Technique for smelting ultra-pure TiNi shape memory alloy

A technology of memory alloy and alloy, which is applied in the field of material metallurgy, can solve the problems of being general, not fully considering the special process of Ni and Ti, and being unable to prevent Ti reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

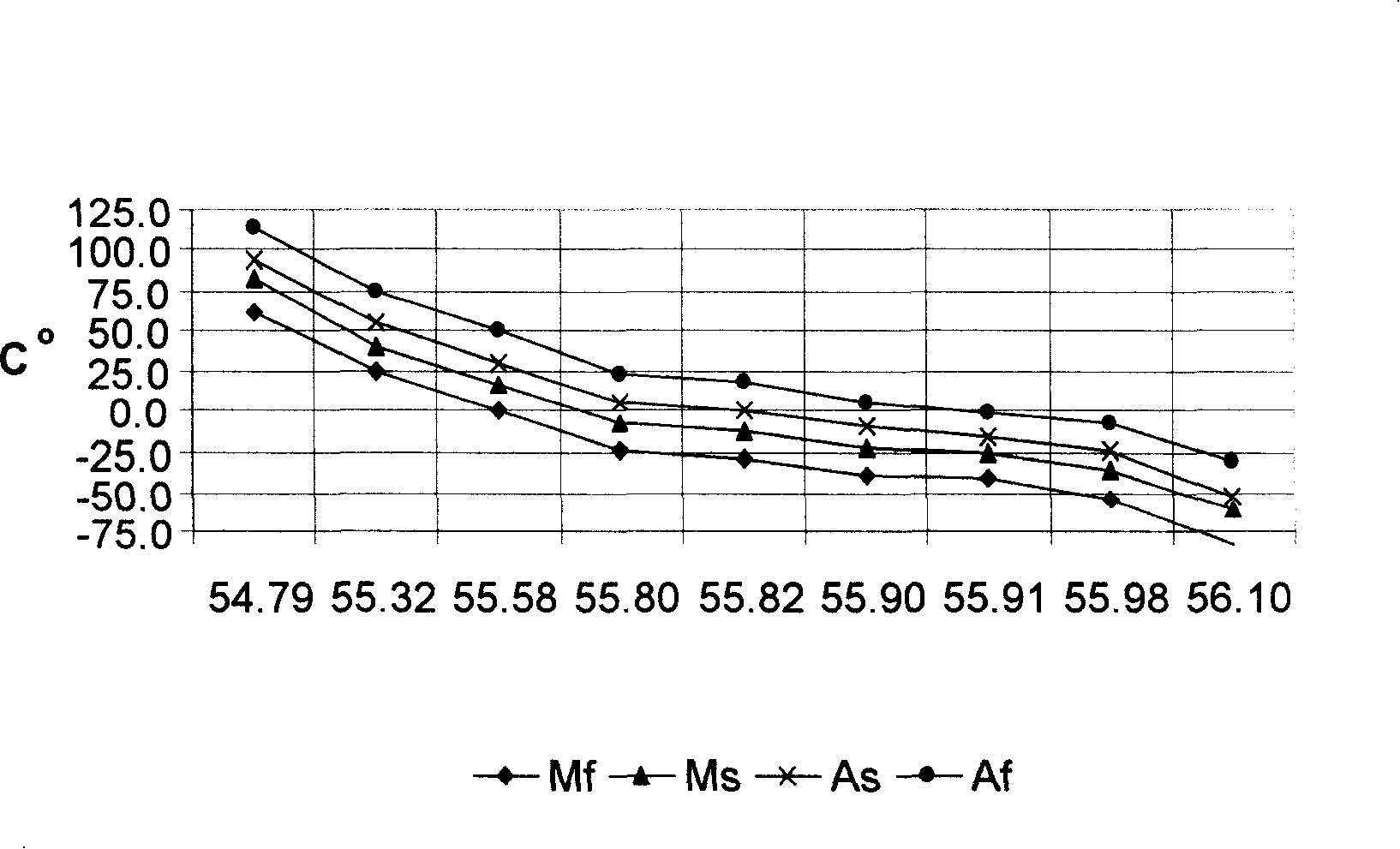

Image

Examples

Embodiment 1

[0046] TiNi shape memory alloy ingots are obtained by ultra-pure smelting of TiNi shape memory alloys. CaO crucibles are used to prepare TiNi shape memory alloy ingots. The specific process:

[0047] 1. Raw material charging, according to the designed composition ratio Ti49.15Ni50.85 atomic ratio to take raw materials, No. 0 Ti and No. 1 Ni, the order of charging is that Ni and 40% Ti are loaded into the crucible at the same time, and the remaining 60% Ti Put it in the hopper for later use.

[0048] 2. Vacuumize to 0.13Pa, flush with argon to 0.08MPa.

[0049] 3. The alloy is melted, and the power is sent to 30kw-20kw-0kw, and the heating is reduced to keep the reaction heat balance of the system and stir evenly.

[0050] 4. Vacuumize, feed the spare 60% Ti in the hopper into the crucible, and flush with argon.

[0051] 5. Power transmission heating, increase the heating power from 0-20KW, keep the reaction heat balance of the system, and stir.

[0052] 6. Alloy refining, r...

Embodiment 2

[0055] TiNiCr shape memory alloy ingots are obtained by ultra-pure smelting of TiNi shape memory alloys. CaO crucibles are used to prepare TiNi shape memory alloy ingots. The specific process:

[0056] 1. Raw material charging, take the raw material according to the designed composition ratio (%) Ti49.15Ni50.85Cr0.3 atomic ratio (the meaning of Cr0.3 is based on the ratio of Ti+Ni=100%at is 0.3%at), 0 No. Ti and No. 1 Ni, the order of charging is that Ni and 40% Ti0.3% Cr are loaded into the crucible at the same time, and the remaining 60% Ti is put into the hopper for standby.

[0057] 2. Vacuumize to 0.13Pa, flush with argon to 0.08MPa.

[0058] 3. The alloy is melted and sent to 30kw1-20kw-0kw, and the heating is reduced to keep the reaction heat balance of the system and stir evenly.

[0059] 4. Vacuumize, feed the spare 60% Ti in the hopper into the crucible, and flush with argon.

[0060] 5. Power transmission heating, 0-20KW increments, keep the system reaction heat b...

Embodiment 3

[0064] TiNiV shape memory alloy ingots are obtained by ultra-pure smelting of TiNi shape memory alloys. CaO crucibles are used to prepare TiNi shape memory alloy ingots. The specific process:

[0065] 1. Raw material charging, take the raw material according to the designed composition ratio (%) Ti49.15Ni50.85V0.5 atomic ratio (the meaning of V0.5 is based on the ratio of Ti+Ni=100%at is 0.5%at), 0 No. Ti and No. 1 Ni, the charging sequence is that Ni and 40% Ti are loaded into the crucible at the same time, and the remaining 60% Ti is put into the hopper for standby.

[0066] 2. Vacuumize to 0.13Pa, flush with argon to 0.08MPa.

[0067] 3. Alloy melting and power transmission 30kw-20kw-0kw, decreasing heating, stirring evenly.

[0068] 4. Vacuumize, feed the spare 60% Ti in the hopper into the crucible, and flush with argon.

[0069] 5. Electric heating, 0-20KW increments, stirring.

[0070] 6. Alloy refining, refining at 1300-1400 degrees for 5 minutes, solidifying the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com