Flexible gas-retardant gas gel, its preparation method and application

A kind of airgel and flexible technology, applied in the field of airgel, can solve the problems of limited use, airgel can not meet product use standards, harmful gas safety hazards, etc., to achieve enhanced mechanical strength, good heat insulation effect, excellent The effect of bending flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

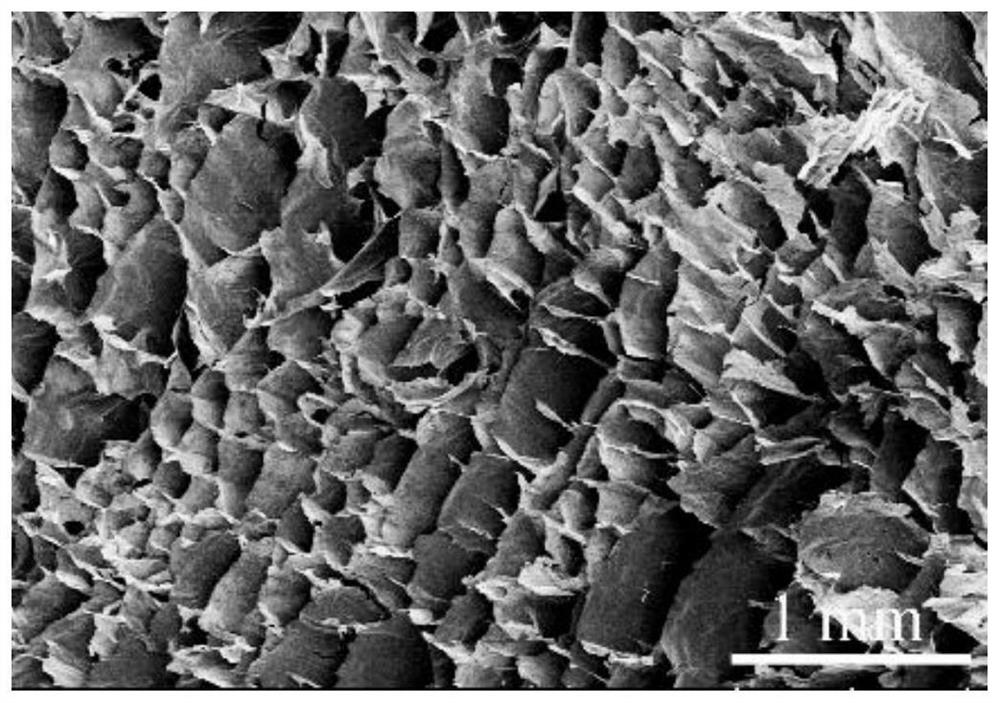

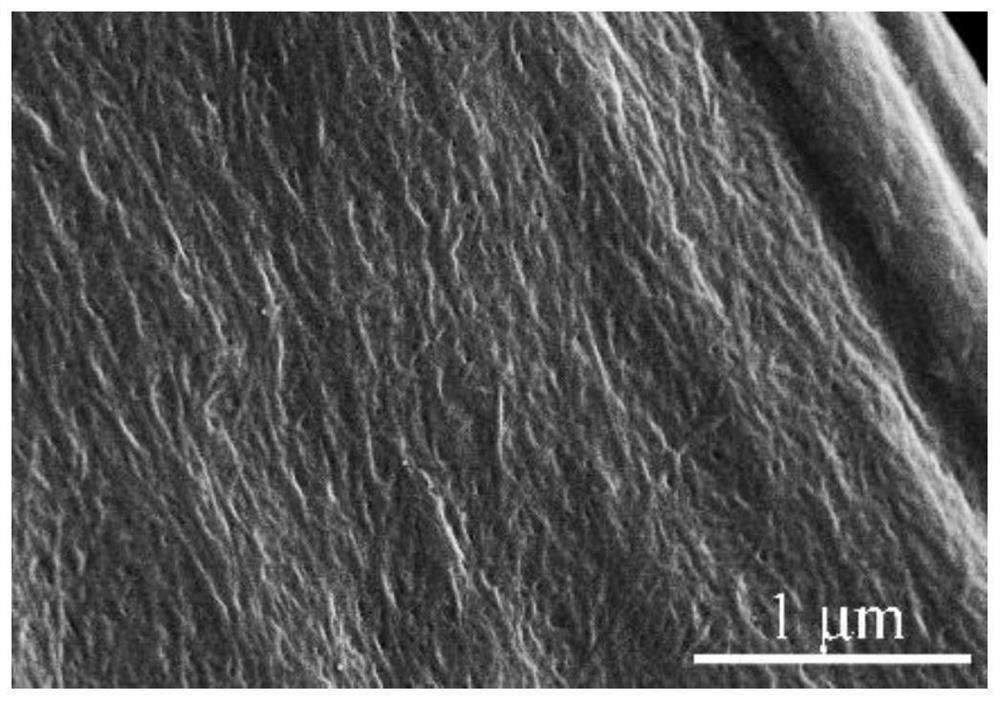

[0055] A preparation method of cellulose nanowires, the specific steps are as follows:

[0056] Disperse the purified cellulose powder in deionized water to obtain a dispersion with a mass fraction of 0.5%; treat the above dispersion with an ultrasonic cell pulverizer with a power of 800W for 30 minutes; The cellulose nanowires were obtained after dispersing for 10 minutes in a homogeneous disperser for 10 minutes.

Embodiment 1

[0058] A method for preparing a flexible gas-retardant gas gel, the specific steps are as follows:

[0059] S1, the above-mentioned cellulose nanofibrils and cellulose nanowires were prepared with deionized water to obtain a suspension with a mass fraction of 0.5%, and the two suspensions were mixed at a mass ratio of 3:1, and 150 g of the mixed suspension was weighed. Suspension: Prepare a sodium alginate solution with a mass fraction of 0.25% and weigh 150g, mix the above-mentioned mixed suspension with the sodium alginate solution, put it in a 500ml beaker, and perform magnetic stirring at 25°C at a speed of 1000r / min , to obtain a biopolymer mixture;

[0060] S2, weigh 0.5625g of methyltrimethoxysilane, add it dropwise to the biopolymer mixture obtained in step S1, adjust the pH to 4 with 0.5mol / L acetic acid; Magnetic stirring for 2h to carry out cross-linking to obtain a cross-linking solution;

[0061] S3, weigh 0.1125g of boric acid and 0.1125g of sodium tetraborate ...

Embodiment 2

[0066] A method for preparing a flexible gas-retardant gas gel, the specific steps are as follows:

[0067] S1, the above-mentioned cellulose nanofibrils and cellulose nanowires were prepared with deionized water to obtain a suspension with a mass fraction of 0.5%, and the two suspensions were mixed at a mass ratio of 3:1, and 150 g of the mixed suspension was weighed. Suspension: Prepare a sodium alginate solution with a mass fraction of 0.5% and weigh 150g, mix the above-mentioned mixed suspension with the sodium alginate solution, put it in a 500ml beaker, and carry out magnetic stirring at 25°C at a speed of 1000r / min , to obtain a biopolymer mixture;

[0068] S2, weigh 0.75g of methyltrimethoxysilane, add it dropwise to the biopolymer mixture obtained in step S1, adjust the pH to 4 with 0.5mol / L acetic acid; Magnetic stirring for 2h to carry out cross-linking to obtain a cross-linking solution;

[0069] S3, weigh 0.15g of boric acid and 0.15g of sodium tetraborate decah...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com