Patents

Literature

183results about How to "Precise control of ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

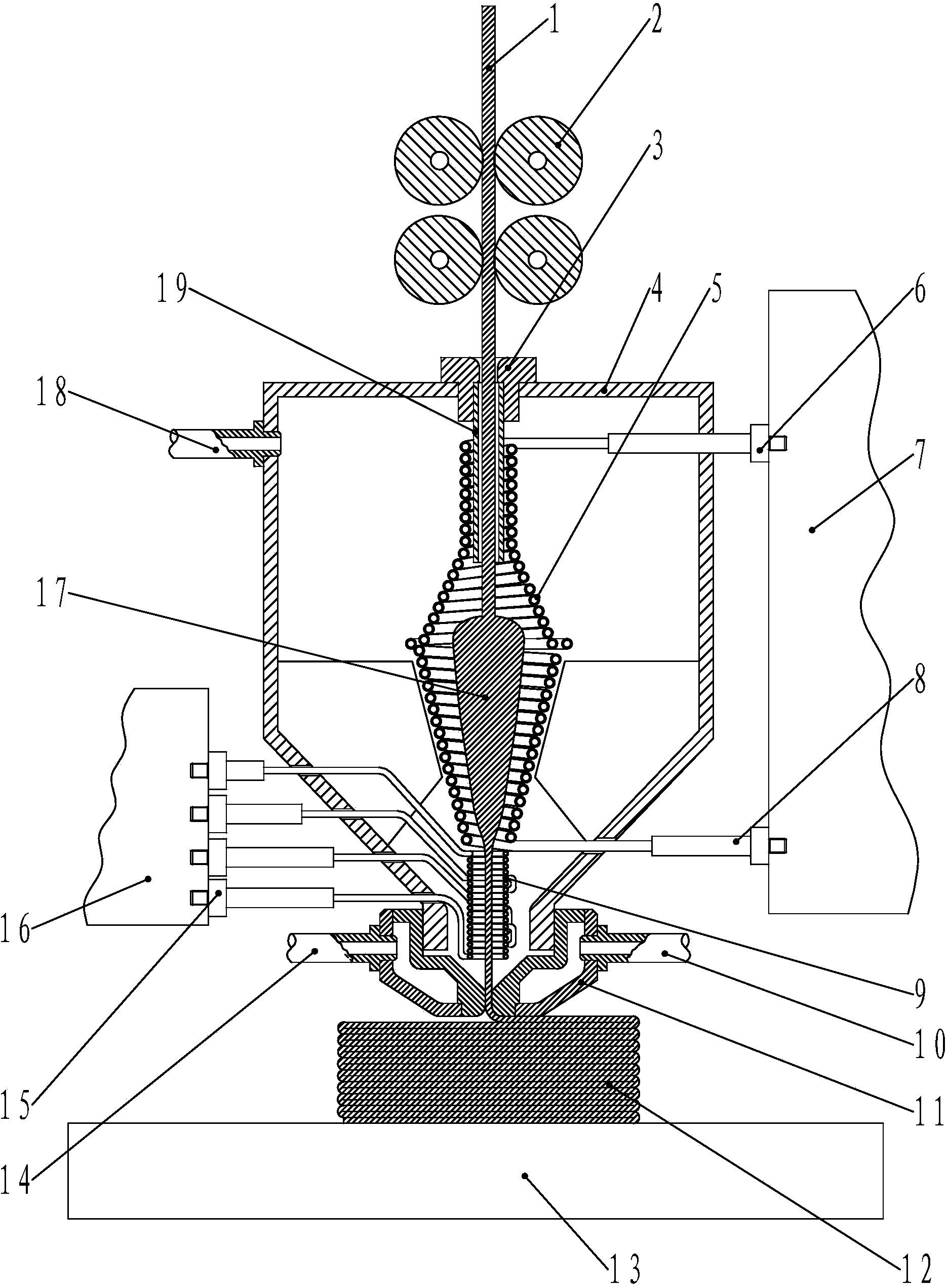

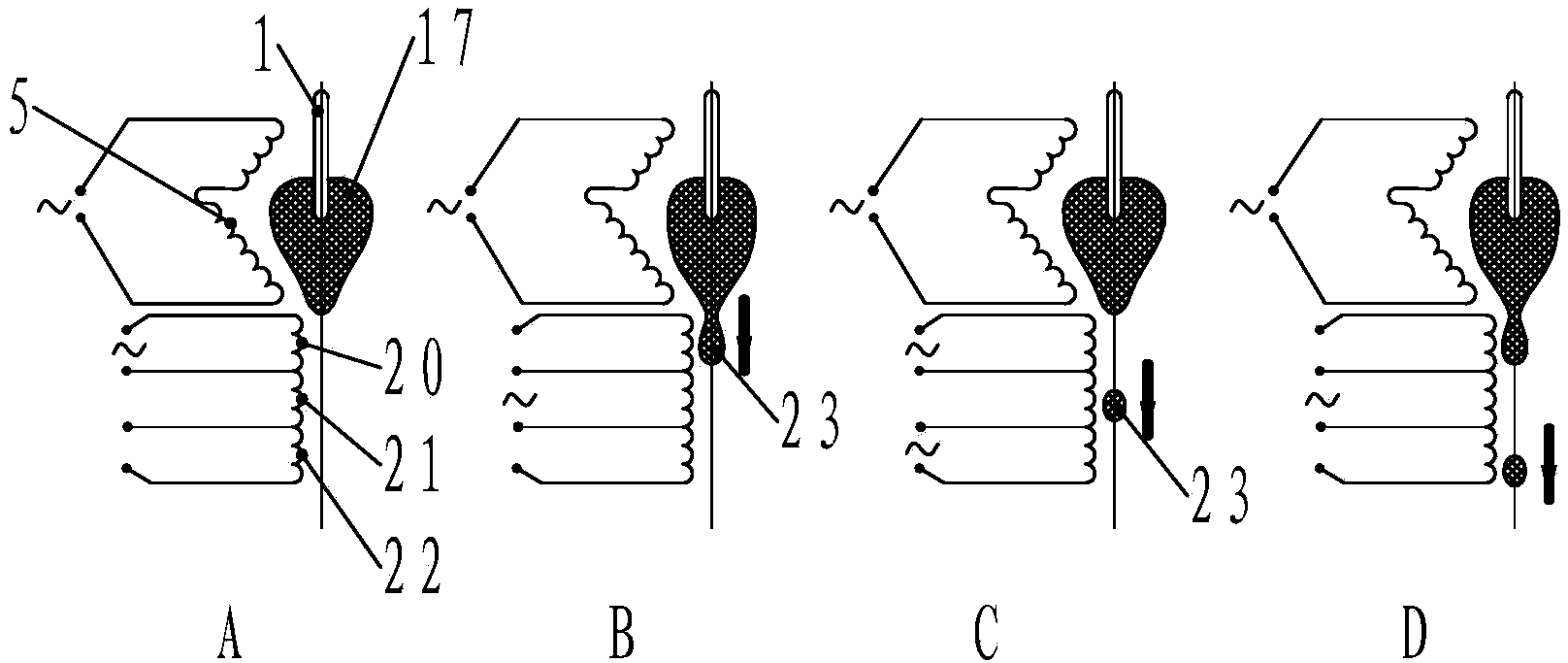

Electromagnetic modulation fusion emitting device

The invention discloses an electromagnetic modulation fusion emitting device which comprises an induction heating coil, a three-phase linear induction heating coil and a spray nozzle, wherein the three-phase linear induction heating coil is arranged under the induction heating coil; a support cylinder is arranged at the periphery of the induction heating coil; the lower end of the support cylinder is connected with the spray nozzle; two ends of the induction heating coil are connected to an alternating power supply; the three-phase linear induction heating coil is arranged into a three-phase four-wire system circuit structure; four ends of the three-phase linear induction heating coil are respectively connected to a three-phase pulse alternating power supply. A levitation melting technology and a linear induction motor principle technology adopted by the electromagnetic modulation fusion emitting device are both common electromagnetic induction technologies in a traditional industry, the process is mature, the manufacturing cost and the durability are superior to those of a selected laser sintering (SLS) technology adopting a high-power laser, and the electromagnetic modulation fusion emitting device is more suitable for applicable in the traditional industry.

Owner:曹炜喜

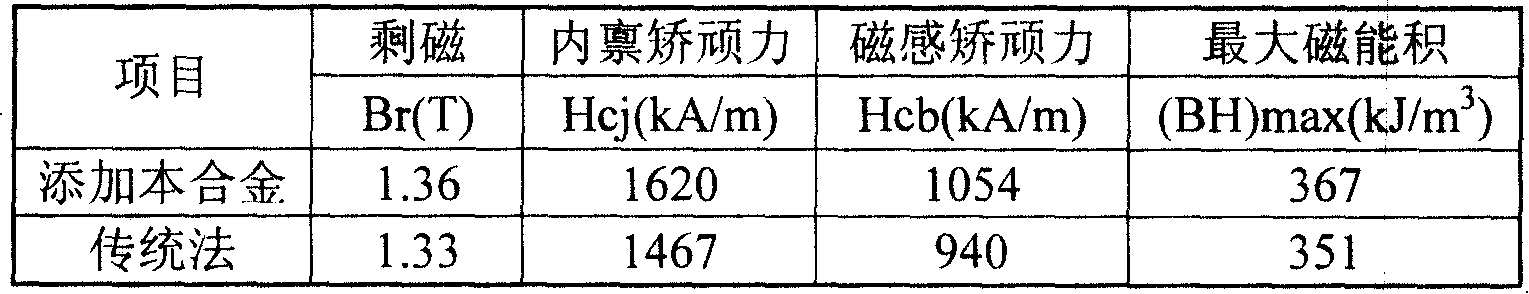

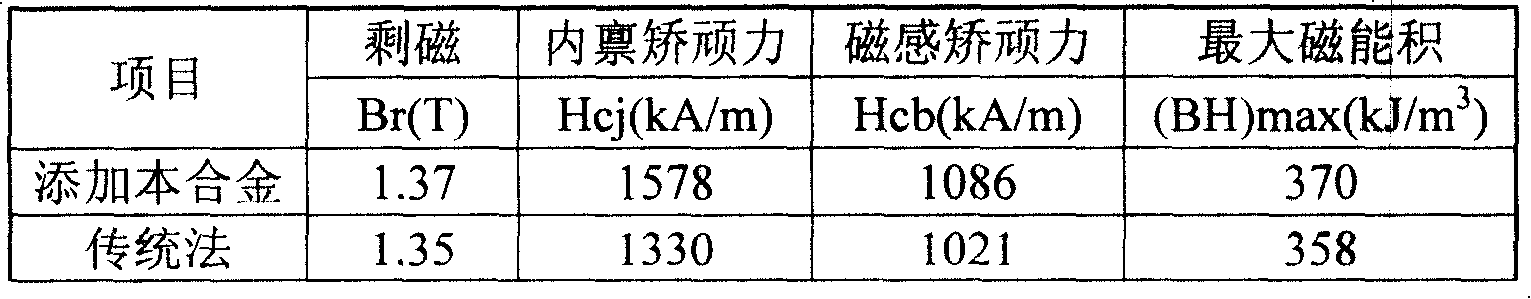

Rare earth alloy

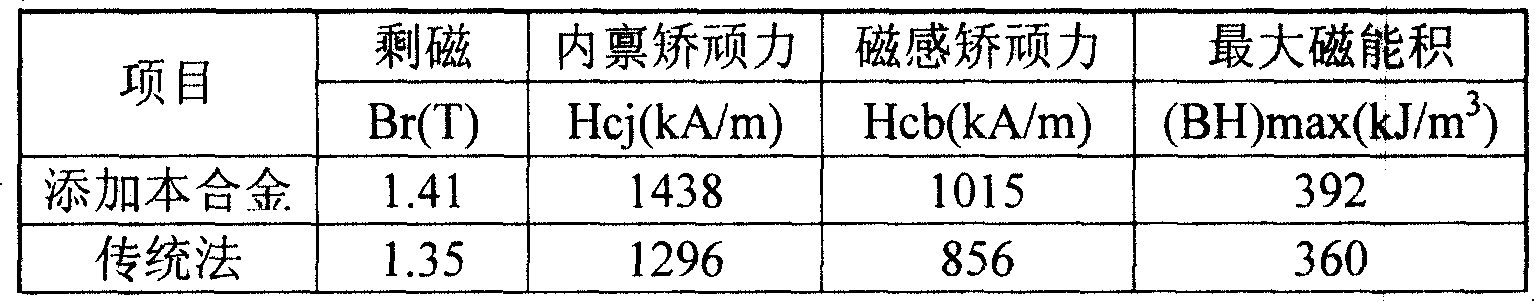

InactiveCN101240392AImprove performancePrecise control of ingredientsMagnetic materialsRare earthAlloy

Owner:GRIREM ADVANCED MATERIALS CO LTD

Heat resistance stainless steel and smelting method thereof

Heat resisting stainless steel and its smelting process are both disclosed herewith. It comprises (wt%): C 0.05-0.10, Si 1.40-2.00, Ce 0.03-0.08, Cr 20.0-22.0, Ni10.0-12.0, N 0.14-0.20, and Mn 0.4-0.80, with impurities of P not more than 0.040 and S 0.030. It is produced by: (1) pouring mother liquid of stainless steel with C (1.2-2.5) into AOD furnace, (2) decarbonizing to C (0.05-0.10), (3) reducing steel liquid and desulfurizing, (4) floss removing and regulating components of steel liquid, (5) pouring out and adding B-iron and Al cakes, (6) feeding Ce wires, (7) regulating temperature and controlling impurities, and (8) continuously casting. It costs low and has good performance at high temperature.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Vacuum induction melting method for reducing nitrogen content in high temperature alloy

ActiveCN105238934AReduce the formation of inclusionsPrecise control of ingredientsIncreasing energy efficiencyNiobiumSuperalloy

The invention discloses a vacuum induction melting method for reducing the nitrogen content in high temperature alloy and belongs to the technical field of high temperature alloy smelting. Niobium which belongs to high nitride-forming elements is added at the later stage of material melting instead of adding along with a furnace and added after N in alloy melt is mostly removed, so that forming of a core with hard-to-decompose nitride inclusion is reduced, and Al, Ti and the like which are prone to be damaged after being burnt and the elements with high affinity to N are added at the later stage of refining. The vacuum induction melting method for reducing the nitrogen content in the high temperature alloy has the advantages that the adding sequence of raw materials is merely required to be adjusted, the operation is simple, the method is easy to implement, and the metallurgical quality of the high temperature alloy in actual industrial production can be remarkably improved.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Bismuth cored wire

The invention discloses a bismuth cored wire. The bismuth cored wire consists of a steel tape sheath and core powder, and is 8 to 20 in diameter or in other diameters or other shapes, the alloy components of the core powder are Ca, Si, S, Fe and Bi, wherein, the content of Ca is 0 to 20 percent by weight, the content of Si is 0 to 15 percent by weight, the content of S is 0 to 10 percent by weight, the content of Fe is 0 to 20 percent by weight, and the content of Bi is 50 to 100 percent by weight. The invention adopts the form of the bismuth cored wire or bismuth composite cored wire, the bismuth cored wire is fed into molten steel by a wire-feeding machine, the recovery rate of bismuth in the molten steel is increased, the cost is reduced, pollution is reduced, moreover, the recovery of bismuth is stable, and component control is accurate.

Owner:SHOUGANG GUIYANG SPECIAL STEEL

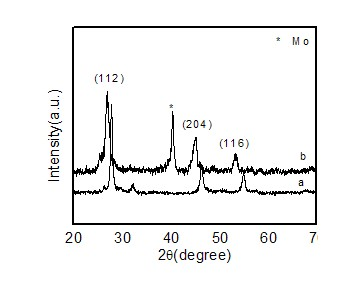

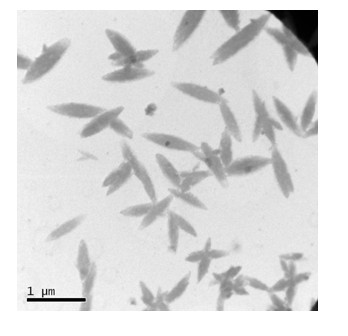

Laminated metal chalcogenide/carbon nanotube flexible compound film material of highly ordered structure and preparation

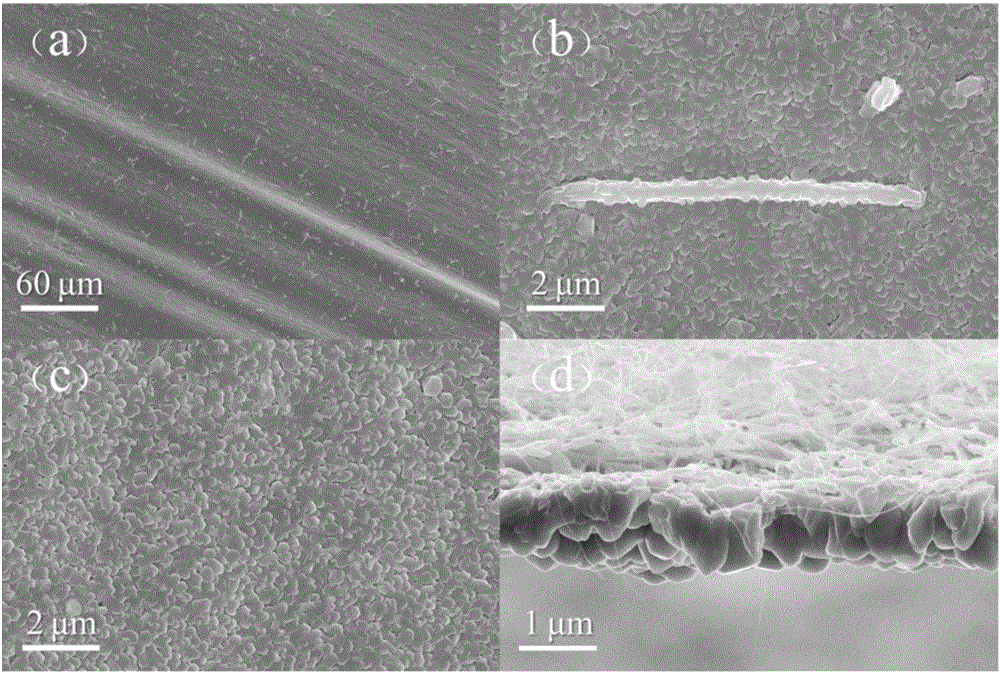

ActiveCN106744820APrecise control of ingredientsPrecise control structureCarbon compoundsVacuum evaporation coatingComposite filmCarbon nanotube

The invention belongs to the field of composite materials and in particular relates to a laminated metal chalcogenide (LMC) / carbon nanotube (CTNs) flexible compound film material of a highly ordered structure and a preparation method thereof. The composite material comprises an ultrathin self-supporting (transparent) CNTs film substrate and an LMC film which uniformly wraps the surface thereof to form the flexible composite film material which has a nanoscale porous structure and a three-dimensional network structure of a high electric channel. The preparation method comprises the following steps: providing an alloy bracket for bearing a self-supporting CNTs film and cleaning the carried CNTs film under a heating condition with plasma; and preparing the LMC / CNTs composite functional film material from the pre-treated CNTs film at an air pressure of 0.2-2Pa and at a temperature of 30-800 DEG C by virtue of a magnetron sputtered deposition technology. According to the material provided by the invention, a crispy laminated metal chalcogenide functional two-dimensional (2D) material and one-dimensional (1D) CNTs are effectively connected to form a three-dimensional (3D) network structure of structural flexibility.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

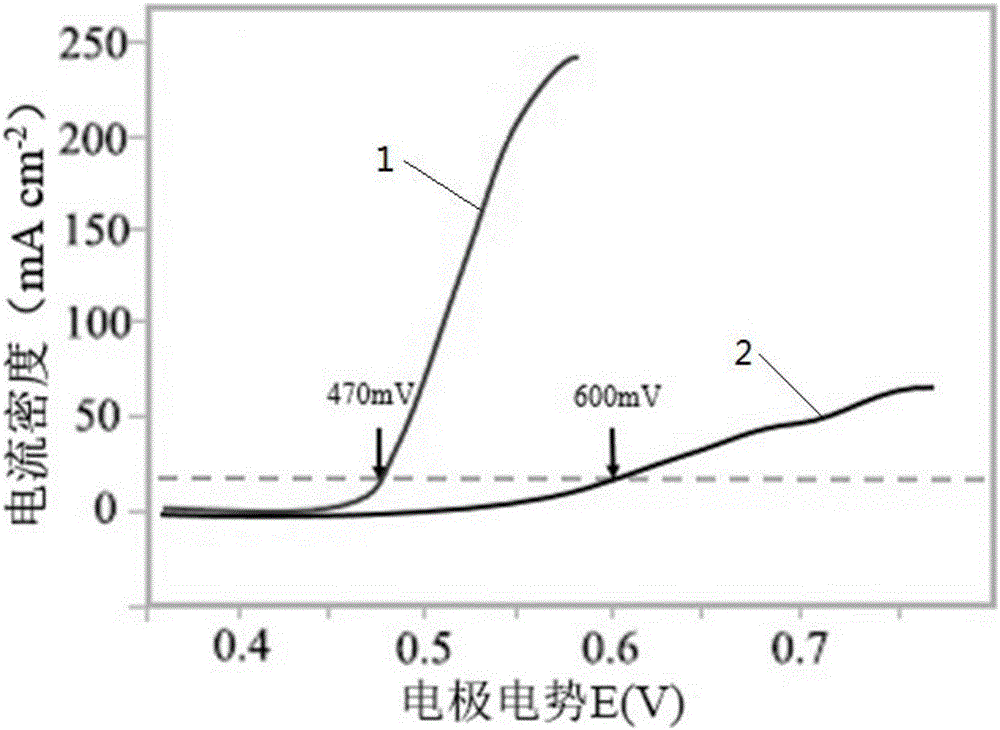

Method for reducing metal and alloy hydroxide gel by hydrogen separated from electrochemistry cathode

InactiveCN101144176APrecise control of ingredientsGuaranteed ingredientsElectrolytic coatingsAlkaline accumulator electrodesPotassiumAlloy

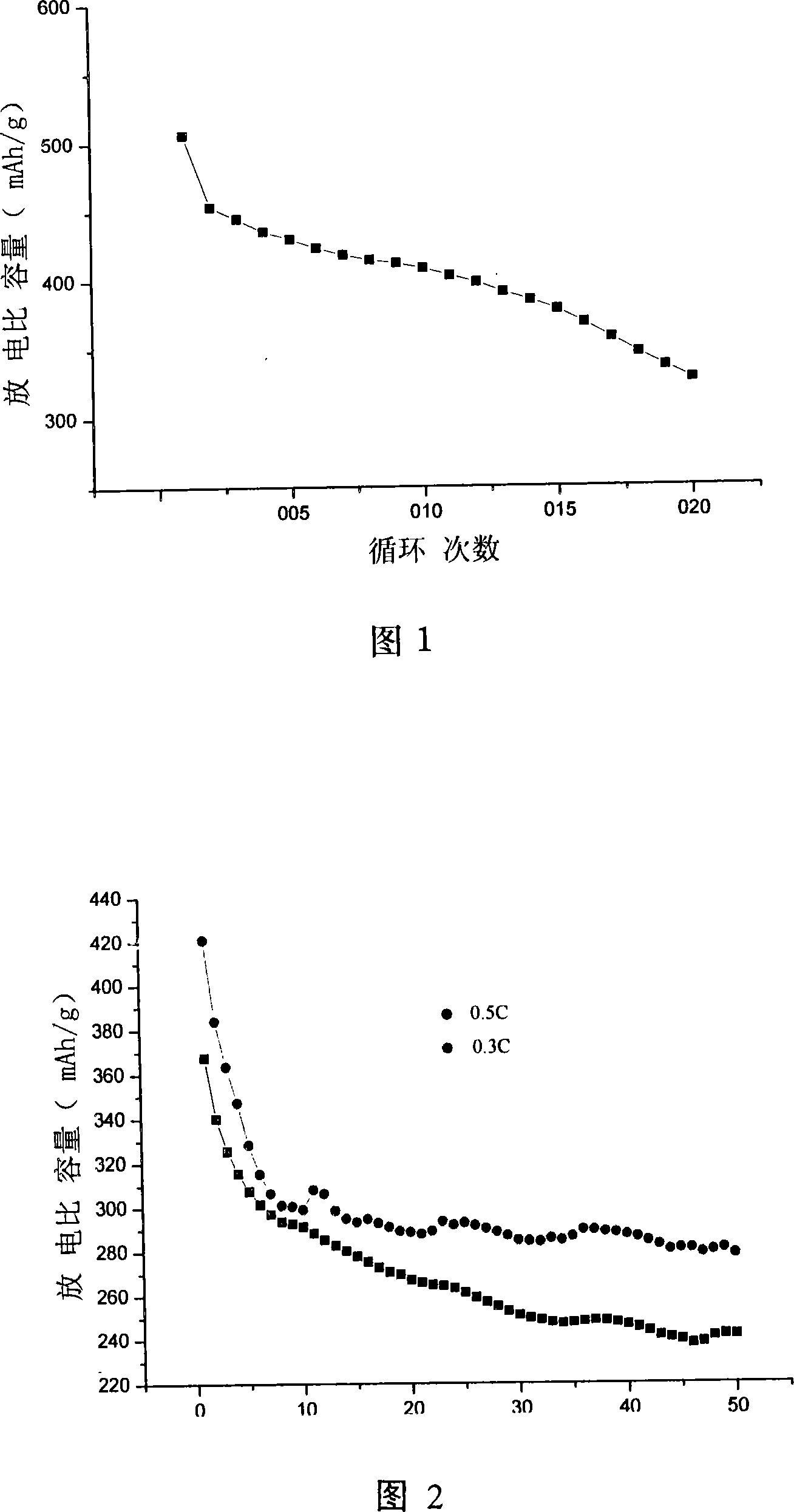

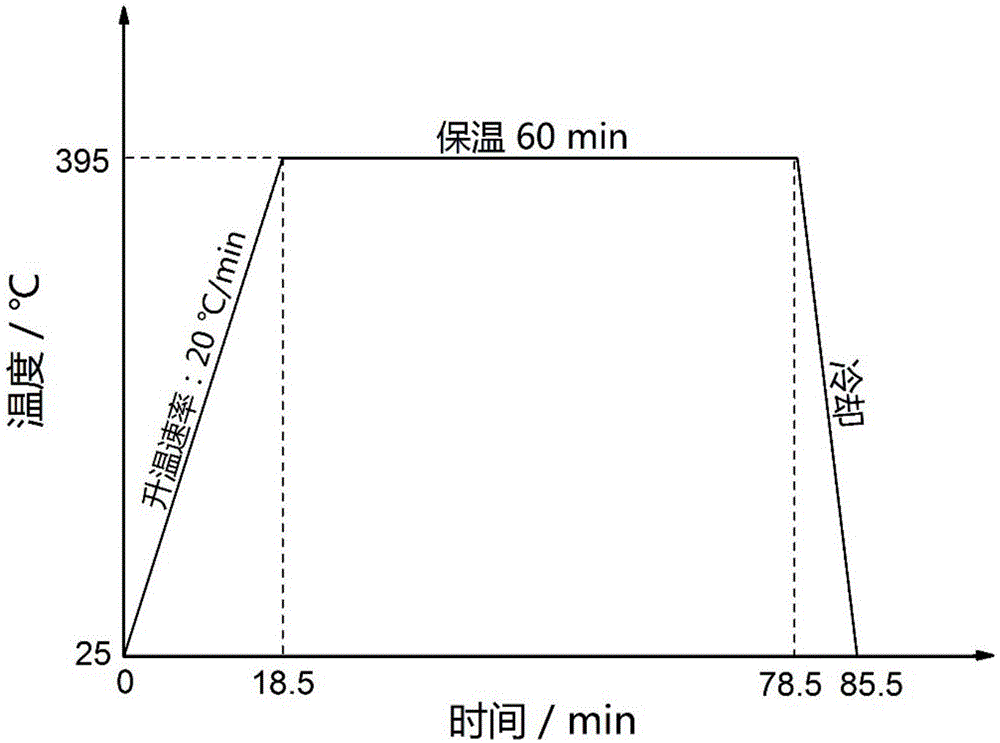

The present invention discloses a method for reducing metal hydroxide gel and metal hydroxide-carbon gel and alloy gel and alloy hydroxide-carbon gel through electrochemical cathodic hydrogen evolution in potassium chloride aqueous solution, and directly further forming and preparing electrode materials of metal and metal-carbon and alloy and alloy-carbon. The electrode prepared by the method can obtain composition of metal: carbon or alloy: carbon with definite proportion, thereby the electrode composition is stable. The tin-carbon gel and tin-cobalt-carbon gel of the present invention is prepared by a definite proportion chemical precipitation method, and overcomes the disadvantage that the coating element content can not be accurately controlled if an electrochemical deposition method is adulterated. The experimental battery consisting of the tin-carbon anode and the lithium sheet cathode prepared with the process has 20 times circulation time and specific capacity of up to 327.4 mAh / g under 0.2 C charging and discharging current; the prepared experimental battery consisting of the tin-cobalt-carbon anode and the lithium sheet cathode has 50 times circulation time specific capacity of up to 278.5 mAh / g under 0.3 C charging and discharging current.

Owner:BEIHANG UNIV

Preparation process of composite copper powder catalyst

ActiveCN102941102AReduce lossesPrecise control of ingredientsMetal/metal-oxides/metal-hydroxide catalystsElectrolysisZinc alloys

The invention provides a preparation process of a composite copper powder catalyst, comprising the steps of cutting an electroplating copper plate into a copper block and machining into copper scales; grinding the copper scales into sheet-shaped copper powder; obtaining sheet pure copper powder through a magnetic selection and air flow grading technology; smelting and atomizing a copper-tin-zinc alloy to prepare needed copper-tin-zinc alloy powder; drying and screening, and grinding to obtain scale-shaped copper-tin-zinc alloy powder; magnetically selecting and screening to obtain the needed copper-tin-zinc alloy powder; and mixing the sheet pure copper powder with the copper-tin-zinc alloy powder according to a ratio to obtain the needed composite copper powder catalyst. According to the preparation process of the composite copper powder catalyst, elements which are harmful to an environment are not introduced in a whole process, the quality stability of a product is good, concave-convex defects of the surface of powder grains are more and the specific surface is large; the catalysis property of the composite copper powder catalyst is obviously better than that of common composite copper powder so that the effect of an organic silicon monomer synthesized metal catalyzing system is improved, the time-space yield of an organic silicon monomer synthesized fluidized bed is increased, a synthesis reaction period is prolonged, the selectivity is improved, the cost is reduced and good economic benefits are created.

Owner:湖南省天心博力科技有限公司

Nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and preparation method therefor

InactiveCN106373690AGood workmanshipHigh saturation magnetic inductionMagnetic materialsThermal insulationAlloy

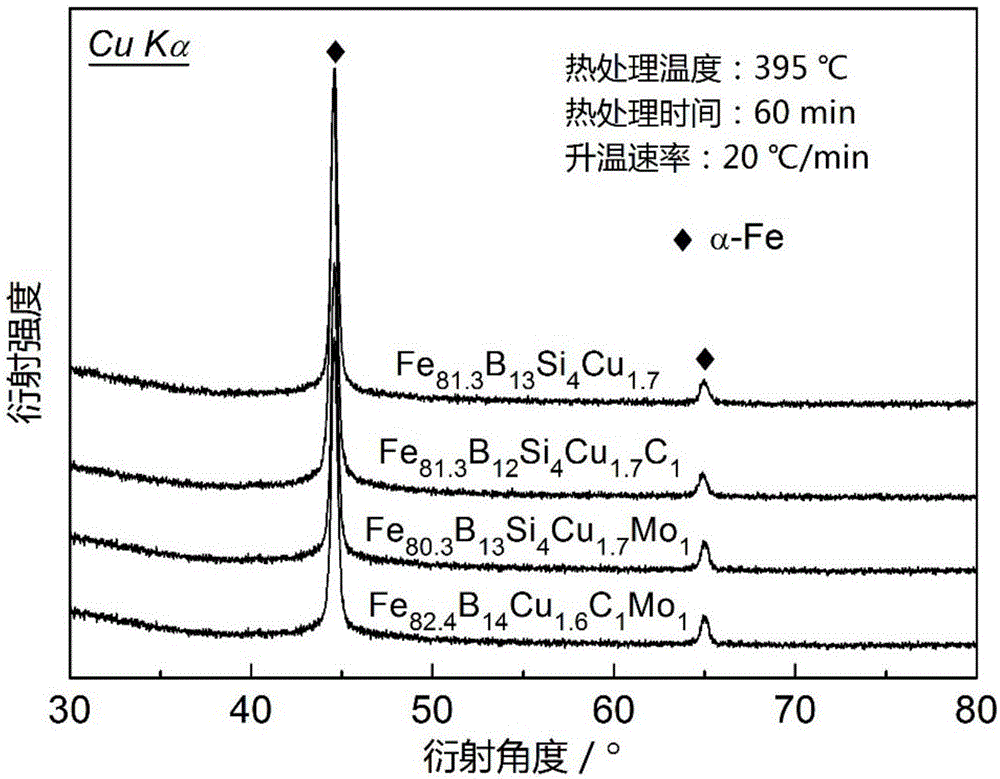

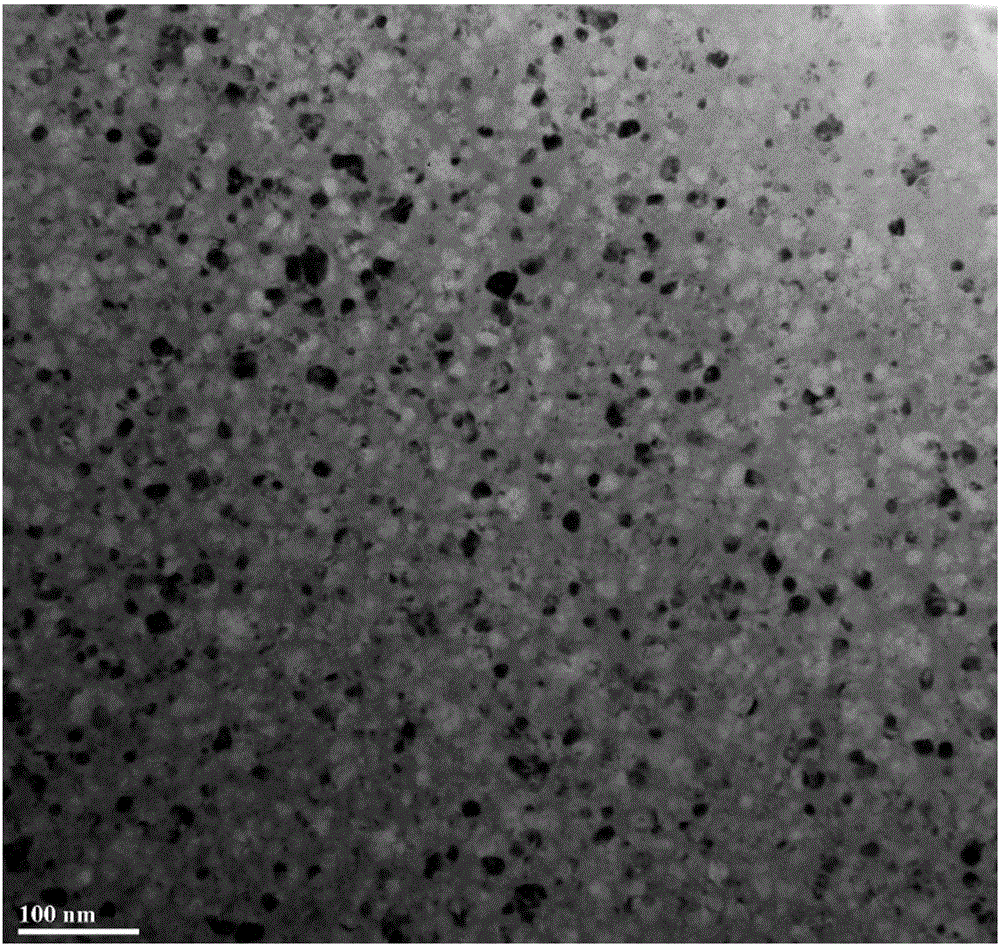

The invention discloses a nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and a preparation method therefor, and belongs to the technical field of a new material. The chemical formula of the nanocrystal magnetically soft alloy is FeBSi<c>Cu<d>C<e>M<f>Z<g>, wherein M is at least one kind of elements Co or Ni; Z is at least one kind of elements Al, Cr, Mn, Ti, Nb, Ta or Mo; a, b, c, d, e, f and g are atomic percentage contents of corresponding elements, and satisfy the formula as follows: a+f is greater than or equal to 80 and less than or equal to 84; b is greater than or equal to 10 and less than or equal to 15; c is greater than or equal to 0 and less than or equal to 6; d is greater than or equal to 1.6 and less than or equal to 2.2; e is greater than or equal to 0 and less than or equal to 2; f is greater than or equal to 0 and less than or equal to 5; and g is greater than or equal to 0 and less than or equal to 2. The alloy is formed by uniformly dispersing an <alpha>-Fe phase, which is obtained by heat treatment of amorphous stripes and has the crystal grain sizes of less than 50nm, into residual amorphous phase tissues, wherein the saturation magnetic induction strength is greater than 1.7T, and the coercivity is less than 15A / m. The alloy has no volatile phosphorus element; in addition, the heat treatment process is simple, and high temperature-rise rate is not required; the heat treatment temperature range and the thermal insulation time range are wide; industrial production can be realized easily; and the nanocrystal magnetically soft alloy and the preparation method therefor are convenient to popularize and use.

Owner:DALIAN UNIV OF TECH

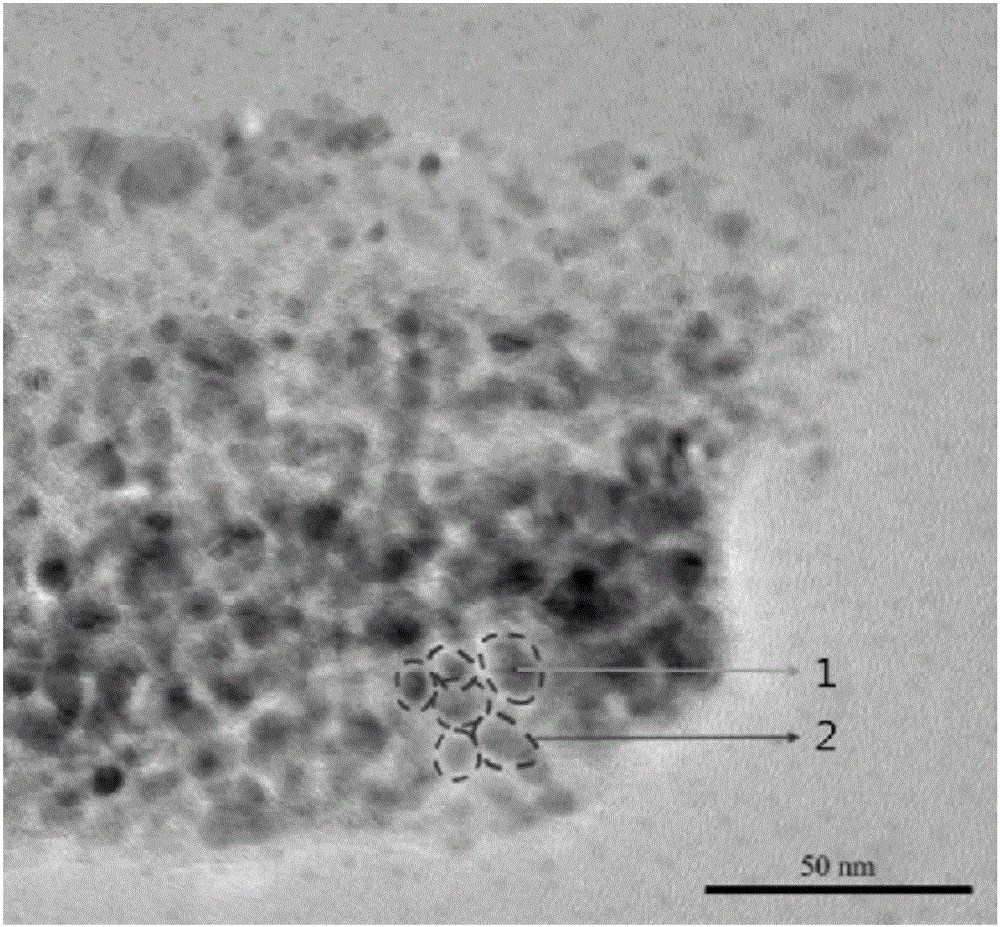

Preparation method for nano-cobalt/graphene core-shell structured electrocatalyst

ActiveCN106532074AGood dispersionEasy to makeMaterial nanotechnologyCell electrodesArgon atmosphereGas phase

The invention discloses a preparation method for a nano-cobalt / graphene core-shell structured electrocatalyst, relates to the preparation method for the electrocatalyst, and aims to solve the problems of high cost, poor stability, short service life, complex preparation process, more influence factors and poor repeatability of the existing fuel cell noble metal catalyst. The preparation method comprises the steps of 1, preparing a foamed nickel substrate; 2, preparing a deep red clear solution; 3, preparing a foamed nickel substrate after reaction; 4, preparing a sheet-shaped cobalt oxide precursor; 5, putting the sheet-shaped cobalt oxide precursor into a plasma-enhanced chemical vapor deposition vacuum apparatus, and heating at certain intensity of pressure in hydrogen and argon atmosphere; and 6, pumping a carbon source gas, and performing depositing at certain radio frequency power, intensity of pressure and temperature to obtain the nano-cobalt / graphene core-shell structured electrocatalyst. The invention discloses the preparation method for the nano-cobalt / graphene core-shell structured electrocatalyst.

Owner:HARBIN INST OF TECH

Preparation method of SiC/C-AlPO4-mullite antioxidation coating for C/C composite material

The invention relates to a preparation method of an SiC / C-AlPO4-mullite antioxidation coating for a C / C composite material, which comprises the following steps: mixing silicon powder and graphite powder to obtain powder A; mixing Al2O3 powder, WO3 powder and B2O3 powder to obtain powder B; mixing the powder A and the powder B to obtain embedded powder C; putting a sample in a graphite crucible, adding the embedded powder C, putting the graphite crucible in a vertical vacuum furnace, heating to react while introducing argon as a protective atmosphere, cooling to room temperature, and cleaning with anhydrous alcohol in ultrasonic waves to obtain a silicon carbide transition layer for the C / C composite material; adding the C-AlPO4 and the mullite powder into methanol, adding iodine to obtain a suspension, and putting the suspension in a hydrothermal kettle, wherein the cathode adopts the C / C composite material with the silicon carbide transition layer; and sealing the hydrothermal kettle, putting the hydrothermal kettle in an ultrasonic-microwave generator, depositing, taking out the sample, and drying to obtain the SiC / C-AlPO4-mullite antioxidation coating for the C / C composite material. The composite coating can protect the C / C composite material at 1500 DEG C in static air for 322 hours, and the oxidative weight loss is less than 2%.

Owner:深圳市贝尔新材料科技有限公司

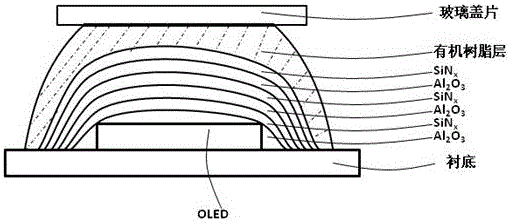

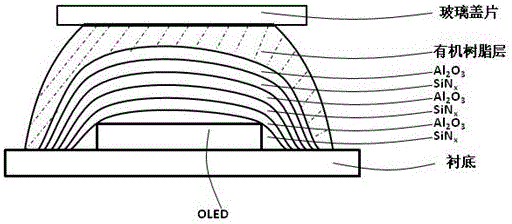

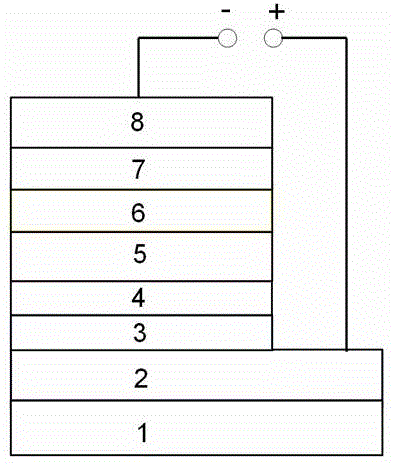

Organic light-emitting device (OLED) packaging structure and method

InactiveCN105679964AImprove compactnessMake up for the shortcomings of not being able to cover dust particles wellSolid-state devicesSemiconductor/solid-state device manufacturingGlass coverThin membrane

The invention discloses an organic light-emitting device (OLED) packaging structure and a method. The packaging structure is characterized by comprising a substrate, the OLED, a thin film packaging layer, an organic resin layer and a glass cover sheet, wherein Al2O3 thin films and SiNx thin films are sequentially overlapped to form the thin film packaging layer. In the packaging method, the Al2O3 thin film is prepared by using an atomic layer deposition technology, the SiNx thin film is prepared by using a plasma chemical vapor deposition or sputtering technology, and thus, the thin film packaging layer has high compactness, water vapor can be prevented from corroding the OLED, and the thin film packaging layer making efficiency is also improved. As the organic resin layer and the glass cover sheet are arranged on the thin film packaging layer, by using the full covering effects of the organic resin layer and the protection effects of the glass cover sheet, the service life of the device is further improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Method for melting manganese-copper alloy through vacuum induction furnace

ActiveCN106148782APrecise control of ingredientsHomogeneous composition and structureAtmosphereVacuum induction furnace

The invention discloses a method for melting manganese-copper alloy through a vacuum induction furnace and belongs to the technical field of copper alloy. The method comprises the following steps that (1) nickel, iron, copper and other pure metal and part of electrolytic manganese are fed along with the furnace; (2) the furnace is vacuumized firstly and then powered on to be heated; (3) after the alloy in the furnace becomes red hot, electrolytic manganese is fed in batches; (4) after all alloy is added, vacuumizing is stopped, and argon is introduced to achieve the shield atmosphere; (5) after the alloy melts through heating, argon bottom-blowing is carried out for stirring; and (6) the alloy is cast into a water-cooling ingot mold after the temperature is increased to 1050 DEG C. Volatilization of Mn and Cu is restrained by adding electrolytic manganese step by step to cool the metal and adopting the high-pressure argon shielding, so that constitution control is more accurate; by the adoption of argon bottom-blowing in the furnace, the problems that alloy slag melting is difficult and electrolytic manganese is prone to floating on a slag layer are solved; and by adopting the water-cooling copper ingot mold for casting, a shrinkage cavity of an ingot is reduced, and finally a manganese-copper alloy ingot uniform in texture and constitution is obtained.

Owner:HEBEI IRON AND STEEL

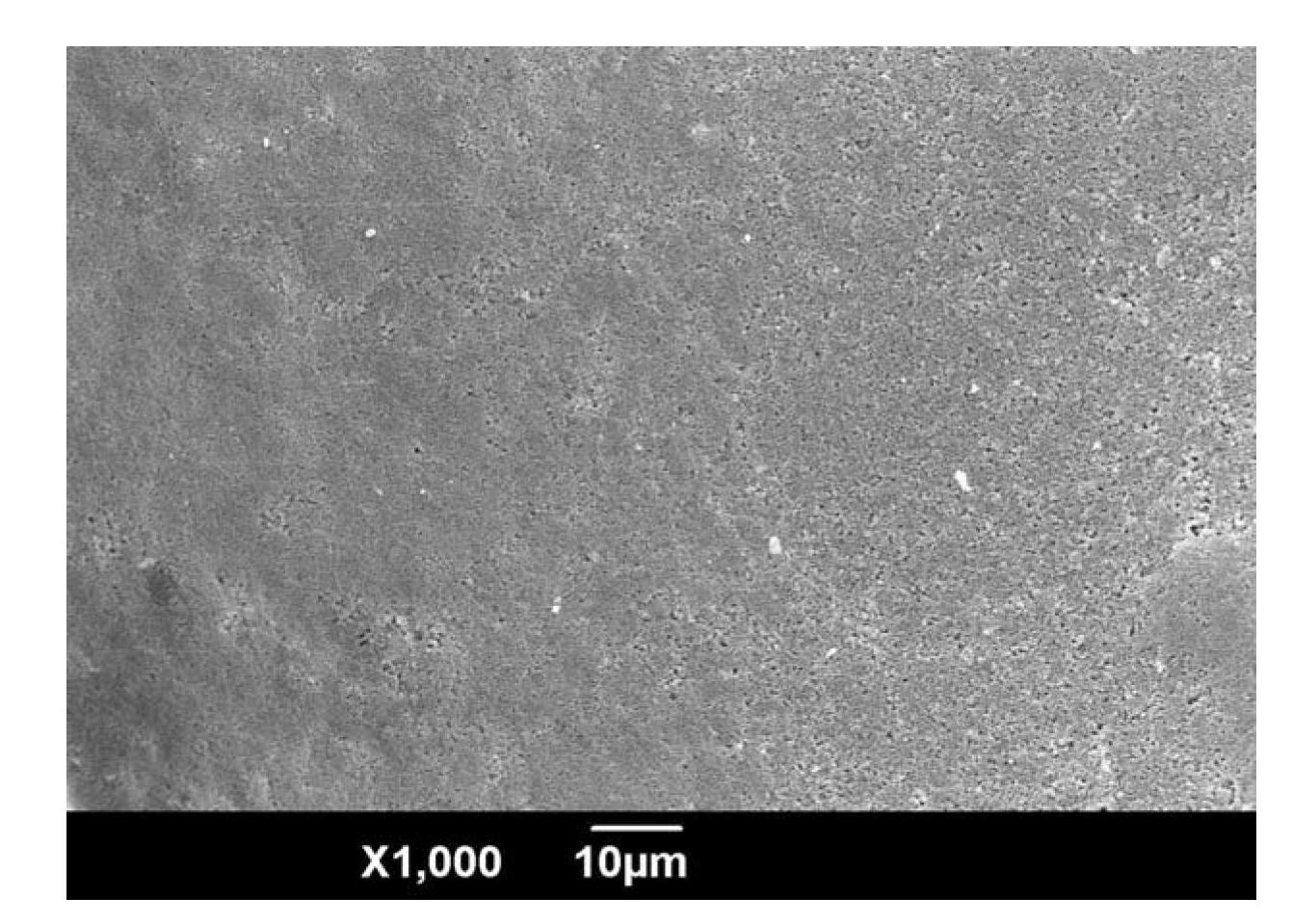

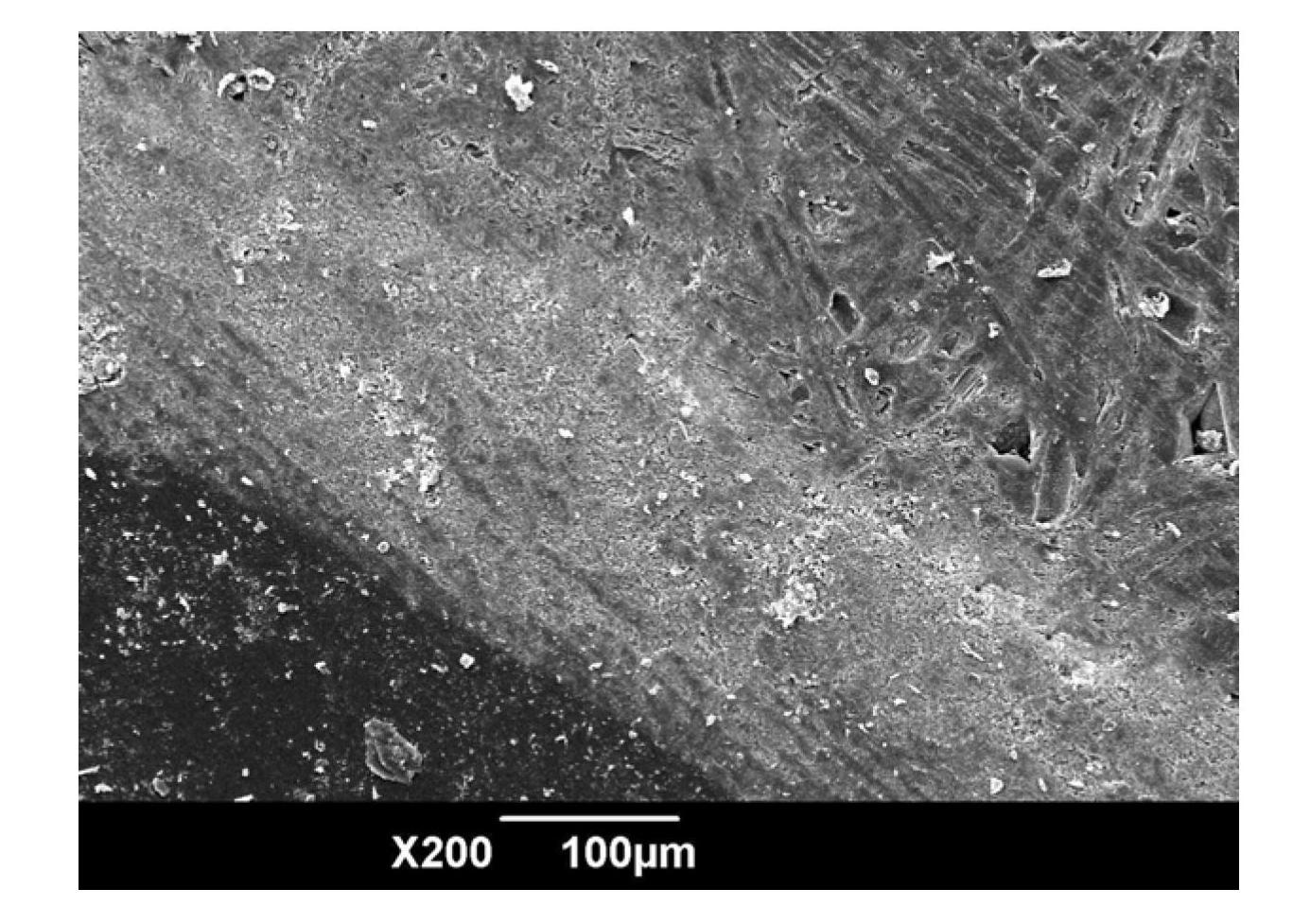

Preparation process for high-silicon super-hard PVD coating

InactiveCN104593737AWon't breakPrecise control of ingredientsVacuum evaporation coatingSputtering coatingVacuum pumpingPower flow

The invention provides a preparation process for a high-silicon super-hard PVD coating. The preparation process comprises the following steps: I, pre-processing a workpiece surface; II, clamping and loading a workpiece; III, performing vacuum-pumping on a furnace chamber; IV, heating the workpiece; V, etching and cleaning a target material and the workpiece; VI, preparing a high-silicon coating; VII, cooling the workpiece. The preparation process is used for obtaining the high-silicon super-hard PVD coating by controlling vacuum degree of a film-coating furnace chamber, bias voltage of a base body, a flow rate of nitrogen gas, target current and the like, wherein the flow rate of the reaction gas nitrogen gas (N2) ranges from 130 sccm to 210 sccm, the bias voltage of the base body ranges from 40 V to 120 V, and the vacuum degree of the furnace chamber ranges from 0.005 mbar to 0.060 mbar. By changing the element components of the coating, high silicon element content is obtained, so that the coating has characteristics of relatively high strength, hardness, wear resistance, high-temperature stability and corrosion resistance. A coating tool prepared by the process can be used for cutting a material with hardness of HRC65, and has relatively good using performances in comparison with a conventional coating.

Owner:SHANGHAI INST OF TECH

Heat machining and heat treatment process of aluminum-silicon alloy plate prepared by powder sintering

The invention discloses a heat machining and heat treatment process of an aluminum-silicon alloy plate prepared by powder sintering. The content of Si in an Al-Si alloy is controlled in a range of 10-40%; after a high-silicon aluminum alloy blank ingot obtained by sintering is uniformly annealed at 300-500 DEG C for heat forging with deformation of not more than 20%, the multi-pass hot rolling with the pass reduction of not more than 30% is performed; or the multi-pass hot rolling with the pass reduction of not more than 30% is directly performed for the blank ingot after homogenization in the step 2; and a product obtained by hot rolling is annealed to obtain the Al-Si alloy plate product. The prepared high-silicon-content aluminum-silicon alloy blank ingot is precise in component control, compact, and short in heat deformation and heat treatment process flow; and the obtained Al-Si alloy plate has such physical and mechanical performances as air tightness, heat conductivity, thermal expansion coefficient, tensile strength and bending strength needed by application of electronic packing materials, reduces the subsequent mechanical workload of the materials, and improves the utilization rate and the production efficiency of the materials.

Owner:HUNAN HYDRO DYNAMIC NEW MATERIAL CO LTD

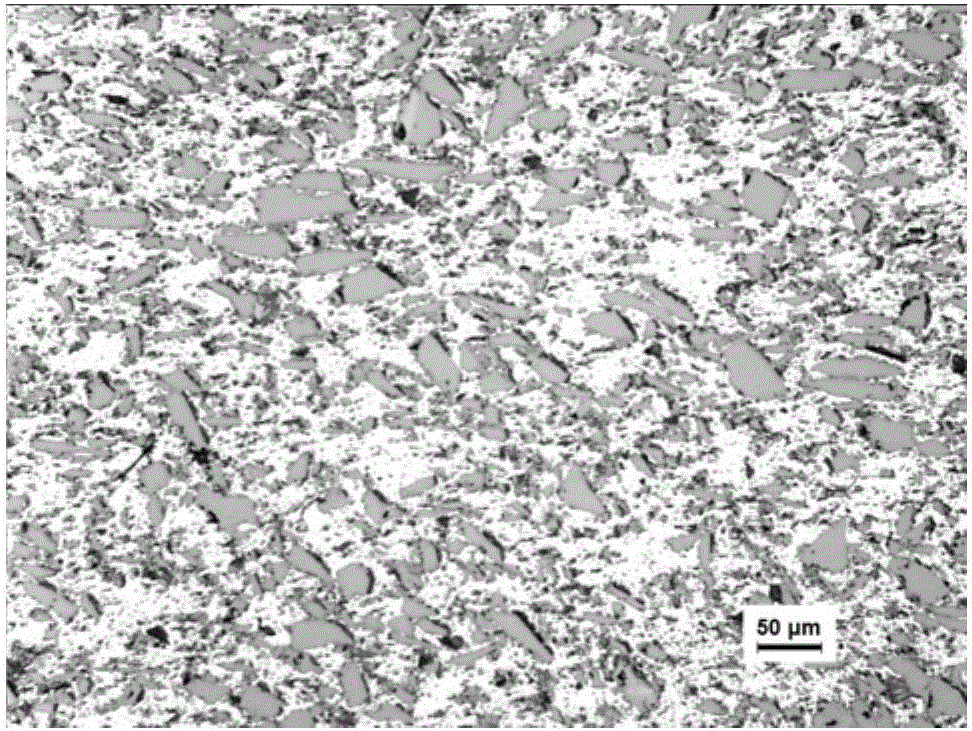

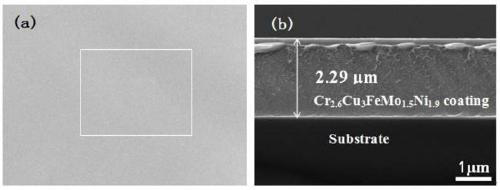

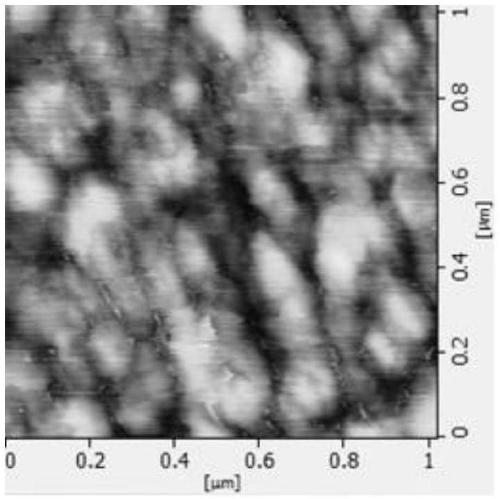

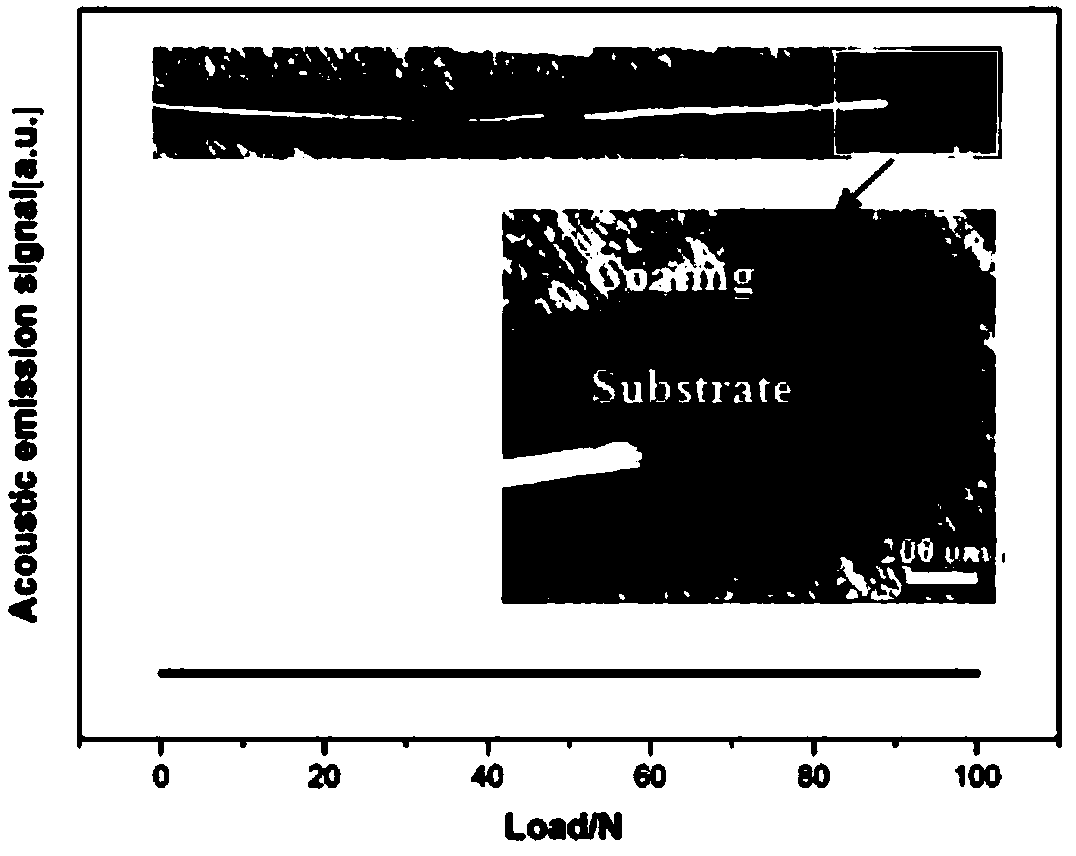

Nuclear zirconium alloy cladding surface high temperature and corrosion resisting high-entropy alloy coating and preparing method thereof

ActiveCN109666911AHigh hardnessImprove high temperature resistanceVacuum evaporation coatingSputtering coatingFault toleranceSputtering

The invention discloses a nuclear zirconium alloy cladding surface high temperature and corrosion resisting high-entropy alloy coating and a preparing method thereof. The high-entropy alloy coating deposited on the surface of a Zr alloy is a CrCuFeMoNi high-entropy alloy, and according to the atomic percents of Cr, Cu, Fe, Mo and Ni in the high-entropy alloy, Cr is 25%-35%, Cu is 20%-30%, Fe is 10%-14%, Mo is 15%-20%, and Ni is 15%-20%. The high-entropy alloy coating is deposited on the surface of the Zr alloy through the multi-target magnetron sputtering technology. According to the CrCuFeMoNi high-entropy alloy coating, the surface hardness of the Zr alloy is improved, corrosion resistance and radiation resistance are improved, good high-temperature resisting performance and corrosion resisting performance are shown, the actual engineering application can be achieved, and the CrCuFeMoNi high-entropy alloy coating is the potential alternative material for accident fault tolerance fuelcladding coatings. The adopted multi-target magnetron sputtering technology is mature, operation is simple, industrial production of the nuclear zirconium alloy cladding surface high temperature andcorrosion resisting high-entropy alloy coating to the engineering field can be achieved, and good development prospects are achieved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

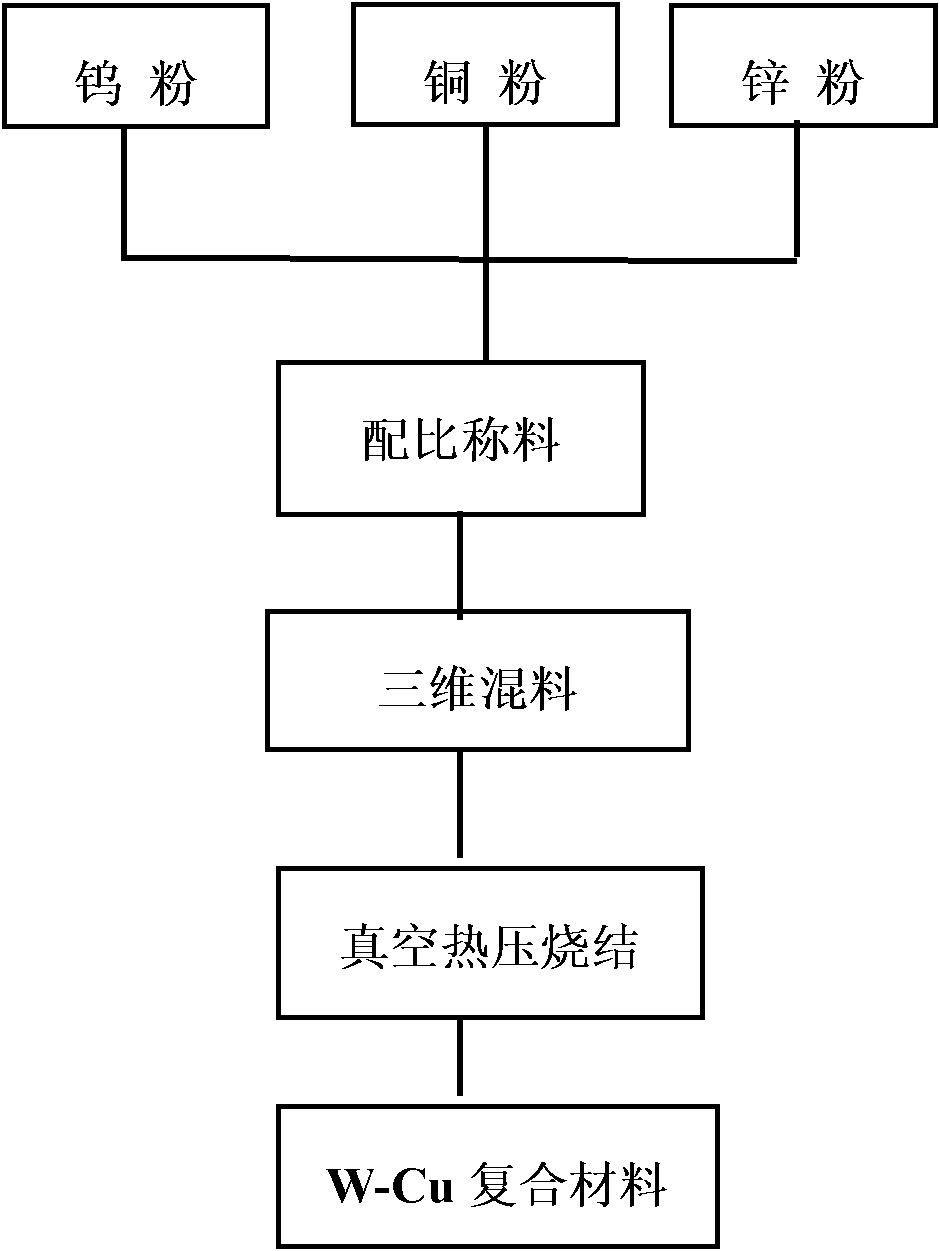

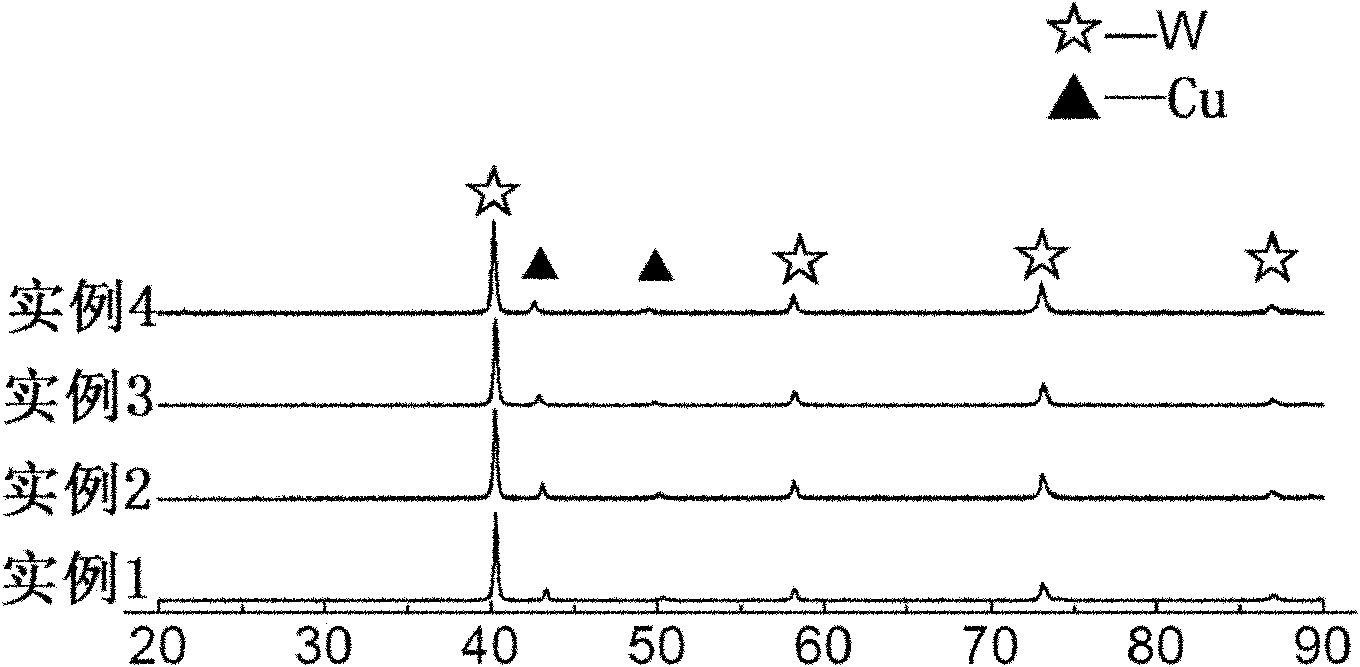

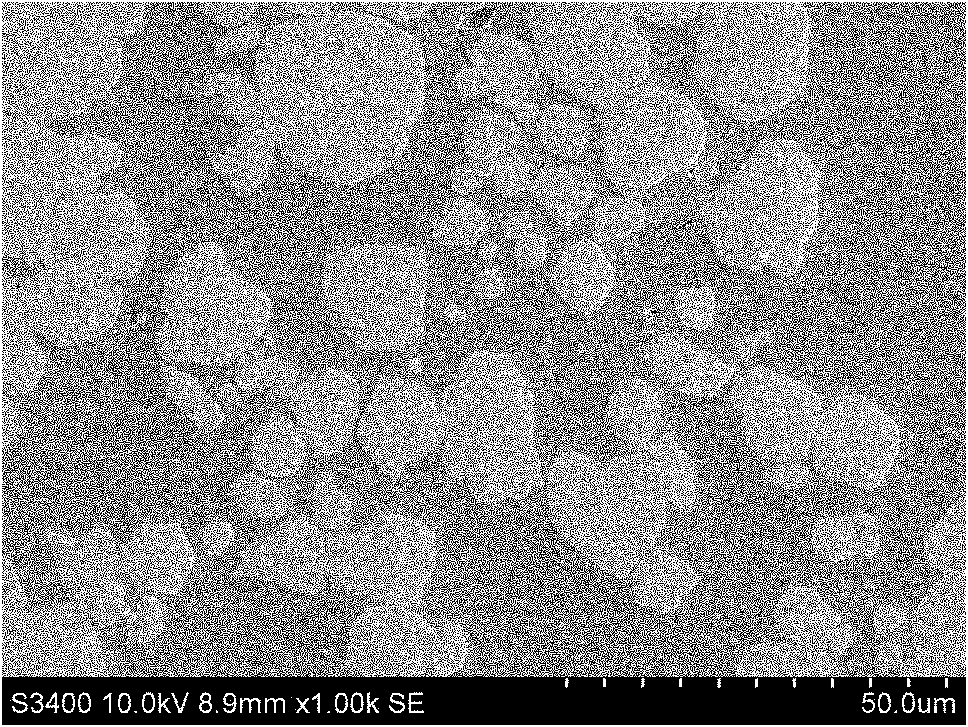

Method for preparing compact W-Cu composite material at low temperature

The invention relates to a method for preparing a compact W-Cu composite material at low temperature, comprising the following steps: carrying out three-dimensional mixing on W power, Cu power and Zn power, wherein the volume fraction ratio of W power to Cu power is (10.0-75.0%): (25.0-90.0%) by volume, and the Zn power is 0.5-2.0% of the total mass of the W power and the Cu power and serves as additive; putting the mixture in a vacuum hot pressing furnace; and carrying out hot pressing sintering on the mixture according to the specified vacuum hot pressing sintering process to obtain the compact W-Cu composite material, wherein the vacuum degree is 1*10<-3>-1*10<-4>Pa, the sintering temperature is 700-900 DEG C, the heat preservation time is 1-4 hours and the applied pressure is 80-200 Mpa in the specified vacuum hot pressing sintering process. The mixture can be sintered at low temperature to obtain the high-compactness W-Cu composite material, and the method has the obvious advantages of simple process, low cost, wide and accurate component adjustment range, and the like.

Owner:WUHAN UNIV OF TECH

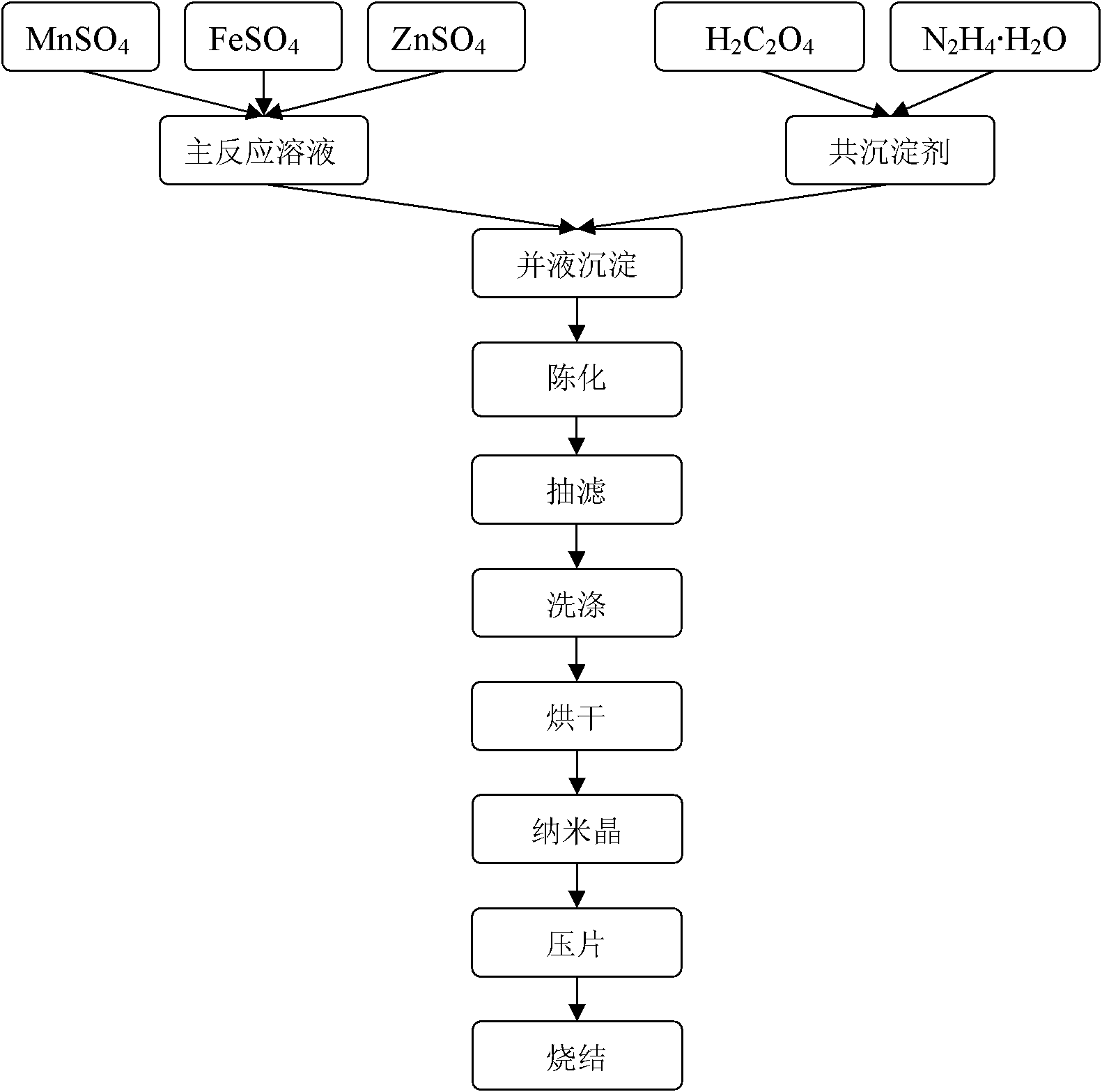

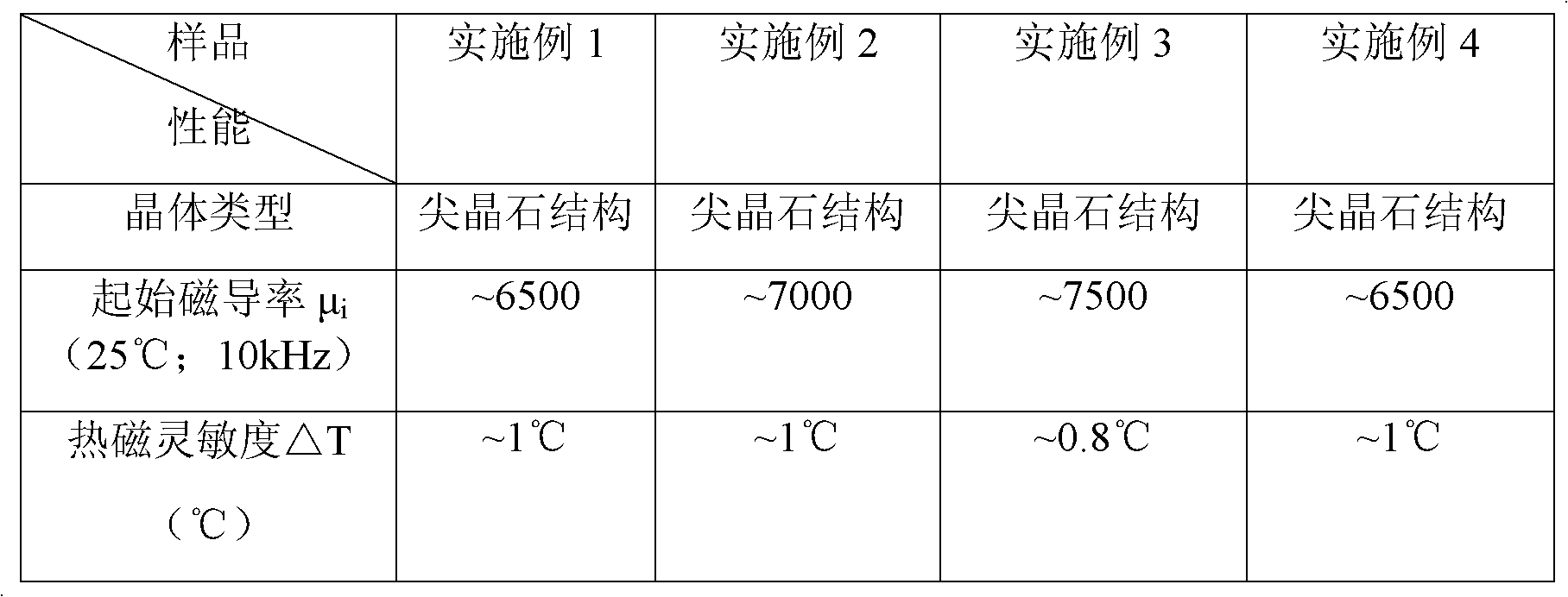

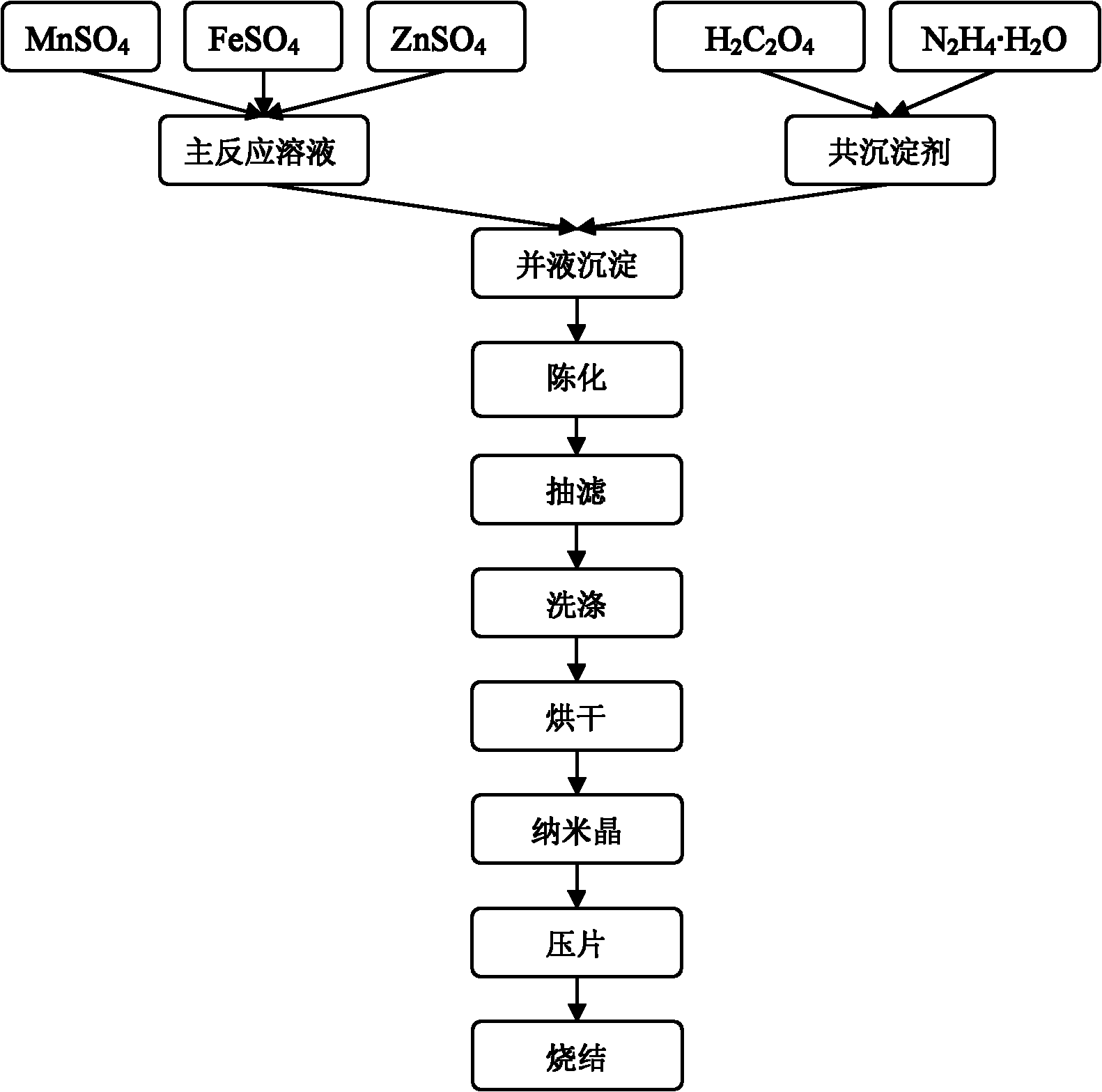

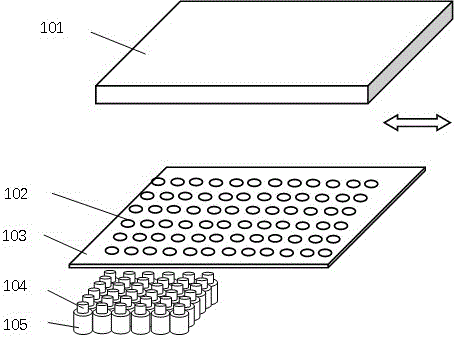

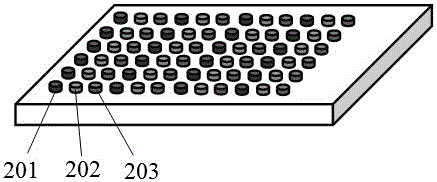

Nano-crystal Mn-Zn ferrite magnetic material with high initial permeability and high thermal-magnetic sensitivity and preparation method of nano-crystal Mn-Zn ferrite magnetic material

The invention relates to a nano-crystal Mn-Zn ferrite magnetic material with high initial permeability and high thermal-magnetic sensitivity and a preparation method of the nano-crystal Mn-Zn ferrite magnetic material. When the Mn-Zn ferrite material is prepared, a raw material is composed of a main reactant and a precipitator, wherein the main reactant comprises the following components in percentage by weight: 68-72% of FeSO4, 8-15% of ZbSO4 and the balance of MnSO4; and the precipitator is hydrazine oxalate (H2C2O4N2H4.H2O). By using the preparation method, the initial permeability of the prepared Mn-Zn ferrite is up to 7500 at 25 DEG C, and the thermal-magnetic sensitivity of the prepared Mn-Zn ferrite is about 1 DEG C. the Mn-Zn ferrite prepared by the method can be widely applied to temperature detection and control systems such as household appliances, industrial machinery and the like.

Owner:苏州天铭磁业有限公司

High-accuracy organic light-emitting device (OLED) component preparation device and method

InactiveCN106435483AReduce spacingReduce pore spacingSolid-state devicesVacuum evaporation coatingOrganic light emitting deviceEvaporation

The invention relates to a high-accuracy organic light-emitting device (OLED) component preparation device and method. The device comprises an evaporation source array, a substrate, a transmission device and a mask plate, and the mask plate is matched with the evaporation source array. A plurality of evaporation sources are arrayed to form the evaporation source array. Materials in the evaporation sources are evaporated vertically upwards to the substrate. Evaporating-plating of the substrate is completed due to the fact that the substrate or the evaporation source array are driven by the transmission device to move, so that an OLED component is formed. According to the high-accuracy OLED component preparation device and method, the distance between the substrate and the mask plate is enlarged, and the influence exerted on evaporating-plating by the mask plate is reduced; the distances between the substrate and the evaporation sources are reduced, so that the evaporation materials are less diffused into the evaporating environment, and the evaporation materials are saved; and in addition, the intervals between every two evaporation sources are reduced, the intervals between every two holes in the mask plate are reduced, the point-to-point evaporation is achieved, the number of subpixels within a unit area is increased, and the preparation of the OLED component with high accuracy is achieved.

Owner:FUZHOU UNIV

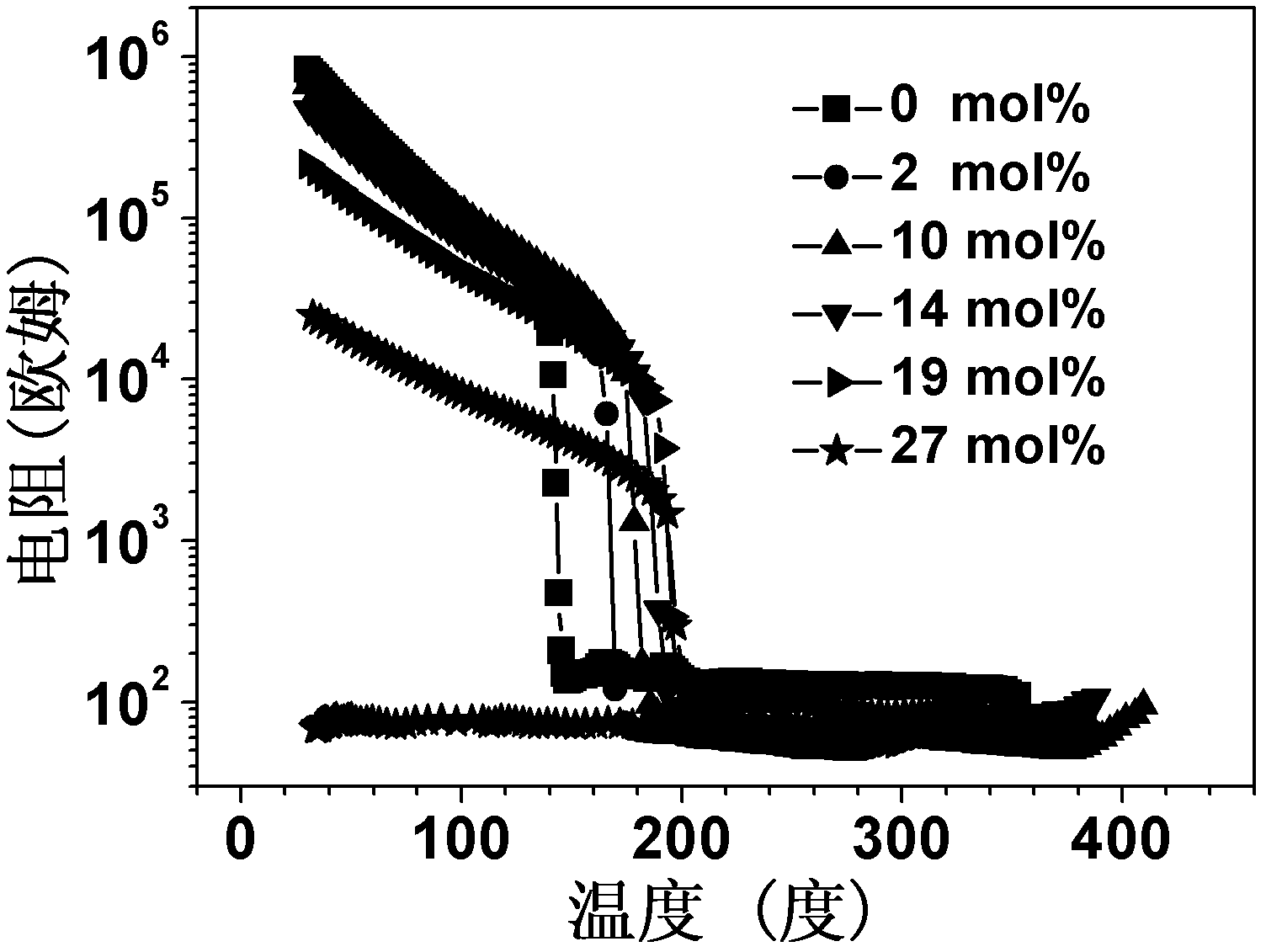

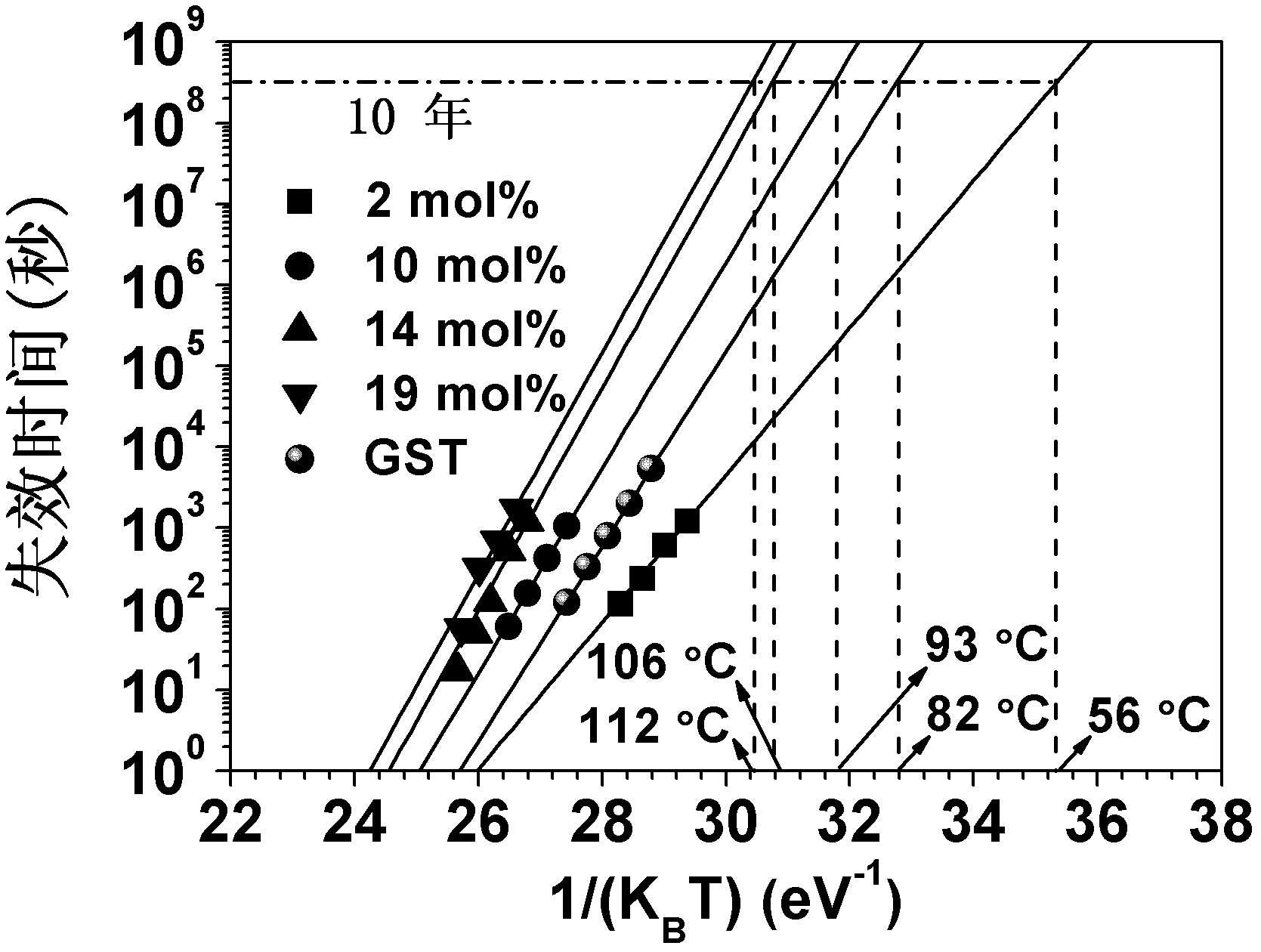

Thin film material for phase change memory and preparation method thereof

ActiveCN102361063AStrong adjustabilityImprove performanceElectrical apparatusOxide semiconductorPhase-change material

The invention provides a thin film material for a phase change memory and a preparation method thereof. The thin film material is a material composed of three elements, namely copper, stibium and tellurium, and a general formula of the material is CuxSbyTez, in which x is greater than 0 and less than or equal to 40, y is greater than or equal to 15 and less than or equal to 85, and z is greater than or equal to 15 and less than or equal to 85. According to the material provided by the invention, different crystallization temperatures, melting points and crystallization rates can be obtained by adjusting contents of the three elements in the material, so that the element ratio of the copper to the stibium to the tellurium is properly adjusted to obtain a higher crystallization temperature, a better thermal stability, a lower melting point and a higher crystallization rate compared with the traditional Ge2Sb2Te5(GST). Moreover, copper interconnection is a mainstream interconnection technology in the current oversized-scale integrated circuit, and the processing technology of the Cu element becomes more mature through the extensive use of the interconnection technology, and therefore, the Cu-Sb-Te phase change material provided by the invention is easy to process and has good compatibility with a COMS (Complementary Metal Oxide Semiconductor).

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

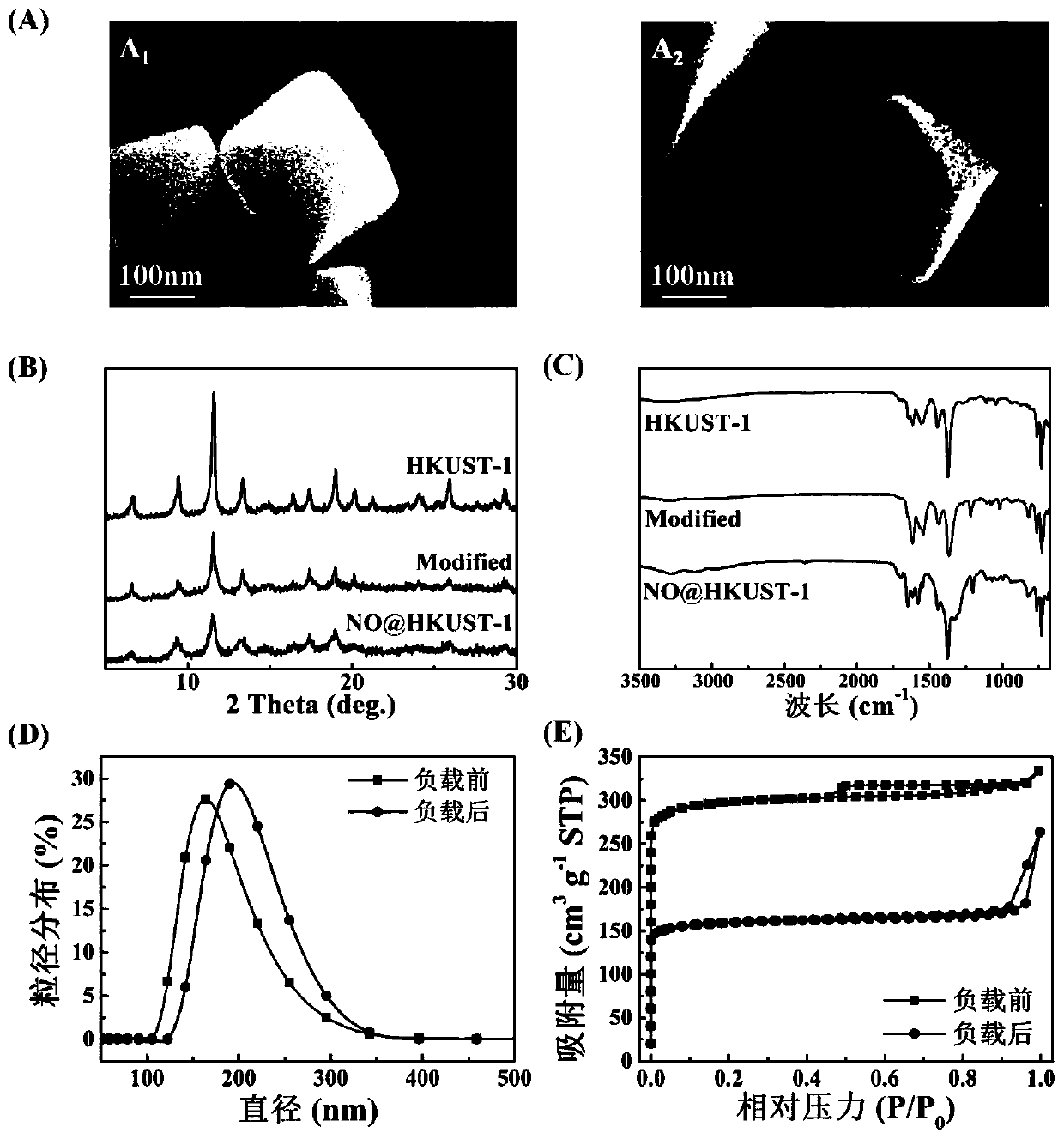

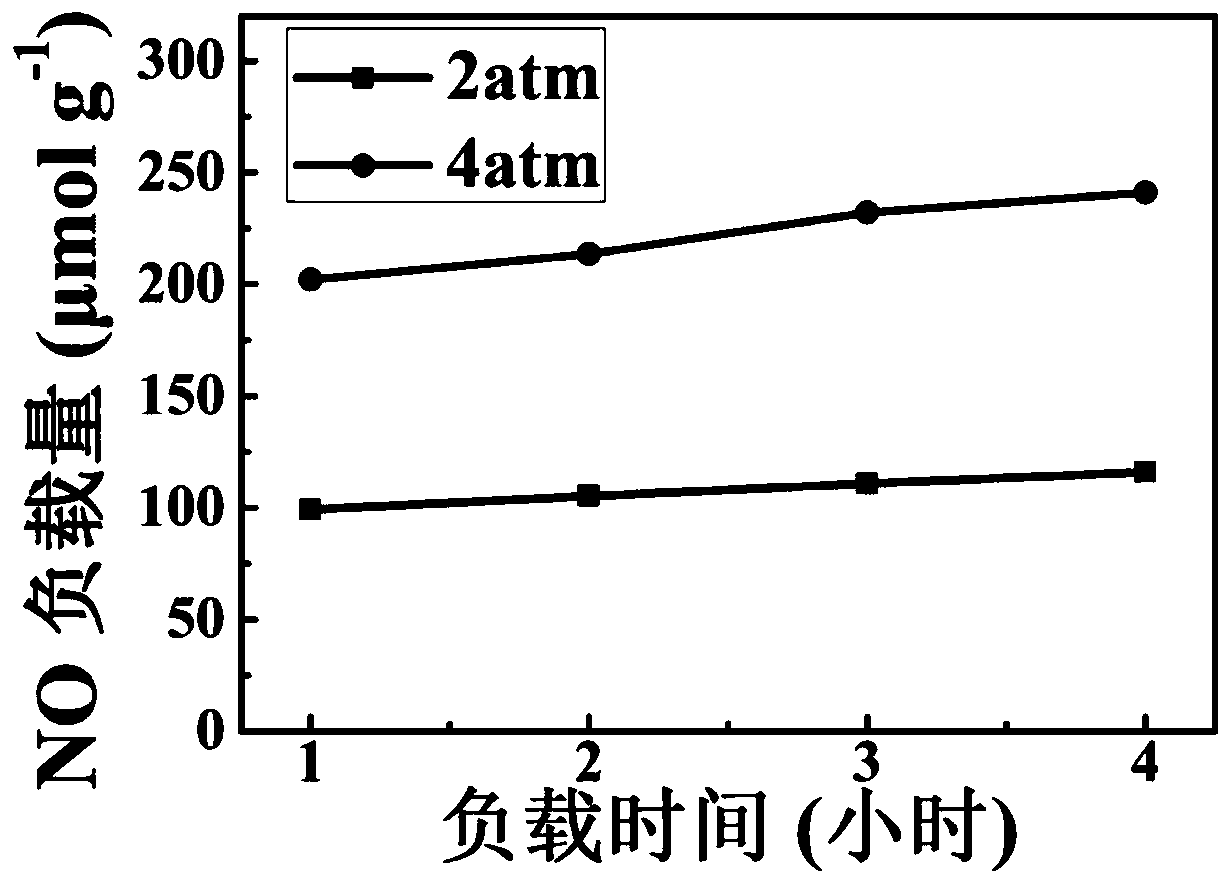

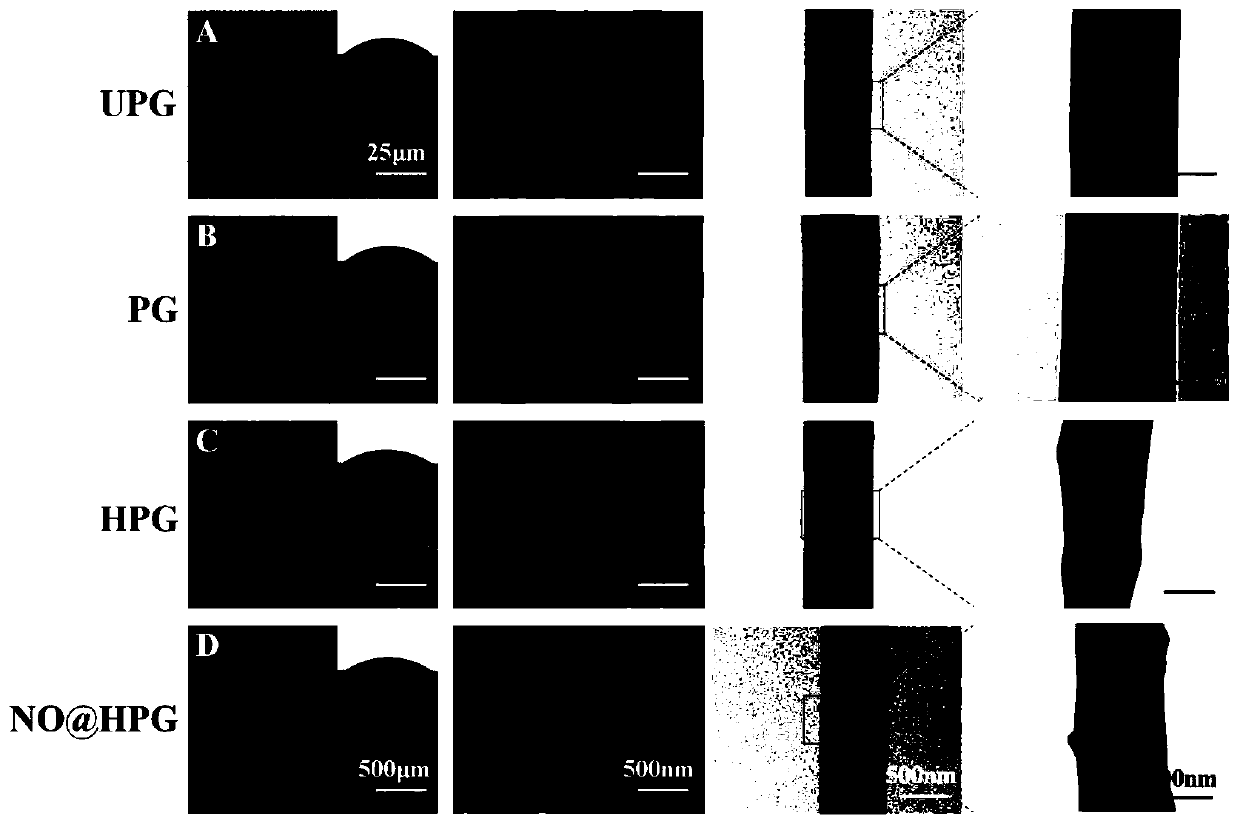

Metal organic framework/electrospinning fiber composite having NO and copper ion slow release synergistic reactions, and preparation method and application

The invention belongs to the field of biomaterials, and particularly relates to a metal organic framework / electrospinning fiber composite having NO and copper ion slow release synergistic reactions, and a preparation method and application. According to the material, a patterning structure is formed through mutual interweaving of fibers having a core shell structure, hydrophobic biomaterials are used as a core layer of the core shell fibers, hydrophilic biomaterials are used as a shell layer of the core shell fibers, and NO loaded copper bases MOF coat the core layer. The preparation method comprises the steps of using a patterned receiving template, dispersing the NO loaded copper bases MOF, enabling an organic solvent in which the hydrophobic biomaterials dissolve to communicate with aninternal needle of a coaxial electrostatic spray head, enabling an organic solvent in which the hydrophilic biomaterials dissolve to communicate with an external needle of the coaxial electrostatic spray head, and preparing the metal organic framework / electrospinning fiber composite through coaxial electrostatic spinning. In order to solve the problems that the wound healing rate of diabetes is low and angiogenesis is insufficient, the material slowly release NO and copper ions, and the NO and the copper ions are in synergistic reactions to jointly promote angiogenesis, collagen deposition, reduction of inflammatory reactions and the like in wound healing, so that the healing period of the wound of the diabetes is greatly shortened.

Owner:SHANGHAI NORMAL UNIVERSITY

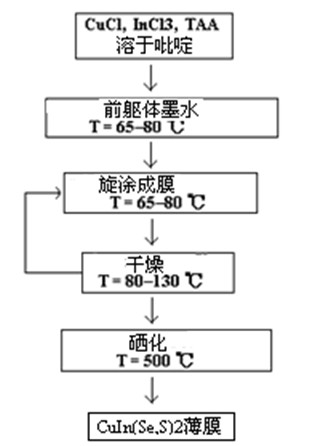

Preparation method of copper indium selenium sulfide thin film for solar cell

InactiveCN102683497APrecise control of stoichiometric ratioReduce carbon residueFinal product manufactureSemiconductor devicesIndiumGas phase

The invention relates to a method for preparing a Culn (Se, S)2 thin film by using a non-vacuum wet chemical method, which comprises the following steps of: (a) precursor ink preparation; (b) precursor thin film preparation; (c) drying; and (d) annealing. Compared a traditional high vacuum-gas phase method, the preparation method of the copper indium selenium sulfide thin film provided by the invention has the advantages of simple process, low cost, strong repeatability, easiness in realization of large-scale production, stable raw material physicochemical property, good safety and high raw material utilization rate, and the rapid development of the copper indium selenium sulfur thin film solar cell industry can be promoted.

Owner:TIANJIN NORMAL UNIVERSITY

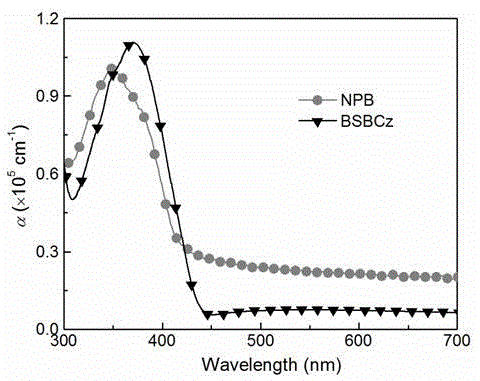

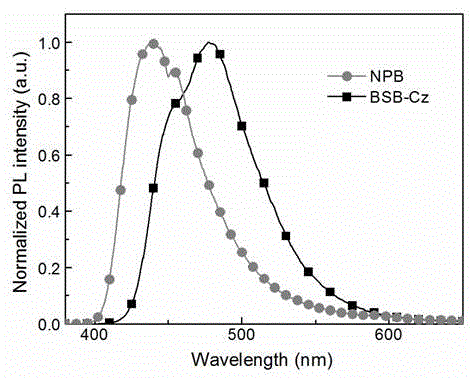

Organic solar cell with exciton blocking and sunlight sensitivity enhancing integrated type hole transport layer and preparation method of organic solar cell

InactiveCN105655491AAvoid exciton quenchingReduce dark current componentSolid-state devicesSemiconductor/solid-state device manufacturingDark currentBlue light

The invention discloses an organic solar cell with an exciton blocking and sunlight sensitivity enhancing integrated type hole transport layer and a preparation method of the organic solar cell. The organic solar cell comprises a substrate, a transparent electrode, a hole injection layer, an exciton blocking layer, a donor layer, a receptor layer, an electronic transmitting layer and a negative electrode. The organic solar cell is characterized in that the exciton blocking layer can effectively block electrons at a positive electrode end through material matching, and dark current components and electron leakage currents of a photovoltaic cell are reduced; ultraviolet light in sunlight can be absorbed for emitting pure blue light or sky blue light, and the number of incidence photons of an active layer of the subsequent organic solar cell is increased. Photo-generated currents are increased for improving the power conversion efficiency of a photovoltaic cell. The organic solar cell achieves dual functions of exciton blocking and sunlight enhancing at the same time through a simple method without other additional optical design or complex processes. The organic solar cell is simple in preparation process, low in device requirement and suitable for mass production.

Owner:SHANGHAI UNIV

Rare-earth-base denitrification catalyst powder and preparation method thereof

PendingCN106669659ASolution to short lifeUniform structure distributionHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystAmmonium paratungstate

The invention discloses a rare-earth-base denitrification catalyst powder and a preparation method thereof. The preparation method comprises the following steps: respectively preparing a metatitanic acid slurry, an ammonium paratungstate solution and a cerous nitrate-lanthanum nitrate mixed solution; transferring the ammonium paratungstate solution into the metatitanic acid slurry to obtain an intermediate mixed solution; transferring the cerous nitrate-lanthanum nitrate mixed solution into the intermediate mixed solution to obtain a metatitanic acid-ammonium paratungstate-cerous nitrate-lanthanum nitrate mixed slurry; regulating the pH value of the solution to the set range to obtain a mixed solution containing titanium, tungsten, cerium and lanthanum; drying; calcining; and grinding to obtain the catalyst powder. The invention aims to provide a rare-earth-base denitrification catalyst powder and a preparation method thereof. The rare-earth-base denitrification catalyst powder is nontoxic and harmless to the human and environment, and has the advantages of high-temperature aging resistance, long service life, wide temperature range and controllable product composition; and the preparation method has the advantages of simple facility request and simple operational process, and can easily implement large-scale industrial production.

Owner:湖北群有长物环保科技有限公司

Silicon carbide and silicon particle reinforced aluminum-copper based composite material and preparation method thereof

Owner:有研金属复材技术有限公司

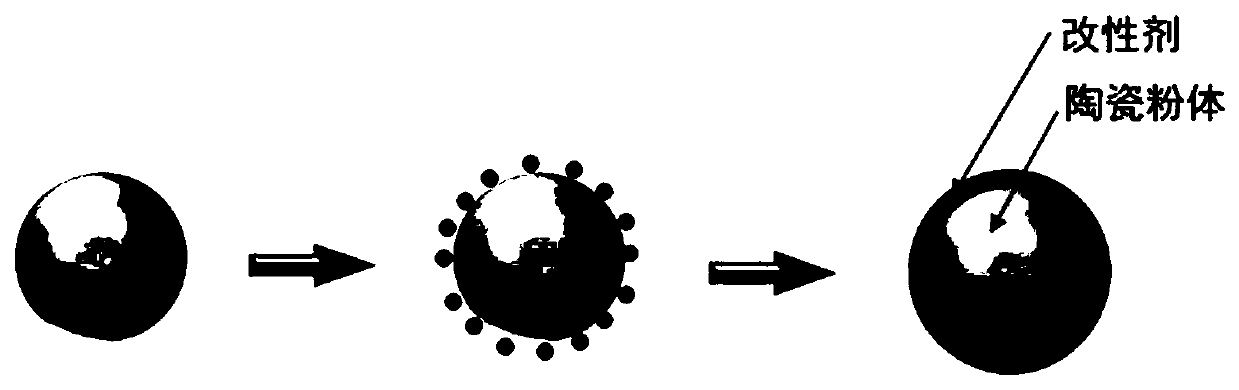

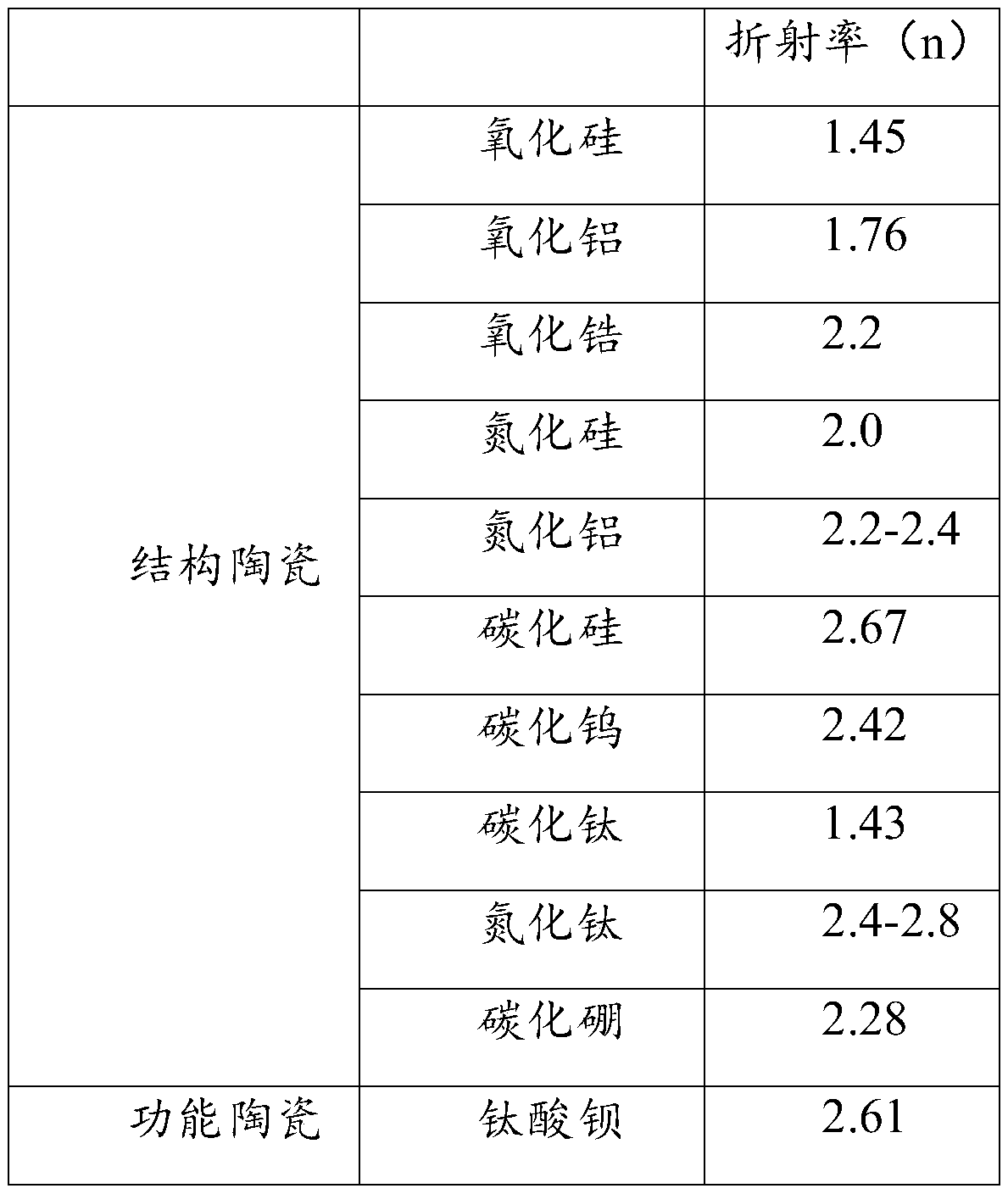

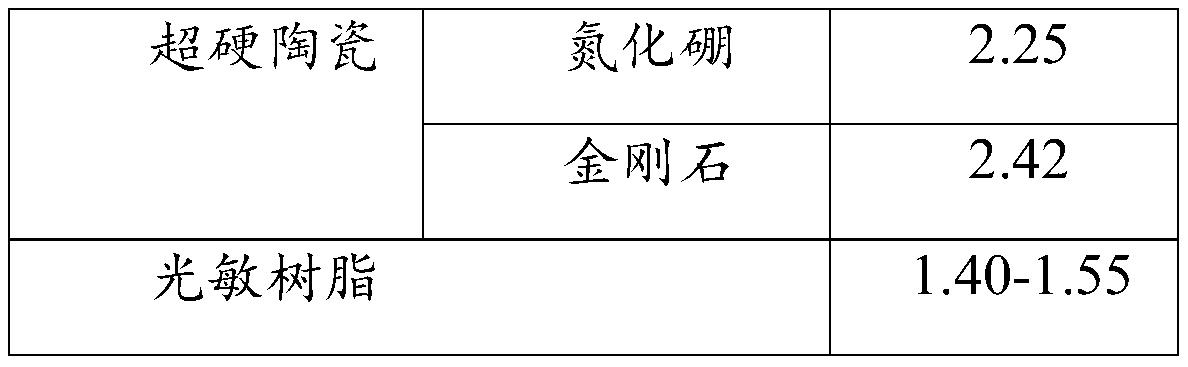

3D printing light-cured ceramic particle and preparation method thereof

InactiveCN111320480APrecise thickness controlPrecise control of ingredientsAdditive manufacturing apparatus3d printLight absorption coefficient

The invention provides a 3D printing light-cured ceramic particle and a preparation method thereof. The 3D printing photocuring ceramic particle comprises a ceramic matrix; wherein the surface of theceramic matrix is coated with a coating layer; and the coating layer is a sintering aid layer, and the sintering aid layer coats the ceramic matrix according to the decreasing order of the refractiveindexes of the sintering aid components. The 3D printing light-cured ceramic particle is prepared by a precipitation method, the thickness and components of the coating layer can be accurately controlled, and meanwhile, a proper coloring agent is added to adjust the light absorption coefficient, so that the 3D printing light-cured ceramic particle is more suitable for the requirements of a ceramiclight-cured molding technology.

Owner:GUANGDONG INST OF NEW MATERIALS

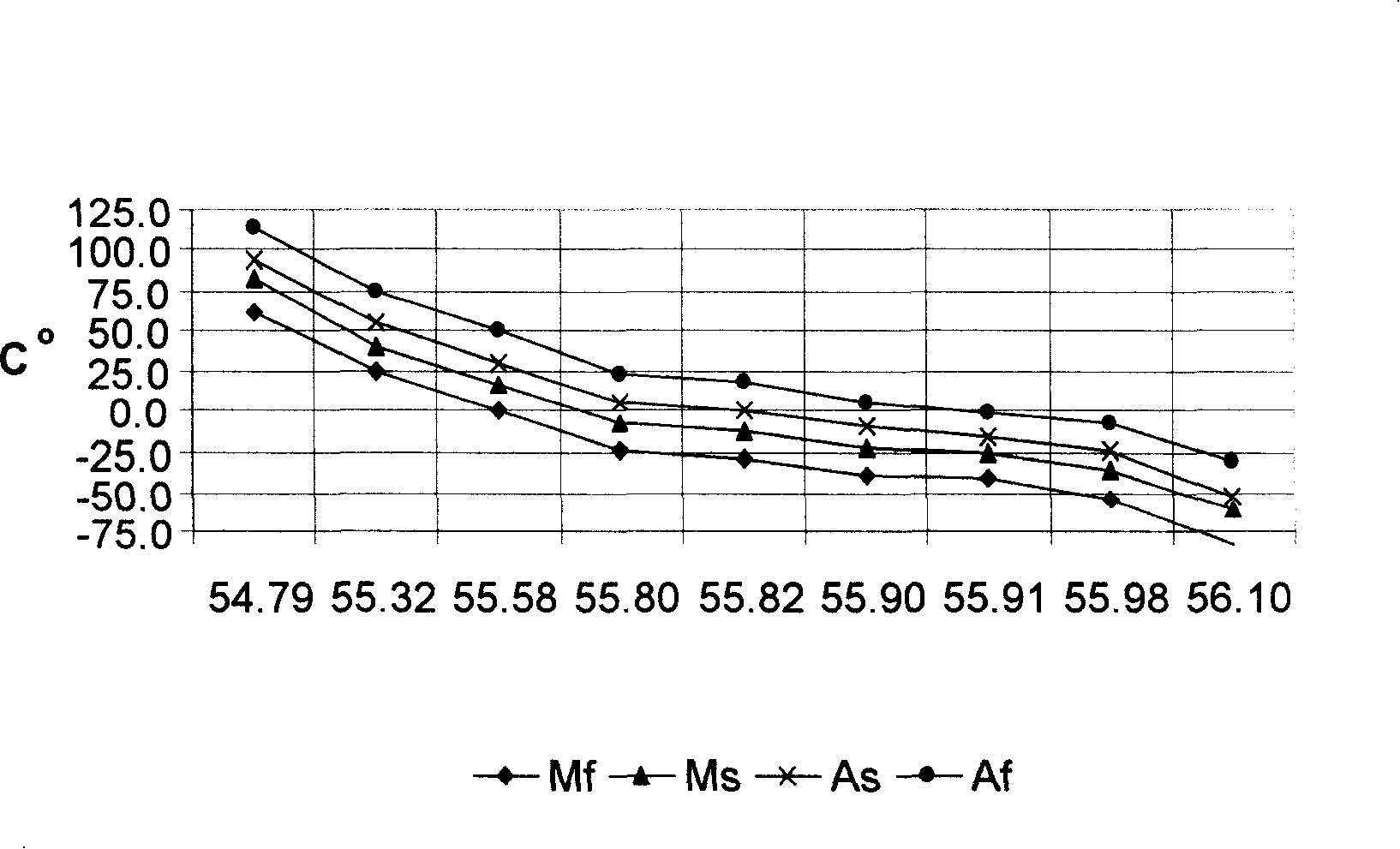

Technique for smelting ultra-pure TiNi shape memory alloy

The invention relates to an ultra-pure smelting process of TiNi shape memory alloy, in particular to an ultra-pure smelting process used in TiNi shape memory alloy. As the TiNi shape memory alloy is a material which highly demands the accuracy of components, wherein the change of the Ni content can lead to the change of transformation temperature of 10 to 20 DEG C, the content of foreign matters should be controlled as 0<500ppmN<30ppm, thereby the material can have the perfect super-elasticity, and the accurate transformation temperature can be achieved according to the components.

Owner:沈阳天贺新材料开发有限公司

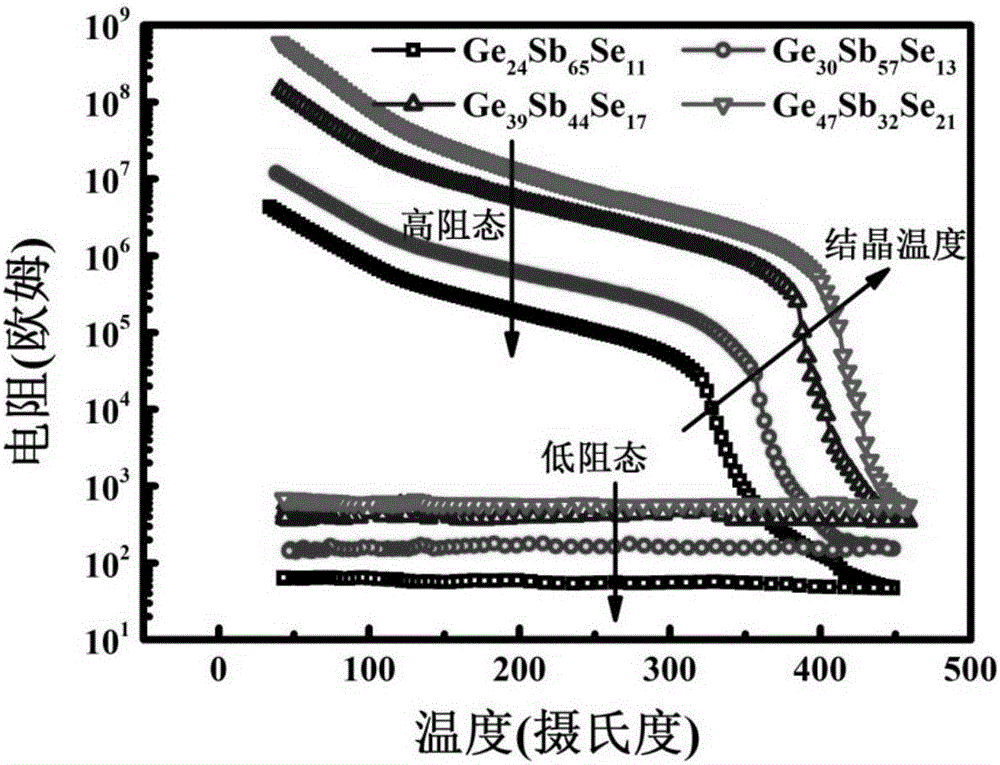

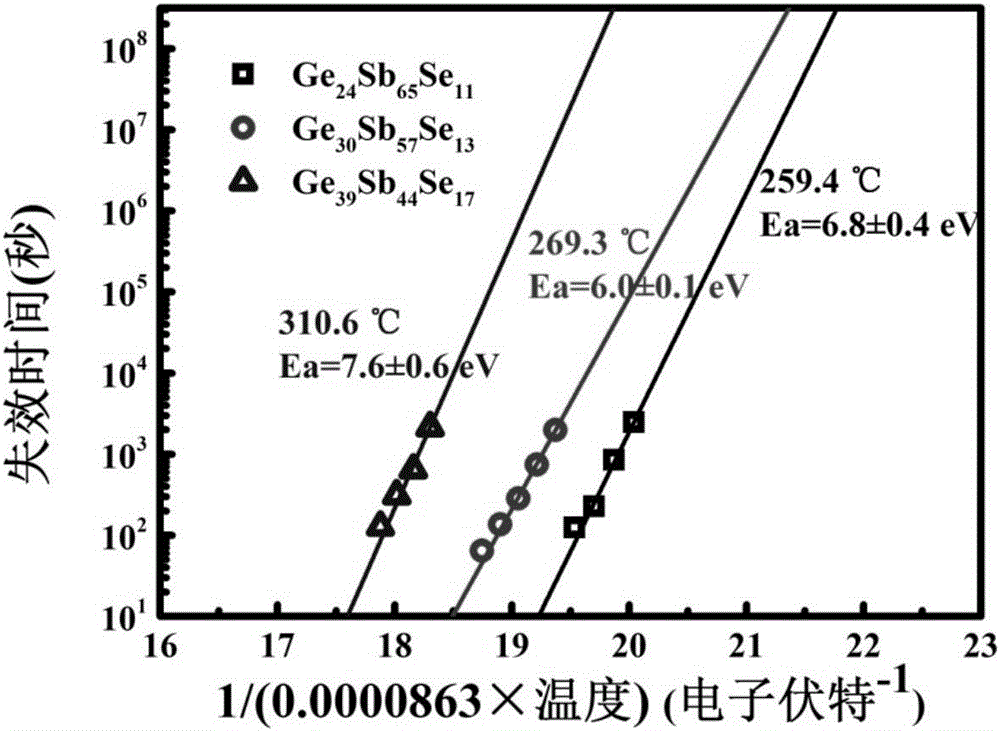

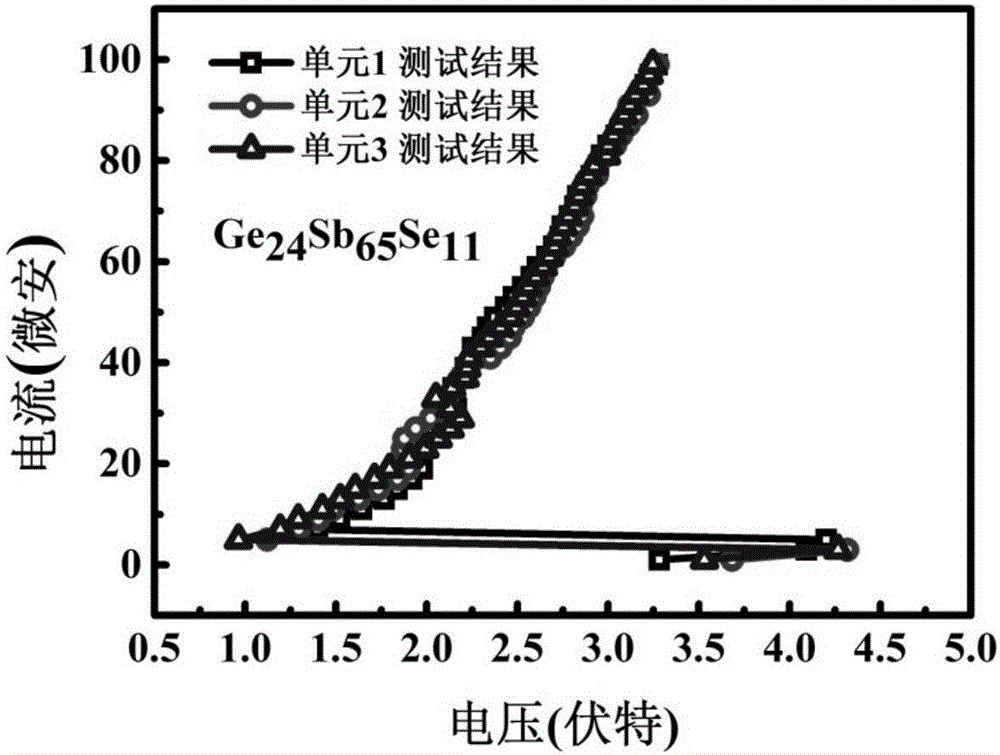

Ge-Sb-Se phase-change material, phase-change memory unit, and preparation method for Ge-Sb-Se phase-change material

InactiveCN106299113AFacilitates precise control of ingredientsPrecise control of ingredientsElectrical apparatusElectrical resistance and conductancePhase-change memory

The invention provides a Ge-Sb-Se phase-change material, a phase-change memory unit, and a preparation method for the Ge-Sb-Se phase-change material. The Ge-Sb-Se phase-change material is a phase-change material which comprises three types of elements: Ge, Sb, and Se. The chemical formula of the Ge-Sb-Se phase-change material is GexSbySez, wherein 20<=x<=50, 30<=y<=70, 5<=z<=25, and x+y+z=100. A memory material with different crystallization temperatures, different resistivity and different crystallization activation energy can be obtained through the adjustment of three types of elements of the Ge-Sb-Se phase-change material. Moreover, the phase-change materials in the system are big in difference before and after a phase change, are stronger in adjustability, and provide specific performance according to the actual needs. Compared with conventional Ge2Sb2Te5, the Ge-Sb-Se phase-change material provided by the invention is better in thermal stability, and is stronger in data holding capability, and is higher in crystallization speed. The preparation method for the Ge-Sb-Se phase-change material is simple in technology, and facilitates the precise control of material components.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

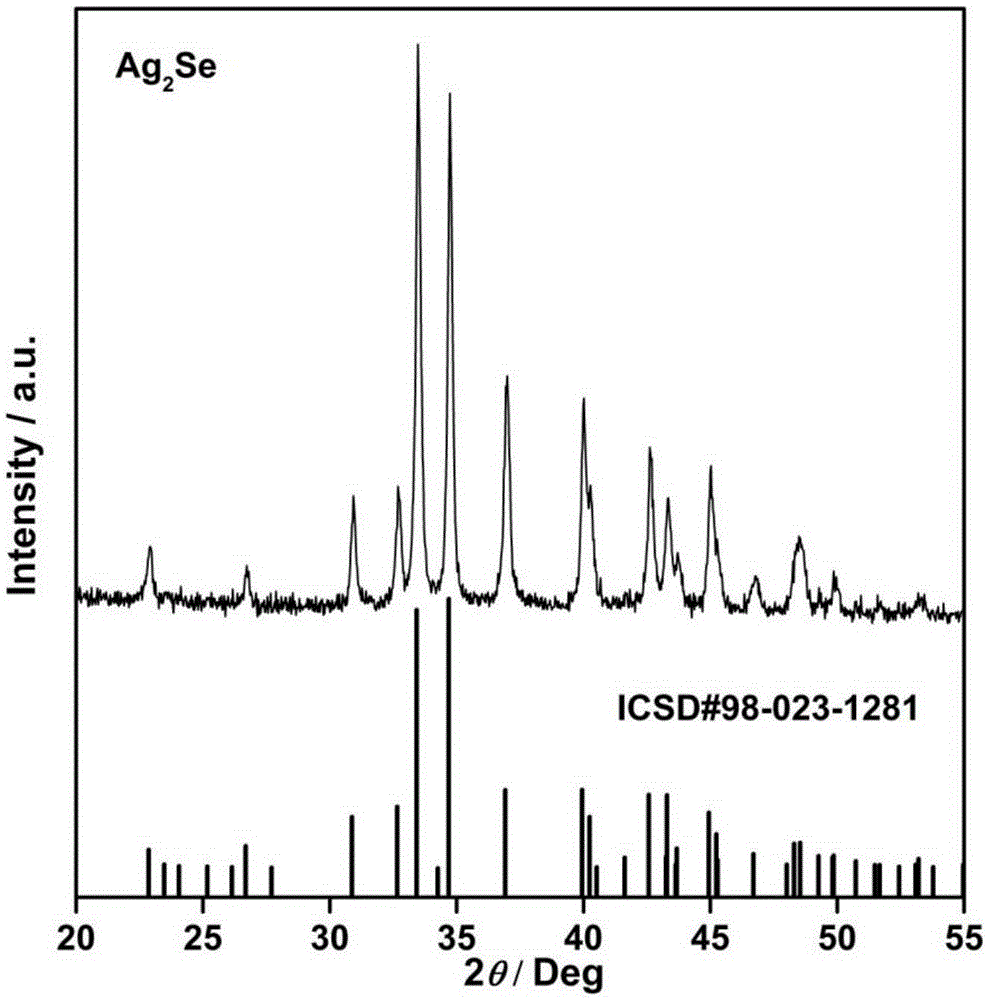

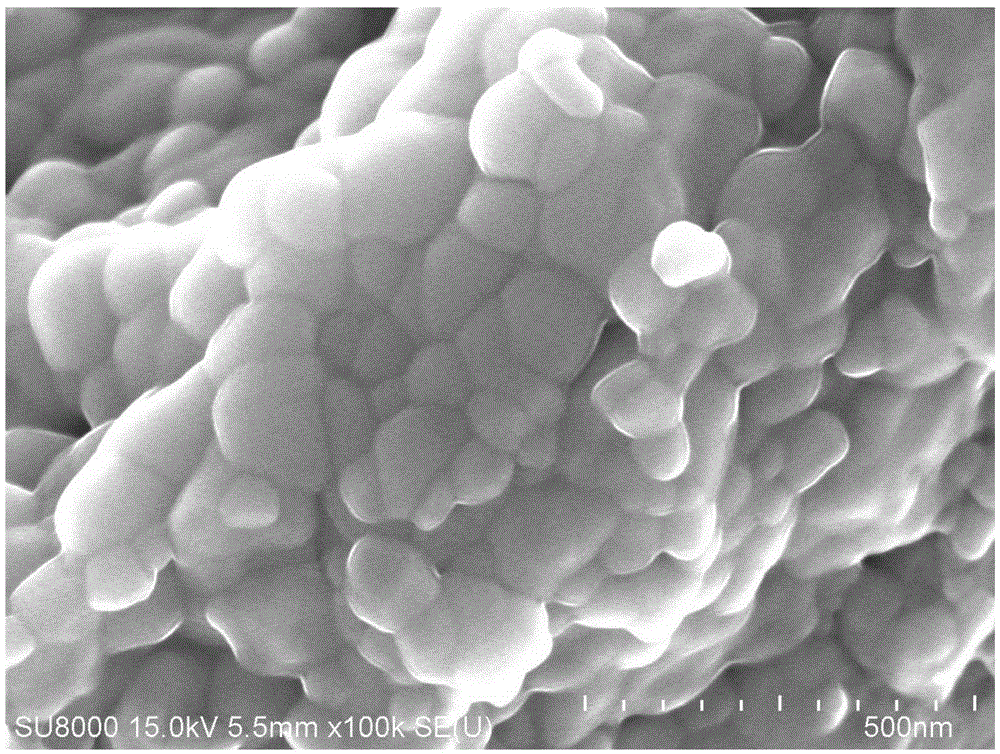

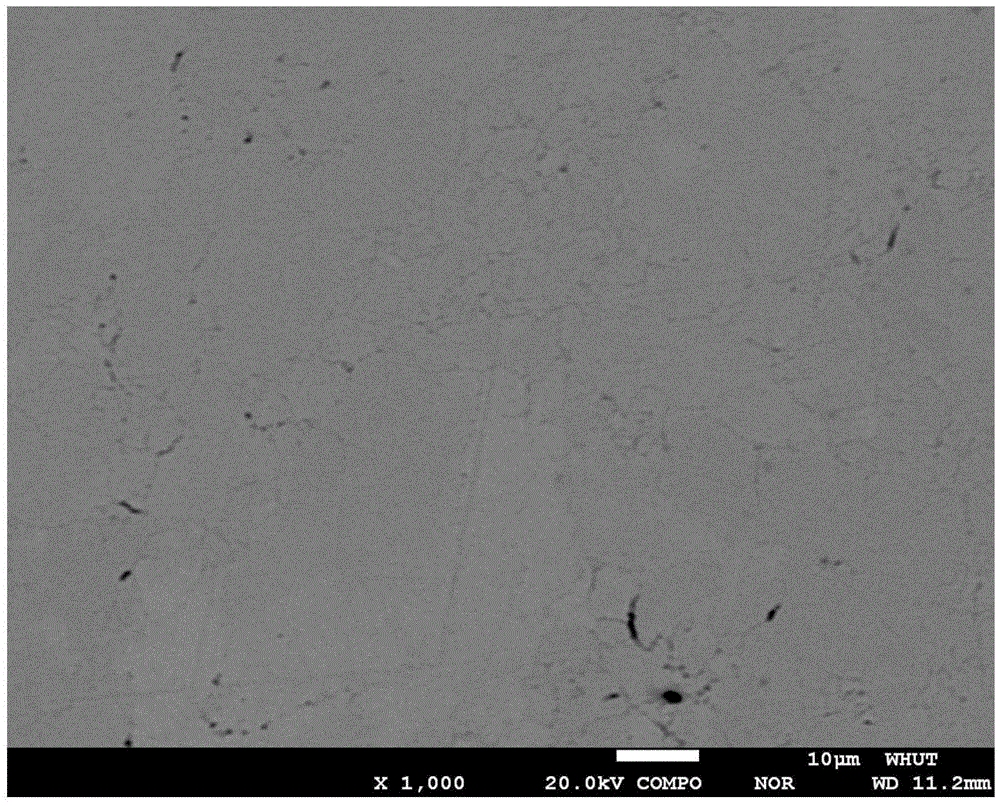

Ultrafast synthetic method of Ag2X block thermoelectric material

ActiveCN105420529ASimple preparation processSuitable for large-scale productionThermoelectric device junction materialsPolymer scienceMixed materials

The invention discloses an ultrafast synthetic method of a Ag2X block thermoelectric material. The ultrafast synthetic method is characterized in that Ag and an X elementary substance are taken as raw materials, high pressure is applied at the normal temperature after the raw materials are mixed uniformly, the mixed materials react and are densified by one step, and the Ag2X block thermoelectric material is prepared, wherein X is Se or Te. The densities of Ag2Se and Ag2Te blocks prepared by the ultrafast synthetic method are above 97%; the relevant preparation time is short, and a technology is simple; in addition, the problem of element volatilization in high-temperature synthetic processes of selenide and telluride is solved; accurate control on components and a microstructure is realized; the thermoelectric properties of obtained products are superior to those of products prepared by the traditional preparation method; ZTmax of obtained Ag2Se is equal to 0.65@107 DEG; ZTmax of obtained Ag2Te is equal to 0.7@127 DEG; and the ultrafast synthetic method lays a good foundation for large-scale preparation and large-scale application of Ag2Seand Ag2Te thermoelectric materials.

Owner:WUHAN UNIV OF TECH

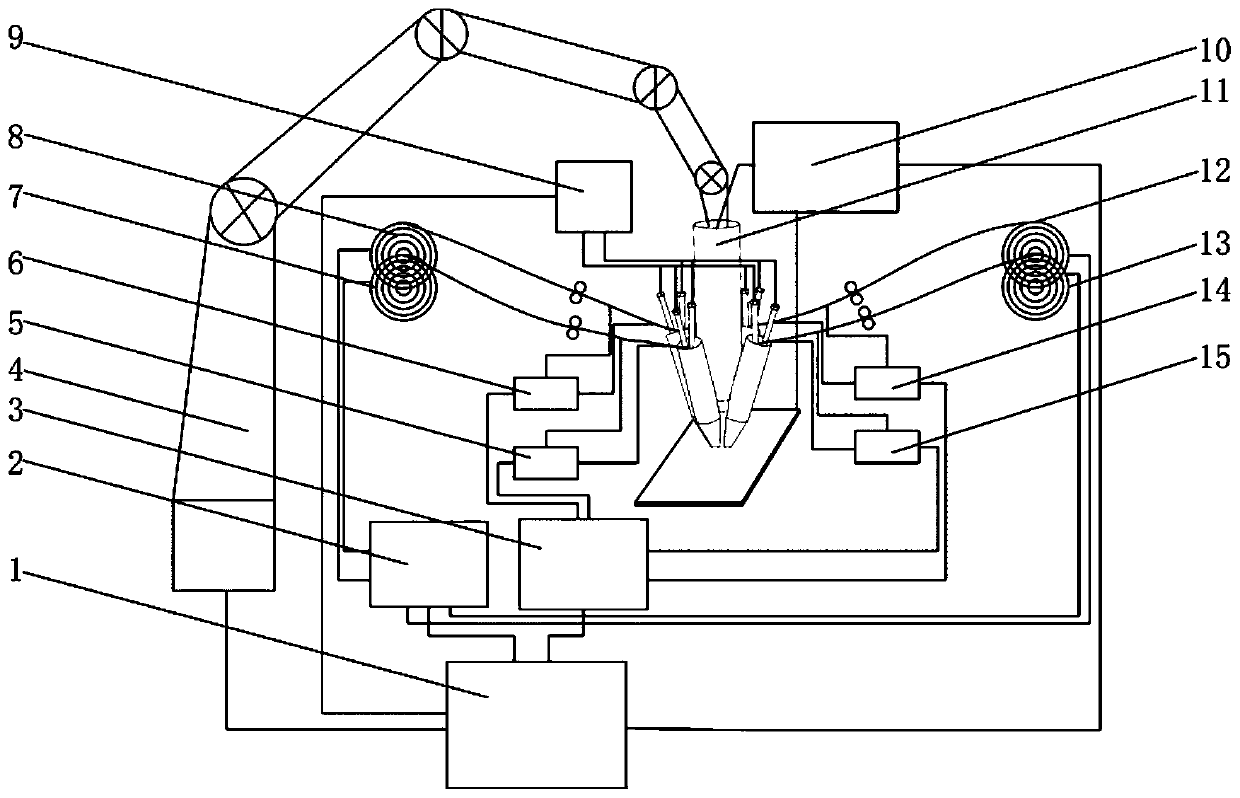

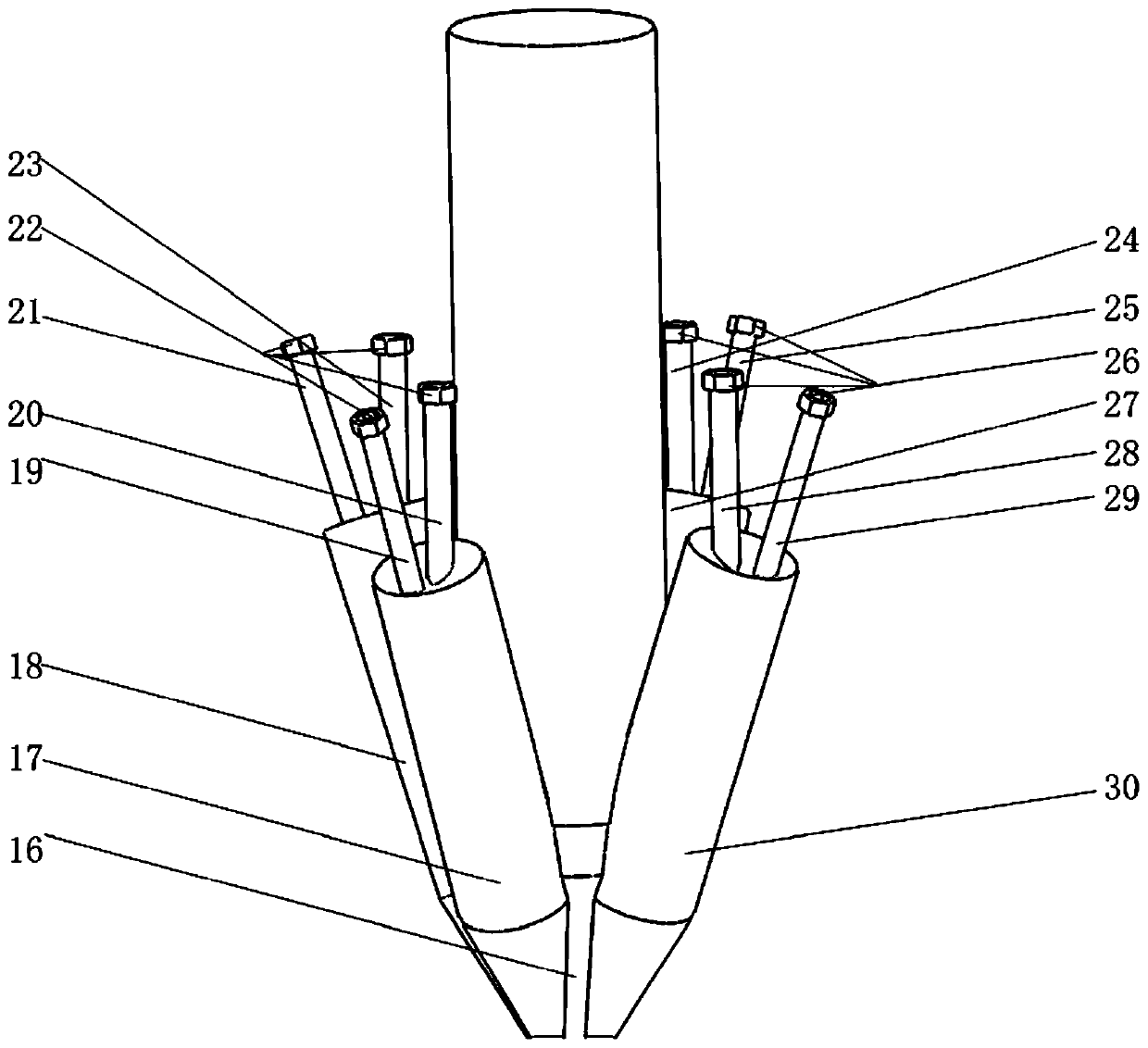

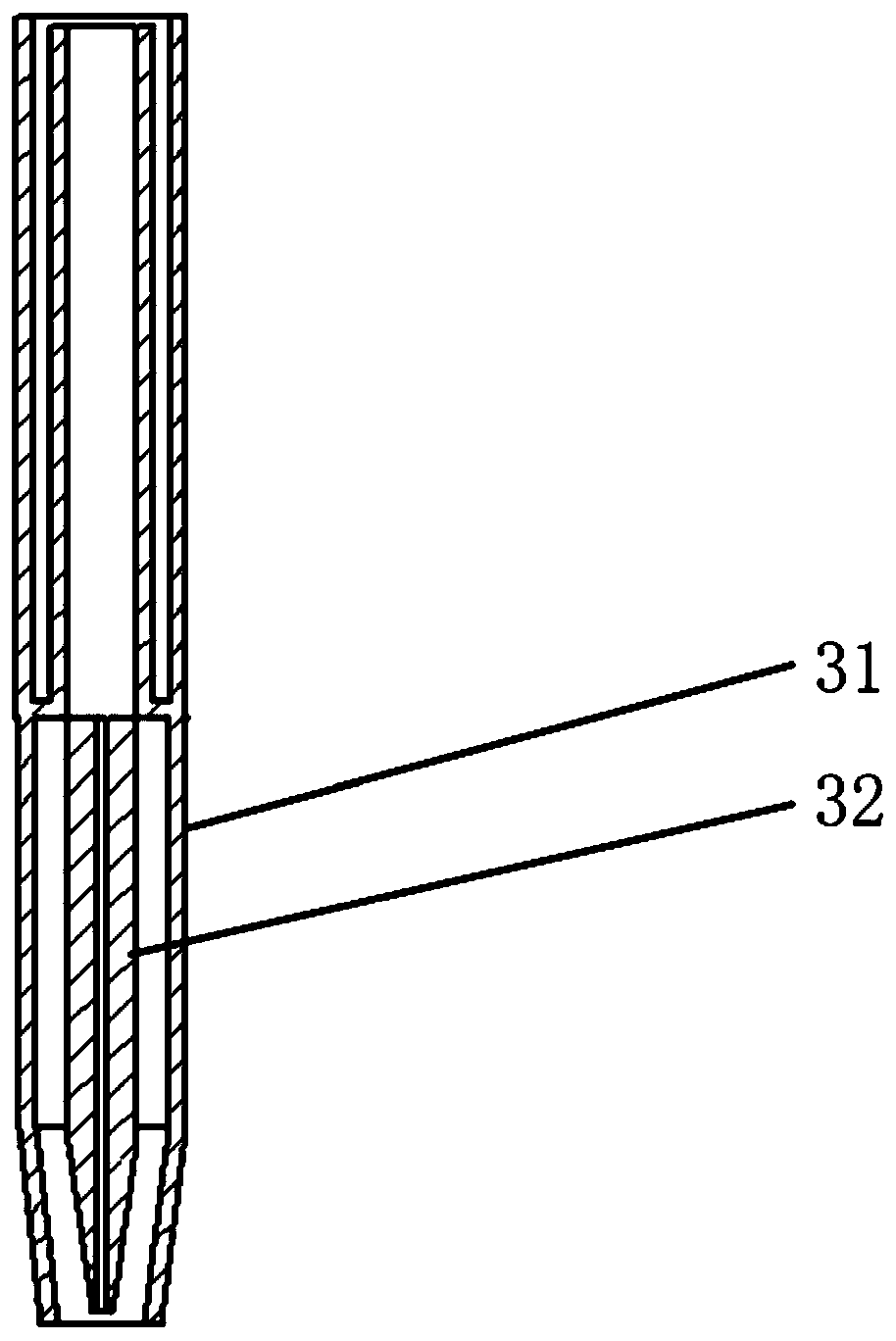

Nozzle-coaxial self-selection multi-hot wire plasma arc metal composite additive method and device

InactiveCN110587075AEfficient preparationLess interferenceAdditive manufacturing apparatusWelding accessoriesWelding power supplySpray nozzle

The invention discloses a nozzle-coaxial self-selection multi-hot wire plasma arc metal composite additive method and device. The additive device comprises a nozzle-coaxial self-selection multi-hot wire welding gun, a welding power supply, a wire feeding mechanism, a hot wire power supply, a water circulation coordination control device, a hot wire power supply coordination control device, a wirecoordination control device and a robot. When the additive device carries out plasma robot arc additive manufacturing, multi-component intermetallic compounds can be directly produced when wires withdifferent materials are adopted, the components of the intermetallic compounds can be adjusted according to the proportion, and an intermetallic compound structural part can be directly produced through arc additive manufacturing; and when wires with the same material are adopted for additive manufacturing, compared with a mode that a single-cold-wire plasma arc is adopted for additive manufacturing according to the tradition, the deposition efficiency can be improved by 5.0-6.0 times, the additive method is a high-efficiency, multi-component and low-cost composite metal material additive mode.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com