Patents

Literature

61results about How to "Increased bending flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

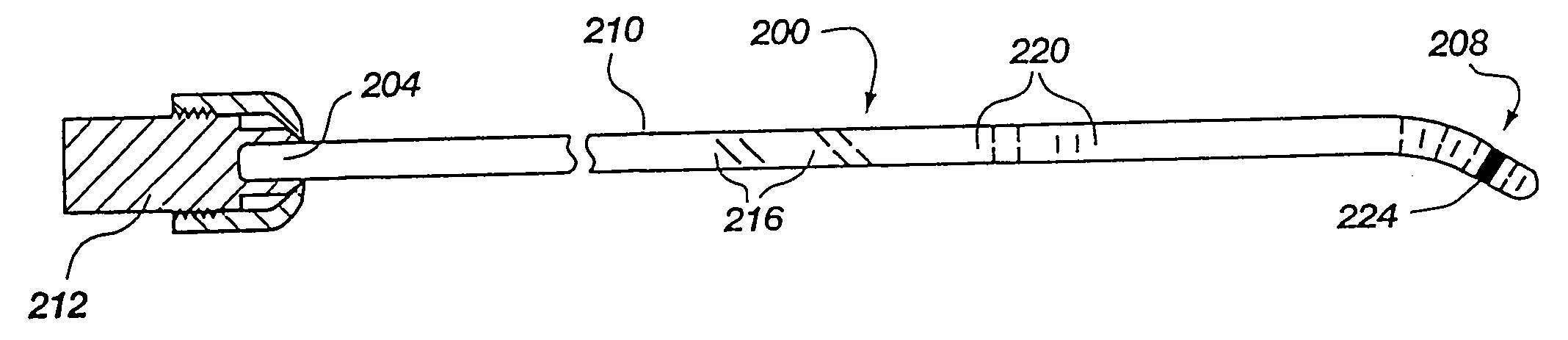

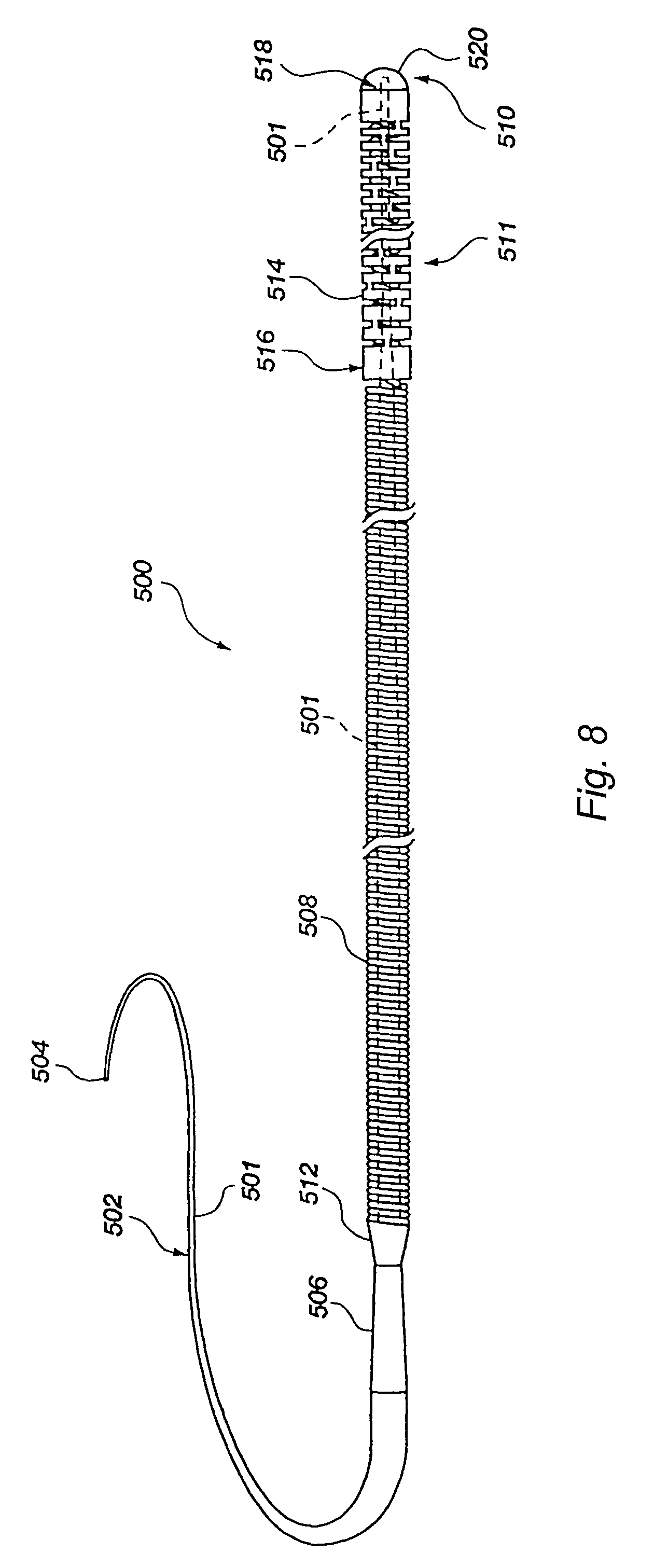

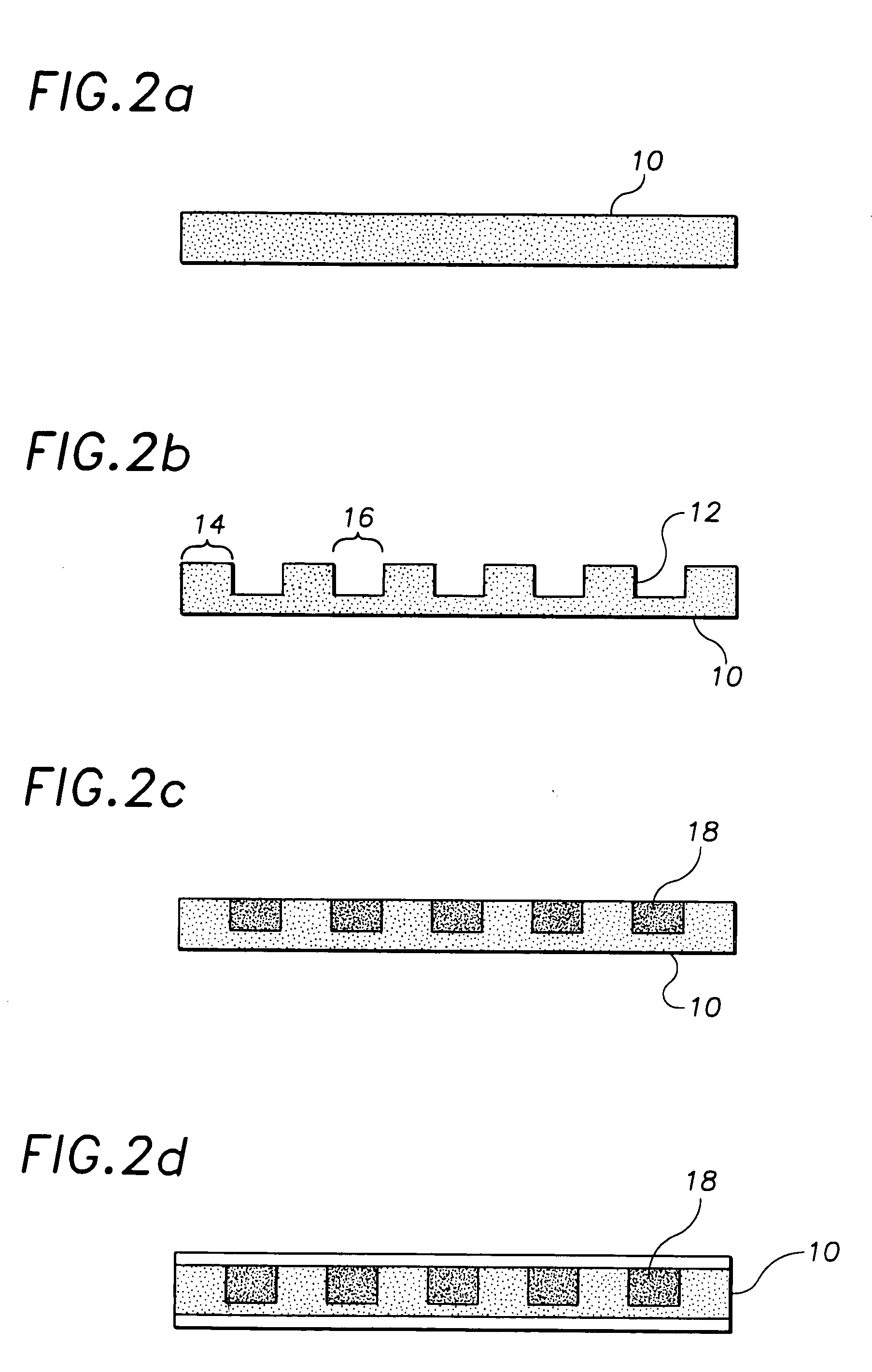

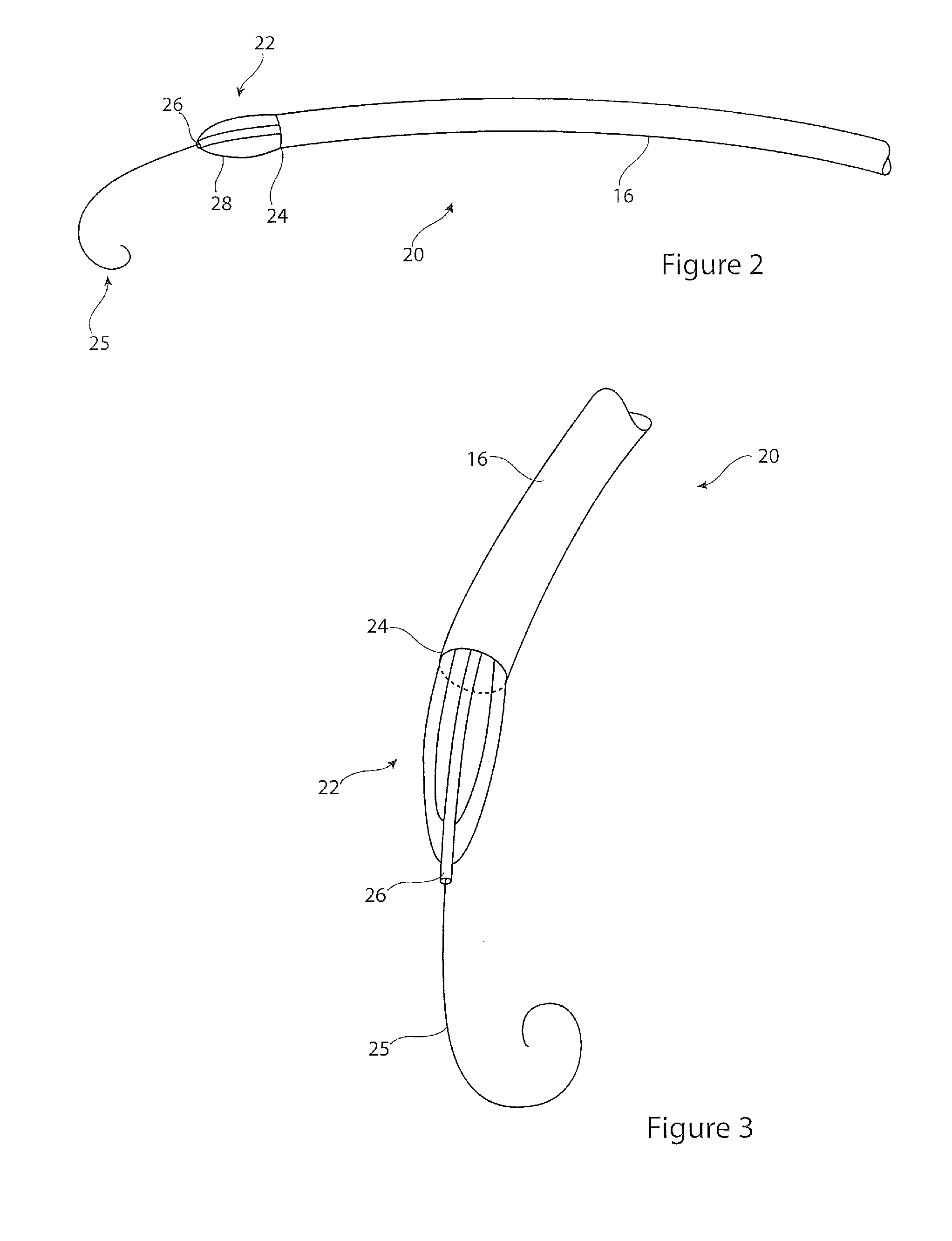

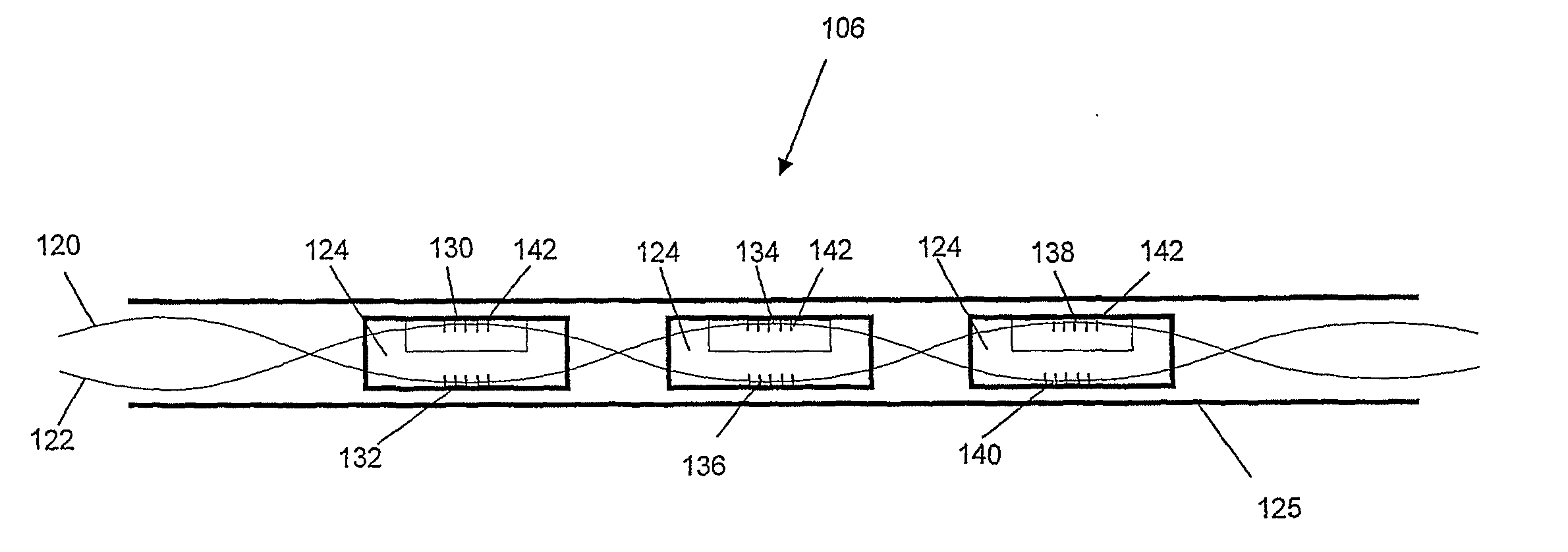

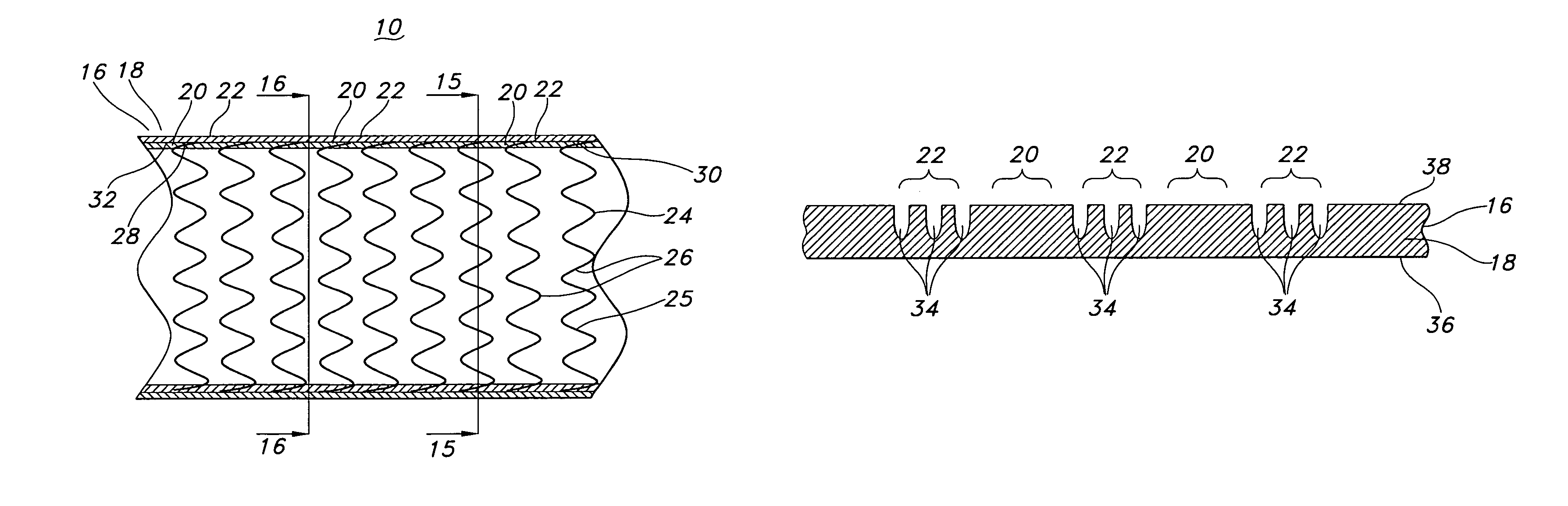

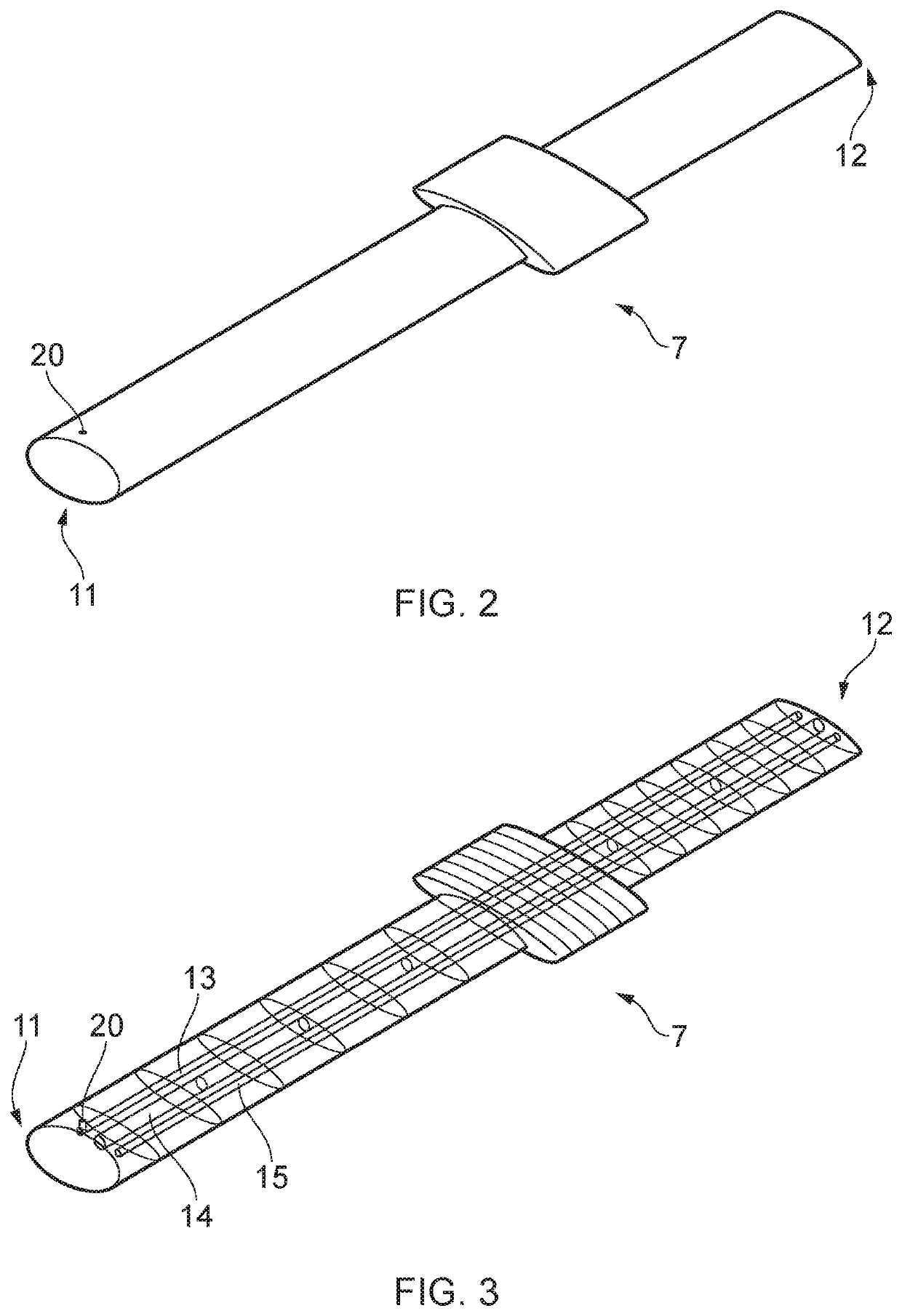

Medical device with collapse-resistant liner and mehtod of making same

InactiveUS20060189896A1Desired flexibility in bendingIncrease stiffnessGuide wiresDiagnostic recording/measuringBand shapeMedical device

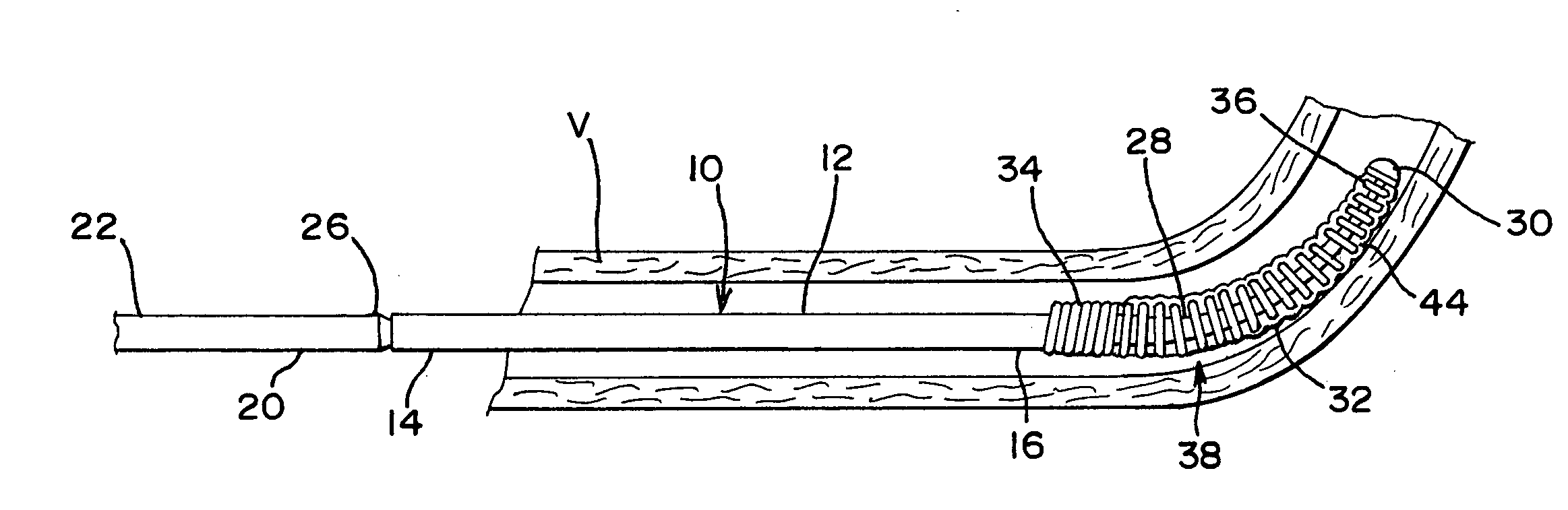

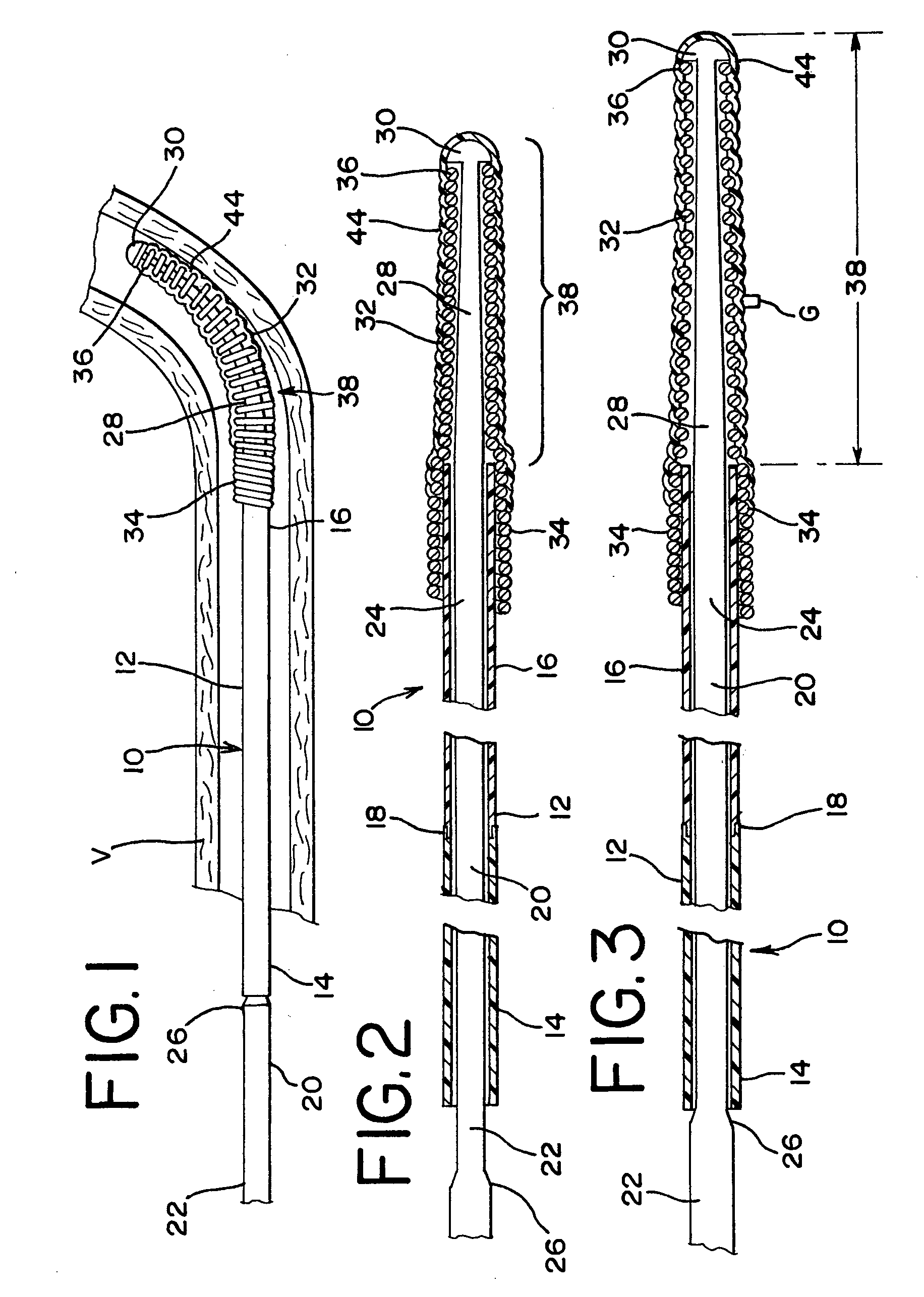

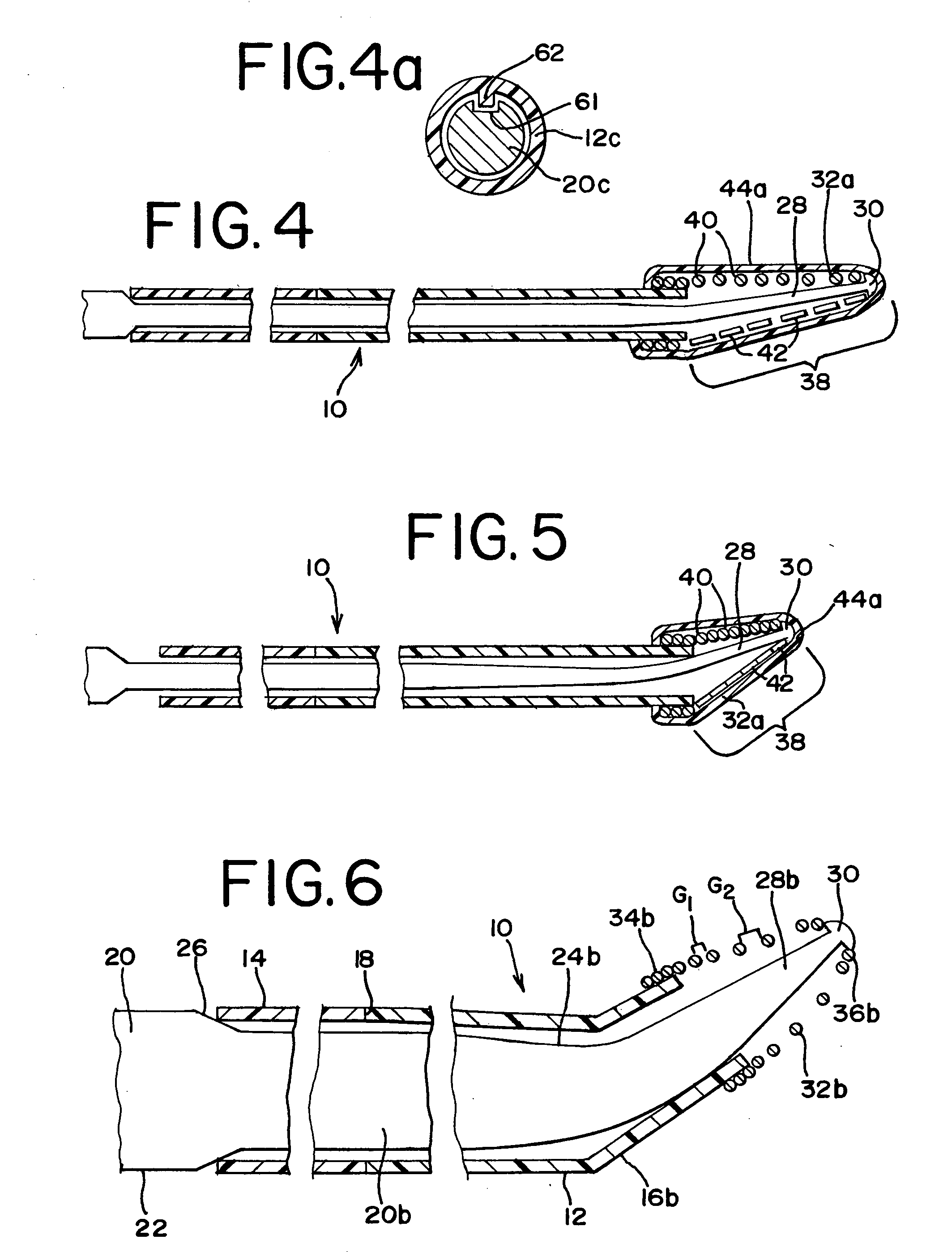

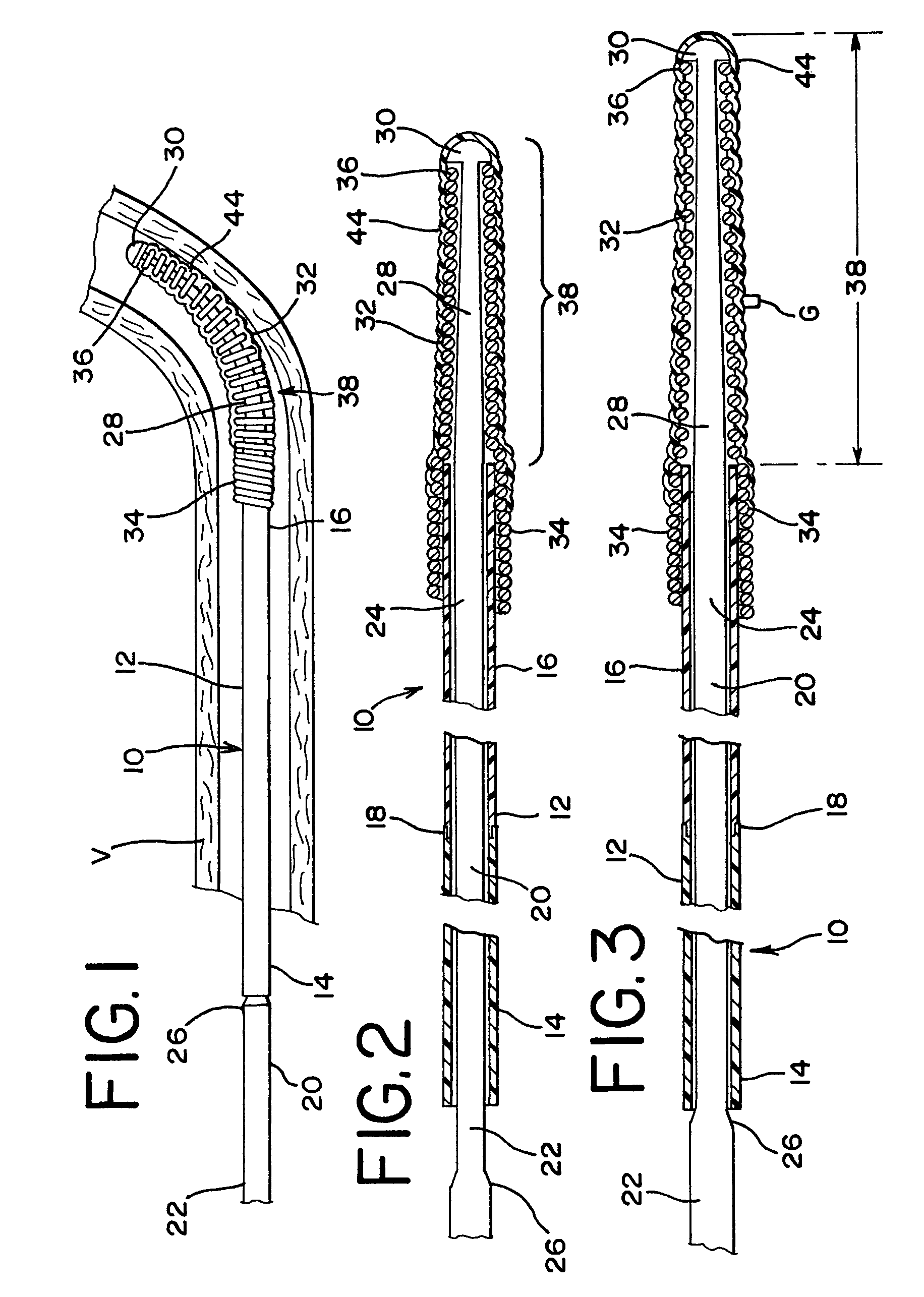

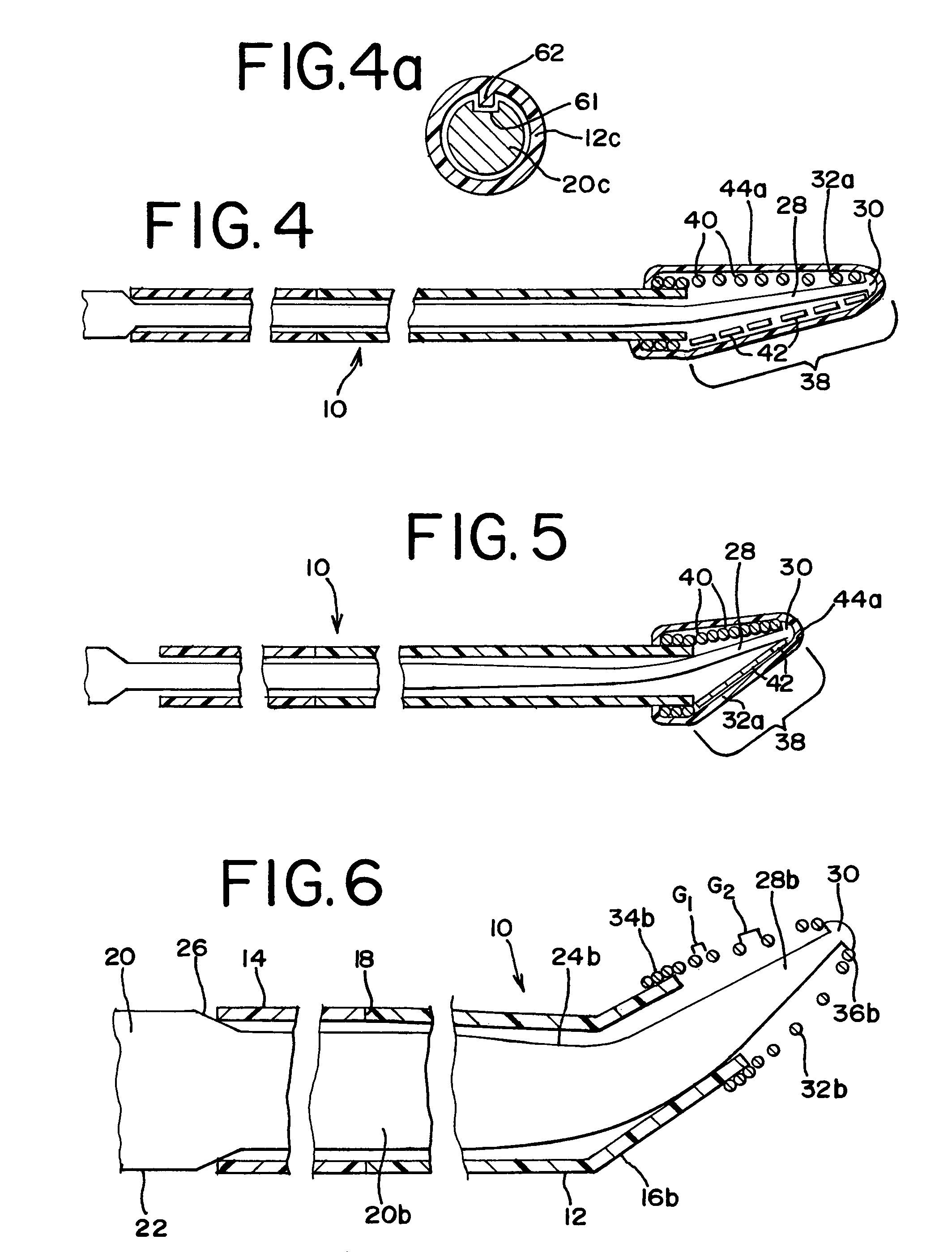

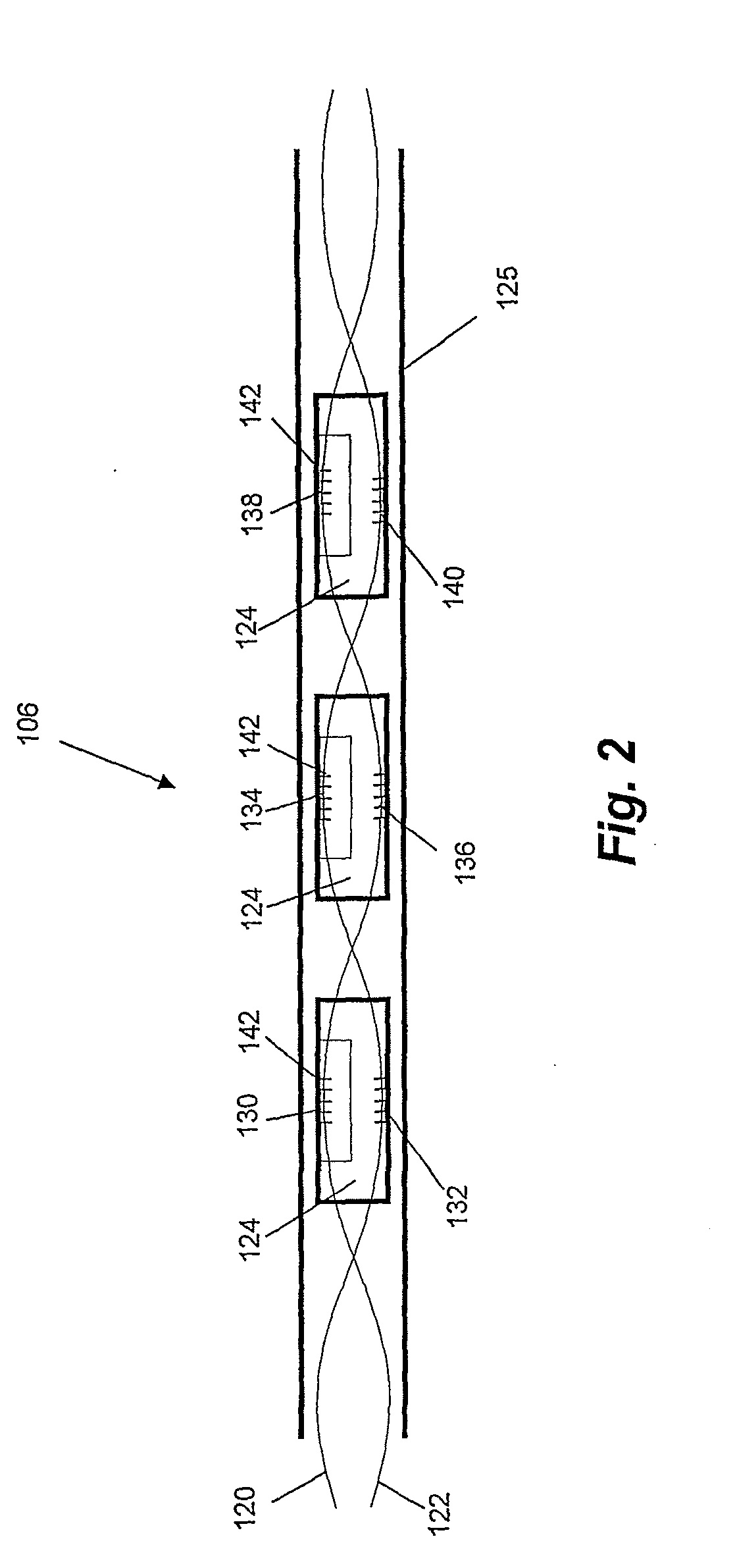

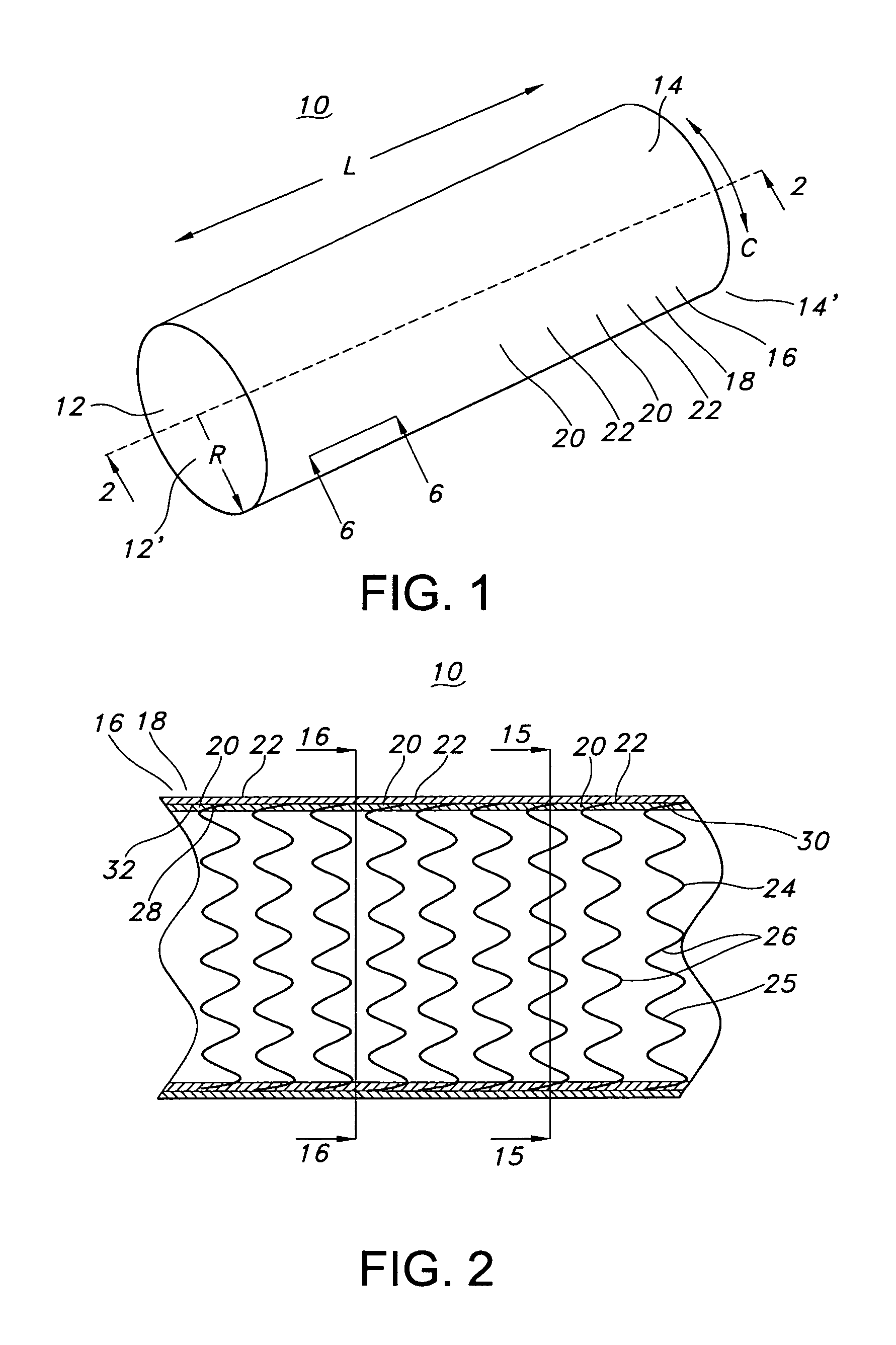

A medical device for guiding through anatomy, such as a catheter or guidewire, with a tubular body that has been slotted to enhance bending flexibility, and a polymer liner with an anti-collapsing structure, and a method of making a medical device with a kink-resistant corrugated tubular member and an anti-collapsing structure. Anti collapsing structures may be helical or annular, and may be wire, such as ribbon wire, grooves in the liner, corrugations, or a braid. Liners may be bonded to the anti-collapsing structure, or may have two layers, with the anti-collapsing structure between the layers. Corrugations may be formed between sections of the anti-collapsing ‘structure with heat, pressure, stretching, compression, a mold, or a combination thereof, and may extend inward or outward. Shape or wall thickness may vary along the length to provide a varying bending stiffness. Slots may be formed in groups of two, three, or more, and adjacent groups may be rotated about the axis forming a helical pattern.

Owner:PRECISION VASCULAR SYST

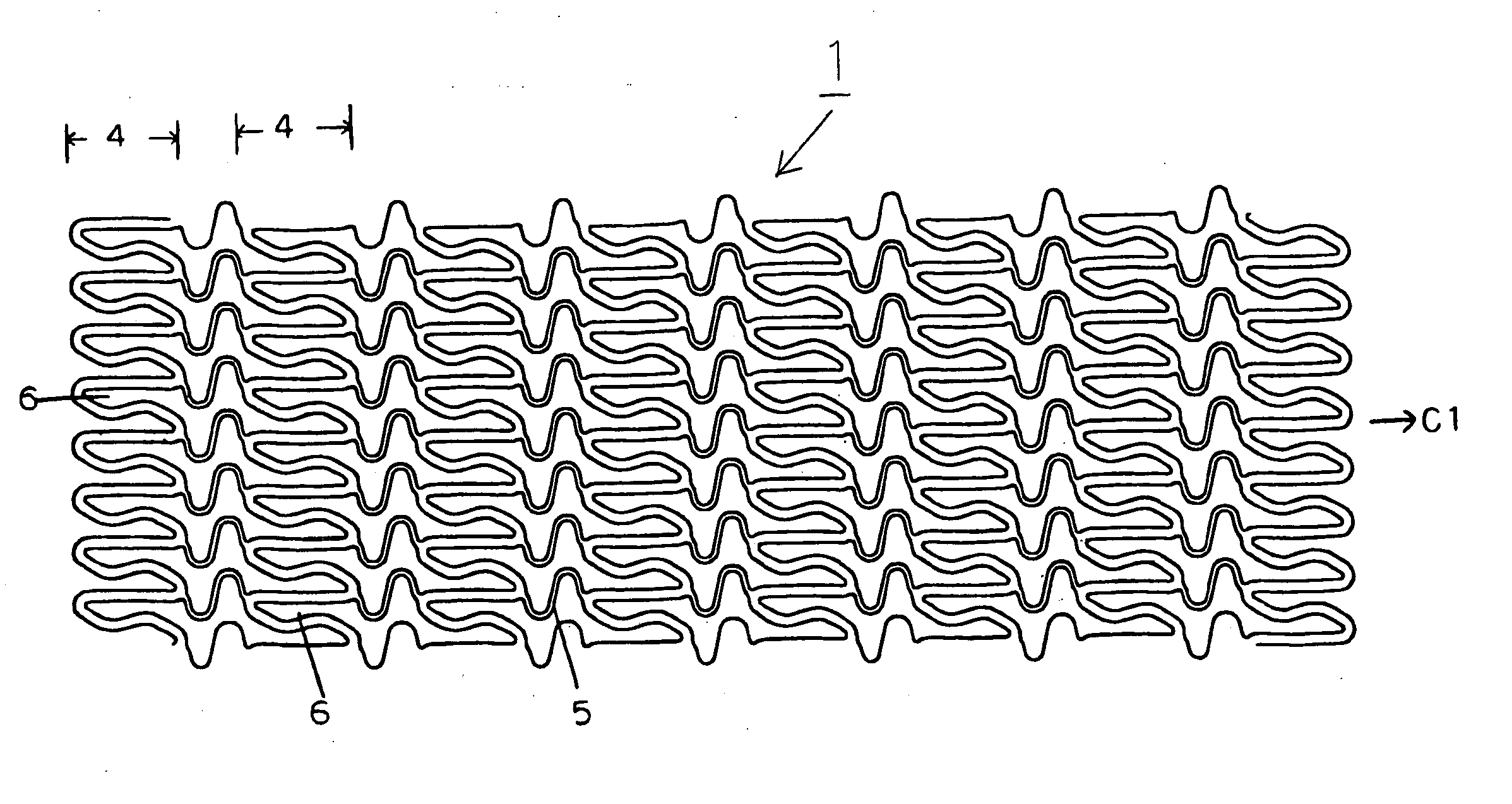

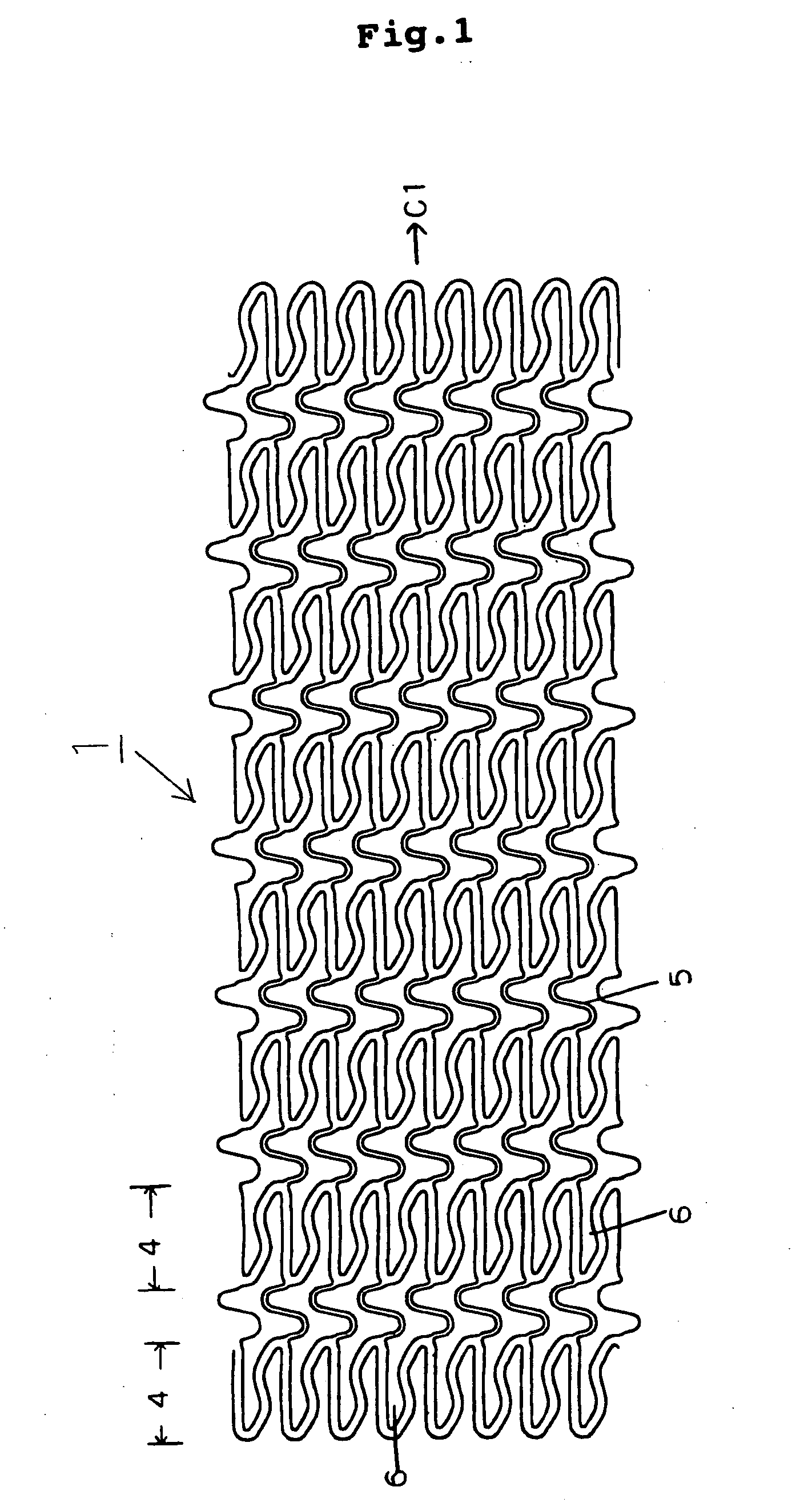

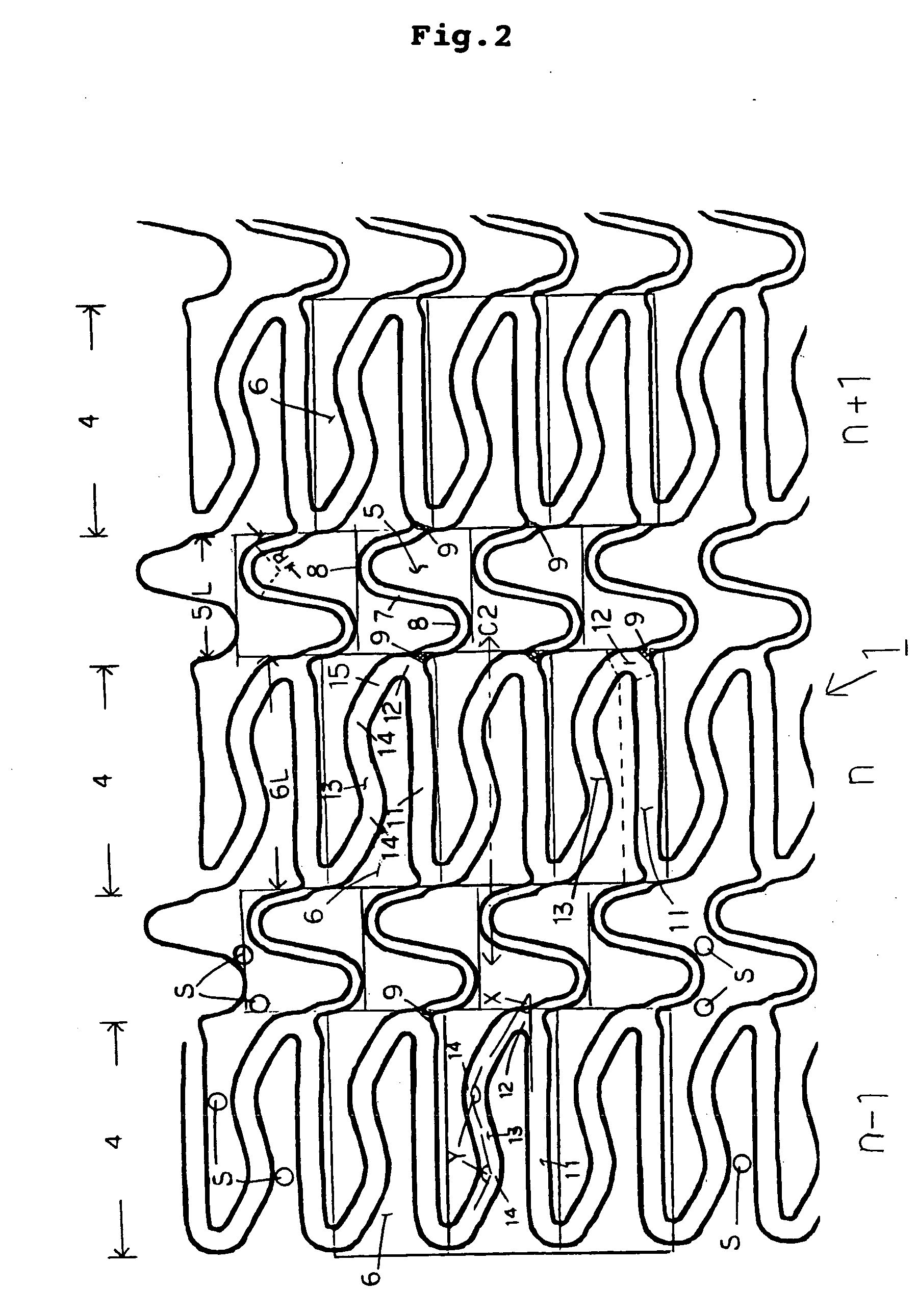

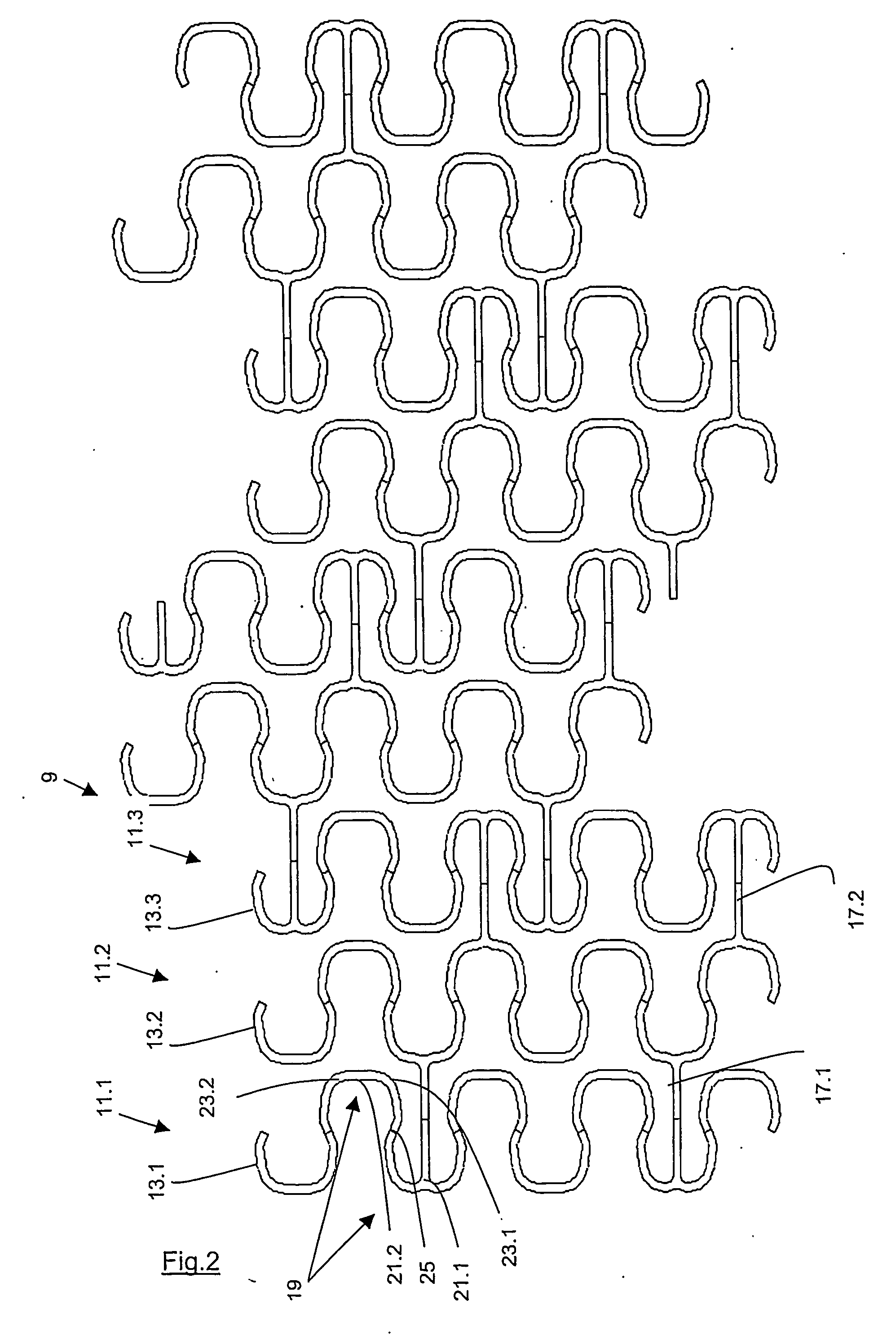

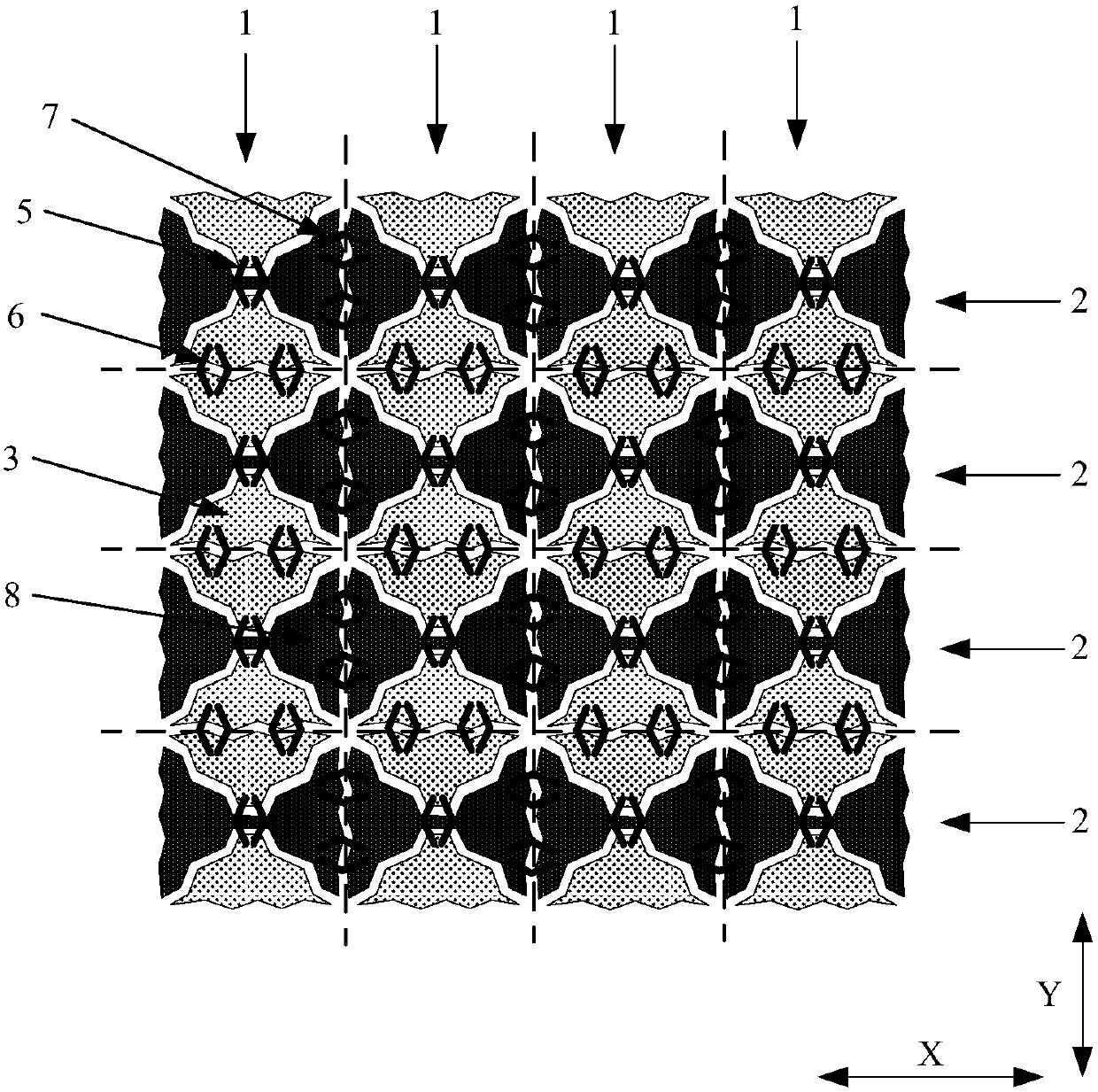

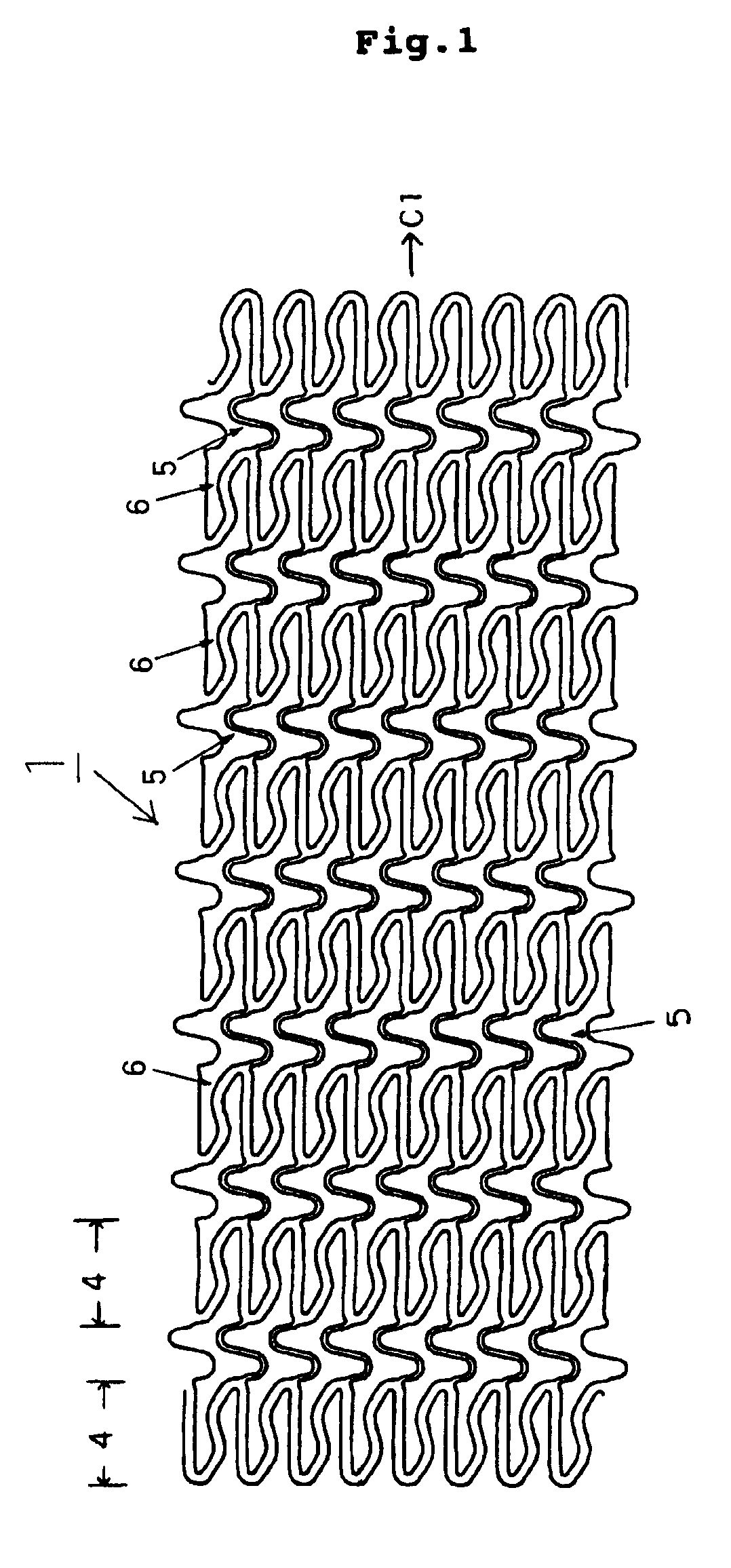

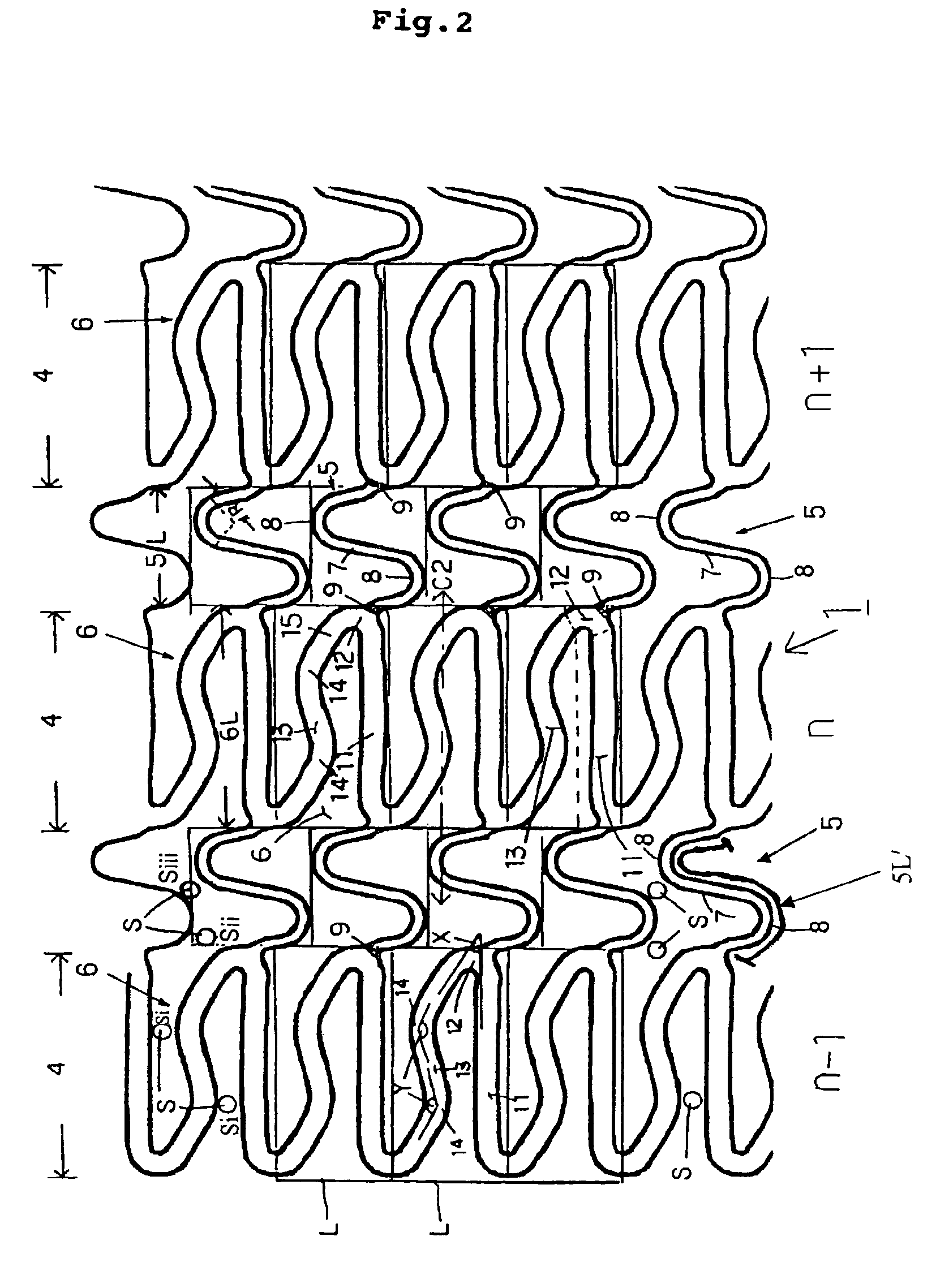

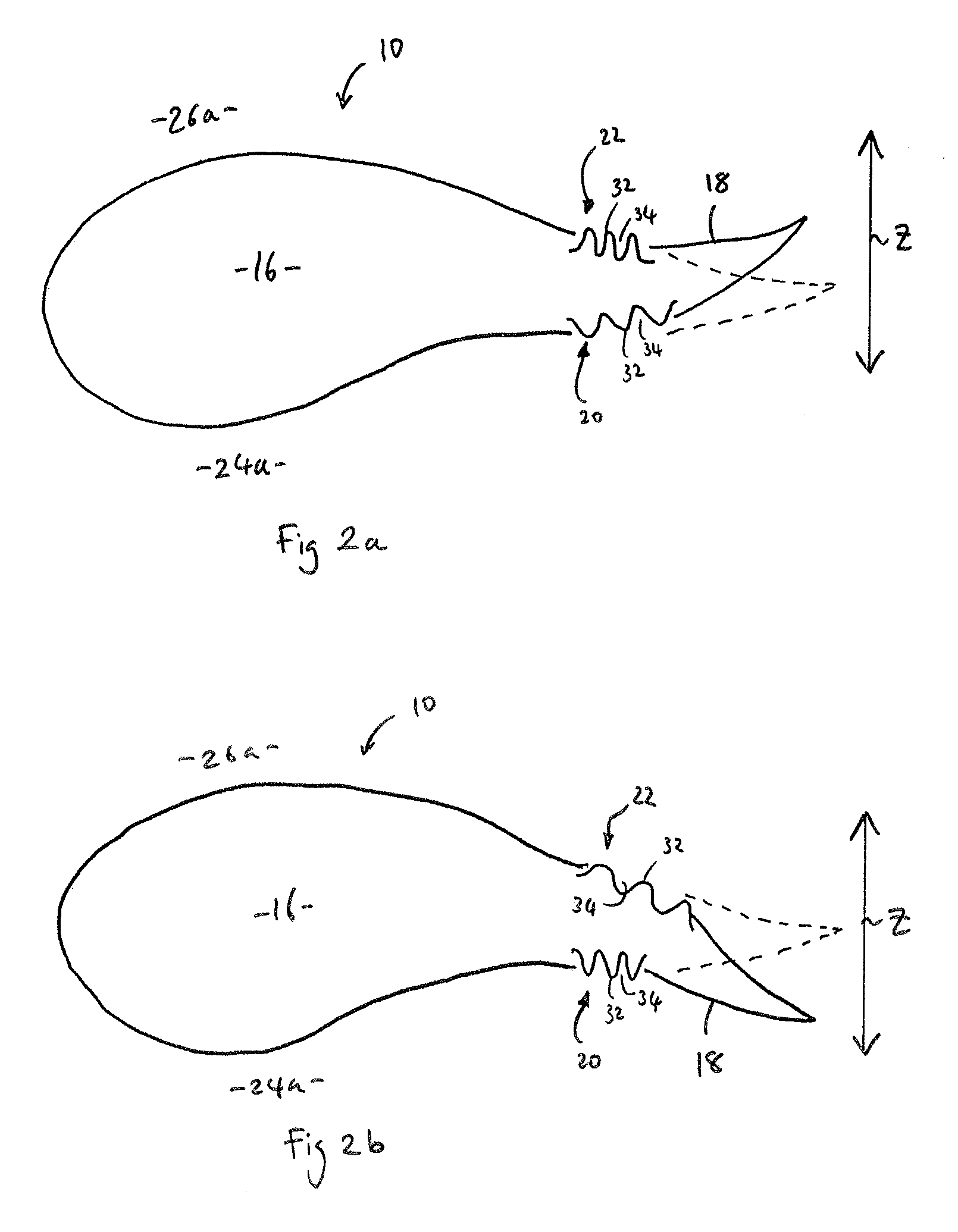

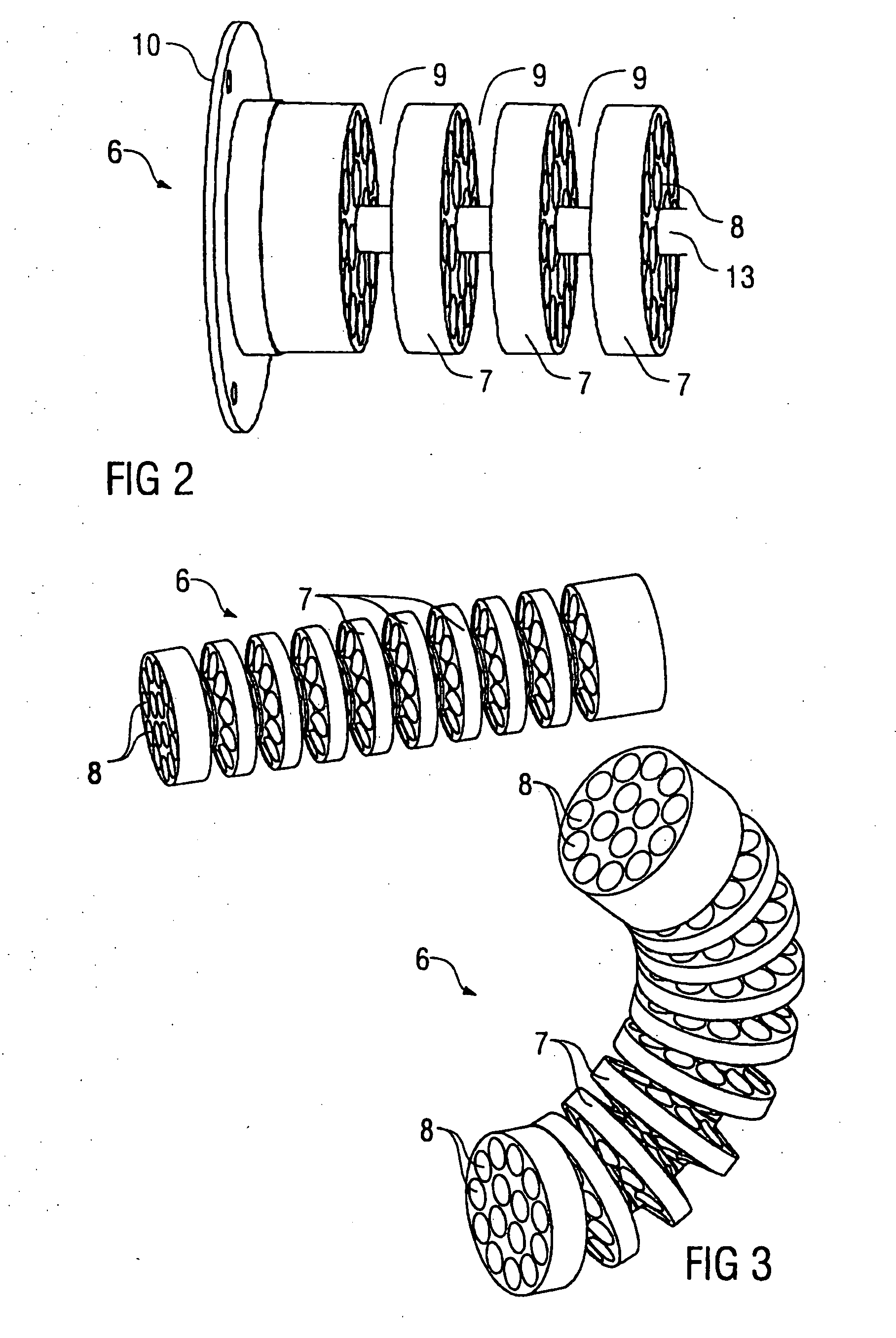

Stent

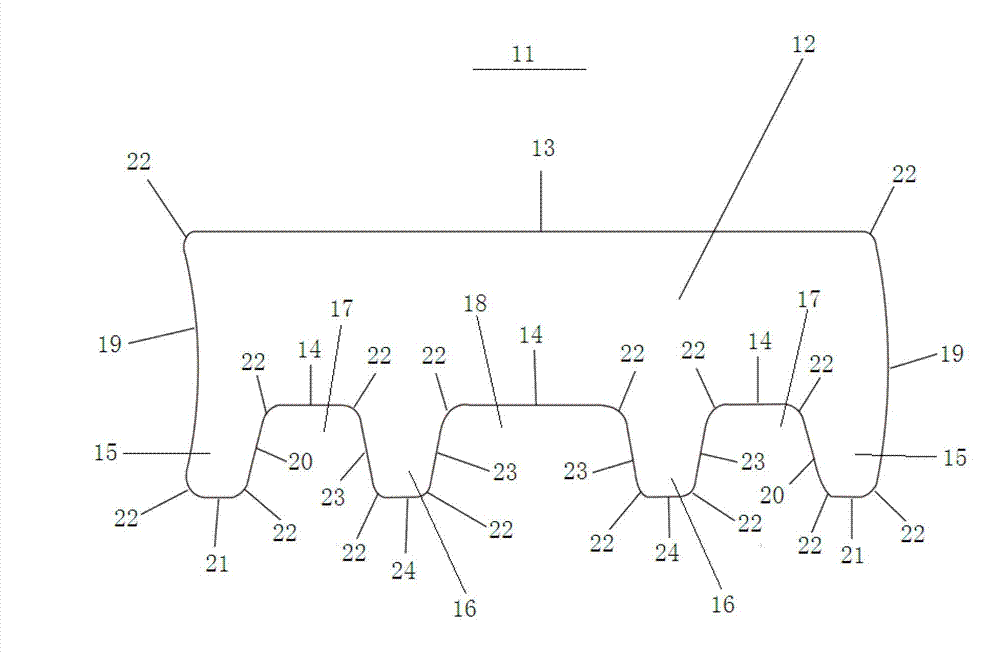

InactiveUS20050015136A1Avoid less flexibilityLarge lengthStentsSurgeryFlare phenomenonInsertion stent

A stent (1) having a generally tubular body formed of ring units formed of a plurality of cells each and being expandable in the radius direction thereof from inside, wherein each ring unit (4) is constituted of the plurality of cells (6) connected to one another above and below and arranged so as to surround the center line (C1) of the stent forming said tubular body, the ring units are arranged in the axial direction of the stent, ring units are connected through at least one site with connector portions (5), each connector portion is formed of curved portions (8) having at least 2 arches and a generally linear portion (7) continued thereto and therefrom, 3 to 8 cells are arranged in the axial direction of the stent per 10 mm of the length of the stent, and the ratio of the length (6L) of the cell in the axial direction of the stent and the length (5L) of the connector portion in the axial direction of the stent is determined such that on the basis that when the length of the cell in the axial direction of the stent is taken as 100, the length of the connector portion in the axial direction of the stent is 50 to 100, thereby high flexibility and radial sustaining force are secured, the stent is improved in capability of dilating a blood vessel, and foreshortening and a flare phenomenon can be prevented.

Owner:KAWASUMI LABORITORIES INC

Medical device with collapse-resistant liner and method of making same

InactiveUS7914466B2Desired flexibility in bendingIncrease stiffnessGuide wiresDiagnostic recording/measuringCatheterMedical device

A medical device for guiding through anatomy, such as a catheter or guidewire, with a tubular body that has been slotted to enhance bending flexibility, and a polymer liner with an anti-collapsing structure, and a method of making a medical device with a kink-resistant corrugated tubular member and an anti-collapsing structure. Anti collapsing structures may be helical or annular, and may be wire, such as ribbon wire, grooves in the liner, corrugations, or a braid. Liners may be bonded to the anti-collapsing structure, or may have two layers, with the anti-collapsing structure between the layers. Corrugations may be formed between sections of the anti-collapsing ‘structure with heat, pressure, stretching, compression, a mold, or a combination thereof, and may extend inward or outward. Shape or wall thickness may vary along the length to provide a varying bending stiffness. Slots may be formed in groups of two, three, or more, and adjacent groups may be rotated about the axis forming a helical pattern.

Owner:PRECISION VASCULAR SYST

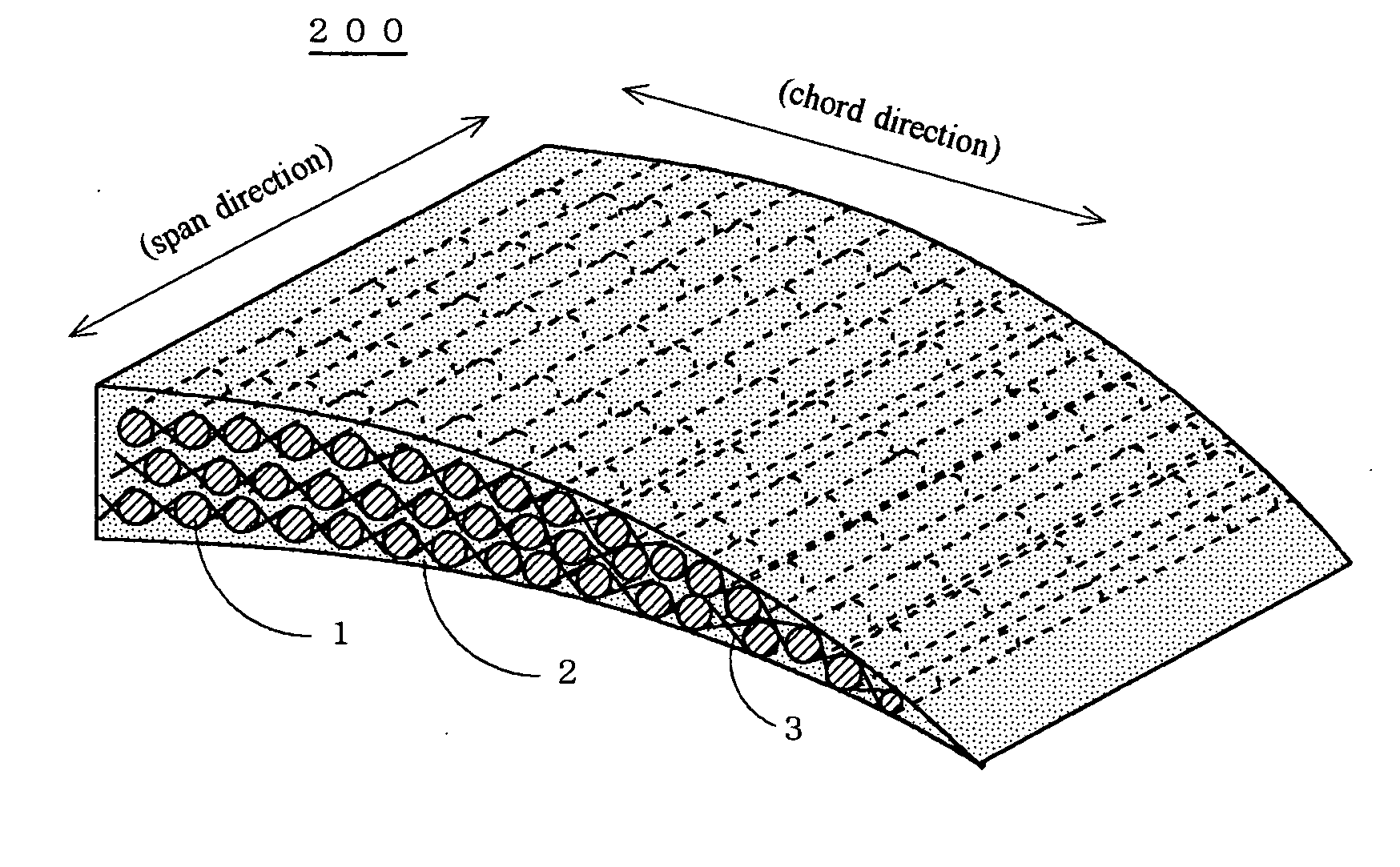

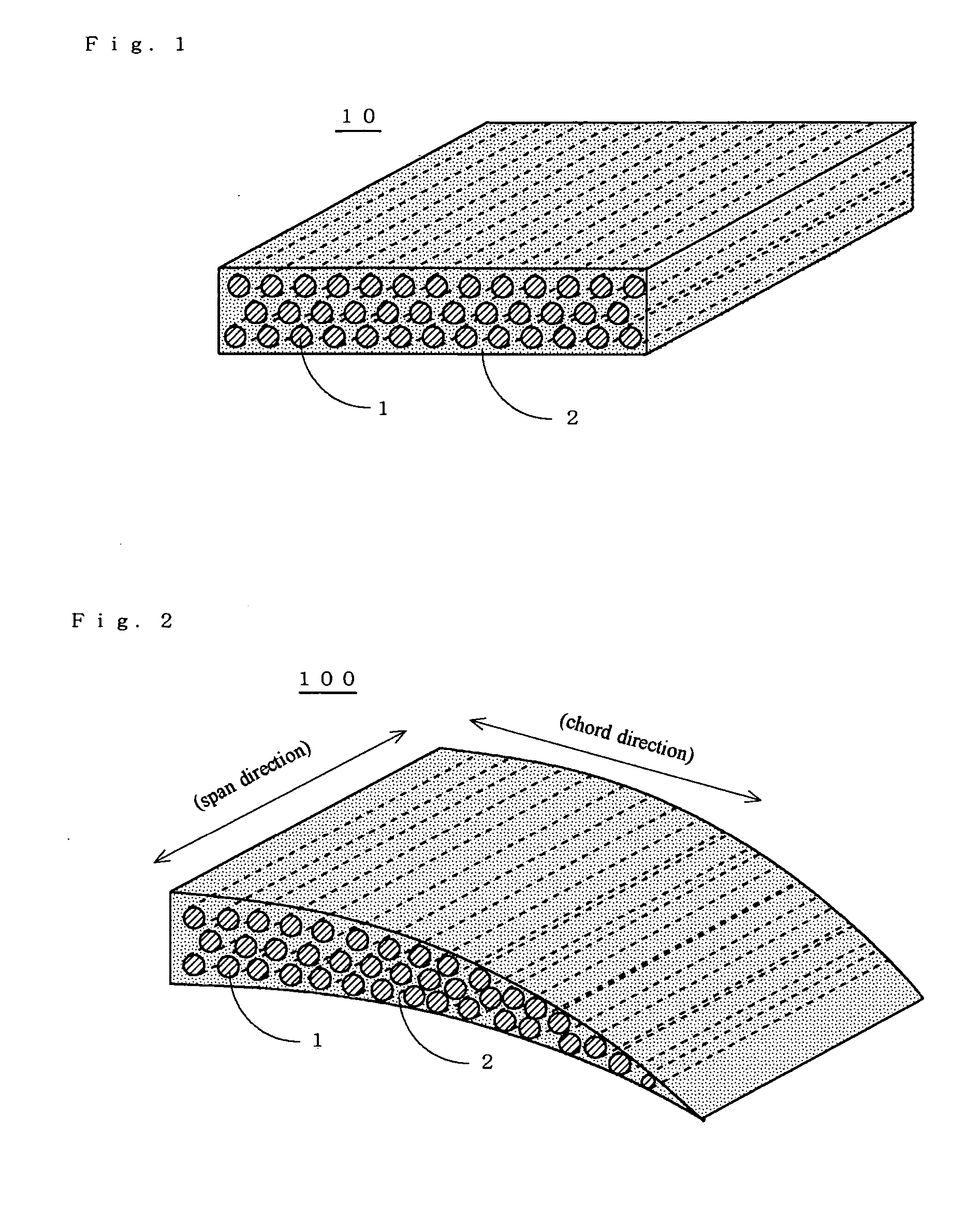

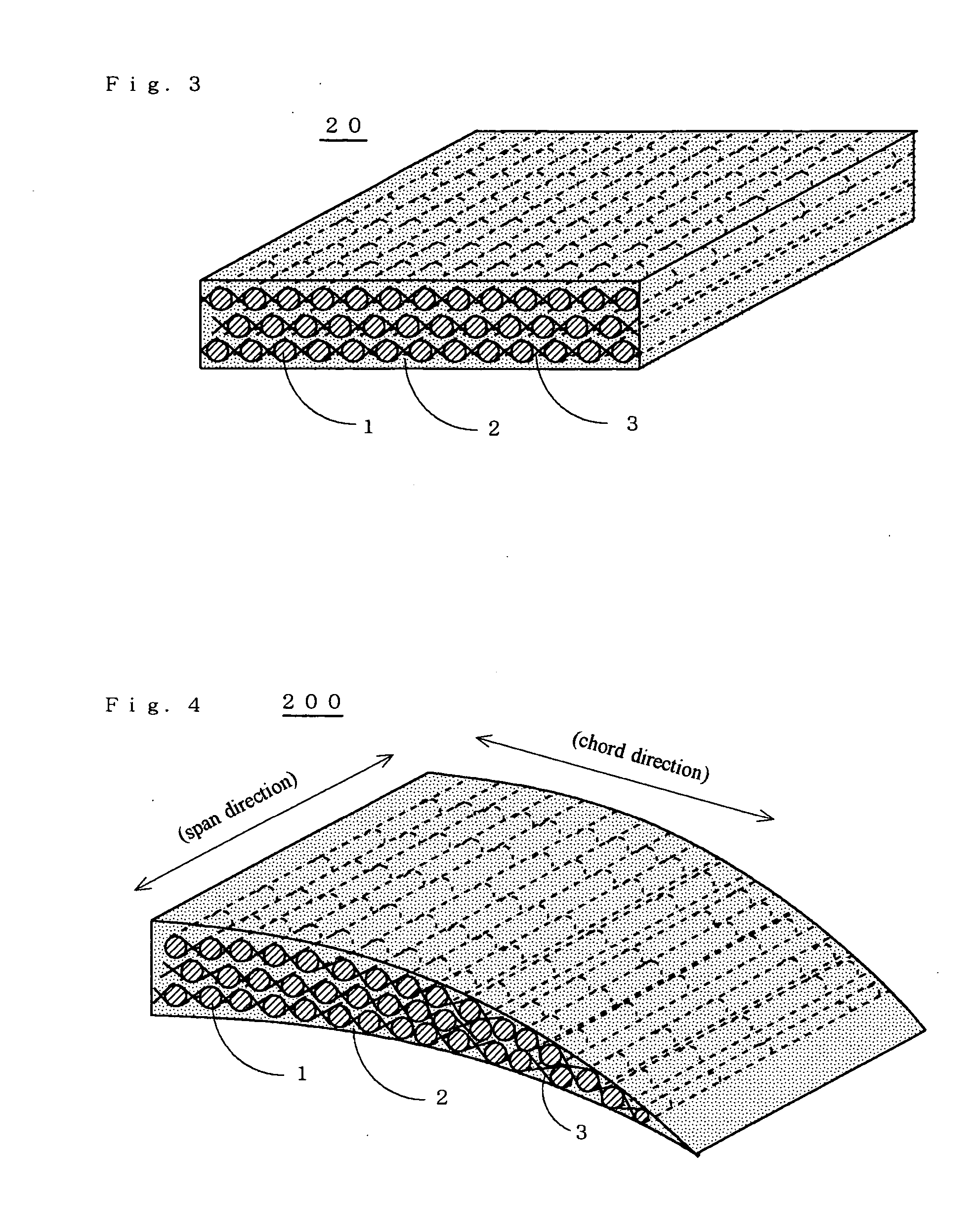

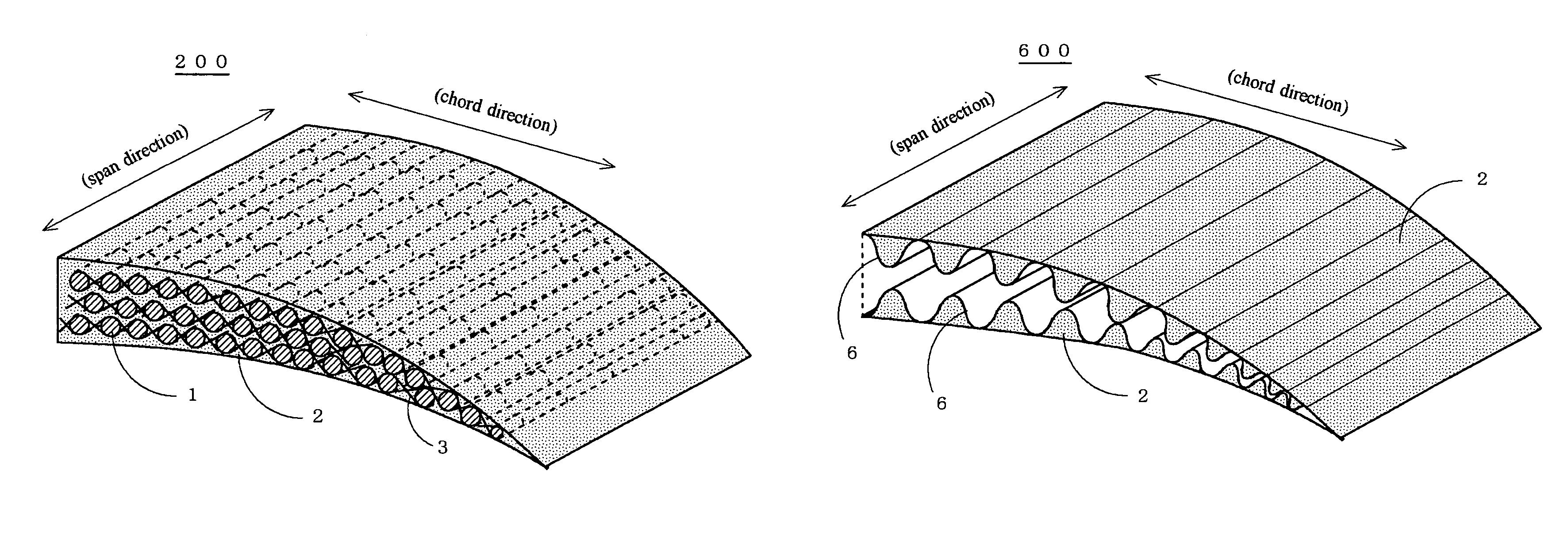

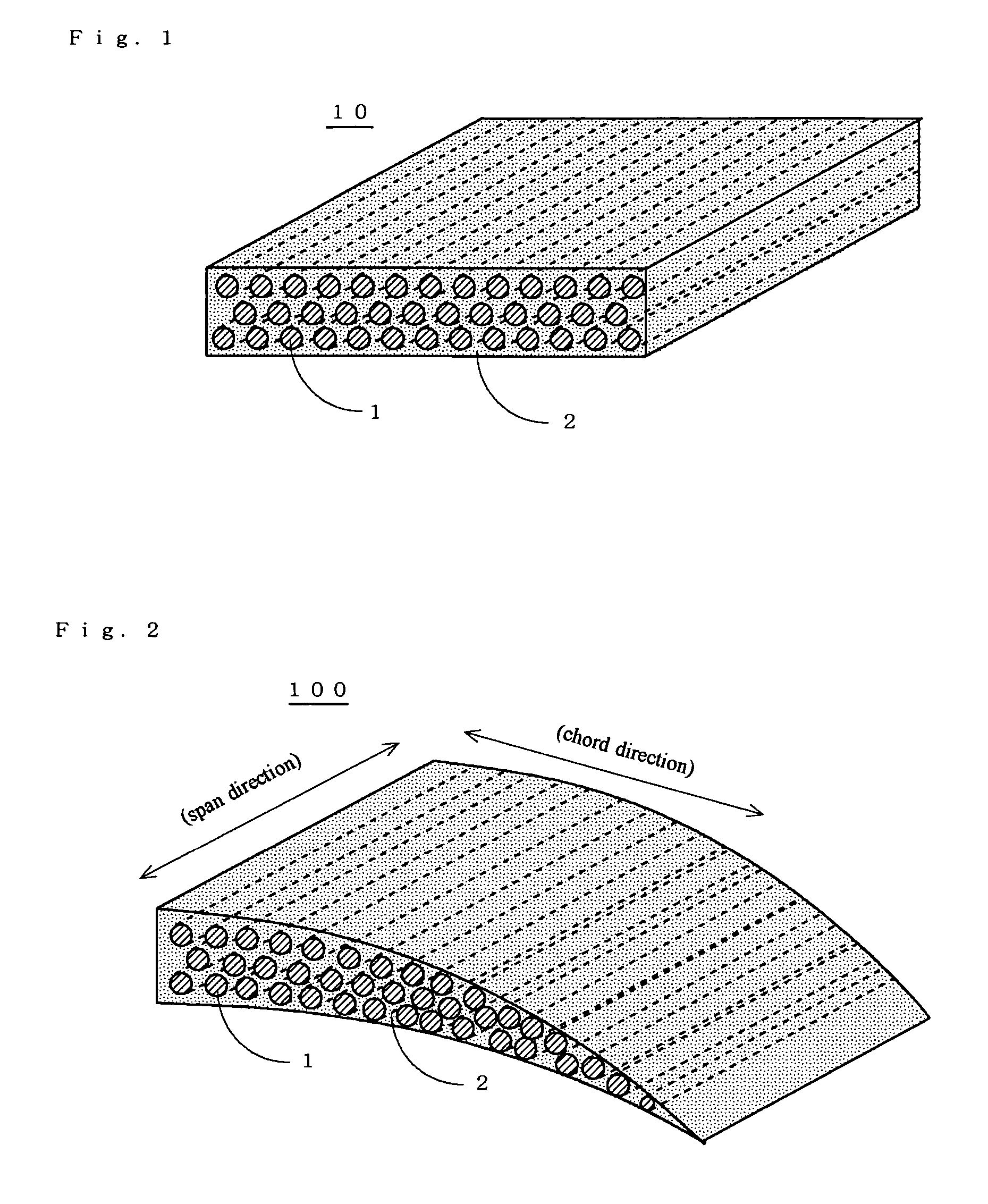

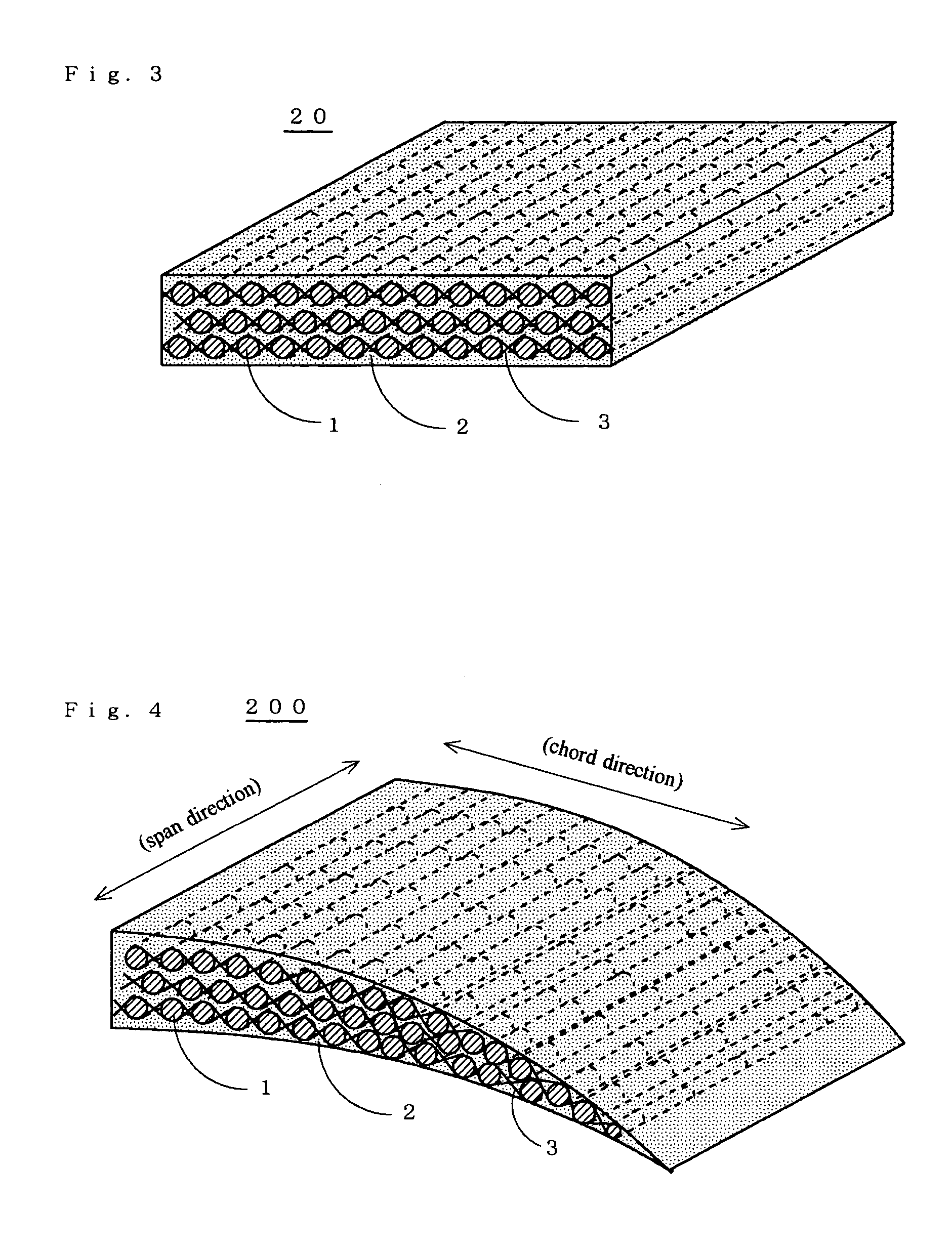

Aircraft wing, aircraft wing composite material, and method of manufacture thereof

InactiveUS20060145031A1Increased bending flexibilityImprove carrying capacityAircraft stabilisationWing adjustmentsAirplaneAerodynamic force

To provide an aircraft wing which has both high bending flexibility in the wing chord direction and high capacity to maintain the wing shape in the wing span direction, and to which morphing aircraft technology can be applied in the high-speed regime where aerodynamic forces are high. The wing is formed by arranging a plurality of CFRP rods having maximum anisotropic stiffness in the axial direction, so as to be parallel to the wing span direction, and filling the gaps between the CFRP rods with an elastic material.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

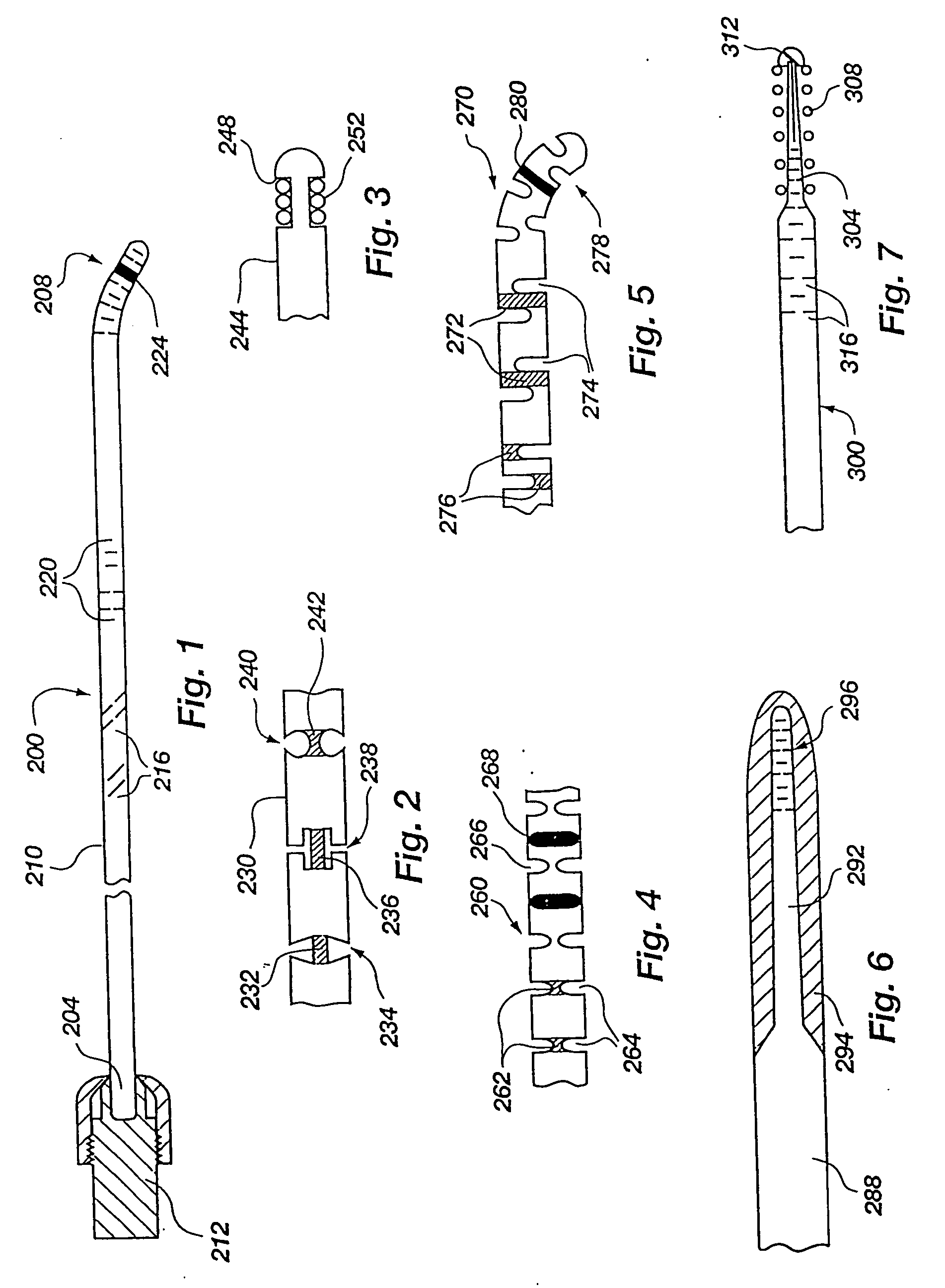

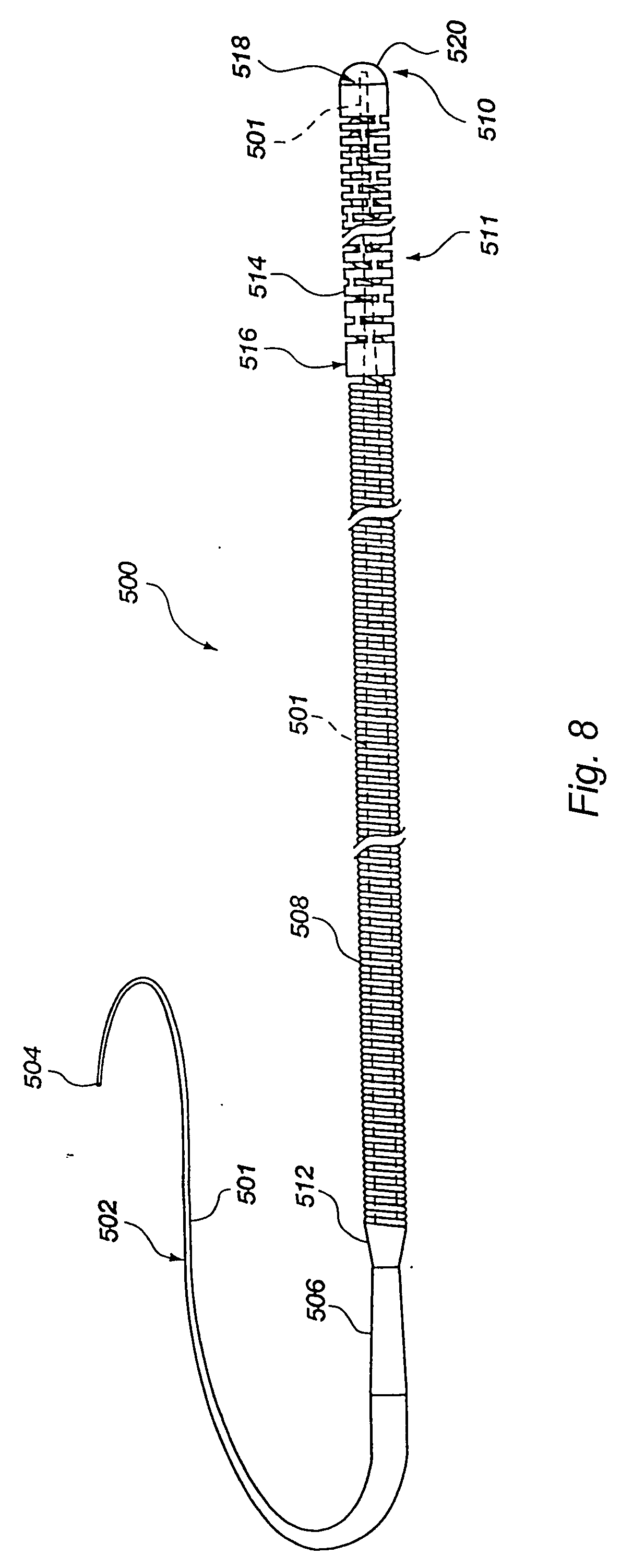

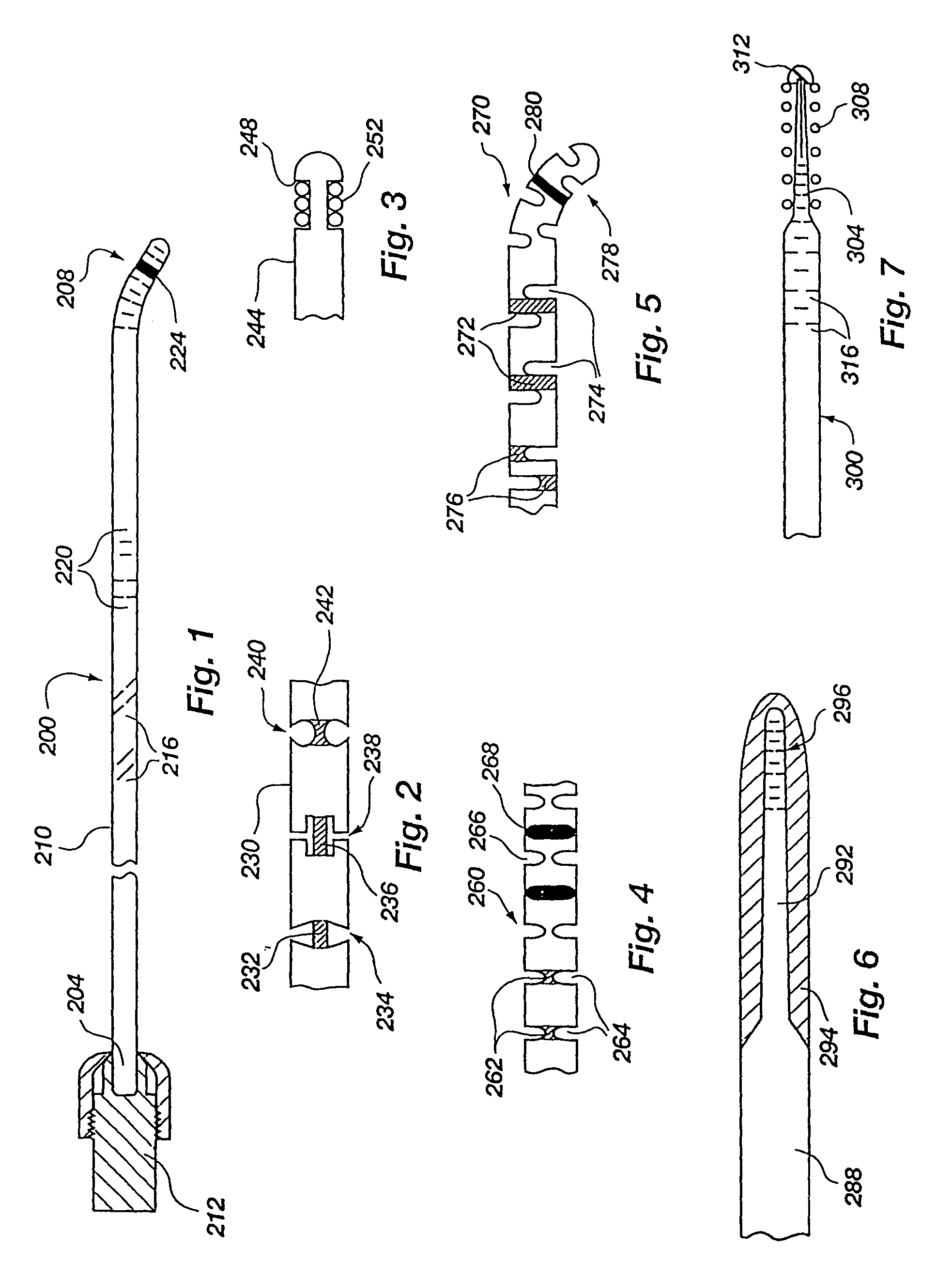

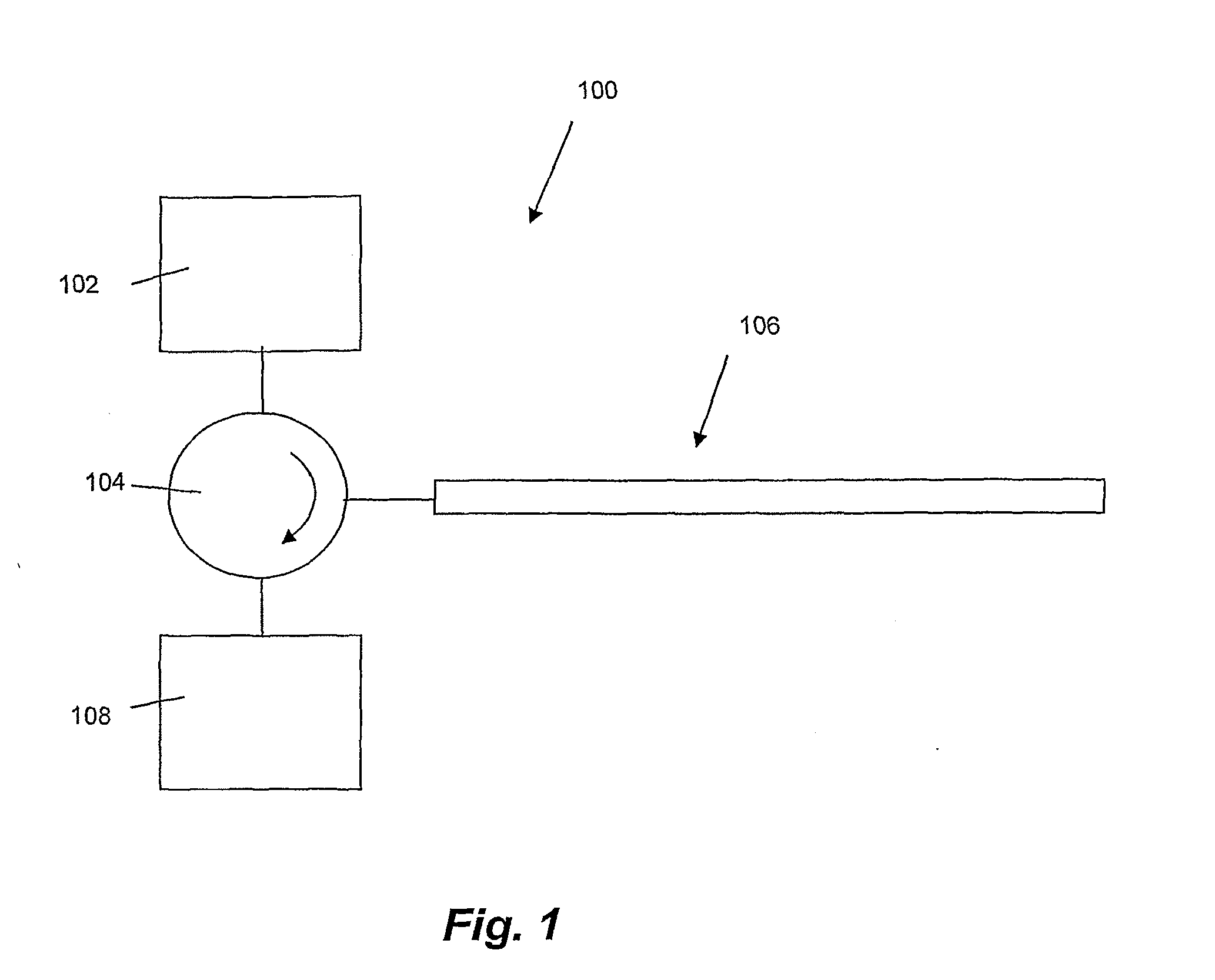

Variable stiffness guidewire

InactiveUS20070149951A1Improve airworthinessRigid enoughGuide wiresDiagnostic recording/measuringVariable stiffnessDistal portion

A guidewire navigable through body vessels of a human subject for delivery of a catheter or the like is provided. The guidewire has a tube which receives a corewire that protrudes beyond a distal portion of the tube. The protruding portion of the corewire is surrounded by a spring and shapeable into a curve or arc. The cross-sectional shape of the spring may be varied in order to promote bending flexibility and curvature or to favor curvature of a chosen type. The corewire is axially movable with respect to the tube, which compresses or stretches the spring to change the stiffness of the spring. The tube has a proximal portion comprised of a relatively rigid material, such as stainless steel, while a distal portion is comprised of a more flexible material, such as a nitinol.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

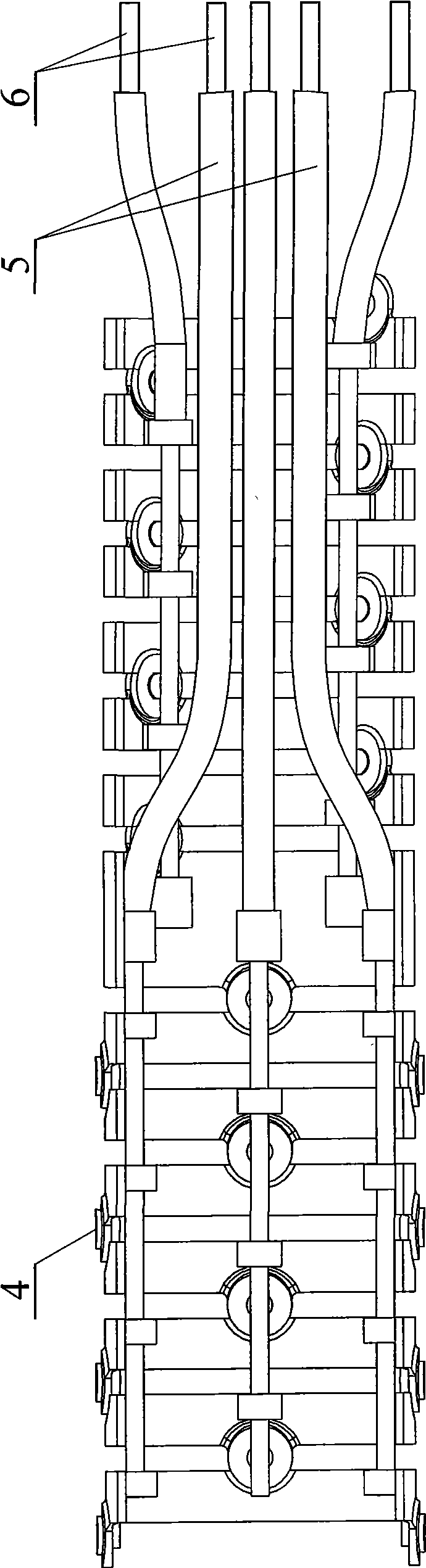

Multi-joint endoscope bending mechanism with force sensing function

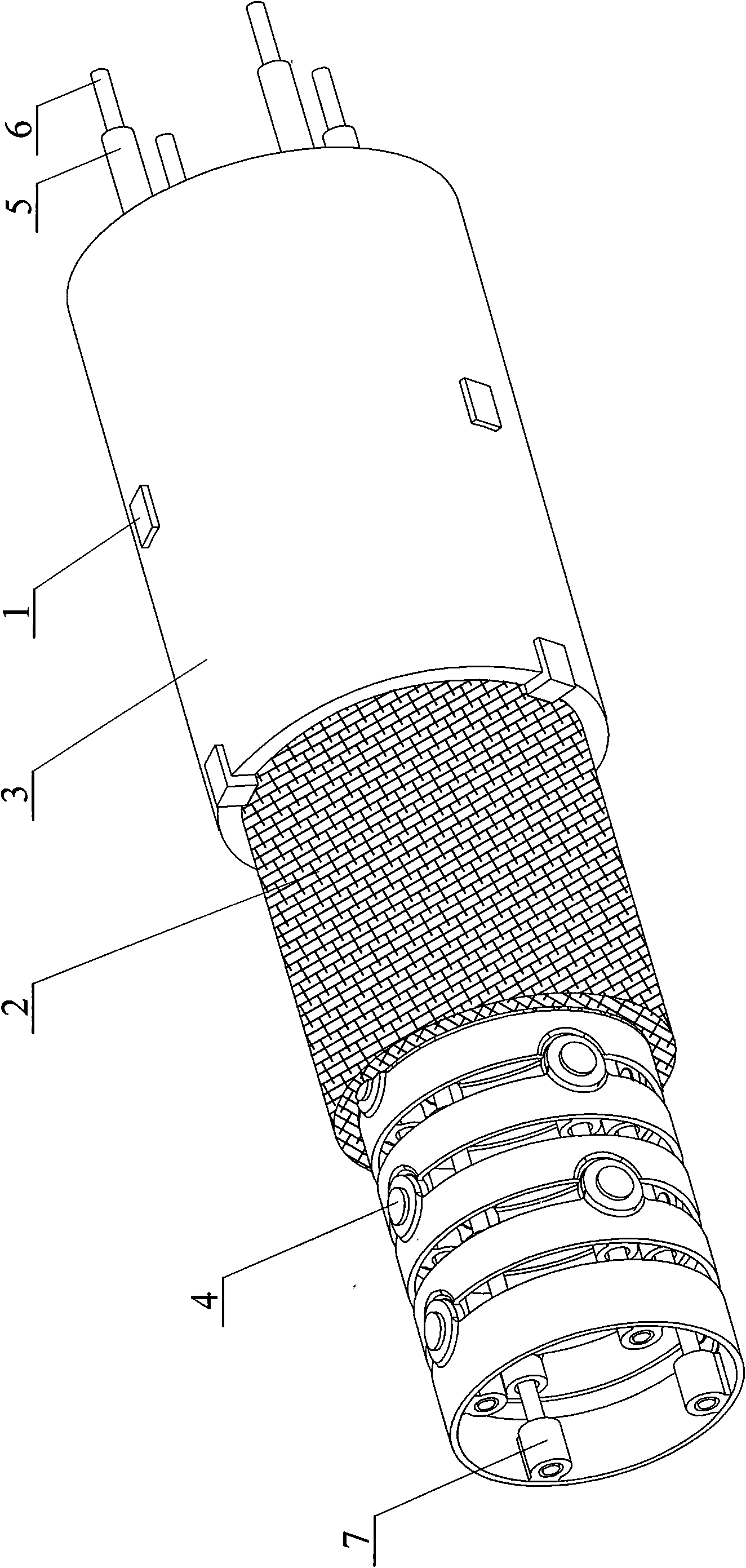

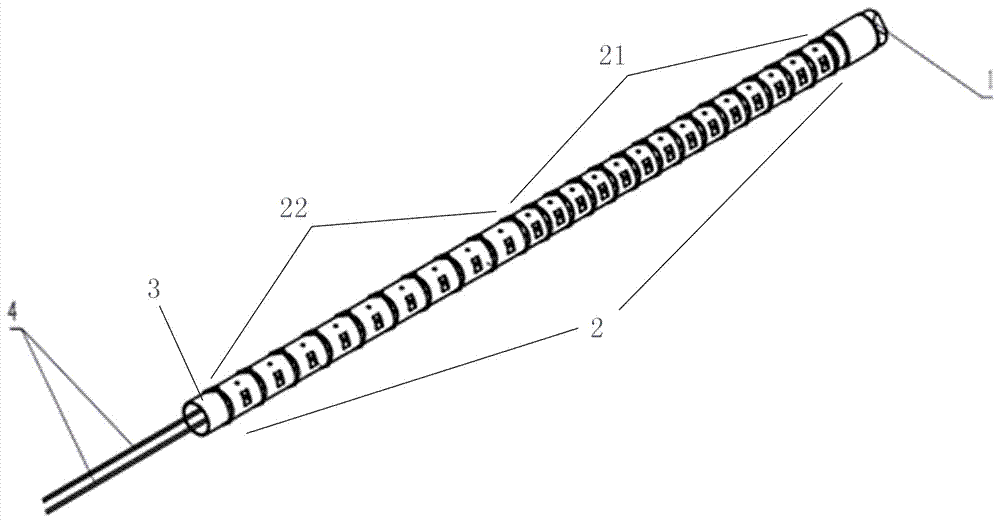

ActiveCN101632572AFlexible Space Composite Bending CapabilityRelieve painSuture equipmentsInternal osteosythesisContact pressureSacroiliac joint

A multi-joint endoscope bending mechanism with a force sensing function relates to an endoscope bending mechanism. In an existing medical endoscope, only one section at a head end of the endoscope is provided with bending controllability, the other parts of the endoscope do not have the function, and the surface of the endoscope is not integrated with a pressure sensor so that the contact pressure between a scope body and the intestinal canal wall can not be sensed. In the multi-joint endoscope bending mechanism, a first and a second connecting ear of a universal ring of two adjacent joints are matched and riveted with rivet clearances; a guide through hole of a guide seat on a universal ring of a start end joint of each bending uni-joint section is fixedly connected with a spring tube; four multi-strand steel wires in the bending uni-joint section pass through each spring tube and each guide through hole and are fixedly connected with a rear end circular ring; five bending uni-joint sections are wrapped by steel wire woven nets and rubber covering films from the inside to the outside; and pressure sensors are embedded in the rubber covering films. The multi-joint endoscope bending mechanism has a flexible spatial complexing bending capability and also a full-direction force sensing function. When used for examining an intestine problem of a patient, the multi-joint endoscope bending mechanism can relieve the pain suffered by the patient and is highly safe.

Owner:HARBIN INST OF TECH

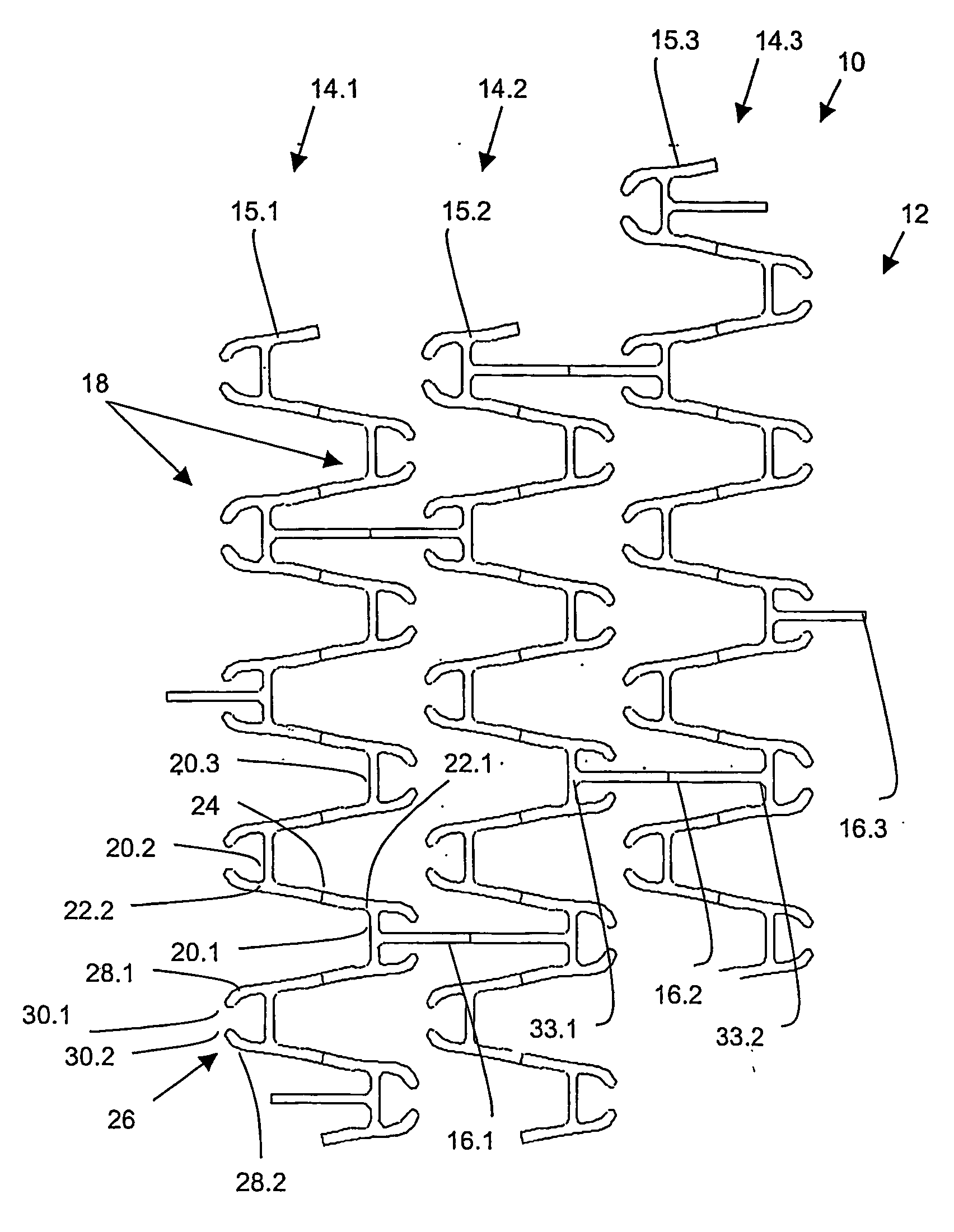

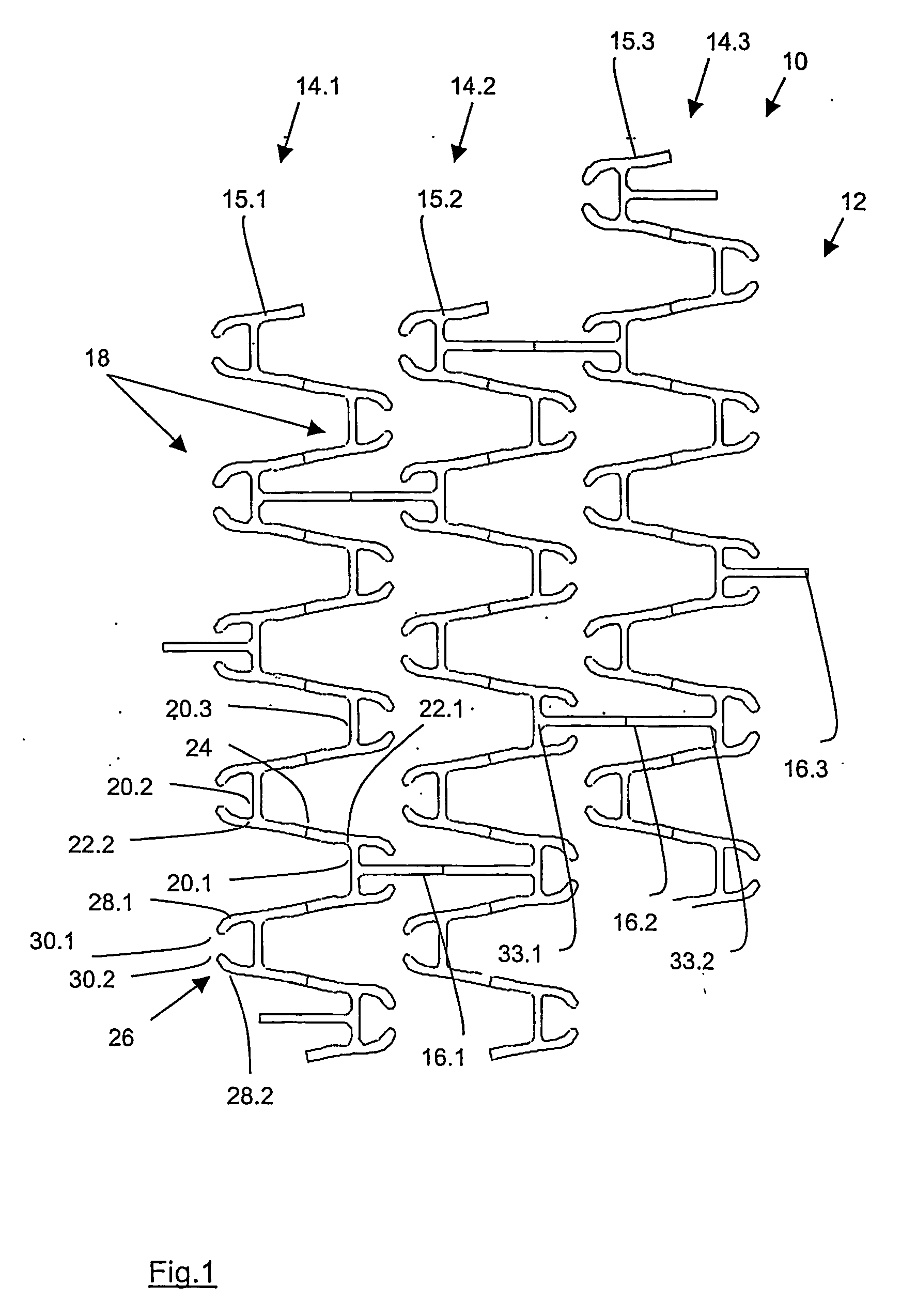

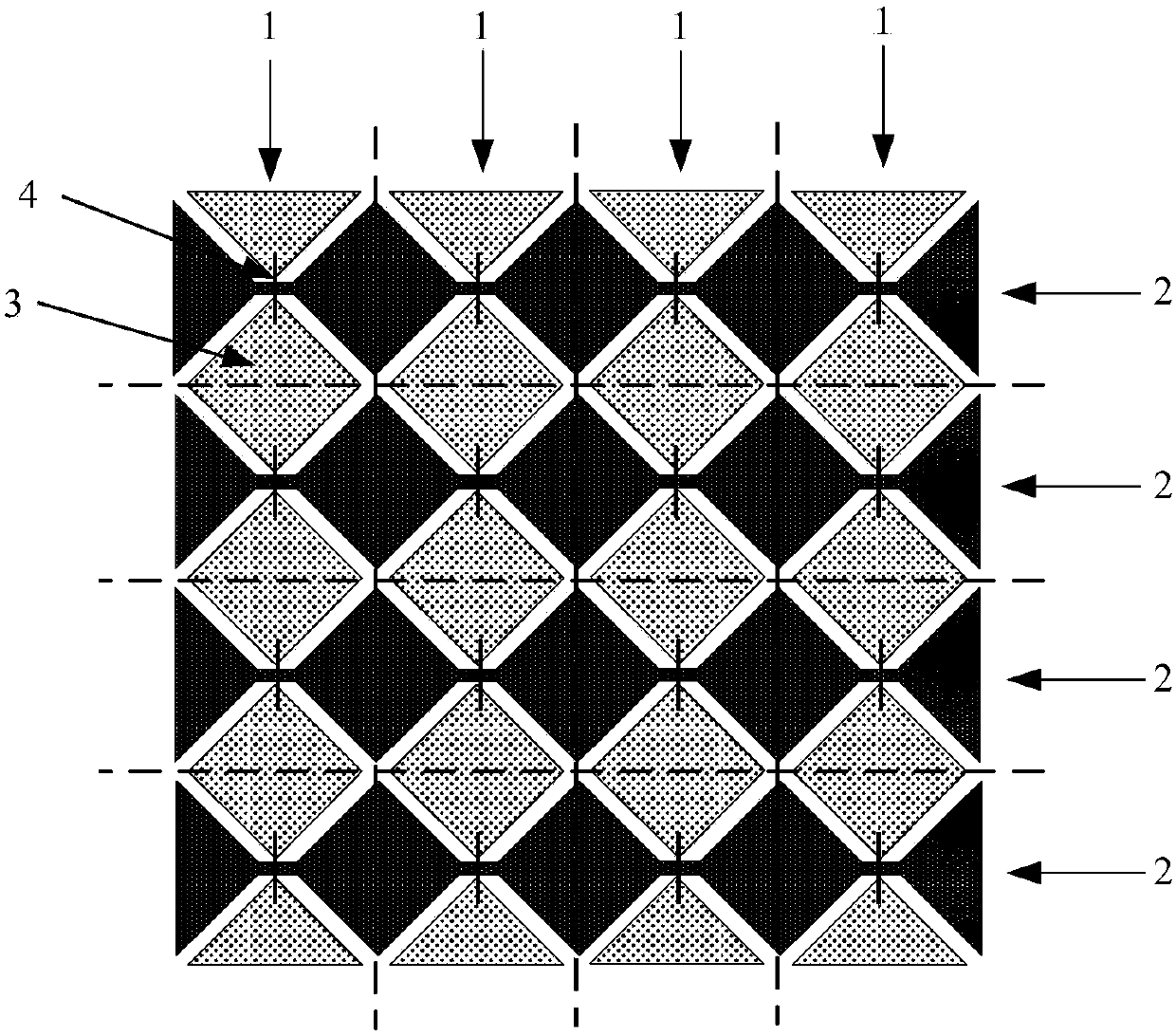

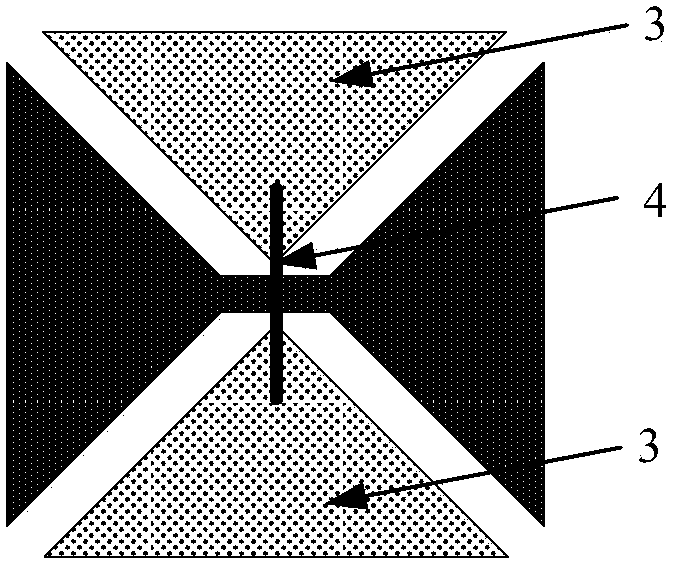

Stents made of a material with short elongation at rupture

InactiveUS20070142899A1Increased bending flexibilityImproves expansion behaviourStentsSurgeryInsertion stentEngineering

The invention relates to stents made of a material with an elongation at rupture of 30% or less and with a tubular base body which entirely or in parts comprises structural segments which are interconnected in longitudinal direction of the stents by means of transverse connectors and in which the structural segments comprise a zigzagging or undulating structure of a brace which is wrapped around the longitudinal axis of the stent. Due to the mechanical properties of the materials used, adaptation of the stent design is required. This is achieved in that in a turning region of the zigzagging or undulating structure the brace comprises a straight bending section aligned in circumferential direction.

Owner:BIOTRONIK AG

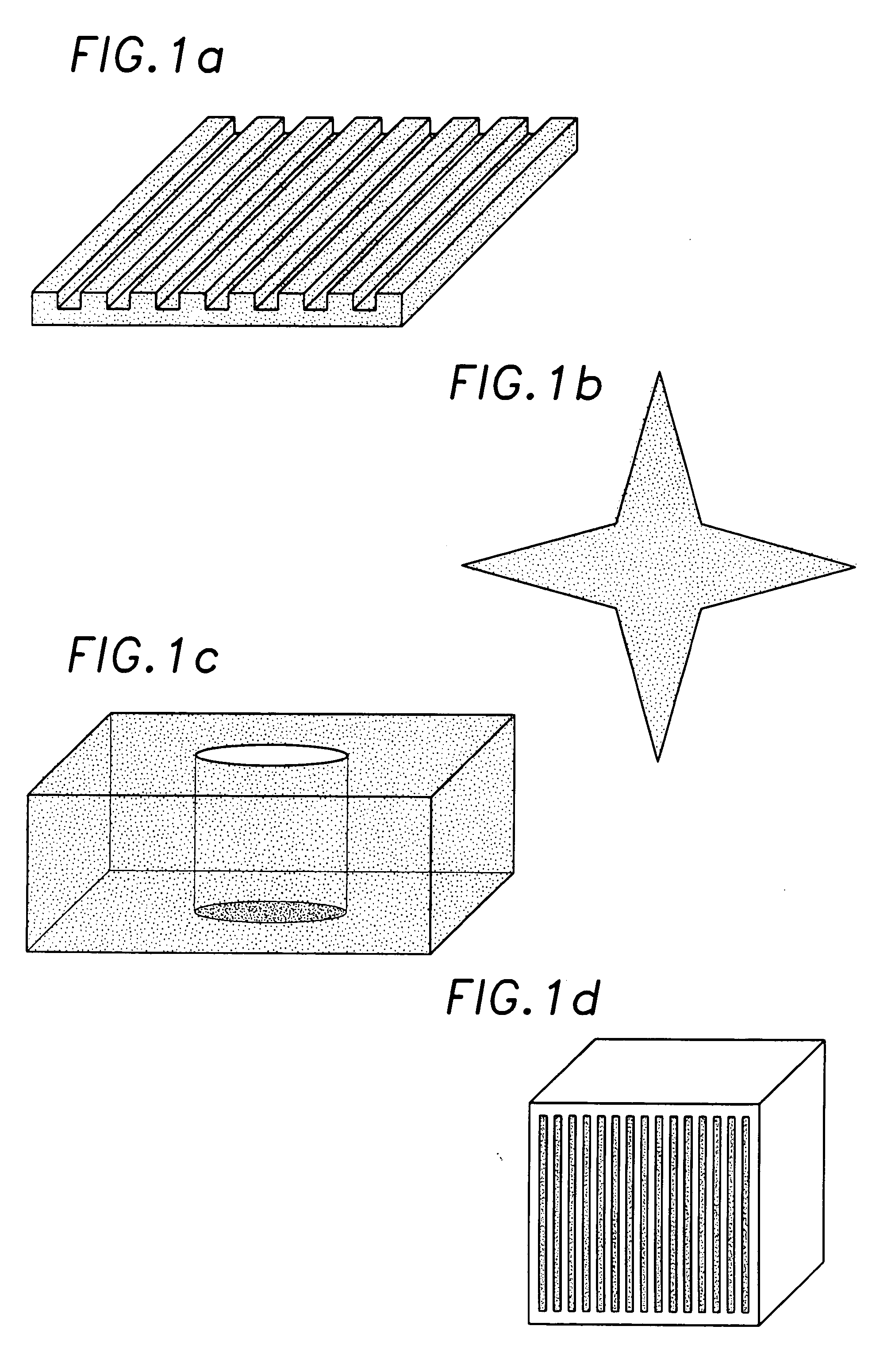

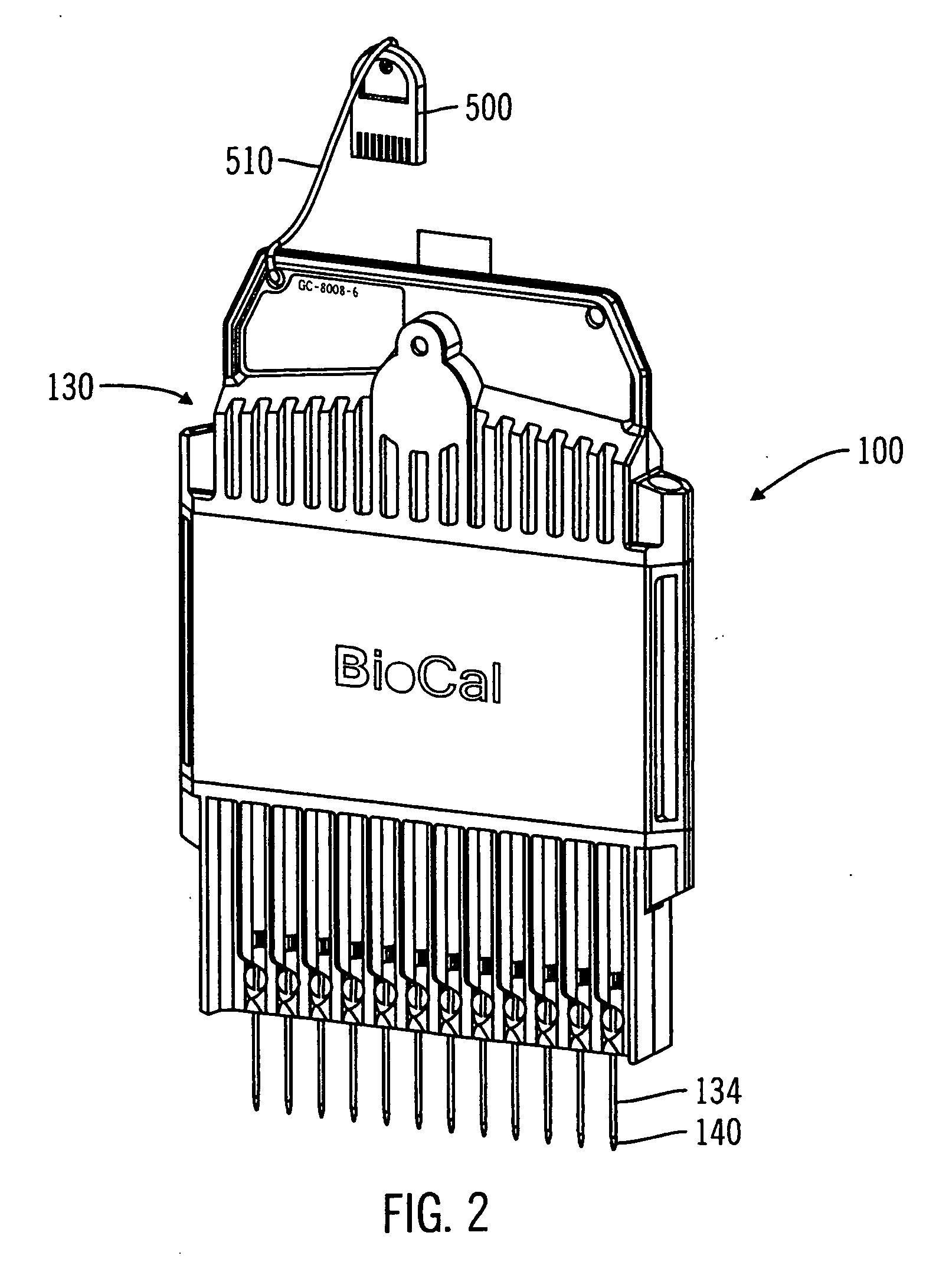

Laser machining of electroactive ceramics

InactiveUS20060006769A1Increased bending flexibilityCost-effectivePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesState of artLaser beam machining

Laser beam machining is applied to form arbitrarily shaped electroactive ceramics for transducers (e.g., electromechanical sensors and actuators). One particularly preferred embodiment of the invention comprises machining parallel grooves in a ceramic plate to improve flexibility. The grooves provide strain relief in bending by relieving Poisson strains transverse to the direction of bending. This embodiment offers the further benefit that planar anisotropy or directionality is introduced in the transducer. The machining process of the invention further enables the production of more complex geometries than those currently known in the art. Because of the flexibility of the machining process, virtually any desired transducer shape may be produced.

Owner:MIDE TECH

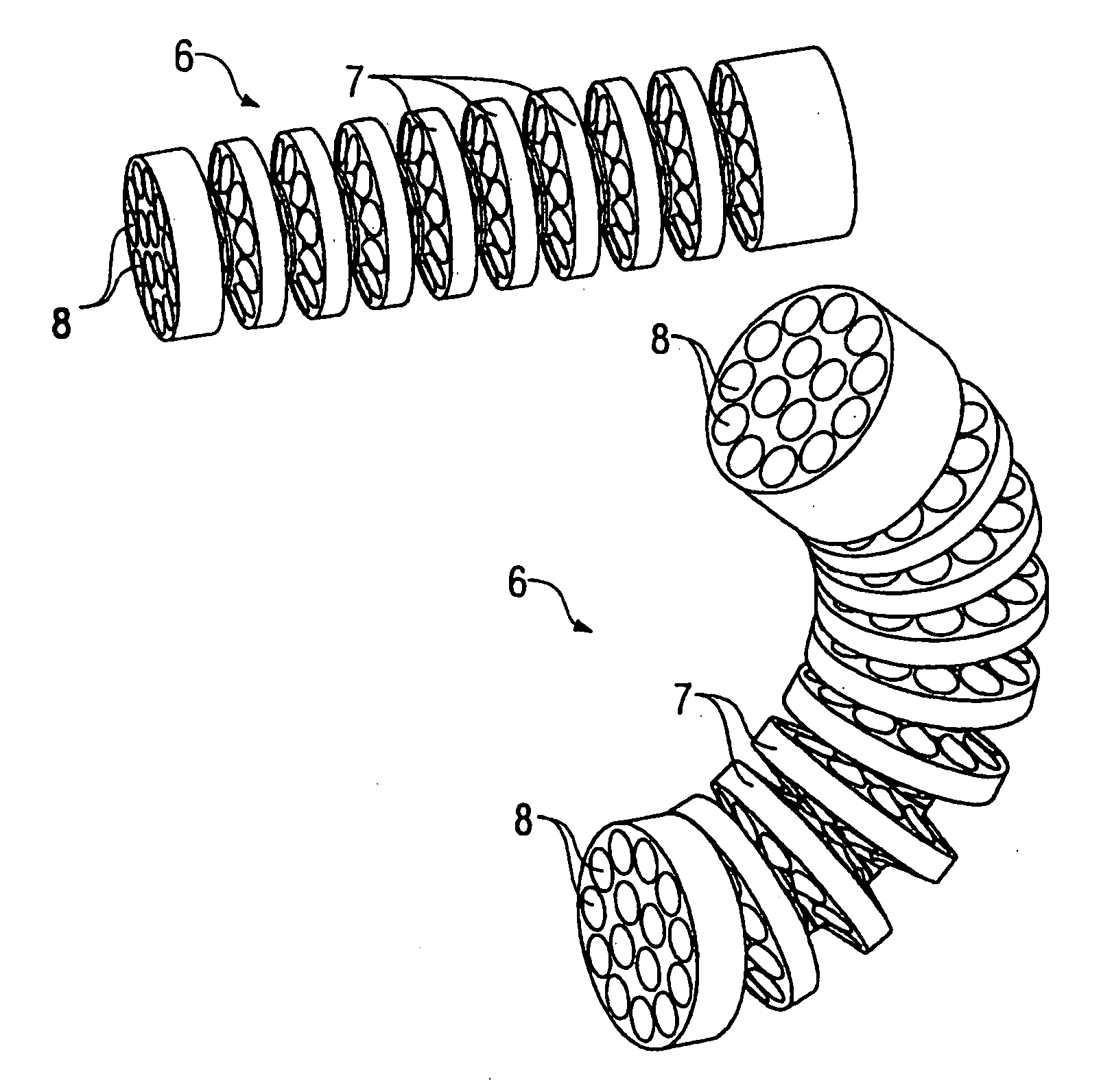

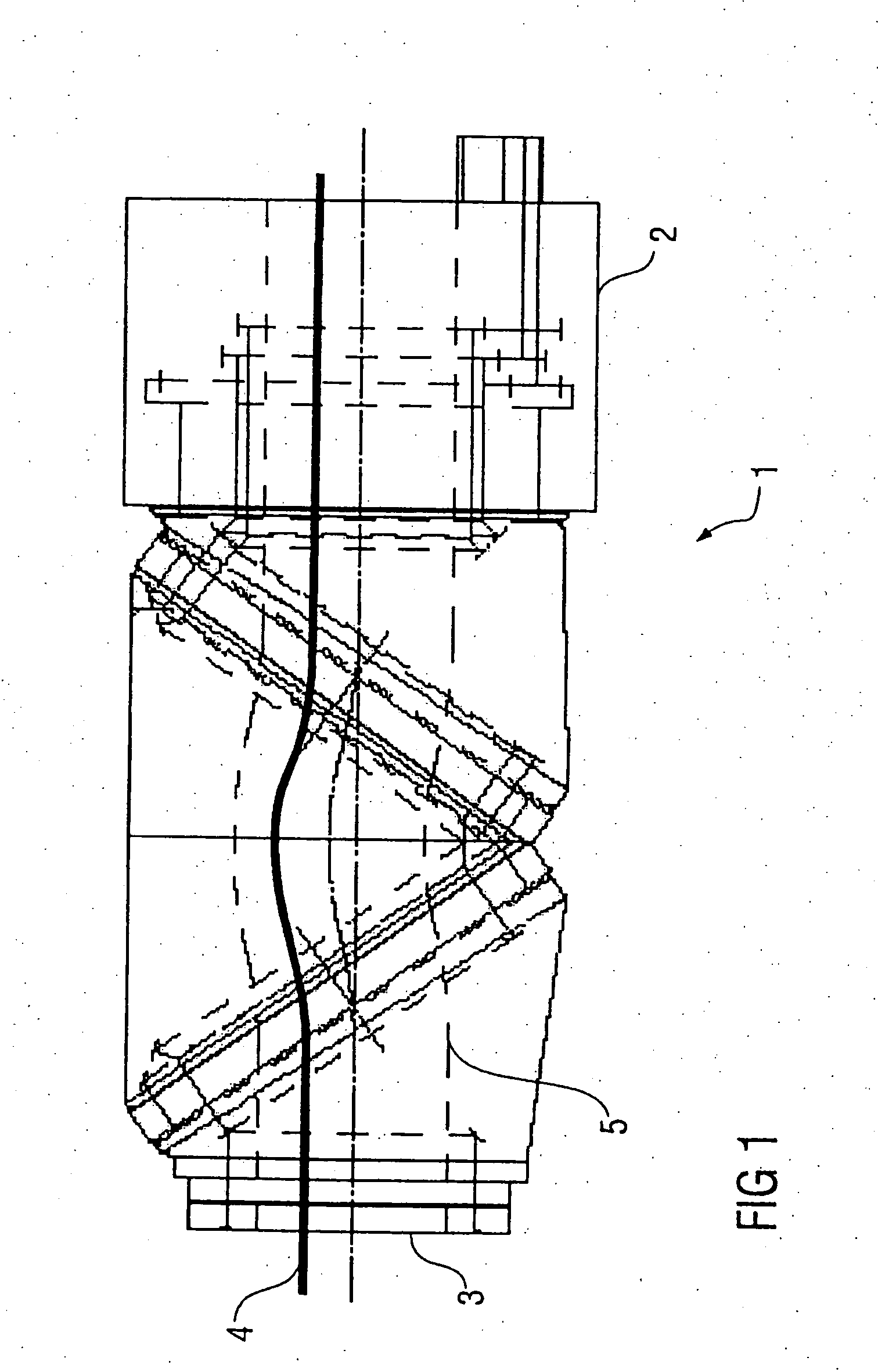

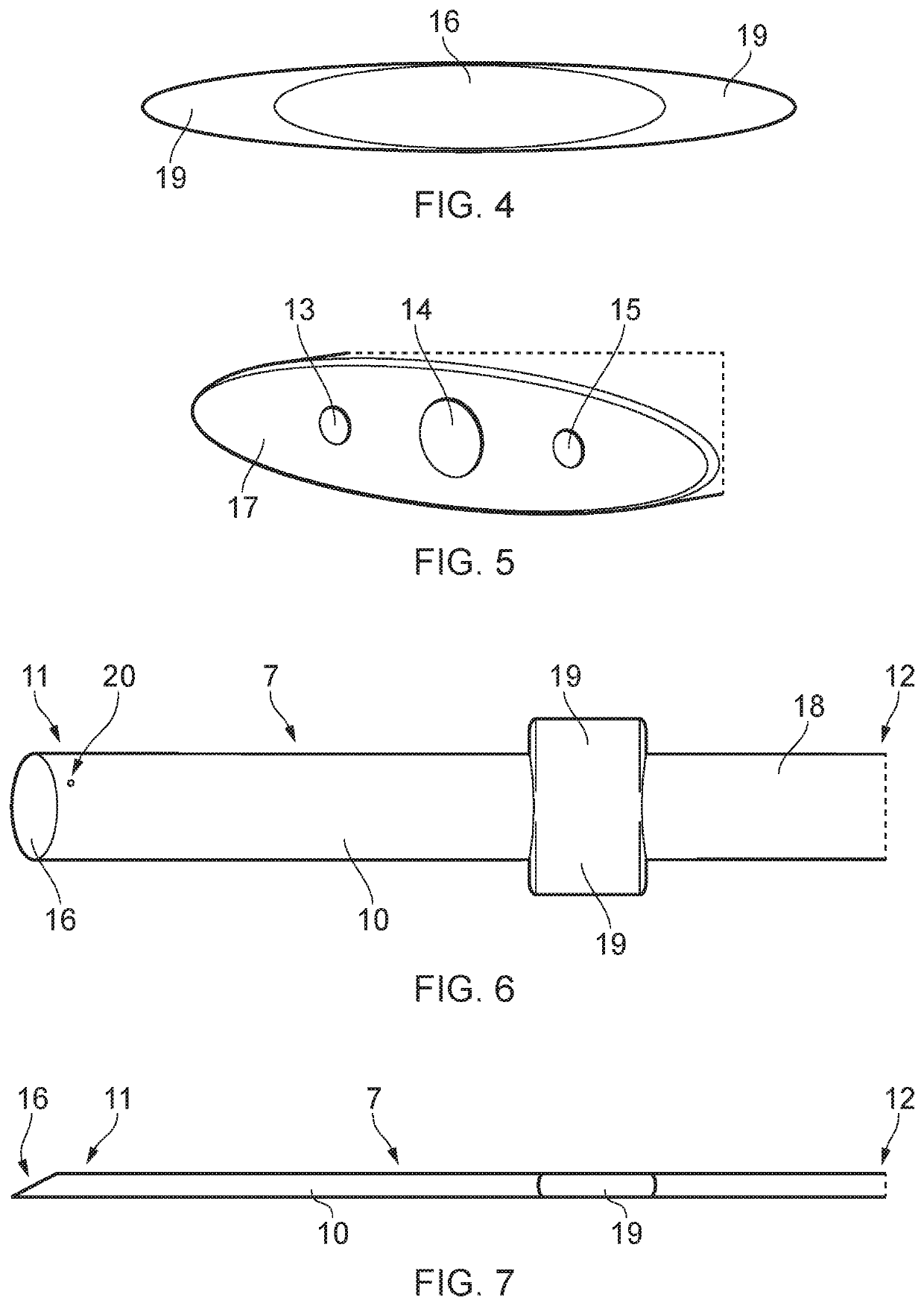

Wind turbine rotor blade

ActiveUS20120169060A1Improve aerodynamic performanceShort lifePropellersWind motor controlLeading edgeTurbine blade

A wind turbine blade is described, which extends in a spanwise direction from a root end to a tip end and defines an aerodynamic airfoil cross-section between a leading edge and a trailing edge in a chordwise direction transverse to the spanwise direction. The blade has a camber in the chordwise direction and includes a blade body and a moveable flap. The flap is moveable relative to the blade body to vary the camber of the blade. A deformable panel is located between the blade body and the moveable flap. The panel has an undulating profile comprising an alternating succession of ridges and troughs, which each extend in a first direction. The panel is formed of a material having anisotropic intrinsic stiffness with maximum anisotropic intrinsic stiffness being transverse to the first direction. In a preferred embodiment, the deformable panel is corrugated.

Owner:VESTAS WIND SYST AS

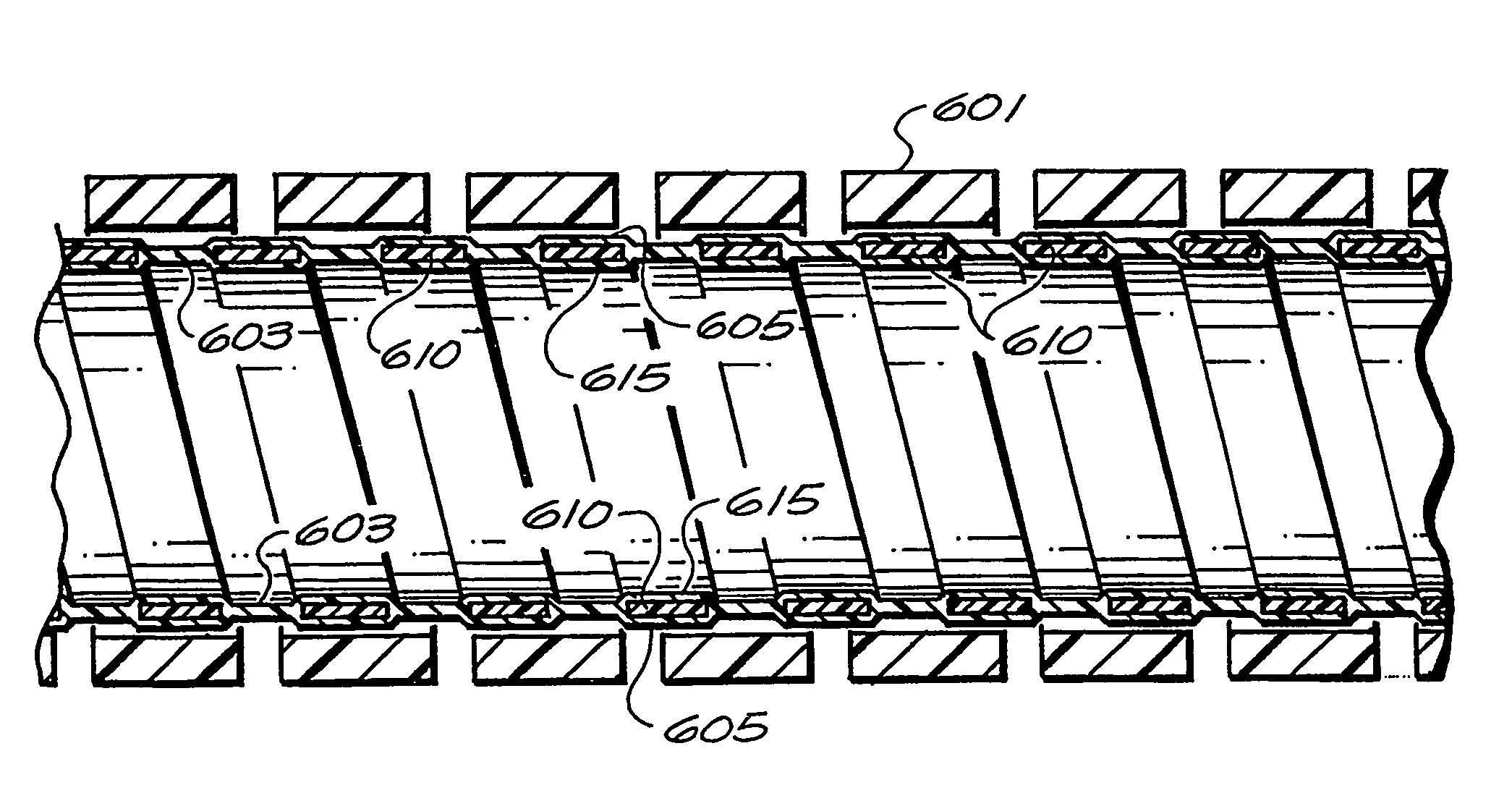

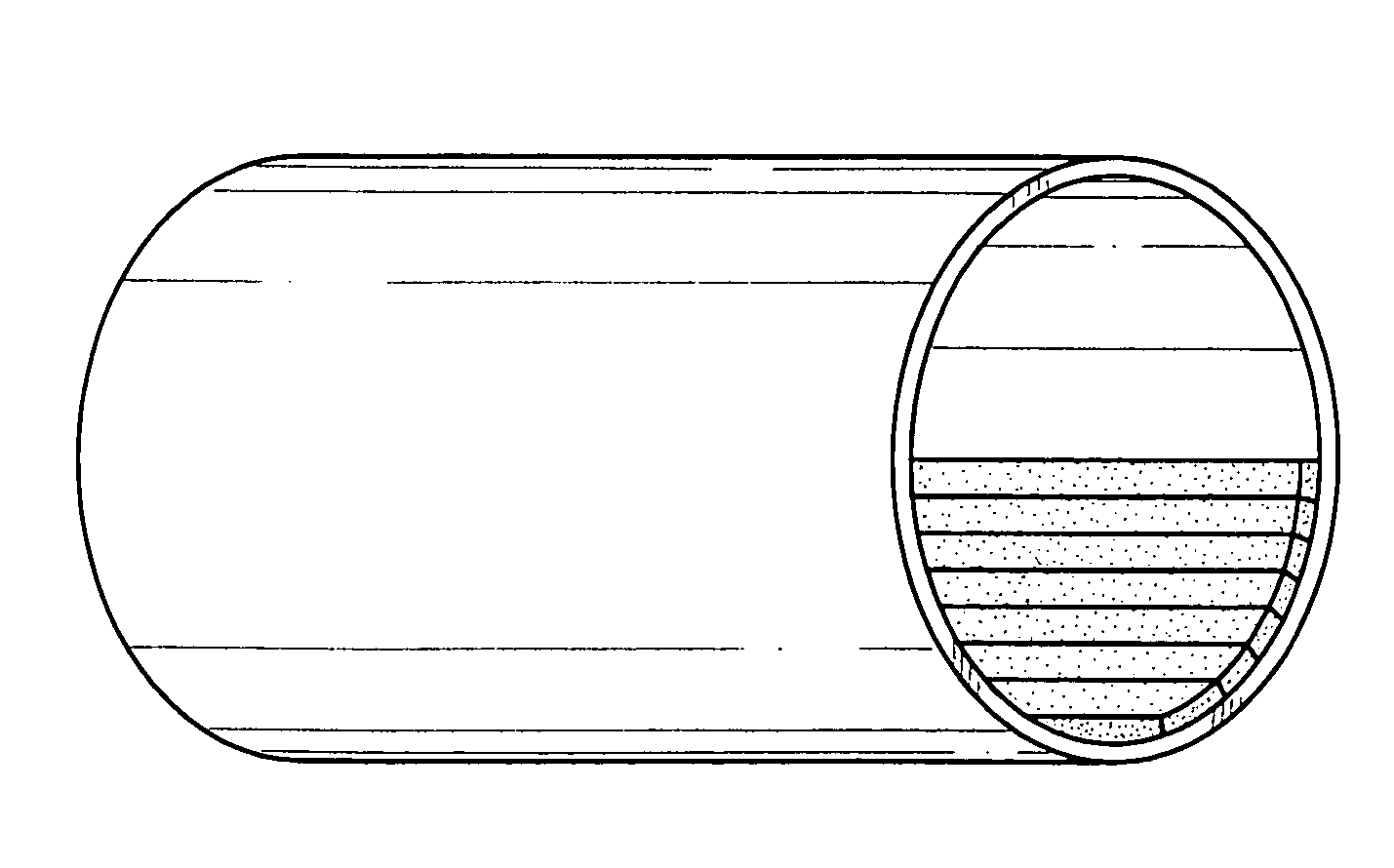

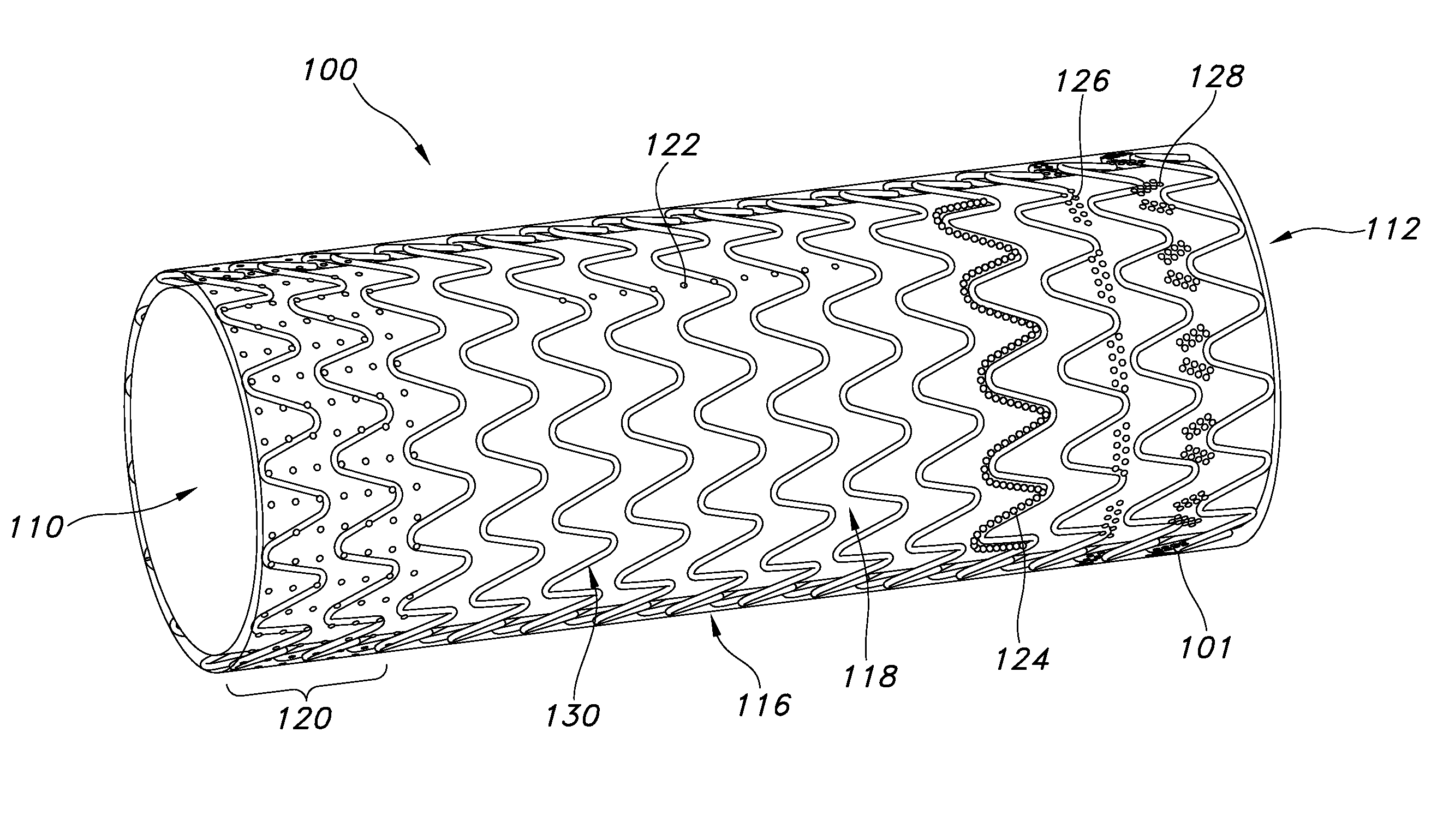

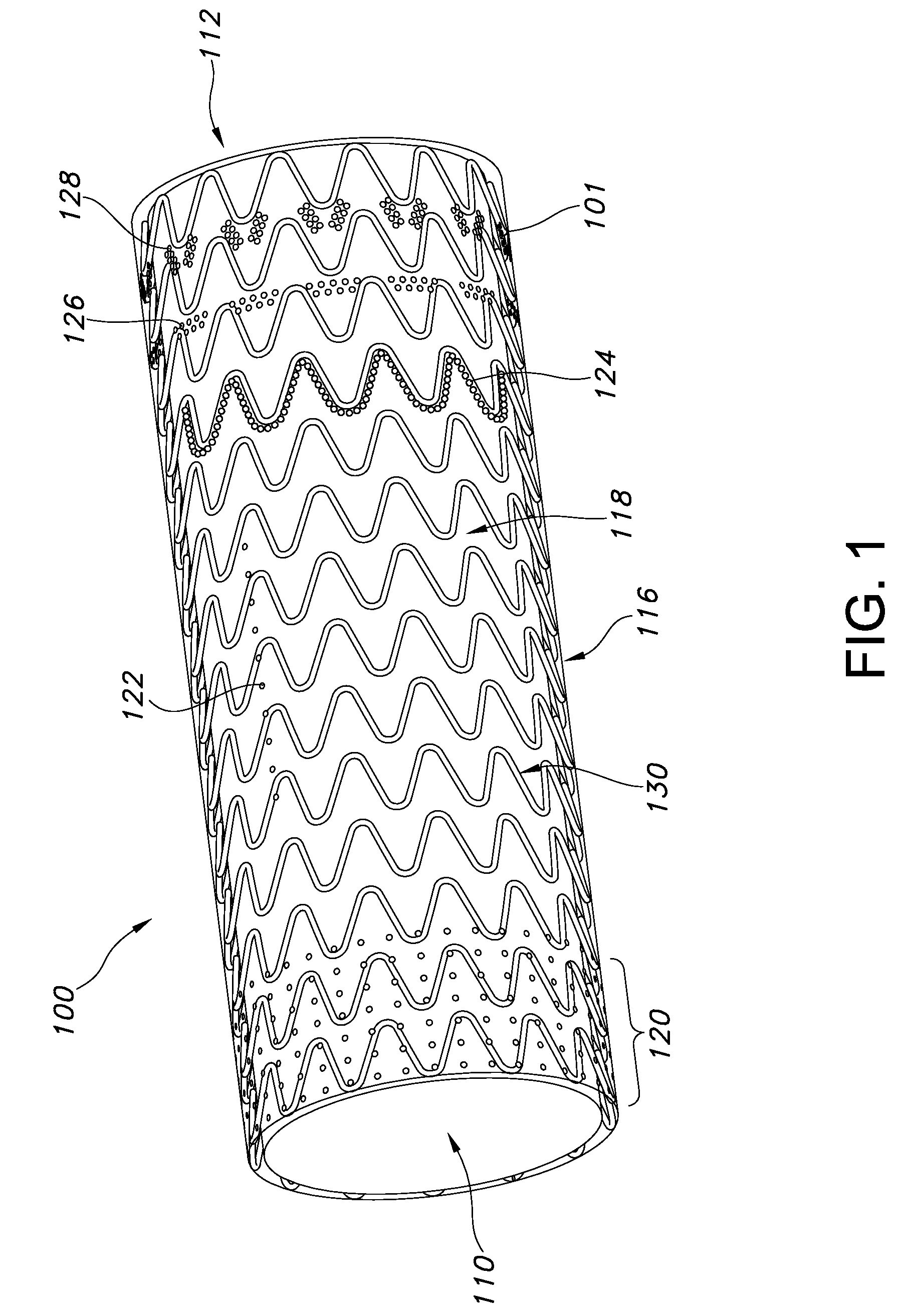

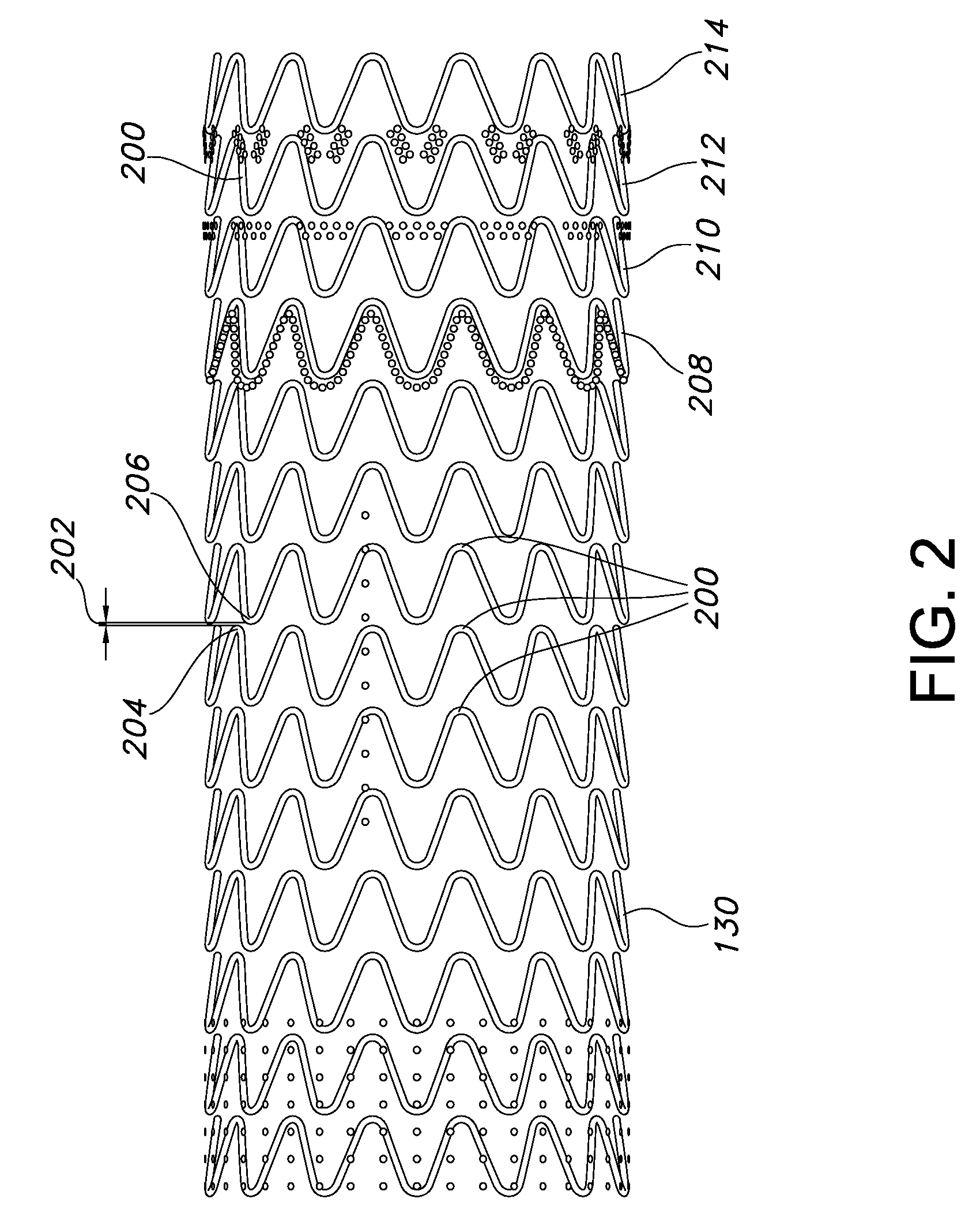

Flexible stent-graft device having patterned polymeric coverings

The present invention provides an endoprosthesis comprising a radially distensible, tubular stent comprising opposed open ends and a stent wall structure having opposed exterior and luminal surfaces; and a continuous and seamless ePTFE tubular covering having a node and fibril structure securably disposed to at least one of the stent surfaces, the graft covering comprising at least two laminated layers, wherein the laminated layers include at least one region where the laminated layers are not securely bonded; and the at least one region has a different bending flexibility from the tubular graft covering.

Owner:LIFESHIELD SCI

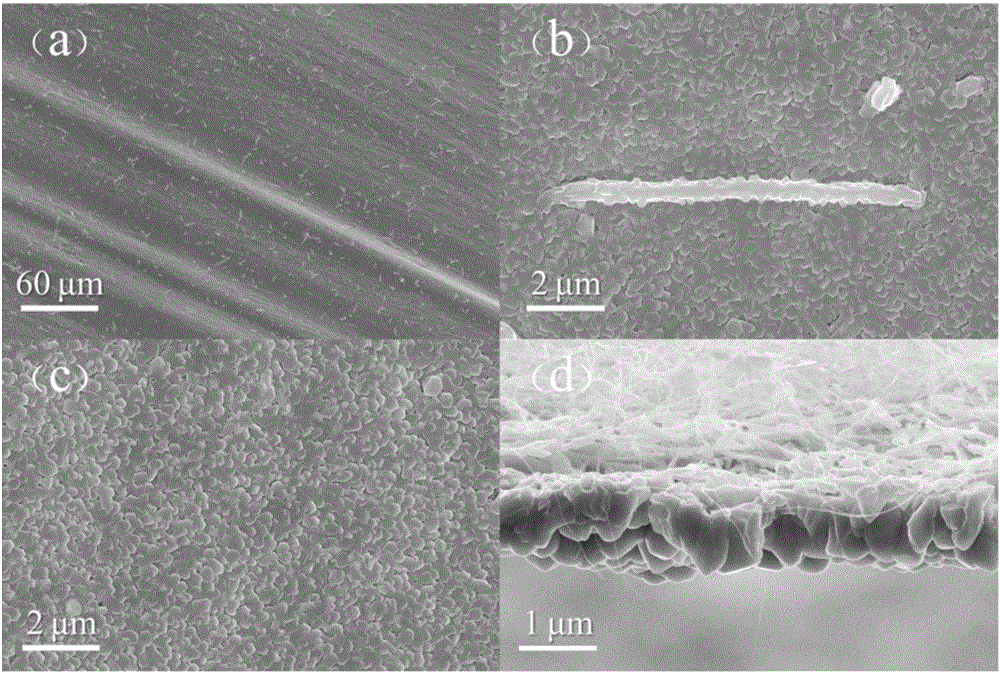

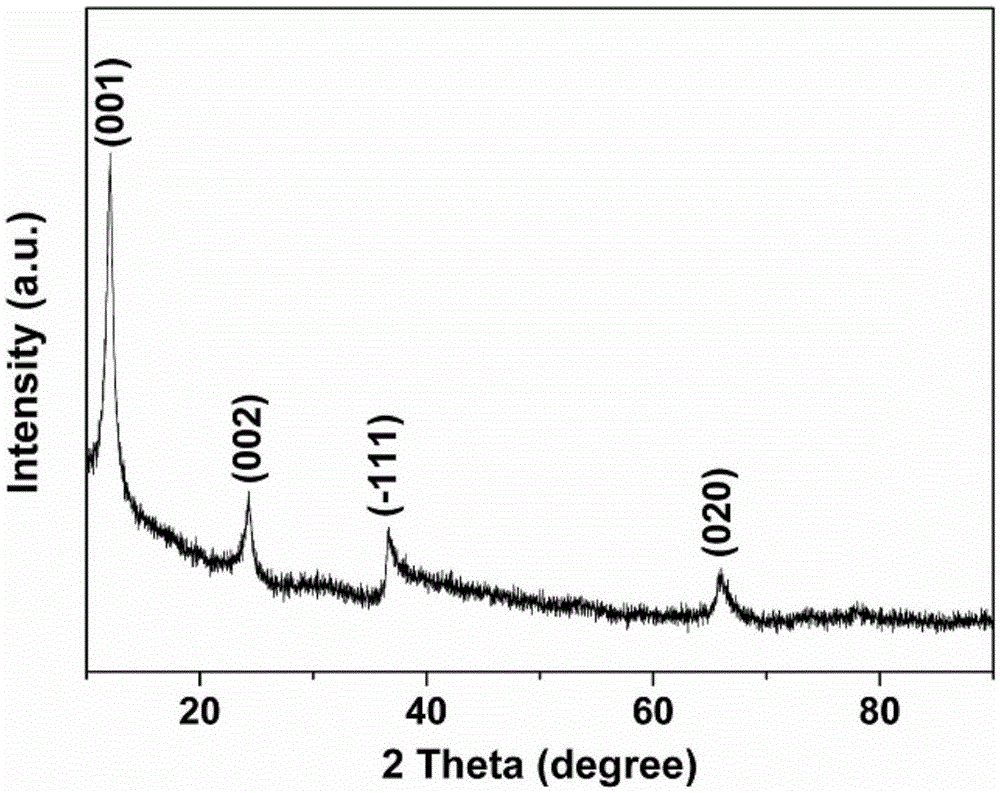

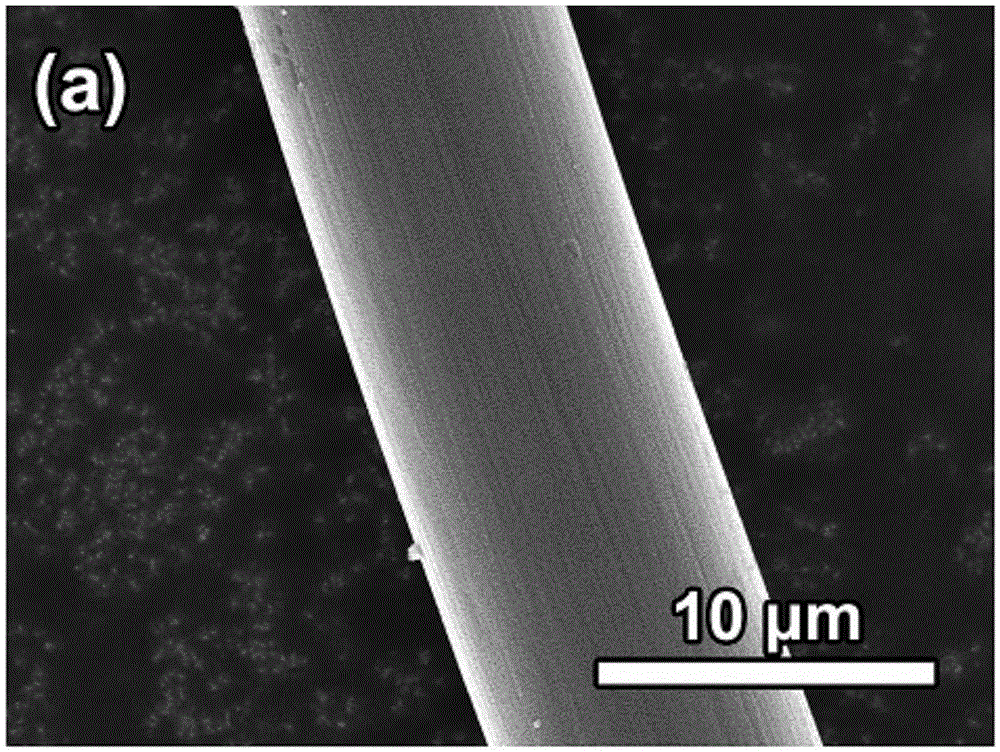

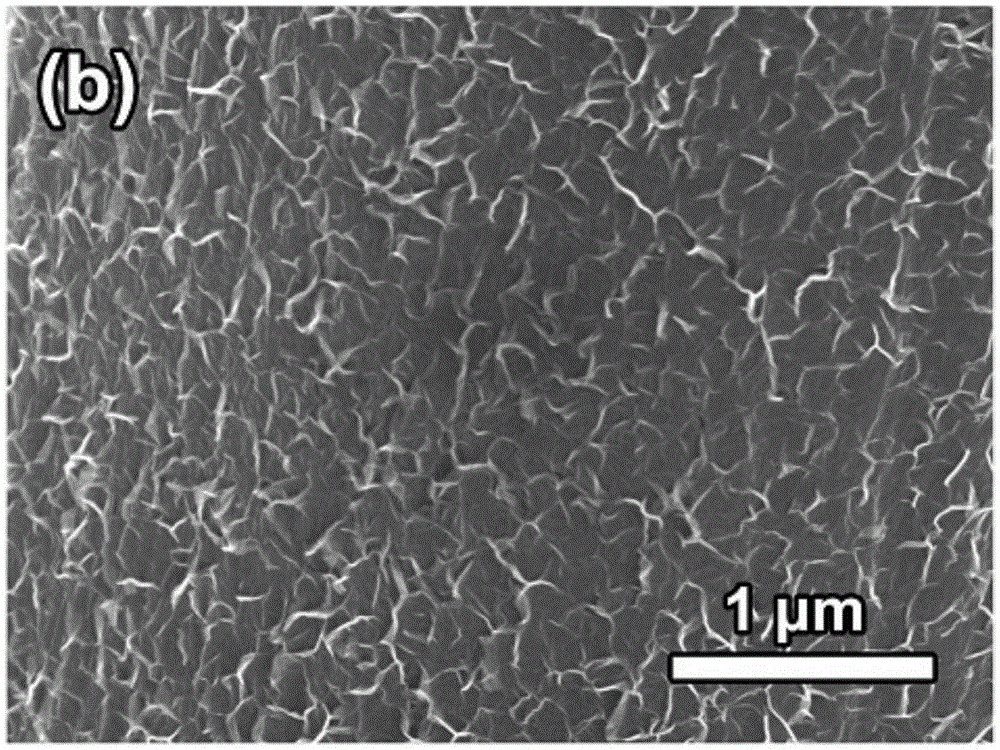

Laminated metal chalcogenide/carbon nanotube flexible compound film material of highly ordered structure and preparation

ActiveCN106744820APrecise control of ingredientsPrecise control structureCarbon compoundsVacuum evaporation coatingComposite filmCarbon nanotube

The invention belongs to the field of composite materials and in particular relates to a laminated metal chalcogenide (LMC) / carbon nanotube (CTNs) flexible compound film material of a highly ordered structure and a preparation method thereof. The composite material comprises an ultrathin self-supporting (transparent) CNTs film substrate and an LMC film which uniformly wraps the surface thereof to form the flexible composite film material which has a nanoscale porous structure and a three-dimensional network structure of a high electric channel. The preparation method comprises the following steps: providing an alloy bracket for bearing a self-supporting CNTs film and cleaning the carried CNTs film under a heating condition with plasma; and preparing the LMC / CNTs composite functional film material from the pre-treated CNTs film at an air pressure of 0.2-2Pa and at a temperature of 30-800 DEG C by virtue of a magnetron sputtered deposition technology. According to the material provided by the invention, a crispy laminated metal chalcogenide functional two-dimensional (2D) material and one-dimensional (1D) CNTs are effectively connected to form a three-dimensional (3D) network structure of structural flexibility.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

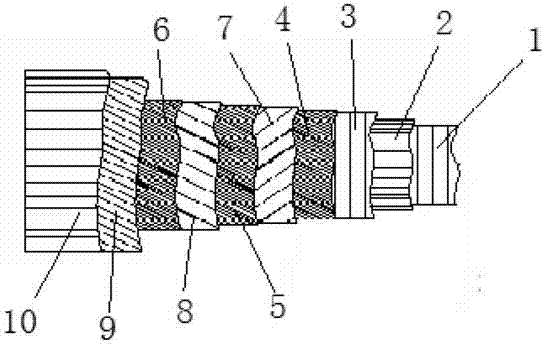

Composite flexible pipe anti-compression armor layer

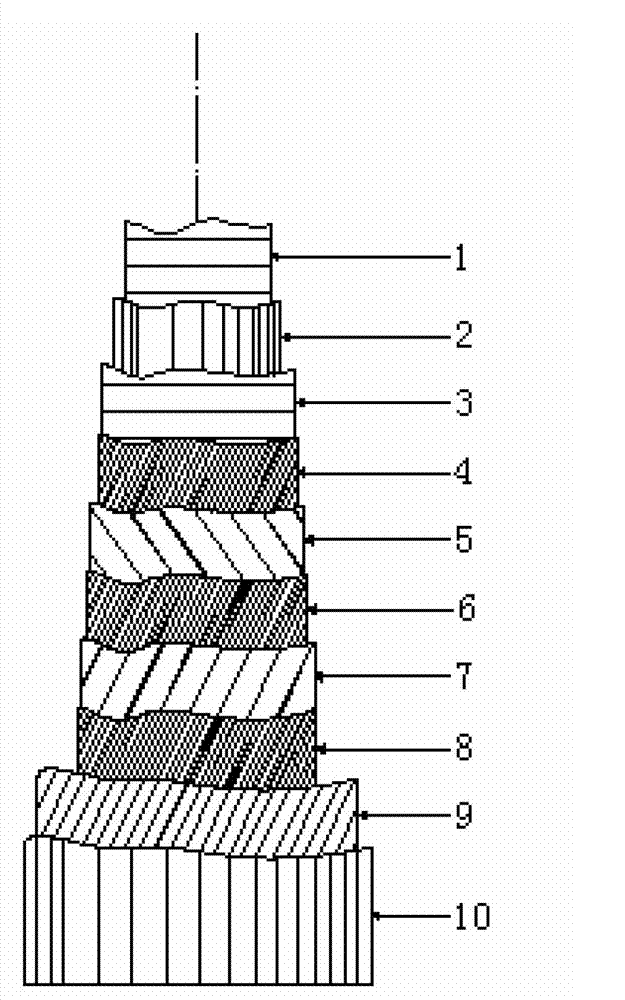

ActiveCN103090125AIncreased bending flexibilityPrevent each other from sliding outFlexible pipesEngineeringMechanical engineering

The invention relates to a composite flexible pipe anti-compression armor layer which comprises a non-bonding composite flexible pipe composed of a framework layer, a lining layer, an anti-compression armor layer, three wear-resisting layers, two anti-tension armor layers, an insulating layer and an outer wrapping layer. The composite flexible pipe anti-compression armor layer is characterized in that the profiled bar armor layer with a w-shaped cross section and the profiled bar armor layer with a c-shaped cross section are arranged between the lining layer and the wear-resisting layers in a mode of winding on the pipe diameter of the lining layer with the winding angle close to 90 degrees, the two the profiled bar armor layers are relatively and mutually buckled and wound, an upper groove is arranged between protruding teeth between two ends of the c-shaped profiled bar armor layer, an inner wall and an outer wall of one protruding tooth are inwards arranged, and an inner wall and an outer wall of the other protruding tooth are outwards arranged. A wide groove and a narrow groove are arranged on the top portion of the w-shaped profiled bar armor layer, the wide groove corresponds to a concave outer wall of the protruding tooth, the narrow groove corresponds to a convex outer wall of the protruding tooth, and each side angle of the c-shaped profiled bar armor layer and the w-shaped profiled bar armor layer are arranged into an arc angle. The composite flexible pipe anti-compression armor layer can be widely used for various anti-compression pipes to transmit liquid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

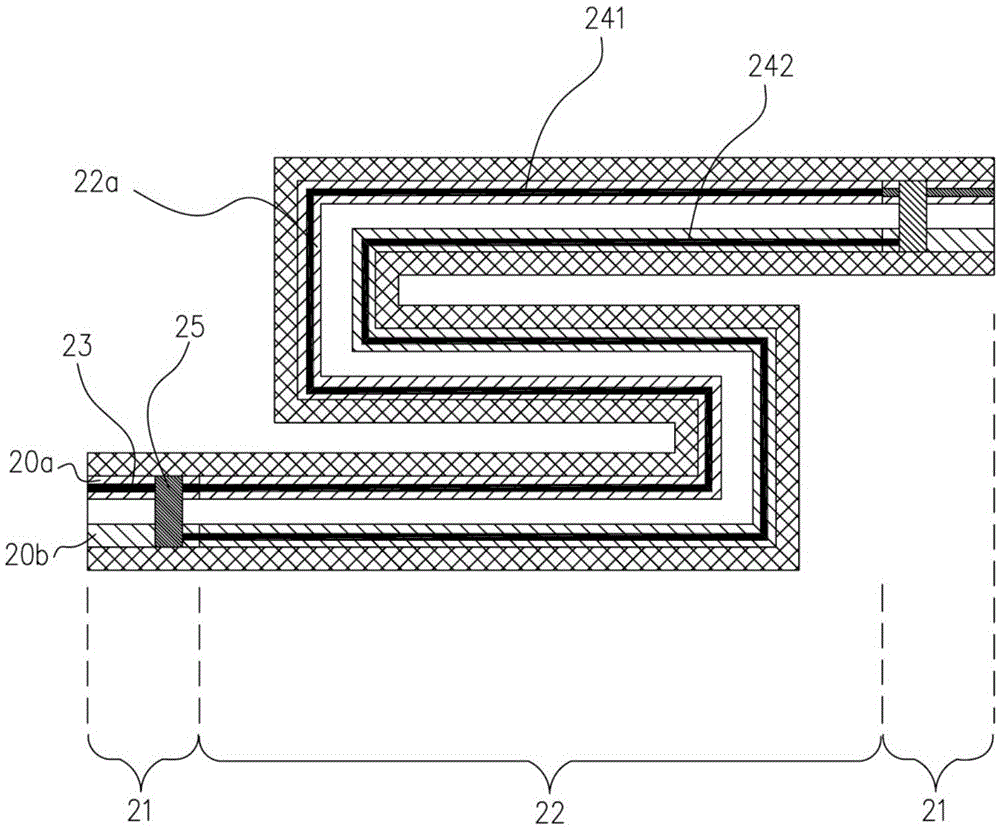

Touch substrate, preparation method thereof and touch device

PendingCN107632740AIncreased bending flexibilityAvoid breakingInput/output processes for data processingComputer scienceElectrode

Owner:BOE TECH GRP CO LTD +1

Variable stiffness guidewire

InactiveUS7867176B2Rigid enoughImprove airworthinessGuide wiresDiagnostic recording/measuringVariable stiffnessDistal portion

A guidewire navigable through body vessels of a human subject for delivery of a catheter or the like is provided. The guidewire has a tube which receives a corewire that protrudes beyond a distal portion of the tube. The protruding portion of the corewire is surrounded by a spring and shapeable into a curve or arc. The cross-sectional shape of the spring may be varied in order to promote bending flexibility and curvature or to favor curvature of a chosen type. The corewire is axially movable with respect to the tube, which compresses or stretches the spring to change the stiffness of the spring. The tube has a proximal portion comprised of a relatively rigid material, such as stainless steel, while a distal portion is comprised of a more flexible material, such as a nitinol.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

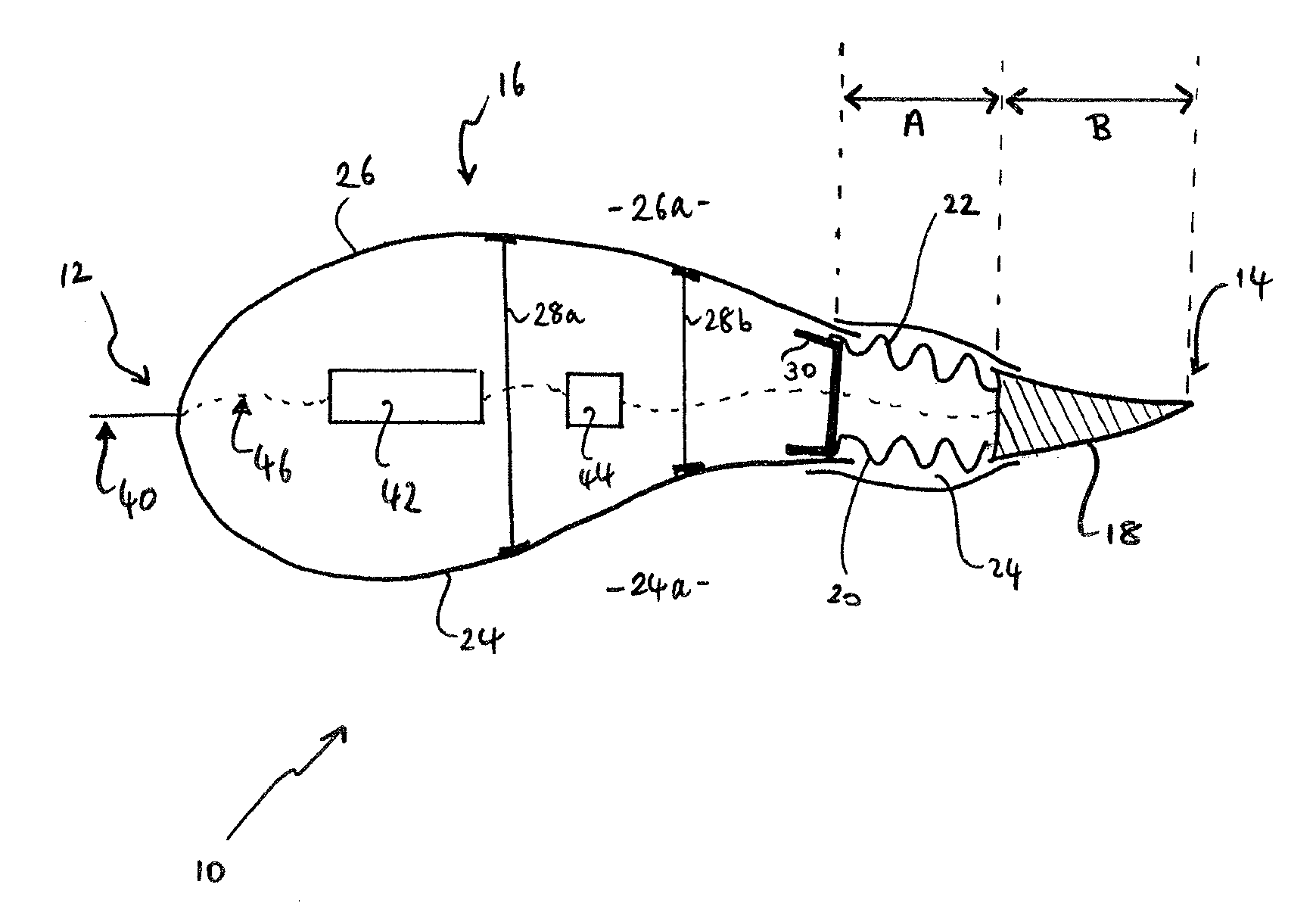

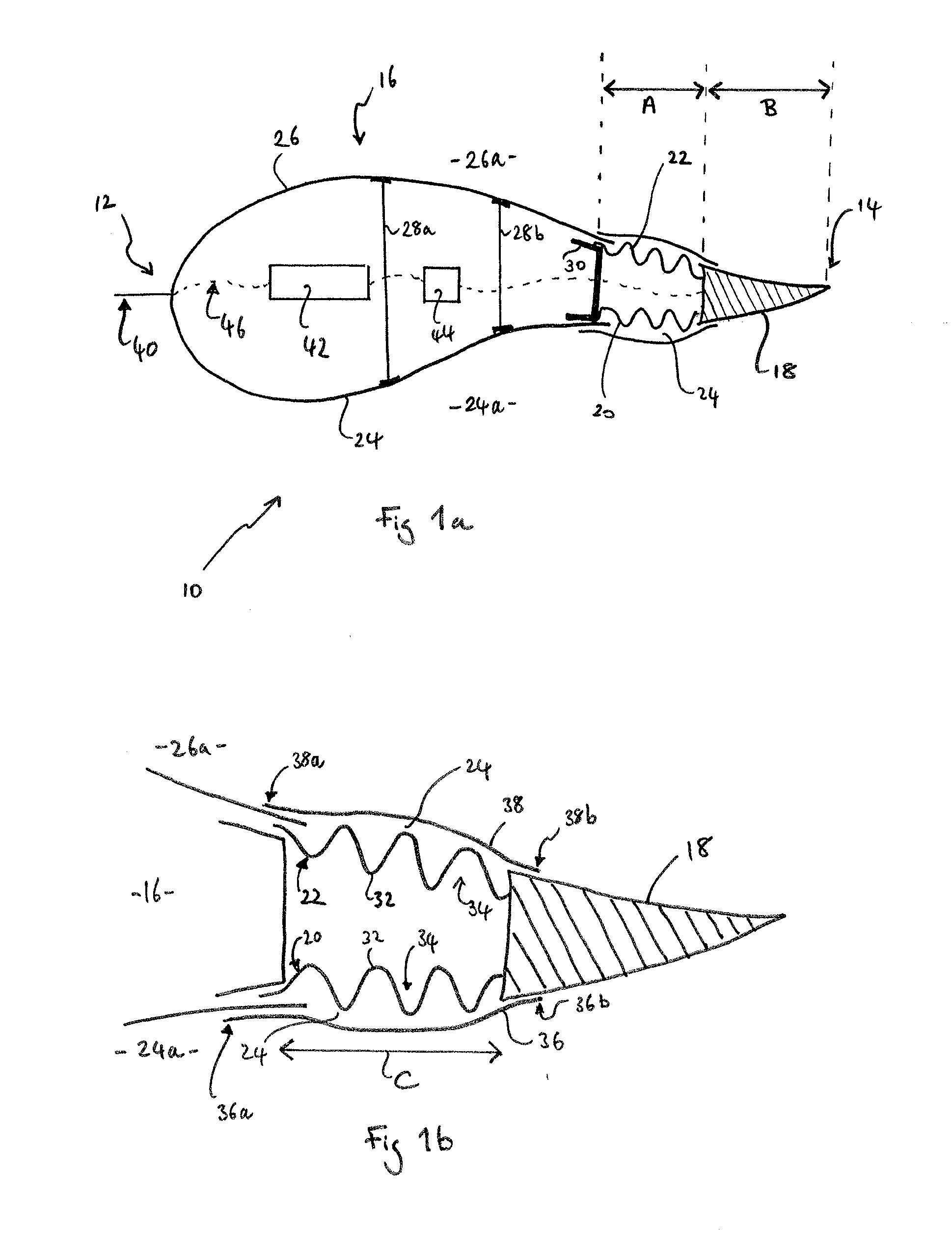

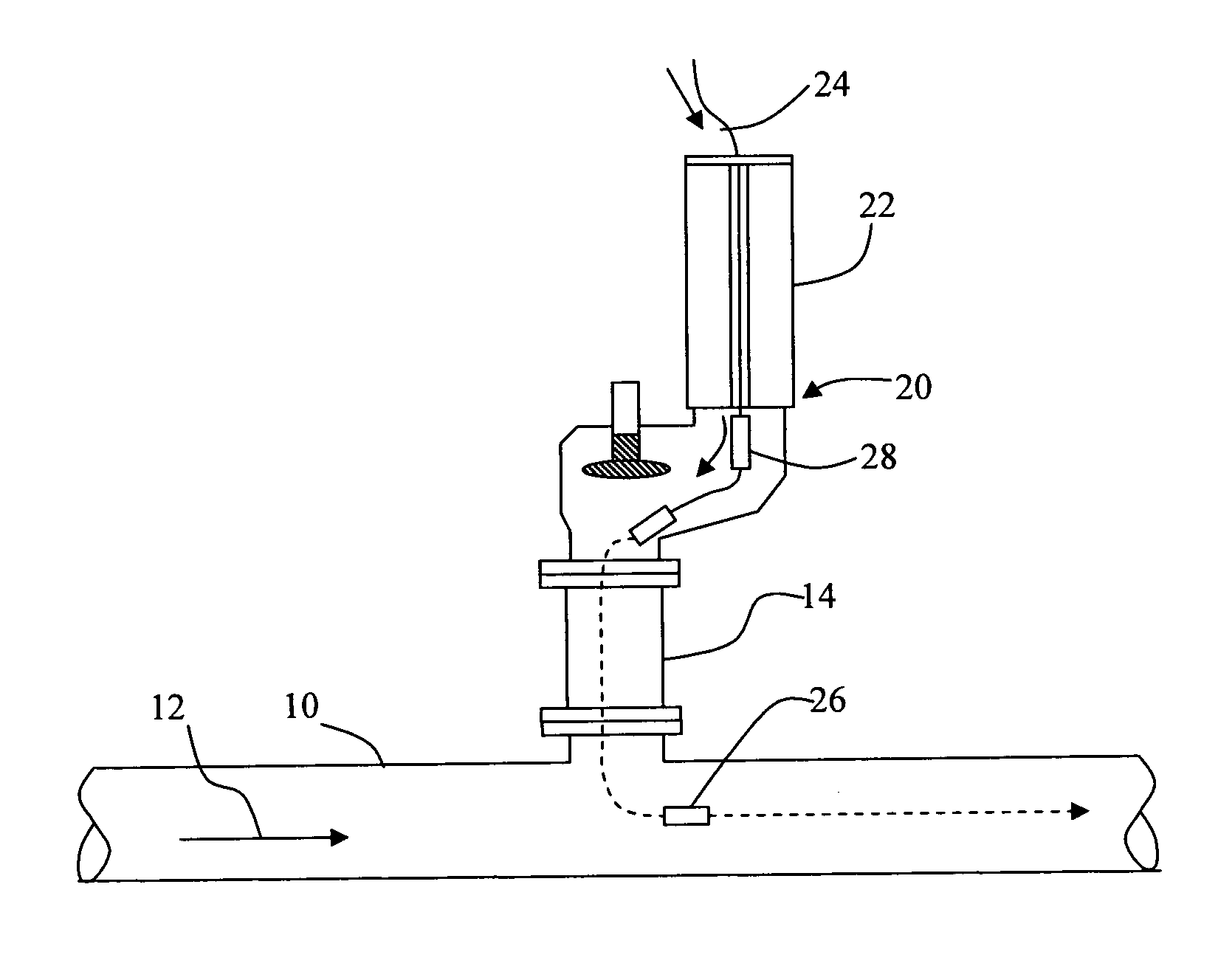

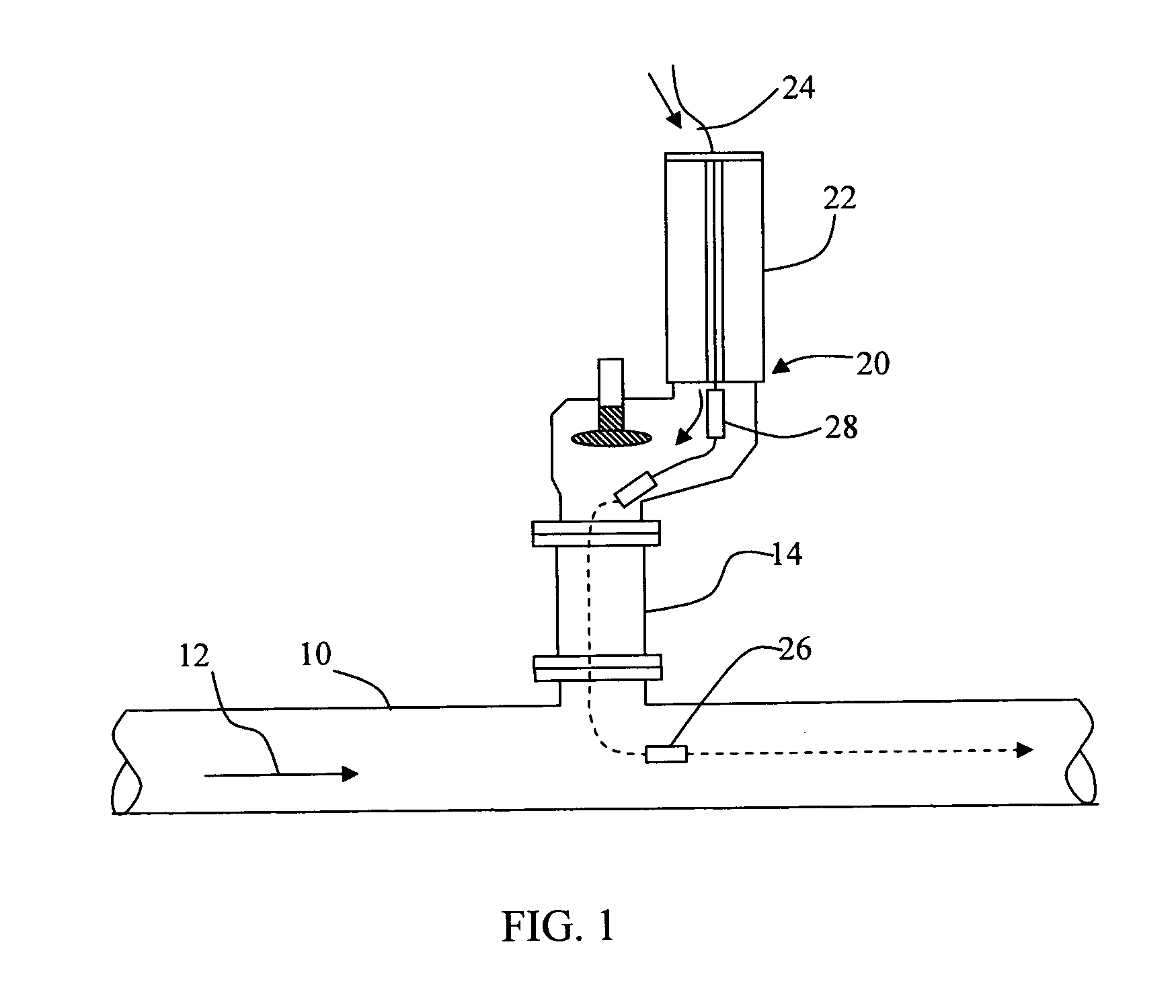

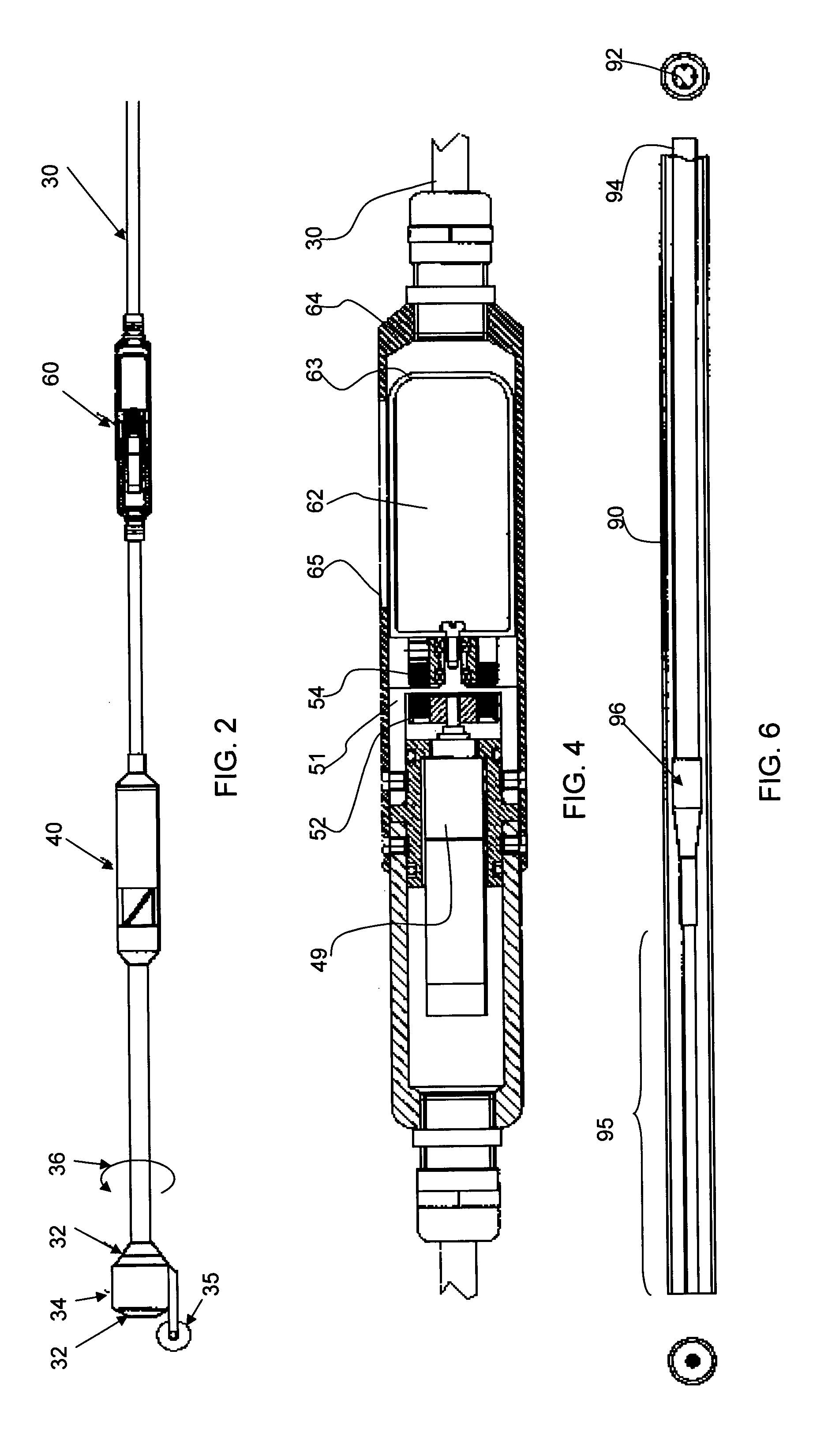

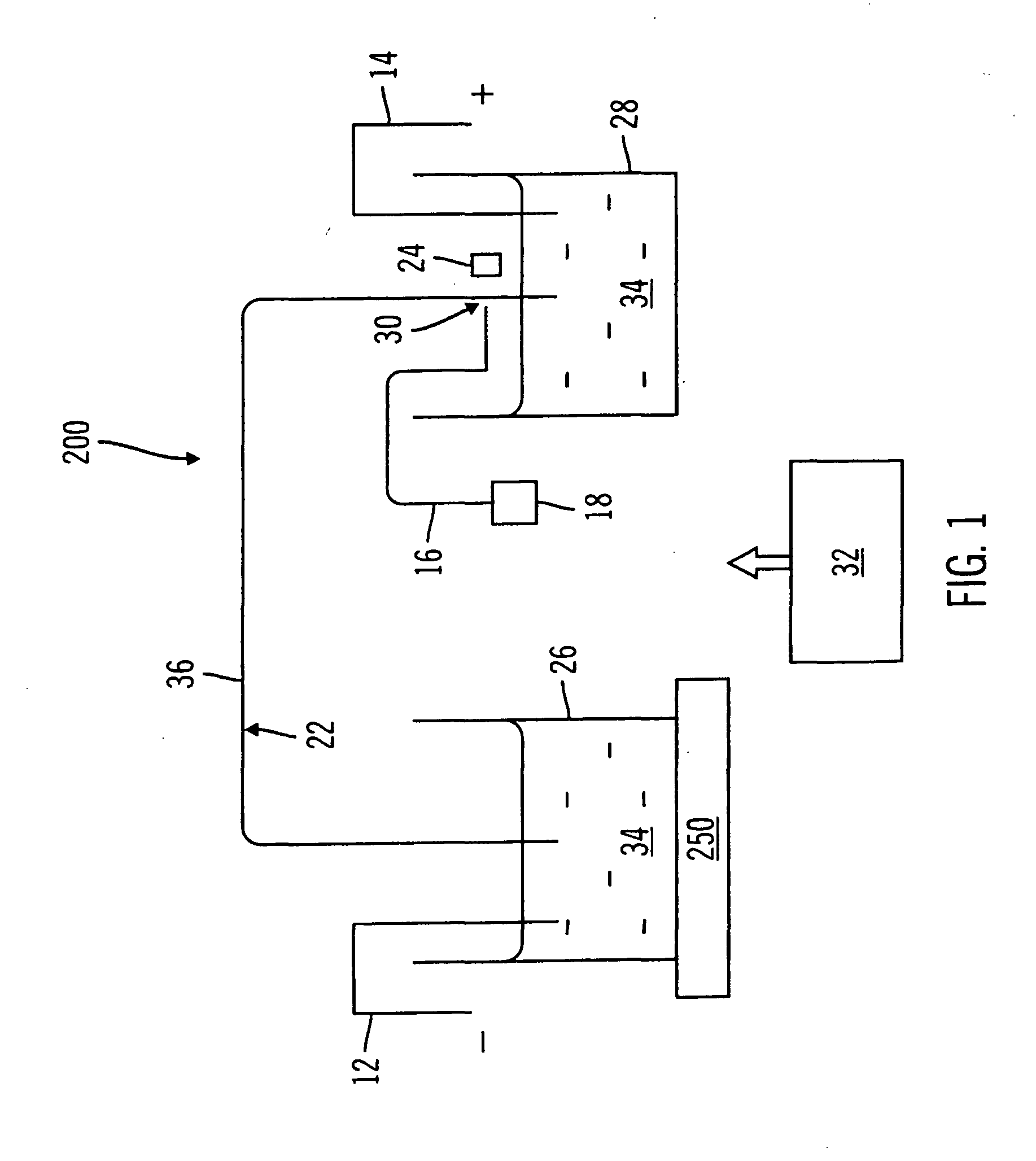

Introducer Assembly and Dilator Tip Therefor

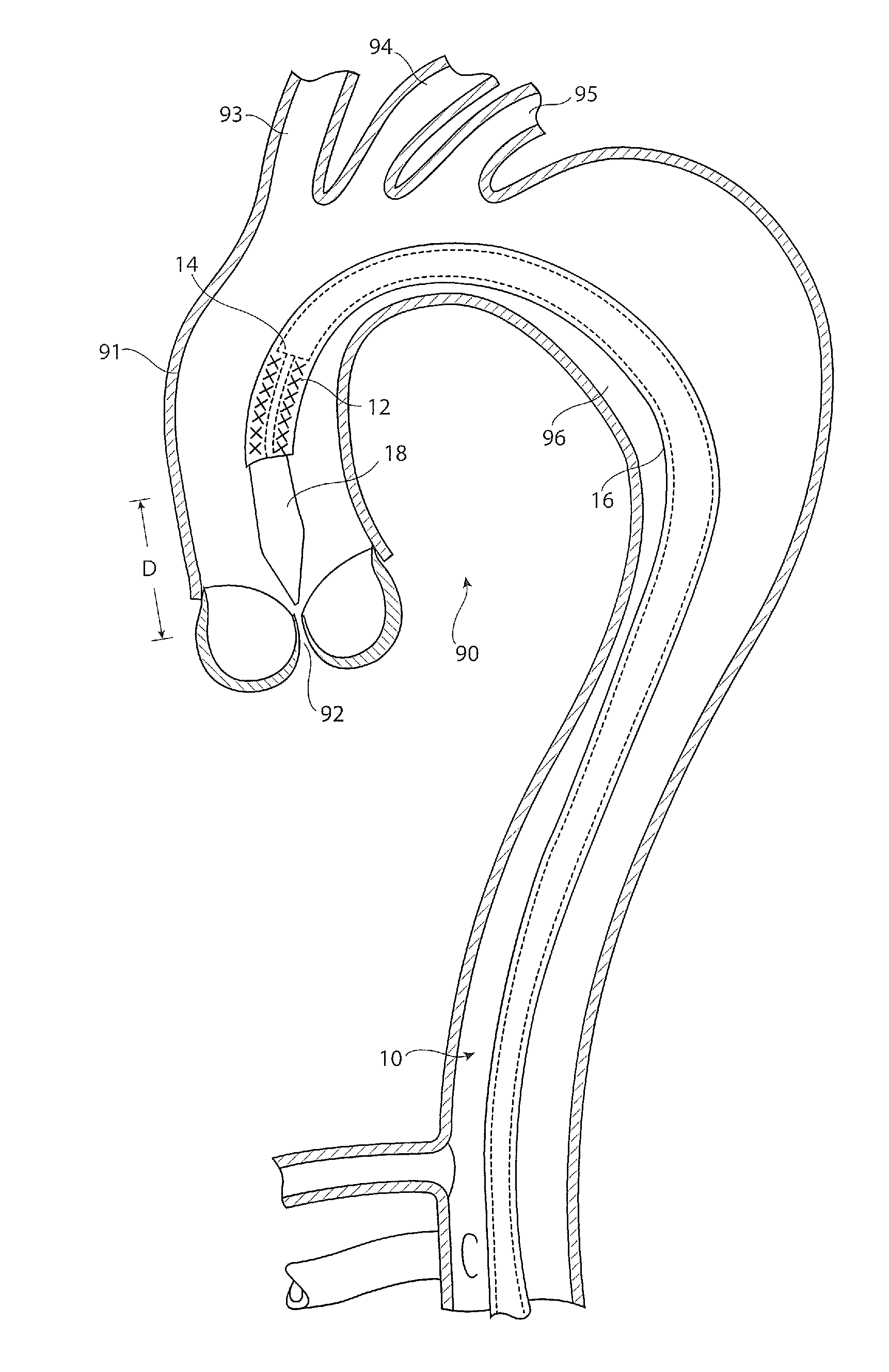

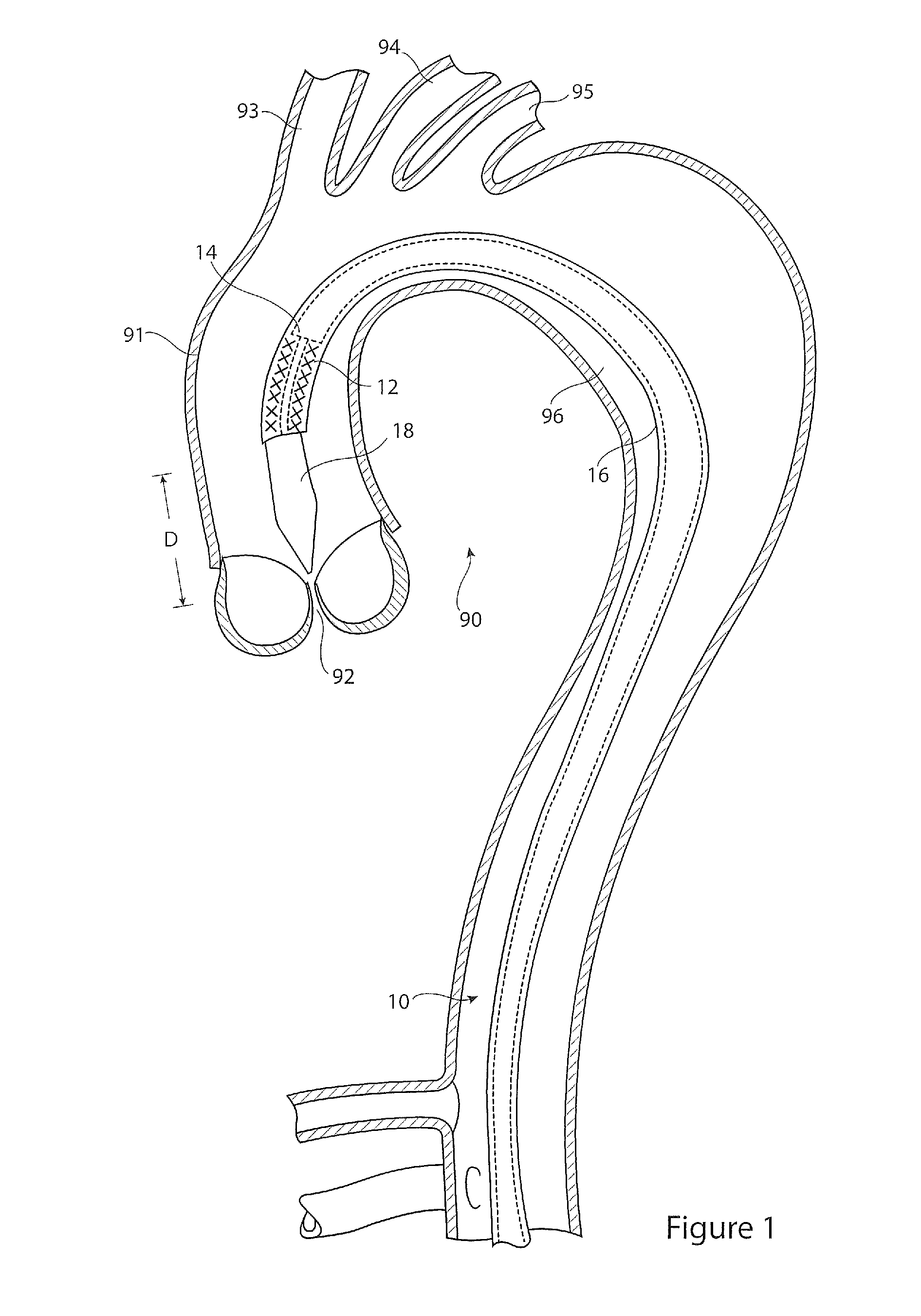

An introducer assembly (20) for the deployment of an implantable medical device (12) such as a stent, stent graft or other medical device, includes a dilator tip (22) which is able to be compressed radially so as to be withdrawn into the introducer assembly (20) so as to position the implantable medical device (12) at the distal most end of the introducer assembly once the dilator tip has been withdrawn. This enables the implantable medical device (12) to be positioned much closer to both parts of a patient's anatomy, for instance much closer to an aortic valve (92). In the preferred embodiment the dilator tip (22) includes an inflatable and deflatable balloon element (28) which is able to be withdrawn into the assembly while the implantable medical device (12) remains in its constrained position in the introducer assembly (20).

Owner:COOK MEDICAL TECH LLC

Aircraft wing, aircraft wing composite material, and method of manufacture thereof

InactiveUS7802759B2Increased bending flexibilityImprove carrying capacityAircraft stabilisationWing adjustmentsAircraft landingAirplane

To provide an aircraft wing which has both high bending flexibility in the wing chord direction and high capacity to maintain the wing shape in the wing span direction, and to which morphing aircraft technology can be applied in the high-speed regime where aerodynamic forces are high.The wing is formed by arranging a plurality of CFRP rods having maximum anisotropic stiffness in the axial direction, so as to be parallel to the wing span direction, and filling the gaps between the CFRP rods with an elastic material.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Water mains inspection and servicing

ActiveUS9234812B2Compact implementationIncreased bending flexibilityAnalysing solids using sonic/ultrasonic/infrasonic wavesThermal drillingEngineeringUltrasound

Owner:JD7

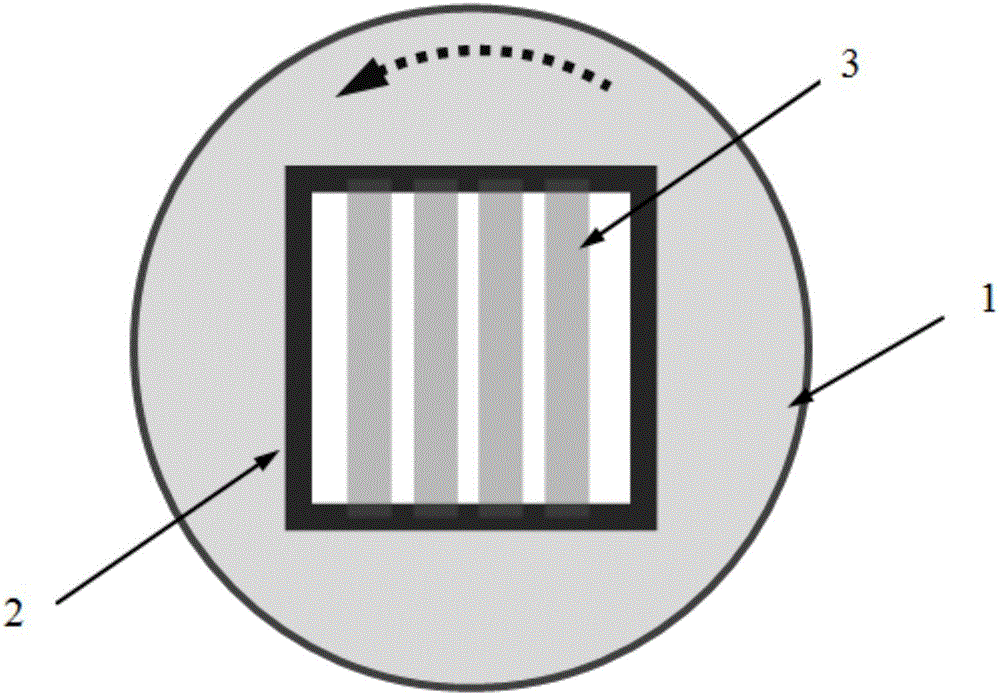

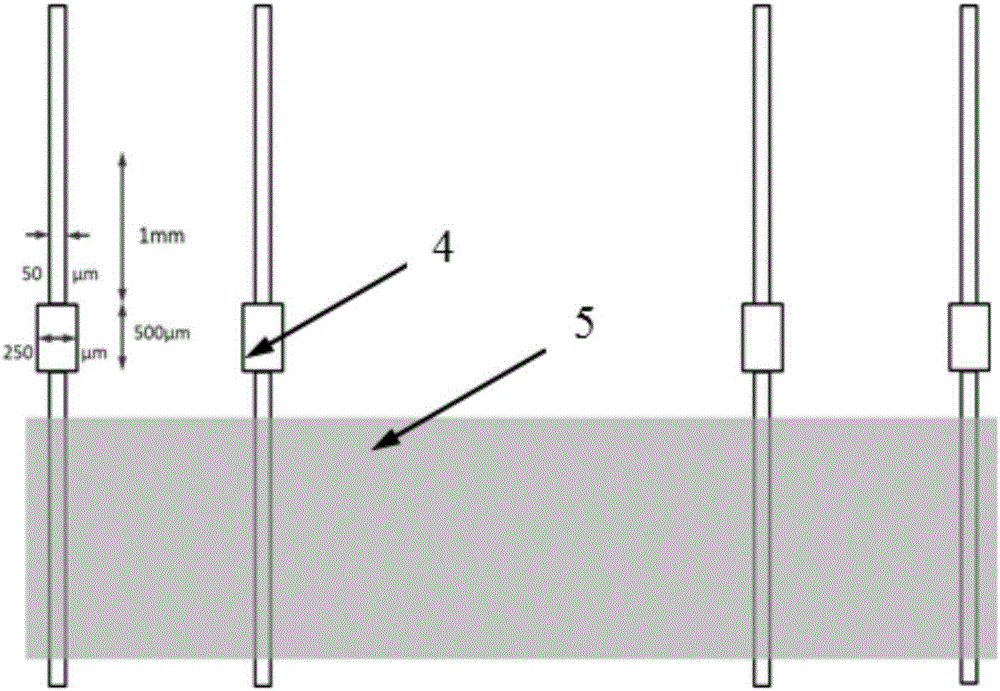

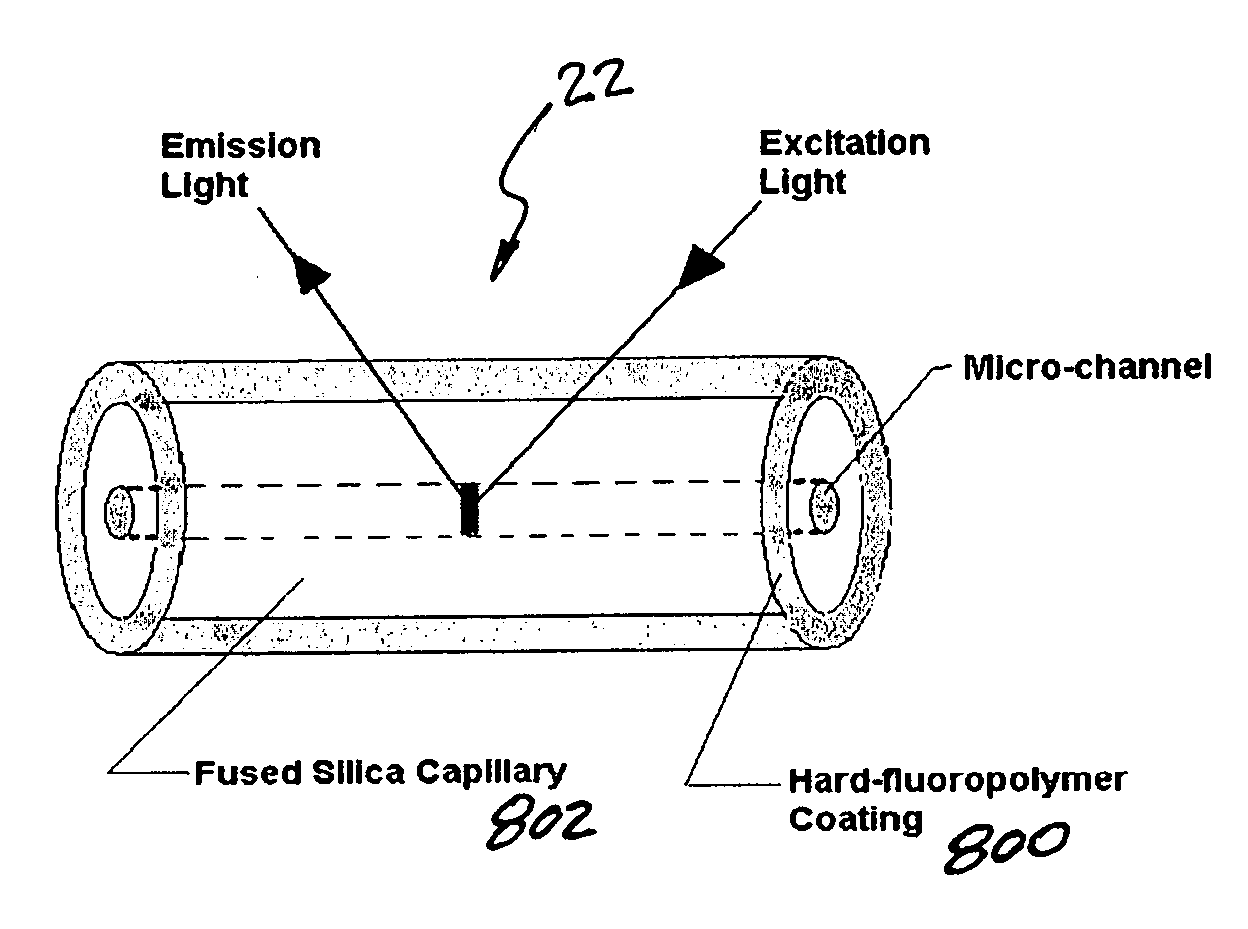

Capillary electrophoresis using clear coated capillary tubes

ActiveUS20100108513A1Low costImproves Structural IntegritySludge treatmentVolume/mass flow measurementFluorescencePliability

A capillary tube having a hard, optically clear external coating or cladding. In one embodiment, the external clear coating comprises hard-fluoropolymer. The hard-fluoropolymer coating bonds to the fused silica glass, providing higher strength and superior static fatigue performance resulting in vastly improved bending flexibility. The thin hard-fluoropolymer coating of capillaries provides higher initial tensile strength, longer lifetime (resistance to stress corrosion or static fatigue) and superior ability to transmit excitation light and emitted light directly through the coating for fluorescence based detection.

Owner:QIAGEN SCIENCES LLC

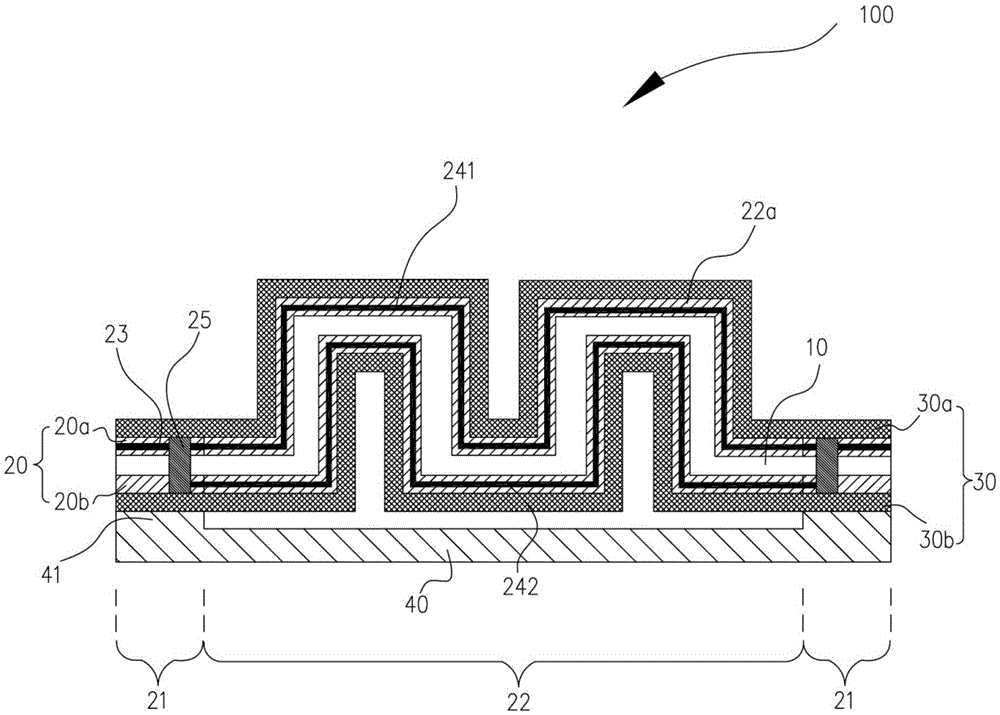

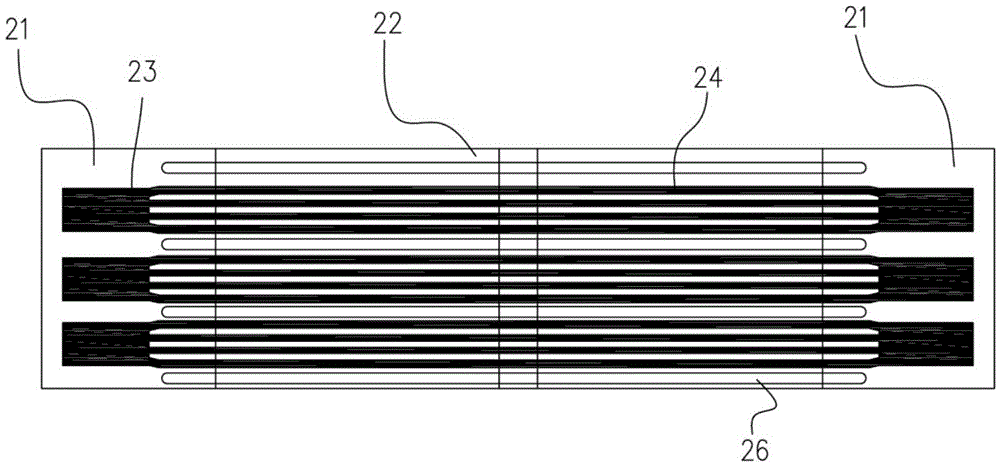

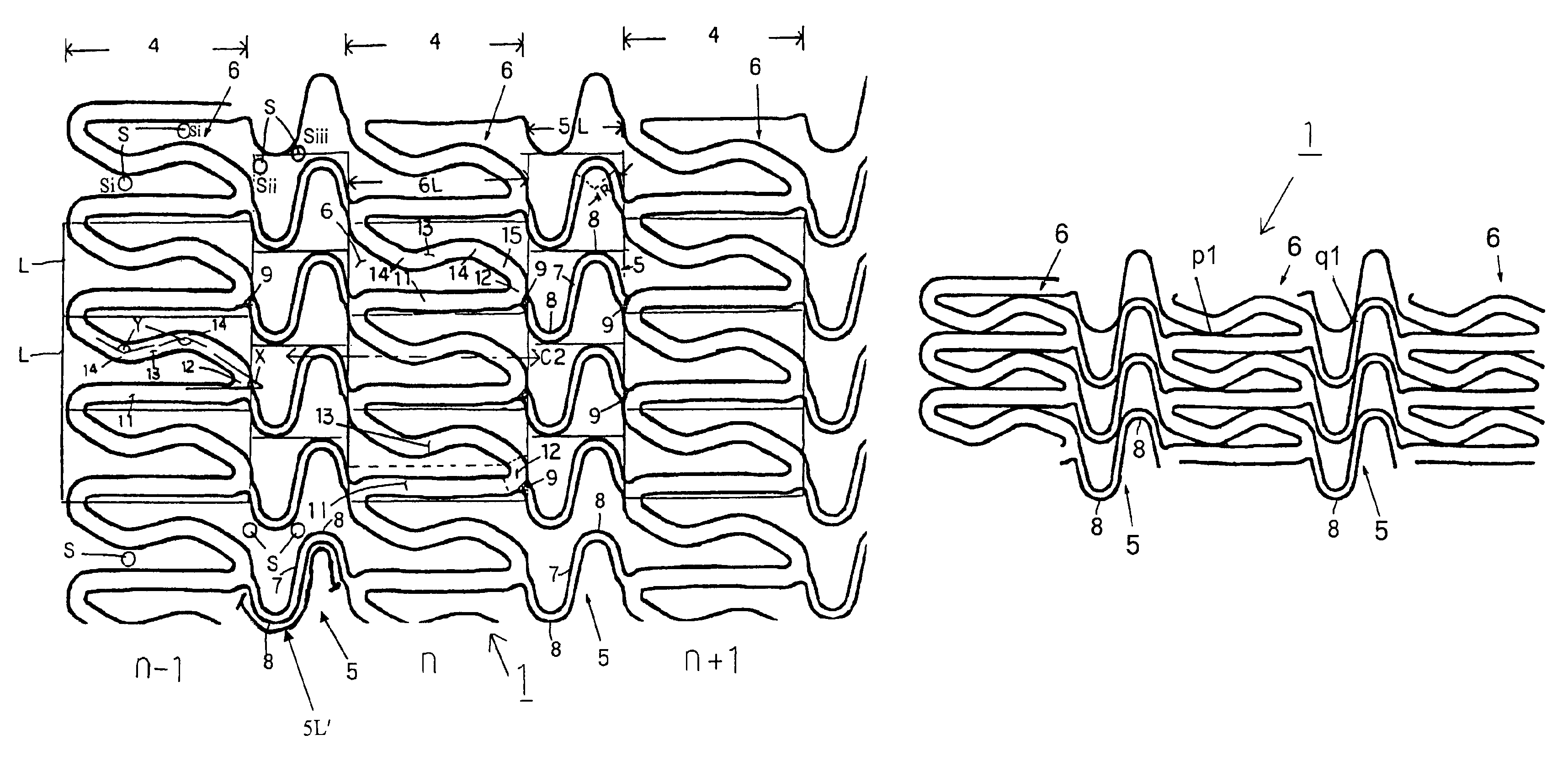

Flexible printed circuit board and mobile terminal

ActiveCN105636339AIncrease the lengthReduce stressPrinted circuit detailsPrinted circuit aspectsComputer terminalEngineering

The invention provides a flexible printed circuit board and a mobile terminal. The flexible printed circuit board comprises a substrate layer, a copper foil layer and a covering membrane. The copper foil layer is arranged on the substrate layer. The copper foil layer comprises two oppositely arranged non-bending parts and a strip-shaped bending part connected between the non-bending parts. Conductive wires are arranged on the non-bending parts. The bending part is of a winding structure. A bending conducive wire is arranged on the bending part and is bent along with the bending part. One end of the bending conductive wire is connected to the conductive wires. The covering layer is laminated on the copper foil layer, and covers the bending part and the non-bending parts. When the overall length of the flexible printed circuit board is not increased, bending flexibility is improved, stress of the bending part is also reduced and flexibility of the bending part of the flexible printed circuit board is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Stent

A stent having a generally tubular body formed of ring units formed of a plurality of cells each and expandable in the radial direction, wherein each ring unit is constituted of cells connected to one another above and below, arranged to surround the center line of the stent, the ring units are arranged in the axial direction of the stent, and are connected with connector portions, each connector portion is formed of curved portions each having an arch and a generally linear portion continued thereto, 3 to 8 cells are arranged in the axial direction per 10 mm of the length of the stent, and the ratio of the length of the cell in the axial direction and the length of the connector portion is determined such that on the basis that when the length of the cell is 100, that of the connector portion 50 to 100, thereby securing flexibility and radial sustaining force.

Owner:KAWASUMI LABORITORIES INC

Wind turbine rotor blade

InactiveUS9086054B2Reduces stiffness)Maximum anisotropic intrinsic stiffnessWind motor controlMachines/enginesLeading edgeTurbine blade

Owner:VESTAS WIND SYST AS

Hose conduit element for a paint robot

ActiveUS20060272311A1Undesirable mechanical stressReduce frictionPipe supportsChain elementsPaint robotEngineering

Owner:DURR SYST INC

Optical device

ActiveUS20110116743A1High sensitivityFlexibility in bendingStrain gaugeFluid pressure measurement by electric/magnetic elementsOptoelectronics

Owner:ARKWRIGHT TECH PTY LTD

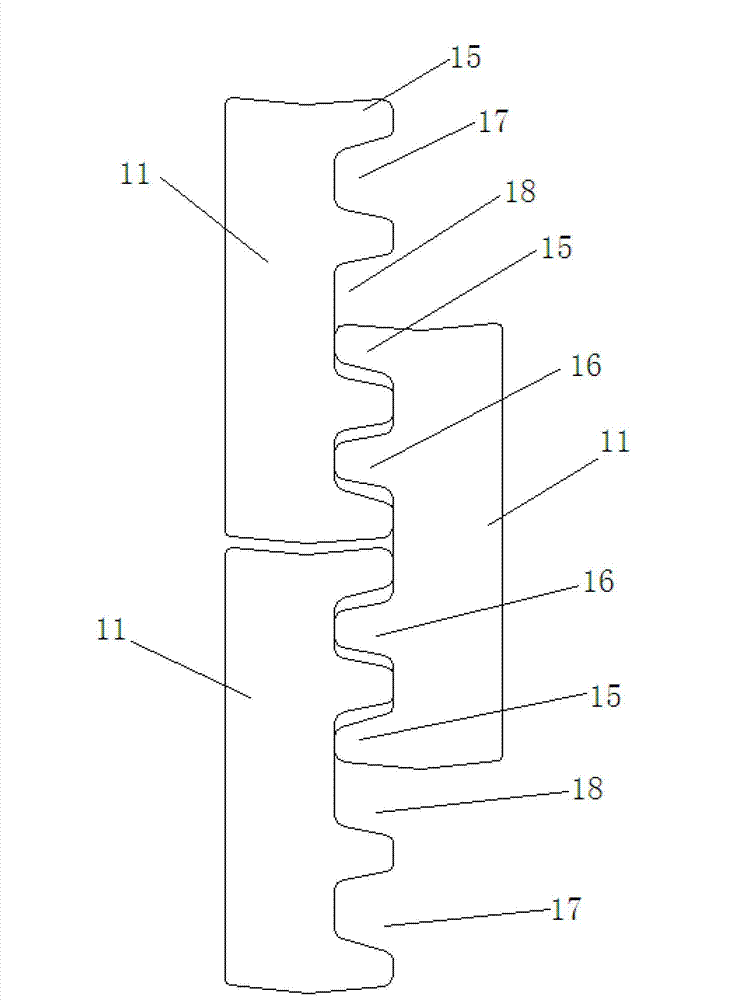

Tooth-shaped-section pressure-resisting armor layer for composite hoses

ActiveCN102927383AIncreased bending flexibilityPrevent each other from sliding outFlexible pipesEngineeringMechanical engineering

The invention relates to a tooth-shaped-section pressure-resisting armor layer for composite hoses. The tooth-shaped-section pressure-resisting armor layer is characterized by being formed by winding and interlocking a profiled bar, wherein the section of the profiled bar is tooth-shaped; the section comprises a girder; the girder comprises a first bottom wall and a second bottom wall along the length direction; an end tooth-shaped structure is integrally arranged at two ends of the second bottom wall toward the same side respectively; two middle tooth-shaped structures are arranged at intervals on the second bottom wall between the two end tooth-shaped structures; end depressed areas are formed between the middle tooth-shaped structures and the adjacent end tooth-shaped structures; a middle depressed area is formed between the two middle tooth-shaped structures; the two end tooth-shaped structures are bent toward the same side; middle tooth-shaped structures of an adjacent profiled bar are inserted into the end depressed areas of the profiled bar; end tooth-shaped structures of two adjacent profiled bars are inserted into the middle depressed area of the profiled bar; the adjacent profiled bars are mutually meshed. The tooth-shaped-section pressure-resisting armor layer has the advantages of strengthening the bending flexibility of the pressure resisting armor layers and effectively preventing the adjacent sections of the pressure resisting armor layers from mutually sliding out, thus being widely applied to the structure setting of the marine composite hoses.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Nitrogen-doped carbon flexible paper and preparing method and application thereof

InactiveCN105826562APromote cyclizationIncreased bending flexibilityCell electrodesFibre chemical featuresNetwork structureMechanical pressure

The invention discloses nitrogen-doped carbon flexible paper and a preparing method and application thereof. Melamine foam is subjected to low-temperature thermal oxidation in the air and then to high-temperature thermal treatment in the presence of inert gases under the action of mechanical pressure, so that the nitrogen-doped carbon flexible paper is obtained. Low-temperature thermal treatment is conducted on the melamine foam firstly to introduce a small number of oxygen-containing functional groups into the melamine foam, so that cyclization of the melamine foam is promoted during high-temperature thermal treatment, the nitrogen-doped carbon paper can have high buckling flexibility, the thickness, density and conductivity of the nitrogen-doped carbon flexible paper are regulated within the flexibility range, flexibility is high, and large-scale production can be achieved easily. The prepared flexible paper has connected carbon network structures, has high buckling flexibility, and can be bent freely. The flexible paper has high oxygen reduction catalytic performance. The prepared nitrogen-doped carbon flexible paper can be used as a self-supporting flexible electrode material of a flexible electric device.

Owner:JIANGXI NORMAL UNIV

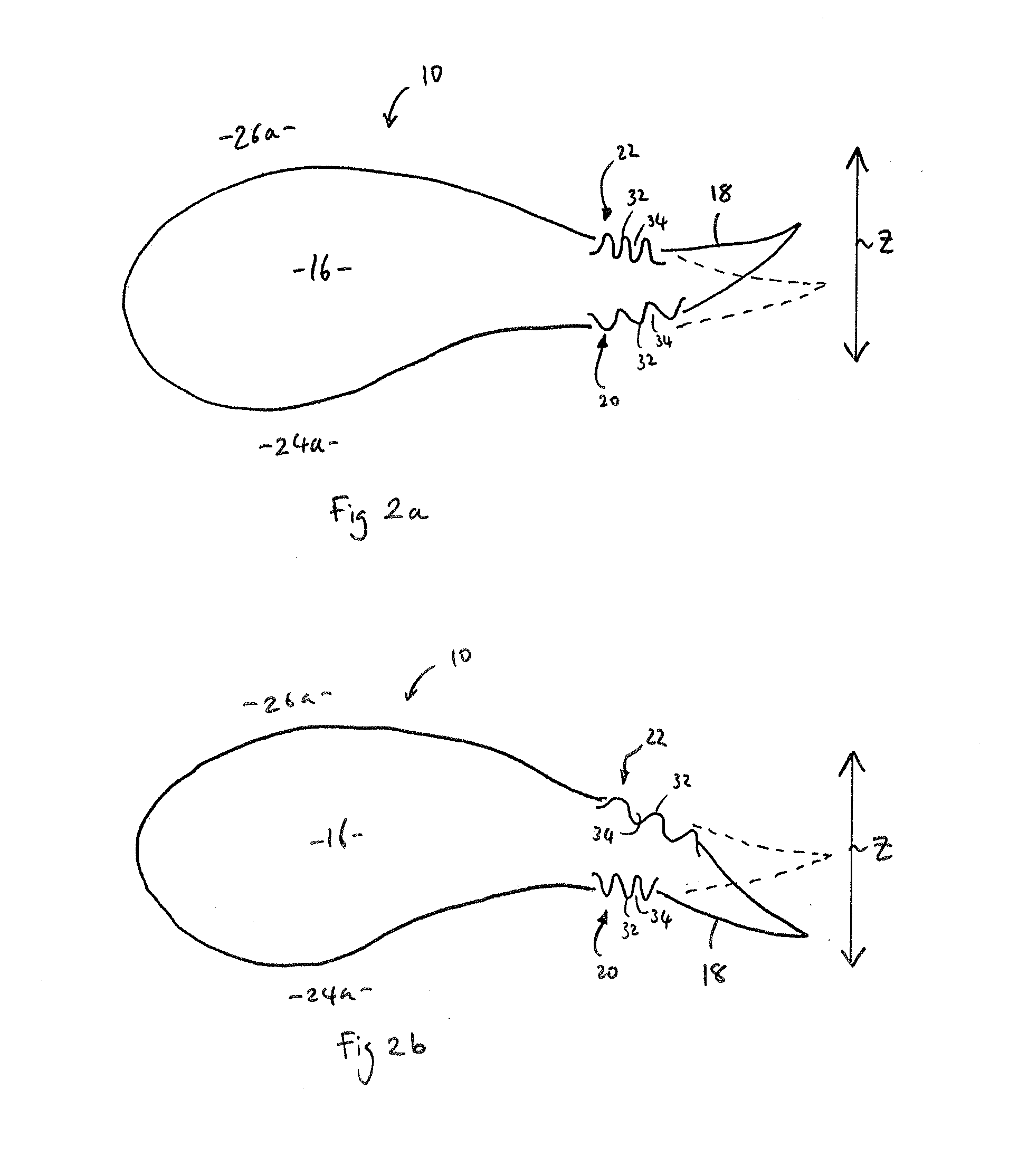

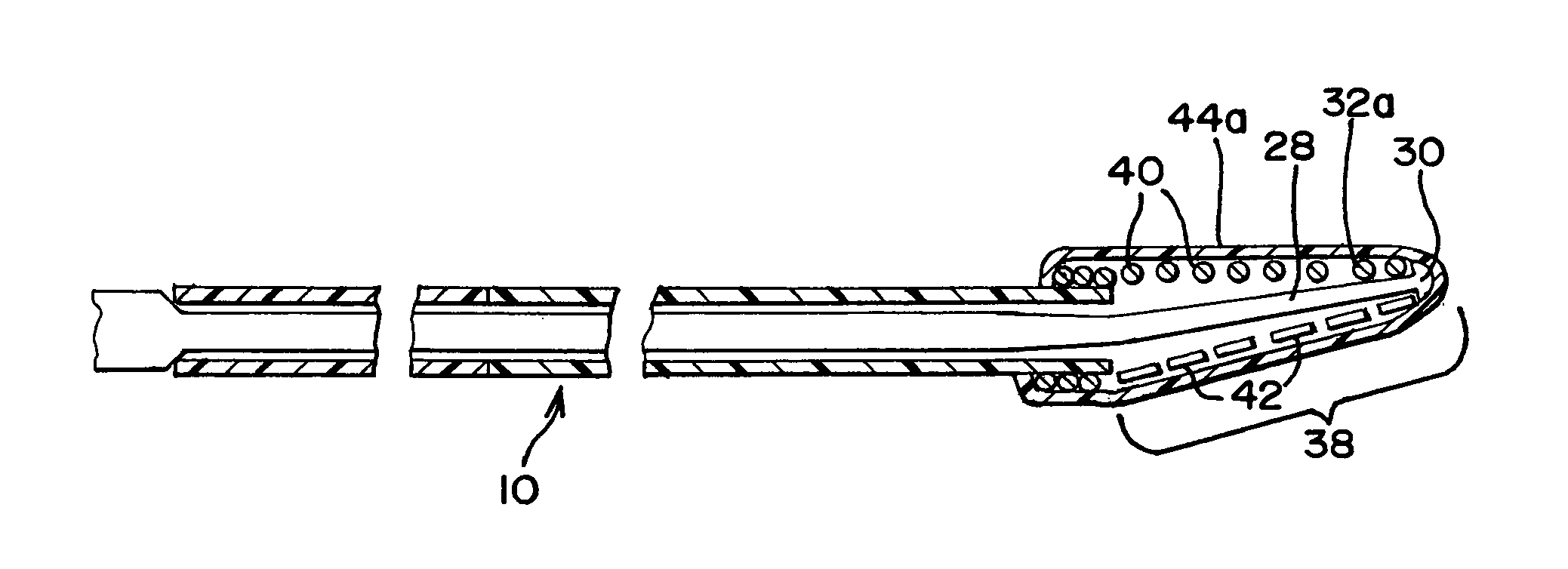

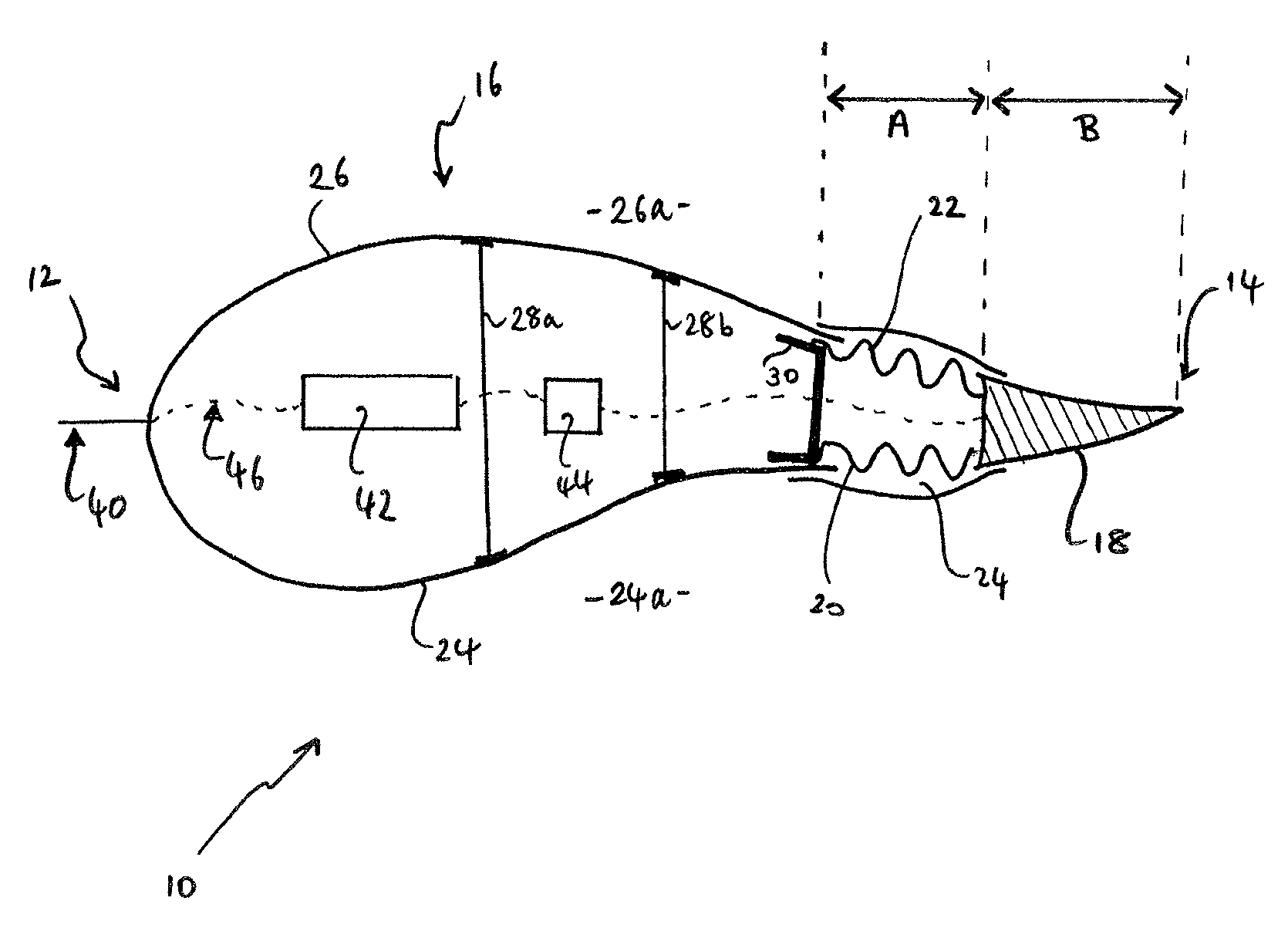

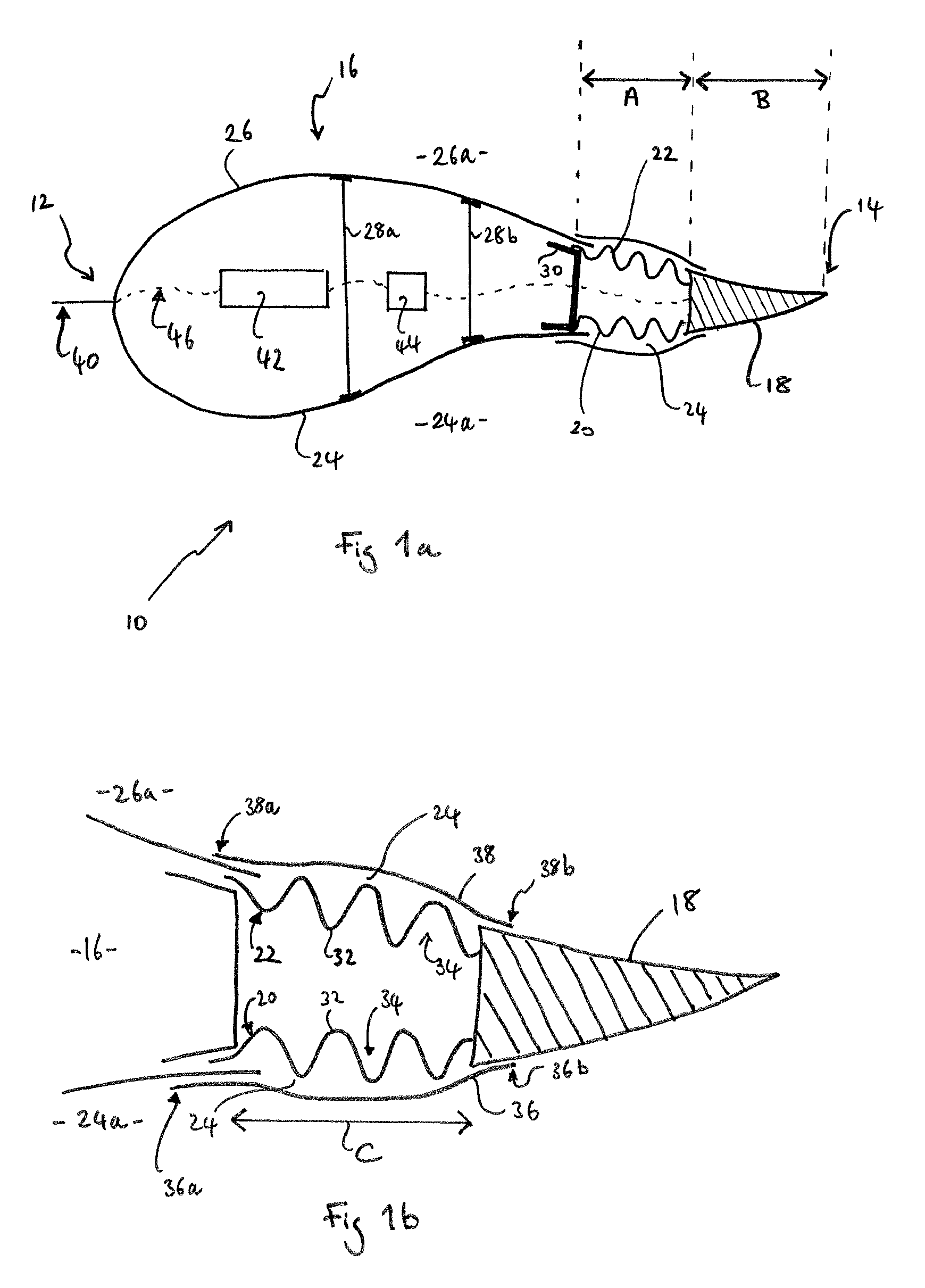

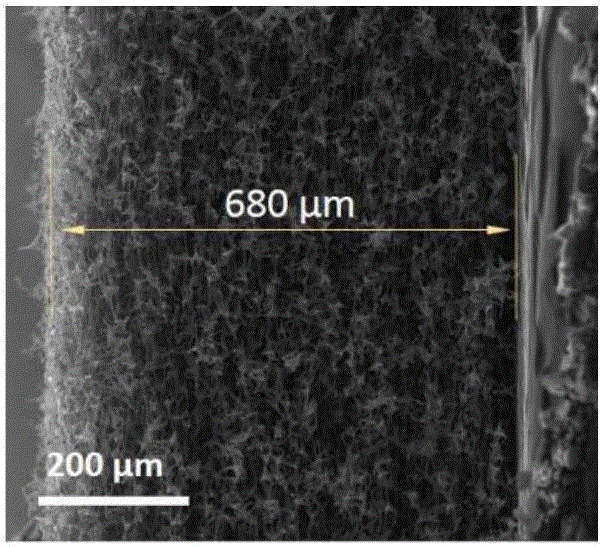

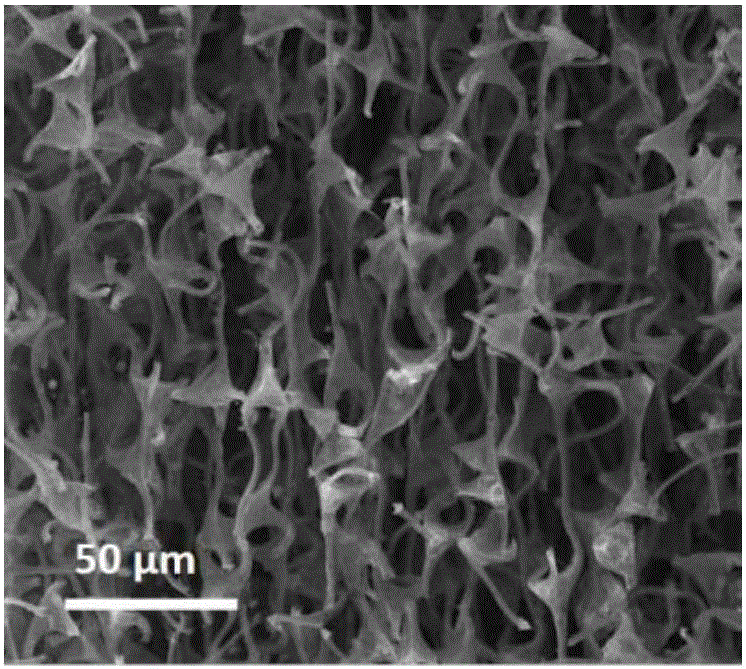

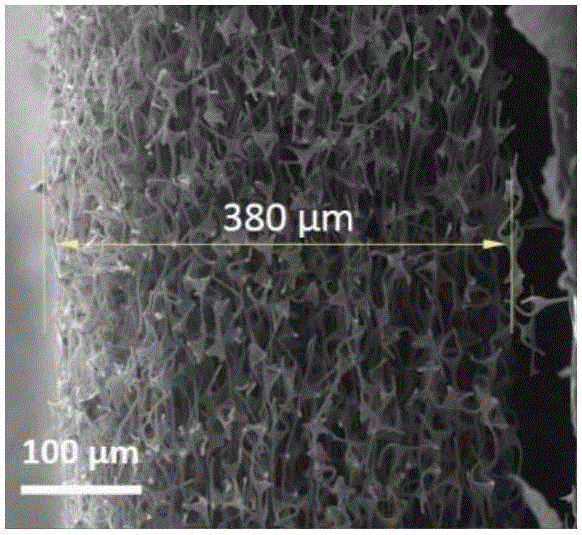

Stent-graft having flexible geometries and methods of producing the same

InactiveUS8025693B2Increase flexibilityIncreased bending flexibilityStentsBlood vesselsFiberContinuous/uninterrupted

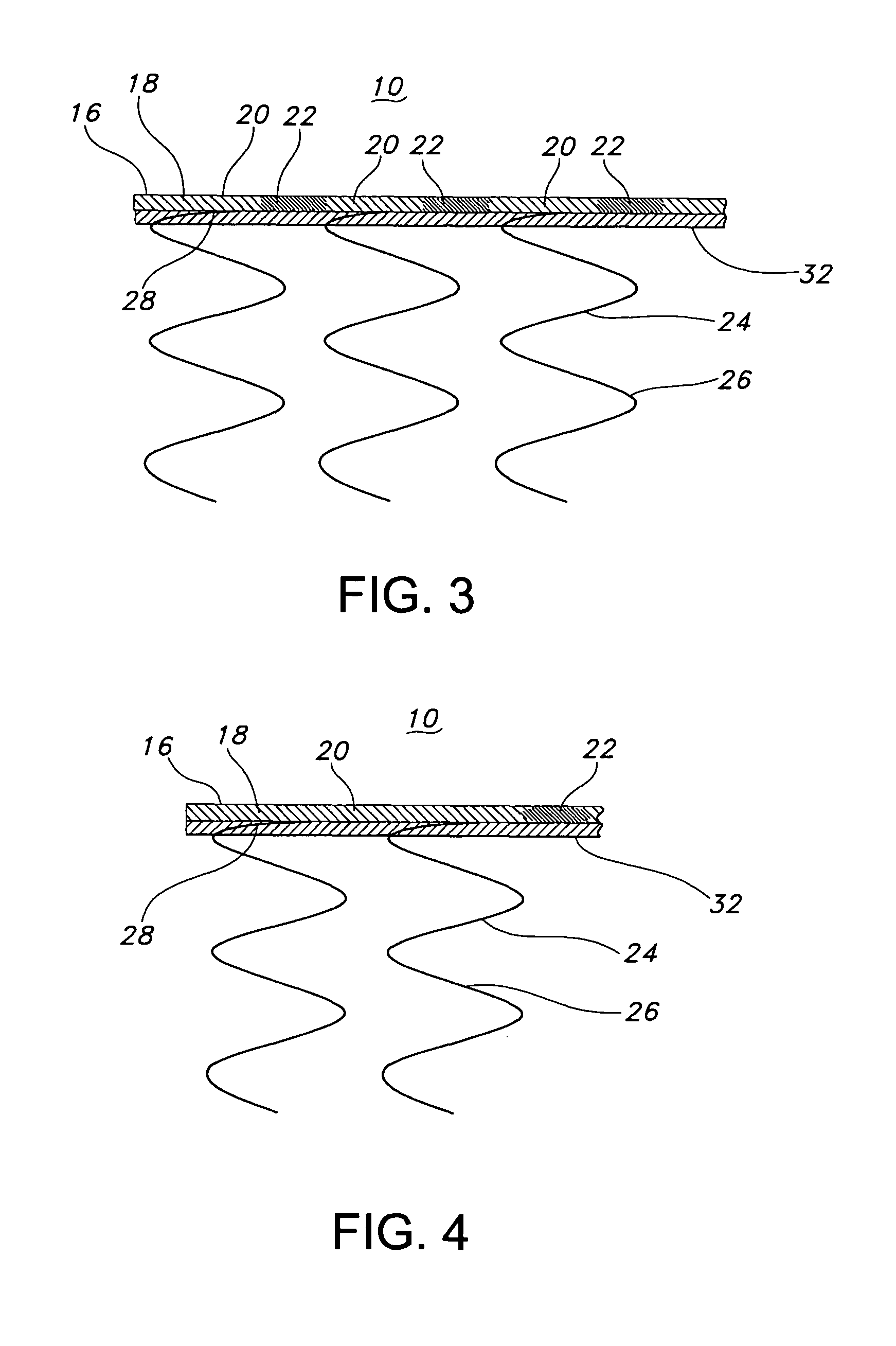

A stent-graft or prosthesis (10) with enhanced flexibility, in particular enhanced bending flexibility, includes a radially distensible stent (24) and at least one continuously uninterrupted ePTFE tubular graft or covering (18) having a node and fibril structure. The tubular stent (24) includes opposed open ends (12′, 14′) and a stent wall structure (26) having opposed exterior (28) and luminal surfaces (30). The ePTFE covering (18) is securably disposed to at least one of the stent surfaces (28, 30). The ePTFE graft or covering (18) includes a tubular wall (16) that is continuously uninterrupted and desirably substantially free of slits, apertures and folds. The ePTFE graft (18) further includes a first region (20) and a second region (22), where the first region (20) has a different bending flexibility from the second region (22).

Owner:LIFESHIELD SCI

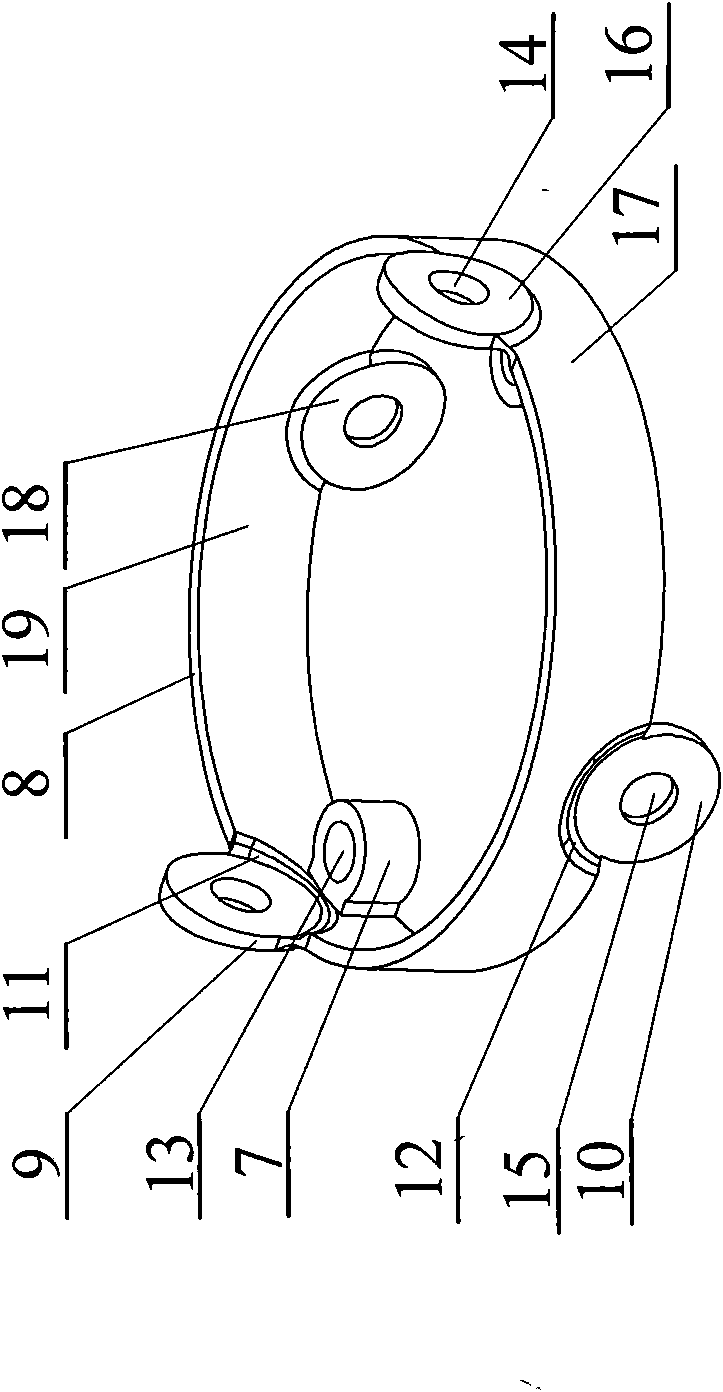

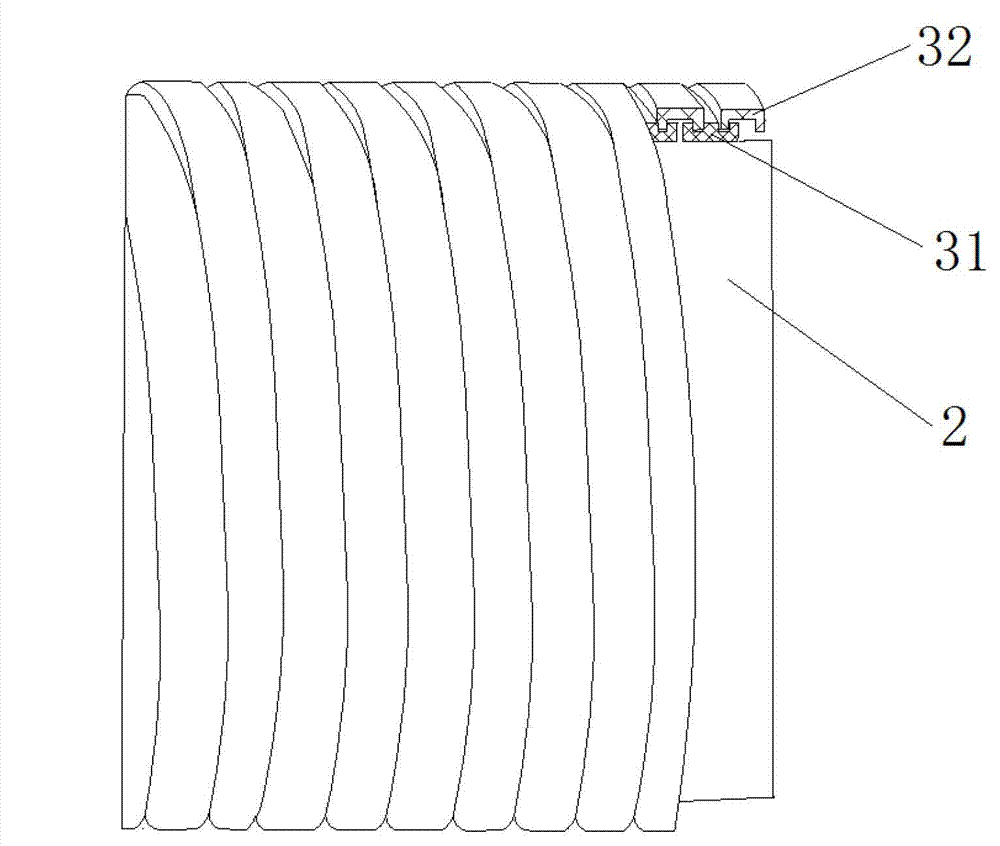

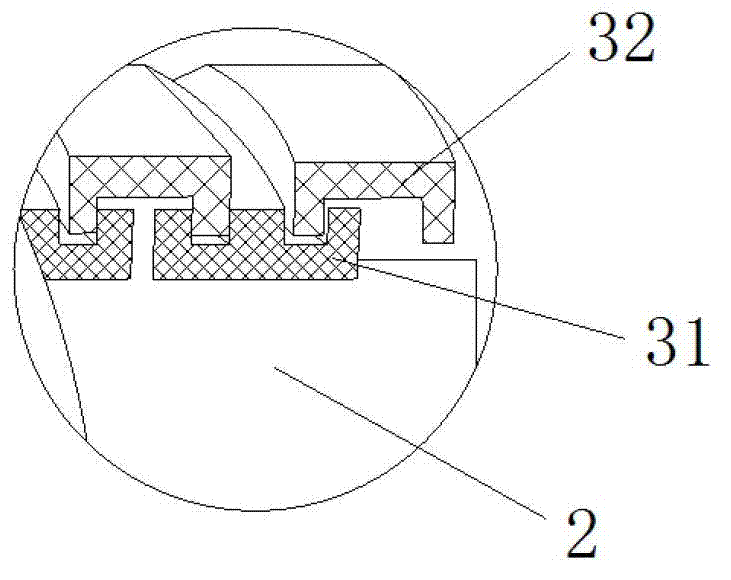

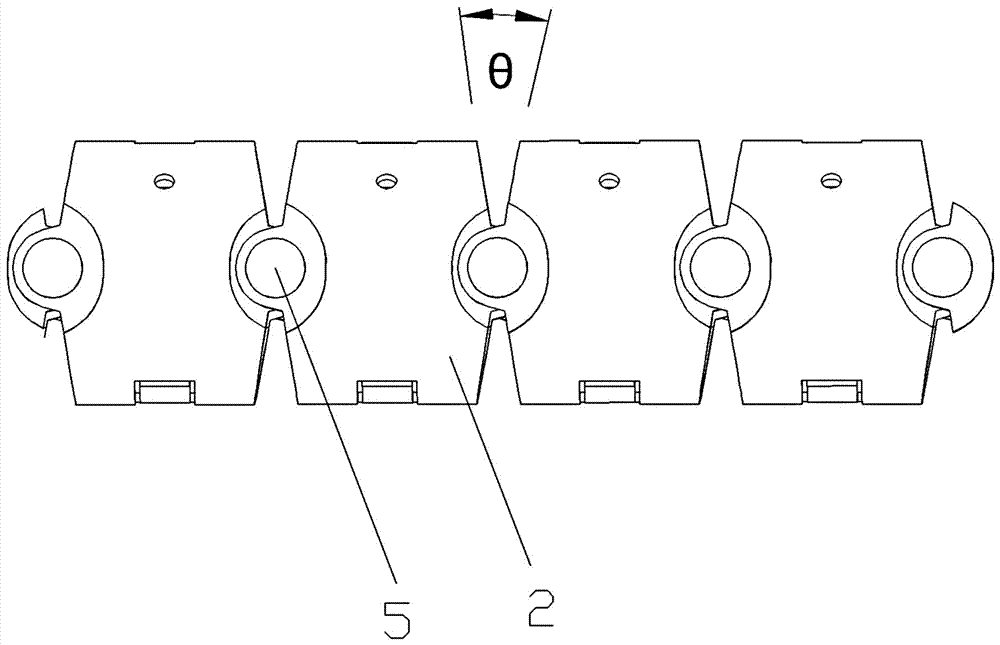

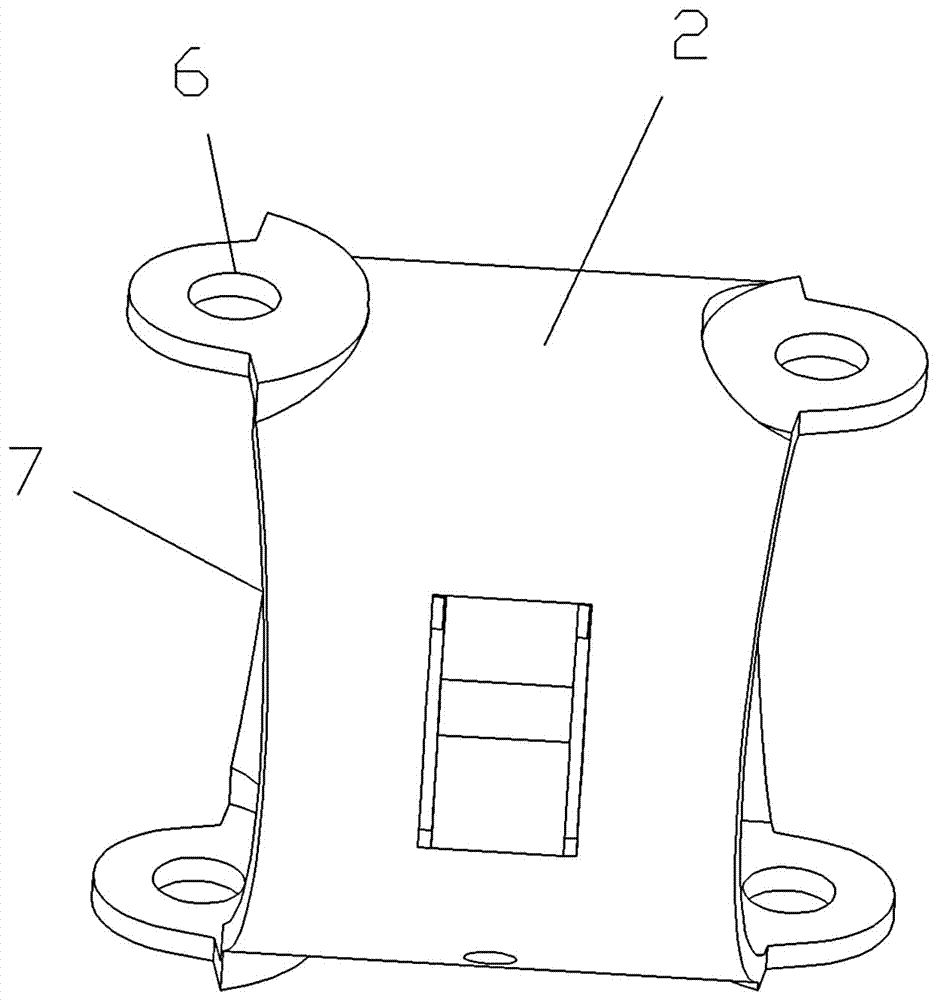

Snake bone of endoscope

The invention discloses a snake bone of an endoscope. The snake bone comprises a front-section ring of the snake bone, a plurality of snake-bone joints and a rear-section ring of the snake bone which are sequentially in rivet joint with one another; the edges of the two sides of each snake-bone joint is in concave arc shapes to make an included angle formed between the edges of the two adjacent snake-bone joints; an included angle of 80-90 degrees is formed between the central connecting line of two arc line stopping plates and the central connecting line of two connecting lugs in each snake-bone joint; an included angle is formed between the edges of every two adjacent snake-bone joints, so that the bending degree between the two adjacent snake-bone joints can be increased, and the bending angle of the whole snake bone is increased; meanwhile, optical fibers for lighting, optical fibers for image transmitting and clamping tubes are conveniently and reasonably distributed, the extrusion between the optical fibers for image transmission and the clamping tubes is reduced, and the service life of the optical fibers for image transmission and the cavity clamping tubes is prolonged.

Owner:安徽航天生物科技股份有限公司

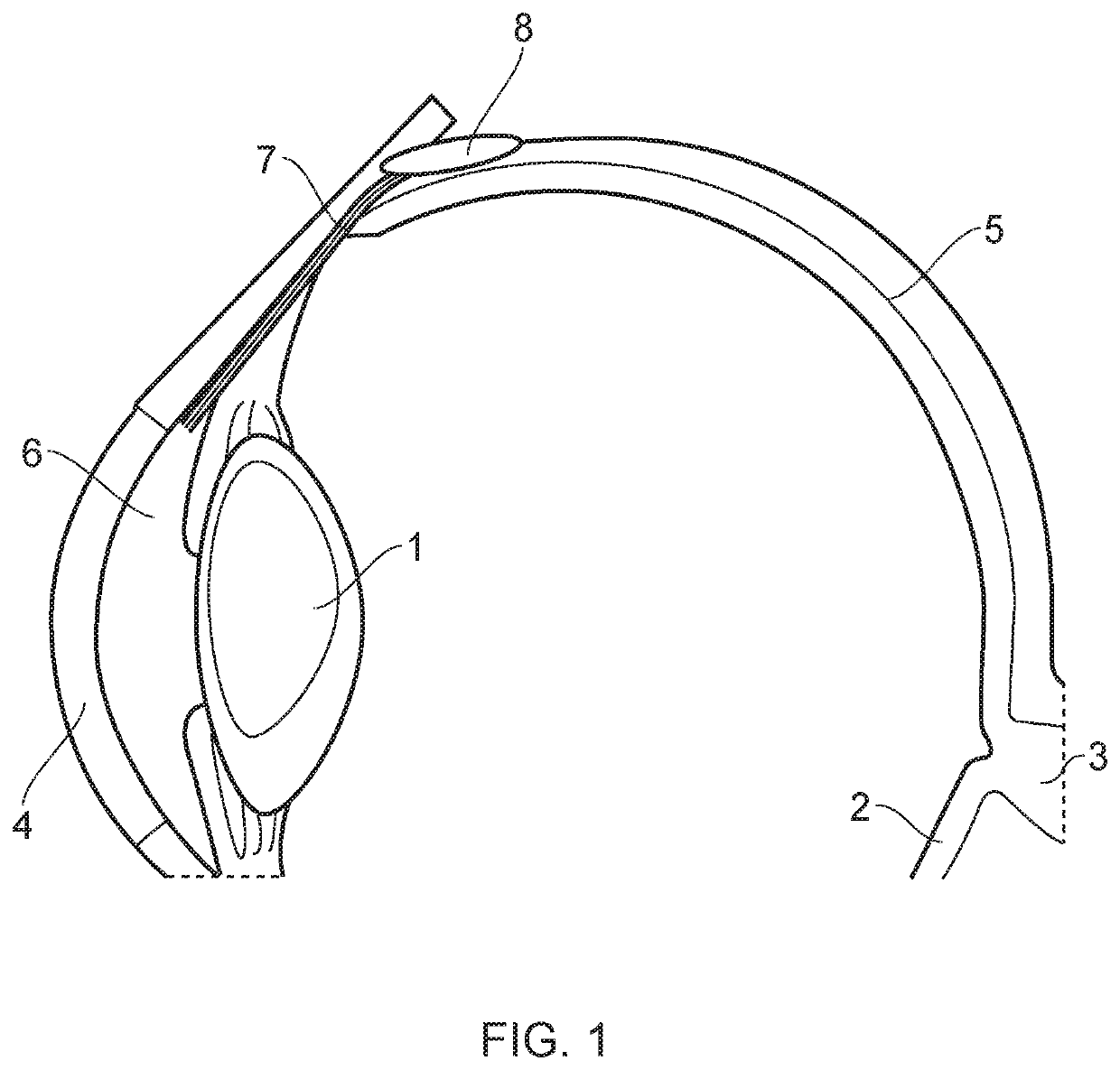

Drainage device and methods

PendingUS20210161713A1Reducing and preventing sideways/lateral movementReducing and preventing and rotationEye surgeryDomestic articlesIntra ocular pressureAqueous humor

A drainage device for use in an eye to drain aqueous humour so as to reduce intraocular pressure or for treating glaucoma. The device has a multi-lumen tube having a first end, a second end opposite the first end, and a plurality of lumen extending between the first end and the second end. At least one of the lumen is sealed at the first end. A flow through the multi-lumen tube is adjusted by forming at least one aperture open in one of the lumen through a wall of the tube and / or sealing at least one aperture open in one of the lumen. The tube has a longitudinal axis through the first end and the second end, and an outer surface extending between the first end and the second end. A cross-section perpendicular to the longitudinal axis has a non-circular shape at the outer surface with an aspect ratio of at least 3:1.

Owner:UCL BUSINESS PLC

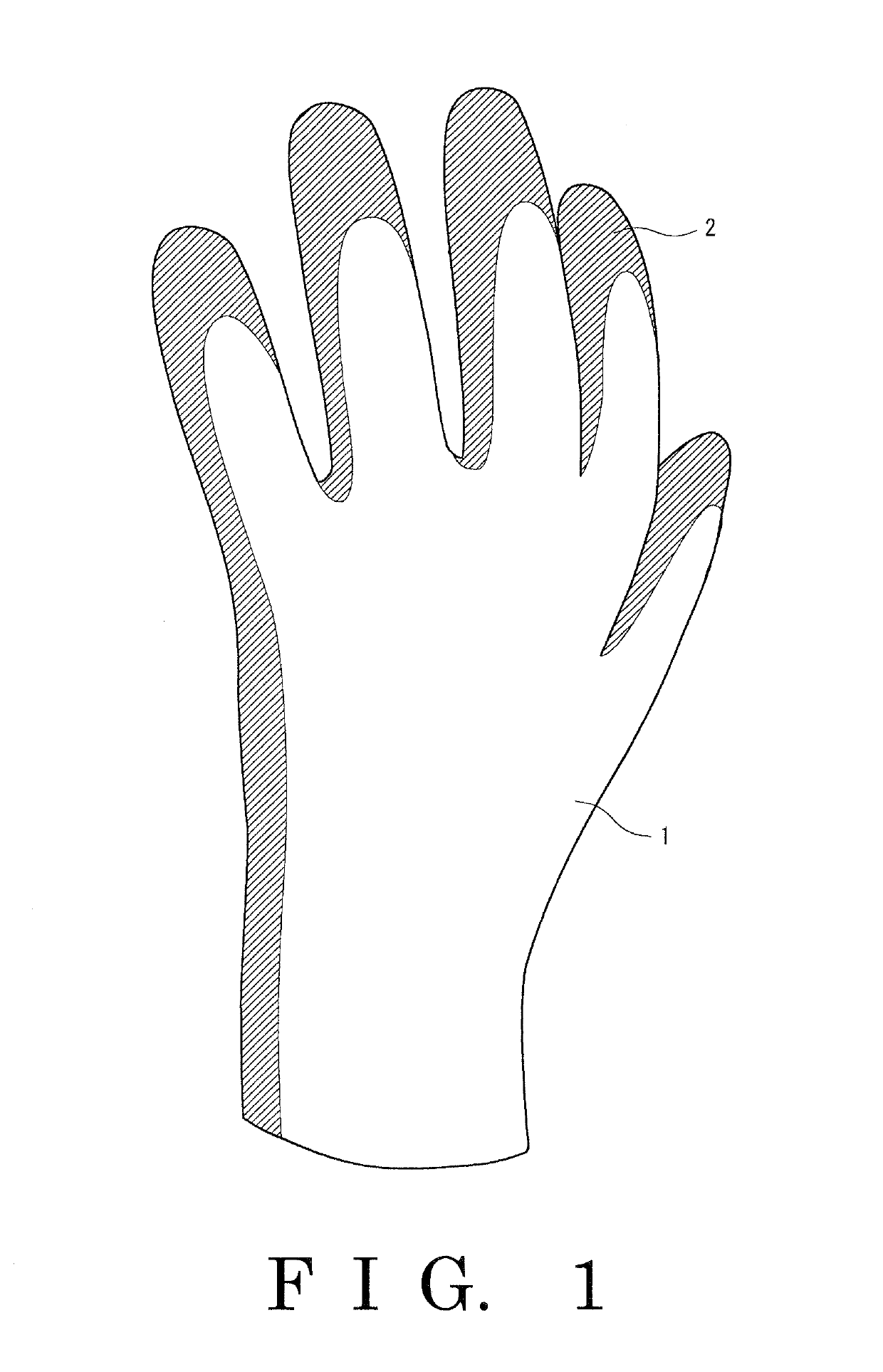

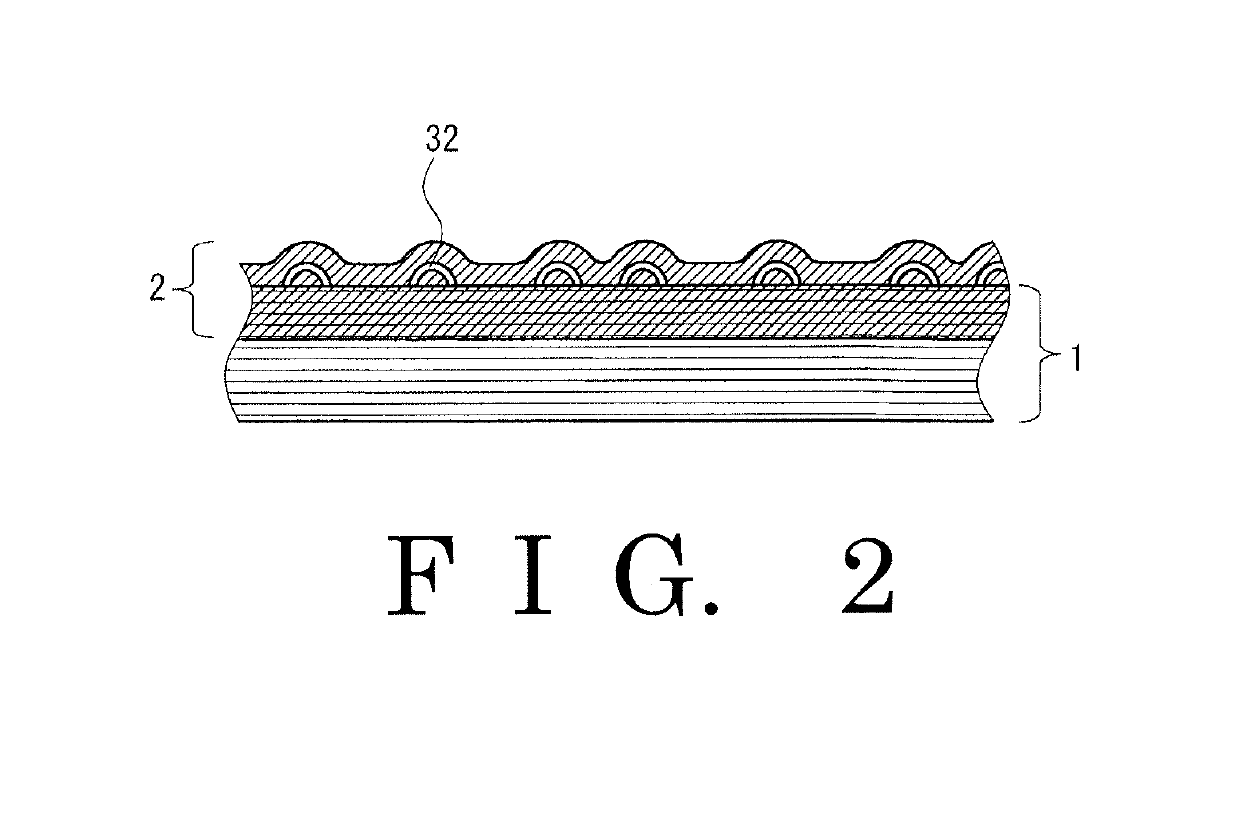

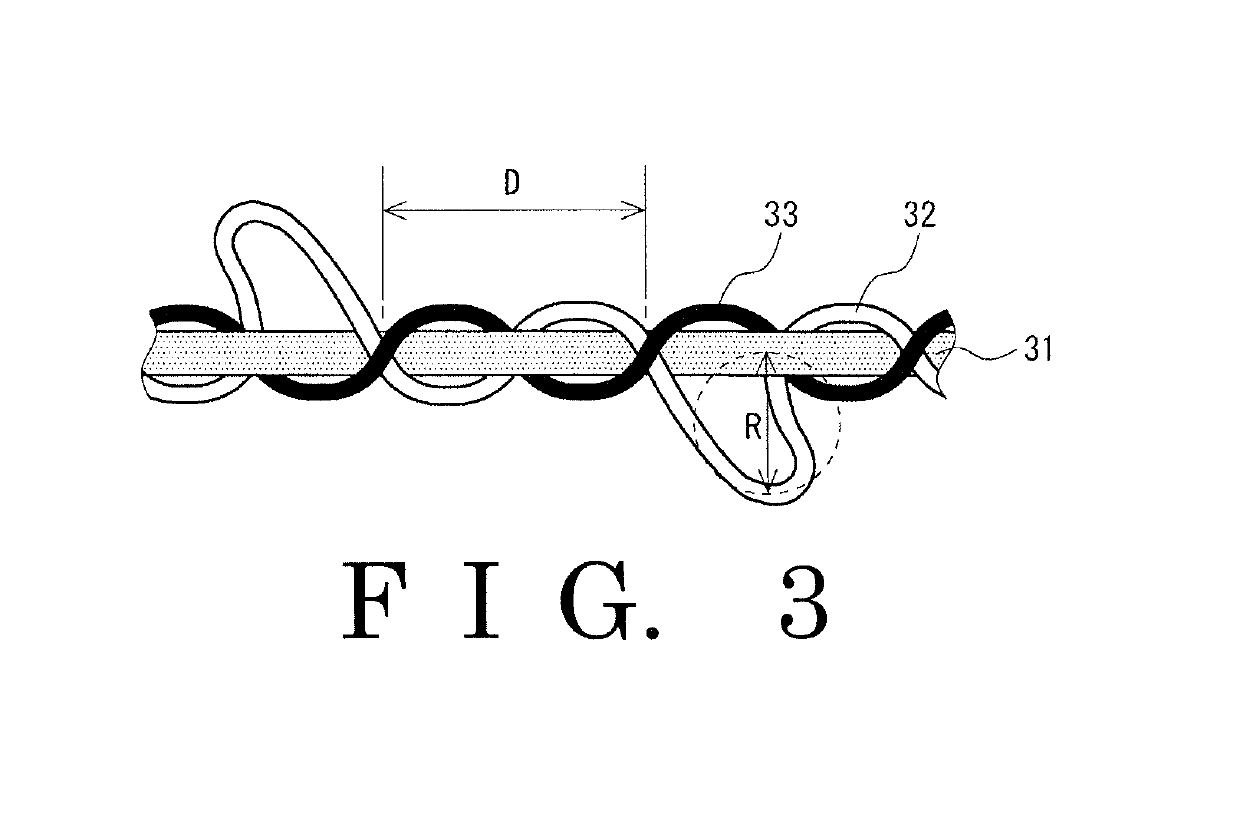

Glove

A glove includes: a glove body made of fibers, the glove body being for covering a hand of a wearer; and a coating layer made of a resin or rubber, the coating layer being overlaid at least on a palm region of the outer surface of the glove body, in which a loop yarn is used as a knitting yarn of the glove body, and irregularities arising from the loop yarn are provided on the surface of the coating layer. The ten-point mean roughness (Rz) of the surface of the coating layer is preferably no less than 300 μm and no greater than 1,200 μm. The average outer diameter of loops of the loop yarn is preferably no less than 1 mm and no greater than 6 mm. The average distance between loops of the loop yarn is preferably no less than 1 mm and no greater than 10 mm.

Owner:SHOWA GLOVE

Knittable asymmetric capacitor and preparation method thereof

InactiveCN105355459ASimple materialReduce the ratioHybrid capacitor electrolytesHybrid capacitor electrodesFiberCarbon fibers

The invention discloses a knittable asymmetric capacitor. The characteristics lie in that an anode and a cathode of the capacitor are respectively knitted by one or more current collectors, the current collectors are carbon fibers or metal wires with the diameter being less than 100mum, the surface of each current collector is sequentially attached with a conductive layer with the thickness being less than 500nm and a polyvinyl alcohol gel with the thickness being 10nm-100nm, the polyvinyl alcohol gel comprises LiCl with the mass fraction being 9%-62.5%, a voltage window E1 of the anode and a voltage window E2 of the cathode meet the conditions that the voltage window E2 is greater than or equal to -1.23V and less than 0V, and that the voltage window E1 is greater than 0V and less than or equal to 1.23V. The invention further discloses a preparation method of the asymmetric capacitor. Through the invention, a defect of low energy density of a knittable capacitor in the prior art is broken through, thereby having very important practical significance for flexible wearable electronic equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com