Sheet Product Comprising at Least Two Plies Joined by Gluing with Non-Uniform Distribution of the Glue

a technology of gluing and sheets, applied in the field of sheets products, can solve the problems of increasing the cost of finished products, reducing the softness of products, and becoming more rigid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

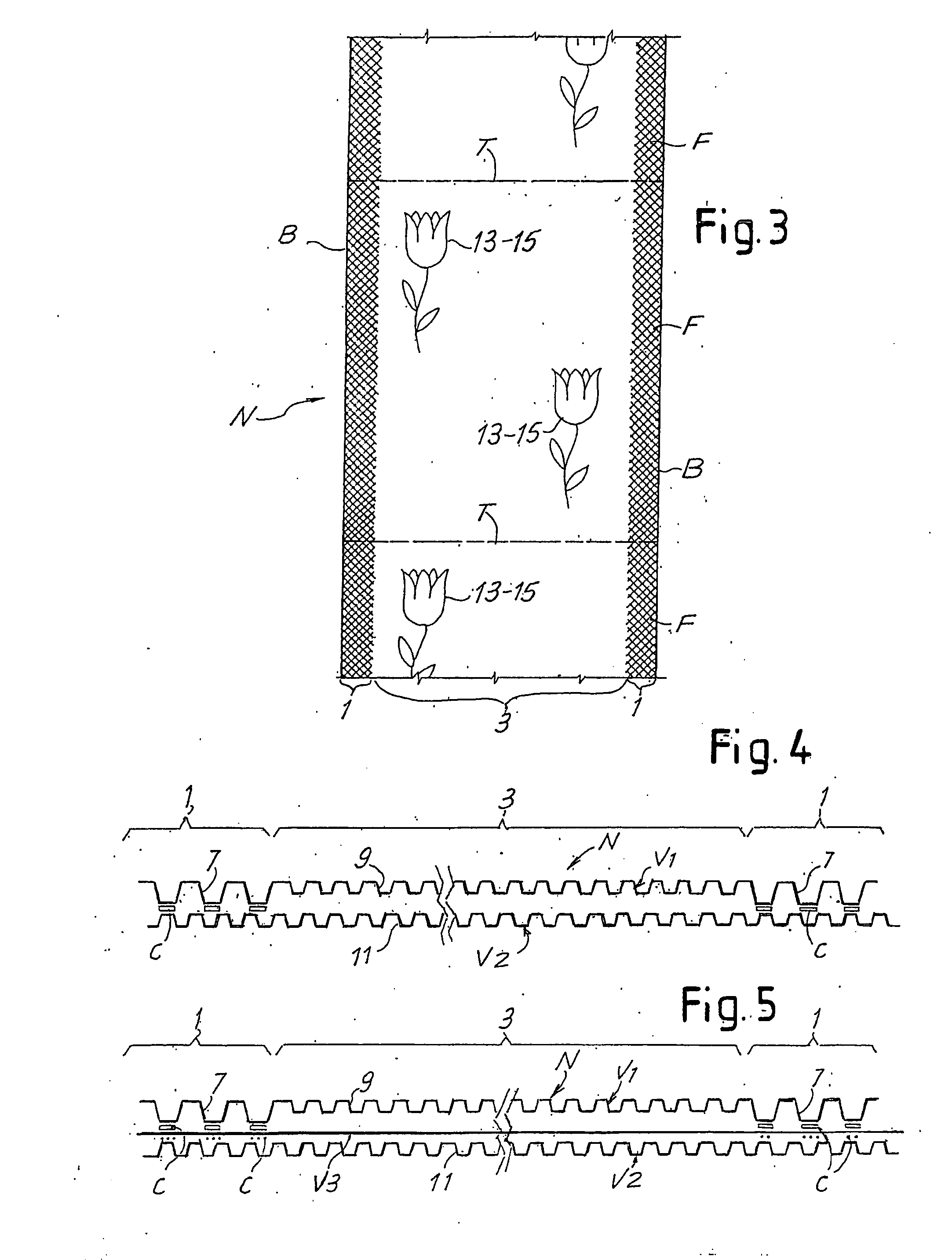

Embodiment Construction

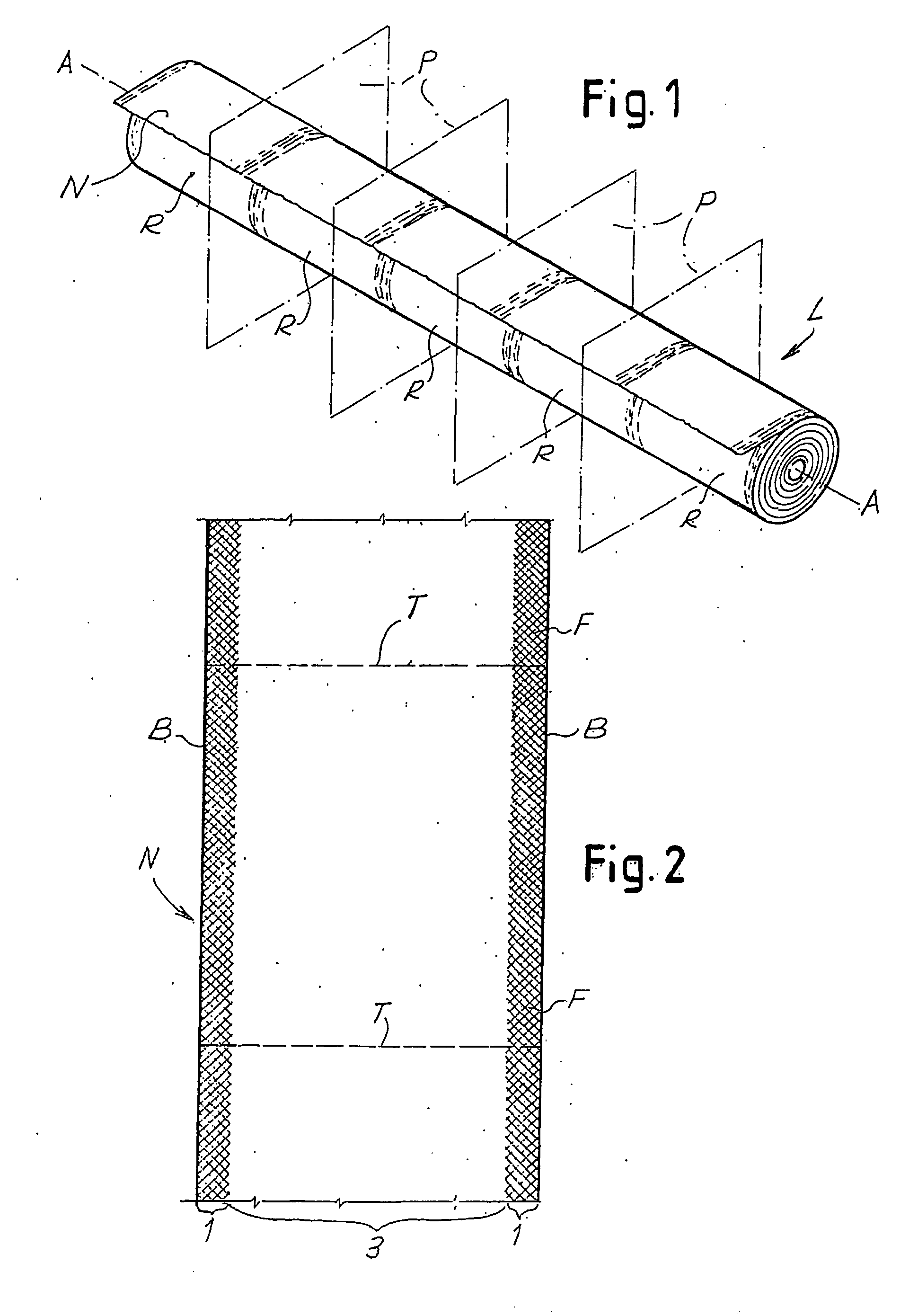

[0027]FIG. 1 shows a log, that is, a roll of considerable axial length, delivered from a rewinding machine, located downstream of an embossing unit which performs, on the tissue paper web material or the like, differentiated embossing with differentiated gluing to obtain the objects mentioned above. The log, indicated as a whole with L, will subsequently be cut orthogonally to the axis A-A thereof, to be divided into a plurality of rolls R of a smaller axial length, corresponding to the final dimension of the product destined for use. The ends of the log have been trimmed to eliminate the irregular portion which forms in this end area during winding.

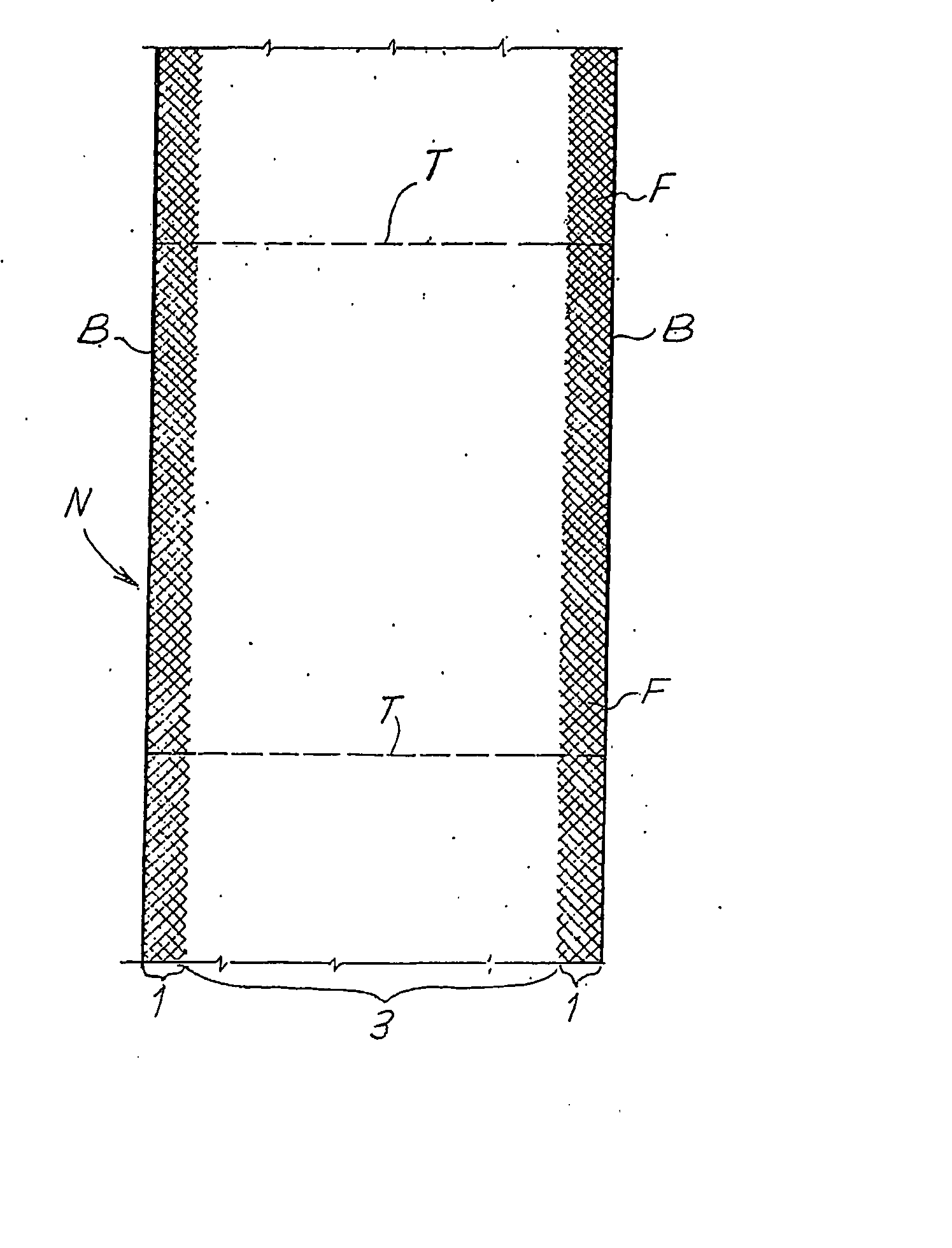

[0028] As shown schematically in FIG. 1 and illustrated in greater detail hereunder by a series of examples of embodiment, the web material indicated as a whole with N of which the log L is composed is embossed differentially with areas with increased embossing at the level of cutting planes P indicated with a dashed line in FIG. 1, alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com