Joint head and parts installation equipment

A technology for jointing heads and components, which is applied to joints, electrical components to assemble printed circuits, electrical components, etc., and can solve problems such as insufficient parallelism of electronic components 13 circuit boards 15, inability to align in parallel, and differences in contact states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

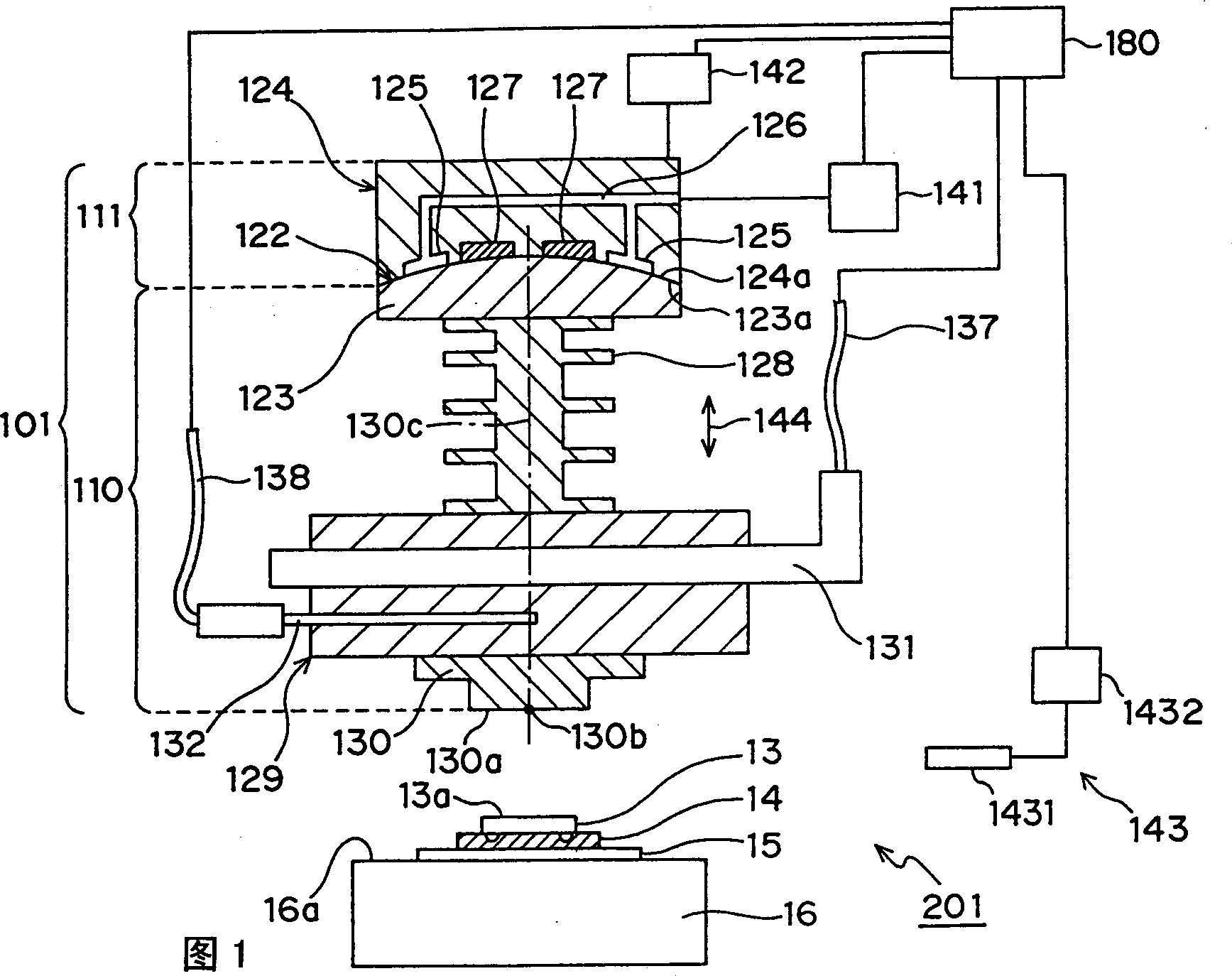

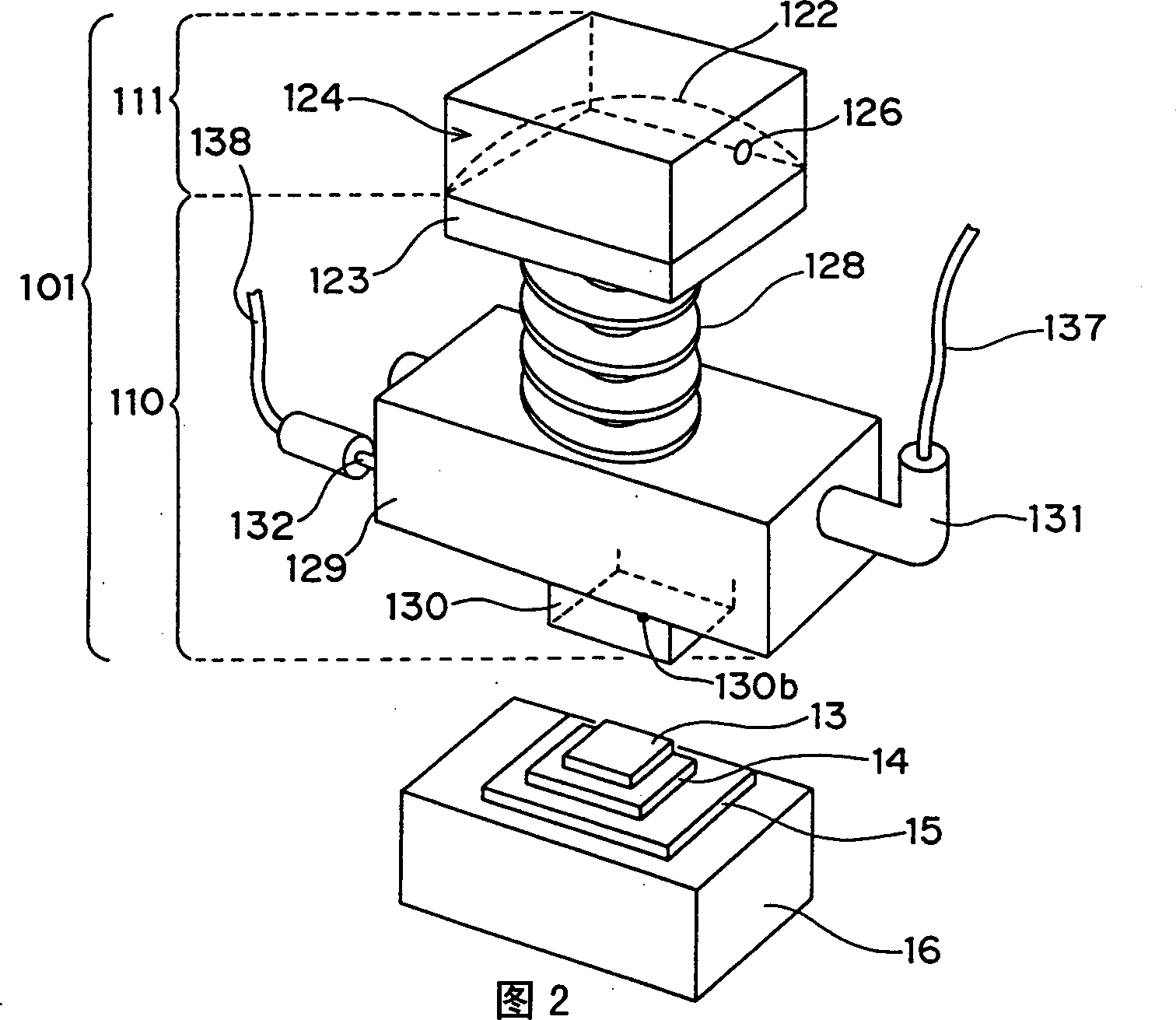

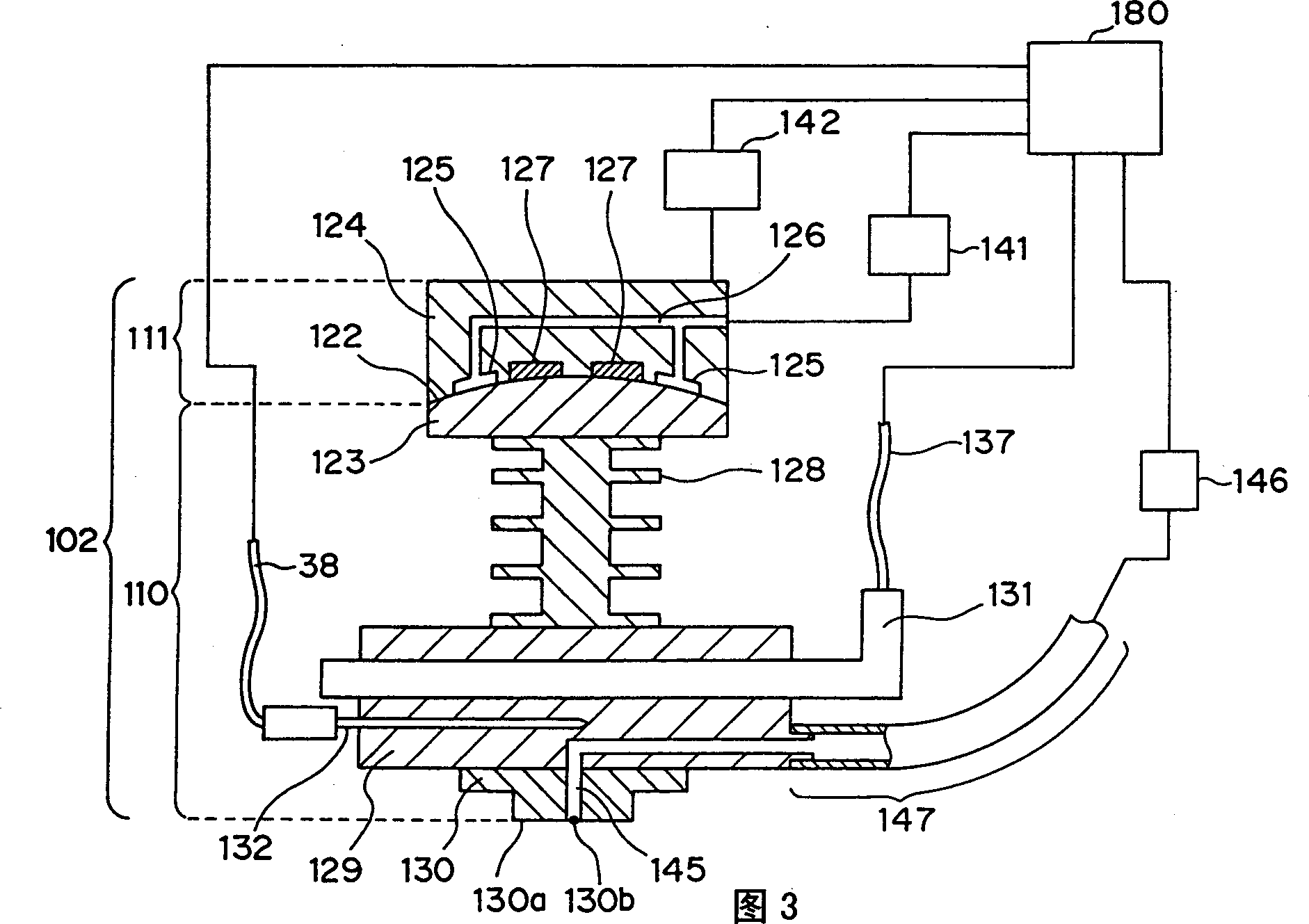

[0051] A bonding head, which is an embodiment of the present invention, and a component mounting apparatus including the bonding head will be described below with reference to the drawings. In addition, in each drawing, the same code|symbol is attached|subjected to the same component. In addition, in this specification, the so-called circuit forming body refers to circuit boards such as resin substrates, paper-phenolic substrates, ceramic substrates, glassy epoxy resin (epoxy glass) substrates, and film substrates; A circuit board such as a substrate or a multilayer substrate; a component; an object forming a circuit such as a frame or a frame. Also, in the present embodiment, a circuit board is taken as an example of a circuit forming body, and an electronic component mounted on the circuit board is taken as an example of a component.

[0052] As shown in FIGS. 1 and 2 , the bonding head 101 of this embodiment is roughly divided into a pressing portion 110 and a support port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com