Self-fixing stator housing

一种定子、弹性体定子的技术,应用在旋转活塞式泵、旋转活塞式机械、机器/发动机等方向,能够解决适用性不尽人意等问题,达到减轻重量、改善联接、节省材料的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

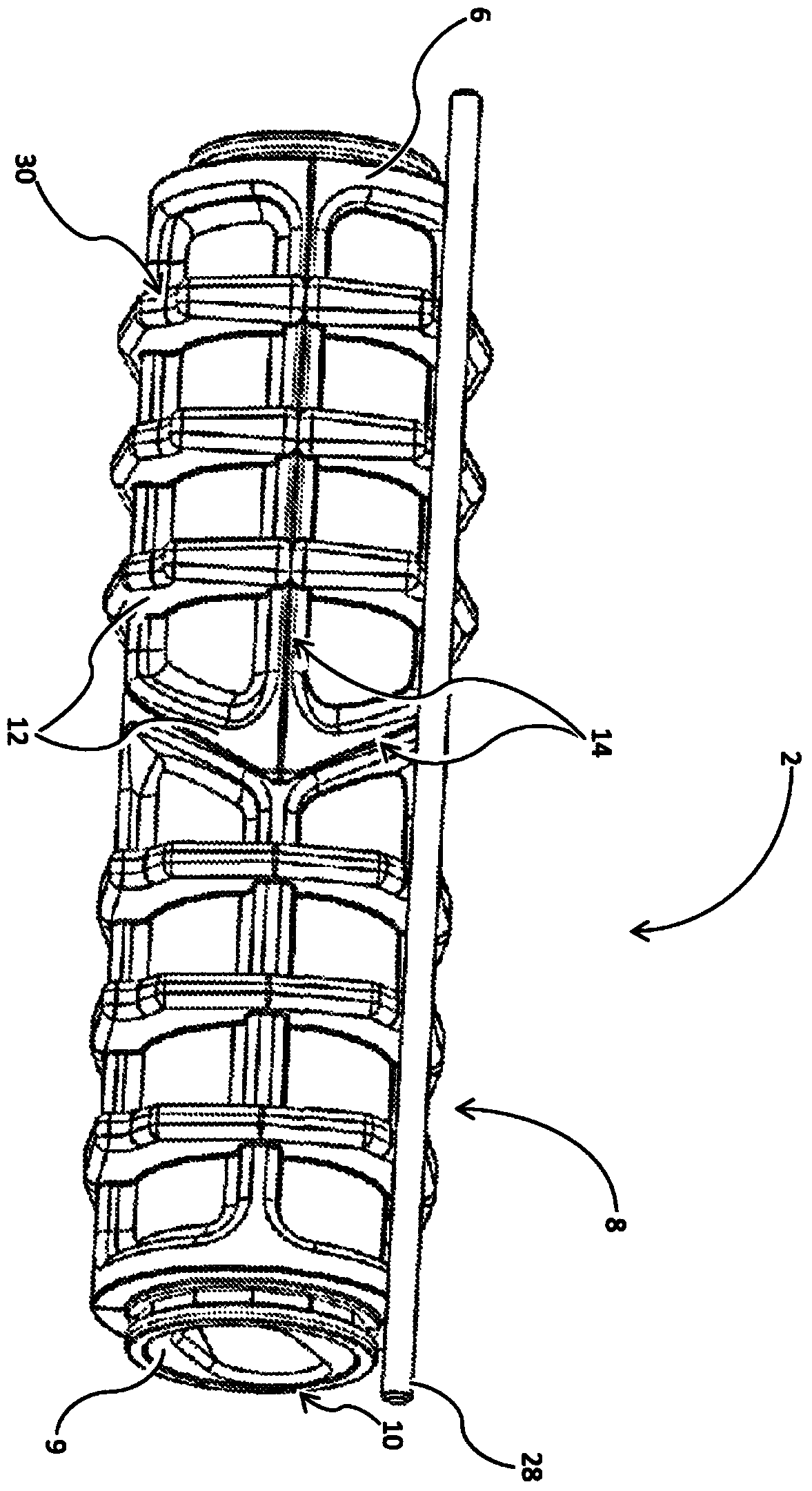

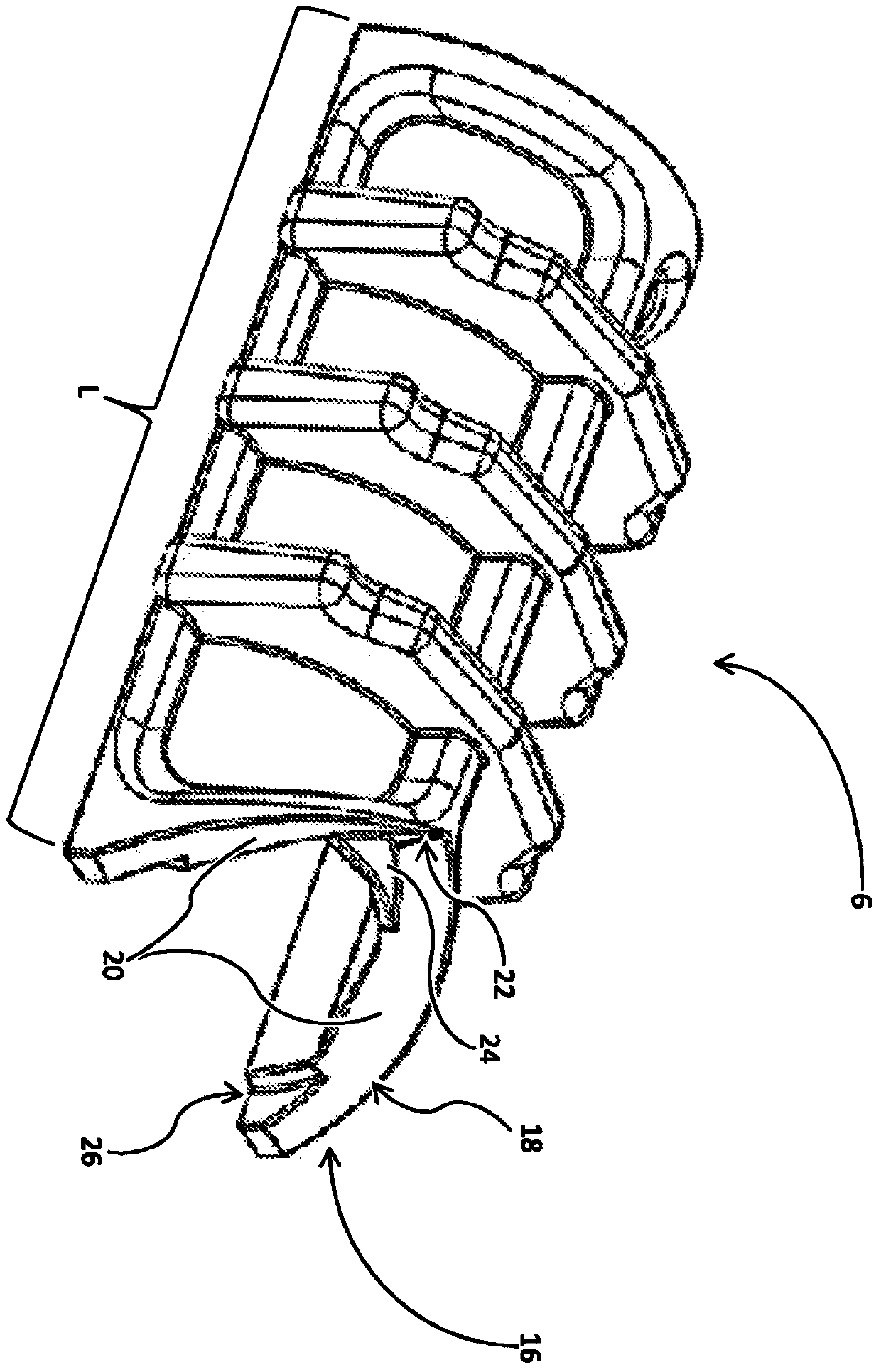

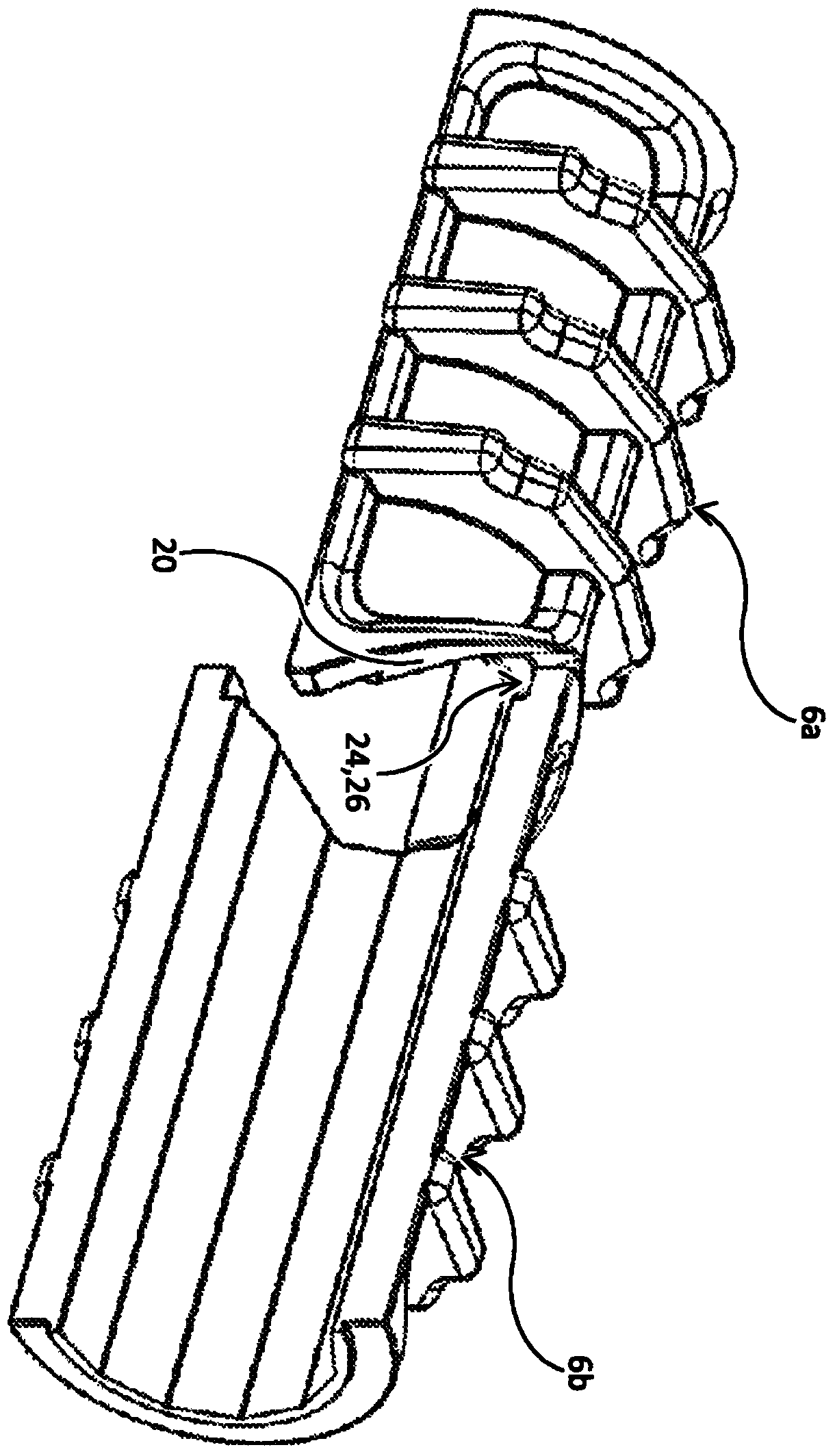

[0038] figure 1 The stator ( 2 ) of an eccentric screw pump ( 4 ) is shown, which is surrounded on its circumference by shell-shaped housing sections ( 6 ) of equal size, which form the stator housing ( 8 ). According to the embodiment of the invention, the housing segments ( 6 ) are arranged on the outer side of the elastomer stator inner part ( 9 ). The stator inner part consists of a gel-like material with elastic properties, while the stator outer cover (8) is made of metallic material. The end face of the elastomer stator inner part (9) has a projection in the form of a flange (10), to which the stator housing (8) is connected on the end face, wherein the stator housing (8) is axially Retained between the flanges (10) and preloaded due to the elastic nature of the stator inner (9).

[0039] The stator housing (8) is also provided with a structural element (12) extending radially from its outer side, which surrounds the stator housing (8) in the form of ribs or webs. Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com