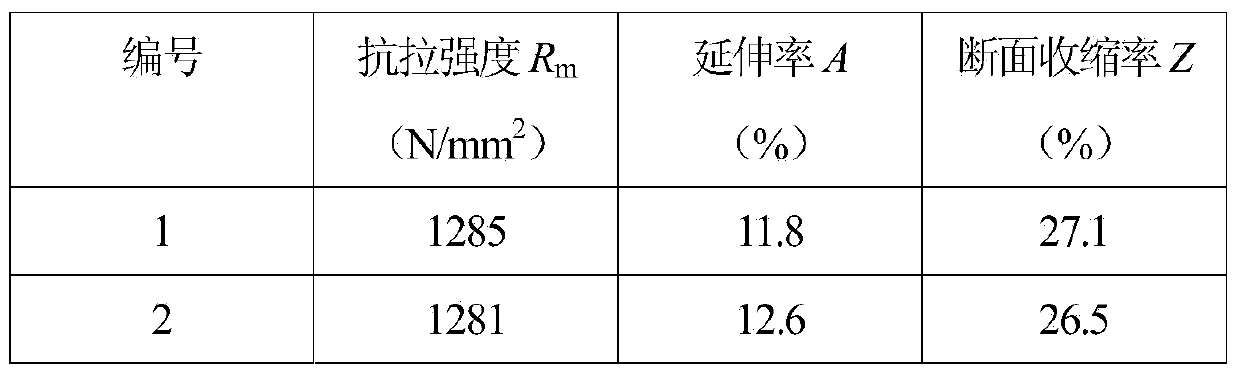

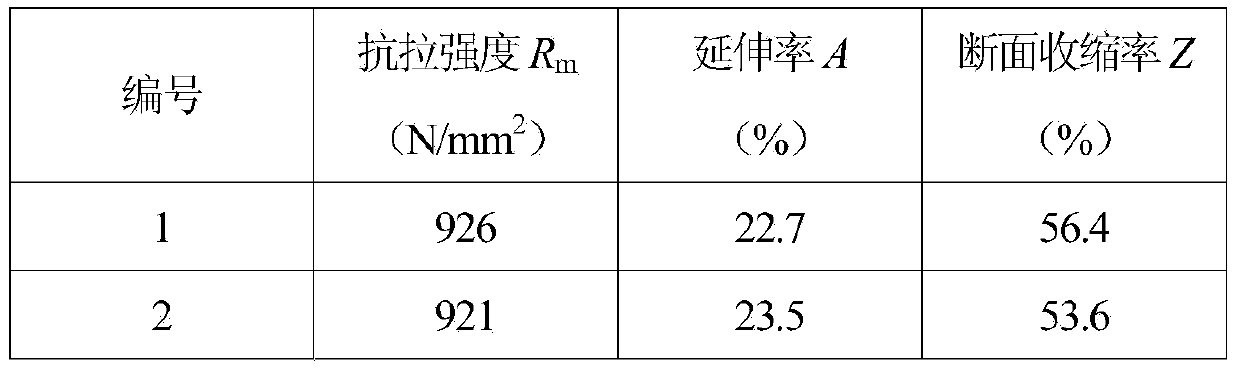

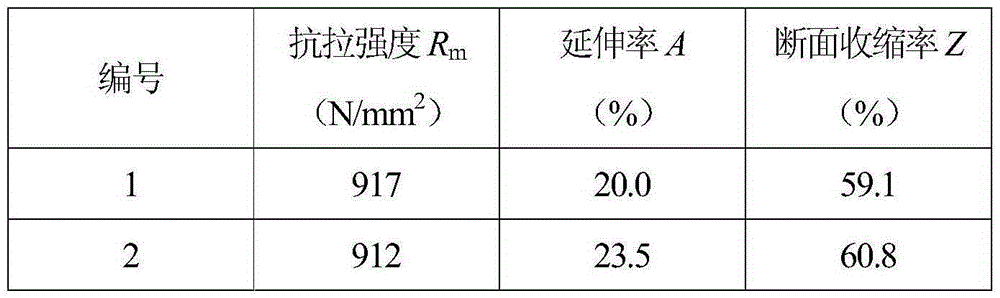

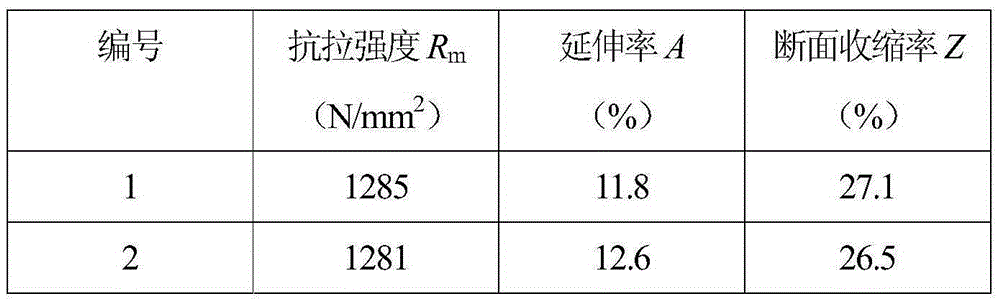

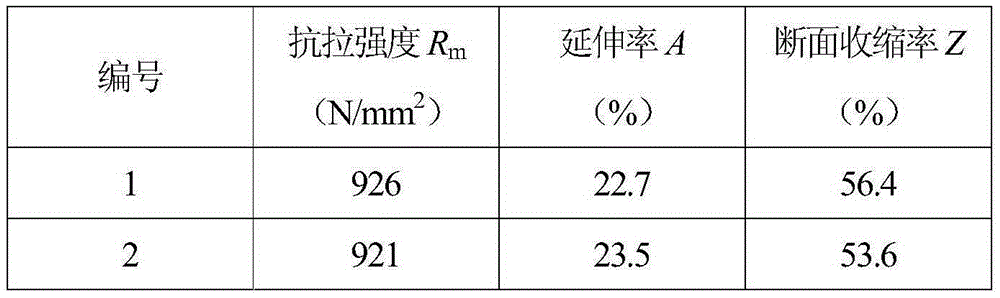

Preparation method of titanium alloy spring made of wire with specially-shaped section

The invention relates to a preparation method of a titanium alloy spring made of a wire with a specially-shaped section and belongs to the technical field of springs. The spring is formed by winding of the titanium alloy wire with the specially-shaped section; the titanium alloy wire comprises the components in percentage by mass as follows: 2-4 of Al, 6-10 of V, 4-8 of Cr, 2-6 of Mo, 2-6 of Zr, 0.1-0.3 of Fe, 0.03-0.15 of Si and the balance of Ti. The section of the titanium alloy spring wire can be rectangular, square, orthohexagonal or oval. The titanium alloy wire wound into the spring is prepared with forging, pressing and hot rolling technologies, the wire is subjected to solution treatment before being wound into the spring, and a finished product of the spring is subjected to aging and strengthening treatment. A titanium alloy which is used for preparing the spring can play a weight reduction role, and meanwhile, the titanium alloy has the good corrosion resistance and the long fatigue life in an ocean environment. With the adoption of the wire with the specially-shaped section, the section area can be increased under the condition that specifications of wires are similar, so that the rigidity of the spring is improved, and the usage requirement of the titanium alloy spring under the high workload can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

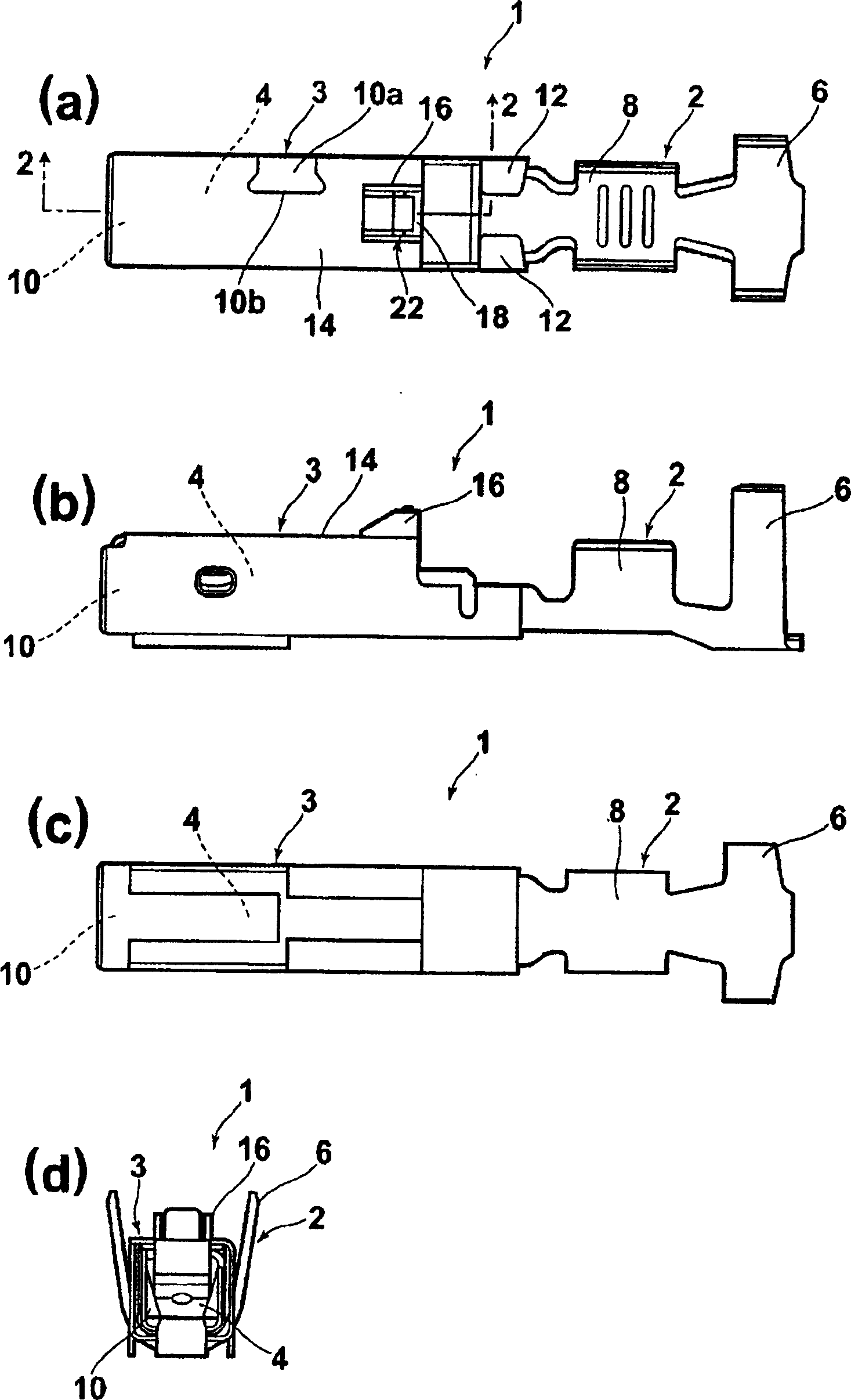

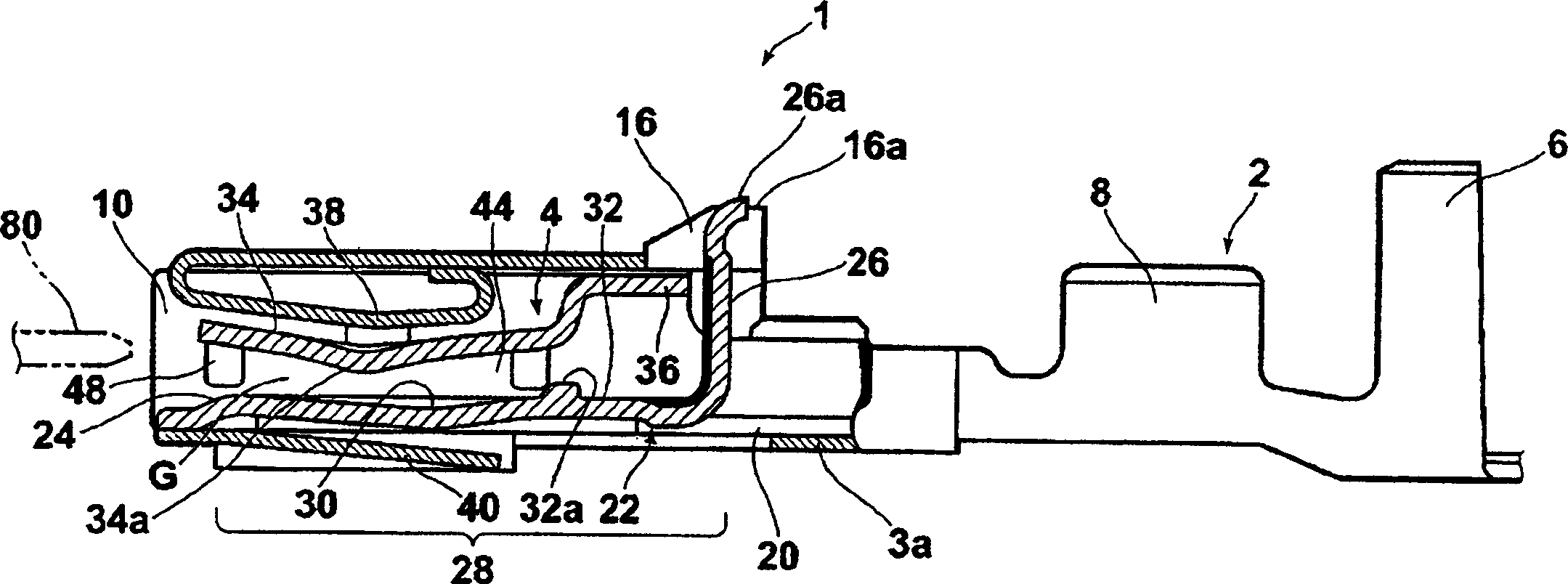

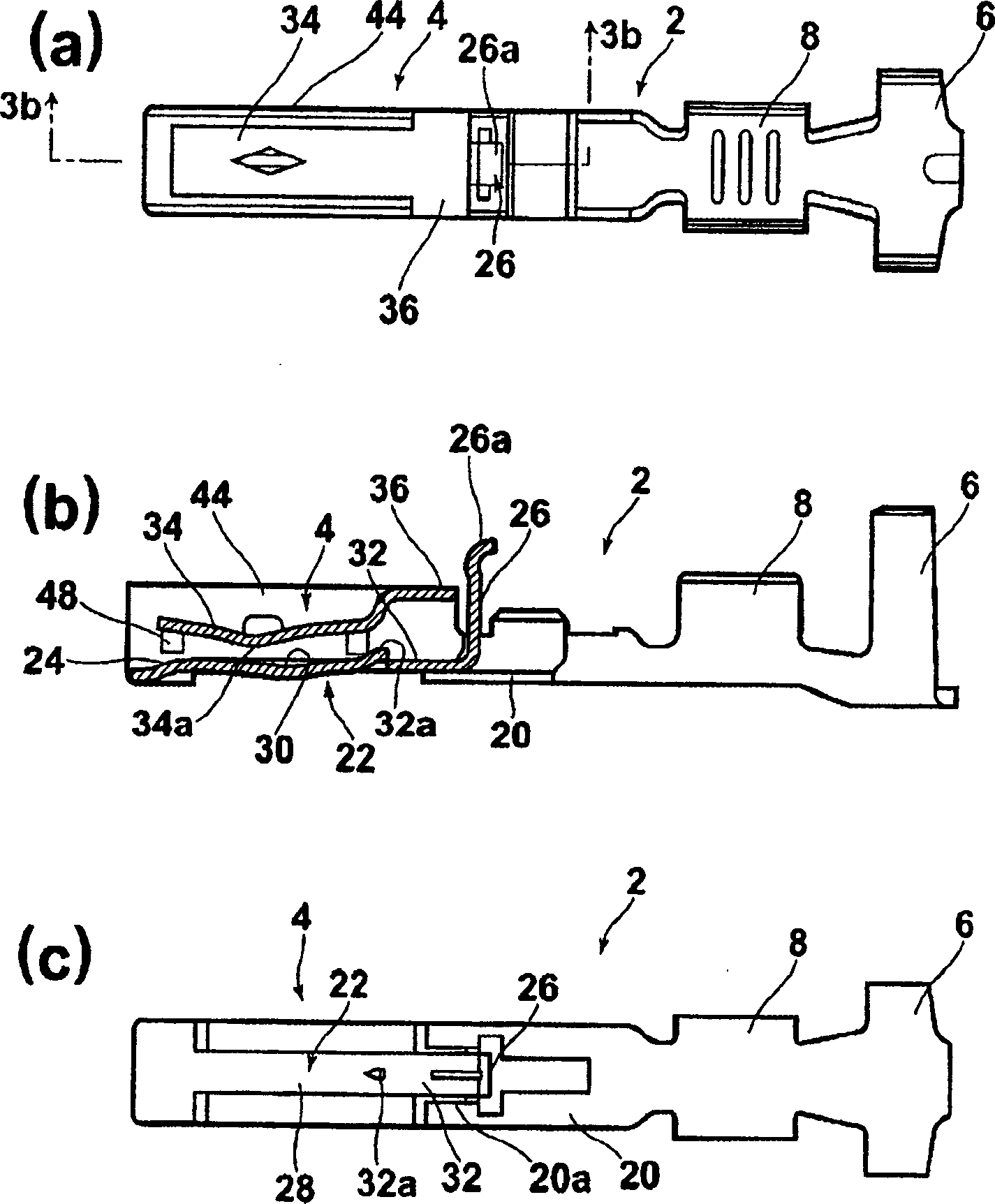

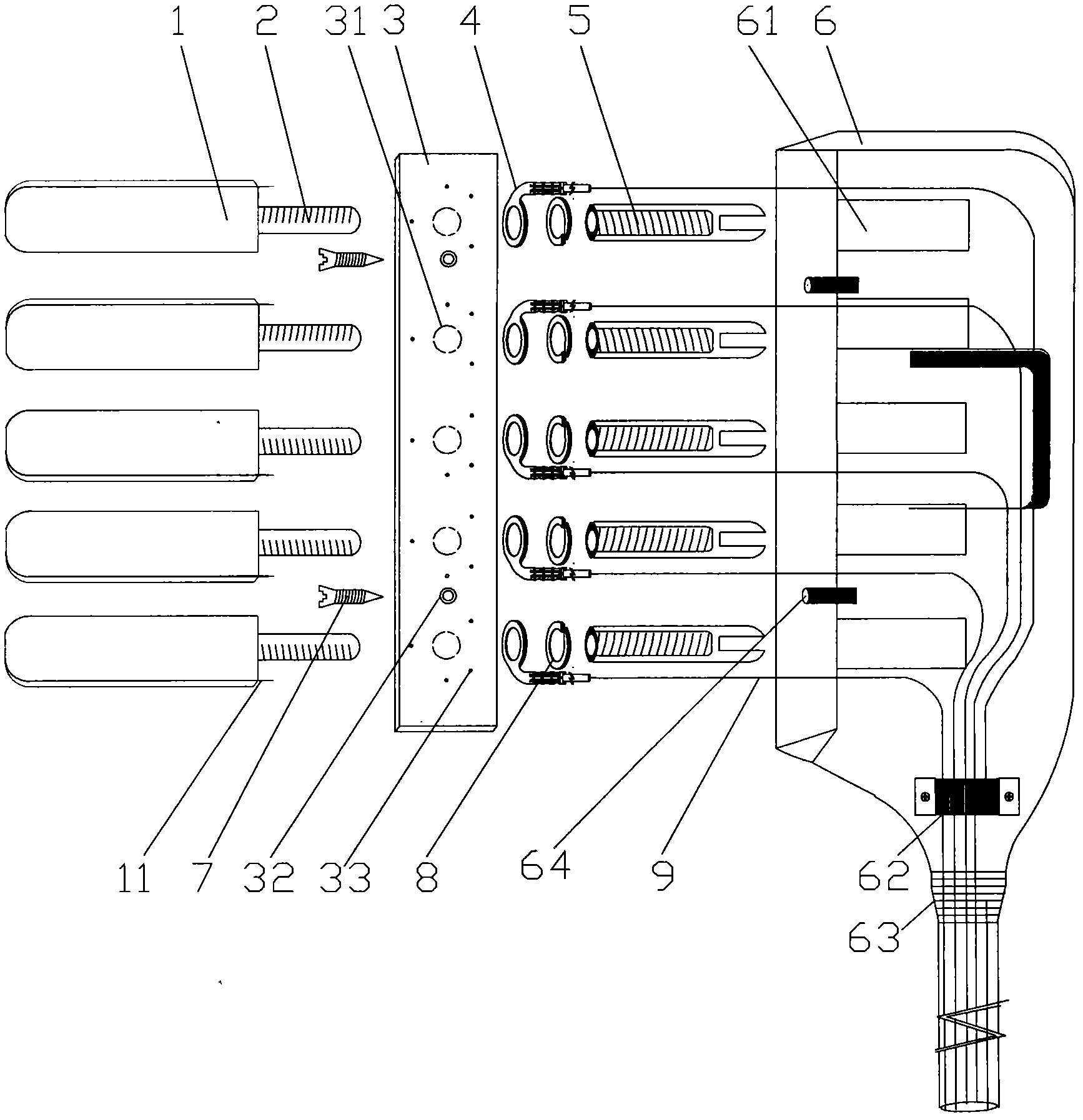

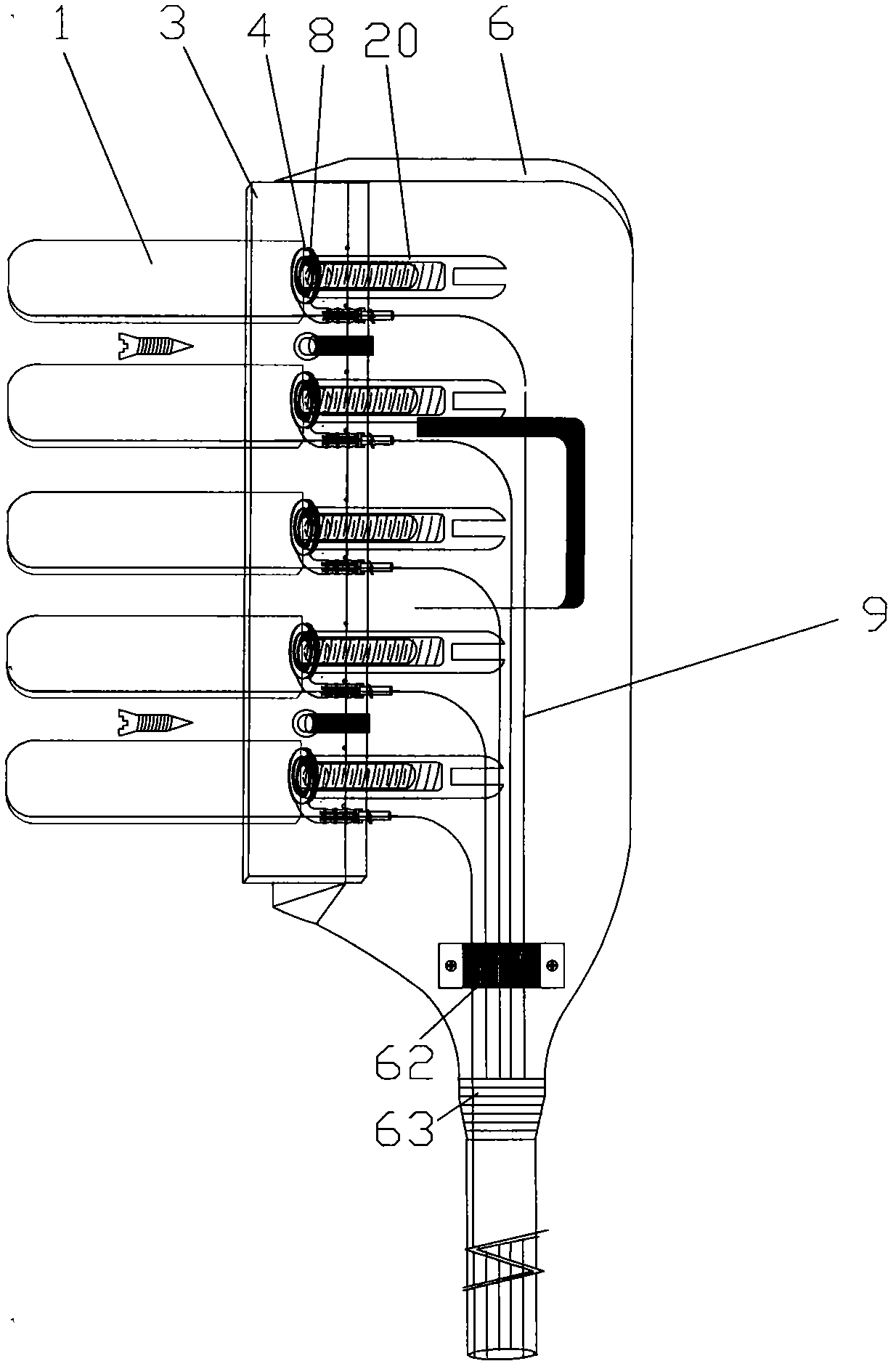

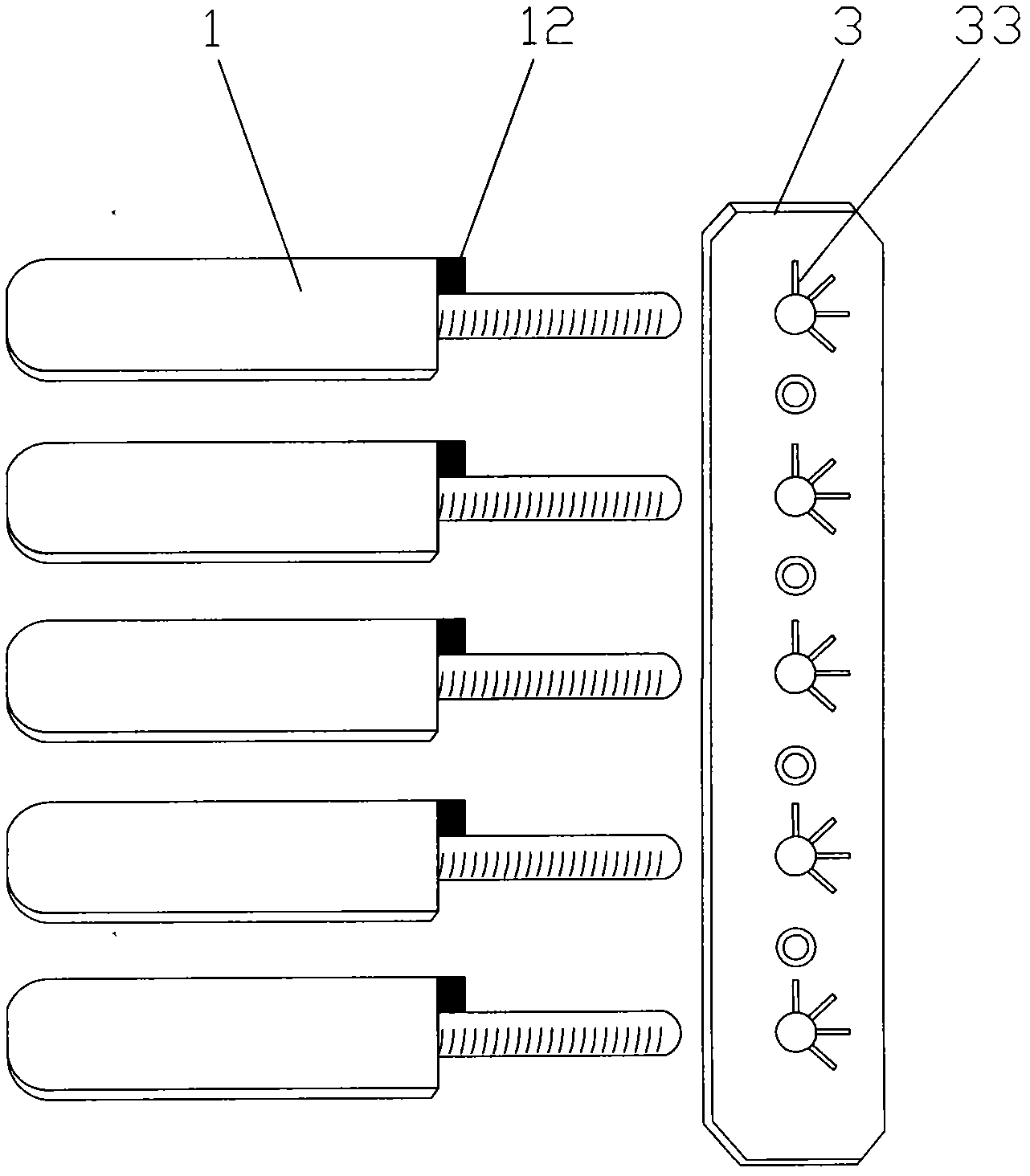

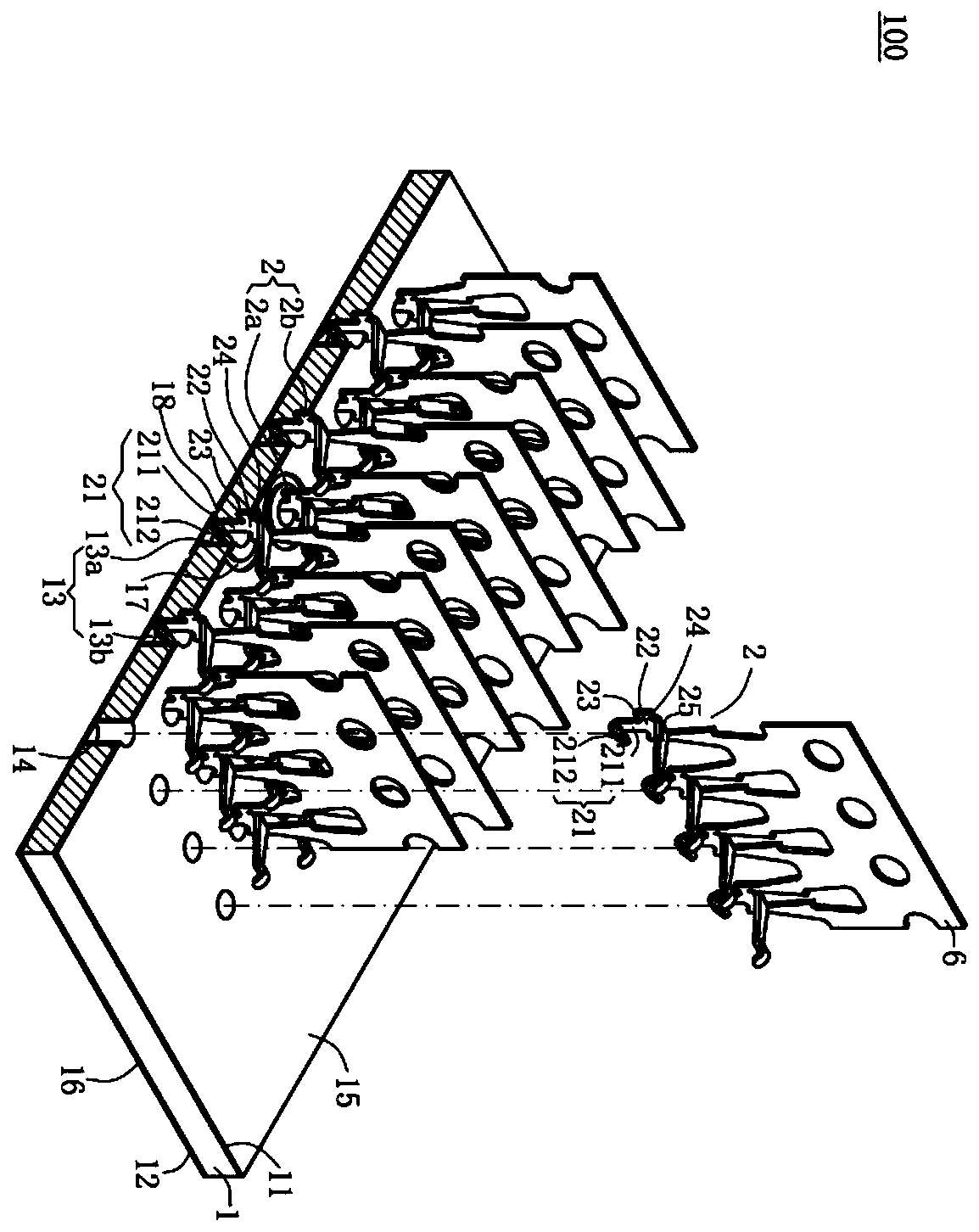

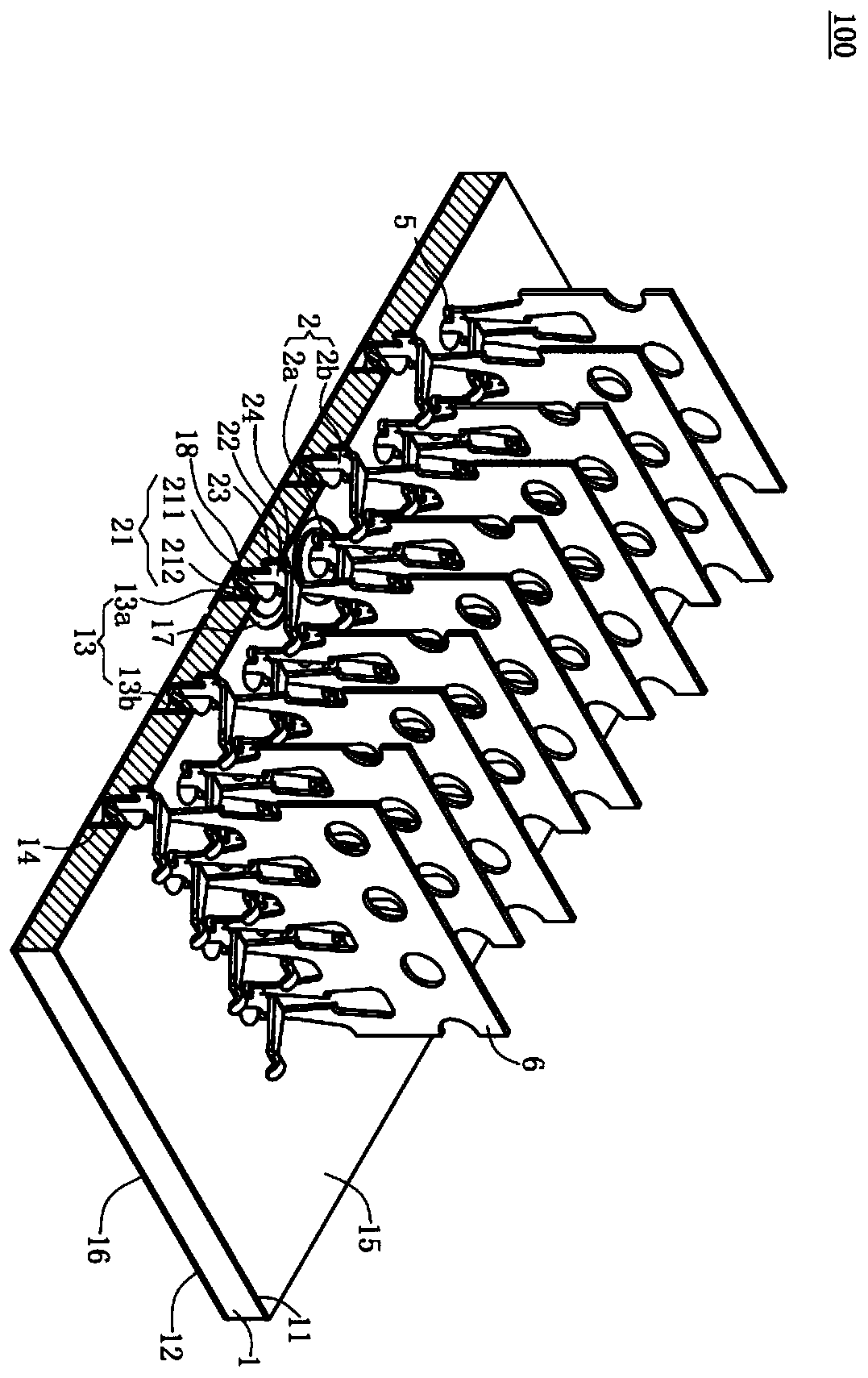

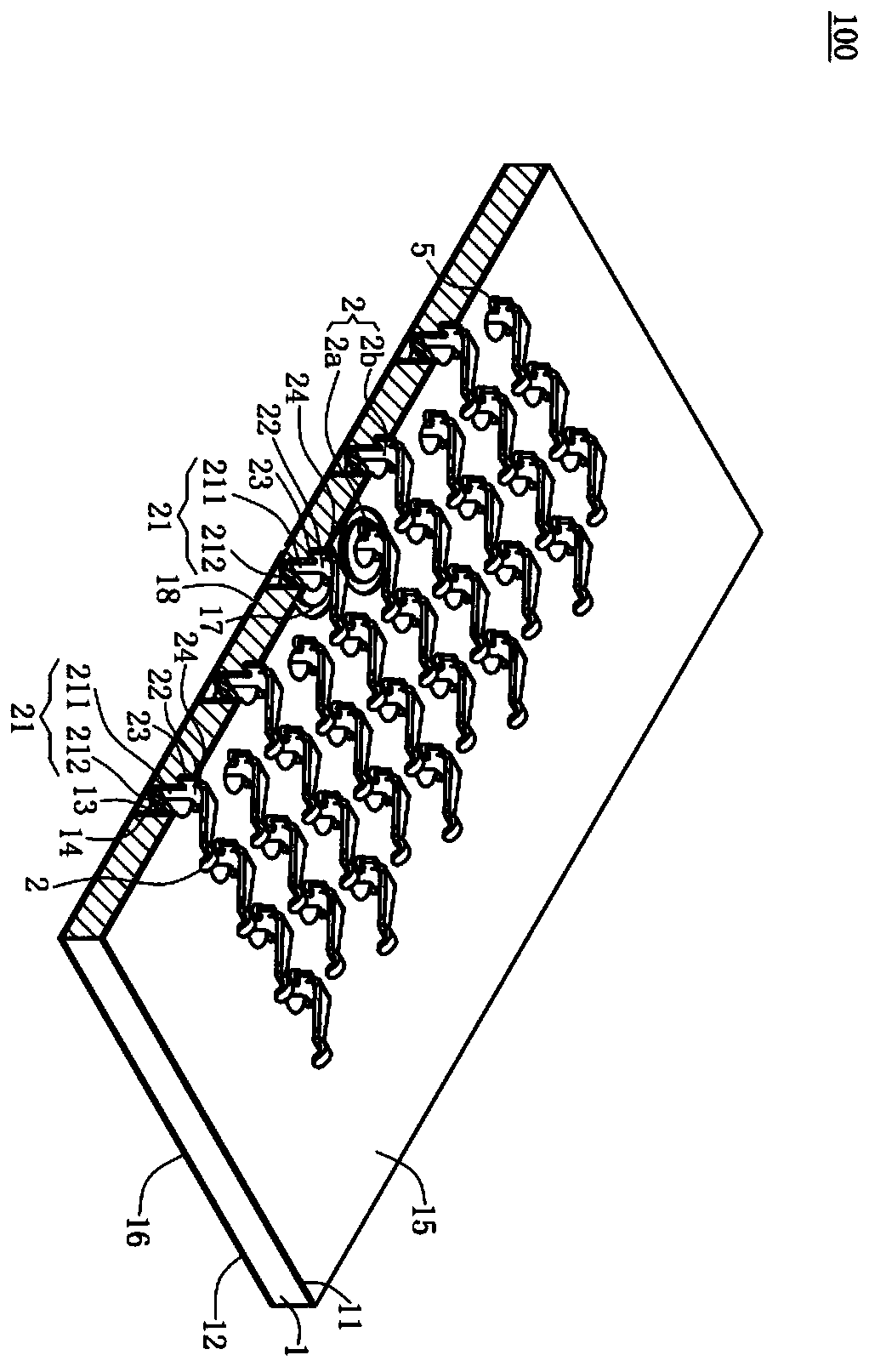

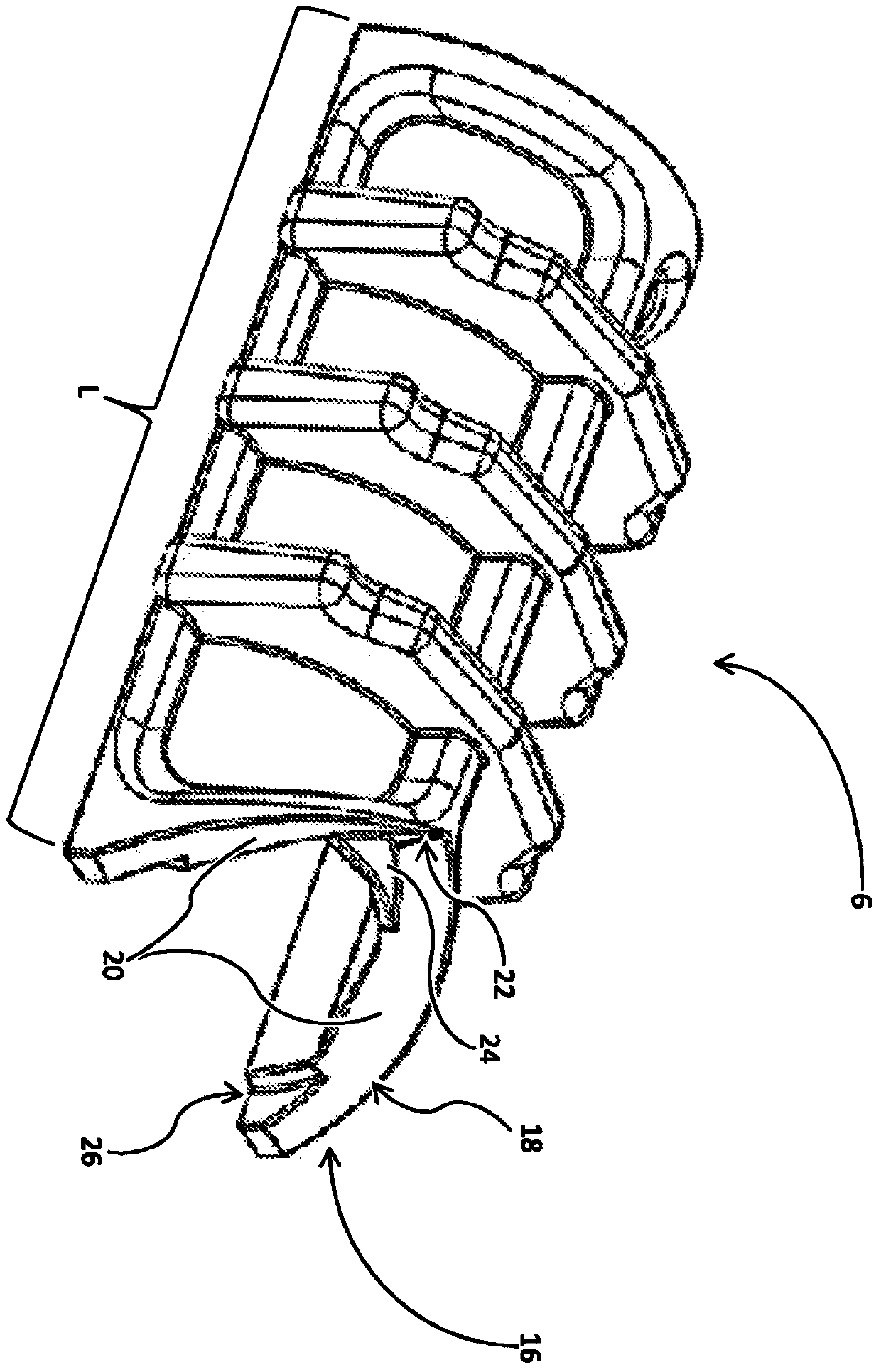

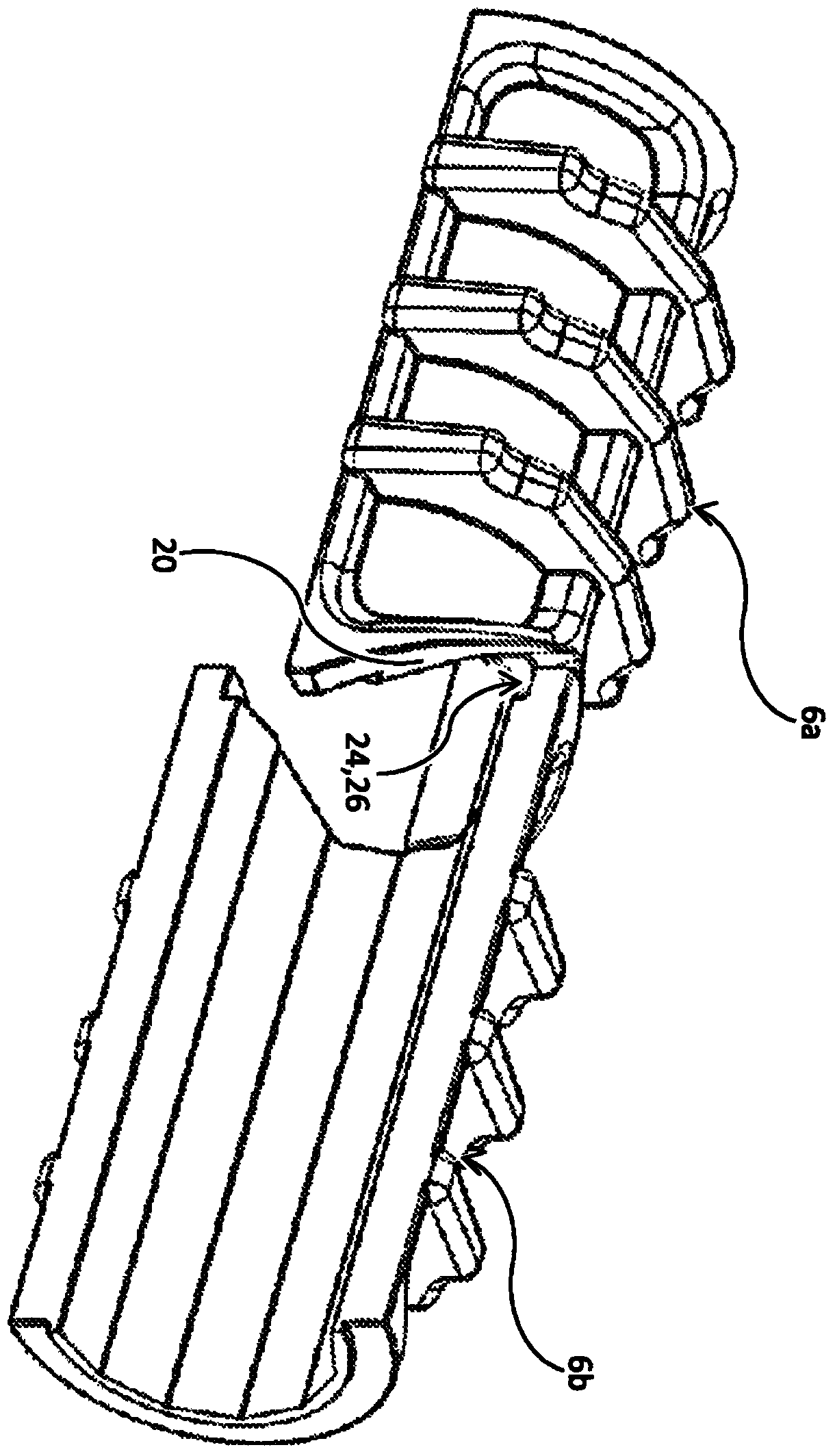

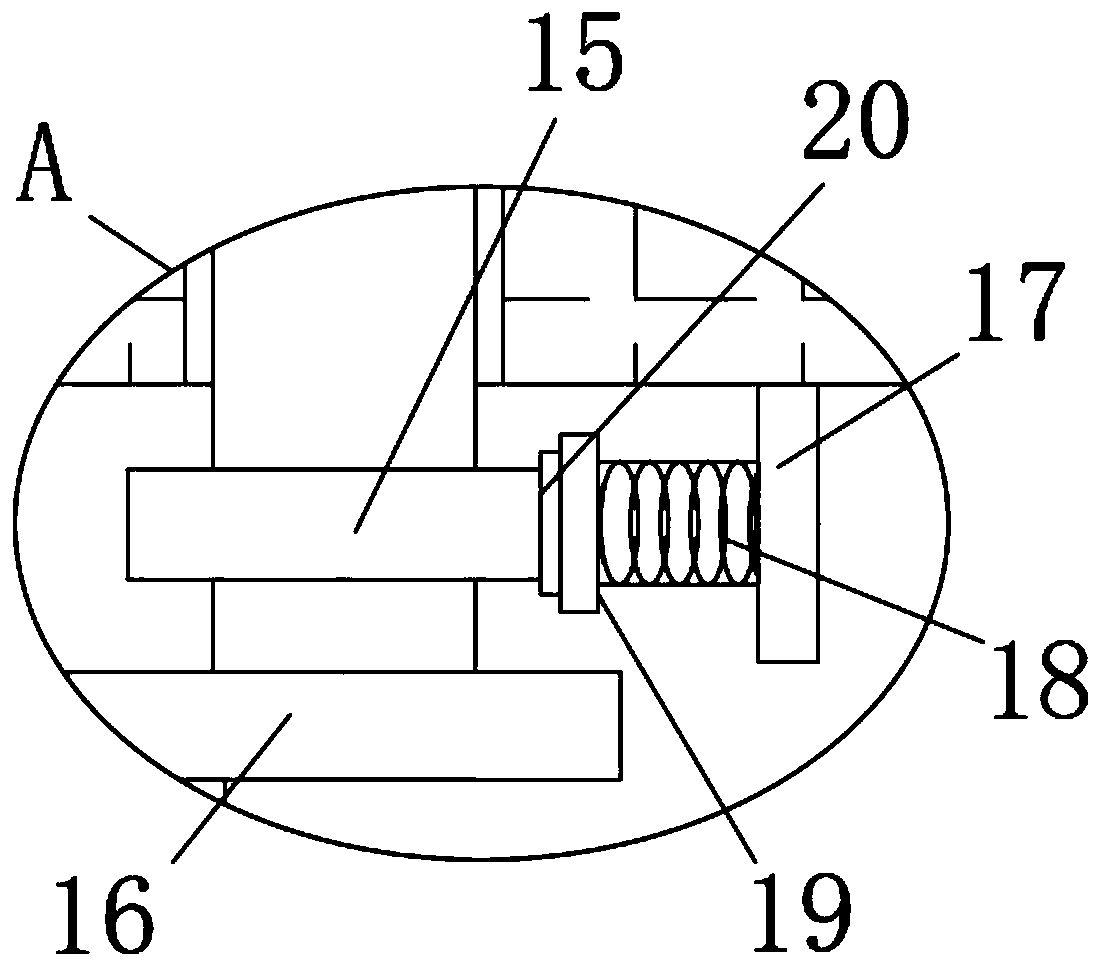

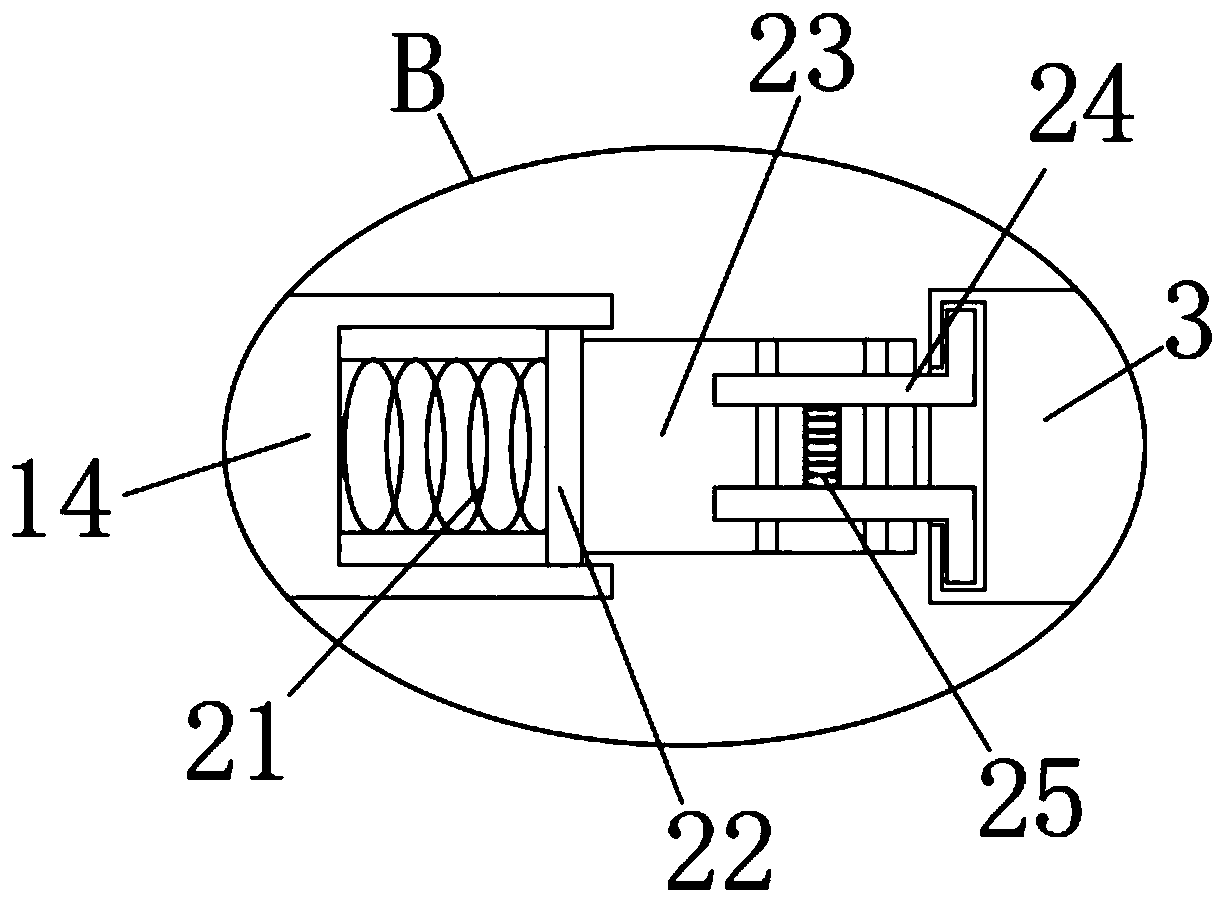

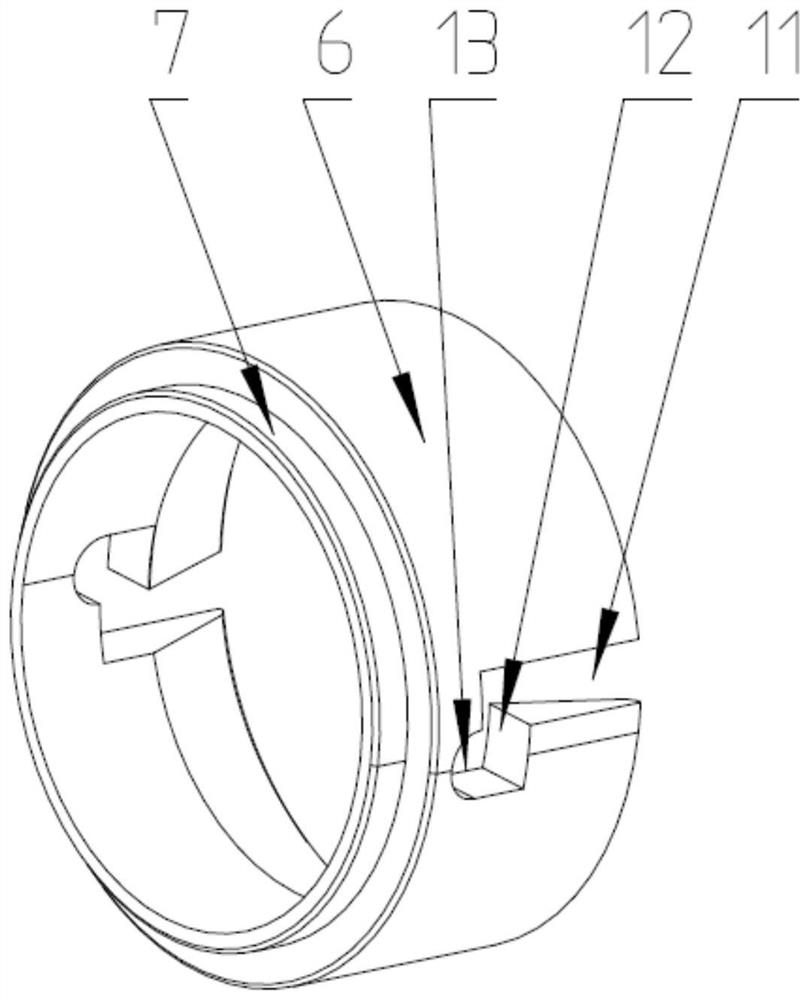

Negative terminal and electric connector using the same negative terminal

InactiveCN1773778AGood operabilityNot easy to reverseContact member manufacturingCoupling contact membersEngineeringElectric wire

The invention provides a female terminal and an electrical connector. The female terminal is not easy to produce micro-sliding wear due to vibration, can obtain strong contact pressure, and has good workability under low insertion force. Also, prevent twisting. A female terminal (1), including two parts, a terminal body (2) and a reinforcing part (3) installed on the terminal body, the terminal body (2) has a plug-in piece that is inserted in the front The elastic contact piece (34) that the terminal (80) contacts, and has the electric wire connecting part (6, 8) that is connected with the electric wire at the back, and the described strengthening part (3) has the spring piece (38), and above-mentioned contact piece ( 34) When deflected due to contact with the above-mentioned blade terminal (80), the spring piece (38) supports the contact piece (34) to strengthen the contact pressure of the above-mentioned contact piece (34).

Owner:TYCO ELECTRONICS JAPAN GK

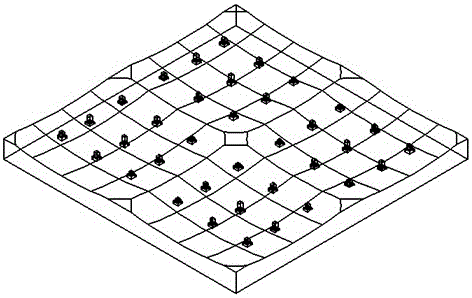

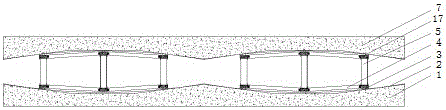

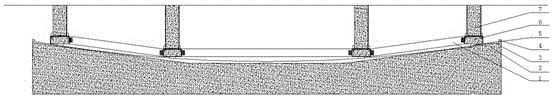

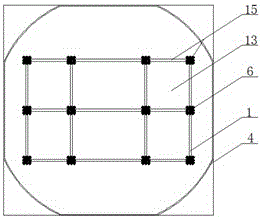

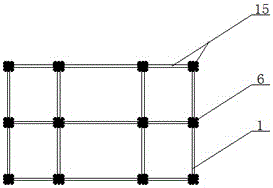

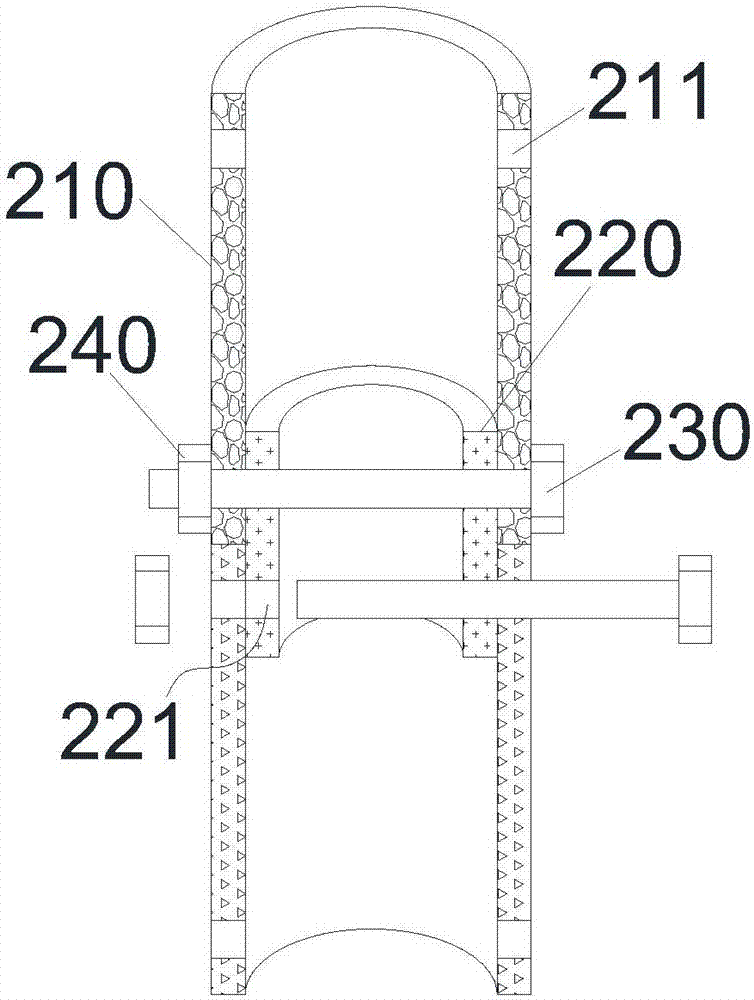

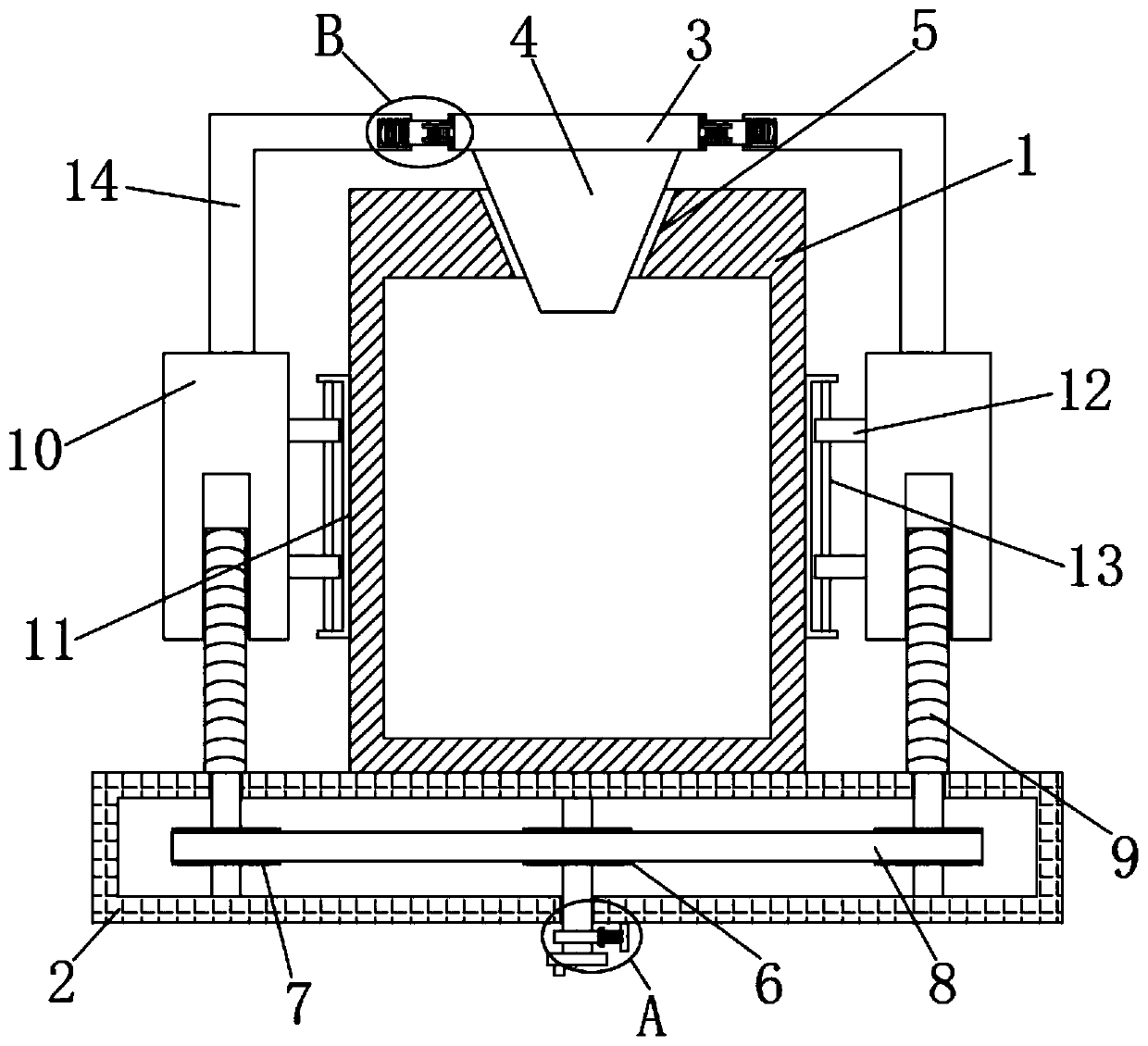

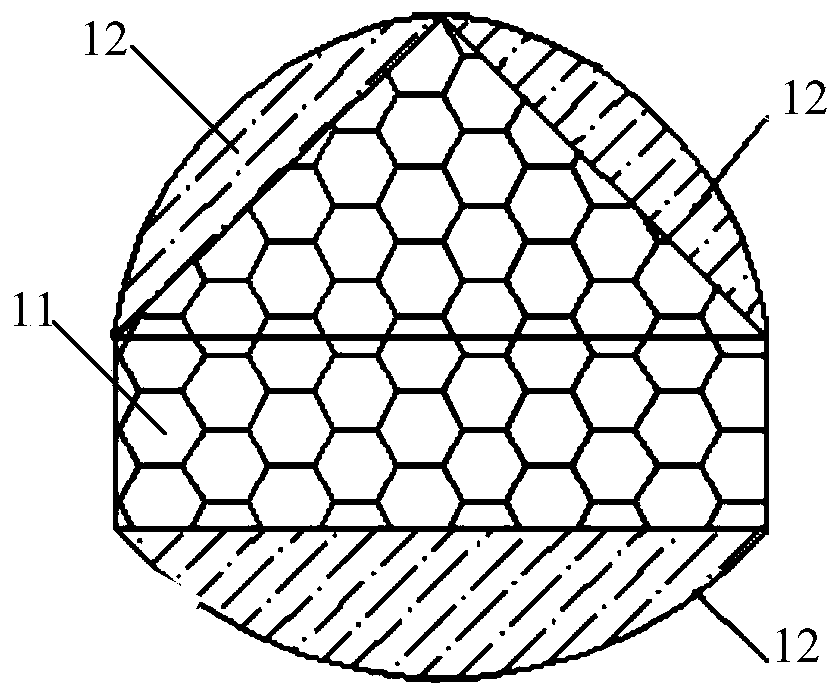

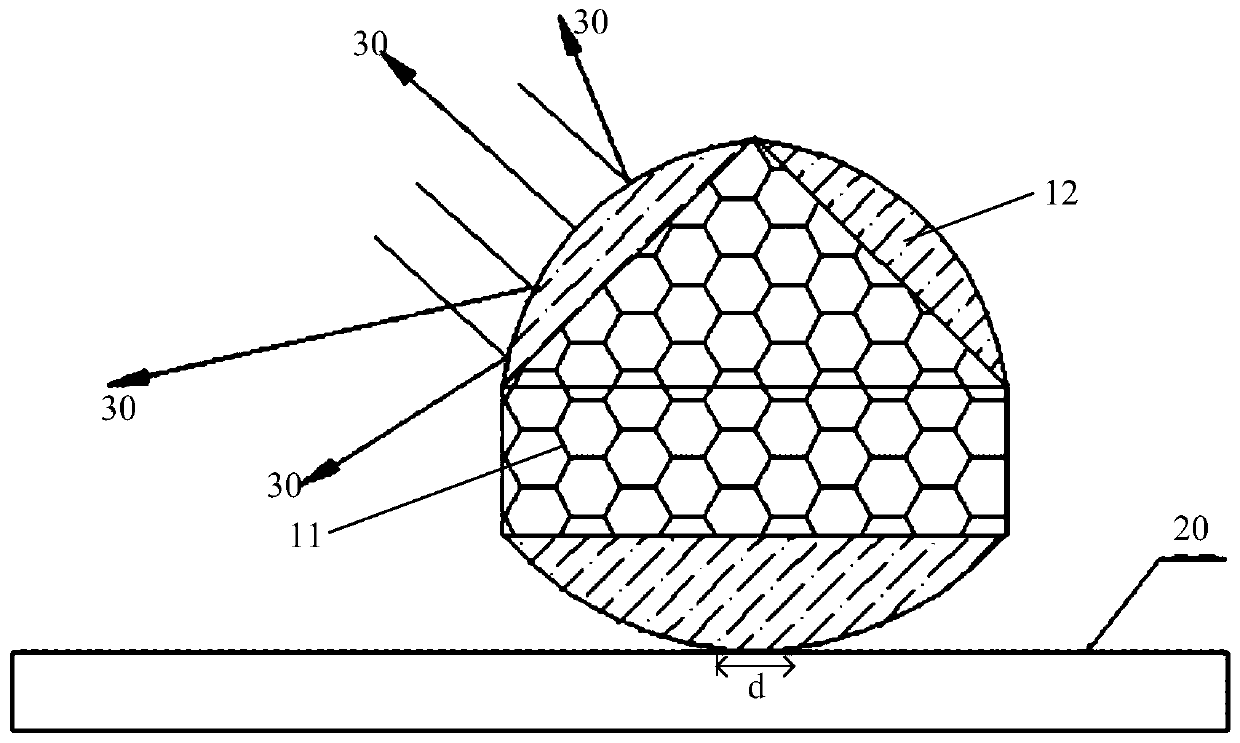

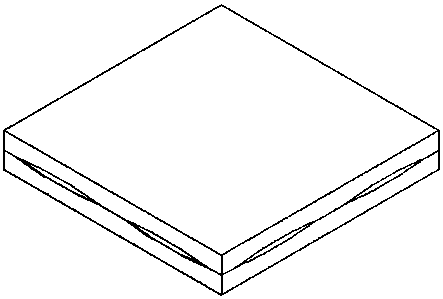

Sliding-friction pendulum combined shock-insulation layer with ultra-large bottom surface

ActiveCN106400972ALarge spanMeet the needs of horizontal deformationProtective buildings/sheltersShock proofingInsulation layerPendulum

The invention discloses a sliding-friction pendulum combined shock-insulation layer with an ultra-large bottom surface. The combined shock-insulation layer comprises an upper spherical shell layer, a lower spherical shell layer and sliding frames. Four arc-shaped spherical faces are arranged on the upper surfaces of the lower spherical shell layer. Four arc-shaped spherical faces are arranged on the lower surface of the upper spherical shell layer. Each sliding frame is composed of a plurality of sliding blocks, upper connecting components, lower connecting components, connecting beams and sliding frame columns, wherein the sliding frame columns are connected between the upper connecting components and the lower connecting components, and the lateral portions of the upper connecting components and the lateral portions of the lower connecting components are connected with the connecting beams. The upper end surfaces of the upper connecting components and the lower end surfaces of the lower connecting components are welded to the sliding blocks. The sliding frames are in overlap joint with the arc-shaped spherical faces of the upper spherical shell layer and the arc-shaped spherical faces of the lower spherical shell layer through the sliding blocks. According to the sliding-friction pendulum combined shock-insulation layer with the ultra-large bottom surface, the sliding frames are formed through connection of the sliding blocks, and the integral shock-insulation layer is formed by the sliding frames, the upper spherical shell layer and the lower spherical shell layer; and the span of the shock-insulation layer is quite large, the allowable deformation, in the horizontal direction, of the shock-insulation layer is far larger than that of a shock-insulation support, and the requirement for horizontal deformation of the shock-insulation layer under an extremely-powerful earthquake can be completely met.

Owner:HARBIN INST OF TECH

Horizontal general plug

ActiveCN102142635AEffort-saving plugging and unpluggingEasy to operateSecuring/insulating coupling contact membersCoupling contact membersEngineeringGasket

Owner:XIAMEN HUIHUANG DECORATION ENG +4

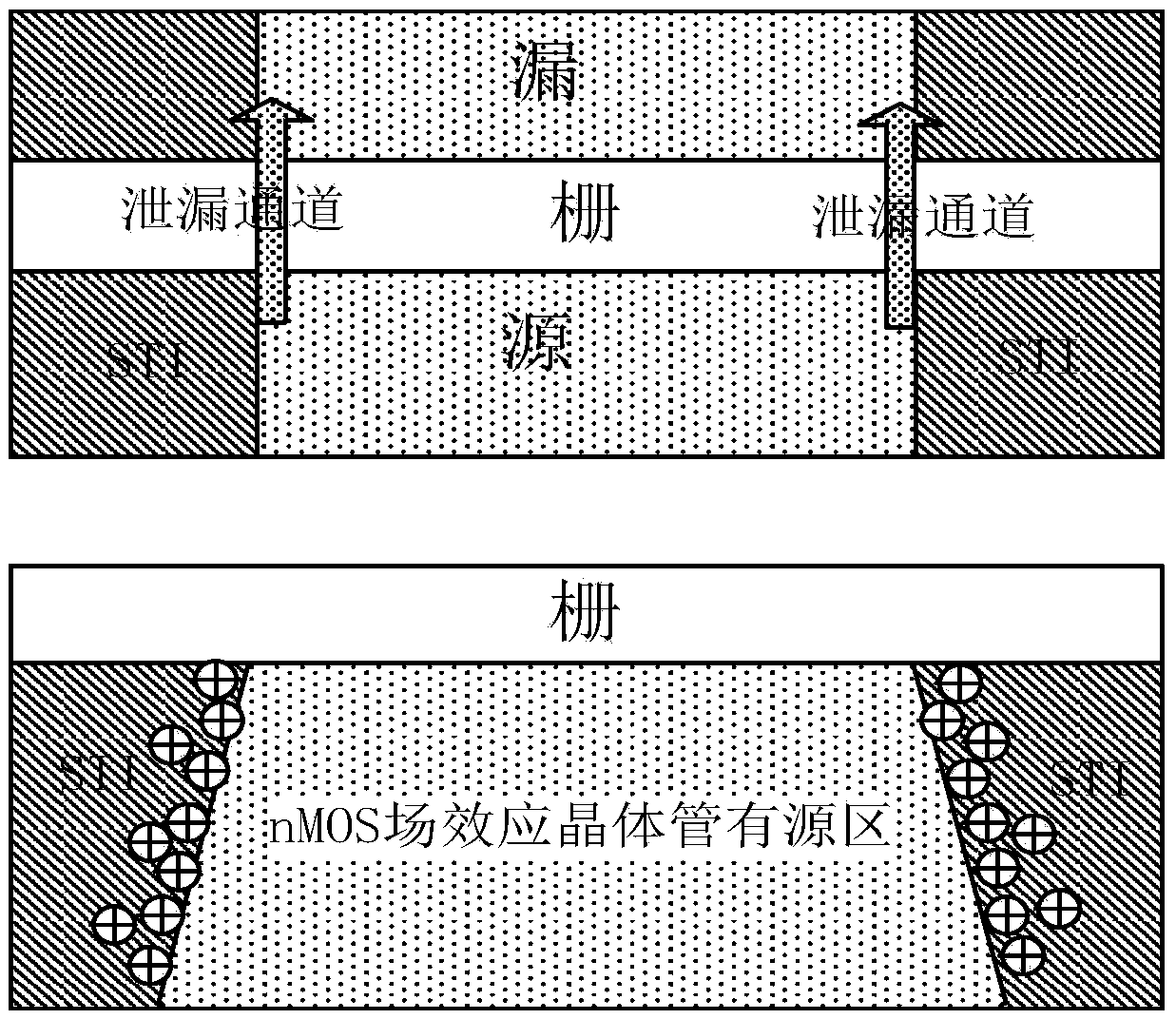

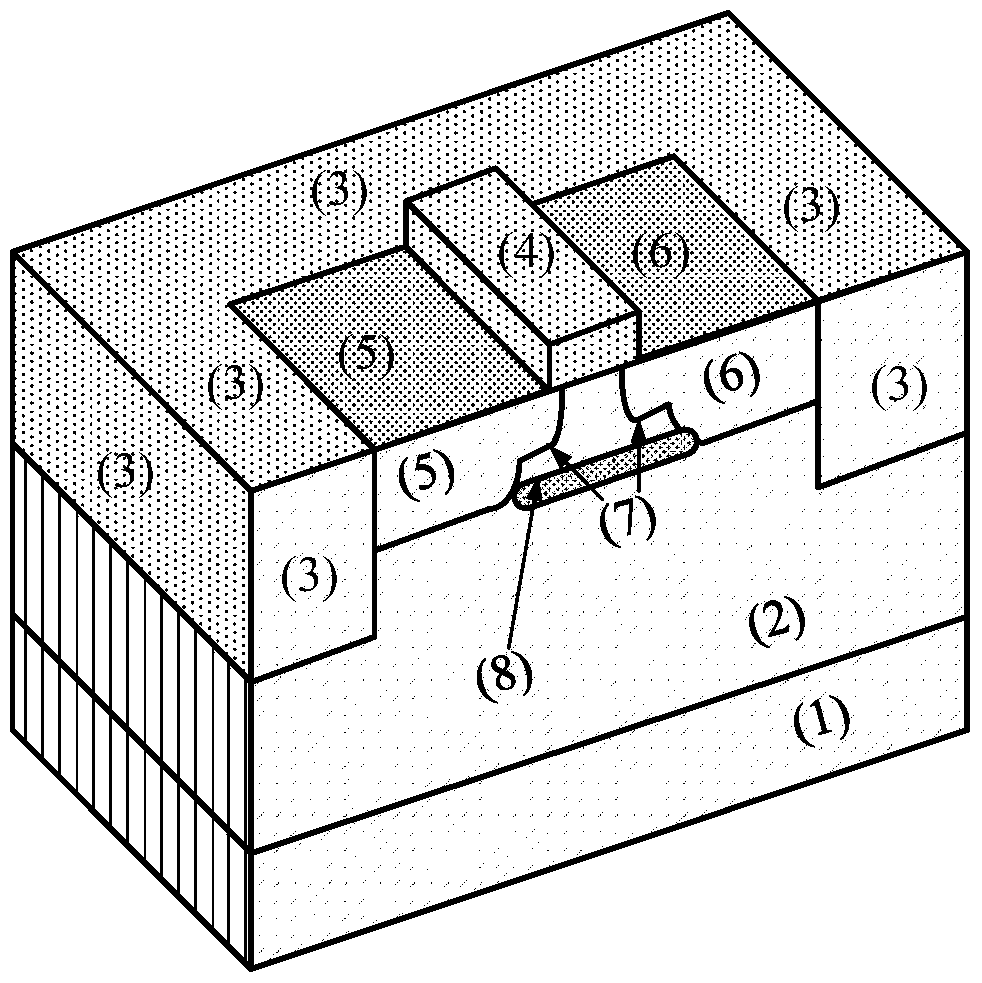

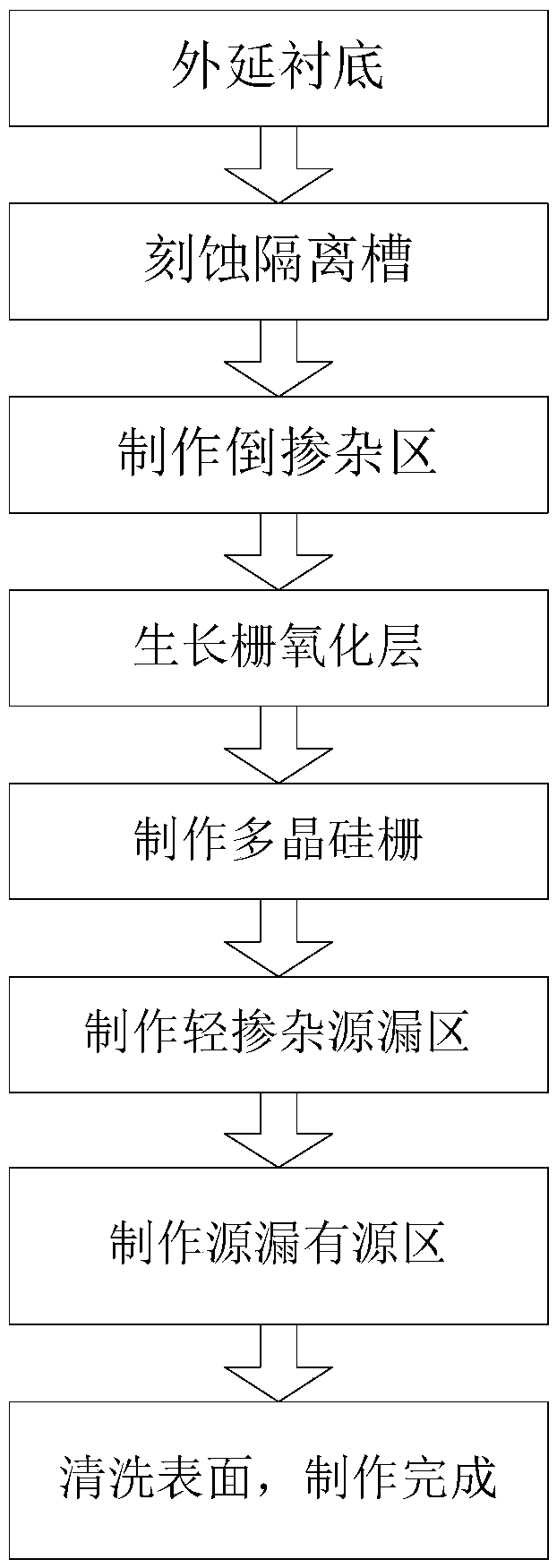

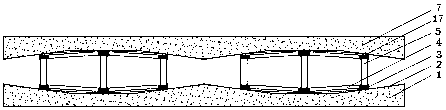

65nm technology-based super-steep reverse-doping radiation-proof MOS field-effect tube

ActiveCN105514169AImprove radiation resistanceDoes not affect integrationSemiconductor/solid-state device detailsSolid-state devicesSubthreshold oscillationsThreshold voltage

The invention discloses a 65nm technology-based super-steep reverse-doping radiation-proof MOS field-effect tube, mainly solving the problems of increased OFF leakage current, threshold voltage drift and subthreshold oscillation amplitude degradation of a conventional 65nm MOS field-effect tube under a total dose radiation environment. The MOS field-effect tube comprises a P-type substrate (1) and an epitaxial layer (2) located on the substrate, wherein an isolation groove (3) is formed around a place above the epitaxial layer, a grid electrode (4) is arranged at the middle above the epitaxial layer, a source region (5) and a drain region (6) are arranged in the epitaxial layer between two side boundaries of the grid electrode and the inner boundary of the isolation groove, light-doping source-drain regions (7) are arranged in the epitaxial layer below the two side boundaries of the grid electrode, a channel is formed in an area between the two light-doping source-drain regions and right below the grid electrode, and a heavy-doping super-steep reverse-doping region (8) is arranged below the channel between the two light-doping source-drain regions. The 65nm technology-based super-steep reverse-doping radiation-proof MOS field-effect tube improves the total dose irradiation resistance of a device, and can be used for the preparation of large scale integrated circuits.

Owner:XIDIAN UNIV

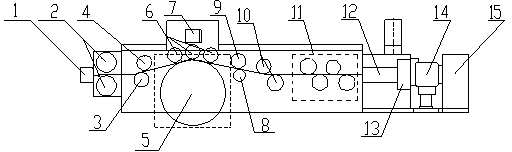

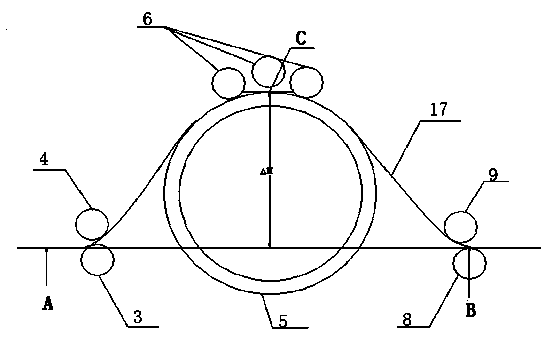

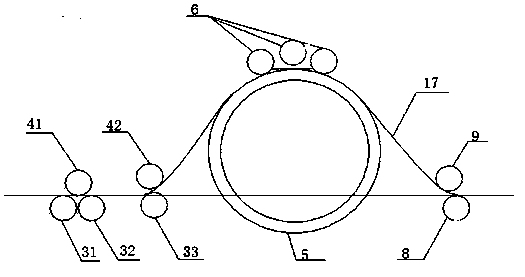

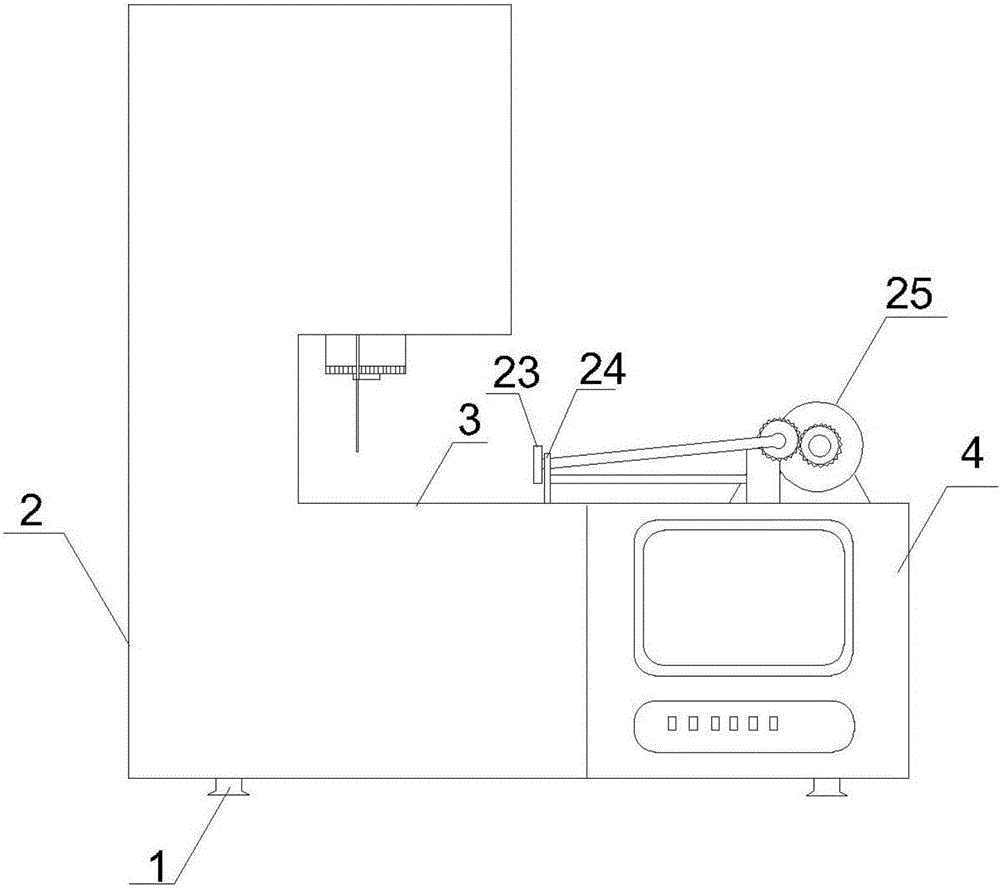

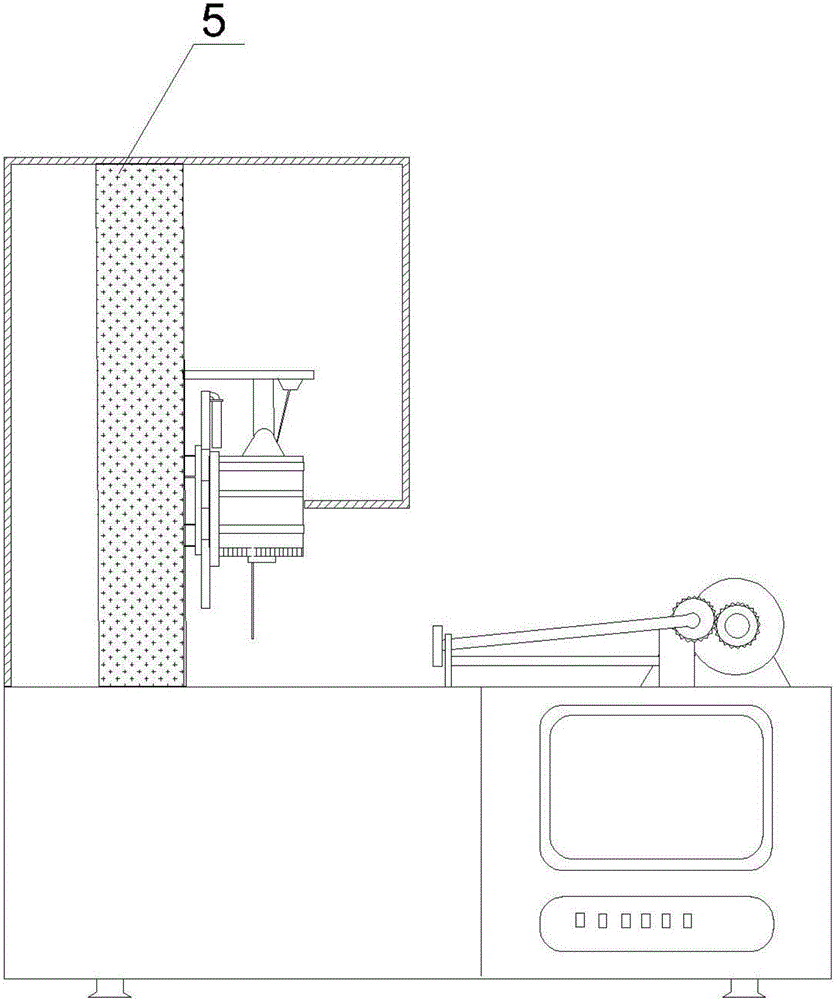

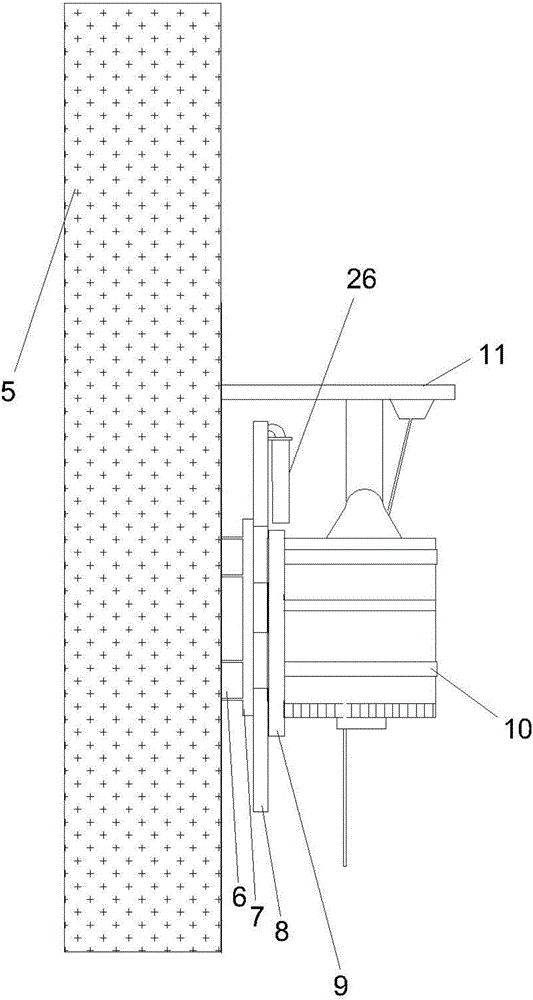

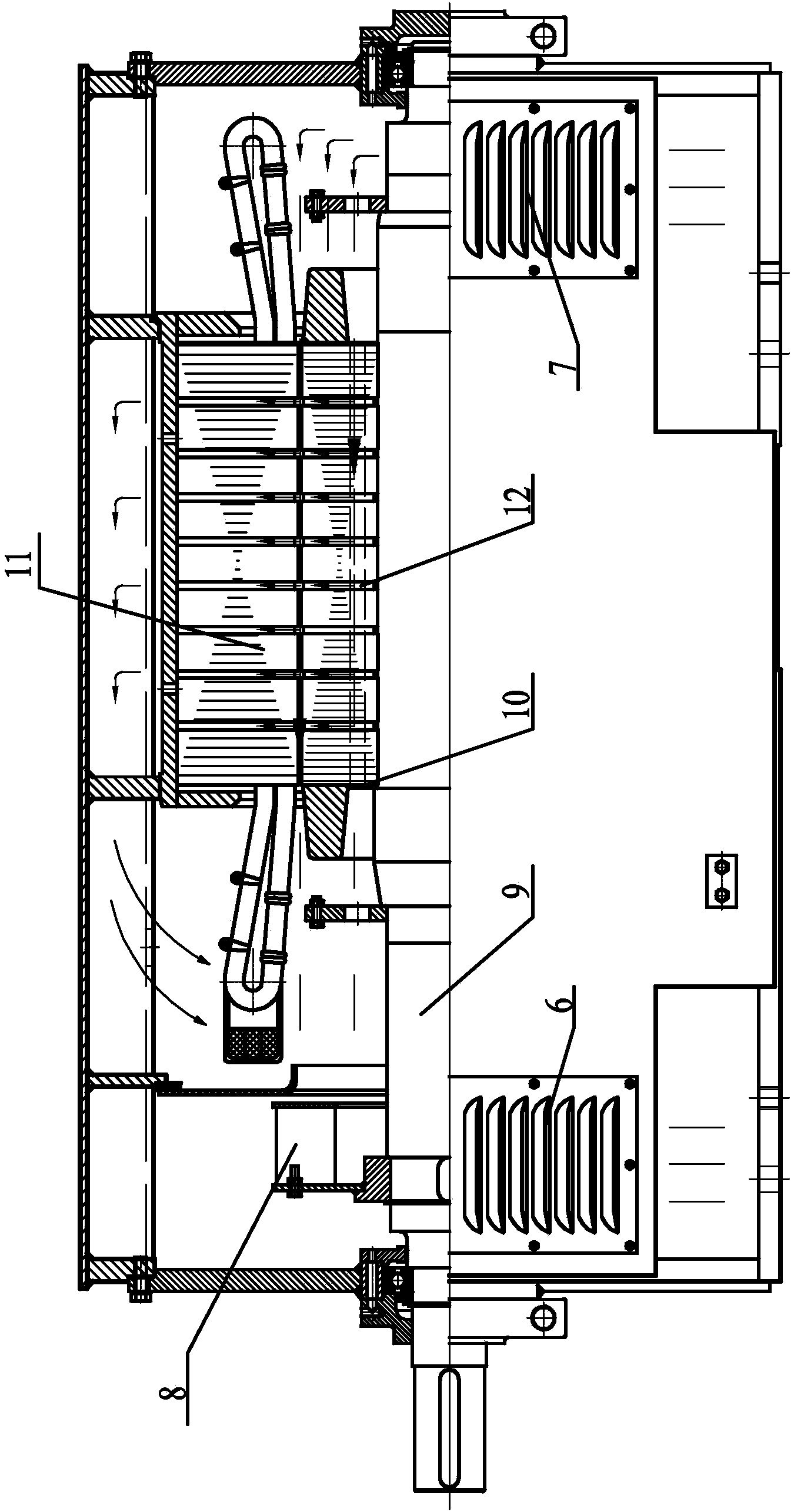

Steel-bar arc-delivering straightening hoop bending machine

The invention relates to a steel-bar arc-delivering straightening hoop bending machine. The steel-bar arc-delivering straightening hoop bending machine is characterized by sequentially comprising a feeding port, a delivering assembly, a guiding assembly, a measuring assembly, a straightening assembly, a material-guiding guide tube, a shearing assembly, a bending assembly and a reverse delivering assembly, wherein the delivering assembly is used for clamping a steel bar and delivers the steel bar backwards, the guiding assembly is used for controlling and guiding the delivering path of the steel bar and achieving arc-delivering through change of displacement of each wheel set in the perpendicular direction, and the measuring assembly is used for measuring the current delivering length of the steel bar. The delivering assembly comprises a pair of delivering wheels, and the two delivering wheels are located on the upper side of the middle axis of the feeding port and the lower side of the middle axis of the feeding port respectively and are symmetrically distributed. The measuring assembly comprises a set of metering wheels which are vertically distributed. The straightening assembly comprises a perpendicular straightening assembly and a horizontal straightening assembly, wherein the horizontal straightening assembly is composed of two sets of plane straightening wheels. The steel-bar arc-delivering straightening hoop bending machine guarantees the quality of the straightened steel bar, improves straightening efficiency, reduces production cost, and has positive significance in straightening and bending of the steel bar.

Owner:姜勇

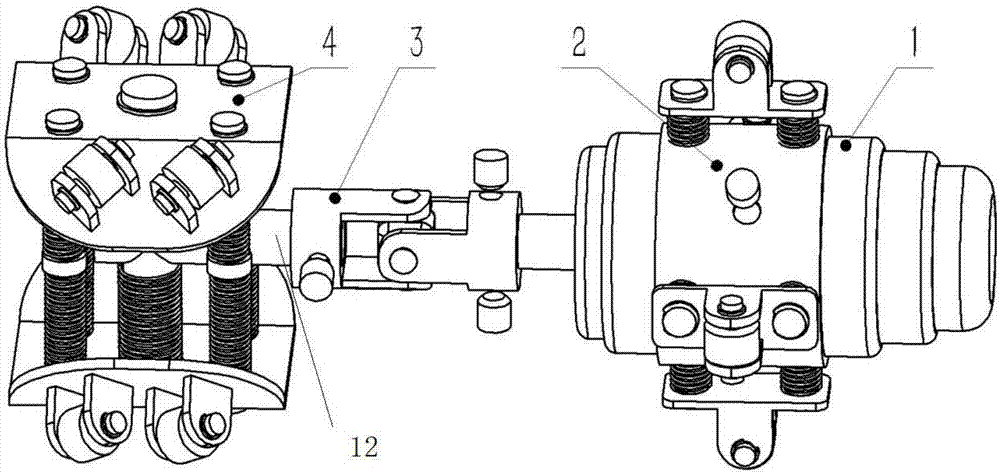

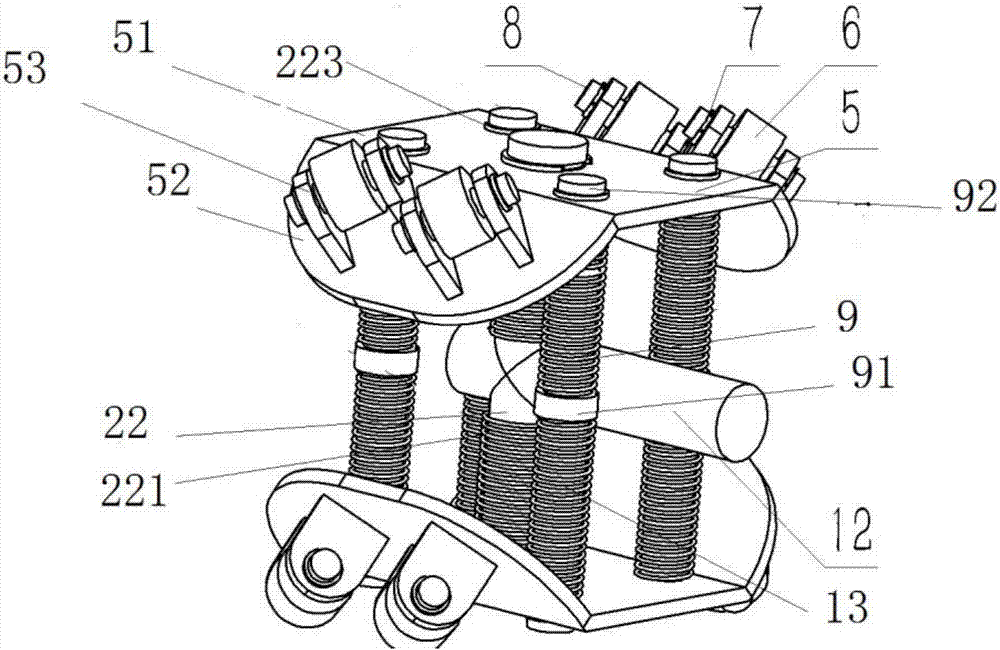

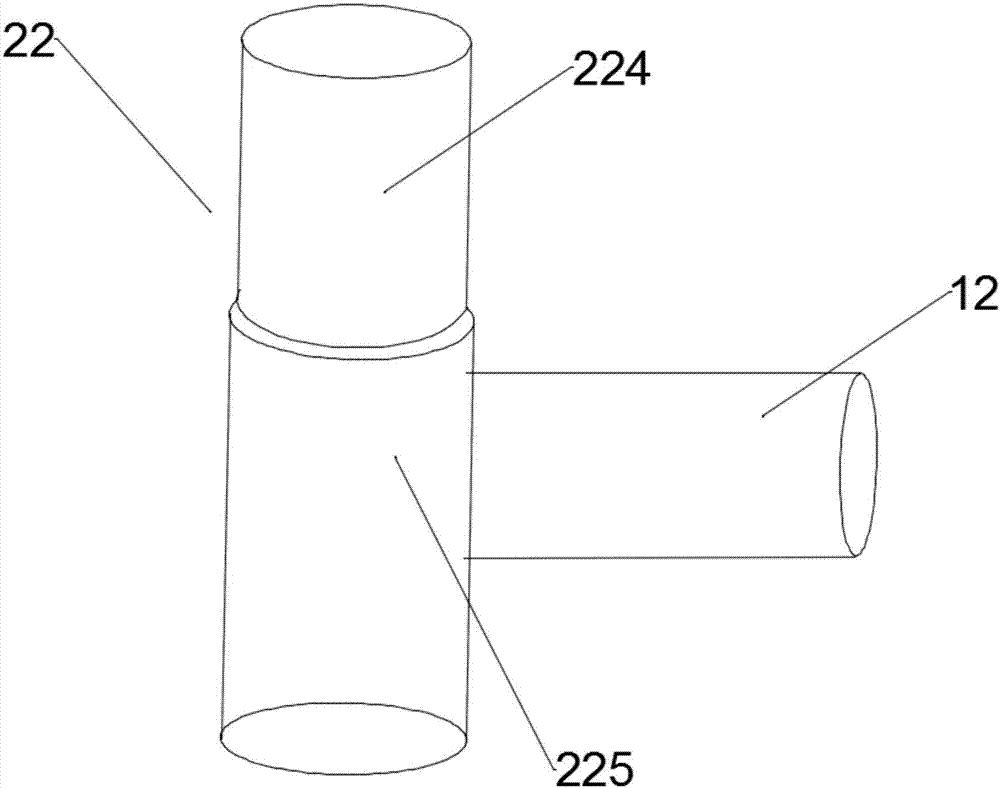

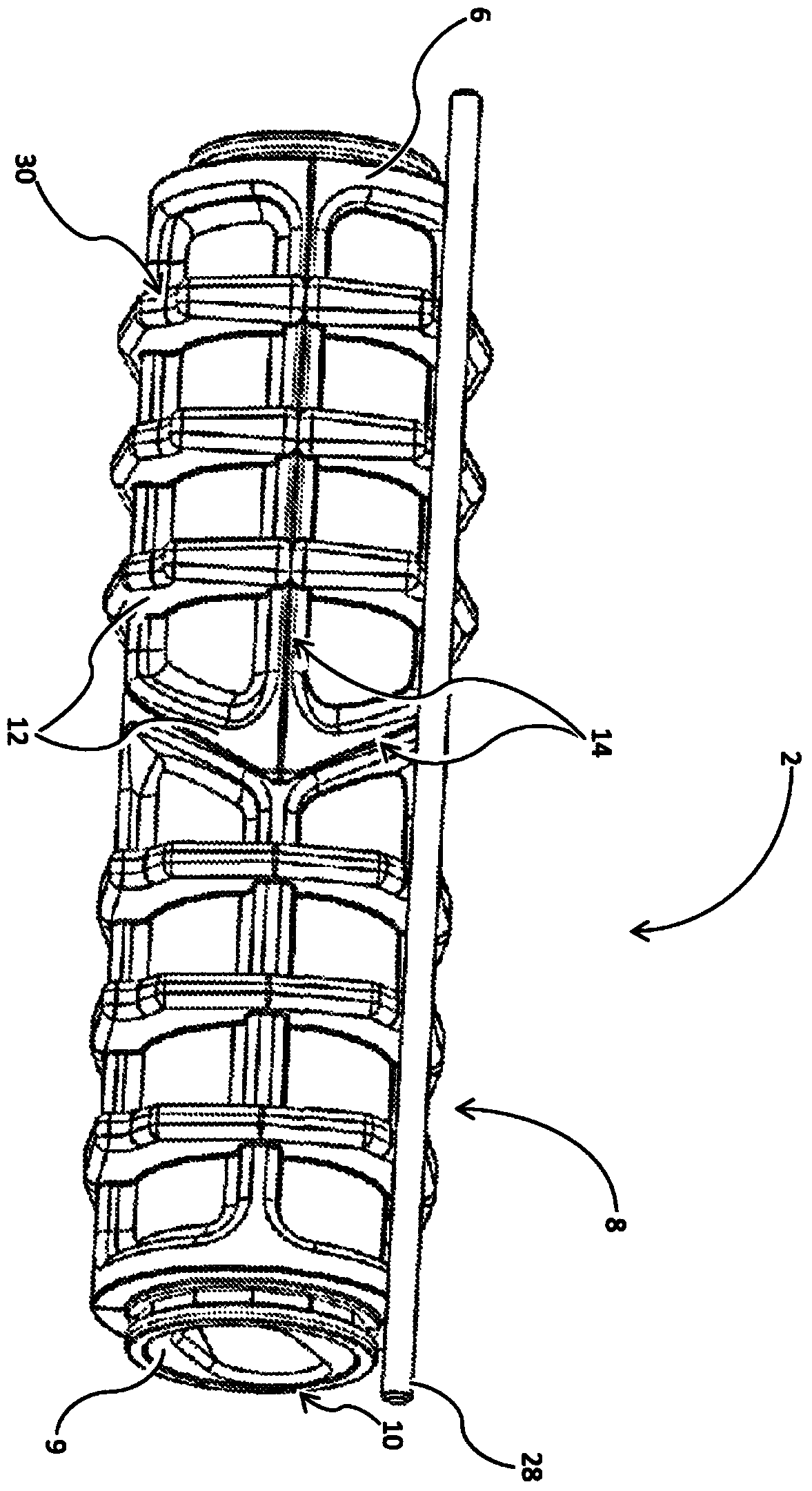

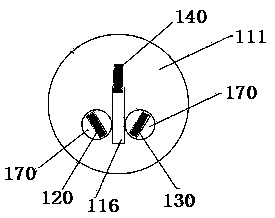

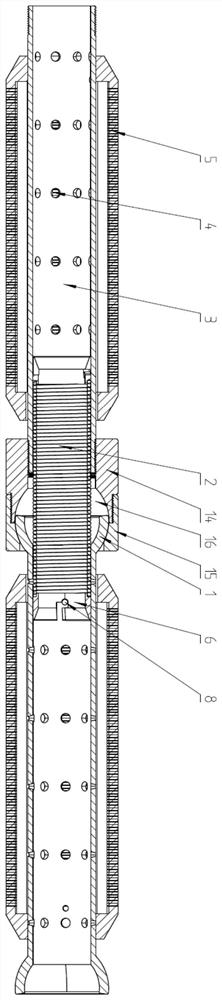

Spiral pipeline inner wall walking device

The invention discloses a spiral pipeline inner wall walking device. The pipeline inner wall walking device comprises a gear motor device, a guide wheel mechanism and a driving wheel mechanism; the guide wheel mechanism sleeves the outer side of the gear motor device; the gear motor device drives the driving wheel mechanism to rotate; the driving wheel mechanism comprises at least two roller supports which are uniformly distributed along the circumferential direction of a rotary shaft; the roller supports are arranged in a manner of being capable of mutually approaching or departing radially along the rotary shaft; the driving wheel mechanism further comprises springs; and elastic force of the springs can drive the roller supports to mutually depart. According to the spiral pipeline inner wall walking device, the springs press fixed plates to drive driving wheels walk along the inner wall of a pipe, so that movement of the driving wheels is more stable; the driving wheels do not twist easily; and the spiral pipeline inner wall walking device is applicable to various different small pipe diameters.

Owner:HRG INT INST FOR RES & INNOVATION

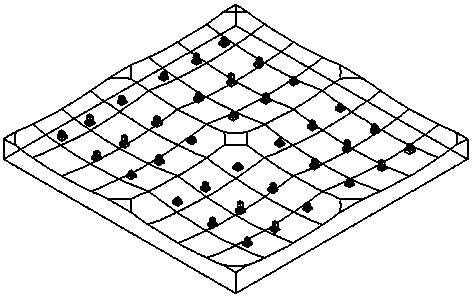

Swinging type shock insulation layer capable of achieving overall sliding friction of bottom surface

ActiveCN106522398AOverall goodEasy to resetProtective buildings/sheltersShock proofingLap jointInsulation layer

The invention discloses a swinging type shock insulation layer capable of achieving overall sliding friction of the bottom surface. The shock insulation layer comprises a bottom surface spherical shell and an upper-portion spherical-surface framework, wherein the lower side of the bottom surface spherical shell and a concrete foundation or a lower structure are cast integrally, and the upper surface is a large-span large-curvature-radius arc spherical surface; the upper-portion spherical-surface framework is formed by connecting a plurality of sliding blocks, connecting beams, load bearing pillars and connecting components, the lower portions of the connecting components are welded to the sliding blocks, the sides of the connecting components are connected with the connecting beams, the upper portions of the connecting components are connected with an upper structure through the load bearing pillars, the sliding blocks are in lap-joint with the upper surface of the bottom surface spherical shell, the lower surfaces of the sliding blocks keep consistent with corresponding positions of the arc spherical surface, and point-contact is avoided. The sliding spherical-surface framework is formed through connection between the sliding blocks and forms the swinging type shock insulation layer capable of achieving overall sliding friction of the bottom surface together with the bottom surface spherical shell. The bottom surface spherical shell has a large span, the allowed deformation in the horizontal direction is far higher than that of a shock insulation support, and the horizontal deformation of the shock insulation layer under super-large shock can be completely met.

Owner:HARBIN INST OF TECH

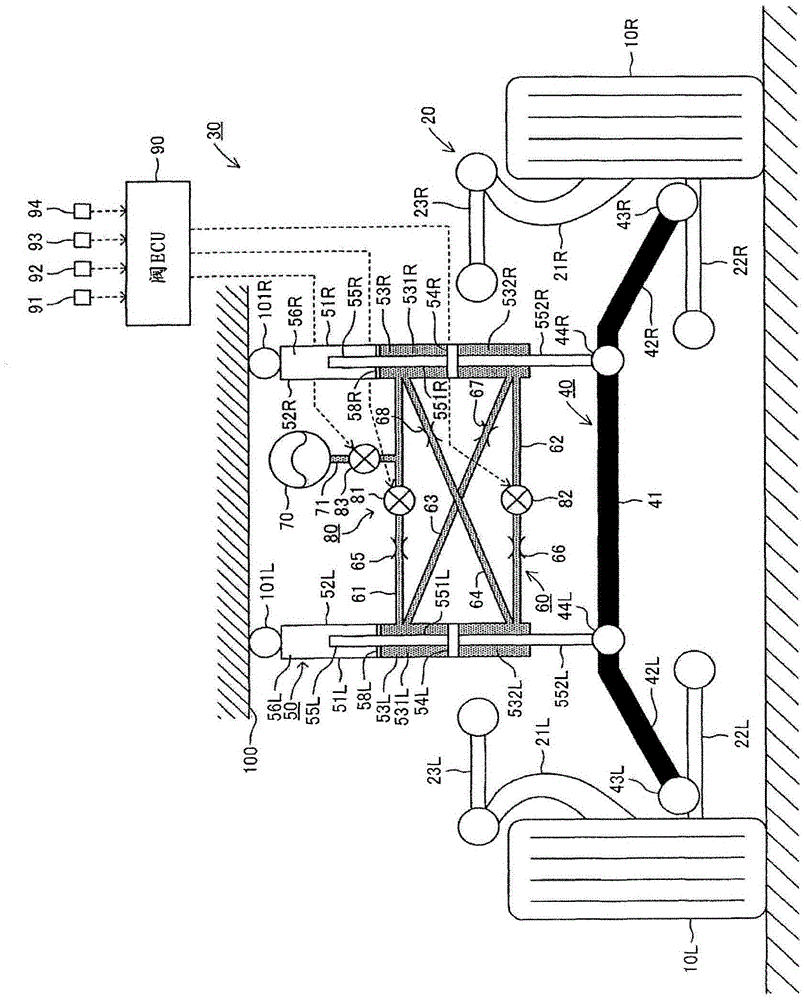

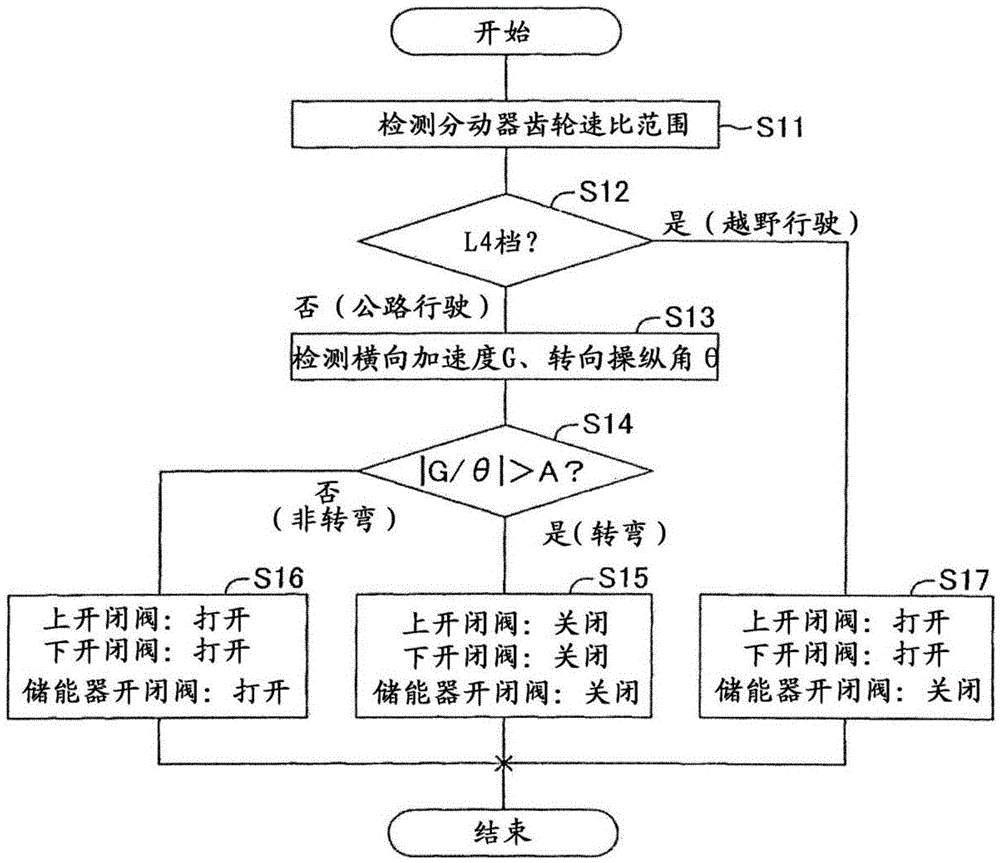

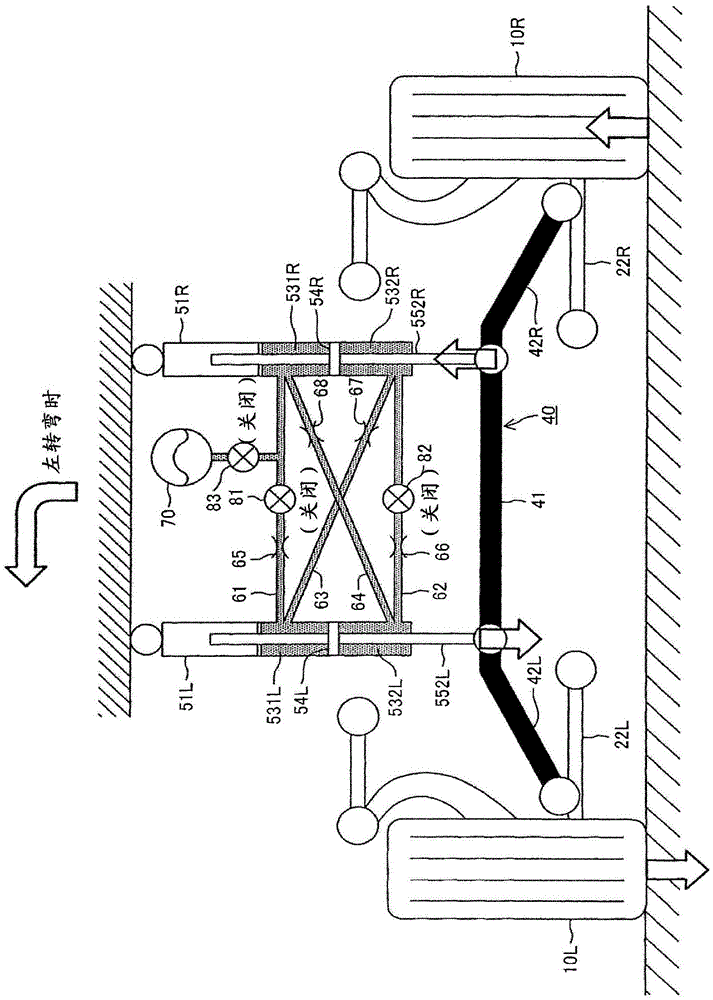

Stabilizer

ActiveCN105774461AThe stability function complies withGood ride comfortInterconnection systemsResilient suspensionsVehicle drivingEnergy storage

The invention provides a stabilizer. The subject of the invention aims at realizing a stabilization function being suitable for the vehicle driving state or according with the hope of a driver. When a vehicle is determined that the vehicle is driven off-road, a valve ECU (90) turns on an upper on-off valve (81) and a lower on-off valve (82) and turns off an energy storage device on-off valve (83). When the vehicle is determined that the vehicle is driven on a road and makes a turn, the valve ECU (90) turns off the upper on-off valve (81), the lower on-off valve (82) and the energy storage device on-off valve (83). When the vehicle is determined that the vehicle does not make a turn, the valve ECU (90) turns on the upper on-off valve (81), the lower on-off valve (82) and the energy storage device on-off valve (83).

Owner:TOYOTA JIDOSHA KK

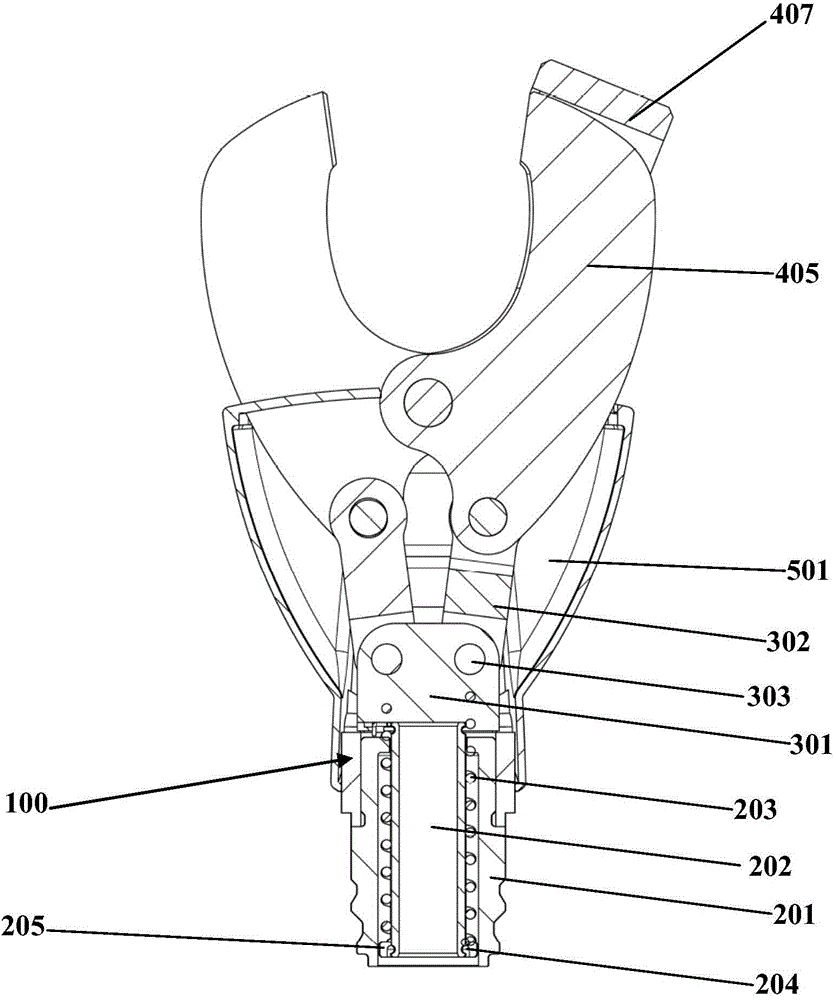

Shearing device and shearing equipment

The invention relates to a shearing device and shearing equipment. The invention provides a shearing device and shearing equipment including the shearing device. The shearing device comprises a support device, a joining device for connecting the support device with a driving source, a linking device arranged in the support device and operatively connected with the joining device, and a shearing part supported on the support device and operatively connected with the linking device, wherein the linking device comprises a first linking component operatively connected with the joining device, and two second connecting components for operatively connecting the first connecting component with the shearing part; the lower parts of the two second connecting components are each provided with a notch; and the second connecting components are connected to the first connecting component through the notches. The shearing device can prevent eccentric loading, can smoothly finish the shearing, and prevents the damage.

Owner:EMERSON PROFESSIONAL TOOLS SHANGHAI

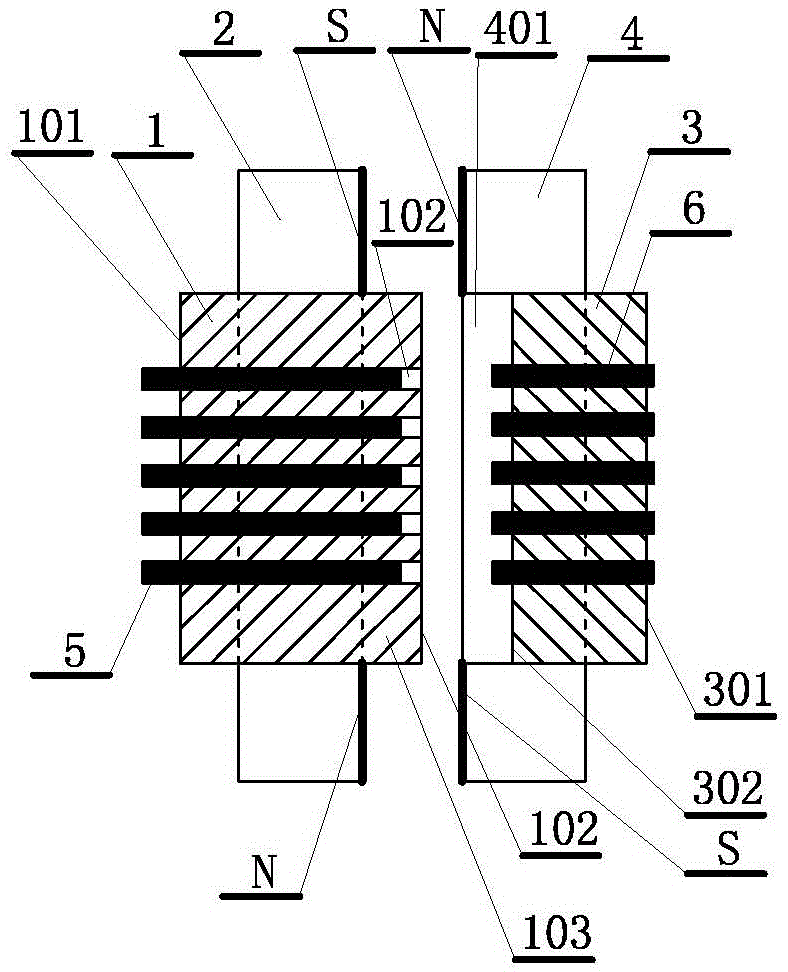

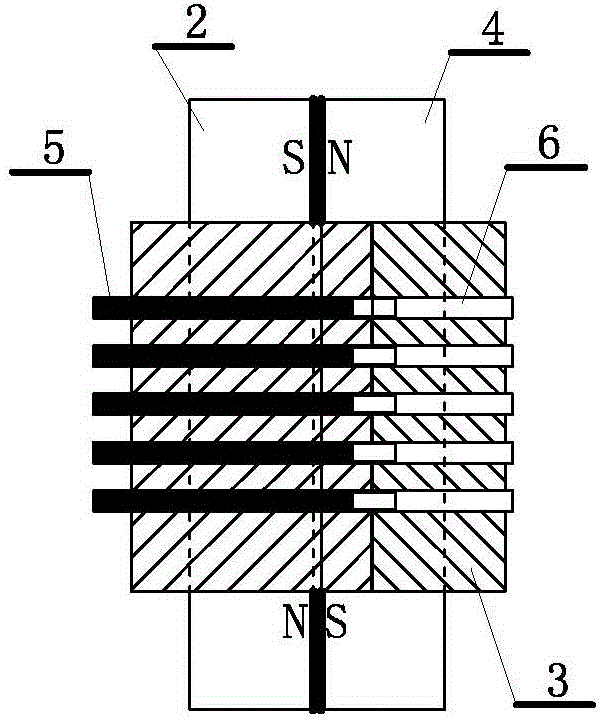

Charging communication interface with anti-static and fool-proof structure

ActiveCN106129713AEasy to plug inNot easy to misplaceEngagement/disengagement of coupling partsIncorrect coupling preventionCommunication interfaceMagnet

The invention discloses a charging communication interface with an anti-static and fool-proof structure. The charging communication interface comprises an interface socket and an interface plug, wherein the interface socket comprises a socket insulator and an annular socket magnet surrounding the socket insulator; the interface plug comprises a plug insulator and an annular plug magnet surrounding the plug insulator; according to the magnetism characteristic of same poles repelling to each other and opposite poles attracting to each other, S pole and N pole positions of the annular socket magnet on the horizontal end face are corresponding to the N pole and S pole attracting positions of the annular plug magnet, as the necessary condition for correct connection. The interface plug and the interface socket according to the invention both adopt magnets; when the directions are correct, the magnets are easily attracted; when the directions are opposite, the magnets repel to each other; the condition of reverse plugging or staggered plugging can be effectively prevented; the invention provides a double-suction type fool-proof anti-touch interface with simple technique and lower cost.

Owner:CONTEC MEDICAL SYST

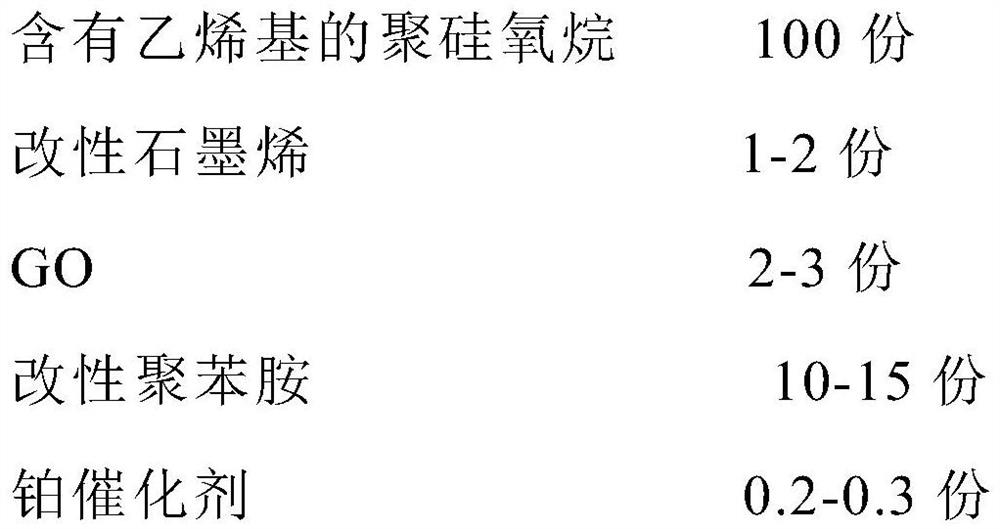

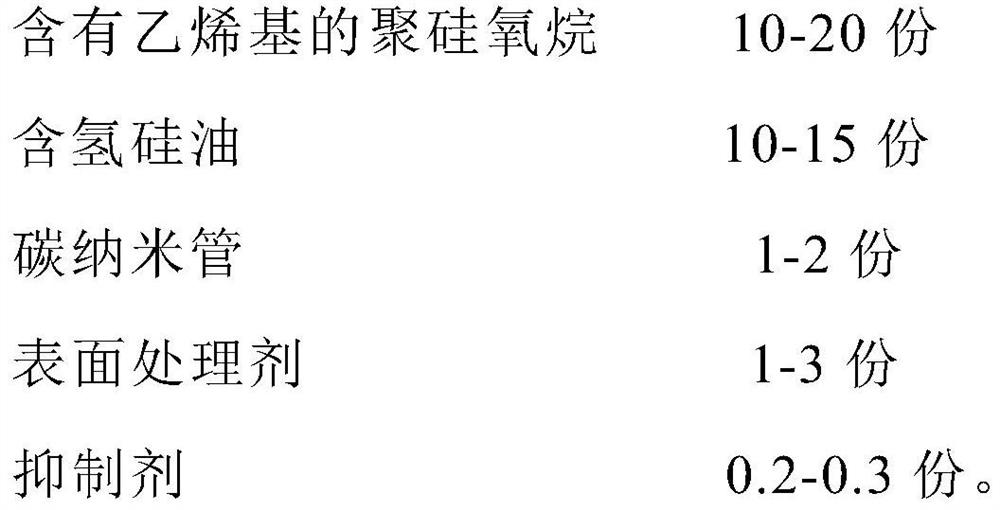

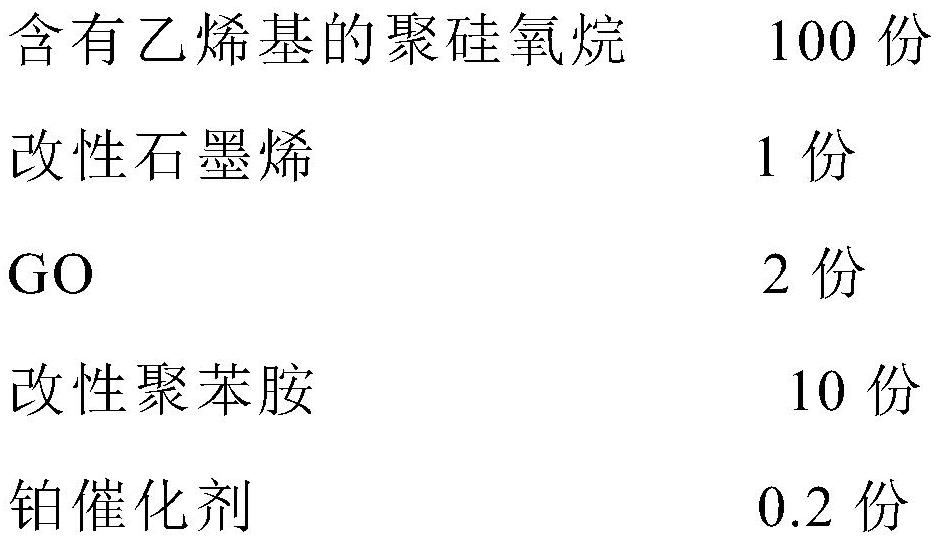

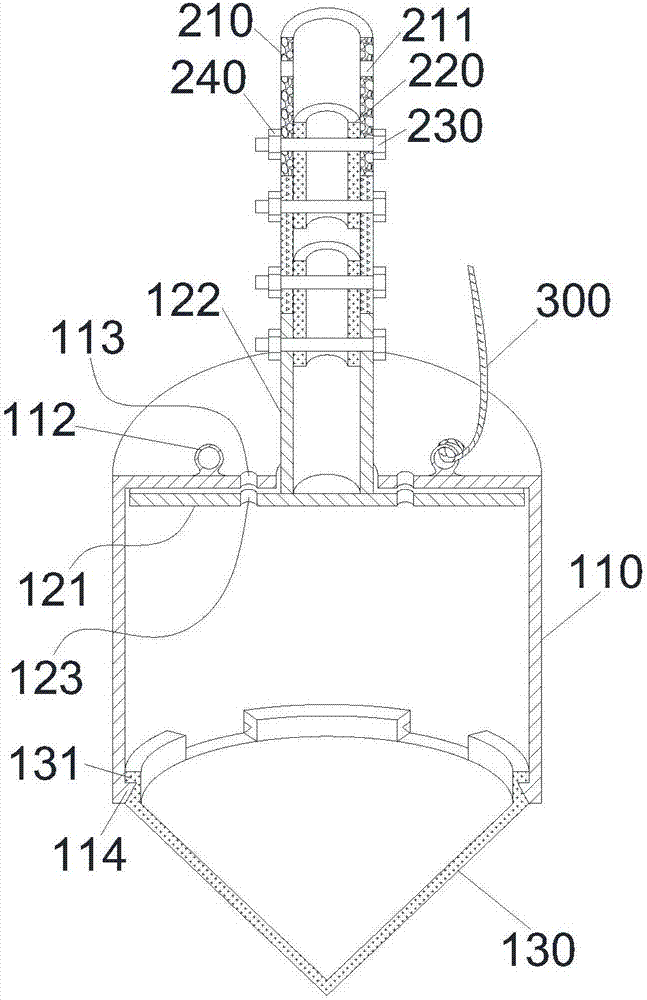

Liquid silicone rubber electromagnetic shielding material

InactiveCN112143236ANot easy to reverseGood linear shapeMagnetic/electric field screeningSilicone fluidChemistry

The invention relates to the field of electromagnetic shielding materials, in particular to a liquid silicone rubber electromagnetic shielding material. In order to add more graphene into the siliconerubber material system and further improve the electromagnetic shielding effect of the silicone rubber material, the invention provides a liquid silicone rubber electromagnetic shielding material, which is characterized in that polymerizable double bonds are introduced into partial graphene molecular structures to obtain modified graphene; the modified graphene can be chemically bonded with the hydrogen-containing silicone oil, and the other part of graphene is dispersed in the silicone rubber material system and cooperates with the carbon nanotubes and the modified polyaniline to form more conductive paths, thereby achieving the purpose of further improving the electromagnetic shielding effect of the silicone rubber material.

Owner:刘涛

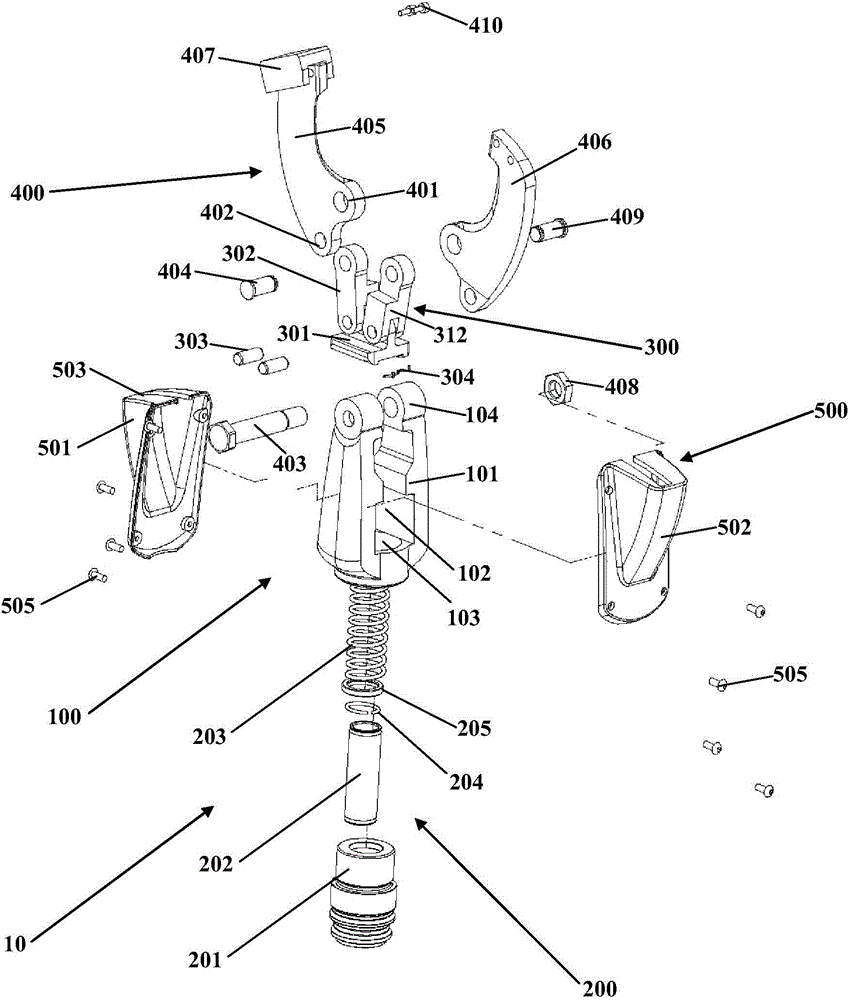

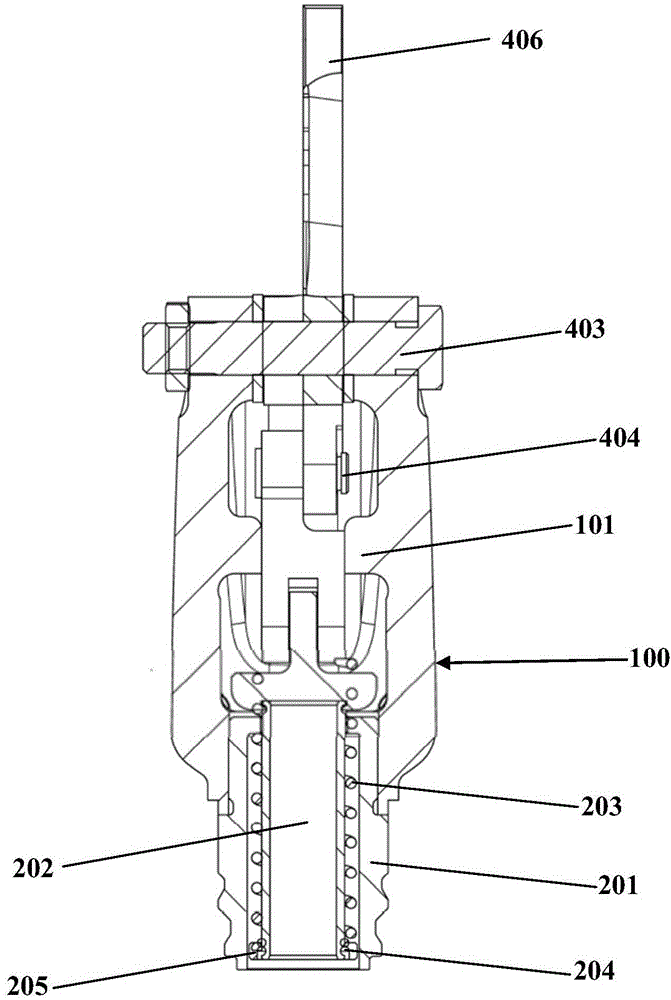

Earth pressure cell embedding device and earth pressure cell embedding method adopting device

The invention provides an earth pressure cell embedding device and an earth pressure cell embedding method adopting the device. The device comprises an embedded cylinder, an embedded rod assembly and a lifting rope. The embedded cylinder comprises an earth placing cylinder, a bulldozing mechanism and an earth supporting mechanism, the lower end of the earth placing cylinder is provided with an opening, a top wall through hole is formed in the center of the top wall of the earth placing cylinder, a lifting part is arranged on the outer side of the top wall of the earth placing cylinder, and a guide wire through hole is formed in the top wall of the earth placing cylinder; the bulldozing mechanism comprises a bulldozing plate and a bulldozing rod vertically arranged in the center of the bulldozing plate; the bulldozing mechanism is nested in the earth placing cylinder, the bulldozing plate is in clearance fit with the earth placing cylinder, and a lower guide wire through hole corresponding to the upper guide wire through hole is formed in the bulldozing plate; the bulldozing rod penetrates through and is in clearance fit with the top wall through hole, and the earth supporting mechanism is stuck at the opening edge of the lower end of the earth placing cylinder; and the embedded rod assembly is composed of a plurality of connecting rods capable of detachably fixing and connecting in series, the lower end of the embedded rod assembly is detachably and fixedly connected with the bulldozing rod, and the lower end of the lifting rope is connected with the lifting part. The earth pressure cell embedding device is ingenious in design; According to the earth pressure cell embedding method adopting the device, distortion of test results is avoided, and materials are saved.

Owner:WUHAN UNIV

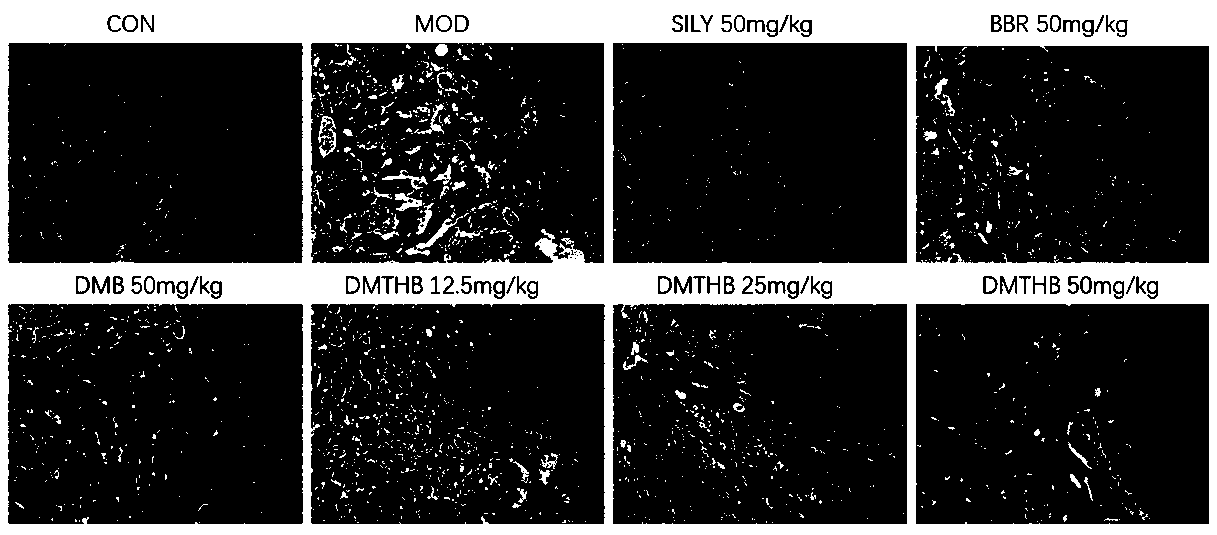

Application of demethylenetetrahydroberberine hydrochloride in preparation of medicine for preventing or treating liver injury

InactiveCN111012781AHigh damage success rateNot easy to reverseOrganic active ingredientsDigestive systemDiseaseHepatoprotective Drugs

The invention relates to the field of biological medicines, and concretely relates to application of demethylenetetrahydroberberine hydrochloride in the preparation of a medicine for preventing and / ortreating liver injury induced by thioacetamide. The demethylenetetrahydroberberine hydrochloride medicine has the advantages of good solubility, good medicine absorptivity and good anti-inflammatoryand antioxidant activity, and has a remarkable treatment effect on thioacetamide-induced acute mild and chronic liver injury; and compared with the traditional liver protection medicine, the demethylenetetrahydroberberine hydrochloride can achieve the treatment purpose under a low oral administration dosage, can improve the patient compliance, and achieves the treatment effect on diseases.

Owner:CHINA PHARM UNIV

Electric connector and assembling method thereof

ActiveCN110034430ANot easy to reverseFirmly assembledLine/current collector detailsPrinted circuit aspectsEngineeringElectrical and Electronics engineering

The invention discloses an electric connector and an assembling method thereof. The electric connector comprises a substrate and a plurality of first terminals, wherein the substrate is provided witha plurality of accommodating holes; each first terminal is provided with a first inserting part which is downwards inserted into the corresponding accommodating hole, a first material connecting partused for being connected with a first material belt, and a first welding part which is arranged outside the corresponding accommodating hole and is welded on the upper surface of the substrate; and the bottom of the first inserting part, the first material connecting part and the first welding part are arranged on the same plane, so that the first terminal is not twisted easily when being folded and inserted into the substrate, thereby enabling the first terminals to be assembled stably.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

Self-fixing stator housing

InactiveCN104271953AImprove rigidityActive connectionRotary piston pumpsRotary piston liquid enginesElastomerEngineering

Owner:NETZSCH PUMPEN & SYST

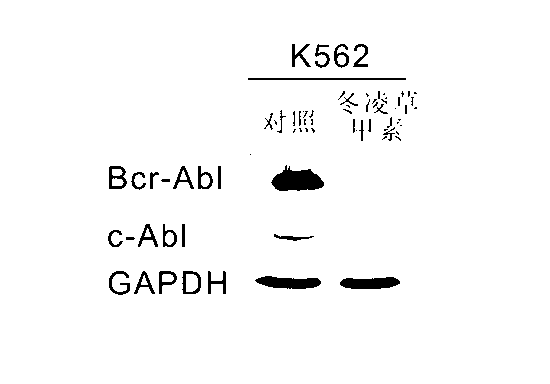

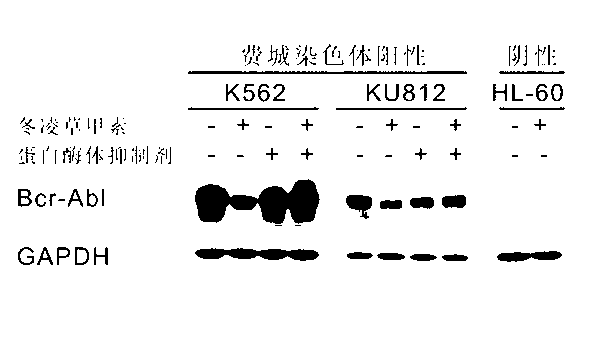

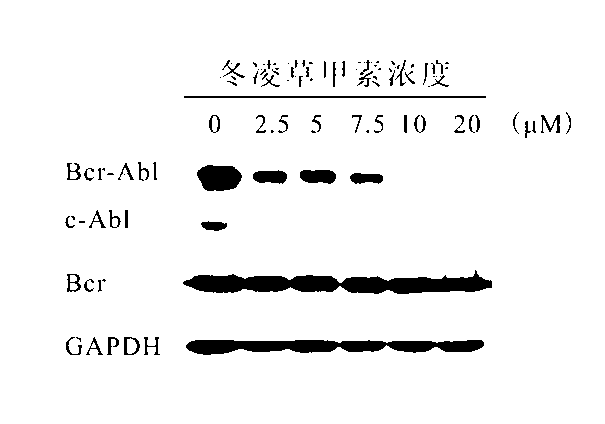

Target degradation Bcr-Abl protein reagent and application of target degradation Bcr-Abl protein reagent in preparing Philadelphia chromosome positive tumor treatment medicine

InactiveCN102895221AInhibits growth and induces apoptosisRapid responseOrganic active ingredientsAntineoplastic agentsPhiladelphia Chromosome PositiveTumor therapy

The invention discloses an oridonin which can be used for treating Philadelphia chromosome positive tumor through degradation of Bcr-Abl fusion protein and relates to an application of the oridonin in preparing a Philadelphia chromosome positive tumor treatment medicine. A large number of studies show that the oridonin is capable of activating Bcr-Abl specific ubiquitination degradation ways and rapidly and efficiently degrading Bcr-Abl oncoprotein, and thereby Philadelphia chromosome positive tumor cells are subjected to remarkable growth inhibition and irreversible cell apoptosis. In a mouse body, the oridonin also can degrade the Bcr-Abl protein and remarkably inhibit growth of the Philadelphia chromosome positive tumor. The oridonin is mainly derived from rabdosia rubescens which is a traditional Chinese medicine and the oridonin has slight toxic effect on human body and is easy to prepare and high in applicability. Besides, the action mechanism of the oridonin is completely different from STI-571 (gleevec) which is a first-line medicine used for leukemia clinical treatment presently, and thereby the oridonin can be used as a potential medicine for treating STI-571 tolerant Philadelphia chromosome positive tumor.

Owner:SUN YAT SEN UNIV

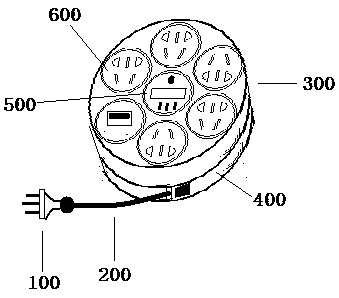

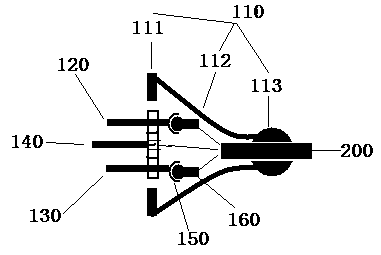

Disc-type extension socket

InactiveCN108963682AAvoid breakingAdjust the length of useTwo-part coupling devicesFlexible lead accommodationElectric power equipmentEngineering

The invention discloses a disc-type extension socket and belongs to the electric power equipment technology field. The extension socket comprises a plug, a power supply line, a box body, a coiling unit, a timing unit and a socket unit. A three-pin plug on the extension socket can be used for a three-hole power socket and can be also used for a two-hole power socket. A power line is in a flat and arc shape and is easy to wind so that a space is saved, and the power line can only be wound unidirectionally so that the power line is not easy to twist. The coiling unit is arranged, can automatically gather a power line and can adjust the usage length of the power line according to an actual condition. The timing unit is arranged to effectively prevent an overcharge accident and can be used to set power utilization in a low price time period. The sockets are rotatably connected to a box body. Socket directions can be arbitrarily adjusted. The sockets comprise a timing socket, a untimed socket and a USB interface socket and a plurality of different demands can be satisfied. The structure is reasonable and compact, the size is small, an appearance is beautiful, there are many functions, practicality is good and safety is high.

Owner:魏长同

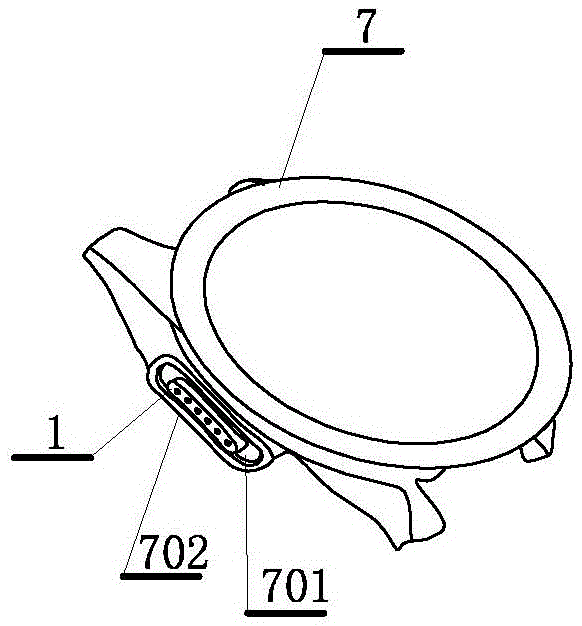

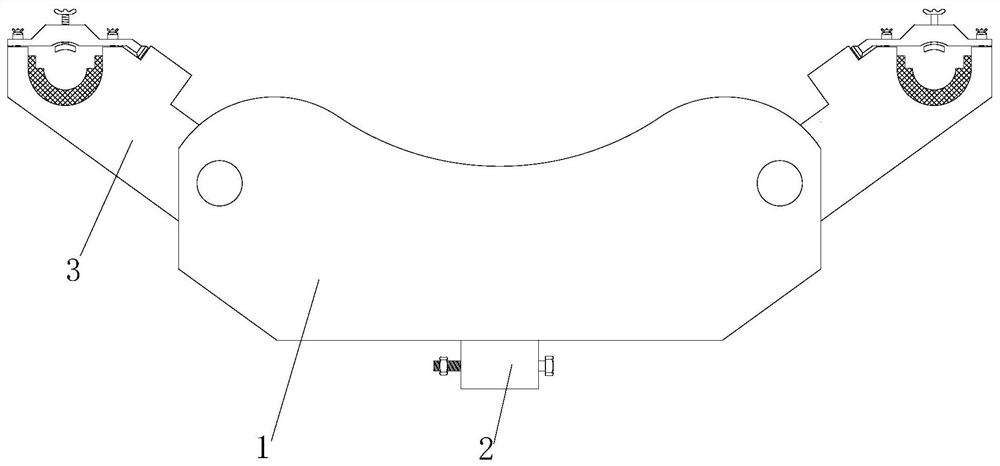

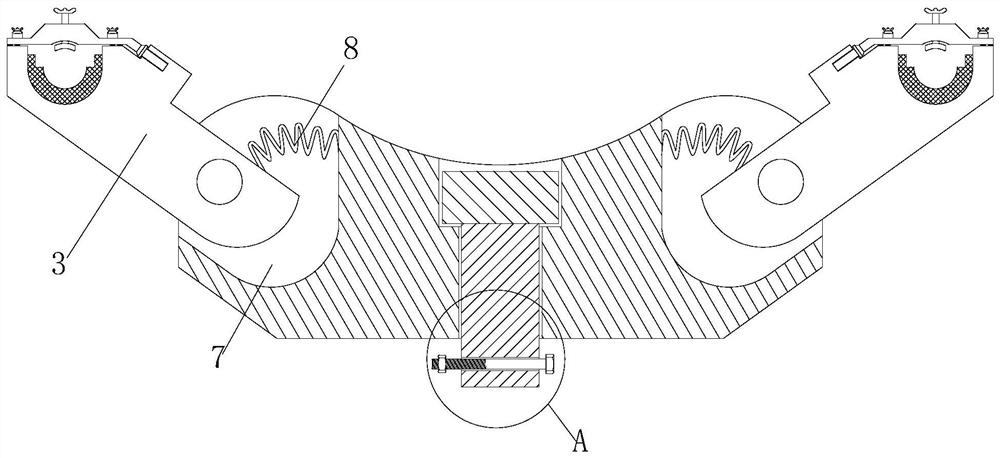

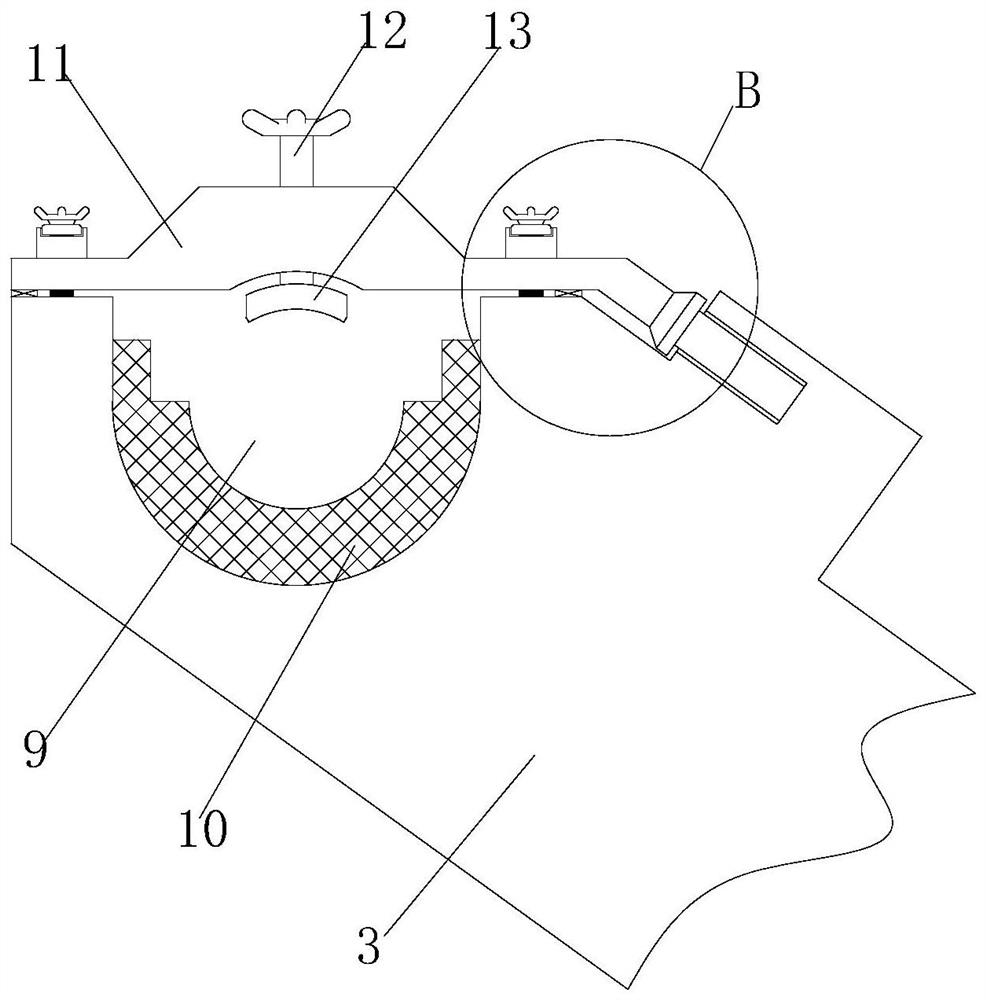

Anti-torsion rotary spacer

ActiveCN112398074AEasy to installEasy to useMaintaining distance between parallel conductorsElectrical and Electronics engineeringGravity center

The invention discloses an anti-torsion rotary spacer. The spacer comprises a body, wire clamps are installed at the two ends of the body, a balancing weight is installed in the middle of the body, movable cavities are formed in the two ends of the body, one ends of the two wire clamps extend into the movable cavities, and compression springs are installed at the tops of the ends, close to the movable cavities, of the two wire clamps. The other ends of the compression springs are fixedly connected with the inner walls of the movable cavities, one end of each wire clamp is provided with a wiregroove, and the bottom of the inner wall of each wire groove is fixedly connected with an insulating cushion block. The balancing weight is arranged in the middle of the body, so that when the body isused, the gravity center can be kept at the position close to the lower portion of the middle, the compression springs are installed at one ends of the two wire clamps, the wire clamps can be kept atthe fixed positions all the time, and therefore the device is not prone to torsion.

Owner:GUIZHOU POWER GRID CO LTD

Numerical control jig saw

The invention relates to a numerical control jig saw. A sawing structure of the numerical control jig saw is arranged on a rack through a slide bar component. The slide bar component comprises a horizontal slide bar as well as a vertical slide bar, so that horizontal or vertical movement of the sawing structure can be controlled by means of pushing sliders matching with the slide bars. In the sawing structure, due to the fact that a drive box and a steering box are arranged separately, setting can be performed by mutual matching of the drive box and the steering box, and a blade can reach the preset position accurately. By controlling coordination of the slide bar component, the drive box and the steering box, curve cutting can be finished accurately.

Owner:SICHUAN HENGXIN YOUBANG FURNITURE CO LTD

Sealing structure capable of adjusting sealing degree

PendingCN110092074AAdjustable sealing degreeFit tightlyClosuresClosure using stoppersEngineeringAtmospheric pressure

Owner:SICHUAN AEROSPACE SYST ENG INST

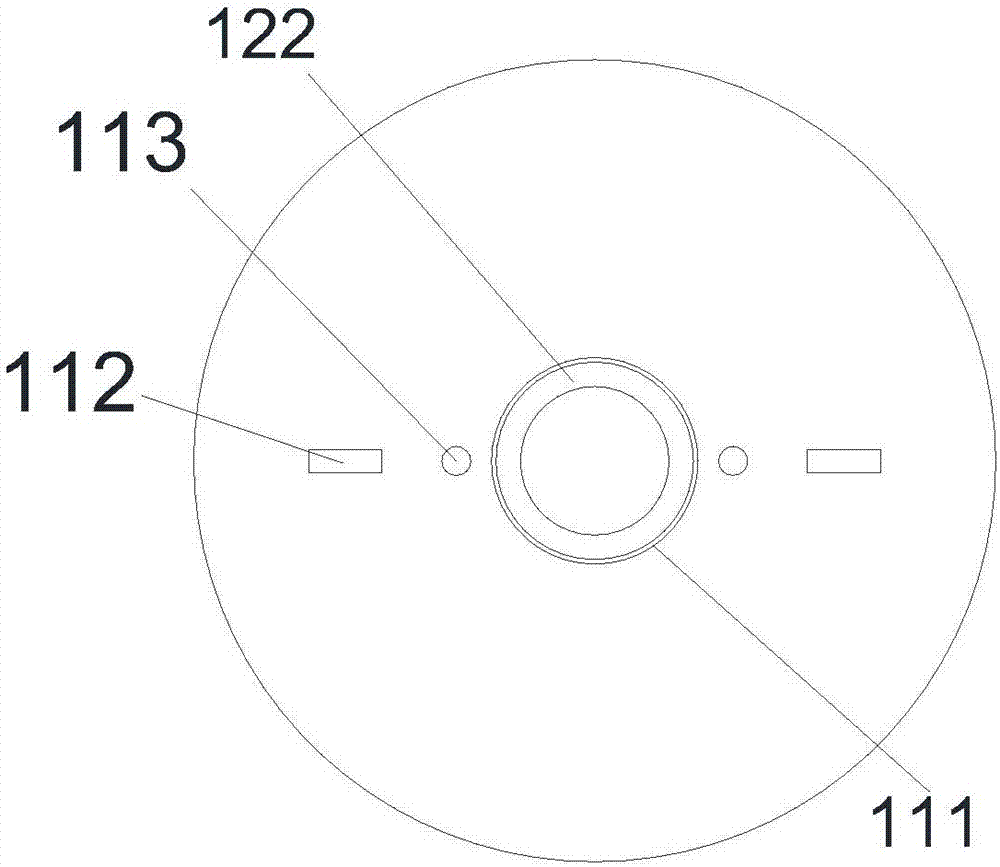

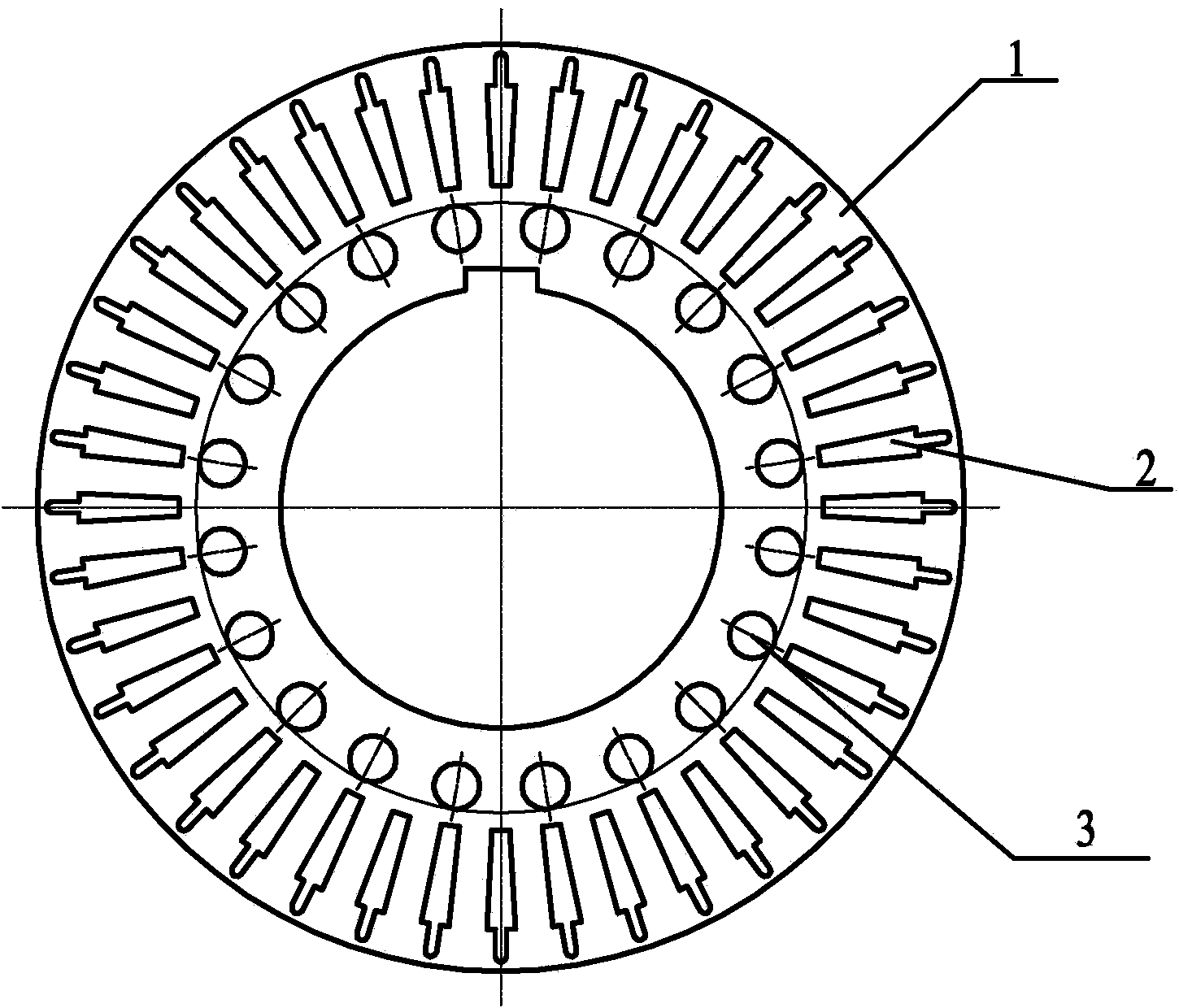

Baffle structure for cast aluminum rotor of high-voltage motor

InactiveCN103532276AMeet ventilation requirementsImprove reliabilityMagnetic circuit rotating partsHigh pressureMaterials science

The invention belongs to the technical field of assembly of cast aluminum rotors for high-voltage motors, and relates to a baffle structure, in particular to a baffle structure for a cast aluminum rotor of a high-voltage motor. The baffle structure for the cast aluminum rotor of the high-voltage motor adopts the technical scheme that a baffle comprises a baffle body; a mounting hole is formed in a central area of the baffle body; the hole diameter of the mounting hole is the same as the inside diameter of a rotor sheet body; and the baffle body on the outer side of the mounting hole can block off air holes in the rotor sheet body. The baffle structure is simple and compact in structure, low in cost, simple to process and manufacture, convenient to operate, and wide in application scope; omission or reverse placement is not easy; and the working reliability of the motor can be improved.

Owner:WUXI ZHONGDA MOTORS

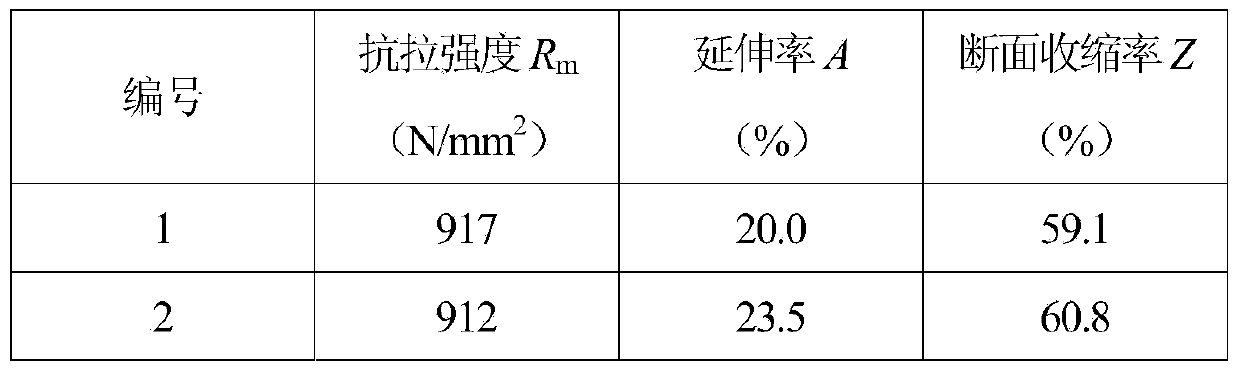

Preparation method of special-shaped section wire titanium alloy spring

The invention relates to a preparation method of a titanium alloy spring made of a wire with a specially-shaped section and belongs to the technical field of springs. The spring is formed by winding of the titanium alloy wire with the specially-shaped section; the titanium alloy wire comprises the components in percentage by mass as follows: 2-4 of Al, 6-10 of V, 4-8 of Cr, 2-6 of Mo, 2-6 of Zr, 0.1-0.3 of Fe, 0.03-0.15 of Si and the balance of Ti. The section of the titanium alloy spring wire can be rectangular, square, orthohexagonal or oval. The titanium alloy wire wound into the spring is prepared with forging, pressing and hot rolling technologies, the wire is subjected to solution treatment before being wound into the spring, and a finished product of the spring is subjected to aging and strengthening treatment. A titanium alloy which is used for preparing the spring can play a weight reduction role, and meanwhile, the titanium alloy has the good corrosion resistance and the long fatigue life in an ocean environment. With the adoption of the wire with the specially-shaped section, the section area can be increased under the condition that specifications of wires are similar, so that the rigidity of the spring is improved, and the usage requirement of the titanium alloy spring under the high workload can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

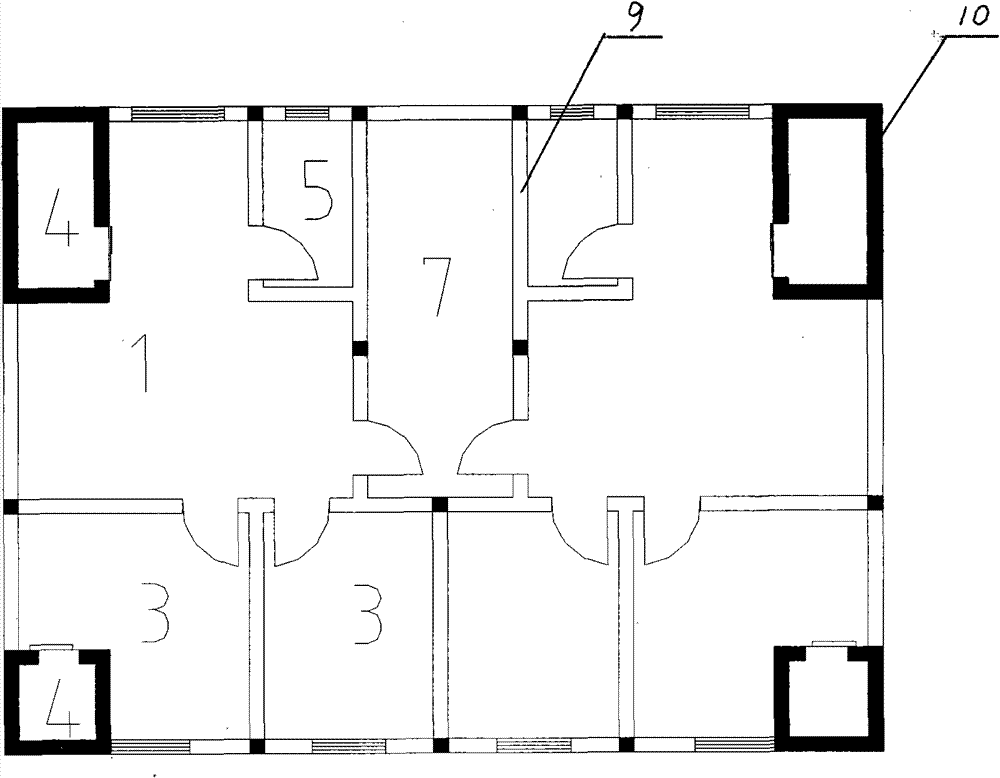

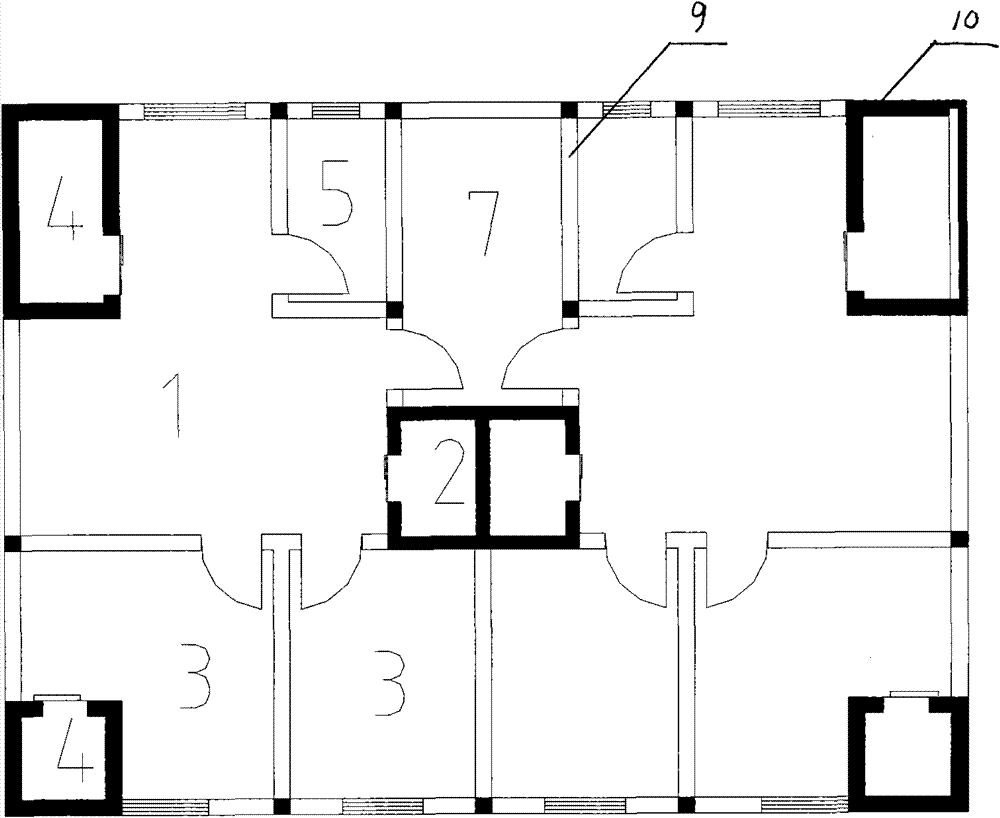

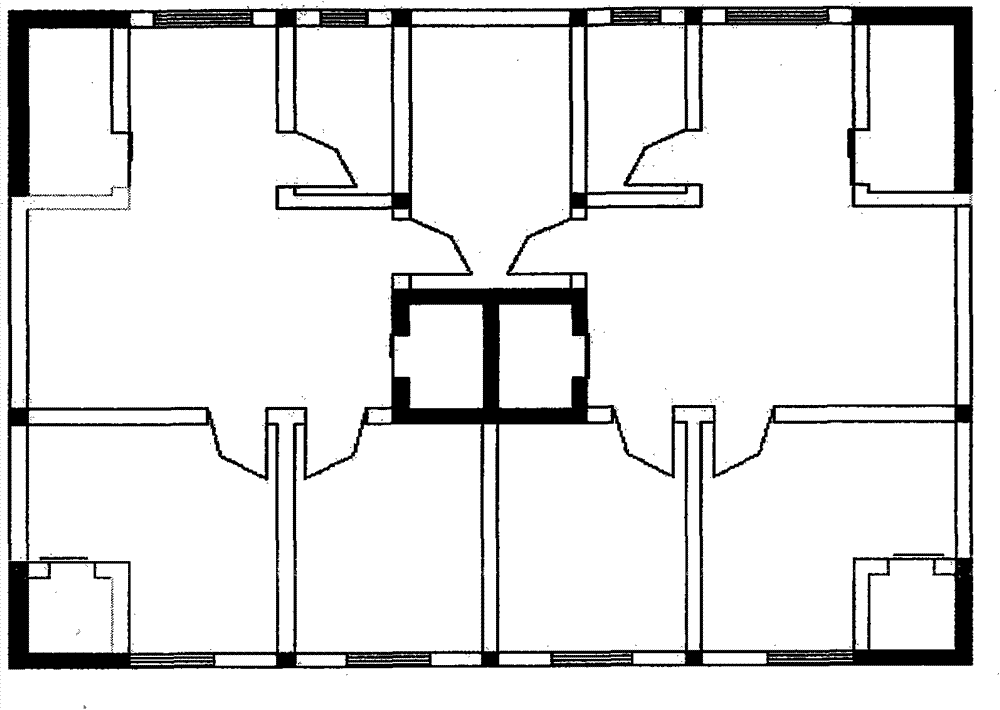

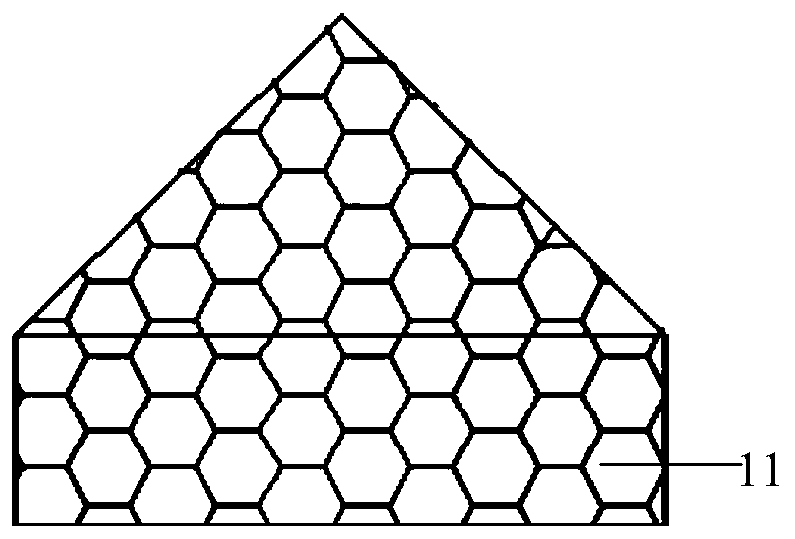

Quakeproof civil residential building

The invention provides a quakeproof civil residential building, which has a multi-floor structure. Each floor has a plurality of use units enclosed by wall bodies and floors and has a ring beam and constructional columns respectively; each wall body of each use unit comprises two parts, namely masonry walls and reinforced concrete shear walls; each reinforced concrete shear wall has the followingtwo structures: (1) a barrel enclosed by walls on the four sides, and (2) an L-shaped two-side structure; and the reinforced concrete shear walls are distributed at the four corners of a user unit, so that the rigidity and mass of the building are distributed equally. In the invention, the reinforced concrete shear wall barrel strengthens the integrity and anti-titling performance of a house. Thebuilding in the invention has high quakeproof performance and high cost performance, is practical and feasible in operation and can be directly used in actual projects. Even when the building is collapsed, the barrel is not collapsed, so that shelters can be provided for people and casualty loss is reduced.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Solder strip and solder strip production method

PendingCN111276558ANot easy to reverseImprove conversion efficiencyPhotovoltaic energy generationSemiconductor devicesPhysicsMechanical engineering

The invention provides a solder strip and a solder strip production method, and relates to the technical field of solar photovoltaics. The solder strip includes a substrate; the outer surface of the substrate comprises at least one inner concave surface. In the present application, in a process that the solder layer fills the outer surface of the substrate, due to the tension effect, the welding flux can fill and level up the inner concave face of the outer surface of the substrate well, the outer surface of the welding strip is smooth, and compared with a welding strip with the outer surfacebeing in an outer circle convex shape, the outer surface of the welding strip is smooth, the light reflection effect can be improved possibly, and the conversion efficiency and the power of the photovoltaic module are improved. Meanwhile, the solder strip is not easy to reverse, the effective welding distance between the solder strip and the battery piece is increased, the welding reliability is improved, and the conversion efficiency and the power of the photovoltaic module are further improved.

Owner:TAIZHOU LERRISOLAR TECH CO LTD

Flexible screen pipe with automatic reset function

ActiveCN114876419ANot easy to reverseSmall running resistanceFluid removalControl theoryMechanical engineering

The invention discloses a flexible screen pipe with an automatic reset function, which relates to the technical field of flexible screen pipes and specifically comprises at least two screen pipes, a reset element and a fixing device, the two ends of each screen pipe are provided with at most two ball heads, namely one end of at least one screen pipe in the two connected screen pipes is provided with a ball head. The two ends of the reset element are connected with the interiors of the two screen pipes correspondingly, reset force is provided for the screen pipes, and the axes of the screen pipes are kept consistent. The fixing device connects the end, provided with the ball head, of one screen pipe with any end of the other screen pipe. Through the arrangement of the reset element, after the flexible screen pipe enters the horizontal section, the axes of all the screen pipes are kept consistent under the action of the reset element, torsion is not likely to happen, the operation resistance is reduced, and the extension length is increased.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Sliding friction pendulum combined shock-isolation layer with super large bottom surface

ActiveCN106400972BLarge spanMeet the needs of horizontal deformationProtective buildings/sheltersShock proofingInsulation layerIsolation layer

The invention discloses a sliding-friction pendulum combined shock-insulation layer with an ultra-large bottom surface. The combined shock-insulation layer comprises an upper spherical shell layer, a lower spherical shell layer and sliding frames. Four arc-shaped spherical faces are arranged on the upper surfaces of the lower spherical shell layer. Four arc-shaped spherical faces are arranged on the lower surface of the upper spherical shell layer. Each sliding frame is composed of a plurality of sliding blocks, upper connecting components, lower connecting components, connecting beams and sliding frame columns, wherein the sliding frame columns are connected between the upper connecting components and the lower connecting components, and the lateral portions of the upper connecting components and the lateral portions of the lower connecting components are connected with the connecting beams. The upper end surfaces of the upper connecting components and the lower end surfaces of the lower connecting components are welded to the sliding blocks. The sliding frames are in overlap joint with the arc-shaped spherical faces of the upper spherical shell layer and the arc-shaped spherical faces of the lower spherical shell layer through the sliding blocks. According to the sliding-friction pendulum combined shock-insulation layer with the ultra-large bottom surface, the sliding frames are formed through connection of the sliding blocks, and the integral shock-insulation layer is formed by the sliding frames, the upper spherical shell layer and the lower spherical shell layer; and the span of the shock-insulation layer is quite large, the allowable deformation, in the horizontal direction, of the shock-insulation layer is far larger than that of a shock-insulation support, and the requirement for horizontal deformation of the shock-insulation layer under an extremely-powerful earthquake can be completely met.

Owner:HARBIN INST OF TECH

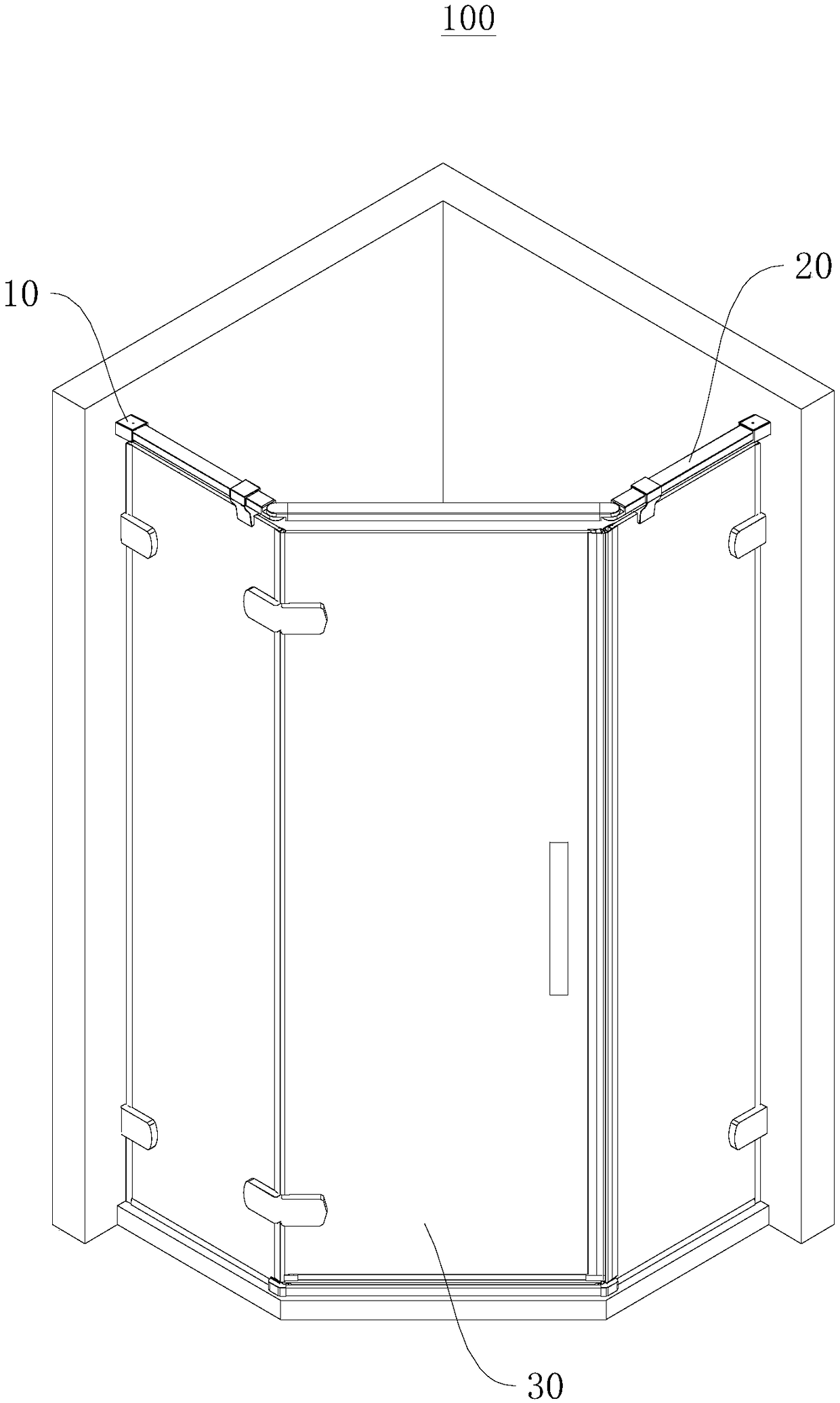

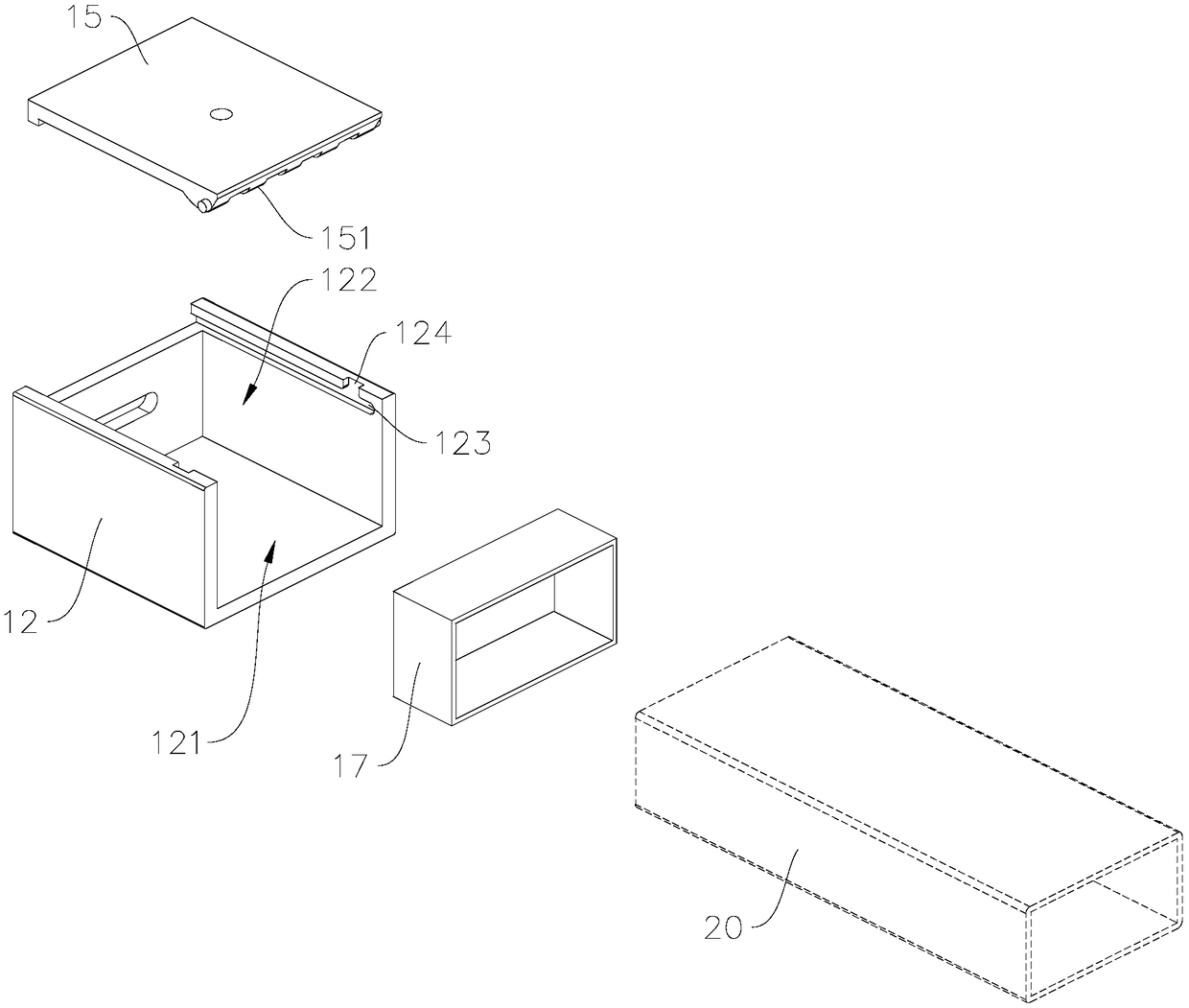

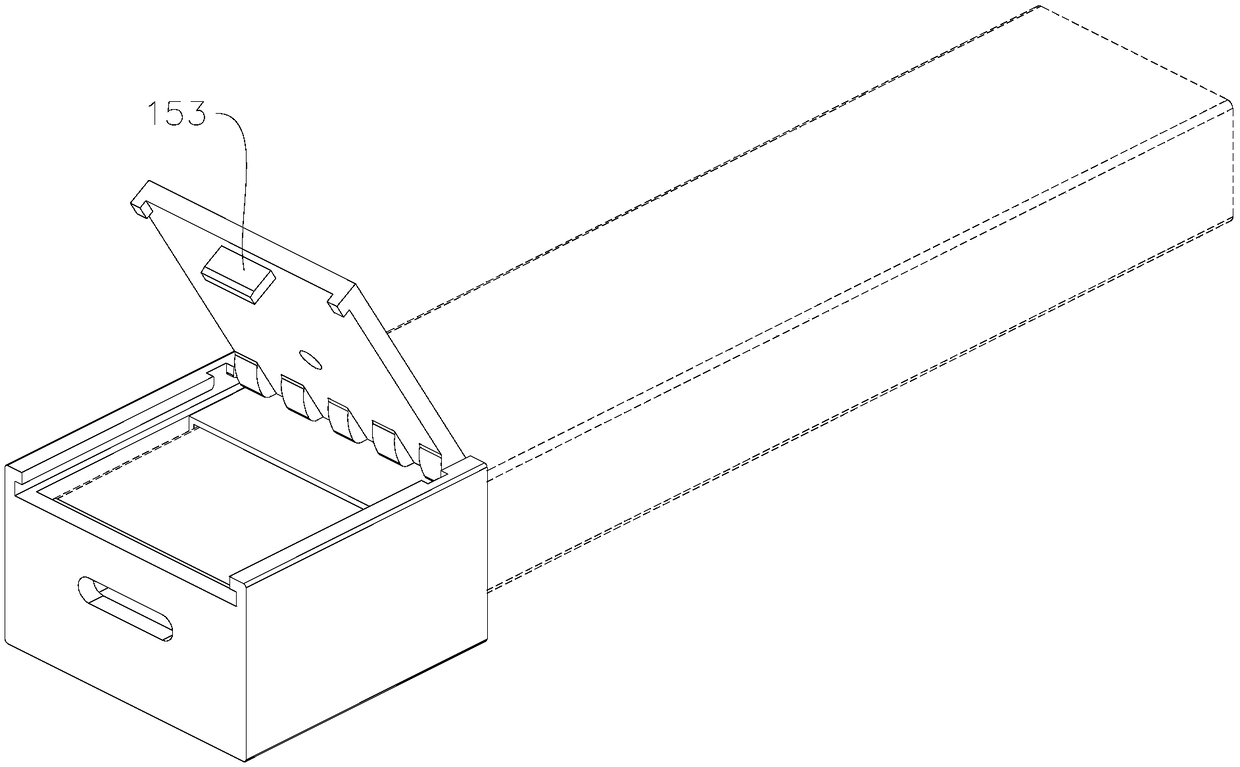

Shower room fixedly connecting structure and shower room partition

The invention discloses a shower room fixedly connecting structure and a shower room partition, and relates to the technical field of pull rod fixing. The shower room fixedly connecting structure comprises a connecting seat and a connecting pressing plate; the connecting seat is used for connecting with the wall surface; the connecting pressing plate is convexly provided with a pressing part, is connected with the connecting seat and can enclose an accommodating opening with the connecting seat; the connecting pressing plate can also rotate relative to the connecting seat so as to abut againstthe connecting seat and drive the pressing part to turn to the accommodating opening; in the process that the pressing part turns to a critical point, the pressing part can gradually increase the acting force applied to the pull rod, after the pressing part crosses the critical point, the connecting pressing plate can be abutted against the connecting seat, and the pressing part can reduce the acting force applied to the pull rod so as to keep the state that the connecting pressing plate abuts against the connecting seat and clamp the pull rod together with the connecting seat. The shower room fixedly connecting structure and the shower room partition are fast installation, and does not easily leave traces on the pull rod during adjusting and does not easily generate abnormal sound.

Owner:GUANGZHOU OUPAI SHOWER EQUIP

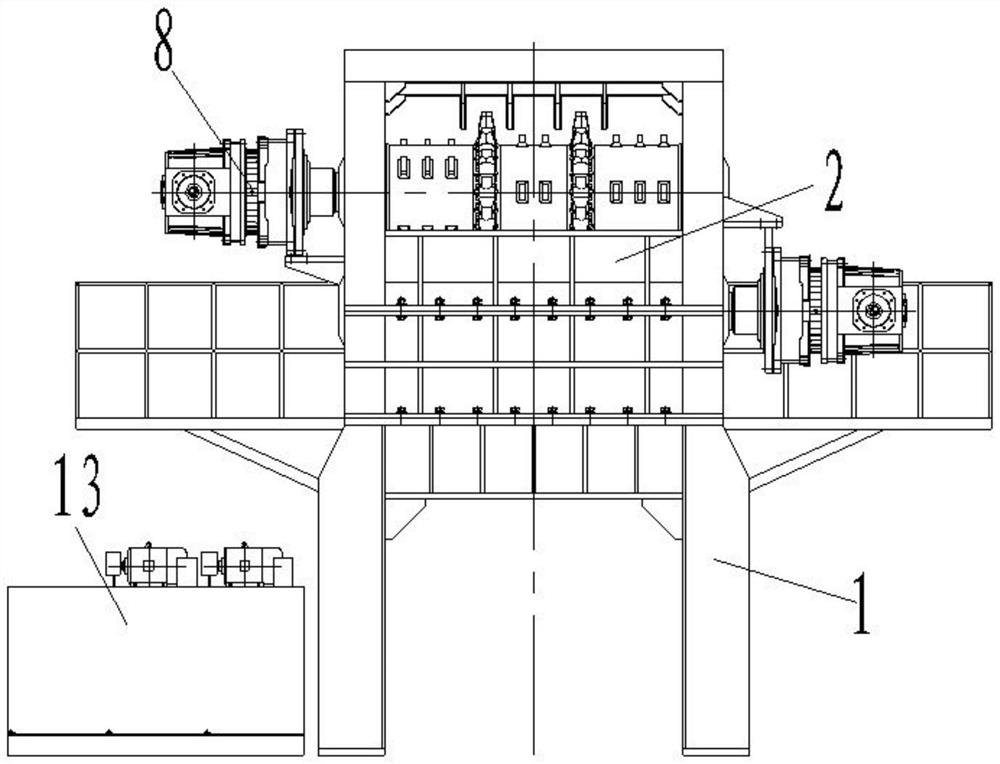

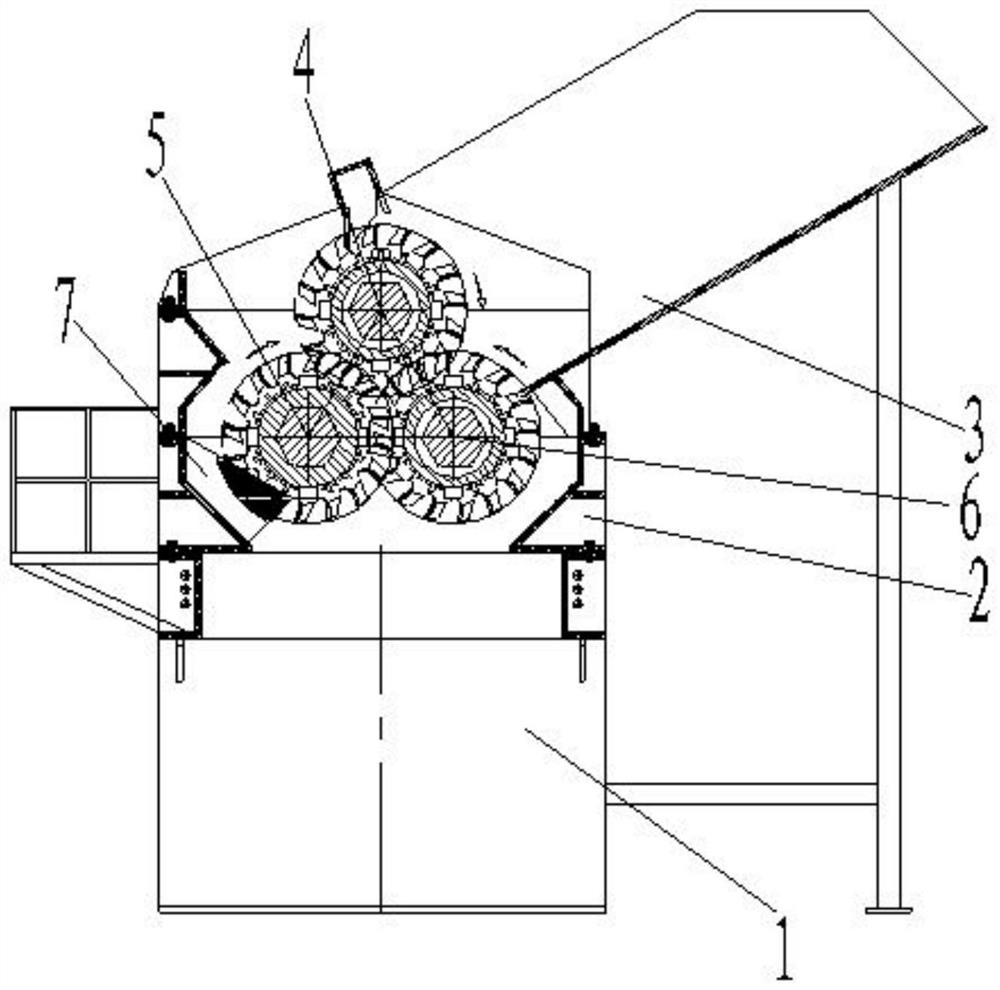

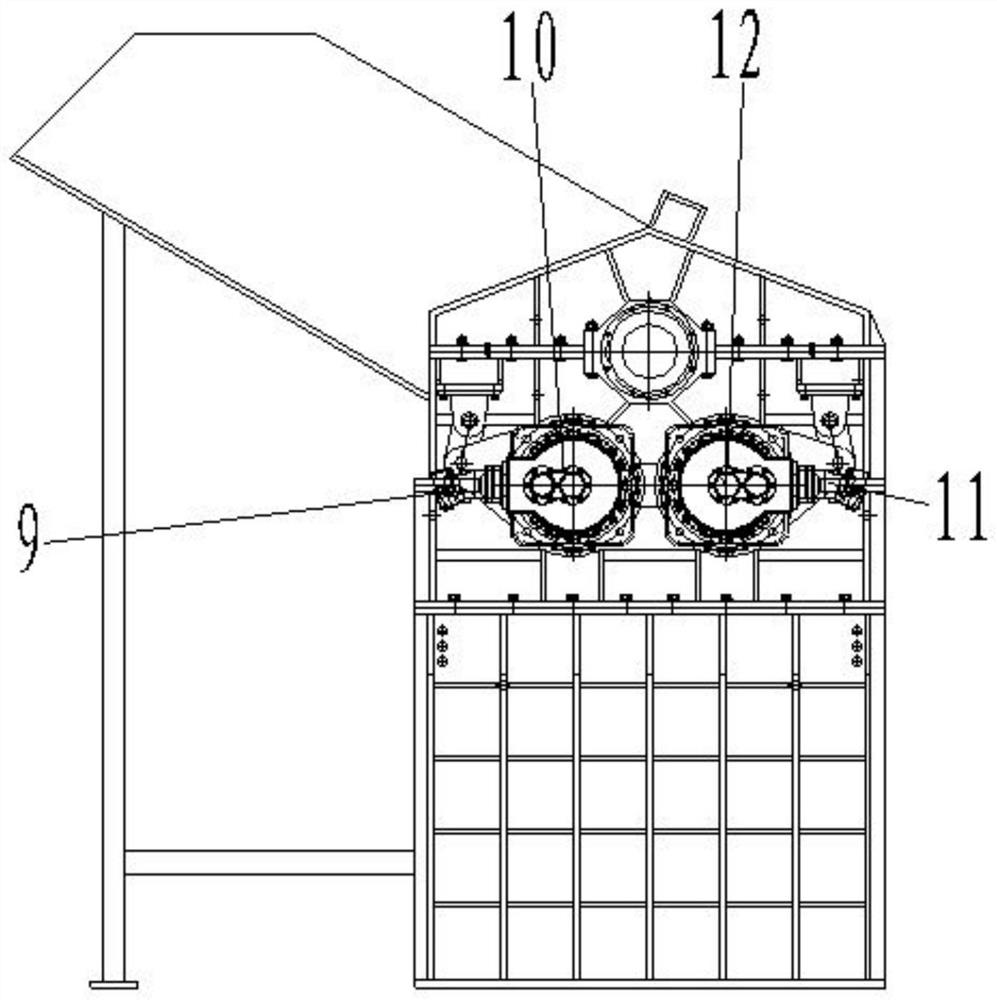

Three-shaft shredding machine

PendingCN113333126AImprove shredding efficiencyLow costGrain treatmentsStructural engineeringMachine

The invention discloses a three-shaft shredding machine which comprises a box body, a first cutter shaft, a second cutter shaft and a third cutter shaft; a shredding cavity is formed in the box body, and a feeding opening communicating with the shredding cavity is formed in the top of the box body; the first cutter shaft is rotatably arranged in the shredding cavity of the box body around a first axis, and a first blade is arranged on the first cutter shaft; the second cutter shaft and the third cutter shaft are rotatably arranged in the shredding cavity of the box body around a second axis and a third axis correspondingly, the second axis and the third axis are located below the two sides of the first axis respectively, the second axis and the third axis are parallel to the first axis respectively, and a second blade and a third blade are arranged on the second cutter shaft and the third cutter shaft correspondingly; and the second blade and the third blade are respectively staggered and matched with the first blade, and the second blade and the third blade are mutually staggered and matched with each other. According to the three-shaft shredding machine, materials are shredded three times after entering the shredding cavity from the feeding opening, and therefore the shredding efficiency is higher compared with other three-shaft shredding machines.

Owner:昆山格锐精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com