Spot welding method for high-strength steel sheet excellent in joint strength

一种高强度钢板、接头强度的技术,应用在焊接/焊接/切割物品、焊接电源、焊接电源等方向,能够解决助长压陷、接头强度降低、难以确保熔核直径等问题,达到防止喷溅、确保熔核直径的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

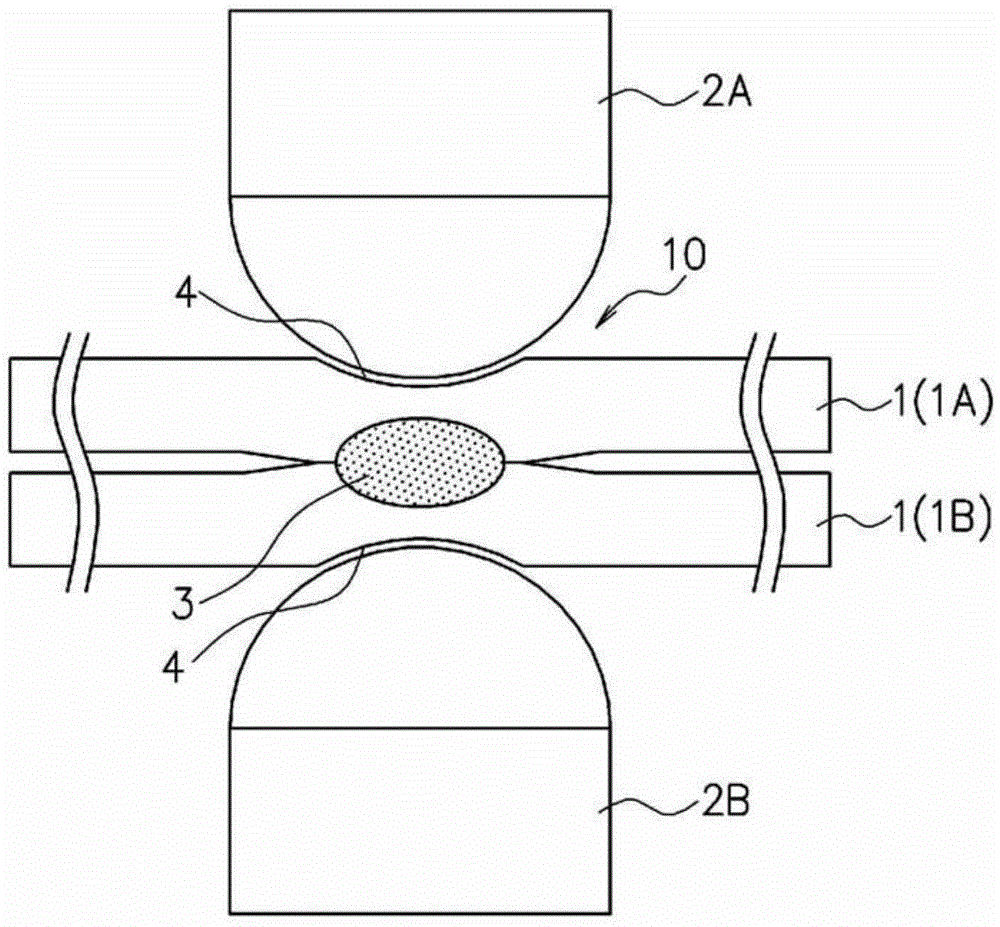

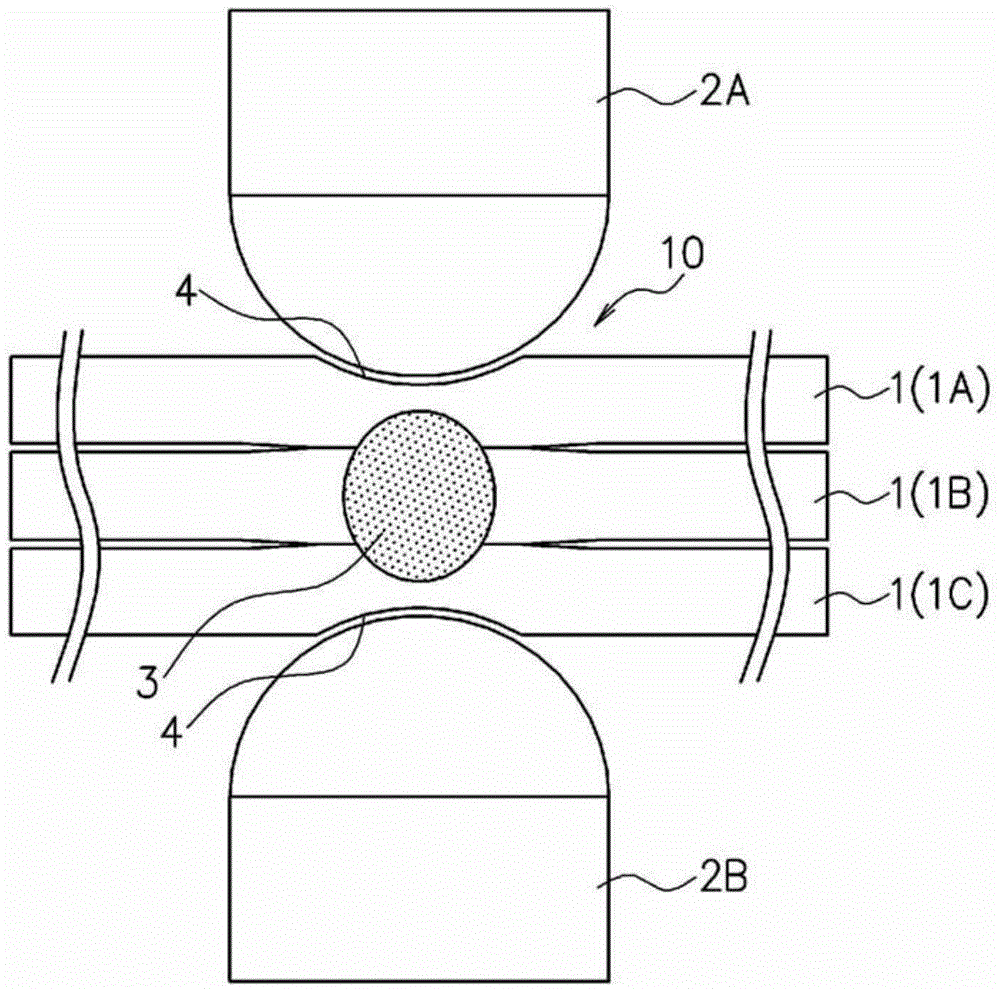

[0086] Hereinafter, a first embodiment of the spot welding method of a high-strength steel sheet according to the present invention will be described. The spot welding method of the high-strength steel plate of the first embodiment is the following method: figure 1 , figure 2 In the case of the spot welded joint 10 as shown, two steel plates 1A, 1B or three steel plates 1A to 1C are welded by resistance spot welding.

[0087]Specifically, as figure 1 As shown, when the two steel plates 1A, 1B are spot welded, the tensile strengths of the two steel plates 1A, 1B are both 780-1850 MPa. Furthermore, the thickness ratio={total thickness of the steel sheets} / {thickness of the steel sheets on the thinner side (thickness per sheet when the thickness is the same)} is in the range of 2-5.

[0088] Such as figure 2 As shown, when spot welding the three steel plates 1A-1C, the tensile strengths of the three steel plates 1A-1C are all 780-1850MPa, or the tensile strengths of the two...

no. 2 approach

[0137] Hereinafter, a second embodiment of the spot welding method of a high-strength steel sheet according to the present invention will be described. In addition, the configuration of the second embodiment will be described with reference to the same drawings as those of the above-mentioned first embodiment, and the same symbols will be assigned to the common configurations, and detailed description thereof will be omitted.

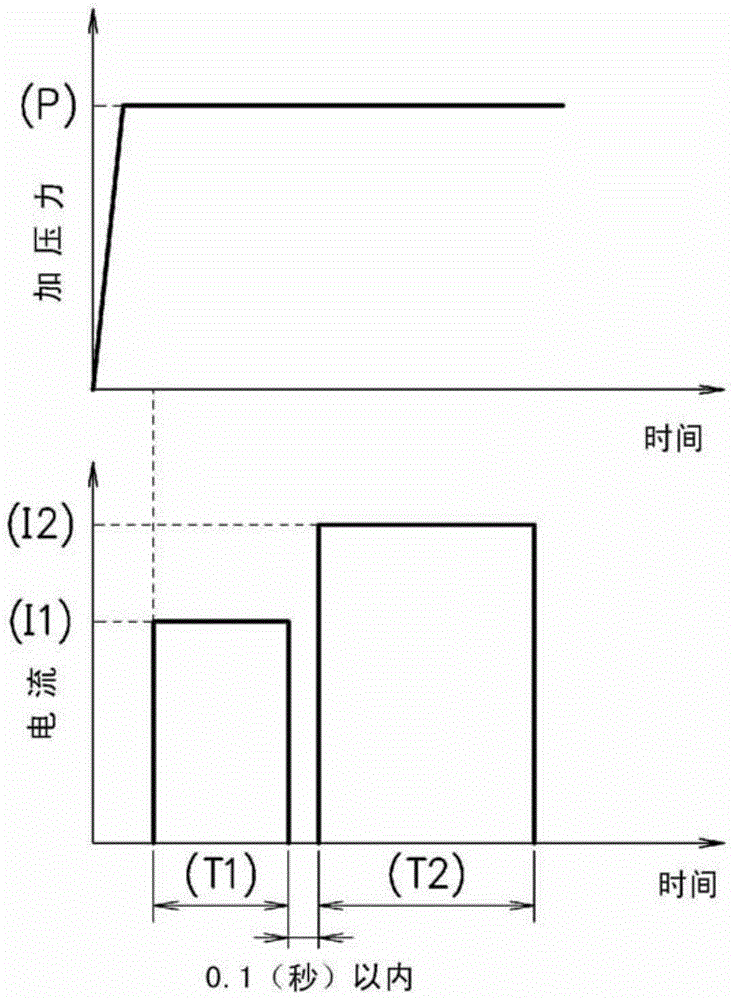

[0138] The spot welding method of the high-strength steel plate of the second embodiment is the same as the first embodiment, and is a method of welding two steel plates 1A, 1B or three steel plates 1A to 1C by resistance spot welding. 1 When at least one of the gaps before spot welding (hereinafter simply referred to as the gap) is 0.5 (mm) or more, the pressing force of the electrodes 2A, 2B in the first energization step and the second The change in the applied pressure in the energization process is different.

[0139] In the second embodiment, spo...

no. 3 approach

[0153] Hereinafter, a third embodiment of the spot welding method of a high-strength steel sheet according to the present invention will be described. In addition, the configuration of the third embodiment will be described with reference to the same drawings as those of the above-mentioned first embodiment and second embodiment, and the same symbols will be assigned to the common configurations, and detailed description thereof will be omitted.

[0154] The spot welding method of the high-strength steel plate according to the third embodiment obtains the spot welded joint 10, after the second energization process as the main energization is completed, the third embodiment with the above-mentioned first embodiment or the second embodiment has the following conditions. The energization process is different in this point.

[0155]Specifically, in the method described in the above-mentioned first embodiment or second embodiment, after the second energization step as the main ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com