Patents

Literature

33results about How to "Favorable joining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

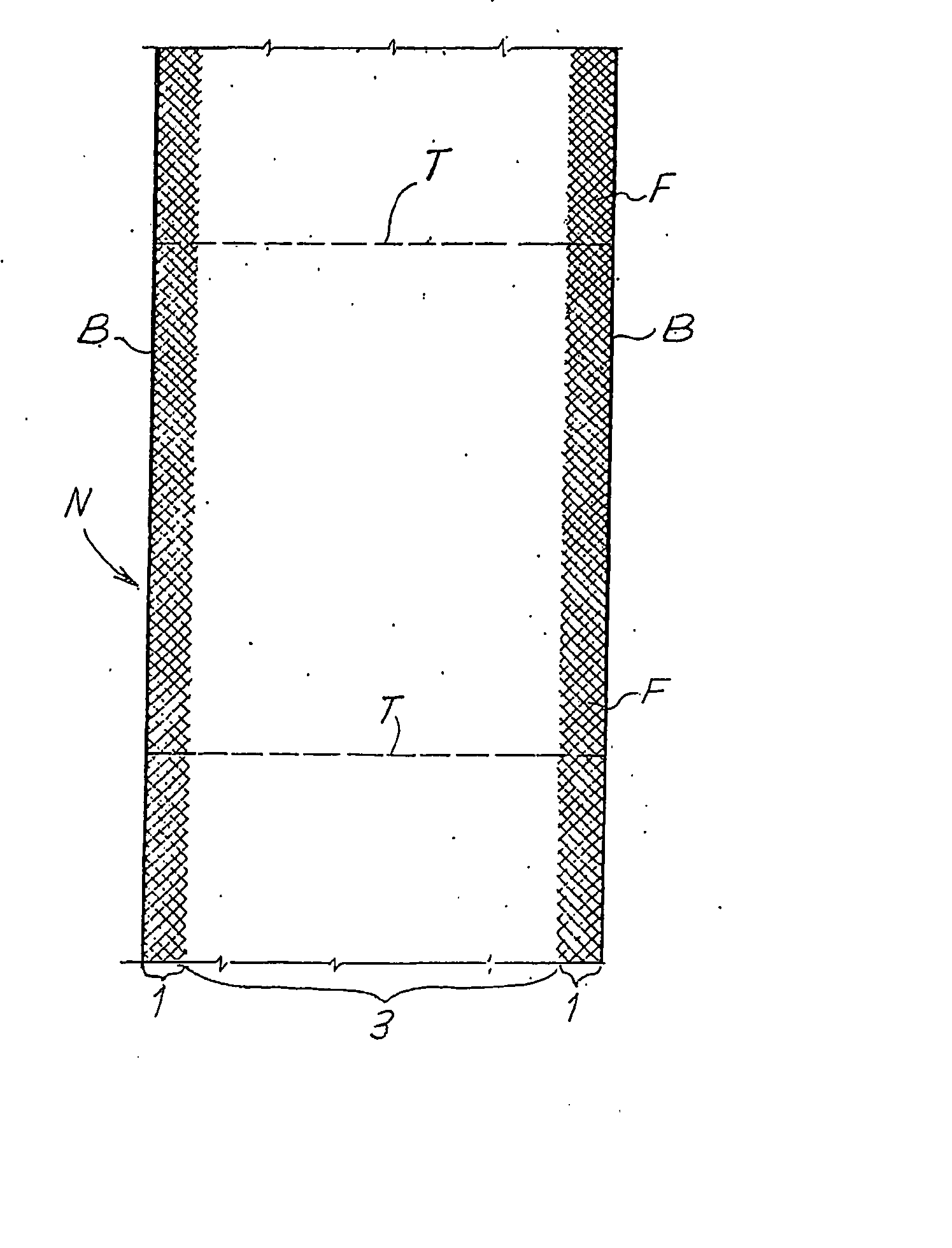

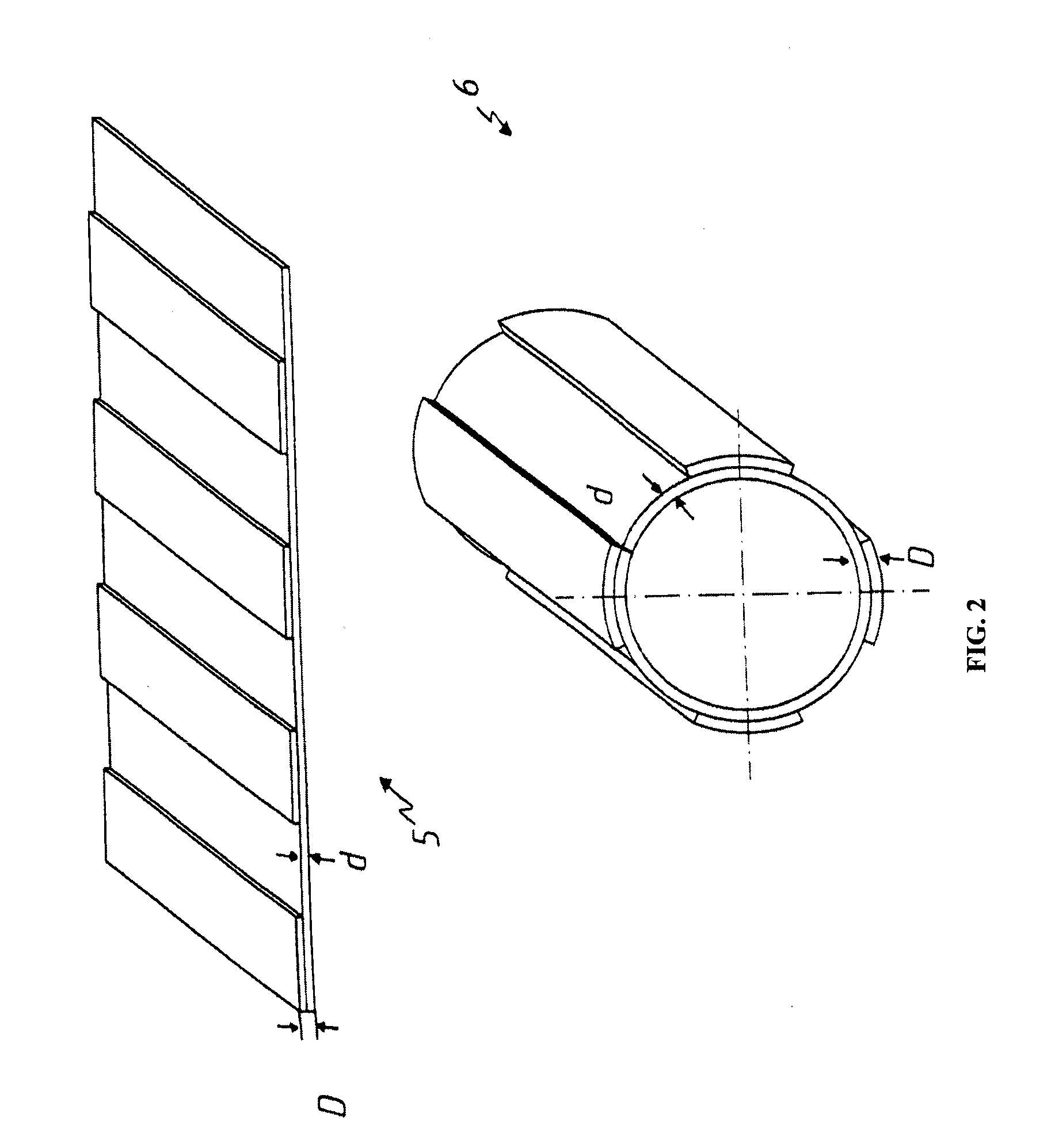

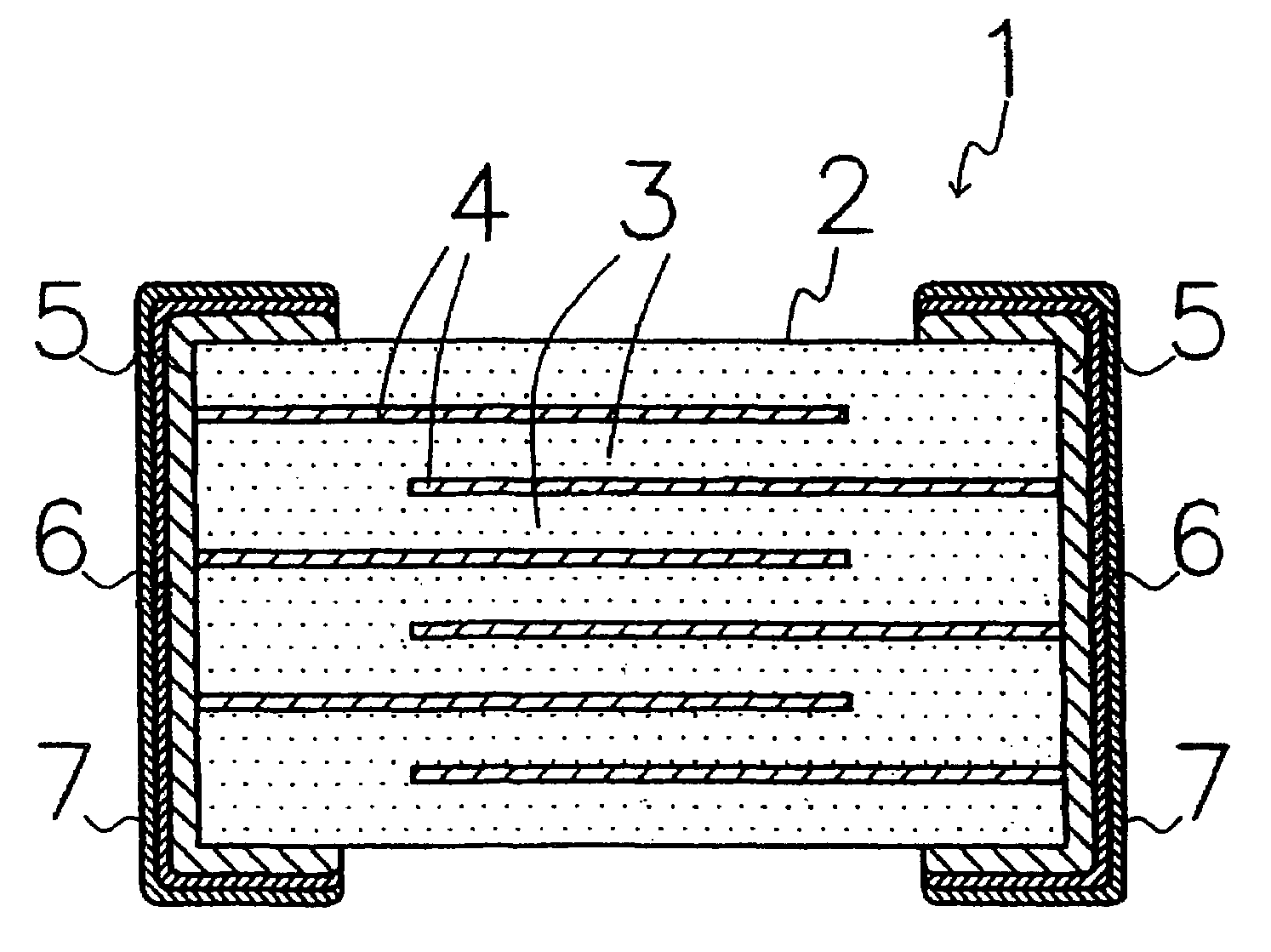

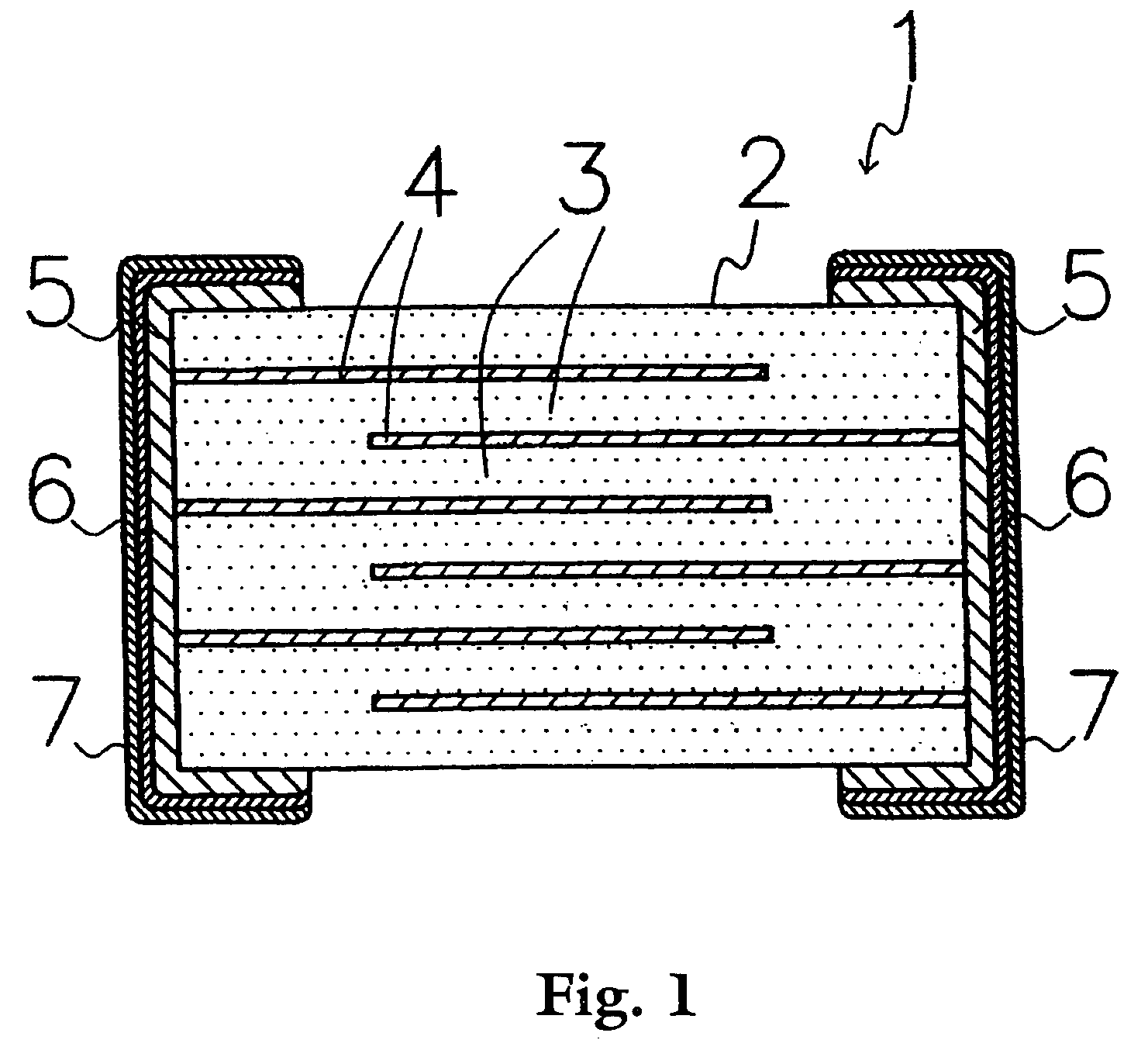

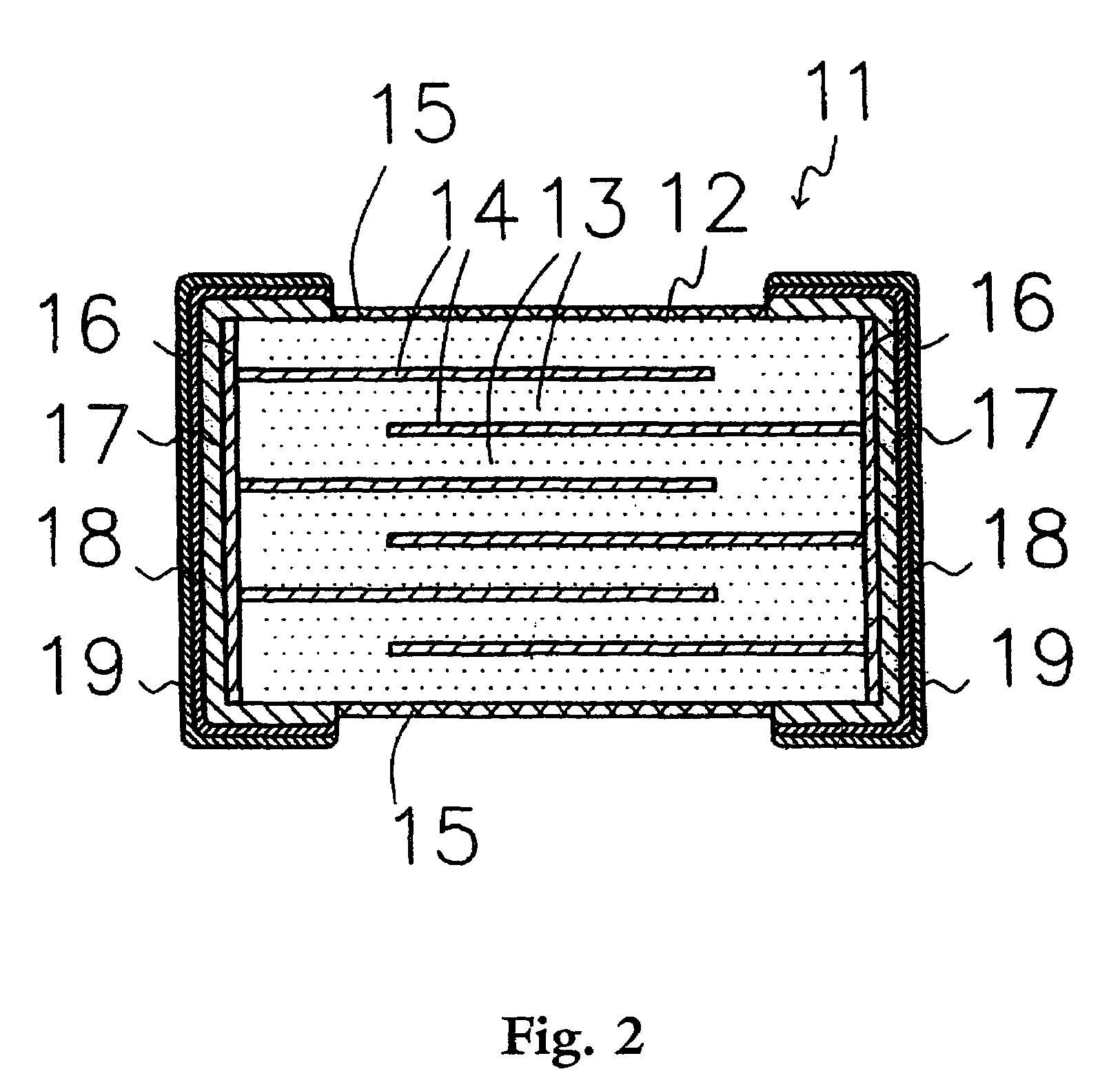

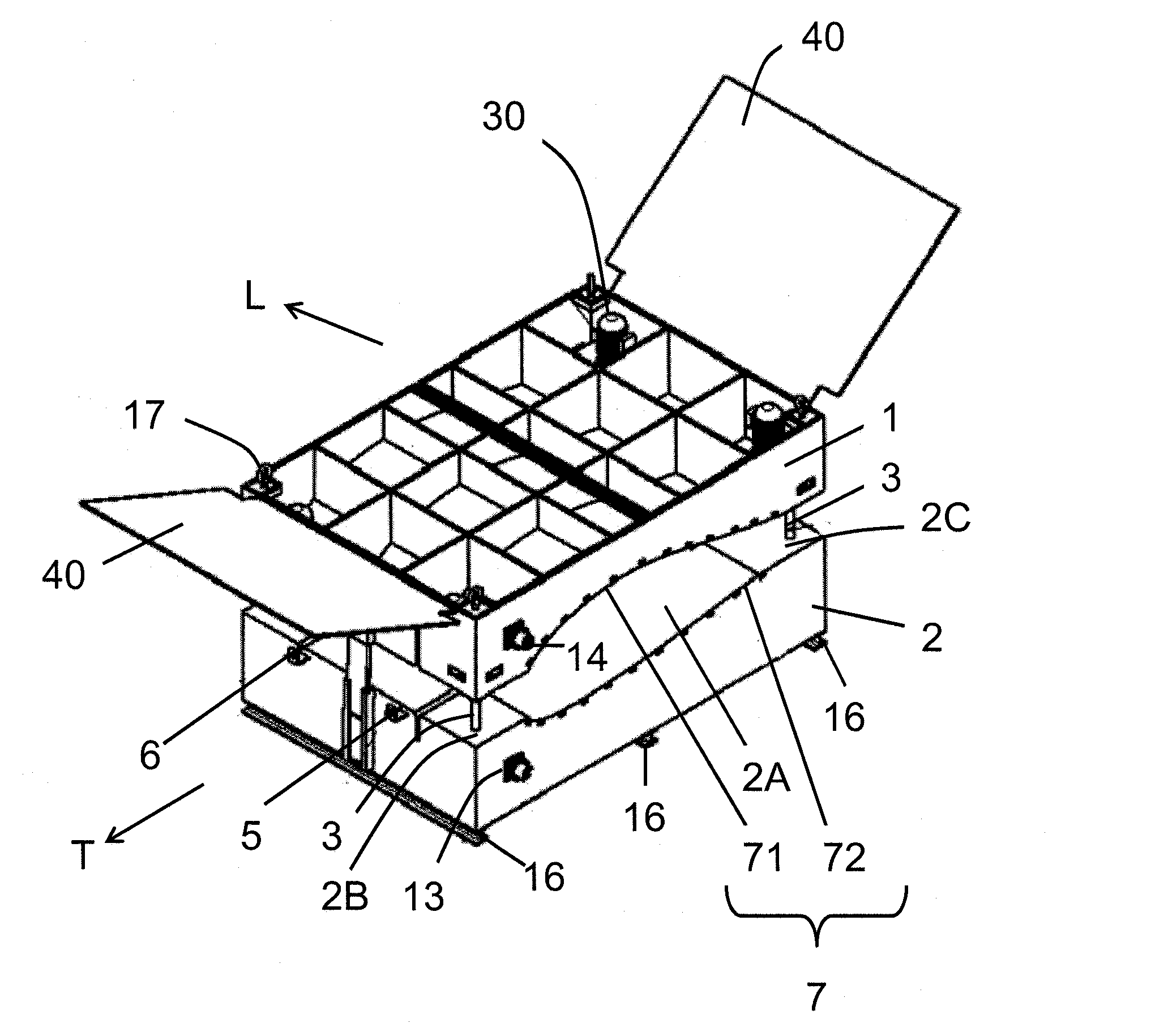

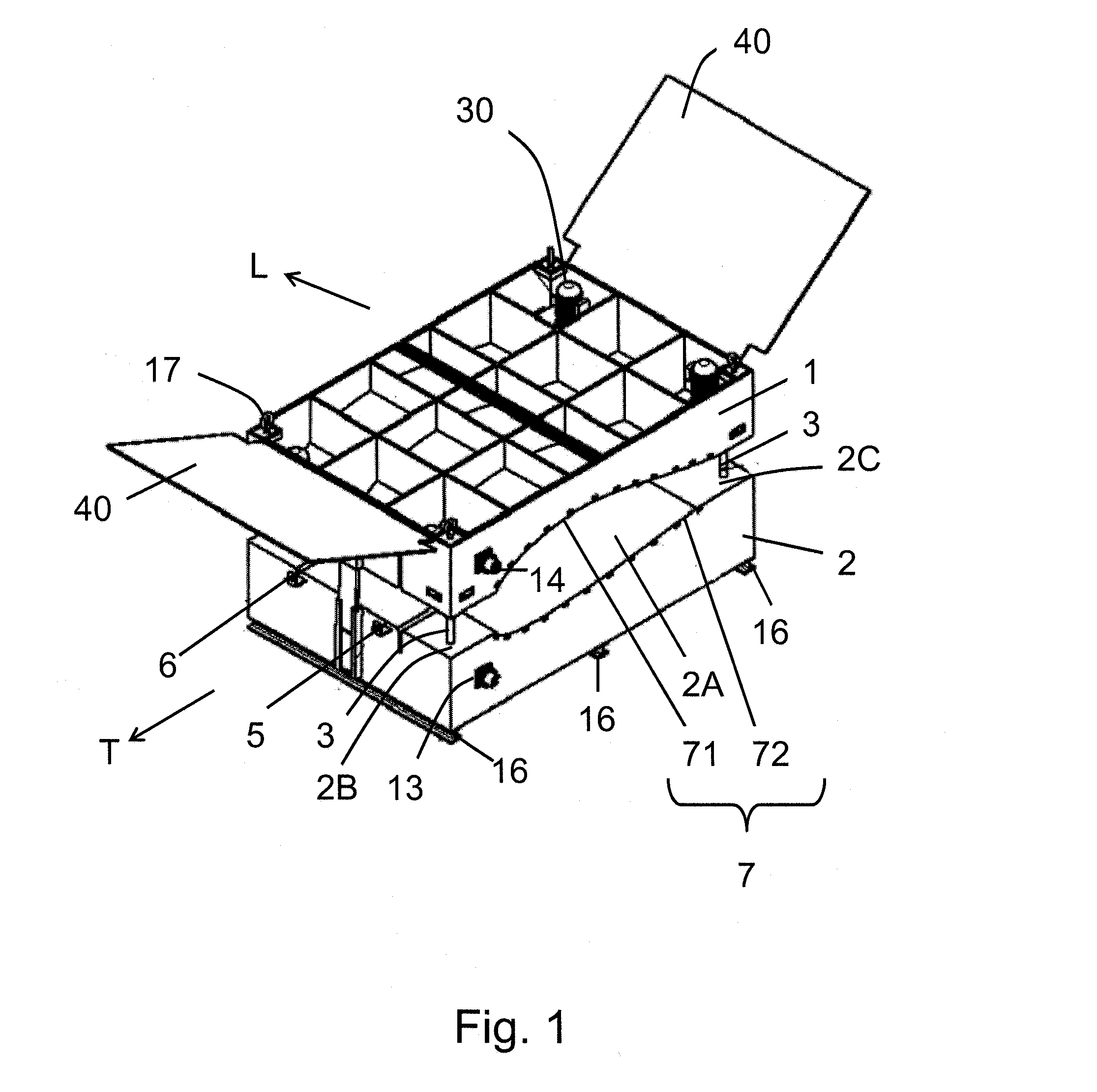

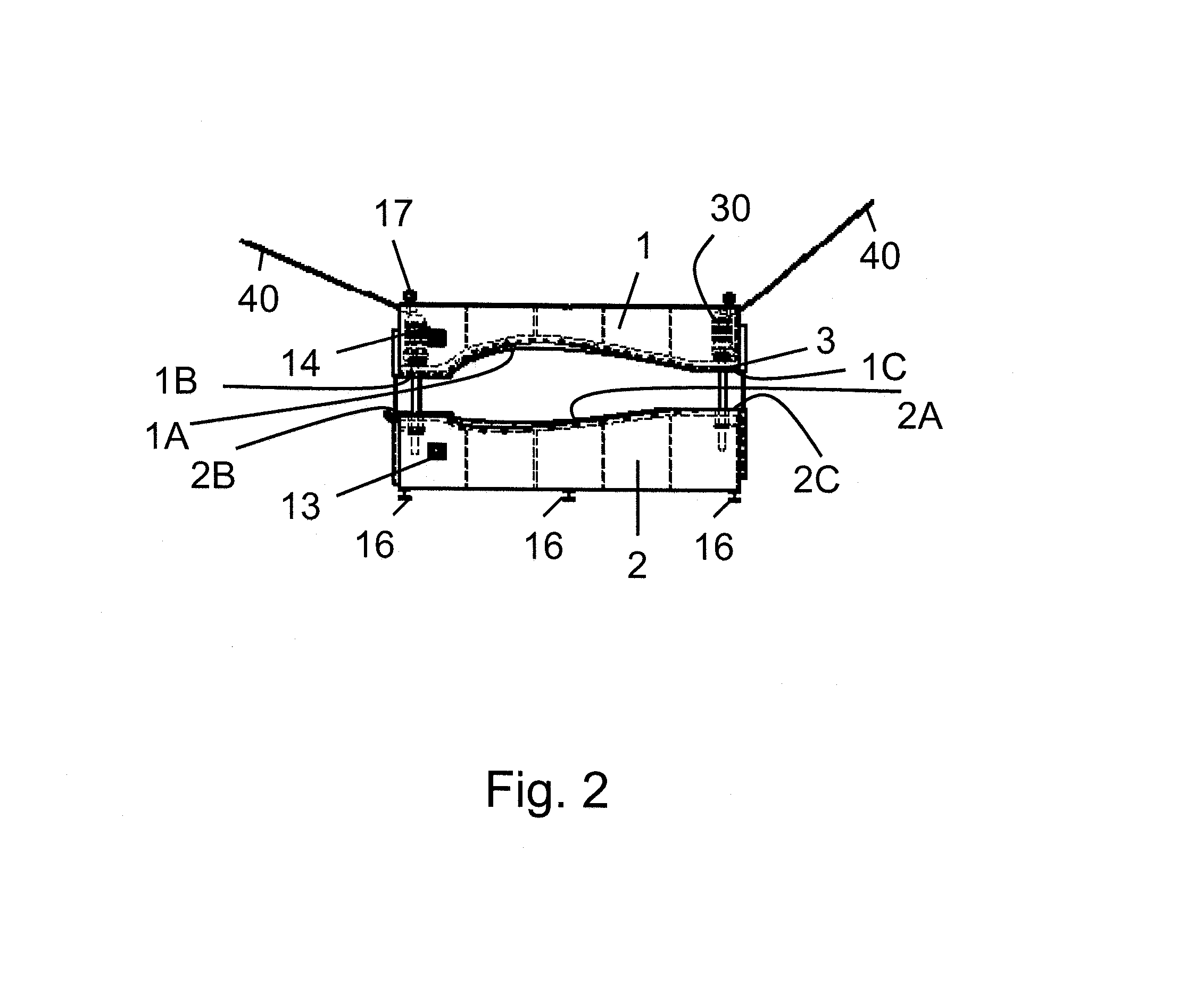

Projection screen for image reproduction devices which are positioned next to and/or above one another

InactiveUS6335829B1Drawback can be obviatedMinimal seamingTelevision system detailsBuilt-on/built-in screen projectorsProjection screenEngineering

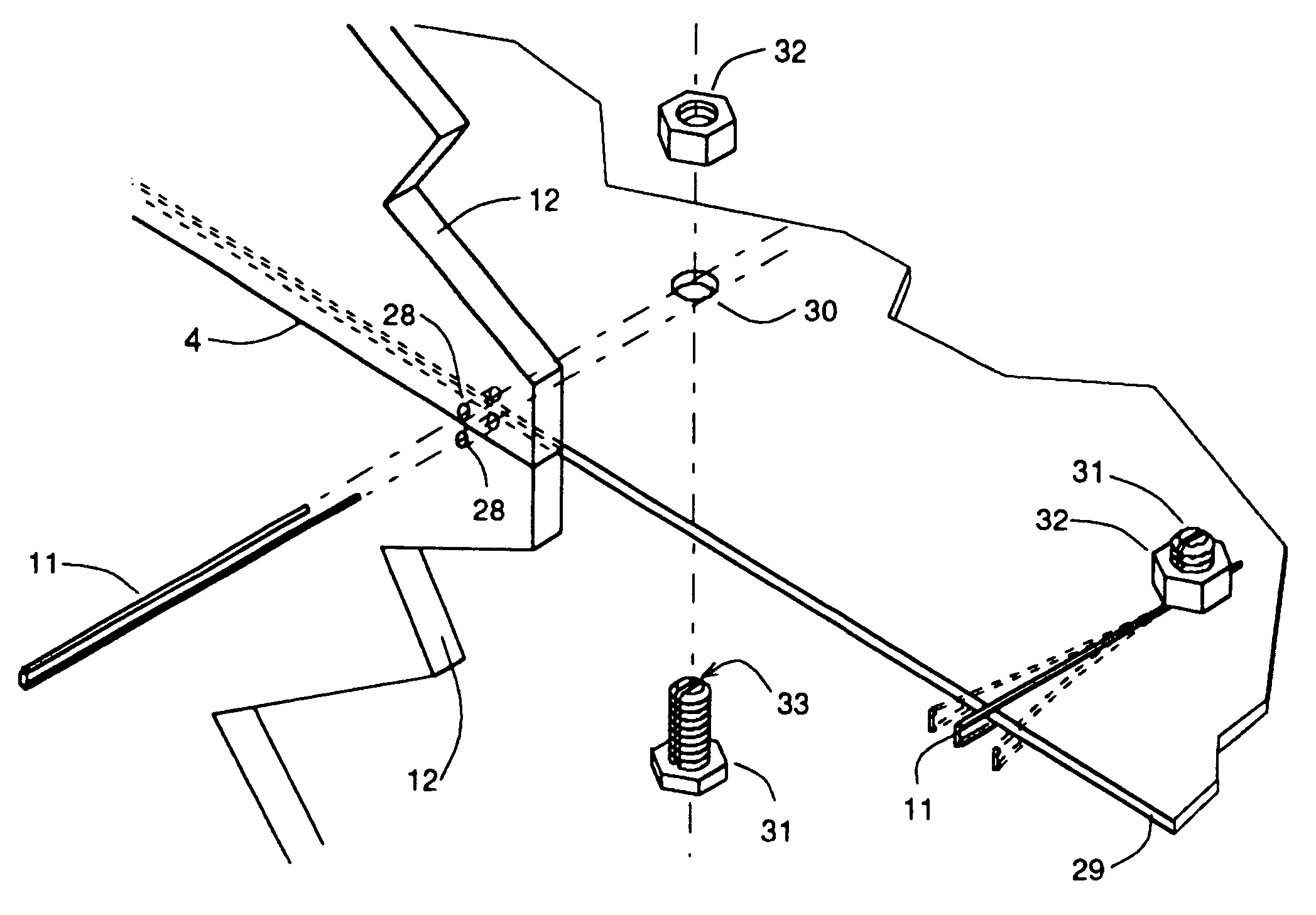

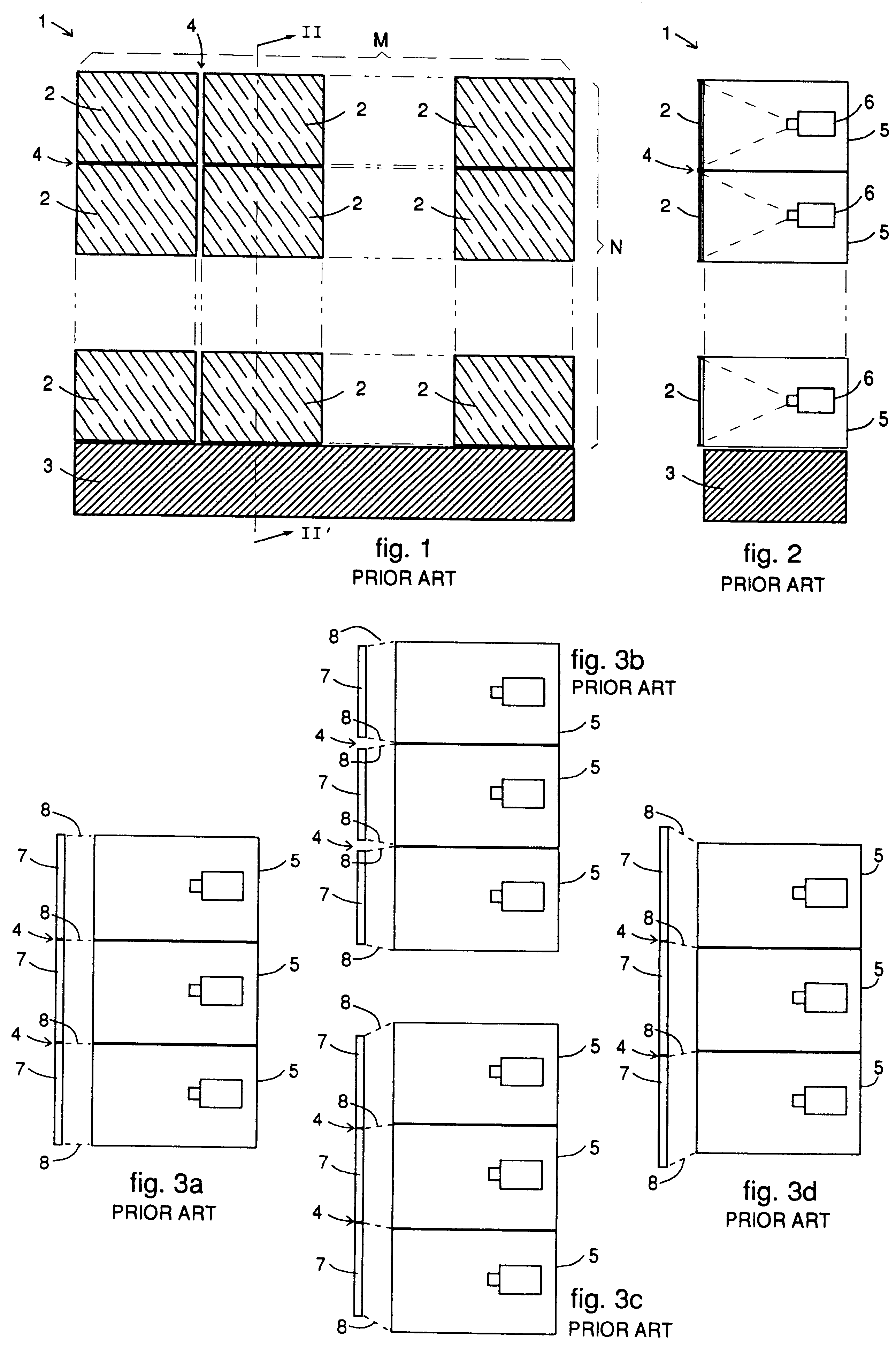

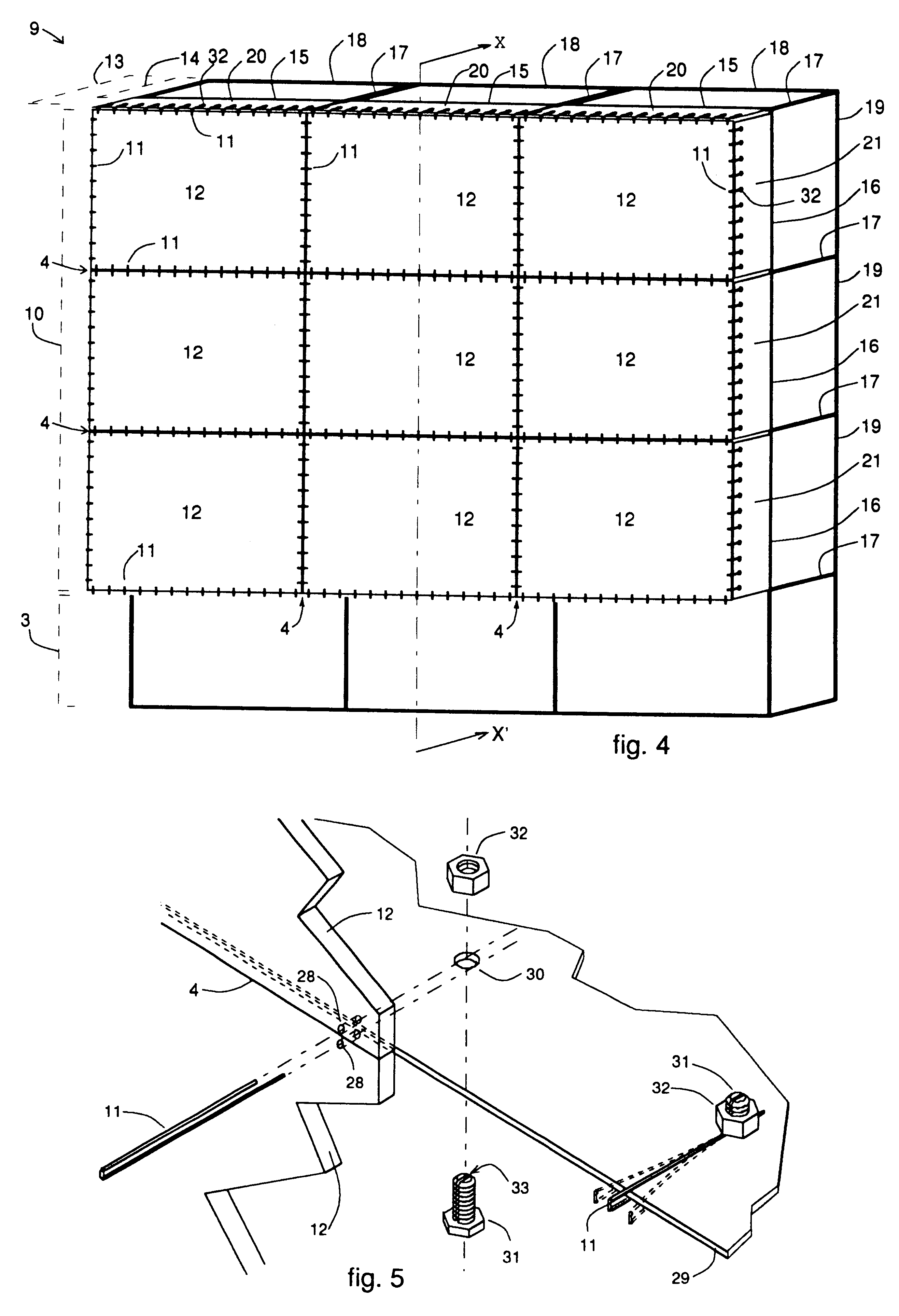

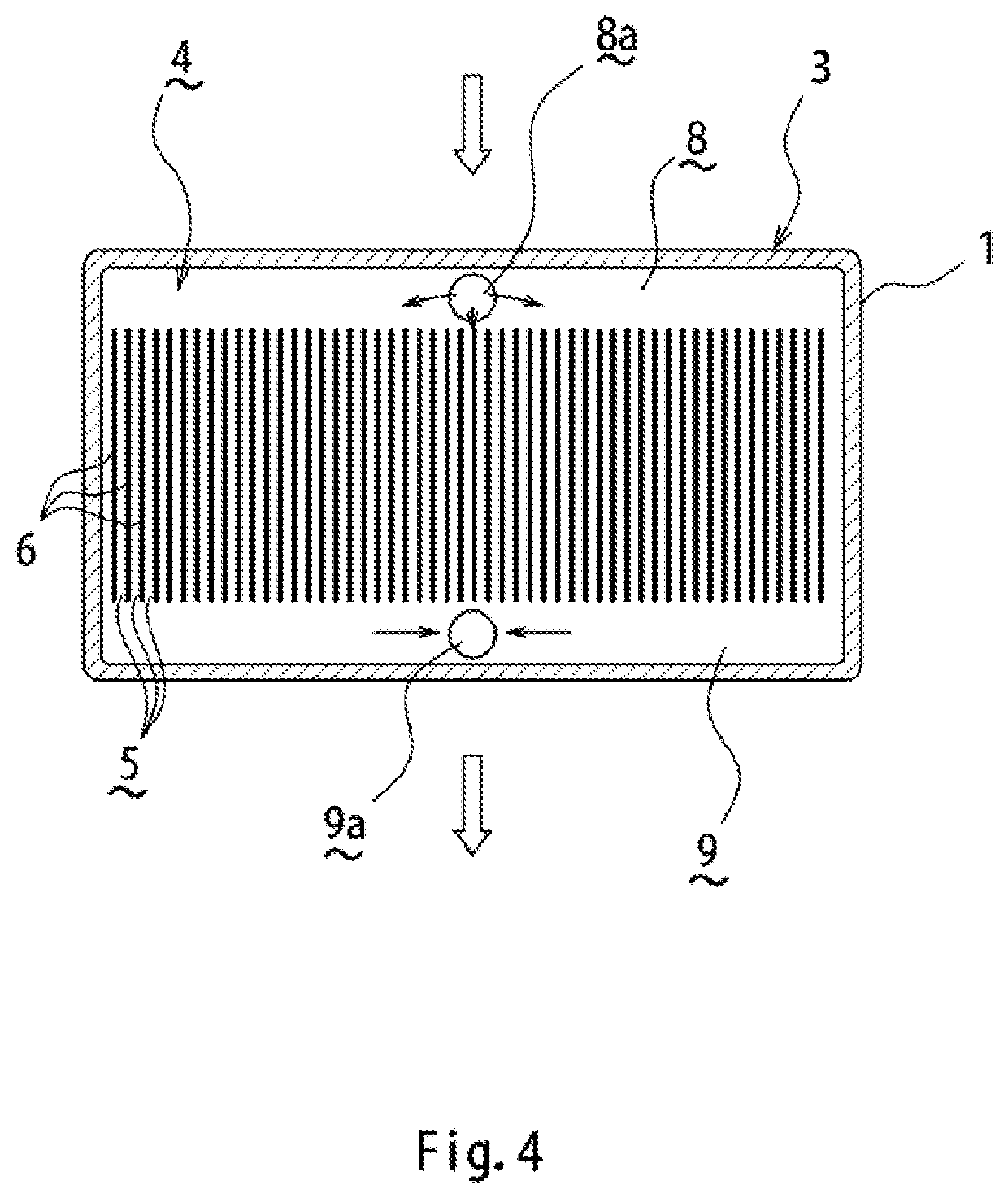

A multi-screen display for rear projection applications includes a supporting structure and a screen comprising a plurality of screen panels which are positioned and attached to one another and to attachment plates by joining wires. The seams between the screen panels are minimal, specifically less than half of a millmetre wide, even in the event of relatively inaccurate installation of the projection screen, in spite of manufacturing tolerances and under changing climatological conditions, such as temperature and relative atmospheric humidity, owing to the fact that the attachment plates to which the screen panels are fixed using the joining wires are deformable and / or movably joined to the supporting structure.

Owner:BARCO NV

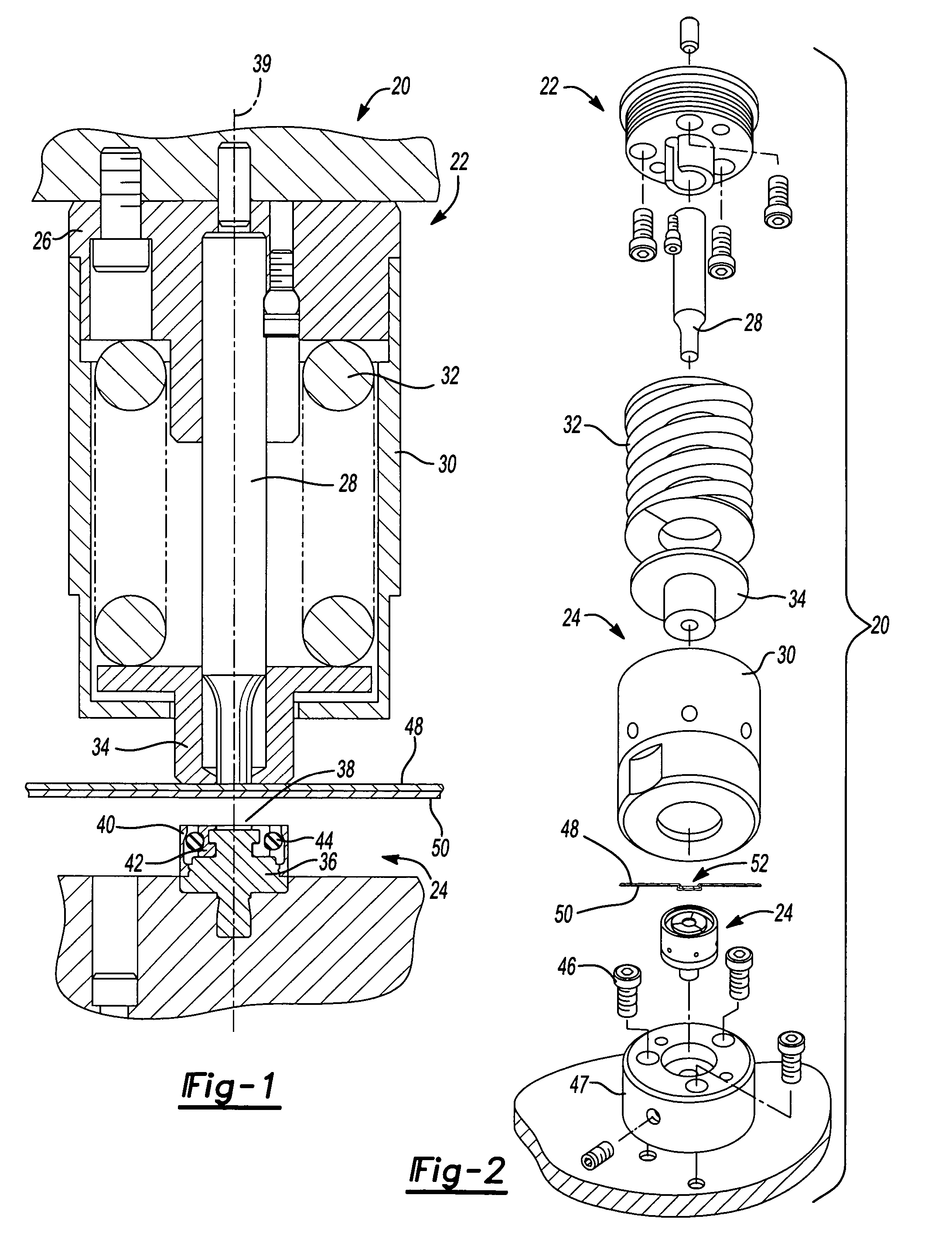

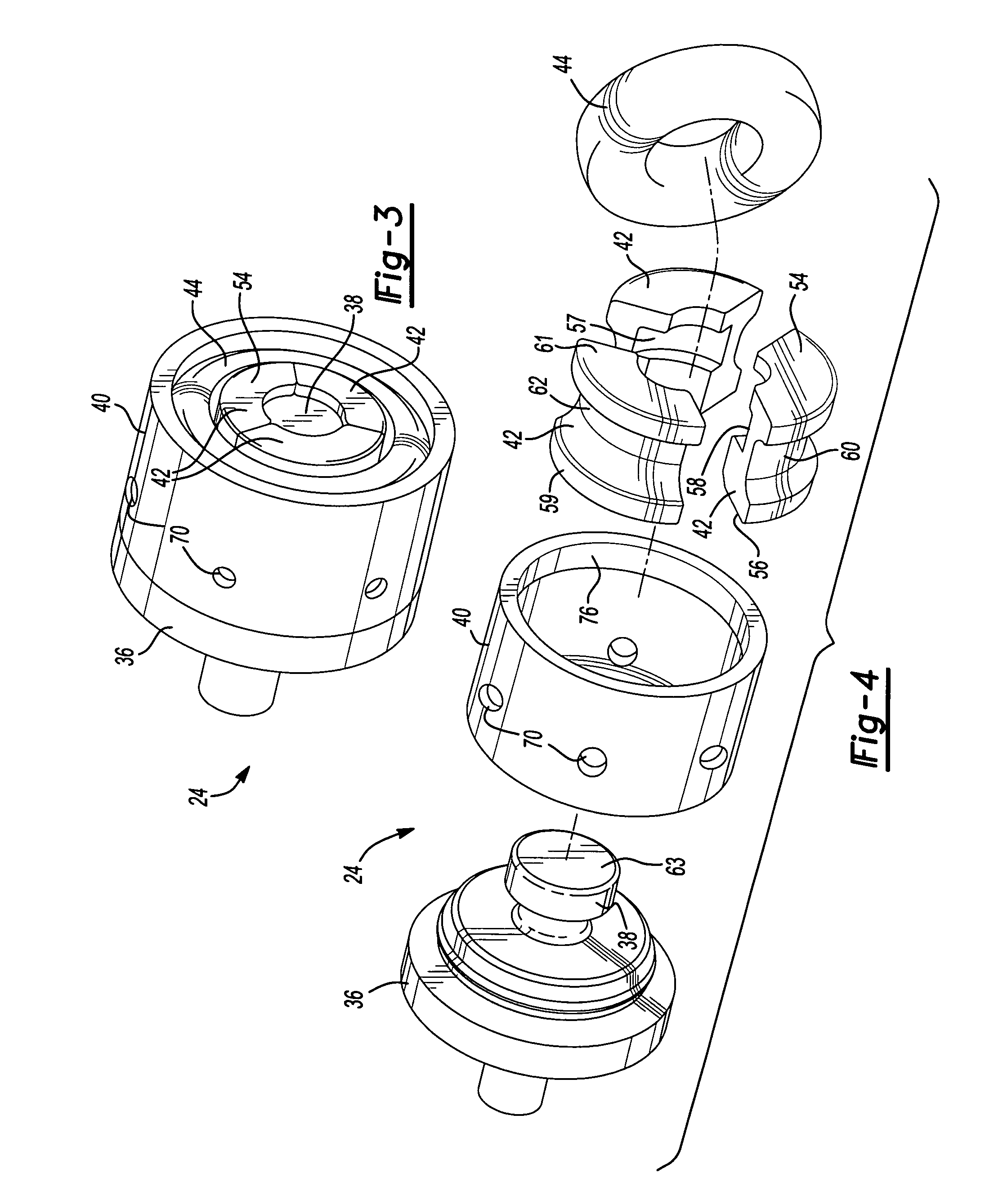

Sheet fastening apparatus and method

InactiveUS7694399B2Less-expensive to manufactureImprove joint qualityLarge fixed membersPositioning apparatusEngineeringKnife blades

A sheet fastening apparatus and method are provided. In another aspect of the present invention, a die assembly for forming a joint between sheets of material is disclosed wherein the die assembly includes an anvil, at least one die blade disposed adjacent to and overlapping a punch-side of the anvil, a flexible retainer, and a shield that coaxially and radially surrounds a portion of the anvil and / or die blade.

Owner:BTM COMPANY

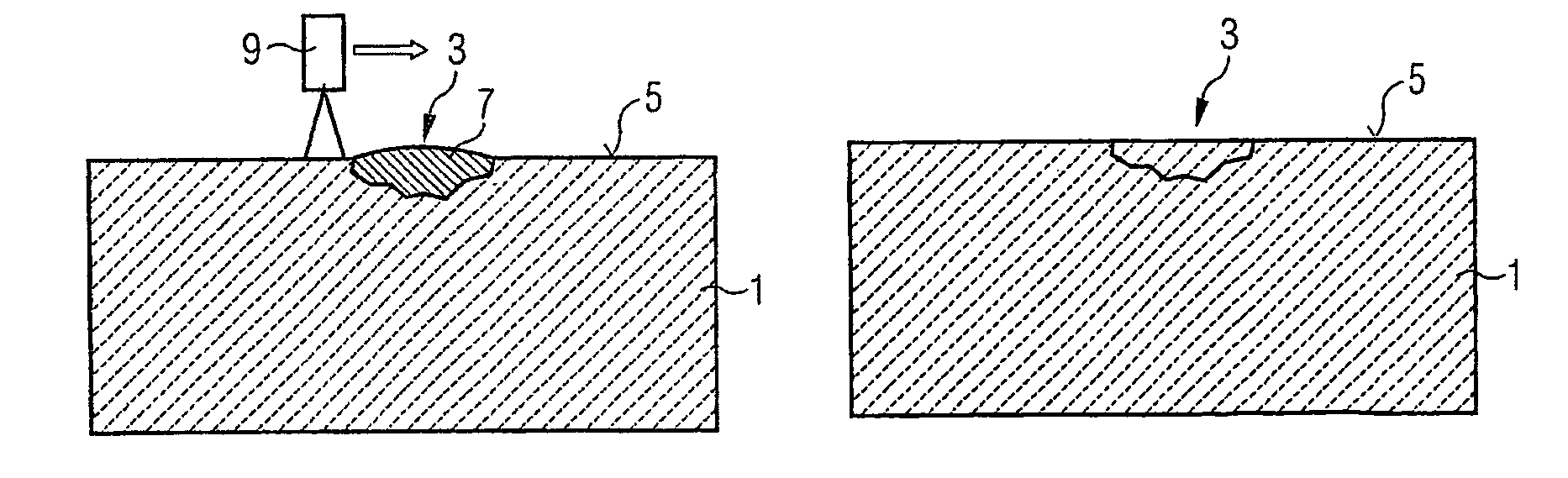

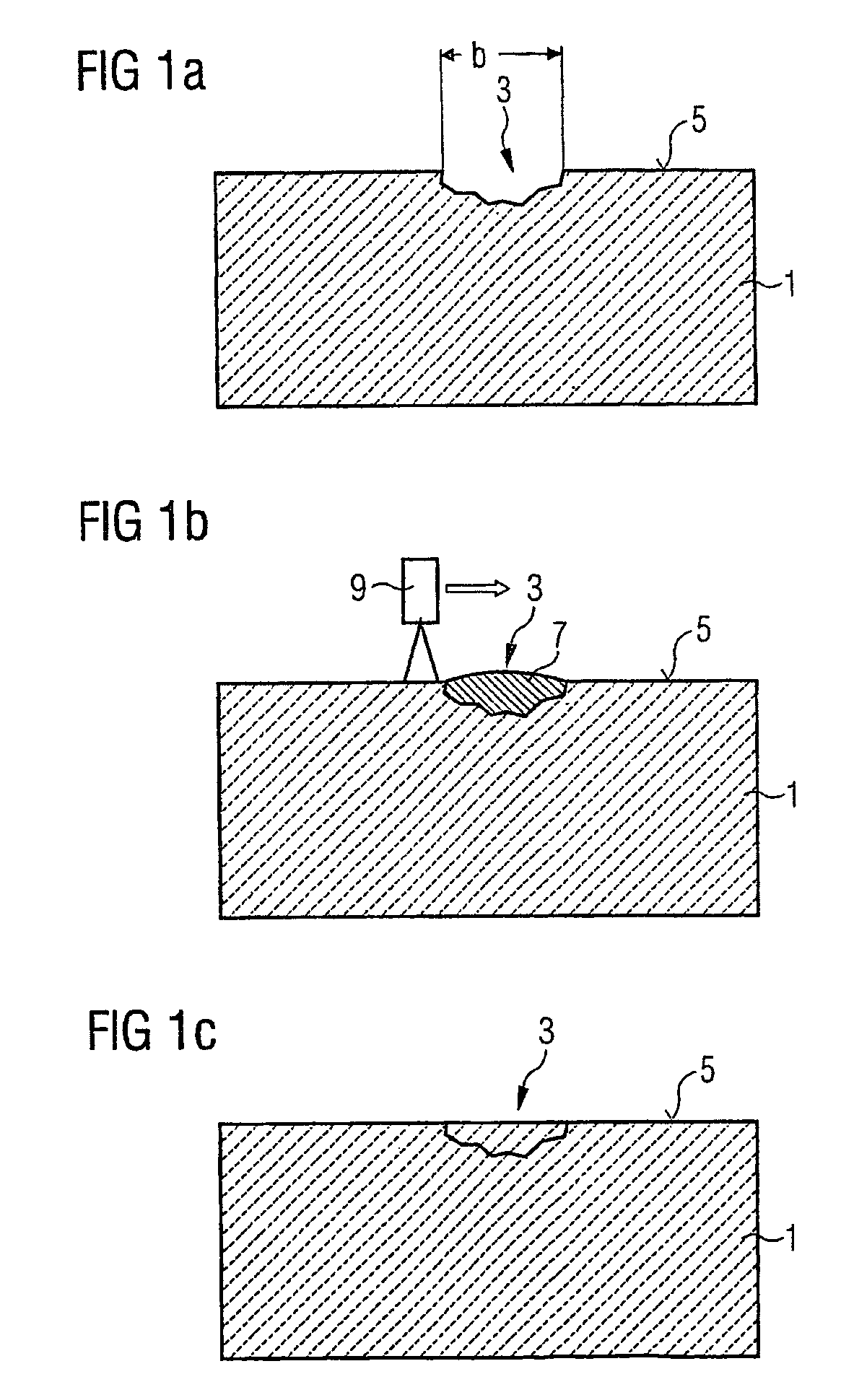

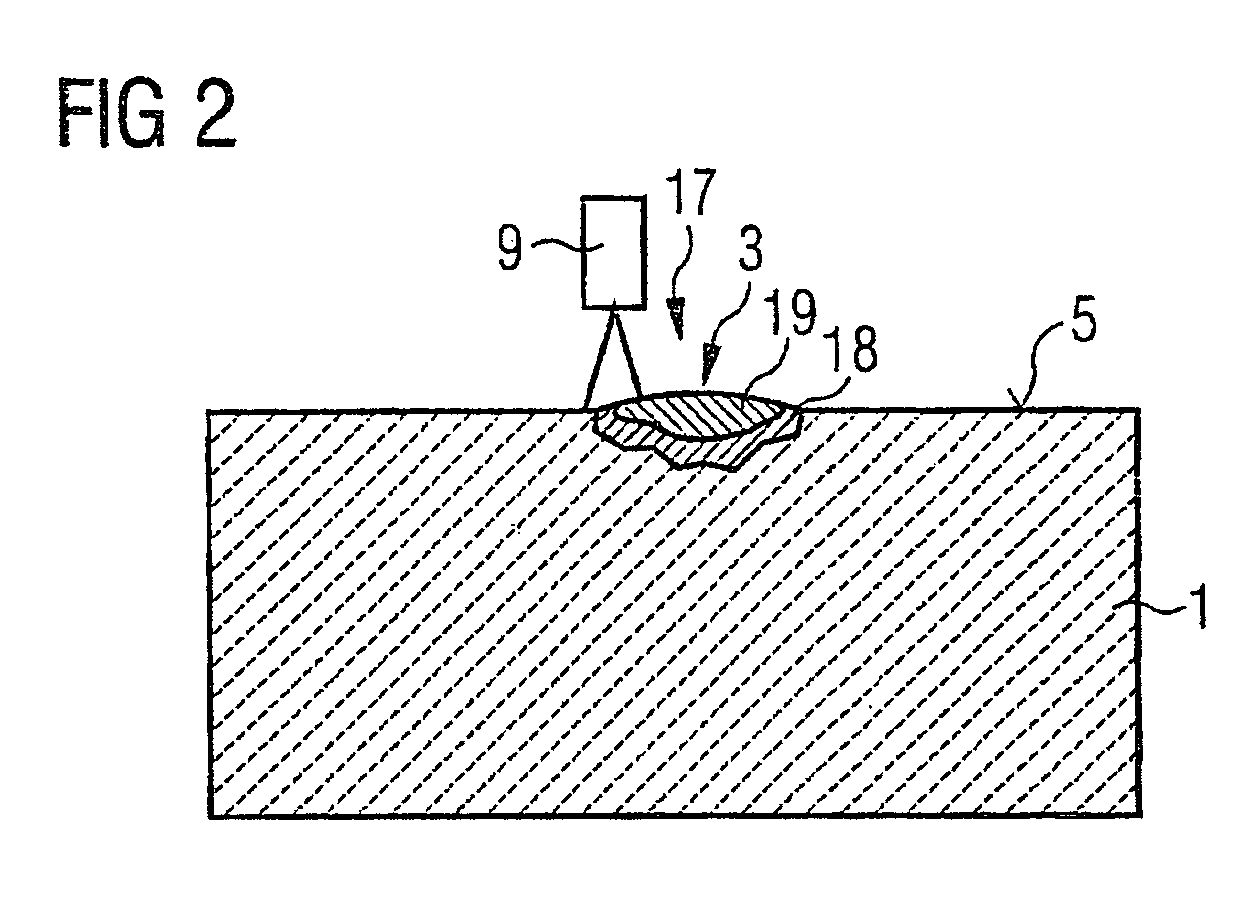

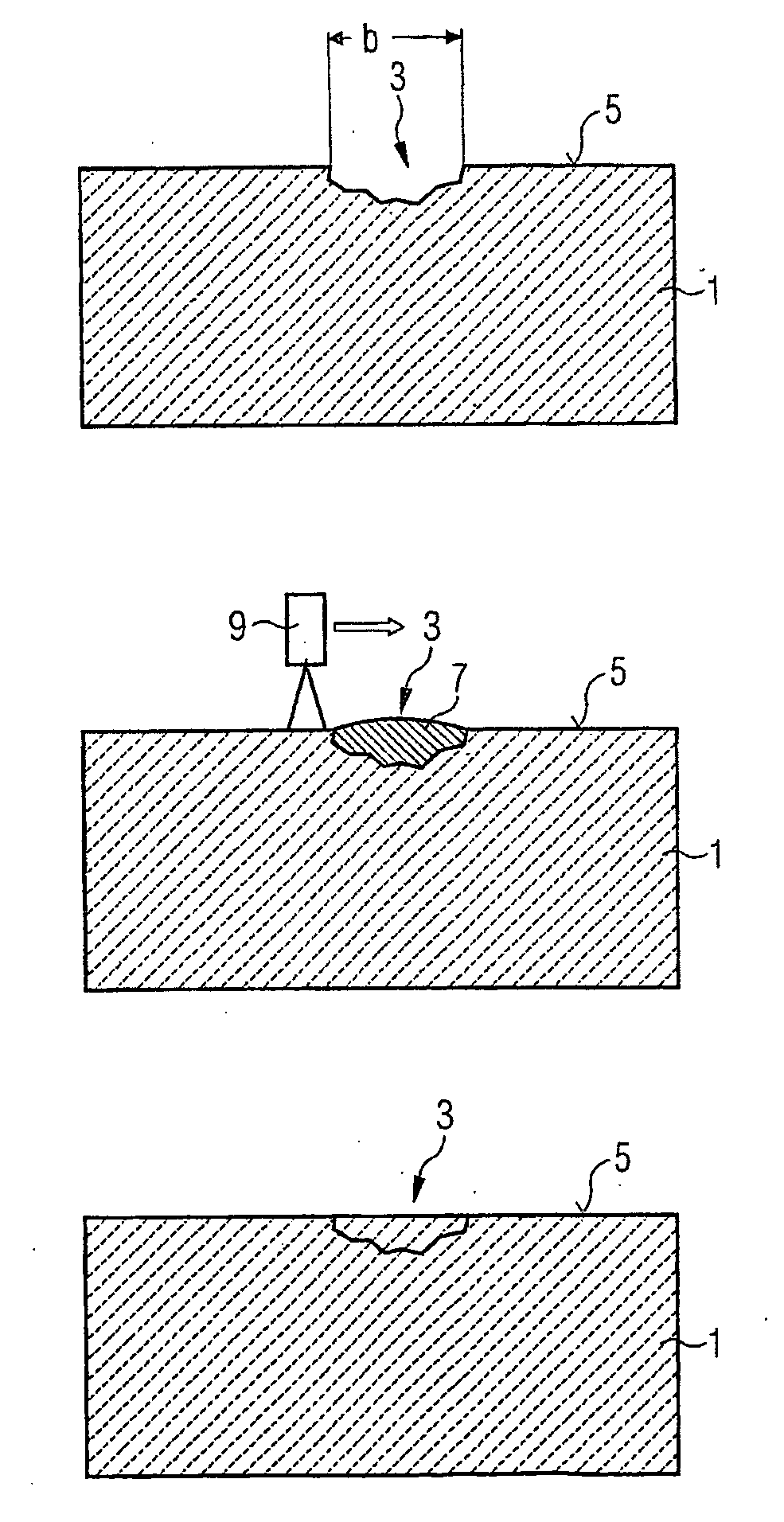

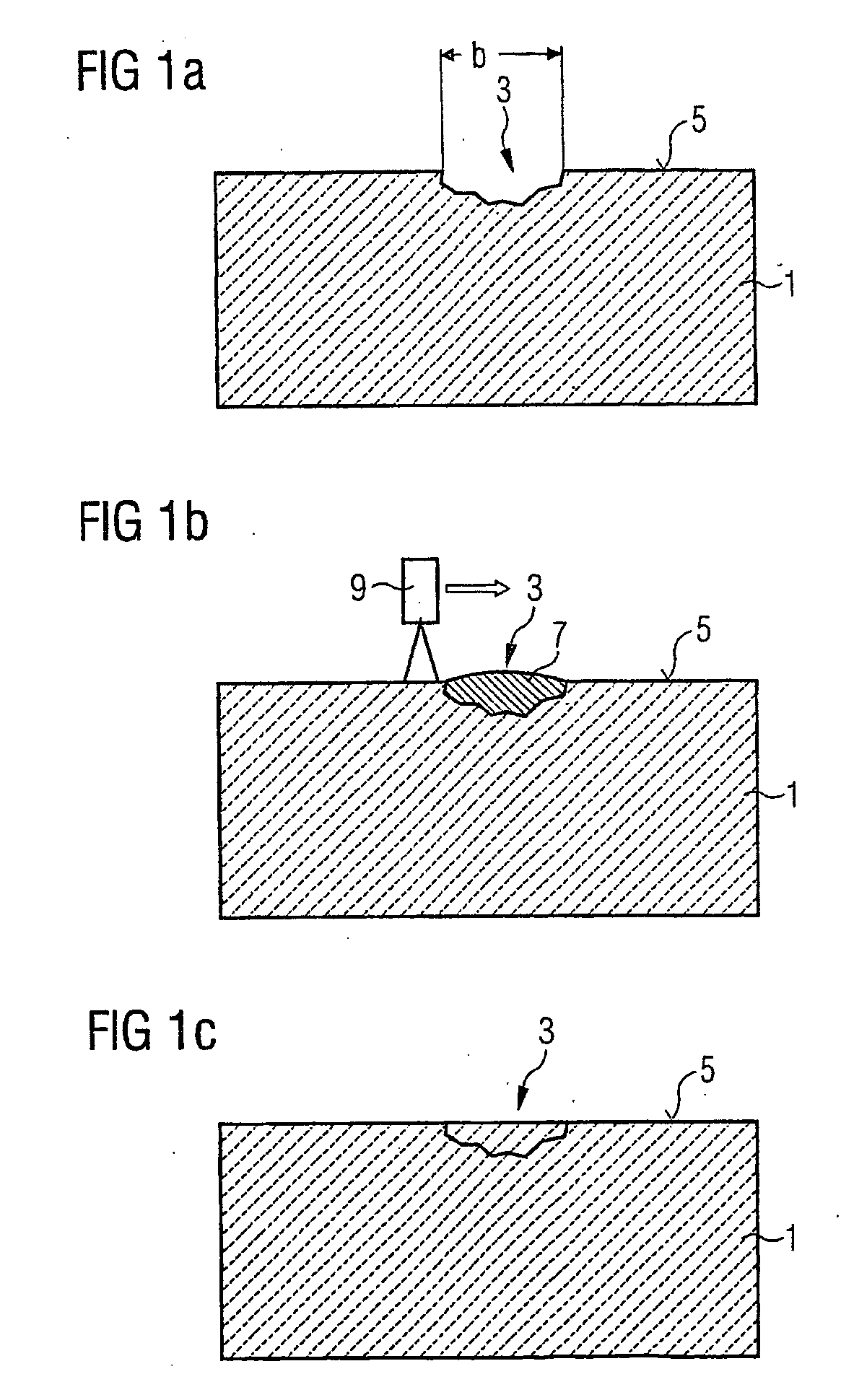

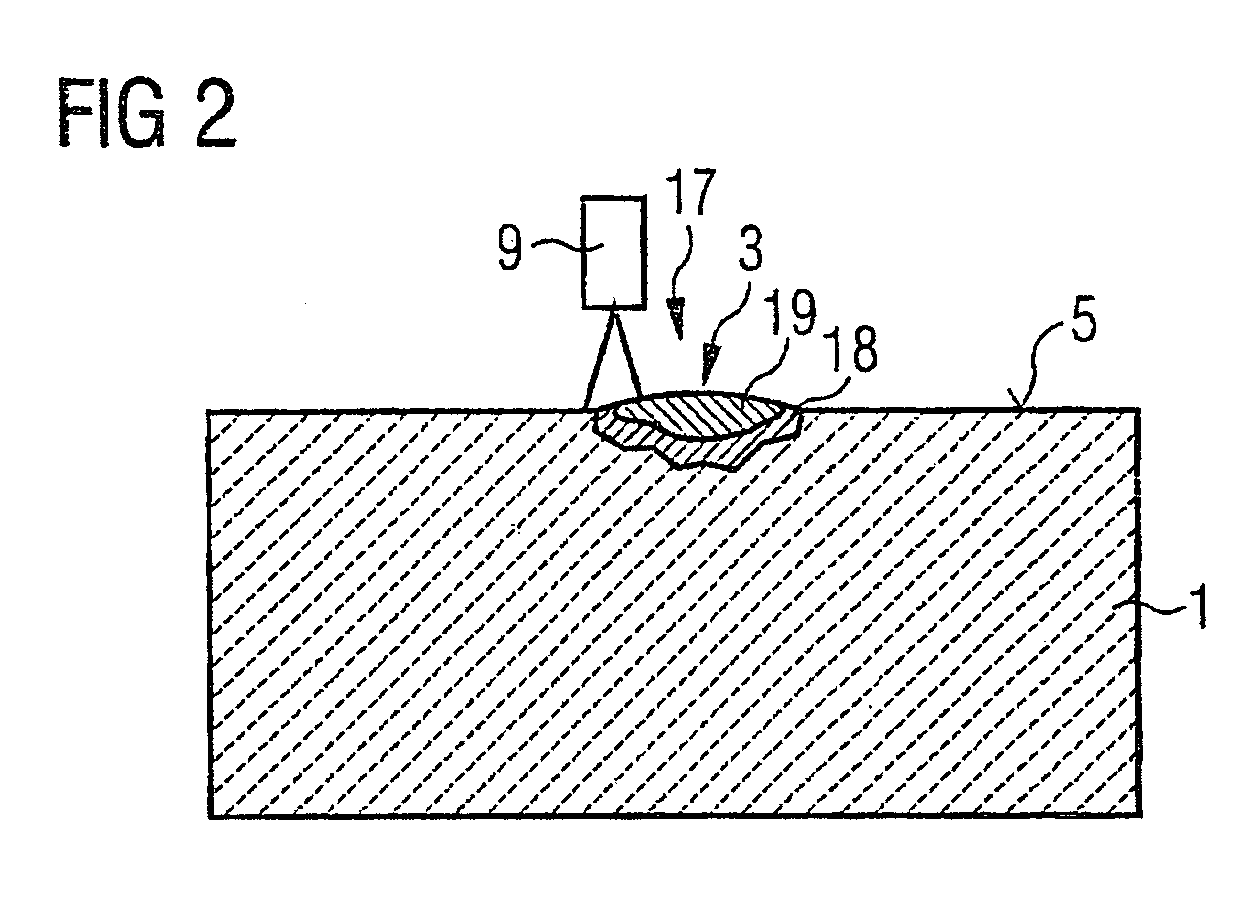

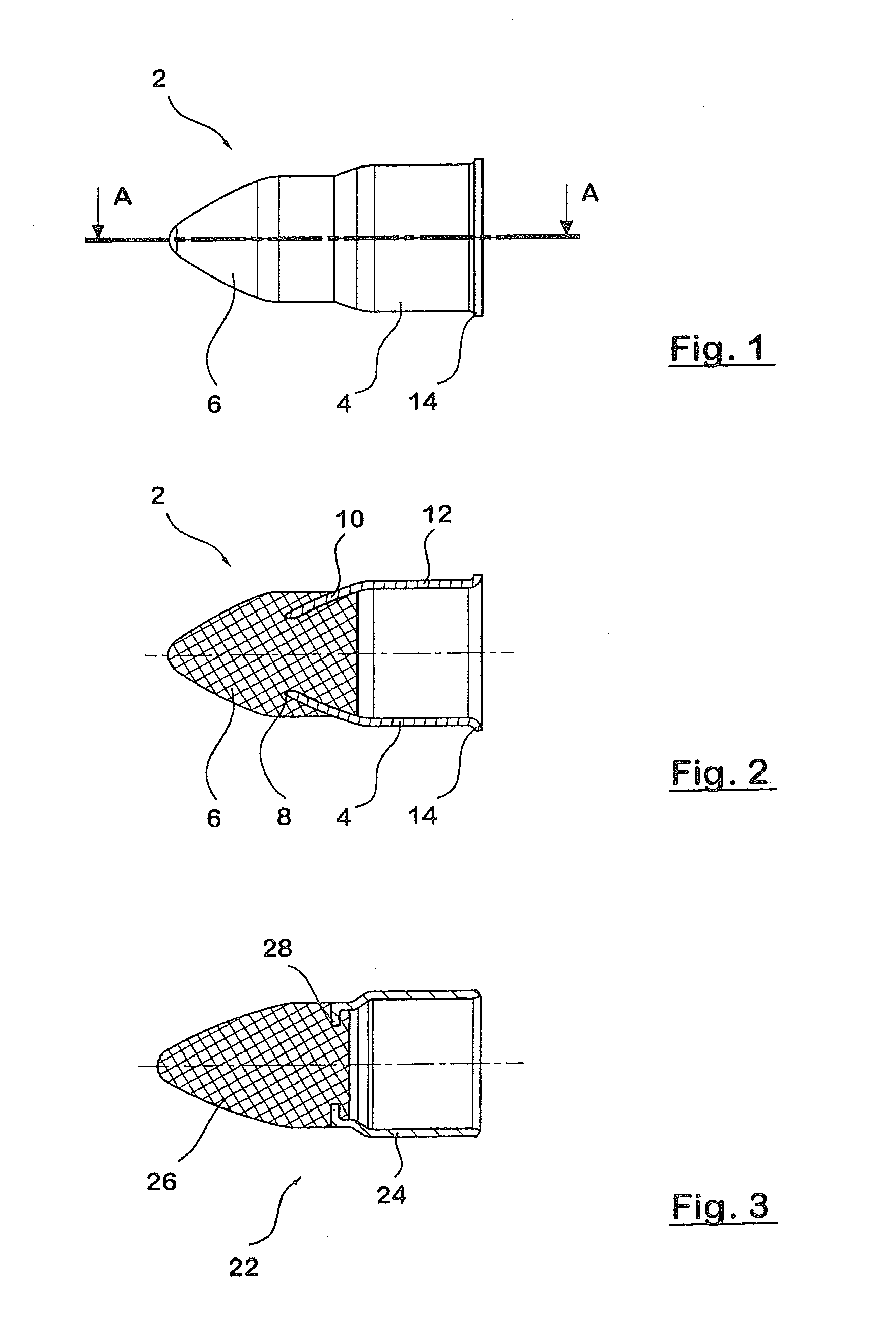

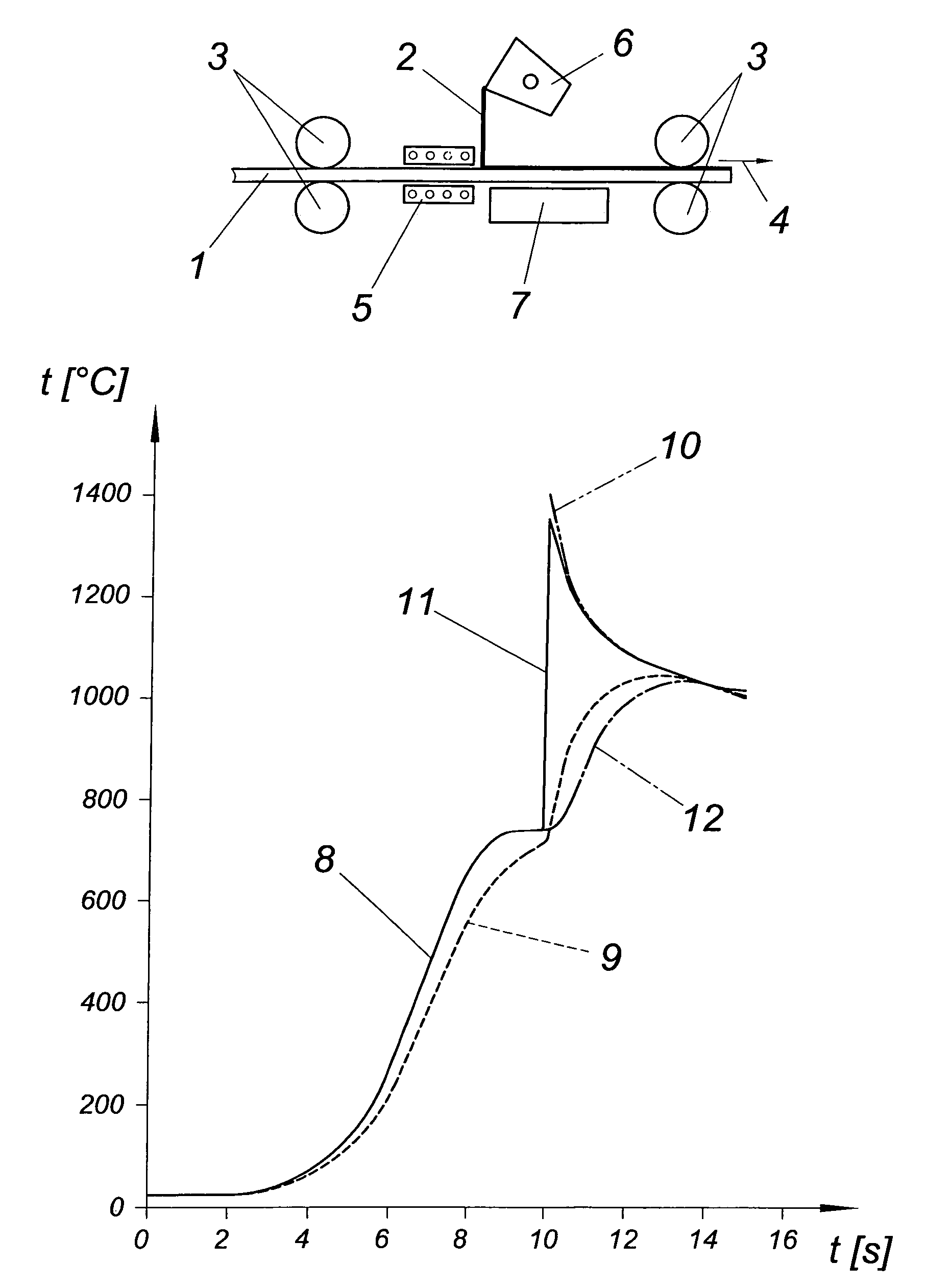

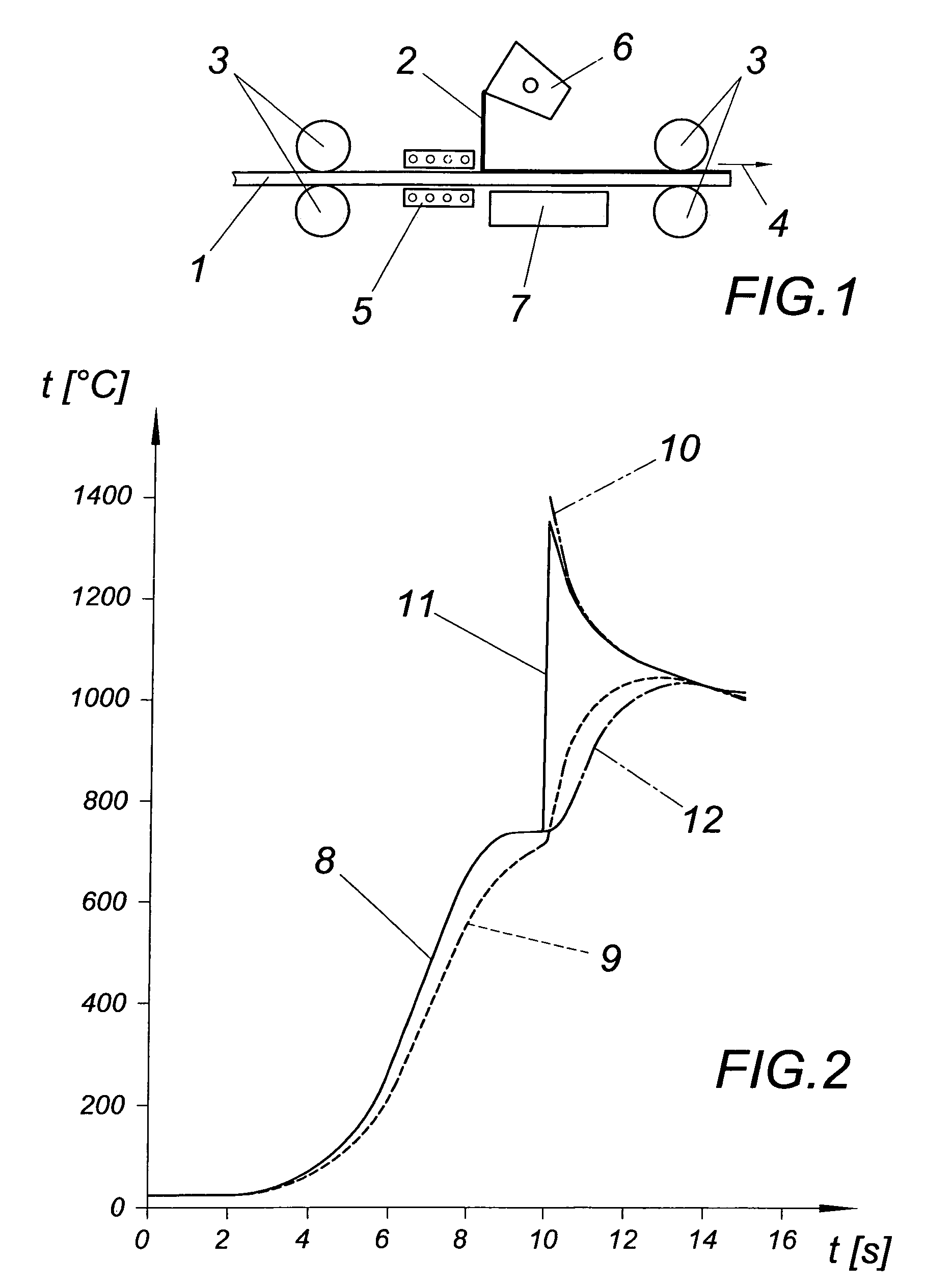

Process for repairing a component comprising a directional microstructure by setting a temperature gradient during the laser heat action, and a component produced by such a process

InactiveUS8141769B2Improve material performanceHigh strengthTurbinesSoldering apparatusTemperature gradientMaterials science

In one aspect, a repair method for repairing components comprising a base material with a directed microstructure is provided. The repair is performed in such a way that the repaired location correspondingly has a directed microstructure like the surrounding base material. A solder is applied in the region of a location to be repaired and is soldered to the component via heat exposure, a temperature gradient, i.e., for instance a temperature variation from a higher temperature to a lower temperature, is thereby produced in the region of the location to be repaired.

Owner:SIEMENS AG

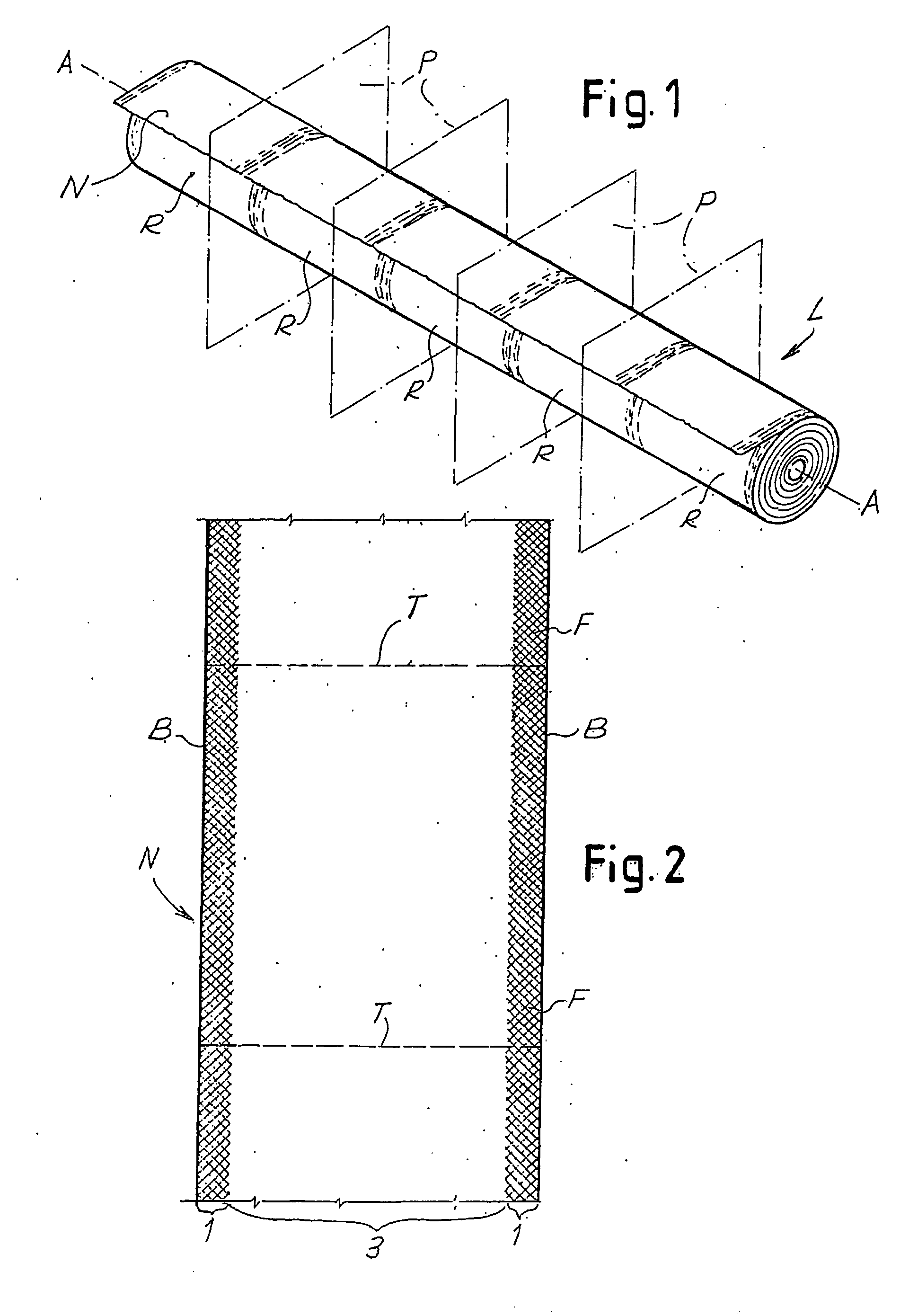

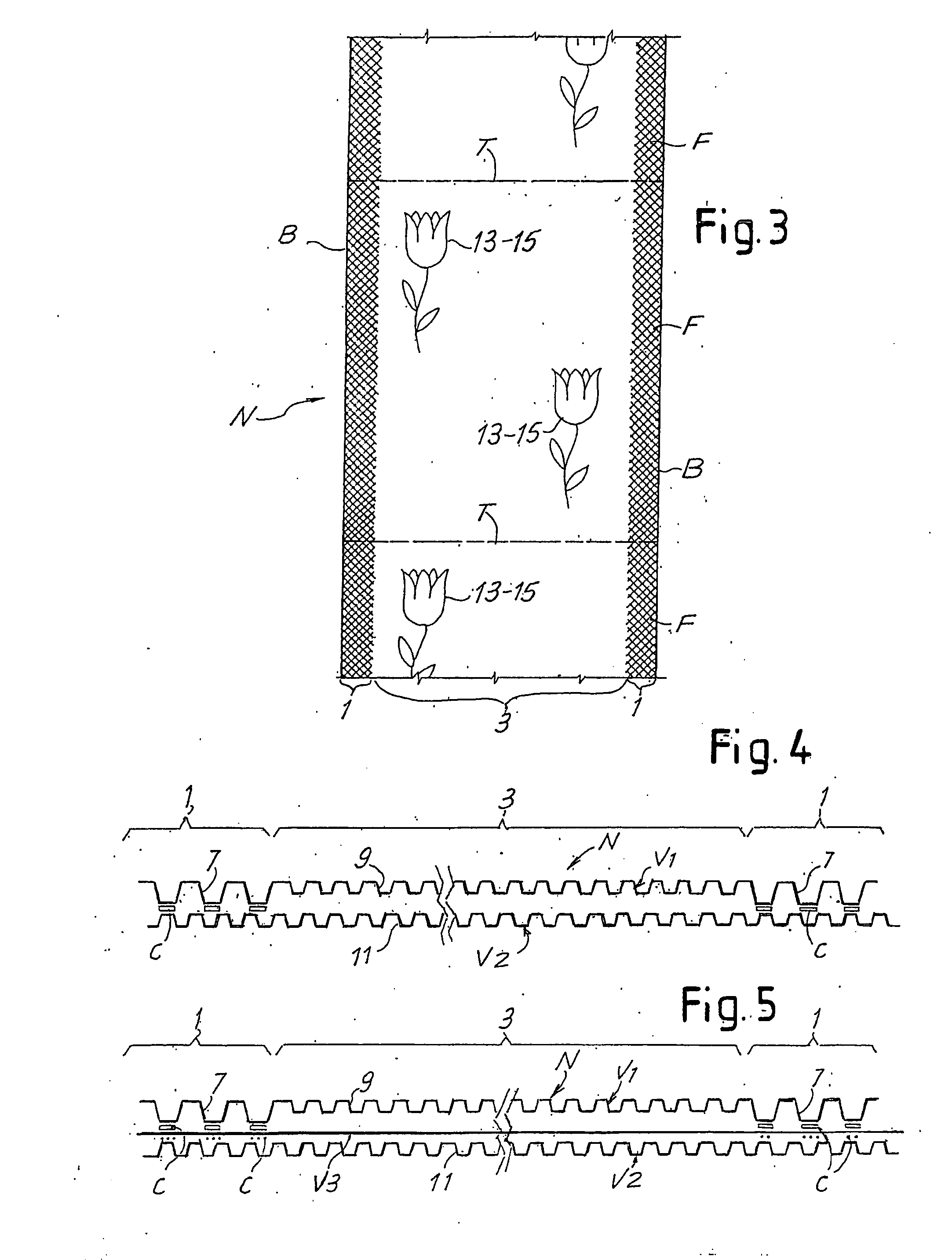

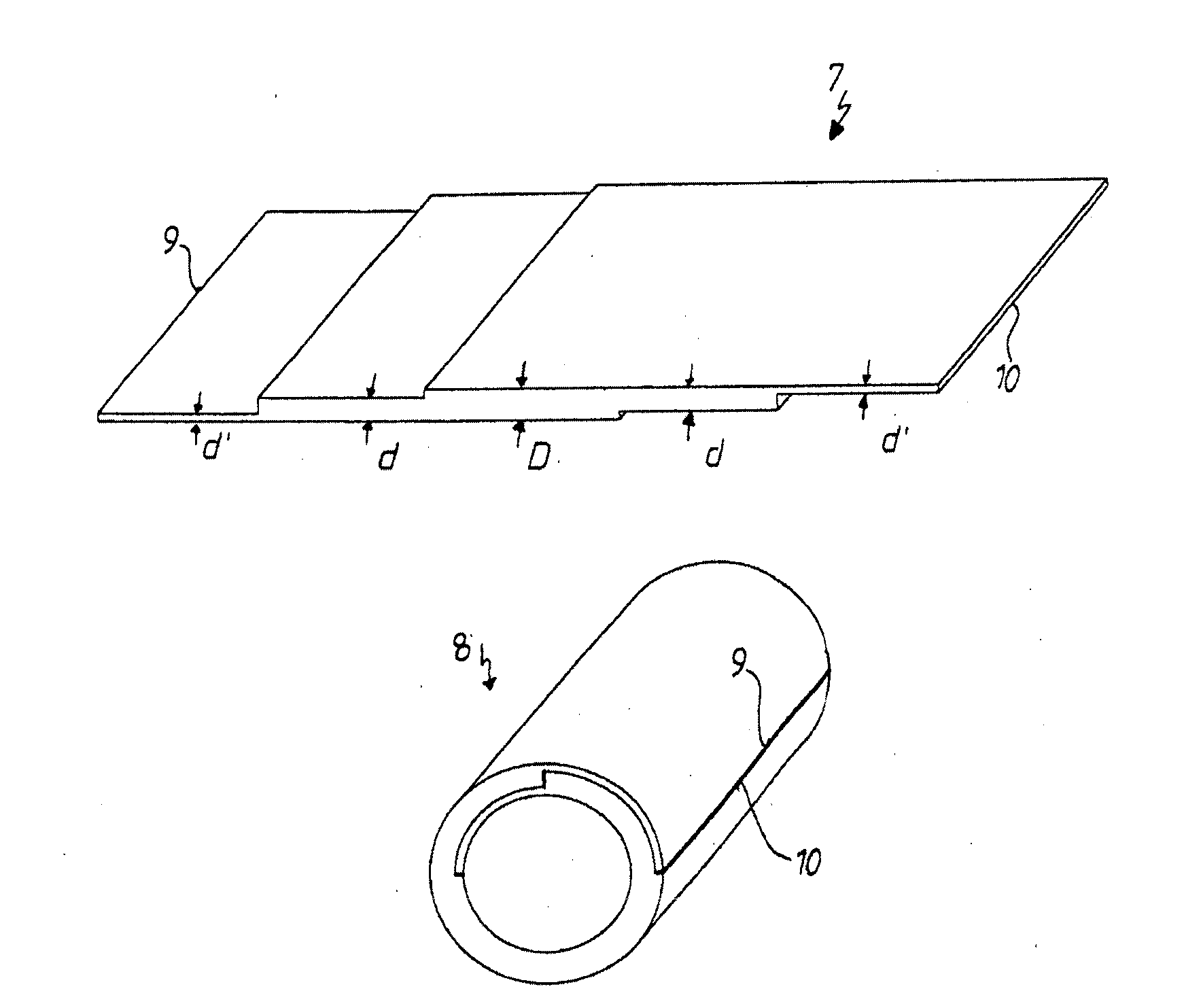

Sheet Product Comprising at Least Two Plies Joined by Gluing with Non-Uniform Distribution of the Glue

InactiveUS20070264461A1Reduce absorptionReduction of consequencesStampsFlexible coversLongitudinal bandsEngineering

The sheet product, such as paper, wound in a roll, comprises at least two plies (V1, V2) joined together by gluing, at least one of which is embossed. The product has longitudinal bands or areas (1, 3) which are characterized by a different quantity of glue, with more glue in proximity to the edges.

Owner:FABIO PERINI SPA

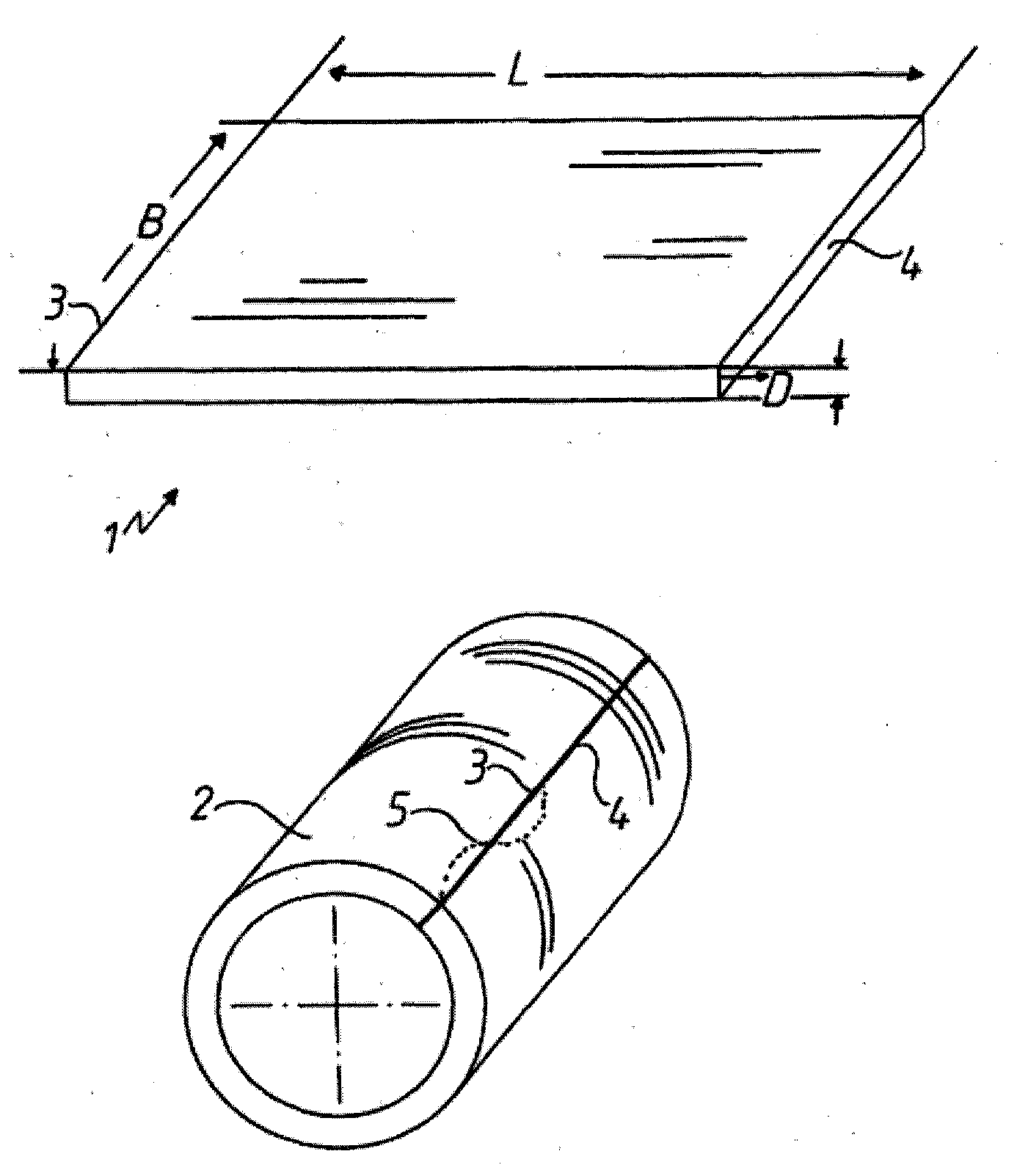

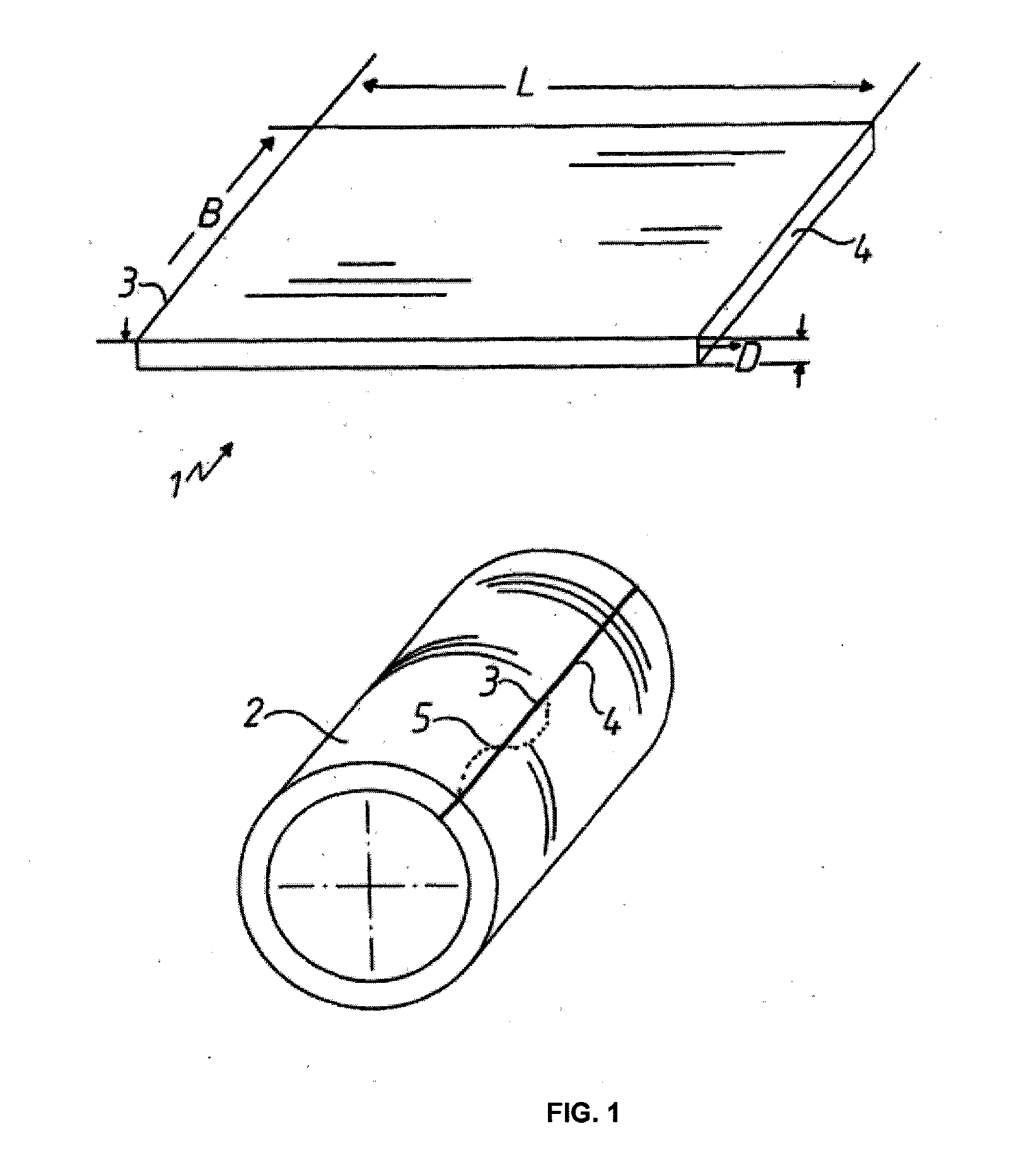

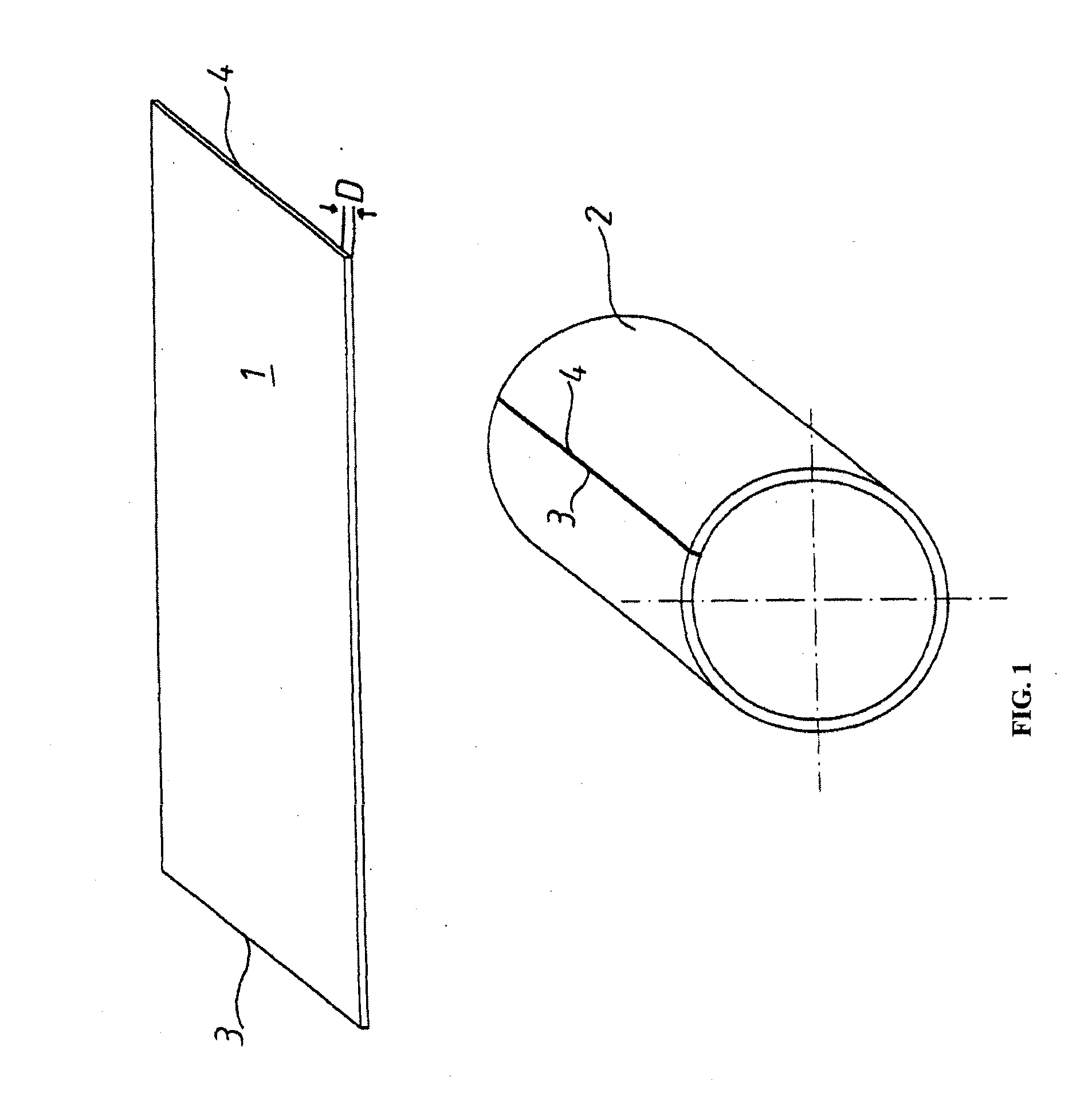

Method for producing metal elements, in particular sealing elements

InactiveUS20120070272A1Favorable joiningMaterial minimizationPump componentsMetal-working feeding devicesTurbochargerForming processes

A method for producing metallic elements, and more particularly sealing elements, wherein a sheet metal strip or a foil strip having a predefinable length, width, and thickness is generated and the sheet metal strip or foil strip is formed to obtain a tube, the mutually opposing end regions or parts, or the entire contact surface of the sheet metal strip or foil strip, are connected to each other non-positively or positively or by bonding, or combinations thereof, and the entire length of the tube, or portions thereof, is subjected to a mechanical shape-forming process so that predefinable contours are introduced into the outer or inner circumferential surface of the tube in defined locations by a means, and the tube is divided into an appropriate number of individual elements, and in particular sealing elements, especially sealing rings for turbochargers.

Owner:FEDERAL MOGUL SEALING SYST

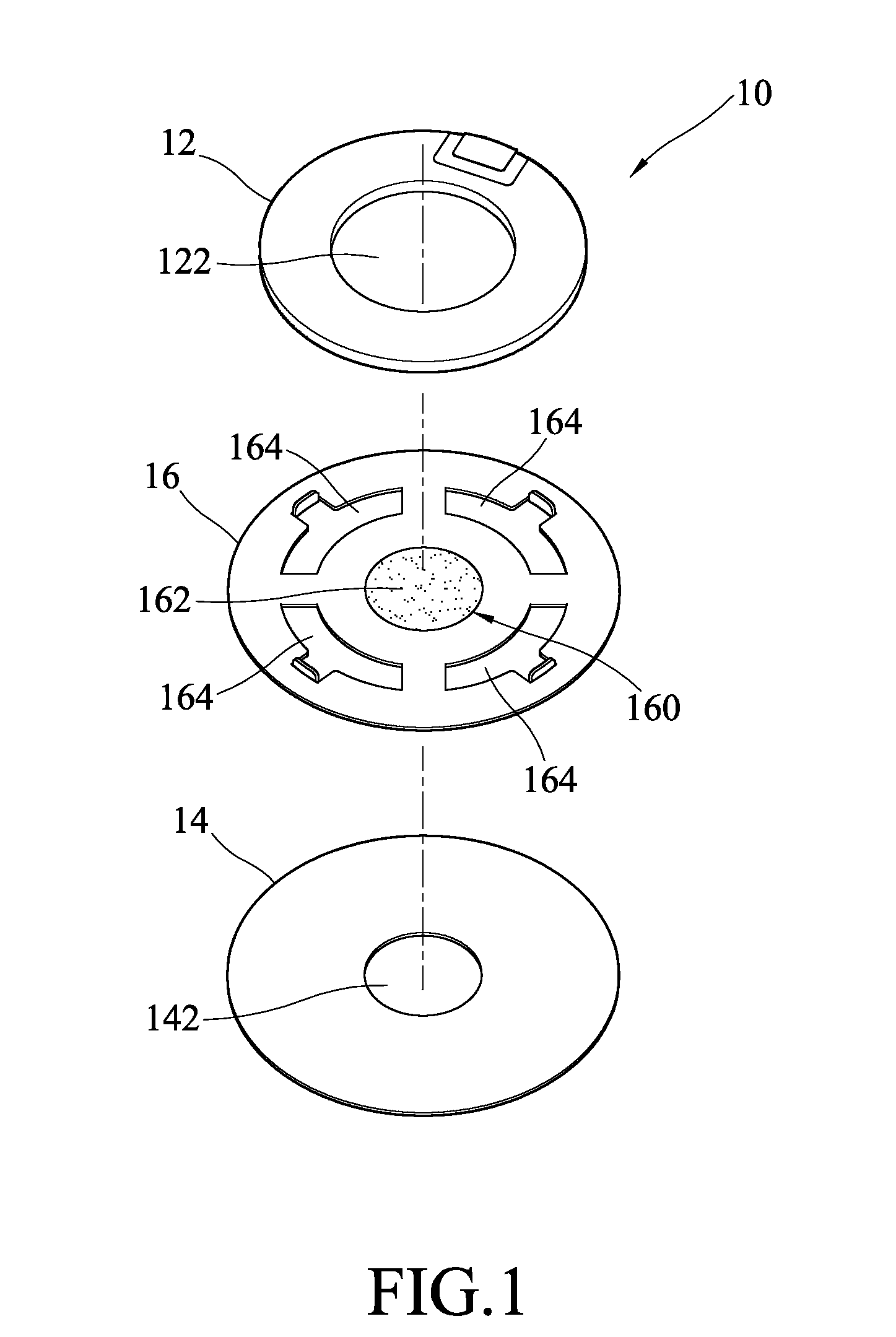

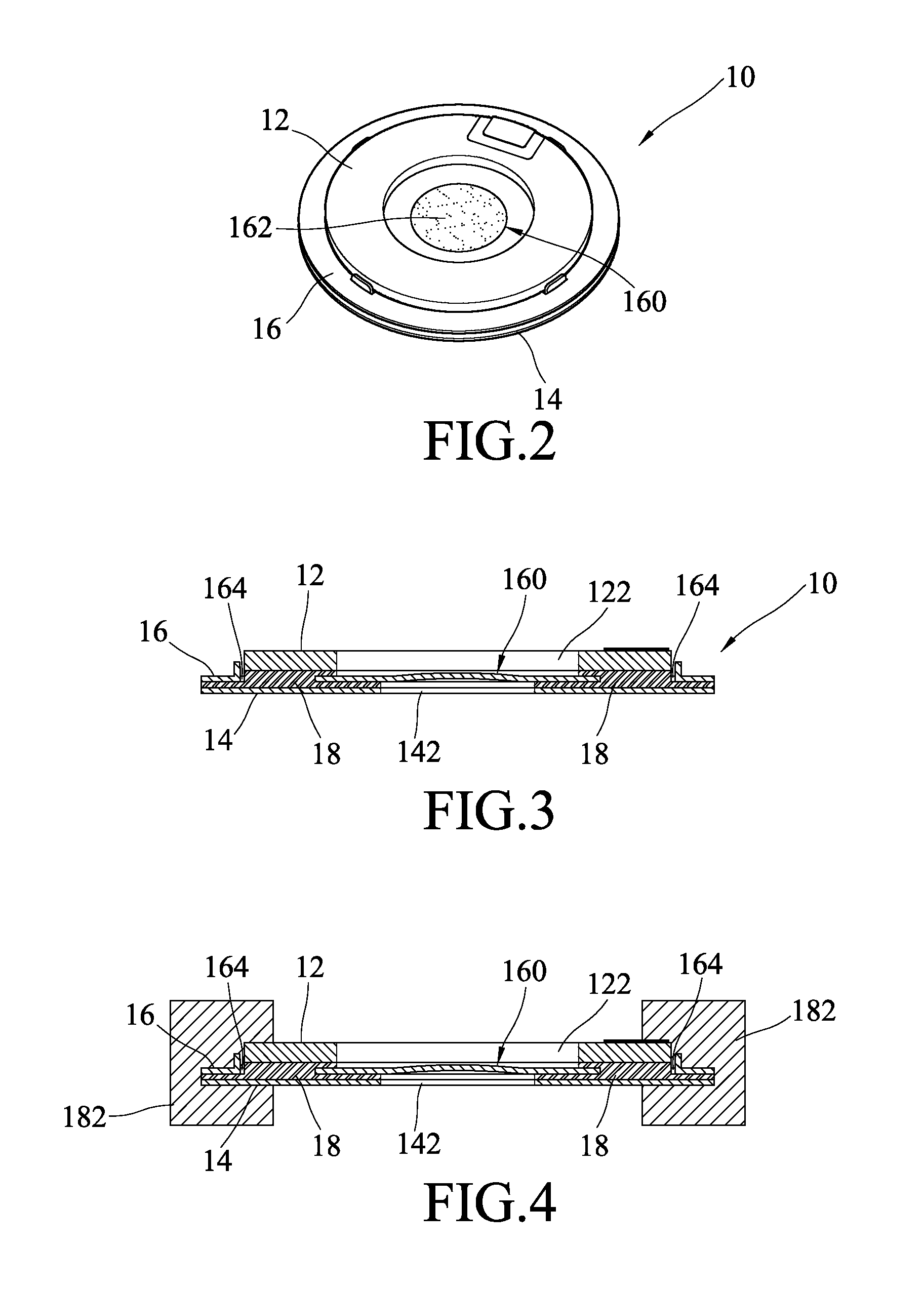

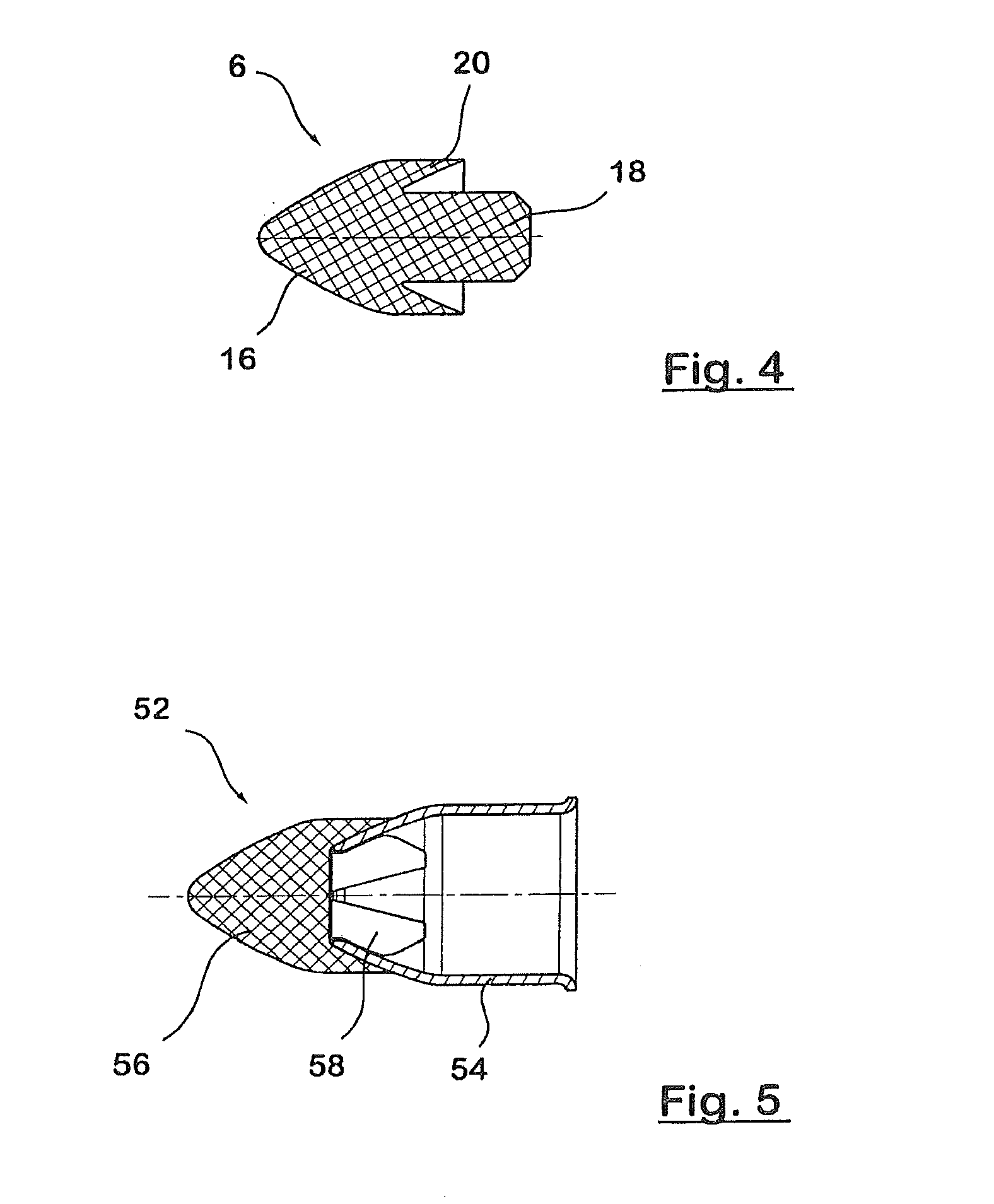

Microdroplet Generation Apparatus

InactiveUS20100213274A1Improve atomizationFavorable joiningMovable spraying apparatusSpray nozzlesEngineeringNozzle

A microdroplet generation apparatus comprises an oscillation plate, a connection plate, a nozzle disc and a bonding material, wherein the nozzle disc is interposed between the oscillation plate and connection plate, and wherein the oscillation plate, connection plate and nozzle disc are joined with the bonding material. The oscillation plate and the connection plate respectively have a first through-hole and a second through-hole corresponding to each other. The nozzle disc has injection holes on the area corresponding to the first and second through-holes. The nozzle disc has via-holes on the area not corresponding to the first through-hole and the second through-hole. The bonding material passes through the via-holes of the nozzle disc to join the oscillation plate and the connection plate and fasten the nozzle disc to between the oscillation plate and the connection plate. Thus, vibration energy can be effectively transmitted from the vibration plate to the nozzle disc.

Owner:HEALTH & LIFE CO LTD

Process for Repairing a Component Comprising a Directional Microstructure by Setting a Temperature Gradient During the Laser Heat Action, and a Component Produced by Such a Process

InactiveUS20100000976A1Improve material performanceHigh strengthTurbinesSoldering apparatusRepair methodTemperature gradient

In one aspect, a repair method for repairing components comprising a base material with a directed microstructure is provided. The repair is performed in such a way that the repaired location correspondingly has a directed microstructure like the surrounding base material. A solder is applied in the region of a location to be repaired and is soldered to the component via heat exposure, a temperature gradient, i.e., for instance a temperature variation from a higher temperature to a lower temperature, is thereby produced in the region of the location to be repaired.

Owner:SIEMENS AG

Method for producing metal sealing elements

InactiveUS20120073343A1Easy to operateSimple toolingEngine sealsArc welding apparatusMetalIntermediate product

A method for producing metallic sealing and stopper elements for flat gaskets by winding or rolling at least one metallic, sheet metal- or foil-like base body to obtain a tube as an intermediate product, bringing the mutually opposing end regions or parts, or the entire contact surface of the tube, into operative connection with each other by way of bonding, non-positive or positive joining techniques, or combinations thereof, contouring the tube or tube sections generated therefrom at least in some regions, and severing at least one annular or disk-shaped component in order to generate a sealing or stopper element in the contoured region of the tube or tube section.

Owner:FEDERAL MOGUL SEALING SYST

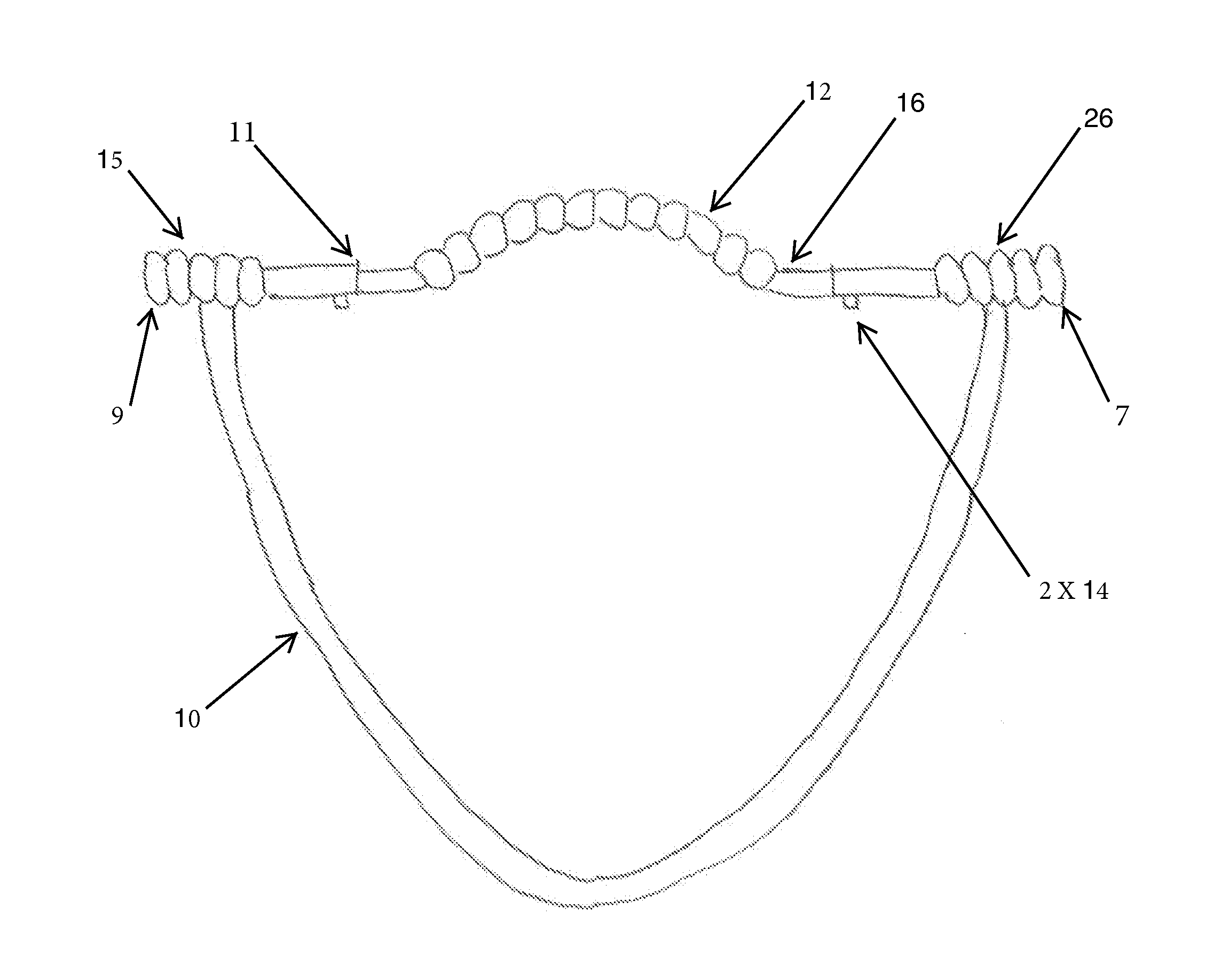

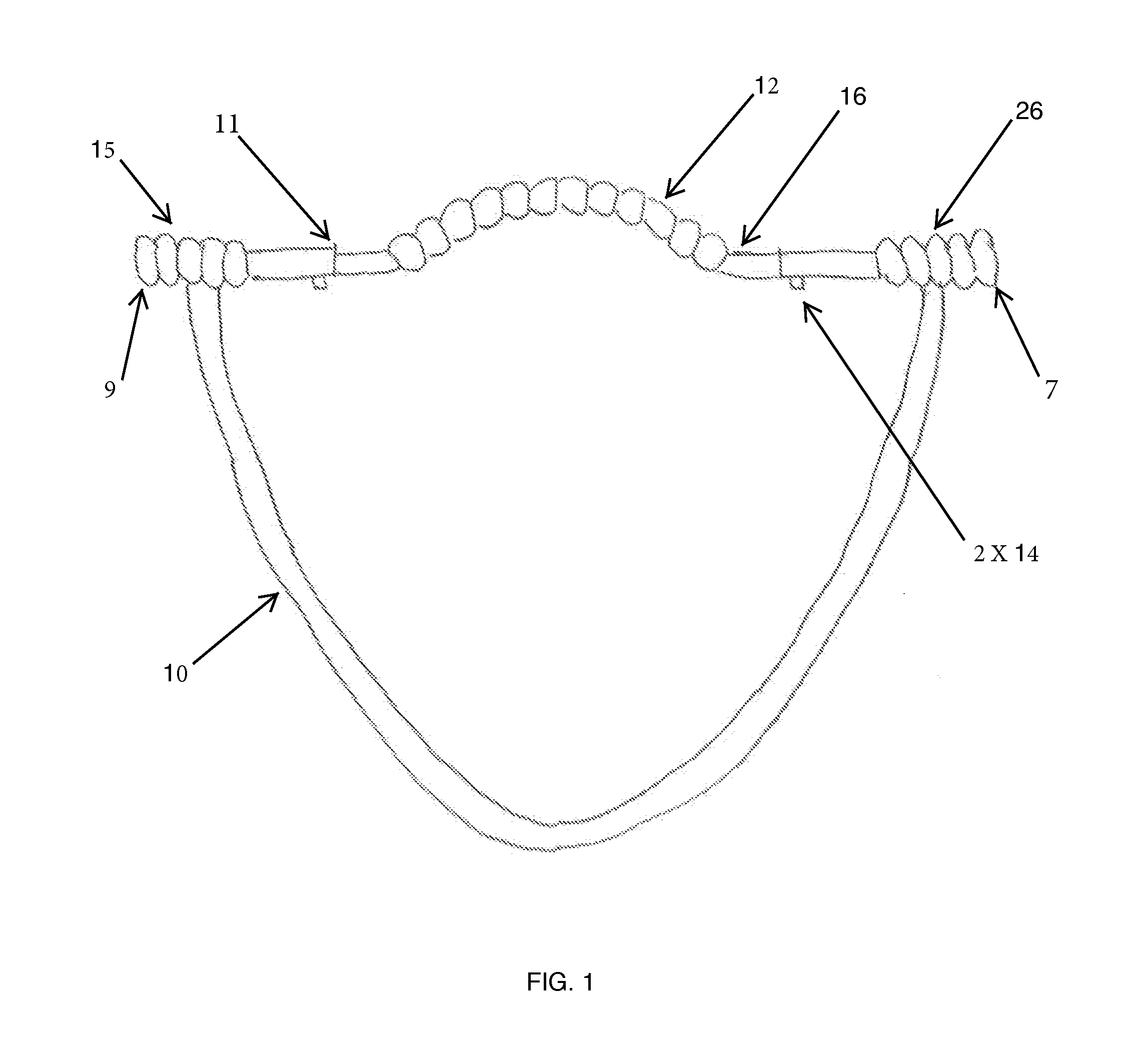

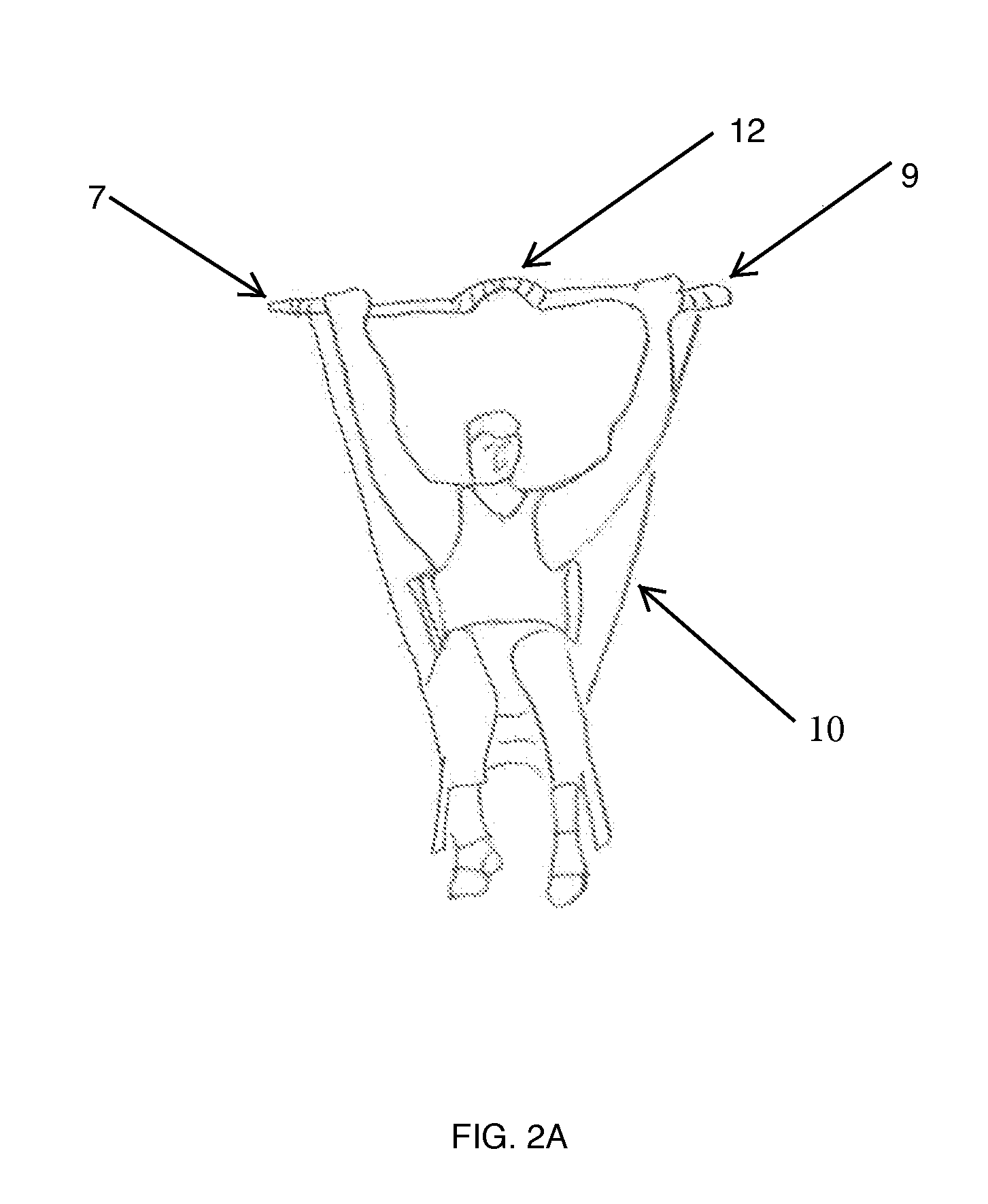

Apparatus for Multi-purpose Exercise

InactiveUS20160074692A1Effectively withstand concentrated stressReduce exposureResilient force resistorsMovement coordination devicesEngineeringAerobic exercise

The apparatus according to this invention involves connection of a tubular bar (7, 9) with gripping features for the hands and behind the neck, to a tension resistant elastic rope for performing various aerobic exercises. The tension resistant rope is guided through to an opening in the tubular bar (60) which then joins to a newly designed retainer (30). The retainer includes a hole (40) for the elastic rope to feed through. As part of the retainer assembly, a fastener (32) is used to couple the elastic rope to the retainer. The improvement of the retainer features an extruded rectangular cut (41) allowing a lightweight and more robust mechanical linkage between the elastic rope and the tubular handle.

Owner:WAYS OF WELLNESS

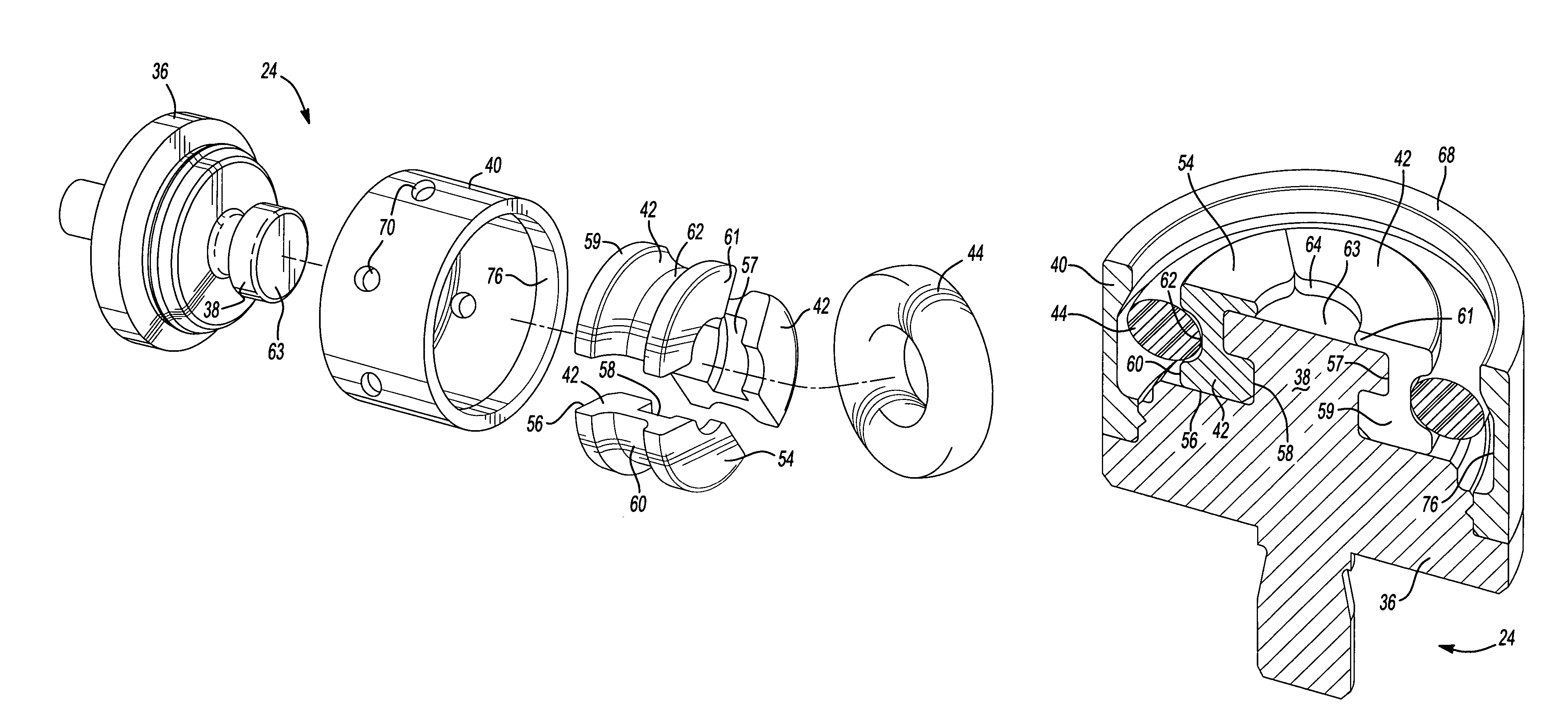

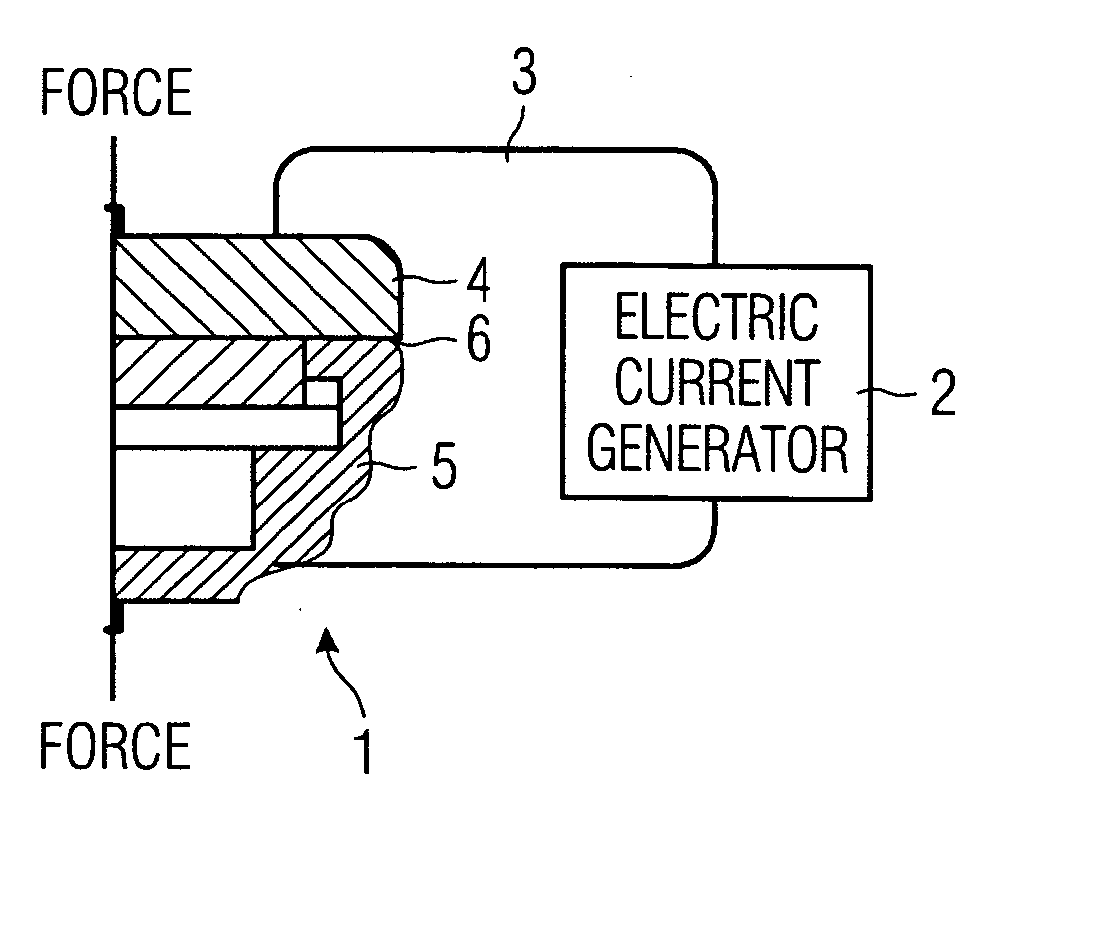

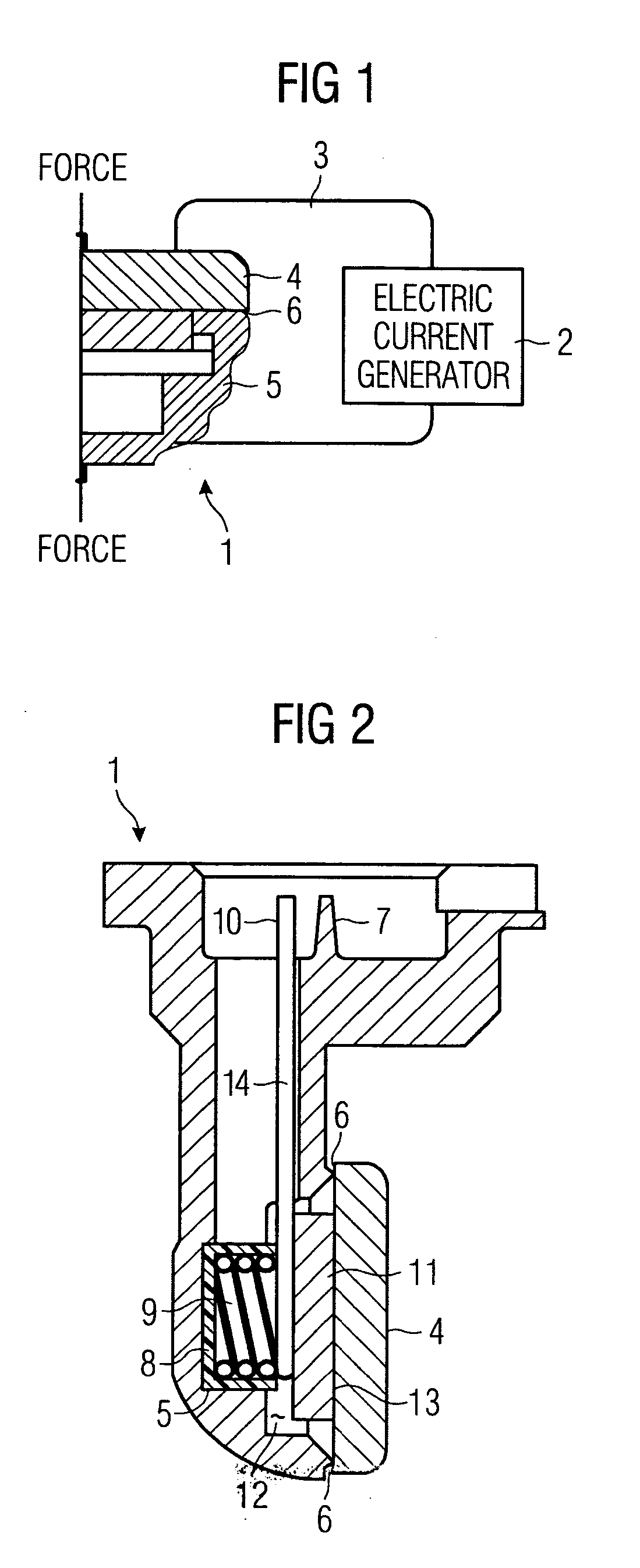

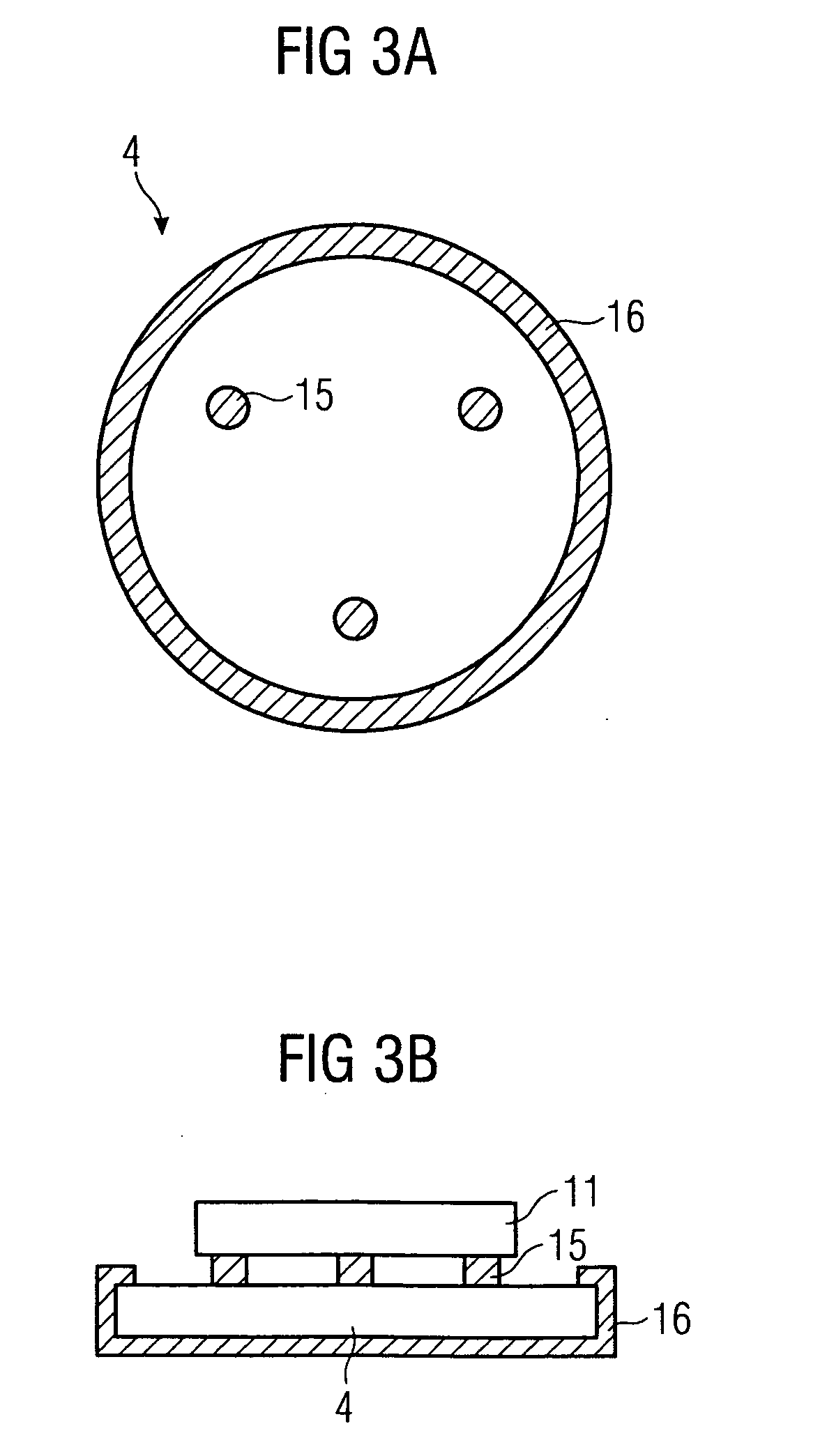

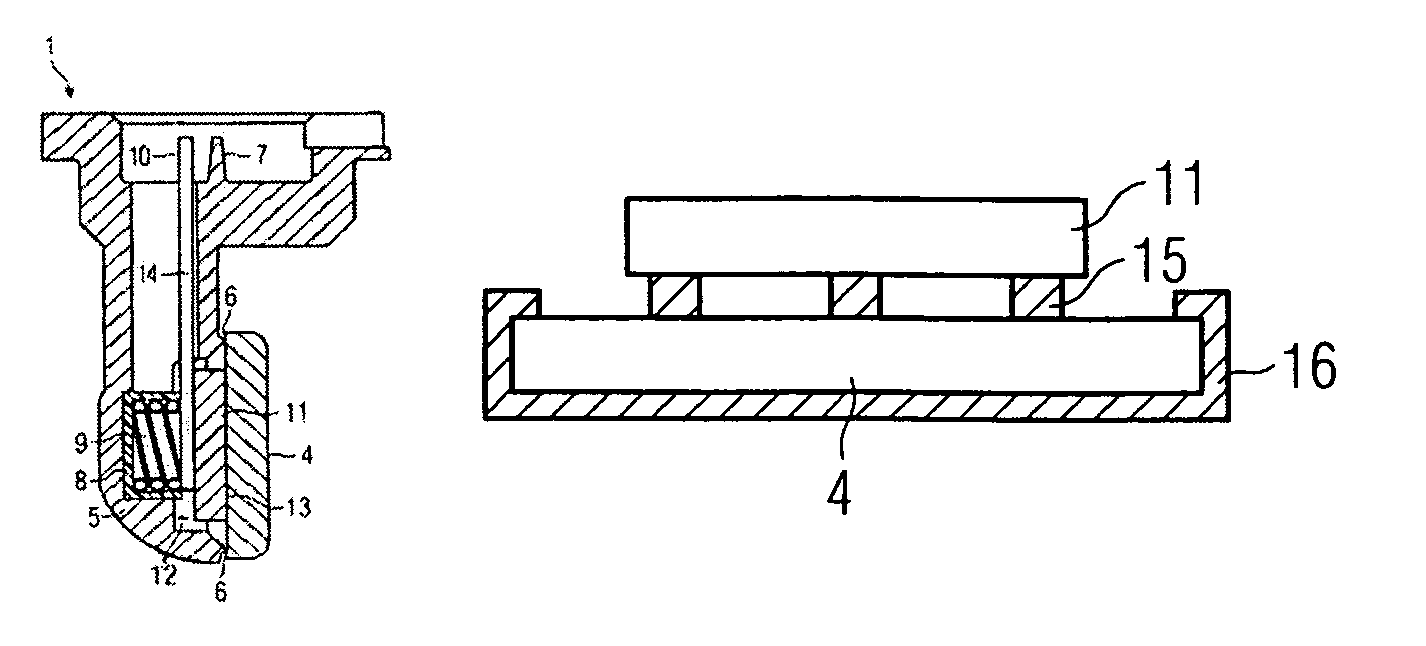

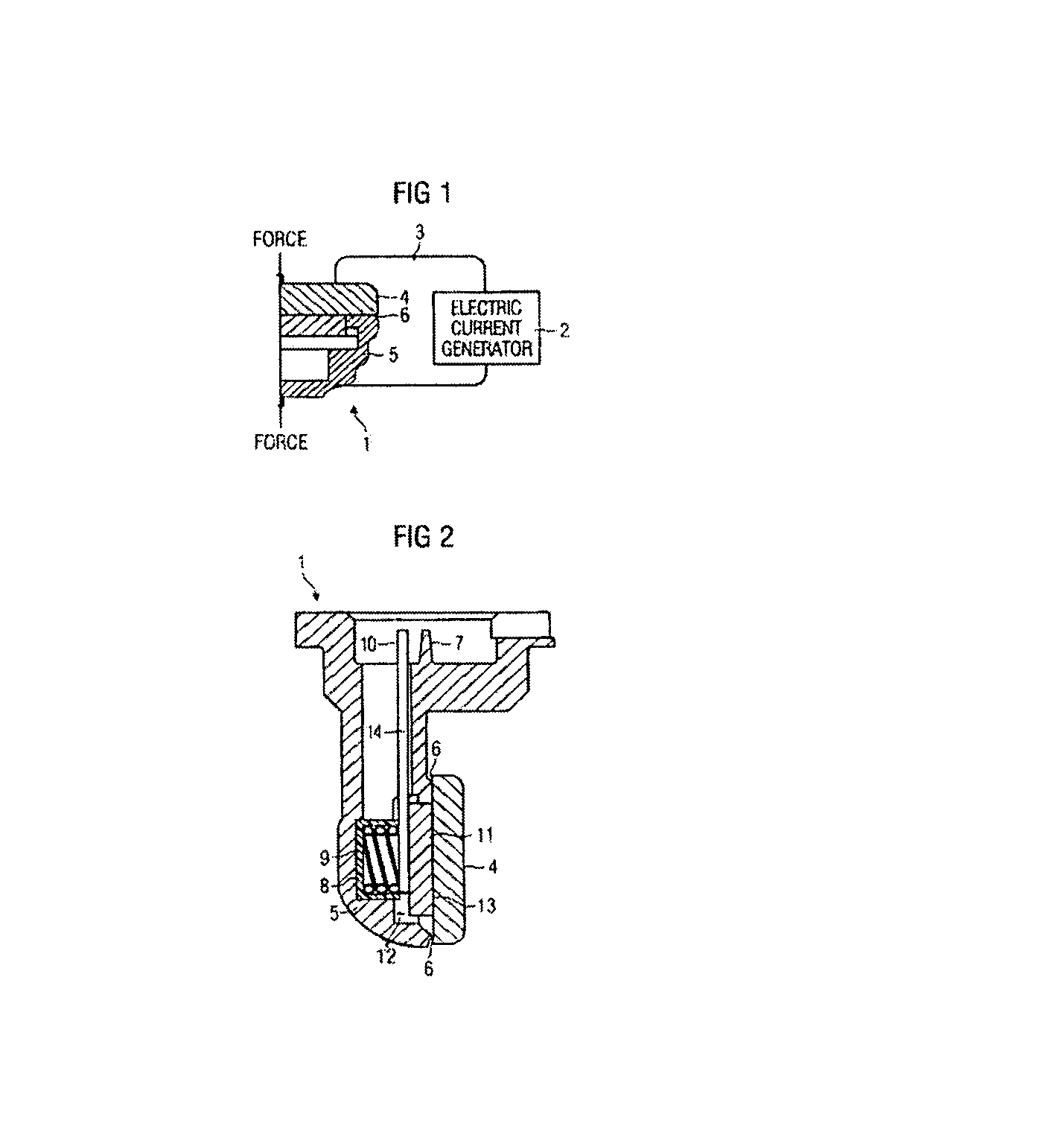

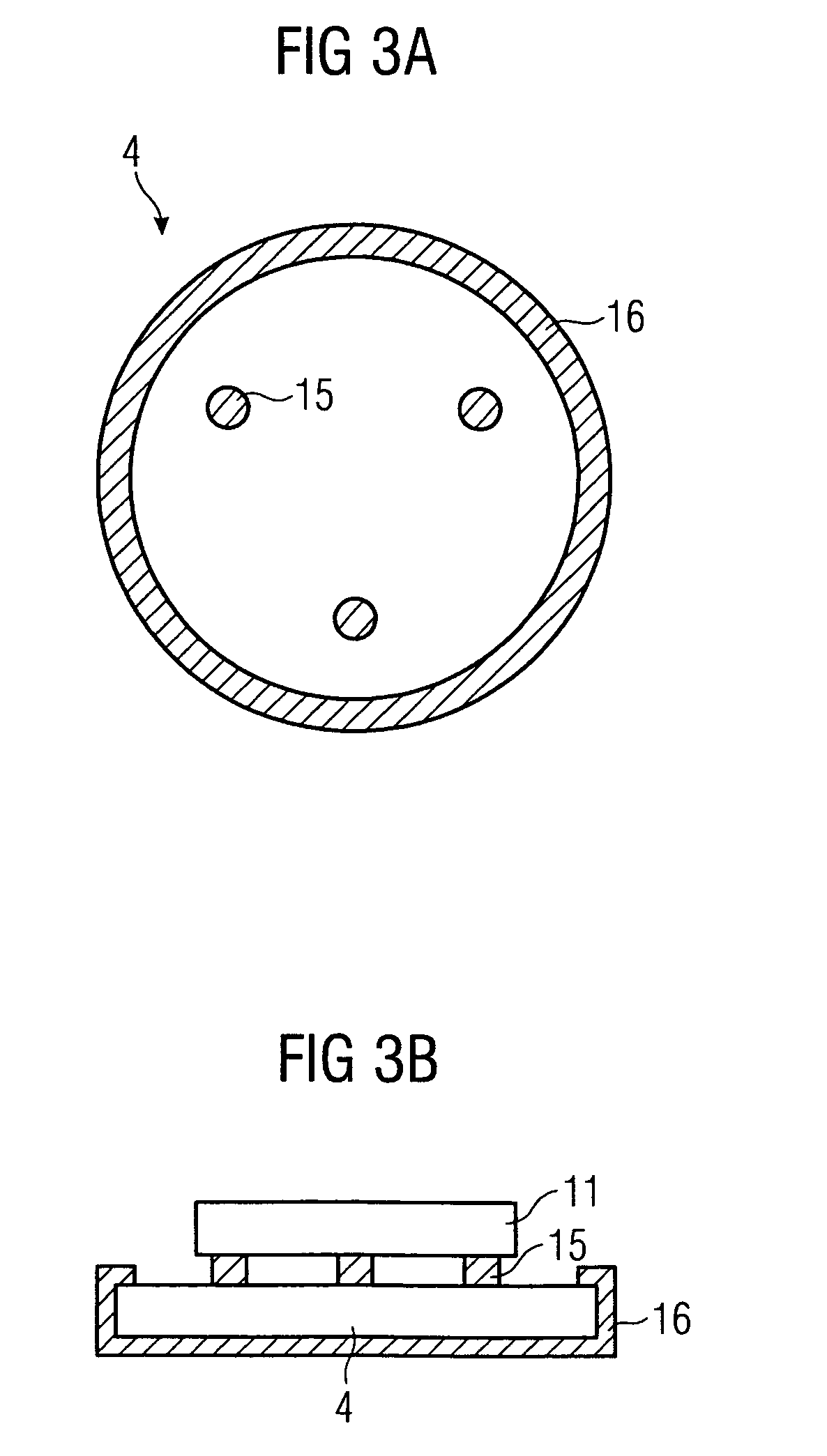

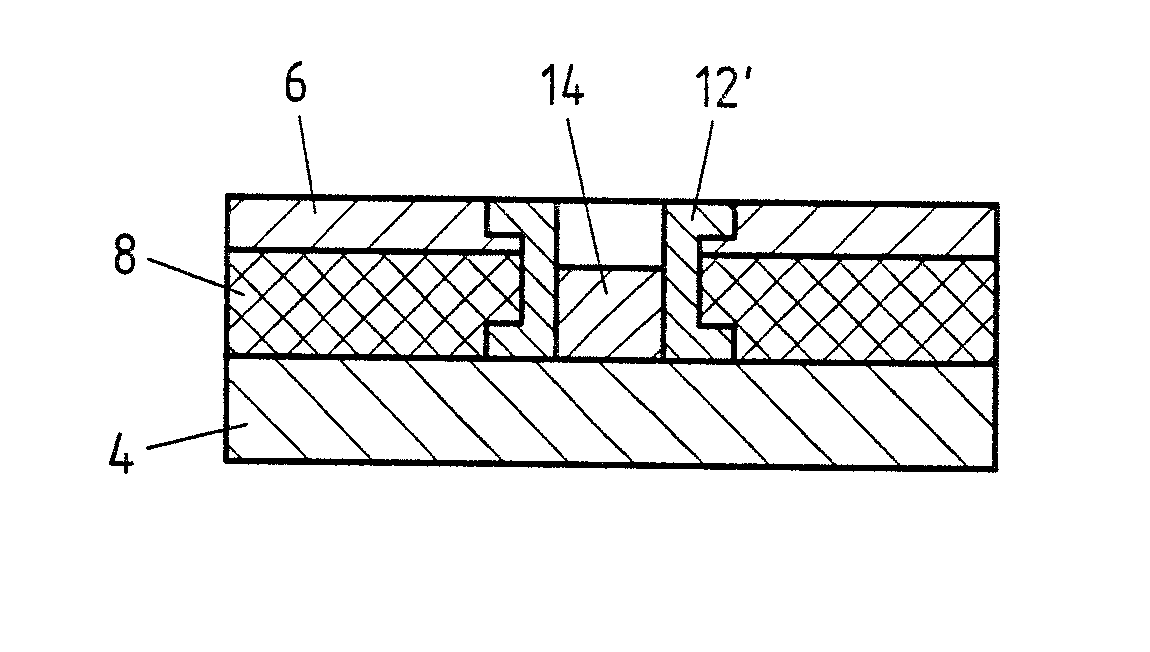

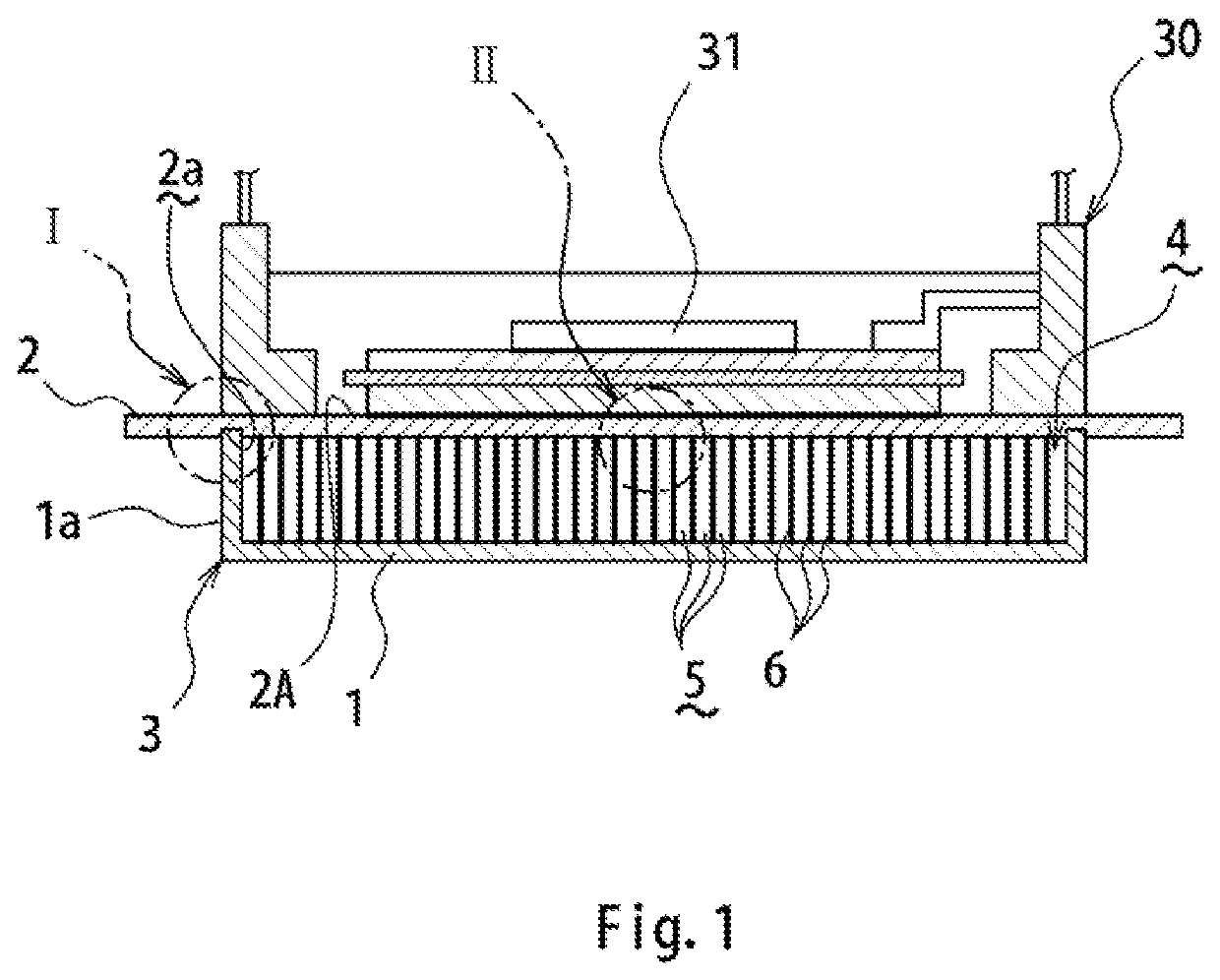

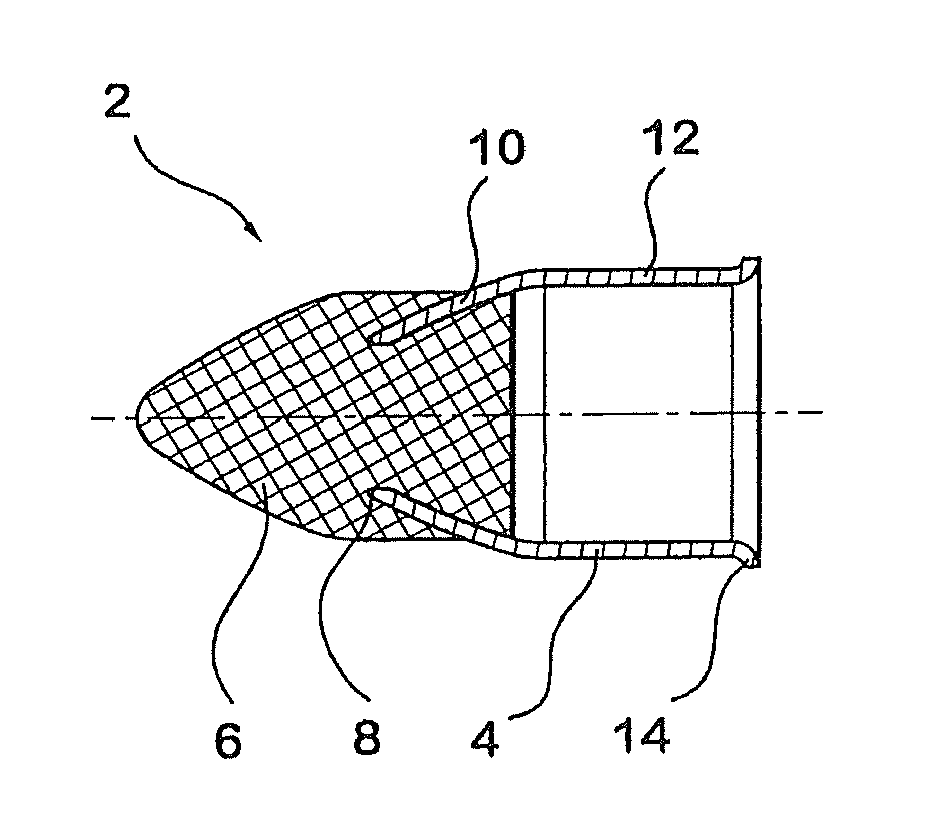

Ultrasonic transducer and method of joining an ultrasonic transducer

InactiveUS20050061084A1Low heat inputEasy to manufacturePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersUltrasonic sensorTransducer

The invention concerns an ultrasonic transducer, which is assembled from several parts. These parts are a protecting plate, a piezoelectric disc and a housing. Joining of the parts for transducers are normally done by means of TIG welding or laser welding, but these are relatively costly processes, which also has an impact on the transducer, especially the piezoelectric disc, due to the heat. In order to reduce the heat load and simultaneously simplify manufacturing an ultrasonic transducer is suggested, in which the protecting plate and the housing consists of electrically conducting materials of different kinds and where joining of housing and plate is done by using a mechanical force influence and an electrical current which flows through plate and housing. Also, a method for joining the parts of an ultrasonic transducer is described.

Owner:SIEMENS AG +1

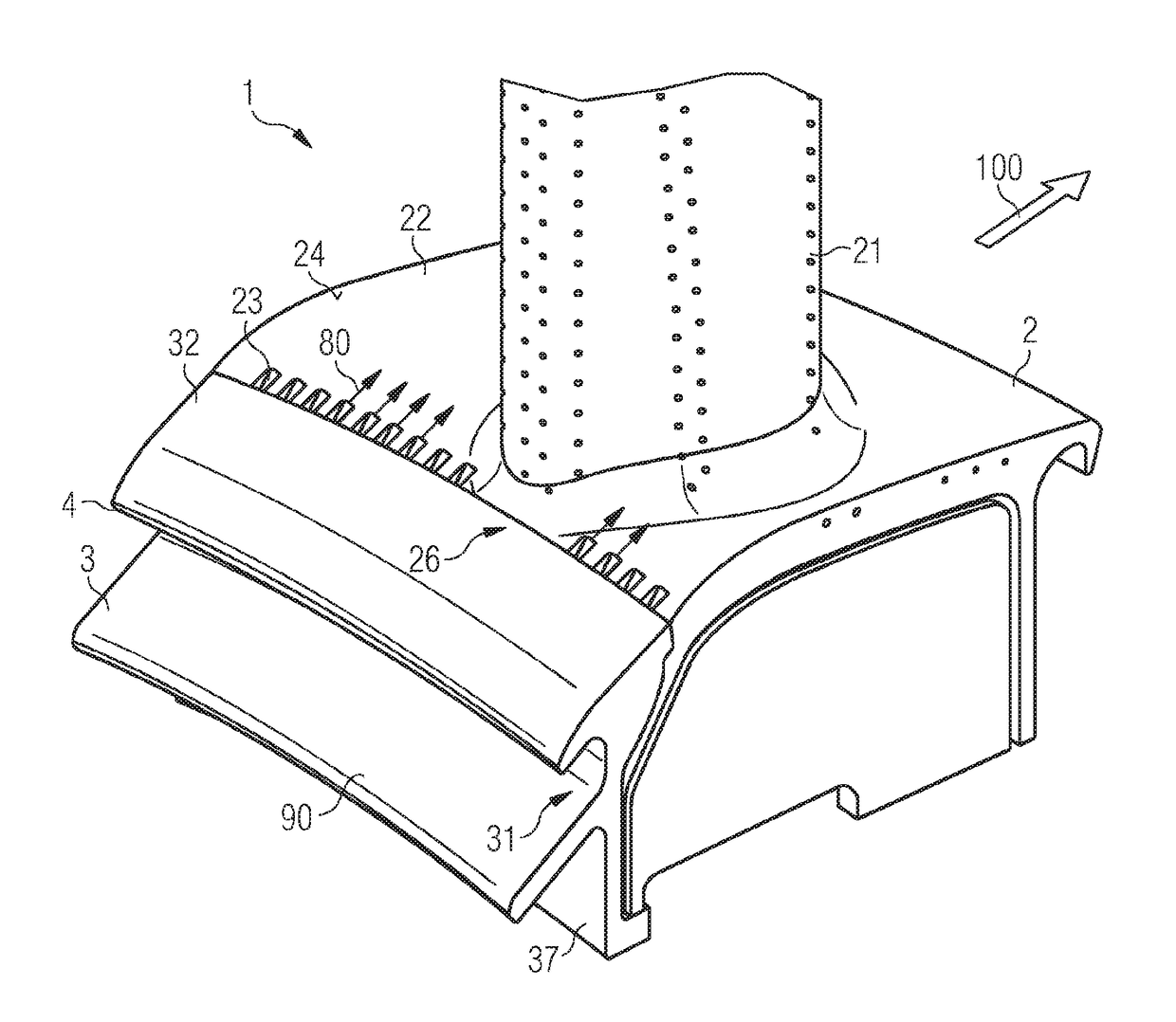

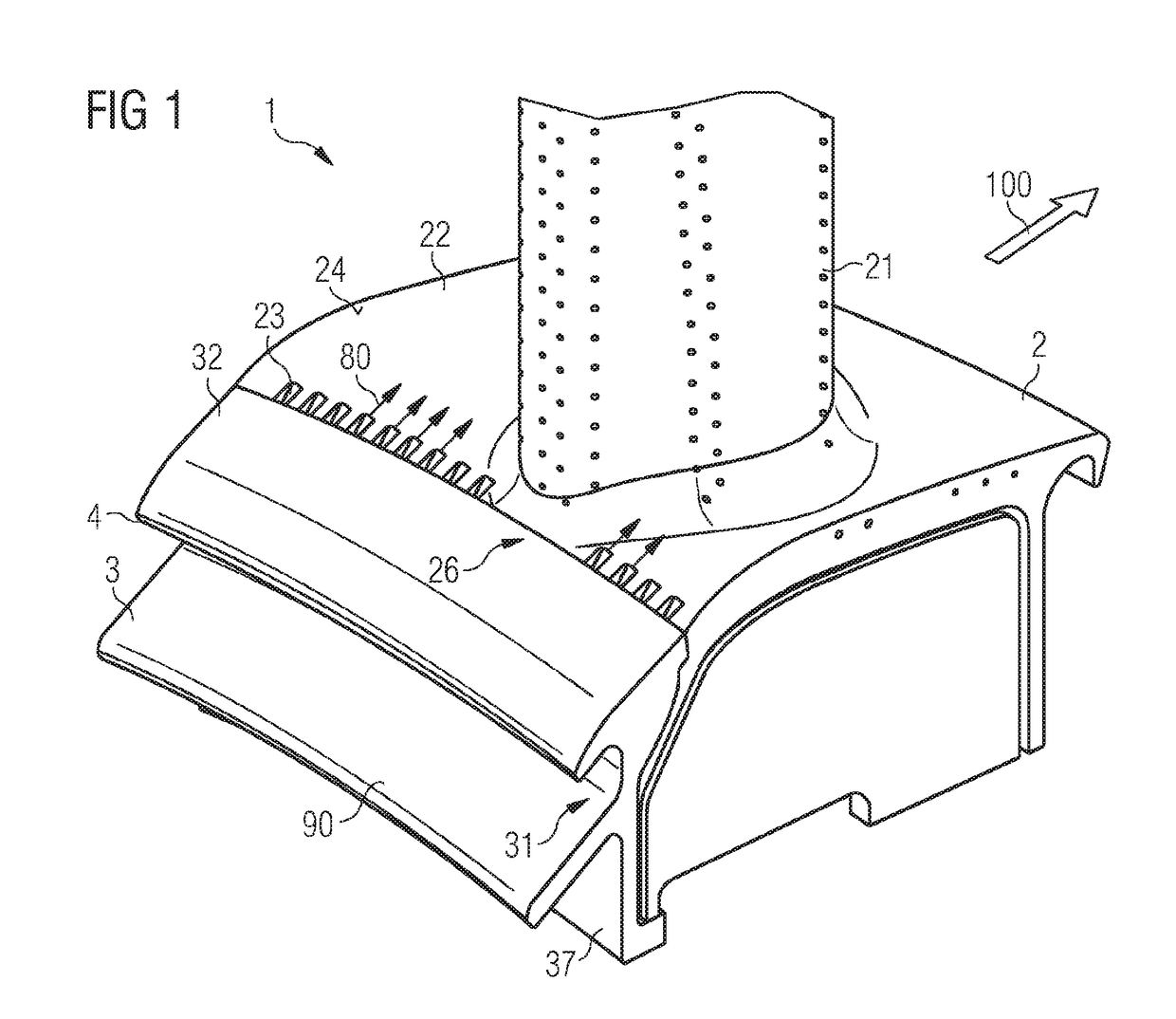

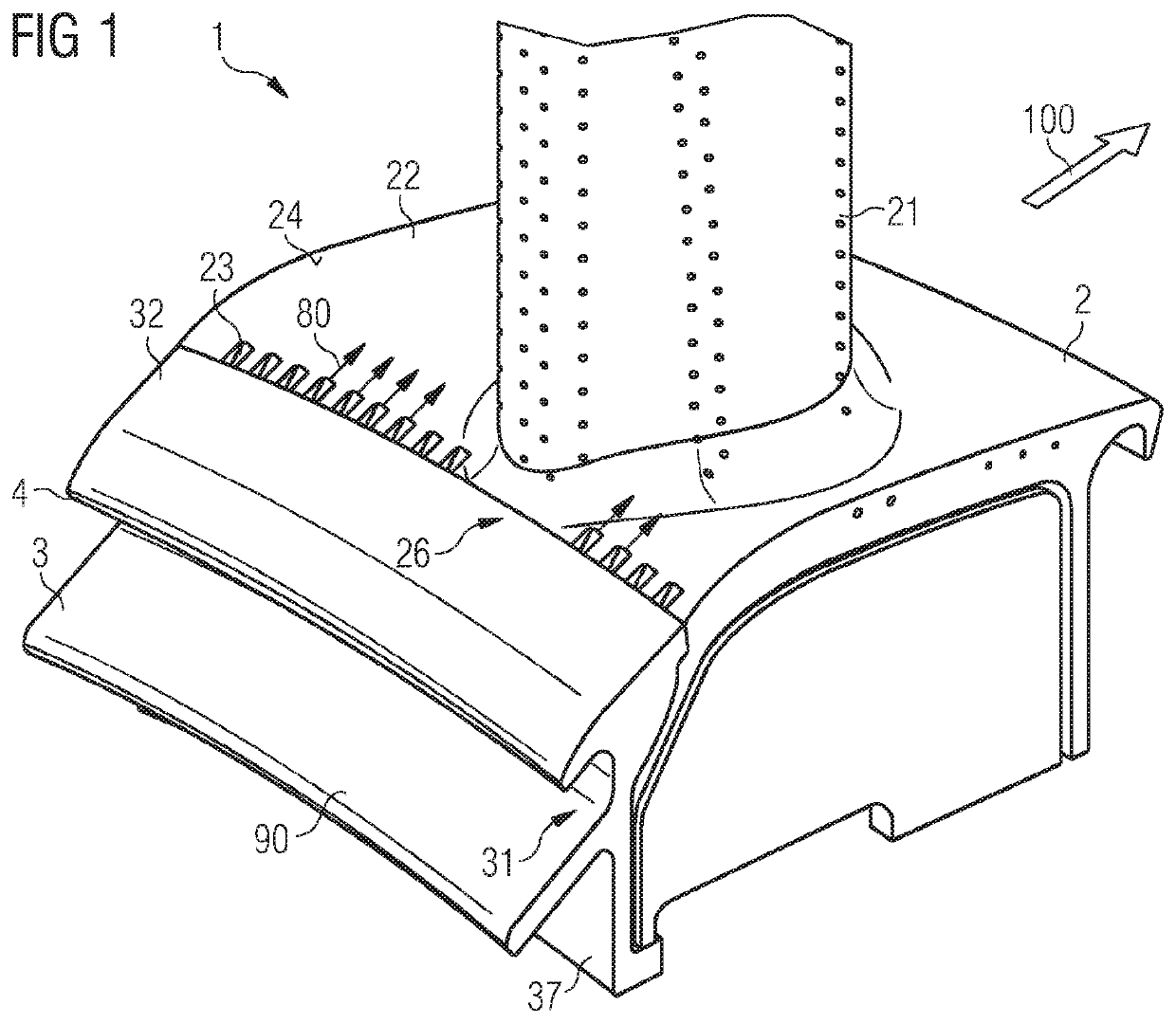

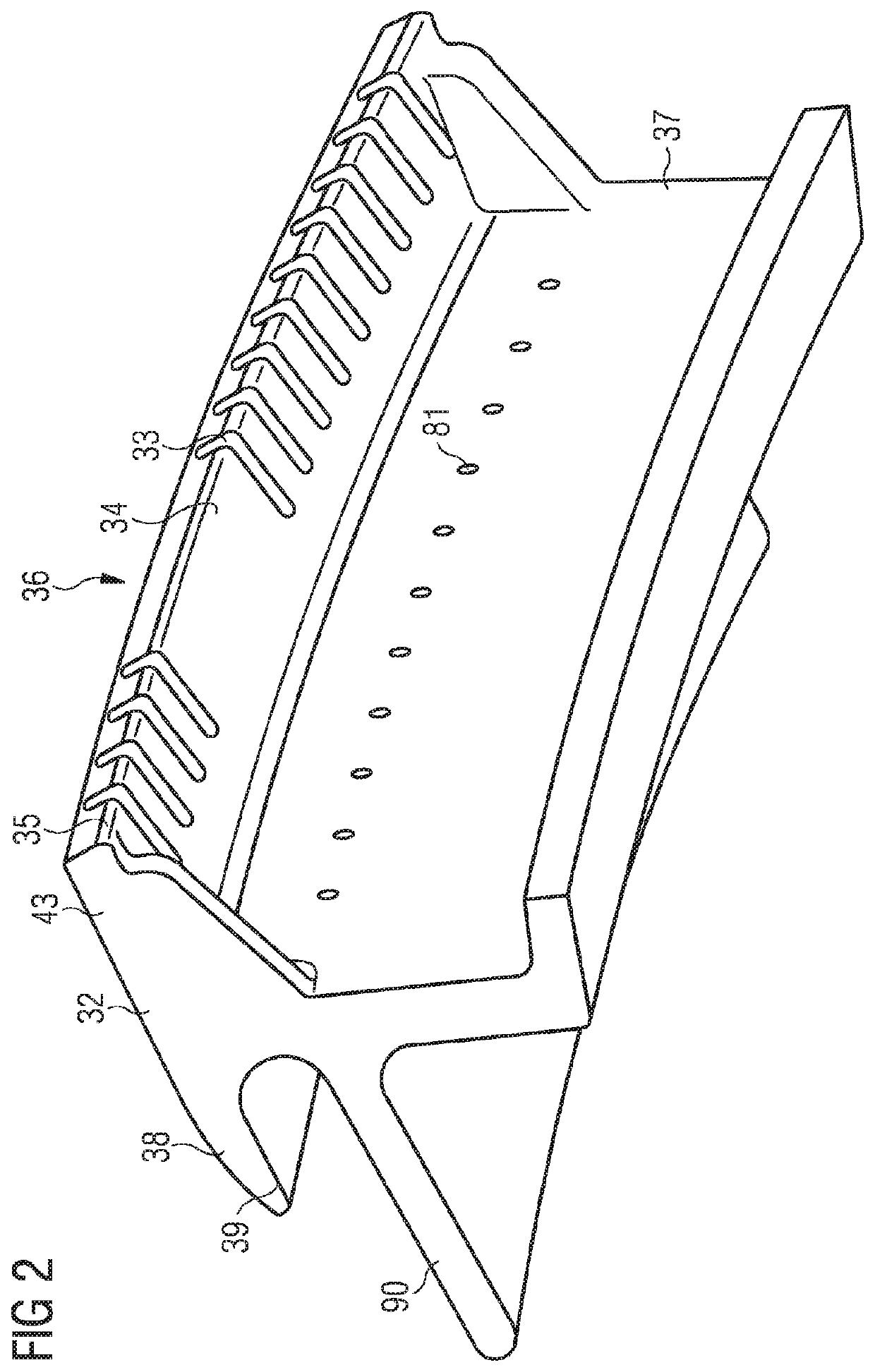

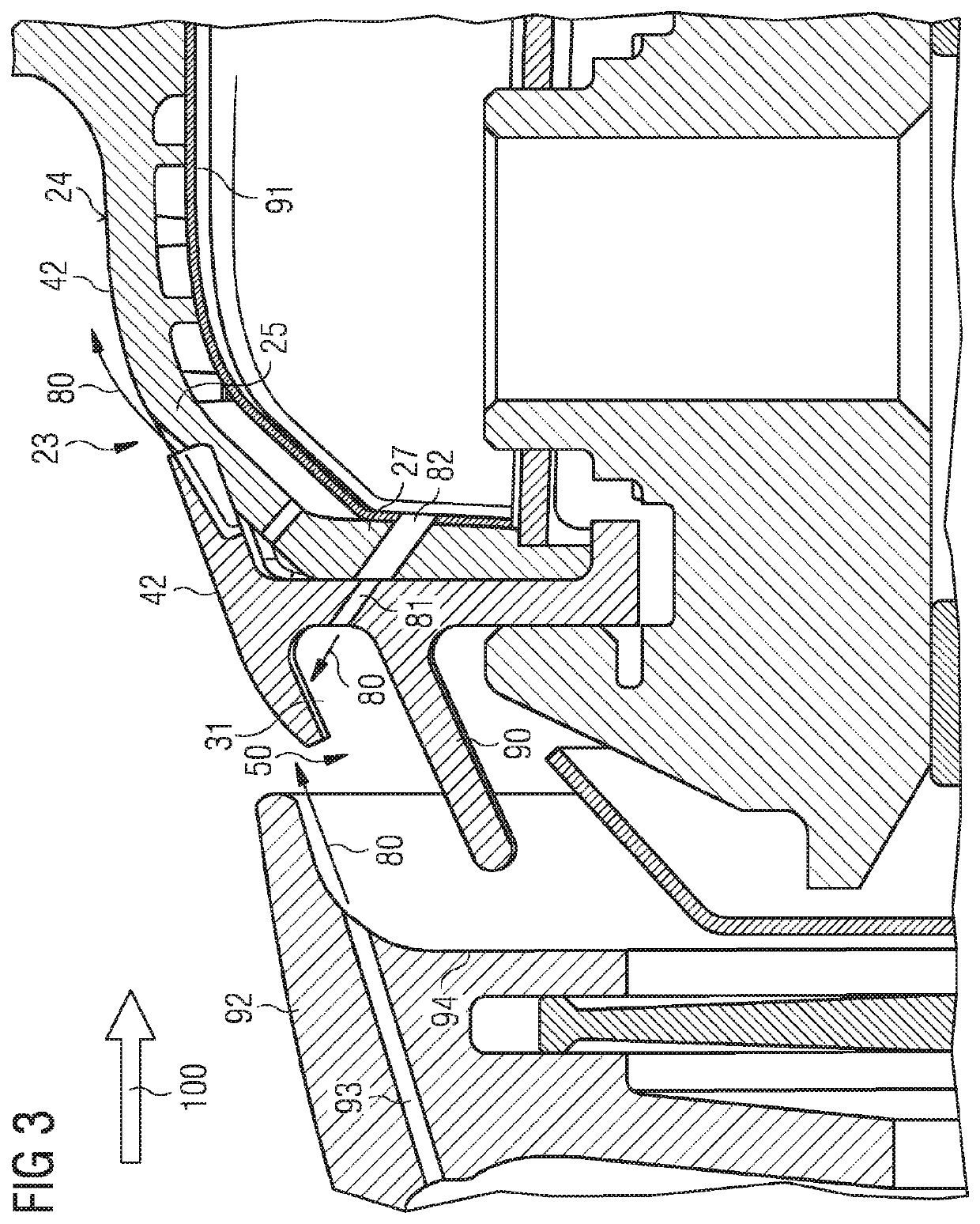

Gas turbine guide vane segment and method of manufacturing

ActiveUS20180195400A1Mitigate such drawbackFavorable joiningBlade accessoriesLeakage preventionLeading edgeWorking fluid

A gas turbine guide vane segment has a first guide vane part with an aerofoil and a first platform section and a second guide vane part with a second platform section. The first guide vane part and the second guide vane part are separately manufactured parts joined together such that the second platform section defines a leading edge of the gas turbine guide vane segment and such that the first platform section and the second platform section form an aligned common platform surface of the gas turbine guide vane segment. The first platform section includes slots in the first platform section for guiding cooling fluid along a surface of the first platform section for film cooling of the surface, the slots being provided at an upstream bend of the first platform section and the slots are provided on a side of the first platform section facing the working fluid.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

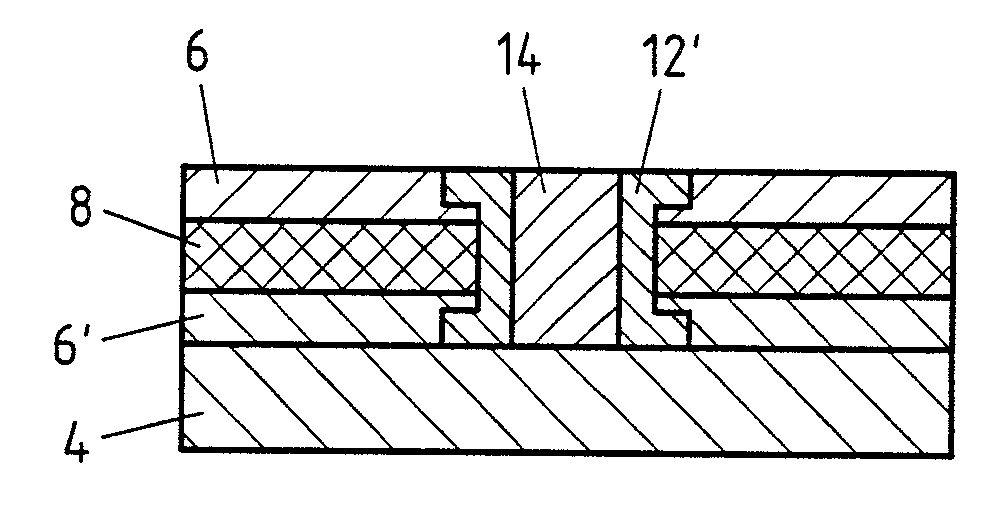

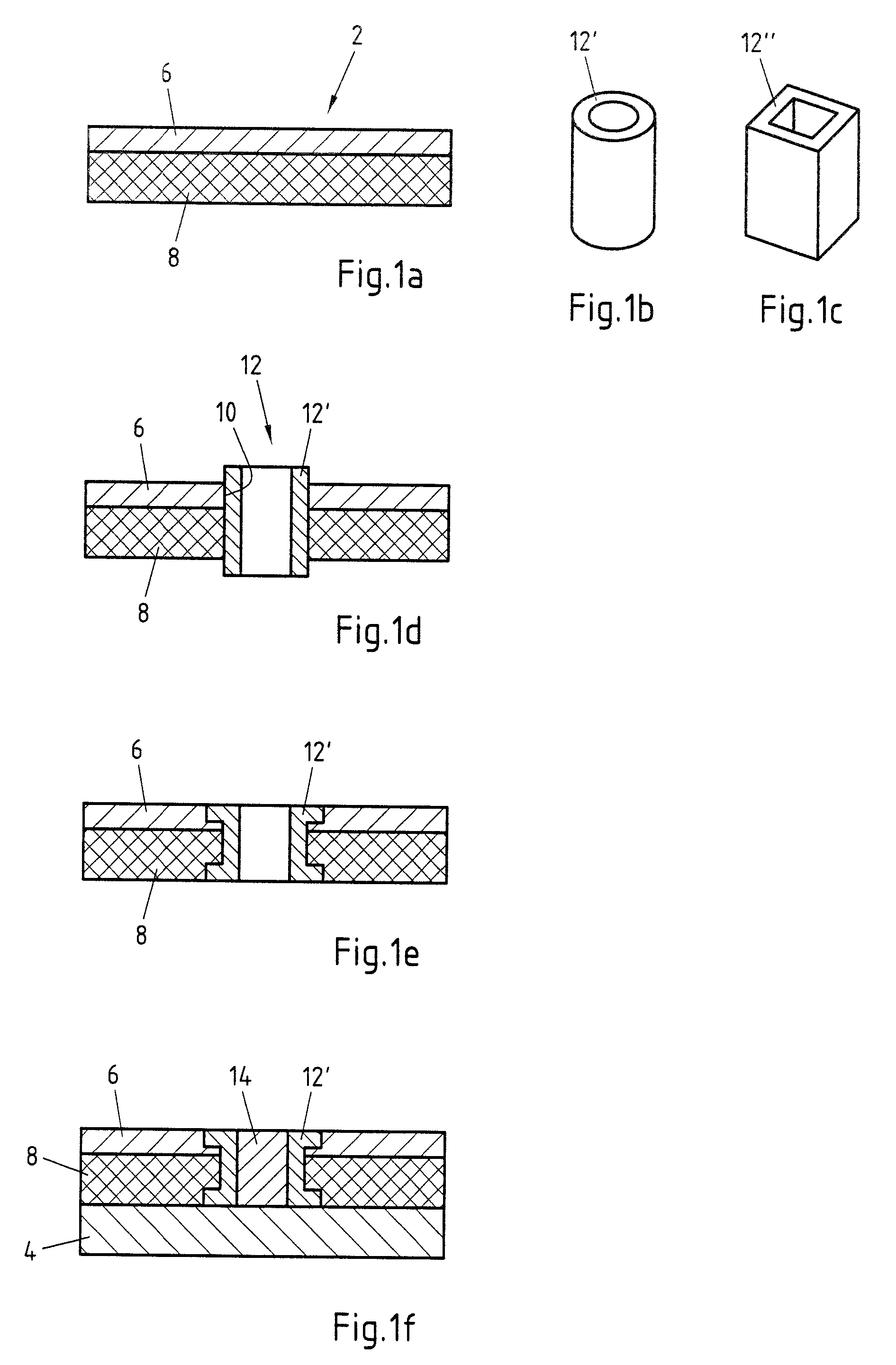

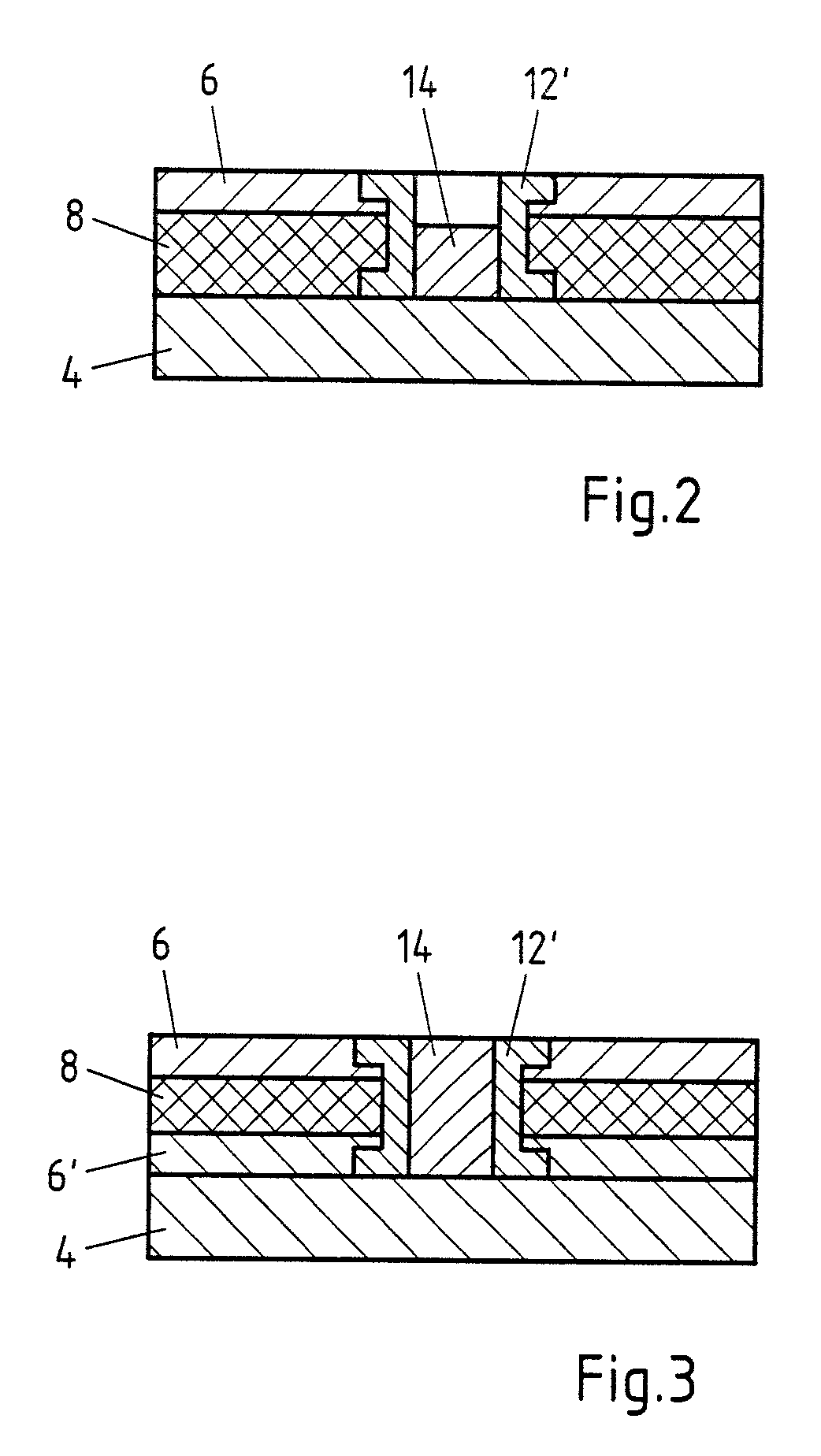

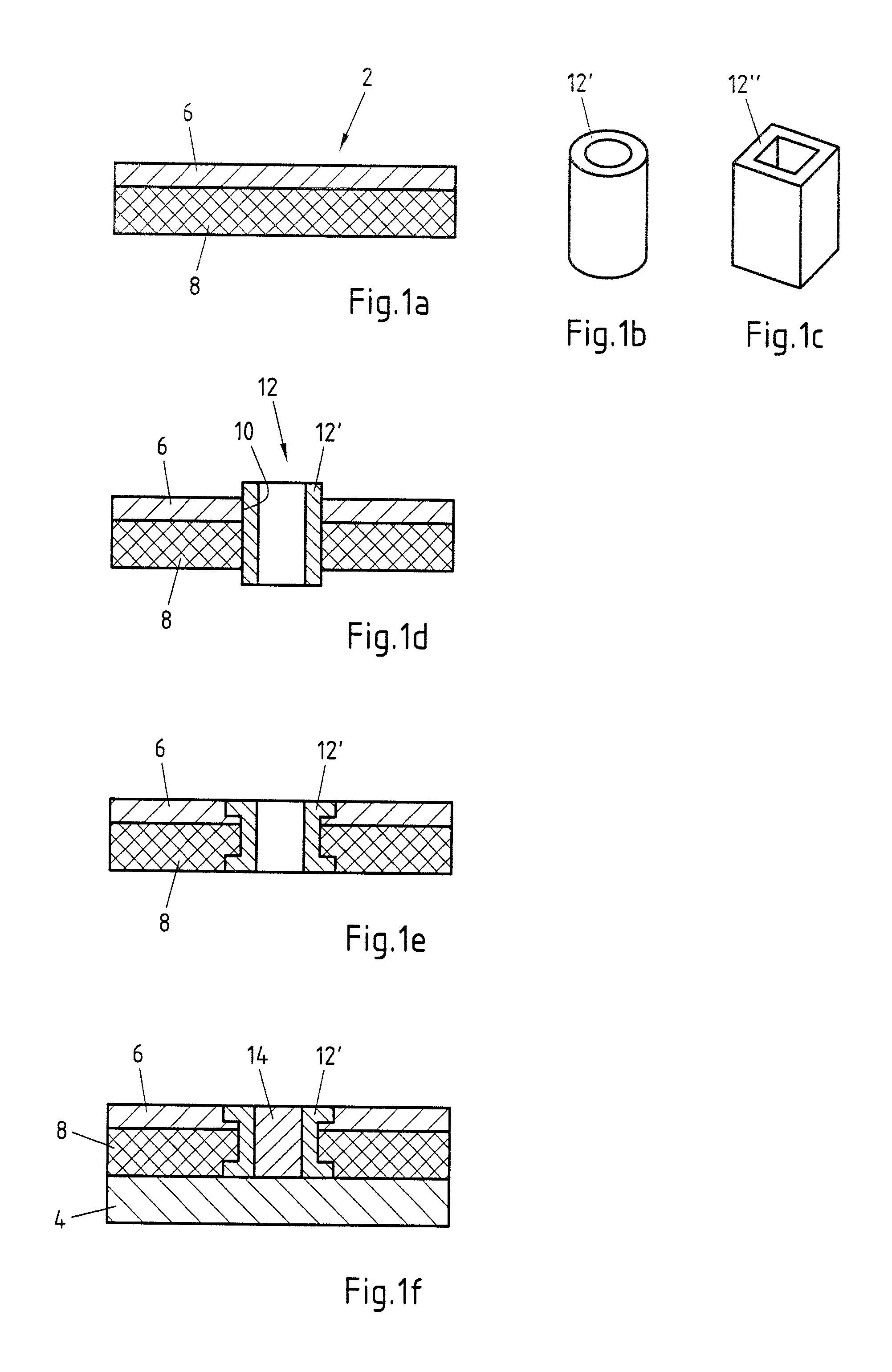

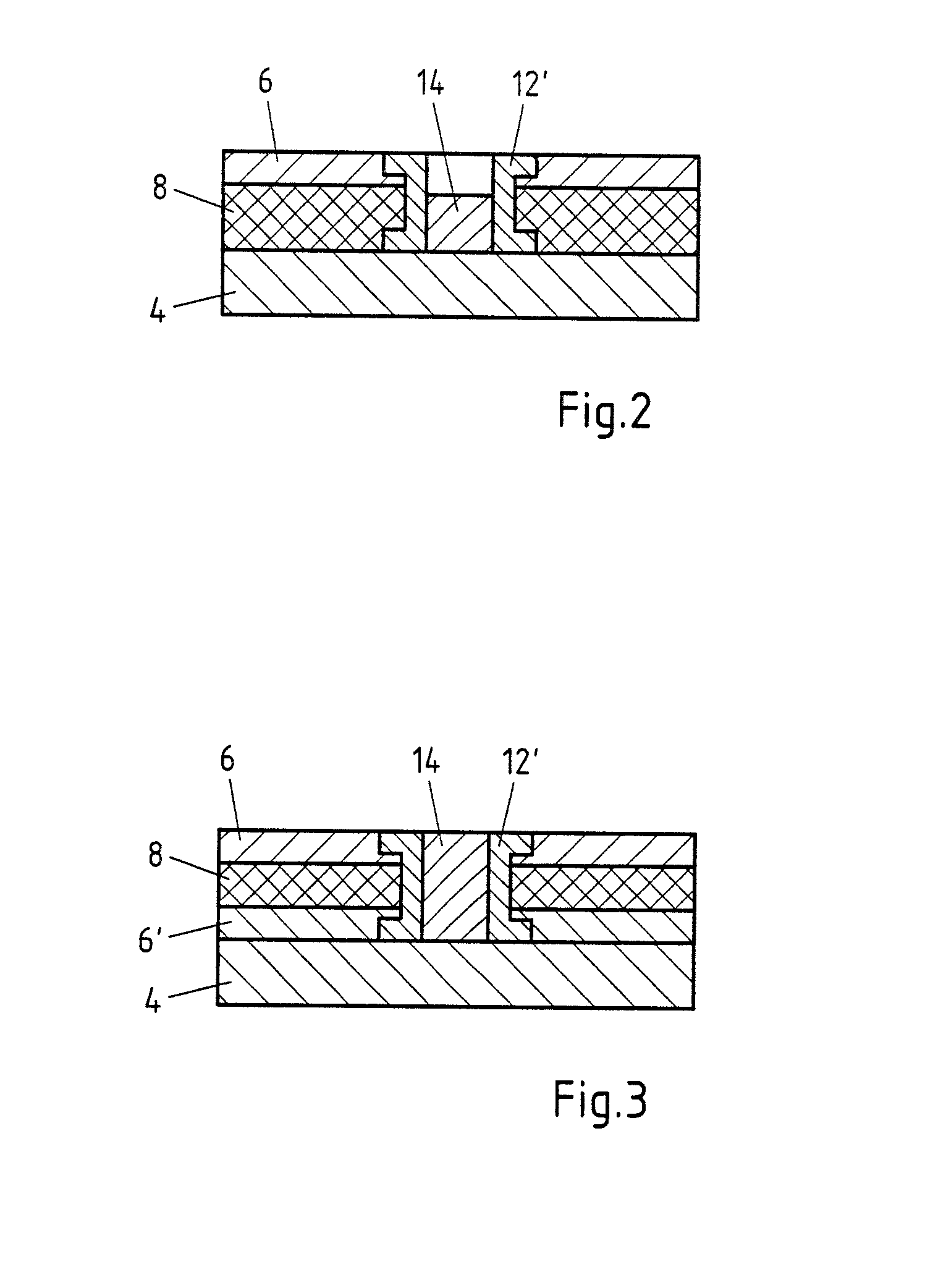

Method for joining a composite sheet to a metallic substrate

ActiveUS9211605B2Firmly connectedDurably joinedSoldering apparatusArc welding apparatusFilling materialsComposite plate

Owner:THYSSENKRUPP STEEL EURO AG

Ultrasonic transducer and method of joining an ultrasonic transducer

InactiveUS7161280B2Low heat inputEasy to manufacturePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersSonificationUltrasonic sensor

Owner:SIEMENS AG +1

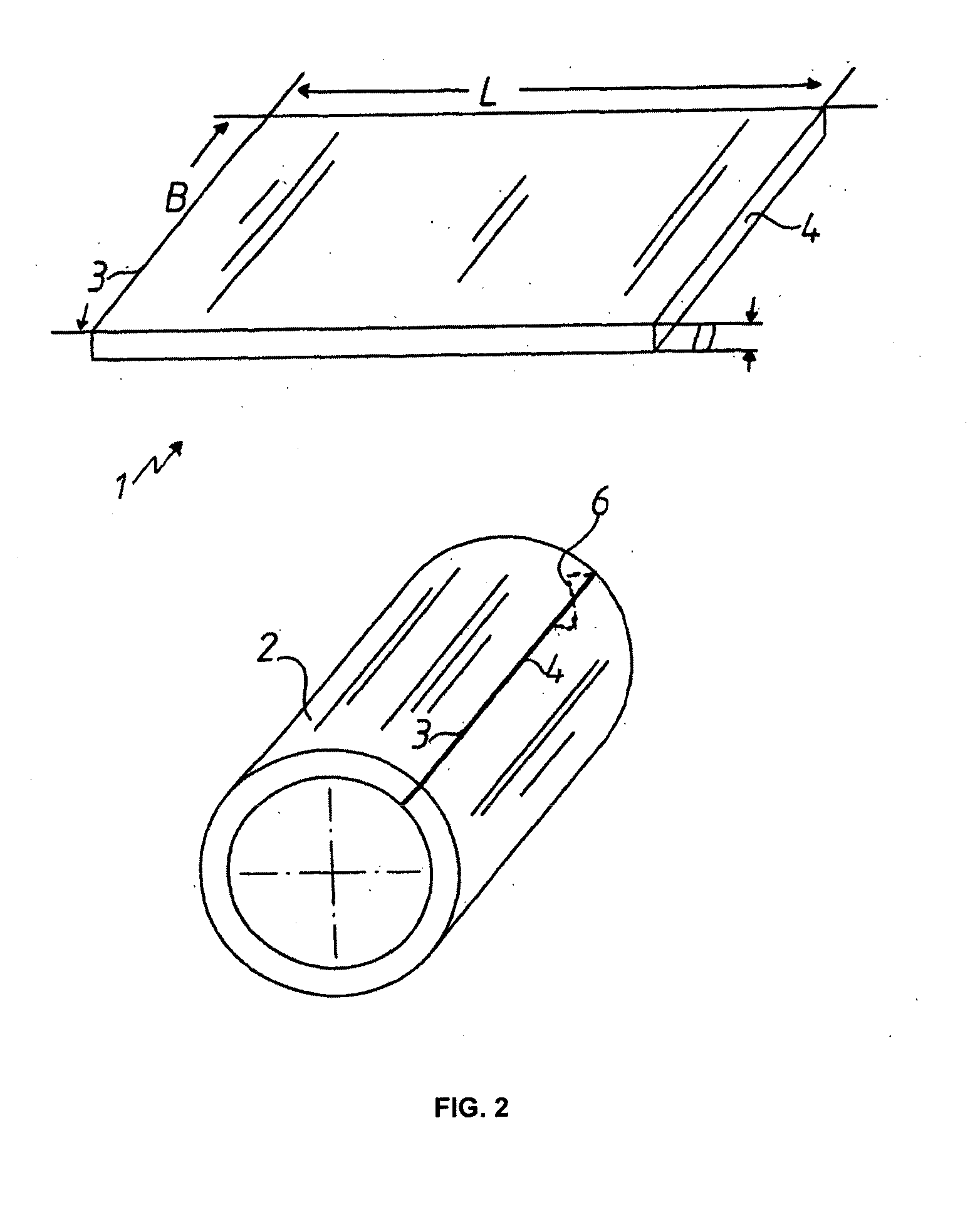

Method for joining a composite sheet to a metallic substrate

ActiveUS20150001004A1Cost-efficient and effective vibration dampingFirmly connectedElectric heatingArc welding apparatusComposite plateMetallic substrate

The invention relates to a method for joining a composite sheet to a metallic substrate, wherein the composite sheet has at least one metallic top layer and at least one non-metallic layer which consists of a plastic material, wherein an opening is introduced into the composite sheet, and wherein at least one joining element is provided which is inserted into the opening of the composite sheet. A method for joining a composite sheet to a metallic substrate with process reliability and of specifying a corresponding structure is achieved by forming the joining element as a metallic sleeve, wherein the metallic sleeve is deformed, so that it joins together with the composite sheet in a form-fit and force-fit manner, and wherein the metallic sleeve is firmly bonded to the substrate with the end pointing towards the substrate using a filler material, wherein the filler material is arranged inside the sleeve.

Owner:THYSSENKRUPP STEEL EURO AG

Method for manufacturing power device cooler

ActiveUS20200321224A1Favorable joiningLow costSemiconductor/solid-state device detailsSolid-state devicesProcess engineeringHeat sink

To provide a method for manufacturing a power device cooler, which not only can accomplish cost reduction and preferable joining between the cooler and a heating element equipped with a power device but also can improve the productivity. After first and second cases and fins that constitute a cooler are brazed by means of a non-corrosive flux and a brazing filler material, the first and second cases and the fins being made of aluminum, flux residues that are attached at least to a heat receiving surface of the first and second cases that is to be joined to a heating element equipped with a power device, are removed by a wet blasting method in which a mixture of an abrasive formed of polygonal alumina particles having a median particle diameter of 4 to 250 μm and a liquid is projected onto the heat receiving surface by compressed air.

Owner:NIPPON LIGHT METAL CO LTD

Wavelength converting element and method of manufacture thereof

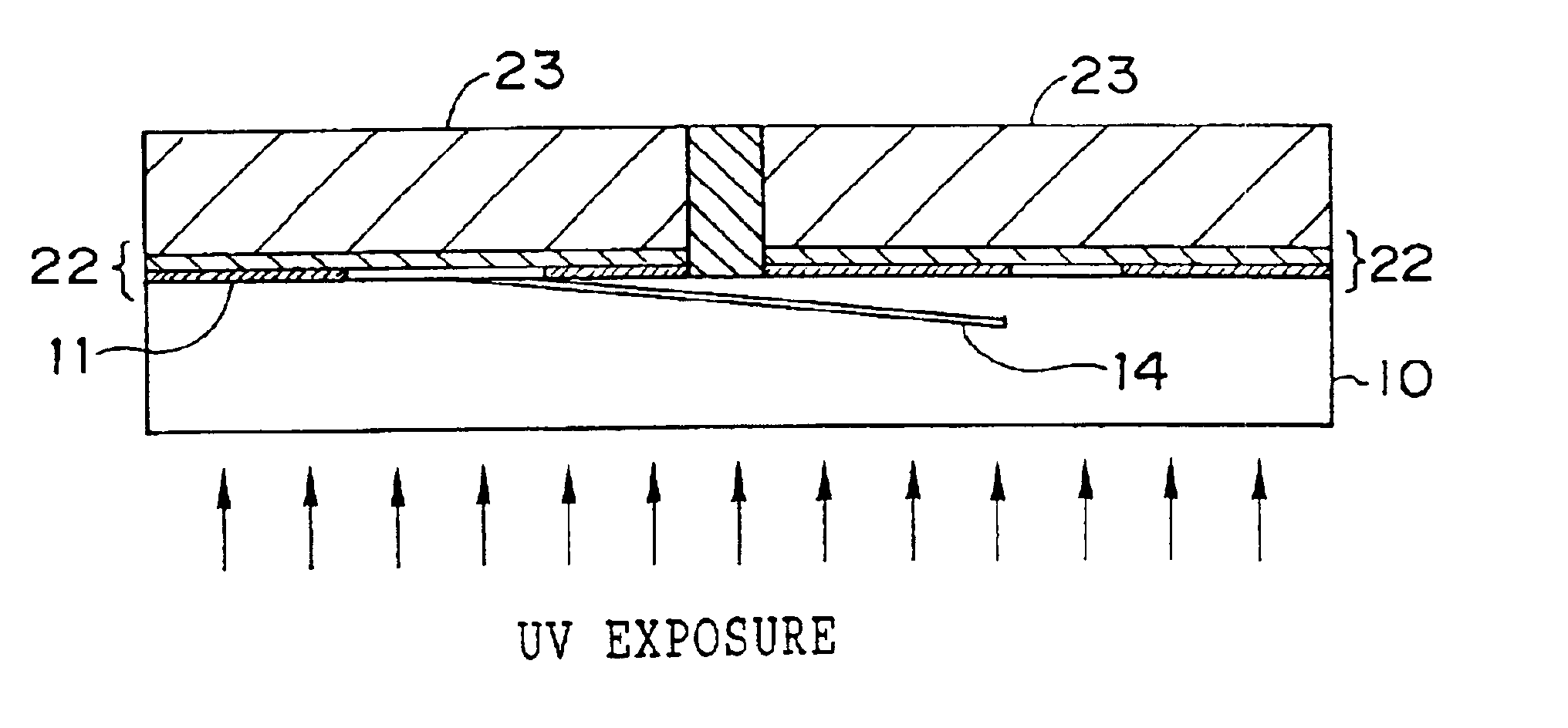

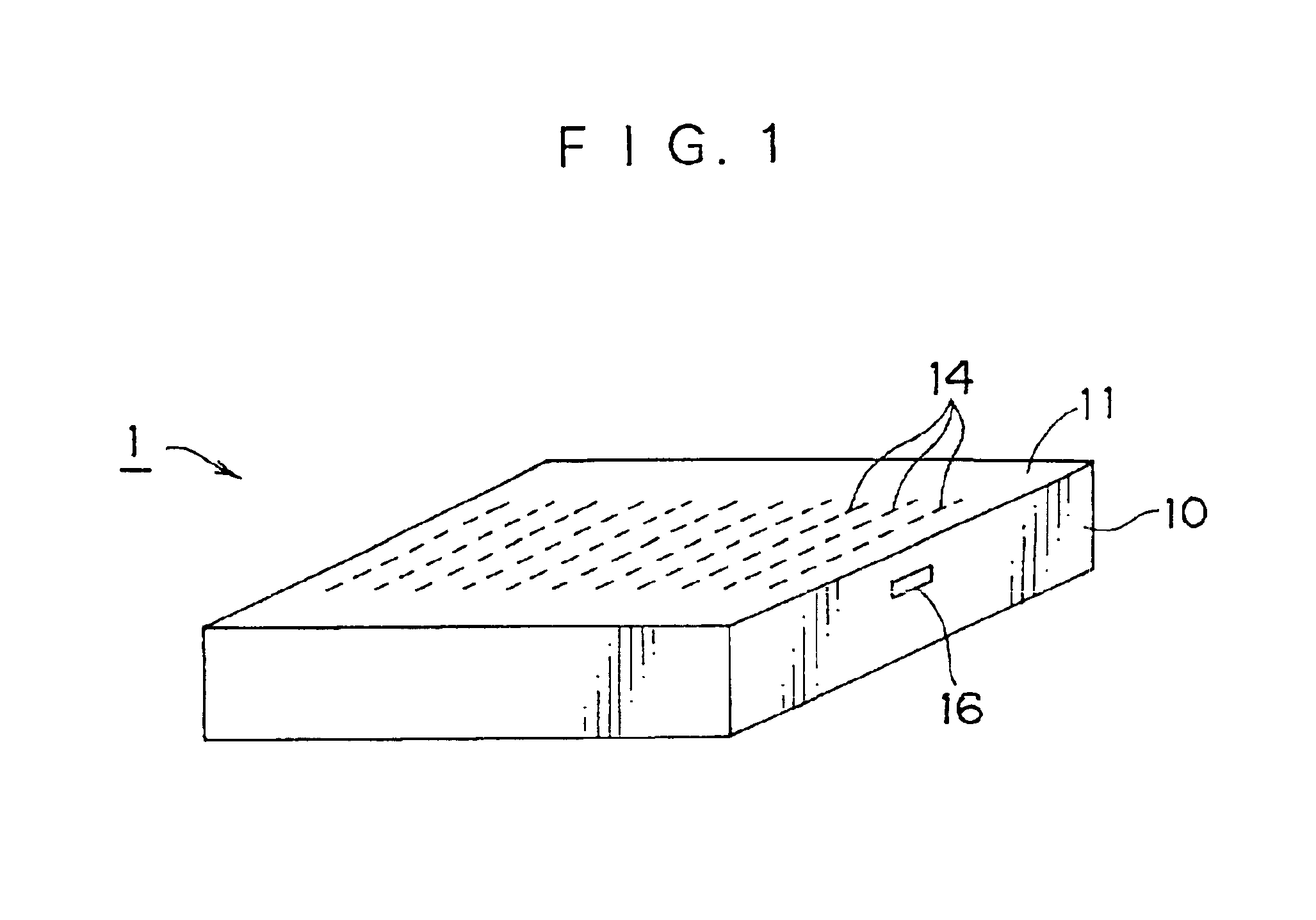

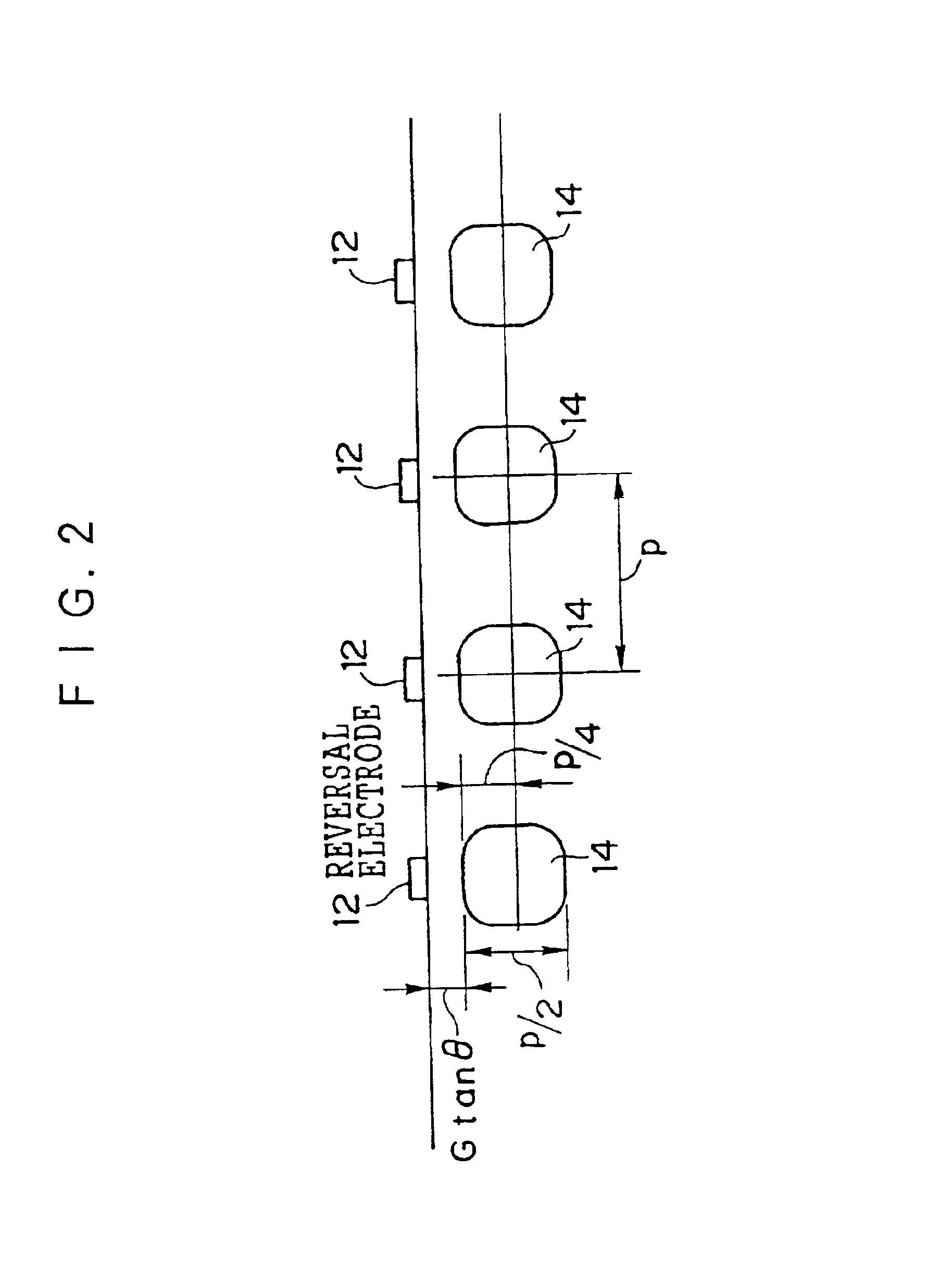

InactiveUS6917463B2Convenience to workReduce film thicknessPhotomechanical apparatusOriginals for photomechanical treatmentPhysicsLight beam

A wavelength converting element is provided in which a fundamental wave with respect to an optical crystal substrate and a peak of a vertical transverse mode of a second harmonic are made to coincide, the converting efficiency is good, and a beam shape which enables good joining to a lens or an optical fiber is obtained. Given that an angle formed by a surface of the optical crystal substrate and a C axis of the optical crystal substrate is θ, a period at which inverted domains are formed is p, and a distance from a distal end of a comb-shaped electrode for forming the inverted domain to a central position of a waveguide is G, in the ion implantation, a concentration peak of the ion implantation is formed at a distance of substantially (G·tanθ+p / 4) from the surface of the optical crystal substrate.

Owner:FUJIFILM CORP +1

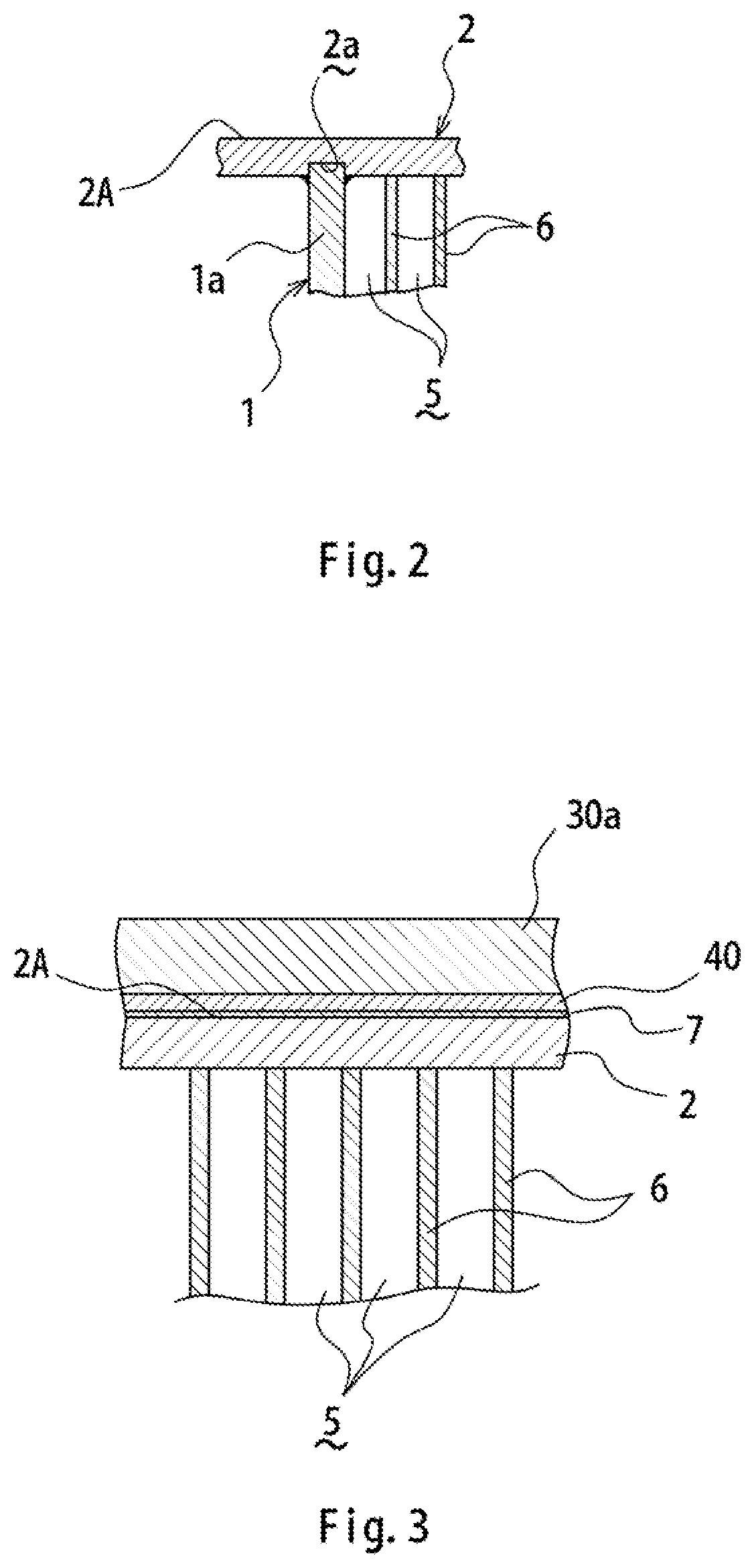

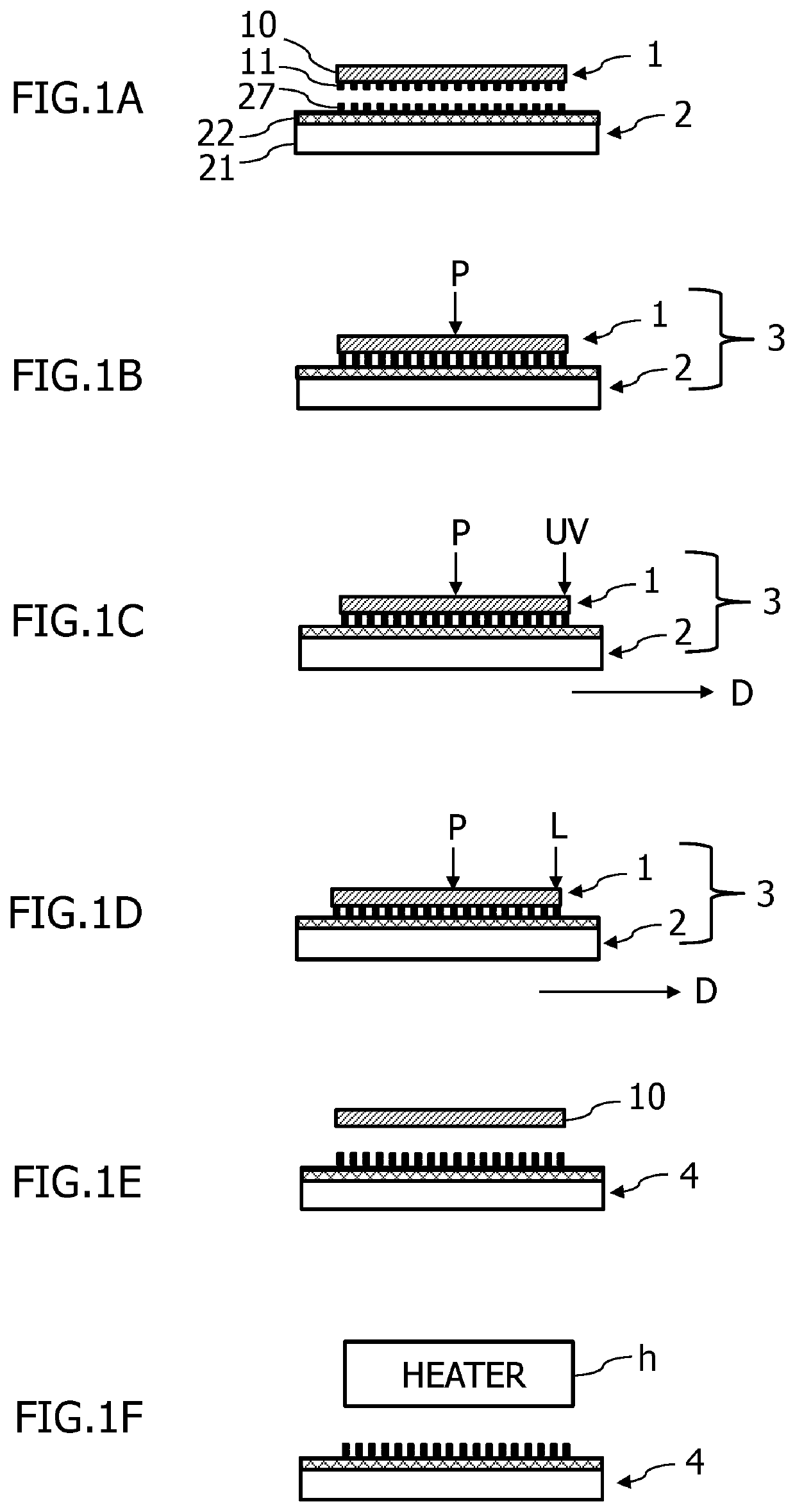

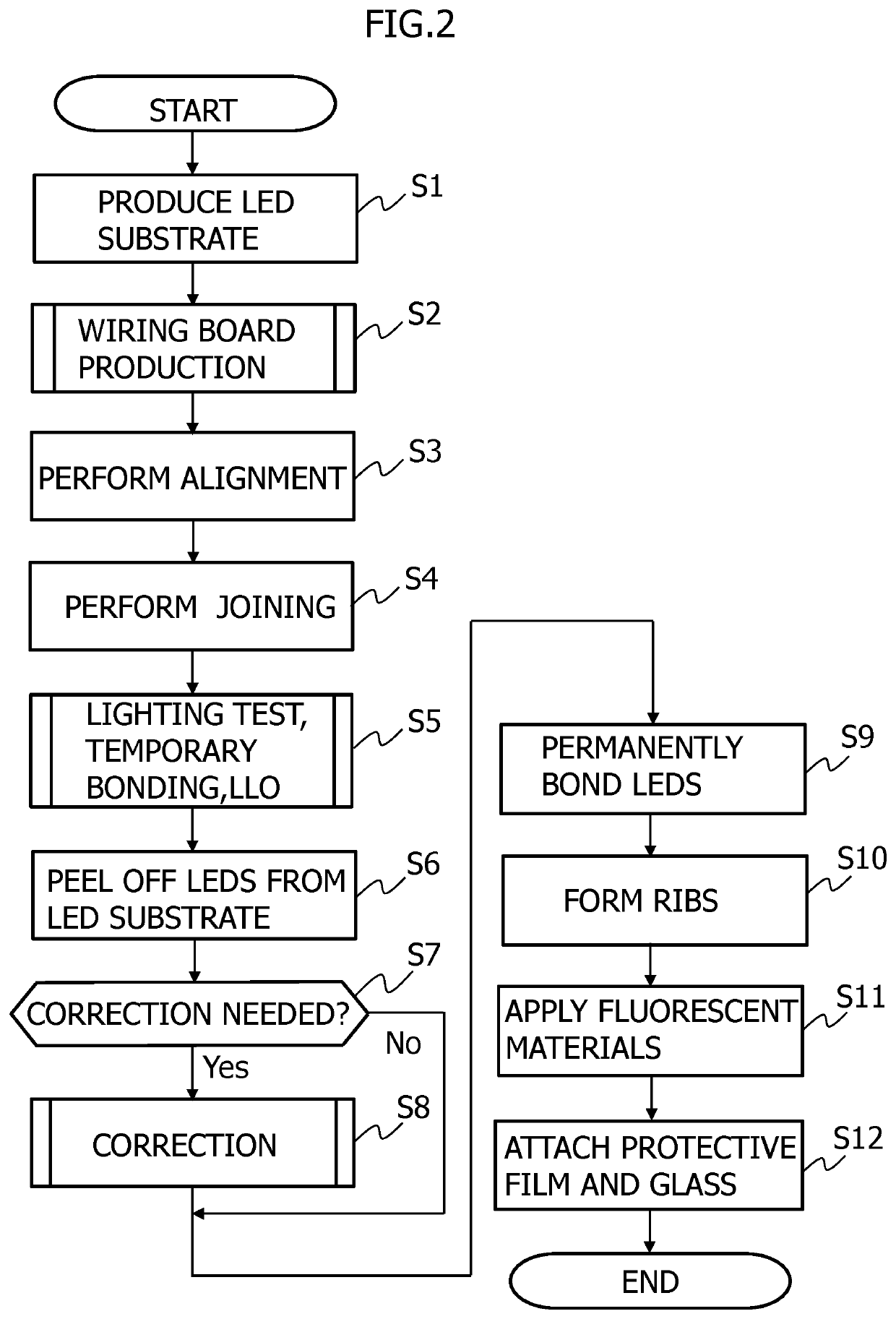

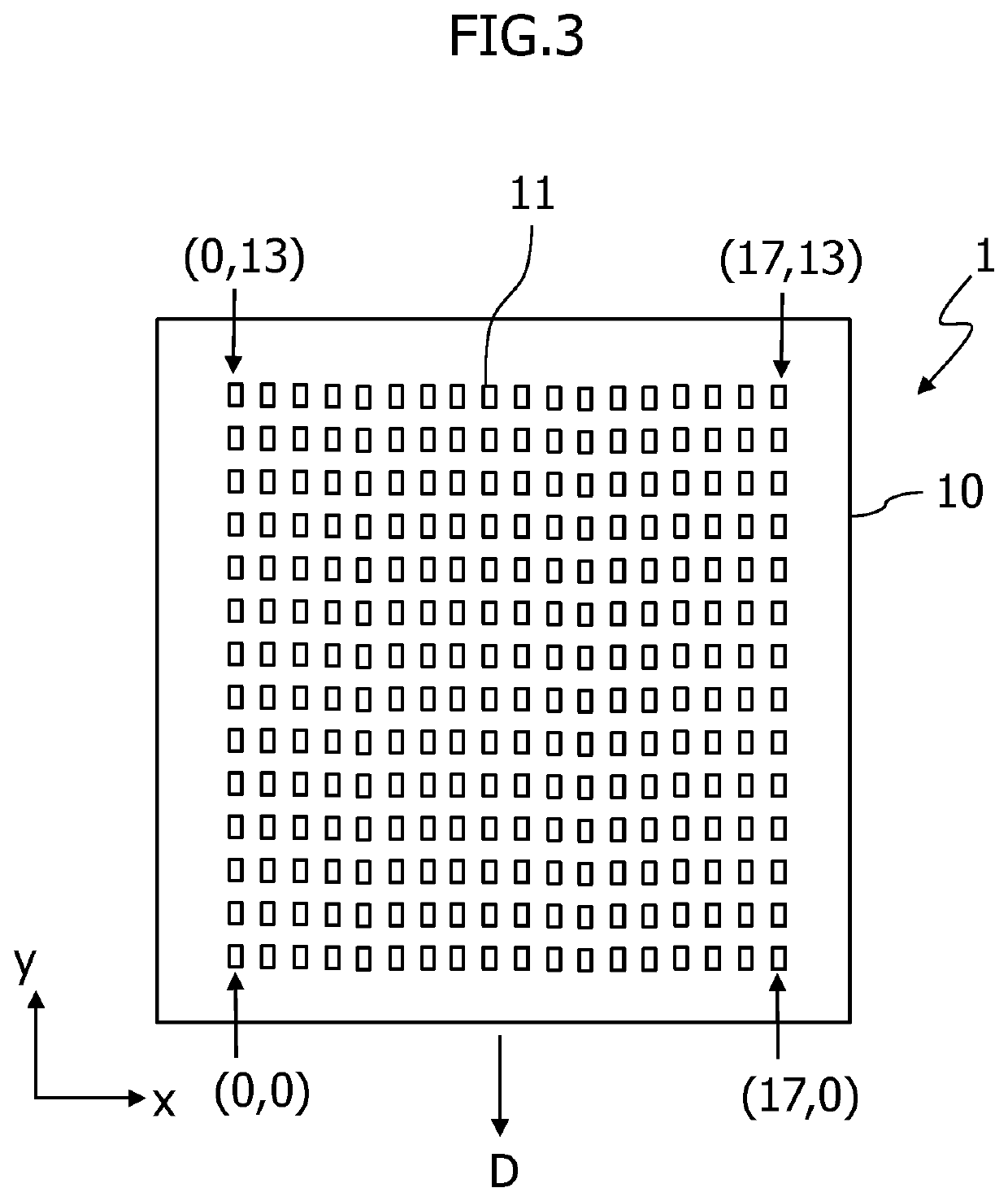

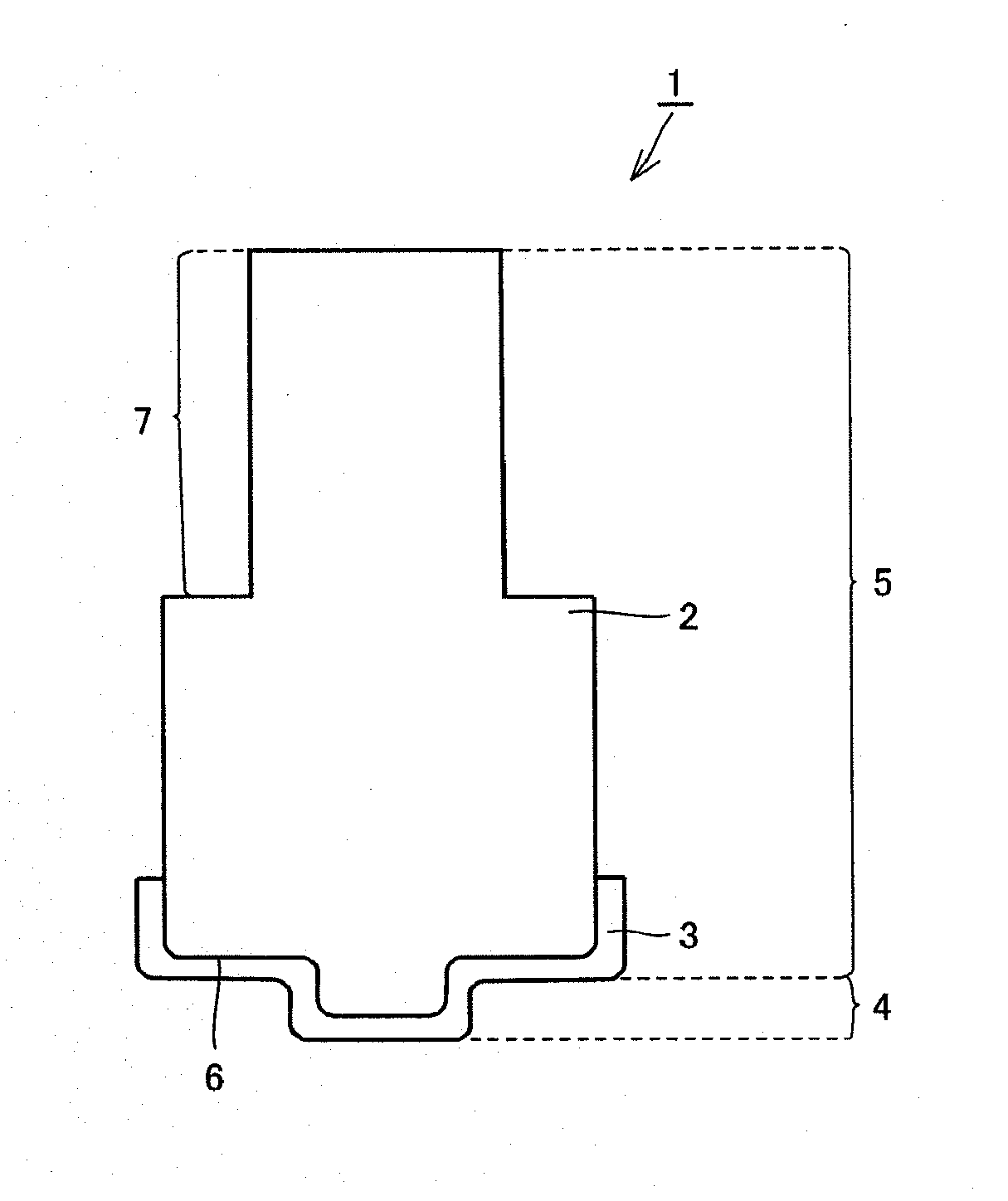

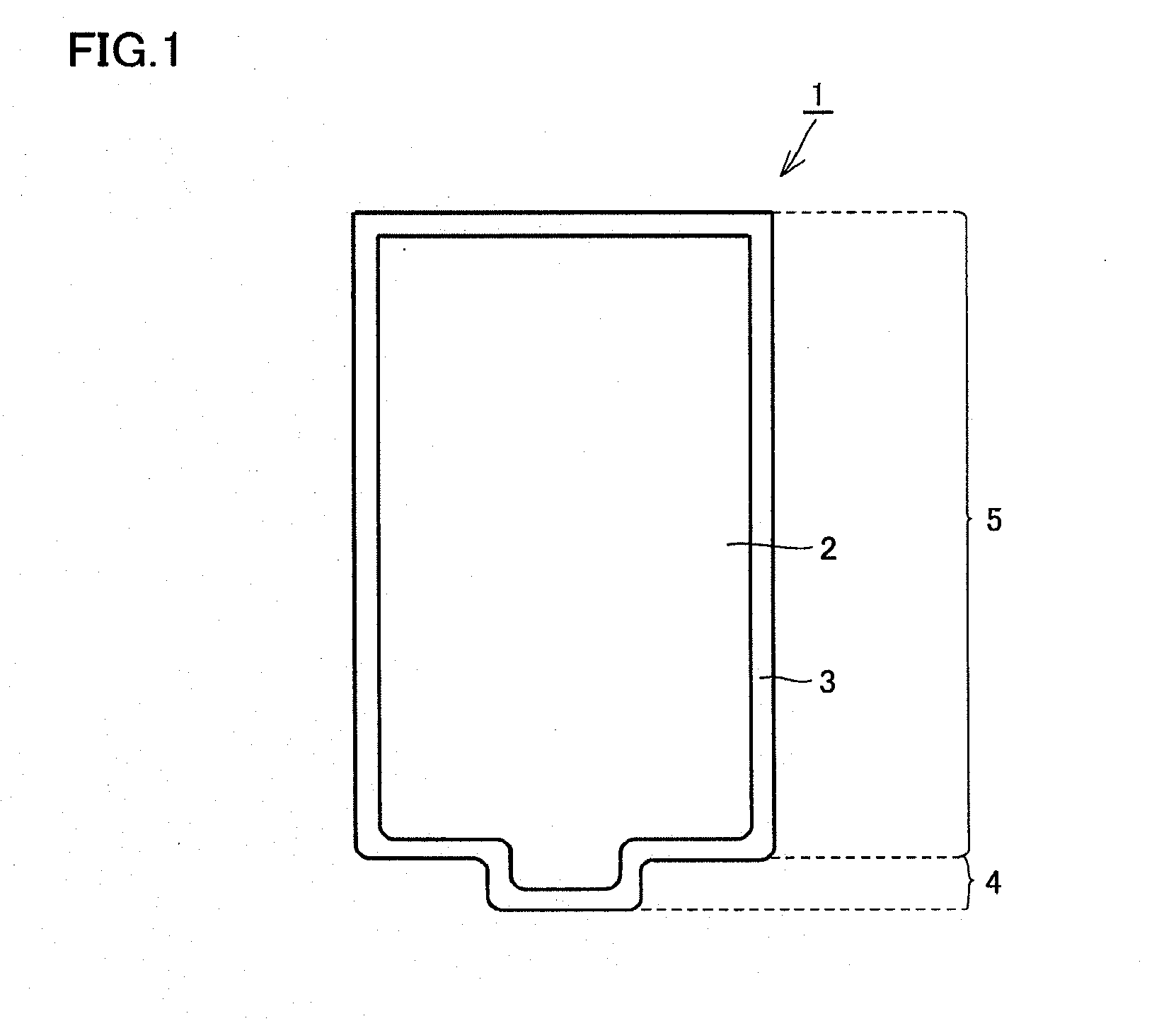

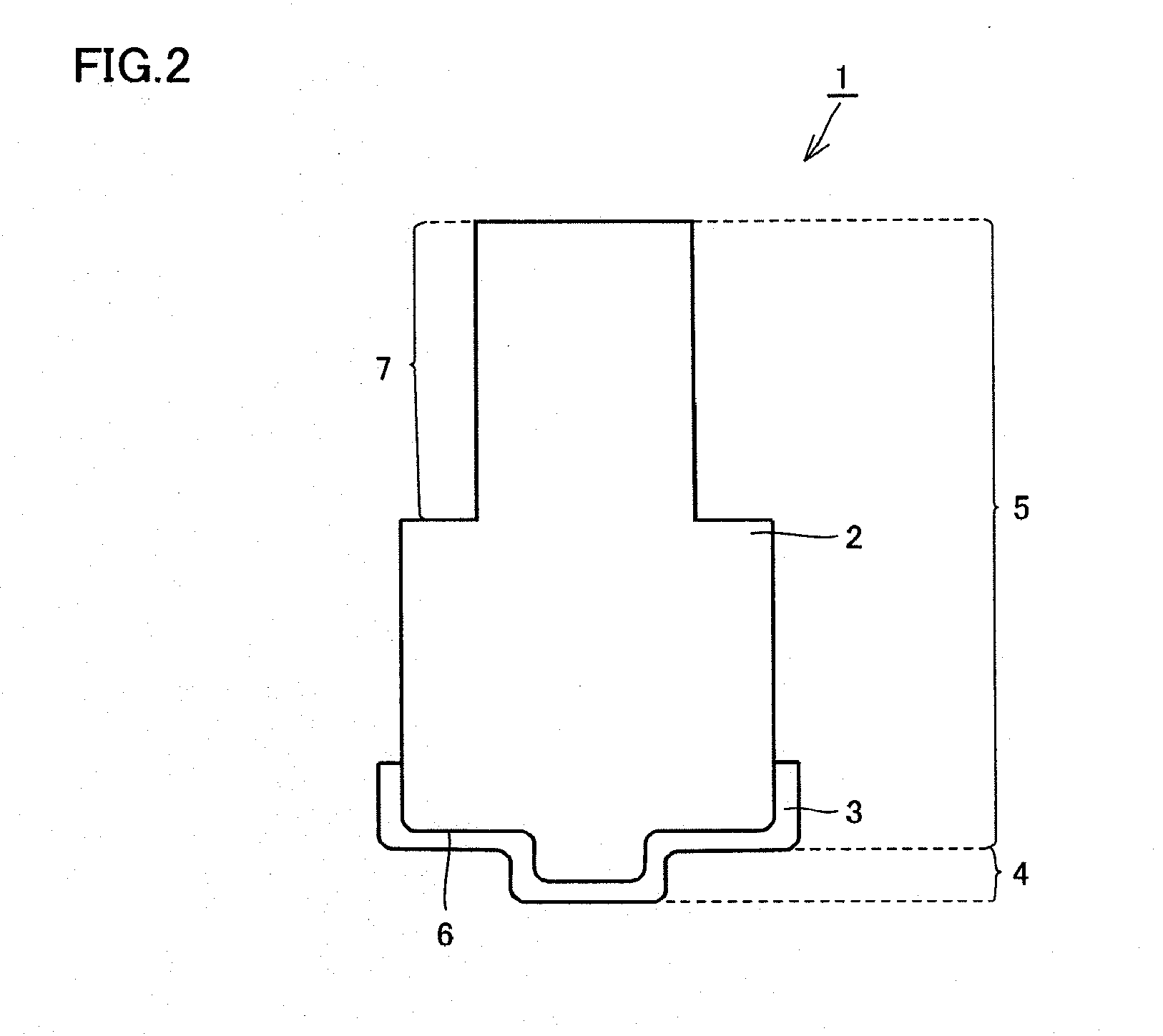

Method For Manufacturing Led Display

InactiveUS20200402867A1Resisting compressionFavorable joiningSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsLED displayUltraviolet lights

The present invention provides a method for manufacturing an LED display including a wiring board and LEDs arranged at a constant distance from the wiring board. The method includes: aligning an LED substrate 1 having LEDs 11 with a wiring board 2, and pressing and joining the LED substrate onto the wiring board. Each LED has a bonding surface. The wiring board includes bonding layers. The aligning step is performed so that the bonding surfaces are joined on the bonding layers in the pressing and joining step. The method further includes: temporarily bonding the LEDs onto the wiring board by curing the bonding layers through irradiation with ultraviolet light UV; peeling off the LEDs from the LED substrate through irradiation with laser light L; and permanently bonding the LEDs onto the wiring board by heating the bonding layers of the LEDs so as to further cure the bonding layers.

Owner:V TECH CO LTD

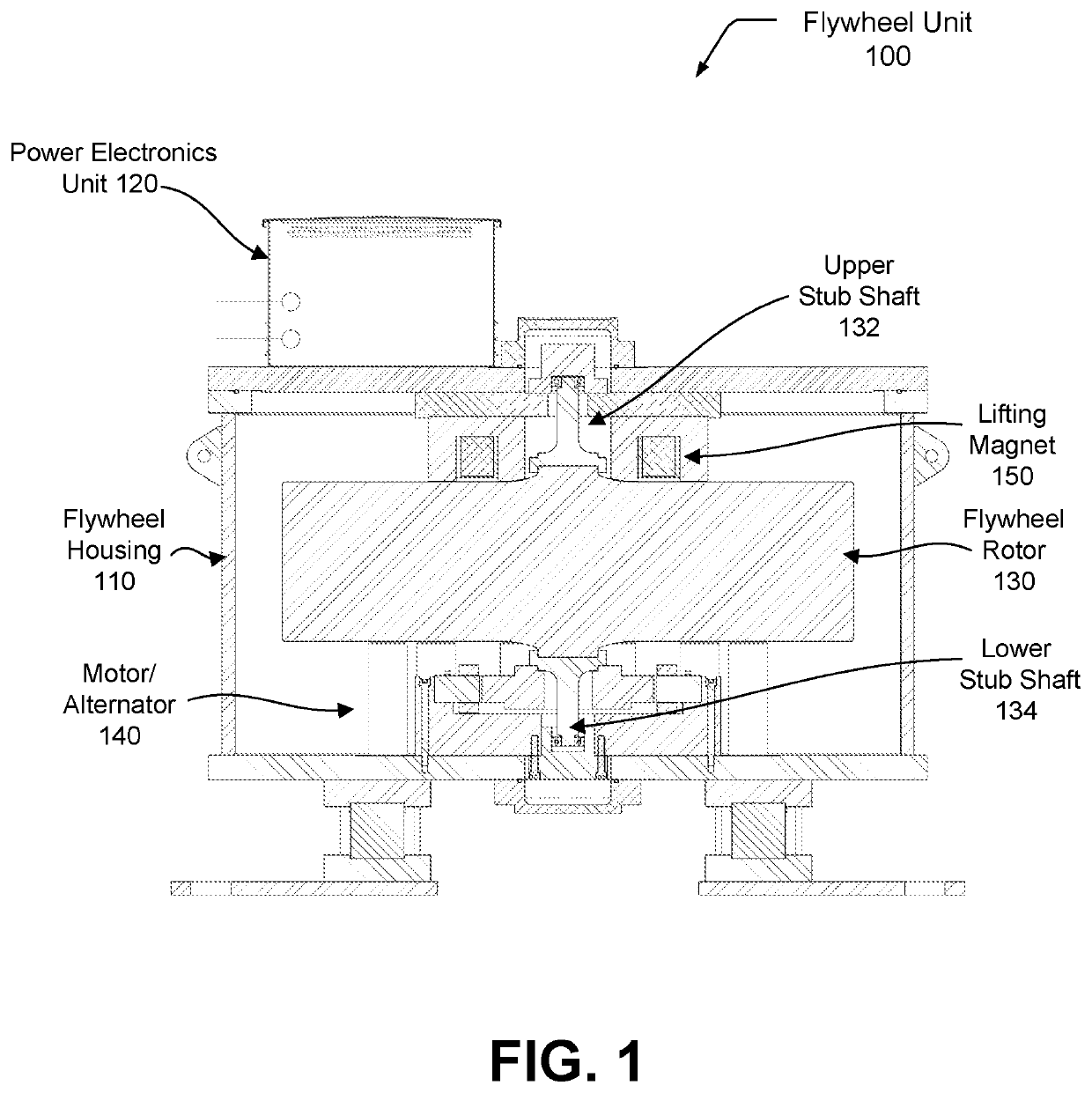

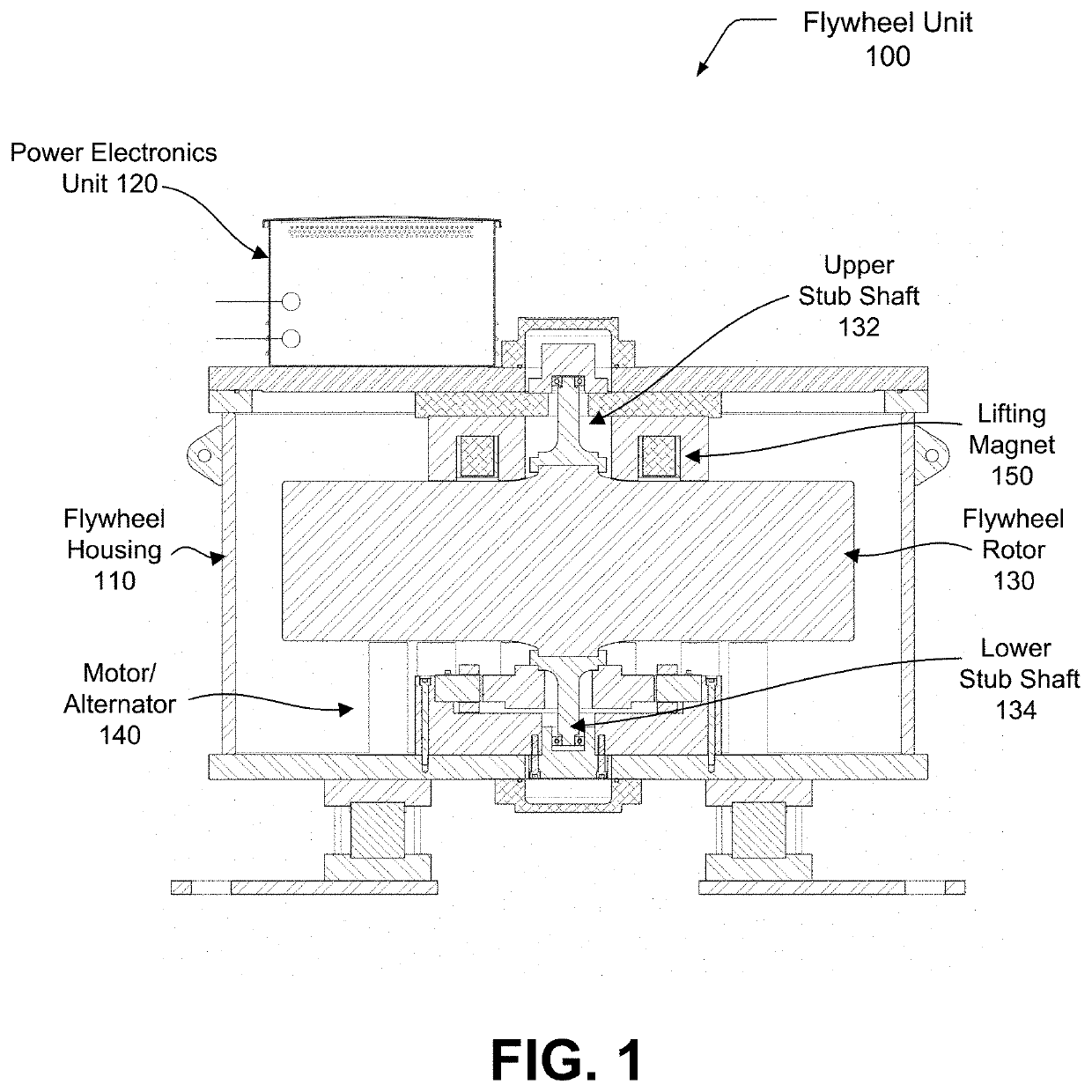

Stacked lamination rotor

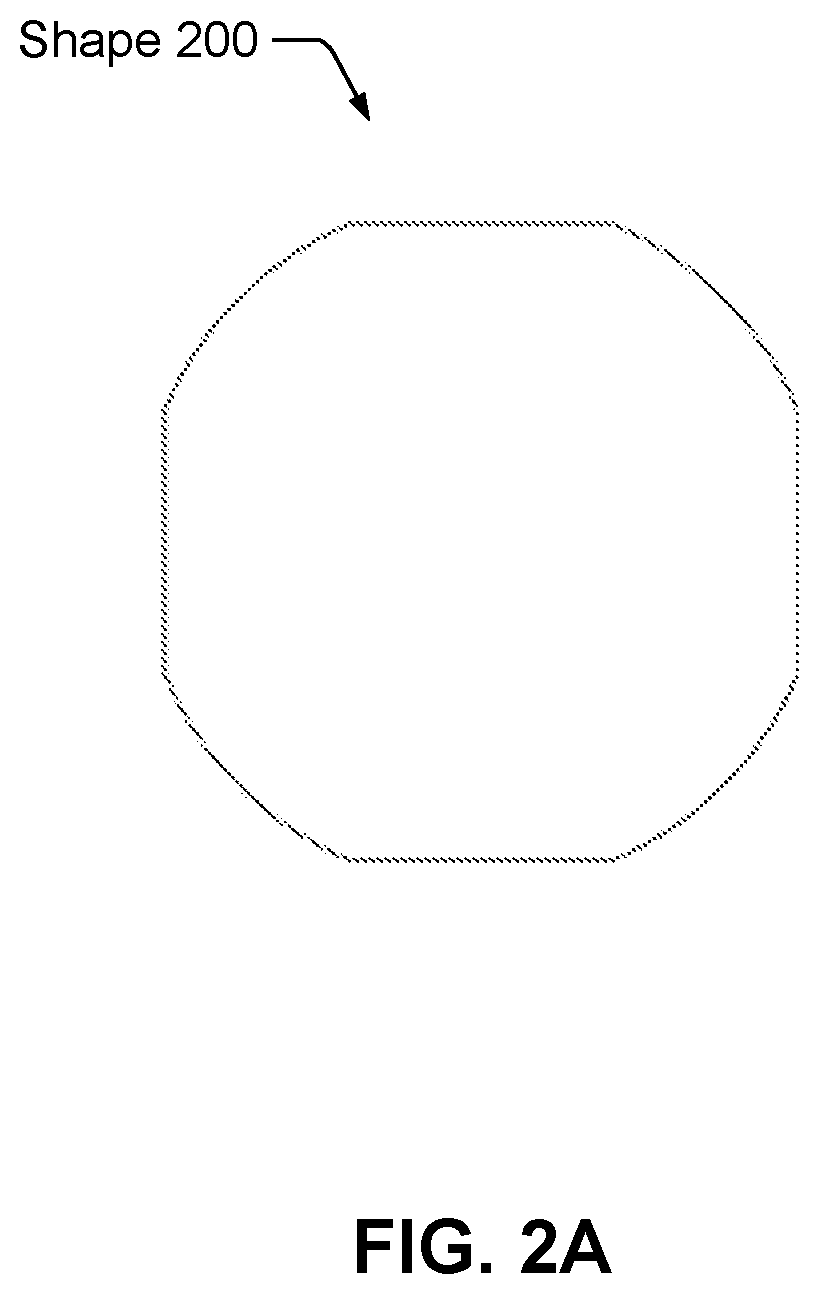

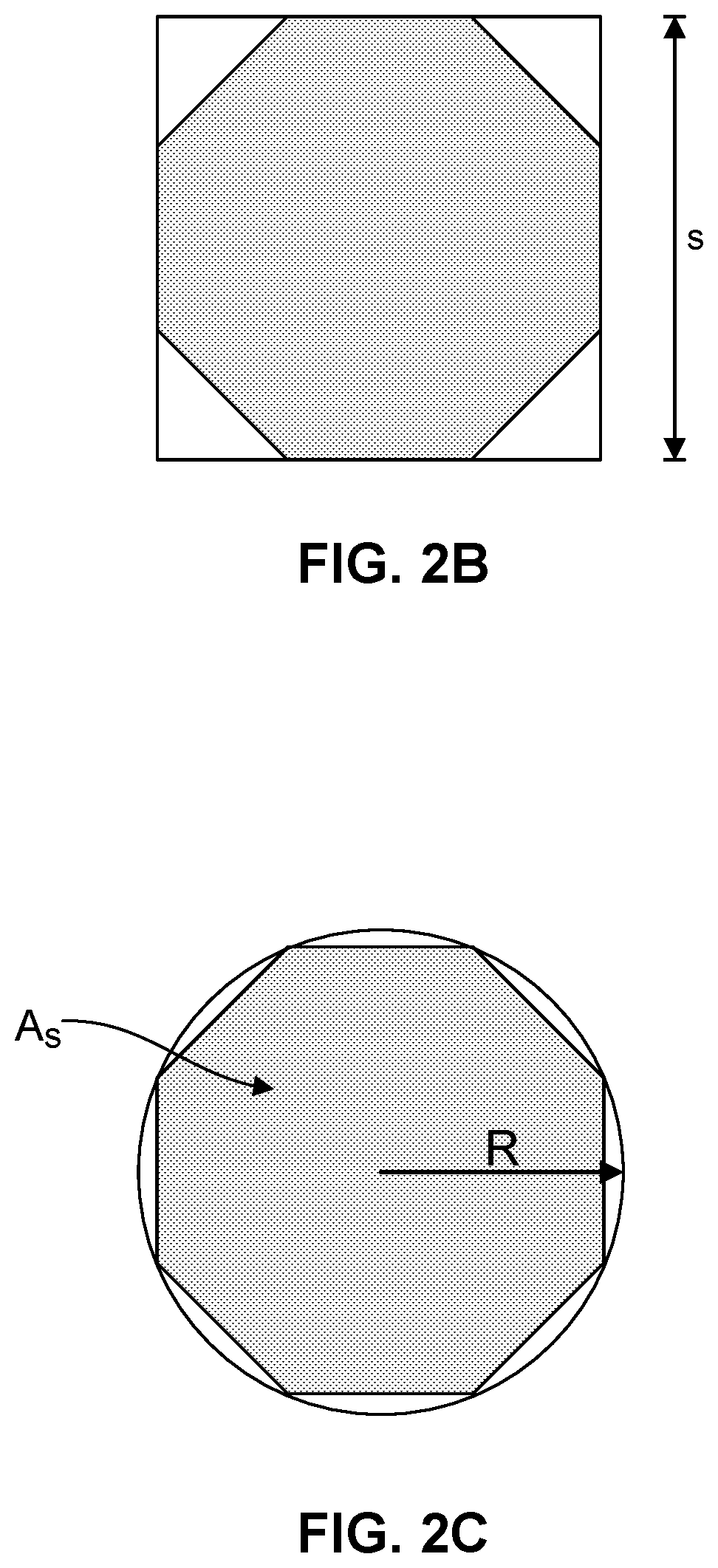

ActiveUS11362558B2Maximize utilizationFavorable joiningMagnetic circuit rotating partsSpringsEngineeringFlywheel

The invention is a flywheel rotor that includes a number of adjacent laminations, stacked one on top of another, where each of the laminations has the same shape and is rotationally symmetric around a center axis, and where the shape is substantially circular and includes a plurality of protrusions on the circumference, and each of the laminations includes at least one hole for at fastening bolts to pass through. The invention typically includes an endplate at each end of stack of laminations and one of the two endplates attaches to a stubshaft.

Owner:AMBER KINETICS

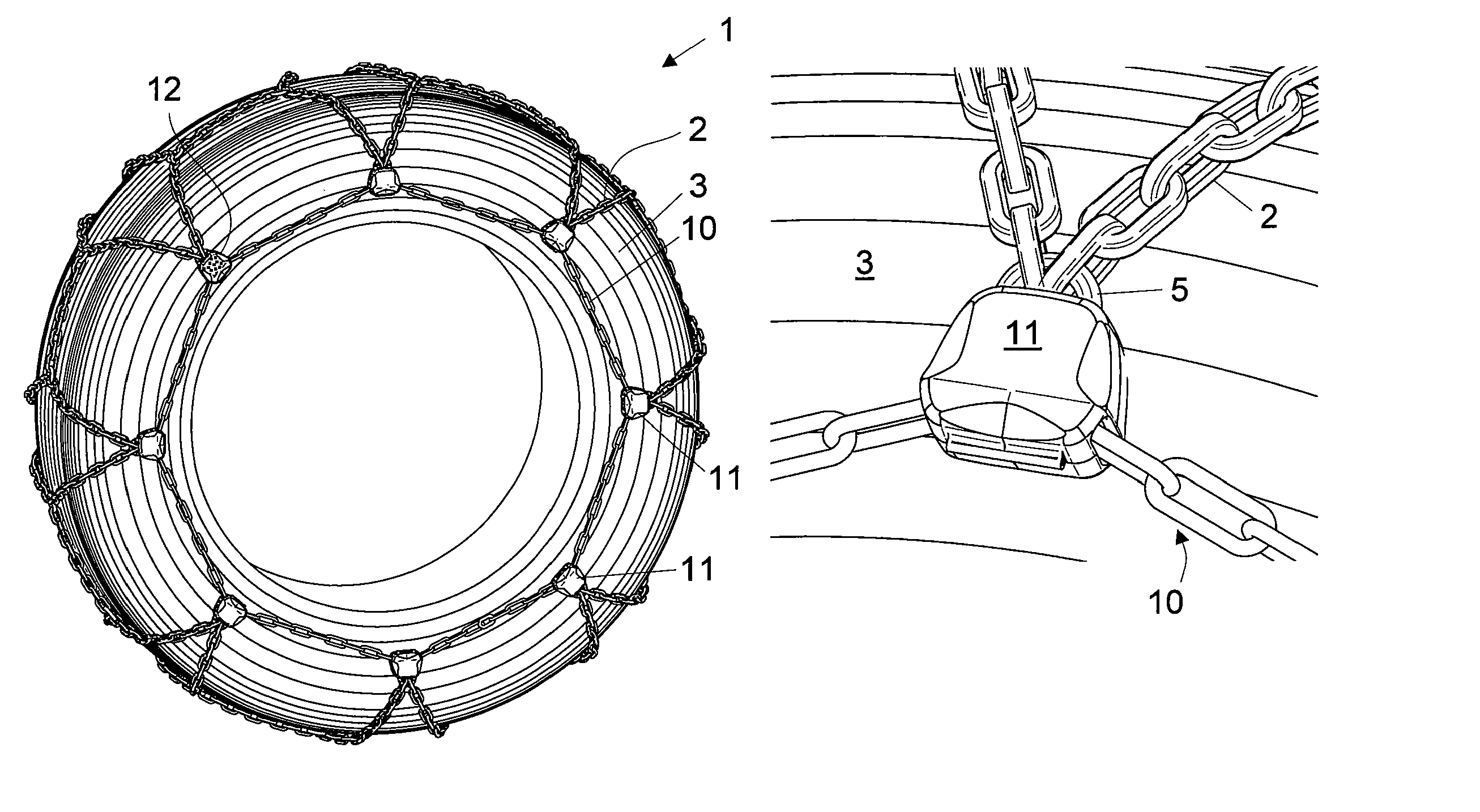

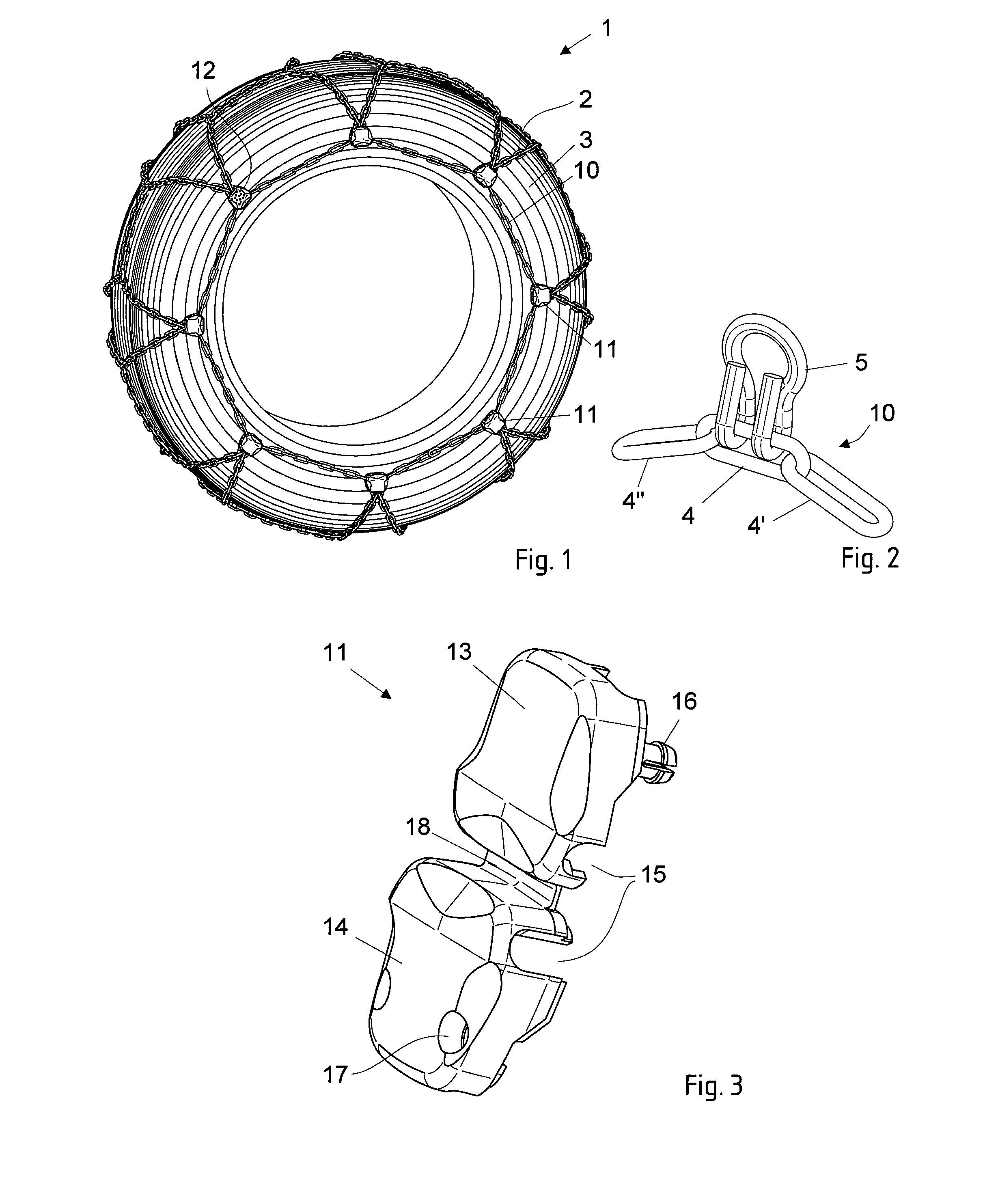

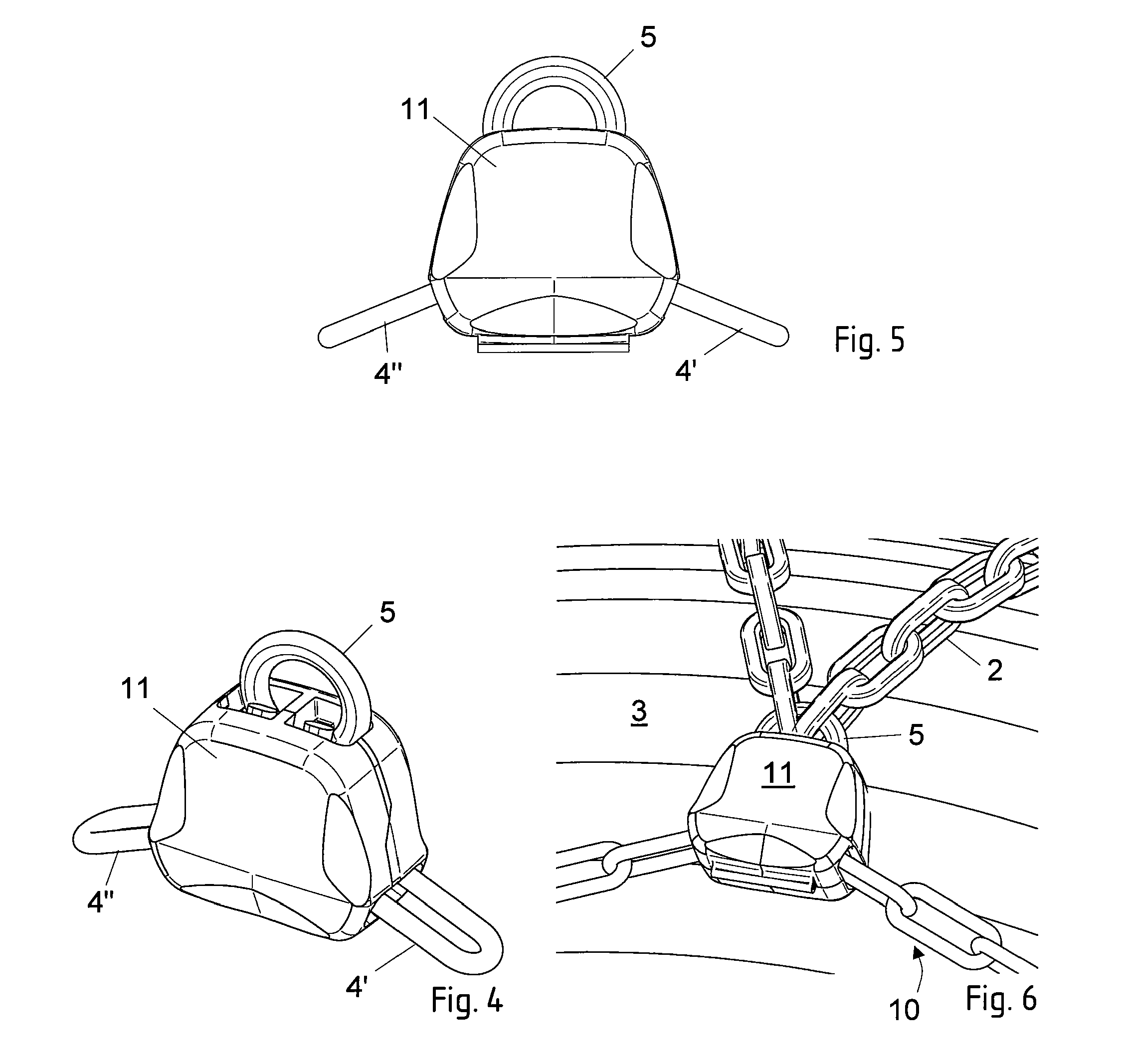

Anti-skid chain with rim protection covering

InactiveUS20100065175A1Favorable joiningEffective protectionTyre tread bands/patternsNon-skid devicesEngineeringChain link

In an anti-skid chain with a continuous chain mesh with track crosses and a side cable fitting on an (outer) tire side when mounted, the track crosses are connected to the side cable by hooks which are hooked into at least one chain link of the side cable, wherein each hook is provided with a rim protection covering surrounding the hook and the at least one chain ink. The rim protection coverings surround the respective chain links of the side cable, while a part of the hook that provides a connection with the track crosses is protruding from the rim protection covering.

Owner:PEWAG SCHNEEKETTEN

Gas turbine guide vane segment and method of manufacturing

ActiveUS10738629B2Favorable joiningReduce gapBlade accessoriesLeakage preventionWorking fluidEngineering

A gas turbine guide vane segment has a first guide vane part with an aerofoil and a first platform section and a second guide vane part with a second platform section. The first guide vane part and the second guide vane part are separately manufactured parts joined together such that the second platform section defines a leading edge of the gas turbine guide vane segment and such that the first platform section and the second platform section form an aligned common platform surface of the gas turbine guide vane segment. The first platform section includes slots in the first platform section for guiding cooling fluid along a surface of the first platform section for film cooling of the surface, the slots being provided at an upstream bend of the first platform section and the slots are provided on a side of the first platform section facing the working fluid.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Method for manufacturing laminated electronic component

InactiveUS7067173B2Prevent oxidationFavorable joiningFixed capacitor dielectricStacked capacitorsCooking & bakingConductive paste

Provided is a Ag-based conductive paste for a terminal electrode which suppresses oxidation of the Ni surface of an internal conductor and therefore brings about excellent joining with Ni even when baking is performed in the atmosphere in the case where Ni is used as the internal conductor of a laminated ceramic electronic component. The conductive paste includes at least one of an Ag powder and an Ag alloy powder, a nickel boride powder, an inorganic binder and an organic vehicle, wherein the quantity of the nickel boride powder is within the range of about 5% by weight or more, but less than about 60% by weight of the total paste.

Owner:MURATA MFG CO LTD

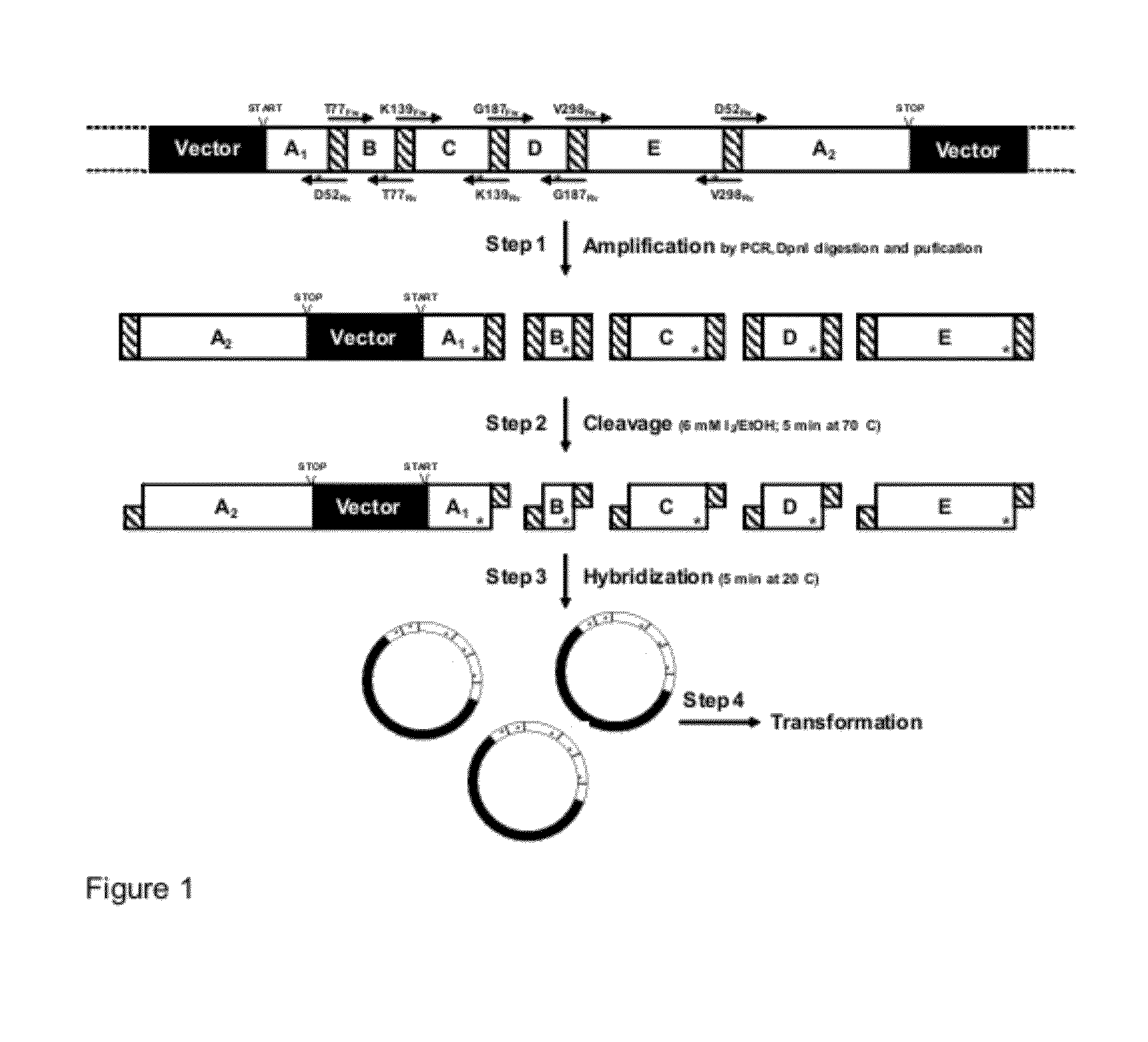

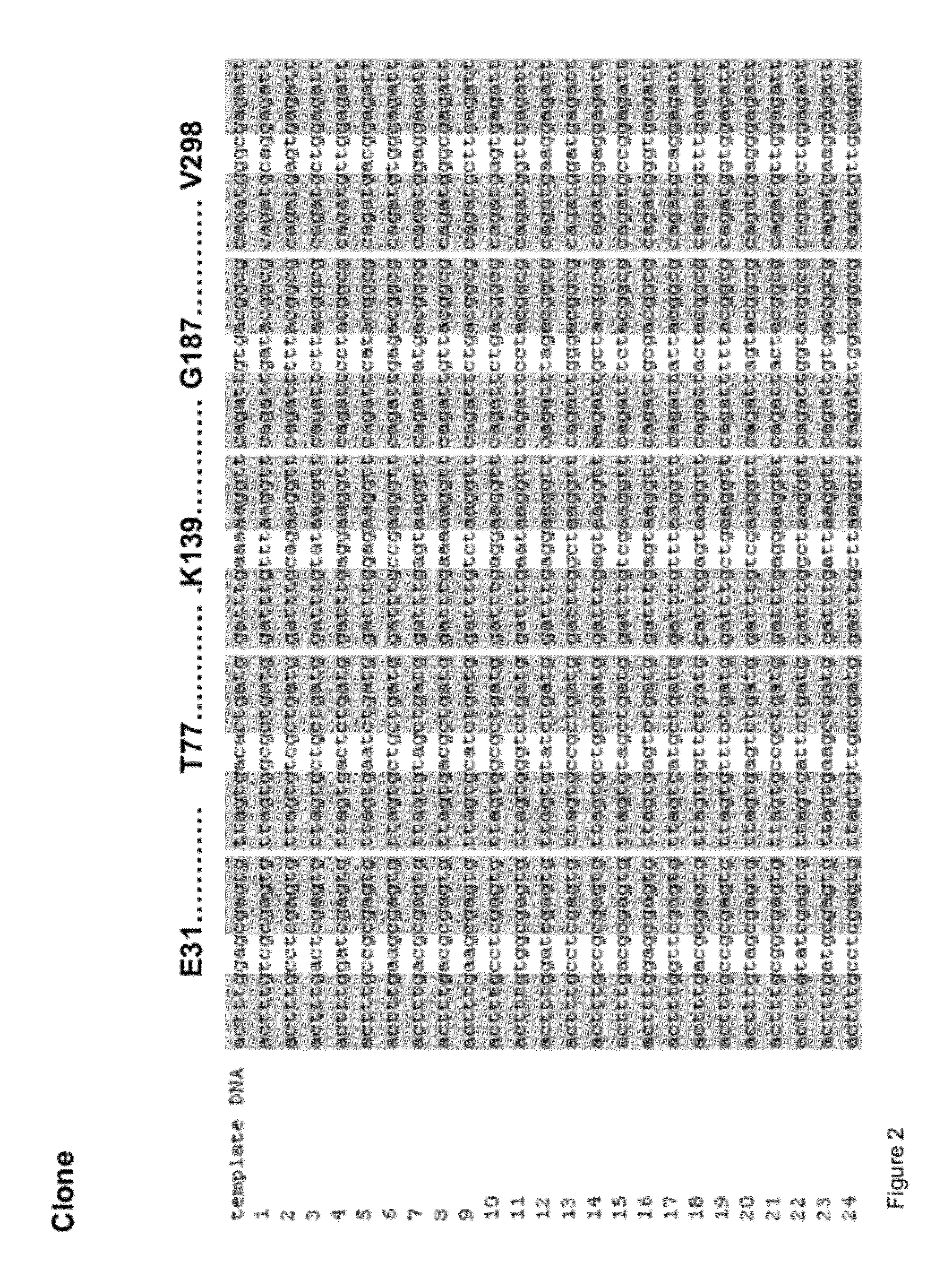

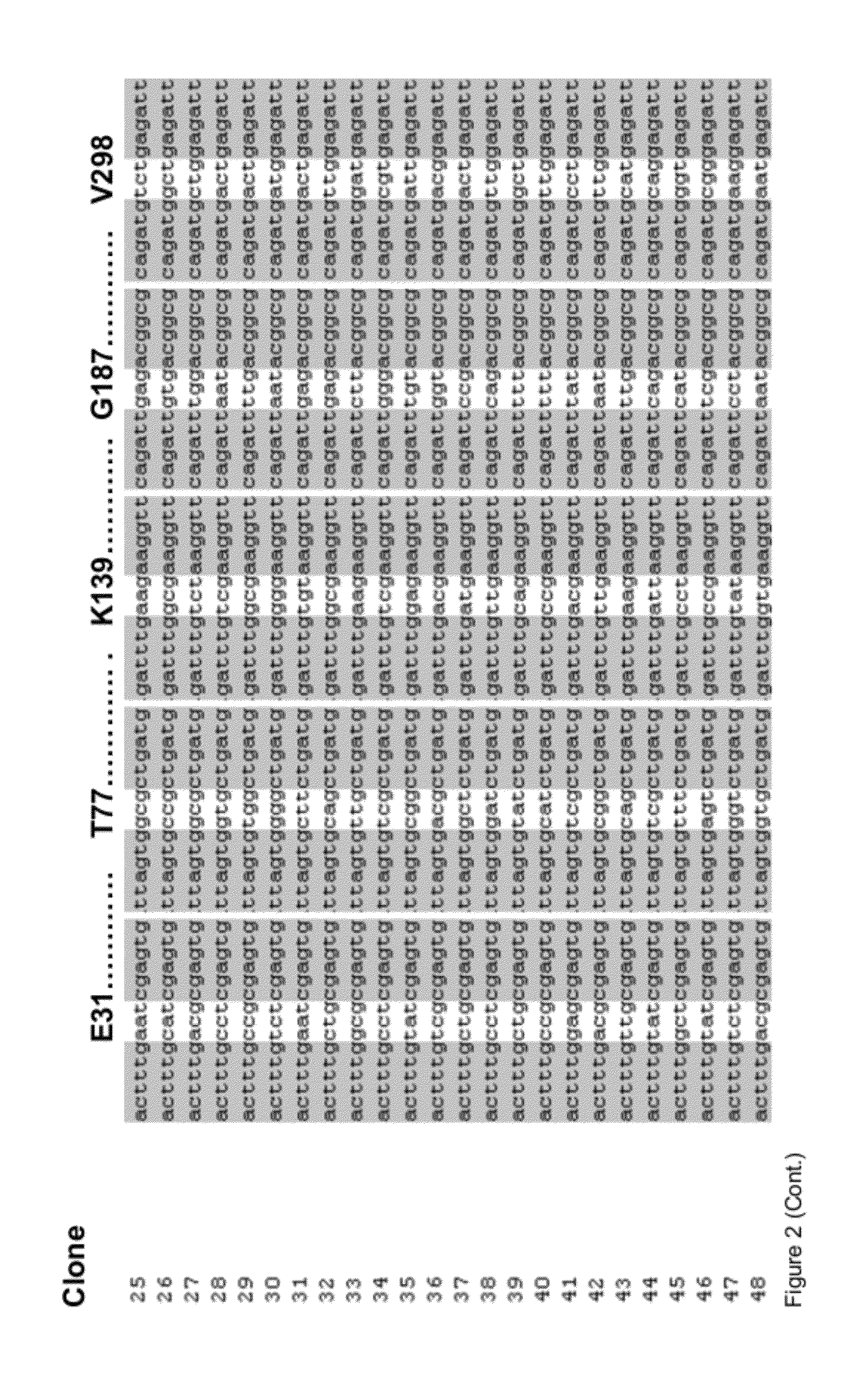

Methods and Materials for Nucleic Acid Manipulation

InactiveUS20120295311A1Improve transformation efficiencyFavorable joiningSugar derivativesOther chemical processesMicroorganismOrganic chemistry

The present invention is concerned with the field of nucleic acid manipulation and particularly DNA manipulation, and uses thereof. Specifically, the invention pertains to methods involving the joining of nucleic acids and uses of such joined nucleic acids, for example for creating transformed microorganisms. Also, the invention pertains to materials useful in such methods.

Owner:RWTH AACHEN UNIVERSITY

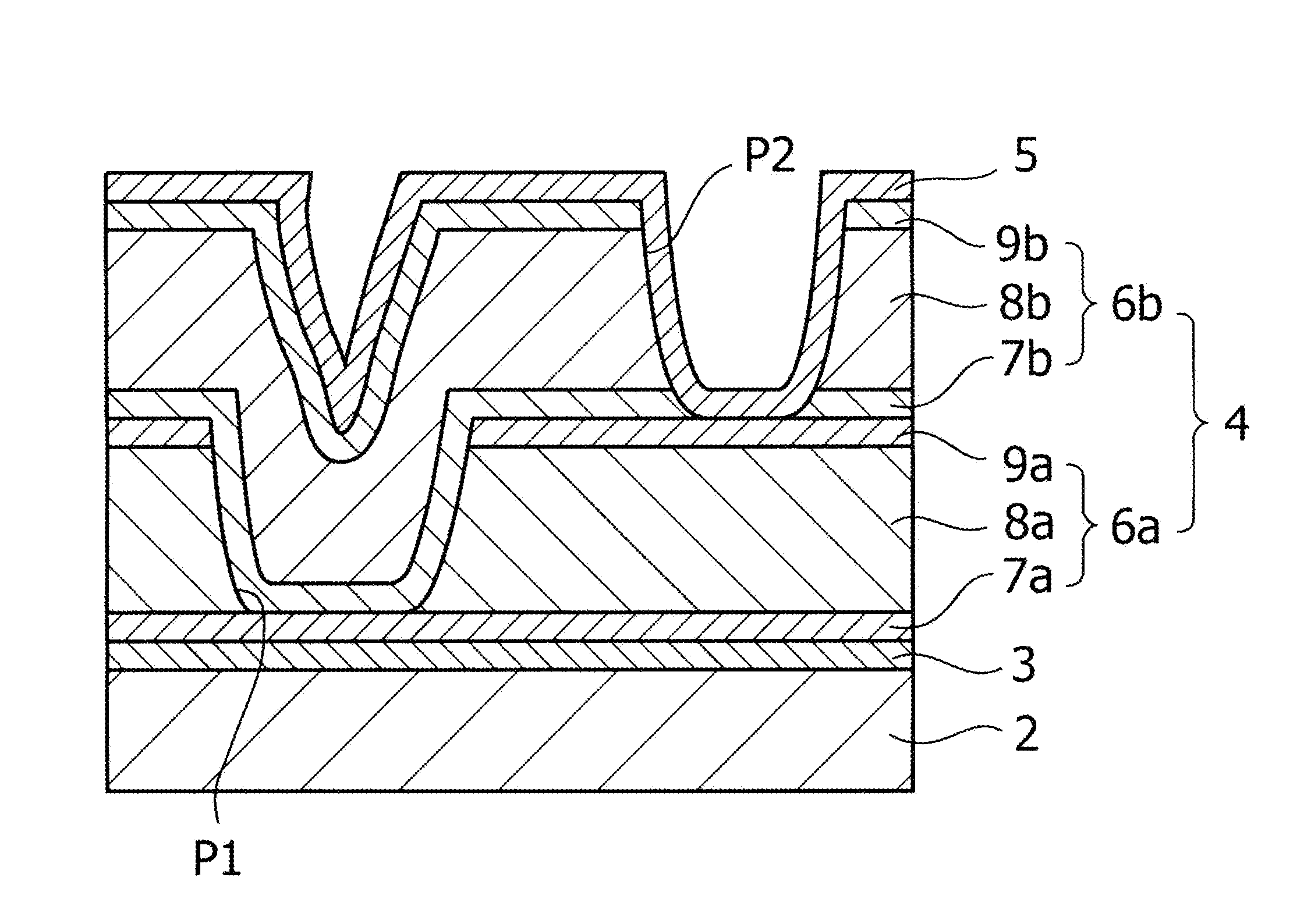

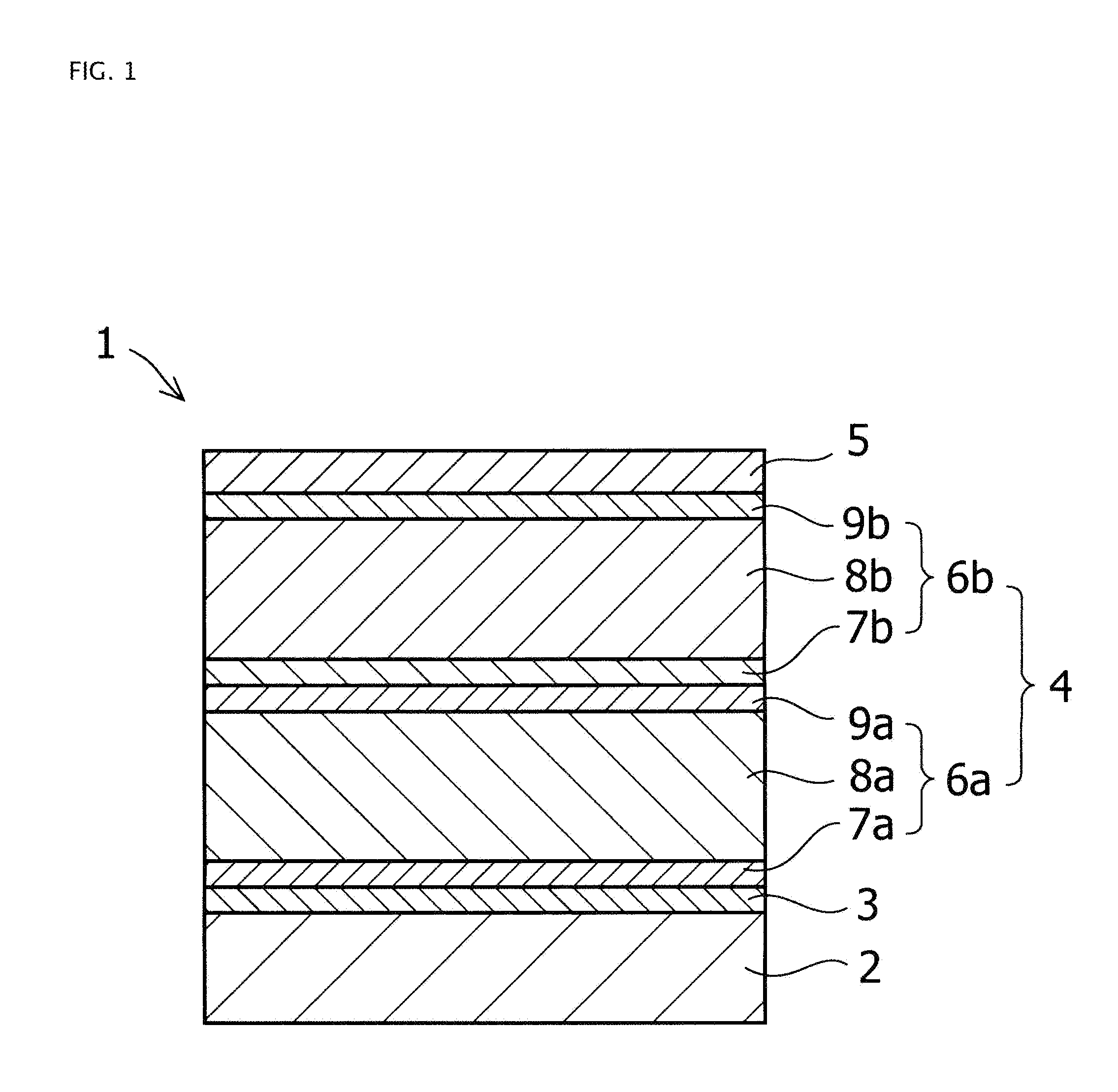

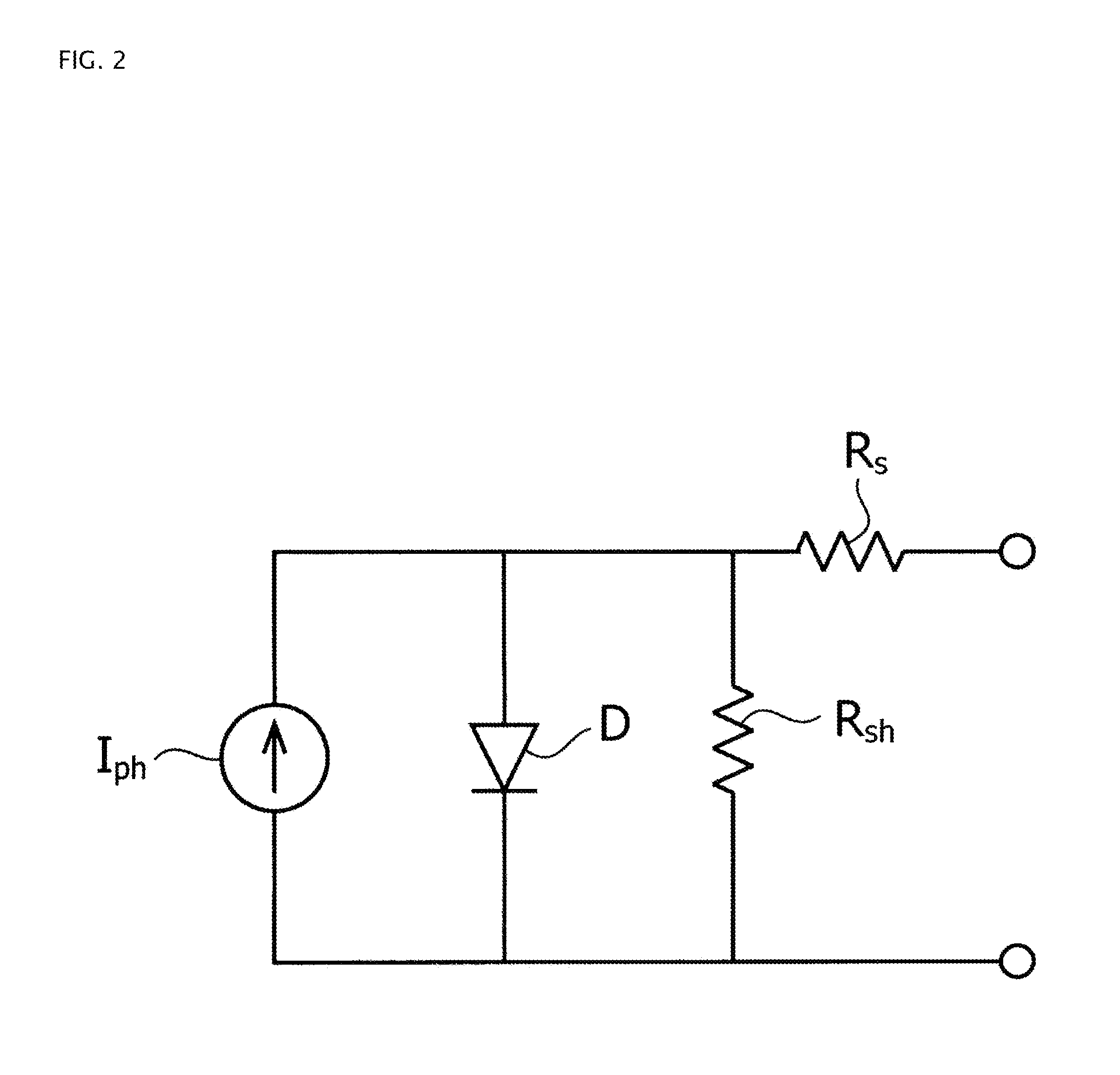

Method for manufacturing photovoltaic cell

InactiveUS20130203213A1Reduce resistanceImprove photoelectric conversion performanceFinal product manufactureSemiconductor/solid-state device manufacturingPhotoelectric conversionEngineering

Provided is a method for manufacturing a photovoltaic cell capable of efficiently preventing deterioration of photoelectric conversion performance caused by adhesion of a foreign substance and occurrence of leakage without lowering manufacturing efficiency. The method for manufacturing a photovoltaic cell having a structure in which a first electrode, a photoelectric conversion layer and a second electrode are laminated on one surface of a substrate in this order, and the photoelectric conversion layer is arranged as a multi-junction type photoelectric conversion layer in which a plurality of photoelectric conversion units are laminated while each photoelectric conversion unit has a plurality of layers, the method including at least one step in which a surface of a layer formed in a process after the thickest layer in a photoelectric conversion unit is formed and before the thickest layer in any one of photoelectric conversion units further laminated is formed is washed in the process.

Owner:FUJI ELECTRIC CO LTD

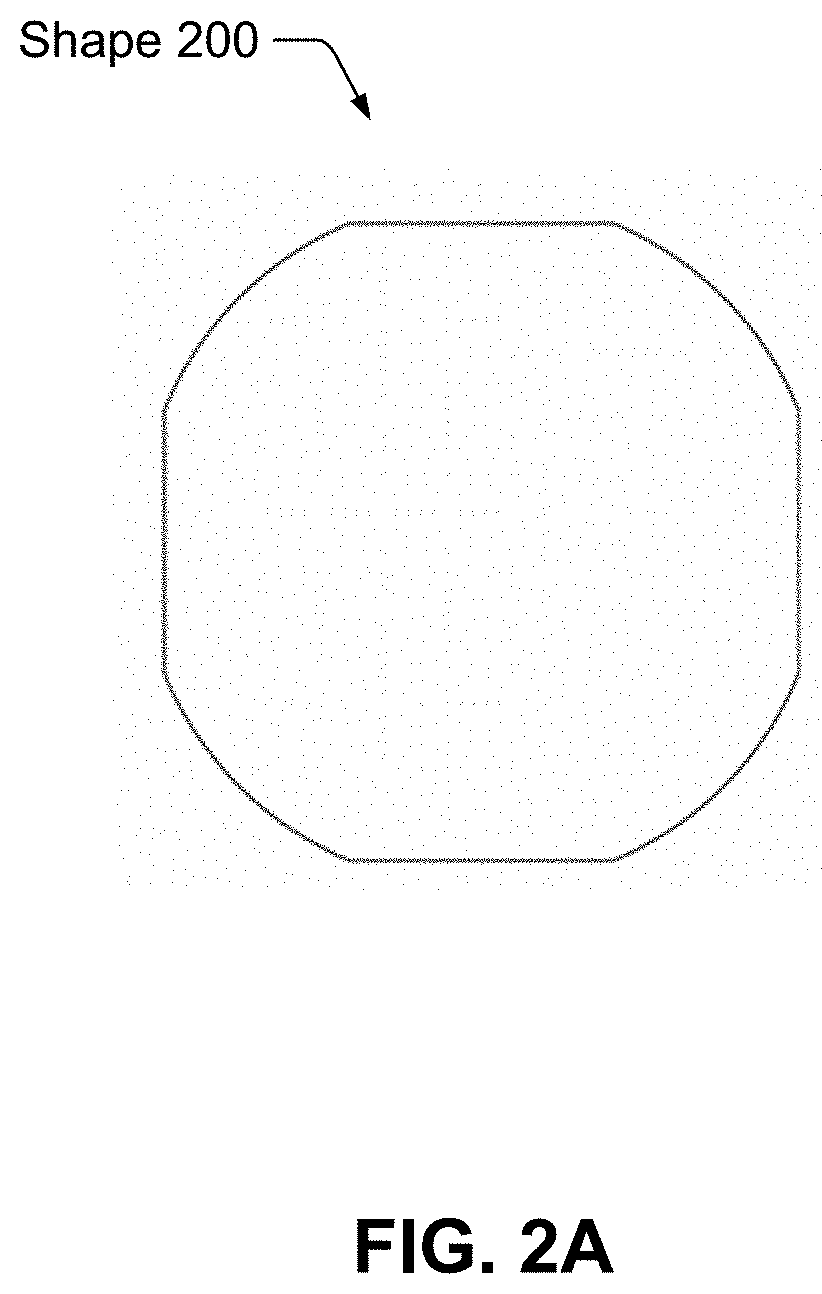

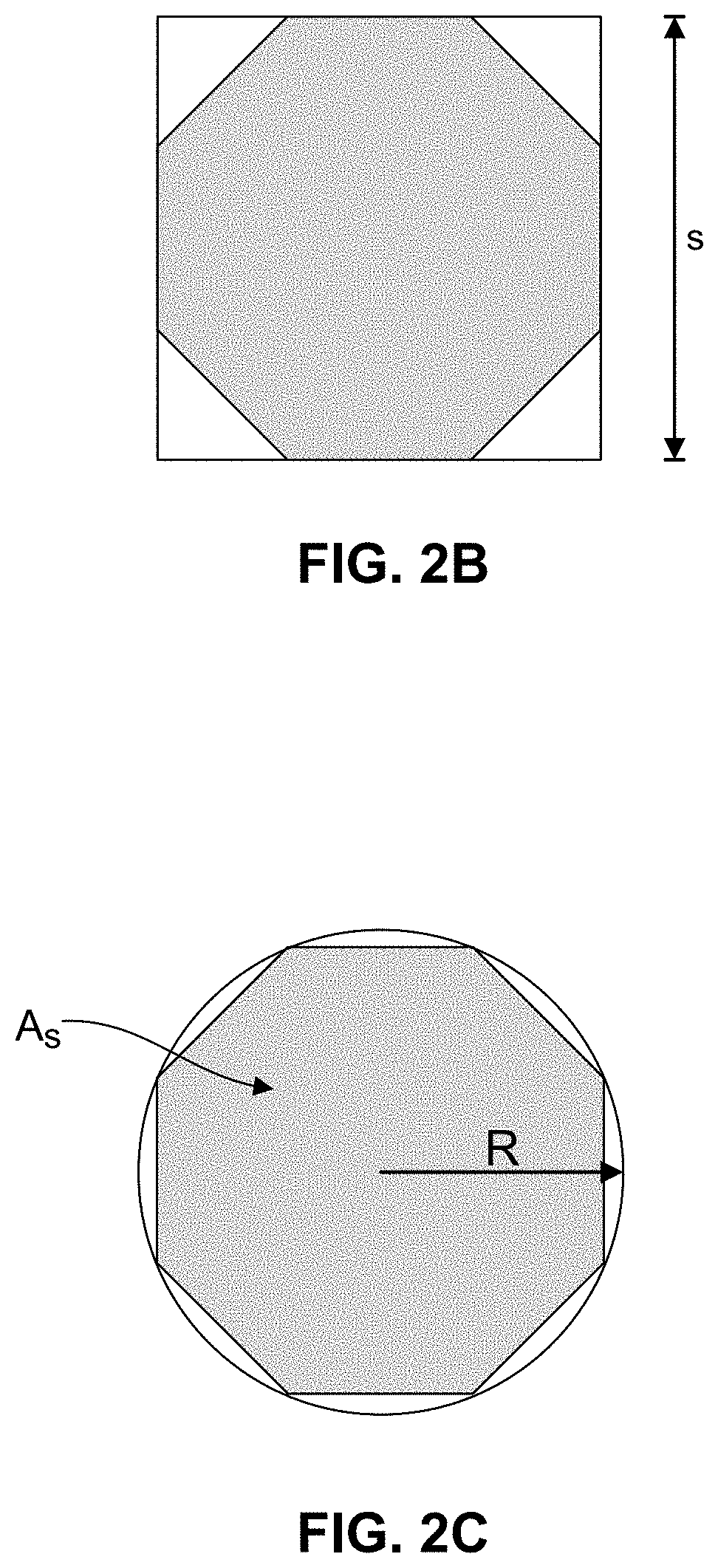

Stacked Lamination Rotor

ActiveUS20200259379A1Maximize utilizationEasy to shapeMagnetic circuit rotating partsSpringsClassical mechanicsStructural engineering

The invention is a flywheel rotor that includes a number of adjacent laminations, stacked one on top of another, where each of the laminations has the same shape and is rotationally symmetric around a center axis, and where the shape is substantially circular and includes a plurality of protrusions on the circumference, and each of the laminations includes at least one hole for at fastening bolts to pass through. The invention typically includes an endplate at each end of stack of laminations and one of the two endplates attaches to a stubshaft.

Owner:AMBER KINETICS

Terminus cap for a drive cable, drive cable, method for the production of a terminus cap, and method for the production of drive cable

InactiveUS20100310309A1Easily and reliably attachedProduced cost-effectivelyRopes and cables for vehicles/pulleyCouplings for rigid shaftsCold formedMotorized vehicle

Owner:MEFLEX TELECONTROL GMBH & CO KG

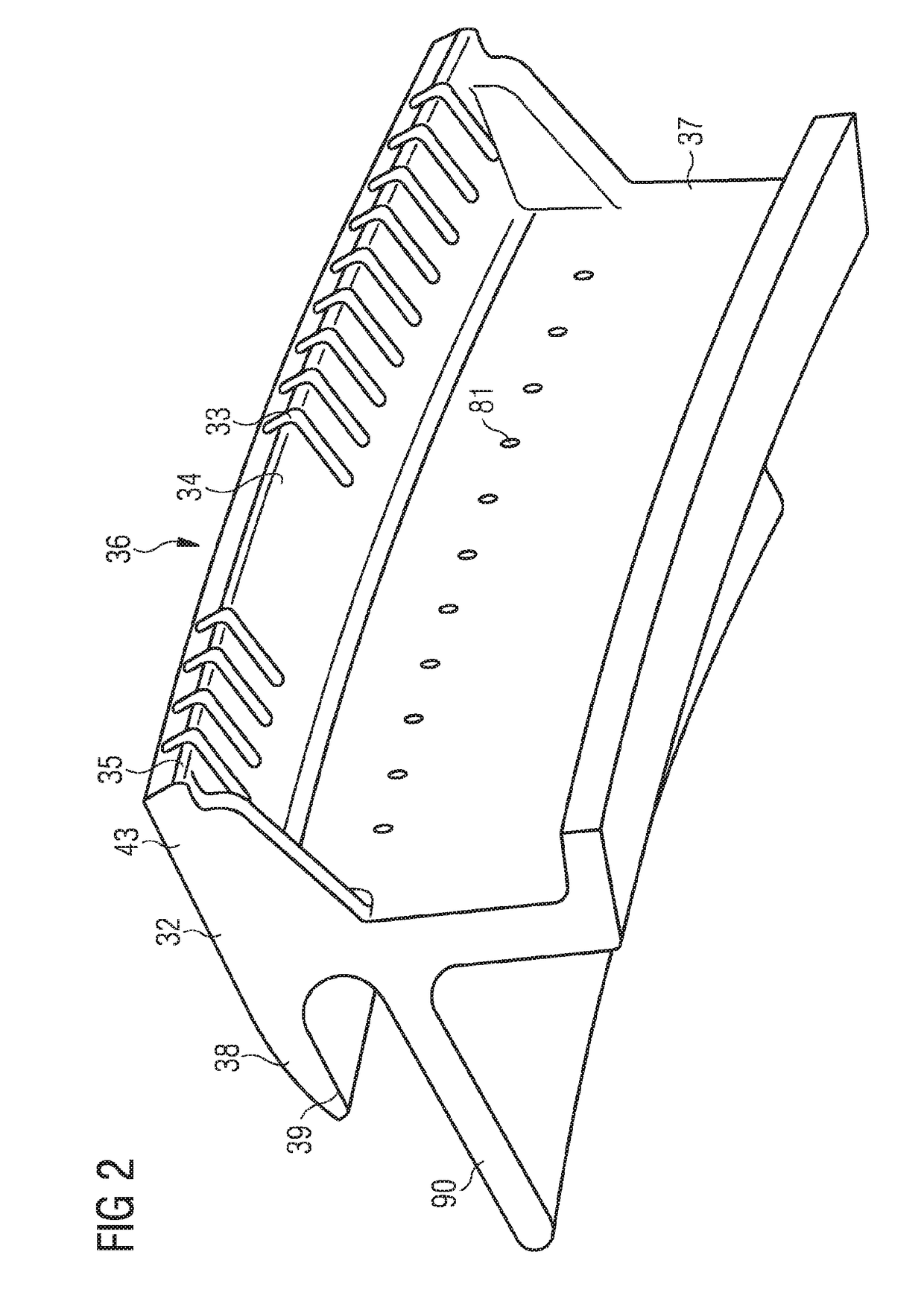

Apparatus for assembling blade sections

InactiveUS20150143696A1Improve joint qualityFavorable joiningEngine manufactureFinal product manufactureMechanical engineering

Owner:YOUWINENERGY

Method for producing a stratified composite material

A method is described for producing a stratified composite material, with a melt of a layer material being cast progressively in a forward feed direction onto a strip-like metal carrier which is heated to a treatment temperature required for the bonding with the layer material and is cooled below the melting temperature after the casting via the metal carrier. In order to provide advantageous casting conditions it is proposed that the metal carrier is heated continuously with a temperature profile prior to the casting of the melt of the layer material in the forward feed direction, which temperature profile decreases towards lower temperatures from a maximum temperature below the treatment temperature in the region of a surface layer receiving the melt towards a core layer of the metal carrier, and that the metal carrier is heated in a surface layer by the melt to the treatment temperature upon casting of the melt which is overheated for this purpose.

Owner:MIBA GLEITLAGER GMBH

Coated rotary tool

InactiveUS20140084044A1Improve wear resistanceShort timeWelding/cutting auxillary devicesVacuum evaporation coatingFriction weldingWear resistance

Owner:SUMITOMO ELECTRIC IND LTD

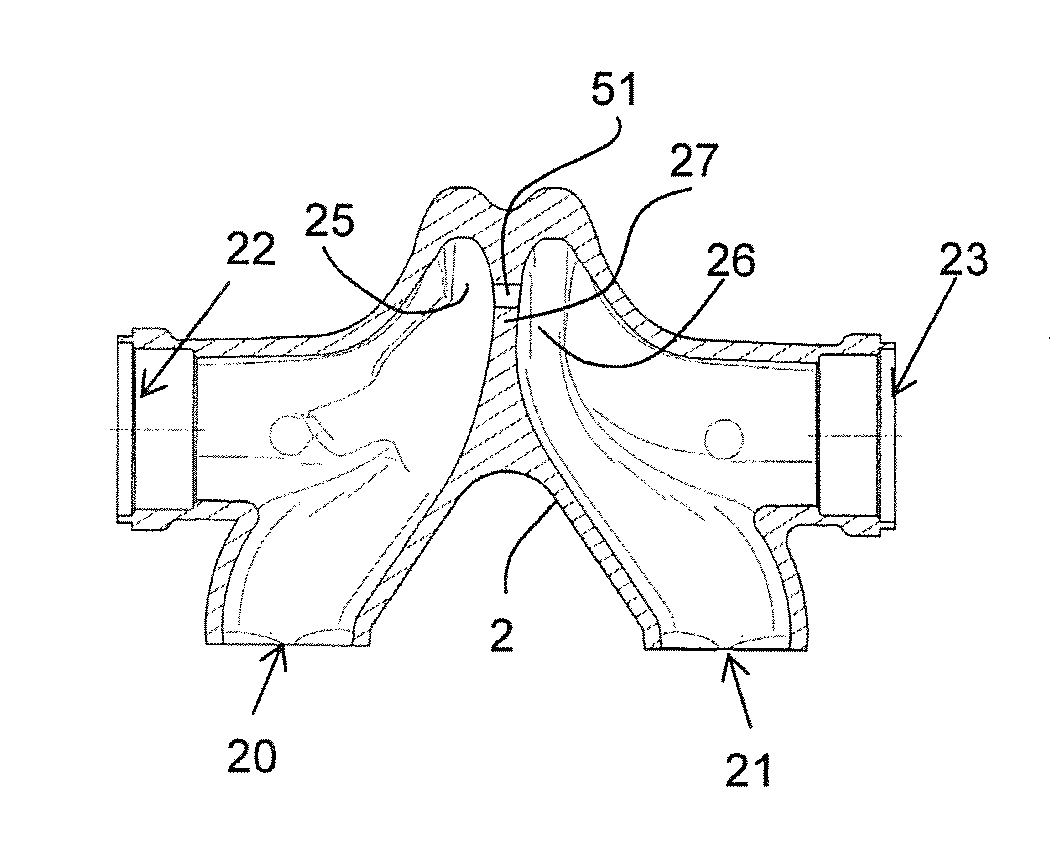

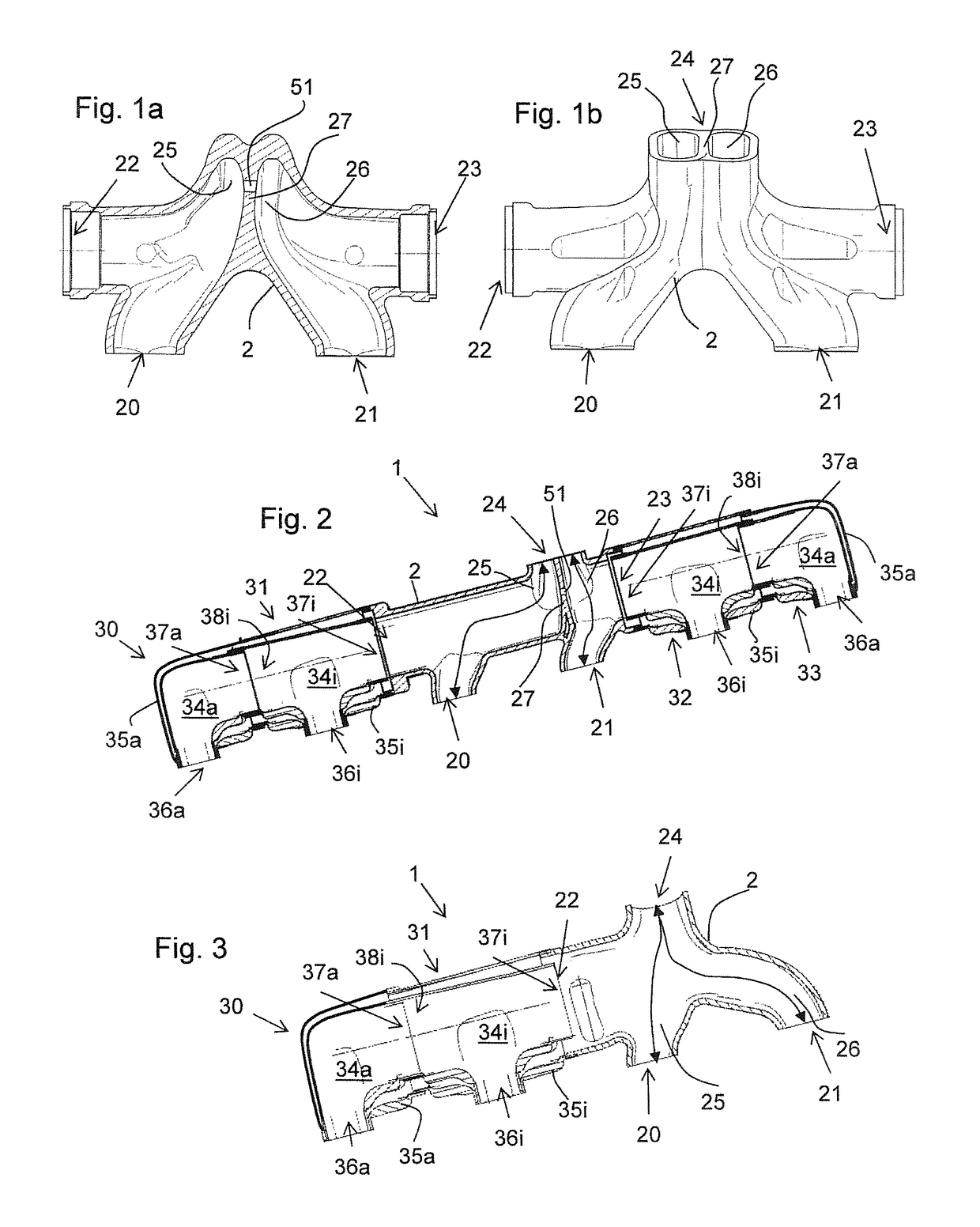

Manifold

ActiveUS20180334946A1Disadvantage is compensatedThe preparation method is simple and economicalInternal combustion piston enginesSilencing apparatusEngineeringInternal combustion engine

A manifold system for an internal combustion engine, having a housing, which is designed as a collecting manifold and which has two inlet openings and an outlet opening for the flow connection of two outlets of an internal combustion engine to an exhaust system and at most two connection openings provided on the housing for connecting a double-shell inner air-gap-insulated manifold. An exhaust system is developed in such a way that, at the same time, the tone of the exhaust gas noise and thus of the exhaust system is optimized over a plurality of important rotational speed ranges of the internal combustion engine by a modular assembly. For this purpose, at least one separate inner air-gap-insulated manifold having a connection opening, an inlet opening, and an outlet opening is provided, which is connected to the housing by the outlet opening, and at least one separate outer air-gap-insulated manifold having an inlet opening and an outlet opening is connected to the connection opening of the inner air-gap-insulated manifold. All air-gap-insulated manifolds are completely formed of sheet metal, and each air-gap-insulated manifold has a separate one- or multi-part inner shell and a one- or multi-part separate outer shell. All inner air-gap-insulated manifolds are structurally or geometrically identical and all outer air-gap-insulated manifolds are structurally or geometrically identical, wherein the inner air-gap-insulated manifolds are not structurally identical and not geometrically identical to the outer air-gap-insulated manifolds.

Owner:TENNECO

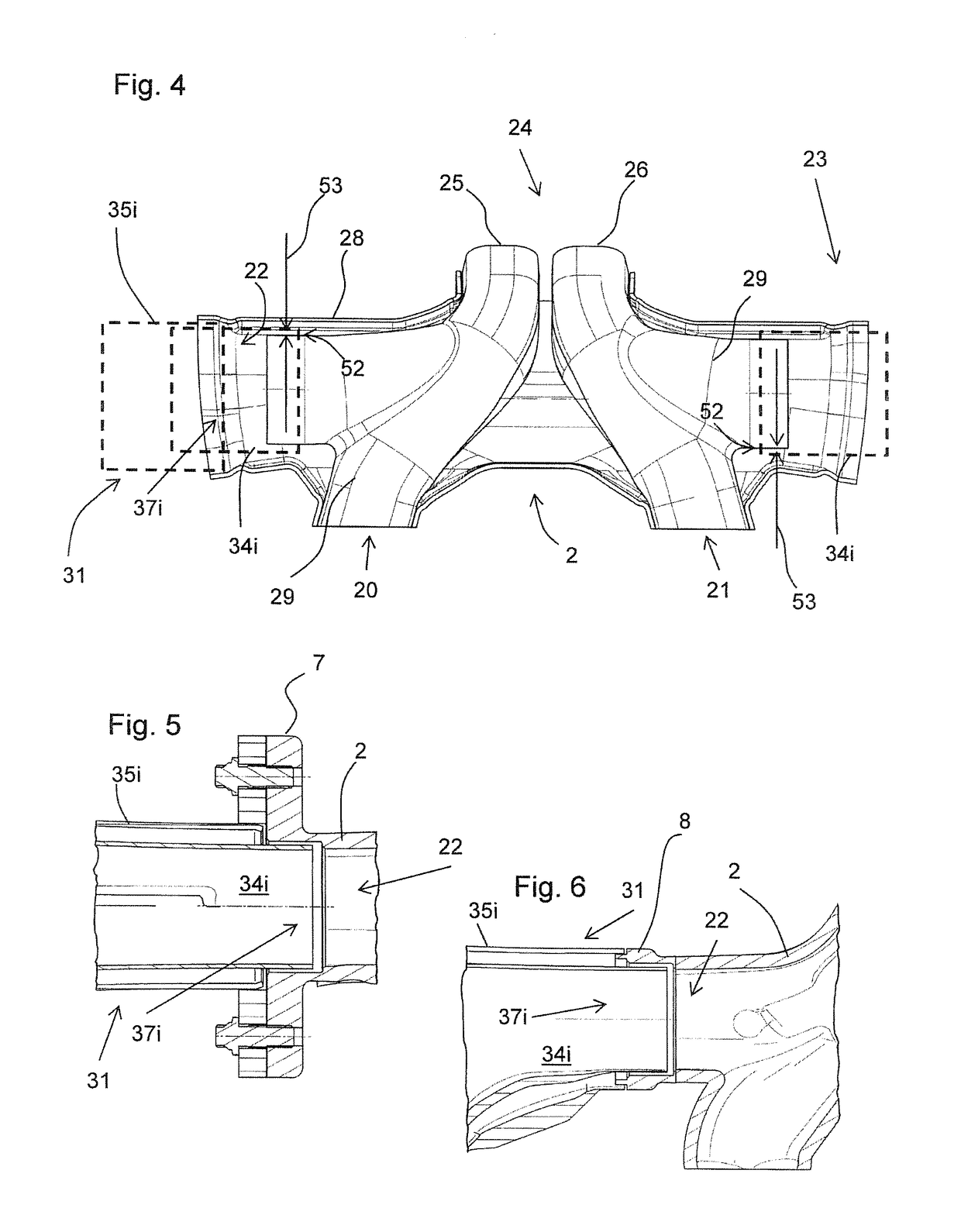

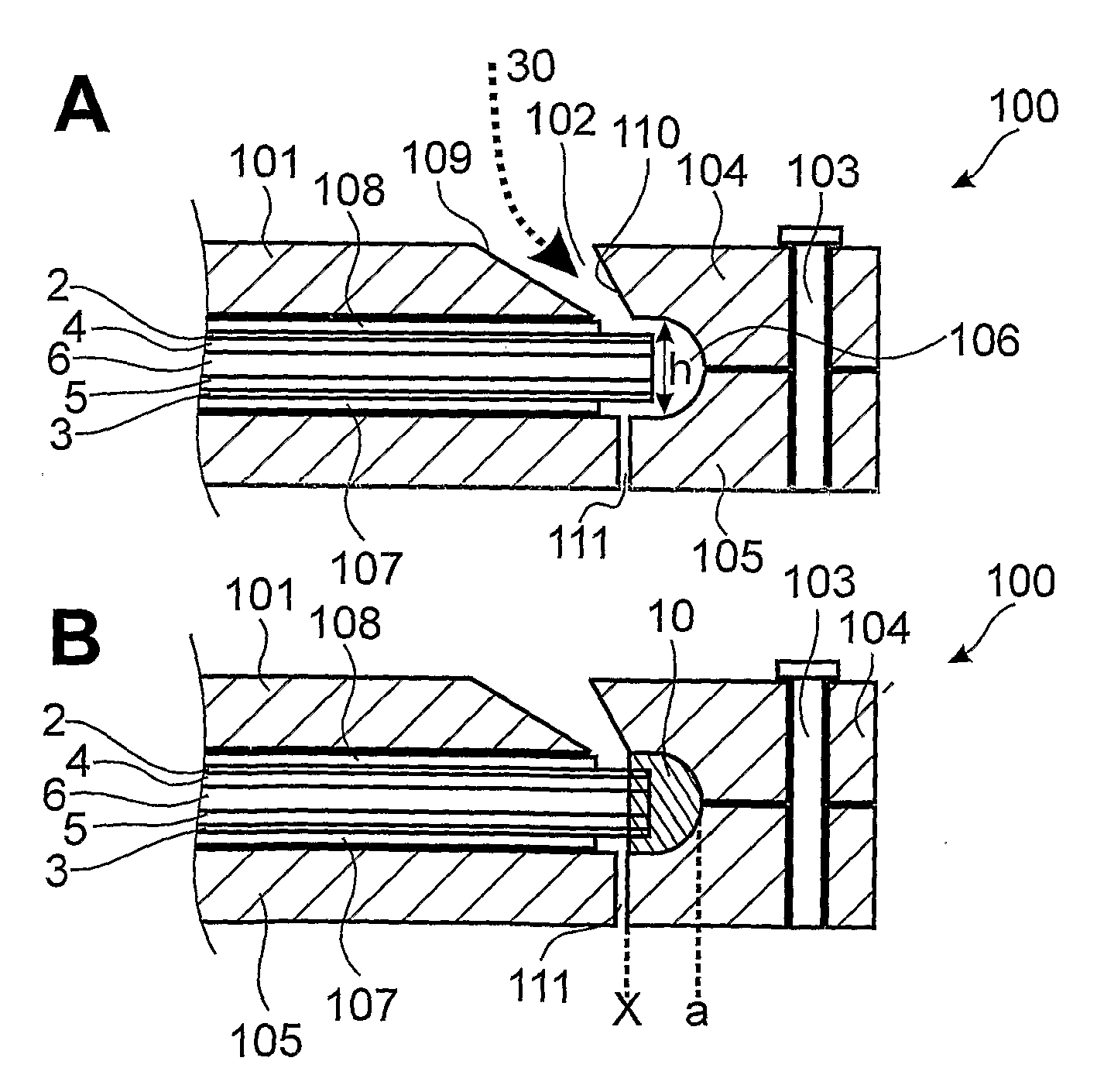

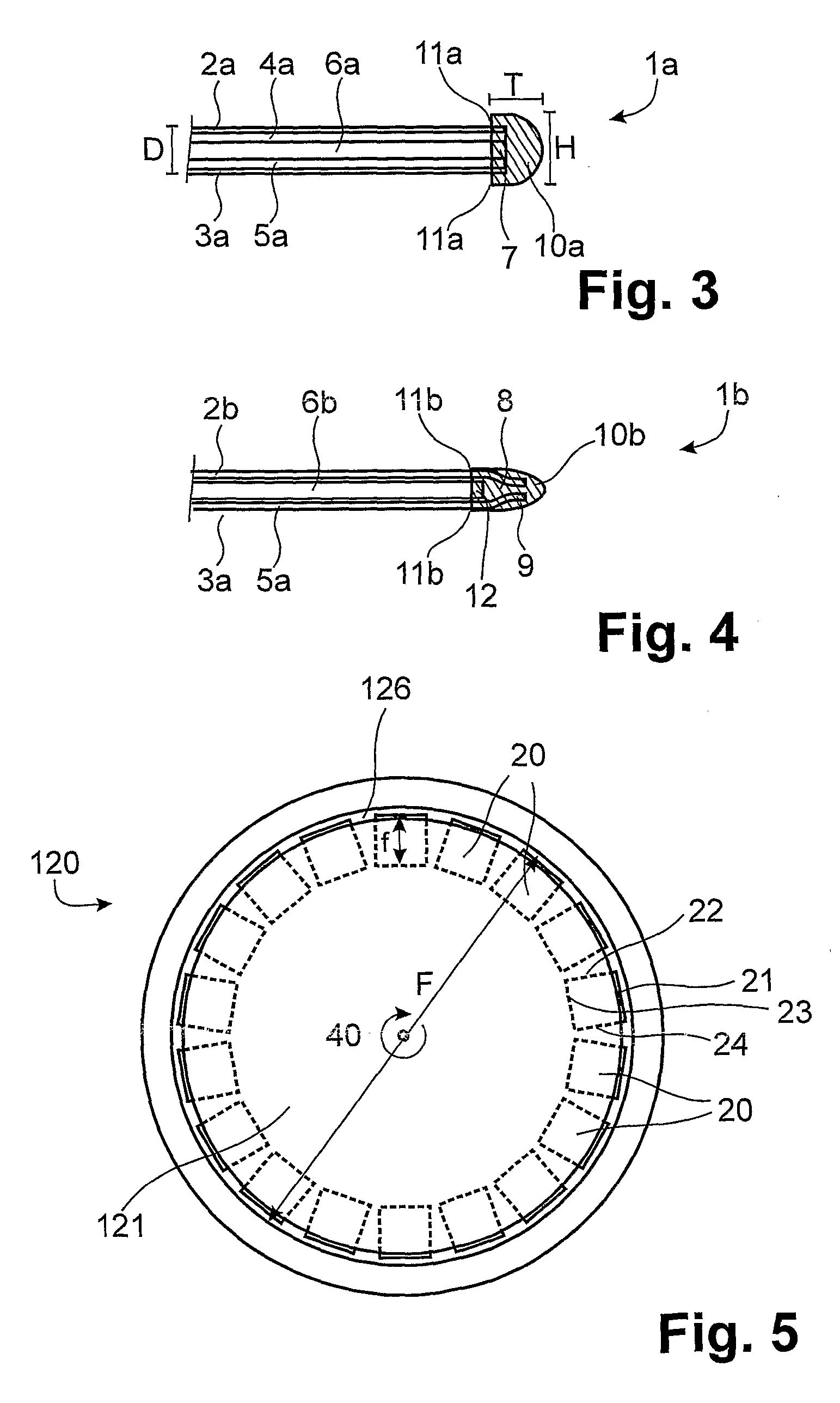

Centrifugal casting method for forming a frame and defining mould therefor

InactiveUS20090206517A1Favorable joiningEasy to holdLaminationLamination apparatusChemical compoundEngineering

The invention relates to a method for forming an edge enclosure. A defining mould (100) is provided, in which at least one disc-shaped element (2, 3, 4, 5, 6) is arranged and which surrounds the element at least at the edge. The at least one element is set in rotation (40), whereby casting compound introduced into the defining mould localises in the edge region (7) of the at least one element and cures there, so as to produce an edge enclosure (10) which at least partially surrounds the at least one element in a form-fitting manner.

Owner:IP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com