Laminated metal chalcogenide/carbon nanotube flexible compound film material of highly ordered structure and preparation

A carbon nanotube thin film and chalcogenide technology, which is applied in the coating process of metal materials, carbon compounds, non-metallic elements, etc., can solve the problems of application limitations, layered two-dimensional materials are difficult to prepare in large quantities, and achieve improved electrical properties , High crystallinity, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

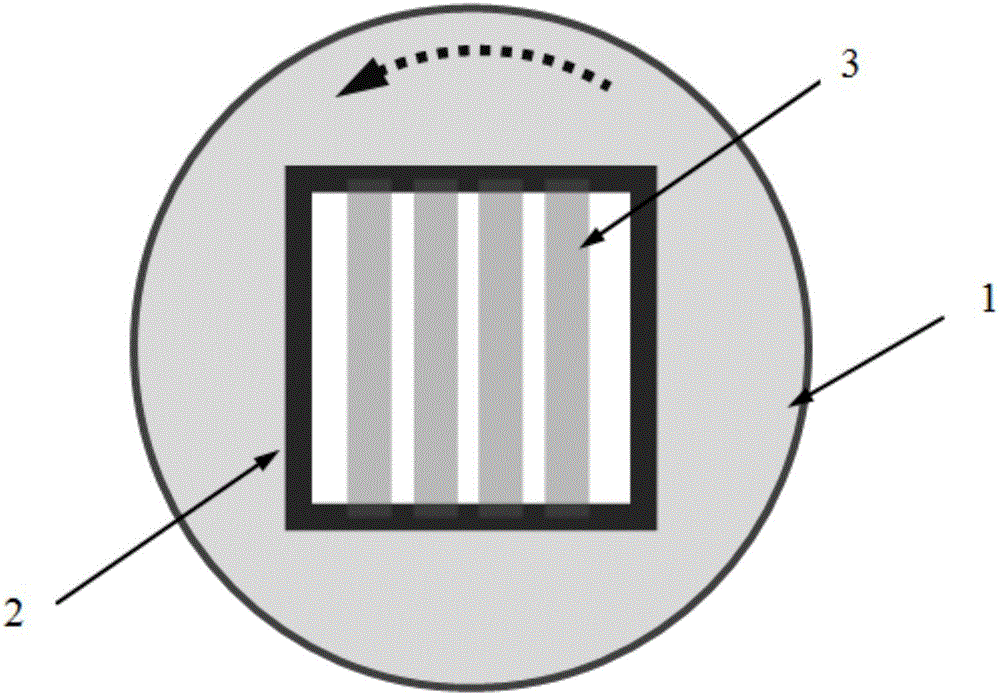

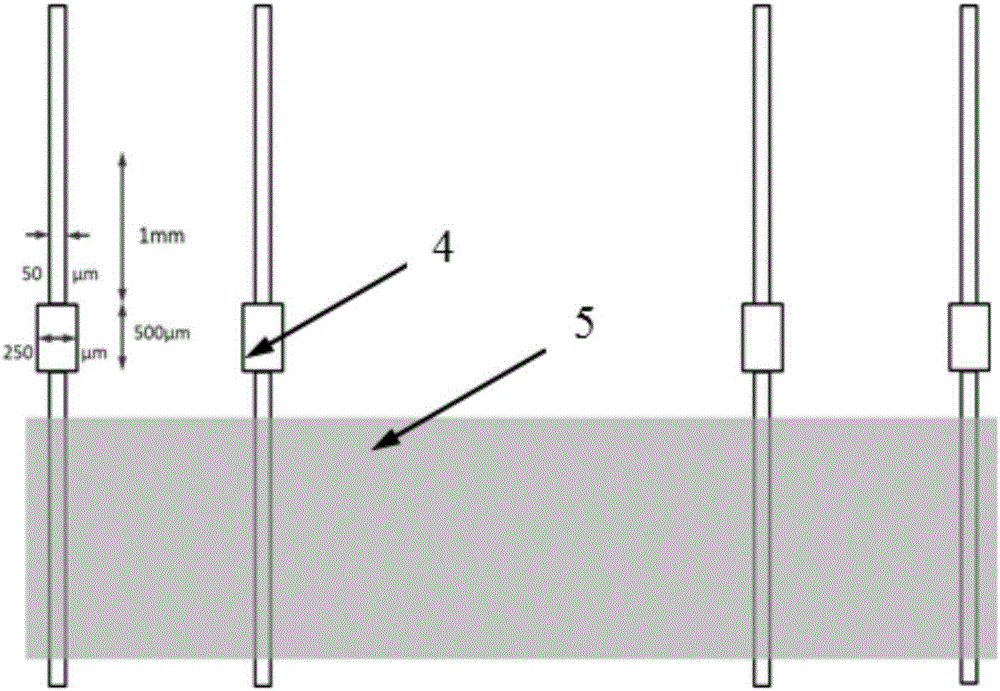

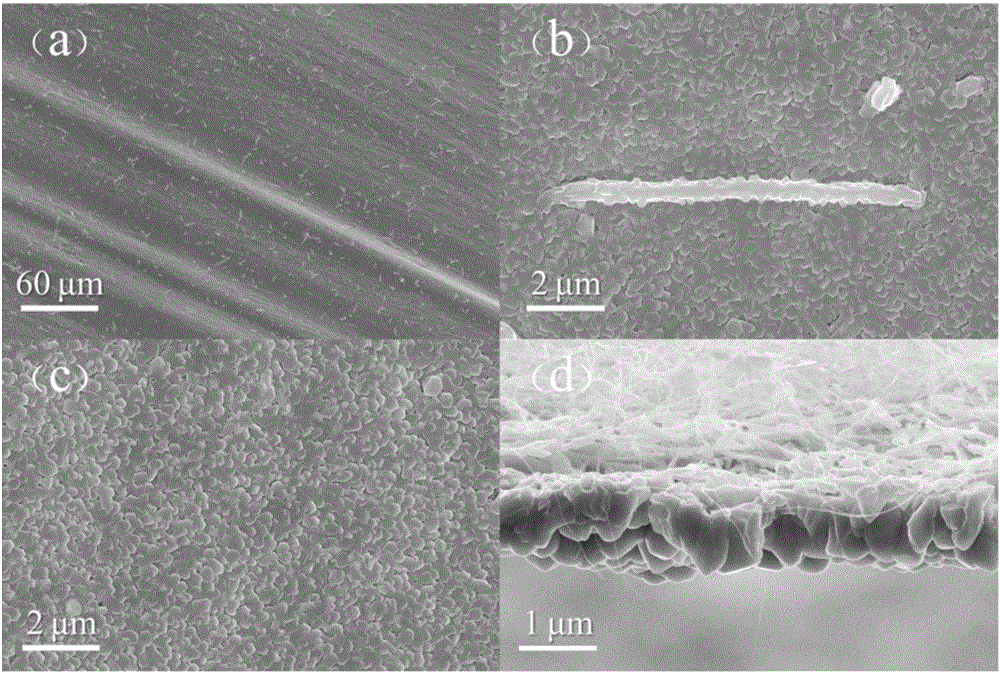

[0054] The LMC / CNTs flexible composite thermoelectric thin film material of the present invention and its preparation method adopt Bi 2 Te 3 / CNTs thermoelectric composite thin film material to illustrate the implementation of the case. A highly ordered flexible self-supporting bismuth telluride (Bi 2 Te 3 ) / carbon nanotubes (CNTs) composite thermoelectric film material, the composite material includes an ultra-thin CNTs film substrate and Bi uniformly deposited on its surface 2 Te 3 Thermoelectric thin film forms a three-dimensional network structure with nanoporous structure and highly conductive channels. Furthermore, thanks to Bi 2 Te 3 The layered crystallographic structure characteristics of the crystal grain, the (00l) crystal surface layer is connected by Te-Te van der Waals force, so it is very easy to slip along the crystal direction and generate twins. The present invention uses this A unique slip mechanism, when the material is bent and deformed, slips and ...

Embodiment 2-7

[0075] Prepared as in Example 1, the difference is that the coating time is different under the condition of 400°C in the high vacuum magnetron sputtering system, which are 30s, 75s, 120s, 300s, 600s and 900s respectively, and the final Bi 2 Te 3 / CNTs thin film composites were characterized for their morphology and structure.

Embodiment 8-9

[0077] Prepare as in Example 1, as Figure 10 As shown, the difference lies in the deposition of different LMC materials at 400°C in a high-vacuum magnetron sputtering system, where (a) is Bi 2 Te 3 The transmission photo (b) is Bi 2 Se 3 The scanned photo of ; (c) is Sb 2 Te 3 It is a transmission photo, and the above three composite materials all show an ordered structure, which fully demonstrates that the composite material with a high and low ordered structure of the present invention is widely applicable to metal chalcogenides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com