Patents

Literature

39results about How to "Composite structure is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED high heat conduction ceramic copper coating heat radiation circuit board

InactiveCN101483217AFast heat conductionStrong conductivityPrinted circuit manufactureCooling/ventilation/heating modificationsCopper foilMagnesium

The invention discloses a Light-Emitting Diode (LED) high heat conduction ceramic bonding copper heat dissipation circuit board characterized in that a copper foil is compounded on both sides of a ceramic chip, a copper-aluminum spinelle eutectic interface is between the copper foil and the ceramic substrate; a circuit formed by two faces of copper foils of the ceramic substrate are interconnected and guided through a sintered via hole. The invention employs the process principle that the low temperature thermal oxidized copper foil and the ceramic can form the eutectic interface. At 1060 DEG C-1080 DEG C, the copper and an oxide film form a trace amount of copper-cuprous oxide eutectic liquid phase. The eutectic liquid phase and aluminum, magnesium, zirconium and oxygen elements in the ceramic form the copper-aluminum spinelle eutectic interface and the copper foil and the ceramic substrate form a firm compound structure. The invention has excellent performance of high heat conduction, strong conduction ability, high adhesive force and low interconnection via hole resistance, and obviously improves the operation life and reliability by applying to the LED chip package.

Owner:宋立峰

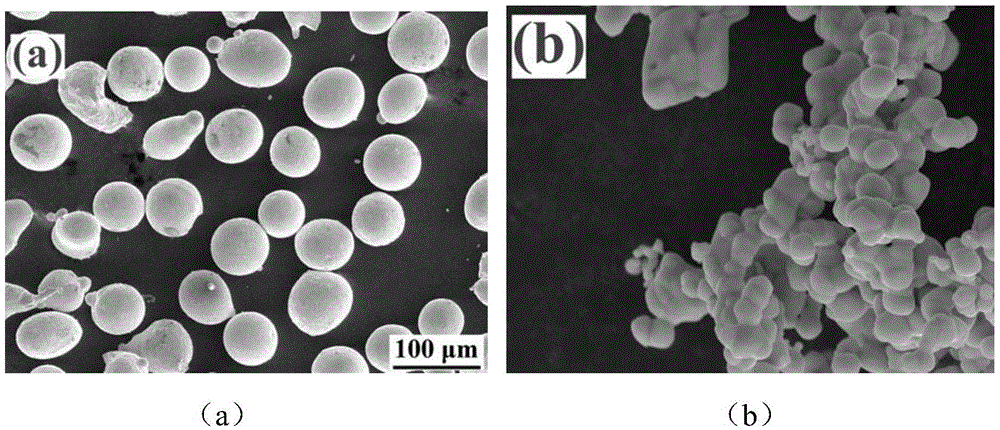

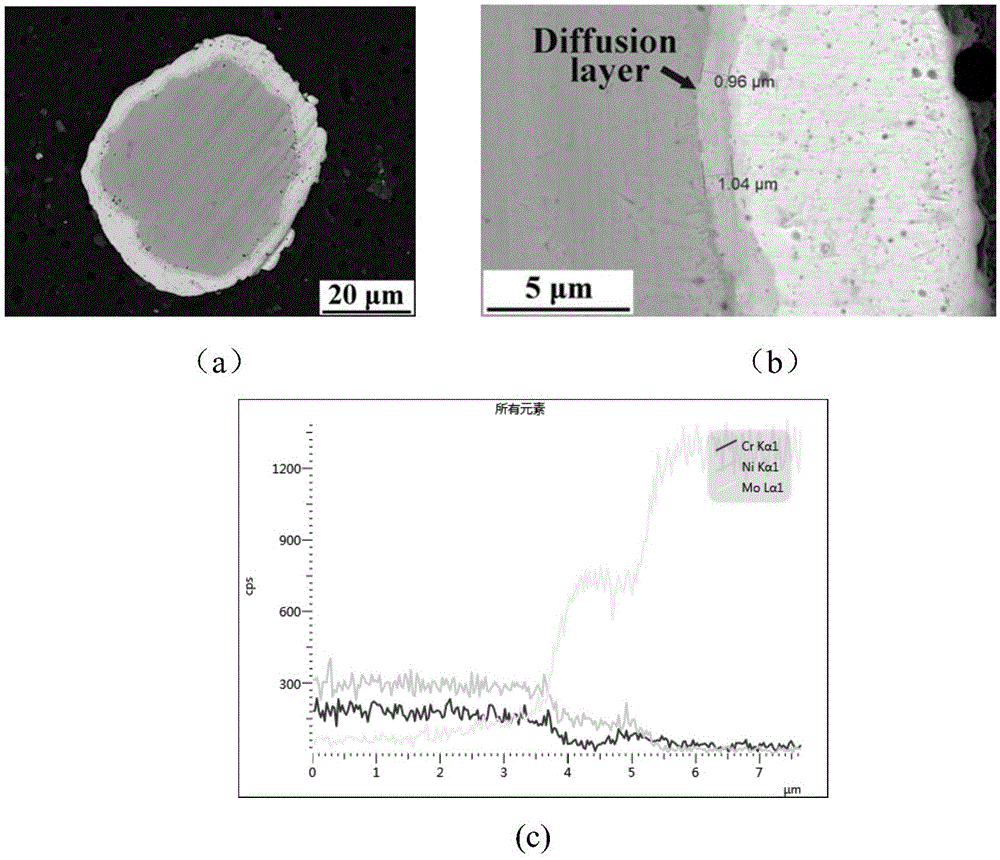

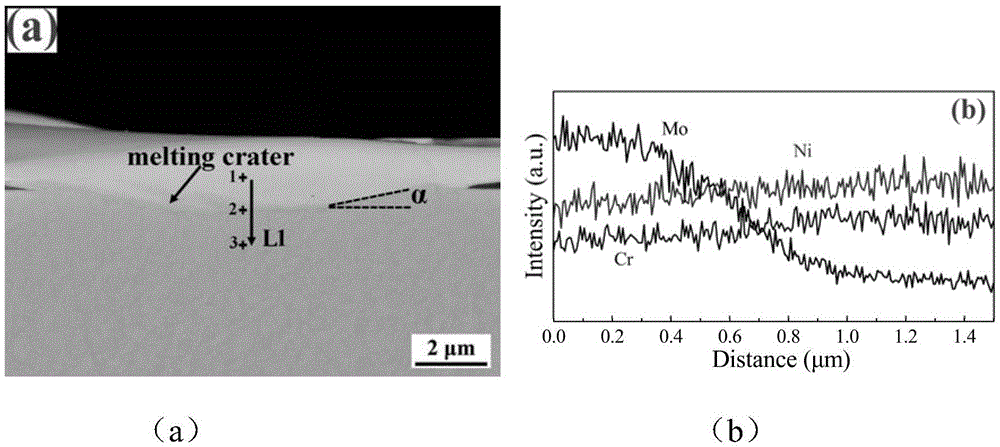

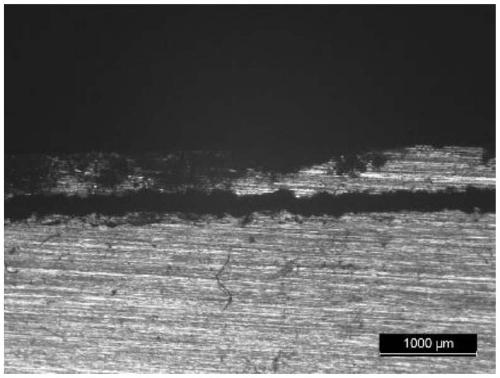

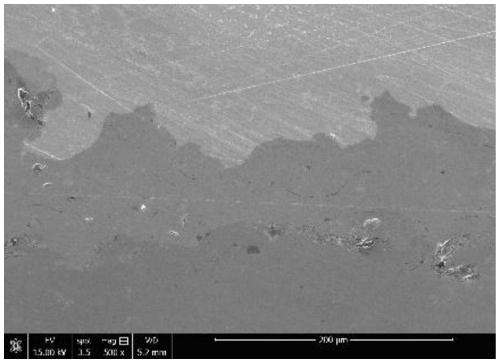

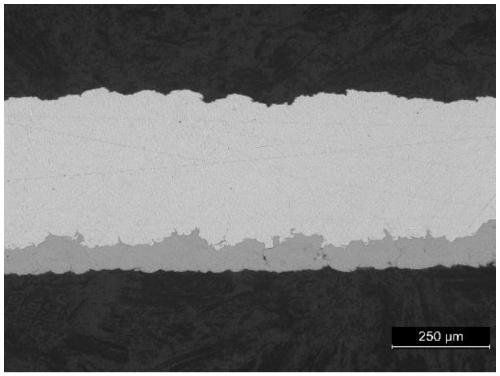

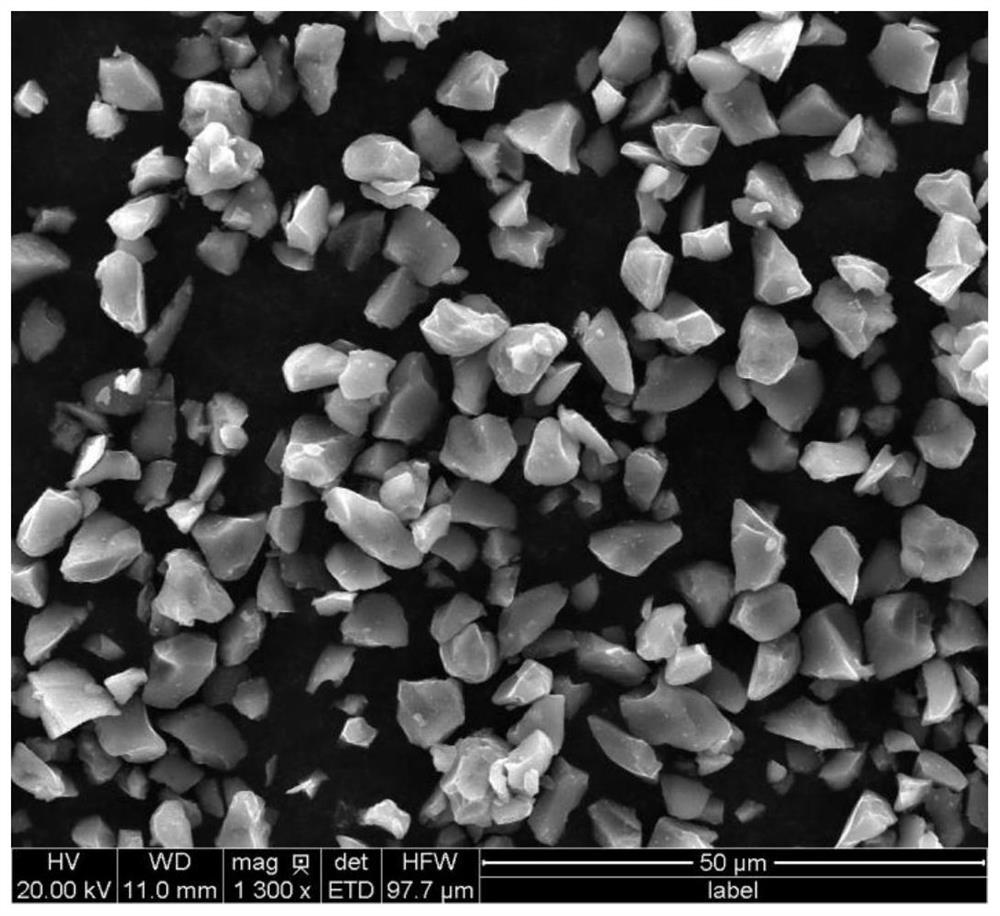

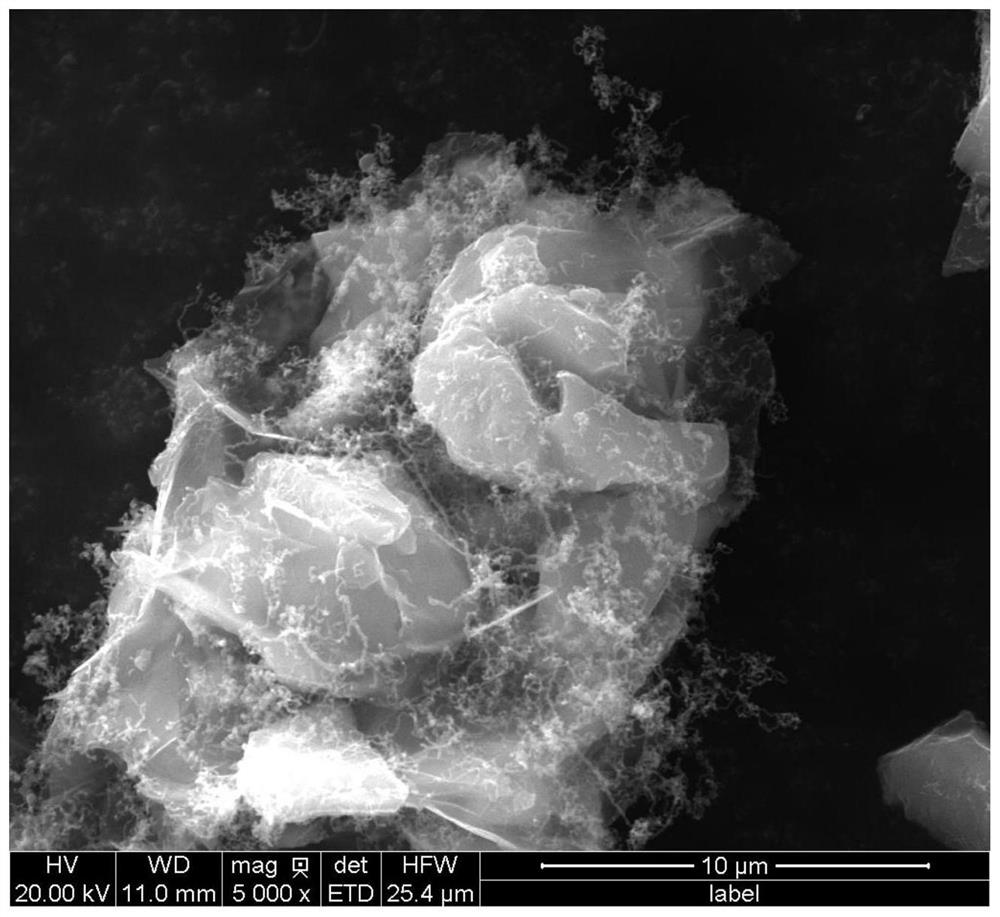

Thermal spraying self-bonding metal alloy powder with coated composite structure

ActiveCN105642885AIncrease temperatureComposite firmMolten spray coatingTransportation and packagingThermal sprayingMetal alloy

The invention discloses a thermal spraying self-bonding metal alloy powder with a coated composite structure and belongs to the technical field of material processing. The metal alloy powder is composite structural powder formed by coating outer-layer metal and coated metal particles, the surfaces of the coated metal particles are uniformly coated with the coating outer-layer metal, a melting point of the coating outer-layer metal is higher than a melting point of the coated metal particles, the coating layer and the coated metal particles are metallurgically bonded to form the composite structural powder. When a metal alloy coating prepared by the composite structural powder is adopted, due to the fact that metallurgical bonding reaction occurs between the coating and a substrate and also occurs among particle layer interfaces in the coating, the interface bonding can be firm, accordingly the bonding strength between the coating and the substrate and the cohesion bonding strength of the particle layers in the coating are remarkably improved, and the long-term usage stability of the coating is ensured. The metal alloy coating prepared by the metal alloy powder has excellent corrosion resistance properties.

Owner:XI AN JIAOTONG UNIV

Air filtration membrane with functions of killing bacteria and removing formaldehyde

ActiveCN107051232AImprove filtering effectPurification and decompositionSemi-permeable membranesBreathing filtersAir filtrationParticulates

The invention discloses an air filtration membrane with functions of killing bacteria and removing formaldehyde. The air filtration membrane is of a three-layer nanofiber membrane composite structure, wherein the upper layer is an activated carbon nanofiber membrane, the middle layer is a pure TiO2 nanofiber membrane, and the lower layer is a nano-silver antibacterial fiber membrane; the pure TiO2 nanofiber membrane is prepared from a high polymer material / TiO2 precursor composite nanofiber membrane through heat treatment, and the high polymer material / TiO2 precursor composite nanofiber membrane is prepared with an electrospinning method; the activated carbon nanofiber membrane is an electrospun activated carbon nanoparticle / high polymer material composite nanofiber membrane; the nano-silver antibacterial fiber membrane is an electrospun nano-silver particle / high polymer material composite nanofiber membrane. The air filtration membrane not only can filter solid particulate pollutants very well, but also is good in breathability, and can remove and decompose formaldehyde in air and filter and kill harmful bacteria in air, thereby guaranteeing health of a respiratory system better.

Owner:保定源汉升新材料科技有限公司

Stirring type fruit-flavor goat milk kefir and preparation method thereof

InactiveCN106615117AImprove uniformityImprove stabilityMilk preparationStaphylococcus lactisFruit juice

The invention relates to stirring type fruit-flavor goat milk kefir, belonging to the field of milk products. The stirring type fruit-flavor goat milk kefir contains the following main components: raw milk, sugar, fruit juice, polymerized whey protein, pectin and a kefir starter, wherein the fruit juice is prepared from concentrated fruit juice through restoration; and a polymerized whey protein solution is prepared by virtue of a neutral thermal polymerization method. By fermenting twice and adding the concentrated fruit juice, a three-dimensional network structure formed by acid gel can exert the effects of thickening, improving the stability of the fruit juice and covering the goaty flavor of the goat milk, so that the problem that the fermented milk products are deteriorated due to the addition of the fruit juice in the prior art is solved. The kefir starter is a commercial ready-to-use starter consisting of lactococcus lactis, leukonid, Streptococcus thermophilus and Lactobacillus acidophilus. The stirring type fruit-flavor goat milk kefir prepared by virtue of the preparation method has the characteristics of high probiotic content, protein content and viscosity, low dehydration shrinking rate and goaty flavor of the goat milk, special flavor, uniform color, fine texture and the like.

Owner:JILIN UNIV

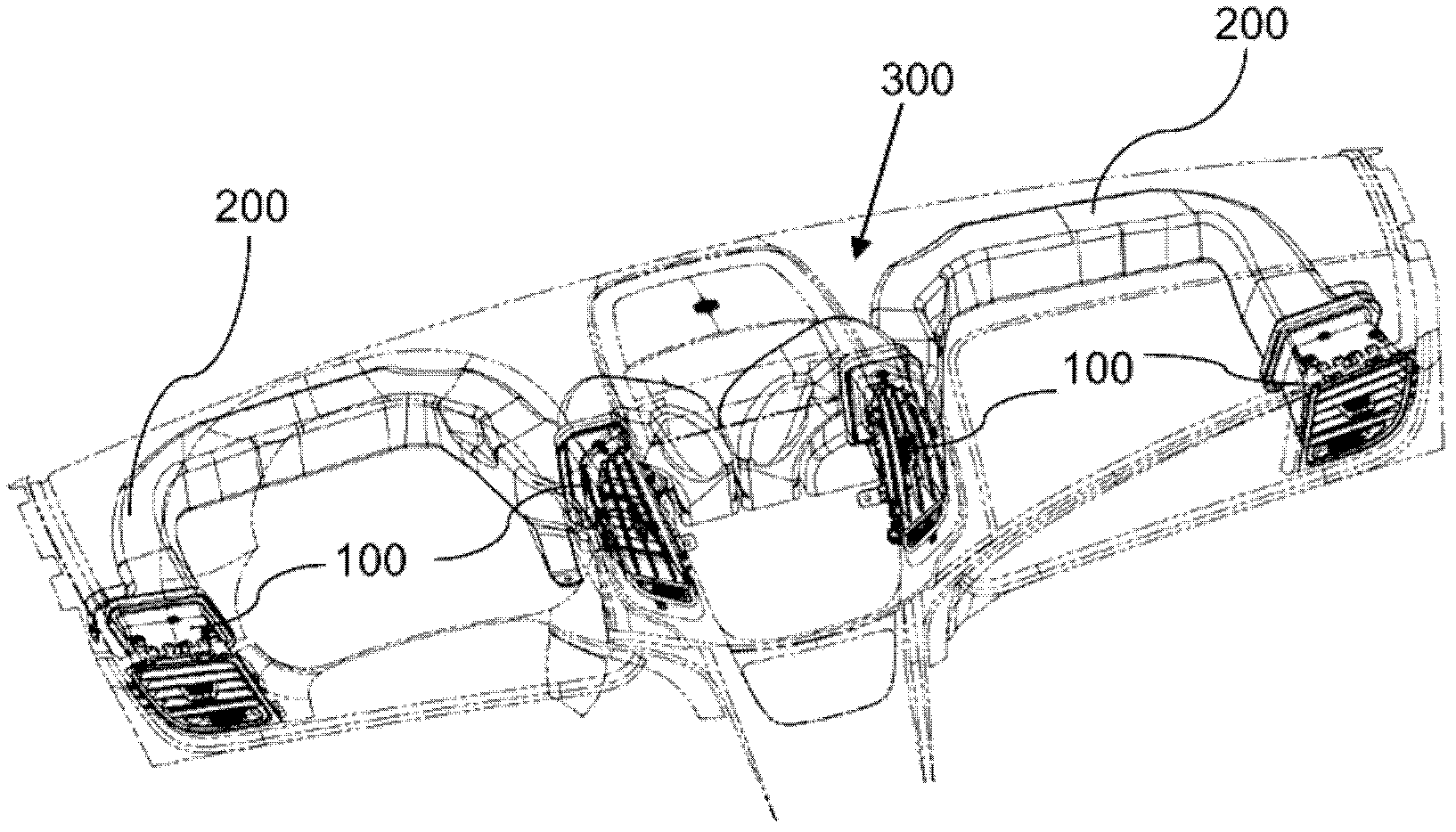

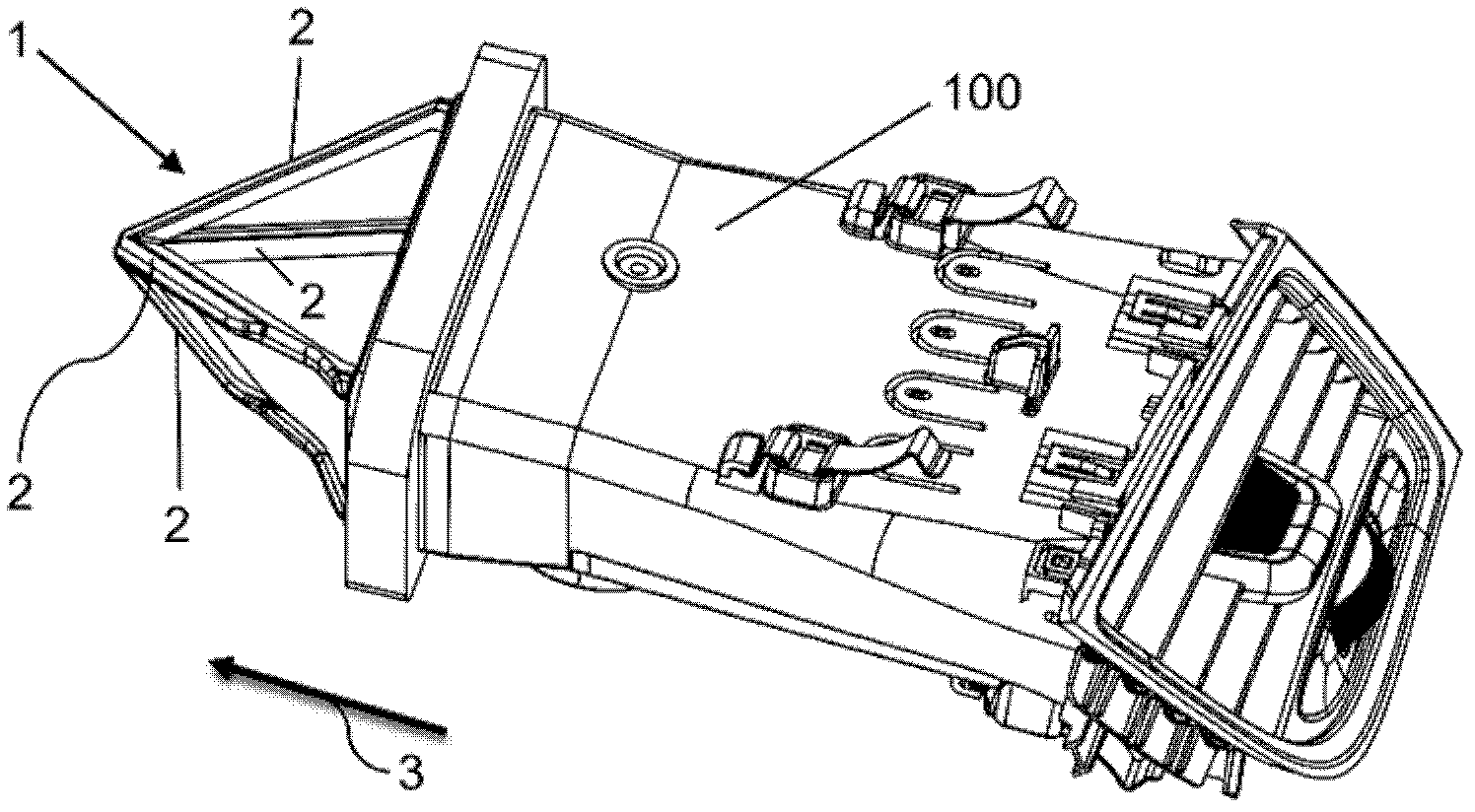

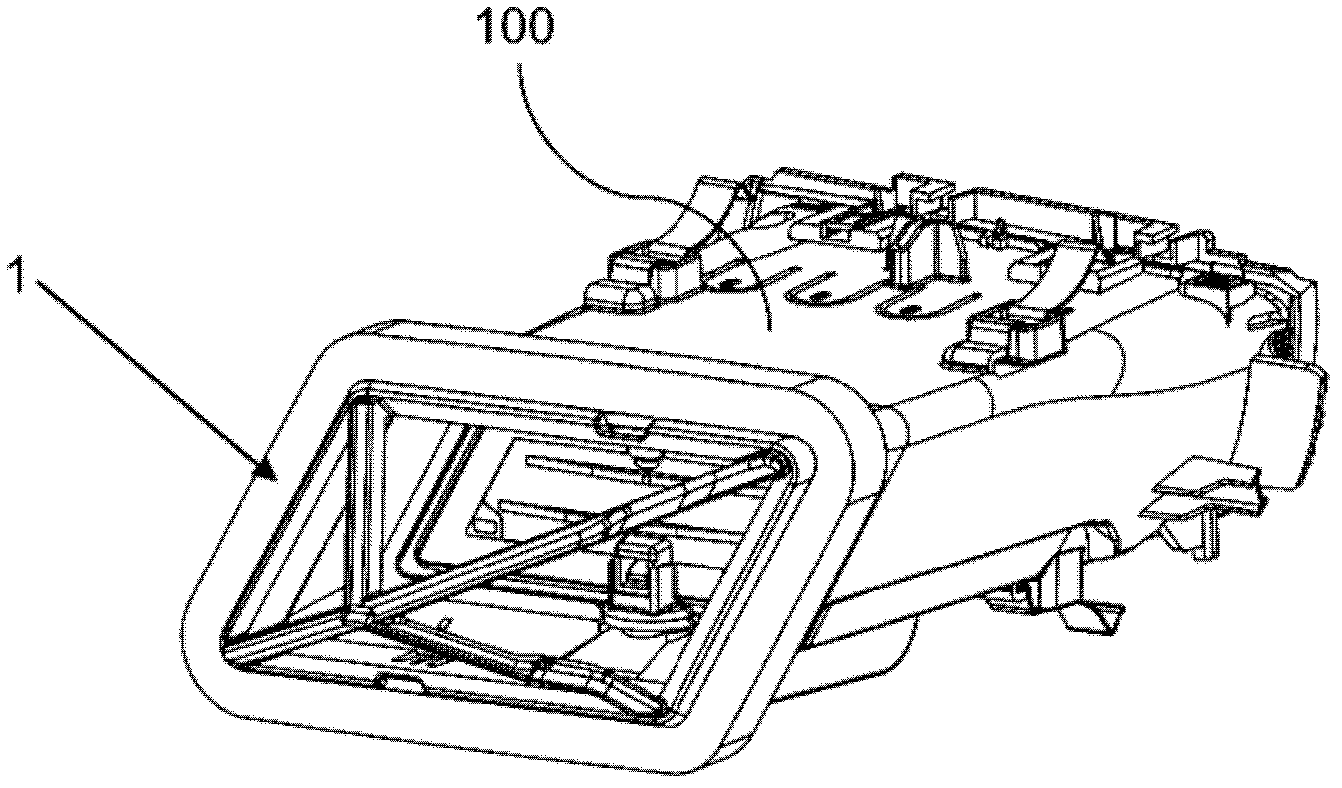

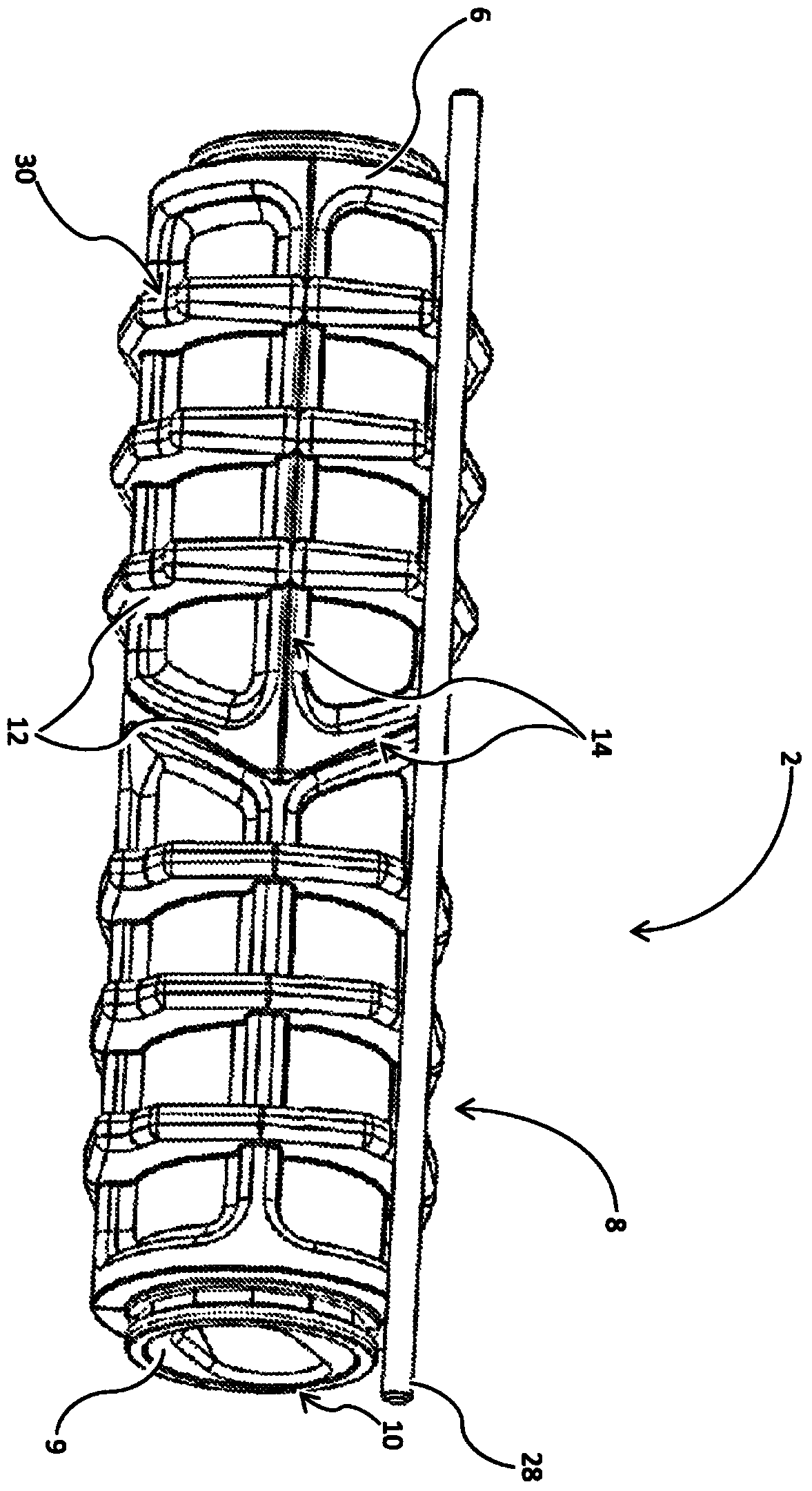

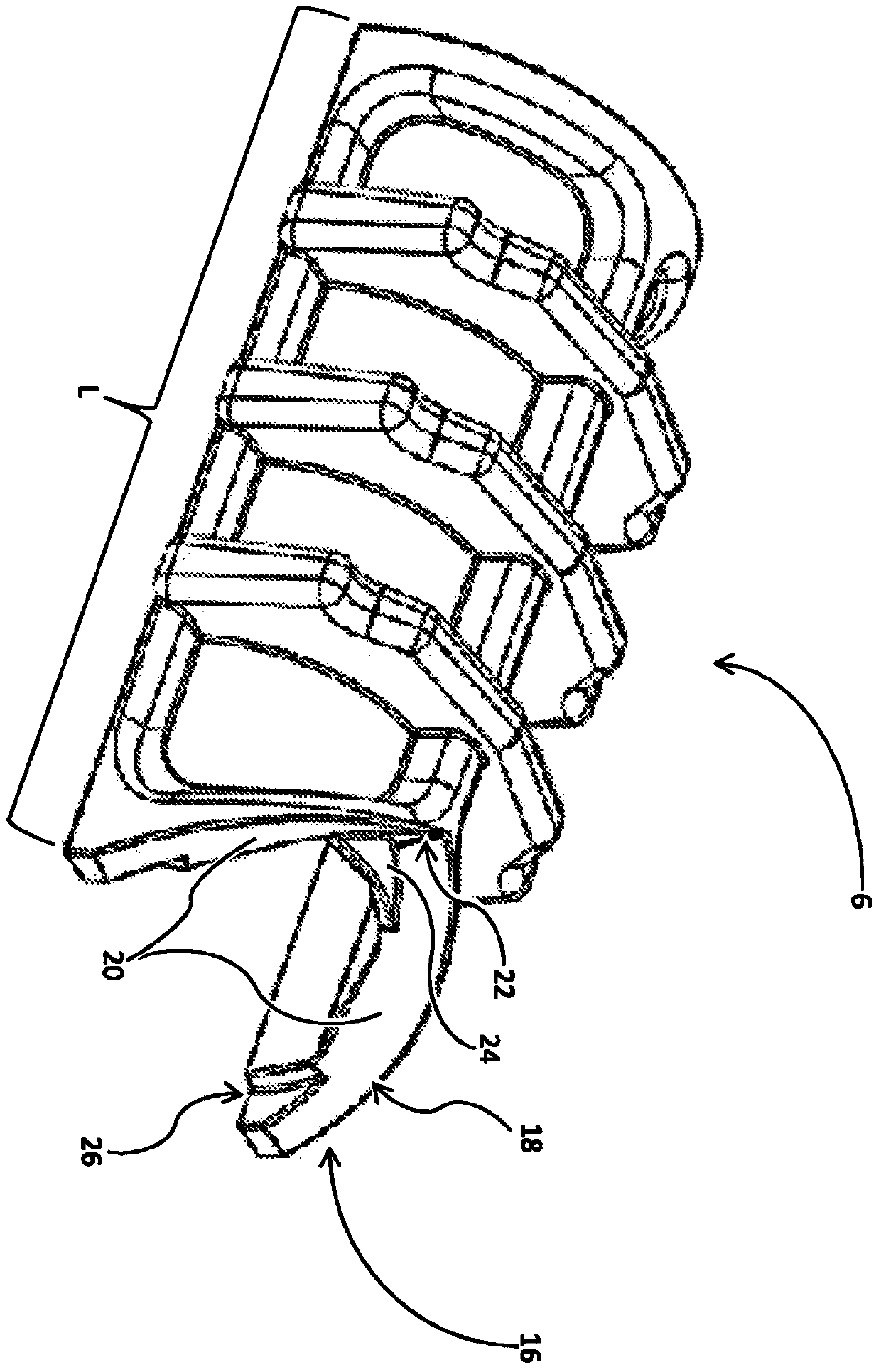

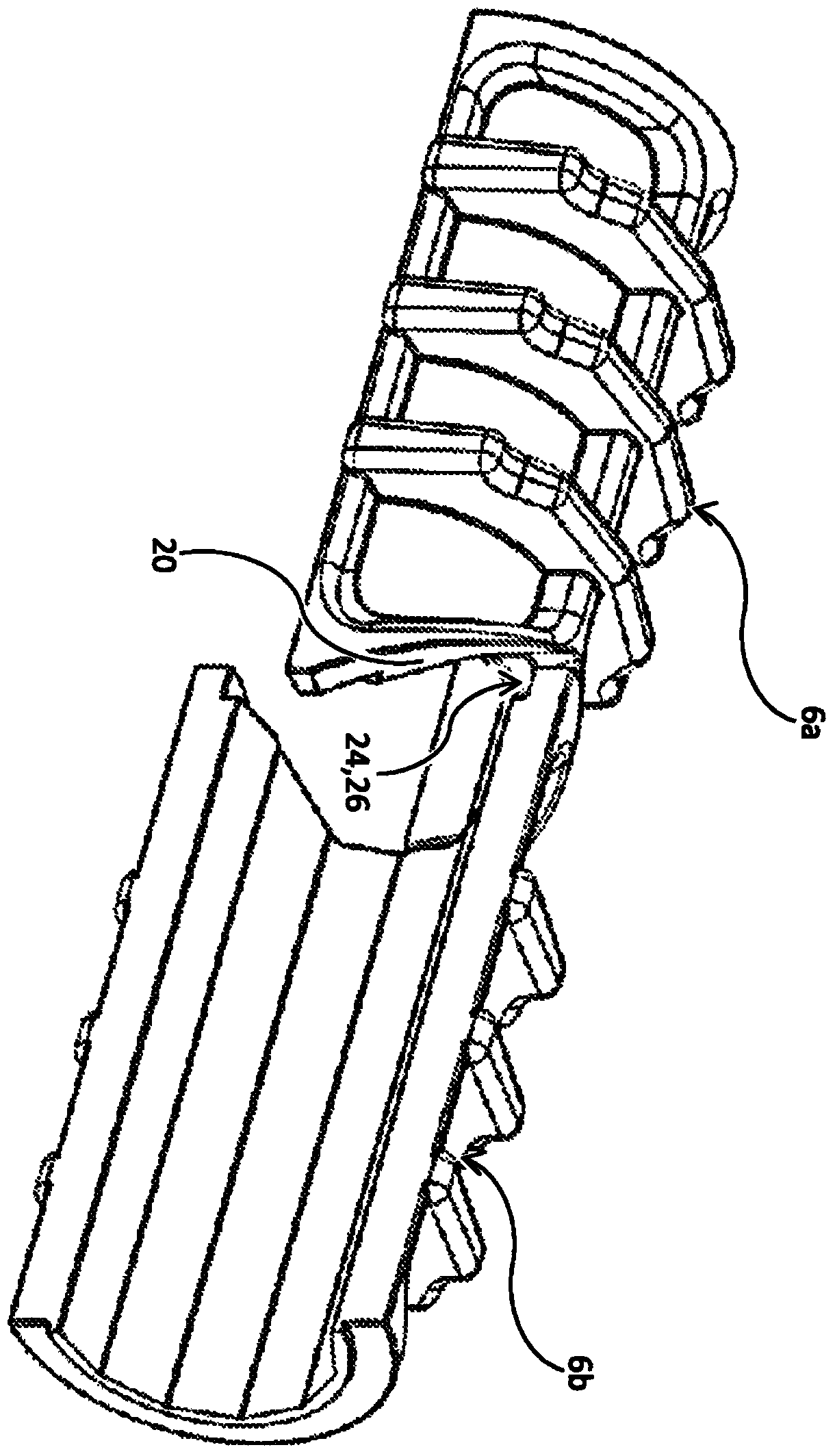

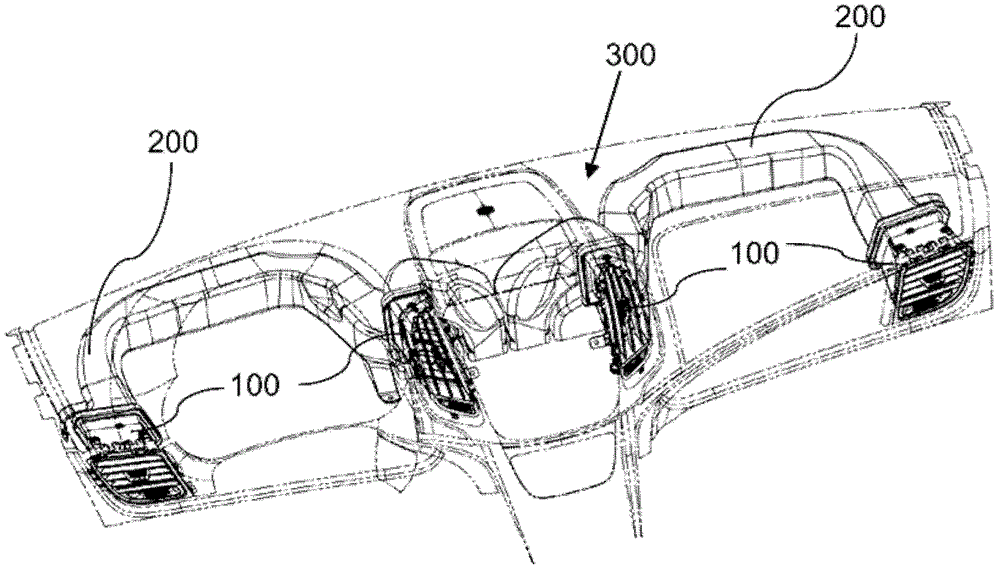

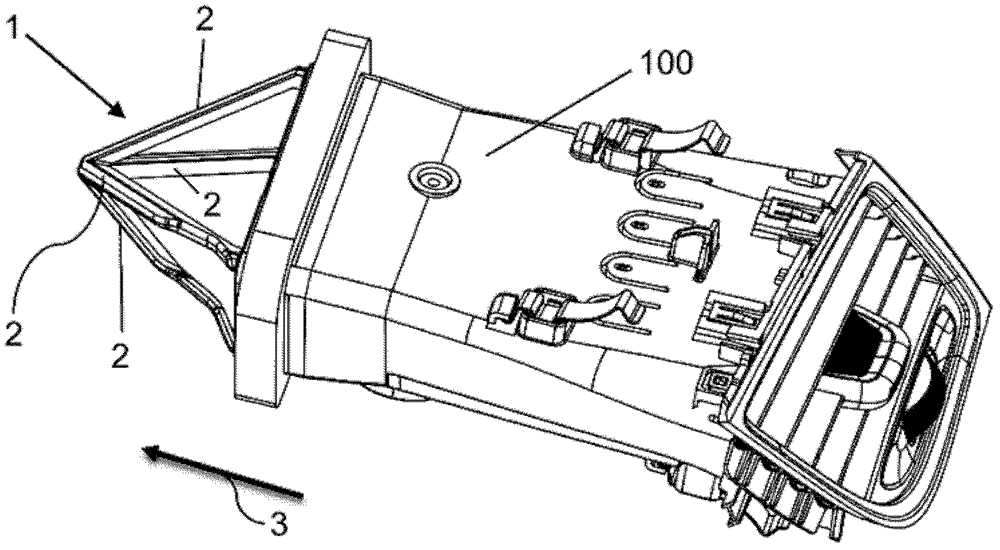

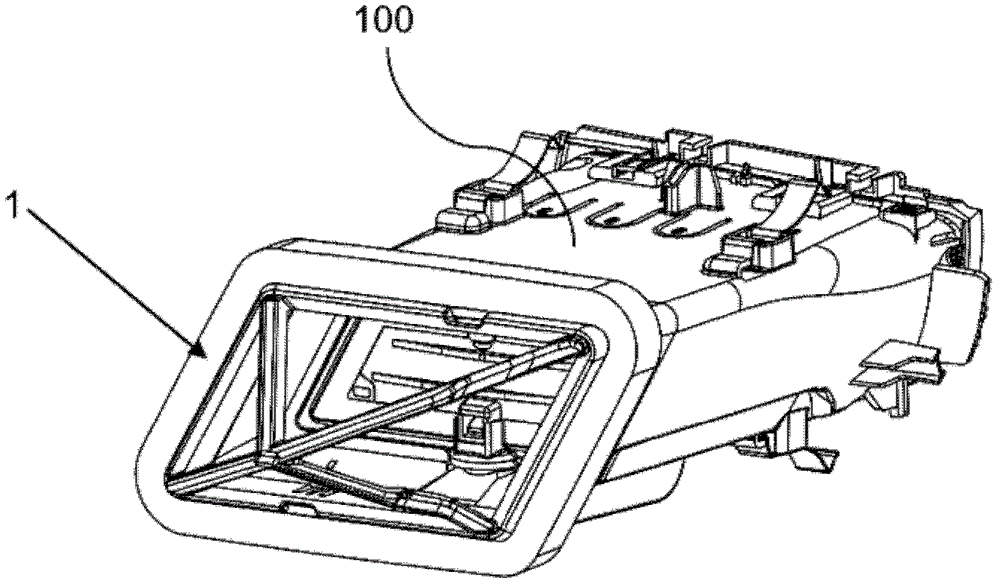

Ventilation nozzle, ventilation duct and installation aid thereof, and dashboard

ActiveCN102616114AAvoid time wastingEasy to moveAir-treating devicesVehicle heating/cooling devicesVentilation ductEngineering

An installation aid (1) is provided for a ventilation nozzle (100) and a ventilation duct of a motor vehicle, which are connected to during the installation, the installation arranged on the ventilation nozzle or the ventilation duct and having a material section (2), which protrudes forward in the installation direction (3) beyond the ventilation nozzle or the ventilation duct when the installation aid is fastened on the ventilation nozzle or the ventilation duct (200) and is at least partially insertable into the ventilation duct or the ventilation nozzle. Before the installation of ventilation nozzle and ventilation duct against one another, with the installation aid fastened on the ventilation nozzle, the material section is fixed in motion with respect to the ventilation nozzle or, if the installation aid is fastened on the ventilation duct, the material section is fixed in motion with respect to the ventilation duct.

Owner:GM GLOBAL TECH OPERATIONS LLC

Preparation method of composite coating on inner wall of reduction furnace bell jar

InactiveCN110424015ARealize integrated manufacturingAvoid pollutionMolten spray coatingSuperimposed coating processManganeseAlloy

The invention discloses a preparation method of composite coating on the inner wall of a reduction furnace bell jar. The preparation method comprises the following steps that a transition layer is prepared, and specially, a transition layer is prepared on the inner wall of the stainless steel bell jar by adopting thermal spraying; raw materials of the transition layer are an alloy consisting of one or more of aluminum, iron, copper, nickel, chromium, zinc, vanadium, manganese, silicon, cobalt, silver, cadmium, zirconium and tungsten; an anti-fouling coating with high density, high bonding strength, high thermal stability and low defect rate are prepared by using gas power spraying on the surface of the transition layer; and the raw materials of the anti-fouling coating are an alloy consisting of one or more of silver, gold and platinum. According to the preparation method, on one hand, the process steps can be simplified, the production cost can be reduced, the problem of the defect ofweld joints of a spliced plate can be solved, on the other hand, the structural stability of the coating can be improved, and the service life of the coating can be prolonged.

Owner:江苏广研新材料技术有限公司

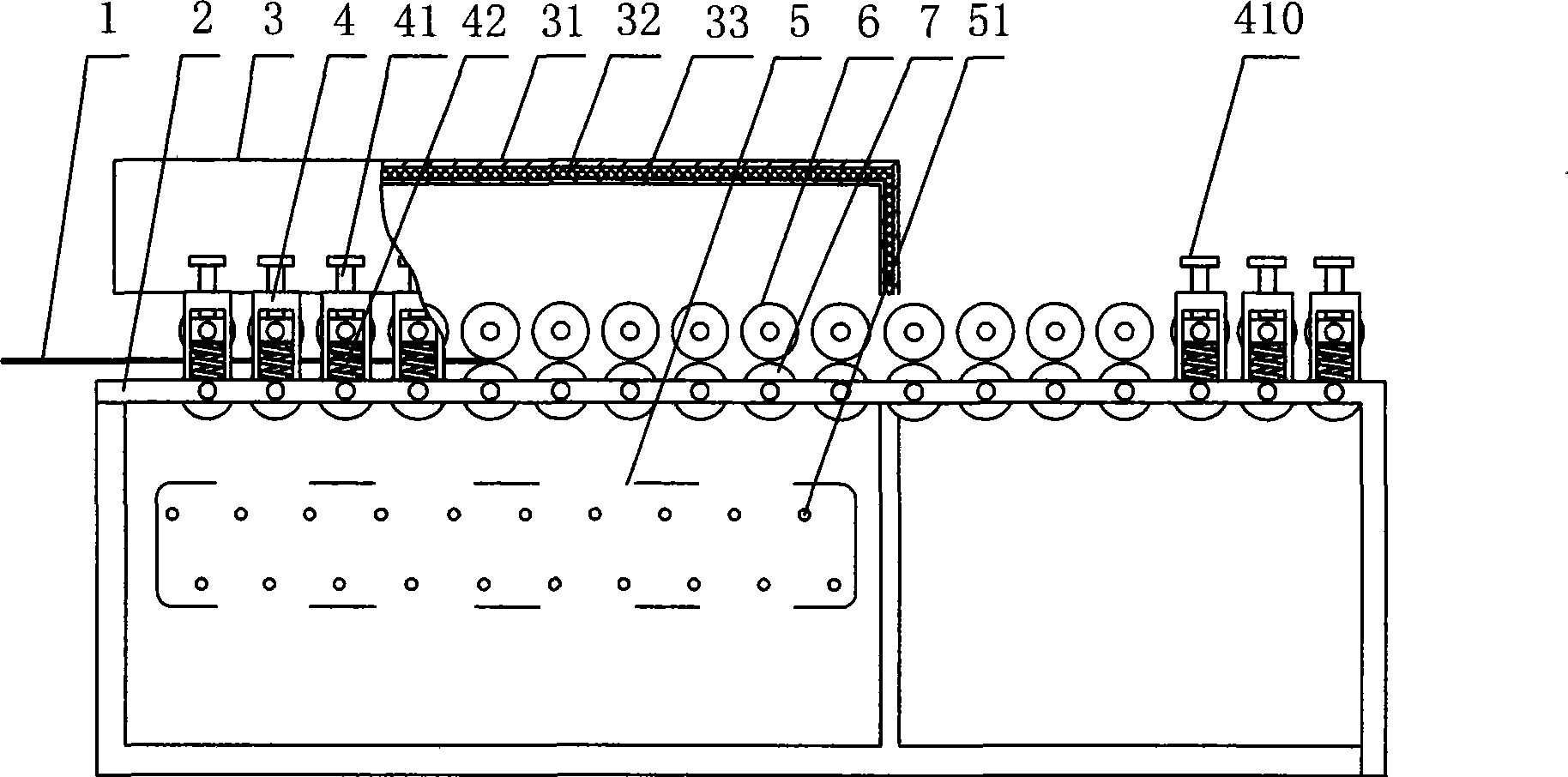

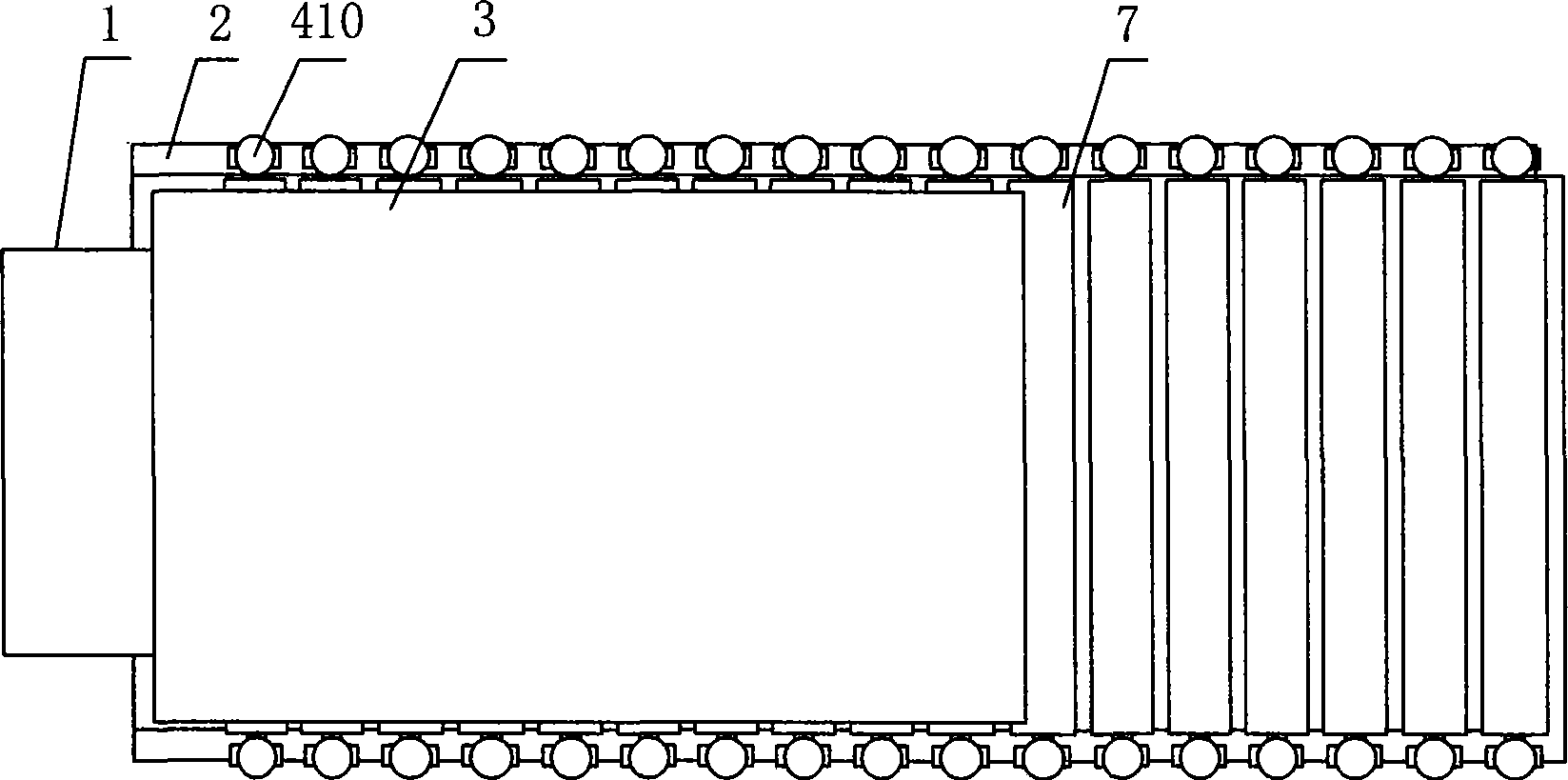

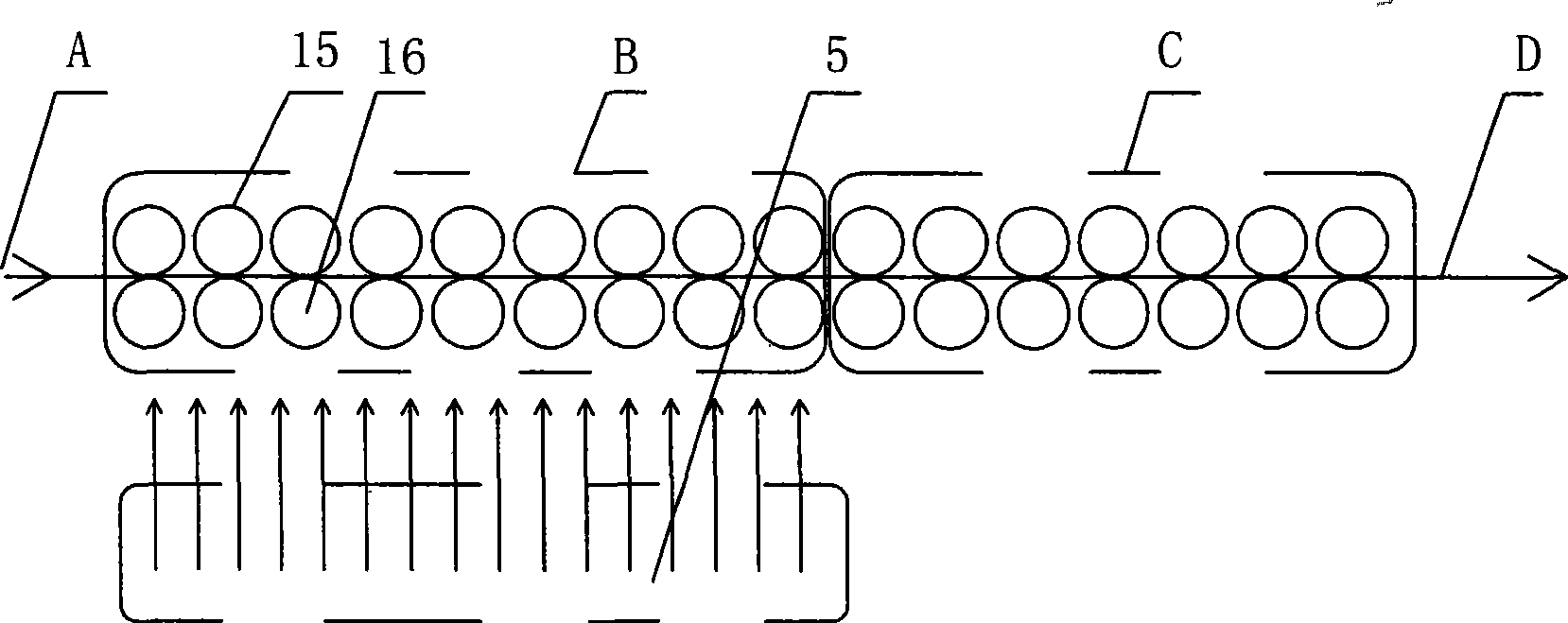

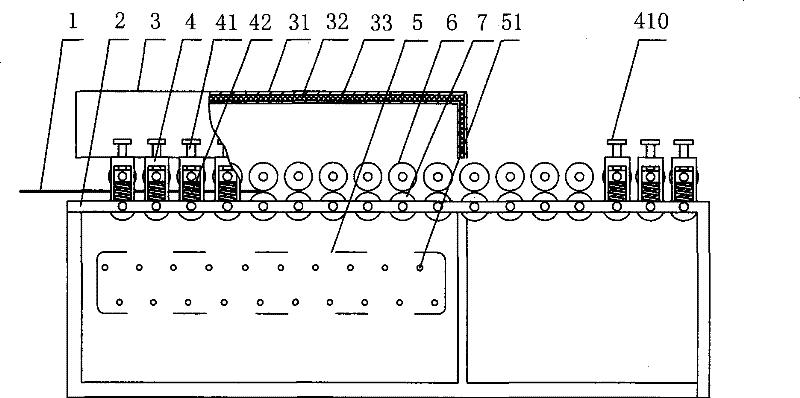

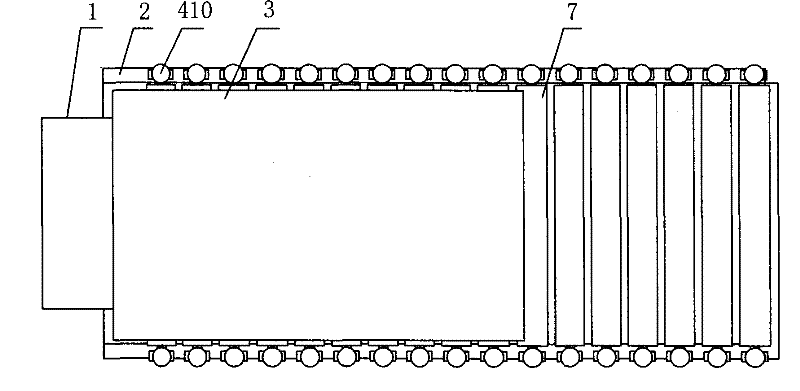

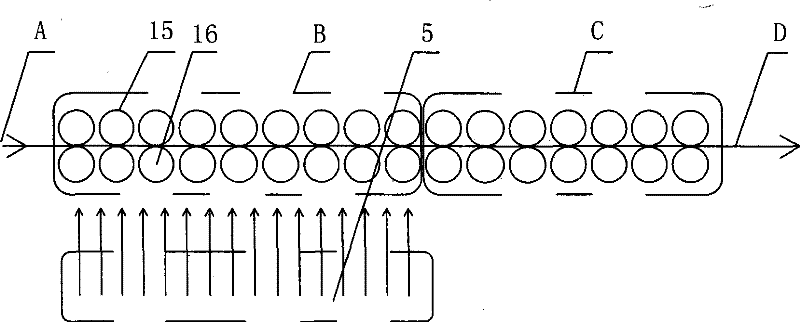

Automatic compound machine of composite shock-absorbing silencing piece

InactiveCN101368605AAvoid it happening againAvoid defects that create air bubblesBraking elementsWeather resistanceUltimate tensile strength

Disclosed is a composite damping silencing plate automatic compounding machine; a plurality of bearing rollers are arranged on the horizontal plane of a frame; pressing rollers are respectively arranged above the bearing rollers and tightly abutted on the bearing rollers to form the opposite rotation relation; a heating device is arranged on the front half region of the frame and under the bearing rollers. The composite damping silencing plate automatic compounding machine has the advantages of advanced compounding mode, high work efficiency, compounding large areas of metal plate material, high automation degree and reducing the work intensity of the workers greatly. The composite damping silencing manufactured by the automatic compounding machine has the advantages of obvious shockproof and silencing effect, strong adhesion intensity between the metal plates, strong anti-impact property, maintaining stable and firm composite structure in harsh operating conditions, good oil resistance, erosion resistance and weathering resistance, maintaining good application performance in the high temperature and low temperature environments.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

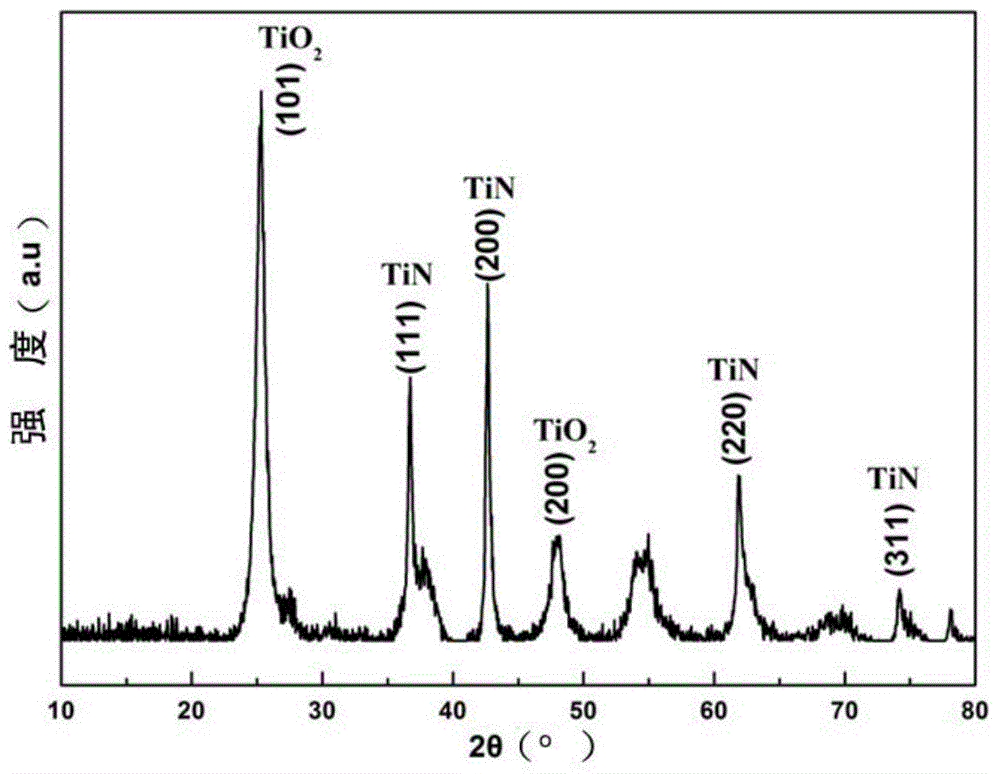

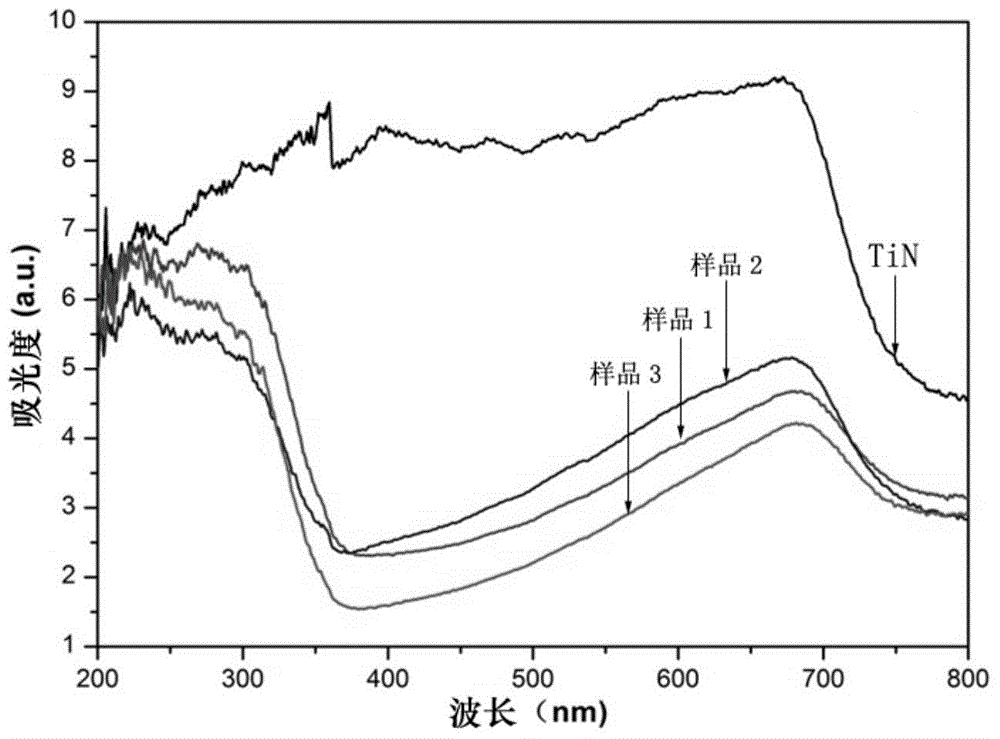

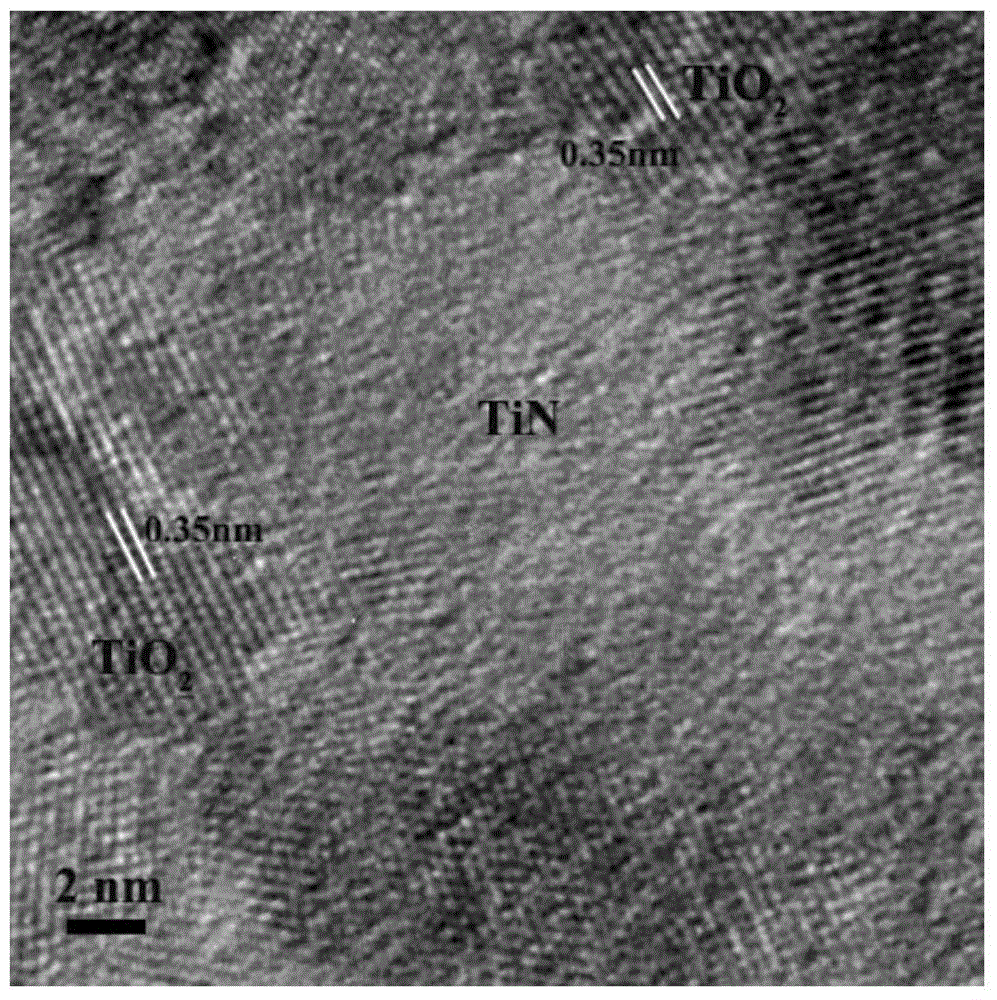

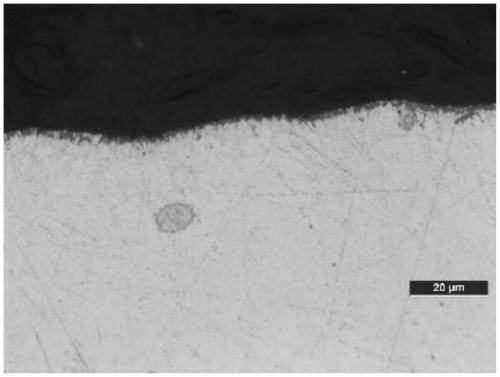

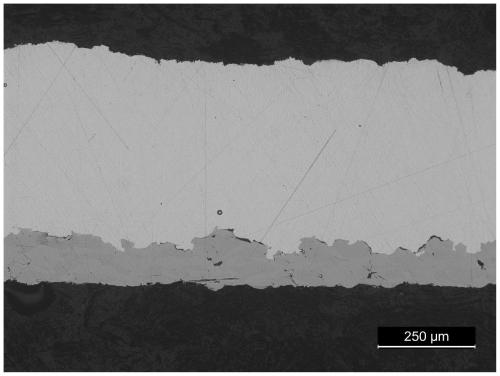

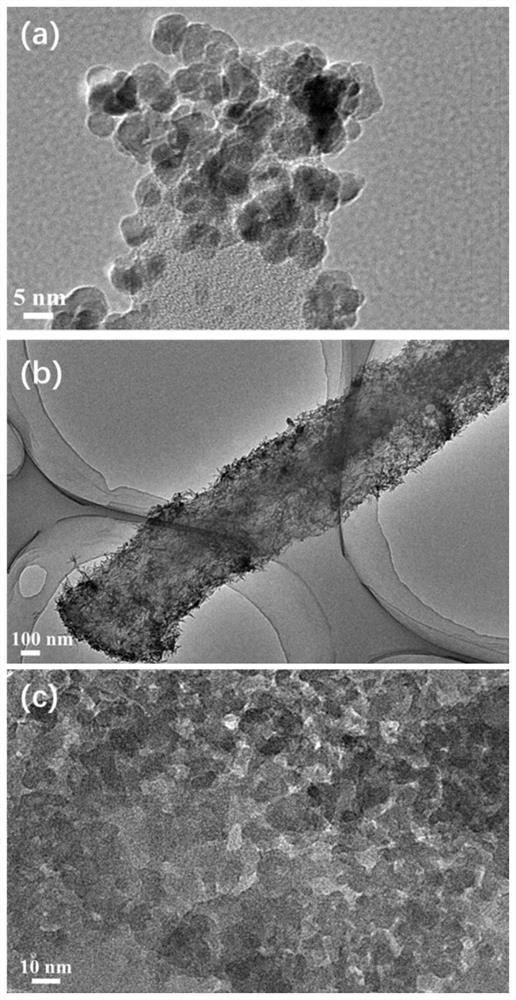

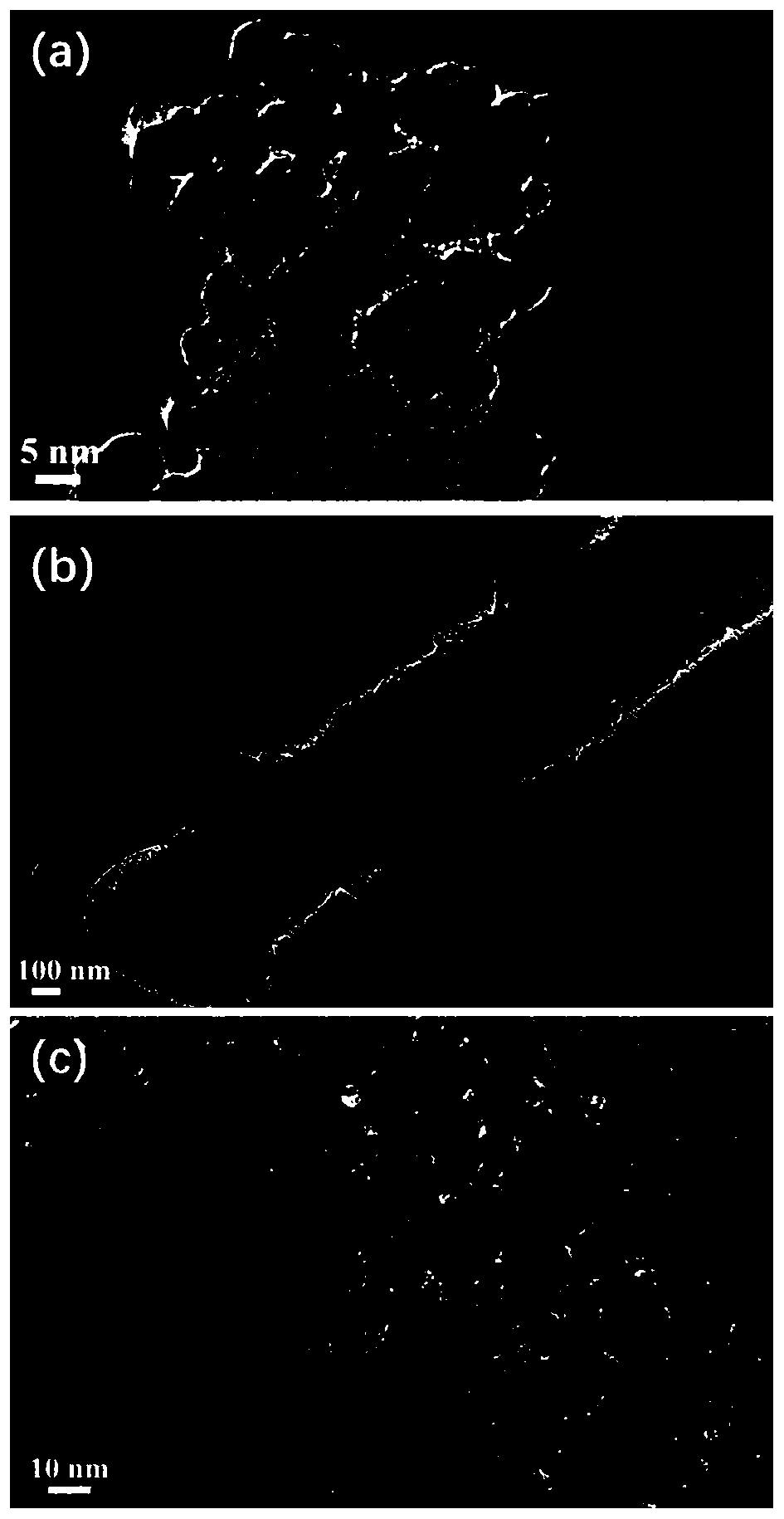

Nano titanium nitride-based composite photocatalytic material as well as preparation method and application thereof

InactiveCN106268896APromote migrationFacilitated DiffusionPhysical/chemical process catalystsWater/sewage treatment by irradiationMaterials preparationSurface oxidation

The invention discloses a nano titanium nitride-based composite photocatalytic material as well as a preparation method and application thereof, belonging to the technical fields of inorganic non-metallic nano material preparation, environmental protection technologies and solar energy utilization. According to the nano titanium nitride-based composite photocatalytic material, controllable surface oxidation is carried out on nanoscale titanium nitride particles, so that a composite photocatalytic material which takes nano titanium nitride as a core and titanium dioxide as a shell is formed. The nano titanium nitride-based composite photocatalytic material has adjustable optical adsorption property, thus being directly used for solving the problems of decomposition of organic matters under visible light, inactivation of microbial pathogens and efficient utilization of solar energy, and especially solving the problem of low photocatalytic efficiency of single-component photocatalytic materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of surface composite coating for bottom plate of reduction furnace

InactiveCN110438431AReduce the cost of raw materials for preparationRealize integrated manufacturingMolten spray coatingSuperimposed coating processHigh entropy alloysMetallurgy

The invention discloses a preparation method of a surface composite coating for a bottom plate of a reduction furnace. The preparation method of the surface composite coating for the bottom plate of the reduction furnace comprises the following steps of preparing a bonding layer: adopting hot spraying for preparing a layer of bonding layer on the inner surface of a stainless steel bell jar, wherein the bonding layer is prepared from one of raw materials: Ni, Ti, Cu, Fe, Zn, C-Co, WC-10Co4Cr, MCrAIY, a high-entropy alloy, NiTi, NiCr and stainless steel; and preparing an antifouling coating: utilizing gas power spraying for preparing the antifouling coating with high compactness, high bonding strength and high heat stability on the surface of the bonding layer, wherein the antifouling coating is prepared from a raw material which is silver powder. According to the preparation method, on one hand, the process step can be simplified, and the production cost is reduced; and on the other hand, the structure stability of the coating can be improved, and the service life of the coating is prolonged.

Owner:江苏广研新材料技术有限公司

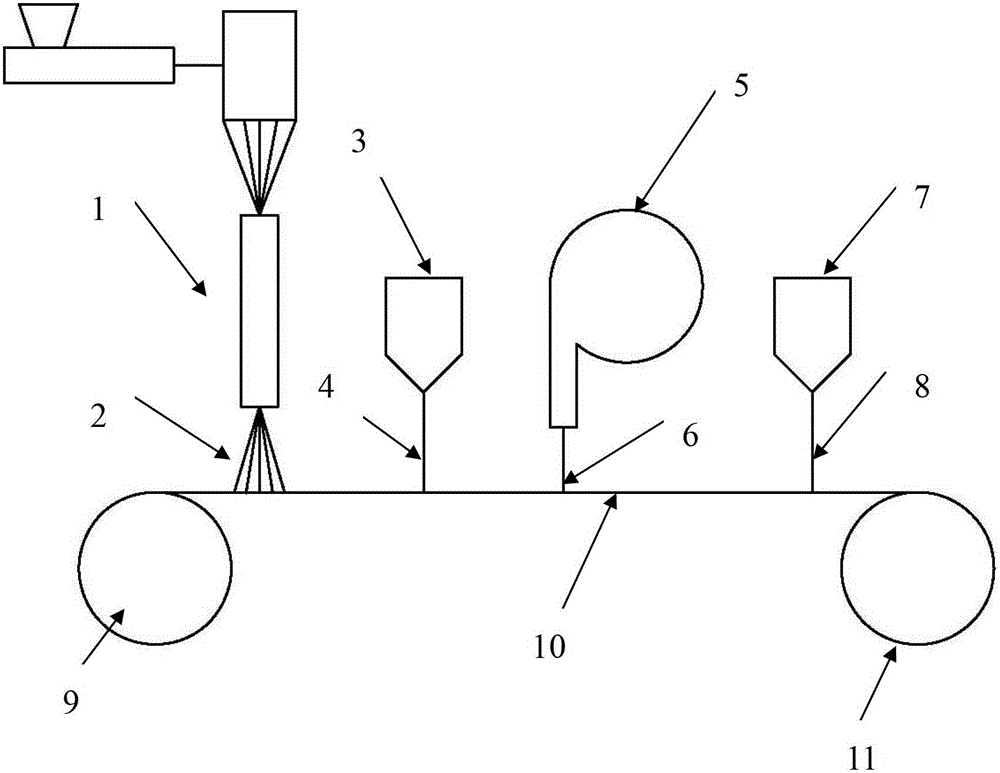

On-line composite manufacturing method of melt-blown fiber and kapok fiber and thermal insulation material thereof

ActiveCN103046230BImprove insulation effectIncrease elasticityNon-woven fabricsThermal insulationKapok fiber

The invention discloses a melt-blown fiber and kapok fiber online compositing manufacture method and a thermal insulation material made of melt-blown fiber and kapok fiber composite. The manufacture method mainly includes the steps: a first melt-blown fiber net forming, namely laying a net on a net belt or fiber layer to form a first melt-blown fiber layer by the aid of first melt-blow spinning equipment; a first kapok fiber net forming, namely laying a net on the first melt-blown fiber layer to form a first kapok fiber layer by the aid of a first air flow net forming device; and adhering the first melt-blown fiber layer and the first kapok fiber layer due to intrinsic residual temperature of melt-blown fibers of the first melt-flown fiber layer. During online compositing, the melt-blow fibers and the kapok fibers are automatically adhered to form a stable composite structure. Advantage complementation of the melt-blow fibers and the kapok fibers enables the thermal insulation material to have fine heat insulating effects of the kapok fibers and high elastic resilience and breathability.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

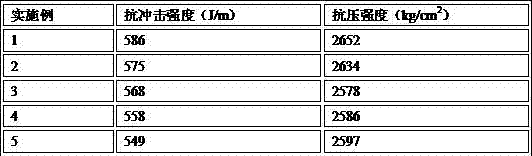

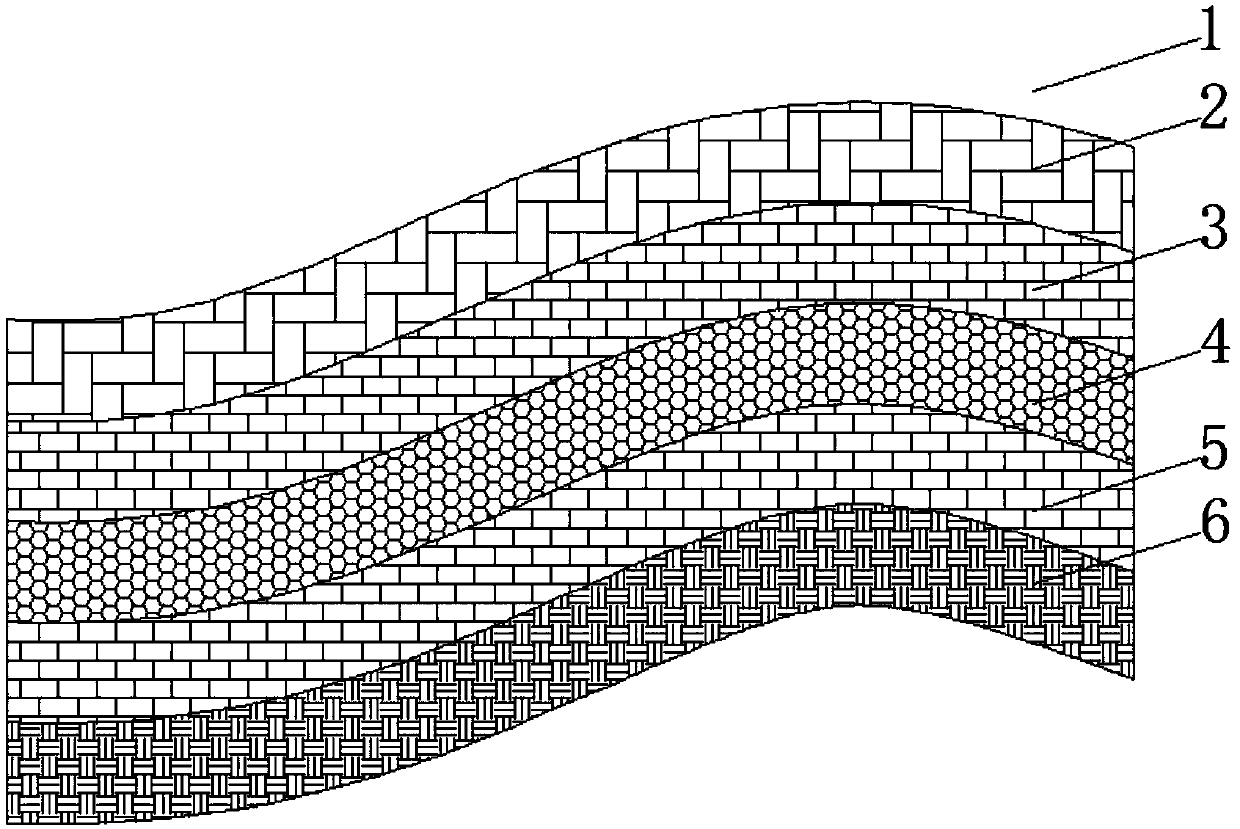

Anti-impact composite kerb and preparation method thereof

InactiveCN107285695AImprove corrosion resistanceImprove temperature resistanceSurface layerPulverized fuel ash

The invention discloses anti-impact composite kerb and a preparation method thereof. The kerb comprises a decorative surface layer and a base layer, wherein the decorative surface layer is prepared from the following raw materials in parts by weight: 80-100 parts of waste plastics, 20-30 parts of pulverized fuel ash, 10-20 parts of silicon dioxide, 5-15 parts of SBS modified asphalt, 3-8 parts of stabilizer, 1-5 parts of a coupling agent and 1-3 parts of antioxidant; and the base layer is prepared from the following raw materials in parts by weight: 50-60 parts of silicate cement, 20-30 parts of quartz sands and 6-12 parts of construction glue powder. The preparation method of kerb comprises the steps of preparing the decorative surface layer, preparing materials of the base layer and combining the decorative surface layer with the base layer. According to the composite kerb and the preparation method, the composite kerb has good corrosion resistance, good temperature resistance, strong tensile strength, strong impact resistance and simple preparation process, and can be easily molded.

Owner:合肥慧林建材有限公司

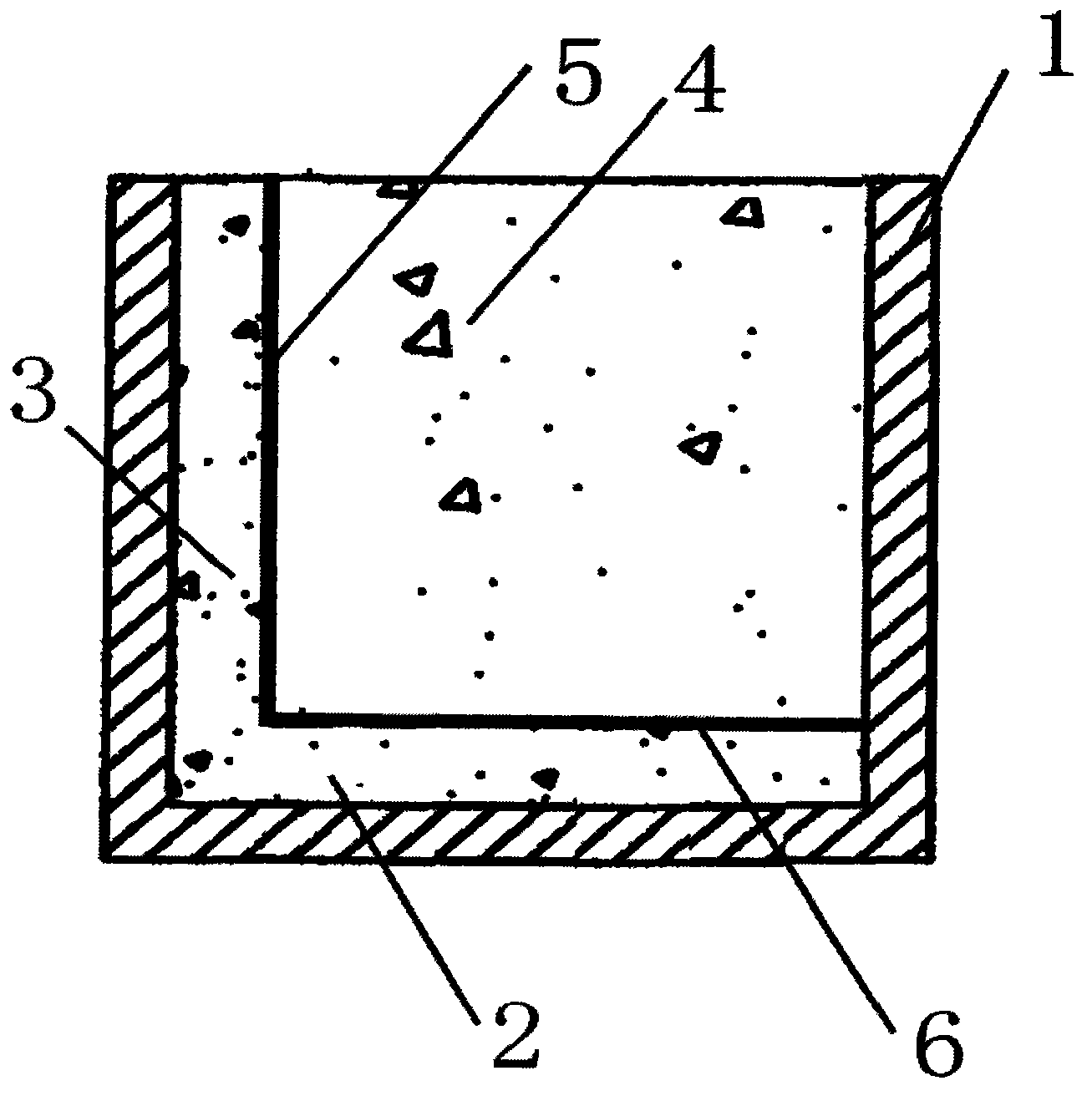

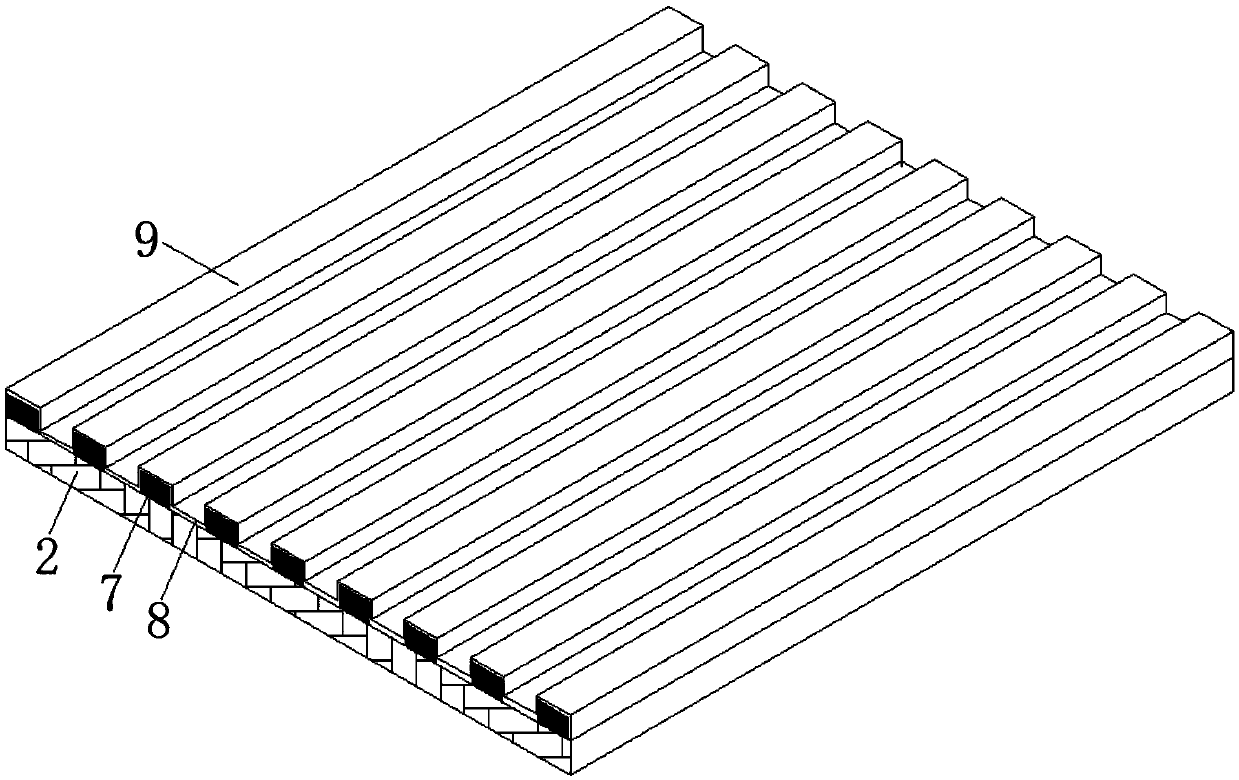

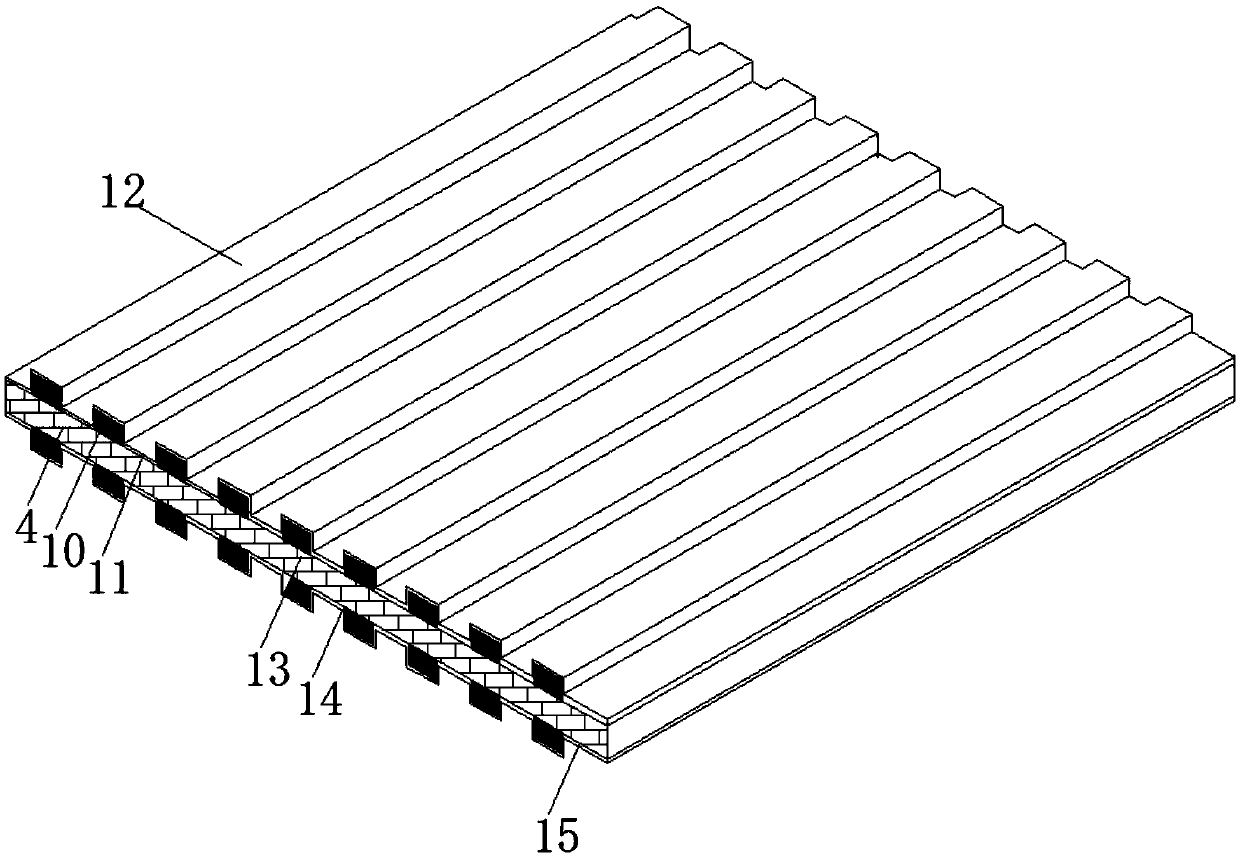

Manufacturing method for color kerbstones

InactiveCN103624865AComposite structure is stableImprove seismic performanceCeramic shaping apparatusSurface layerMetallurgy

The invention provides a manufacturing method for color kerbstones. The method includes the steps that firstly, a layer of color concrete is laid on a bottom layer of a die 1 to form a color surface layer 2; secondly, a rectangular steel wire mesh 5 is placed on the color surface layer 2 and vertical to the bottom layer of the die 1, an interval is reserved between the steel wire mesh 5 and one side of the die 1, a rectangular steel wire mesh 6 is horizontally placed on the color surface layer 2, one side of the steel wire mesh 6 is aligned to the lower edge of the steel wire mesh 5 to form a right angle, and the other sides of the steel wire mesh 6 are aligned to side walls of the die; thirdly, the color concrete is injected into the interval between the steel wire mesh 5 and the die to form a color surface layer 3, common concrete is injected to the other side of the steel wire mesh 5, and a basic body 4 is formed; fourthly, the die is covered with a cover plate, and the color concrete and common concrete in the die are flattened and compacted. The color kerbstones are firm in composite structure, and color surface layers do not easily fall out.

Owner:许春雷

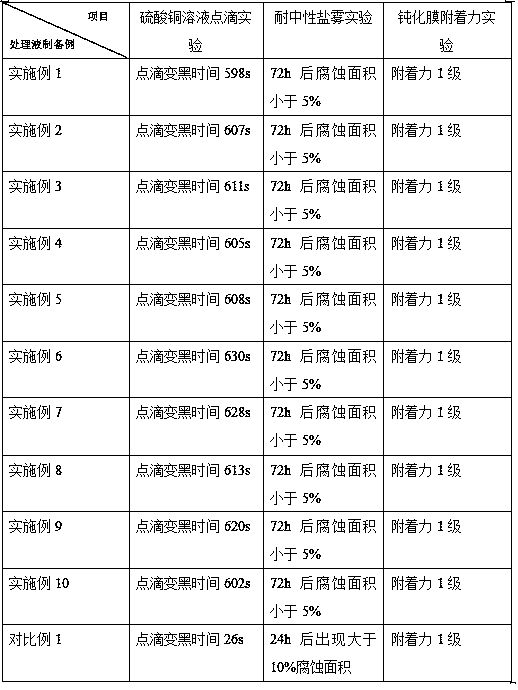

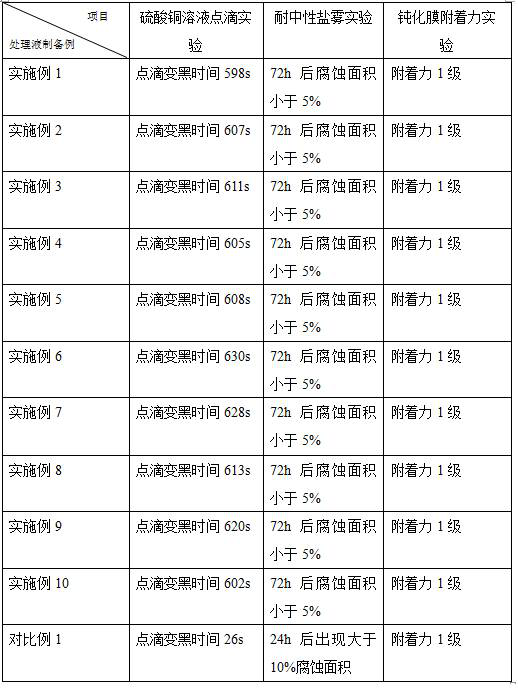

Zinc-plating material surface processing liquid with compound biological polysaccharide and preparation method thereof

ActiveCN109097765AComposite structure is stableImprove corrosion resistanceMetallic material coating processesInulinPhysical chemistry

The invention relates to the field of metal surface processing, in particular to metal surface passivation processing liquid, specifically, is zinc-plating material surface processing liquid with compound biological polysaccharide and a preparation method thereof. The zinc-plating material surface processing liquid with the compound biological polysaccharide comprises inulin, organosilane, an inorganic slow-release agent, nanometer silica sol, a pH regulator, and deionized water. The zinc-plating material surface processing liquid has good liquidity and better passivation anti-corrosion effect. The passivation liquid has excellent corrosion resistance. The passivation liquid is applied to a zinc-plating plate, after drying, a dropping experiment is conducted with a 5% copper sulfate solution, the longest blackening time of a drop can be as long as 630s, the adhesive force of a passivation film can reach the first level, after 72 hours of a neutral salt spray resistance test, the corrosion area is less than 5%, and therefore excellent passivation effect is achieved.

Owner:南京京科新材料研究院有限公司

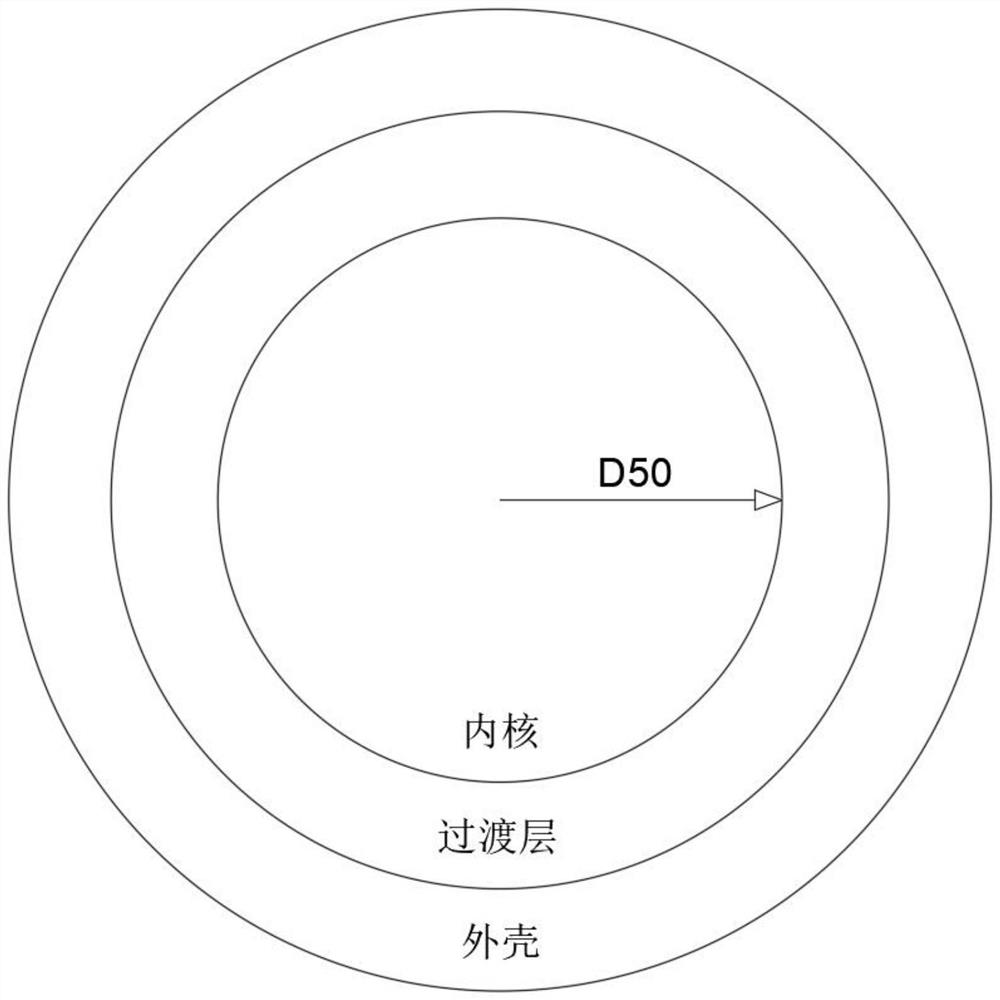

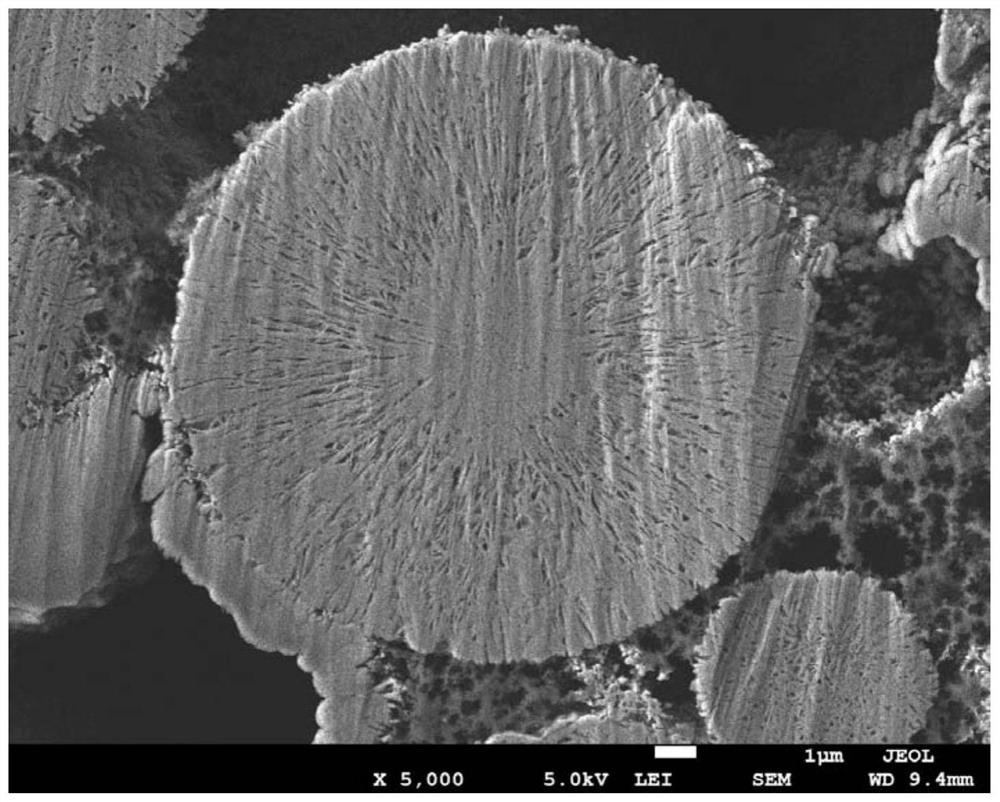

Lithium-rich manganese-based ternary composite precursor, positive electrode material and preparation method of positive electrode material

ActiveCN114649525AHigh specific capacityHigh lithium diffusion capacityCell electrodesManganeseCobalt salt

The invention discloses a lithium-rich manganese-based ternary composite precursor, a positive electrode material and a preparation method of the positive electrode material, and the positive electrode material is spherical or sphere-like particles, is formed by compounding three layers of materials, and comprises an inner core, a transition layer and a shell. The preparation method of the positive electrode material comprises the following steps: mixing a first nickel salt, a first cobalt salt, a first manganese salt, a first aluminum salt and an M2 salt to obtain a first metal liquid; second nickel salt, second cobalt salt, second manganese salt, second aluminum salt and M3 salt are mixed to obtain second molten metal; the first molten metal and the second molten metal are mixed to form third molten metal; carrying out a first mixing reaction to obtain a manganese-rich hydroxide core; forming a transition layer outside the inner core through a second mixing reaction; forming a ternary hydroxide shell outside the transition layer through a third mixing reaction to obtain a precursor; and mixing the precursor with a lithium source, and sintering to obtain the positive electrode material. The lithium ion diffusivity of the whole material can be remarkably improved, and the thermal stability, the first efficiency, the cycle performance and the rate capability of the material are remarkably improved.

Owner:南通金通储能动力新材料有限公司

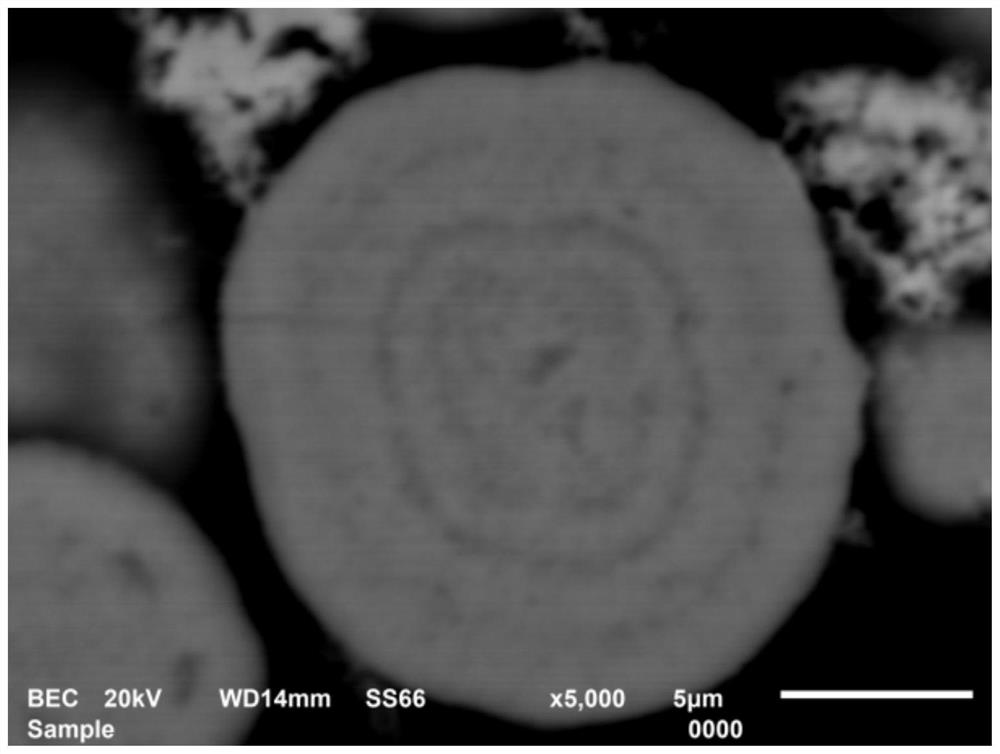

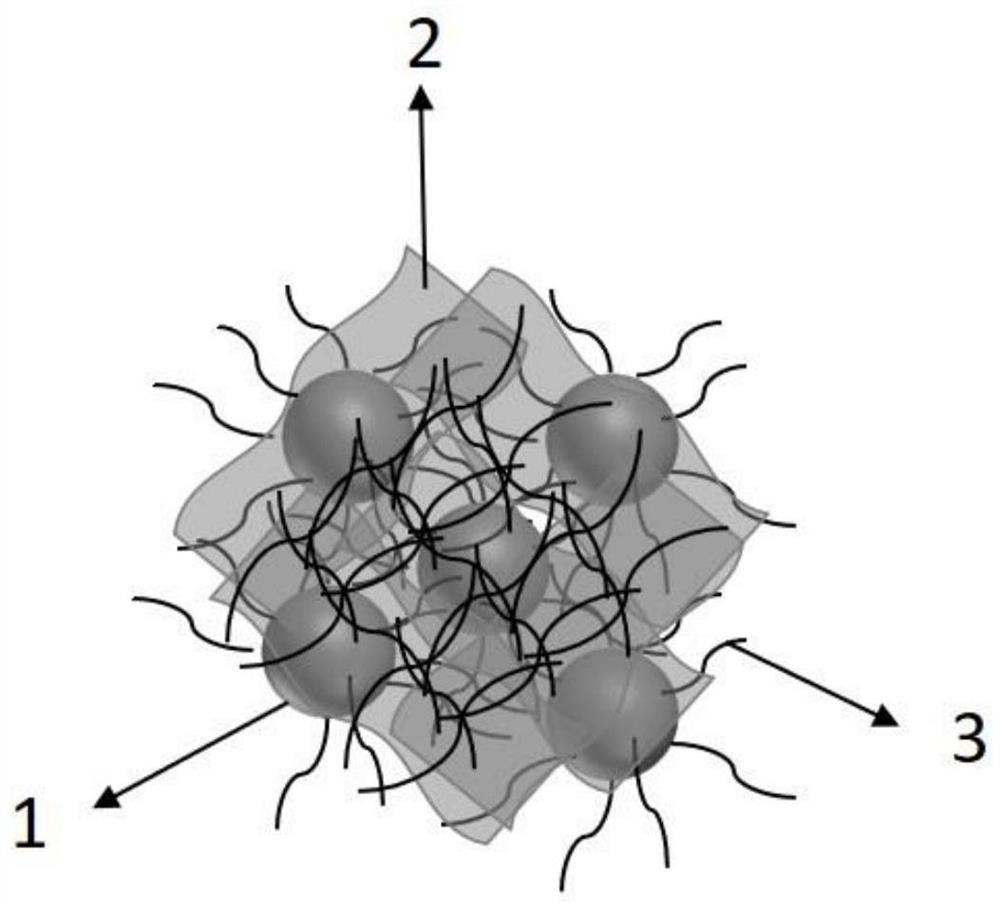

SiOx@C-CNT-G composite negative electrode material, preparation method and lithium ion battery

ActiveCN112259728AComposite structure is stableInhibit swellingSecondary cellsNegative electrodesCarbon layerElectrolytic agent

The invention provides a SiOx@C-CNT-G composite negative electrode material, which is provided with a plurality of secondary particles, the secondary particles comprise SiOx@C particles, carbon nanotubes and graphene sheets, the SiOx@C particles are SiOx particles coated with a nano carbon layer, and the carbon nanotubes grow in situ on the nano carbon layer of the SiOx@C particles; the graphene sheets are in bridge connection with the SiO@C particles through the carbon nanotubes; wherein the mass fraction of SiOx in the SiOx@C-CNT-G composite material is 60-90%. The graphene composite three-dimensional structure can provide space for volume expansion of SiOx particles, meanwhile, in-situ growth of CNT improves the conductivity and structural stability of the composite material, volume expansion of the material in the charging and discharging process is reduced, the contact surface of SiOx and an electrolyte is reduced through coating of graphene, and the stability of an SEI film of the composite material is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Self-fixing stator housing

InactiveCN104271953AImprove rigidityActive connectionRotary piston pumpsRotary piston liquid enginesElastomerEngineering

Owner:NETZSCH PUMPEN & SYST

Flexible flame-retardant aerogel as well as preparation method and application thereof

The invention discloses flexible flame-retardant aerogel as well as a preparation method and application thereof, and belongs to the technical field of aerogel. The flexible flame-retardant aerogel is prepared from the following raw materials: nanocellulose, sodium alginate, organosilane, boric acid, sodium tetraborate decahydrate, calcium carbonate and D-(+)-gluconic acid delta-lactone, and the nanocellulose comprises cellulose nanowires and cellulose nanofibers with carboxyl-rich surfaces. According to the invention, the degree of association between single nanocellulose is improved by utilizing the morphological structure characteristic of high length-diameter ratio of the cellulose nanowires so as to improve the flexibility of the aerogel, and the intrinsic flame retardant property of sodium alginate and the synergistic flame retardance of the boron-based flame retardant are utilized, so that the aerogel has wide application prospects in the fields of aerospace, buildings, special-shaped part flame retardance, heat insulation and the like.

Owner:DONGHUA UNIV

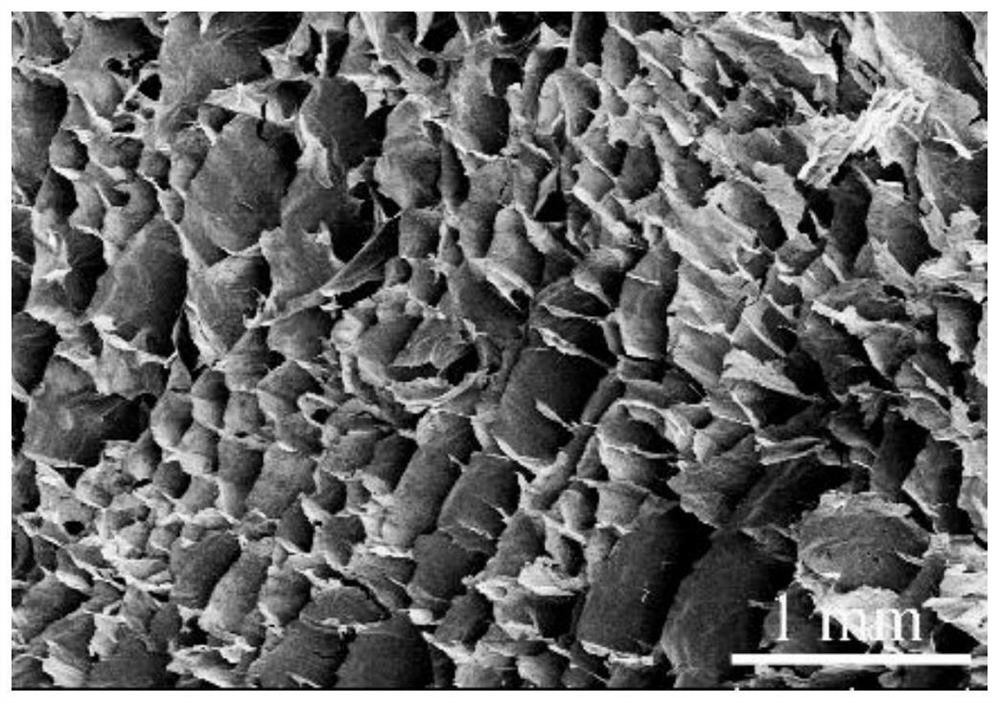

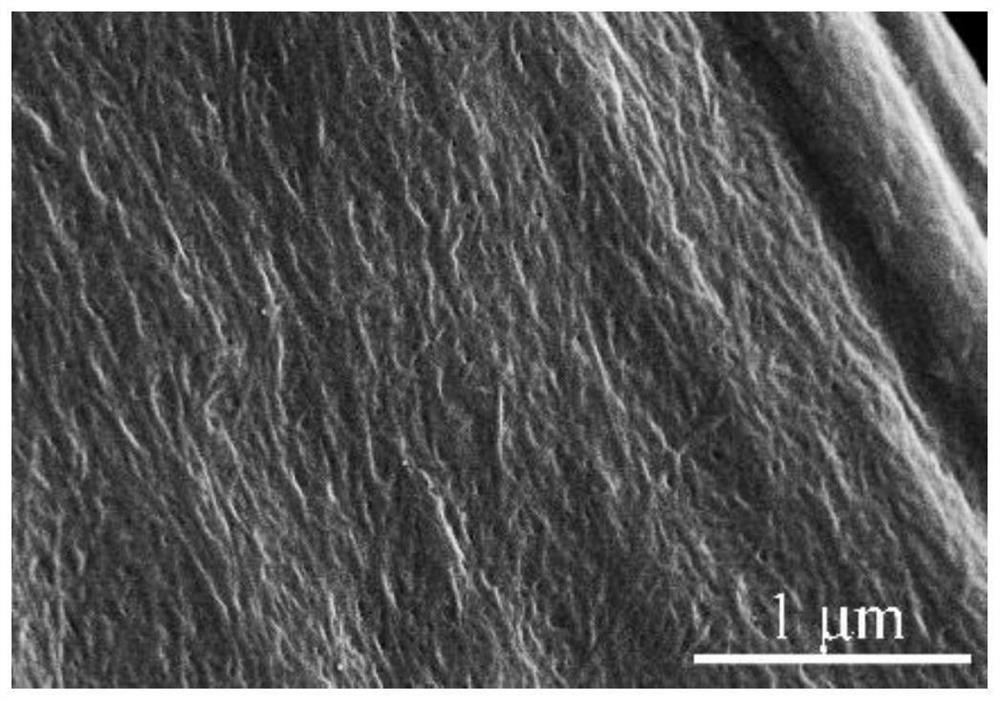

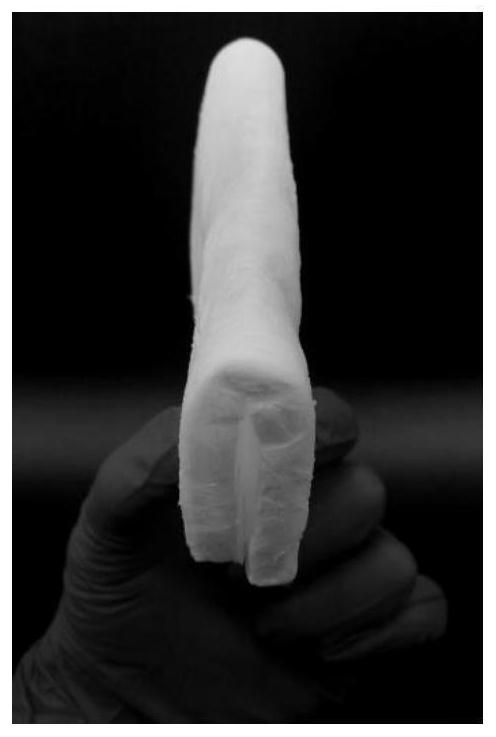

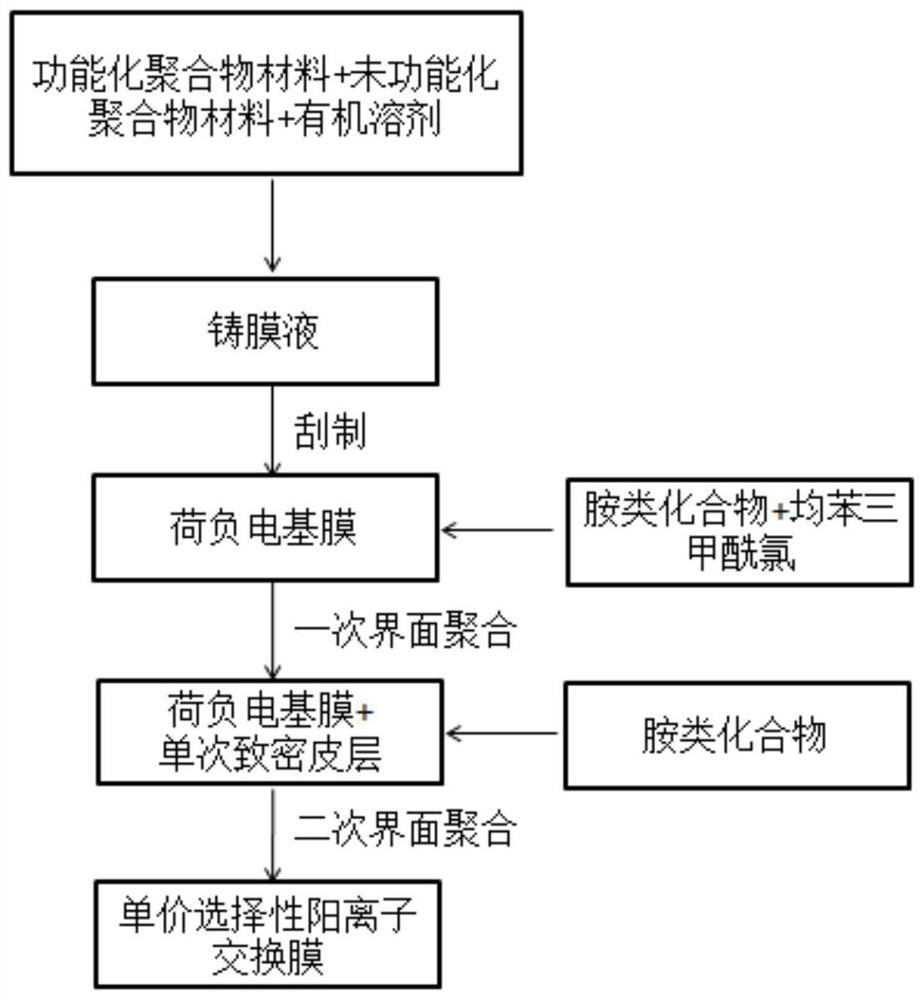

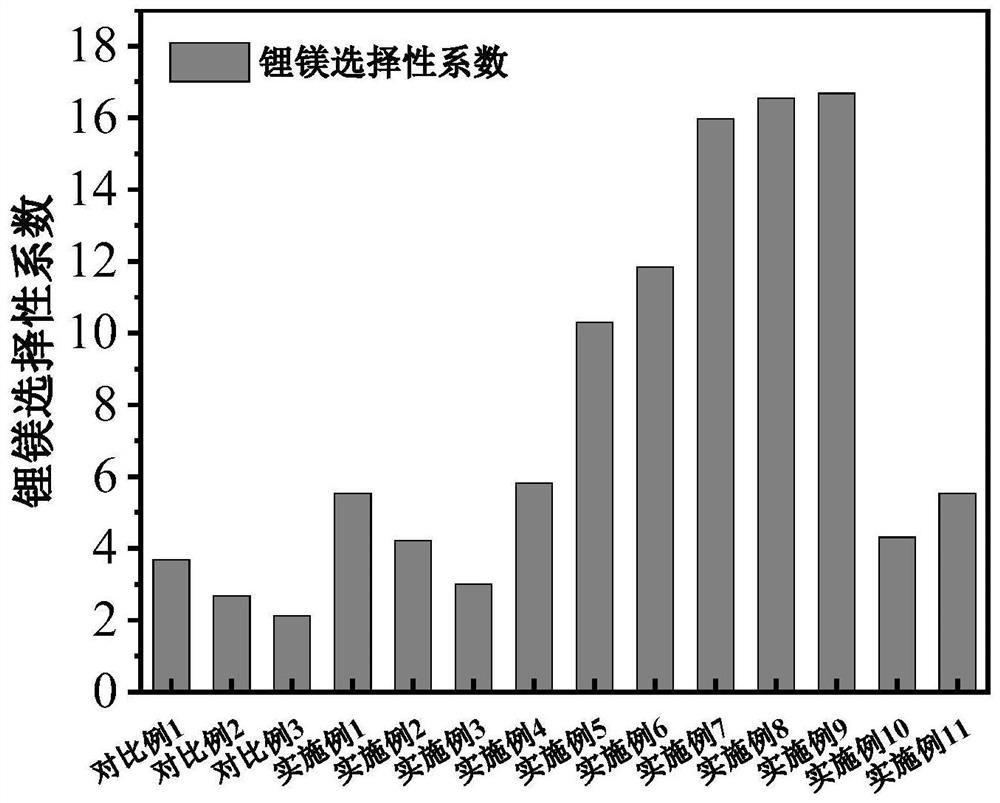

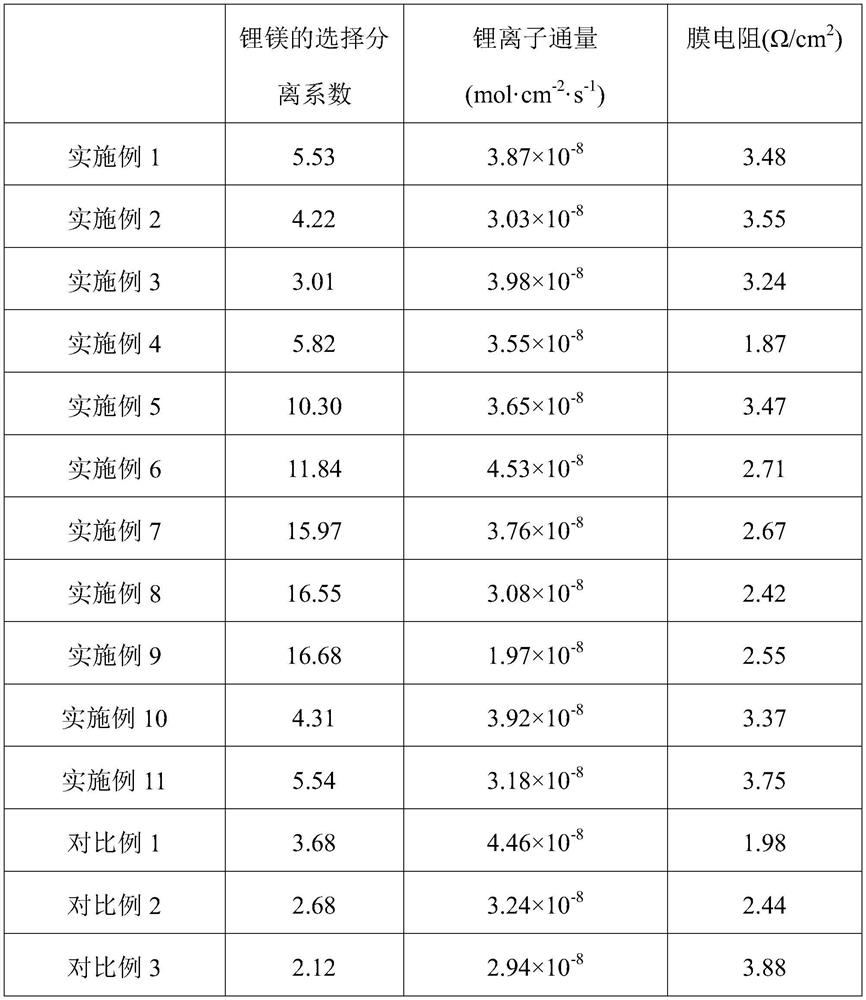

Monovalent selective cation exchange membrane as well as preparation method and application thereof

PendingCN114713295AComposite structure is stableRealize extraction and utilizationGeneral water supply conservationCation exchangersPolymer sciencePolymer chemistry

The invention provides a monovalent selective cation exchange membrane as well as a preparation method and application thereof. The preparation method comprises the following steps: defoaming a membrane casting solution of a blended polymer material, and scraping to obtain a membrane to obtain a negatively charged base membrane; the blended polymer material comprises a functionalized polymer material and a corresponding non-functionalized polymer material; sequentially contacting the surface of the negatively charged base membrane with a water phase solution and an oil phase solution for primary interfacial polymerization, and then contacting with the water phase solution for secondary interfacial polymerization to obtain the monovalent selective cation exchange membrane. The simple and mild preparation method is adopted, through two interfacial polymerization reactions, a compact anti-charge skin layer is constructed on the surface of the negative charge base membrane, and efficient separation of monovalent and multivalent cations by the monovalent selective cation exchange membrane is achieved.

Owner:HEBEI UNIV OF TECH

Automatic compound machine of composite shock-absorbing silencing piece

InactiveCN101368605BAvoid it happening againAvoid defects that create air bubblesLaminationLamination apparatusWeather resistanceEngineering

Disclosed is a composite damping silencing plate automatic compounding machine; a plurality of bearing rollers are arranged on the horizontal plane of a frame; pressing rollers are respectively arranged above the bearing rollers and tightly abutted on the bearing rollers to form the opposite rotation relation; a heating device is arranged on the front half region of the frame and under the bearing rollers. The composite damping silencing plate automatic compounding machine has the advantages of advanced compounding mode, high work efficiency, compounding large areas of metal plate material, high automation degree and reducing the work intensity of the workers greatly. The composite damping silencing manufactured by the automatic compounding machine has the advantages of obvious shockproofand silencing effect, strong adhesion intensity between the metal plates, strong anti-impact property, maintaining stable and firm composite structure in harsh operating conditions, good oil resistance, erosion resistance and weathering resistance, maintaining good application performance in the high temperature and low temperature environments.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

Ventilation nozzles, ventilation channels and their assembly aids, dashboard

ActiveCN102616114BEasy to moveConstant cross sectionAir-treating devicesVehicle heating/cooling devicesEngineeringBreathing

Owner:GM GLOBAL TECH OPERATIONS LLC

Five-in-one composite kraft paper

PendingCN109849440AComposite structure is stableQuality assuranceFlexible coversWrappersPulp and paper industryKraft paper

The invention relates to the technical field of composite kraft paper, in particular to five-in-one composite kraft paper. The composite kraft paper comprises a composite kraft paper body, and the composite kraft paper body comprises a kraft paper layer, a first PE film layer, a PE woven fabric layer, a second PE film layer and an EPE layer; the end surface of the kraft paper layer and the first PE film layer is fixedly provided with kraft paper convex portions, positions, located on the end surface of the kraft paper layer, of two adjacent kraft paper convex portions are fixedly provided withkraft paper concave portions, the kraft paper convex portions and the kraft paper concave portions are provided with a first adhesive layer, and the first PE film layer is adhered to the first adhesive layer; and one end surface, far away from the first adhesive layer, of the first PE film layer is adhered to a second adhesive layer, the second adhesive layer is arranged on upper PE woven fabricconvex portions and upper PE woven fabric concave portions, and the upper PE woven fabric convex portions and the upper PE woven fabric concave portions are fixedly arranged on the end surface of thePE woven fabric layer. According to the composite kraft paper provided by the invention, through the above arrangement, the properties of the composite kraft paper, such as tensile strength, punctureresistance, waterproofing and shock absorption can be greatly improved.

Owner:长春兴德世通汽车工程技术有限公司

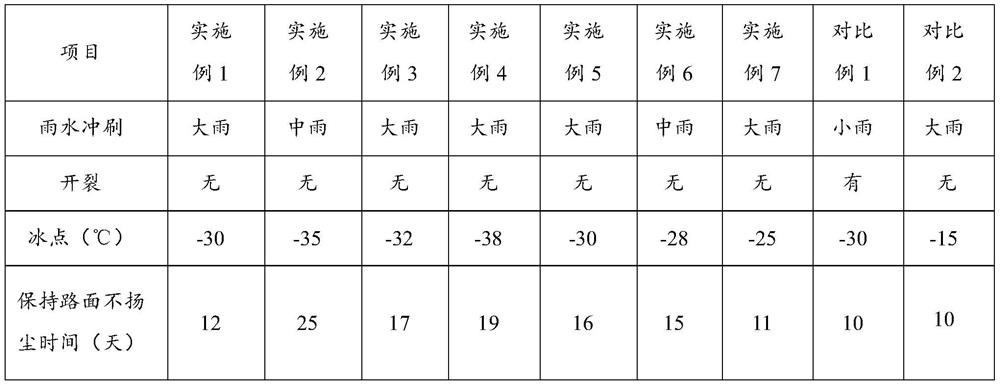

Anti-rainwater dust suppressant and preparation method thereof

ActiveCN111019609BImprove film formationImprove crack resistanceOther chemical processesActive agentSurface-active agents

The rainproof and dust suppression agent provided by the invention comprises the following raw materials: water-soluble polymer; organic bentonite; water-soluble starch; moisturizing agent; surface active agent; binder and water. Among them, the water-soluble polymer is used as the skeleton material, which can be closely combined with other components through interactions such as hydrogen bonds to form a stable composite structure; the surfactant is conducive to the infiltration of dust, and has the same properties as the water-soluble polymer. Good compatibility and binding ability; the humectant and the binder work together to retain water, resist evaporation, and resist wind erosion; organic bentonite and water-soluble starch combine with each other to increase the firmness of the film through π‑π electron interaction , and cooperate with other components to improve the film-forming properties of the dust suppressant and the performance of anti-rain erosion and anti-cracking; the rain-proof and dust-suppressant can not only prevent rain erosion and cracking through the synergistic effect of various components, but also have Excellent adhesion and fast film-forming properties, increase the surface strength and quickly form a film on the surface.

Owner:北京南瑞怡和环保科技有限公司

Cellulose/nano-inorganic particle composite pigment and its preparation method and application

ActiveCN110698728BIncrease surface areaImprove coloring efficiencyPigment treatment with macromolecular organic compoundsCellulosePolymer science

The invention discloses a cellulose / nano inorganic particle composite pigment and its preparation method and application, belonging to the technical field of dyeing pigments. The composite pigment is composed of cellulose and nano-inorganic particles grown in situ on the surface and inside of the cellulose, the size of the nano-inorganic particles is 20-300nm, and the mass fraction of the nano-inorganic particles in the composite pigment is 8-10% . The nano inorganic particles are one of iron red, iron yellow and Prussian blue. The composite pigment is applied to the dyeing of polymer products such as plastic, resin or rubber. The present invention uses cellulose as a raw material, adopts a specific process to grow nano-inorganic particles in situ inside and on the surface of cellulose, and the obtained composite pigment has a durable and firm coloring ability, and when applied to the coloring of a polymer matrix, it can improve the color of the matrix while dyeing. mechanical properties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

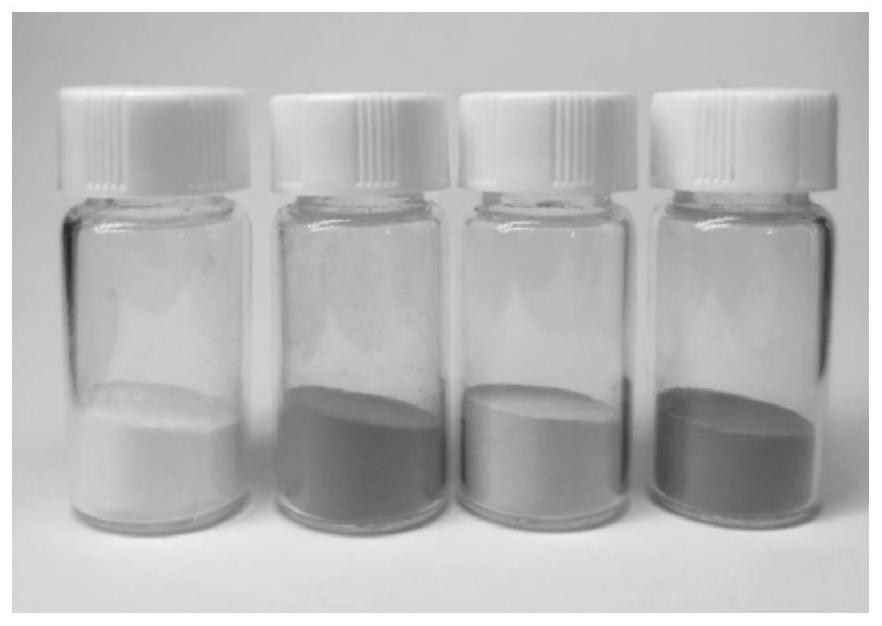

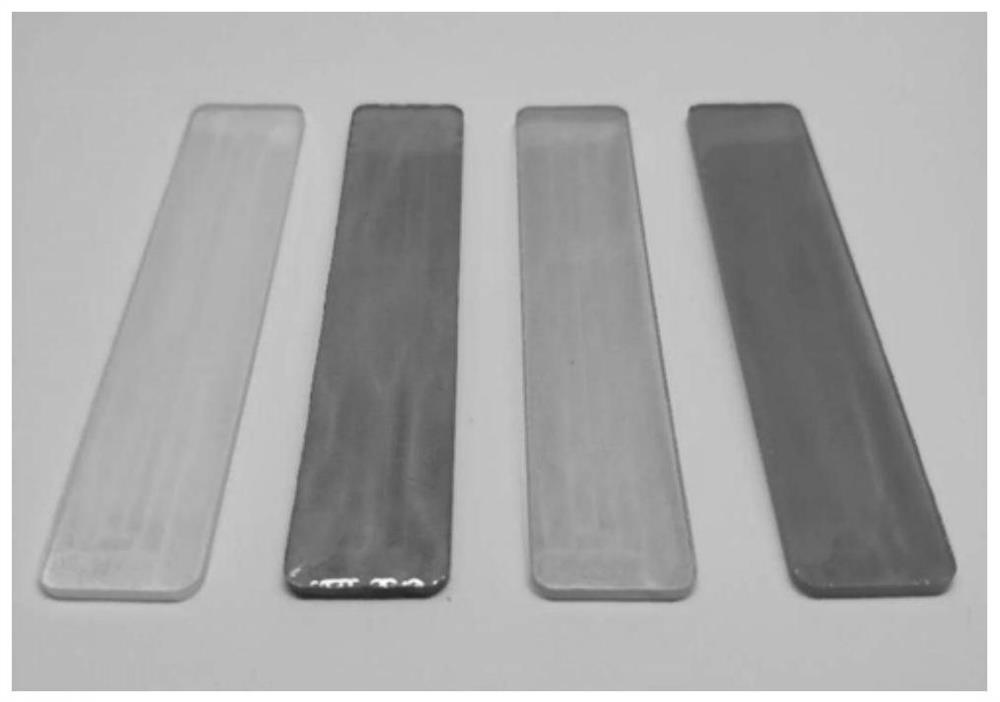

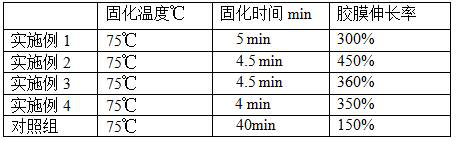

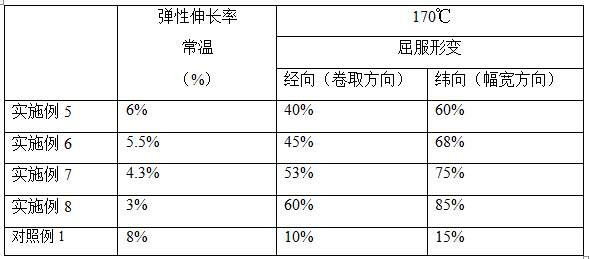

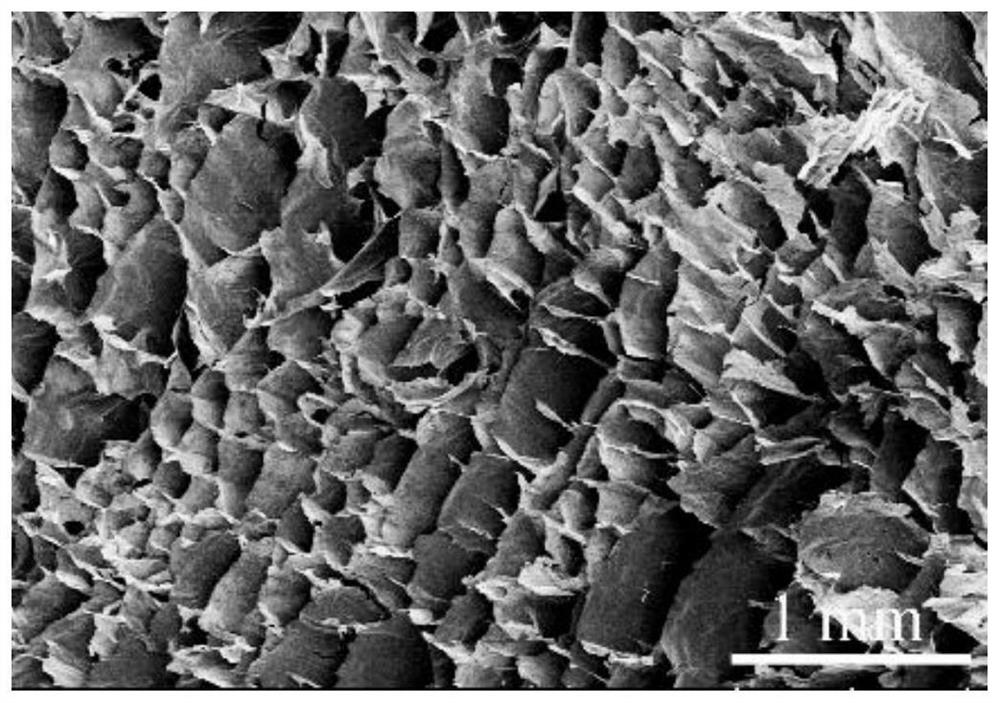

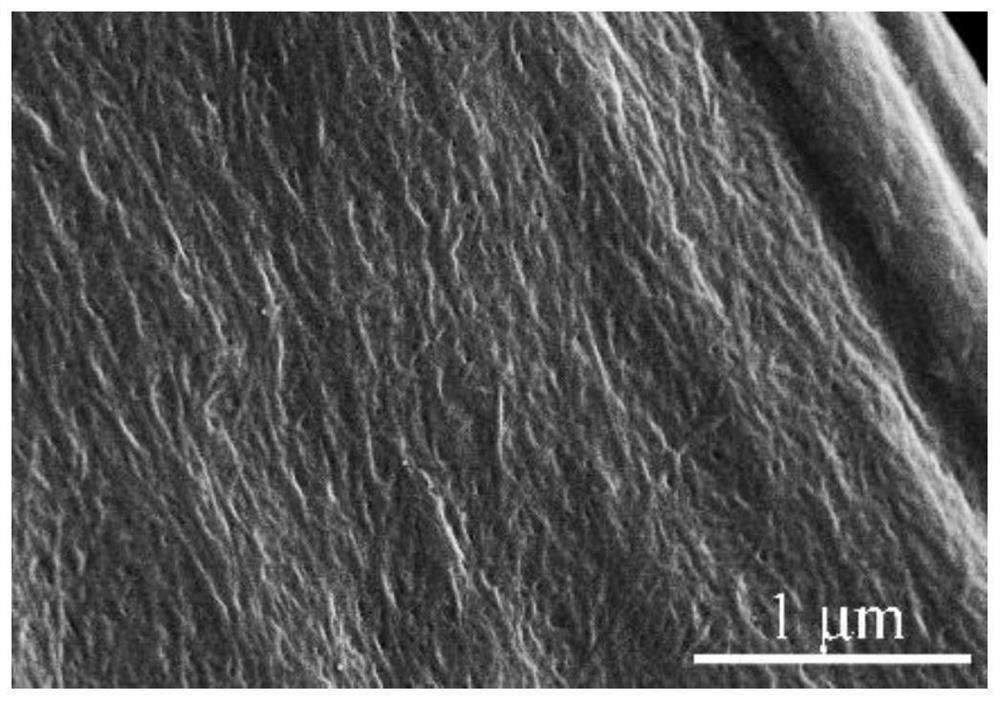

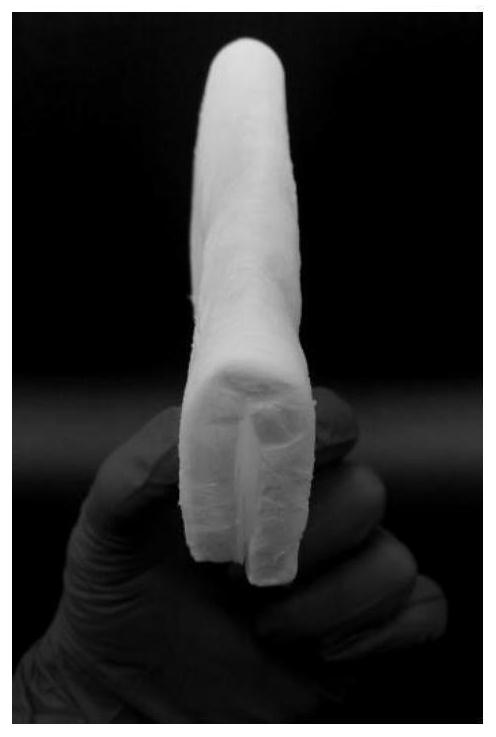

Thermoplastic electrostatic flocking fabric as well as preparation method and application thereof

ActiveCN112921672ALow curing temperatureHigh elongationConstructions elementsCoatingsEpoxyThermoplastic

The invention discloses thermoplastic electrostatic flocking fabric as well as a preparation method and application thereof. The electrostatic flocking fabric is composed of a surface layer, a middle layer and a bottom layer, wherein the surface layer is fiber fluff, the middle layer is a glue curing layer, and the bottom layer is base cloth; the glue curing layer is electrostatic flocking glue and is composed of a mixed monomer, an emulsifier, an initiator, a cross-linking agent and water, and the mixed monomer comprises methyl methacrylate, dibutyl maleate, butyl acrylate, ethyl acrylate and epoxy resin. The electrostatic flocking glue is low in curing temperature, and is high in elongation and softness of glue film, and when the electrostatic flocking glue is applied to preparation of the thermoplastic electrostatic flocking fabric, a formed composite structure is stable, yield deformation can be improved, and the forming requirement is met after mechanical foaming; the electrostatic flocking fabric is stable in size at normal temperature, has the elastic elongation of 5-8%, can generate plastic deformation, which is uniform and free of tearing and cracking phenomena, at a thermal state (150-170 DEG C), and can be applied to a new material required by an embedded automobile carpet foot pad.

Owner:SHANDONG HUACHENG HIGH TECH ADHESIVE

A kind of production process of passenger car air duct with polyurethane scrap mold making and three-dimensional core material structure polyurethane foam

ActiveCN108724545BGood insulation propertiesImprove toughnessDomestic articlesGlass fiberManufacturing technology

The invention discloses a passenger car air channel production technology adopting three-dimensional core material structure polyurethane foaming. By means of the method of additionally arranging a heat preserving layer filled through polyurethane leftover materials, compared with an existing foaming mould manufacturing technology, the heat preserving performance of the mould can be better, glassfiber has excellent toughness and strength, by means of reasonable preparation, the service life of the mould can be prolonged, resin is added into the leftover materials, the mould can have coagulability, and forming of the mould can be promoted. The polyurethane glass fiber enhanced hard foaming leftover materials are used as mould filler, recycling and reusing of resources can be achieved, andthe cost investment of the mould is reduced. By means of the form of adding the heat preserving layer for the mould, polyurethane materials keep the constant temperature in the transferring and foaming process, and the good mobility is achieved. Three-dimensional core materials are used, the use quantity of the polyurethane materials can be reduced, weight reduction of products is achieved, and the production period is shortened.

Owner:GUIZHOU HUAYUN AUTOMOBILE DECORATING PART MFG CO LTD

A kind of bactericidal and aldehyde-removing air filter membrane

ActiveCN107051232BImprove filtering effectPurification and decompositionSemi-permeable membranesBreathing filtersAir filtrationFiber

The invention discloses an air filtration membrane with functions of killing bacteria and removing formaldehyde. The air filtration membrane is of a three-layer nanofiber membrane composite structure, wherein the upper layer is an activated carbon nanofiber membrane, the middle layer is a pure TiO2 nanofiber membrane, and the lower layer is a nano-silver antibacterial fiber membrane; the pure TiO2 nanofiber membrane is prepared from a high polymer material / TiO2 precursor composite nanofiber membrane through heat treatment, and the high polymer material / TiO2 precursor composite nanofiber membrane is prepared with an electrospinning method; the activated carbon nanofiber membrane is an electrospun activated carbon nanoparticle / high polymer material composite nanofiber membrane; the nano-silver antibacterial fiber membrane is an electrospun nano-silver particle / high polymer material composite nanofiber membrane. The air filtration membrane not only can filter solid particulate pollutants very well, but also is good in breathability, and can remove and decompose formaldehyde in air and filter and kill harmful bacteria in air, thereby guaranteeing health of a respiratory system better.

Owner:保定源汉升新材料科技有限公司

Flexible gas-retardant gas gel, its preparation method and application

Owner:DONGHUA UNIV

Surface treatment solution for galvanized material containing composite biological polysaccharide and preparation method thereof

ActiveCN109097765BComposite structure is stableImprove corrosion resistanceMetallic material coating processesInulinZinc

Owner:南京京科新材料研究院有限公司

Cellulose/nano inorganic particle composite pigment, preparation method therefor and application of cellulose/nano inorganic particle composite pigment

ActiveCN110698728AIncrease surface areaImprove coloring efficiencyPigment treatment with macromolecular organic compoundsCelluloseInorganic particle

The invention discloses a cellulose / nano inorganic particle composite pigment, a preparation method therefor and an application of the cellulose / nano inorganic particle composite pigment and belongs to the technical field of dyeing pigments. The composite pigment is prepared from cellulose and nano inorganic particles which grow on the surface and interior of the cellulose in situ, wherein the nano inorganic particles have the size of 20nm to 300nm, and the mass percent of the nano inorganic particles in the composite pigment is 8% to 10%. The nano inorganic particles comprise one of iron oxide red, iron oxide yellow and Berlin blue. The composite pigment is applied to dyeing of polymeric products such as plastics, resin or rubber. According to the cellulose / nano inorganic particle composite pigment, the preparation method therefor and the application of the cellulose / nano inorganic particle composite pigment, the cellulose serves as a raw material, the nano inorganic particles grow onthe surface and interior of the cellulose in situ by employing a specific process, and the obtained composite pigment has durable and firm coloring power; and when the composite pigment is applied tocoloring of polymeric matrixes, mechanical properties of the matrixes can be improved while the matrixes are dyed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

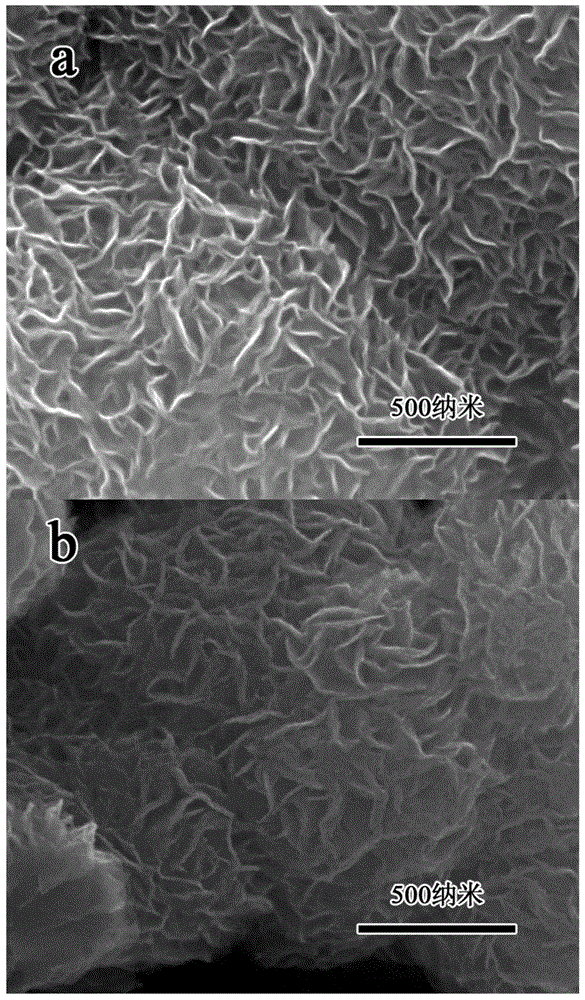

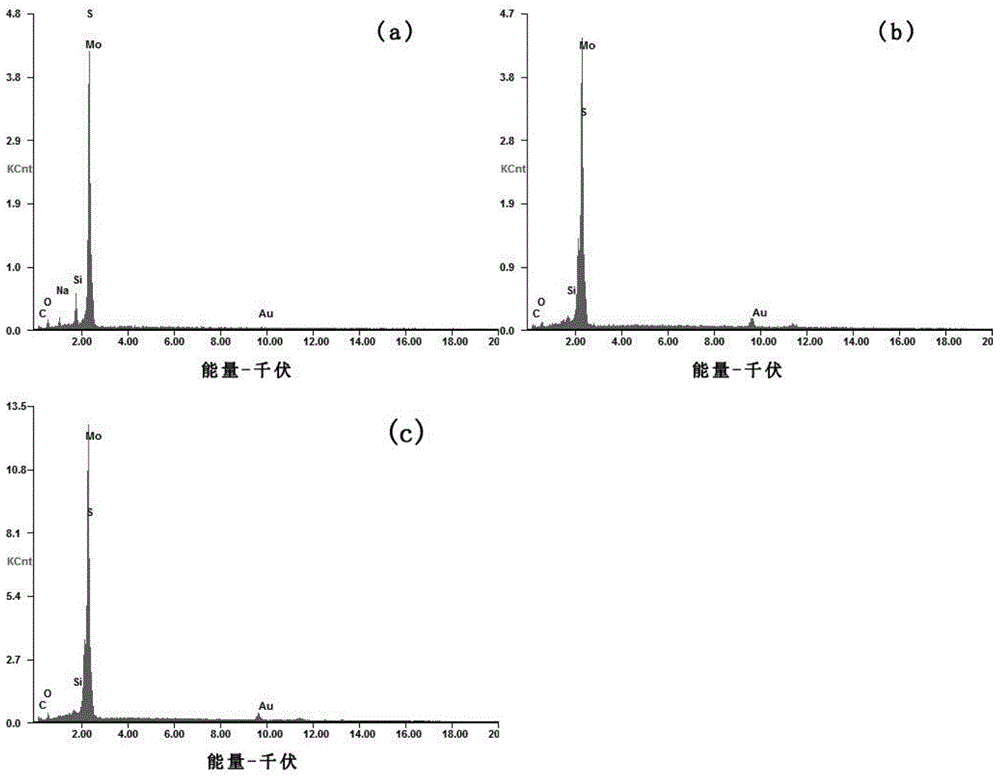

A kind of molybdenum disulfide composite nano-gold photocatalyst and preparation method thereof

ActiveCN104722316BSimple methodEasy to operatePhysical/chemical process catalystsNanoparticlePhysical chemistry

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com