Patents

Literature

121results about How to "Improve joint quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

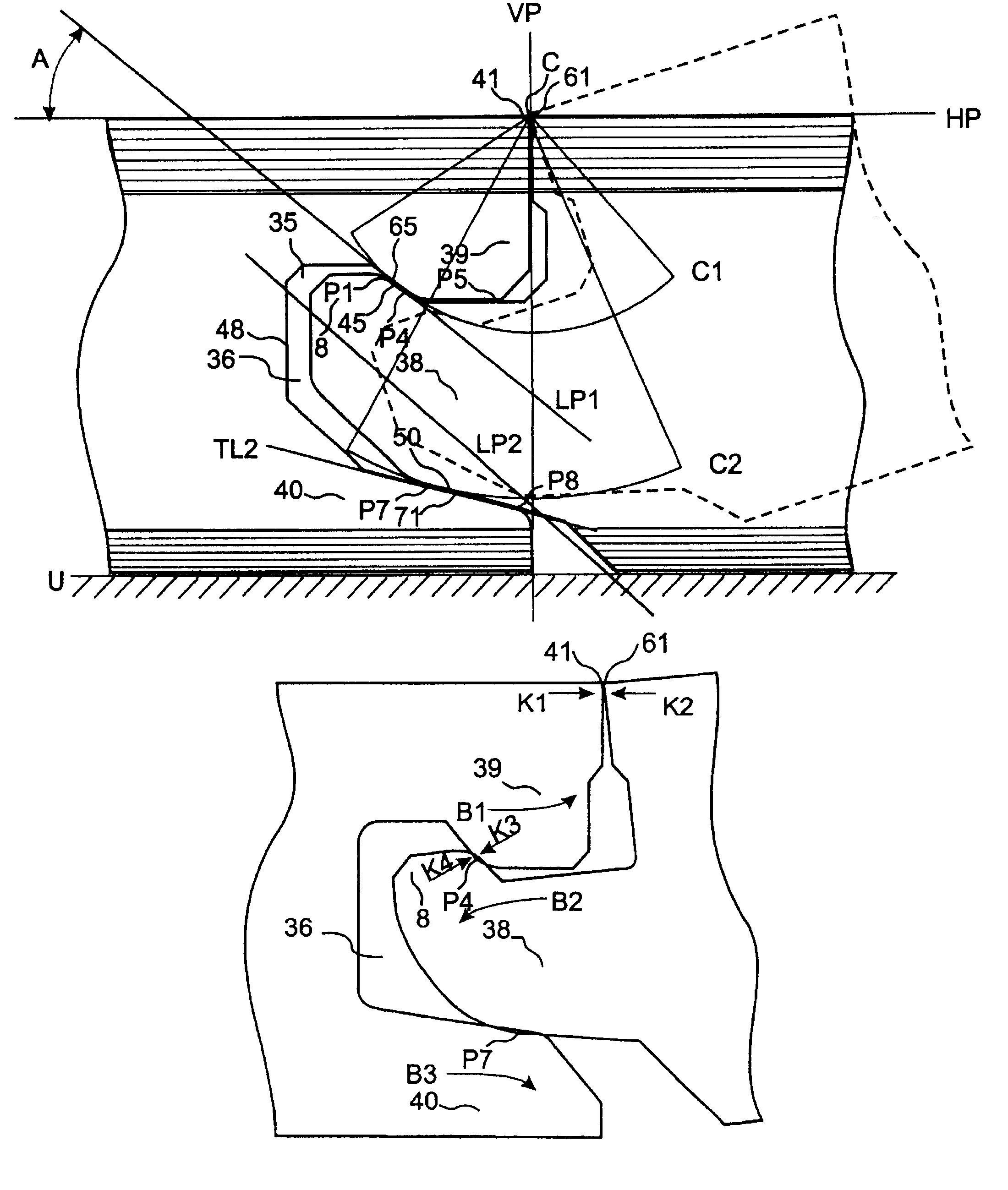

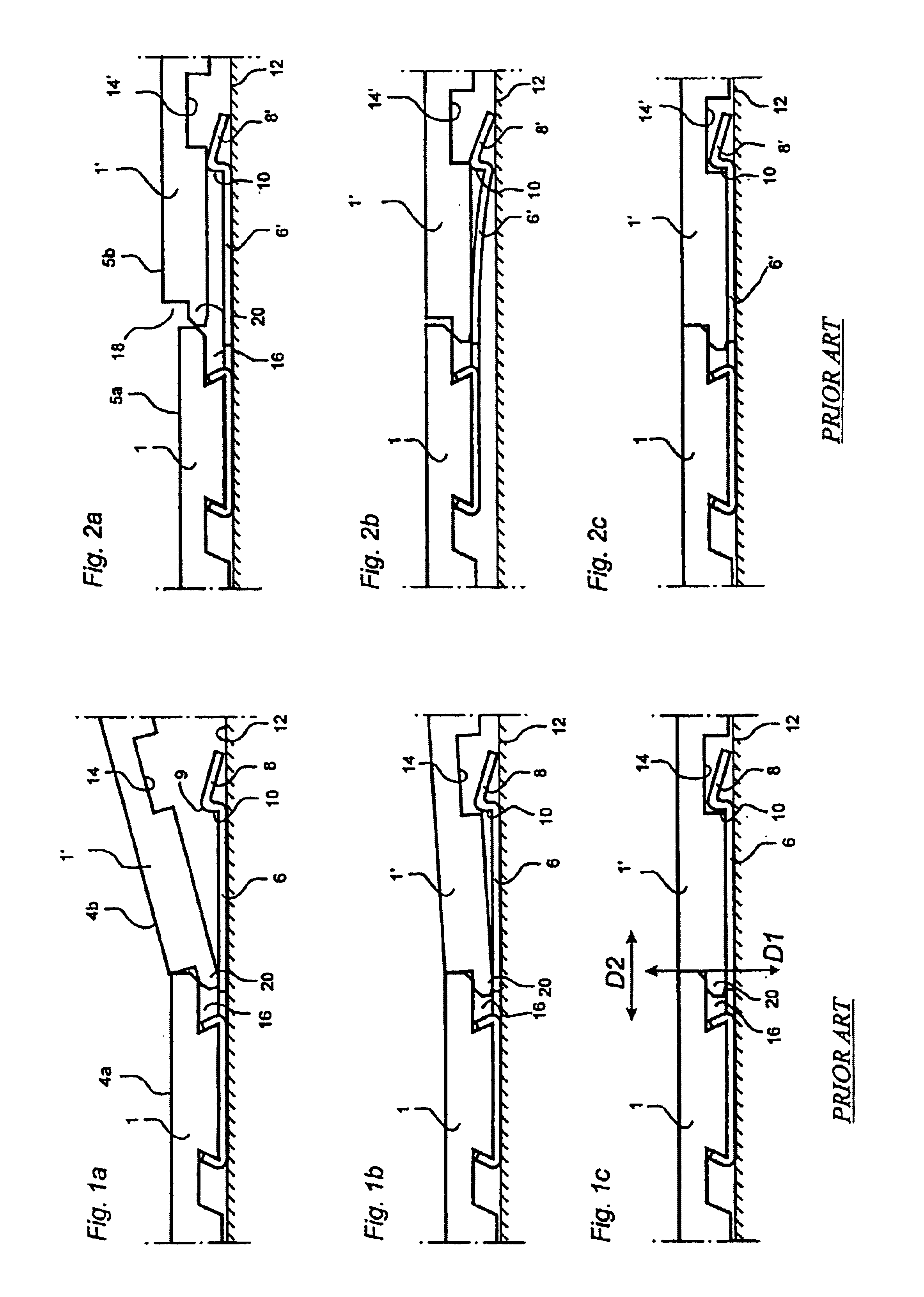

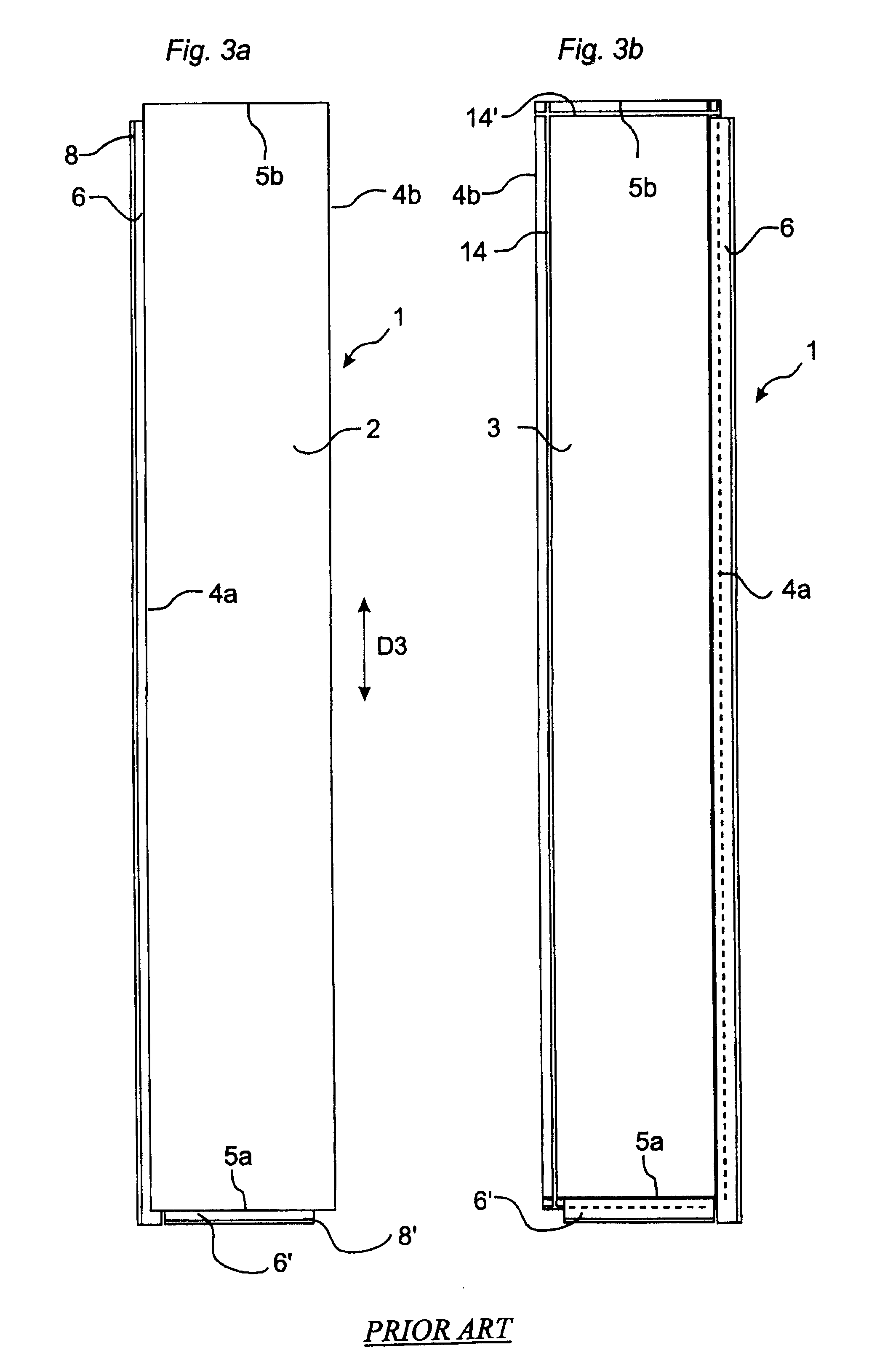

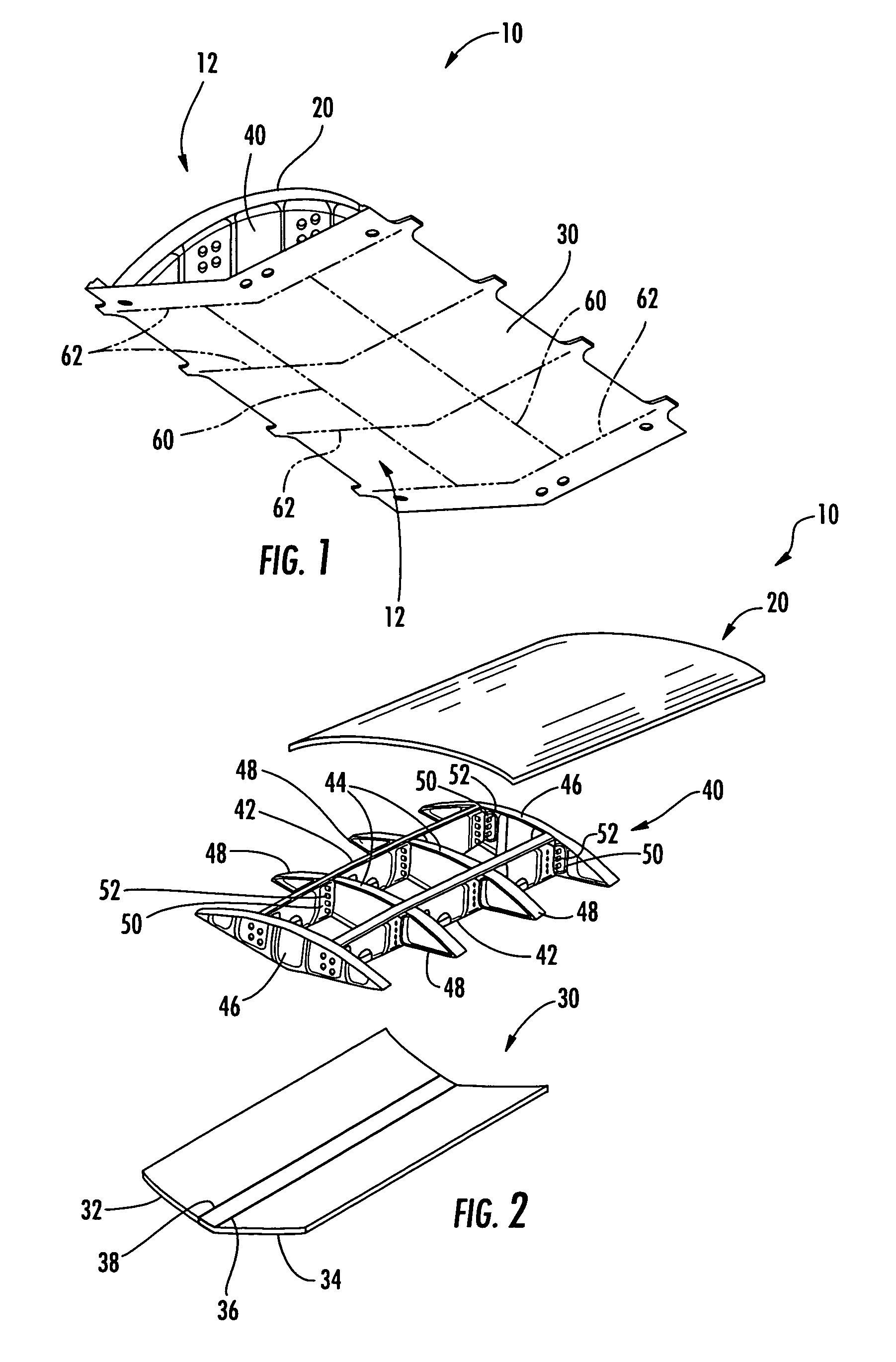

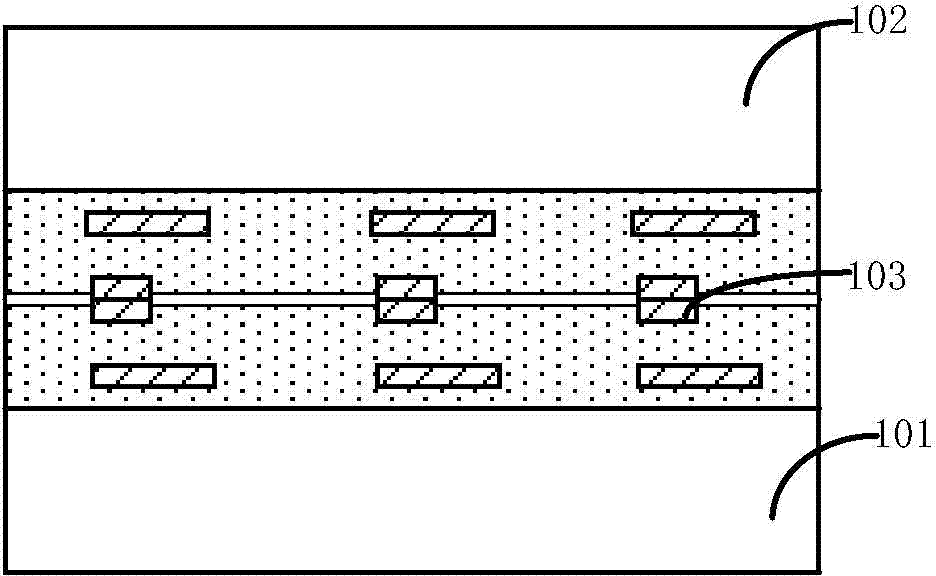

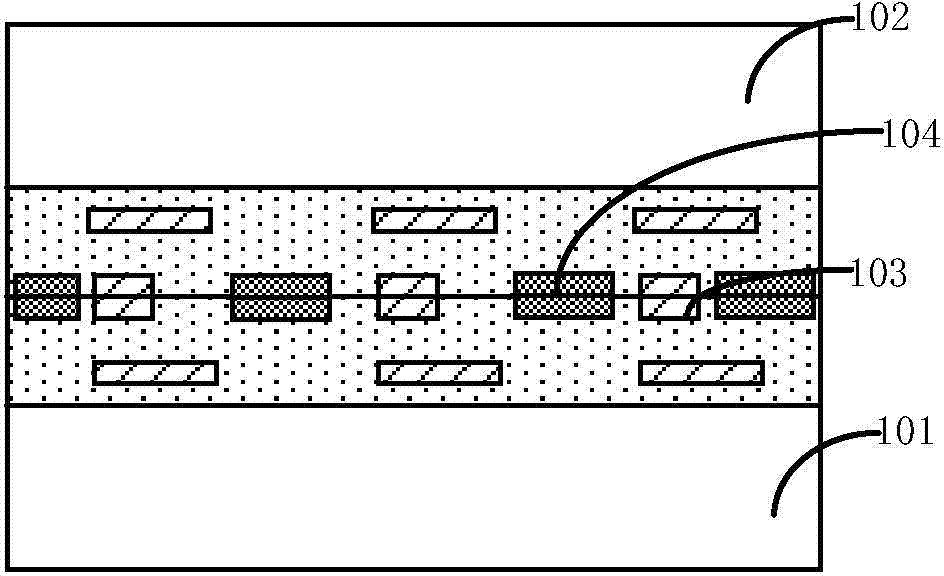

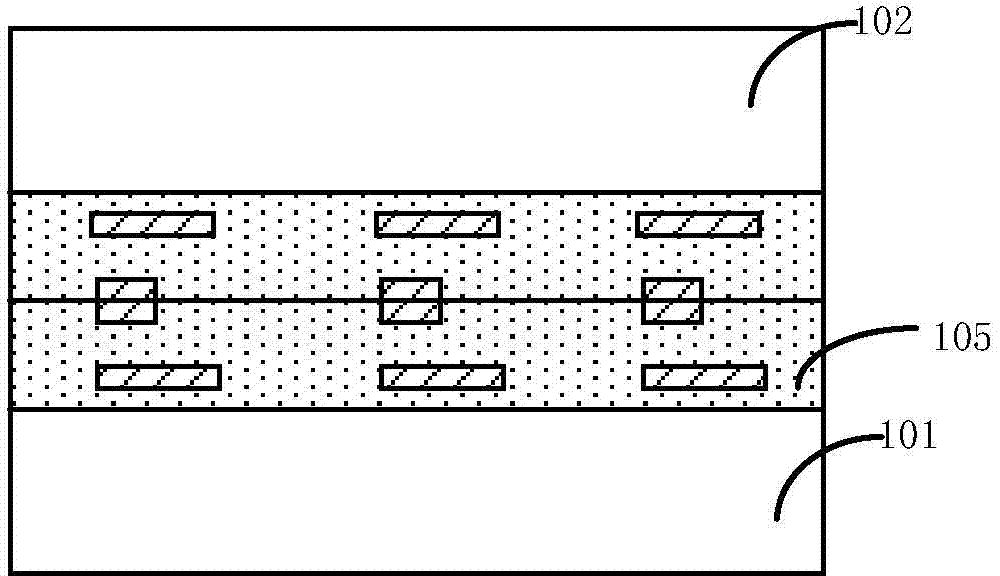

Floorboards and methods for production and installation thereof

InactiveUS6851241B2Improve material utilizationImprove overall utilizationWallsBuilding repairsEngineering

A floorboard and an openable locking system therefor comprise an undercut groove on one long side of the floorboard and a projecting tongue on the opposite long side of the floorboard. The undercut groove has a corresponding upwardly directed inner locking surface at a distance from its tip. The tongue and the undercut groove are formed to be brought together and pulled apart by a pivoting motion which has its center close to the intersection between the surface planes and the common joint plane of two adjoining floorboards.

Owner:VÄLINGE INNOVATION AB

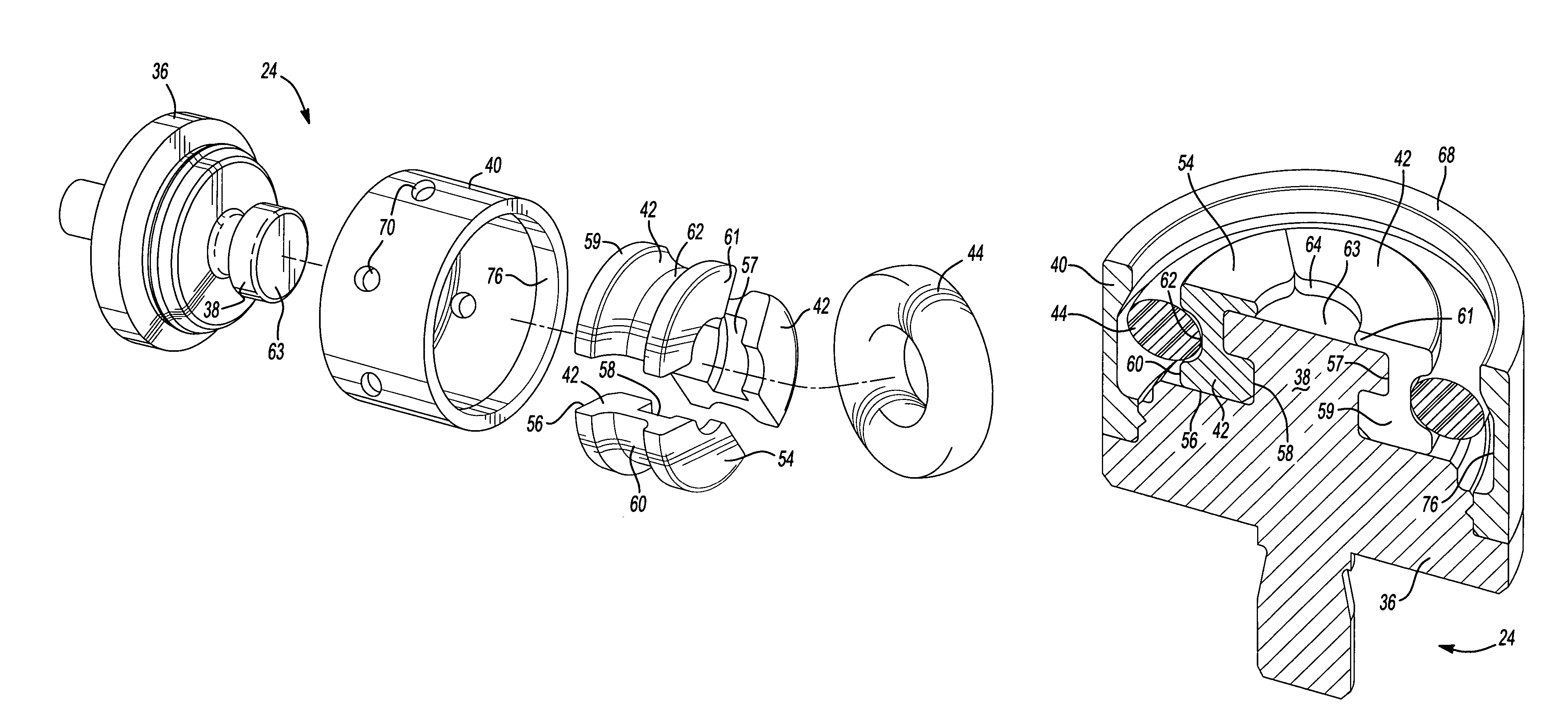

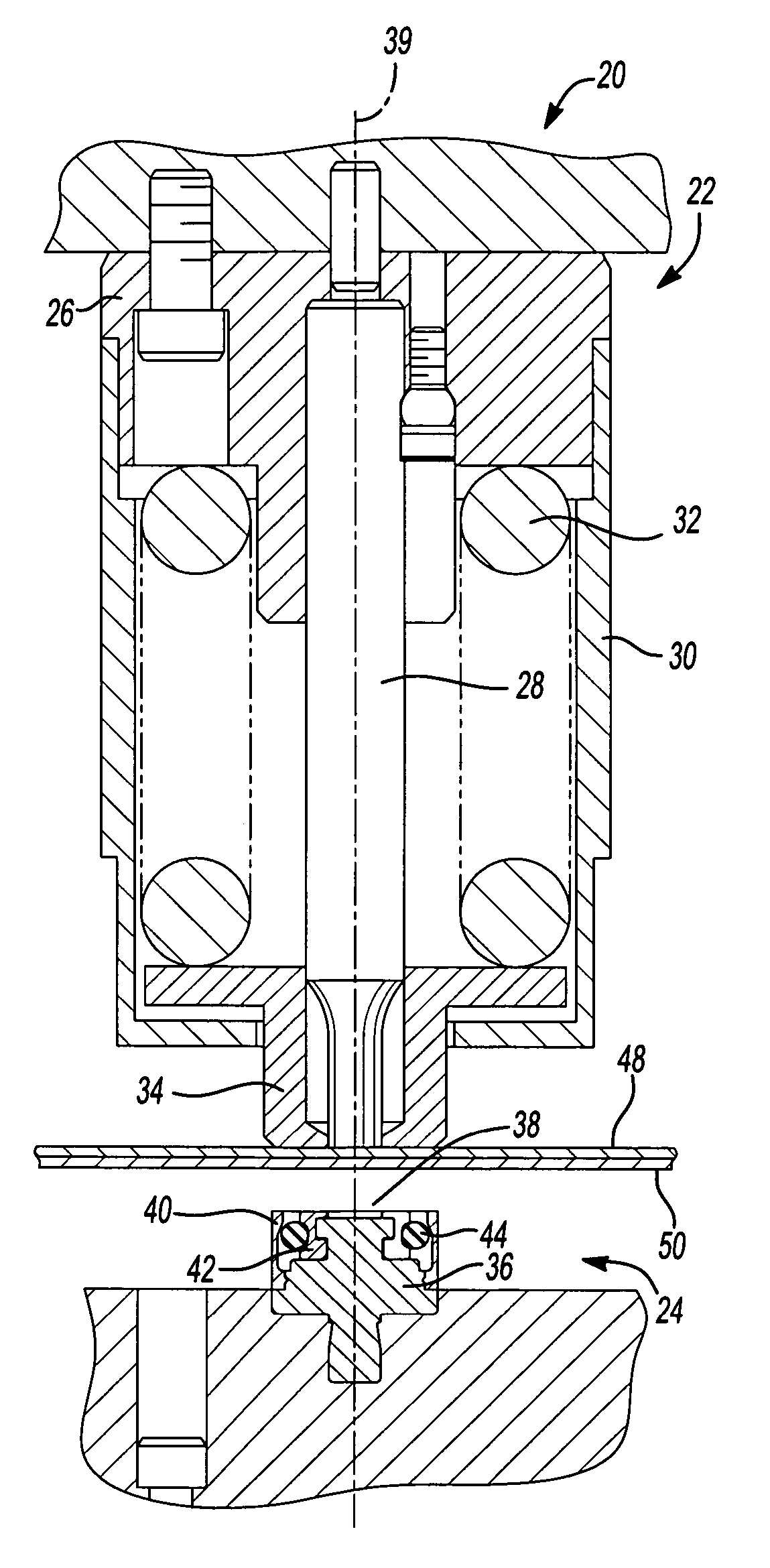

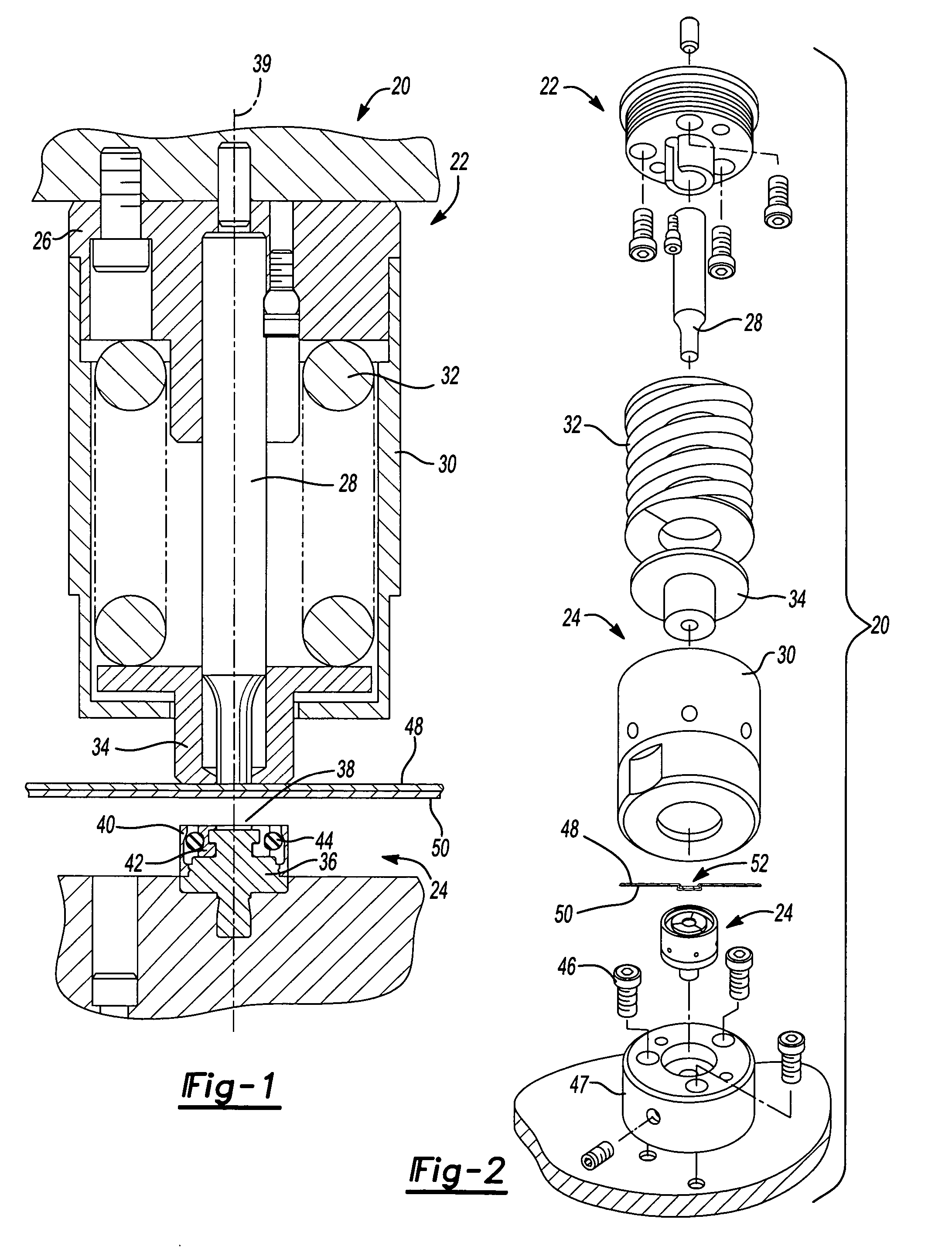

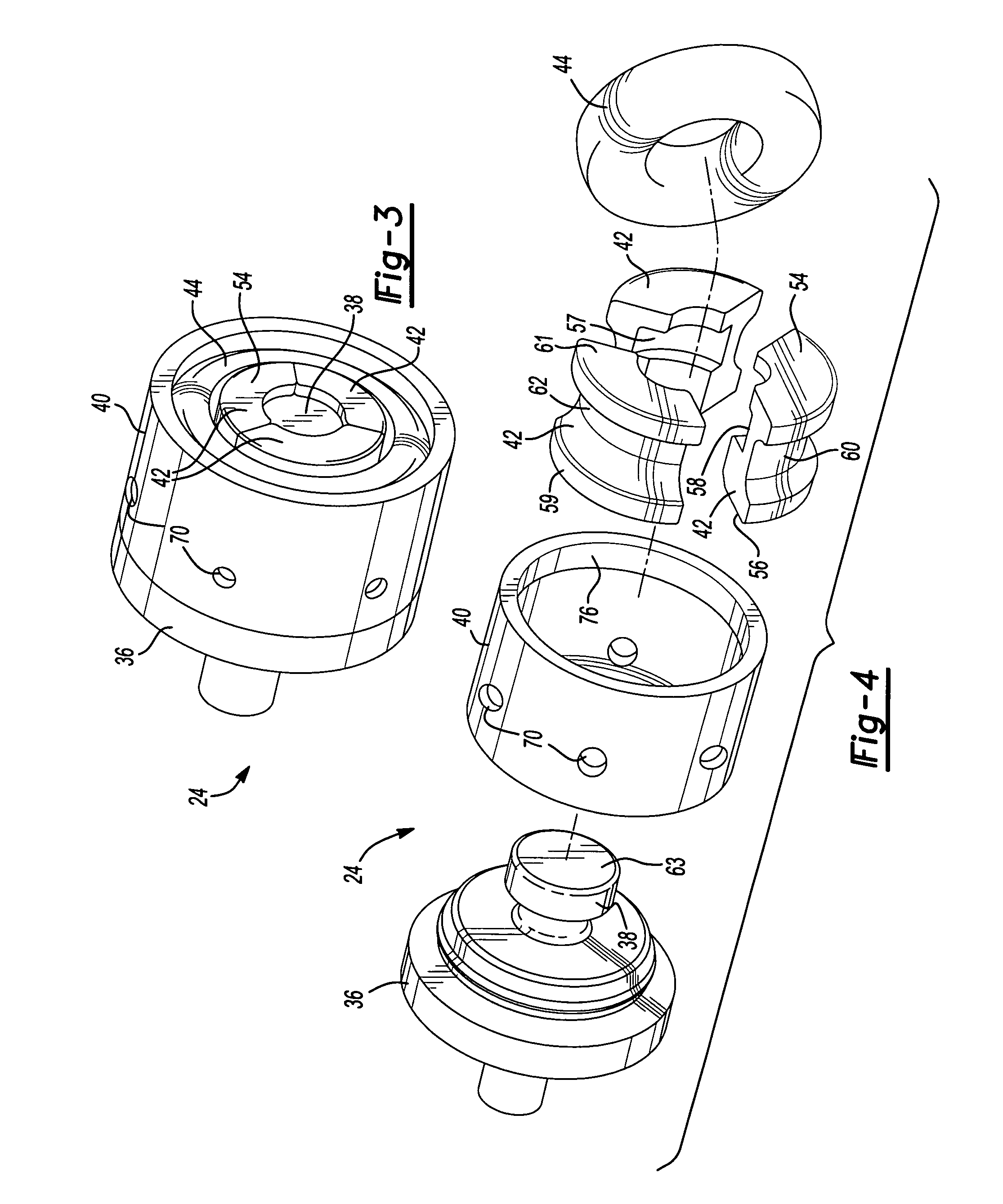

Sheet fastening apparatus and method

InactiveUS7694399B2Less-expensive to manufactureImprove joint qualityLarge fixed membersPositioning apparatusEngineeringKnife blades

A sheet fastening apparatus and method are provided. In another aspect of the present invention, a die assembly for forming a joint between sheets of material is disclosed wherein the die assembly includes an anvil, at least one die blade disposed adjacent to and overlapping a punch-side of the anvil, a flexible retainer, and a shield that coaxially and radially surrounds a portion of the anvil and / or die blade.

Owner:BTM COMPANY

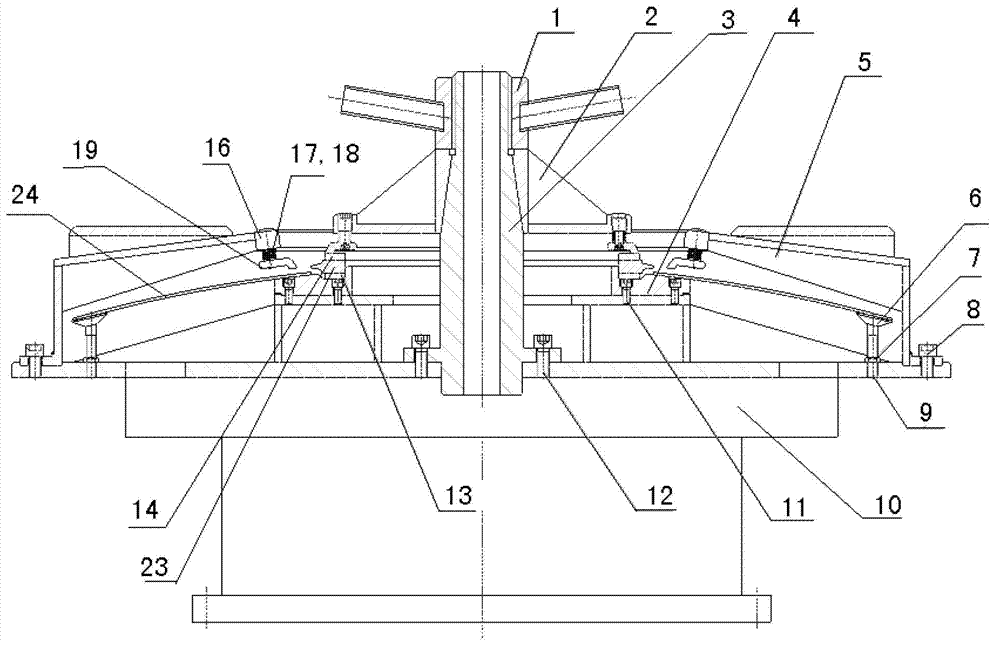

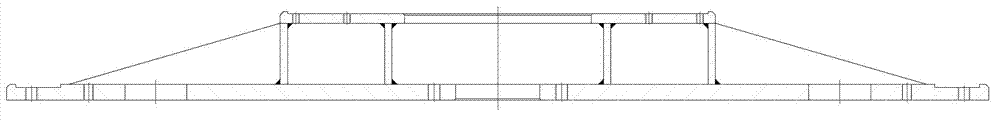

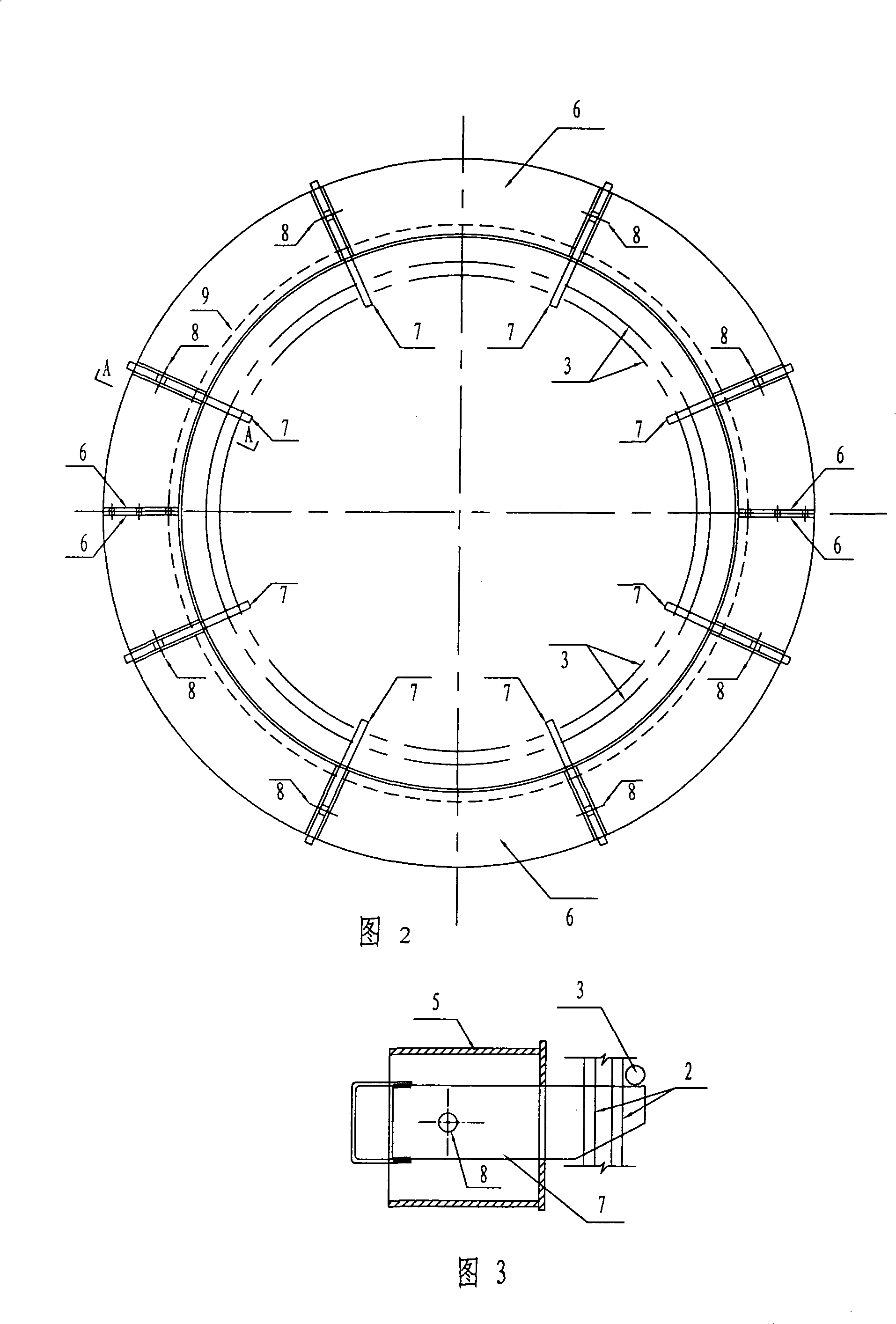

Positioning support device used for stirring, rubbing and welding circular seam of flange disc of top cover of storage box

ActiveCN102886600APlay a role in positioning and pressingPlay the role of positioning the center of rotationNon-electric welding apparatusTransition functionEngineering

The invention belongs to a machining process device of an aerospace product, and in particular discloses a positioning support device used for stirring, rubbing and welding a circular seam of a flange disc of a top cover of a storage box. The machining process device comprises a positioning supporting rotary support, wherein a circular base plate is arranged above the positioning supporting rotary support; an outer pressing ring is arranged above the circular base plate; round holes coaxial with a central hole at the lower bottom surface of the positioning supporting rotary support are arranged in the circular base plate and a center of the outer pressing ring; a central shaft is arranged inside the hole; the lower end of the central shaft is fixed on the positioning supporting rotary support; an outer clamping ring is arranged on the circular base plate; the outer clamping ring is connected with the outer pressing ring through a fastening structure; and a lock wire nut is arranged at the top end of the central shaft. The outer clamping ring, the outer pressing ring and the unique fastening structure have a positioning clamping function to a whole welding product; the outer clamping ring and the central shaft are concentric so as to have a function of positioning a rotation center; a design of the fastening structure has a transition function to connection of a whole positioning support device in a mode that bearing outer pressure is converted into a clamping force, and thus the machining process device is applicable to requirements on high precision in welding and assembling.

Owner:CAPITAL AEROSPACE MACHINERY +1

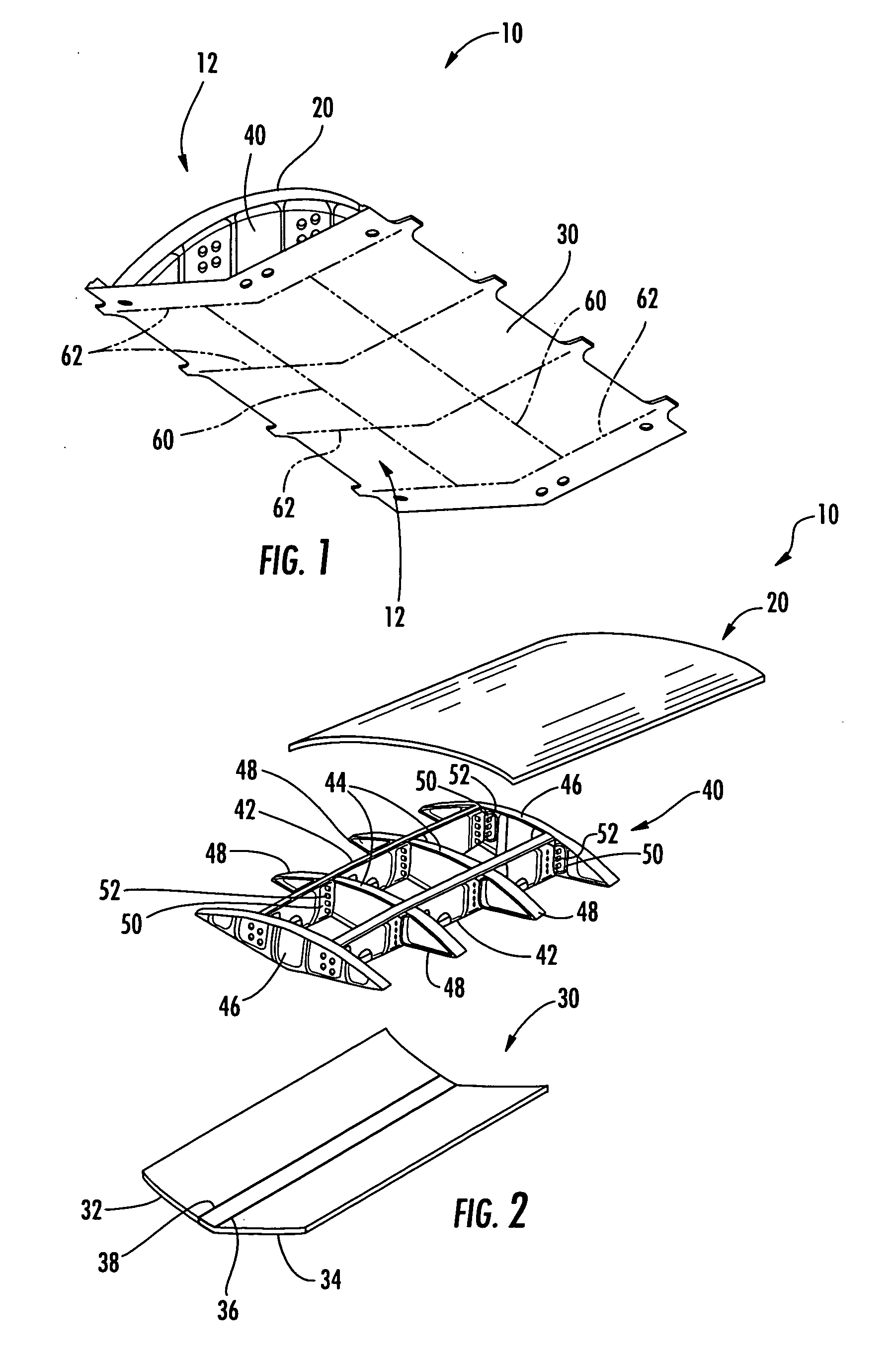

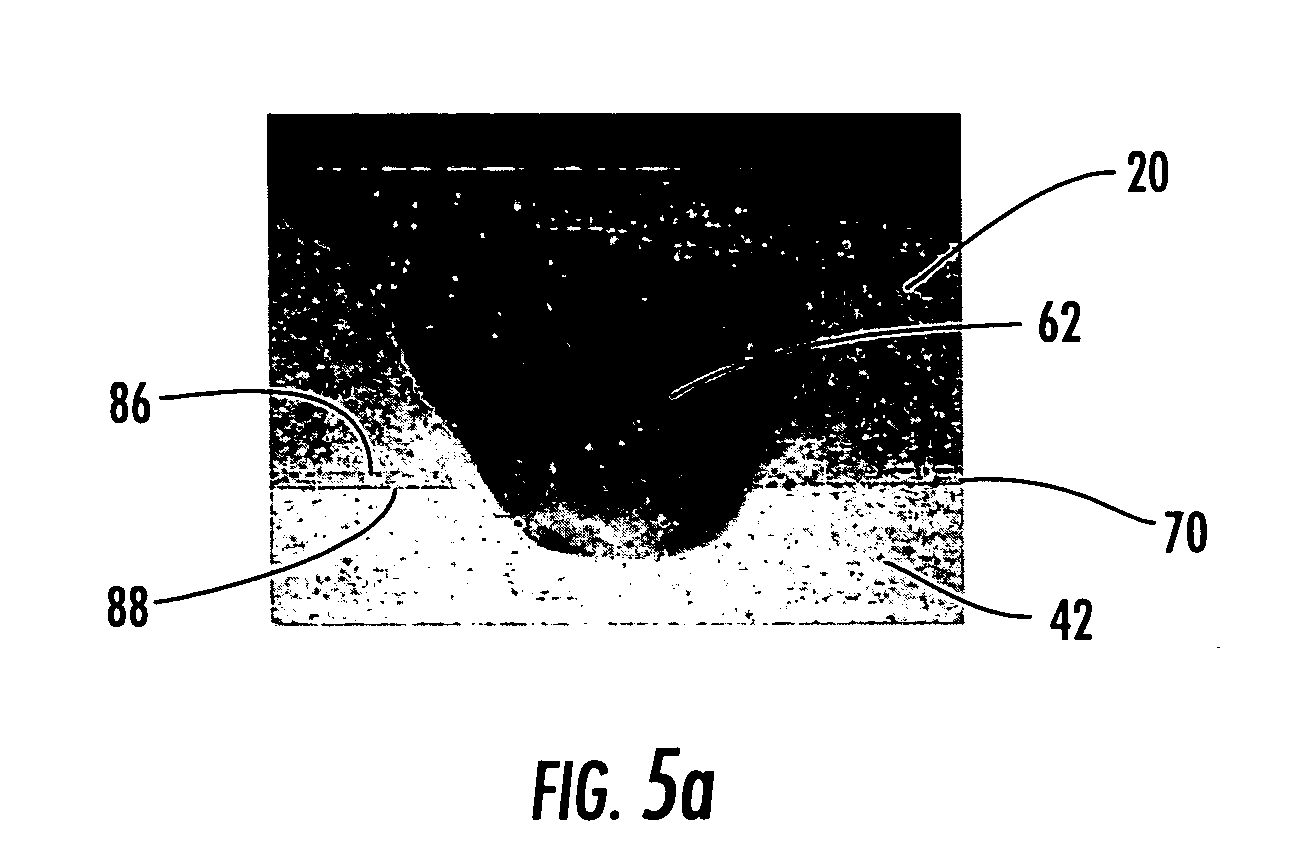

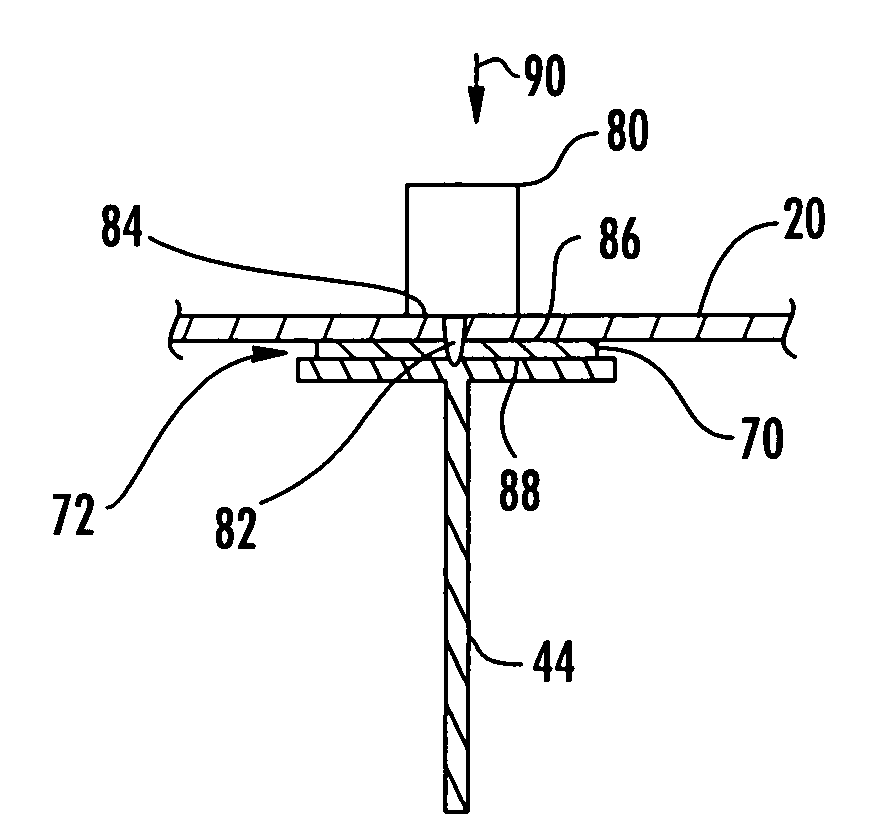

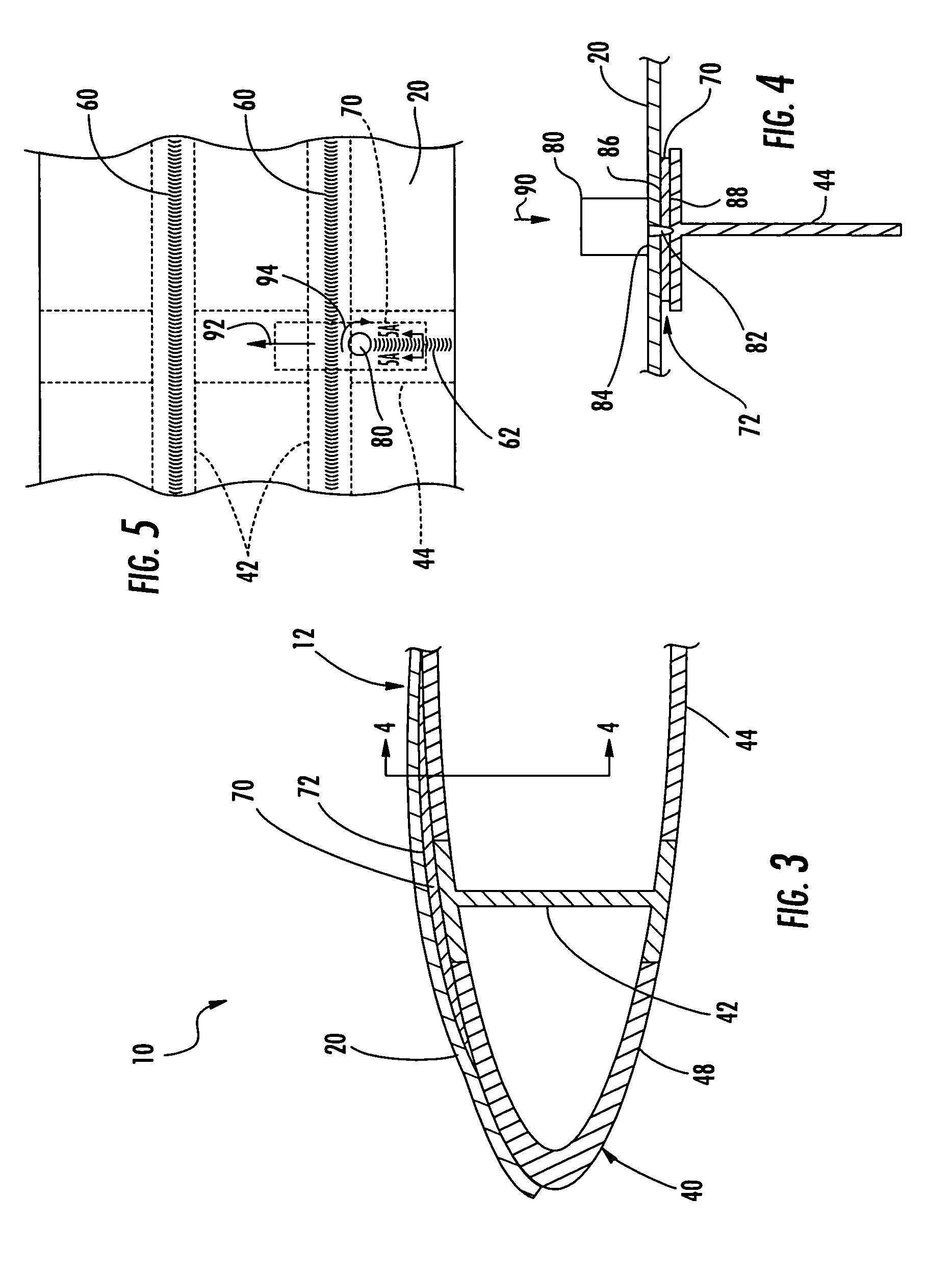

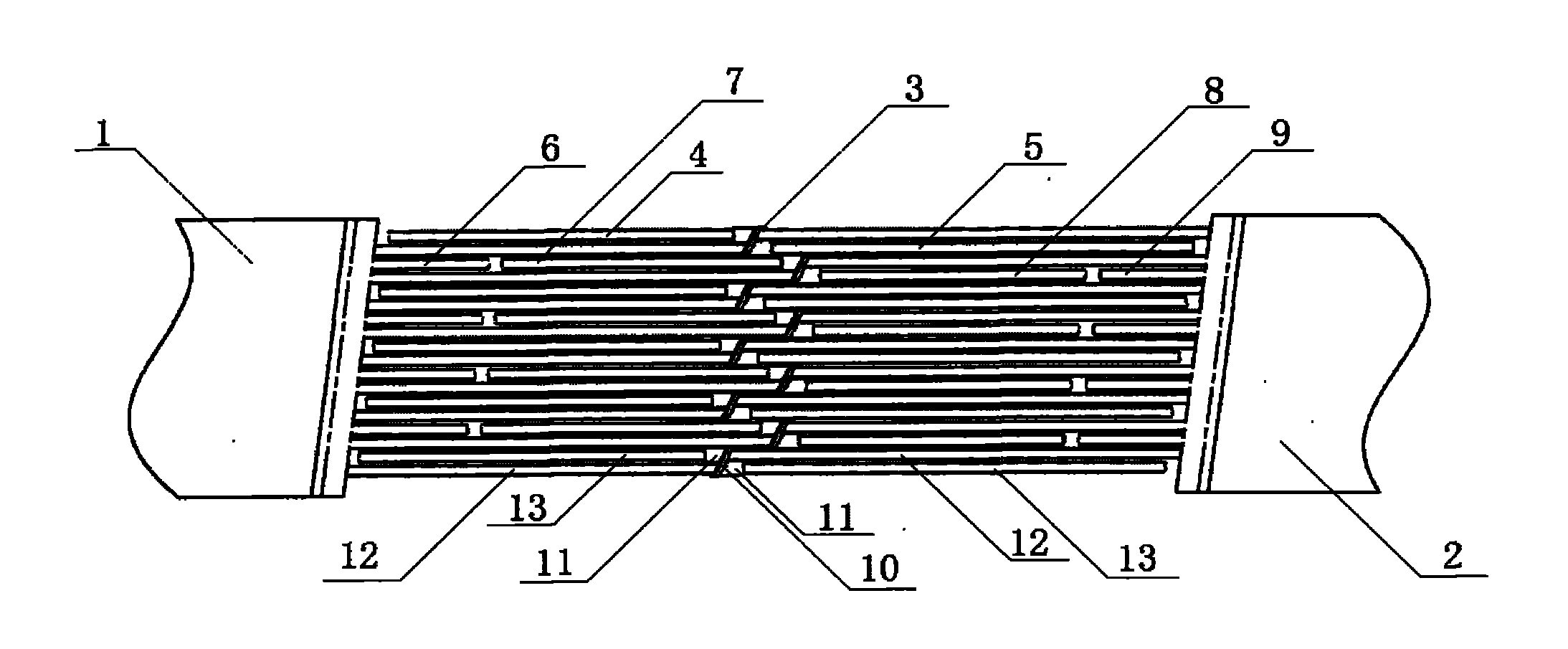

Friction stir welding of joints with shims

ActiveUS20060027630A1Promote formationImprove joint qualityWelding/cutting auxillary devicesAuxillary welding devicesSubstructureBiomedical engineering

A method of friction stir welding joints with shims and an associated structural assembly is provided. The structural assembly includes one or more skin members that are disposed and friction stir welded to a substructure. A shim is disposed in a space defined by the other members of the assembly, e.g., between adjacent skin members or between a skin member and the substructure. The shim can be friction stir welded to the other members. That is, the adjacent skin members can be connected via the shim, and / or the skin members can be connected to the substructure via the shim. In some cases, the skin members and the substructure are relatively stiff, and the shim substantially fills the space to reduce flexing of the members during the friction stir welding operation.

Owner:THE BOEING CO

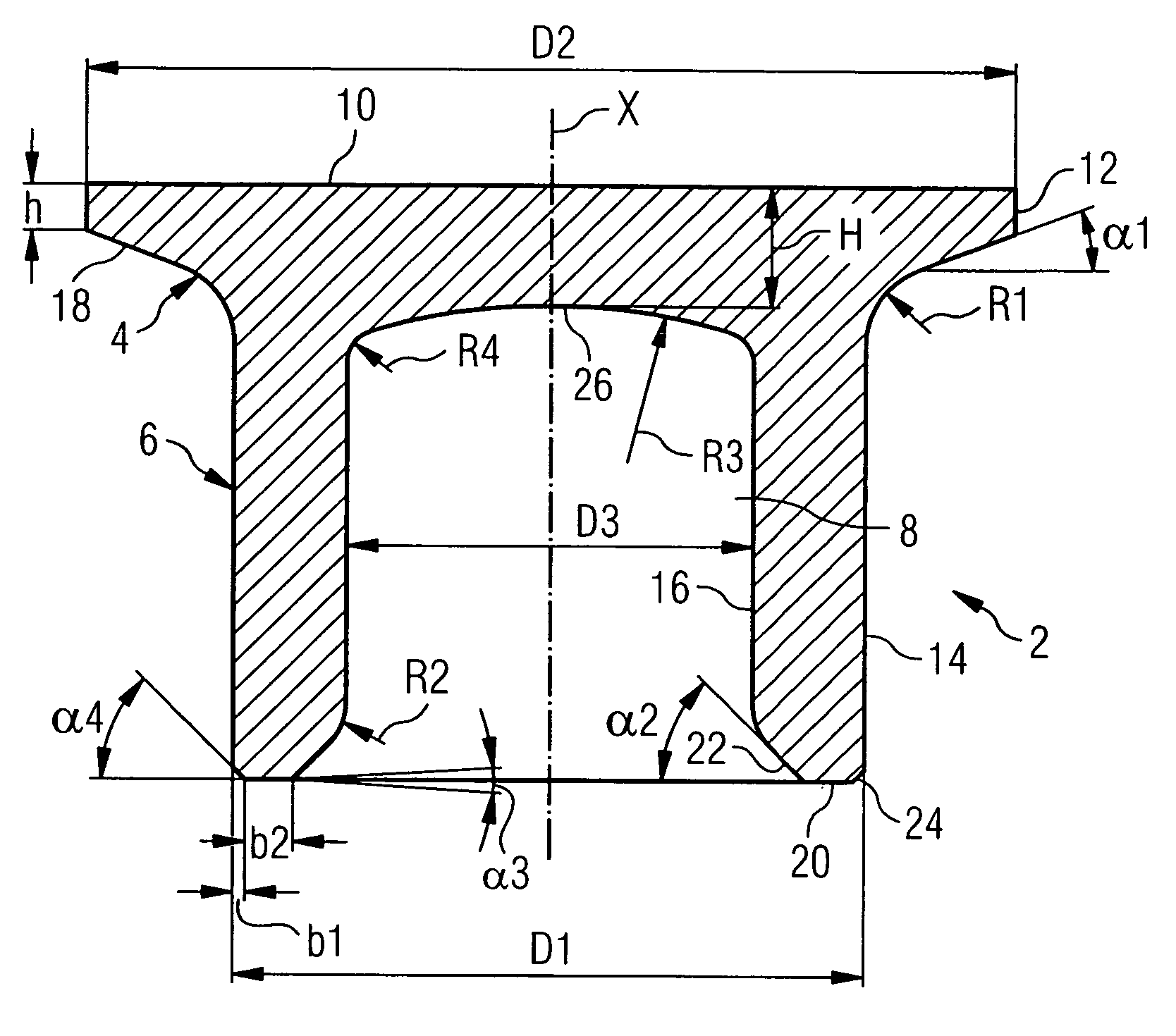

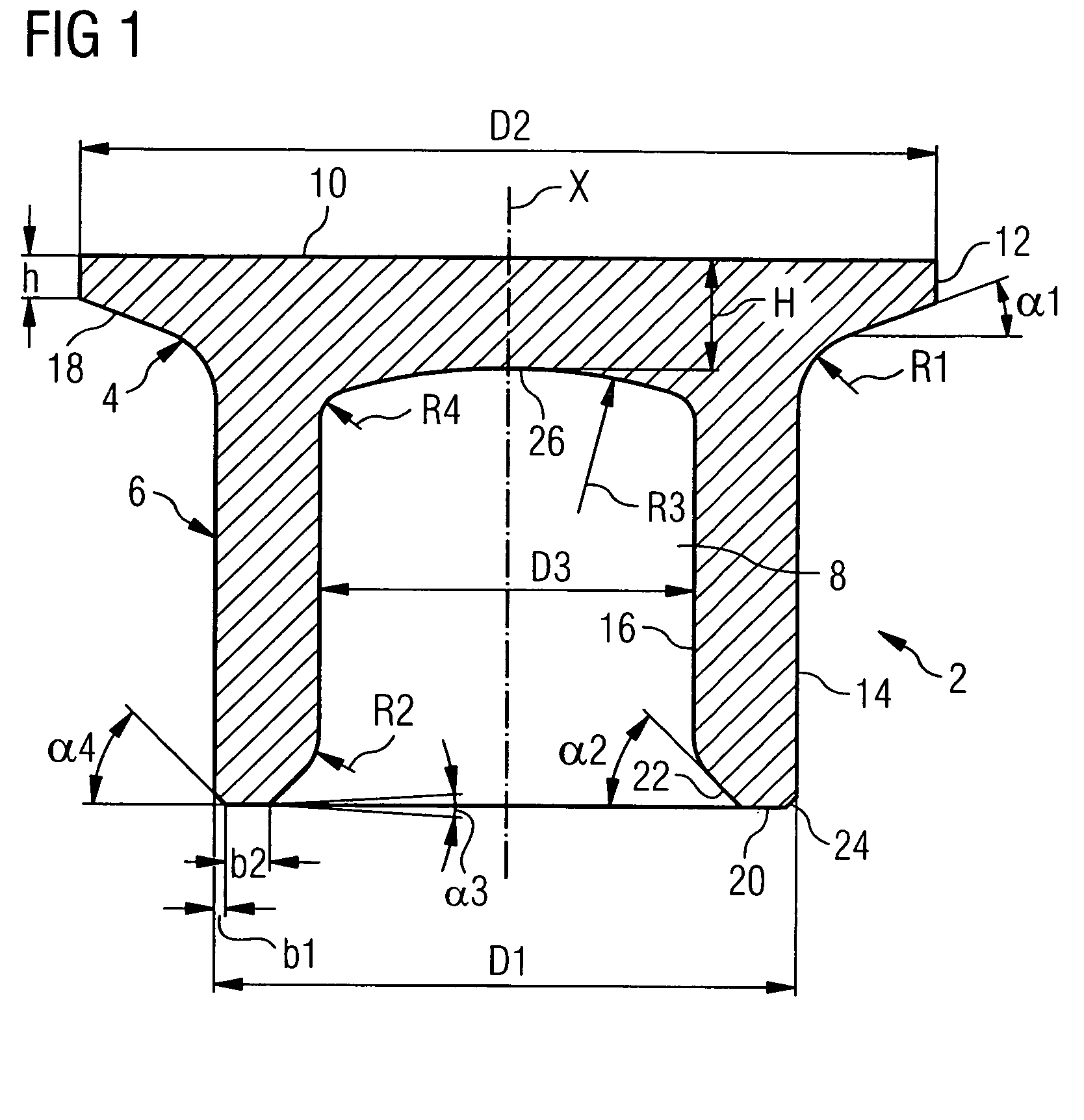

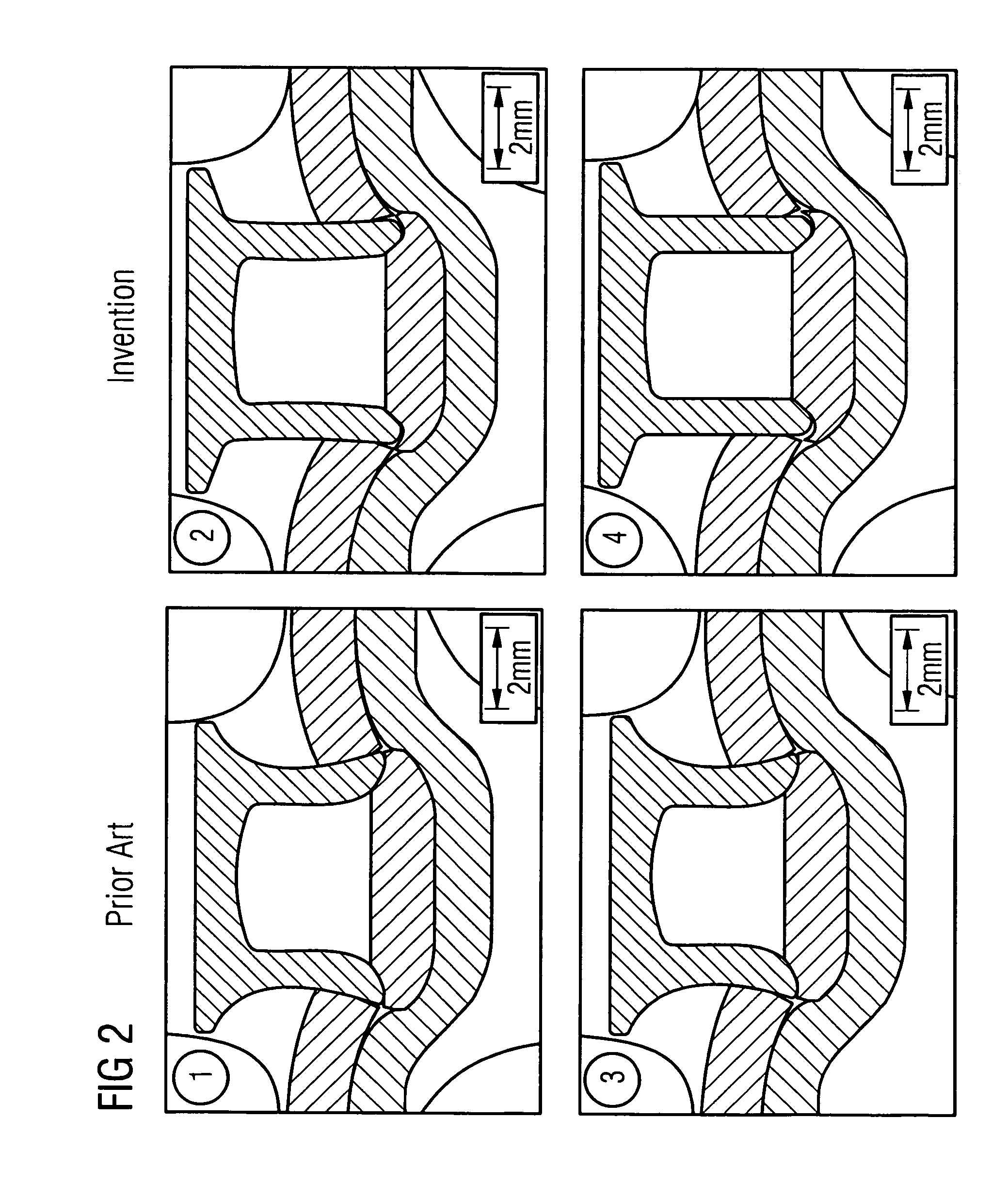

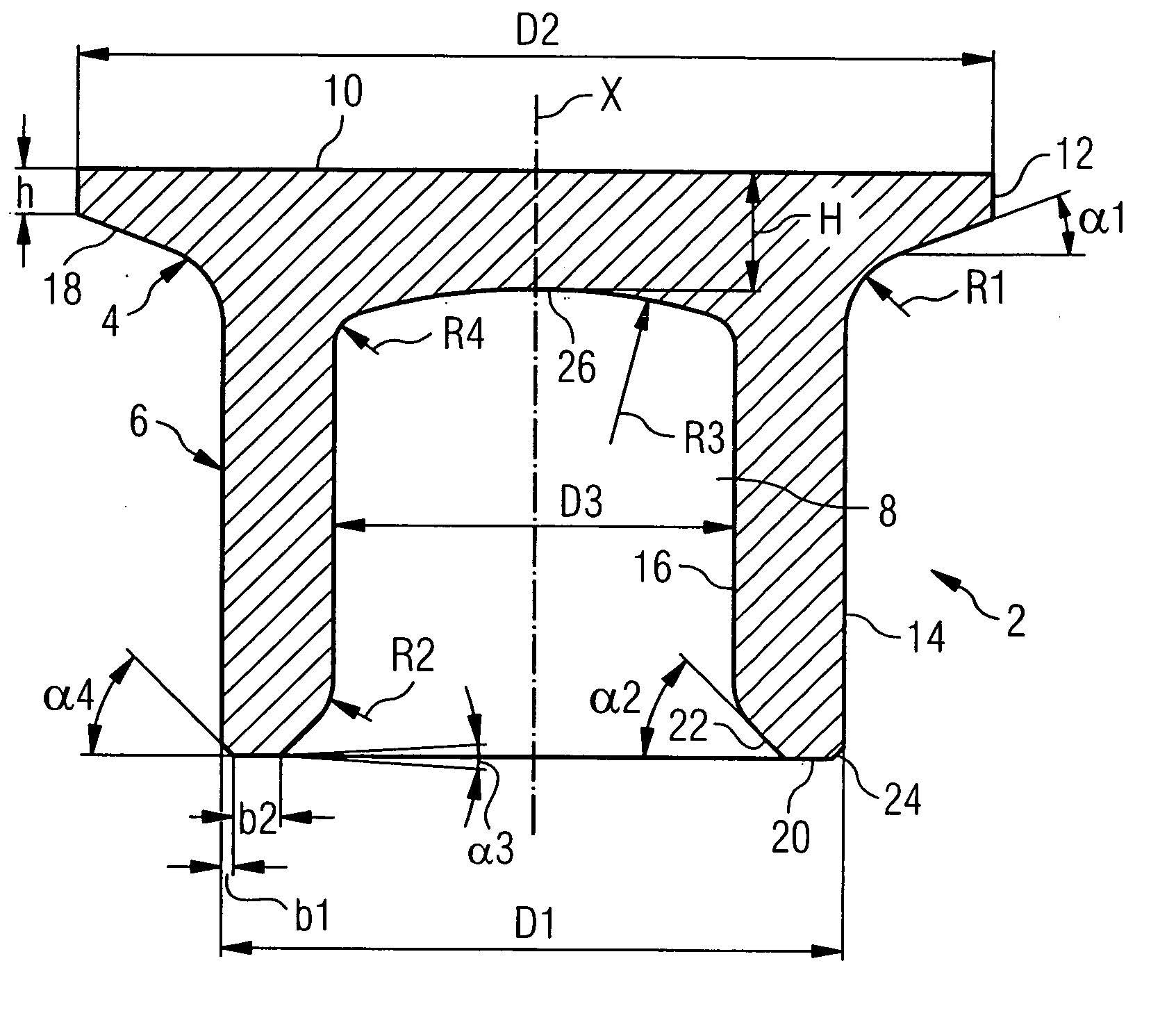

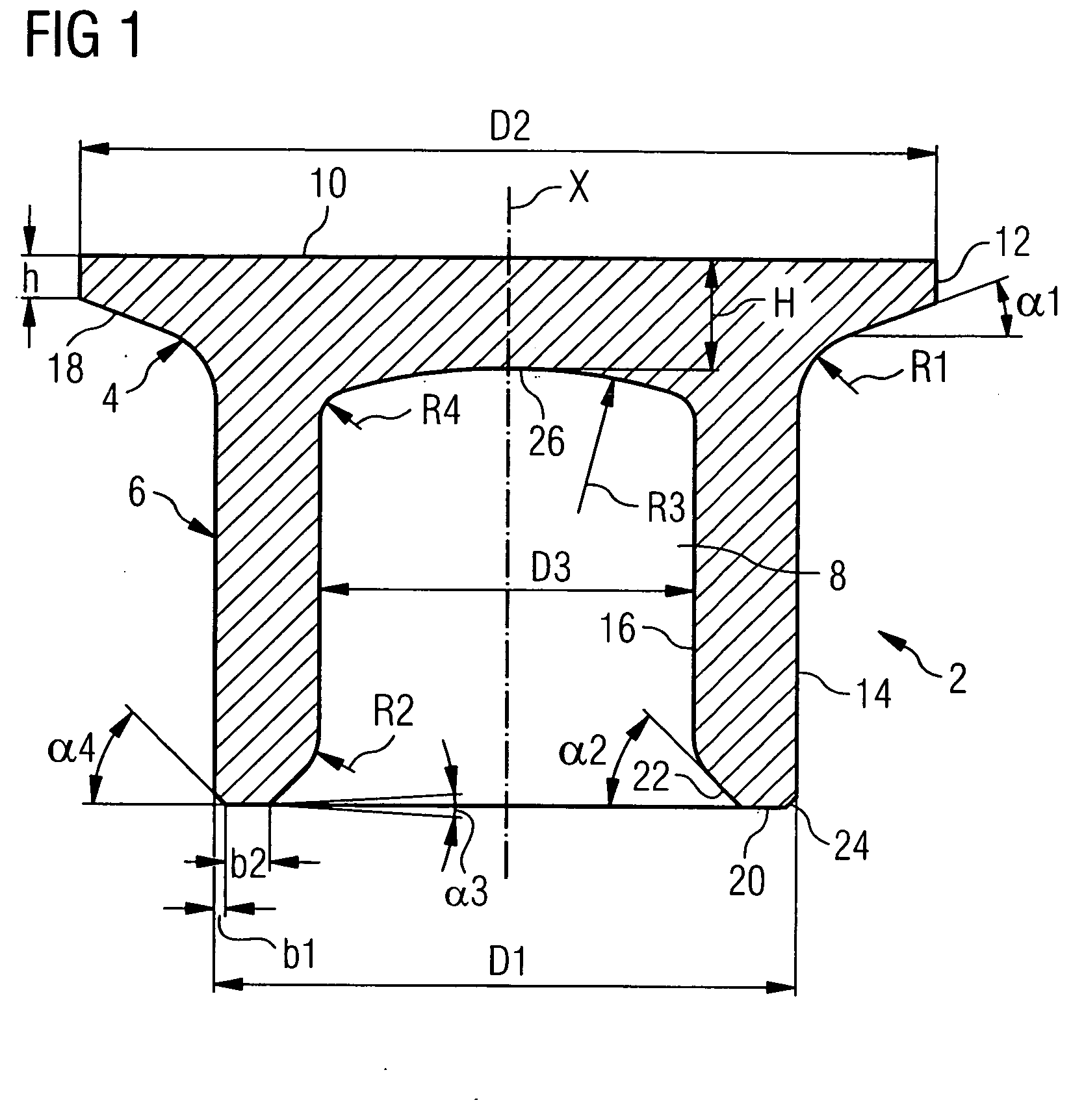

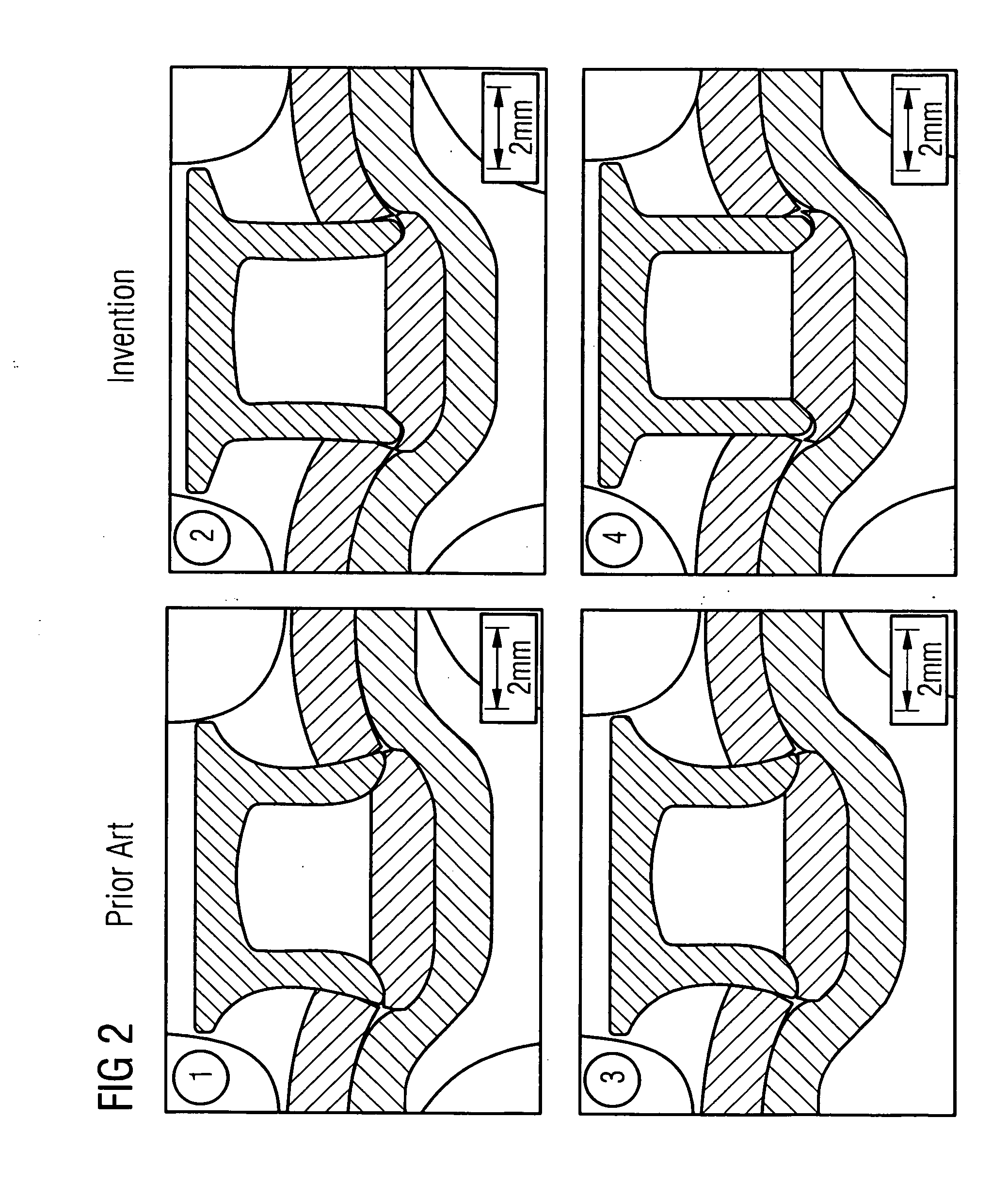

Self-piercing rivet

A self-piercing rivet of a special rivet geometry is described, which in particular is suitable for joining high strength steel sheets, but can also be used for other metal sheets. The self-piercing rivet is in particular characterized by a special underhead geometry as well as a special geometry of the rivet foot (cutting region). Thus the self-piercing rivet has an underhead chamfer which with a radial plane of the self-piercing rivet encloses an angle of 20°+5° / −5° and merges tangentially into the cylindrical outer surface of the rivet shank via a radius. In the region of the rivet foot the self-piercing rivet has a plane shank face, which extends essentially at a right angle to the rivet axis and which merges “smoothly” into the cylindrical inner surface via a shank inner surface and a radius. In comparison to conventional self-piercing rivets the special rivet geometry enables lower joining forces and tensile forces in the joining operation, an optimized load bearing performance and an optimum joint quality of the self-piercing rivet joint as well as minimum gap formation between the rivet and the metal sheet.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

Self-piercing rivet

A self-piercing rivet of a special rivet geometry is described, which in particular is suitable for joining high strength steel sheets, but can also be used for other metal sheets. The self-piercing rivet is in particular characterized by a special underhead geometry as well as a special geometry of the rivet foot (cutting region). Thus the self-piercing rivet has an underhead chamfer which with a radial plane of the self-piercing rivet encloses an angle of 20°+5° / −5° and merges tangentially into the cylindrical outer surface of the rivet shank via a radius. In the region of the rivet foot the self-piercing rivet has a plane shank face, which extends essentially at a right angle to the rivet axis and which merges “smoothly” into the cylindrical inner surface via a shank inner surface and a radius. In comparison to conventional self-piercing rivets the special rivet geometry enables lower joining forces and tensile forces in the joining operation, an optimized load bearing performance and an optimum joint quality of the self-piercing rivet joint as well as minimum gap formation between the rivet and the metal sheet.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

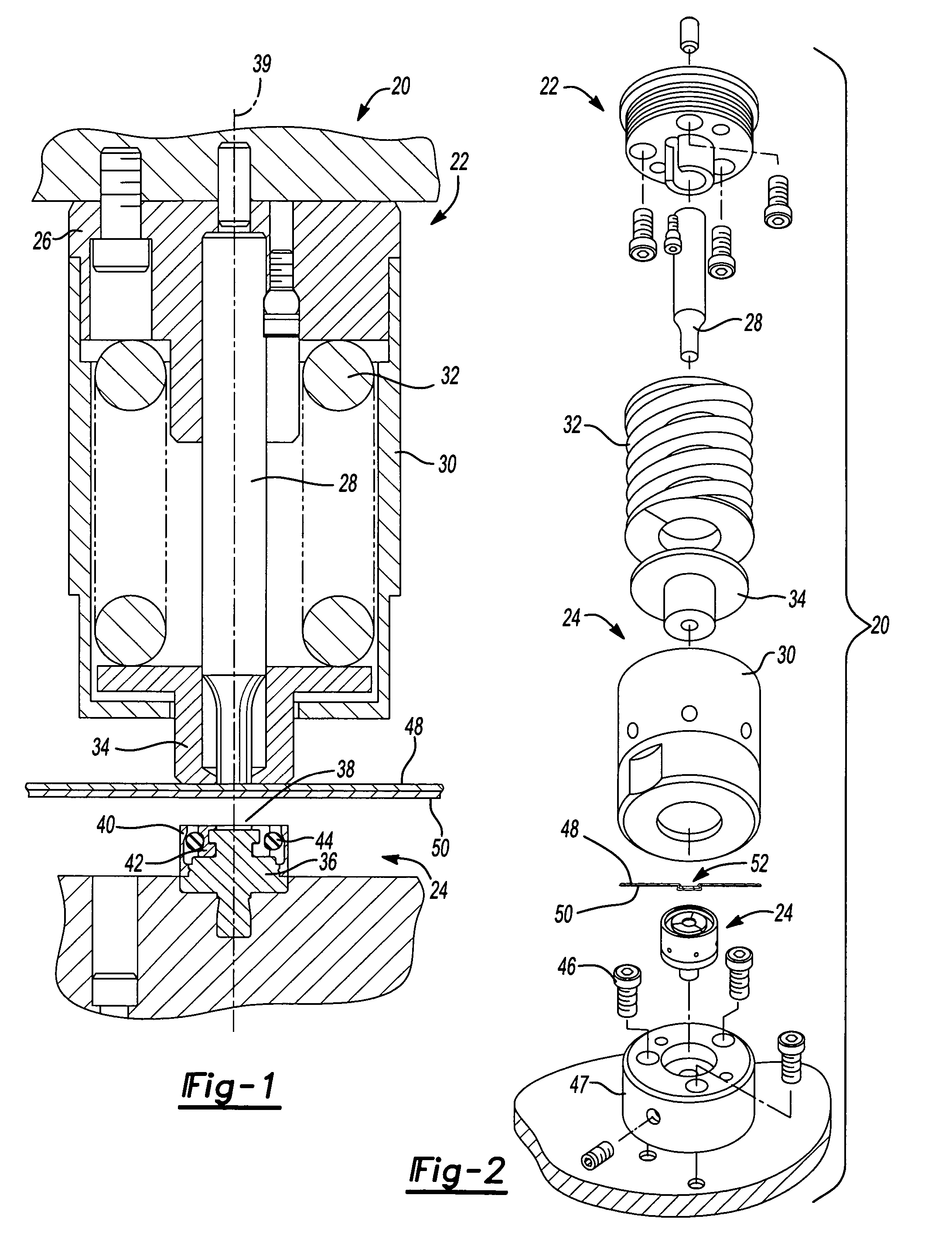

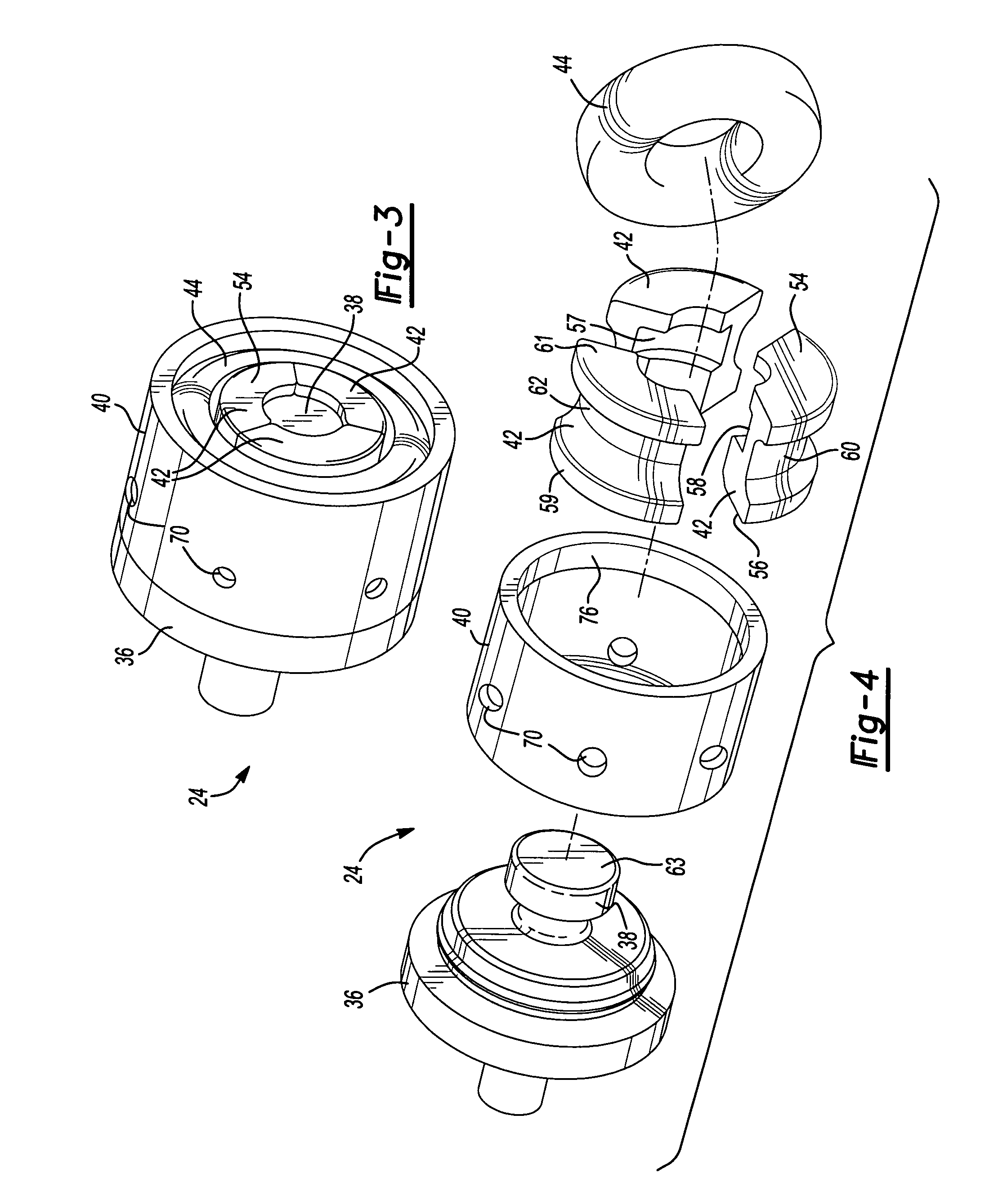

Sheet fastening apparatus and method

InactiveUS20060196034A1Improve joint qualityLess-expensive to manufactureShaping toolsRopes and cables for vehicles/pulleyEngineeringSheet material

A sheet fastening apparatus and method are provided. In another aspect of the present invention, a die assembly for forming a joint between sheets of material is disclosed wherein the die assembly includes an anvil, at least one die blade disposed adjacent to and overlapping a punch-side of the anvil, a flexible retainer, and a shield that coaxially and radially surrounds a portion of the anvil and / or die blade.

Owner:BTM COMPANY

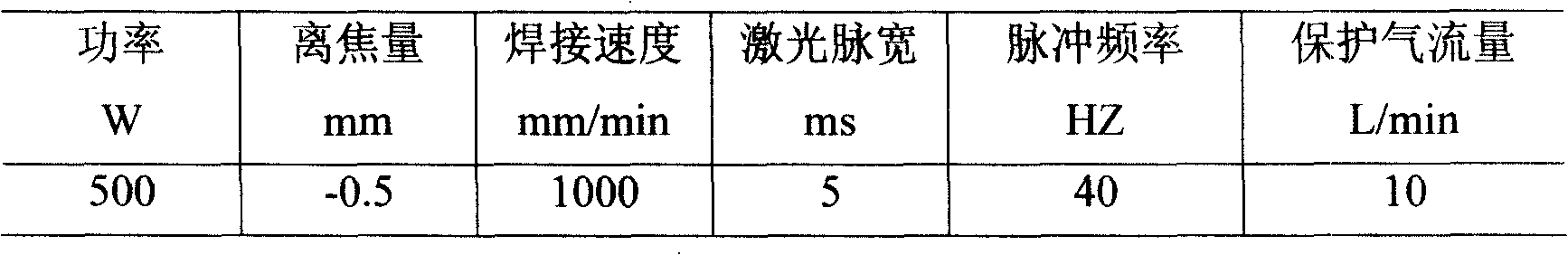

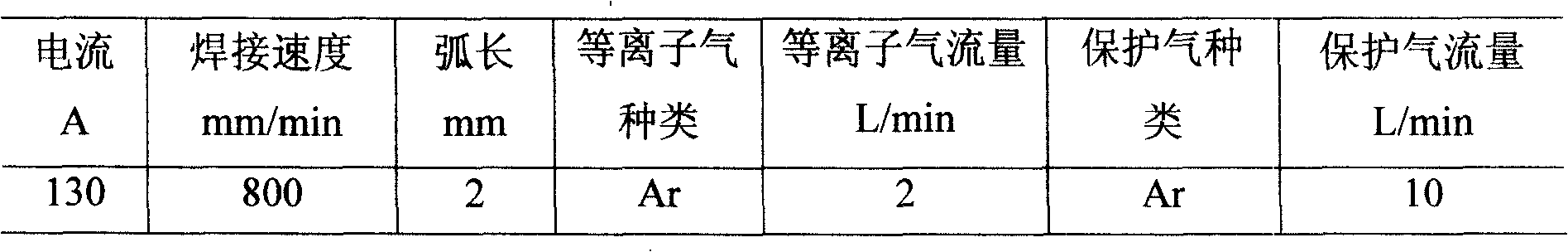

Activator for magnesium alloy welding

InactiveCN101244497AWell formed weldImprove joint qualityArc welding apparatusWelding/cutting media/materialsAlcoholActive agent

The invention relates to an active agent applying to magnesium alloy welding, belonging to the material engineering technical field, which is characterized in that: the active agent is composed of TiO2, Cr2O3, MgO, MnO2, and CaO and the weight proportion is TiO2: 40 to 70%, Cr2O3: 5 to 20%, MgO: 2 to 20%, MnO2: 5 to 20%, CaO: 5 to 20%. Firstly, the active agent is grinded to powder, then is dried and cooled; secondly, the active agent is mixed with acetone or alcohol and then is equally coated or sprayed on the surface of the welding bead; finally, after the acetone or the alcohol is volatilized, welding can be implemented. The active agent has the advantages that: the weld penetration can increase at least twice; the weld joint of magnesium alloy is well moulded; the joint is of high quality and the intensity can be above the 95% of the intensity of the parent metal; the deformation due to welding is reduced; the invention is of easy operation and high productivity.

Owner:DALIAN UNIV OF TECH

Friction stir welding of joints with shims

ActiveUS7487901B2Promote formationImprove joint qualityWelding/cutting auxillary devicesAuxillary welding devicesFriction reductionSubstructure

A method of friction stir welding joints with shims and an associated structural assembly is provided. The structural assembly includes one or more skin members that are disposed and friction stir welded to a substructure. A shim is disposed in a space defined by the other members of the assembly, e.g., between adjacent skin members or between a skin member and the substructure. The shim can be friction stir welded to the other members. That is, the adjacent skin members can be connected via the shim, and / or the skin members can be connected to the substructure via the shim. In some cases, the skin members and the substructure are relatively stiff, and the shim substantially fills the space to reduce flexing of the members during the friction stir welding operation.

Owner:THE BOEING CO

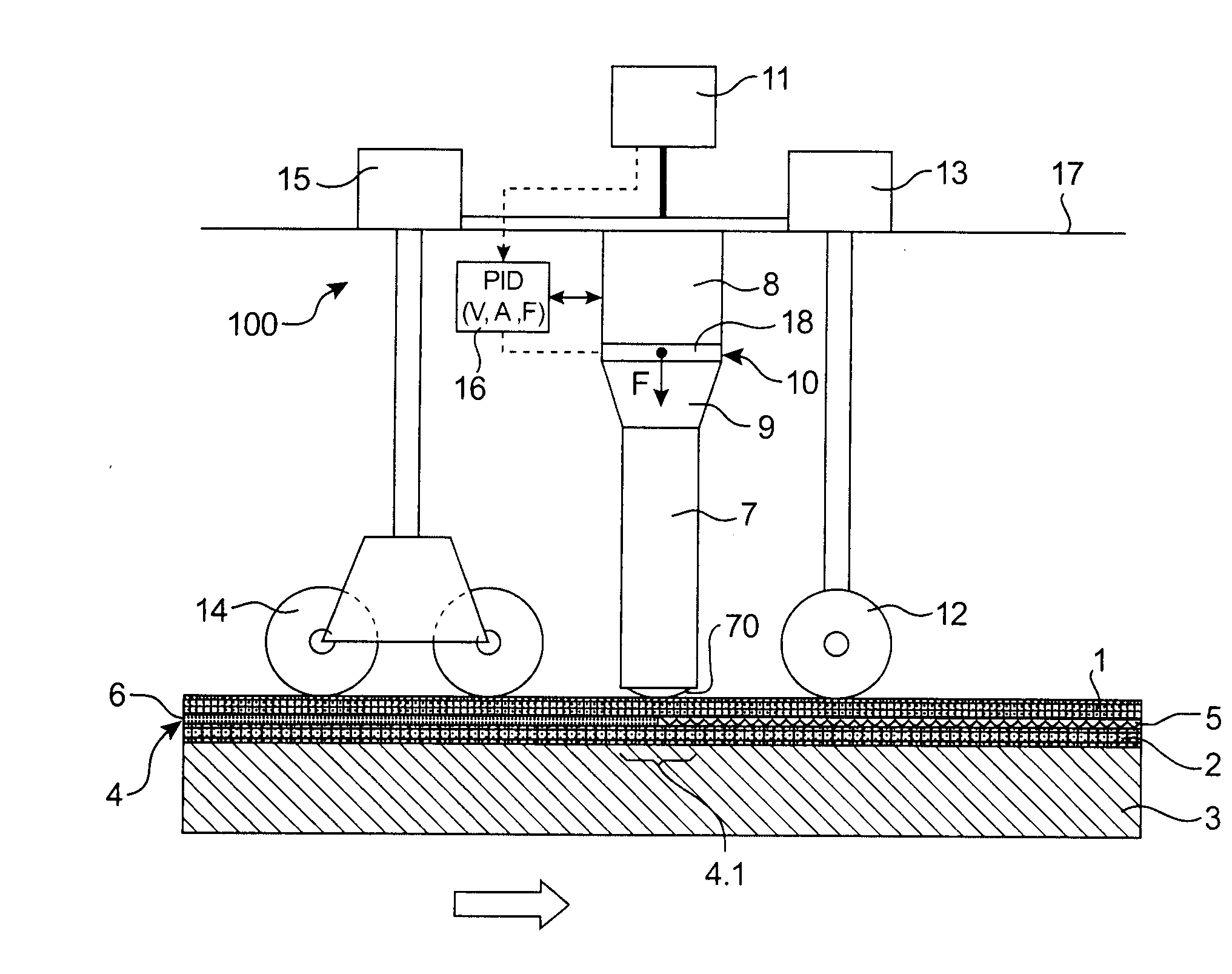

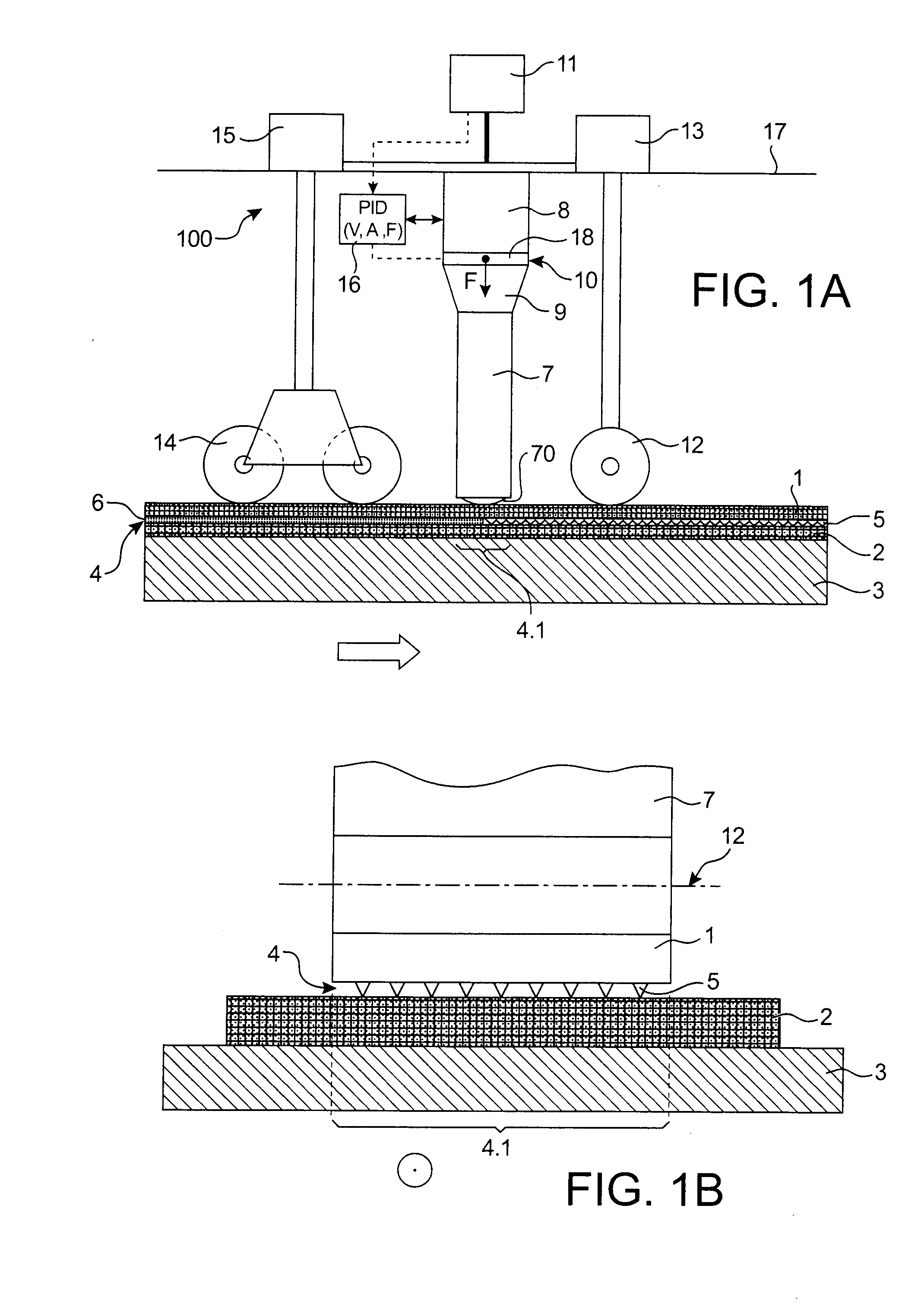

Ultrasonic Assembly Method

InactiveUS20080210360A1Improve automationLow costLamination ancillary operationsLaminationEnergy controlBiomedical engineering

A method for assembling at least two rigid thermoplastic material based parts. The two parts are superposed to have at least one interface zone, wherein at least one of the two parts includes one or plural energy directors, protruding, situated in the interface zone. At least one excited ultrasonic source is brought into contact with one of the two parts, the ultrasonic source applying a compression effort to the two parts in a region of the interface zone located opposite the ultrasonic source. The ultrasonic source is continuously displaced at the interface zone to form a continuous welded joint by fusion of the thermoplastic material in the region positioned opposite the ultrasonic source. Such a method may find particular application for assembly of stratified parts.

Owner:EURON AERONAUTIC DEFENCE & SPACE

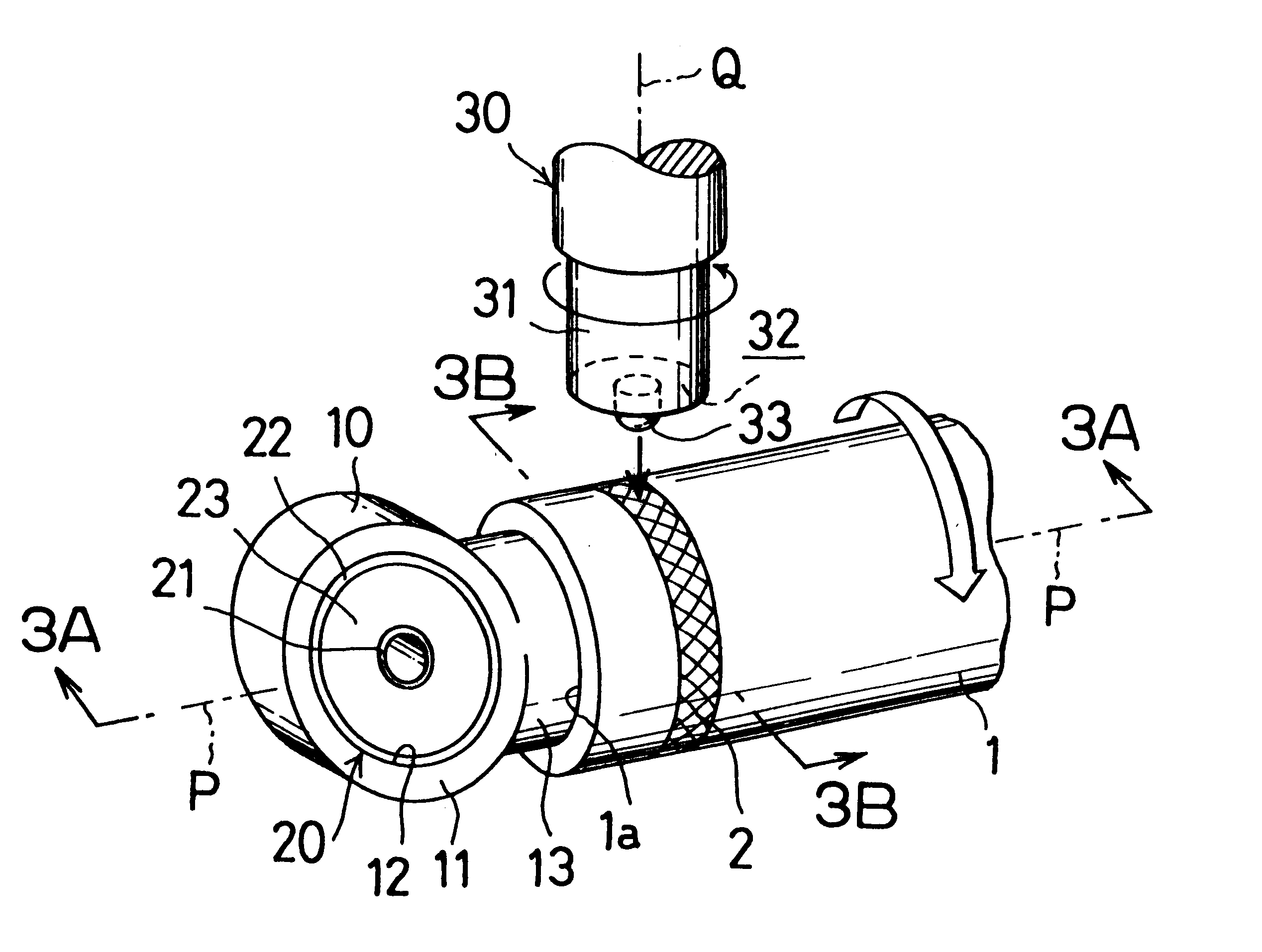

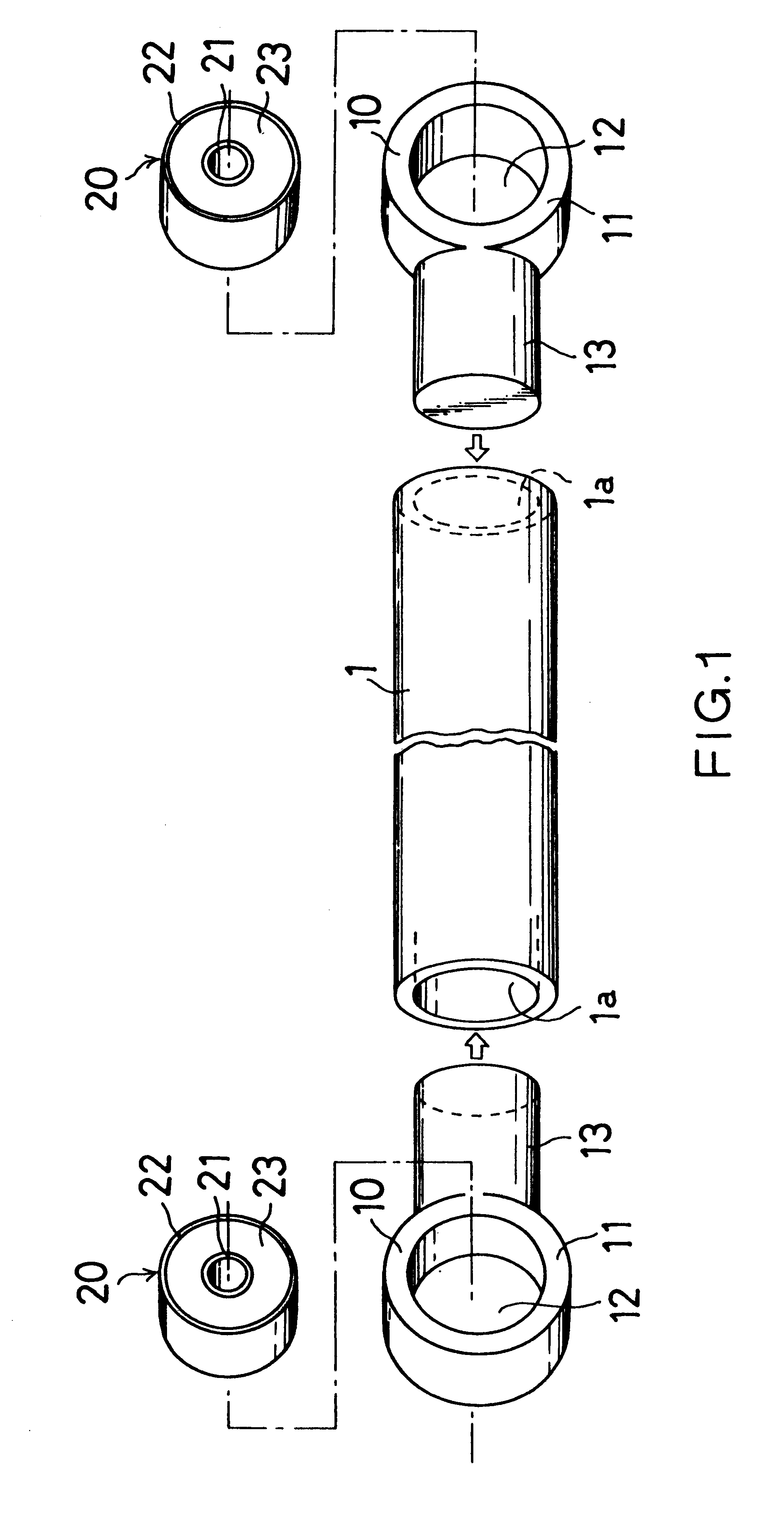

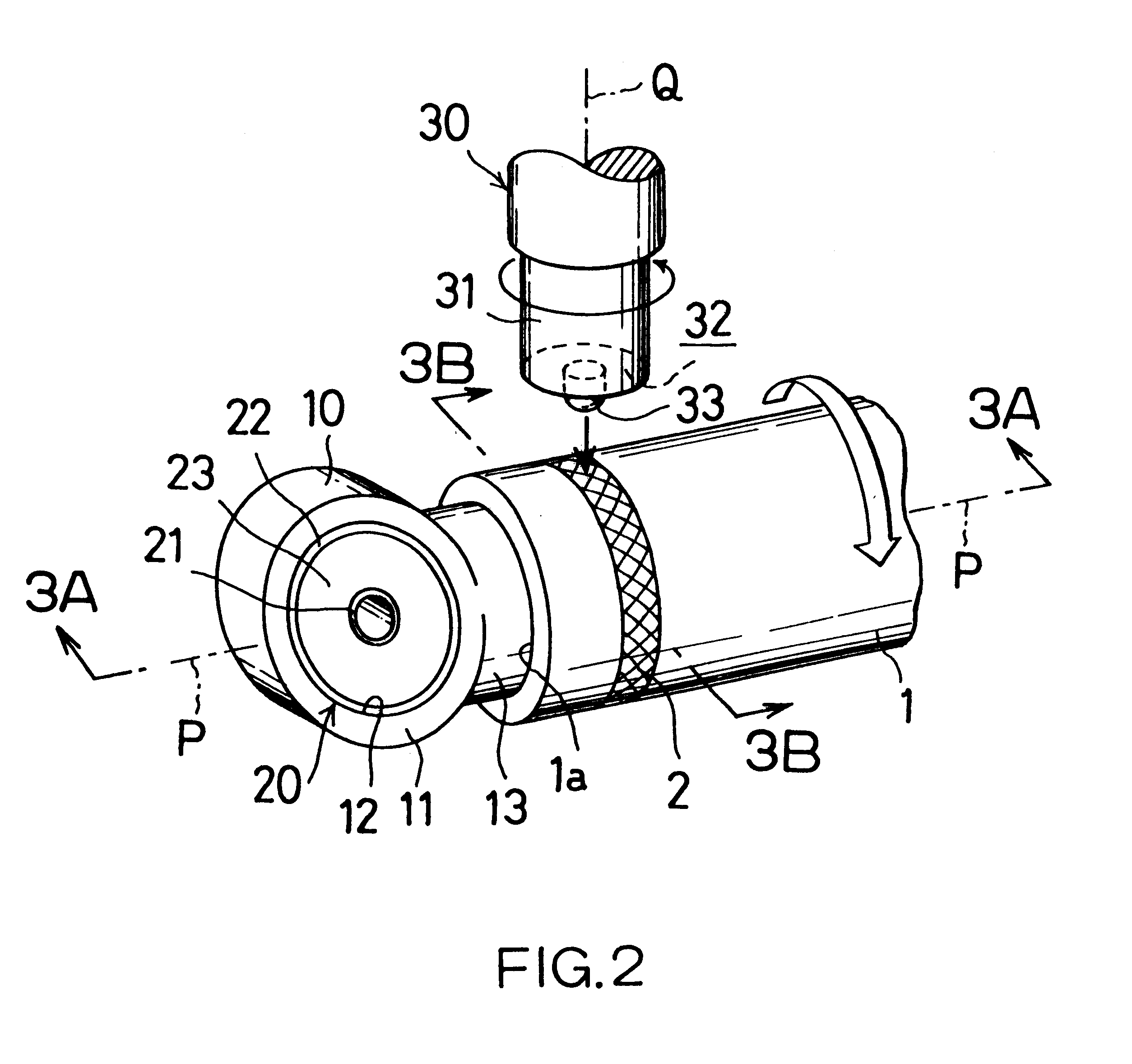

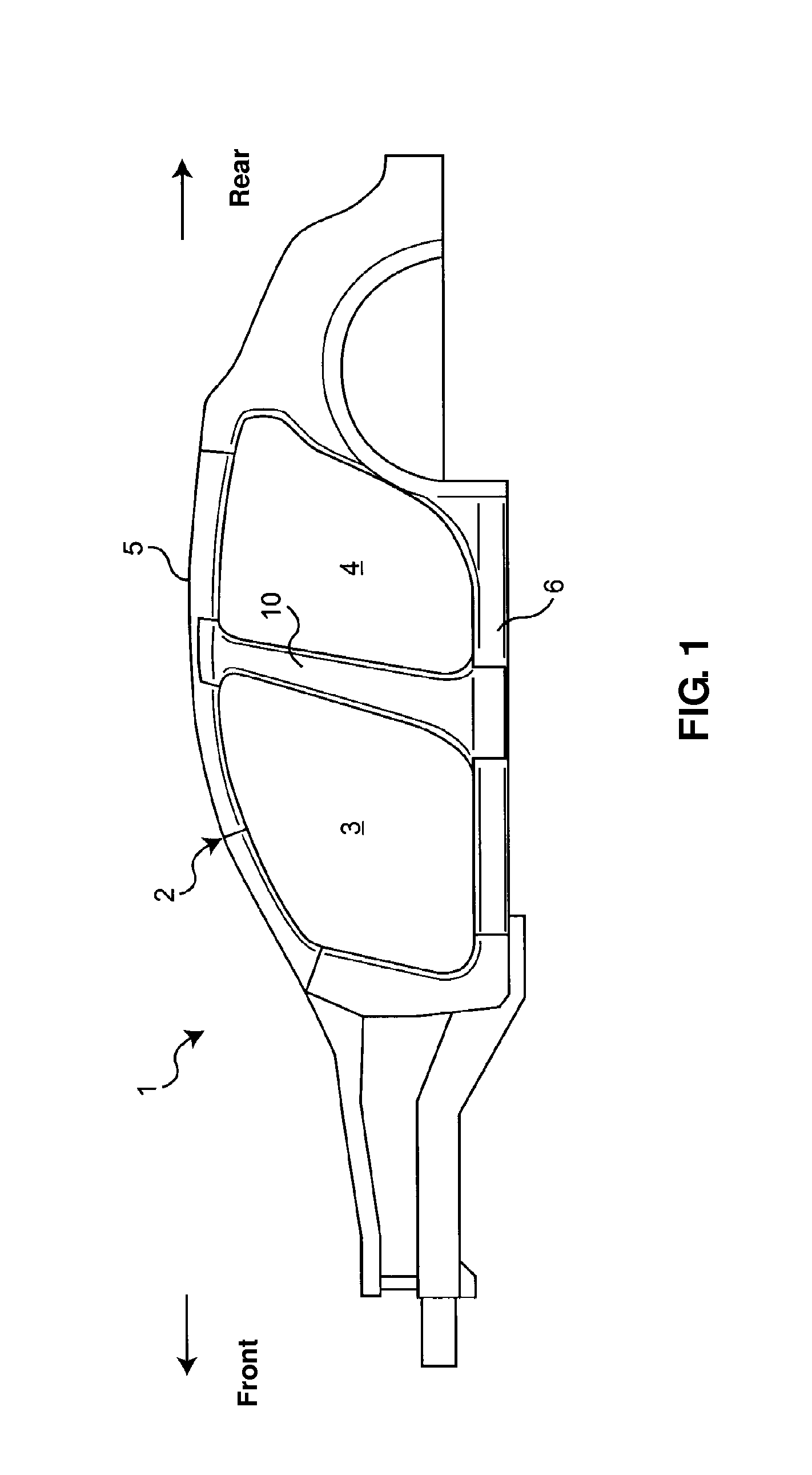

Connected structure and method for manufacturing the same

InactiveUS6244496B1Improve production efficiencyImprove joint qualityPivoted suspension armsWelding/soldering/cutting articlesEngineeringMechanical engineering

A connected structure includes a supporting member and a bushing mounting member connected thereto. The supporting member is made of a pipe having a round cross-sectional shape. The bushing mounting member includes a bushing mounting portion for mounting a bushing having a rubber elastic member and a connecting portion protruded from the bushing mounting portion. The connecting portion is press-fitted into an opening at one end of the supporting member, and the connecting portion and the supporting member are joined together along a circumference of the supporting member by a friction agitation joining method. Accordingly, the connecting member which is light in weight and high in strength with an improved efficiency for utilizing the surrounding space and a predetermined characteristics of a bushing can be obtained.

Owner:SUMITOMO RIKO CO LTD +1

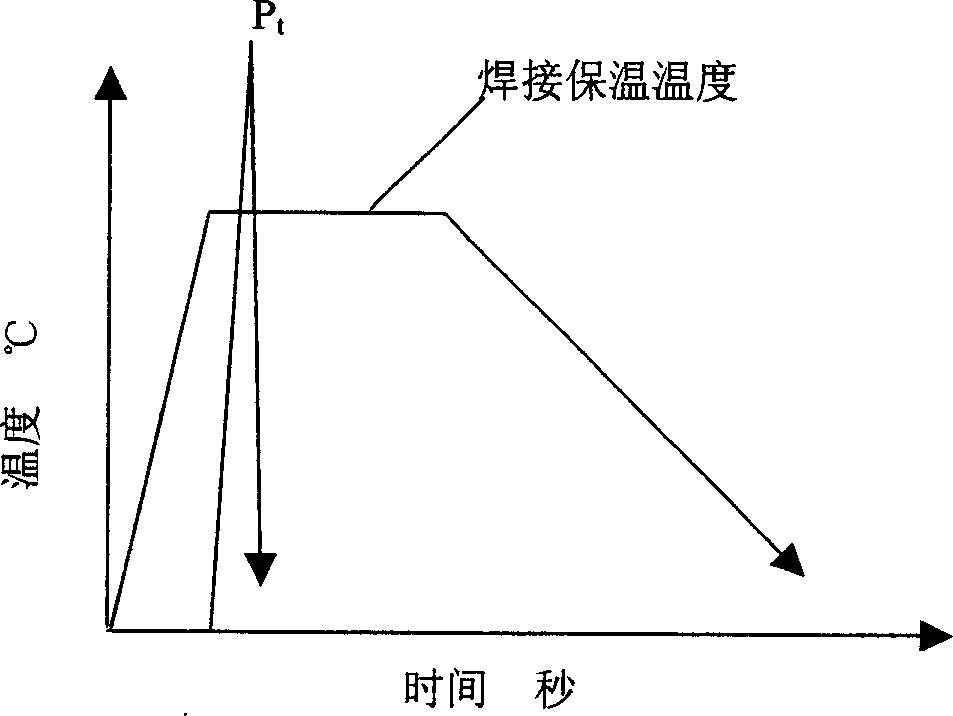

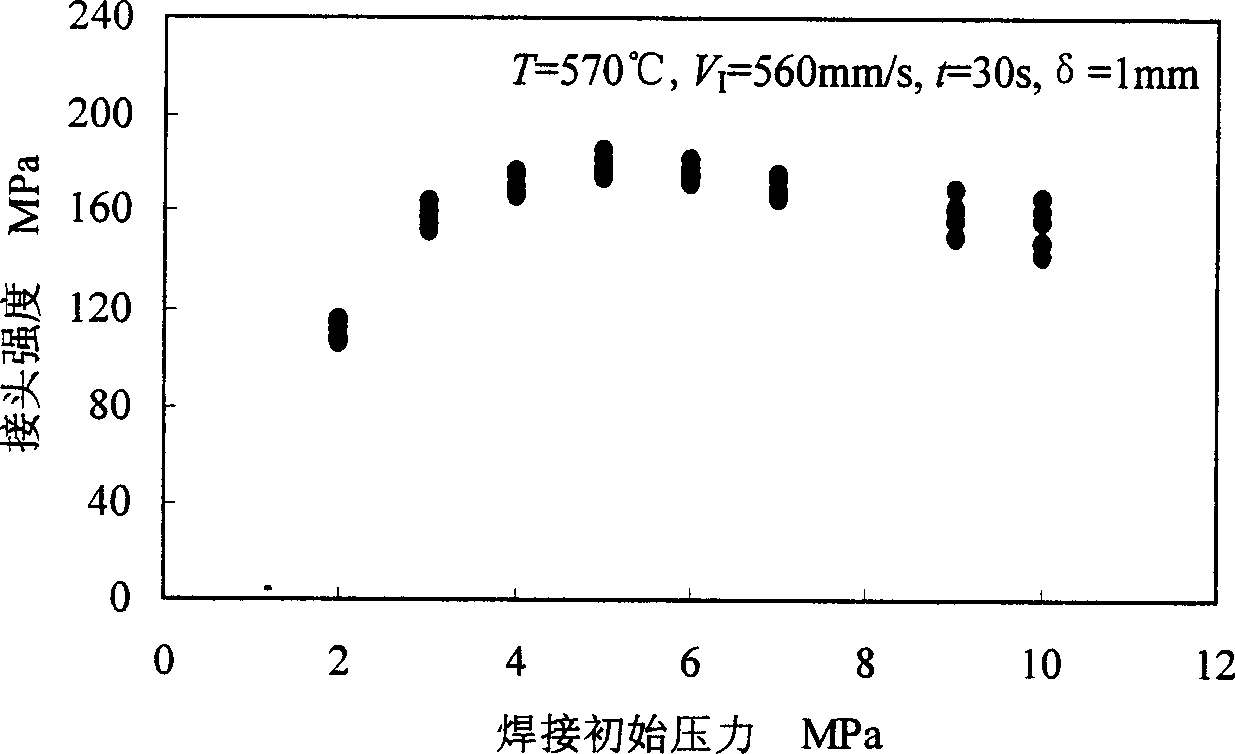

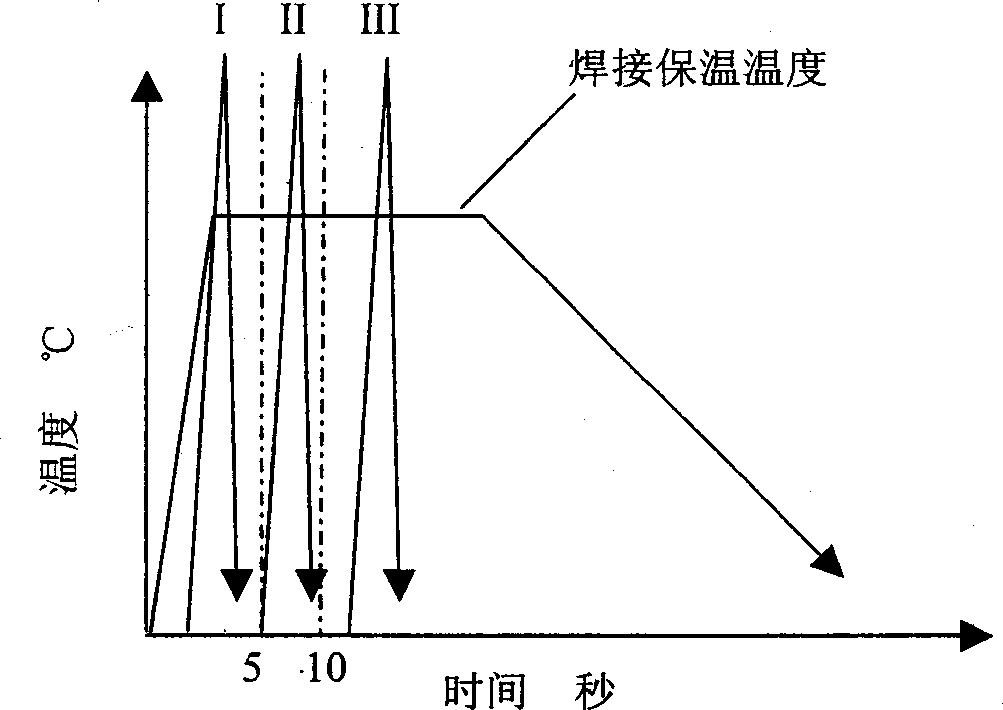

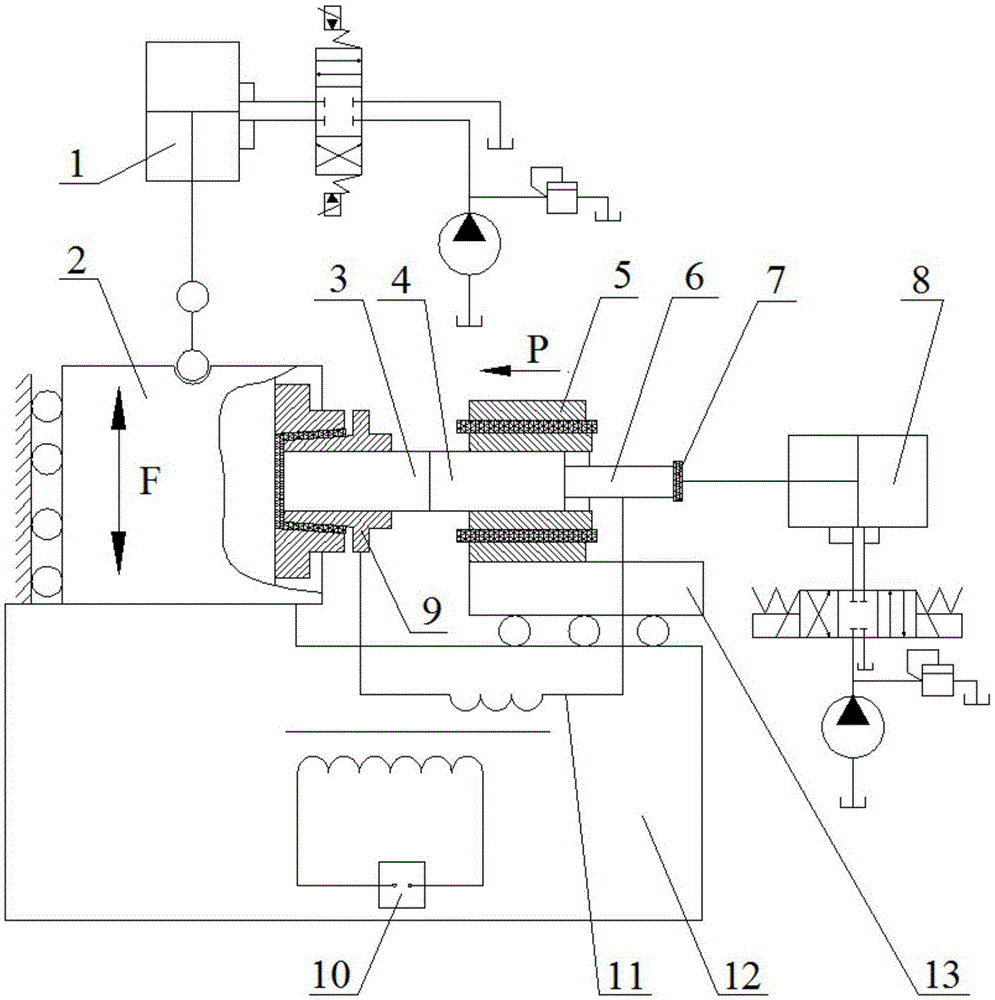

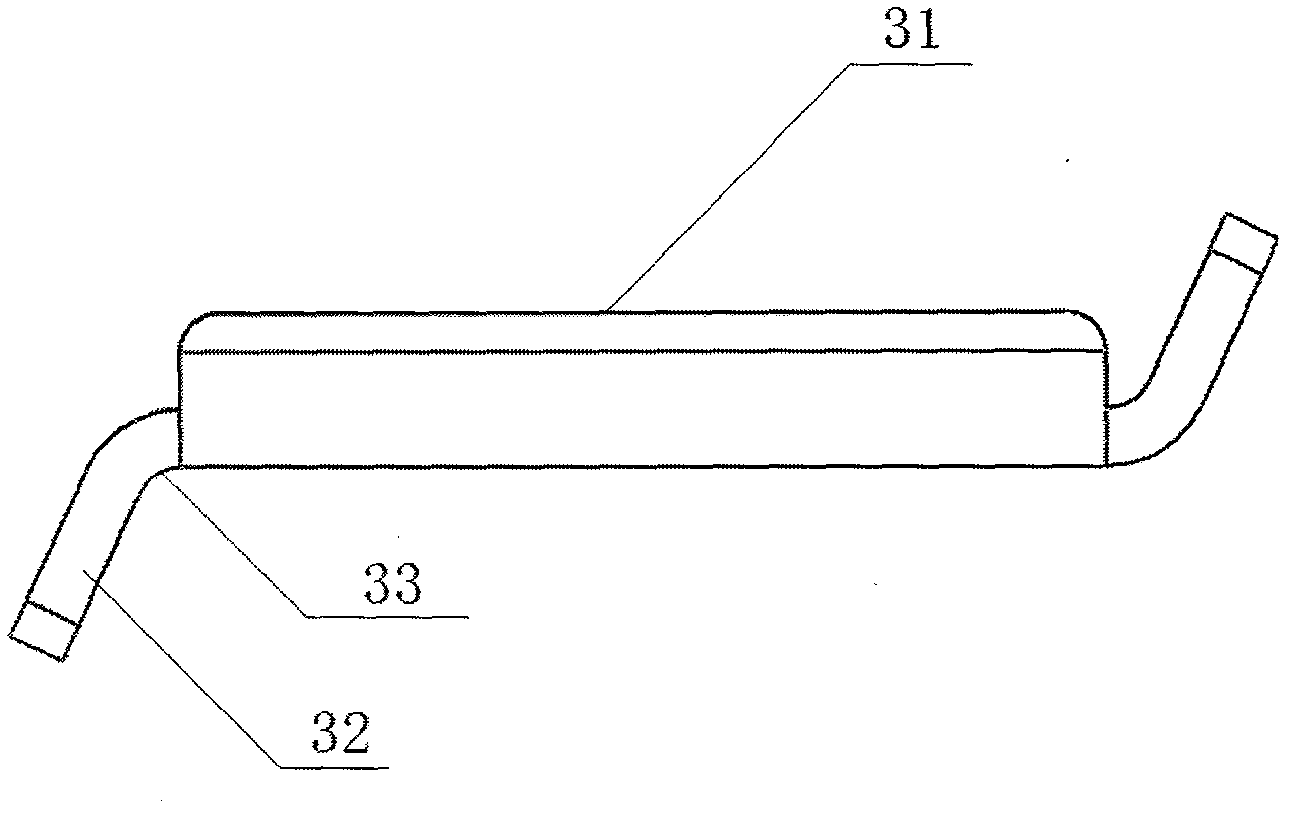

Novel process of liquid phase impact diffusion welding for aluminium-based composite material

InactiveCN1546269AImprove joint qualityImprove joint strengthNon-electric welding apparatusMetalDiffusion welding

The invention proposes a new aluminium compound material liquid phase impacting diffusion welding process which belongs to diffusion welding technology field. The invention solves the low quality of aluminium compound material diffusion welding. The invention mainly includes: the welding thermal reservation selection is in the aluminium compound material liquid and solid phase temperature period, in the temperature range whose liquid phase volume piece-rate is 20-35% correspondent to the base body liquid phase, the thermal reservation time is 30 seconds, at first applies initial welding pressure is 5MPa, the impacting pressure is 80-120MPa, the impacting speed is applied after the welding temperature thermal reservation for 5-10 seconds, the impacting temperature is 350-700mm / s. the impacting allying time interval is 0.0001-0.01 seconds. The invention applies to aluminium compound material made up of aluminum material 6061, 6063, 2014, 2A12, 5A06, 6A02, 7A04, ZL101, ZL102 and enhancing material SiC, Al2O3, TiC, AIN.

Owner:HARBIN INST OF TECH

Linear friction-current compound heat source welding method

InactiveCN105562953AReduce loadSmooth vibration outputWelding apparatusFriction weldingElectrical resistance and conductance

The invention discloses a linear friction-current compound heat source welding method for solving the technical problem of weak joint quality in welding of a large-area workpiece by a traditional linear friction welding method. Current is introduced into a friction pair when performing linear friction welding; and a welding interface is heated by using resistance heat. When a welding interface material reaches a visco-plastic state and generates deformation, that is, when a stable friction phase is reached, the current is cut off by a power supply control device; quick workpiece alignment is controlled; and higher welding upset force is applied to the workpiece to finish the workpiece welding. A compound heat source heating mode can realize the welding of high-heat-strength and large-area workpiece, relieves the load of a machine tool, is stable in vibration output of the machine tool, is excellent in controllability, can form an excellent closed welding interface in the welding process, and improves the joint quality in linear friction welding of the large-area workpiece.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

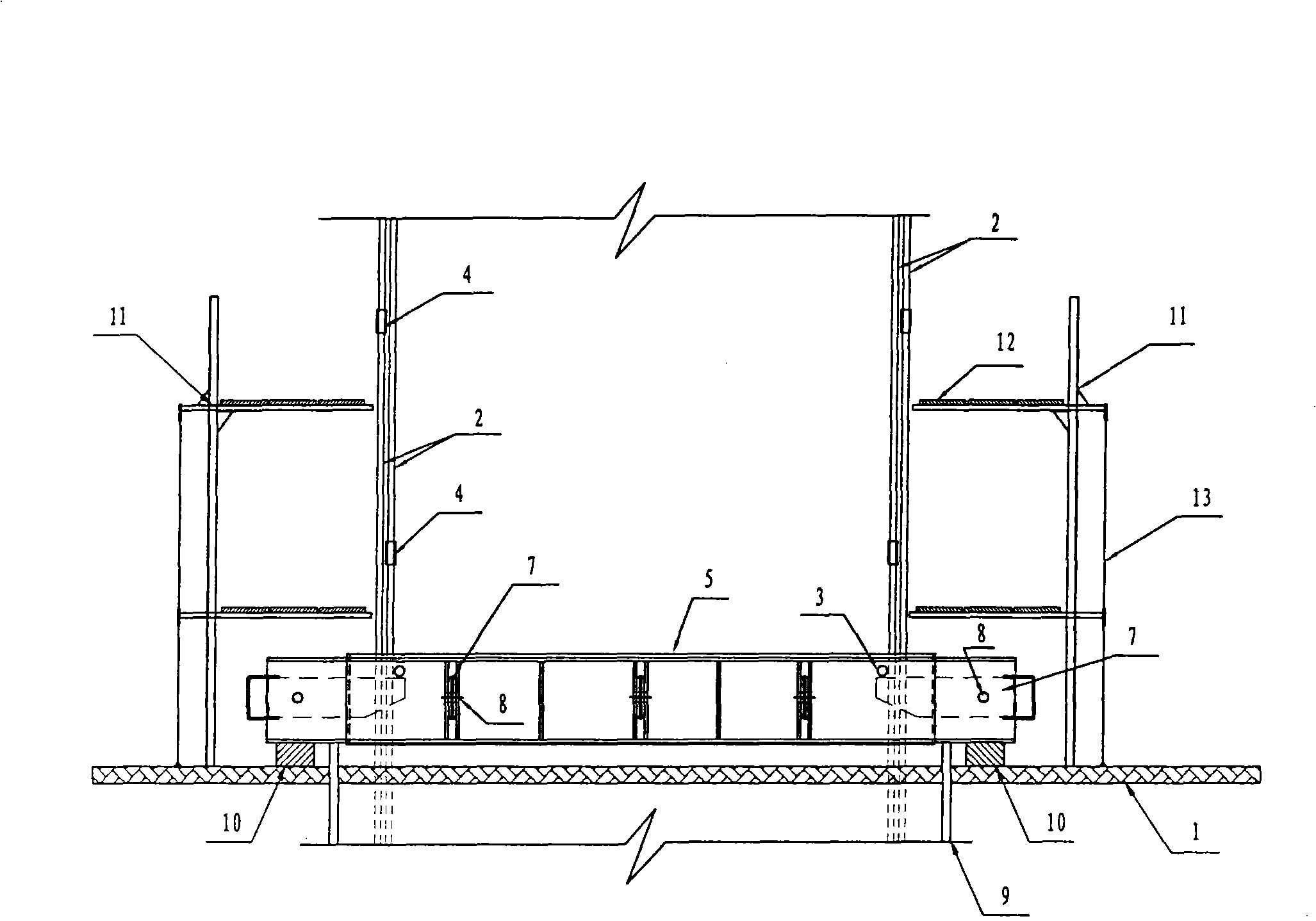

Reinforcement cage quick-assembling positioning system

InactiveCN101338561AShort installation timeLow usage feeBridge erection/assemblyBulkheads/pilesRebarUltimate tensile strength

The invention relates to a reinforcing cage rapid assembling and positioning system, which comprises a drilling platform, a reinforcing cage main reinforcement, a reinforcing cage hoop, reinforcing cage main reinforcement connectors, a end fixing ring, a end fixing ring splicing plate, end fixing ring movable inserting plates, a end fixing ring movable inserting plate pin, a drilling pile steel sleeve, a packing block, an operation platform, an operation platform scaffold board and an operation platform safety cable. The system has the advantages that two hemicyclic steel rings are spliced into the end fixing ring, and the assembling labor intensity of the end fixing ring is reduced; a reinforcing cage in the lower layer is hung by adopting eight movable inserting plates uniformly arranged on the end fixing ring, thereby the expansion of the tip beating ring is easily realized; the main reinforcement connectors in the upper and in the lower layers can be simultaneously spliced by adopting a double layered platform; the whole system has the advantages of reasonable loading, high connector quality, high construction efficiency, low labor intensity, short pile-forming period and low construction cost, and is particularly applied to the rapid assembling of the long pile reinforcing cage with double layered main reinforcement and large diameter.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

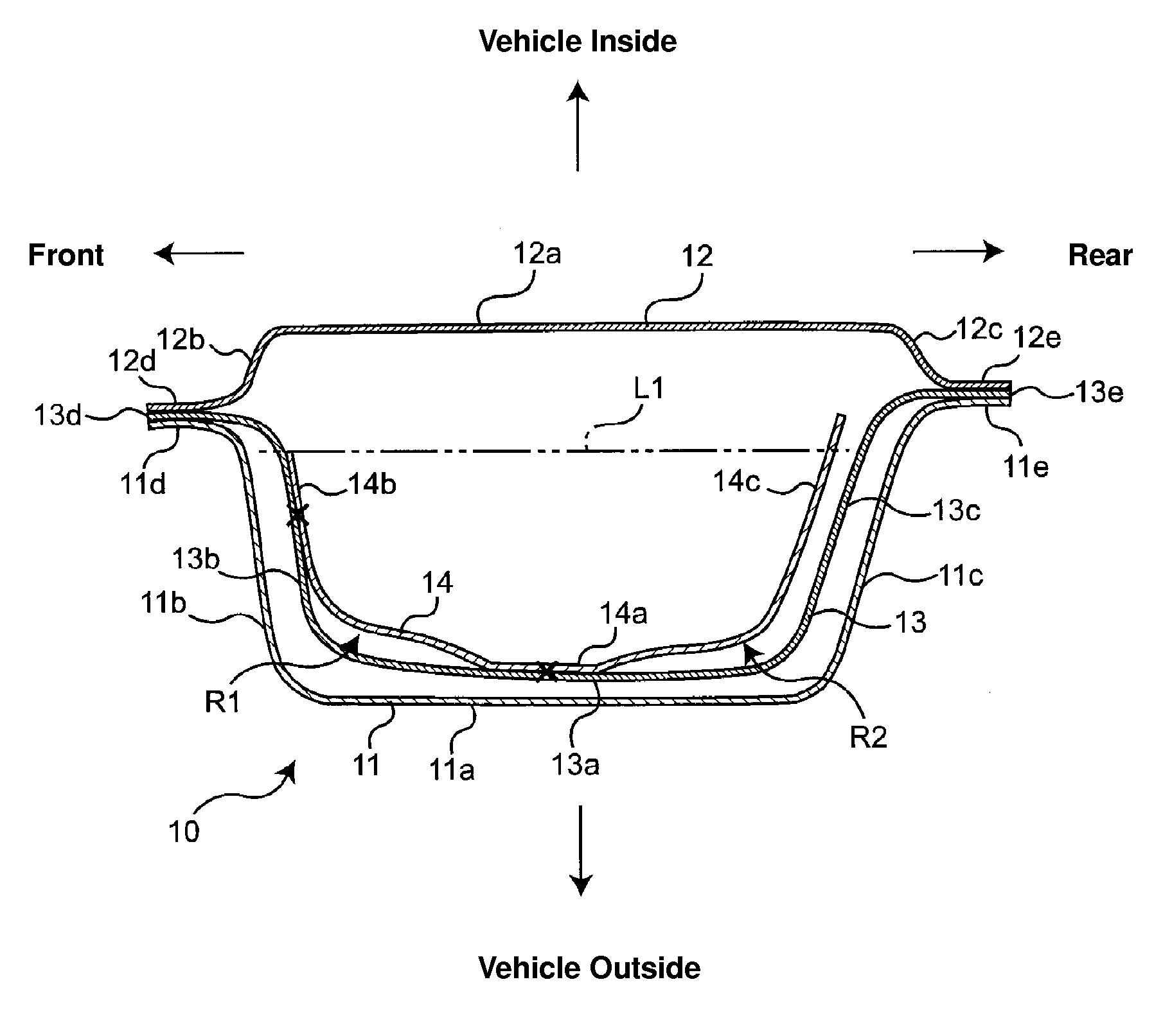

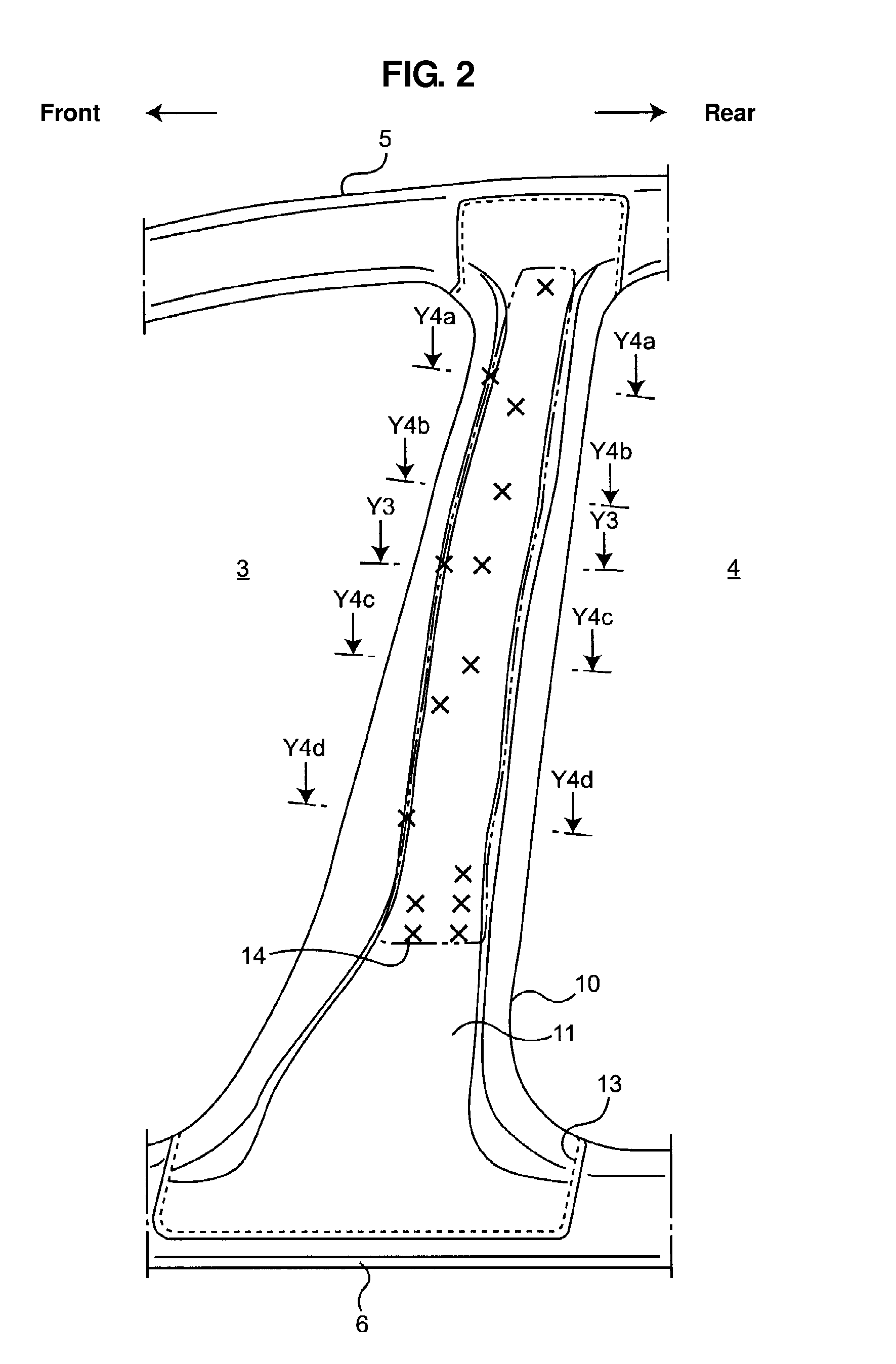

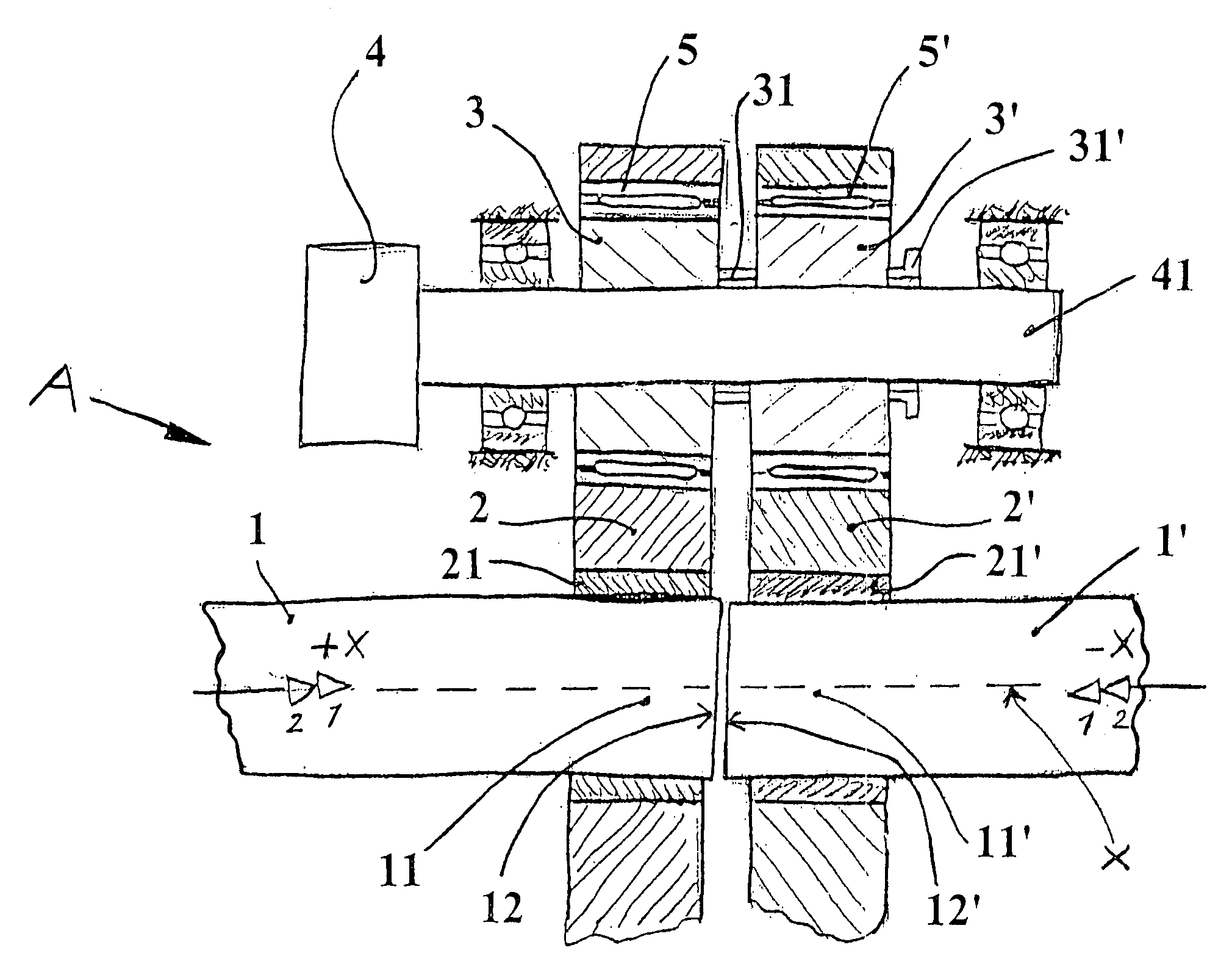

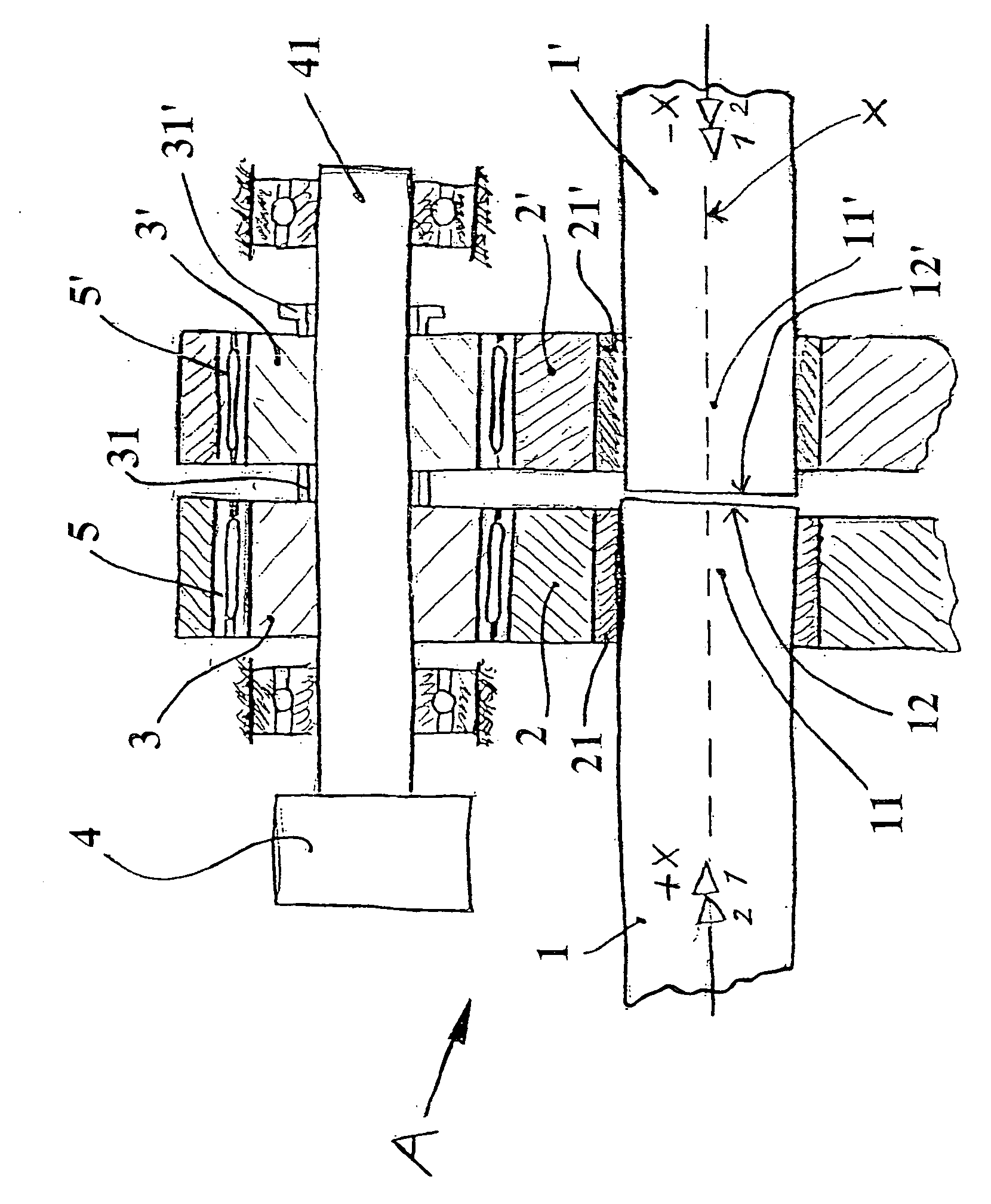

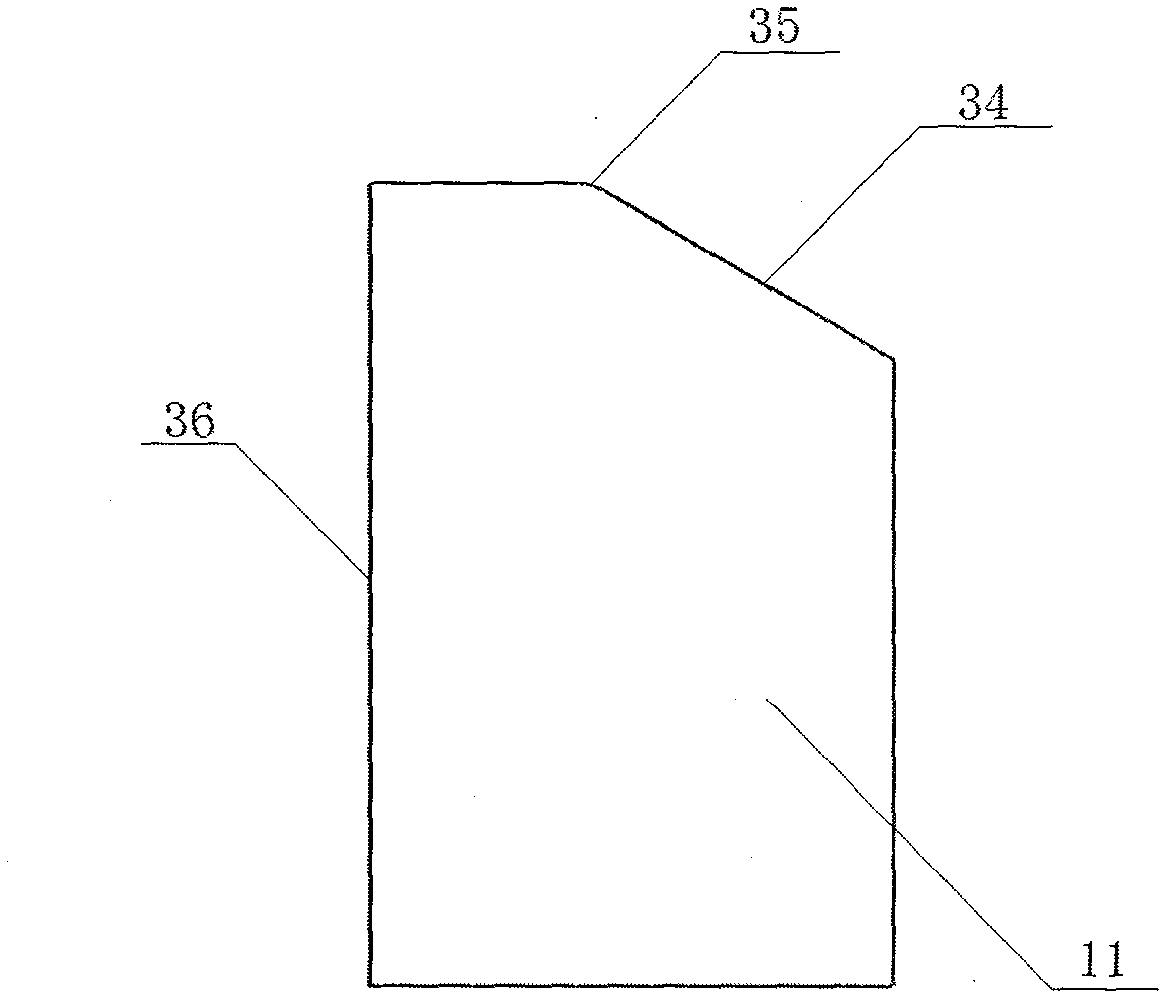

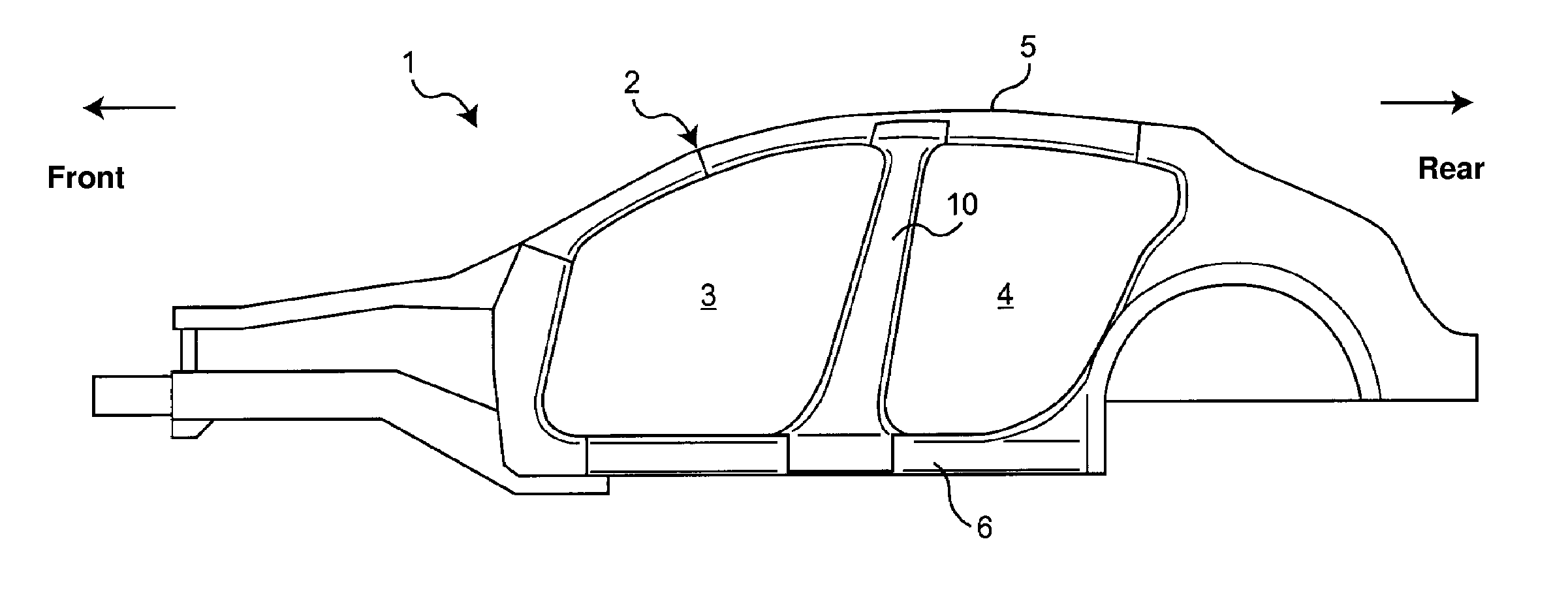

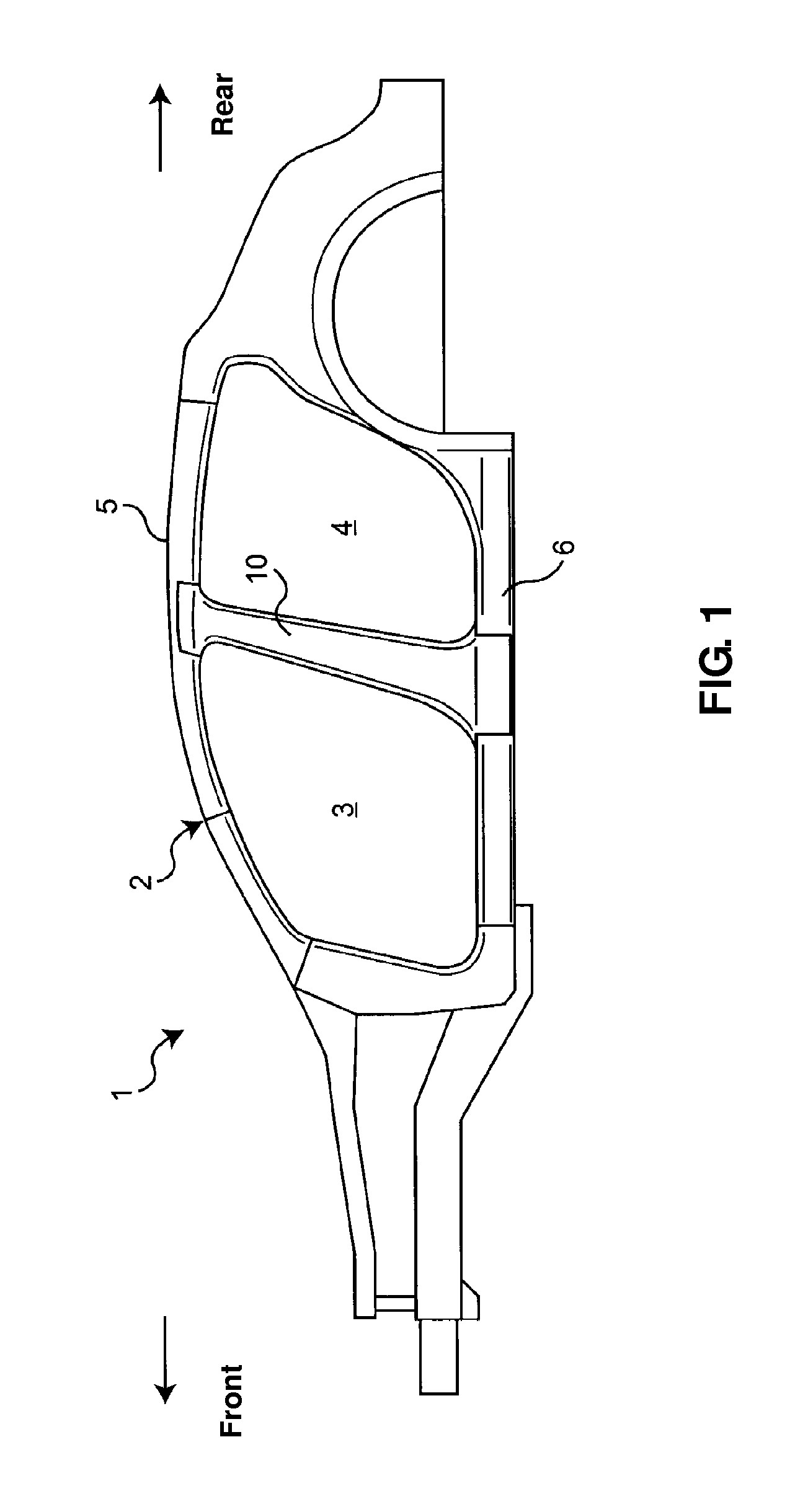

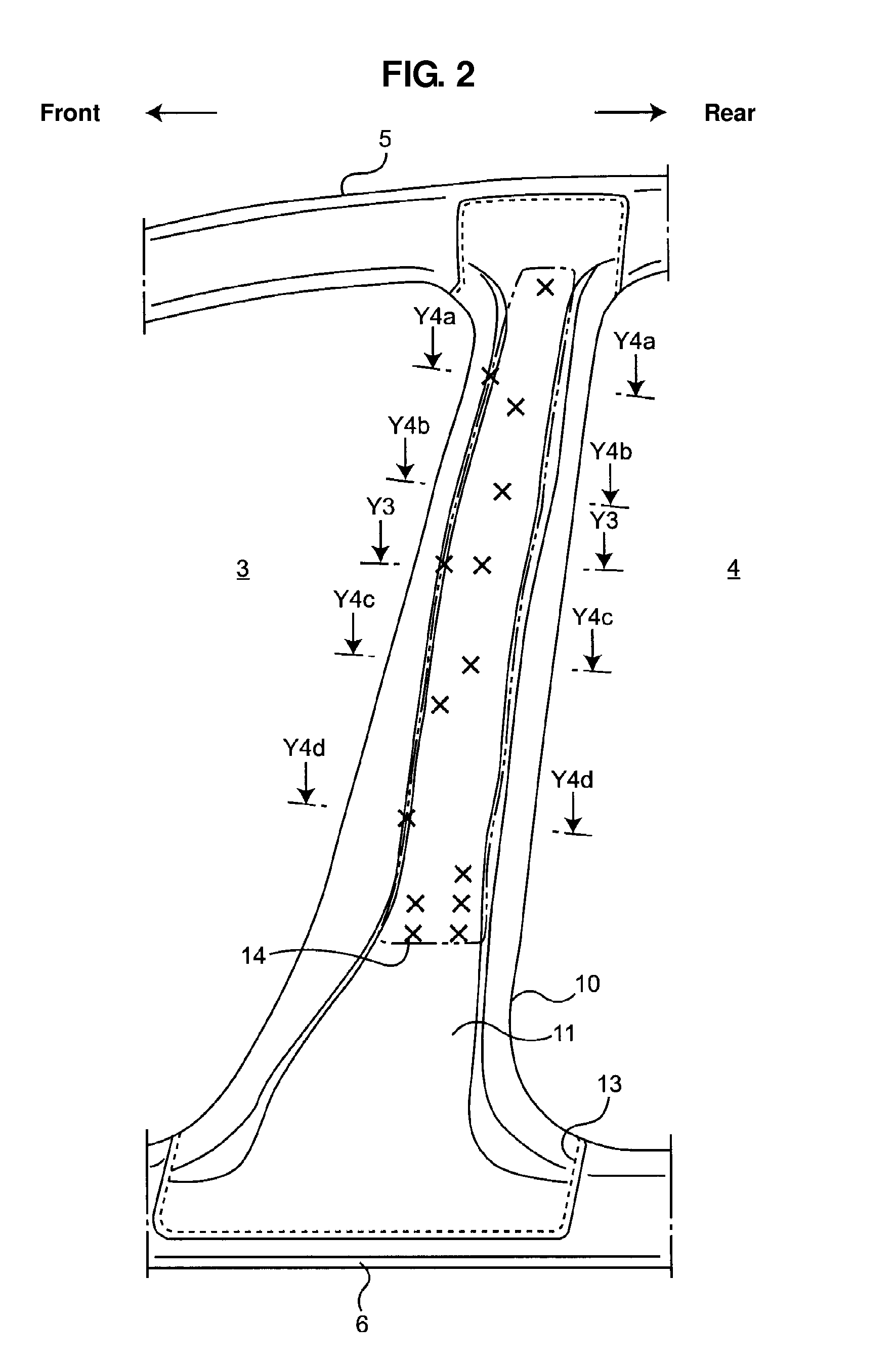

Vehicle-body side portion structure of vehicle

ActiveUS20140028056A1Improve joint qualityImprove productivityVehicle seatsSuperstructure subunitsEngineeringFlange

A center pillar includes a first reinforcement panel which is arranged between an outer panel and an inner panel, comprises a bottom wall portion, both-side vertical wall portions extending in a vehicle width direction from the bottom wall portion, and both-side flange portions, and has a cross section formed in substantially a hat shape. A second reinforcement panel comprising a bottom wall portion and both-side vertical wall portions and having a cross section formed in substantially a U shape is arranged inside the first reinforcement panel. The second reinforcement panel is joined to the first reinforcement panel such that only the bottom wall portion and one of the both-side vertical wall portions are joined to the bottom wall portion and one of the both-side vertical wall portions, respectively.

Owner:MAZDA MOTOR CORP

Device and method for joining the faces of parts

InactiveUS20090145948A1Quality improvementImprove joint qualityRailsWelding/cutting auxillary devicesFriction weldingEngineering

Device for joining faces of parts having great longitudinal extension by friction welding. The device includes first and second clamping arrangements structured and arranged to position ends of the parts against one another. At least one of the first and second clamping arrangements is axially movable with respect to another of the first and second clamping arrangements. At least one of the first and second clamping arrangements is movable along a direction that is parallel to a part cross-sectional plane defined by an end face of one of the parts.

Owner:VOEST ALPINE SCHIENEN GMBH

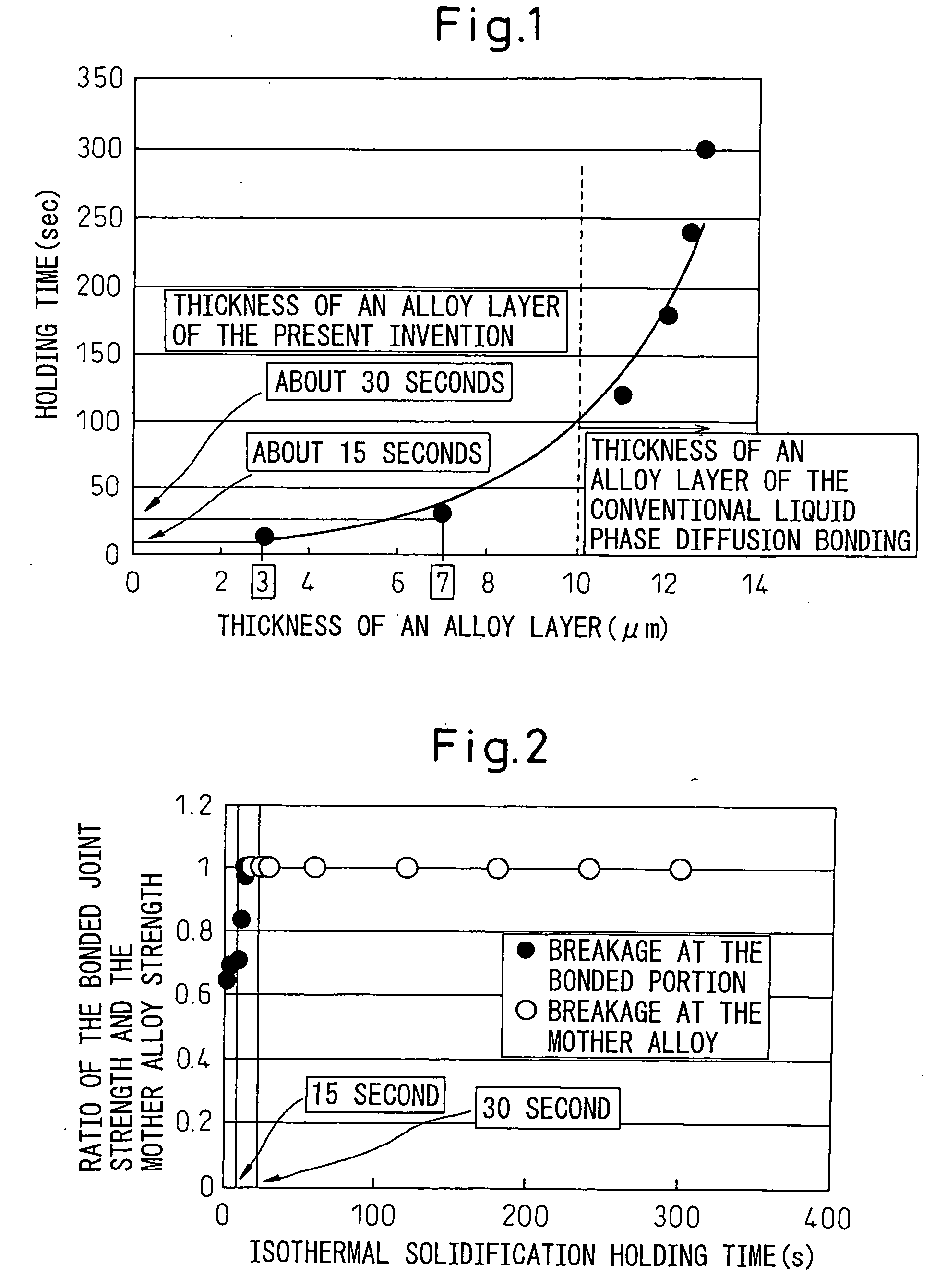

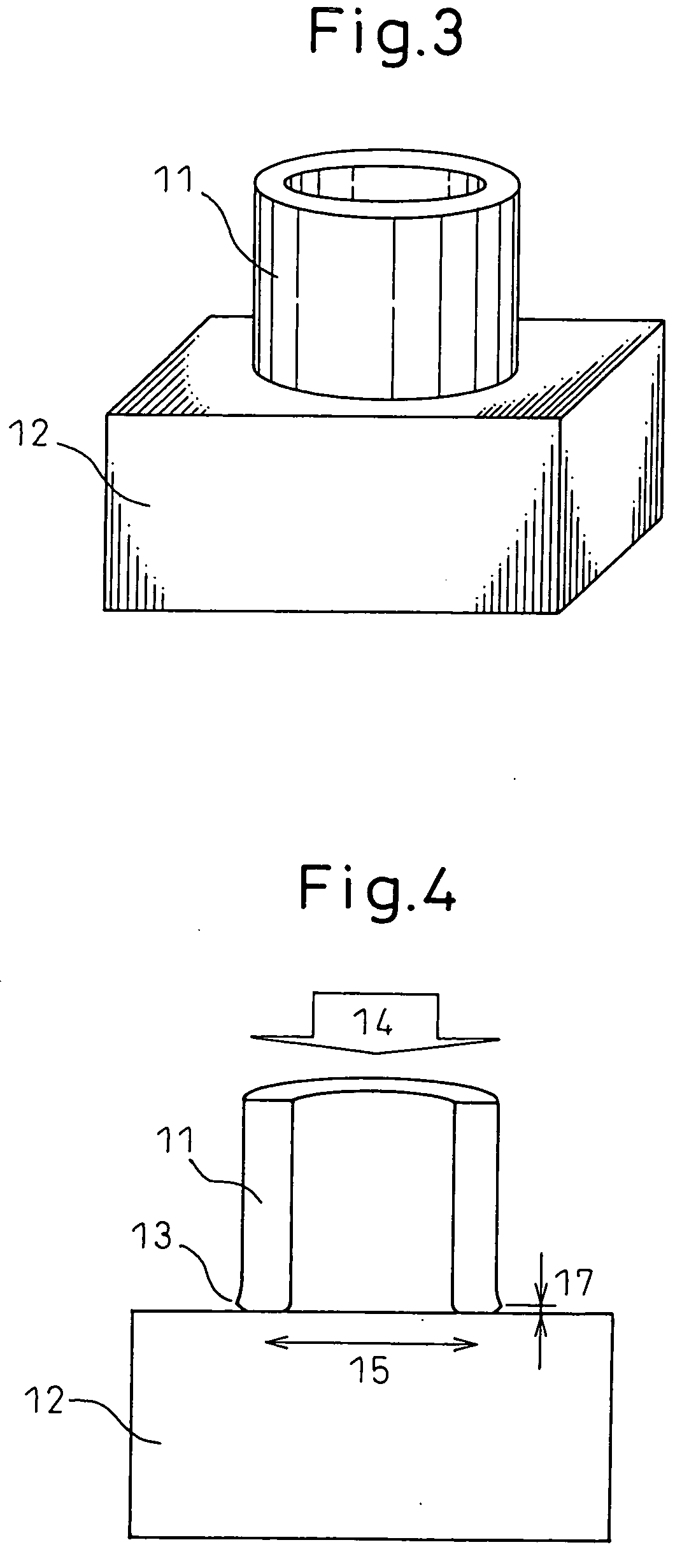

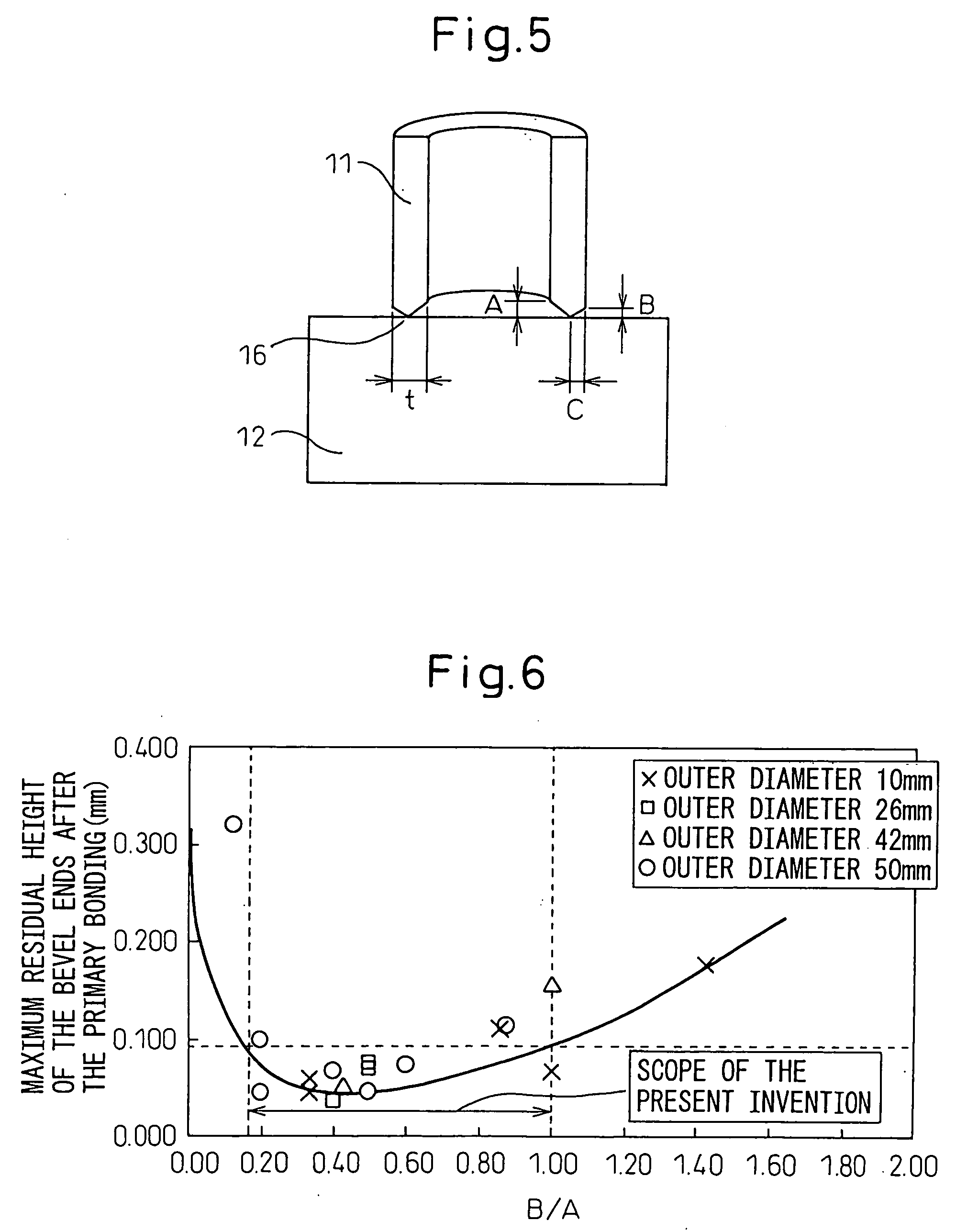

Liquid phase diffusion welding method for metallic machine part and metallic machine part

ActiveUS20060163321A1Improve joint qualityShorten bonding timeCamsValve arrangementsProduction rateElectrical resistance and conductance

A liquid phase diffusion bonding method for a metal machine part superior in the quality of the joint and the productivity enabling the bonding time to be shortened, achieving homogenization of the bonding structure and improving the tensile strength, fatigue strength, and joint quality and reliability. This liquid phase diffusion bonding method of a metal machine part is characterized interposing an amorphous alloy foil for liquid phase diffusion bonding at bevel faces of metal materials, performing primary bonding by melt bonding said amorphous alloy foil and said metal material by resistance welding to form a joint, then performing secondary bonding by liquid phase diffusion bonding by reheating said joint to at least the melting point of said amorphous alloy foil, then holding it there to complete the solidification process of said joint.

Owner:NIPPON STEEL CORP +1

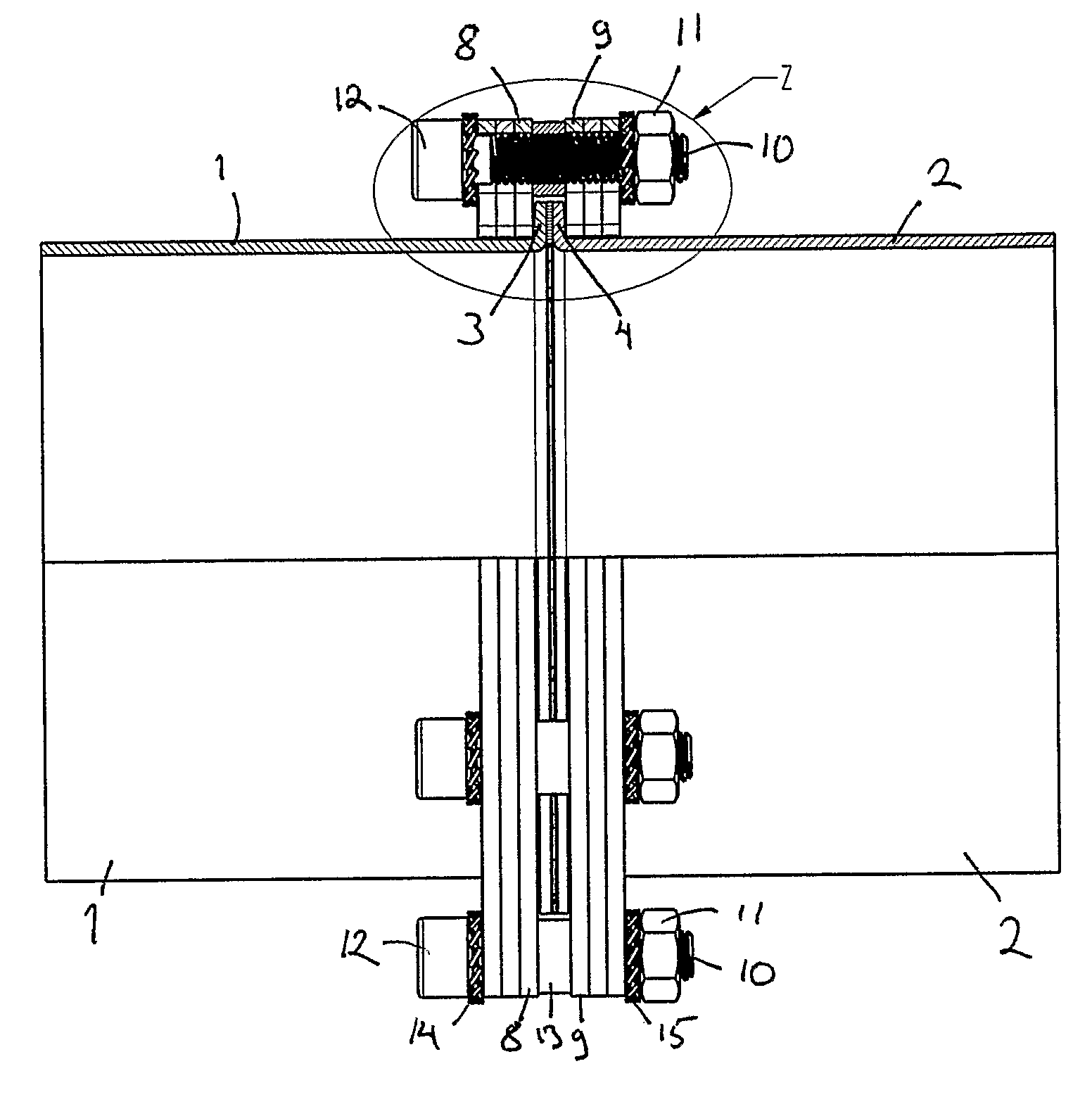

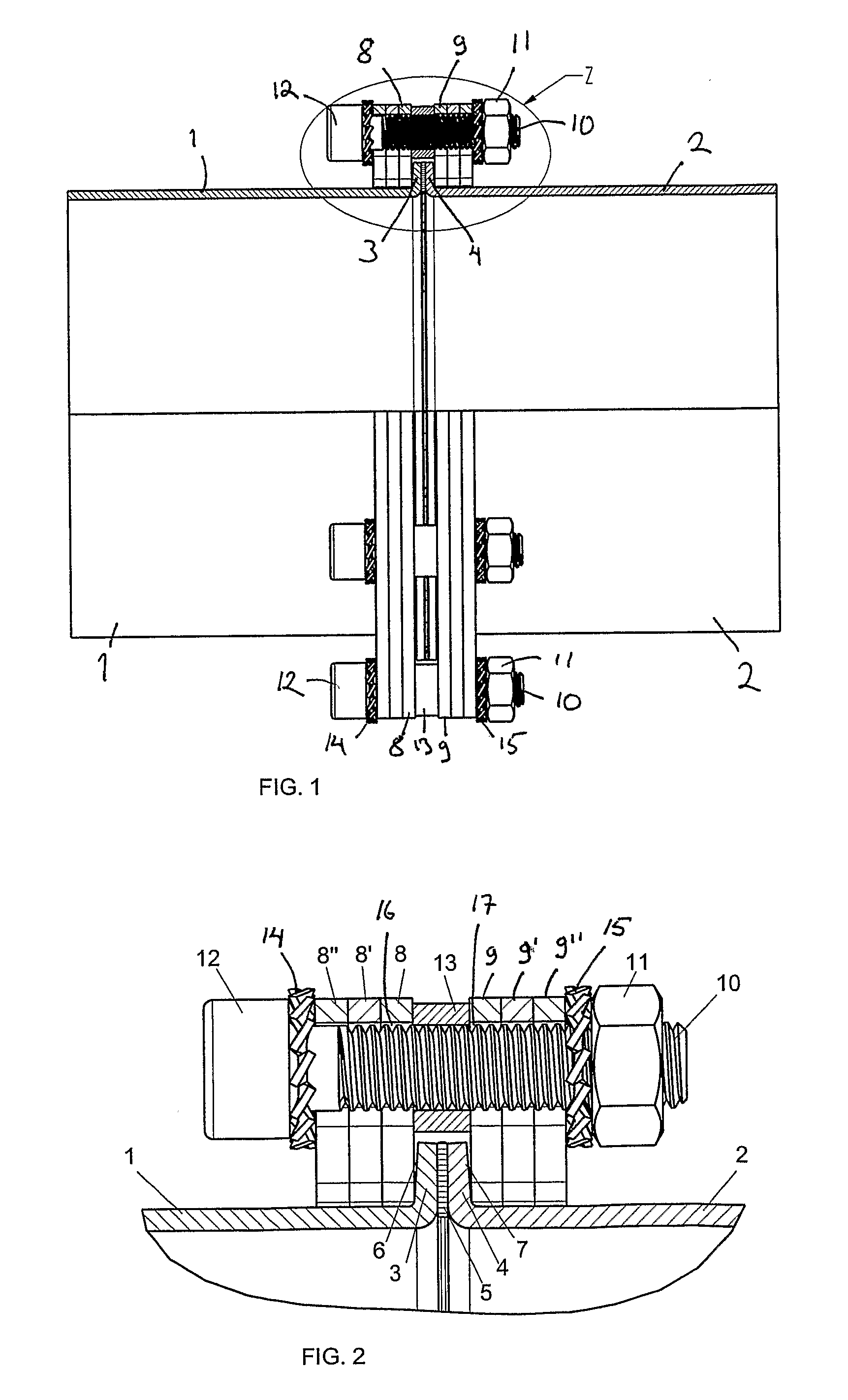

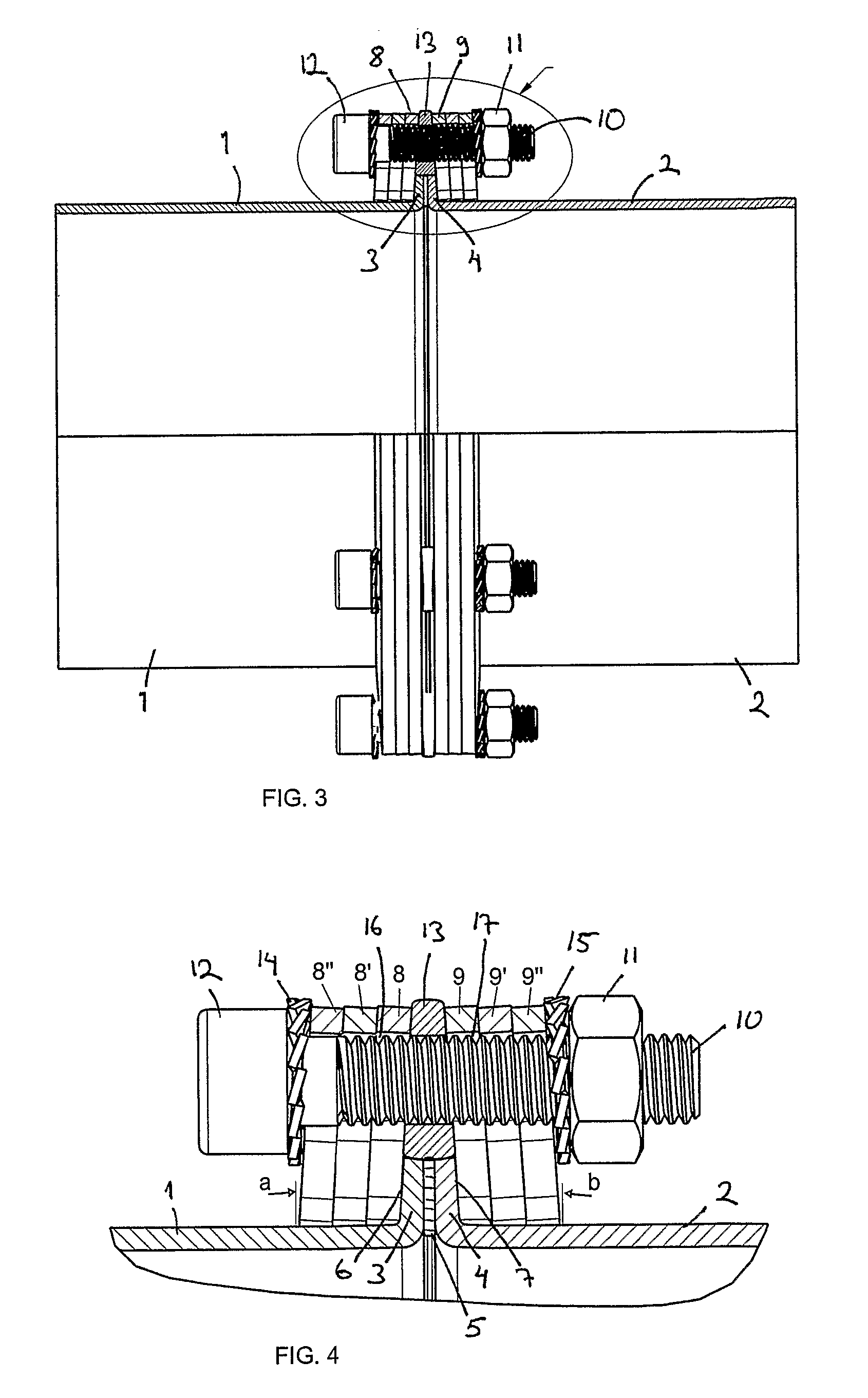

Pipe Joint

InactiveUS20080093847A1Versatile solutionImprove and accelerate assemblySleeve/socket jointsFlanged jointsFlange

A pipe joint consisting of the end portions of pipe sections (1, 2) to be joined together, said end portions having a collar (3, 4) preferably protruding substantially perpendicularly, and of flange parts (8, 9) placed on different sides of the collars relative to the junction and tightened by means of suitable fastening elements, such as screws (10) and nuts (11). The flange part (8, 9) has been arranged to be adaptable against the shoulder of the collar (3, 4), most suitably against its back surface (6, 7), at least when the joint is being tightened.

Owner:SUNDHOLM GORAN

Welding procedure of 0Cr11Ni2MoNbV light sheet material handwork tungsten electrode argon arc

InactiveCN101412142AGood lookingImprove internal qualityArc welding apparatusFurnace typesWeld seamSolvent

The invention provides a process for welding a 0Cr11Ni2MoNbV veneer material with manual argon tungsten-arc welding. The process comprises the following steps: a veneer sample is subject to polishing and scrubbing by acetone solvent before welding; welding is carried out on a straight slit clamp with a red copper pad; argon protection is aerated to the back of the clamp; gas lens is arranged in a nozzle of a welding gun; filler metal with two different ingredients are adopted during welding respectively; each welding seam is completed by two weld beads with smaller current; a sample of H0Cr20Ni10Ti welding wire with phi of between 1.6 and 2.5 is filled in the welding seam in supplying state before welding; and a sample of H0Cr11Ni2MoVNb welding wire is filled in the welding seam, is subject to quenching and high tempering thermal refining before welding, and is subject to heating treatment for eliminating stress after welding. The invention has the advantages of nice appearance and good inside quality of a welding joint, good mechanical performance of the joint at room temperature and high temperature, good protection effect, high quality of the joint, simple and convenient operation, wide application range and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Novel method for configuring and connecting steel ropes

The invention relates to a novel method for configuring and connecting steel ropes. In order to solve the problems of low strength, low safe reliability, and the like of an interface in vulcanized glued connection with a traditional steel rope core conveyor belt, a novel method for configuring the steel ropes is adopted for increasing the ratio of staggered arrangement of the steel ropes at two ends of the conveyor belt and increasing the insert-plug resistance of the steel ropes in rubber, high-strength steel ropes are connected with a lock latch, the steel ropes in parallel staggered arrangement are tensioned and locked, the originally parallel arrayed steel rope main bodies are connected together and a tensioning force is supplied, so that the quality and safety of the connector of the steel rope core conveyor belt are essentially increased, the constant strength connection of the interface and the conveyor belt is realized and the usage with same service life is realized. Adhesive and solidifying rubber are used for gluing a thin rubber sheet, a reinforcing rubber sheet, edge rubber, upper covering rubber and lower covering rubber and wrapping the steel ropes in the area of the interface of the conveyor belt, so as to finish the cold splicing connection of the interface of the steel rope core conveyor belt. The novel method is huge in practical significance.

Owner:李超

Straight conveyor belt finger-model connector and preparation method thereof

ActiveCN103072786AIncreased warp strengthHigh warp strengthConveyorsBeltsAdhesive cementStructural engineering

The invention belongs to the technical field of a rubber conveyor belt product, and particularly relates to a straight conveyor belt finger-model connector and a preparation method thereof. The straight conveyor belt finger-model connector comprises a straight finger-model skeleton structure, wherein the straight finger-model skeleton structure comprises a straight canvas layer; a rubberizing layer is arranged on the surface of the straight finger-model skeleton structure; a textile layer playing a reinforcement effect is arranged on the rubberizing layer; and a coverage rubber layer is arranged on the textile layer. The preparation method of the straight conveyor belt finger-model connector comprises the following steps of (1) stripping coverage adhesive; (2) removing residual adhesive; (3) cutting a finger model; (4) coating adhesive cement; (5) splicing the finger model; (6) forming a finger-model connector; and (7) vulcanizing the finger-model connector. Due to the adoption of the straight conveyor belt finger-model connector, the strength of the connector is improved; and the preparation method is simple and easy to operate.

Owner:YANKUANG GRP CO LTD +1

Vehicle-body side portion structure of vehicle

ActiveUS8851556B2Improve joint qualityImprove productivityVehicle seatsSuperstructure subunitsFlange

Owner:MAZDA MOTOR CORP

Solid-liquid two-phase region brazing method for high volume fraction silicon carbon particle reinforced aluminium matrix composite

ActiveCN103801783AIncrease stiffnessImprove diffusion abilityWelding/cutting media/materialsWelding/soldering/cutting articlesAluminium matrixKovar

The invention discloses a solid-liquid two-phase region brazing method for a high volume fraction silicon carbon particle reinforced aluminium matrix composite and relates to a brazing method for the high volume fraction silicon carbon particle reinforced aluminium matrix composite. The invention aims to solve the problems that connection of an existing high volume fraction silicon carbon particle reinforced aluminium matrix composite or welding of the existing high volume fraction silicon carbon particle reinforced aluminium matrix composite with a kovar alloy needs to be carried out under a low temperature lower than the temperature of a base metal solidus and in the brazing process, the existing high volume fraction silicon carbon particle reinforced aluminium matrix composite needs to be plated with a metal layer. The method comprises the following steps: 1, washing the silicon carbon particle reinforced aluminium matrix composite and the kovar alloy; 2, carrying out acid pickling and alkali cleaning on the silicon carbon particle reinforced aluminium matrix composite; 3, fixing a brazing filler metal, the silicon carbon particle reinforced aluminium matrix composite and the kovar alloy; 4, carrying out welding. The solid-liquid two-phase region brazing method is used for connection of the high volume fraction silicon carbon particle reinforced aluminium matrix composite or brazing of the composite and the kovar alloy.

Owner:泰格尔科技有限公司

Semi-automatic jointing method for open-end-spinning

InactiveCN102758278AIncrease success rateImprove joint qualityContinuous wound-up machinesOpen-end spinning machinesYarnSemi automatic

The invention discloses a semi-automatic jointing method for open-end-spinning, and belongs to the technical field of spinning. The traditional semi-automatic jointing method has the disadvantages of low jointing efficiency, low jointing quality, limited rotation speed of a revolving cup during the jointing and heavy manual workload. The semi-automatic jointing method comprises a jointing preparation process and a jointing process, wherein a winding mechanism automatically raises a creel after receiving a yarn breaking signal; packaged yarn ends are found manually; the length of the yarn ends are fixed, a spinning box is opened for clearing impurities, the spinning box is closed, and the yarn ends are put into a doffing tube; an inductor on the spinning box sends out a jointing request signal; a jointing trolley moves to be positioned at a position of a concrete spindle level after receiving a jointing instruction signal; the revolving cup is rotated and gradually accelerated to ensure that the jointing trolley controls the feeding of cotton slivers and the lead-out of the yarns after the jointing is performed at the revolving speed; the yarns which are led out are in temporary storage transition; the creel automatically descends and starts to wind the yarns; the transition yarns are wound by virtue of package, the processes of leading the yarns and controlling the feeding of the cottons are back to the spindle level of a spinning machine, so that the jointing process is finished; and moreover, the jointing efficiency and the jointing quality are improved, the manual workload is reduced.

Owner:ZHEJIANG RIFA TEXTILE MASCH CO LTD

Laser auxiliary hot-pressure welding device and welding method for connecting titanium / aluminum dissimilar materials

InactiveCN103273206AEasy to weldLow costWelding/soldering/cutting articlesWelding apparatusLap jointTitanium alloy

The invention provides a laser auxiliary hot-pressure welding device and welding method for connecting titanium / aluminum dissimilar materials. The implementation process of the laser auxiliary hot-pressure welding device and welding method comprises the following steps that titanium alloy base metal and aluminum alloy base metal are arranged on a workbench after being connected in a lap joint mode according to the principle that the titanium alloy base metal is arranged above the aluminum alloy base metal; after a microprocessor is started, according to a preset pressure value and a preset stepping speed of the workbench, the microprocessor controls the rotation speed of a stepping motor, a pressure control valve controls the working pressure of an air cylinder, a pressure test of an idler wheel is conducted first, then pressure by the idler wheel at a welding point on the base metal is transmitted through a pressure sensor, and the air cylinder is controlled in time so as to amend the pressure value; laser beams are irradiated on a weld joint of the base metal connected in the lap joint mode, the idler wheel is used for acting on the dissimilar materials, and the dissimilar materials mutually diffuse under the pressure action so that the purpose of welding can be achieved. According to the laser auxiliary hot-pressure welding device and welding method for connecting the titanium / aluminum dissimilar materials, brittle intermetallic compounds generated when the titanium / aluminum dissimilar materials are connected can be reduced remarkably, welding of thin dissimilar metal plates is easy to realize, welding efficiency is high, welding cost is low, the quality of a connector is high because the content of the intermetallic compounds is small, the welding cost is quite low, and the quality of the connector is good.

Owner:NANCHANG HANGKONG UNIVERSITY

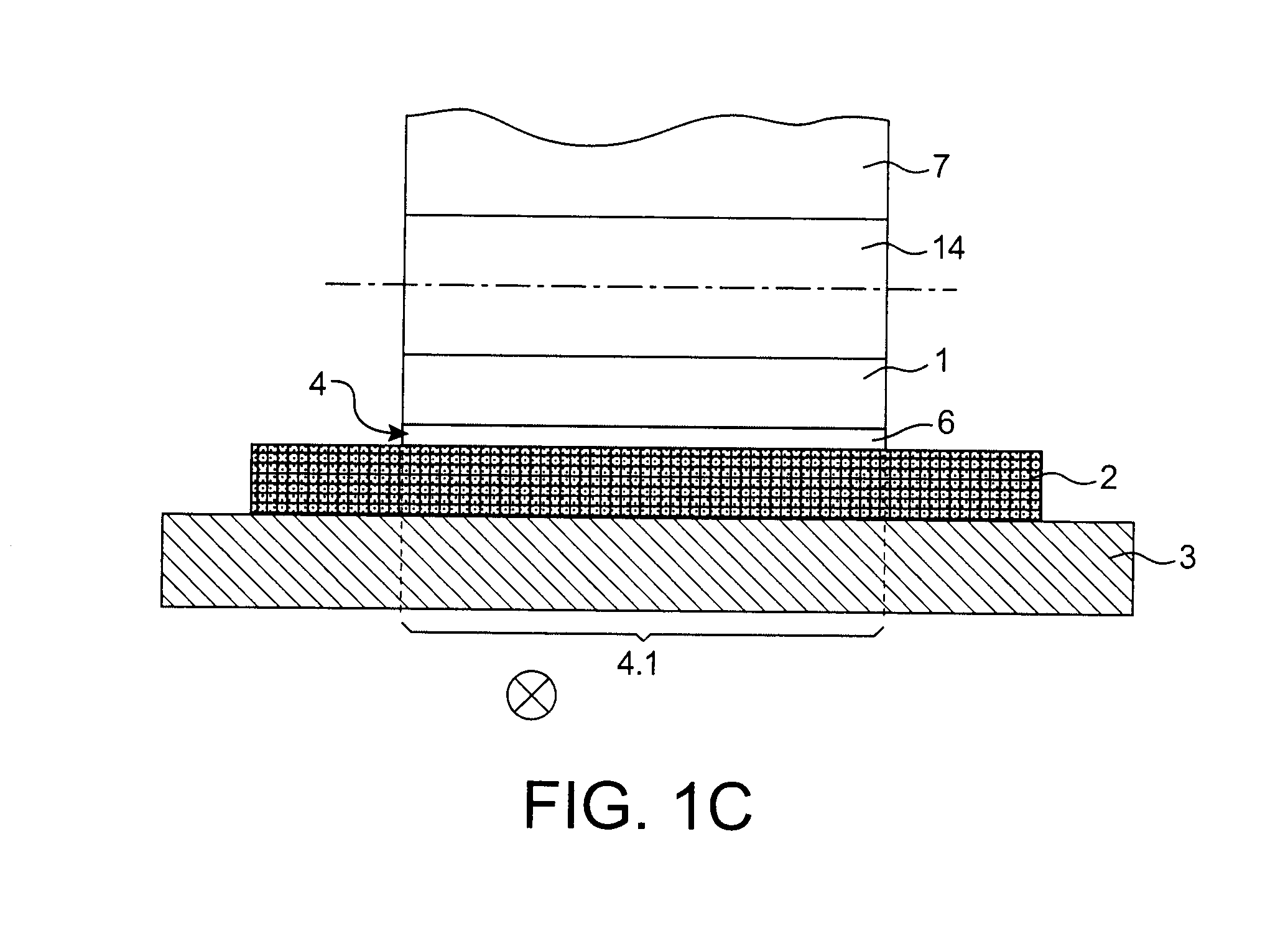

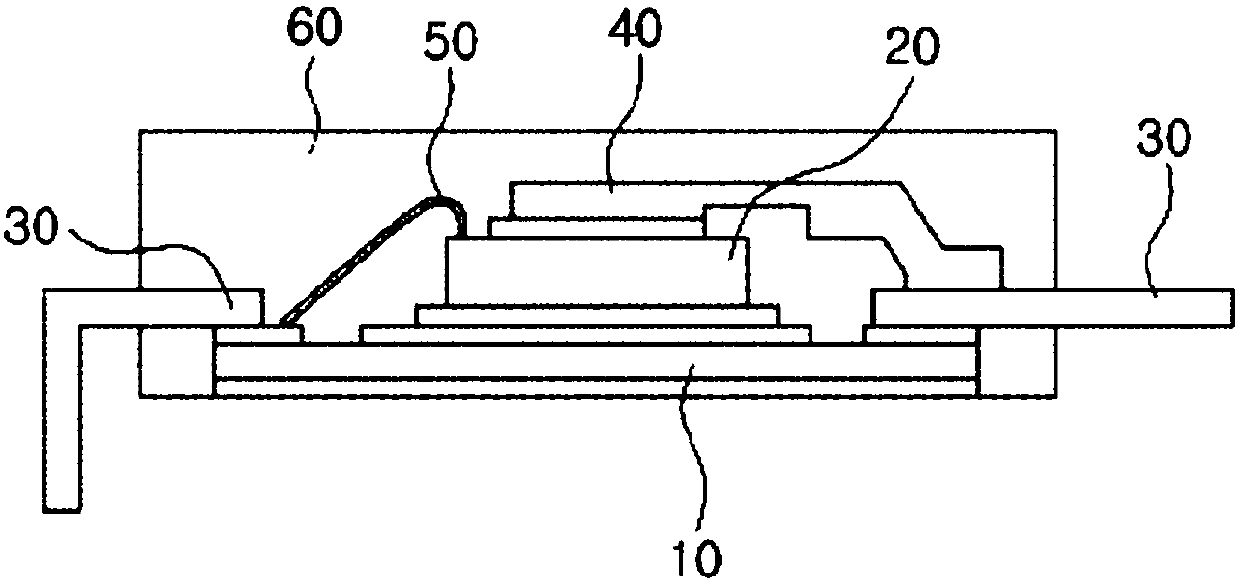

Semiconductor device and manufacturing method thereof

InactiveCN104752322AReduce stressImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesBonding processPolyimide dielectric

The invention relates to a semiconductor device and a manufacturing method thereof. The method comprises steps: a substrate is provided, and an element and an interconnection structure above the element are formed on the substrate; a benzocyclobutene dielectric layer or a polyimide dielectric layer is formed on the substrate; a metal pad is formed on the dielectric layer to be connected with the interconnection structure; and two wafers comprising the dielectric layer and the metal pad are bonded. In order to solve the problems in the prior art, a new material is selected as the dielectric layer in the horizontal wafer Cu-Cu bonding technology, benzocyclobutene (BCB) or polyimide is selected as the dielectric layer, bonding between the upper wafer and the lower wafer is realized, BCB of the upper wafer and the lower wafer can be melted together during the bonding process, a bonding pair free of a void is formed, and the bonding quality is improved. The BCB can serve as a blocking layer, and the problem of metal diffuse (such as Cu diffuse) between the wafers can be solved completely.

Owner:SEMICON MFG INT (SHANGHAI) CORP

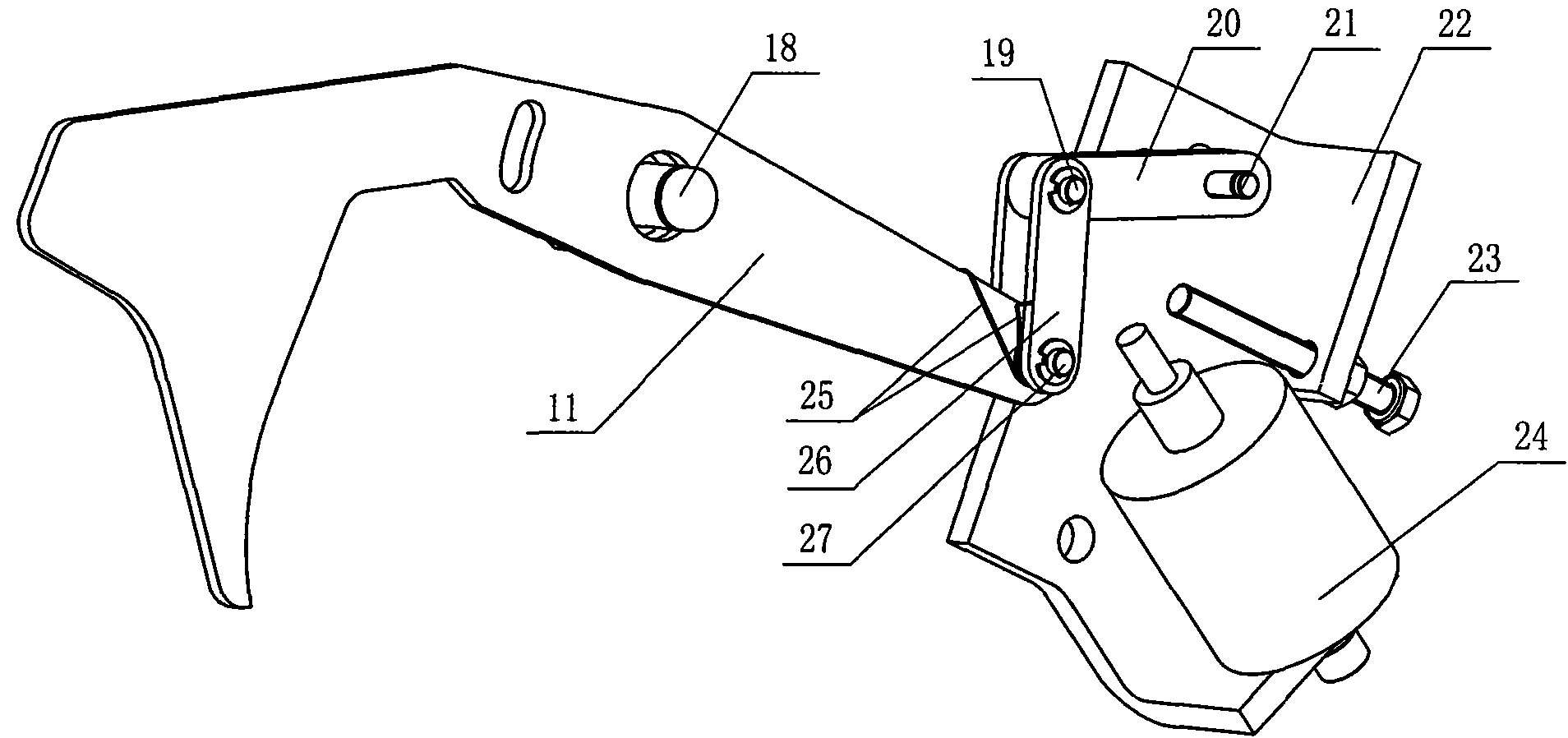

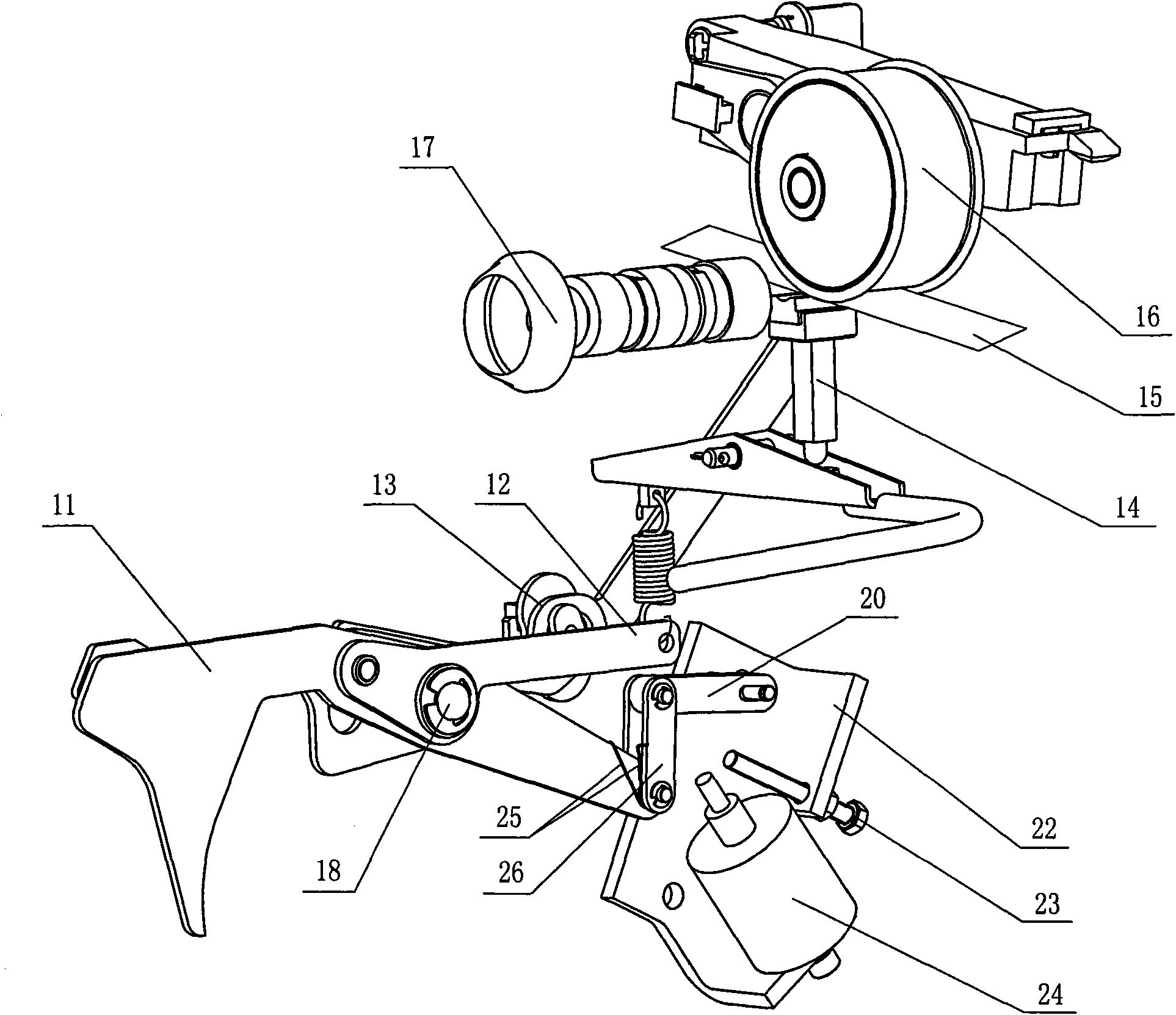

Control mechanism for delay start of spinning device rotor

ActiveCN101899731AImprove joint qualityQuality improvementContinuous wound-up machinesOpen-end spinning machinesFiberYarn

The invention relates to a control mechanism for the delay start of a spinning device rotor, belonging to the field of spare parts of a spinning machine and solving the technical problem that the spinning joint quality of a traditional semi-automatic rotor spinning machine is influenced because damaged cotton fiber at the head of cotton silver can not be removed. The control mechanism for the delay start of the spinning device rotor comprises a hook pull rod with a shaft hole arranged in the middle and is characterized in that a hook pull rod position locking device is arranged at the tail of the hook pull rod for locking and releasing the position of the hook pull rod, and the delay start of the spinning device rotor is controlled by a pinch roller linkage mechanism and a brake linkage mechanism which are connected with the tail end of the hook pull rod so as to remove the damaged fiber at the head of the cotton silver and improve the quality of broken yarn joints.

Owner:ZHEJIANG RIFA TEXTILE MASCH CO LTD

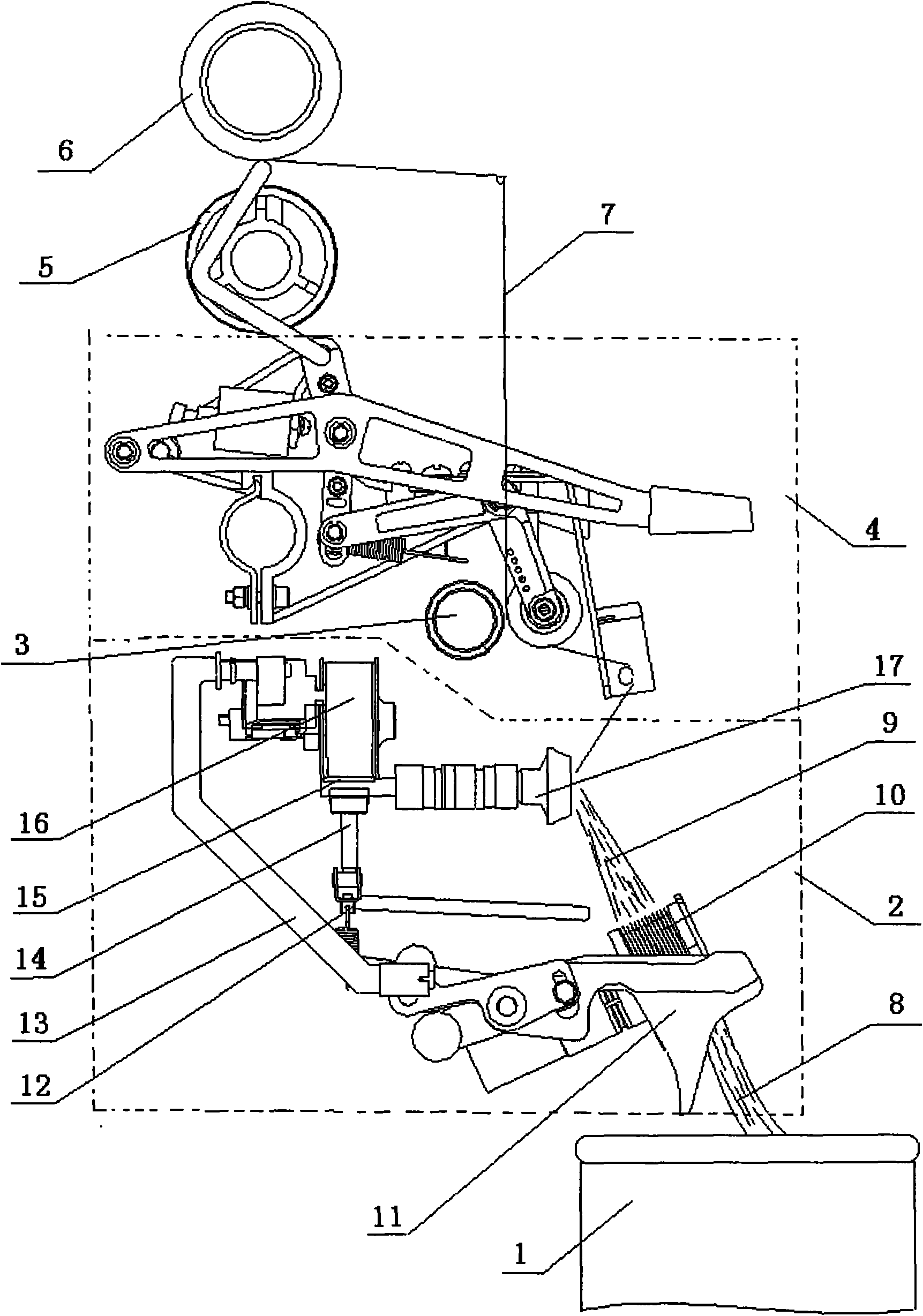

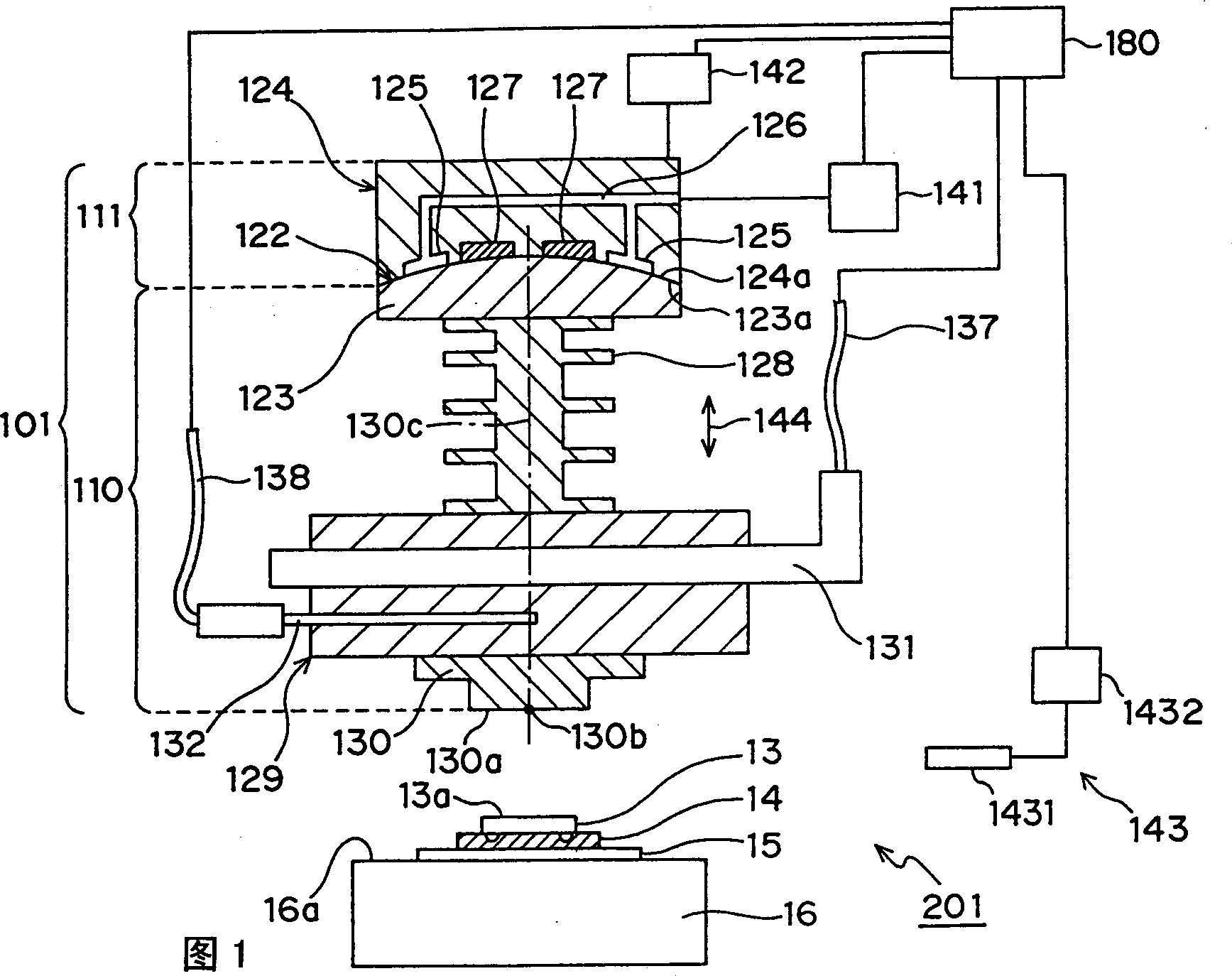

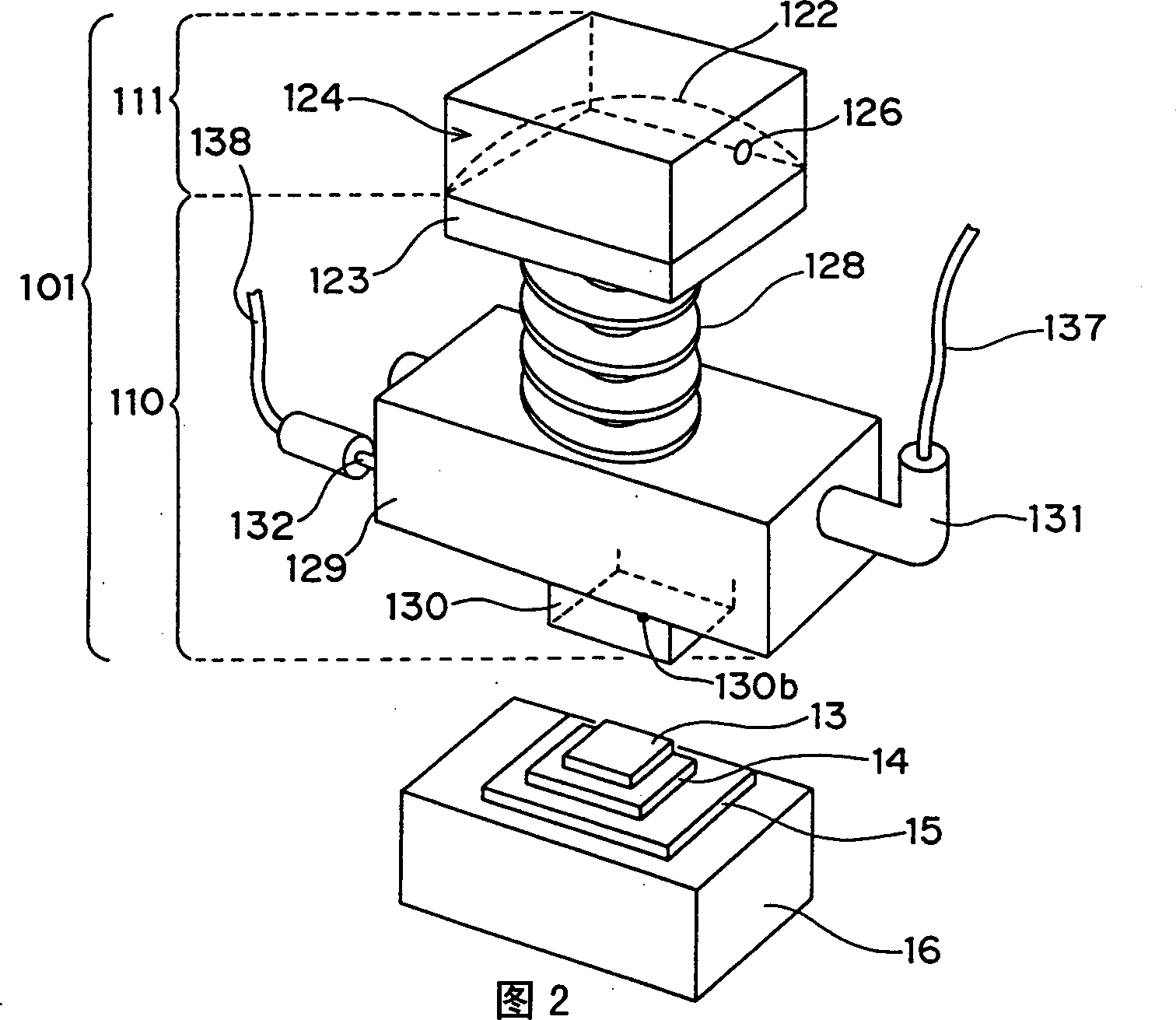

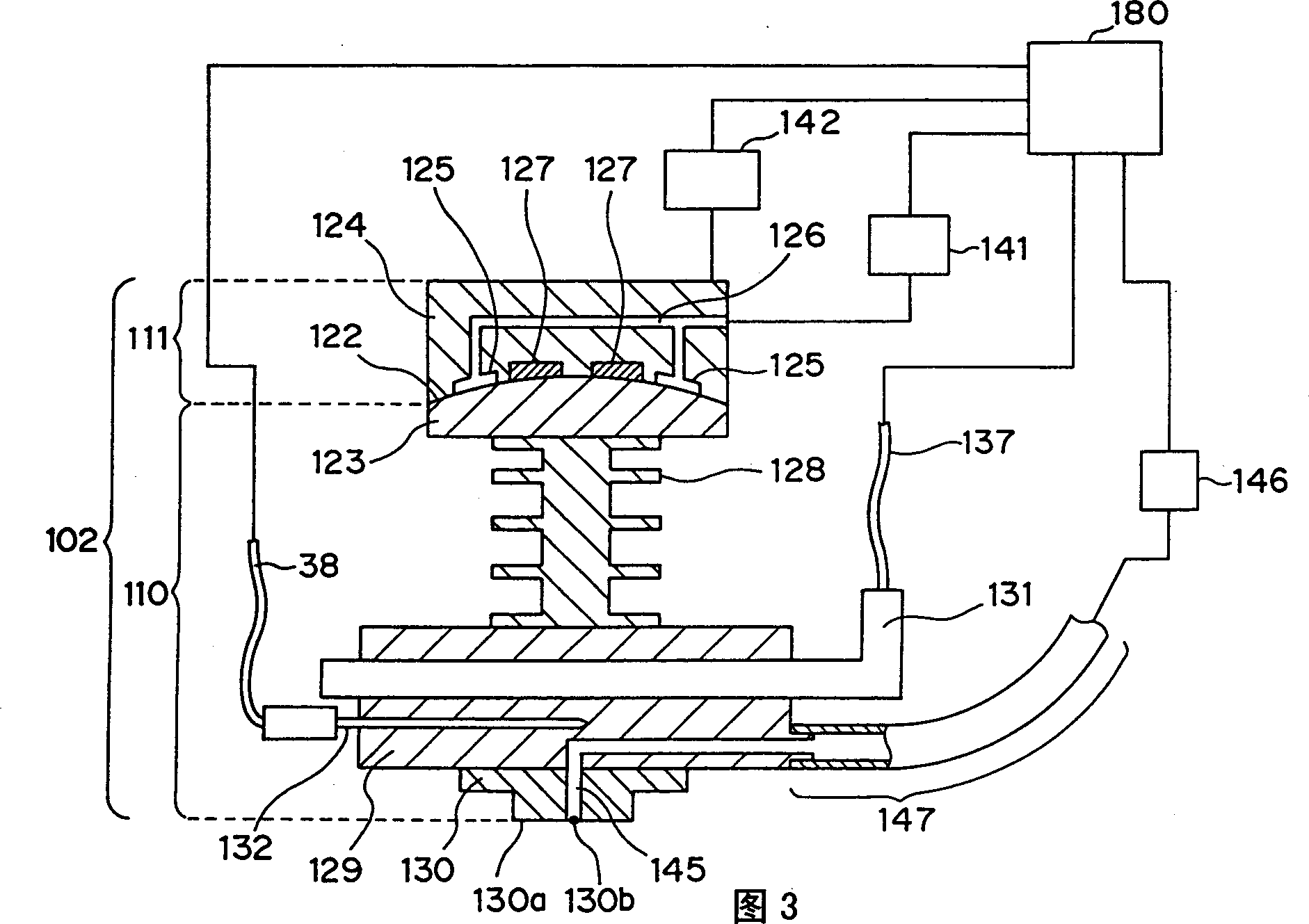

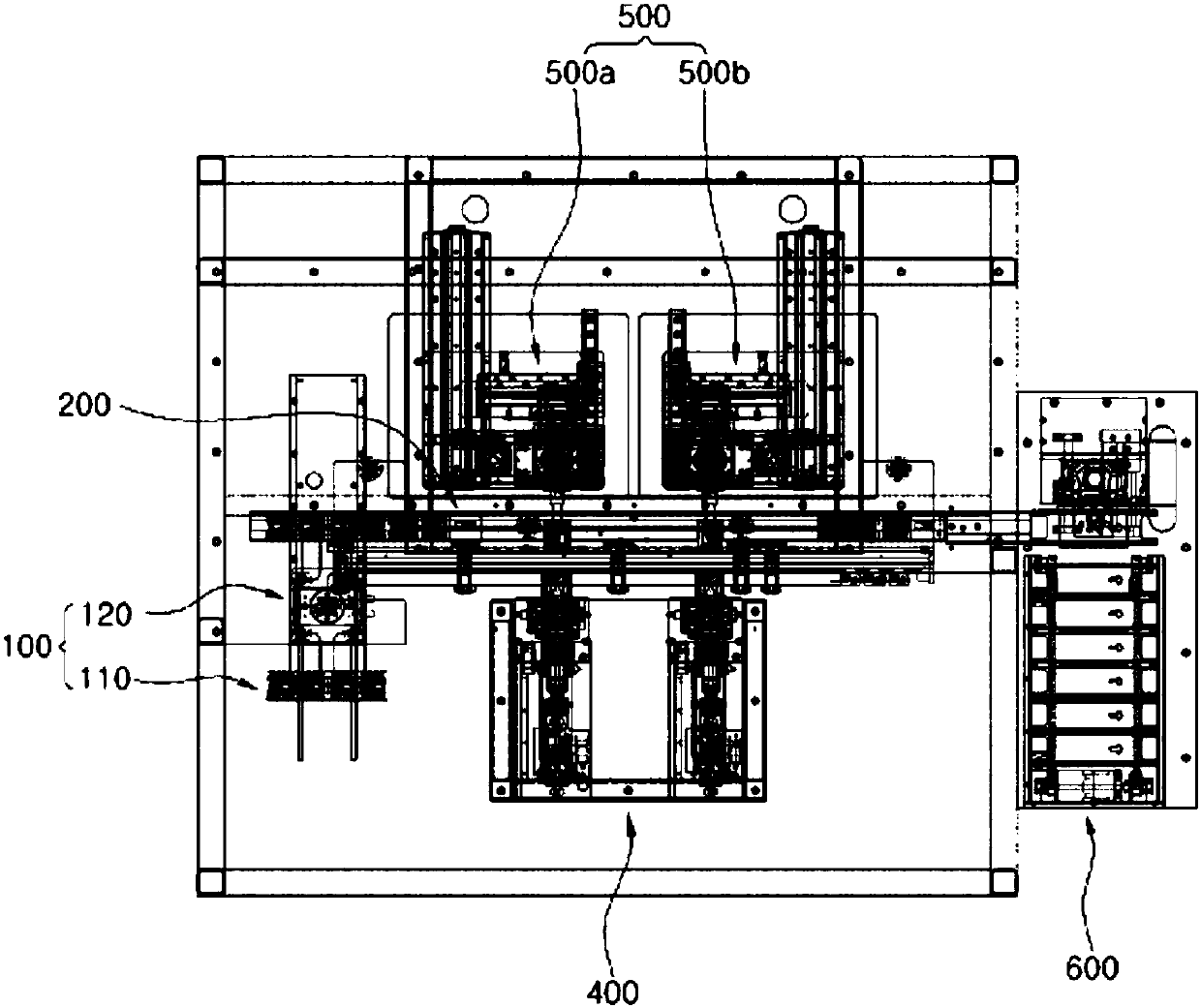

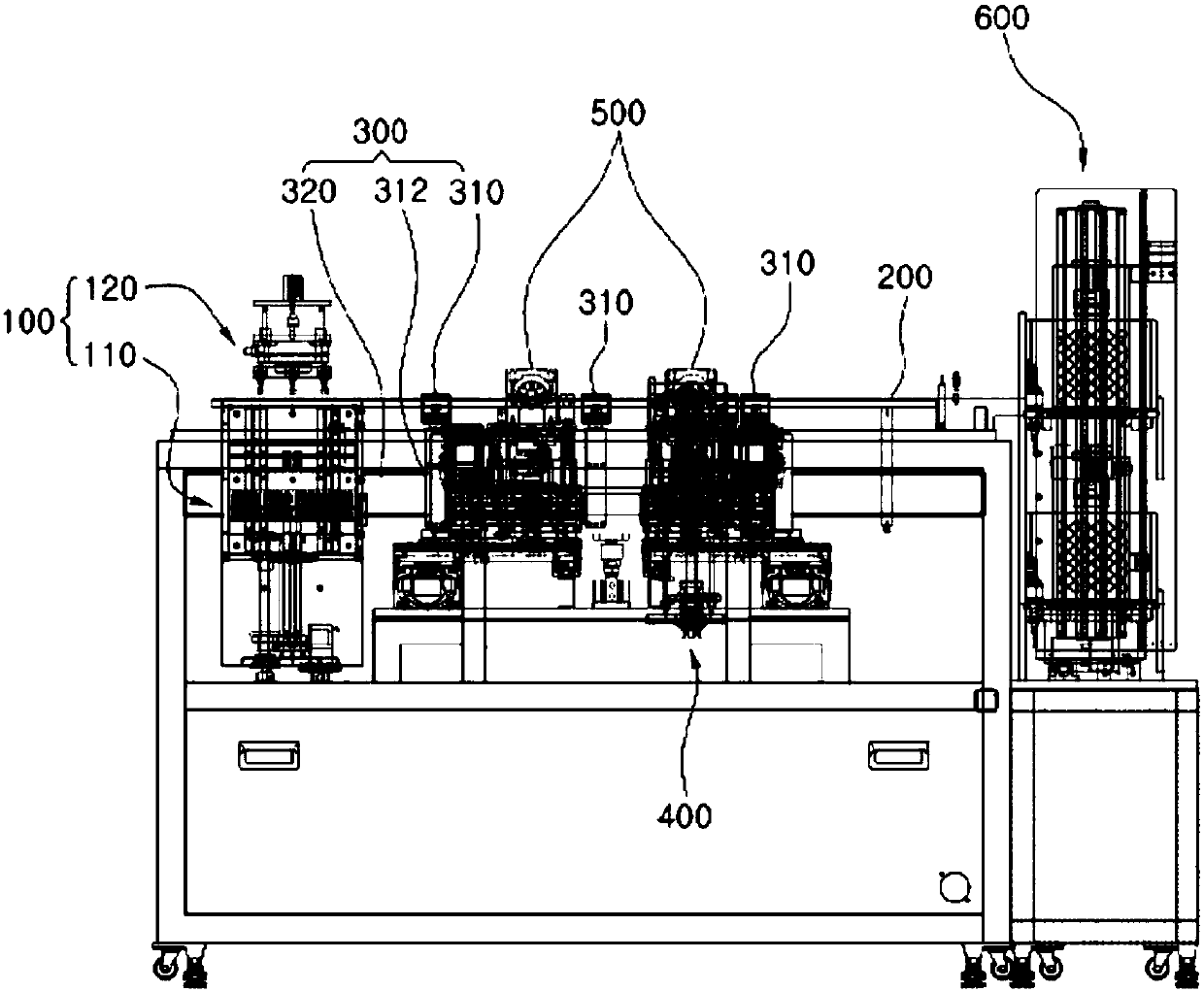

Joint head and parts installation equipment

InactiveCN1366337AEasy to set upImprove joint qualityPrinted circuit assemblingJointsEngineeringMechanical engineering

A bonding head includes an inclination preventing member 129 capable of preventing the inclination of the pressing portion 110 relative to the support portion 111, and setting the pressing surface 130a and the mounting surface 16a in an approximately parallel state. Therefore, the pressing surface can be provided with a higher degree of parallelism with respect to the bonding stage 16 than conventionally, and components and circuit-formed bodies can be bonded with high bonding quality.

Owner:PANASONIC CORP

Hybrid friction stir welding for dissimilar materials through electroplastic effect

ActiveUS20150375335A1Improve joint efficiencyPreserve tool lifeResistance welding apparatusNon-electric welding apparatusPower flowHigh density

A hybrid Friction Stir Welding approach and device for dissimilar materials joining employing Electro-Plastic Effect. The approach and device include an introduction of high density, short period current pulses into traditional friction stir welding process, which therefore can generate a localized softened zone in the workpiece during plastic stirring without significant additional temperature increase. This material softened zone is created by high density current pulses based on Electro-Plastic Effect and will move along with the friction stir welding tool. Smaller downward force, larger processing window and better joint quality for dissimilar materials are expected to be achieved through this hybrid welding technique.

Owner:RGT UNIV OF MICHIGAN

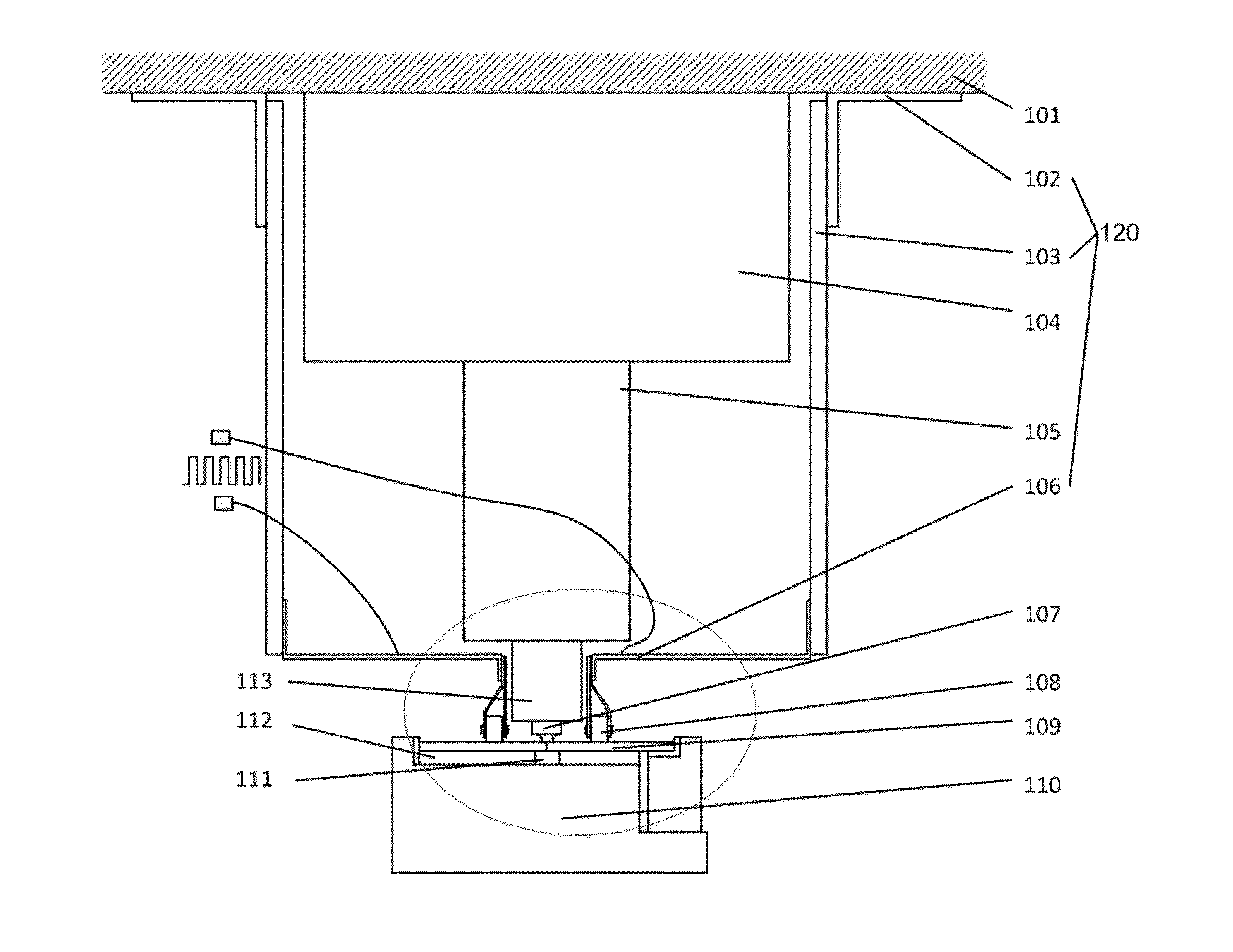

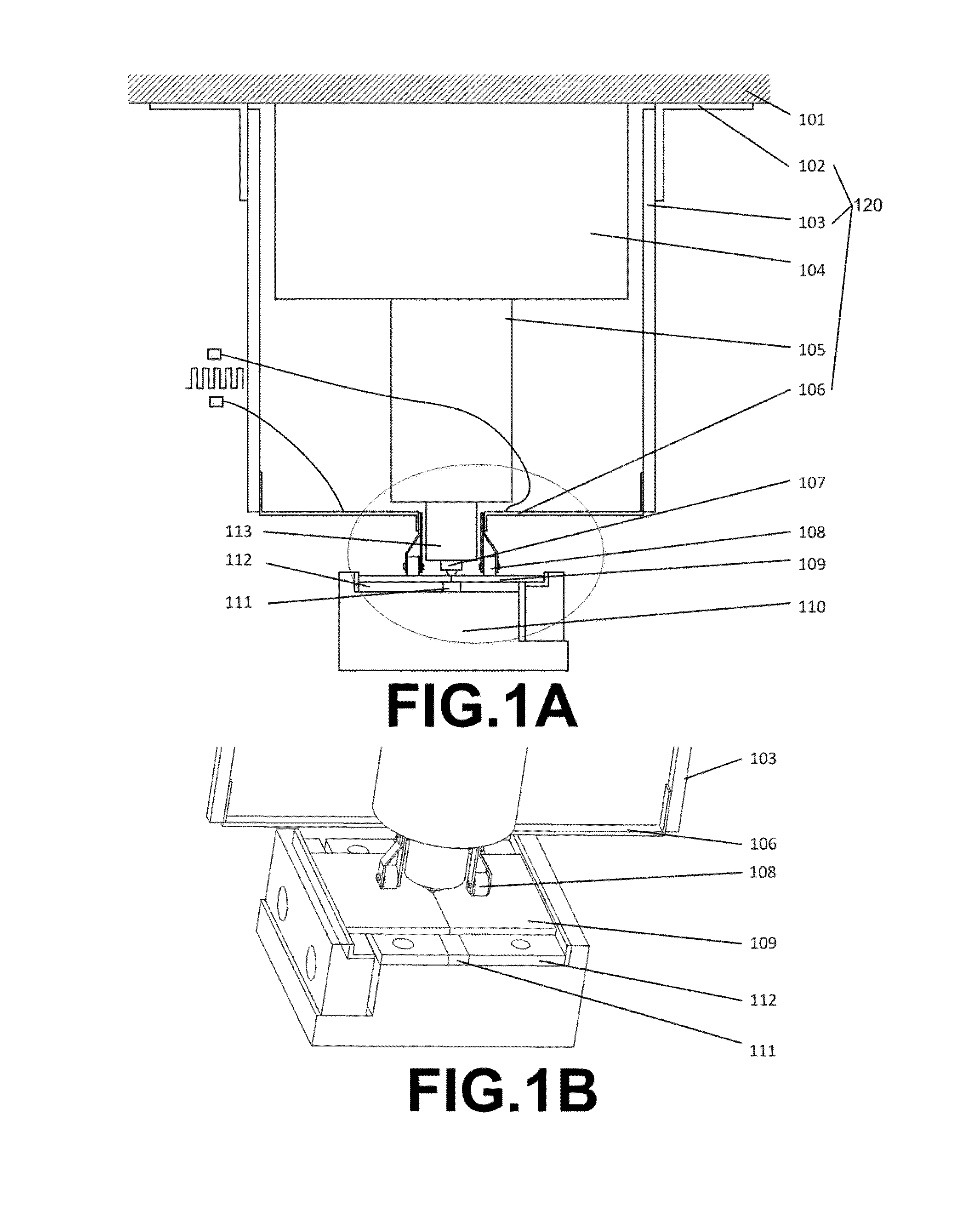

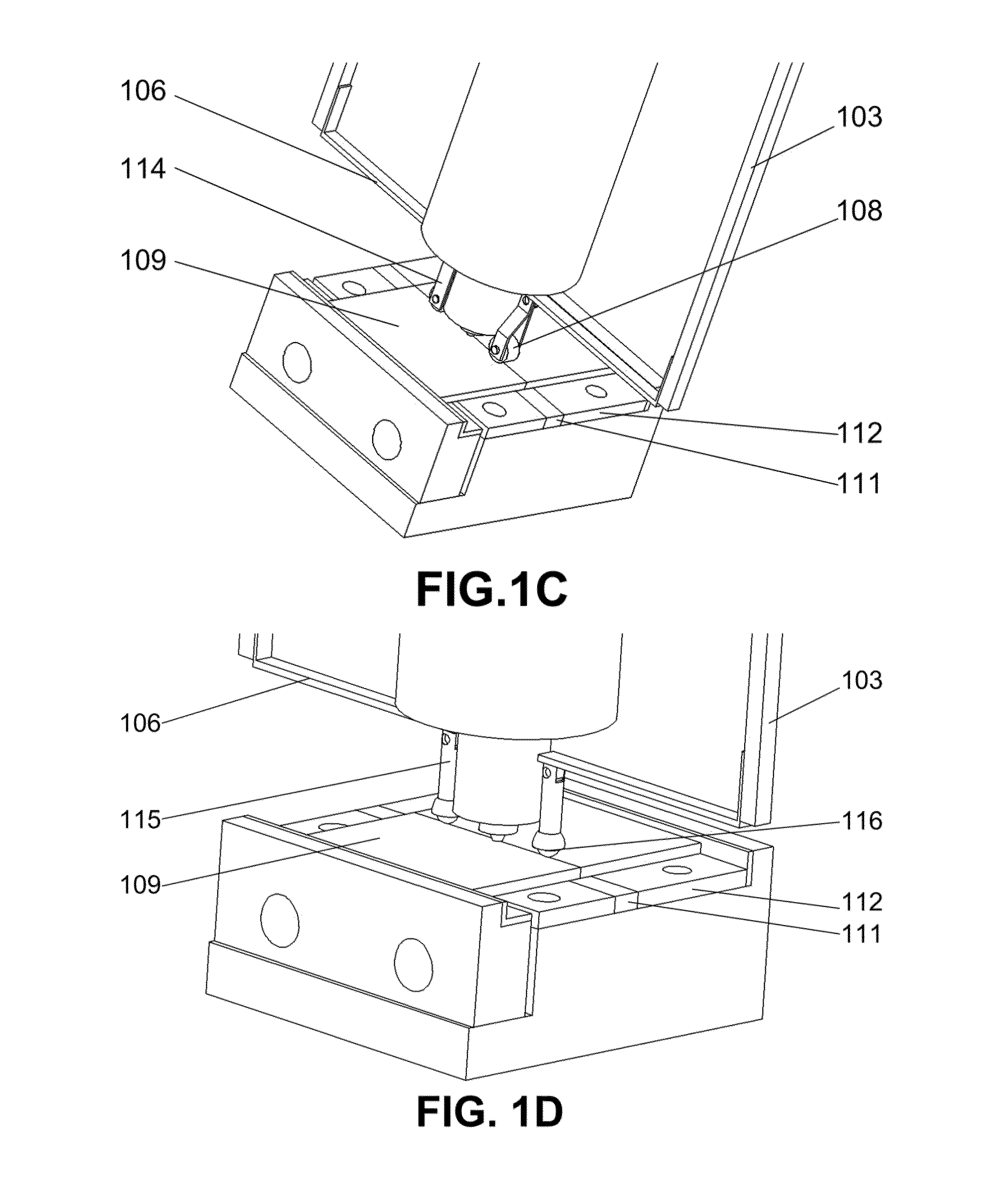

Ultrasonic-welding joining apparatus of semiconductor substrate

ActiveCN107636811AAvoid it happening againImprove joint qualitySemiconductor/solid-state device detailsSolid-state devicesUltrasonic weldingSemiconductor package

The invention discloses an ultrasonic-welding joining apparatus of a semiconductor substrate. The present invention relates to an ultrasonic-welding joining apparatus and, more particularly, to an apparatus for joining, using ultrasonic welding, a lead frame on a DBC substrate of a semiconductor package. The ultrasonic-welding joining apparatus according to the present invention comprises: a lead-frame loading part for supplying a lead frame; a substrate loading part for supplying a DBC substrate; an index rail in which the DBC substrate and the lead frame are seated; an ultrasonic-welding part for joining, using ultrasonic welding, the lead frame and the DBC substrate seated in the index rail; and an unloading part for carrying out the lead frame and the DBC substrate joined by the ultrasonic-welding part.

Owner:JMJ KOREA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com