Nozzle-coaxial self-selection multi-hot wire plasma arc metal composite additive method and device

A plasma arc and metal composite technology, applied in the direction of additive processing, metal processing equipment, arc welding equipment, etc., can solve the problems of limited improvement of wire melting efficiency, difficulty in continuous surfacing welding, and reduced space accessibility. Improve additive efficiency and forming accuracy, high-efficiency and fast plasma additive manufacturing, and reduce interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further describe the present invention below in conjunction with accompanying drawing

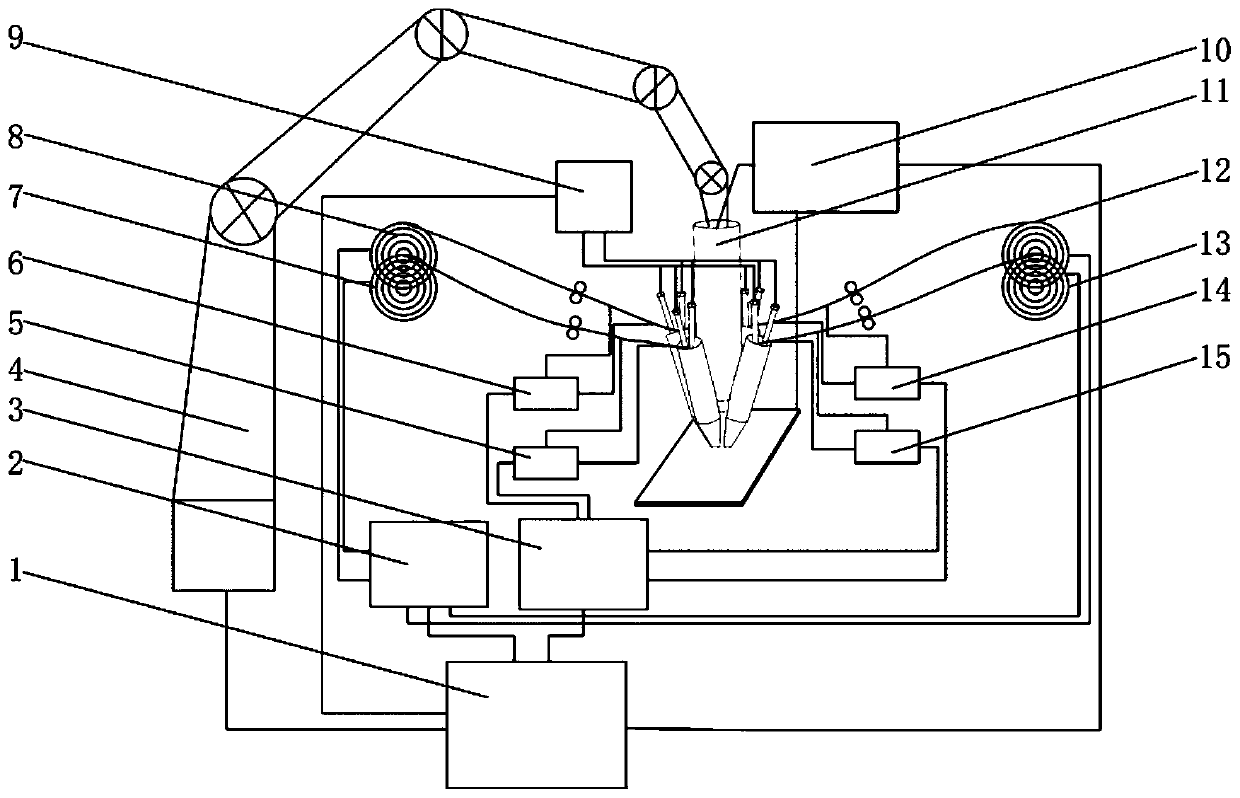

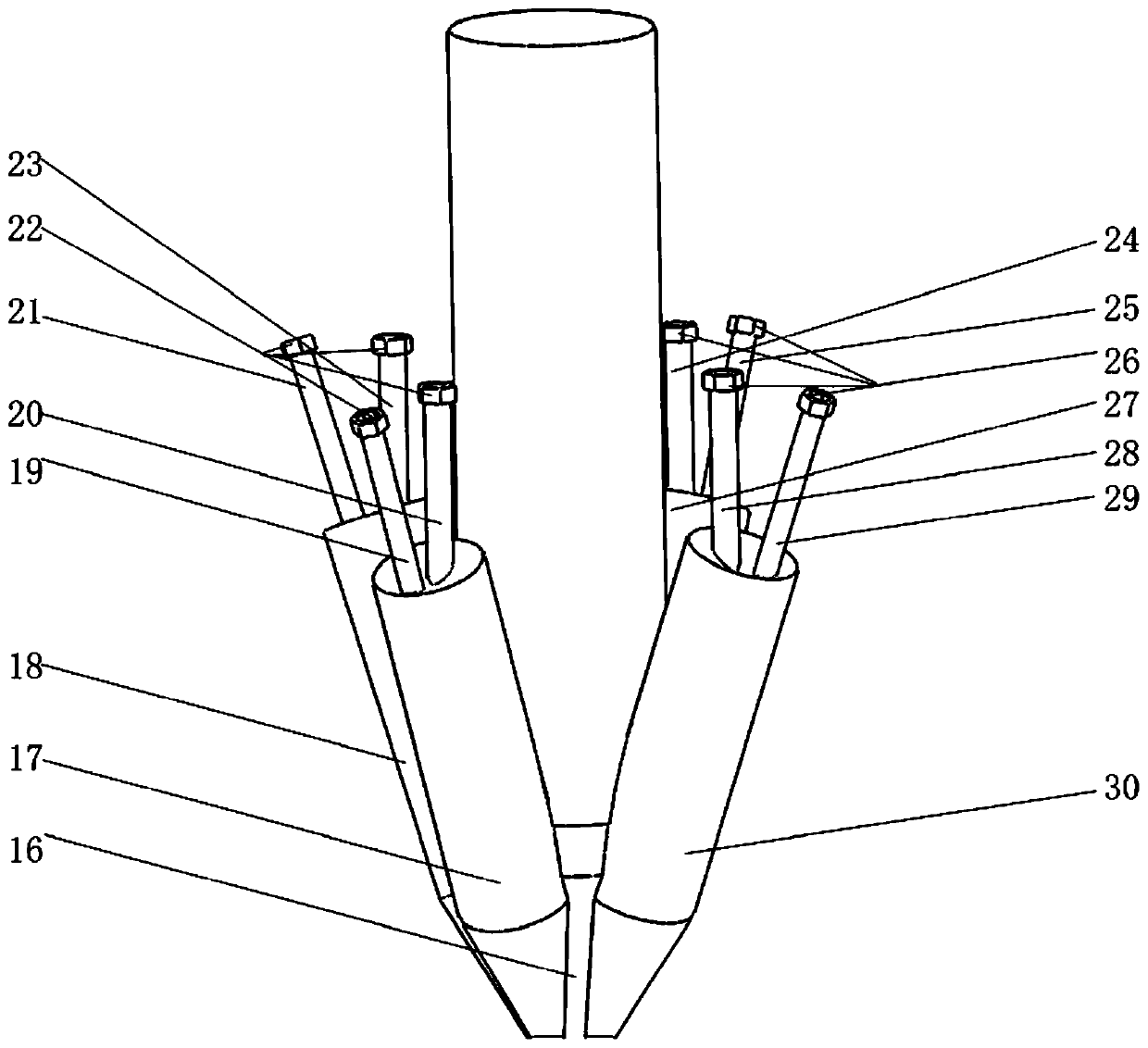

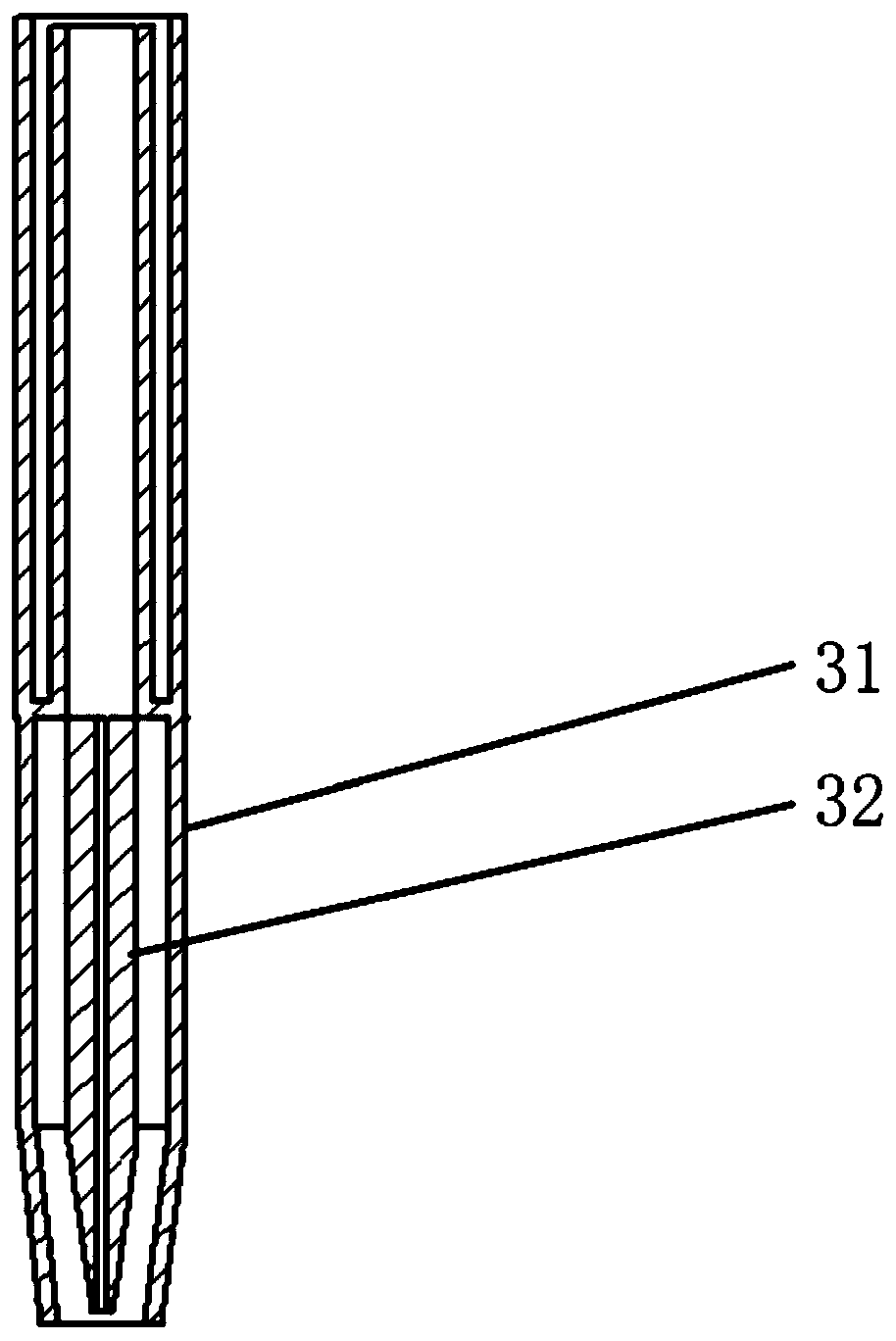

[0027] Nozzle coaxial self-selection multi-heat wire plasma arc metal composite additive device, mainly composed of nozzle coaxial self-selection multi-heat wire welding torch, welding power supply, wire feeding mechanism, hot wire power supply, hot wire power supply coordination control device, and wire material coordination control device, a water cycle coordination control device and a robot body. The positive and negative poles of the welding power supply are connected to the substrate and the tungsten electrode respectively, and the wire material coordination control device is connected to the wire feeding mechanism and the robot control cabinet, and the working state and wire feeding speed of the wire feeding mechanism are adjusted according to the signal sent by the robot control cabinet; The wire power supply coordination control device is connected with the heating wire powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com