Patents

Literature

198results about "Welding electric supplies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

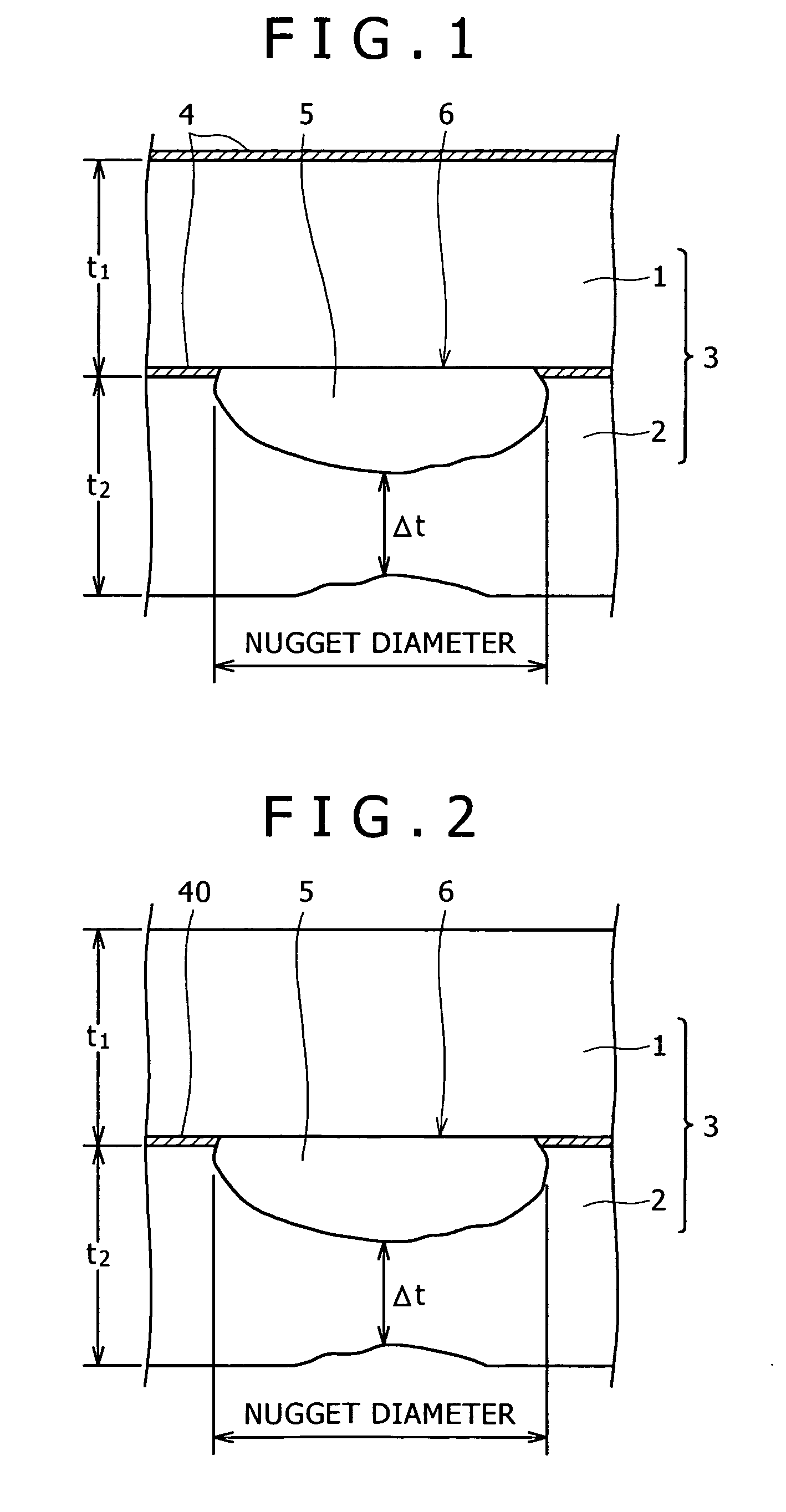

Method of resistance spot welding of high tensile strength steel sheet and welding joint manufactured by the method

ActiveUS20140305912A1Strength in tensionHigh tensile strengthWelding electric suppliesElectrical resistance and conductanceEngineering

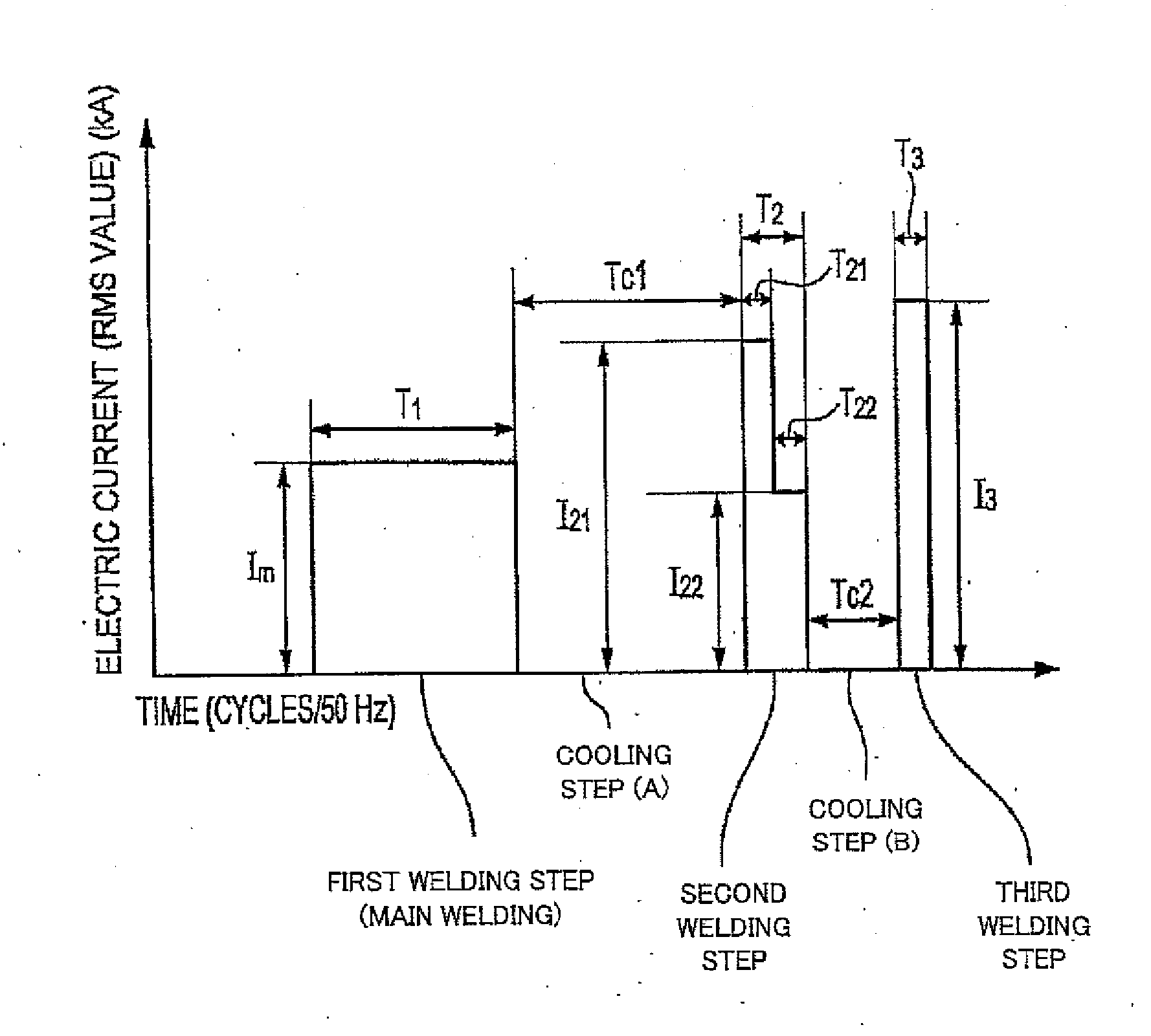

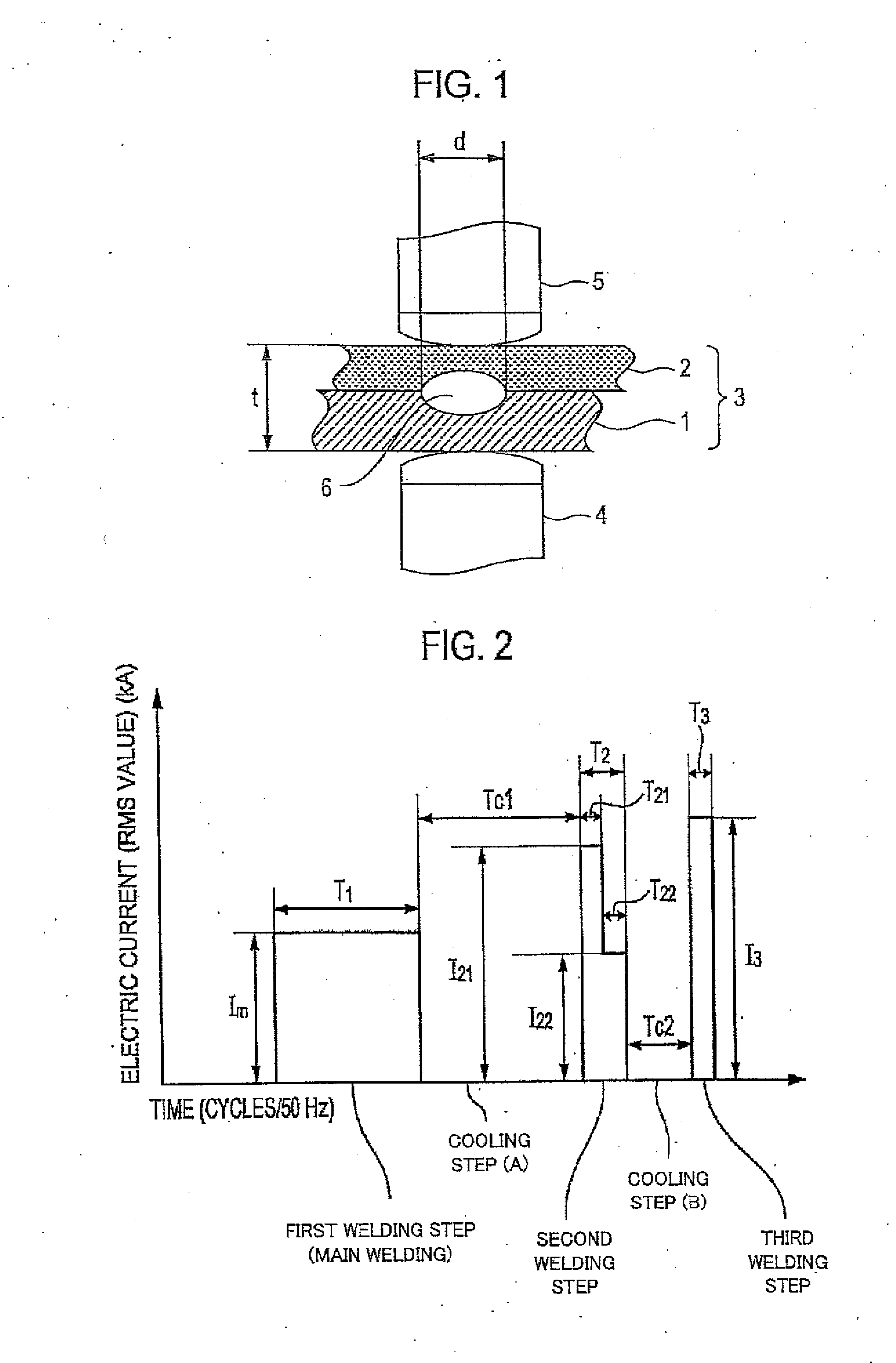

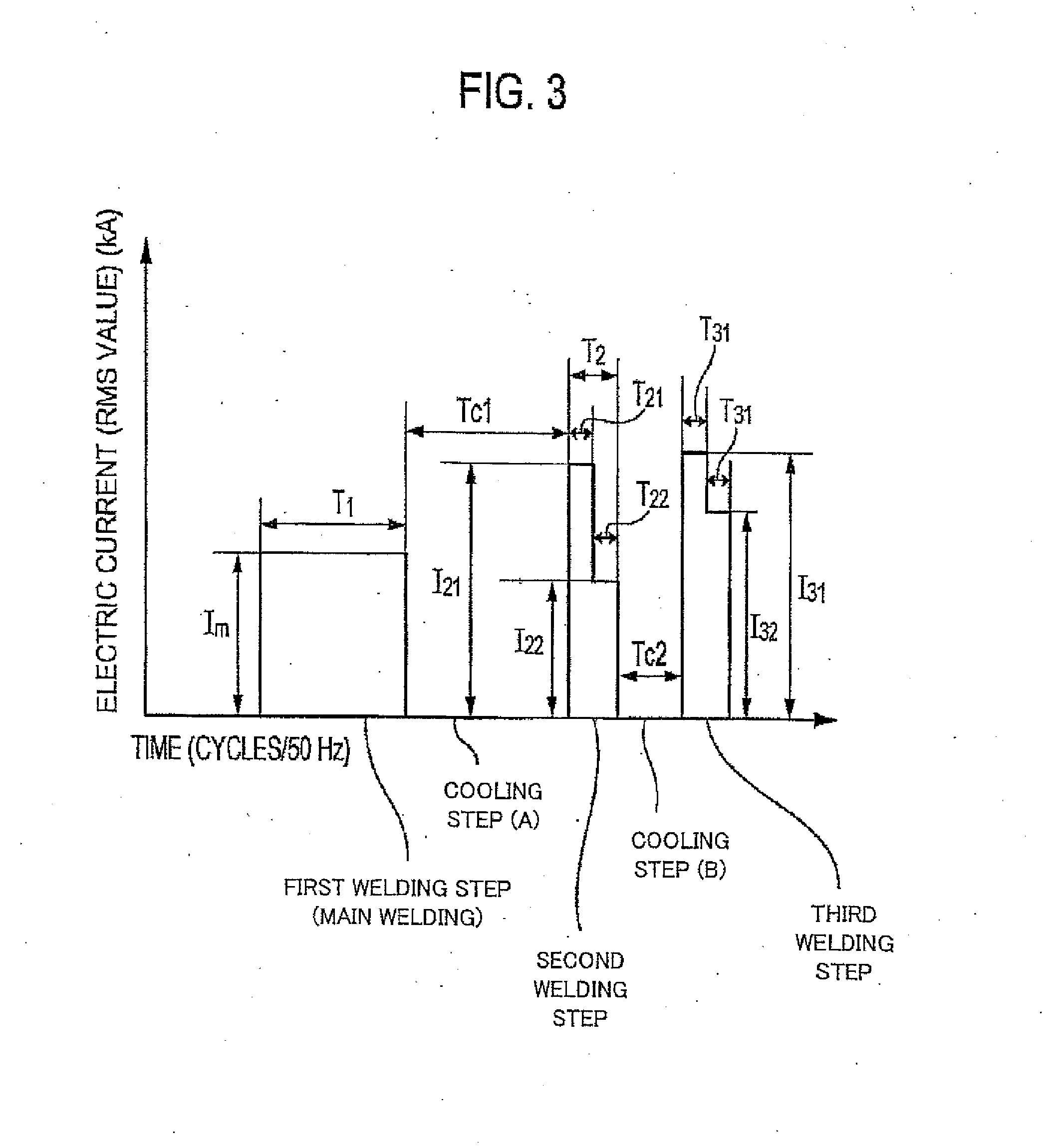

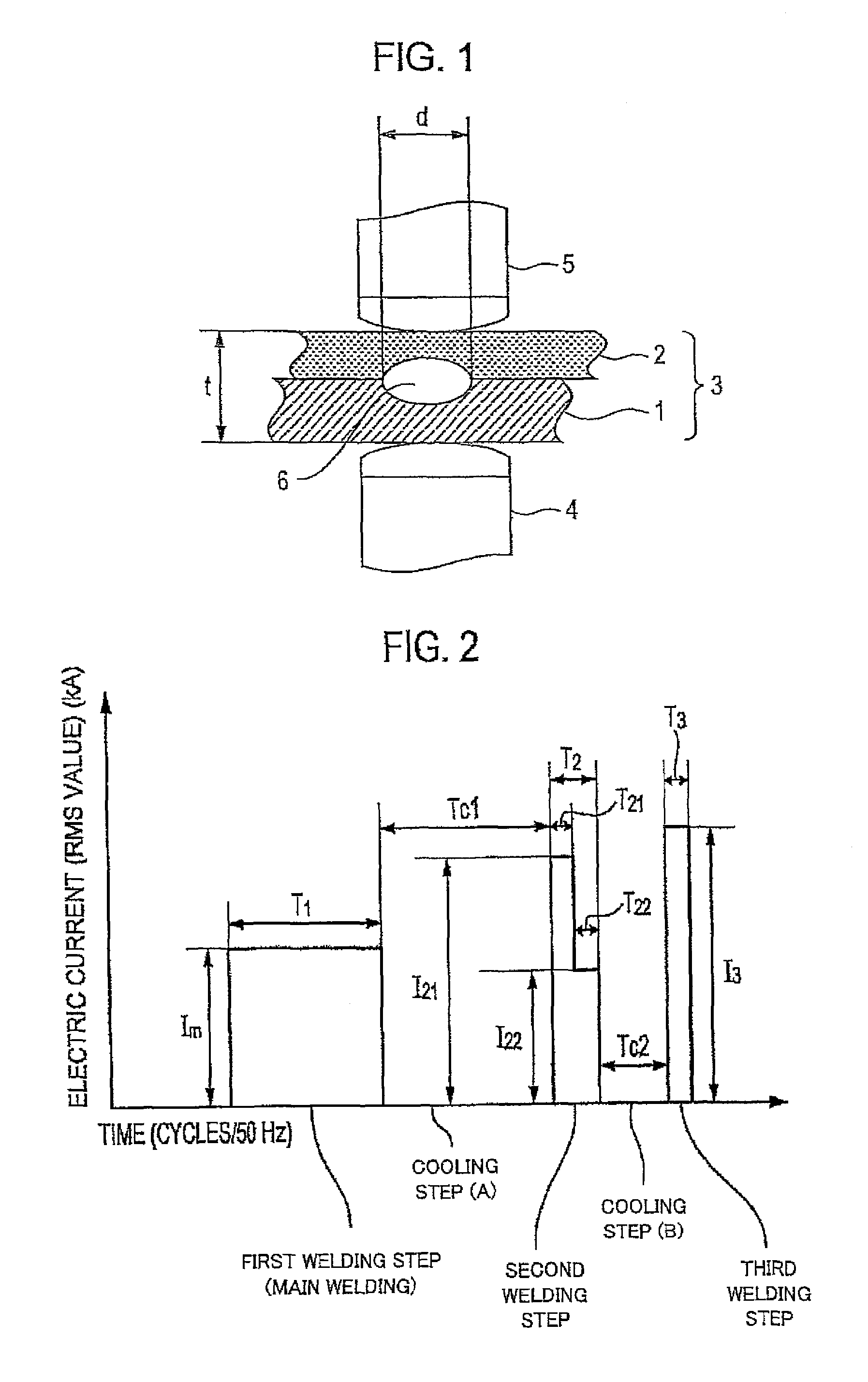

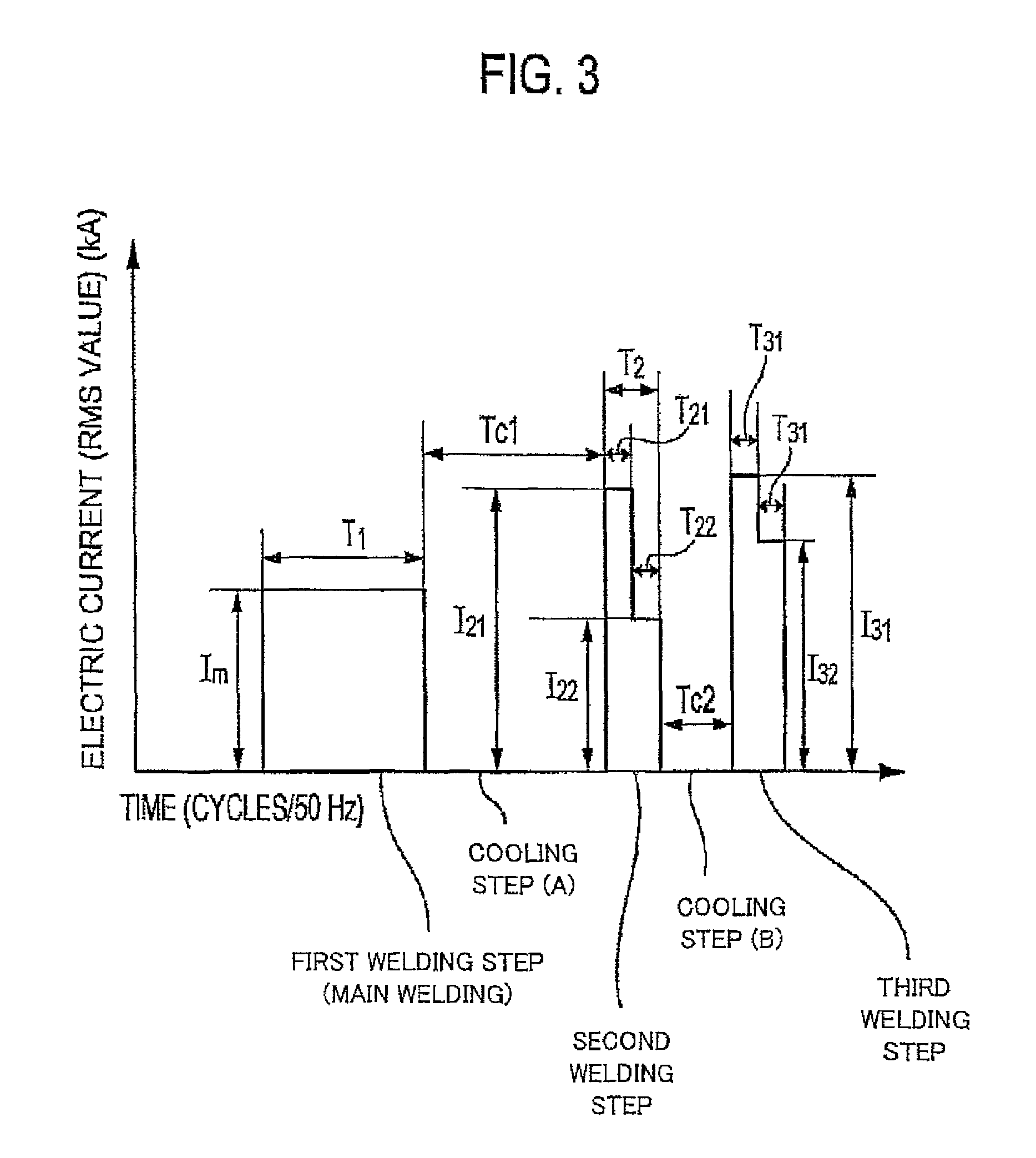

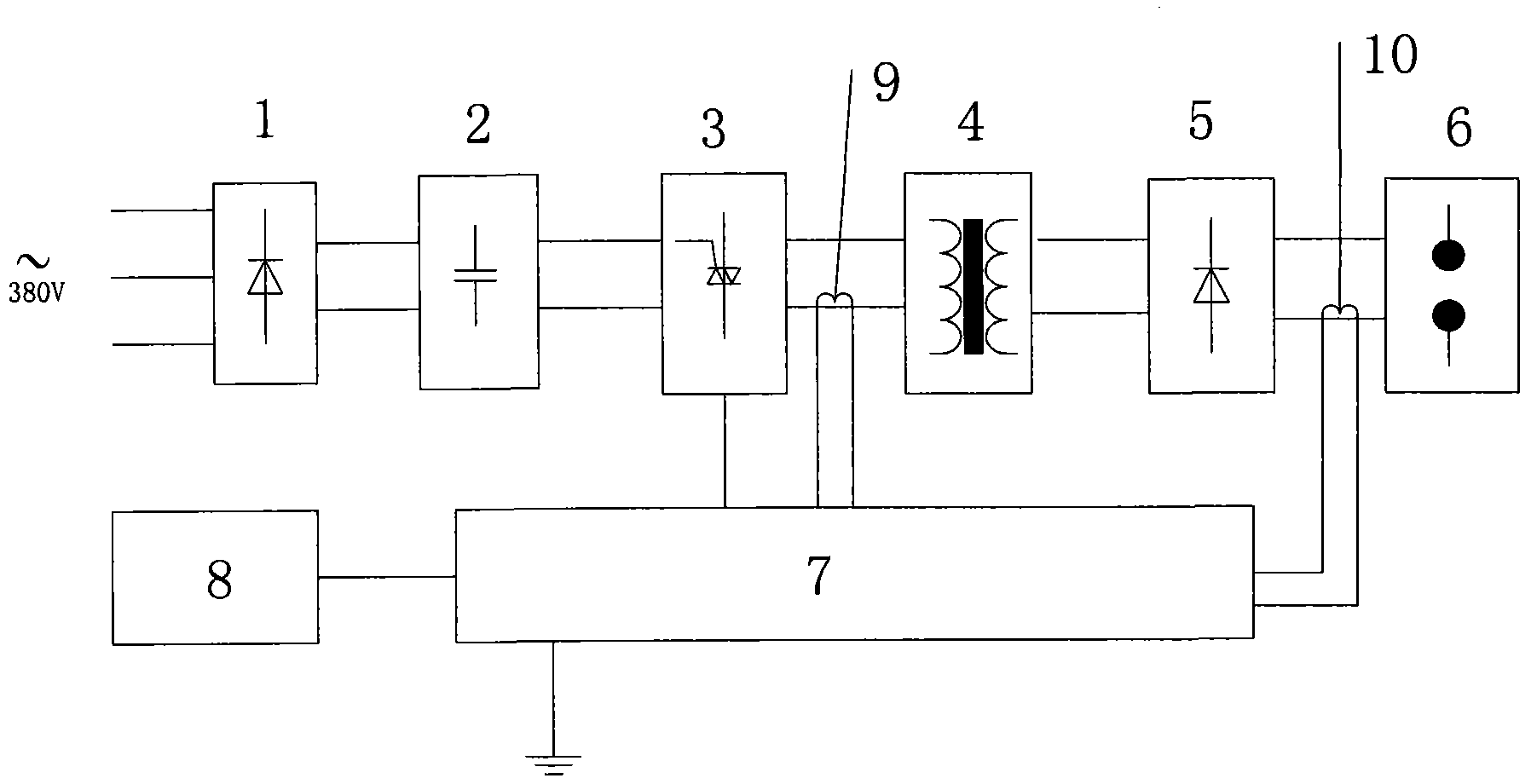

Provided is a method of resistance spot welding of welding a sheet set including a high strength steel sheet with which a high joint strength can be achieved even for a high Ceq material. A method of resistance spot welding a sheet set of two or more lapped steel sheets by weld the sheet set while clamping and pressing the sheet set between a pair of welding electrodes includes a first welding step of applying an weld current Im (kA) and forming a nugget having a nugget diameter d (mm) that satisfies the following inequality (1); a cooling step, subsequent to the foregoing first welding, of cooling the sheet set while continuing to press the sheet set; and a second welding step of performing two-step welding,3×√tm≦d≦6×√tm (1),where tm is the thickness (mm) of the thinnest one of the foregoing two or more steel sheets.

Owner:JFE STEEL CORP

Spot welding method for high-strength steel sheet excellent in joint strength

ActiveCN104661784AImprove reliabilityHigh strengthWelding electric suppliesWelding/soldering/cutting articlesPower flowSheet steel

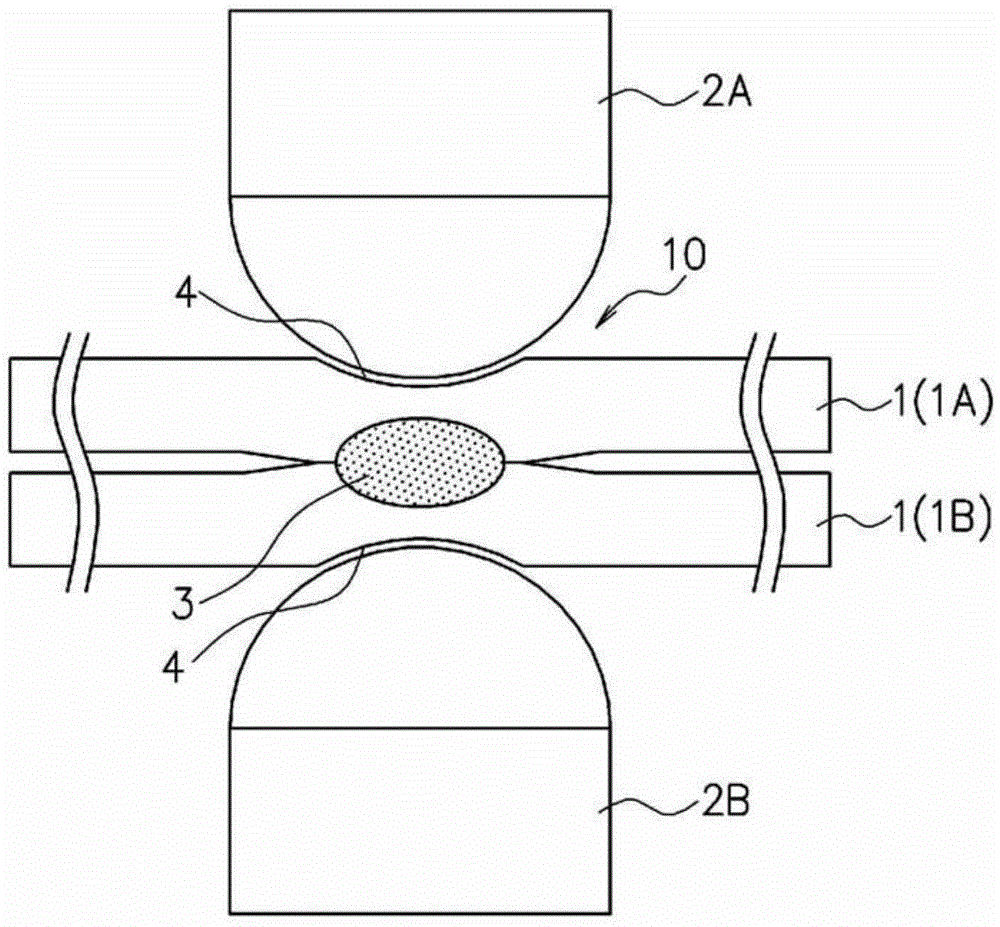

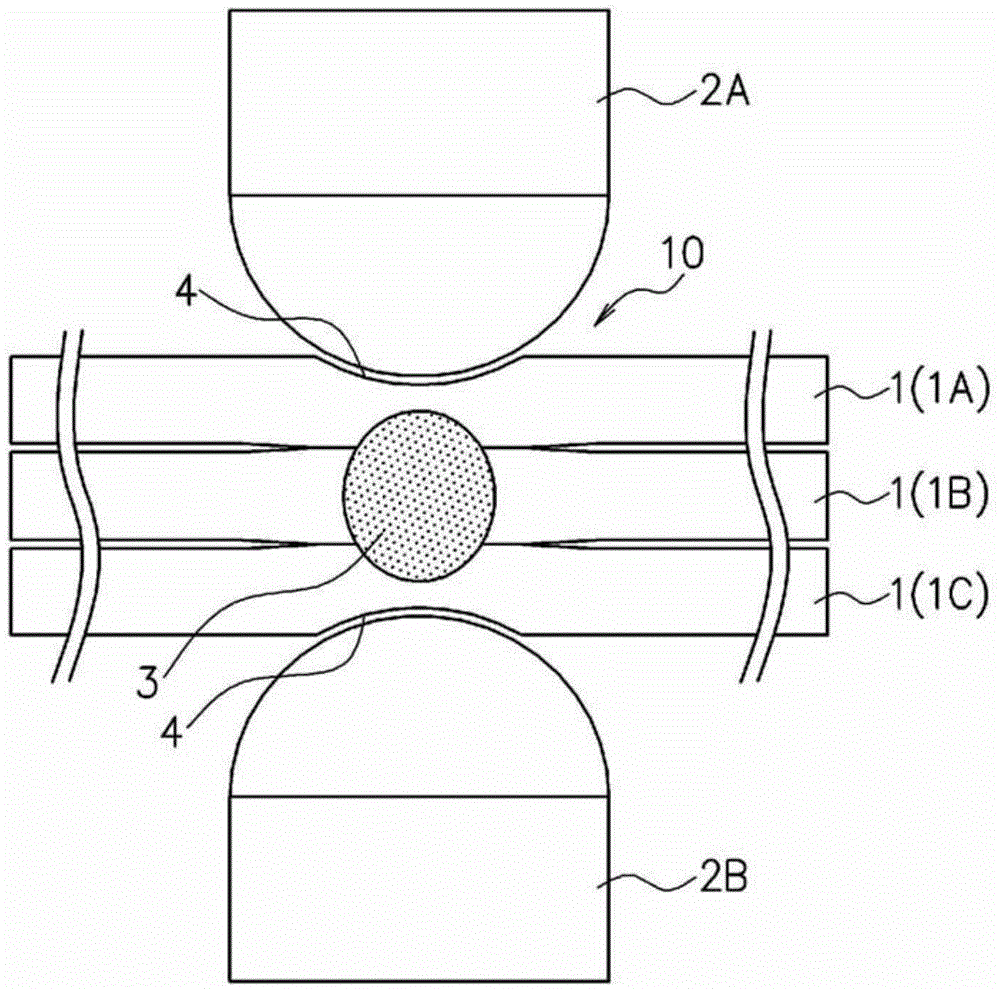

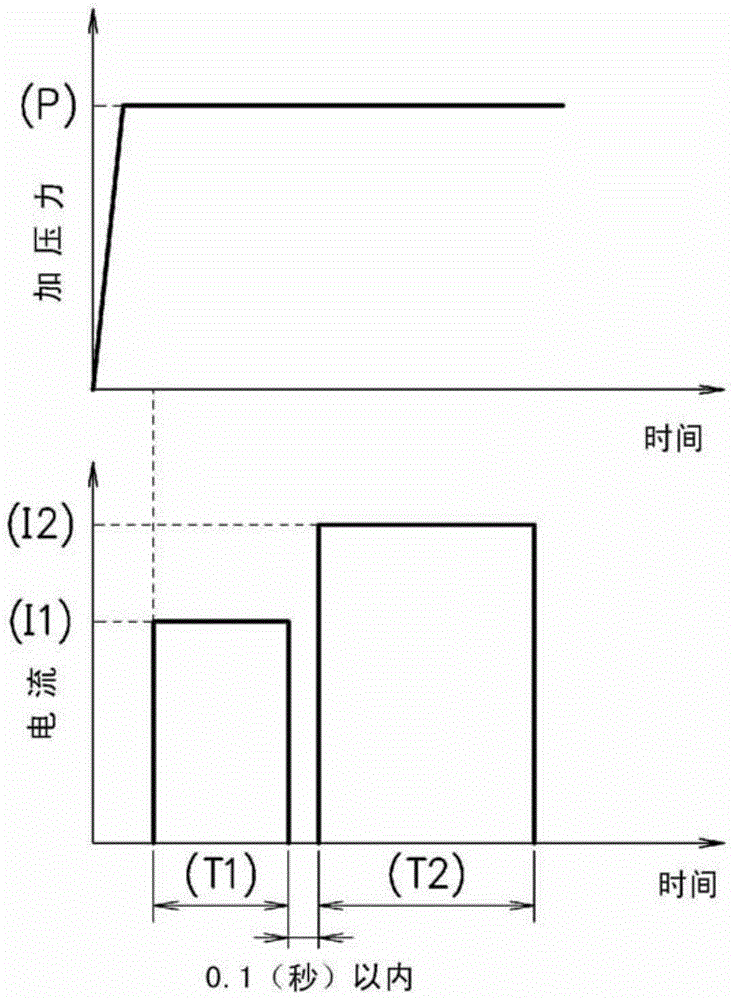

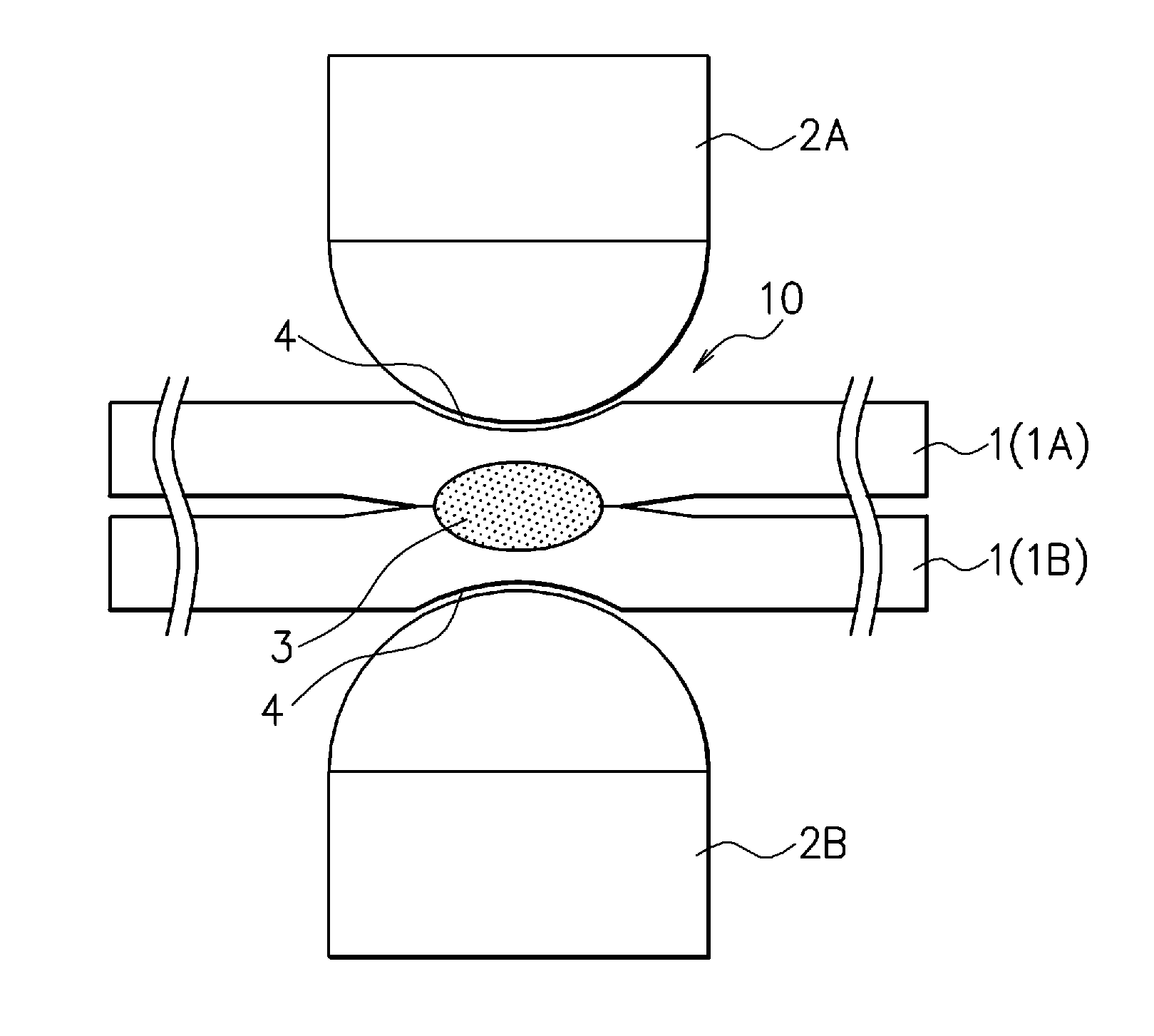

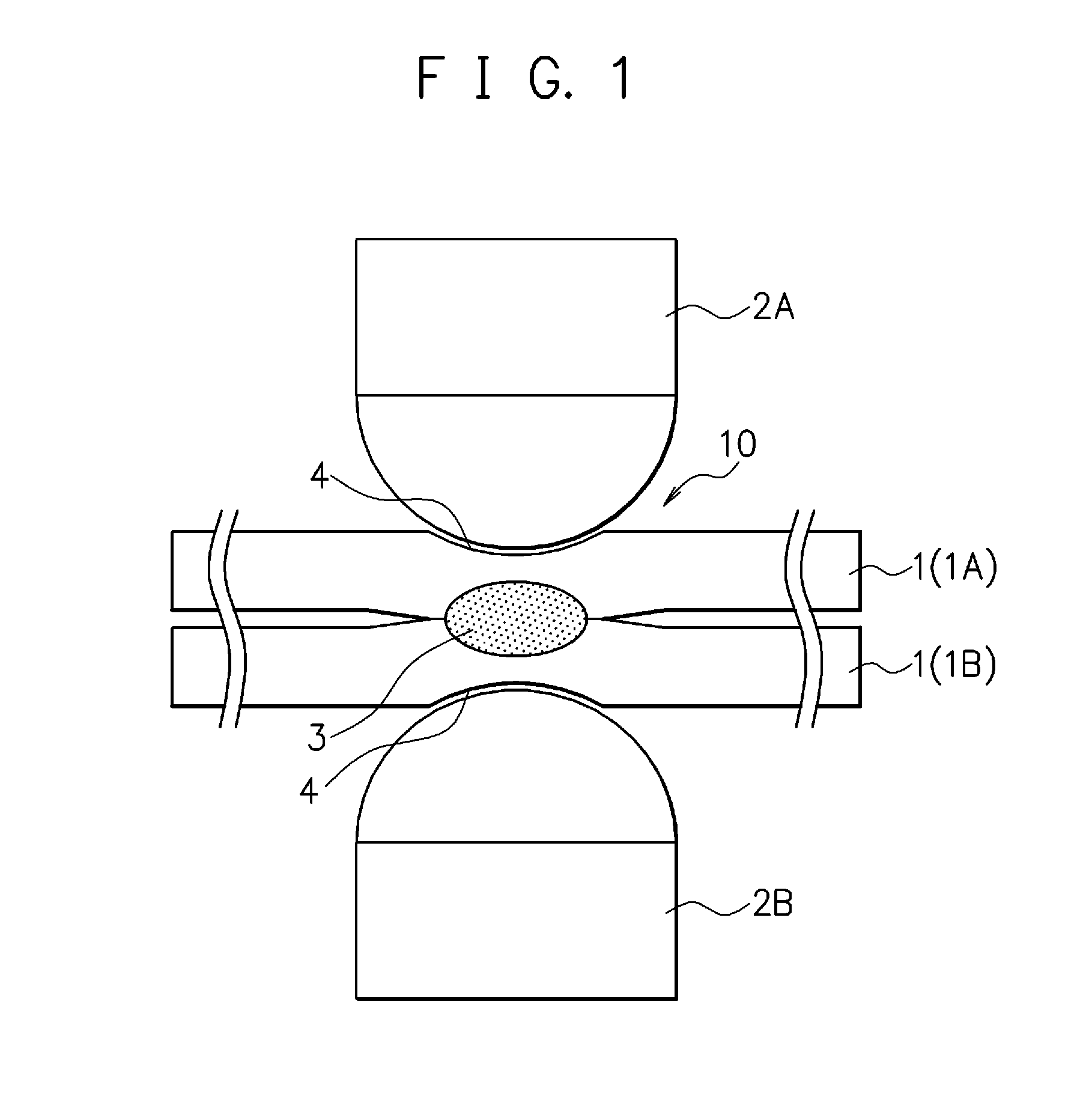

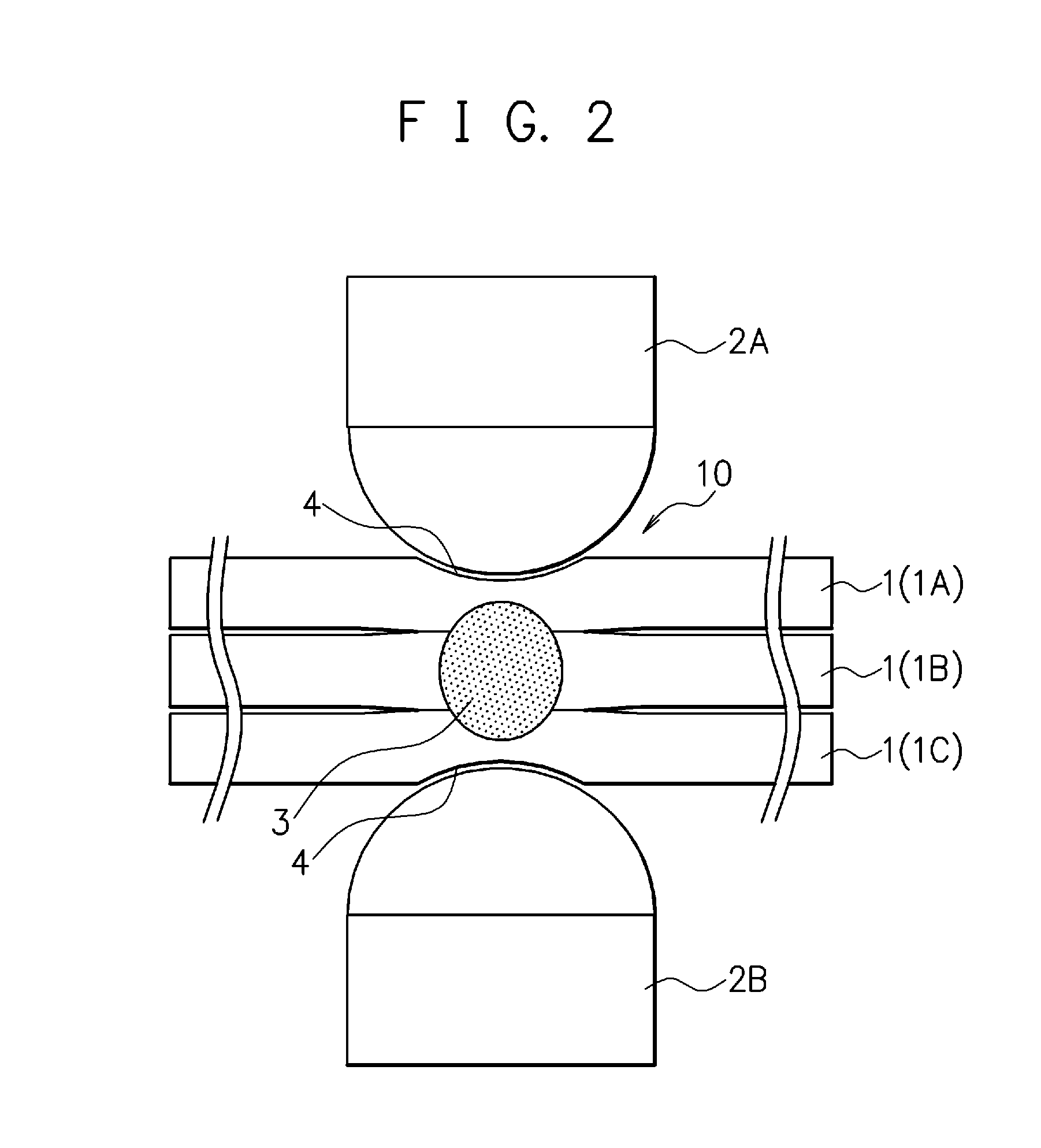

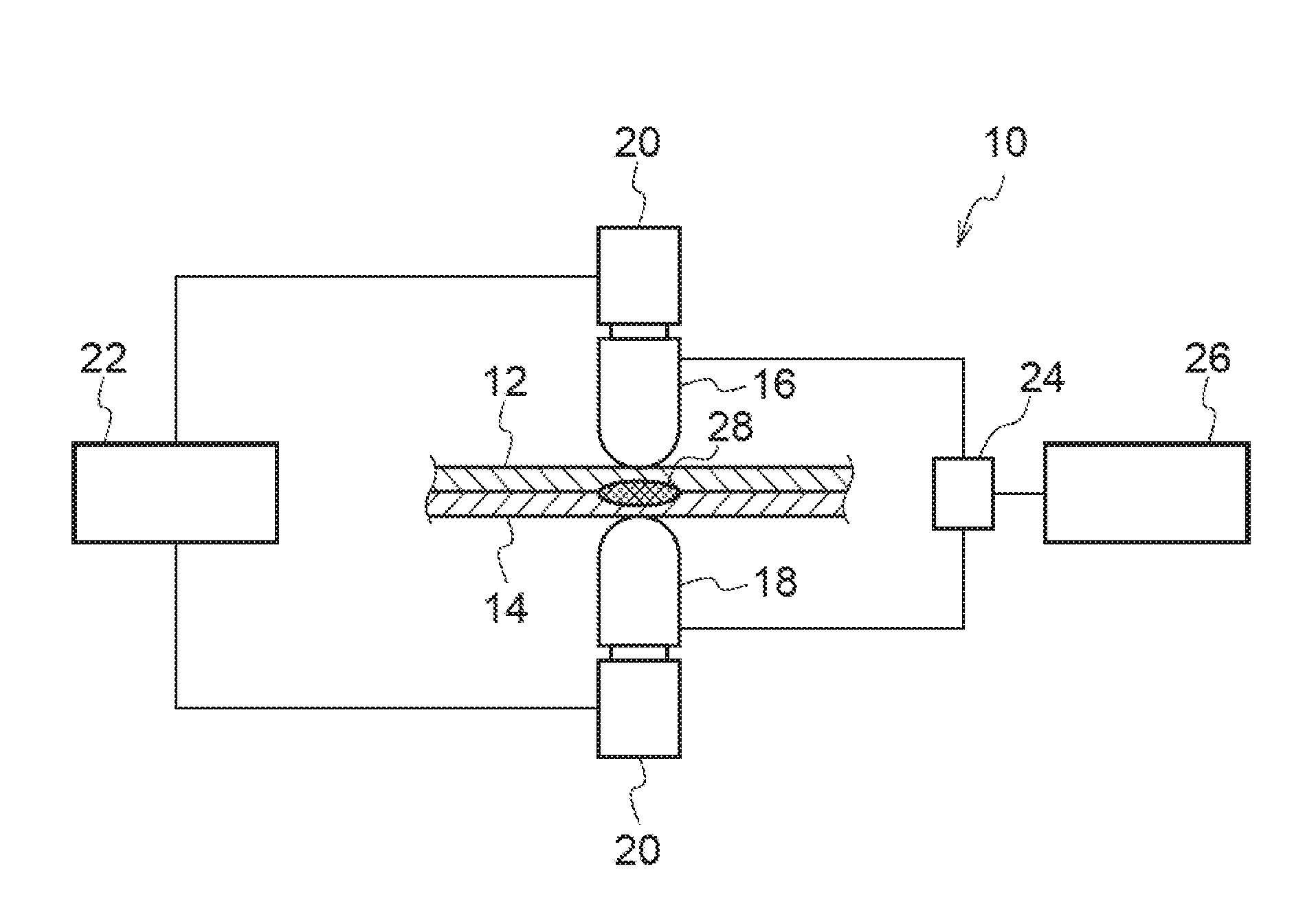

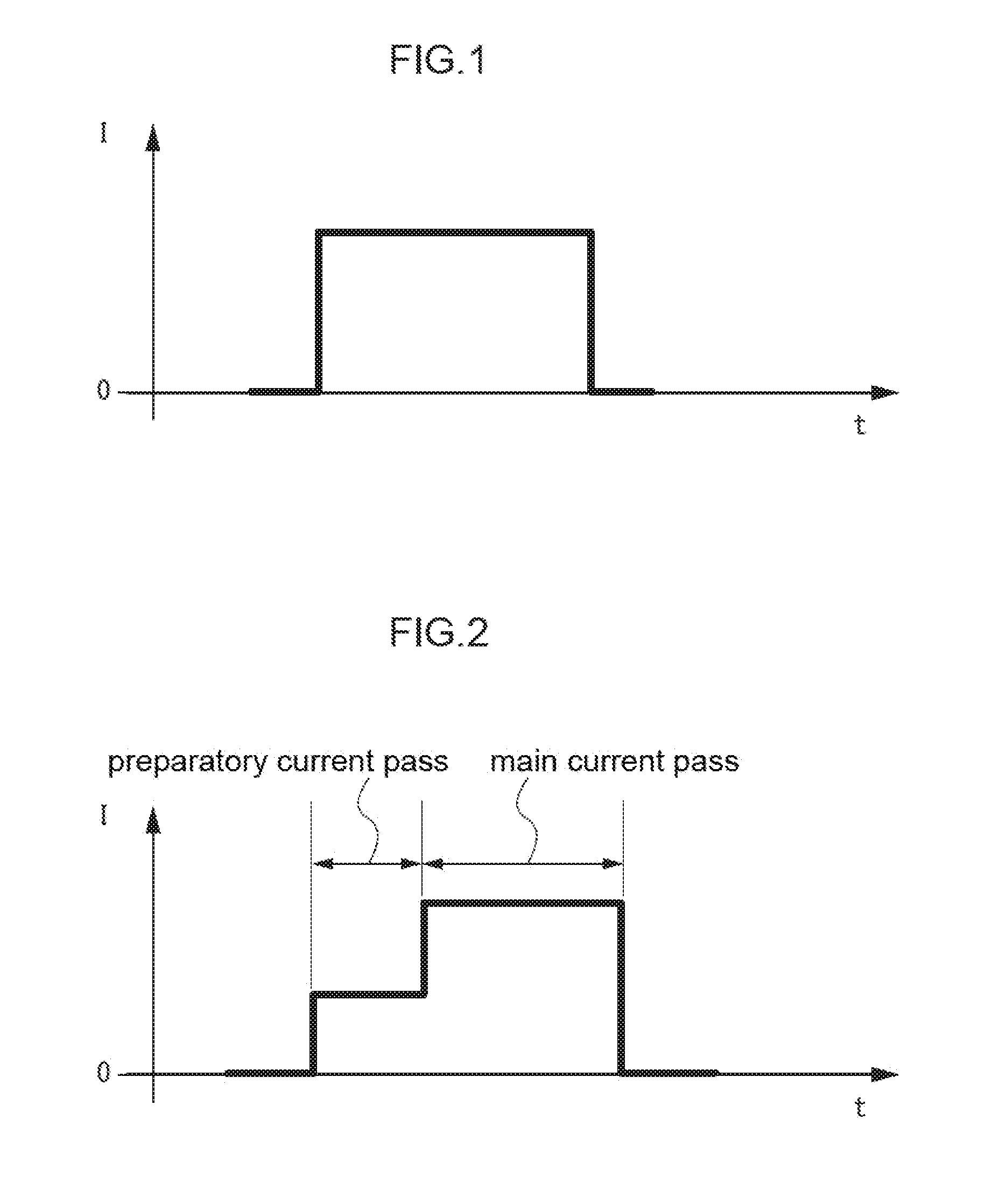

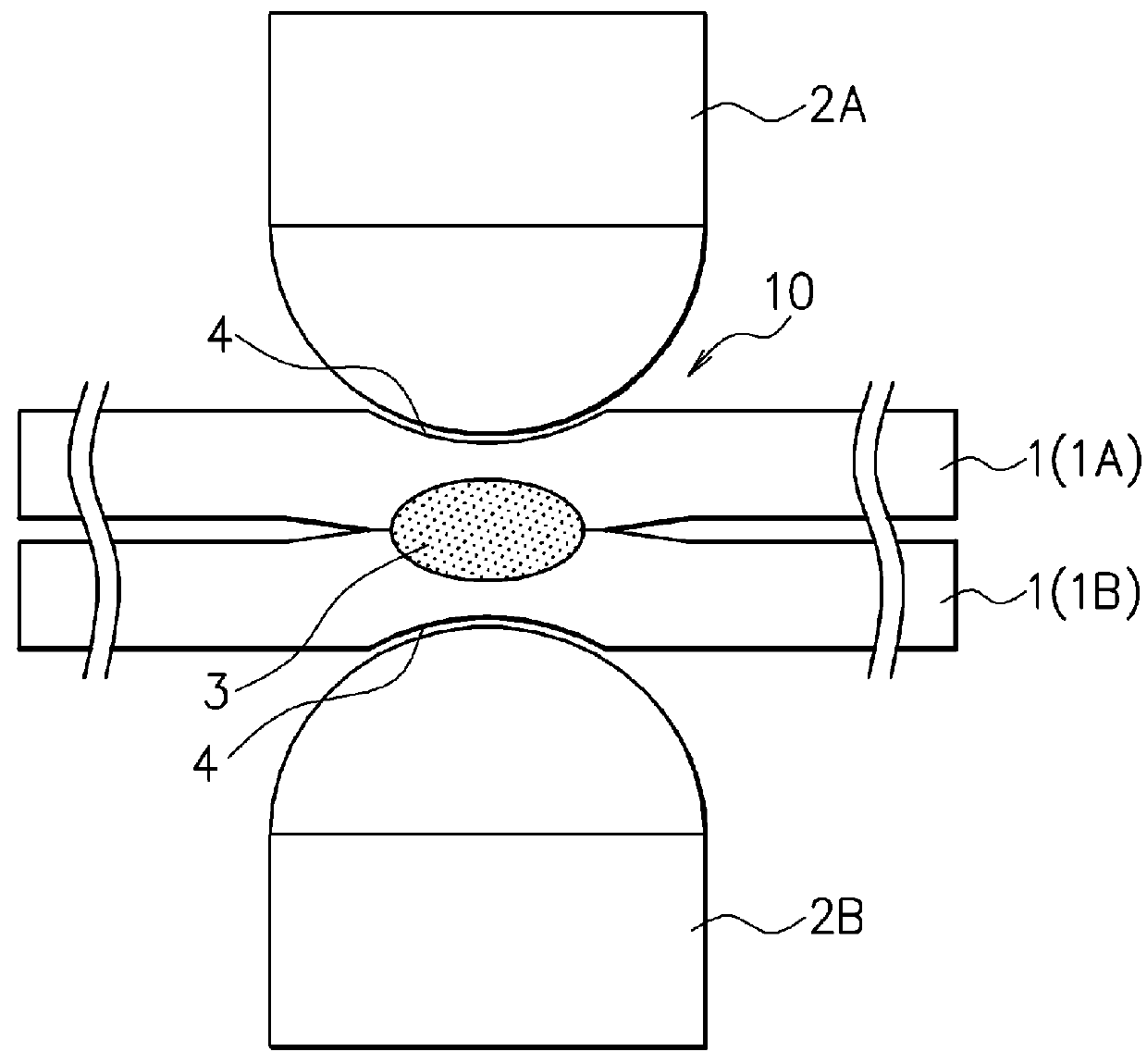

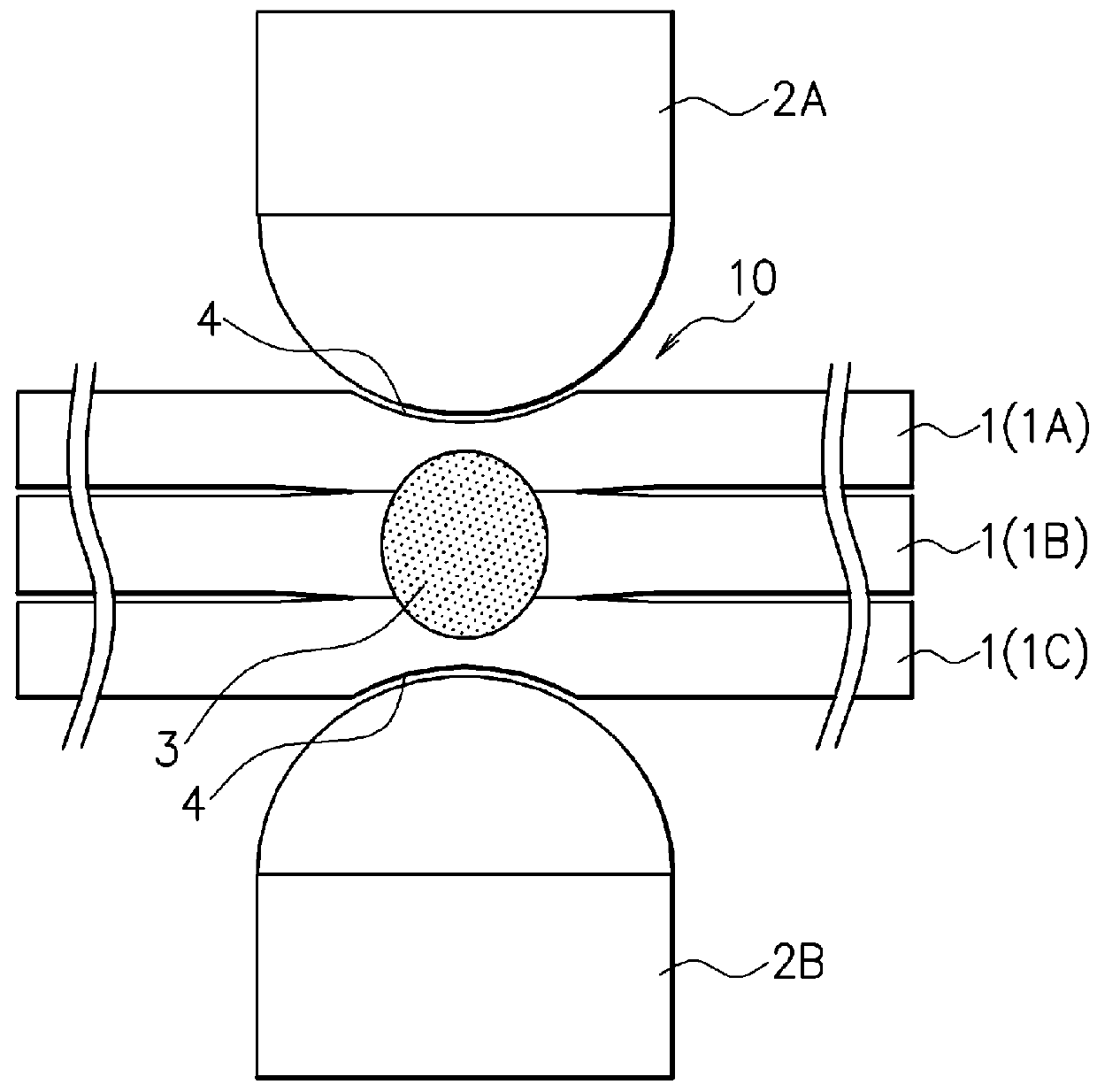

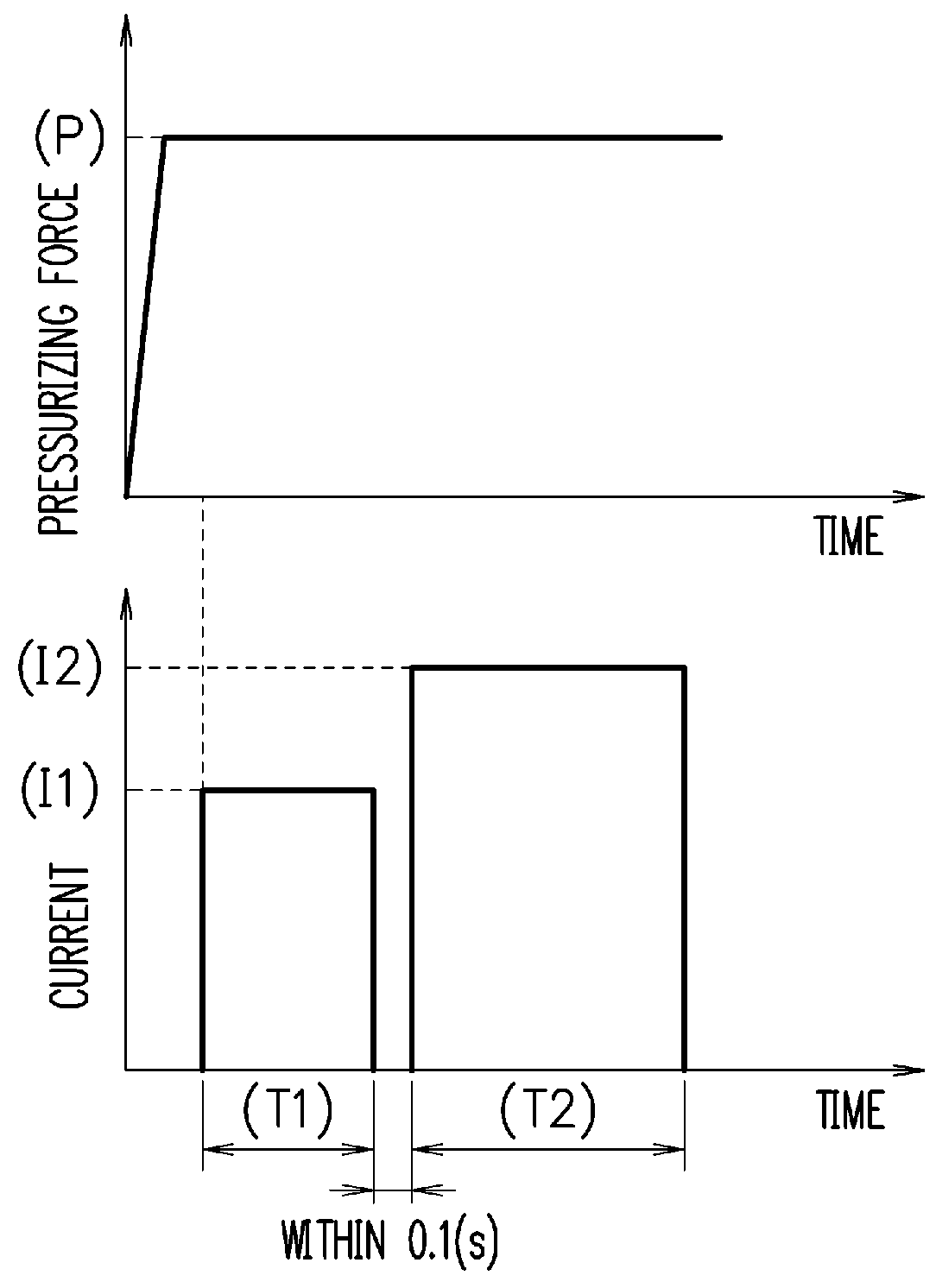

When two high-strength steel sheets (1A, 1B) having a sheet thickness ratio of 2 to 5, inclusive, and both having a tension strength of 780 MPa to 1850 MPa, inclusive, are overlapped with each other and resistance spot welding is performed, a first energizing process that is a preliminary energization with an applied pressure of P1 kN and a welding current of I1 kA and a second energizing process that is a main energization with an applied pressure of P2 kN and a welding current of I2 kA are performed, wherein the sheet thickness ratio is defined as the ratio of the total steel sheet thickness to the thickness of a steel sheet on the thinner side (the thickness per sheet if the two steel sheets (1A, 1B) have the same thickness). The applied pressures P1 and P2 are set to a constant applied pressure of P = P1 = P2 through the first energizing process and the second energizing process. In addition, when an average sheet thickness of the steel sheets (1A, 1B) is assumed to be t mm, the applied pressure P is set in the range expressed by the formula {0.5 ≤ P ≤ 3.0t(1 / 3)}. The welding current I1 is set in the range of 30% to 90%, inclusive, of the welding current I2. The second energizing process is initiated within 0.1 s after the completion of the first energizing process.

Owner:NIPPON STEEL CORP

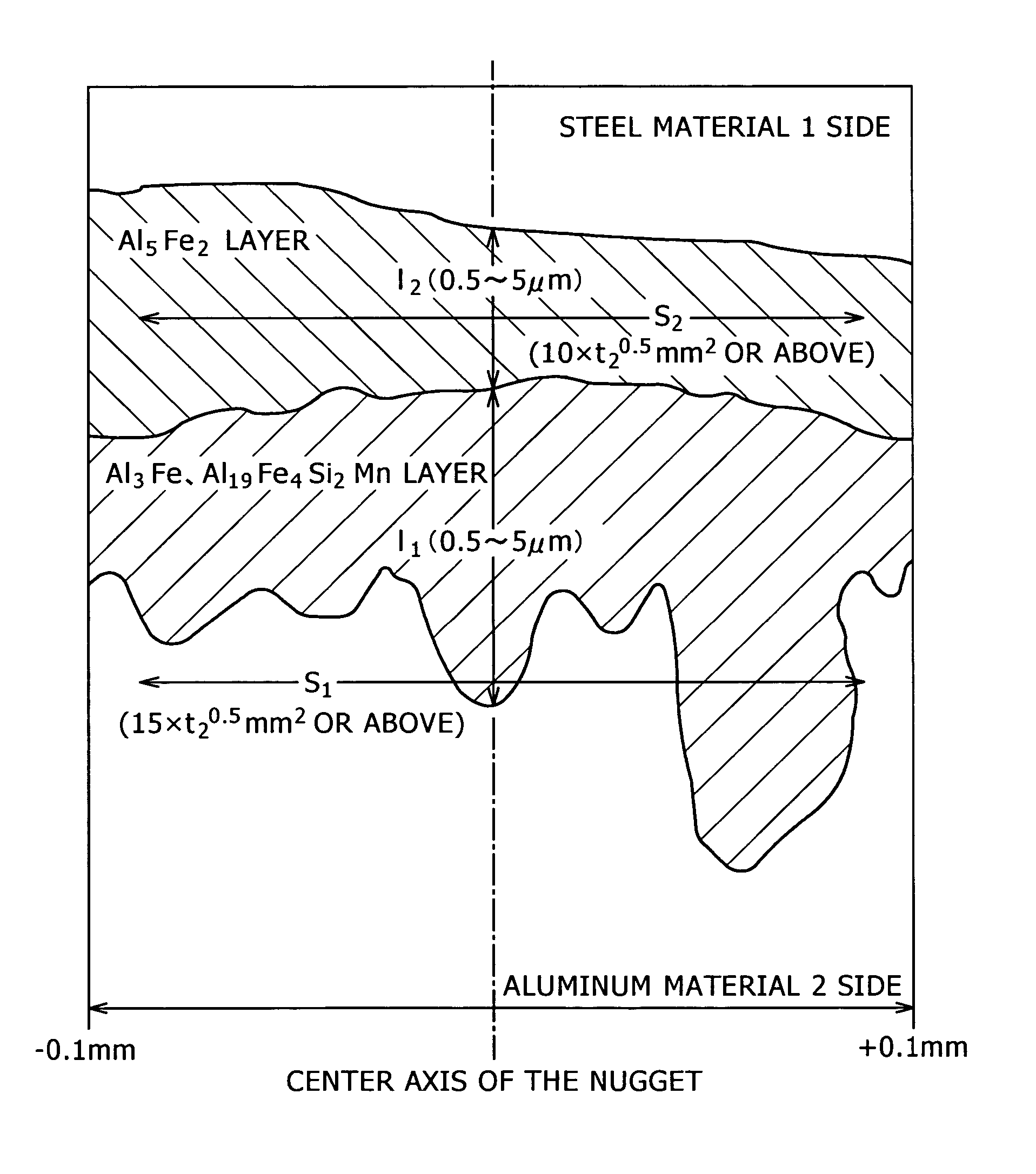

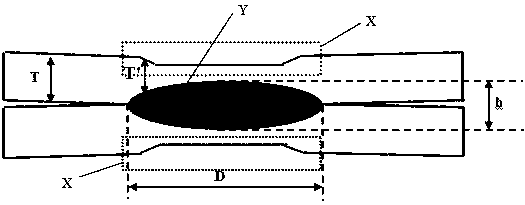

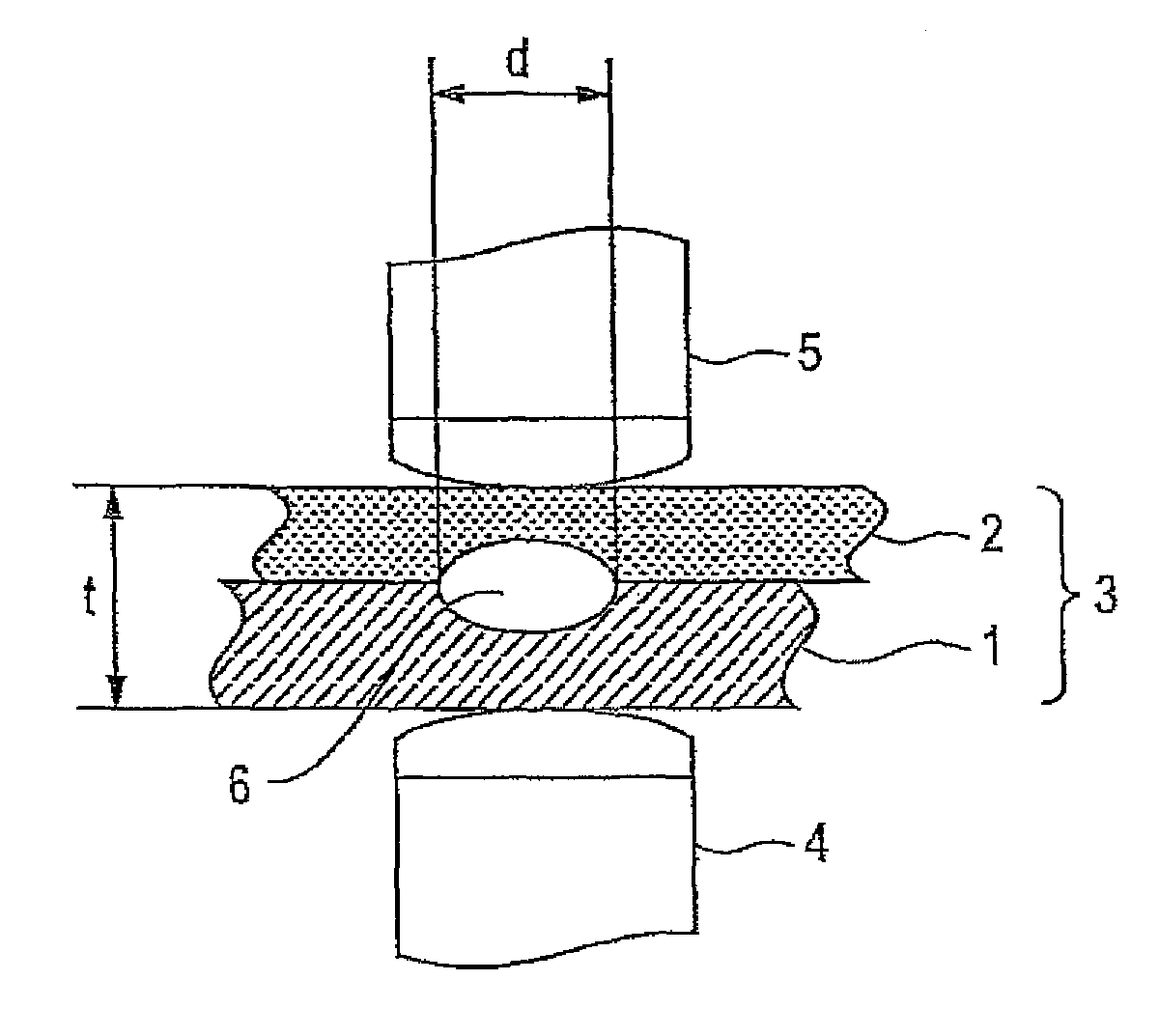

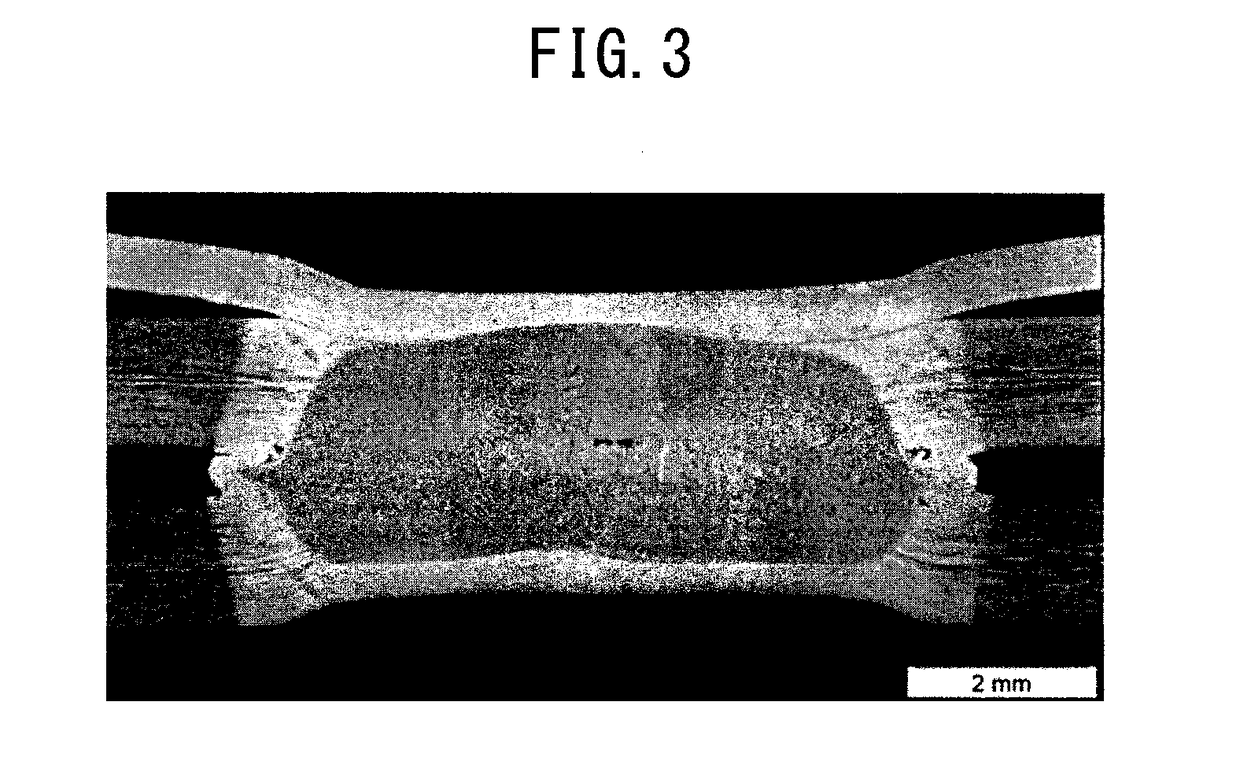

Joined body of dissimilar materials comprising steel material and aluminum material, and joining method therefor

InactiveUS7951465B2Improve welding strengthSatisfactory repeatabilityHot-dipping/immersion processesContact member assembly/disassemblyReaction layerSpot welding

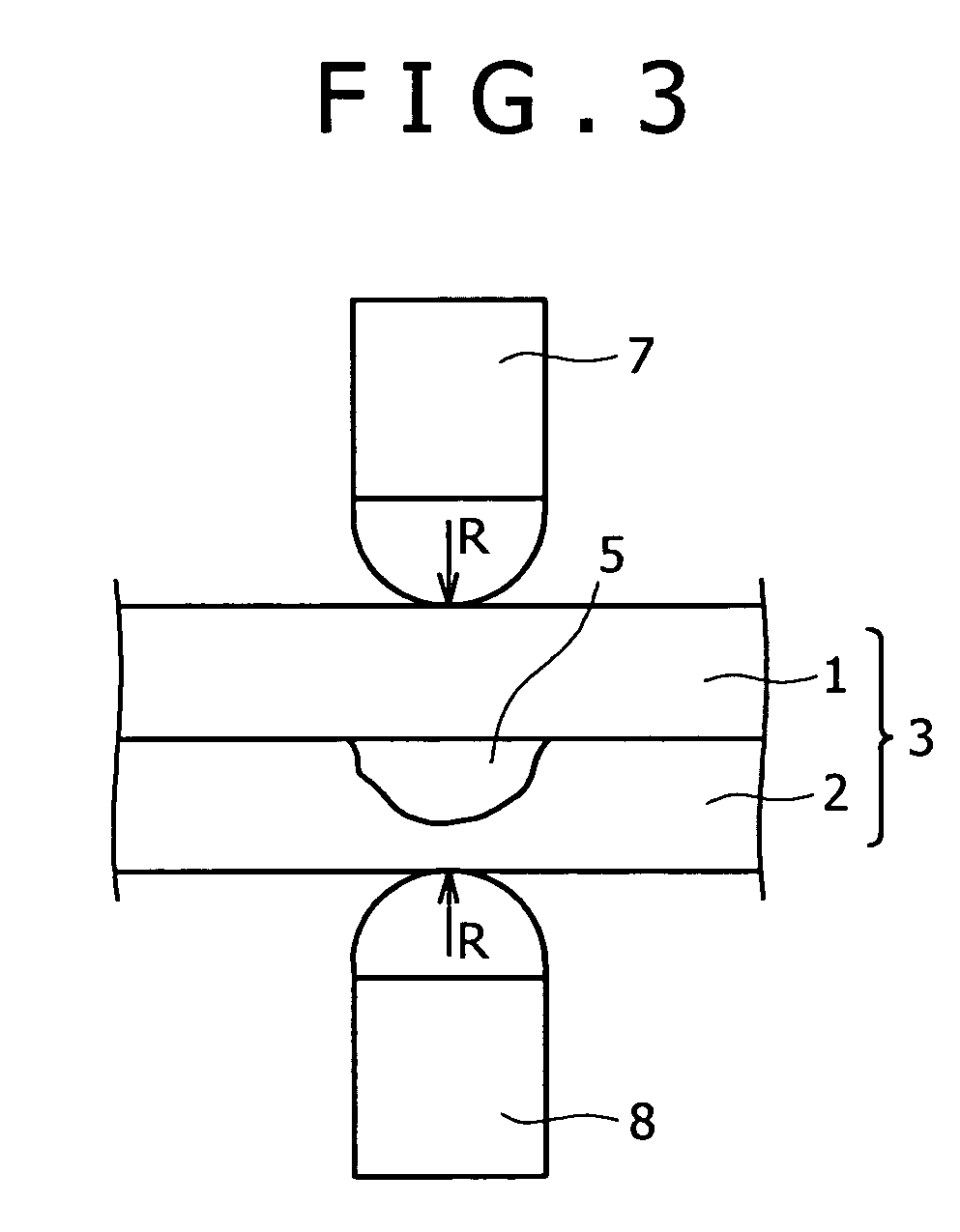

To provide a steel-aluminum welded material and a spot welding method therefor having high weld strength.The steel-aluminum welded material 3 includes a steel material 1 and an aluminum material 2 having predetermined widths. The area of a nugget 5 of a spot-welded part is determined as a function of the thickness of the aluminum material 2, and the area of a part of the nugget 5 corresponding to a part having a thickness in a range between 0.5 and 10 μm of an interface reaction layer 6 is defined as a function of the thickness of the aluminum material 2.

Owner:KOBE STEEL LTD

Spot welding method of high-strength steel sheets excellent in joint strength

ActiveUS20150174690A1Improve reliabilityHigh strengthWelding electric suppliesElectrical resistance and conductanceHigh intensity

When two high-strength steel sheets (1A, 1B) whose sheet thickness ratio={the sum of sheet thicknesses of the steel sheets} / {the sheet thickness of the thinner steel sheet (when they have the same thickness, the sheet thickness per one sheet)} is within a range of not less than 2 nor more than 5 and which both have tensile strength of not less than 780 MPa nor more than 1850 MPa are stacked to be subjected to resistance spot welding, a first welding step being pre-welding with a pressurizing force P1 kN and a welding current I1 kA and a second welding step being main welding with a pressurizing force P2 kN and a welding current I2 kA are performed, the pressurizing forces P1, P2 are set to a fixed pressurizing force P=P1=P2 all through the first welding step and the second welding step and are set within a range expressed by {0.5≦P≦3.0t(1 / 3)}, where t mm is an average sheet thickness of the steel sheets (1A, 1B), the welding current I1 is set within a range of not less than 30% nor more than 90% of the welding current I2, and the second welding step is started within 0.1 s after the first welding step is finished.

Owner:NIPPON STEEL CORP

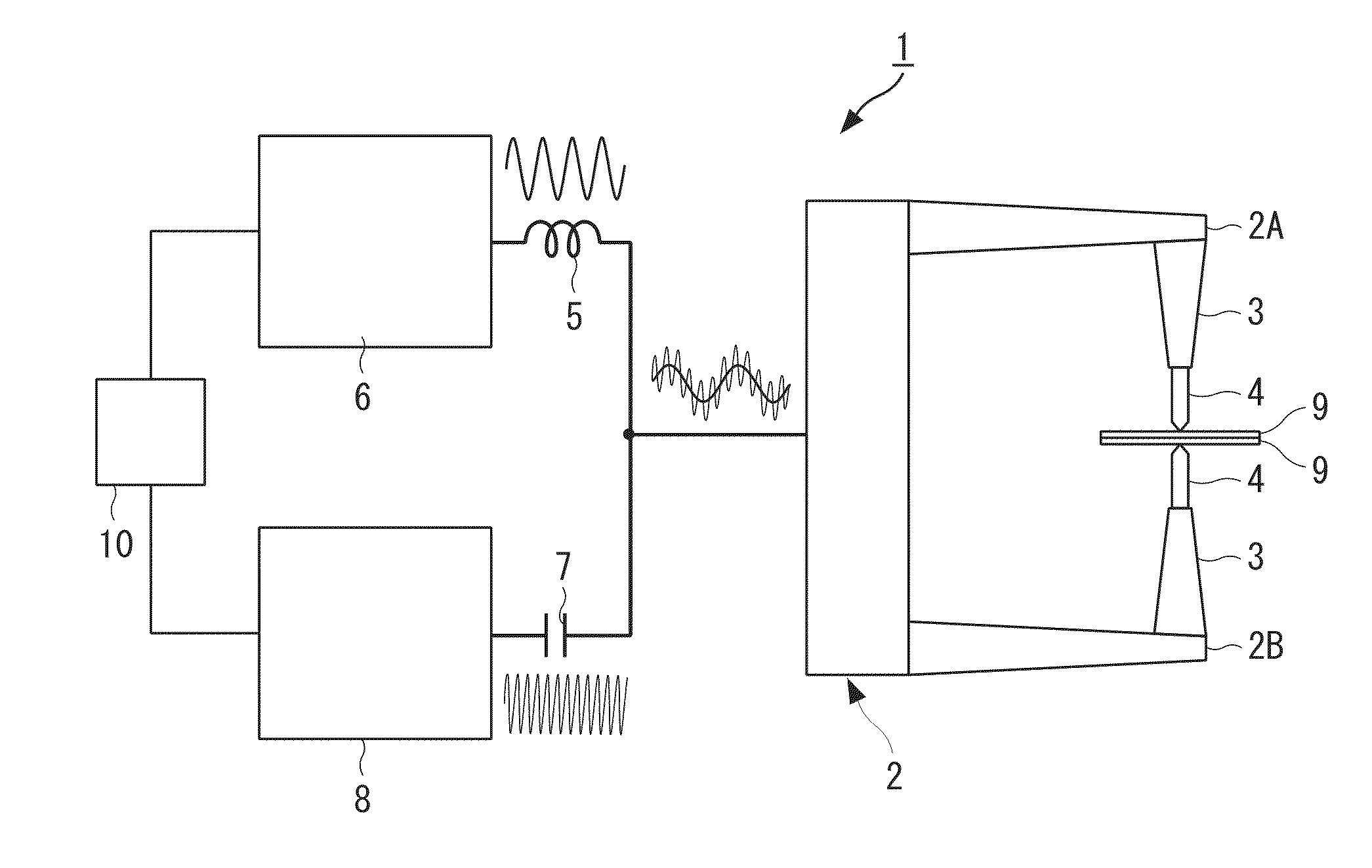

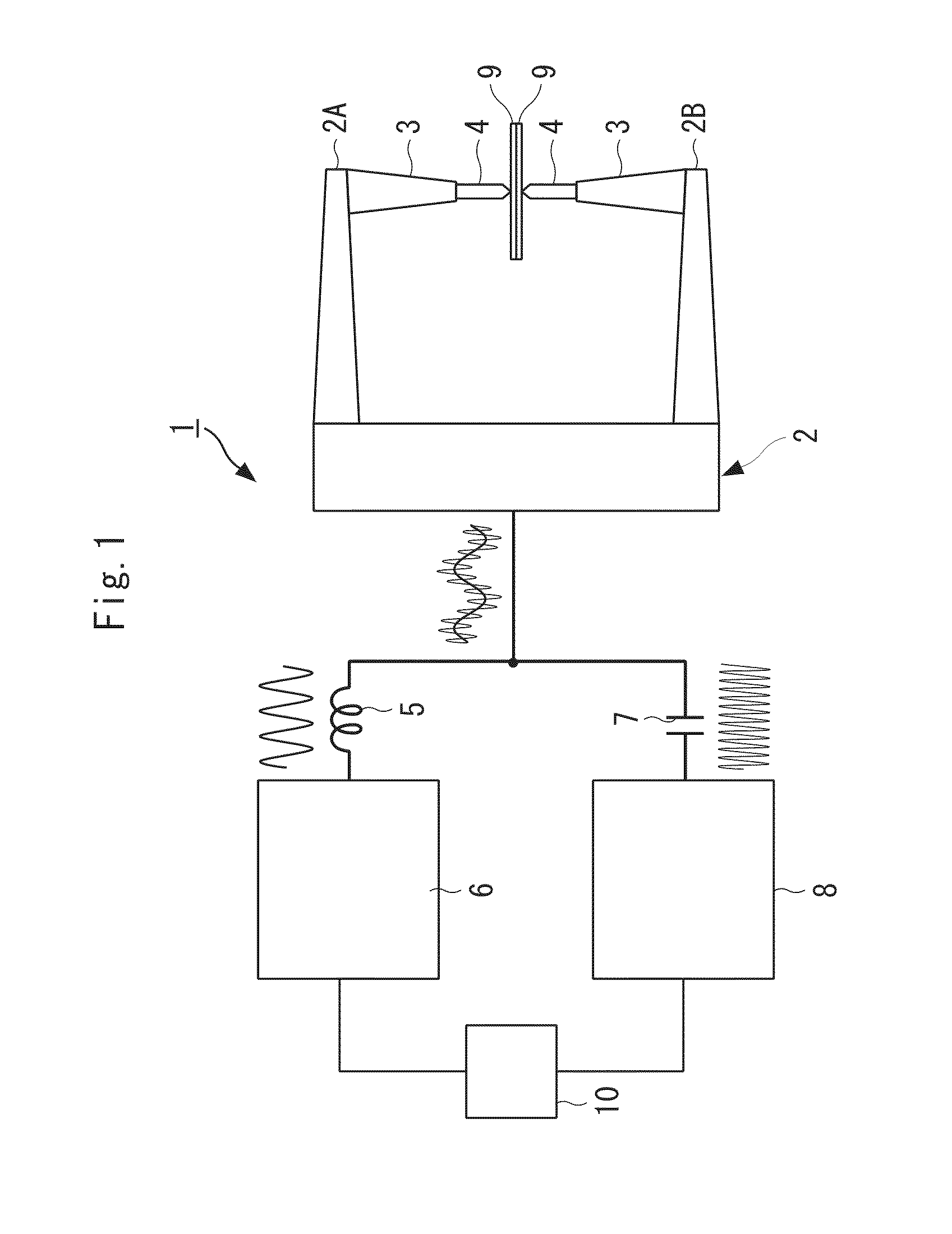

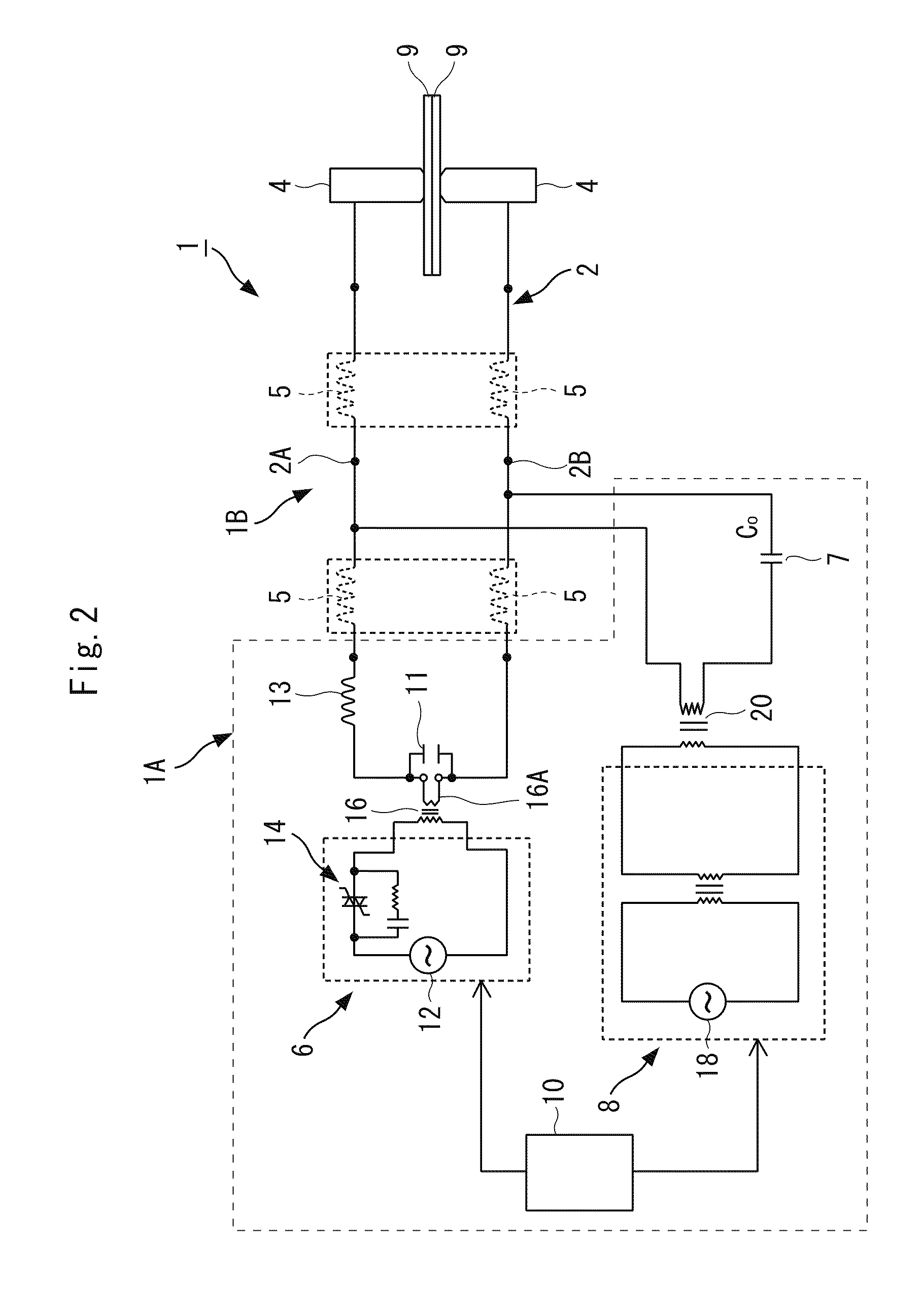

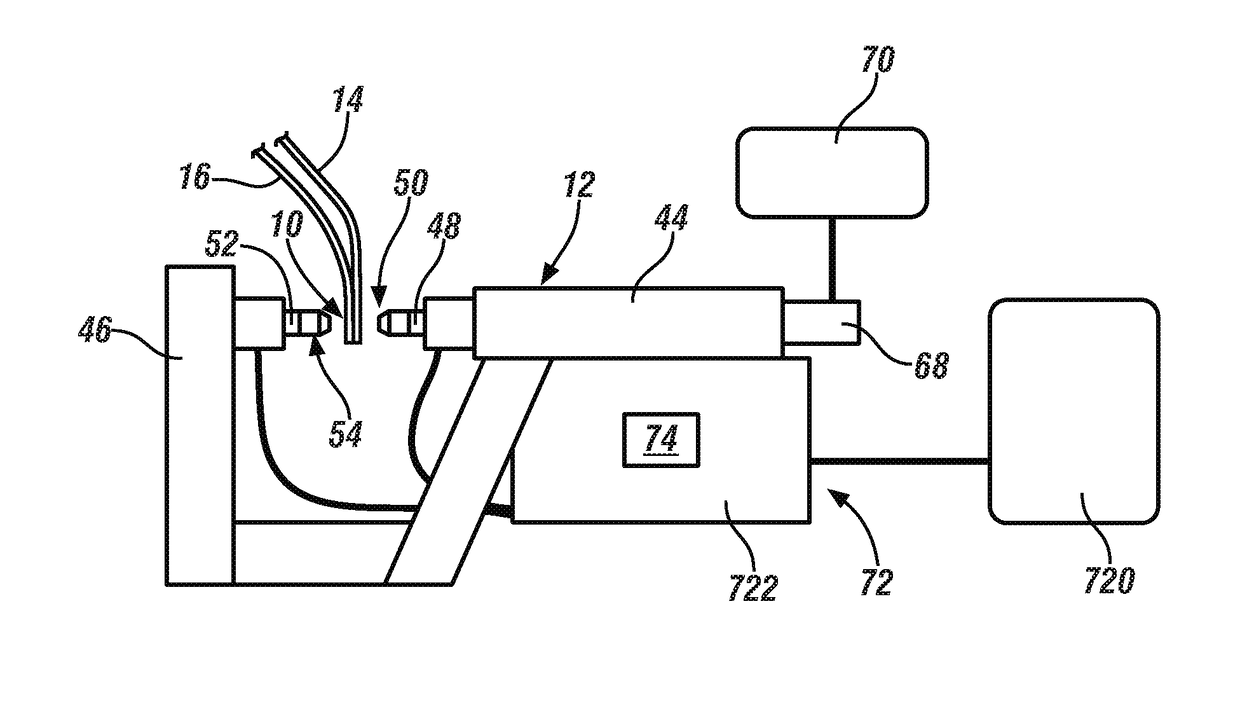

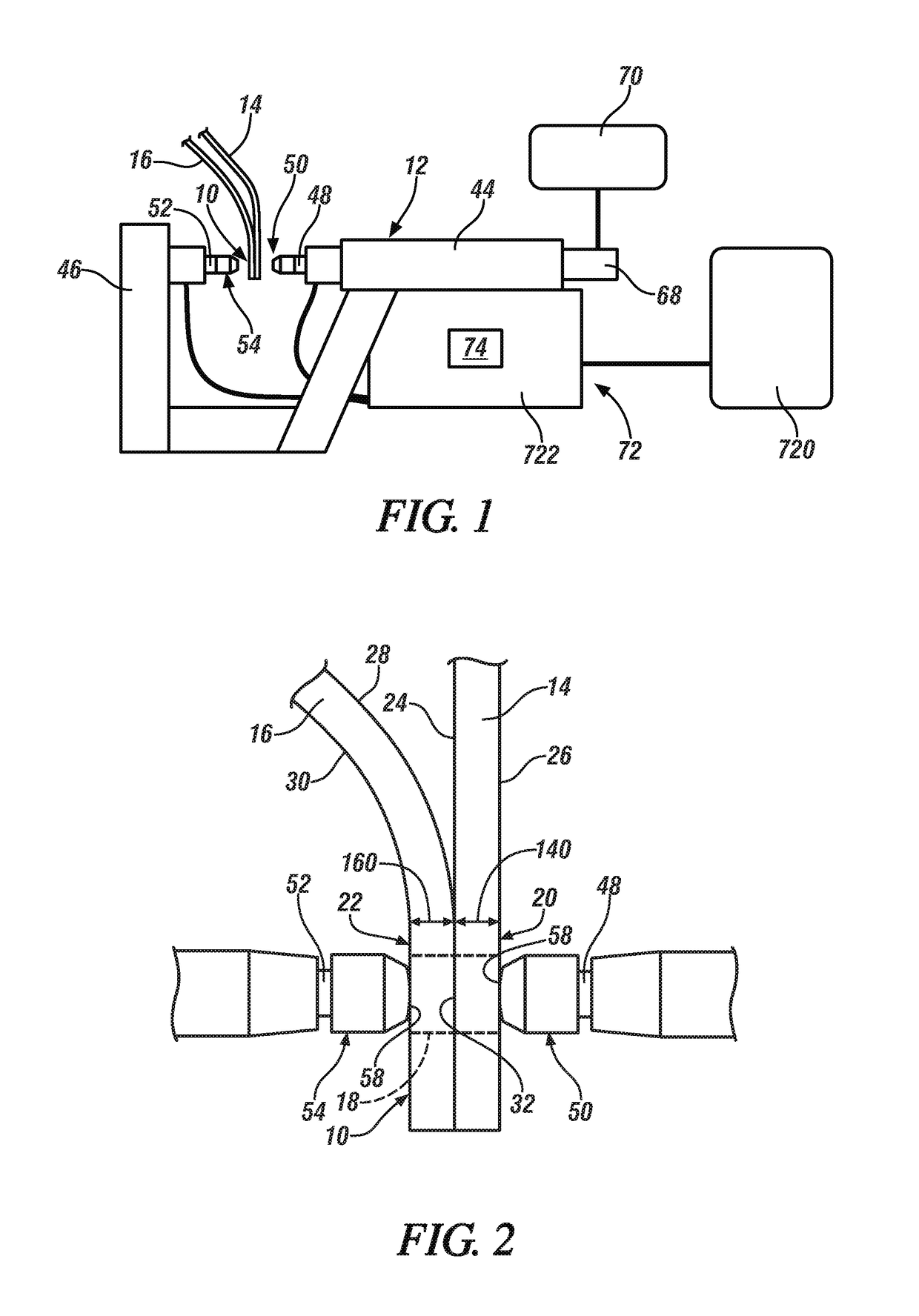

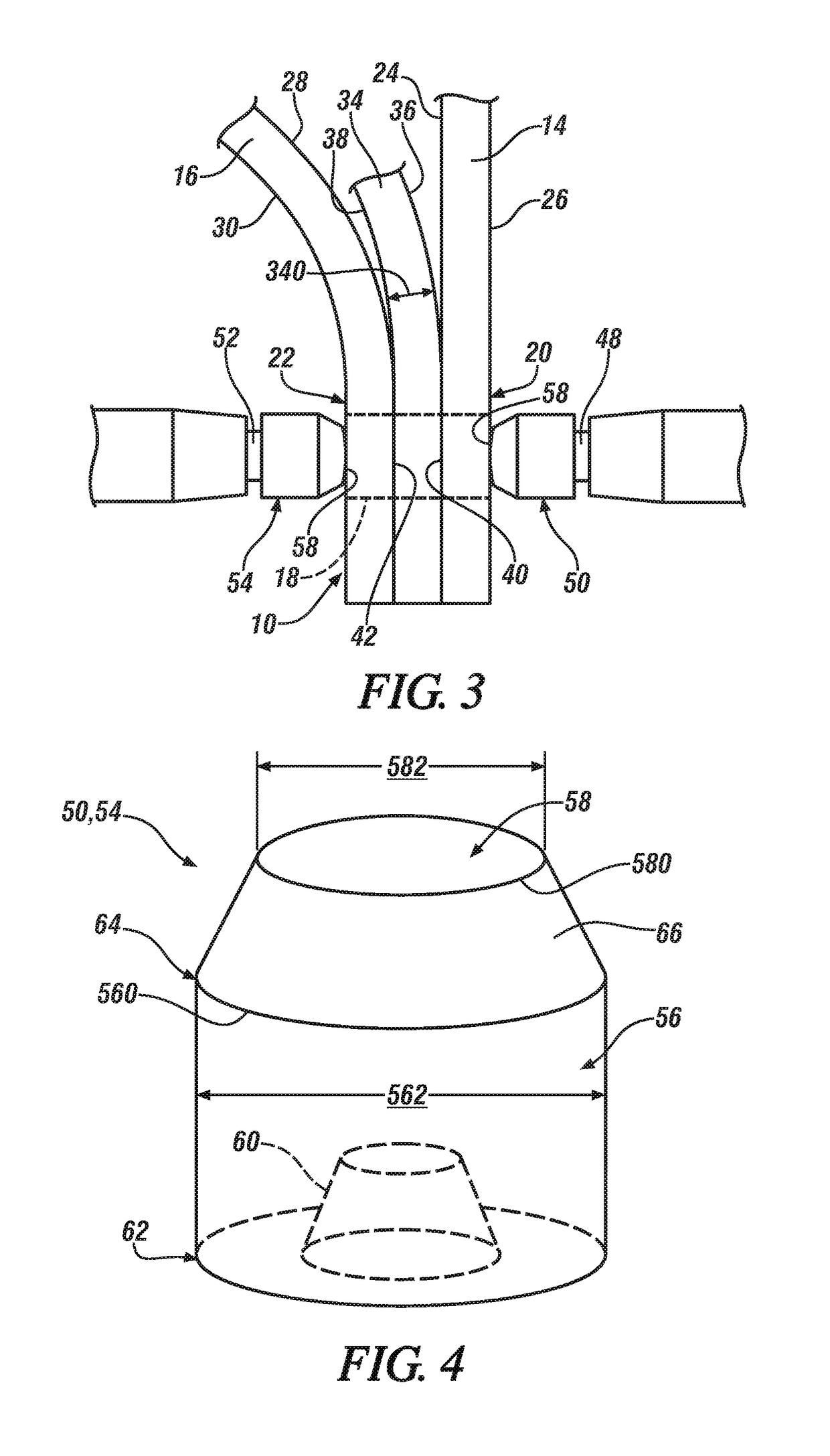

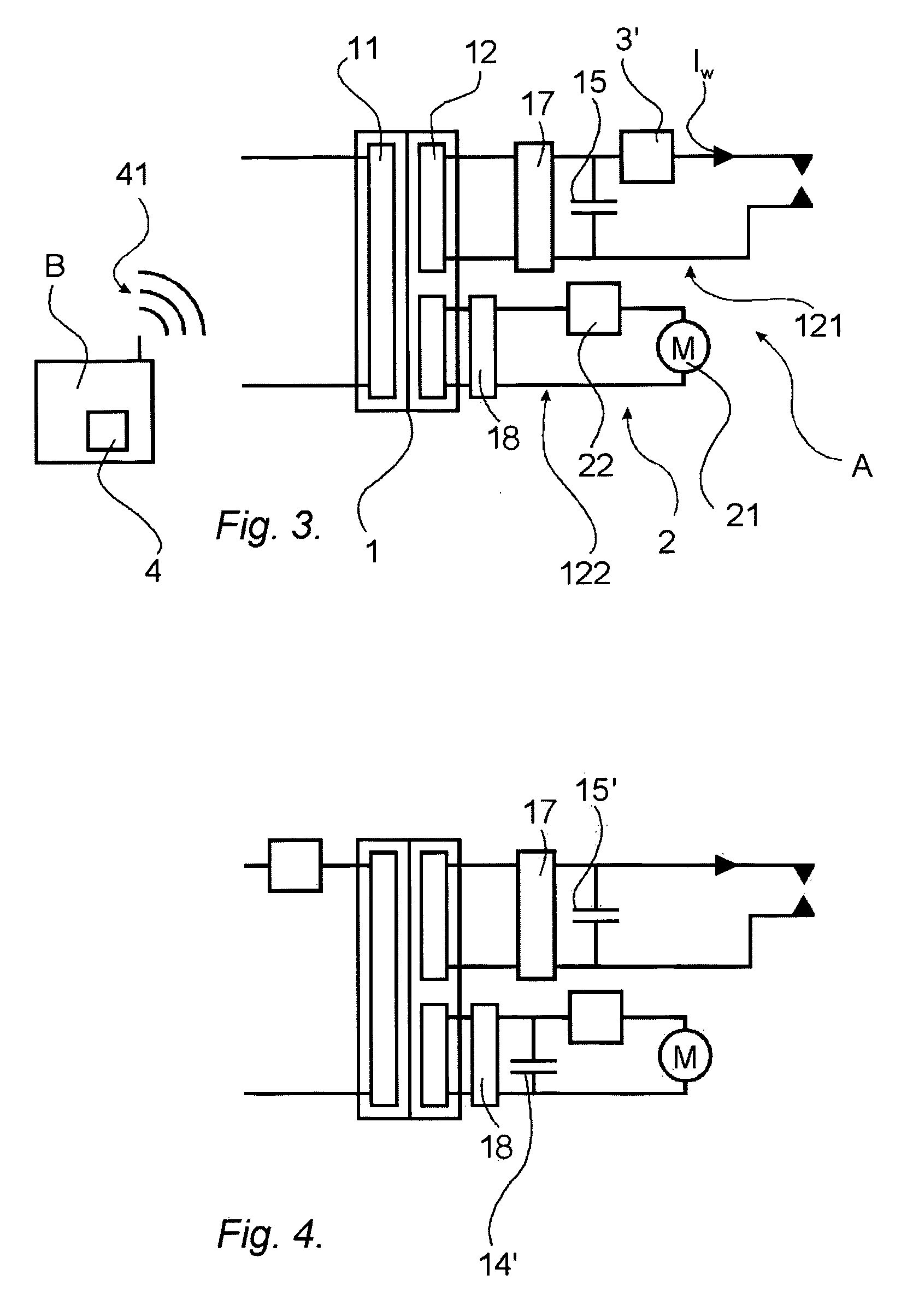

Welding equipment for metallic materials and method for welding metallic materials

InactiveUS20110303655A1Simple configurationFlexible heating treatmentArc welding apparatusWelding electric suppliesMetallic materialsSpot welding

A welding equipment for metallic materials capable of performing heat treatment such as tempering based on partial heating in spot welding is provided. The welding equipment 1 sandwiches metallic materials 9 with a pair of electrodes 4, 4, and heats different regions of the metallic materials 9 by energization, with the pair of electrodes 4, 4 maintained at the same position with respect to the metallic materials 9. The welding equipment includes a first heating means 6 connected to the pair of electrodes 4, 4 for heating and welding the internal region of the circle defined by projecting the cross-sectional area of the axis of the electrodes on the metallic materials by applying power having a low first frequency, a second heating means 8 for heating a ring-shaped region along the circle by applying power having a second frequency that is higher than the first frequency, and an energization control unit 10 for independently controlling the first and the second heating means 6, 8.

Owner:NETUREN CO LTD +1

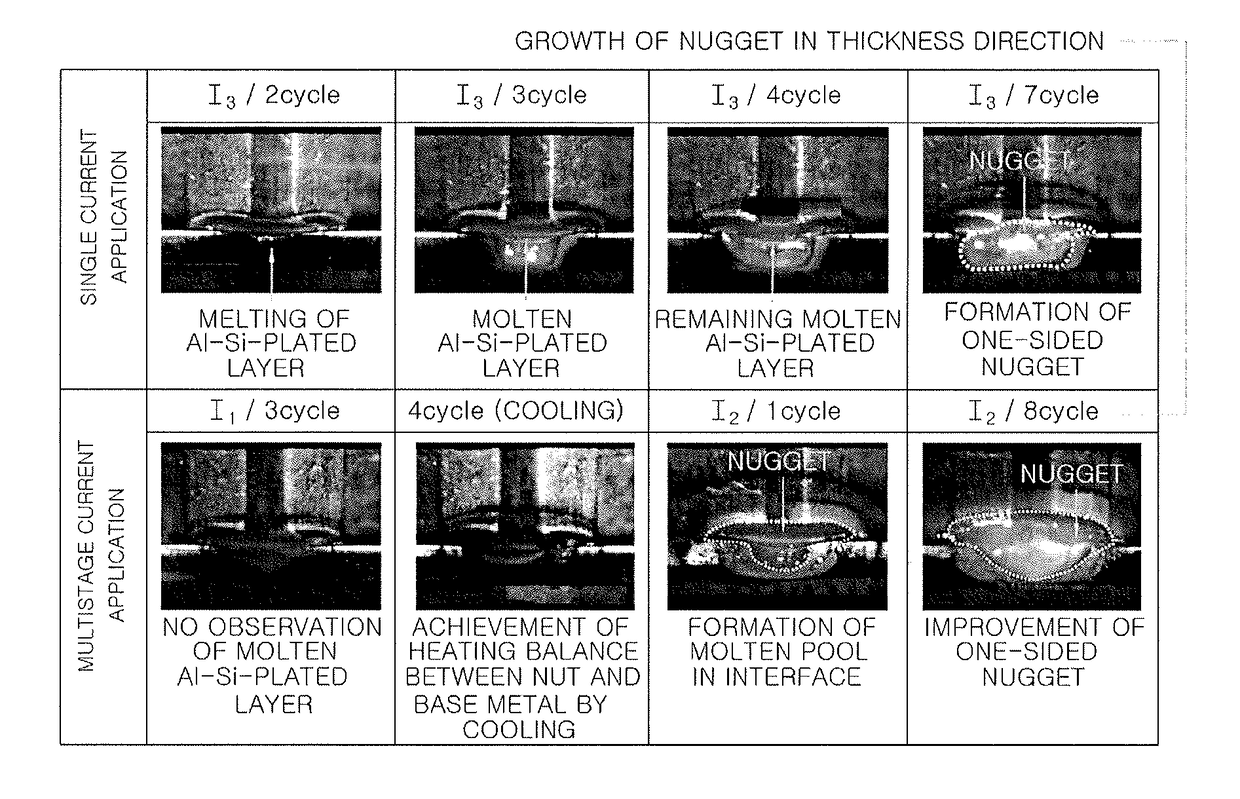

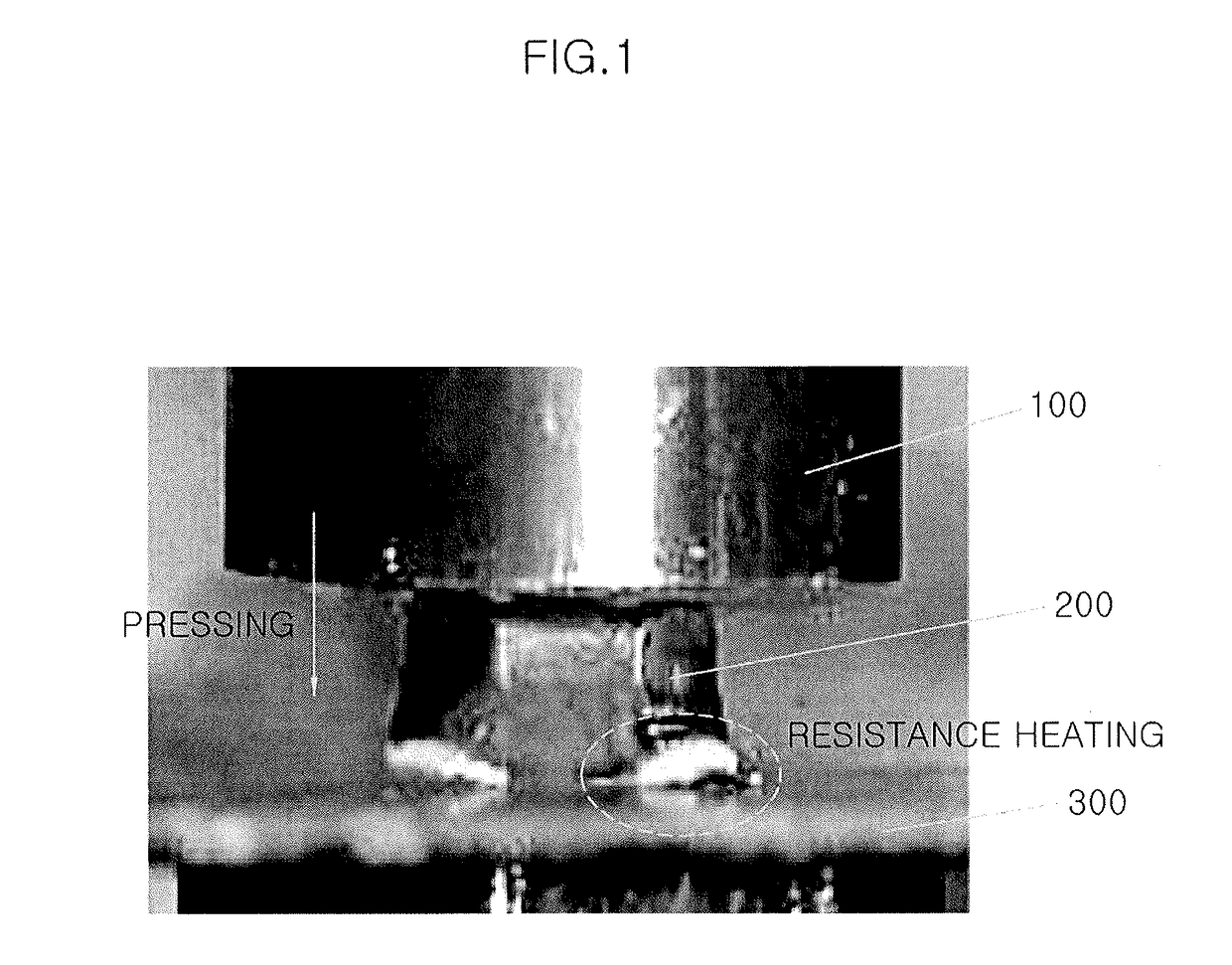

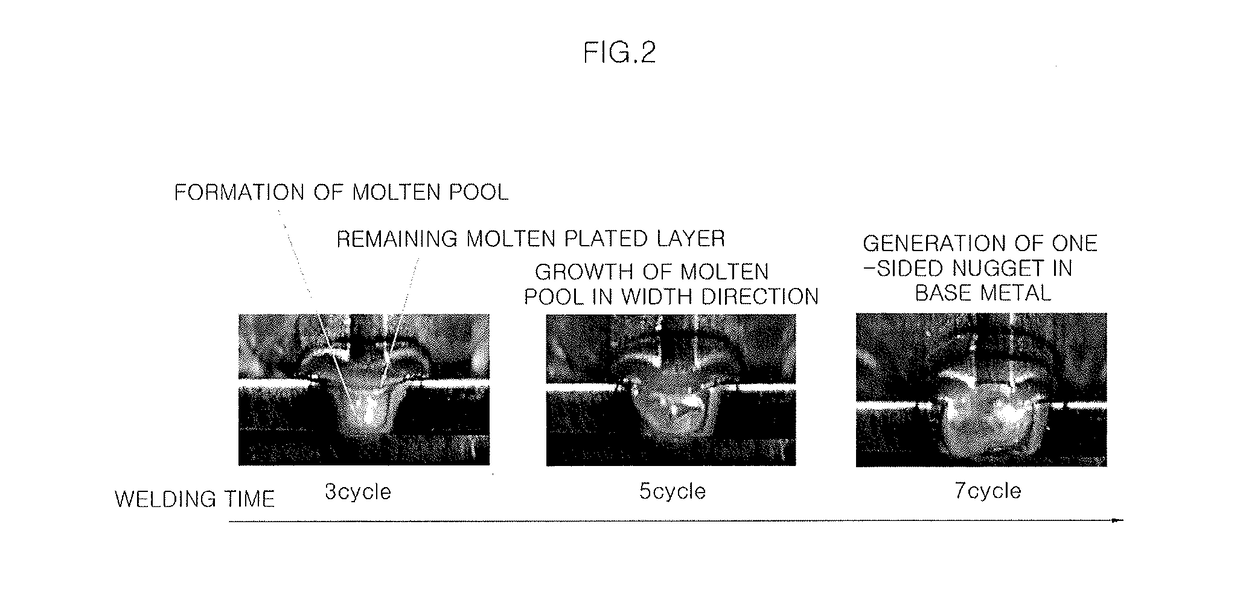

Method of projection welding hardware to steel sheet for hot stamping

ActiveUS20180250766A1Enlarge weld nuggetsImprove welding strengthHot-dipping/immersion processesArc welding apparatusHot stampingElectroplating

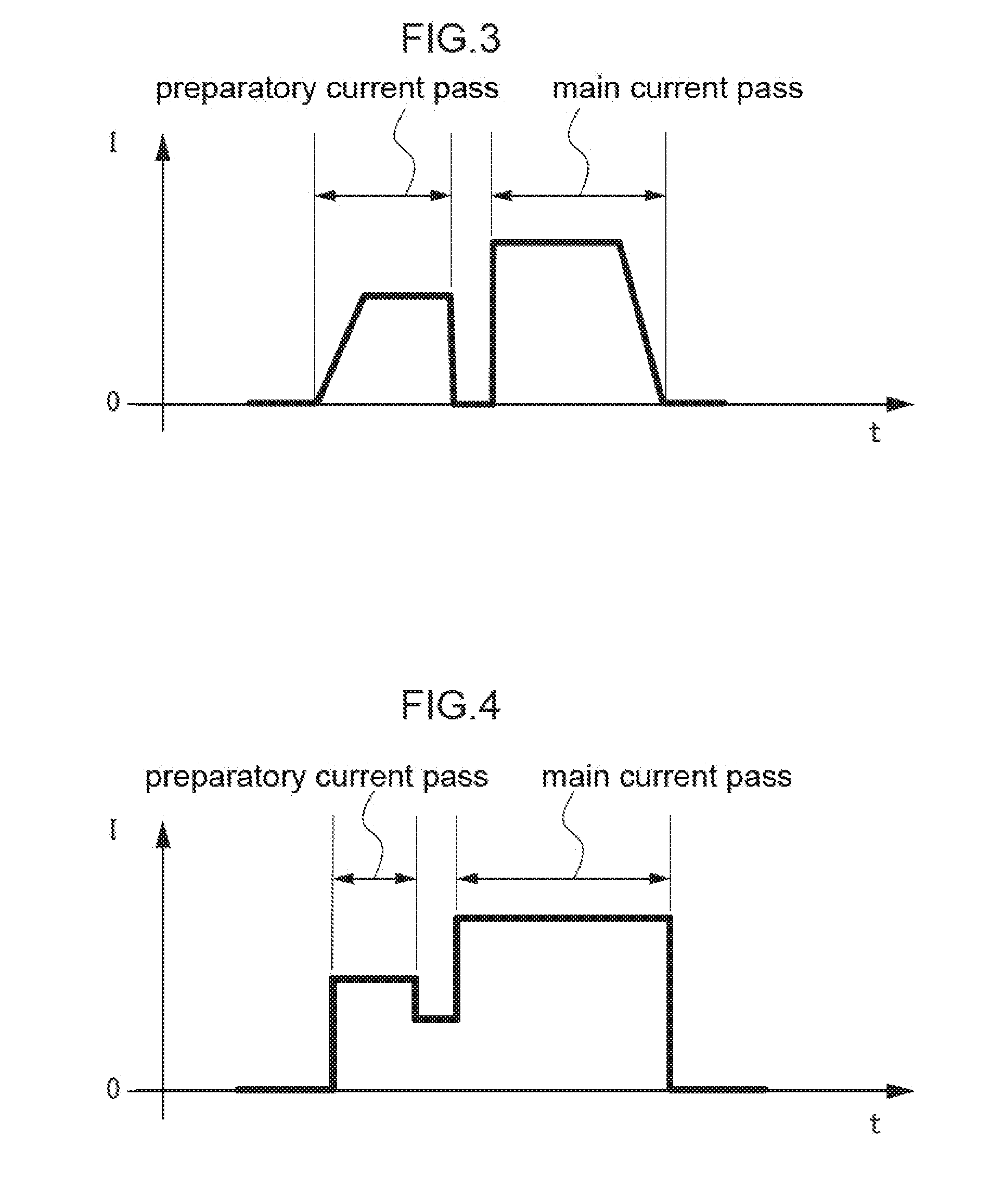

A method of projection welding hardware to a plated steel sheet for hot stamping, may include pressing hardware and a plated steel sheet in a state in which a welding projection on the hardware is in contact with the plated steel sheet, supplying a primary current to the hardware and the plated steel sheet in a state in which they are pressed, and supplying a secondary current to the hardware and the plated steel sheet.

Owner:HYUNDAI MOTOR CO LTD +1

Resistance spot welding method

A resistance spot welding method including: a pulsation process of clamping a sheet assembly of two or more overlapped steel sheets including at least one high tensile steel sheet using a pair of welding electrodes that are connected to a spot welding power source employing an inverter direct current method, and performing plural repetitions of current passing and current pass stopping, while pressing the steel sheets with the welding electrodes; and a continuous current pass process in which, after the pulsation process, current is passed continuously for a longer period of time than a maximum current pass time of the pulsation process, while pressing the steel sheets with the welding electrodes.

Owner:NIPPON STEEL CORP

Liquid phase diffusion welding method for metallic machine part and metallic machine part

ActiveUS20060163321A1Improve joint qualityShorten bonding timeCamsValve arrangementsProduction rateElectrical resistance and conductance

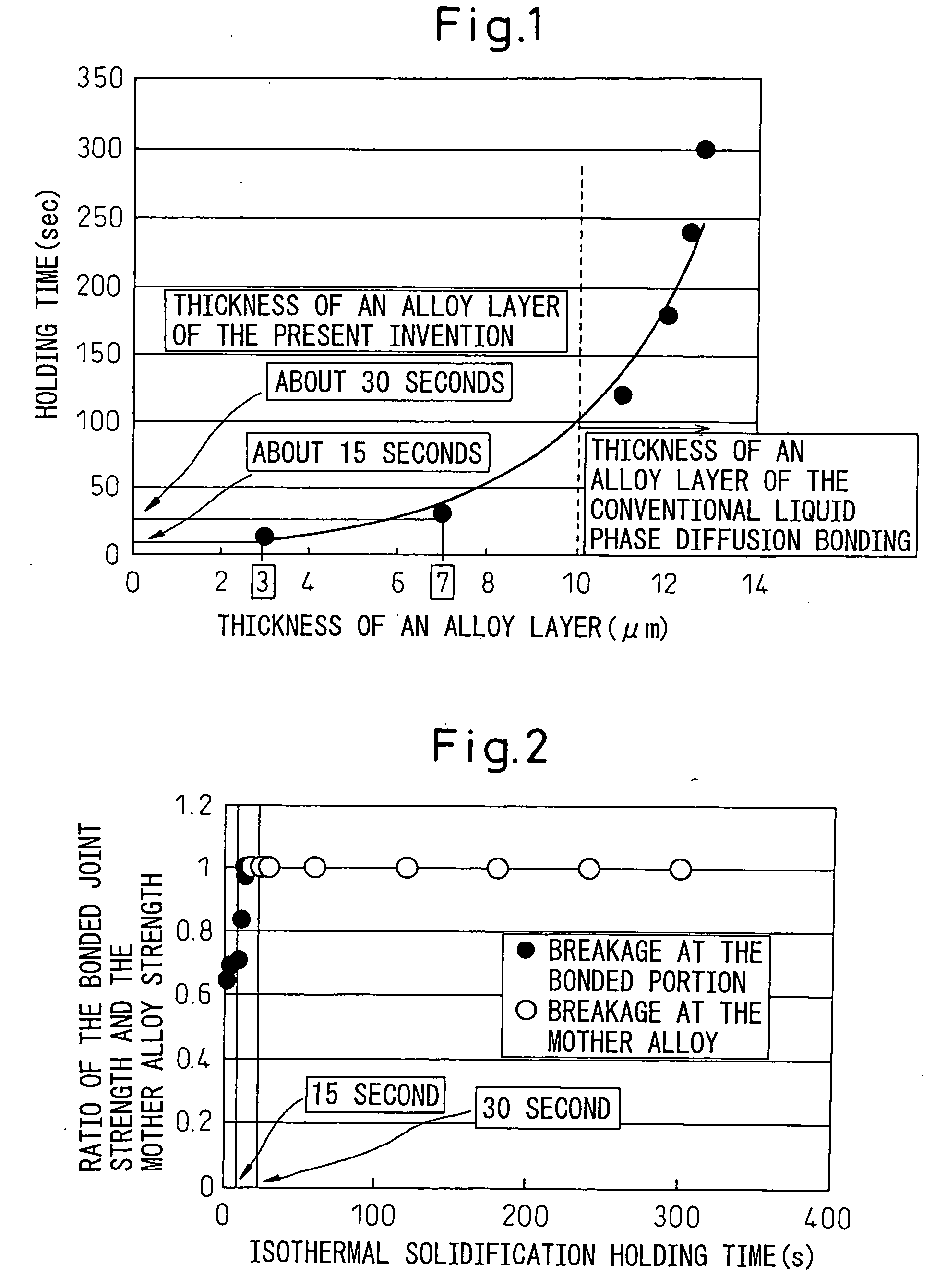

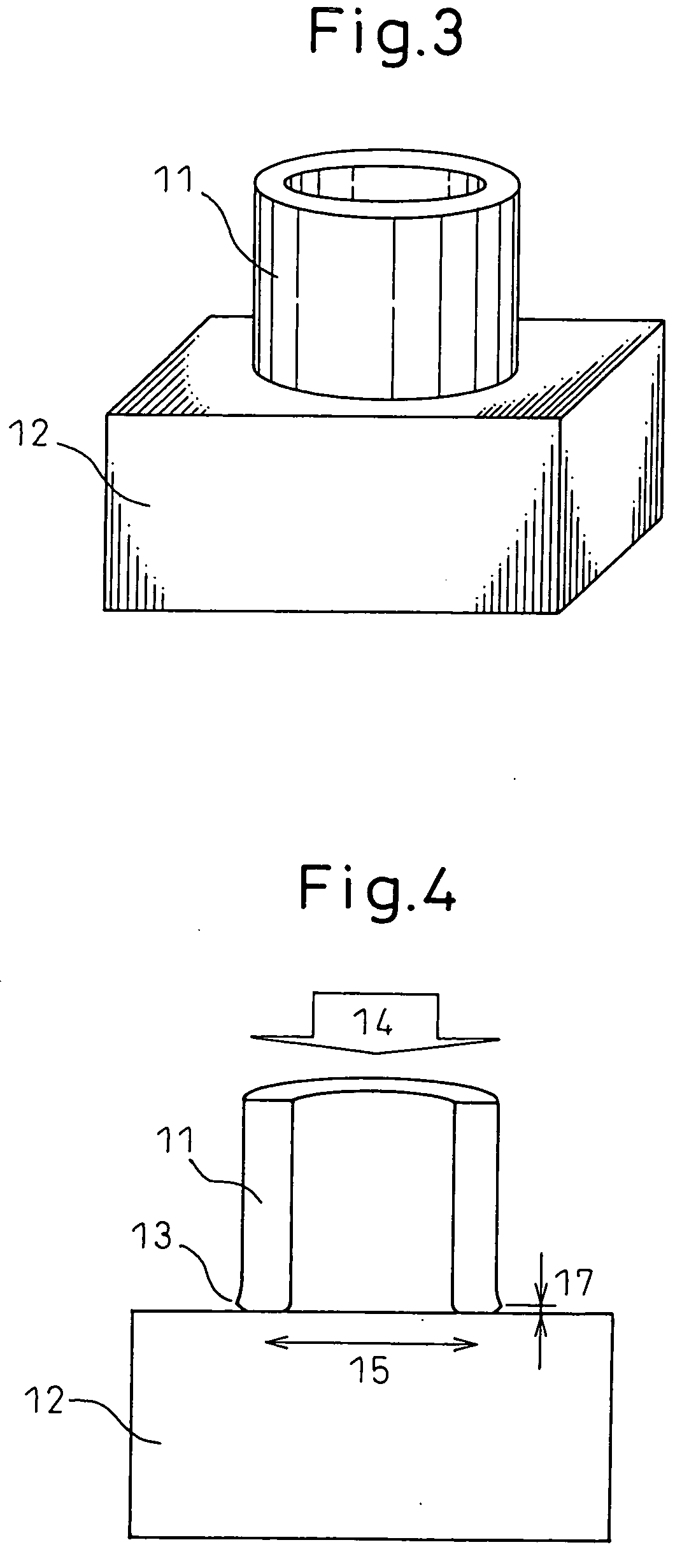

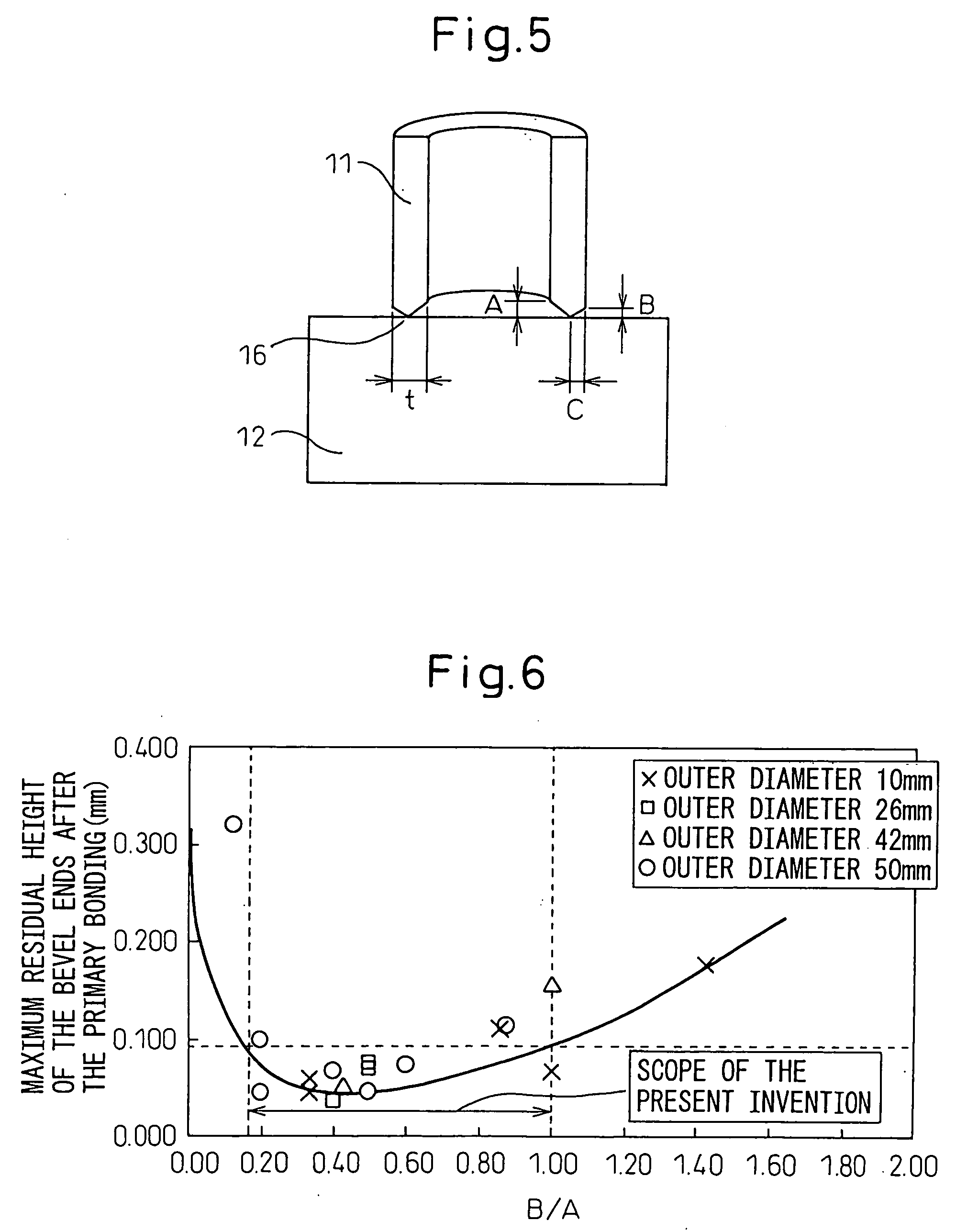

A liquid phase diffusion bonding method for a metal machine part superior in the quality of the joint and the productivity enabling the bonding time to be shortened, achieving homogenization of the bonding structure and improving the tensile strength, fatigue strength, and joint quality and reliability. This liquid phase diffusion bonding method of a metal machine part is characterized interposing an amorphous alloy foil for liquid phase diffusion bonding at bevel faces of metal materials, performing primary bonding by melt bonding said amorphous alloy foil and said metal material by resistance welding to form a joint, then performing secondary bonding by liquid phase diffusion bonding by reheating said joint to at least the melting point of said amorphous alloy foil, then holding it there to complete the solidification process of said joint.

Owner:NIPPON STEEL CORP +1

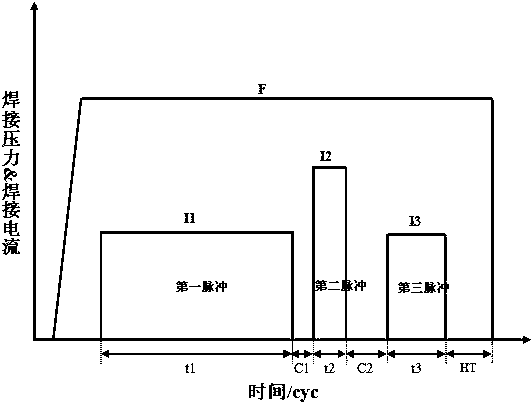

Galvanized high-strength steel resistance spot welding method with good joint performance

ActiveCN108015401AImprove plasticityImprove the fracture modeWelding electric suppliesElectrical resistance and conductanceCrazing

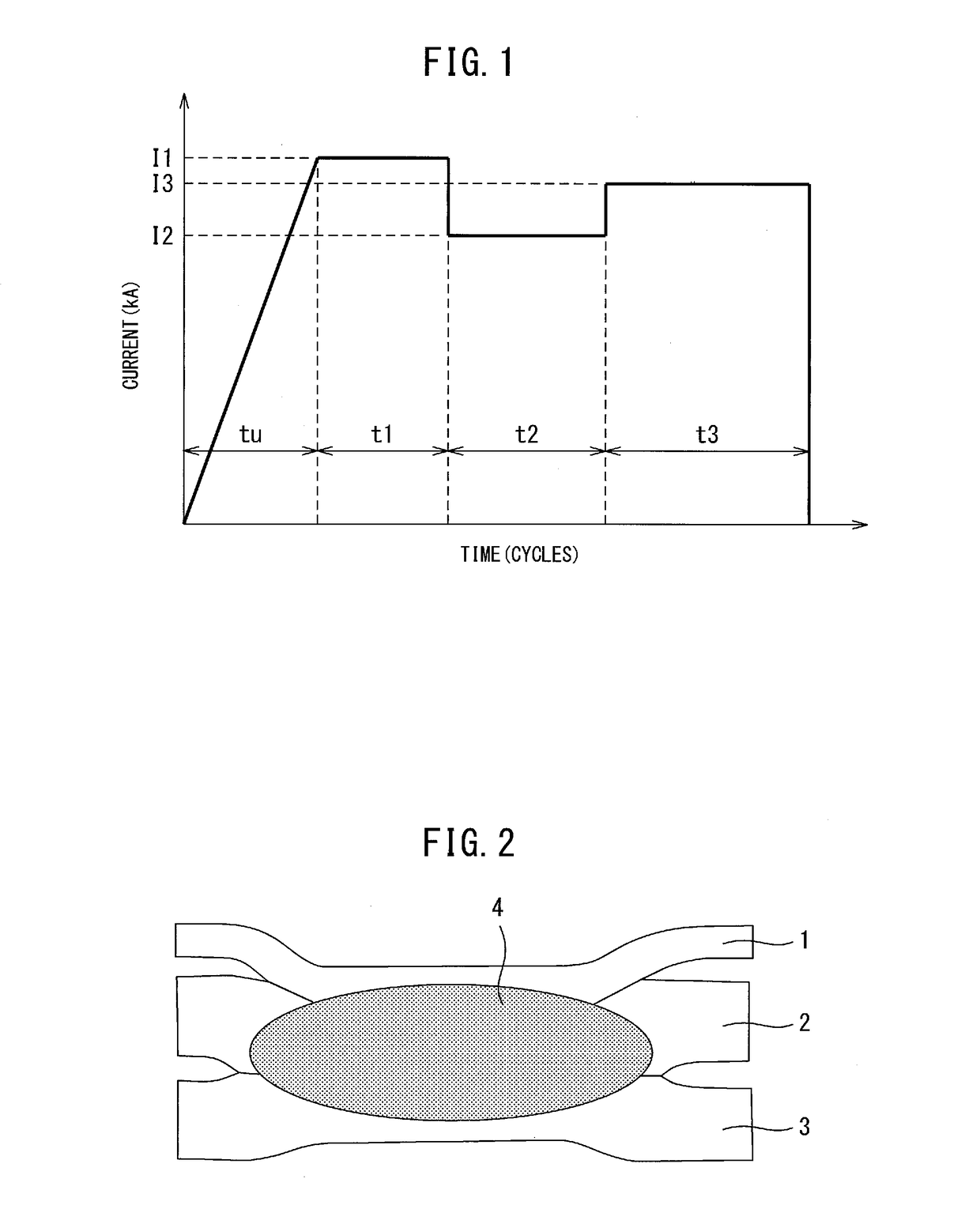

The invention relates to a resistance spot welding method of a galvanized steel plate with tensile strength larger than or equal to 590 Mpa. According to the galvanized high-strength steel resistancespot welding method with the good joint performance, three welding pulses are used in a spot welding period; the first welding pulse and the second welding pulse are used for generating a nugget and restraining the generation of the liquid metal embrittlement (LME) crack, wherein the first welding pulse generates the nugget with the diameter of 3.75 T<1 / 2>-4.25 T<1 / 2>, and the T in the formula isthe plate thickness; the second welding pulse makes the nugget grow slowly; the third welding pulse is a slow-cooling pulse and is used for improving the plasticity of the welding spot. According to the first welding pulse, by setting the time t1 of the first welding pulse and carrying out a test, the welding current I1 of the first welding pulse is obtained, wherein the welding current I1 of thefirst welding pulse is the welding current corresponding to when the nugget with the diameter of 3.75 T<1 / 2>-4.25 T<1 / 2> is generated; and the welding current I2 and the time t2 of the second weldingpulse and the welding current I3 and the time t3 of the third welding pulse are obtained by calculating the welding current I1 and the time t1 of the first welding pulse.

Owner:BAOSHAN IRON & STEEL CO LTD

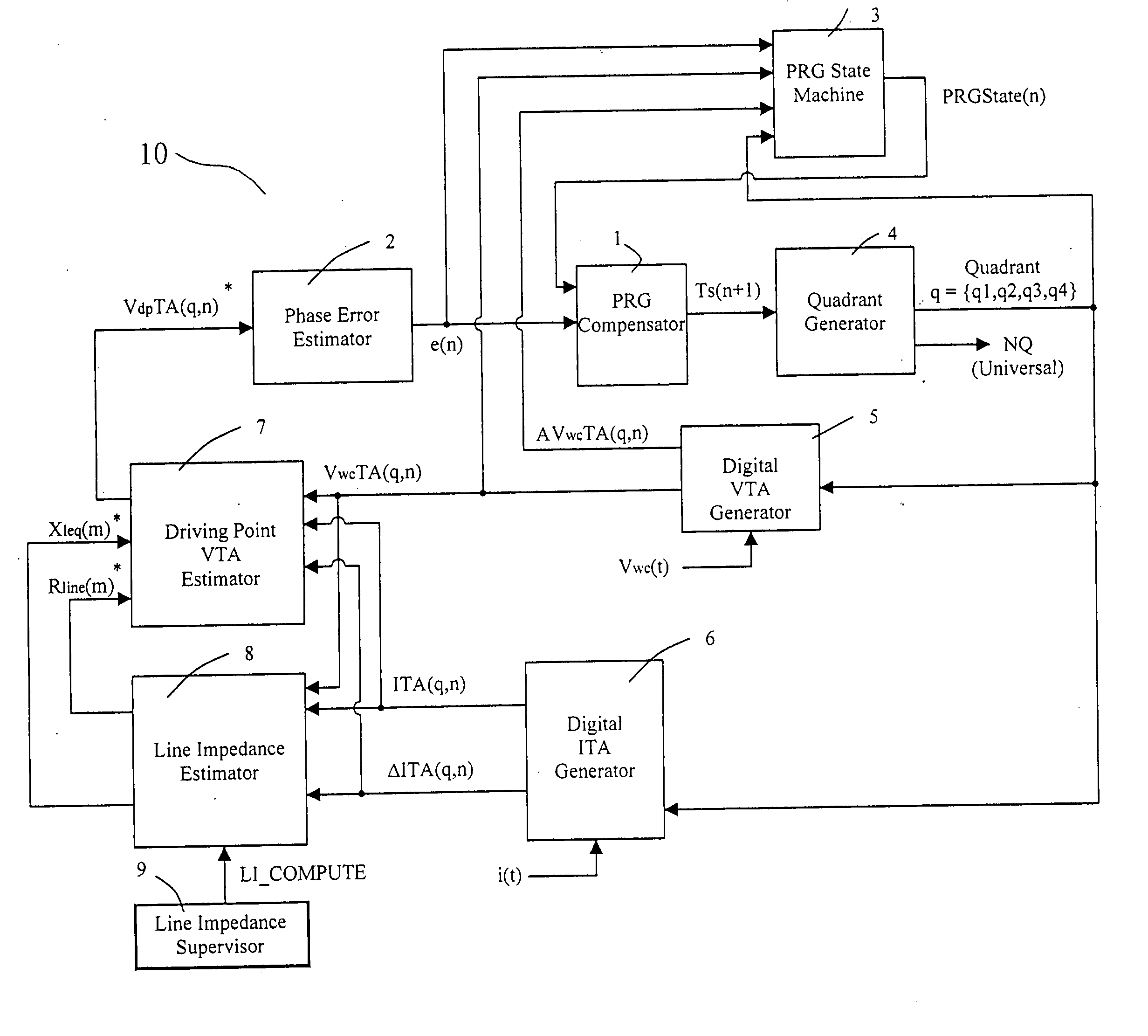

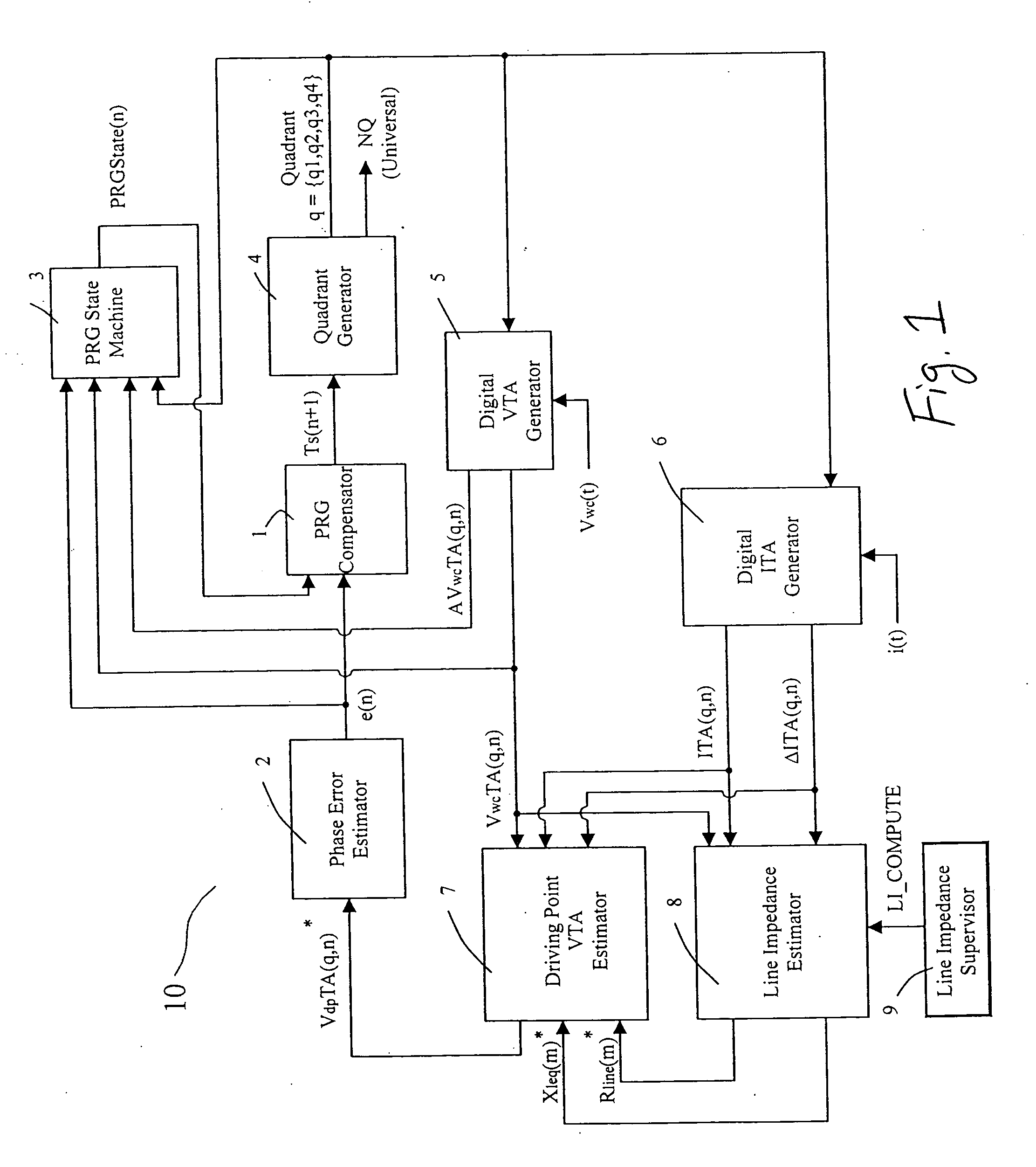

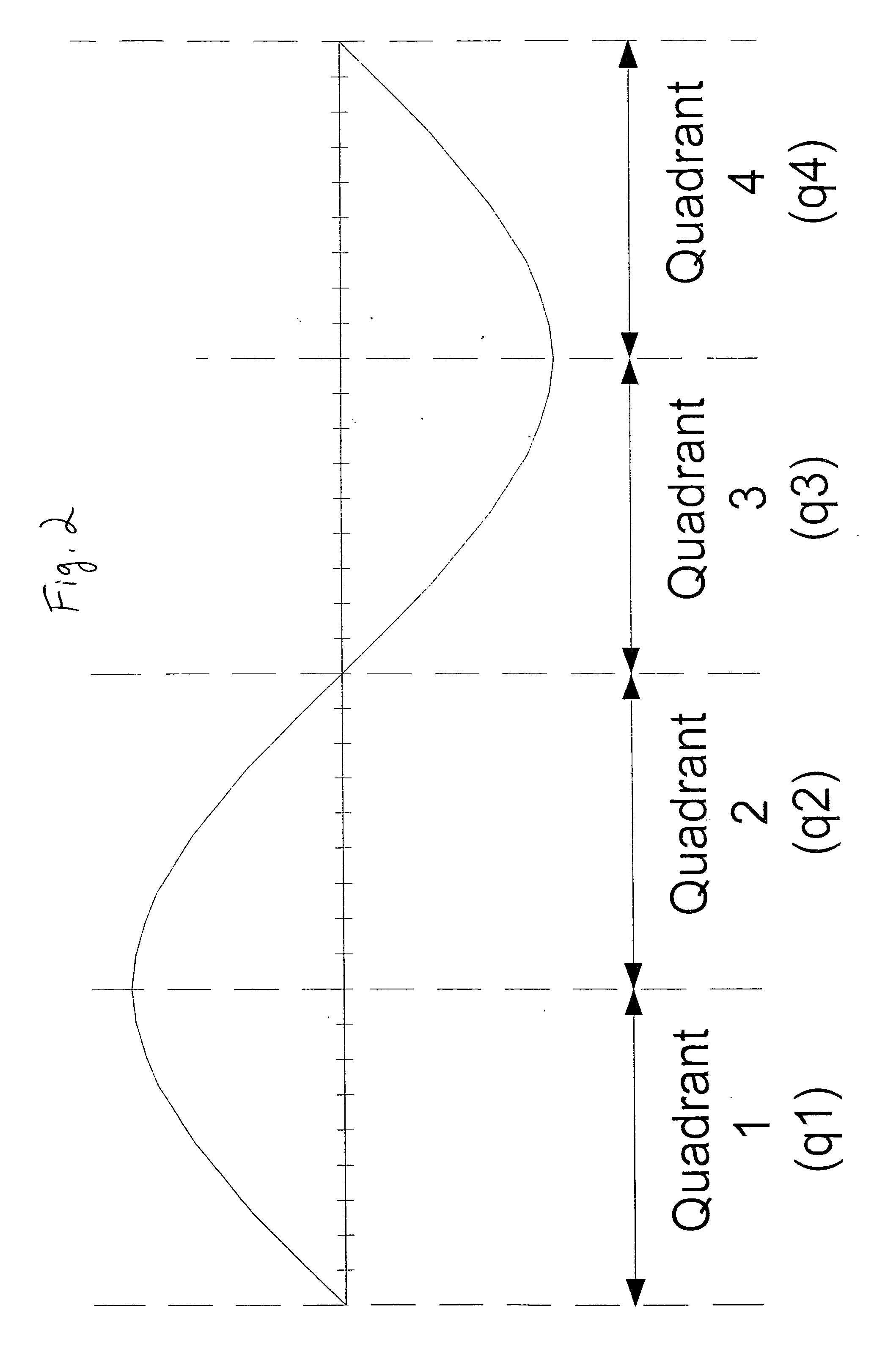

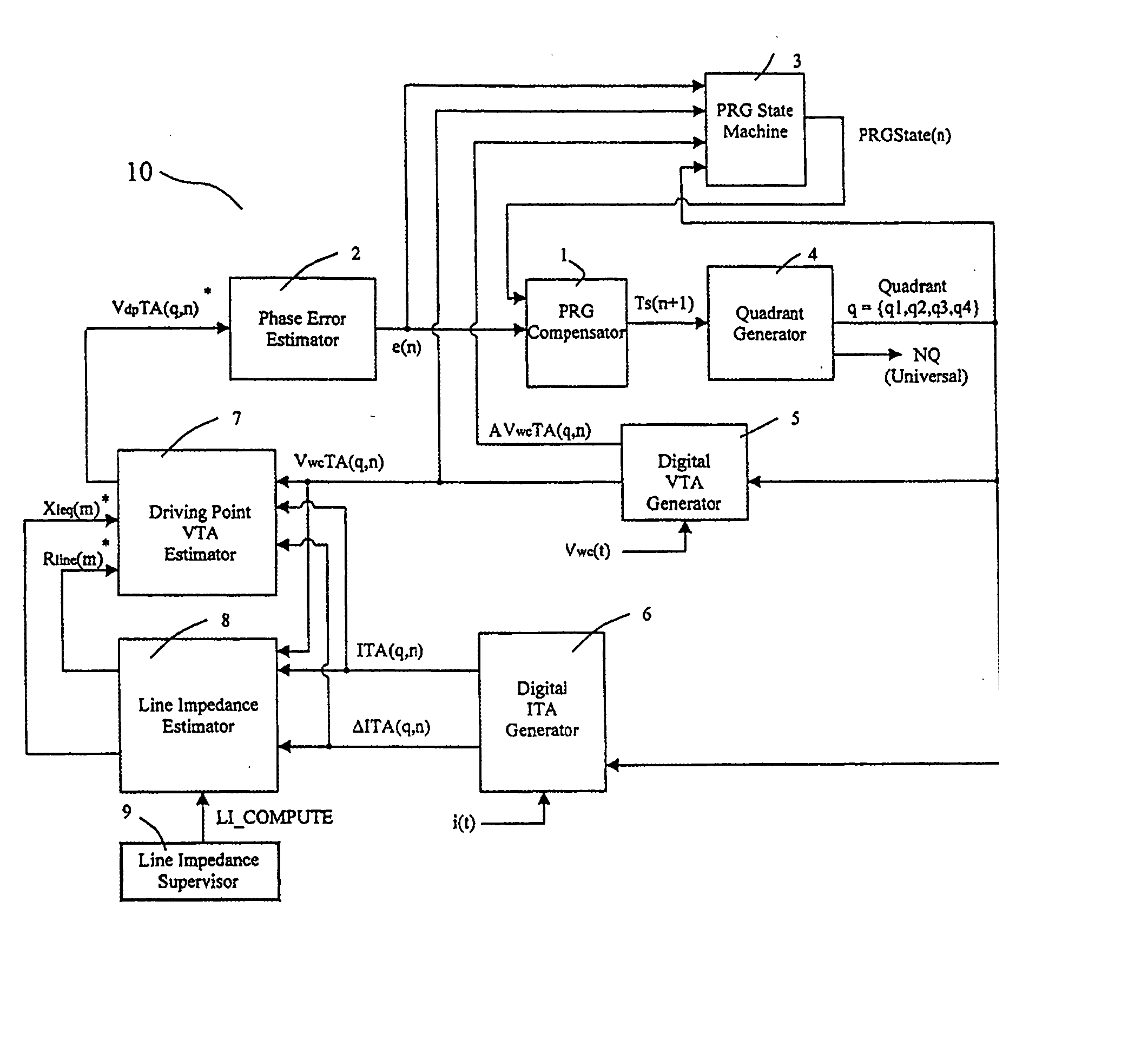

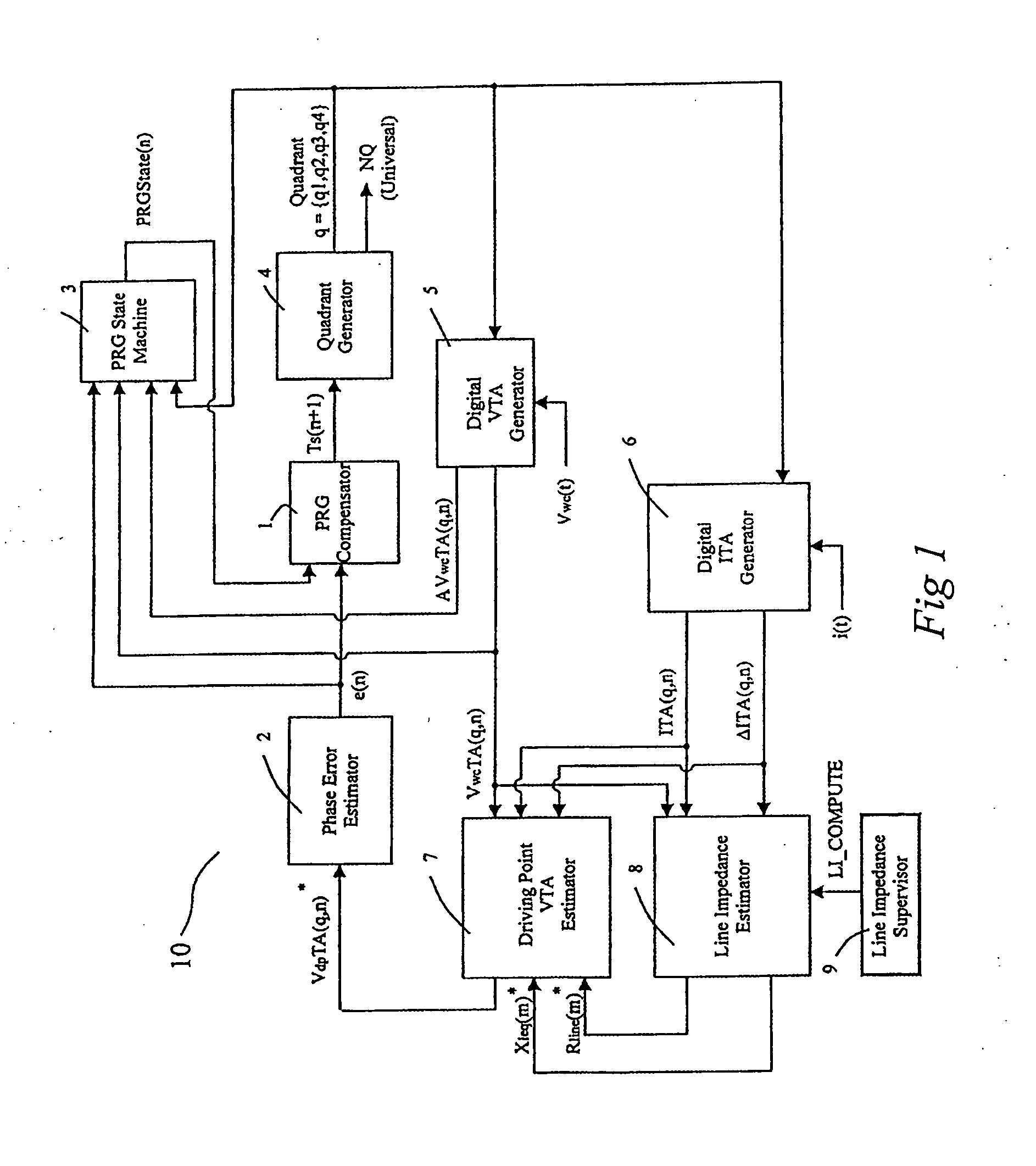

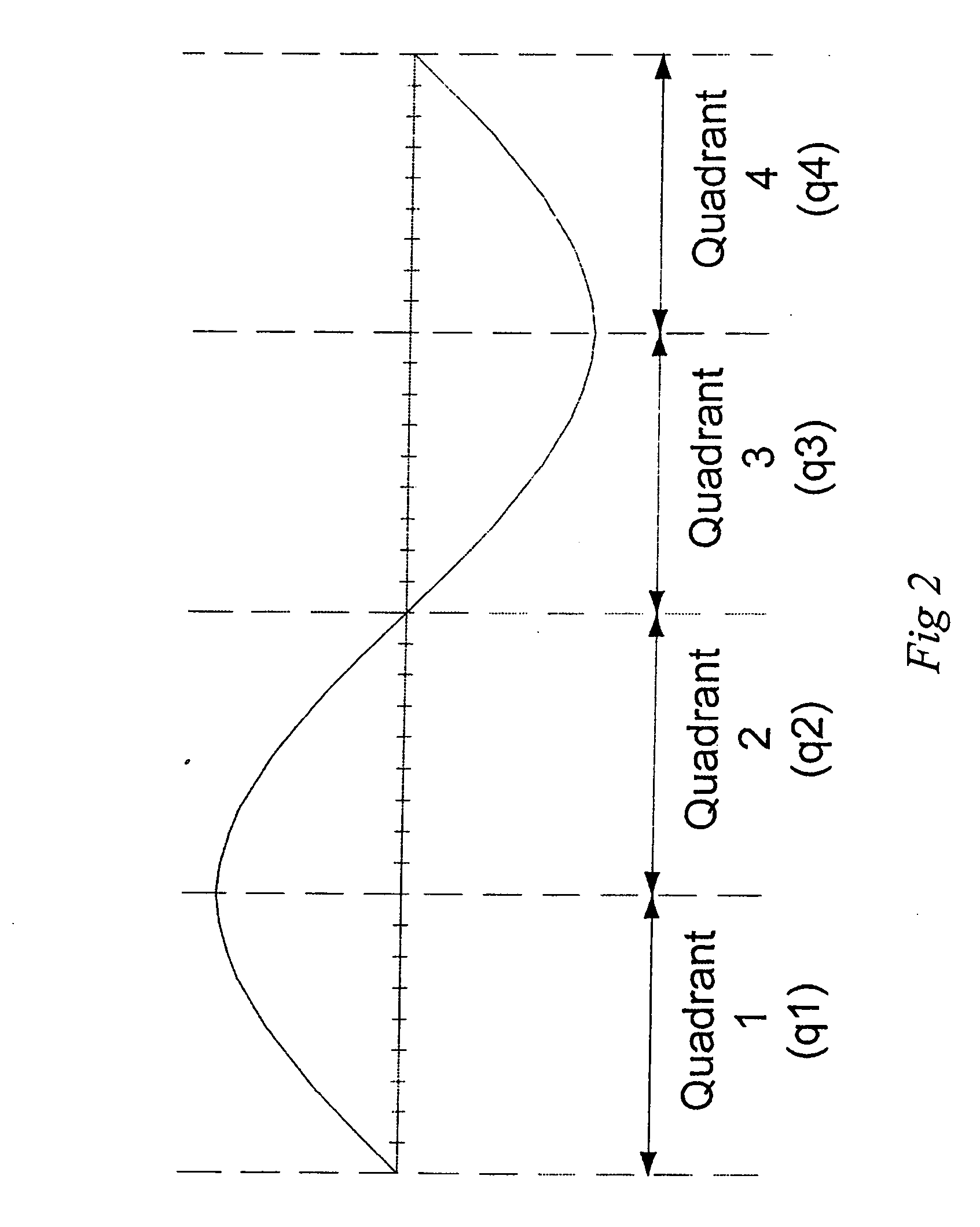

Phase reference generator with driving point voltage estimator

InactiveUS20070085518A1Easy to trackAccurate timingWelding electric suppliesElectric variable regulationElectrical resistance and conductanceElectrical current

A phase reference generator for use in a resistance weld control. The phase reference generator including a digital signal processor having a digital volt-time area generator to generate a volt-time area of an observed voltage; a digital current-time area and current-difference-time area generator to generate a current-time area of an observed current and a current-difference-time area of the observed current; a line impedance estimator; and, a driving point voltage area estimator configured to receive values from the digital volt-time area generator, the digital current-time area generator and current-difference-time area generator, and the line impedance estimator and generate estimates of the driving point voltage.

Owner:SCHNEIDER AUTOMATION INC

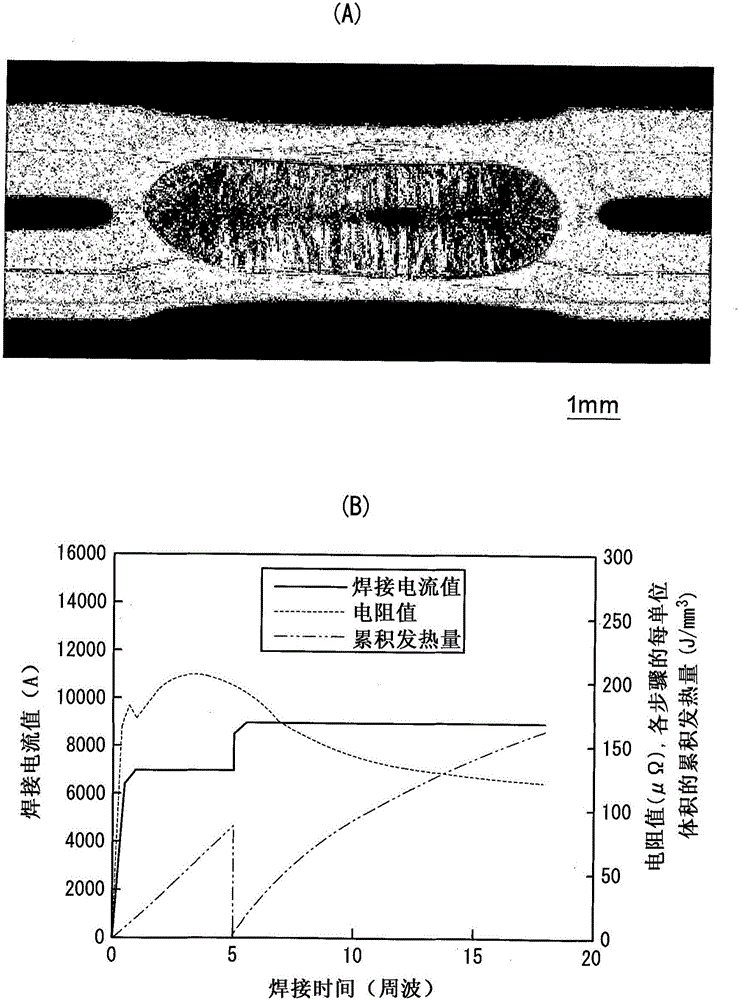

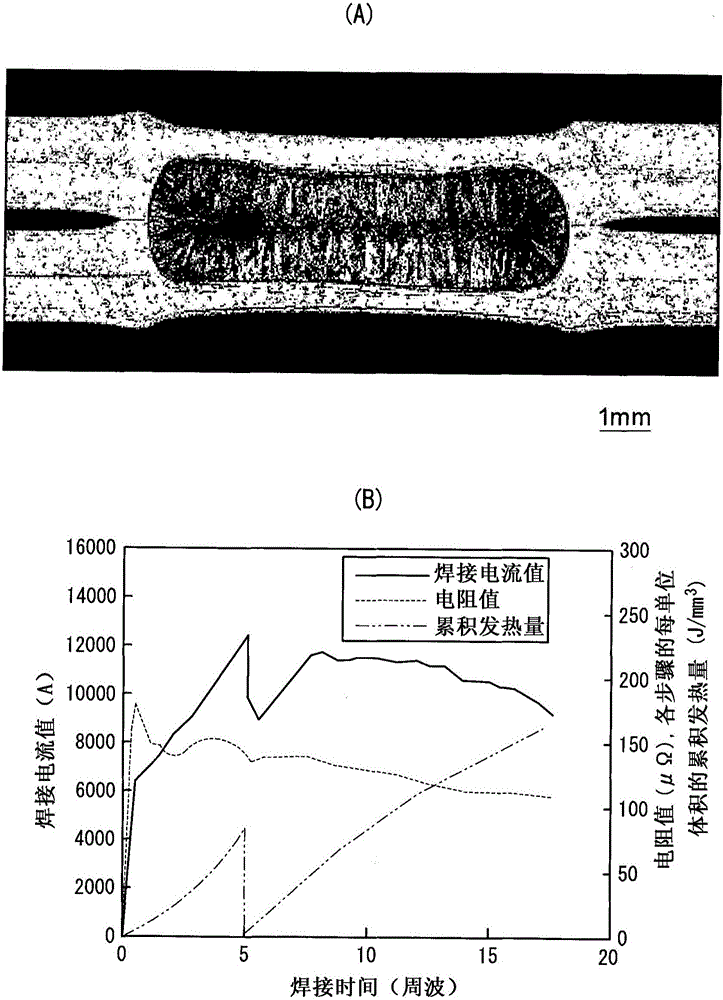

Resistance spot welding method

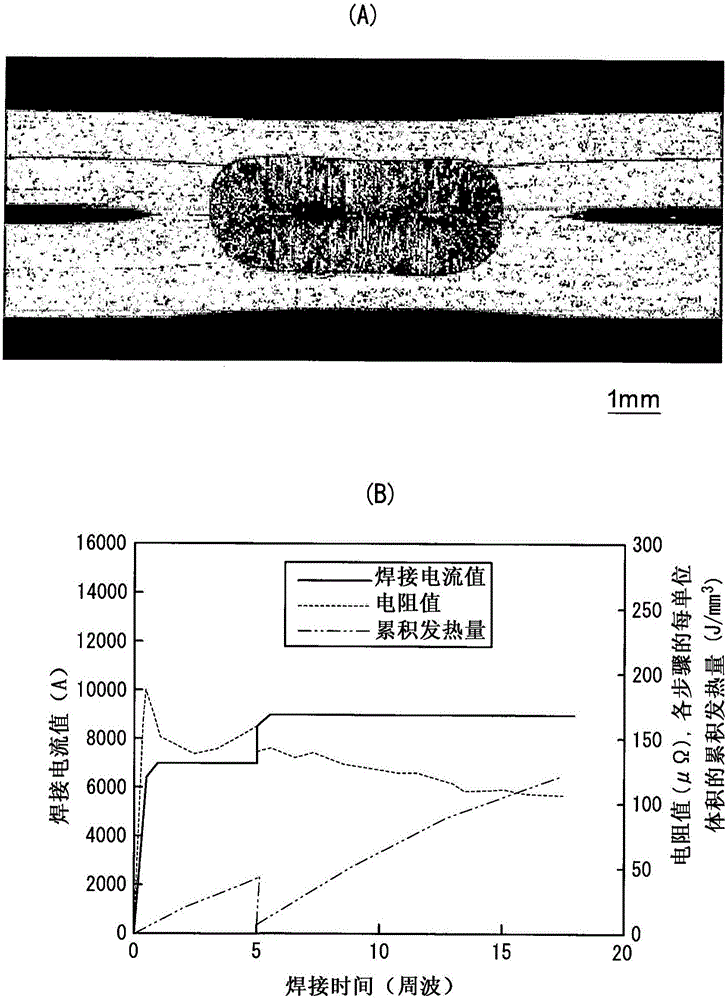

ActiveCN106132622AGood nuggetWelding electric suppliesWelding/cutting media/materialsElectrical resistance and conductanceEngineering

The objective of the invention is to provide a resistance spot welding method with which a nugget having a suitable diameter can be obtained even under special welding conditions, without increasing the energization time and without the generation of expulsions. The invention is a resistance spot welding method in which an energization pattern is divided into multi-stage steps having two or more stages, and in which test welding and main welding are performed. In the test welding, the energization is performed using a constant current that has a different current value for each step, and the time variation of the instantaneous amount of heat generated per unit volume, and the accumulated amount of heat generated per unit volume are stored as target values. In the main welding, if the amount of time variation of the instantaneous amount of heat generated per unit volume deviates from the results of the test welding during any step, the amount of energization is controlled in such a way that the difference is compensated for during the remaining energization time in said step. The configuration is such that in the test welding, if the energization current in a first step is Ia and the energization current in second and subsequent steps is Ix, the relationship 0.3 x Ix<= Ia <Ix is satisfied.

Owner:JFE STEEL CORP

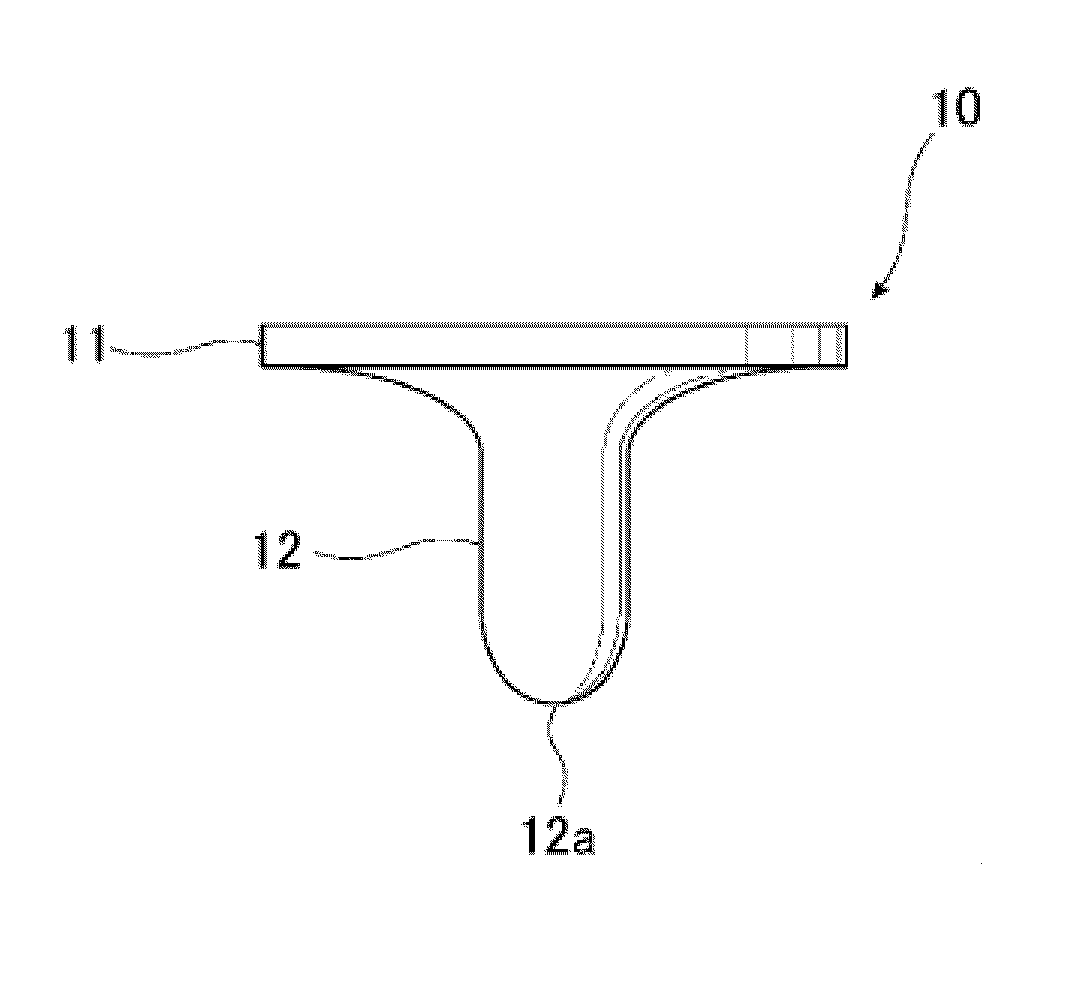

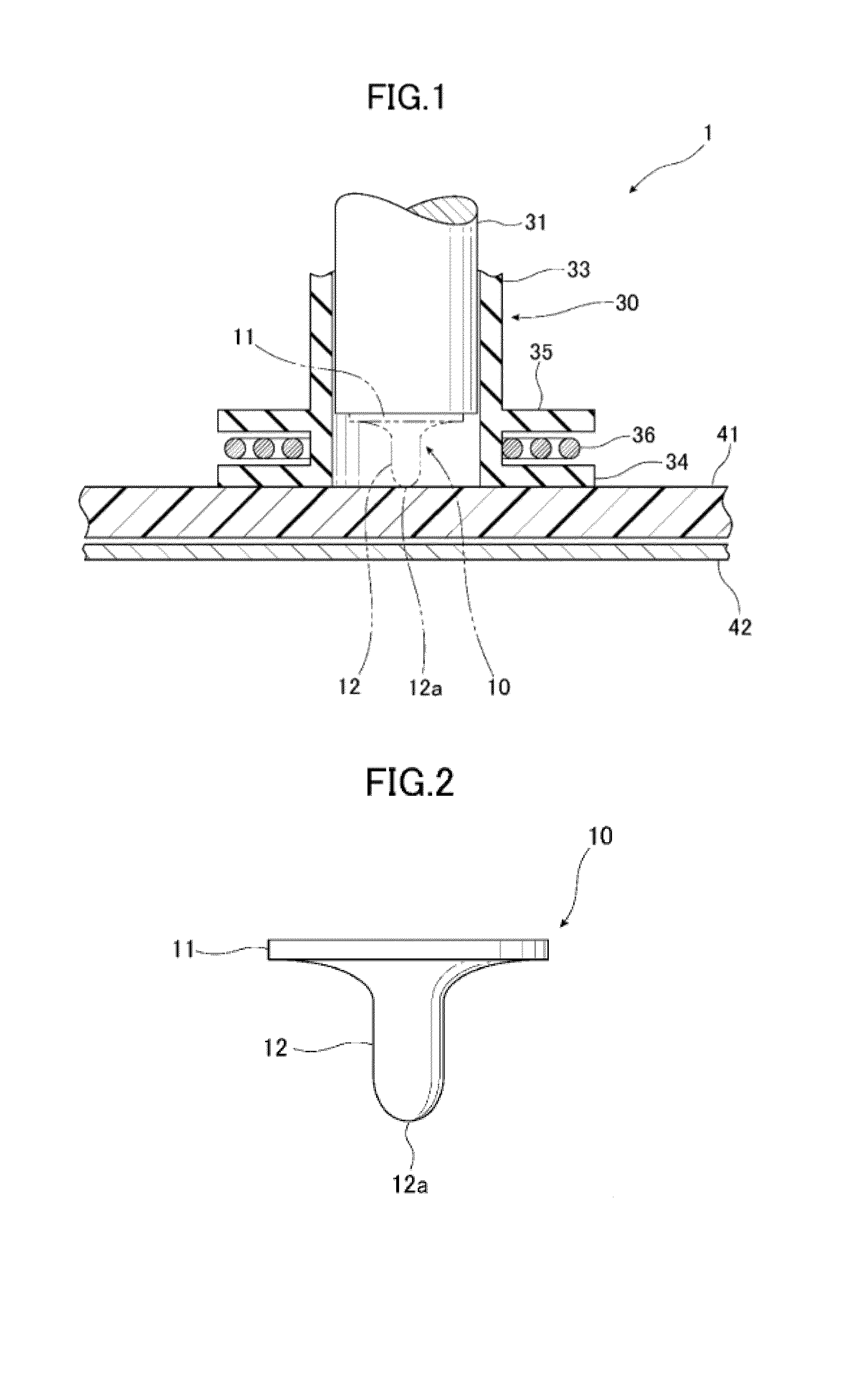

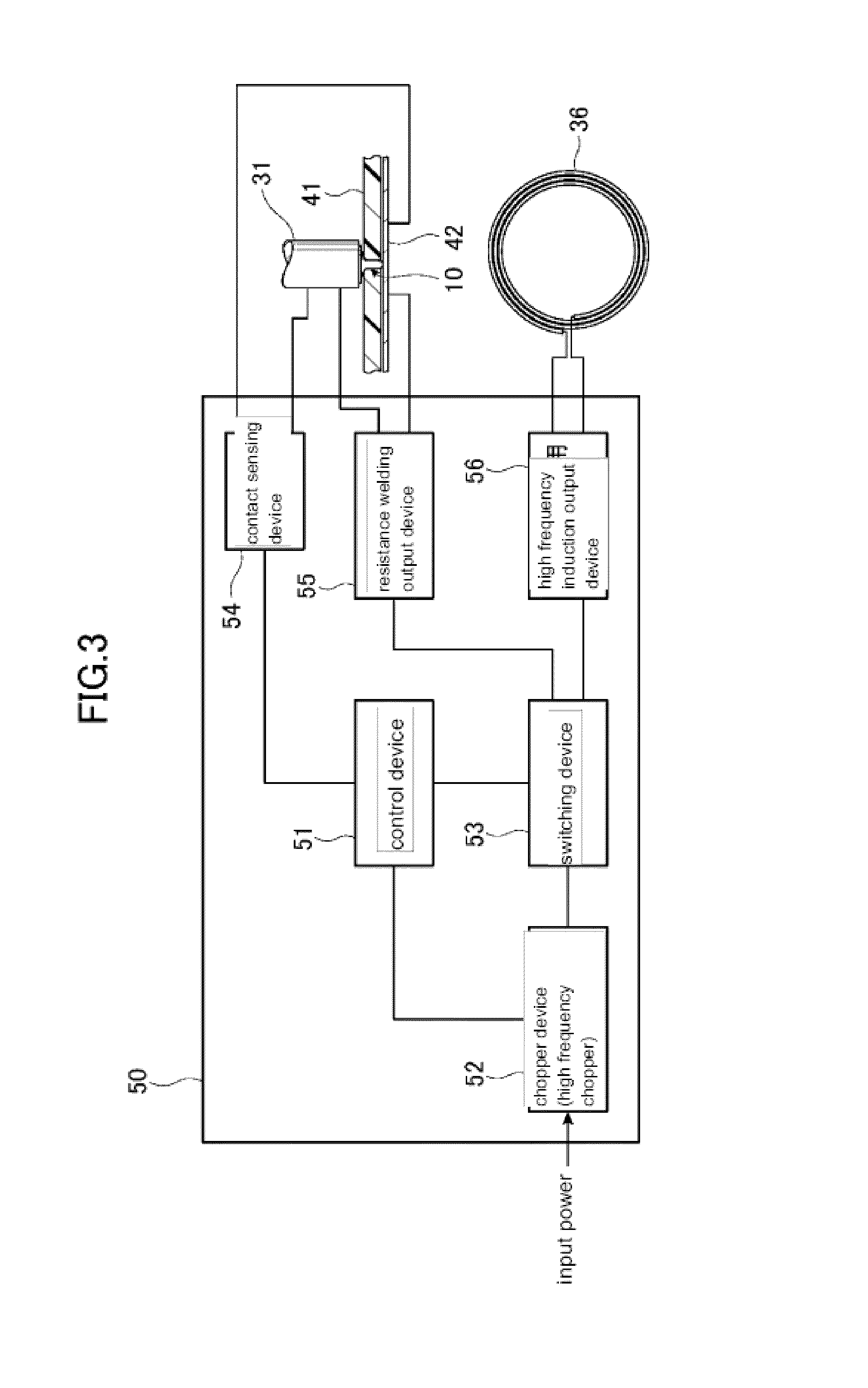

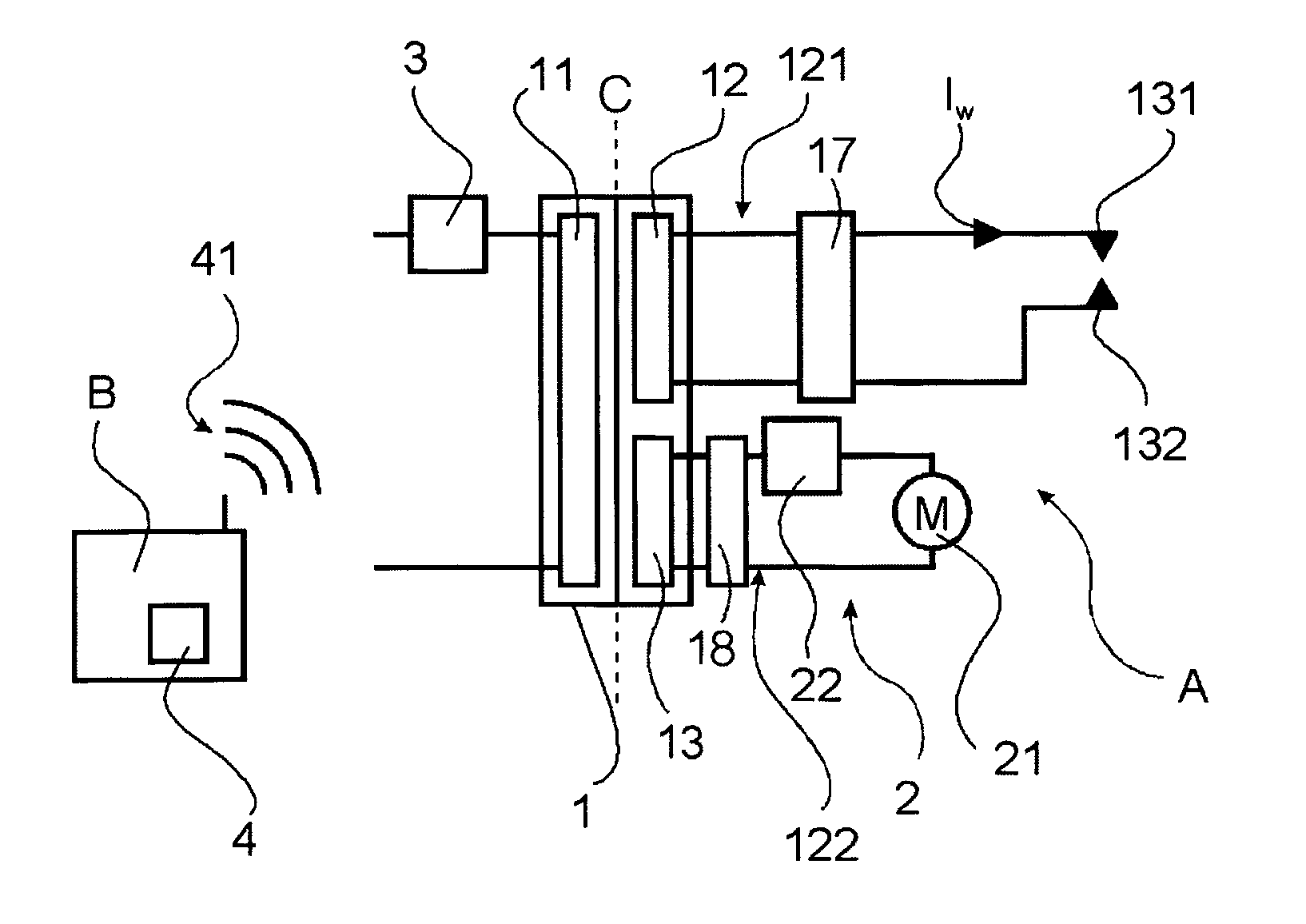

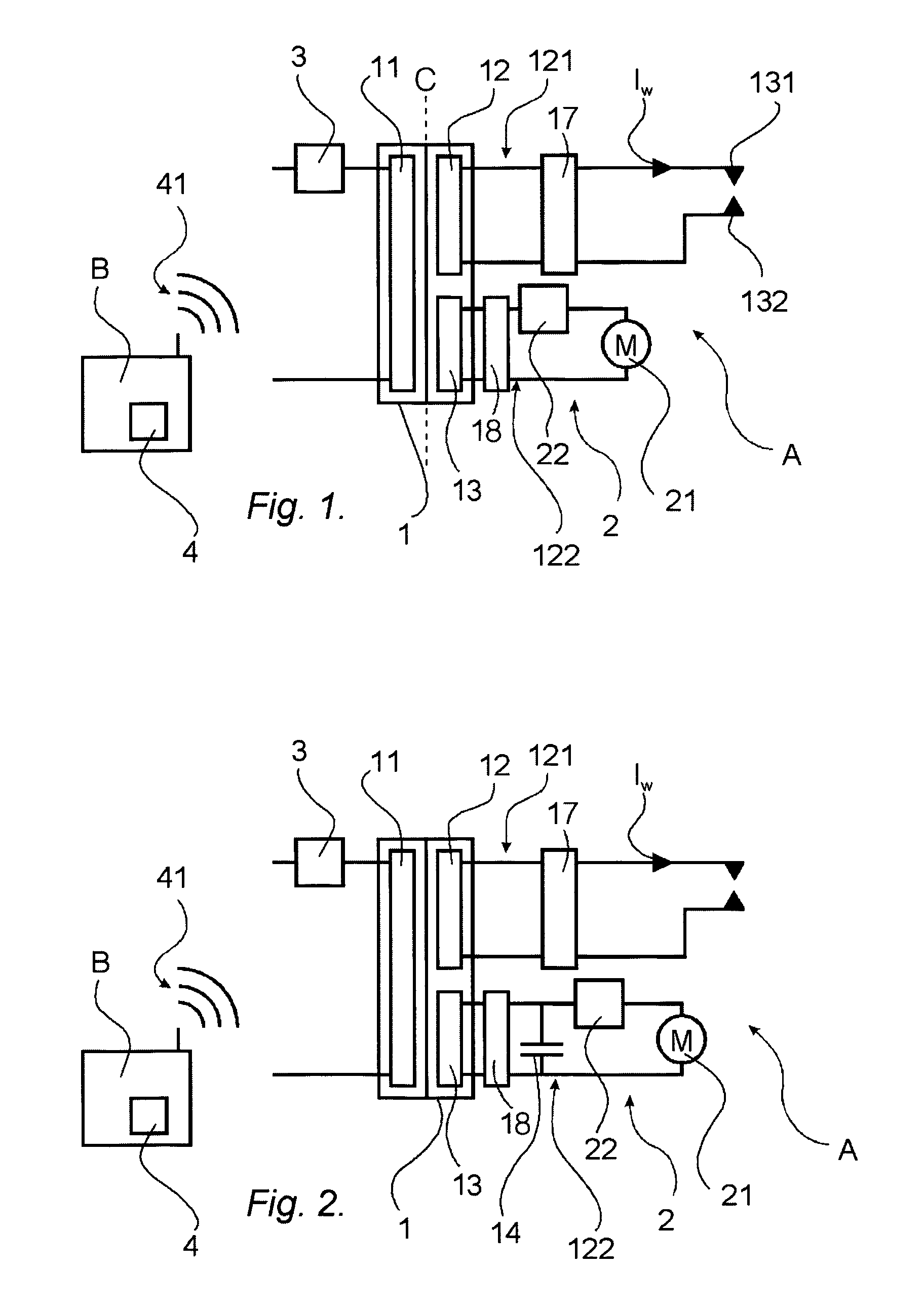

Joining device and joining method

ActiveUS20160262214A1Coil arrangementsWelding electric suppliesHigh frequency powerWelding power supply

A joining device for connecting a metal member and a resign member with a metal fastener including a penetrating tip comprises: a cylindrical nosepiece; a high frequency electromagnetic induction coil around the nosepiece; an electrode punch for pressing the fastener into the resign member; a electronic chopper for producing a high frequency current; a high frequency power supply for supplying an induction current to the induction coil; a welding power supply for supplying a welding current between the electrode punch and the metal member; a contact detector for sensing when the fastener tip touches the metal member; and a switching unit for automatically switching from the induction current to the welding current when the contact detector senses that the tip has contacted the metal member.

Owner:NEWFREY

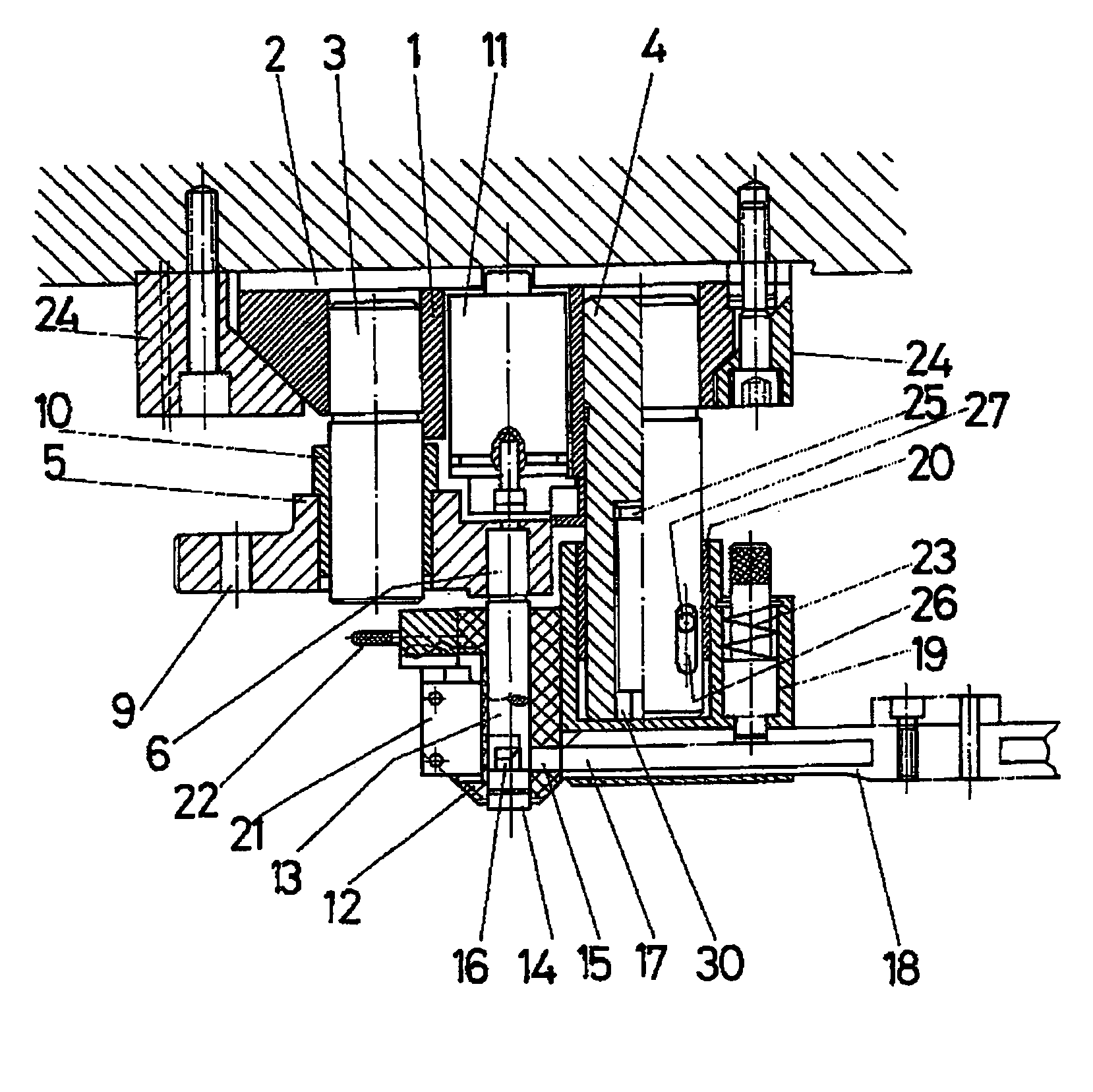

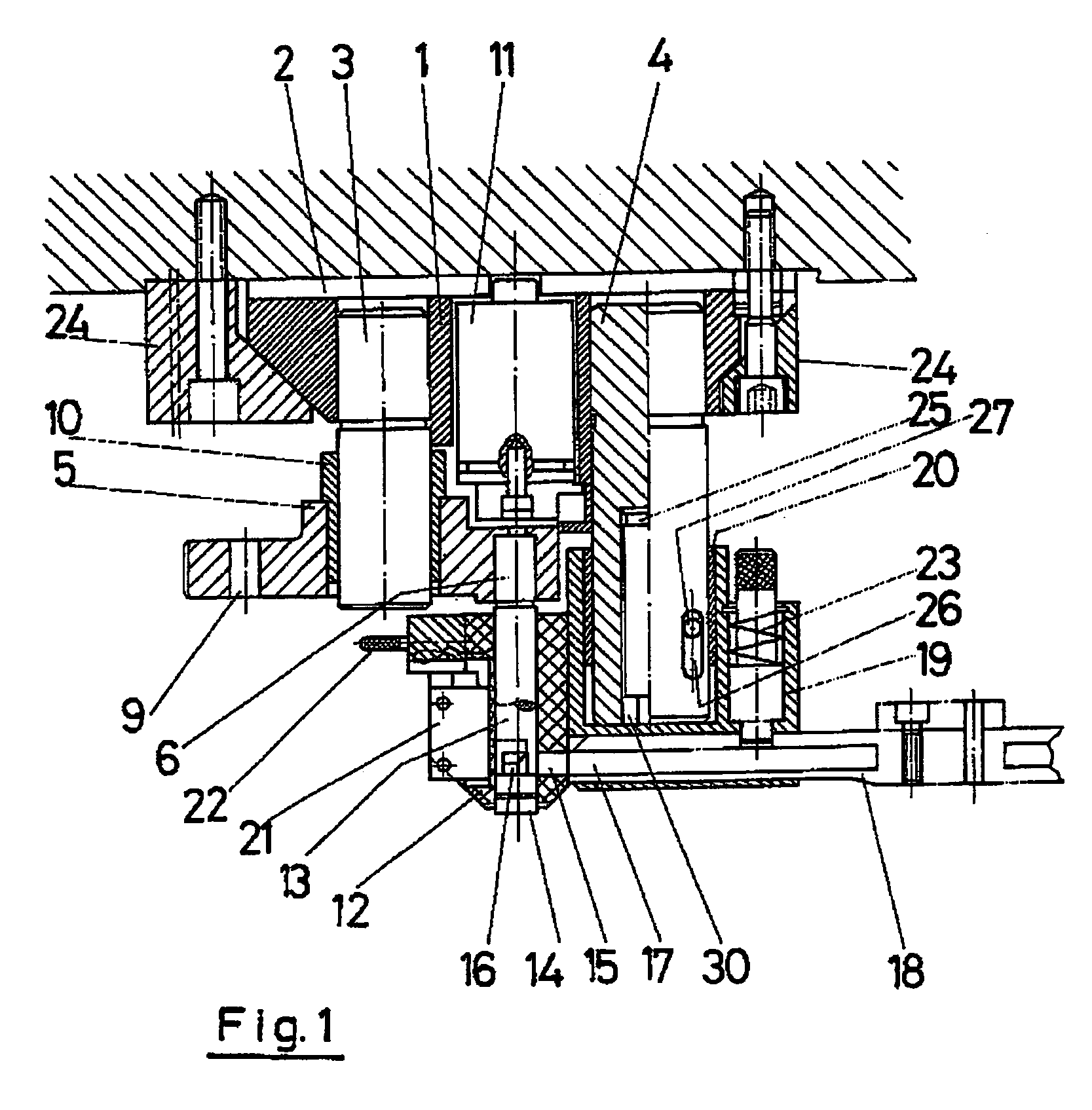

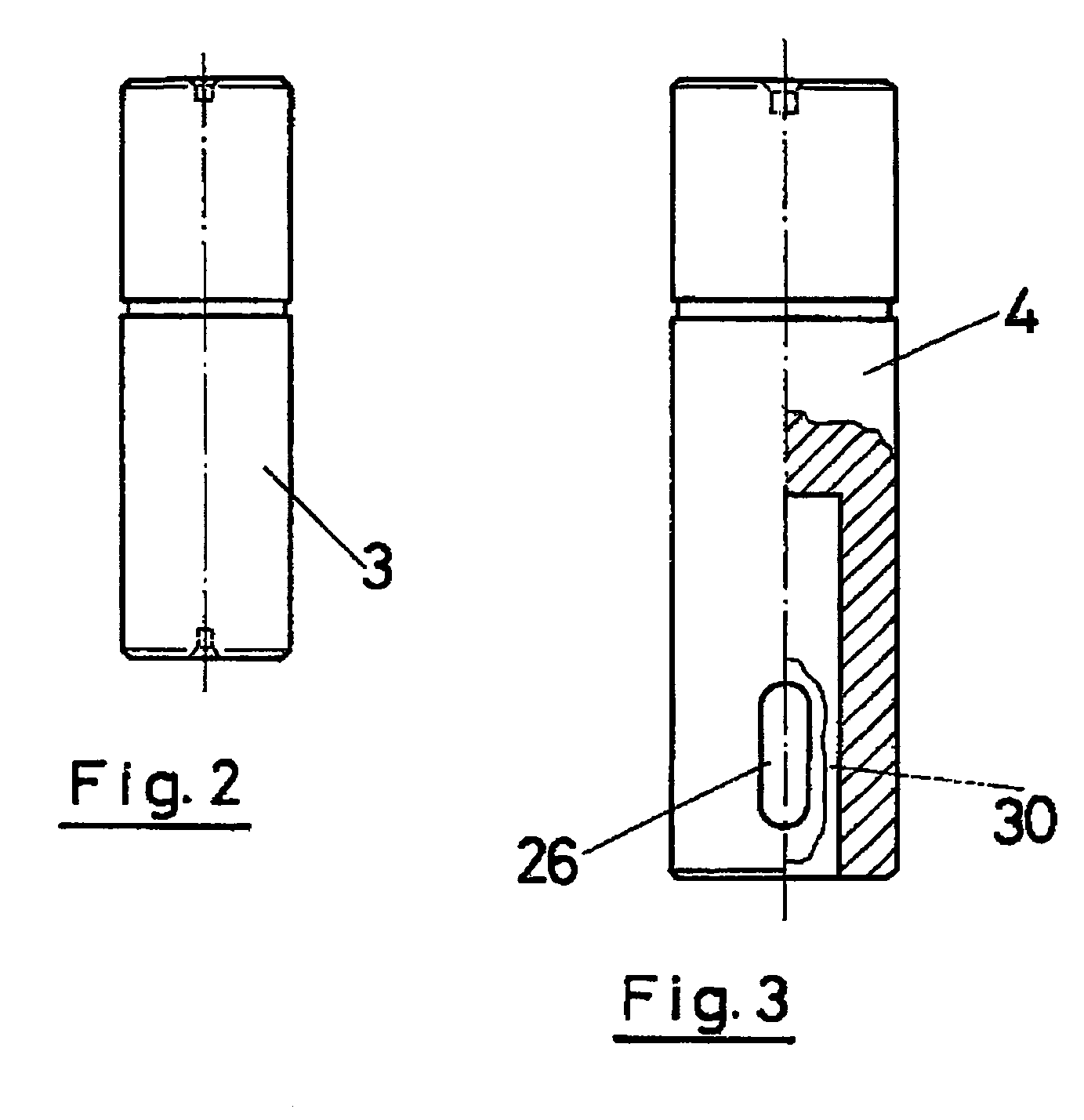

Welding device

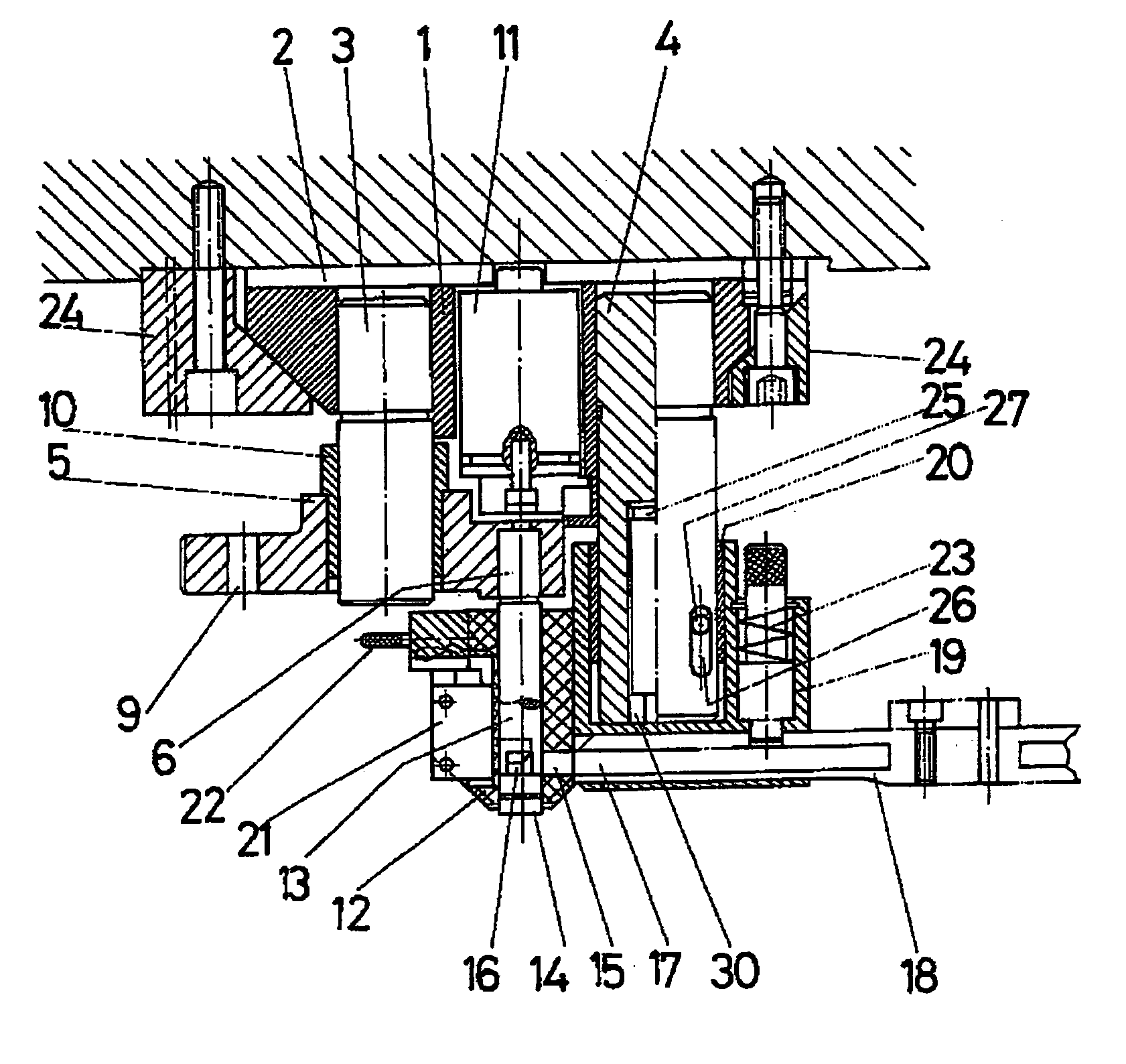

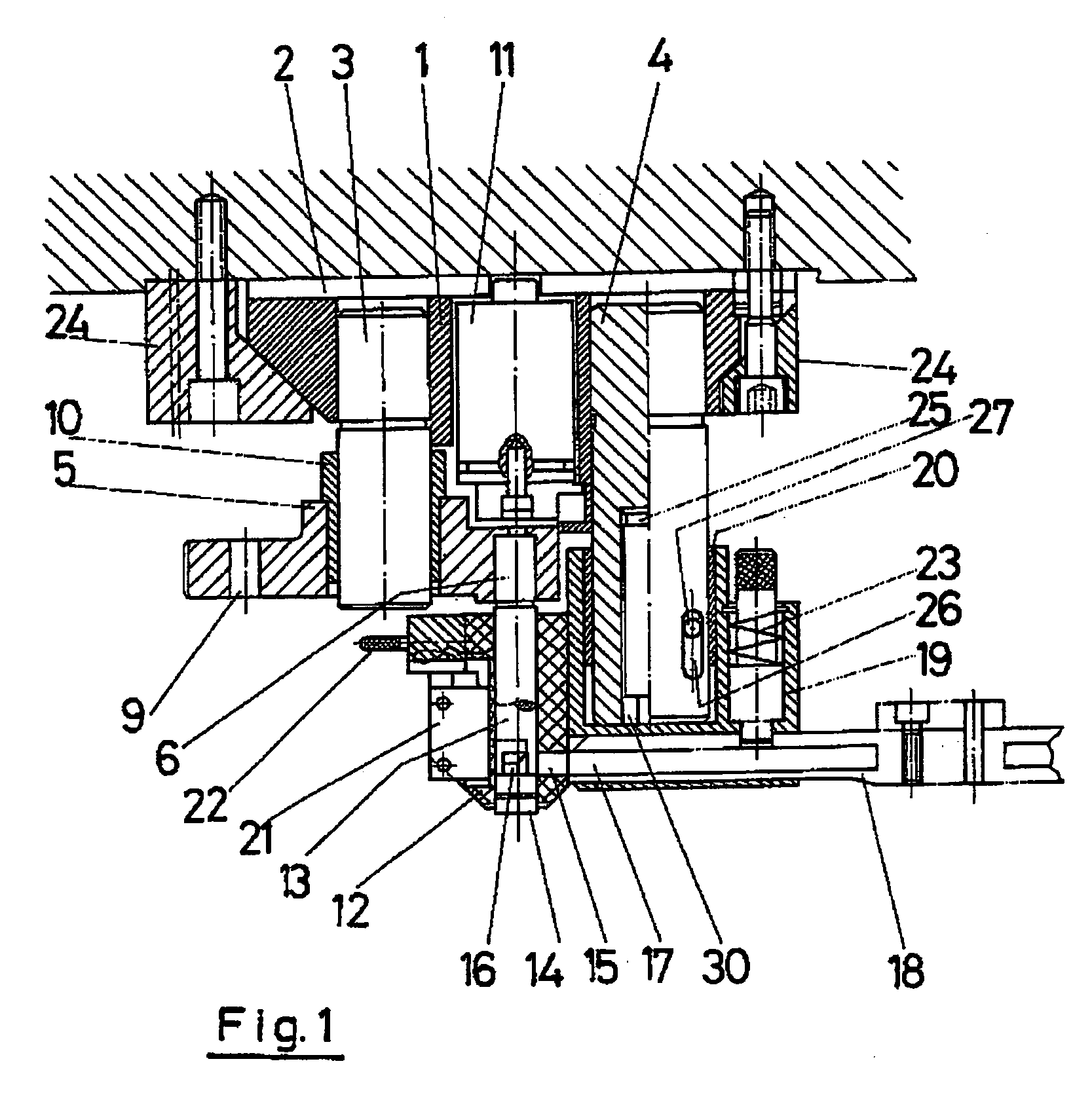

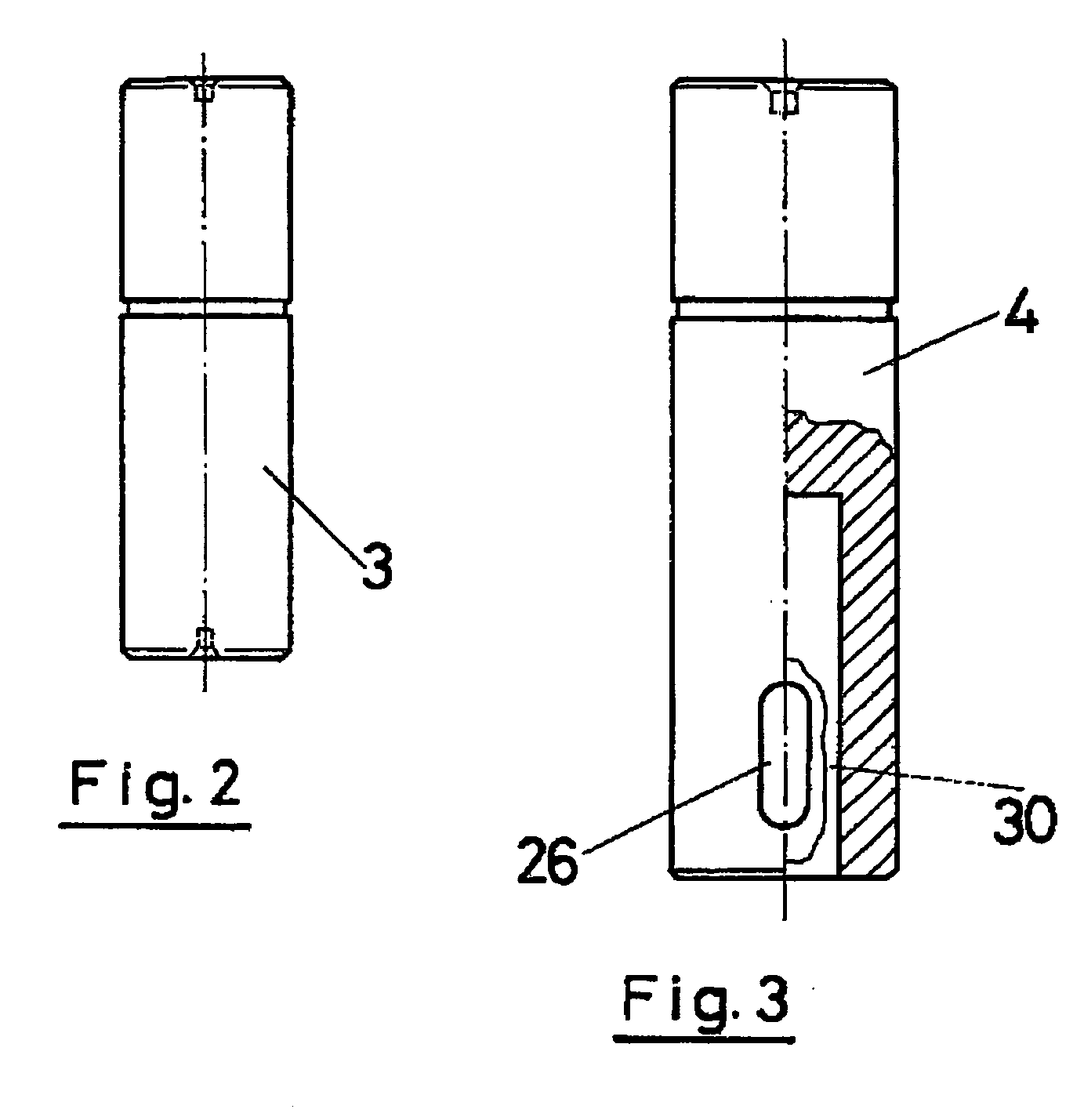

ActiveUS7170025B2Reduce decreaseSufficient forceResistance electrode holdersWelding/cutting auxillary devicesElectrical resistance and conductanceGas cylinder

IMPROVED RESISTANCE WELDING DEVICE that includes a mobile electrode in a support assisted by a spring, gas cylinder or expansion element, allowing its movement on being compressed so that the time lapse for the welding is sufficiently long to be effective, without altering the movement cycle of the press into which it is installed. The support has one or several columns, the electrode being supported sliding along one and with a rod housed on the inside of a positioning device, also axially movable, into which the small parts to be welded are received through a conduit. The positioning device, made from an insulated material, preferably ceramic, has some fixing clamps for said part until the welding is made pushed by the electrode rod through a lower window.

Owner:TAMP ING EUROPA SUR

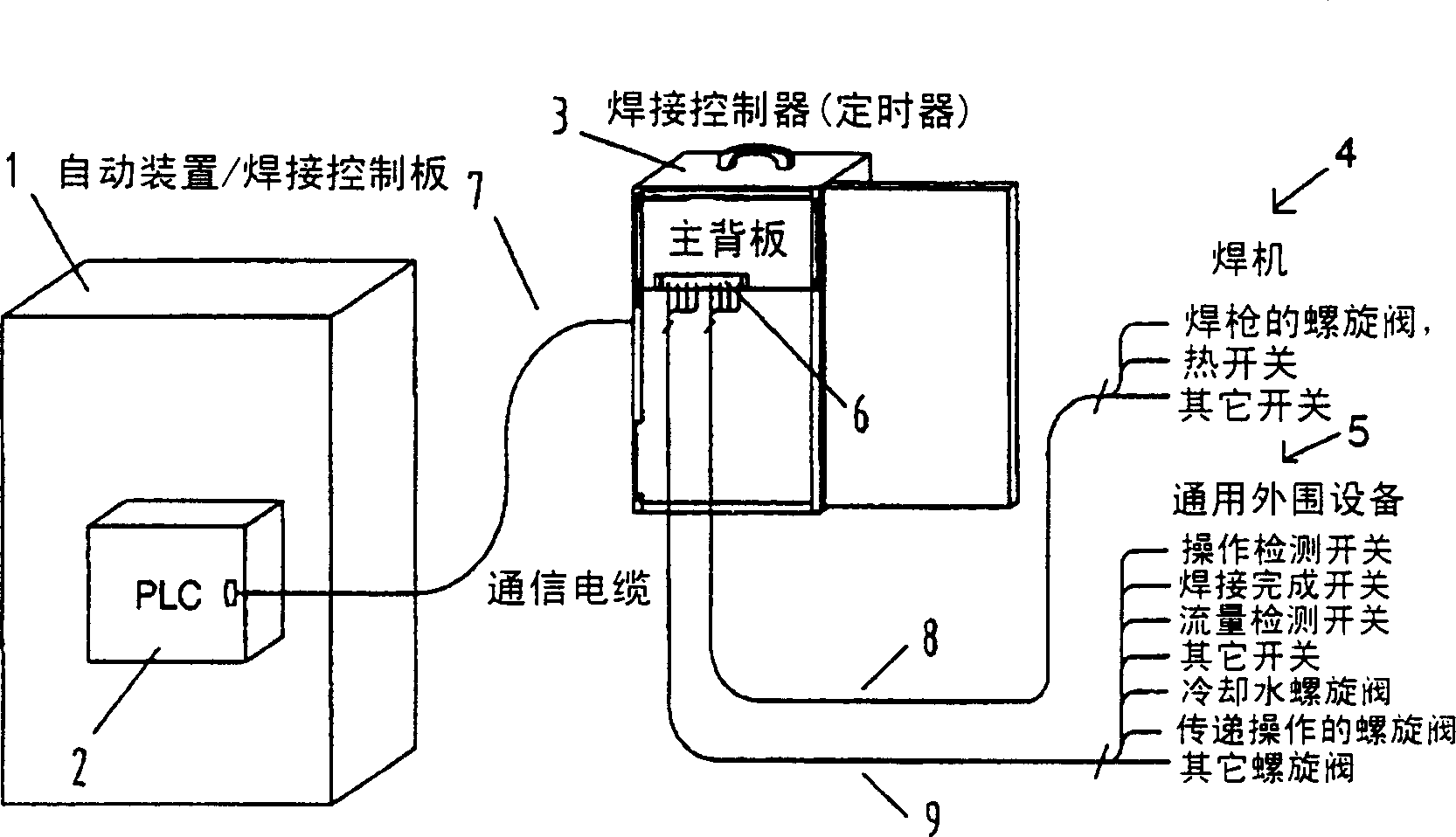

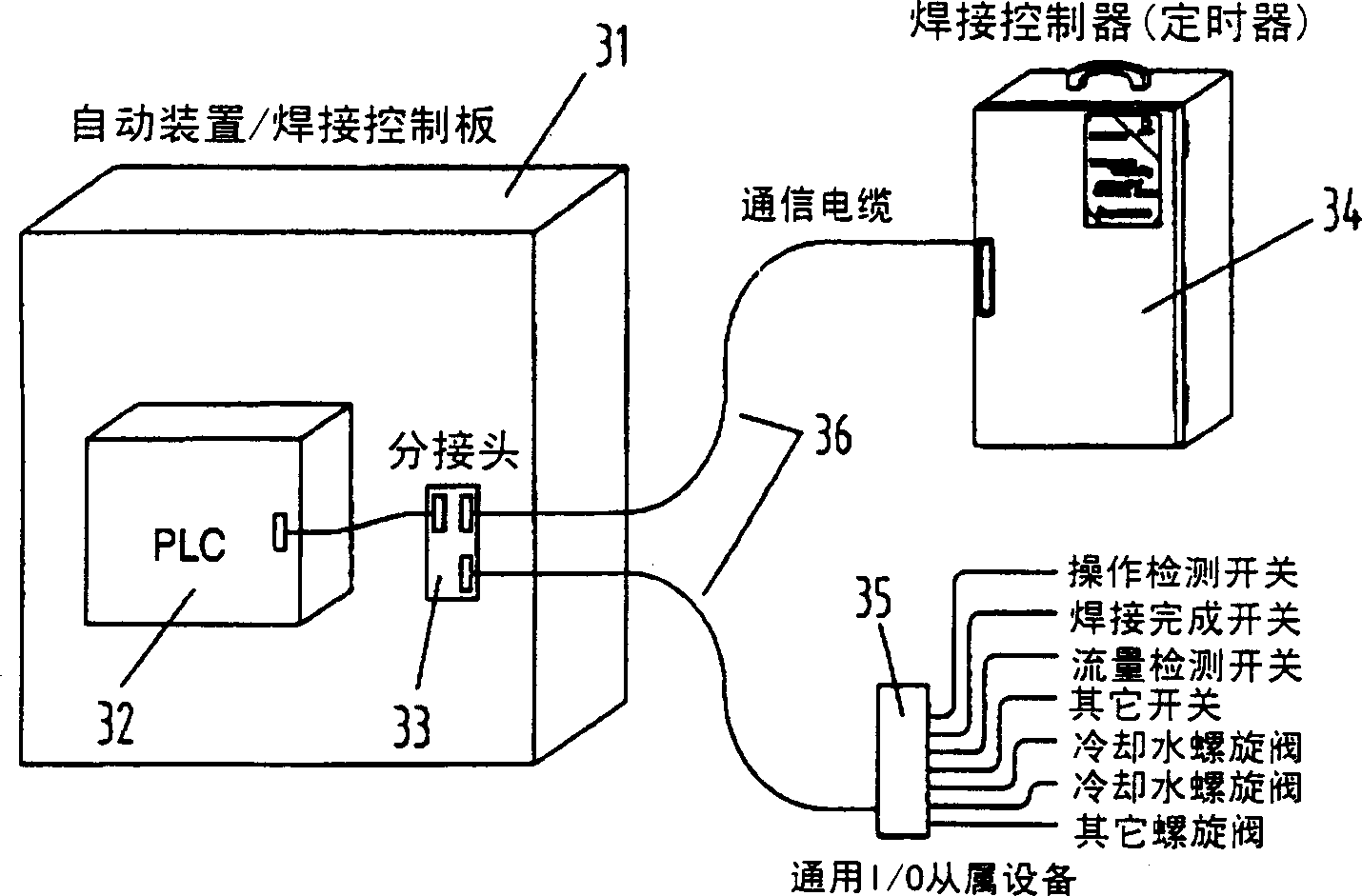

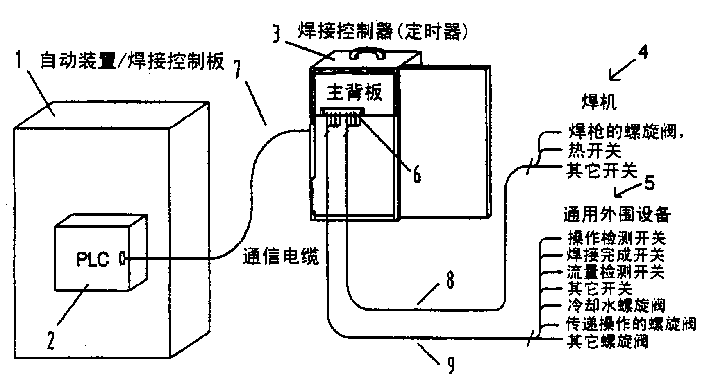

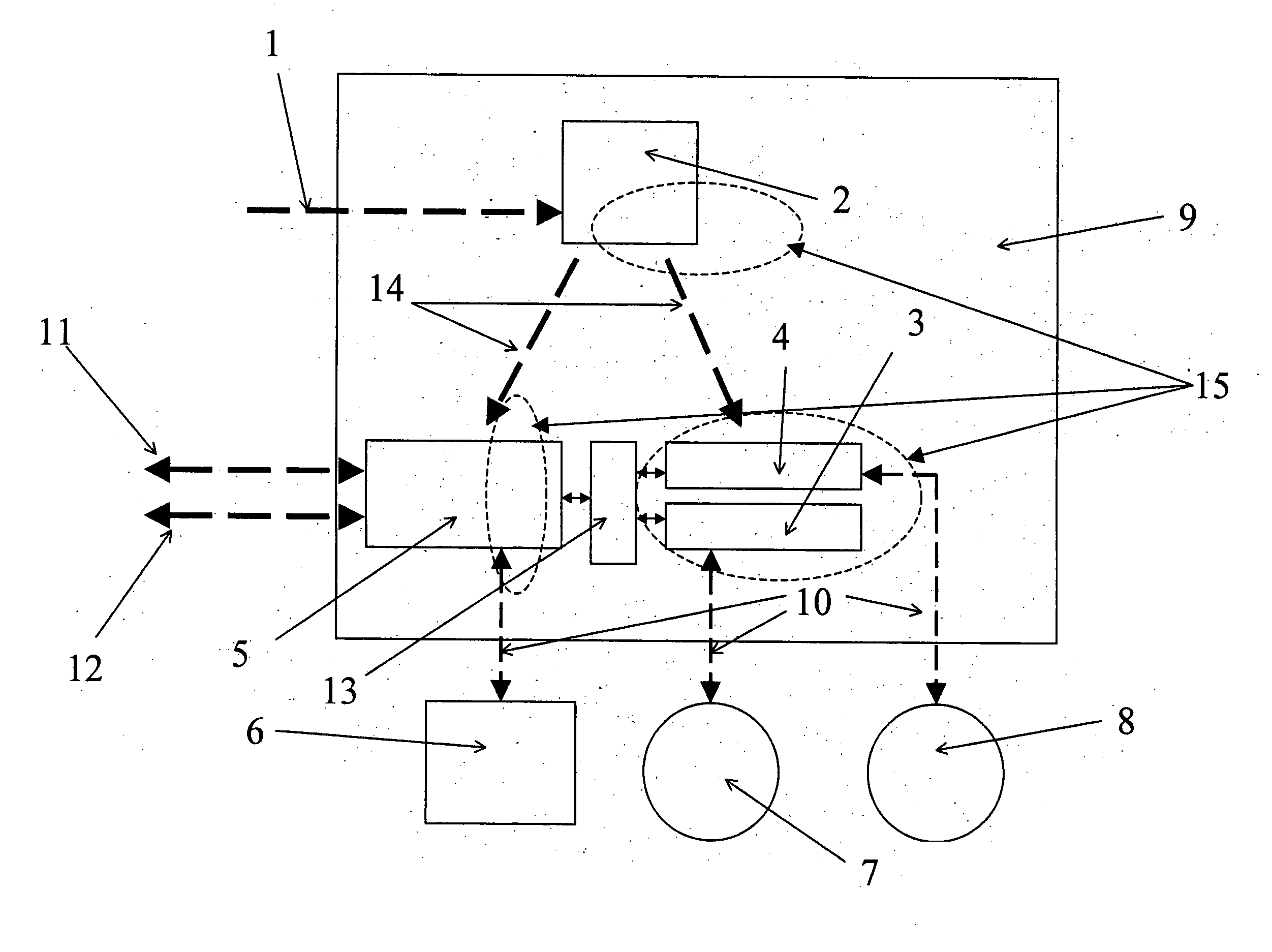

Welding system

InactiveCN1383952AShorten the lengthEfficient use ofWelding/cutting auxillary devicesArc welding apparatusProgrammable logic controllerField bus

A welding system capable of shortening length of connection lines and the of effectively utilizing devices as a whole. The system comprises a welding controller (3) provided with an I / O interface (6), a controller (1) provided with a programmable logic (2) and connected to the I / O interface (6) of the welding controller (3) through a field bus interface (7) serving as communication means, a welding machine (4) and a general-purpose peripheral equipment (5), wherein the welding controller (3) controls the welding machine (4) and the general-purpose peripheral equipment (5) upon receipt of instructions from the programmable logic controller (2) through the field bus interface (7).

Owner:OHARA

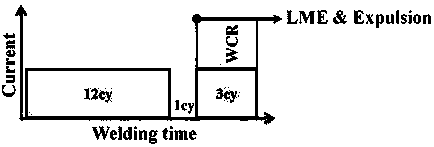

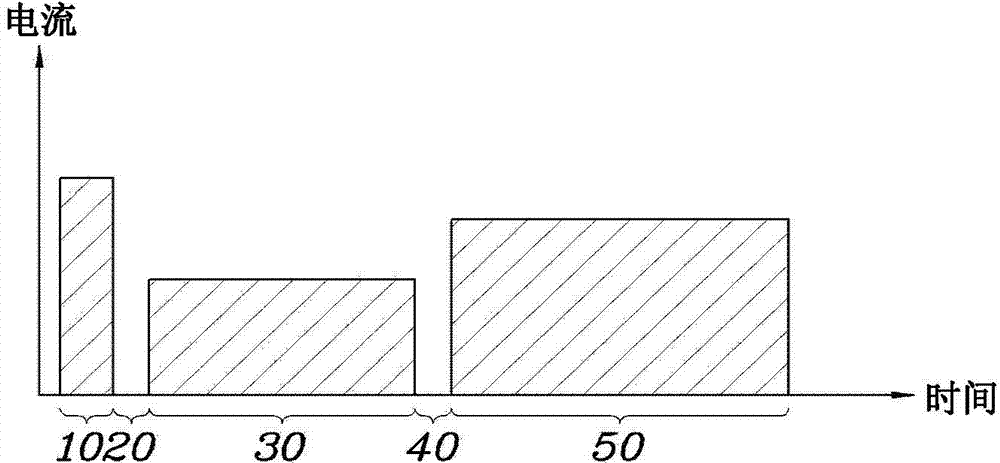

Spot welding method for high strength steel sheet

InactiveCN104722905AWelding electric suppliesWelding/soldering/cutting articlesEngineeringHigh intensity

A spot welding method for a high strength steel sheet is provided. The method includes a first pulse step for applying electric current of about 8 to 9 kA about 1 to 3 cy and a first cooling step for cooling for about 1 to 3 cy. In addition, the method includes a second pulse step for applying electric current less than the electric current applied in the first pulse step and a second cooling step for cooling for about 1 to 3 cy. A third pulse step includes applying electric current greater than the electric current applied in the second pulse step.

Owner:HYUNDAI MOTOR CO LTD +1

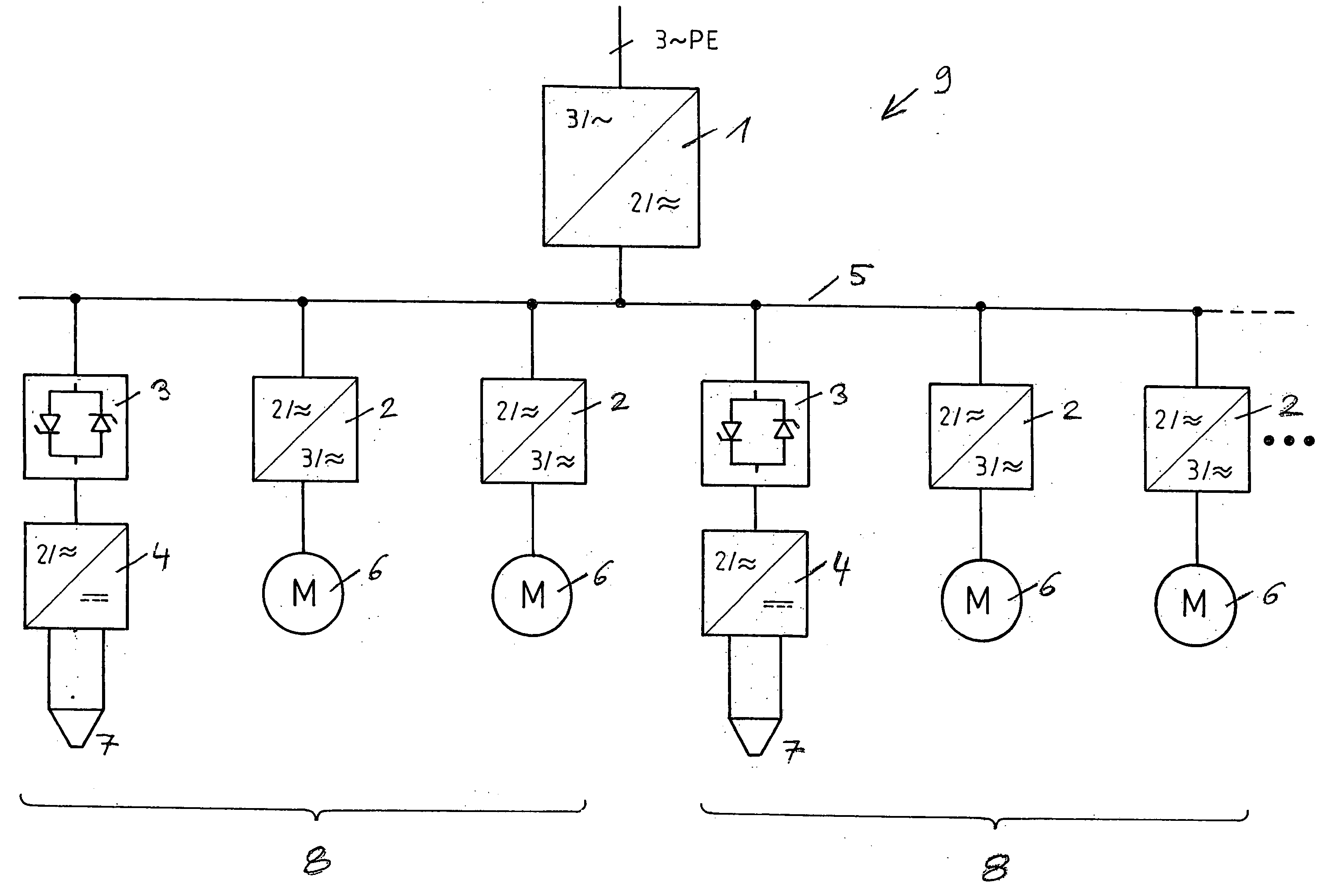

Power supply for resistance welding units

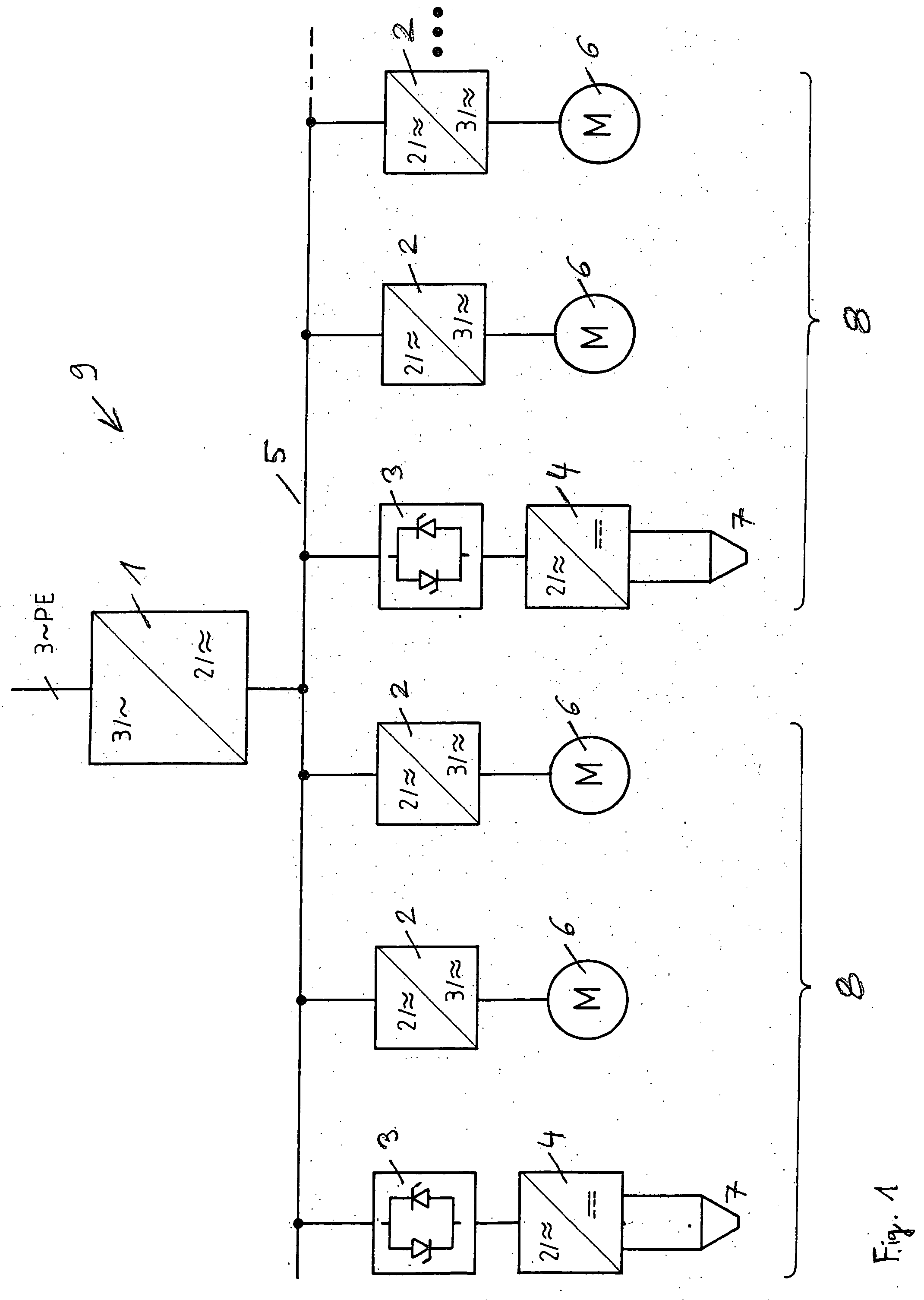

InactiveUS20060138095A1Easy to liftImplementation is smallArc welding apparatusWelding electric suppliesElectrical resistance and conductanceTransformer

A device for resistance welding includes a welding clamp housing, a welding transformer, a welding clamp, a welding clamp drive for operating welding clamp and a power supply by alternating supply voltage, which may be built as small as possible and may be simple to expand, the power supply being implemented by a main converter and by drive and welding converters, the output of main converter being connected to the inputs of drive and welding converters, the inputs of drive and welding converters being connected to one another and the connection being implemented by an a.c. voltage intermediate circuit.

Owner:BOSCH REXROTH AG

Spot welding method of high-strength steel sheets excellent in joint strength

ActiveUS10040145B2Improve reliabilityHigh strengthWelding electric suppliesWelding/soldering/cutting articlesHigh intensitySpot welding

When two high-strength steel sheets (1A, 1B) whose sheet thickness ratio={the sum of sheet thicknesses of the steel sheets} / {the sheet thickness of the thinner steel sheet (when they have the same thickness, the sheet thickness per one sheet)} is within a range of not less than 2 nor more than 5 and which both have tensile strength of not less than 780 MPa nor more than 1850 MPa are stacked to be subjected to resistance spot welding, a first welding step being pre-welding with a pressurizing force P1 kN and a welding current I1 kA and a second welding step being main welding with a pressurizing force P2 kN and a welding current I2 kA are performed, the pressurizing forces P1, P2 are set to a fixed pressurizing force P=P1=P2 all through the first welding step and the second welding step and are set within a range expressed by {0.5≤P≤3.0t(1 / 3)}, where t mm is an average sheet thickness of the steel sheets (1A, 1B), the welding current I1 is set within a range of not less than 30% nor more than 90% of the welding current I2, and the second welding step is started within 0.1 s after the first welding step is finished.

Owner:NIPPON STEEL CORP

Welding apparatus

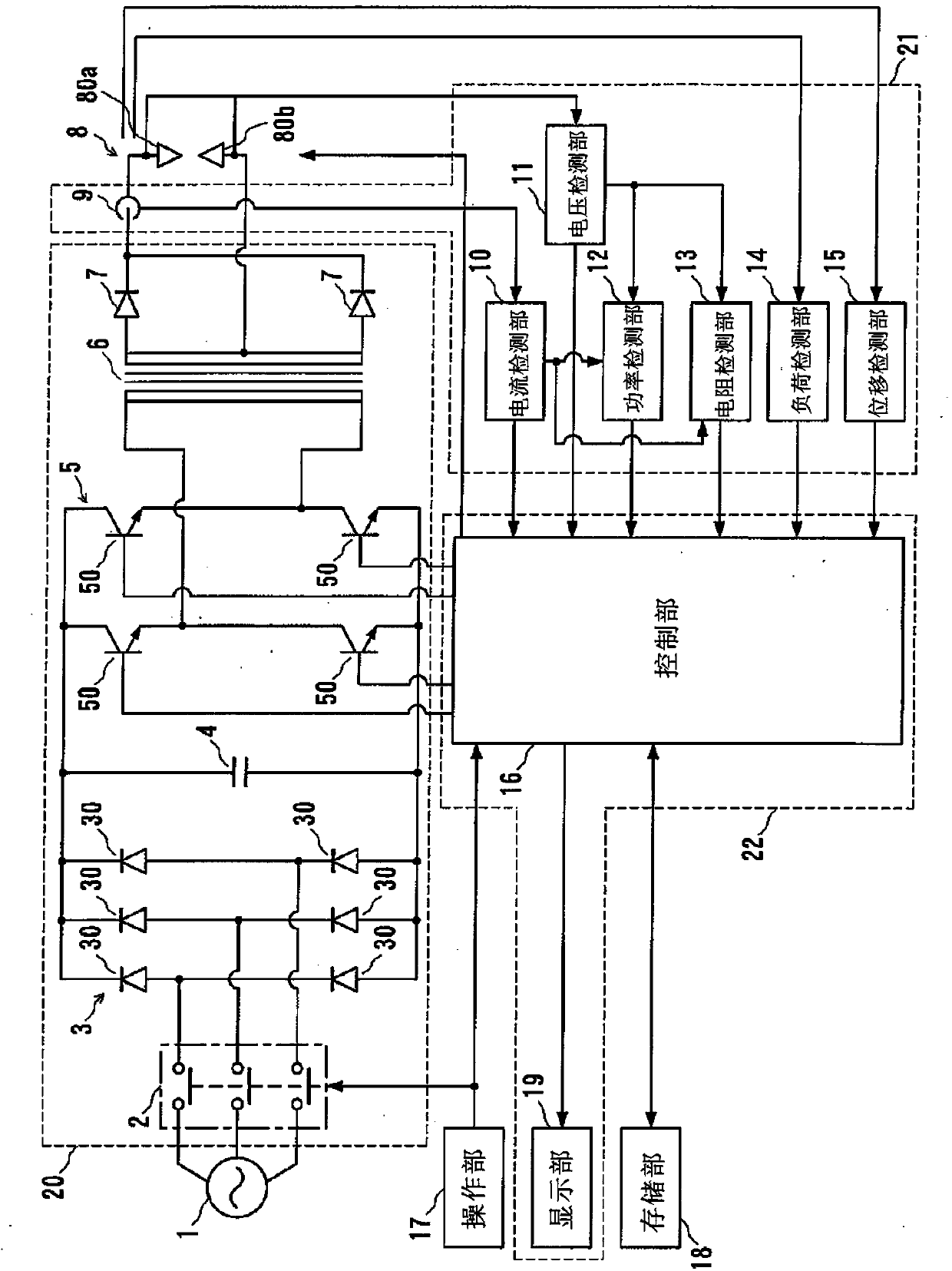

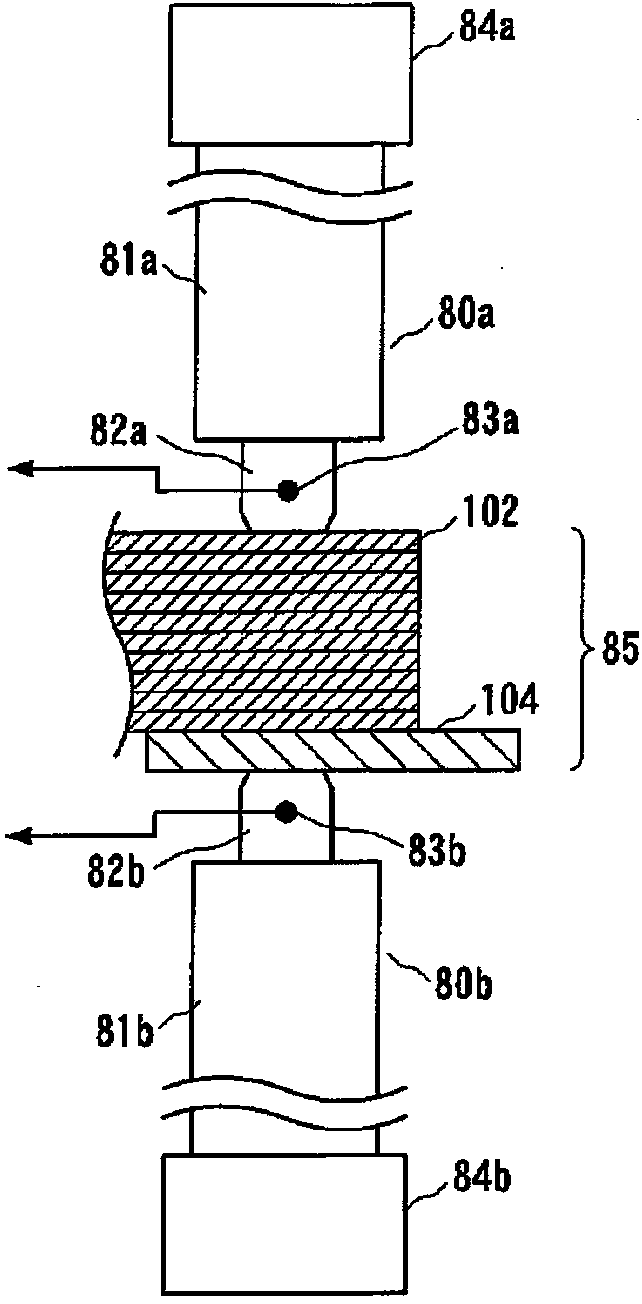

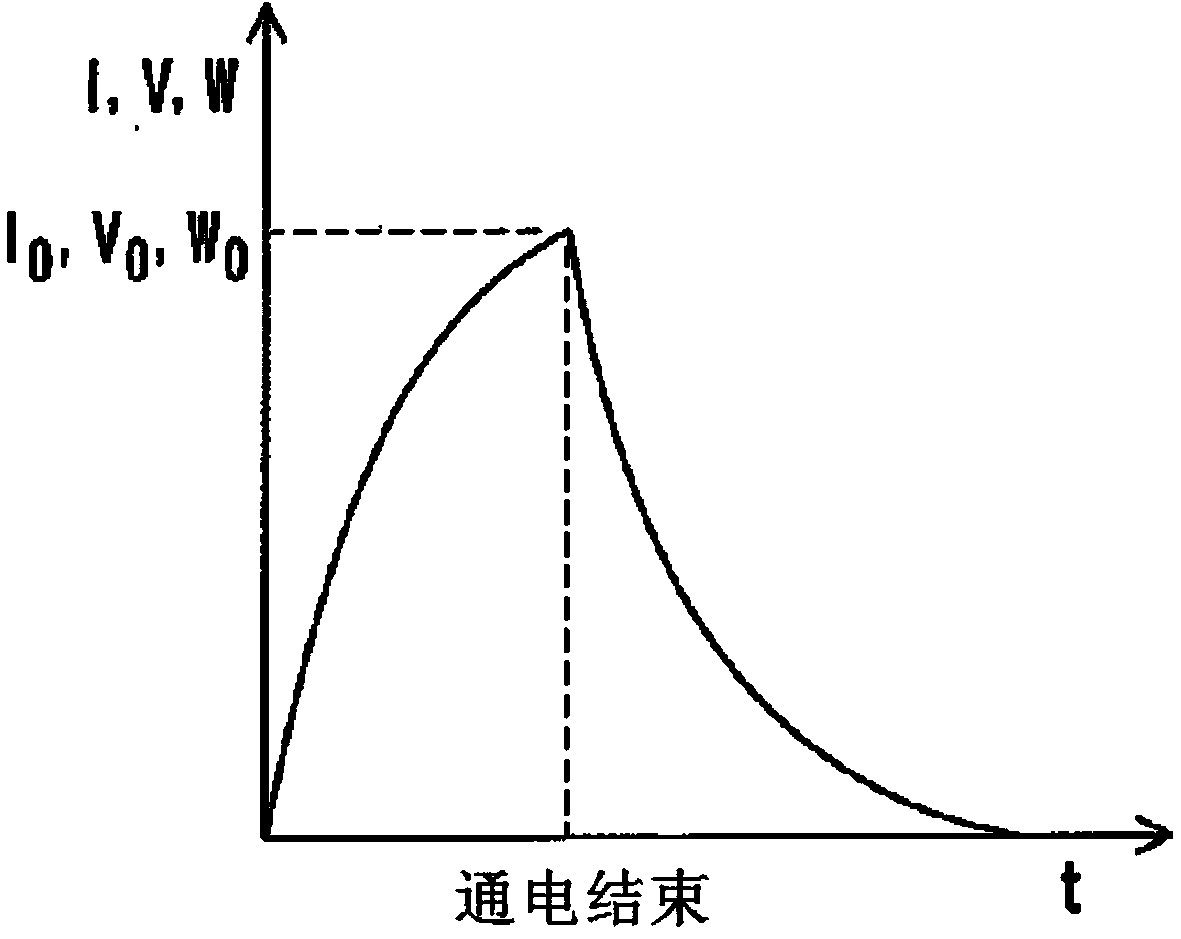

ActiveCN103962695AWelding electric suppliesWelding monitoring devicesWelding power supplyEngineering

The invention provides a welding apparatus, comprising electrodes (80a,80b) abutted against a to-be-welded object, a welding power source (20), a detection unit (21) for detecting physical quantities related to the to-be-welded object in welding, and a control unit (16). The control unit supplies current to the electrodes (80a,80b) from the welding power source (20) according to indications from an external part, and thus welding is started, current supplied to the electrodes (80a,80b) is cut off when the detected physical quantities reach predetermined ending condition values in the welding process. The physical quantities is at least one of welding current, welding voltage, welding power, resistance between the electrodes, load applied to the to-be-welded object, and displacement of the to-be-welded object in a thickness direction.

Owner:NIPPON AVIONICS CO LTD

Resistance welding device

ActiveUS20050284848A1Resistance electrode holdersWelding/cutting auxillary devicesElectrical resistance and conductanceGas cylinder

IMPROVED RESISTANCE WELDING DEVICE that includes a mobile electrode in a support assisted by a spring, gas cylinder or expansion element, allowing its movement on being compressed so that the time lapse for the welding is sufficiently long to be effective, without altering the movement cycle of the press into which it is installed. The support has one or several columns, the electrode being supported sliding along one and with a rod housed on the inside of a positioning device, also axially movable, into which the small parts to be welded are received through a conduit. The positioning device, made from an insulated material, preferably ceramic, has some fixing clamps for said part until the welding is made pushed by the electrode rod through a lower window.

Owner:TAMP ING EUROPA SUR

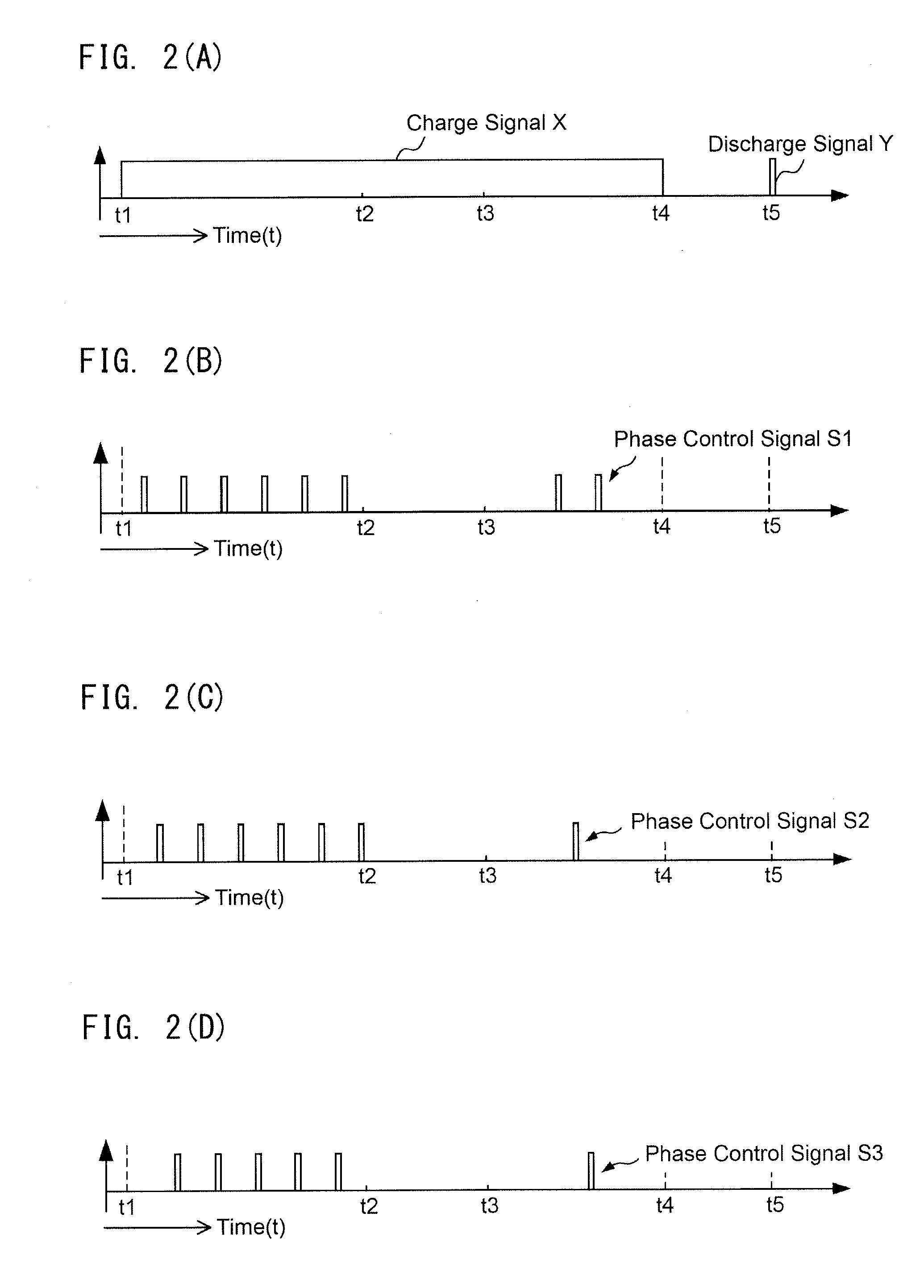

Capacitor-type welding device and capacitor-type welding method

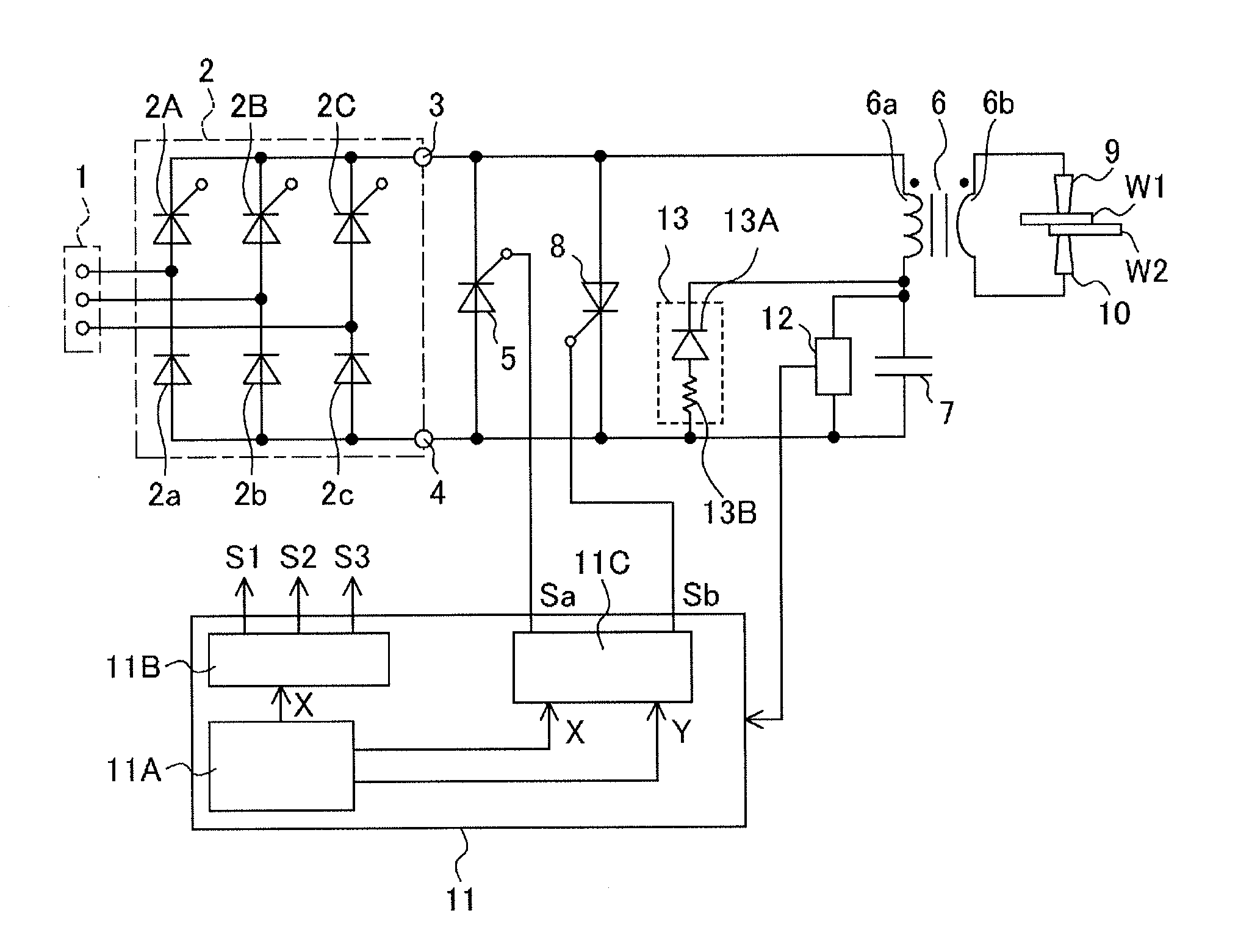

ActiveUS20140374389A1Reduce power lossLow costArc welding apparatusWelding electric suppliesEngineeringInductor

An economical capacitor-type welding device and capacitor-type welding method that have a small power loss, that can be made compact, and that reliably control a charging circuit without being affected by the inductance of a charging path. In an exemplary capacitor-type welding device and an exemplary capacitor-type welding method of the invention, a bypass switching element having a forward-blocking function is connected in parallel to output terminals of a charging circuit, and the bypass switching element is brought into a conduction state to allow a backflow current, which is caused to flow by a magnetic energy stored in the inductance of a primary winding or an inductor included in the charging path, to bypass the charging circuit. A discharge switching element is brought into a conduction state after the bypass switching element enters the non-conduction state and recovers the forward-blocking function.

Owner:ORIGIN ELECTRIC CO LTD

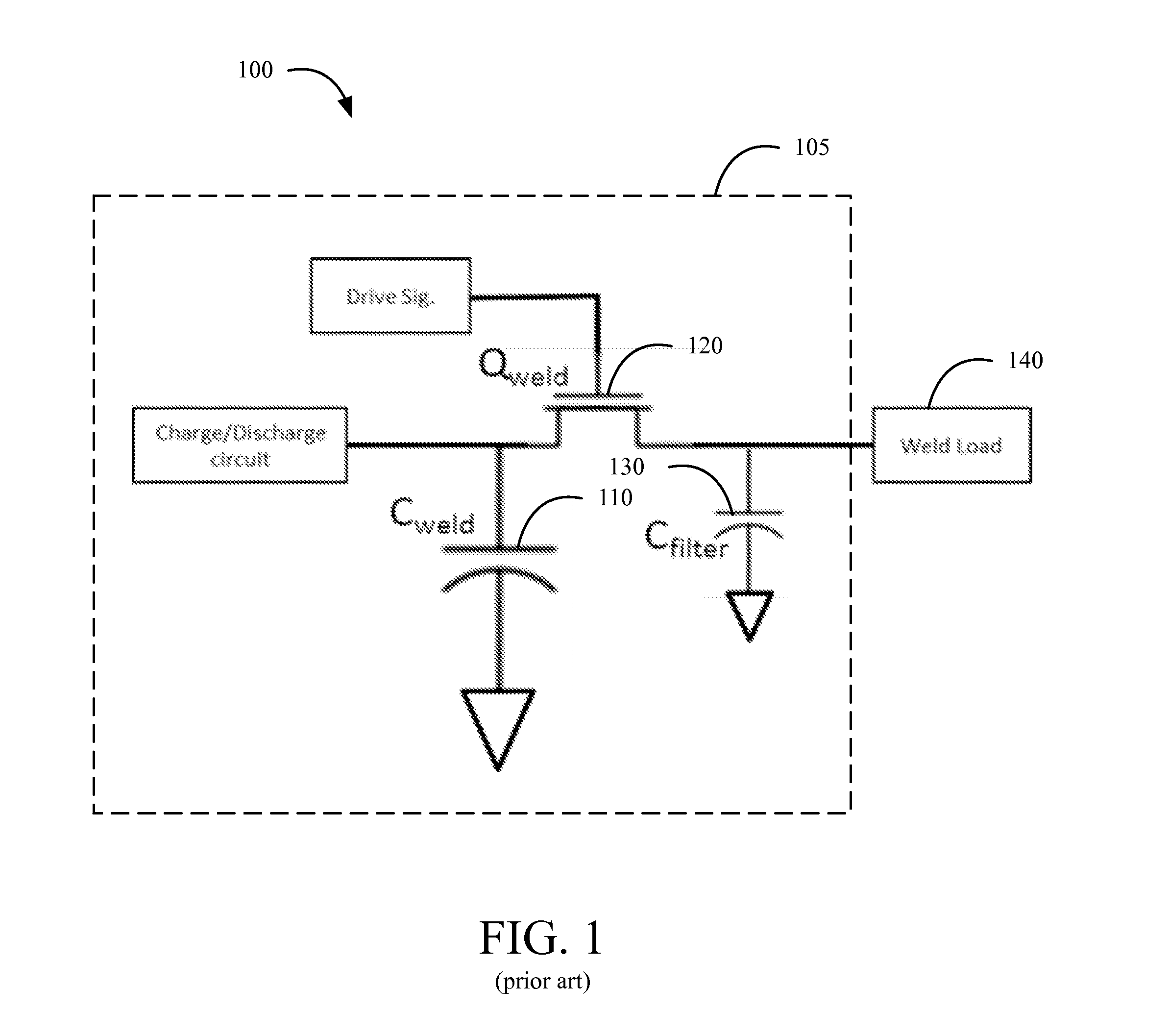

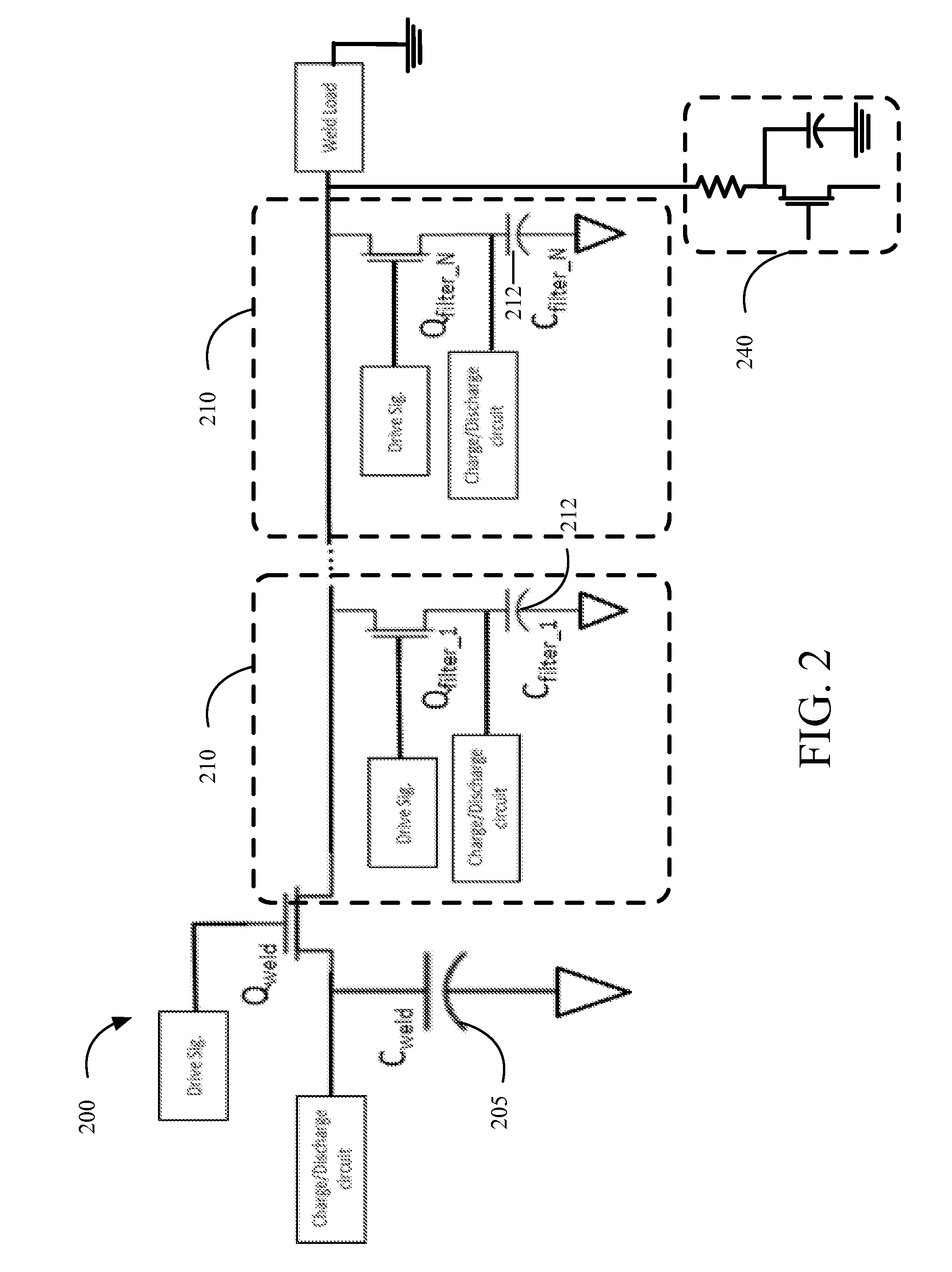

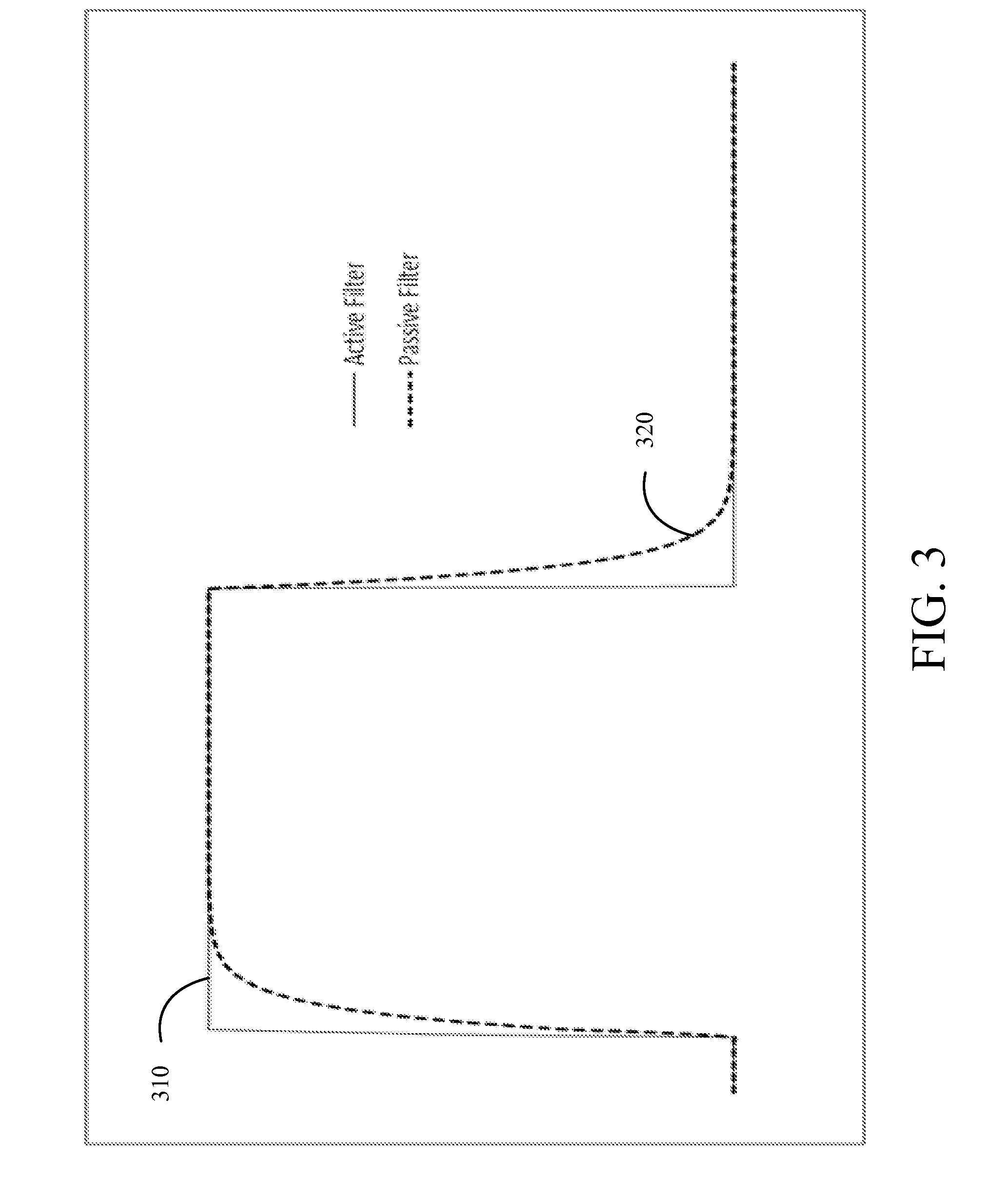

Welder With Active Linear DC Filtering Circuit

InactiveUS20150174693A1Arc welding apparatusWelding electric suppliesElectrical resistance and conductanceWelding process

A linear DC welder for enhanced welding capabilities comprises one or more active filtering circuits. The active filtering circuit(s) are capable of producing a variety of user-configurable and user-controllable custom waveforms for use in various welding applications. The custom waveforms may be created and combined via the use of overlay waveforms and, in at least some preferred embodiments of the present invention, include agitation waveforms. The overall operation of the welder, including the power supply and the active filtering circuit can be controlled via an integrated feedback cycle that provides for the monitoring and adjustment of multiple weld process parameters including volts, amps, power, resistance, and displacement. Additionally, a low current ignition (“LCI”) circuit may also be included to provide for additional welding options.

Owner:ASTLE AARON +3

Power pulse method for controlling resistance weld nugget growth and properties during steel spot welding

ActiveUS20170072502A1Rapid quenchingUniform hardnessWelding electric suppliesWelding/soldering/cutting articlesElectrical resistance and conductanceAlloy

A method of resistance spot welding steel workpieces—at least one of which includes a high-strength steel substrate having a tensile strength of 1000 MPa or greater—involves passing a pulsating DC electrical current between a pair of aligned welding electrodes that are pressed against opposite sides of a workpiece stack-up that includes the steel workpieces. The pulsating DC electrical current delivers sufficient power through the weld site by way of electrical current pulses to initiate and grow a molten steel weld pool at each faying interface within the workpiece stack-up that solidifies into a weld nugget of uniform hardness. In other words, each of the weld nuggets formed by the pulsating DC electrical current does not include soft, coarse, and alloy deficient shell regions that tend to reduce the strength of the weld nugget.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and system for estimating driving point voltage

InactiveUS20070182420A1Control performanceEasy to trackWelding electric suppliesFault locationElectrical resistance and conductanceElectricity

Owner:SCHNEIDER AUTOMATION INC

Spot Weld Gun

InactiveUS20080272092A1Easy to changeSimple designResistance electrode holdersElectrode supporting devicesElectric power transmissionPower flow

A spot weld gun with thereto belonging power transmission being achieved by means of a rotating transformer including one primary side and one secondary side for transporting electrical power over a rotating joint. The one secondary side is adapted to provide both required power to the weld current and any required auxiliary power.

Owner:ABB (SCHWEIZ) AG

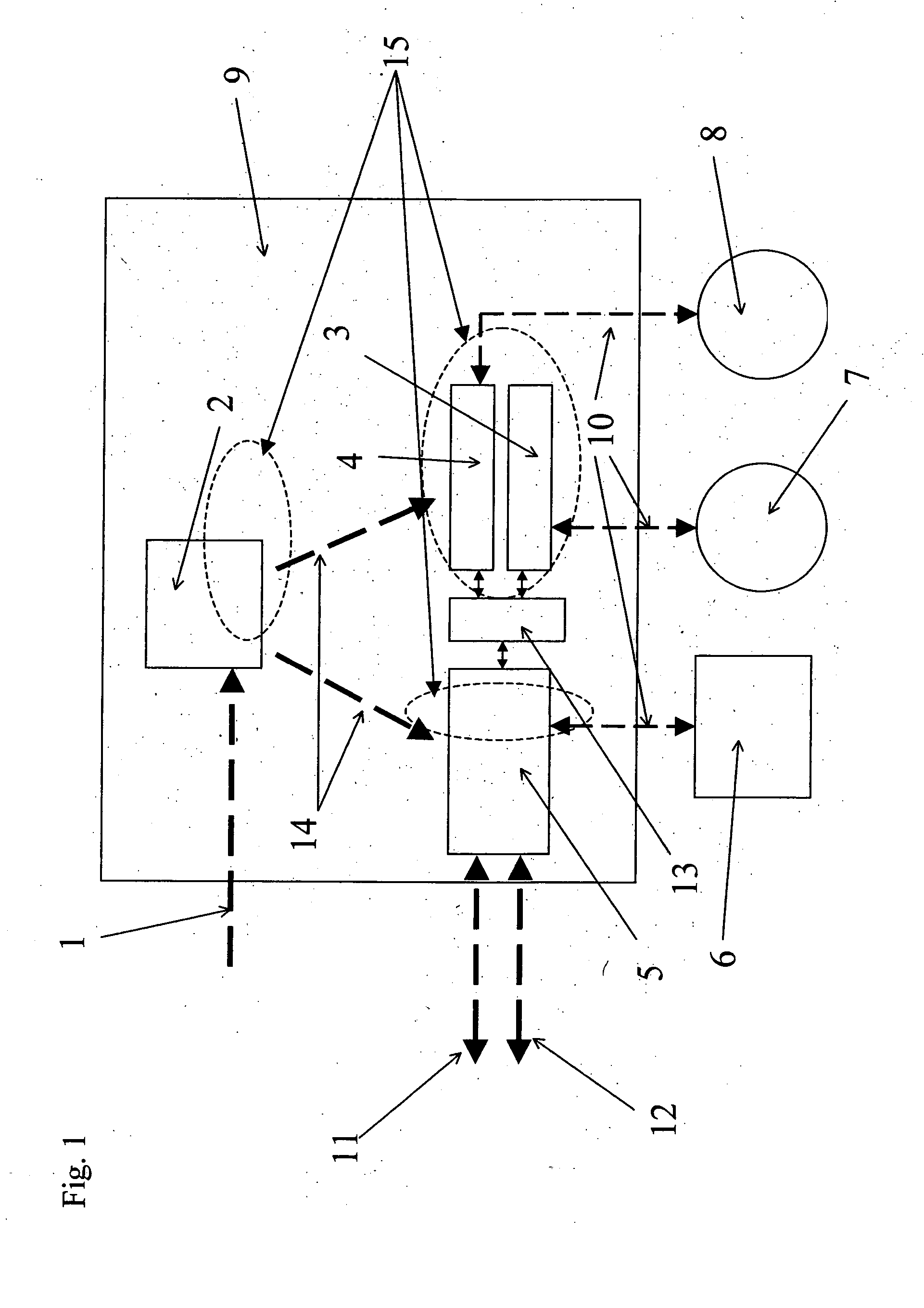

Resistance welding system

InactiveUS20050061777A1Reduce in quantitySimple processArc welding apparatusWelding electric suppliesElectrical resistance and conductanceEngineering

An apparatus for resistance welding with a welding system has an energy supply system, a welding convertor, a welding process control, a servowelding tong, a servotong control, wherein the welding convertor, the welding process control, the energy supply system and the servotong control form a structural unit.

Owner:BOSCH REXROTH AG

Method of resistance spot welding of high tensile strength steel sheet and welding joint manufactured by the method

ActiveUS9475147B2Strength in tensionHigh tensile strengthWelding electric suppliesWelding monitoring devicesElectrical resistance and conductanceEngineering

Provided is a method of resistance spot welding of welding a sheet set including a high strength steel sheet with which a high joint strength can be achieved even for a high Ceq material. A method of resistance spot welding a sheet set of two or more lapped steel sheets by weld the sheet set while clamping and pressing the sheet set between a pair of welding electrodes includes a first welding step of applying an weld current Im (kA) and forming a nugget having a nugget diameter d (mm) that satisfies the following inequality (1); a cooling step, subsequent to the foregoing first welding, of cooling the sheet set while continuing to press the sheet set; and a second welding step of performing two-step welding,3×√tm≦d≦6×√tm (1),where tm is the thickness (mm) of the thinnest one of the foregoing two or more steel sheets.

Owner:JFE STEEL CORP

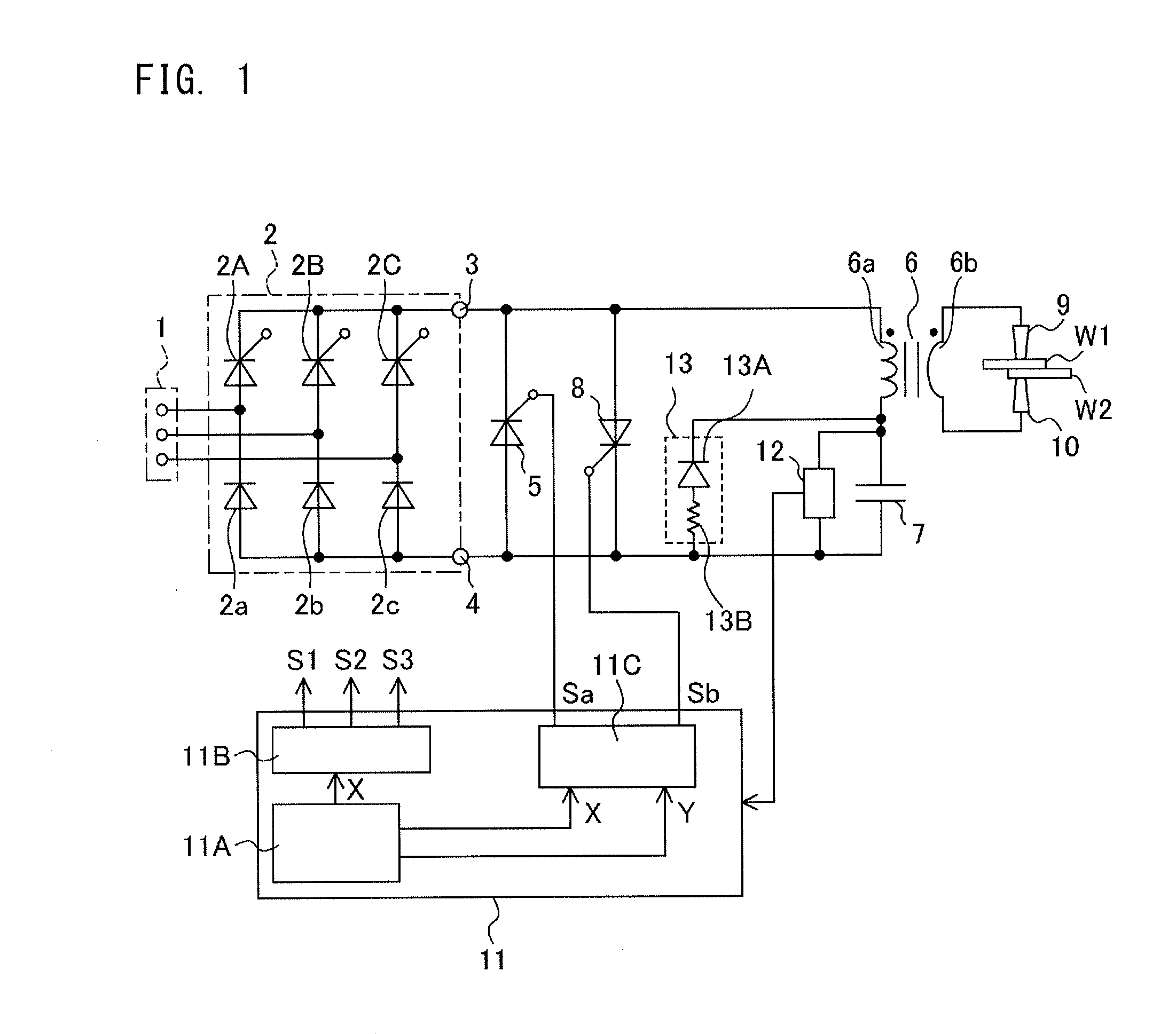

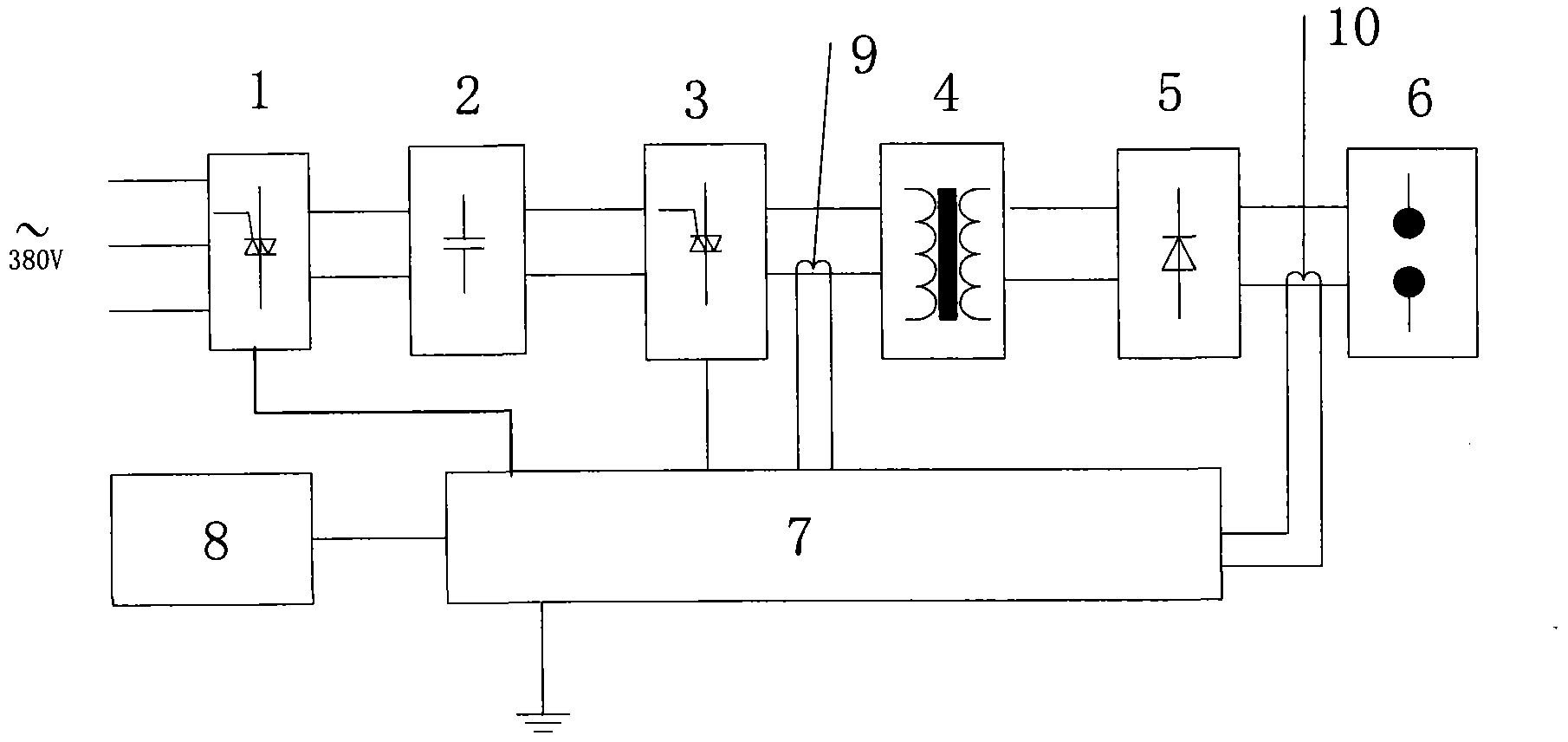

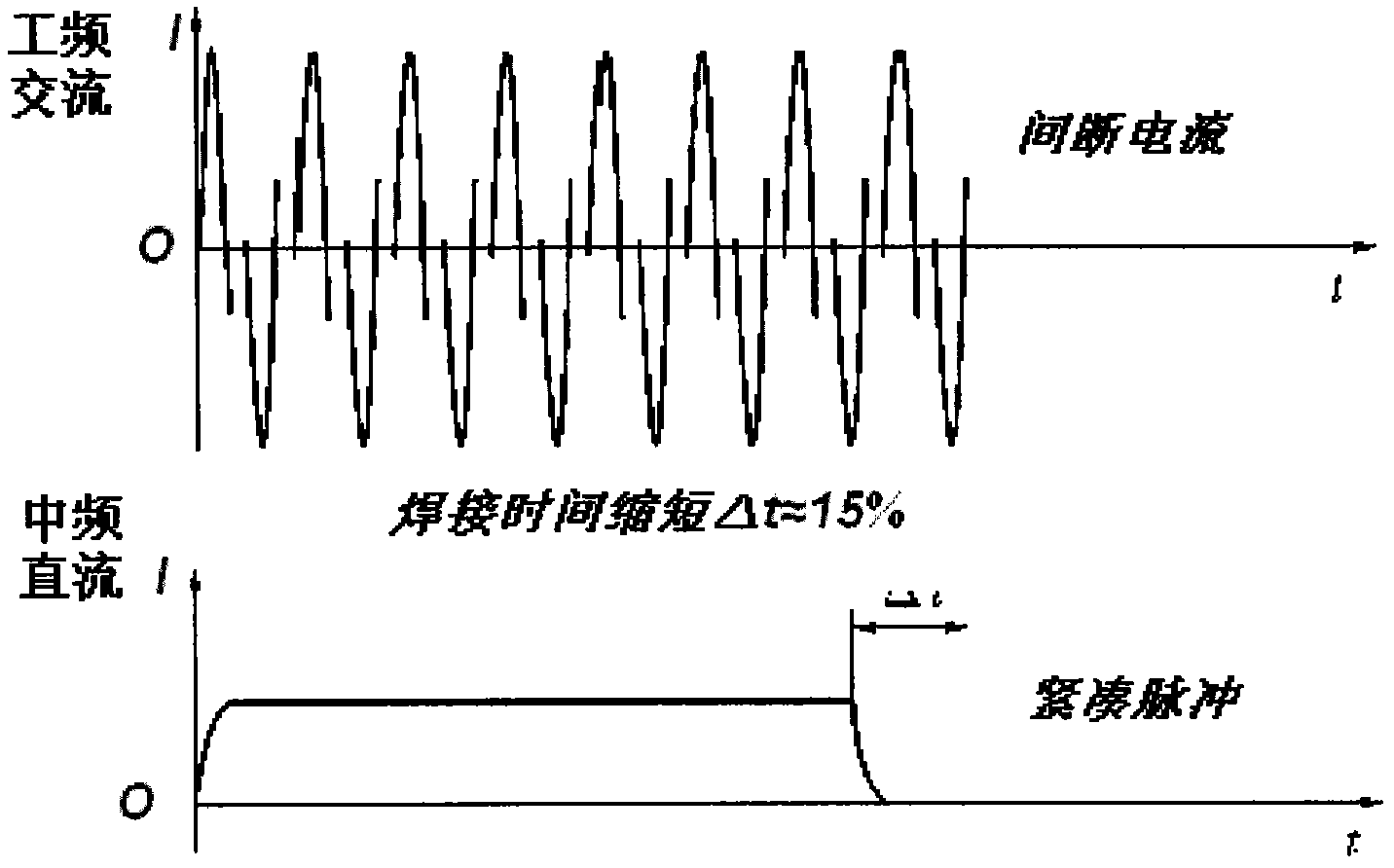

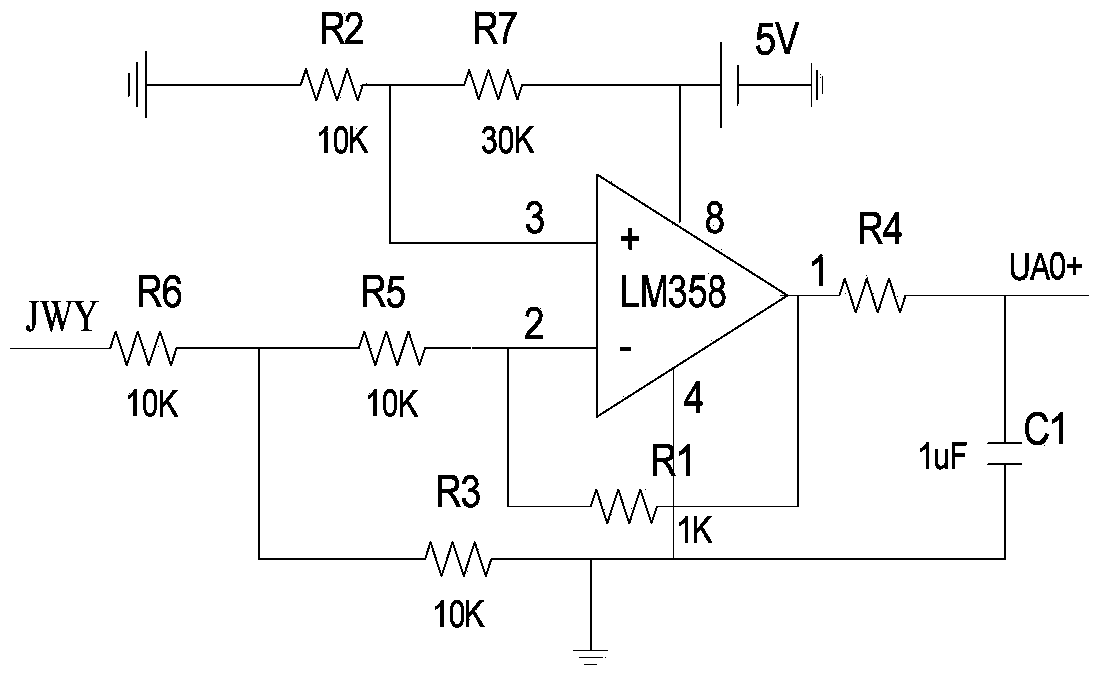

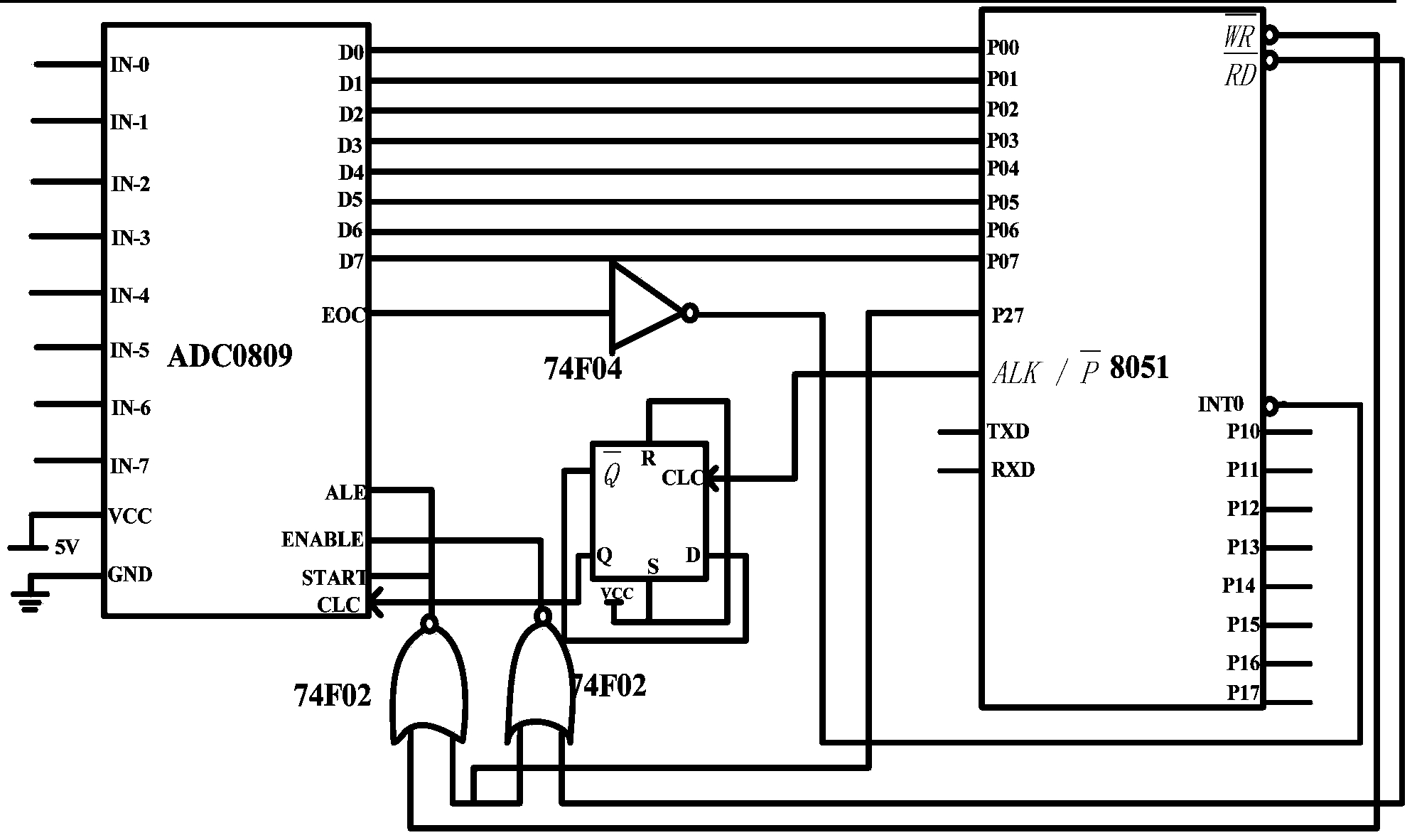

Manual intermediate frequency resistance welding control cabinet

InactiveCN103862158AImprove welding qualityImprove welding efficiencyWelding electric suppliesTransformerPower factor

A manual intermediate frequency resistance welding control cabinet comprises a power circuit part and a control circuit part. The power circuit part comprises a three-phase alternating current supply, a three-phase full-bridge rectifying circuit, a filter circuit, an inverter circuit, an intermediate frequency transformer, a one-valve output protection circuit and an output electrode, wherein the three-phase alternating current supply, the three-phase full-bridge rectifying circuit, the filter circuit, the inverter circuit, the intermediate frequency transformer, the one-valve output protection circuit and the output electrode are sequentially connected. The control circuit part comprises a central processing unit, a clock circuit and a sensor circuit. The sensor circuit comprises a primary current sensor and a secondary current sensor, the primary current sensor is coupled to the output end of the inverter circuit and connected with the central processing unit after A / D conversion, the secondary current sensor is coupled to the output end of the one-way output protection circuit and connected with the central processing unit after A / D conversion, and the control port of the central processing unit and the control end of the inverter circuit are connected. By the adoption of the manual intermediate frequency resistance welding control cabinet, welding quality and welding efficiency are both obviously improved, meanwhile, intermediate frequency welding power factors are high, and compared with traditional alternating current welding, power consumption is small, and pollution is low.

Owner:合肥国声电子通信有限责任公司

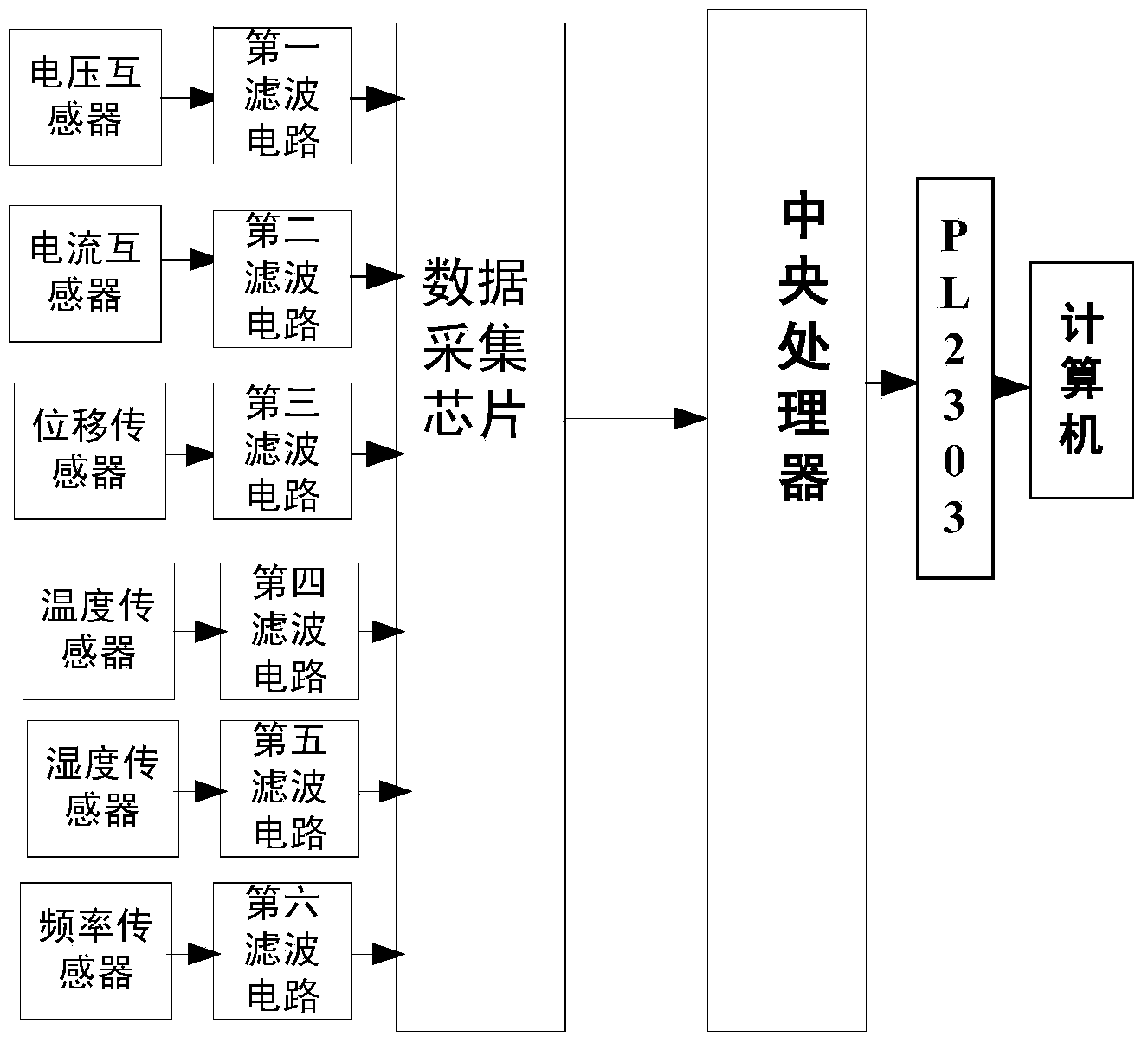

Device and method for detecting intensity of welding joint of electric resistance welding

InactiveCN103624391AAccurate predictionAvoid unevennessWelding electric suppliesMetal working apparatusElement spaceElectrical resistance and conductance

The invention relates to a device and a method for detecting the intensity of a welding joint of the electric resistance welding, and belongs to the technical field of welding. The invention provides a model for processing data by a nonlinear simplex method, and the problem of data distribution information nonuniformity is solved, so the information distribution is more reasonable, the element attribute information of the welding joint and the element space information of the welding joint can be fully applied, the bonding intensity of welding joints can be accurately predicated, the timely improvement is realized through the device, the labor and the materials are saved, and the cost is reduced.

Owner:沈阳众瀛高科技股份有限公司

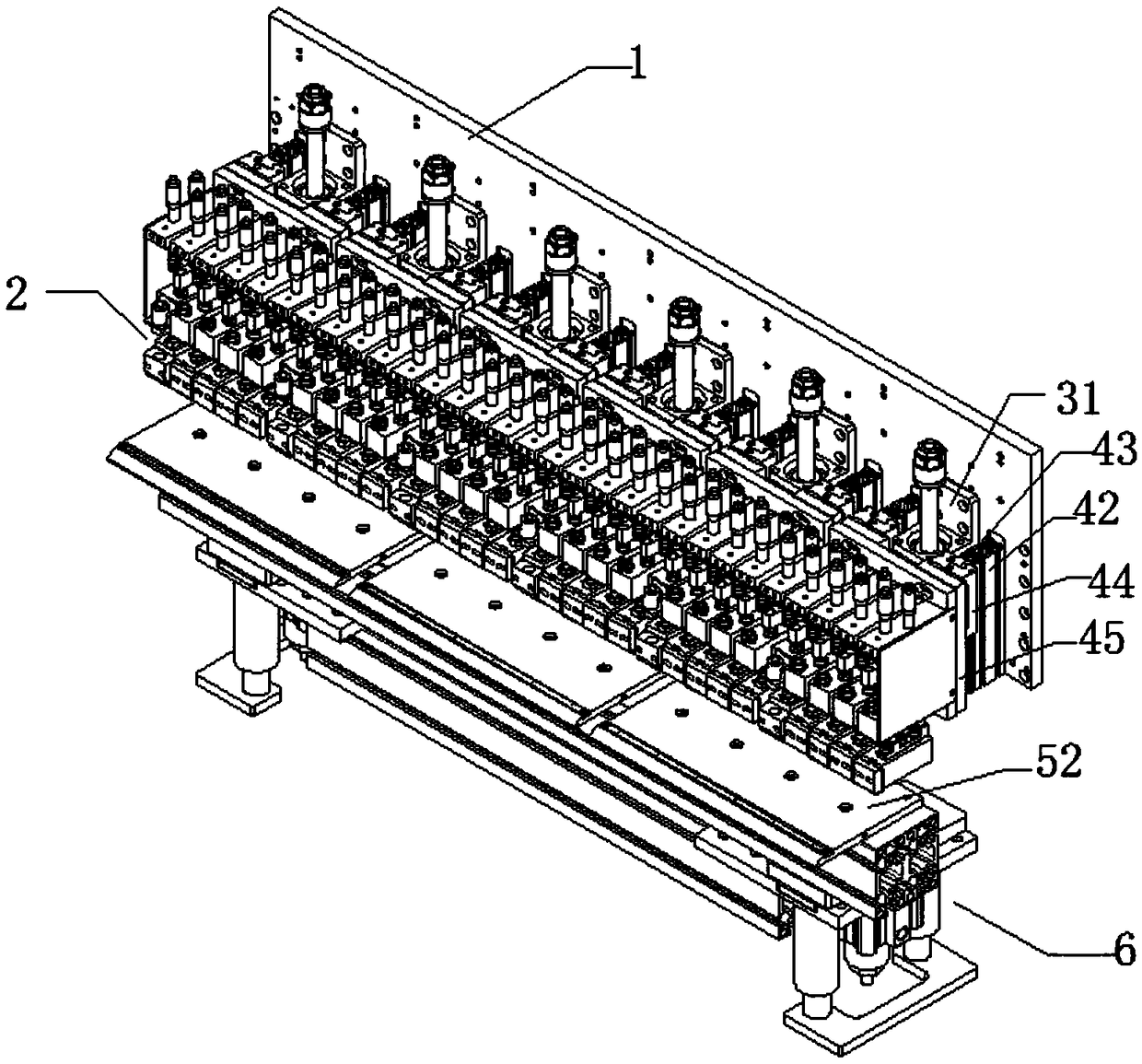

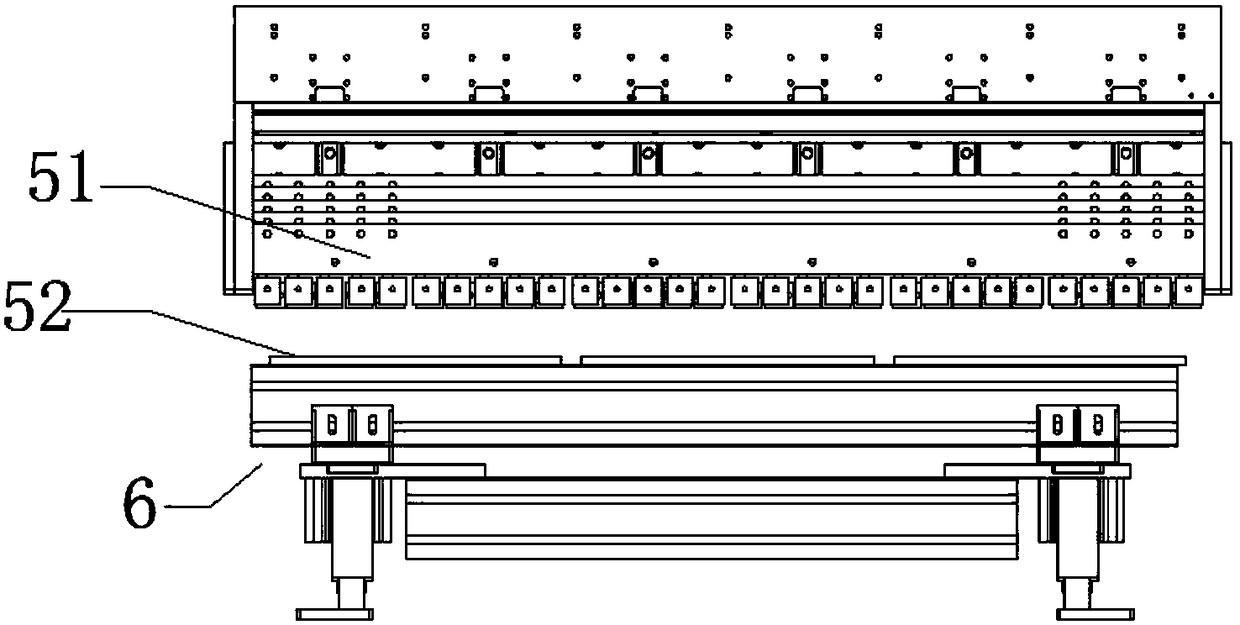

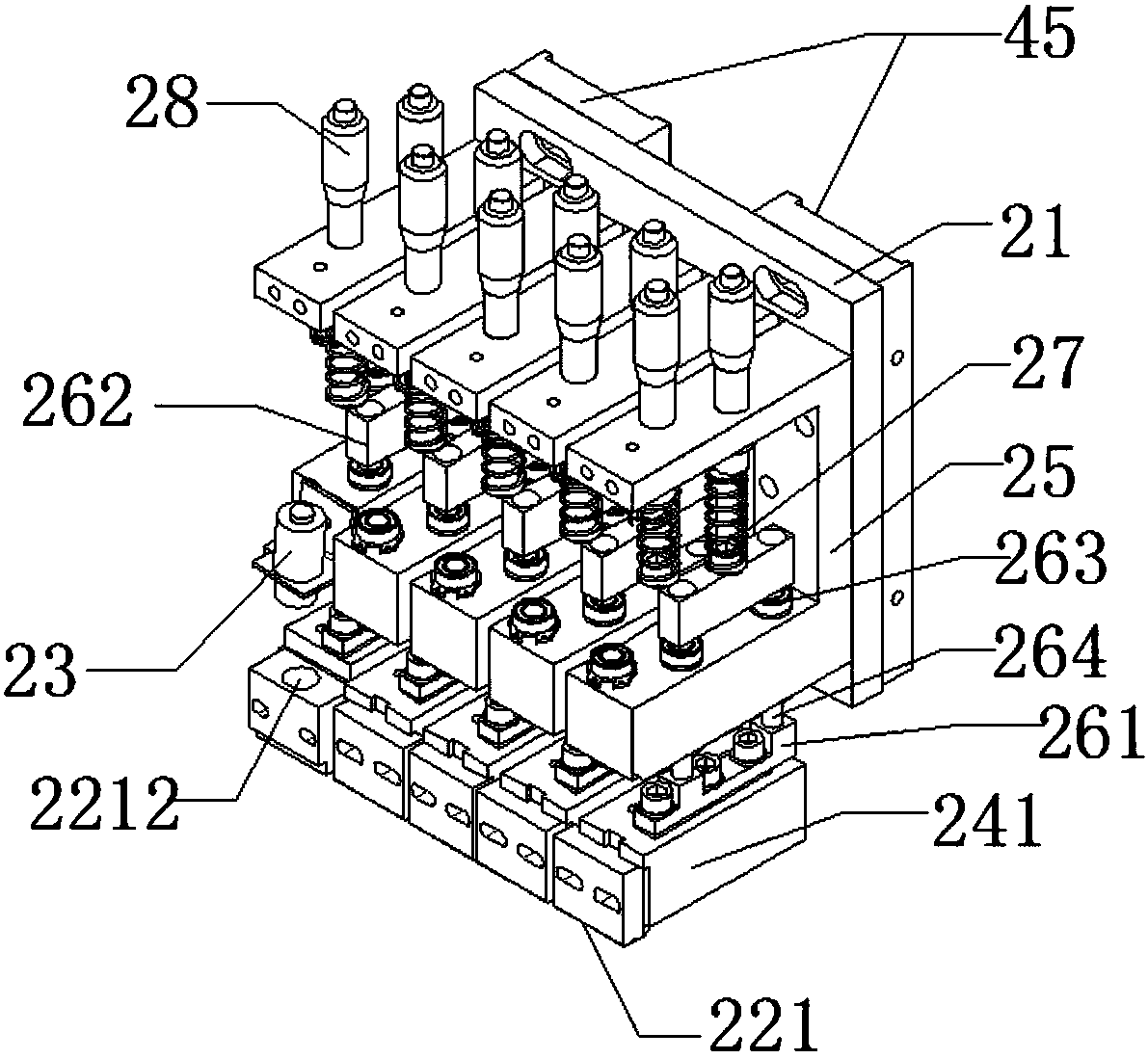

Improved bus bar welding machine head

ActiveCN109317803AAvoid high or low soldering temperatureLow soldering temperatureWelding electric suppliesWelding monitoring devicesEngineeringCopper

The invention discloses an improved bus bar welding machine head. The improved bus bar welding machine head comprises an anode main supporting plate, welding assemblies, connecting assemblies, liftingassemblies and an electrode copper plate assembly, wherein each welding assembly is movably fixed to the front plate surface of the anode main supporting plate in a liftable manner through one connecting assembly and one lifting assembly; and the electrode copper plate assembly provides a welding current for the welding assemblies. According to the invention, the improved bus bar welding machinehead comprises the multiple welding assemblies, each welding assembly comprises a plurality of welding heads, and welding efficiency is greatly improved; the positive and negative welding heads adoptup-down alignment welding, the welding heads and welding bars are in continuous long-line contact, the situation that the welding heads and the welding bars are in poor contact as the welding bars aretoo short is avoided, and welding quality is guaranteed; and the positions of the welding heads in the welding machine head can be changed, so that the welding machine head can adapt to welding of bur bars of various specifications, lifting operation of the welding assemblies in welding operation can be independently controlled by the lifting assembles, and welding flexibility is further improved.

Owner:苏州娄格自动化科技有限公司

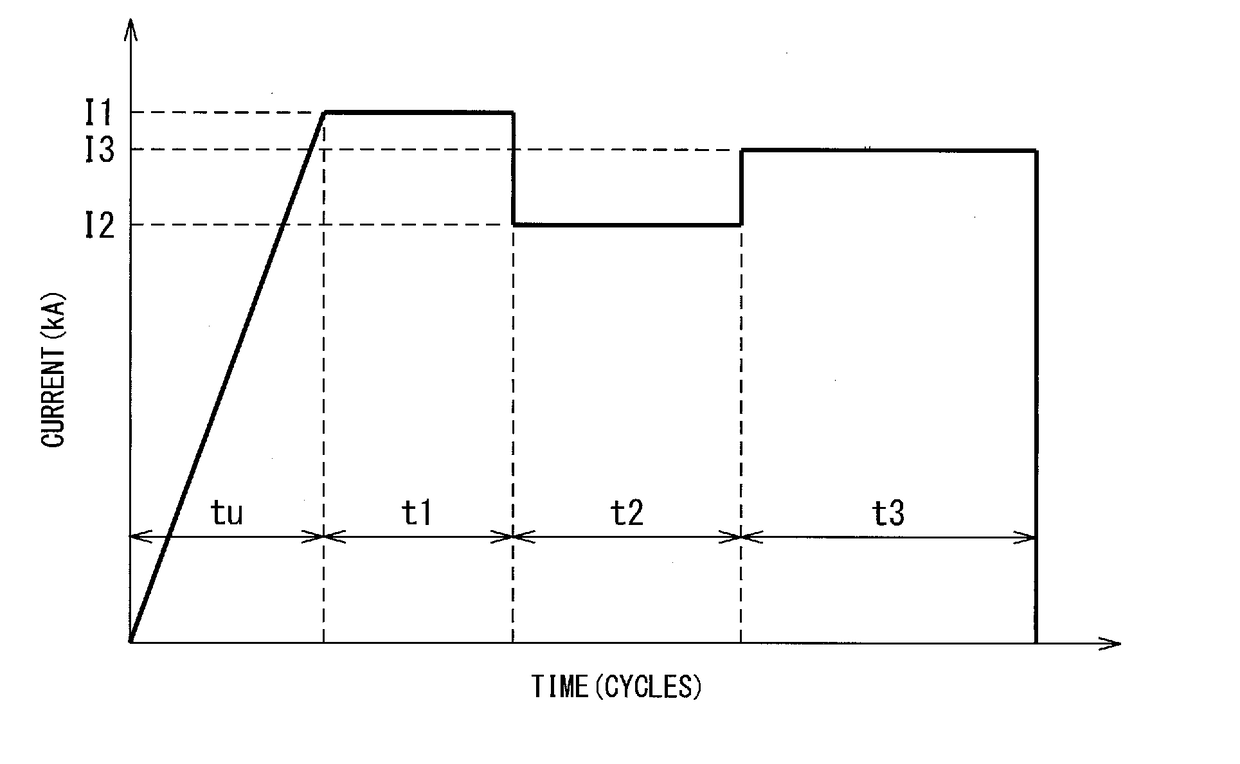

Spot welding method

The spot welding method of the present invention has steps of preliminary conduction, first conduction, second conduction, and third conduction:Preliminary conduction: Conduction method aimed at improving closeness of contact surfaces of steel sheets and reducing sheet gaps by gradually increasing the welding current (for example, upslope conduction). If rapidly applying current, current would be locally carried and that part would melt resulting in expulsion, so this is a conduction method gradually running current (for example upslope conduction) to avoid local heating.First conduction: Conduction method running a constant welding current and using the heat generated by the electrical contact resistance between steel sheets to cause the formation of a nugget when preliminary conduction results in close contact surfaces between the steel sheets.Second conduction: Conduction method making the current lower than the first conduction to suppress inside expulsion while making the nugget grow in the diametrical direction.Third conduction: Conduction method making the current higher than the second conduction and making the nugget grow not only in the diametrical direction, but also mainly in the sheet thickness direction when the nugget size becomes a certain extent of size at the second conduction step.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com