Knittable asymmetric capacitor and preparation method thereof

A capacitor, asymmetric technology, applied in the field of asymmetric capacitors and its preparation, can solve the problem of low energy density of capacitors, achieve good bending flexibility and electrochemical stability, wide application prospects, and improve the effect of flexible weaving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the asymmetric capacitor of the present invention comprises the following steps:

[0042] (1) Select one or more carbon fibers or metal wires with a diameter of less than 100 μm as the positive current collector and the negative current collector, and then deposit a positive conductive layer and a negative conductive layer with a thickness of less than 500 nm on the surface of the positive current collector and the negative current collector, respectively, The voltage window of the positive electrode conductive layer and the negative electrode conductive layer on the surface unit length of the positive electrode current collector and the negative electrode current collector and the amount of charge of the load are balanced; + In the electrolyte, the voltage window of the positive conductive layer E 1 and the voltage window E of the negative electrode conductive layer 2 Meet, -1.23V≤E 2 1 ≤1.23V, 4:5≤|E 1 |:|E 2 |≤5:4, the amount of charge Q...

Embodiment 1

[0047] Step 1: Electrode Preparation

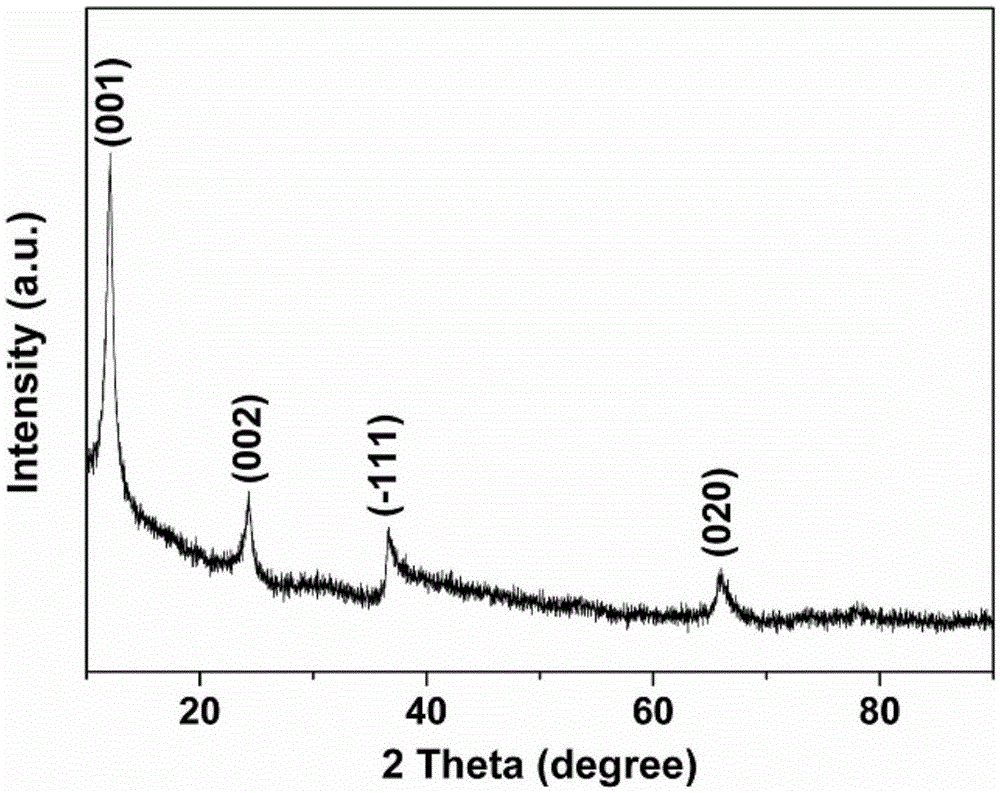

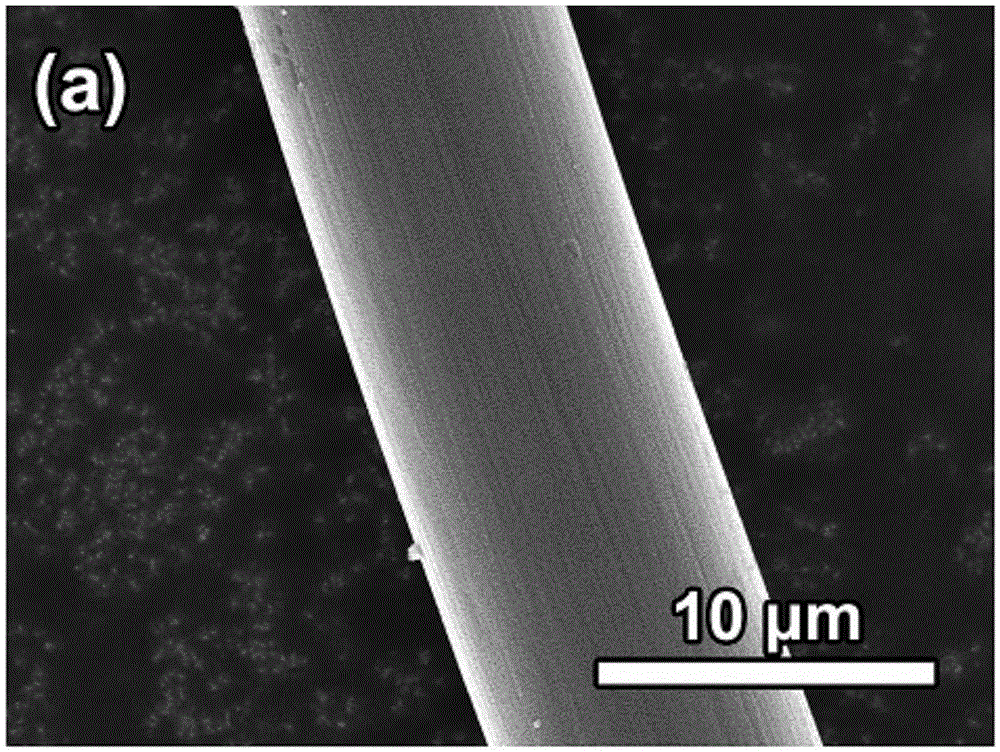

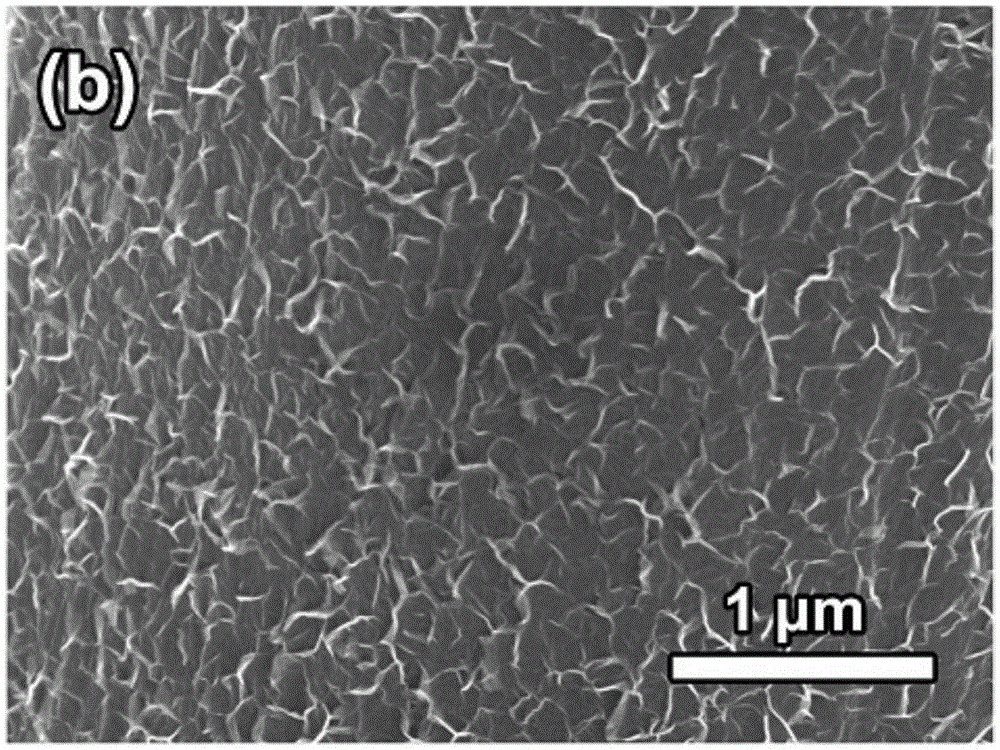

[0048] MnO 2 / Preparation of carbon fiber cathode material

[0049] S1. A carbon fiber with a length of 20 cm, a diameter of 10 μm, and a mass of 0.2 g was ultrasonically cleaned with acetone, ethanol, and water for 10 min, taken out and soaked in 20 ml of concentrated hydrochloric acid (H + The concentration is 12mol / L) and sonicated for 5min.

[0050] S2. 1mmol potassium permanganate, 0.5ml concentrated hydrochloric acid (H + The concentration is 12mol / L) is dissolved in the deionized water of 35ml, is mixed with permanganate solution, and described permanganate solution contains the MnO of 29mmol / L 4 - and 1.5mol / L of H + ; The carbon fiber that step (1) obtains is put into permanganate solution, and is transferred to autoclave lining, is put into 85 ℃ of baking ovens and reacts 20min; Reaction finishes and cools down to room temperature naturally, takes out sample and cleans with deionized water for 3 and dried under vacuum at ...

Embodiment 2

[0060] (1) Use cyclic voltammetry to generate polypyrrole on carbon fiber as the positive electrode, and use hydrothermal method to generate cobalt selenide on titanium wire as the negative electrode. By controlling the experimental parameters, the positive electrode material and negative electrode material per unit length can reach Charge balance, wherein the diameter of carbon fiber and titanium wire is 100μm;

[0061] (2) Dissolve 1g of lithium chloride and 10g of PVA powder in 89ml of deionized water, and stir at 90°C until the solution is clear and transparent. Soak the polypyrrole / carbon fiber electrode and the cobalt selenide / titanium wire electrode prepared in step (1) in the above PVA-LiCl solution for 10 minutes, take it out and dry it in an oven at 45°C for 10 minutes. Align a polypyrrole / carbon fiber with a cobalt selenide / titanium wire at the front and rear ends, place them side by side, dry in the air overnight, and remove excess water in the electrolyte to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com